Patents

Literature

132 results about "Anti-gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-gravity (also known as non-gravitational field) is creating a place or object that is free from the force of gravity. It does not refer to the lack of weight under gravity experienced in free fall or orbit, or to balancing the force of gravity with some other force, such as electromagnetism or aerodynamic lift. Anti-gravity is a recurring concept in science fiction, particularly in the context of spacecraft propulsion. Examples are the gravity blocking substance "Cavorite" in H. G. Wells's The First Men in the Moon and the Spindizzy machines in James Blish's Cities in Flight.

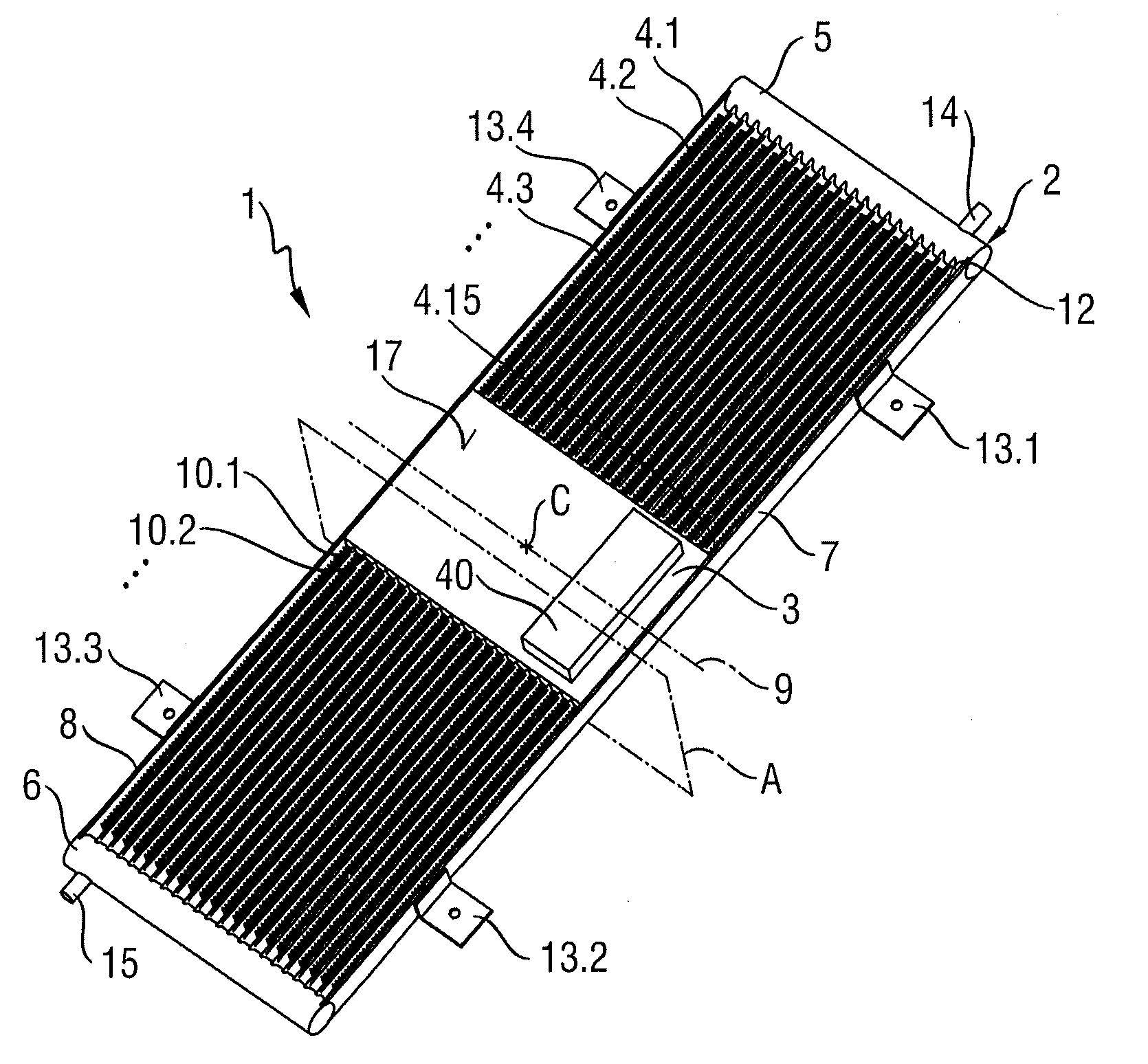

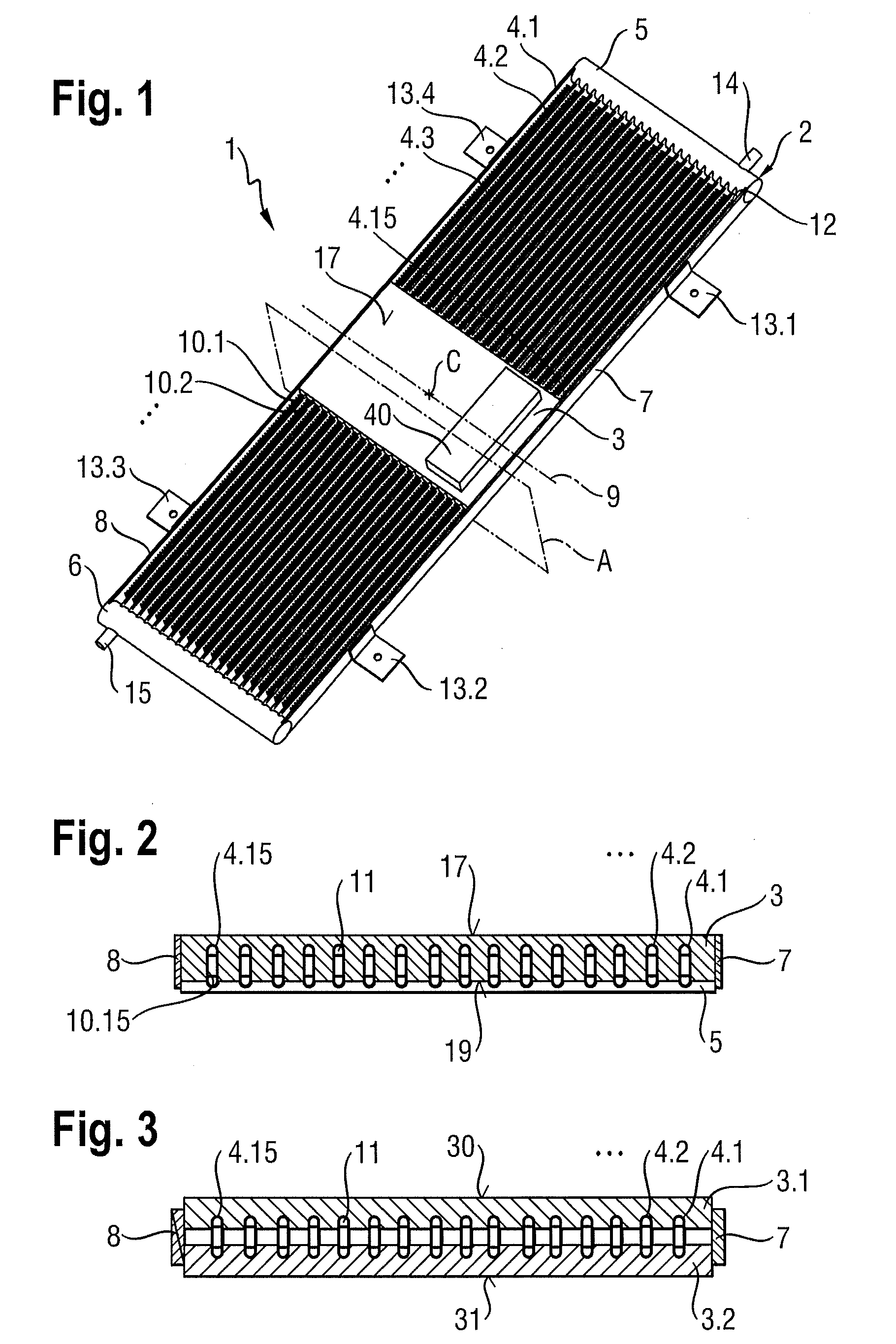

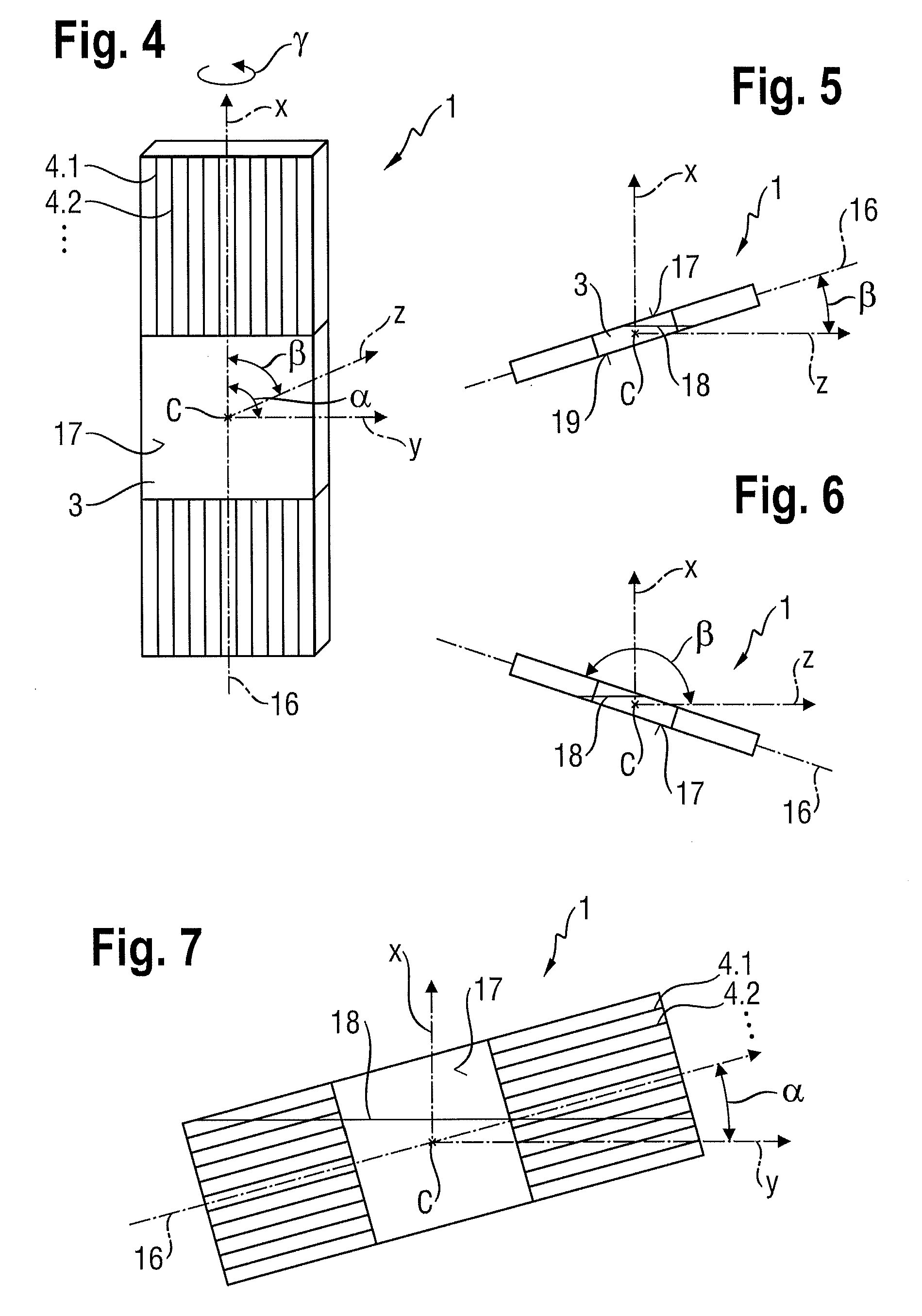

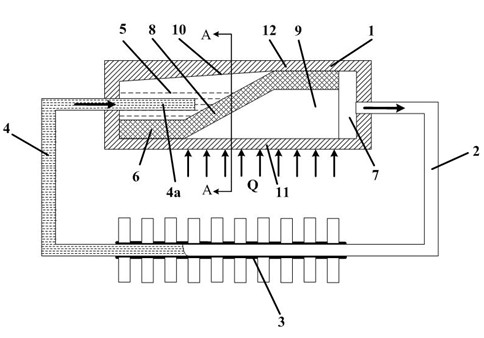

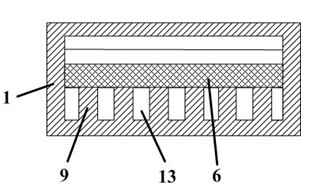

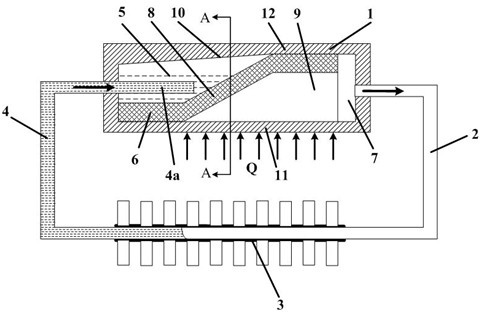

Anti-gravity thermosyphon heat exchanger and a power module

InactiveUS20100315781A1Easy to installNot need much spaceSemiconductor/solid-state device detailsSolid-state devicesAnti-gravityComputer module

A thermosyphon heat exchanger according to the disclosure includes a set of linear conduit elements and a heat exchange plate mounted in a heat receiving region on the conduit elements. The longitudinal axes of the conduit elements extend in a first direction in a plane defined by the flat side of the heat exchange plate. The conduit elements project above the heat receiving region in the first direction on a first side and an opposing second side such that the extension of the conduit elements on each side of the heat exchange region is suitable for constituting a condensing region for condensing a refrigerant vaporized in the heat receiving region if the first direction is arranged vertically.

Owner:ABB RES LTD

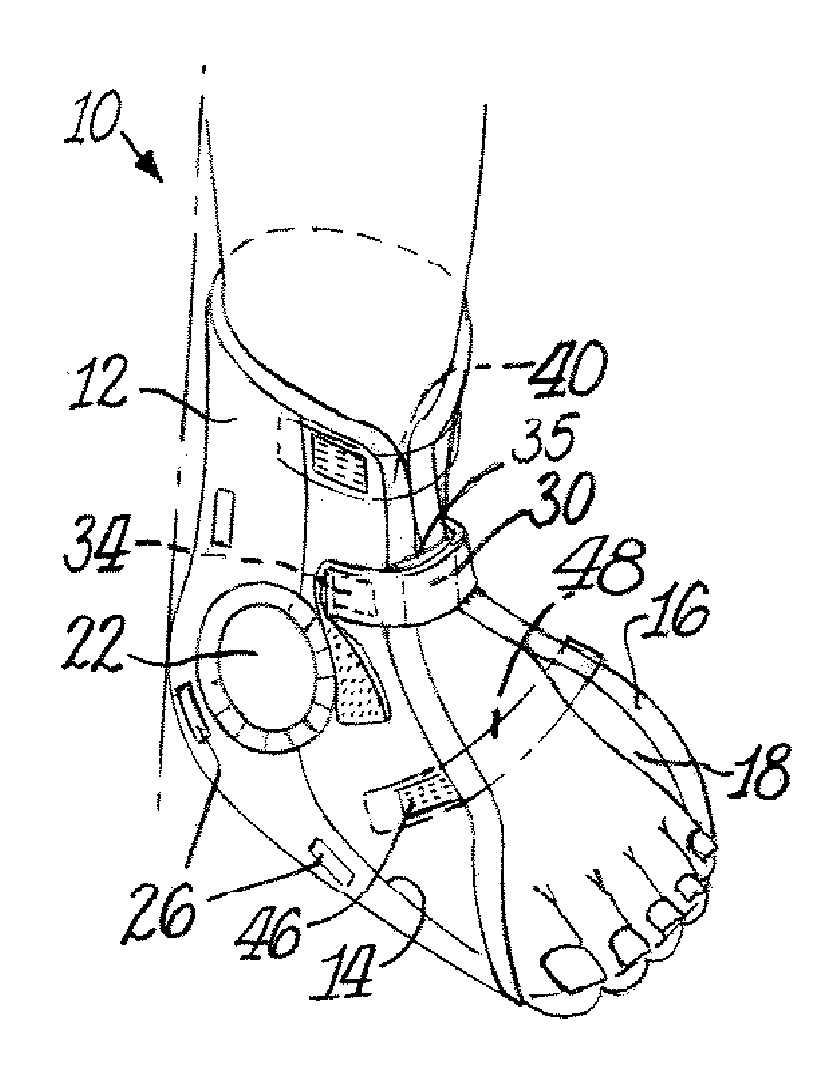

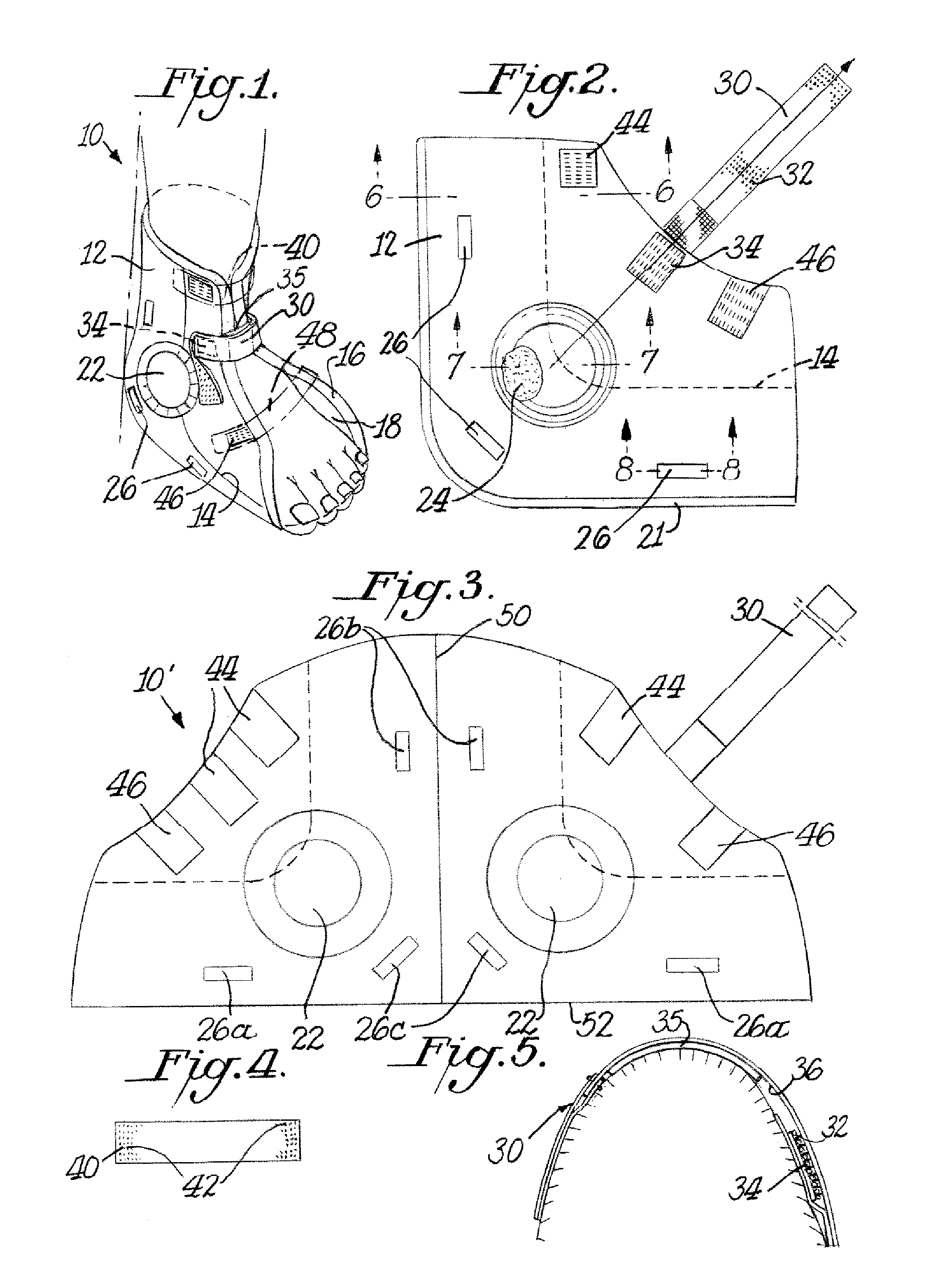

Anti-gravity decompressant for lower extremities

InactiveUS7455651B2Increase air circulationEngage with obstructionOperating chairsRestraining devicesAnti-gravityAnkle region

A textile anti-gravity decompressant for protecting a patient's heel and ankle includes a padded portion at an ankle region, and ventilation holes formed through the textile covering. The protector further has a strap closure with a fastener that mates with a fastener provided on the outer surface of the textile covering, and where the strap closure includes a patch or other covering over a portion of the fastener to prevent said strap closure from being secured too tightly over a person's heel or ankle.

Owner:MOLLICA NATALIA

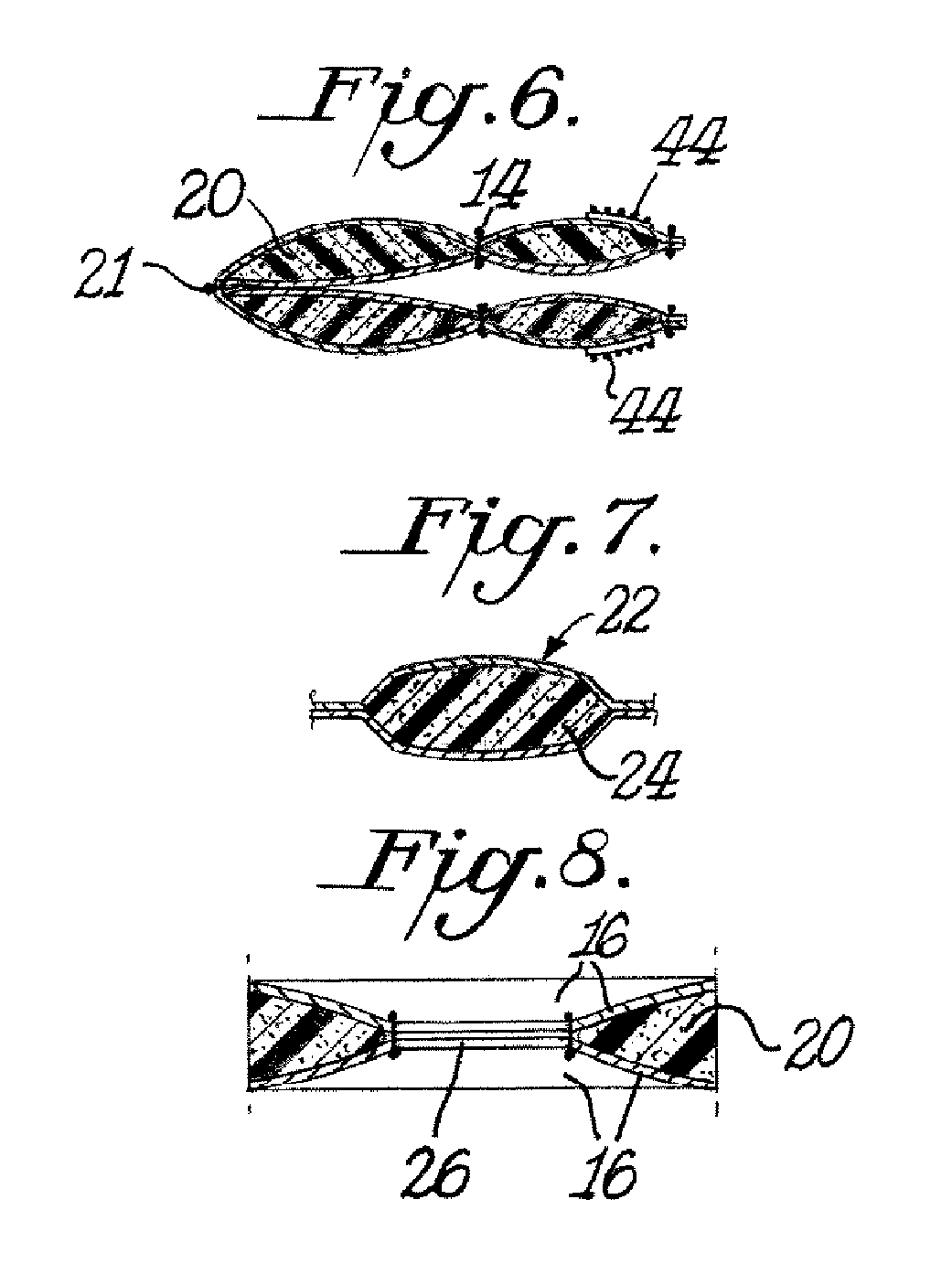

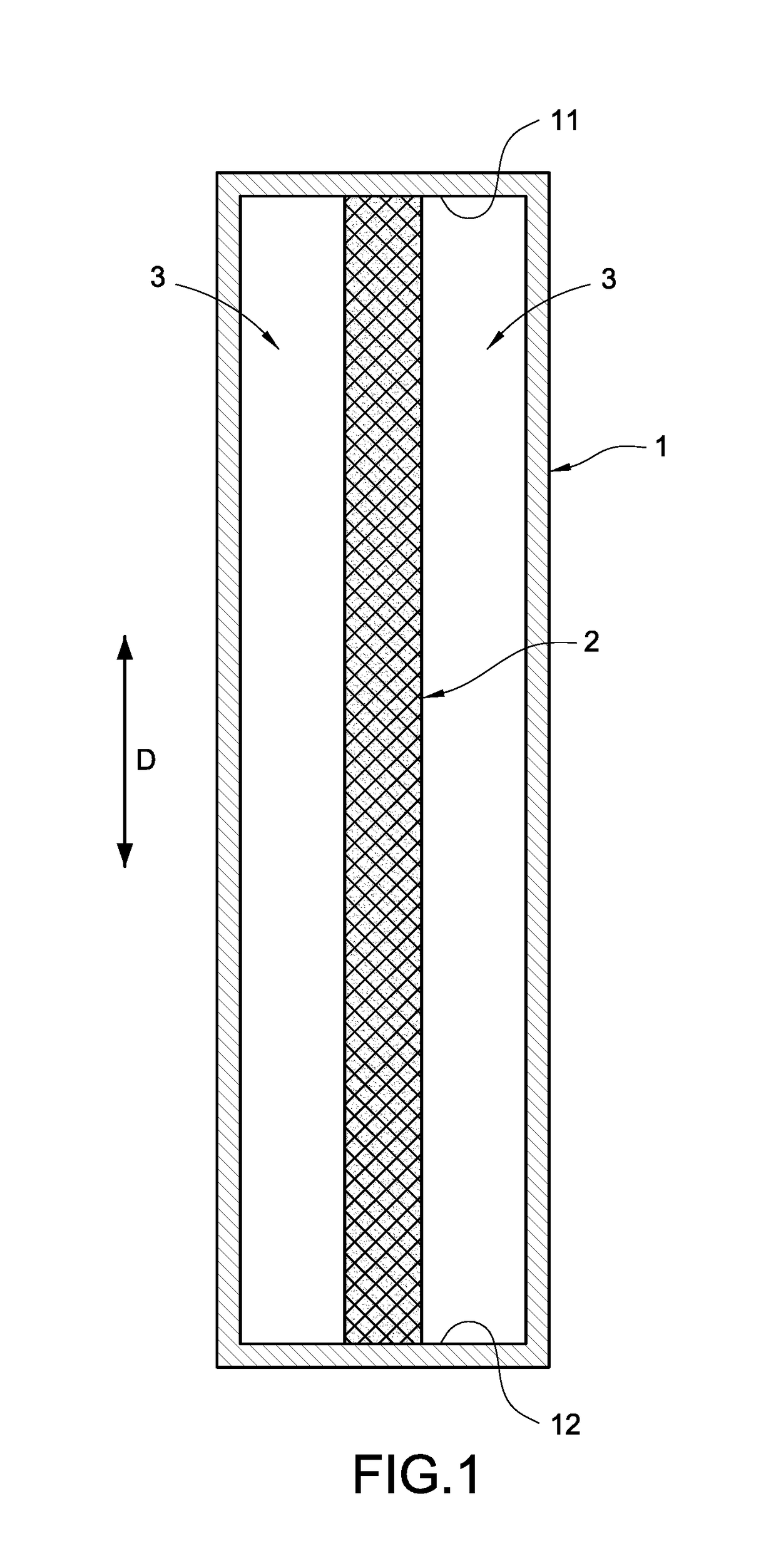

Anti-gravity heat pipe

ActiveCN105674780AStrong dependencePhase change endothermic uninterruptedIndirect heat exchangersHeat exchange apparatusAnti-gravityEngineering

The invention discloses an anti-gravity heat pipe which comprises a pipe shell, a liquid storage device, a shape memory spring, a piston and a working medium, wherein the hot end of the anti-gravity heat pipe is higher than the cold end; the liquid storage device is adjacent to the hot end and serves as a containing space for the working medium and is used for storing the working medium to cool the hot end; one end of the shape memory spring is connected with the hot end and generates thermal contact while the other end is connected with the piston; when the hot end is heated to a threshold, the shape memory spring is heated and deformed and drives the piston to push the working medium to supplement the working medium into the liquid storage device; and when the hot end is cooled to a threshold by the supplemented working medium, the shape memory spring is cooled and recovers to the original state. The anti-gravity heat pipe disclosed by the invention breaks through the capillary limitation, the structure is relatively simple, other auxiliary devices such as an isolator, a liquid storage device and a bubbler are not required, additional power consumption is avoided, external force drive is unnecessary, the heat-into-power conversion efficiency is high, and the drive ability is strong.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

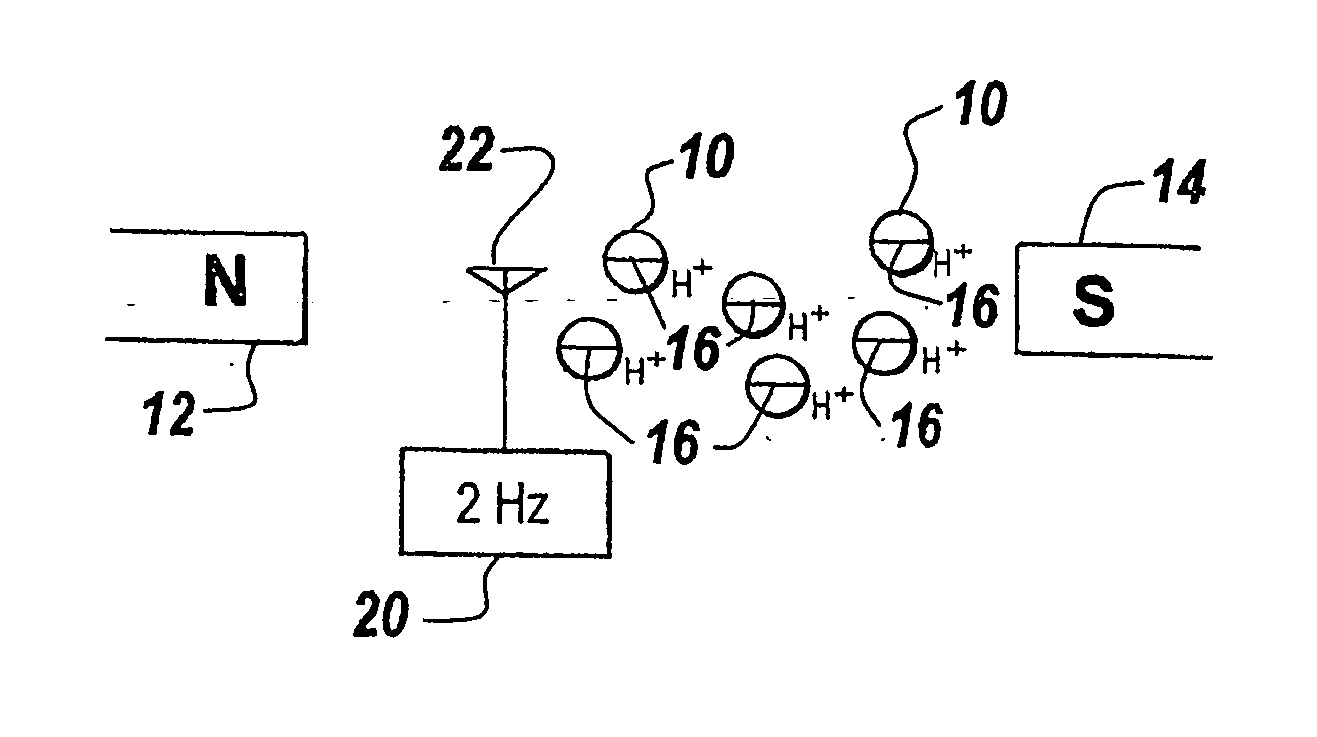

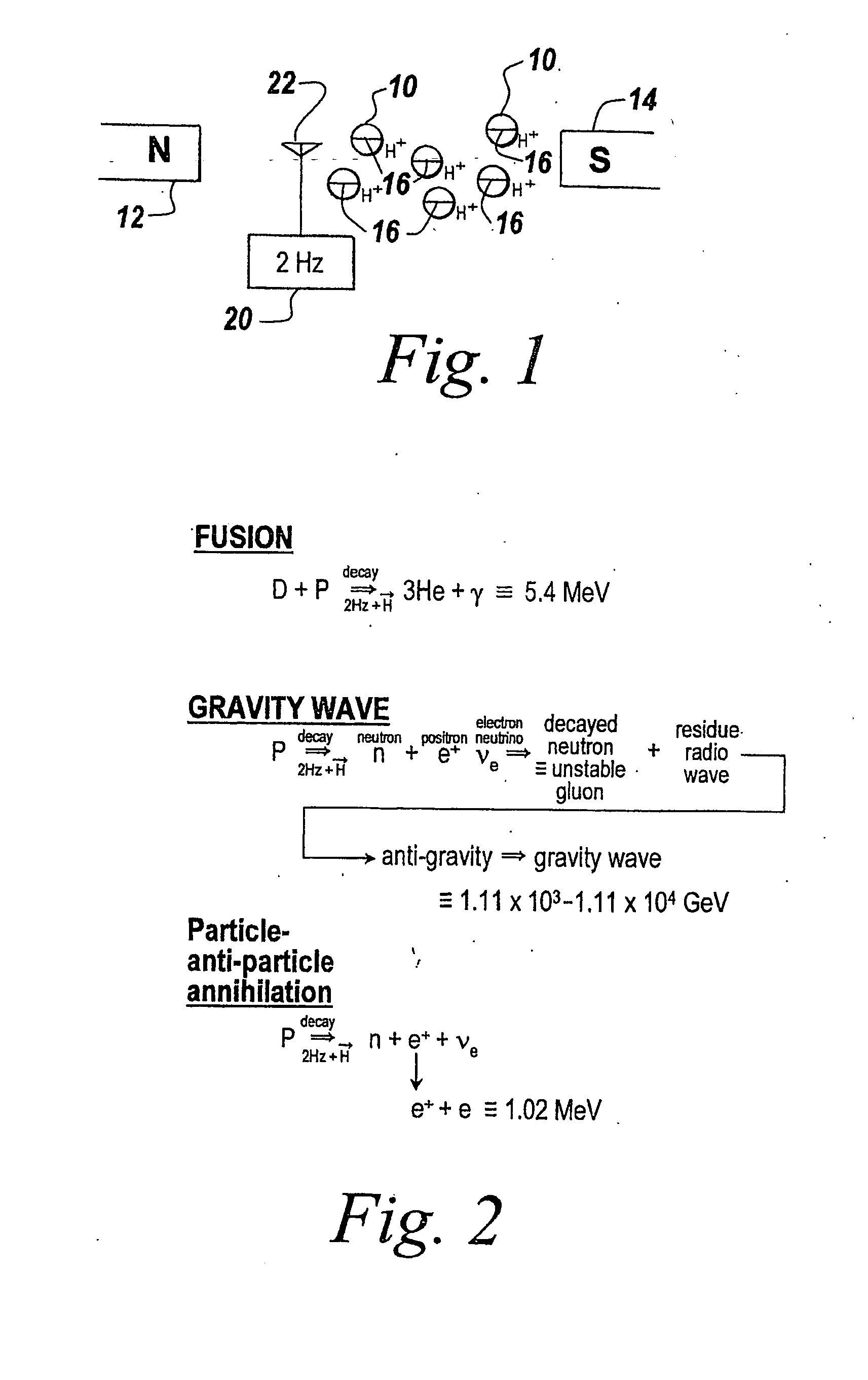

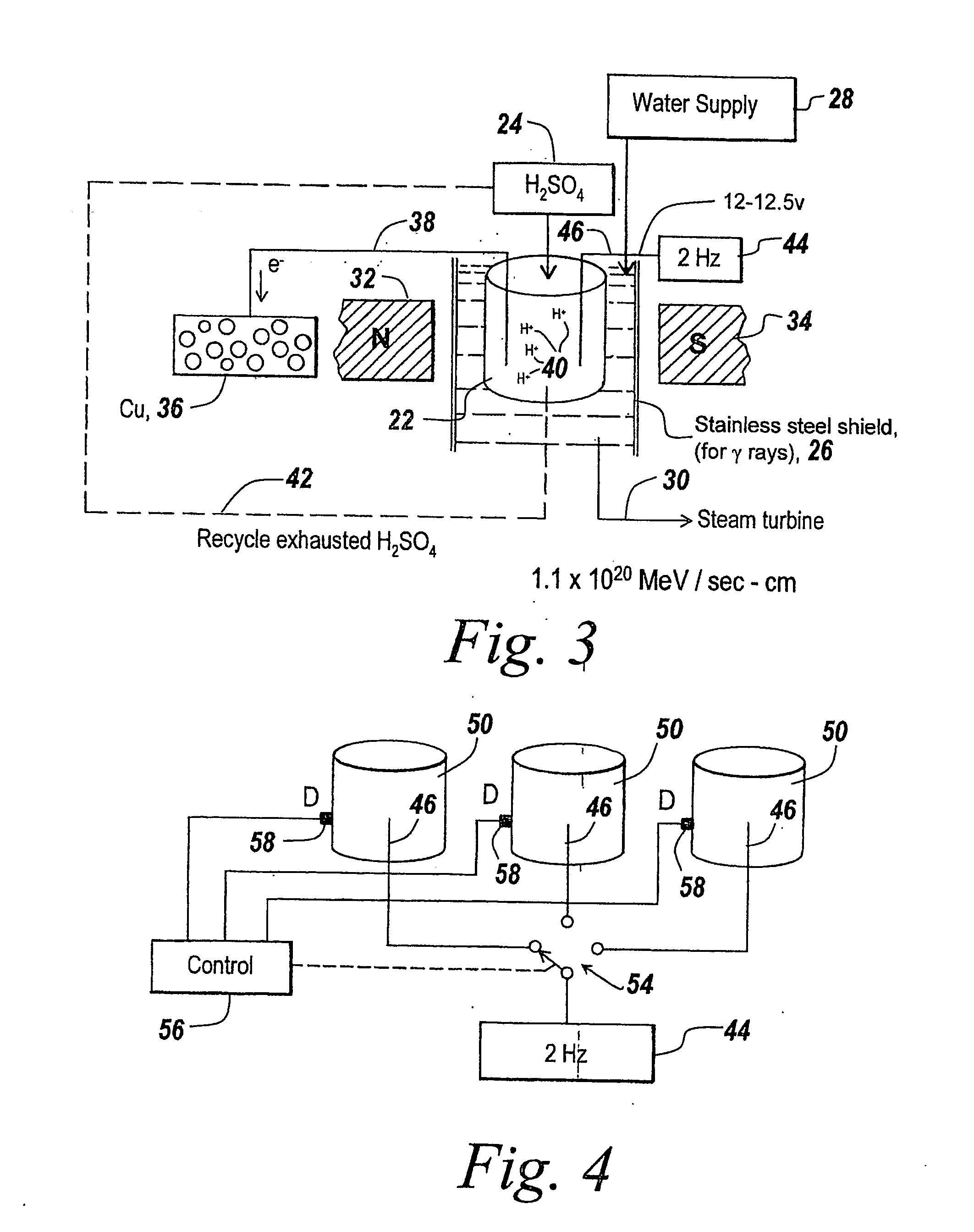

Method and apparatus for the production of energy

InactiveUS20060029178A1Simple methodEasy to mergeRadiation/particle handlingConversion outside reactor/acceleratorsAnti-gravityProton

A proton held aligned in a sufficiently strong magnetic field maintaining the low energy state for the body can be decayed with cyclic 2 Hz radio waves to provide one of three types of energy: fusion, gravity waves and anti-gravity, and particle-antiparticle annihilation. New elements may also be formed as a result of the ability to rapidly decay protons at room temperature.

Owner:TAHAN A CHRISTIAN

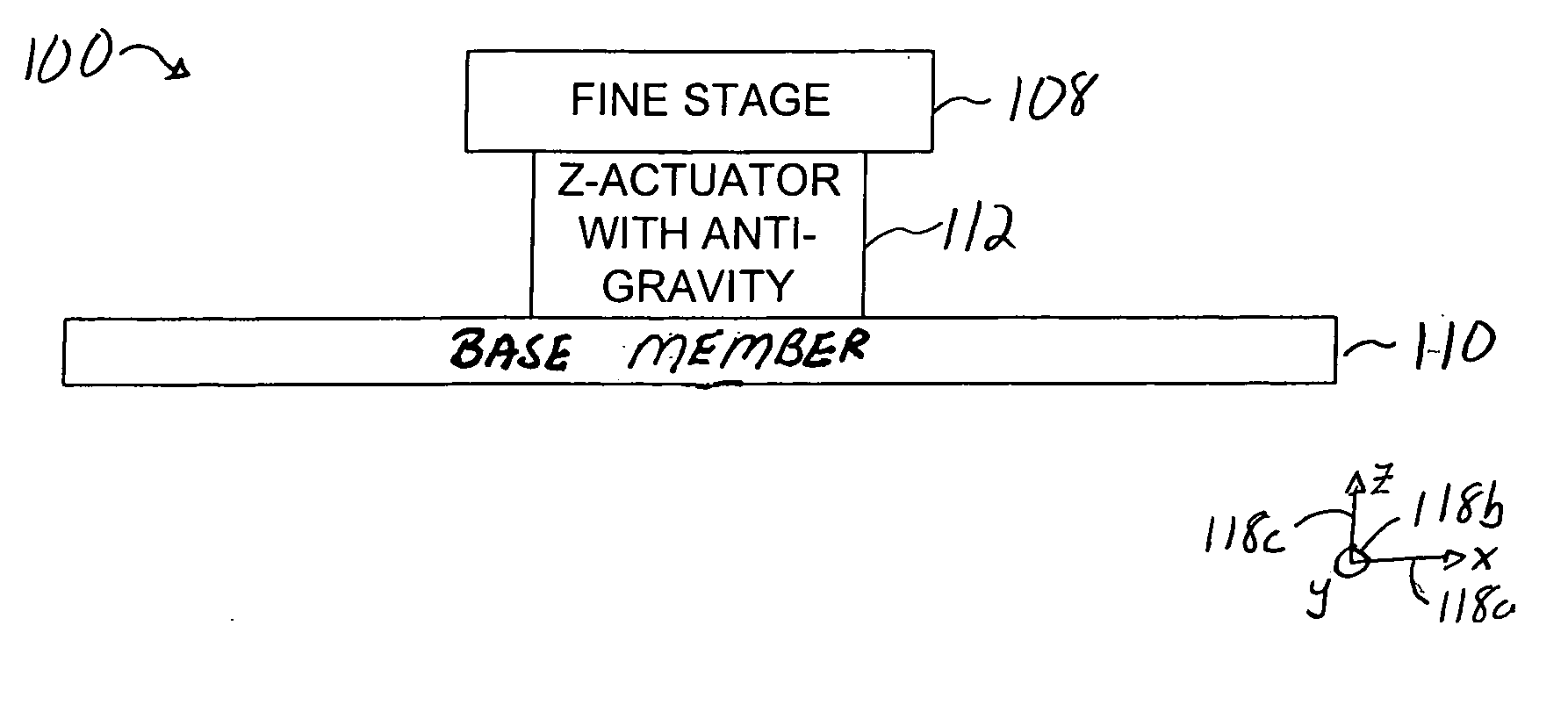

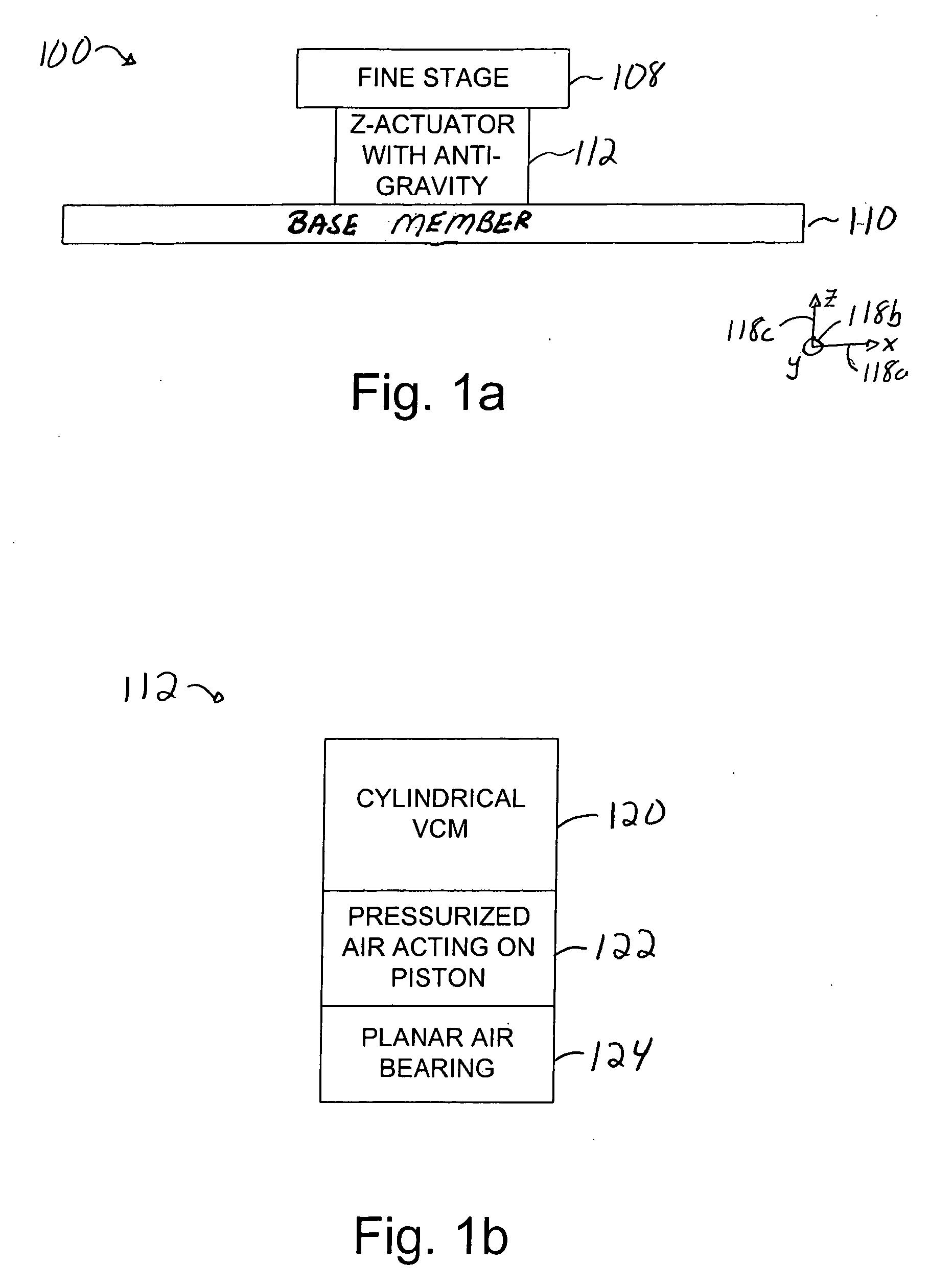

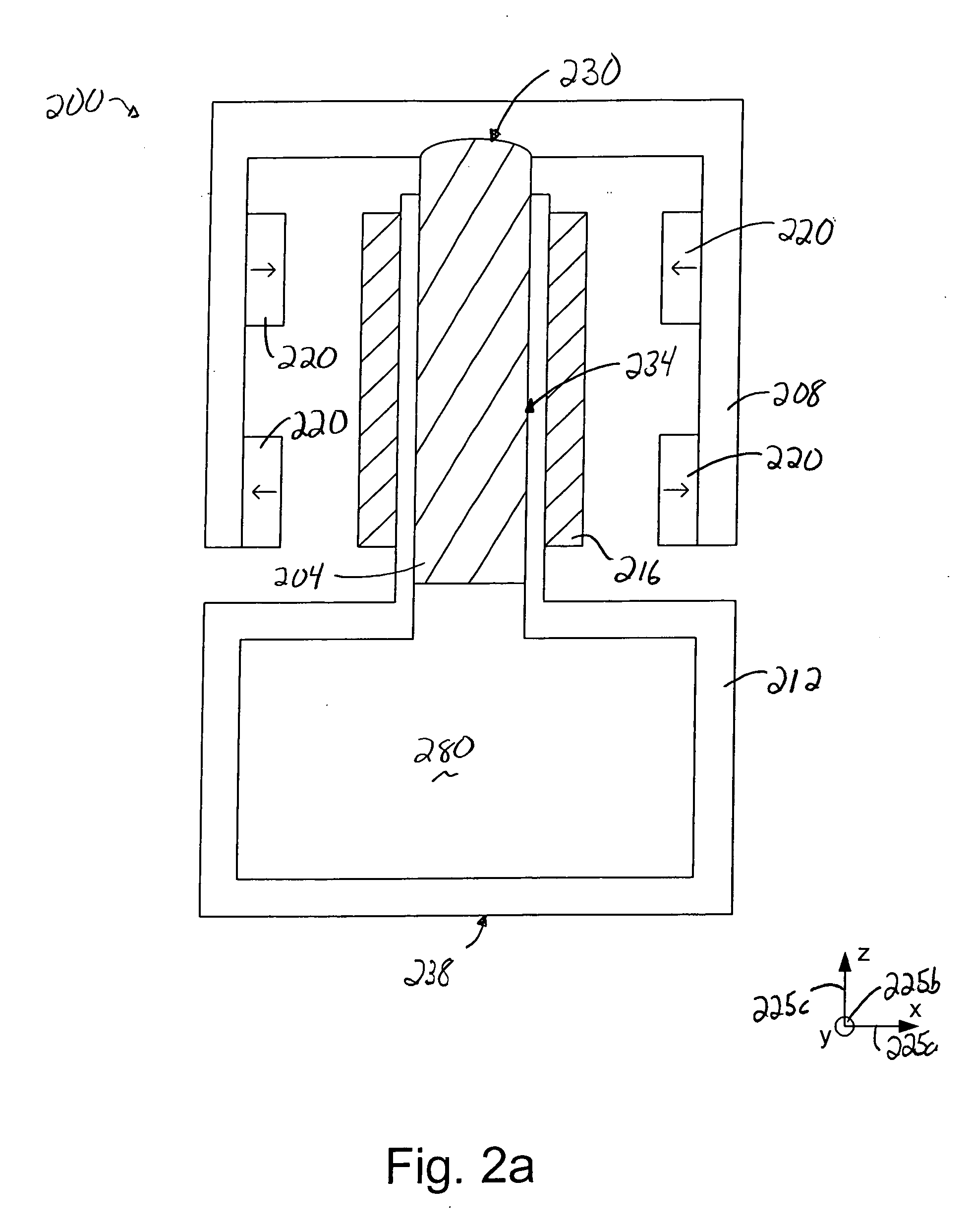

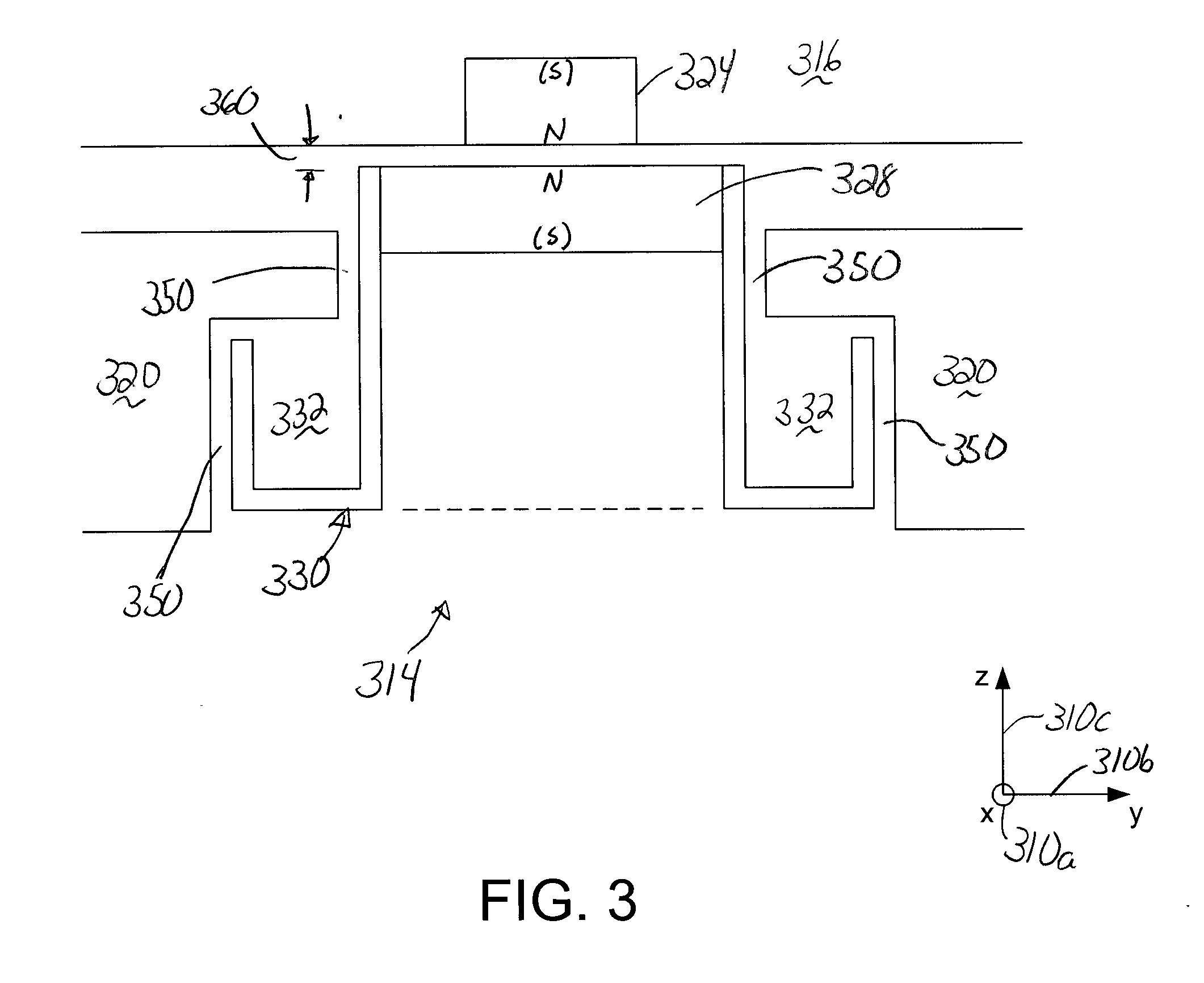

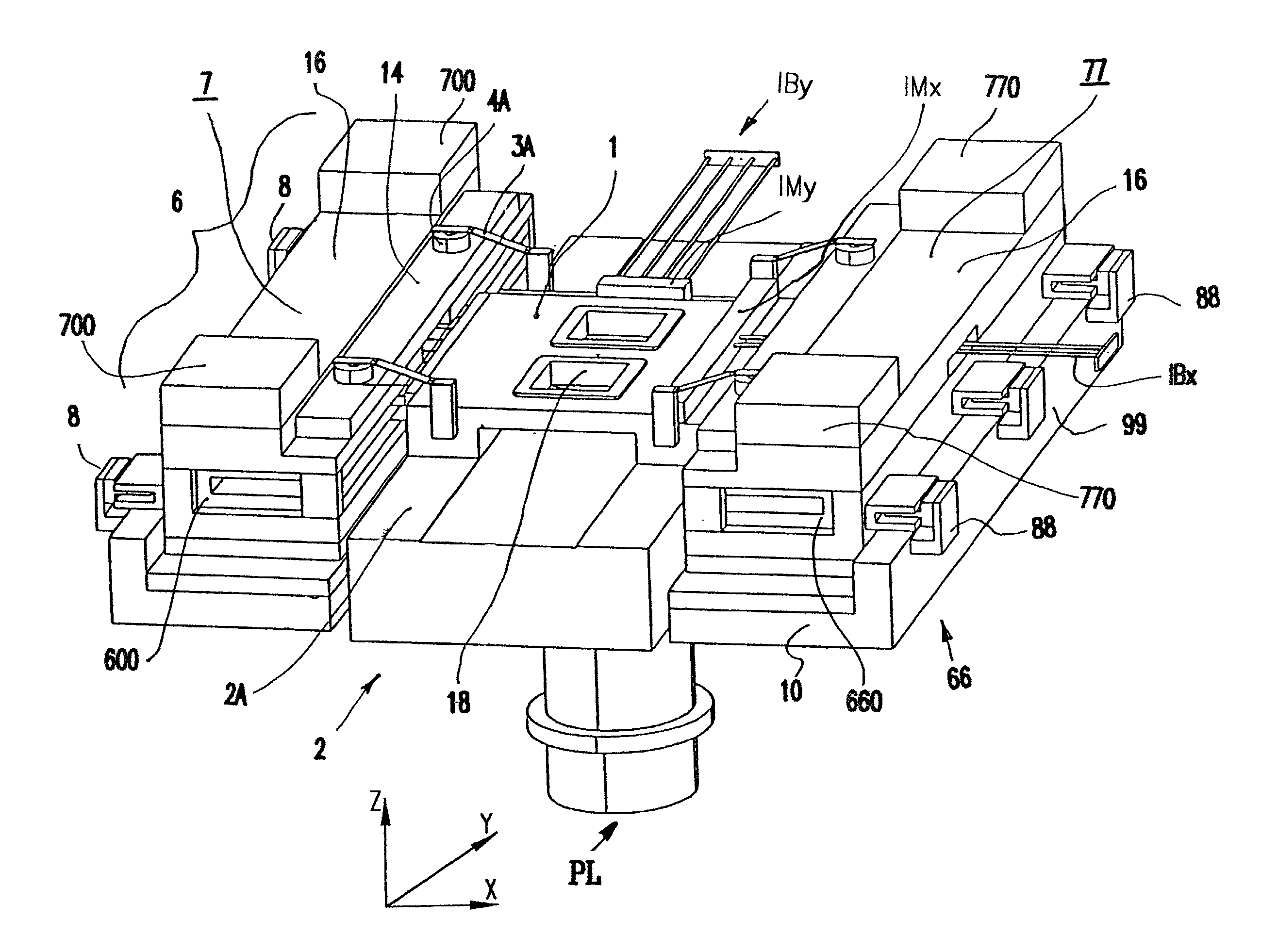

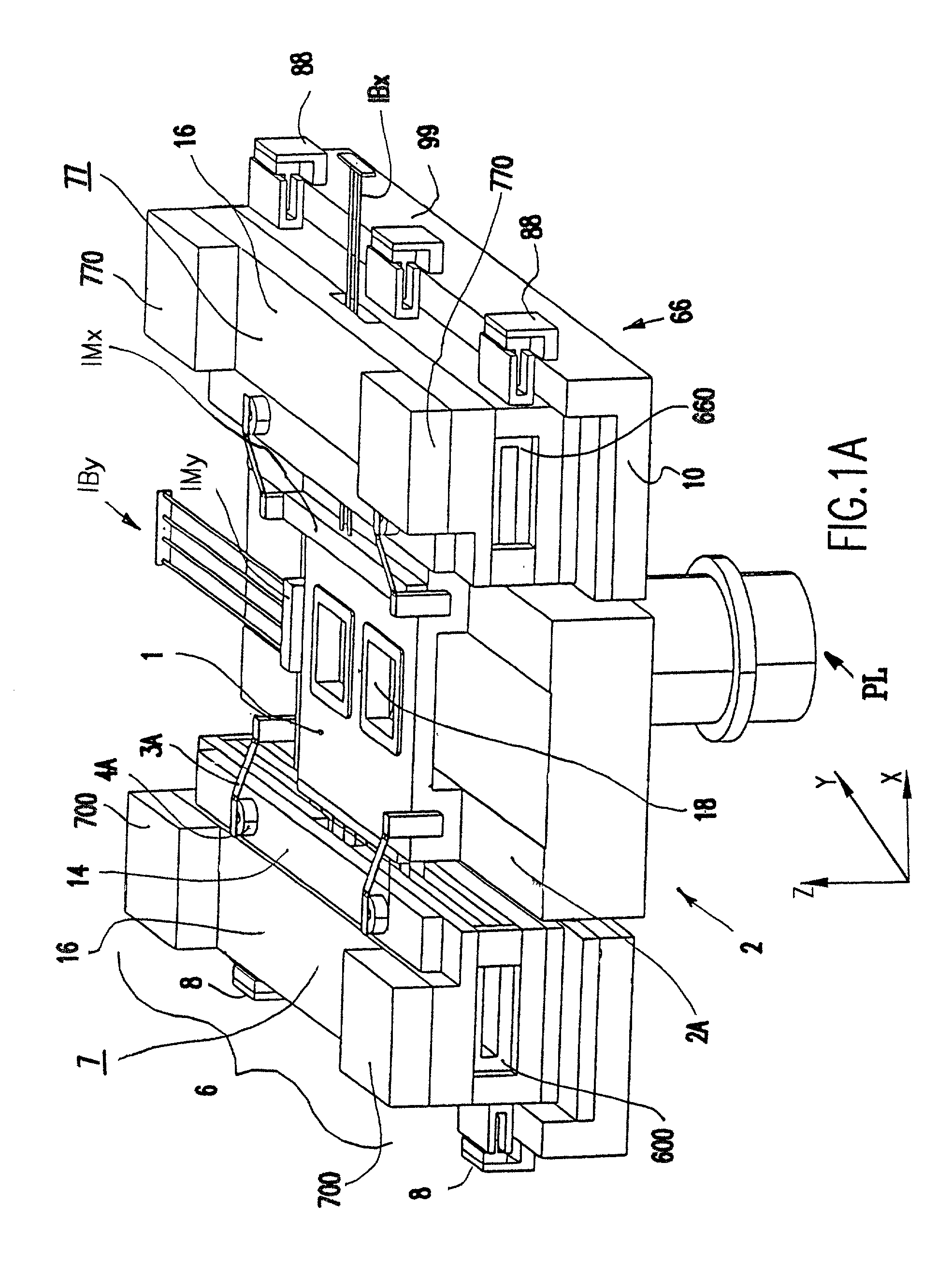

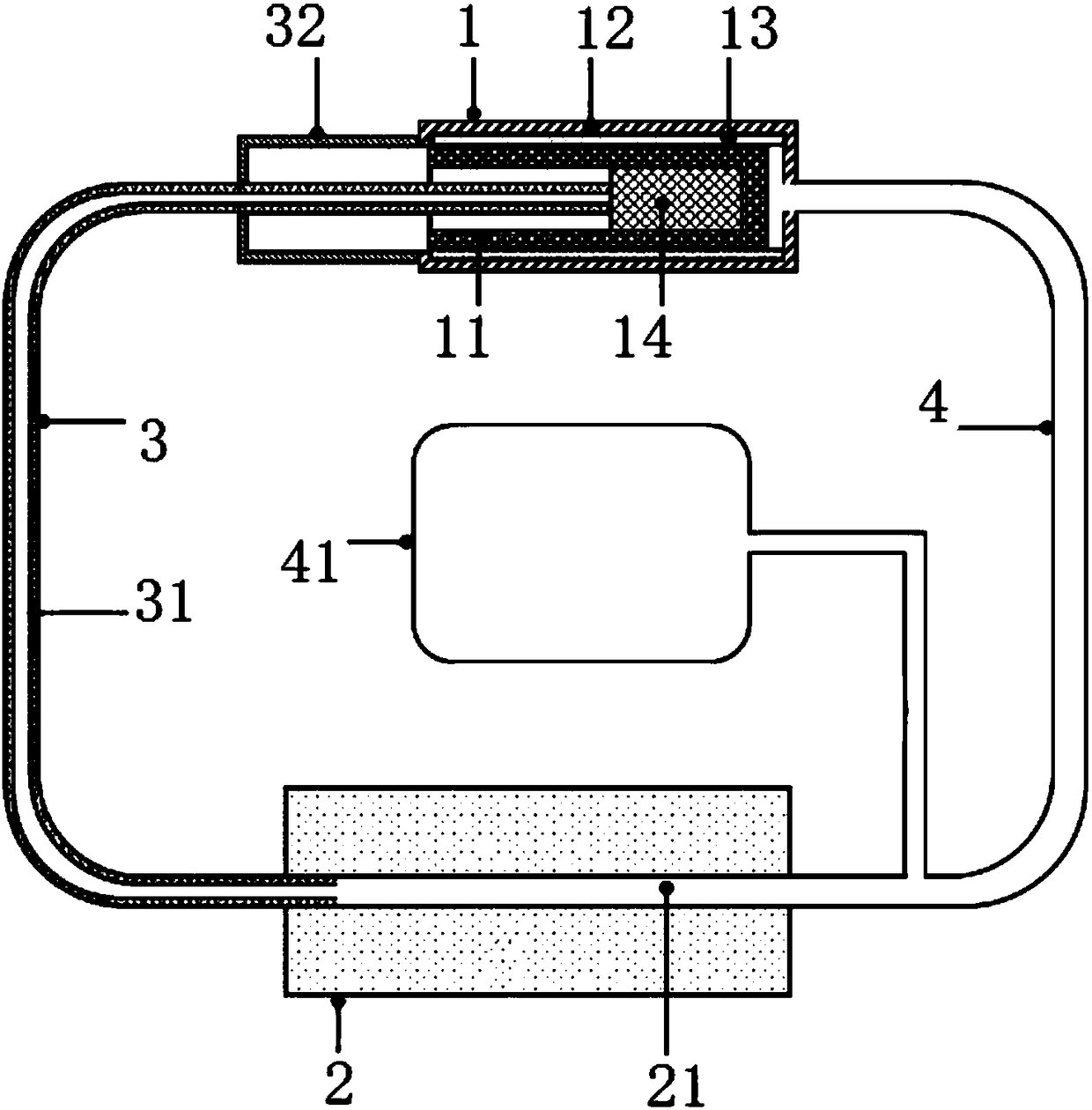

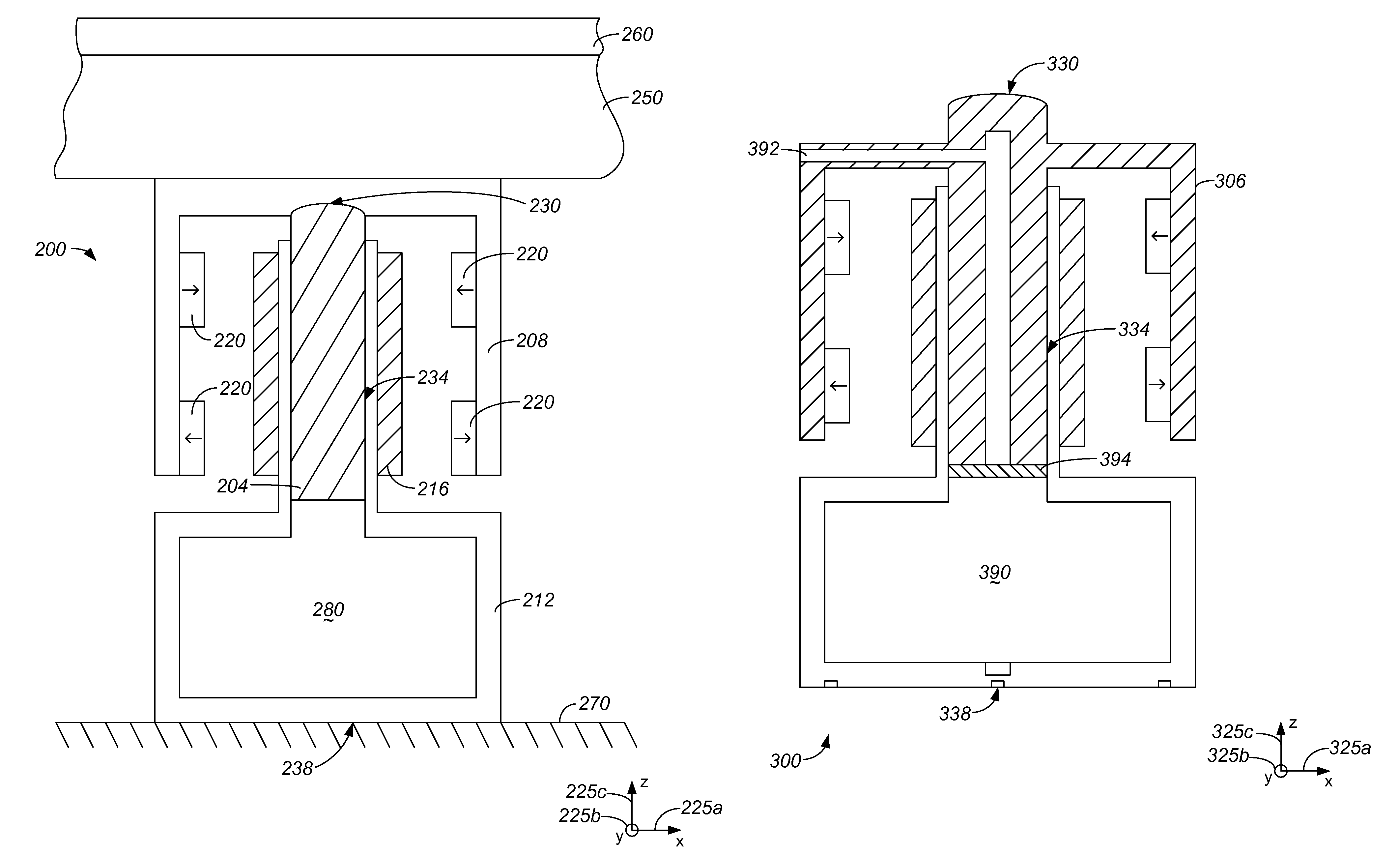

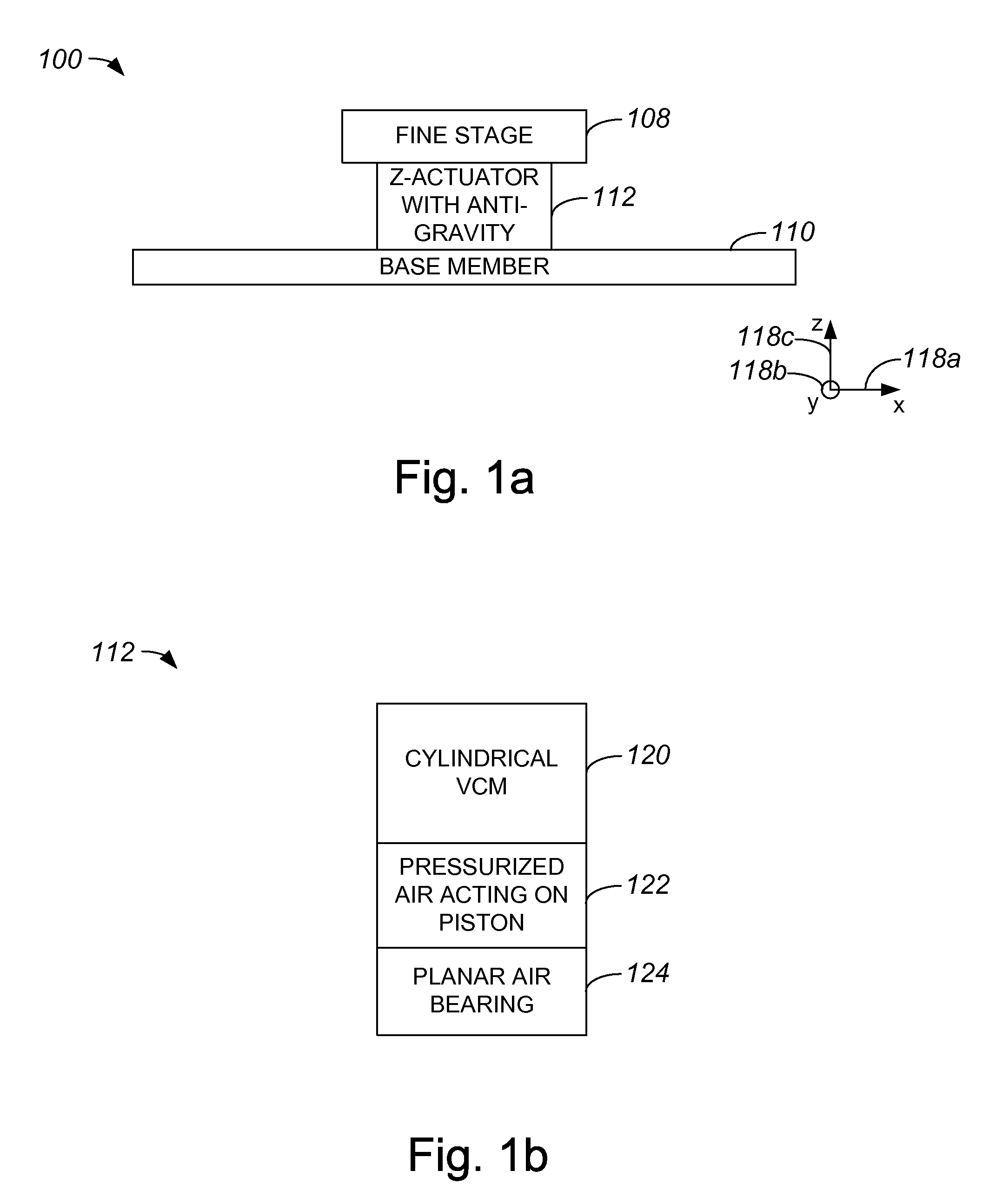

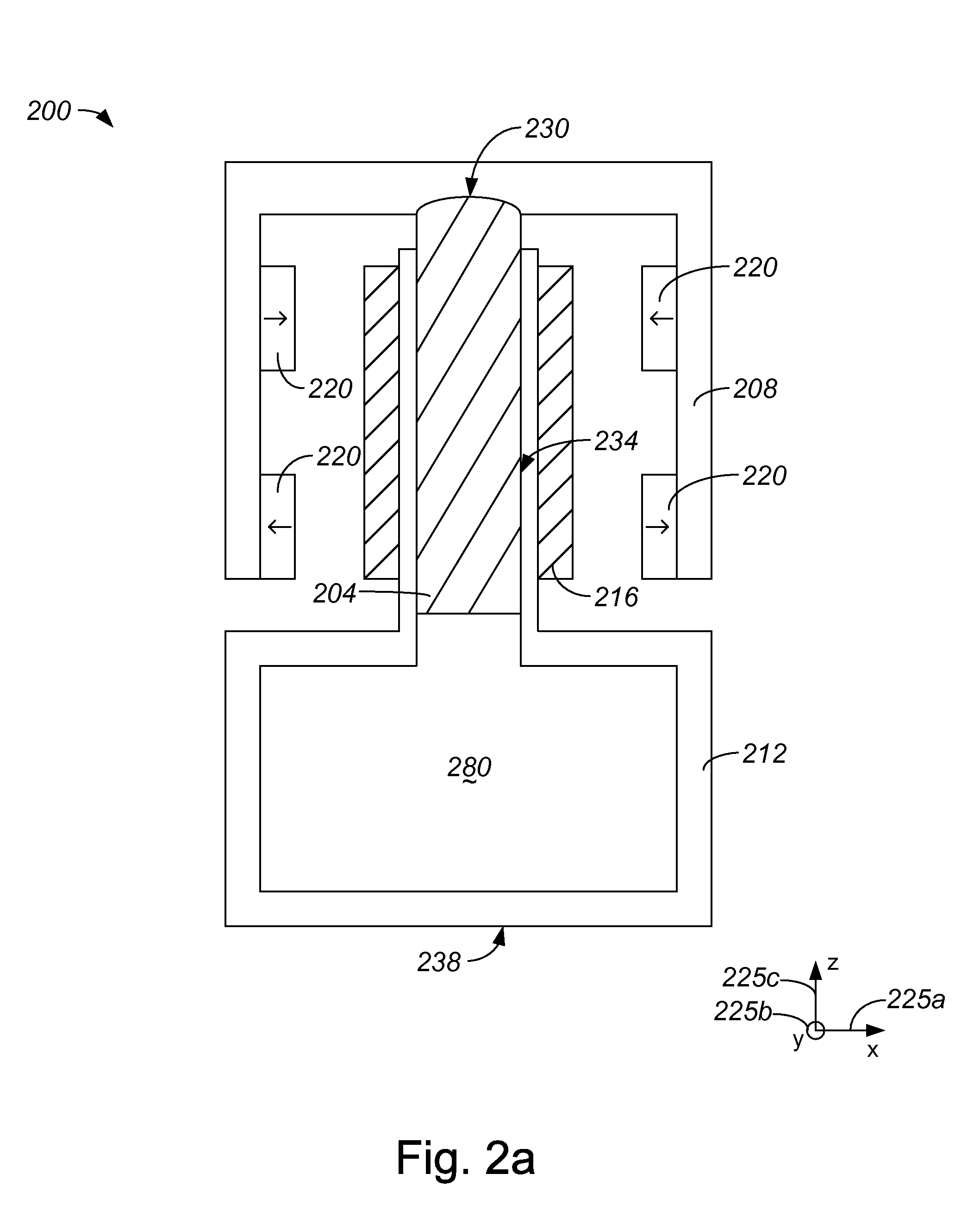

Z actuator with anti-gravity

InactiveUS20060061219A1Easy to operateMagnetic circuitPhotomechanical apparatusAir bearingAnti-gravity

Methods and apparatus which are suitable for actuating a stage relative to a z-axis and supporting the weight of the stage against the force of gravity are disclosed. According to one aspect of the present invention, an actuator device includes a first arrangement, a magnetic system, a piston, and a guide bearing arrangement. The first arrangement includes a yoke and a center pole, and the magnetic system includes a magnet that is coupled to the yoke as well as a coil which cooperate to function as a voice coil motor. The piston supports at least a weight associated with the first arrangement, and the guide bearing arrangement includes a planar air bearing that enables the device to move over an external surface.

Owner:NIKON CORP

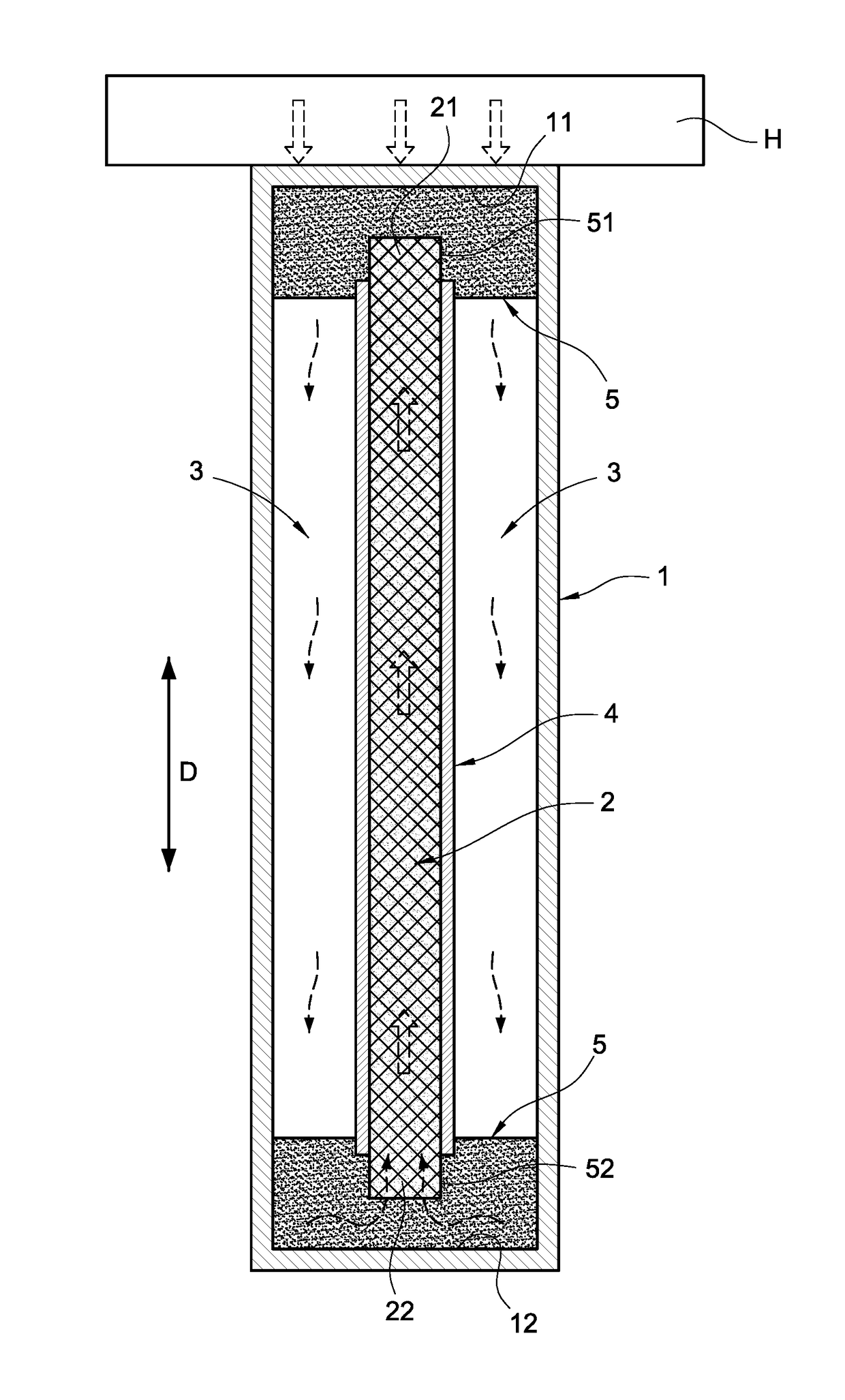

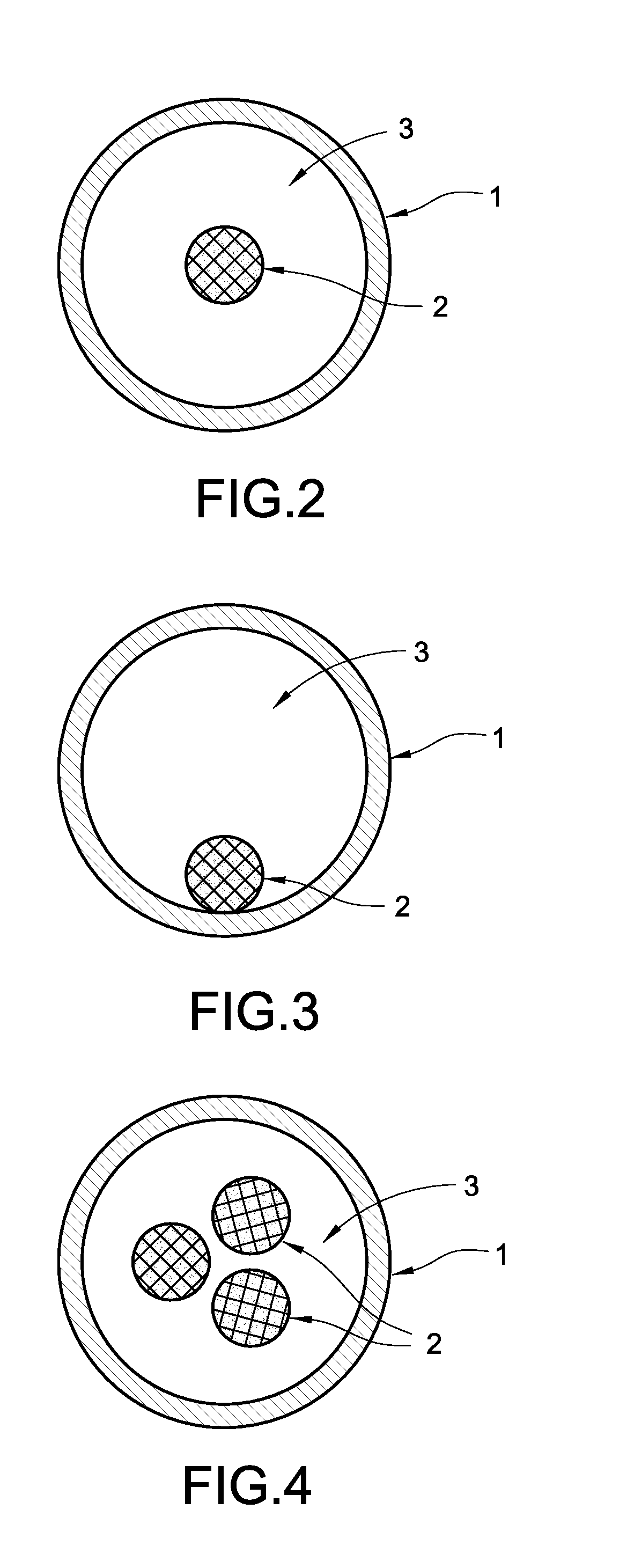

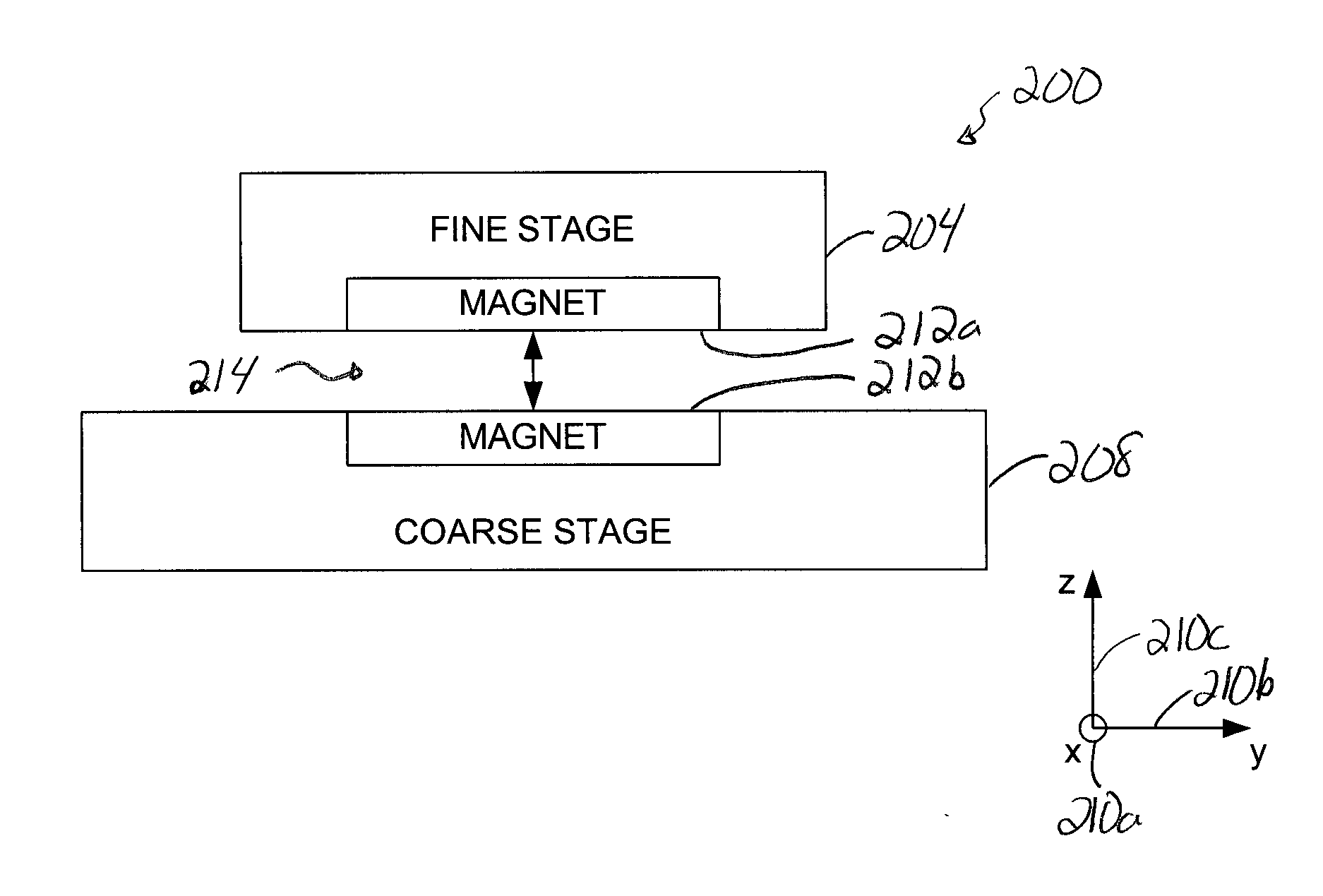

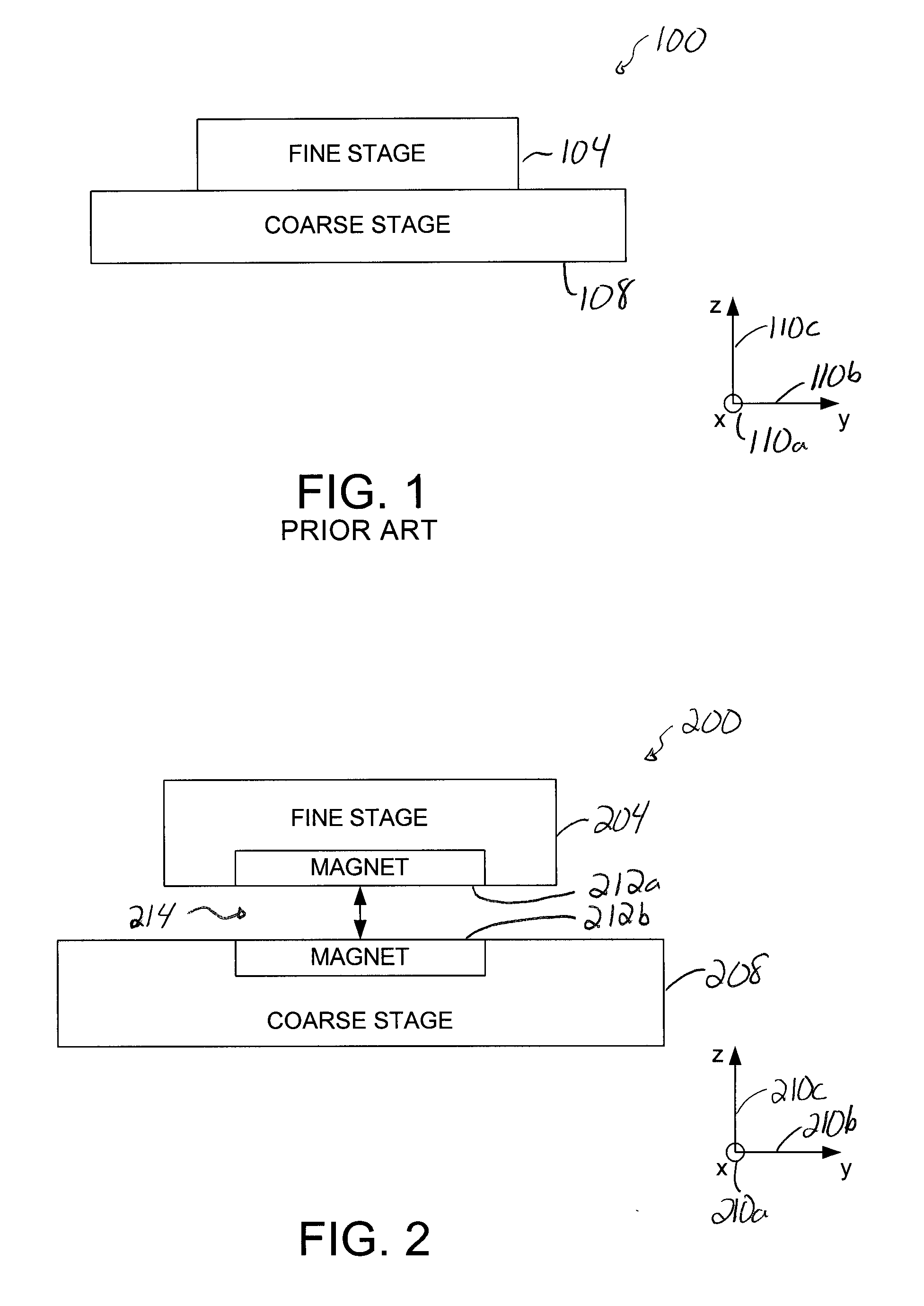

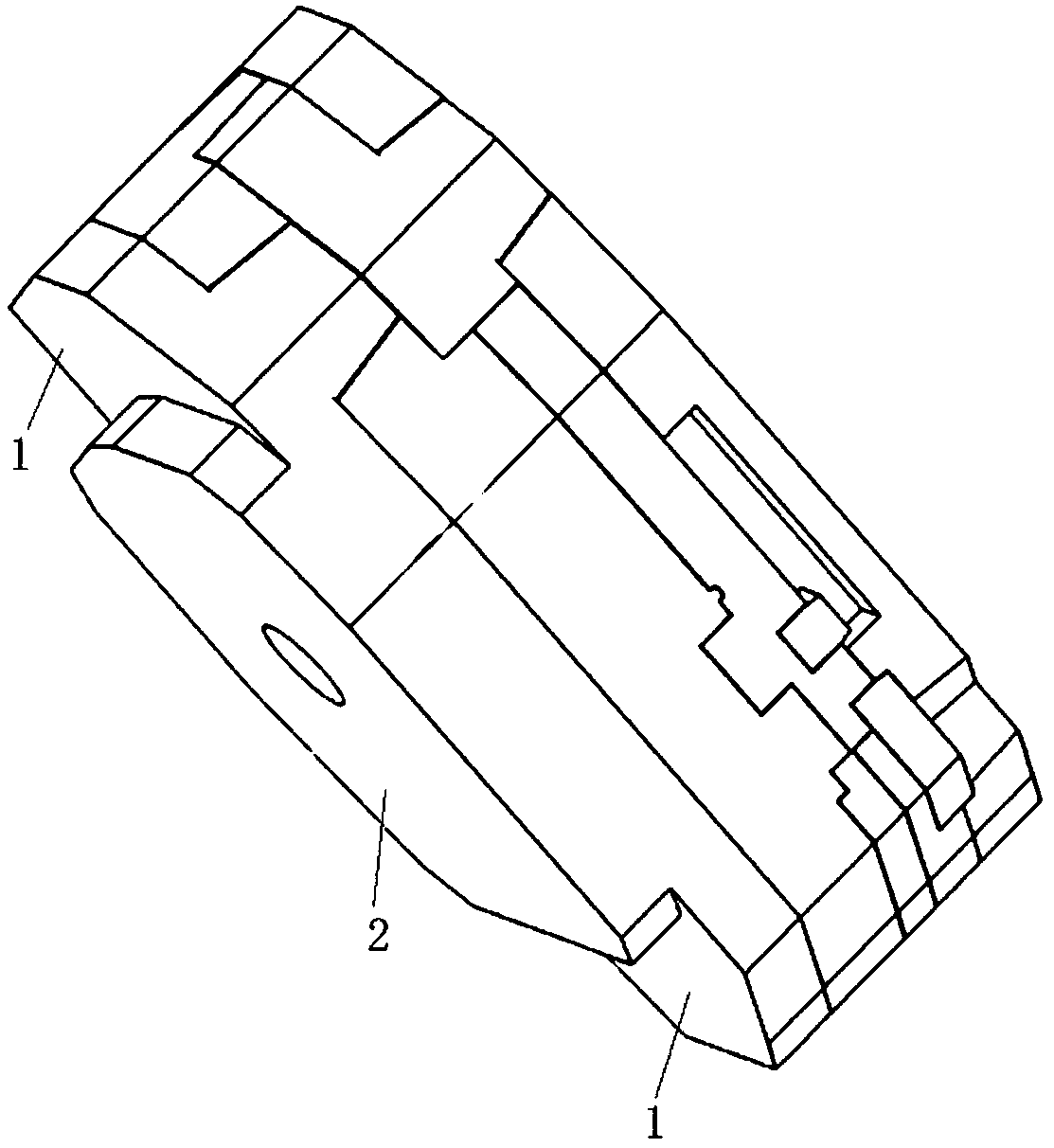

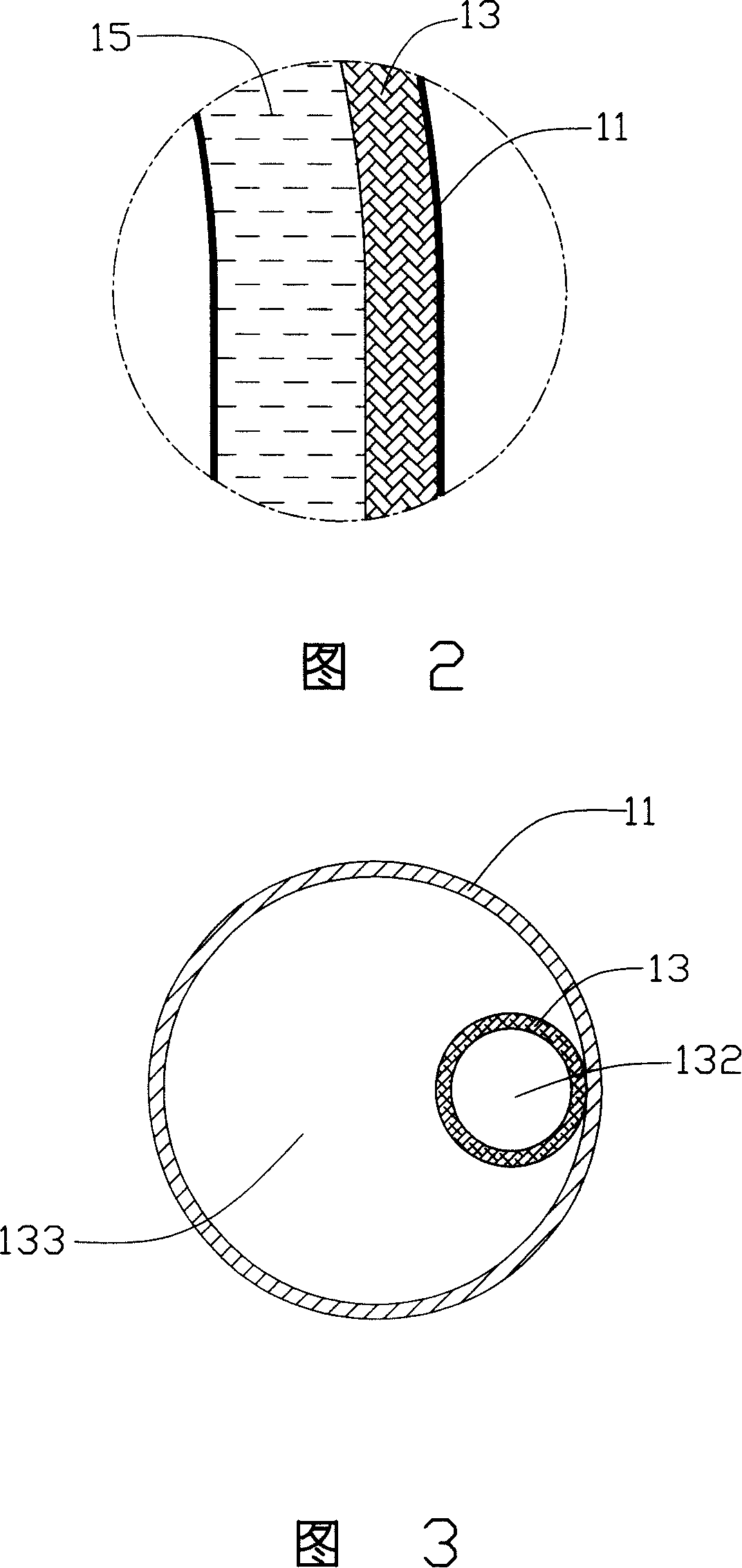

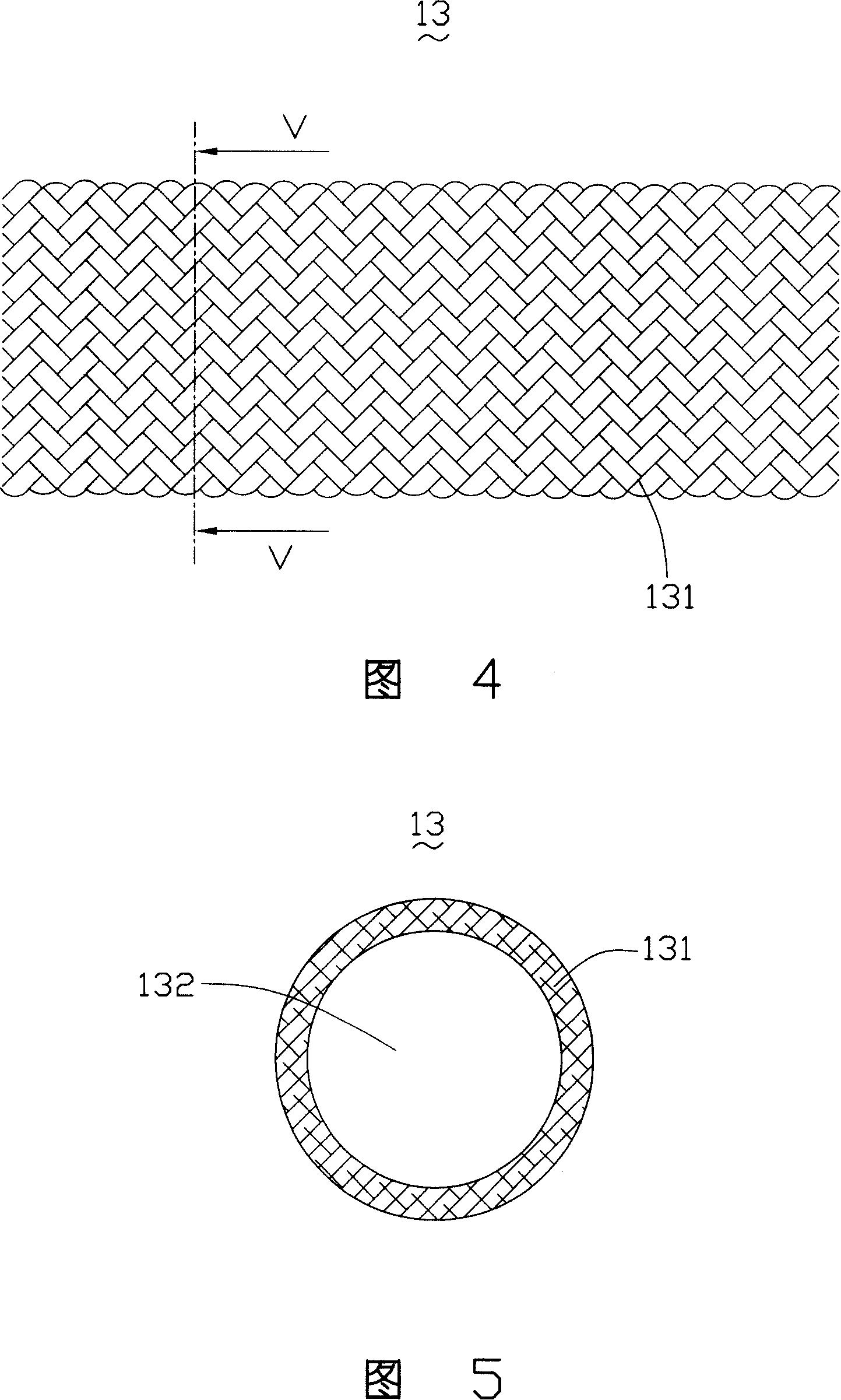

Anti-gravity heat pipe device

ActiveUS20170241717A1Counteract gravityGuaranteed to workIndirect heat exchangersAnti-gravityEngineering

A heat pipe device includes an outer pipe and at least one first capillary structure. The outer pipe is a hollow pipe and has a defined lengthwise direction, and the first capillary structure is accommodated along the lengthwise direction and positioned in the outer pipe, and at least one steam channel is formed between the first capillary structure and the outer pipe. Even if the heat pipe device is upside down, the heat pipe still can resist gravity and work normally to achieve the effect of using the heat pipe without being limited by the using direction.

Owner:COOLER MASTER CO LTD

Anti-Gravity Device for Supporting Weight and Reducing Transmissibility

InactiveUS20070236854A1Low stiffnessReduce transfer ratePhotomechanical apparatusRelaysAir bearingAnti-gravity

Methods and apparatus for supporting the weight of a first stage of a stage apparatus using magnets are disclosed. According to one aspect of the present invention, and apparatus includes a first structure, a second structure, and an anti-gravity device. The anti-gravity device has a first magnet and a piston arrangement that includes a second magnet. The first magnet is coupled to the first structure, and the piston arrangement is movably interfaced with the second structure through an air bearing. The first magnet and the piston arrangement cooperate to support the first structure over the second structure relative to a vertical axis.

Owner:NIKON CORP

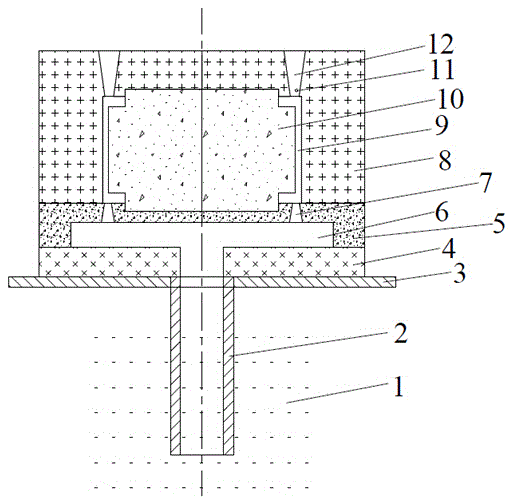

Method for V-method shaping anti-gravity pouring of aluminum alloy casting

ActiveCN104308081AImprove internal qualityHigh dimensional accuracyFoundry mouldsFoundry coresAnti-gravityLiquid metal

The invention provides a method for V-method shaping anti-gravity pouring of an aluminum alloy casting, which is applied to the technical field of casting. The method for the V-method shaping anti-gravity pouring of the aluminum alloy casting comprises the following steps: V-method shaping, resin sand core making or V-method core making is adopted; resin sand shaping or shaping and sand making are formed by a V method; a lower box and a middle box adopt the V method or the resin sand shaping; an anti-gravity pouring manner is adopted and a metal separation plate has sealing and bearing effects; metal liquid is filled into a transverse pouring gate, an inner sprue, a casting and an open riser under the effect of pressure along a liquid rising pipe from bottom to top in an anti-gravity direction; and the open riser is formed in the top of the casting and a liquid level detector is used for stopping pressurizing when the filling height of the metal liquid reaches the liquid level detector, so that the liquid metal is suspended at the position. The method can be used for producing the aluminum alloy casting with good inner quality, high size precision and excellent surface quality; and sand is convenient to clean, working conditions are good and the cost is saved.

Owner:SHENYANG RES INST OF FOUNDRY

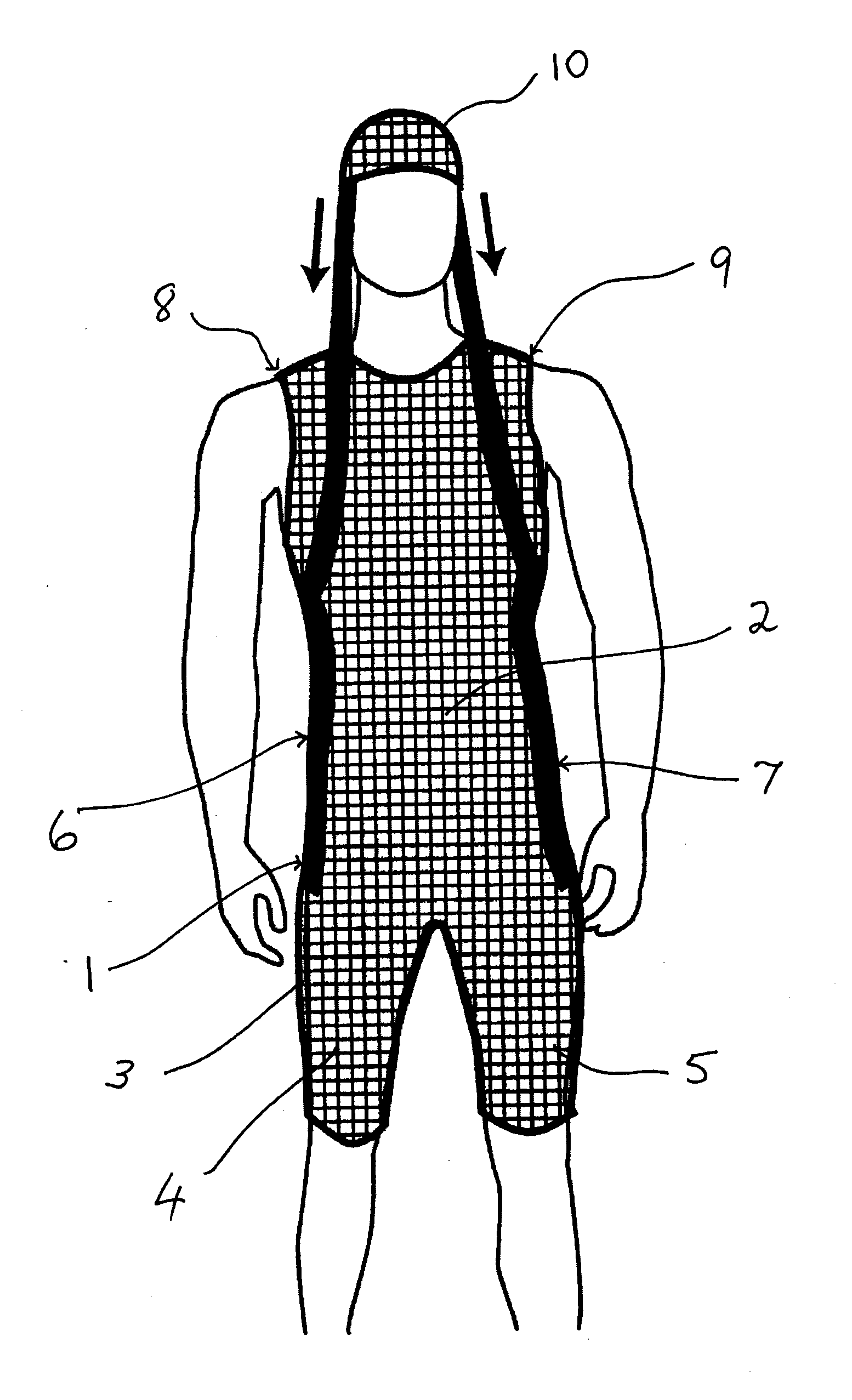

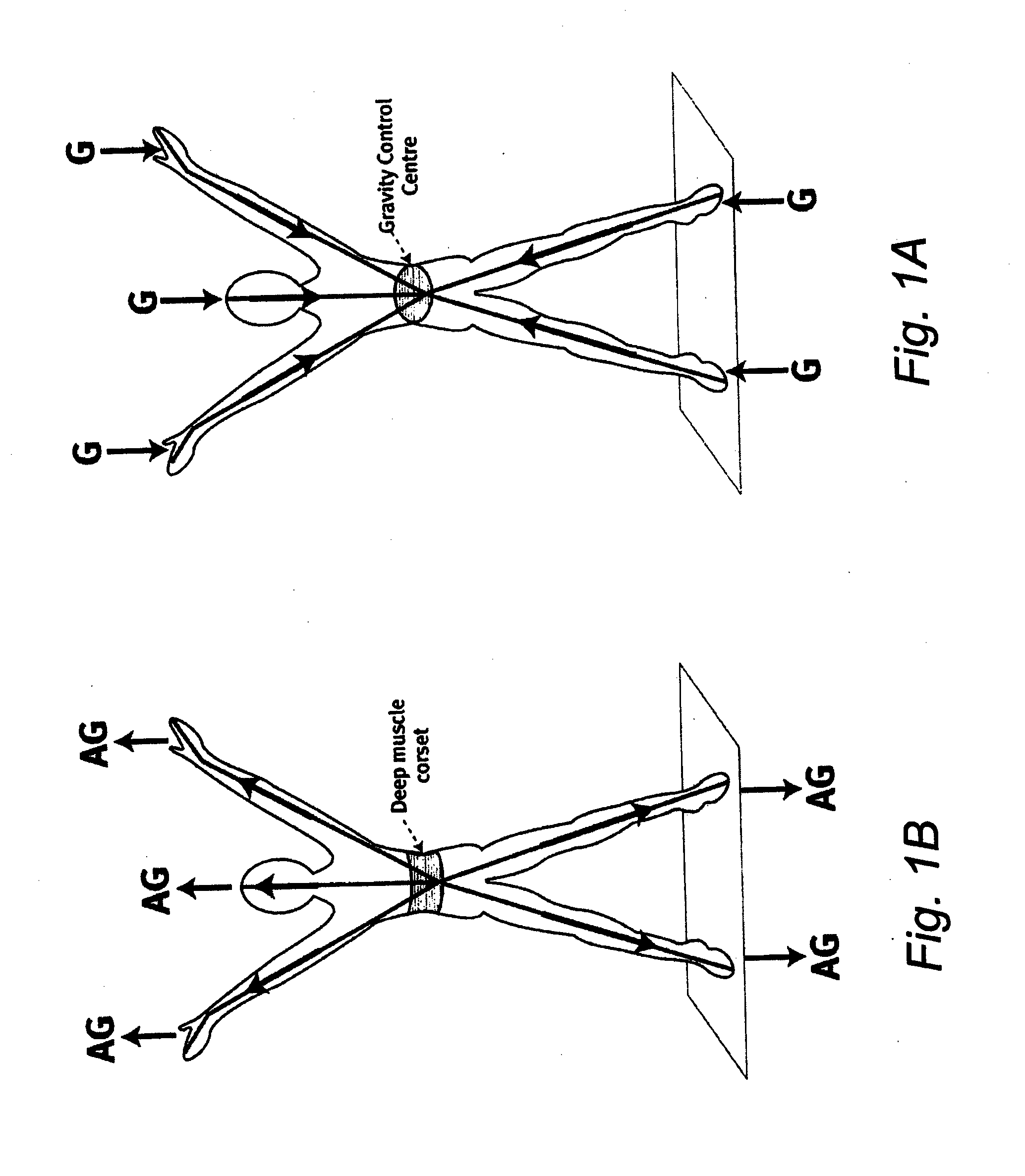

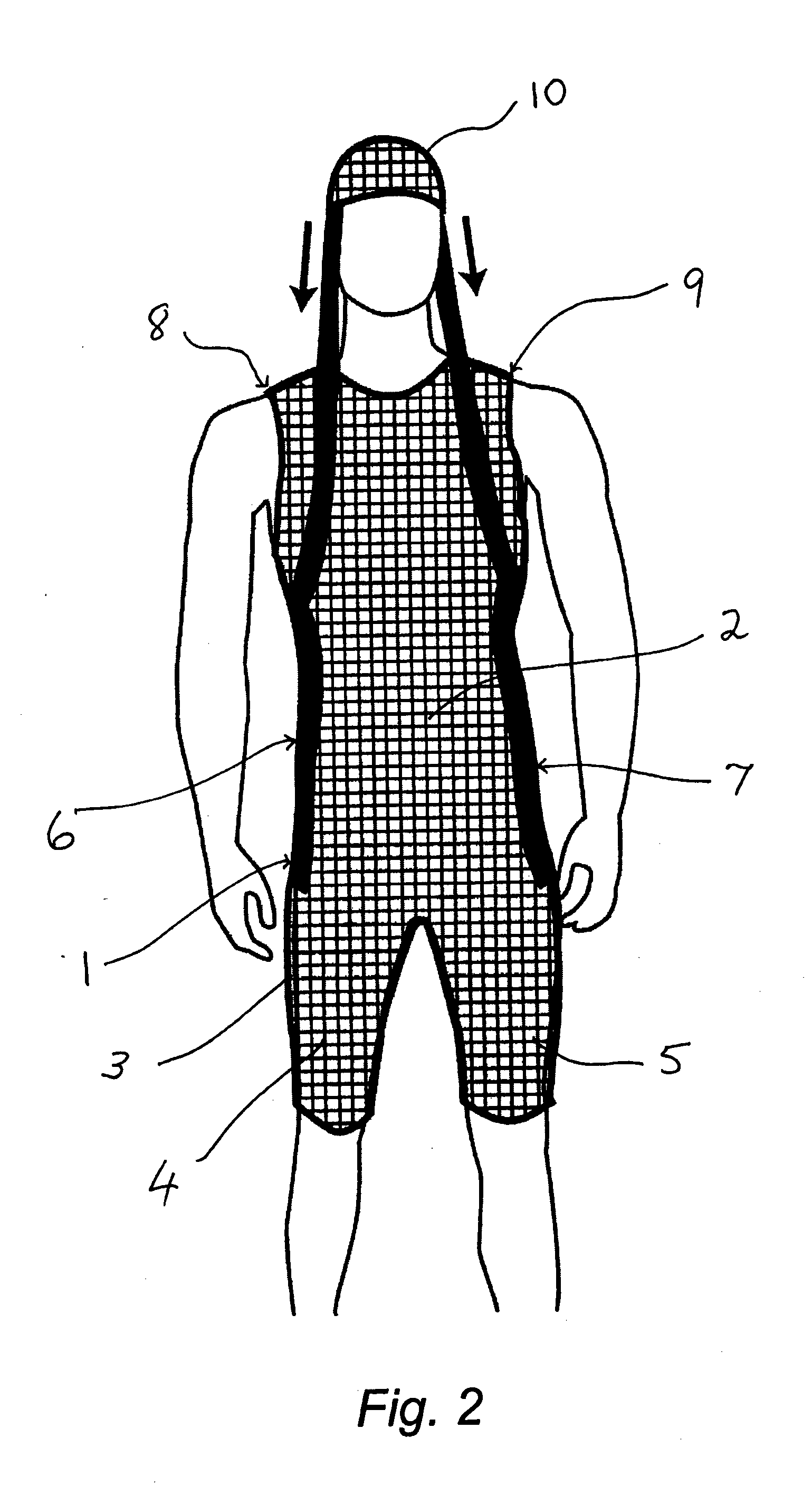

Antigravity whole body exercise garments

ActiveUS20130130874A1Increase activity levelFacilitate the antigravity musclesResilient force resistorsProtective garmentCoronal planeAnti-gravity

The invention provides an antigravity muscle exerciser comprising a garment which when worn by a user is close-fitting and covers at least the torso of said user. The garment comprises separate top and bottom portions or is a one-piece article, and has incorporated therein first portions of flexible material on each side of the torso which extend from the pelvis to beyond a respective shoulder where the portions are contiguous with a second portion of flexible material which extends across the top of the head of the user in a coronal plane. The portions of flexible material in combination have a length and elasticity which creates axial compression between the top of the head and the pelvis. The invention also provides a method of utilising the garment exercising deep posture and anti-gravity muscles.

Owner:GRAVITY FITNESS AUSTRALIA

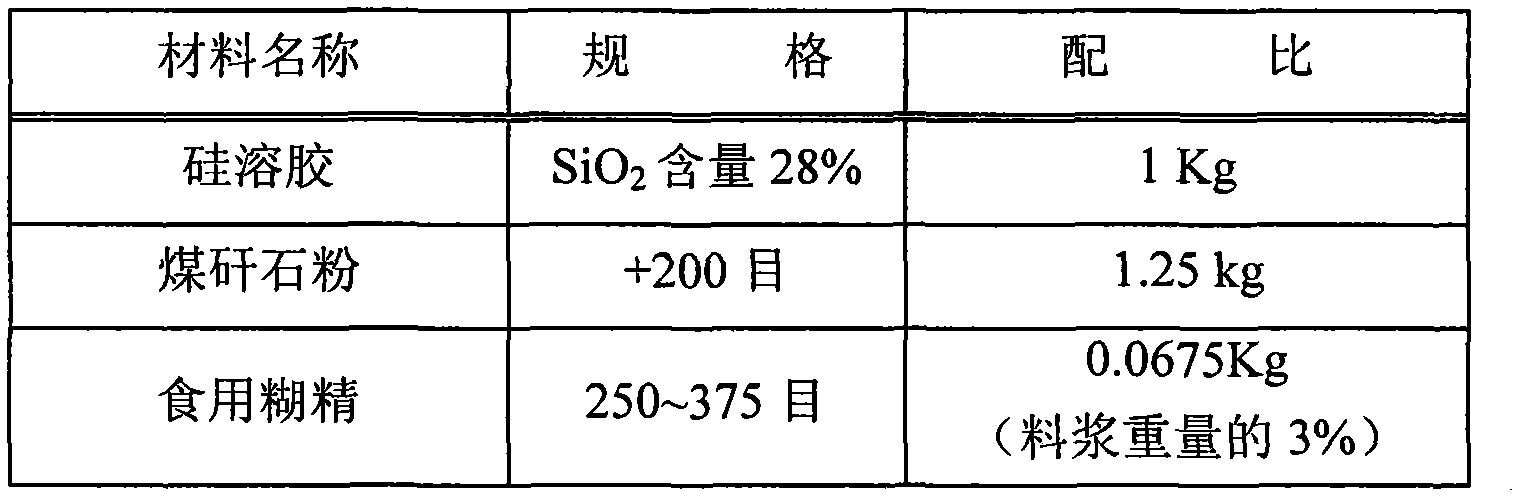

Method for preparing high-air permeability and high-strength ceramic shell mold for anti-gravity casting

ActiveCN101927321AFewer coats of paintSatisfy breathabilityFoundry mouldsFoundry coresFiberAnti-gravity

The invention discloses a method for preparing a high-air permeability and high-strength ceramic shell mold for anti-gravity casting, and belongs to the field of investment casting. The method comprises the following steps of: preparing back coating slurry, and back-coating a first layer of coating and a second layer of coating; adding a temperature-resistant carbon fiber rope: drying the second back coating for 20 to 24 hours, and winding the temperature-resistant carbon fiber rope in the specification of 12-24K / strand and with the monofilament diameter of 6 mu m at intervals of 1 to 3mm; coating a third back coating and a subsequent back coating on the shell mold until the sixth layer or seventh layer, and after all back coating is coated, dewaxing and roasting a module to prepare the ceramic shell mold. The method has the advantages that: the air permeability and the strength of the ceramic shell mold reach the expected level; and anti-gravity casting experiments by using the shell mold prove that 70 percent of TiAl alloy turbocharger turbine wheels have complete mold-filling.

Owner:BEIJING CISRI GAONA TECH +1

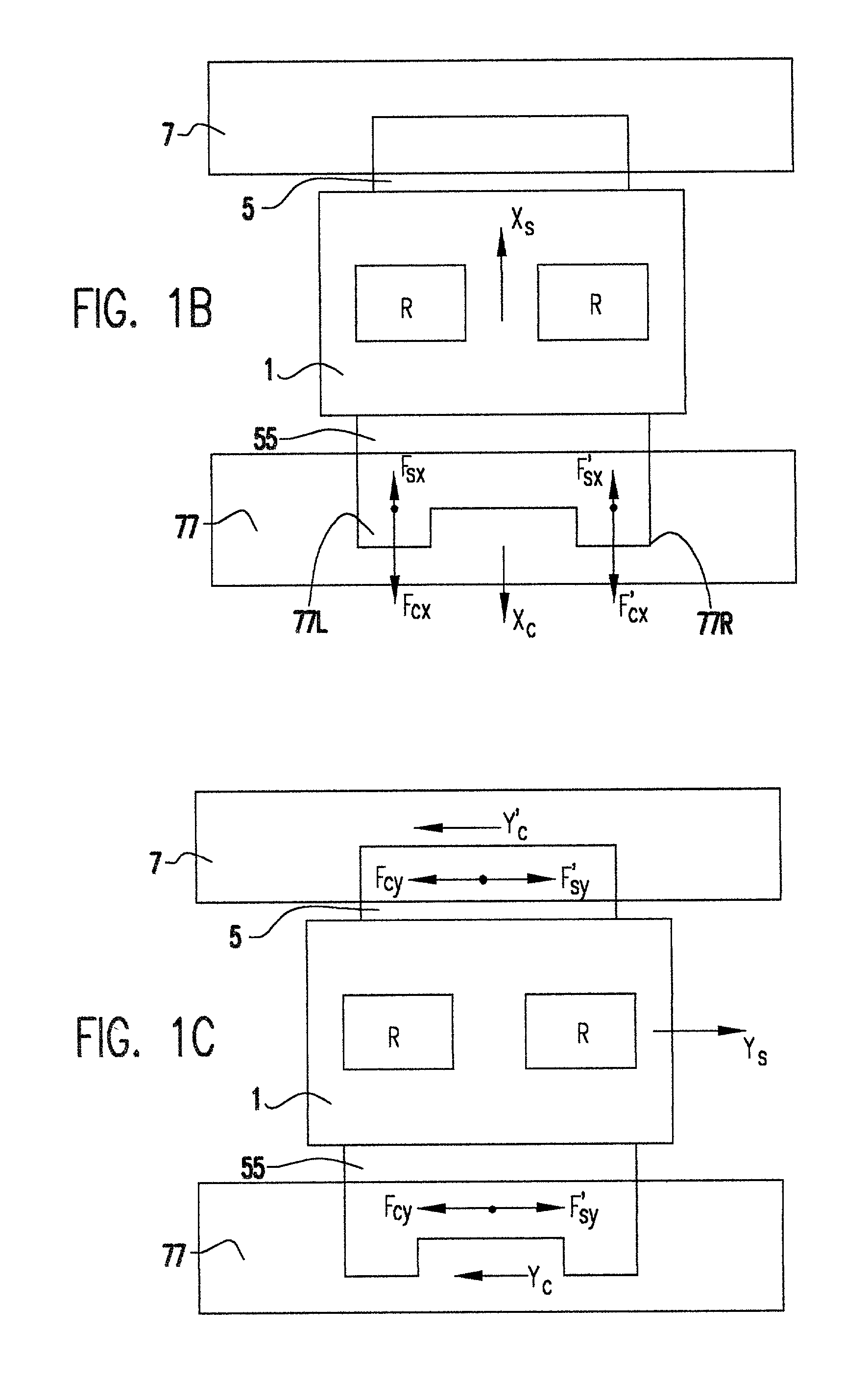

Reticle stage with reaction force cancellation

InactiveUS20030067592A1Photomechanical exposure apparatusMicrolithography exposure apparatusAnti-gravityThree degrees of freedom

A three-degree-of-freedom guideless reticle stage is used with a reaction force-countermass assembly. An anti-gravity device such as a flexure is provided between the reticle stage and the reaction force-countermass assembly. The anti-gravity device offsets the weight of the stage to the reaction force-countermass assembly. Improved reticle-positioning is provided, with minimized distortion to the stage base, reduced forces on the frame, high servo bandwidth, three-degree-of-freedom positioning, high throughput, minimized geometry and low moving mass.

Owner:NIKON CORP

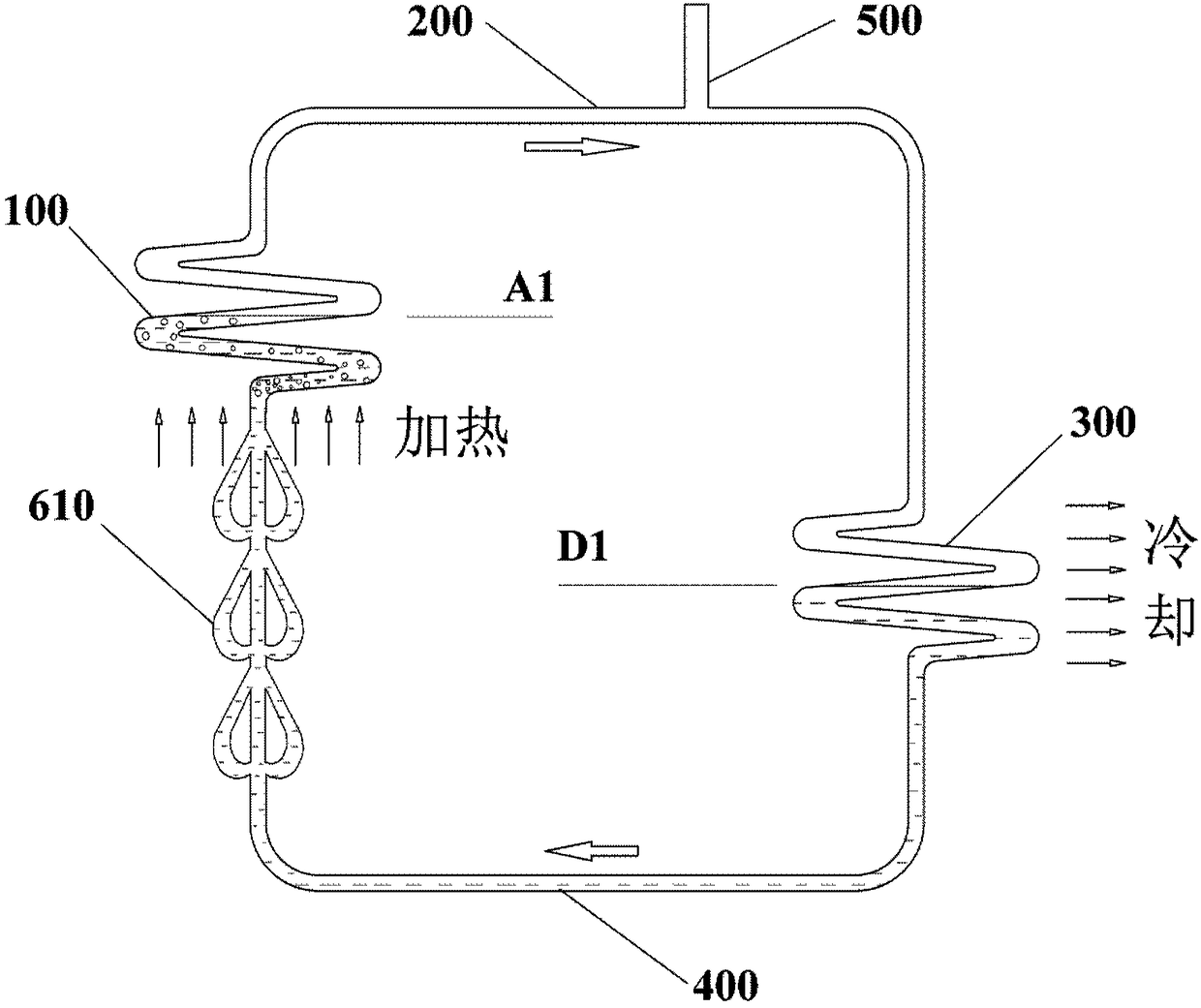

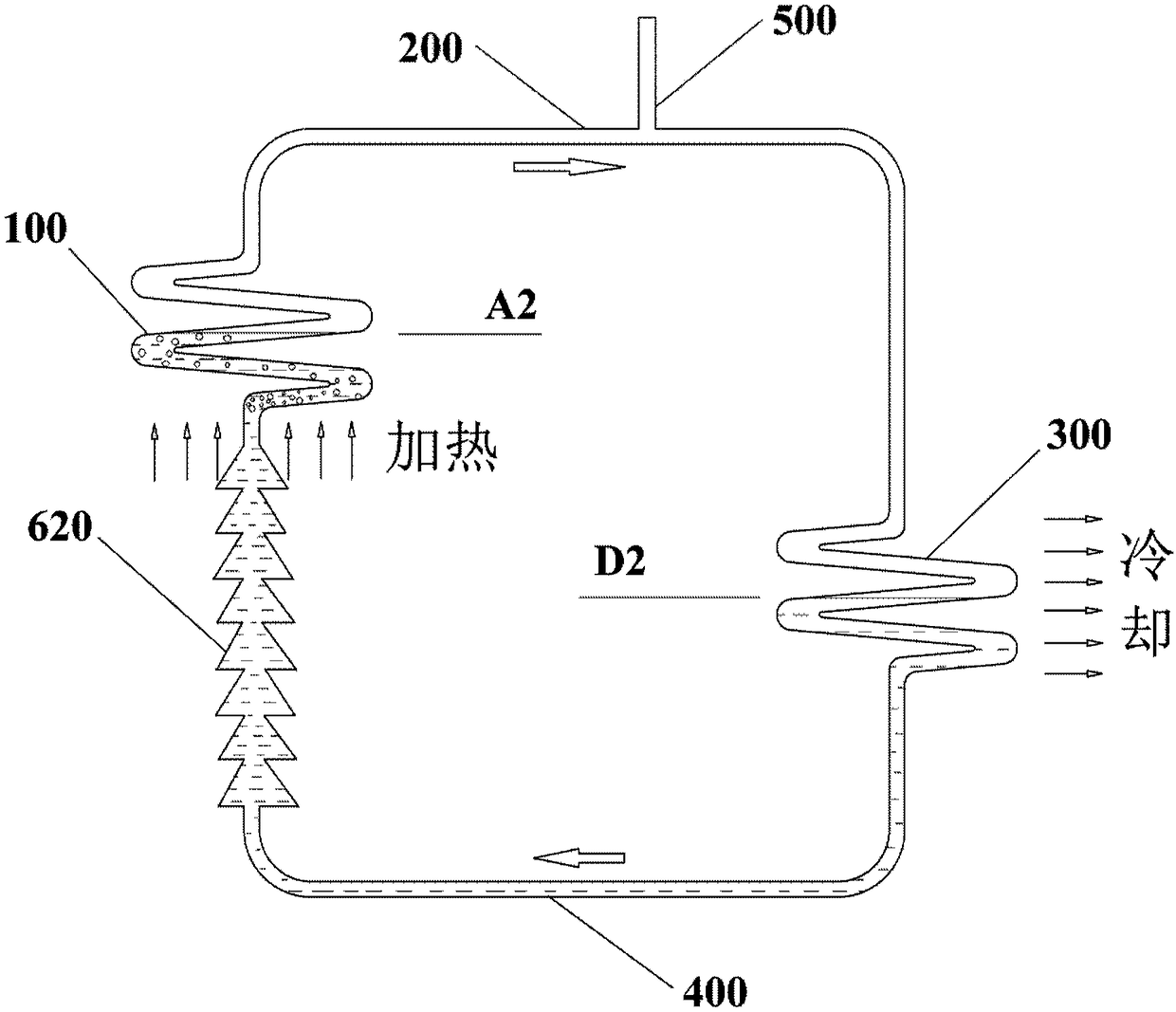

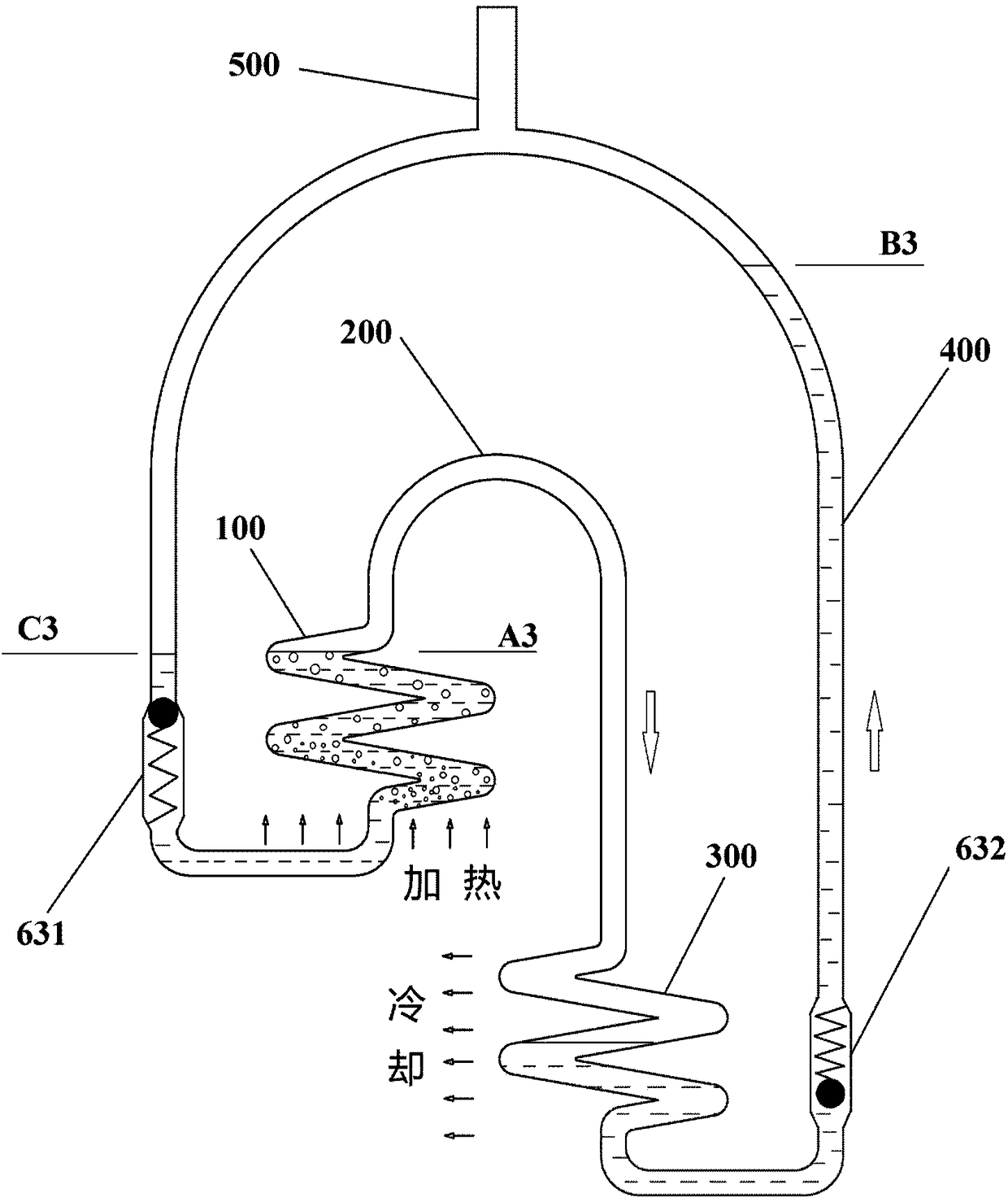

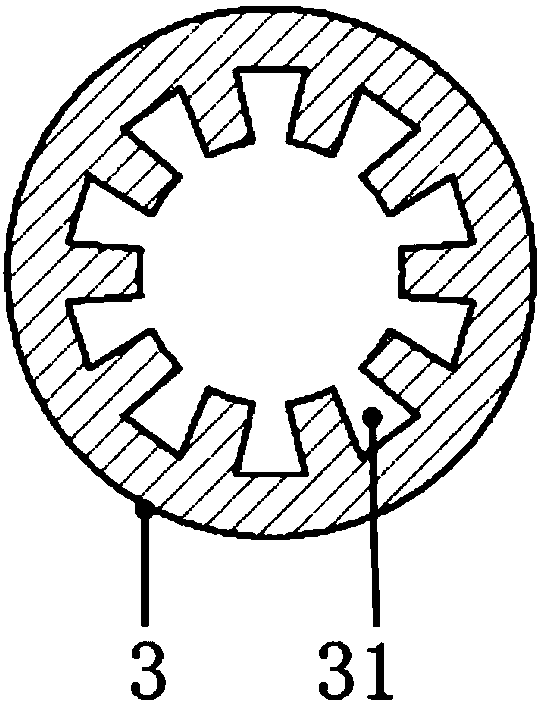

High heat flow anti-gravity heat pipe

ActiveCN108168342AFacilitate one-way flowStrong anti-gravity heat transfer effectIndirect heat exchangersTerrainAnti-gravity

The invention provides a high heat flow anti-gravity heat pipe. On the basis of reserving a traditional heat pipe evaporation and condensation heat exchange mechanism, a capillary core structure obstructing medium flowing is omitted, the saturated pressure difference accompanying the cold and hot end temperature difference is directly utilized as driving force, one-way flowing of media is facilitated through an asymmetrical flow channel structure constituted by a flow direction guiding device comprising a Tesla valve, a multi-section reducer pipe, one-way valves, a float valve and the like, and thus the higher anti-gravity heat transfer effect is achieved. The high heat flow anti-gravity heat pipe does not need additionally-applied power, bending, deformation and flexible arrangement can be achieved, limitation of the actual terrain and topography or the equipment structure layout can be overcome, the high heat flow anti-gravity heat pipe is especially suitable for the situations thatin the acceleration changing environment where wobbling, or inclining or posture changing or the like exists, a heat source is higher than a cold source in position, and heat needs to be transmitted downwards, and has wide application prospects.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Anti-gravity casting moulding method for 3D printing sand mould

ActiveCN109175307AEasy to carryInhibit sheddingAdditive manufacturing apparatusAnti-gravitySelf locking

The invention discloses an anti-gravity casting moulding method for a 3D printing sand mould. The anti-gravity casting moulding method comprises the following the steps of: designing a casting systemaccording to the characteristic of a casting; parting the casting of the designed casting system by adopting a three-dimensional map-making software, and arranging a water-glass sand mould and a self-locking workpiece placing platform at the bottom end of a pouring cup; adding support according to the parting results, adopting pre-coated sand to print sand moulding blocks added with the support, and a core, and roasting different sand moulding blocks after printing is completed; and adopting a wooden mould and water-glass sand to manufacture a pouring gate, assembling the sand mould and the water-glass sand pouring gate, jointing a self-locking tool, adopting an anti-gravity low-pressure way to cast the sand mould, thereby obtaining the casting. The anti-gravity casting moulding method solves the sand mould box-lifting problem as a result of great anti-gravity casting mould-filling pressure, enables the 3D printed sand mould to be free of phenomena such as cracks, delamination and evenbreakage, enables the dimension tolerance of the casting to reach HB6103 CT6 level, enables weight and volume deviation of the casting to be lower than or equal to 5%, and enables production cost ofthe casting to be greatly reduced.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

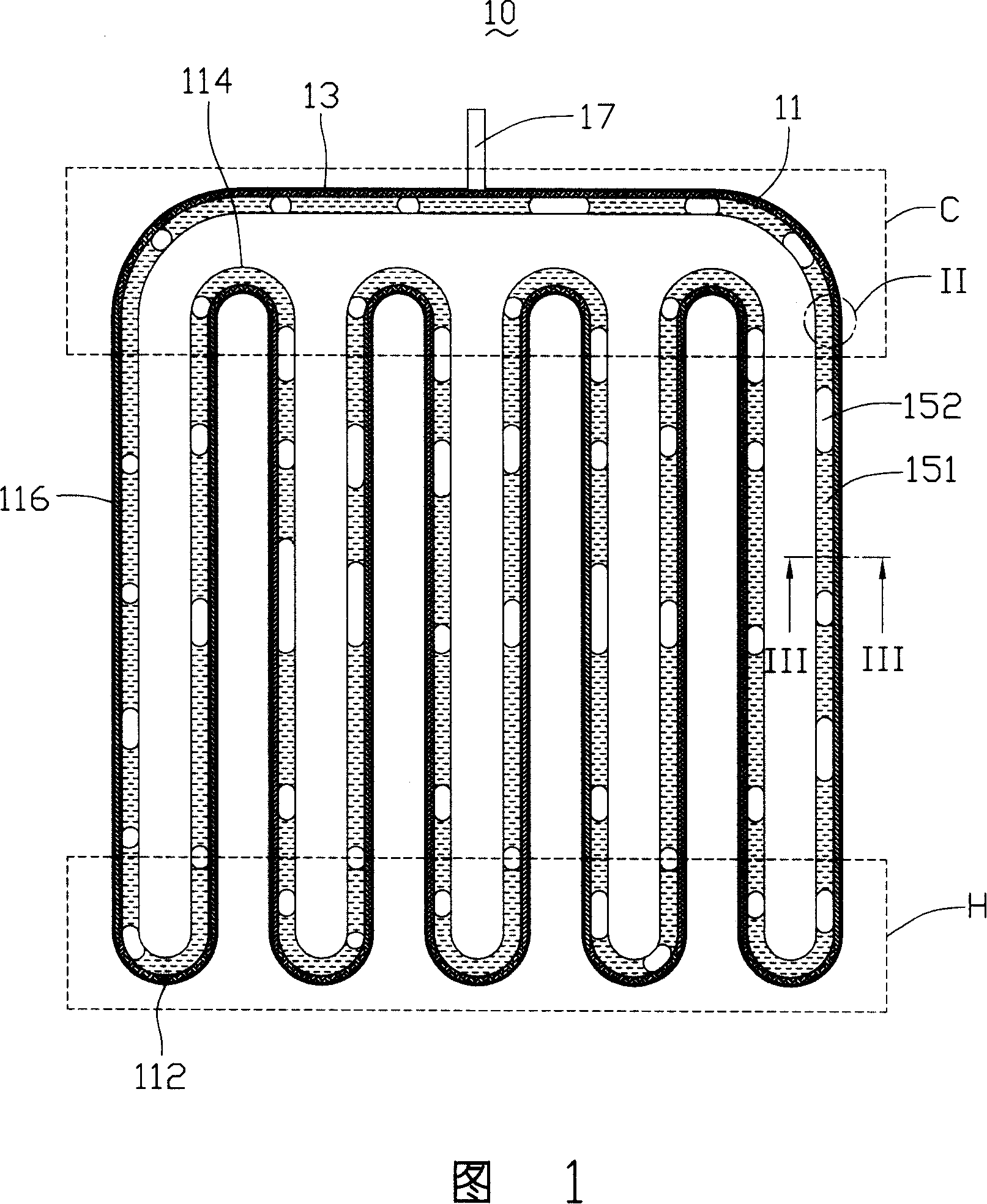

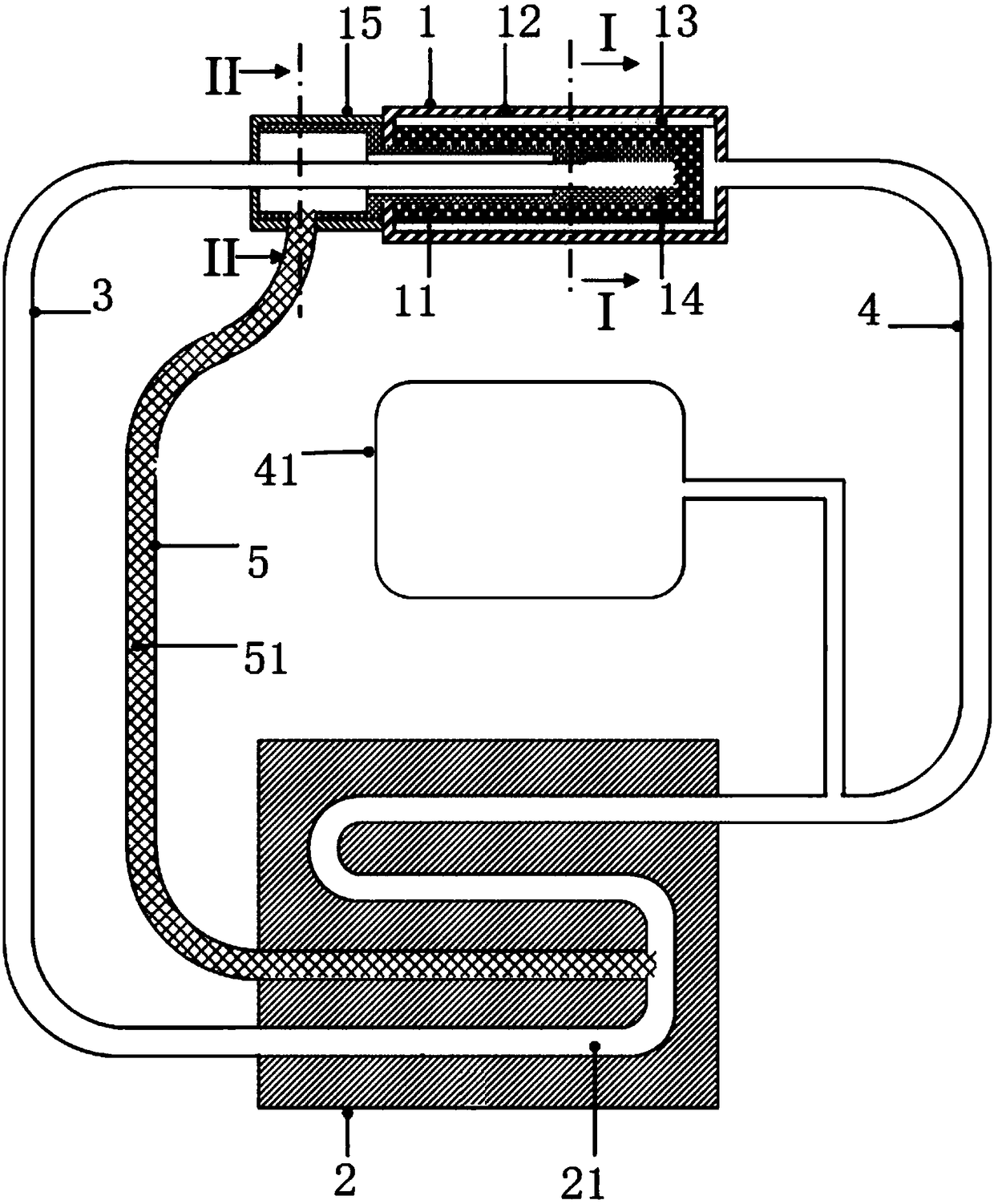

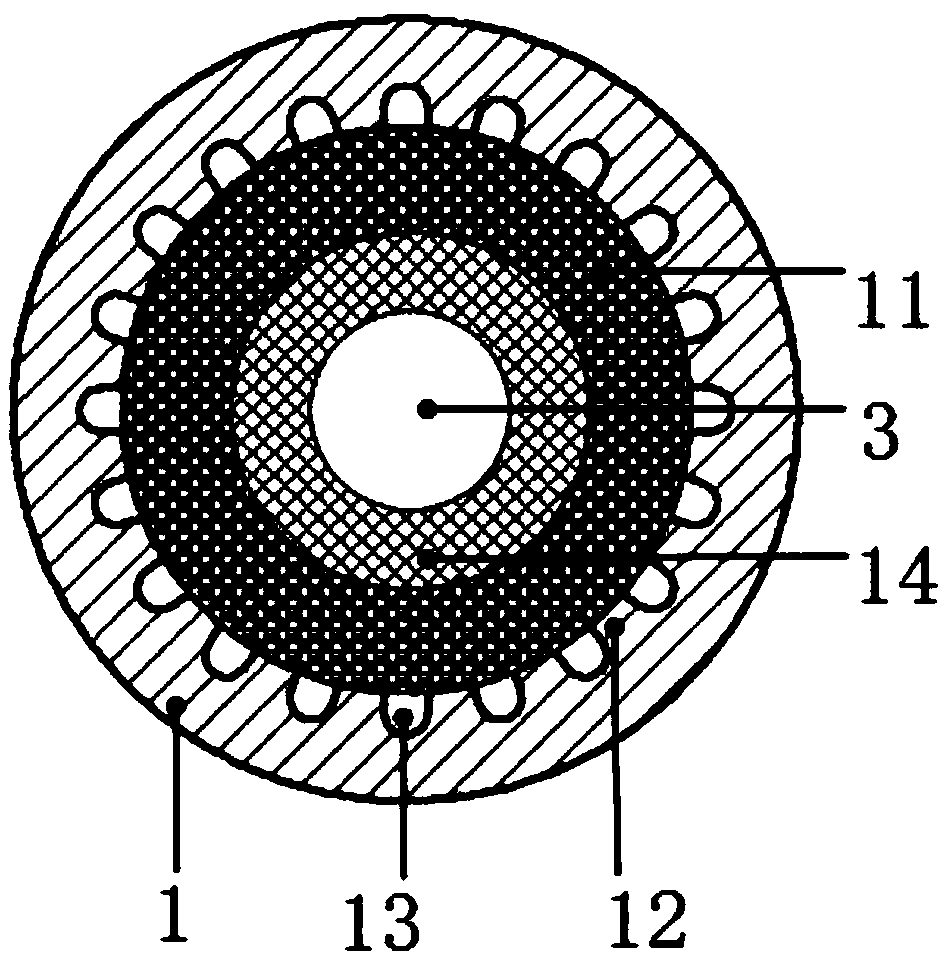

Pulsation type heat pipe

InactiveCN101131306AStrong weight resistanceEasy to startIndirect heat exchangersWorking fluidAnti-gravity

This invention is pulse type heat tube. It includes capillary tube, working fluid in the capillary tube and vessel inside of the capillary tube. The said capillary tube is composed of several heat absorbing sections and several heat eliminating sections. There is hollow channel in the vessel. There is gap between the wall of vessel and capillary inner wall. The capillary force generated from the vessel can drive the working fluid flowing in the capillary tube, in order to increase the anti-gravity capacity of the pulse type heat tube. It makes the working fluid evenly distributed. This invention can be easily started in low heat transferring. It is adequate for temperature sensitive electronic elements.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

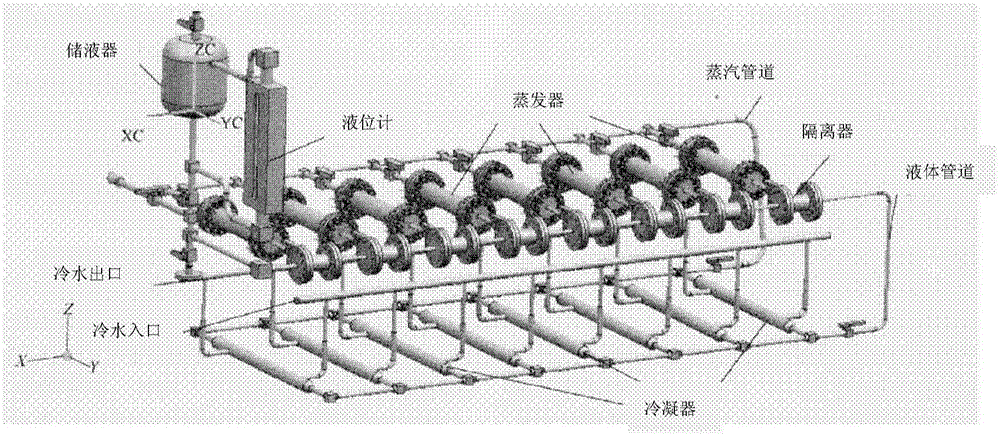

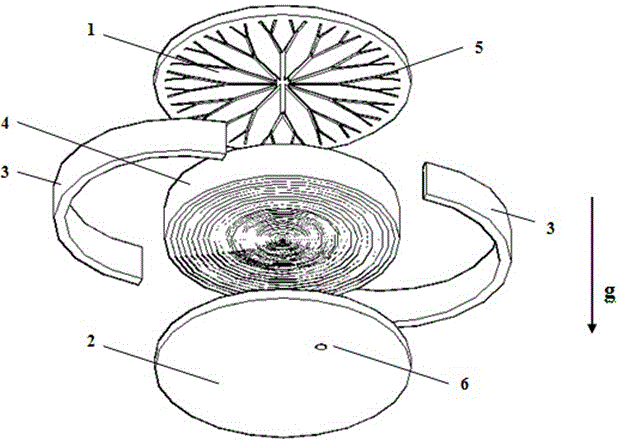

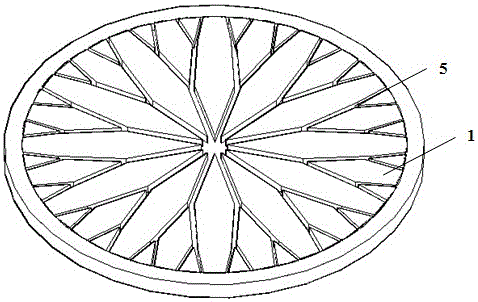

Self-circulation gas-liquid two-phase flow phase change heat exchanger

ActiveCN106152846AEnhance condensation heat transfer capacityReduce the degree of interactionIndirect heat exchangersAnti-gravityMain channel

The invention discloses a self-circulation gas-liquid two-phase flow phase change heat exchanger. The self-circulation gas-liquid two-phase flow phase change heat exchanger comprises an evaporation plate, a condensation plate, and a wall surface positioned between the evaporation plate and the condensation plate; and a capillary cavity is formed in the wall surface, and is provided with a liquid sucking core and a working medium positioned in the liquid sucking core and with gas and liquid two phases. The self-circulation gas-liquid two-phase flow phase change heat exchanger is characterized in that a groove structure is formed in the inner surface of the evaporation plate; grooves are gradient branched grooves outwards branched and extending in the radial direction from the center; the liquid sucking core is a gradient liquid sucking core with high capillary force in an axis area and low capillary force in a peripheral area; the axis area of the liquid sucking core is aligned to the center of the groove structure to form a main channel of a liquid working medium; and the peripheral area of the liquid sucking core is aligned to the branched grooves of the groove structure to form a main channel of a gaseous working medium. The heat exchanger can effectively improve circulation of gas and liquid working mediums under the condition of anti-gravity, improves the heat transfer performance, and provides guarantee for efficient and reliable operation of electronic devices.

Owner:南京艾科美热能科技有限公司 +1

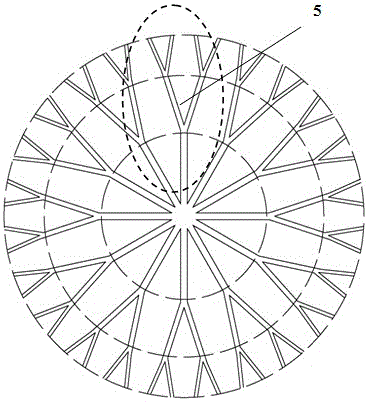

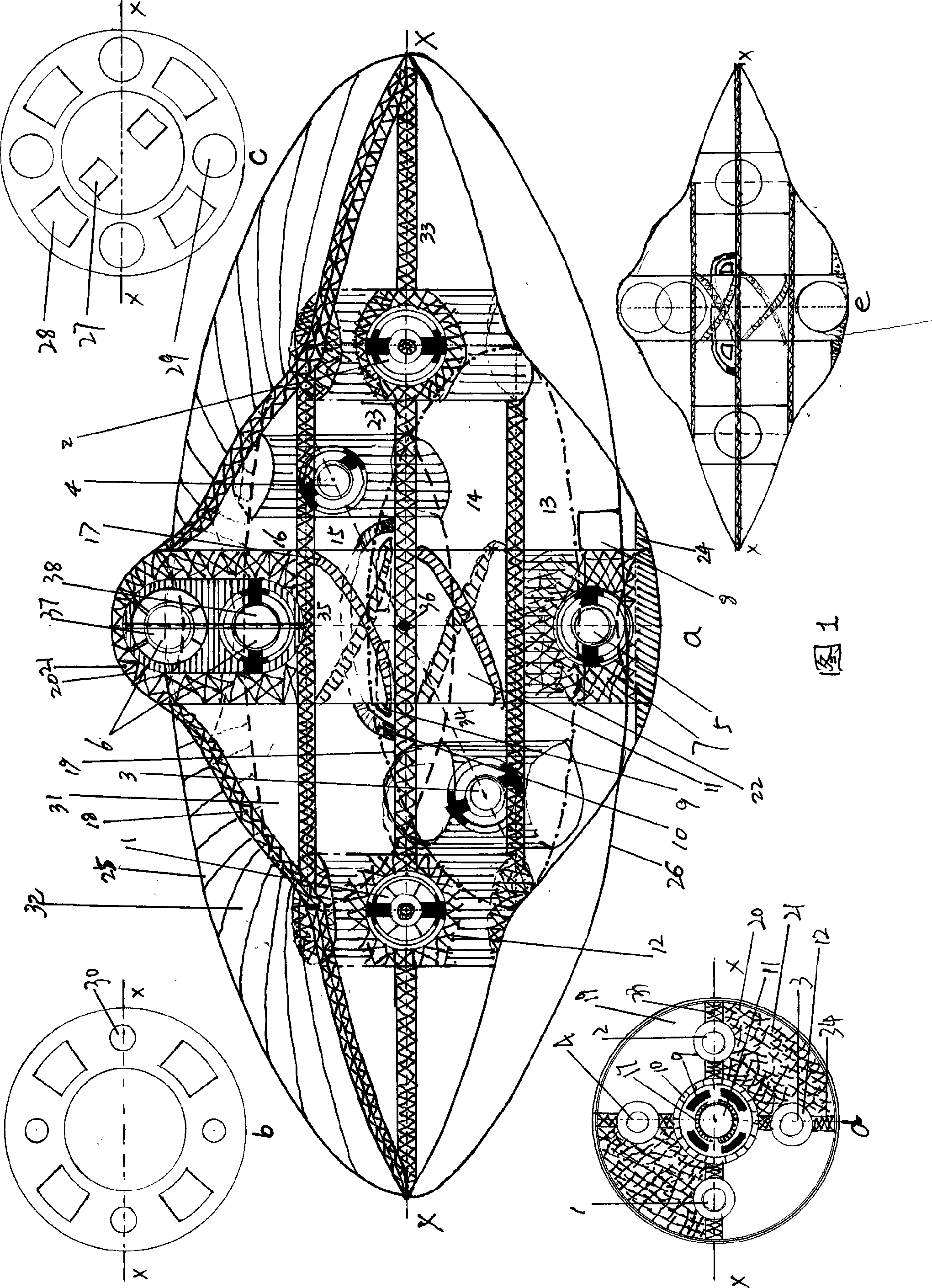

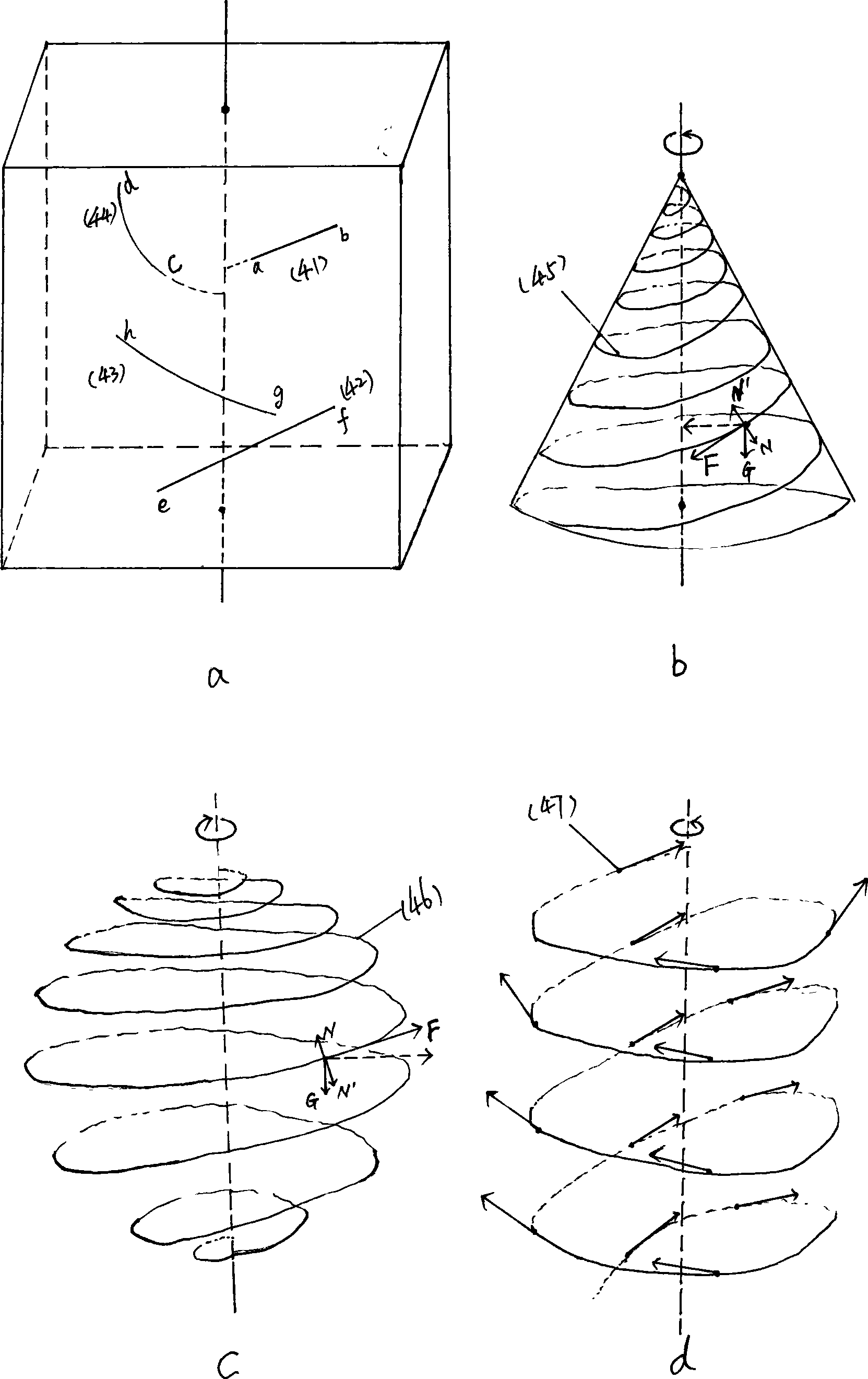

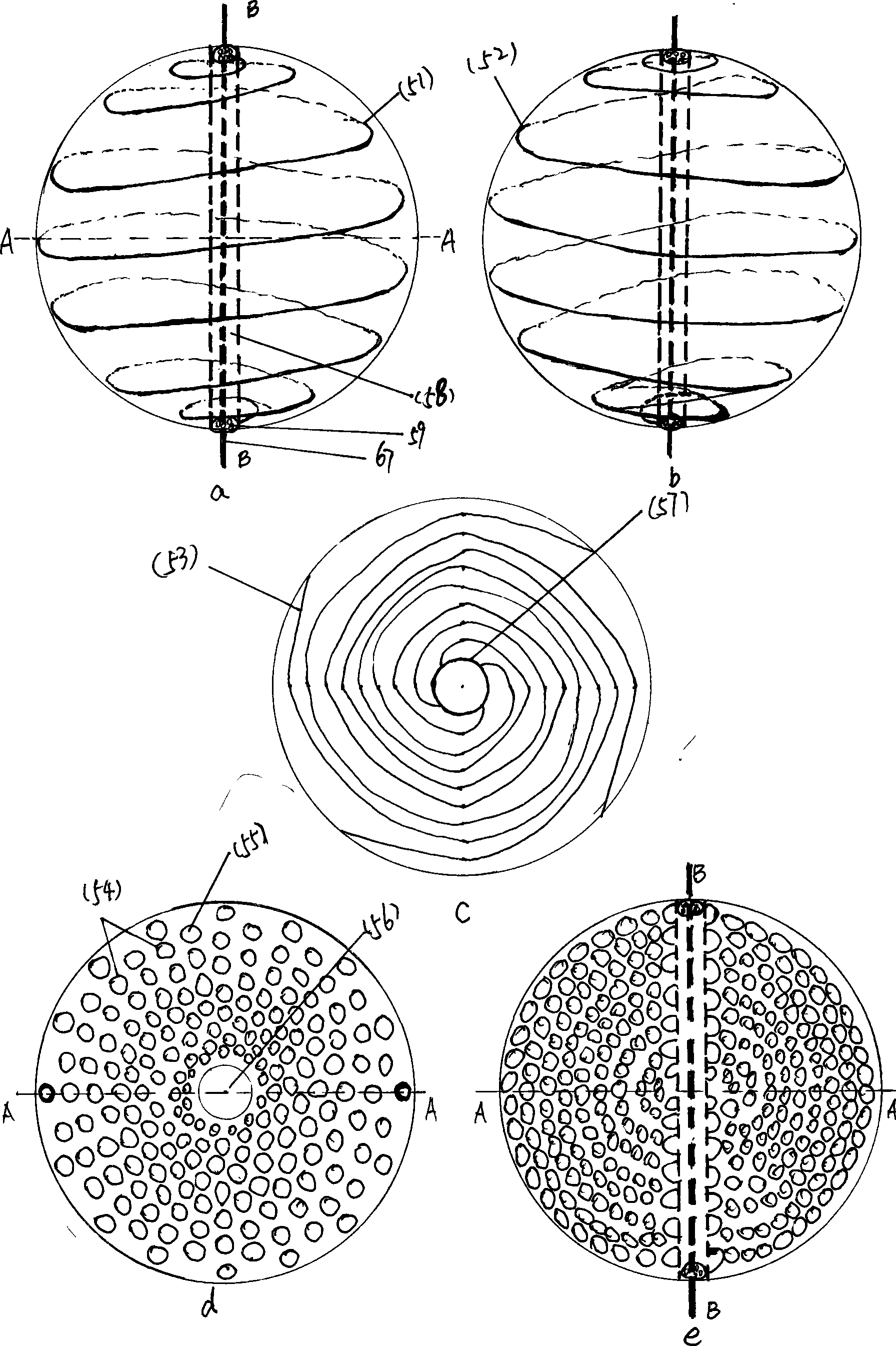

Anti-gravity method and anti-gravity device thereof used as dish form multiway aerial craft for rotating and stopping in air

InactiveCN101372259ASafe life and workSafe life life workAircraftsVehicle dynamicsMagnetic tension force

The invention relates to an antigravity method and a dish-shaped flying vehicle which takes an antigravity device as power, and can rotate, stop or do multidirectional flying in the sky, belonging to the fields of physics, aeronautic and astronautic vehicle dynamics and flying vehicle design and manufacture. An antigravity power unit, in which superconductive electromagnetic force is used for controlling the antigravity device to generate direct pushing force, is taken as power, thus overcoming the disadvantage that an flying vehicle adopting the conventional technique and a common power unit as the power can fly by relying on the working force of external air and reverse ejection force generated by fuel burning and realizing that the working force in a sealed device breaks through barriers to work externally; the flying vehicle includes the power unit which is arranged in a three dimensional and six directional way, a main support pillar and an auxiliary support pillar for supporting and a dish-shaped sealed structural body formed by connecting a series of triangular brackets; by adopting electrical energy as power, the flying vehicle can cause the main body and a rotating body to rotate and stop by magnetic force and can fly freely. No pollution and noise are generated in use, and the flying vehicle can be produced into different sizes for transportation, aerial work, space, land and sky and seabed shuttle, even interstellar flight, etc.

Owner:姚春志

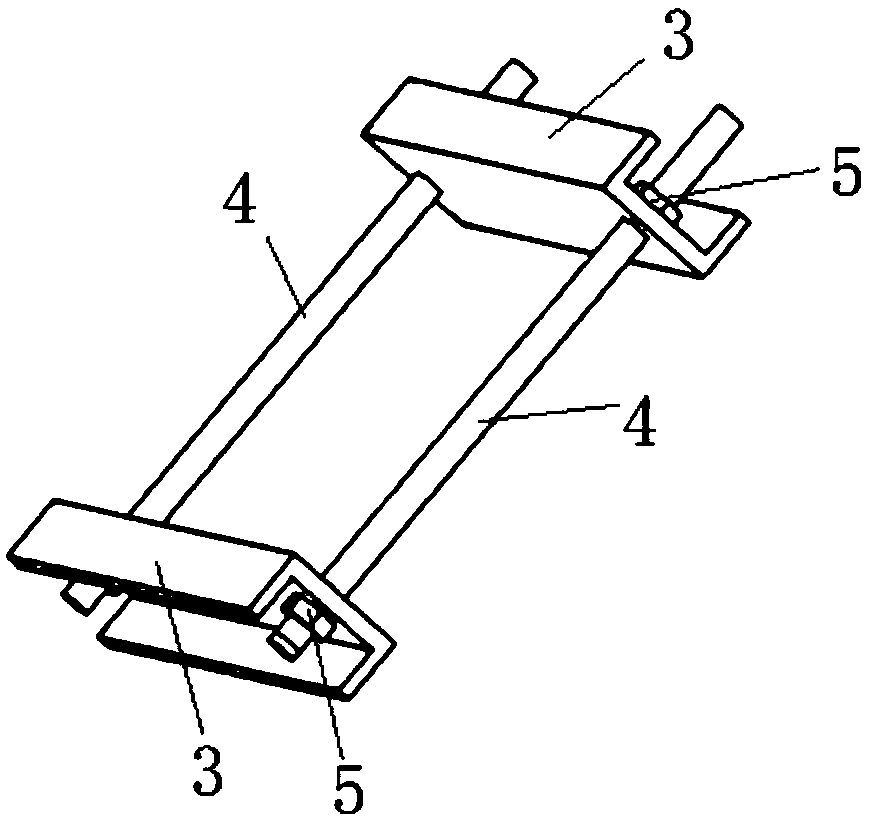

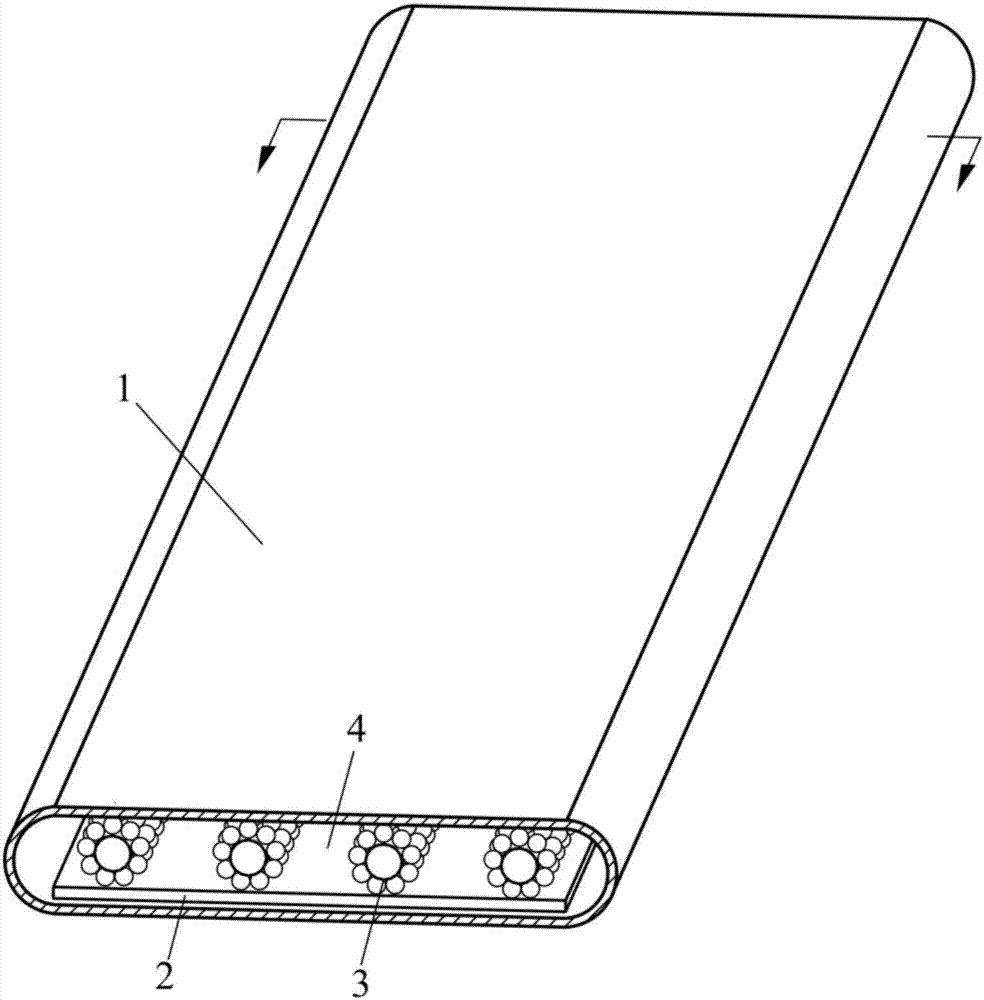

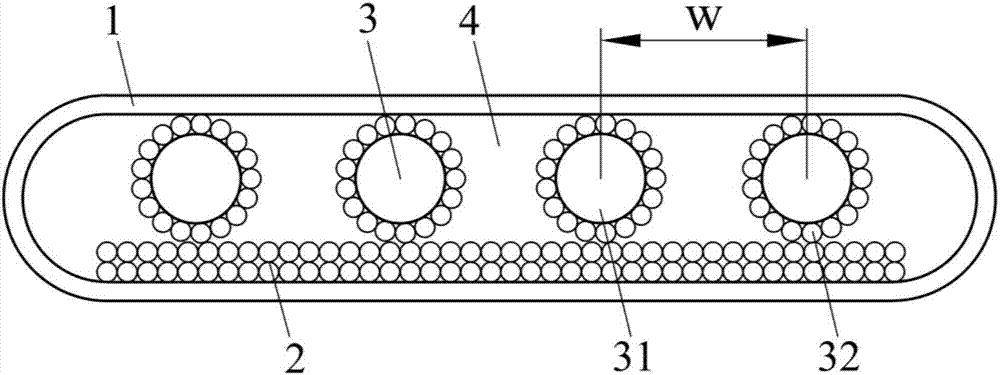

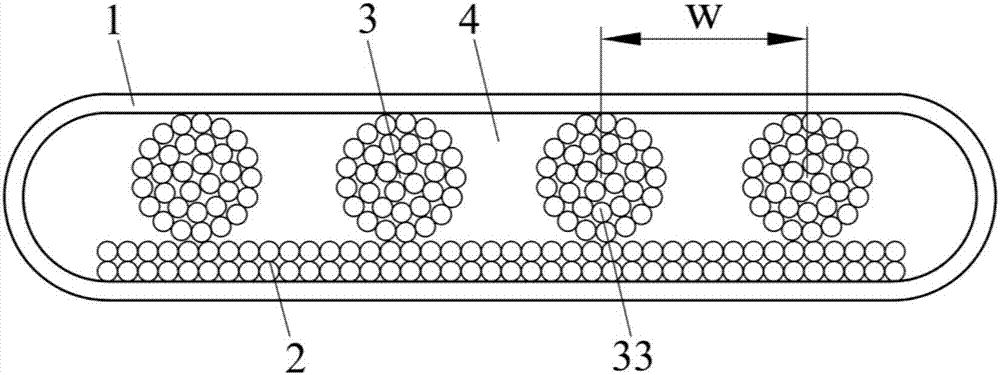

Ultra-thin flat panel heat pipe and manufacturing method thereof

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

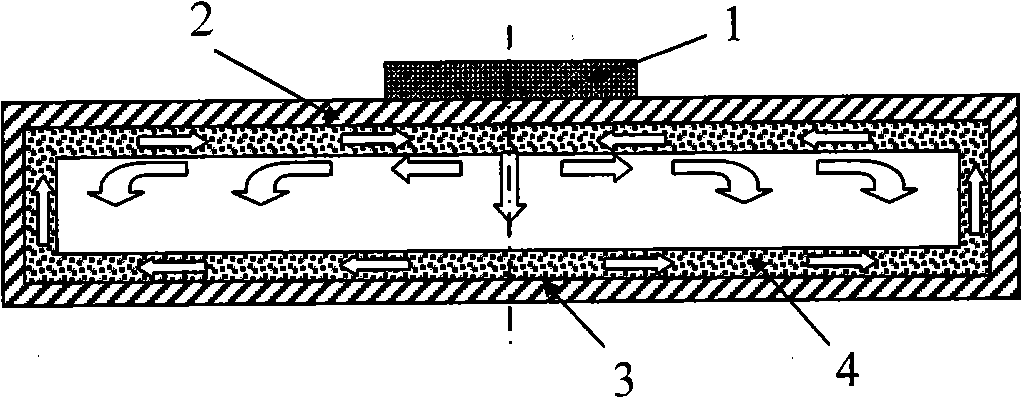

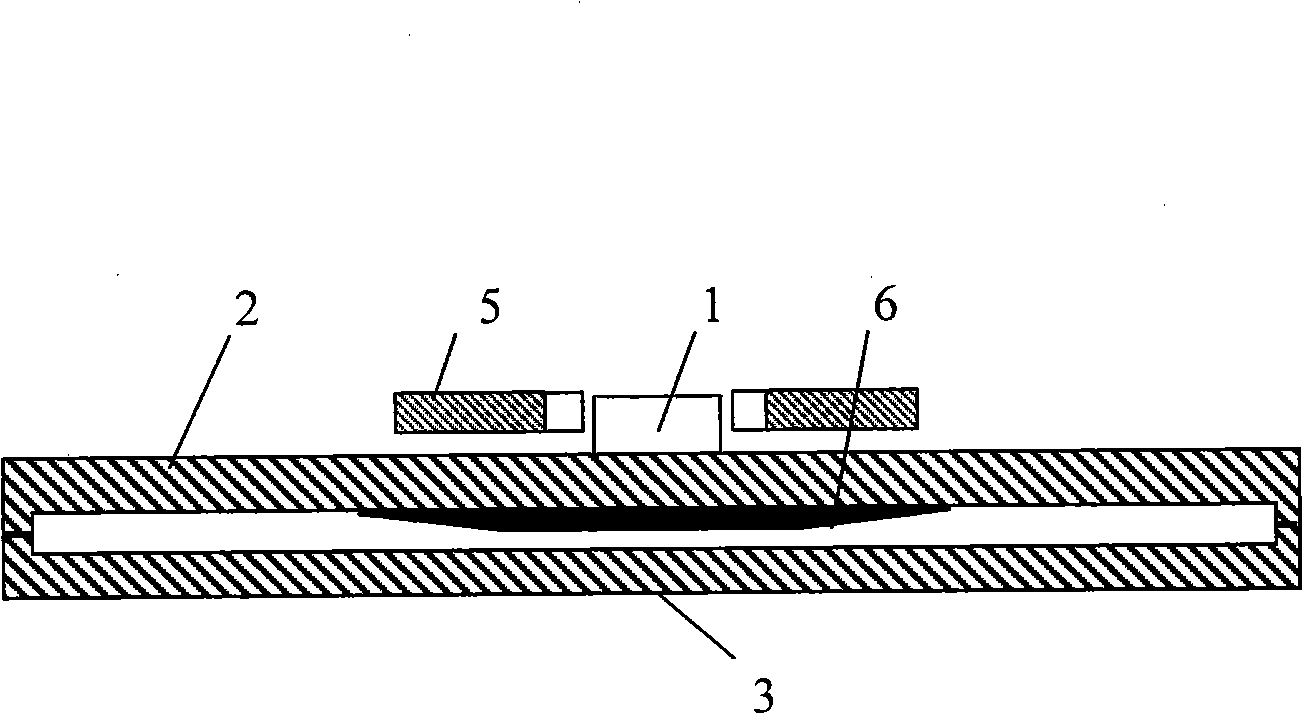

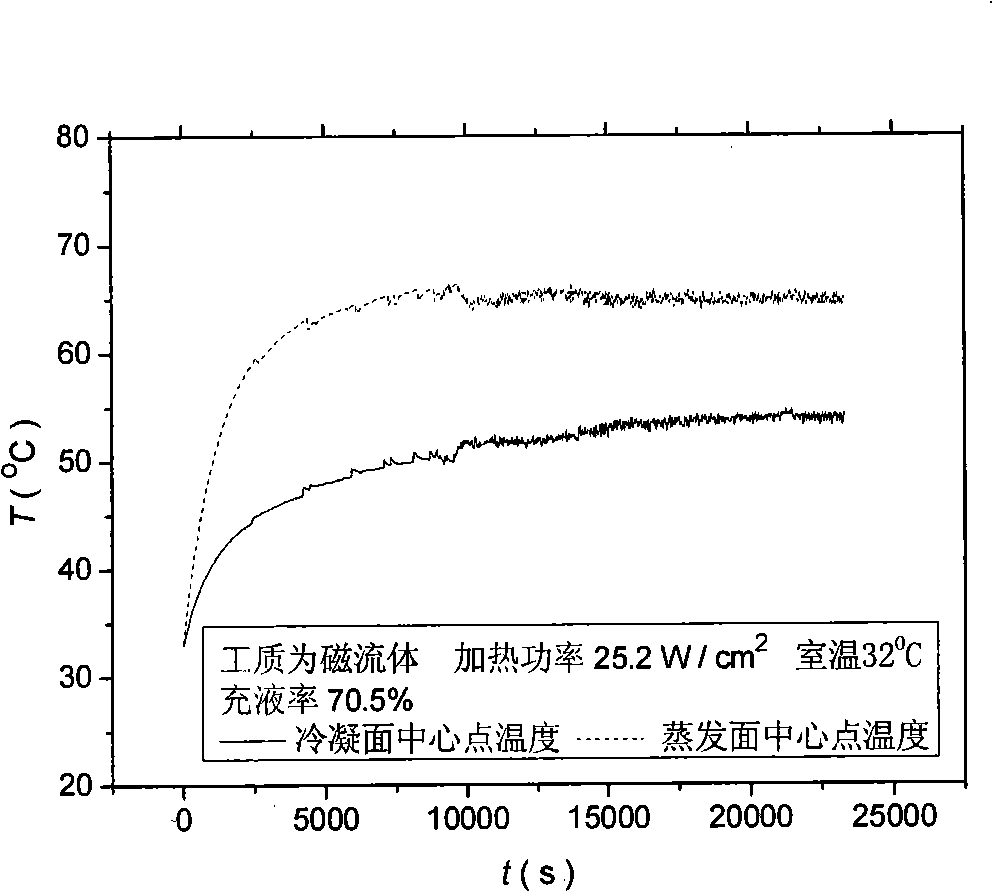

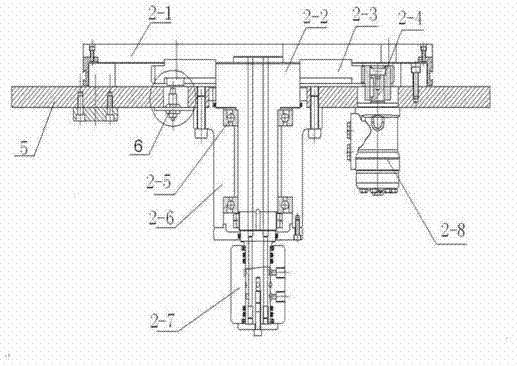

Magnetofluid flat plate hot pipe soaking device

InactiveCN101281003AStrong attractionWork lessIndirect heat exchangersCooling/ventilation/heating modificationsAnti-gravityEngineering

The invention relates to a magnetic fluid flat heat pipe soaking machine that can be used as the soaking machine in an electronic apparatus cooling device. The invention aims to solve deficiency that a capillary core in the flat heat pipe soaking machine is hard to place and the capillary force is not enough. The whole magnetic fluid flat heat pipe is welded by an evaporate face flat (2) and a condensate flat (3). The flat heat cavity is provided with no any capillary structure. After extracting vacuum for the flat heat pipe, the flat heat pipe is filled with magnetic fluid as working substance. A magnet (5) is placed adjacent to an electronic apparatus (1) on an outer side of the evaporate face flat. The flat heat pipe can save design of the capillary liquid absorbing core. Placing additionally magnetic filed not only intensifies the working substance to boil, but also accelerates the working substance to flow back, which enables the magnetic fluid flat heat pipe to work under anti-gravity condition.

Owner:BEIJING UNIV OF TECH

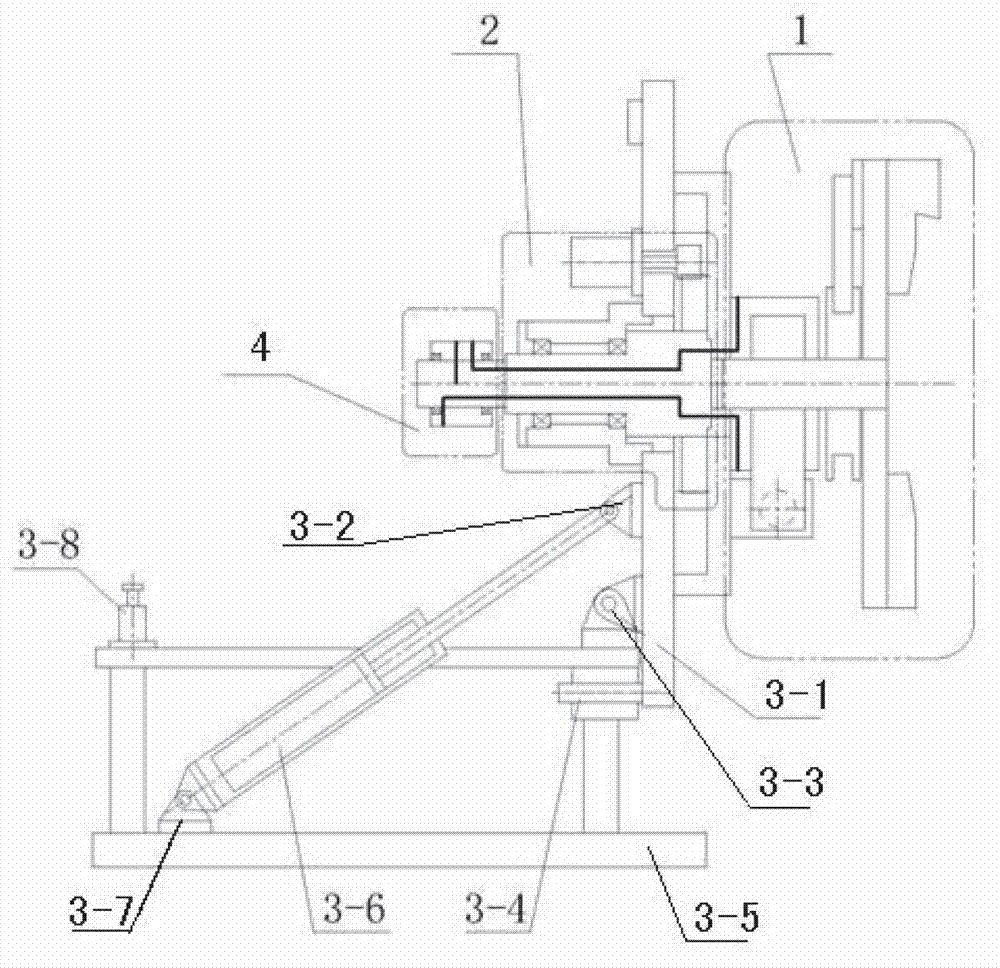

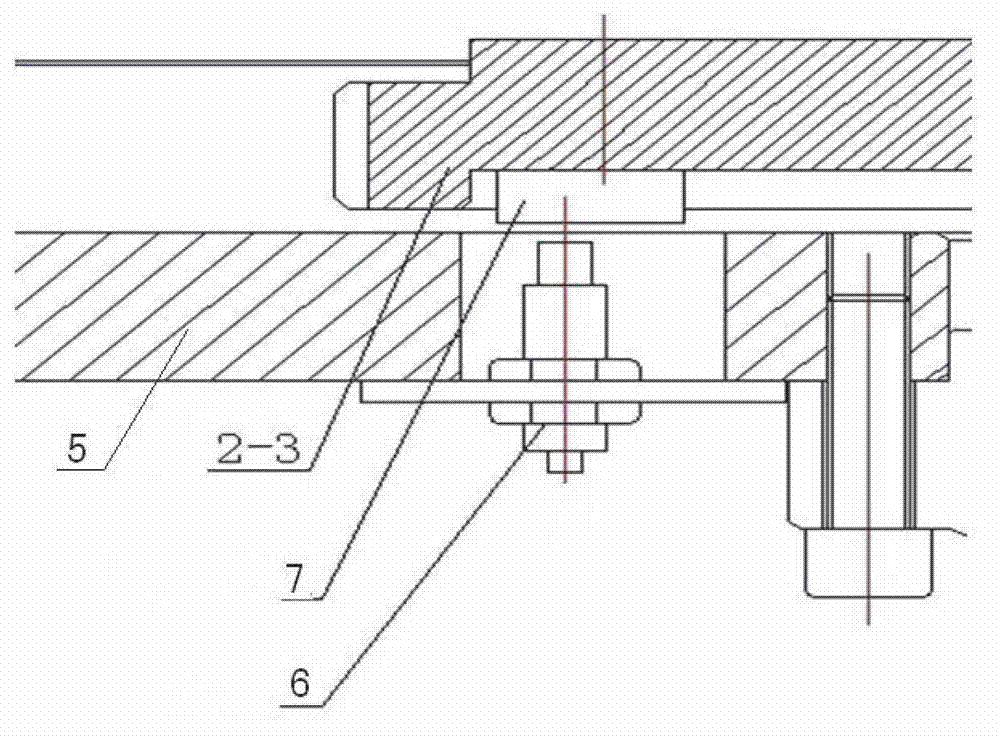

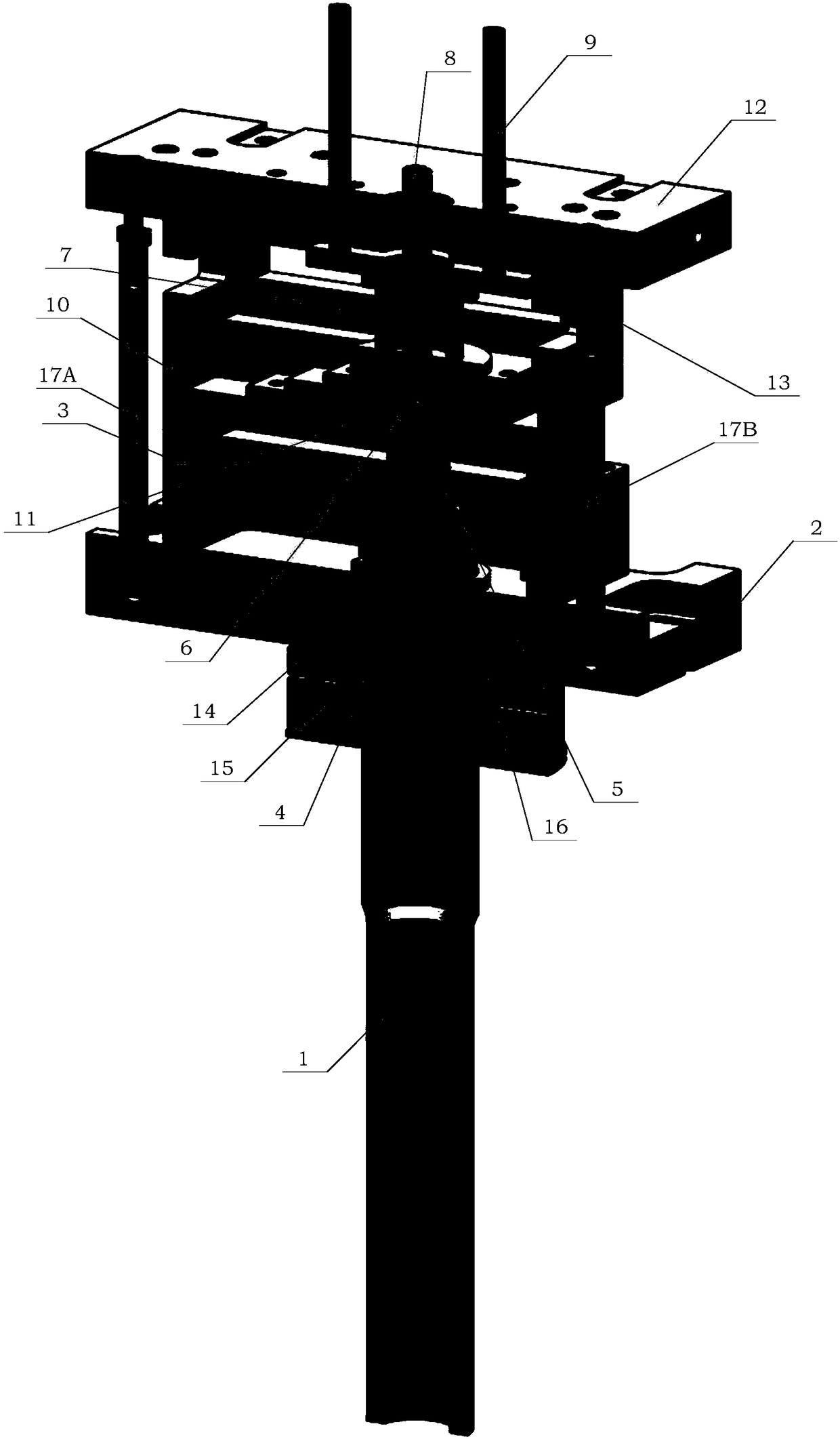

Positioning self-centering main shaft chuck capable of overturning plus or minus 180 degrees

InactiveCN102896352AReduce difficultyReduce labor intensityChucksMetal working apparatusHydraulic motorAnti-gravity

The invention discloses a positioning self-centering main shaft chuck capable of overturning plus or minus 180 degrees. The main shaft chuck comprises a swingable clamping expansion chuck (1), a main shaft rotating mechanism (2), a turnover mechanism (3) and a three-loop swivel joint (1). The positioning self-centering main shaft chuck is characterized in that a hydraulic motor (2-8) drives a driven bull gear (2-3) and the main shaft rotating mechanism to rotate; a blank wheel hub is horizontally clamped through self-centering linked three claws to determine a machining center,; after a dead head is cut through the main shaft chuck in positive rotation, the main shaft chuck stops rotating; a hydraulic anti-gravity valve locks a clamp; after reverse slow 180-degree positioning is performed to the chuck, lateral waste material is machined; and after a sensing block (7) is sensed through a photoelectric switch (6), the chuck is immediately stopped, and the machining is finished. The positioning self-centering main shaft chuck has the advantages that the clamp is not required to be centered and positioned manually, centre positioning and overturning are completely automatic, and plus or minus 180 degrees position are automatically determined during machining. The chuck can be conveniently matched with a magic hand to realize automatic work piece loading and unloading, so that unmanned machining can be implemented.

Owner:江苏天宏智能装备有限公司

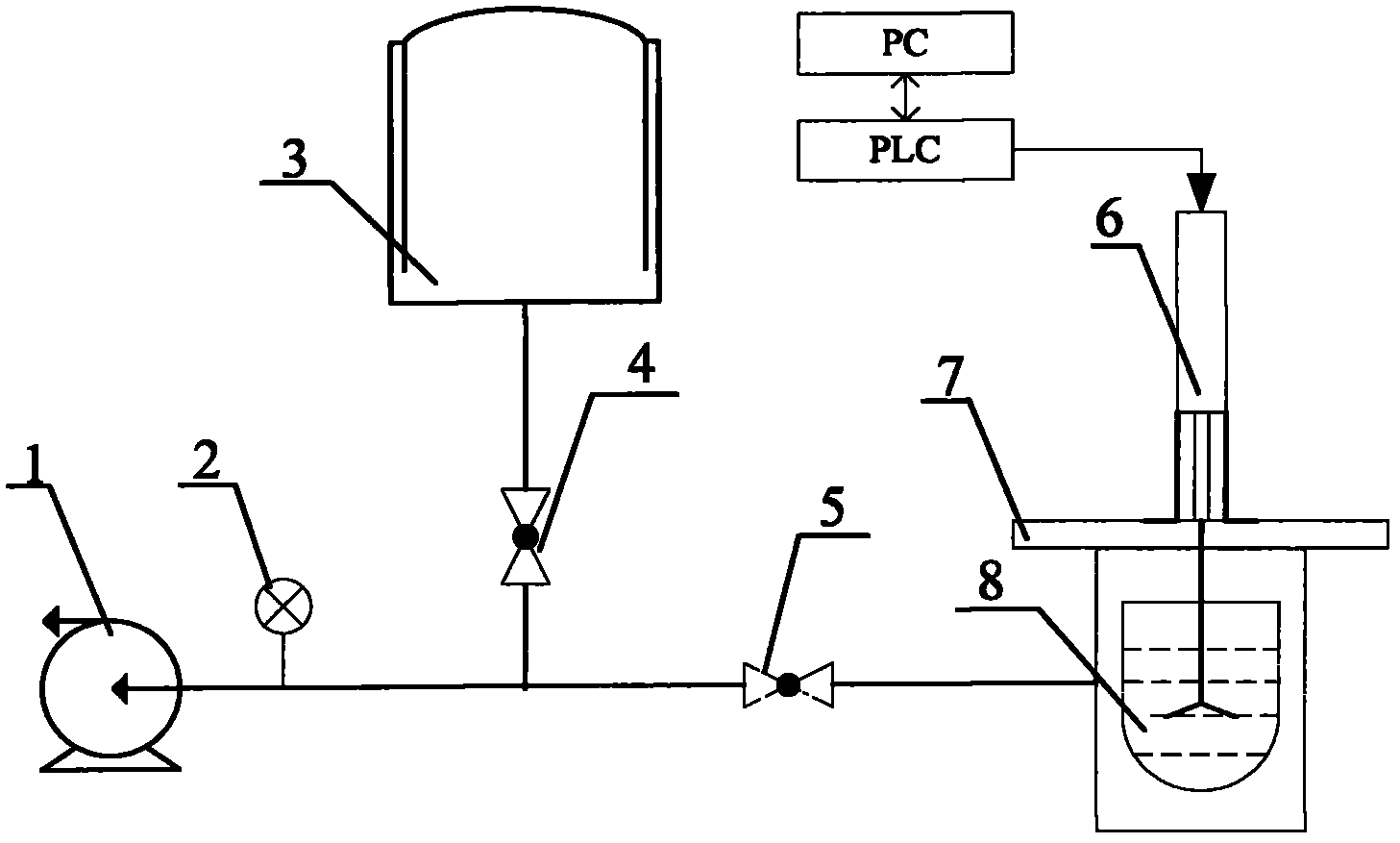

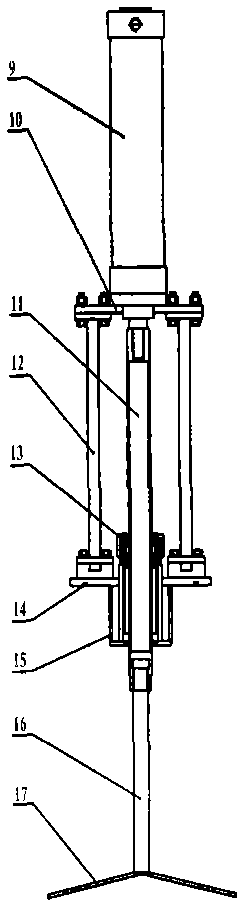

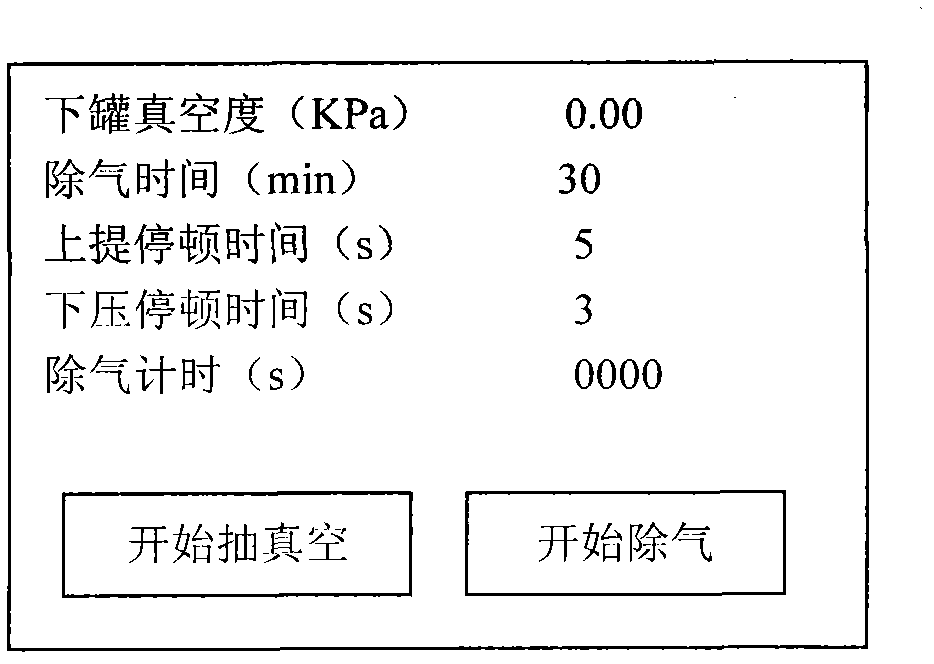

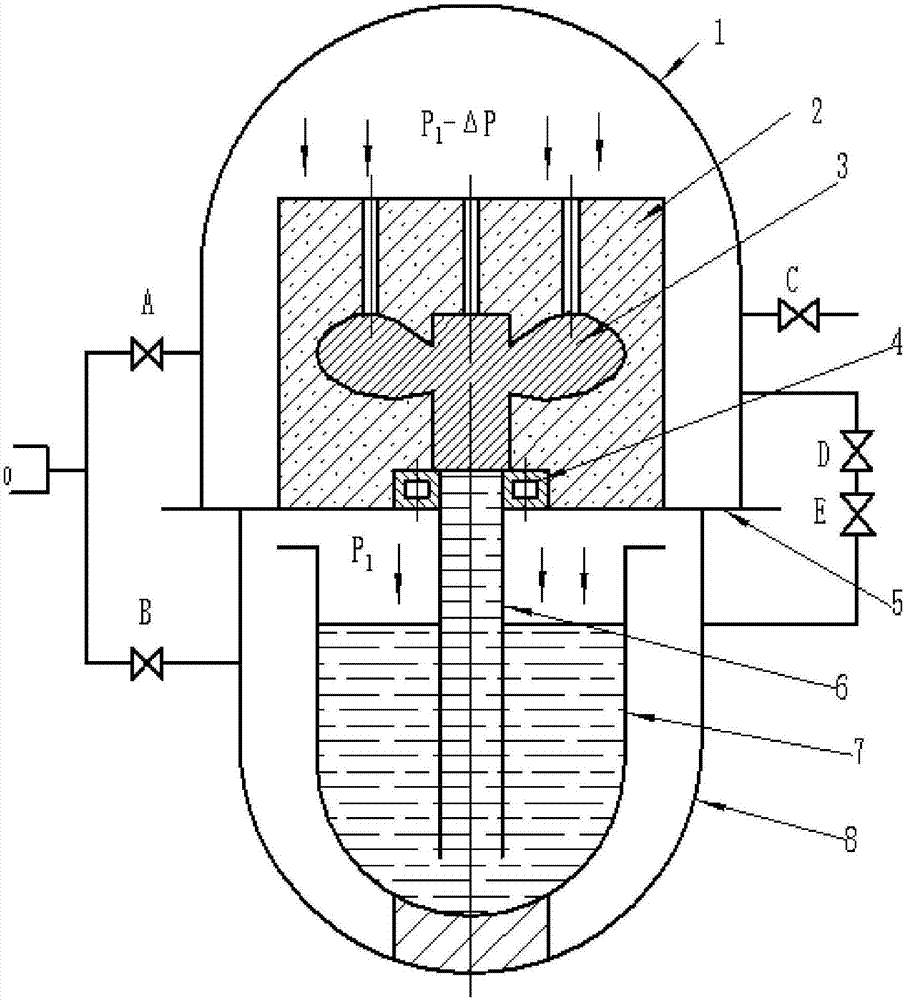

Aluminum alloy vacuum lifting degassing device

The invention relates to an aluminum alloy vacuum lifting degassing device, which comprises a vacuum pump, a lifting vacuum degassing machine, a vacuum buffer tank, a sealed middle partition plate and an equipment lower tank. When the alloy liquid is fully smelted, the middle partition plate is placed on the lower tank, and the lifting vacuum degassing machine is placed on the middle partition plate. The vacuum pump is started to evacuate the lower tank. The metal liquid in a crucible is stirred by vertical lifting of the lifting vacuum degassing machine, and the gas dissolved by the alloy liquid is automatically separated and diffused under the action of negative pressure so as to reduce the gas content of the alloy liquid, improve the quality of the alloy liquid and improve the quality of castings. The device is a furnace front alloy liquid degassing and purifying treatment device suitable for anti-gravity casting comprising low-pressure casting, differential pressure casting and pressure adjustable casting, has simple structure, is easy to operate, has no environmental pollution, and meets the requirement of actual production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

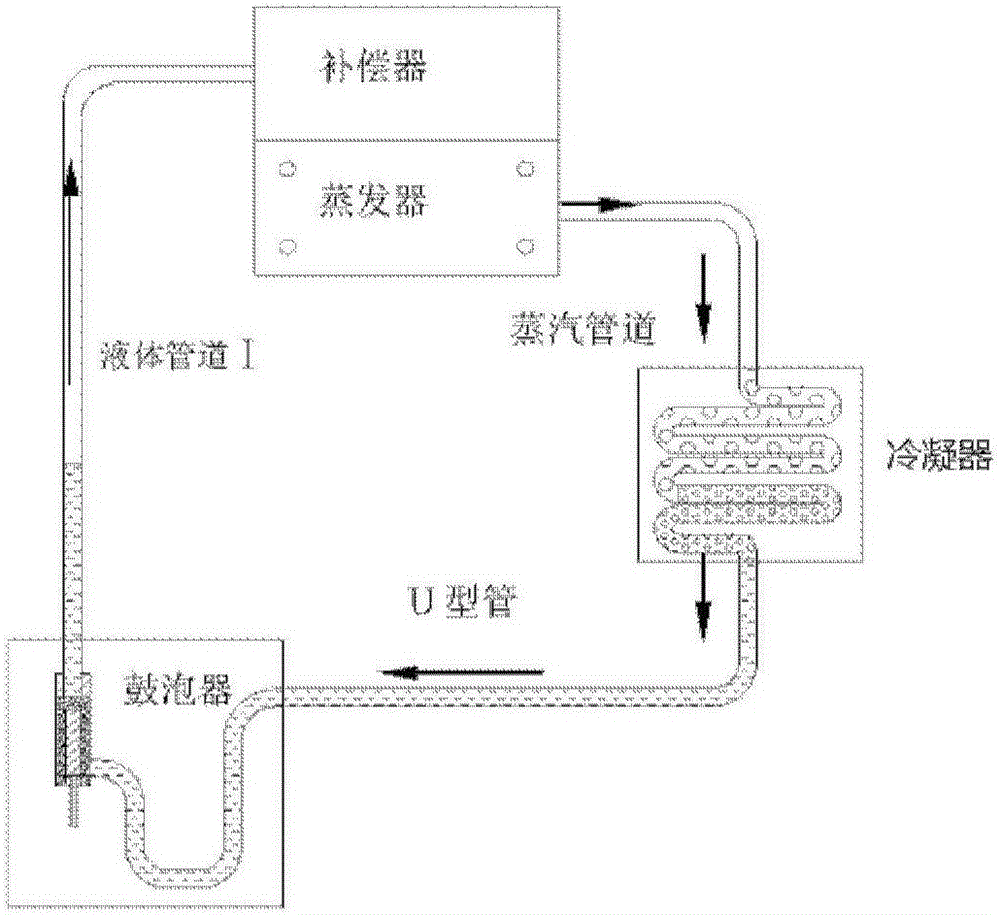

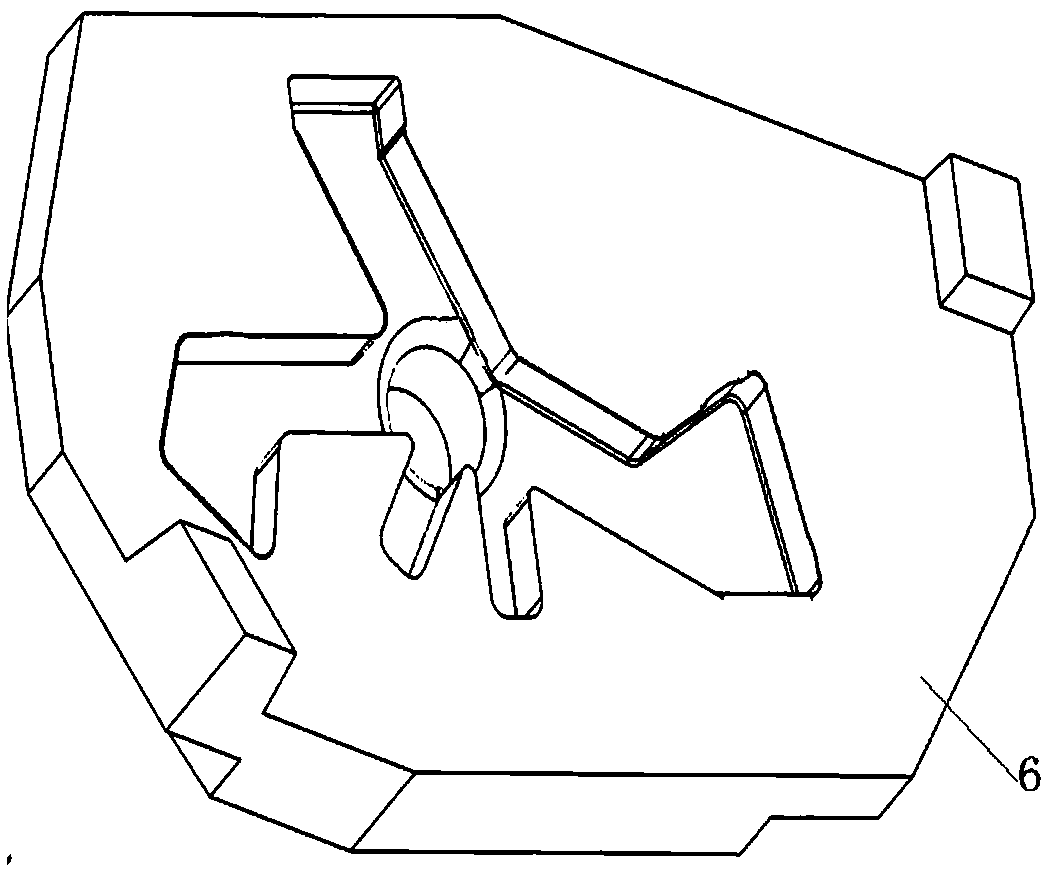

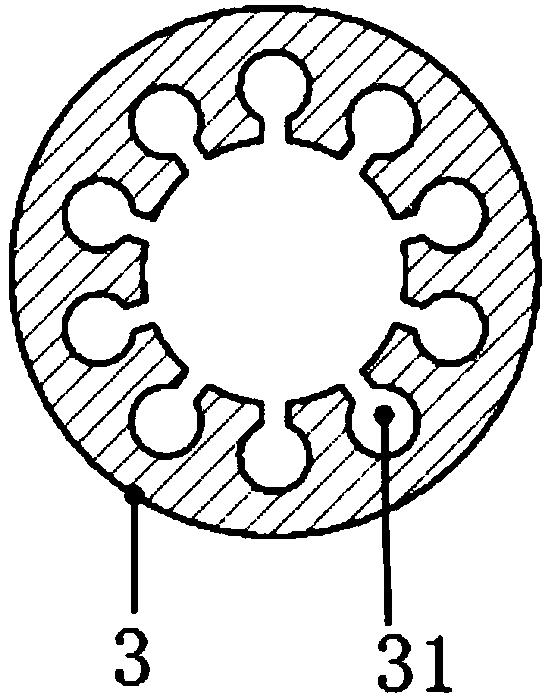

Compact type loop heat pipe device

ActiveCN102425968AShorten the transportation distanceImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesAnti-gravityGas phase

The invention relates to a compact type loop heat pipe device which comprises an evaporation part, a gas phase pipeline, a condensation part and a liquid phase pipeline. The gas phase pipeline and the liquid phase pipeline are communicated, and further, form a closed circulation passage; a compensation chamber, a capillary structure, a vapor chamber and a support wall are arranged inside the evaporation part; the capillary structure is clung to the heating surface and is extended from an end part of the compensation chamber to a non-heating surface along the flowing direction of a working medium in the evaporation part; a compensation chamber section of the capillary structure, which is clung to the inner wall of the compensation chamber, and a non-heating section of the capillary structure, which is clung to the non-heating surface, are connected together through an obliquely-arranged oblique section; the compensation chamber is communicated with the liquid phase pipeline; and the vapor chamber is communicated with the gas phase pipeline. According to the compact type loop heat pipe device, the heat-dissipating efficiency is increased through changing the placement manner of the capillary structure, so that the evaporation area per unit length is larger, the structure of the loop heat pipe device is designed to be more compact, the normal work under various arrangement conditions can be realized, and the compact type loop heat pipe device has excellent anti-gravity performance.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

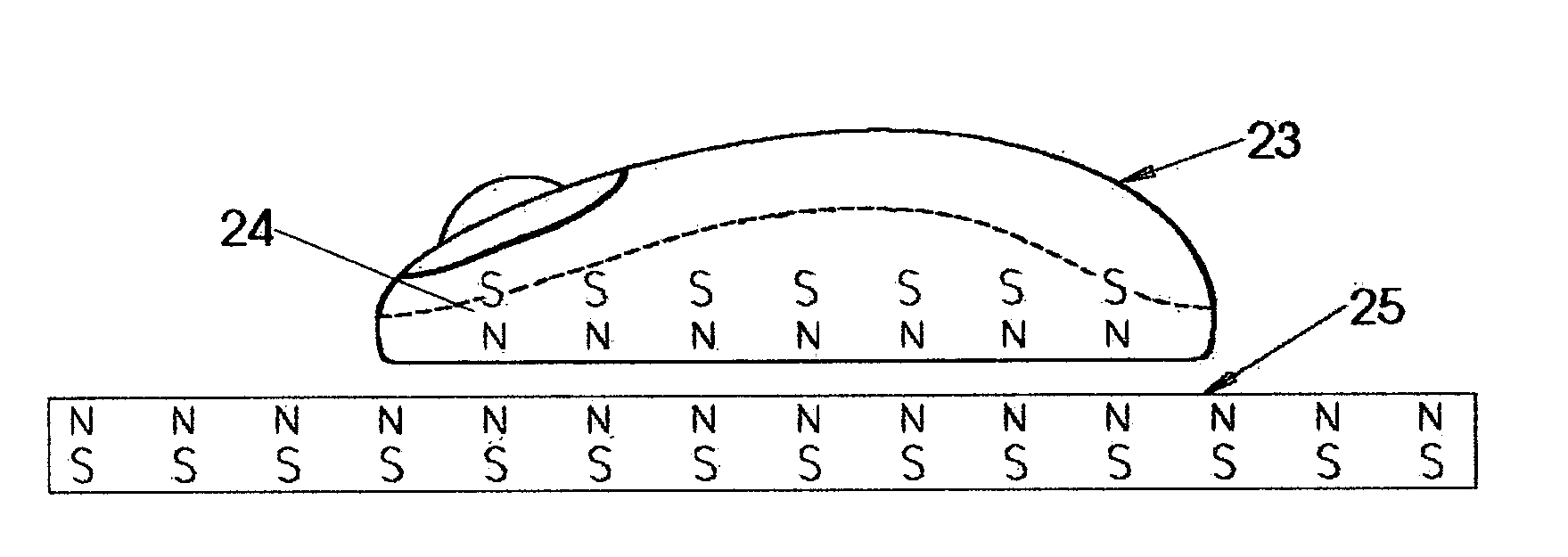

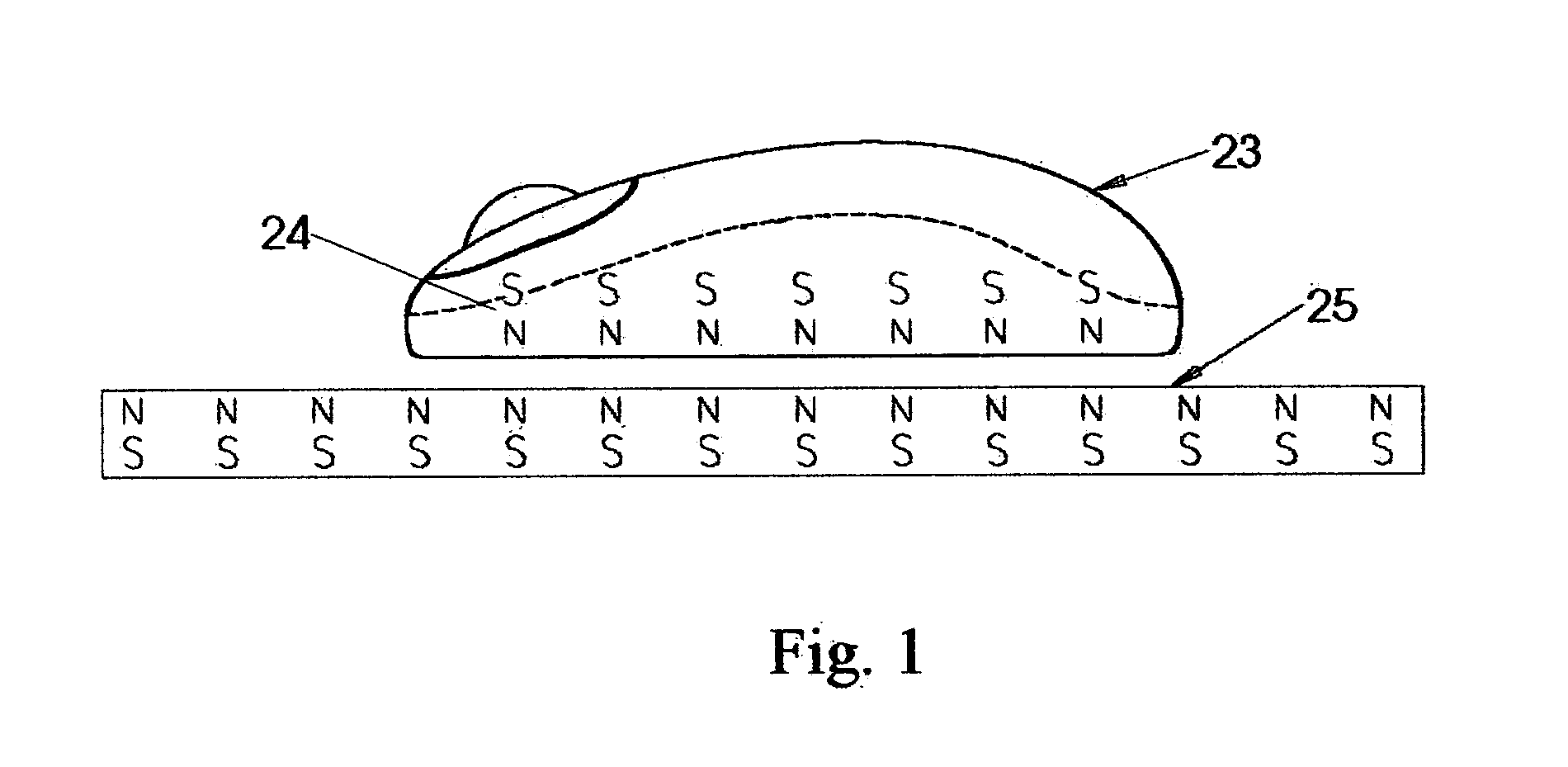

Anti-gravity Mouse

InactiveUS20110122064A1Cathode-ray tube indicatorsInput/output processes for data processingGraphicsAnti-gravity

A hand-held computer mouse for controlling a graphical pointer on a computer display characterized by incorporating permanent magnet or electromagnet to repel a magnetic surface to reduce or eliminate friction during usage, thereby making the pointer manipulating device sensitive to the slightest movement of a hand, and thinning the barrier between mind and physical world.

Owner:DENG XIAOMING

Anti-gravity household relaxation health-preserving chair

InactiveCN104323615AEasy maintenanceEasy for daily maintenanceVibration massageStoolsAnti-gravityAgricultural engineering

The invention discloses an anti-gravity household relaxation health-preserving chair composed of a base, a backrest, a seat frame, a leg frame, armrests, a main oil pump, an auxiliary oil pump, a vibrating motor and springs. The seat frame is connected onto the base through the springs, and the vibrating motor is arranged at the bottom of the seat frame; the backrest and the leg frame are respectively connected to two ends of the seat frame through hinges; one end of the main oil pump is connected with the rear of the backrest, and the other end of the main oil pump is connected with one side of the base; one end of the auxiliary oil pump is connected with the rear of the leg frame, and the other end of the auxiliary oil pump is connected to the base; the armrests are arranged between the backrest and the seat frame, one end of each armrest is connected with the backrest, and the other end of each armrest is connected with the seat frame; and projections are uniformly arranged at the upper parts of the backrest, the seat frame and the leg frame. The anti-gravity household relaxation health-preserving chair disclosed by the invention has an integral simple structure and is free of a particularly complicated mechanical structure, thereby reducing the cost to a certain extent and ensuring relatively convenient overhaul and daily maintenance of the health-preserving chair.

Owner:段伟

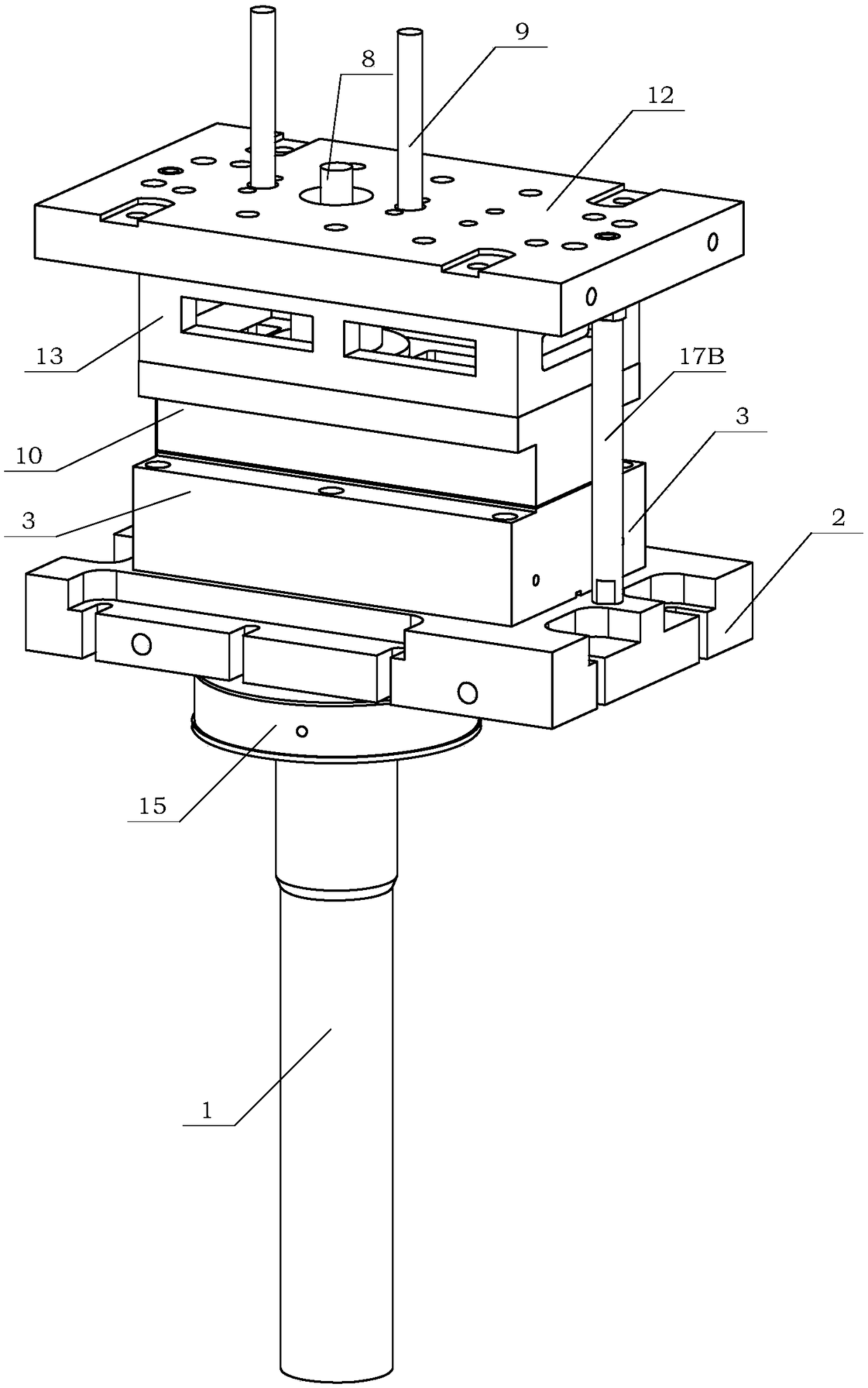

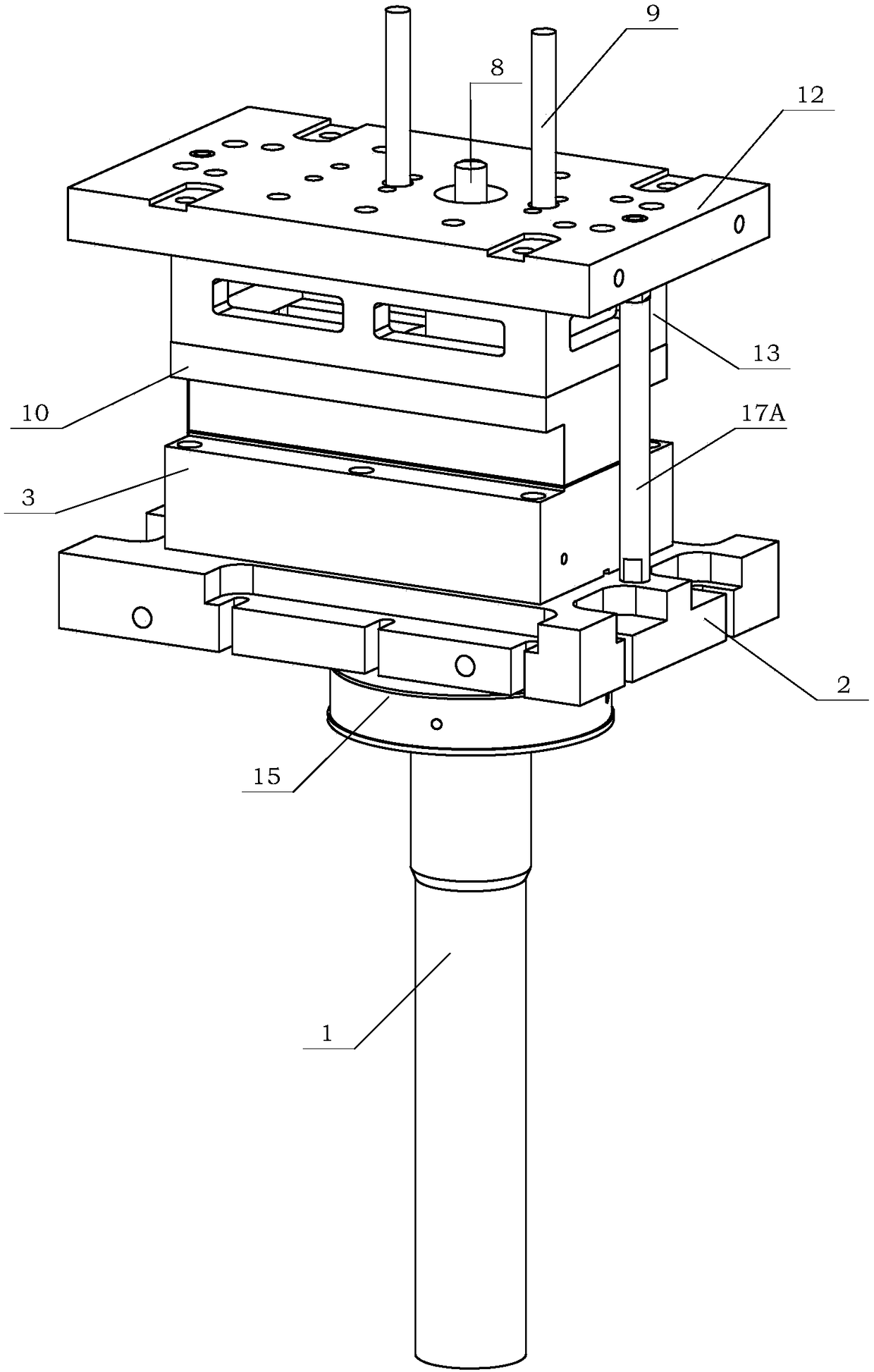

Low-pressure mold-filling high-pressure solidification casting device and casting method

InactiveCN108326256AAvoid air holesAvoid defects such as secondary oxidation inclusionsAnti-gravityMold filling

The invention discloses a low-pressure mold-filling high-pressure solidification casting device and a casting method, which can be used in an anti-gravity casting machine or an extrusion casting machine. The device comprises a casting mold, a metal melt lifting channel and a shunting cone, wherein a mold cavity is formed in the casting mold, the shunting cone can move up and down, and the shuntingcone has the effects of shunting and guiding metal melt at a liquid lifting stage and pressing a filter screen, so that a mold is stably filled with the metal melt in a mode of laminar flow. After the mold is filled, the shunting cone moves downwards to press a sprue bushing so as to form a sealing structure, and a metal melt inlet of the sprue bushing and the mold cavity is sealed. Then high pressure charging is performed on the metal melt, so that the metal melt is solidified at high pressure, the pressure range can reach 0.1 MPa to 160 MPa, and the defects of shrinkage cavities, shrinkageporosity, inclusions, slag inclusions and the like are avoided. Additionally, optimum structural design is performed on the shunting cone, so that low-pressure controllable stable mold filling and high-pressure solidification forming of the metal melt are guaranteed. While the metal melt in the mold cavity is applied by a pressure mechanism, the metal melt in the metal melt lifting channel cannotform a solidification shell, so that the service life of equipment is prolonged.

Owner:BEIHANG UNIV

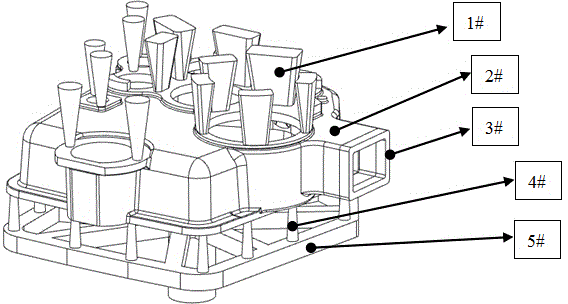

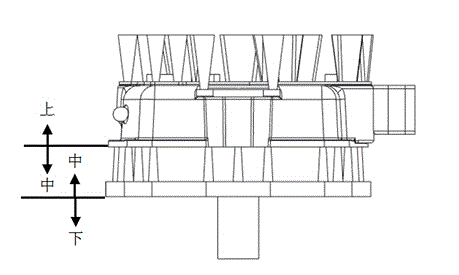

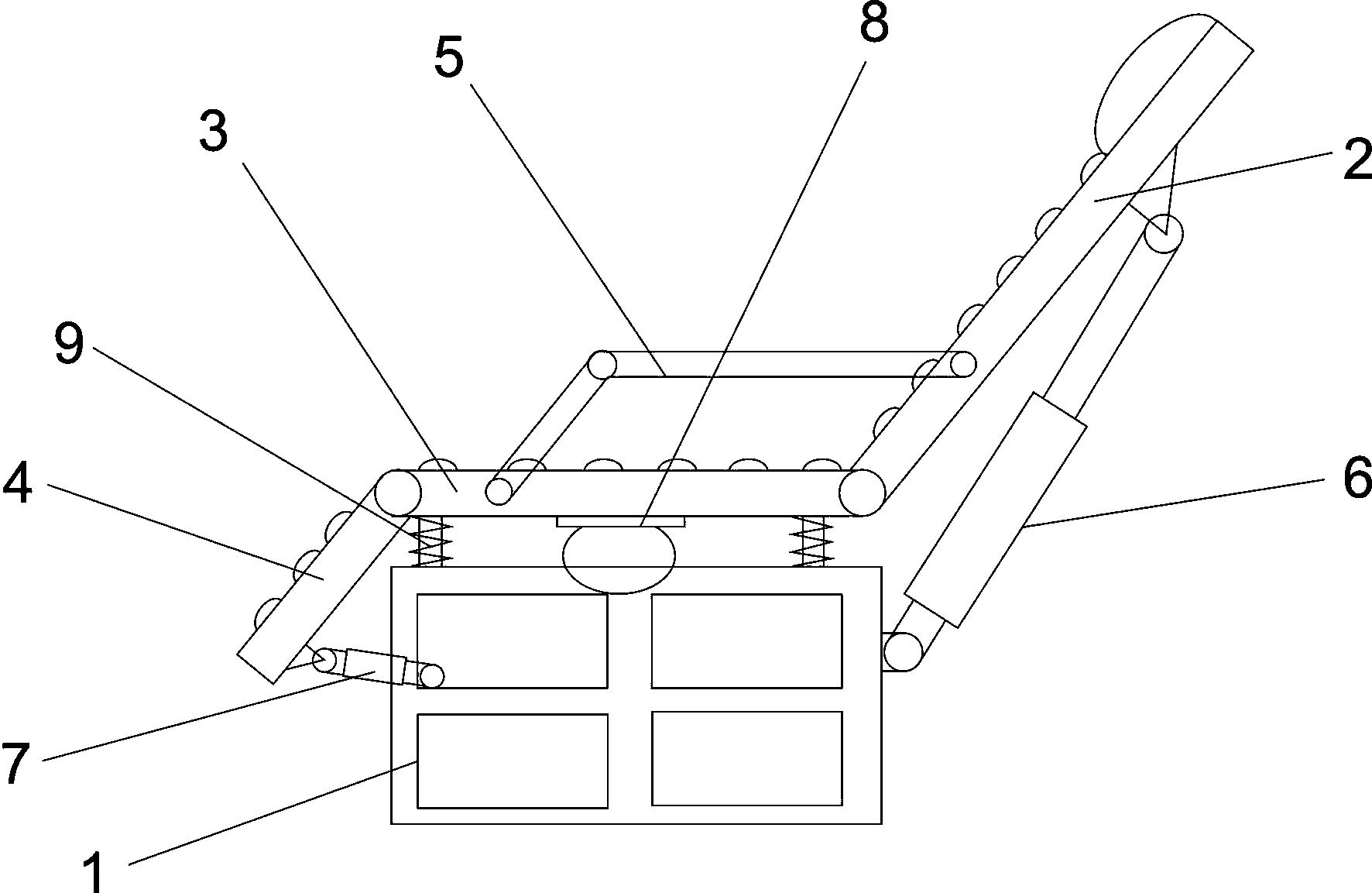

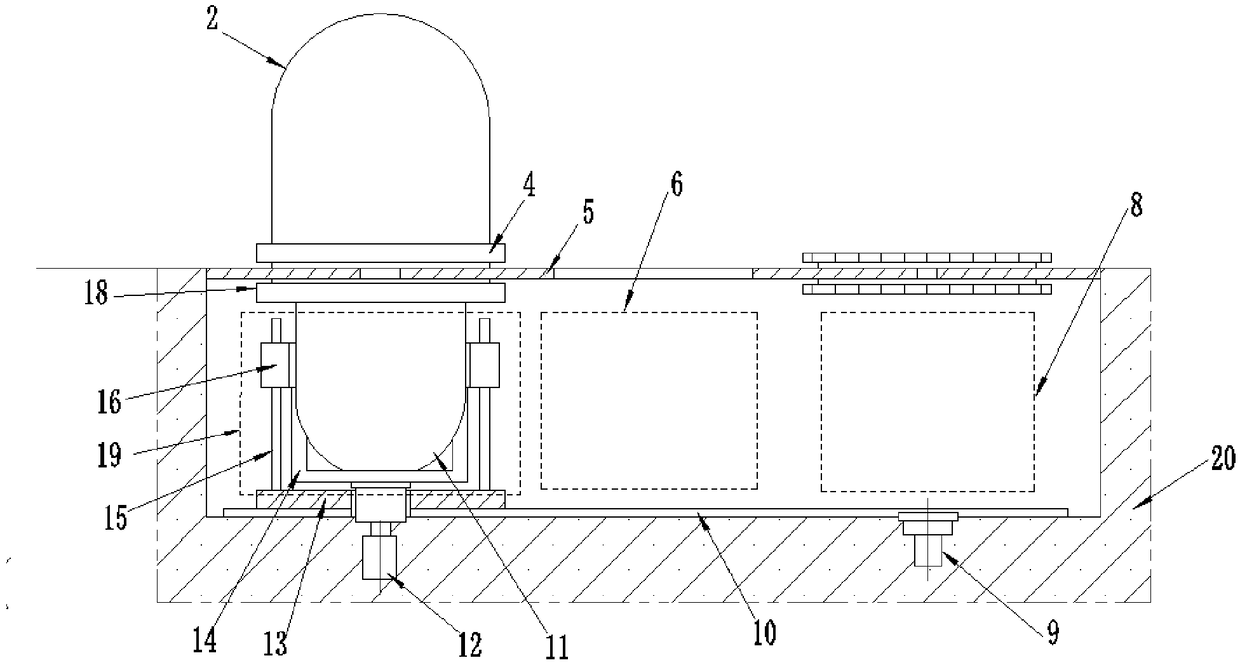

Double-station anti-gravity casting machine of large copper alloy propeller for ship

The invention relates to a double-station anti-gravity casting machine of a large copper alloy propeller for a ship. The double-station anti-gravity casting machine is used for solving the problems that large copper alloy propellers prepared through an existing gravity casting method are low in technological yield and mechanical property and anti-gravity casting machines are simplex in function. Acasting machine body of the casting machine is of a box structure. A working platform is located on the top surface of a box of the casting machine body. A molten copper ladle loading and unloading station, a low-pressure casting station and a counter-pressure casting station are arranged in the casting machine body, the counter-pressure casting station is arranged on the left side of the moltencopper ladle loading and unloading station, and the low-pressure casting station is arranged on the right side of the molten copper ladle loading and unloading station. The double-station anti-gravitycasting machine is beneficial for forming large thin-walled complex castings, has the double stations, and is stable in operation and accurate in control. The double-station anti-gravity casting machine is suitable for casting the large copper alloy propeller for the ship.

Owner:HARBIN INST OF TECH

Micro-channel structure auxiliary driven loop heat pipe

PendingCN108267036AGuaranteed reliabilityGuaranteed stability against gravityIndirect heat exchangersAnti-gravityMicro-loop heat pipe

The invention relates to heat control equipment, and provides a micro-channel structure auxiliary driven loop heat pipe. The micro-channel structure auxiliary driven loop heat pipe comprises an evaporator and a condenser. A liquid outlet of the condenser communicates with a liquid inlet of the evaporator through a liquid pipeline, a gas outlet of the evaporator communicates with a gas inlet of thecondenser through a gas pipeline, multiple micro-channels are formed in the inner wall of the liquid pipeline and sequentially distributed in the circumferential direction of the liquid pipeline at intervals, and stretch in the length direction of the liquid pipeline, a liquid absorption core is arranged in the evaporator, one end of each micro-channel stretches into the condenser, and the otherend of each micro-channel is connected with the liquid absorption core. The micro-channels are formed in the inner wall of the liquid pipeline, a liquid-state working medium can be conveyed with the help of the capillary effect of the micro-channels, supply of the liquid-state working medium can be continuously provided for the evaporator without gravity assisting and additional power consumption,and the starting reliability and the anti-gravity working stability of the loop heat pipe are guaranteed.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Z actuator with anti-gravity

InactiveUS7462958B2Easy to operatePiezoelectric/electrostriction/magnetostriction machinesMagnetic circuitAnti-gravityAir bearing

Methods and apparatus which are suitable for actuating a stage relative to a z-axis and supporting the weight of the stage against the force of gravity are disclosed. According to one aspect of the present invention, an actuator device includes a first arrangement, a magnetic system, a piston, and a guide bearing arrangement. The first arrangement includes a yoke and a center pole, and the magnetic system includes a magnet that is coupled to the yoke as well as a coil which cooperate to function as a voice coil motor. The piston supports at least a weight associated with the first arrangement, and the guide bearing arrangement includes a planar air bearing that enables the device to move over an external surface.

Owner:NIKON CORP

Loop heat pipe with auxiliary liquid conveying pipeline

The invention relates to heat control equipment, in particular to a loop heat pipe with an auxiliary liquid conveying pipeline. The loop heat pipe comprises an evaporator and a condenser; a liquid outlet of the condenser communicates with a liquid inlet of the evaporator through a liquid pipeline; a gas outlet of the evaporator communicates with a gas inlet of the condenser through a gas pipeline;and the condenser, the liquid pipeline, the evaporator and the gas pipeline communicate in sequence to form a loop. The loop heat pipe further comprises the auxiliary liquid conveying pipeline communicating with the evaporator and the condenser, a first capillary structure is arranged in the auxiliary liquid conveying pipeline, and a liquid absorbing core is arranged in the evaporator. The loop heat pipe is additionally provided with the auxiliary liquid conveying pipeline, the first capillary structure is arranged in the auxiliary liquid conveying pipeline, liquid work media can be conveyedthrough the capillary action of the first capillary structure, continuous liquid work media supplying can be provided for the evaporator without gravity assistance and additional power dissipation, and the starting reliability and the anti-gravity working stability of the loop heat pipe are ensured.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

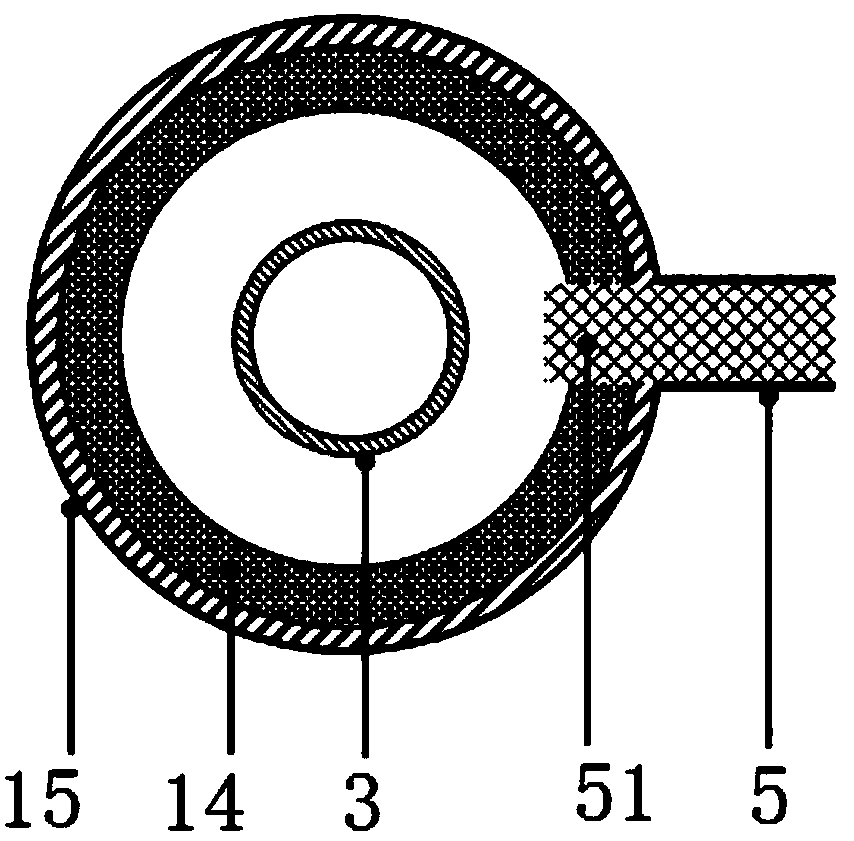

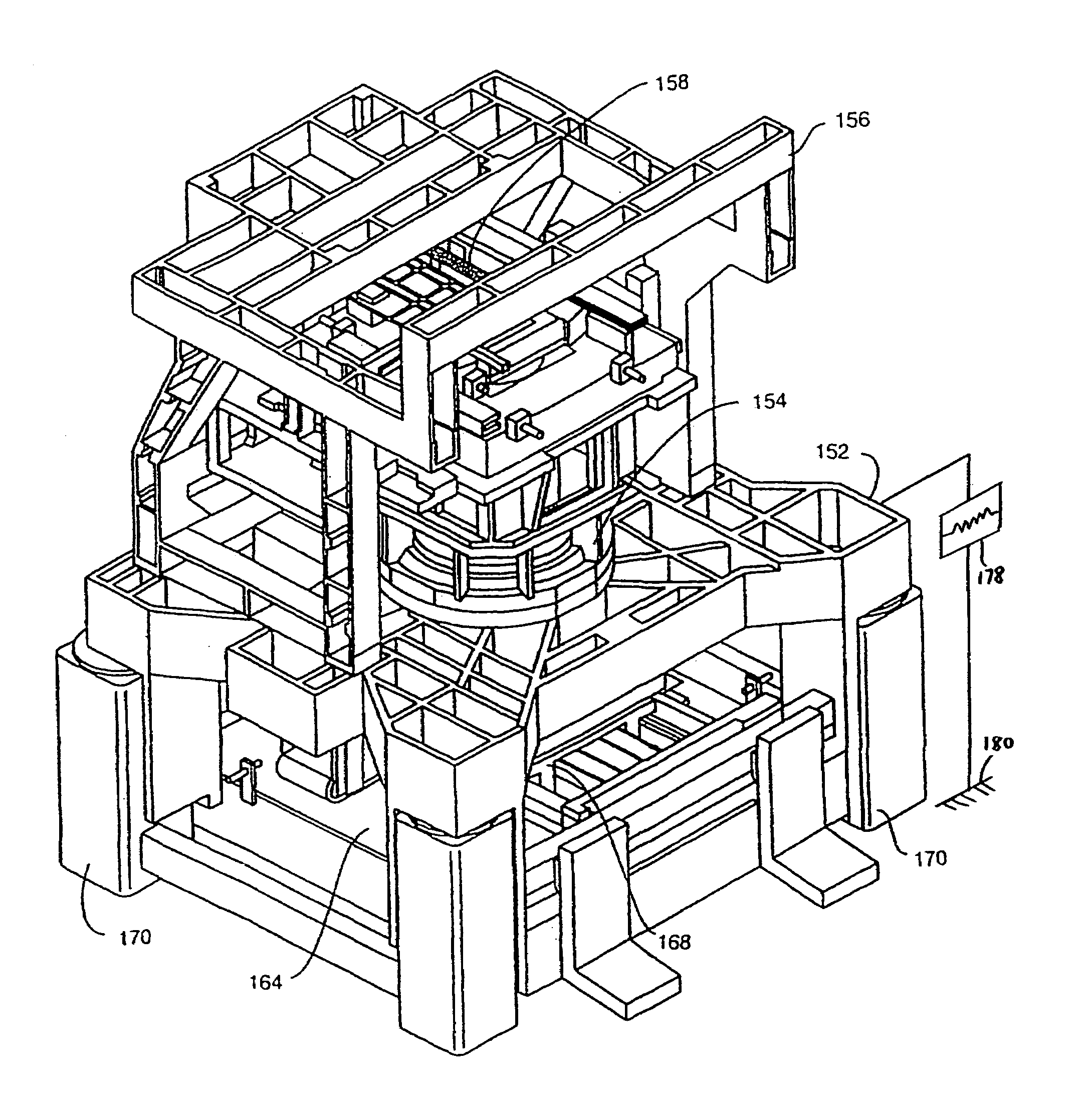

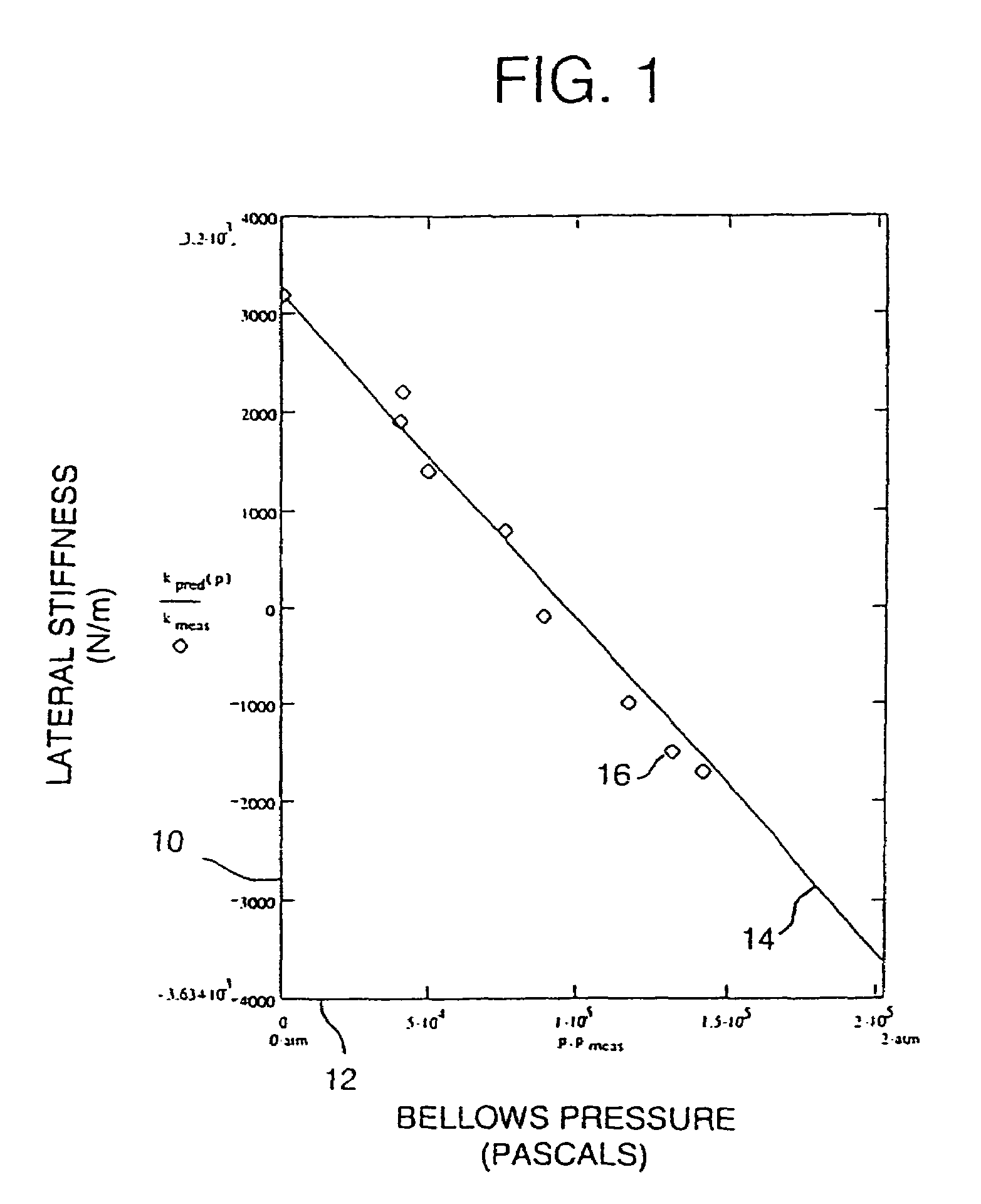

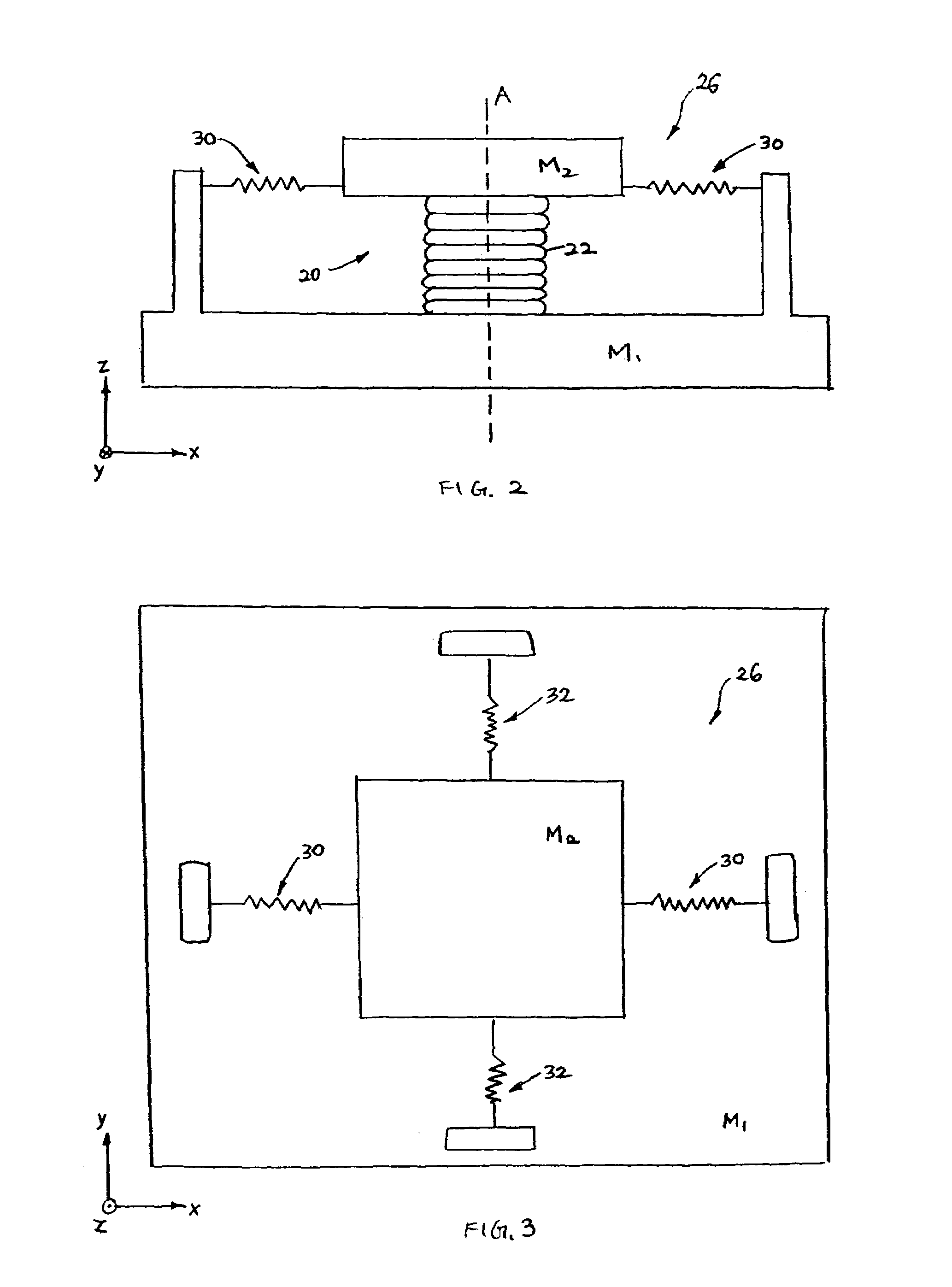

Bellows with spring anti-gravity device

ActiveUS7087906B2Avoid spreadingIncrease lateral stiffnessElectric discharge tubesThermometers using material expansion/contactionUltrasound attenuationVibration attenuation

Embodiments of the present invention are directed to apparatus and methods of attenuating vibration, particularly for modern stepper machines and other types of vibration sensitive equipment. The attenuation system exhibits good vibration attenuation in the axial or support direction, and exhibits low or substantially zero lateral stiffness to prevent transmission of any vibrations between any of various portions of the machine. In one embodiment, an apparatus for attenuating transmission of lateral vibration between a first mass and a second mass comprises a vibration attenuation device including at least one bellows oriented along a support axis. The at least one bellows is connected between the first mass and the second mass and has an interior volume pressurized with a fluid to an internal fluid pressure which is greater than a zero-stiffness pressure such that the vibration attenuation device exhibits a negative lateral stiffness. A positive stiffness device is coupled between the first mass and the second mass. The positive stiffness device has a positive lateral stiffness which may be substantially equal to or greater than the negative lateral stiffness in magnitude.

Owner:NIKON CORP

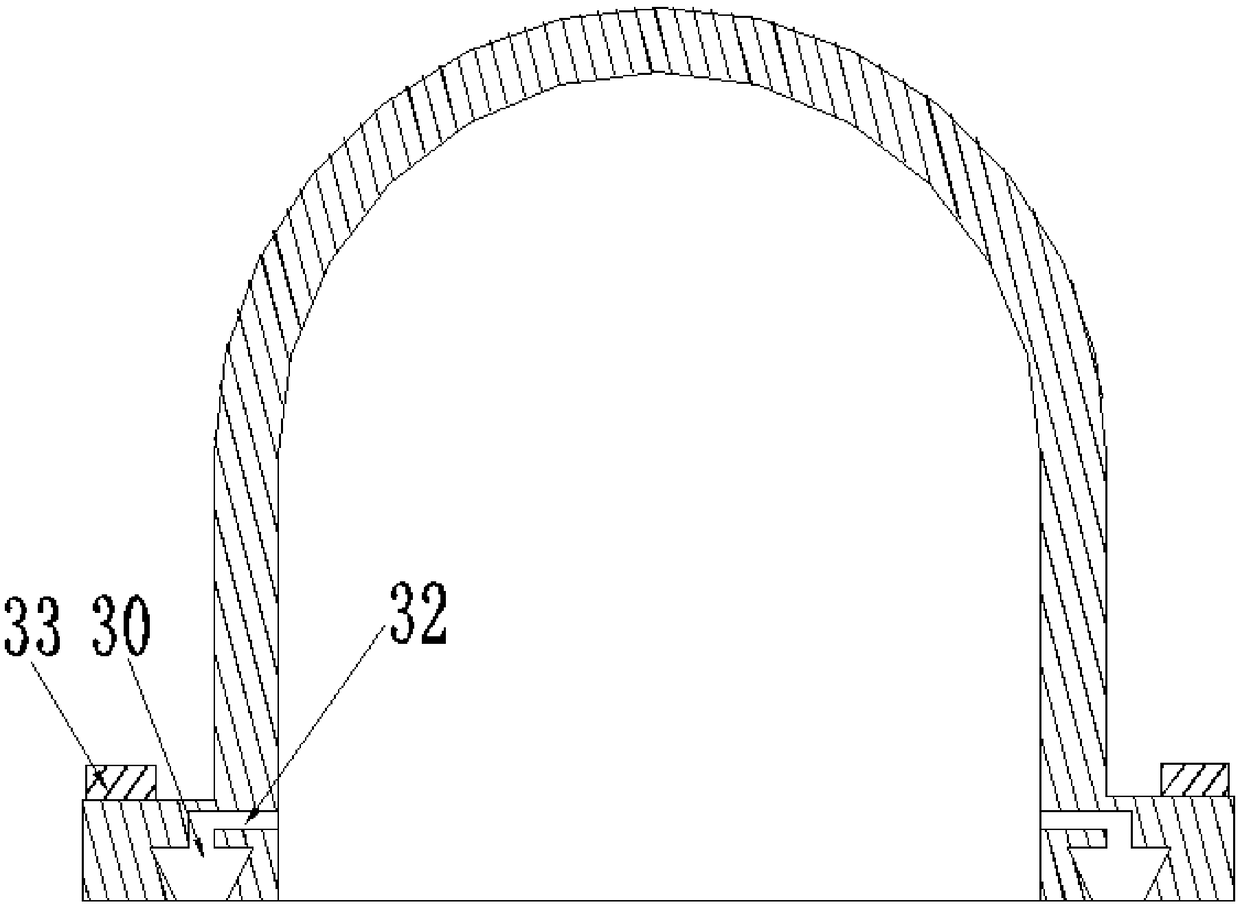

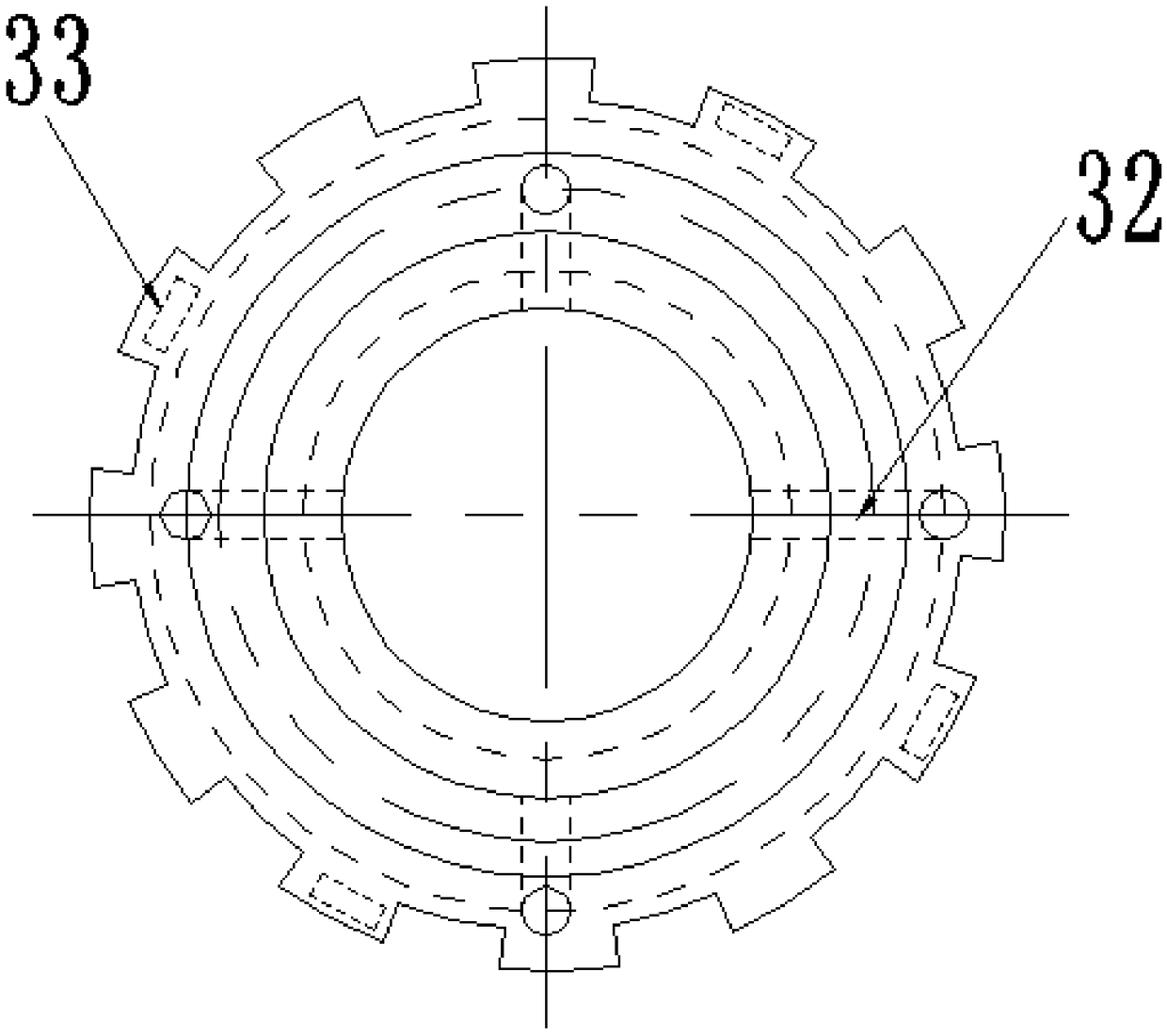

Anti-gravity forming air cooled throat ascending feed cutoff method for copper alloy propeller for large ship

The invention belongs to the field of ship manufacturing, and relates to an anti-gravity forming air cooled throat ascending feed cutoff method, in particular to an anti-gravity forming air cooled throat ascending feed cutoff method for a copper alloy propeller for a large ship. The method aims to solve the problems that a long time is needed from liquid cooling to a solid state of the copper alloy propeller for the large ship, and after mold filling and an ascending liquid and pressure maintaining curve are finished, a sprue above an ascending liquid pipe must be blocked to cut off ascending feed. An upper tank, a casting mold, a propeller casting, an air cooled throat, a middle partition plate, the ascending feed pipe, a molten copper ladle and a lower tank are included; the upper tank, the middle partition plate and the lower tank are sequentially arranged from top to bottom; the casting mold is arranged inside the upper tank; the molten copper ladle is arranged in the lower tank; the lower portion of the ascending feed pipe is inserted into the molten copper ladle; the upper end of the ascending feed pipe is inserted into the lower surface of the casting mold; and the air cooled throat is arranged at the upper end of the ascending feed pipe in a sleeving mode.

Owner:HARBIN INST OF TECH +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com