OLED display panel and electronic equipment including same

A technology for display panels and electron transport layers, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of slow material mobility, crosstalk, and poor cleaning effect of evaporation mask, so as to solve difficult cleaning and avoid crosstalk. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077]

[0078] Add 5g (13.8mmol) of intermediate 1, 2.3g (6.9mmol) of intermediate 2, 30.9mg (0.138mmol) of palladium acetate and 1.1g (13.9mmol) of sodium tert-butoxide into a 500mL three-necked flask. The flask was replaced with nitrogen, and 100 mL of dehydrated toluene and 0.12 mL (0.276 mmol) of tri-tert-butylphosphine were injected into the flask. Place in an oil bath, slowly heat to 110°C and stir for 8 hours, then let stand overnight. The formed solid was dissolved in dichloromethane, washed with 300 mL of saturated brine, and the organic layer was dried over magnesium sulfate. Recrystallization was carried out using a mixed solvent of toluene and ethanol to obtain 4.3 g (5.0 mmol) of the target compound with a yield of 72%. Mass spectrum M / Z = 900.6 was obtained by LC-MS.

Embodiment 2

[0080]

[0081] Add 5g (14.3mmol) of intermediate 1, 2.3g (6.9mmol) of intermediate 2, 30.9mg (0.138mmol) of palladium acetate and 1.1g (13.9mmol) of sodium tert-butoxide into a 500mL three-necked flask. The flask was replaced with nitrogen, and 100 mL of dehydrated toluene and 0.12 mL (0.276 mmol) of tri-tert-butylphosphine were injected into the flask. Place in an oil bath, slowly heat to 110°C, stir for 8 hours, and let stand overnight. The formed solid was dissolved in dichloromethane, washed with 300 mL of saturated brine, and the organic layer was dried over magnesium sulfate. Recrystallization was carried out using a mixed solvent of toluene and ethanol to obtain 4.5 g (5.17 mmol) of the target compound with a yield of 75%. Mass spectrum M / Z = 876.5 was obtained by LC-MS.

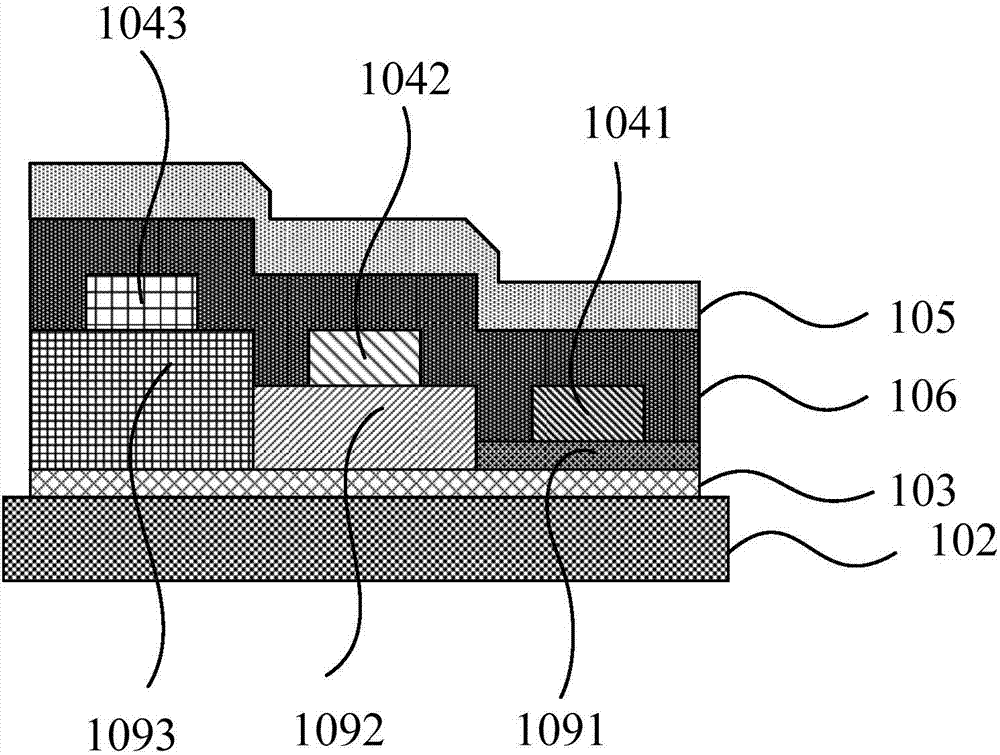

[0082] Example 1

[0083] preparation specific Figure 4 The fabrication process of the OLED display panel with the structure shown is as follows:

[0084] On a glass substrate, form a reflec...

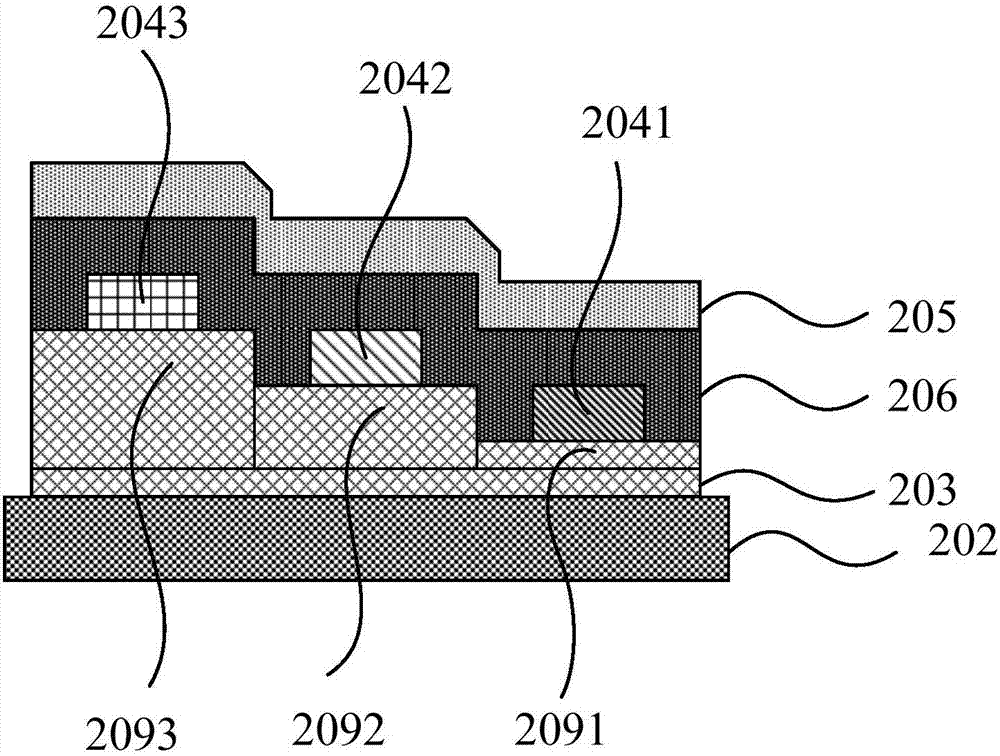

Embodiment 3

[0088] The difference from Example 1 is that the material of the hole transport layer is replaced by Its hole mobility is 2.5×10 -4 cm 2 / V·S, the solubility in NMP is 12g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mobility | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com