Compact type loop heat pipe device

A loop heat pipe, compact technology, applied in the field of compact loop heat pipe devices, can solve the problems of large thickness of the loop heat pipe evaporator, small transmission distance of the working medium, and inability to return the working medium, so as to shorten the transportation distance and compact structural design , Improve the effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described below in conjunction with specific embodiments.

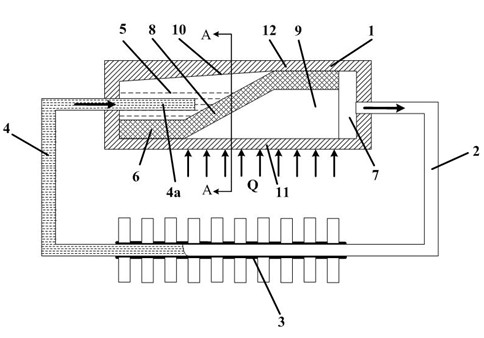

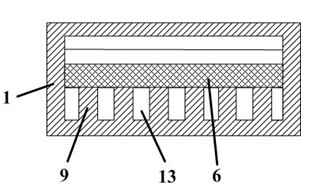

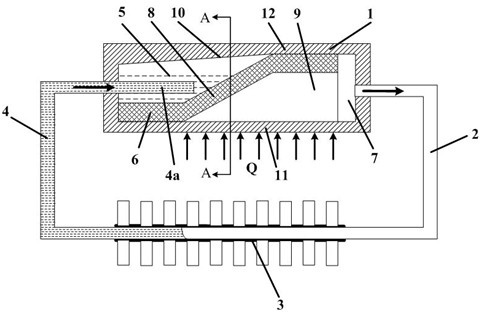

[0021] Such as figure 1 Shown is a schematic structural view of the compact loop heat pipe device of the present invention, figure 2 for figure 1 A-A sectional view in . The compact loop heat pipe device of the present invention includes an evaporation part 1, a gas phase pipeline 2, a condensation part 3 and a liquid phase pipeline 4, and constitutes a closed circulation channel. One end of the evaporator 1 is connected with a liquid phase pipeline 4 , and the other end is connected with a gas phase pipeline 2 . The airtight circulation channel is filled with working medium in gas phase or liquid phase.

[0022] The evaporating part 1 is in the shape of a plate, the plate side close to the condensing part 3 is a heating surface 11 , and the plate side away from the condensing part 3 is a non-heating surface 12 . A compensation chamber 5 , a capillary structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com