Patents

Literature

110results about How to "Improve heat uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

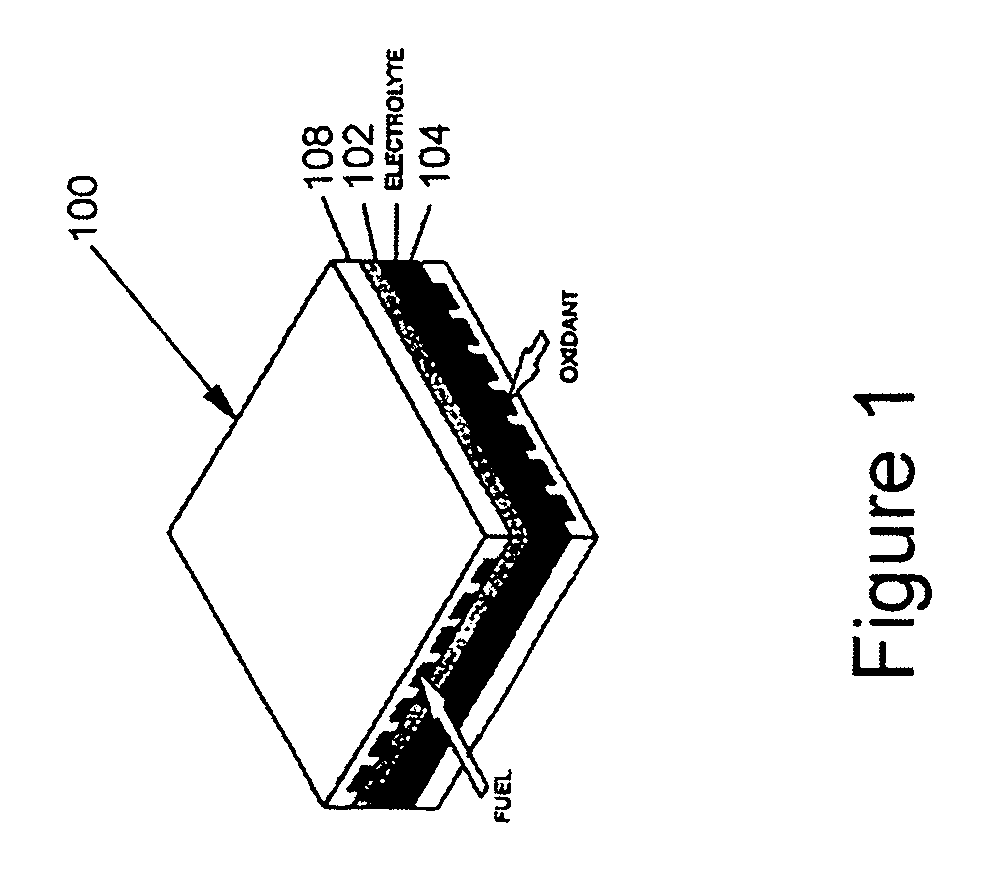

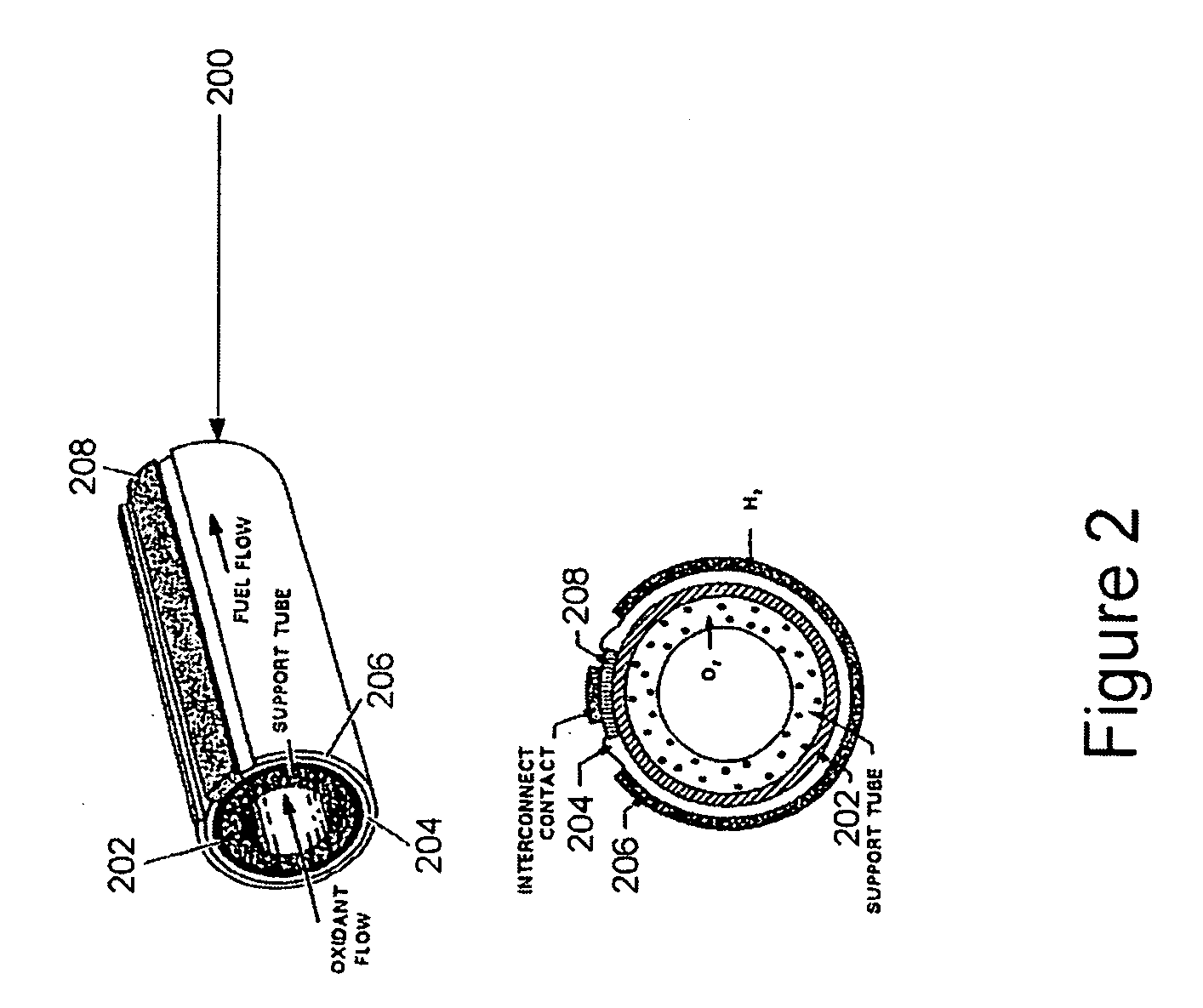

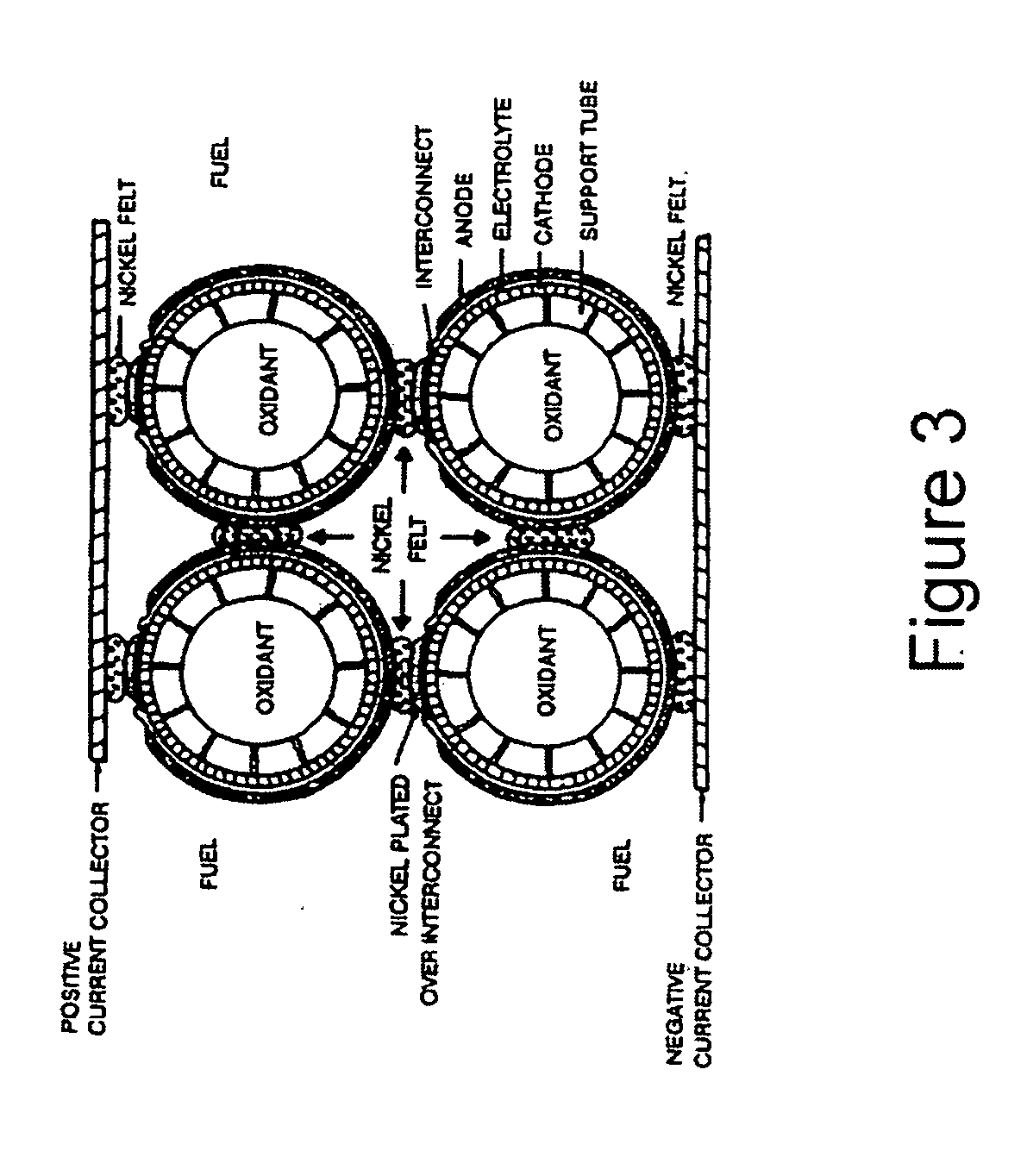

Tubular solid oxide fuel cells

InactiveUS20050037252A1Strong electrical contactImprove power densityFuel cells groupingCell electrodesFuel cellsThermal expansion

An anode-supported tubular fuel cell stack includes interconnect structures that are oxidation resistant at high temperature, flexible to accommodate thermal expansion stress and to provide strong electrical contact, have low electrical resistance, and are inexpensive and light weight. The interconnect structures may be formed out of metal sheet, which provide improved heat homogeneity throughout the fuel cell stack because of the high thermal conductivity of the metal. The interconnect structures are further shaped to provide resilience or spring-like features to allow movement between the tubular cells. Thus good electrical contact, thermal stress release, and shock absorption are simultaneously achieved.

Owner:EVOGY

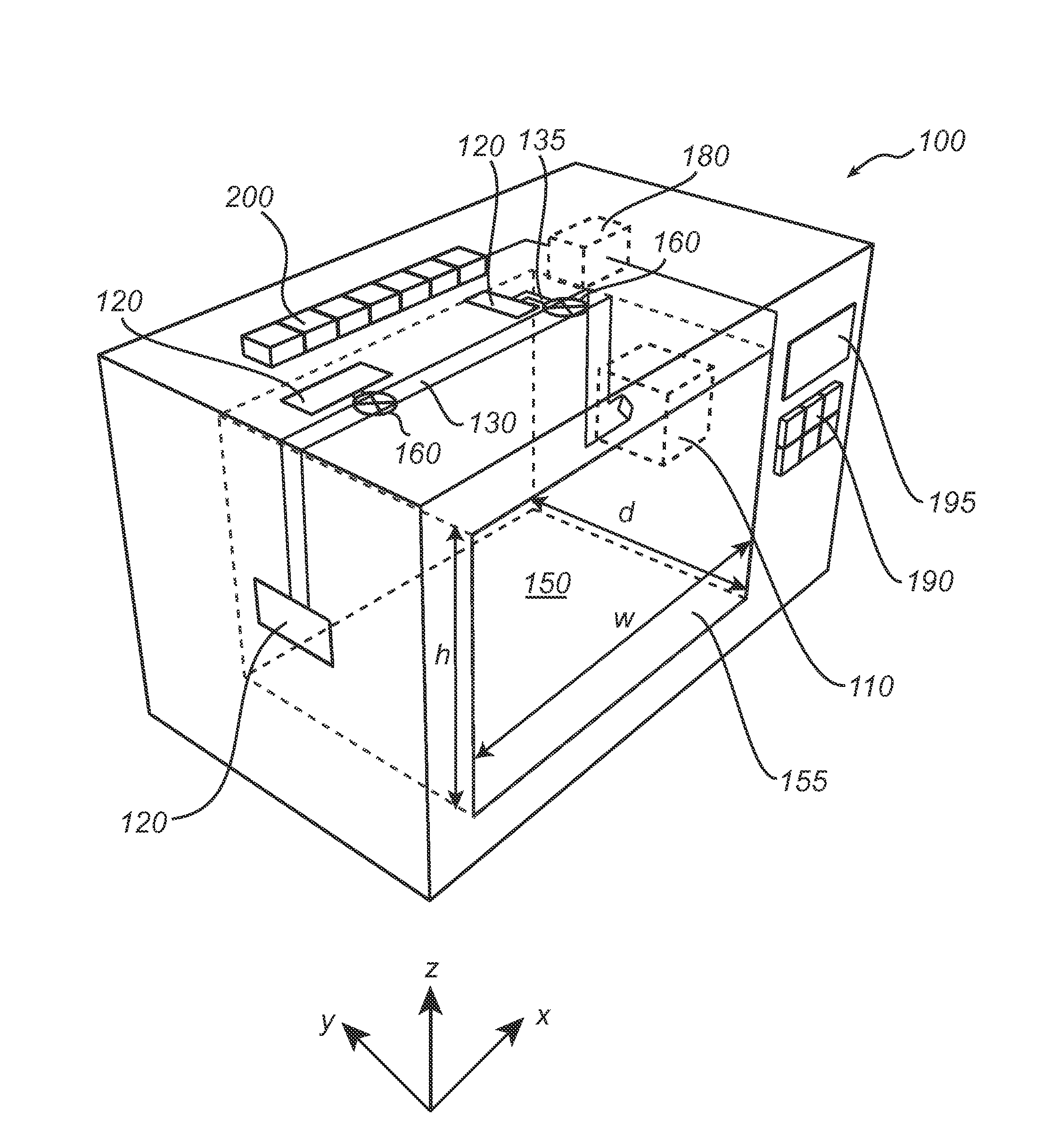

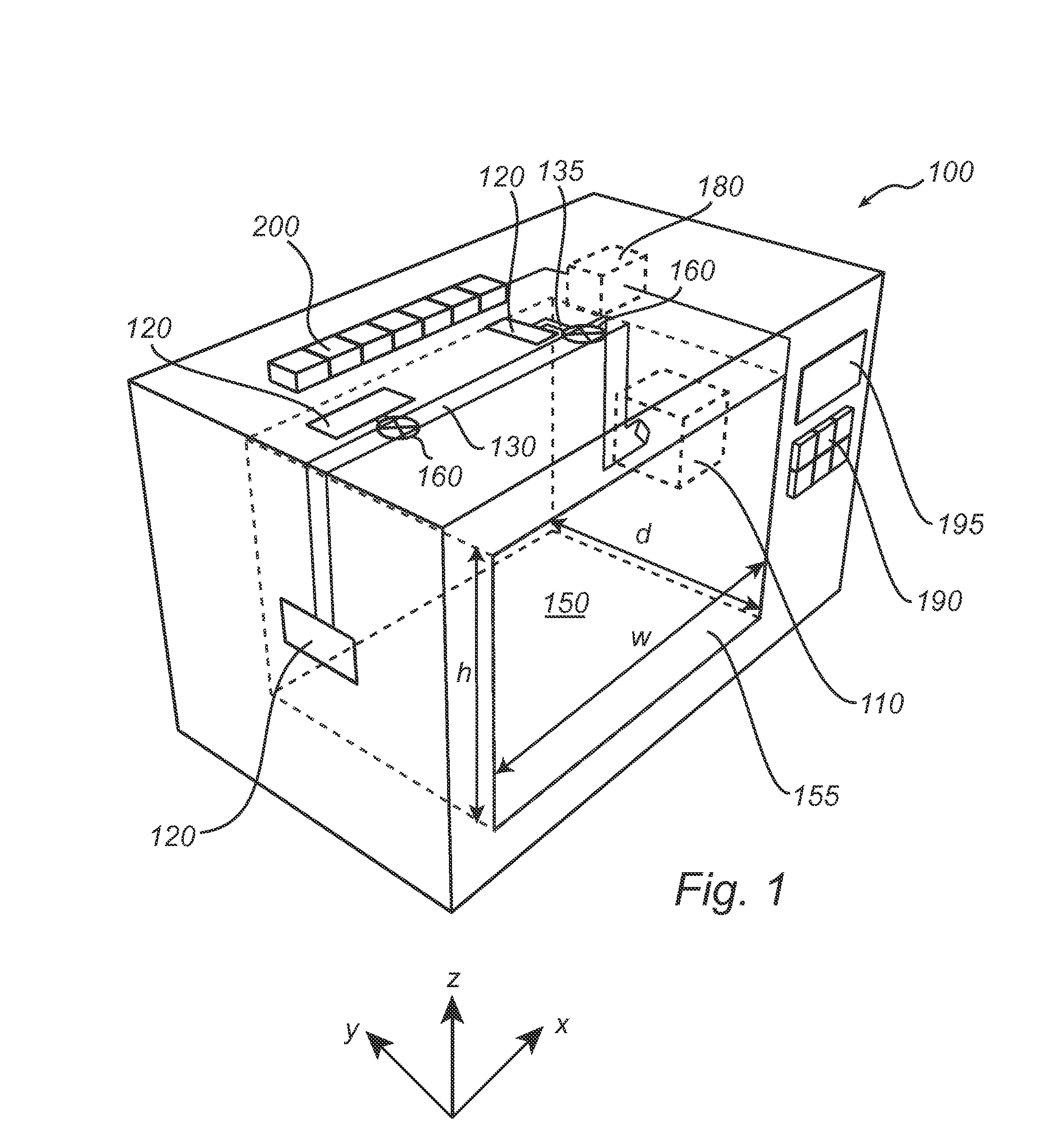

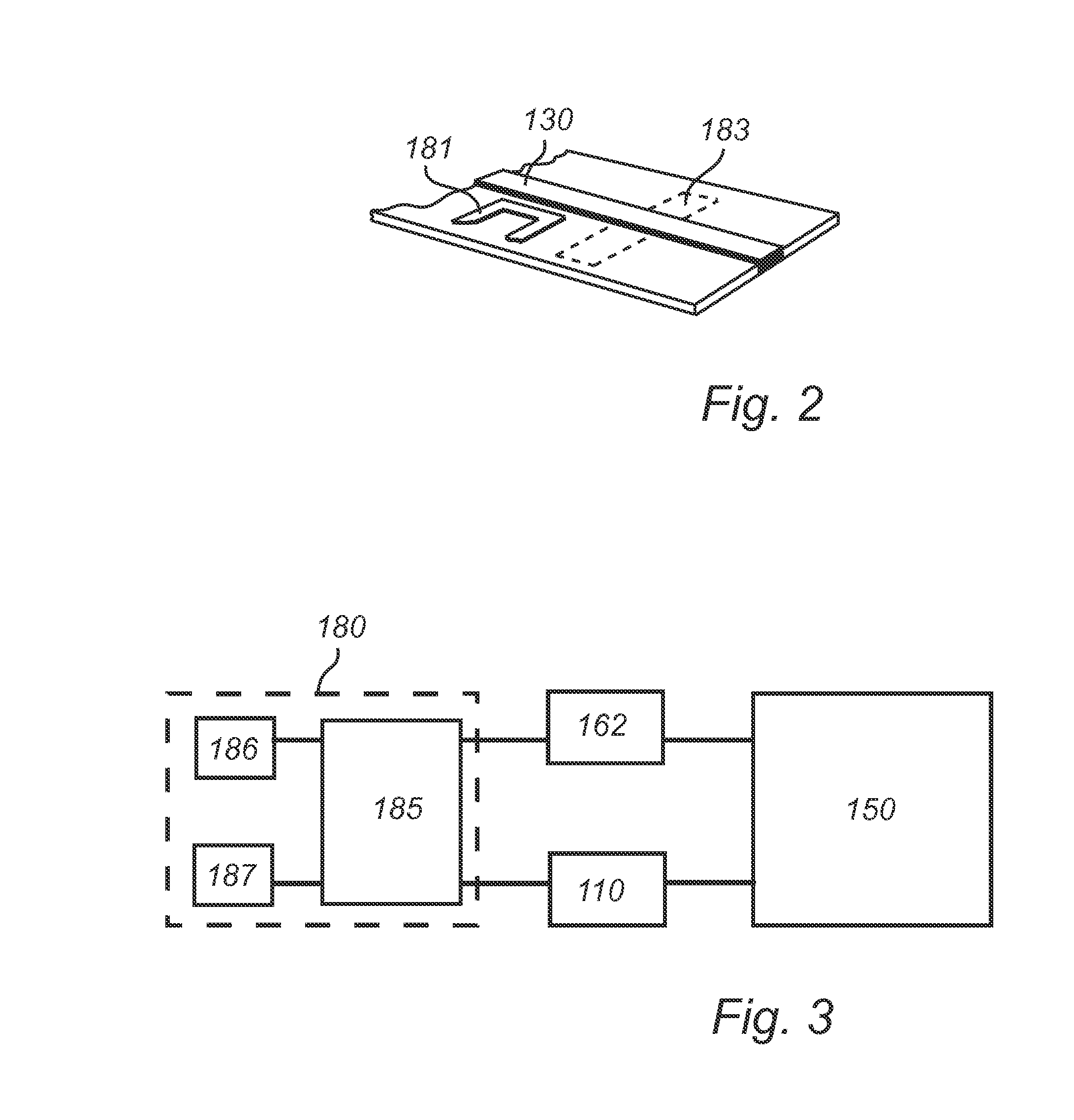

Microwave oven switching between predefined modes

ActiveUS20100155392A1Mechanically durableImprove energy efficiencyDielectric heating circuitsMicrowave heatingMicrowave ovenEngineering

A microwave oven and method for heating a load using microwaves are provided. The microwave oven comprises a cavity adapted to receive a load. The cavity is designed to support at least two predefined mode fields. For each predefined mode field, a resonance frequency in the cavity is known. Further, the microwave oven comprises a frequency-controllable microwave source for feeding microwaves into the cavity via at least one feeding port. The method comprises the steps of measuring a signal reflected from the cavity as a function of the operating frequency of the microwave source and identifying resonance frequencies in the cavity based on the measured signal. Further, the method comprises the steps of selecting, for the predefined modes, at least two of the identified resonance frequencies based on the known resonance frequencies and switching the operating frequency of the microwave source using the selected frequencies. The present invention is advantageous in that it enables uniform heating of the load in the cavity.

Owner:WHIRLPOOL CORP

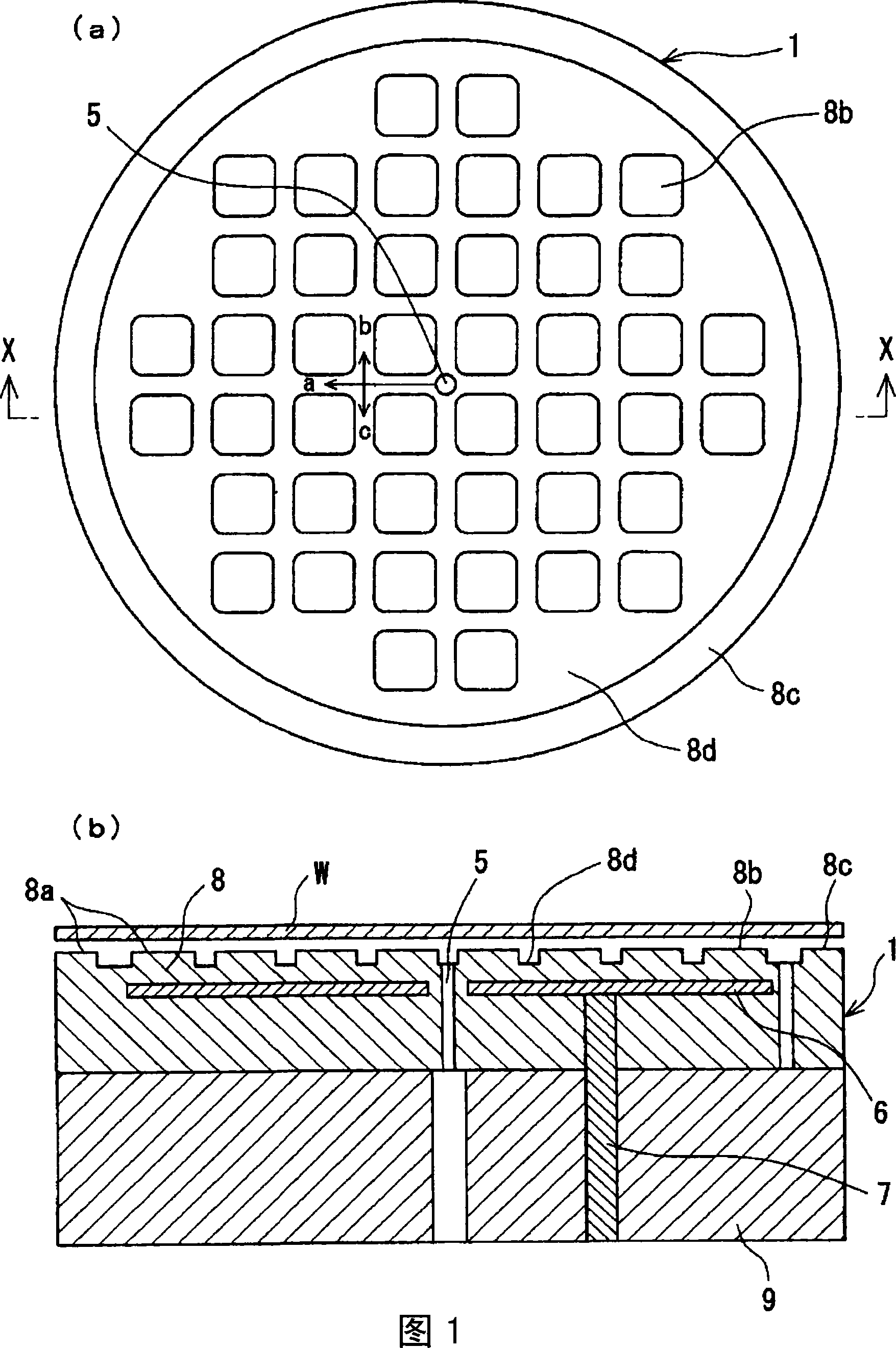

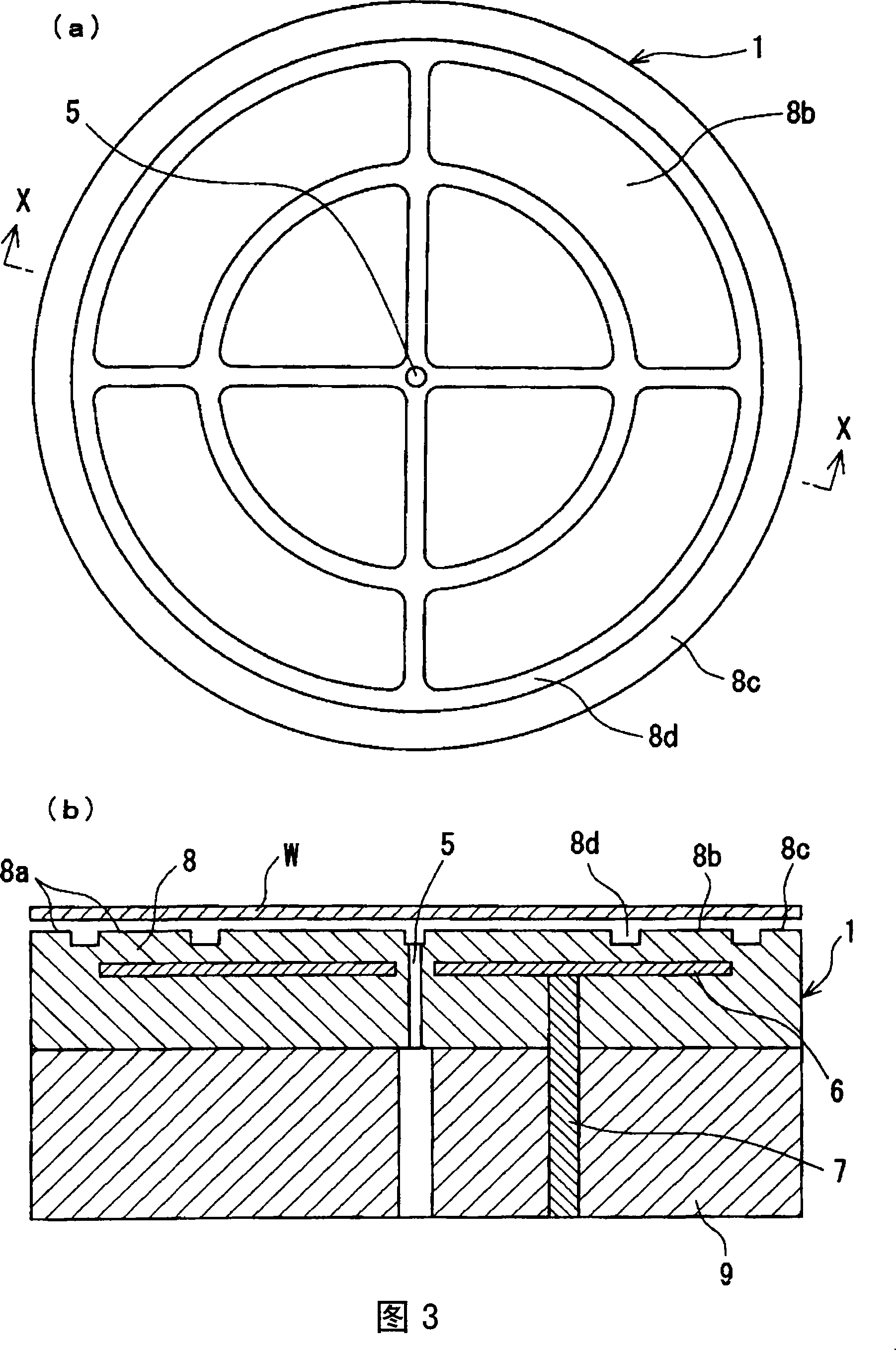

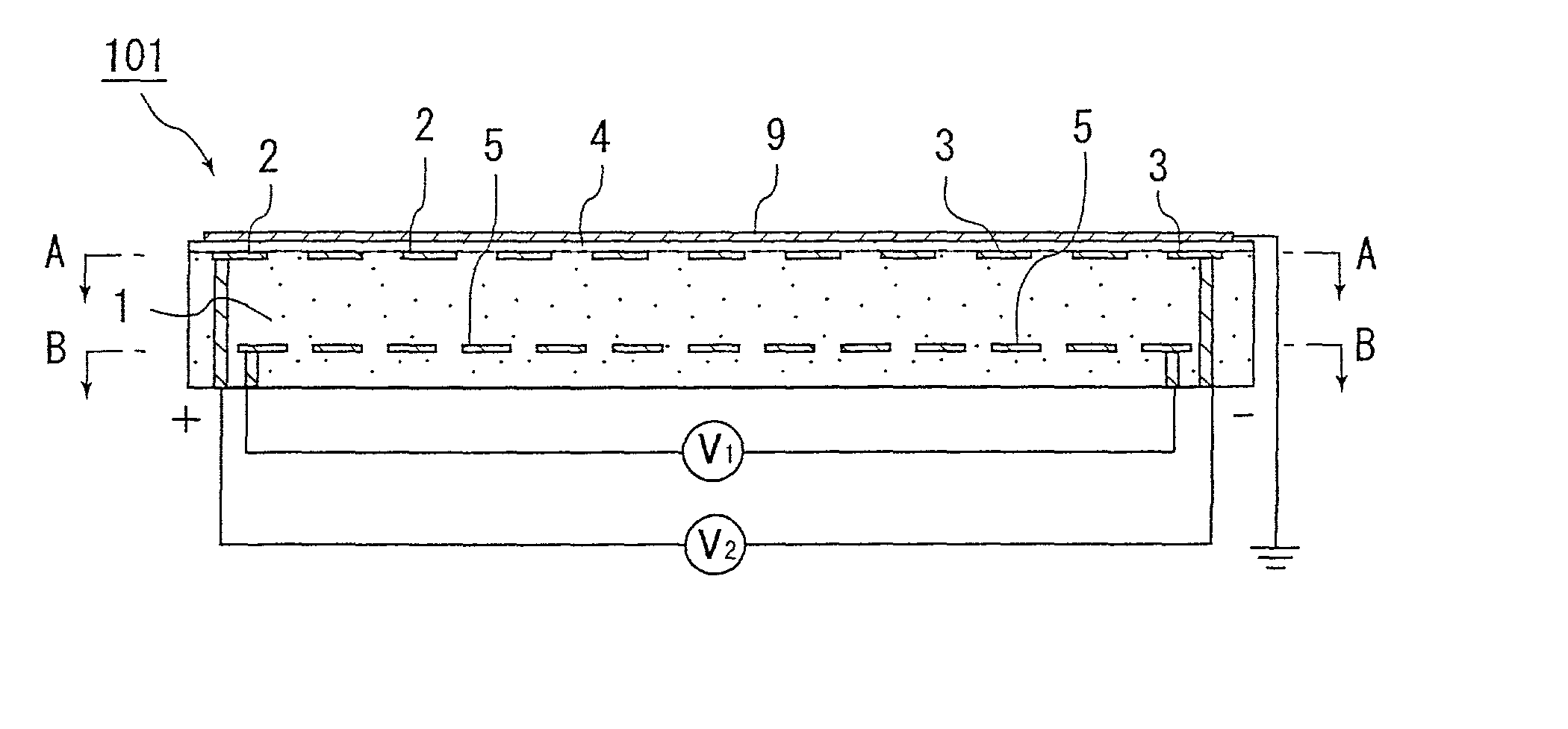

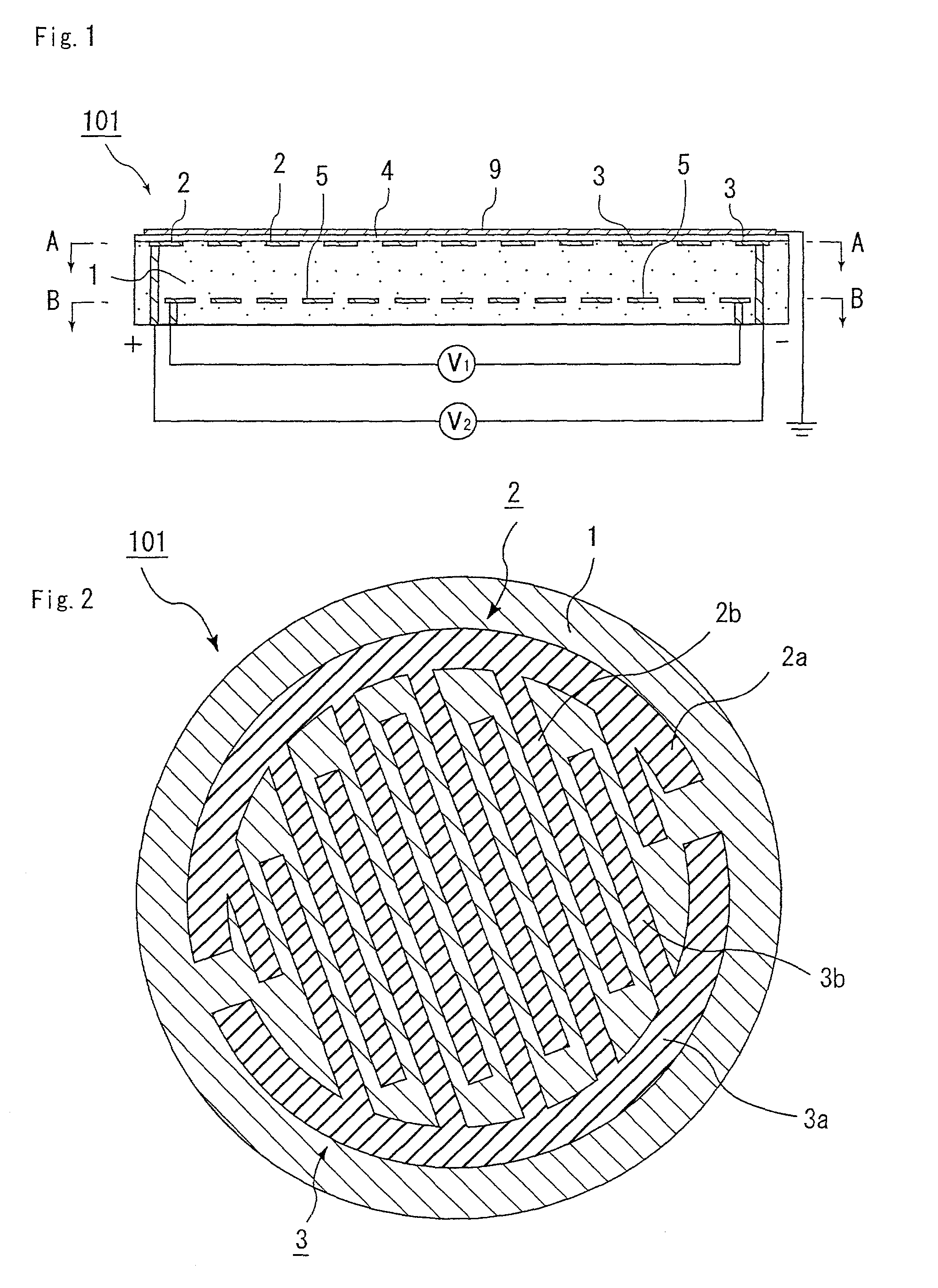

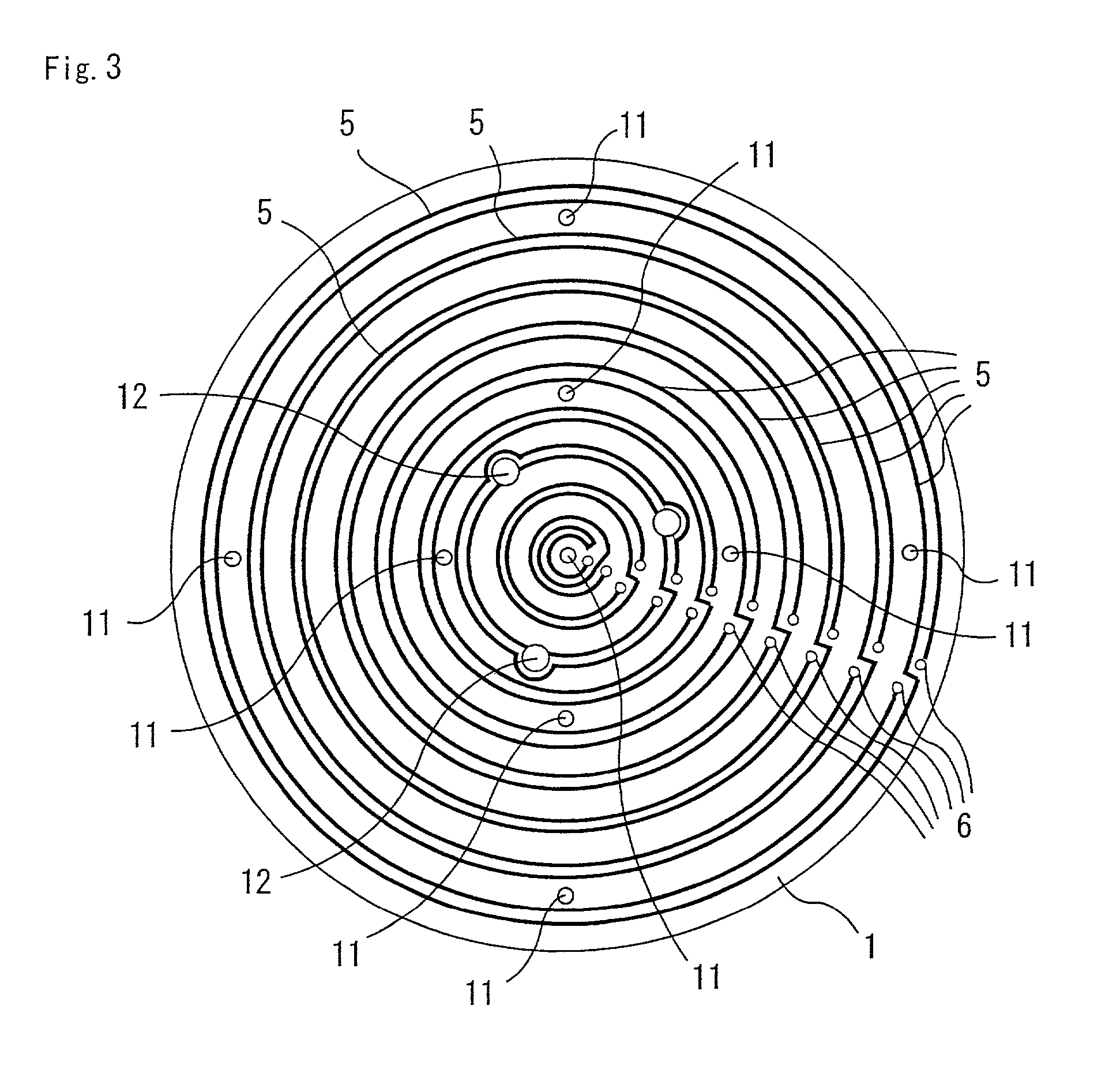

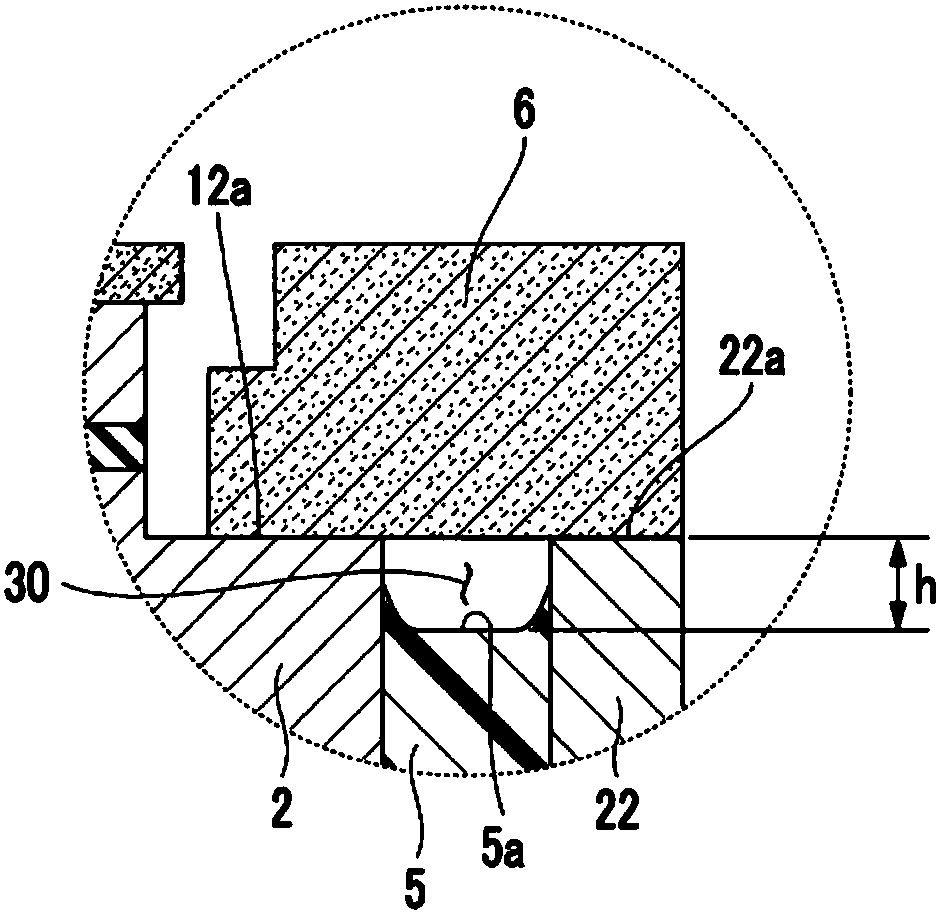

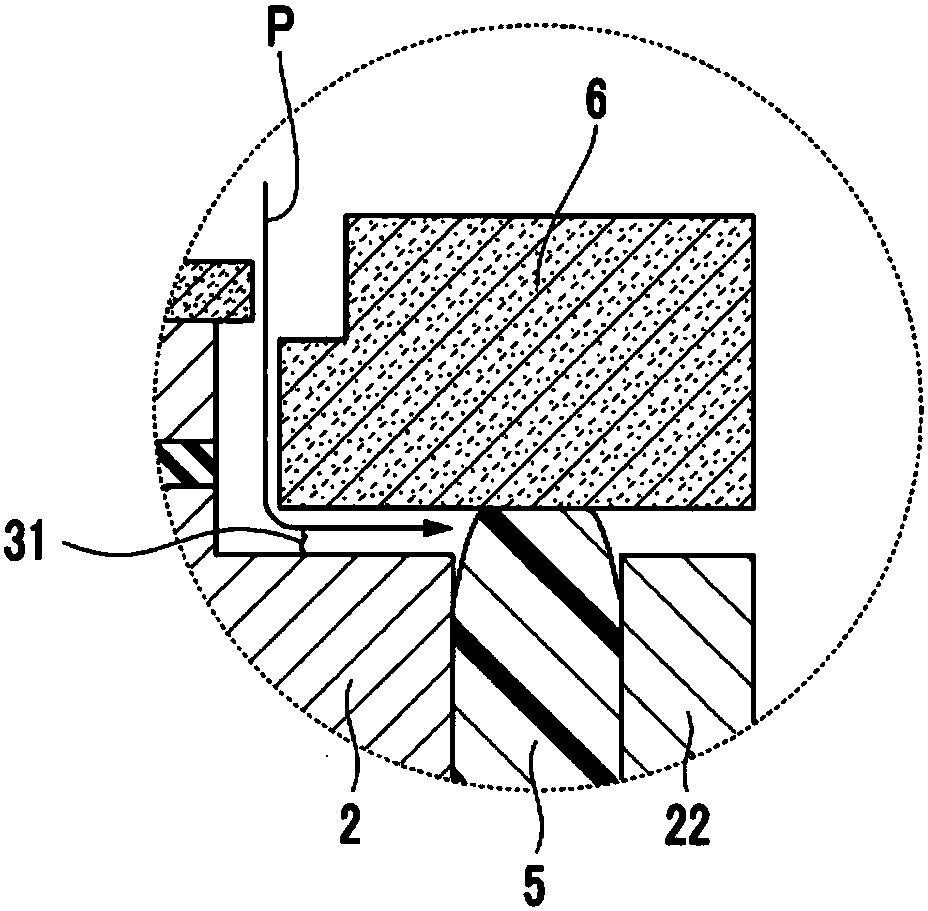

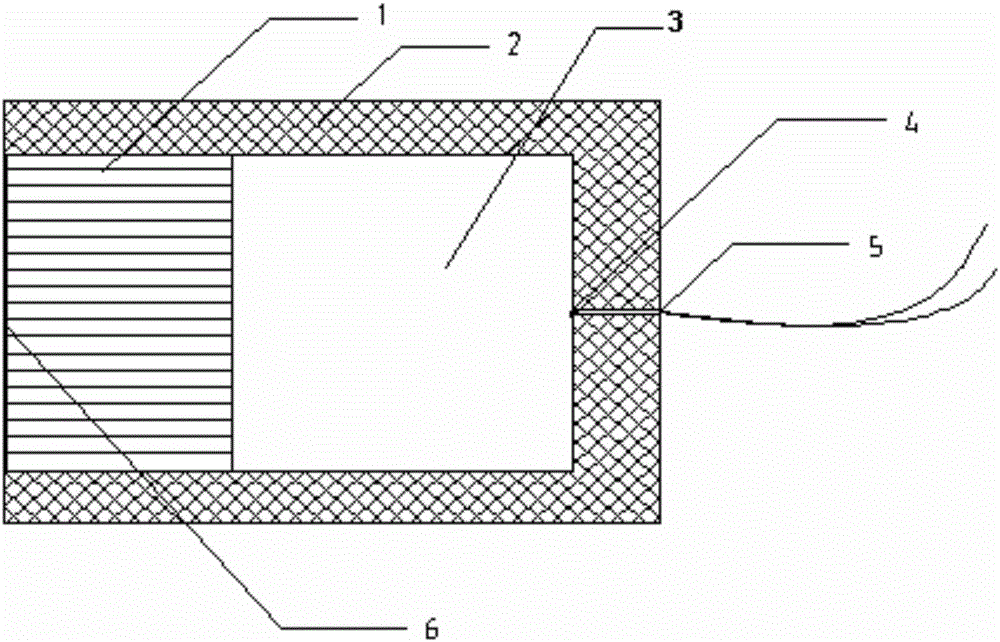

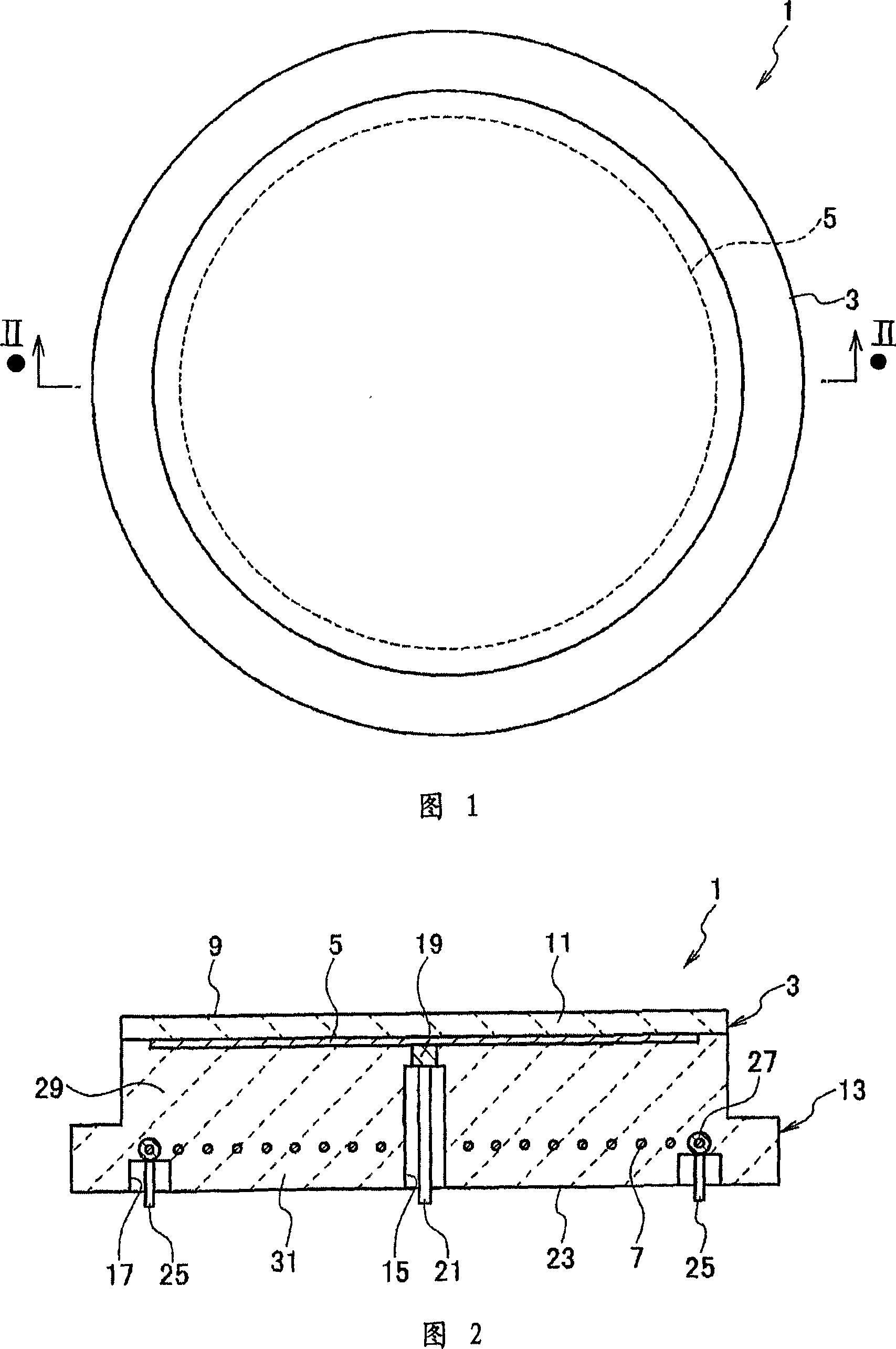

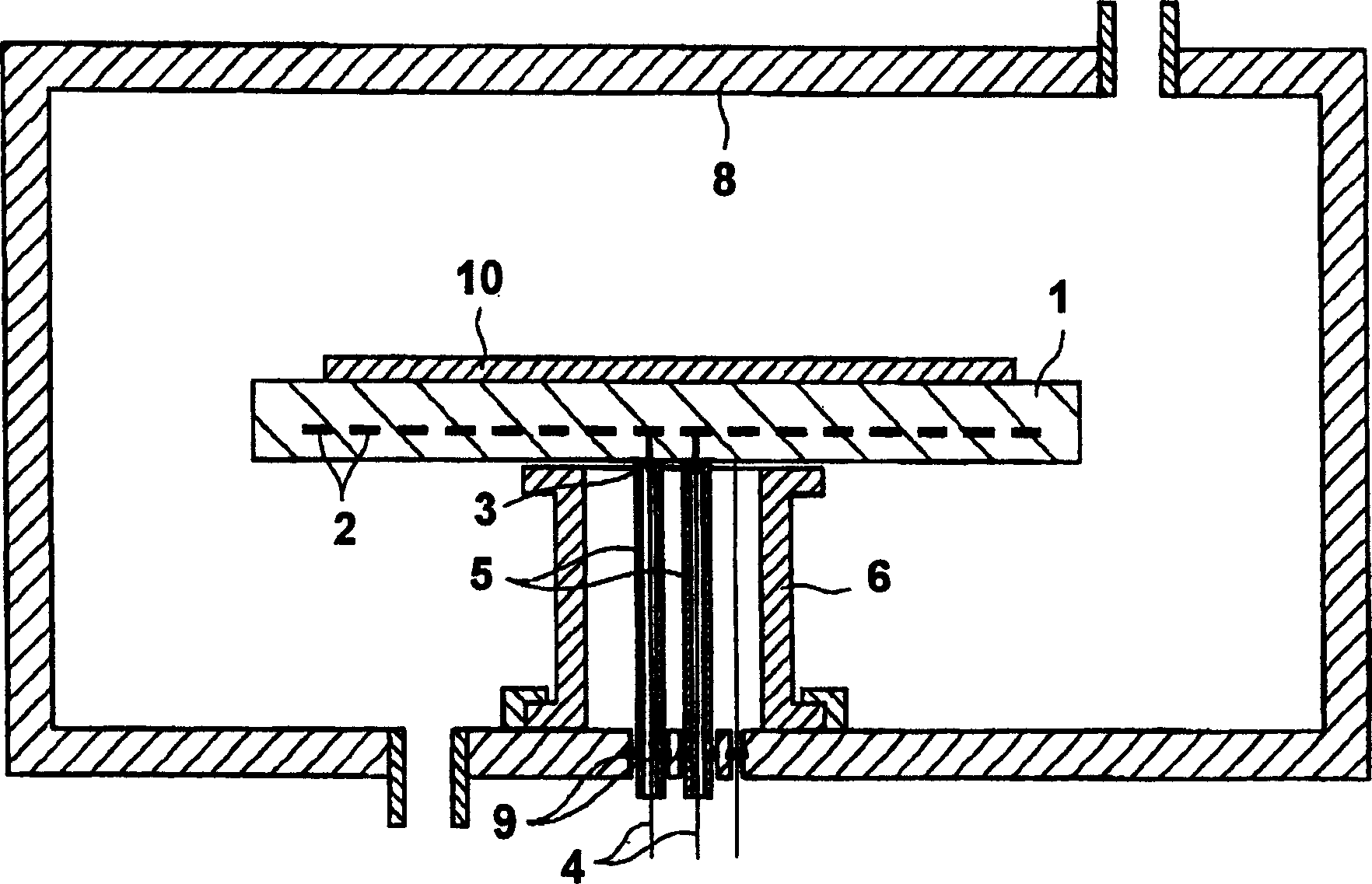

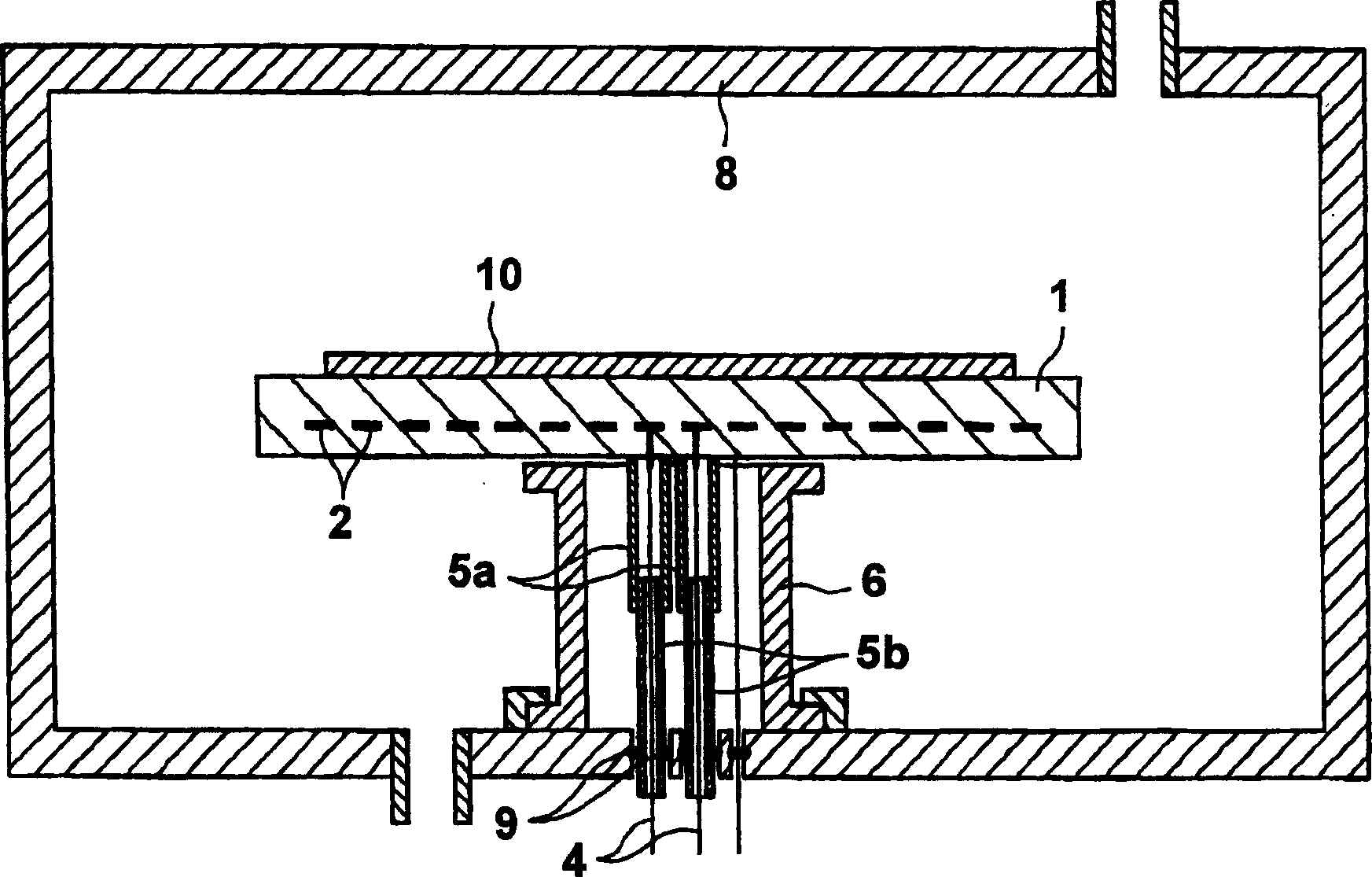

Electrostatic chuck

InactiveCN101010791AShorten the timeImprove heat uniformitySemiconductor/solid-state device manufacturingElectrostatic holding devicesHigh resistanceVoltage

A purpose of the present invention is to provide an electrostatic chuck which has such a high uniformity of heat that the time for arriving at a saturated temperature is short, and which has a high resistance property against the cycle of a voltage. To achieve above-mentioned purpose, there is provided an electrostatic chuck comprising a plate-shaped body which has a pair of main surfaces, on one of which a wafer is placed, and electrodes for adsorbing the wafer, which are provided on the other surface of the plate-shaped body or in the plate-shaped body, characterized in that it comprises at least one through-hole for guiding gases, which is formed in the plate-shaped body, gas tunnels which are formed by several convex parts and are formed so as to be communicated with the through-hole, wherein the shape of the convex part is shaped to have 4 sides and 4 arc-shaped parts for connecting the 4 sides and wherein the convex parts are regularly provided on the surface for placing a wafer.

Owner:KYOCERA CORP

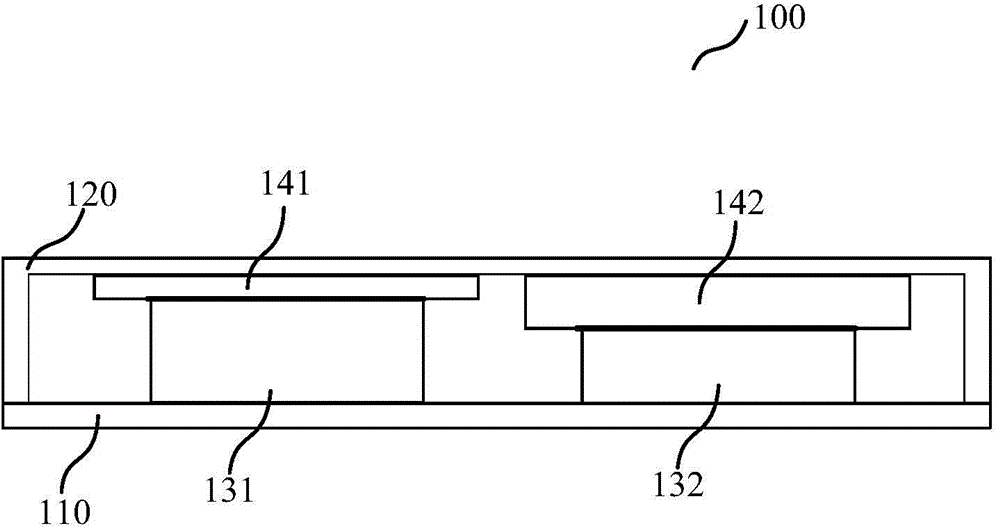

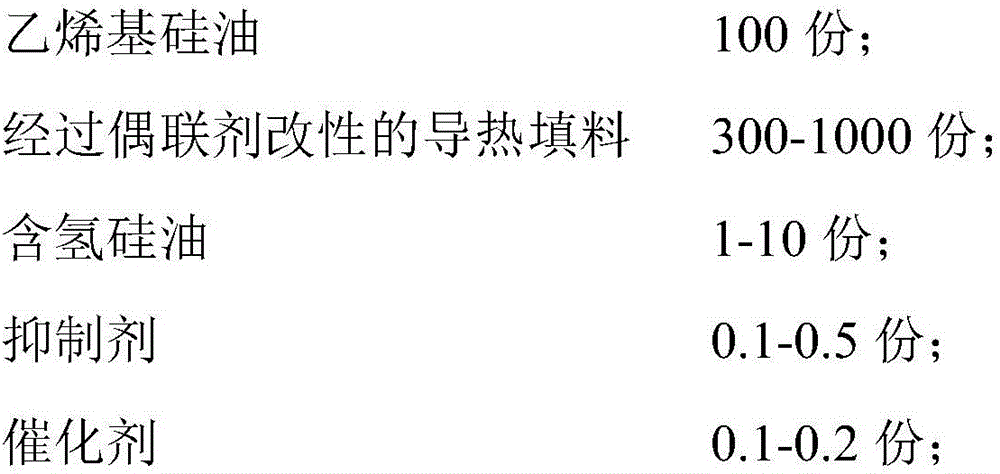

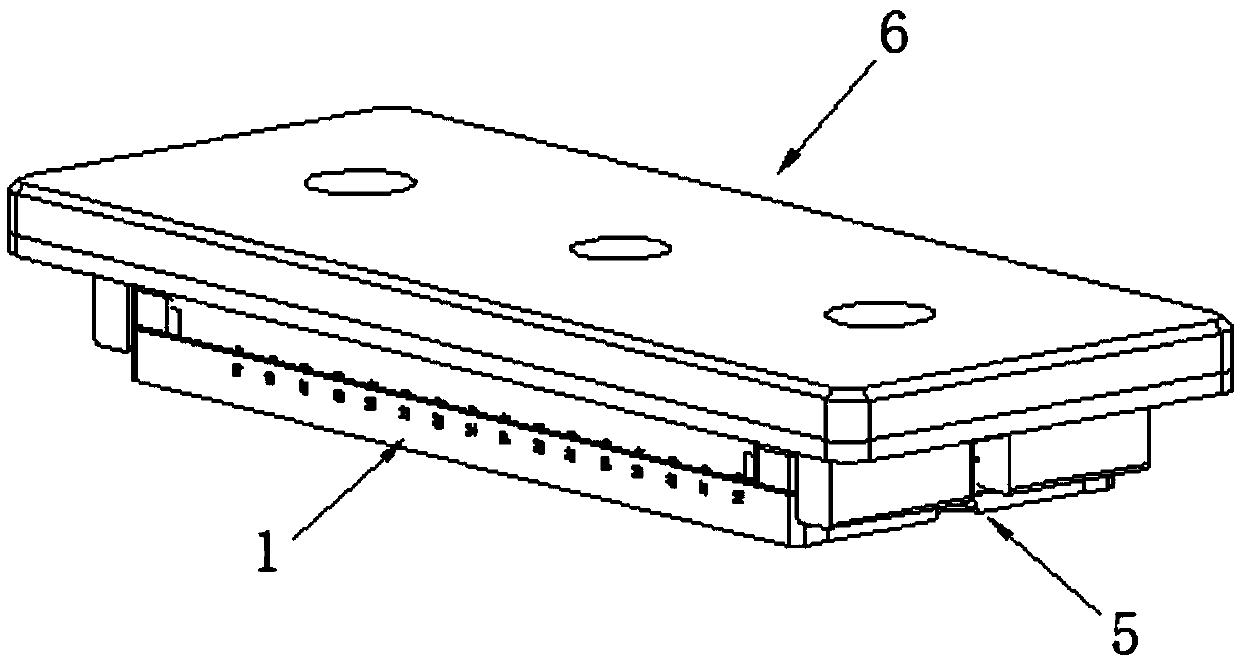

Heat dissipation device for electronic equipment

ActiveCN105338783AThe same thicknessImprove thermal conductivityCooling/ventilation/heating modificationsHeat conductingElectric equipment

The invention provides a heat dissipation device for electronic equipment. The electronic equipment comprises a circuit board, wherein the circuit board is provided with a plurality of electronic devices, and the plurality of electronic devices generate heat in operation. The heat dissipation device comprises a heat conducting bracket which is fixed on the circuit board and covers the plurality of electronic devices, and the heat conducting bracket performs heat conduction with the electronic devices so as to carry out heat dissipation on the electronic devices. The side surface, which is close to the circuit board, of the heat conducting bracket comprises a first region and a second region, wherein the first region corresponds to positions of the electronic devices whose height is not greater than a first threshold on the circuit board; and the second region corresponds to positions of the electronic devices whose height is greater than the first threshold on the circuit board, and the heat conducting bracket is sunk inwards so as to form a plurality of grooves. The heat dissipation device provided by the invention can enable heat to be transferred to the metal bracket from heat generating elements quickly and more effectively, thereby improving the heat dissipation effect.

Owner:LENOVO (BEIJING) LTD

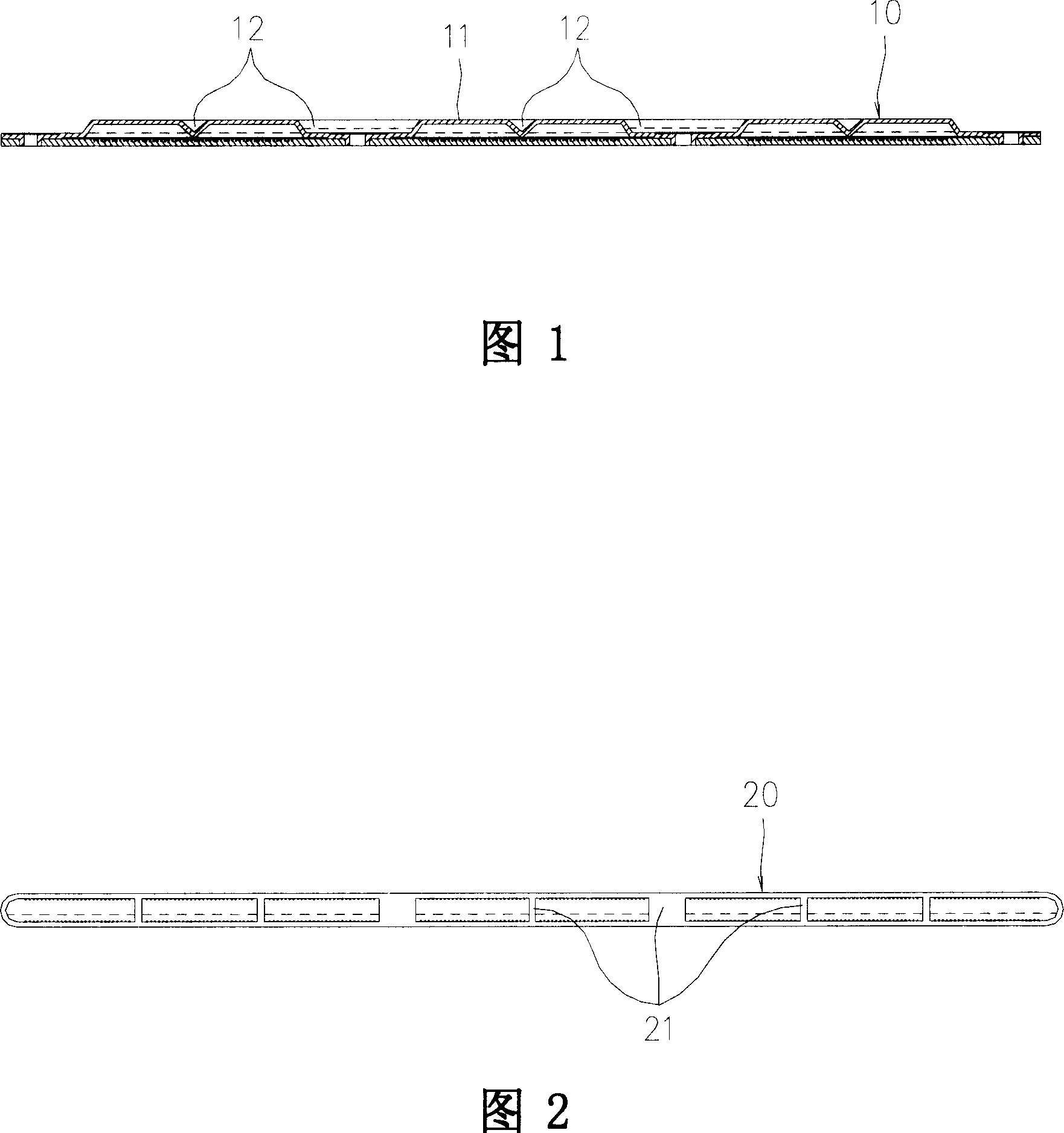

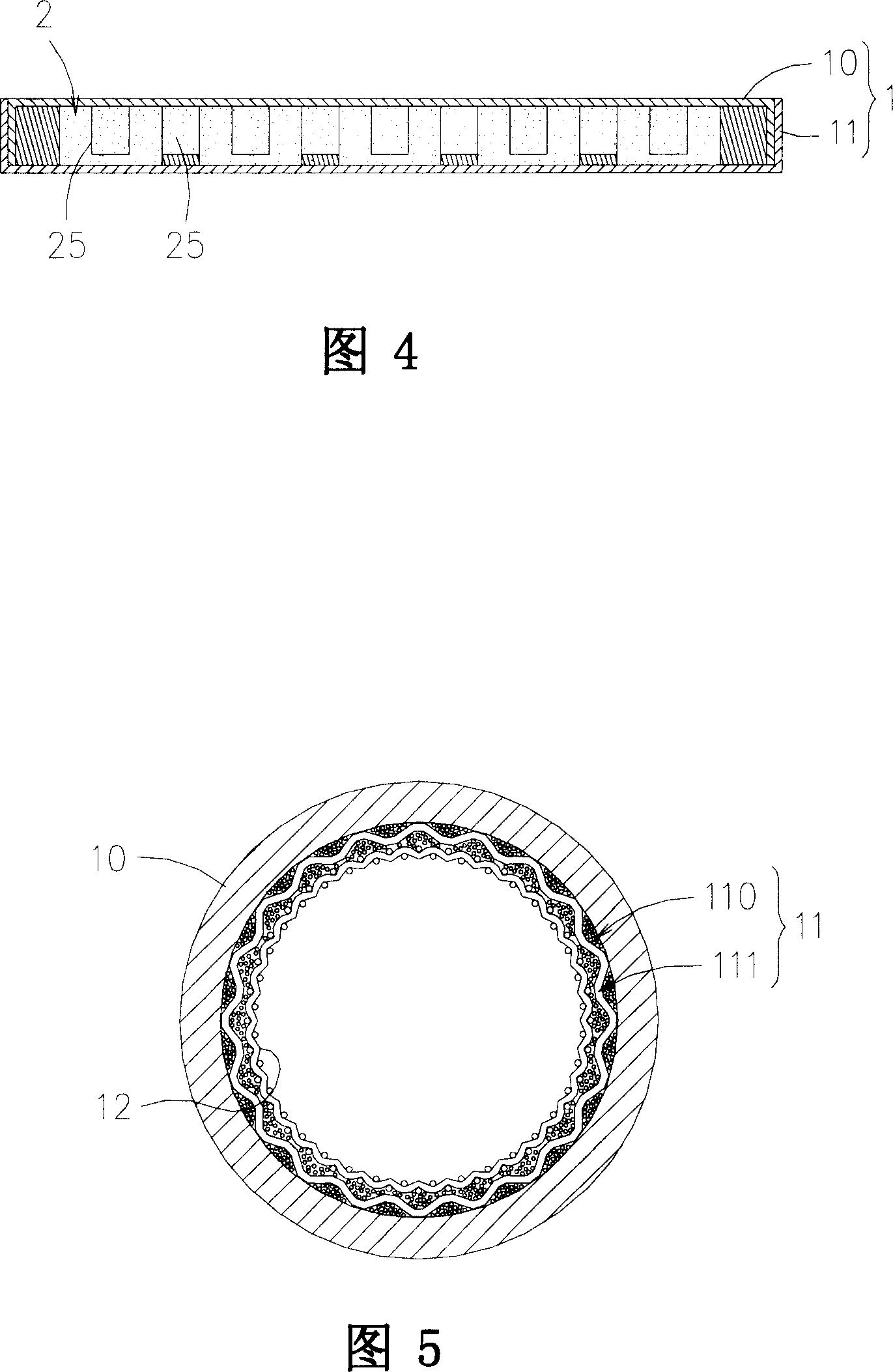

Penetrating support structure and its production

The inventive structural support is made of the braided wire or is made of sheet or block material to form a sheet-shaped concave-convex structure with several throughholes by punching, etching, electroplating or electroforming processes. The structural support is combined in the cavity of liquid-vapour two phases cooling assembly and is fit with a capillary structural layer.

Owner:奇科技股份有限公司

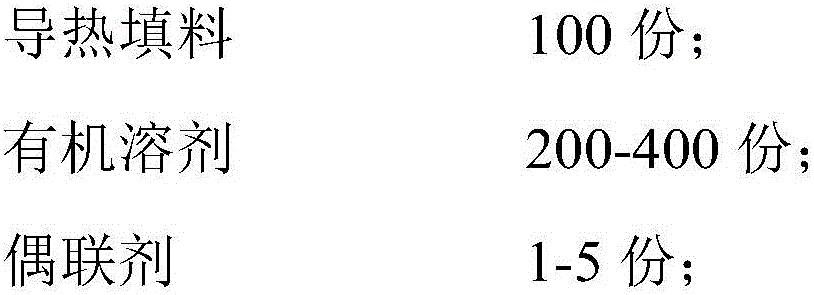

Preparation method of graphene heat conducting silica gel pad

ActiveCN106832961AImprove heat uniformityImprove heat transfer efficiencyGrapheneHeat-exchange elementsHydrogenHeat conducting

The invention provides a preparation method of a graphene heat conducting silica gel pad. The preparation method comprises the following steps: growing a single-layer graphene thin film on the surface of a metal foil piece by adopting a chemical vapour deposition method, so that a graphene thin film / metal foil piece is obtained; preparing coupling agent modified heat conducting filler, mixing the coupling agent modified heat conducting filler, vinyl silicone oil, hydrogen-containing silicone oil, an inhibitor and a catalyst to form mixed materials, carrying out rolling treatment, and then tabletting under heating condition, so that a heat conducting silica gel pad is obtained; fitting the graphene surface of the graphene thin film / metal foil piece with a heat release adhesive tape, carrying out surface polishing on a metal foil piece surface of the graphene thin film / metal foil piece, and then putting in etching liquor until the metal foil piece is completely dissolved, so that a graphene thin film / heat release adhesive tape is obtained; and rinsing the graphene thin film / heat release adhesive tape with deionized water, drying, then fitting the surface, pasted with the graphene thin film, of the graphene thin film / heat release adhesive tape, and then removing the heat release adhesive tape.

Owner:YAHAM OPTOELECTRONICS CO LTD

Large-gauge magnesium alloy long and flat ingot semicontinuous casting device

ActiveCN108637200AMelt temperature gradient decreasesReduce temperature gradientType distributionIngot

The invention discloses a large-gauge magnesium alloy long and flat ingot semicontinuous casting device. The large-gauge magnesium alloy long and flat ingot semicontinuous casting device comprises a distribution disk, a crystallizer and a dummy bar head. A height adjustment device is arranged above the distribution disk. The distribution disk is a monomer type distribution disk or a split type distribution disk. The monomer type distribution disk is of an integral structure formed by a rectangular side wall and a trapezoid bottom groove. One rectangular distribution port is arranged in each corner of the side wall. The split type distribution disk is formed by a plurality of rectangular grooves through a fixing supporting base plate in a fixedly connected manner, and is provided with rectangular distribution ports in the corners. A third cold water tank is arranged below a first cold water tank. The interior of a square groove above the dummy bar head is of a stepped two-layer groove type structure. A cavity is formed inside a base of the dummy bar head. The large-gauge magnesium alloy long and flat ingot semicontinuous casting device can be used for producing and preparing magnesium alloy flat ingots of various dimensions and specifications and with stable quality, and the tearing tendency of the ingots is effectively reduced.

Owner:NORTHEASTERN UNIV

Ceramic substrate for semiconductor production and inspection devices

InactiveUS7011874B2Improve thermal uniformityReduce heat transferFurnaces without endless coreLiquid surface applicatorsElectrical conductorMetallurgy

The object of the present invention is to provide a ceramic substrate that can provide a substantially uniform temperature distribution to a surface of the ceramic substrate where a semiconductor wafer is treated. A ceramic substrate for a semiconductor-producing / examining device according to the present invention is a ceramic substrate having a conductor formed on a surface of the ceramic substrate or inside the ceramic substrate, wherein said substrate is containing oxygen and having a disc form, the diameter thereof exceeding 250 mm and a thickness thereof being 25 mm or less.

Owner:IBIDEN CO LTD

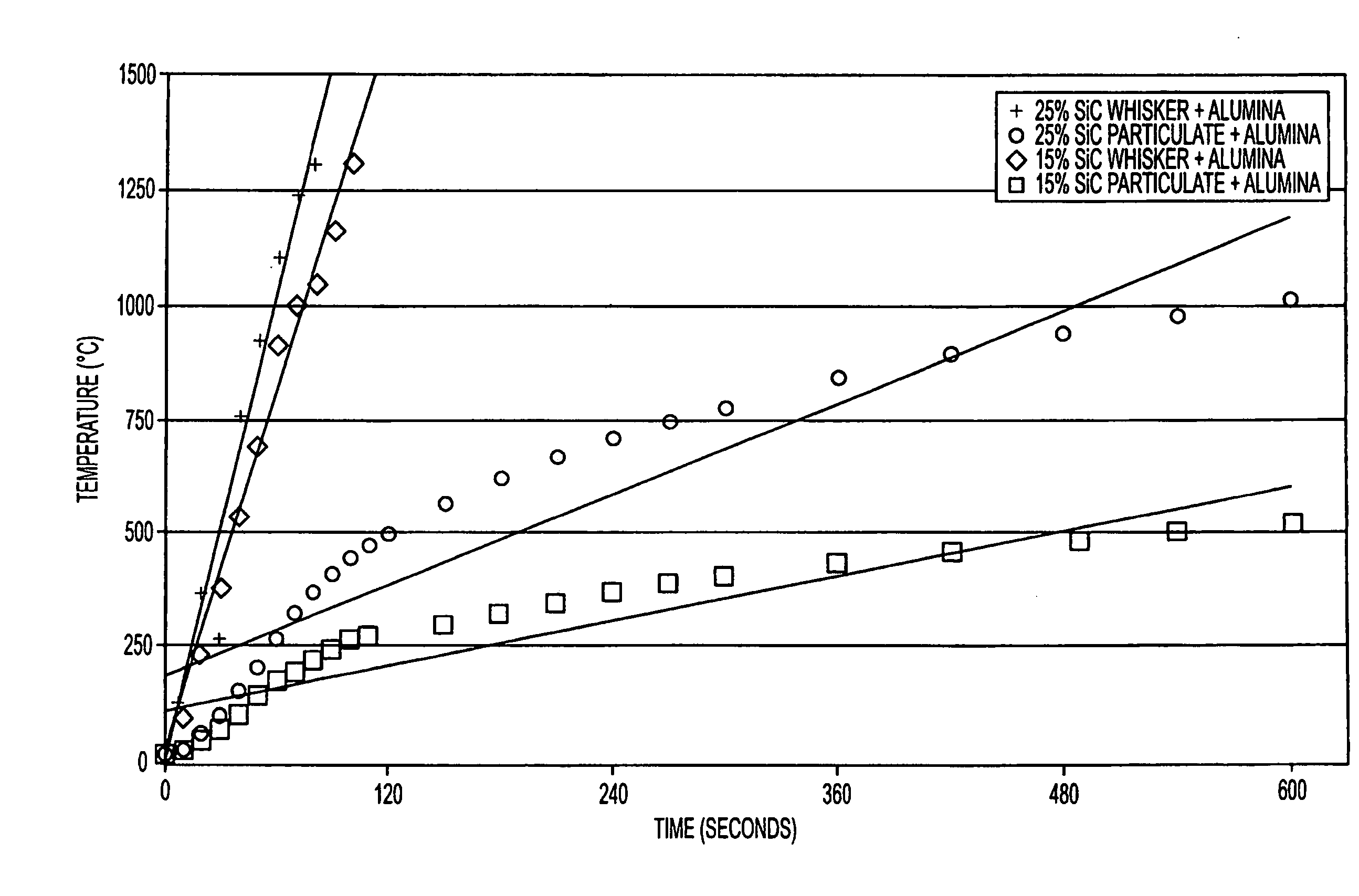

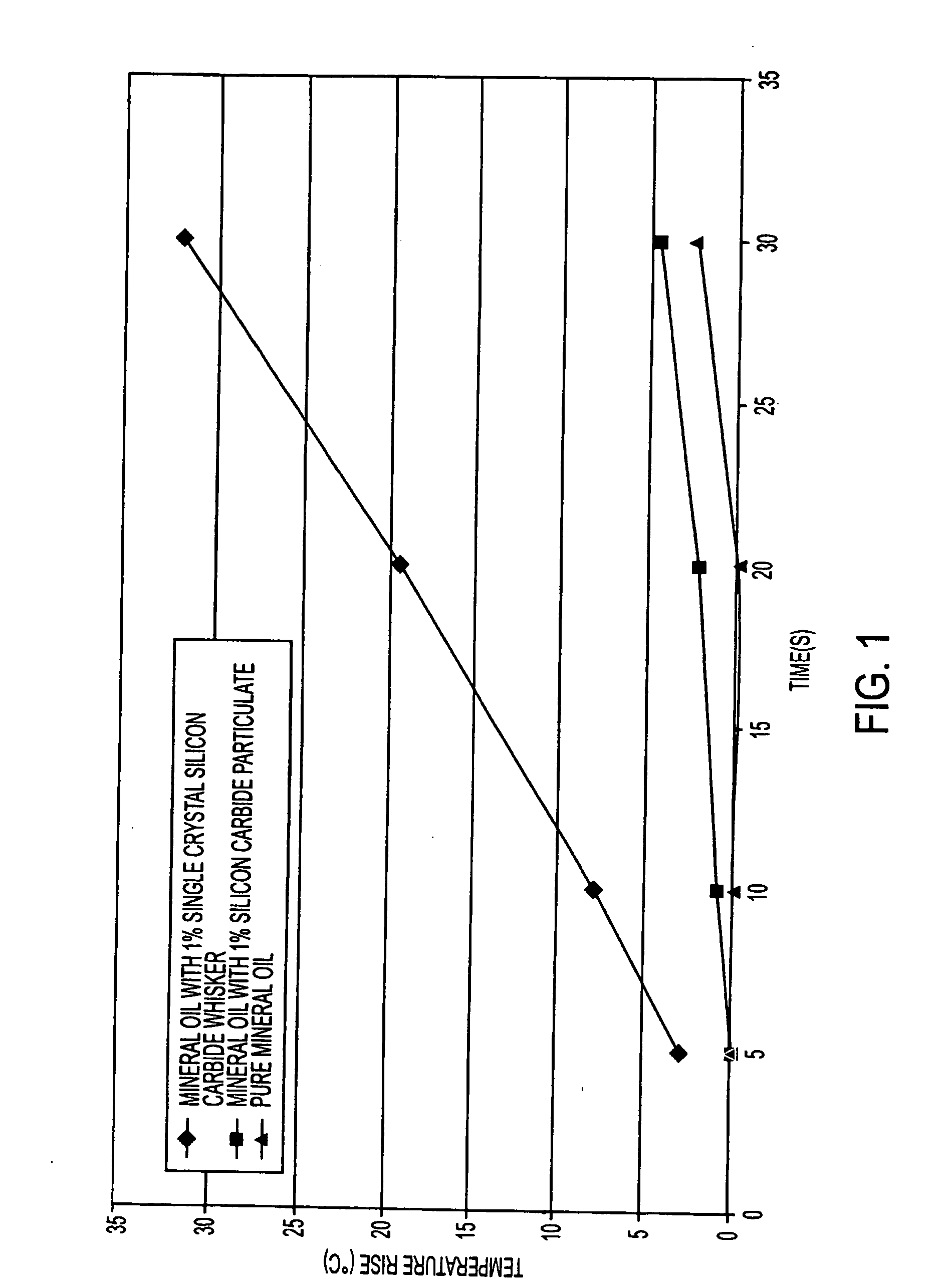

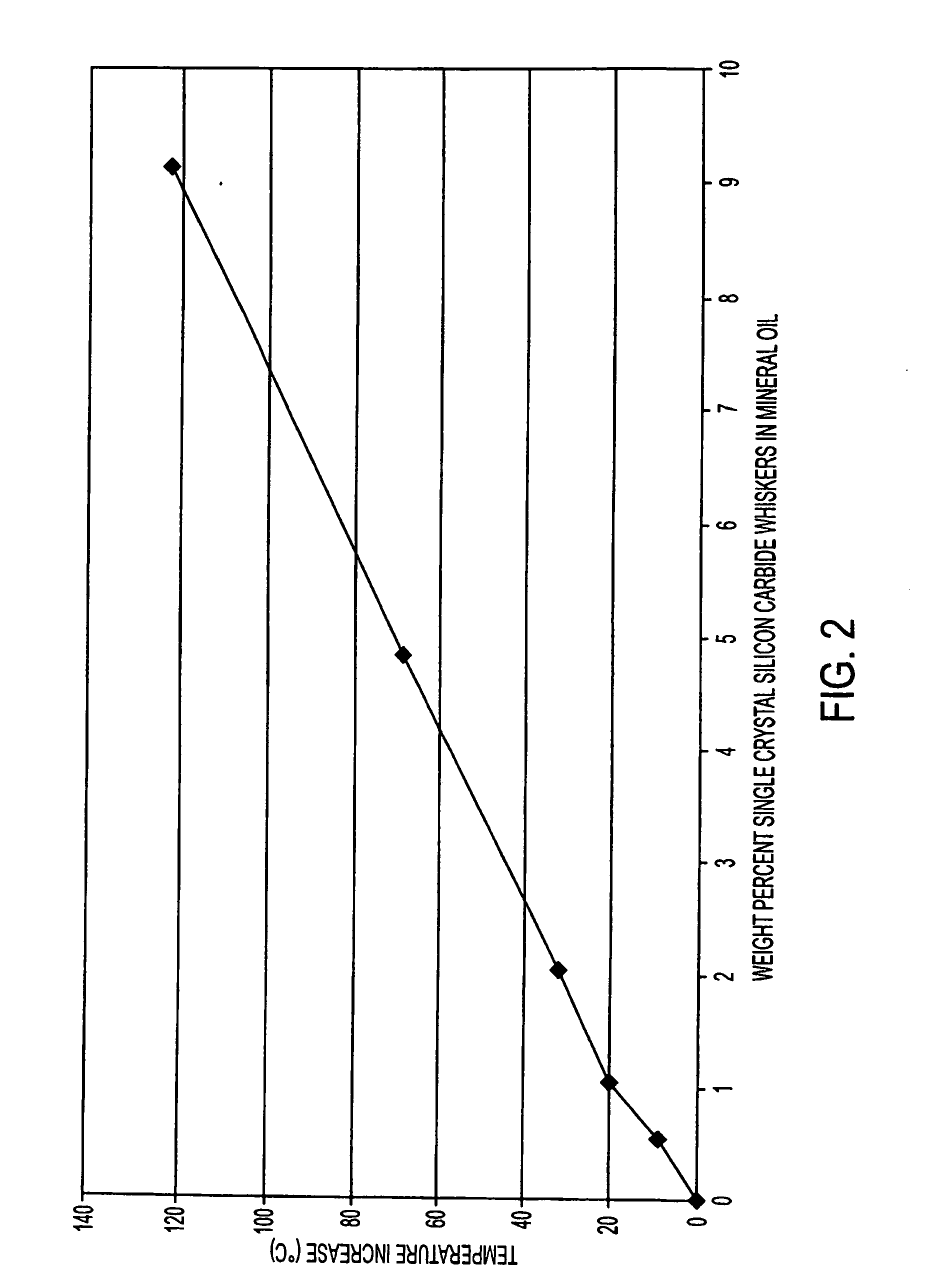

Composite materials and devices comprising single crystal silicon carbide heated by electromagnetic radiation

InactiveUS20070235450A1Improved field uniformityImprove heat uniformityMicrowave heatingThin material handlingElectromagnetic radiationFiber

Owner:ADVANCED COMPOSITE MATERIALS

Process for producing superfine high-purity quartz glass pipe for high-temperature sensor

ActiveCN101805116AWith superfineHigh temperature resistanceRadiation pyrometryGlass shaping apparatusOperabilityPerformance index

The invention relates to a process for producing a superfine high-purity quartz glass pipe for a high-temperature sensor, which is characterized by comprising the following steps of: finely selecting quartz blocks as raw materials, wherein the particle size of the quartz blocks is 20-30 mm, and the content of SiO2 is above 99%; sequentially carrying out soaking in hydrochloric acid, roasting, water quenching, mechanical pulverization, iron removal, soaking in mixed acid, high-temperature stirring and washing and high-temperature chloridization on the raw materials to obtain high-purity quartz sand; then throwing the high-purity quartz sand in a quartz furnace for smelting, pulling into a quartz glass pipe, and then scouring, cutting, trimming, ultrasonic cleaning and dehydroxylating so that a finished product is obtained. The quartz glass pipe produced and prepared by the process has the superfine and ultrathin features, has the characteristics of high-temperature resistance, molten steel and glass liquid-washing resistance, corrosive resistance, high heat transfer speed, good soaking performance, large strength, long service life, no bursting under shock heating and cooling condition, strong process operability, scale production and the like, and completely accords with the requirements of various performance indexes of the quartz glass pipe used as an outer protective pipe of the high-temperature sensor.

Owner:连云港市盛昌照明电器有限公司

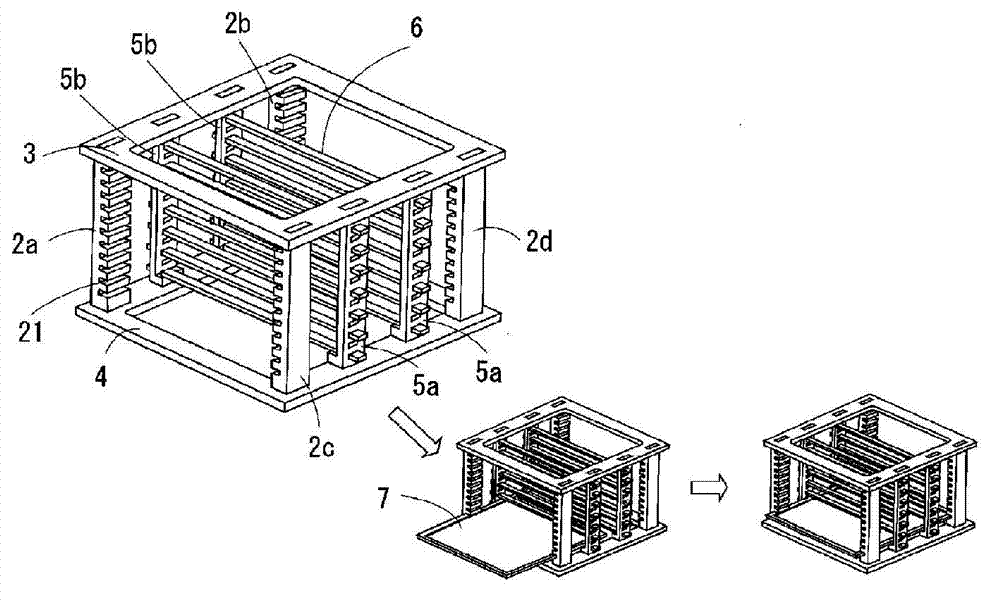

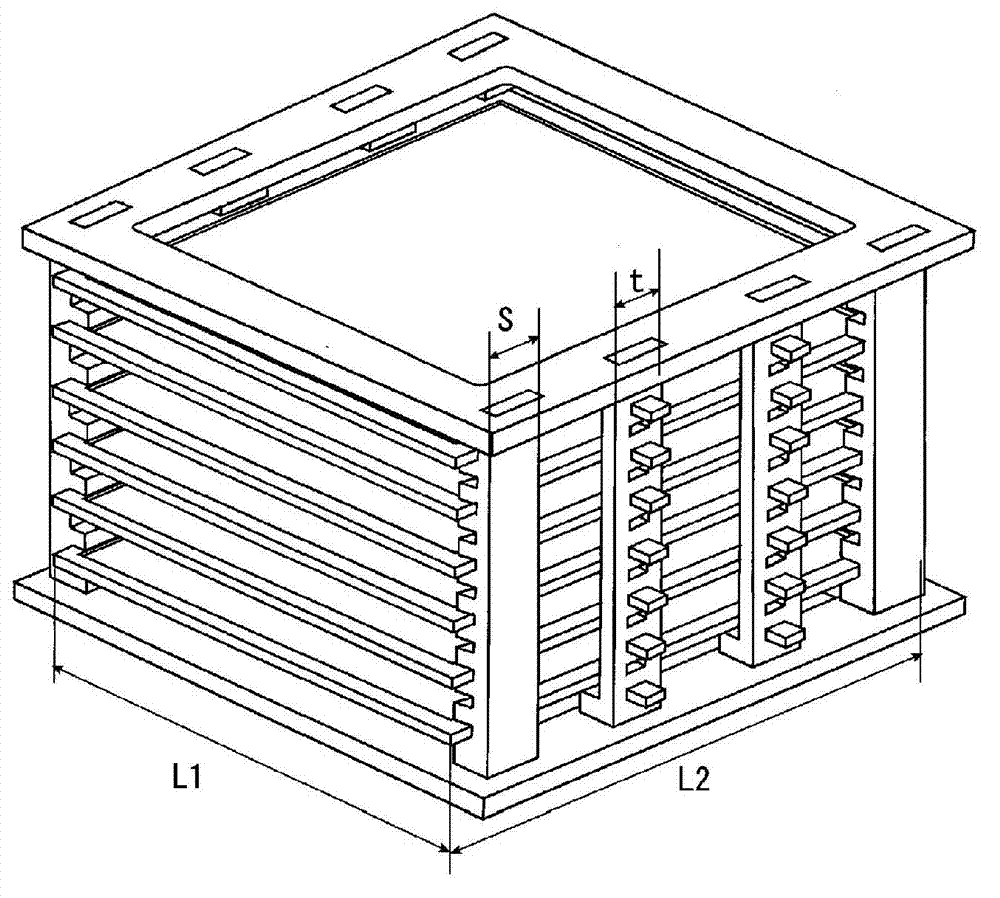

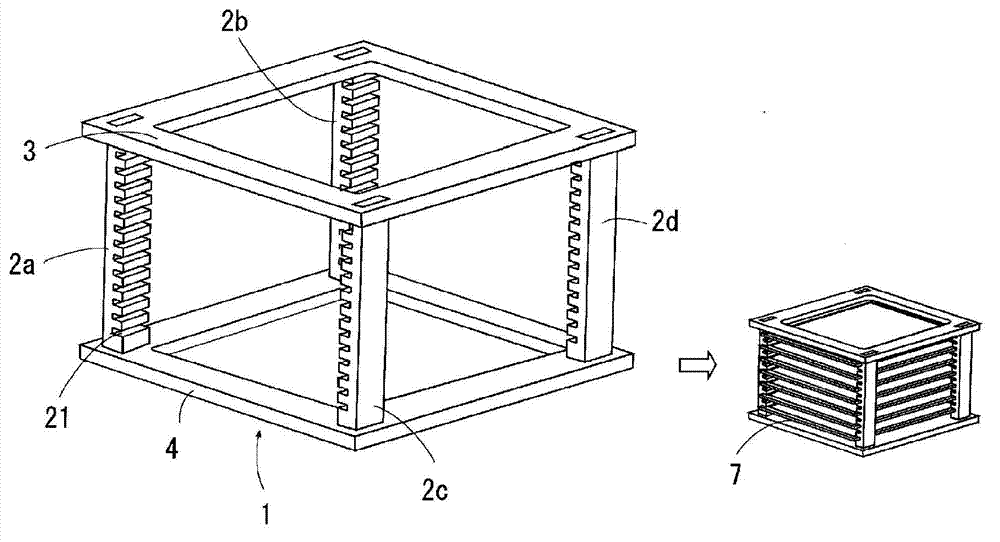

Rack for firing

ActiveCN103097845AEasy to passIncrease heat radiation rateCharge supportsCharge manipulationSetterEngineering

Provided is a rack for firing which holds a plurality of flat board-like setters at multiple levels in the perpendicular direction by means of a setter holding means, and fires electronic ceramic elements at multiple levels. The setter holding means is composed of a material composed of Si-SiC containing 0.01-30 % of Si or recrystallized SiC or Si3N4-SiC, and the setter holding means holds each of the flat board-like setters with 70-100 % of the outer circumferential side surface thereof exposed. Consequently, the rack has excellent energy efficiency, mass-production efficiency, and uniform heating characteristics at each of the multiple levels in the multiple-level firing.

Owner:NGK INSULATORS LTD +1

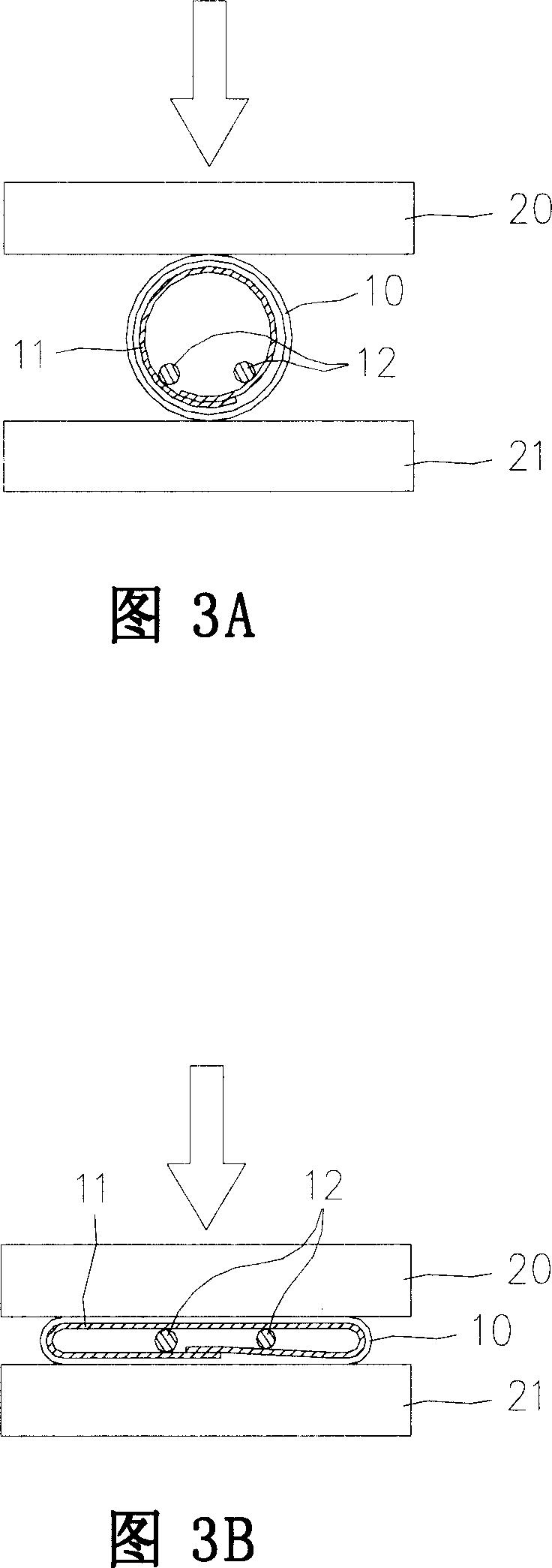

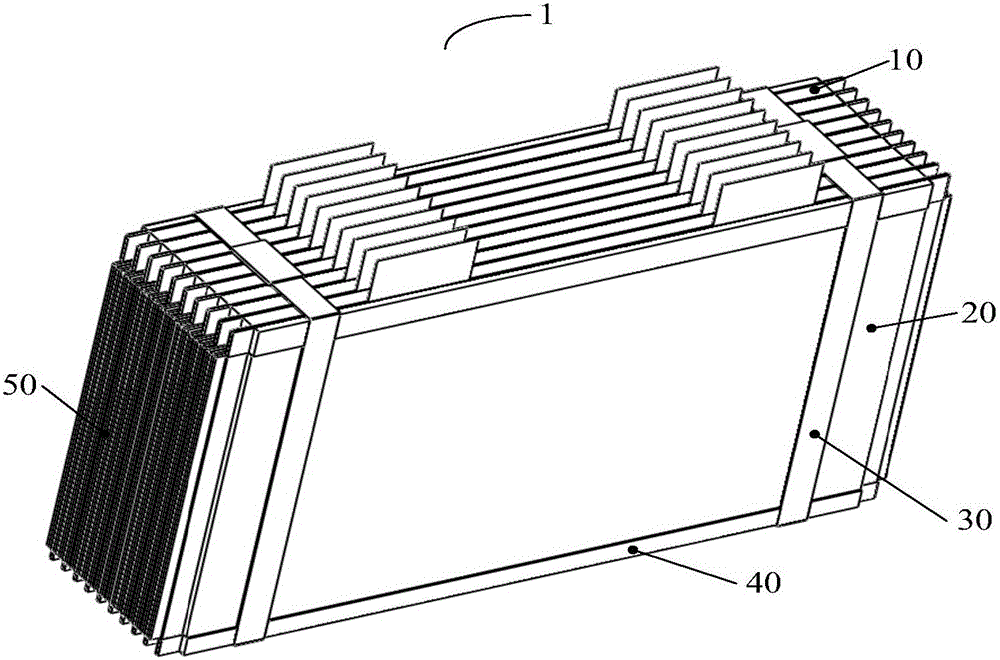

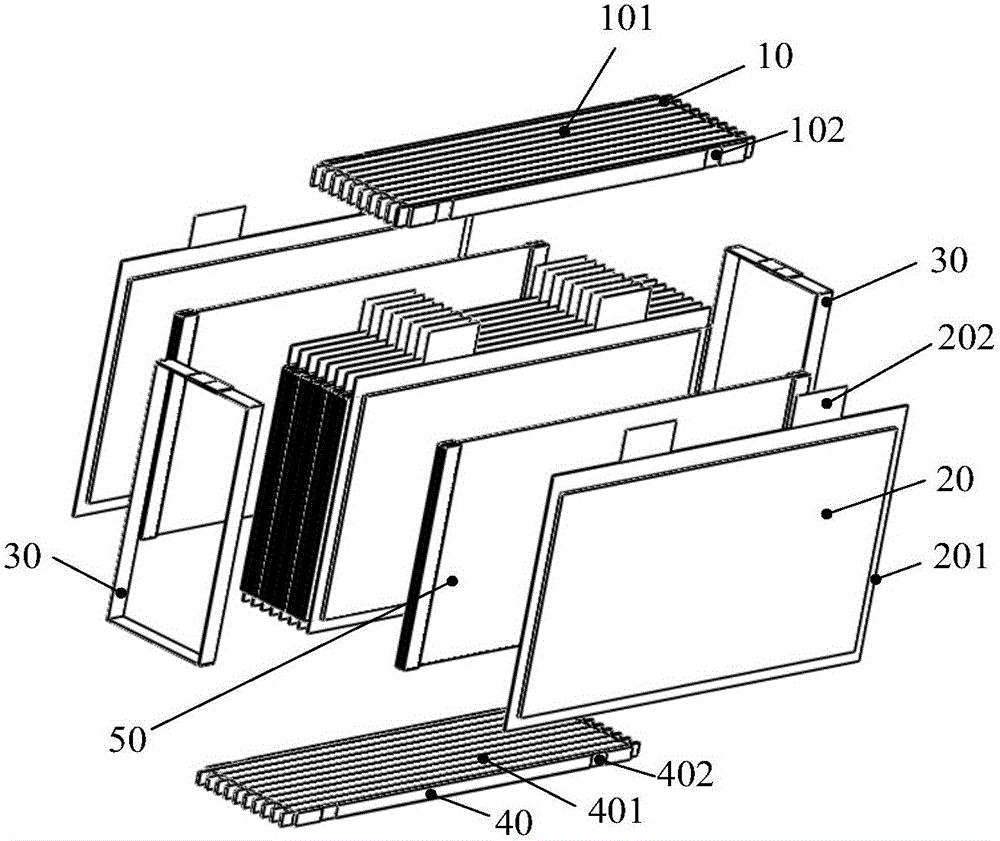

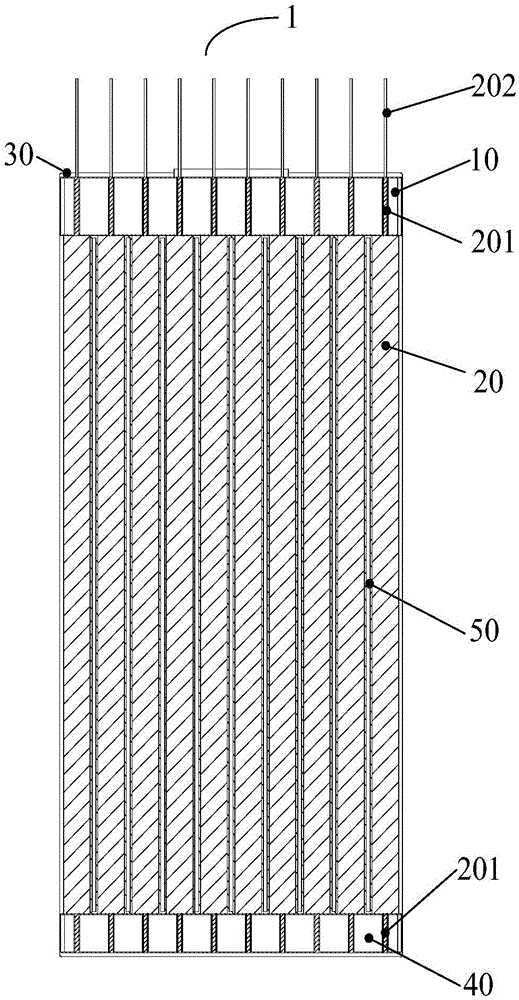

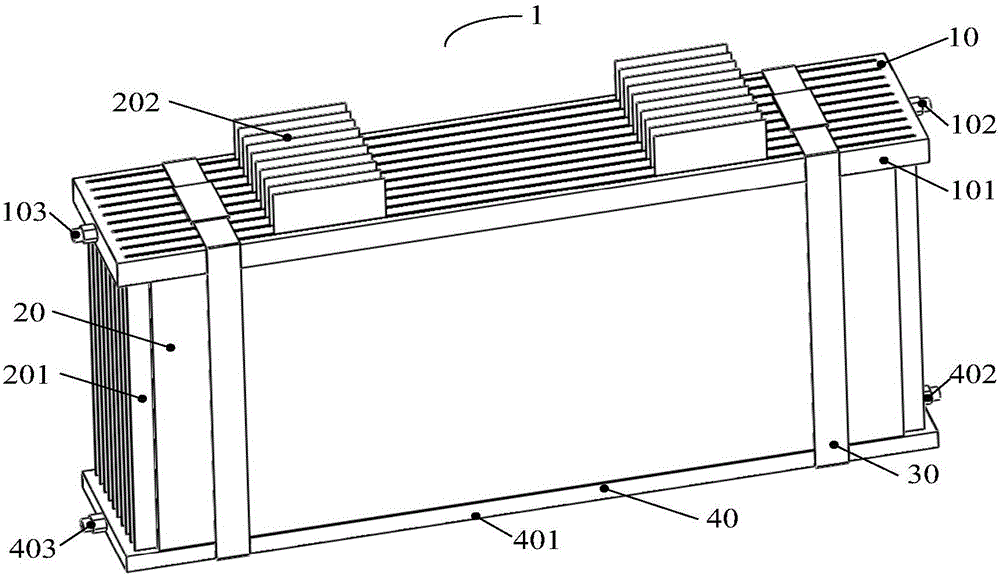

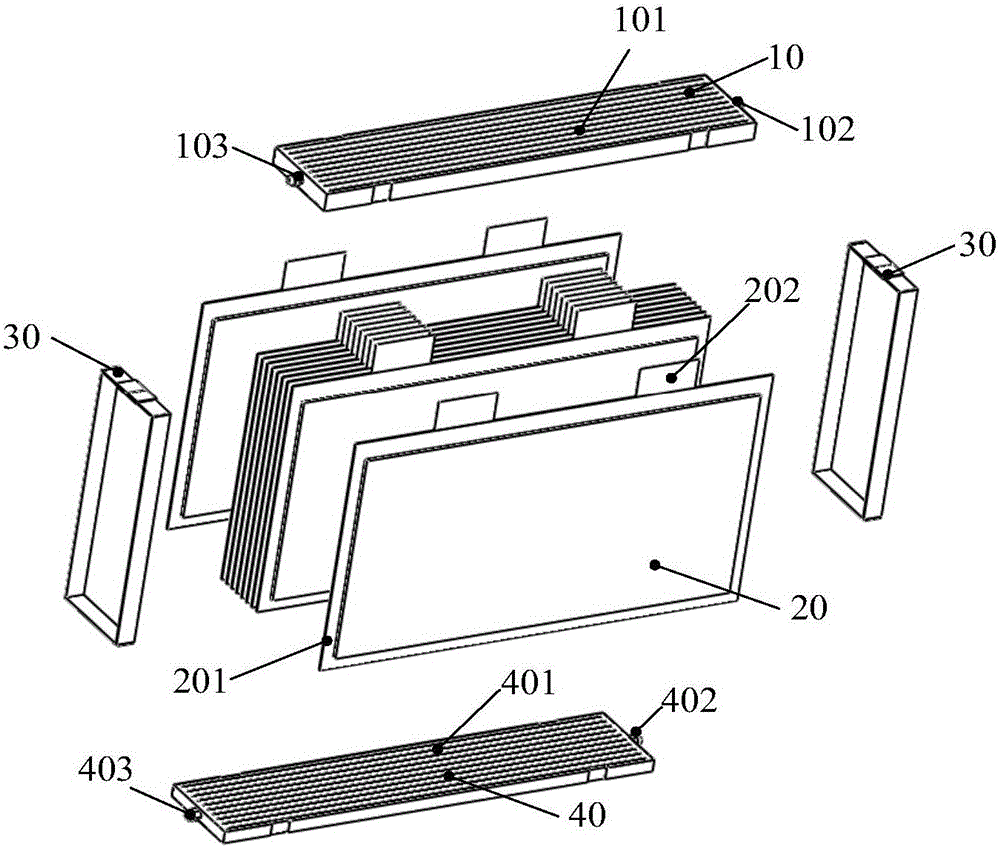

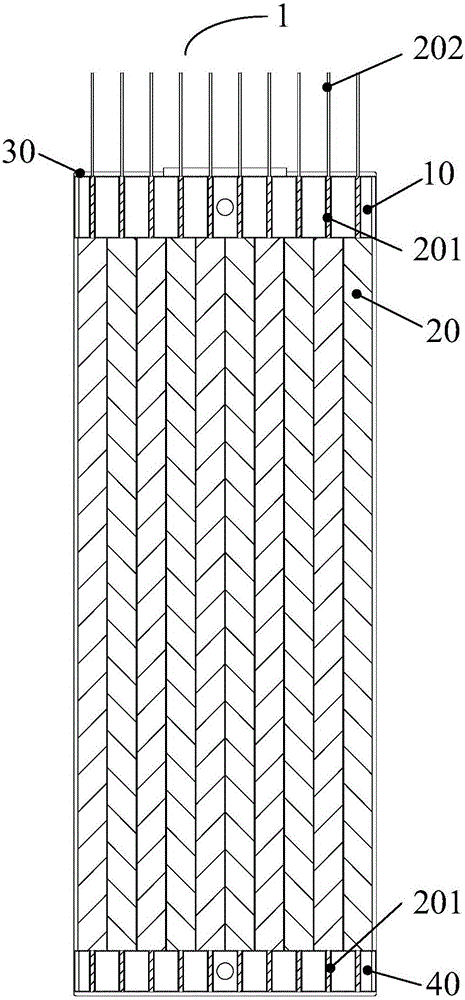

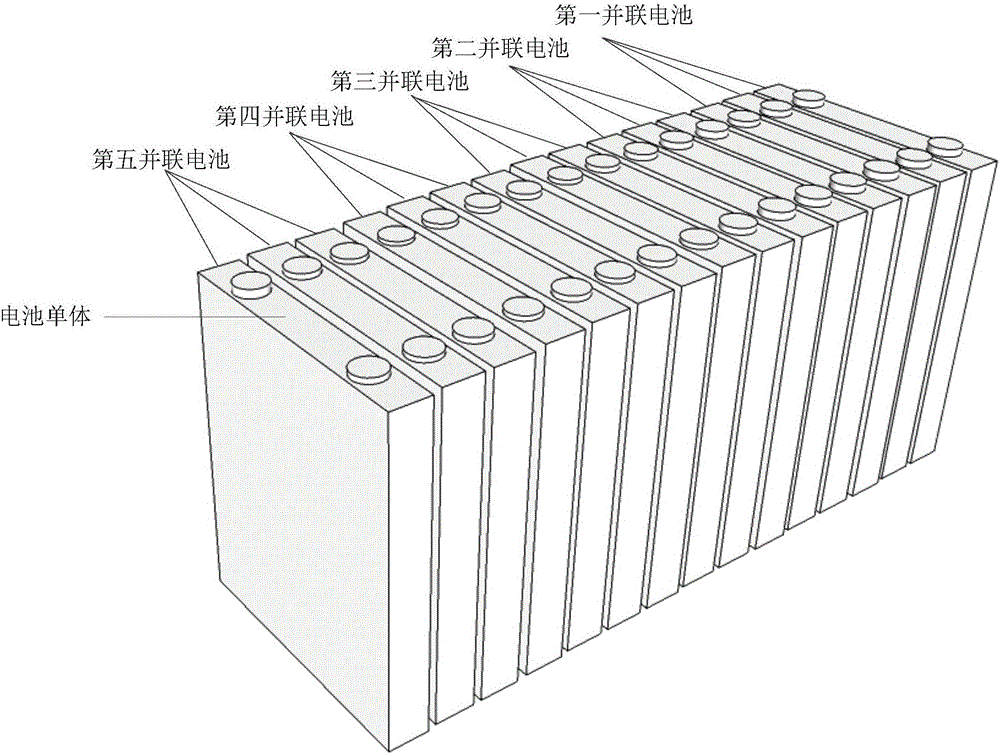

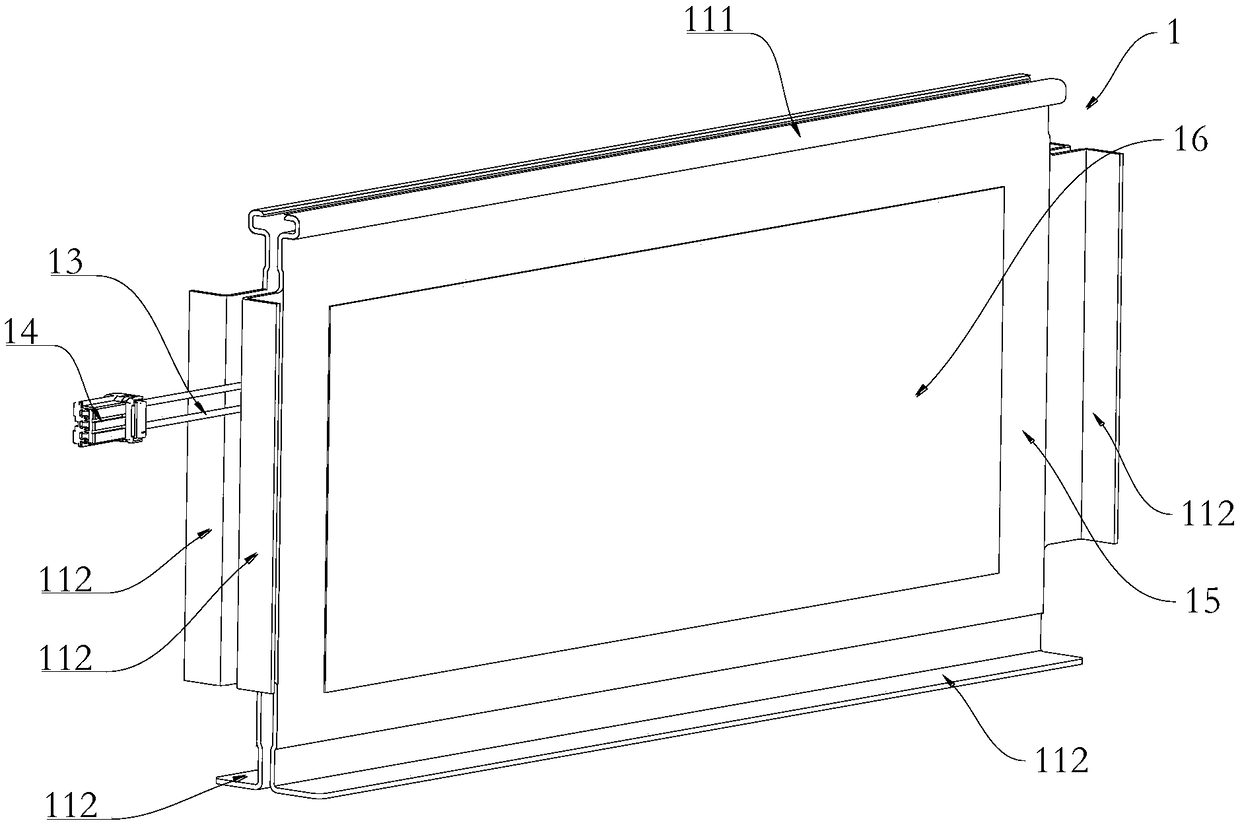

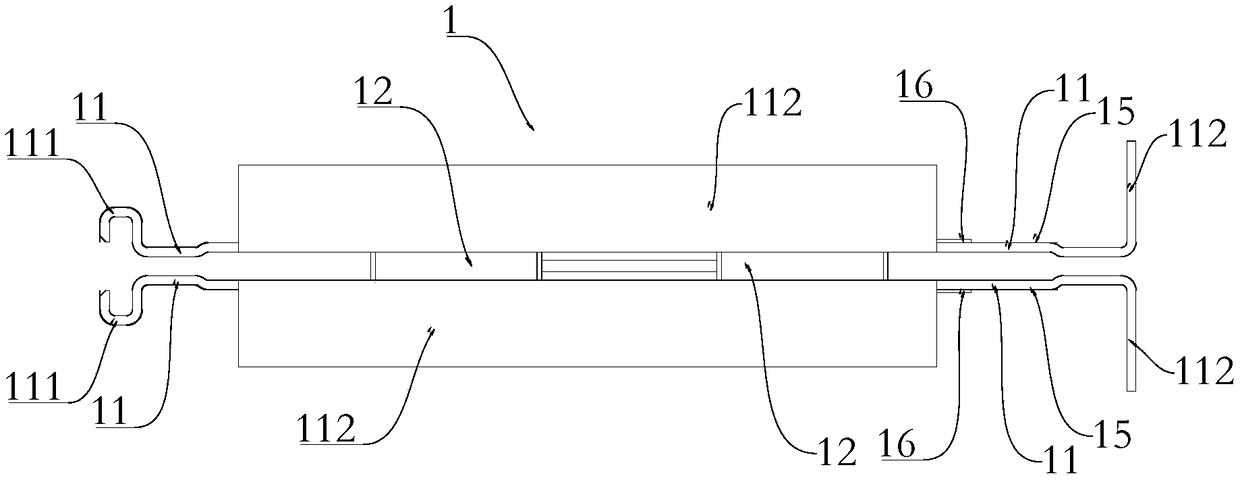

Battery module with flat heat pipes and cooling method

ActiveCN105703038AAchieve continuous coolingImprove heat uniformitySecondary cellsBoiling pointEvaporation

The invention discloses a battery module with flat heat pipes and a cooling method. The battery module comprises a shell and a plurality of single batteries, wherein the plurality of single batteries are arranged in the shell in a lamination way, the battery module also comprises a tab fixing device, a packing belt, a bottom fixing device and a plurality of flat heat pipes, one of the flat heat pipes is arranged between each two single batteries, the packing belt is hooped in a gap of the tab fixing device and a gap of the bottom fixing device, and sealing edges of the single batteries are fixed in a through groove of the tab fixing device and a through groove of the bottom fixing device. According to the method, a low-boiling point liquid is heated to be vaporized, is condensed on the side walls inside fins and flows to a phase change generation region, liquid supply required for liquid evaporation is met, thus, complete circulation is formed, the battery is continuously cooled, and the soaking performance the cooling performance of a battery pack are further improved.

Owner:上海康赛制冷设备有限公司

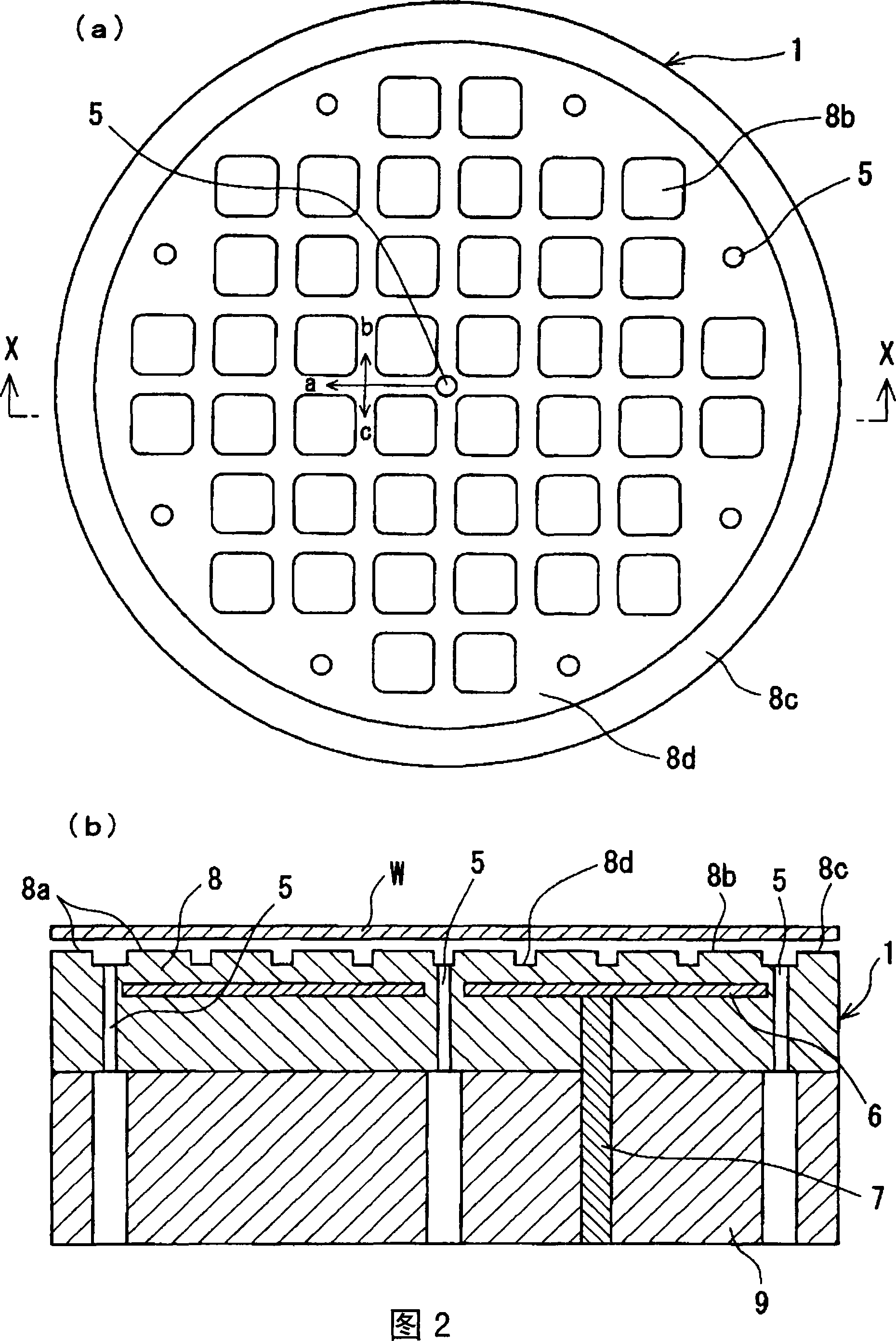

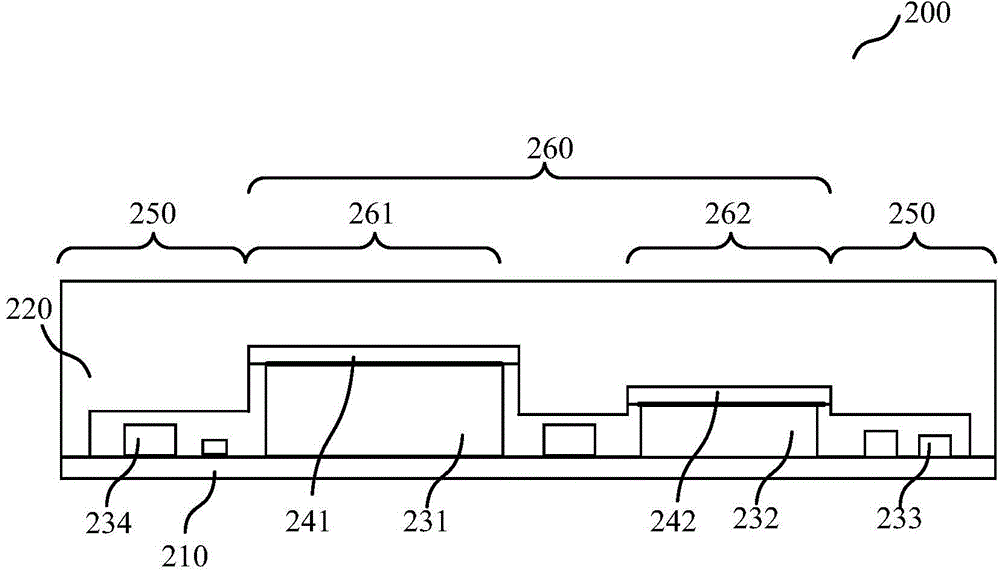

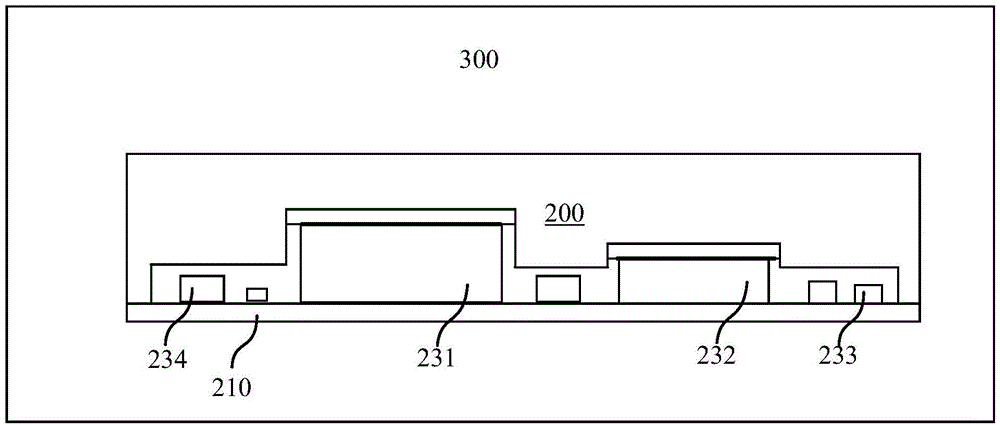

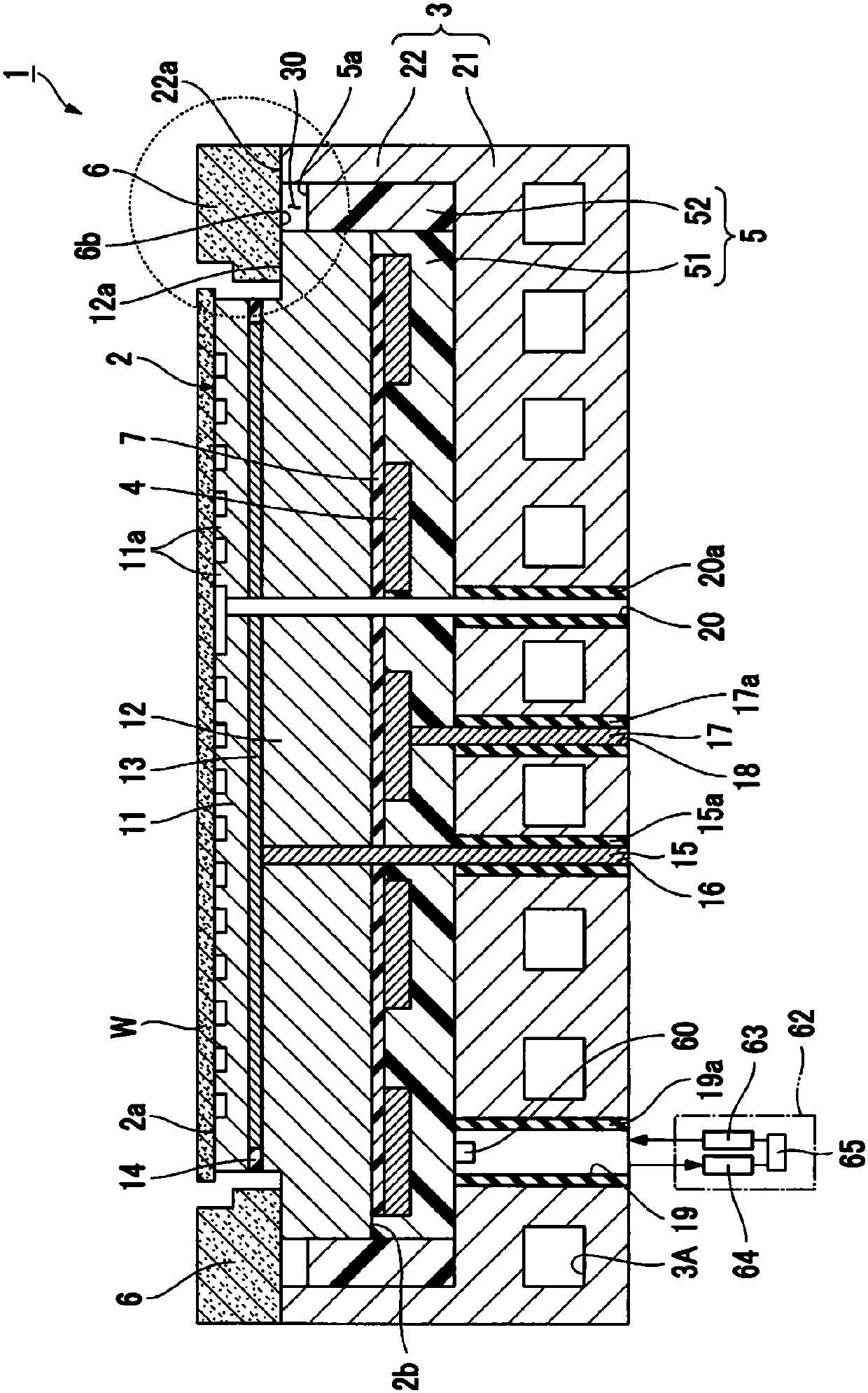

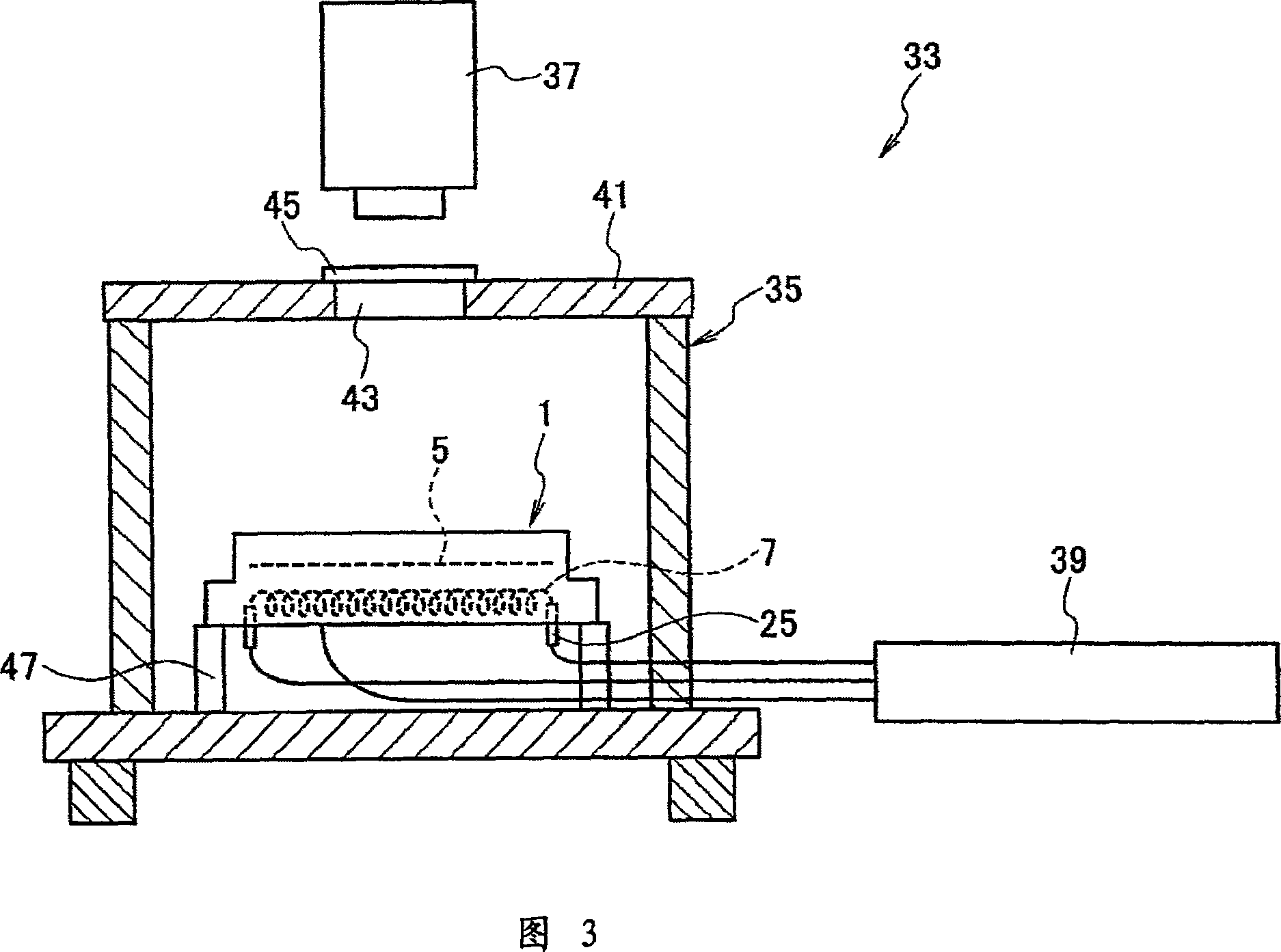

Electrostatic chuck device

ActiveCN108028219AAvoid erosionImprove heat uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingMechanical engineeringPhysics

An electrostatic chuck device according to the present invention is provided with: an electrostatic chuck portion having a placement surface on which a plate-shaped sample is placed; a temperature adjustment base portion disposed so as to face a surface opposite to the placement surface of the electrostatic chuck portion; a bonding portion for bonding the electrostatic chuck portion and the temperature adjustment base portion; and an annular focus ring that surrounds the placement surface. A volume of a space surrounded by the electrostatic chuck portion, the focus ring, the bonding portion, and a dam portion of the temperature adjustment base portion is larger than a volume expansion amount in use temperature of the bonding portion.

Owner:SUMITOMO OSAKA CEMENT CO LTD

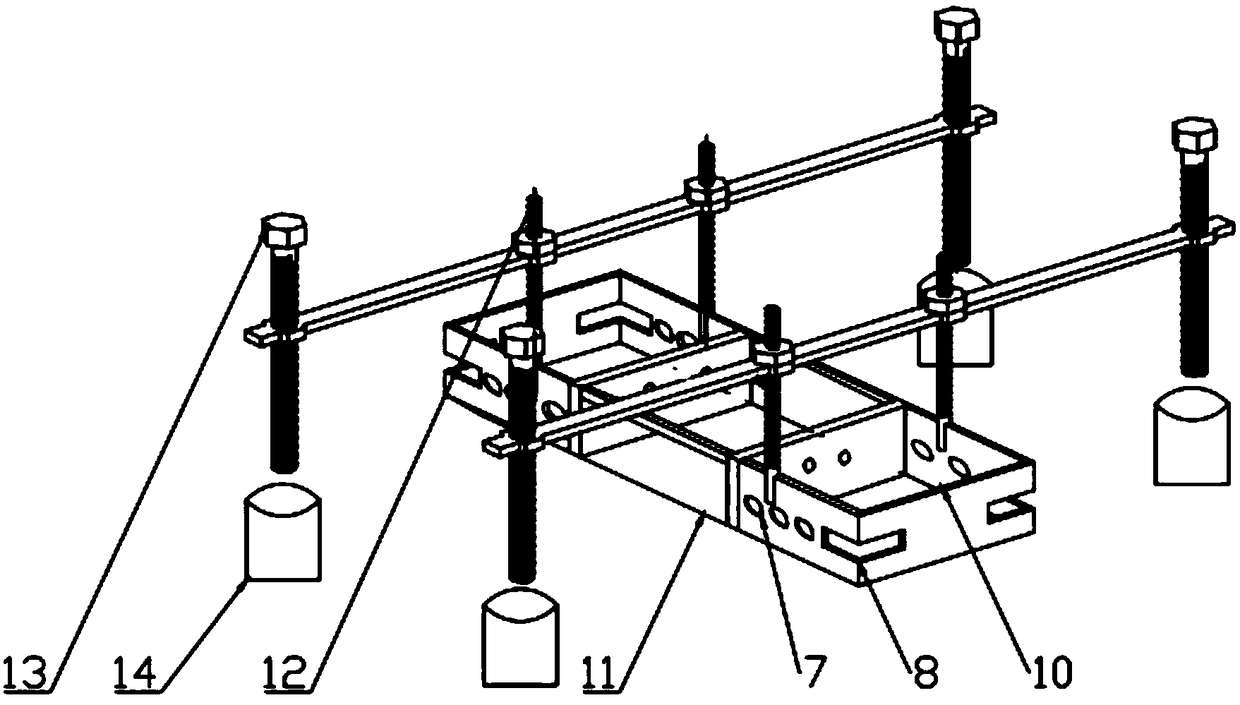

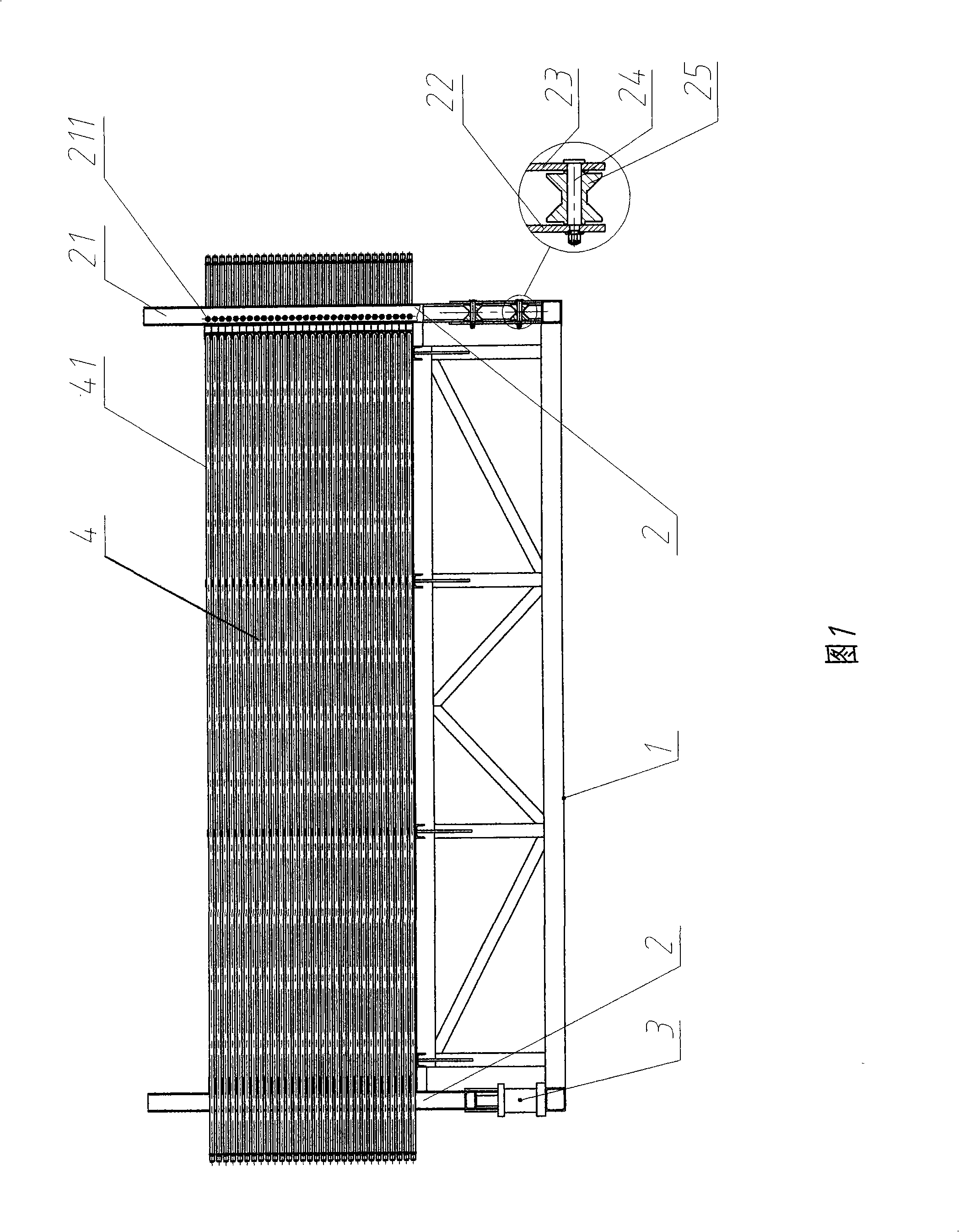

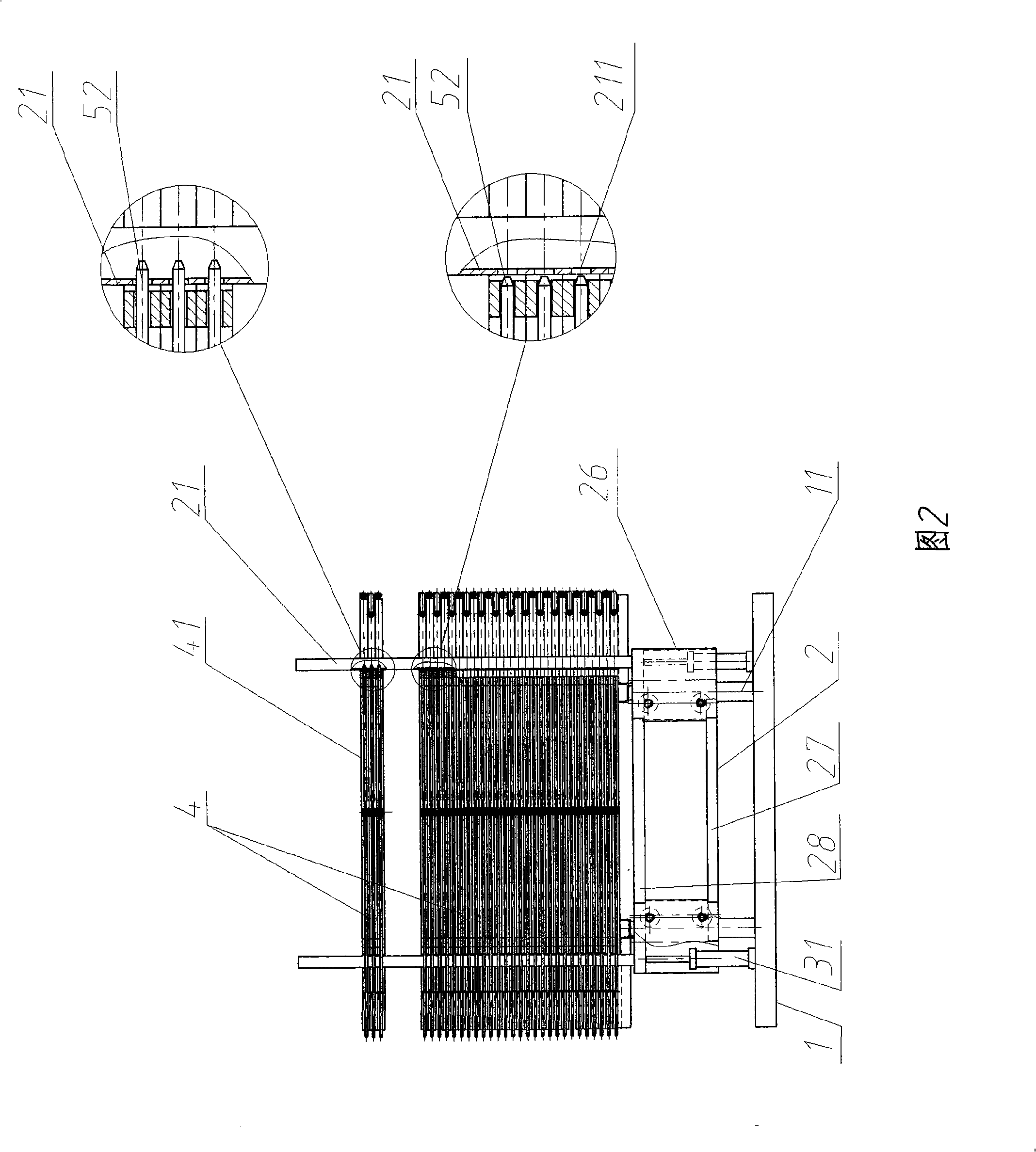

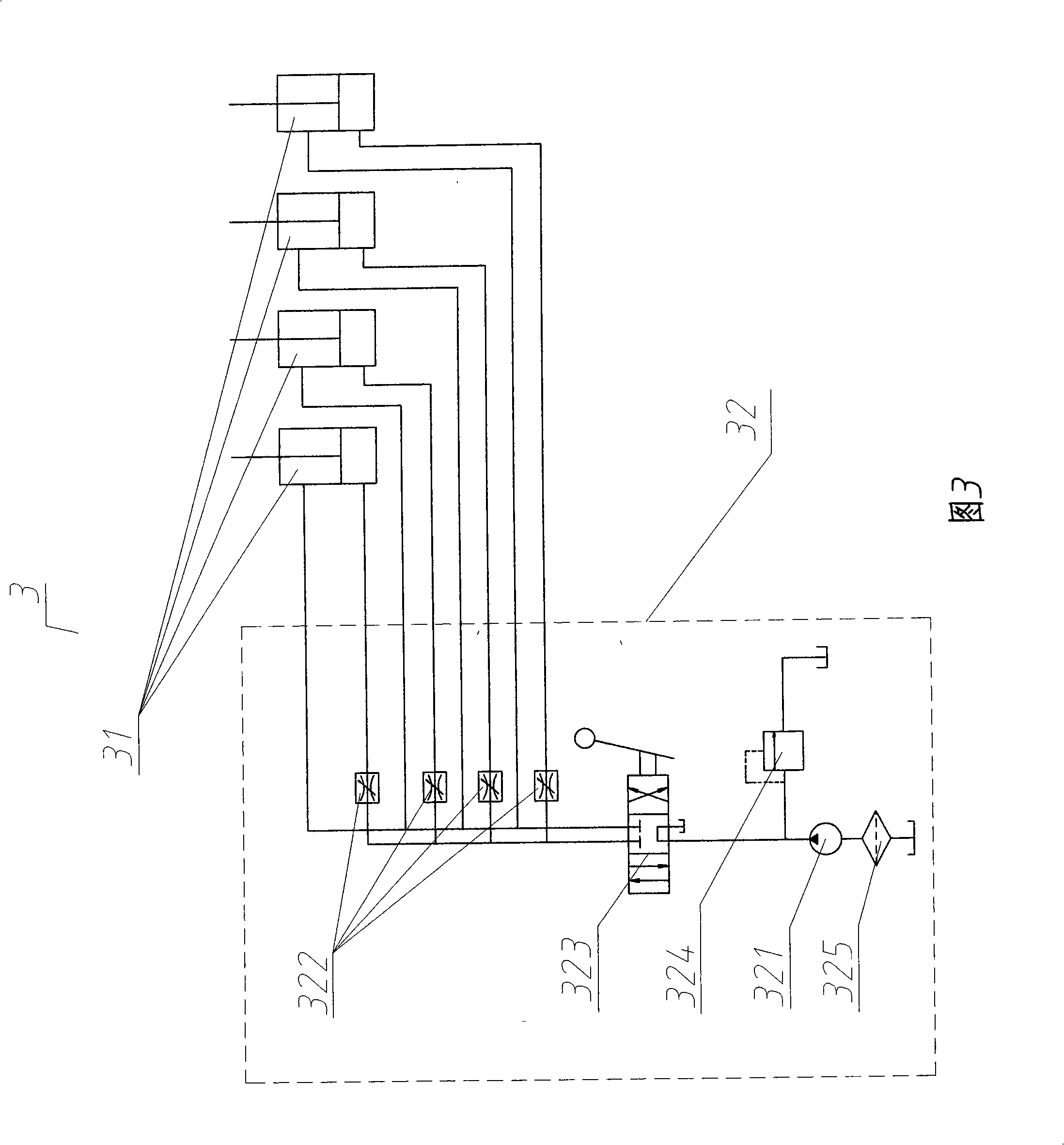

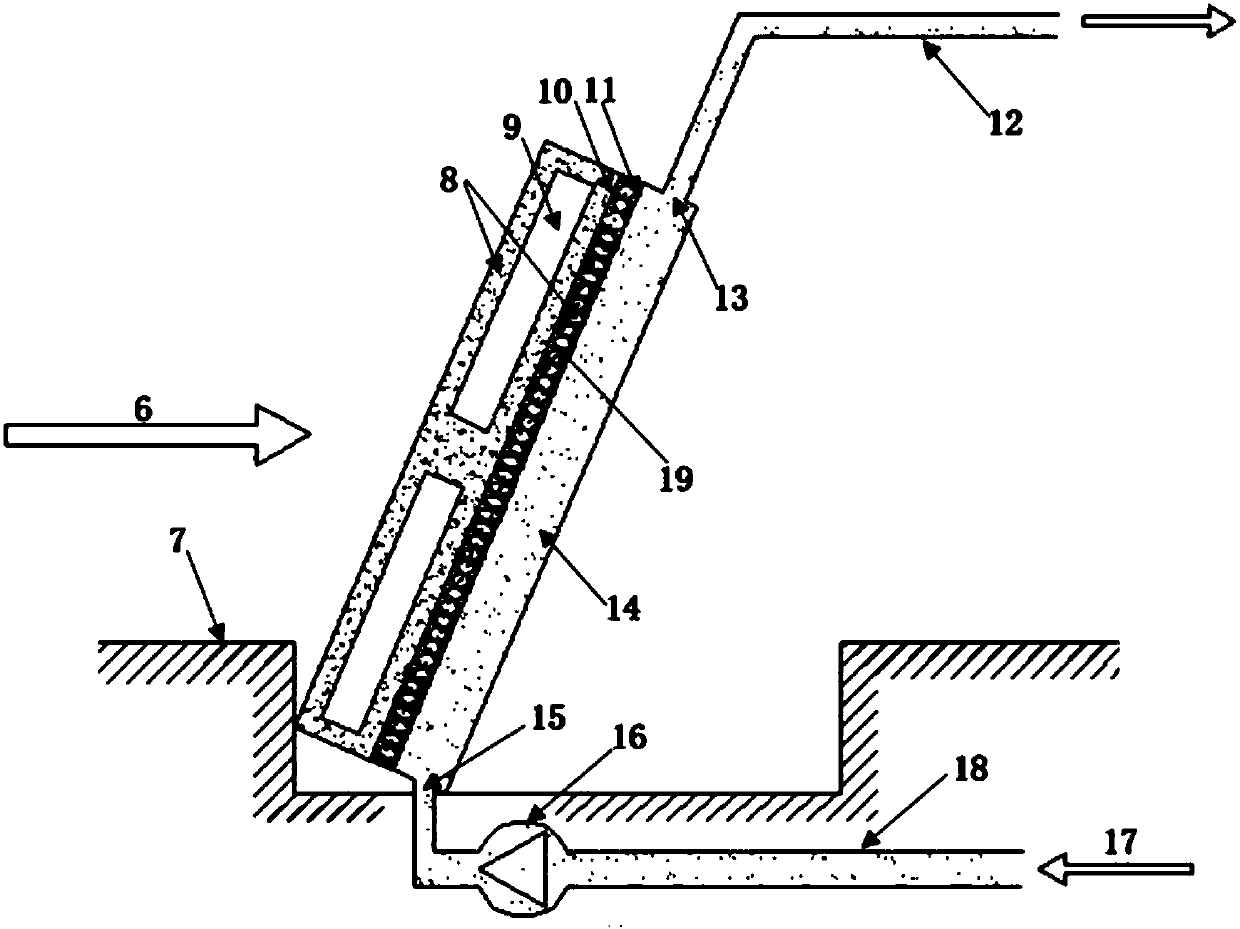

Solid multi-layer type single-plate dryer

InactiveCN101514865AIncrease profitAvoid pollutionDrying solid materials with heatDrying machines with local agitationHeat conductingMiniaturization

The invention provides a solid multi-layer type single-plate dryer, which comprises a baseframe, two lifting frame units, a hydraulic system, a heat conducting pipe coil assembly and positioning bolt mechanisms, wherein the baseframe is placed with the heat conducting coil pipe assembly; the two lifting units laterally stand at both ends of the baseframe; and the hydraulic system is arranged below a top lifting beam of the lifting units, provided with four two-way oil cylinders, and controlled by a hydraulic station to lift and fall back. Heat conducting coil pipe units are independent components, form the heat conducting coil pipe assembly by overlapping a plurality of layers, and are devices for inputting a heat source, radiating and drying. Both ends of the heat conducting coil pipe unit are fixedly connected with a set of the positioning bolt mechanisms respectively, and bolt rods of the positioning bolt mechanisms are closed or exculpated with positioning holes on the lifting frames so as to control the heat conducting coil pipe units to lift, and carry out material filling and discharging operation. The solid multi-layer type single-plate dryer has the advantages of three dimensions, small size, small occupation area, direct heating of wood plate surfaces, quick drying, high heat efficiency, energy conservation and low consumption. A single plate is not easy to warp and deform, so that the solid multi-layer type single-plate dryer also has the advantages of high finished product rate and simple operation, and is universal drying equipment.

Owner:漳州市北林大技术有限公司

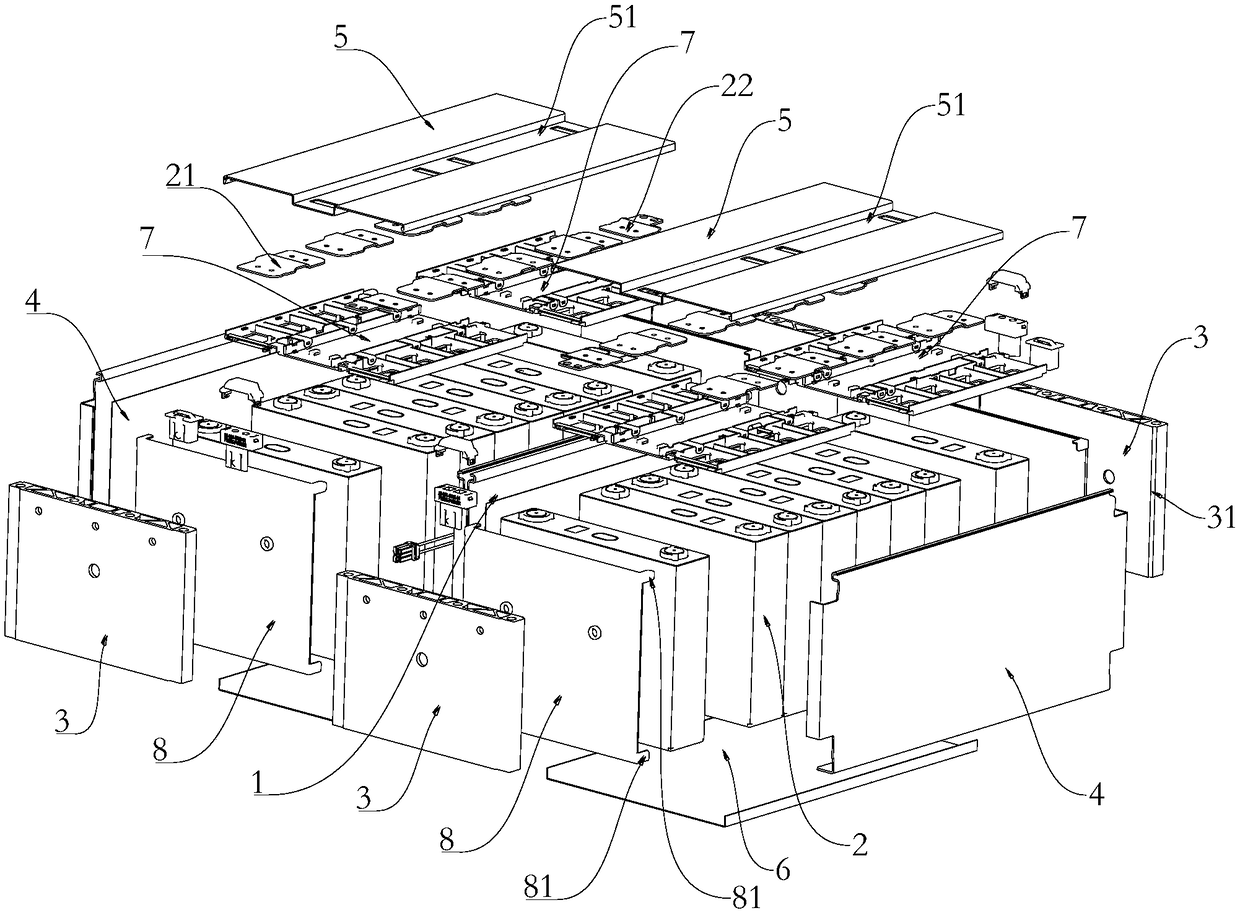

Partial cooling battery module suitable for softly-packaged lithium ion battery

ActiveCN105846011AAvoid squeezing each otherImprove securitySecondary cellsElectrical batteryEngineering

The invention discloses a partial cooling battery module suitable for a softly-packaged lithium ion battery. The partial cooling battery module comprises a shell and multiple single batteries, wherein the multiple single batteries are arranged in the shell in a laminated manner; the partial cooling battery module also comprises a tab cooling apparatus, packing belts and a bottom cooling apparatus; and the sealing edges of the single batteries are tightened in a tab through slot of the tab cooling apparatus and a cooling through slot of the bottom cooling apparatus through the packing belts. According to the partial cooling battery module, more heat generated by the tabs can be exported, so that the battery tabs can be effectively cooled, and the soaking performance and the radiating performance of the battery pack can be improved; and in addition, mutual extrusion of the batteries caused by expansion due to heat generated in operation can be avoided, so that the safety of the battery can be improved.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

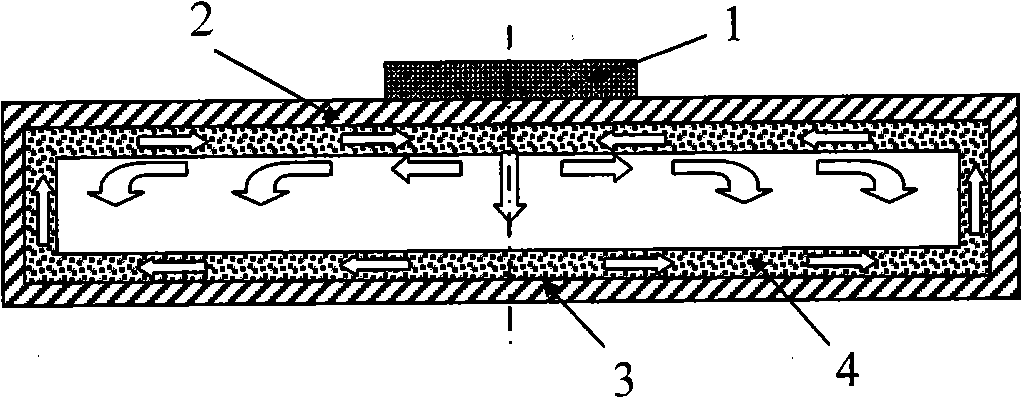

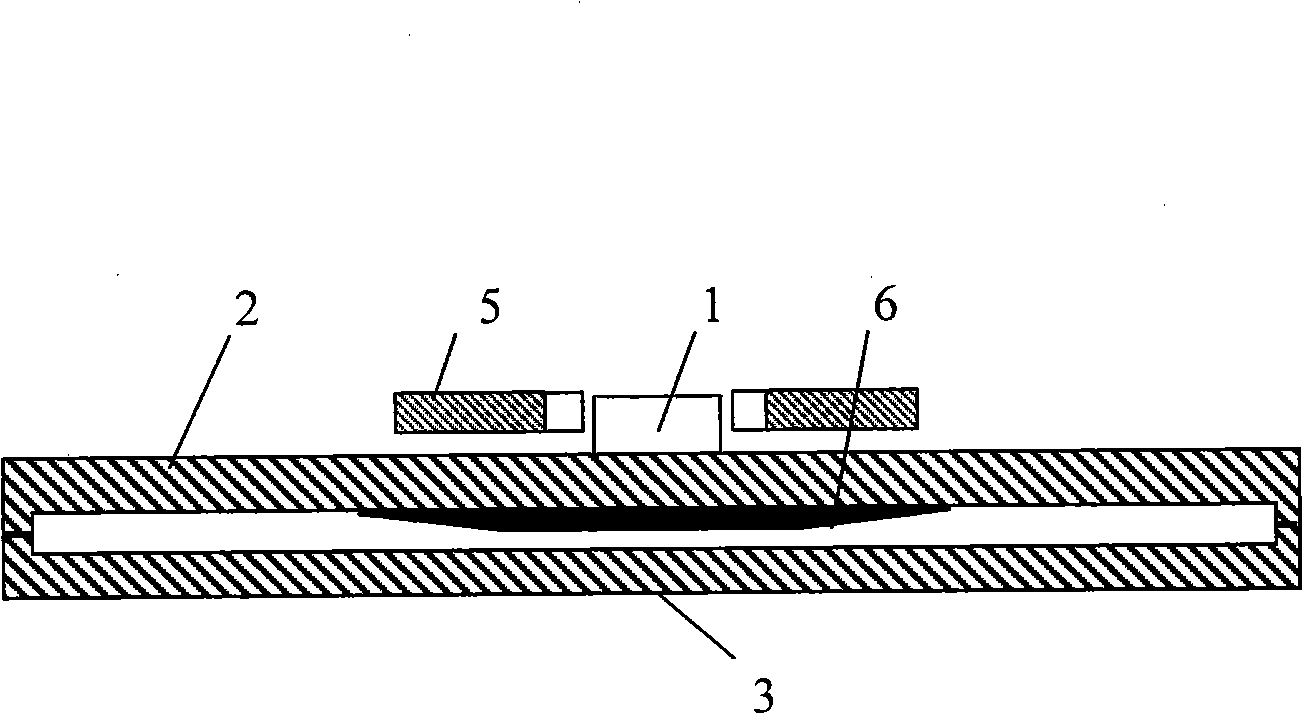

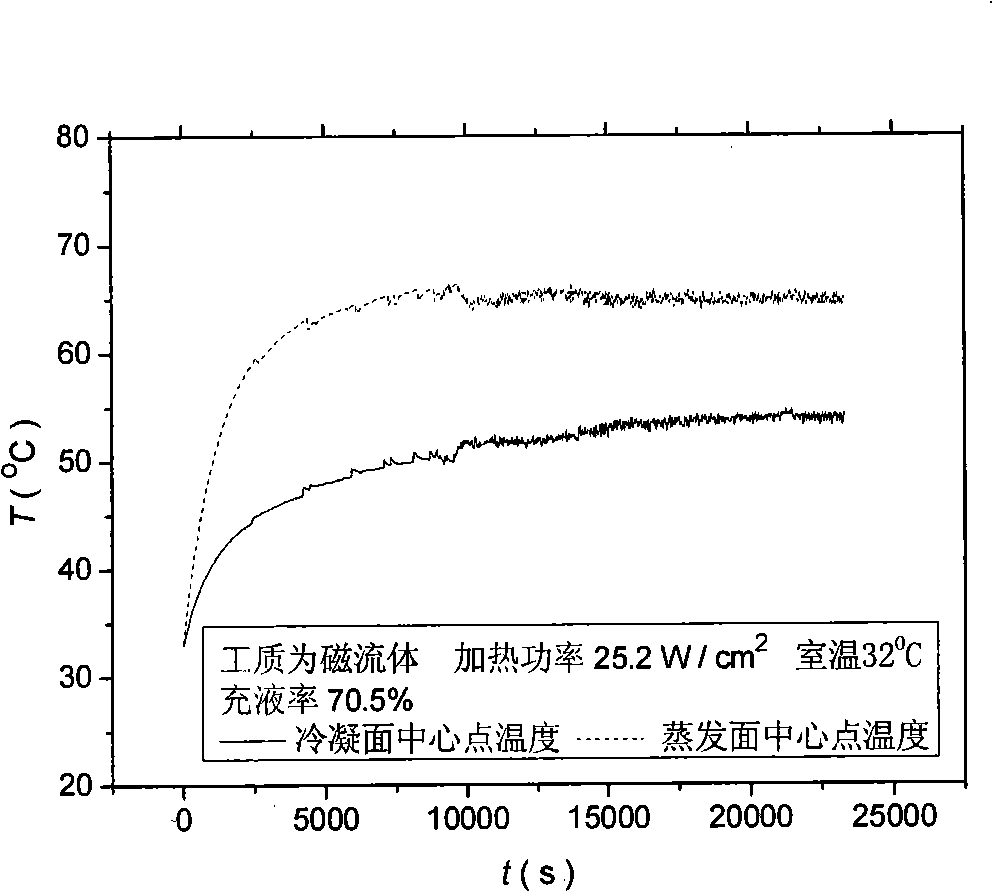

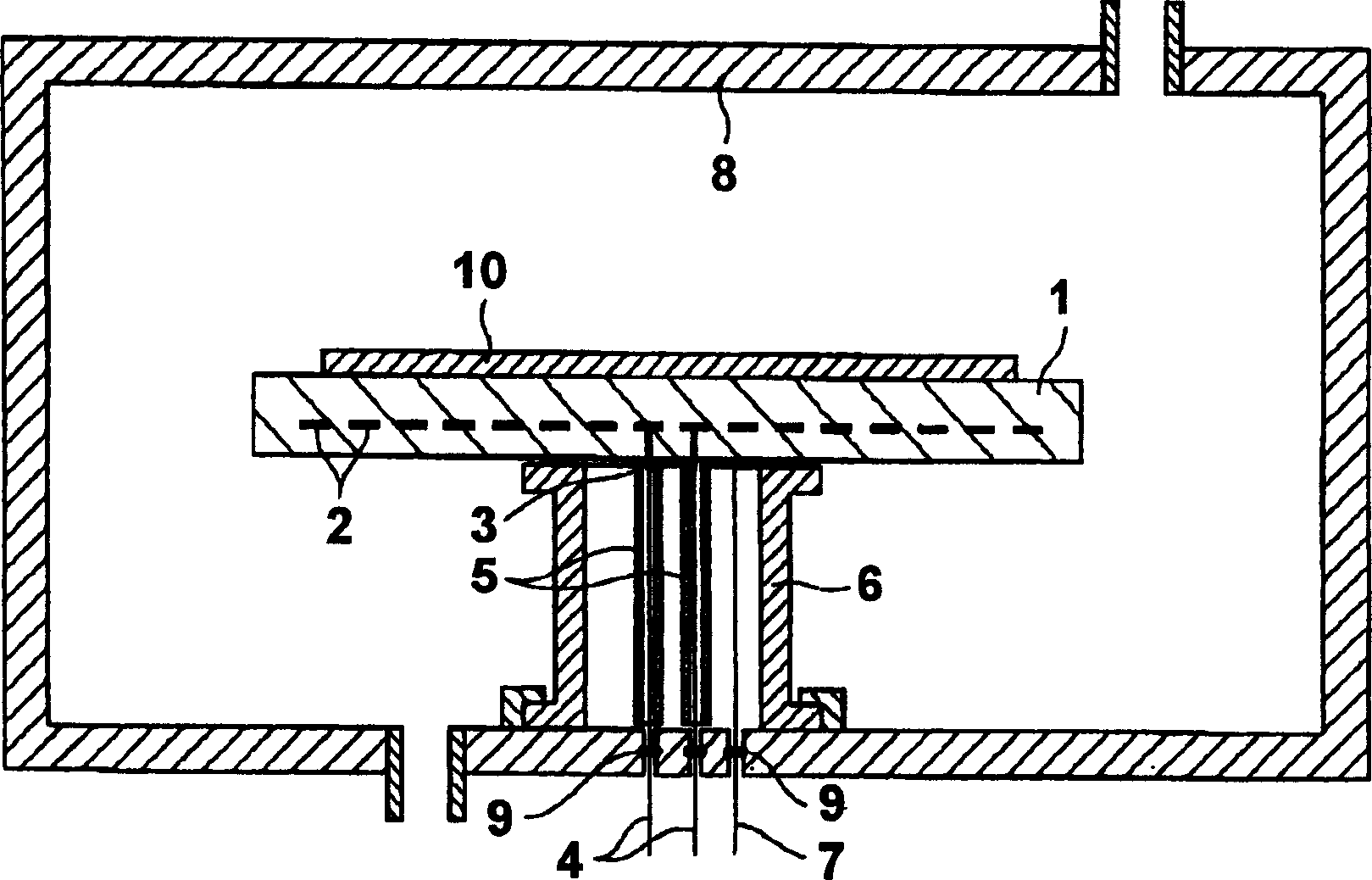

Magnetofluid flat plate hot pipe soaking device

InactiveCN101281003AStrong attractionWork lessIndirect heat exchangersCooling/ventilation/heating modificationsAnti-gravityEngineering

The invention relates to a magnetic fluid flat heat pipe soaking machine that can be used as the soaking machine in an electronic apparatus cooling device. The invention aims to solve deficiency that a capillary core in the flat heat pipe soaking machine is hard to place and the capillary force is not enough. The whole magnetic fluid flat heat pipe is welded by an evaporate face flat (2) and a condensate flat (3). The flat heat cavity is provided with no any capillary structure. After extracting vacuum for the flat heat pipe, the flat heat pipe is filled with magnetic fluid as working substance. A magnet (5) is placed adjacent to an electronic apparatus (1) on an outer side of the evaporate face flat. The flat heat pipe can save design of the capillary liquid absorbing core. Placing additionally magnetic filed not only intensifies the working substance to boil, but also accelerates the working substance to flow back, which enables the magnetic fluid flat heat pipe to work under anti-gravity condition.

Owner:BEIJING UNIV OF TECH

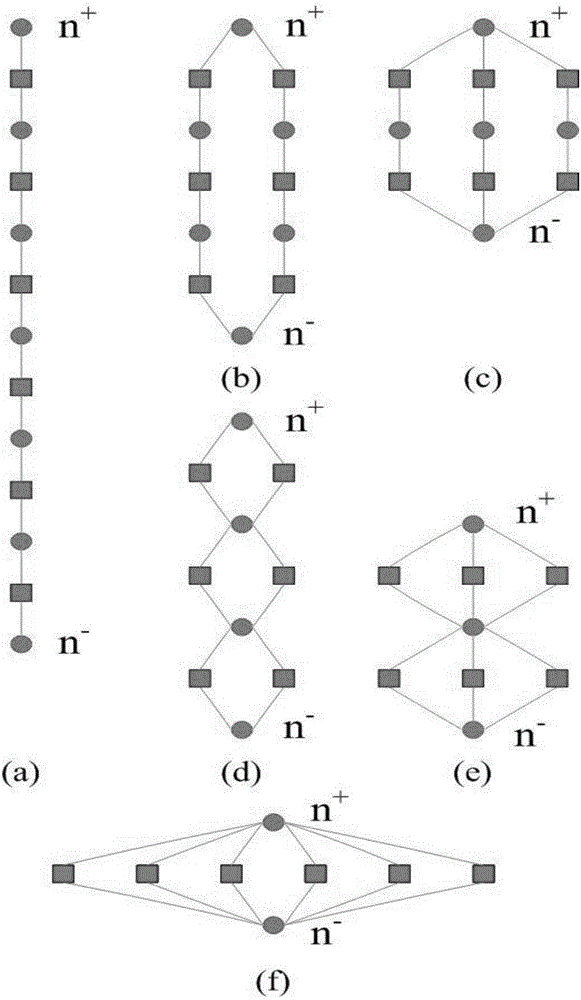

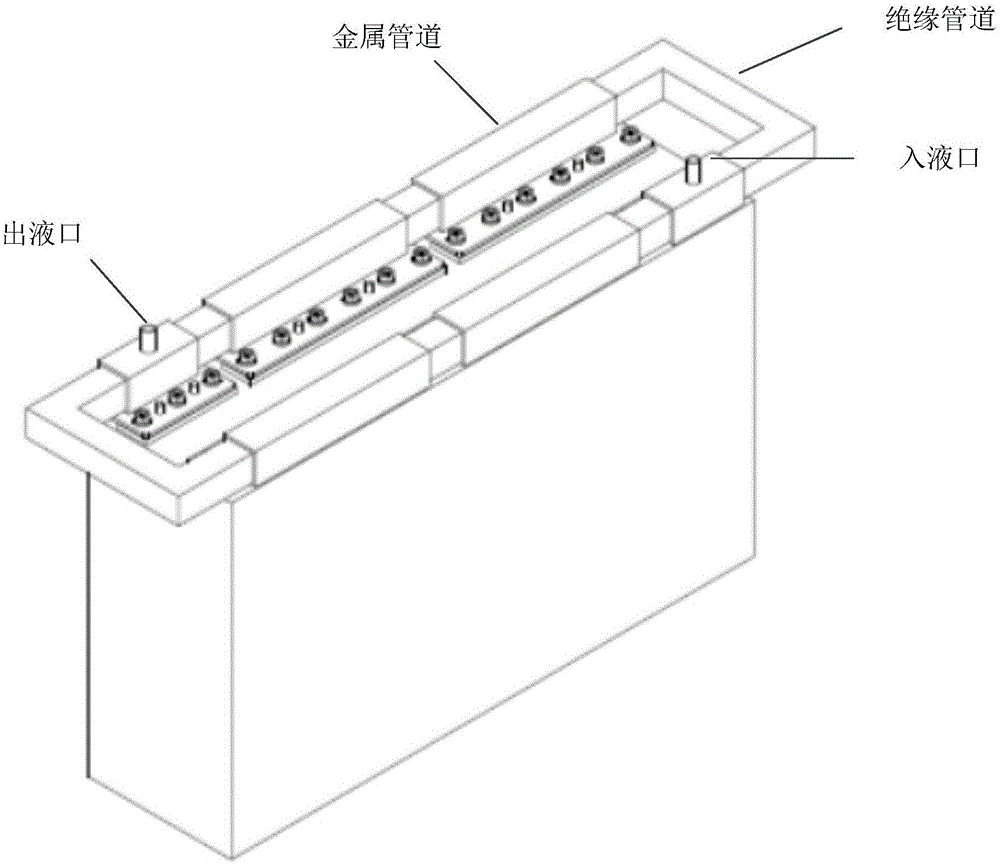

Lithium ion battery pack tab liquid cooling based on liquid cooling

ActiveCN106129527AResolve temperature differencesImprove heat uniformitySecondary cellsEngineeringTemperature difference

The invention discloses a lithium ion battery pack tab liquid cooling based on liquid cooling. The liquid cooling device comprises a closed liquid cooling pipeline, and heat conductive cooling liquid arranged in the liquid cooling pipeline. The liquid cooling pipeline comprises metal pipelines and insulation pipelines which are arranged alternately. The metal pipelines fit the tab collector sheets of the lithium ion battery pack and are used for conducting the heat of lithium ion battery pack tabs. The insulation pipelines are connected with the metal pipelines. The liquid cooling pipeline also comprises a liquid inlet and a liquid outlet which are closeable and openable and are used for importing and exporting the heat conductive cooling liquid. The heat conductive cooling liquid is insulation liquid with a heat conductive cooling function. According to the device, the tabs at different locations of the lithium ion battery pack are connected through a heat conductive loop, and the heat conductive cooling liquid is injected into the loop. The temperature difference problem of the battery tabs at different locations in the charge / discharge process of the battery pack is solved. The device has good soaking effect, is simple in structure, is easy to disassemble and expand, and is applicable to lithium ion batteries of different combinations.

Owner:江苏卓岸电源科技有限公司

Ceramic wall surface composite plug type heat flux sensor applicable to high-enthalpy, medium and low heat flux environment

ActiveCN106706166ASmall difference in coefficient of linear expansionConducive to uniform temperatureCalorimeterThermal insulationCeramic coating

The invention provides a ceramic wall surface composite plug type heat flux sensor applicable to high-enthalpy, medium and low heat flux environments. The ceramic wall surface composite plug type heat flux sensor relates to the field of ceramic wall surface heat flux sensor design. The heat flux sensor comprises a graphene column, a rigid ceramic thermal insulation sleeve, a red copper column, a thermocouple and a ceramic coating, wherein one axial end of the graphene column is fixedly connected with the red copper column, and another axial end of the graphene column is coated with the ceramic coating; the outer side wall of the graphene column and the axial end surface (away from the graphene column) of the red copper column are coated with the rigid ceramic thermal insulation sleeve; and the end surface of the red copper column is provided with the thermocouple. The ceramic wall surface composite plug type heat flux sensor solves the problem that the ceramic coating cannot be prepared on the surface of the red copper column directly, alleviates the thermal diffusion in the plane direction, effectively avoids the problems of low thermal conductivity coefficients and slow thermal response of the ceramic material, and provides a more precise calorimetric sensor for hypersonic-speed aircraft ground thermal protection texts.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

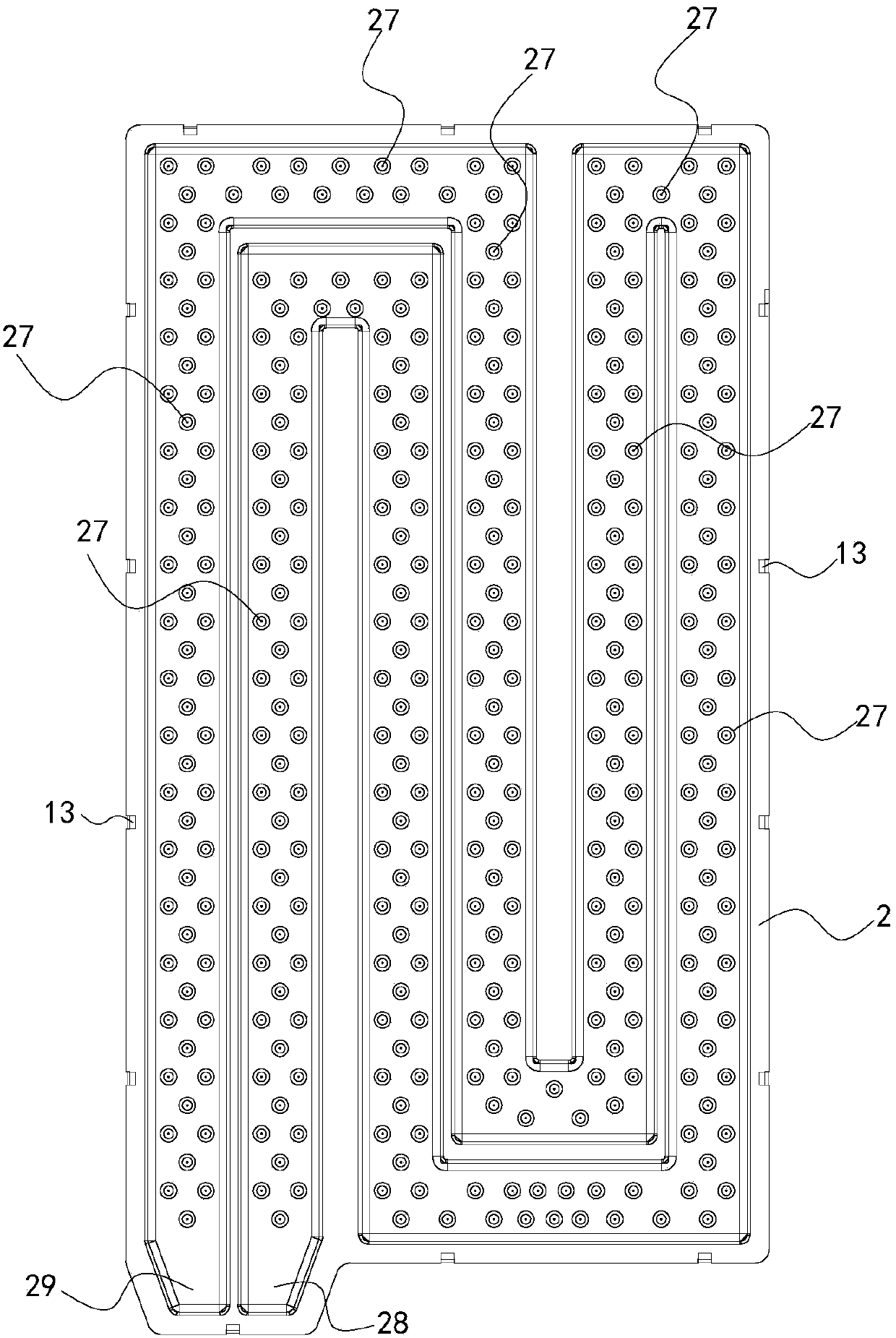

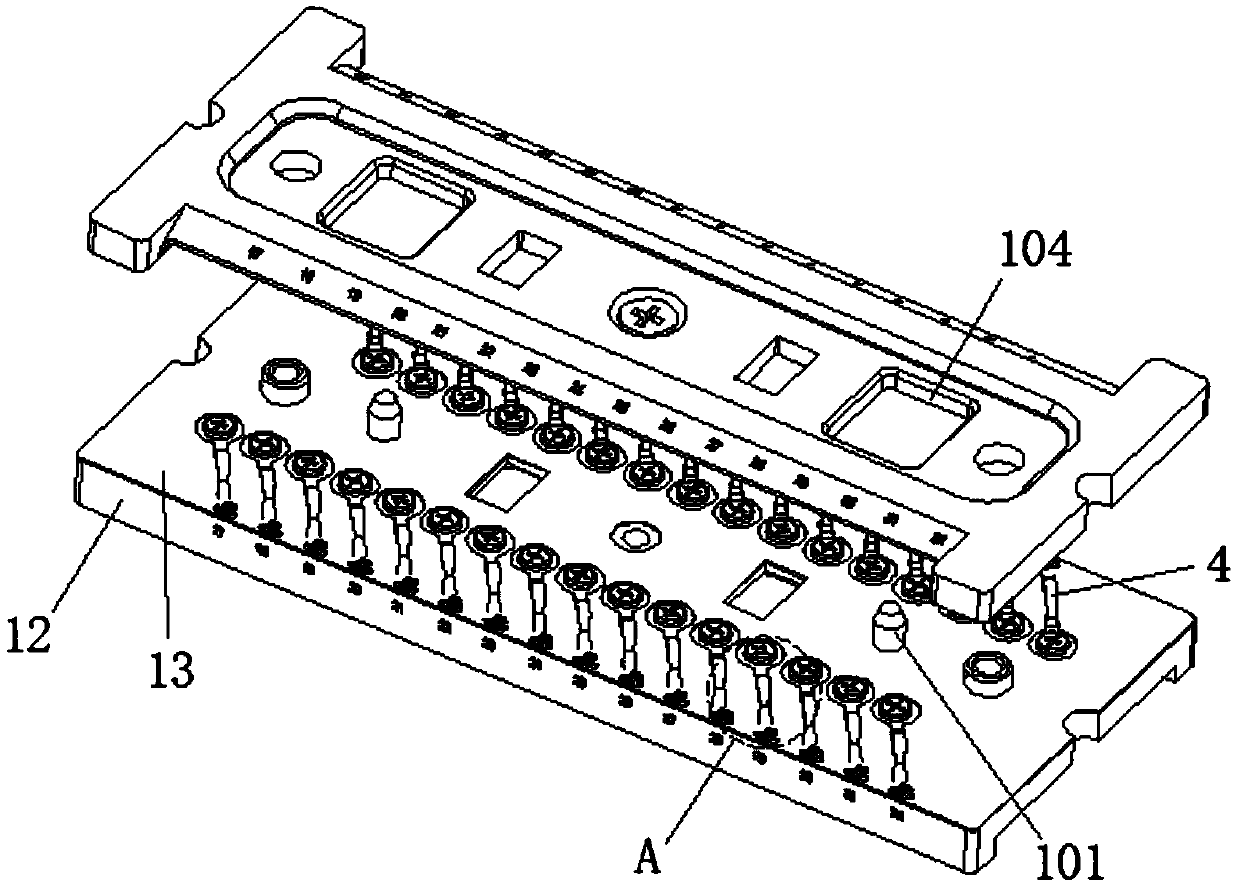

Power battery water-cooling plate for brazing

InactiveCN107863587ASimple structureImprove pressure resistanceSecondary cellsBatteriesPower batteryEngineering

The invention relates to a power battery water-cooling plate for brazing. The power battery water-cooling plate comprises an upper plate and a lower plate, wherein the upper plate is buckled with thelower plate, the upper plate and the lower plate are fixed by brazing, a runner is formed between the upper plate and the lower plate and is used for a cooling liquid to flow, the runner comprises a liquid inlet runner and a liquid return runner which are arranged in parallel, an inlet and an outlet of the runner are arranged in parallel, a liquid inlet is formed in a position, corresponding to the inlet, of the upper plate, and a liquid outlet is formed in a position, corresponding to the outlet, of the upper plate. The power battery water-cooling plate is formed by only combining the upper plate and the lower plate, is simple in structure, good in pressure resistance, light in weight and high in heat exchange efficiency and is difficult to leak; by arranging the liquid inlet runner and the liquid outlet runner in parallel, the thermal equalization performance of a battery module is greatly improved; and the upper plate and the lower plate are fixed by brazing, the production efficiency is high, the weight of a battery module water-cooling system is reduced, the heat exchange capability of the water-cooling plate is improved, good temperature uniformity is achieved, and the powerbattery water-cooling plate is suitable for rapid production on a large scale.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

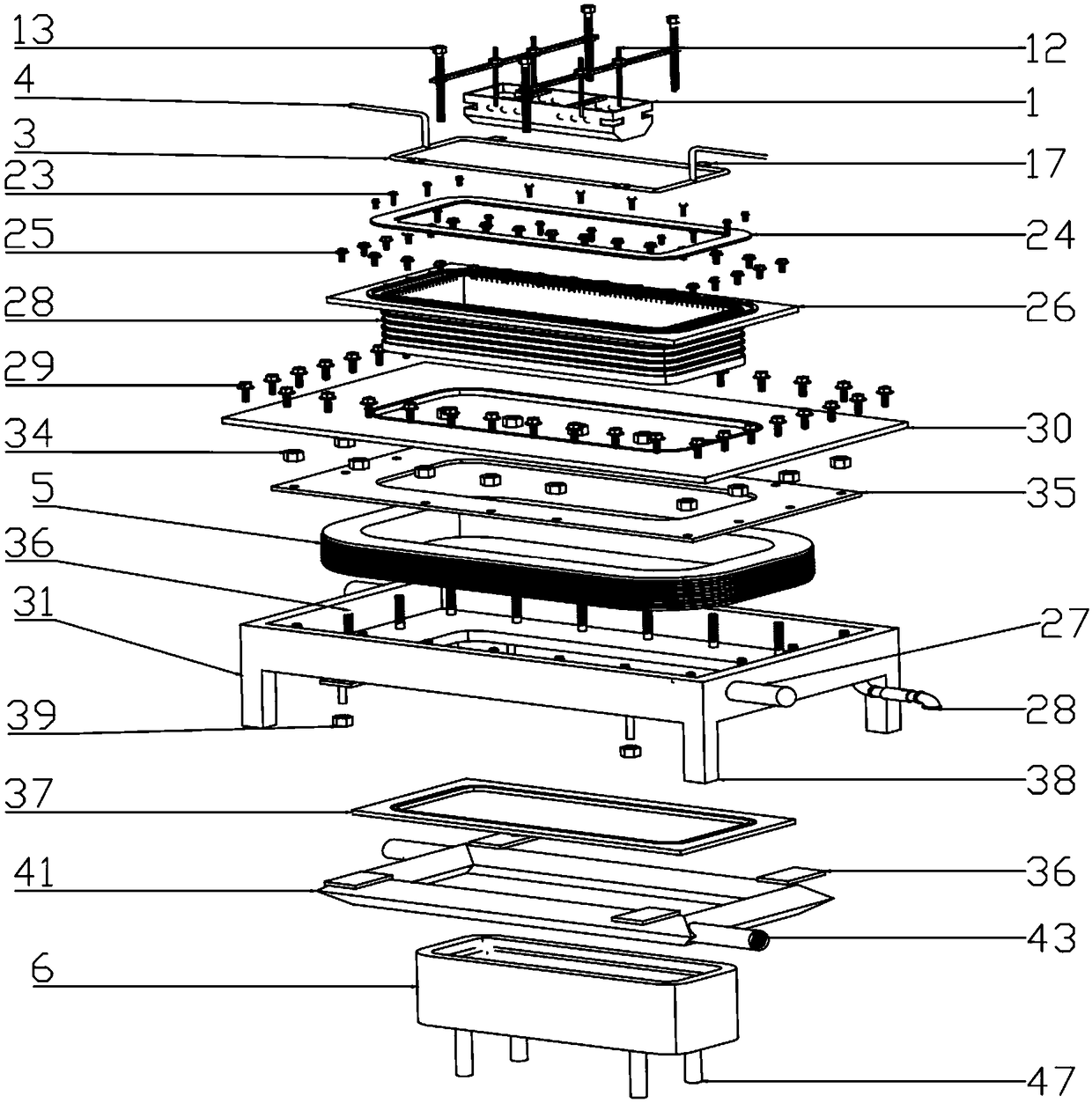

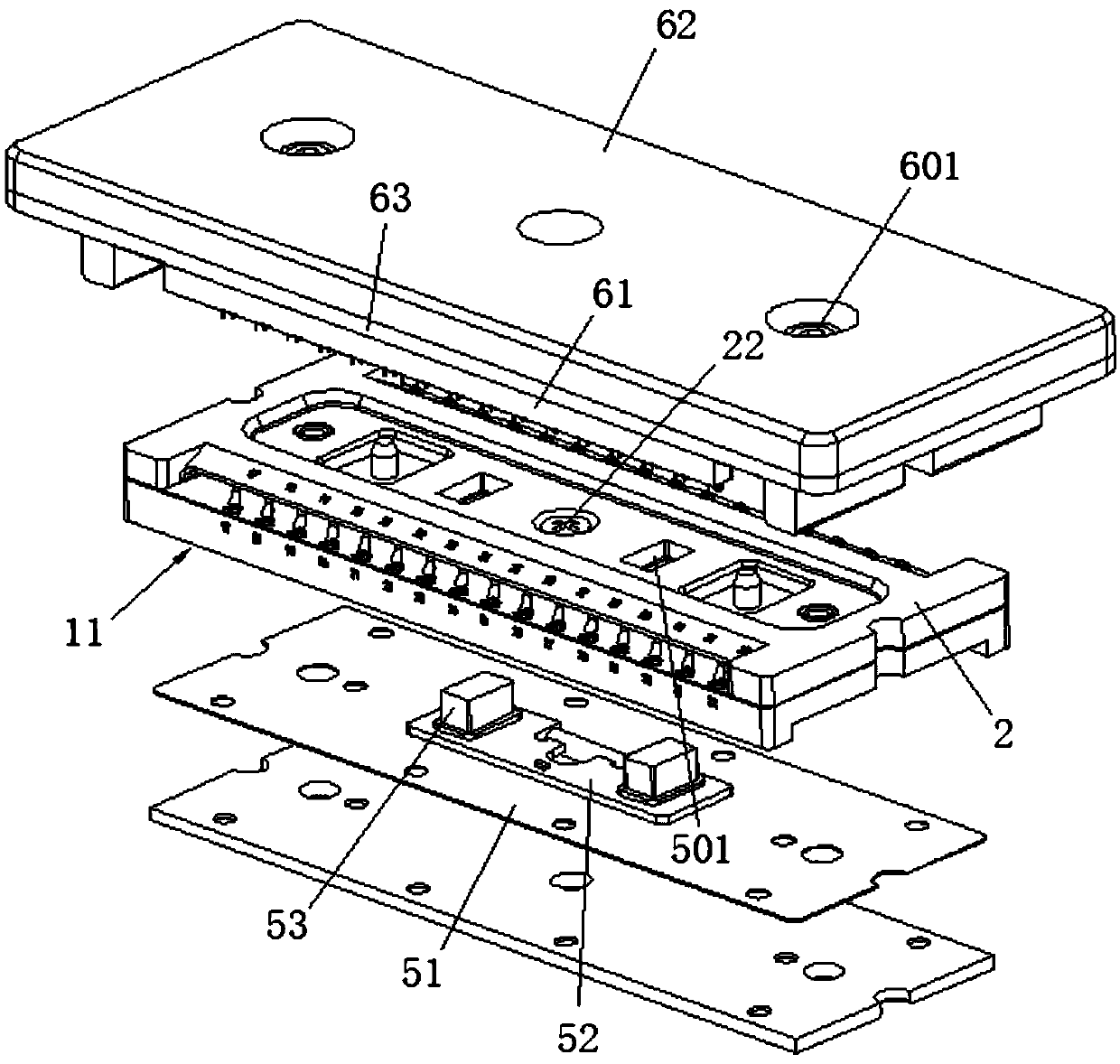

Integrated fixture of laser chip

PendingCN109596867AStable pressureGuaranteed extrusion strengthWork holdersMeasurement instrument housingEngineeringControl circuit

The invention discloses an integrated fixture of a laser chip. The integrated fixture comprises a chip positioning seat for loading chips, a test module and a heat module; the chip positioning seat comprises base shrapnel and a shrapnel gland; multiple positioning slots for the embedding of the chips are formed on an upper surface of the base; the shrapnel comprises a connecting part, a deformation part and a positioning part arranged on the base; each positioning lost is provided with a positioning right angle, and a right angle positioning gap is formed at the end part of the positioning part, and the shrapnel gland and the deformation part are in extrusion contact; multiple pins corresponding to the chips are arranged at a lower surface of a PCB board, the pins contact with the chips bypenetrating a cover plate, and connecting contacts are arranged at two ends of the PCB board; the heating module comprises a heating plate and a control circuit board. The integrated fixture disclosed by the invention has the advantages of being strong in applicability and convenient for use.

Owner:STELIGHT INSTR CO LTD

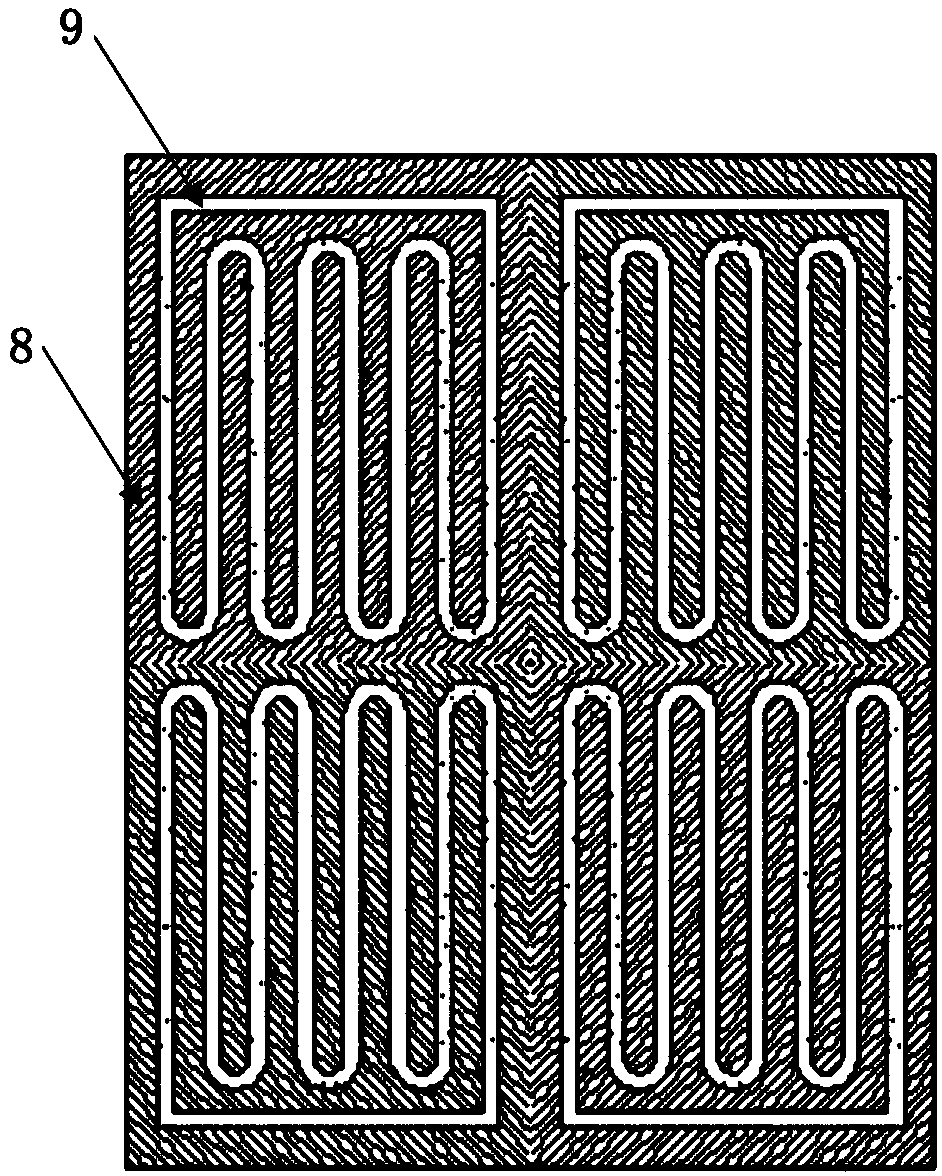

Electrostatic chuck with heater

ActiveCN101110383APrevent proliferationImprove heat uniformitySemiconductor/solid-state device manufacturingElectrical resistance and conductanceNiobium

The present invention provides an electrostatic chuck with a heater, comprising: a base made of a sintered body containing alumina; an electrode provided on the upper side of the base; and a resistance heating element embedded in the lower side of the base, the above-mentioned The base includes a dielectric layer from the electrodes to the upper surface of the base and a support member from the electrodes to the lower surface of the base. This electrostatic chuck with heater is characterized in that the carbon content in the dielectric layer is 100 ppm or less, the carbon content in the support member is 0.03 to 0.25 wt %, and the resistance heating element is formed in a coil shape and its main component is niobium. .

Owner:NGK INSULATORS LTD

High-enthalpy phase-change silicone pad and preparation method thereof

ActiveCN109705804AWith resistance to cold and heat shockImprove sealingNon-macromolecular adhesive additivesMacromolecular adhesive additivesParaffin waxFire retardant

The invention discloses a high-enthalpy phase-change silicone pad and a preparation method thereof. The silicone pad includes, by mass, vinyl silicone oil 10-25%, paraffin phase-change microcapsules 50-85%, a crosslinker 0.5-5%, a flame retardant 5-15%, a binder 0.5-4%, a diluent 2-6%, a platinum catalyst 0.01-0.04%, and an inhibitor 0.005-0.02%; all the components add to 100% by mass. The silicone pad has a wide phase change range of 25-70 DEG C, is high in phase-change enthalpy of 100-140 J / g, has excellent flexibility and adhesion force, and certain flame-retarding level and insulation effect. The phase-change material has great sealability, can resist cold and hot impact, and is long in service life.

Owner:深圳航美新材料科技有限公司

Blast deflector

ActiveCN107585321AFacilitated DiffusionFast thermal responseNoise reduction installationsHoneycombCell space

The invention discloses a blast deflector. The blast deflector comprises a thermal diffusion layer, a structure layer and a cooling layer, wherein the thermal diffusion layer comprises one or more thermal diffusion modules; each thermal diffusion module comprises a closed circuit pulsating heat pipe and solid-liquid phase transformation materials; the structure layer adopts a lattice sandwich structure, and comprises an upper panel, a lower panel, basic cells and solid-liquid phase transformation materials; the cooling layer comprises a seawater cooling plate and a seawater transporting pump;the seawater cooling plate comprises a water inlet, a water outlet, a water diversion tank, a water collecting tank and a honeycomb type fractal flow channel network; the closed circuit pulsating heatpipes are arranged on the thermal diffusion layer in a module manner; when the center of the surface of the blast deflector is impacted by fuel gas, the characteristics that when any part of the closed circuit pulsating heat pipe is heated, the heat transfer characteristics are hardly changed, the thermal responding speed is high and the heat transfer capacity is excellent are utilized, the solid-liquid phase transformation materials stuffed in the space of a non-closed circuit pulsating heat pipe on the thermal diffusion layer and a non-basic-cell space on the structure layer are used for absorbing and storing massive melting heat in a phase transformation manner, so that heat quantity on the thermal diffusion layer is rapidly diffused, and good soaking performance is realized.

Owner:SOUTHEAST UNIV

Method for preparing ZrN-Al2O3-ZrO2 multiphase ceramic material by aluminum nitride-zirconium dioxide reactive sintering

The invention relates to a method for preparing a ZrN-aluminum nitride2O3-ZrO2 multiphase ceramic material by aluminum nitride-zirconium dioxide reactive sintering, belonging to the field of high-temperature ceramic materials. The multiphase material is prepared from the following raw materials in percentage by mass: 5-40% of aluminum nitride fine powder, 60-95% of monoclinic zirconium dioxide fine powder, and 1-1.5% of sintering accelerator (CaF2 or ZrB2 or MoSi2) fine powder (additional). The method comprises the following steps: dryly mixing the raw materials, adding anhydrous ethanol, and wetly mixing; removing ethanol from the slurry, adding a rosin ethanol solution, stirring, and standing in a sealed environment to obtain a blank; and molding the blank, drying, and keeping the temperature at 1400 DEG C for 6-8 hours in a dynamic nitrogen atmosphere to obtain the ZrN-Al2O3-ZrO2 multiphase ceramic material. The multiphase material has the advantages of high soaking capacity, small thermal expansion coefficient and favorable thermal shock resistance, is assisted by a microcrack toughening mechanism, and can provide a novel high-temperature ceramic material for the fields of steel and non-ferrous metallurgy, construction materials, electronics and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

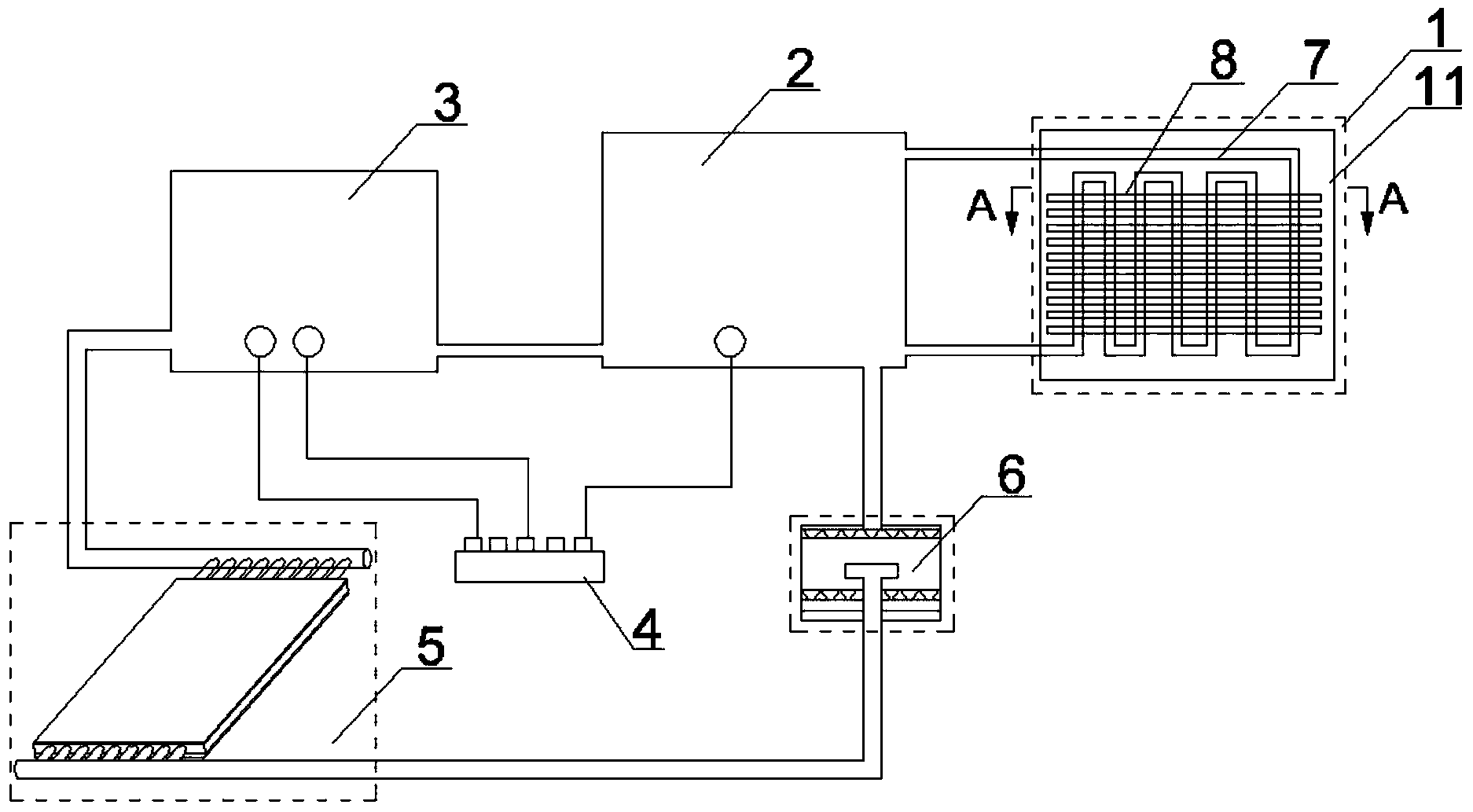

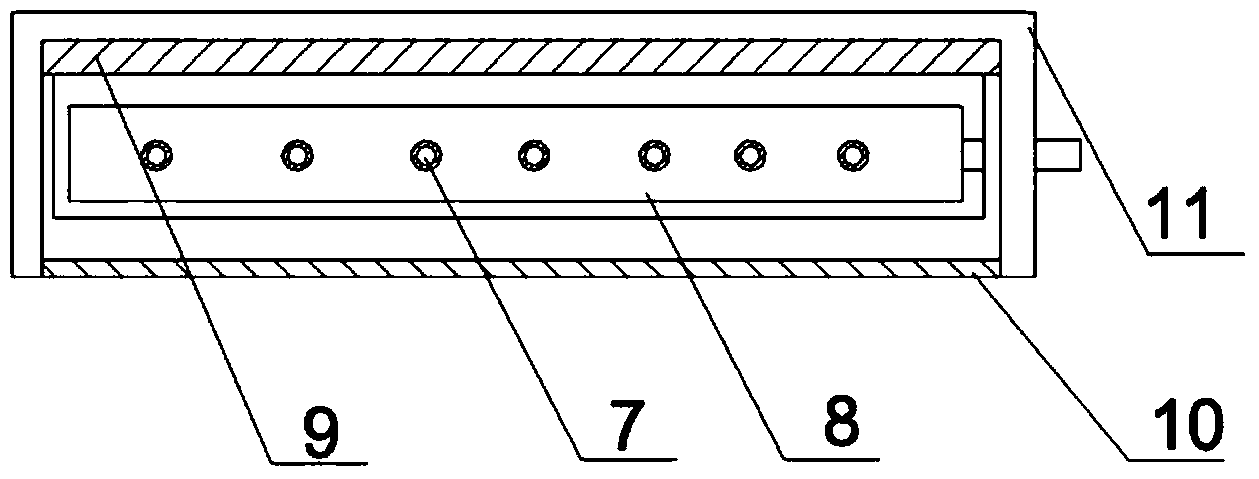

Solar energy floor heating system based on heat conduction graphite film

InactiveCN104180427AHeating up fastEvenly heatedLighting and heating apparatusSpace heating and ventilation detailsInsulation layerThermal insulation

The invention discloses a solar energy floor heating system based on a heat conduction graphite film. The solar energy floor heating system based on the heat conduction graphite film comprises a solar thermal collector, a water storage tank with a thermal insulation layer, a concurrent heating water tank, a temperature controller, an indoor laying system and a dual filter, wherein the solar thermal collector comprises a heat absorption coil pipe, a heat absorption piece, a heat insulation layer, a light transmitting cover and a box, the solar thermal collector is connected with the water storage tank with the thermal insulation layer, the indoor laying system comprises a water pipe, the heat conduction graphite film, a floor, cement mortar and a thermal insulation board, the dual filter is arranged on a backflow segment between the indoor laying system and the water storage tank with the thermal insulation layer, and the dual filter comprises an inverted cone hole, a T-shaped pipe, a filter screen and a filtration cotton layer. The solar energy floor heating system based on the heat conduction graphite film uses solar energy as a heat source, saves energy and protects environment, can be used in both villages and cities, uses the heat conduction graphite film as a soaking layer, is simple and easy to implement, and good in soaking effect, reduces floor deformation rate, and thereby prolongs service life of a floor. The purpose of filtering water at low cost is achieved by using the solar energy floor heating system based on the heat conduction graphite film, which is simple in structure.

Owner:韩巧

Holder for semiconductor production system

InactiveCN1557015AReduce the temperatureIncrease manufacturing costSemiconductor/solid-state device manufacturingHot plates heating arrangementsReactive gasEngineering

Owner:SUMITOMO ELECTRIC IND LTD

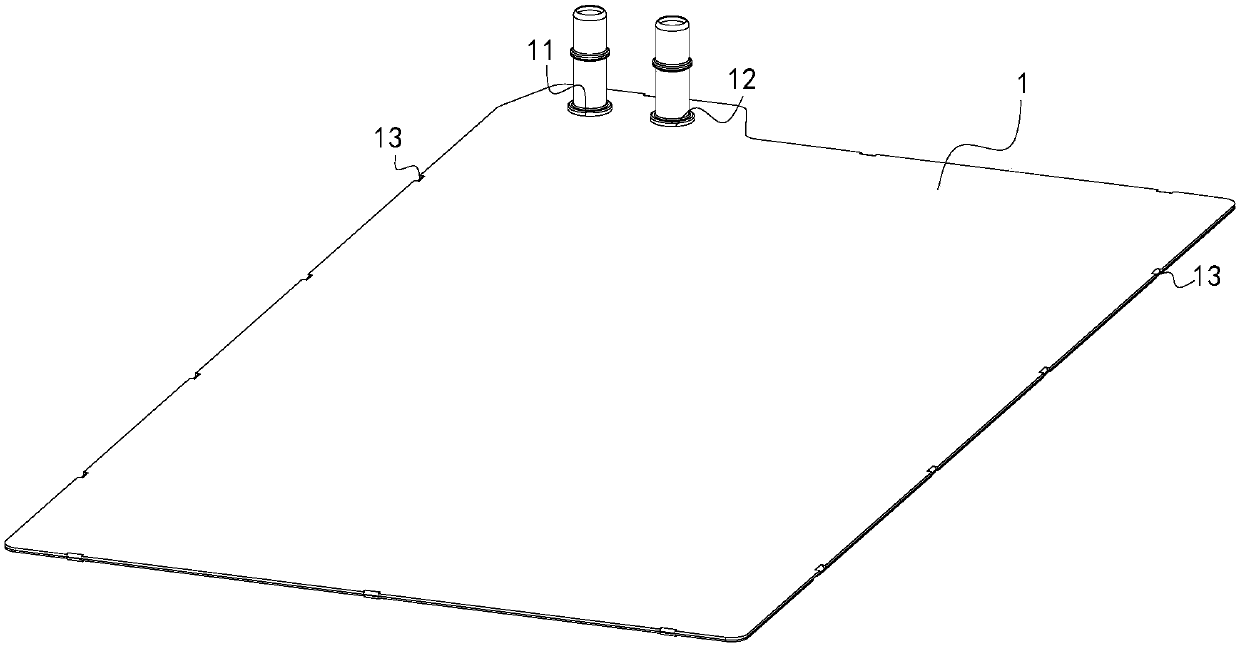

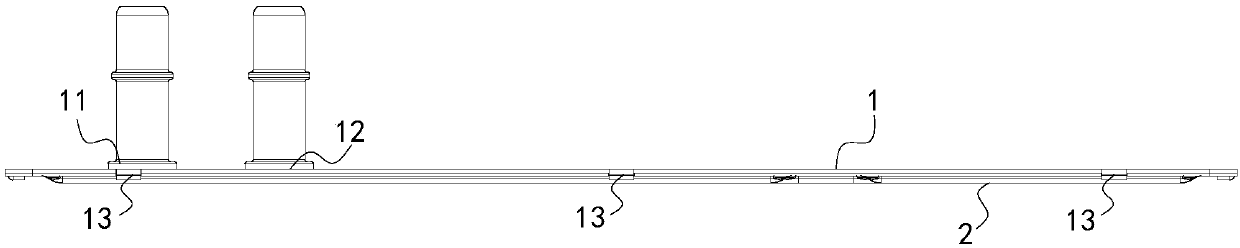

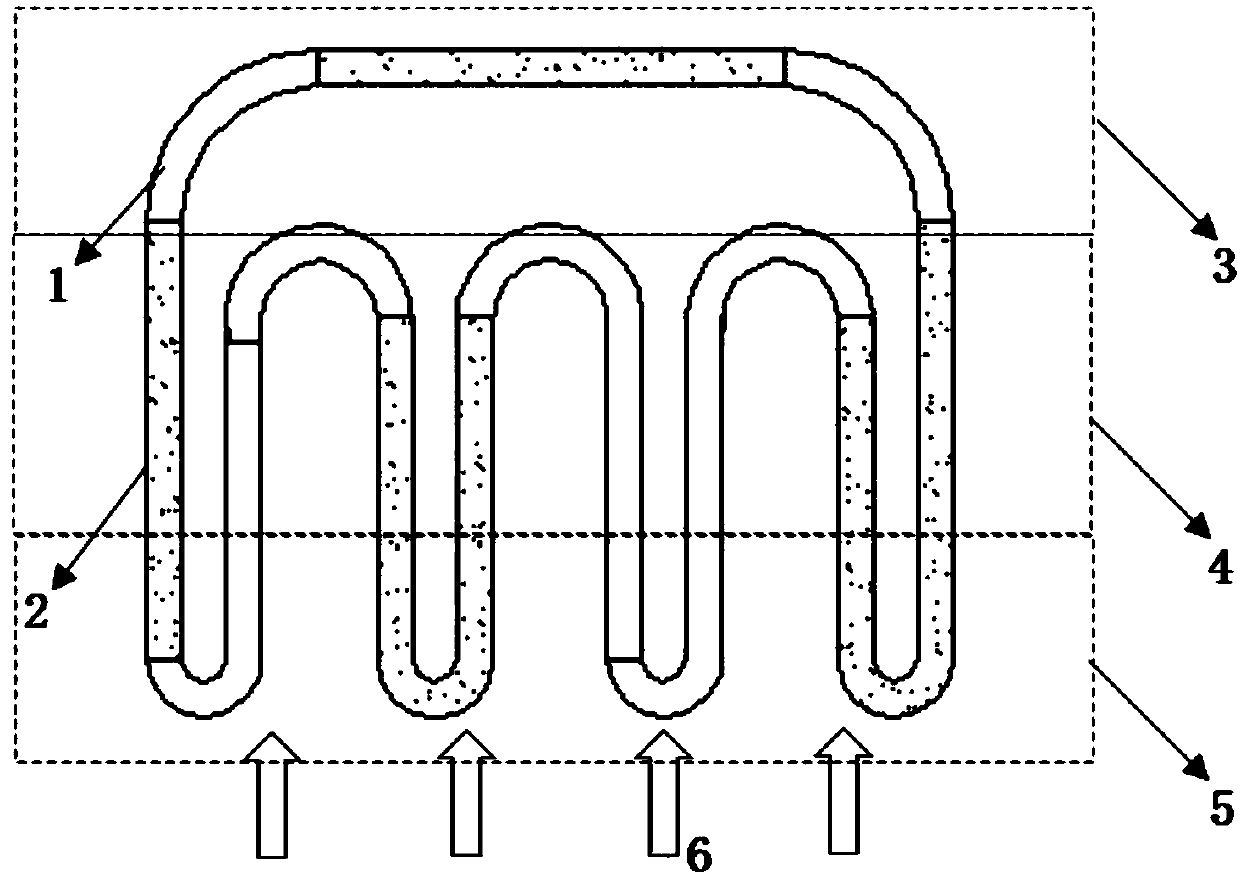

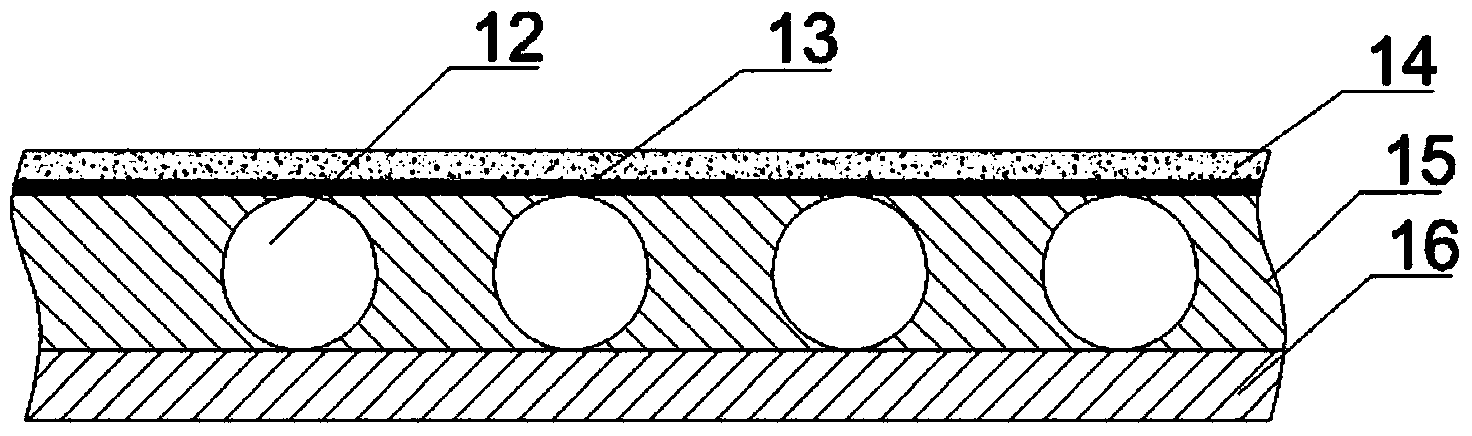

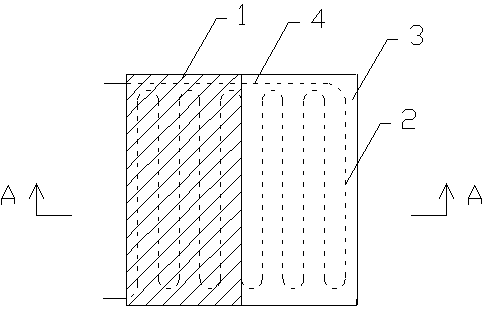

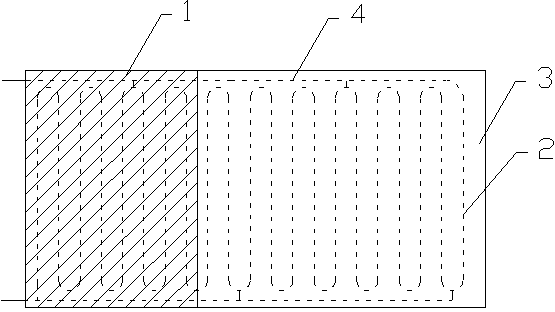

Carbon fiber heating ground mattress

InactiveCN103269530AImprove heat uniformityGood radiation protectionLighting and heating apparatusElectric heating systemFiberCarbon fibers

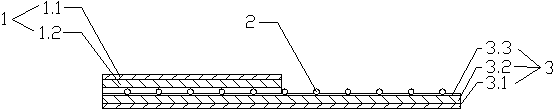

The invention relates to a carbon fiber heating ground mattress which is characterized by comprising an aluminum foil glass fabric layer (1), carbon fiber heating wires (2), an aluminum foil glass fabric adhesive tape layer (3) and two inner conductive wires (4), the aluminum foil glass fabric layer (1), the two inner conductive wires (4) and the aluminum foil glass fabric adhesive tape layer (3) are arranged from top to bottom in sequence, a single carbon fiber heating wire (2) or multiple carbon fiber heating wires (2) connected in parallel are connected between the two inner conductive wires (4), and the outer ends of the inner conductive wires (4) stretch out of the aluminum foil glass fabric layer (1) and the aluminum foil glass fabric adhesive tape layer (3). The carbon fiber heating ground mattress has the advantages of being good in even heating performance, good in radiation protection performance, high-temperature resistant, long in service life, dual-purpose in a dry paving mode and a wet paving mode, and especially convenient to mount and pave.

Owner:叶卫东

A battery module heating device and a battery module

PendingCN109256510AMaximize absorptionIncrease profitSecondary cellsCell component detailsEngineeringCell contact

The invention relates to a battery module heating device and a battery module. The heating device comprises two connecting plates and heating elements. The two connecting plates are arranged oppositeto each other. A mounting gap is reserved between the two connecting plates. The heating elements are arranged in the mounting gap and are fixedly connected with the two connecting plates respectively. The heating device of the invention, A heating element is arranged between the two connecting plates. When the heating device is used in the battery module, the two connecting plates can be heated by the heating element respectively, and the cell contacting with the connecting plate can be heated, so that the heat energy generated by the heating element can be absorbed by the cell maximally, andthe utilization rate of energy can be improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

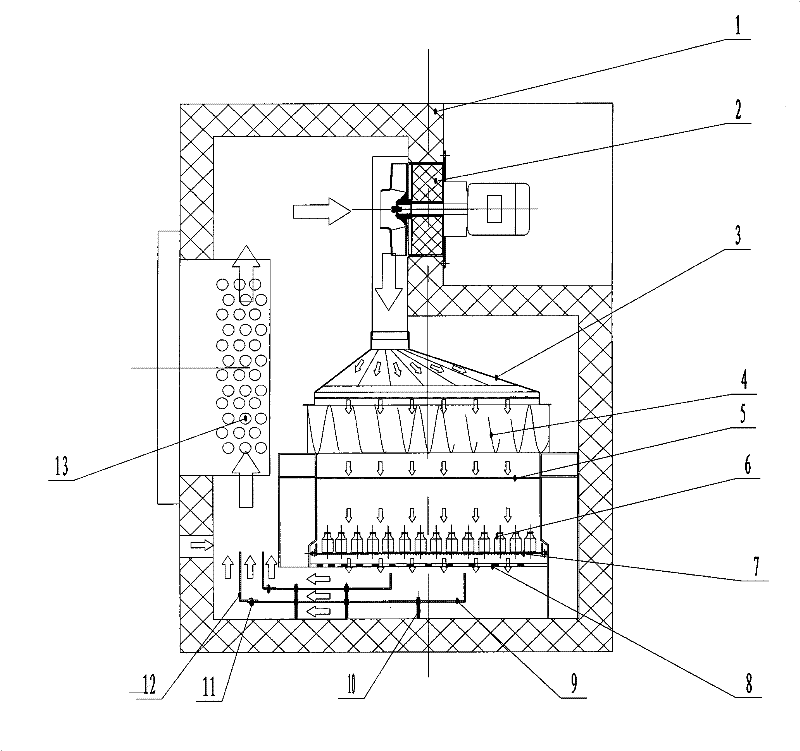

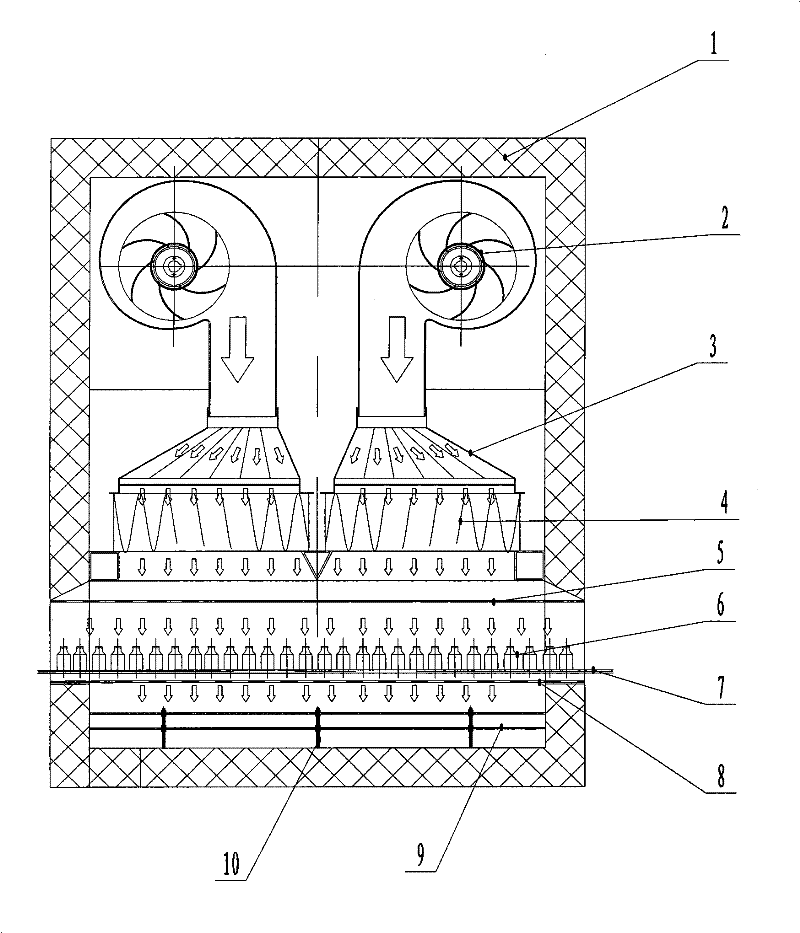

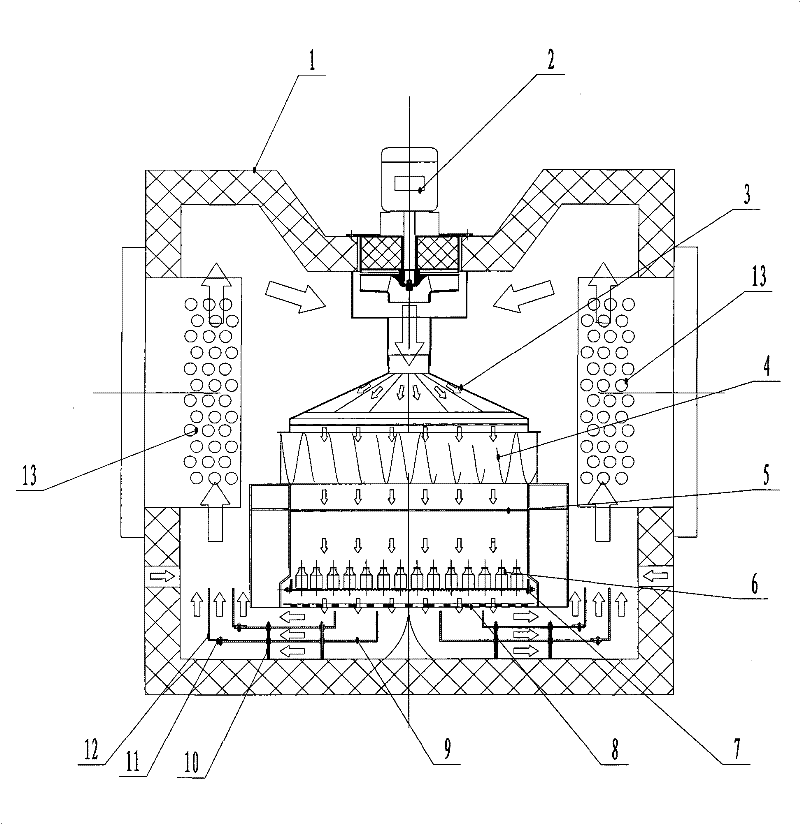

Flow equalizing apparatus used in heated air circulation sterilization dryer for heating cavity

ActiveCN101548787BImprove efficiencyQuality improvementFood preservationDrying gas arrangementsAir heaterWaste management

Owner:TRUKING TECH LTD

Method for preparing ZrN-Al2O3-ZrO2 multiphase ceramic material by Al-ZrO2-N2 reactive sintering

The invention relates to a method for preparing a ZrN-Al2O3-ZrO2 multiphase ceramic material by Al-ZrO2-N2 reactive sintering, belonging to the field of high-temperature ceramic materials. The multiphase material is prepared from the following raw materials in percentage by mass: 5-30% of metal aluminum fine powder, 70-95% of monoclinic zirconium dioxide fine powder, and 1-1.5% of sintering accelerator (CaF2 or ZrB2 or MoSi2) fine powder (additional). The method comprises the following steps: dryly mixing the raw materials, adding anhydrous ethanol, and wetly mixing; removing ethanol from the slurry, adding a rosin ethanol solution, stirring, and standing in a sealed environment to obtain a blank; and molding the blank, drying, and keeping the temperature at 1400 DEG C for 6-8 hours in a dynamic nitrogen atmosphere to obtain the ZrN-Al2O3-ZrO2 multiphase ceramic material. The multiphase material has the advantages of high soaking capacity, small thermal expansion coefficient and favorable thermal shock resistance, and can provide a novel high-temperature ceramic material for the fields of steel and non-ferrous metallurgy, construction materials, electronics and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com