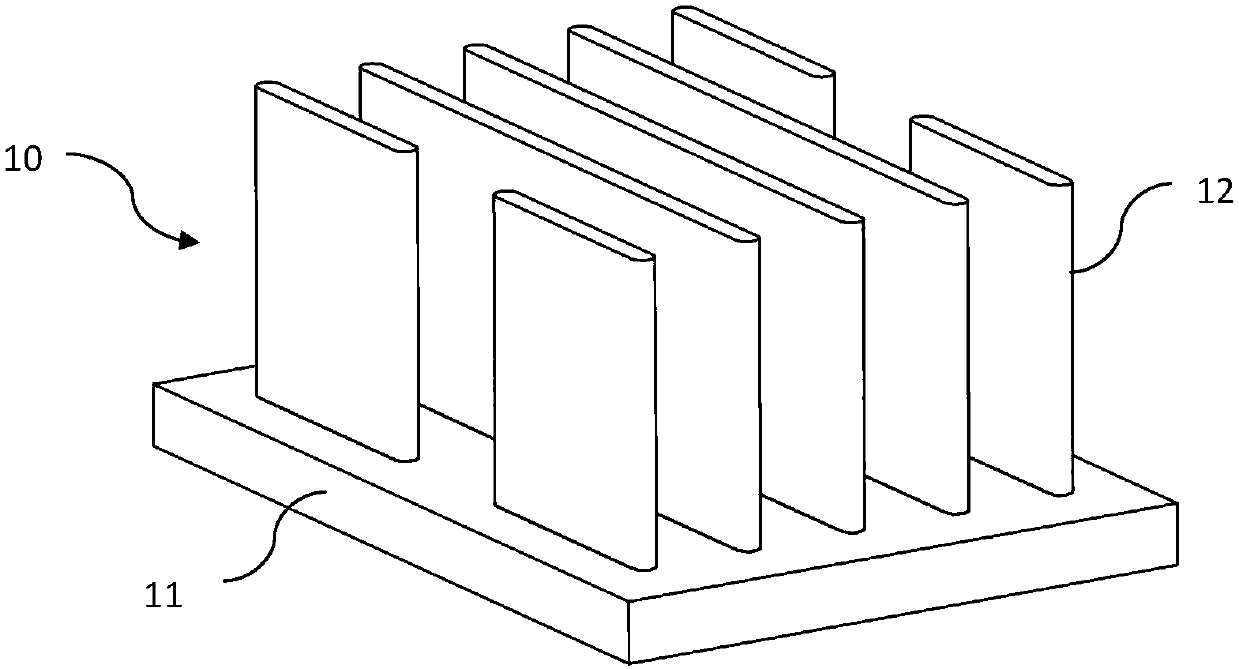

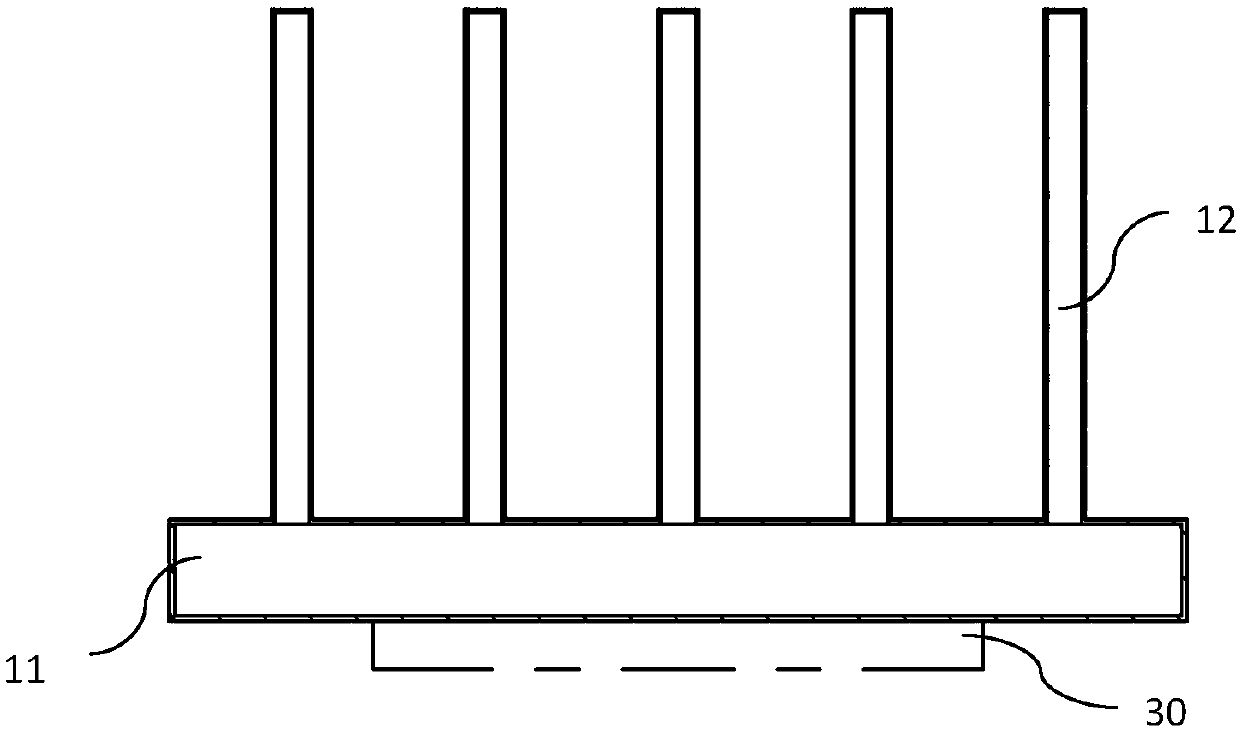

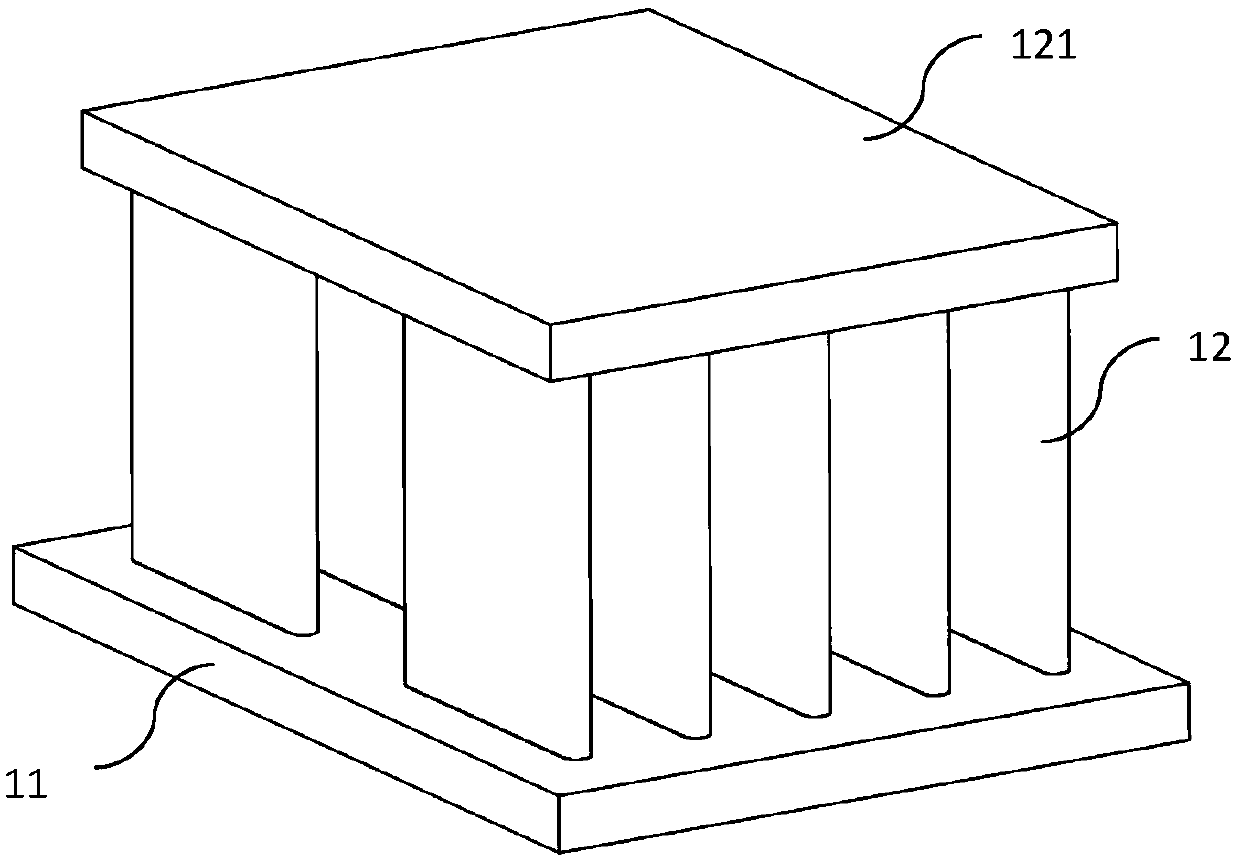

Phase change heat dissipation device

A heat dissipation device and phase conversion heat technology, which is applied in heat exchange equipment, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of environmental pollution, high heat flux density, device loss, etc., and achieve uniform temperature and heat source The effect of small temperature difference and small overall temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better understand the purpose, structure and function of the present invention, the phase change heat dissipation device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0045] In the present invention, relevant terms are defined as follows:

[0046]Heat flux: The heat transferred through a unit area per unit time is called heat flux, q=Q / (S*t)——Q is heat, t is time, S is the cross-sectional area, and the unit of heat flux is J / (m 2 s).

[0047] Heat transfer limit: The maximum heat flux density transferred by a phase-change heat sink (including heat pipes) is related to size, shape, phase-change heat medium, and operating temperature. Commonly used heat pipes have capillary limits, carry limits, boiling limits, sound velocity limits, and viscosity The heat transfer limit such as the limit, and the heat transfer capacity of the heat pipe is determined by the smallest limit value.

[0048] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com