Dividing wall type heat exchanger

A technology of heat exchangers and thermally conductive substrates, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of large space occupation, mismatch of pump power consumption and heat transfer capacity, and uncompact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

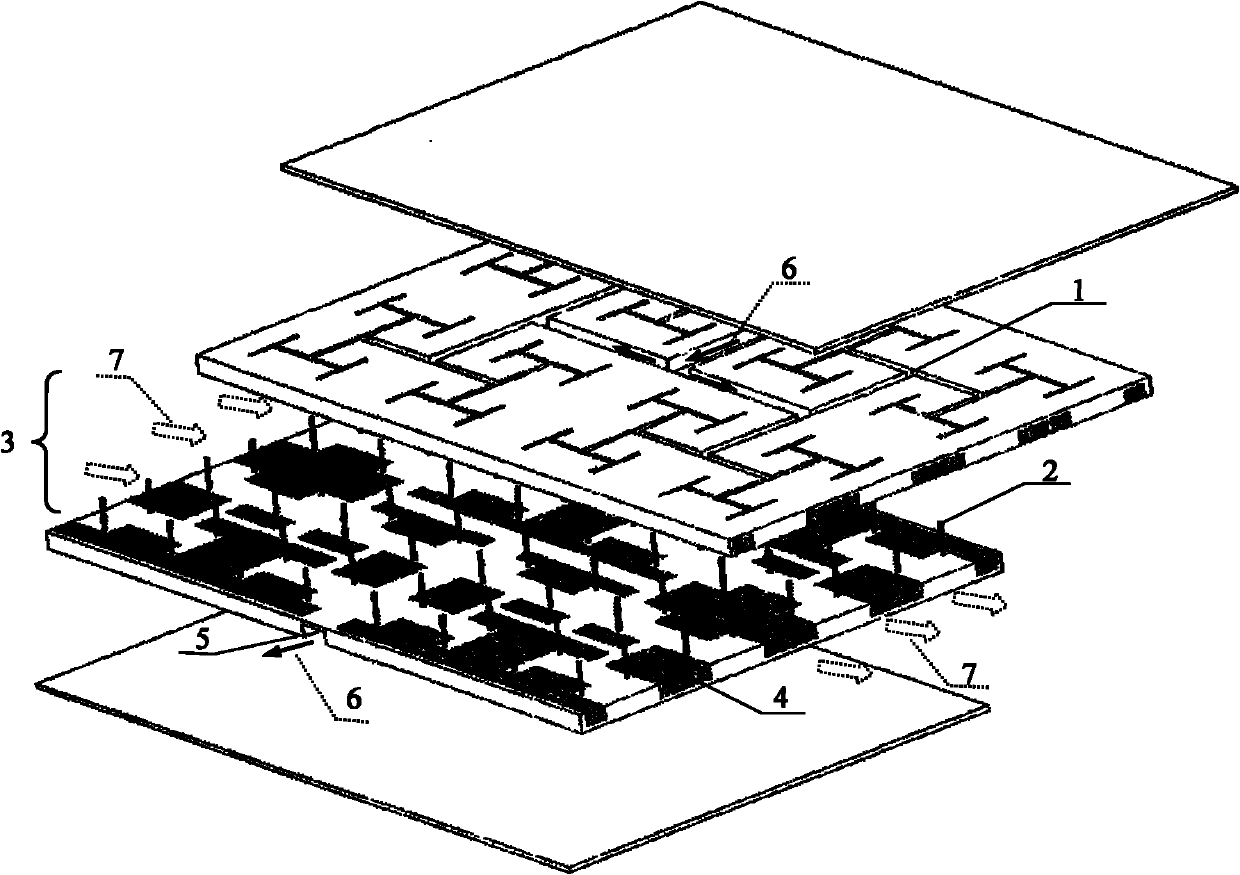

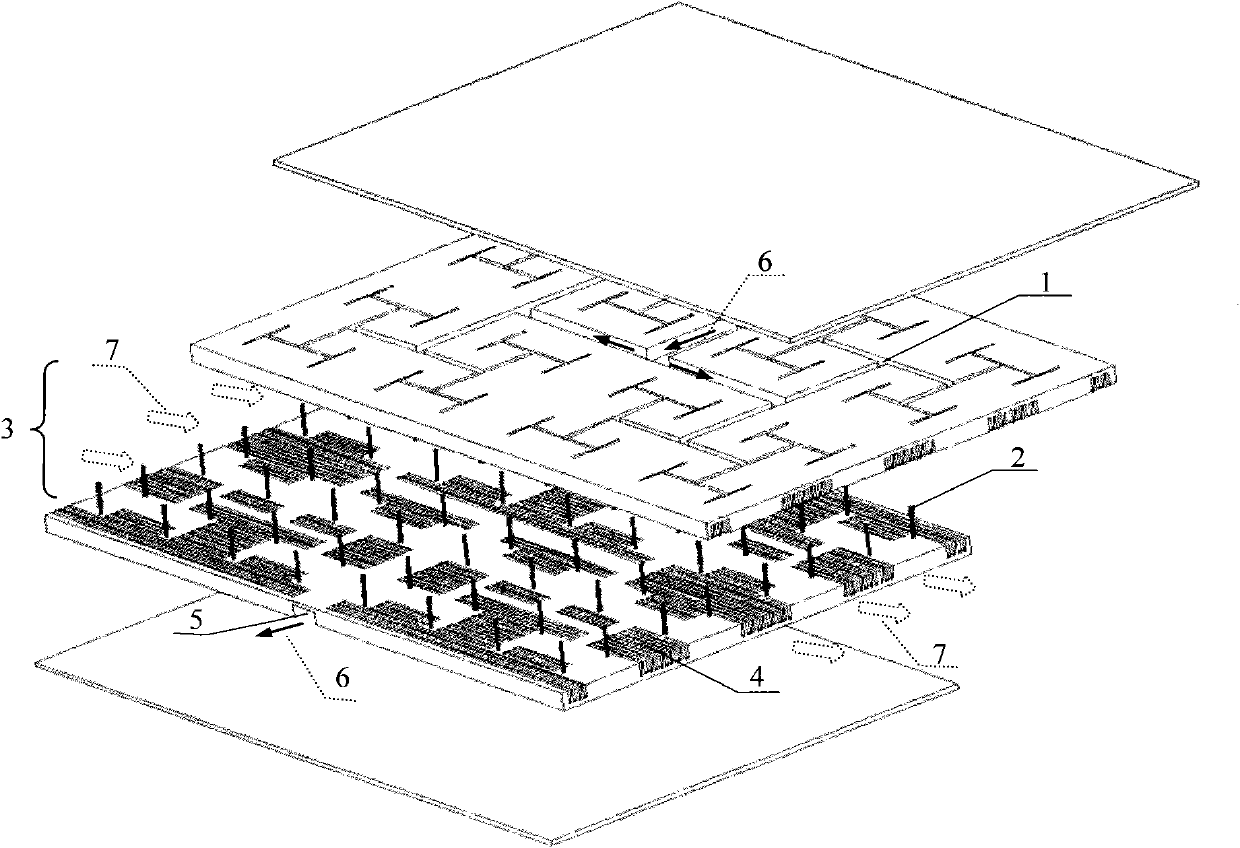

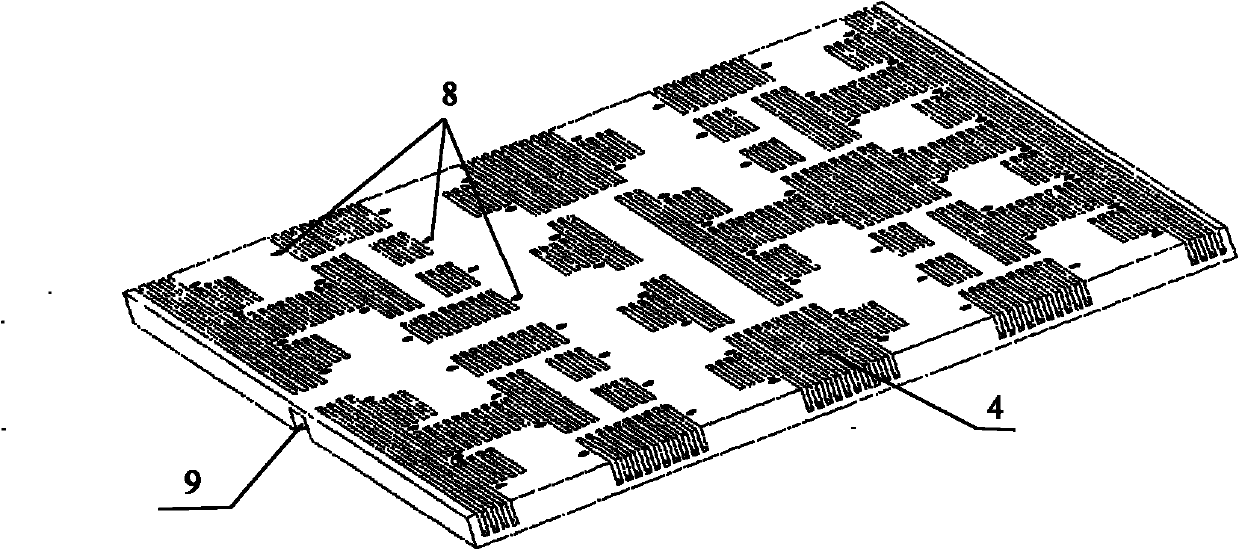

[0020] This explanation is further described in conjunction with the accompanying drawings:

[0021] The structure of the dividing wall heat exchanger proposed by the present invention is as follows: figure 1 As shown, the partitioned wall heat exchanger is manufactured from a high-efficiency heat-conducting substrate, and an upper-layer tree-shaped flow channel network 1 is arranged on the inner side of the upper surface of the substrate, and the structure of the upper-layer tree-shaped flow channel is consistent with the Branches at all levels such as figure 2 as shown ( figure 2 Among them, 10, 11..., 16 represent the 0th level, the 1st level, ... the 6th level flow channel), the flow channel network is spread out in a planar manner, and the flow channel network contains at least 2 levels, each The first-level channel is connected to the next-level channel with the number of bifurcations N=2, and the intersection angle α between the upper and lower flow channels is 180 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com