Magnesium oxysulfate board structure and formula and processing technique thereof

A technology of magnesium oxysulfide board and formula, which is applied in the direction of building structure, construction, covering/lining, etc., can solve the problems of large thickness error of the board, inconvenient use of deep processing, etc., and achieve the effect of reducing thickness error and overcoming anti-halogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

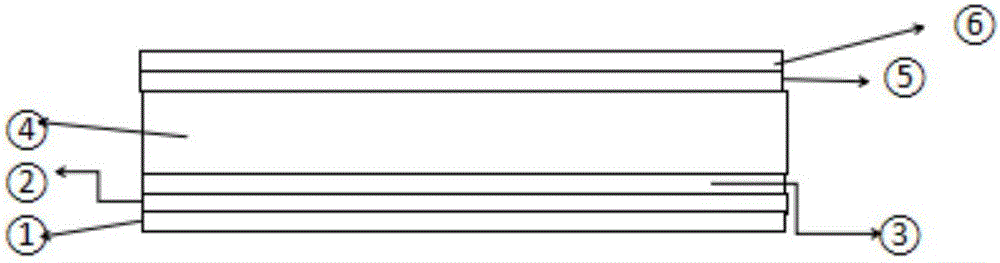

[0067] As shown in the figure, this implementation processes a magnesium oxysulfide fireproof board, including a middle layer material 4, and the top of the middle layer material 4 is sequentially provided with a glass fiber cloth-5 and a sanding layer 6; the bottom of the middle layer material 4 is sequentially arranged Glass fiber cloth two 3 and primer layer 1; the formula of described primer layer 1 is:

[0068] Lightly burned magnesia: 100 parts;

[0069] Magnesium sulfate heptahydrate: 40 parts;

[0070] Water: 50 parts;

[0071] Talcum powder: 20 parts;

[0072] Latex powder: 6 parts;

[0073] Modifier: 1 part;

[0074] 3 parts of pigment;

[0075] The formula of the middle layer material 6 is:

[0076] Lightly burned magnesia: 100 parts;

[0077] Magnesium sulfate heptahydrate: 40 parts;

[0078] Water: 60 parts;

[0079] Sawdust: 20 parts;

[0080] Other fillers: 4 parts;

[0081] Modifier: 1 part;

[0082] Pigment: 1 part;

[0083] The recipe for sanding l...

Embodiment 2

[0122] As shown in the figure, this implementation processes a magnesium oxysulfide fire door lining board, including a middle layer material 4, and the top of the middle layer material 4 is sequentially provided with a glass fiber cloth-5 and a sanding layer 6; the middle layer material 4 The glass fiber cloth 2 3 and the primer layer 1 in sequence below;

[0123] The formula of the primer layer 1 is:

[0124] Lightly burned magnesia: 100 parts;

[0125] Magnesium sulfate heptahydrate: 50 parts;

[0126] Water: 55 parts;

[0127] Talcum powder: 30 parts;

[0128] Latex powder: 9 parts;

[0129] Modifier: 2 parts;

[0130] 5 parts of pigment;

[0131] The formula of the middle layer material 6 is:

[0132] Lightly burned magnesia: 100 parts;

[0133] Magnesium sulfate heptahydrate: 50 parts;

[0134] Water: 70 parts;

[0135] Sawdust: 30 parts;

[0136] Other fillers: 15 parts;

[0137] Modifier: 2 parts;

[0138] Pigment: 4 parts;

[0139] The recipe for sanding...

Embodiment 3

[0178] As shown in the figure, this implementation processes a special plate for magnesium oxysulfide purification, including a middle layer material 4, and the top of the middle layer material 4 is sequentially provided with a glass fiber cloth-5 and a sanding layer 6; the bottom of the middle layer material 4 is sequentially Secondary glass fiber cloth 2 3 and primer layer 1;

[0179] The formula of the primer layer 1 is:

[0180] Lightly burned magnesia: 100 parts;

[0181] Magnesium sulfate heptahydrate: 50 parts;

[0182] Water: 61 parts;

[0183] Talcum powder: 40 parts;

[0184] Latex powder: 12 parts;

[0185] Modifier: 3.5 parts;

[0186] 7 parts of pigment;

[0187] The formula of the middle layer material 6 is:

[0188] Lightly burned magnesia: 100 parts;

[0189] Magnesium sulfate heptahydrate: 65 parts;

[0190] Water: 80 parts;

[0191] Sawdust: 40 parts;

[0192] Other fillers: 25 parts;

[0193] Modifier: 3.5 parts;

[0194] Pigment: 7 parts;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com