Patents

Literature

87results about How to "Small thickness error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel radiation crosslinked polyethylene thin foam and preparation method thereof

InactiveCN107090113AHigh mechanical strengthHigh tensile strengthFlat articlesWeather resistanceRadiation

The invention discloses novel radiation crosslinked polyethylene thin foam and a preparation method thereof, and relates to the technical field of foam plastic material. The novel radiation crosslinked polyethylene thin foam designed by the invention is prepared from the following raw materials in percentage by mass: 42-87.9% of a main material and the balance of auxiliary materials; the main material adopts LDPE; the auxiliary materials comprise a POE constituent strengthening auxiliary, an EPDM constituent weather-proof additive and an azobisformamide constituent foaming agent; and the strengthening auxiliary, the weather-proof additive and the foaming agent respectively account for 5-30%, 1-10% and 5-10% of the radiation crosslinked polyethylene thin foam by mass. The material has relatively ideal intrinsic mechanical strength as well as greatly improved aging resistance and weather resistance.

Owner:湖州长园特发科技有限公司

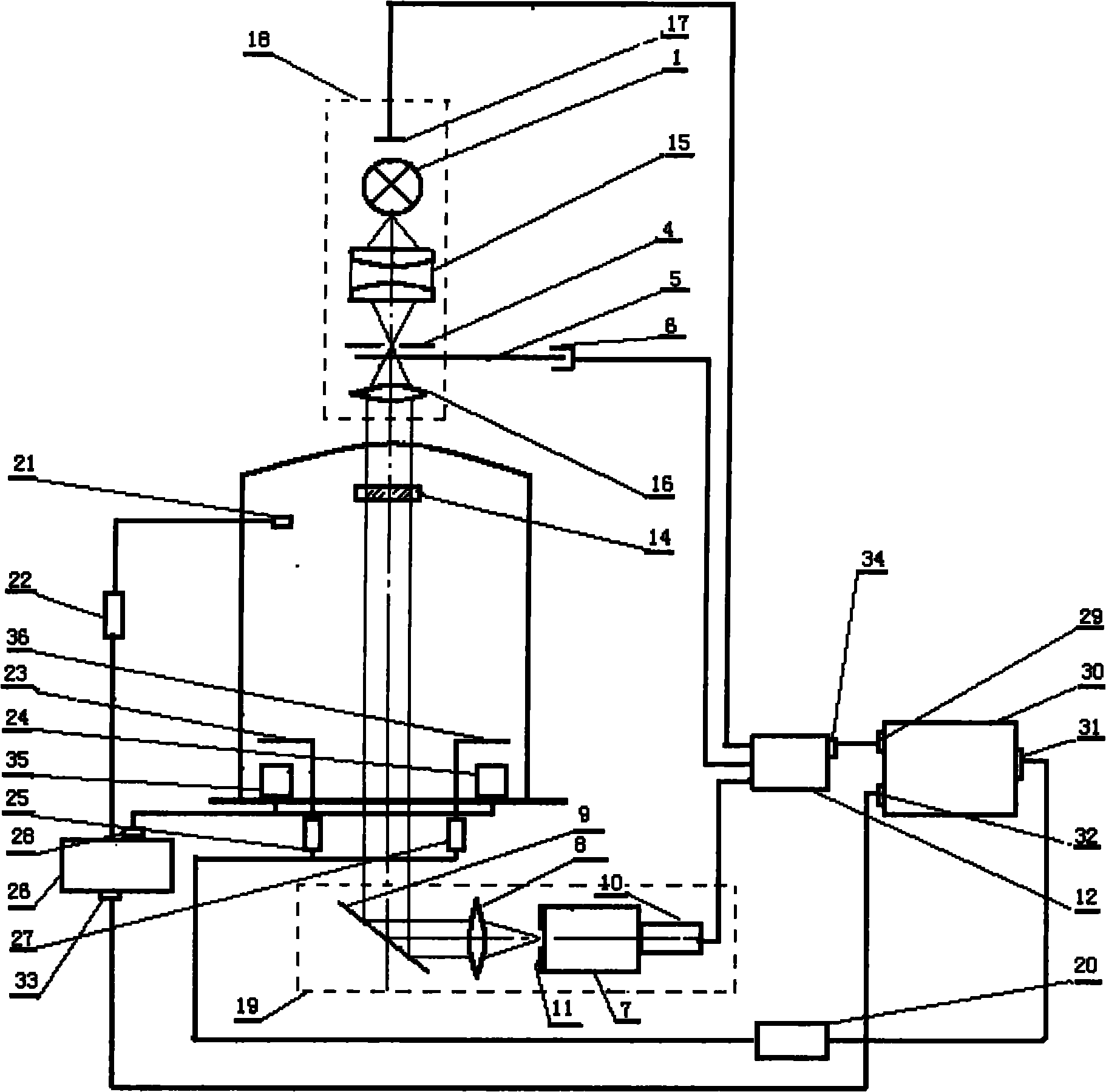

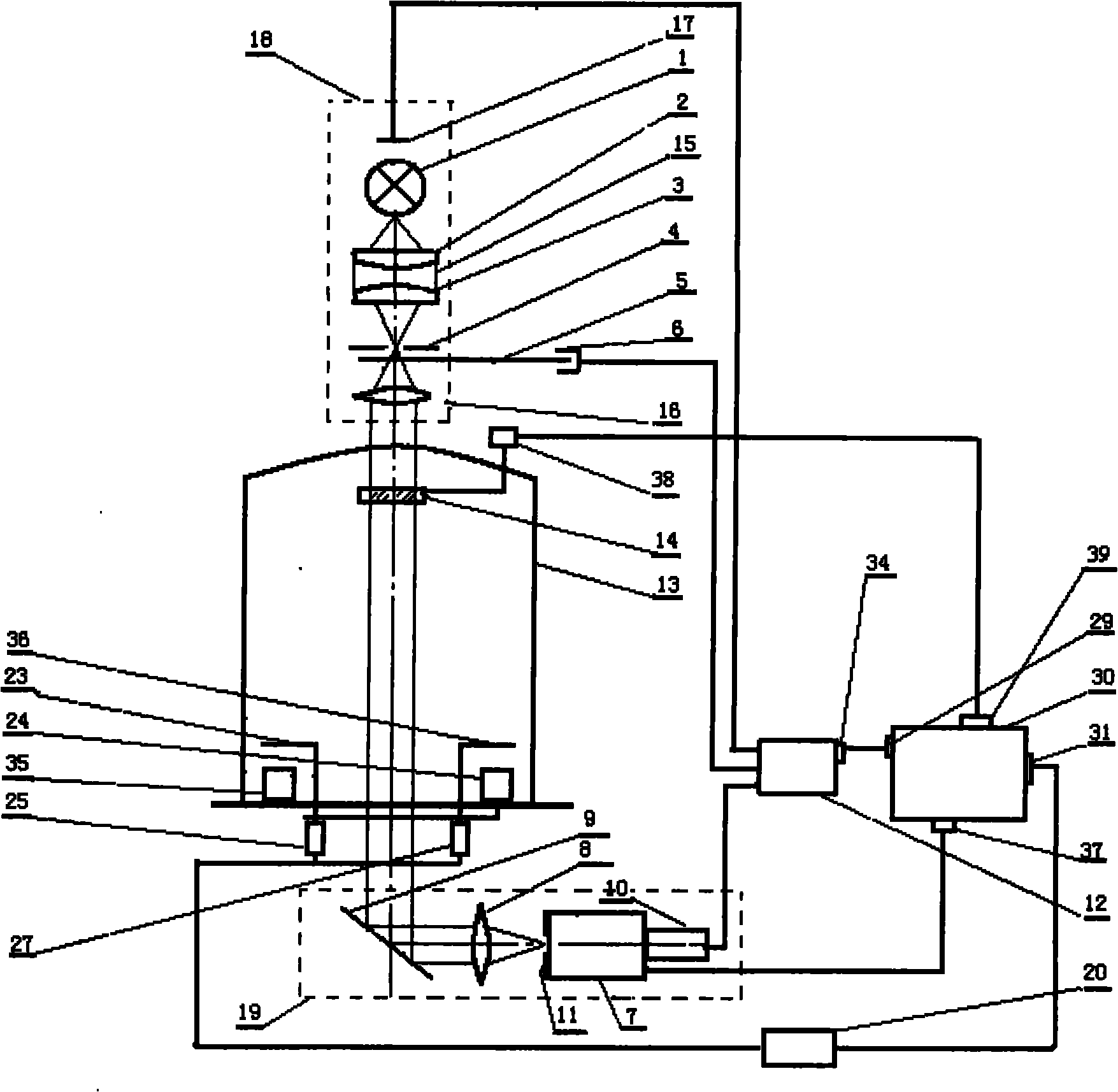

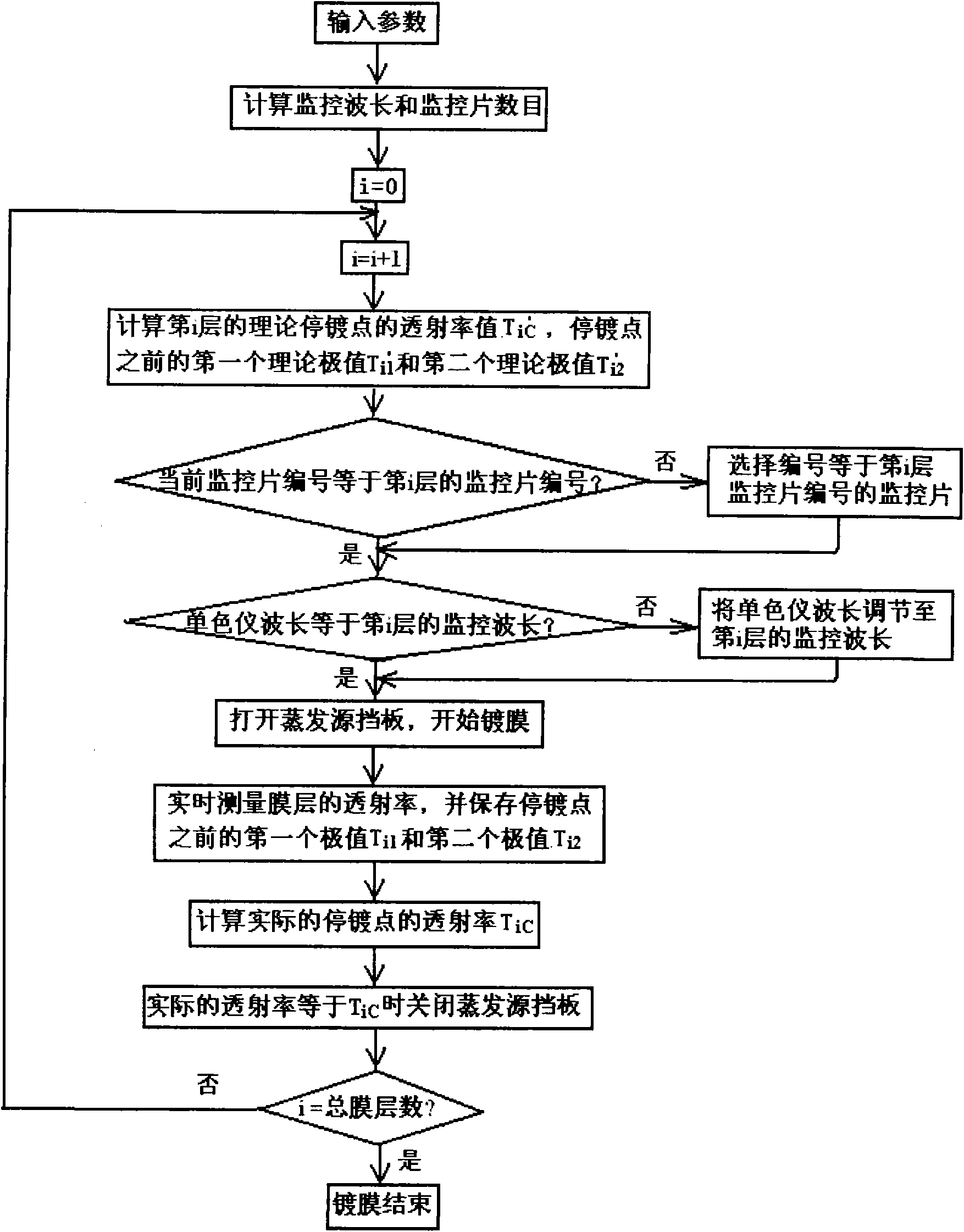

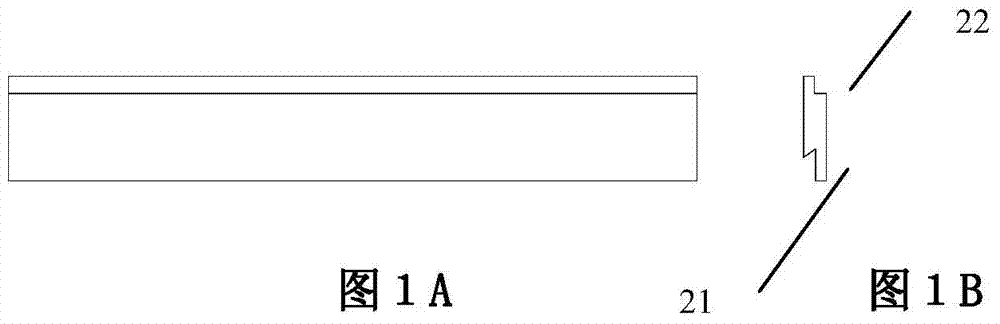

Film thickness monitoring method capable of increasing spectral characteristics of film

ActiveCN102191475ADirect Monitoring of Optical DepthReduce control errorVacuum evaporation coatingSputtering coatingCoating systemMonitoring system

The invention relates to a film thickness monitoring method capable of increasing spectral characteristics of film, for a computer-controlled coating device. The method comprises the following steps: (1) inputting coating parameters to a computer before coating; (2) selecting the monitoring wavelengths and monitoring glass number satisfying the limited conditions through the calculation of the computer to obtain a coating monitoring table of the coating system, wherein lambda Min<lambda<lambda Max and the coating monitoring table contains sequential films of the coating system, the corresponding monitoring wavelengths and monitoring glass serial numbers; and (3) coating and the like. By adopting the method, the monitoring wavelengths and required mininum monitoring glass number can be automatically selected; by adopting the proportional film thickness monitoring method, the film thickness monitoring error can be reduced, the film thickness monitoring precision can be increased and the normalized coating system and the non-normalized coating system can be monitored. Under the condition that the control precision of the film thickness monitoring system is not changed, the spectral characteristics of the film can be effectively increased.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

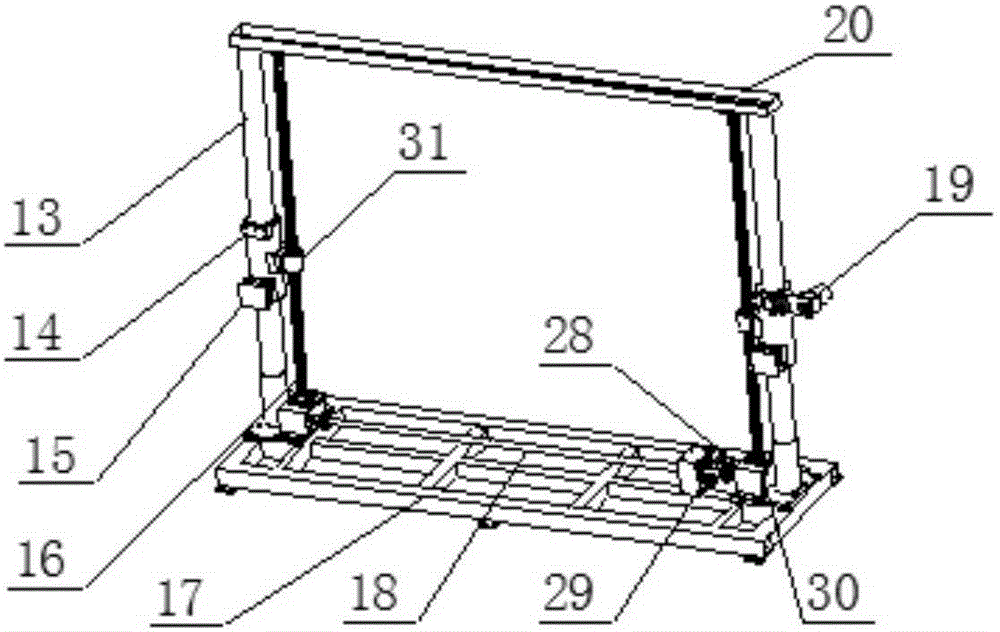

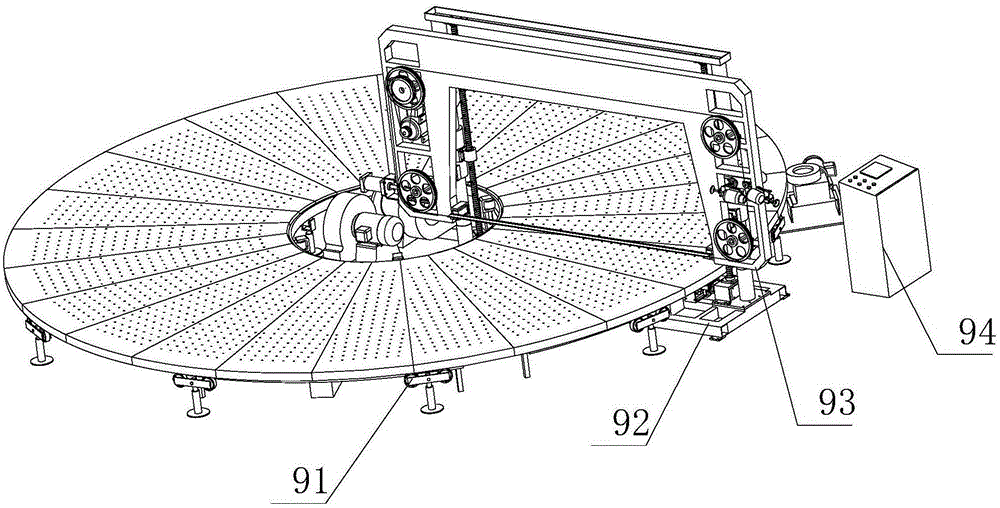

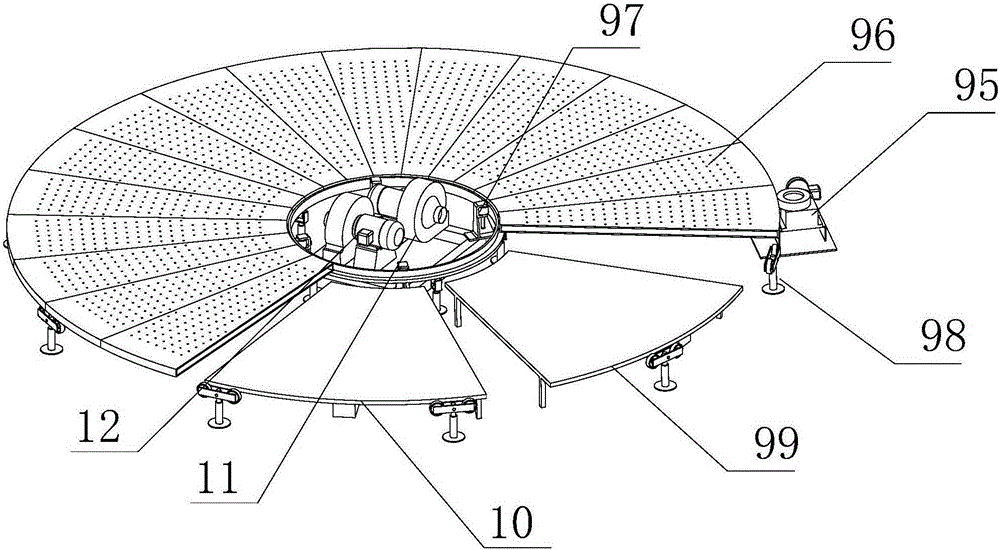

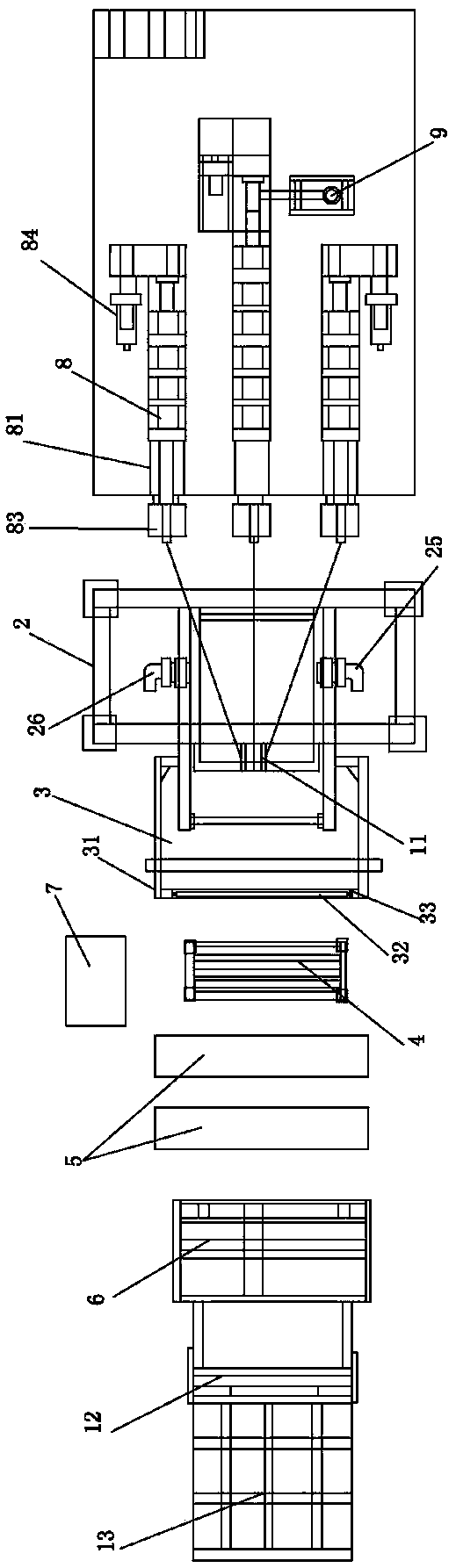

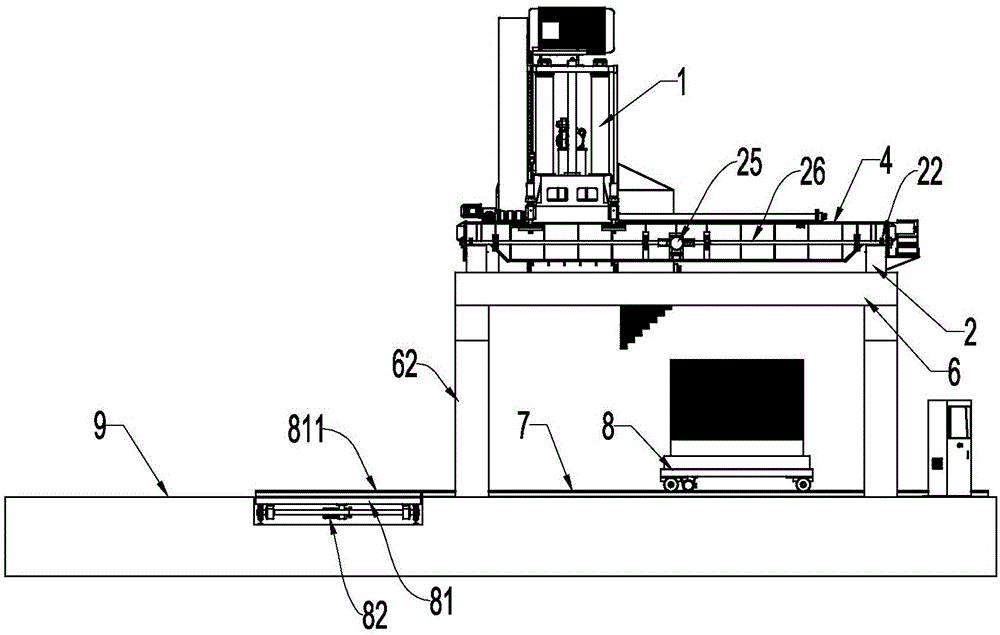

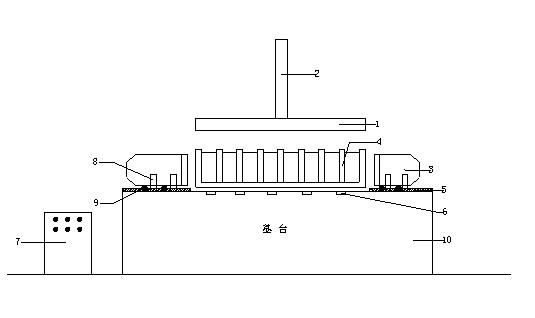

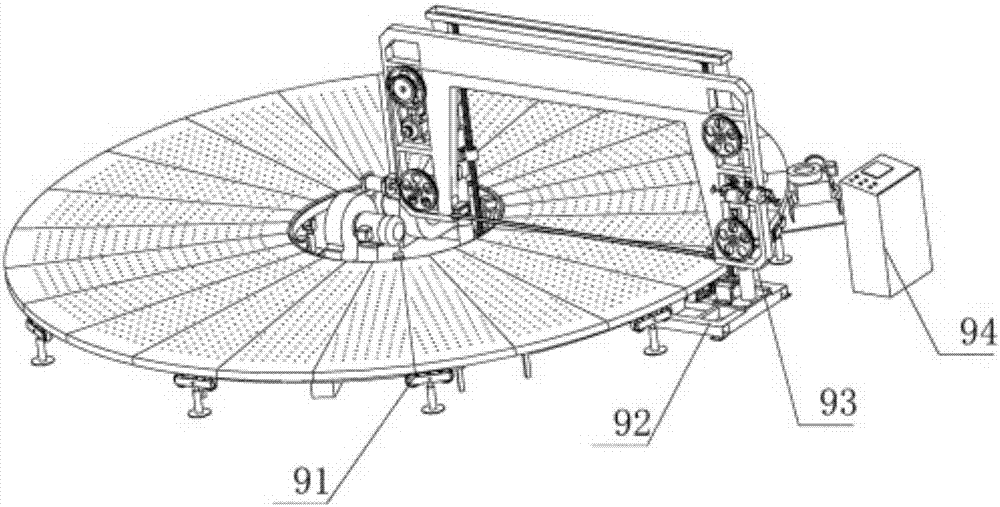

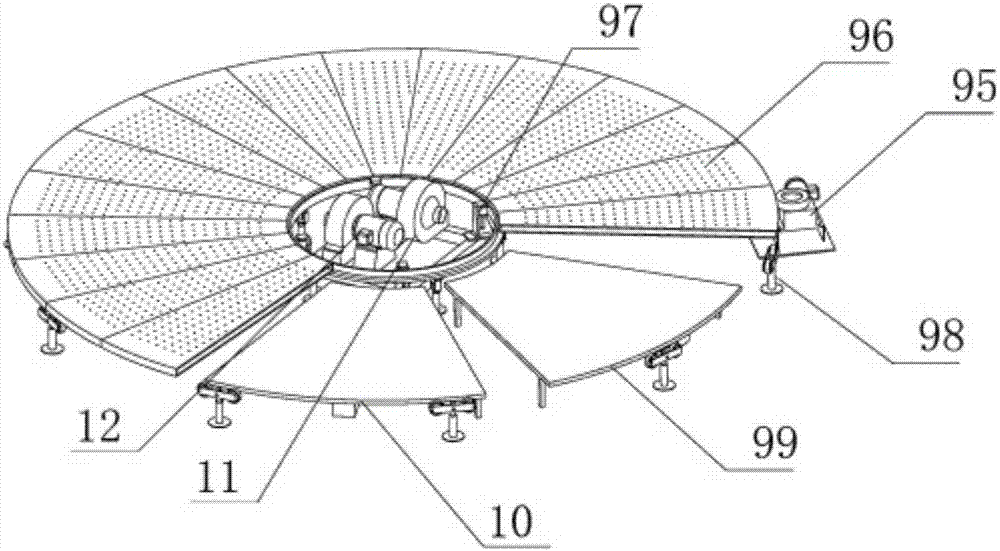

Full-automatic sponge disk horizontal cutting machine

ActiveCN105171808AImprove work efficiencyEasy to operateMetal working apparatusCircular discEngineering

The invention provides an efficient full-automatic sponge disk horizontal cutting machine. The full-automatic sponge disk horizontal cutting machine comprises a platform and a main machine frame. The main machine frame and a tool rest are connected together. The platform is horizontally placed below the tool rest. An electric cabinet which controls the main machine frame and a plurality of motors on the tool rest to work is arranged on the side of the platform. A pneumatic tensioning device and an angle adjusting device are arranged on the main machine frame. The cutting thickness and the cutting frequency are set on the electric cabinet, then the tool rest is moved to the proper position, a start button on the electric cabinet is pressed to drive a tool belt on the tool rest to work, a friction driving wheel on the platform drives platform plates to rotate, and therefore the cutting work is accomplished. By the adoption of the full-automatic sponge disk horizontal cutting machine, the working efficiency of cutting of sponge sheets is improved, the thickness error of the sponge sheets is reduced, the surface quality of the sponge sheets is improved, and the working strength of workers is reduced.

Owner:郴州市艾立克机械制造有限公司

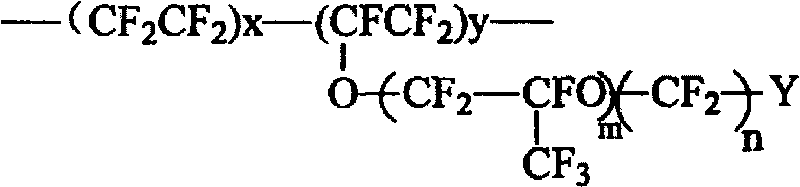

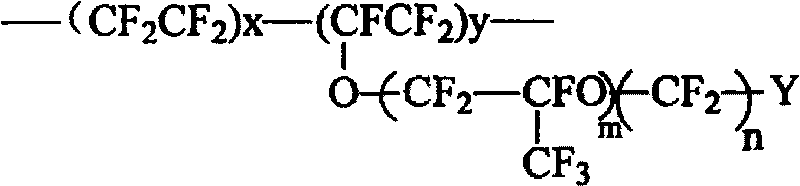

Method for preparing perfluorocarboxylic acid ion membranes by liquid surface tape casting method

ActiveCN101759864AImprove uniformitySimplify cumbersome operationsFinal product manufactureSolid electrolyte fuel cellsHigh densityThin layer

The invention relates to a method for preparing perfluorocarboxylic acid ion membranes, which is characterized in that the method comprises the following steps: (1) dissolving perfluorocarboxylic acid resin into a solvent for forming a uniform perfluorocarboxylic acid resin solution A; (2) adding materials with low melting point and high density into a heatable container, heating the container for dissolving the materials, and forming uniform liquid B in the container; (3) preheating the perfluorocarboxylic acid resin solution A and pouring the perfluorocarboxylic acid resin solution A onto the surface of the liquid B protected by nitrogen gas so that a thin layer solution is formed on the surface of the liquid B through casting; (4) heating the liquid B, then carrying out program temperature reduction, and continuously introducing the nitrogen gas for protection in the whole process; and (5) evaporating most or all of the solvent in the perfluorocarboxylic acid resin solution A to obtain the perfluorocarboxylic acid ion membrane on the surface of the liquid B. The perfluorocarboxylic acid ion membrane prepared by the invention can be applied to composite layers of sodium hudroxide use ion membranes, and has the advantages of uniform thickness, difficult bubble generation and stable performance, and the invention provides reliable carboxylic acid layer ion membranes for producing the sodium hudroxide use ion membranes.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

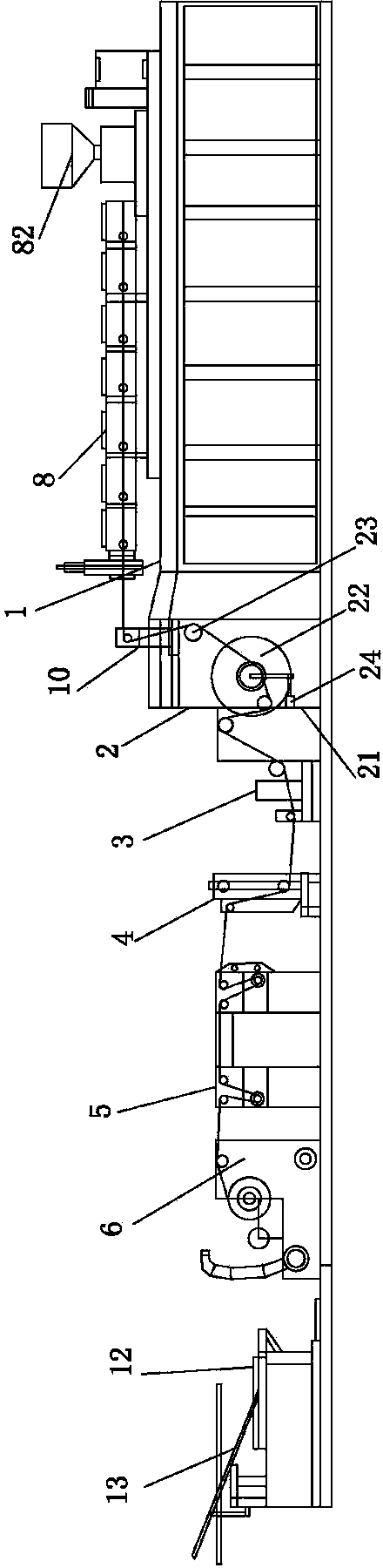

Winding film tape-casting production line

InactiveCN104002417ASmall thickness errorIncrease productivityCoatingsProduction lineMeasurement device

The invention discloses a winding film tape-casting production line which comprises a feeder machine, a casting device, a thickness measurement device, a swing device, a drawing device, a winding device and an electrical control cabinet, wherein the feeder machine is provided with a plurality of plastic extrusion devices; a feeding end of one plastic extrusion device is provided with an offcut feeding device; one side of the casting device is provided with a mould device; discharge ends of all the plastic extrusion devices are respectively communicated with a mould head on the mould device; a discharge end of the mould device is connected with a feeding end of the casting device; a discharge end of the casting device is connected with a feeding end of the thickness measurement device; a discharge end of the thickness measurement device is connected with a feeding end of the swing device, a discharge end of the swing device is connected with a feeding end of the drawing device; a discharge end of the drawing device is connected with a feeding end of the winding device; a core-pulling device and a paper tube release unloading device are arranged at one side of the winding device. The winding film tape-casting production line has the advantages of being high in production efficiency, low in error of the thickness of the produced winding film, high in transparency and the like; a dry laminating method is adopted, and working procedures such as automatically packaging are available.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Method for preparing semihomogeneous cation exchange membrane

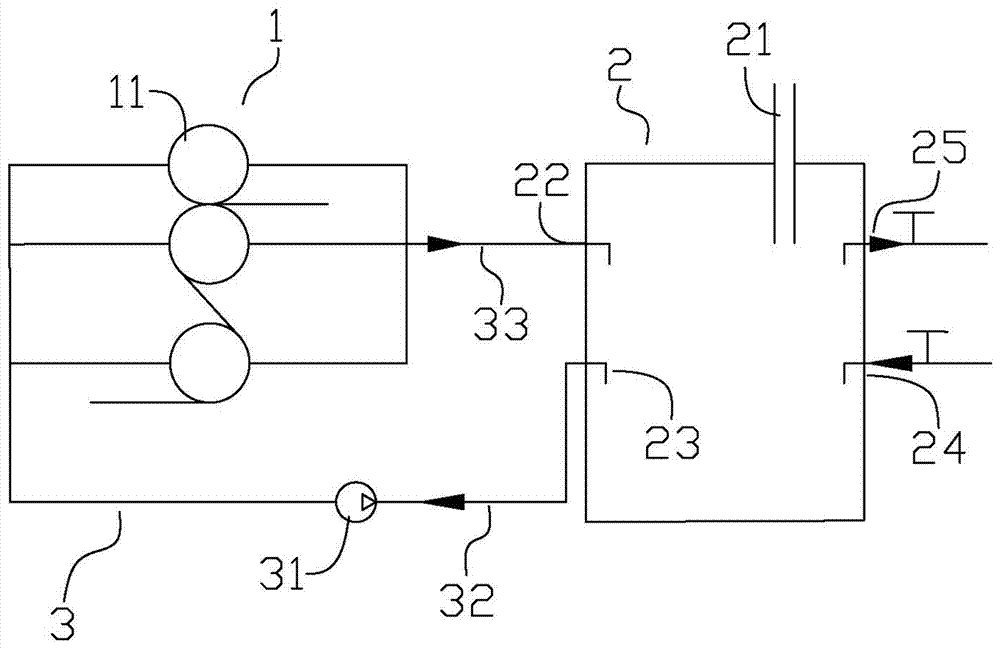

The invention discloses a method for preparing a semihomogeneous cation exchange membrane, and the method comprises the following steps: step 1), thermoplastic polyethylene-sulfonated polystyrene based cation exchange composite resin powder, non-thermoplastic cross-linked sulfonated polystyrene cation exchange resin powder, polyethylene powder and polyisobutylene powder are mixed evenly; step 2), a prefabricated membrane is obtained by successively melting blending in an internal mixer, discharging slices with a two-roller open mill, continuously rolling with a four-roller machine, cooling with a cold roll machine and cutting with a cutting machine; and step 3), the upper surface and the lower surface of the prefabricated membrane are covered with reinforced mesh cloth, and the semihomogeneous cation exchange membrane is obtained by pressing with a hot press. Sulfonic acid groups with cation exchange effect in the semihomogeneous cation exchange membrane prepared by the method are connected mutually without interruption, so that membrane surface resistance is greatly reduced. All kinds of membrane-forming materials are well compatible and tightly bonded, selective transmission of the membrane is higher, and the comprehensive performance is better than that of a heterogeneous cation exchange membrane in the prior art.

Owner:HANGZHOU IONTECH ENVIRONMENTAL TECH

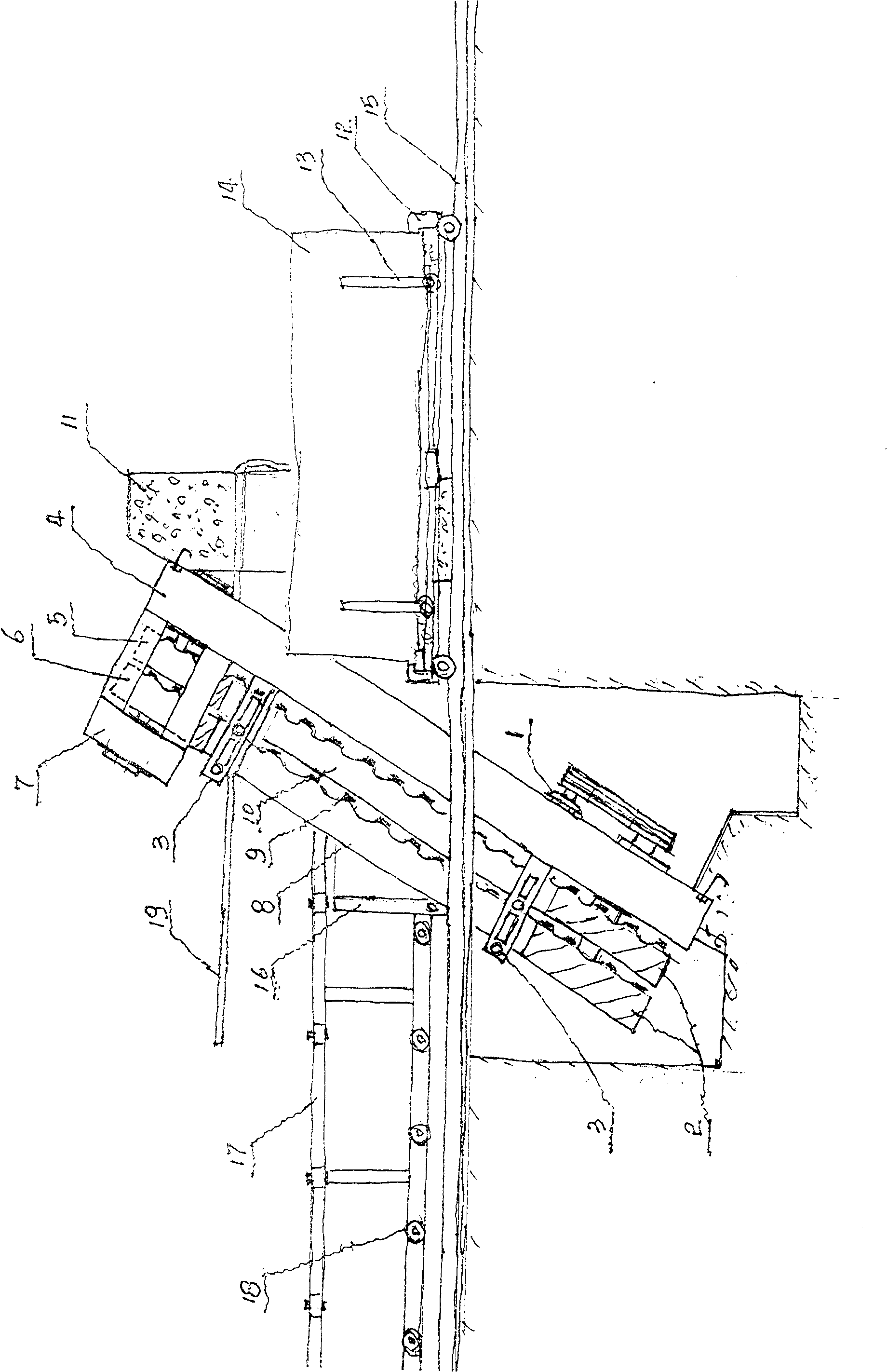

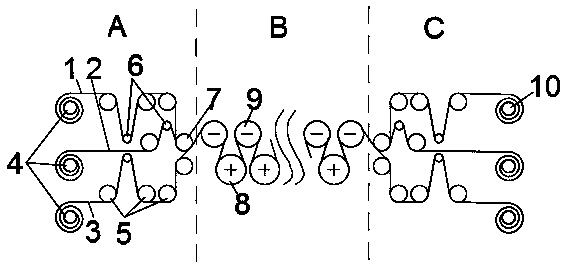

Incline type double-belt diamond saw machine

InactiveCN101357489AHigh yieldSmall thickness errorStone-like material working toolsNumerical controlFrequency conversion

The sloping-type double-strip diamond saw machine is aslope arranged on a column by a large frame with enough intensity. Two pairs of light flywheels with the diameter of 1600mm-1610mm are arranged on the large frame, and two driving flywheels are connected together at the lower end of the large frame and rotate under the driving of the driving motor. Two driven flywheels at the upper end of the large frame are respectively and correspondingly arranged on the slideways with different tensioners. The thickness of boards is made by anti-slip circles with different thickness. Two welding edge of the diamond knife head is strip steel in form of wave with the width of 200mm and the thickness of 1.4mm, the strip steel is welted into a circle and arranged on the two flywheels. The knife head is welted on the wave-shaped chimb by laser. When the host machine rotates, the knife head and the saw blades do high-speed rotation movement from top to down in the eight roller-type controllers. The cooling water pipe is located at the two sides of the top end of the saw blade and sprinkles water over the incision line of the saw blade. Under the driving of the frequency conversion motor, the flat vehicle filled with crude materials facilitates the crude materials to pass through the edge of the crude materials at different speeds and the demanded thickness under the control of the numerical control stowing tool. The working form that the saw blade B is at the front and the saw blade C is at the rear is formed gradually, and the two boards after being cut fall on the transportation bracket wheel which is horizontal to the bottom of the crude materials. When the flat vehicle returns to the stop point, the two boards on the bracket wheel are rotated by a plurality of bracket wheels simultaneously in the guard to the storage point, and the numerical control stowing tool carries out a second circulation to the thickness designed by pulsion of the crude materials.

Owner:陈双英

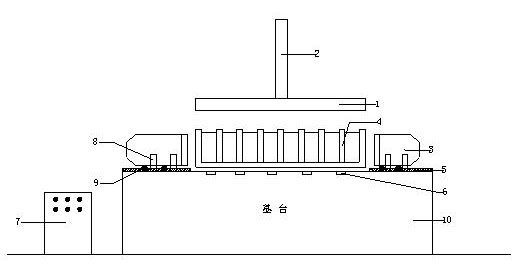

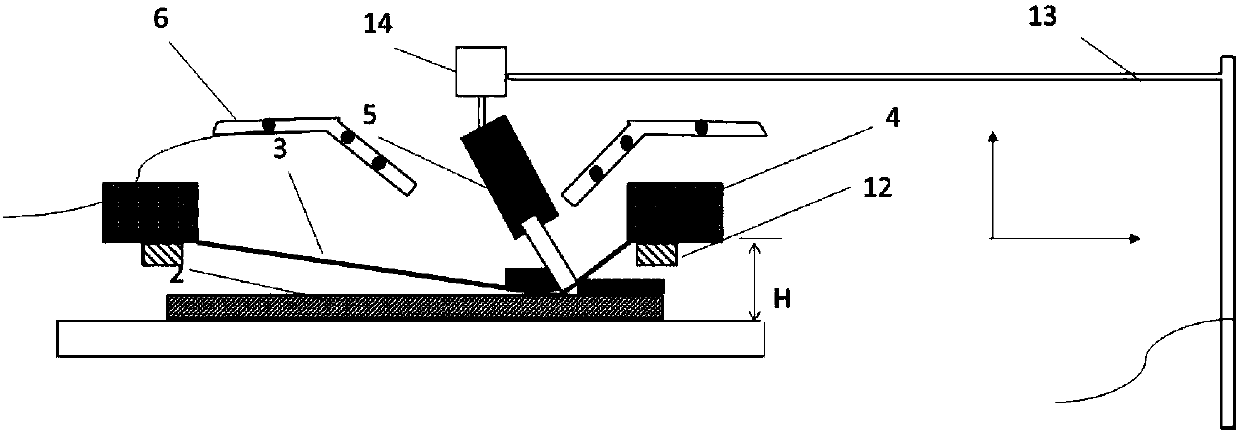

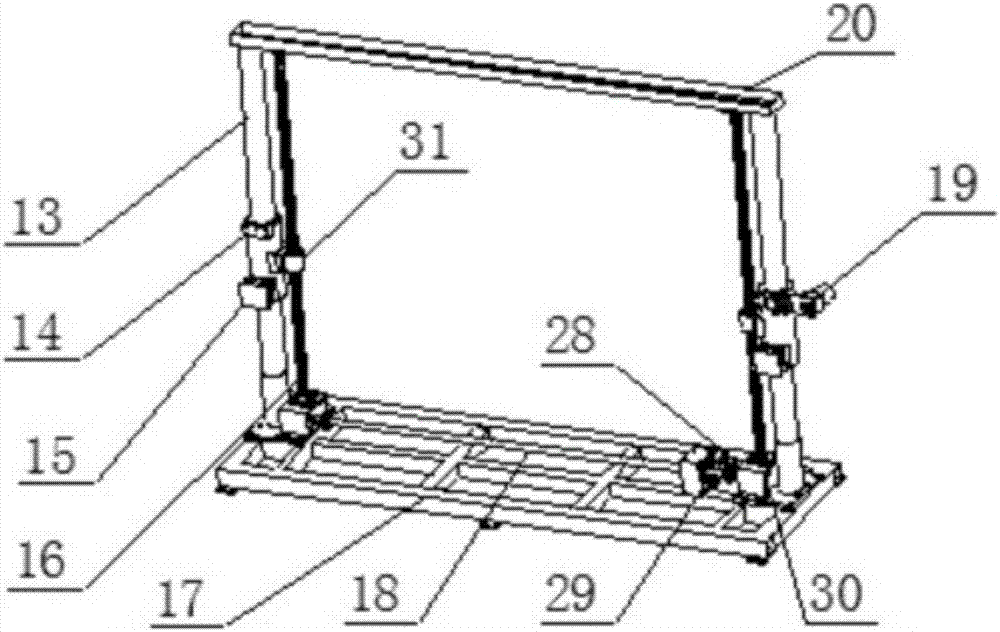

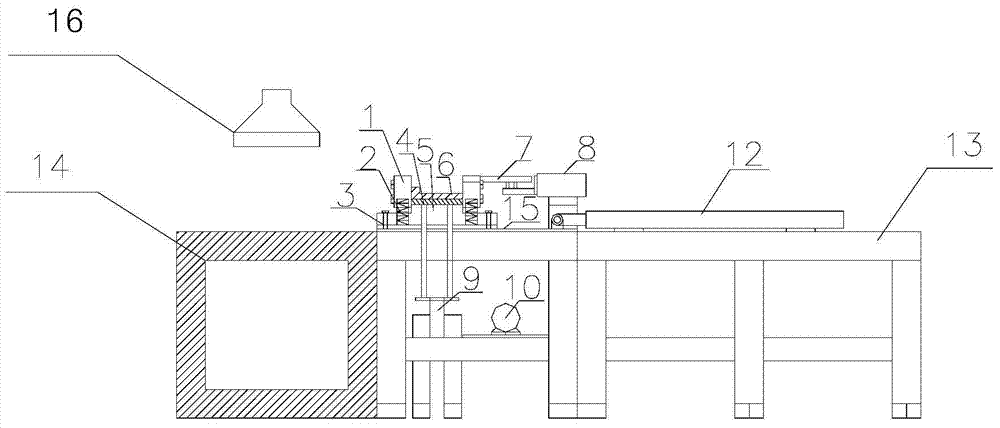

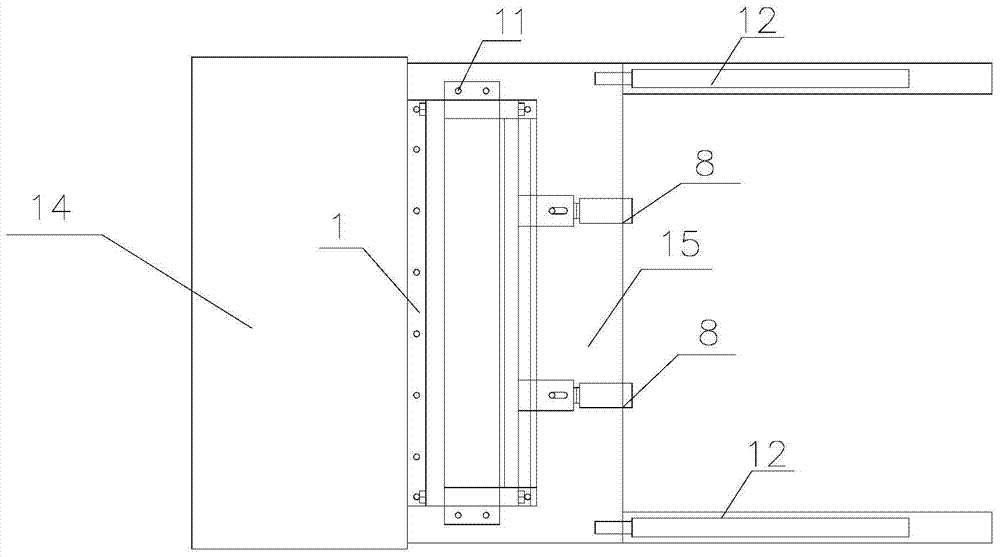

Reciprocating type automatic spraying machine and control method thereof

ActiveCN105499025AReduce spray volumeSmall thickness errorSpraying apparatusReciprocating motionEngineering

The invention discloses a reciprocating type automatic spraying machine and a control method thereof. The reciprocating type automatic spraying machine comprises a stander and a gun frame, wherein the gun frame is provided with a spray gun and a guide rail; the spray gun is arranged on the stander, a swinging head device capable of moving along the guide rail is arranged on the guide rail, and the spray gun is rotatably connected to the swinging head device along the movement direction of the swinging head device. According to the reciprocating type automatic spraying machine, the reciprocating horizontal movement and the rotation of a swinging head of the spray gun can be synchronously realized, the thickness of the coating on to-be-coated surfaces corresponding to two ends of the guide rail can be reduced, and the spraying thickness is relatively uniform.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

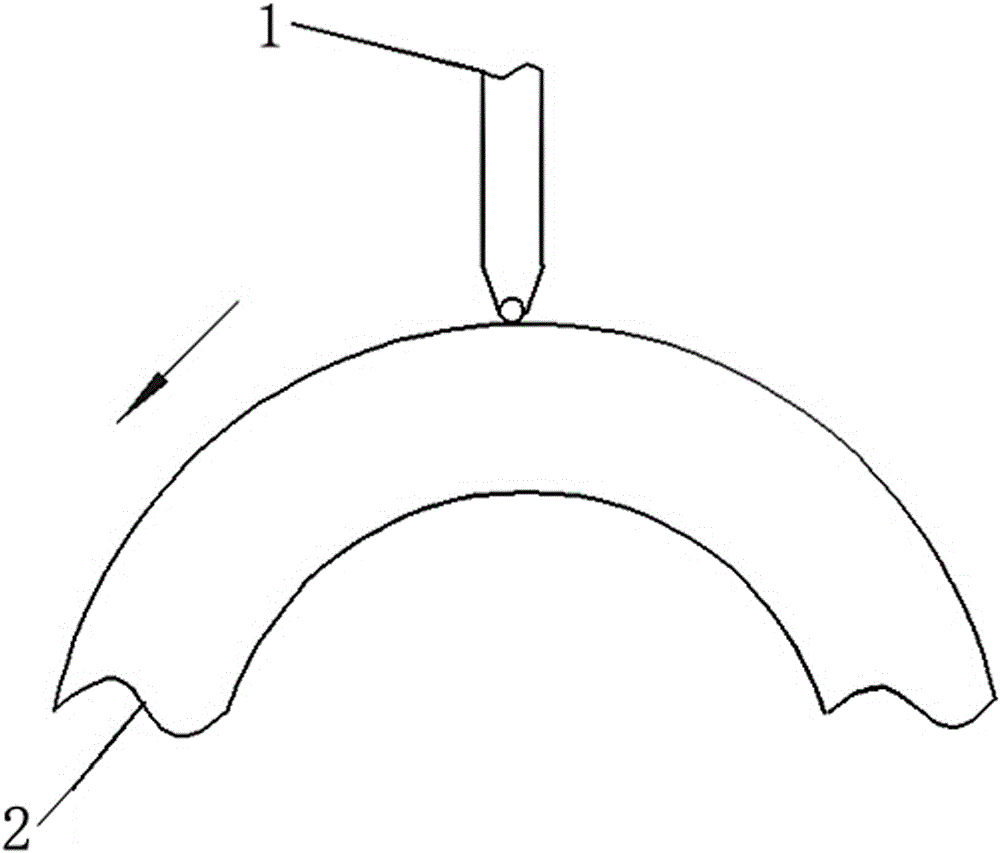

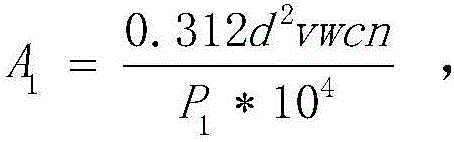

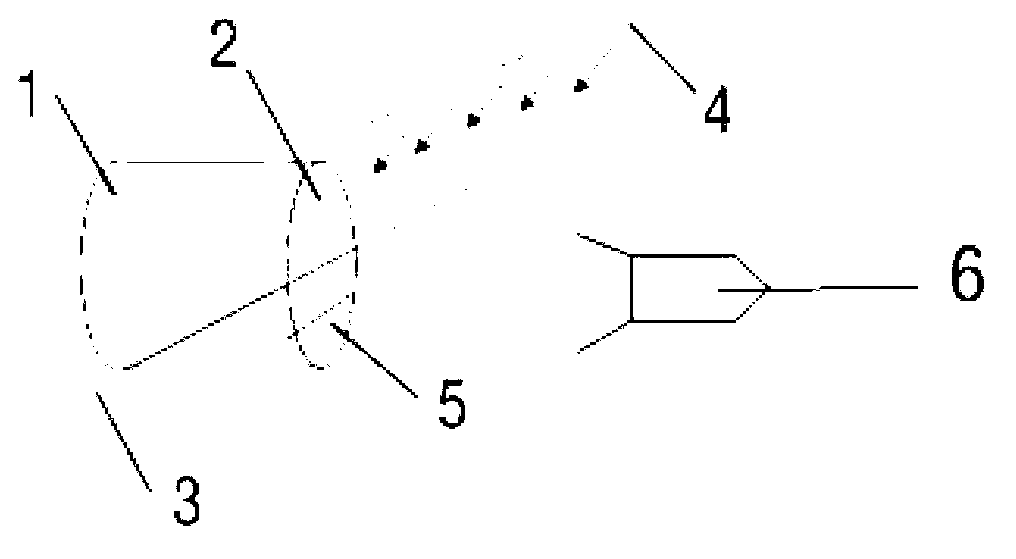

Pixel-method-based tire tread profiling twining method

ActiveCN105034424ASolve the tread shape description problemSmall thickness errorTyresAdaptive controlTruckShape control

The invention discloses a pixel-method-based tire tread profiling twining method. The method comprises three steps of pixel-method-based tire tread profiling twining, shape control over twining adhesive tape and controlling of a ring opening and profiling process. The pixel-method-based tire tread profiling twining comprises the steps that interspace mapping of a multi-dimensional coordinate of tire tread is established, and a pixel-method-based profiling mathematical model and an algorithm are established. The pixel-method-based tire tread profiling twining method has the beneficial effects that by establishing the novel model which is oriented to a tread shape of an object, the aim of the tread shape description allowed by any tread twining technologies can be achieved, and the accuracy requirement of the mathematical model of the tread twining technologies of a truck tire, an agricultural tire, an engineering tire, a diagonal tire of a special tire and a radial tire is totally met. The thickness error of the profiled tire tread is less than 1.5 mm, the error of the two ends of the tire side is less than 3 mm, and the weight error of the tire tread is within 0.5%.

Owner:GUILIN UNIV OF ELECTRONIC TECH

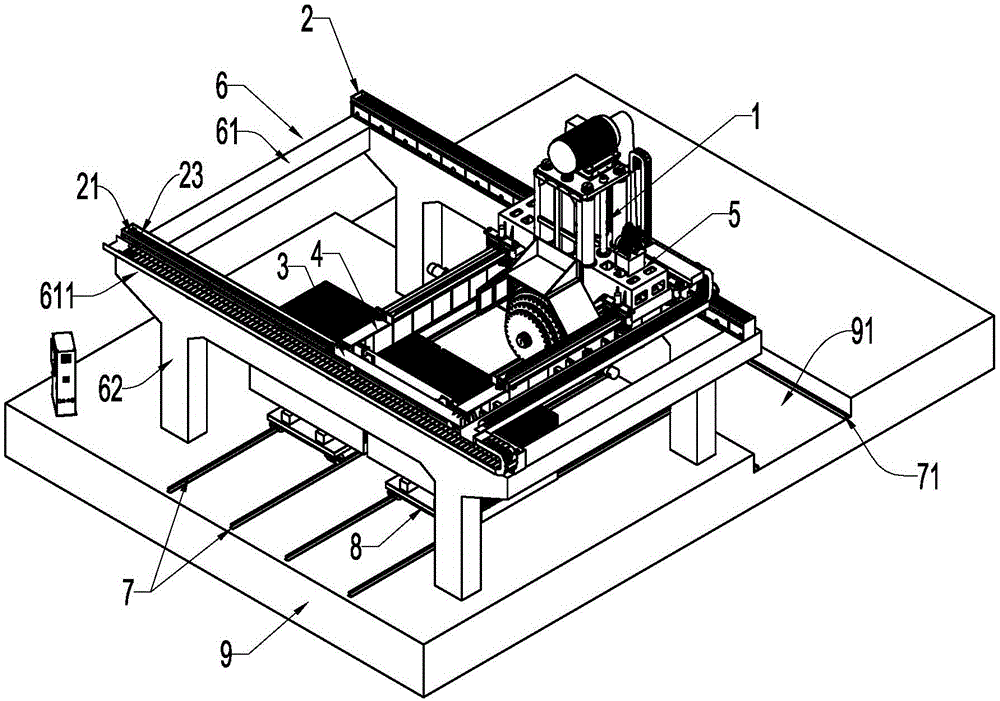

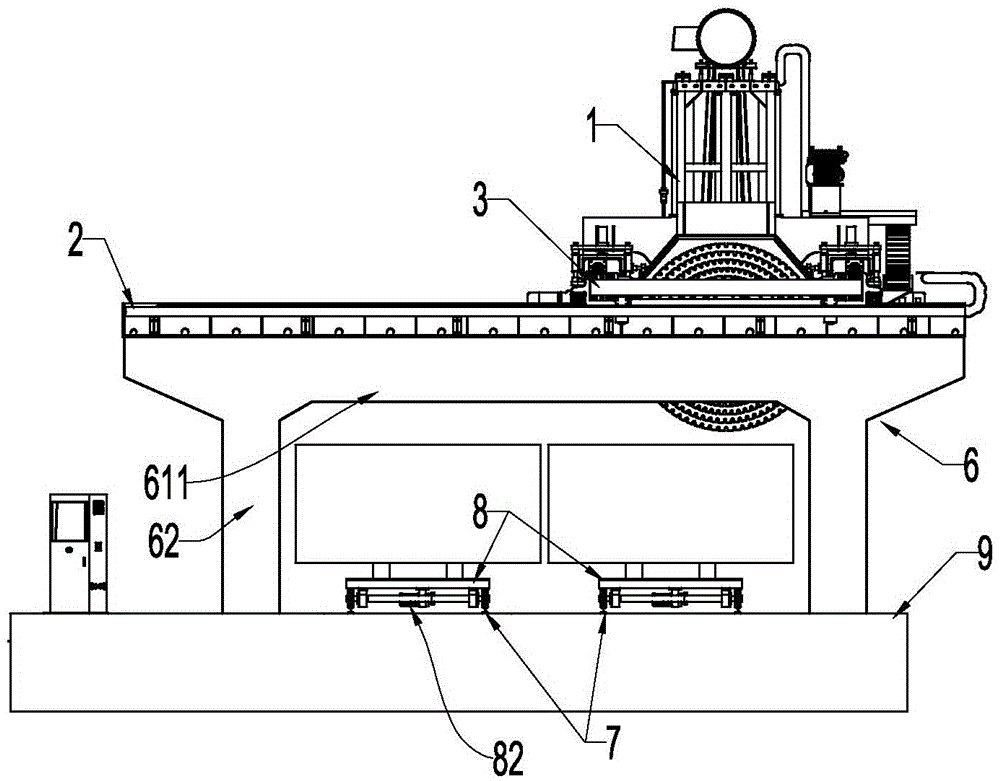

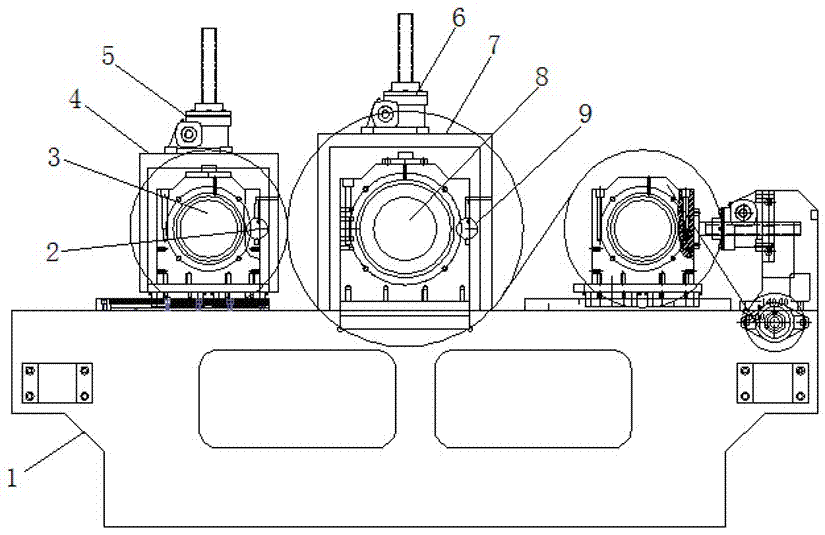

Multi-disc frame saw assembly

InactiveCN105108909AGuaranteed stabilityGuaranteed accuracy requirementsWorking accessoriesStone-like material working toolsCircular discGear wheel

The invention relates to a multi-disc frame saw assembly which comprises a frame saw and a workbench. The frame saw comprises a walking frame capable of walking on longitudinal rails and a sawing machine. Two transverse rails perpendicular to the longitudinal rails are arranged on the walking frame and provided with a walking crossbeam, and the sawing machine is arranged on the walking crossbeam. The workbench comprises a gantry frame, first-layer rails and stone carrying vehicles. The two transverse guide rails are each provided with a lead screw and a transverse linear guide rail side by side, and the walking crossbeam is driven by the lead screws to move for fragmentation. The two longitudinal rails are each provided with a gear row and a longitudinal linear guide rail side by side, and the walking frame is driven by gears mounted at the four corners to move. Two pairs of first-layer rails are arranged on the ground of the workbench, second-layer rails are arranged in an end sinking groove of the workbench, and a transfer vehicle walking on the second-layer rails is connected with the stone carrying vehicles on the first-layer rails. Cutting and stone loading and unloading are achieved at the same time, and high-efficiency running without interference is achieved.

Owner:FUJIAN PROVINCE HUALONG MACHINERY

Tool for controlling pouring thickness of concrete floor

InactiveCN103122695AReasonable structureSimple structureBuilding material handlingFloor slabStructural engineering

Owner:ZHONGTIAN CONSTR GROUP

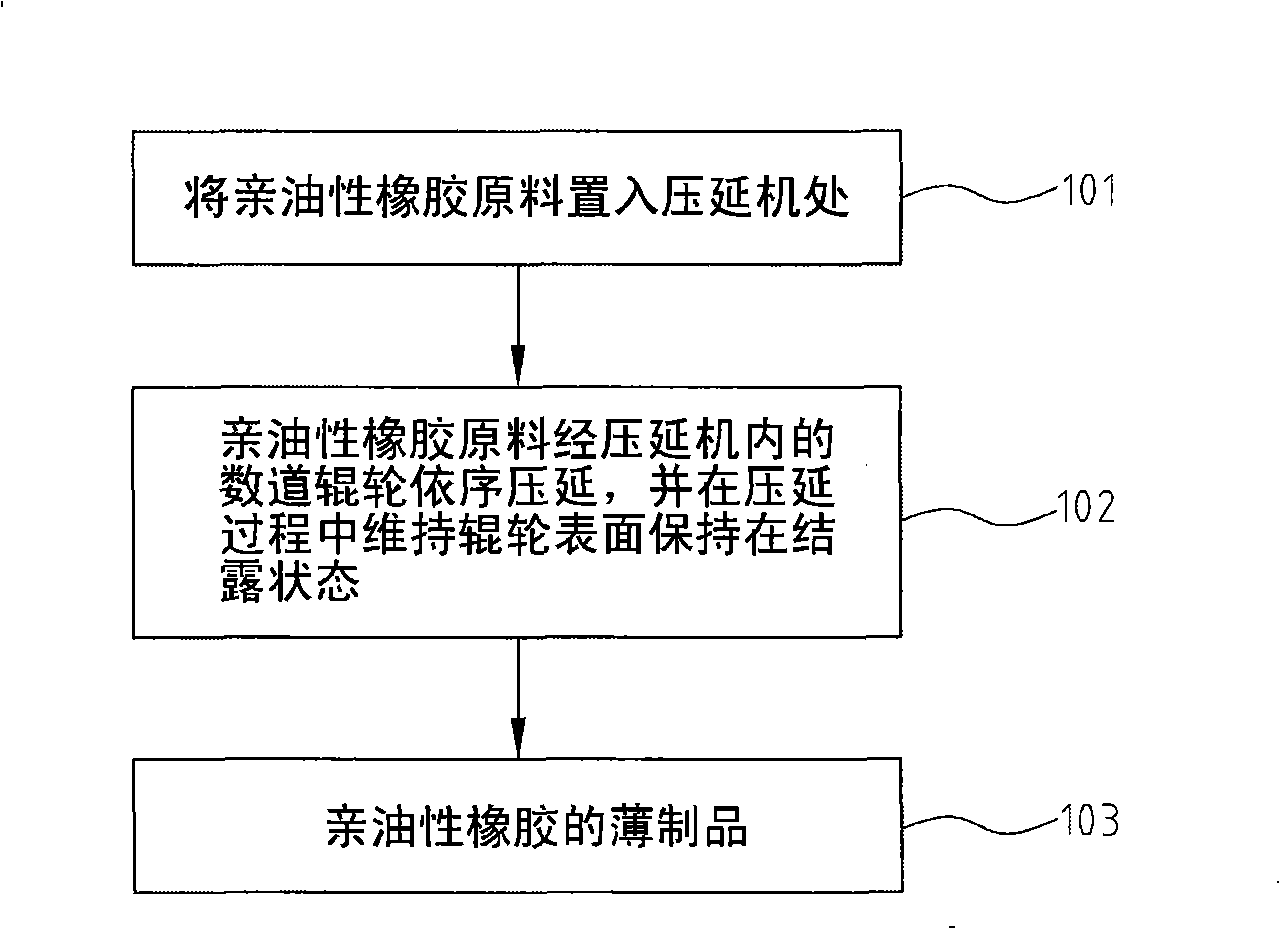

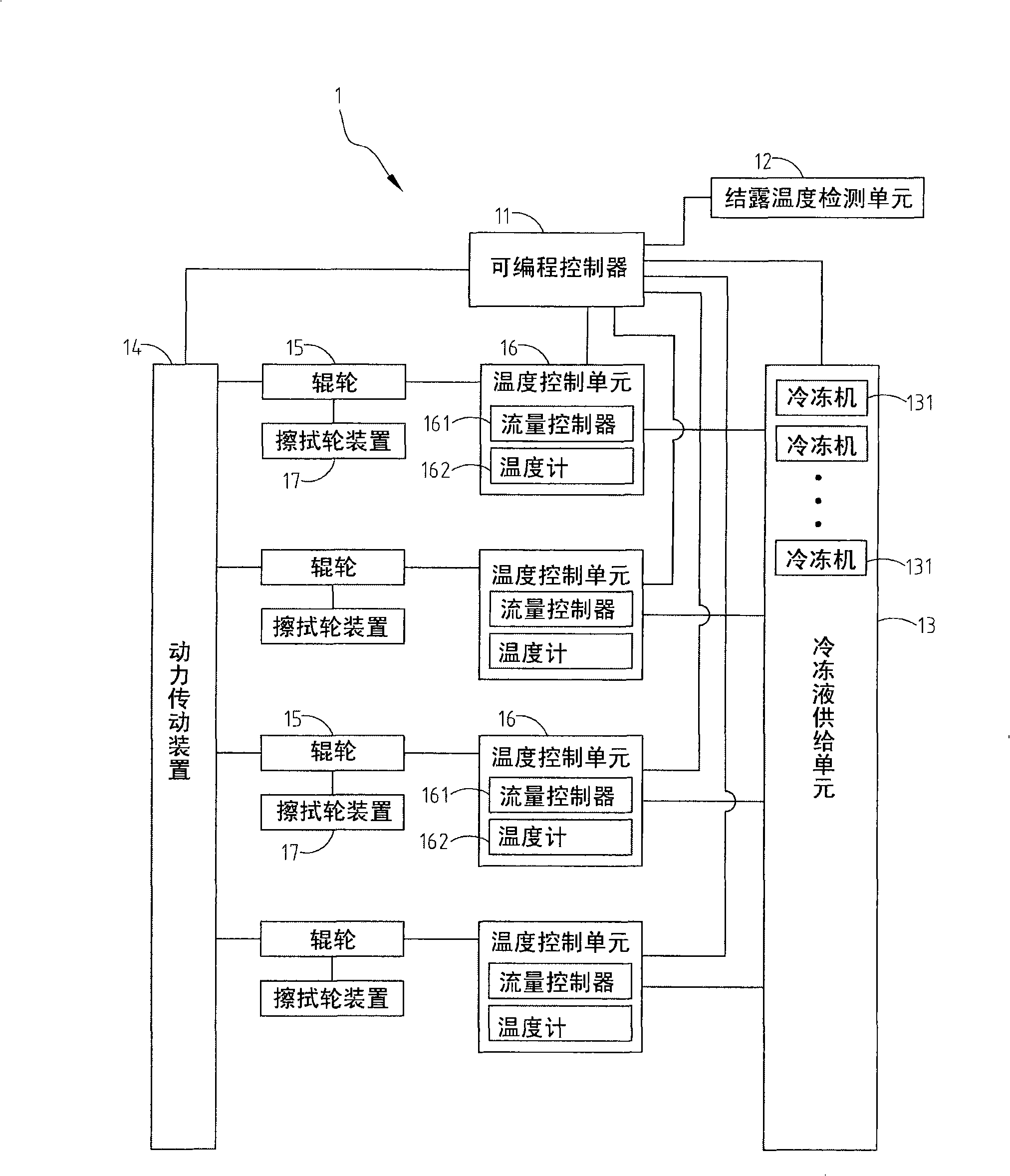

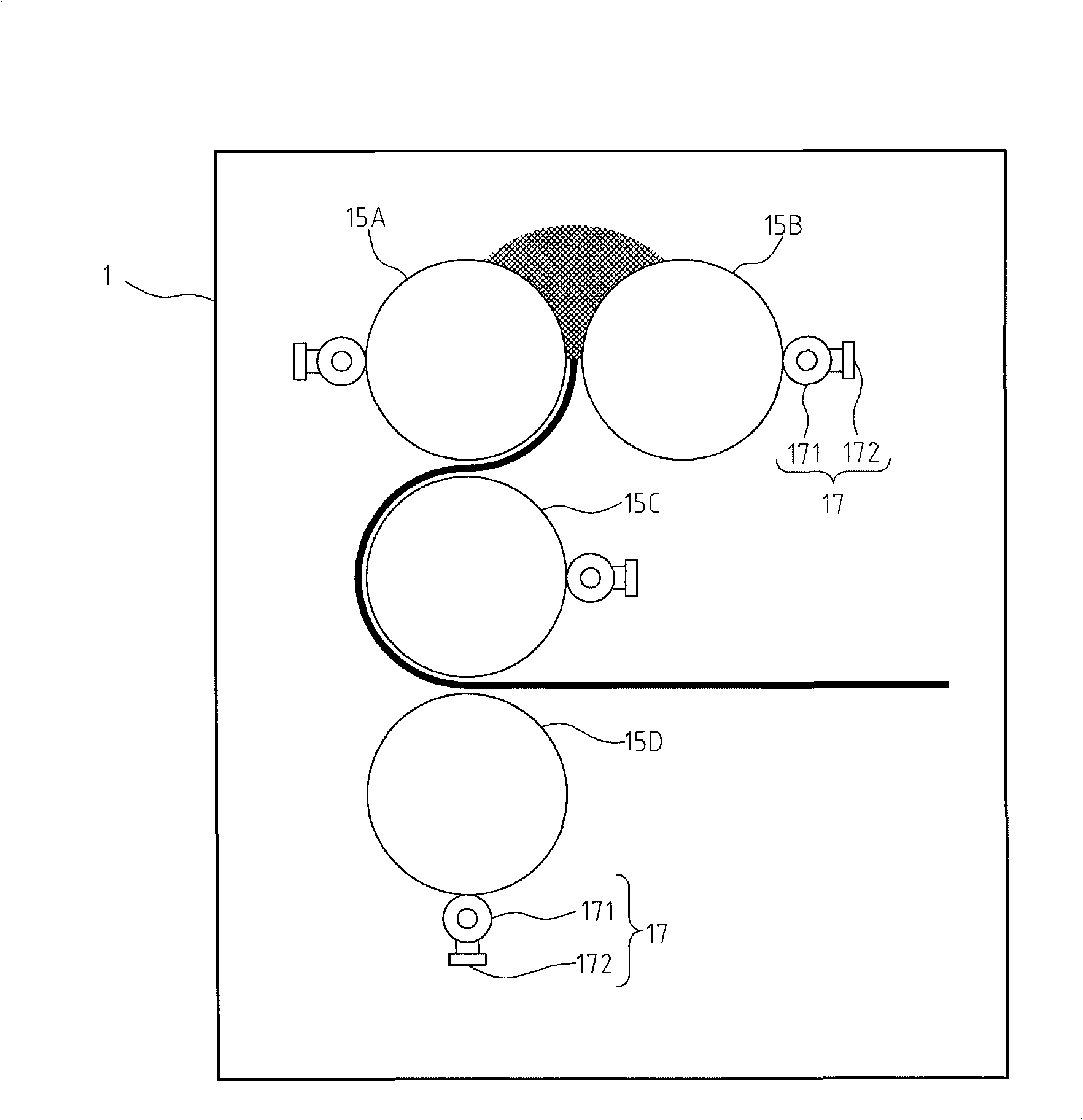

Production process for calendering lipophilic rubber thin products

InactiveCN101306565AReduce manufacturing costSmall thickness errorFlat articlesRubber materialSpecial design

The invention relates to a method for calendaring and producing a thin rubber product with special design by using the physical property of synthetic rubber. The method comprises the following steps: placing a rubber material in a calendar; calendaring the material through a plurality of rollers in sequence; and directly producing the wide thin rubber product, with thickness below 0.5mm in the calendaring manner. In order to keep the surfaces of the rollers in better condensation state in the calendaring process, the surfaces of the rollers are adjusted to different temperature according the property and the condition of the lipophilic rubber material, so as to obtain the continuous wide thin rubber product. Since the lipophilic rubber material further comprises silicone rubber, chloroprene rubber, etc, through the method, the wide thin rubber product with thickness below 0.5mm can be directly produced in the calendaring manner, the thickness error of the product is small and the production cost is also reduced.

Owner:鑫昌机械工业股份有限公司

Manufacture method of semihomogeneous anion-exchange membrane

ActiveCN106512761ASimple structureGood compatibilitySemi-permeable membranesThermoplasticPolystyrene

The invention discloses a manufacture method of a semihomogeneous anion-exchange membrane, comprising the following steps: 1) mixing thermoplastic polyethylene-quaternary amino polystyrene anion-exchange composite resin powder, non-thermoplastic crosslinked quaternary amino polystyrene anion-exchange resin powder, polyethylene powder and polyisobutylene powder according to a ratio; 2) melt-blending by an internal mixer, extruding by a two-roller open mill, continuously rolling by a four-roller mill, cooling by a cold-roll, and cutting by a cutting machine so as to obtain a prefabricated membrane; and 3) coating upper and lower surfaces of the prefabricated membrane with enhanced screen cloth, and compacting by a hot press so as to obtain the semihomogeneous anion-exchange membrane product. According to the prepared anion-exchange membrane product, internal quaternary amine groups with anion exchange effect are connected to each other and ceaseless such that membrane area resistance is greatly reduced. Various film forming materials have good compatibility and are tightly combined. Selective transmittance of the membrane is higher, and comprehensive properties of the membrane are obviously better than comprehensive properties of a conventional homogeneous anion-exchange membrane.

Owner:HANGZHOU IONTECH ENVIRONMENTAL TECH

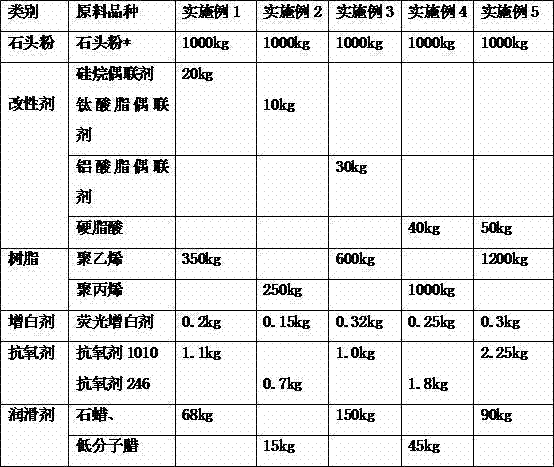

Manufacture method of synthetic paper

The invention discloses a manufacture method of synthetic paper, which is used for manufacturing the synthetic paper with resin as a base material and stone powder as filler. The process steps include stone power drying-stone power modifying-banburying pelleting of the stone powder and the resin-flow calendar extruding raw paper of the synthetic paper-raw paper heating drawing- corona processing-coating processing. Compared with the film blowing method, the manufacture method improves filling quantity of inorganic powder by more than 10% and especially increases the paper pattern processing process. Craquelure is formed on the surface of the synthetic paper after drawing, so that printing ink can be easily adsorbed, and the writing and printing performances of the synthetic paper are much closer to those of plant fiber paper.

Owner:蔡茂友

Method and device for producing natural ultrathin stone by using combination saw

InactiveCN102029654AHigh degree of automationThe device is stableStone-like material working toolsClapboardManufacturing engineering

The invention provides a method for producing a natural ultrathin stone by using a combination saw. The method comprises the following steps of: machining a quarry stone into a rough plate of which the thickness is 2 to 3cm; machining the rough plate into a thick plate meeting decoration requirement according to needs of the product, wherein the machined thick plate is respectively clamped in a combined clapboard with a hard plastic liner and is fixed and locked, and the width of the combined clapboard corresponds to the breadth of the combination saw; and cutting the thick plate in the combined clapboard with the combination saw which aligns to the central line of the thick plate to obtain the ultrathin stone. By the method, the problem that the ultrathin stone is broken because of the resonance of the ultrathin stone plate when the traditional combination saw machines the plate is solved; more than ten even tens of big ultrathin stone plates can be machined by the method; and the engineering requirement of architectural decoration can be met.

Owner:吉林吉大蓝创科技有限公司

Fully automatic printer for aluminum base plate

PendingCN107757083AWith automatic feedingWith automatic positioning calibrationScreen printersScreen printingScreen printingThermal insulation

The invention provides a four-column-type fully automatic printer for an aluminum base plate, and the four-column-type fully automatic printer comprises an automatic material inlet system, an automatic printing system and an automatic material outlet system. The automatic material inlet system conveys the aluminum plate through a conveyor belt; the automatic printing system comprises a printing screen plate, screen frames, a scraper, spray mouths, a workbench and automatic lifting columns, and the automatic printing system prints heat-conducting and insulating glue on the aluminum plate evenly; the material outlet system conveys the aluminum plate with the surface being printed a dense uniform insulation layer through the conveyor belt for the output; in a silk-screen printing system, theworkbench is supported by four automatic lifting columns, the surface of the workbench is provided with horizontal sliding electric guide rails in a paved manner, and the silk-screen printing system further comprises height sensors, a scraper moving rod and a rotating head; and the rotating head connects the scraper moving rod and the scraper, the height sensors are installed under the screen frames, and the workbench, the scraper moving rod, the spray mouths, positioning sensors and the height sensors are all connected with a general control platform and are controlled. The four-column-type fully automatic printer for the aluminum base plate has the characteristics of automatic material feeding, automatic positioning calibration, automatic printing and high production capacity.

Owner:乾乐欣展新材料技术(上海)有限公司

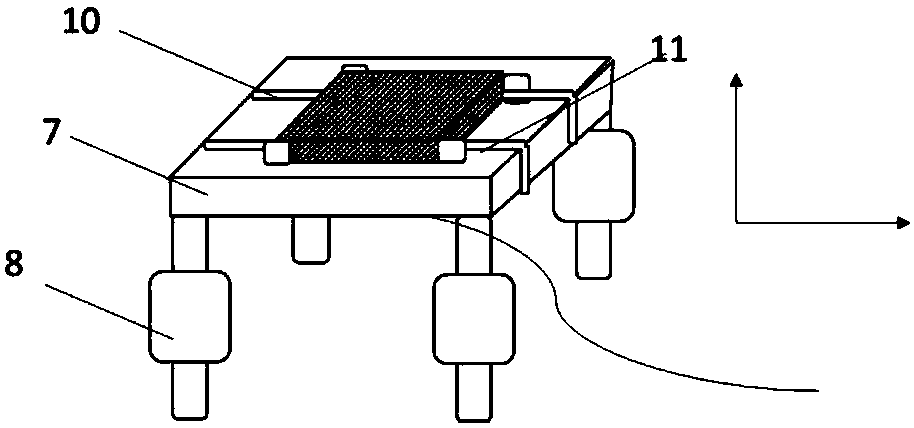

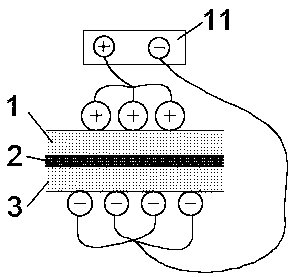

Compound lithium strip production device and method

PendingCN107644973AReduce thicknessSmall thickness errorElectrode manufacturing processesFinal product manufactureLithiumElectricity

The invention relates to a compound lithium strip production device and a compound lithium strip production method. The device comprises a winding and unwinding mechanism, a laminating roller and a power supply piece. The method comprises the following steps: 1, laminating a strip-shaped lithium source, a solid electrolyte and a compound lithium strip matrix, enabling the strip-shaped solid electrolyte to be located between the strip-shaped lithium source and the strip-shaped compound lithium strip matrix during fitting; 2, respectively electrically connecting the strip-shaped lithium source with a positive electrode of a power supply and electrically connecting the compound lithium strip matrix with a negative electrode of the power supply; 3, switching on power supply, enabling the lithium ion of the lithium source to penetrate through the solid electrolyte to move towards the compound lithium strip matrix according to the electrochemical reaction between the positive electrode and the negative electrode, reducing the electron on the compound lithium strip matrix, and producing the metal lithium so as to obtain a compound lithium strip. The invention provides the novel technologyfor producing the compound lithium strip, a lithium layer is electroplated on the compound lithium strip matrix through an electrochemical method, the procedure is simple and efficient, the electroplated lithium layer is even in thickness and is quite thin, and the strict requirement of the compound lithium strip on the thickness is met.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

Manufacturing method of fuel cell separator, and fuel cell

InactiveCN1739217ASmall sizeSmall thickness errorFinal product manufactureSolid electrolyte fuel cellsFuel cellsEngineering

Owner:DAINIPPON INK & CHEM INC

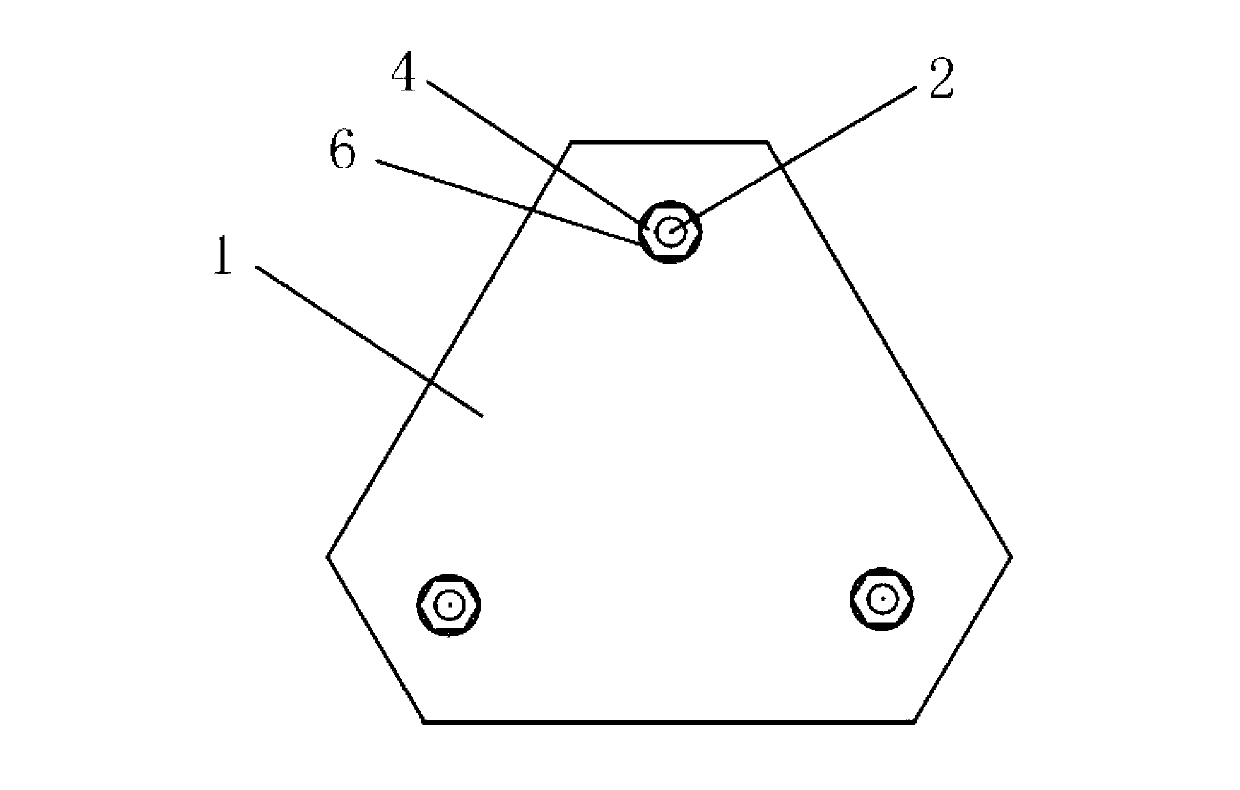

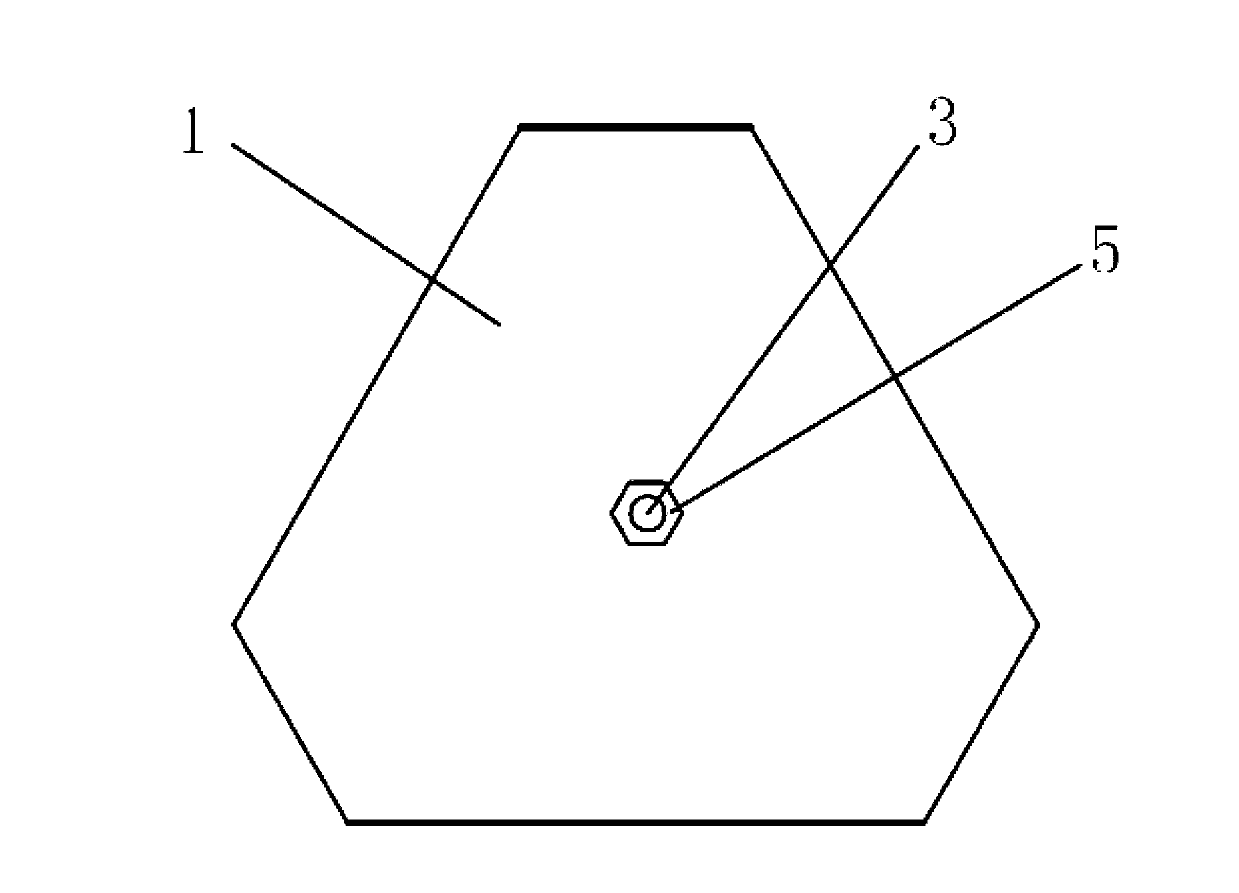

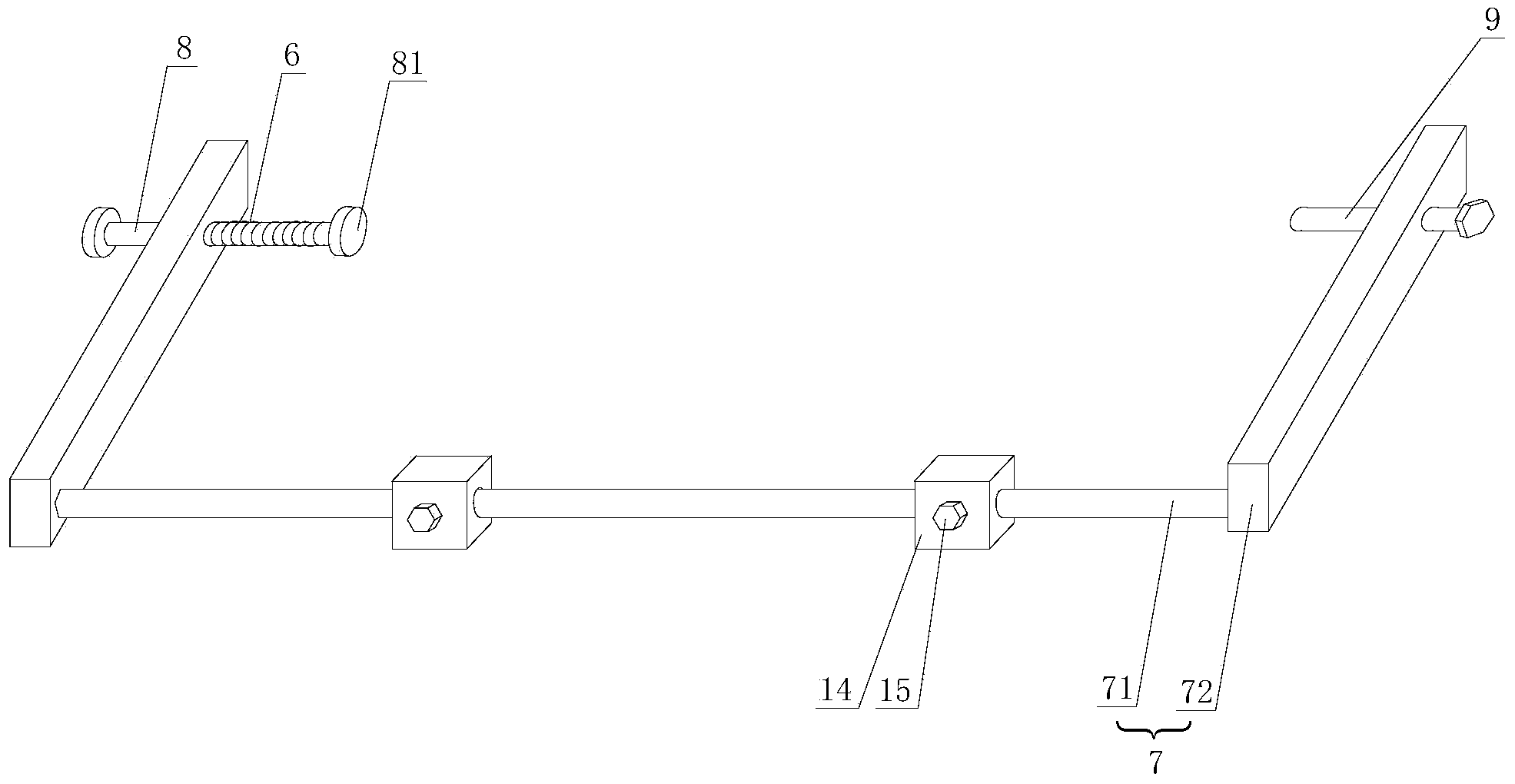

Cylindrical silicon rod clamp

The invention provides a cylindrical silicon rod clamp, aiming at solving the problem that more inferior-quality products of silicon wafers are produced when an existing cylindrical silicon rod clamp is used for clamping a silicon rod. The cylindrical silicon rod clamp comprises a fixing device and a positioning device, wherein the fixing device comprises a lower pressing block provided with four guiding columns; a thread is arranged at the upper part of each guiding column; the fixing device further comprises a lower module, an upper module, an upper pressing block and four pressing nuts; an upper arc-shaped groove is formed in the lower surface of the upper module and a lower arc-shaped groove is formed in the upper surface of the lower module; the positioning device comprises a rotary connection device, a bracket, a sliding rod and an adjusting bolt; the sliding rod is arranged on the bracket in a penetrating manner and is provided with scales; a stopping block is arranged at each of the left and right ends of the sliding rod; the sliding rod is sleeved with a spring. The cylindrical silicon rod clamp is provided with the positioning device and the fixing device of a silicon rod, so that the silicon rod is convenient to position and fix; the commonality is strong; the positioning device can be used for more accurately positioning the silicon rod; the thickness error of the silicon wafers is reduced and the quality of the silicon wafers is improved.

Owner:ZHEJIANG HUIHONG SOLAR ENERGY CO LTD

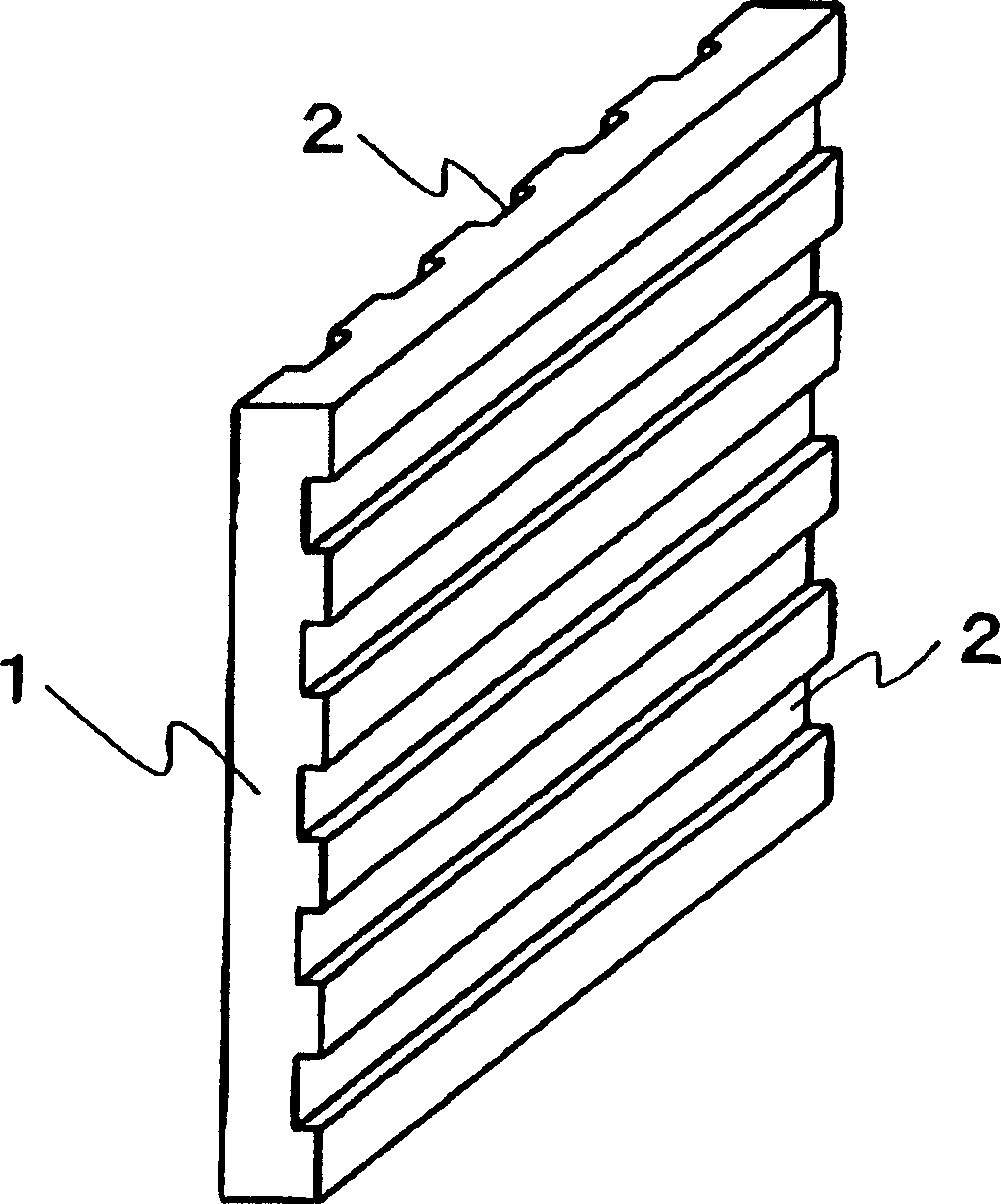

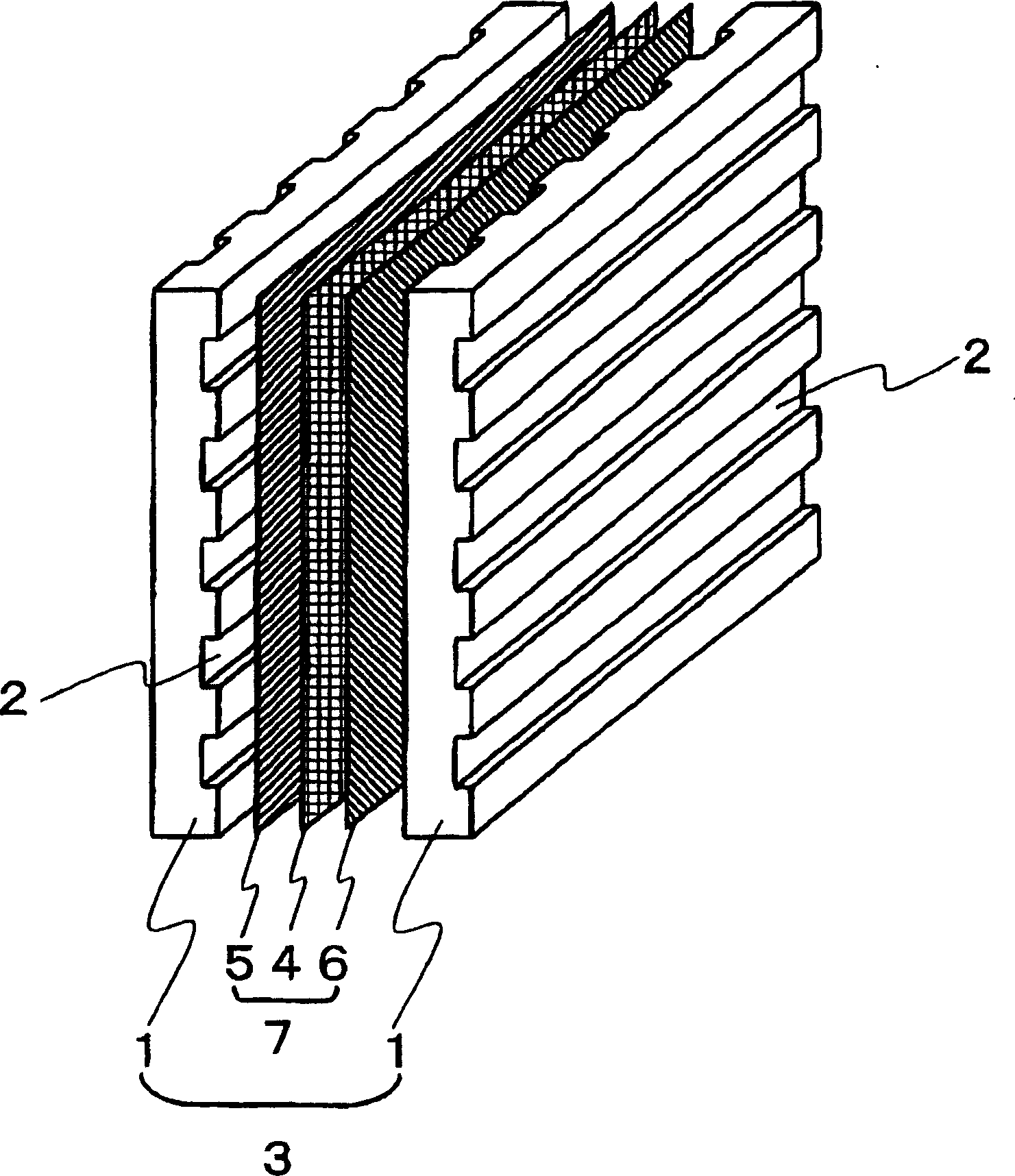

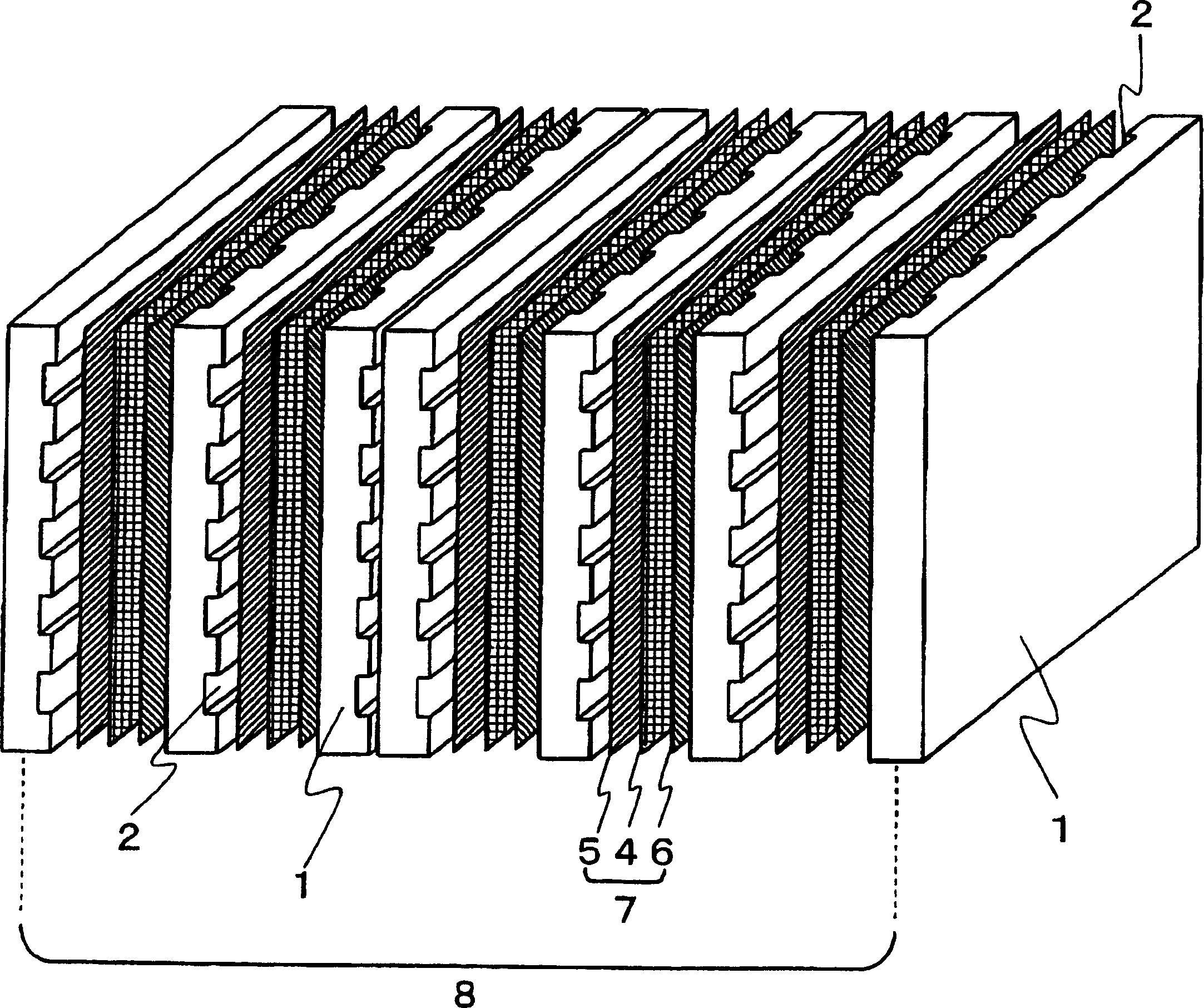

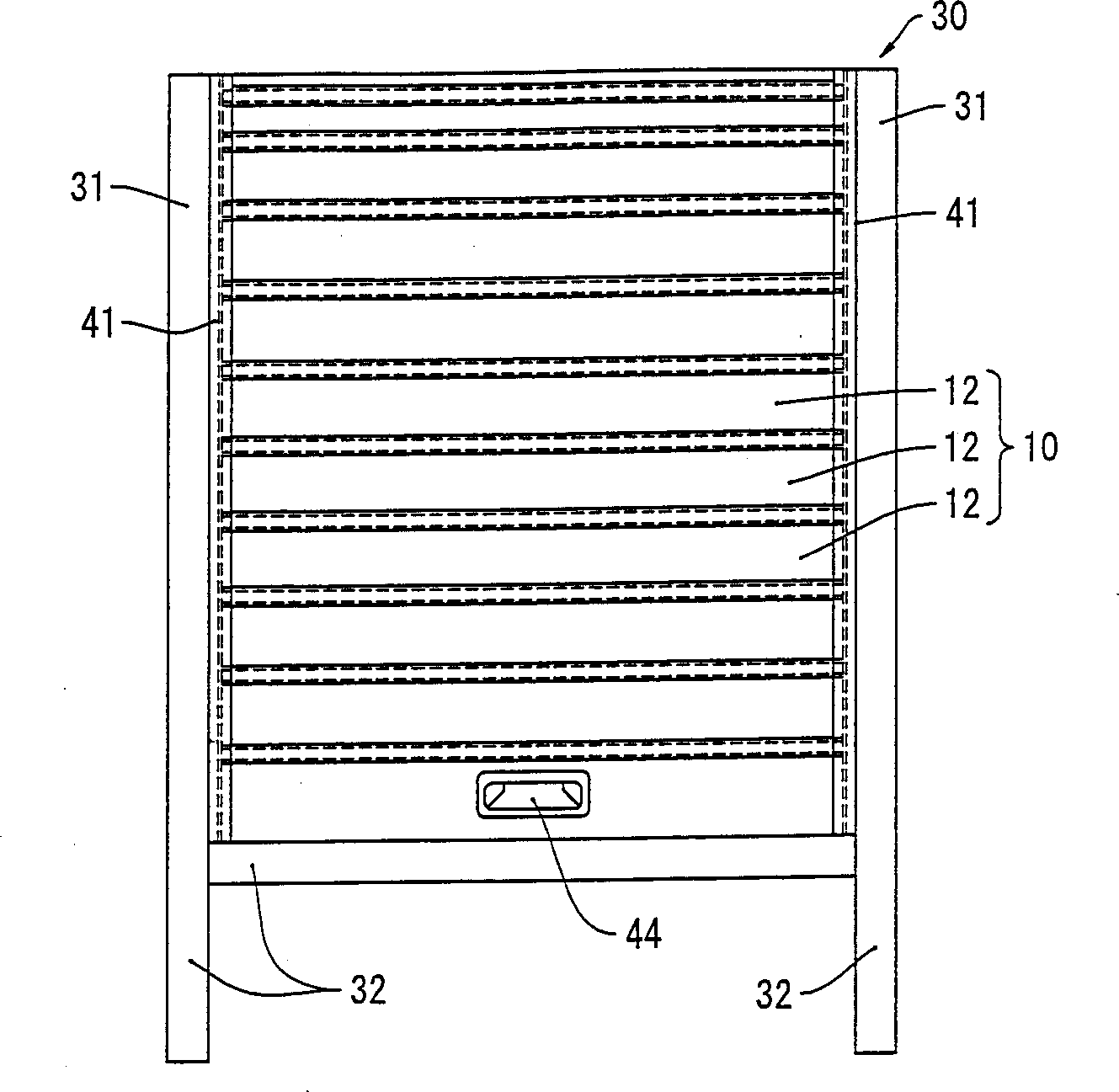

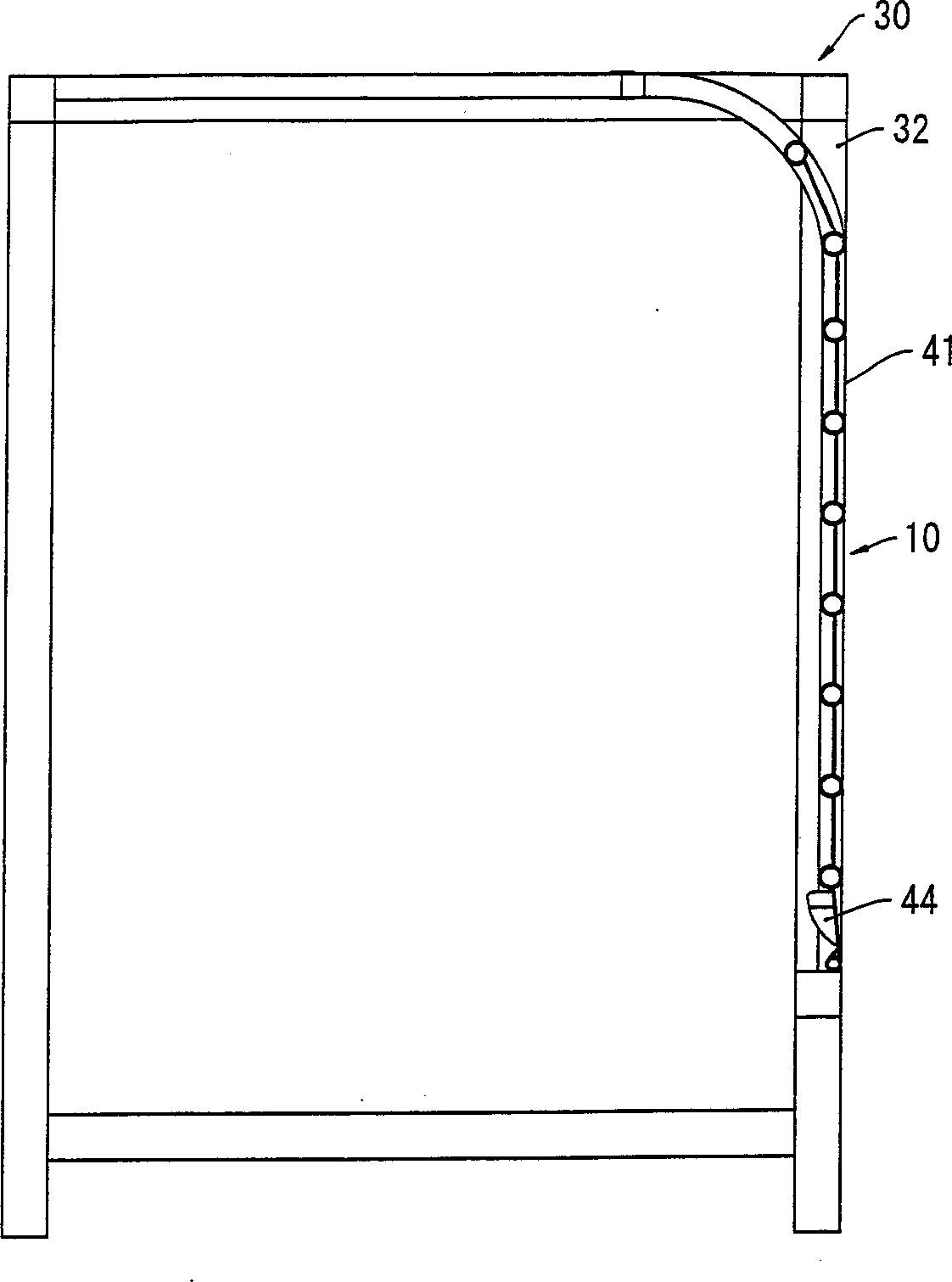

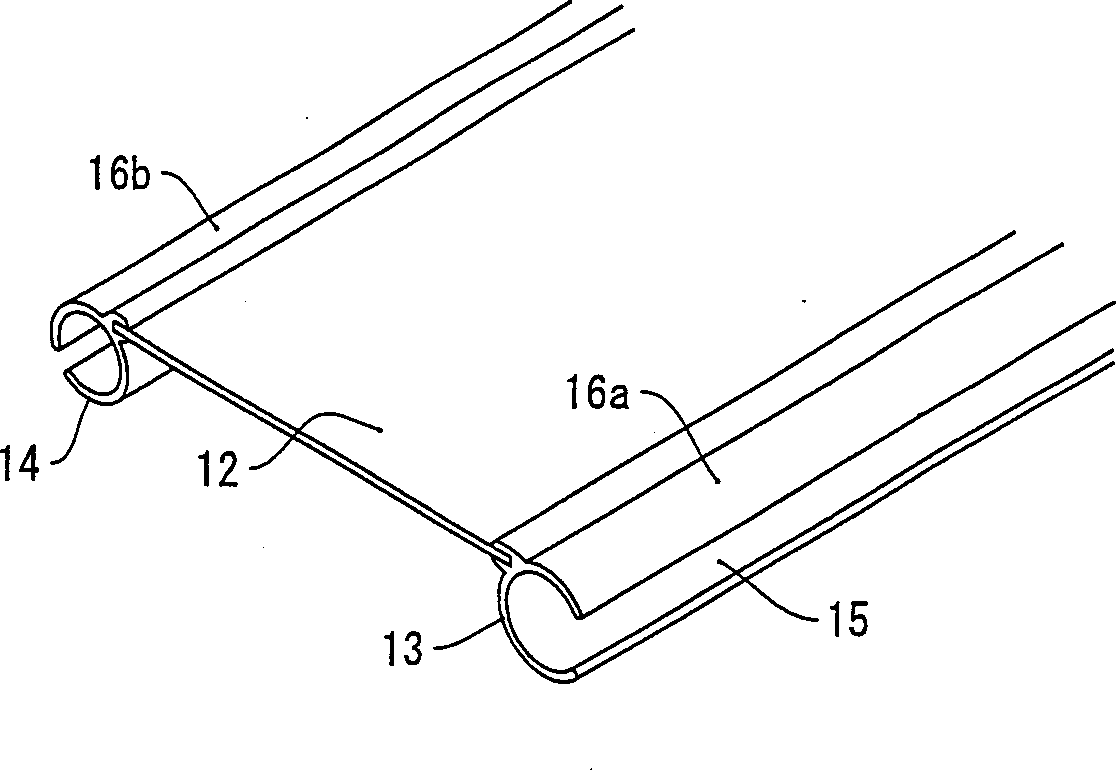

Opening-closing plate for rolling door

InactiveCN1354316AHigh transparencyAvoid deformationShutters/ movable grillesMechanical engineeringEngineering

A shutter panel (10) in which respective longer sides of slats (12) made of synthetic resin are connected through hinge mechanisms to be freely bendable manner, wherein the hinge mechanisms include one hinge member and another hinge member. Each hinge member has a connecting groove that is opened outwardly. By fitting and coupling the longer sides of the slats into the connecting grooves respectively, smooth opening and closing of the shutter panel (10)can be performed because of decreasing warpage or irregularities in thickness of slats (12) or the hinge members and enabling smooth bending of respective slats (12) connected by the hinge mechanisms.

Owner:ISEL CO LTD

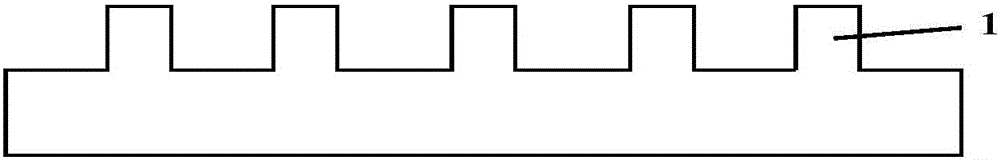

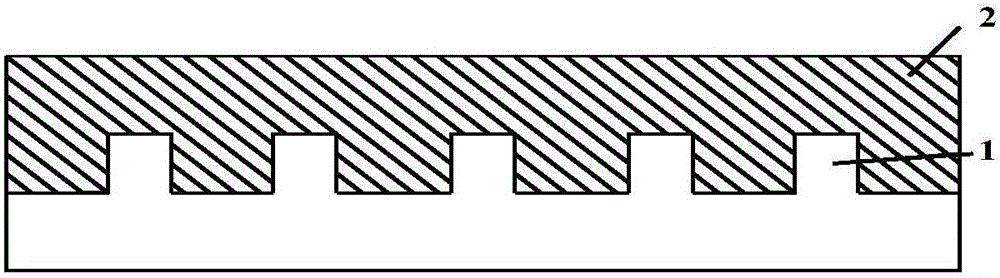

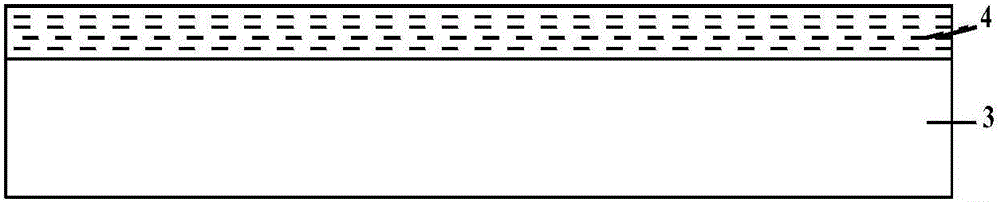

Compound-based semiconductor ultrathin substrate manufacturing method

InactiveCN106409671AGuaranteed thickness toleranceSmall thickness errorSemiconductor/solid-state device manufacturingLithographic artistOrganic solvent

The invention discloses a compound-based semiconductor ultrathin substrate manufacturing method. The method includes 1) manufacturing a device in a compound-based epitaxial material layer; 2) and then forming an isolated table top of a device to be packaged on the right side of a compound semiconductor substrate sheet by means of lithography and etching methods, and etching to the depth of 3-10 micrometers; 3) coating a photoresist on the right side of the compound semiconductor substrate sheet; 4) growing 20 nm of protective medium silica on a temporary substrate sheet; 5) bonding the compound semiconductor substrate to the temporary substrate sheet; 6) performing rapid thinning, slow thinning, polishing on the compound-based semiconductor substrate sheet until the thickness of the compound-based substrate is thinned to 20-30 micrometers; 7) etching the back side of the substrate by means of plasma etching until the epitaxial layer outside the table top are fully etched; and 8) removing the adhesive and photoresist by organic solvent immersion to obtain a compound-based semiconductor device having a substrate thickness of 3 to 10 micrometers.

Owner:DONGGUAN GUANGXIN INTPROP SERVICES CO LTD

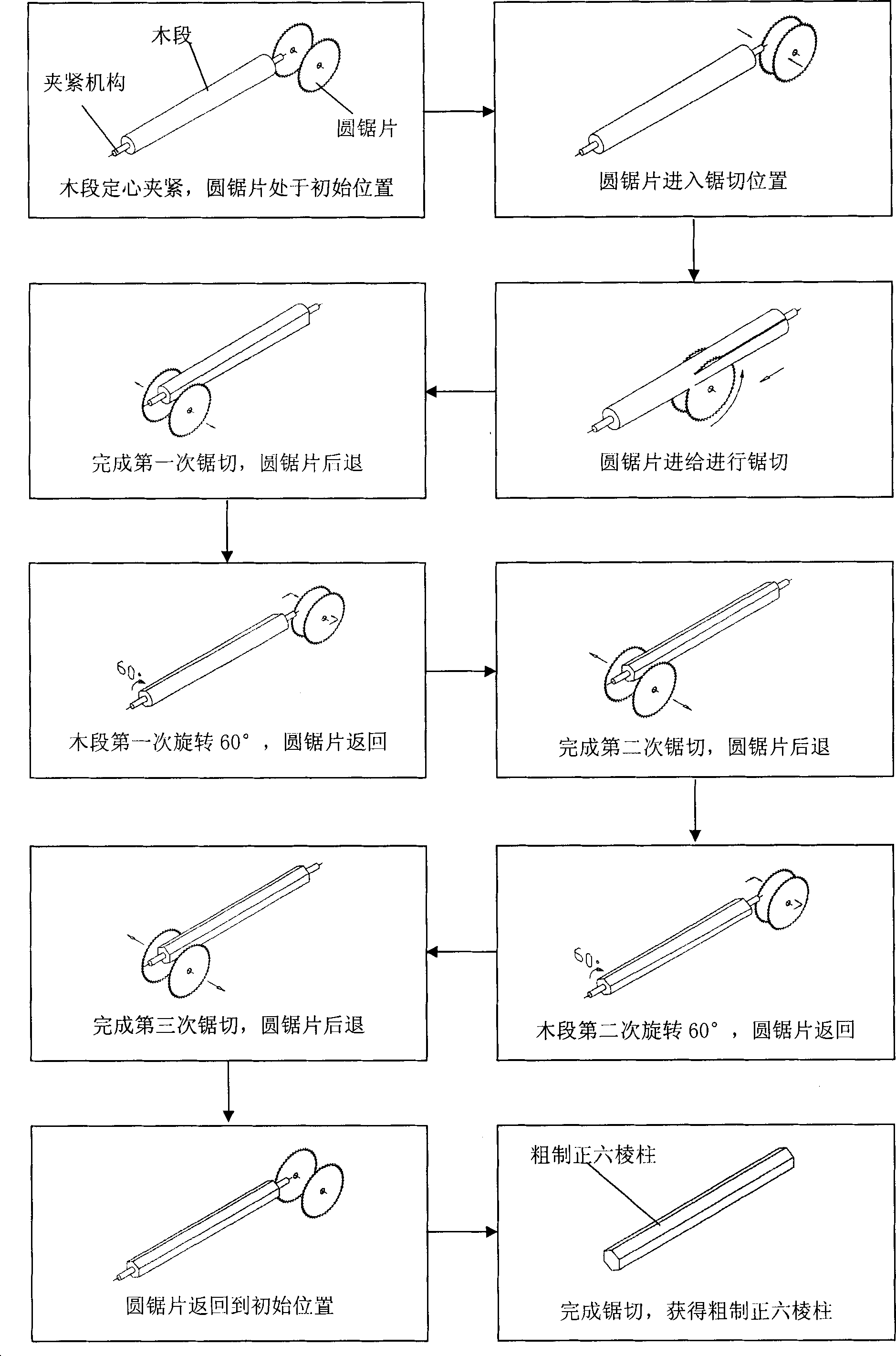

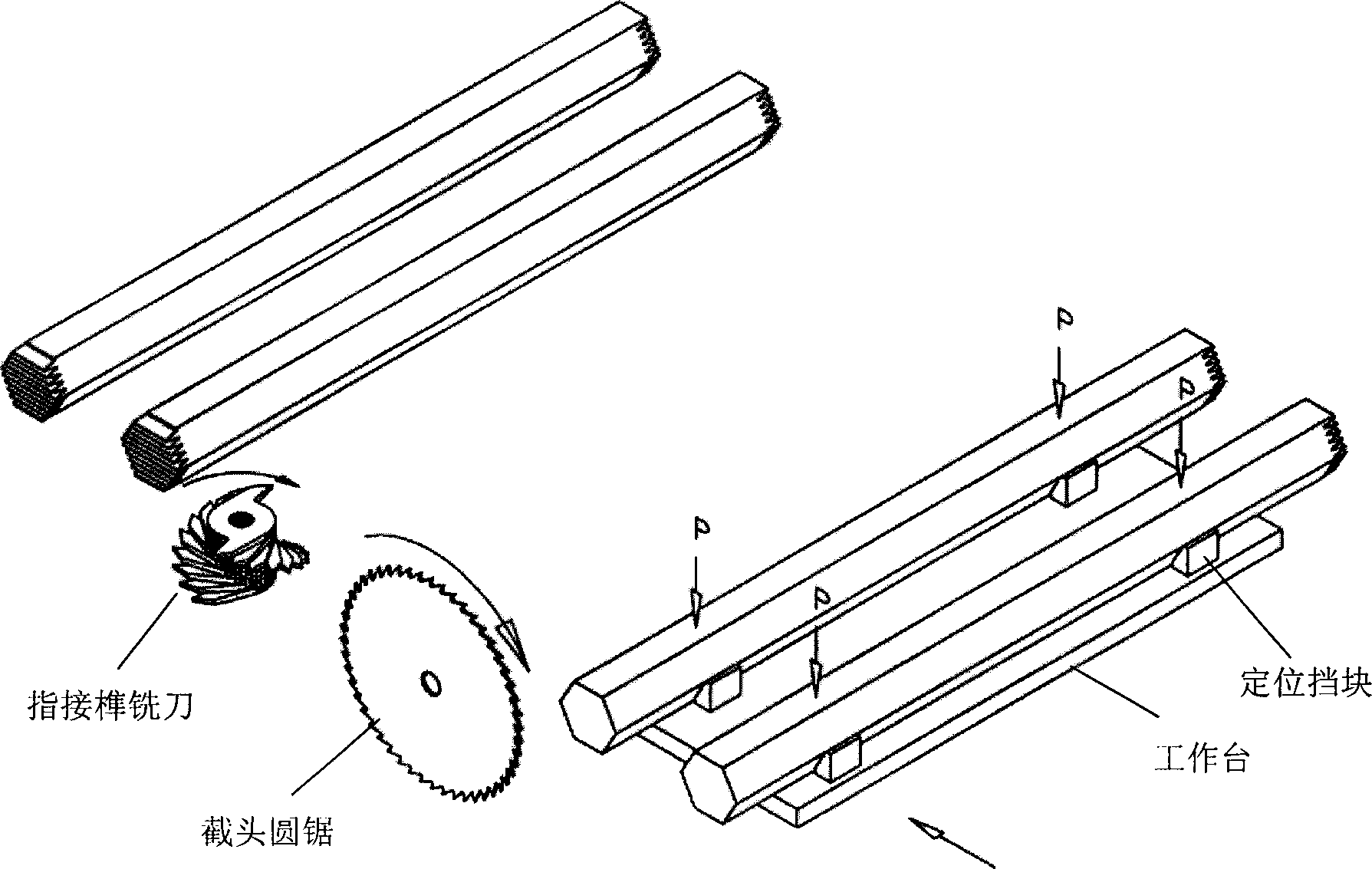

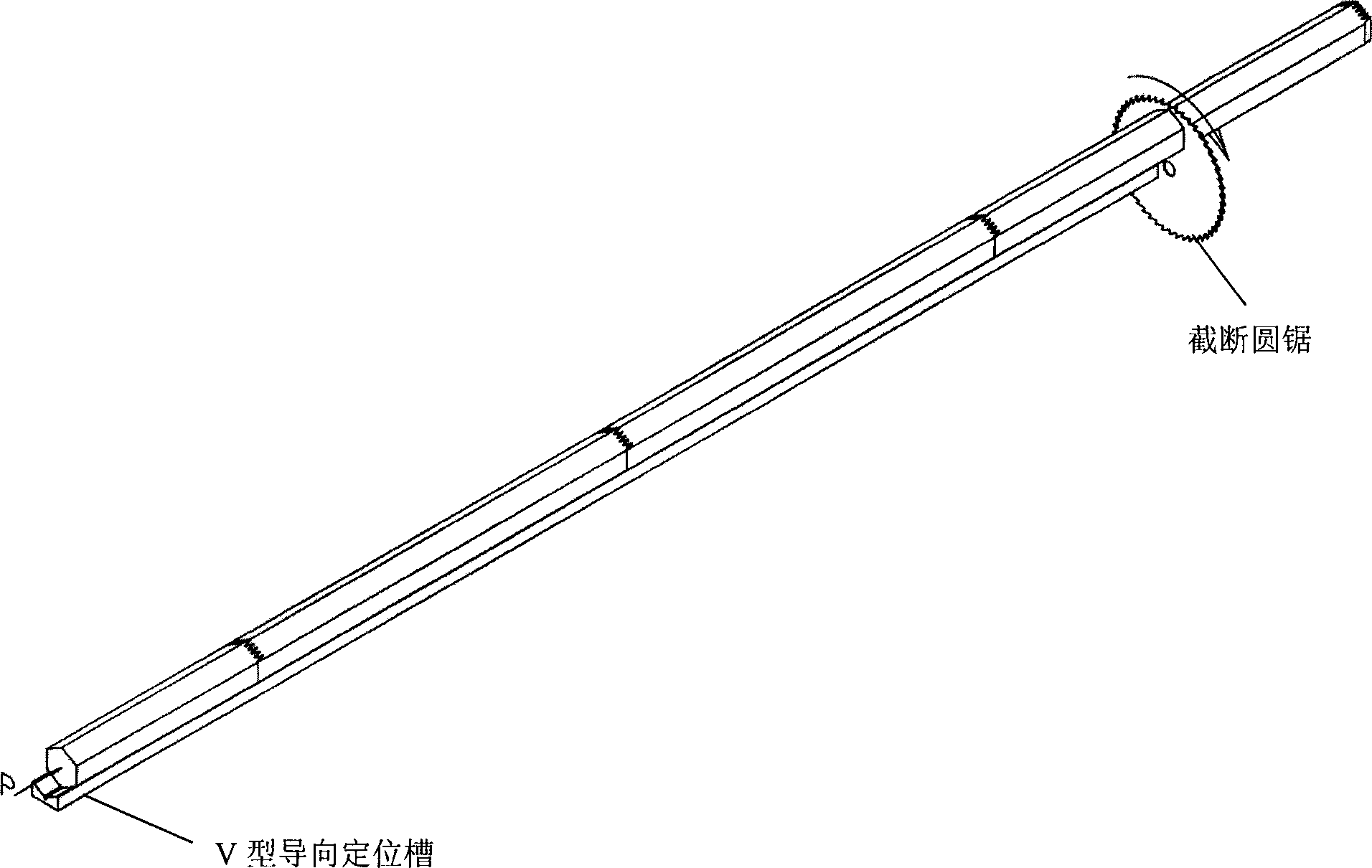

Method for preparing large-size sheet by using small-diameter wood

ActiveCN103341890BIncrease profitReduce curvatureWood veneer joiningWood mortising machinesFinger jointEngineering

The invention discloses a method for preparing a large-size sheet by using small-diameter wood. The method comprises the steps of: cutting small-diameter wood with a diameter of 6-11cm into wood sections with lengths of 1m, grouping into 5 groups according to the diameter of the small head and the 10mm difference, and drying until the water content is 12 percent; sawing the wood sections into rough regular hexagonal prisms, inscribed circles of bottom surfaces of which are 46mm, 56mm, 66mm, 76mm and 86mm, extending through a finger joint tenon and cutting according to the specification, milling into refine regular hexagonal prisms, inscribed circles of bottom surfaces of which are 40mm, 50mm, 60mm, 70mm and 80mm; symmetrically splitting the regular hexagonal prisms into quadraprisms through the maximum diagonal plane; symmetrically splitting the regular hexagonal prisms into pentagonal prisms through a plane vertical to the side surfaces of the hexagonal prisms; and selecting the quantities of the refine regular hexagonal prisms, and the pentagonal prisms and the quadraprisms, thereby obtaining a rectangular large-section glued wood beam through coating, assembling and bidirectional-pressurizing, and sawing into the large-size sheet with the thickness of 5-20mm. According to the method, the utilization rate and the use value of the small-diameter wood are improved.

Owner:江西兴创木业有限责任公司

Full-automatic sponge disc horizontal cutting machine

InactiveCN107972101AImprove work efficiencyEasy to operateMetal working apparatusCircular discElectric machinery

The invention provides a full-automatic sponge disc horizontal cutting machine which comprises a platform and a main rack. The main rack is connected with a knife rest. A platform is horizontally place under the knife rest. The side face of the platform is provided with an electric control cabinet for controlling a plurality of motors on the main rack and the knife rest to work. The main rack is provided with a pneumatic tensioning device and an angle adjusting device. According to the horizontal cutting machine, the cut thickness and the number of cutting times are set on the electric controlcabinet, then the knife rest is moved to a proper position, a starting part on the electric control cabinet is pressed to drive a knife belt on the knife rest to operate, a friction drive wheel on the platform drives a table plate to rotate, and cutting work is completed. The device improves working efficiency of cutting sponge sheets, reduces thickness errors of the sponge sheets, improves the surface quality of the sponge sheets, and reduces work intensity of workers.

Owner:宁波江北文增新材料科技有限公司

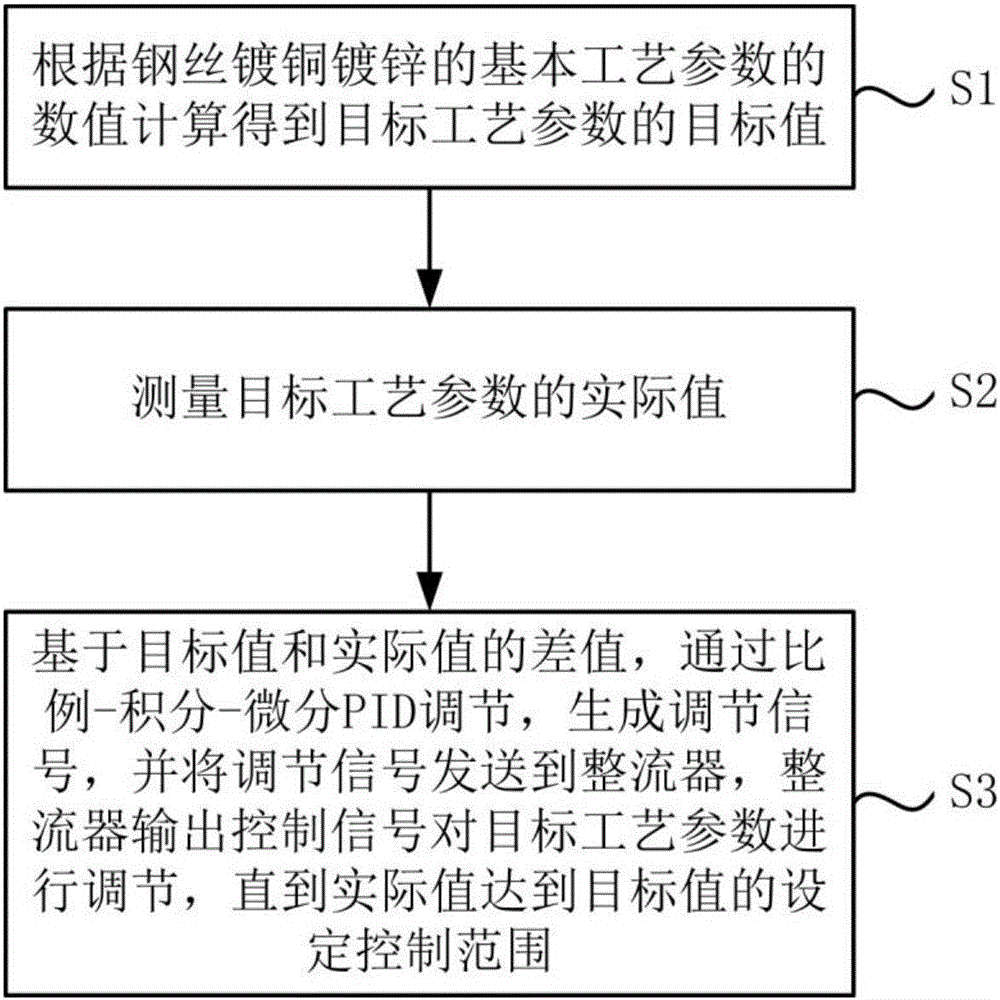

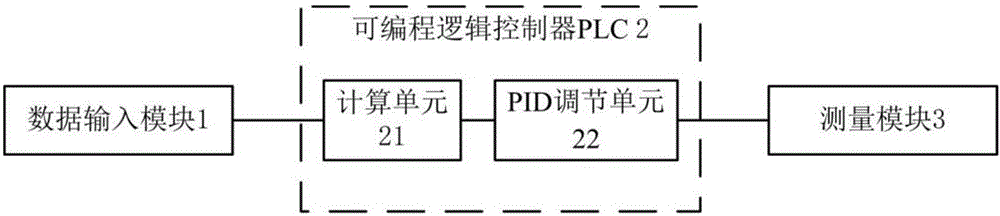

Copper and zinc plating method of steel wires and automatic control system

The invention discloses a copper and zinc plating method of steel wires and relates to the field of electro-plating of steel wires. The method includes the steps of: a) according to basic process parameter values of copper and zinc plating of the steel wires, calculating target values of target process parameters; b) measuring actual values of the target process parameters; c) on the basis of the difference value between the actual values and the target values, generating a regulation signal through proportion-integration-differential (PID) regulation and sending the regulation signal to a rectifier, which then outputs a control signal according to the regulation signal to regulate the target process parameters until the actual values reach a preset control range of the target values. The method can automatically and accurately control the process of plating copper and zinc on the steel wires, saves time and labor intensity, can form uniform copper and zinc layers, is low in thickness error, is good in plating layer quality stability and repeatability, and has high production efficiency.

Owner:WUHAN TONGLI SMART SYST CO LTD

Axial cross type press roll extruding machine and axial cross type rolling process

The invention discloses an axial cross type press roll extruding machine which comprises a machine frame. A first press roll and a second press roll are arranged on the machine frame. The first press roll is a movable roll and mounted on a first fixing frame. The first press roll is connected with a first lifting mechanism through a first transmission bearing at one end, and the first lifting mechanism is used for driving the first press roll to move up and down on the first fixing frame. The second press roll is a fixed roll and mounted on a second fixing frame. The second press roll is connected with a second lifting mechanism through a second transmission bearing at one end, and the second lifting mechanism is used for driving the second press roll to move up and down on the second fixing frame. According to the axial cross type press roll extruding machine, the first press roll and the second roll are oppositely arranged in a crossing mode instead of being oppositely arranged in a horizontal mode by adjusting the first lifting mechanism and the second lifting mechanism, the two rolls are changed into point contact from original linear contact, roll surface deformation caused by opposite pressing of the rolls is effectively avoided, and therefore the extruding machine can be applied to producing different sheets.

Owner:HUIZHOU KOSTA MACHINERY

Forward pressing and lateral pushing concrete outer wall hanging plate forming machine and forming method

The invention discloses a forward pressing and lateral pushing concrete outer wall hanging plate forming machine and a forming method. The forming machine comprises a fixed frame, and a loading mold frame, a forward pressing part, a transverse pushing part and a mold frame push-pull part assembled on the fixed frame, wherein the forward pressing part and the transverse pushing part are separately positioned at the two sides of the loading mold frame, and move relative to the loading mold frame; and the loading mold frame is movably mounted on the tabletop of the fixed frame, and is linked with the mold frame push-pull part in the horizontal direction. A concrete mixture is vertically pressed and laterally pushed in the pressing process, so that the mechanization rate is improved, the labor intensity of workers is reduced, the floor area in the production process is small, and the electric control mechanization is realized.

Owner:CHINA BUILDING MATERIALS ACAD

Fire-proof decorative board manufacturing process

InactiveCN106827770ASmall thickness errorHigh densityLaminationLamination apparatusRoom temperatureEngineering

The invention discloses a fire-proof decorative board manufacturing process. The fire-proof decorative board manufacturing process comprises the following steps: conducting cold pressing on a rolled plate by using a 600-1200 tons press at room temperature for 1-2 min; and feeding the cold-pressed plate into a curing room with temperature of 35-50 degrees centigrade to stand for 2-5 hours so as to obtain a fire-proof decorative board. The fire-proof decorative board manufacturing process disclosed by the invention has the advantages that the density and flatness of the decorative board can be obviously increased and the thickness error of the decorative board can be reduced. Compared with the decorative board which is not cold-pressed, the decorative board manufactured by the fire-proof decorative board manufacturing process has the advantages that the thickness error of the whole board can be reduced from 0.5-1 mm to 0.1 mm and the density of the decorative board can be also increased by more than 20%.

Owner:李石燕

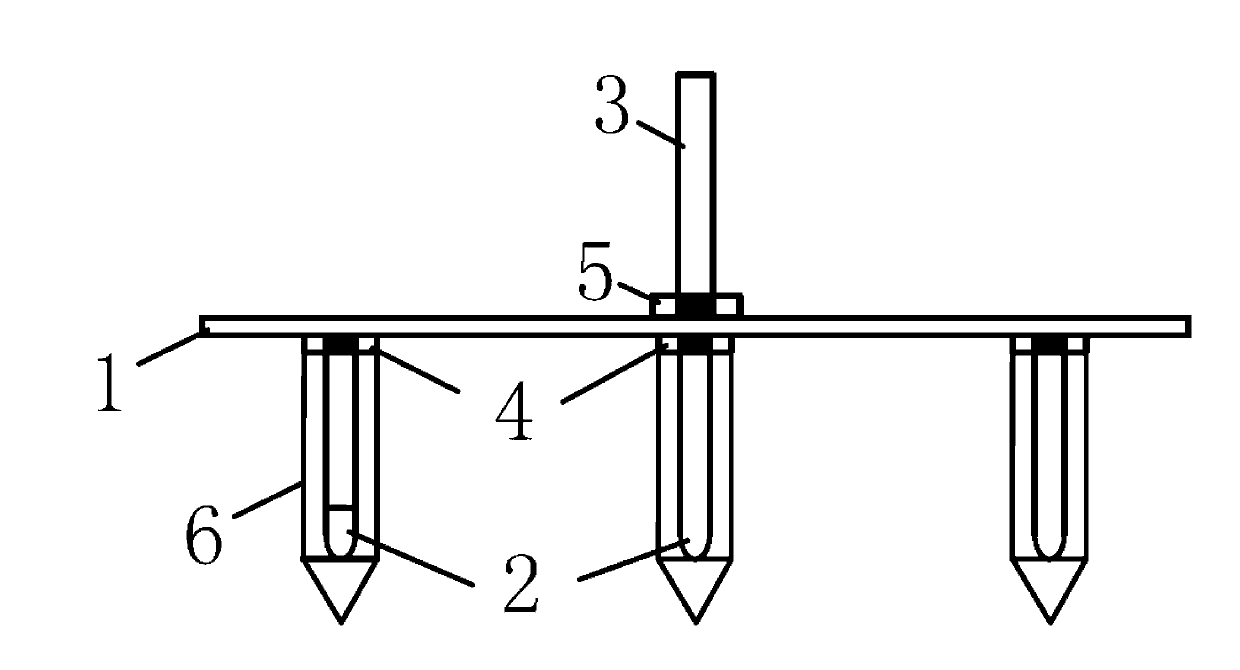

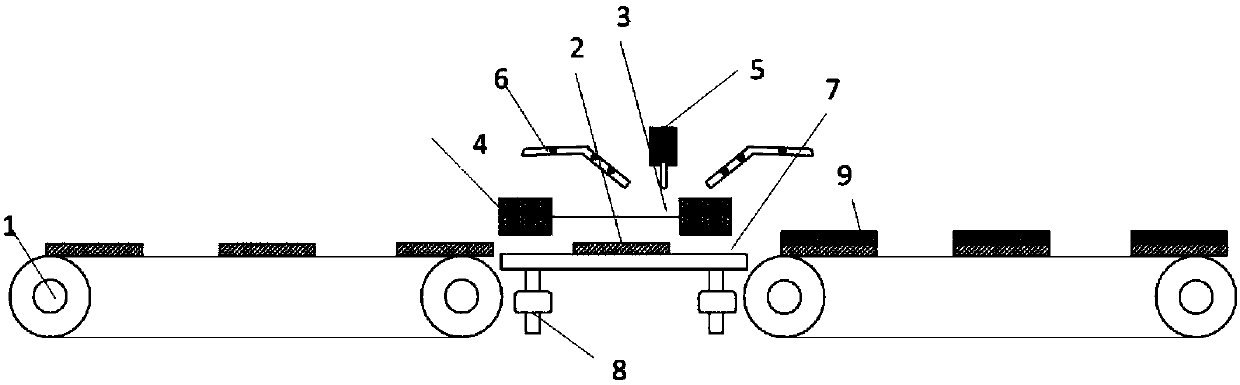

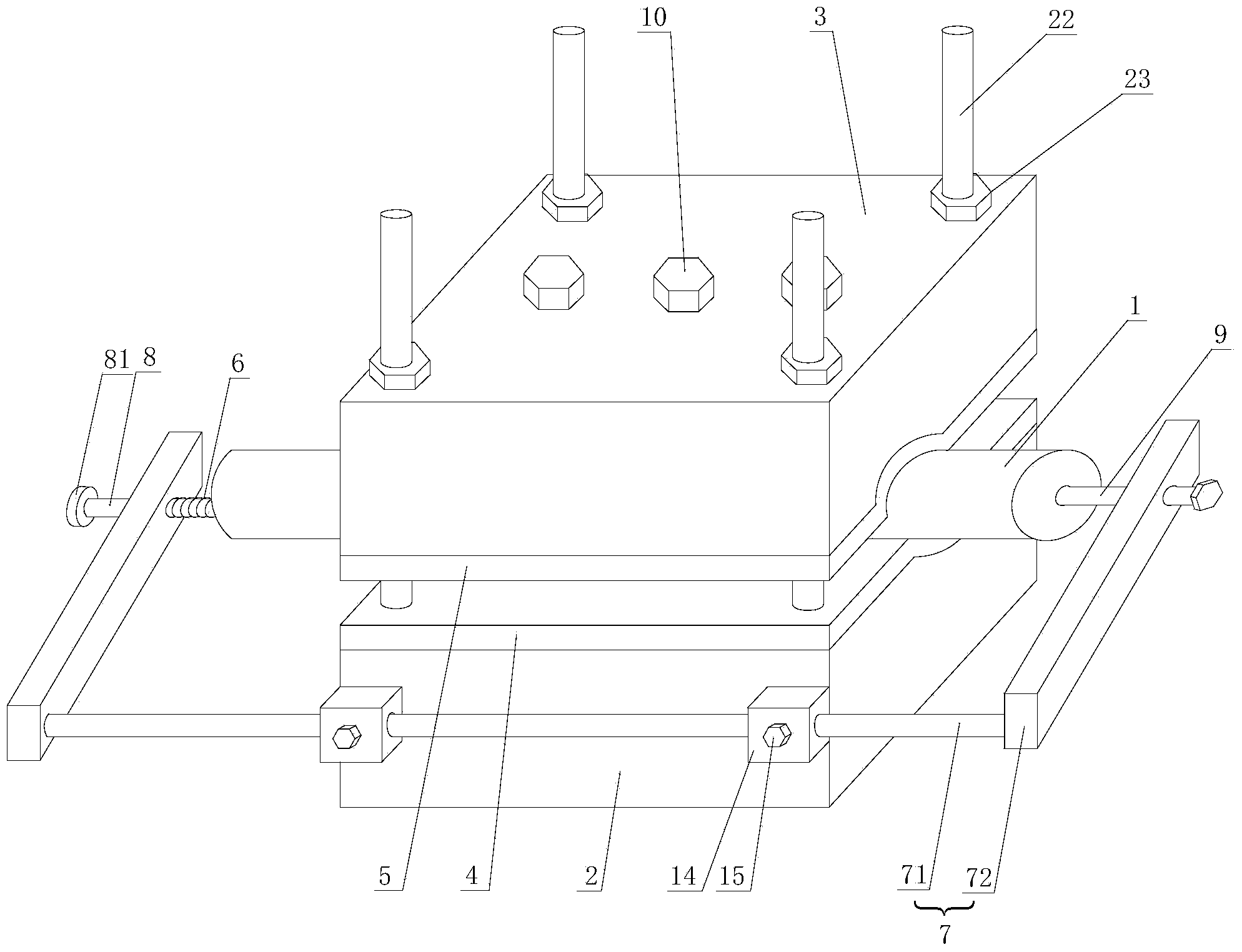

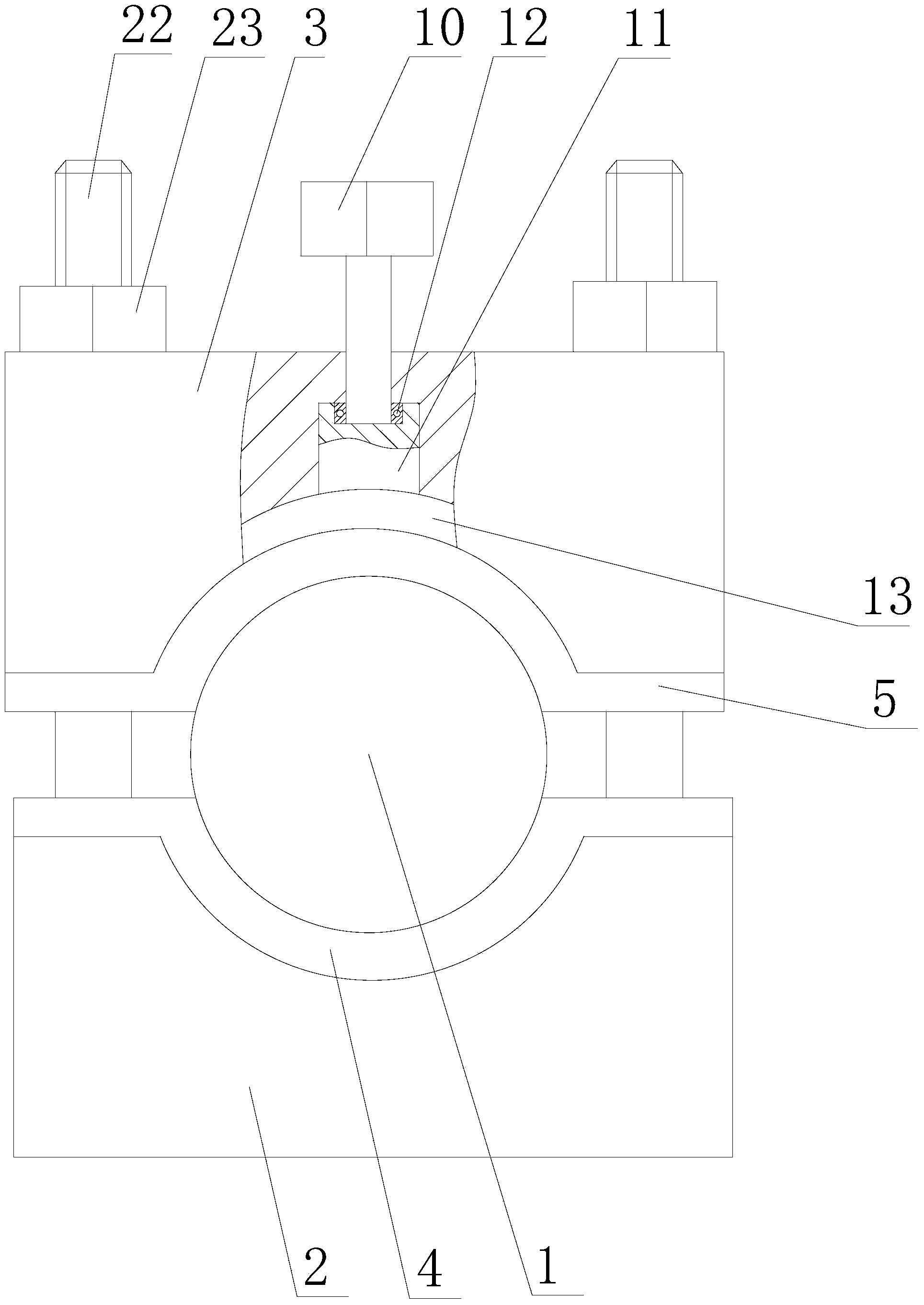

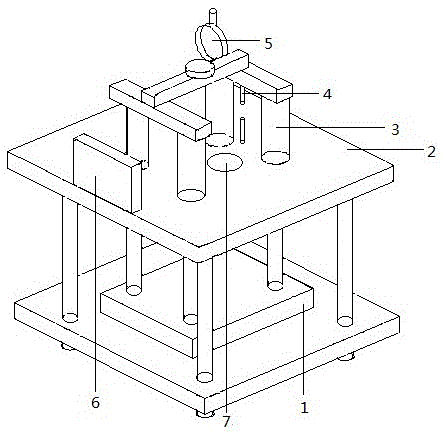

Soft-packaged lithium battery thickness measuring device

PendingCN105423979AImprove accuracyStrong consistencyMeasurement devicesElectrical batteryMeasurement device

The invention discloses a soft-packaged lithium battery thickness measuring device, relates to the field of manufacturing of batteries, and specifically relates to lithium ion production equipment or methods. The device is characterized by comprising a lower base (1) and an upper base (2), wherein a wire guiding frame (3) is arranged on the upper base (2), a puncture needle (4) is arranged below the wire guiding frame (3), a thickness tester (5) is arranged on one side of the wire guiding frame (3), a control system (6) is arranged on the side of the upper base (2), a level (7) is arranged at the top of the upper base (2), and the upper base (2) is spaced from the lower base (1) by an adjustable strut and is parallel to the lower base (1). The device not only overcomes the defects of low accuracy, low consistency, narrow application range and low contrastable significance in present test of soft-packaged lithium ion batteries, but also has the advantages of high accuracy, strong consistency, wide application range and strong contrastable significance; and the thickness of the tested soft-packaged battery is maximum thickness, so the device has great modular design reference significance relative to a micrometer for testing random thickness.

Owner:FOSHAN CITY XINYUAN ELECTRONICS CO LTD

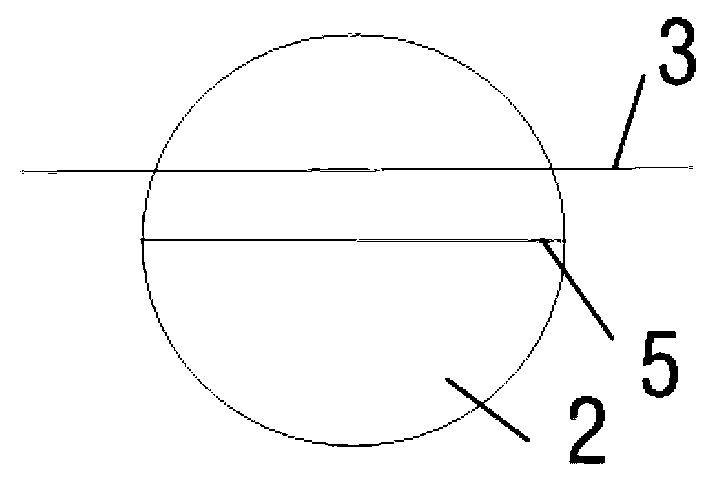

Silicon carbide monocrystal cutting line positioning method

The invention relates to a silicon carbide monocrystal cutting line positioning method. A line source is used for illuminating a cutting line right in the straight front of a bottom face of a crystal. The cutting line casts a shadow line on the bottom face of the crystal and detects the distance between the cutting line and the shadow line. The distance is used as a benchmark to adjust the position of the crystal so that the cutting line is kept parallel to the bottom face of the crystal and crystal sheets uniform in thickness are cut out.

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

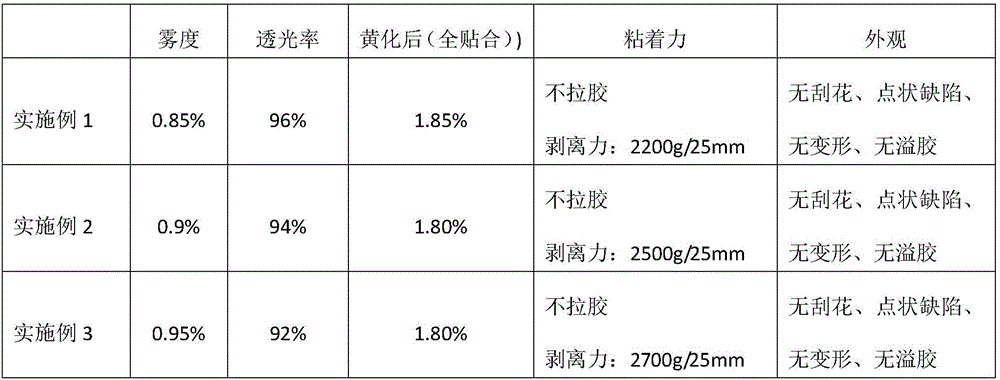

Solvent-free type environment-friendly semi-curing optical adhesive tape and preparation method thereof

ActiveCN106433499AExcellent adhesionIncreased durabilityFilm/foil adhesivesGraft polymer adhesivesSolvent freeCarboxylic acid

The invention relates to the field of an optical adhesive tape and especially relates to a solvent-free type environment-friendly semi-curing optical adhesive tape and a preparation method thereof. The preparation method comprises the following steps: firstly, causing the polycarbonate diol with low molecular weight and the carboxylic acid with unsaturated double bond have esterification reaction; adding acrylate monomer and photoinitiator and performing polymerization reaction under ultraviolet radiation, thereby acquiring a pre-polymer; uniformly mixing the pre-polymer, the acrylate monomer, the chain transfer agent and the photoinitiator and then coating, and coating the mixture between two layers of release films under ultraviolet irradiation, thereby acquiring the solvent-free type environment-friendly semi-curing optical adhesive tape. The solvent-free type environment-friendly semi-curing optical adhesive tape provided by the invention has the characteristics of excellent water resistance, durability, yellowing resistance, high hardness and adhesive strength, low cure shrinkage rate, environmental protection, and the like.

Owner:CHANGZHOU HUAKE POLYMERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com