a muffler

A technology for mufflers and appliances, applied in mufflers, machines/engines, engine components, etc., can solve the problems of increased back pressure, too fast jet flow rate, and too strong reflected wave intensity, so as to reduce back pressure and eliminate narrow-band noise. , Solve the effect of airflow reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

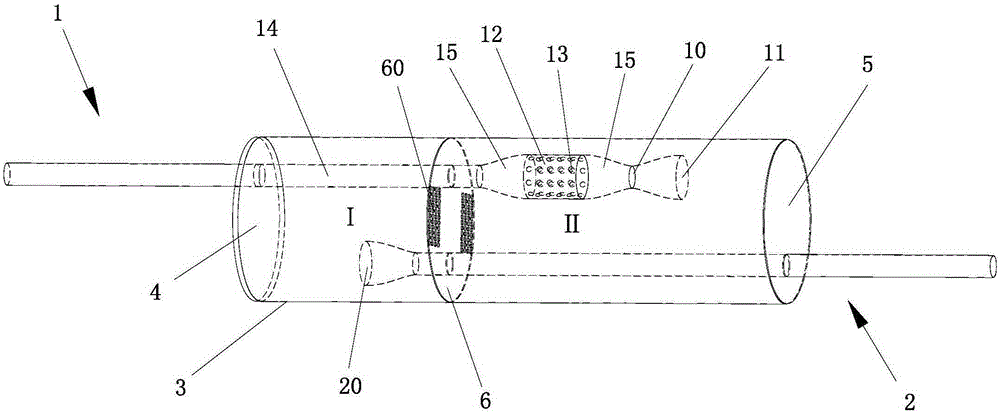

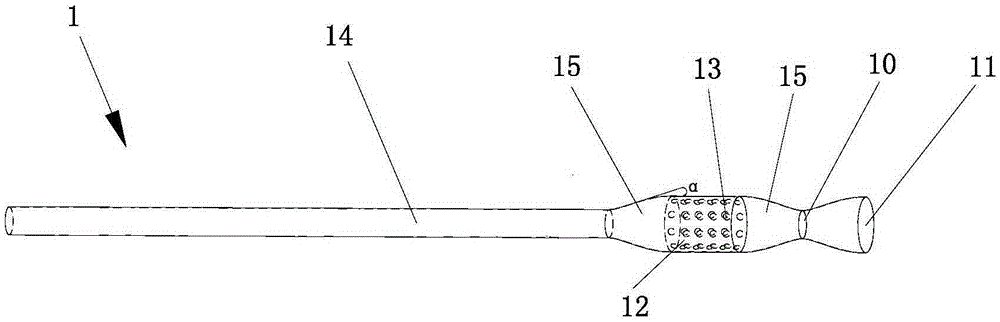

[0021] The present invention will be further described below through a muffler with a specific structure and in conjunction with the accompanying drawings.

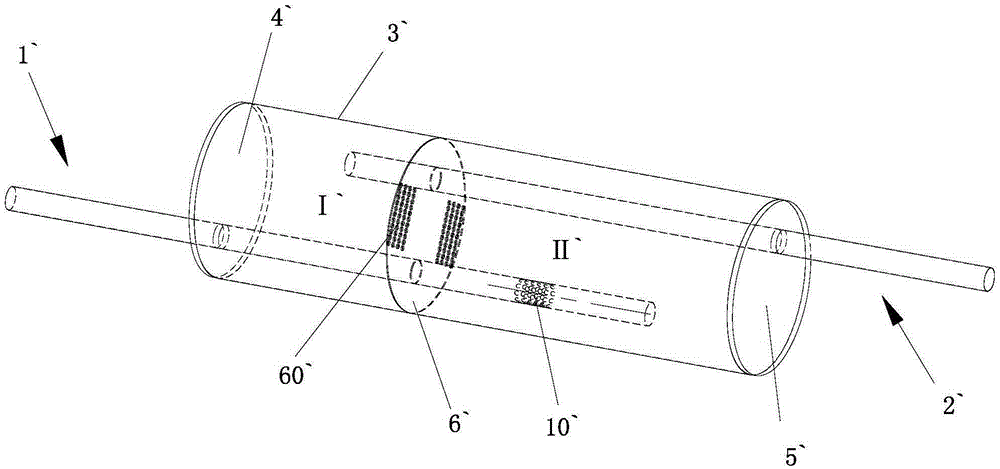

[0022] Such as Figure 2~3 As shown, a muffler includes an inner insertion pipe structure, a cylinder body 3, a first end cap 4 and a second end cap 5 fixedly arranged at both ends of the cylinder body 3, and the first end cap 4 and the second end cap 5 are all connected to the The cylinder 3 is sealed and connected, and a partition 6 is fixed in the cylinder 3 along the direction perpendicular to the axial direction of the cylinder 3. The partition 6 divides the cylinder 3 into a first chamber I and a second chamber II. A plurality of evenly distributed through-holes 60 are opened on 6, and the through-holes 60 communicate the first chamber I and the second chamber II.

[0023] The inner cannula structure includes an air intake inner cannula 1 and an air outlet inner cannula 2, and the air intake inner cannula 1 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com