Anti-gravity forming air cooled throat ascending feed cutoff method for copper alloy propeller for large ship

A copper alloy and marine technology, which is applied in the field of anti-gravity forming air-cooled throat cut-off liquid, and copper alloy propeller anti-gravity forming air-cooled throat cut-off liquid for large ships, can solve problems such as a long time, and achieve convenient operation. , the structure is simple, the effect is conducive to safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

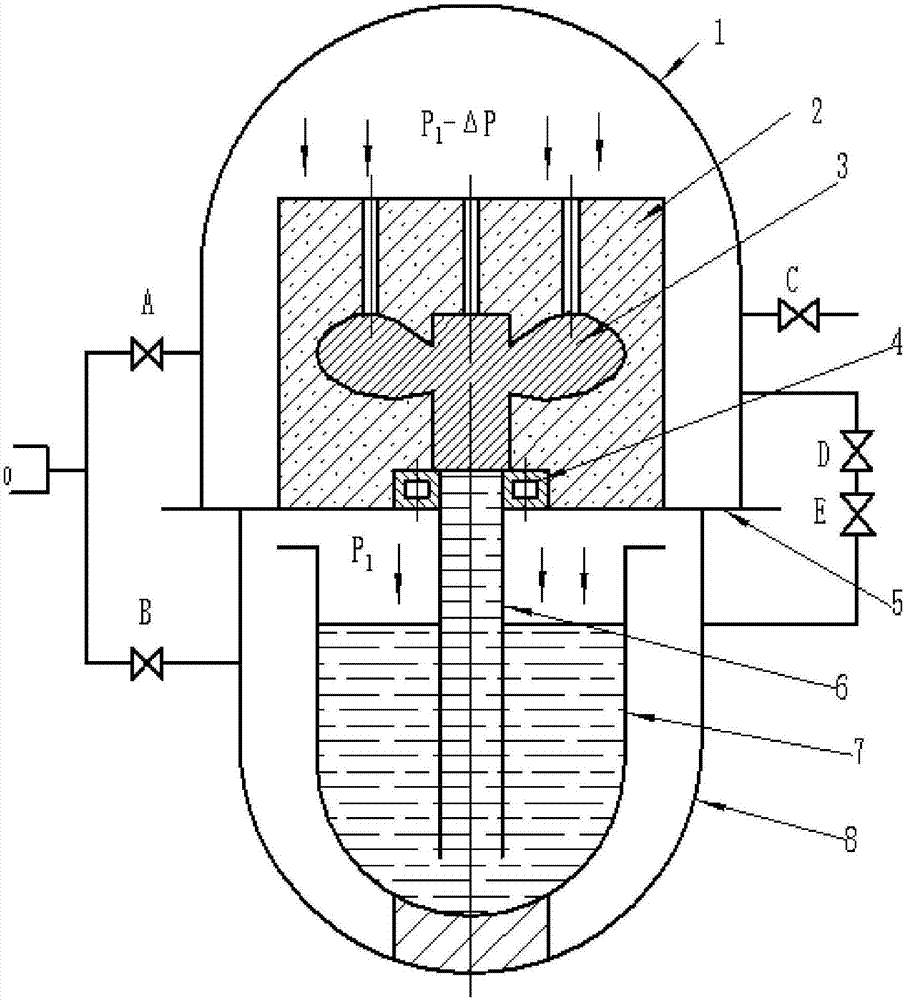

[0013] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the forming device used in the anti-gravity forming air-cooled throat cut-off liquid lifting method for a copper alloy propeller for a large ship in this embodiment includes an upper tank 1, a mold 2, a propeller casting 3, an air-cooled throat 4, and a partition Plate 5, riser pipe 6, copper water ladle 7 and lower tank 8, upper tank 1, middle partition 5, and lower tank 8 are arranged sequentially from top to bottom, mold 2 is set in upper tank 1, copper water ladle 7 Set in the lower tank 8, the lower part of the riser pipe 6 is inserted into the copper water bag 7, the upper end of the riser pipe 6 is inserted into the lower surface of the mold 2, and the air-cooled throat 4 is set on the upper end of the riser pipe 6;

[0014] The specific steps of the copper alloy propeller anti-gravity forming air-cooled throat cut-off liquid rising method for large ships are as follows:

[0015] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com