Soft-packaged lithium battery thickness measuring device

A technology of thickness measurement and lithium battery, which is applied in the direction of measuring devices and instruments, can solve the problems of little comparison significance, narrow application range, and poor accuracy, and achieve the effect of wide application range, strong comparison significance, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

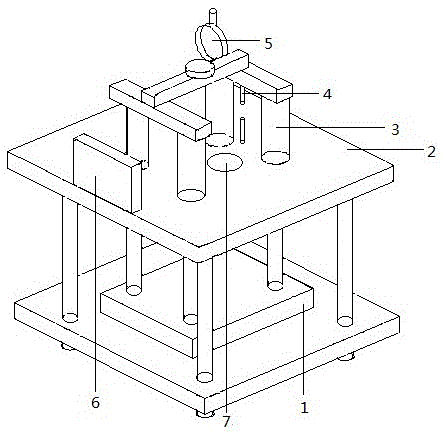

[0018] Such as figure 1 As shown, a soft pack type lithium battery thickness measuring device, the present invention includes a lower base 1, an upper base 2, a guide wire frame 3 is arranged on the upper base 2, and a needle 4 is arranged below the wire guide frame 3 , one side of the guide wire frame 3 is provided with a thickness gauge 5, the side of the upper base 2 is provided with a control system 6, and the top surface of the upper base 2 is provided with a level 7, between the upper base 2 and the lower base 1 Adjustable pillars are used for overhead, and the upper base 2 is parallel to the lower base 1 .

[0019] The needles 4 are made of the following materials: 2.15% lithium metaaluminate, 82.8% iron, 6.9% carbon, 1.22% nickel, 1.48% manganese, 4.2% copper oxide, and 1.25% mercury.

[0020] A barometer is included in the control system, and its air pressure is 0.5mpa.

[0021] Packet counter in the control system to record the number of tested batteries, the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com