Electric motor stator assembly machine

A motor stator and assembly machine technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve problems such as low work efficiency, damage to stator components, and reduced price competitiveness of motors, so as to achieve good quality stability, reduce labor intensity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

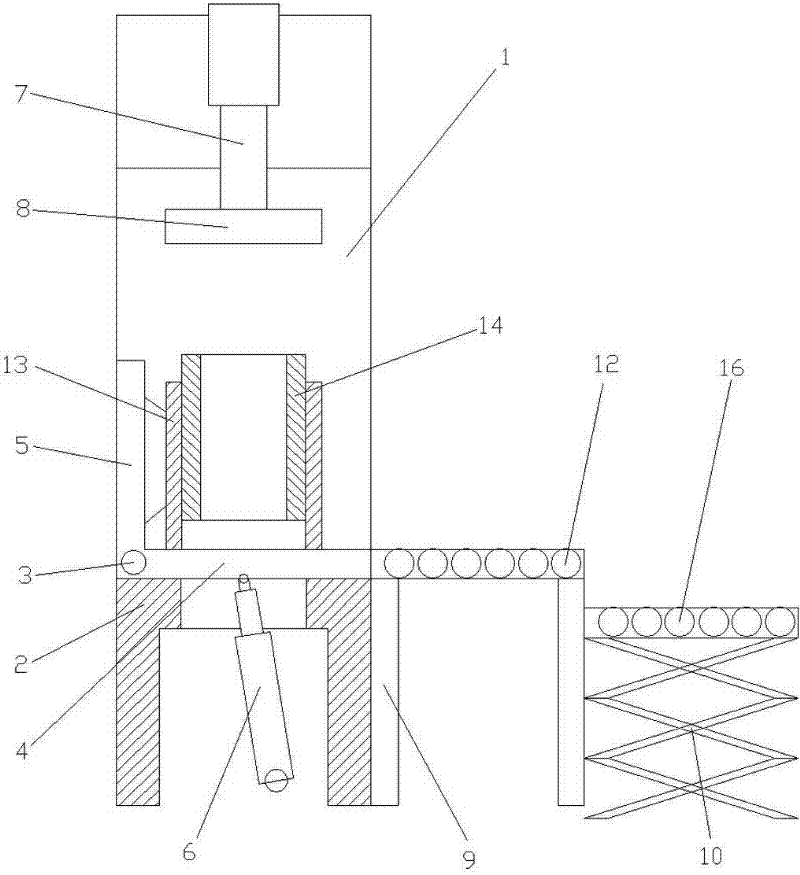

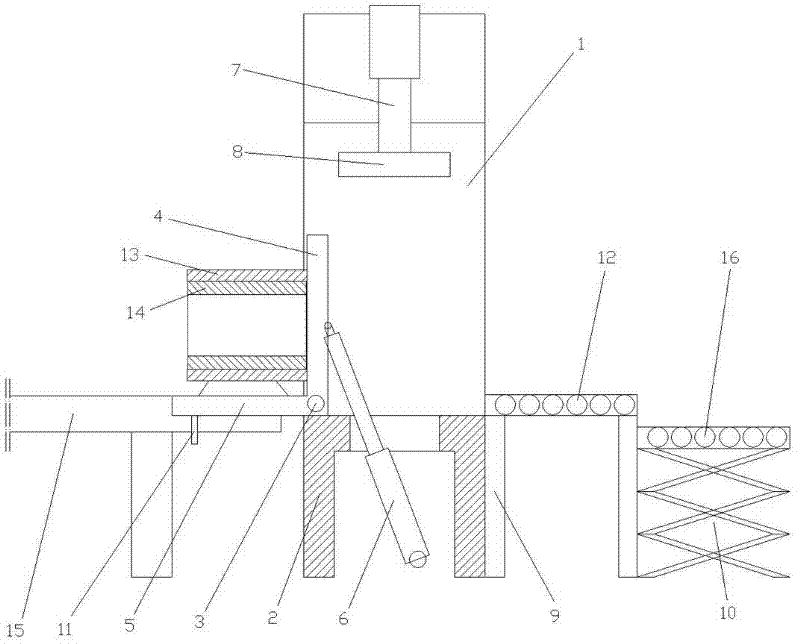

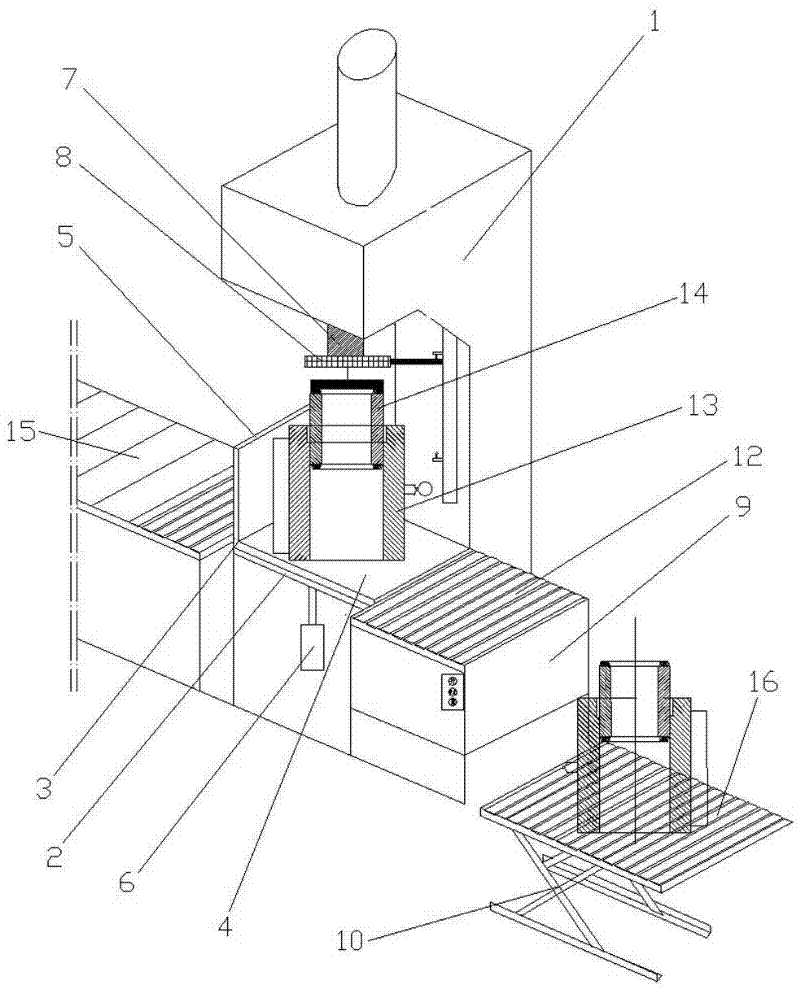

[0012] Such as Figure 1-Figure 3 As shown, the present invention discloses a motor stator assembling machine. The motor stator assembling machine of the present invention can be properly refitted by using an ordinary hydraulic machine tool 1. The refitting items mainly include: the hydraulic machine tool 1 A top plate 8 is fixed on the machine head 7, and the size of the top plate 8 should match the size of the stator assembly 14 to be assembled; the workbench 2 of the hydraulic machine tool 1 has an L-shaped overturn frame 3, and the The overturn frame 3 has a pressure bearing plate 4 and a base support plate 5, and one side of the pressure bearing plate 4 is connected at right angles to a side of the base support plate 5, and the side of the pressure bearing plate 4 and the base support plate 5 The joint is rotatably connected to one side of the workbench 2, and a jacking device 6 is connected below the pressure bearing plate 4, and the jacking device 6 is usually an oil cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com