Radial heat transfer miniature channel heat pipe

A channel heat pipe and micro technology, applied in aerospace thermal control, heat dissipation of electronic devices, and micro heat pipes, can solve the problems of poor temperature uniformity, insufficient heat transfer limit, occupying space, etc., to achieve uniform temperature distribution and improve heat transfer. Thermal limit, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, features, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

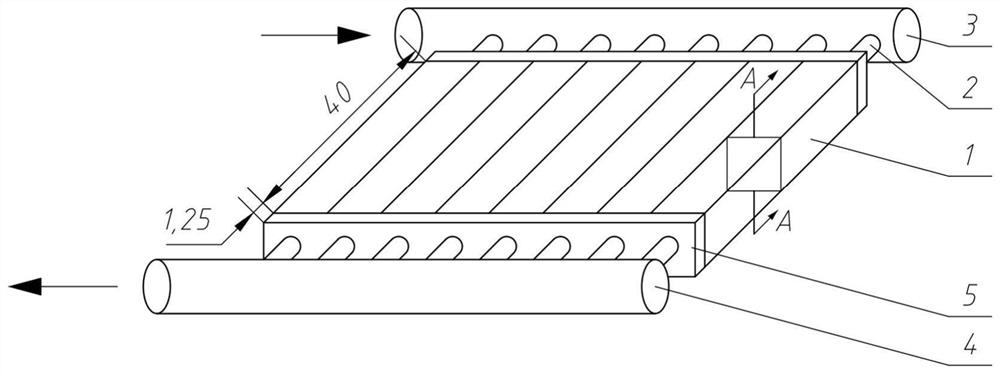

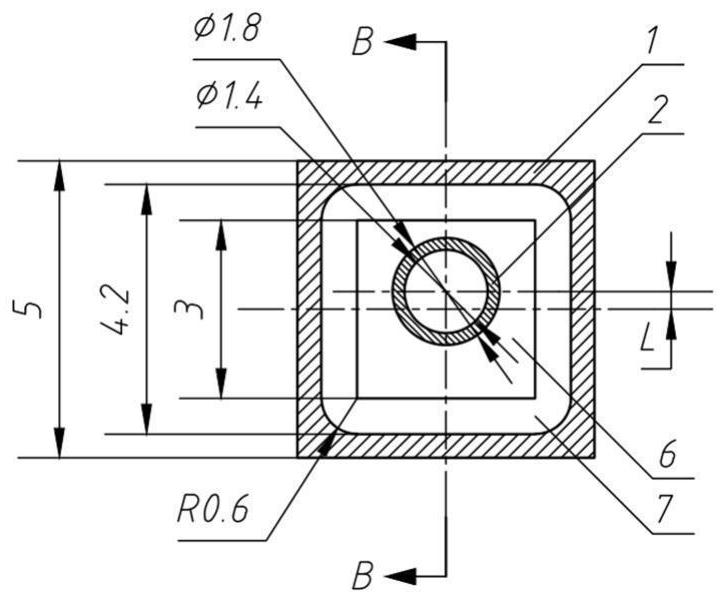

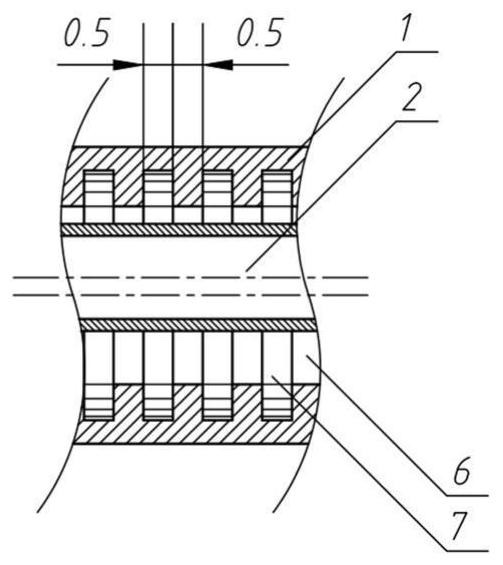

[0028] Such as figure 1 As shown, it is a micro-channel heat pipe for radial heat transfer in the embodiment of the present invention. The device includes an outer pipe 1, an inner pipe 2, a cooling water inlet pipe 3, a cooling water outlet pipe 4, an end cover 5, a steam Cavity 6, capillary force channel 7. The outer tube 1 is a microchannel with a rectangular cross-section; the outer tube 1 is sleeved outside the inner tube 2, and the two ends of the inner tube 2 protrude from the outer tube and communicate with the cooling water inlet pipeline 3 and the cooling water outlet pipeline 4 respectively; Eight outer tubes 1 and inner tubes 2 are arranged side by side to form a heat pipe with a flat plate shape as a whole; part bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com