Copper and zinc plating method of steel wires and automatic control system

A technology of copper plating and steel wire, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of large thickness error of copper layer and zinc layer, poor precision control repeatability, poor uniformity, etc., to reduce the error of copper layer and zinc layer , good stability and repeatability, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

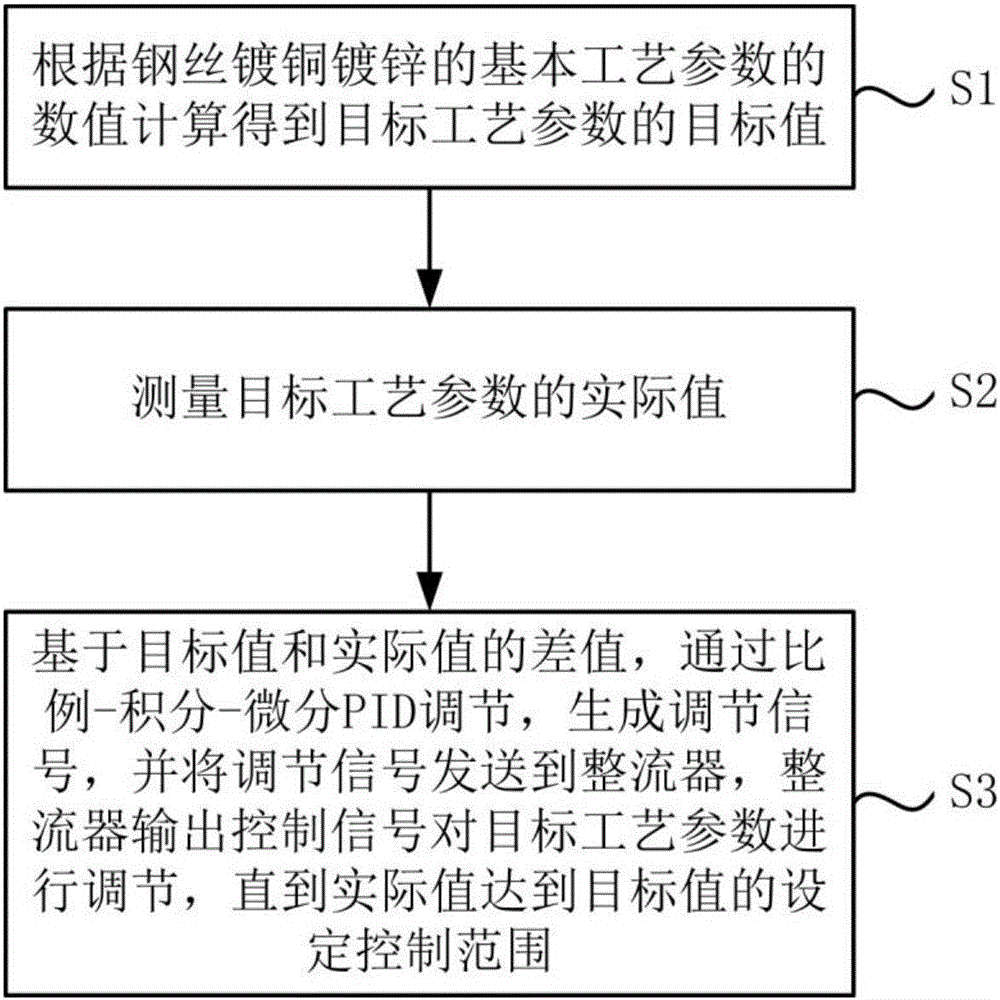

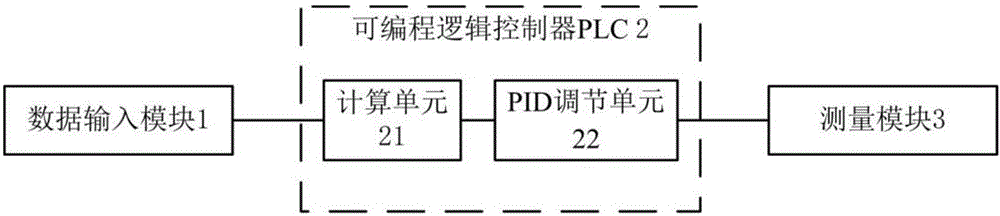

[0047] Such as figure 1Shown, a kind of copper wire galvanizing method comprises the following steps:

[0048] S1. Calculate the target value of the target process parameter according to the numerical value of the basic process parameter of copper plating and galvanizing of steel wire.

[0049] Basic process parameters include the number of steel wires to be copper-coated and galvanized, wire diameter, wire travel speed, total weight ratio of the coating, percentage of copper content in the coating, plating current efficiency and the number of plating pumps that are turned on.

[0050] The number of steel wires ranges from 1 to 24, the steel wire diameter ranges from 0.5 to 3.5 mm, the travel speed ranges from 10 to 120 m / min, and the total weight ratio of the coating layer ranges from 2 to 10 g / Kg.

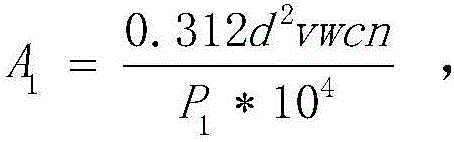

[0051] The number of steel wires, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com