Anti-gravity casting moulding method for 3D printing sand mould

An anti-gravity casting and forming method technology, applied in the direction of additive processing, etc., can solve the problems of poor feeding stability of the gating system, large deviations in weight and volume, and increased wall thickness of castings, etc., to achieve low production costs, increase friction, The effect of reducing the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

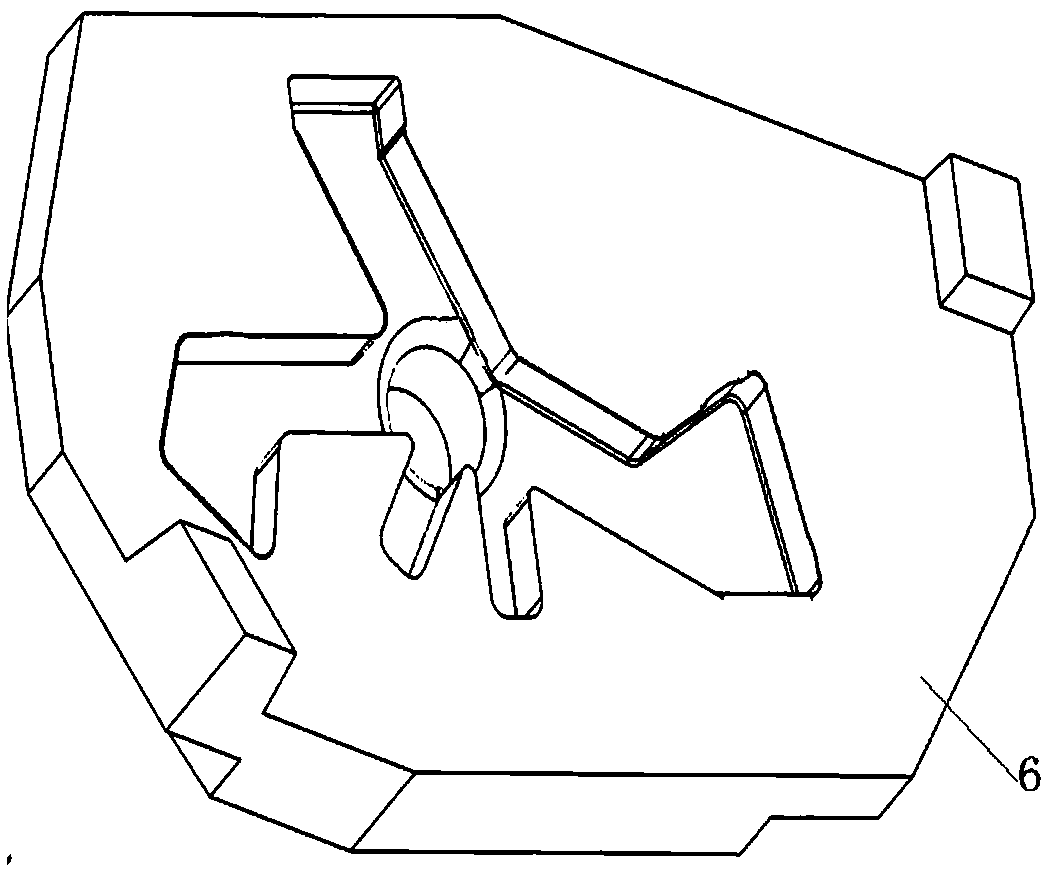

[0051] Taking a casting with a size of 560×245×190mm as an example, the material is ZL114A, there are 11 oil pipes in total, there are many bosses and different shapes, and the casting is divided into many sand blocks. The specific steps for its implementation are as follows:

[0052] Step 1: According to the characteristics of the casting, design the gating system, and increase the length of the sprue cup and the plane area of the bottom end appropriately. Among them, increase the length of the sprue cup to 100mm, after increasing the bottom plane area, the distance from the edge of the sand mold to the sprue cup should not be less than 180mm;

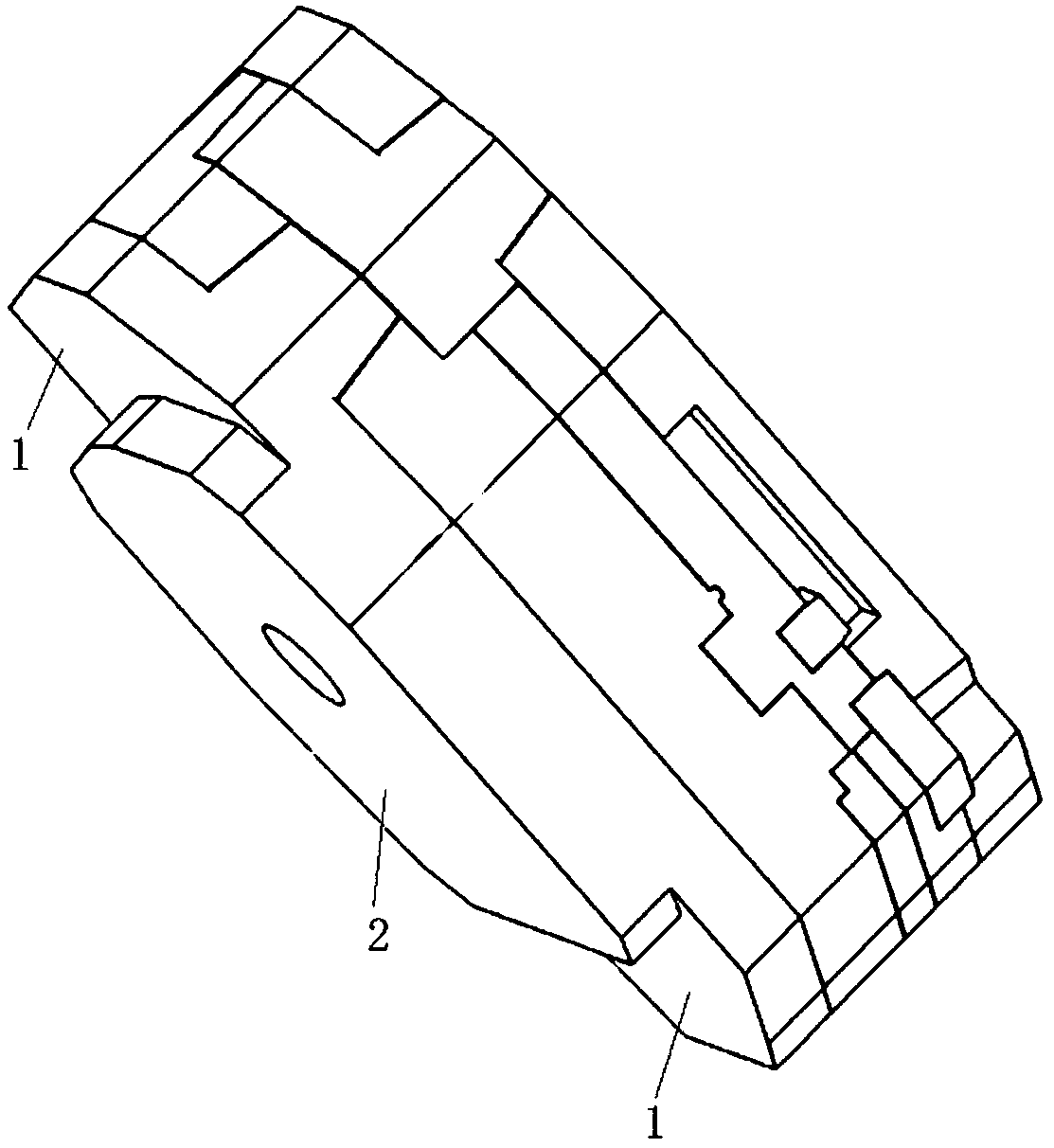

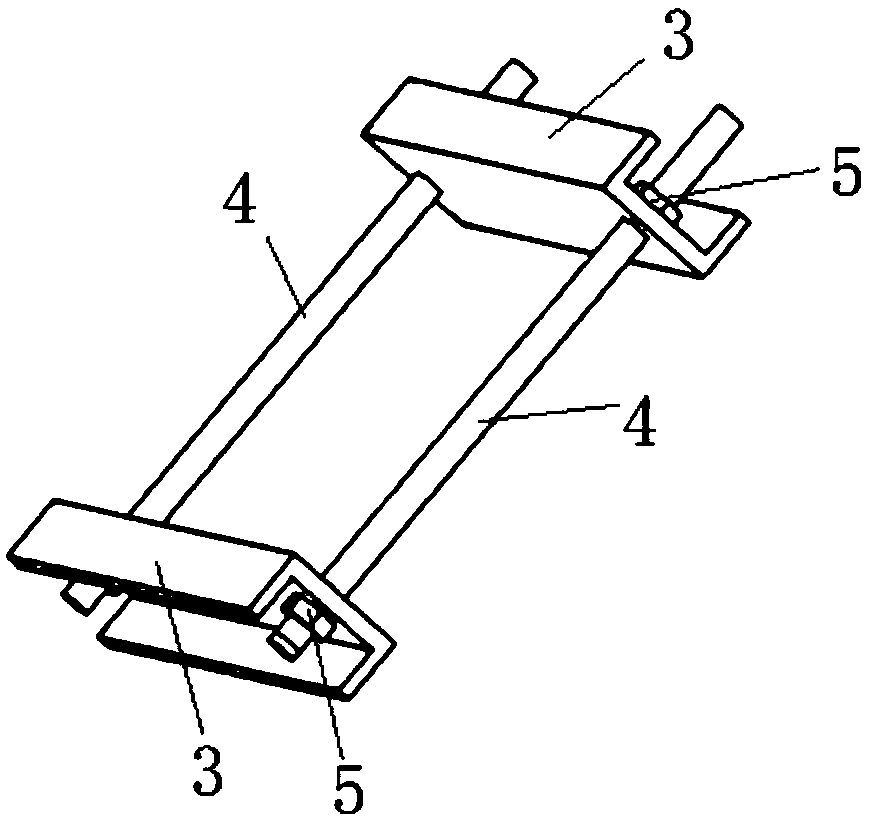

[0053] Step 2: Use three-dimensional drawing software to divide the castings with the designed gating system, and set a water glass sand molding fixing and self-locking tooling platform at the bottom of the sprue cup. The height of the platform is 80mm, such as figure 1 shown.

[0054] Step 3: According to the typing result in step...

Embodiment 2

[0067] by size Take a casting with an overall wall thickness of 10mm as an example. The material is ZL105. The casting is in the shape of a basin with a large arc and a hollow inner cavity. The required filling pressure difference is relatively large, and the large end face leads to huge filling pressure. At the same time, the cost of the 3D printing sprue sand mold is extremely high. The specific steps for its implementation are as follows:

[0068] Step 1: According to the characteristics of the casting, design the gating system, and increase the length of the sprue cup and the plane area of the bottom end appropriately. Among them, the length of the sprue cup is increased to 120mm, and after increasing the bottom plane area, the distance from the edge of the sand mold to the sprue cup is not less than 220mm;

[0069] Step 2: Use three-dimensional drawing software to divide the castings with the designed gating system, and set a water glass sand molding fixing and self-l...

Embodiment 3

[0083] Taking a casting with a size of 295mm×180mm×240mm as an example, the material is ZL114A, the casting is closed in a hemispherical shape, the wall thickness of the whole body is 4mm, and it is hollow. The specific steps for its implementation are as follows:

[0084] Step 1: According to the characteristics of the casting, design the gating system, and increase the length of the sprue cup and the plane area of the bottom end appropriately. Among them, the length of the sprue cup is increased to 80mm, and the bottom plane area is increased, and the distance from the edge of the sand mold to the sprue cup is not less than 160mm;

[0085] Step 2: Use three-dimensional drawing software to divide the castings with the designed gating system, and set a water glass sand molding fixing and self-locking tooling platform at the bottom of the sprue cup. The height of the platform is 70mm.

[0086] Step 3: According to the typing result in step 2, add supports to facilitate taking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com