Driver board automated production line

An automated production line and driver technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of lower driver assembly quality, high labor intensity, and low production efficiency, achieving short product replacement cycles and ensuring production The effect of improving takt time and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

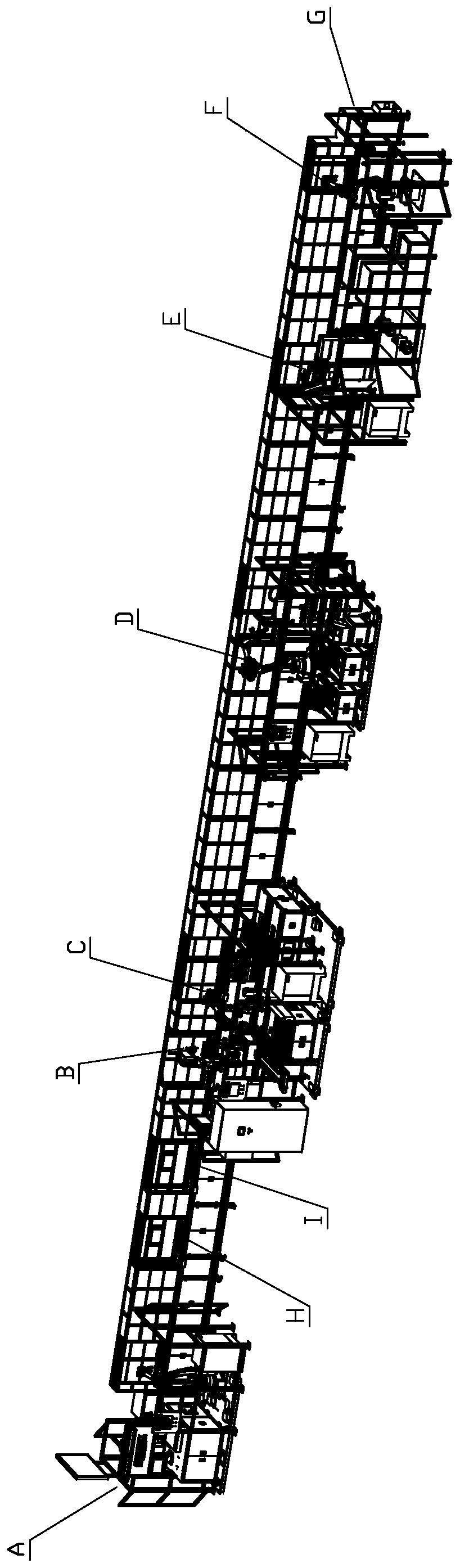

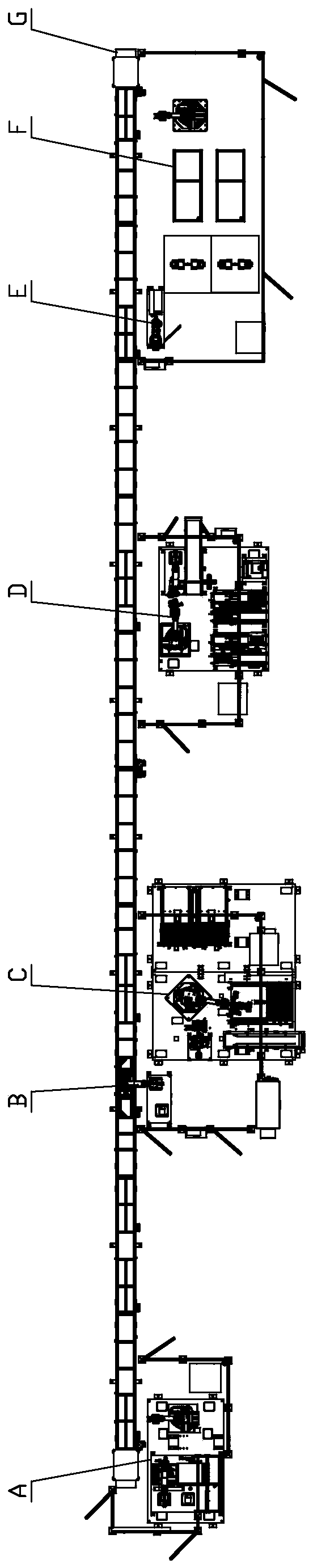

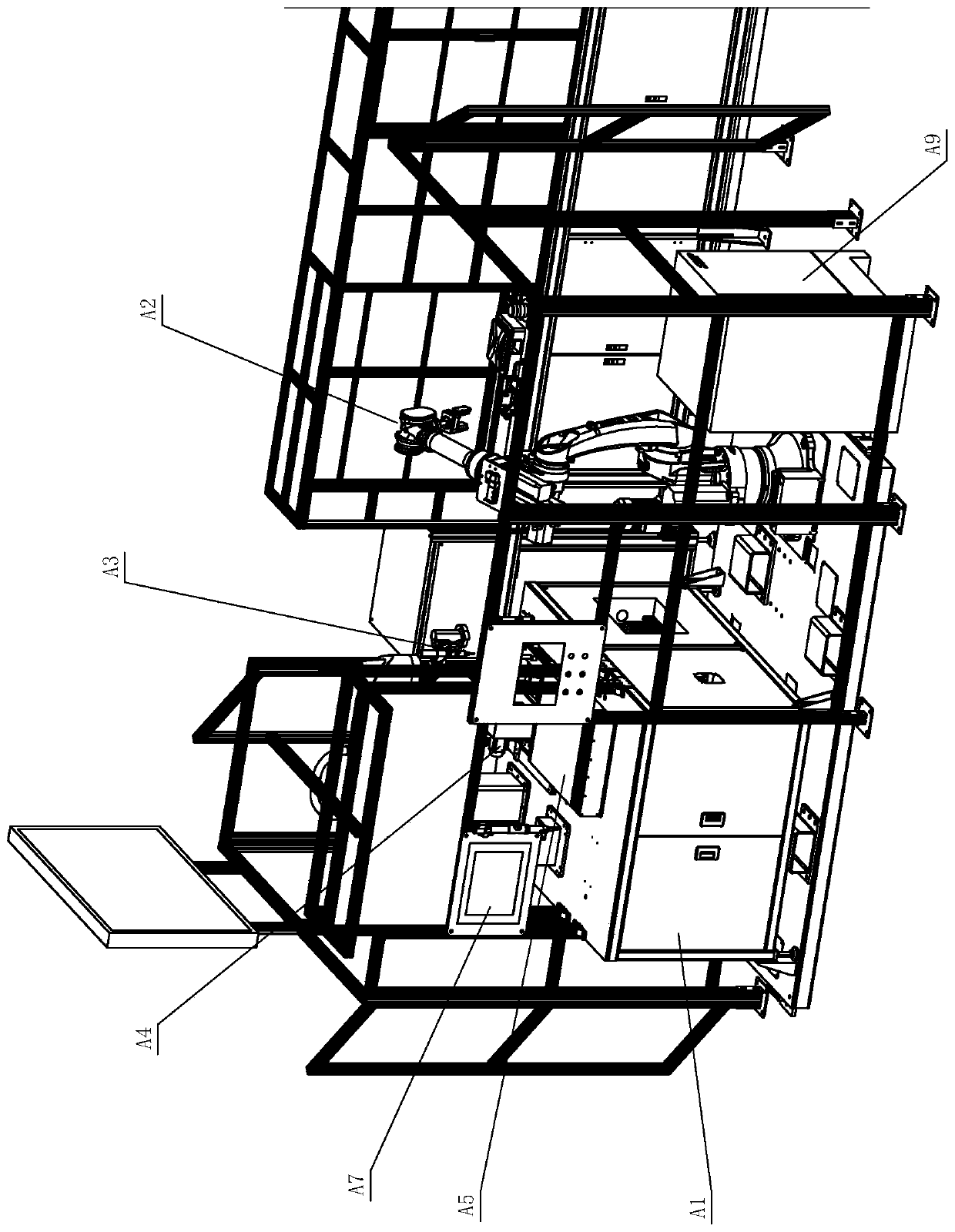

[0063] see Figure 1-Figure 6 , the driver board automated production line, including

[0064] The tooling plate circular conveying line G is used to transport the tooling base plate G3 carrying the semi-finished product K (the semi-finished product K is any one of the first semi-finished product, the second semi-finished product K4 and the third semi-finished product K7, etc.) to different assembly and inspection work position; the first manual assembly station H and the second manual assembly station I are sequentially set on the tooling plate circulation conveying line G; the first manual assembly station H is used for manually installing the left plastic case and locking hexagonal studs, And lock the ground wire screw; the second manual assembly station I is used to manually insert the fan cable, install the fan, scan the code control board, and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com