Magnetofluid flat plate hot pipe soaking device

A technology of flat heat pipes and magnetic fluids, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve problems such as insufficient capillary force and difficult arrangement of capillary cores, and achieve good heat uniformity, Increase the thermal efficiency of phase change and enhance the effect of boiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

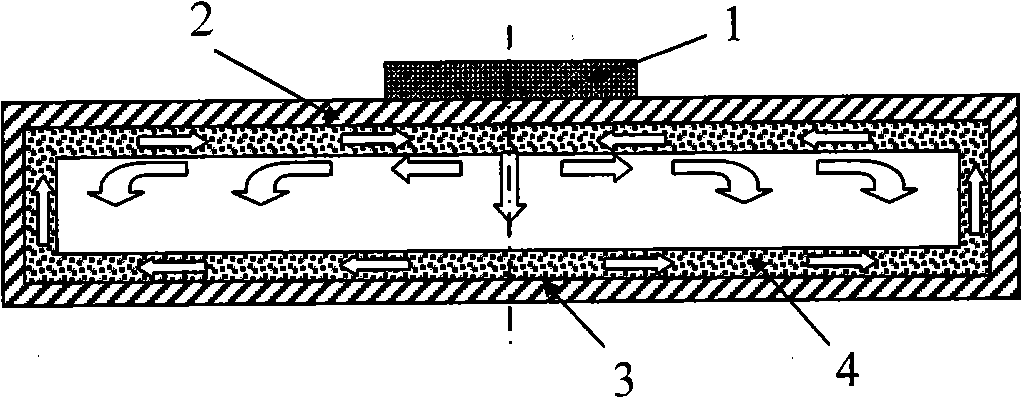

[0022] Embodiments of the present invention are specifically described below in conjunction with the accompanying drawings:

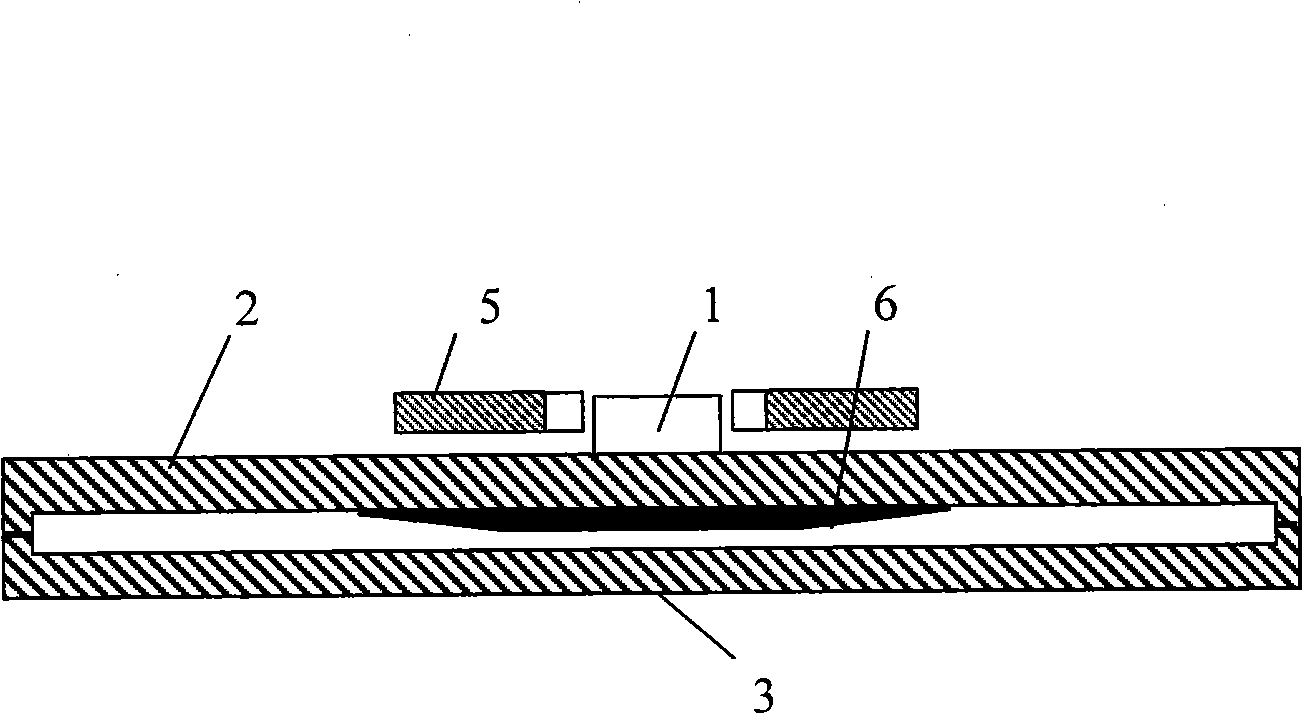

[0023] In this embodiment, the evaporating surface plate 2 and the condensing surface plate 3 are welded together. There is no capillary structure in the flat heat pipe cavity. After the flat heat pipe is evacuated, it is filled with magnetic fluid as a working fluid. A magnet 5 is arranged near the electronic device 1 outside the evaporation surface plate as an external magnetic field.

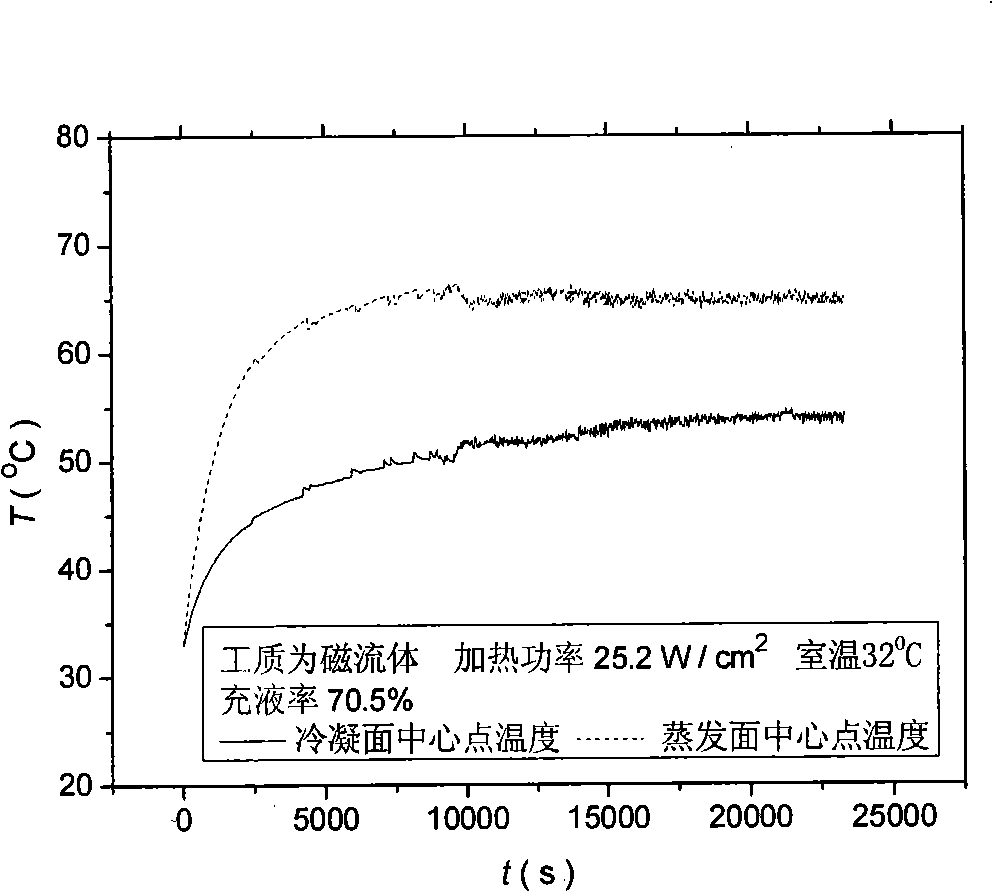

[0024] The specific structure diagram of the magnetic fluid flat heat pipe in this embodiment is as follows figure 2 shown. The diameter of the disc-shaped flat heat pipe is 85mm, and the material is red copper. The inner cavity height is 1 mm, and there is no capillary wick structure inside the cavity. The thicknesses of the evaporation surface plate 2 and the condensation surface plate 3 of the flat heat pipe are both 3 mm. An annular magnet 5 is placed outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com