Optical diffusion film and backlight module using same

A technology of optical diffusion and light diffusion layer, which is applied in the field of diffusion film, can solve the problems of high energy consumption of light sources, unfavorable environmental protection, high price, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

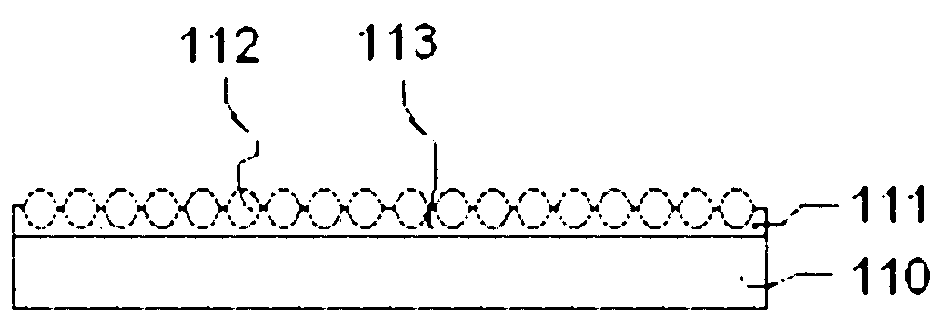

[0025] like image 3 As shown, the optical diffusion film of the present invention includes a transparent base film 110 and a light-diffusing layer 111 on one surface of the transparent base film 110, wherein the light-diffusing layer 111 further includes cross-linked transparent polymer spherical particles 112 whose particle size distribution is monodisperse And polymer adhesive 113. The transparent base film 110 is a PET polyester film with a thickness of 125 microns; the thickness of the light diffusion layer 111 is 25 microns; the average particle diameter of the cross-linked transparent polymer spherical particles 112 is 20 microns, and the particle size distribution is 1.01. Transparent polymer spherical particle is PMMA, and its addition accounts for 15% of light diffusion layer 111 weights; Polymer adhesive is the polyester polyol (Huafeng Group, JF-PE-3030) of solid content 50%; Curing agent is toluene diisocyanate.

[0026] The specific production method is: in a d...

Embodiment 2

[0028] like image 3 As shown, the optical diffusion film of the present invention includes a transparent base film 110 and a light-diffusing layer 111 on one surface of the transparent base film 110, wherein the light-diffusing layer 111 further includes cross-linked transparent polymer spherical particles 112 whose particle size distribution is monodisperse And polymer adhesive 113. The base film 110 is a PET polyester film with a thickness of 250 microns; the thickness of the light diffusion layer 111 is 30 microns; the average particle diameter of the cross-linked transparent polymer spherical particles 112 is 5 microns, the particle size distribution is 1.05, and the cross-linked transparent polymer Polymer spherical particle is PMMA, and its addition accounts for 18% of diffusion layer weight; Polymer adhesive is polyester polyol (Huafeng Group, JF-PE-3030) of solid content 50%; Curing agent is diphenylmethane diisocyanate.

[0029] The specific production method is: i...

Embodiment 3

[0031] like image 3 As shown, the optical diffusion film of the present invention includes a transparent base film 110 and a light-diffusing layer 111 on one surface of the transparent base film 110, wherein the light-diffusing layer 111 further includes cross-linked transparent polymer spherical particles 112 whose particle size distribution is monodisperse And polymer adhesive 113. The base film 110 is a PC film with a thickness of 125 microns; the thickness of the light diffusion layer 111 is 25 microns; the average particle diameter of the cross-linked transparent polymer spherical particles 112 is 20 microns, and the particle size distribution is 1.03. The spherical particles are PMMA, and its addition accounts for 10% of the weight of the diffusion layer; the polymer adhesive is polyurethane resin (Huafeng Group, JF-A-5030) with a solid content of 40%; isocyanate.

[0032] The specific production method is: in a dust-free environment above 10,000 grades, mix the cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com