Patents

Literature

116results about How to "The solution is not easy to clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimetazidine dihydrochloride sustained-release tablet and preparation method thereof

InactiveCN102885795AThe solution is not easy to cleanSimple preparation stepsOrganic active ingredientsPharmaceutical non-active ingredientsTrimetazidine DihydrochlorideSustained Release Tablet

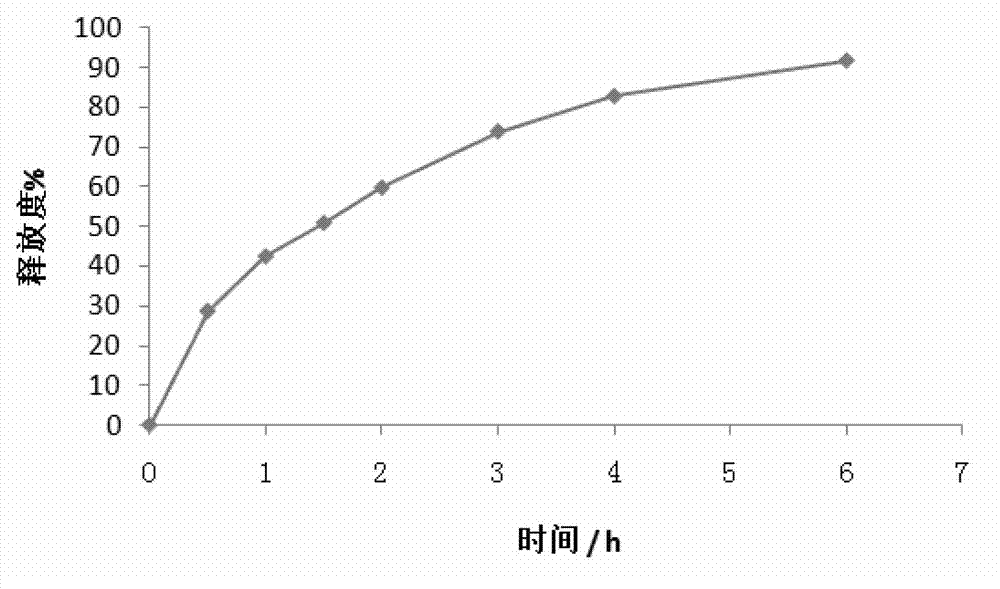

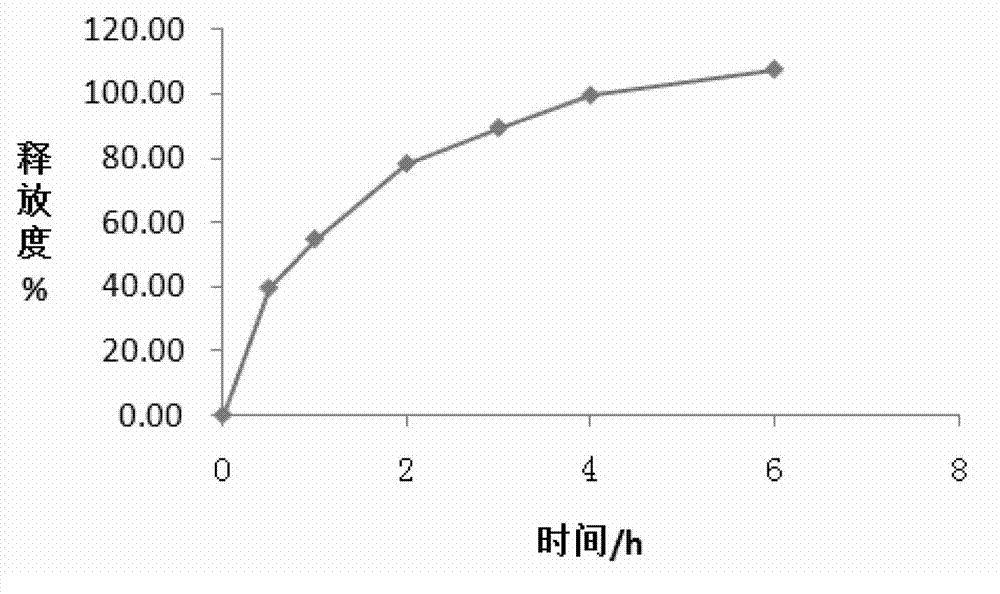

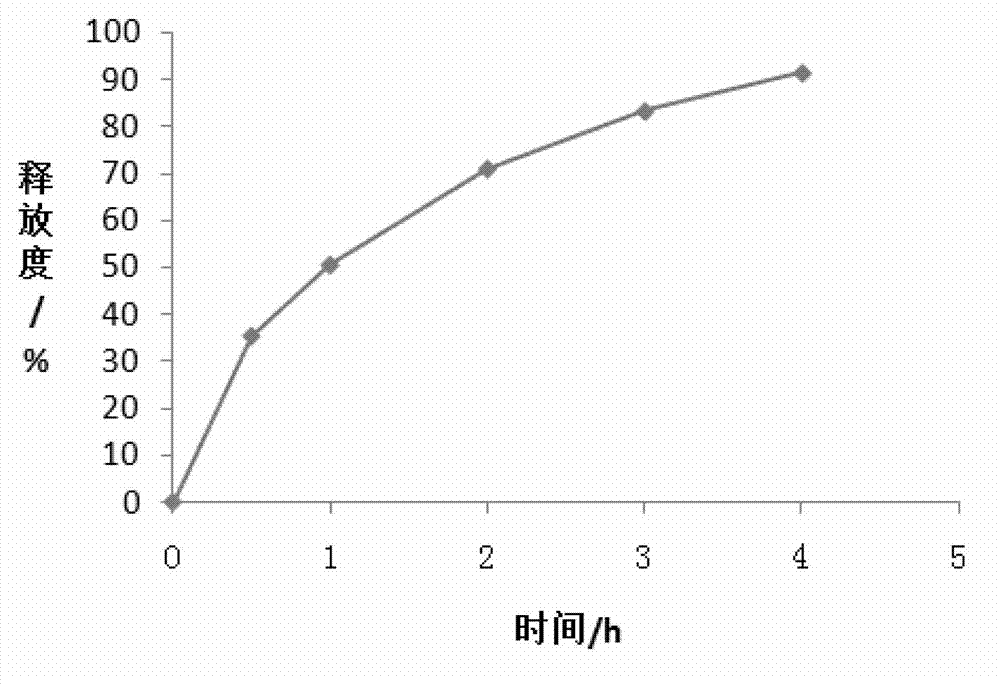

The invention discloses a trimetazidine dihydrochloride sustained-release tablet and a preparation method thereof. The trimetazidine dihydrochloride sustained-release tablet comprises the following constituents in percentage by mass: 5-60% of trimetazidine dihydrochloride, 10-25% of sustained-release framework material, 1-8% of adhesive, 20-80% of filler, 0.1-5% of glidant and 0.2-3% of lubricant. According to the trimetazidine dihydrochloride sustained-release tablet, medicine can be slowly and uniformly released by adding the sustained-release framework material, so as to achieve regulation and control for a release speed, reduce the peak-valley ratio of the medicine, improve the efficacy, reduce the toxic and side effects of the medicine, reduce daily medicine-taking times and enhance the compliance of the patient on the medicine. The preparation method of the trimetazidine dihydrochloride sustained-release tablet disclosed by the invention is simple in process, does not need specially process production equipment, and is low in cost and good for batch amplification and industrialized production for products.

Owner:AC PHARMA CO LTD

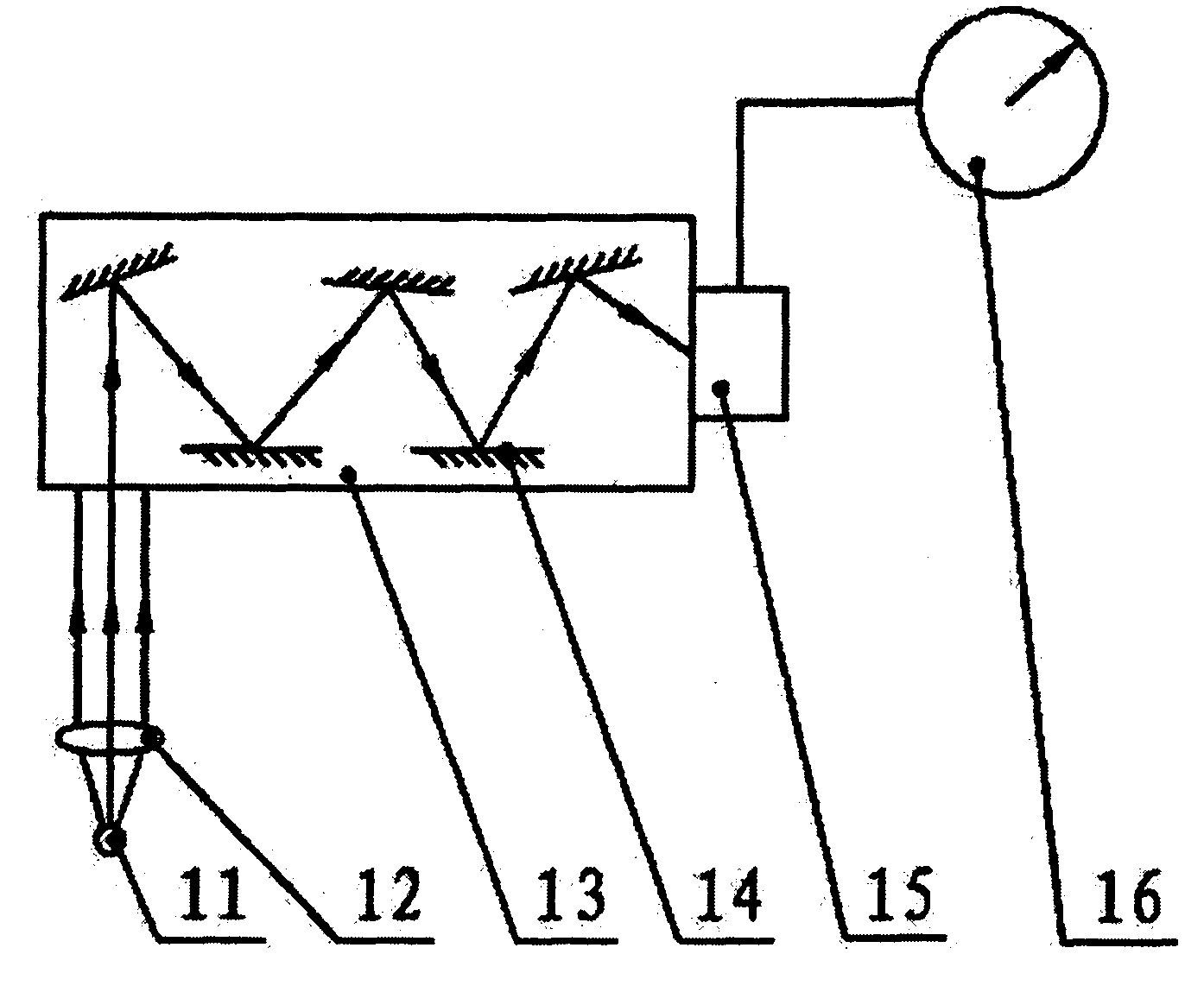

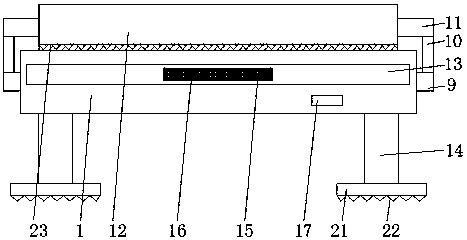

Smoke detector sensitivity detecting device based on obscuration principle

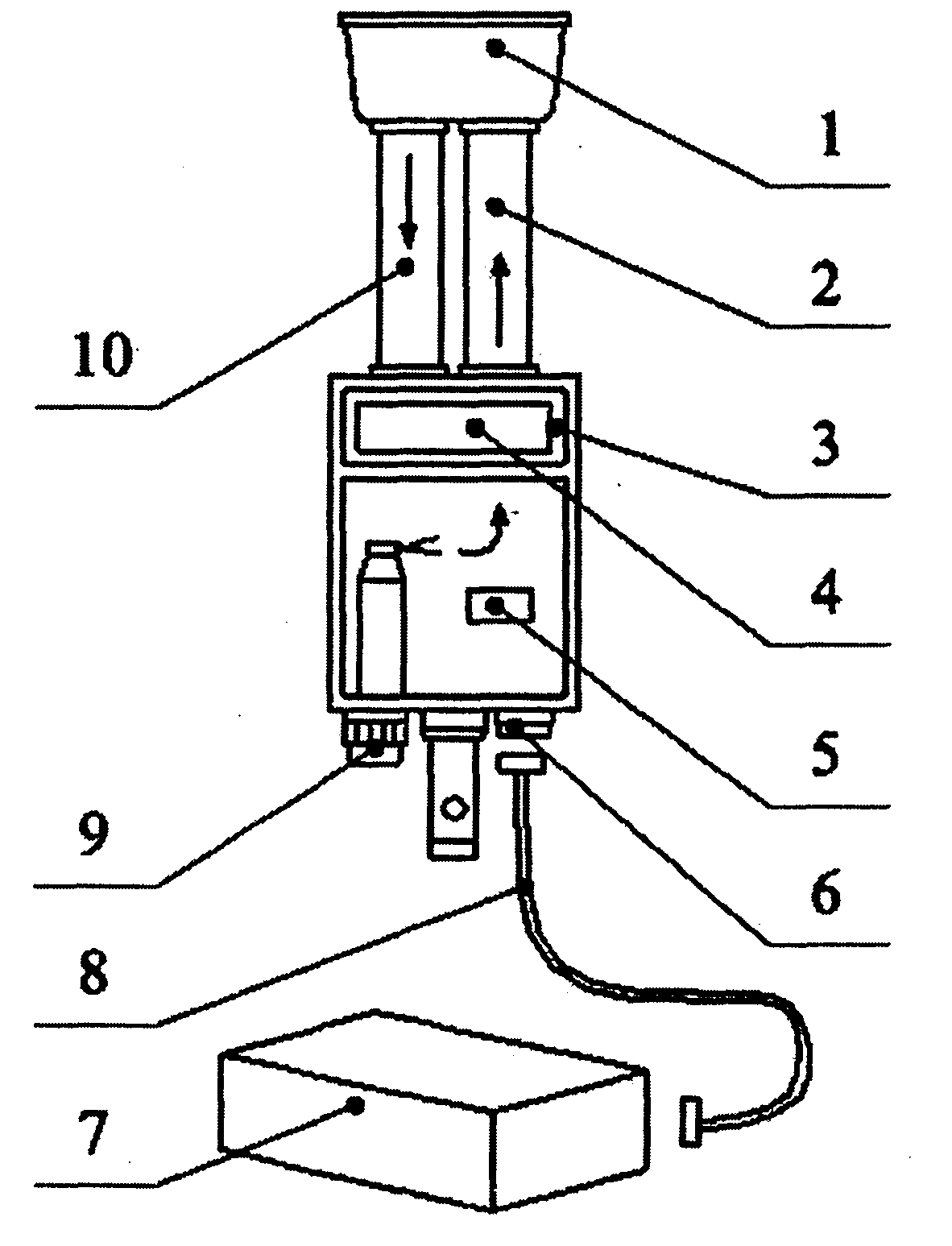

InactiveCN102163364ASolve easy to extinguishResolution timeColor/spectral properties measurementsFire alarm smoke/gas actuationEngineeringAerosol generator

The invention belongs to fire safety detecting equipment, relating to a smoke detector sensitivity detecting device based on the obscuration principle. The device provided by the invention is structurally characterized by comprising a testing loop, an aerosol generator, an air flow control fan and a processor, wherein the testing loop is composed of a testing barrel, a reflow tube, a testing room and a transparent smoke cup; and a smoke concentration detecting system based on the dimming principle is arranged in the testing room, and is composed of an alignment optical system, an absorption pool, a photoelectric detector and a galvanometer. When the device provided by the invention is used for detecting, aerosol smoke enters the absorption pool, the photoelectric detector receives the absorbed light intensity information after an incident light is absorbed and attenuated by the aerosol in the absorption pool, an obscuration coefficient can be obtained through the data processing, then the detected smoke concentration is obtained to be displayed on the liquid crystal display of the processor and compared with a standard concentration of a smoke detector alarm, the quantitative detection on the flexibility of the smoke detector can be realized depends on the alarming of an audible and visible alarm.

Owner:CHANGCHUN UNIV OF SCI & TECH

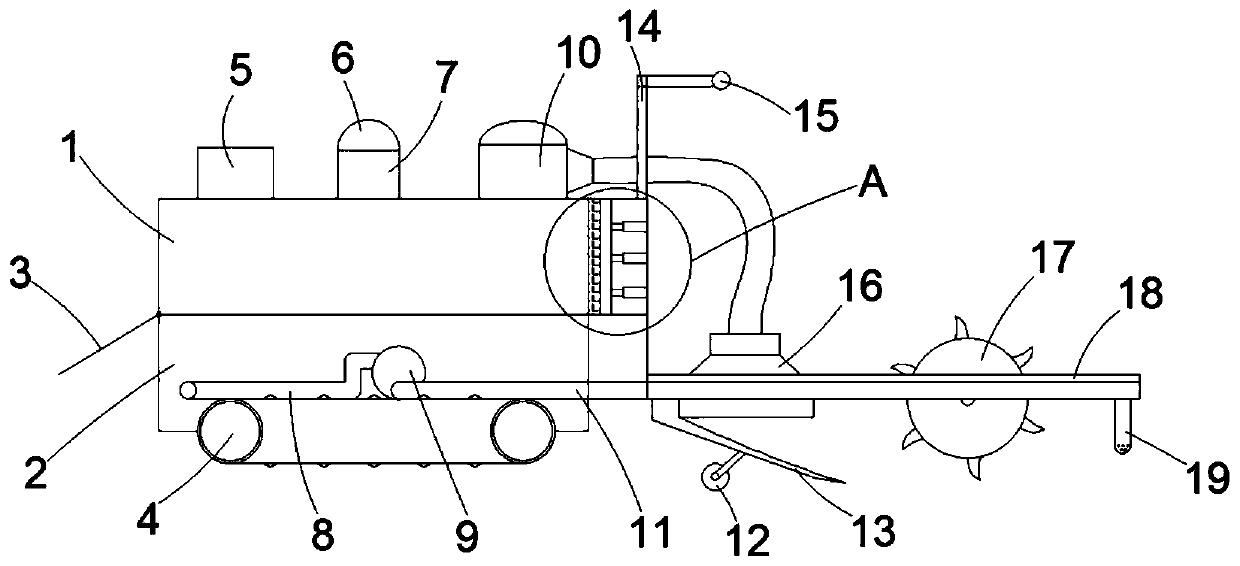

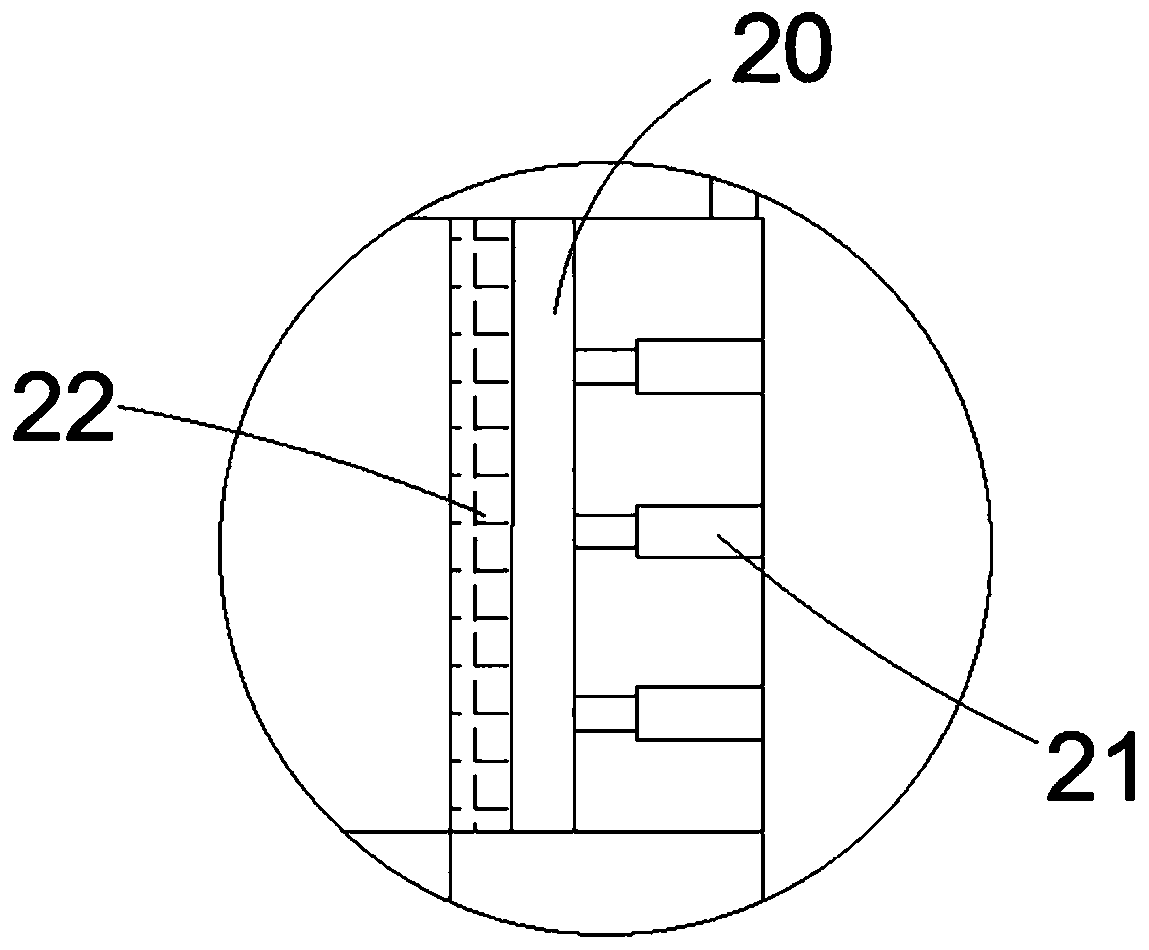

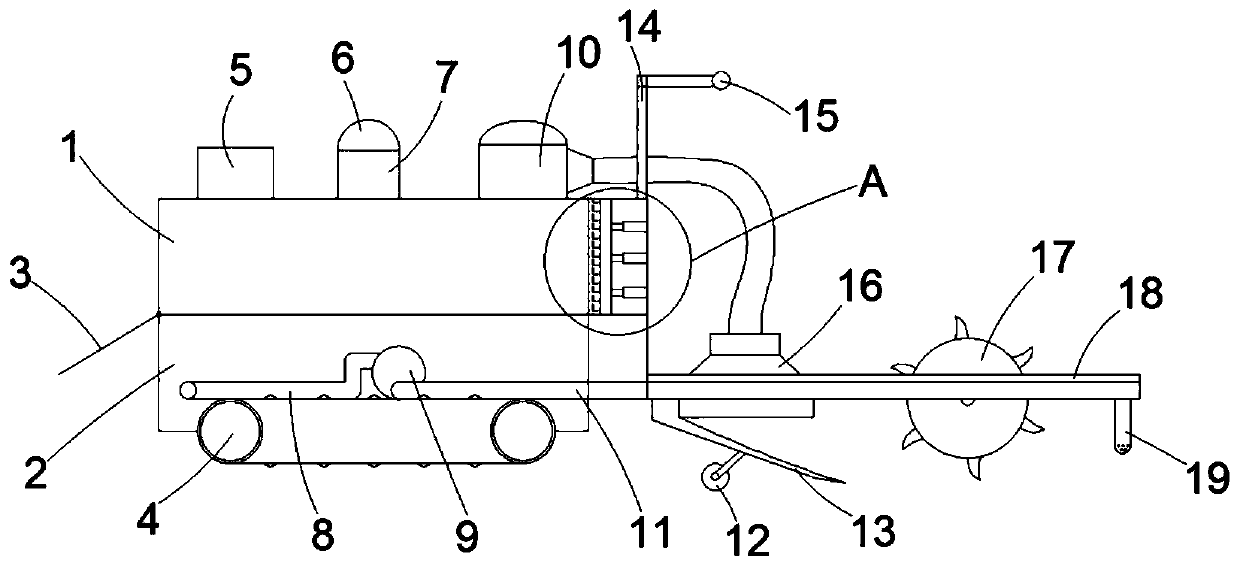

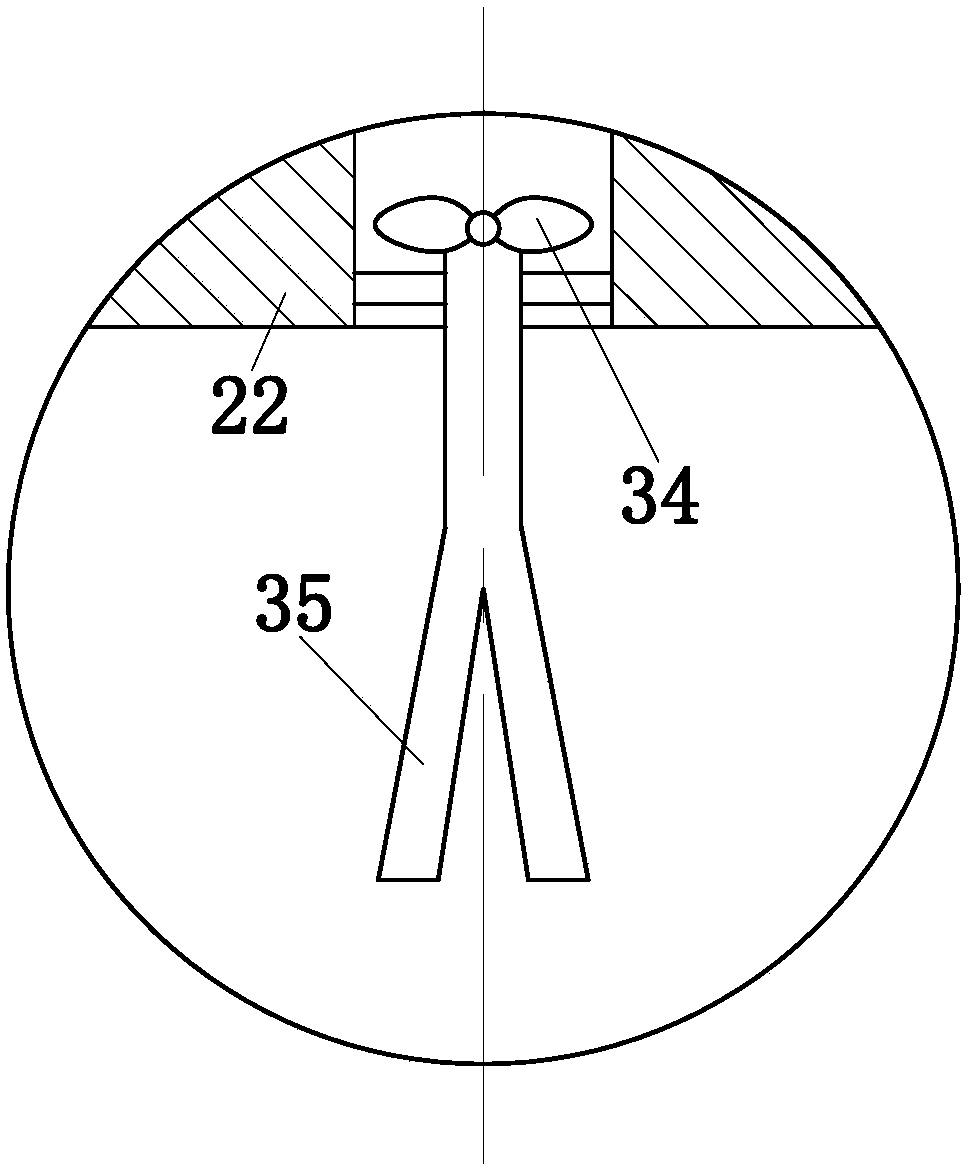

River sewage pipe network dredging robot

The invention relates to the technical field of sewage pipe network dredging, in particular to a river sewage pipe network dredging robot. The river sewage pipe network dredging robot comprises a chassis and a front suspension, crawler wheels and a separation box are installed on the chassis, the separation box comprises a sludge cavity and a water cavity, a water filter partition layer is arranged between the sludge cavity and the water cavity, an extrusion device is arranged in the sludge cavity, a water spraying head, a crushing device and a sludge suction disk are installed on the front suspension, the sludge suction disk communicates with the sludge cavity through a first pumping pipeline, and the water spraying head communicates with the water cavity through a second pumping pipeline; and the river sewage pipe network dredging robot further comprises a power supply device, a control device, a signal receiving and transmitting device and a camera shooting device. According to theriver sewage pipe network dredging robot, the problem that dry and hard sludge is inconvenient to clear is solved, the clearing efficiency is improved, and the operation intensity of dredging workersis relieved.

Owner:惠州市水电建筑工程有限公司

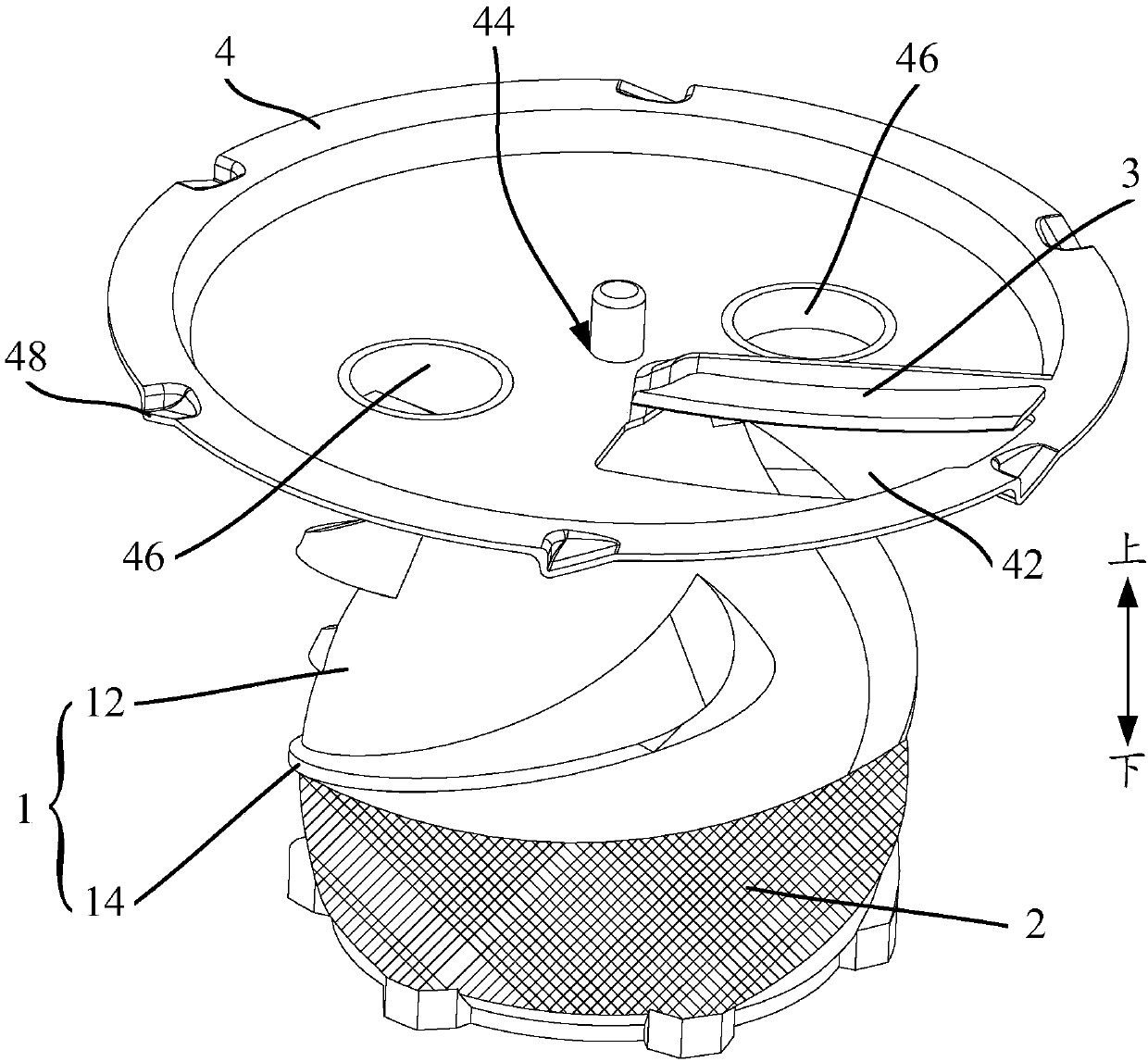

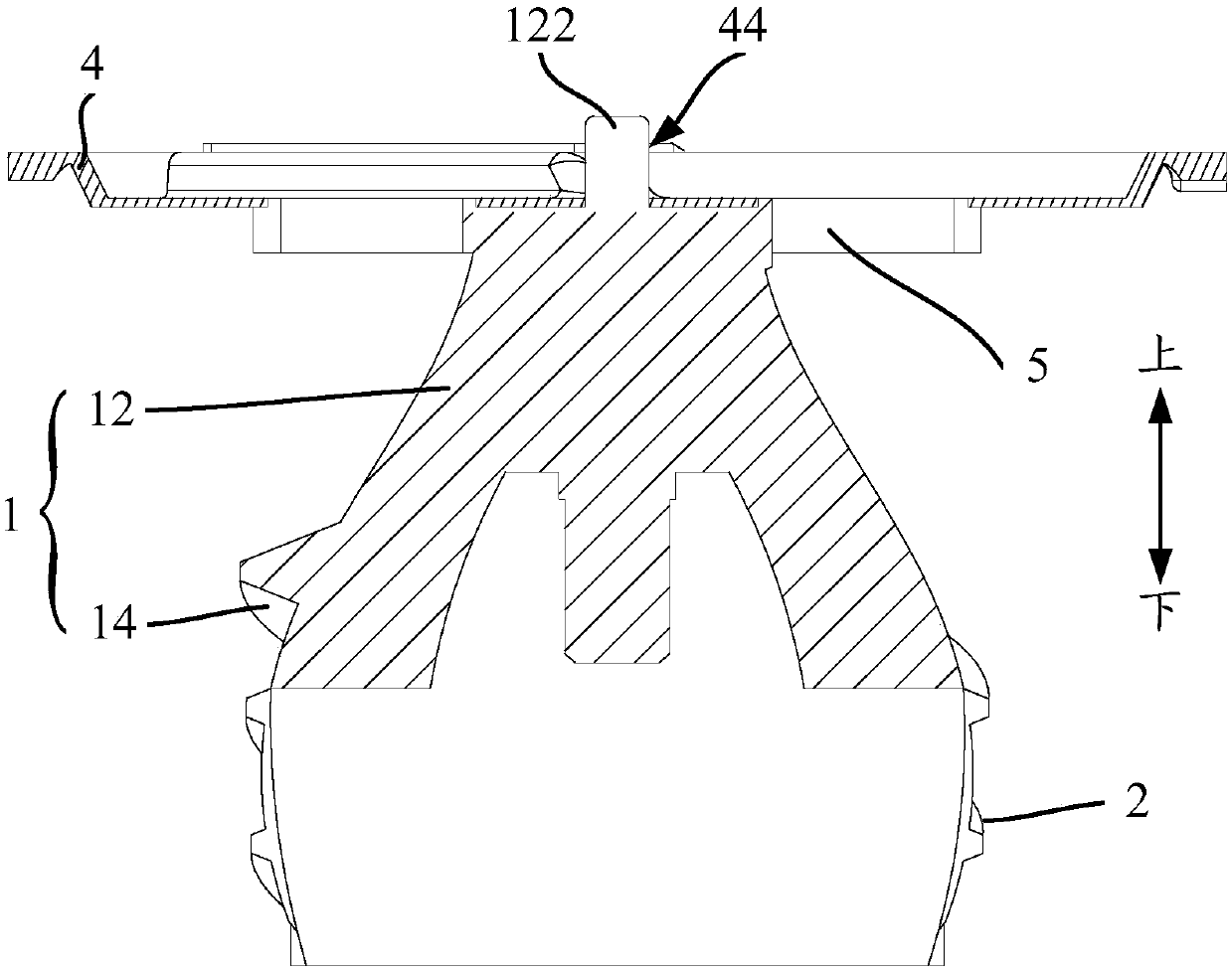

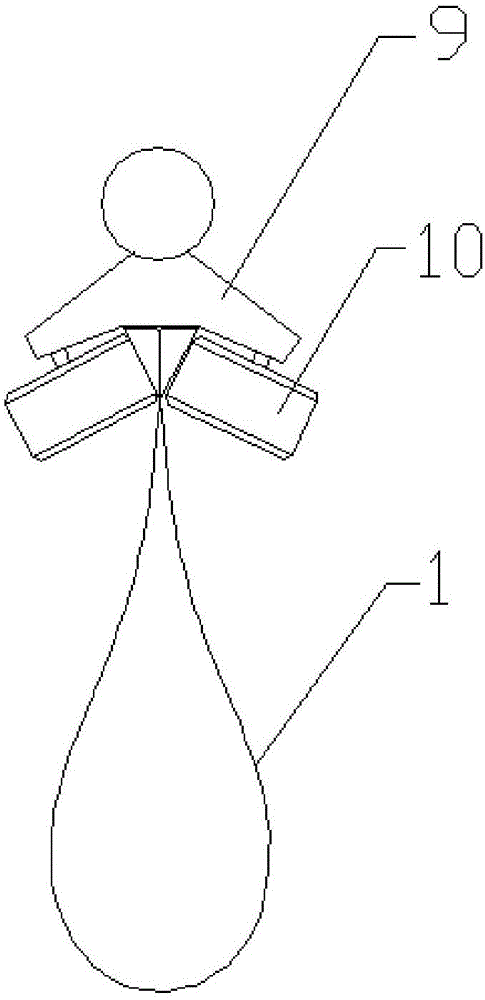

Screw rod and food processor

The invention provides a screw rod and a food processor. The screw rod comprises a screw rod body and a blade, wherein a juicing net is arranged at a first end of the screw rod body; the blade is mounted at a second end of the screw rod body. According to the technical scheme provided by the invention, the blade is arranged at the second end of the screw rod body, therefore, after hard food materials or crude fiber food materials and the like enter a juicing cup and before the screw rod carries out squeezing, the blade is utilized for cutting the hard food materials or crude fiber food materials and the like into small broken blocks, thus the food materials cut by the blade can be easily squeezed to be broken by the screw rod, the clamping of the screw rod seldom occurs, meanwhile, the food materials are cut into the small broken blocks in advance, so that particles of food dregs are small, and thus the food dregs can be easily discharged and can not block a dreg discharge hole. In addition, the hard food materials or crude fiber food materials and the like are cut into the small broken blocks in advance, therefore, the food materials can be sufficiently squeezed by the screw rod in the juicing cup to form juice, and thus the juice yield is improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Pivoted window with flowerpots

InactiveCN103291185AFlexible and convenient to useThe solution is not easy to cleanWing arrangementsSpecial door/window arrangementsSash windowRotation control

The invention provides a pivoted window with flowerpots. The window can be cleaned conveniently, and the flowerpots can be placed on the pivoted window. The pivoted window with the flowerpots mainly comprises window sashes, a rotation control shaft, flowerpot frames, water accommodating trays and the like. The rotation control shaft is mounted in the center of a vertical border of a fixing window frame, and the left window sash and the right window sash are sleeved on the rotation control shaft via an upper rocker arm and a lower rocker arm and can circularly rotate around rotary shafts. The flowerpots can be mounted on the upper portions or the lower portions of the window sashes and are fixed onto the window frame by screws, flowerpot locking devices are arranged in the middles of the flowerpot frames, and the water accommodating trays are arranged at the bottoms of the flowerpot frames. The pivoted window has the advantages that front and rear surfaces of openings of the flowerpots are planes, two sides of each flowerpot are arc-shaped, the middles of the flowerpots are concave, and accordingly the flowerpots are small in occupied space when placed on the pivoted window, and are matched with the flowerpot frames so as to be fixed advantageously.

Owner:付聪慧

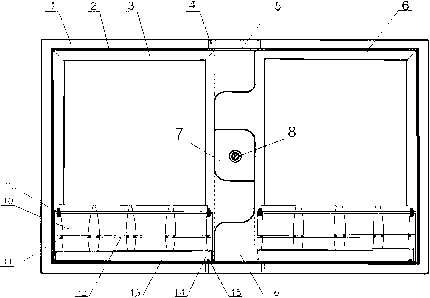

Device overhaul stand flushing system

ActiveCN104399696AEasy to cleanImprove efficiencyCleaning using liquidsWater flowWorking environment

The invention discloses a device overhaul stand flushing system which comprises multiple supporting plates, a water trough and a flushing head. Gaps are reserved among the supporting plates, the supporting plates are arranged on the water trough, supporting columns arranged in the water trough are arranged at the bottoms of the supporting plates, the water trough is of a groove structure and formed in the ground, and the flushing head is connected to a water pump. The device overhaul stand flushing system adopts the water trough and the supporting plates with the gaps and can flush a coal mining mechanical device through the flushing head, coal residues fall onto the smooth and clean supporting plates, water flows into the water trough through the gaps, the problems of difficult cleaning, inconvenient coal residue removal, inconvenient operation, low cleaning efficiency and poor working environment existing in the prior art are effectively solved, dirty water produced after flushing can be timely discharged, a clean working environment can be provided, convenient cleaning, convenient operation, convenient coal residue removal, convenient manufacture and maintenance, high equipment cleaning efficiency and clean and hygienic working place are achieved, and the device overhaul stand flushing system has the advantage of being simple in structure.

Owner:GUIZHOU PANJIANG MINING MACHINERY

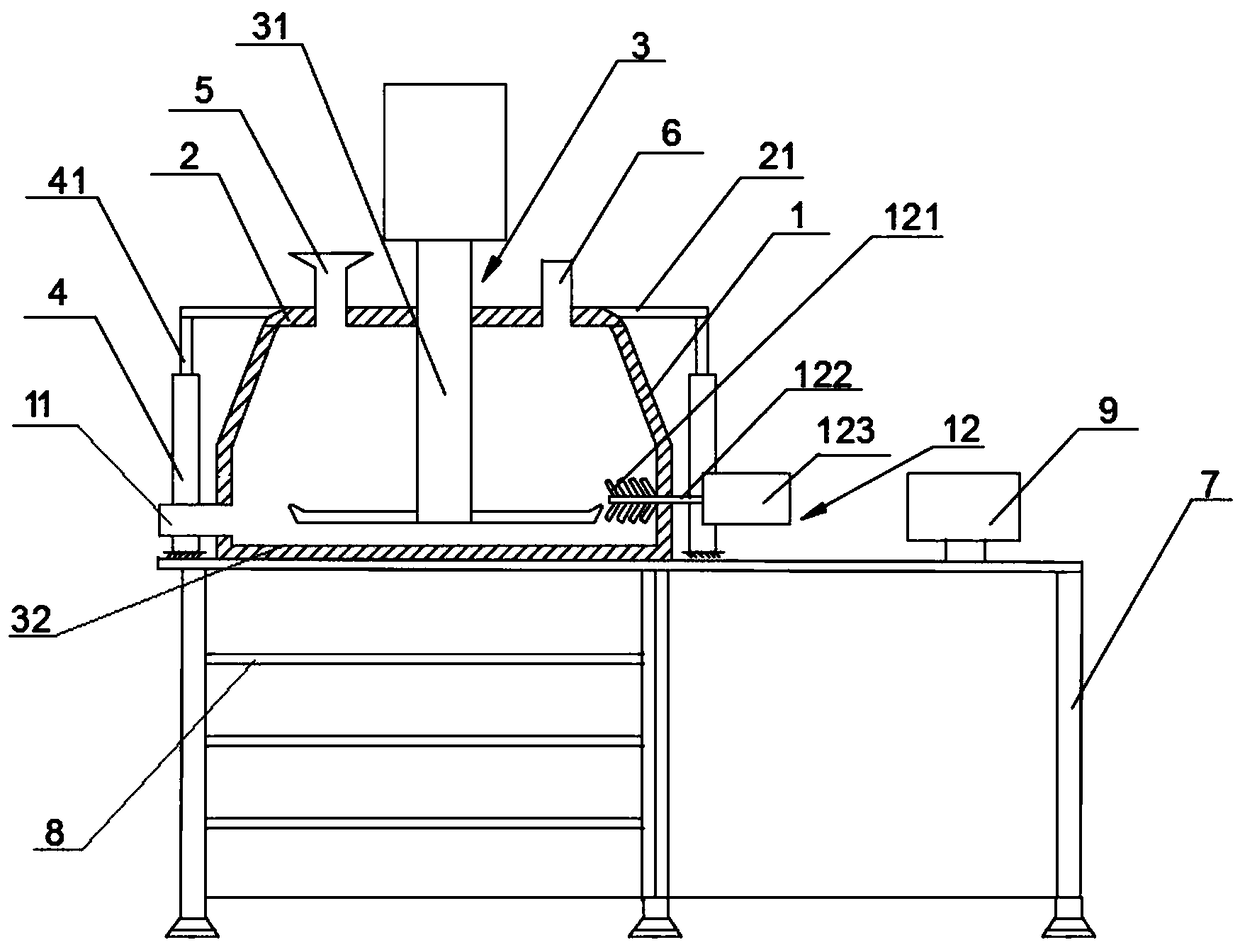

Preparation method of special pig feed for sow postpartum care

InactiveCN112120120AScientific and reasonable structureEasy to useFeeding-stuffFood processingProcess engineeringMixing tank

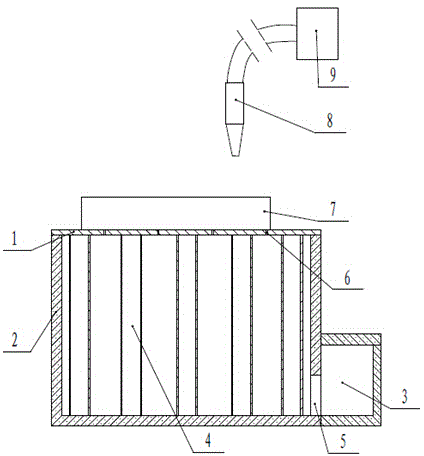

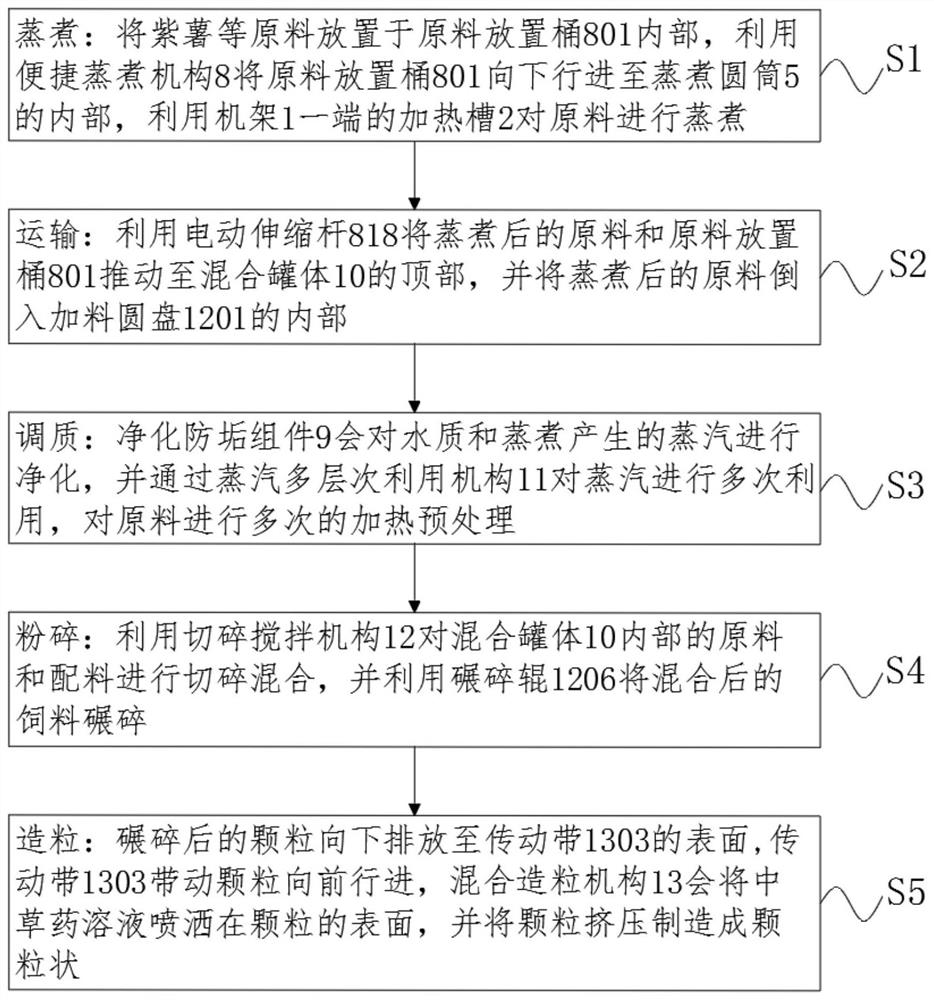

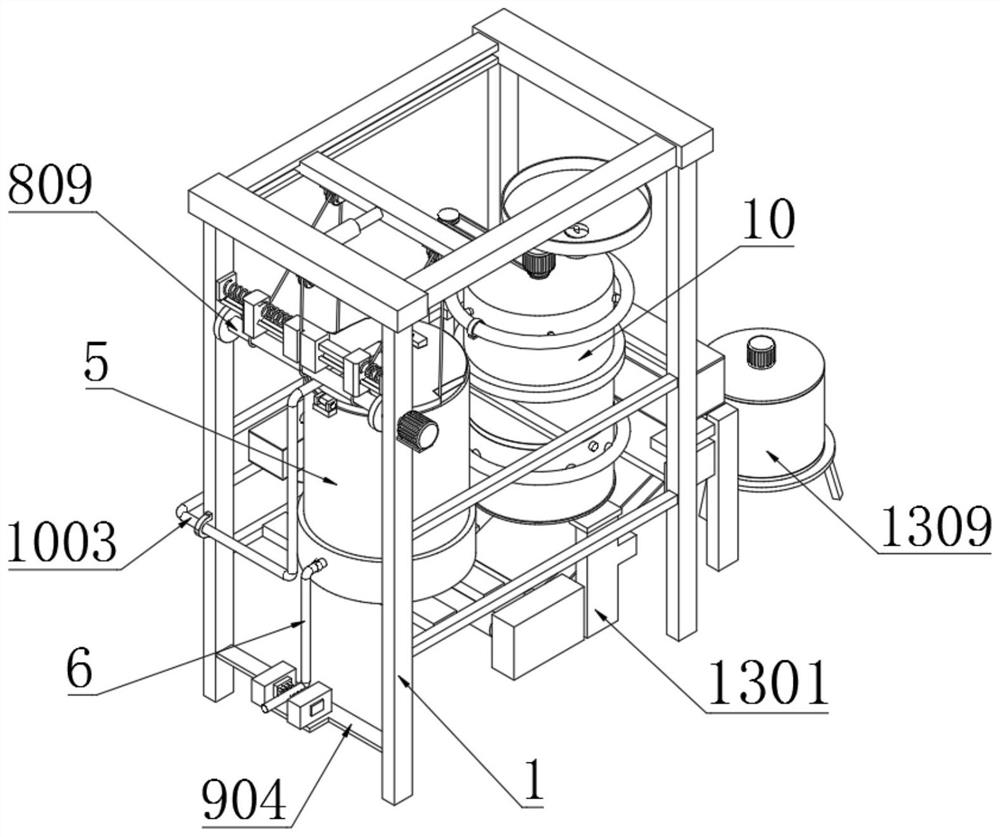

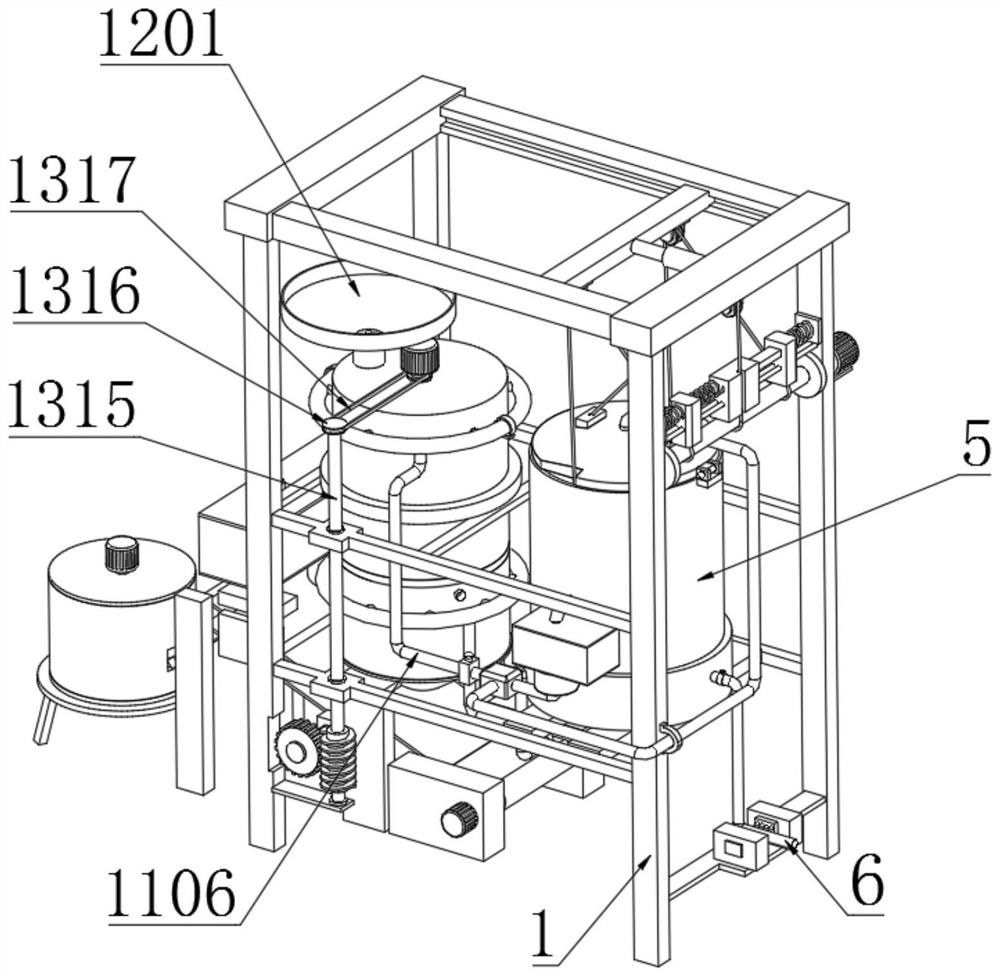

The invention discloses a preparation method of special pig feed for sow postpartum care, including steps, cooking: placing purple sweet potatoes and other raw materials in a raw material barrel, moving the raw material barrel downwards into a cooking cylinder by using a convenient cooking mechanism, and cooking the raw materials by using a heating tank at one end of a rack; transportation: usingan electric telescopic rod to push the cooked raw materials and raw material barrel to the top of a mixing tank, and pouring the cooked raw materials into a feeding disc. The present invention is convenient for placing raw materials and taking out cooked raw materials, and the top cover will turn over with rising and falling of the raw material barrel, so that the top cover and the raw material barrel moving synchronously. There is no need to open and close the cover manually, the workload is reduced and the working efficiency is improved. The electric telescopic rod is used to push the crossrod to move forward and backward, which can drive the raw material barrel to one side of the feeding disc, reducing the time of manual transportation, and avoiding operators hands scald caused by processing cooked raw materials.

Owner:陈阳

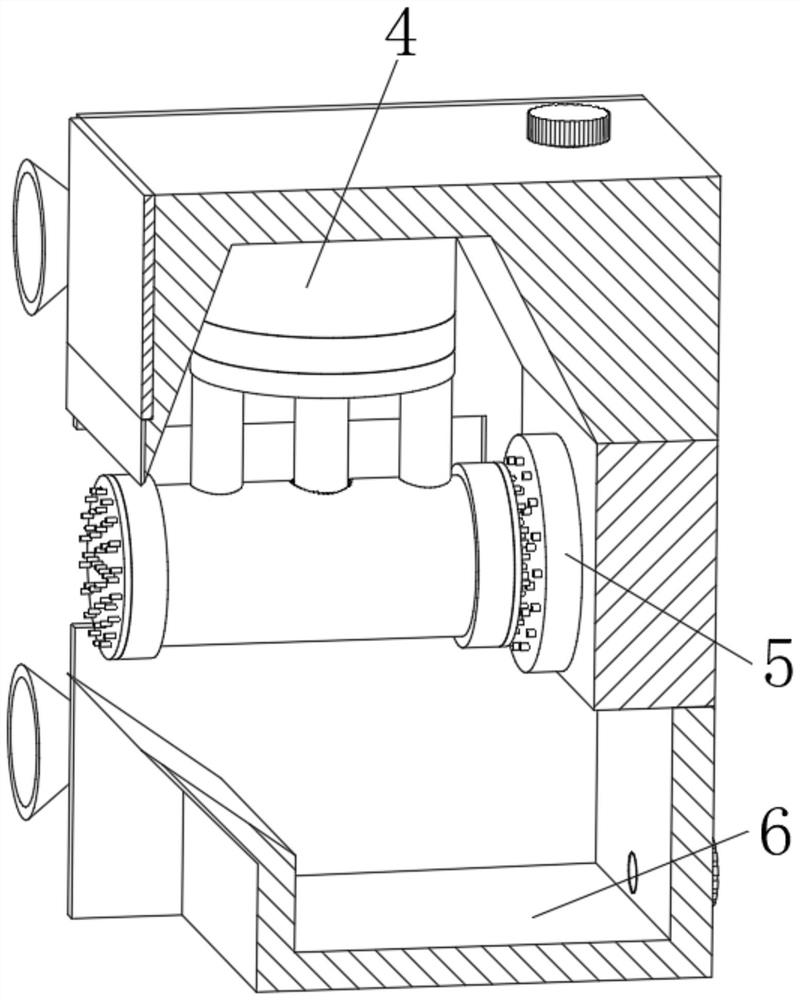

Plastic-wood plate cutting and recycling integrated equipment

InactiveCN111185950AQuality assurancePromote environmental protectionWood working apparatusGrain treatmentsAgricultural engineeringWood plank

The invention discloses plastic-wood plate cutting and recycling integrated equipment. The plastic-wood plate cutting and recycling integrated equipment comprises a crushing box, an operating table, afiltering frame, a sleeve rod and a fixing ring, a feeding inlet is formed in the top end of the crushing box, a third driving motor is fixedly connected to the outer side of the crushing box, an output shaft of the third driving motor is fixedly connected with a rotating shaft, sliding grooves are formed in supporting plates, an L-shaped plate is fixedly connected to the end, close to the thirddriving motor, of the filtering frame, a second driving motor is fixedly connected to the outer side of the crushing box, an output shaft of the second driving motor is fixedly connected with a rotating plate, and a connecting rod is fixedly connected to the end, deviating from the second driving motor, of the rotating plate. According to the plastic-wood plate cutting and recycling integrated equipment, by arranging a dust collector, a guiding pipe, the crushing box and a crushing roller, generated sweeps and wood particles can be recycled and crushed to be conveniently reprocessed into a wood plate, environmental protection is facilitated, the recycling effect is achieved, and the problem that the sweeps and wood particles generated during cutting are not utilized, and consequently, environmental protection is not facilitated is solved.

Owner:浙江格林特木塑材料有限公司

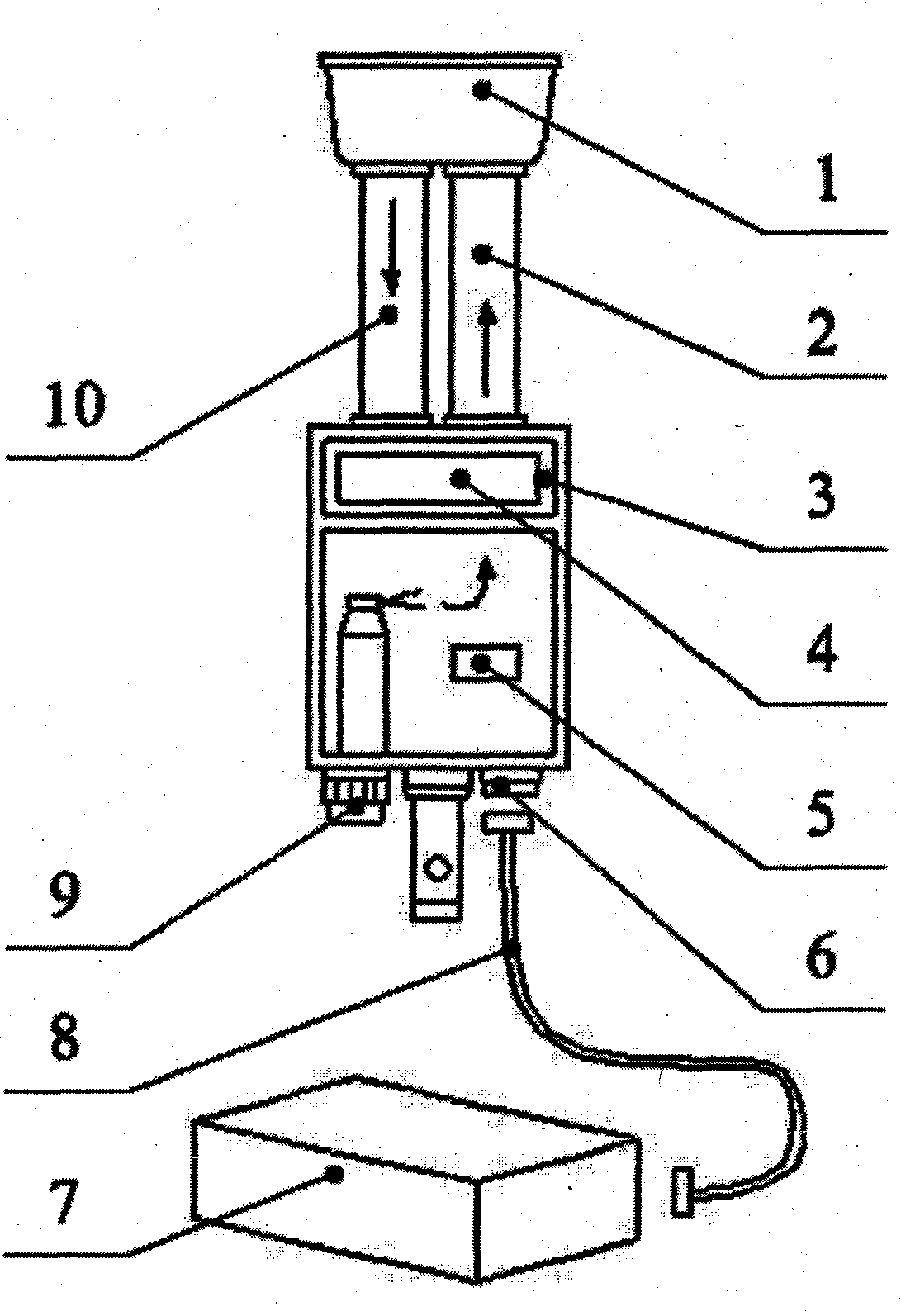

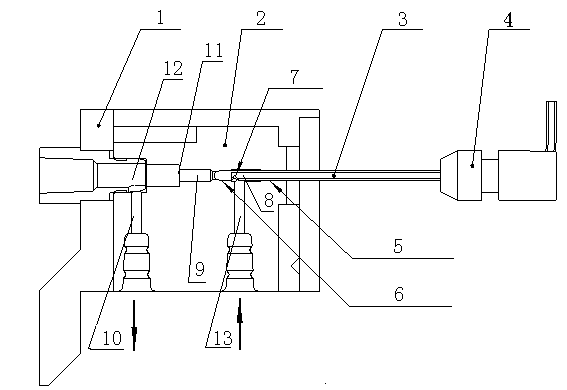

Automatic sampling needle cleaning device and method

ActiveCN103521480AThe solution is not easy to cleanAvoid inaccurate test resultsHollow article cleaningLaboratory glasswaresInlet channelContamination

The invention provides an automatic sampling needle cleaning device and method. The automatic sampling needle cleaning device comprises the sampling needle and a connection mouth, wherein a sampling needle movement channel is formed in the connection mouth and is sequentially provided with a first sealing node, a first cavity, a second sealing node, a second cavity and a connection mouth outer shell sealing node; a liquid inlet channel communicated with the first cavity is formed below the first cavity; the connection mouth outer shell sealing node is provided with a liquid discharge channel communicated with the sampling needle movement channel. According to the automatic sampling needle cleaning device and method, the inner wall and outer wall of the sampling needle and the connection mouth can be cleaned completely, the problem that after sampling is conducted, residual samples on the sampling needle and the connection mouth are difficult to clean completely is solved effectively, and the problem that due to cross contamination of the samples, a test result of an instrument is not accurate can be prevented effectively.

Owner:SHENZHEN CORNLEY BIO MEDICAL CO LTD +1

High-altitude curtain wall cleaning robot

ActiveCN112471955AThe solution is not easy to cleanFully automatedCarpet cleanersFloor cleanersEngineeringMachine

The invention discloses a high-altitude curtain wall cleaning robot comprising a machine body, a fixing device used for fixing the machine body and a glass curtain wall and being convenient to move, and a cleaning device that is used for cleaning the glass curtain wall and has the functions of wiping the curtain wall, cleaning a brush head of the cleaning device, receiving sewage and the like; thehigh-altitude curtain wall cleaning robot solves the problem that the high-altitude curtain wall is difficult to clean, the cleaning device is arranged, the glass curtain wall can be cleaned conveniently. And meanwhile, the functions of wiping the curtain wall, cleaning the brush head, receiving sewage and the like are achieved, the fixing device is arranged, the machine body and the glass curtain wall can be fixed and moved conveniently, the device is convenient and fast to operate, automation of curtain wall cleaning is achieved, the working efficiency is improved, and people can use the robot conveniently.

Owner:MILESTONE TECH (SUZHOU) CO LTD

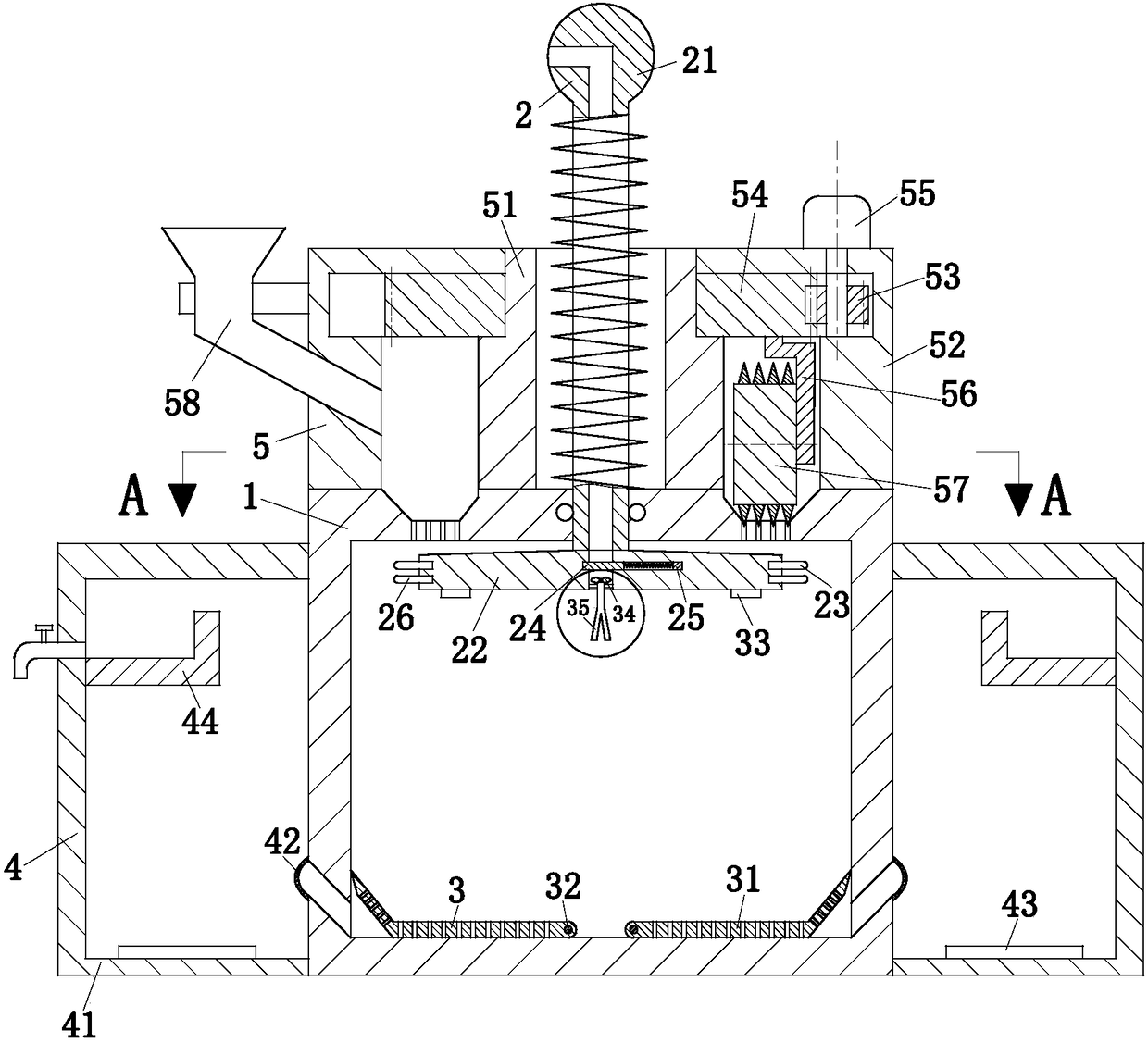

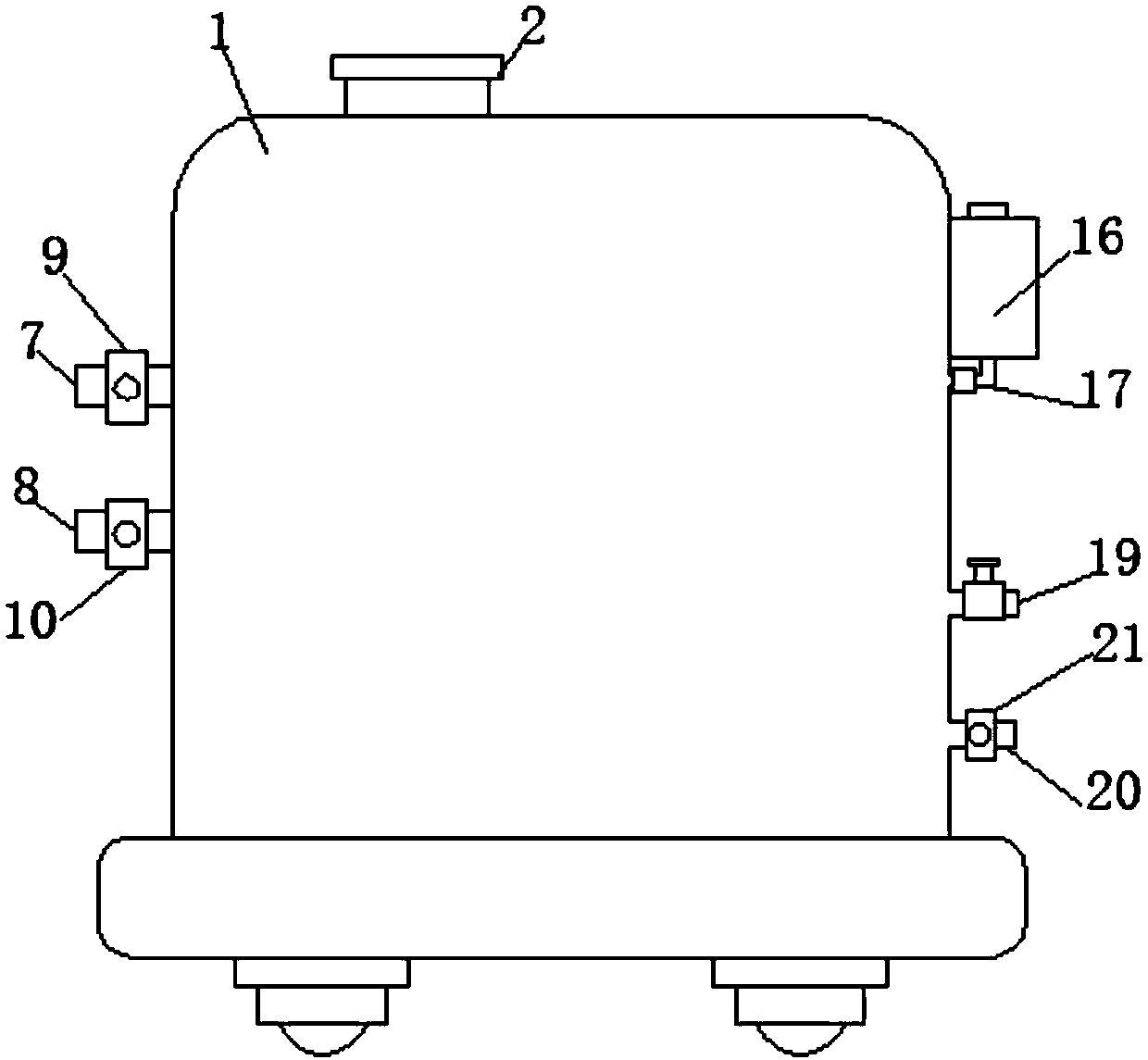

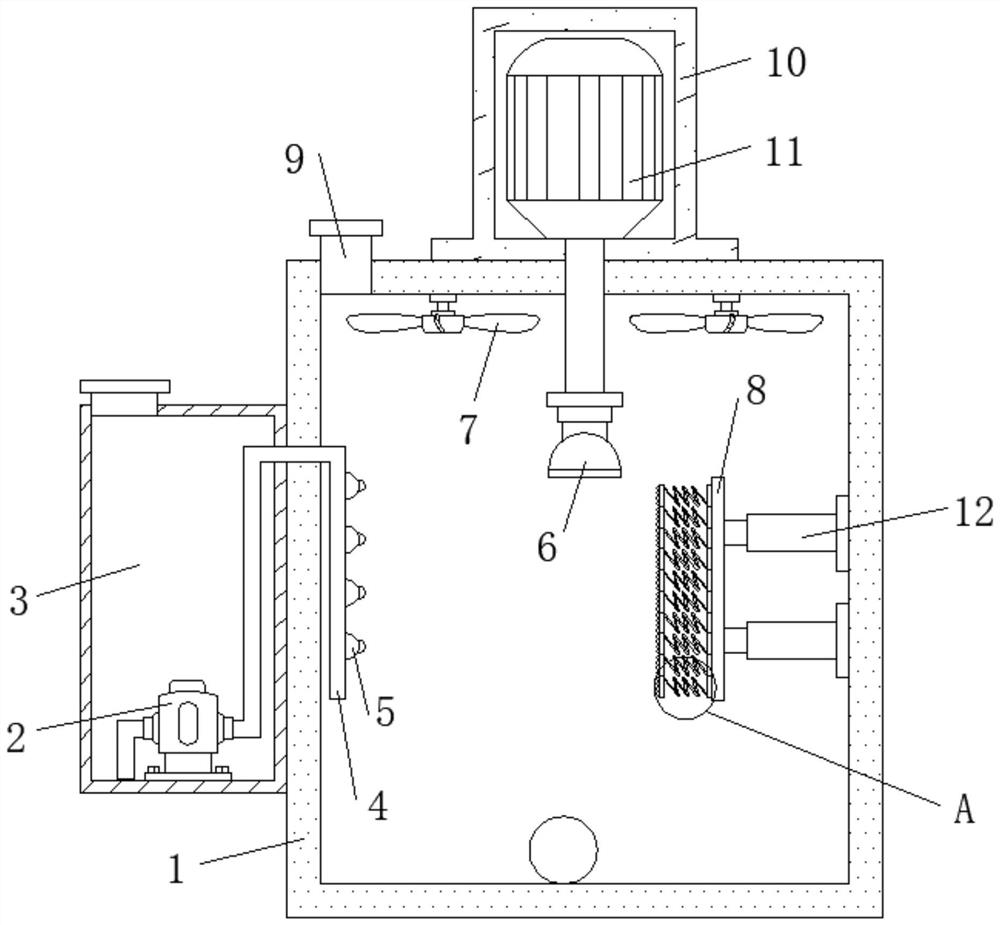

Chinese medicine medicated wine distillation extraction system

ActiveCN108283965AImprove efficacyImprove drinking effectHollow article cleaningAlcoholic beverage preparationMedicinal herbsAbsorption capacity

The invention belongs to the technical field of medicated wine fabrication and particularly provides a Chinese medicine medicated wine distillation extraction system. The Chinese medicine medicated wine distillation extraction system comprises a tank body, a material pressing module, a stirring module, a distillation module and a material smashing module, the material pressing module is located inside the tank body and is used for making soaked medicated wine enter the distillation module for distillation, the stirring module is used for realizing stirring of the medicated wine in the soakingprocess and before being pressed into the distillation module, effective constituents in medicine materials are made to overflow, the distillation module is located on the outer side of the tank bodyand is used for realizing distillation of the medicated wine, extracting the effective constituents in the medicated wine succinctly and improving the effect of the medicated wine, and the material smashing module is located on the tank body and is used for realizing smashing of the medicine materials. According to the Chinese medicine medicated wine distillation extraction system, by means of distillation extraction on the medicated wine, the absorption capacity of the human body to the medicated wine is enhanced, meanwhile, cleaning can be realized, and a soaking device is guaranteed to be clean.

Owner:安徽道源堂中药饮片有限公司

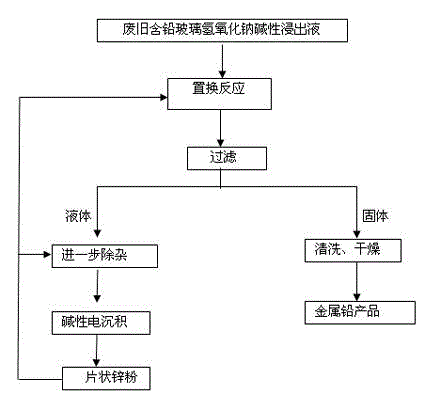

Method for extracting metallic lead from alkaline leaching solution of waste lead-containing glass

InactiveCN104593602AEnlarging the contact surface areaIncrease replacement speedProcess efficiency improvementGalvanic depositionActive agent

The invention discloses a method for extracting metallic lead from alkaline leaching solution of waste lead-containing glass. The method disclosed by the invention comprises the following steps of: heating the alkaline leaching solution of lead-containing glass to 50-80 DEG C; then, adding flaked metal zinc powder generated by electro-deposition and a surface active agent while stirring to carry out displacement, wherein the mass ratio of lead to zinc powder in the leaching solution is (0.29-0.31):1; and the addition amount of the surface active agent is 1-10mg / L; and then, carrying out solid-liquid separation, adding the metal zinc powder into filtrate again so as to remove the impurity, namely lead; electrically depositing solution with lead removed, repetitively using the obtained flaked metal zinc powder in replacement reaction, and returning the solution to leach the lead-containing glass. According to the invention, the problem that sponge metallic lead obtained by direct electro-deposition is difficultly cleaned in the thick alkaline leaching solution of the lead-containing glass is solved; simultaneously, the zinc powder obtained after electro-deposition does not need to be cleaned and can be directly used for replacement reaction of the leaching solution of the lead-containing glass in a circulating manner; and thus, closed-loop circulation of the solution is realized.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY +1

Sewage treatment device for water conservancy building

InactiveCN107814445AThe solution is not easy to cleanSolve the problem that is not easy to separate outTreatment involving filtrationMultistage water/sewage treatmentDraining tubeDrive motor

The invention discloses a sewage treatment device for a water conservancy building, which comprises a casing, a water inlet pipe is fixedly connected to the water inlet on the top left side of the casing, and large particle filter nets are fixedly connected to the inner walls of both sides of the water inlet pipe. A partition is fixedly connected between the inner top and the bottom of the housing. In the present invention, a casing, a water inlet pipe, a large particle filter screen, a partition, a first filter screen, a second filter screen, a first impurity removal pipe, a second impurity removal pipe, a first on-off valve and a second on-off valve are mutually arranged. Cooperate to solve the problem that the impurities in the existing water conservancy building sewage treatment device are not easy to clean up. The pipe, the third switch valve and the control valve cooperate with each other to solve the problem that the small particle impurities are not easy to be separated out in the existing water conservancy construction sewage treatment device.

Owner:盱眙县生产力促进中心

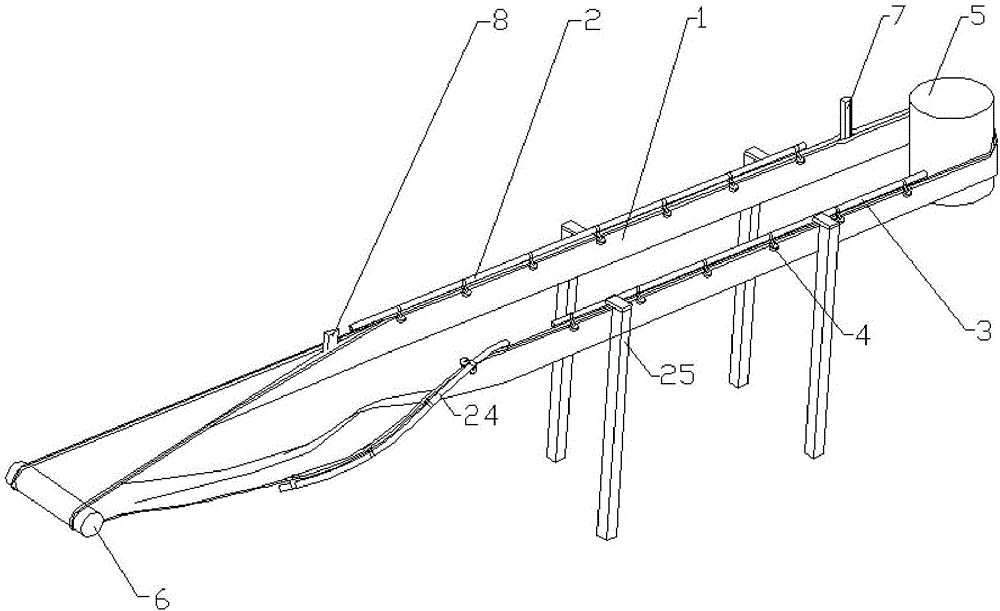

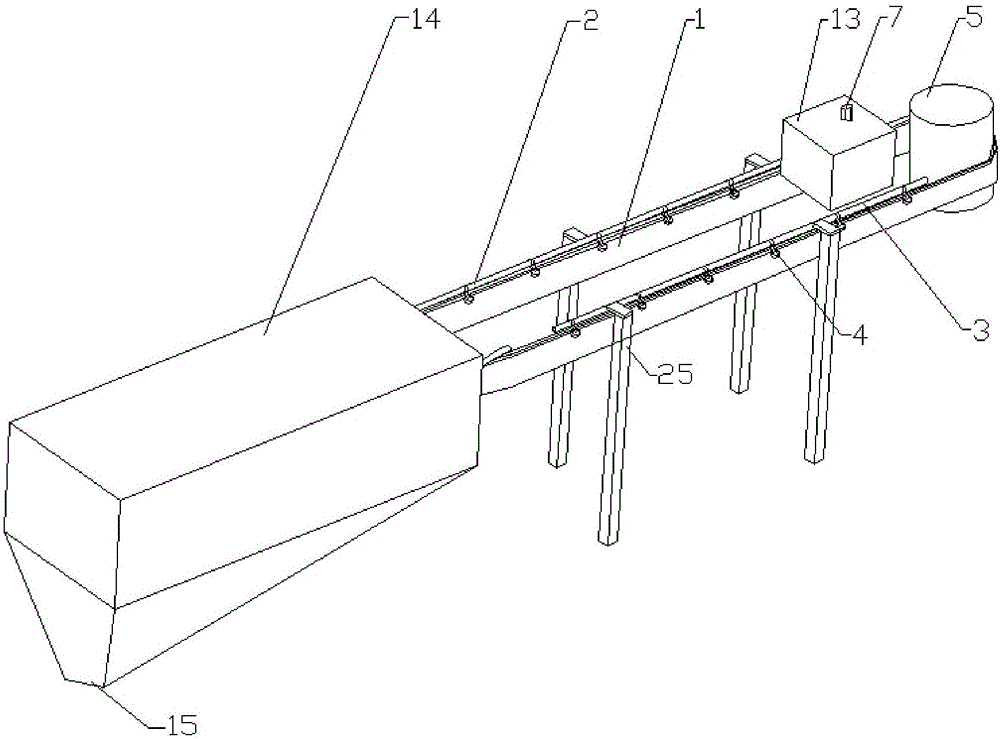

Closed conveyor

InactiveCN106743145ARealize unloadingRealize circular conveyingConveyorsConveyor partsSteering wheelButt joint

The invention discloses a closed conveyor, relates to a material conveyor, and aims to solve the problems of incapability of realizing closed conveying and incapability of changing the conveying direction in a traditional belt conveyor. Left and right mounting frames are arranged in parallel; left and right side edges of a conveying belt are upwards turned and tightly bonded to form a pipe shape or a cylinder shape; and after the conveying belt is matched and connected with a conveying mechanism on the right mounting frame in sequence, the conveying belt is bypassed through a steering wheel from right to left, then, is matched and connected with a conveying mechanism on the left mounting frame, is gradually unfolded to bypass through an unloading roller from top to bottom, and is overturned up and down to seal with the back end for butt joint to form a closed loop. The conveying belt is kept in a sealed state to realize closed material conveying; the conveying distance is changed through changing the lengths of the mounting frames and the conveying belt; and the direction of the conveying belt is changed through adding an auxiliary steering wheel and adjusting the extending directions of the mounting frames to realize turning conveying or high-height-fall conveying or even vertical conveying. The closed conveyor is used for material conveying.

Owner:NANO PHARM TECH MACHINERY EQUIP

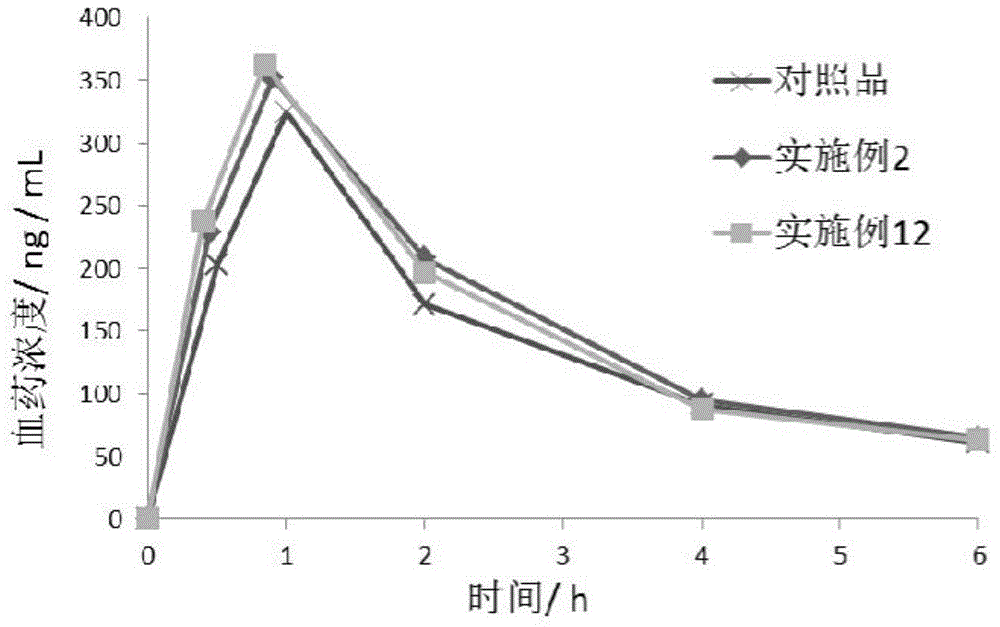

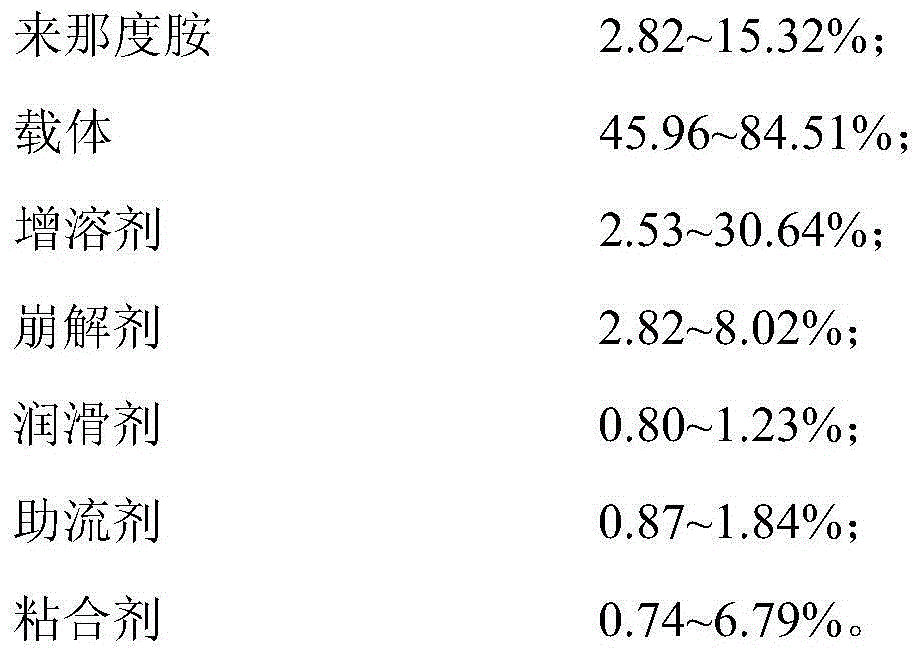

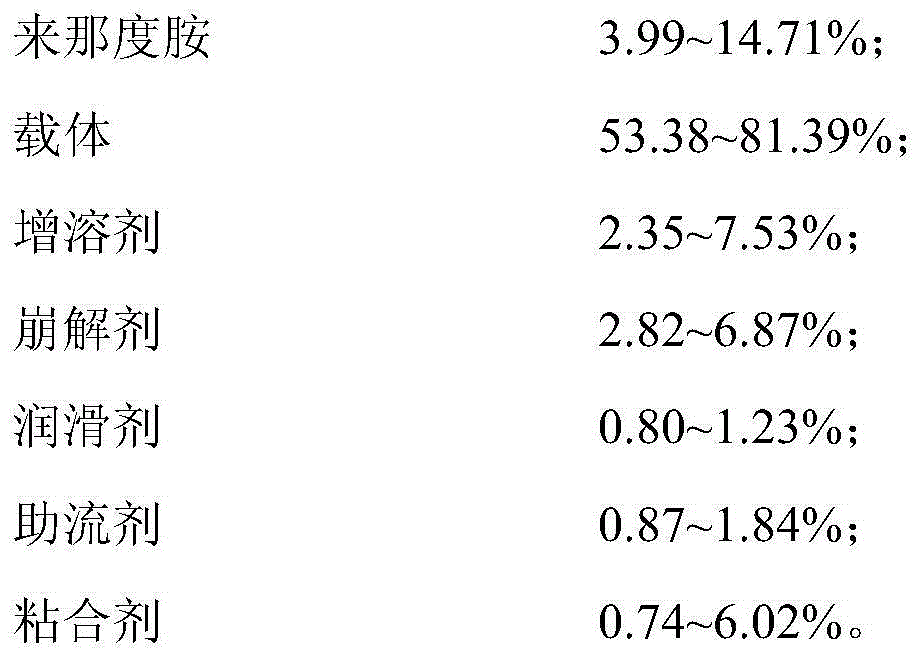

Composite for treating myelodysplastic syndrome and preparation method thereof

ActiveCN103705485BImprove bioavailabilityGood water solubilityOrganic active ingredientsPill deliverySolubilityAdhesive

The invention discloses a composite for treating myelodysplastic syndrome. The composite comprises the following components: lenalidomide, a carrier, a solubilizing agent, a disintegrating agent, a lubricating agent, a flow aid and an adhesive, wherein the carrier is a mixture of any one or several of a high-molecular water-soluble polymer, a water-soluble small molecule compound, a hydrophilic auxiliary material and an inorganic carrier; the solubilizing agent is a mixture of one or several of lauryl sodium sulfate, poloxamer, beta. cyclodextrin and a derivative thereof, polysorbate and polyoxyethylene alkyl ether. The invention also provides a preparation method of the composite, and the preparation method comprises the steps of grinding, mixing, dry granulation, total mixing and tabletting or capsule filling. The preparation method disclosed by the invention effectively enhances the water solubility and bioavailability of the lenalidomide; the dry granulation preparation process simplifies the preparation steps, reduces the cost, saves the energy resources, reduces the labor expenditure and realizes the energy conservation and environment protection in production.

Owner:AC PHARMA CO LTD

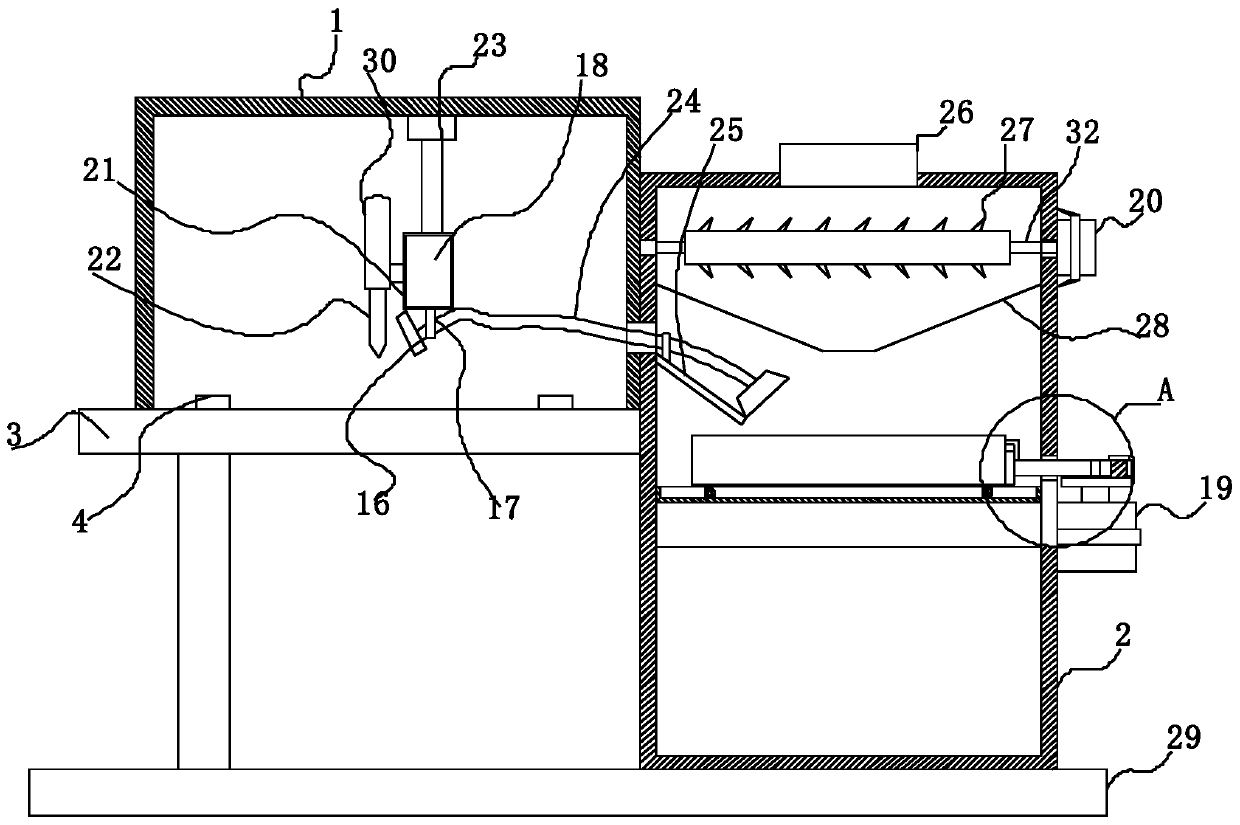

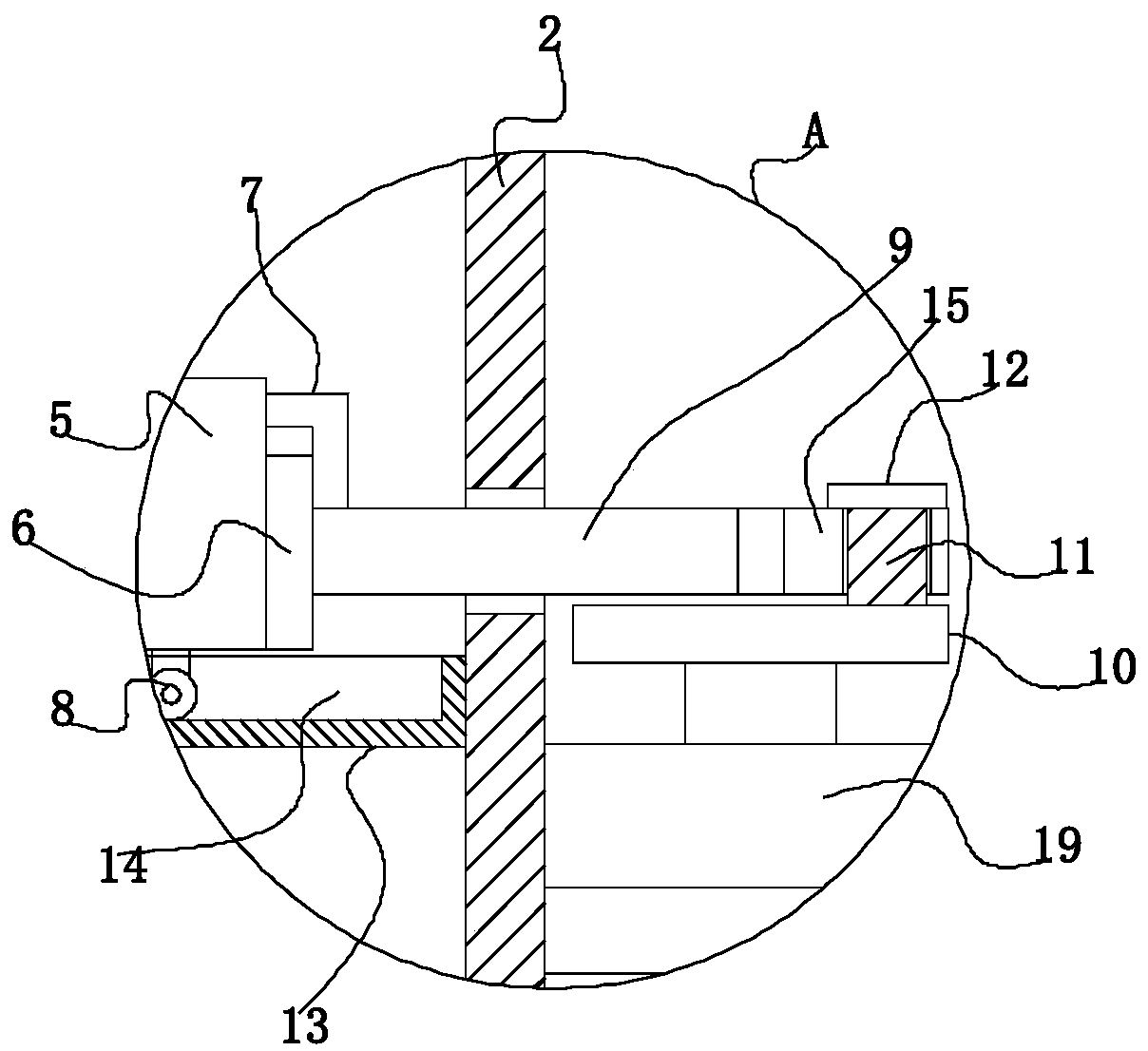

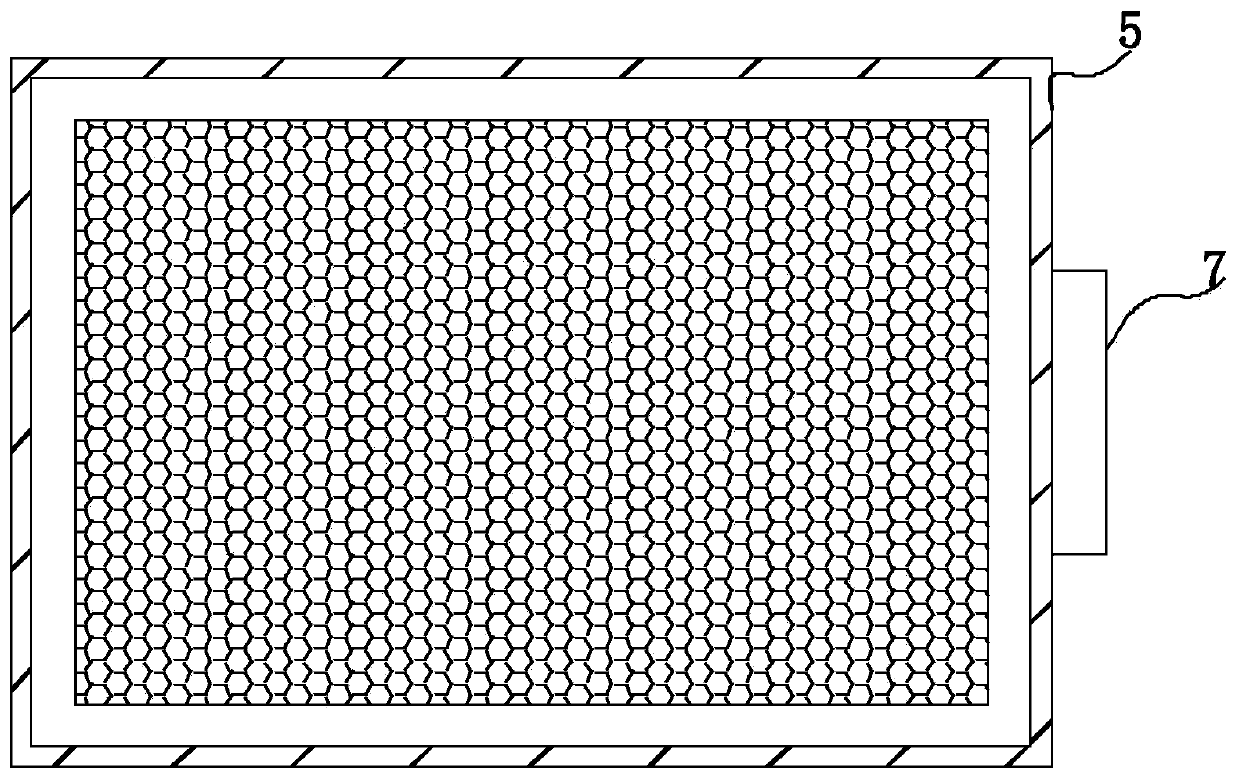

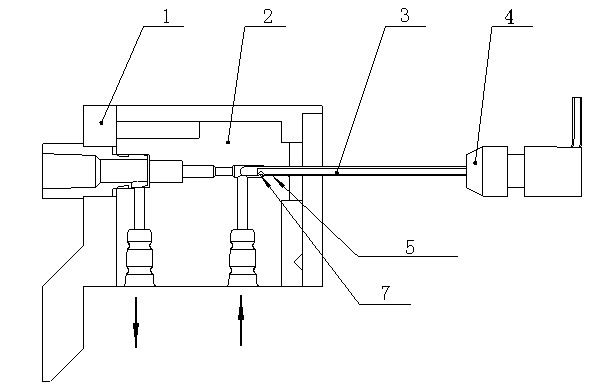

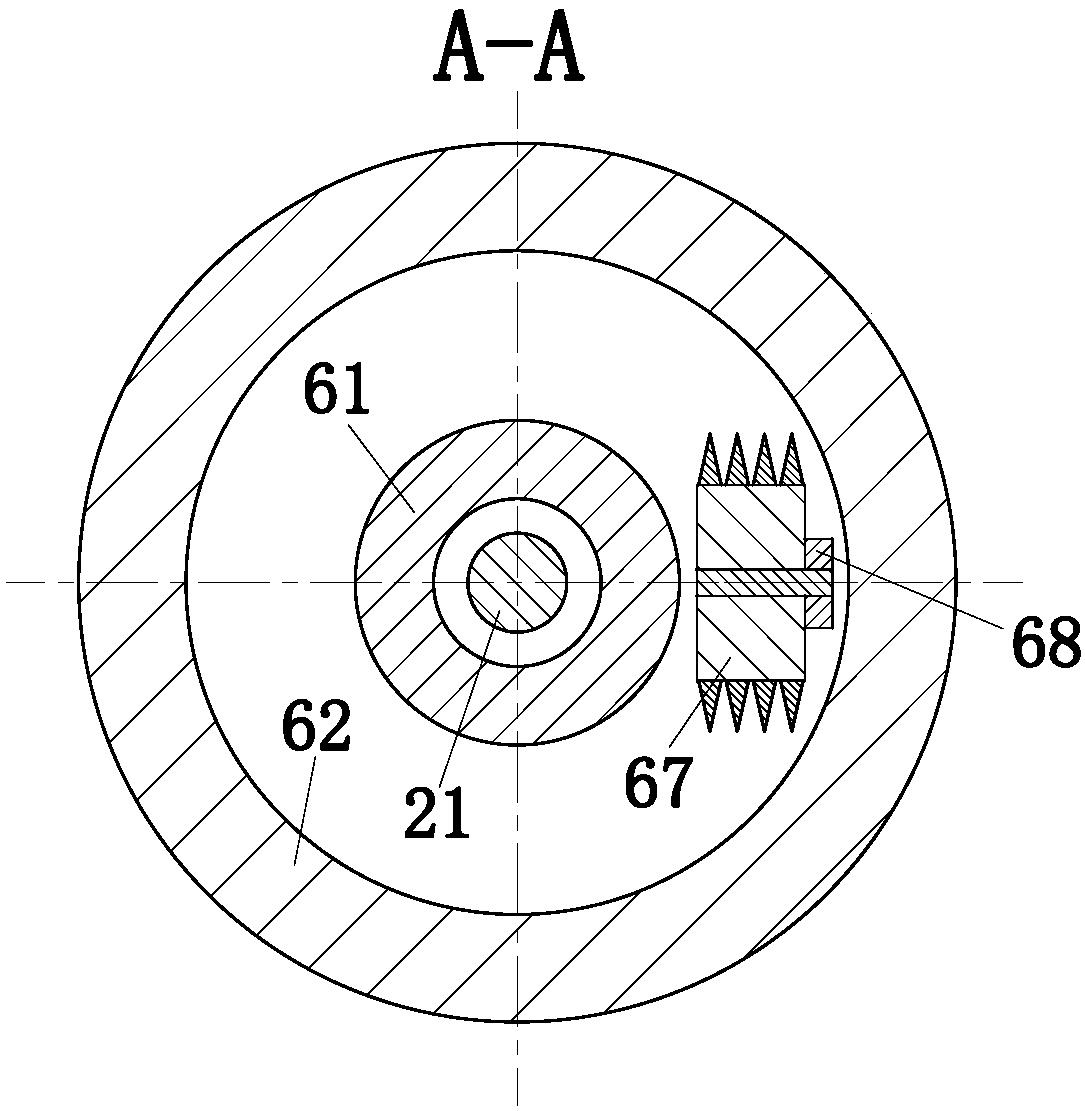

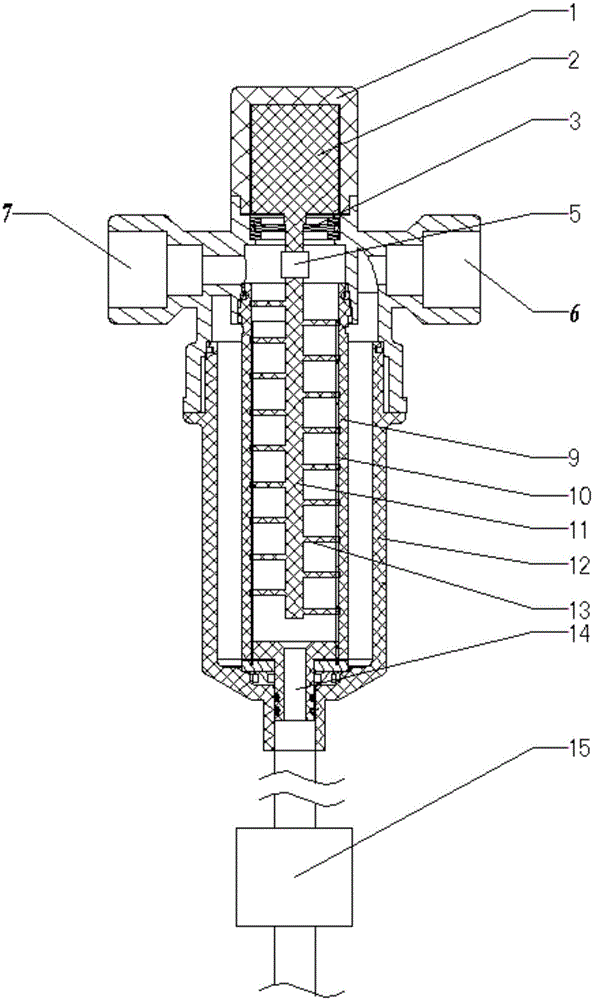

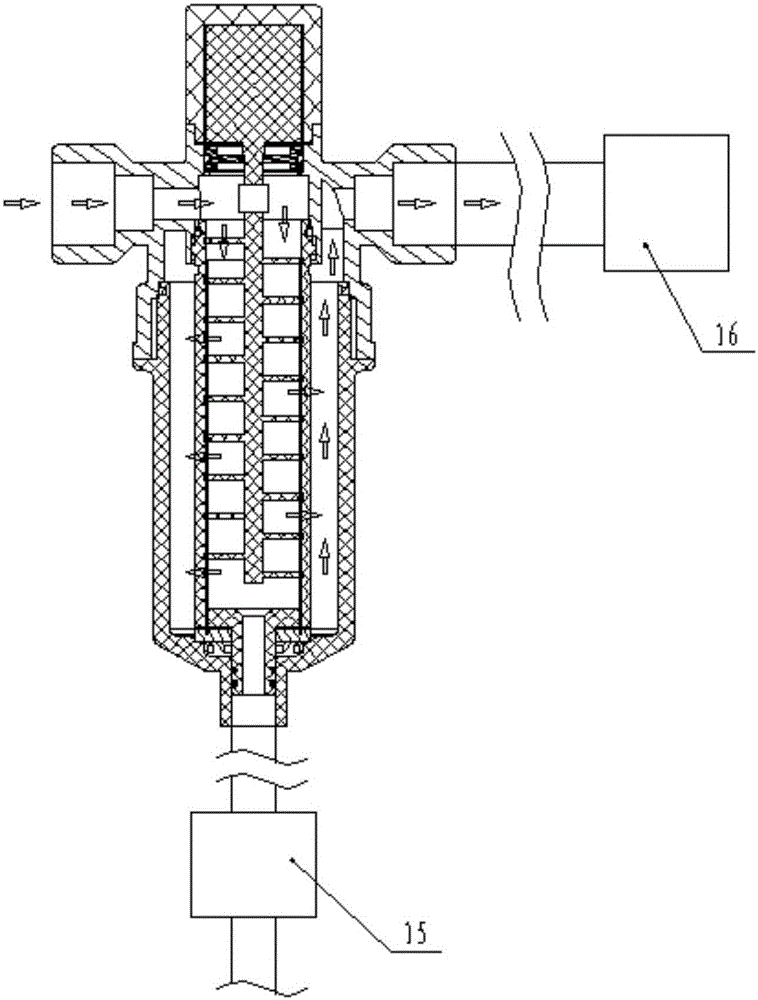

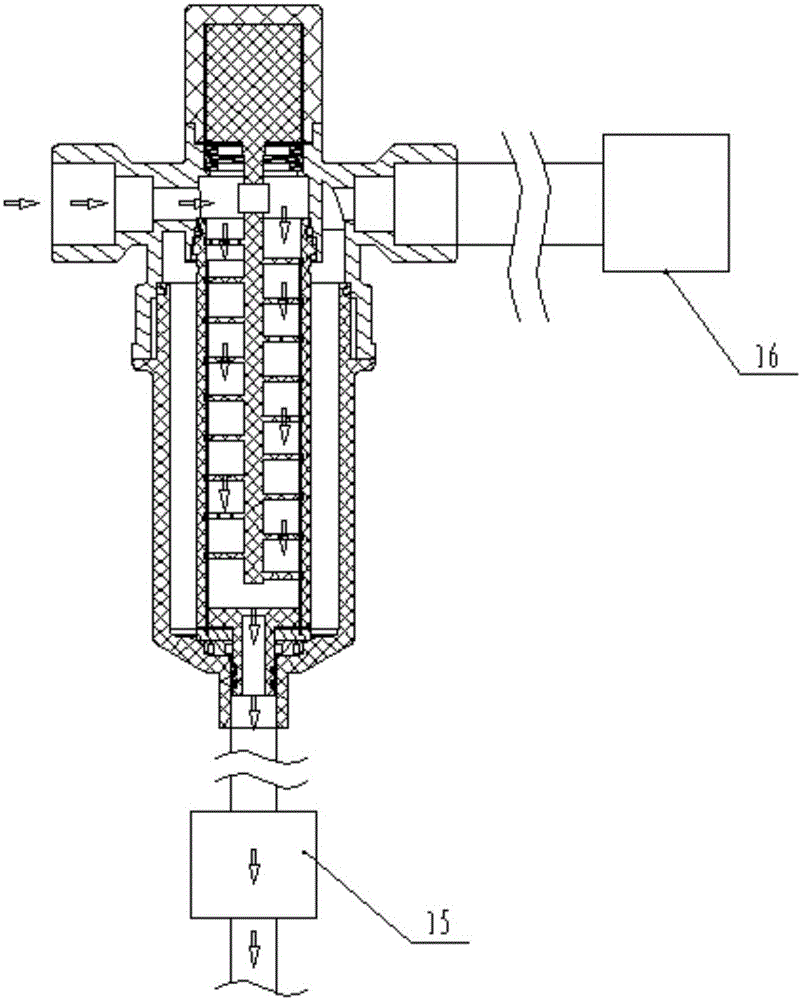

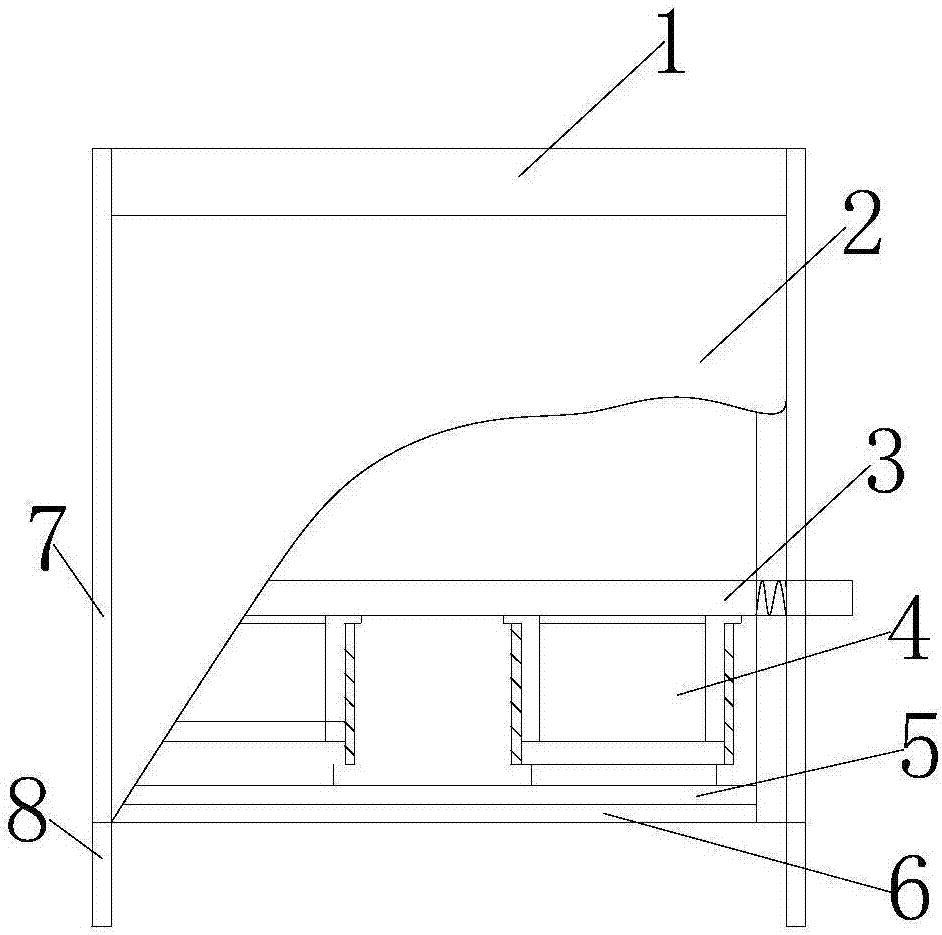

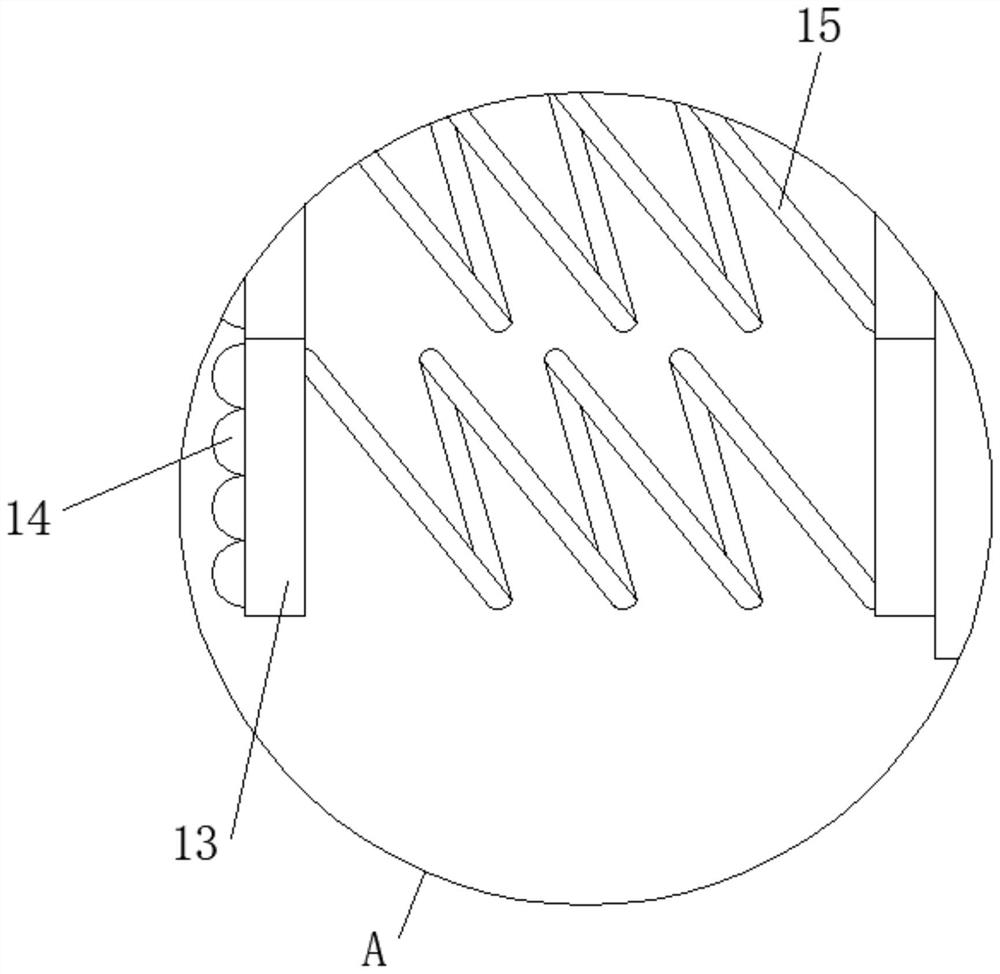

Prefilter with self-cleaning function and cleaning device of prefilter

InactiveCN105126415AThe solution is not easy to cleanReduce cleaning and maintenance costsStationary filtering element filtersFilter elementSelf cleaning

The invention relates to the field of water purification equipment and discloses a prefilter with a self-cleaning function and a cleaning device of the prefilter. The prefilter with the self-cleaning function comprises a housing, a filter screen (10) mounted in the housing and further comprises the cleaning device. The cleaning device comprises a motor (2), a rotary shaft (11) and brush hairs (13) fixedly arranged on the rotary shaft (11); the rotary shaft (11) extends into the filter screen (10), the motor (2) drives the rotary shaft (11) to rotate, and the brush hairs (13) rotate along the rotary shaft (11) to clean the inner wall of the filter screen (10). According to the prefilter provided by the invention, the filter screen is internally cleaned by using the cleaning device, so that the problem that the filter screen of the prefilter is hard to clean is thoroughly solved, the cleaning and maintaining costs of the filter are lowered, the surface of the filter screen is not easily blocked, the filter element of a water purifier is protected to the maximum extent, the service life of the filter element of the water purifier is greatly prolonged, and cogent benefits are brought to consumers.

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

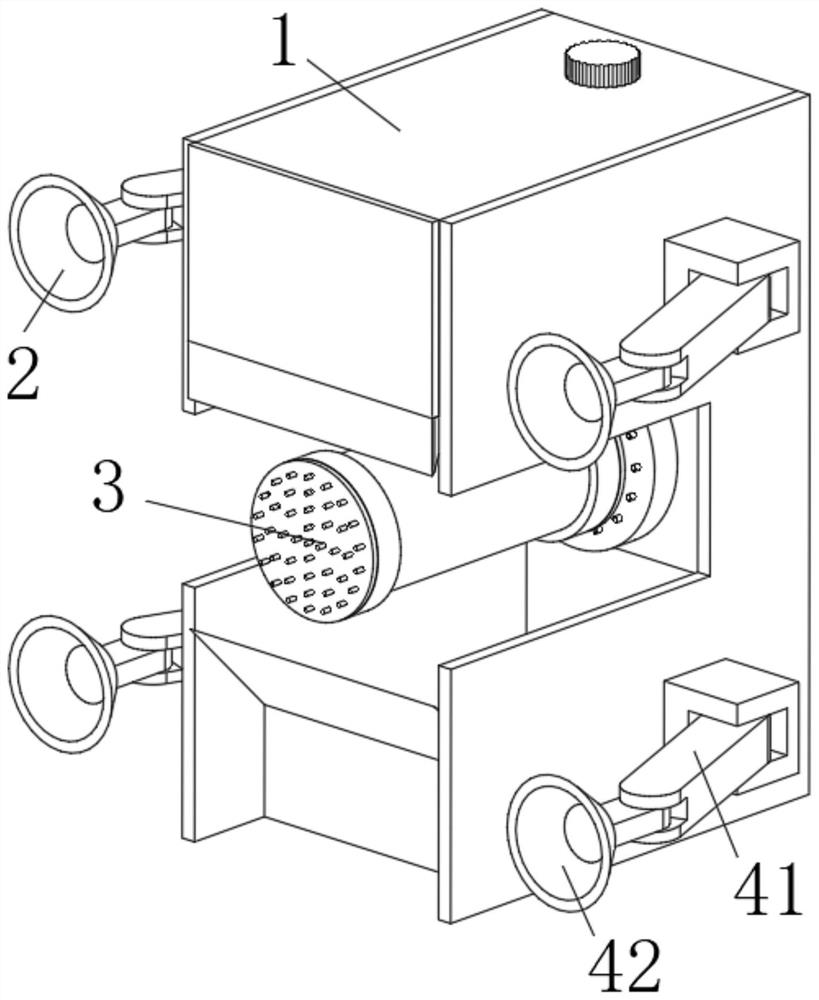

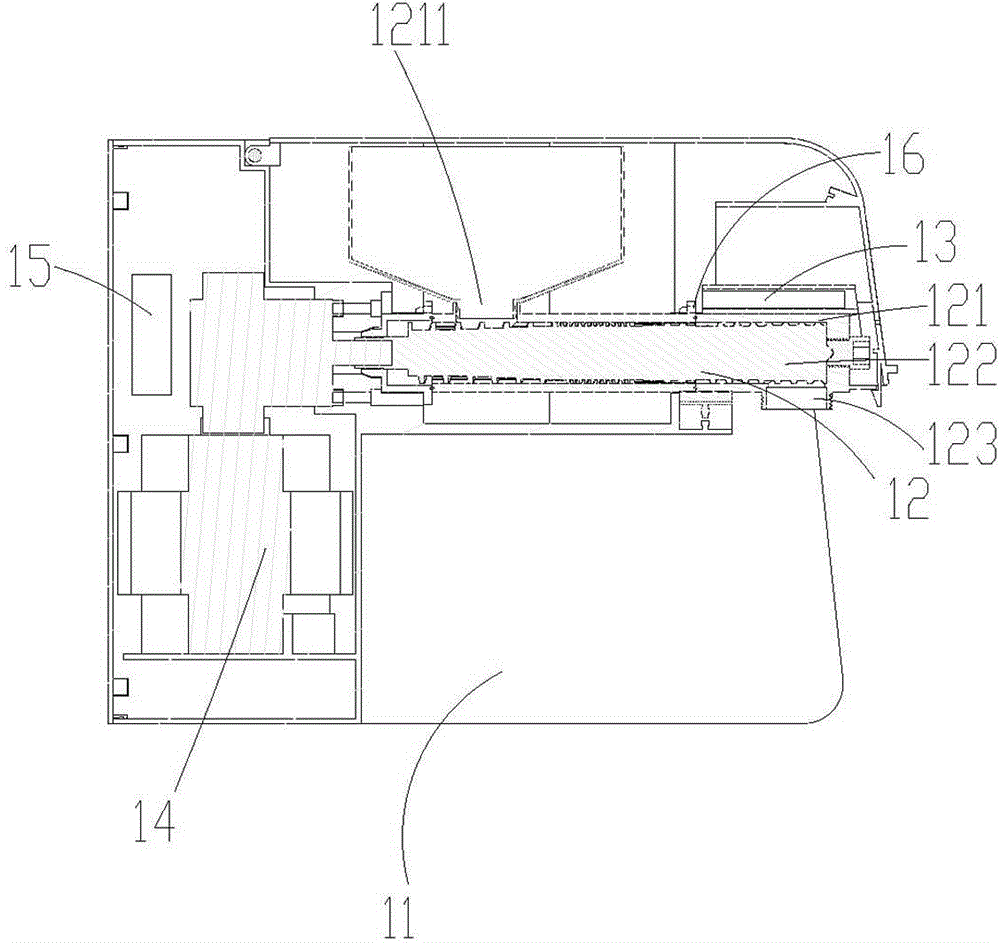

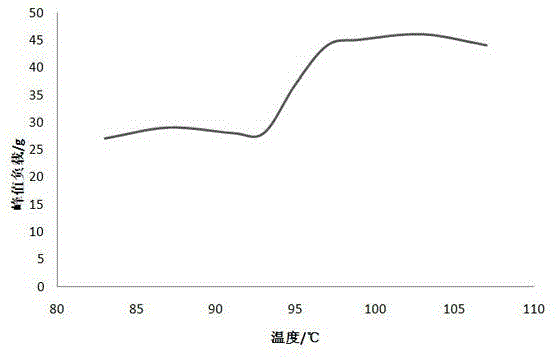

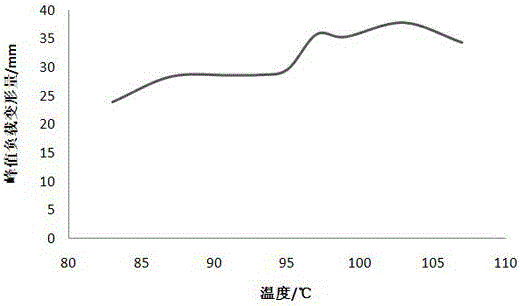

Rice noodle preparation method of household rice noodle machine and household rice noodle machine

ActiveCN104621443AHelp shapeImprove gelatinization efficiencyFood shapingFood preparationWarming processEngineering

The invention relates to a rice noodle preparation method of a household rice noodle machine and the household rice noodle machine. The rice noodles preparation method of the household rice noodle machine comprises the following steps: a feeding stage, namely driving a screw rod to rotate by a drive system and feeding raw materials into an extrusion grinding cavity by the screw rod; a curing and noodle-extruding stage, namely driving the screw rod to rotate by the drive system, grinding the raw materials by the screw rod, mixing, simultaneously curing the raw materials, and extruding into rice noodles from the ground, crushed, mixed and cured raw materials through a molding die head; and a once warming process, namely heating a extrusion crushing cavity by a heating device before the curing and noodle-extruding stage, so that the temperature of the extrusion crushing cavity ascends to T1, and the range of T1 is 80-110 DEG C, and feeding the rice material into the extrusion grinding cavity for curing after the once warming process is additionally added in the rice noodle preparation process, so that the hardness of the rice material is reduced, and the crushing of the rice material by virtue of a crushing, extruding and molding system in the curing and noodle-extruding stage is facilitated, and forming of the rice noodles are facilitated.

Owner:JOYOUNG CO LTD

Method for preparing traditional Chinese medicine scurf-removing hair shampoo

InactiveCN104958226AThe solution is not easy to cleanSolve the problem of bad hair combingCosmetic preparationsHair cosmeticsBiotechnologyThioketone

The invention discloses a method for preparing traditional Chinese medicine scurf-removing hair shampoo, and belongs to the technical field of daily chemicals. The method comprises the following steps: boiling cacumen biotae, soapberry, roots of common peony and folium artemisiae argyi with water so as to obtain a traditional Chinese medicine extract, and further performing reduced pressure distillation on the extract, thereby obtaining a thick ointment; uniformly mixing the thick ointment, tea tree essential oil, squalane, bispyrithione, zinc pyrithione, ethylenediamine tetraacetic acid, decyl polyglucoside, diazolidinyl urea, sodium chloride, an anionic surfactant, an ampholytic surfactant, essence, a preservative and deionized water, heating, keeping the temperature, and cooling; adding cetostearyl alcohol, disiloxanoxy-pyrrolidone linoleic acid phospholipid, citric acid and amino silicon oil into the obtained mixture, heating, keeping the temperature, and cooling, thereby obtaining the traditional Chinese medicine scurf-removing hair shampoo. By adopting the plant hair shampoo disclosed by the invention, the problems that hair is not easy to clear by using ordinary hair shampoo and is poor in combability can be solved.

Owner:傅兴琴

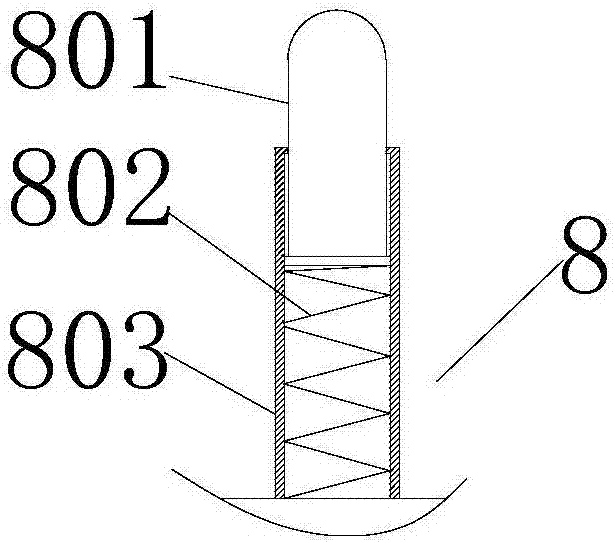

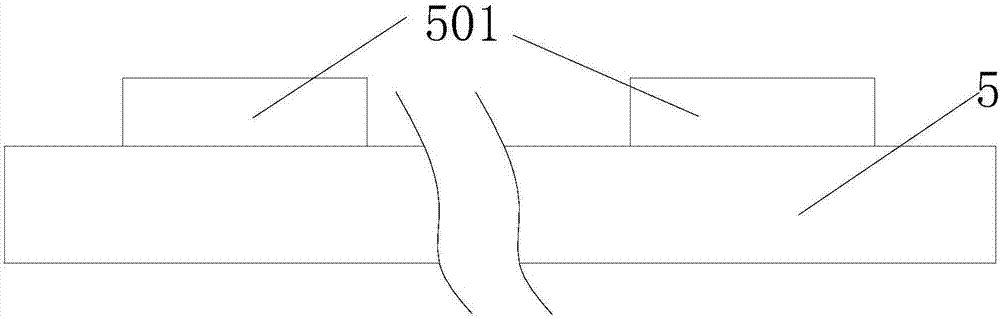

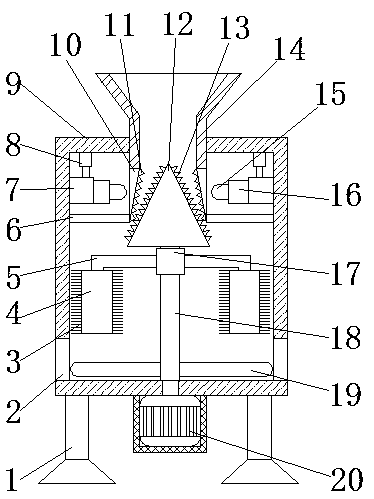

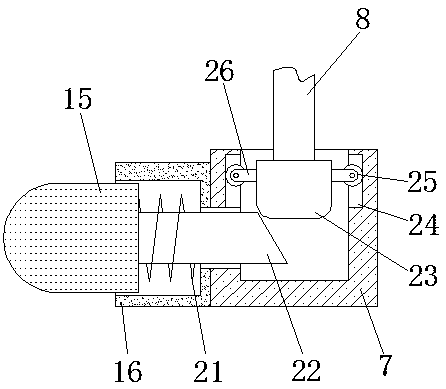

Multifunctional moxibustion box

InactiveCN107374949AAvoid burnsEasy to disassembleDevices for heating/cooling reflex pointsHuman bodyThermal insulation

The invention provides a multifunctional moxibustion box. The box is characterized by comprising a box body, a fixed part, moxibustion barrels, a thermal insulation layer, a contact layer and supporting feet, wherein the fixed part is installed in the box body in a thread connection mode, and the upper end of the moxibustion barrel is fitted to the lower end of the fixed part; the moxibustion barrels are all arranged at the upper end of a partition board, the partition board is arranged at the bottoms of the moxibustion barrels, and the contact layer is arranged at the bottom of the box body. According to the multifunctional moxibustion box, the moxibustion barrels are fixed through magnetic adsorption blocks arranged at the bottom of the partition board, which avoids scald phenomena caused by falling off of the moxibustion barrels; meanwhile, each moxibustion barrel is combined by a cylinder and a mugwort stick tray, so that the moxibustion barrels can be disassembled conveniently, which solves the problem that the moxibustion barrels are not easy to clean; through the design mode of arranging a groove at the bottom of the box body, moxibustion can be conducted on different acupuncture points of the human body to meet the needs of different people, so that a safe, hygienic and convenient moxibustion environment is provided for users.

Owner:利辛县冯氏养生馆

Agricultural product grinding device

InactiveCN109092415AThe solution is not easy to cleanAchieve fixationHollow article cleaningGrain treatmentsBristleAgricultural engineering

The invention discloses an agricultural product grinding device. The agricultural product grinding device comprises two supporting legs, and a shell is fixedly connected between the tops of the two supporting legs. A feeding tube is arranged at the bottom of the shell in a communicating mode, and connecting plates are fixedly connected to two sides of the bottom of the feeding tube. First grindingteeth are fixedly connected to the opposite sides of the two connecting plates, and a motor is fixedly connected to the bottom of the shell. The output end of the motor penetrates into an inner cavity of the shell and is fixedly connected with a rotating rod. According to the agricultural product grinding device, through the match usage of the supporting legs, discharge holes, bristles, rotatingdrums, a connecting frame, fixing plates, fixed shells, electric telescopic rods, the shell, the connecting plates, the first grinding teeth, a fixing block, second grinding teeth, the feeding tube, knocking blocks, fixing frames, a rotating sleeve, a rotating rod, a guide plate, the motor, tension springs, linking blocks, moving blocks, sliding grooves, pulleys and linking plates, the problem that an existing agricultural product grinding device is inconvenient to clean is solved.

Owner:甘肃枣一枣农产品科技发展有限公司

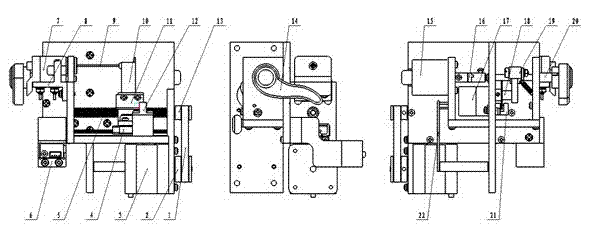

Sampling system for automatically identifying samples and sampling method for sampling system

ActiveCN102890159AThe solution is not easy to cleanAvoid inaccurate test resultsMaterial analysisEngineeringIdentification device

The invention provides a sampling system for automatically identifying samples and a sampling method for the sampling system. The sampling system comprises a sampling device, a sample identifying device and a detecting device, wherein the sampling device comprises a lead screw, a sampling arm, a sampling needle and a sampling nozzle; the sampling arm is connected with the lead screw; the sampling needle is fixed to the sampling arm and is inserted into the sampling nozzle; the sample identifying device comprises a rotary cam, a rotating shaft, an oscillating roller, a detecting arm, a coupler and a rotary encoder; the oscillating roller is arranged on the rotary cam, is connected with the rotating shaft and is used for controlling oscillation of the detecting arm; the rotating shaft is connected with the rotary encoder through the coupler; the rotary cam is provided with a light shading plate; the detecting device is arranged below the light shading plate and comprises a first optocoupler and a second optocoupler; the first optocoupler is used for detecting the initial position of the sampling needle; and the second optocoupler is used for detecting the position of the detecting arm.

Owner:SHENZHEN CORNLEY BIO MEDICAL CO LTD +1

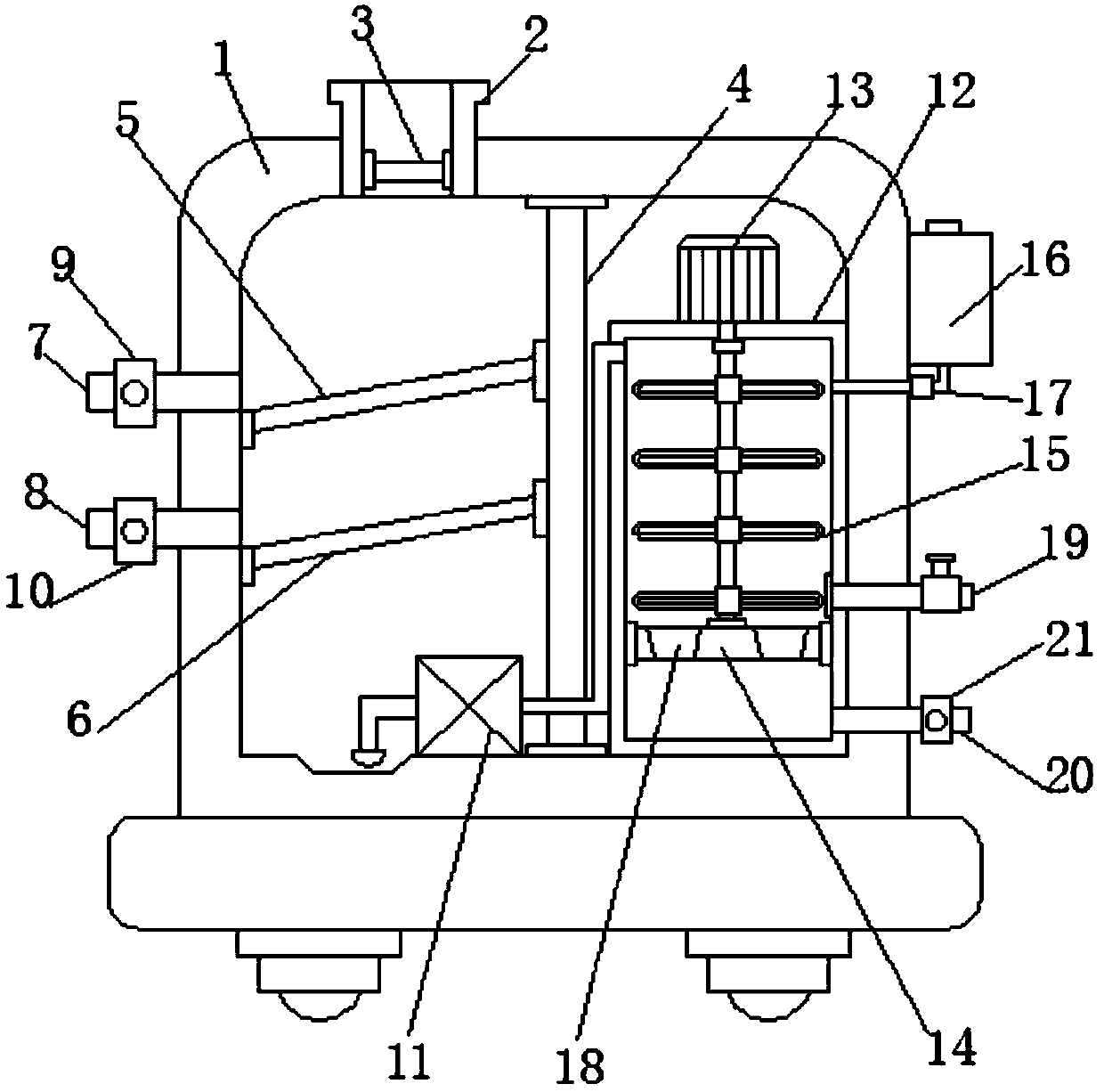

Efficient wet process mixing granulating machine

PendingCN109012487AThe solution is not easy to cleanGuaranteed cleanlinessGranulation in stationary drums/troughsBiochemical engineeringProduction quality

The invention discloses an efficient wet process mixing granulating machine, which comprises a boiler, wherein a boiler cover is arranged on the boiler; a stirring assembly is arranged on the boiler cover and comprises a stirring shaft and a stirring paddle; the stirring shaft is connected with the boiler cover; the stirring paddle is arranged at the lower end of the stirring shaft and is near thebottom of the boiler. The stirring assembly is arranged on the boiler cover; , so that the problem that the cleaning of the stirring paddle and the boiler is difficult is solved; further, the cleanness degree of the stirring paddle and the boiler are ensured; the condition of medicine crossed pollution condition is avoided; meanwhile, the material is mixed without dead cornercompletely; the material mixing efficiency is effectively promoted; the final quality of the medicine production is improved; in addition, the use of a sealing ring is not needed; the conditions that the sealing ring becomes old, causing that the materials are polluted, and the process water seeps are avoided; the production quality and production safety are improved; the work intensity of workers is reduced; the quality is ensured; the production efficiency is also improved.

Owner:重庆市药研院制药有限公司

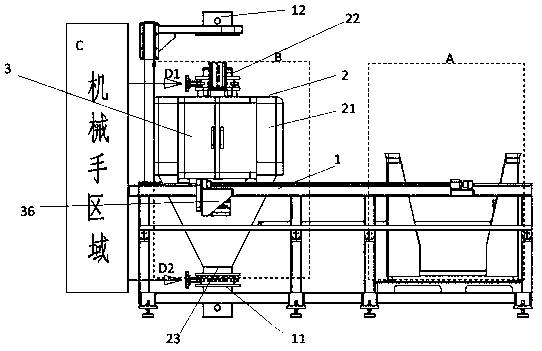

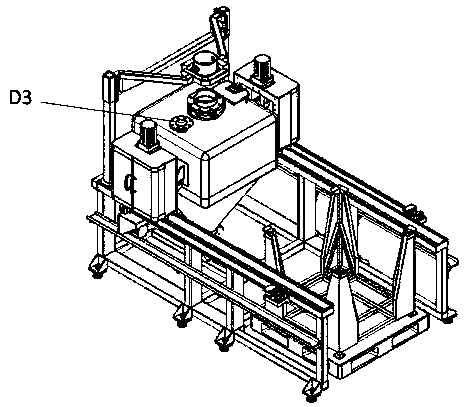

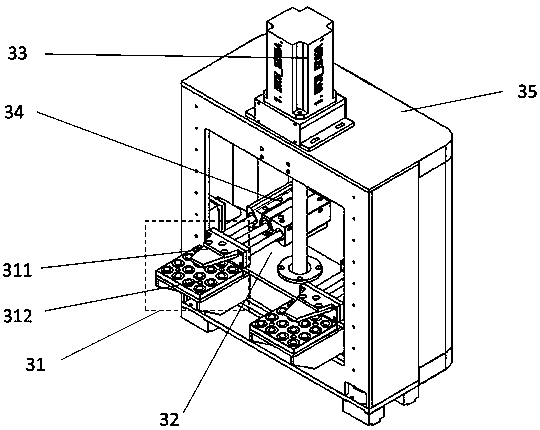

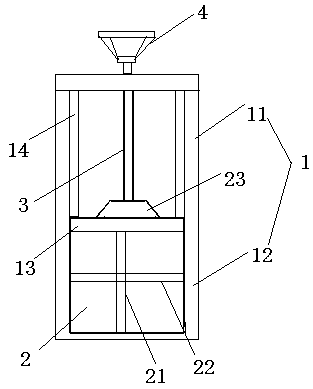

Automatic docking system, transfer module and ASCS transfer system

ActiveCN109733871AAvoid contactAvoid pollutionLoading/unloadingConveyor partsTransfer systemEngineering

The invention discloses an automatic docking system which comprises a frame body, a stock bin, a transport machine and a transfer module, wherein the frame body is used for mounting the transfer module, and a chamber for containing powder materials is formed in the stock bin; the transport machine is used for transferring the stock bin; and the transfer module is glidingly arranged on the frame body and is used for carrying the stock bin on the transport machine to a designated location. The automatic docking system can avoid friction between the power materials and a transmission mechanism soas to avoid crystal damage, can avoid environmental pollution, and is easy to clean a feed opening.

Owner:江苏道金智能制造科技股份有限公司

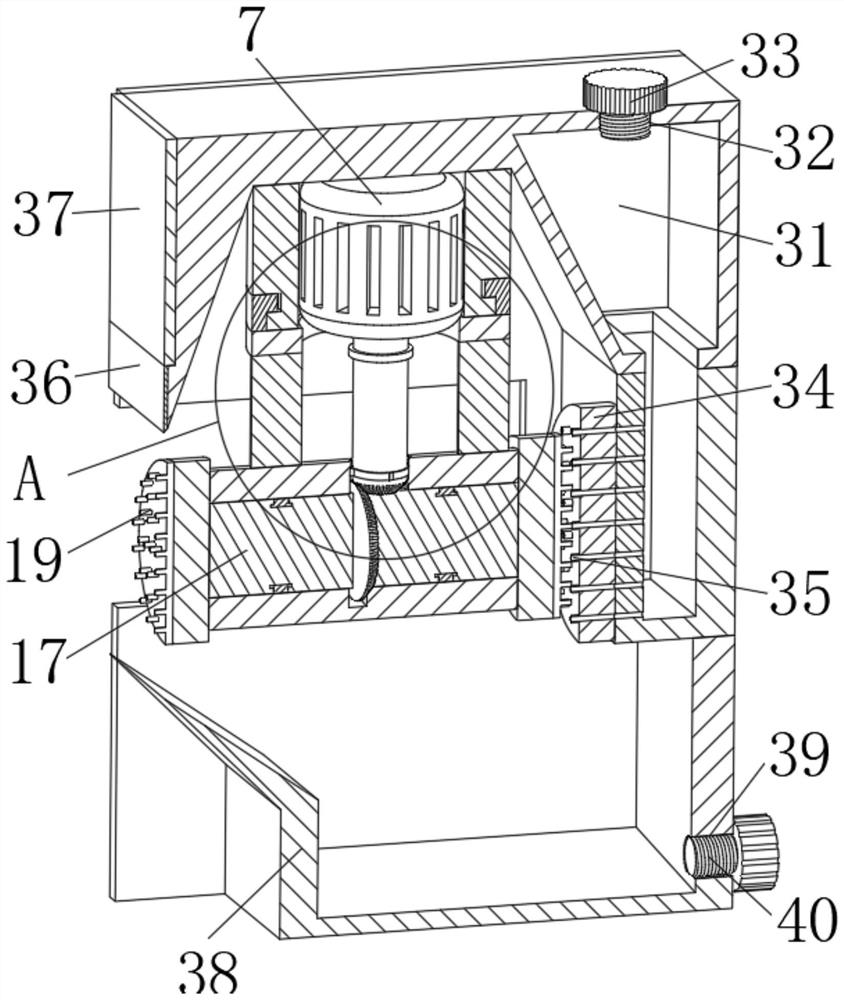

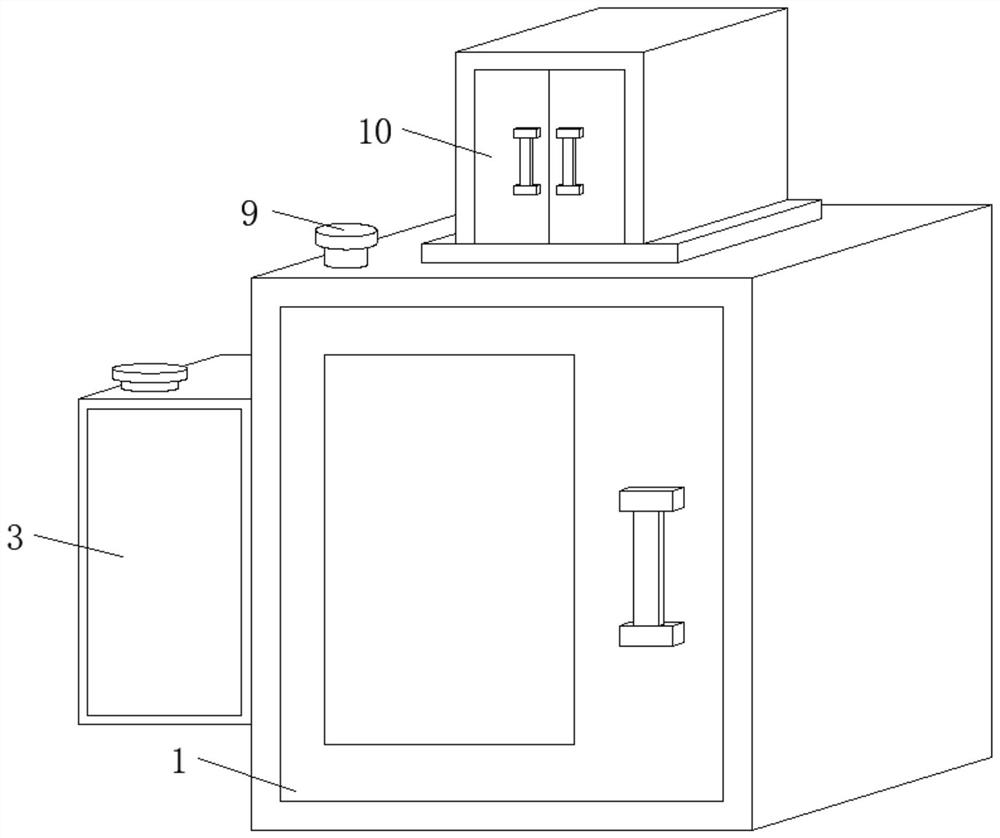

Washing device for drilling equipment

InactiveCN111889436AThe solution is not easy to cleanFacilitates high-pressure continuous flushingDrying gas arrangementsCleaning using toolsElectric machineDrive shaft

The invention discloses a washing device for drilling equipment. Aiming at the problems that a drill bit is not easy to clean and sundries are not easy to remove, the following technical scheme is provided: the washing device comprises a box body, a flushing mechanism is arranged on the outer wall of one side of the box body, a motor box is fixed to the middle position of the outer wall of the topof the box body through bolts, a motor is fixed to the inner wall of the bottom of the motor box through bolts, one end of an output shaft of the motor is in key connection with a transmission shaft,one end of the transmission shaft is located in the box body, an electromagnetic chuck is fixed to one end of the transmission shaft through bolts, a brushing mechanism is arranged on the inner wallof the side, away from the flushing mechanism, of the box body, and fans are fixed to two sides of the inner wall of the top of the box body through bolts. After electric telescopic rods are fed intothe surface wall of the drill bit, slight extrusion is carried out, different spring plates carry out extrusion to different degrees according to the shape of the drill bit and attach to the drill bit, and then the surface wall of the drill bit can be conveniently washed.

Owner:SINOPEC SHENGLI PETROLEUM ENG

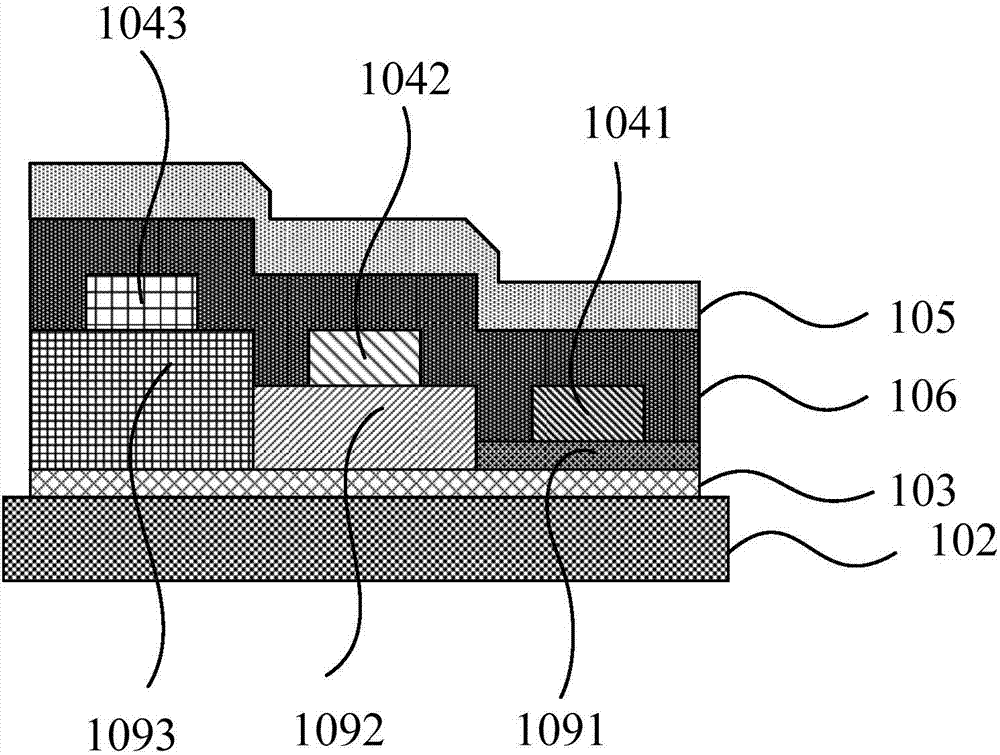

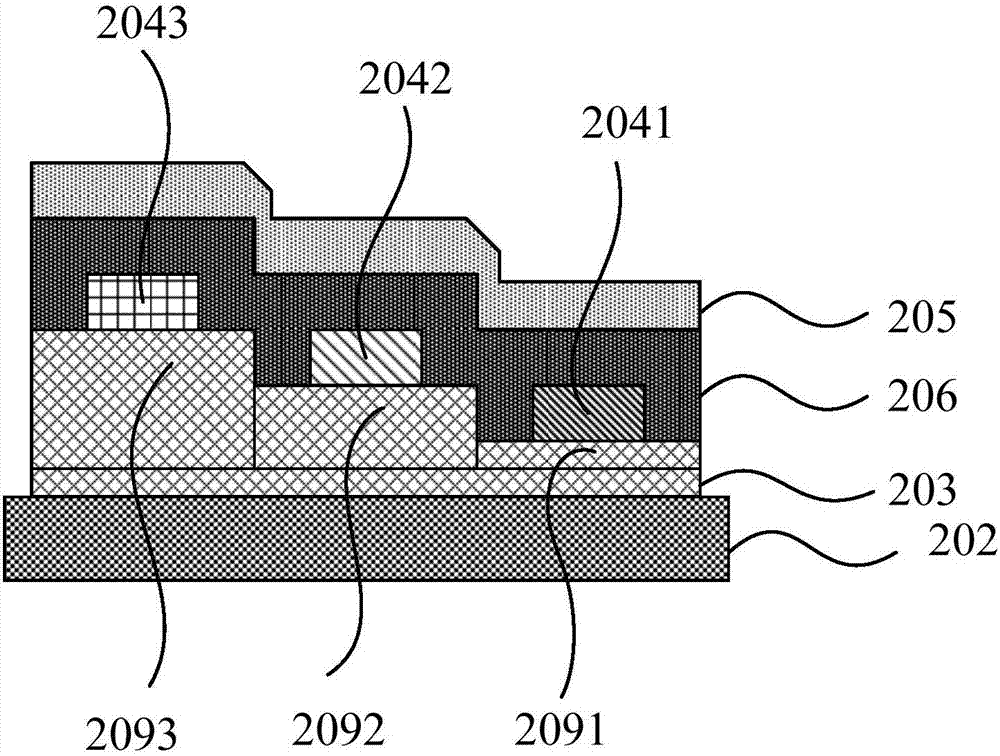

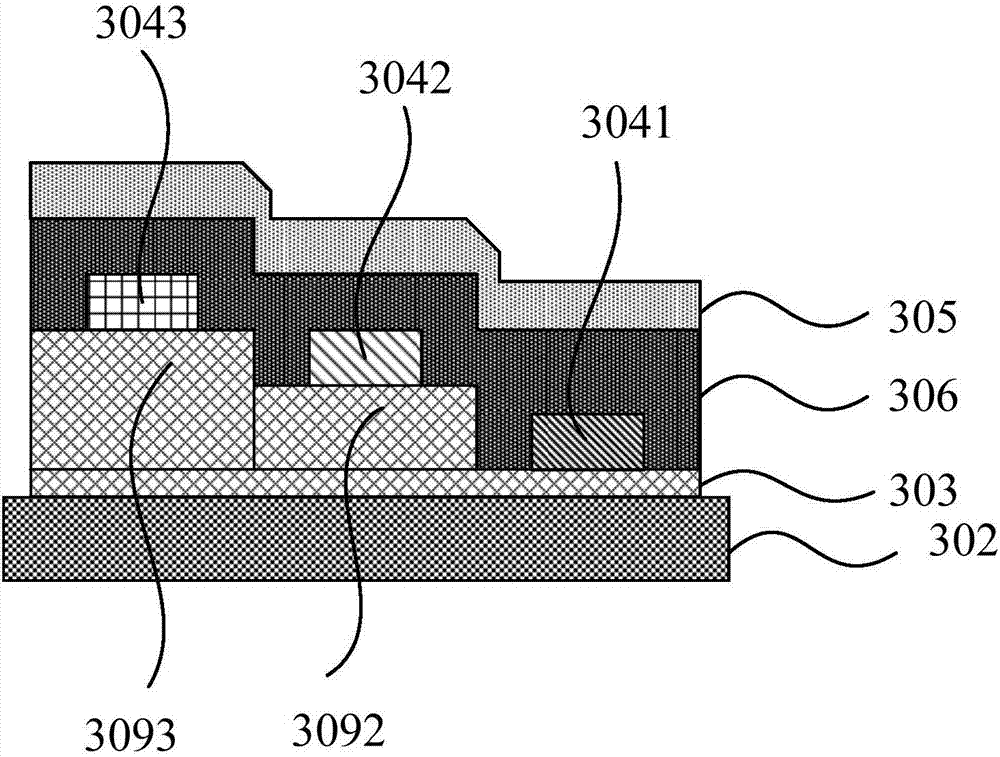

OLED display panel and electronic equipment including same

ActiveCN107275362AAvoid crosstalkThe solution is not easy to cleanSolid-state devicesSemiconductor/solid-state device manufacturingSolventSolubility

The present invention relates to an OLED display panel including a first electrode, and a first hole transport layer, a second hole transport layer, an electron transport layer, and a second electrode which are formed in sequence over the first electrode. The second electrode is formed on the electron transport layer. At least two light emitting units are disposed on the second hole transport layer, the electron transport layer covers the light emitting units, and the material of the electron transport layer fills gaps in the adjacent light emitting units, and the first hole transport layer includes a hole transport material having a hole mobility of 9 * 10 <-5> to 5 * 10 <-4> cm 2 / V.S. The hole transport material has a solubility of not less than 10 g / L in N-methylpyrrolidone below 25 DEG C. In the present invention, the hole transporting material with the specific hole mobility is selected as the common hole transport layer, which can avoid crosstalk between different pixels, and can specifically solve the problem that MASK is not easily cleaned due to the specific solubility range of the MASK cleaning solvent.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

Manual self-cleaning type valve wedge disc for oil exploitation

InactiveCN107606200AThe solution is not easy to cleanCleaning using toolsSlide valveSelf cleaningEngineering

Owner:苏州昌田机械设备制造有限公司

Acer truncatum hair blacking oil

ActiveCN105943442AHigh activityEasy to cleanCosmetic preparationsHair cosmeticsPinelliaAdditive ingredient

The invention discloses acer truncatum hair blacking oil. The acer truncatum hair blacking oil is prepared from, by weight, 55-65 parts of acer truncatum seed oil, 9-11 parts of black sesame oil, 9-11 parts of black peanut oil, 14-16 parts of black walnut powder, 2.5-3.5 parts of polygonum multiflorum powder, 1-1.5 parts of black pedate pinellia powder and 0.5-1 part of boletus aereus powder. The acer truncatum hair blacking oil can sufficiently activate tyrosinase, greatly enhance the activity of tyrosinase, promote quick fissiparity of melanocyte, effectively black white hair, nourish hair and enable the hair to be smooth. The raw materials are natural components, no chemical material is contained, and the situation that toxic substance enters the human body through the skin and is accumulated in the human body will not occur. The acer truncatum hair blacking oil can be washed away easily even when the skin and clothes are contaminated by the acer truncatum hair blacking oil.

Owner:重庆毕麦生物科技有限公司

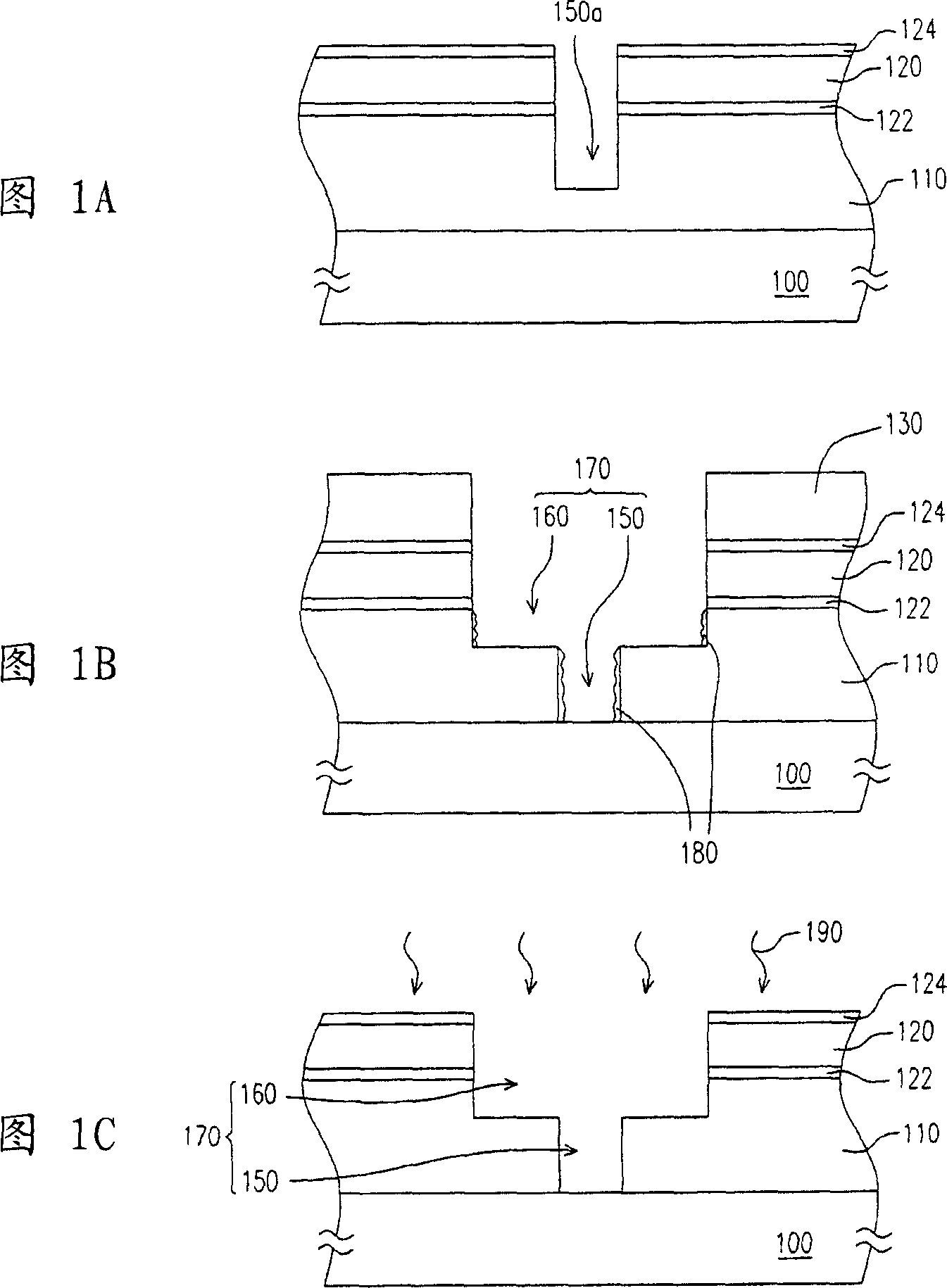

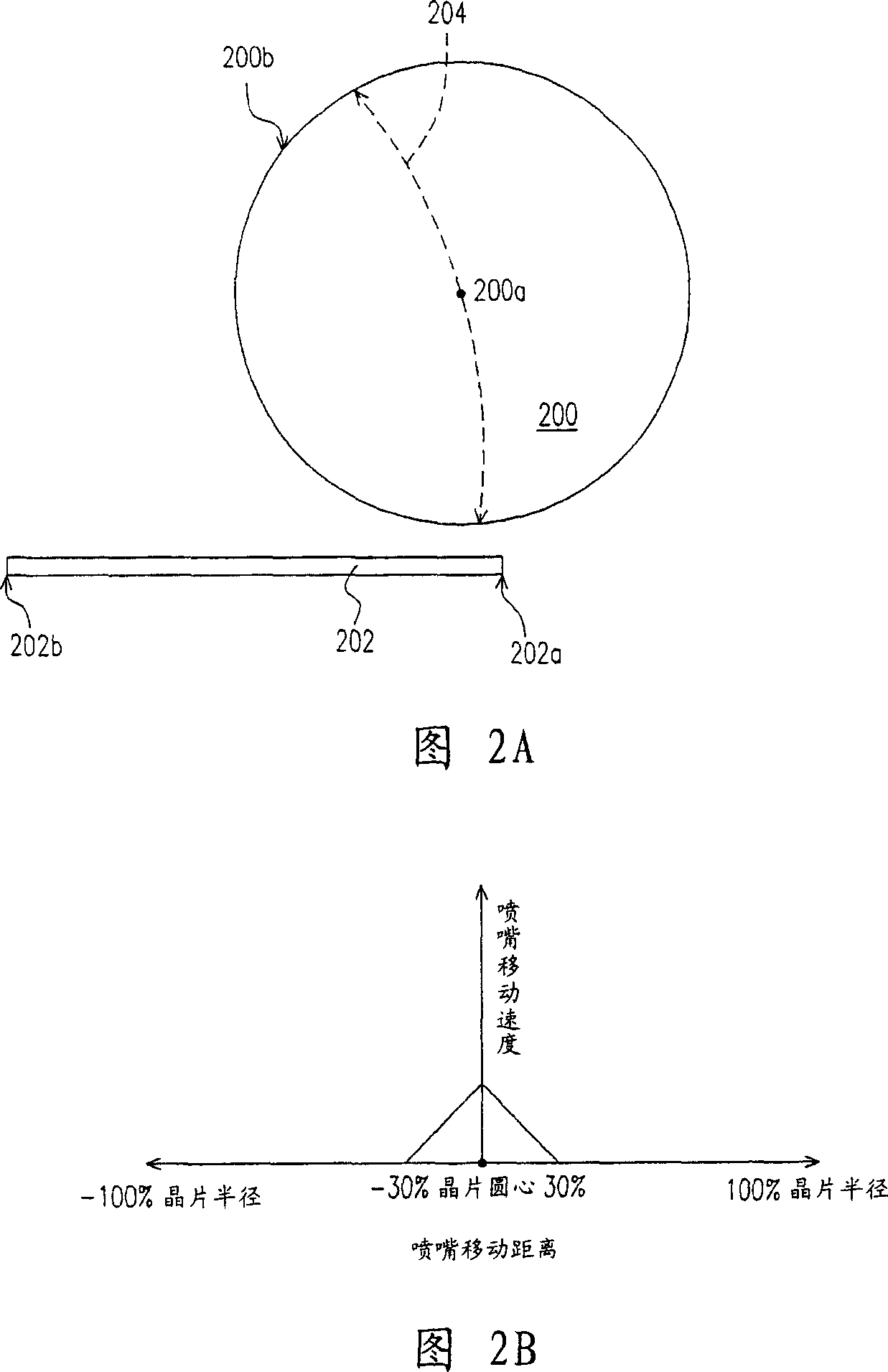

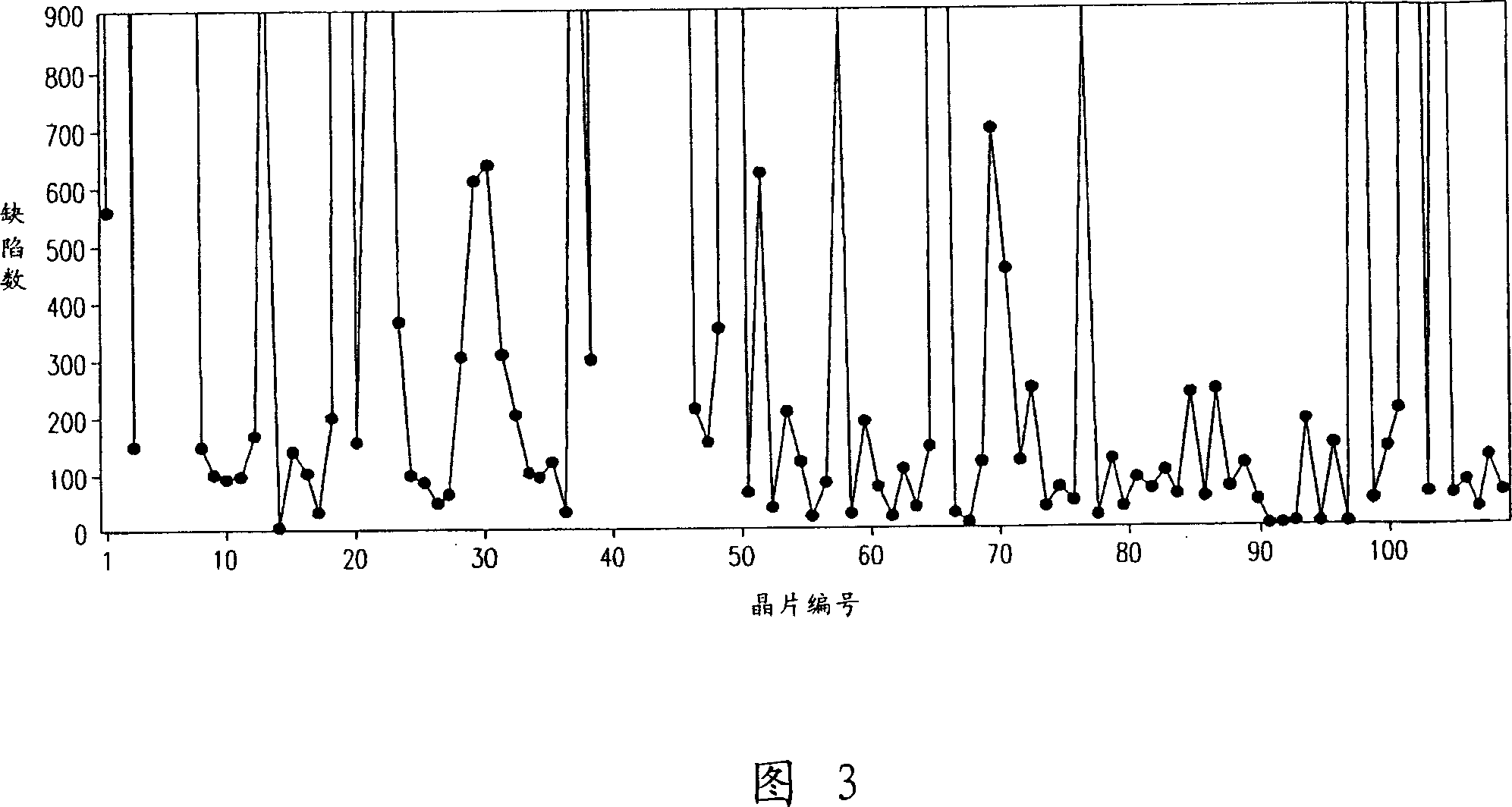

Chip washing process and method for forming opening therefor

ActiveCN1937171AOptimal cleaning effectCleaning results are stableSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringRADIUS

The technique for cleaning out wafers is suitable to be carried out after an etching procedure is executed for a wafer. The wafer possesses center of circle, radius and edge of a wafer. The method includes operations: a nozzle transfers cleaning solution above the wafer; the nozzle moves along a moving path by using wafer center of circle as center; back and forth movement is carried out above neighborhood of center of wafer.

Owner:UNITED MICROELECTRONICS CORP

Mechanical part machining table facilitating chip removal

InactiveCN107813266AEasy chip removalSimple structureWork benchesMaintainance and safety accessoriesDrive wheelMechanical components

The invention provides a machine part processing table which is convenient for chip removal, and relates to the field of machine part processing. The processing table for mechanical parts that is convenient for chip removal includes a processing table body, a base is fixedly connected to the front side of the inner wall of the processing table body, and a motor is fixedly connected to the end of the base away from the inner wall of the processing table body. The output end is fixedly connected with a driving wheel. The mechanical parts processing table that is easy to remove chips, through the motor installed inside the processing table body, under the rotation of the motor, through the cooperation of the driving wheel, driven wheel, slider, chute and belt, it can drive the moving bar on the belt to move. As a result, when the moving rod is moving, the movement of the scraper is driven by the cooperation between the connecting rod and the fixed fast, so as to realize the one-time cleaning of the debris on the processing table body, making the cleaning work simple and efficient, and solving the problem of mechanical parts The debris generated during processing is not easy to clean up.

Owner:WUXI HENGTENG PRECISION MACHINERY CO LTD

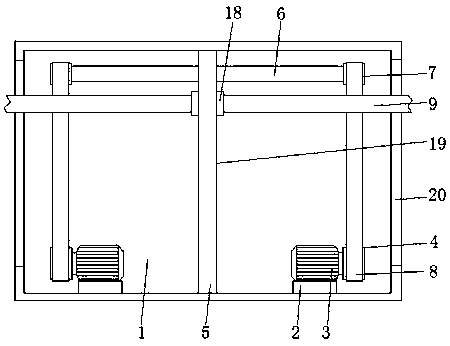

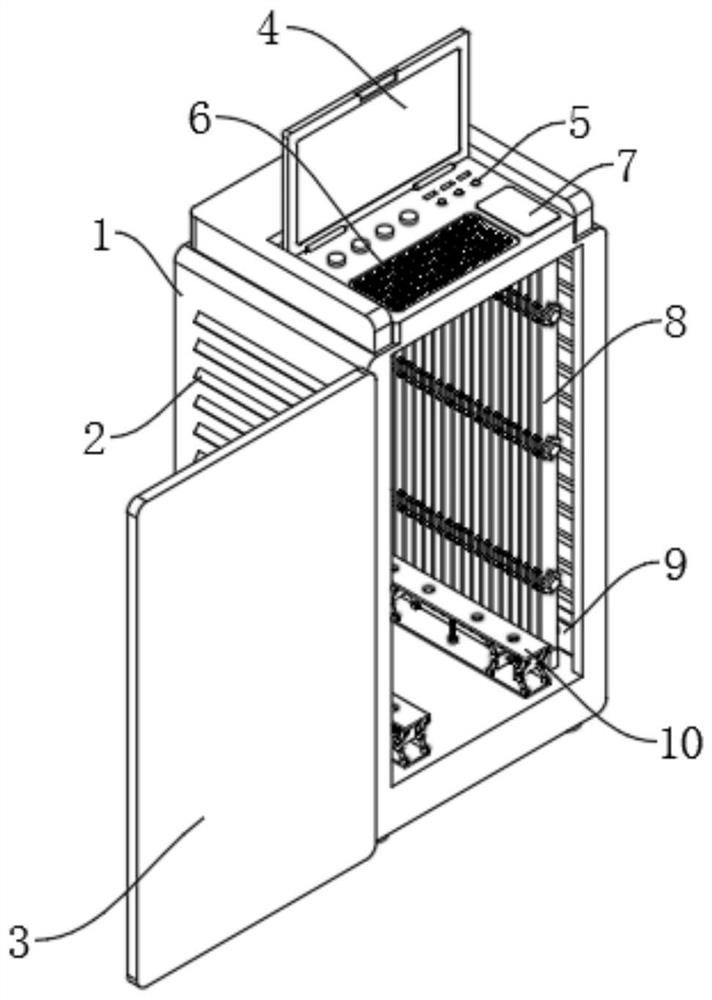

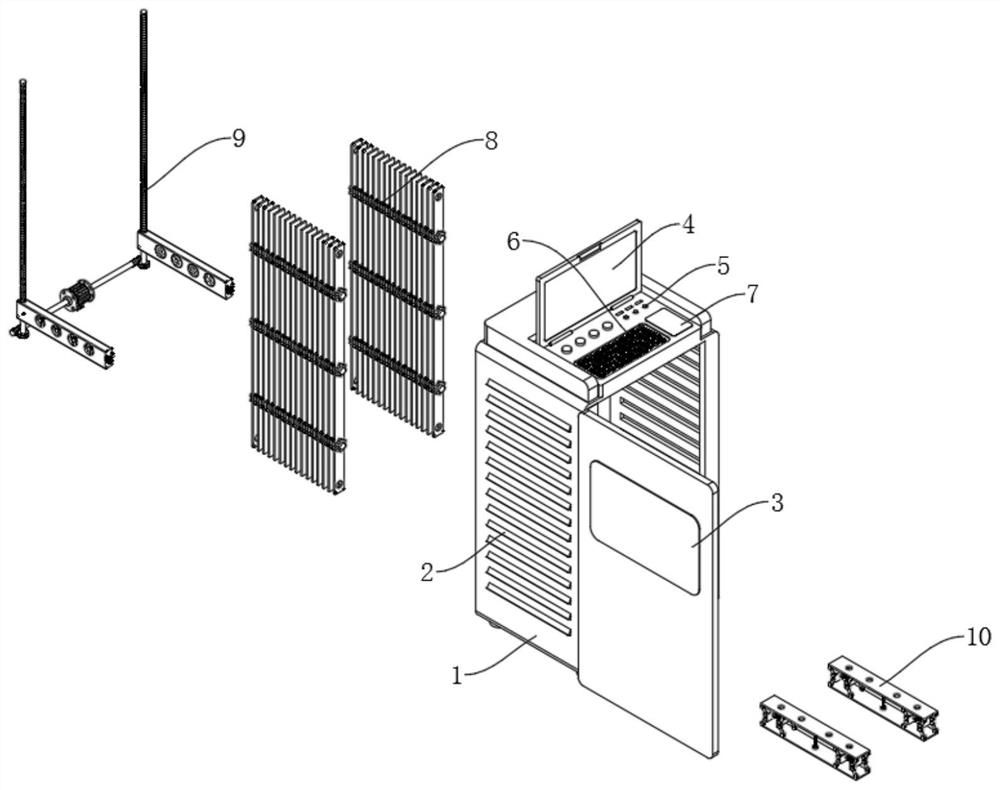

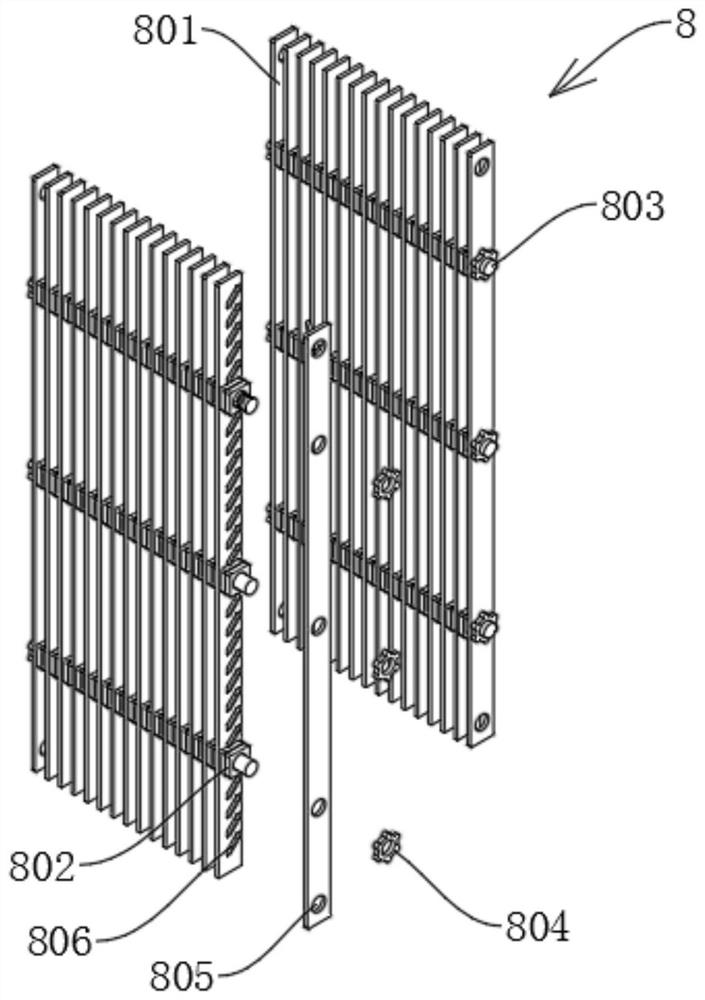

Computer control device and control method of product processing equipment

InactiveCN111694416AReal-time temperature monitoringRealize the purpose of focusing on heat dissipationDigital data processing detailsVertical edgeEngineering

The invention discloses a computer control device and control method of product machining equipment, and belongs to the technical field of control devices. The computer control device and control method of product processing equipment comprise a mounting cabinet body, a cabinet door, a safety lock and a heat dissipation grid. The bottom surface of the mounting cabinet body is fixedly connected with antiskid supporting legs. Hinges are fixedly mounted on a vertical edge of the mounting cabinet body, and the cabinet door is movably connected to the mounting cabinet body through the hinges. The safety lock is fixedly mounted at the end, far away from the hinges, of the cabinet door, and the safety lock is also fixedly connected with a handle. The heat dissipation grid is fixedly connected tothe side wall of the mounting cabinet body. A mounting plate is fixedly connected to the bottom end of the interior of the mounting cabinet body, and a fixed mounting frame is fixedly connected to themounting plate. Clamping blocks are fixedly connected to the inner top face of the mounting cabinet body and the mounting plate, and a heat absorption mechanism is further installed in the mounting cabinet body. The problem that an existing design is simple in heat dissipation structure and poor in heat dissipation effect is effectively solved.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com