Mechanical device for realizing cyclic motion of workpiece on multiple working platforms in same plane

A work platform and workpiece moving technology, applied in the field of mechanical devices, can solve problems such as inconvenient movement, falling contents, mold pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

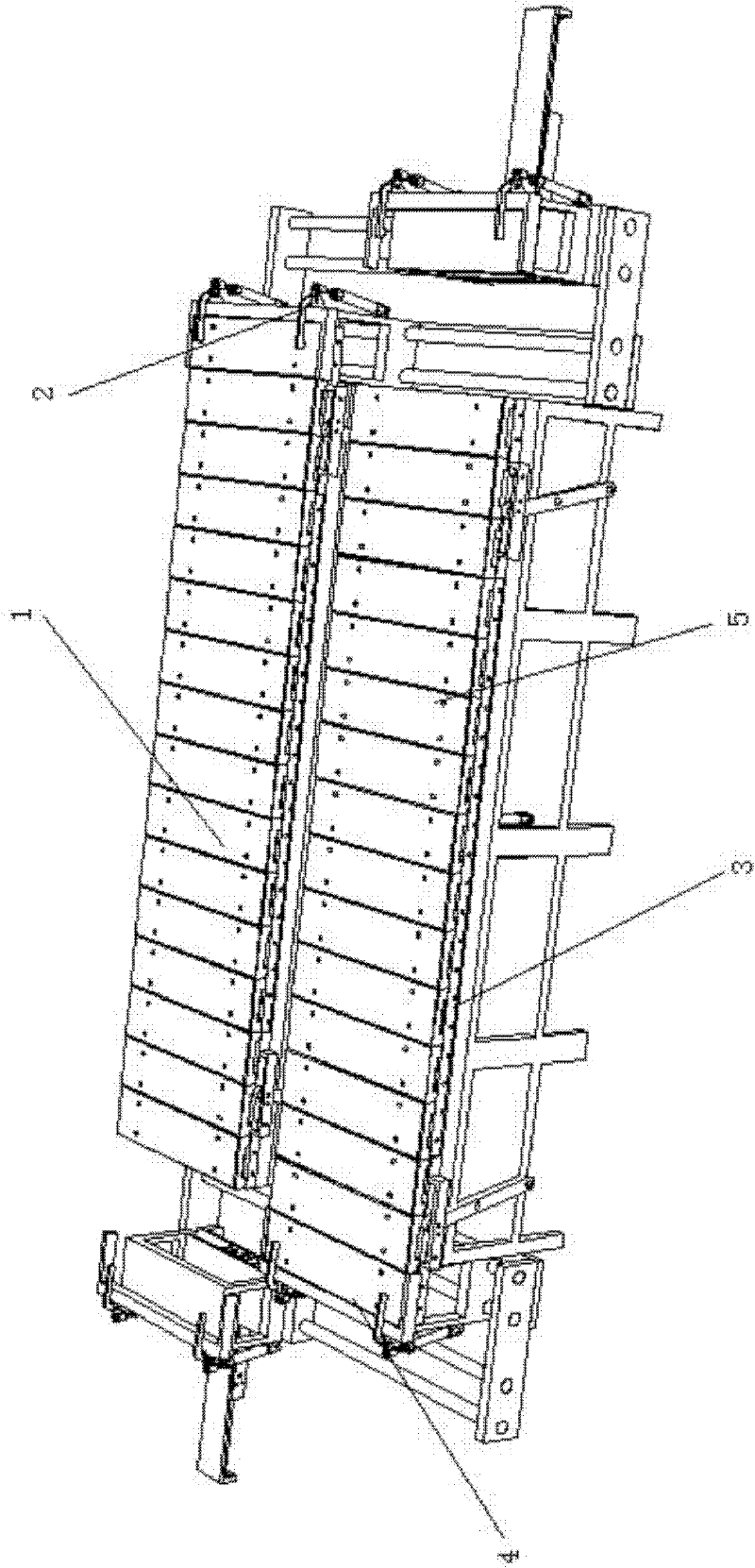

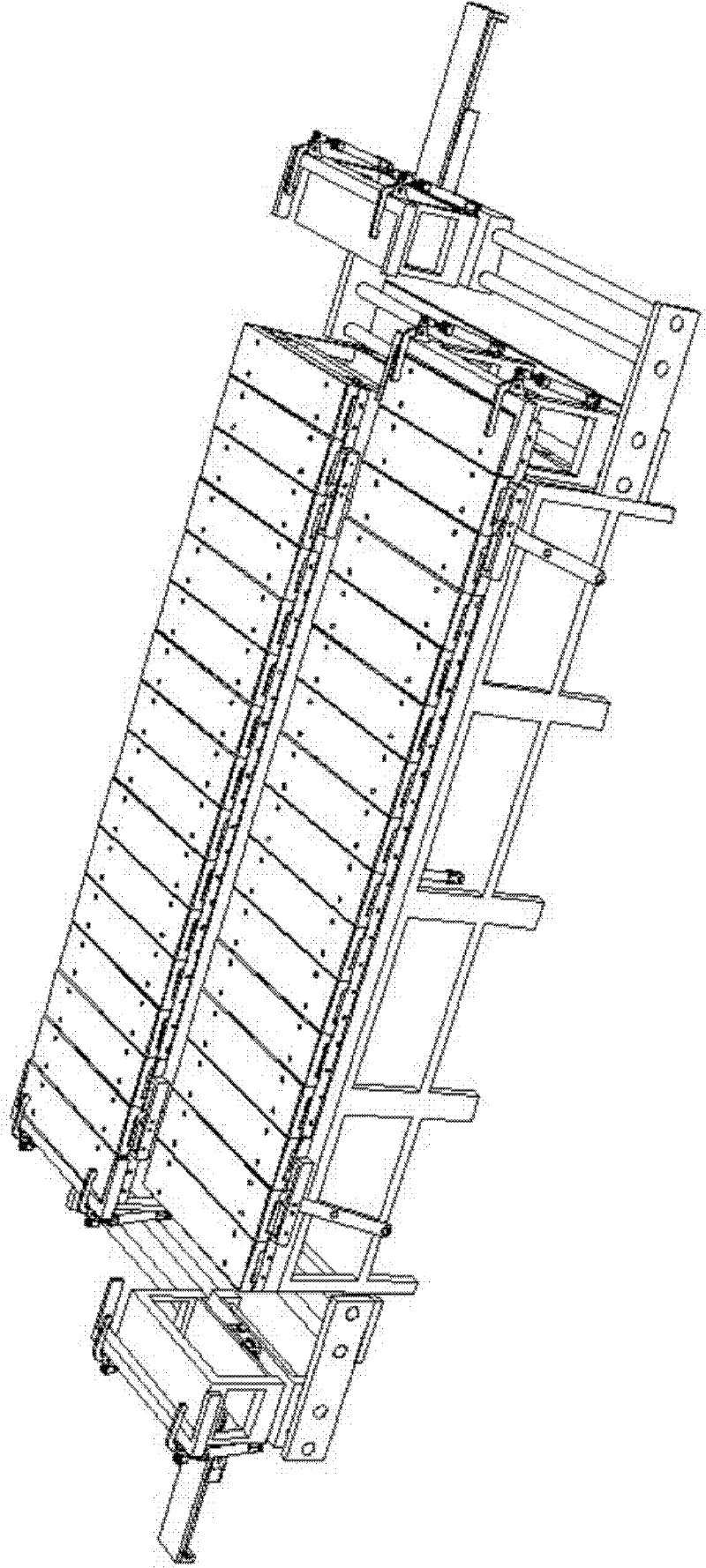

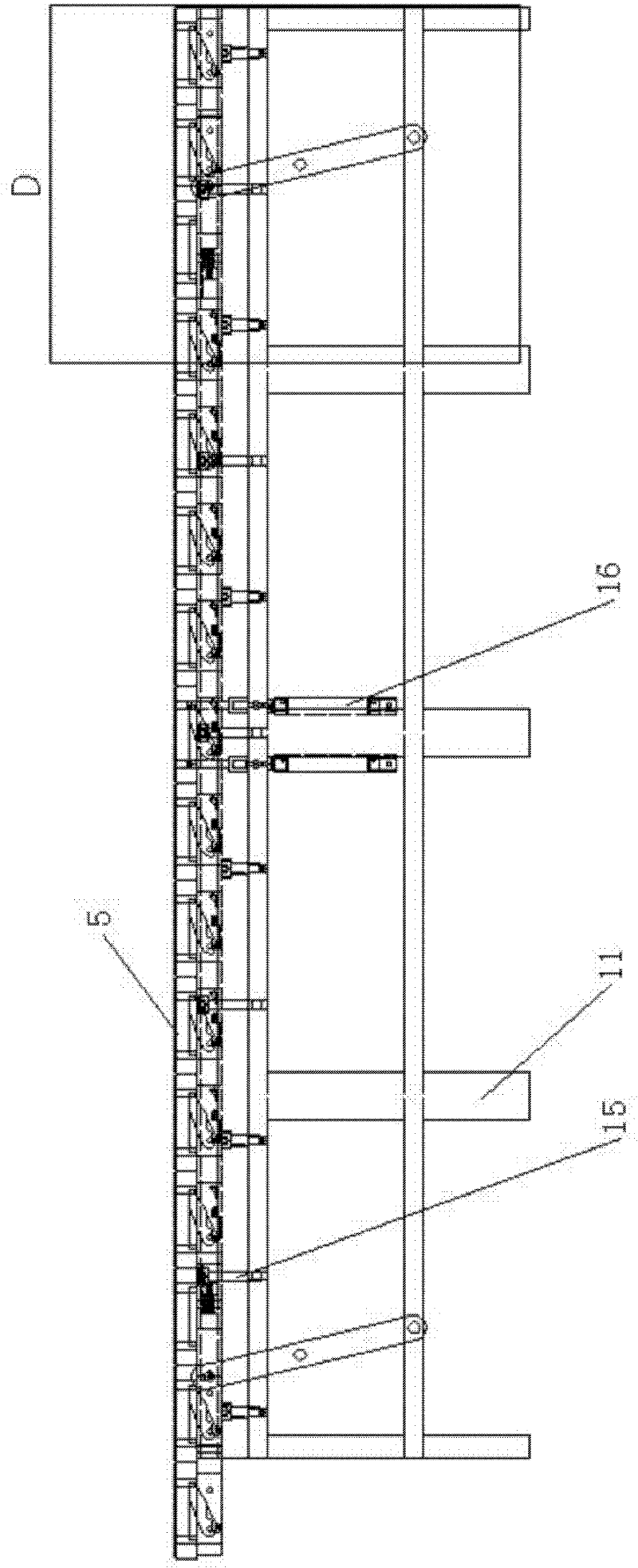

[0028] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 and figure 2 As shown, the mechanical device of the present invention that realizes the circular movement of workpieces on multiple work platforms on the same plane includes a workpiece pallet and more than one circular conveying basic unit for conveying the workpiece pallet, and each circular conveying basic unit includes a positive To the working platform 1, the forward moving platform 2, the reverse working platform 3 and the reverse moving platform 4, the forward working platform 1, the forward moving platform 2, the reverse working platform 3, and the reverse moving platform 4 are connected end to end To form a circular conveying system, the forward worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com