Patents

Literature

42results about How to "Realize circular conveying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

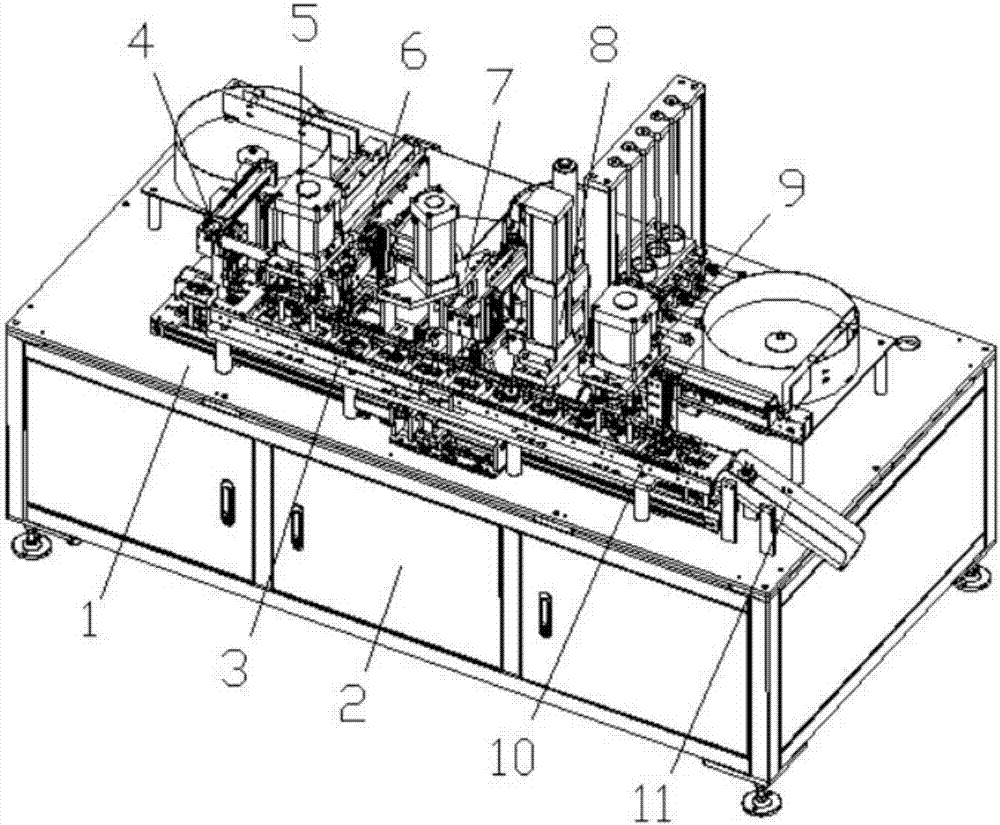

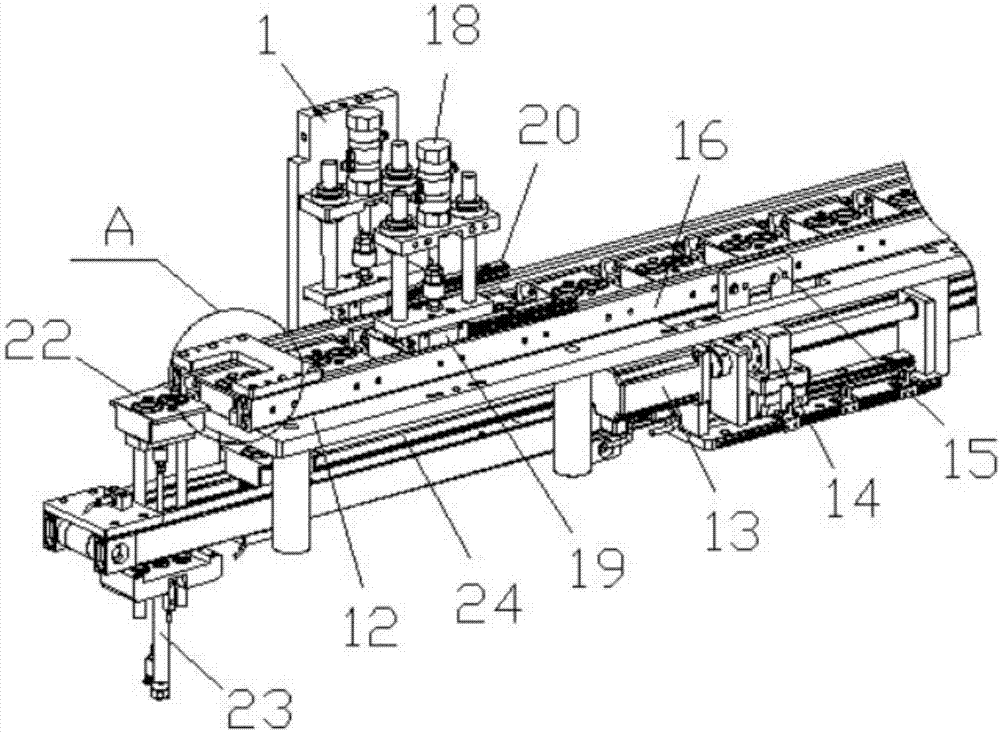

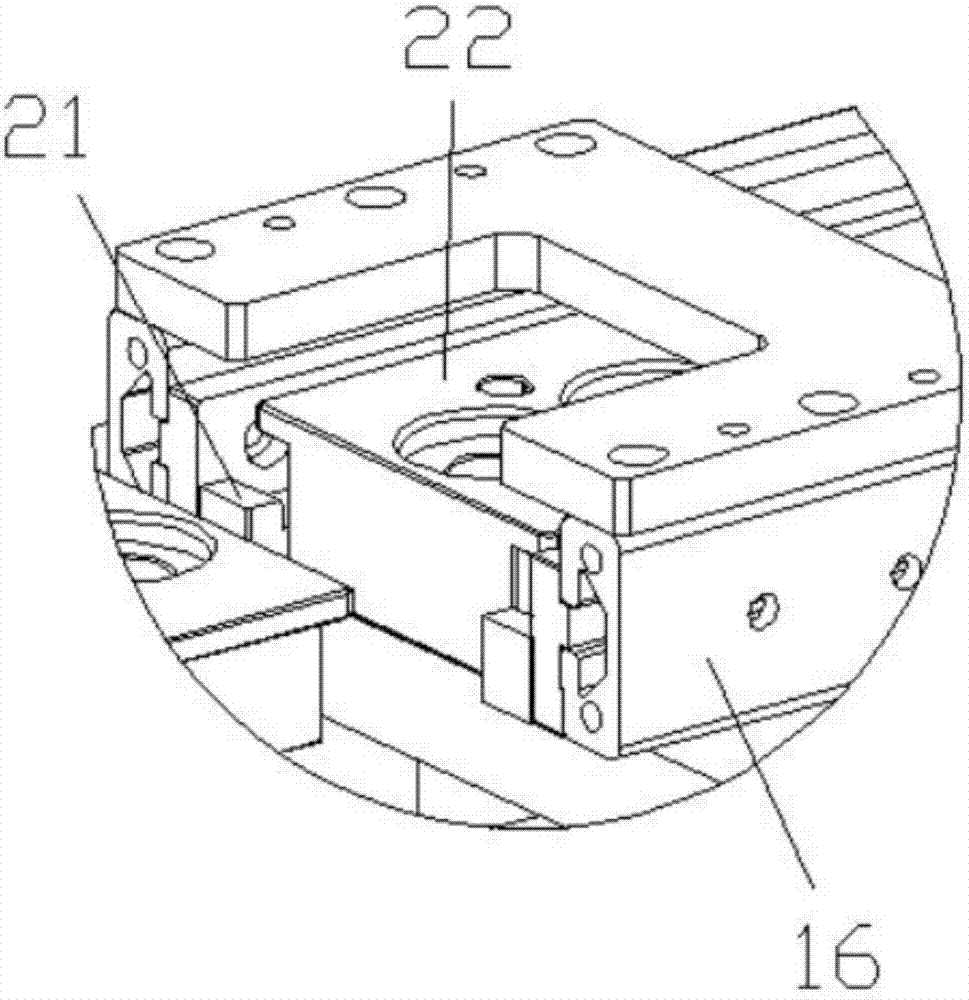

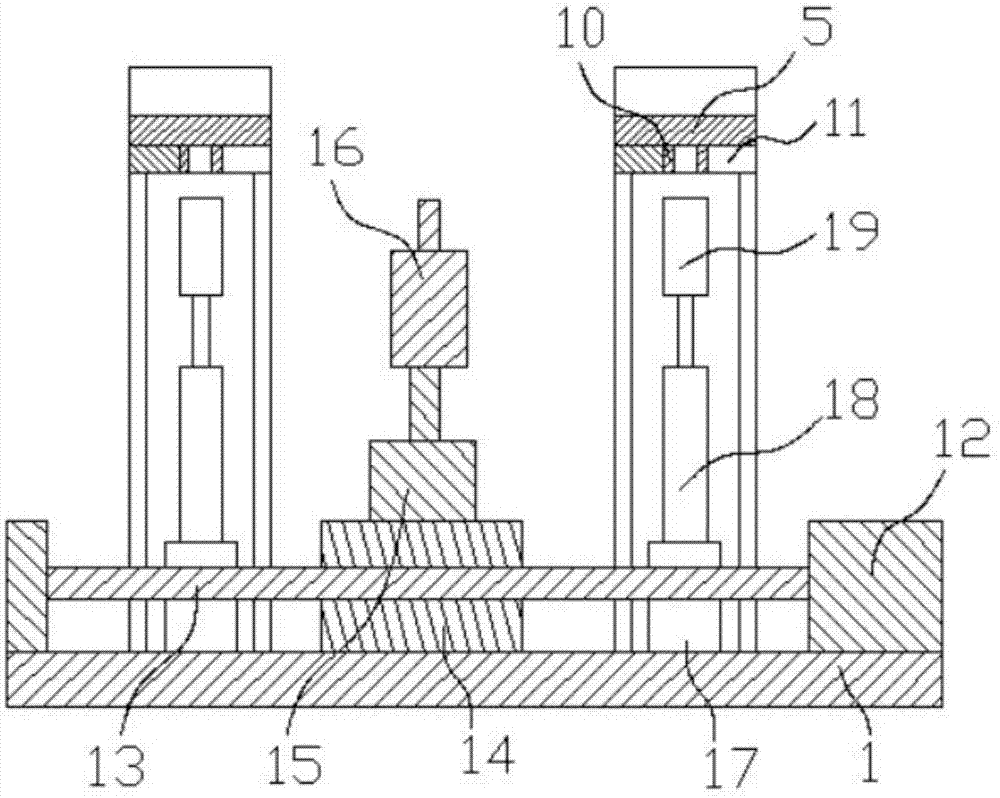

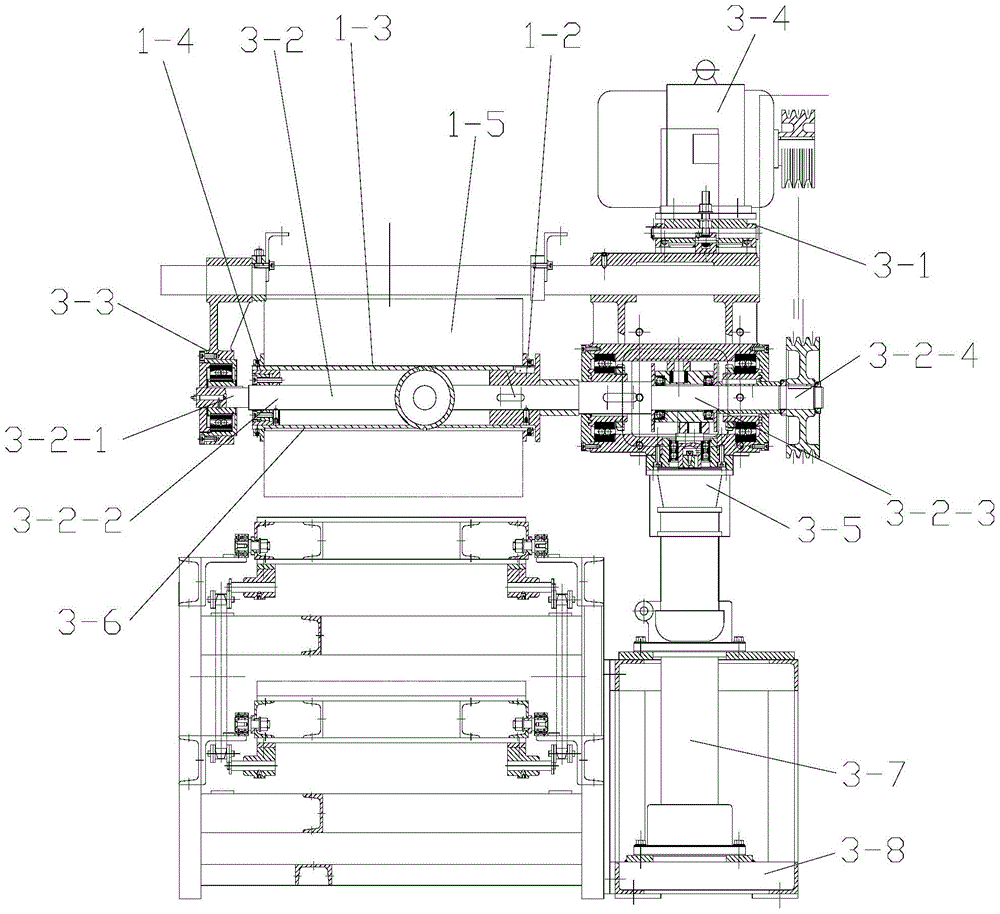

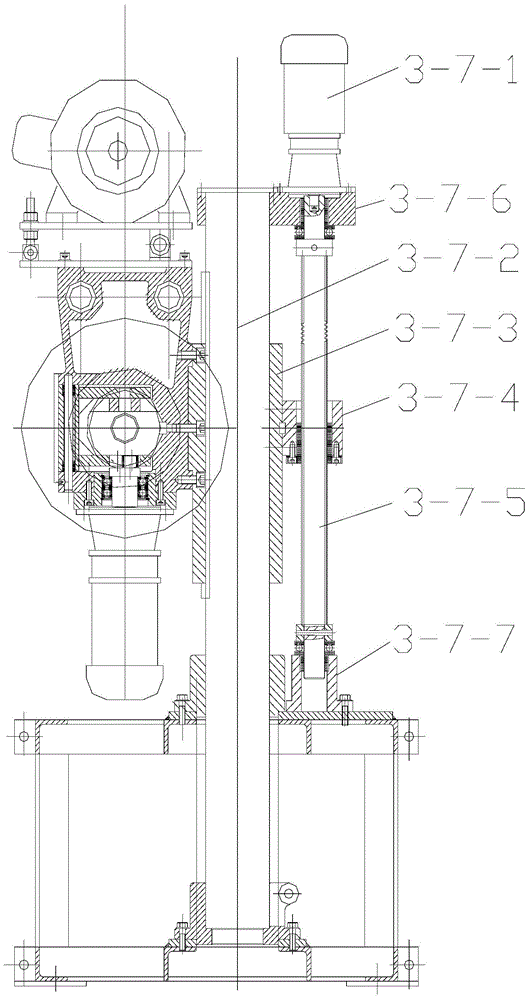

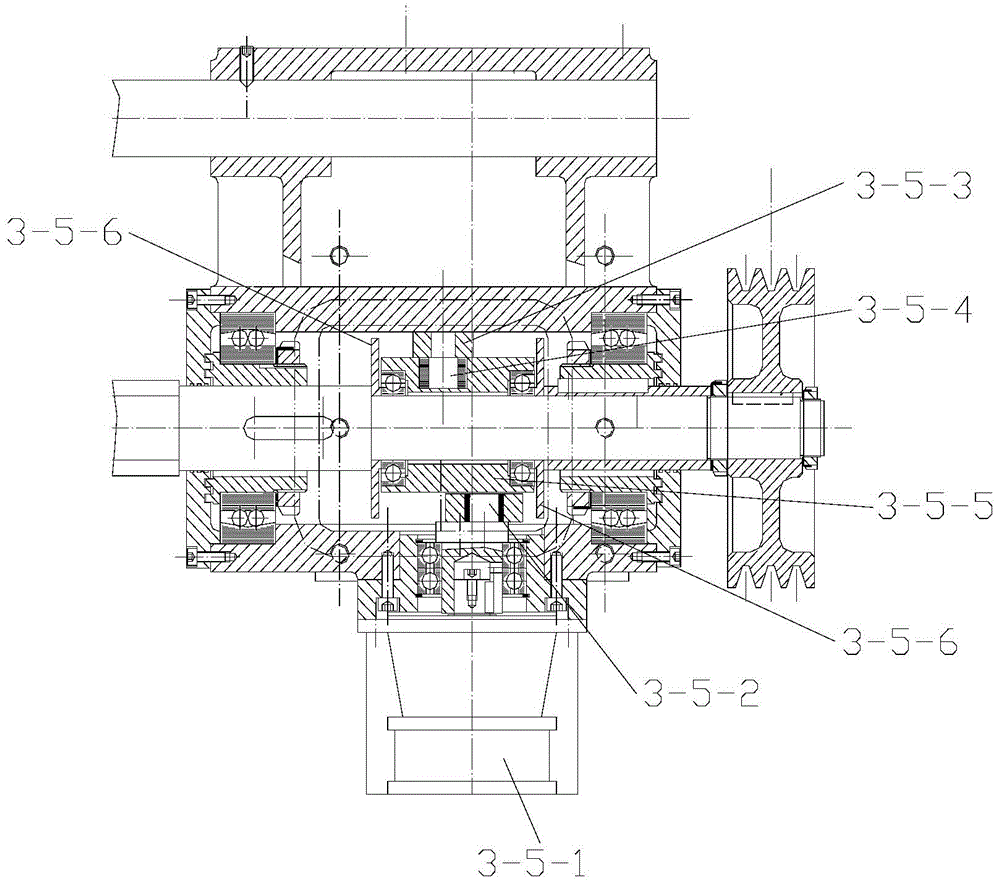

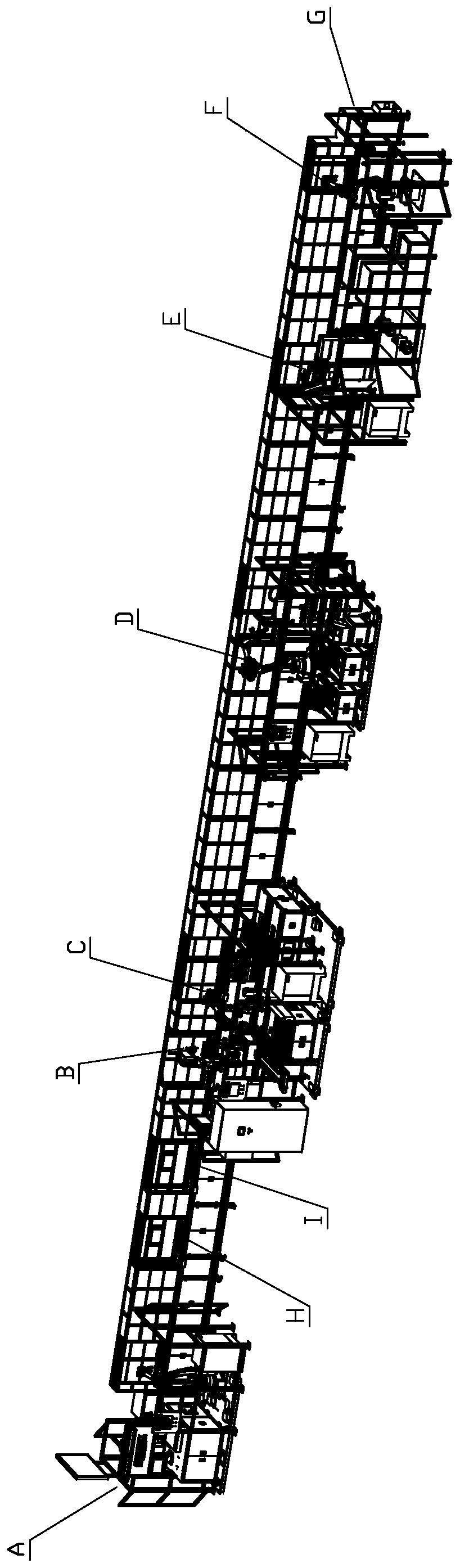

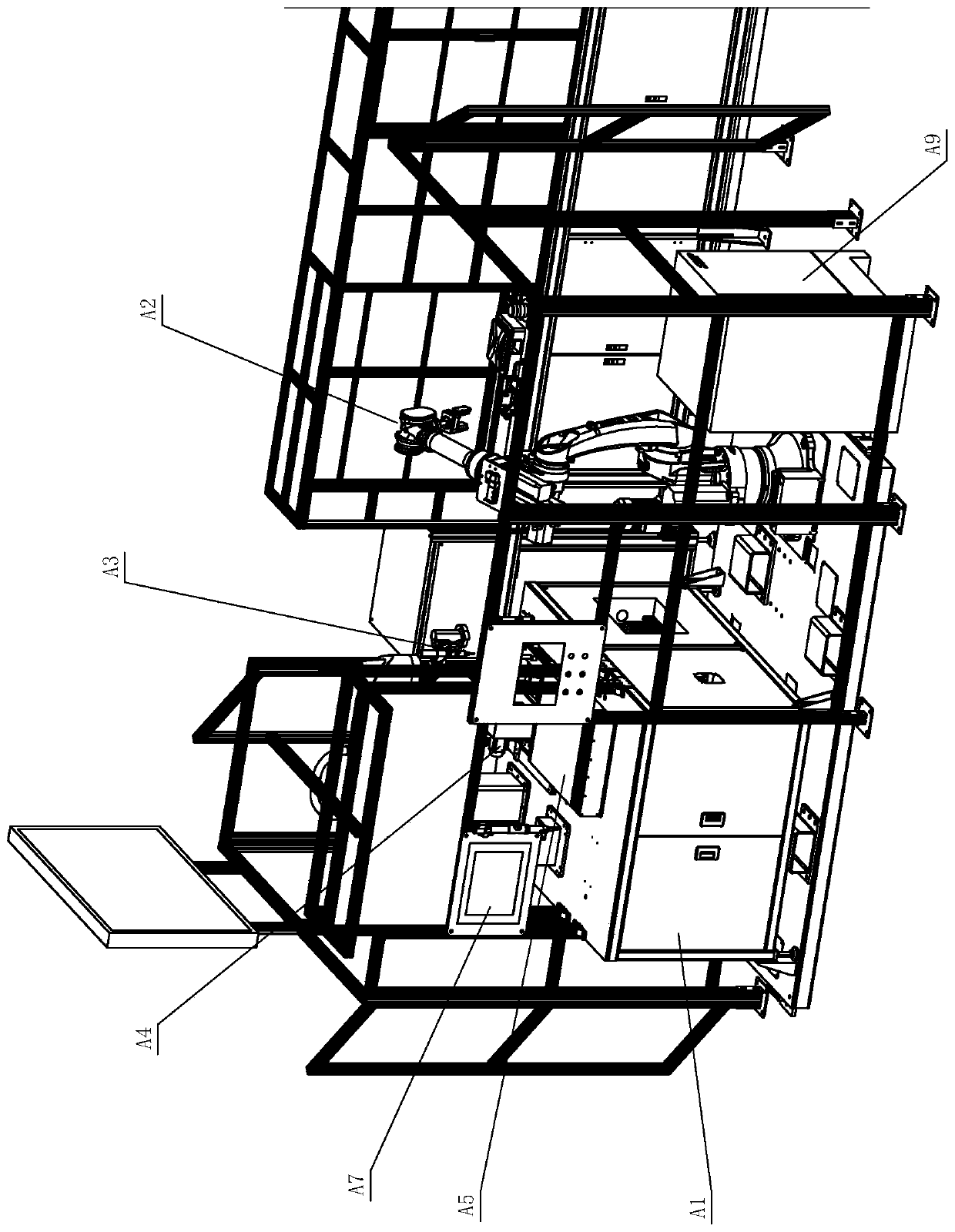

Automatic gear shaft assembling machine

InactiveCN107571008AHigh matching precisionImprove assembly efficiency and yieldAssembly machinesManipulatorBall bearing

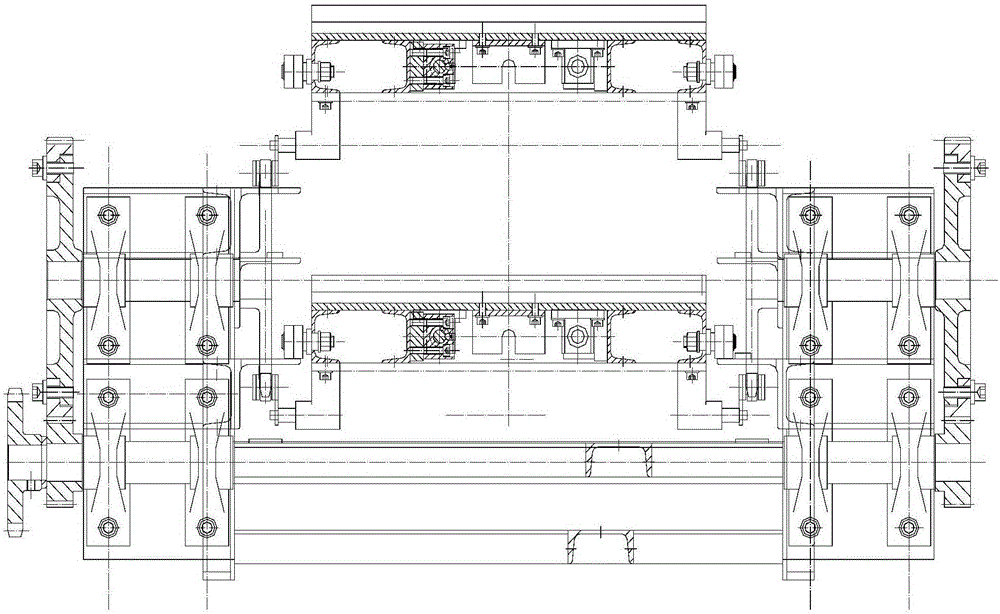

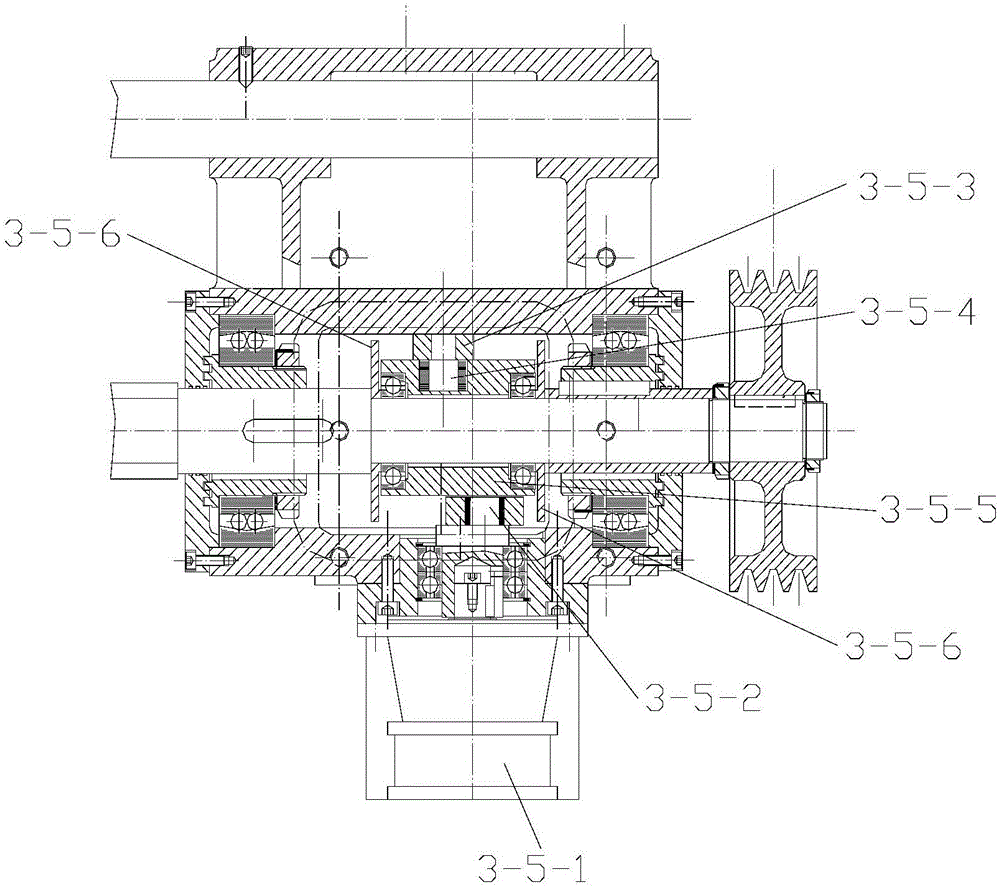

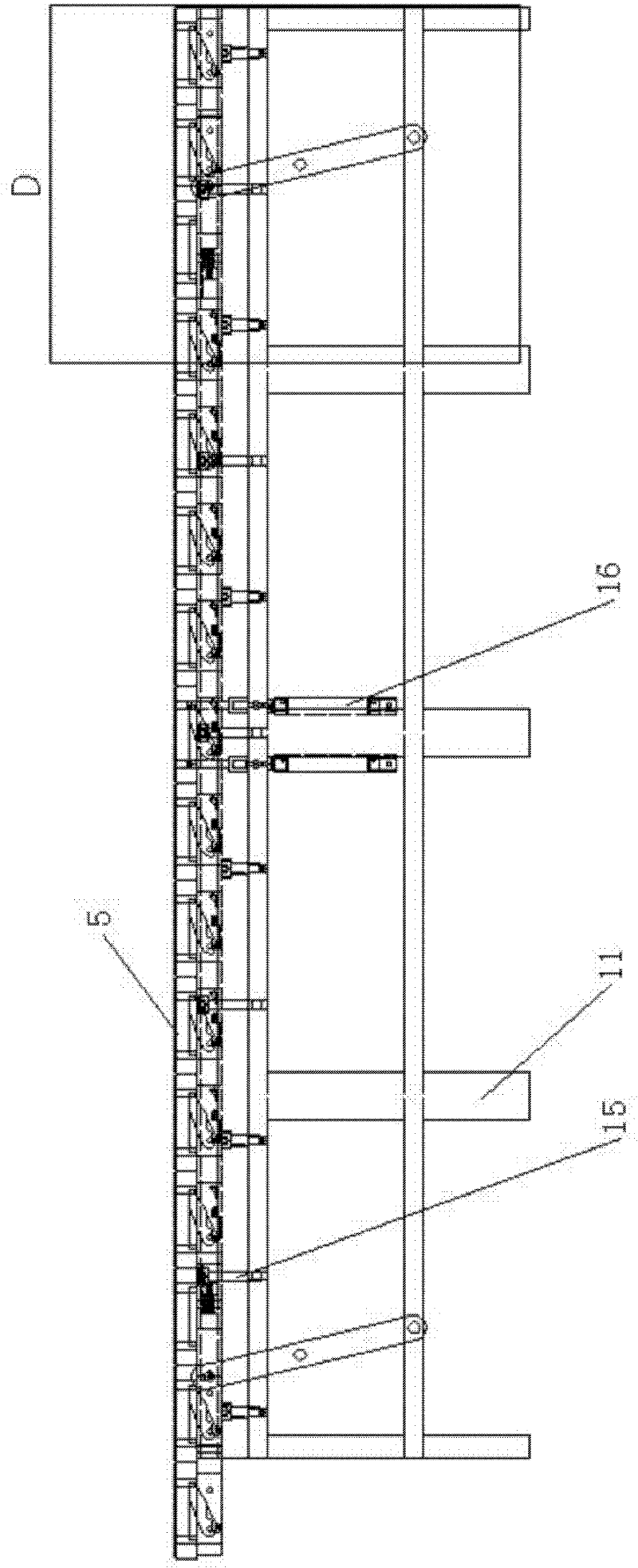

The invention relates to an automatic gear shaft assembling machine. The rack is provided with a carrier conveying device. The carrier conveying device comprises a carrier conveying base. Carrier feeding movable air cylinders are arranged on the front side and the rear side of the carrier conveying base and connected with a carrier feeding movable base. The carrier feeding movable base is connected with a carrier feeding movable block. A carrier feeding clamping block matched with a carrier is arranged on the inner side of the carrier feeding movable block. A carrier feeding lifting matched sliding rail is arranged at the upper portion of the carrier feeding movable block and matched with a carrier feeding lifting matched sliding block. The upper portion of the carrier feeding lifting matched sliding block is matched with a carrier feeding lifting air cylinder on the rack. The rack is provided with a ball bearing feeding device, a shaft rod feeding device, an overturning device, a clamping ring feeding device, a gear feeding device, a clamping bearing feeding device and a discharging mechanical arm. According to the automatic gear shaft assembling machine, automatic ball bearing and shaft rod assembling can be achieved, and the assembling efficiency and the yield are greatly improved.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

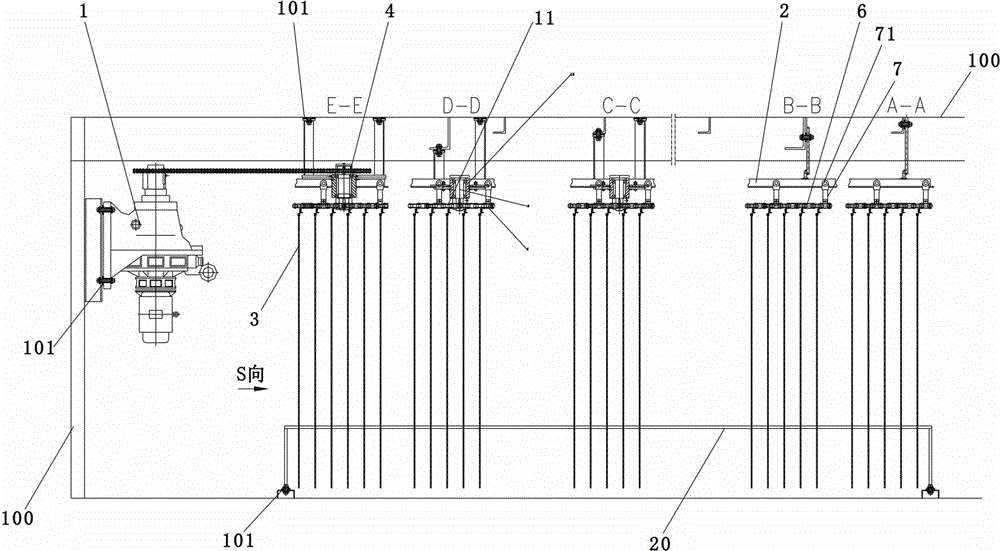

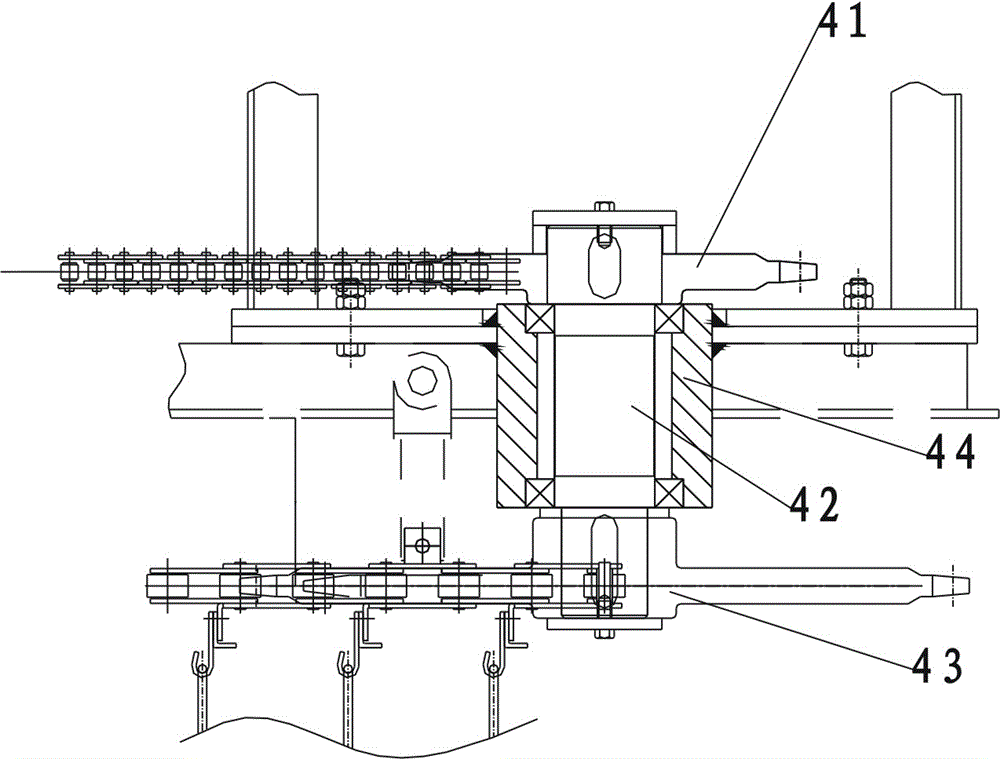

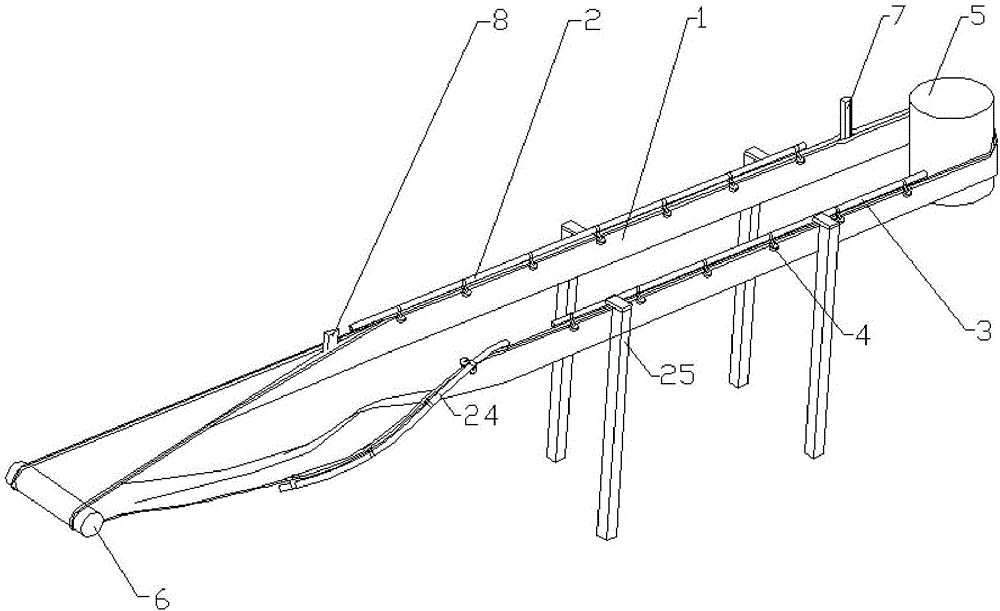

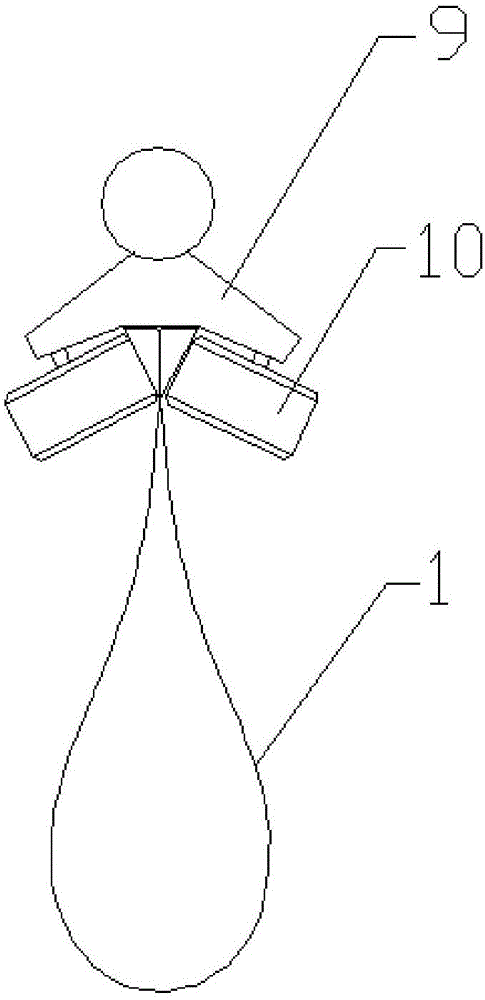

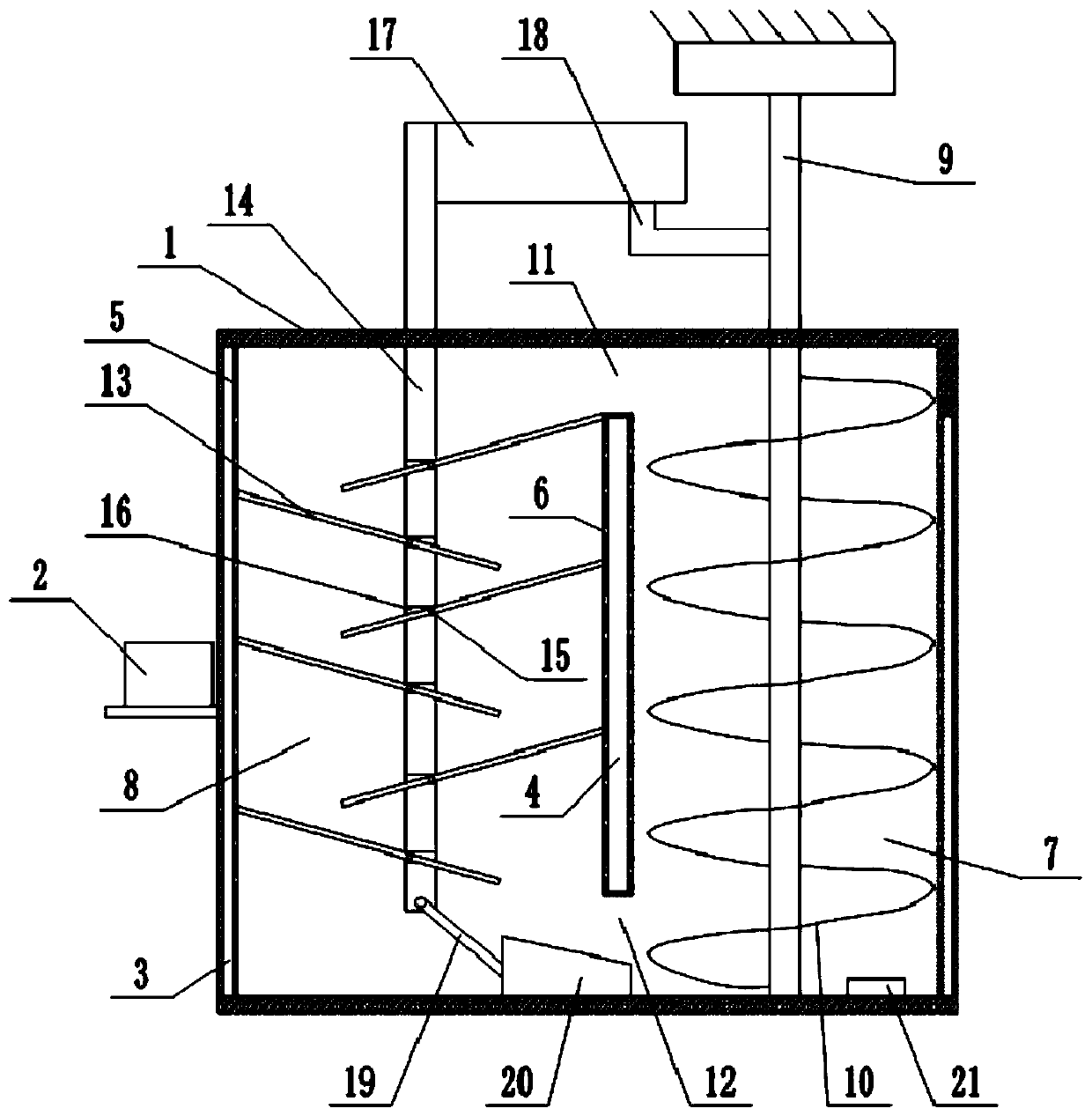

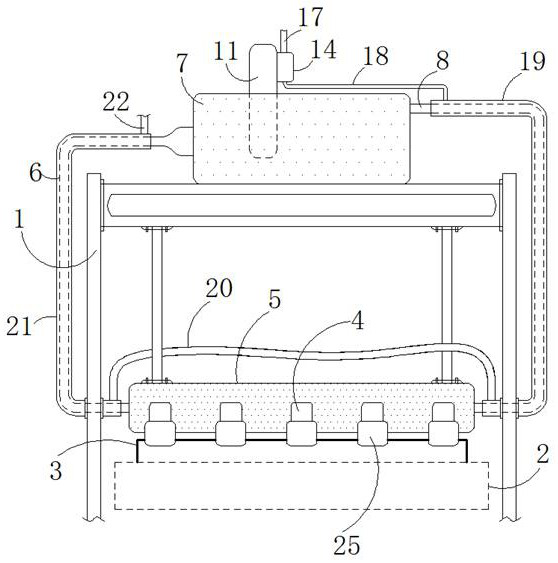

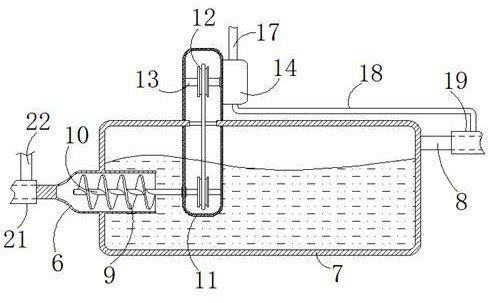

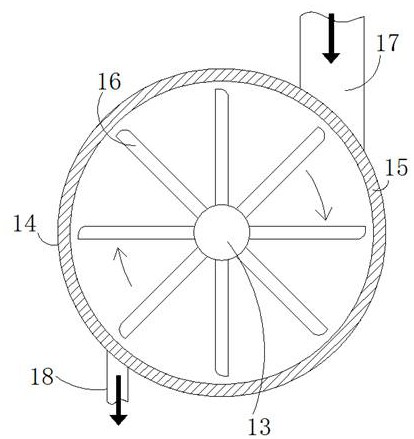

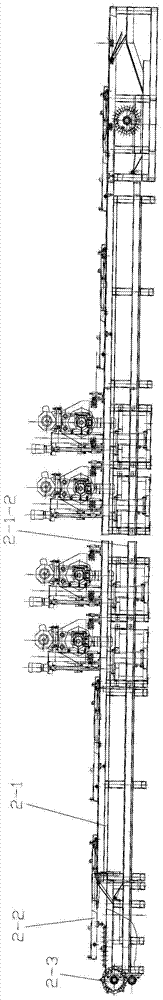

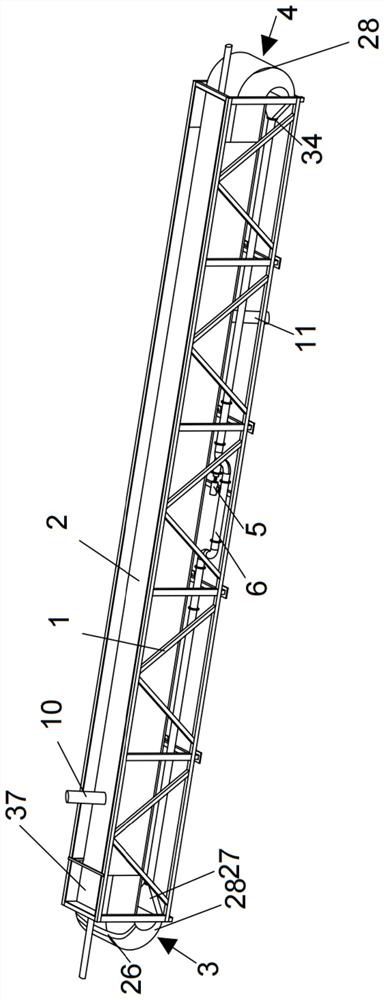

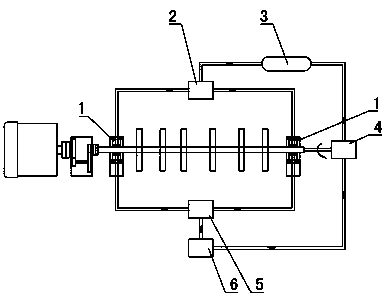

Automatic continuous drying system of large ocean fishing boat

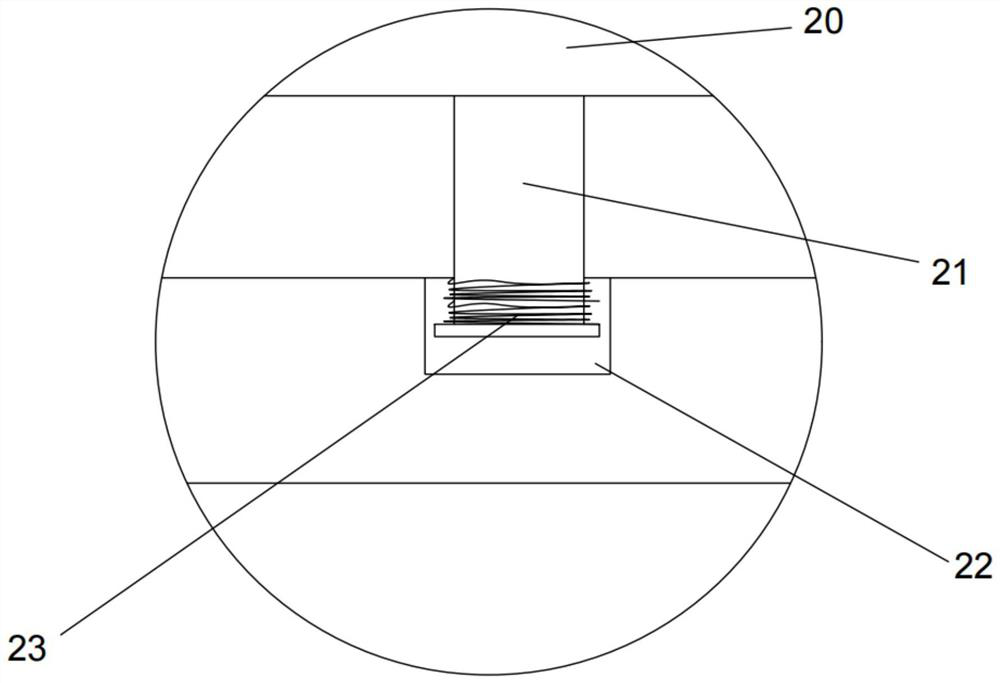

ActiveCN104567308ARealize circular conveyingSafe, stable and efficient continuous motionDrying machines with progressive movementsDrying solid materialsDrive wheelSpatial structure

The invention discloses an automatic continuous drying system of a large ocean fishing boat. The automatic continuous drying system comprises a fixed bin, wherein the fixed bin is internally provided with a drying machine and a conveying device; the conveying device comprises a driver, a chain wheel, a rail and a trawl board; the driver is fixedly connected with the fixed bin; the rail is fixedly connected with the fixed bin; the chain wheel is in transmission connection with the driver; the chain wheel comprises first driving wheels and support wheels; the first driving wheels and the support wheels are respectively arranged at different positions according to spatial arrangement, and the numbers of the first driving wheels and the support wheels are set as required; the first driving wheels are in transmission connection with the support wheels by virtue of chain belts; the chain belts are fixedly provided with sliding devices; the sliding devices are movably connected with the rail and are fixedly connected with hooks; the hooks are used for hanging the trawl board. By virtue of reasonable design on the equipment structure, the special spatial structure and transporting environment of a boat body are met, and meanwhile, continuous and circulating drying treatment of fresh fish goods can be rapidly and uniformly realized.

Owner:舟山利远机械有限公司

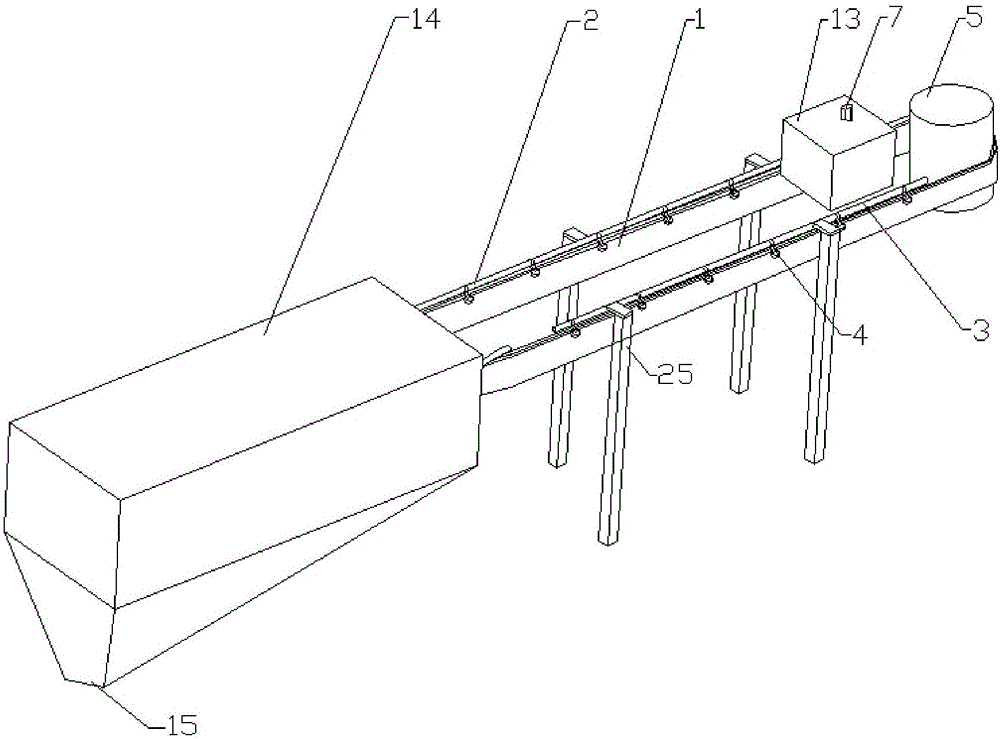

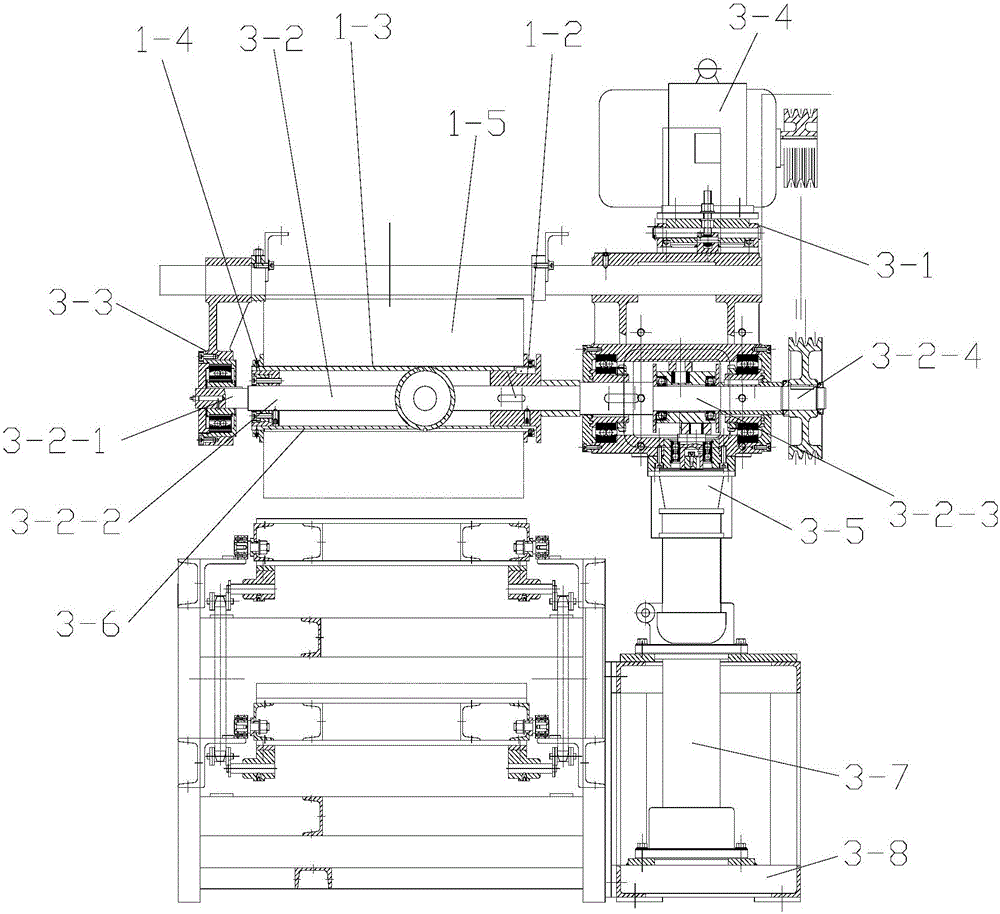

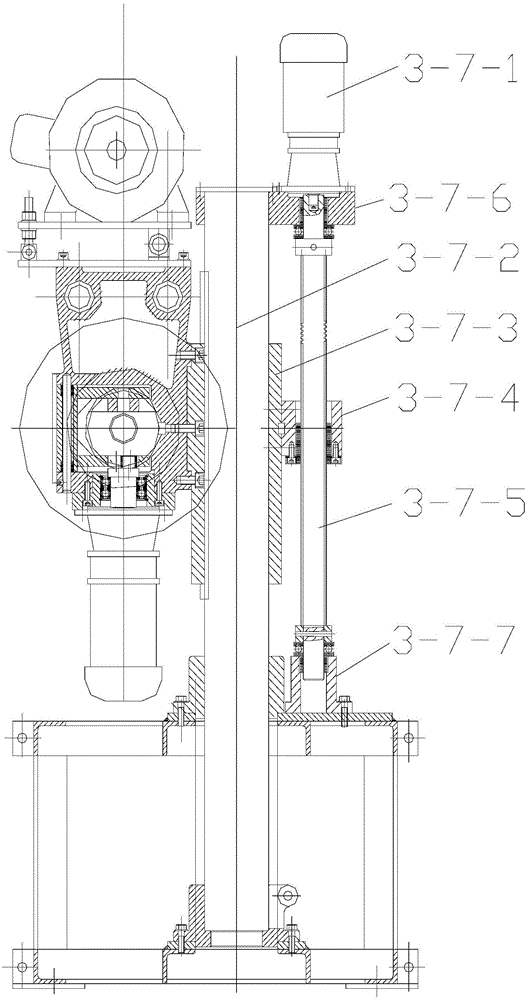

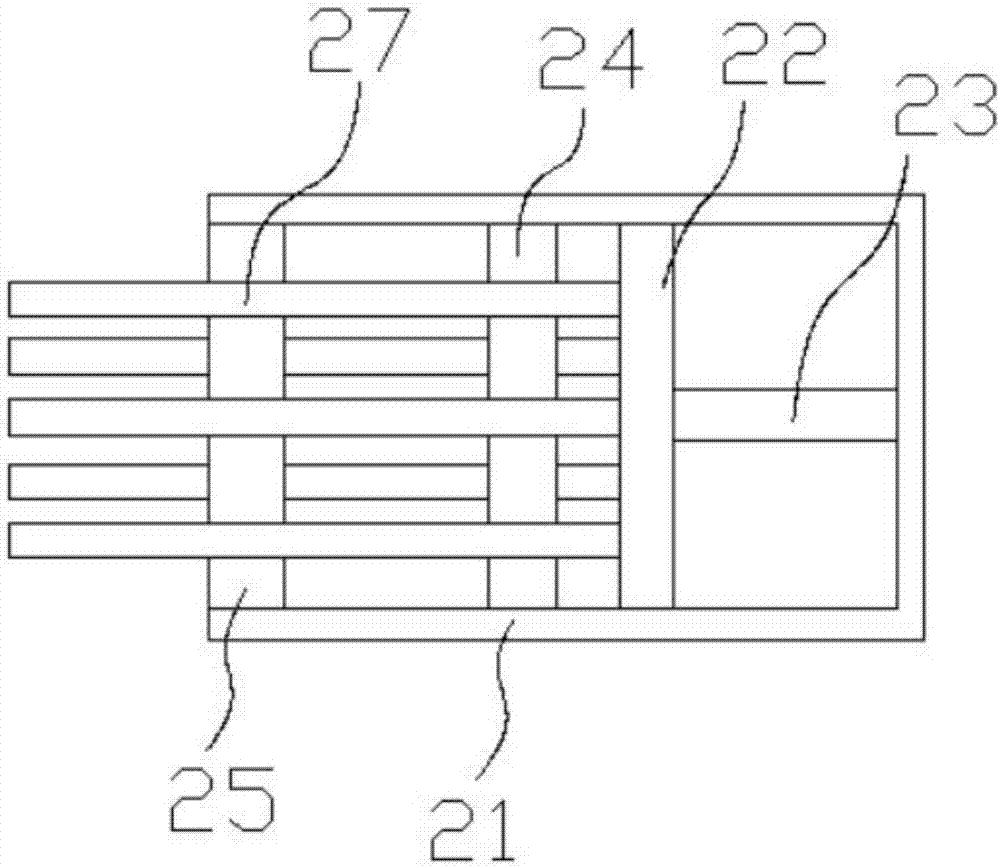

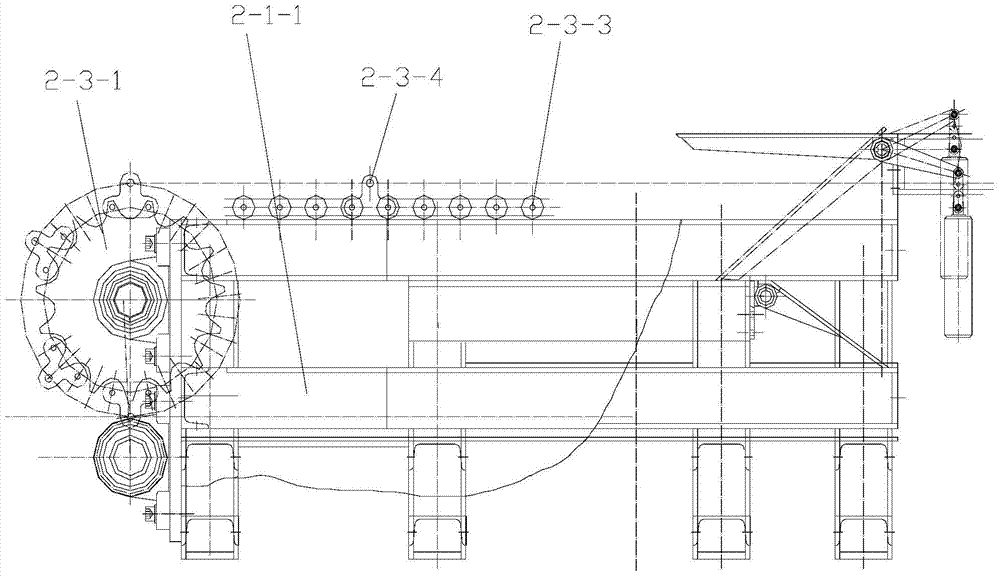

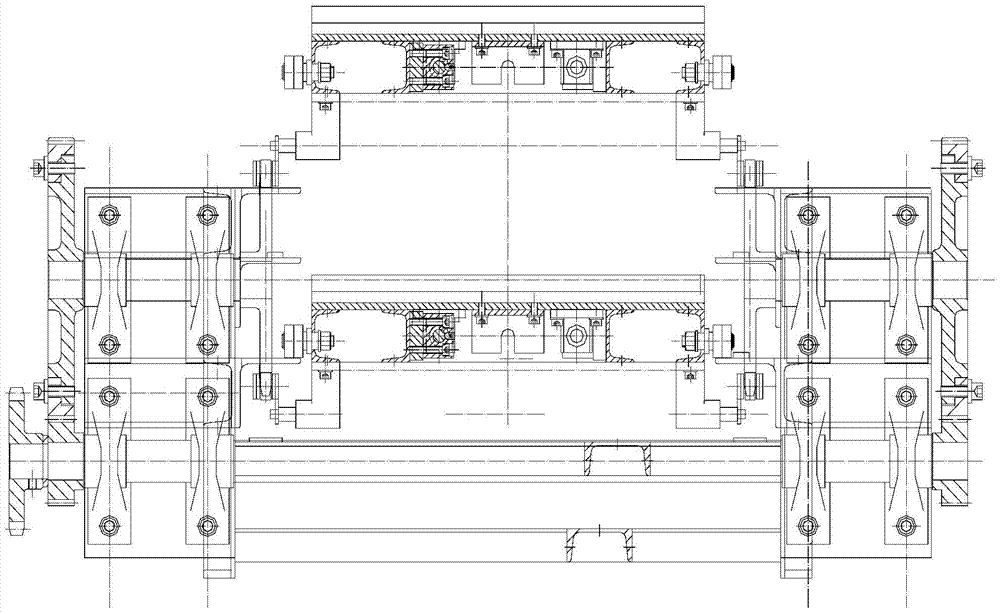

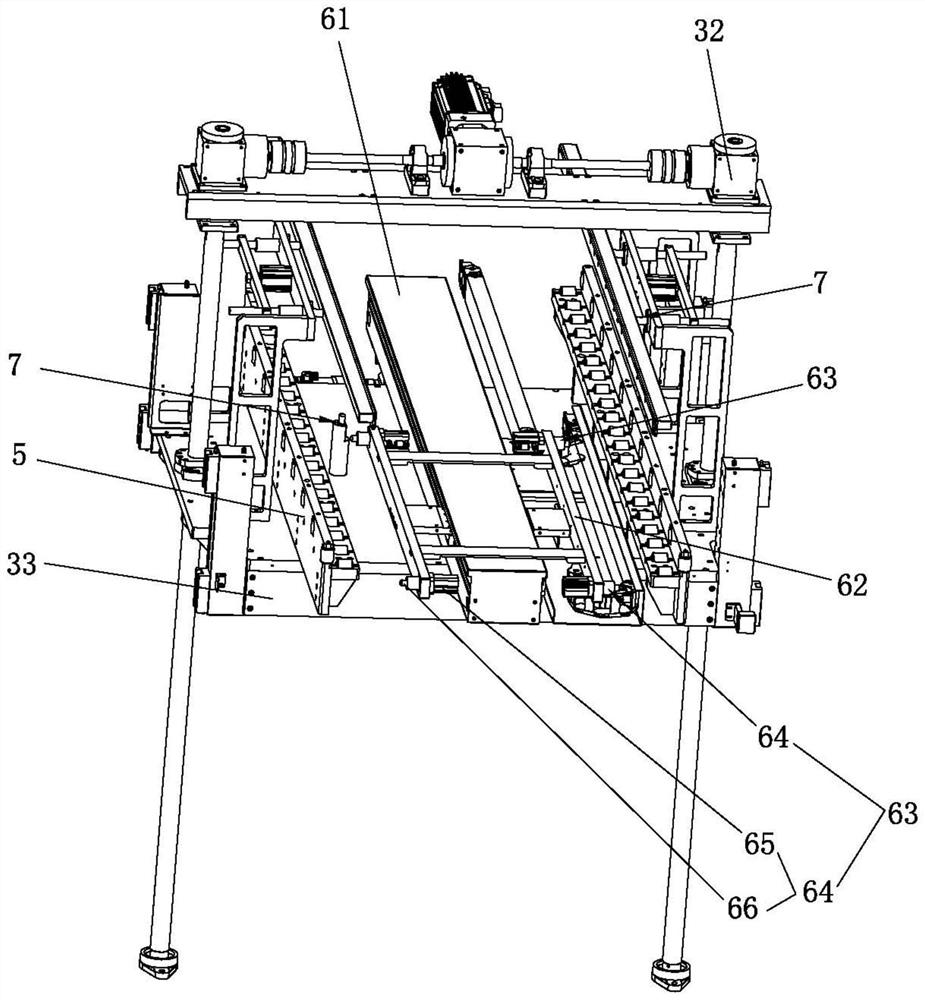

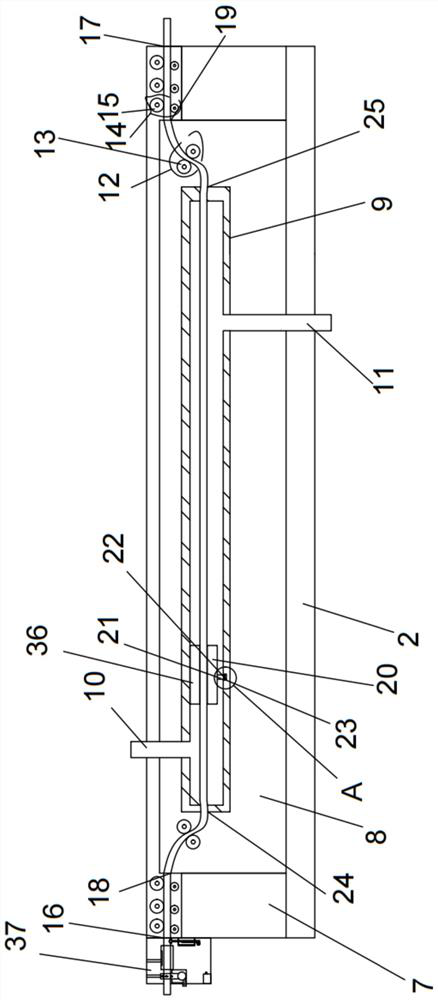

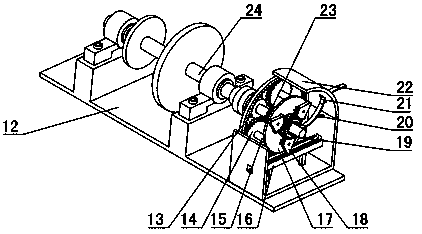

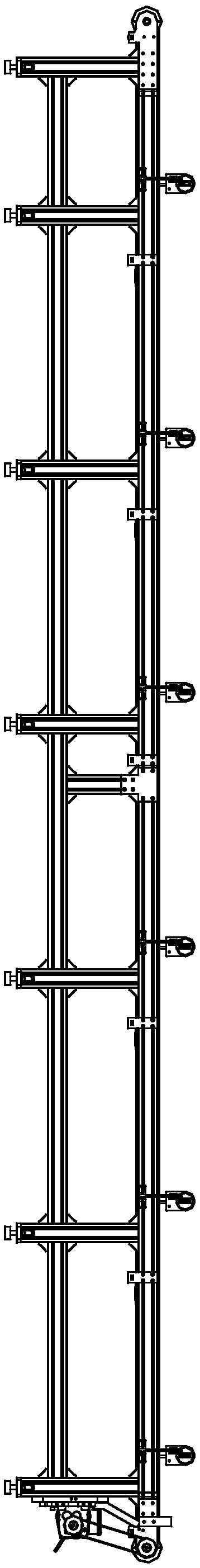

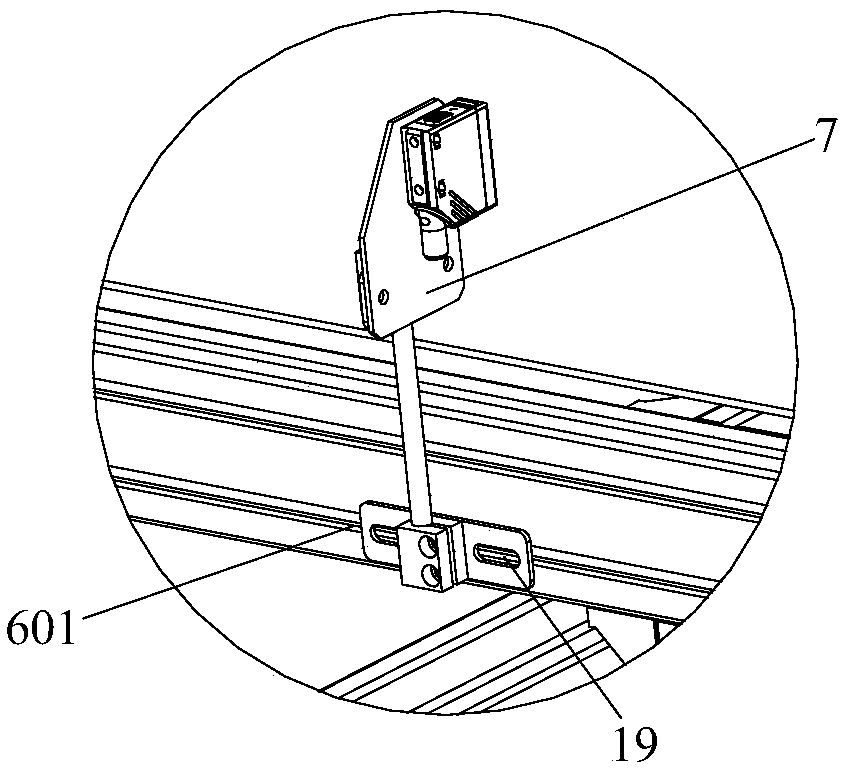

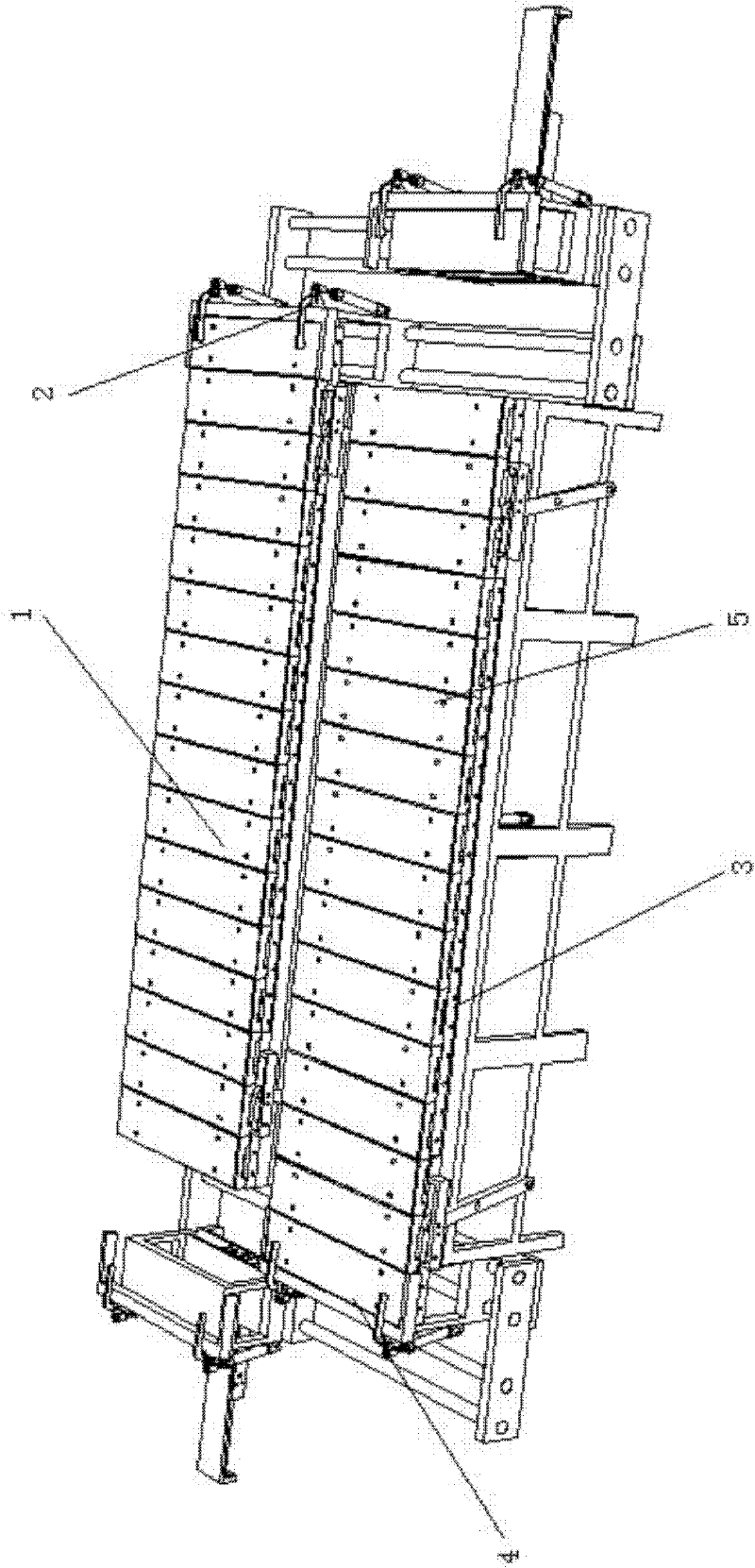

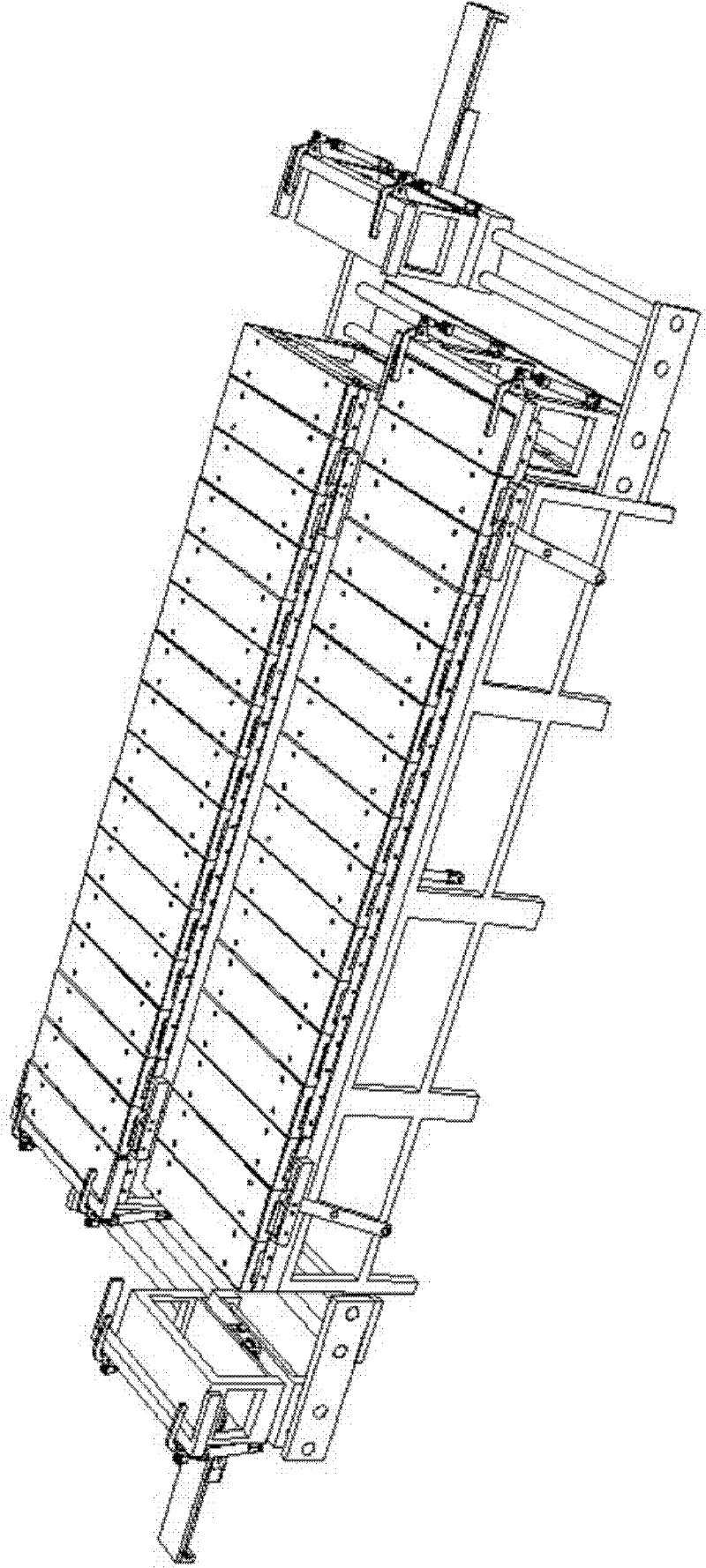

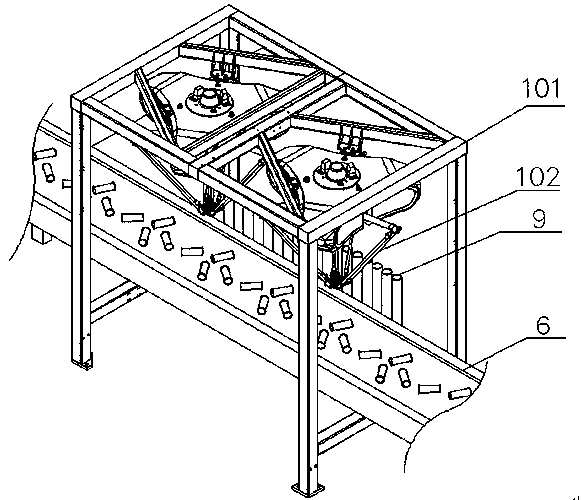

Circulating conveying device for materials

The invention relates to a circulating conveying device for materials, and belongs to the technical field of conveying devices. The circulating conveying device comprises a conveying frame, a conveying trolley which comprises front wheel and a rear wheel and is used for carrying materials, a chain transmission mechanism pulling the front end of the conveying trolley, a motor for driving the conveying trolley to horizontally move anticlockwise in a plane through the chain transmission mechanism, an upper guide rail, a lower guide rail, a front middle guide rail, a rear middle guide rail, a rear sinking guide rail, a front upper skew bridge, a front lower skew bridge, a rear lower skew bridge, a rear lower skew slope, a rear upper skew bridge and a rear upper valve, wherein the upper guide rail, the lower guide rail, the front middle guide rail, the rear middle guide rail and the rear sinking guide rail are horizontally installed on the conveying frame and used for supporting the rear wheel of the conveying trolley, and the front upper skew bridge, the front lower skew bridge, the rear lower skew bridge, the rear lower skew slope, the rear upper skew bridge and the rear upper valve are installed on the conveying frame. The circulating conveying device has the beneficial effects that the structure is ingenious, operation is convenient, the conveying trolley can horizontally move to conduct transportation in the vertical plane in a circulating manner, and the materials can be conveyed in a circulating manner.

Owner:PEARL RIVER PIANO GROUP

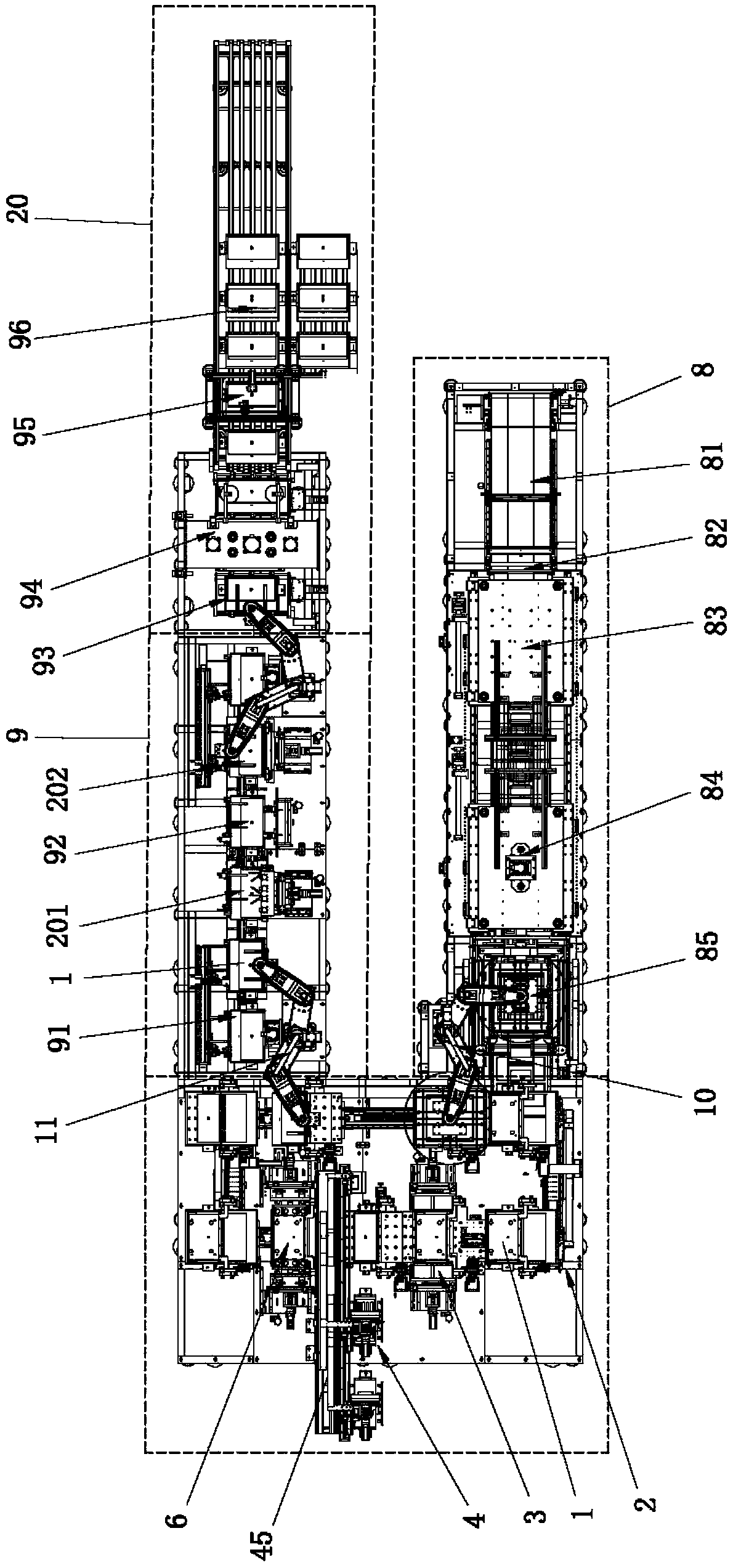

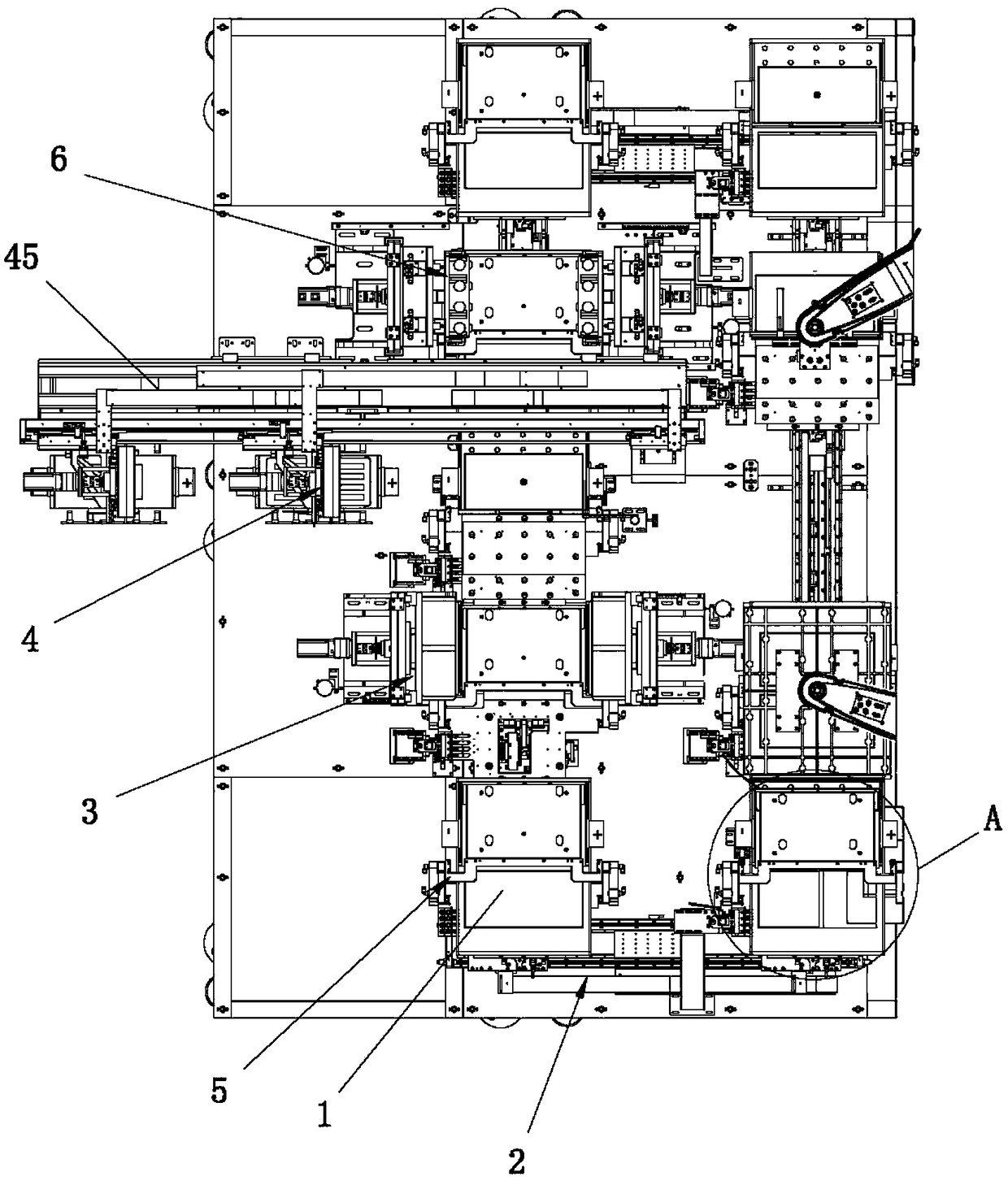

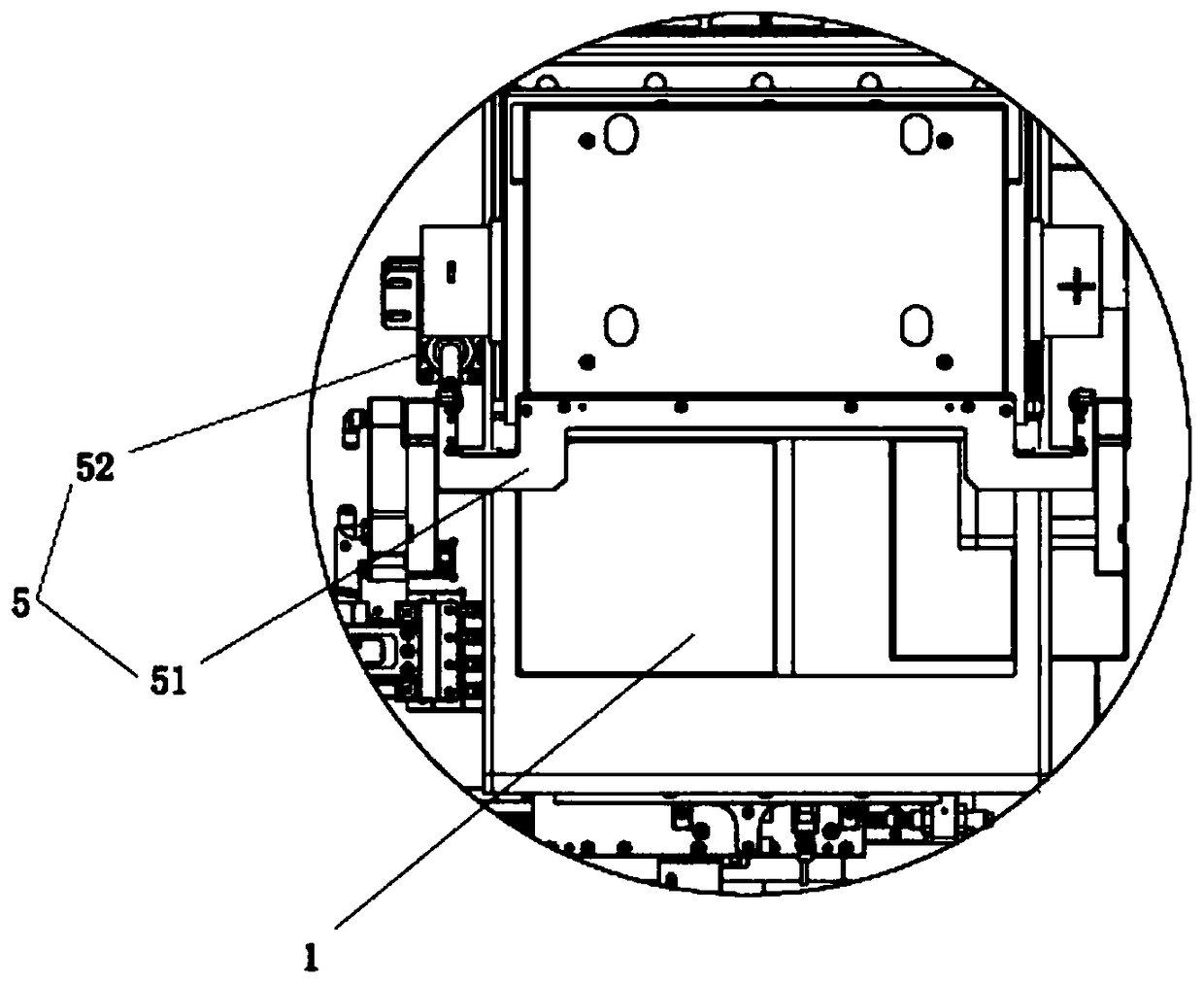

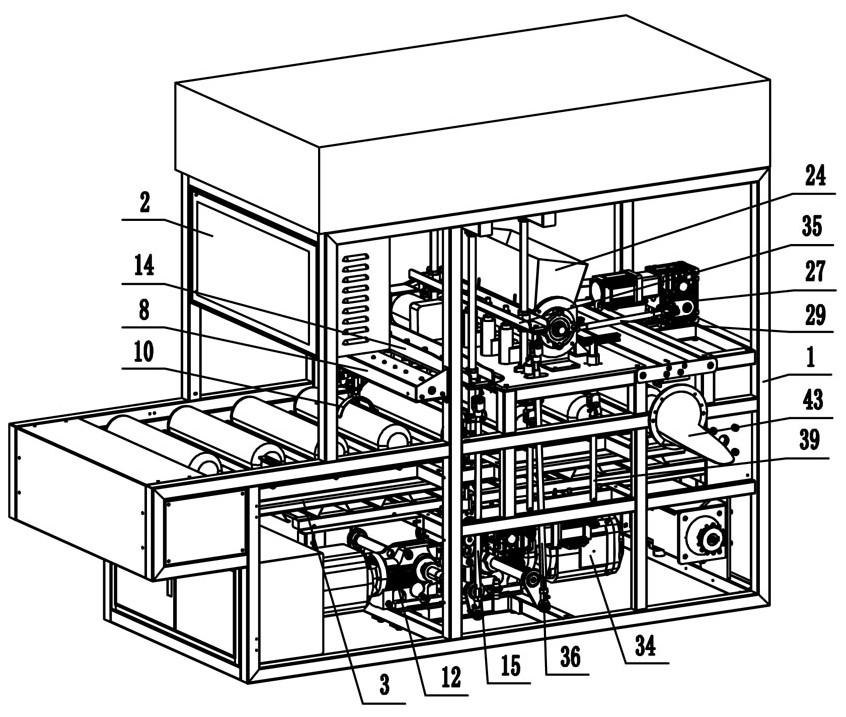

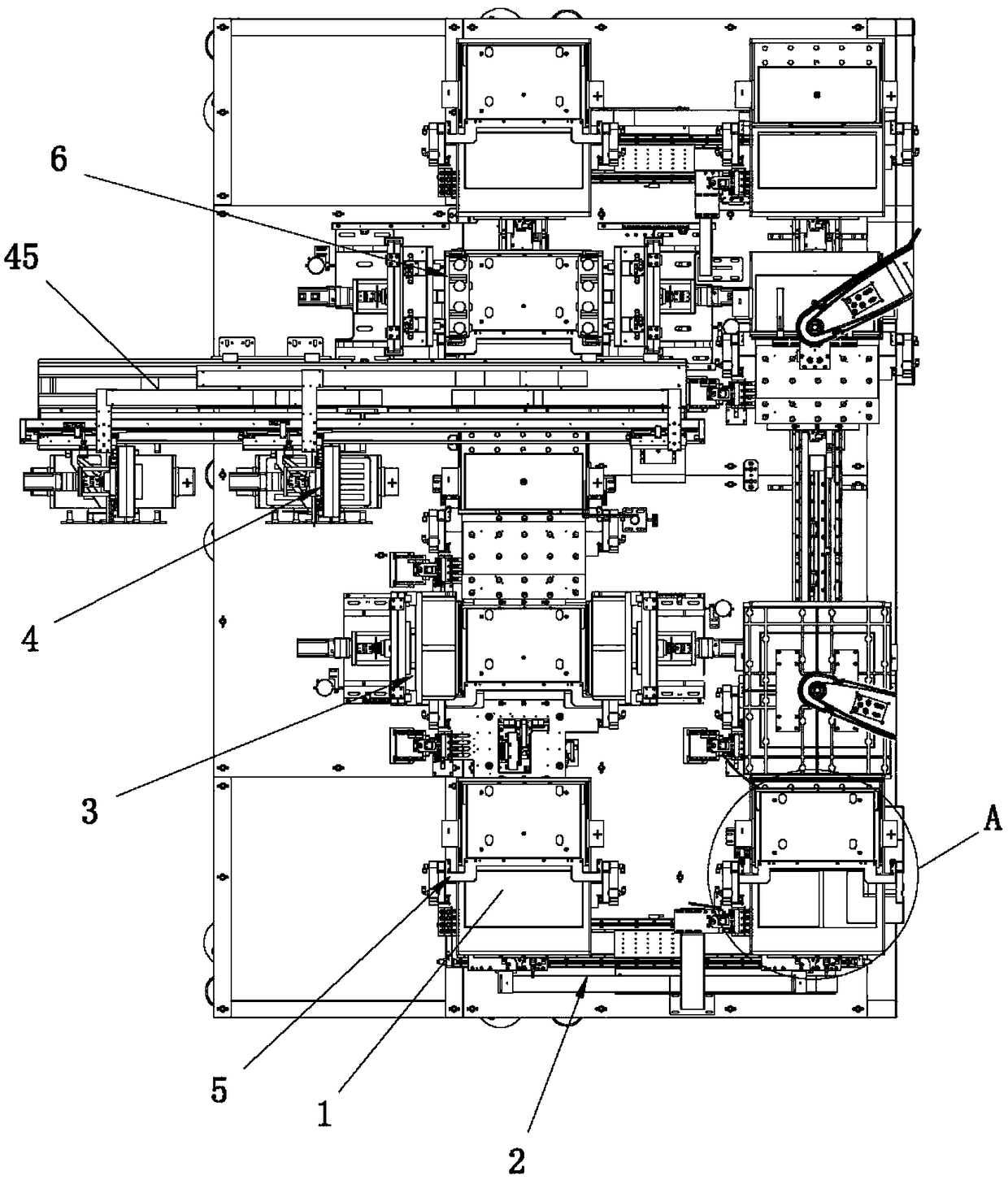

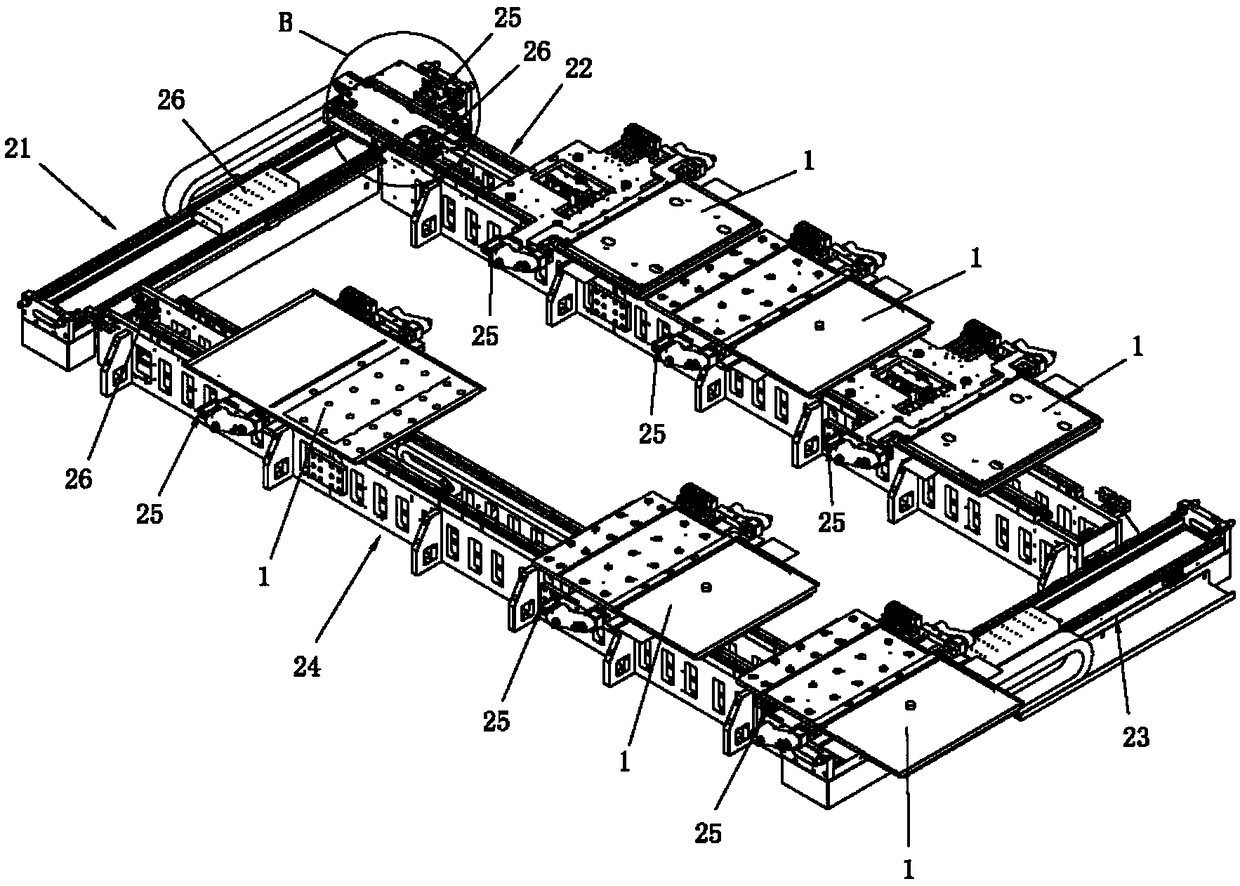

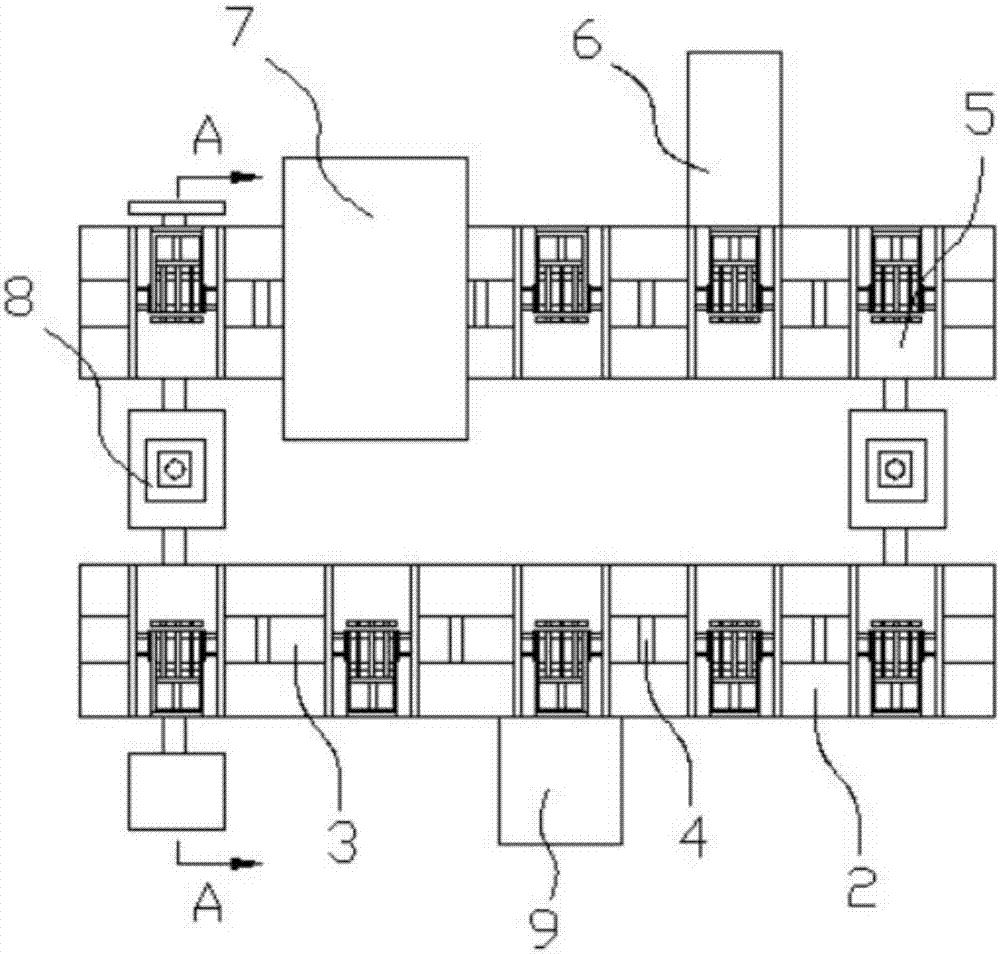

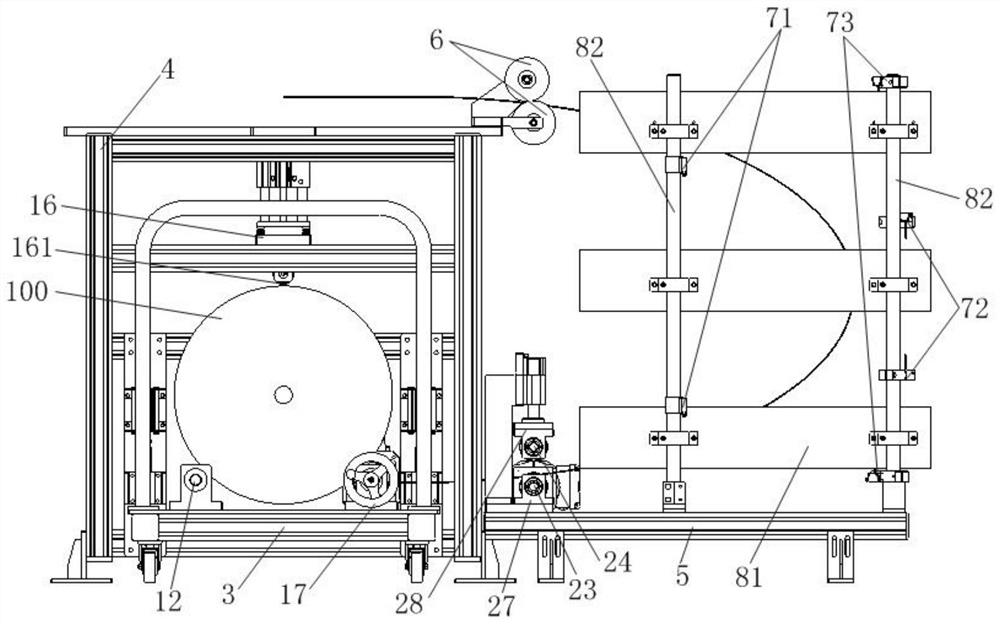

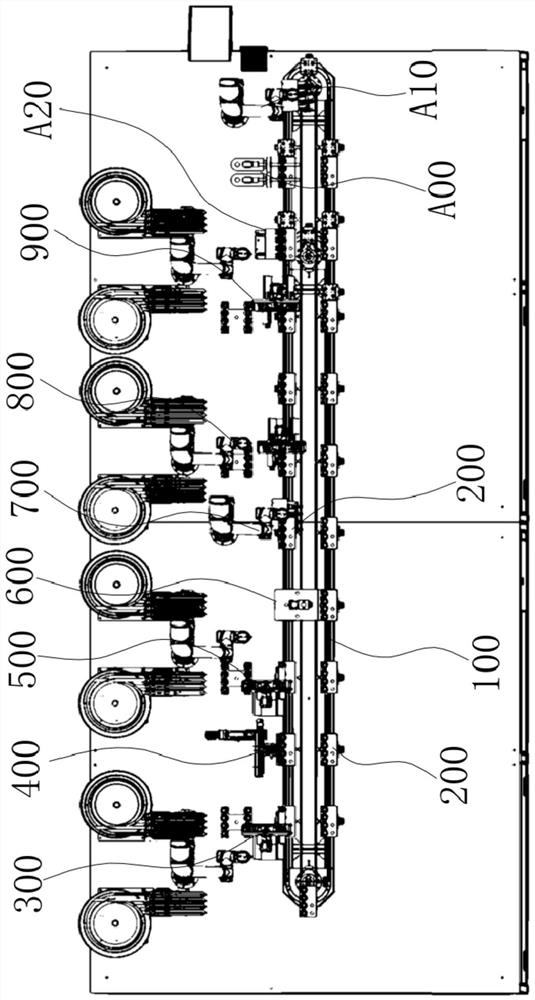

Soft package power battery production line

PendingCN109509906APromote circulationRealize circular conveyingAssembling battery machinesFinal product manufacturePlastic filmPower battery

The invention relates to the technical field of battery production and in particular relates to a soft package power battery production line. The soft package power battery production line comprises abattery packaging circulating section, an aluminum-plastic film molding feeding section, a battery blanking circulating section and a battery blanking testing section, wherein an aluminum-plastic film shell molded by the aluminum-plastic film molding feeding section is conveyed to the battery packaging circulating section through a feeding mechanical arm; a battery packaged by the battery packaging circulating section is conveyed to the battery blanking circulating section through a blanking mechanical arm; the battery packaging circulating section comprises a circulating conveying device, and an edge cutting device, a material taking and discharging device, a folding mechanism and a packaging device which are arranged around the circulating conveying device respectively; the folding mechanism is arranged on a positioning jig. The soft package power battery production line is compact in structure and the automation degree of a production line is improved; the circulating conveying device is of a square structure and is used for conveying the positioning jig; the occupied area is reduced and the efficiency and stability of packaging processing are also improved, so that the efficiency, stability and manufacturing precision for producing soft package power batteries are improved.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

Closed conveyor

InactiveCN106743145ARealize unloadingRealize circular conveyingConveyorsConveyor partsSteering wheelButt joint

The invention discloses a closed conveyor, relates to a material conveyor, and aims to solve the problems of incapability of realizing closed conveying and incapability of changing the conveying direction in a traditional belt conveyor. Left and right mounting frames are arranged in parallel; left and right side edges of a conveying belt are upwards turned and tightly bonded to form a pipe shape or a cylinder shape; and after the conveying belt is matched and connected with a conveying mechanism on the right mounting frame in sequence, the conveying belt is bypassed through a steering wheel from right to left, then, is matched and connected with a conveying mechanism on the left mounting frame, is gradually unfolded to bypass through an unloading roller from top to bottom, and is overturned up and down to seal with the back end for butt joint to form a closed loop. The conveying belt is kept in a sealed state to realize closed material conveying; the conveying distance is changed through changing the lengths of the mounting frames and the conveying belt; and the direction of the conveying belt is changed through adding an auxiliary steering wheel and adjusting the extending directions of the mounting frames to realize turning conveying or high-height-fall conveying or even vertical conveying. The closed conveyor is used for material conveying.

Owner:NANO PHARM TECH MACHINERY EQUIP

Mushroom stick inoculation machine

ActiveCN113317133AStable deliveryRealize circular conveyingLavatory sanitoryCultivating equipmentsProcess engineeringChain conveyor

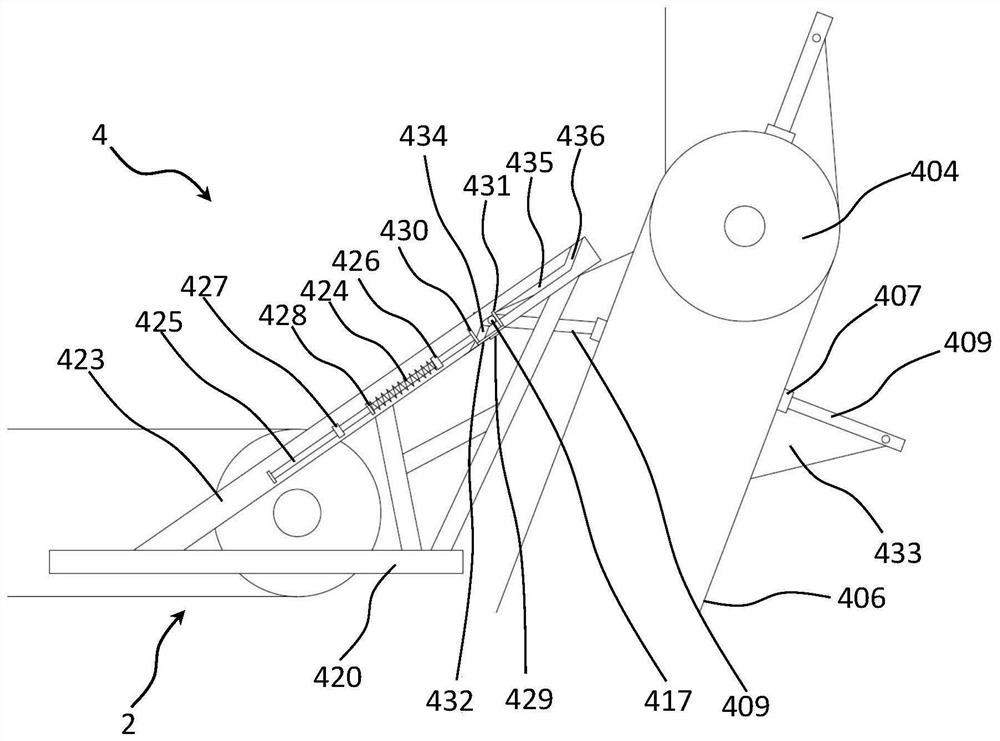

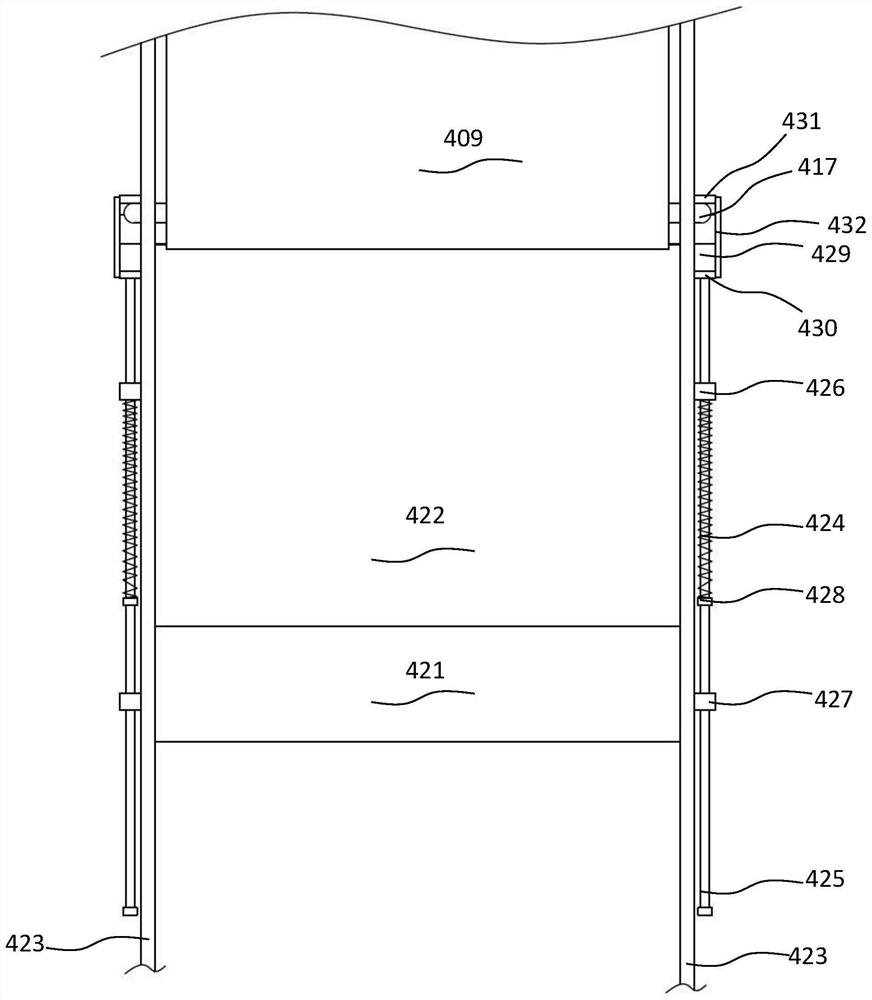

The invention relates to a mushroom stick inoculation machine. The mushroom stick inoculation machine comprises an inoculation rack, a control box, a mushroom stick conveying device, a disinfection device, a punching device, a seed pushing and injecting device, a flattening device and bag discharging devices, wherein the mushroom stick conveying device comprises a chain conveyor and a plurality of trays arranged on the chain conveyor; the disinfection device comprises a synchronous belt sliding table I, a disinfection support and an atomizing nozzle; the punching device comprises a punching mechanism and a bag pressing mechanism; the seed pushing and injecting device comprises a stirring charging barrel, an electric seed pushing mechanism and an electric seed injecting mechanism; the bag discharging devices are arranged on one side of the flattening device at intervals; bag outlet chutes are further arranged at the positions, corresponding to the bag discharging devices, of the two sides of the inoculation rack. The mushroom stick inoculation machine is pure electric equipment; compared with traditional pneumatic equipment, use of an air compressor is avoided, fluctuation of air source pressure does not need to be worried about, meanwhile, complex wiring of air pipelines and the like is avoided, transmission is conducted through a mechanical structure, the action process is visual and clear, overhaul and maintenance are convenient, and application and popularization can be achieved.

Owner:河南日星智能装备有限公司

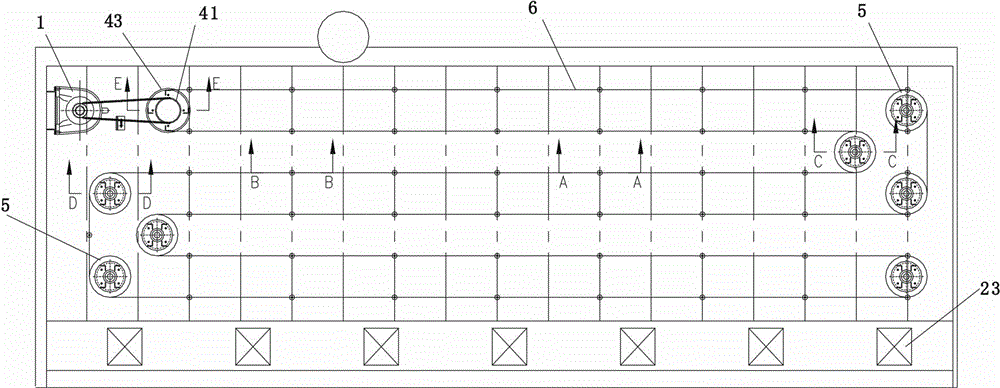

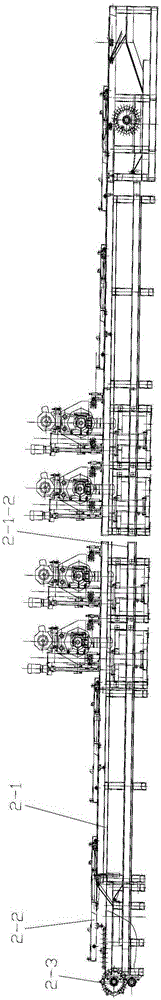

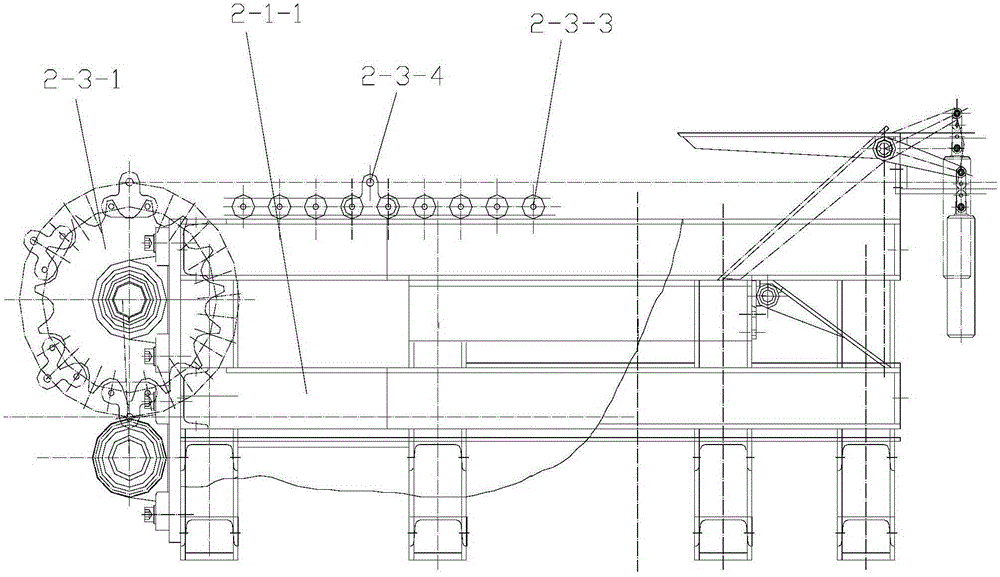

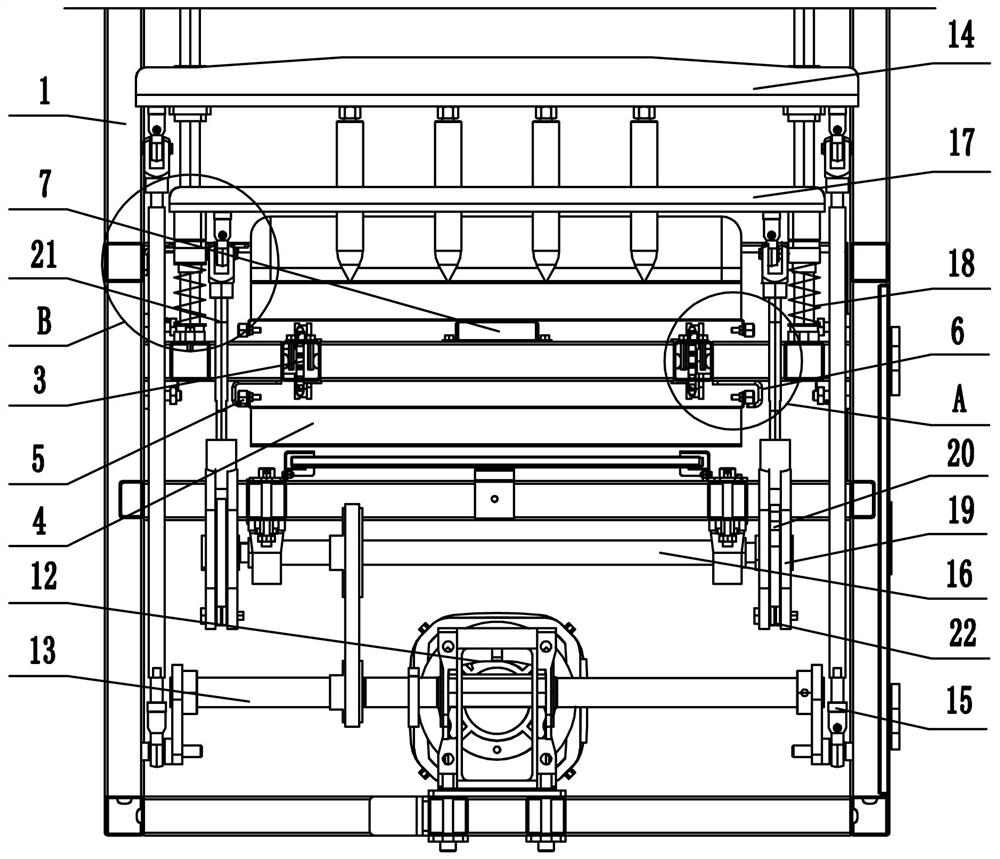

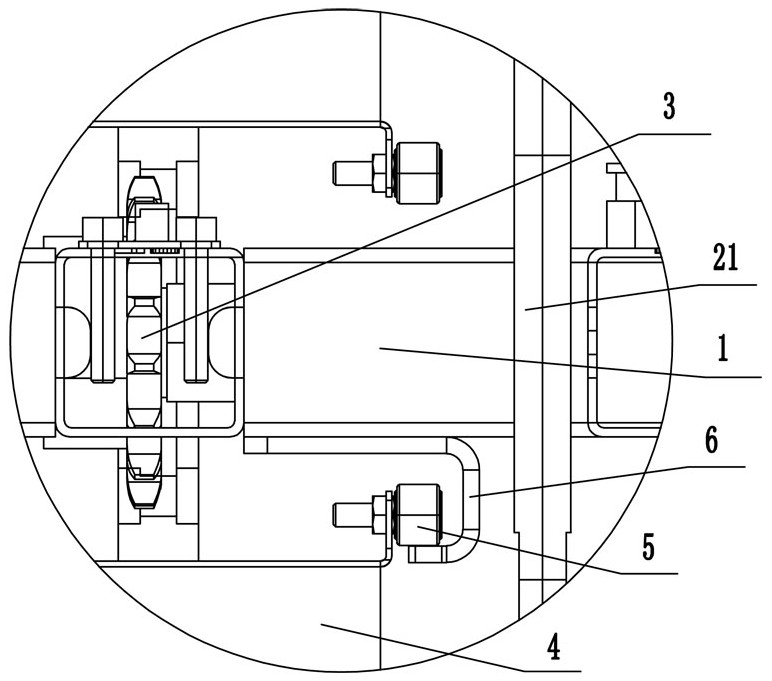

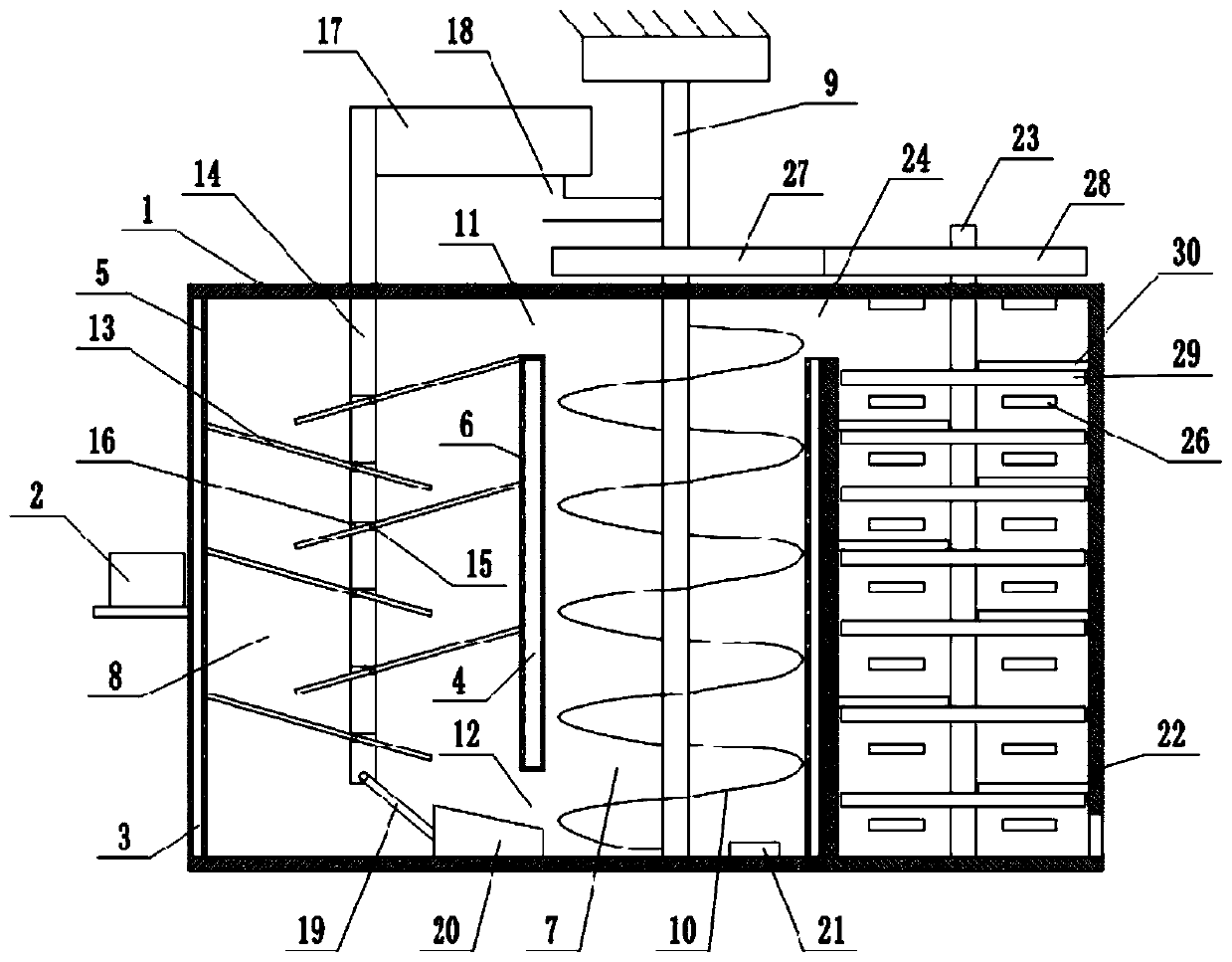

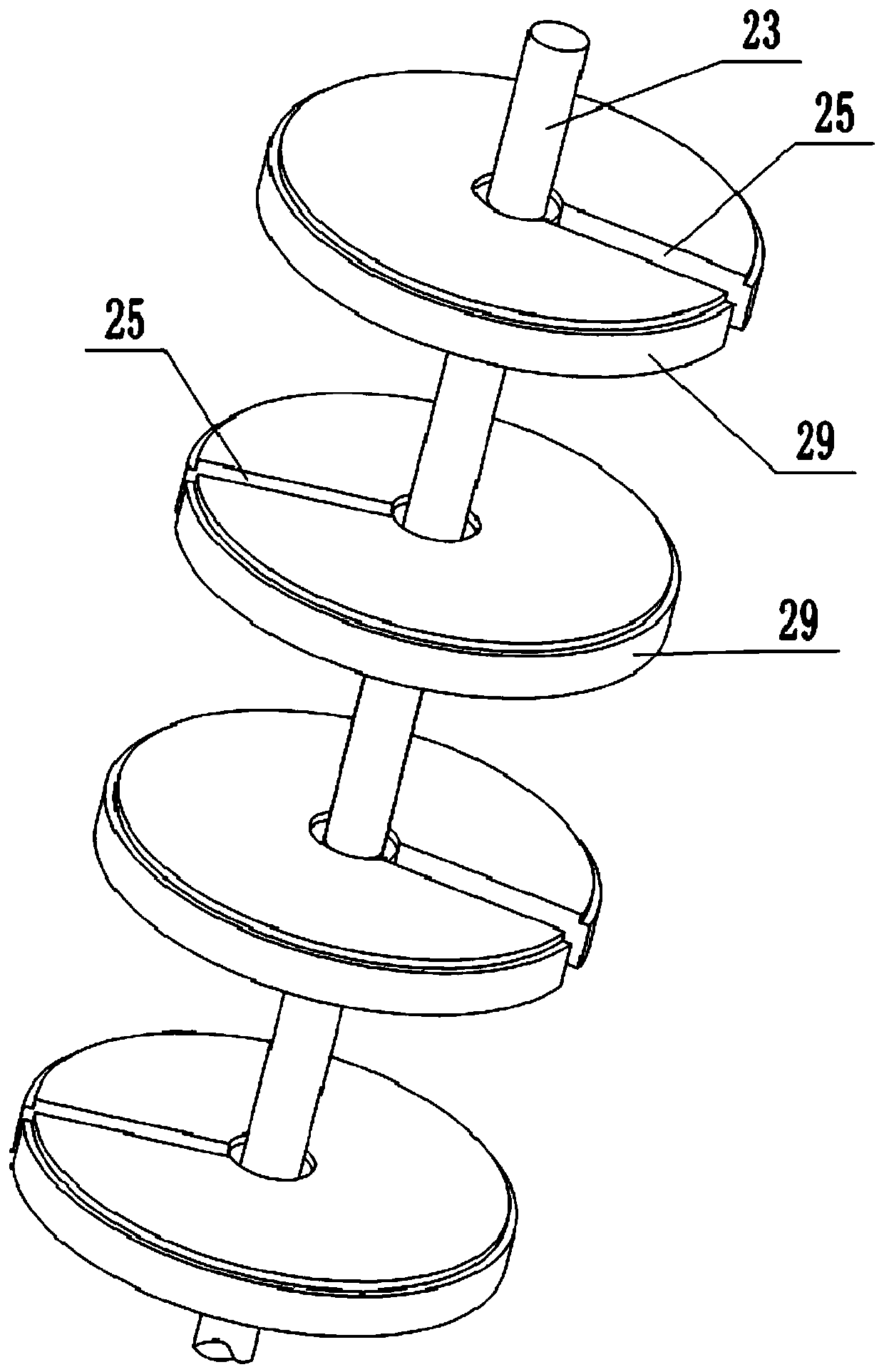

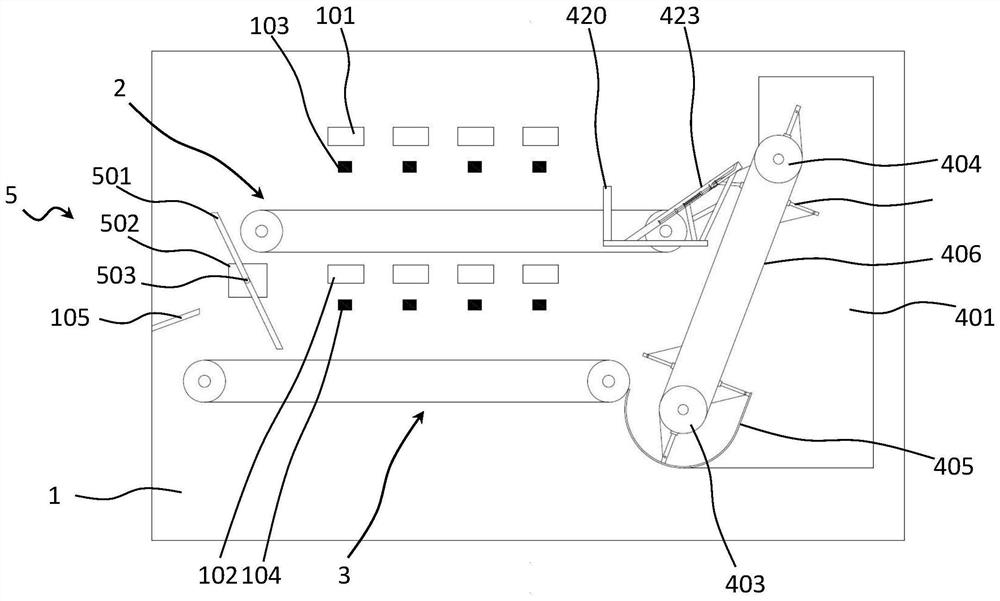

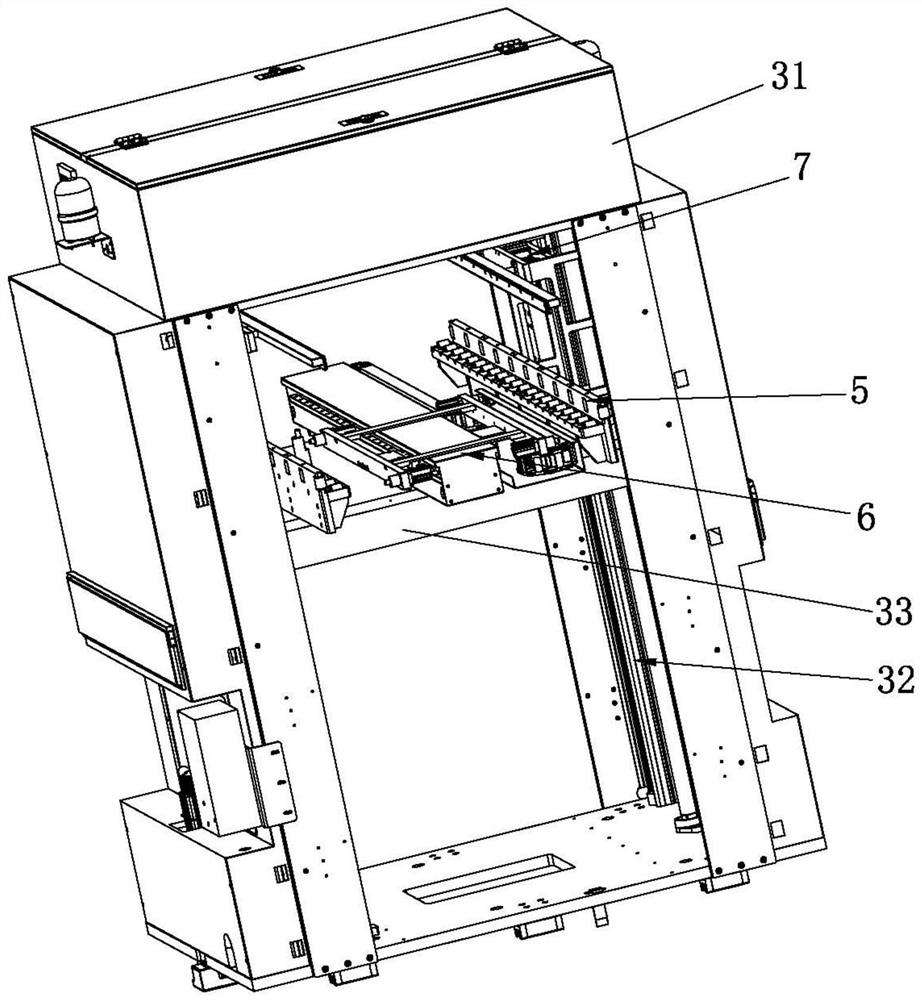

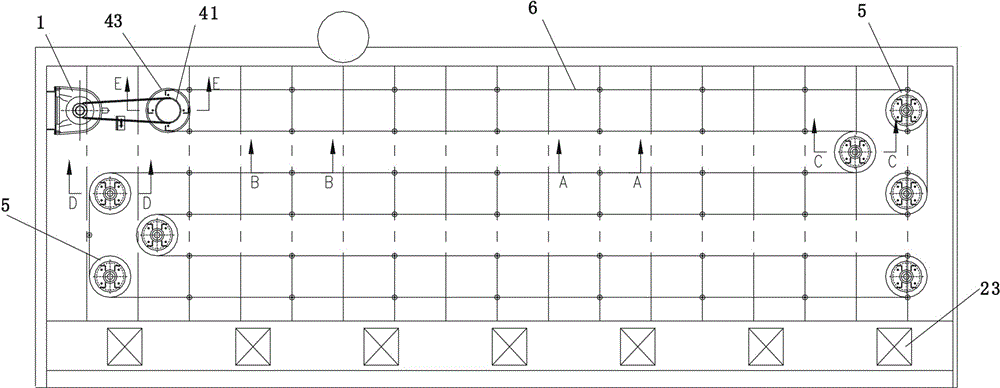

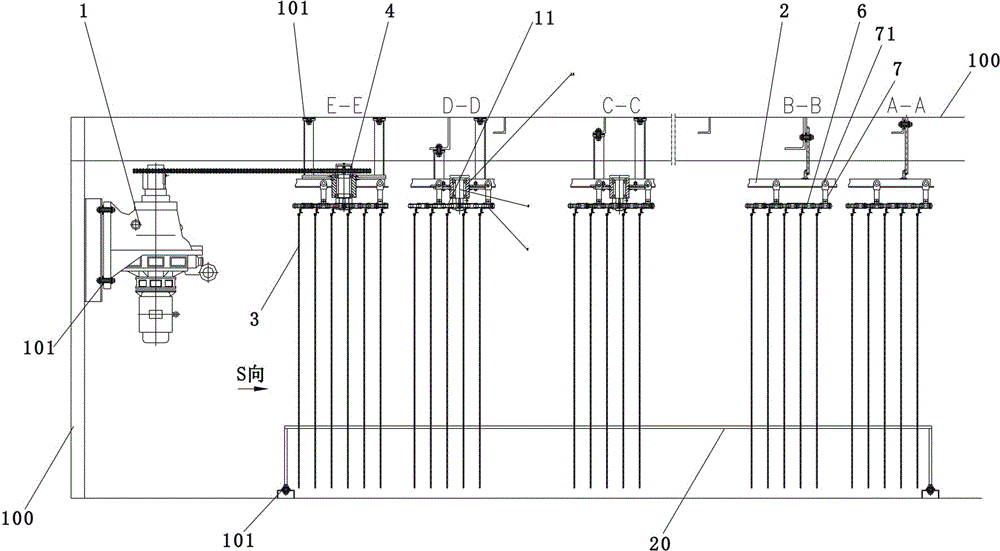

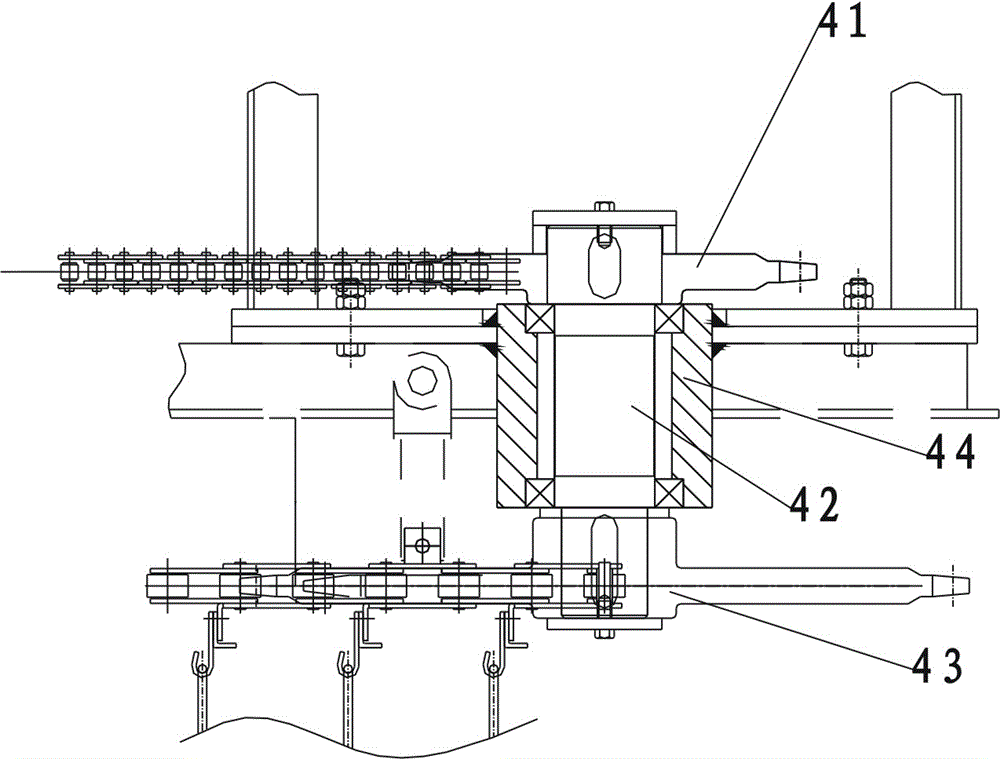

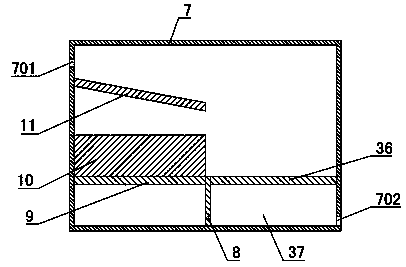

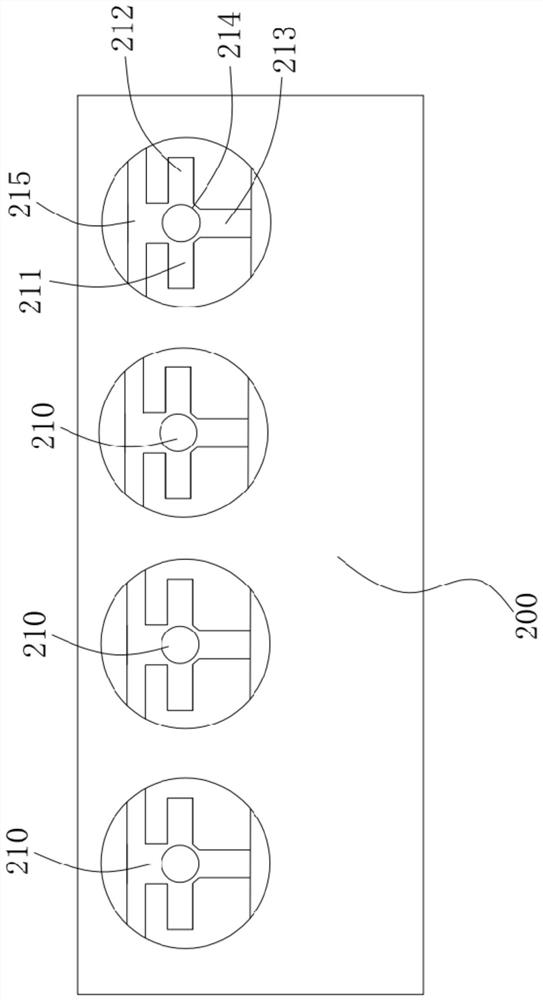

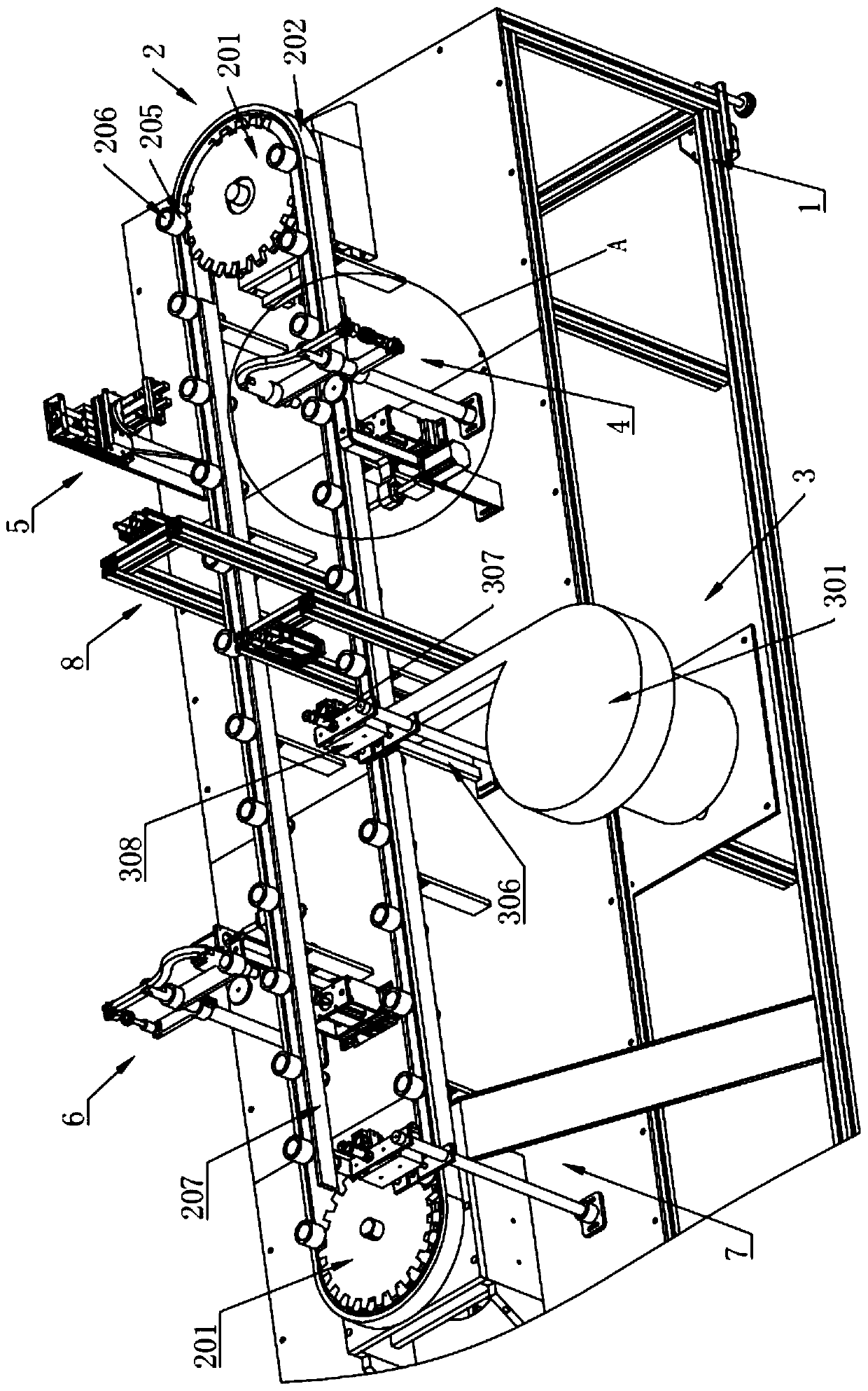

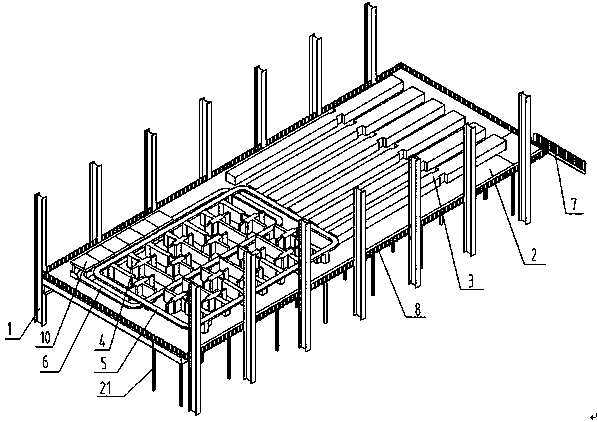

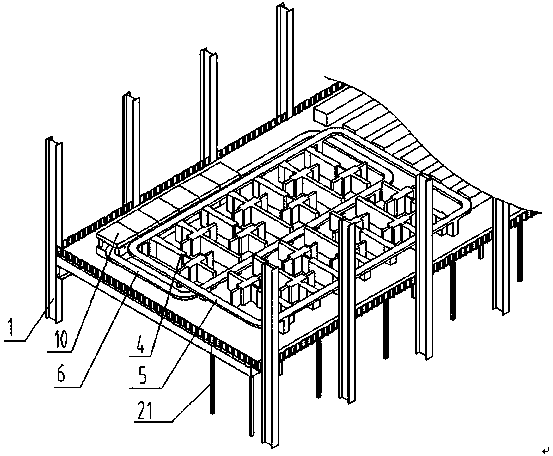

Piano plate polishing system

ActiveCN105150082AIngenious structureEasy to operateGrinding wheel securing apparatusPolishing machinesEngineeringSmall footprint

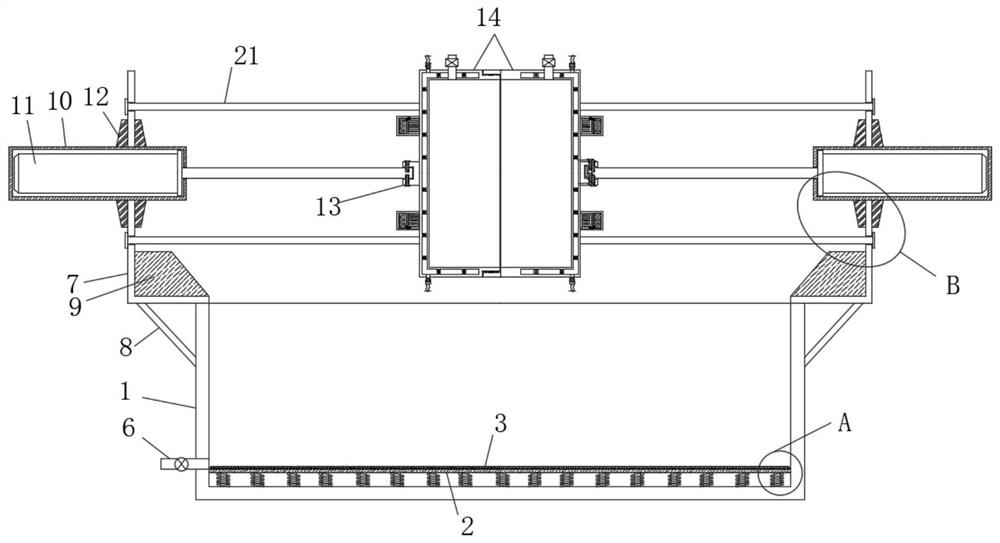

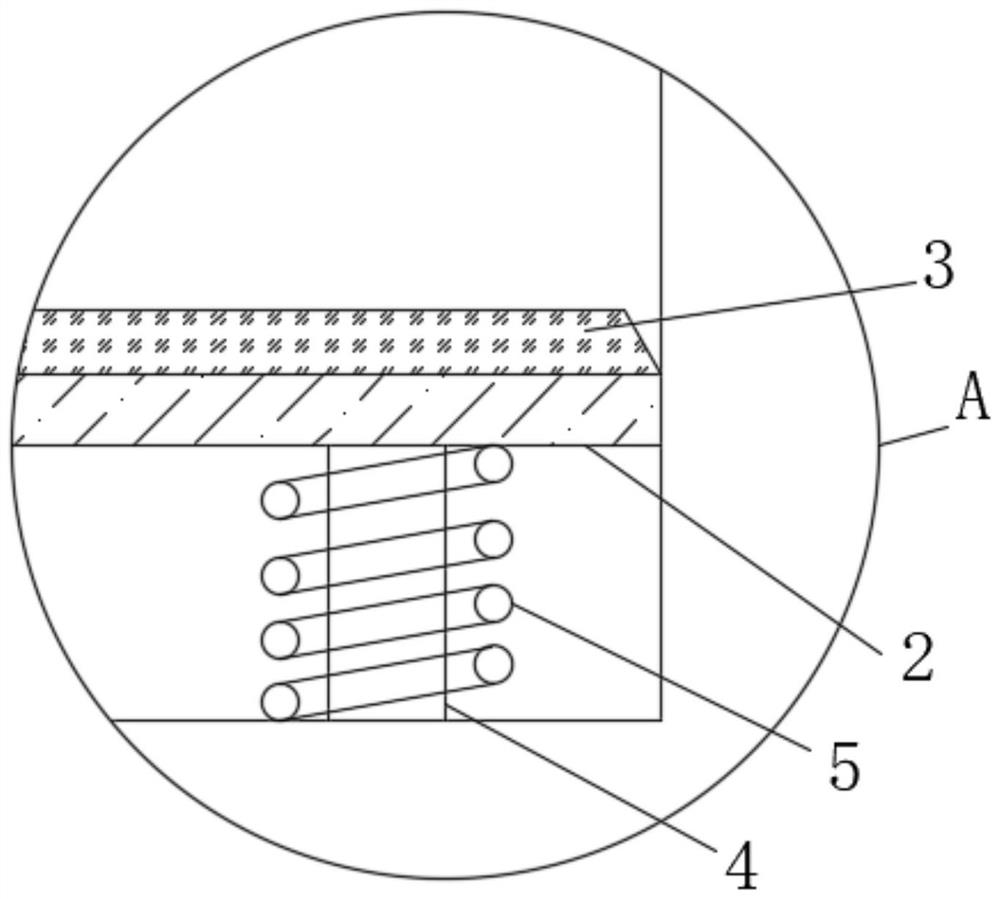

The invention belongs to the technical field of polishing equipment, and relates to a piano plate polishing system which comprises a material circulating conveying device and a plurality of polishing machines. The material circulating conveying device horizontally moves and circularly conveys horizontally-placed piano plates along a conveying line. The polishing machines polish the piano plates. The conveying line comprises an upper horizontal section, a front-end connecting section, a lower horizontal section and a rear-end connecting section which are sequentially arranged in the conveying direction. The rear-end connecting section is connected with the upper horizontal section. The lower horizontal section is located under the lower horizontal section. The multiple polishing machines are sequentially arranged along the upper horizontal section. The piano plate polishing system has the advantages of being ingenious in structure, convenient to operate, small in occupied area and high in polishing efficiency.

Owner:PEARL RIVER PIANO GROUP

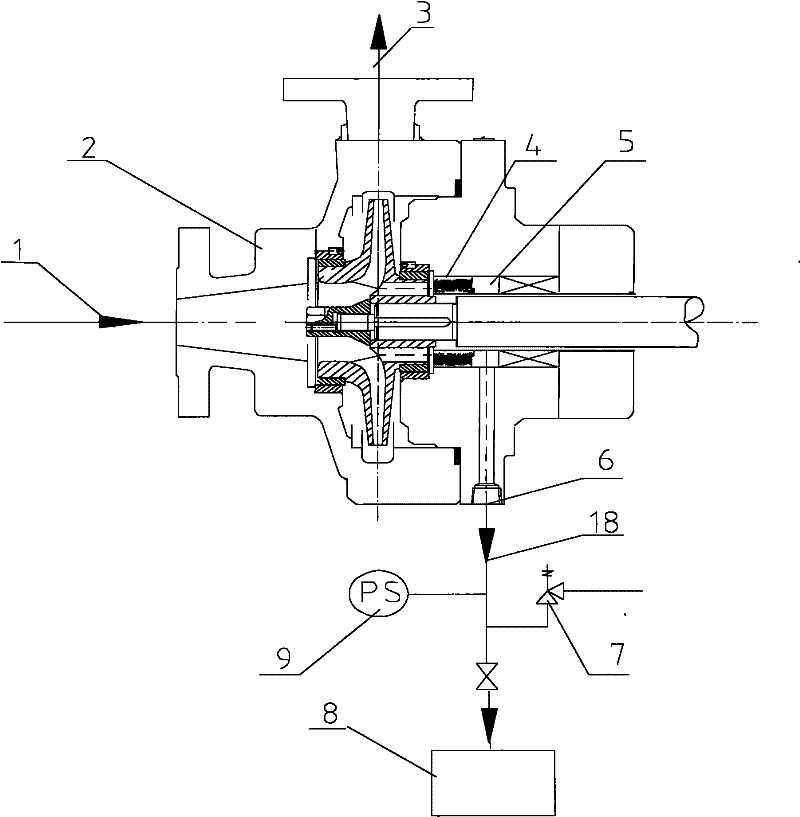

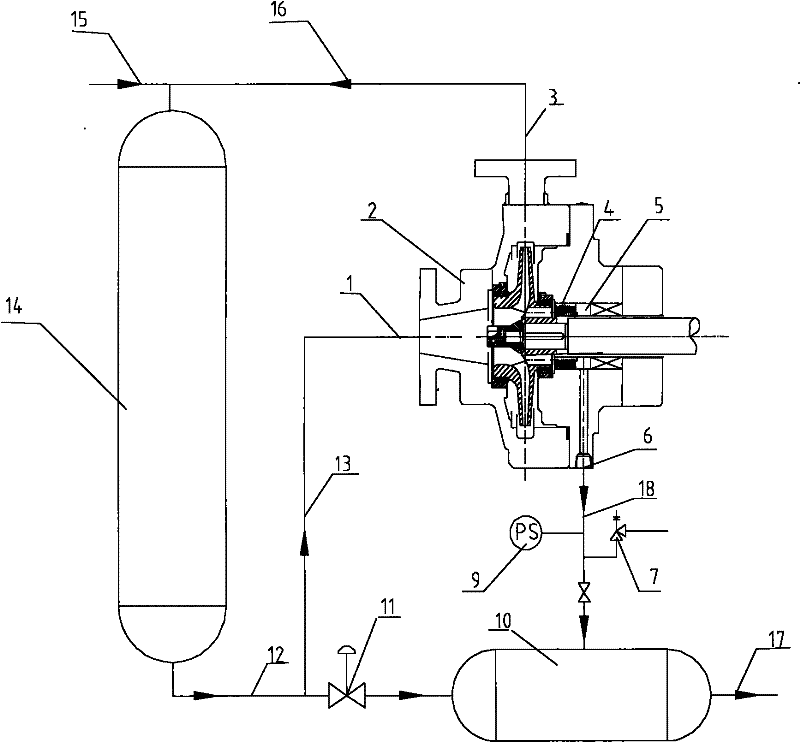

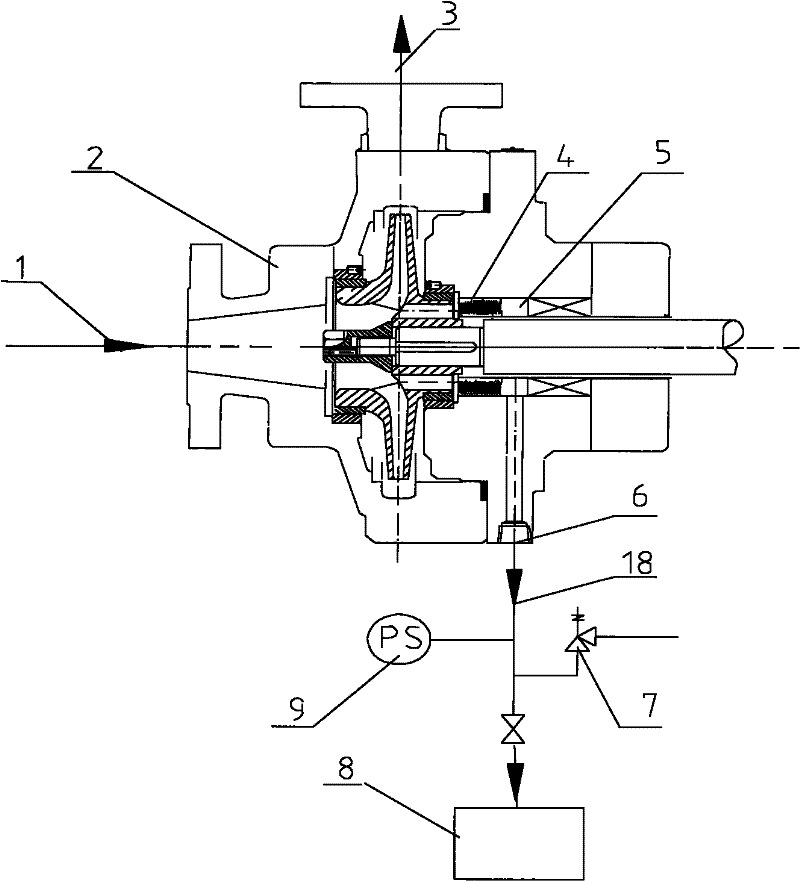

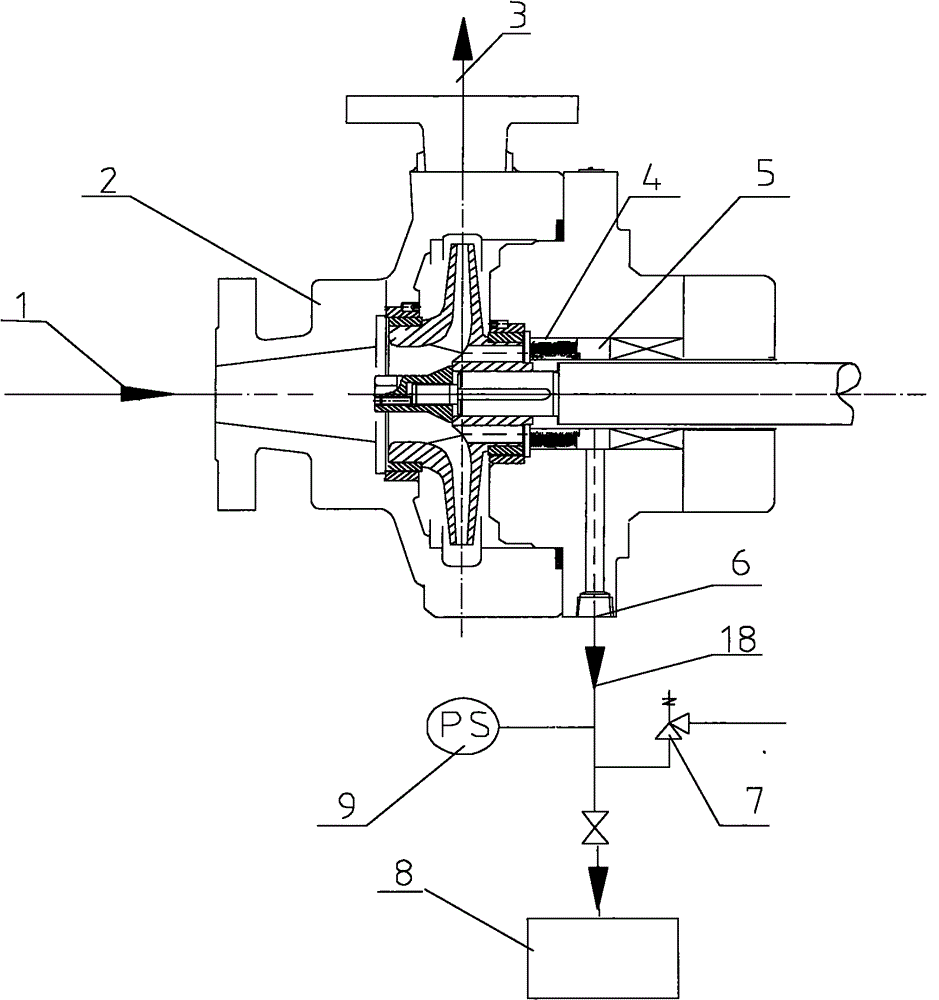

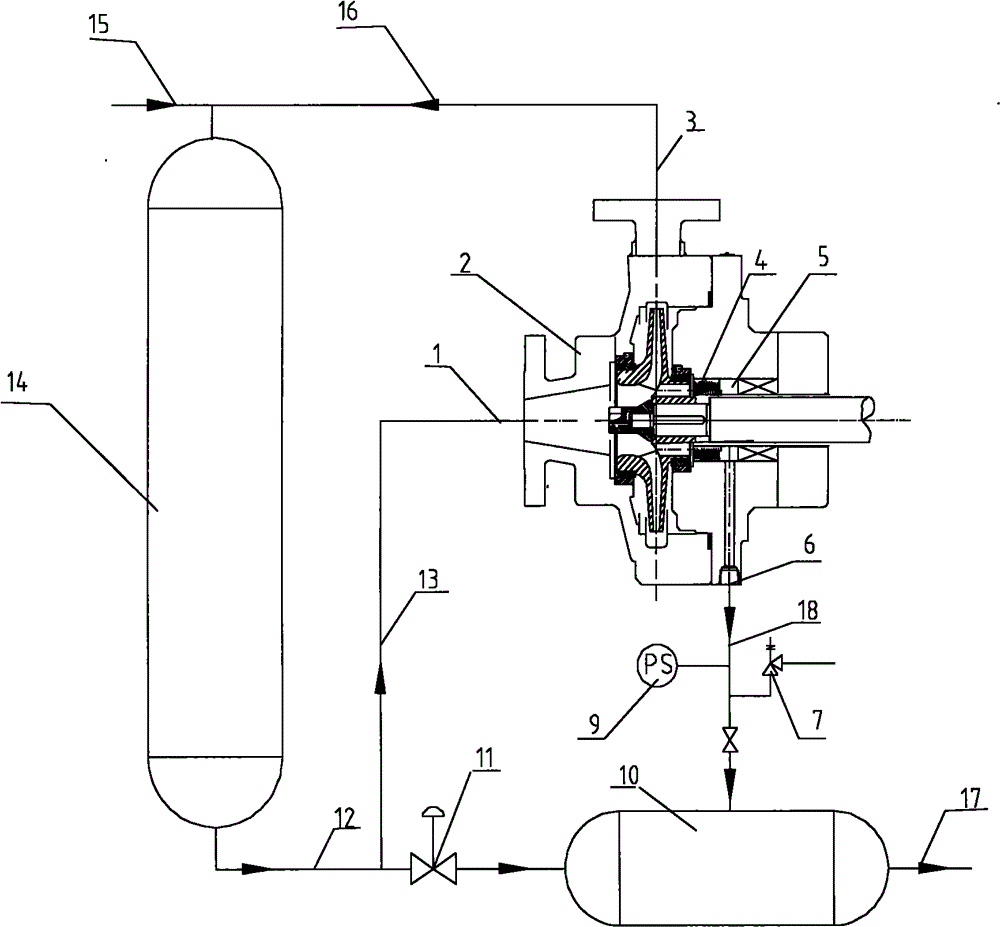

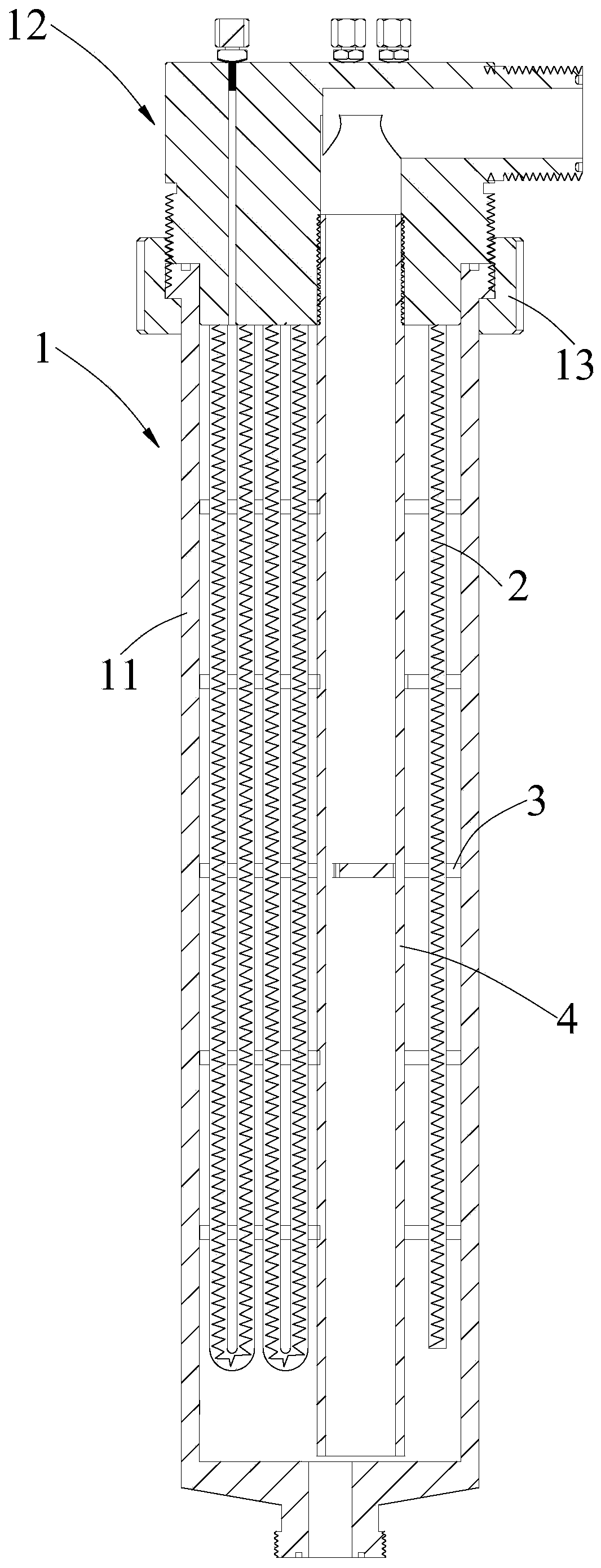

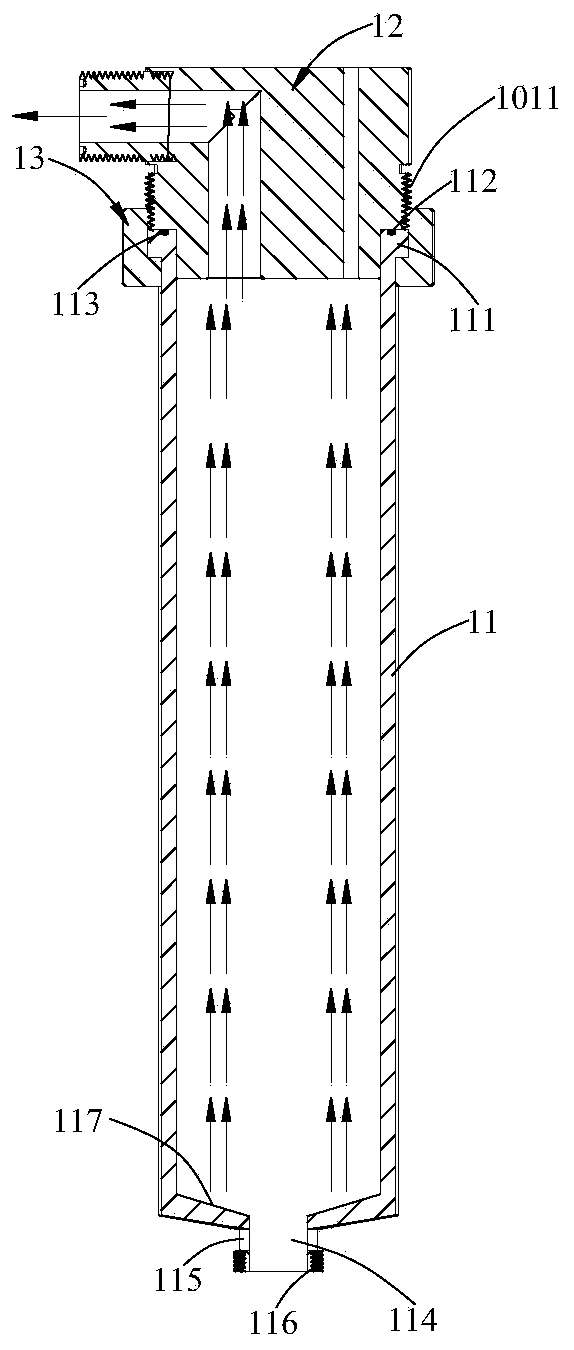

A method for reducing the pressure of pump sealing chamber

ActiveCN102269177ARealize circular conveyingRelieve pressureSpecific fluid pumpsPump componentsHigh pressure chamberHigh pressure

The invention discloses a method for reducing the pressure of a pump sealing cavity, which is characterized in that it comprises the following steps: 1) high-pressure fluid enters the pump body from the inlet of the pump, and is discharged from the pump body after being pressurized by the pump; The liquid discharged from the balance drum or throttling bush is led to the low-pressure container outside the pump body. The invention overcomes the problem that the prior art pump inlet and outlet are both high-pressure sealing chambers with high pressure and difficulty in sealing.

Owner:CHINA PETROCHEMICAL CORP +1

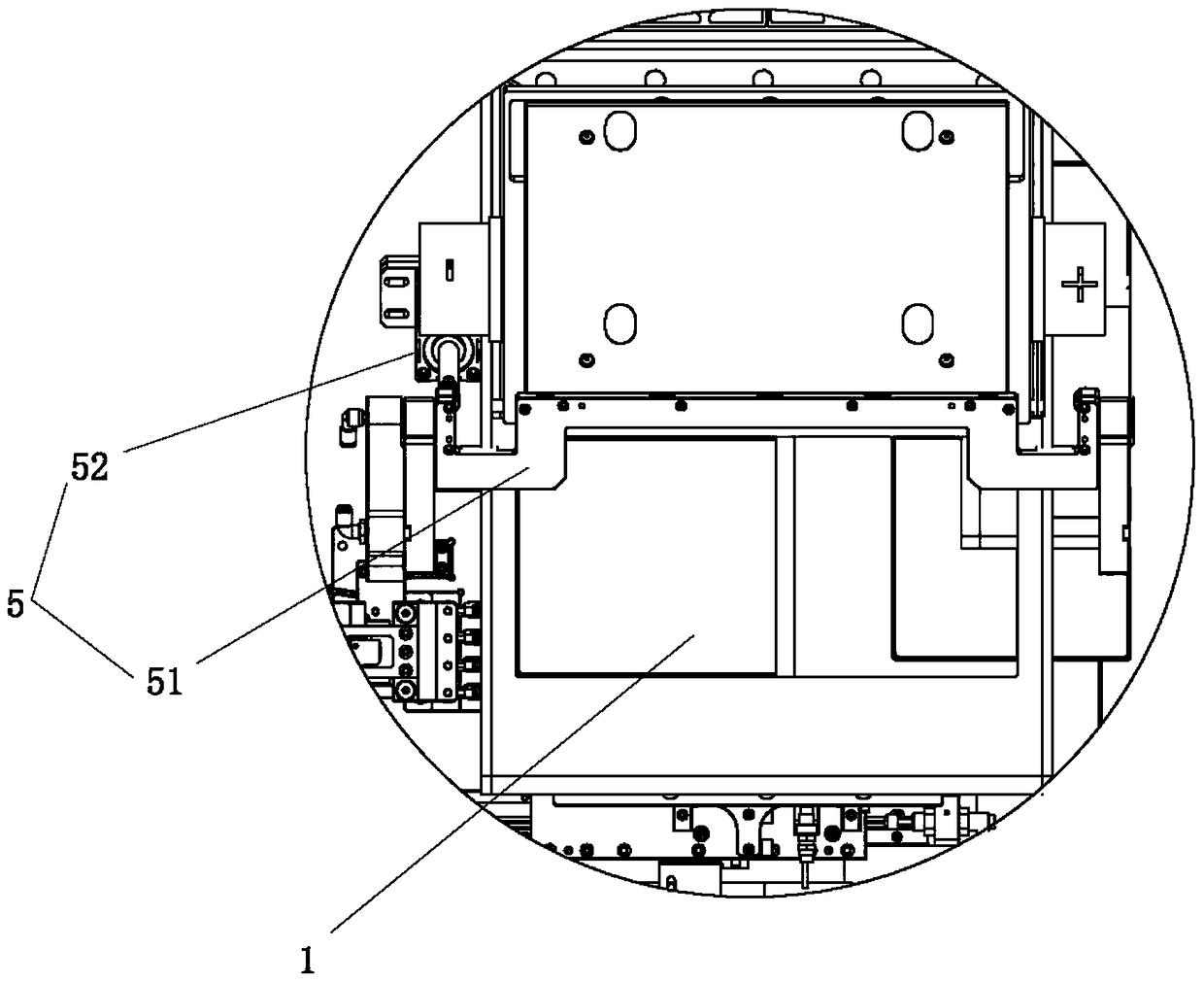

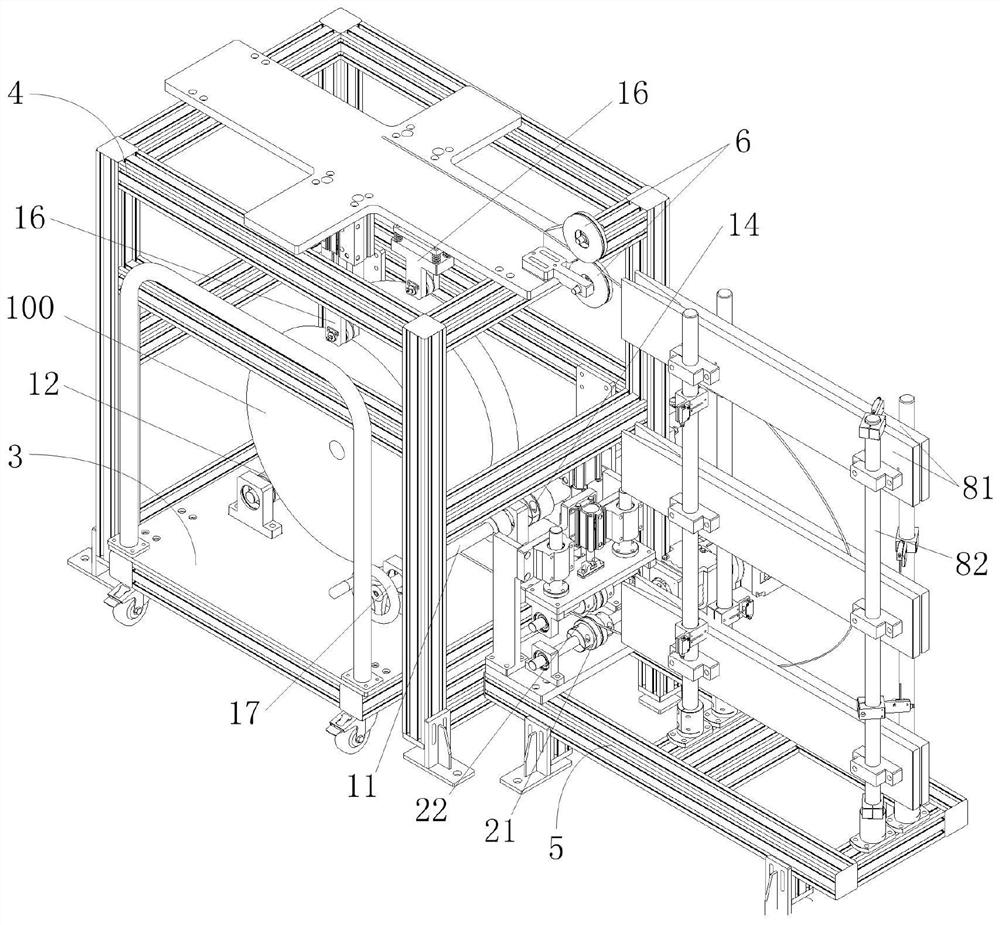

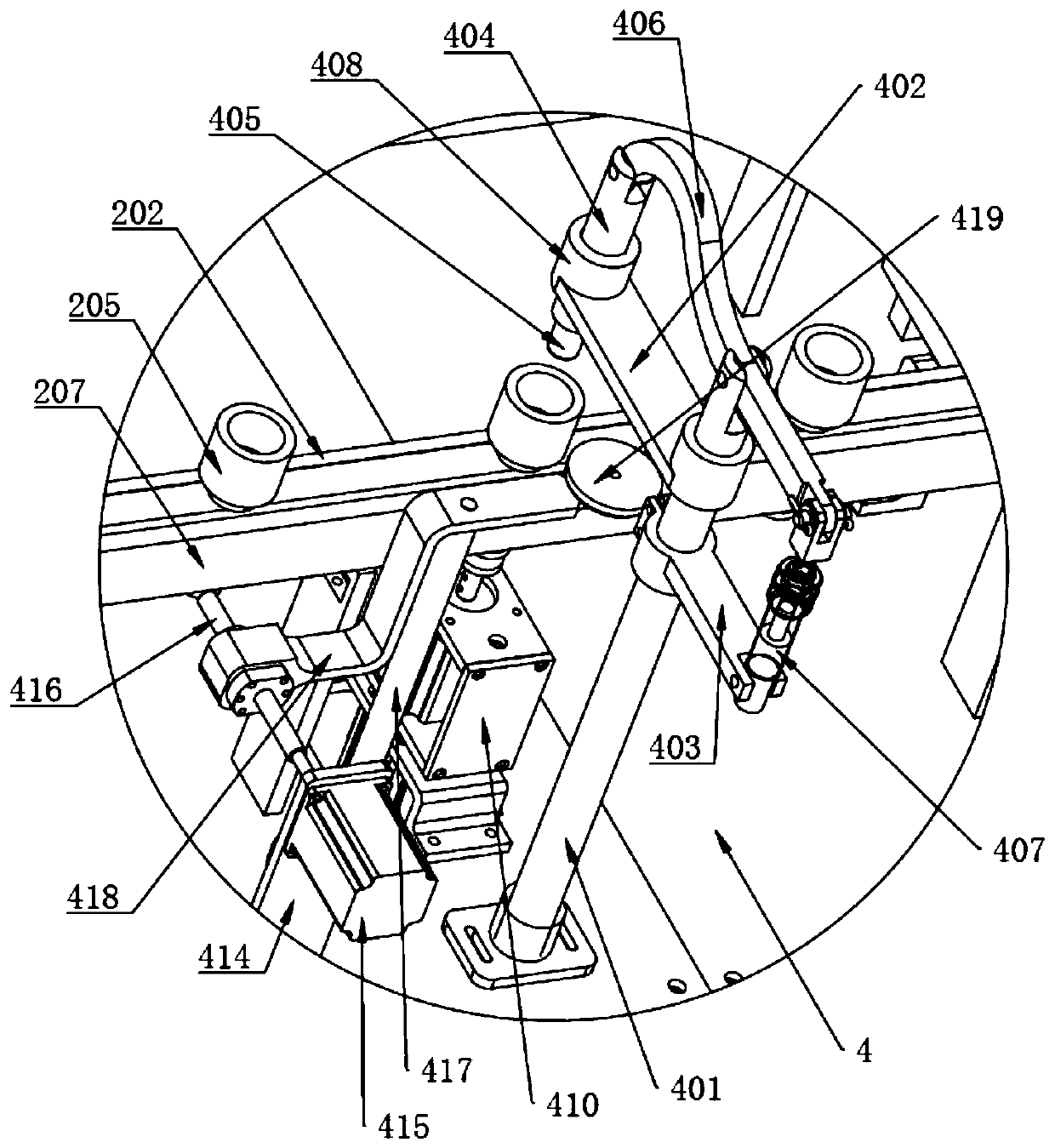

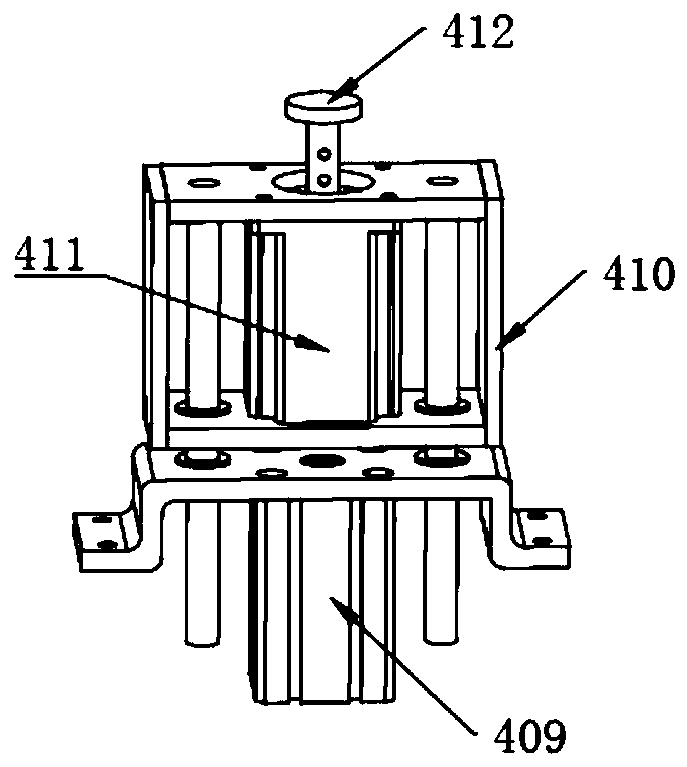

Battery packaging circulation equipment

PendingCN109509907AImprove manufacturing precisionPromote circulationAssembling battery machinesFinal product manufactureEngineeringPlastic film

The invention relates to the technical field of battery production equipment, in particular to battery packaging circulation equipment which comprises a positioning jig used for bearing an aluminum-plastic film shell, a circulating transportation device used for transporting the positioning jig and is in a square shape, a trimming device used for trimming the aluminum-plastic film shell borne by the positioning jig, a material taking and putting device used for taking and putting a cell on the trimmed aluminum-plastic film shell, a turning mechanism used for turning over the aluminum-plastic film shell borne by the positioning jig to coat the cell and a packaging device used for packaging the turned aluminum-plastic film shell and the cell; the trimming device, the material taking and putting device and the packaging device are arranged surrounding the circulating transportation device; and the turning mechanism is arranged on the positioning jig. The battery packaging circulation equipment provided by the invention has a compact structure and automatically packaging and processing the aluminum-plastic film shell and the cell; and in addition, the circulating transportation devicewith the square shape performs transports the positioning jig, so that the occupying area is shortened, and the packaging processing efficiency, the stability and the manufacturing accuracy are improved.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

Double-layer metal pin assembling machine for plug

InactiveCN107959215AExtrudeImprove efficiencyContact member assembly/disassemblyBiomedical engineeringAssembly machine

The invention relates to a double-layer metal pin assembly machine for plugs, comprising a frame, a conveying mechanism, a pin device, a welding device and a blanking device. Lifting cylinder and pin pick and place device. The pin pick and place device includes a pick and place body. The center of the lower part of the pick and place body is provided with an arc-shaped groove with an arc of 180 degrees. The lower part of the arc-shaped groove is equipped with an opening and closing device. There is a pressing slot on the main body of the device, the upper part of the pressing slot is provided with a pin pressing cylinder, the lower part of the pin pressing cylinder is connected to a pin pressing block, and the front side of the pick-and-placer is provided with a pin pushing installation block. The lower part of the pin push-in mounting block is provided with a pin push-in lift cylinder, and the pin push-in lift cylinder is connected with the pin push-in lift block. The present invention can not only realize the downward pressing of the pin, but also realize the metal pin The needle insertion operation is realized through the jack, which can meet the two-layer metal needle insertion of the double-layer and half-socket.

Owner:DONGGUAN UNIV OF TECH

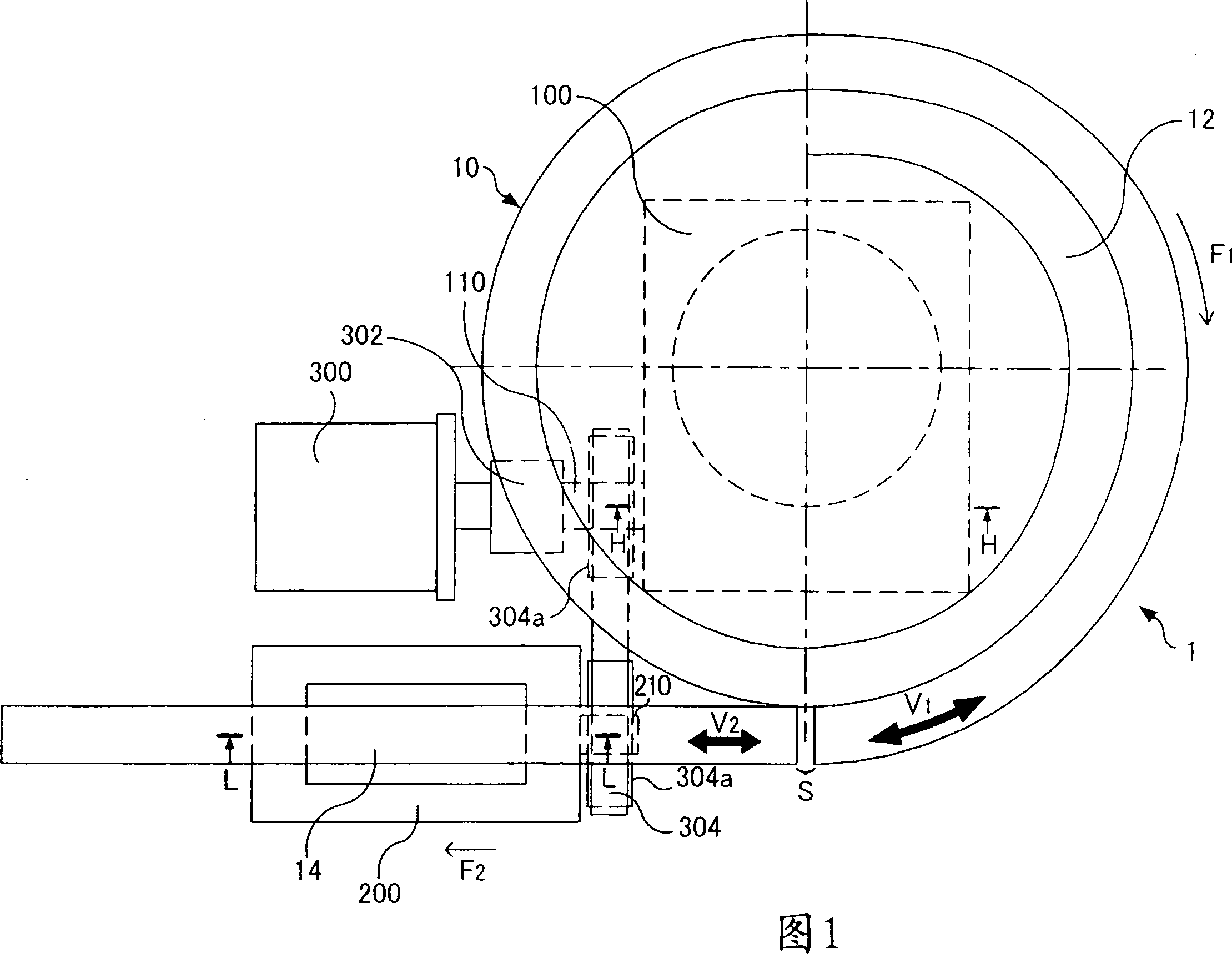

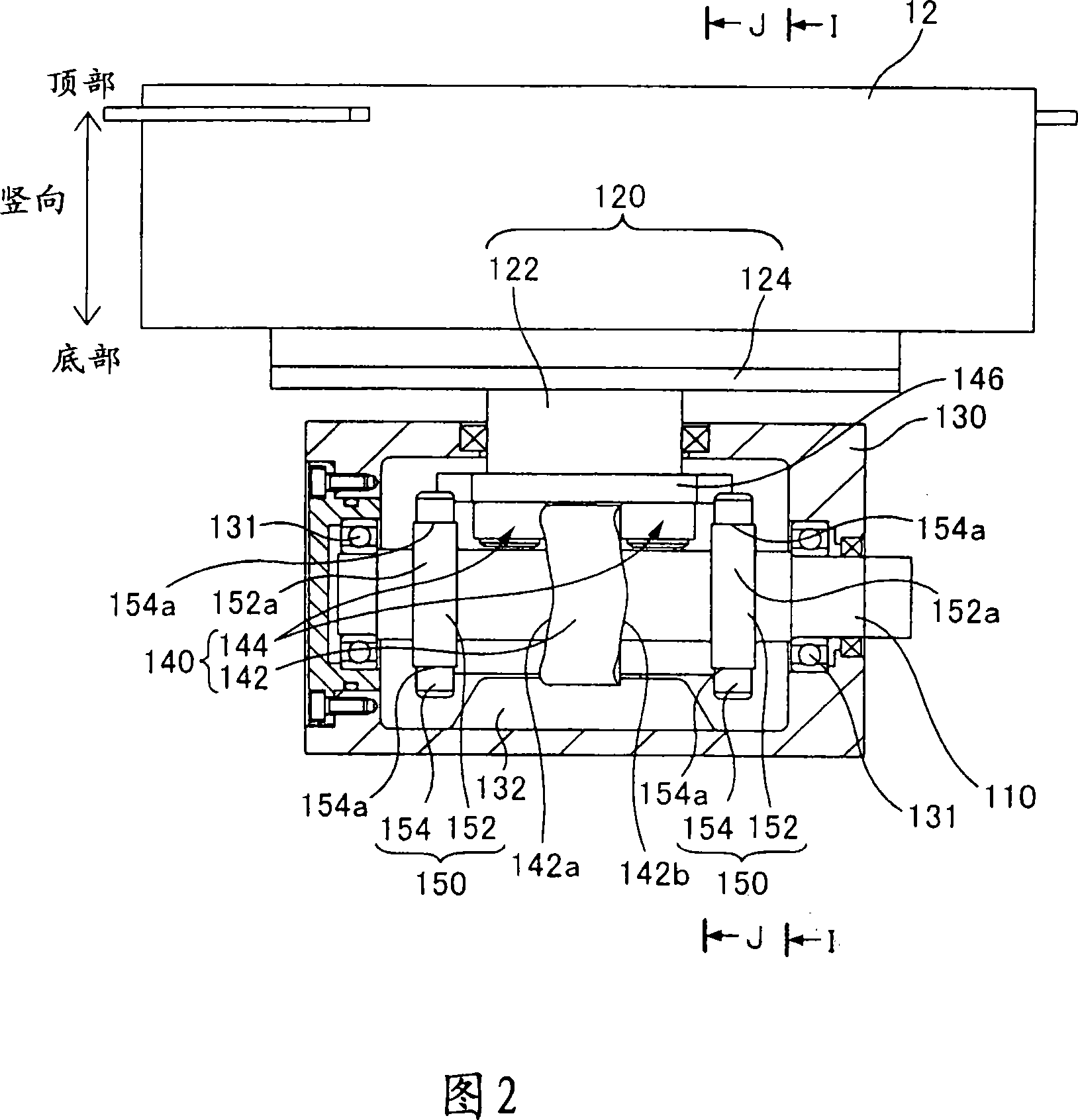

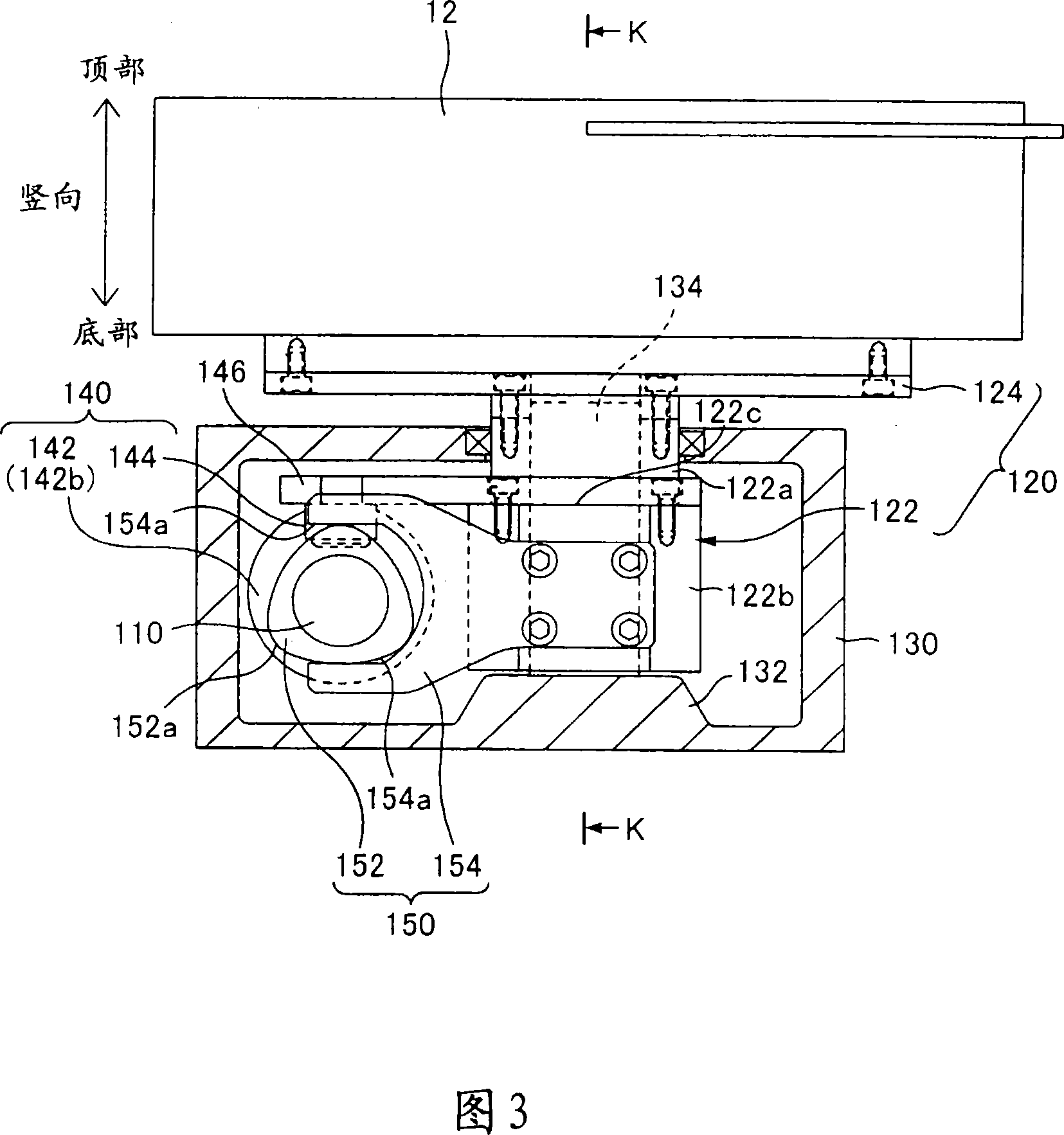

Product transport apparatus

A product transport apparatus is provided that includes a transport section (10) that oscillates in a transport direction and in a vertical direction in order to transport a product; a plurality of oscillation imparting sections (100,200) including a first cam mechanism (140,240) for causing the transport section to oscillate in the transport direction and a second cam mechanism (150,250) for causing the transport section to oscillate in the vertical direction; and a single driving source (300) that drives the plurality of oscillation imparting sections.

Owner:SANKYO SEISAKUSHO

Sterilization and disinfection equipment for liquid organic fertilizer production

ActiveCN110898239AImprove the effect of sterilization and disinfectionExtended tumble timeLavatory sanitoryHeatAgricultural engineeringOrganic fertilizer

The invention relates to the technical field of liquid organic fertilizer production, and discloses sterilization and disinfection equipment for liquid organic fertilizer production, which comprises afirst box body, a partition plate, a first chamber, a second chamber, a screw shaft and a screw blade, a plurality of rolling net plates are hinged in the second chamber; a swing mechanism for enabling the rolling net plate to swing up and down is arranged in the second chamber; a mounting plate is arranged at the side part of the first box body; a steam generating device is arranged on the mounting plate; a steam flowing cavity is formed in the side wall of the first box body, the steam flowing cavity is communicated with the steam generating device, a plurality of first spraying openings are formed in the inner wall of the first box body, and the first spraying openings are communicated with the steam flowing cavity. According to the scheme, materials can be dispersed, steam can enter amiddle layer and a bottom layer of the materials more easily, the contact time of the materials and the steam is prolonged, meanwhile, the materials circularly move in the first chamber and the second chamber, the materials make contact with the steam more sufficiently, and the sterilization and disinfection effect of the materials is greatly improved.

Owner:天府立春(成都)农业发展有限公司

Flat copper wire feeding device and wire feeding method

ActiveCN111731926AStable conveying attitudeAvoid bendingFilament handlingManufacturing dynamo-electric machinesCopper wireDrive shaft

The invention discloses a flat copper wire feeding device and wire feeding method. The wire feeding device comprises a wire roller transportation trolley, a feeding rack and a wire feeding mounting rack, wherein the wire roller conveying trolley is provided with a first driving shaft and a first driven shaft which are used for driving a wire roller loaded with a coiled flat copper wire to rotate;the feeding rack is used for receiving the wire roller transportation trolley and is provided with a first driving part which can be jointed with the first driving shaft to transmit power; the wire feeding mounting rack is provided with a pair of driving rollers composed of a driving roller and a driven roller, the driving rollers are provided with annular grooves, and the two annular grooves in the pair of driving rollers are correspondingly arranged to form a conveying groove for conveying the flat copper wire harness; and when the flat copper wire harness is conveyed, the linear speed of the pair of driving rollers is greater than that of the first driving shaft, so that the flat copper wire harness led out from the wire roller passes through the conveying groove in a tensioned state. The flat copper wire conveying device can solve the problems that flat copper wire harnesses which are wound on the wire roller are prone to being bent, deformed and intertwined when being conveyed.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Traditional Chinese medicine decoction piece air drying device

PendingCN112985038AImprove the speed of moisture removalGuaranteed medicinal propertiesDrying gas arrangementsEngineeringMechanical engineering

The invention discloses a traditional Chinese medicine decoction piece air drying device which comprises a rack, an upper layer conveying mechanism, a lower layer conveying mechanism and a feeding mechanism. The upper layer conveying mechanism and the lower layer conveying mechanism are both mounted on the rack, and the traditional Chinese medicine decoction pieces conveyed out of the discharging end of the upper layer conveying mechanism fall off onto the lower layer conveying mechanism. The feeding mechanism is installed on the rack and used for conveying the traditional Chinese medicine decoction pieces at the discharging end of the lower layer conveying mechanism to the feeding end of the upper layer conveying mechanism. The rack is provided with a plurality of upper layer fans used for blowing air to the traditional Chinese medicine decoction pieces on the upper layer conveying mechanism, and the rack is provided with a plurality of lower layer fans used for blowing air to the traditional Chinese medicine decoction pieces on the lower layer conveying mechanism. Through the design of the upper layer fans and the lower layer fans, the air can be continuously blown to the traditional Chinese medicine decoction pieces on the upper layer conveying mechanism and the lower layer conveying mechanism, the traditional Chinese medicine decoction pieces on the upper layer conveying mechanism and the lower layer conveying mechanism can be air-dried, the water removing speed of the traditional Chinese medicine decoction pieces is effectively increased, and the medicine property of the traditional Chinese medicine decoction pieces is guaranteed.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

Finished product discharging device of injection molding machine

InactiveCN112721058ARealize circular conveyingFast molding speedInjection molding machineInjection moulding

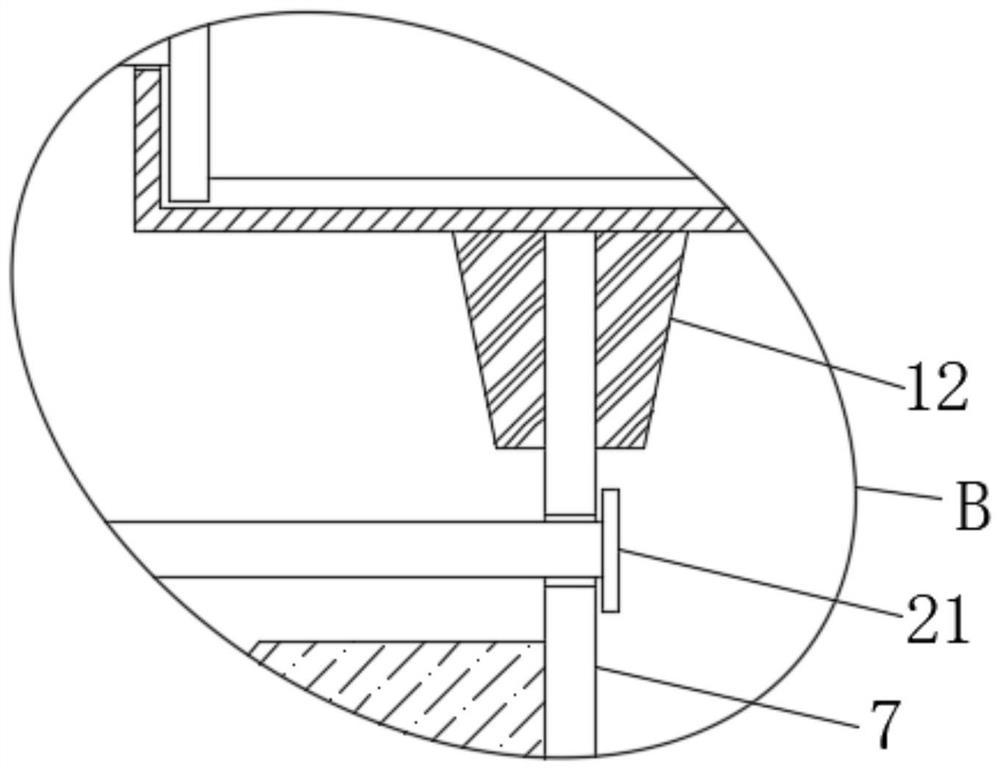

The invention relates to the technical field of injection molding machines, in particular to a finished product discharging device of an injection molding machine. The finished product discharging device comprises a water tank, a supporting plate is arranged on the inner wall of the water tank, a cushion pad is arranged on the top surface of the supporting plate, a supporting column is arranged between the bottom surface of the supporting plate and a bottom plate of the water tank, a spring is arranged on the outer side of the supporting column in a sleeving manner, a water escape valve pipe is inserted into the outer wall of the water tank, a mounting rack is arranged on the top surface of the water tank, a diagonal bar is arranged between the bottom surface of the mounting rack and the outer wall of the water tank, and a reinforcing plate is arranged on the surface of the mounting rack. The finished product discharging device of the injection molding machine has the beneficial effects that the two sets of horizontally-spliced mold frames are adopted for injection molding, injection valve pipes are additionally arranged at the tops of the mold frames to supplement materials to the interior of a molding cavity, the splicing position of two injection molds is sealed through a rubber limiting ring and a rubber clamping ring, and after a product is formed, the two sets of injection molds are separated, and a plastic product falls into the water tank to be cooled.

Owner:熊辉

Surface sizing system special for corrugated paper composite processing

ActiveCN113714039AAvoid premature coolingRealize circular conveyingLiquid surface applicatorsSpraying apparatusProcess engineeringConveyor belt

The invention discloses a surface sizing system special for corrugated paper composite processing. The surface sizing system comprises a support, a conveyor belt, a corrugated paper core, sizing blocks, a sizing box and a hot glue box, wherein the support is arranged above the conveyor belt, and the corrugated paper core is located above the conveyor belt; and an auger plate rotates along with a transverse shaft and conveys hot glue in the hot glue box into a glue feeding pipe in a pressurized manner. According to the surface sizing system special for corrugated paper composite processing, heat preservation operation can be conducted on a pipeline for conveying paper glue through flowing media such as hot oil or hot water, so that the paper glue is prevented from being cooled too early; and meanwhile, circulating conveying of the paper glue can be achieved through running of a flowing driving structure of the media, and due to the structural design of the sizing blocks and the sizing box, the sizing blocks can only smear the paper glue on the top end of the corrugated paper of the wave-shaped structure and the contact face of the corrugated paper and a paper layer through movement and guiding of the wave-shaped structure of the corrugated paper, so that waste and glue leakage of the paper glue are effectively avoided.

Owner:深圳市鸿鑫盛包装制品有限公司

Material circulation conveying device

The invention relates to a circulating conveying device for materials, and belongs to the technical field of conveying devices. The circulating conveying device comprises a conveying frame, a conveying trolley which comprises front wheel and a rear wheel and is used for carrying materials, a chain transmission mechanism pulling the front end of the conveying trolley, a motor for driving the conveying trolley to horizontally move anticlockwise in a plane through the chain transmission mechanism, an upper guide rail, a lower guide rail, a front middle guide rail, a rear middle guide rail, a rear sinking guide rail, a front upper skew bridge, a front lower skew bridge, a rear lower skew bridge, a rear lower skew slope, a rear upper skew bridge and a rear upper valve, wherein the upper guide rail, the lower guide rail, the front middle guide rail, the rear middle guide rail and the rear sinking guide rail are horizontally installed on the conveying frame and used for supporting the rear wheel of the conveying trolley, and the front upper skew bridge, the front lower skew bridge, the rear lower skew bridge, the rear lower skew slope, the rear upper skew bridge and the rear upper valve are installed on the conveying frame. The circulating conveying device has the beneficial effects that the structure is ingenious, operation is convenient, the conveying trolley can horizontally move to conduct transportation in the vertical plane in a circulating manner, and the materials can be conveyed in a circulating manner.

Owner:PEARL RIVER PIANO GROUP

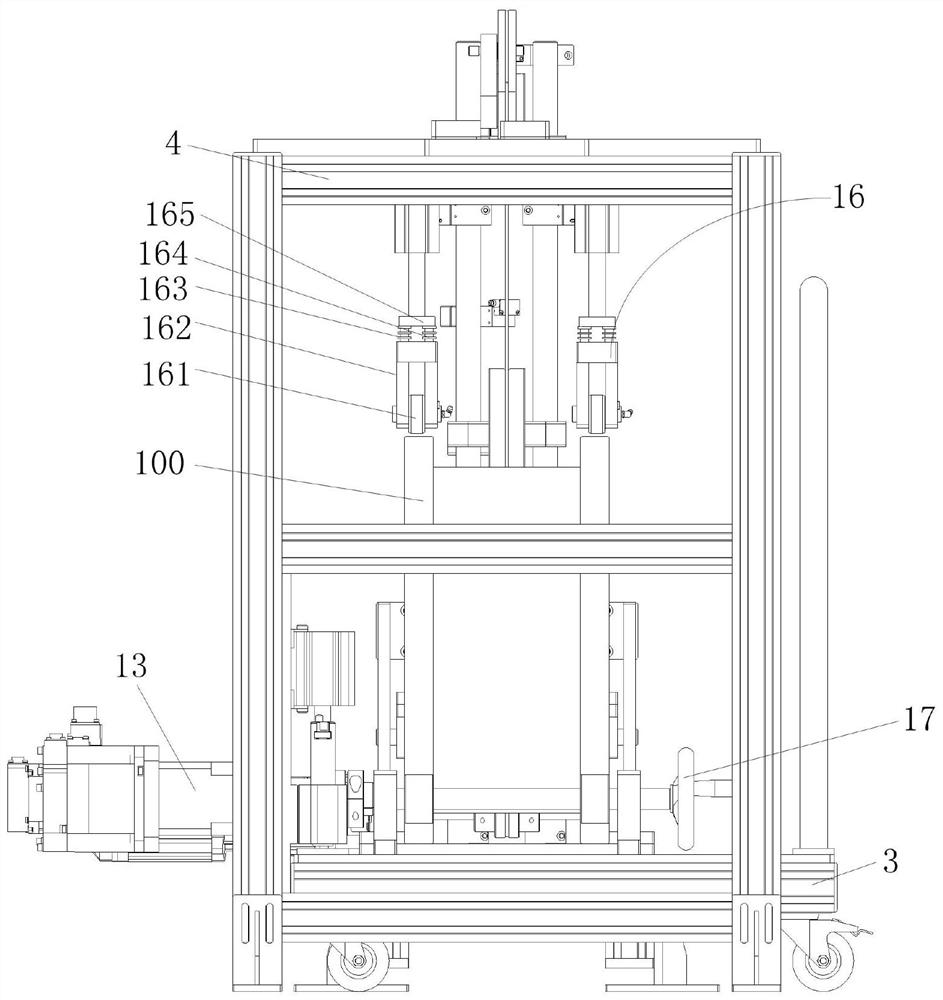

Circulating material taking and discharging equipment for battery infiltration

PendingCN114803352AIncrease productivityGuaranteed positioning accuracyCharge manipulationLi-accumulatorsElectrical batteryControl engineering

The invention relates to the technical field of battery production machines, in particular to circulating material taking and discharging equipment for battery infiltration. Comprising an infiltration clamp, a conveying driving mechanism, a conveying vehicle connected with the conveying end of the conveying driving mechanism, an infiltration box arranged on the lateral outer side of the conveying vehicle, and a first bearing sliding table arranged in the conveying vehicle. The wetting box comprises a box door, a box body and an opening and closing driving mechanism, and the opening and closing driving mechanism is arranged outside the box body and used for driving the box door to open or close a side opening of the box body; the taking and placing mechanism is used for transferring the infiltration clamp borne by the first bearing sliding table into the infiltration box or transferring the infiltration clamp in the infiltration box to the first bearing sliding table. According to the invention, the circulating conveying of the infiltration clamp is automatically realized, the labor intensity and the labor cost of infiltration processing are reduced, and the battery production efficiency is improved.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

A method for reducing the pressure of the sealing cavity of a high-pressure circulating pump

ActiveCN102269177BRealize circular conveyingRelieve pressureSpecific fluid pumpsPump componentsEngineeringCirculating pump

The invention discloses a method for reducing the pressure of a pump sealing chamber, which is characterized in that it comprises the following steps: 1) high-pressure fluid enters the pump body from the inlet of the pump, and is discharged from the pump body after being pressurized by the pump; The liquid discharged from the balance drum or throttling bush is led to the low-pressure container outside the pump body. The invention overcomes the problem that the prior art pump inlet and outlet are both high-pressure sealing chambers with high pressure and difficulty in sealing.

Owner:CHINA PETROCHEMICAL CORP +1

A piano plate polishing system

ActiveCN105150082BIngenious structureEasy to operateGrinding wheel securing apparatusPolishing machinesPianoSmall footprint

The invention belongs to the technical field of polishing equipment, and relates to a piano plate polishing system which comprises a material circulating conveying device and a plurality of polishing machines. The material circulating conveying device horizontally moves and circularly conveys horizontally-placed piano plates along a conveying line. The polishing machines polish the piano plates. The conveying line comprises an upper horizontal section, a front-end connecting section, a lower horizontal section and a rear-end connecting section which are sequentially arranged in the conveying direction. The rear-end connecting section is connected with the upper horizontal section. The lower horizontal section is located under the lower horizontal section. The multiple polishing machines are sequentially arranged along the upper horizontal section. The piano plate polishing system has the advantages of being ingenious in structure, convenient to operate, small in occupied area and high in polishing efficiency.

Owner:PEARL RIVER PIANO GROUP

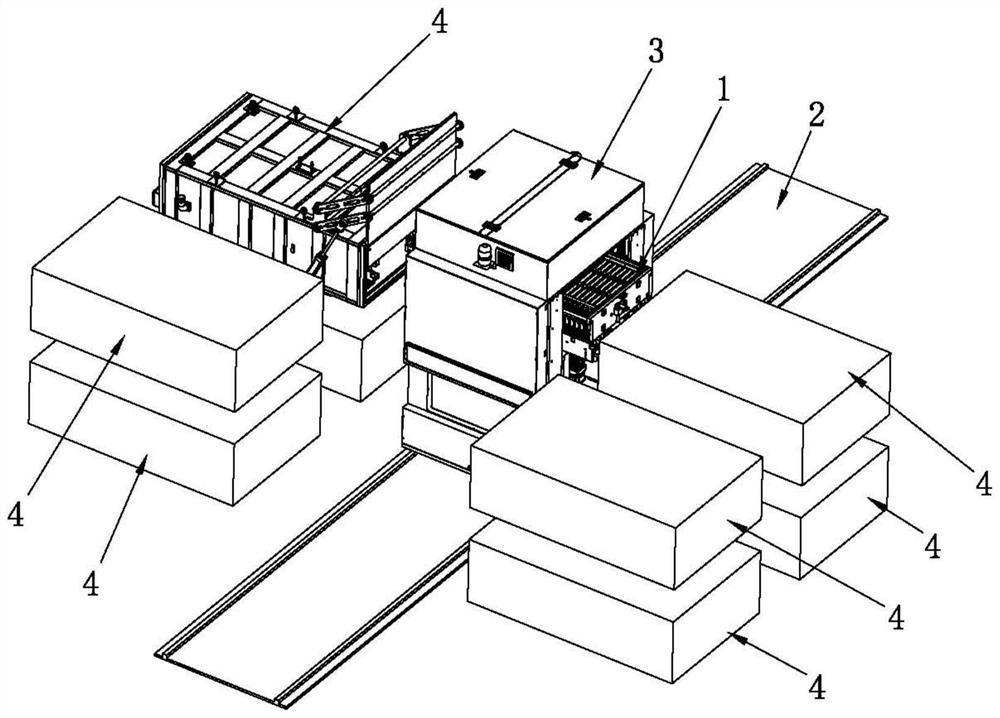

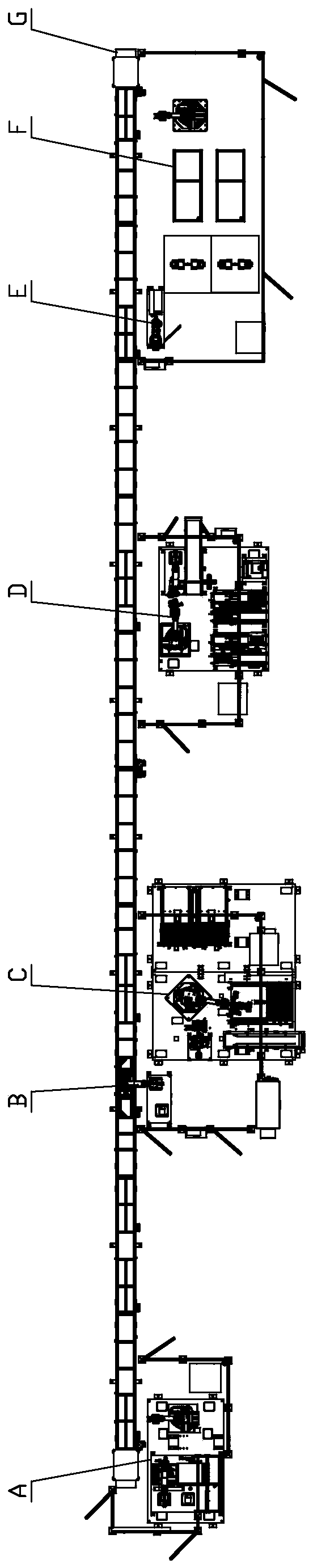

Driver board automated production line

ActiveCN108393686BRealize automated productionHigh degree of automationAssembly machinesProduction lineWorking environment

The invention discloses an automatic production line for driver boards. The automatic production line comprises a tool plate circulating conveying line, and further comprises a driver control board assembling device, a first manual assembling station, a second manual assembling station, a control board screw locking device, a driver shell assembling device, a driver bottom plate / fan cover assembling device, a driver labeling device and a driver load detecting device which are sequentially arranged along the tool plate circulating conveying line; the tool bottom plate circulating conveying lineis used for sequentially conveying tool bottom plates loaded with semi-finished products to the corresponding stations of the driver control board assembling device, the driver shell assembling device, the driver bottom plate / fan cover assembling device, the driver labeling device and the driver load detecting device; and the first manual assembling station and the second manual assembling station are located between the driver control board assembling device and the control board screw locking device. The automatic production line has the characteristics of being high in automation degree, short in product renewal and replacement period, stable in production quality, high in production efficiency, and capable of effectively improving the working environment.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Cooling device for data line processing

InactiveCN113470893ARealize circular conveyingReal-time detection of stress conditionsMeasurement devicesCleaning using toolsPhysicsWater pipe

The invention discloses a cooling device for data line processing. The cooling device comprises a mounting bracket, a square groove body, a water return area, a water outlet area, a water return pipe and a water suction pump, wherein a square conveying channel is arranged on each of the left and right sides in the square groove body, a cooling cylinder is connected between the two square conveying channels, an air cooling bin is arranged in the cooling cylinder, a first guide assembly is further arranged in the cooling cylinder, a second guide assembly is arranged in the square groove body, a main wire inlet is formed in the left side of the square groove body, a main wire outlet is formed in the right side of the square groove body, a fixed guide plate located on the upper portion and a movable guide plate located on the lower portion are arranged on the inner wall of the air cooling bin, an adjusting rod is connected to the lower portion of the movable guide plate, the lower portion of the adjusting rod is inserted into a sliding groove in the inner wall of the air cooling bin, the adjusting rod is sleeved with an adjusting spring, one end of the adjusting spring abuts against the upper end of the sliding groove, the other end of the adjusting spring abuts against the lower portion of the adjusting rod, and a heat exchanger is arranged on the water return area. The structure improves the cooling effect.

Owner:深圳市高易洋线材科技有限公司

Automatic continuous drying system for large ocean-going fishing vessels

ActiveCN104567308BRealize circular conveyingSafe, stable and efficient continuous motionDrying machines with progressive movementsDrying solid materialsDrive wheelSpatial structure

The invention discloses an automatic continuous drying system of a large ocean fishing boat. The automatic continuous drying system comprises a fixed bin, wherein the fixed bin is internally provided with a drying machine and a conveying device; the conveying device comprises a driver, a chain wheel, a rail and a trawl board; the driver is fixedly connected with the fixed bin; the rail is fixedly connected with the fixed bin; the chain wheel is in transmission connection with the driver; the chain wheel comprises first driving wheels and support wheels; the first driving wheels and the support wheels are respectively arranged at different positions according to spatial arrangement, and the numbers of the first driving wheels and the support wheels are set as required; the first driving wheels are in transmission connection with the support wheels by virtue of chain belts; the chain belts are fixedly provided with sliding devices; the sliding devices are movably connected with the rail and are fixedly connected with hooks; the hooks are used for hanging the trawl board. By virtue of reasonable design on the equipment structure, the special spatial structure and transporting environment of a boat body are met, and meanwhile, continuous and circulating drying treatment of fresh fish goods can be rapidly and uniformly realized.

Owner:舟山利远机械有限公司

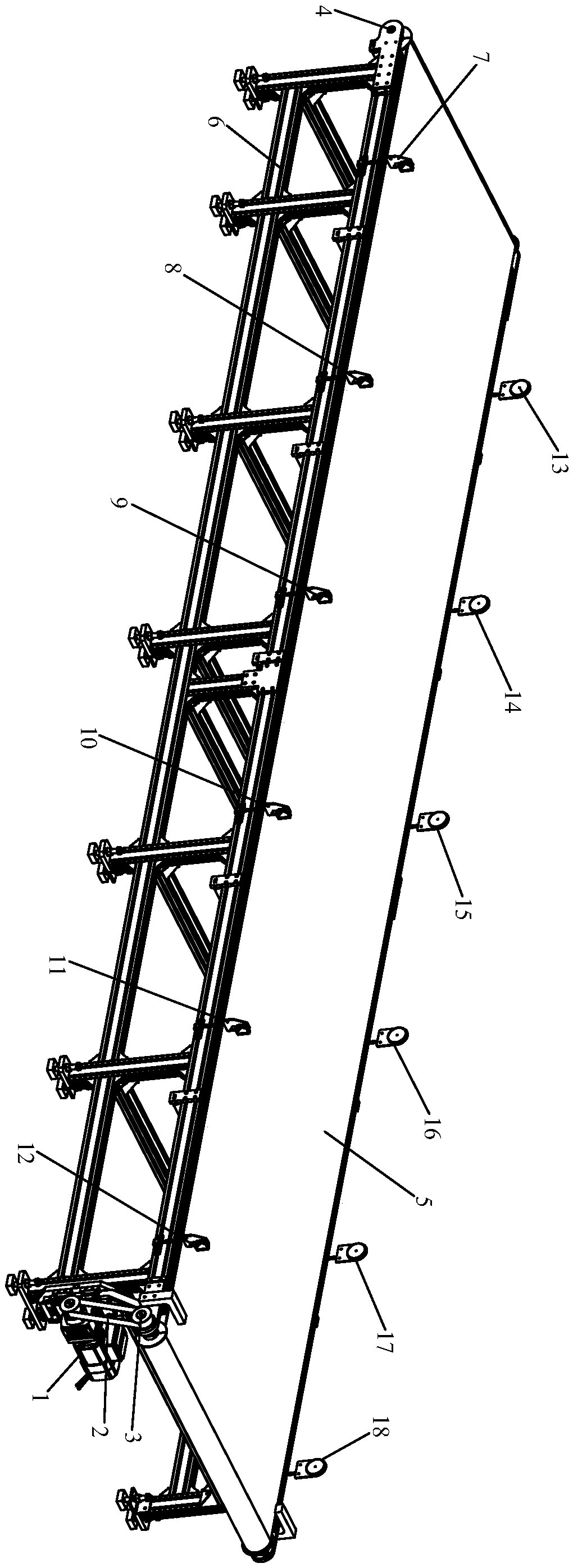

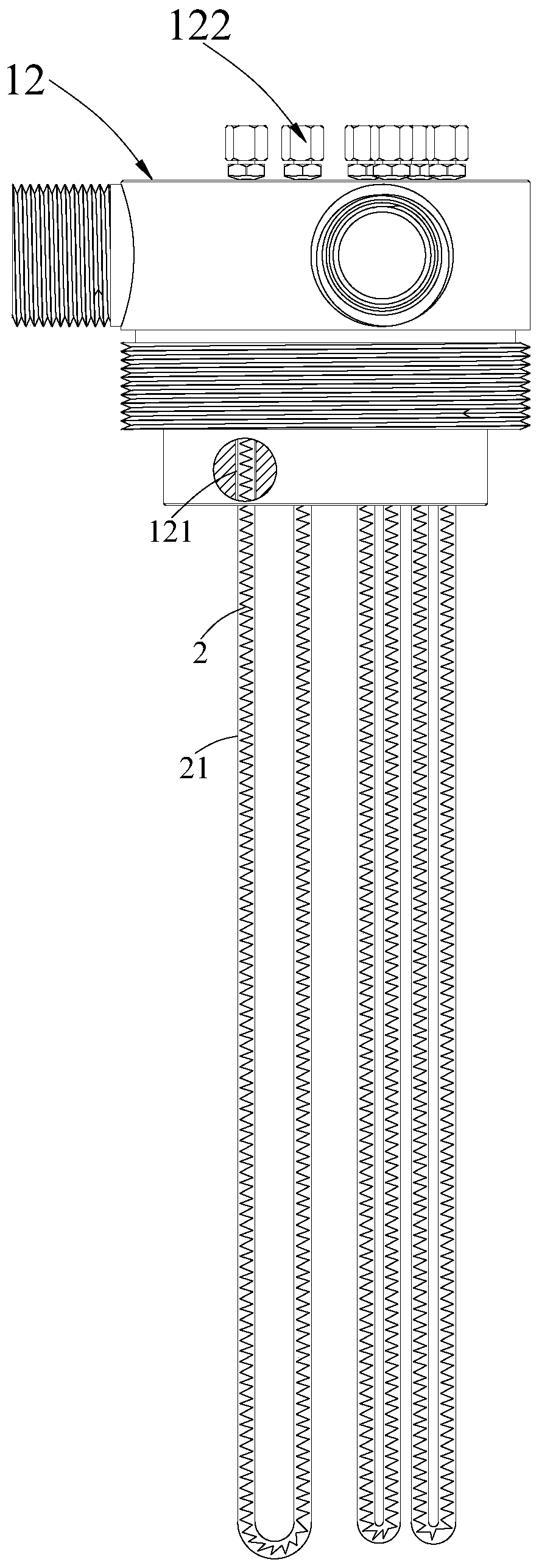

An Adaptive Circulating Lubrication System for Sliding Bearings

InactiveCN107366820BAffect lifeShort lifeValve arrangementsBearing componentsEngineeringSelf adaptive

The invention provides a self-adaptive circulating lubricating system for a sliding bearing and belongs to the technical field of bearing lubricating systems. The self-adaptive circulating lubricating system is characterized by comprising a filter (2), a pressure-cutting oil supply device (4) and a heat exchanger (6); the liquid outlet end of the filter (2) communicates with the liquid inlet end of the pressure-cutting oil supply device (4), and the liquid outlet end of the pressure-cutting oil supply device (4) communicates with the liquid inlet end of the heat exchanger (6); the sliding bearing (1) is provided with an oil inlet hole and an oil outlet hole, the liquid inlet end of the filter (2) communicates with the oil outlet hole of the sliding bearing (1), and the liquid outlet end of the heat exchanger (6) communicates with the oil inlet hole of the sliding bearing (1); and a rotary shaft for mounting the sliding bearing (1) is connected with the power input end of the pressure-cutting oil supply device (4). The self-adaptive circulating lubricating system for the sliding bearing has the beneficial effects that by simplifying an external circulating structure of the sliding bearing, lubricating oil is circulated by the adoption of the same power source, the capacity of a main drive device is fully utilized, the occupied area is saved, and the consumption of the electric energy is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Belt conveyor suitable for automobile welding production line

InactiveCN108820775AWith storage functionRealize circular conveyingConveyorsControl devices for conveyorsProduction lineEngineering

The invention discloses a belt conveyor suitable for an automobile welding production line. The belt conveyor comprises a rack, a conveyor belt, a driving device and a control device. The conveyor belt is provided with a feeding position and n storage positions. The n storage positions are arranged in sequence in the conveying direction of the conveyor belt. When the control device detects workpieces in the feeding position, the conveyor belt conveys the workpieces in the feeding position to the first storage position, and meanwhile, the conveyor belt conveys the workpieces located in the previous storage position to the later storage position. The belt conveyor suitable for the automobile welding production line has the storage function, achieves the effect of cyclic conveying of workpieces, can enable an operator to complete taking of all the workpieces in the storage positions and the feeding position simultaneously, thereby achieving the effect that one operator is responsible forthe multiple positions. The belt conveyor has the advantages of low cost and high reliability and can reduce the quantity of field staff and improve the working efficiency.

Owner:ANHUI RUIXIANG IND

Mechanical device for realizing cyclic motion of workpiece on multiple working platforms in same plane

InactiveCN102009823BRealize circular conveyingRealize positioning installation/unlockingConveyorsEngineeringPower apparatus

Owner:BIOMAX ECOLOGICAL ENG

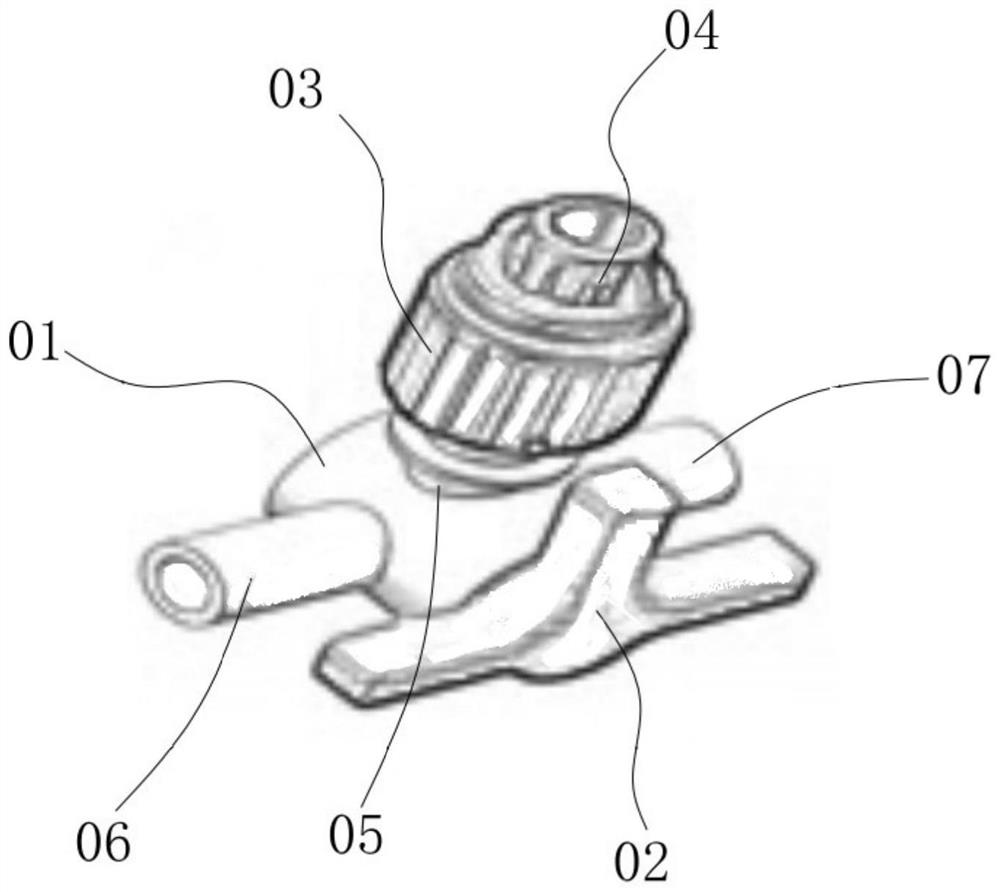

Three-way valve body automatic assembly method and three-way valve automatic assembly line

PendingCN114211229AReduce control difficultyRealize automatic assemblyMetal working apparatusChinese charactersEngineering

The invention discloses an automatic three-way valve body assembling method and an automatic three-way valve assembling line, and the assembling method can position a first component in two assembling states by arranging a workpiece positioning jig with a positioning groove shaped like a Chinese character'gan '. According to the assembly mechanism, workpieces can be transferred between different assembly mechanisms only through one set of workpiece positioning jigs and one conveying line, the workpiece positioning jigs are located on the same conveying line, the positions of the workpiece positioning jigs are fixed and synchronous, the problem that the positions of two conveying mechanisms need to be matched is solved, and the assembly efficiency is improved. By combining the feeding mechanism, the oil injection mechanism, the first assembling mechanism, the press-fitting mechanism, the second assembling mechanism, the third assembling mechanism, the detection mechanism and the discharging mechanism, full-process automatic assembling and detection of the three-way valve body can be achieved on the basis of a simpler structure, the takt time of the whole process can range from 0.4 S / Pcs to 0.8 S / Pcs, efficiency is high, and the control difficulty of the whole assembling line can be lowered.

Owner:UNIVAC PRECISION PLASTICS SIP

Gas-liquid heater and working method thereof

The invention relates to a gas-liquid heater and a working method thereof. The gas-liquid heater comprises a bearing container and a heating wire arranged in the bearing container. The gas-liquid heater is characterized in that the bearing container is filled with the heating wire in a snake-shaped distribution mode, the length direction of the heating wire is parallel to the length direction of the bearing container, and a heated object is heated in a reciprocating mode in the length direction of the bearing container. According to the gas-liquid heater, filling and circulating conveying of the heated object are achieved through the arrangement of the bearing container, the heated object in the bearing container is heated through the arrangement of the heating wire, and reciprocating circulating heating of the gas-liquid heater is facilitated through the heating wire distributed in the snake shape and the heating wire with the length direction parallel to the length direction of the bearing container, and the good heating effect is ensured.

Owner:常州科讯精密机械有限公司

Fat bin forming machine

The invention discloses a fat bin forming machine, which comprises a frame provided with an annular feeding mechanism, wherein one side of the annular feeding mechanism is provided with a feeding mechanism, the frame positioned at the downstream of the feeding mechanism is sequentially provided with a first pressing forming mechanism, a material turnover mechanism, a second pressing forming mechanism and a reclaimer mechanism; the feeding mechanism, the first pressing forming mechanism, the material turnover mechanism, the second pressing forming mechanism and the reclaimer mechanism are annularly arranged along the annular feeding mechanism; and gas heating devices are arranged on the frame at positions corresponding to the first press forming mechanism and the second pressing forming mechanism. Mechanization, continuity and mass processing of raw materials of a fat bin are realized, the processing efficiency is greatly improved, the forming effect is consistent and the forming quality is good; at the same time, the labor intensity of the staff is greatly reduced, the labor quantity is effectively reduced, and the labor cost is greatly reduced.

Owner:山东国班机器人有限公司

Pipeline conveying line and conveying method

The invention discloses a pipeline conveying line and conveying method. The pipeline conveying line comprises a supporting frame and a bearing platform connected with the supporting frame. Multiple pipe manufacturing / pipe cutting devices, multiple pipe body machining devices, an outer ring line rail and an inner ring line rail are arranged on the bearing platform. The pipe manufacturing / pipe cutting devices are arranged on the outer side of the outer ring line rail and are used for conveying manufactured pipe bodies to the outer ring line rail. The outer ring line rail surrounds the peripheryof the pipe body machining devices and is used for conveying the pipe bodies manufactured by the pipe manufacturing / pipe cutting devices to the pipe body machining devices. The output ends of the pipebody machining devices are opposite to the inner ring line rail, and the pipe body machining devices are used for conveying the machined pipe bodies to the inner ring line rail. The invention furthercomprises a conveying method of the pipeline conveying line. The site occupied area is greatly reduced, and cost is reduced; and equipment can operate independently and does not interfere with one another, and production efficiency is greatly improved.

Owner:远大可建科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com