Patents

Literature

30results about How to "Increase heat transfer limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

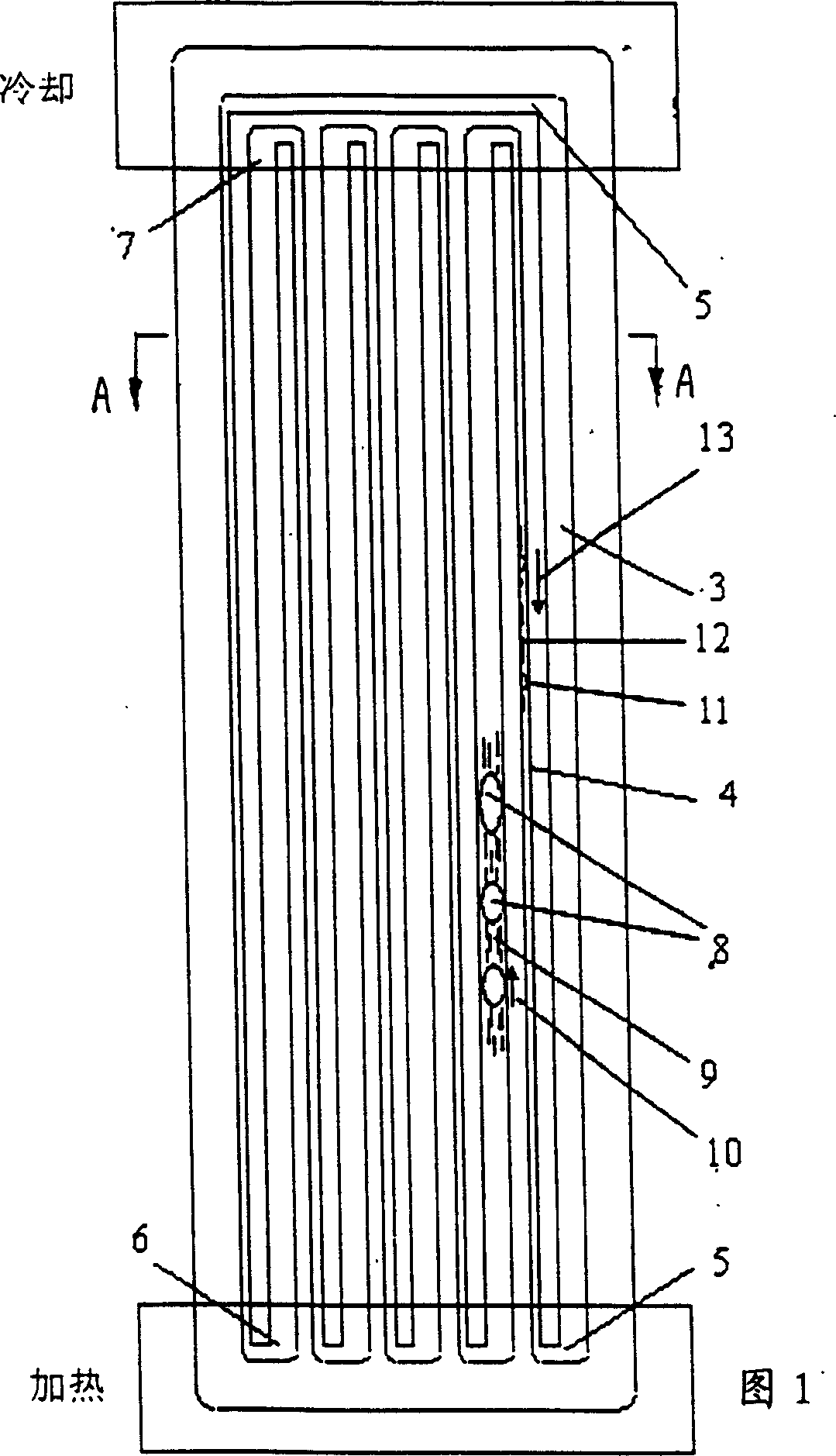

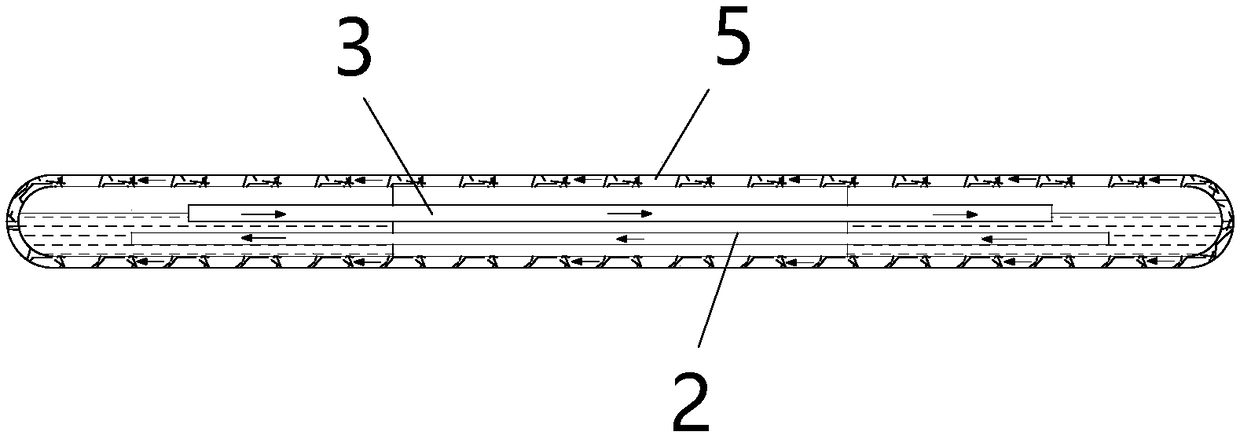

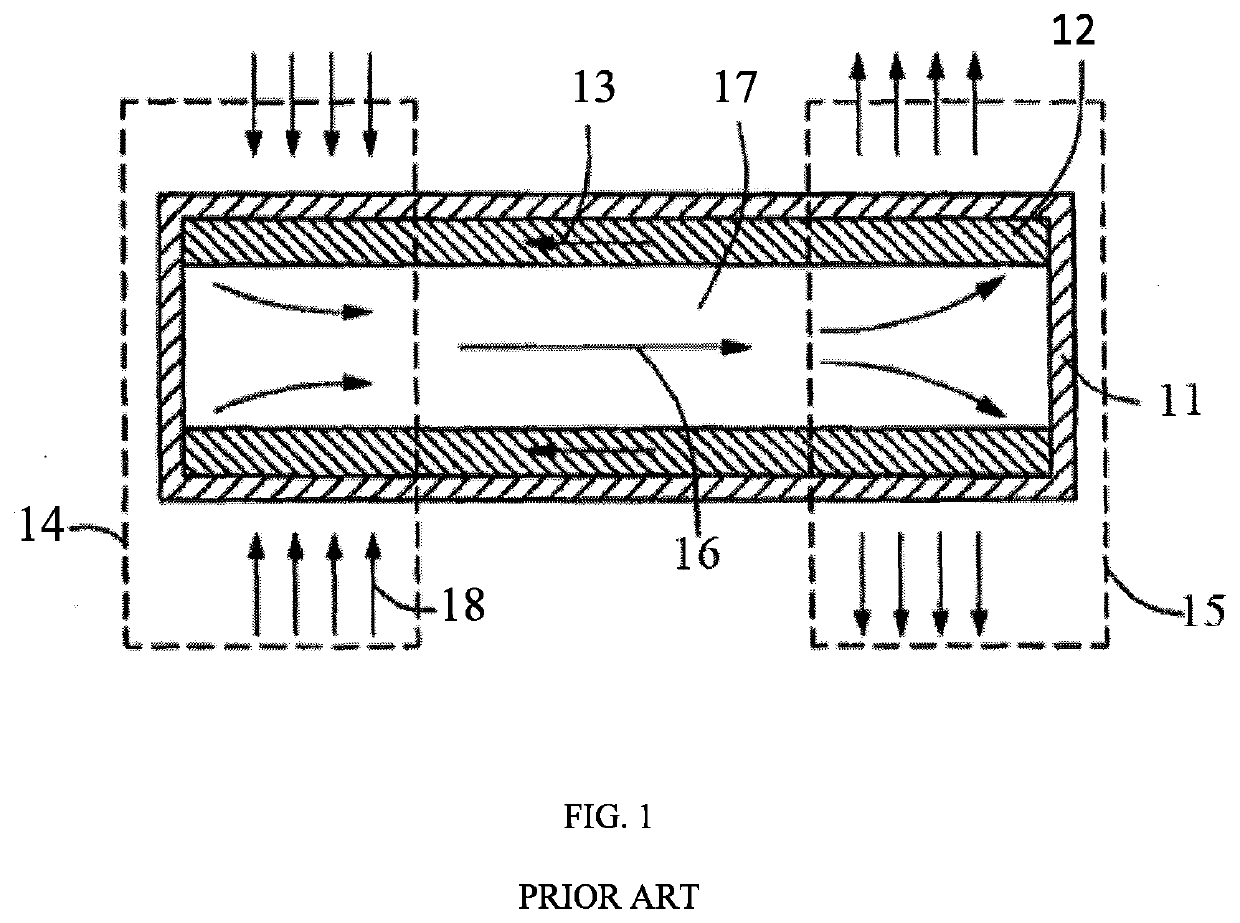

Circulation flowing pulsating heat pipe for cooling electronic device

InactiveCN1684252AIncrease heat transfer limitReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

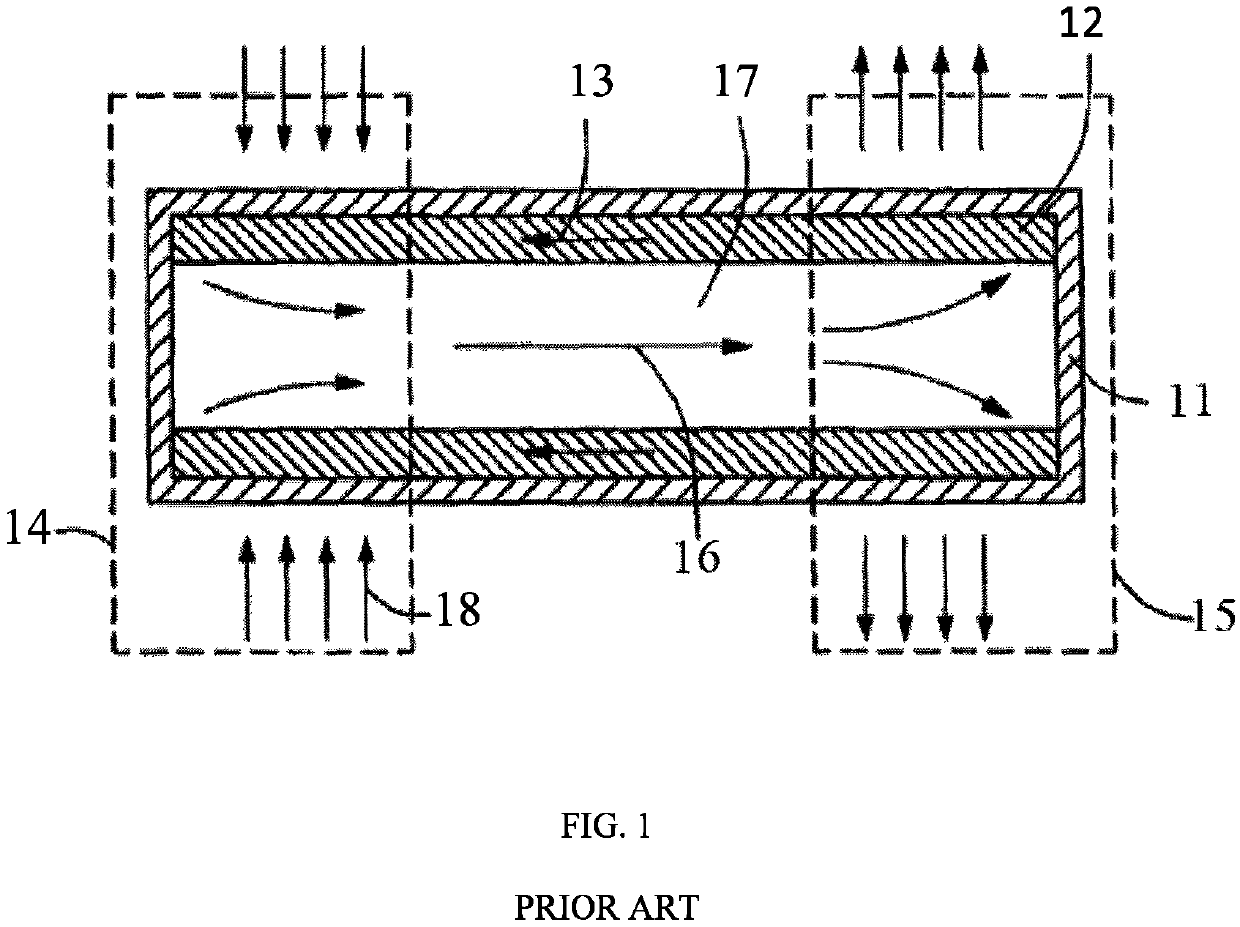

This invention relates to a circulation flow pulsation thermal tube suitable for cooling spare part of semiconductor devices and other solid devices composed of two connected and mutually parallel-arrayed thick straight channel and thin straight channel, two adjacent channels are connected by an angle pipe. A heat conduction working solution forms a single-way plug flowing under the pressure generated by heat action in the channel, which absorbs heat and evaporates at the heating section and discharges heat and condenses at the radiation section. This invented pulsation thermal tube has high conduction limit and low resistance.

Owner:CENT SOUTH UNIV

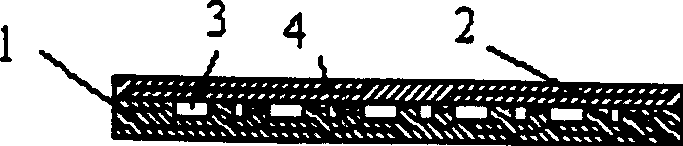

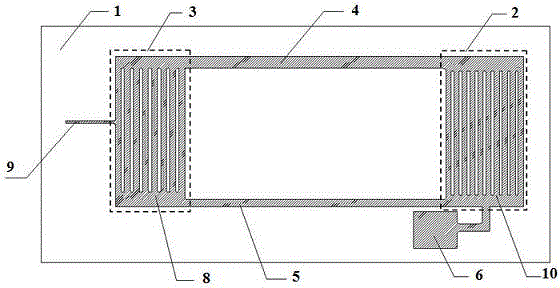

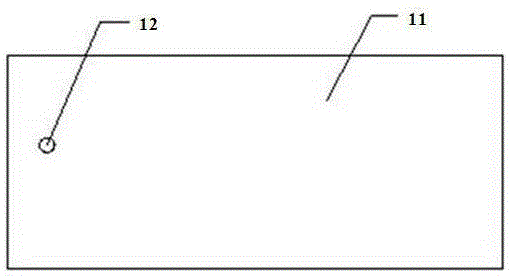

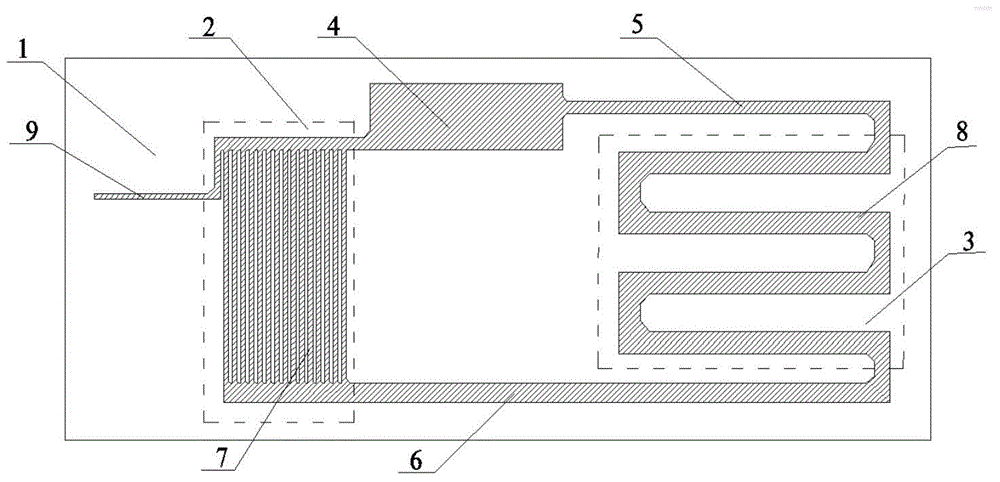

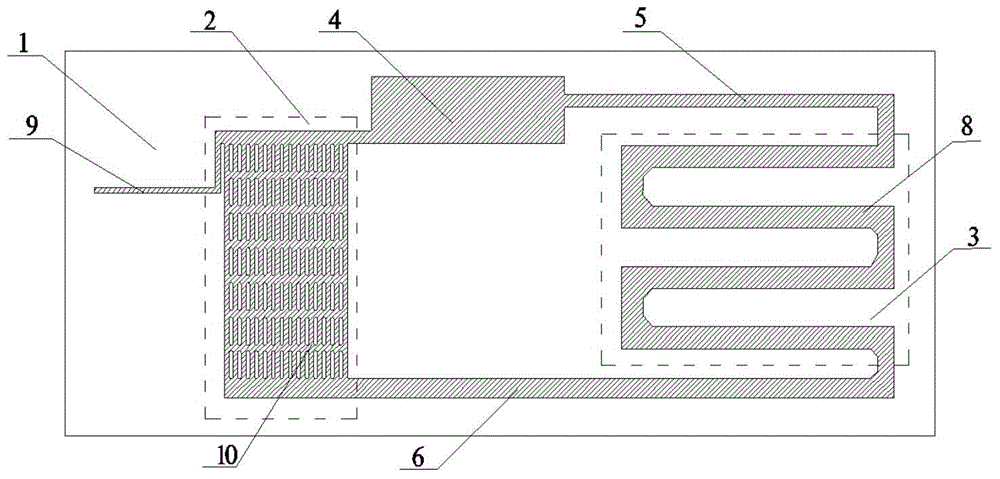

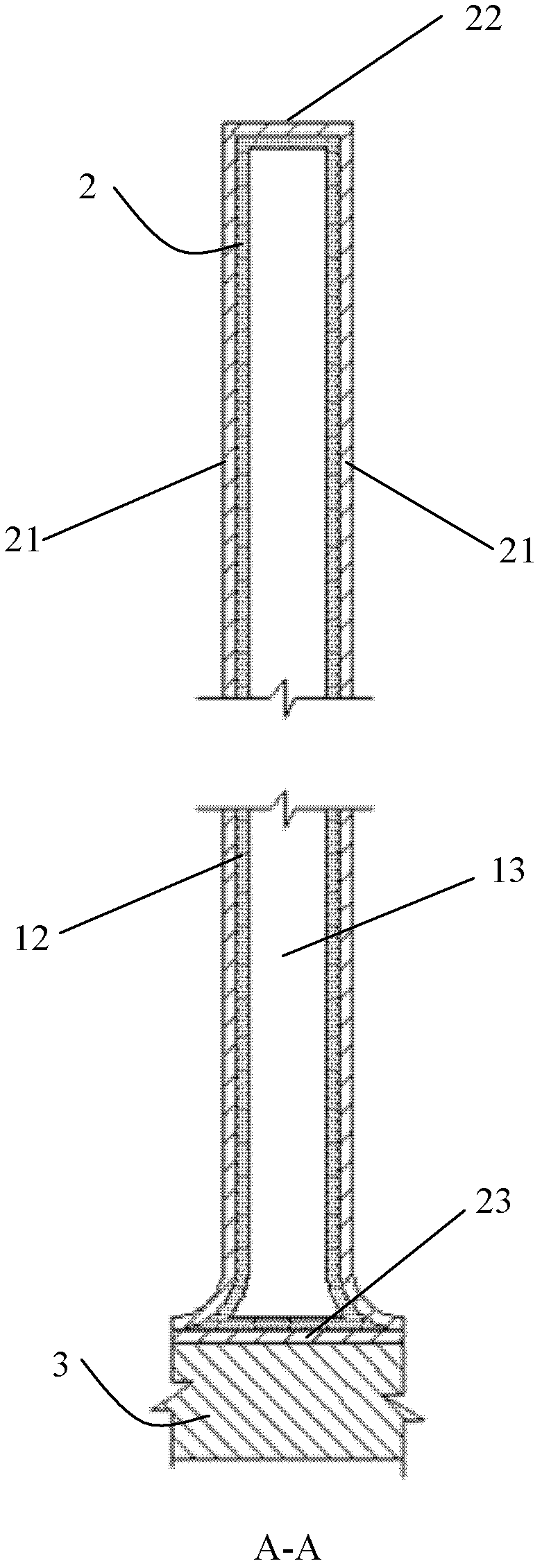

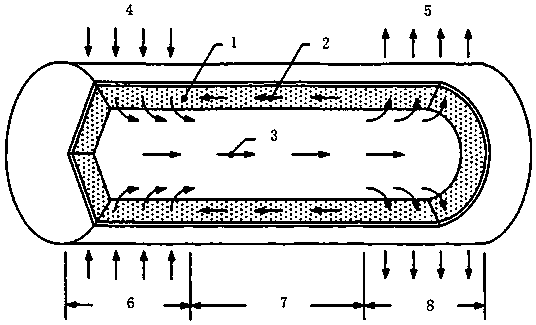

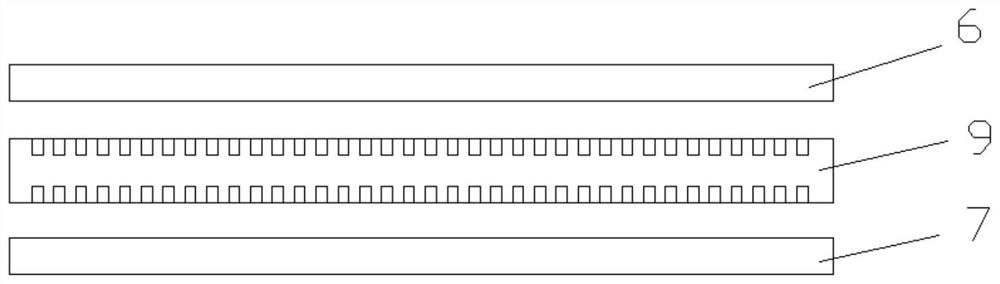

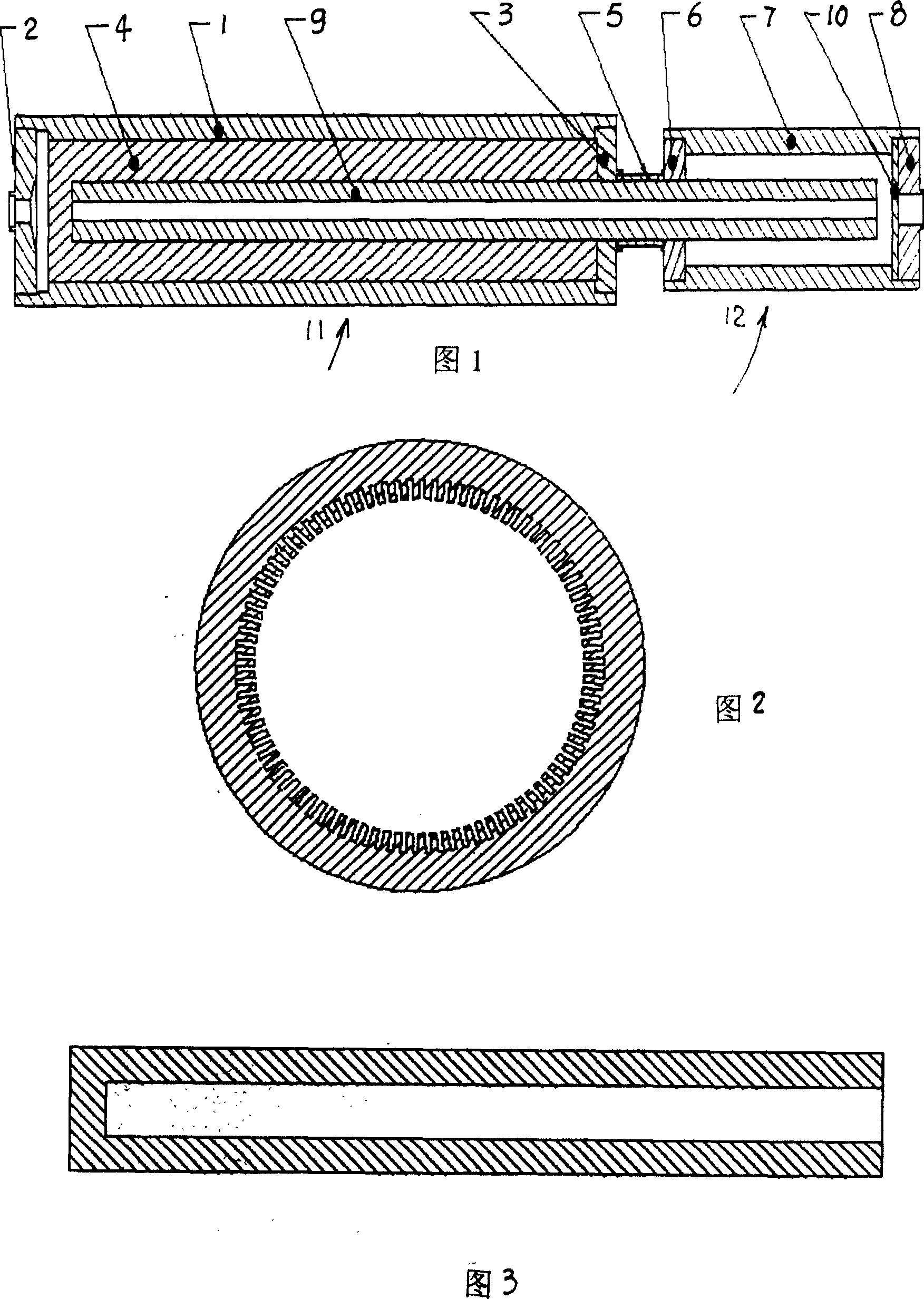

Micro silicon-based capillary pump loop cooler

InactiveCN105161473AImprove cooling effectImprove carrying capacityDecorative surface effectsSemiconductor/solid-state device detailsGlass chipSilicate glass

The invention relates to a micro silicon-based capillary pump loop cooler. The micro silicon-based capillary pump loop cooler is characterized by comprising a pair of semiconductor silicon chips and heatproof boron silicate glass which are bonded, wherein a surface of the silicon chip (1) contacting with the boron silicate glass is etched with an evaporator (2), a condenser (3), a vapor phase channel (4), a liquid phase channel (5), a liquid storage chamber (6) and a silicon chip vacuum-pumping / liquid injection channel (9), a vacuum-pumping / liquid injection hole (12) is processed on the boron silicate glass (11), the evaporator (2) and the condenser (3) are respectively arranged at two ends of the silicon chip (1) and are mutually communicated through the vapor phase channel (4) and the liquid phase channel (5) to realize heat exchange, the liquid storage chamber (6) is communicated with a liquid inlet of the evaporator (2), and the silicon chip vacuum-pumping / liquid injection channel (9) is communicated with vacuum-pumping / liquid injection hole (12) processed on the boron silicate glass (11). The micro silicon-based capillary pump loop cooler has advantages of simple structure, convenient manufacturing and good heat radiation effect.

Owner:江苏中圣压力容器装备制造有限公司

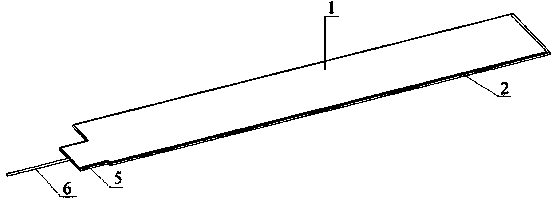

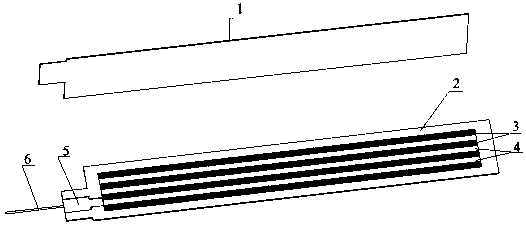

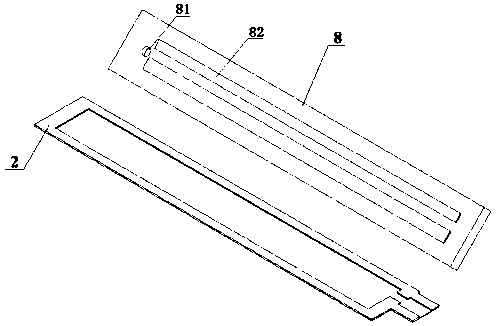

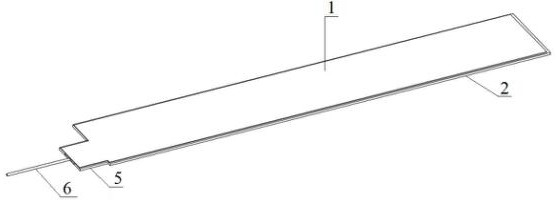

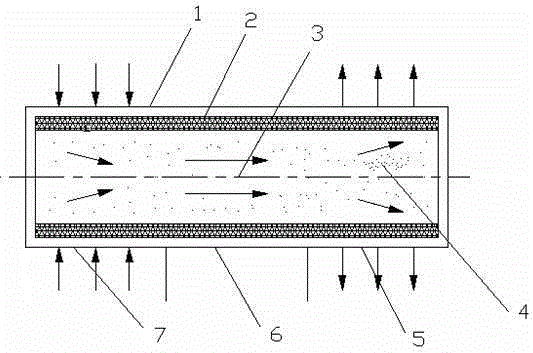

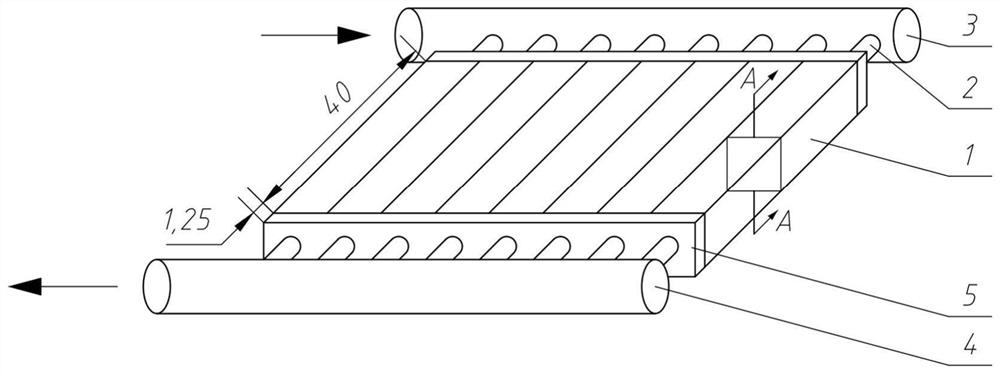

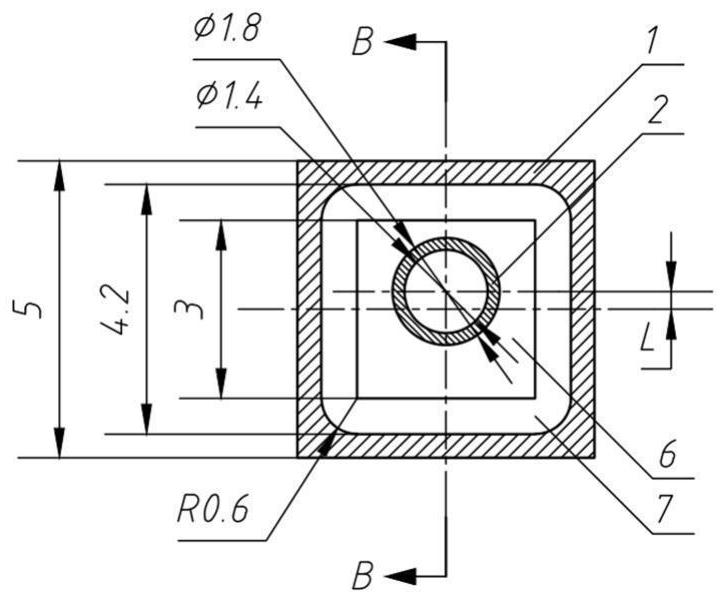

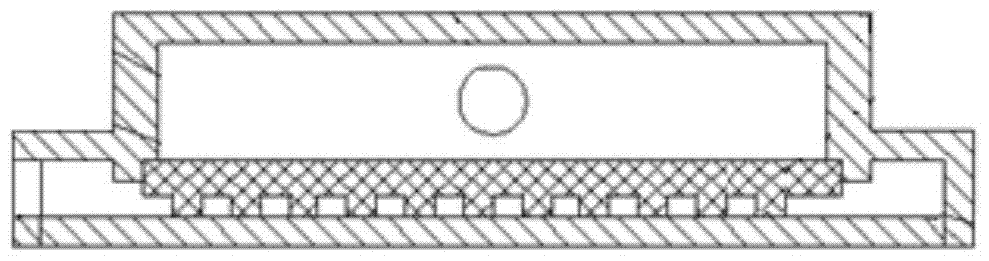

Ultra-thin flat heat pipe and manufacturing process thereof

ActiveCN109443060AIncrease heat transfer limitPrevent collapseIndirect heat exchangersMiniaturizationProcess engineering

The invention relates to the technical field of heat dissipating devices, in particular to an ultra-thin flat heat pipe and a manufacturing process thereof. A bottom plate and a cover plate which arebuckled and packaged are included, the bottom plate is provided with a cavity internally provided with a plurality of capillary structures arranged in parallel, gas flow channels for a heat pipe working medium to flow therein is formed between the adjacent capillary structures, and each capillary structure includes a plurality of liquid flow channels arranged in parallel. A gas working medium flows in the gas flow channels, and a liquid working medium flows in the capillary structures, so that gas-liquid separation of the working media is achieved, the flow resistance is reduced, and the heattransfer limit of the heat pipe is increased; and the ultra-thin flat heat pipe is simple in structure and easy to manufacture, can realize industrial production line production, has strong heat transfer capacity, is small in thickness of heat pipe, can meet the requirement for heat dissipation of electronic devices in a narrow space, meets the needs of integration and miniaturization of electronic components, and has good practicability and applicability .

Owner:GUANGDONG UNIV OF TECH

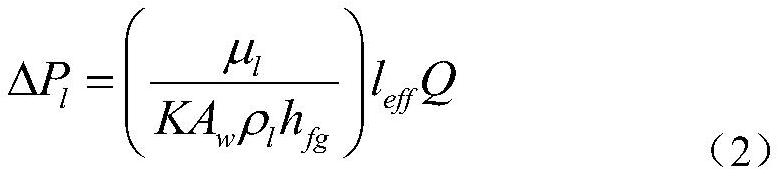

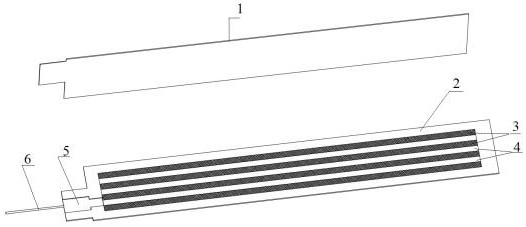

Ultra-thin flat panel heat pipe and manufacturing method thereof

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

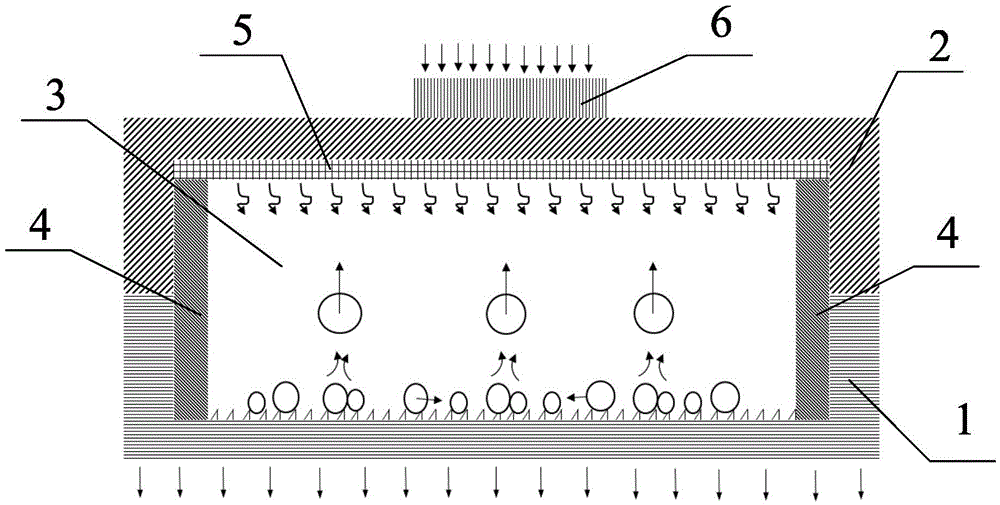

Phase change heat dissipation device

PendingCN109612314ASmall temperature differenceDiffusion fastIndirect heat exchangersModifications using liquid coolingPositive pressureWorking temperature

The invention discloses a phase change heat dissipation device which comprises a phase change component, wherein a phase change heat exchange medium is arranged in the phase change component, when thephase change heat exchange medium arranged in the phase change component is configured to a work state of the phase change heat dissipation device, the atmospheric pressure in the phase change component is more than 0.15MPa. When the phase change heat dissipation device is at work, the work temperature range is 30-80 DEG C, internal pressure is far larger than a standard atmospheric pressure, under a positive pressure non-vacuum environment, heat-flow density of a heating source is large, absolute pressure of a phase change component evaporation part is high, relative pressure difference of different parts of the phase change component under the same temperature difference condition is large, and more phase change mediums can be driven by the pressure difference so as to reinforce the heat exchange ability. With adoption of the phase change heat dissipation device, the mobility of the internal phase change heat exchange medium is improved, the heat-flow density of heat transfer is improved, and efficient heat dissipation is easily realized.

Owner:ZHUZHOU ZHIRE TECH

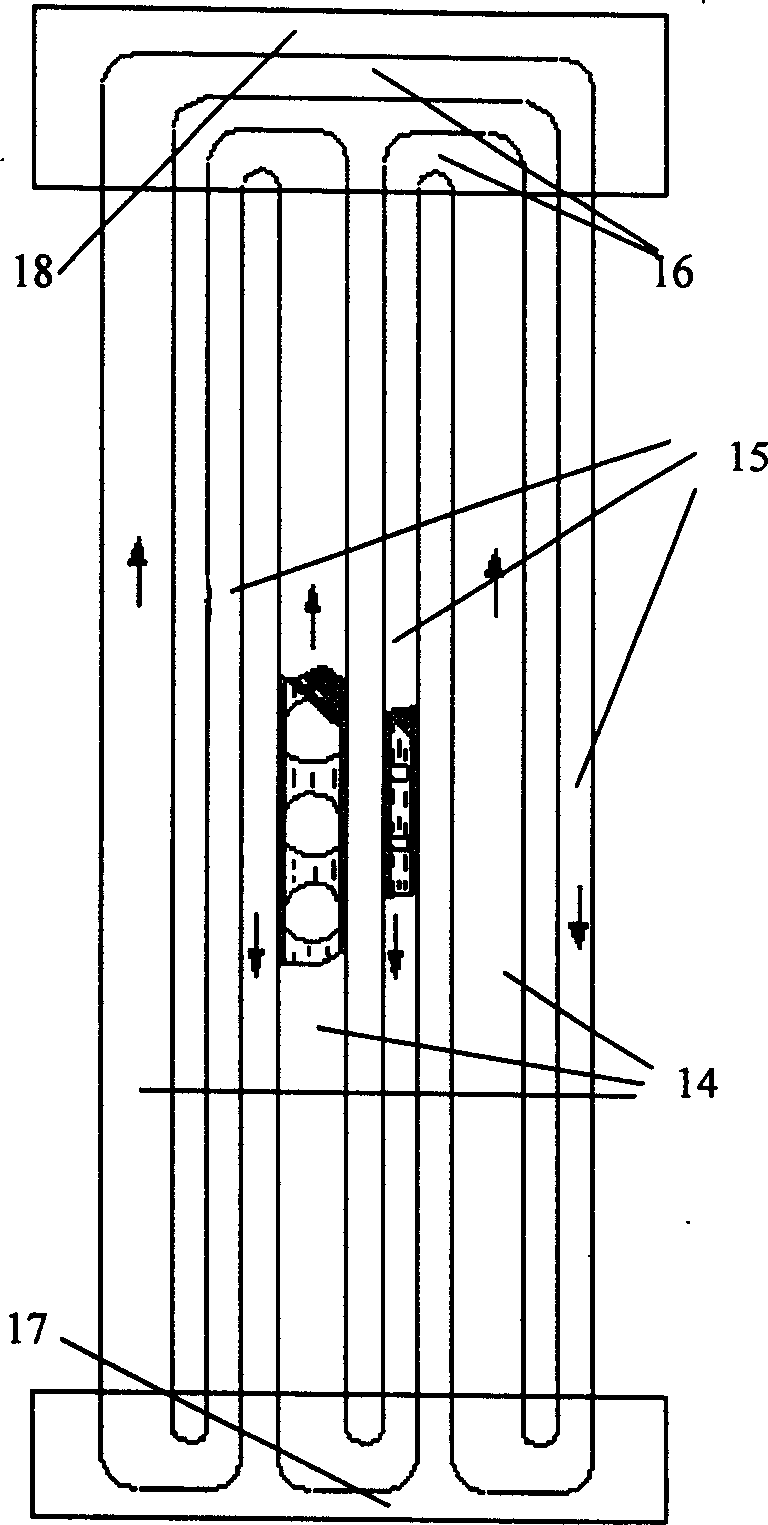

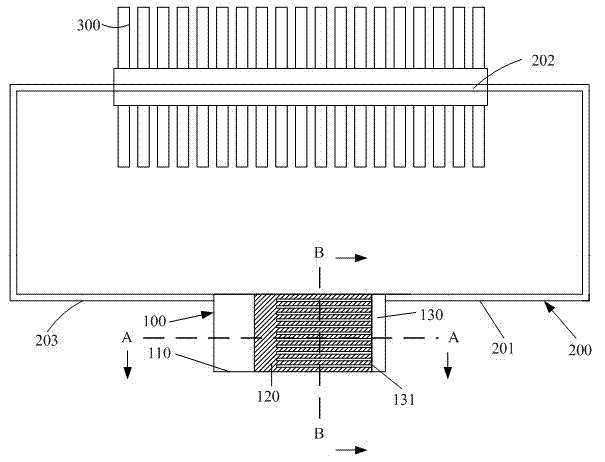

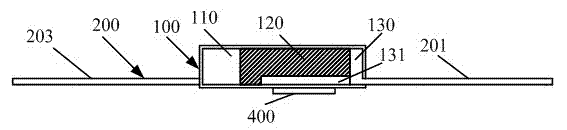

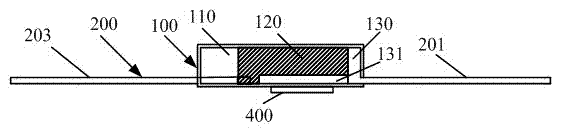

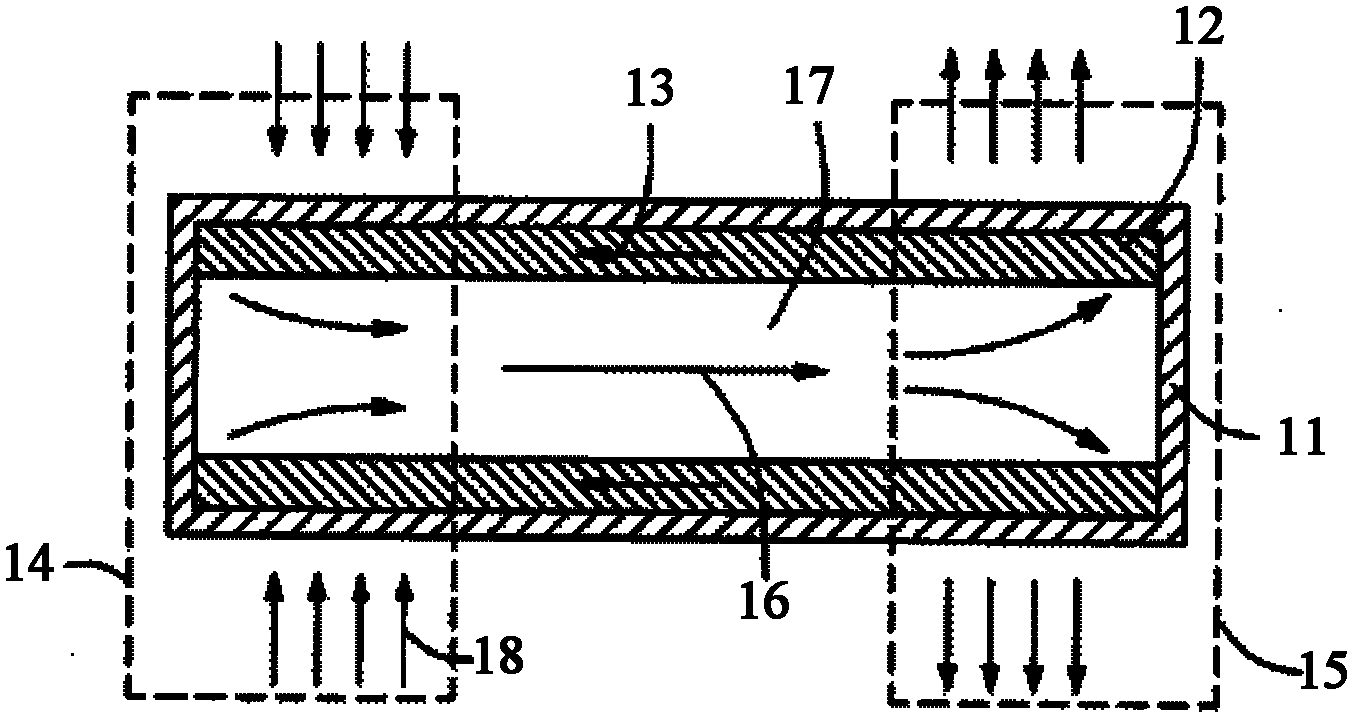

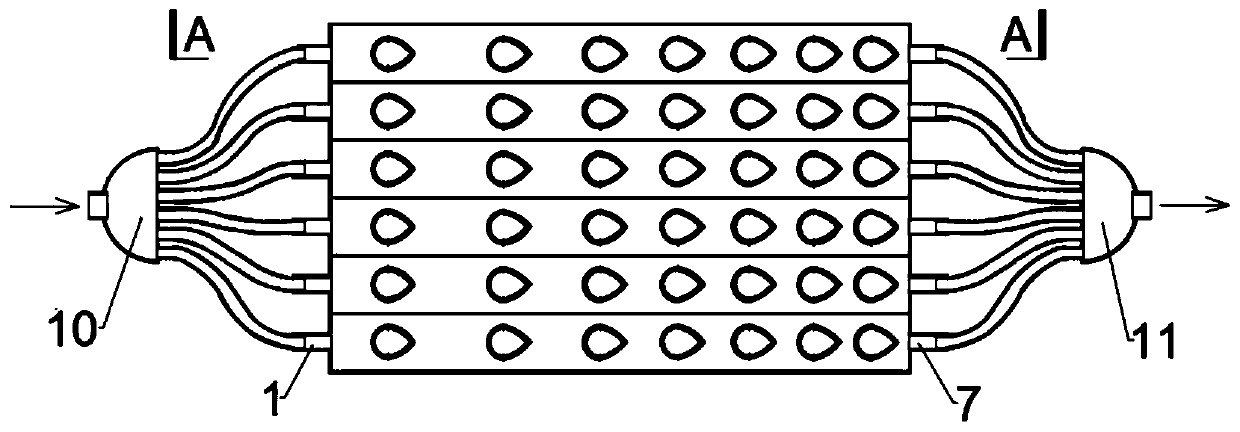

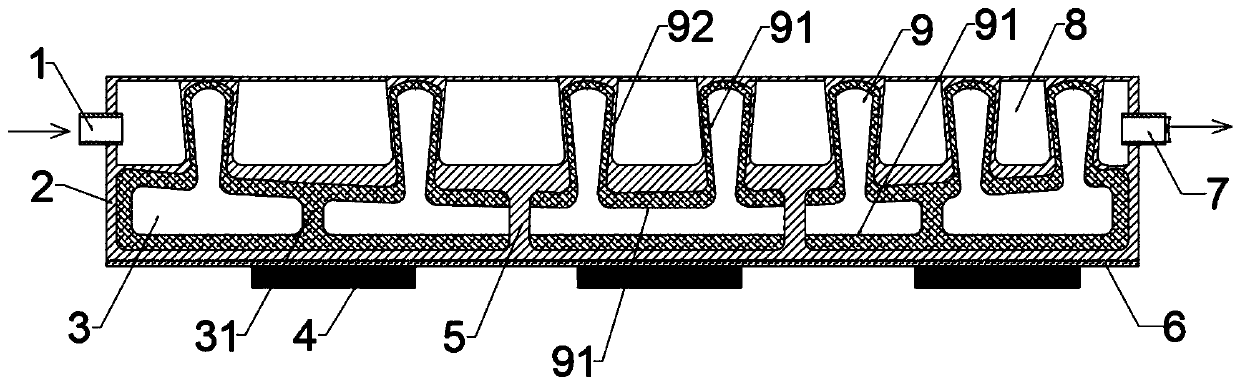

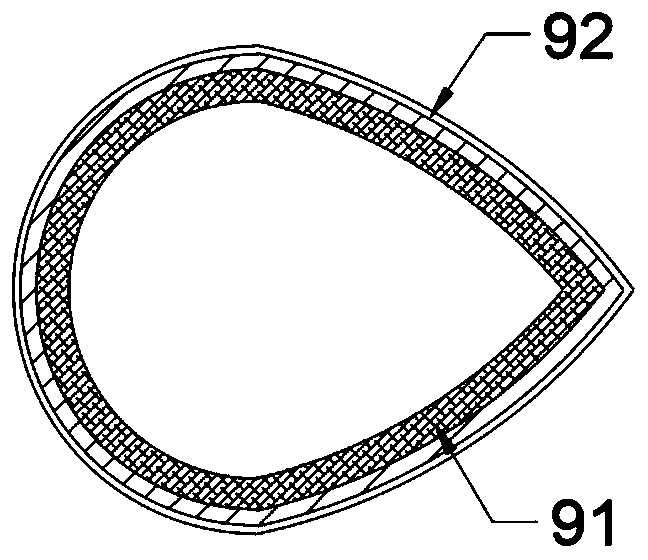

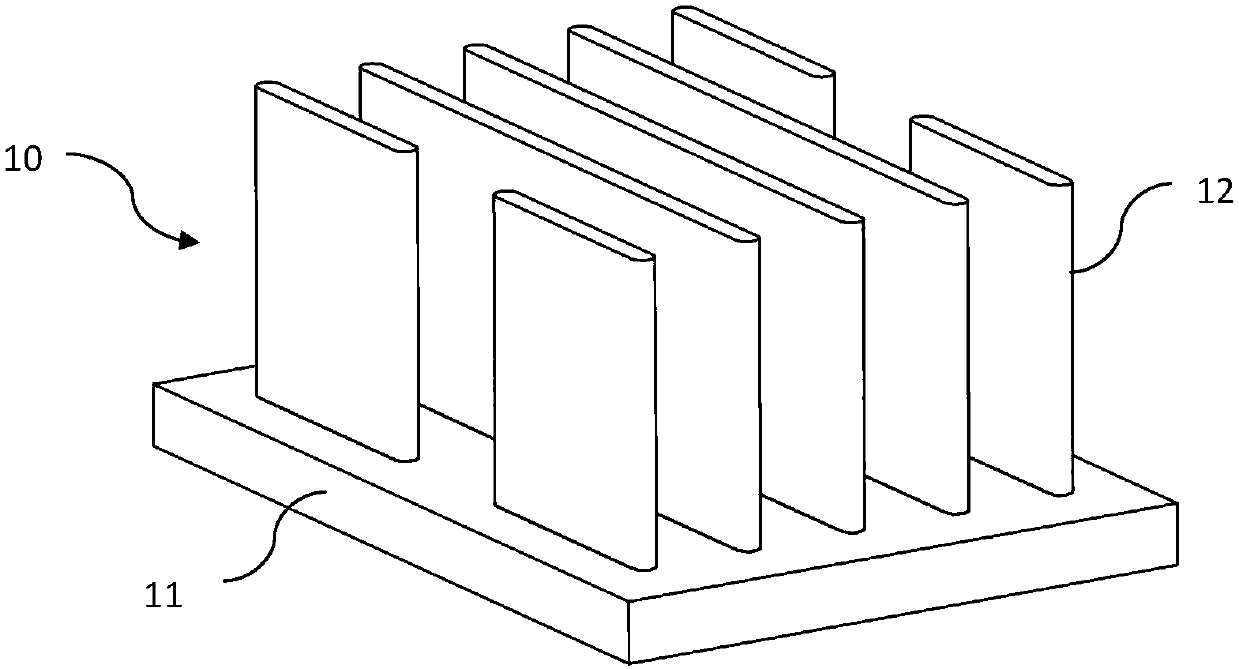

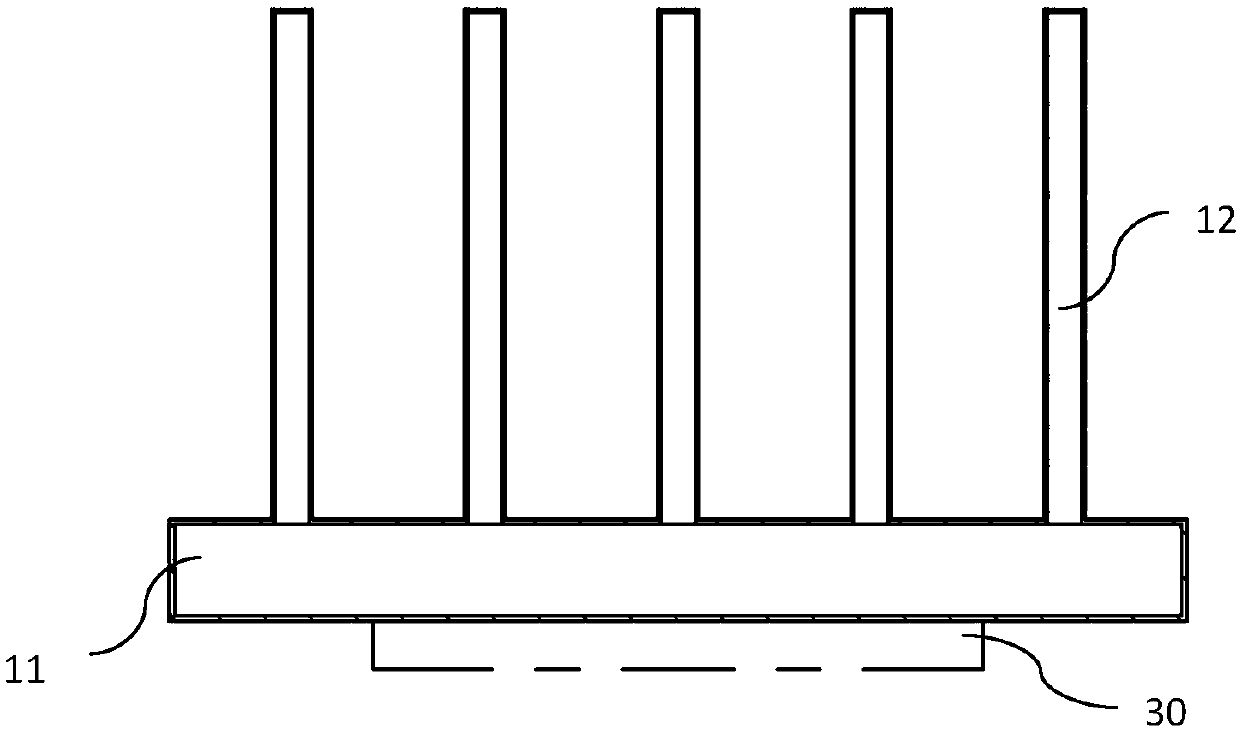

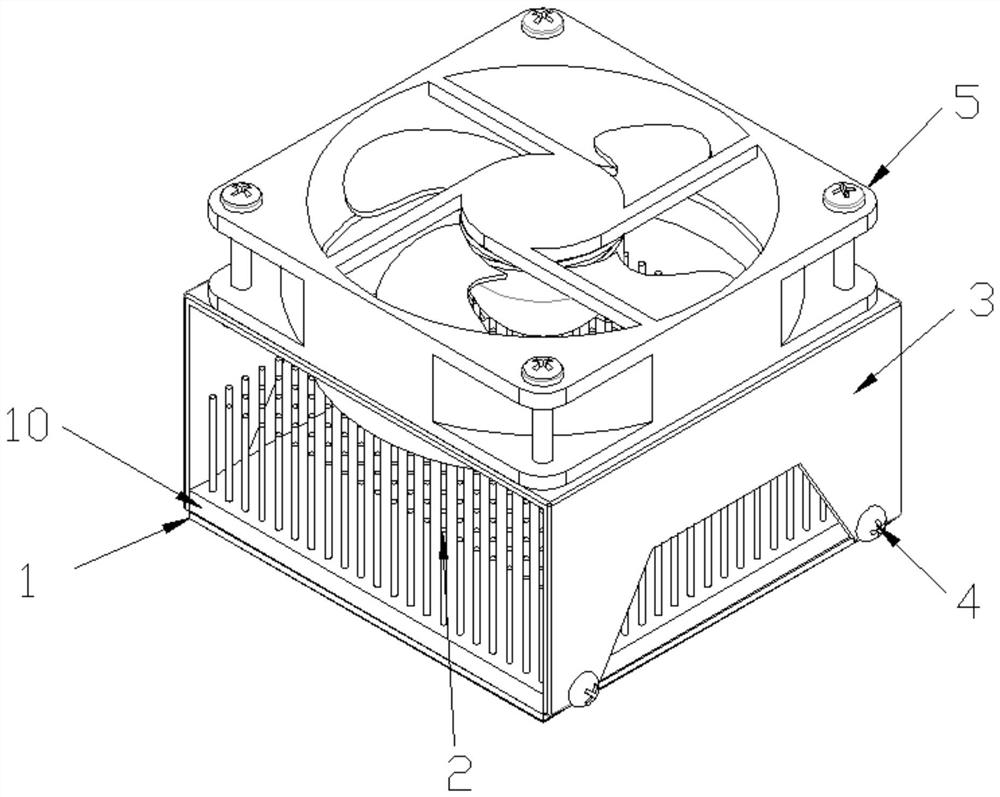

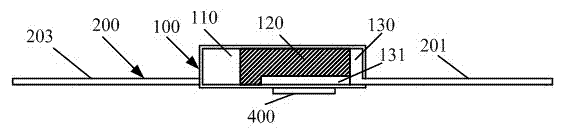

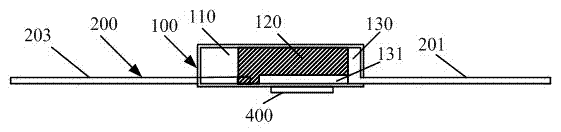

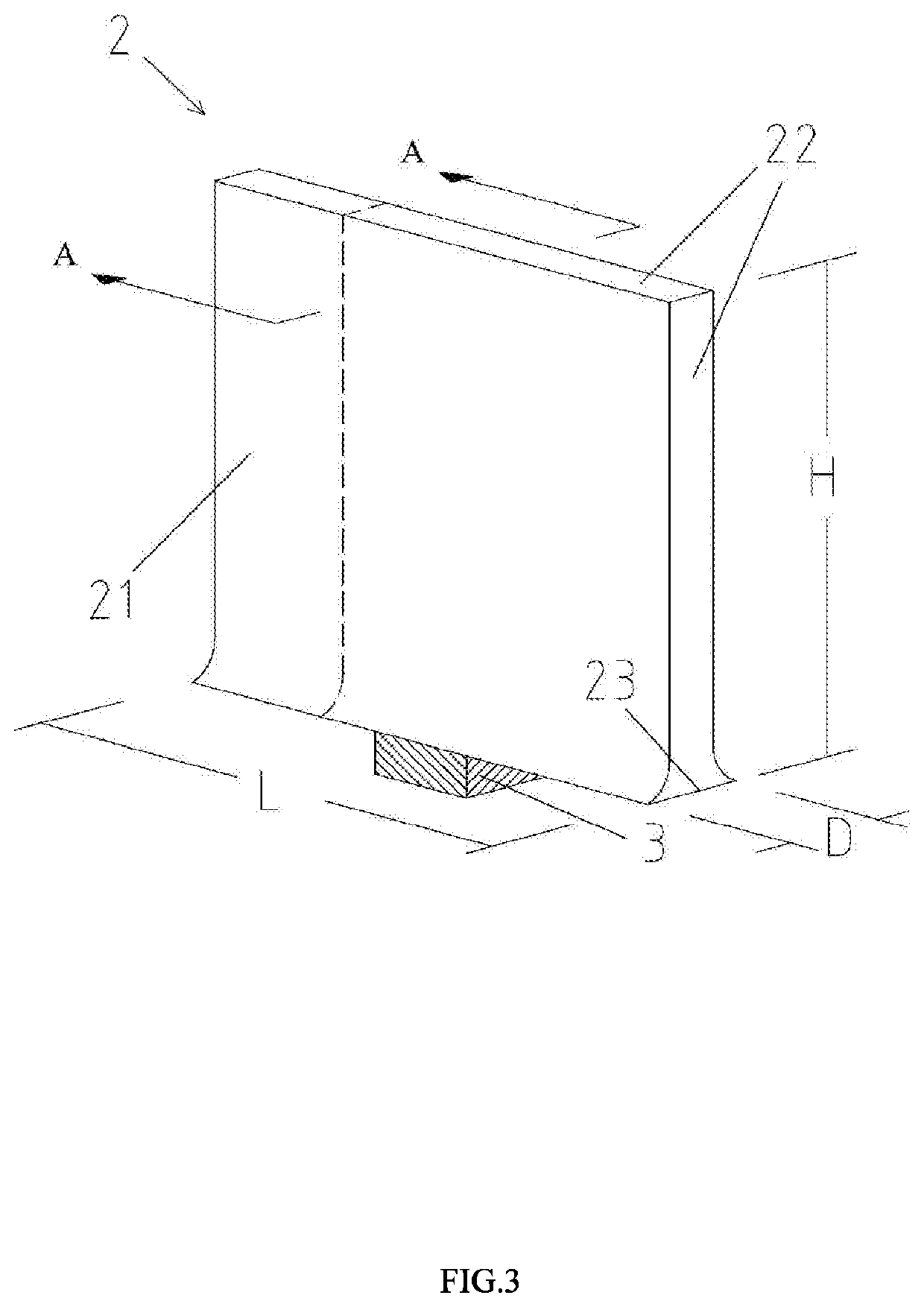

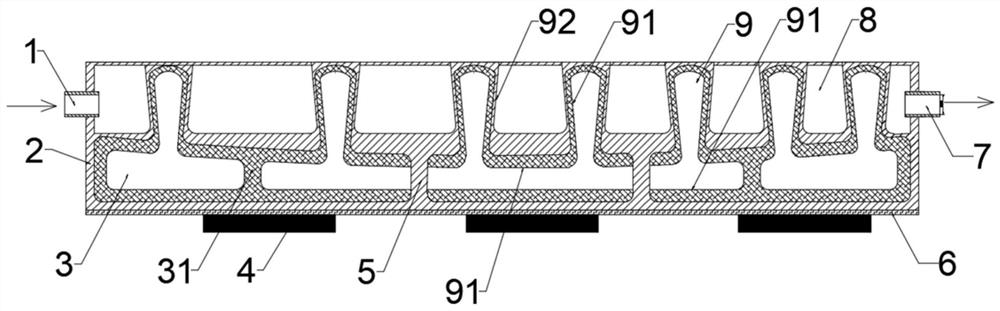

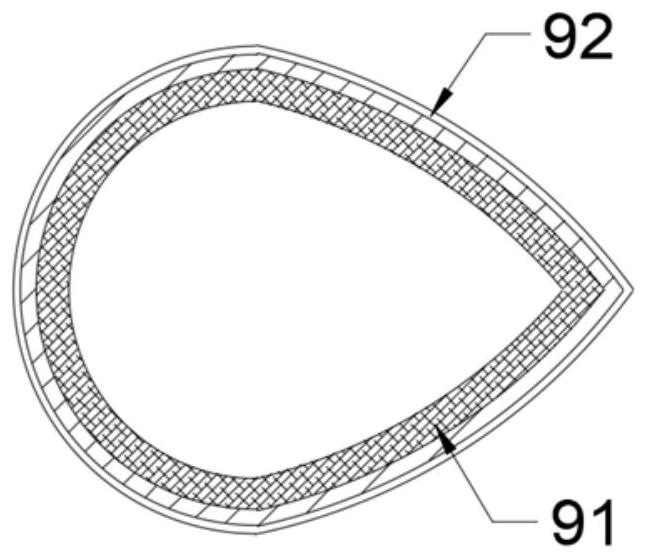

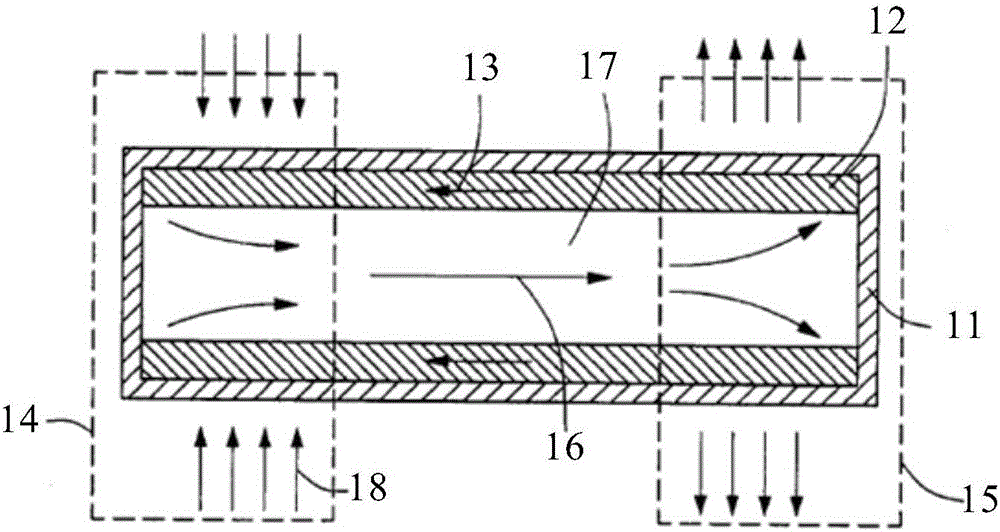

Circulation radiator, and manufacturing method and components thereof

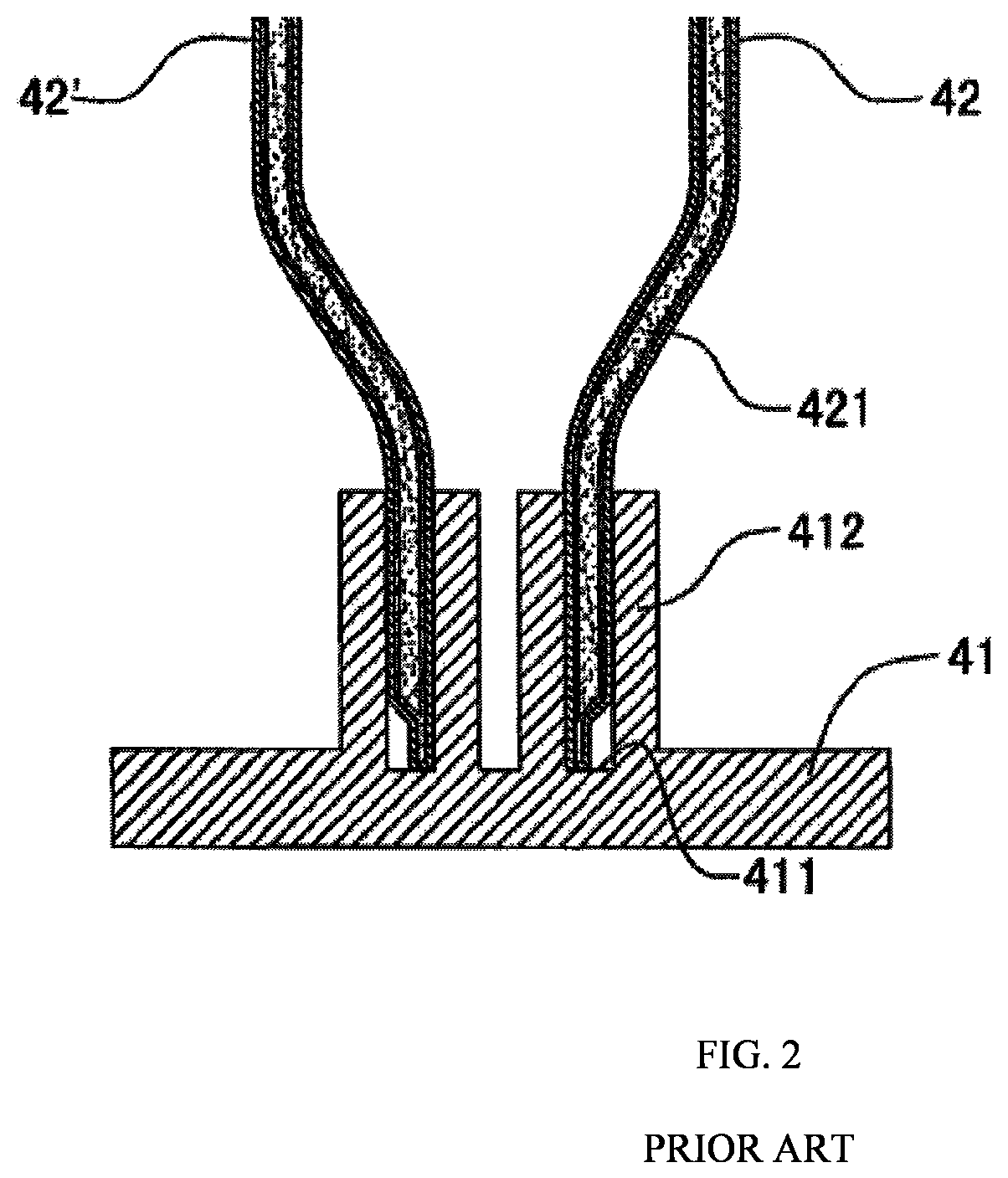

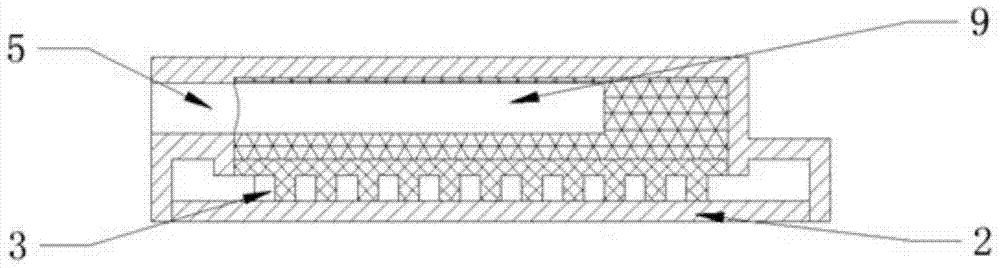

ActiveCN102208375AAvoid deformationNot easy to damageSemiconductor/solid-state device detailsSolid-state devicesVapor liquidWorking fluid

The invention discloses a circulation radiator, and a manufacturing method and components thereof. The components of the circulation radiator comprise a pipeline, a heat dissipation mechanism and a vapor-liquid cavity; the heat dissipation mechanism is contacted with the pipeline, a capillary structure is arranged in the vapor-liquid cavity; the vapor-liquid cavity is divided into a liquid storage cavity and an evaporation cavity by the capillary structure; one end of the pipeline is connected with the evaporation cavity; the other end of the pipeline is connected with the liquid storage cavity or the capillary structure; the evaporation cavity comprises at least one steam channel; and the pipeline and the vapor-liquid cavity provide a low-pressure hermetic sealed channel. Compared with the prior art which employs one evaporation cavity, the invention has the advantages that: the whole capillary structure has stronger supporting force, so that the whole vapor-liquid cavity is difficult to deform and damage under the conditions of high temperature and high pressure; the evaporation cavity consisting of a plurality of the steam channels facilitates the evaporation of liquid in the evaporation cavity, so that vapor can reach a longer distance, heat dissipation of the long distance can be realized, a heat transfer limit based on the single-way circular flow of working fluid is greatly increased; and under the condition of the same heat dissipation and transfer capability, the vapor-liquid cavity provided by the scheme has lesser thickness, so that the volume of the radiator is reduced.

Owner:锘威科技(深圳)有限公司

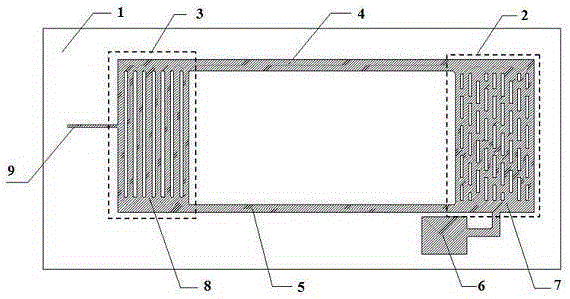

Silicon-based miniature loop heat pipe cooler

InactiveCN104406440ASafe and reliable working performanceReduce and balance temperature differencesIndirect heat exchangersClosed loopBorosilicate glass

The invention provides a silicon-based miniature loop heat pipe cooler, which comprises a semiconductor silicon wafer and a heat-resisting borosilicate glass sheet which are bonded together; an evaporator, a condenser, a liquid compensator, a liquid-phase channel, a vapor-phase channel and a vacuumizing / liquid injection micro-channel are etched on the surface, in contact with the borosilicate glass sheet, of the silicon wafer; two ends of the evaporator and two ends of the condenser are connected respectively through the liquid-phase channel and the vapor-phase channel to form a closed loop; a liquid storage cavity is arranged on the liquid-phase channel; the evaporator comprises small conduits; the condenser comprises a condensation serpentine channel; the evaporator is communicated with the vacuumizing / liquid injection micro-channel; a vacuumizing / liquid injection hole which can be communicated with the vacuumizing / liquid injection micro-channel is processed in the borosilicate glass sheet. The silicon-based miniature loop heat pipe cooler provided by the invention can be directly integrated with a semiconductor microelectronic chip, and therefore the temperature and the temperature gradient of the chip are effectively reduced, the 'hotspot' problem caused by local high heat flow is reduced and weakened, and the safe and reliable operation of the chip is ensured.

Owner:JIANGSU UNIV

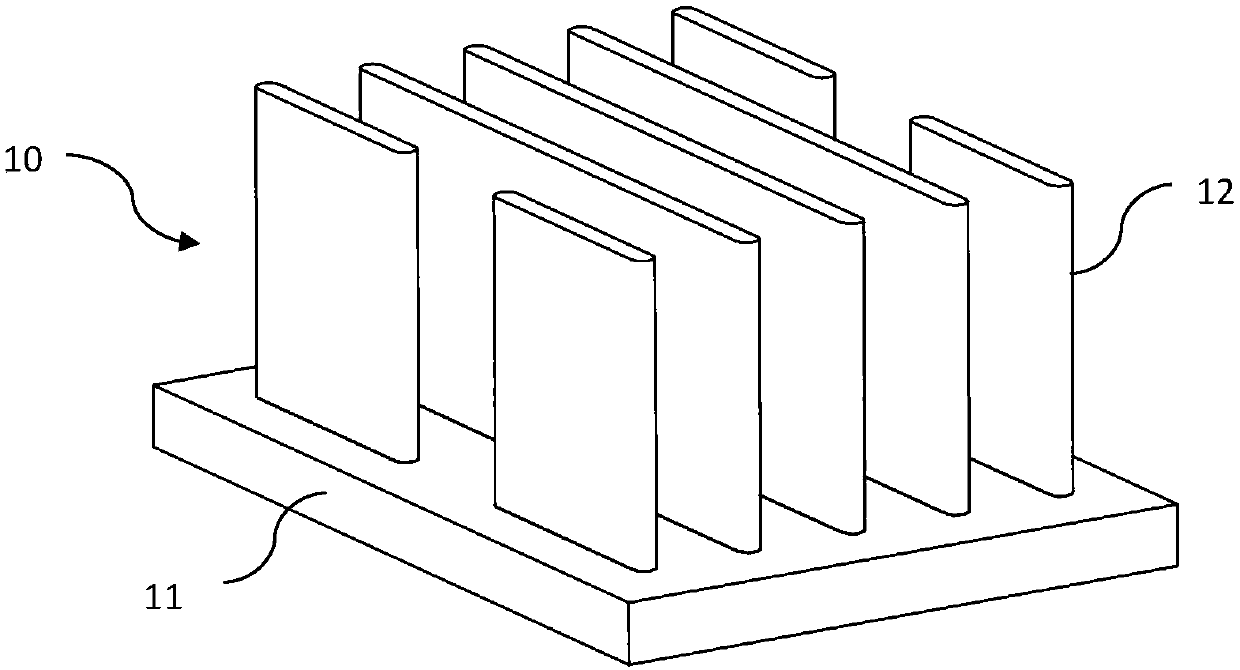

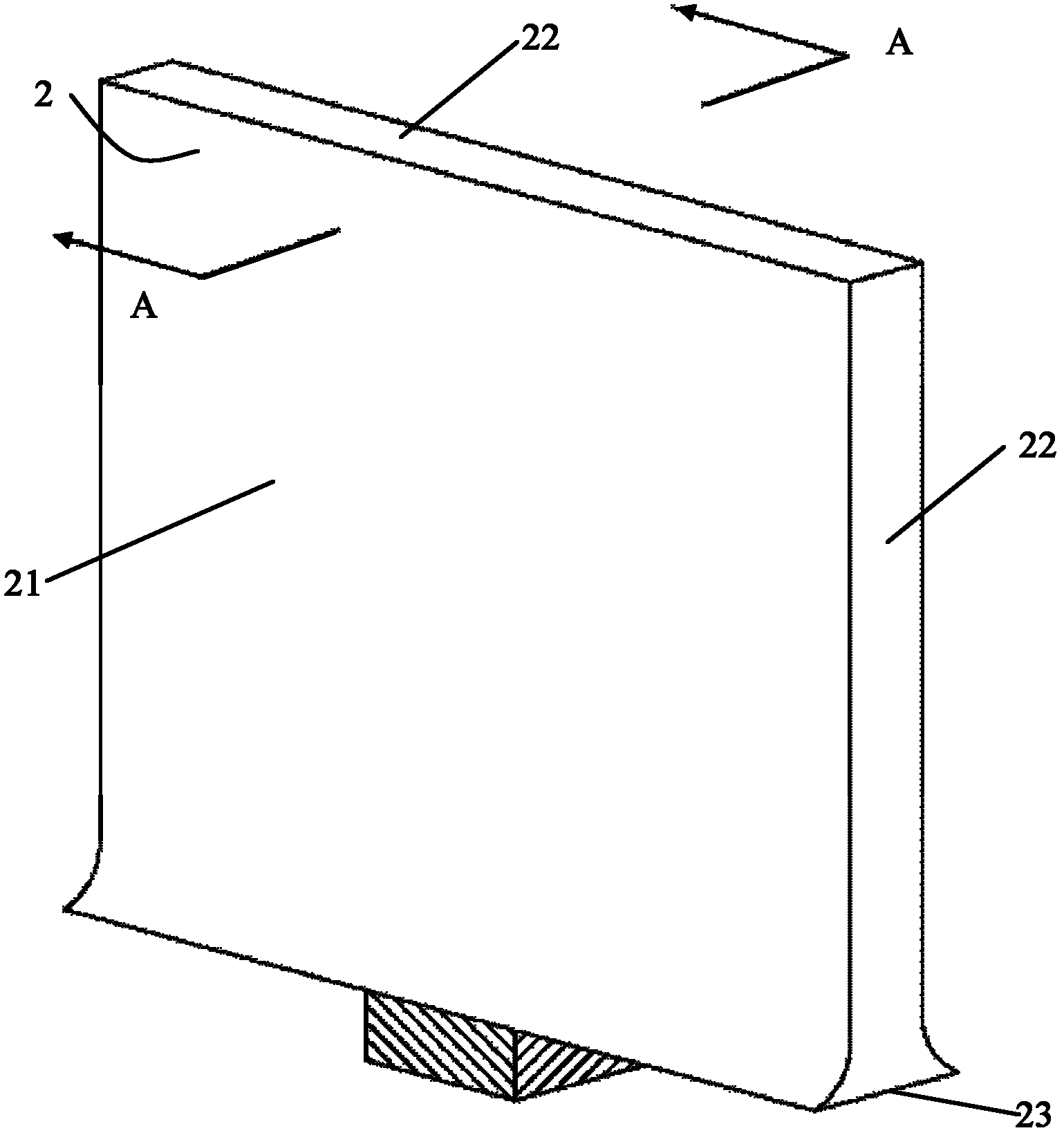

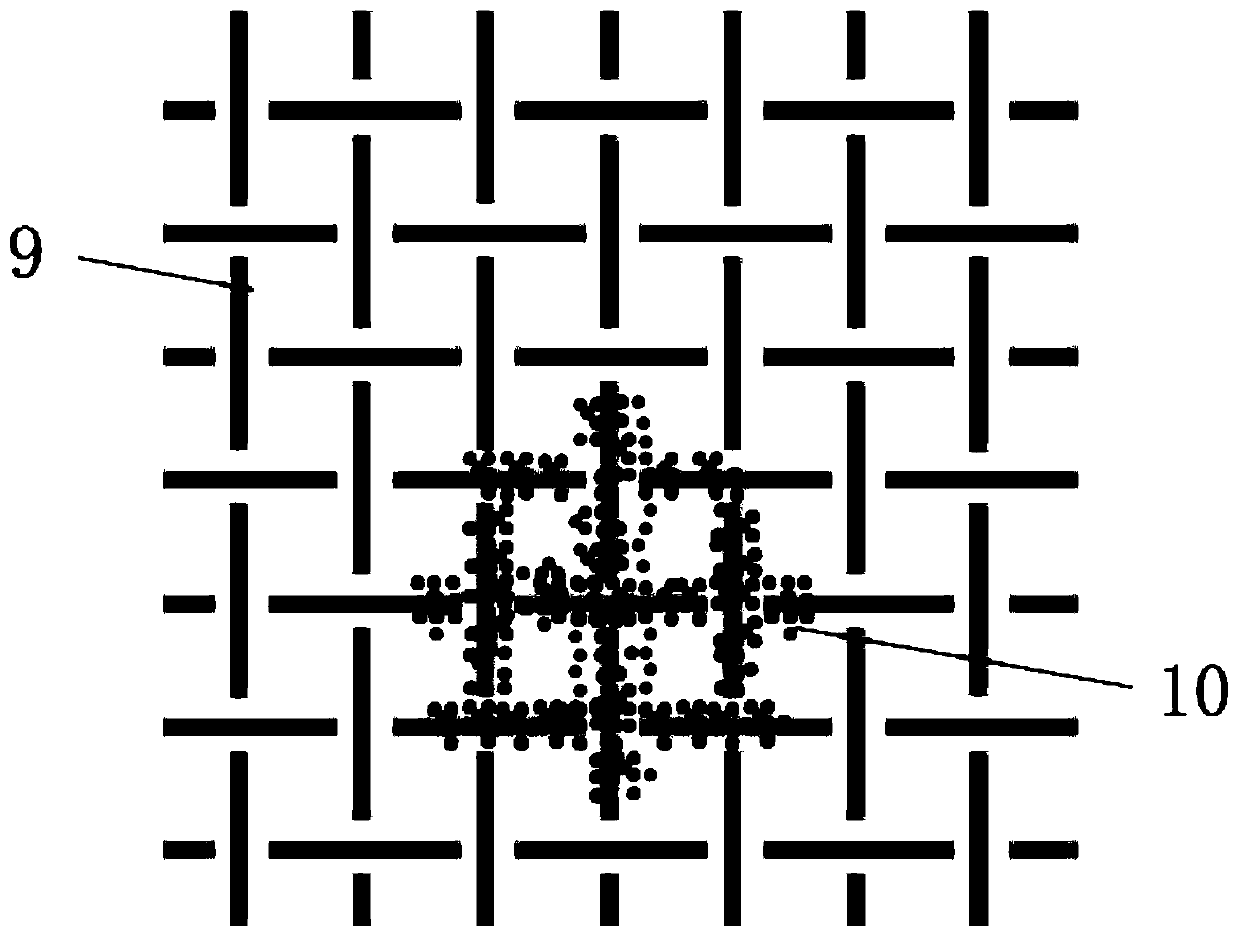

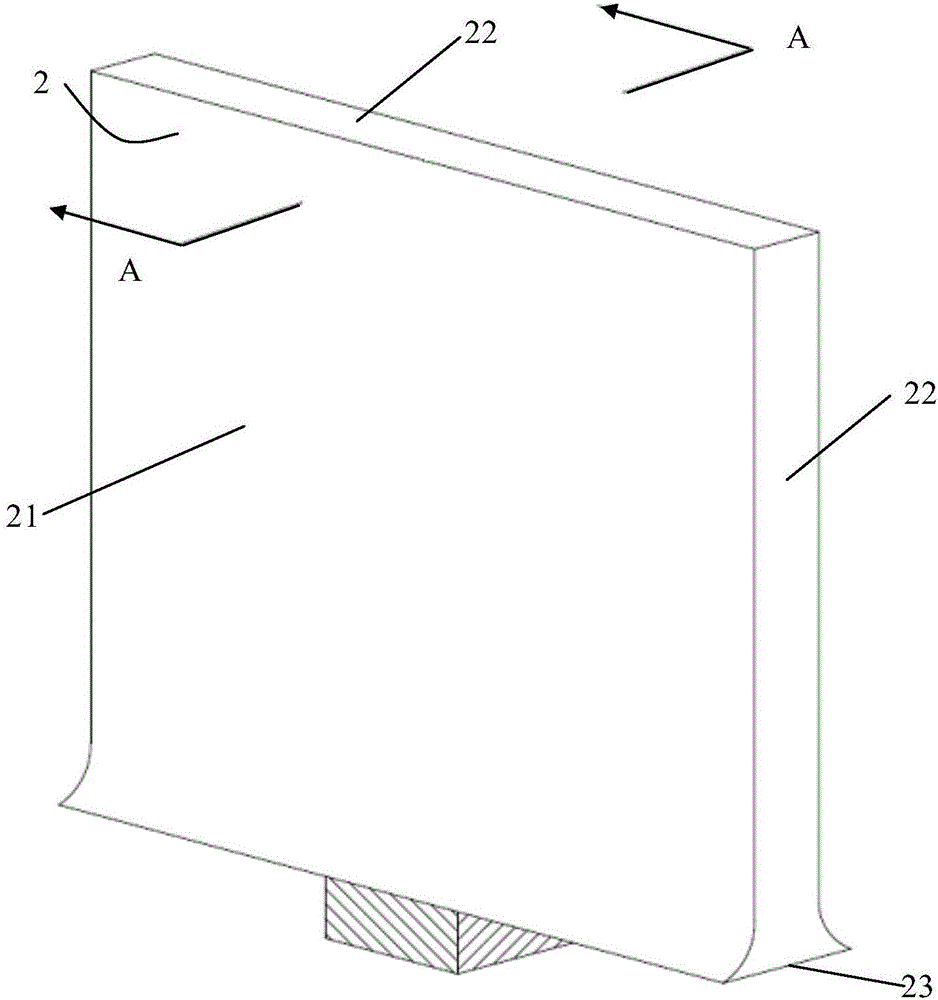

Heat fin

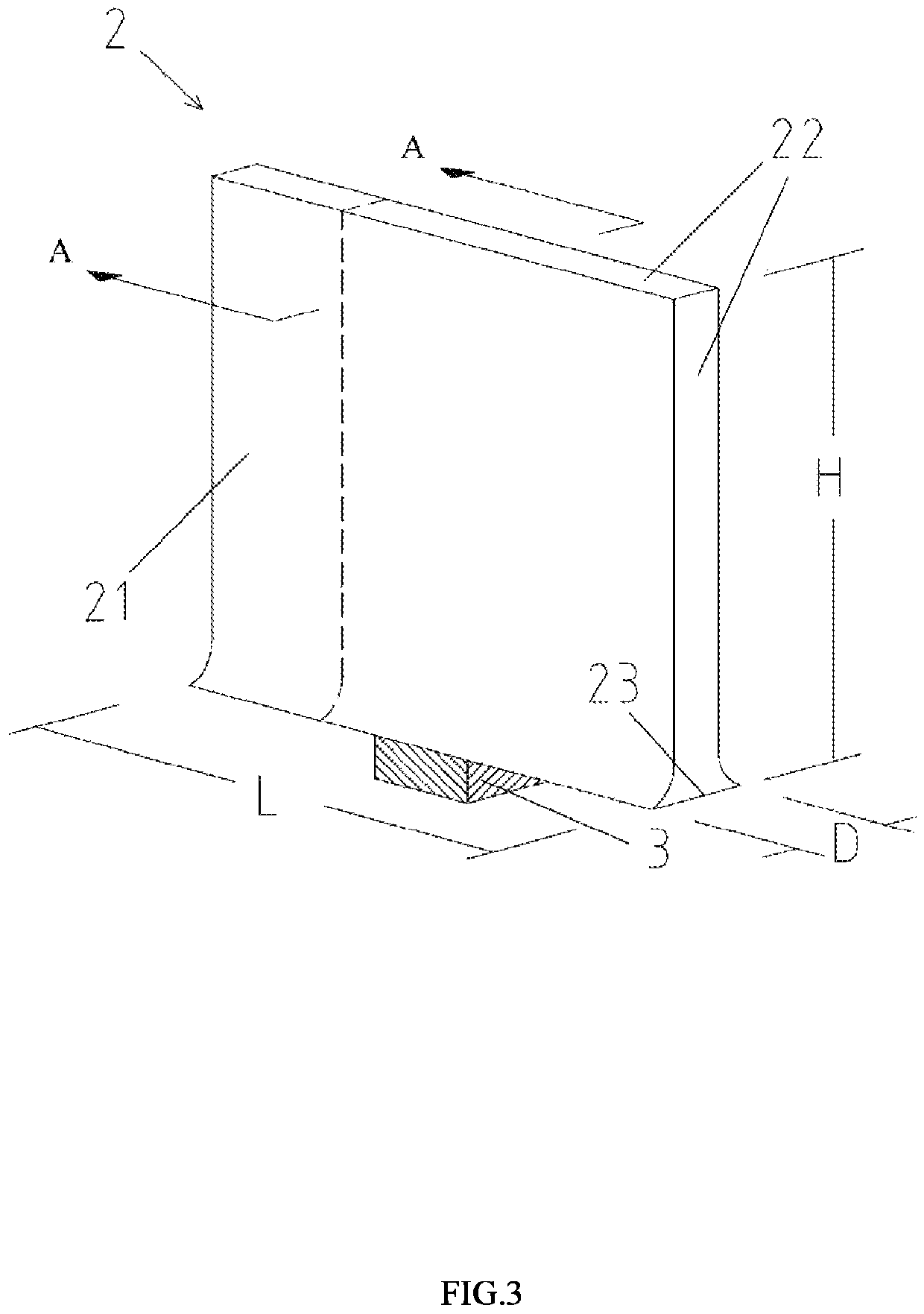

InactiveCN103217036AWide reflow widthAvoid premature dryingIndirect heat exchangersHeat flowEvaporation

The invention discloses a heat fin, which comprises two side panels, a frame for connecting the two side panels, a capillary structural layer and a phase changing working medium, wherein the two side panels and the frame form a hollow thin-plate shell; the capillary structural layer is closely attached onto the inner wall of the shell; the phase changing working medium is sealed in the shell; a local part of the edge of each side panel or a local part of the frame is used as an evaporation area, and the rest part of each side panel or the rest part of the shell is used as a condensation area. Due to the adoption of the heat fin, the area of a steam conveying passage, the reflux width of the liquid working medium and the direct heat radiation area of the condensation area are increased, the distance from the center of the evaporation area to the edge of the evaporation area is shortened, the heat conduction limit is greatly improved, and a higher heat flow density is obtained.

Owner:张跃

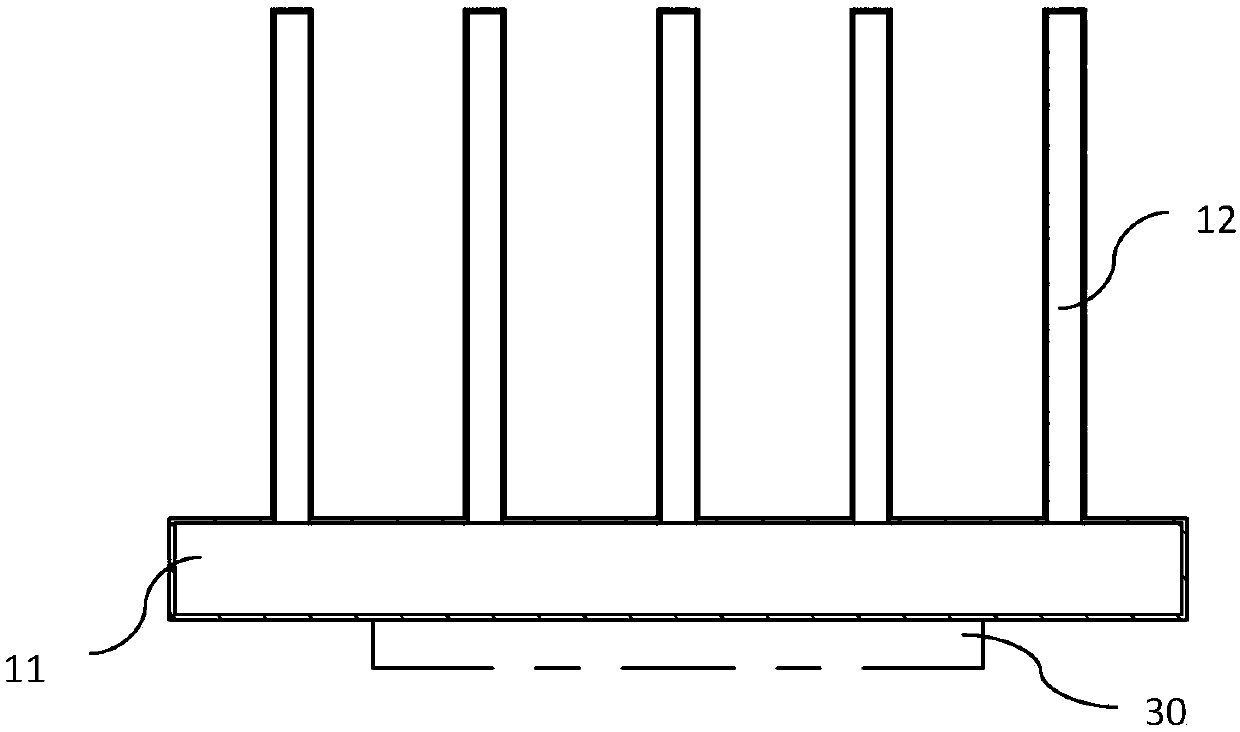

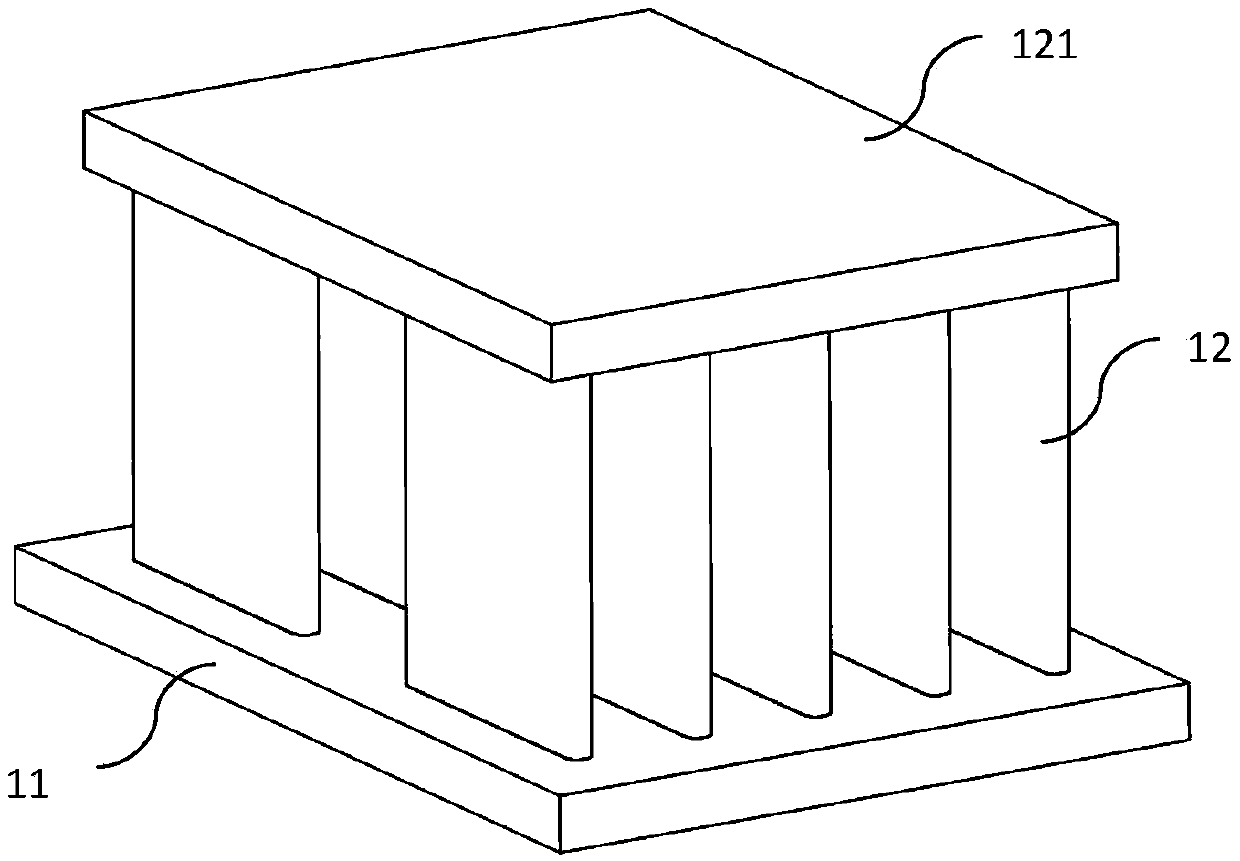

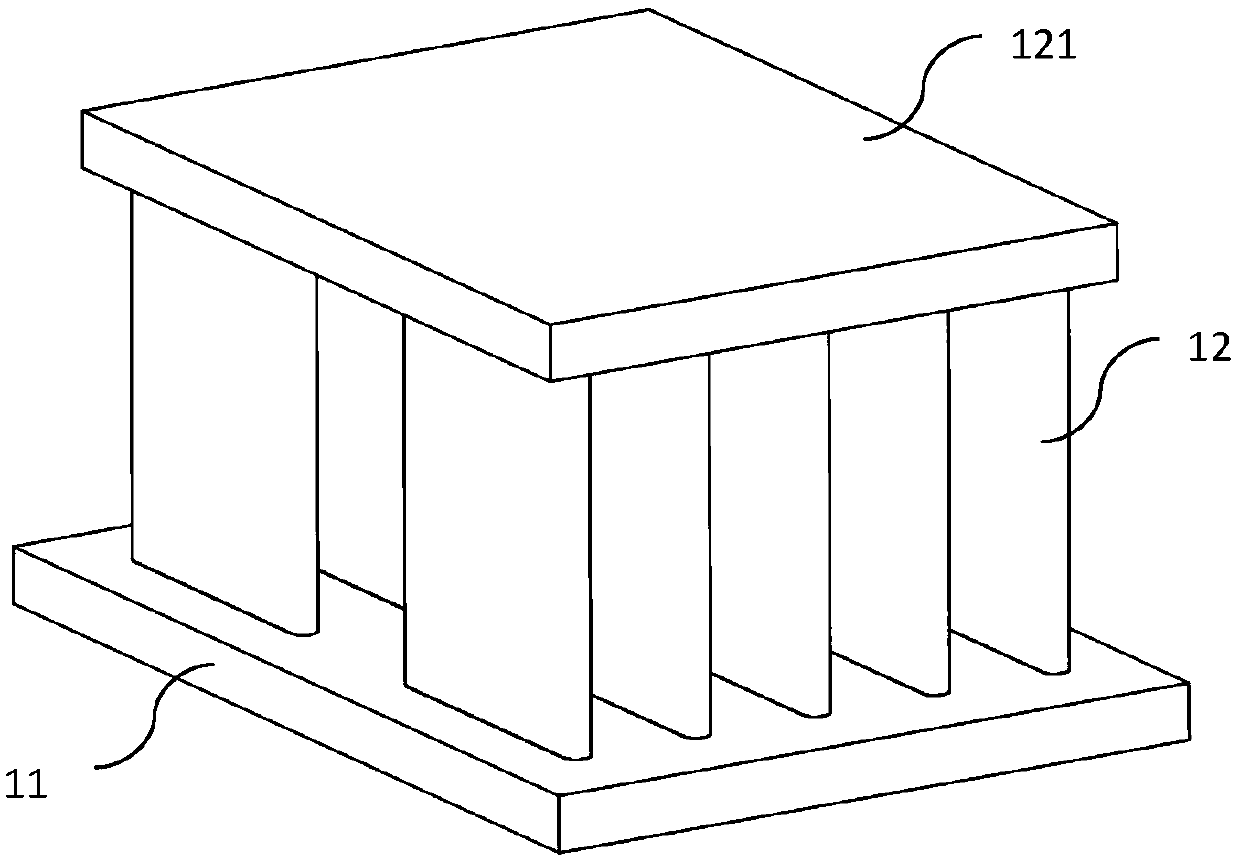

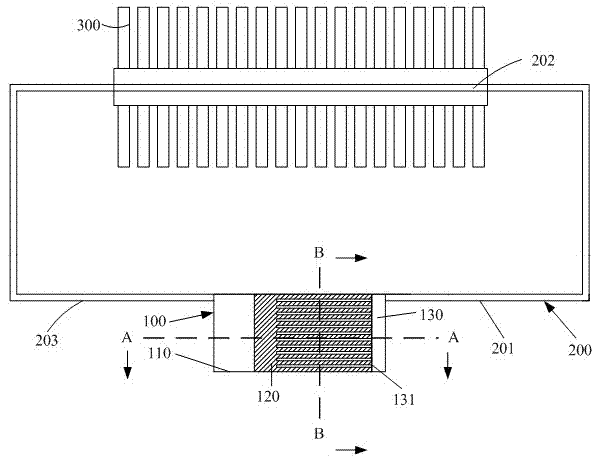

Composite liquid-cooling heat pipe radiator

ActiveCN111083911AImprove cooling effectIncrease cooling areaSemiconductor/solid-state device detailsSolid-state devicesRefrigerantCooling fluid

The invention belongs to the technical field of heat transfer, and particularly relates to a composite liquid-cooling heat pipe radiator. The composite liquid-cooling heat pipe radiator comprises a flat plate heat pipe, wherein heat generated by a heating component is transferred to a bottom plate of the flat plate heat pipe, a top plate of the flat plate heat pipe is provided with protrusions perpendicular to the bottom plate of the flat plate heat pipe, the protrusions form a tubular heat pipe, and an inner cavity of the flat plate heat pipe is communicated with an inner cavity of the tubular heat pipe. The composite liquid-cooling heat pipe radiator further comprises a shell. The flat plate heat pipe and the tubular heat pipe are both located in the shell, and the bottom plate of the flat heat pipe is attached to the bottom surface of the shell in a sealed mode; an area defined by the outer surface of the flat plate heat pipe, the outer surface of the tubular heat pipe and the innerwall of the shell forms a cooling liquid channel; and the shell is provided with a cooling liquid inlet and a cooling liquid outlet. According to the radiator, the tubular heat pipe is combined withthe flat plate heat pipe, so that the radiator can be attached to a flat surface of the heating component and has a good radiating effect; and meanwhile, heat released by a refrigerant of a condensation section is taken away through liquid cooling, and compared with air convection heat dissipation, the heat exchange capacity of the composite heat pipe with the outside is improved.

Owner:ZHEJIANG UNIV

Phase change heat dissipation device

PendingCN109612315ASmall temperature differenceIncrease contact areaSemiconductor/solid-state device detailsIndirect heat exchangersEvaporationTemperature difference

Owner:ZHUZHOU ZHIRE TECH

Treatment method of alkali metal heat pipe liquid absorption core

InactiveCN111076592AIncrease heat transfer limitReduce volumeIndirect heat exchangersPhysicsChemistry

The invention belongs to the technical field of nuclear reactors, and particularly relates to a treatment method of an alkali metal heat pipe liquid absorption core. The treatment method includes thefollowing steps that 1, basic principles are confirmed; 2, materials are prepared; 3, nano-particles are deposited on a silk screen, and the alkali metal heat pipe liquid absorption core is formed; and 4, the alkali metal heat pipe liquid absorption core is applied to a heat pipe. The heat transfer limit of the heat pipe can be increased.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

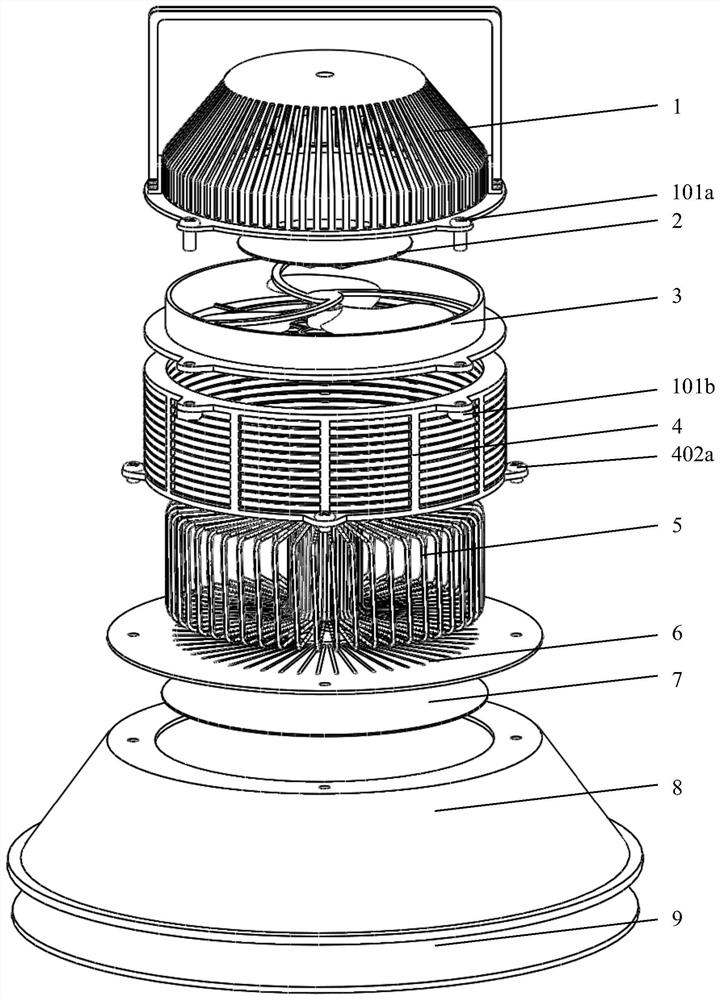

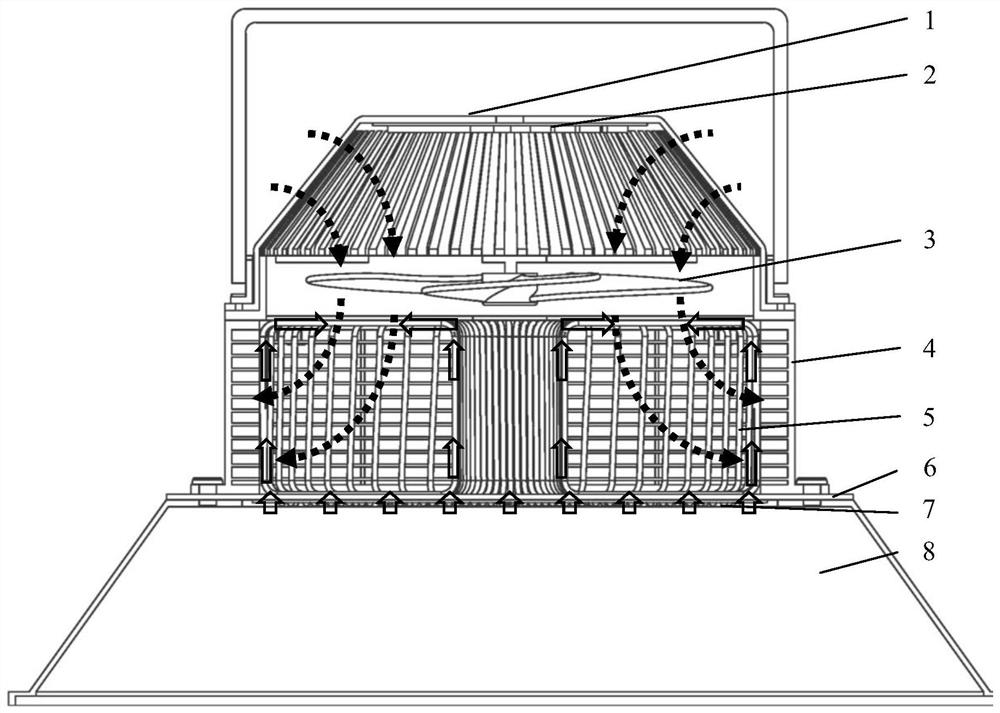

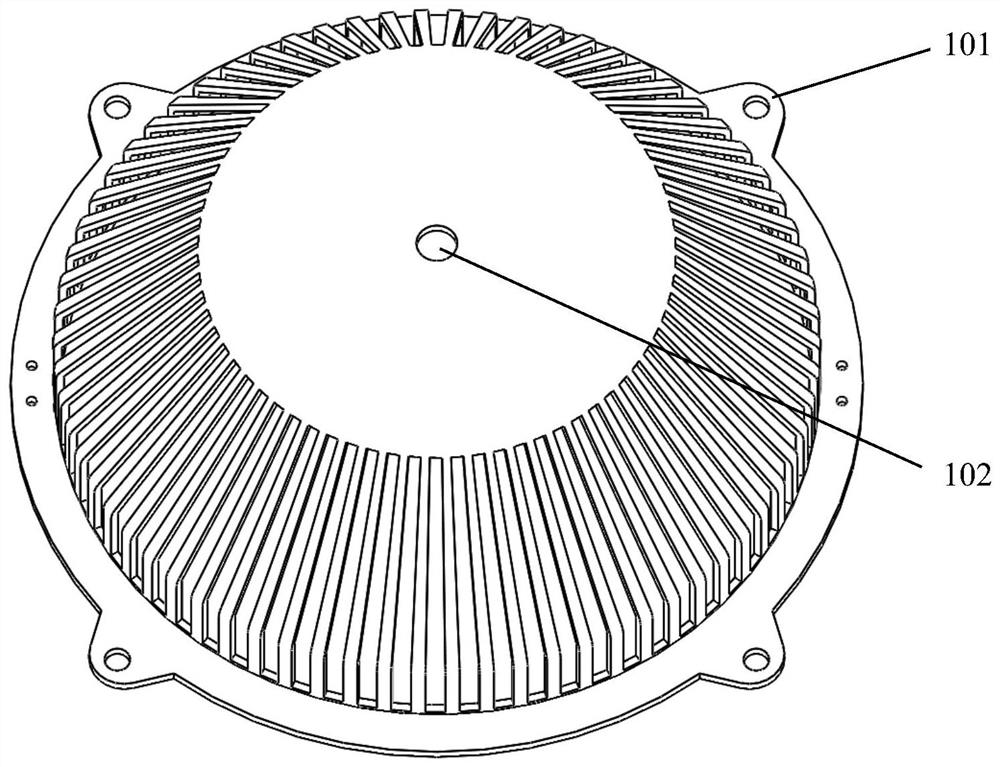

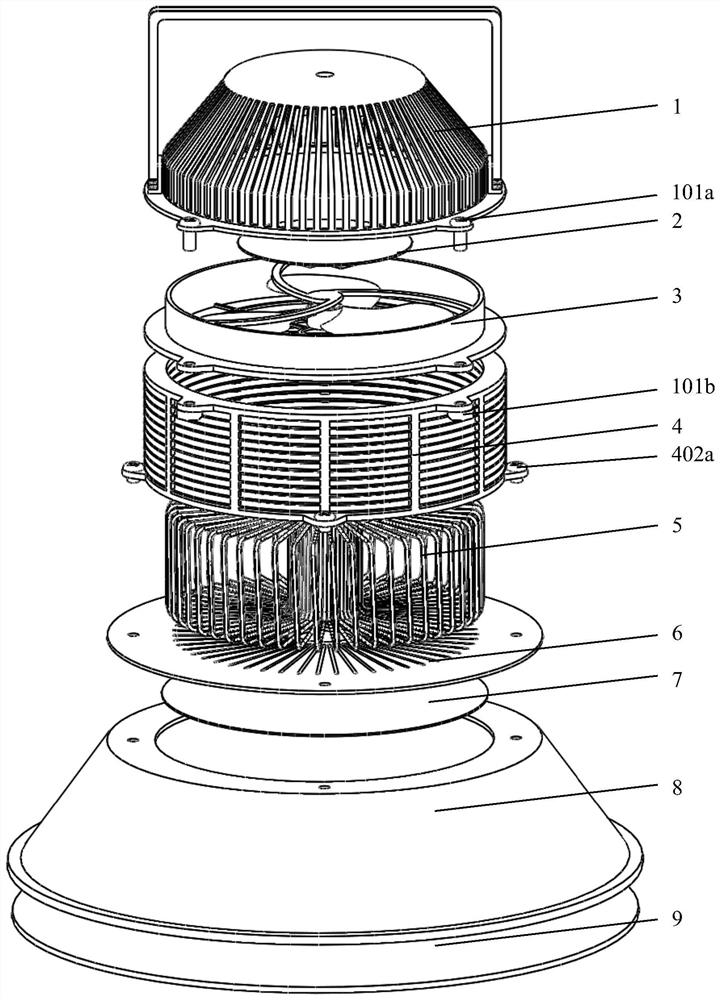

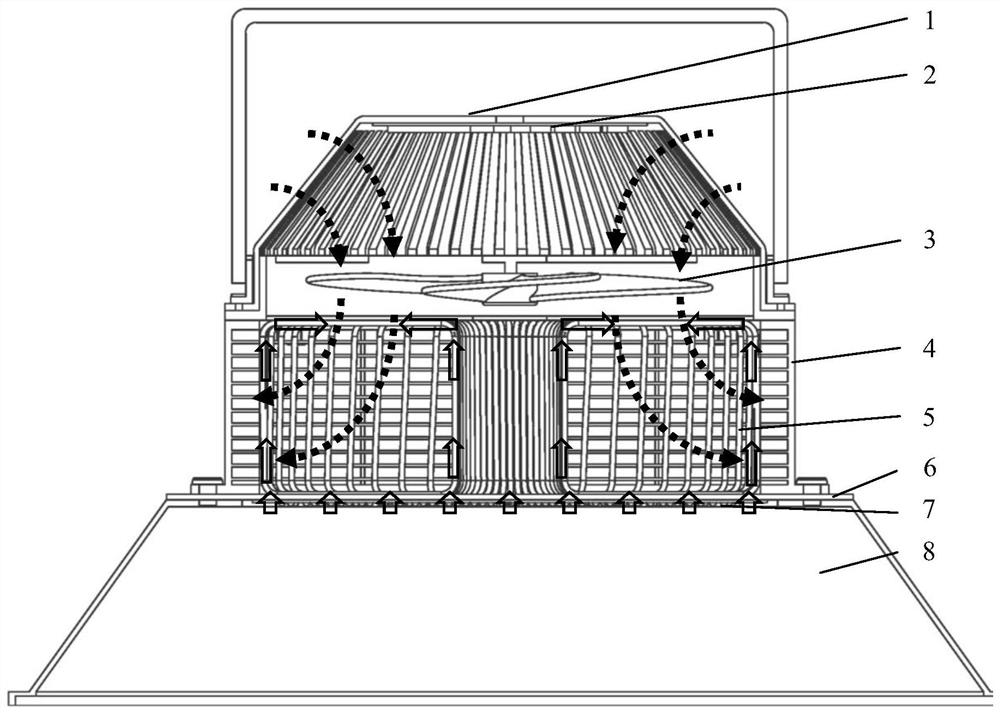

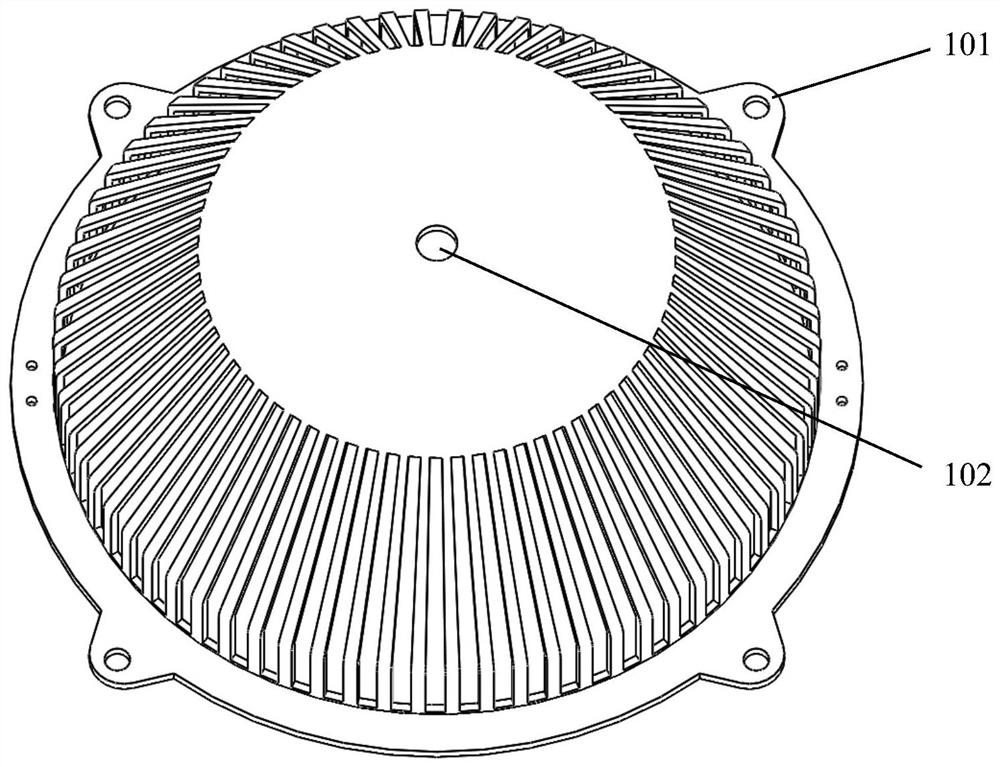

High-power LED lamp heat dissipation device

ActiveCN111720805ARaise the "burn dry" limitEliminate performance impactLighting heating/cooling arrangementsLight fasteningsGlass coverEngineering

The invention relates to a high-power LED lamp heat dissipation device, and belongs to the technical field of LED heat dissipation. The high-power LED lamp heat dissipation device comprises an upper lampshade, a circuit board, a heat dissipation fan, a ribbed shell, a gas-liquid pulsating phase change heat pipe, a mounting base, an LED lamp bead integrated board, a lower lampshade and a glass cover plate. The high-power LED lamp heat dissipation device takes the gas-liquid pulsating phase change heat pipe as a core heat transfer component, and heat production of a bottom high-power LED lamp bead array is efficiently transmitted to a three-dimensional space and dissipated quickly; a self-wetting fluid working medium filled in the pipe can automatically moisten the evaporation section of theheat pipe, and the "drying" limit of the heat pipe can be effectively improved; and the capillary suction produced by micro grooves on the inner wall of the heat pipe can further enhance the wettability of the working medium to the inner wall of a whole pipe body, so that the temperature uniformity and heat transfer limit are further improved. Compared with an existing metal ribbed LED lighting and heat dissipation device and traditional heat pipe LED lighting and heat dissipation devices such as capillary heat pipes and gravity heat pipes, the high-power LED lamp heat dissipation device hasbetter heat transfer performance, higher heat transfer limit and better working adaptability.

Owner:YANGZHOU UNIV +1

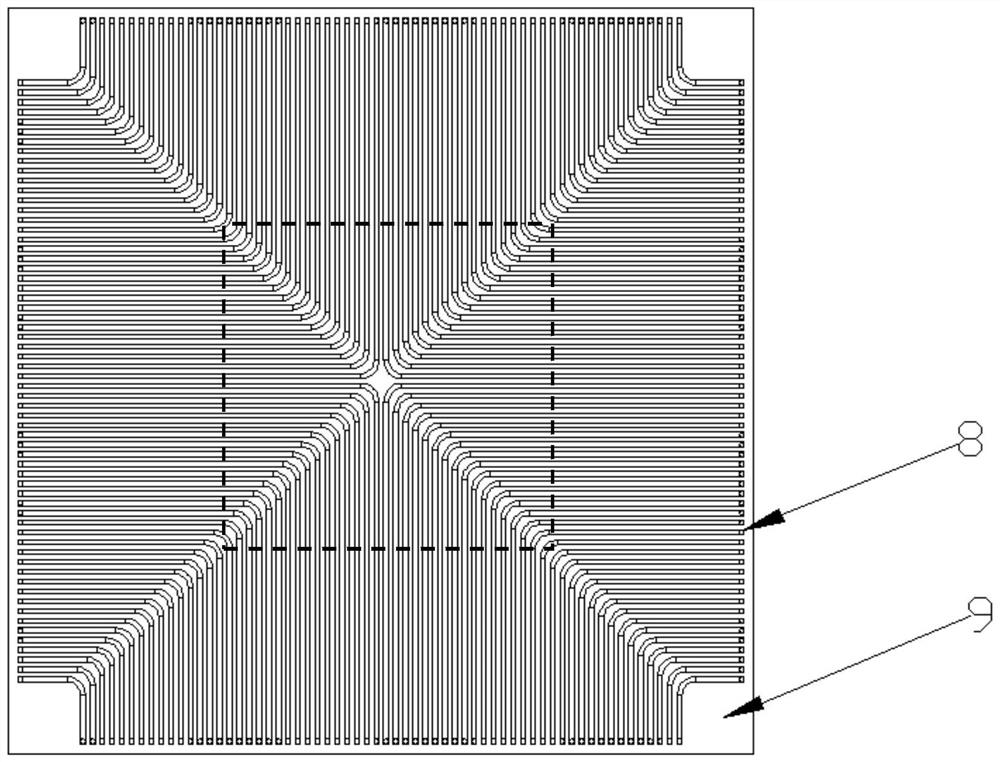

Preparation method of double-sided micro-channel flat pulsating heat pipe and application thereof to high-power chip heat dissipation device

InactiveCN113008057AIncrease heat transfer limitIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention discloses a preparation method of a double-sided micro-channel flat plate pulsating heat pipe and application of the double-sided micro-channel flat plate pulsating heat pipe to a high-power chip heat dissipation device. The device comprises a method for preparing the double-sided micro-channel flat plate pulsating heat pipe, the two opposite surfaces of the double-sided micro-channel flat plate pulsating heat pipe are an evaporation end face and a condensation end face respectively, the evaporation end face and the condensation end face are both provided with identical micro-channels, the micro-channels on the two surfaces are communicated with each other, and the double-face micro-channel flat plate pulsating heat pipe is filled with working media in a sealed mode; a heat dissipation unit is fixedly connected to the upper portion of the evaporation end face of the double-face micro-channel flat plate pulsating heat pipe; and the chip is fixedly installed on the evaporation end face, and heat dissipation of the chip is achieved through circulation of a working medium on the evaporation end face and the condensation end face.

Owner:JIANGSU UNIV

Liquid metal pulse heat pipe

InactiveCN109489459ALarge working temperature zoneImprove efficiencyIndirect heat exchangersHeat transfer efficiencyBoiling point

The invention relates to the technical field of heat pipes, and discloses a liquid metal pulse heat pipe. The liquid metal pulse heat pipe comprises a pipe body, a rising pipeline and a returning pipeline; a heating chamber and a heat dissipation chamber which are independent mutually are sequentially constructed in the pipe body from bottom to top, and a low-boiling-point working medium and liquid metal are arranged in the heating chamber from top to bottom in a layered mode; the rising pipeline is arranged in the pipe body and penetrates through the heating chamber and the heat dissipation chamber; the returning pipeline is arranged in the pipe body and penetrates through the heating chamber and the heat dissipation chamber; and the returning pipeline and the rising pipeline are arrangedin a spaced mode. By heating the heating chamber, the low-boiling-point working medium is heated and evaporated into a gaseous work medium, and under the effect of the gas pressure, the liquid metaland the gaseous work medium are alternately conveyed from the heating chamber to the heat dissipation chamber along the rising pipeline in a segmented mode, and then conveyed from the heat dissipationchamber back to the heating chamber along the return pipeline; and the liquid metal pulse heat pipe has the advantages of high heat transfer efficiency and large heat transfer limit.

Owner:YUNAN JINGCHUANG LIQUID METAL THERMAL CONTROL TECH RES & DEV CO LTD

A kind of ultra-thin flat heat pipe and its manufacturing method

ActiveCN107167008BEasy to moveImprove mechanical propertiesIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

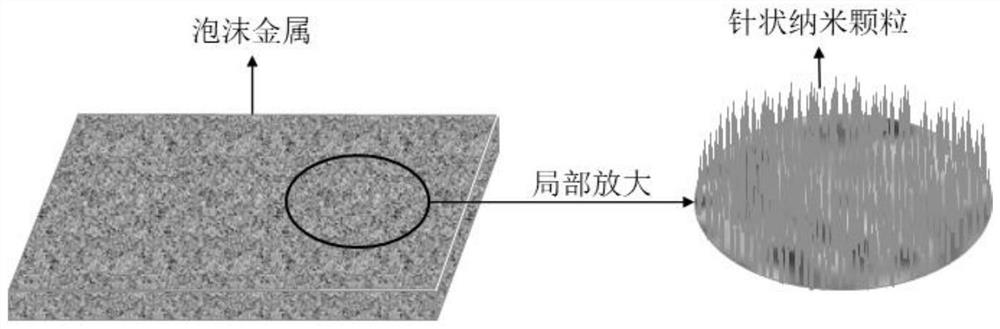

Alkali metal heat pipe wick and preparation method thereof and heat pipe

PendingCN114018077ASmall apertureImprove wettabilityIndirect heat exchangersNanoparticlePhysical chemistry

The invention discloses an alkali metal heat pipe wick and a preparation method thereof and a heat pipe. The alkali metal heat pipe wick comprises foam metal, and alkali metal needle-shaped nanoparticles are formed on the surface of the foam metal. The preparation method comprises the following steps of: immersing foam metal into a mixed solution containing alkali metal ions, and then taking out the foam metal for high-temperature baking. A micro-nano composite capillary structure is formed by redox reaction and a method of compounding needle-shaped nanoparticles on the surface of foam metal, the micropore diameter is further reduced, meanwhile, the wettability of a working medium in the micropores of the capillary structure is improved, the contact angle is reduced, and the capillary limit is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A kind of ultra-thin flat heat pipe and its manufacturing process

ActiveCN109443060BIncrease heat transfer limitPrevent collapseIndirect heat exchangersManufacturing technologyProcess engineering

The present invention relates to the technical field of heat dissipation devices, and more specifically relates to an ultra-thin flat heat pipe and its manufacturing process, including a bottom plate and a cover plate snap-fitted and packaged, and the bottom plate is provided with concave holes with several capillary structures arranged in parallel. In the cavity, a gas flow channel for the flow of the working fluid of the heat pipe is formed between adjacent capillary structures, and the capillary structure includes several liquid flow channels arranged in parallel. The gas working medium flows in the gas flow channel, and the liquid working medium flows in the capillary structure, so as to realize the gas-liquid separation of the working medium, reduce the flow resistance, and improve the heat transfer limit of the heat pipe; and the invention has simple structure and simple manufacture, and can It realizes industrial assembly line production, and has strong heat transfer capacity. The thickness of the heat pipe is small, which can meet the heat dissipation of electronic devices in narrow spaces, and meet the needs of integration and miniaturization of electronic components. It has good practicability and applicability. .

Owner:GUANGDONG UNIV OF TECH

Circulation radiator, and manufacturing method and components thereof

ActiveCN102208375BAvoid deformationNot easy to damageSemiconductor/solid-state device detailsSolid-state devicesVapor liquidWorking fluid

The invention discloses a circulation radiator, and a manufacturing method and components thereof. The components of the circulation radiator comprise a pipeline, a heat dissipation mechanism and a vapor-liquid cavity; the heat dissipation mechanism is contacted with the pipeline, a capillary structure is arranged in the vapor-liquid cavity; the vapor-liquid cavity is divided into a liquid storage cavity and an evaporation cavity by the capillary structure; one end of the pipeline is connected with the evaporation cavity; the other end of the pipeline is connected with the liquid storage cavity or the capillary structure; the evaporation cavity comprises at least one steam channel; and the pipeline and the vapor-liquid cavity provide a low-pressure hermetic sealed channel. Compared with the prior art which employs one evaporation cavity, the invention has the advantages that: the whole capillary structure has stronger supporting force, so that the whole vapor-liquid cavity is difficult to deform and damage under the conditions of high temperature and high pressure; the evaporation cavity consisting of a plurality of the steam channels facilitates the evaporation of liquid in the evaporation cavity, so that vapor can reach a longer distance, heat dissipation of the long distance can be realized, a heat transfer limit based on the single-way circular flow of working fluid is greatly increased; and under the condition of the same heat dissipation and transfer capability, the vapor-liquid cavity provided by the scheme has lesser thickness, so that the volume of the radiator isreduced.

Owner:锘威科技(深圳)有限公司

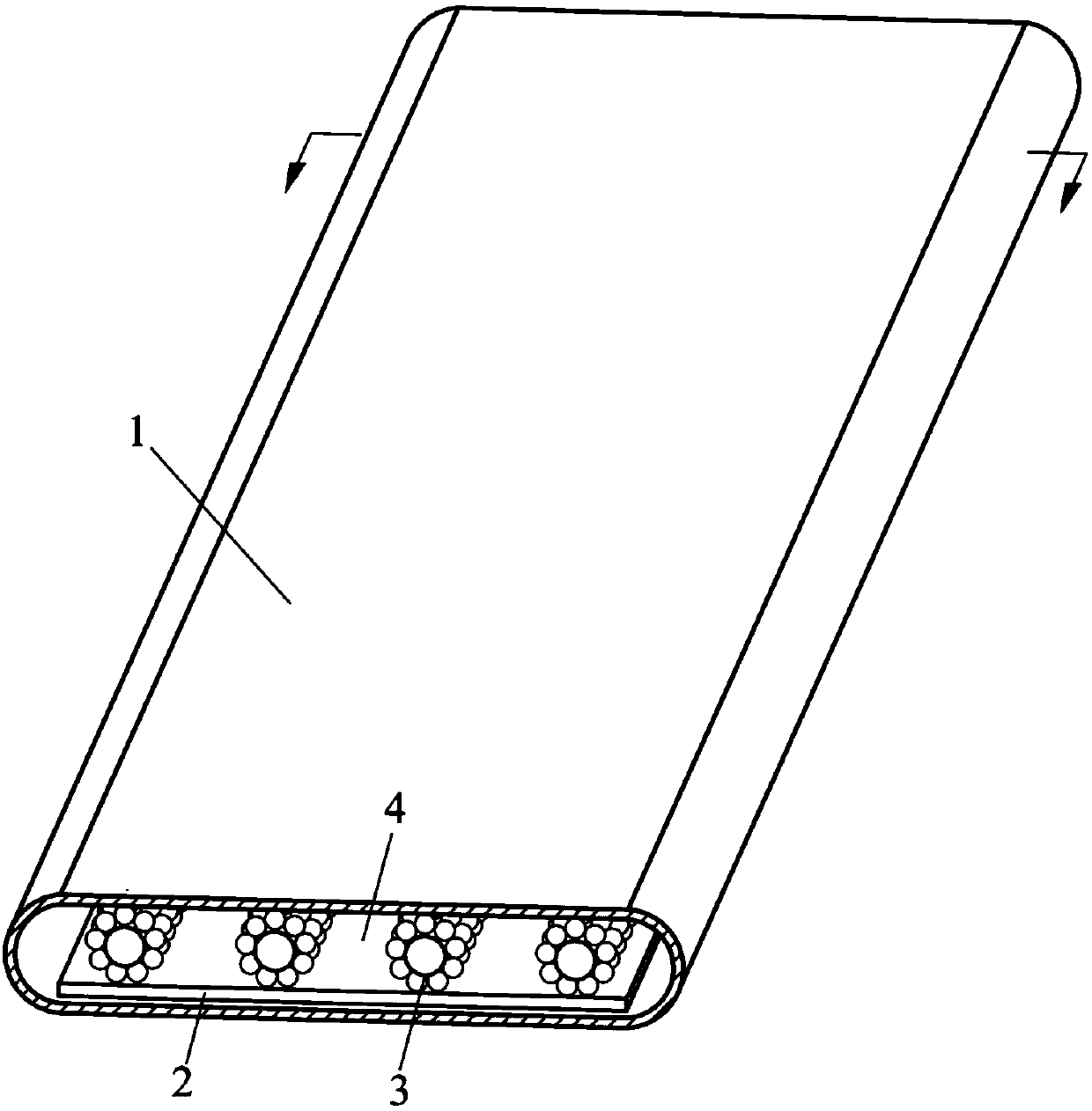

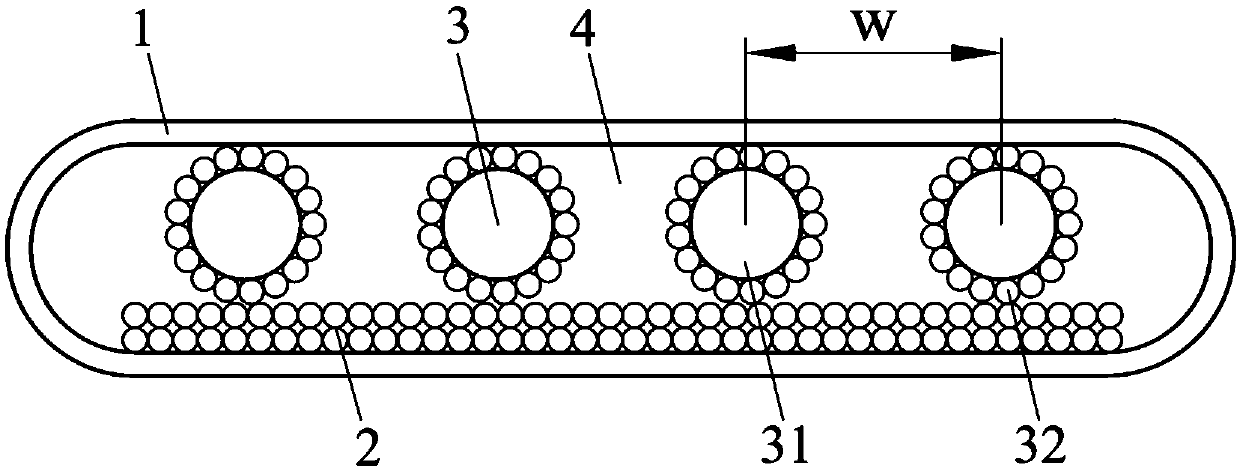

Heat-wing

ActiveUS20190353429A1Increase heat transfer limitLarge passage widthSemiconductor/solid-state device detailsIndirect heat exchangersHeat fluxCondenser (heat transfer)

A heat-wing includes: a sealed hollow chamber including two plates and a frame connecting the two plates; a capillary structure layer closely attached to an inner surface of the chamber; and a phase transition working medium sealed in the chamber. A portion of the frame or a portion of a periphery of one of the two plates serves as an evaporation area of the heat-wing, and the rest portion of the chamber serves as a condensation area of the heat-wing. The heat-wing has an increased vapor passage area, liquid working medium flow-back passage width and condenser heat transfer area and a reduced evaporator center-to-edge distance, and is hence capable of achieving a great improvement in heat transfer limit and heat flux density.

Owner:ZHANG YUE

A vacuum chamber vapor chamber

InactiveCN103687455BSpeed up circulationPromote circulationCooling/ventilation/heating modificationsEngineeringCopper

The invention discloses a vapor chamber, which comprises a bottom plate and a cover plate, wherein the bottom plate and the cover plate are hermetically connected to construct a hollow enclosed cavity; the bottom plate is provided with a super-hydrophobic surface which is taken as the condensing area of the vapor chamber; the cover plate is provided with a super-hydrophilic surface which is taken as the evaporating area of the vapor chamber; foam copper is buried in the enclosed cavity by pressing; one end of the foam copper is connected with the cover plate, and the other end of the foam copper is connected with the bottom plate, thereby facilitating return of a working medium from the condensing area to the evaporating area. According to the vapor chamber, the heat exchange performance of the evaporating area and the condensing area of the vapor chamber is enhanced, the heat exchange capability of the vapor chamber is enhanced by using circular flow of the working medium in the evaporating area and the condensing area, and the heat exchange limit of the vapor chamber is increased.

Owner:SHANGHAI JIAOTONG UNIV

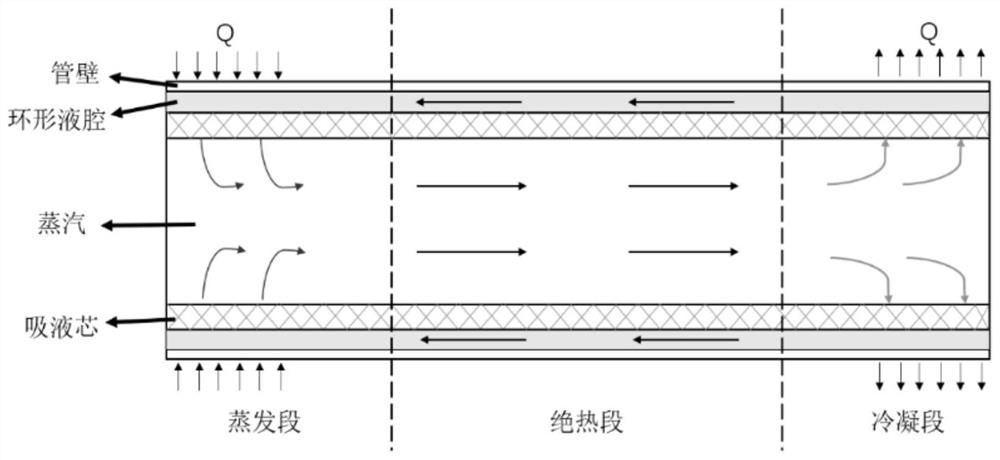

Heat pipe and manufacturing method thereof

InactiveCN103994682BImprove heat transfer efficiencySolve the problem of insufficient heat dissipation capacity of high heat fluxIndirect heat exchangersHeat exchange apparatusWater basedThermal insulation

Owner:JIANGSU UNIV OF SCI & TECH

Heat-wing

ActiveUS11448469B2Increase the areaIncrease heat transfer limitSemiconductor/solid-state device detailsHeat exhanger finsHeat fluxCondenser (heat transfer)

A heat-wing includes: a sealed hollow chamber including two plates and a frame connecting the two plates; a capillary structure layer closely attached to an inner surface of the chamber; and a phase transition working medium sealed in the chamber. A portion of the frame or a portion of a periphery of one of the two plates serves as an evaporation area of the heat-wing, and the rest portion of the chamber serves as a condensation area of the heat-wing. The heat-wing has an increased vapor passage area, liquid working medium flow-back passage width and condenser heat transfer area and a reduced evaporator center-to-edge distance, and is hence capable of achieving a great improvement in heat transfer limit and heat flux density.

Owner:ZHANG YUE

A composite liquid-cooled heat pipe radiator

ActiveCN111083911BImprove cooling effectIncrease cooling areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringRefrigerant

The invention belongs to the technical field of heat transfer, and particularly relates to a composite liquid-cooling heat pipe radiator. The composite liquid-cooling heat pipe radiator comprises a flat plate heat pipe, wherein heat generated by a heating component is transferred to a bottom plate of the flat plate heat pipe, a top plate of the flat plate heat pipe is provided with protrusions perpendicular to the bottom plate of the flat plate heat pipe, the protrusions form a tubular heat pipe, and an inner cavity of the flat plate heat pipe is communicated with an inner cavity of the tubular heat pipe. The composite liquid-cooling heat pipe radiator further comprises a shell. The flat plate heat pipe and the tubular heat pipe are both located in the shell, and the bottom plate of the flat heat pipe is attached to the bottom surface of the shell in a sealed mode; an area defined by the outer surface of the flat plate heat pipe, the outer surface of the tubular heat pipe and the innerwall of the shell forms a cooling liquid channel; and the shell is provided with a cooling liquid inlet and a cooling liquid outlet. According to the radiator, the tubular heat pipe is combined withthe flat plate heat pipe, so that the radiator can be attached to a flat surface of the heating component and has a good radiating effect; and meanwhile, heat released by a refrigerant of a condensation section is taken away through liquid cooling, and compared with air convection heat dissipation, the heat exchange capacity of the composite heat pipe with the outside is improved.

Owner:ZHEJIANG UNIV

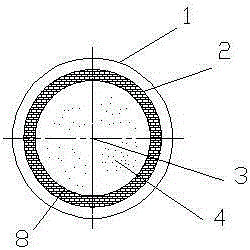

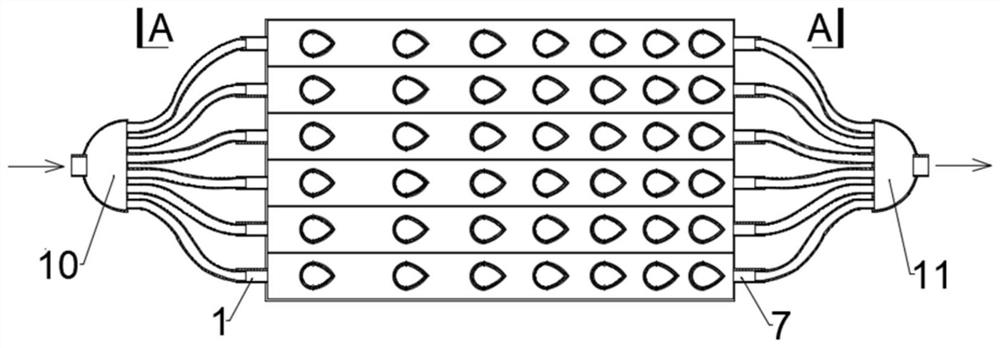

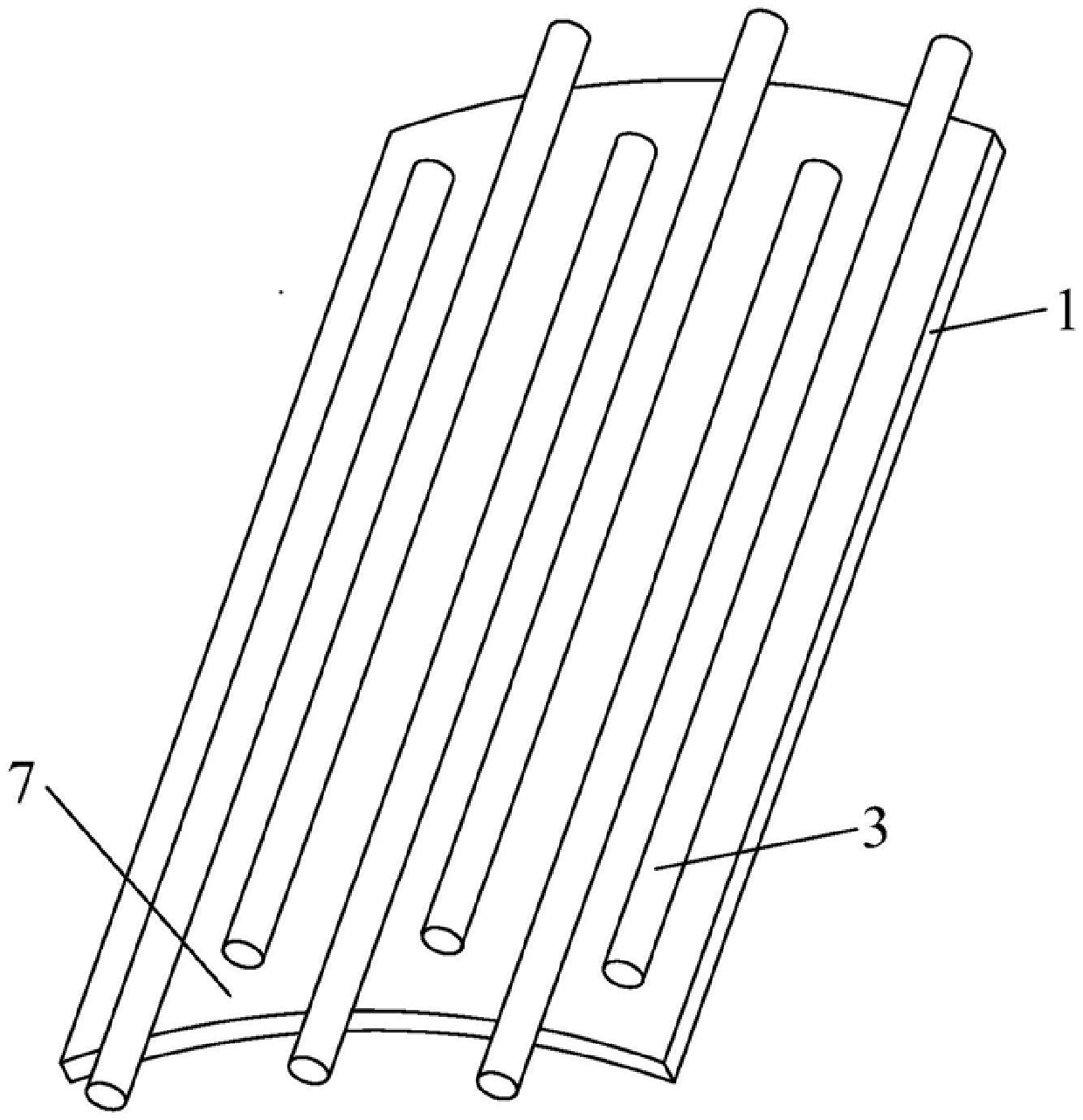

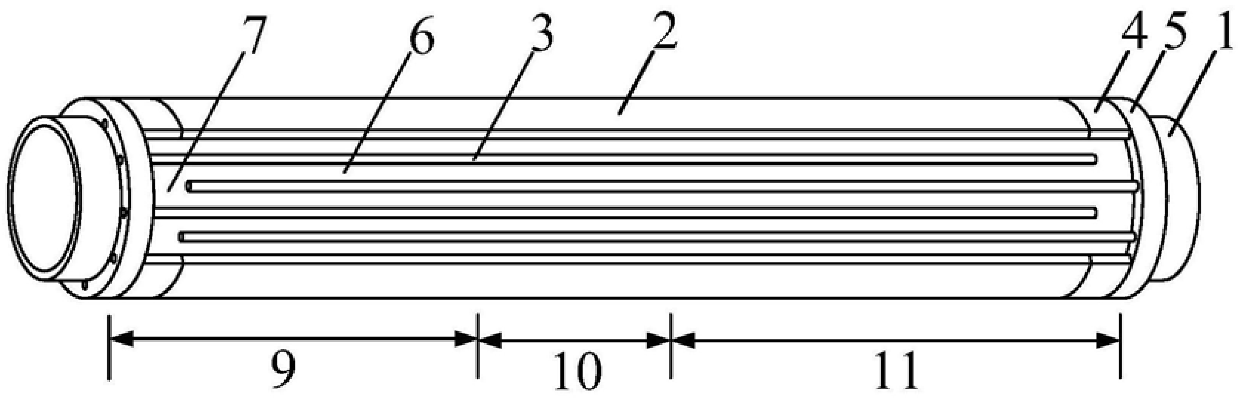

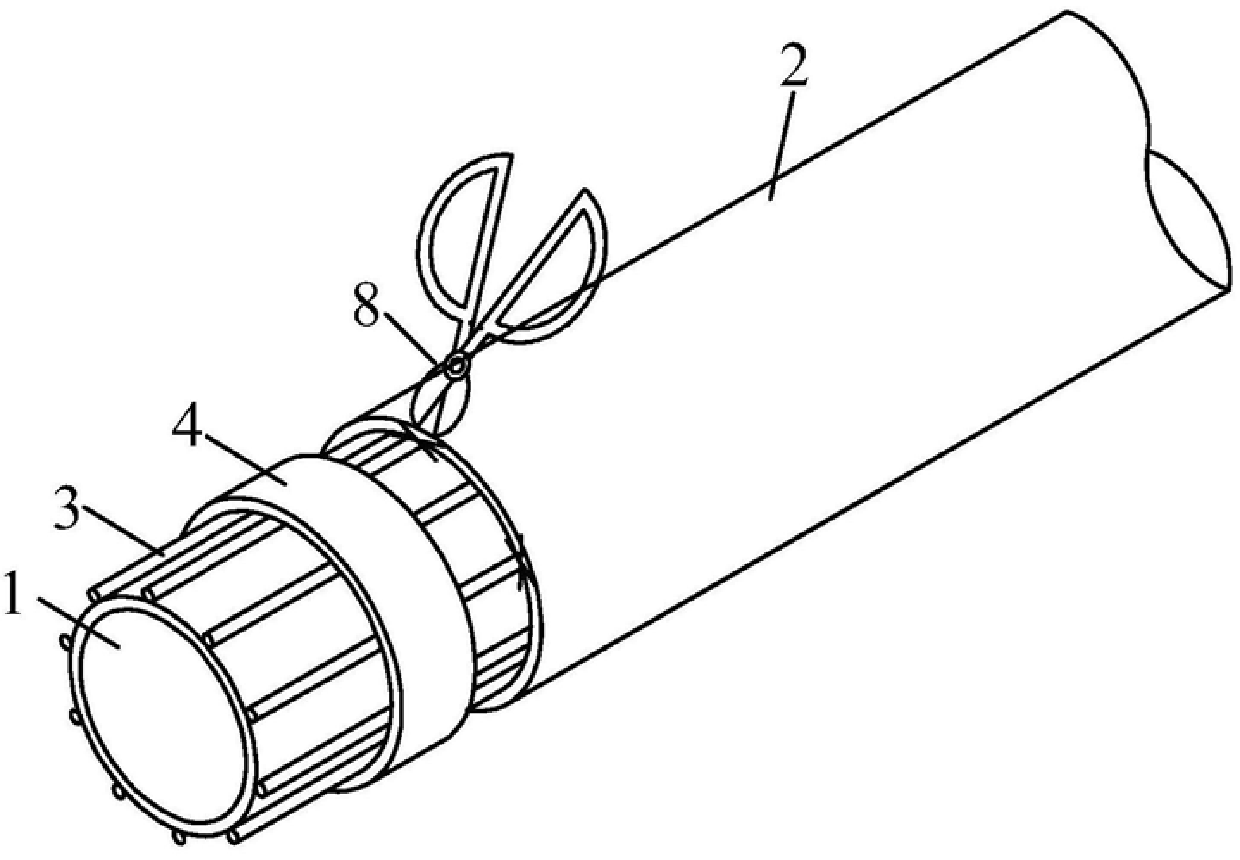

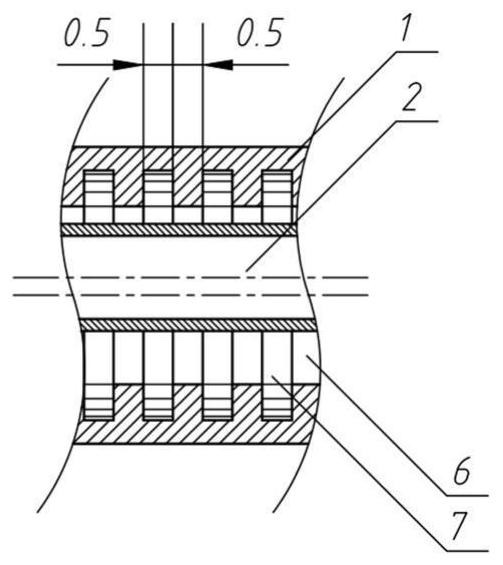

Large-scale ring type pulsating heat pipe

InactiveCN110595240AExpand large-scale application scenariosAchieve deliveryIndirect heat exchangersHeat transfer modificationAnti-gravityHeat flow

The invention belongs to the field of passive heat transfer, and relates to a large-scale ring type pulsating heat pipe. The pulsating heat pipe comprises an inner pipe 1, an outer pipe 2, a metal wire 3, a copper ring 4, a sealing ring 5, a gas-liquid channel 6 and a U-shaped elbow channel 7, wherein the inner tube 1 and the outer tube 2 are coaxially arranged, the metal wire 3 with the diametersmaller than the thickness of an annular gap is penetrated at the annular gap formed between the inner tube 1 and the outer tube 2, the metal wire 3, the inner tube 1 and the outer tube 2 are tightlyattached through adopting a mechanical method, the copper ring 4 and the sealing ring 5 are sequentially sleeve at the two sides of the inner tube 1, and then the two sides are welded and sealed intoa whole; and an hole is formed at one side of the copper ring 4 to weld a liquid filling pipe. The large-scale ring type pulsating heat pipe has the advantages of being high in space utilization rate,large in heat flow density, good in heat transfer efficiency and heat transfer limit, stable in operation, flexible in installation and arrangement, excellent in anti-gravity operation characteristics, easy in realizing large scale of the single pulsating heat pipe and the centralized arrangement of multiple heat pipes, compact in structure, small in size, light in weight and low in cost, and issuitable for industrial mass production.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Hot fin

InactiveCN106839845AWide reflow widthAvoid premature dryingIndirect heat exchangersTransmission channelEvaporation

The invention discloses a hot fin, comprising two side panels, a side frame for connecting the side panels so as to form a hollow thin panel shaped shell body, a capillary structure layer closed to the inner wall of the shell body, and a phase change working medium sealed in the shell body, wherein a part of the side frame is used as an evaporation zone and contacted with the surface of the hot source; the rest part of the shell body is used as a condensing zone. The hot fin adds the steam transmission channel area, the backflow width of a liquid working medium and the direct radiating area of the condensing zone, shortens the distance from the center of the evaporation zone to the edge of the evaporation zone, greatly improves the heat transfer limit so as to acquire higher hot flow density.

Owner:张跃

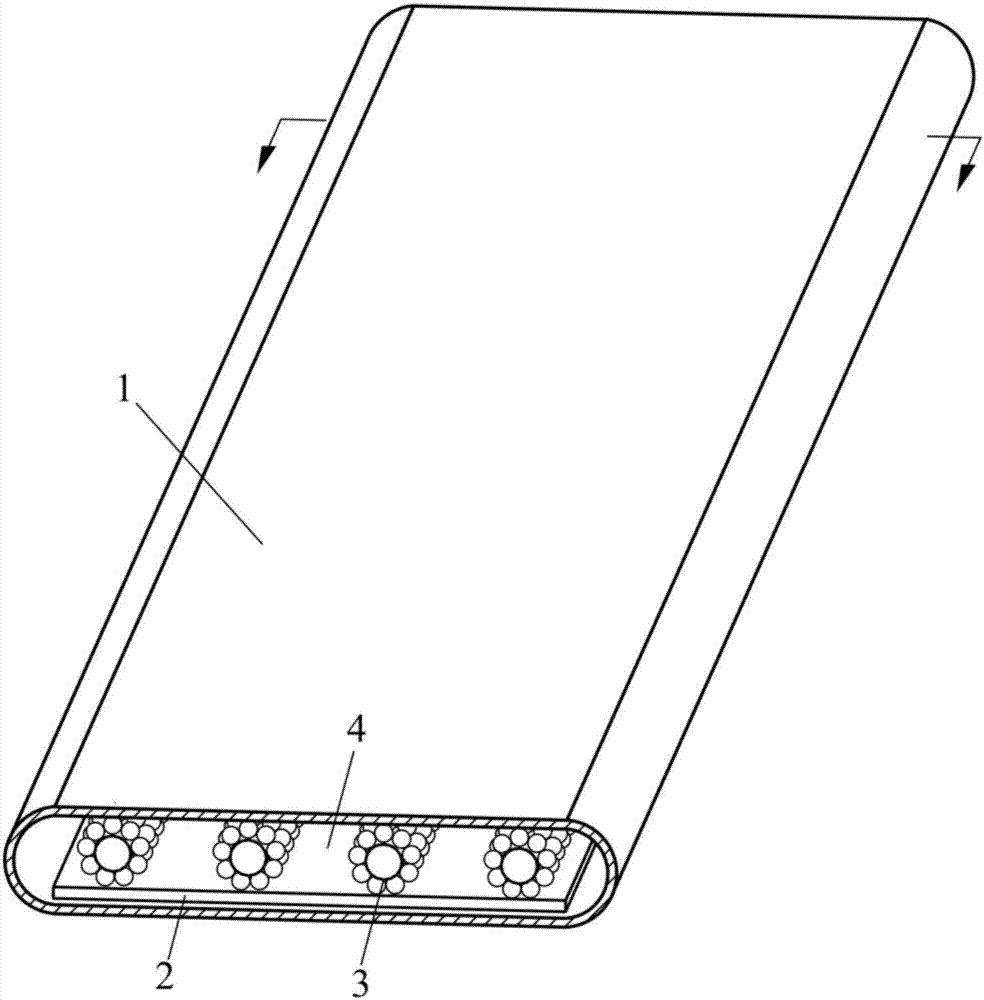

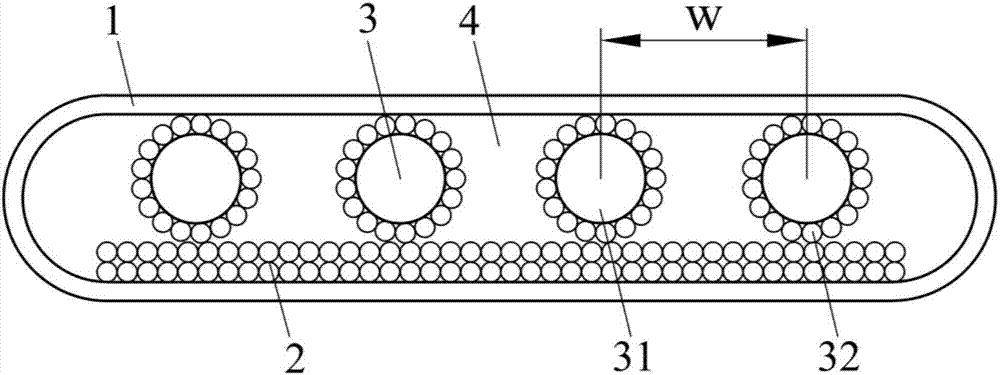

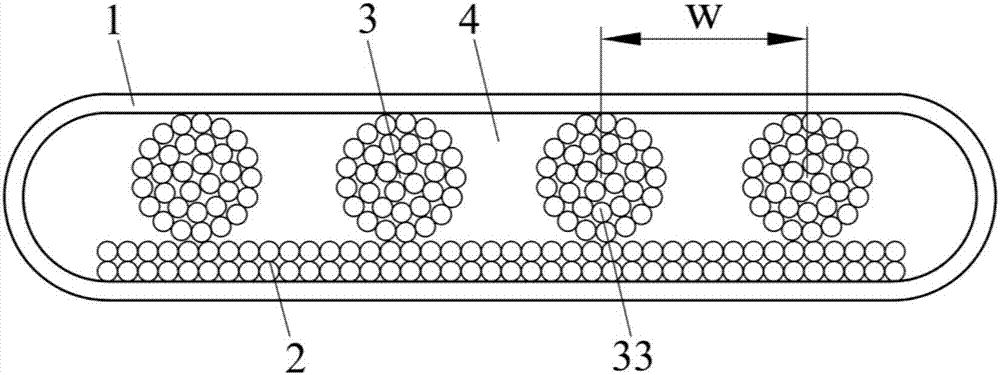

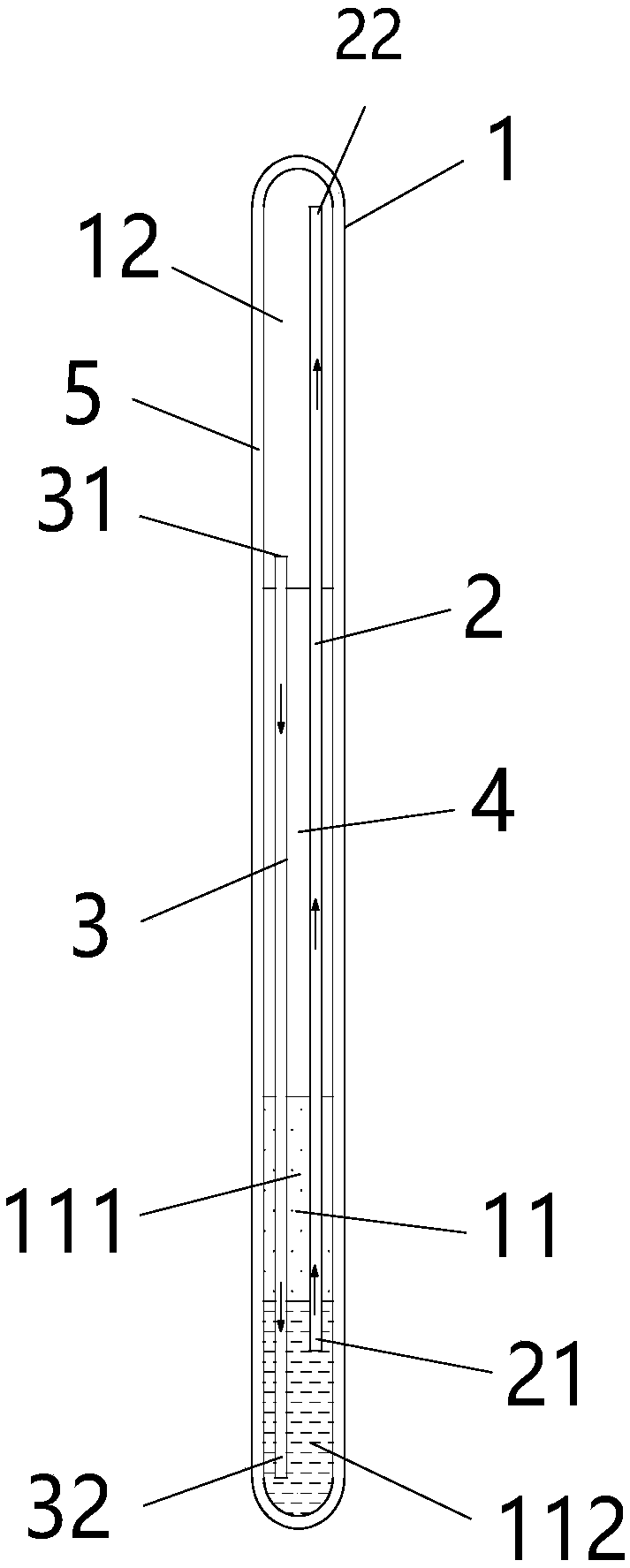

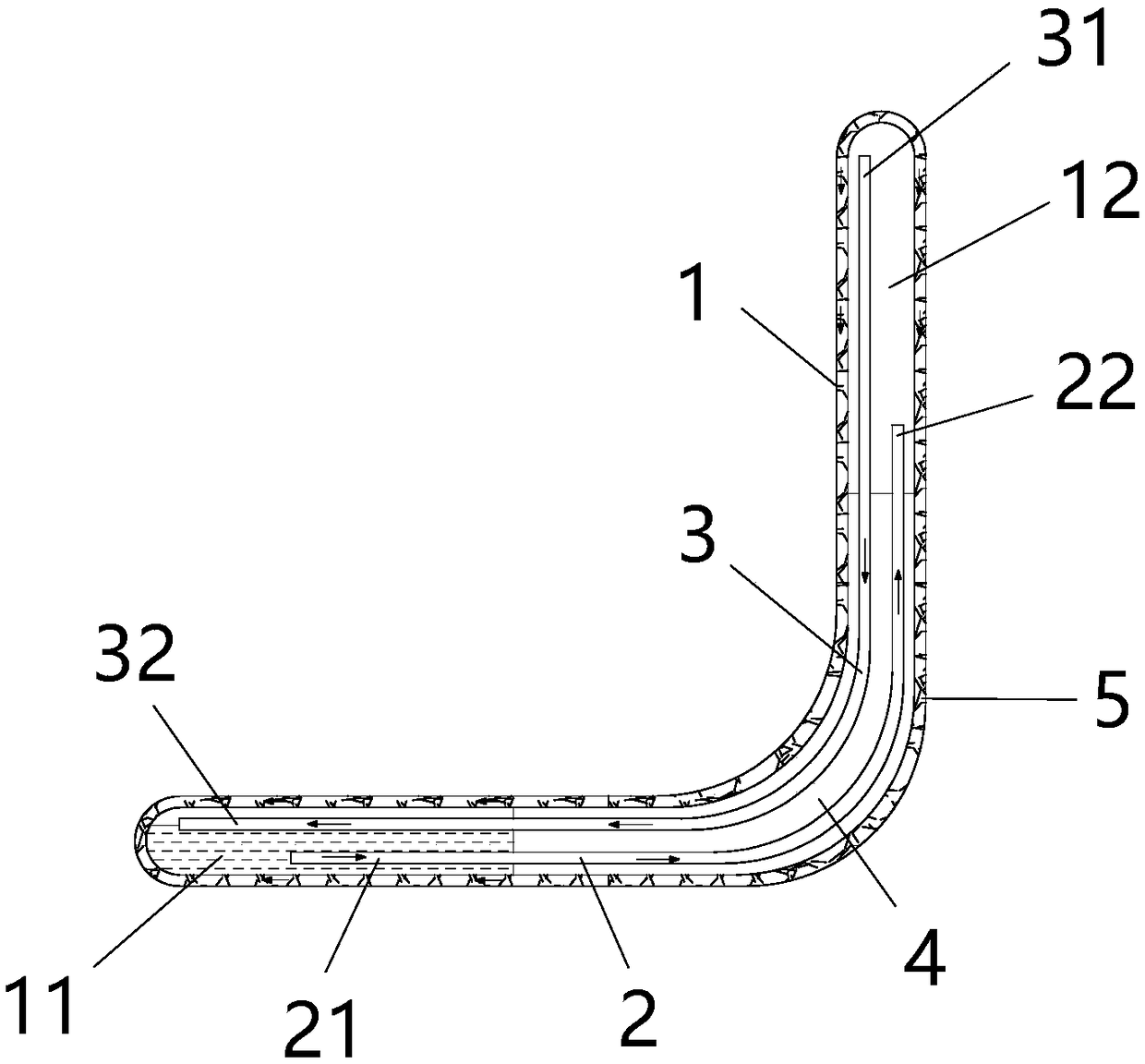

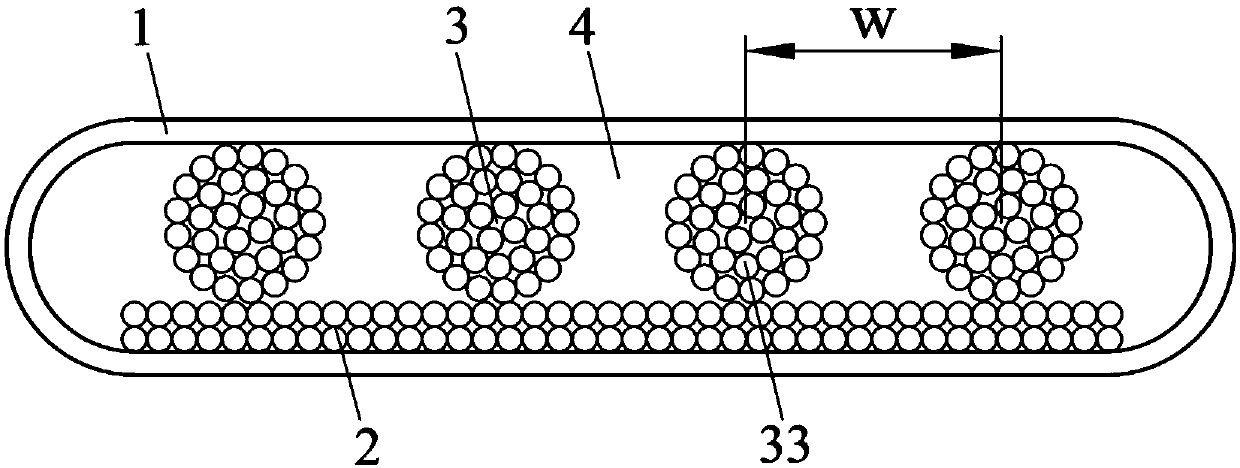

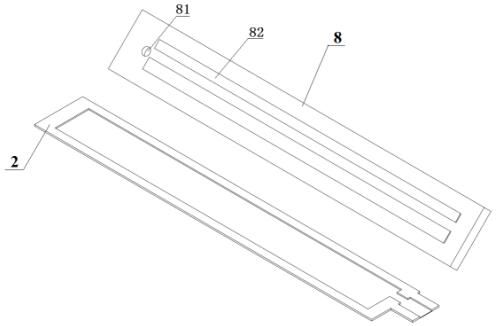

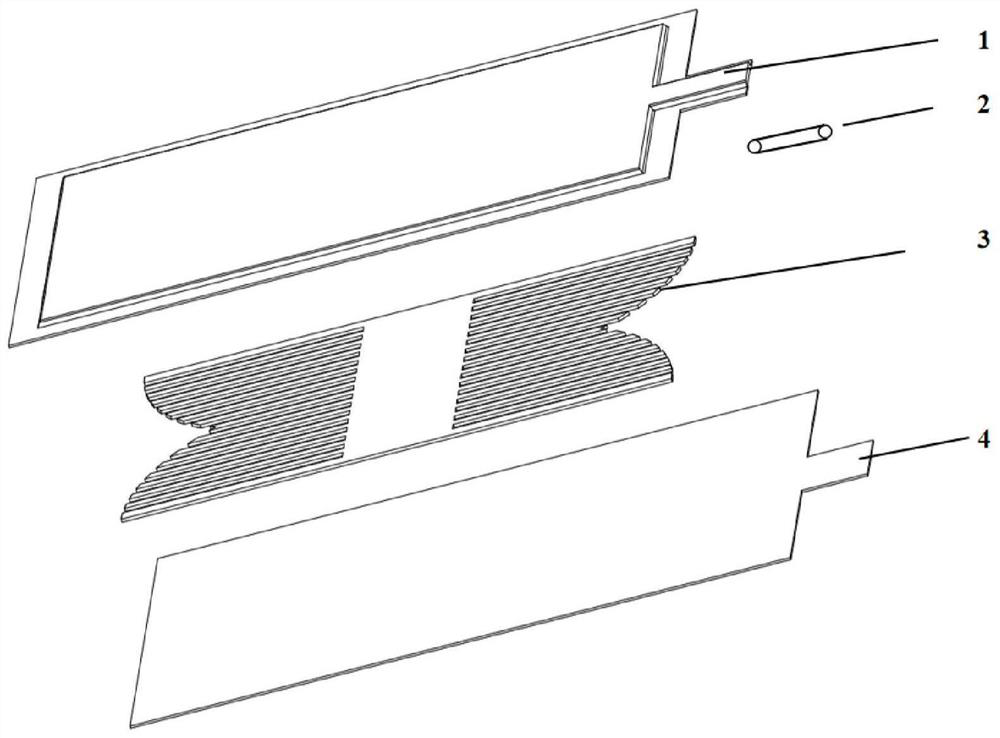

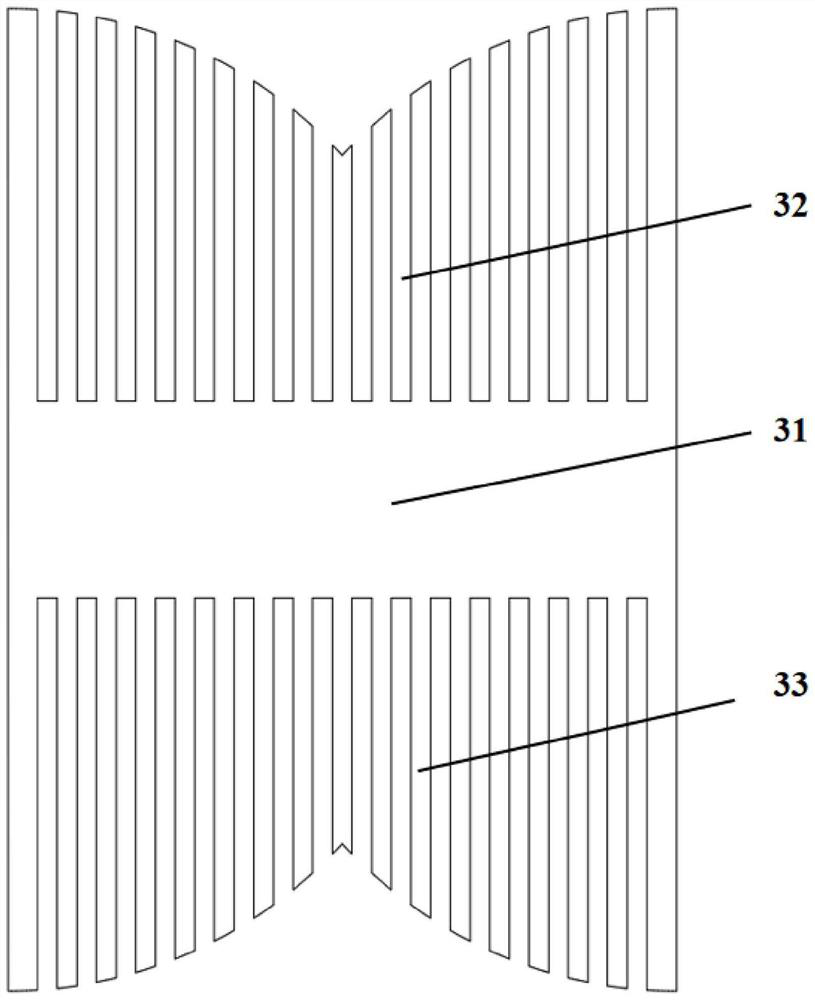

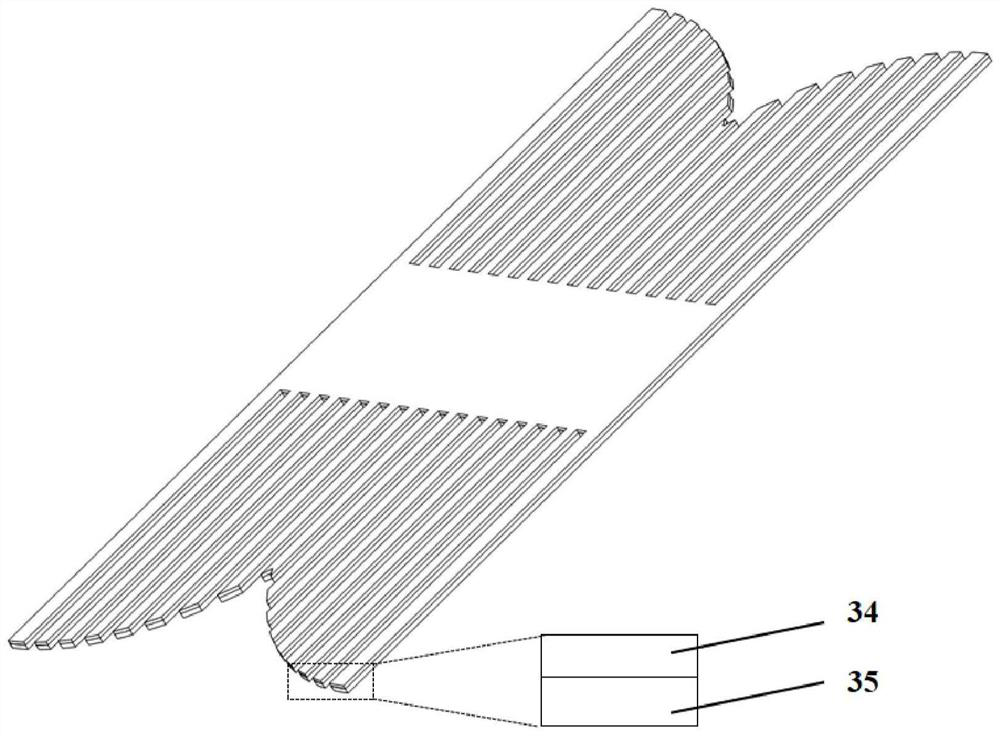

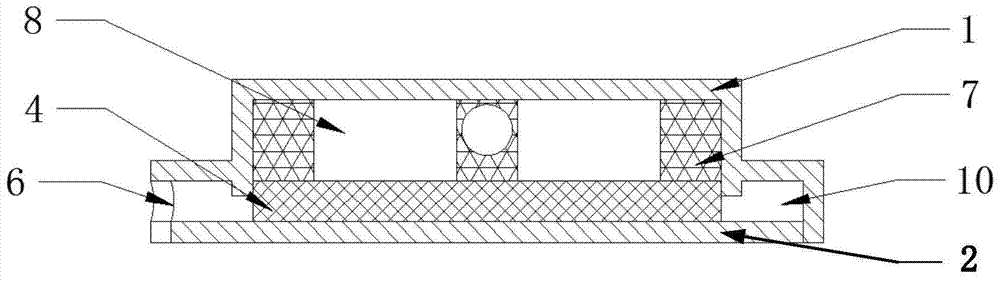

Ultrathin vapor chamber, preparation method thereof and electronic equipment

PendingCN114857967AExcellent capillary performanceAchieve separationIndirect heat exchangersModifications using liquid coolingEngineeringMaterials science

The invention provides an ultrathin vapor chamber which comprises an upper shell plate (1) and a lower shell plate (4), and the periphery of the upper shell plate (1) and the periphery of the lower shell plate (4) are welded to form a closed cavity. The liquid injection pipe (2) is arranged on the closed chamber and is used for vacuumizing the closed chamber and injecting liquid into the closed chamber; the liquid absorption core structure (3) is arranged in the closed cavity, the liquid absorption core structure (3) comprises a central liquid absorption core (31) and a plurality of channel-shaped liquid absorption cores (32) which are distributed on the two sides of the liquid absorption core (31) and are arranged in parallel, the channel-shaped liquid absorption cores (32) form liquid backflow channels, and steam diffusion channels (33) are formed between the adjacent channel-shaped liquid absorption cores (32); the central liquid absorbing core (31) and the channel-shaped liquid absorbing core (32) are respectively composed of a first liquid absorbing core (34) and a second liquid absorbing core (35) which are stacked, the porosity of the liquid absorbing core structure (3) changes in a gradient mode in the direction from the first liquid absorbing core (34) to the second liquid absorbing core (35), and a super-hydrophilic nanometer structure is formed on the surface of the liquid absorbing core structure (3).

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A high-power LED lamp heat sink

ActiveCN111720805BRaise the "burn dry" limitEliminate performance impactLighting heating/cooling arrangementsLight fasteningsThermodynamicsLED lamp

Owner:YANGZHOU UNIV +1

Radial heat transfer miniature channel heat pipe

InactiveCN113587695AReduce space consumptionIncrease heat transfer limitIndirect heat exchangersEngineeringRefrigerant

The invention discloses a radial heat transfer miniature channel heat pipe which comprises outer pipes, inner pipes, a cooling water inlet pipeline, a cooling water outlet pipeline, an end cover, a steam cavity and a capillary acting force channel. The outer pipe is a micro-channel with a rectangular section; the outer pipes are arranged outside the inner pipes in a sleeving mode, and the multiple outer pipes are adjacently arranged side by side to form the heat pipe of which the overall structure is in a flat plate shape. The space between the outer pipe and the inner pipe is a steam cavity, the steam cavity is filled with refrigerants, and the refrigerants can generate gas-liquid phase change. The inner wall face of the outer pipe is provided with a capillary acting force channel, and the liquid refrigerant can be distributed on all the wall faces of the outer pipe through capillary acting force. By changing the structure and the heat transfer mode of an existing micro heat pipe and replacing axial heat transfer with a radial heat transfer mode, the heat transfer limit is improved, the temperature uniformity and the space occupation of the micro heat pipe in the axial direction are improved, and the micro heat pipe can adapt to the working conditions of rotary motion and double-face heating.

Owner:ZHEJIANG UNIV

Deep cold loop heat tube

InactiveCN1328566CAvoid reverse flowSmooth startIndirect heat exchangersMicro-loop heat pipeLoop heat pipe

The deep cooling loop heat pipe includes main evaporator and liquid chamber connected serially via connecting pipe. The main evaporator has casing of stainless steel pipe with axial grooves in the inside surface and main tubular liquid absorbing core of sintered stainless steel powder. The liquid chamber has stainless steel wire screen filled between the right end cap and the casing. There are also capillary connecting part, which has central inside hole, is set inside the hole of the main liquid absorbing core and extends via the connecting pipe to the liquid chamber, and annular coarse stainless steel wire sheet filled between the capillary connecting part and the liquid chamber casing. The present invention can avoid reverse flow of the work medium to ensure the successful starting of deep cooling loop heat pipe, and can raised the heat transferring limit of deep cooling loop heat pipe for stable operation performance.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

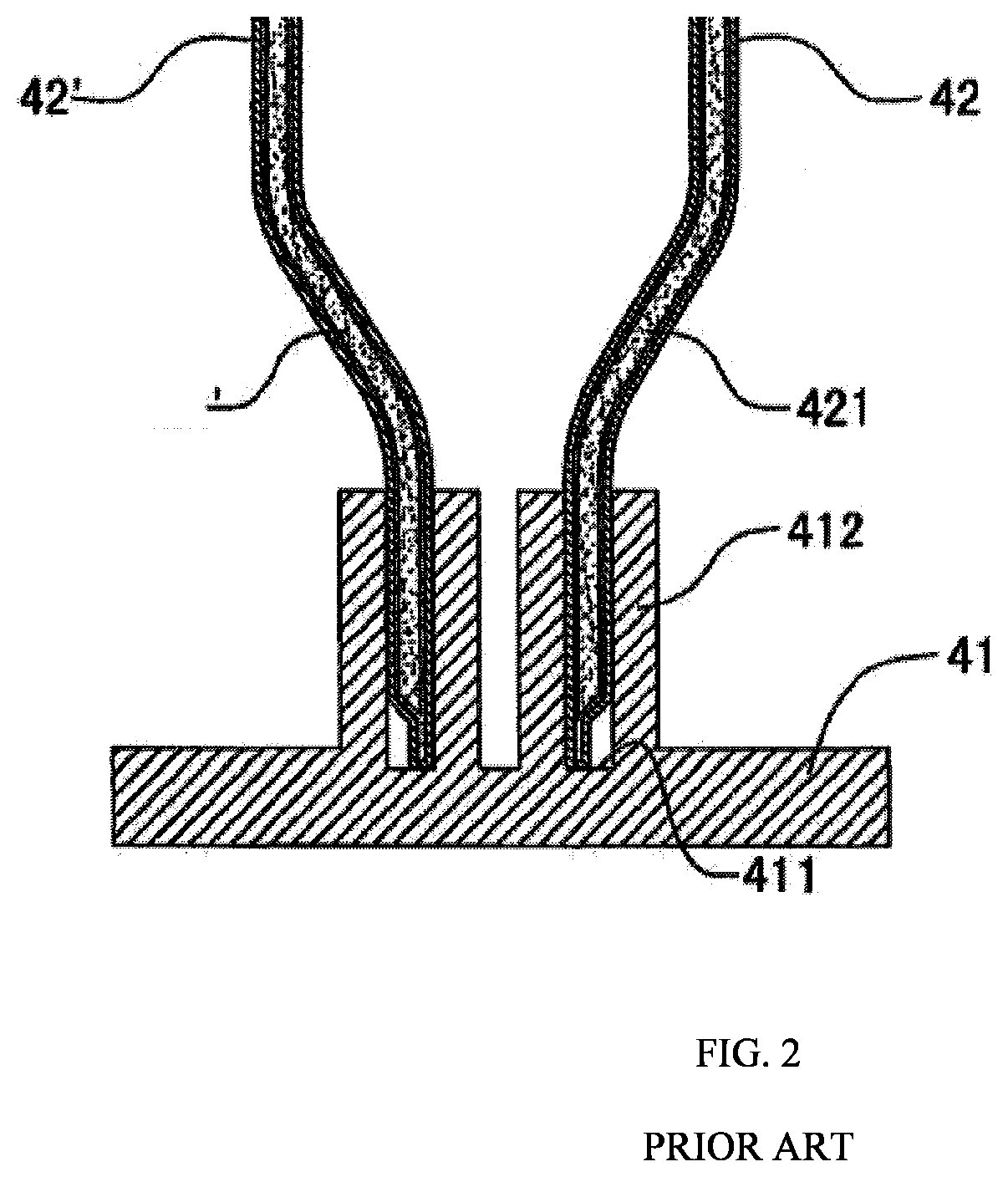

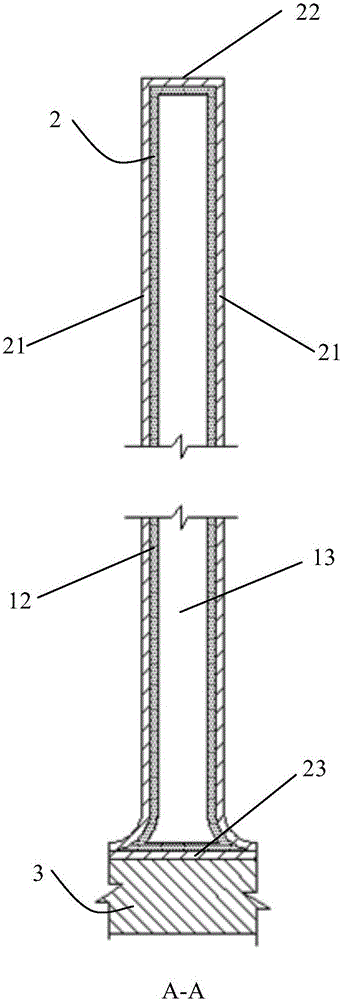

A secondary core evaporator and its application

ActiveCN105352349BReduce backflow resistanceAvoid frackingIndirect heat exchangersEngineeringContact heat

The invention discloses a secondary core evaporator and application thereof. The secondary core evaporator comprises an upper body, a lower end cover, a main capillary core and a secondary core, wherein the upper body is connected with the lower end cover, and is provided with an inlet and an outlet; the inlet is connected with a liquid pipeline provided with multiple holes in the tail end; the main capillary core and the secondary core are accommodated in a closed space, and are respectively and tightly contacted with the lower end cover and the upper body; the secondary core has an annular structure; a straight rib for dividing the secondary core into two cavities is radially distributed along the annular structure in the secondary core; the cavities serve as compensation cavities for storing working mediums; a hole way is formed in the straight rib; the tail end of the liquid pipeline is directly inserted into the hole way; a steam groove way is formed in the main capillary core; and a space surrounded by the periphery of the steam groove way, the upper body and the lower end cover serves as a steam collecting cavity for collecting steam. The secondary core evaporator reduces the backflow resistance, the contact heat resistance and the back heat conduction of supercooling liquid, lowers the temperature of the compensation cavities, improves the system power, and improves the heat transfer limitation.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com