Patents

Literature

800 results about "Glass fabric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixture containing fluororesin and prepreg prepared from same, and copper clad laminate

ActiveCN106854330AEasy to operateMild preparation conditionsSynthetic resin layered productsGlass/slag layered productsPolymer scienceResin matrix

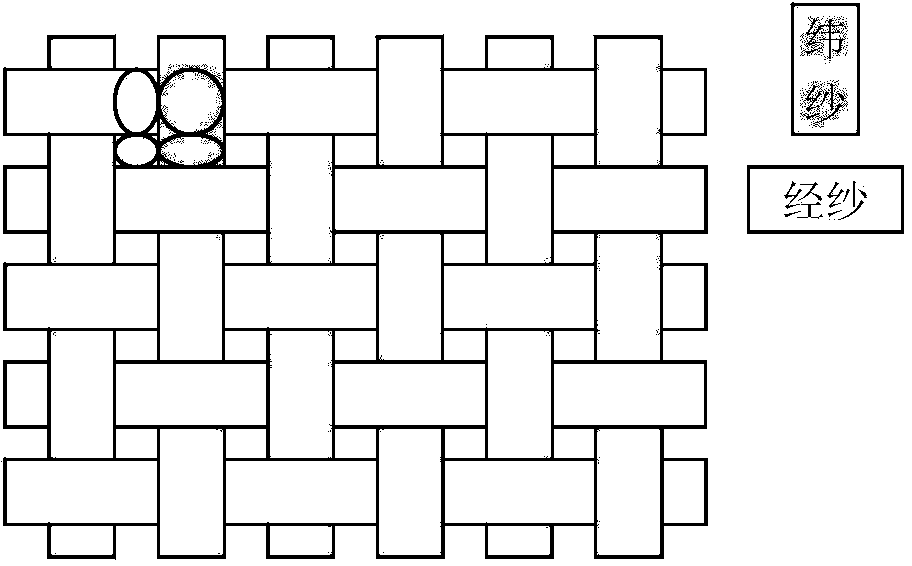

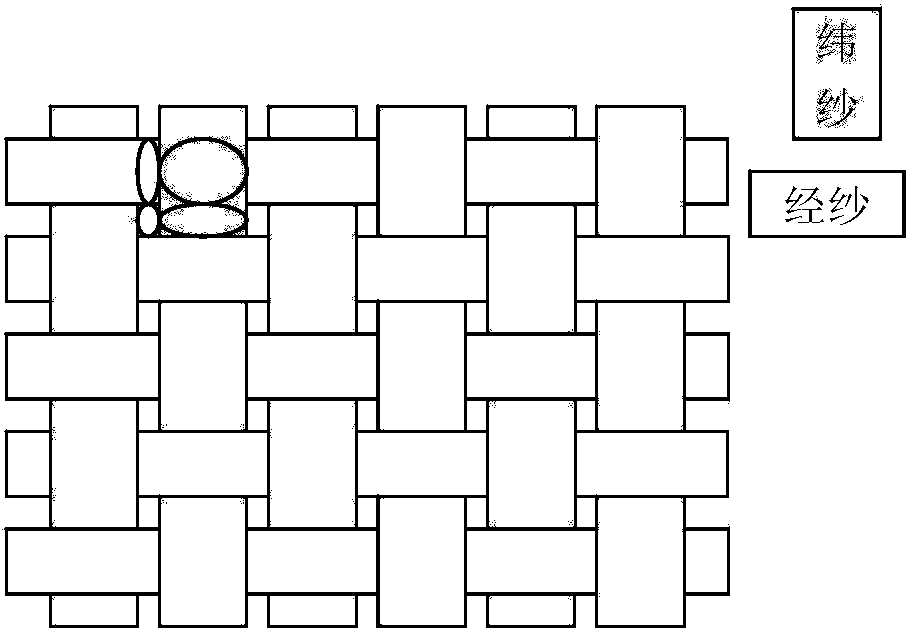

The invention specifically relates to a mixture containing fluororesin and a preparation method thereof, belonging to the field of communication materials. A prepreg prepared by impregnating a glass fabric in dispersion liquid of the mixture containing fluororesin and then carrying out drying and the like has uniform glue content, good impregnation quality, strong resin adhesion, smooth surface and appropriate toughness and viscosity. The invention also relates to a high-frequency copper clad laminate prepared from the prepreg, or a film or copper foil made of the mixture containing fluororesin. The prepared copper clad laminate has good thermal-mechanical properties, excellent dielectric properties and high copper foil strength, and can meet requirements on the comprehensive properties of substrate materials in the field of high-frequency communication. According to the invention, the processing properties of traditional fluororesin are greatly improved by using fluorine-containing resin with a low melting point; and a coupling agent is cooperatively used, so interaction between an inorganic filling material and glass fabric and a resin matrix is improved, dispersibility of the inorganic filling material, processing aids and the like in the fluororesin is enhanced, and the overall performance of the copper clad laminate is made more stable.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

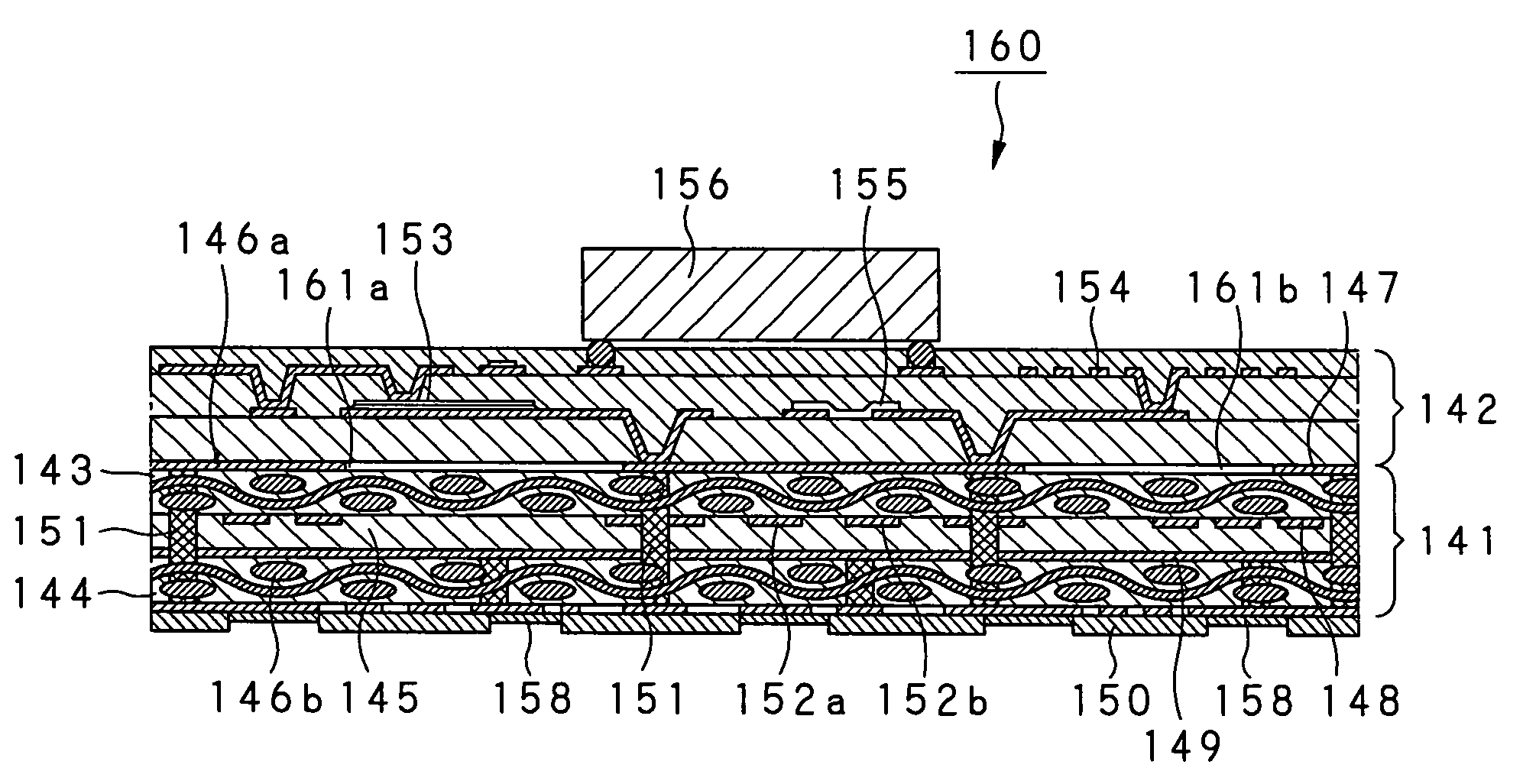

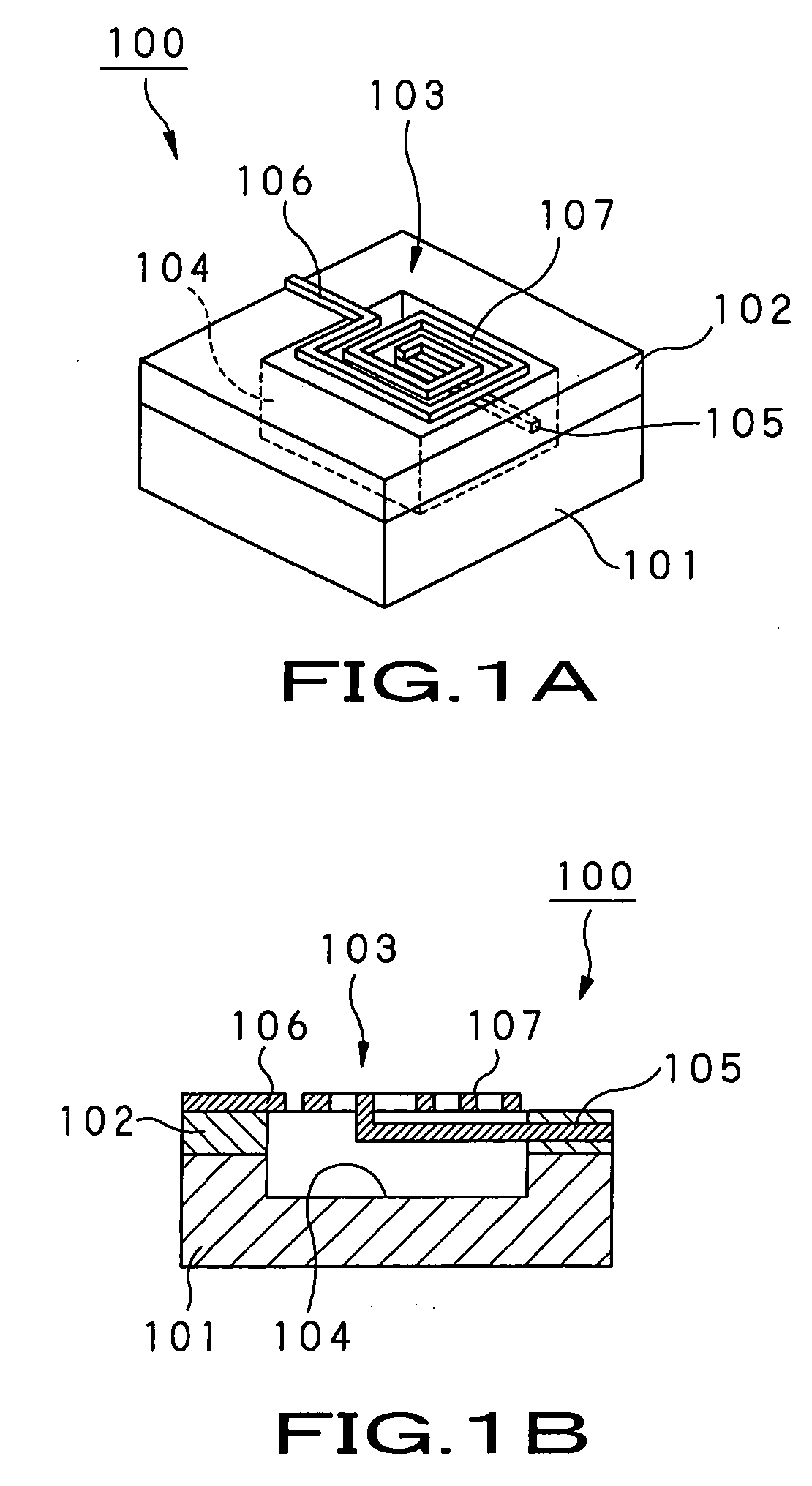

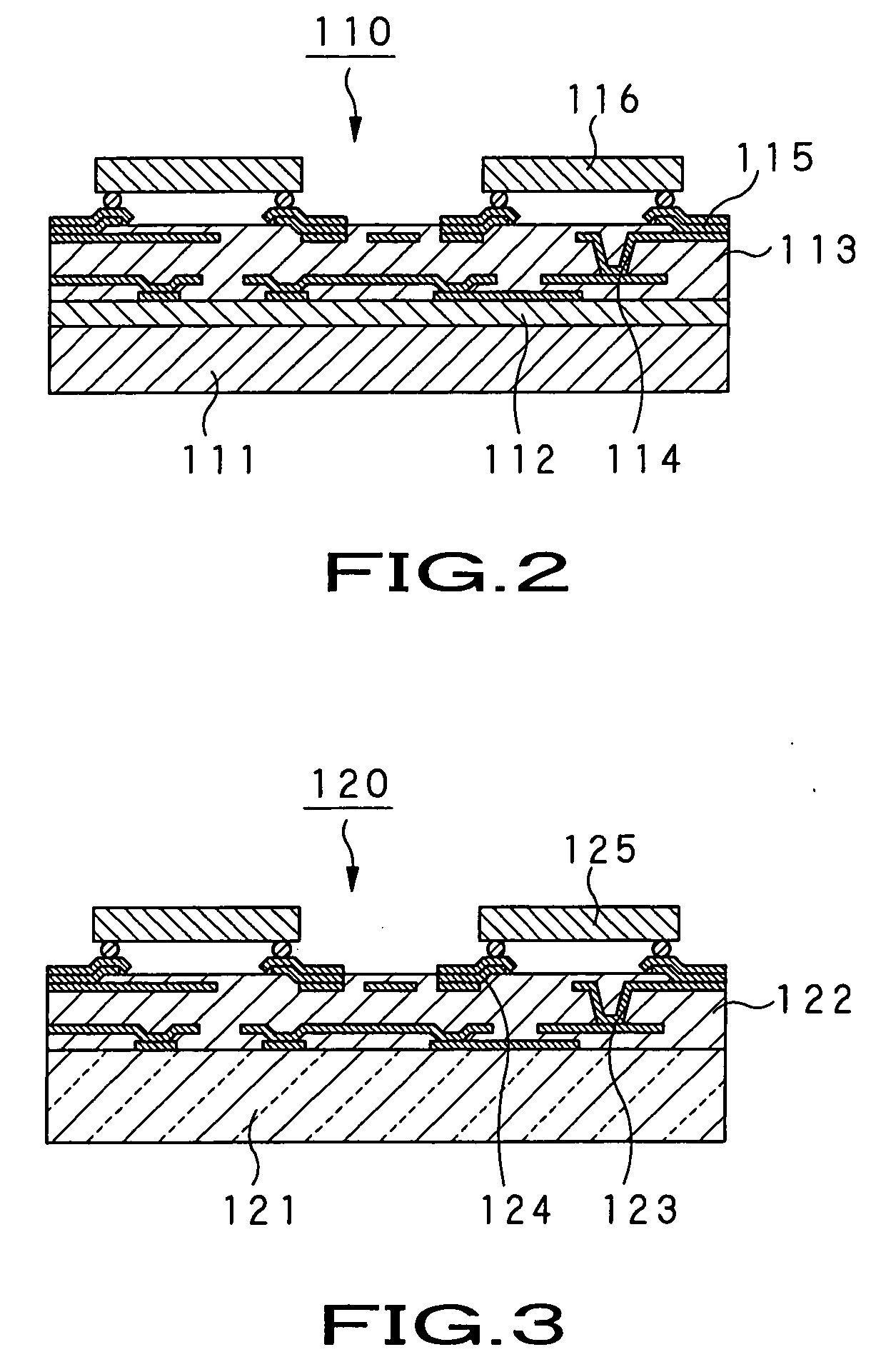

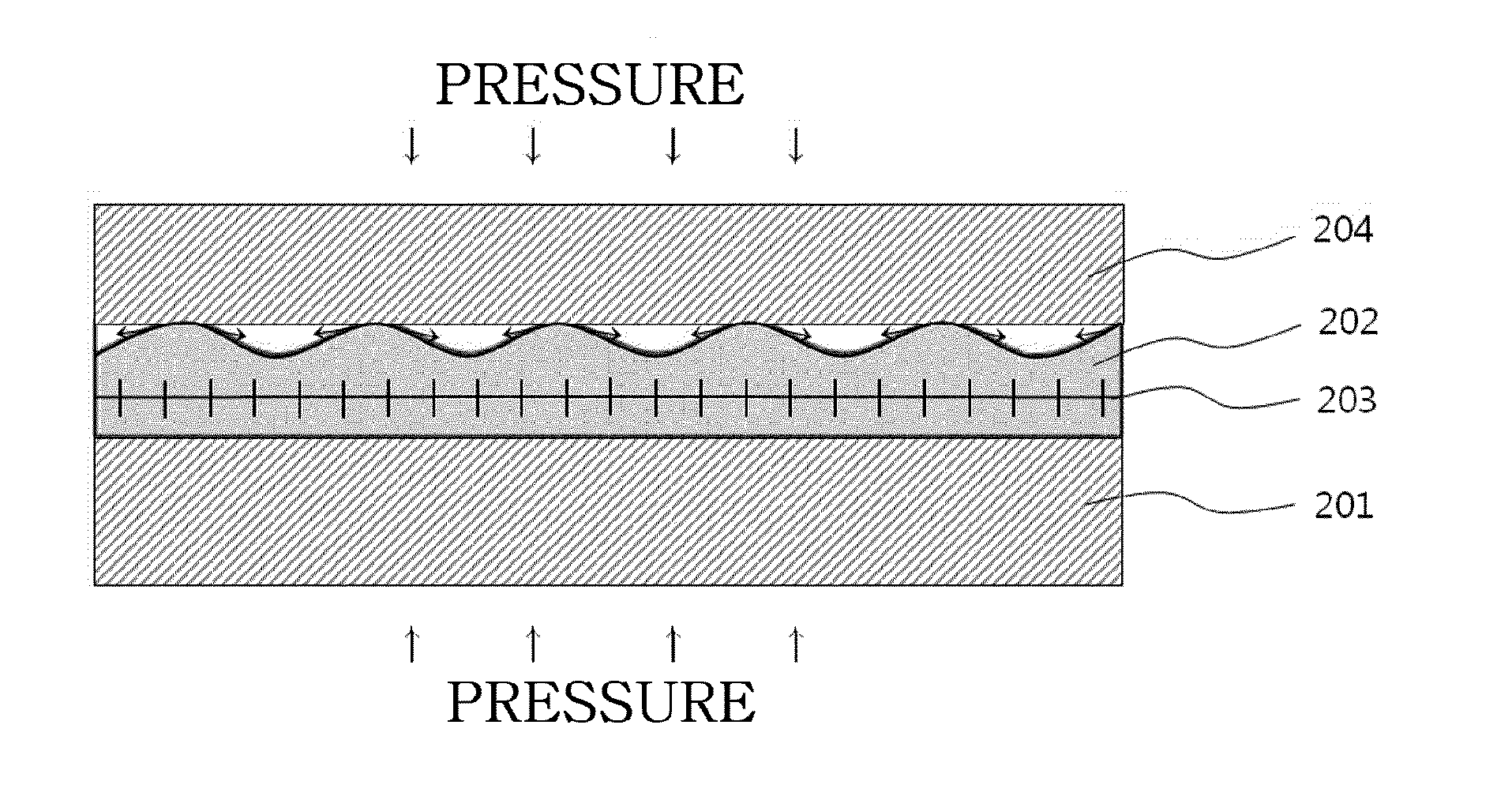

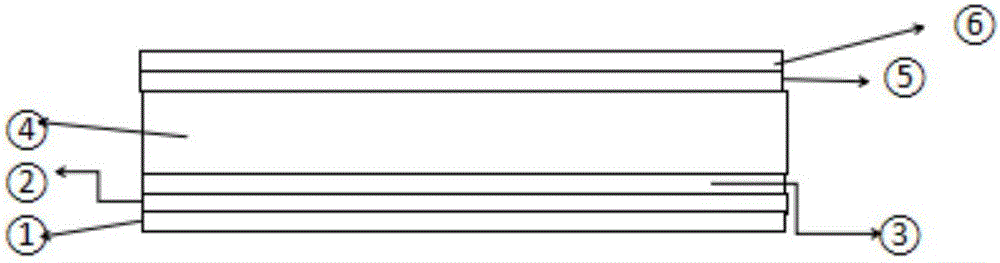

High-frequency module and its manufacturing method

InactiveUS20050146403A1Low costHigh precisionSemiconductor/solid-state device detailsHigh frequency circuit adaptationsGlass fiberEngineering

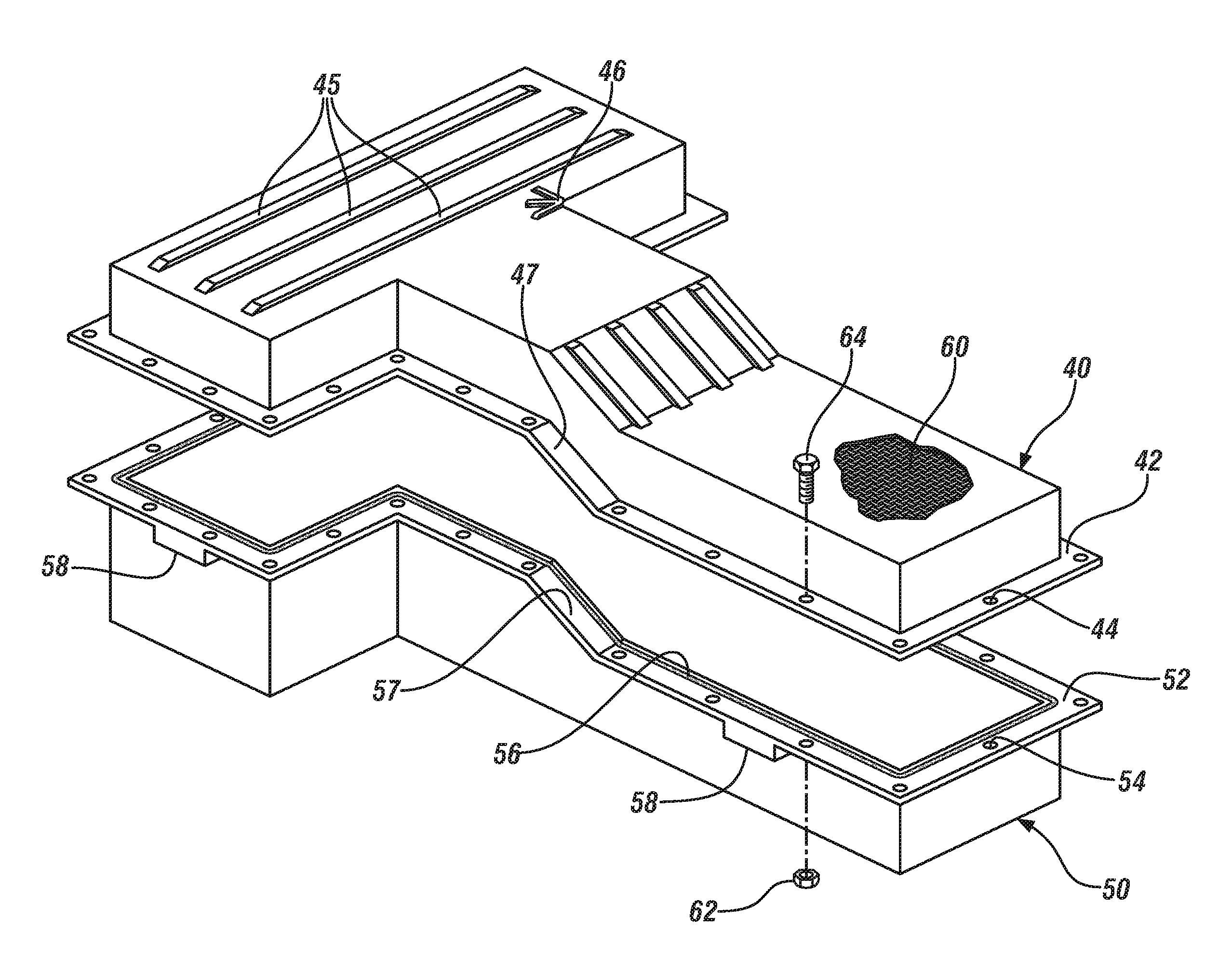

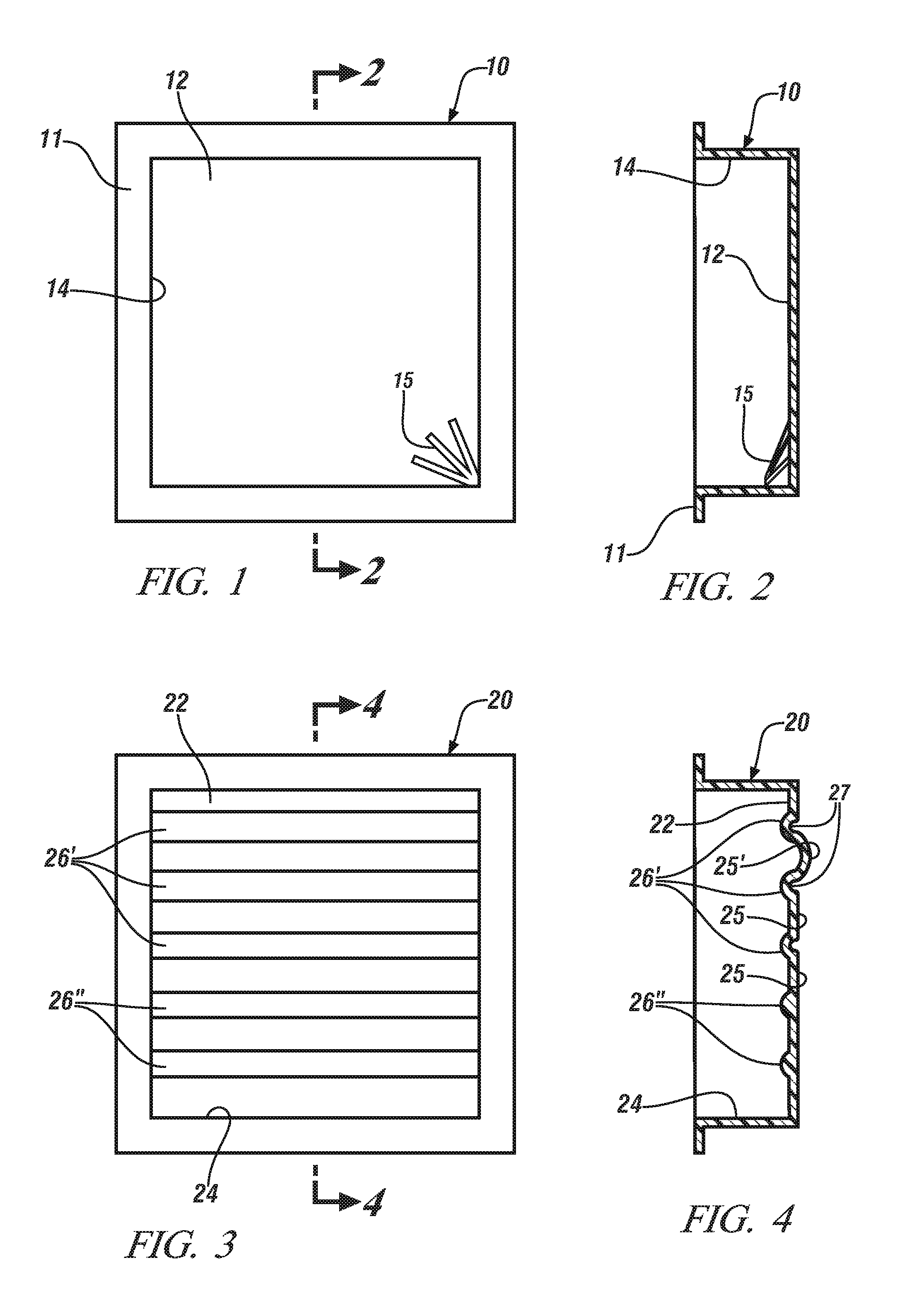

A high-frequency module having a communication function is provided which includes a base substrate block (2) formed from organic substrates (11, 12), the organic substrate (11) having wiring layers (14, 15) formed on main sides, respectively, thereof while the organic substrate (12) has wiring layers (16, 17) formed on main sides, respectively, thereof, the base substrate block (2) having a buildup surface formed by flattening an uppermost layer, and an elements block (3) formed from organic insulative layers (26, 28) formed on the buildup surface of the base substrate block (2) and in which a plurality of conductive parts (19, 20, 32) forming passive elements and distributed parameter elements, which transmit a high-frequency signal, are formed along with wiring layers (27, 29). The conductive parts (19, 20, 32) in the elements block (3) are formed correspondingly to portions of the organic substrate (11) in the base substrate block (2) where no woven glass fabric is laid.

Owner:SONY CORP

Circuit substrate and preparation method thereof

ActiveCN103755989ALow dielectric constantSolve the signal delay problemPrinted circuit liquid treatmentFilm/foil adhesivesGlass fiberSignal delay

The invention provides a preparation method of a bonding sheet forming a circuit substrate. The method comprises a step of pretreating a glass fabric by use of a pretreatment glue solution of which the dielectric constant (Dk) is the same with or close to the Dk value of the adopted glass fabric. The invention also provides a bonding sheet and a circuit substrate prepared by the method. The preparation method of the circuit substrate provided by the invention does not need equipment transformation and adjustment, the cost is relatively low, the difference of the dielectric constant of the prepared circuit substrate in the longitudinal direction and latitudinal direction is less, and the problem of signal delay can be effectively solved.

Owner:GUANGDONG SHENGYI SCI TECH

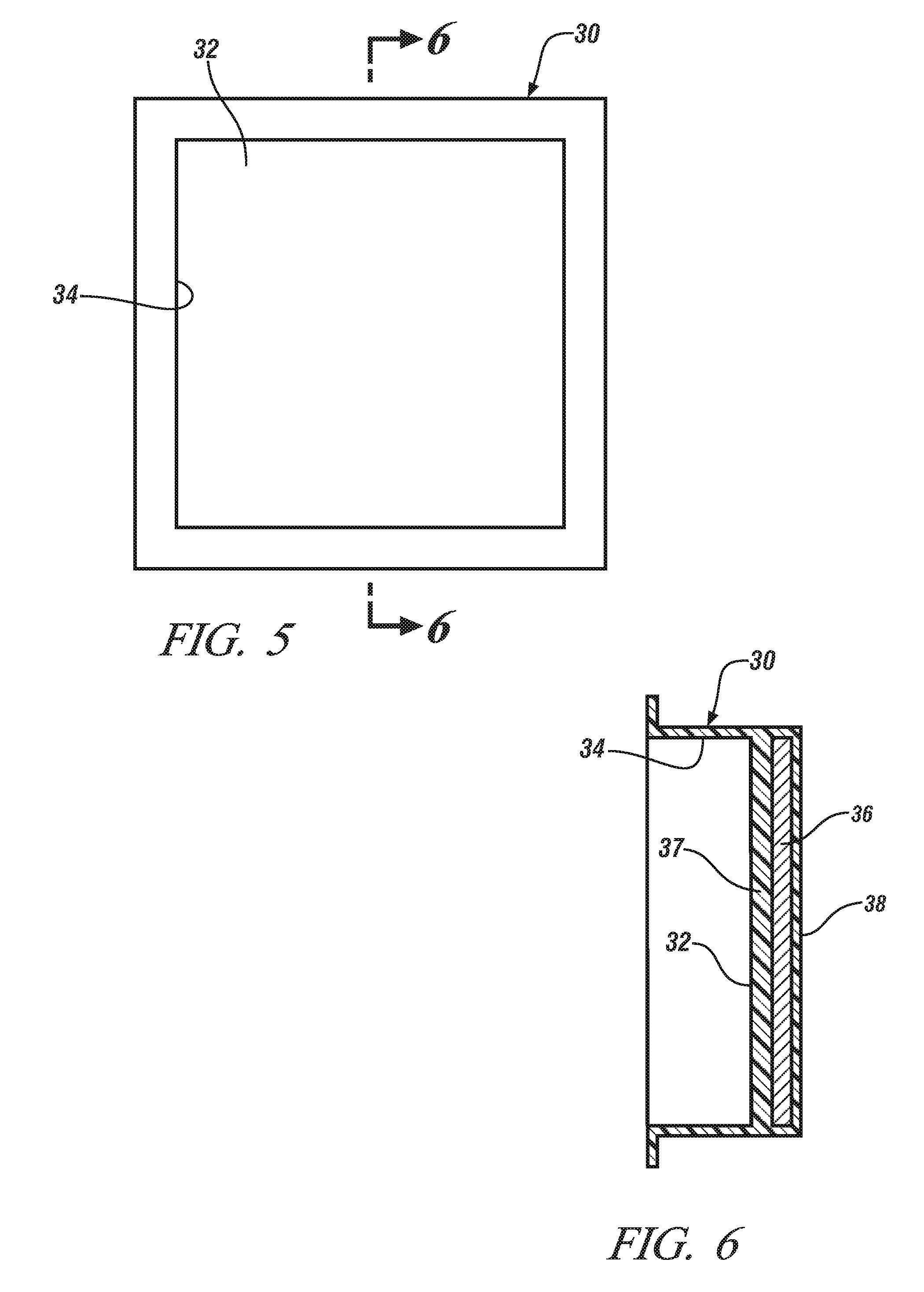

Fabric composite support or enclosure for an automotive battery pack

ActiveUS9331321B2Increase stiffnessHigh strengthSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsAutomotive batteryEngineering

A battery enclosure comprising a support and a cover fabricated from a thermoset or thermoplastic polymer reinforced by at least a woven fabric reinforcement is described. In an embodiment the reinforcement is a woven glass fabric.

Owner:GM GLOBAL TECH OPERATIONS LLC

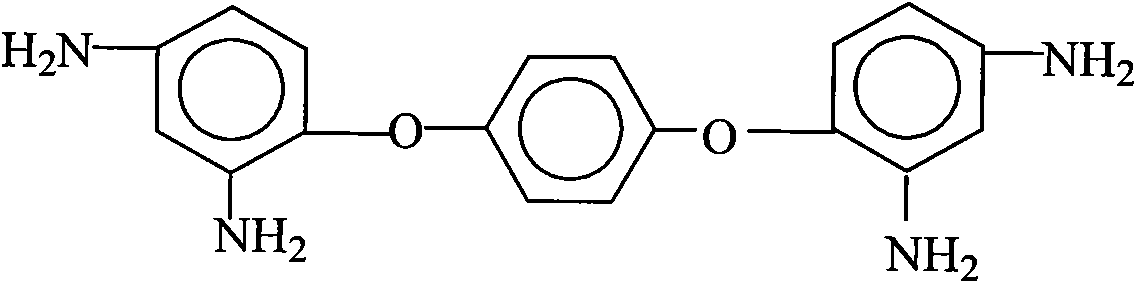

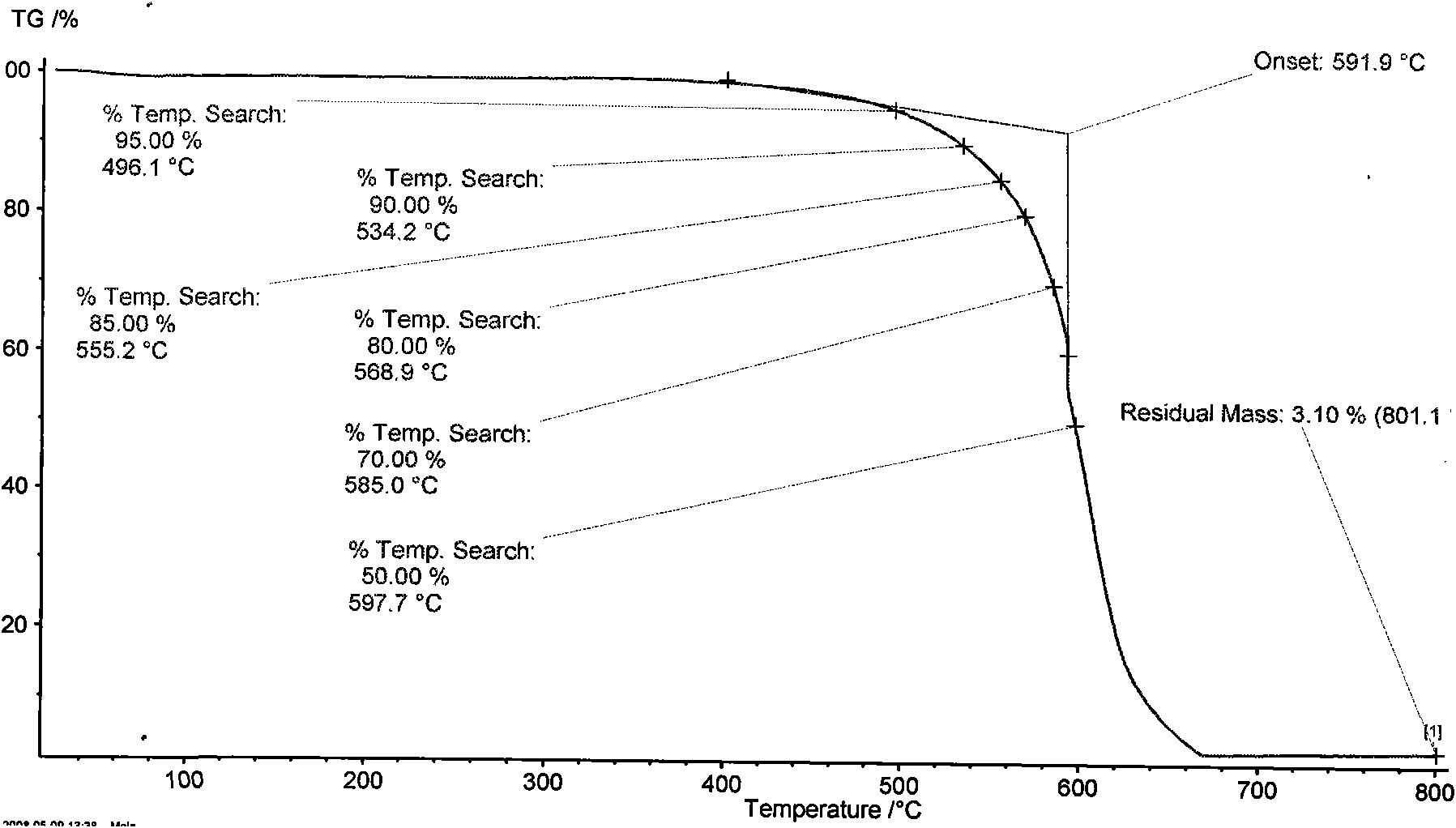

Preparation method of high-temperature resistant polyimide glass fabric laminated board

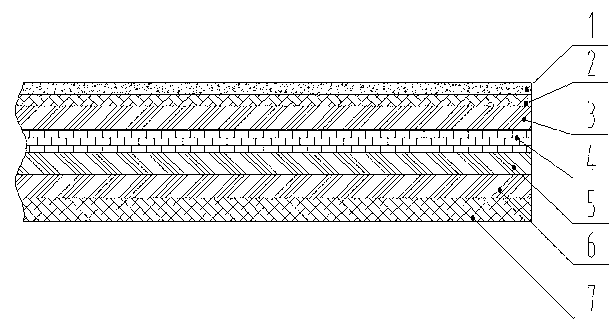

The invention relates to a preparation method of a high-temperature resistant polyimide glass fabric laminated board, which comprises the following steps: (1) adding 1,4-bis(2,4-diaminophenoxy) benzene and maleic anhydride to a non-proton organic solvent with strong polarity, then adding aromatic diamine monomer, aromatic dibasic anhydride and initiator, and stirring for dissolving to obtain a component A; (2) adding 1,4-bis(2,4-diaminophenoxy) benzene and maleic anhydride to a non-proton organic solvent with strong polarity, stirring and reacting for 2 hours to obtain a component B; and (3) mixing the component A and the component B evenly to obtain a polyimide precursor resin solution, impregnating the glass fabric in the resin solution, and obtaining the high-temperature resistant polyimide glass fabric laminated board after preliminary drying semi-curing and high-temperature press thermo-curing. The high-temperature resistant polyimide glass fabric laminated board prepared in the invention has excellent heat resistance, can be applied to high-temperature resistant electro-insulating material and high-temperature resistant structural part material of aerospace vehicles, and has wide application prospects.

Owner:DONGHUA UNIV +1

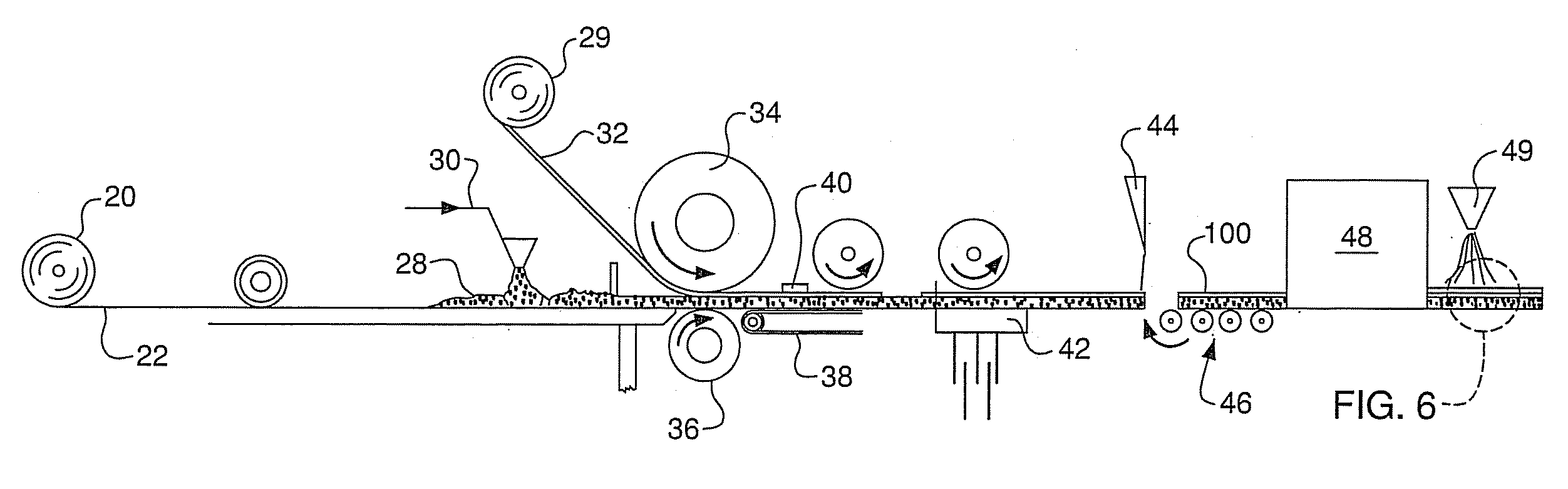

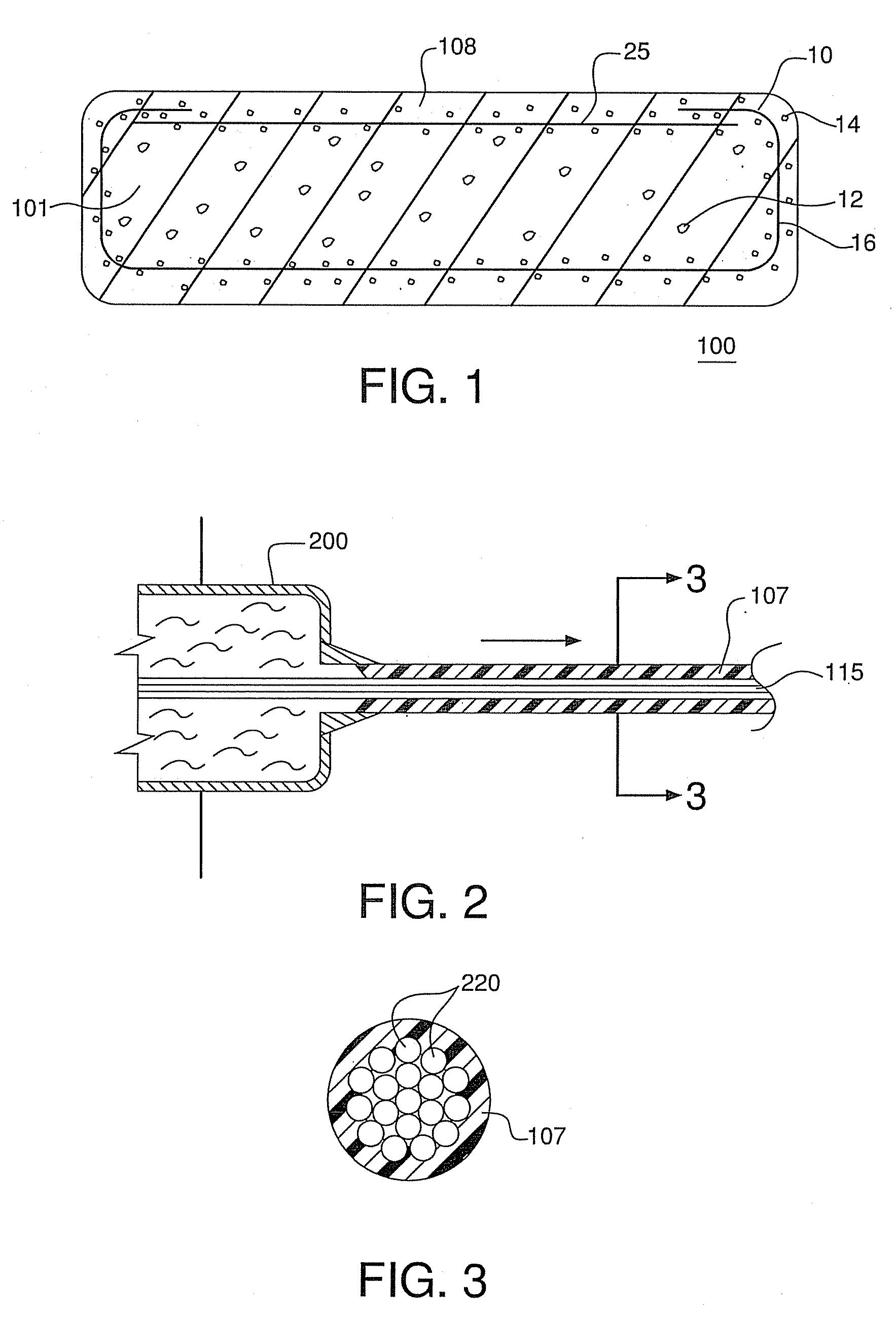

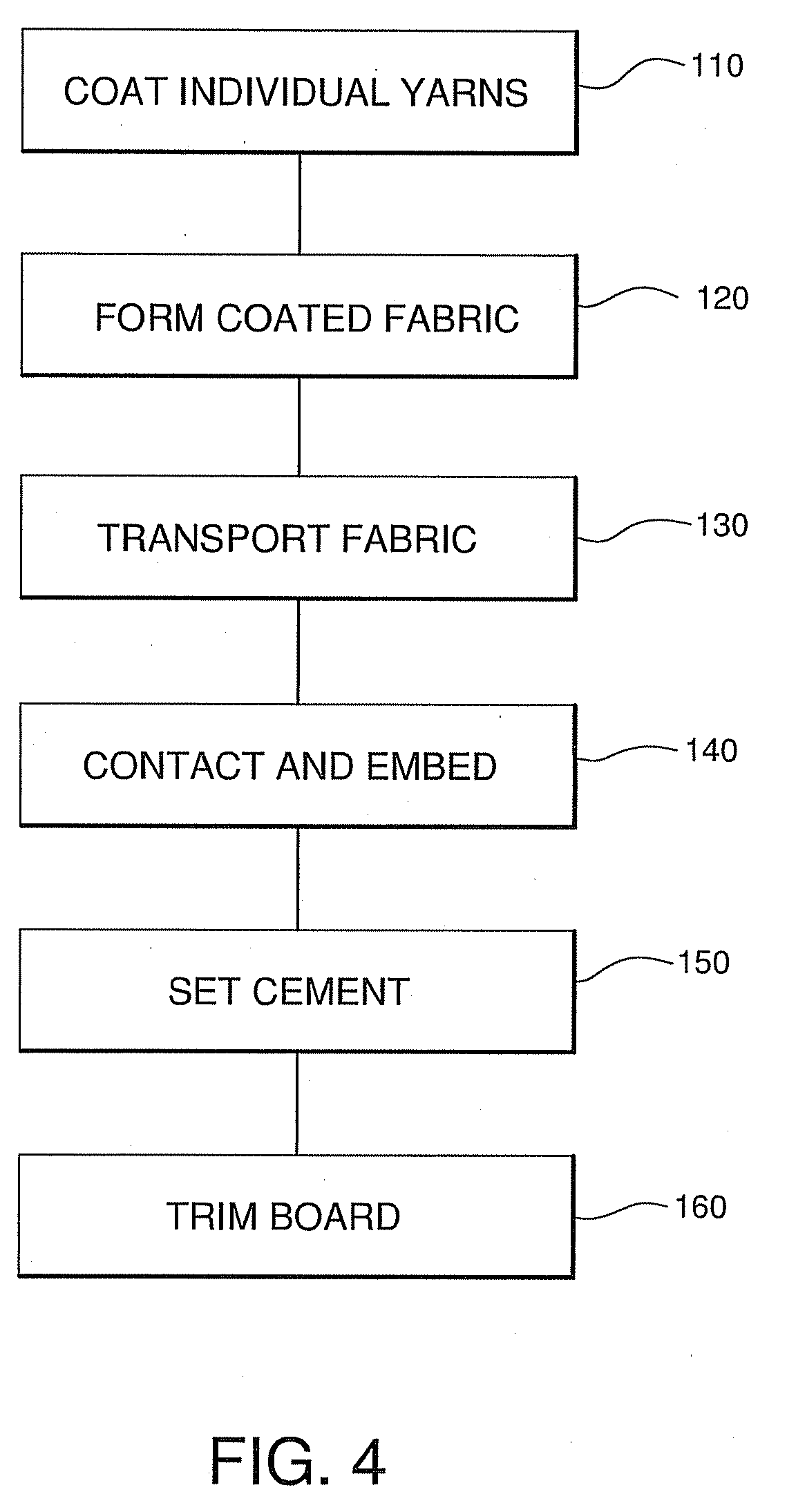

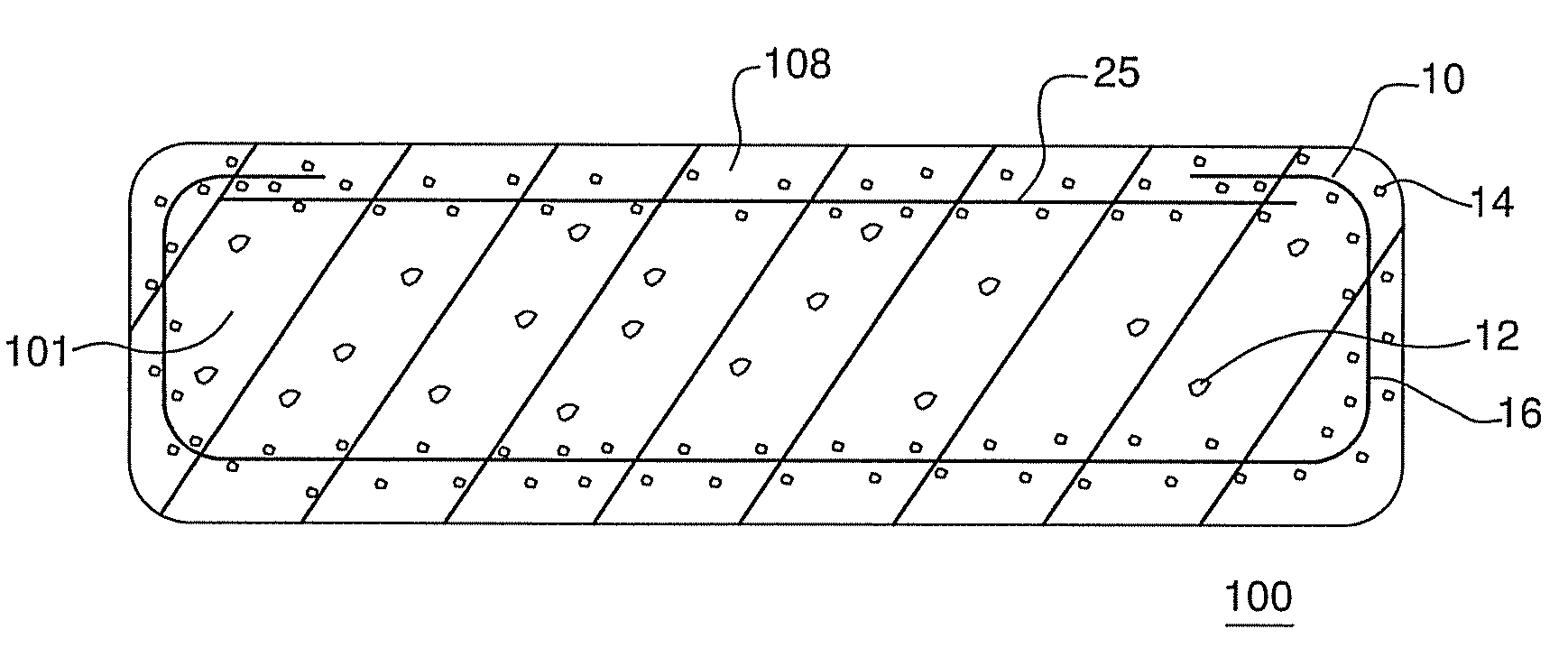

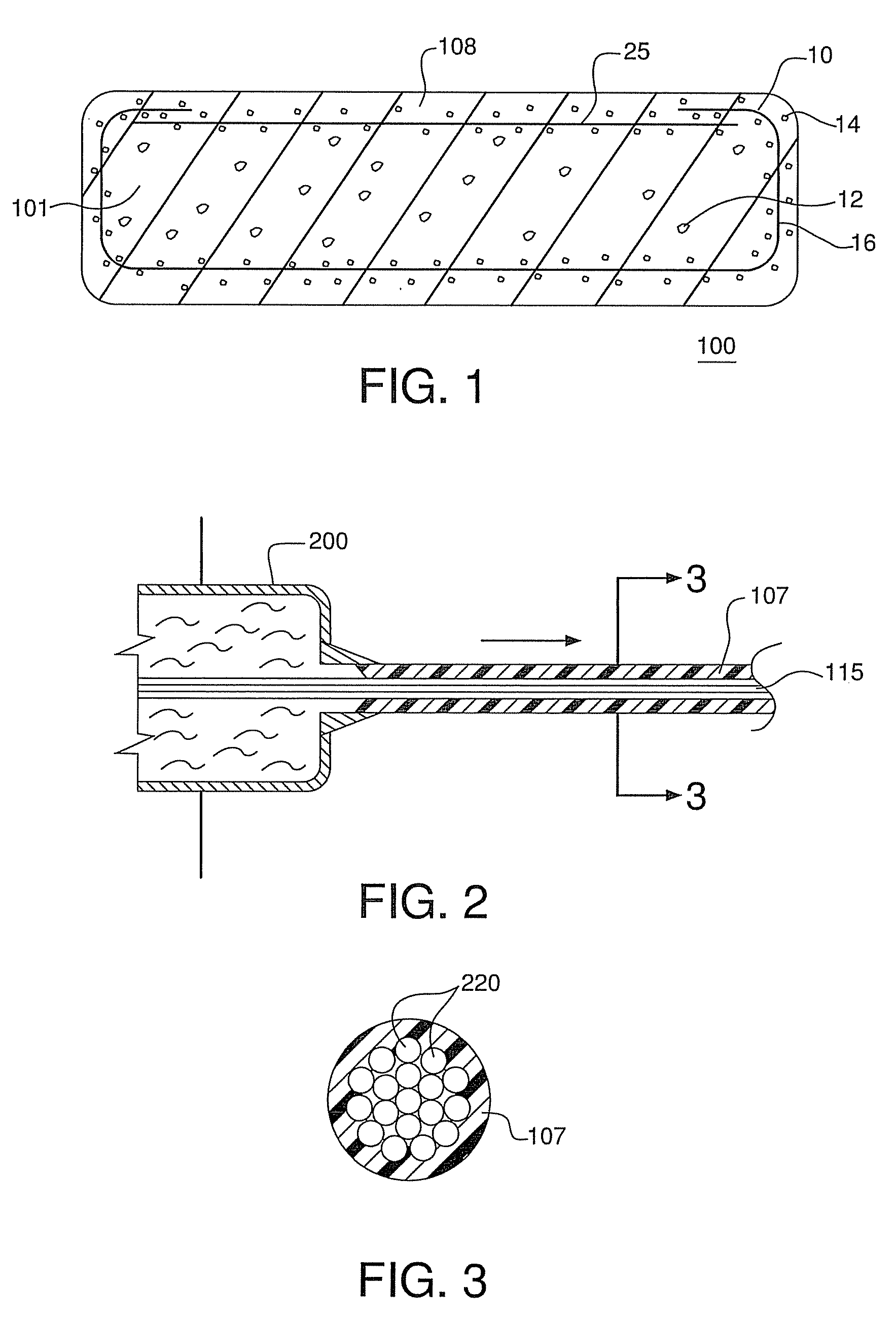

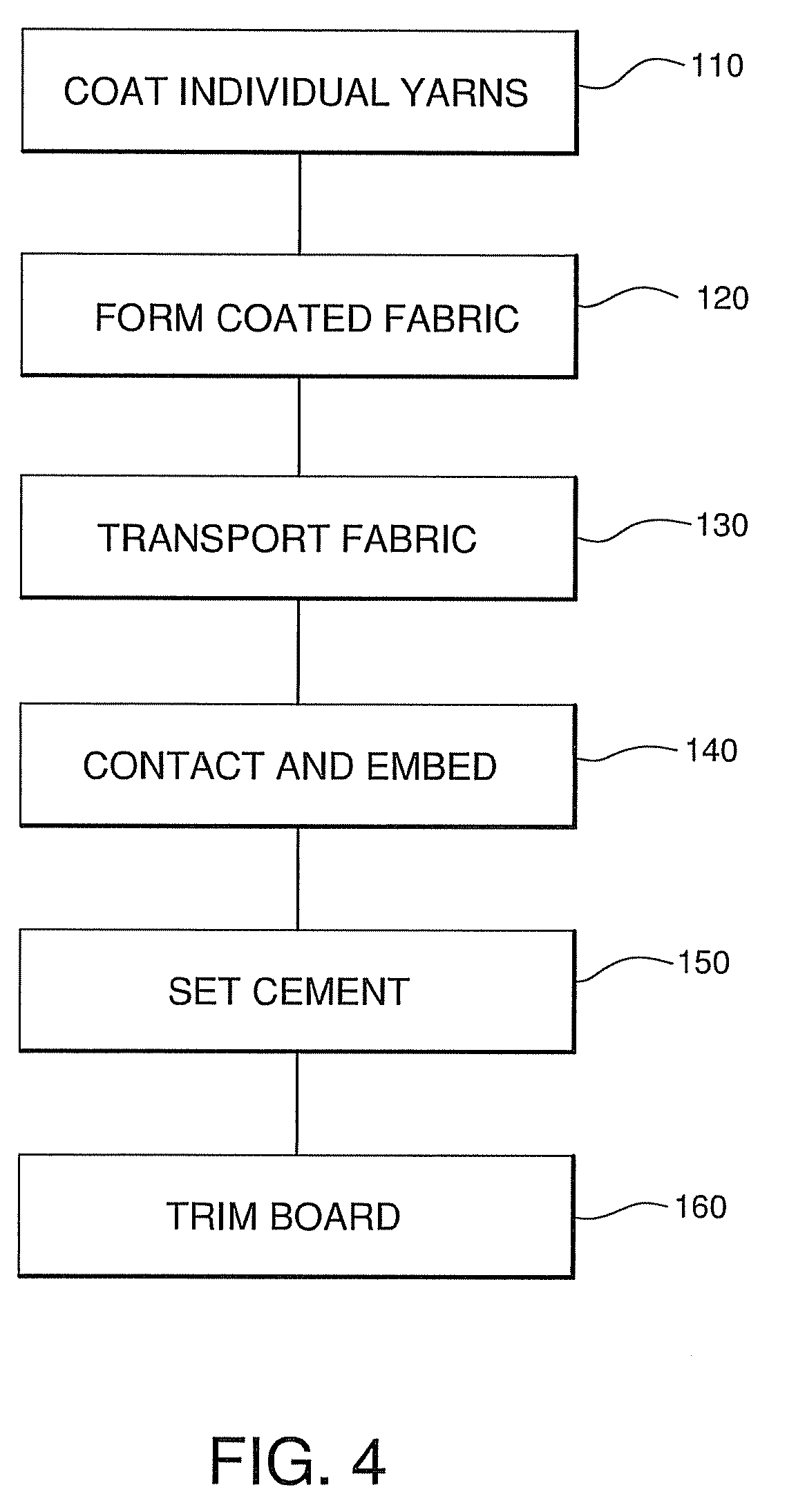

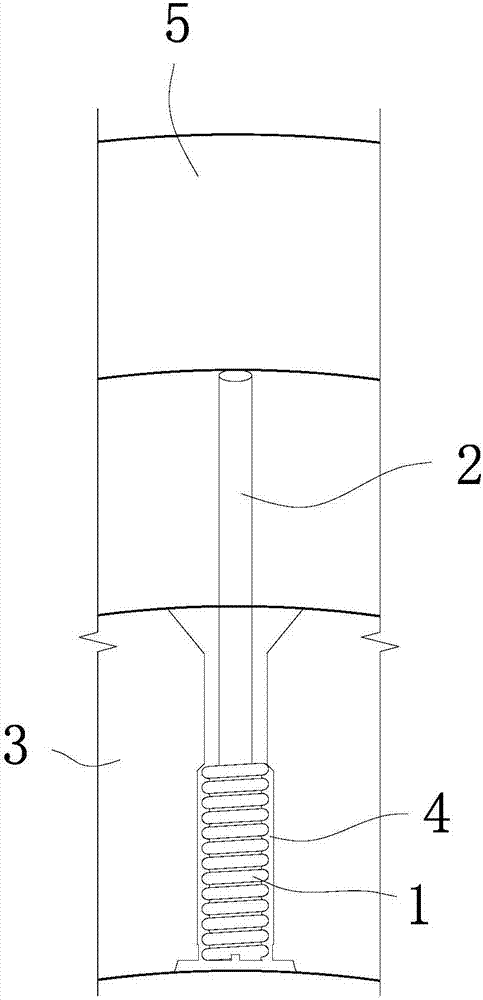

Polyolefin coated fabric reinforcement and cementitious boards reinforced with same

ActiveUS20100151757A1Increase line speedEasy to crackGlass making apparatusConstruction materialGlass fiberYarn

The present invention provides glass fiber fabric reinforcements, cement boards, and glass fiber coatings for such reinforcements. The glass fiber fabric reinforcement includes a glass fabric containing multiple yarns containing glass filaments and a polymeric coating disposed onto the multiple yarns to form a coated glass fabric. The polymeric coating comprises a polyolefin based copolymer composition whereby the glass fabric has a Gurley Stiffness measurement of about 100-3000 mg and an ASTM D 638 (2% Secant) modulus of compression of about 1-100 MPa. The reinforcement is sufficiently drapable and lacking in shape memory so as to be curved around the edge of a cement board during the manufacture of same.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Polyolefin coated fabric reinforcement and cementitious boards reinforced with same

The present invention provides glass fiber fabric reinforcements, cement boards, and glass fiber coatings for such reinforcements. The glass fiber fabric reinforcement includes a glass fabric containing multiple yarns containing glass filaments and a polymeric coating disposed onto the multiple yarns to form a coated glass fabric. The polymeric coating comprises a polyolefin based copolymer composition whereby the glass fabric has a Gurley Stiffness measurement of about 100-3000 mg and an ASTM D 638 (2% Secant) modulus of compression of about 1-100 MPa. The reinforcement is sufficiently drapable and lacking in shape memory so as to be curved around the edge of a cement board during the manufacture of same.

Owner:SAINT GOBAIN ADFORS CANADA LTD

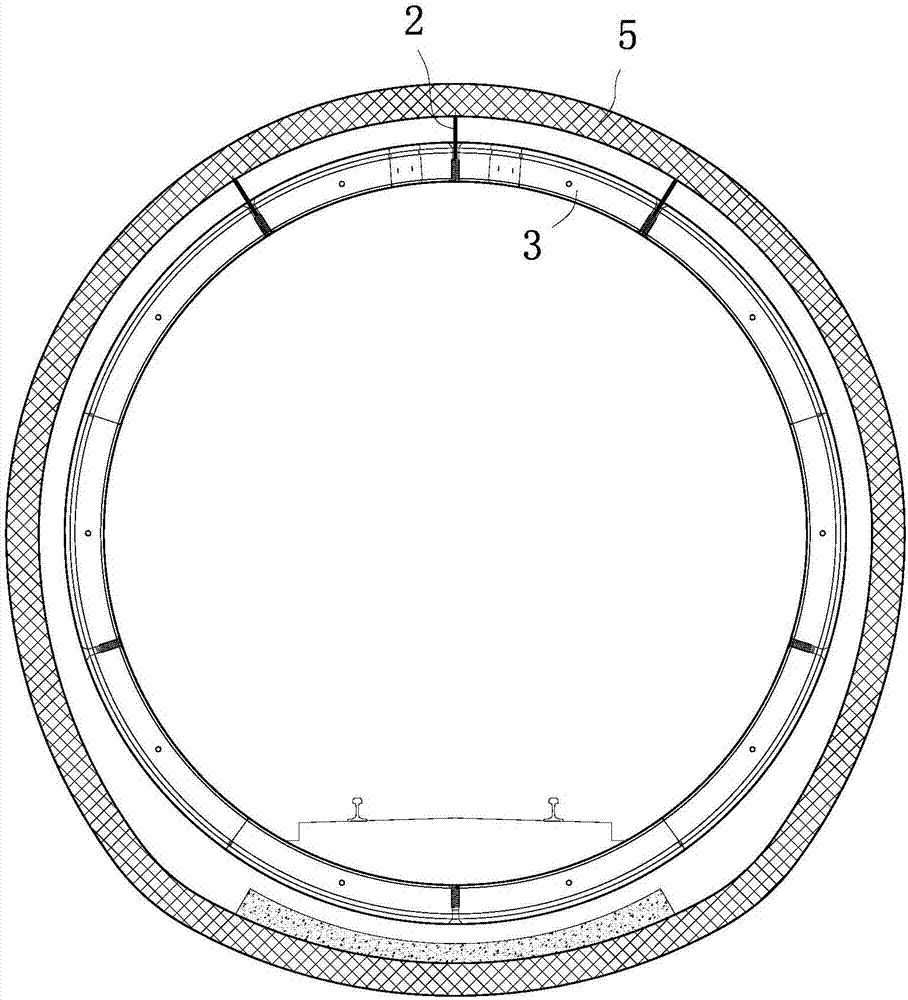

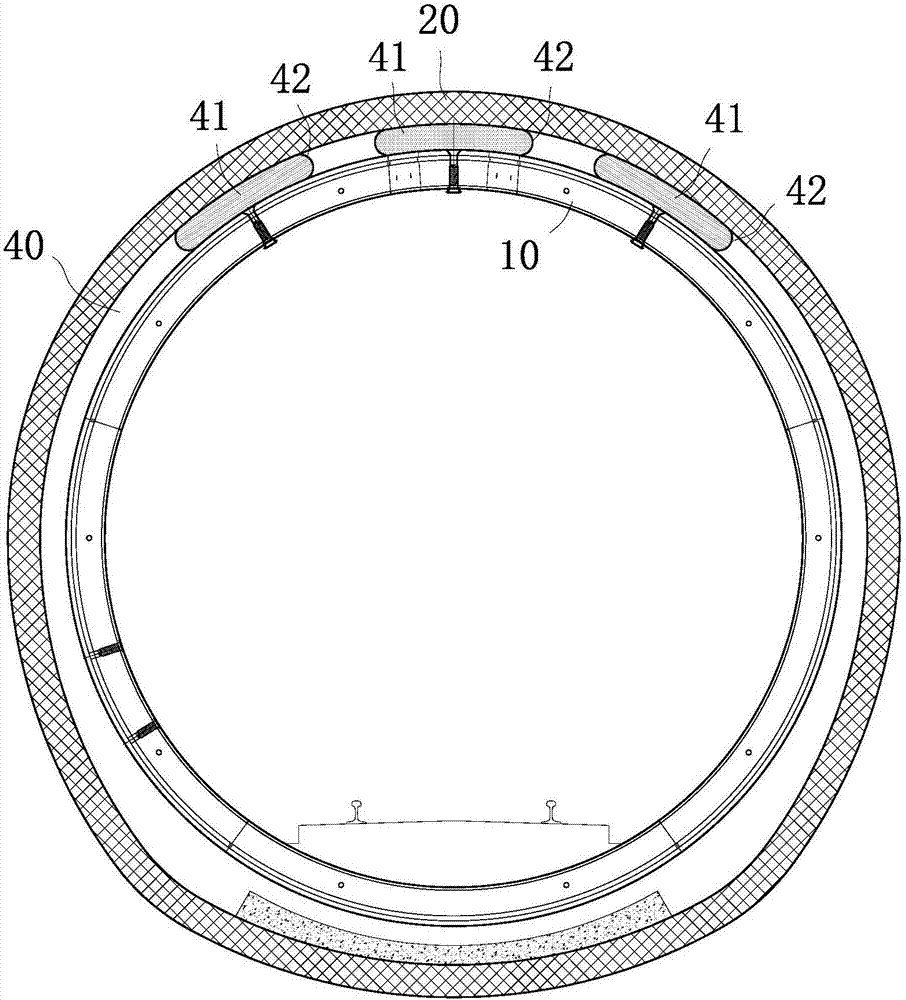

Duct piece floating resisting structure capable of passing through mine tunnel through shield empty pushing and construction method

PendingCN107130979AAvoid crackingAvoid deformationUnderground chambersTunnel liningStress concentrationCement slurry

The invention discloses a duct piece floating resisting structure capable of passing through a mine tunnel through shield empty pushing and a construction method. The duct piece floating resisting structure comprises a grouting bag body arranged between a mine tunnel primary lining and a shield duct piece, wherein the open end of the grouting bag body extends out of a grouting hole of the shield duct piece; a dual-liquid grouting duct member with threads can be screwed into the grouting hole of the shield duct piece; cement slurry and water glass are simultaneously injected into the grouting bag body through the dual-liquid grouting duct member; a cloth bag can restrain a range of formation of a floating resisting structural body, so that the block-shaped floating resisting structural body which has certain intensity and with which a gap between the mine tunnel primary lining and the shield duct piece is filled can be effectively formed; the gap between the mine tunnel primary lining and the shield duct piece is filled with the floating resisting structural body in a block-shaped surface contact manner, so that cracking and deformation of the duct piece due to local stress concentration can be effectively prevented; meanwhile, three floating resisting structural bodies which are arranged in a spacing manner at the upper part of the shield duct piece are relatively large in range, so that a tunnel can be well wrapped and tightened, and displacement and deformation of the shield duct piece are completely limited.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

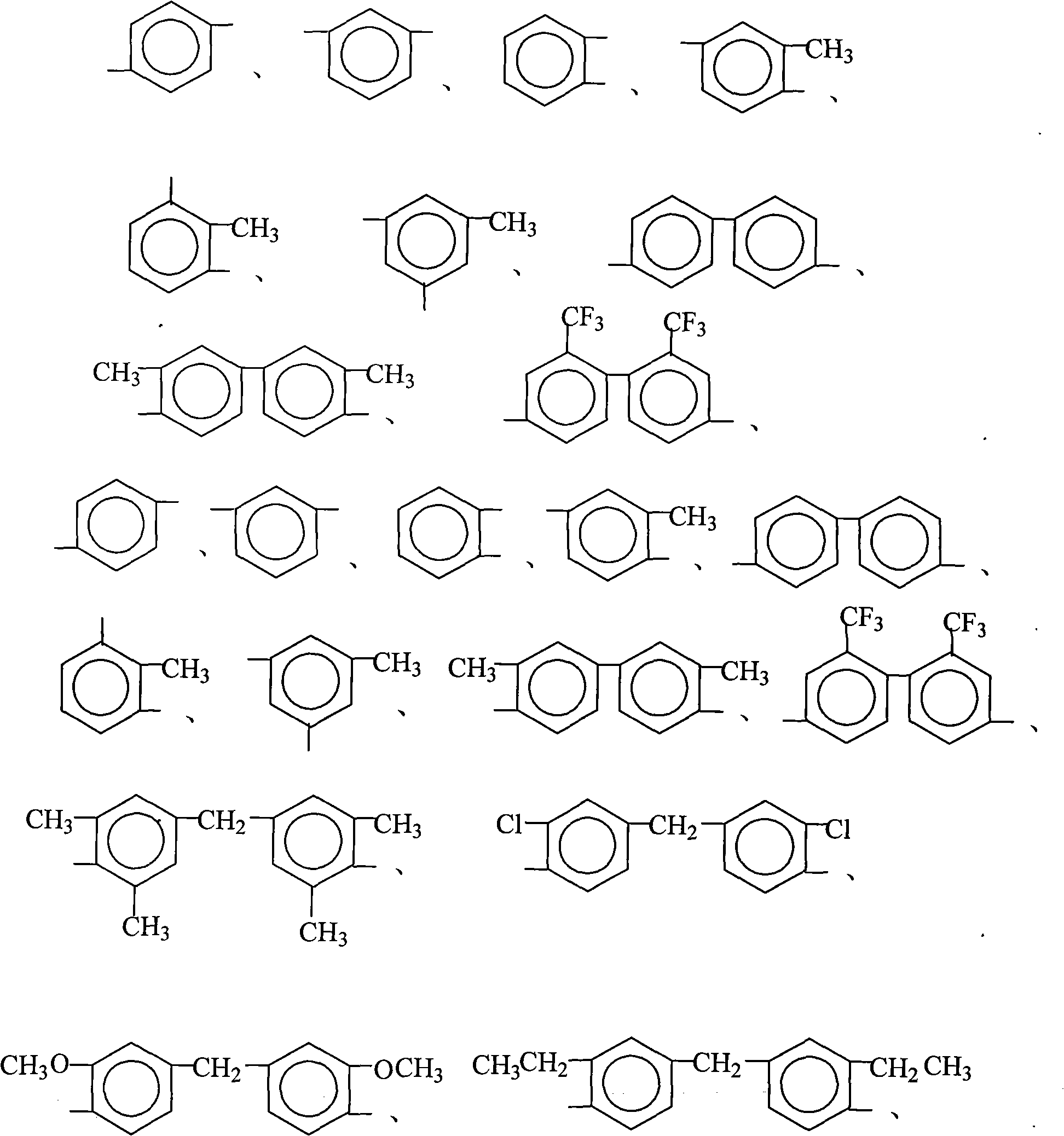

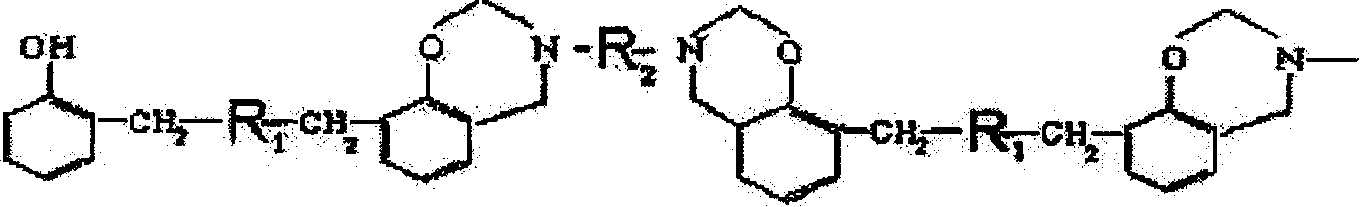

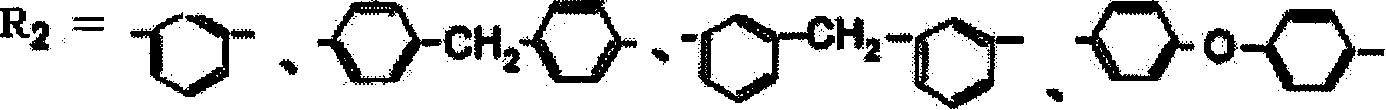

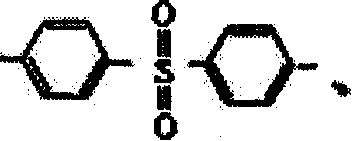

Benzoxazine resin containing aralkyl structure, its preparation method and use

The preparation method for benzoazine with aralkyl group comprises: adding phenols compound as 80-100 weight shares and 80-120 aralkyl compound into the reaction kettle; with 1-4 acidic catalyst, stirring to react for 1-3h at 80-140Deg; cooling to below 50Deg; adding 30-40% formaldehyde liquid as 160-360 weight shares and 4-8 basic catalyst to adjust pH value within 6-9; adding solvent and 40-120 diamine to reflux reaction for 2-8h at 85-95Deg; finally, vacuum dewatering at 80-40Deg. This product is used mainly to manufacture high-performance constructional material fit more than 180Deg, the electrically insulating material, or glass fabric and extruding material with vitrifying temperature more than 175Deg.

Owner:SICHUAN DONGCAI ENTERPRISE GRP CO LTD

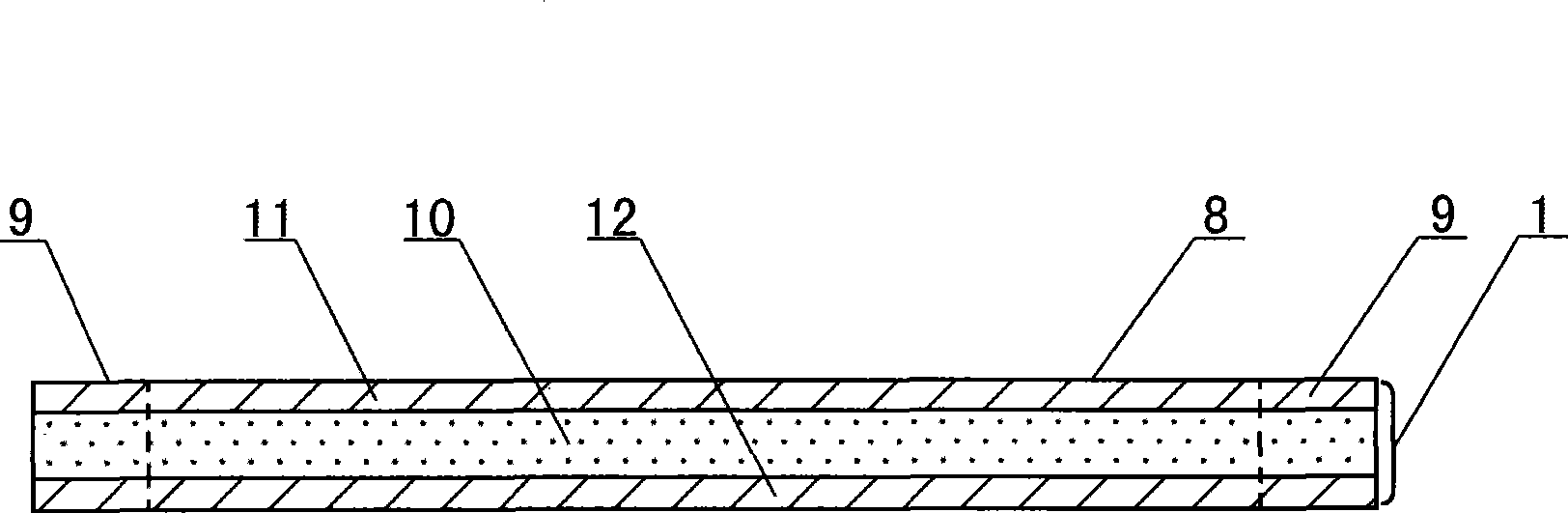

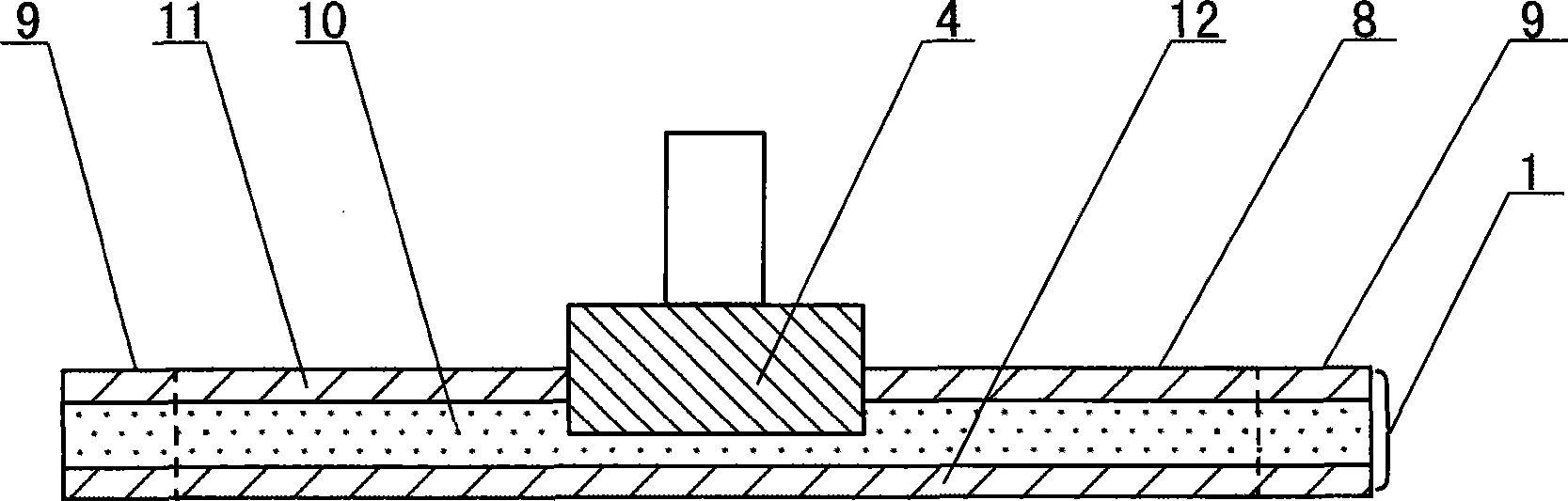

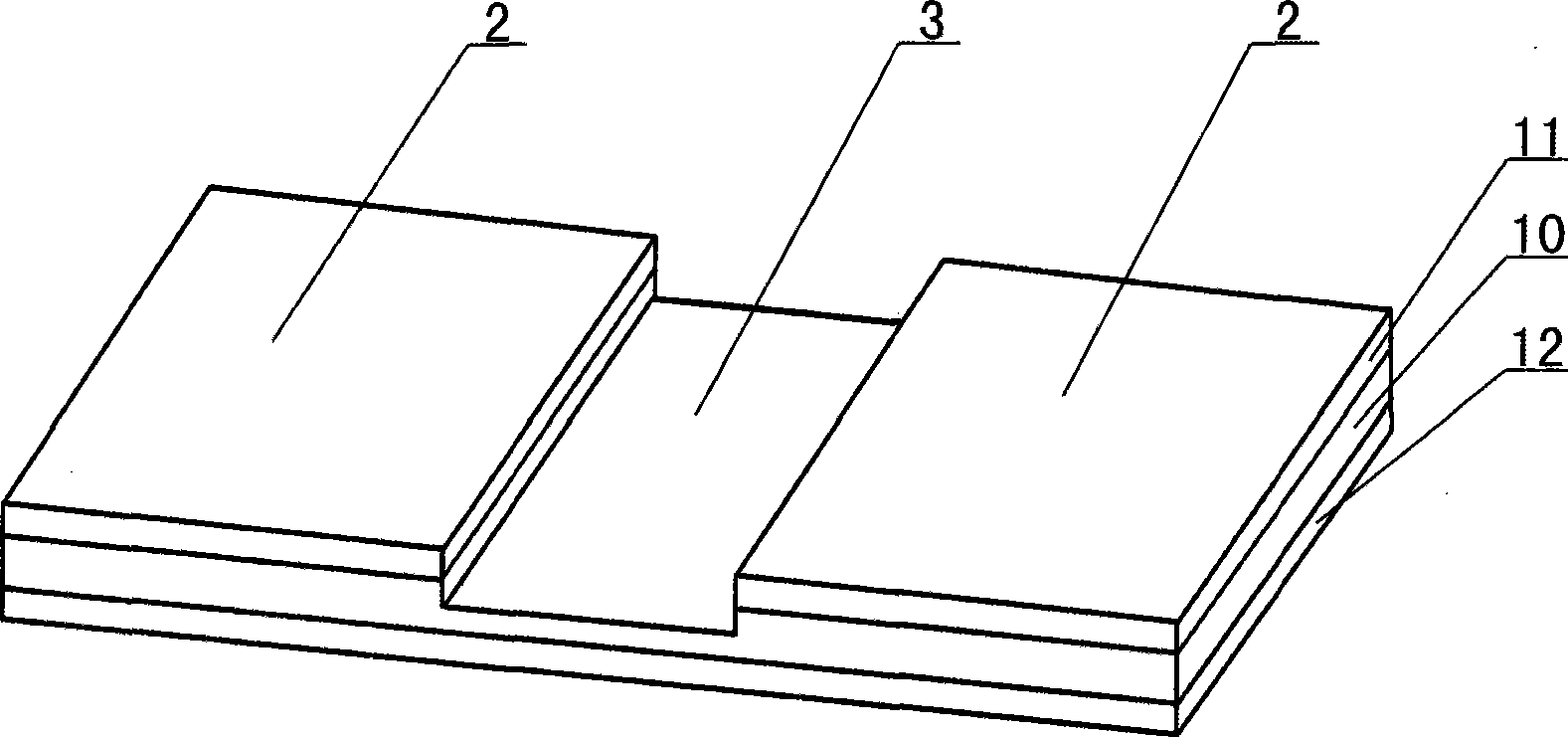

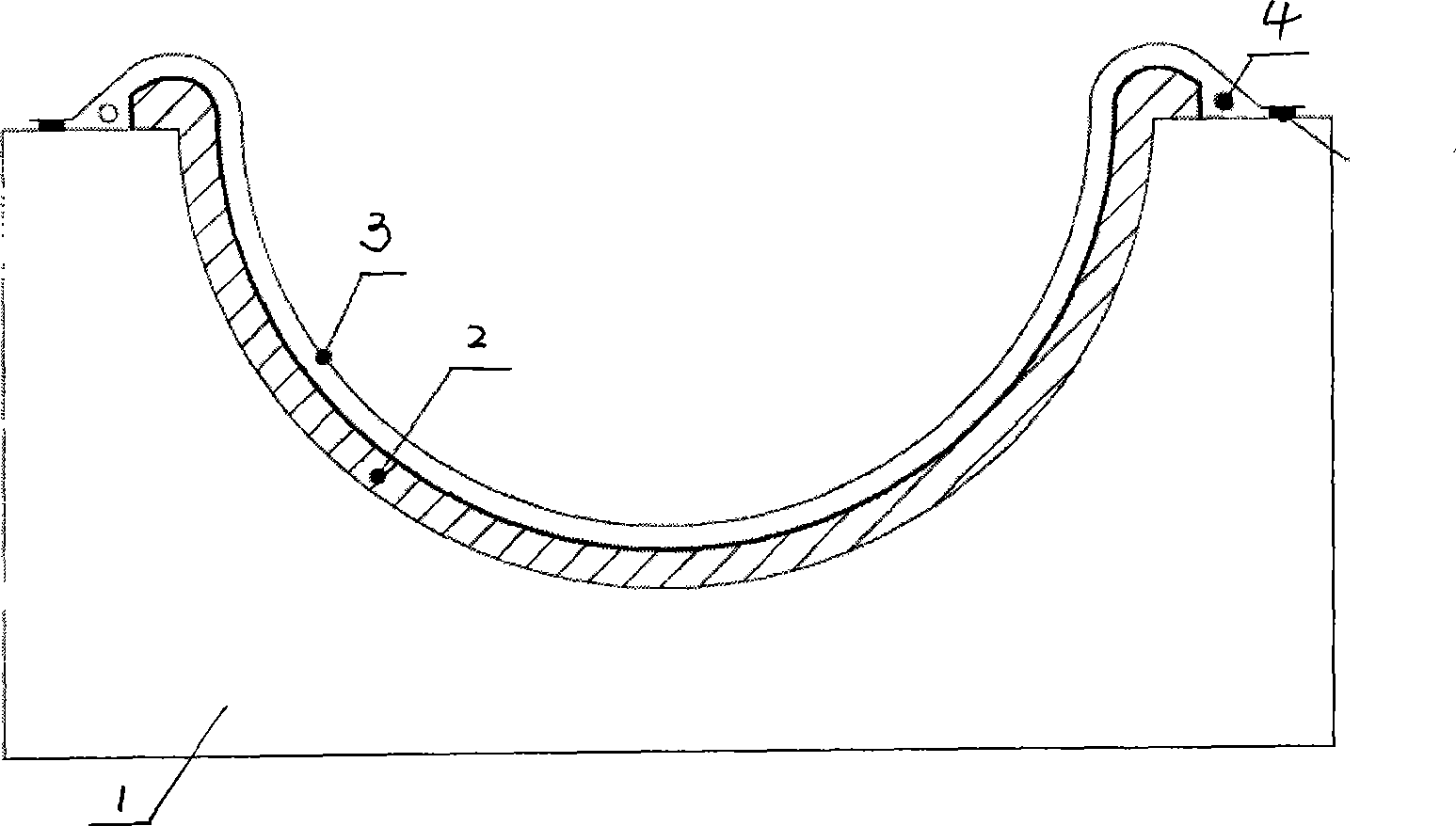

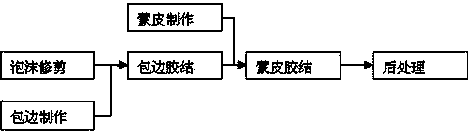

Manufacturing method for semi-flexible printed circuit board

InactiveCN101365298AOvercome the disadvantage of high water absorptionLow costSynthetic resin layered productsPrinted circuit manufactureHigh rateEngineering

A production method of a semi-flexible printed circuit board comprises the following steps of: (1) preparing a sheet metal; (2) dividing the sheet metal into a molding area and a shaping area; (3) dividing the molding area into a plate area and a flexible area in advance in the molding area; (4) processing the sheet medal as follows: (4.1) processing of the pattern of the sheet metal and (4.2) processing the flexible bent area of the sheet metal so that the flexible area becomes thinner and can be bent; and (5) removing the shaping area and getting the semi-flexible printed circuit board. The invention adopts cheap general rigid materials such as glass fabric-epoxide resin copper pour foil, and the like to replace expensive flexible copper pour plate materials such as polyimide, and the like, thereby greatly reducing the cost. At the same time, the invention has the advantages of simple machinery process, high rate of finished products and high reliability. The semi-flexible printed circuit board produced by the method particularly suits vehicle-borne products with higher reliability requirement.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

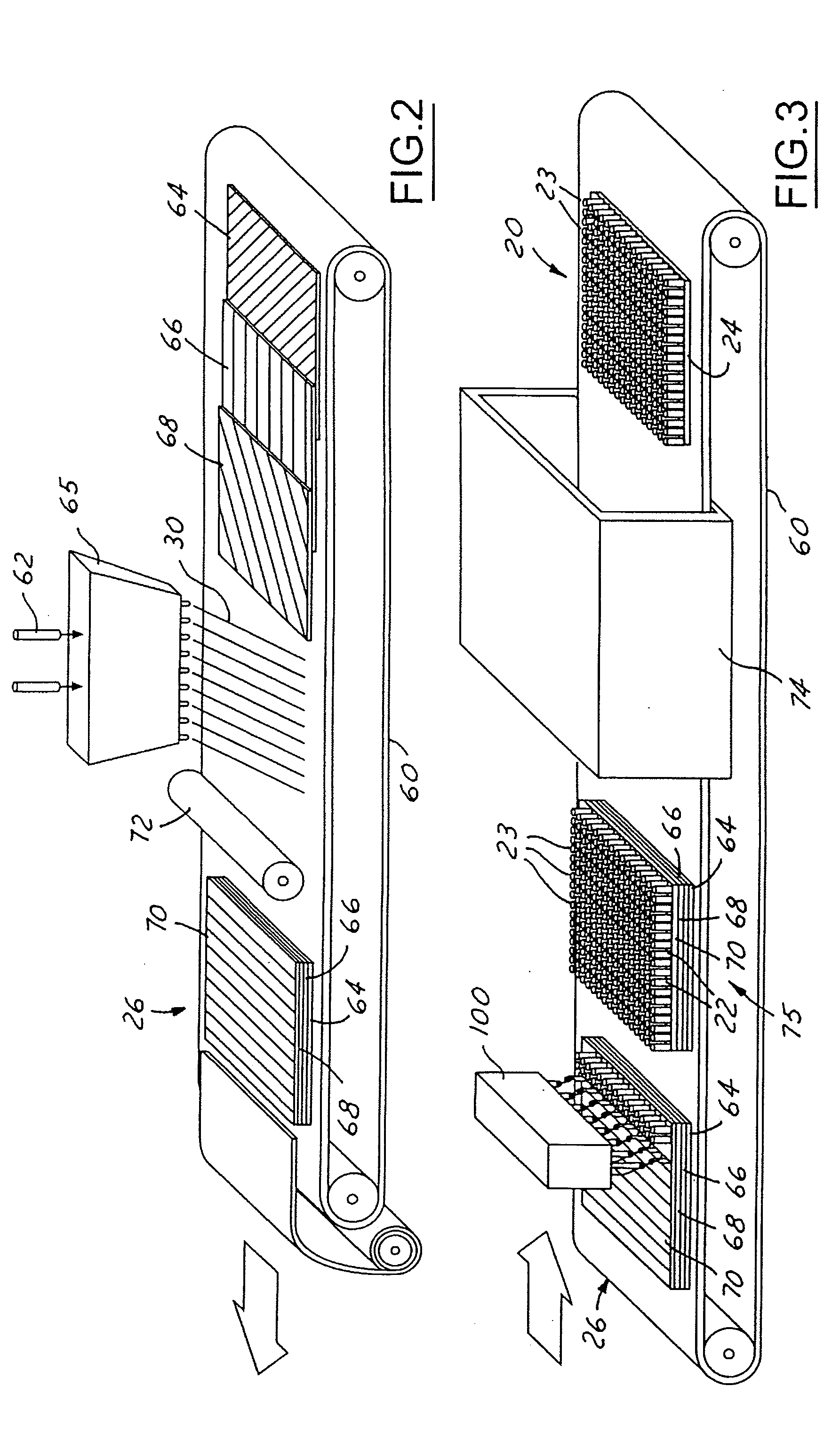

Method for producing polyurethane plate for automobile ceiling

InactiveCN101628498AAvoid easy delaminationSimple production processSynthetic resin layered productsLaminationGlass fiberProduction line

The invention discloses a method for producing a polyurethane plate for an automobile ceiling, which comprises the following steps: flatly laying non-woven fabrics on a caterpillar belt of a compound machine; sequentially scattering short-cutting glass fibre and hot-melting adhesive powder on the non-woven fabrics; then melting and compounding at 160-250 DEG C at the pressure of 0.2-1MPa, cooling and rolling to obtain an adhesive glass fabric; sequentially decoiling, stacking and flatly laying the adhesive glass fabric and a bonding film on a working platform of a compound production line from bottom to top and placing a polyurethane rigid foam plate; sequentially scattering short-cutting glass fiber and hot-melting adhesive powder on the polyurethane rigid foam plate; flatly laying the hot-melting adhesive film and heating to 160-250 DEG C by a heating plate of the compound machine; carrying out hot-press compounding at the pressure of 0.2-1MPa and cooling to obtain a polyurethane multilayer composite plate. The invention has simple production process and stable product quality and solves the problem of easy delamination of the polyurethane plate produced by the prior one-step method.

Owner:浙江华江科技股份有限公司

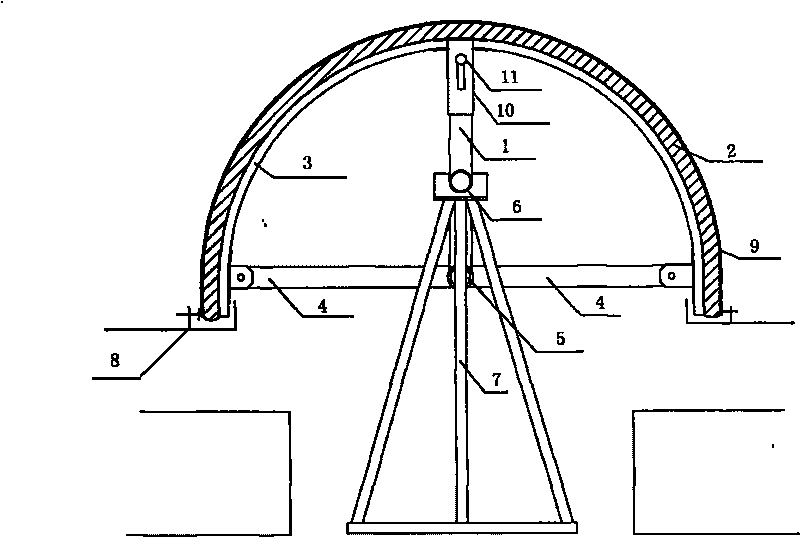

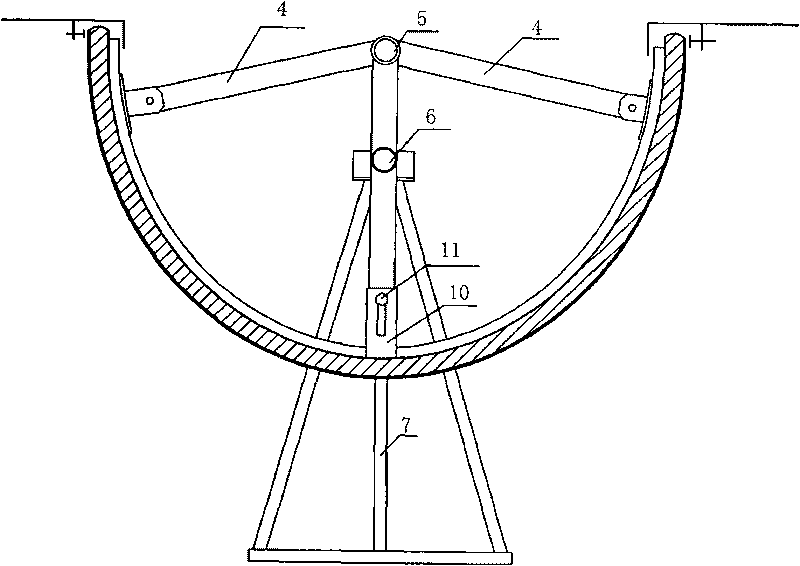

Method for manufacturing megawatt wind power generator blade root

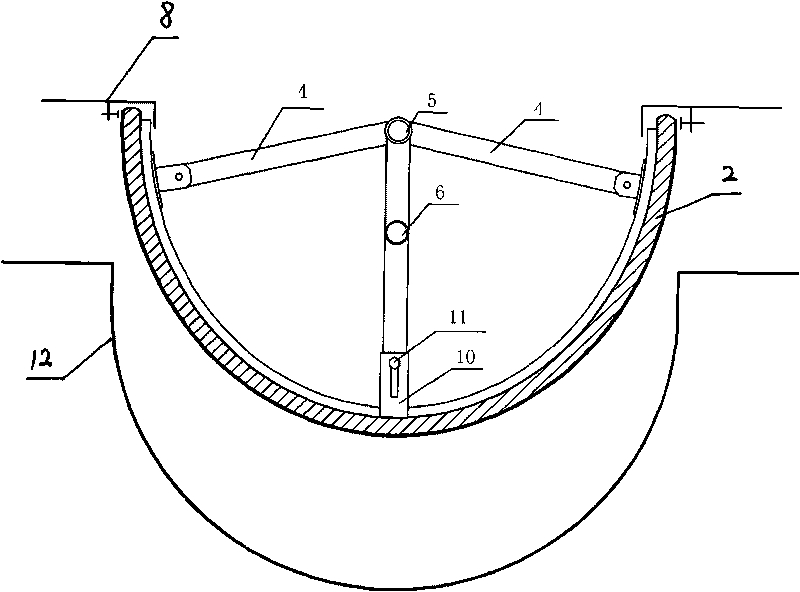

The invention relates to a method for making a blade root of a megawatts level aerogenerator, which comprises the following steps: firstly, making a single insert female die, and laying a glass cloth required to be prefabricated according to blade design paper in the female die; secondly, laying a vacuum bag on the outermost layer, sealing the periphery, vacuumizing, compacting all the laid layers, placing a glass reinforced plastics cambered supporting plate on the vacuum bag, supporting two sides of the cambered supporting plate with transverse supporting rods, and stopping vacuumizing; and thirdly, laying a plurality layers of glass fiber cloth in a blade root mould in advance, lifting up an insert and placing the insert into the blade root mould, sealing the peripheries of the vacuum bag and the blade root mould, vacuumizing again, injecting glue, and finally curing and moulding the product. The method overcomes the collapse and the corrugation of the glass cloth on two sides of the blade mould, has the advantages of simple and convenient production, high efficiency, and easily manufactured insert, does not generate a gap because of the good matching of the shapes of the glass cloth laid in the insert and the blade mould, and avoids the easy generation of a dried region in the glass cloth under a cured insert.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

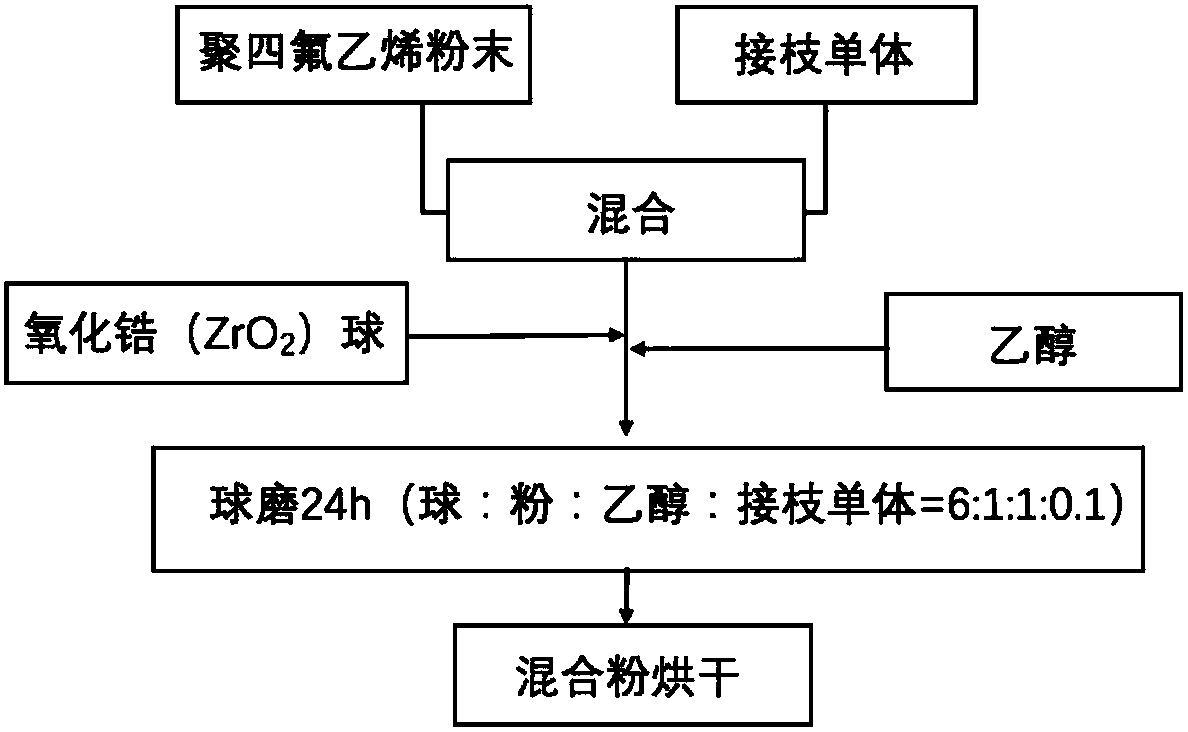

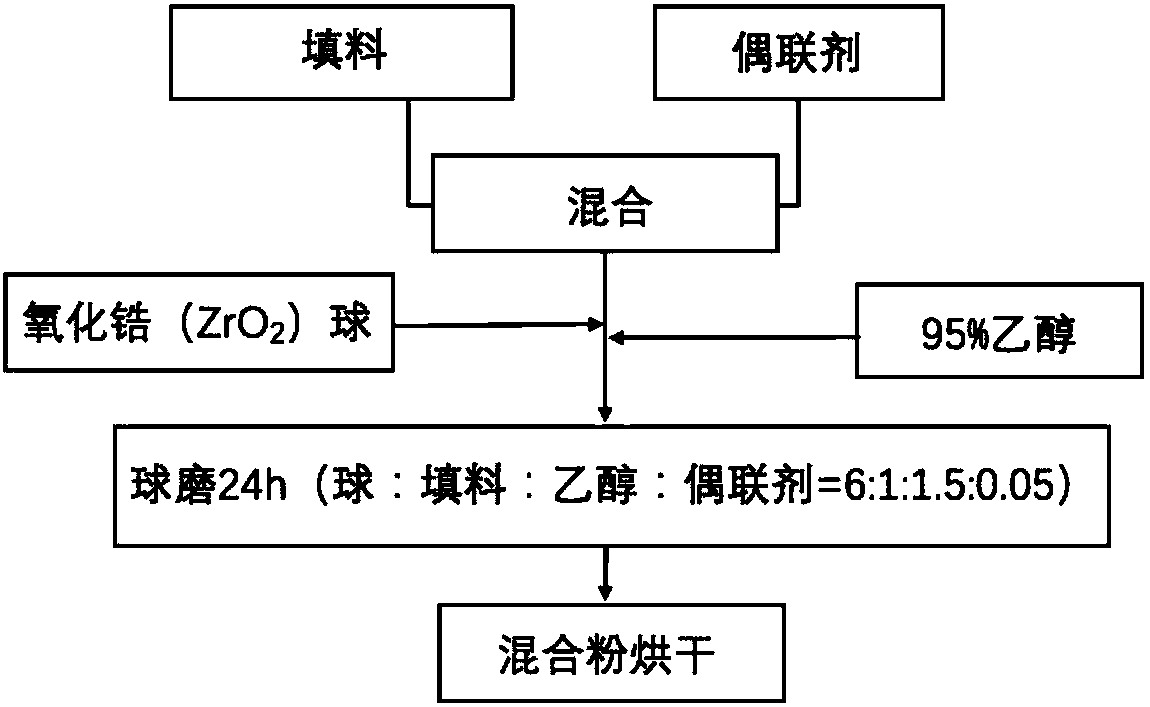

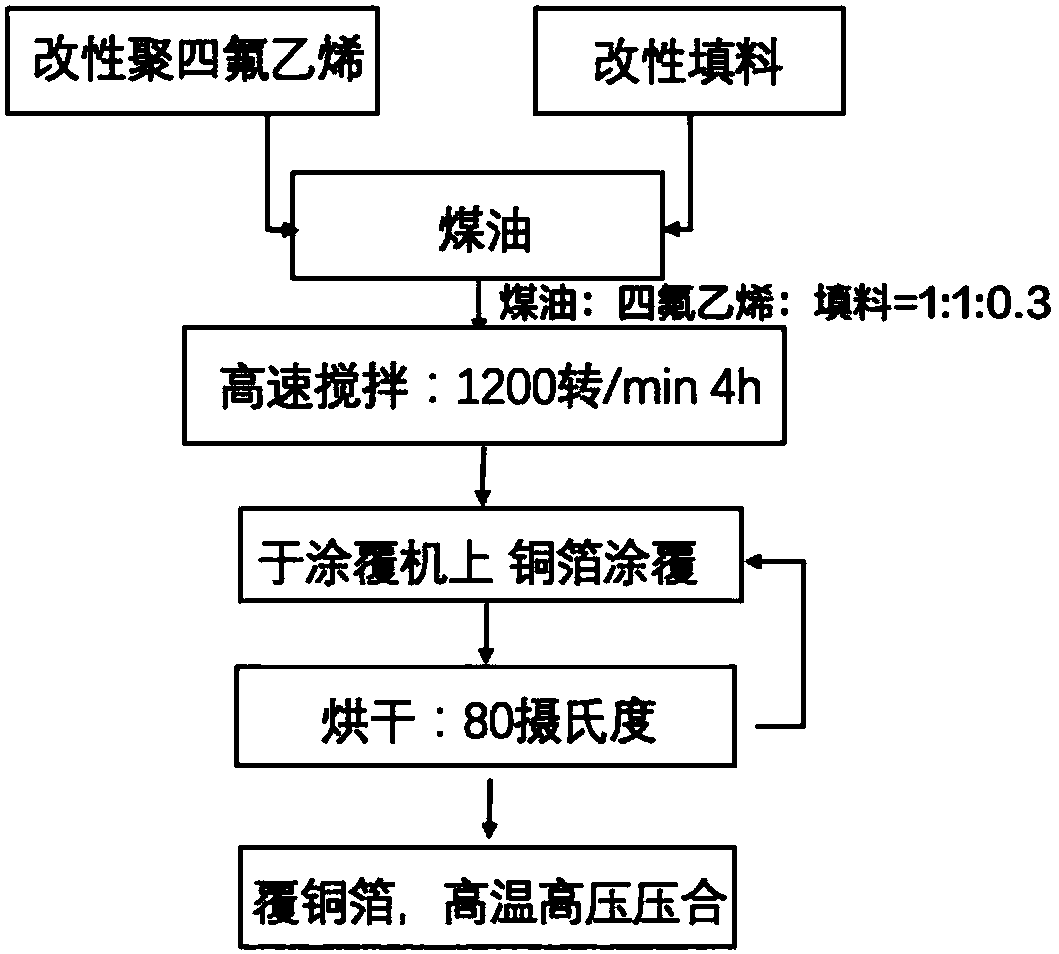

Manufacturing method of modified teflon copper-clad plate

ActiveCN108189520ASmall coefficient of thermal expansionGood dimensional stabilityLaminationLamination apparatusKeroseneSlurry

The invention discloses a manufacturing method of a modified teflon copper-clad plate. The method comprises the following steps: (1) modifying sodium-naphthalene treated teflon through a grafting monomer to obtain modified teflon; (2) modifying a filler through a coupling agent to obtain a modified filler; (3) dispersing the modified teflon obtained in the step (1) into kerosene, then adding the modified filler obtained in the step (2), mixing to obtain a slurry; (4) coating the slurry obtained in the step (3) on a copper foil, and pressing to obtain the modified teflon copper-clad plate. Thepressed copper-clad plate does not contain a glass fabric and effectively avoids the effect of glass weaving; the pressed teflon copper-clad plate has the advantages of stable dielectric property, lowcoefficient of thermal expansion, good size stability and the like.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

Blade of wind-driven generator and manufacturing method thereof

InactiveCN102797646AImprove the strength of forceExtend your lifeFinal product manufactureWind energy generationWind drivenLightning rod

The invention provides a blade of a wind-driven generator. The blade comprises a housing, a web and a root flange, wherein the housing is divided into an upper housing and a lower housing which respectively comprise main beams, prefabricated components, root preformed parts and paving layers; each paving layer comprises a glass fabric, a balsa core and a foam core; the webs are positioned between the upper housing and the lower housing of the blade; and the root flange is adopted to connect the blade and a main body of the wind-driven generator. The invention also provides a manufacturing method of the blade of the wind-driven generator. The manufacture method comprises the following steps: preparing the root preformed parts, the main beams and the prefabricated components in individual dies; paving the root flanges, the root prefabricated parts, the main beams and the prefabricated components in a housing die together with the glass fabrics, the balsa cores, the foam cores and lightning rods; pouring resin into the housing die through a vacuum pouring technology so as to form the upper housing and the lower housing of the blade; integrally adhering the upper housing and the webs, and overturning the same for 180 degrees to adhere with the lower housing by closing the dies; and then removing the dies to obtain the blade of the wind-driven generator. The blade of the wind-driven generator manufactured by the method provided by the invention has the advantages of high stressing intensity and long service life.

Owner:TPI COMPOSITES (TAICANG) CO LTD

Novel enhanced high temperature tapes for high velocity Oxy fuel processes

InactiveUS20070110942A1Increase resistanceHigh strengthFilm/foil adhesivesAdhesive articlesMetal foilAdhesion strength

A finished high velocity oxy fuel (HVOF) tape used with, for example, during known HVOF processing imparts high temperature silicone pressure sensitive adhesives that provide enhanced adhesion strength to provide a firm adhesion to its own backing and unexpectedly leave no residue upon removal from metals. The novel enhanced tapes are made up of coated or uncoated, woven or non-woven glass cloth and ceramic based fabric laminated to at least one side of a metal-foil using a silicone based laminating adhesive, which is then laminated with another layer of a pre-selected combination of the same materials and coated with a high temperature silicone pressure sensitive adhesive and wound to itself to make a self wound tape or covered adhesive assembly with a release liner to make a laminated sheet for die cut samples, among other things. Applications including military and commercial aircraft, automobiles and metal finishing usages leverage of on the unique and inherent benefits of the novel enhanced tapes of the instant teachings.

Owner:SCAPA NORTH AMERICA

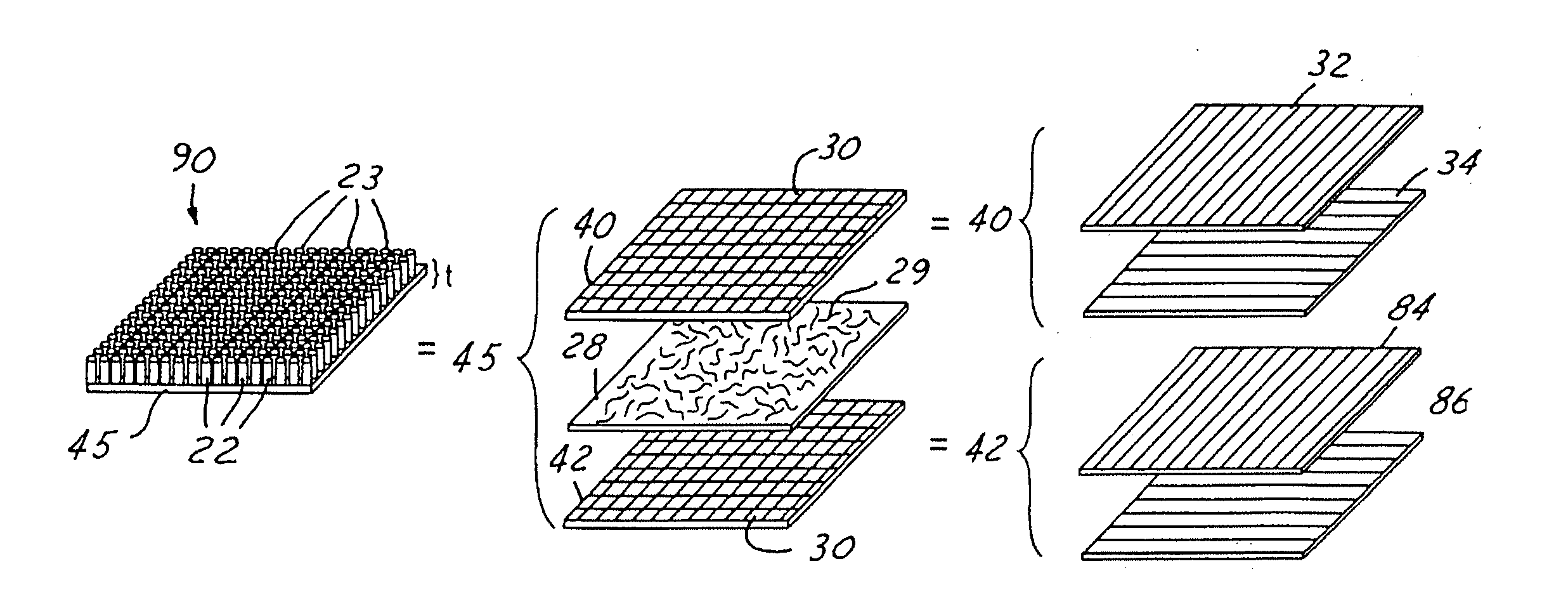

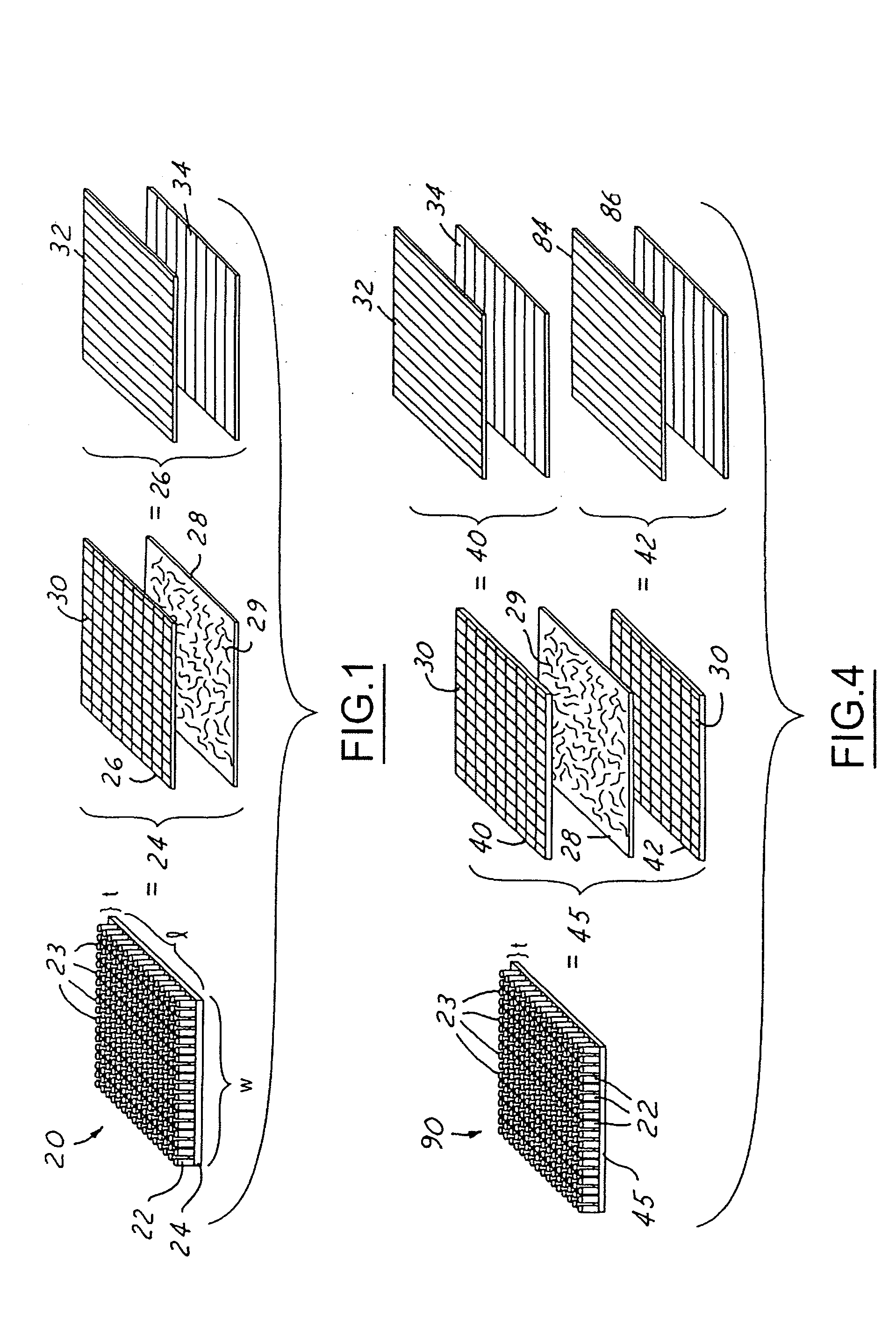

Recyclable tufted carpet with improved stability and durability

InactiveUS20050233107A1Good dimensional stabilityReduce skewTufting apparatusSynthetic resin layered productsGlass fiberWrinkle skin

A recyclable tufted carpet meeting EPA recyclable content standards and having improved dimensional stability that reduces skew, bow, and wrinkles during manufacture and installation is formed by combining prior art primary and secondary backings into a single, fiber-reinforced primary backing layer. Consolidating either a glass fiber fabric layer, a glass veil, or a glass mat with a fiber-reinforced extruded film forms the fiber-reinforced primary backing layer. An additional glass fabric fiber layer can also be introduced to the primary backing to provide additional dimensional stability.

Owner:OCV INTELLECTUAL CAPITAL LLC

Preparation method of ceramifiable silicon rubber composite belt for fire-resistant cable

ActiveCN103236309AHigh strengthGood flexibilityInsulated cablesInsulatorsComposite ceramicSilicon rubber

The invention belongs to the technical field of an insulating material for a cable, and discloses a preparation method of a ceramifiable silicon rubber composite belt for a fire-resistant cable. The composite belt comprises a glass cloth reinforcing layer and a silicon rubber layer, wherein the silicon rubber layer is prepared from a ceramifiable silicon rubber composition which comprises organosilicon rubber compound and composite ceramic powder; and the weight ratio of the organosilicon rubber compound to the composite ceramic powder is 1:1-1.2. The preparation method comprises the following steps: preparing high-strength organosilicon rubber compound; preparing composite ceramic powder; performing silicone-acrylate emulsion treatment of glass cloth; and calendering the composite belt. The ceramifiable silicon rubber composite belt for the fire-resistant cable prepared by the method has extremely high strength and good flexibility and can be used for manufacturing the fire-resistant cable in place of a mica tape; after a cable lapped by using the ceramifiable silicon rubber composite belt is ablated for 180 minutes in flame of 650-950 DEG C, the circuit can still work normally; and the method is easy to operate, has high yield and can realize batch production.

Owner:广东安迪新材料科技有限公司

Preparation method for high temperature-resistant waterborne polyurethane adhesive

ActiveCN103013423AImprove performanceImprove high temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkPolyurethane adhesive

The invention discloses a preparation method for high temperature-resistant waterborne polyurethane adhesive. The method comprises the following steps: preparation of base resin: generating a NCO-terminated prepolymer with butanone as solvent through the reaction between polyether glycol and diisocyanate, cooling, dripping chain extender, adding epichlorohydrin for terminal sealing, and then adding glacial acetic acid for adjusting the pH value in a range of 5 to 7, adding de-ionized water, stirring at a high speed for dispersing, adding treated nanometer silicon dioxide, adding antifoaming agent, and removing the butanone in vacuum to obtain the base resin of the high temperature-resistant waterborne polyurethane adhesive; and waterborne epoxy resin as curing agent is cross-linked with the base resin to obtain the adhesive. The cationic waterborne polyurethane adhesive, prepared by the method, has higher binding strength for composition of glass fabrics and PET (Polyethylene Terephthalate); as the epichlorohydrin is added in the system, the flame retardance of the adhesive is further improved; and as the epoxy resin is added, the high temperature resistance of the adhesive is improved; and the adhesive is waterborne polyurethane adhesive for the glass fabrics with excellent performance.

Owner:NANTONG GAOMENG NEW MATERIAL

Composite plastic floor and manufacturing method thereof

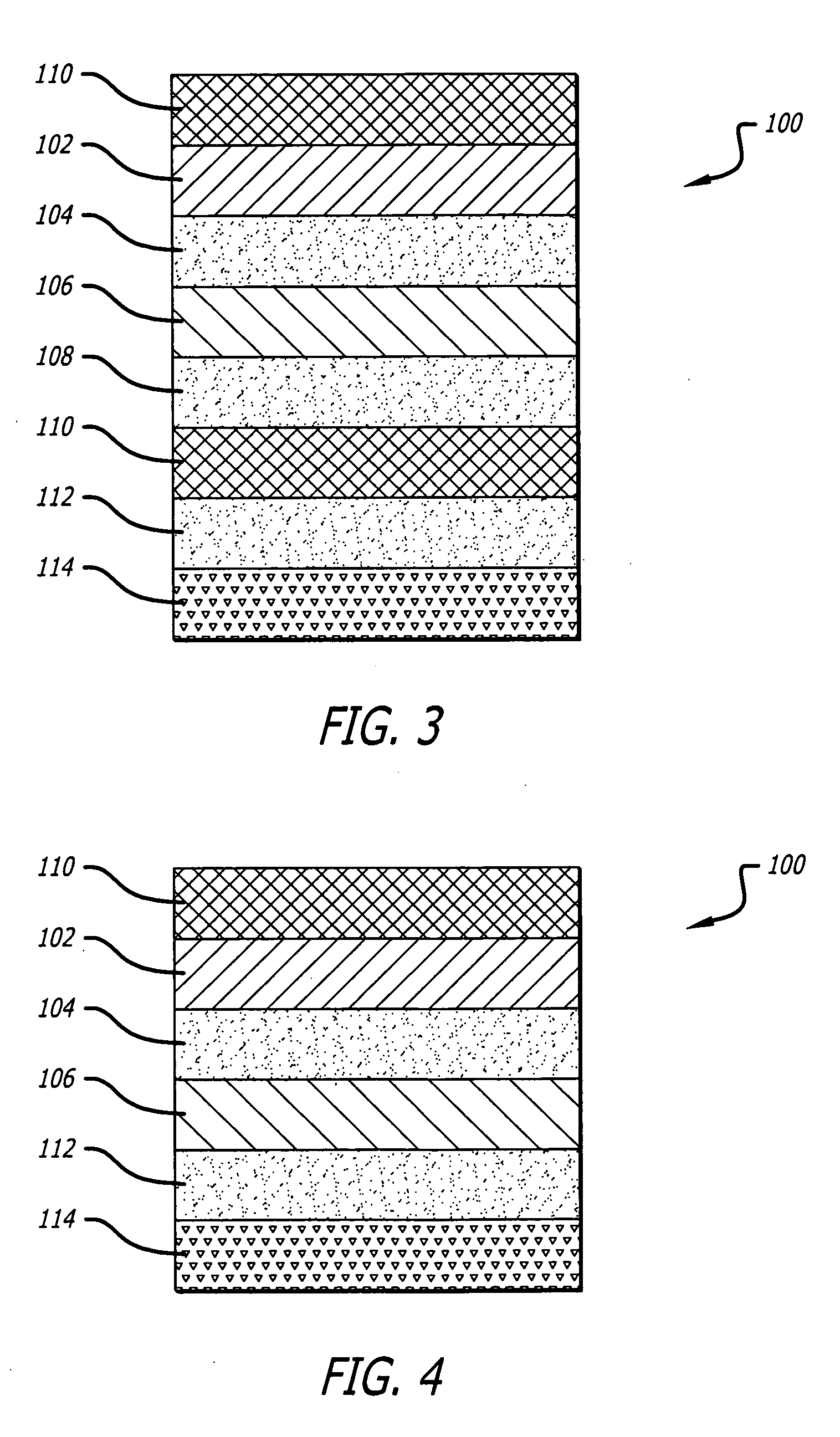

InactiveCN103074990AImprove structural strengthImprove toughnessSynthetic resin layered productsLaminationTextile printerPolyvinyl chloride

The invention discloses a composite plastic floor, which comprises a wearing layer, a printing layer, a middle layer and a bottom layer, wherein the printing layer is a textile printing film; and the middle layer and the bottom layer are polrvinyl chloride sheets. The improvement made by the invention comprises: the middle layer is of a multi-layer polrvinyl chloride sheet combination structure, and glass fabrics are respectively arranged between each two polrvinyl chloride sheets of the middle layer; and the wearing layer is a transparent film with an outer surface being coated with a colourless UV (Ultraviolet) coating layer. The invention also discloses a manufacturing method of the composite plastic floor. The manufacturing method comprises the following process steps of: hot pressing, preserving, film spraying, tempering, natural aging, punching and slotting. The composite plastic floor manufactured by the invention has good wear resistance, long service life, simplicity in manufacturing, lower production cost, small deformation due to expansion and contraction, and high strength and toughness.

Owner:TAIZHOU HUALI PLASTIC

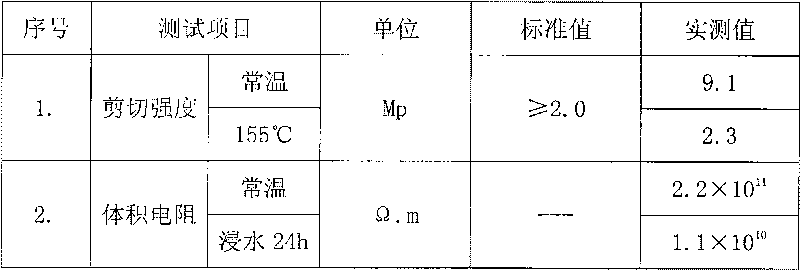

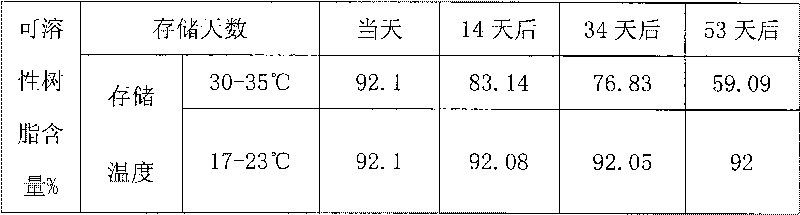

Adhesive, preparation method thereof, and epoxy glass fabric prepared from adhesive

ActiveCN101696349AFair priceNot easy to storePlastic/resin/waxes insulatorsFibre treatmentImidePolymer science

The invention discloses an adhesive, a preparation method thereof, and an epoxy glass fabric prepared from the adhesive. The adhesive comprises the following components in percentage by mass: 10 to 11 percent of tung oil, 2 to 3 percent of maleic anhydride, 38 to 40 percent of methylbenzene, 5 to 6 percent of bismaleimide resin, 17 to 19 percent of 601 epoxy, 11 to 12 percent of novolac epoxy and 15 to 16 percent of filler. The improvement on the formula design of the adhesive and the preparation method is carried out by adopting a plurality of technical means, and alkyd resin is mainly modified to improve the heat resistance; and a toughening agent, a cosolvent and a latent curing agent are selected, and all the selected component materials have moderate cost and are easy to purchase. The epoxy glass fabric product produced by the method is difficult to adhere and is easy to store in the storing process, does not fall off rubber powder or pollute environment, and has no influence on the health of operators.

Owner:CHINA XIDIAN GRP CO LTD

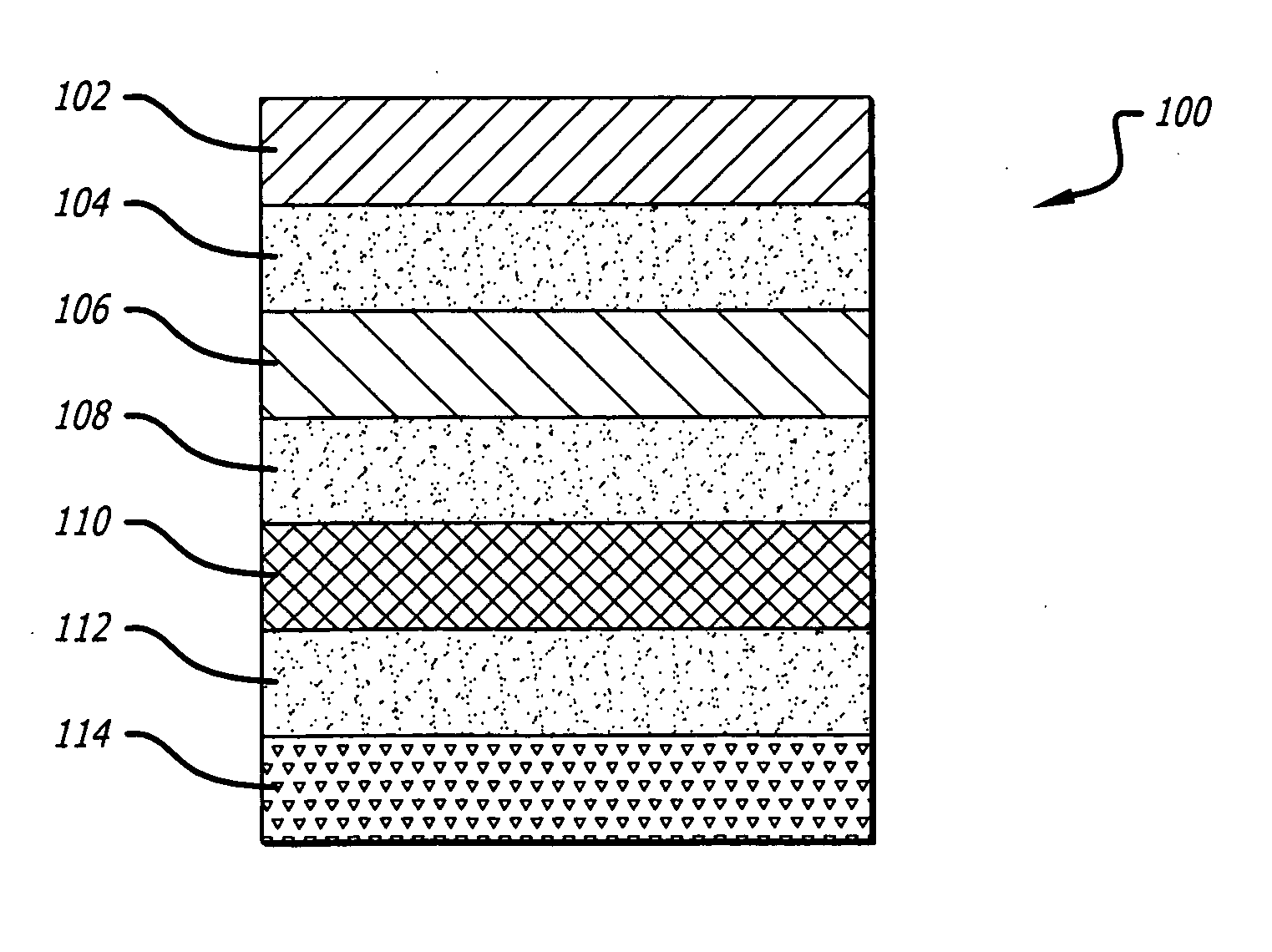

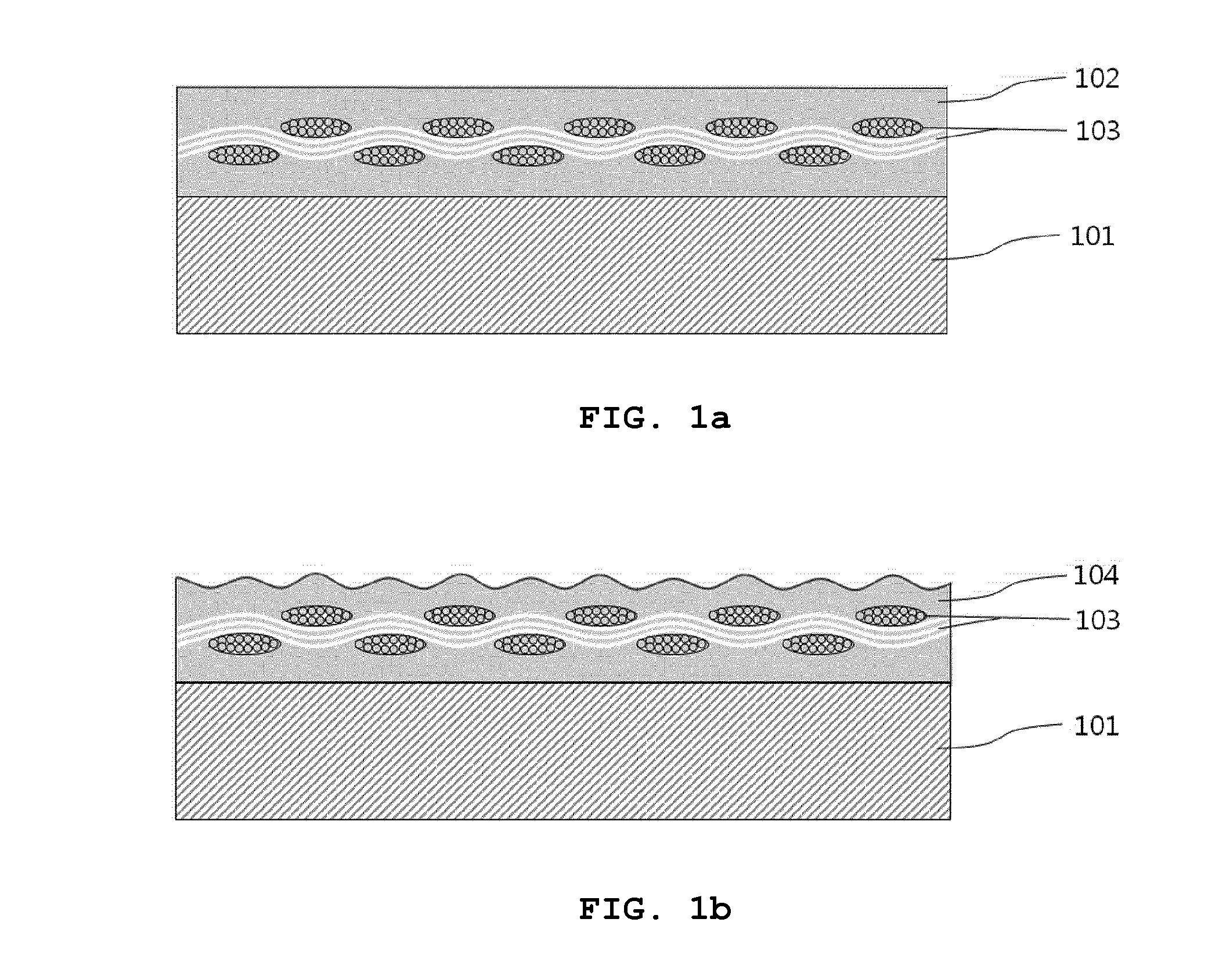

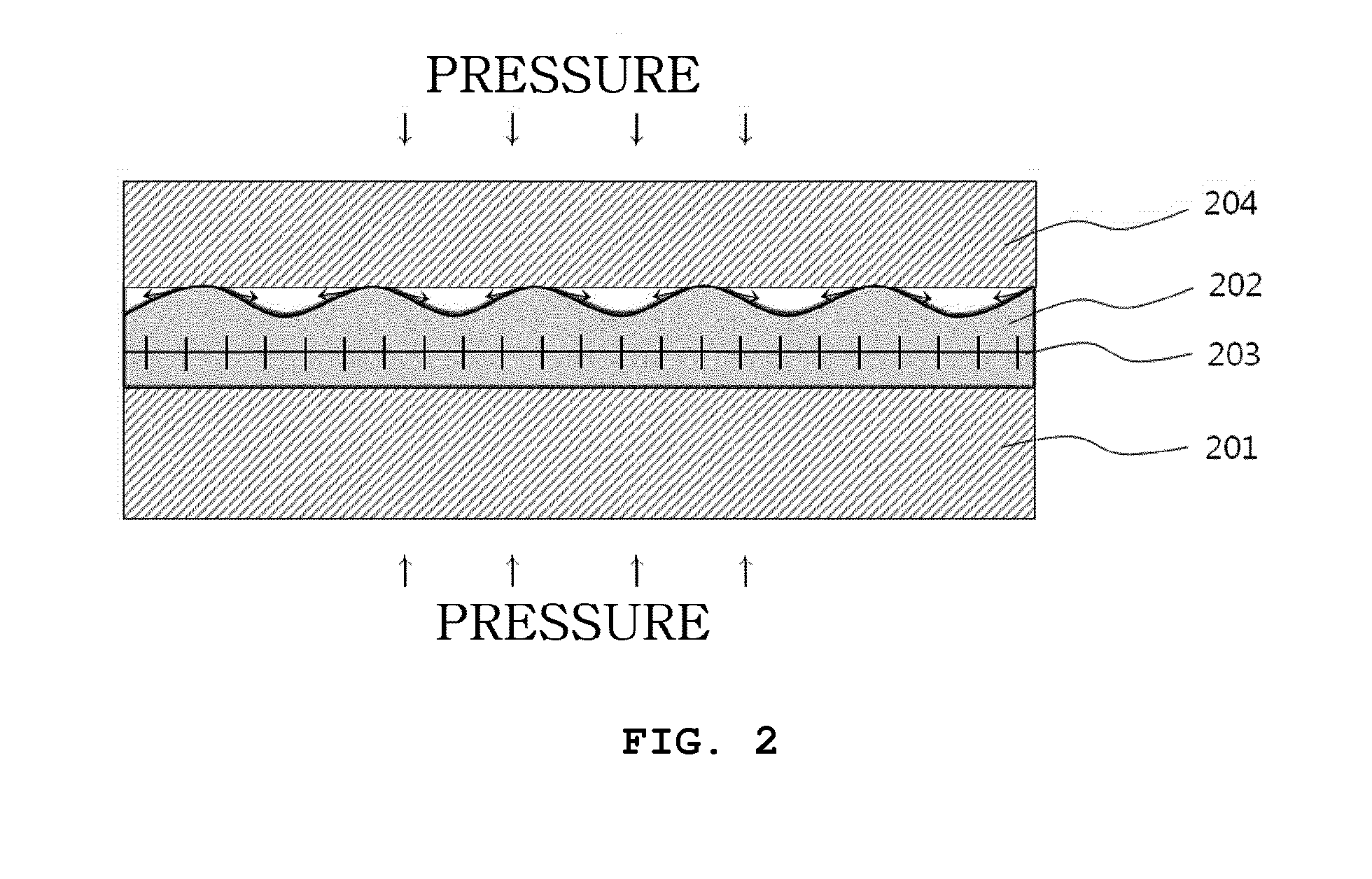

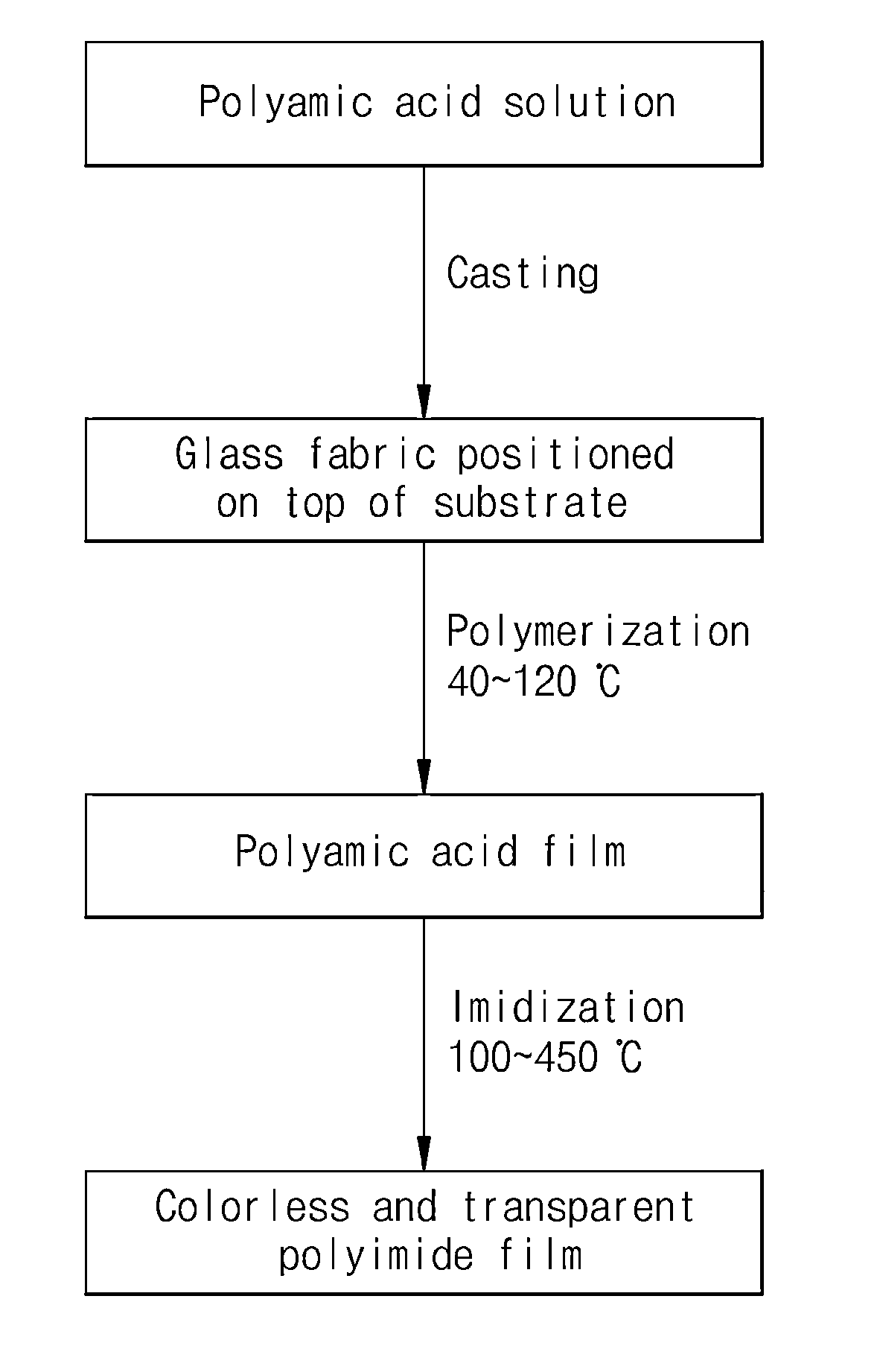

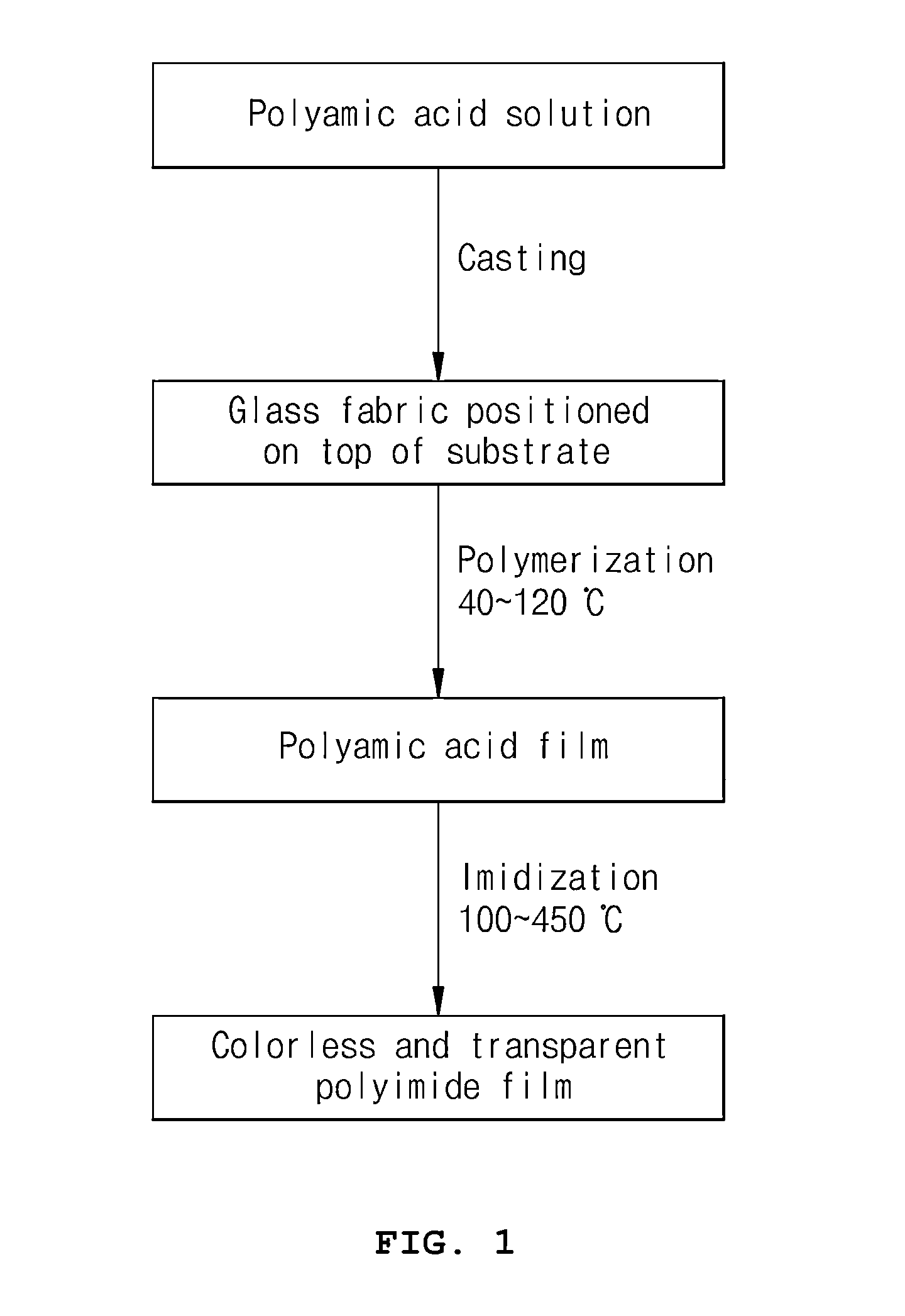

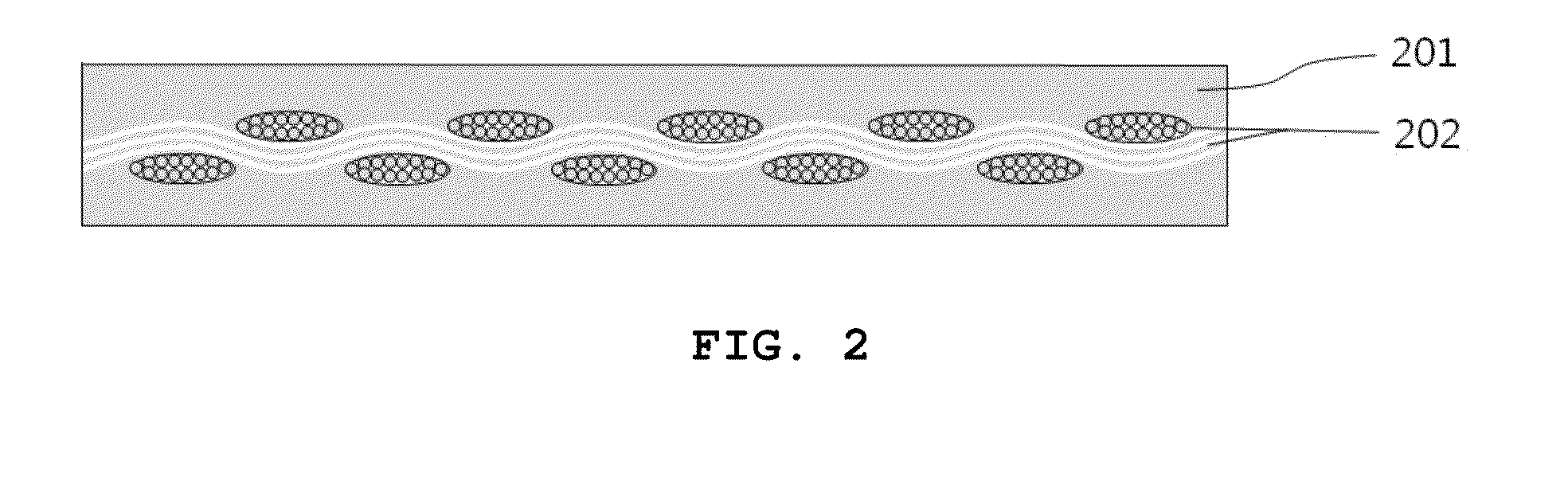

Method of manufacturing colorless transparent polyimide film having impregnated glass fabric and of flattening surface thereof

ActiveUS20160009882A1Prevent surface scatteringHigh optical transmittancePretreated surfacesGlass/slag layered productsDisplay deviceEngineering

Disclosed is a method of manufacturing a colorless transparent polyimide film having impregnated glass fabric, wherein the surface of the polyimide film substrate having impregnated glass fabric is flattened by two flattening steps using a roll-to-roll process, thereby solving problems with an increase in surface roughness of the polyimide substrate when manufacturing the polyimide film having impregnated glass fabric in order to enhance thermal and mechanical properties of a film for use in flexible display substrates and in cover windows for flat panel displays and mobile phones. As the surface roughness of the polyimide film having impregnated glass fabric is flattened to the level of ones of nm from the level ranging of tens of nm to ones of μm, a thin film transistor process can be performed on the polyimide film substrate and the polyimide film is increased in optical transmittance and transparency and can thus be utilized as flexible display substrates and cover windows for flat panel displays and mobile phones.

Owner:KOREA ADVANCED INST OF SCI & TECH

Multifunctional magnesium oxysulfate ecological plate

The invention discloses a multifunctional magnesium oxysulfate ecological plate which comprises a base material, a framework material and a coating material, and is characterized in that the base material comprises the following components by mass percent: 100Kg magnesium oxide, 40Kg heptahydrate magnesium sulfate, 70 to 90Kg water, 0.6Kg modifier aluminium sulphate, 35Kg fly ash and 35 to 45 Kg saw dust; the skeleton layer of the multifunctional magnesium oxysulfate ecological plate is made of glass fabric and non-woven fabric; the coating material comprises the following components by mass percent: 100kg magnesium oxide, 400Kg heptahydrate magnesium sulfate, 45 to 55kg water, 0.6Kg modifier aluminium sulphate and 35Kg fly ash. Since the heptahydrate magnesium sulfate is used as a cementing material in the composition of the multifunctional magnesium oxysulfate ecological plate, defects of weak water resistance, moisture absorption and efflorescence, crack and deformation, insufficient rigidity and the like in a conventional glass magnesium board are overcome, and the flexibility and the durability of the plate are enhanced. The multifunctional magnesium oxysulfate ecological plate meets the decoration requirements of inner and outer walls, and has the characteristics of simplicity and convenience in construction, and wide application range.

Owner:仪陇县民信高分子材料科技有限公司

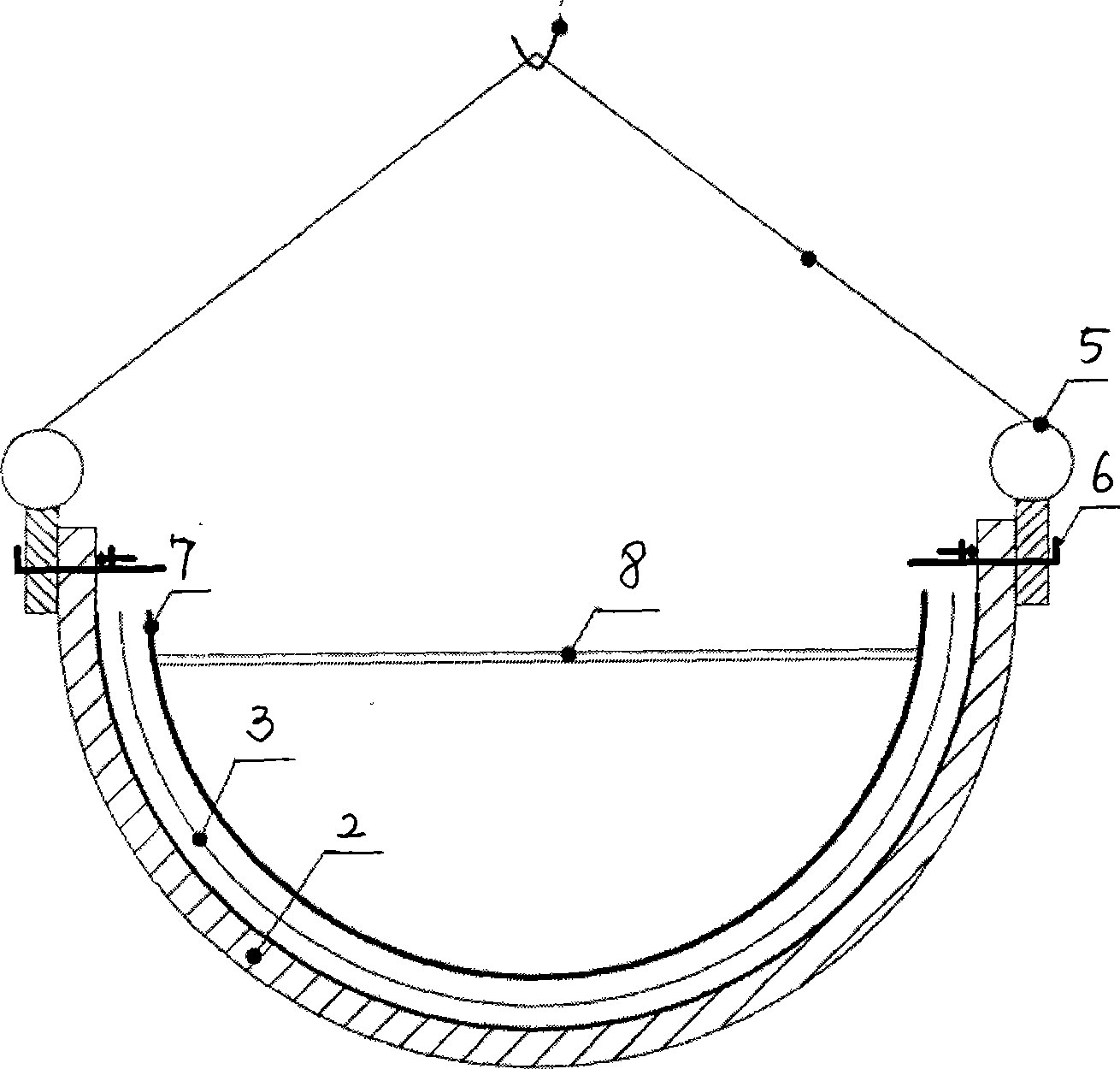

Manufacturing method for root part of megawatt wind turbine blade

The invention discloses a manufacturing method for a root part of a megawatt wind turbine blade, which comprises the following steps of: making a root part insertion component on an auxiliary mechanism; overturning and hanging the insertion component; because the curvature radius of the insertion component when hanging into a blade die is less than that of the blade die, the fabric of the root part insertion component can well adhere to the surface of the die; and continuously layering the left root part fabric on the surface of the inserted root part insertion component fabric; after the layering is completed, filling a resin under vacuum; and curing and shaping. Because the inserted insertion component is a dry fabric, the over 100 layers of fabric on the root part can be filled together, so the phenomenon that a dry area is easy to appear in a glass fabric under the cured insertion component is avoided. The manufacturing method avoids the phenomena, such as collapse, fold and the like, caused by directly layering by the traditional handwork and is an improvement on the conventional method.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

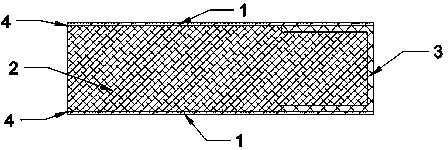

Lightweighting high-strength composite material vehicle shelter panel

ActiveCN104018617AReduce heat transferReduce thermal stressSynthetic resin layered productsLaminationFiberCarbon fibers

The invention provides a lightweighting high-strength composite material vehicle shelter panel, which comprises a sheath, an intermediate foam interlayer, a peripheral bound edge and a structural adhesive. The sheath takes a carbon fiber satin fabric prepreg and a glass fabric prepreg as raw materials, a vacuum baking oven technology is employed for forming, the peripheral bound edge employs a U-shaped structure, the carbon fiber satin fabric prepreg is taken as a raw material, an autoclave technology is employed for forming, and the foam interlayer employs PVC foam. Compared with the prior art, the composite material sheath has small thermal conduction coefficient and zero thermal expansion coefficient, thermal stress between sheath and the epoxy structural adhesive is little, so that the sheath and the structural adhesive are difficulty to degum, and the degumming phenomenon due to thermal deformation under high temperature can be solved. sheath, foam and bound edge employ one shot forming, the surface is smooth and flat, the assembling part is less, assembling cost and assembling time are greatly reduced, daily maintenance is easy, the weight is light, bearing is large, and the impact intensity is high.

Owner:HENGSHEN

Magnesium oxysulfate board structure and formula and processing technique thereof

InactiveCN106193507ASmall thickness errorReduce Chloride ContentCovering/liningsBoard structureDeep processing

The invention discloses a magnesium oxysulfate board structure. The magnesium oxysulfate board structure comprises a middle-layer material (4), and is characterized in that first glass fabric (5) and a sanding layer (6) are sequentially arranged on the middle-layer material (4), and second glass fabric (3) and a bottom pulp layer (1) are sequentially arranged under the middle-layer material (4). The magnesium oxysulfate board structure has the beneficial effects that after sanding is conducted through a reasonable formula and processing technique, the thickness error of a board is reduced to be within + / -0.3 mm, using and deep processing in the later stage are facilitated, and the magnesium oxysulfate board structure is suitable for application and popularization.

Owner:常州布鲁科技有限公司

Ceramifiable silicon rubber composite belt

ActiveCN103236294AHigh strengthGood flexibilityCeramicsInsulated cablesComposite ceramicFumed silica

The invention belongs to the technical field of a heat-conducting interface material, and discloses a ceramifiable silicon rubber composite belt, which comprises a glass cloth reinforcing layer and a silicon rubber layer, wherein the silicon rubber layer is prepared from a ceramifiable silicon rubber composition; the ceramifiable silicon rubber composition comprises organosilicon rubber compound and composite ceramic powder; the weight ratio of the organosilicon rubber compound to the composite ceramic powder is 1:1-1.2; the organosilicon rubber compound comprises vinyl terminated methyl vinyl silicon rubber, methyl vinyl silicon rubber, hydrogen containing silicone oil and fumed silica with different vinyl contents; and the composite ceramic powder comprises silicon carbide, alumina, zirconia, boron oxide and montmorillonite. The ceramifiable silicon rubber composite belt has extremely high strength and good flexibility and can be used for manufacturing a fire-resistant cable in place of a mica tape; and after a cable lapped by using the ceramifiable silicon rubber composite belt is ablated for 180 minutes in flame of 650-950 DEG C, the cable can still work normally.

Owner:广东安迪新材料科技有限公司

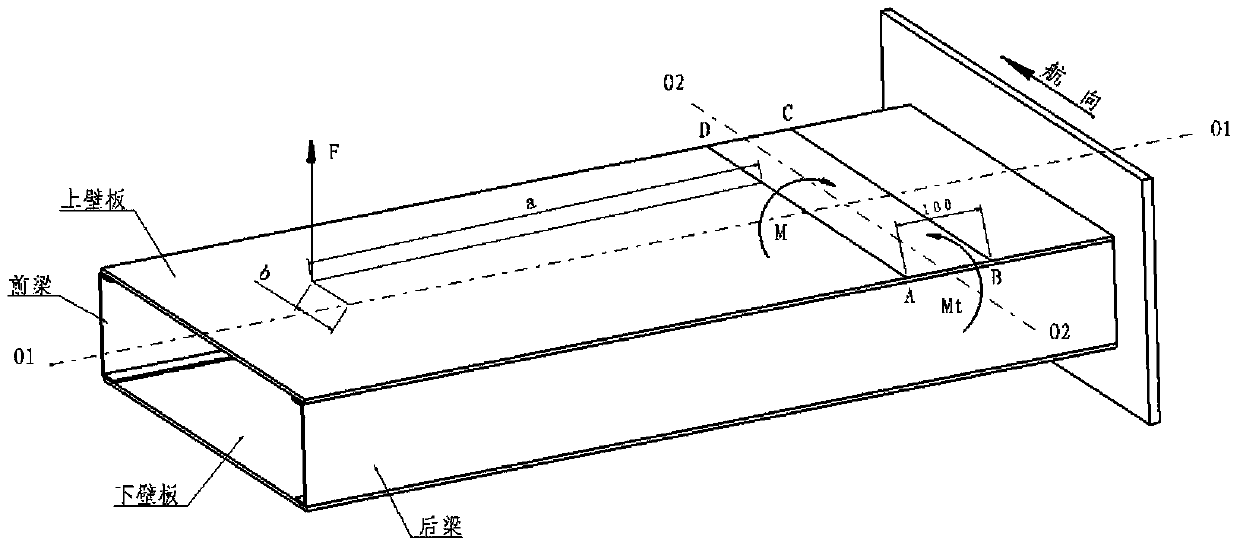

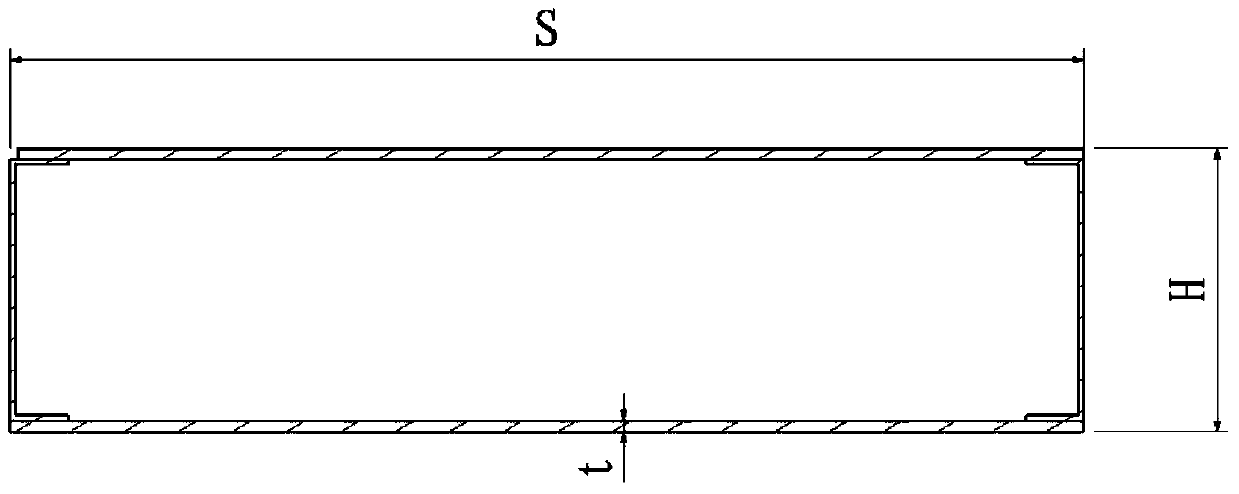

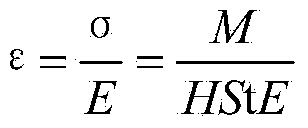

Method for designing structure of large-scale composite material reinforced wall plate

ActiveCN103729498AAccurately determineFast resultsSpecial data processing applications3D modellingElement modelMetallic materials

The invention discloses a method for designing the structure of a large-scale composite material reinforced wall plate, and belongs to the field of structural design of aircraft composite materials. The method comprises the steps that according to the design of the composite materials, shearing stress gamma and positive stress epsilon are selected to be used, the specific value of the equivalent elastic modulus E to the shear modulus G of a metal-material box section wall board is calculated, according to the specific value, the layering proportion of a composite material laminated plate in an inspection area is determined, then the number, angle and sequence of initial layered layers in the inspection area are determined according to the situation of the stress, the layer angle information and material performance data are input to a finite element model to solve the stress and check stability, after iteration, the number, sequence and angle of skin stringer layered layers are determined, it is ensured that all the layers are symmetrically balanced, digital modeling is adopted, and three-dimensional annotations, glass cloth layering, materials, processing notes and other information are digitized. According to the method, the design and manufacturing period of the large-scale composite material reinforced wall plate is greatly shortened, and meanwhile the quality of the product is greatly improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

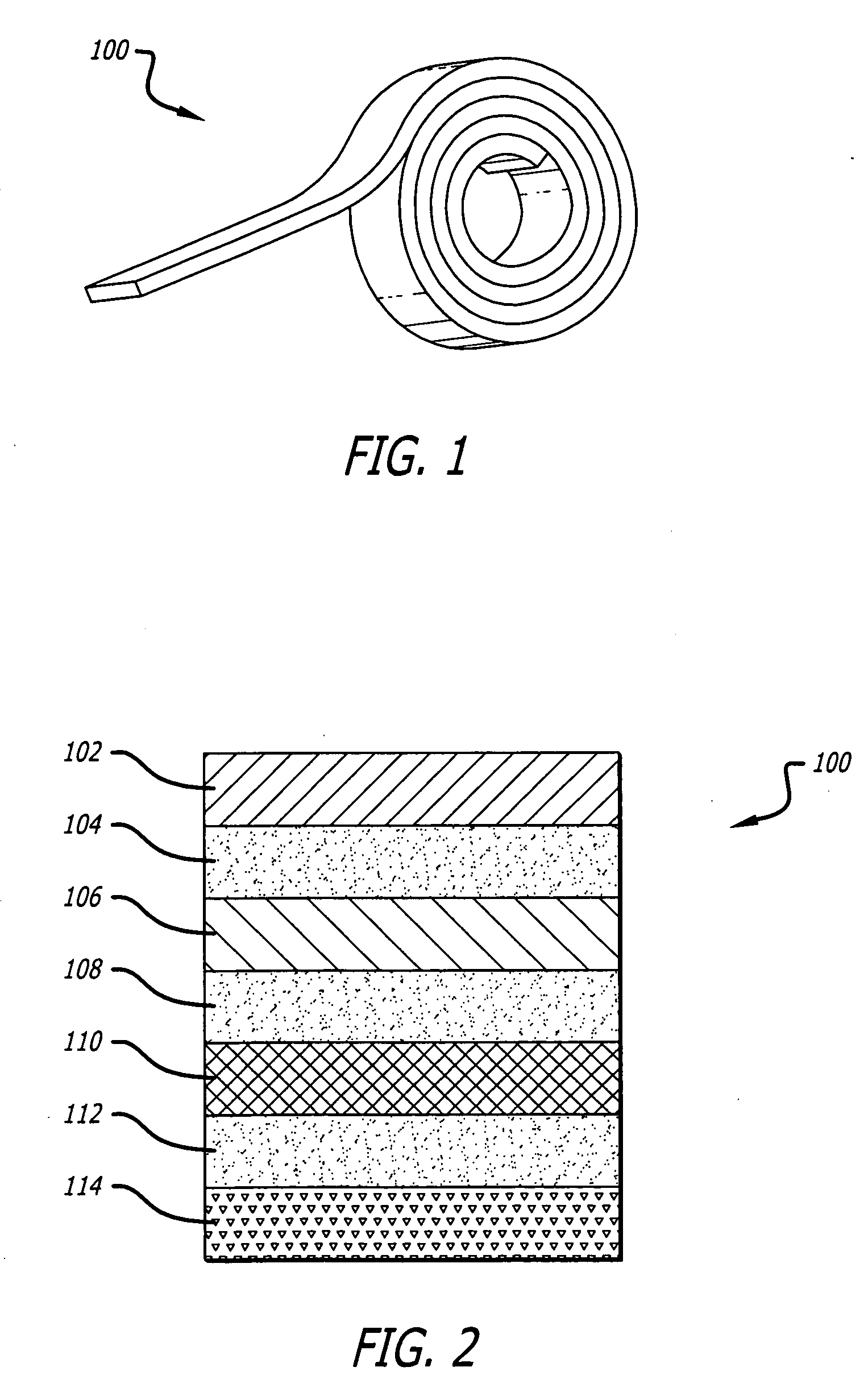

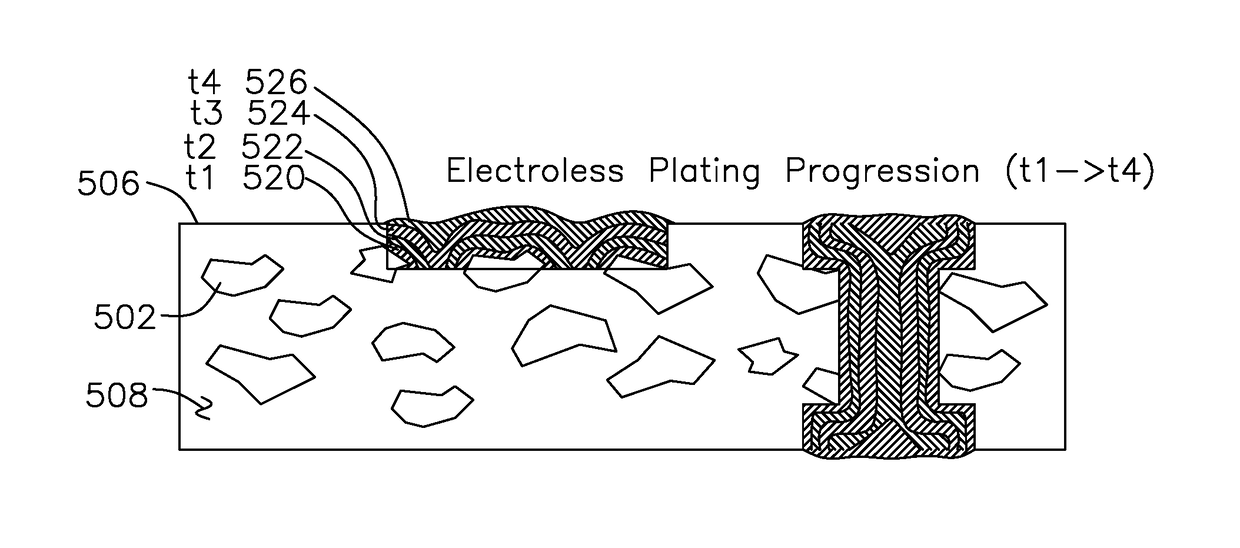

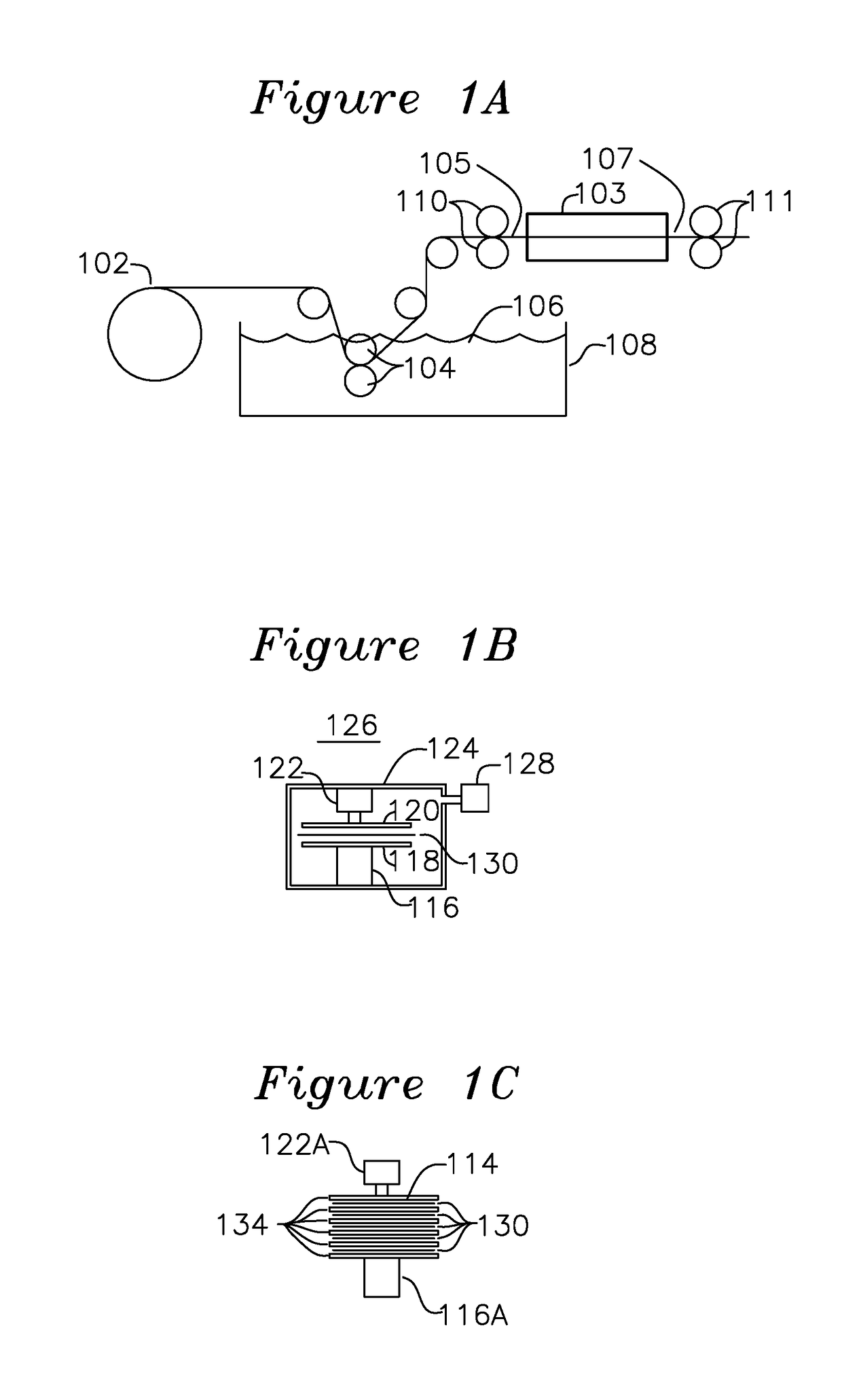

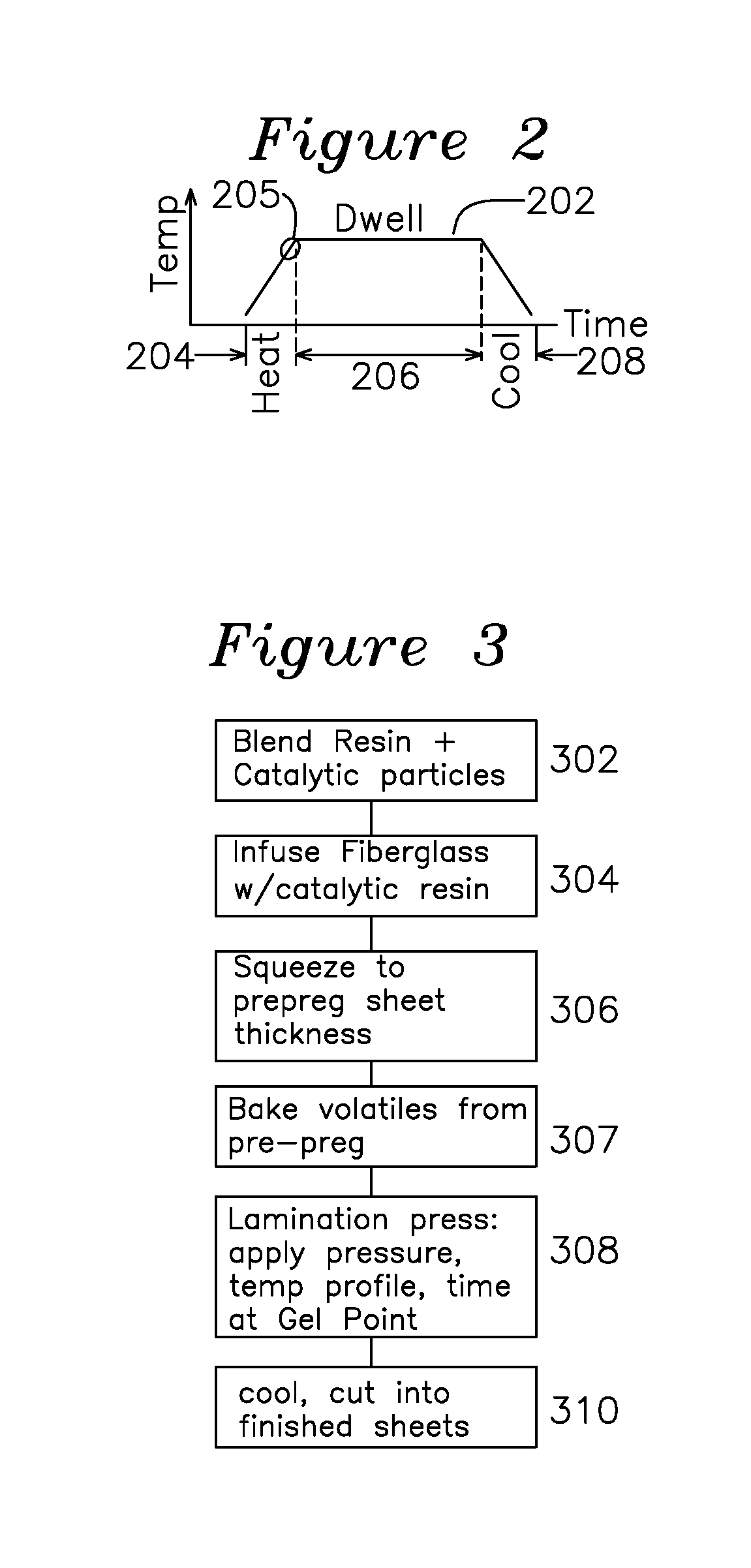

Catalytic laminate apparatus and method

ActiveUS9706650B1Insulating substrate metal adhesion improvementPrinted circuit aspectsHomogeneous catalysisCatalytic particle

A catalytic resin is formed by mixing a resin and either homogeneous or heterogeneous catalytic particles, the resin infused into a woven glass fabric to form an A-stage pre-preg, the A-stage pre-preg cured into a B-stage pre-preg, thereafter held in a vacuum and between pressure plates at a gel point temperature for a duration of time sufficient for the catalytic particles to migrate away from the resin rich surfaces of the pre-preg, thereby forming a C-stage pre-preg after cooling. The C-stage pre-preg subsequently has trenches formed by removing the resin rich surface, the trenches extending into the depth of the catalytic particles, optionally including drilled holes to form vias, and the C-stage pre-preg with trenches and holes placed in an electroless bath, whereby traces form in the trenches and holes where the surface of the cured pre-preg has been removed.

Owner:CATLAM LLC

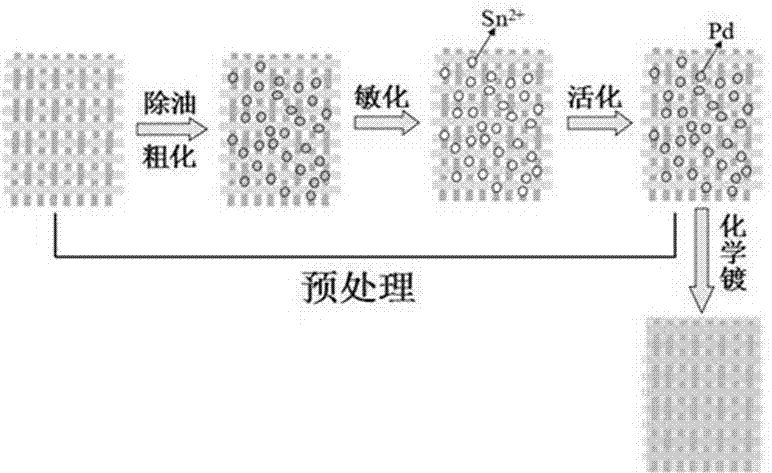

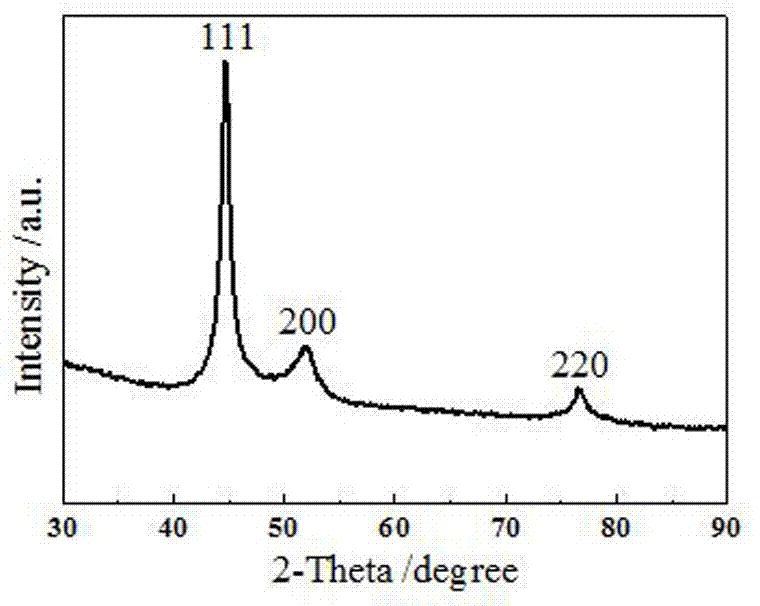

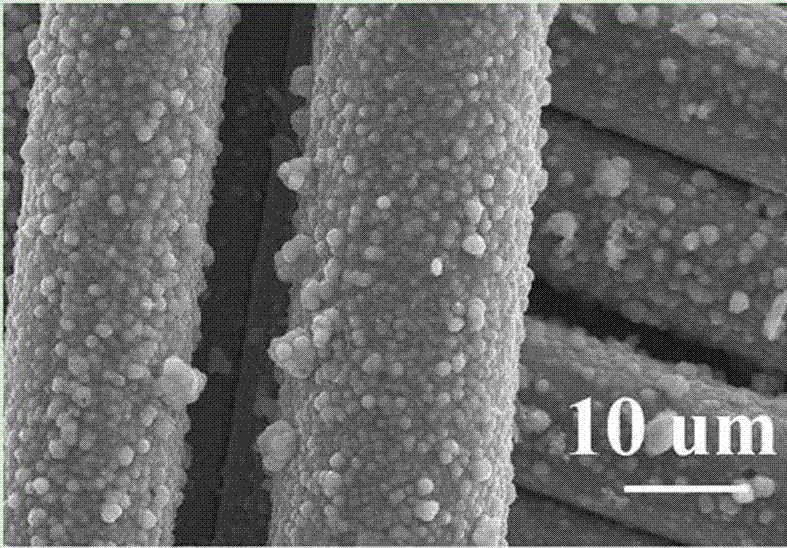

Preparing method for nickel plating glass fiber fabric/epoxy resin electromagnetic shielding composite material

The invention relates to the field of fiber enhanced resin base functional composite materials, in particular to a nickel plating glass fiber fabric and a method for preparing an epoxy resin electromagnetic shielding composite material with the nickel plating glass fiber fabric as a functional material. Firstly, the glass fiber fabric is subjected to surface pretreatment, so that the surface of the glass fiber fabric has certain catalytic activity. The specific pretreatment technology comprises the steps of oil removing, roughening, sensitization and excitation. Then, the surface of the glass fiber fabric is plated with metal nickel through a chemical plating method. The prepared nickel plating glass fabric is immersed in an epoxy resin base body, and the electromagnetic shielding composite material is prepared through a laminating forming method. Or, the prepared nickel plating glass fiber fabric is laid in the die, and then the epoxy resin electromagnetic shielding composite material is prepared through the RTM forming technology. The volume resistivity of the prepared electromagnetic shielding composite material is 10<-3>omega.cm, the shielding effectiveness can reach 60dB or above within the frequency range of 2-18 GHz, and good mechanical performance is achieved.

Owner:ZHONGBEI UNIV

Method for manufacturing colorless transparent glass-fabric reinforced polyimide film for flexible displays

ActiveUS20140238594A1Improve mechanical propertiesImprove thermal propertiesSynthetic resin layered productsLaminationPolyimide substrateOptical transparency

A method of manufacturing a colorless transparent polyimide film having reinforced glass fabric for flexible displays, suitable for use in increasing optical transmittance of a polyimide substrate having reinforced glass fabric for flexible displays. This method enables the glass fabric and the colorless transparent polyimide film to be matched in refractive index when the glass fabric is reinforced in the colorless transparent polyimide film to enhance thermal and mechanical properties of a substrate for flexible displays, thus satisfying high optical transparency and optical transmittance of 85% or more, required of a substrate for flexible displays, and thereby the colorless transparent polyimide film having reinforced glass fabric can be used as a substrate for flexible displays.

Owner:KOREA ADVANCED INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com