Patents

Literature

1327results about How to "Achieve heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

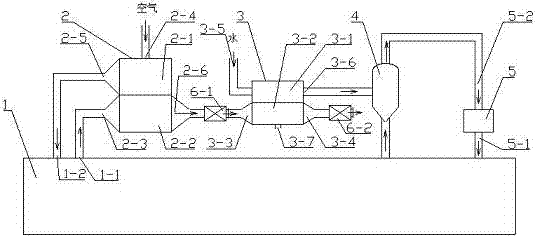

Heat pump-driven membrane-type liquid dehumidification and energy storage device

InactiveCN101975421AAchieve dehumidificationAvoid enteringHeat recovery systemsLighting and heating apparatusWater vaporEngineering

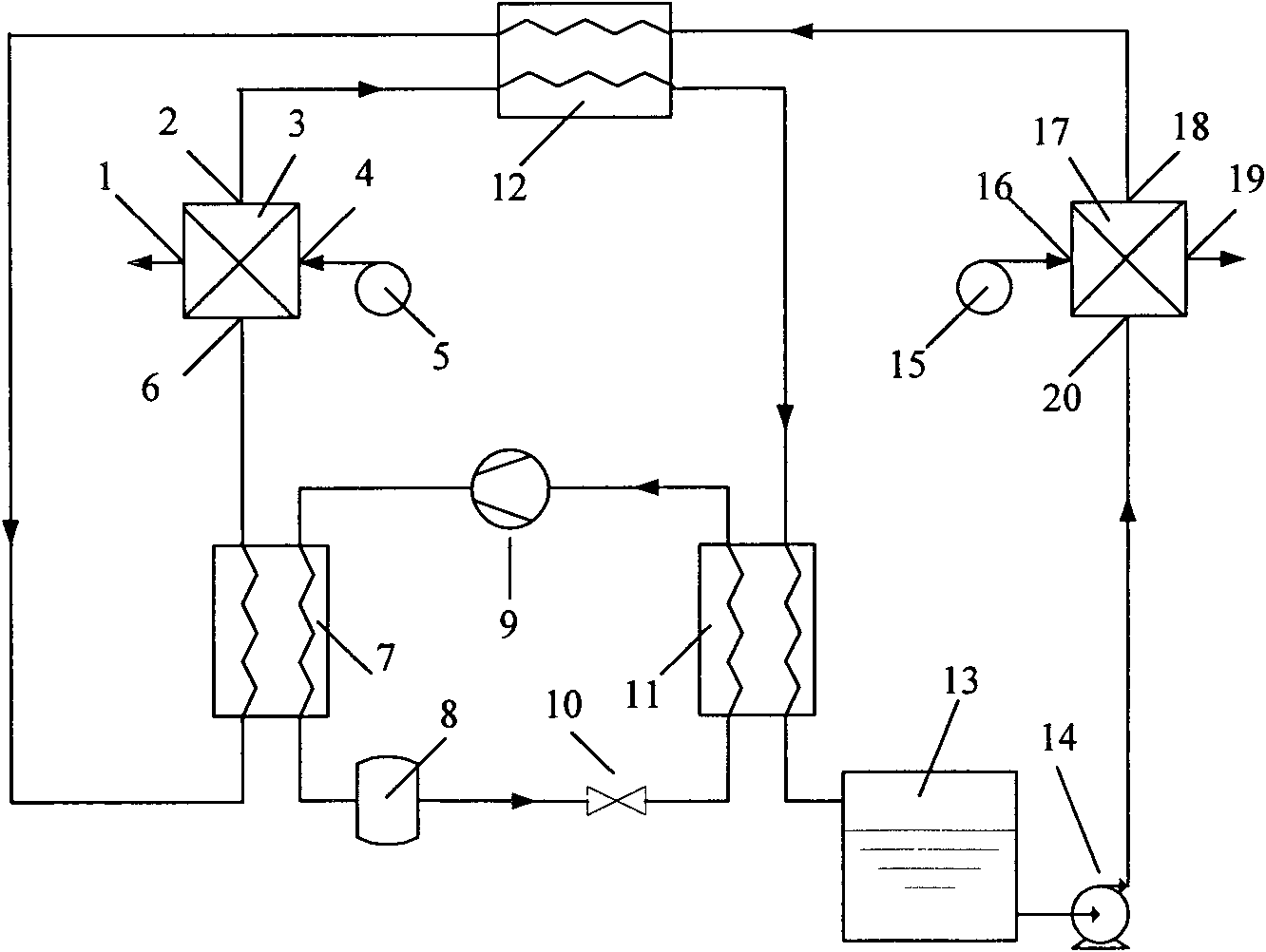

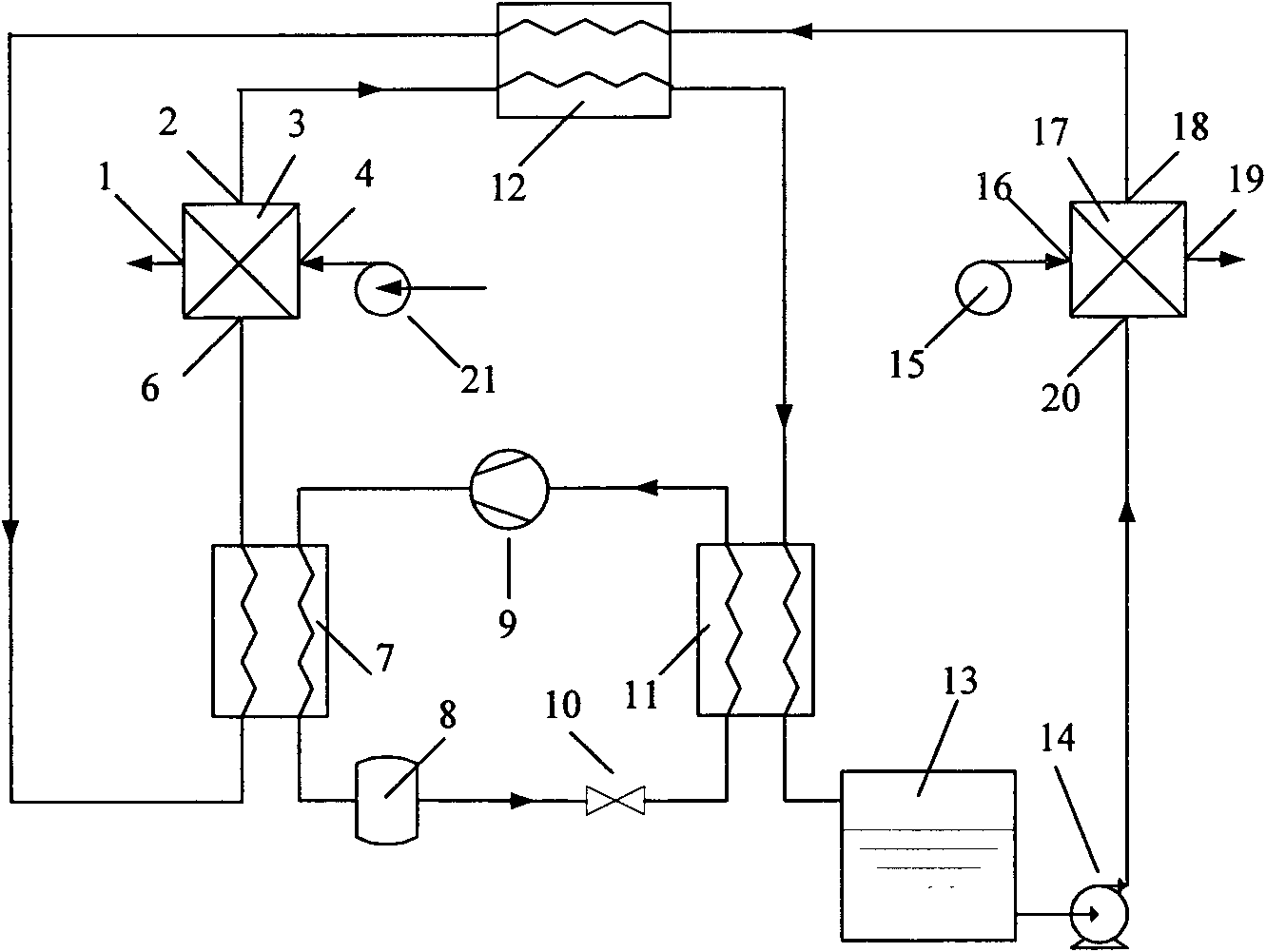

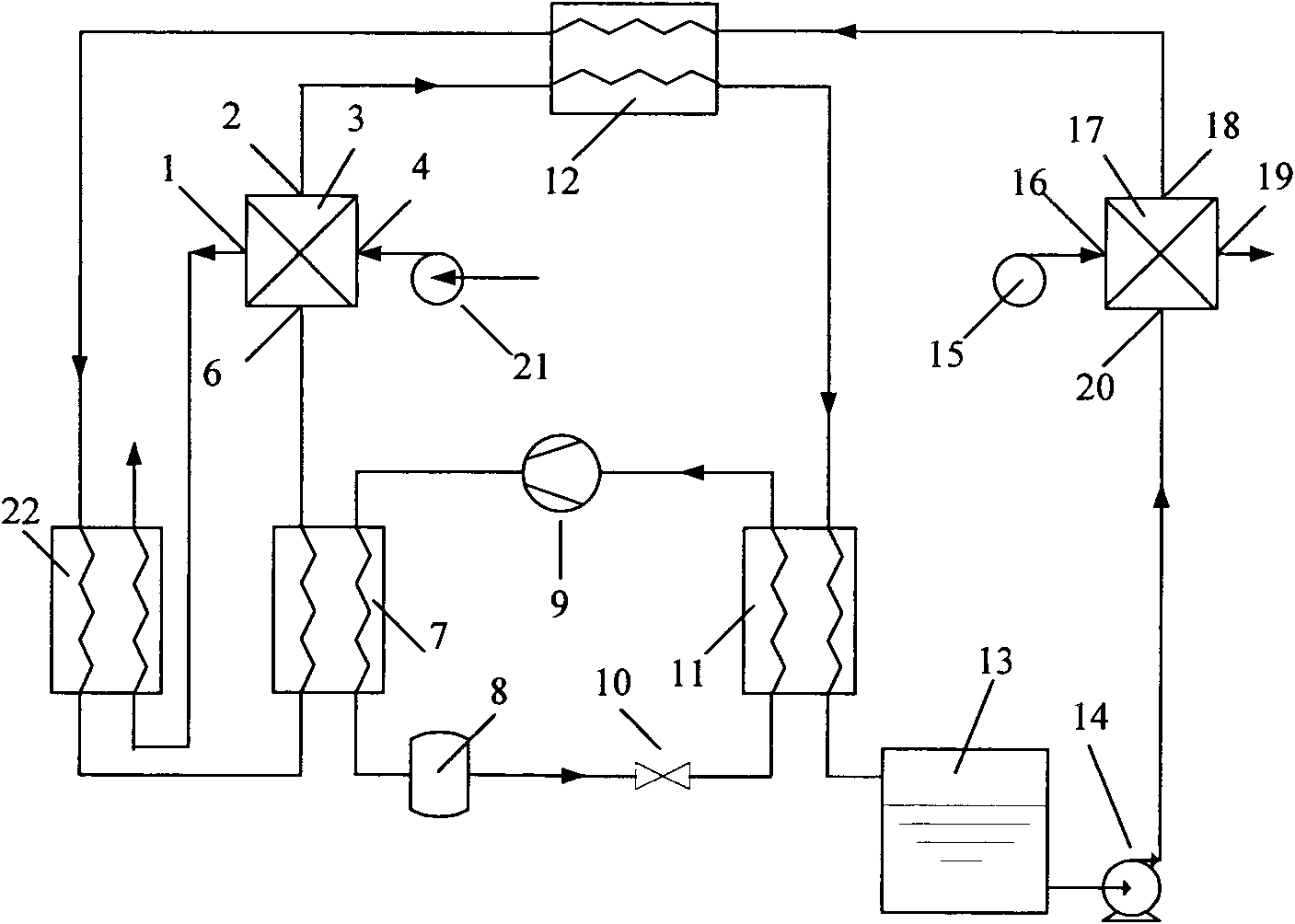

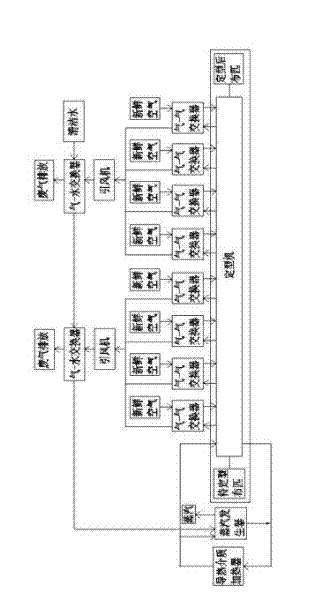

The invention discloses a heat pump-driven membrane-type liquid dehumidification and energy storage device which comprises a dehumidification solution storage tank, a solution pump, a dehumidifier, a first heat exchanger, a fan, a regenerator and a heat pump. The heat pump is a closed circulation loop composed of an evaporator, a compressor, a condenser, a refrigerant reservoir and an expansion valve or a capillary tube which are connected in turn; the dehumidification solution storage tank is connected with the dehumidifier through the solution pump; the dehumidifier is connected with the first heat exchanger and the condenser of the heat pump in turn and then is connected with the liquid inlet of the regenerator; the liquid outlet of the regenerator is connected with the first heat exchanger and the evaporator of the heat pump in turn and then is connected with the dehumidification solution storage tank; the air inlets of the dehumidifier and the regenerator are both connected with the fan; and the dehumidifier and the regenerator are both membrane components capable of isolating the dehumidification solution flowing through the membrane components from the air. The membrane has selective permeability, only allows steam to permeate and can effectively prevent the tiny droplets of the dehumidification solution from being carried in the air; and moreover, the device has the advantage of high utilization rate of energy.

Owner:SOUTH CHINA UNIV OF TECH

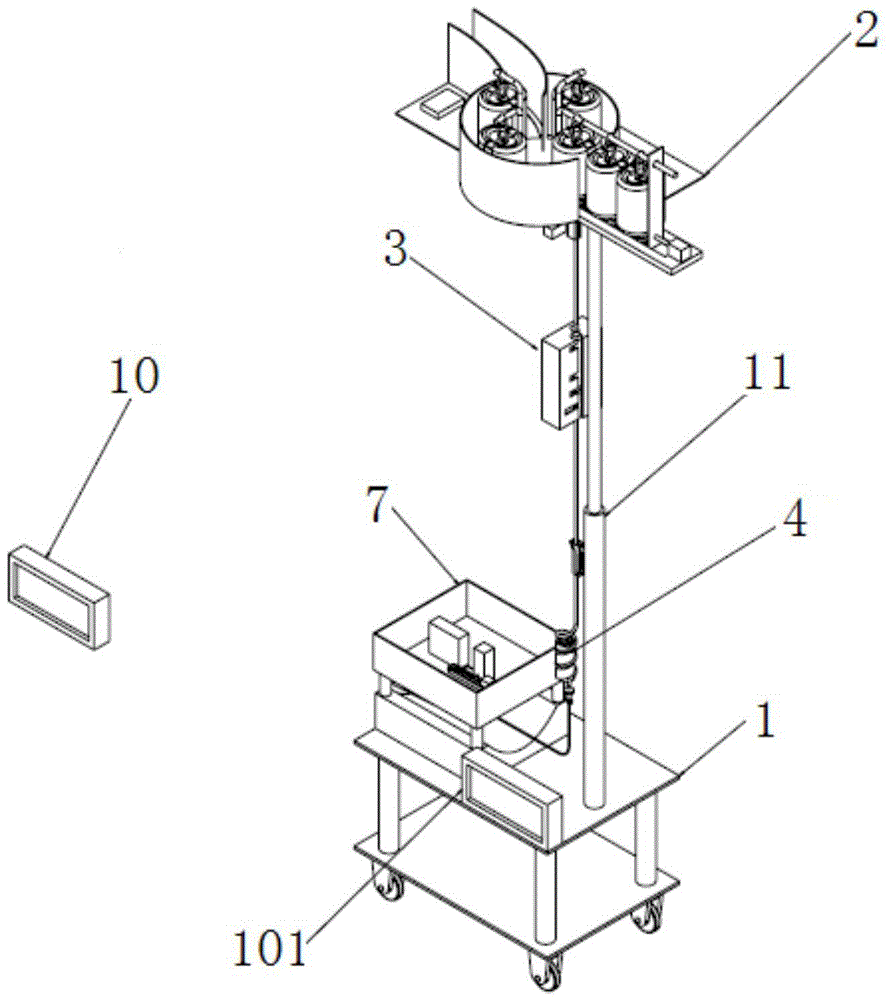

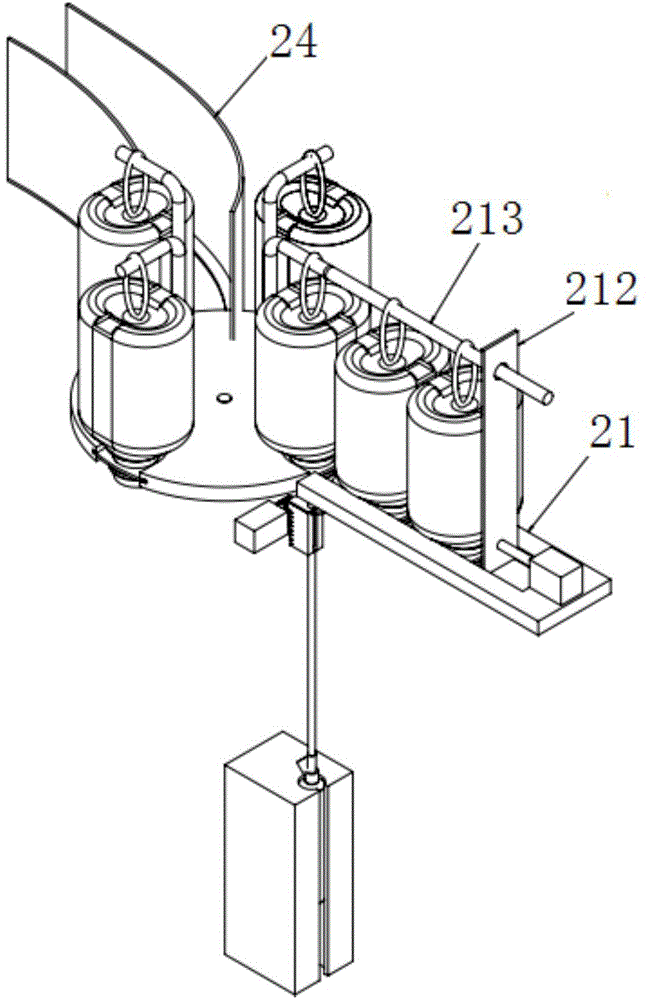

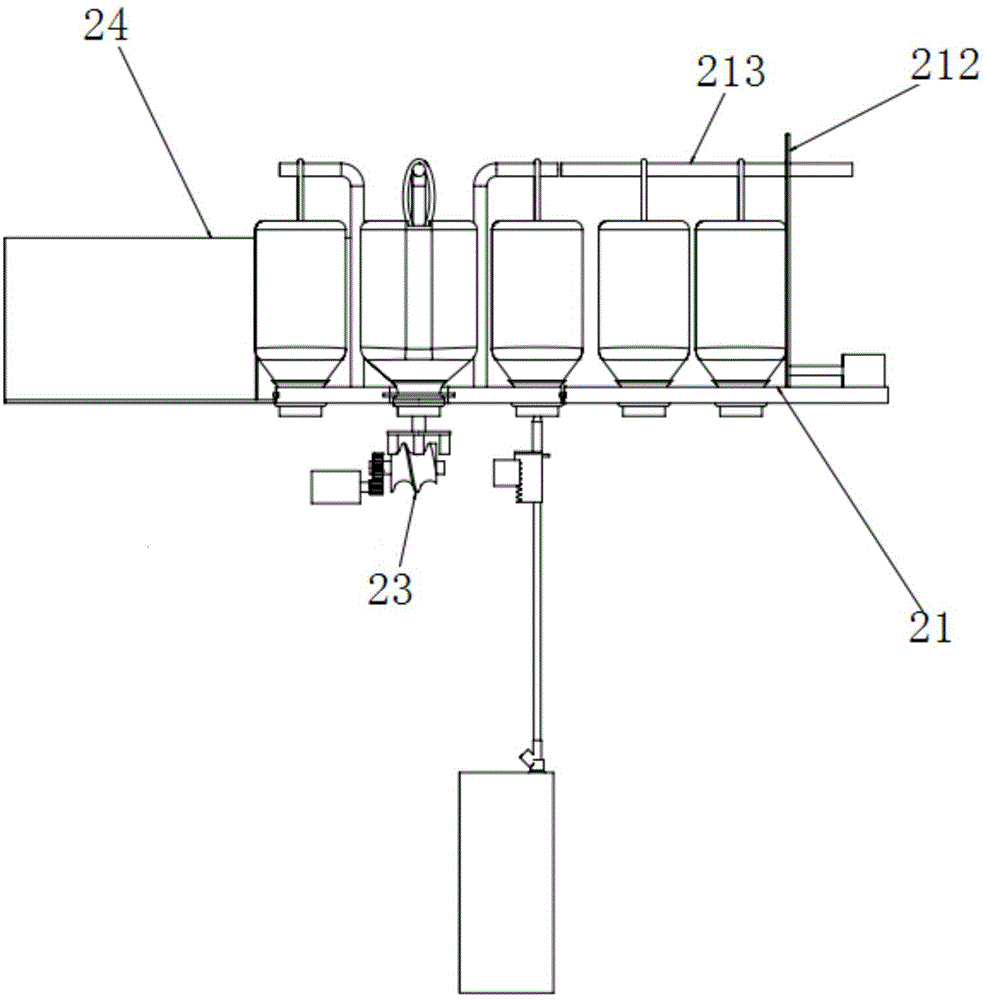

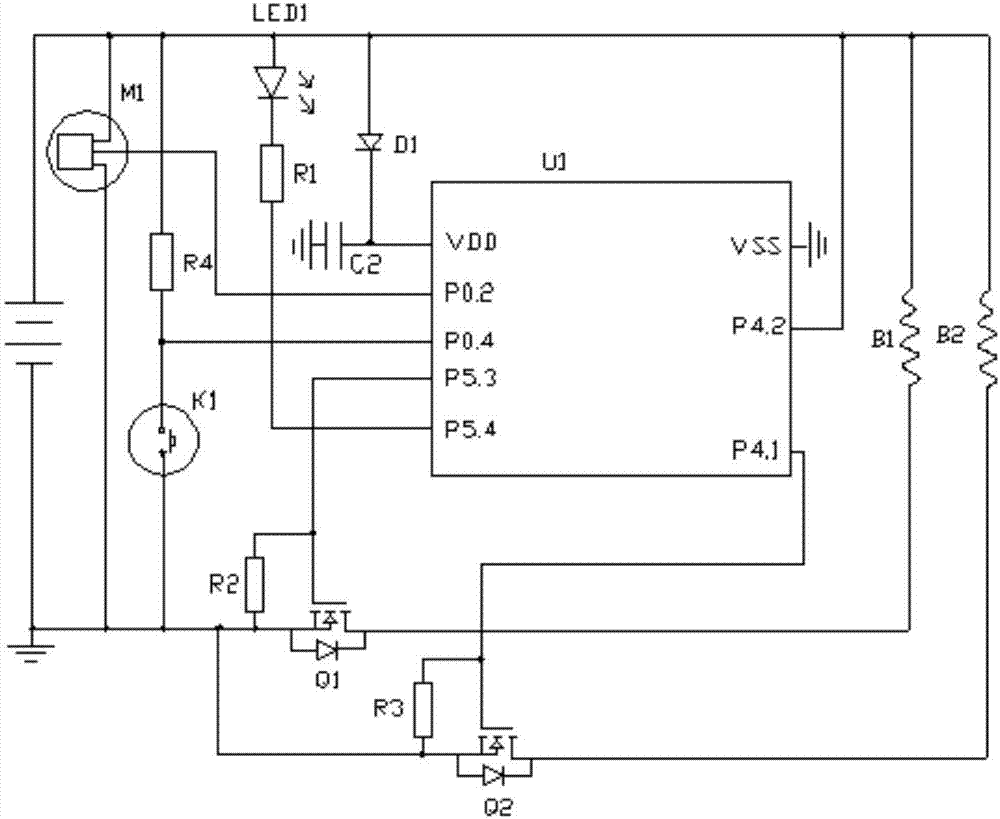

Intelligent infusion device

ActiveCN104784771AMonitor drop rateRealize automatic integrationFlow monitorsLiquid temperatureAutomatic control

The invention discloses an intelligent infusion device. The intelligent infusion device comprises an infusion bottle control mechanism, a puncture outfit mechanical arm mechanism, an infusion liquid dynamic monitoring mechanism, an infusion liquid temperature control mechanism, an automatic needle plugging and unplugging mechanism, a central control station and a central control unit. The central control unit corresponds to the puncture outfit mechanical arm mechanism, the liquid dynamic monitoring mechanism, the liquid temperature control mechanism and the automatic needle plugging and unplugging mechanism. The intelligent infusion device has the advantage that automatic integration in the infusion process can be achieved, which is concretely embodied in that an infusion bottle can be automatically changed; infusion dripping speed, flowing speed and liquid bubbles are monitored, the infusion dripping speed and flowing speed are controlled, and the bubbles are eliminated in time; in the infusion process, an infusion tube is heated, and heating temperature is automatically controlled; through control of mechanical arms, automatic needle plugging and unplugging are achieved; the central receiver controls controllers of all units, so that control over all stages in the infusion process is achieved.

Owner:深圳文健医疗科技有限公司

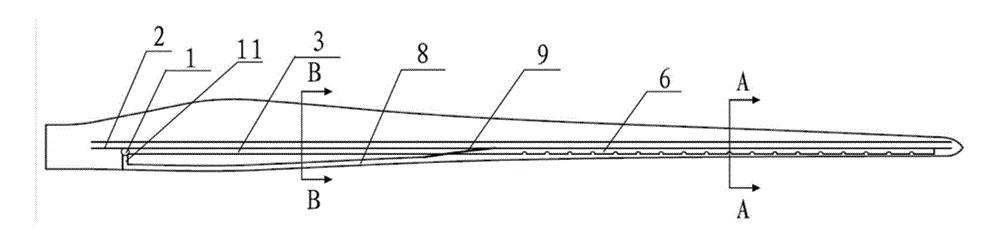

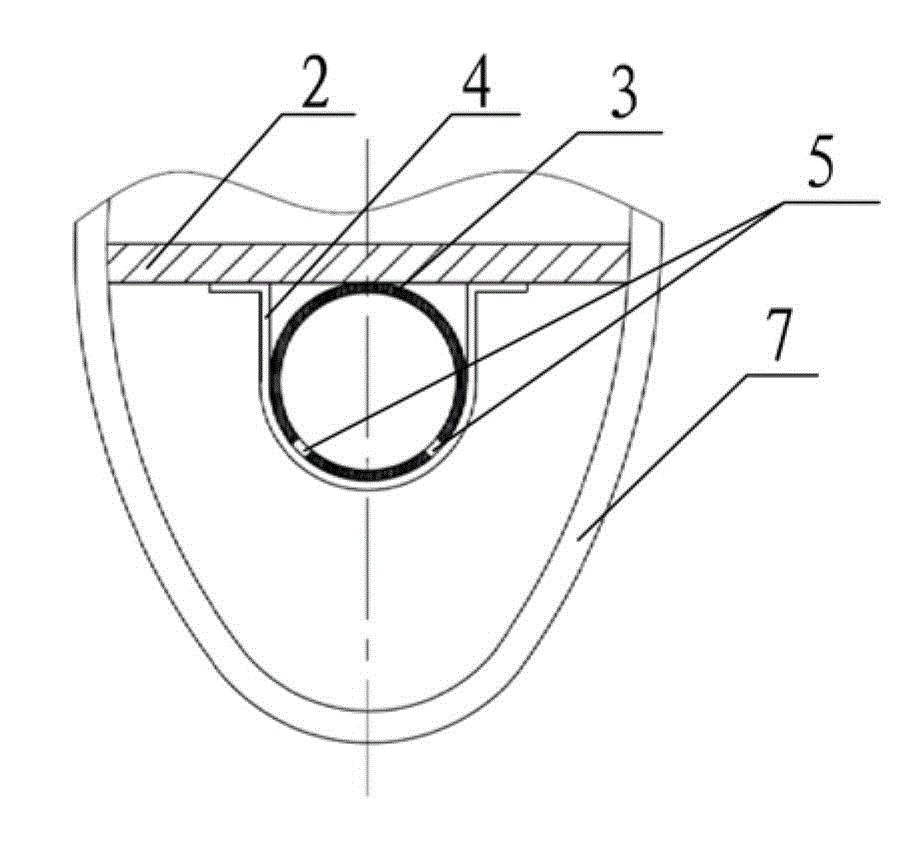

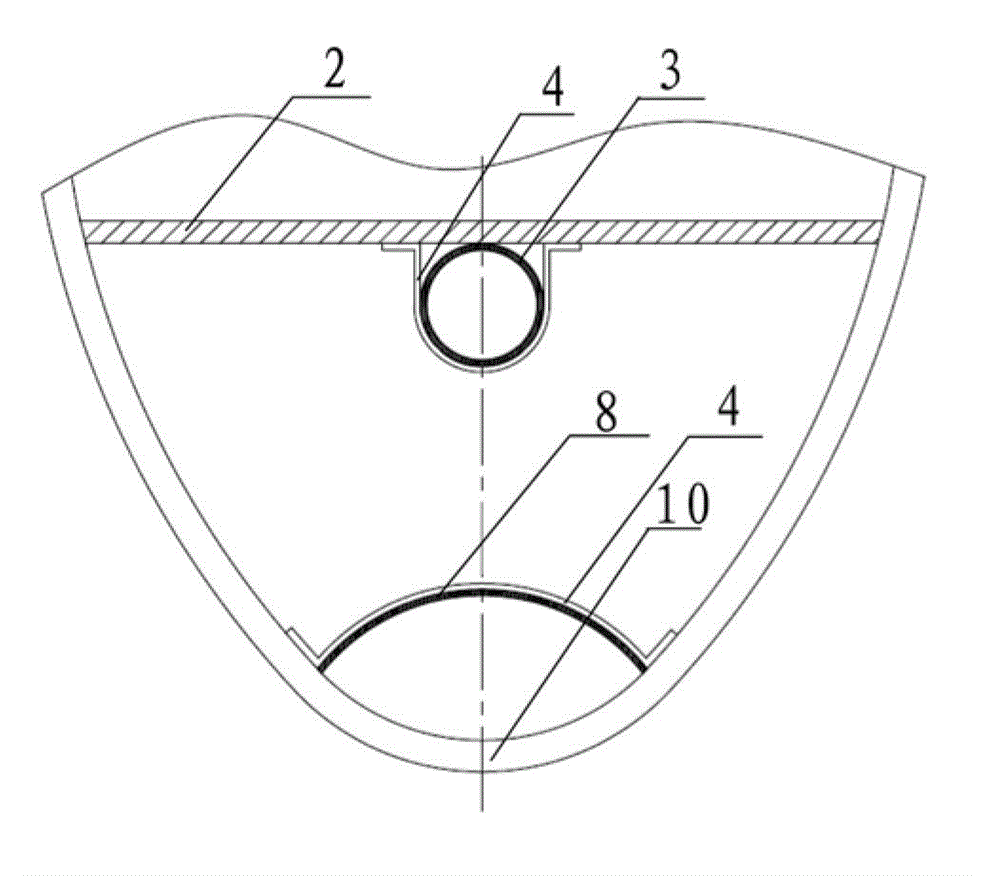

Wind wheel blade with antiicing and deicing functions

ActiveCN102748243ARealize centralized heatingEnables efficient concentrated heating of the blade leading edge shellMachines/enginesWind energy generationThermal energyLeading edge

The invention relates to a wind wheel blade with antiicing and deicing functions, and the wind wheel blade comprises a shell, and a shear web capable of dividing the interior of the shell into a leading edge cavity and a trailing edge cavity, wherein a heating device is arranged in the leading edge cavity and consists of a heating type air blower arranged close to the root of the blade, and an insulating pipeline connected with the air outlet of the heating type air blower; the insulating pipeline is provided with a flute-shaped pipe with a gas orifice at the corresponding sections from the middle of the blade to the blade tip, and the opening direction of the gas orifice faces to the leading edge of the blade; and air flow exhausted by the gas orifice is circulated to the air inlet of the heating type air blower. The wind wheel blade is reasonable in pipe structure form and distribution mode, hot air flow focally heats the leading edge of the blade, especially the blade shell from the middle of the blade to the blade tip, so that the recycling of the hot air flow can be realized, and the utilization rate of heat can be improved.

Owner:GUODIAN UNITED POWER TECH

Intelligent transfusion device and operation method thereof

ActiveCN104248790AEliminate air bubblesRealize automatic integrationInfusion devicesFlow controlProcess engineeringManipulator

The invention discloses an intelligent transfusion device and an operation method thereof. The intelligent transfusion device comprises a transfusion bottle fixing mechanism, a bottle plug piercing mechanism, a dynamic transfusion liquid monitoring / controlling mechanism, a transfusion liquid temperature-control mechanism, an automatic needle plugging and unplugging mechanism, a central receiver and central control units corresponding to the bottle plug piercing mechanism, the liquid dynamic monitoring / controlling mechanism, the liquid temperature-control mechanism and the automatic needle plugging and unplugging mechanism. The intelligent transfusion device has the advantages that by the intelligent transfusion device, automatic integration in a transfusion process is realized; transfusion bottles can be automatically changed; the dripping speed, the flow speed and liquid bubbles can be monitored during transfusion; the dripping speed and the flow speed of transfusion liquid are controlled and the air bubbles can be timely eliminated; a transfusion tube can be heated in a transfusion process; the heating temperature is automatically controlled; a needle can be plugged or unplugged automatically under the control of a manipulator; and various stages of a transfusion process are controlled by controllers which are used for controlling the various units through the central receiver.

Owner:深圳煜睿医疗设备有限公司

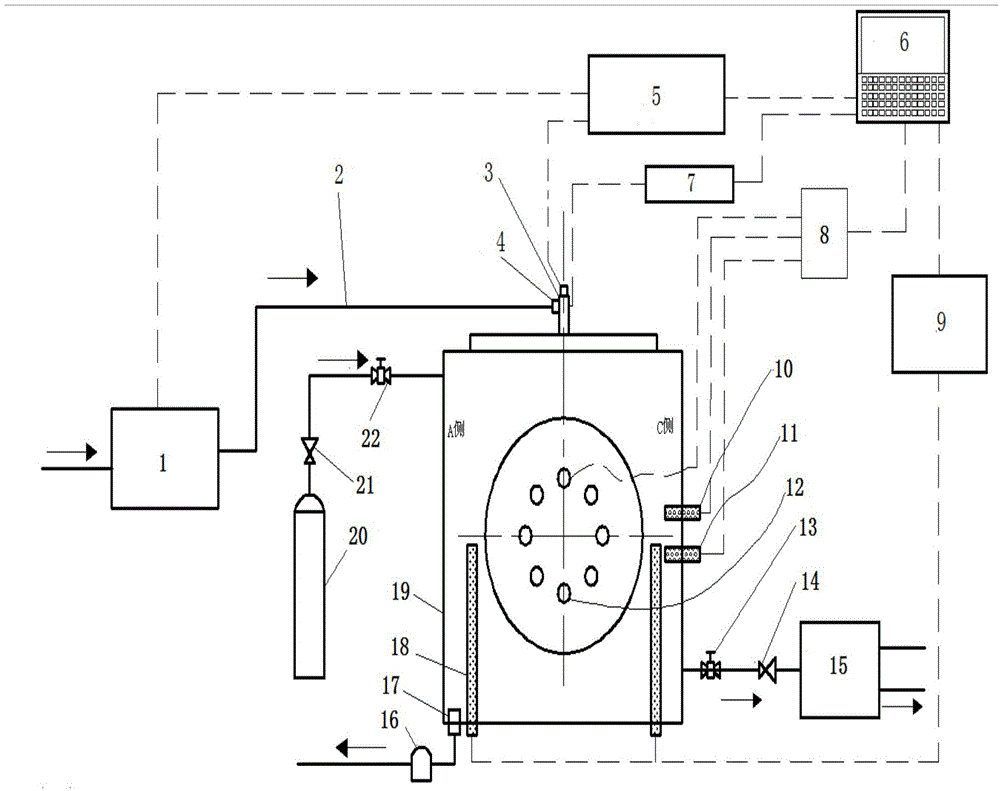

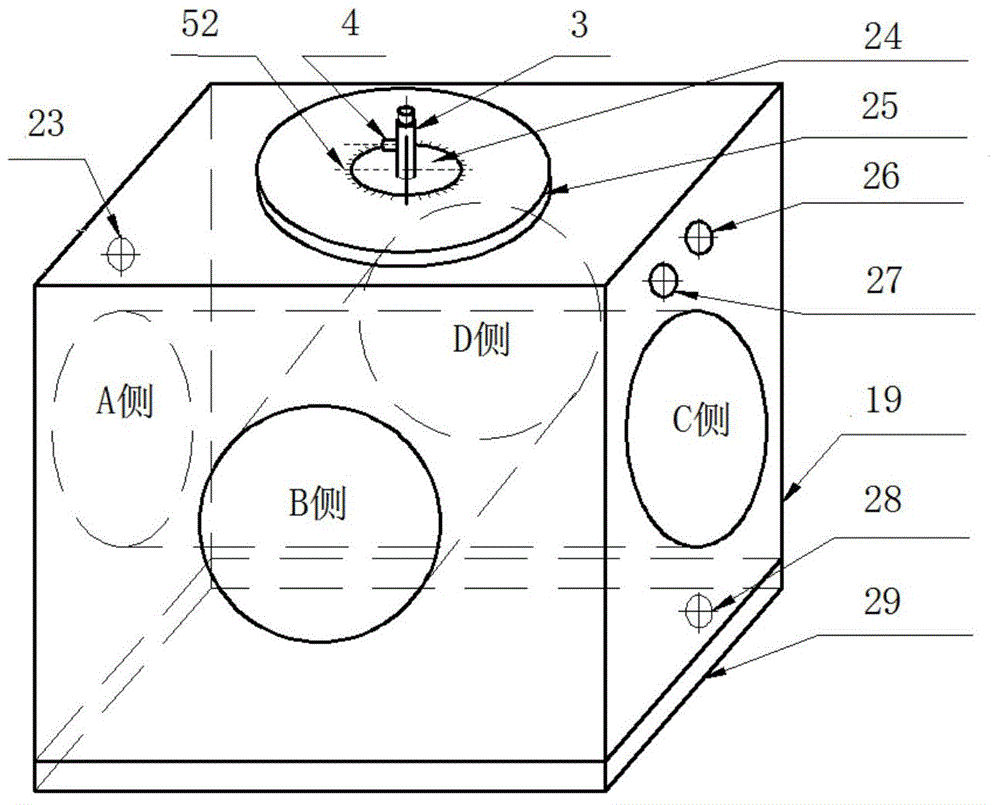

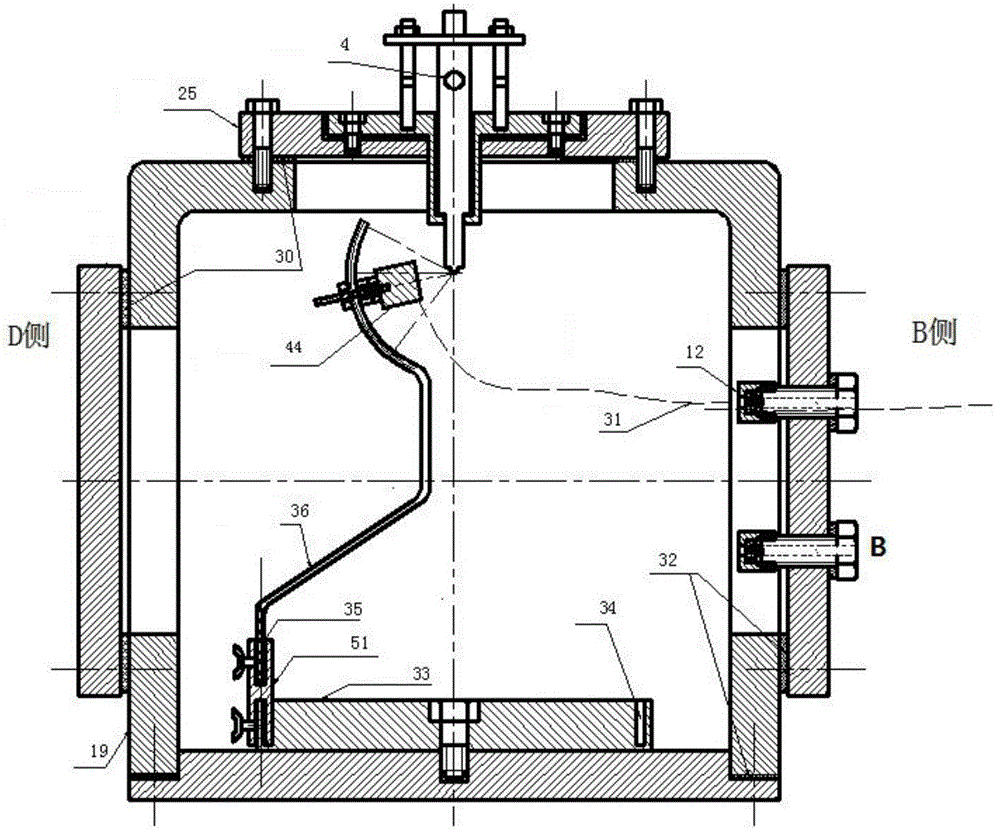

Device for testing material properties in high-temperature hydrogen environment

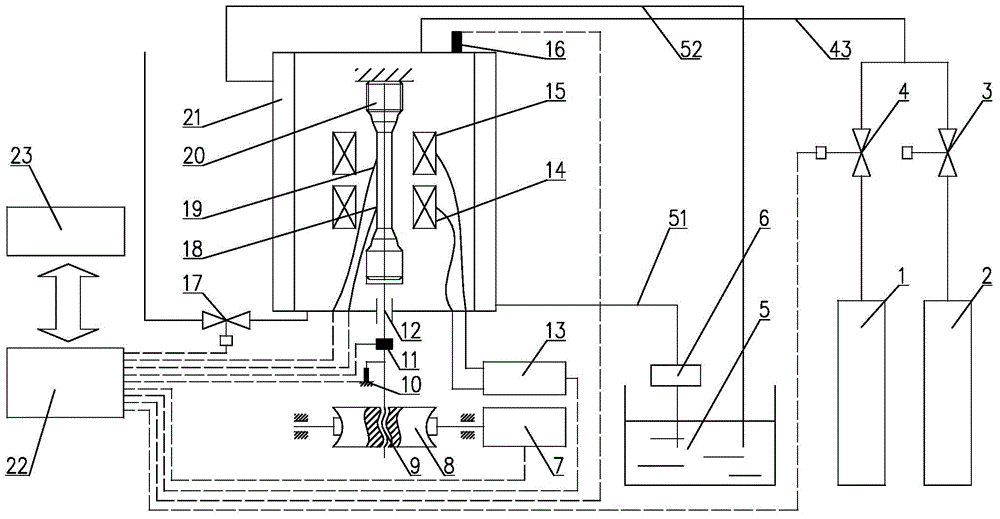

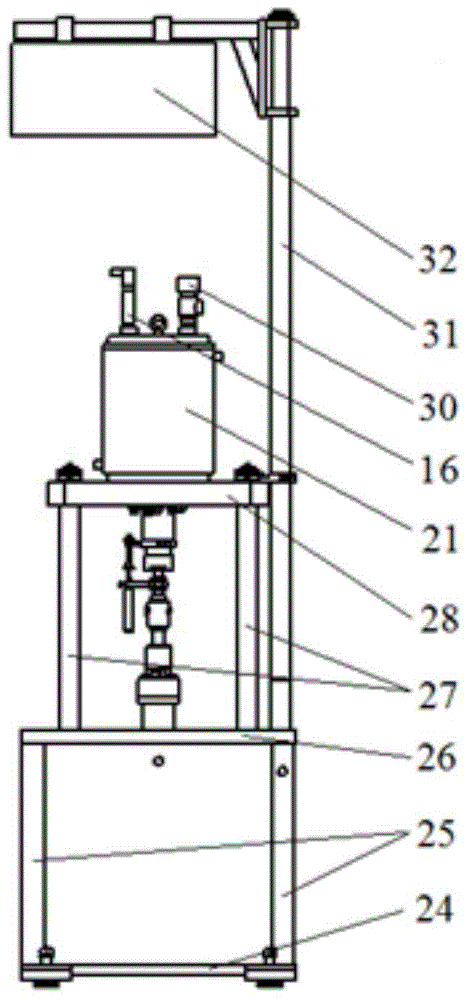

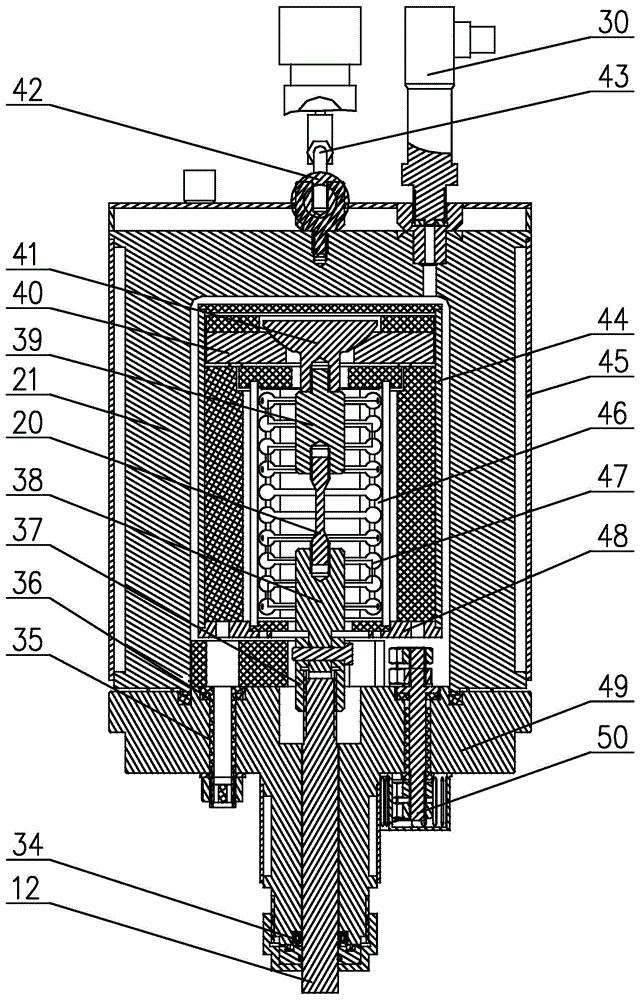

ActiveCN104897476AReasonable and reliable device structureShort heat transfer chainWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesProcess engineeringHydrogen supply

The invention relates to a device for testing material properties in a high-temperature hydrogen environment. The device comprises a hydrogen environment box and a host machine loading framework, wherein a test sample is arranged in the hydrogen environment box; a pull rod is mounted on the host machine loading framework; the hydrogen environment box is arranged on the host machine loading framework; an upper clamping part, a lower clamping part and an electrical heating component are arranged in the hydrogen environment box; the pull rod penetrates through the hydrogen environment box and is fixedly connected with the lower clamping part; the hydrogen environment box is connected with a hydrogen supply pipe; an air-relief solenoid valve is arranged on the hydrogen environment box. The device further comprises sensors and a control component, wherein the sensors are used for monitoring test sample stress load, test sample deformation, test sample environment temperature and test sample ambient hydrogen pressure; the control component is used for monitoring and processing the information collected by the sensors. The device can be used for testing the creep property, stress rupture property and tension-tension alternating load fatigue property of a metal material in the hydrogen environment, can ensure the accuracy of testing results, works reliably and stably and has high efficiency.

Owner:HEFEI GENERAL MACHINERY RES INST +1

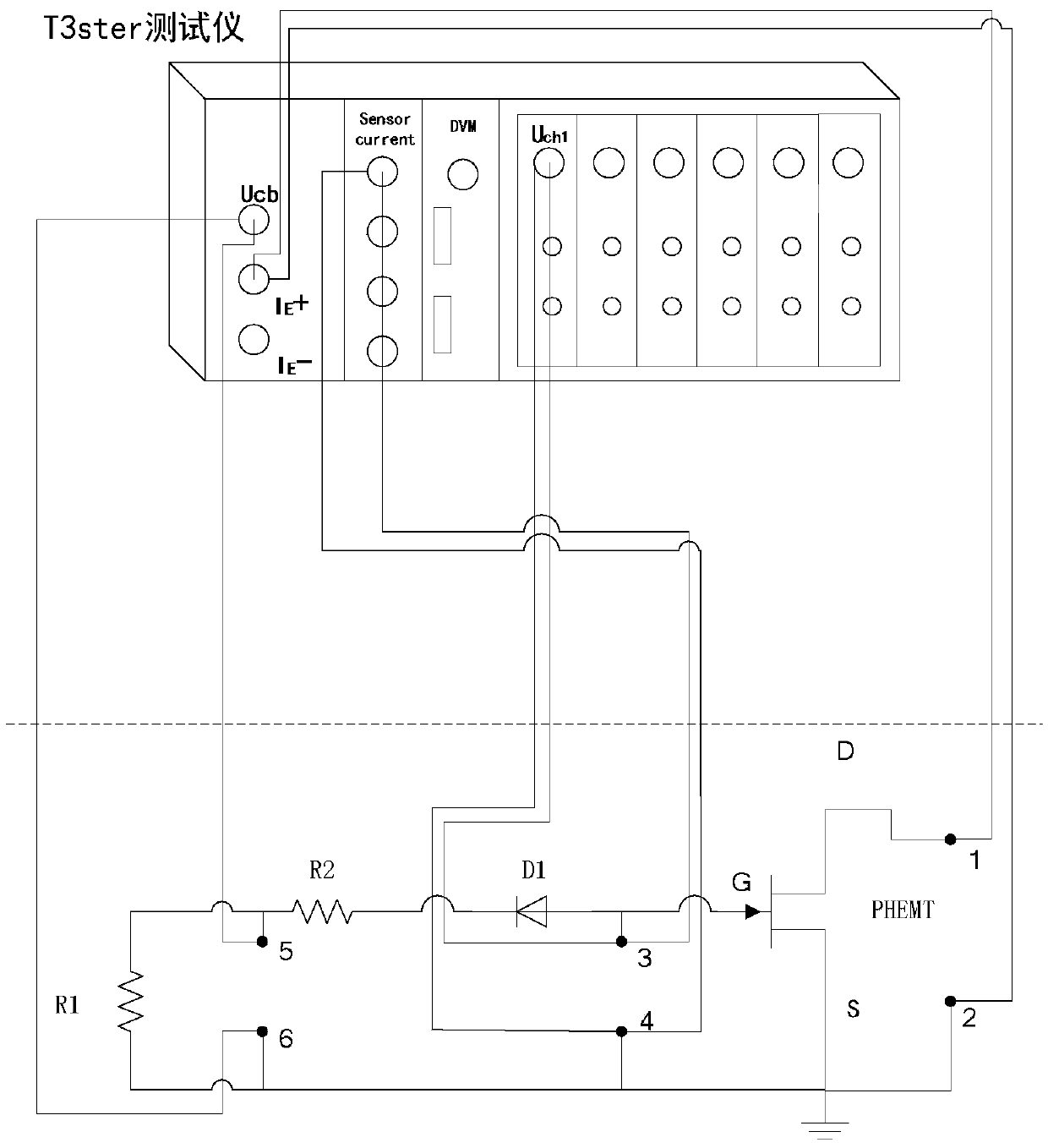

Heat resistance measurement method for pseudomorphic high electron mobility transistor (PHEMT)

ActiveCN105510794AEasy to operateImprove switching characteristicsMaterial heat developmentIndividual semiconductor device testingTemperature measurementHigh-electron-mobility transistor

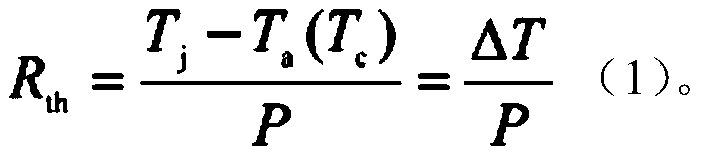

The invention discloses a heat resistance measurement method for a pseudomorphic high electron mobility transistor (PHEMT); by adopting the heat resistance measurement method, the temperature measurement is accurate, and damage to the PHEMT and measurement errors are not easy to cause. The method is implemented by the following technical scheme: a semiconductor heat resistance measurement instrument T3ster provides a current source to load current between a drain electrode and a source electrode of the PHEMT; a channel of the PHEMT is heated by the internal resistance of the transistor, then a T3ster peripheral control circuit performs instantaneous circuit switching, and the heating is stopped instantaneously; in the process, a voltage output end Ucb of the T3ster enables a fast recovery diode to be positively biased, under the effect of partial voltage of a divider resistor R1 connected with the Ucb on the Ucb, pinch-off voltage between a grid electrode G and the source electrode S of the PHEMT to be measured is generated, and reversal of biasing between the grid electrode G and the source electrode S of the PHEMT is realized; after the circuit switching, positive biasing between the grid electrode G and the source electrode S is realized, and the voltage drop reflects a temperature. Heat resistance is obtained according to a temperature change value measured by the T3ster by using data processing software Master of the T3ster in a computer.

Owner:10TH RES INST OF CETC

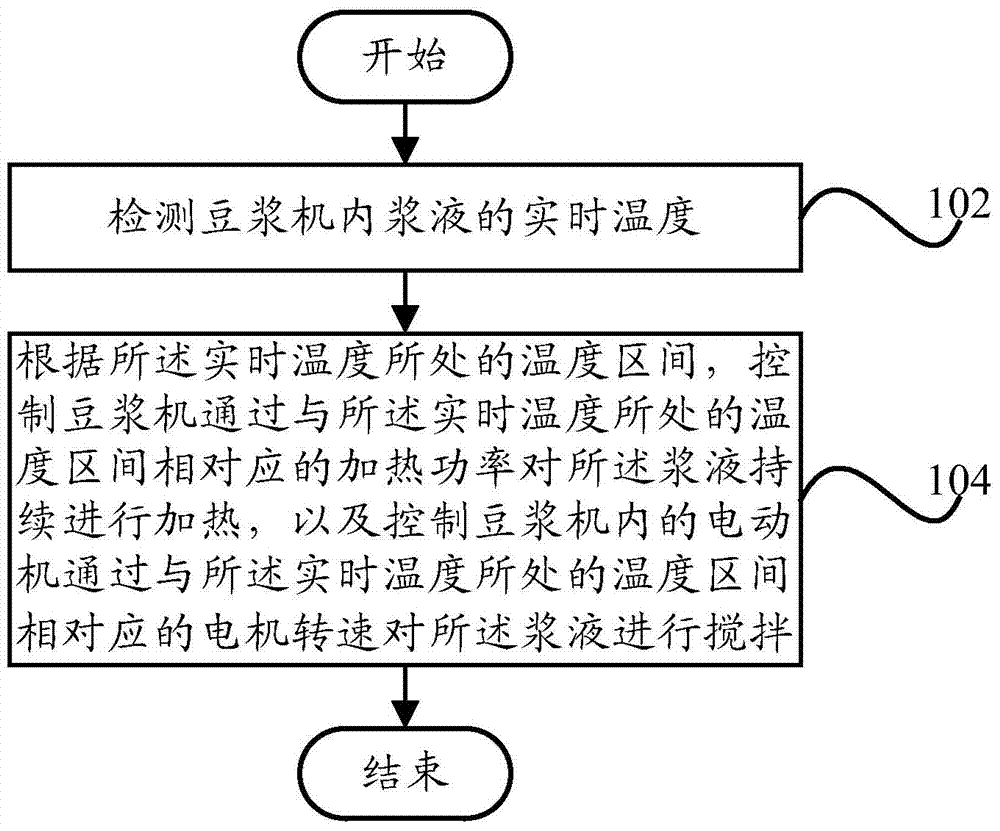

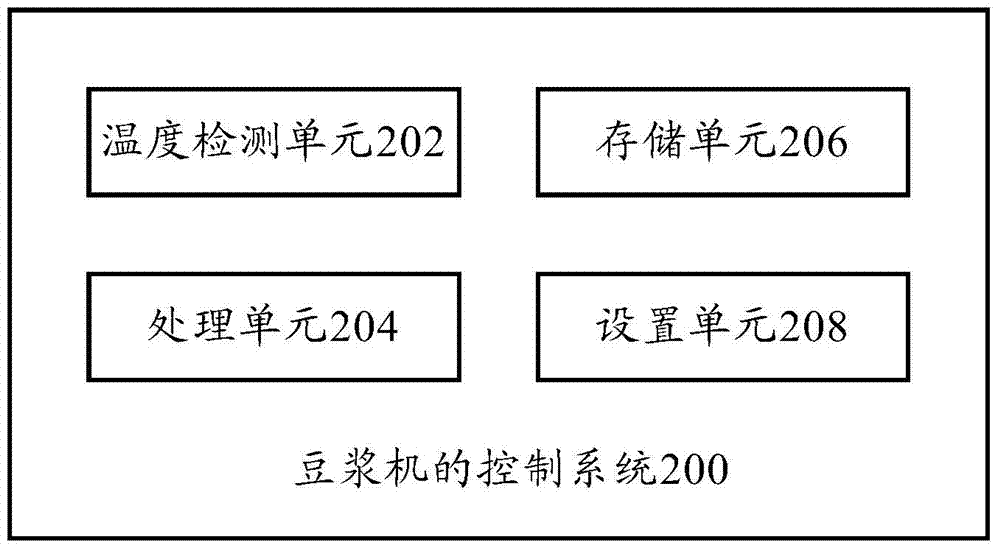

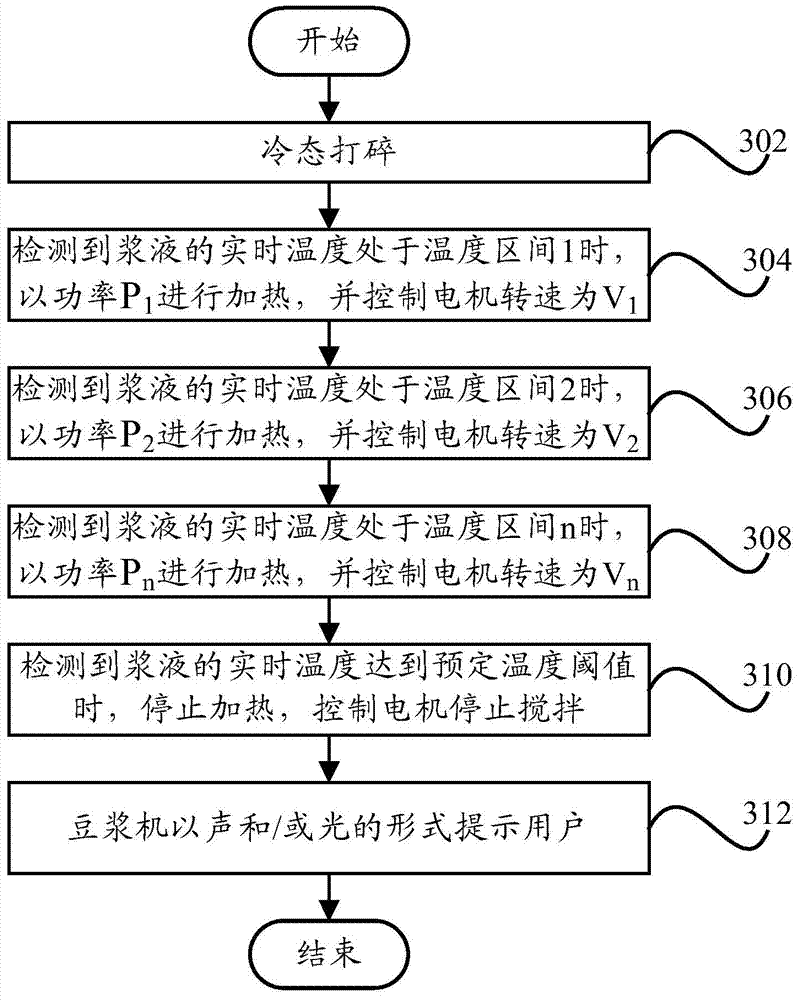

Method and system for controlling soybean milk machine and soybean milk machine

The invention provides a method and system for controlling a soybean milk machine and the soybean milk machine. The method for controlling the soybean milk machine includes the steps of detecting the real-time temperature of soybean milk in the soybean milk machine; according to the temperature interval of the real-time temperature, controlling the soybean milk machine to continuously heat the soybean milk with the heating power corresponding to the temperature interval of the real-time temperature, and controlling a motor in the soybean milk machine to stir the soybean milk at the motor rotating speed corresponding to the temperature interval of the real-time temperature. By means of the technical scheme, on the premise that foaming overflowing or burnt bottom sticking of the soybean milk is avoided, it can be guaranteed that the soybean milk machine can continuously carry out heating, and it is guaranteed that the soybean milk has the abundant nutritional ingredients.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

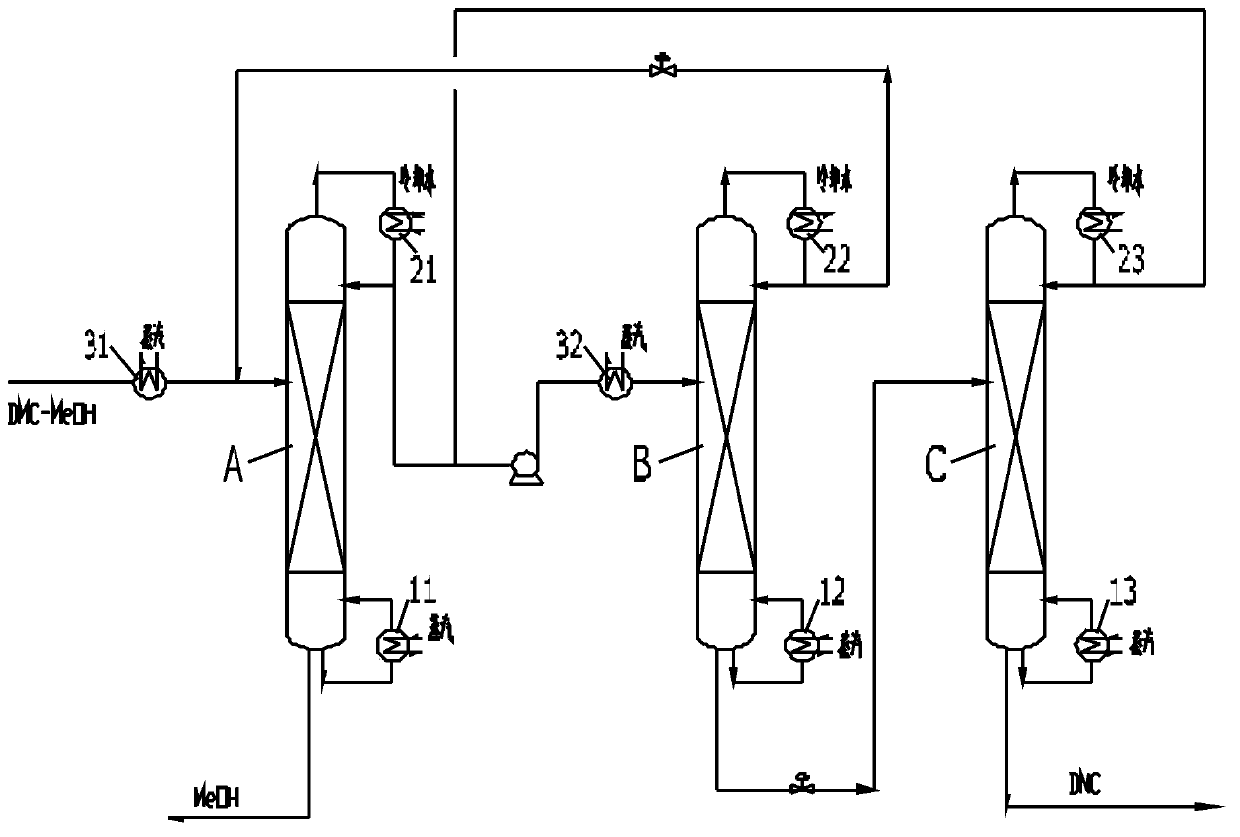

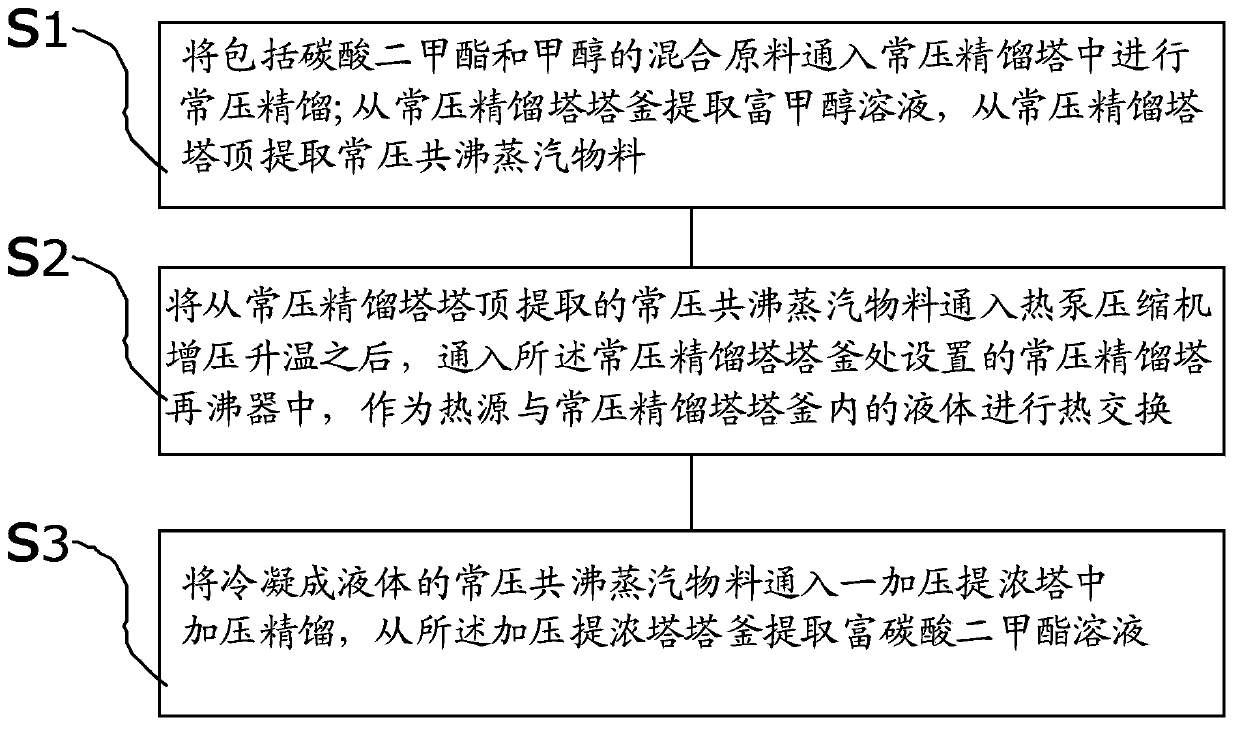

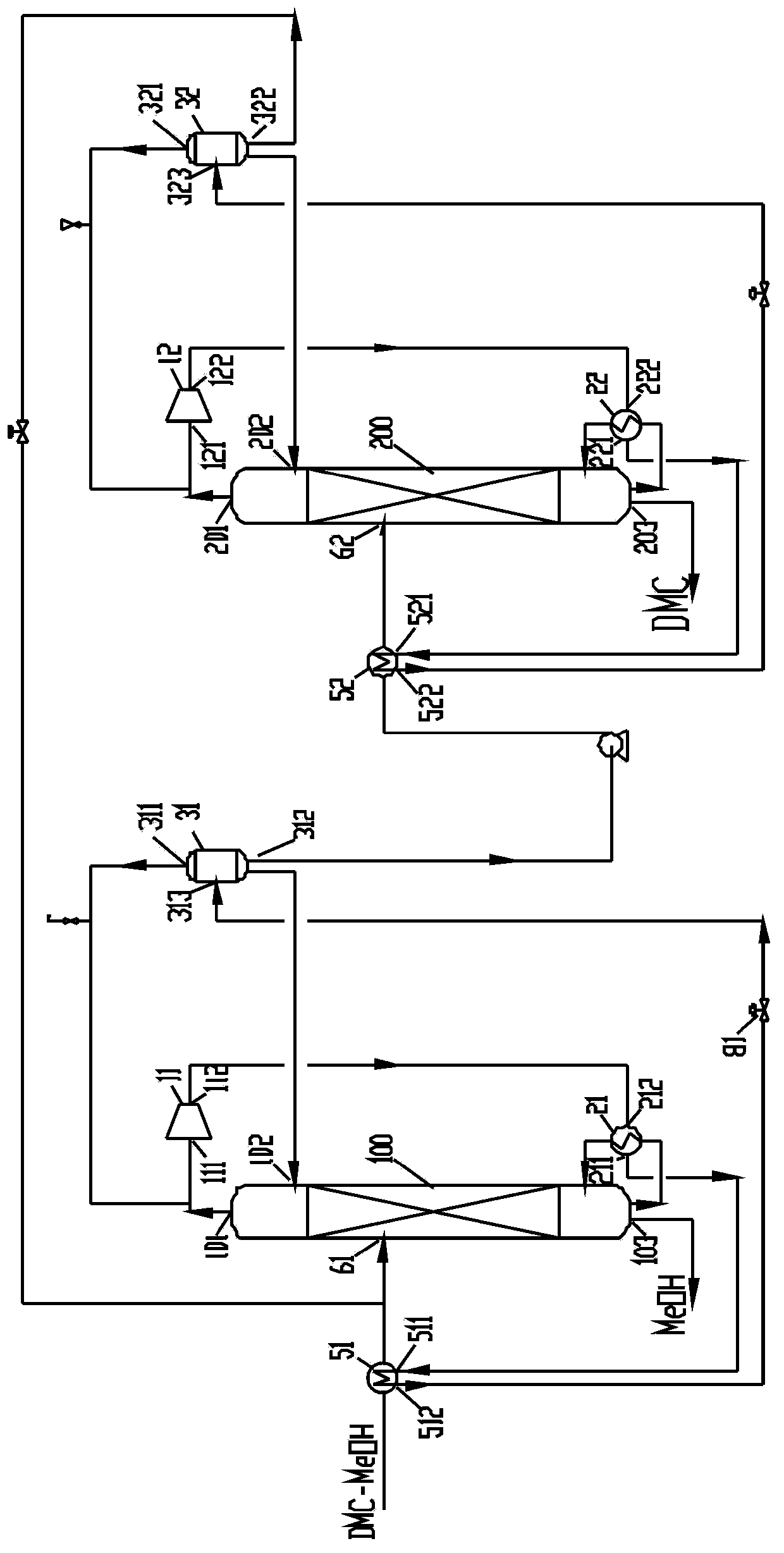

Method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and apparatus thereof

InactiveCN103626656AReduce energy consumptionLow costCarbamic acid derivatives preparationOrganic compound preparationReboilerSelf-condensation

The invention provides a method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and an apparatus thereof. In the dimethyl carbonate and methanol through pressure-swing distillation of the heat pump, an atmospheric azeotropic steam material obtained from the top of an atmospheric rectification tower is supercharged and heated by a heat pump compressor, and is introduced to a reboiler at the bottom of the atmospheric rectification tower as a heat source, so a liquid in the atmospheric rectification tower is heated, and the self-condensation of the atmospheric azeotropic steam material is completed. Compared with traditional atmospheric azeotropic steam material condensation through using cooling water and kettle liquid heating realized through an extra external heat source, the method in the invention properly improves the temperature and the pressure of an atmospheric azeotropic steam through the heat pump compressor to make the atmospheric azeotropic steam realize the kettle liquid heating and the reasonable and effective energy cycle as a heat source; and the cost generated by the pump heat compressor is far lower than the cost of traditional cooling water and the external heat source, so a good economic benefit is generated.

Owner:YASHENTECH CORP

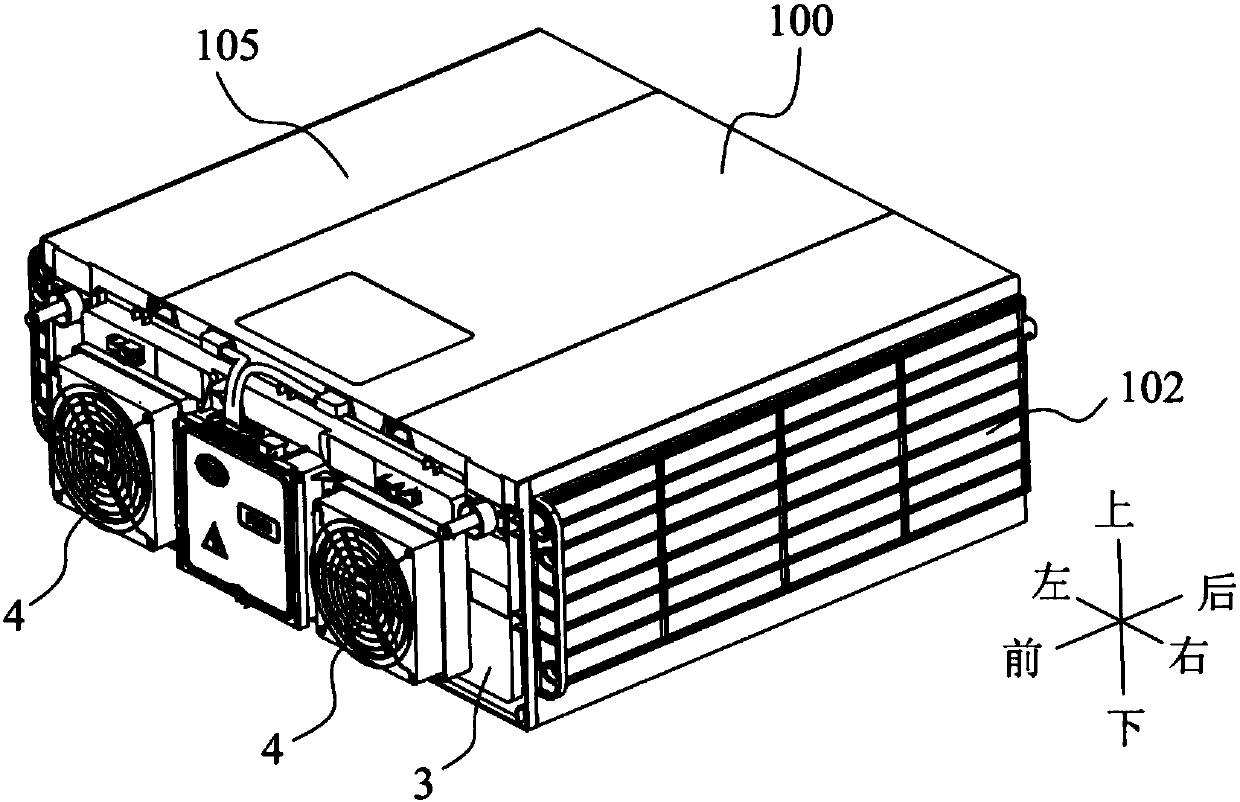

Battery module, power battery pack and automobile

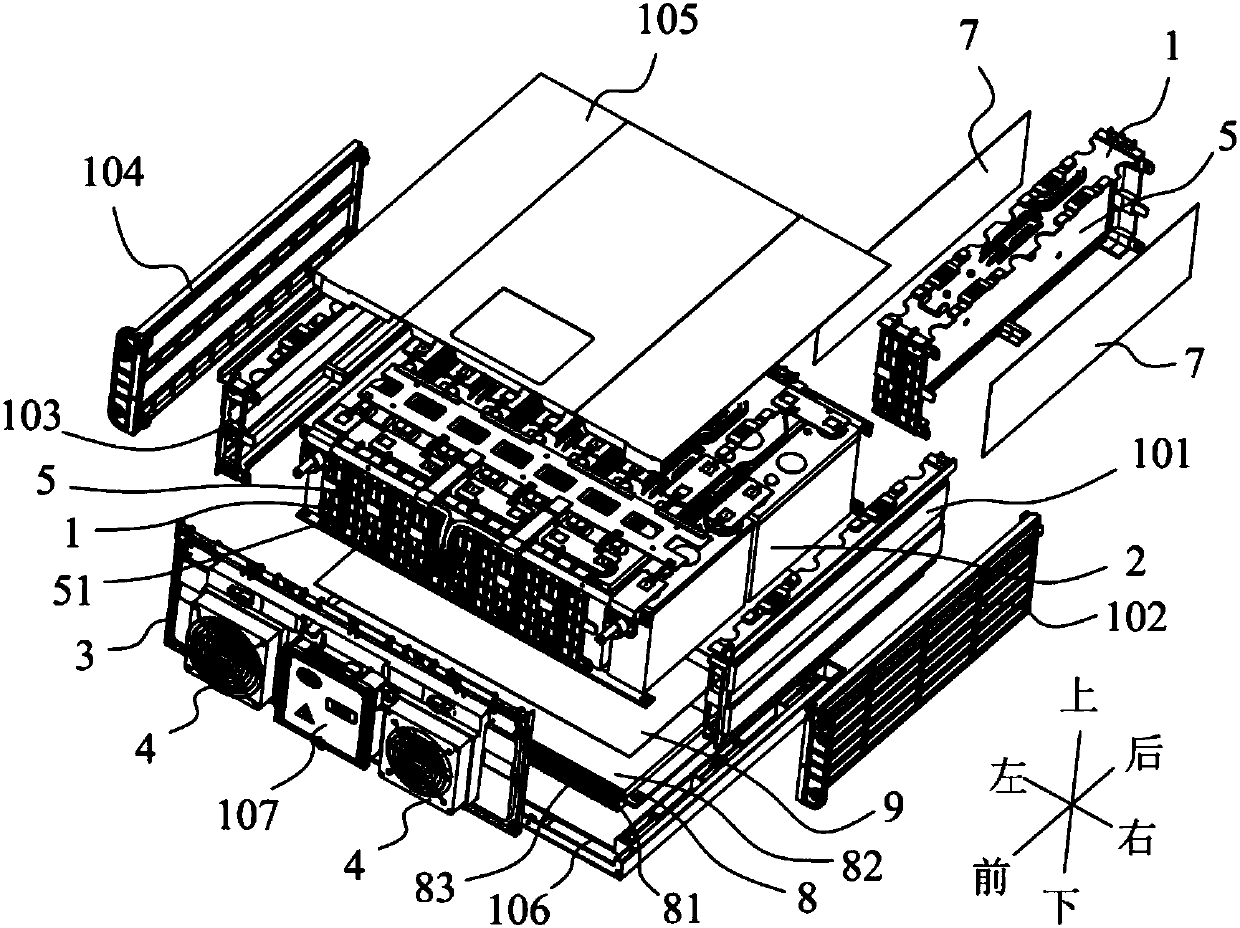

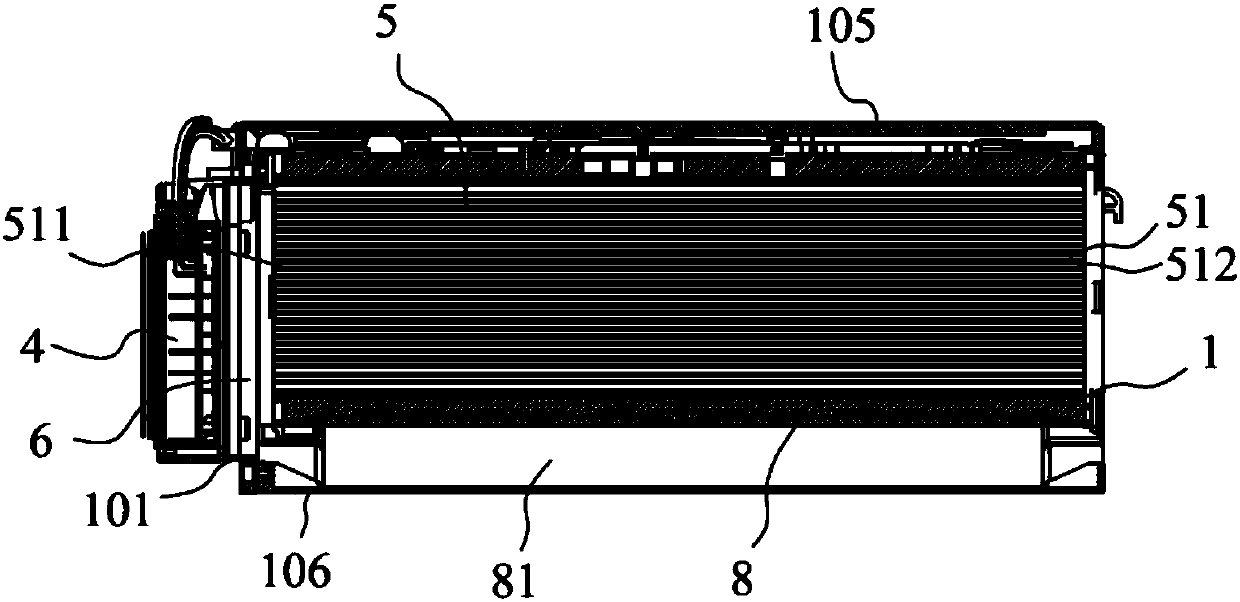

ActiveCN107785511AImprove cooling efficiencyRealize heat dissipationSecondary cellsCell lids/coversElectrical batteryHigh rate

The invention relates to a battery module, a power battery pack and an automobile. The battery module comprises a plurality of middle separation plates which are stacked along the left-right directionof the battery module, a plurality of single batteries, a mounting plate arranged at the front side of the battery module and a draught fan fixed on the mounting plate, wherein middle heat dissipation air plates are arranged on the middle separation plates; middle heat dissipation air channels which are through along the front-rear direction are formed in the middle heat dissipation air plates; left side faces of the middle heat dissipation air plates are subjected to heat exchange with right side surfaces of the single batteries at the left side; right side faces of the middle heat dissipation air plates are subjected to heat exchange with left side surfaces of the single batteries at the right side; each middle heat dissipation air channel is provided with a first air opening and a second air opening; a chamber is arranged between a mounting plate and a front end face of each single battery; the first air openings are communicated with the chambers and the second air openings are formed in the rear side of the battery module and are communicated with the outer part of the battery module. The battery module provided by the invention is high in heat dissipation efficiency and theheat dissipation problem in a rapid charge / discharge process (3C to 6C high-rate charging and discharging) is solved.

Owner:BYD CO LTD

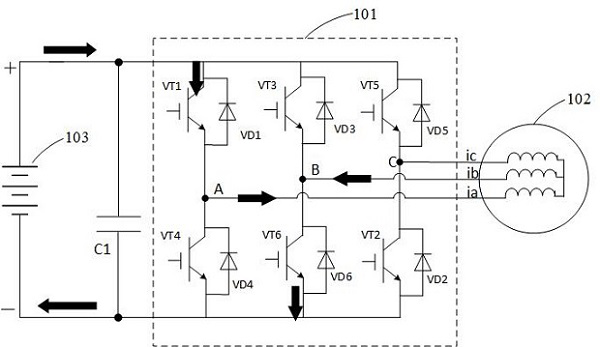

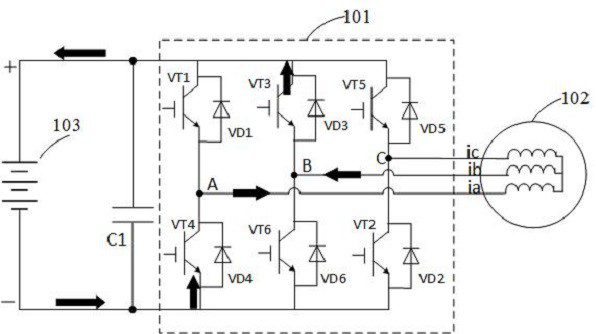

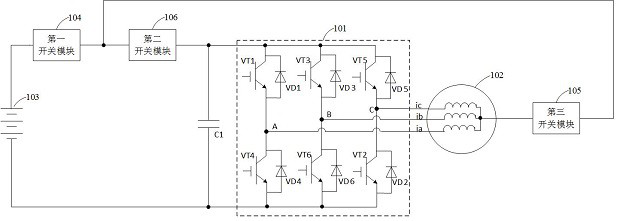

Vehicle, energy conversion device and control method thereof

ActiveCN111660875ASimple structureAvoids the problem that the heating rate is also severely slowed downCharging stationsCell temperature controlInternal resistanceElectric capacity

The technical scheme of the invention provides a vehicle, an energy conversion device and a control method thereof. The energy conversion device comprises a first switch module, a second switch module, a bus capacitor, a bridge arm converter, a motor winding and a third switch module; the first switch module, the motor winding, a bridge arm converter and the bus capacitor are applied to a motor driving circuit and a heating circuit, so that the output torque of a motor can be realized, and the internal resistance of a battery can be heated; newly added circuit elements are avoided, so that a circuit structure is simplified; the bus capacitor participates in the charging and discharging process in the heating circuit, so that a large amount of current is prevented from passing through the bus capacitor when a battery pack discharges, and the current passing through the battery pack drops significantly, and the heating efficiency of the battery pack is improved; the connection between the third switch module and the second switch module is arranged to replace the connection between the third switch module and the battery pack, so that a wiring harness distance is shortened, and the wiring harness use cost is finally saved.

Owner:BYD CO LTD

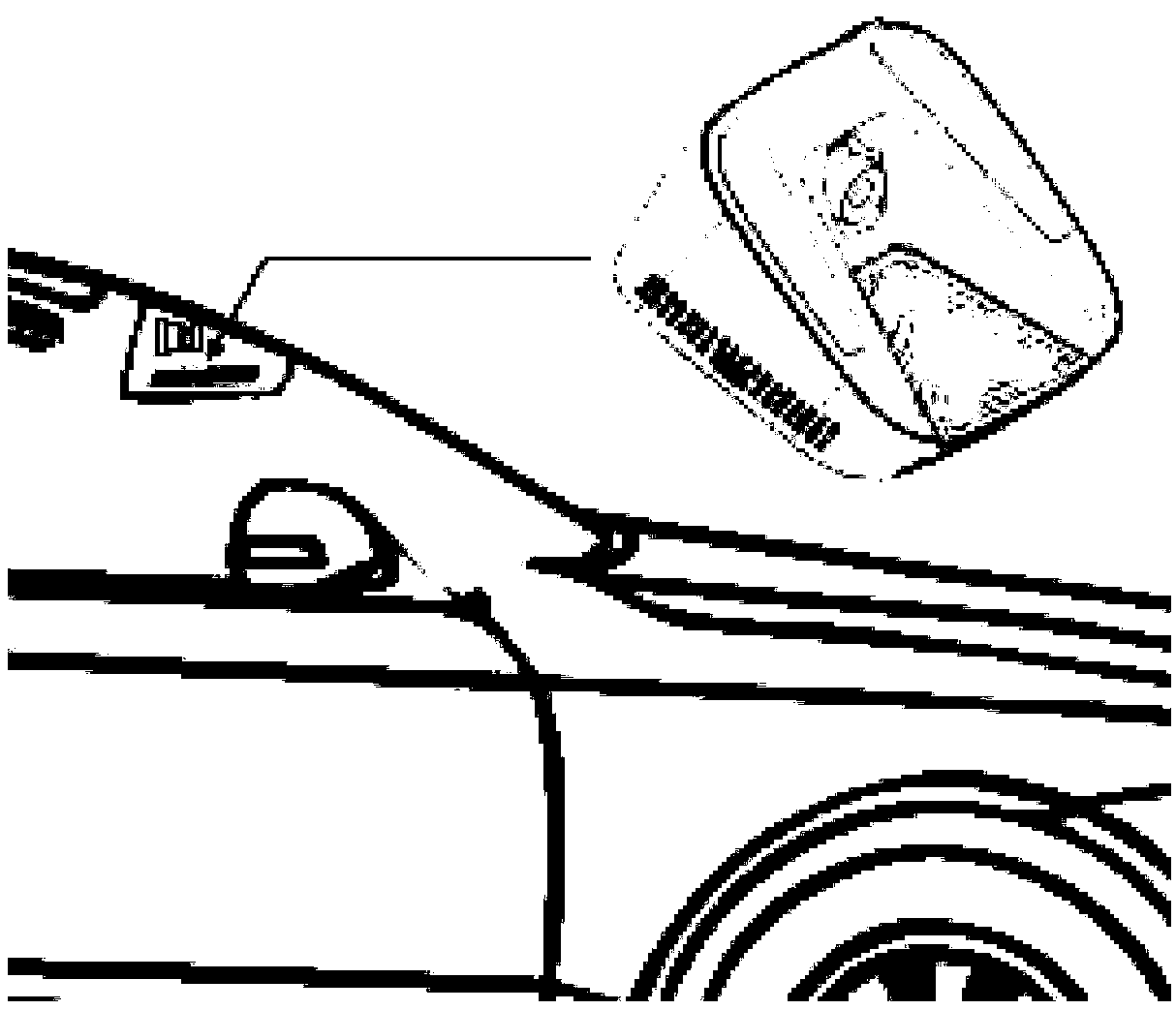

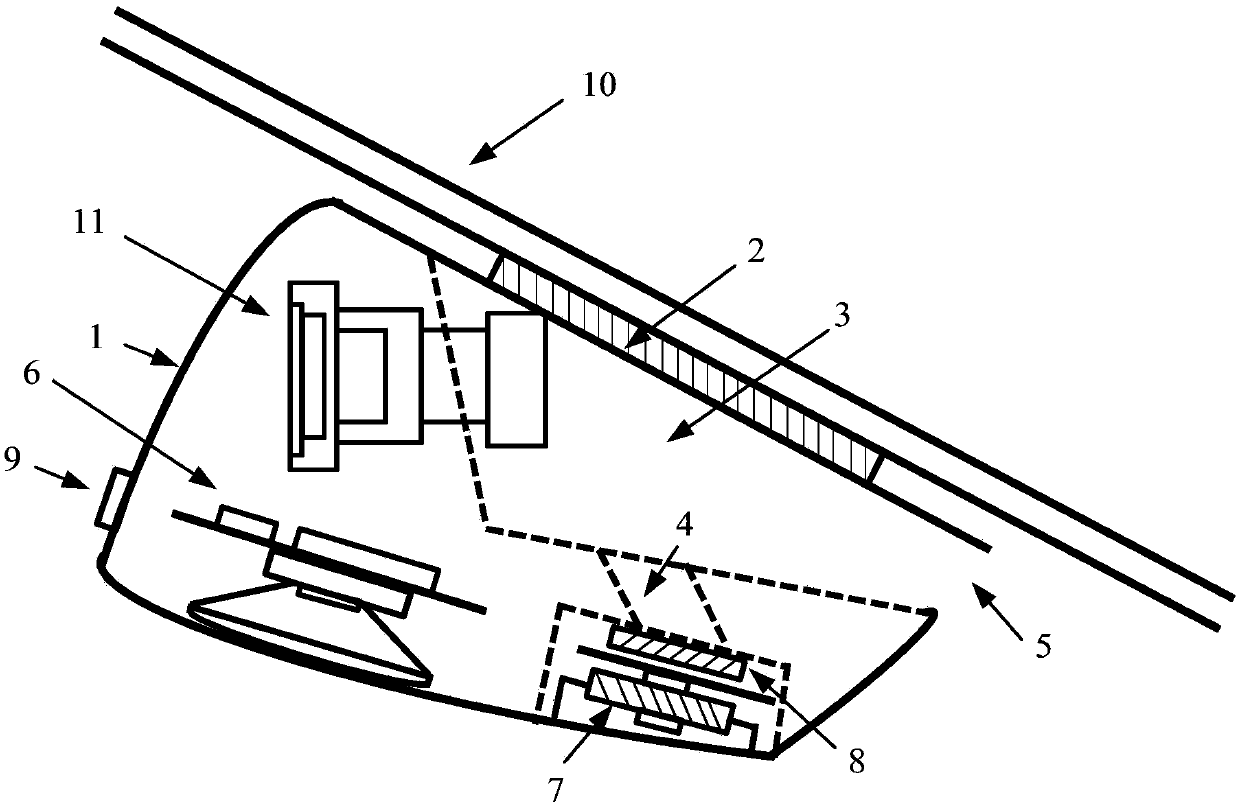

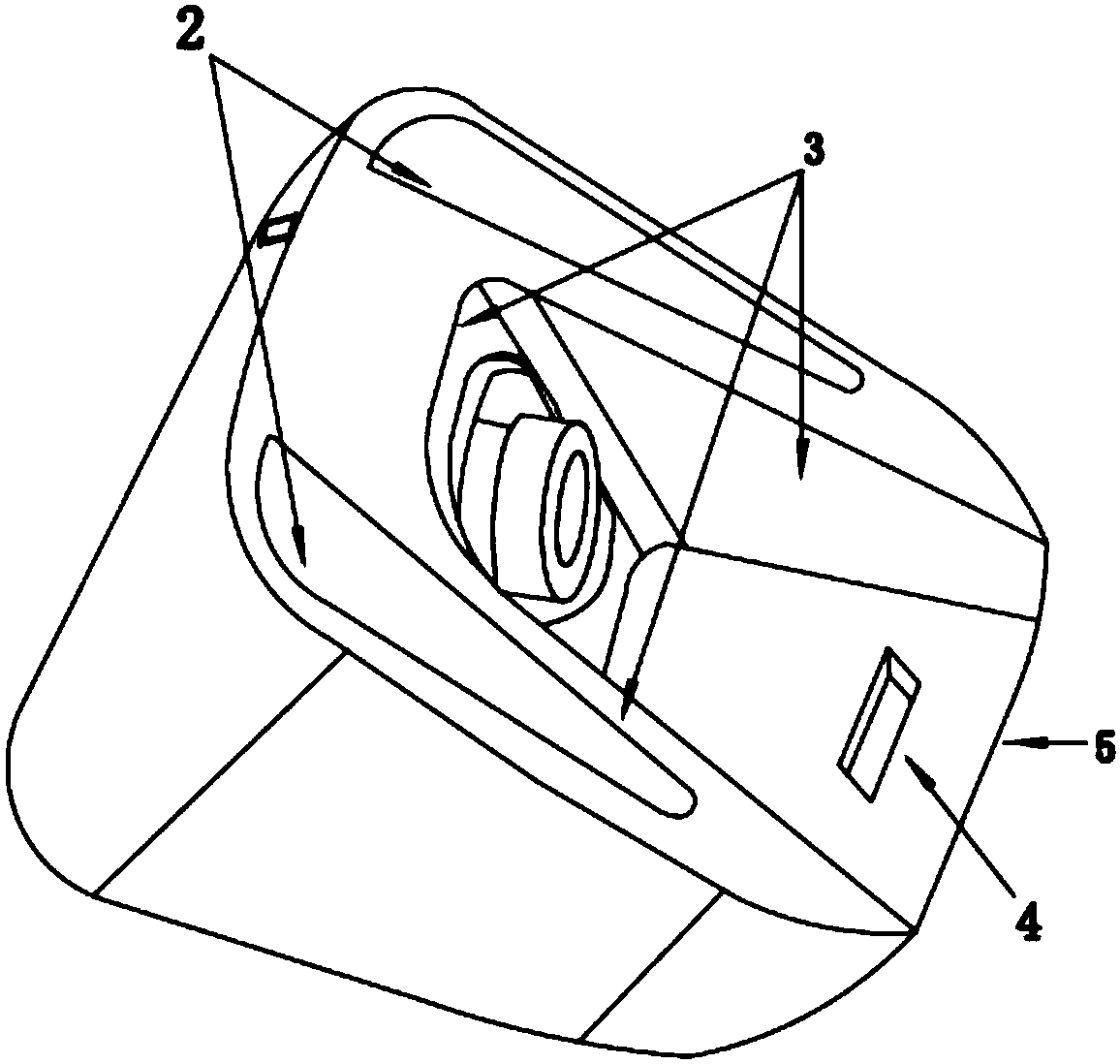

Automobile auxiliary driving system camera demisting device

ActiveCN107856642AGuaranteed to workGuaranteed imaging effectAir heatersVehicle cleaningControl circuitComputer engineering

The embodiment of the invention discloses an automobile auxiliary driving system camera demisting device. The device comprises a shell, a camera, a fan, a heater and a control circuit, wherein the camera, the fan, the heater and the control circuit are arranged in the shell. The shell comprises a pasting part for fixing the shell to a front windshield of an automobile. An air hood is composed of agroove formed in the side, provided with the pasting part, of the shell and the front windshield. An air outlet is located in one side of the air hood. An air inlet is formed in the groove. The fan is arranged next to the air inlet. The heater is arranged between the fan and the air inlet. The camera for shooting images outside the front windshield extends to the groove from the inner portion ofthe shell. The control circuit is connected with the fan and the heater so as to control the fan and the heater to be started or stopped and start or stop the demisting function of the camera. By theadoption of the technical scheme, mist on the auxiliary driving camera can be conveniently and quickly removed when an image imaging effect is guaranteed, and the driving experience of a driver is enhanced.

Owner:大众问问(北京)信息科技有限公司

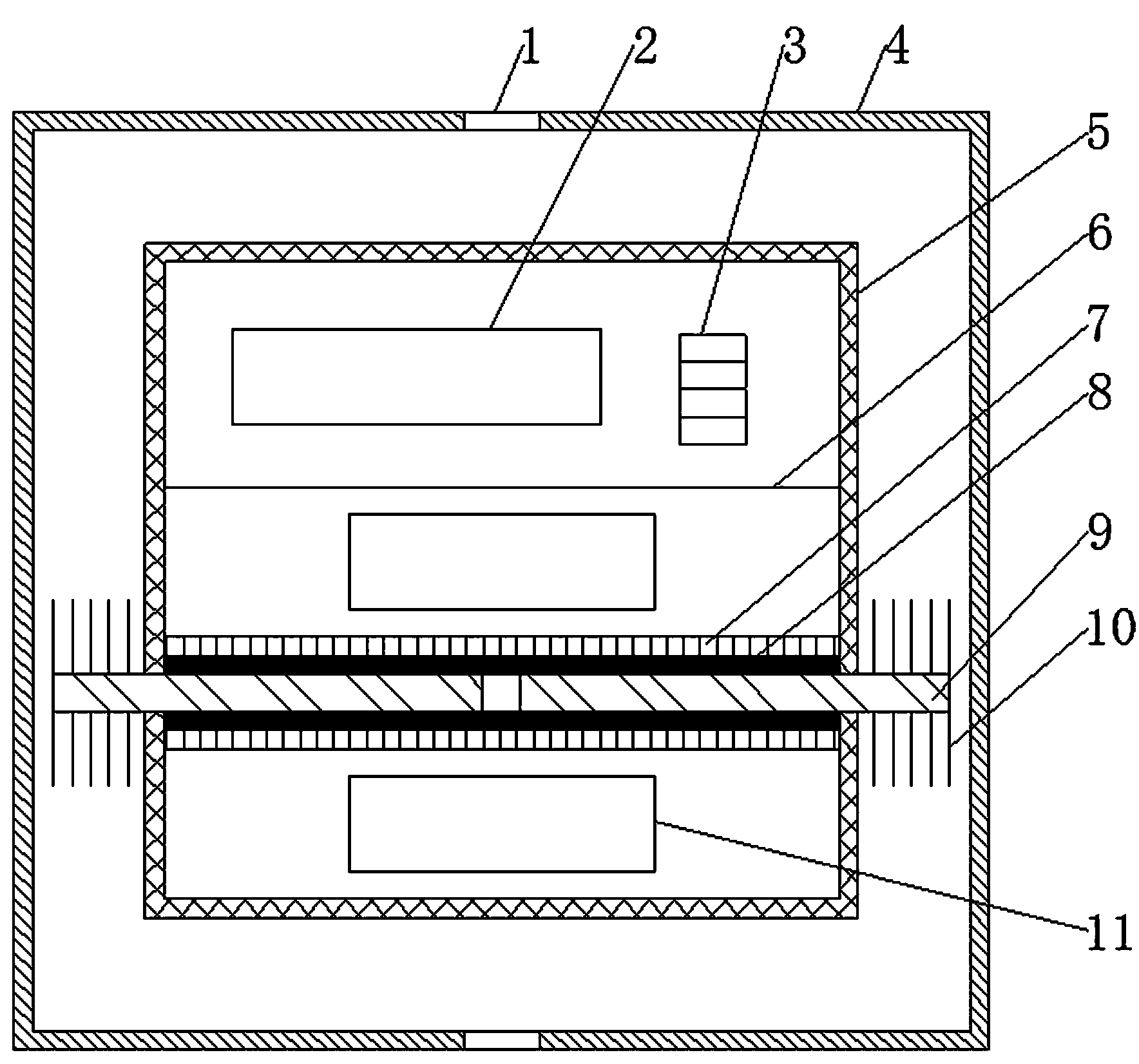

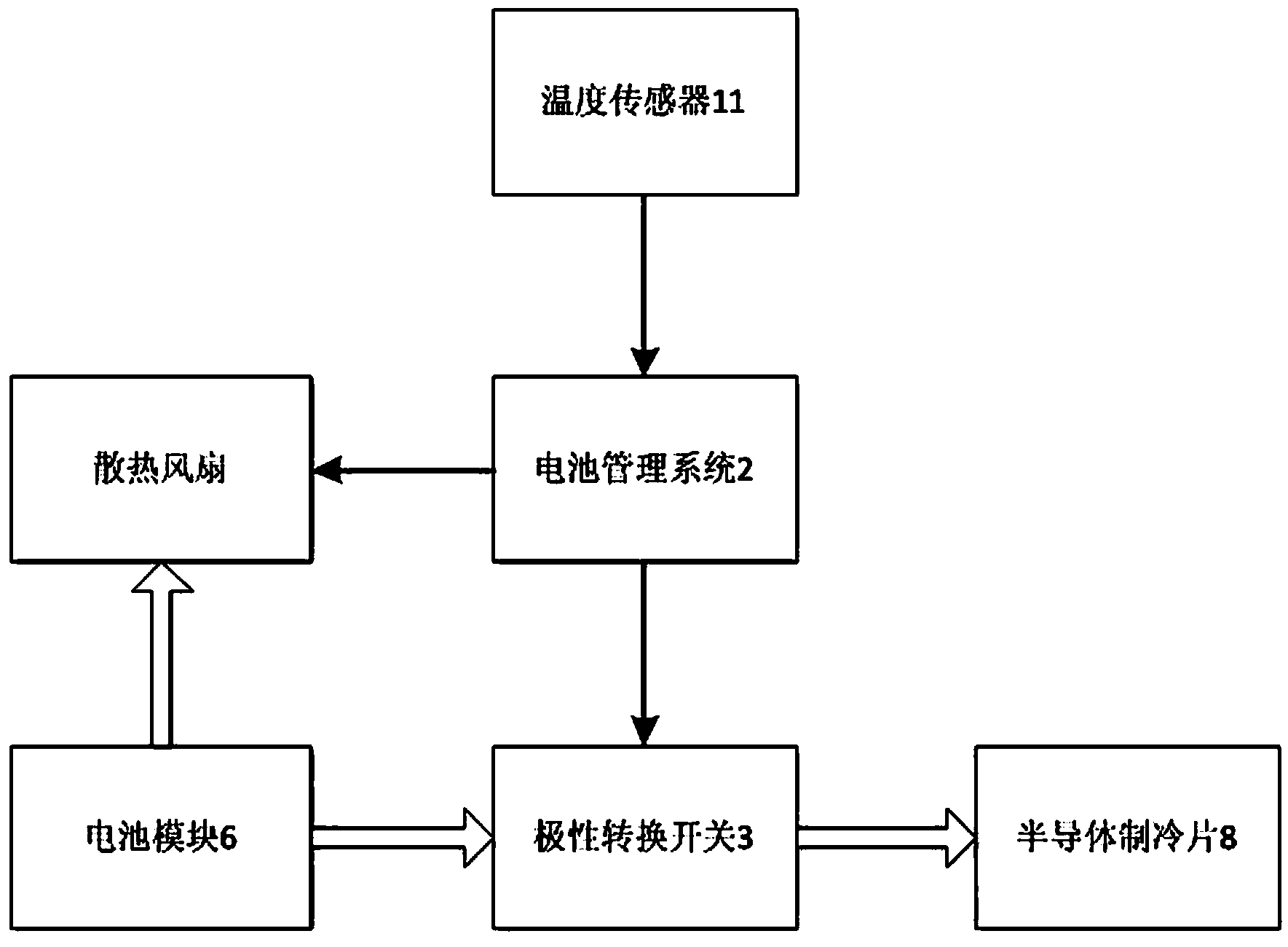

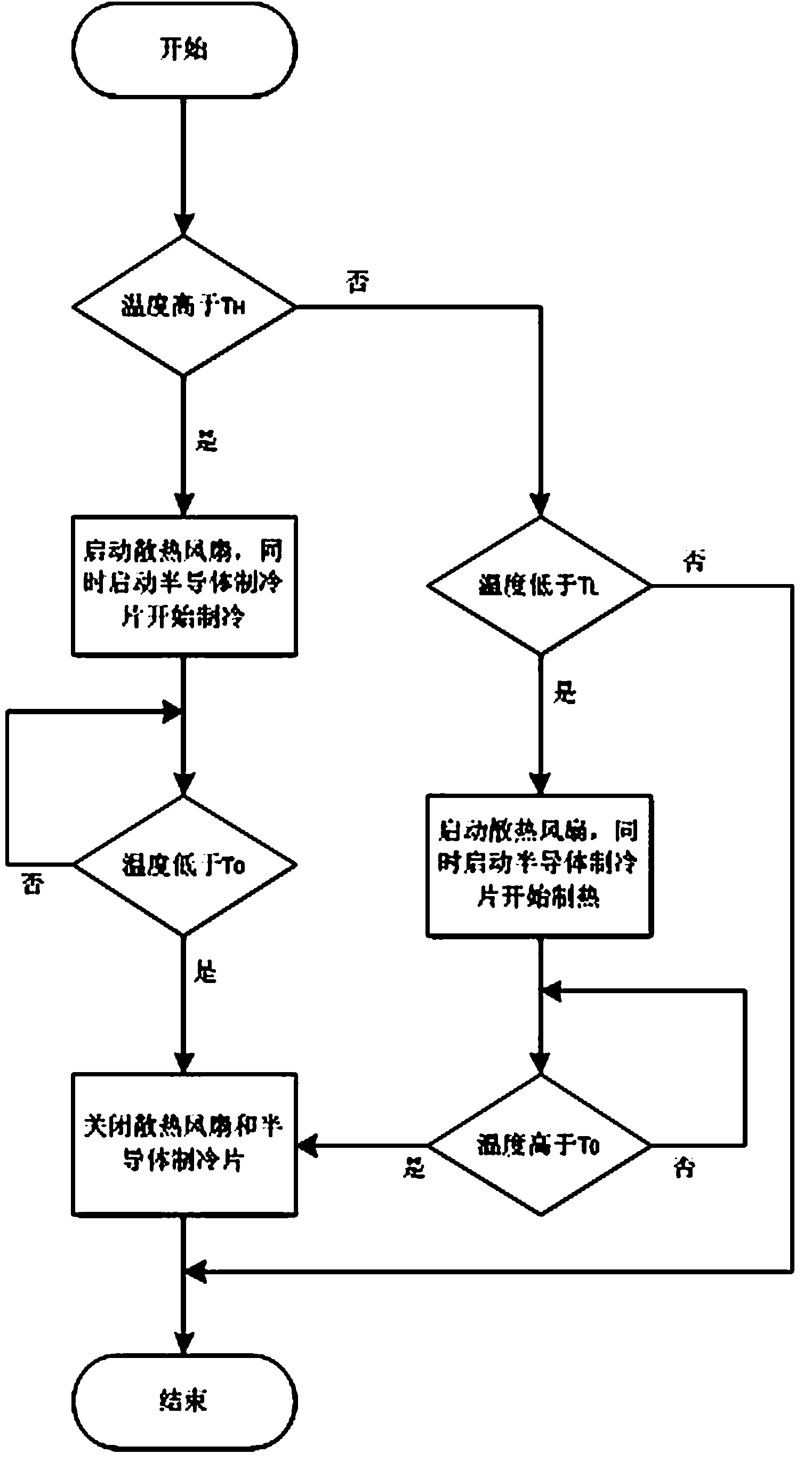

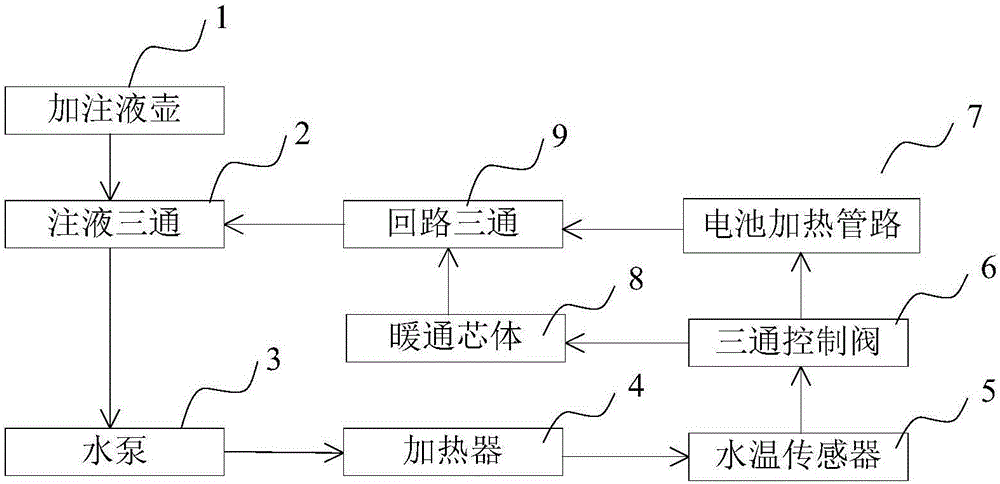

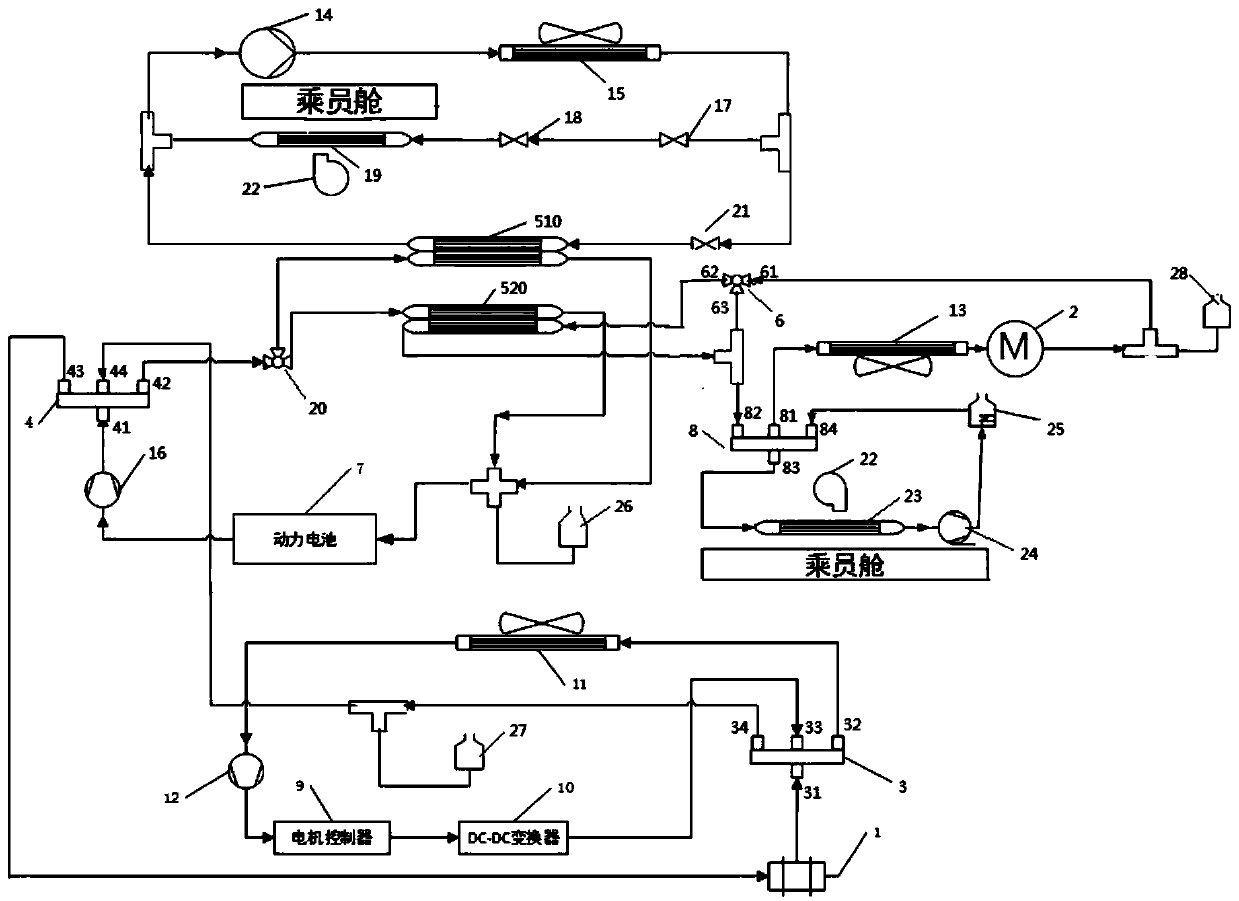

Battery box heat management system and method for electric automobile

InactiveCN103531864AAchieve coolingAchieve heatingCell temperature controlBattery isolationThermodynamicsHeat management

Owner:SANMENXIA SUDA TRANSPORTATION ENERGY SAVING TECH

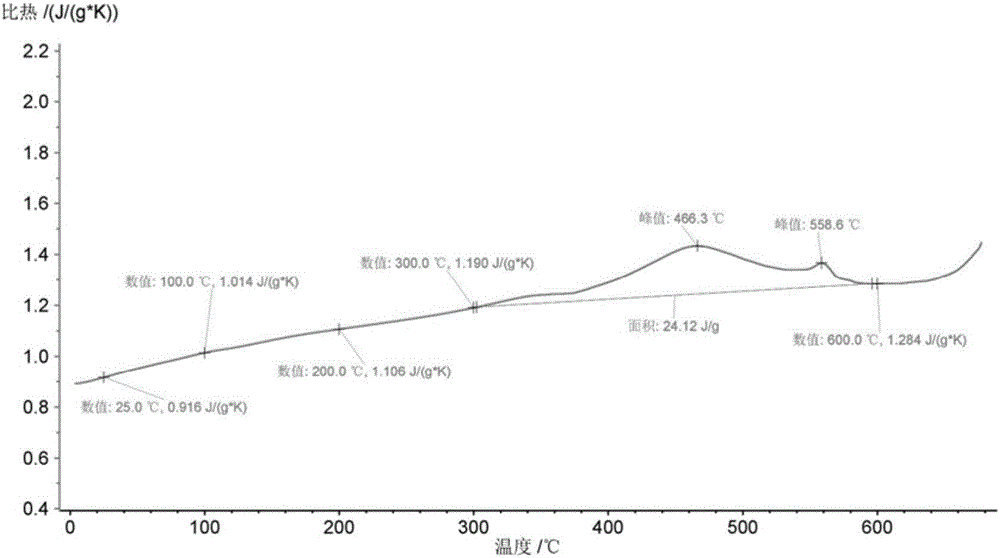

Solid composite phase-change thermal storage material and preparation method thereof

InactiveCN106701034ANo pollution in the processHigh heat storage densityHeat-exchange elementsVolumetric Mass DensityHydroforming

The invention discloses a solid composite phase-change thermal storage material, belonging to the technical field of energy storage materials. The solid composite phase-change thermal storage material comprises water, sodium carbonate, potassium carbonate, magnesium oxide, kieselguhr, quartz sand and kaolin. The thermal storage material is non-toxic, harmless and free of pollution. The invention further discloses a preparation method of the solid composite phase-change thermal storage material. The preparation method comprises the following steps: stirring, rubbing sand, filtering, performing hydraulic molding, and performing sintering molding. By adopting the preparation method, the thermal storage density is improved, the thermal storage density of the material is 2 times better than that of a common material, the thermal storage material can endure high temperature, can be heated to be greater than 650 DEG C, and is not liable to efflorescence when being used for a long time.

Owner:BEIJING SONDEX ENERGY TECH

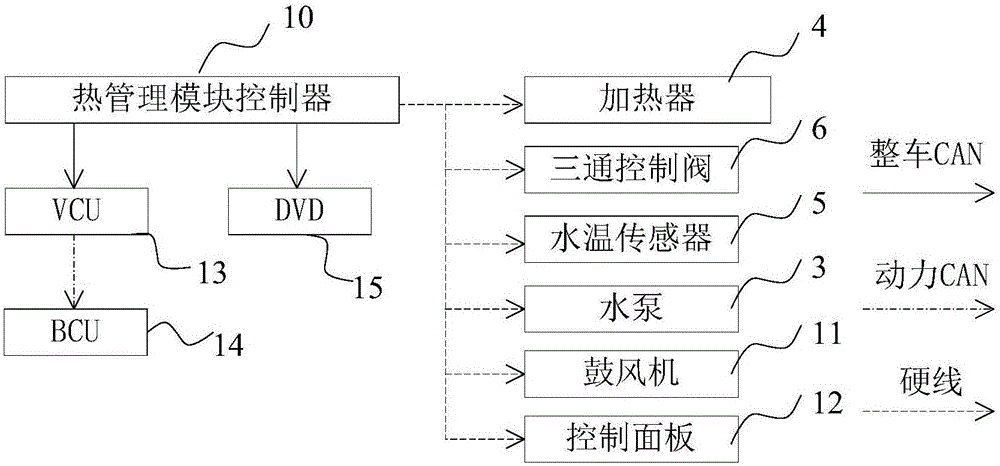

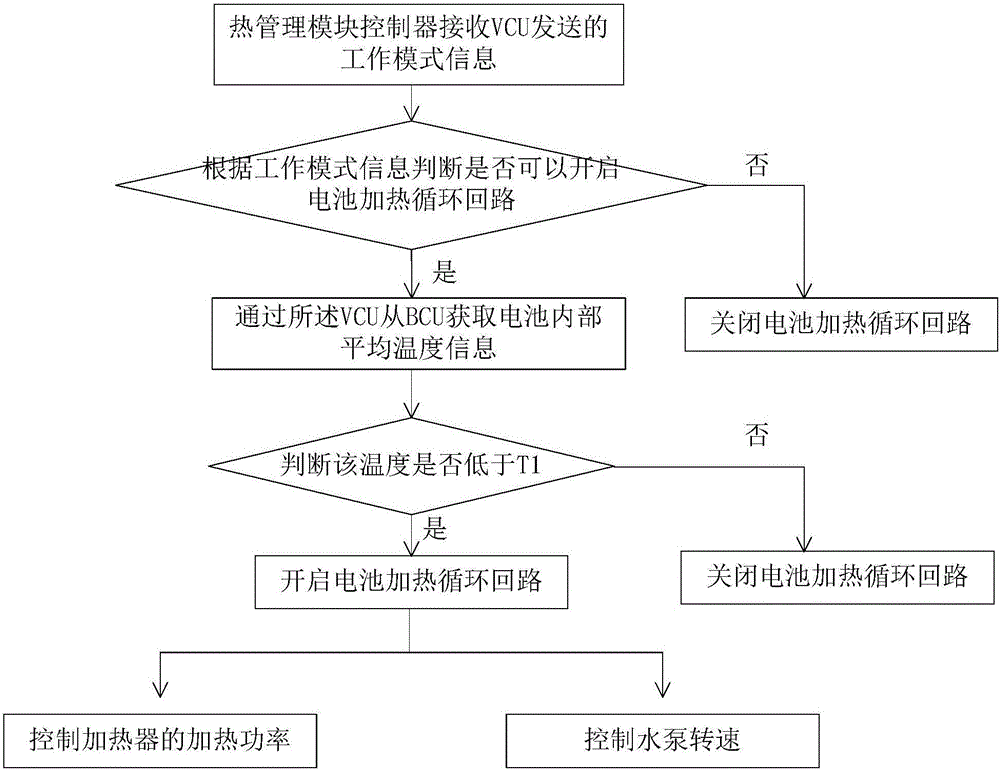

Battery heating system and battery heating control method

ActiveCN106602179AAchieve heatingFix this technical issue that isn't workingSecondary cellsPower batteryHeat management

The invention discloses a battery heating system and a battery heating control method. The battery heating system comprises a liquid injection pot, a water pump, a heater, a battery heating pipeline and a heat management module controller. The battery heating control method comprises: the heat management module controller receives working mode information sent by a VCU, and judges whether a battery heating cycle loop can be opened or not; if the battery heating cycle loop can be opened, average temperature information obtained by averaging multiple detection points in a battery is obtained from a BCU through the VCU; furthermore, whether the average temperature is lower than the first specified temperature TI or not is judged; if not, the battery heating cycle loop is closed; if so, the heating power of the heater in the battery heating cycle loop is started and controlled; and the rotation speed of the water pump in the battery heating cycle loop is started and controlled. By means of the battery heating system and the battery heating control method disclosed by the invention, the purposes of heating a power battery and performing heating management can be realized; and thus, normal use of a battery of an automobile battery in a low-temperature environment can be ensured.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

Waste gas treatment and waste heat recovery device and method thereof

InactiveCN102268796AHigh recovery rateAchieve recyclingHeating/cooling textile fabricsStationary tubular conduit assembliesWaste heat recovery unitThermal energy

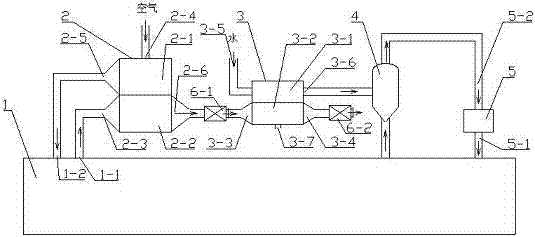

The invention provides a waste gas treating and waste heat recycling device. The device comprises a setting machine, a thermal conductive medium heater, a steam generator and a gas-gas exchanger, and further comprises a gas-liquid exchanger, wherein the gas-liquid exchanger includes a liquid chamber and a gas chamber which are independent mutually; the gas chamber is provided with a gas inlet anda gas outlet; the gas inlet is connected with the waste gas outlet of the gas-gas exchanger by a draught fan, and the gas outlet is connected with the draught fan; the liquid chamber is provided witha water inlet and a water outlet; the water outlet is connected with the steam generator; the thermal conductive medium heater and the setting machine form a return circuit therebetween by an outlet medium pipe and a return medium pipe; and the steam generator is arranged on the return circuit. In addition, the invention further provides a waste gas treating and waste heat recycling method. The waste gas treating and waste heat recycling device disclosed by the invention is simple in structure and simple in operation, makes full use of heat energy of waste gases, reduces production cost, and is energy-saving and environmentally-friendly.

Owner:桐乡市好阳光能源科技有限公司

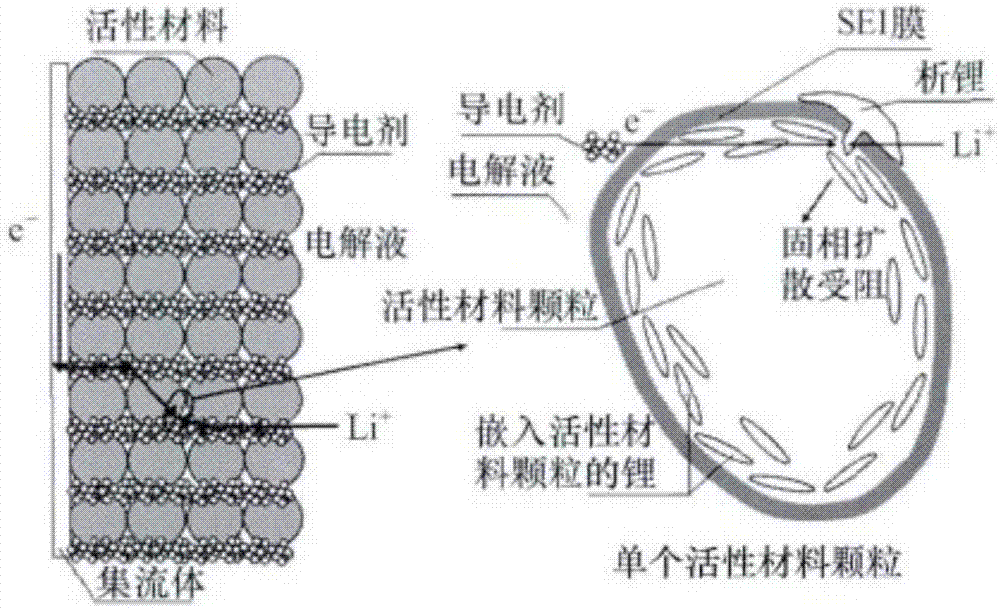

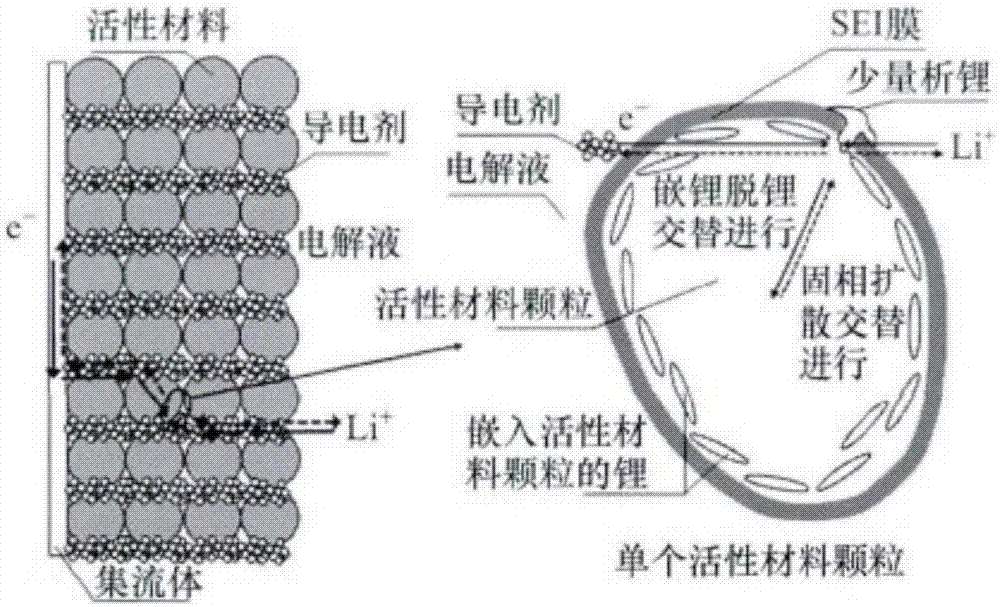

Low-temperature heating device for lithium-ion battery and electric car

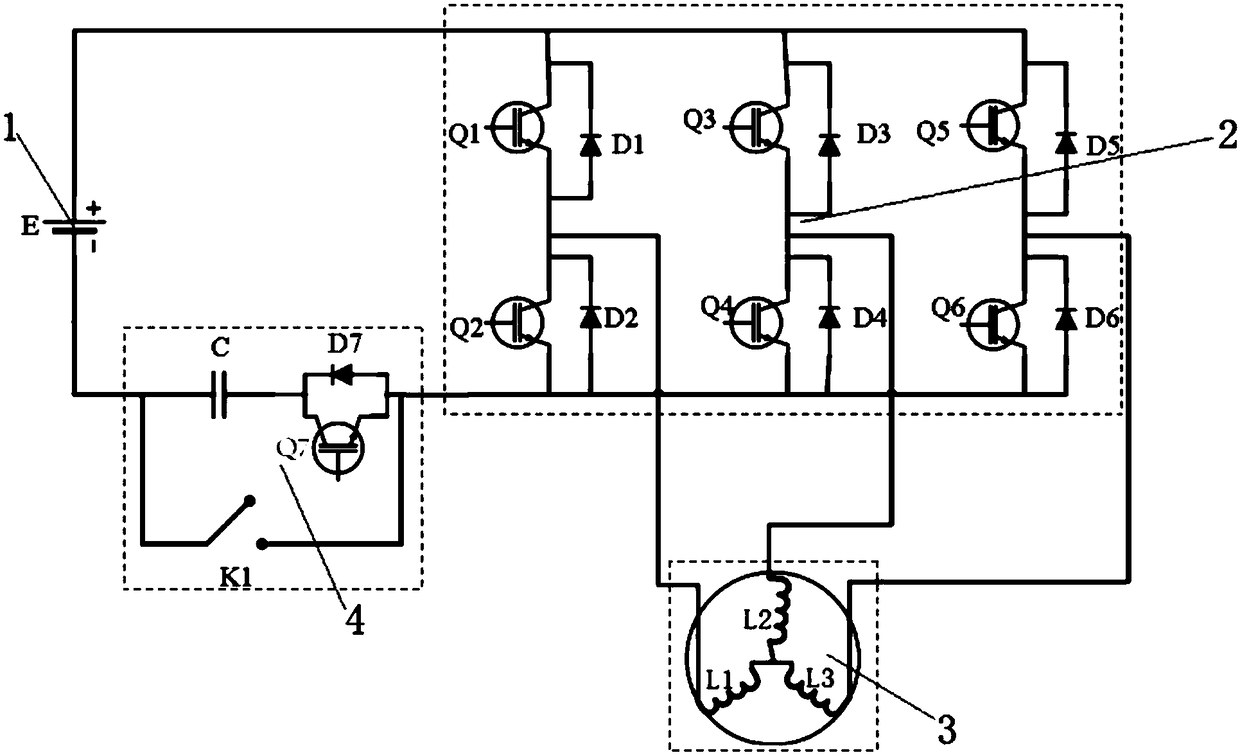

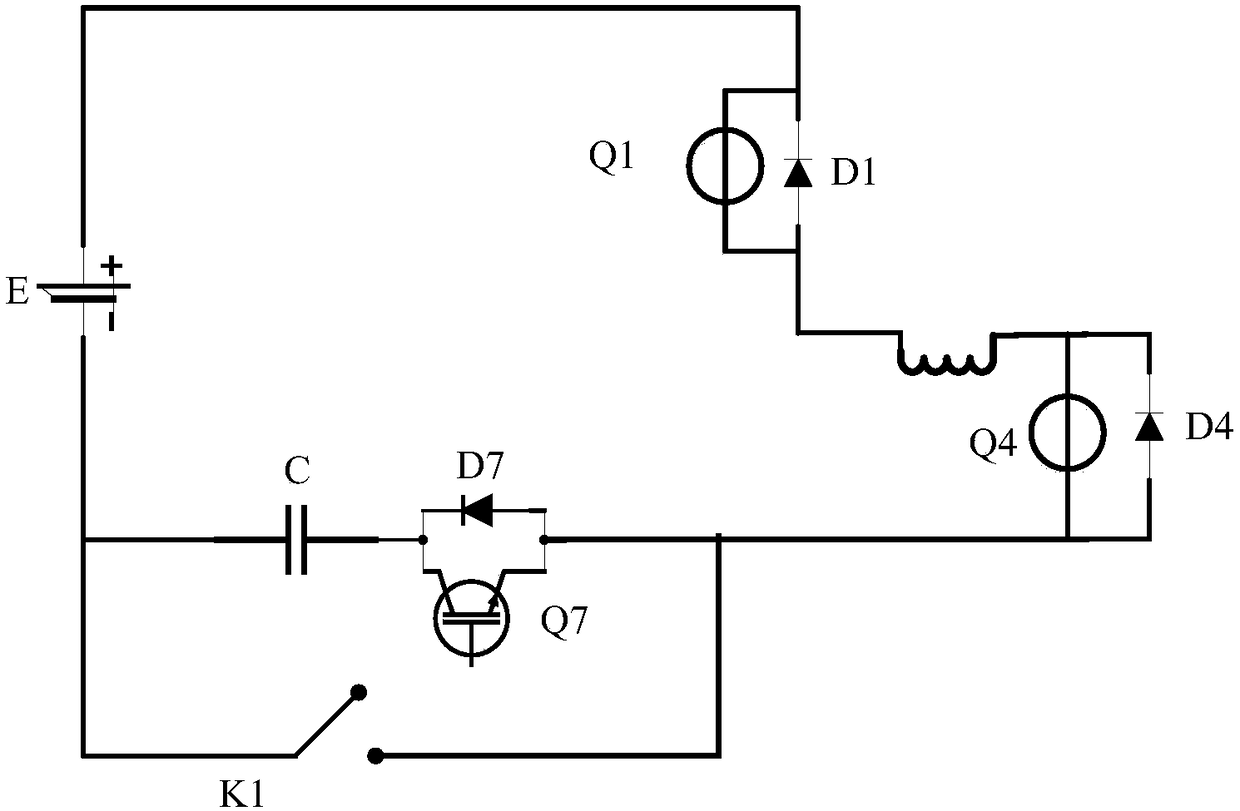

ActiveCN108511822ALow costSimple structureSecondary cells servicing/maintenanceElectrical batteryElectric cars

The invention relates to a low-temperature heating device for a lithium-ion battery; the low-temperature heating device comprises the lithium-ion battery, two power devices of a motor controller and two winding inductors of a motor; the low-temperature heating device also comprises a heating control circuit arranged between the power devices of the motor controller and a negative electrode of thelithium-ion battery. The lithium-ion battery, the two power devices of the motor controller, the two winding inductors of the motor and the heating control circuit are successively connected to form acircuit. The heating control circuit comprises a capacitive element, an additional power device and a switching device. The capacitive element and the additional power device are connected in seriesand then connected in parallel with the switching device. An LC oscillating circuit is formed by the capacitive element and the winding inductors through opening and closing of the switching device and the additional power device respectively, and the high-frequency alternating current is generated. According to Joule's law, the heat is generated in the battery, and then the interior of the battery is heated. The device can be used for quickly and efficiently heating, and has uniform speed and good effect.

Owner:BEIHANG UNIV

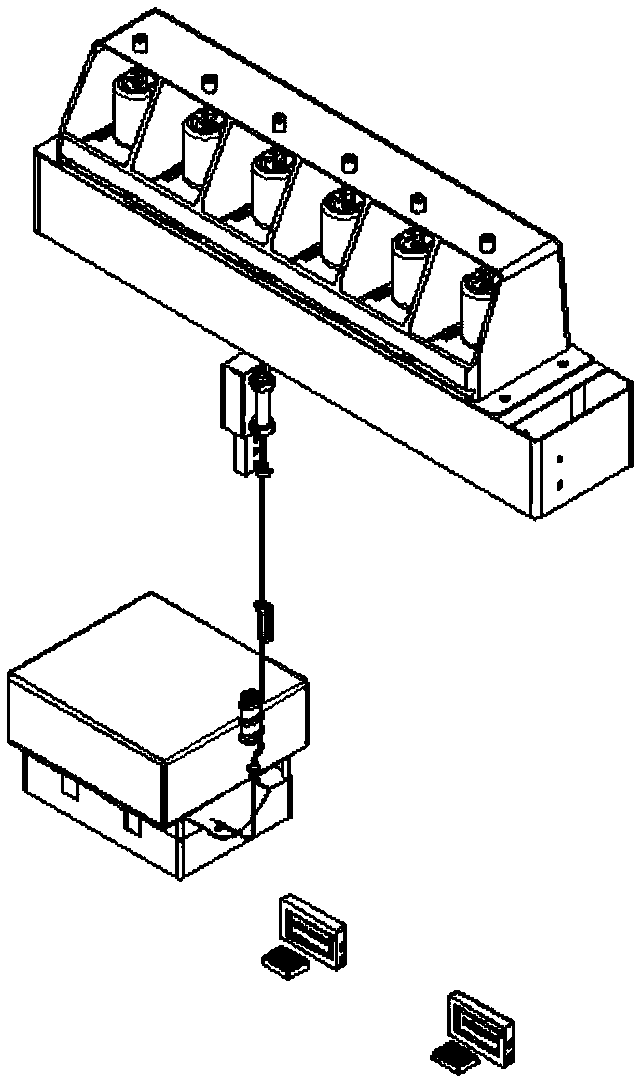

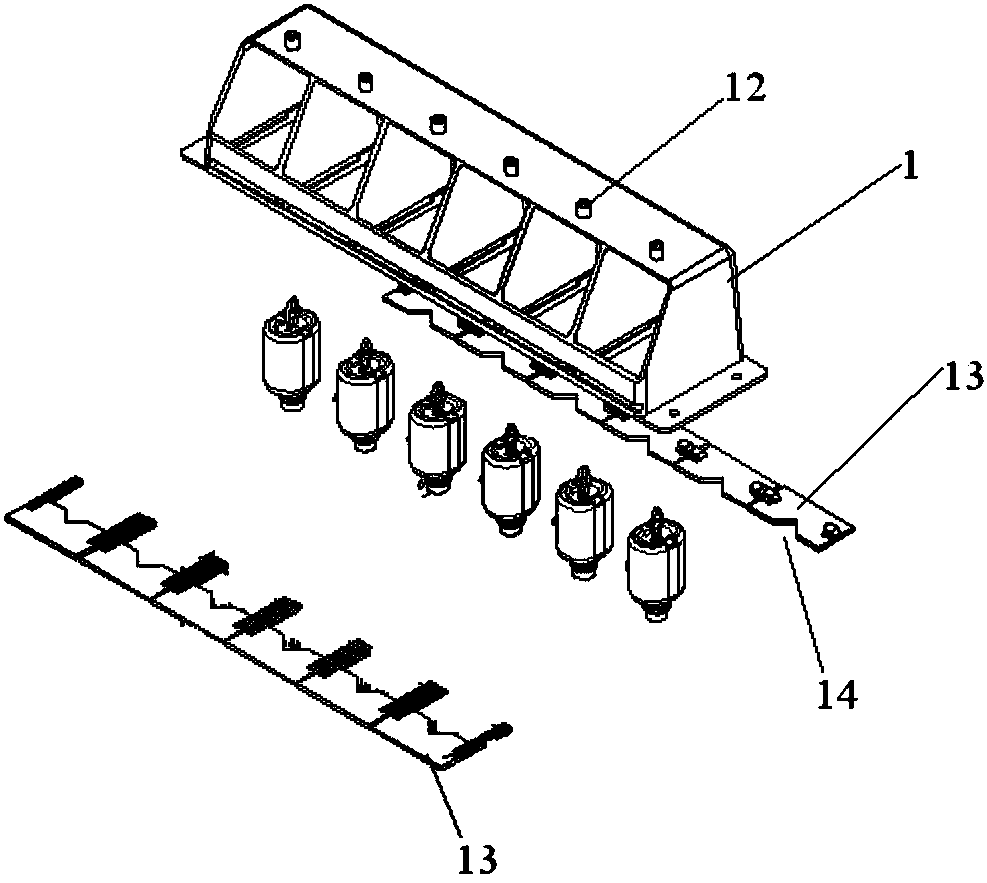

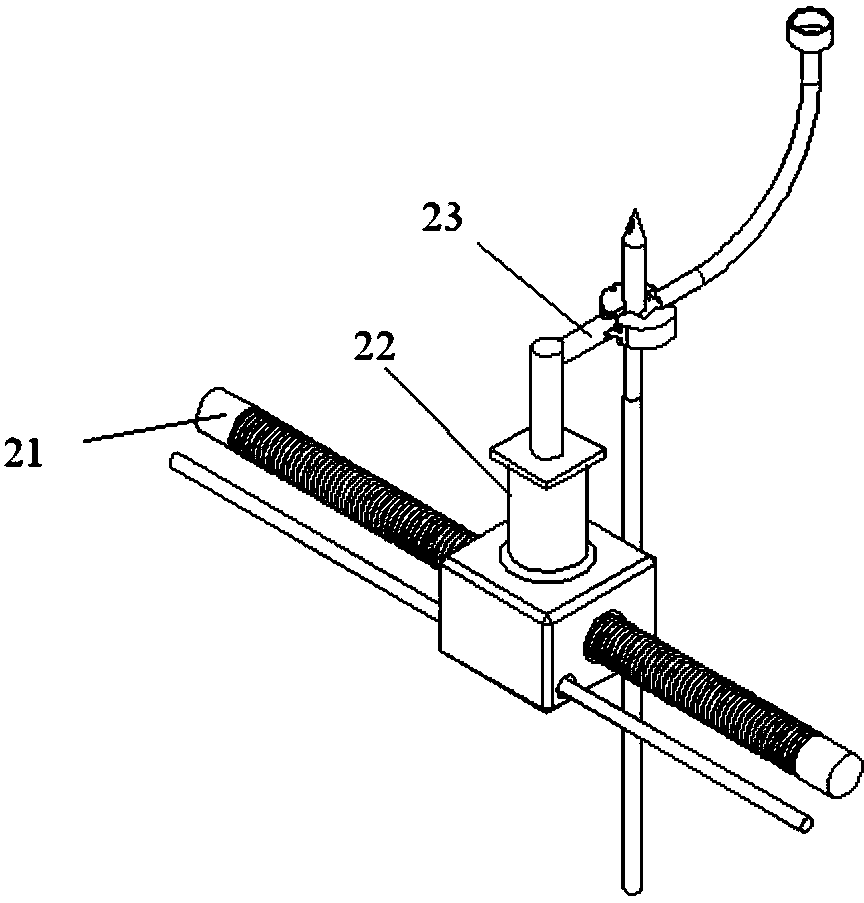

Measuring device for oil injection rule of each hole of oil injection nozzle of diesel engine

InactiveCN104405553AAccurate measurementAchieve heatingEngine testingFuel injection apparatusData acquisitionDiesel engine

The invention provides a measuring device for an oil injection rule of each hole of an oil injection nozzle of a diesel engine. The measuring device comprises a constant volume bomb matrix with holes in the upper end face, a data acquisition and analysis system and a computer, wherein at least sensor devices same as the holes of the to-be-measured oil injection nozzle in number are arranged in the constant volume bomb matrix; each sensor device comprises a force sensor, a bracket and a pedestal; each pedestal is positioned on a lower end cover of the constant volume bomb matrix; the end face, close to the to-be-measured oil injection nozzle, of each force sensor connected with the corresponding bracket is perpendicular to the axis of a to-be-measured injection hole; the data acquisition and analysis system is connected with the computer; at least one side end face of the constant volume bomb matrix is provided with at least one hole allowing a signal line to pass through; one end of the signal line is connected with the corresponding force sensor, and the other end of the signal line is connected with the data acquisition and analysis system. According to the device, accurate measurement of the oil injection rule of each hole of the porous oil injection nozzle can be realized; the signals measured by all the force sensors can be collected by the multi-channel data acquisition and analysis system; the measuring device has actual application significance.

Owner:JIANGSU UNIV

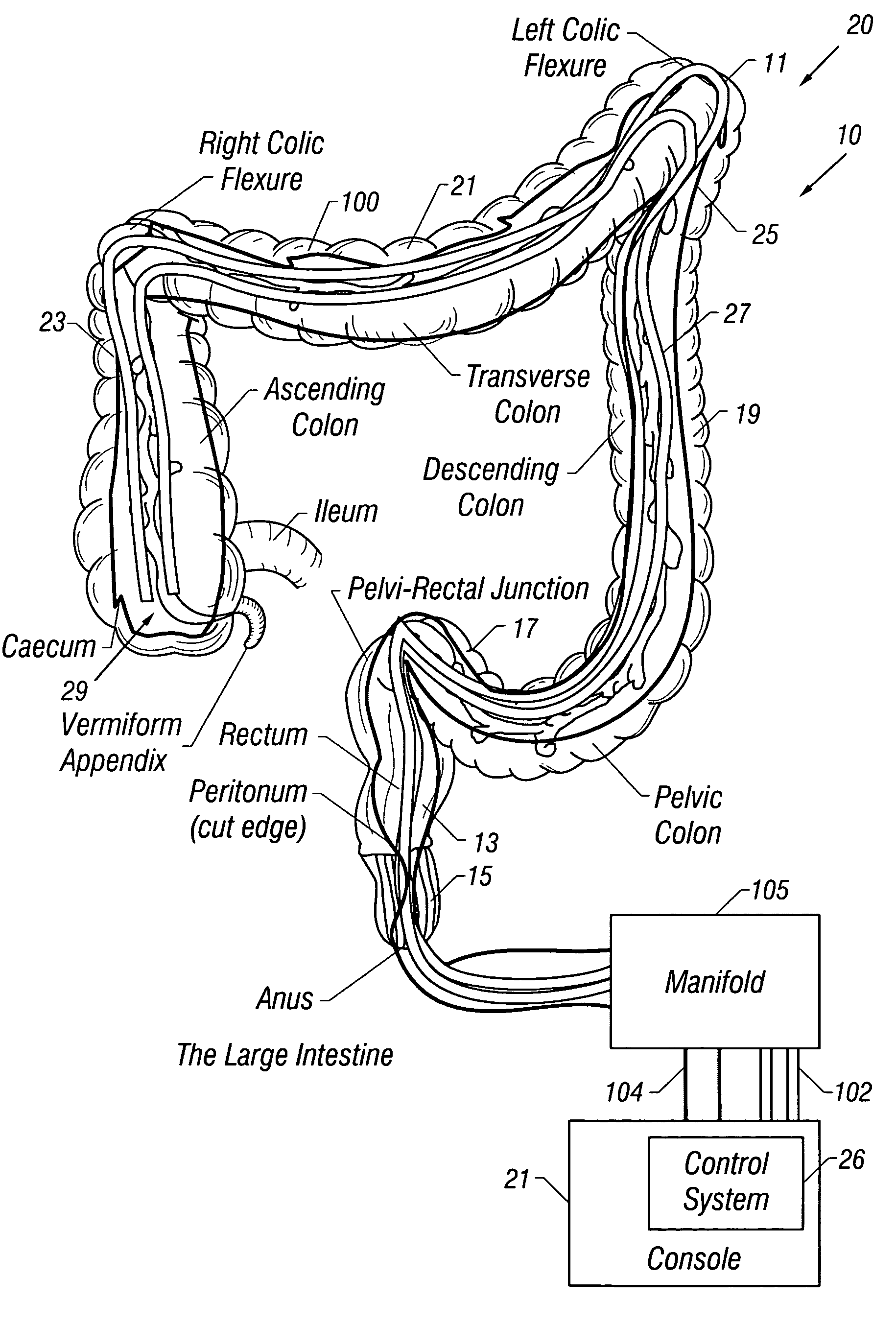

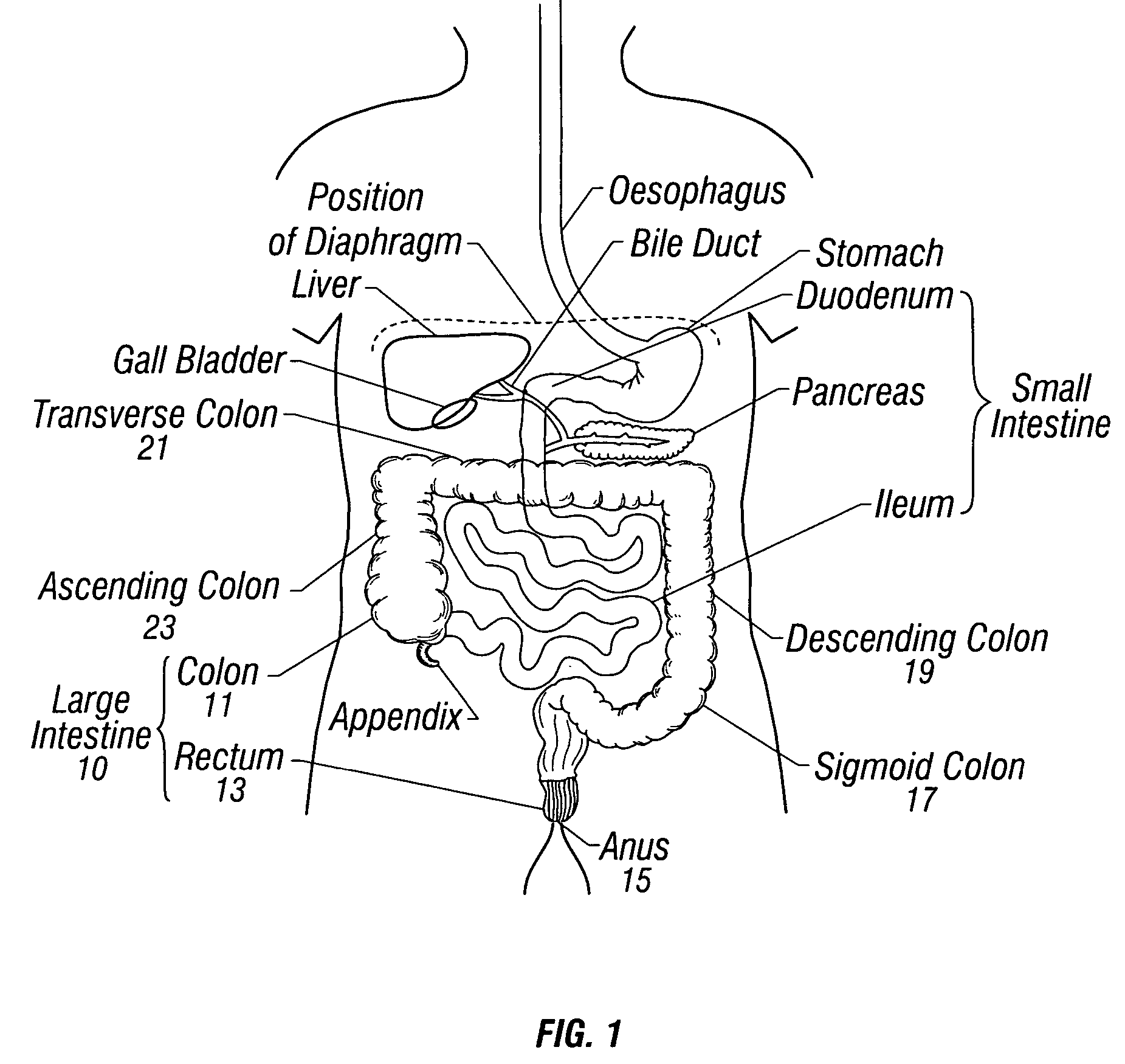

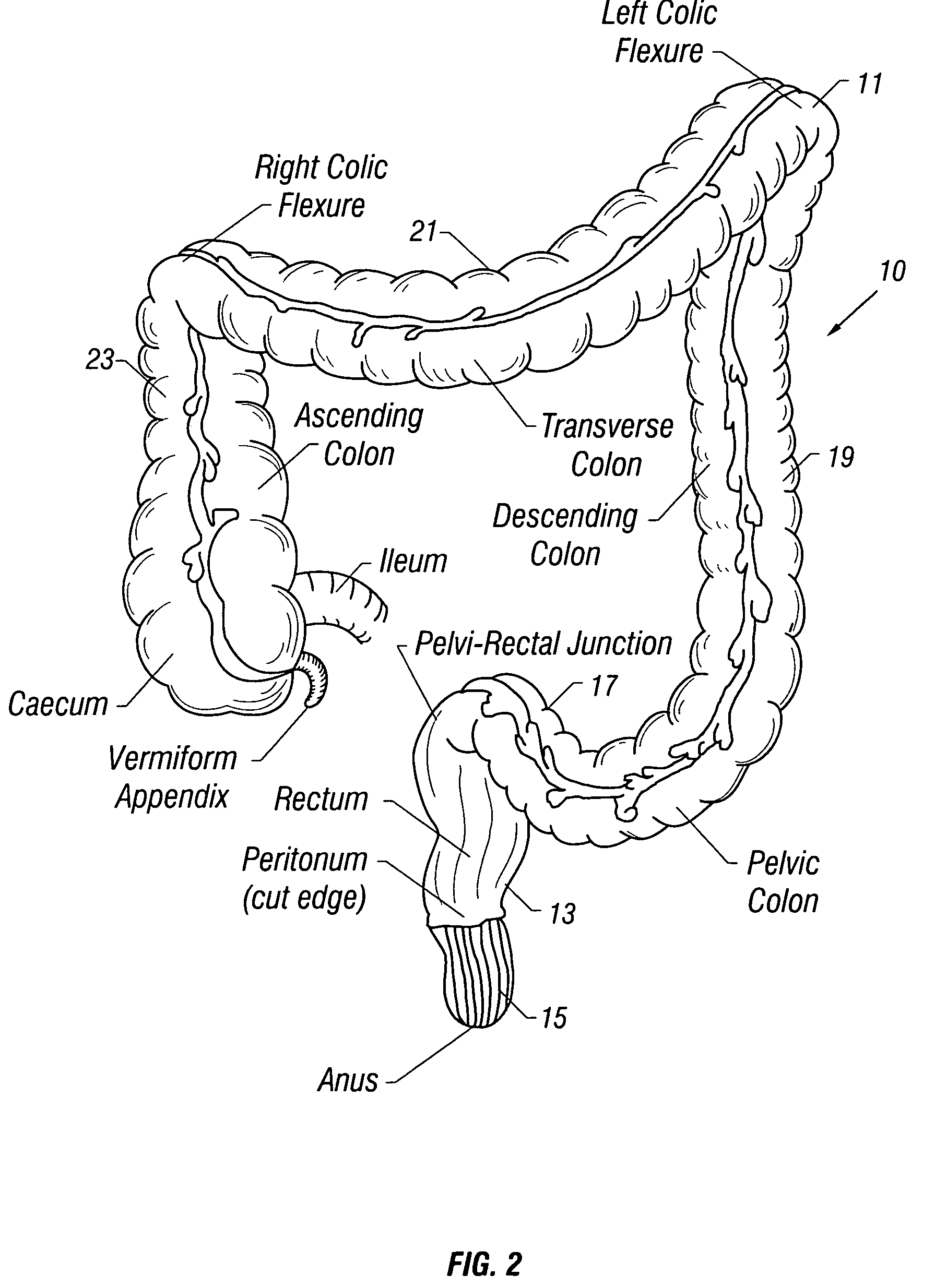

Therapeutic heating and cooling via temperature management of a colon-inserted balloon

InactiveUS7491223B2Increase flexibilityEasy to insertSurgical instrument detailsTherapeutic coolingGeneral surgeryCatheter device

A method and apparatus is provided for heating or cooling at least a selected portion of a patient's body. The method begins by inserting a catheter having a balloon into the colon or stomach of the patient. A heated or chilled fluid is conducted through a supply lumen of the catheter and into the balloon. The fluid is evacuated from the balloon through a return lumen of the catheter.

Owner:ZOLL CIRCULATION

Novel composite sensing optical cable

InactiveCN104183334ALarge resistanceUniform heatingCommunication cablesCross connectionTemperature measurement

The invention discloses a novel composite sensing optical cable comprising a carbon fiber filament, temperature-sensitive fibers, power supply wires, a sheath, and an insulating wrapping layer. The carbon fiber filament, the temperature-sensitive fibers, the power supply wires, and the sheath are wrapped in the insulating wrapping layer. The carbon fiber filament is wrapped in the sheath. More than one temperature-sensitive fiber and a pair of the power supply wires are provided. The carbon fiber filament and the surrounding power supply wires are in crossed connection so as to form a parallel circuit. Power is supplied simultaneously such that the optical cable is uniformly heated at long distance by means of a fact that the carbon fiber filament generates heat after being supplied with power. The temperature-sensitive fibers are wrapped in the carbon fiber filament or arranged in parallel with the carbon fiber filament. The carbon fiber filament is heated after being supplied with power so as to uniformly heat the optical cable. Temperature measurement at various points along the cable is achieved by means of distributed fiber temperature measurement technology. The optical cable can be uniformly heated for long distance (more than 2km) and long-distance leakage can be detected.

Owner:SUZHOU NANZEE SENSING TECH

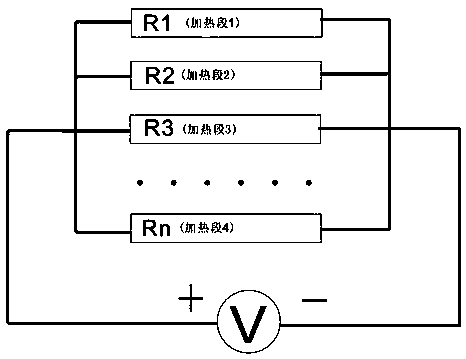

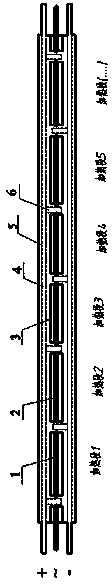

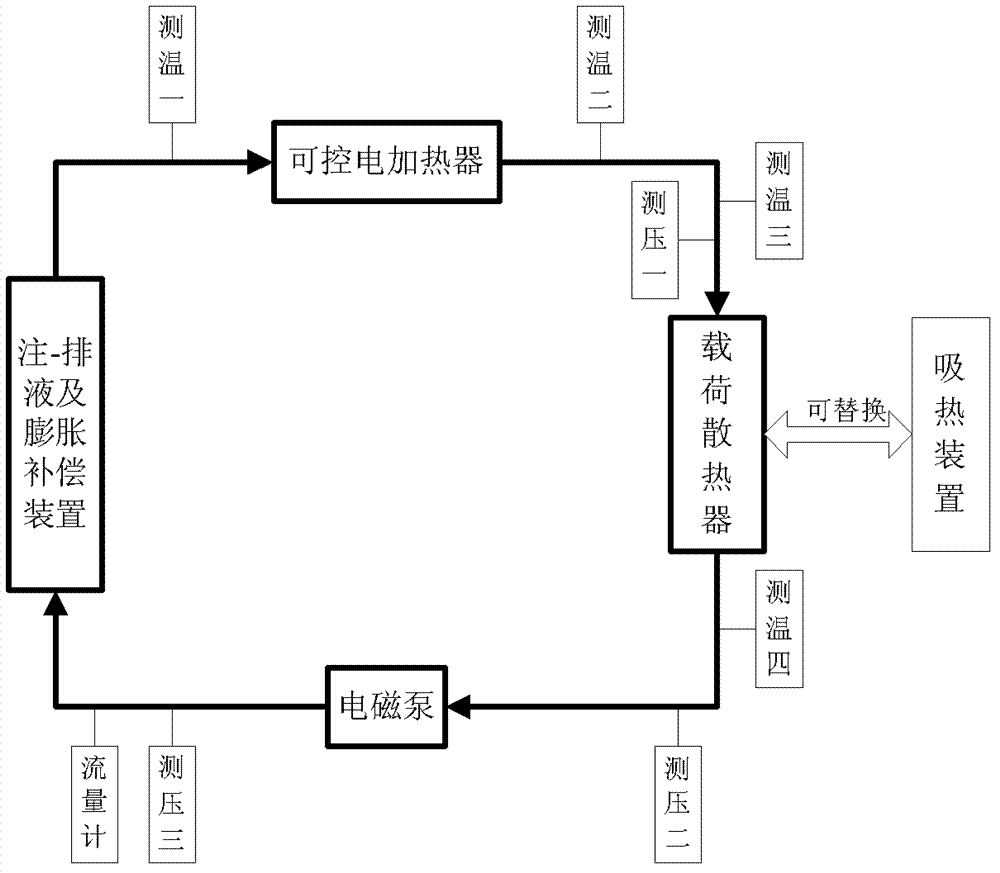

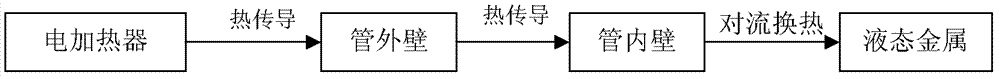

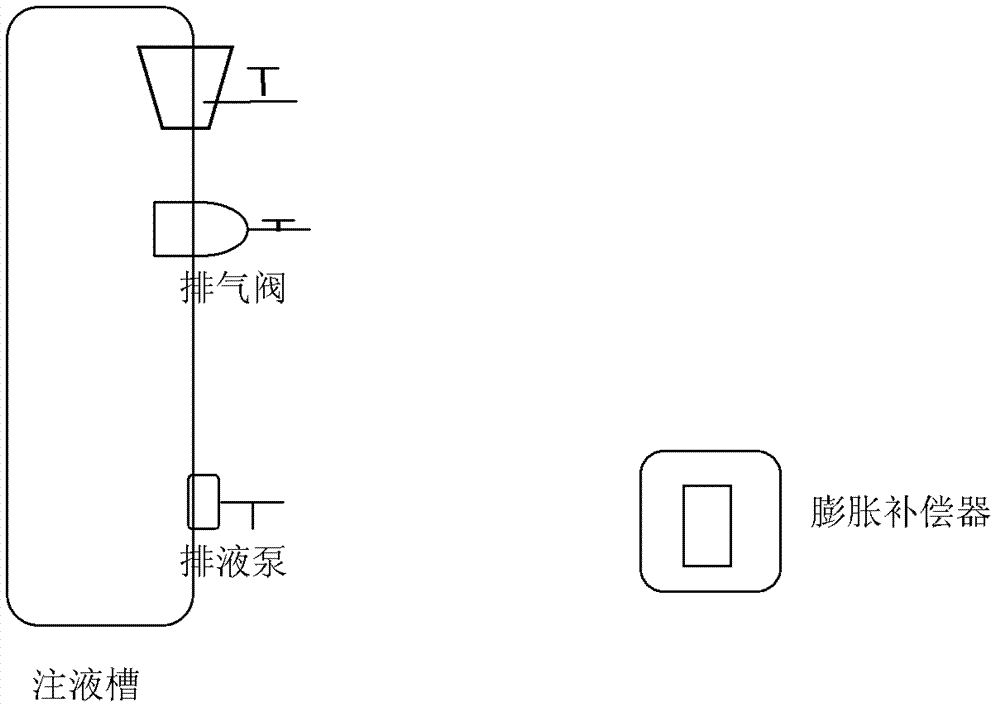

Electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus

ActiveCN103091355AAchieve cycleCircular heat transfer realizationMaterial heat developmentEngineeringThermal expansion

The invention belongs to a heat transfer performance measurement technology, and particularly relates to an electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus, wherein a purpose of the present invention is to verify and evaluate a heat transfer performance and a heat transfer control performance of the electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus. The electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus comprises: an electromagnetic pump, a controllable electric heater, a loading heat dissipator, a liquid injection-discharge device, an expansion compensation device, a measurement sensor and pipelines, wherein connection in series of various component is achieved with the pipelines, every component contains a hollow flow channel for liquid metal circulation, and a liquid metal flowing sequence is that: a liquid metal is injected into the whole testing apparatus through the liquid injection-discharge device and the expansion compensation device, then flows to the controllable electric heater through the pipeline, then flows to the loading heat dissipator after heating by the controllable electric heater, and returns to the liquid injection-discharge device through the electromagnetic pump. The electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus has the following advantages that: heating, circulation, and temperature and pressure detection of the liquid metal can be achieved, thermal expansion and contraction of the liquid metal can be compensated, gas in the liquid metal can be automatically discharged, and the problem of electromagnetic pump driven liquid metal circulation heat transfer performance testing is solved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

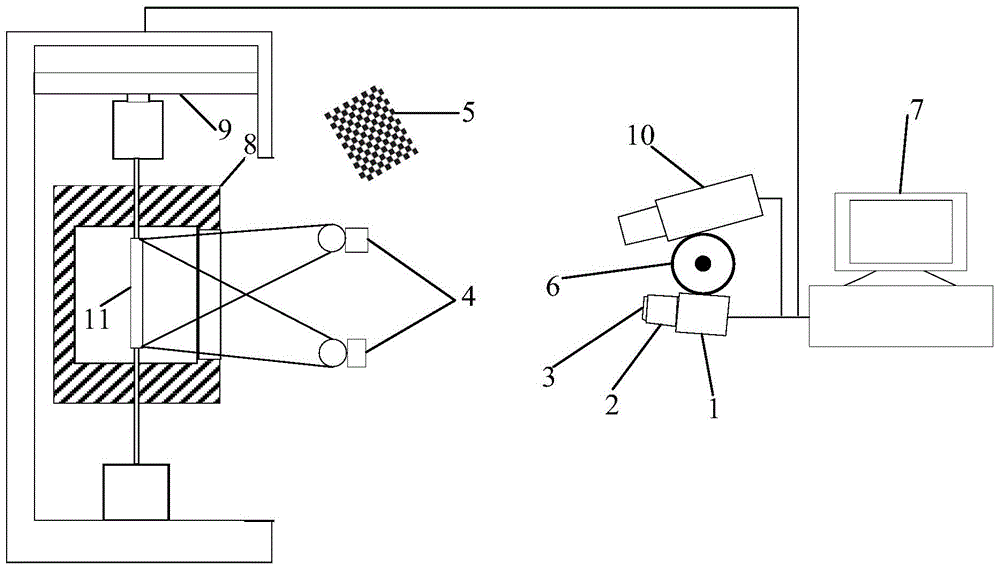

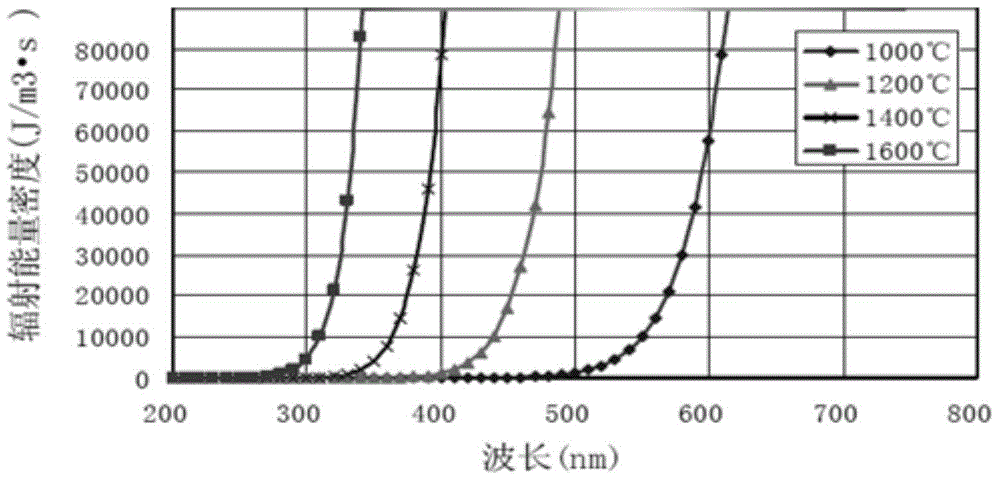

Ultraviolet illumination DIC (digital image correction)-based mechanical property loading measuring system and method for high-temperature material

ActiveCN104535412AReal-time measurementAvoid decorrelation effectsMaterial strength using tensile/compressive forcesUsing optical meansImaging processingFull field

The invention discloses an ultraviolet illumination DIC (digital image correction)-based mechanical property loading measuring system and method for a high-temperature material. The measuring system is characterized by comprising the following steps: projecting an ultraviolet light source on the surface of a to-be-measured sample which is in a set temperature environment and in a set loaded state; and collecting images of the surface of the to-be-measured sample by using an ultraviolet sensitive image collection module to acquire collection images on the surface of the to-be-measured sample, corresponding to different temperatures, moments and loading forces, and carrying out DIC image processing on the collected images to acquire full-field thermal deformation information of the surface of the to-be-measured sample. The system and the method disclosed by the invention can be used for effectively achieving the non-contacted measurement of full-field strain of the material with the temperature being over 1000 DEG C.

Owner:HEFEI UNIV OF TECH

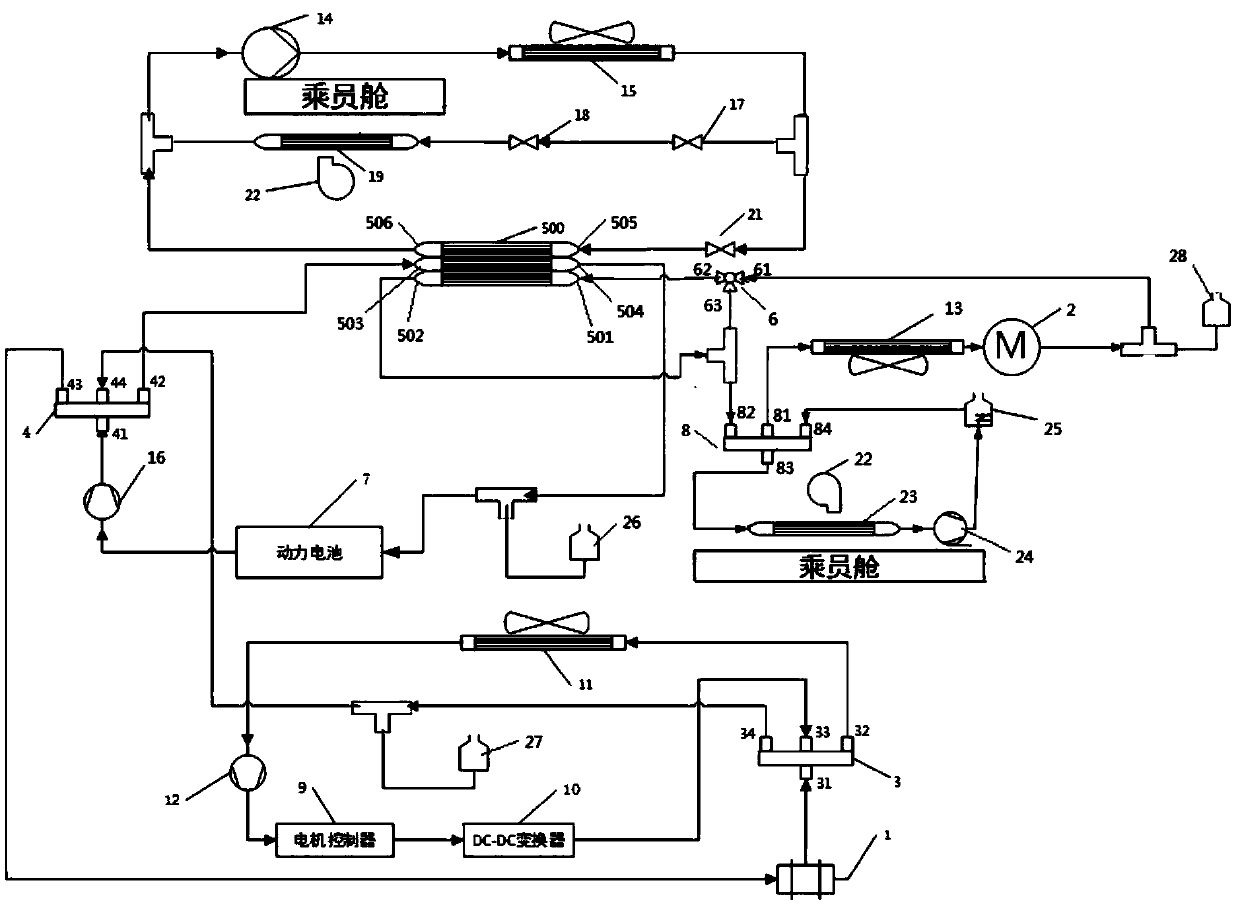

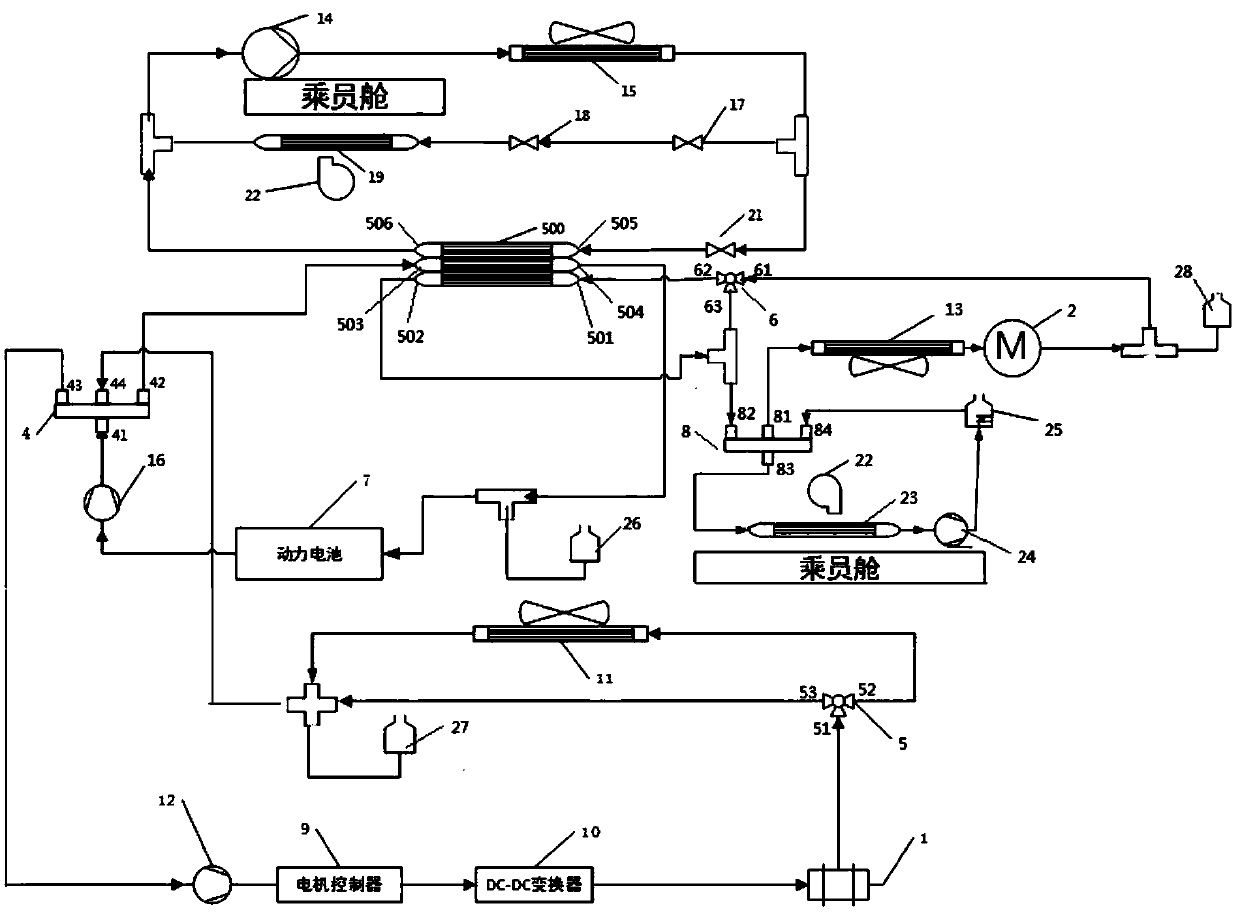

Vehicle thermal management system, control method thereof and vehicle

ActiveCN111231618AExchangeAchieve heatingAir-treating devicesSecondary cellsHeat managementElectrical battery

The invention relates to a vehicle thermal management system, a control method thereof and a vehicle. The vehicle heat management system comprises a battery and electric drive heat management system and an engine and warm air core body heat management system. The air conditioning system exchanges heat with the battery and electric drive heat management system through the heat exchanger; the engineand warm air core body heat management system comprises an engine cooling liquid flow path, a heating flow path and a first four-way valve. The engine cooling liquid flow path, the heating flow pathand the flow path where the battery and the battery in the electric drive heat management system are located are connected or disconnected through the first four-way valve, so that heat transfer amongthe cooling liquid flow path, the heating flow path and the flow path where the battery in the electric drive heat management system is located is achieved.

Owner:BYD CO LTD

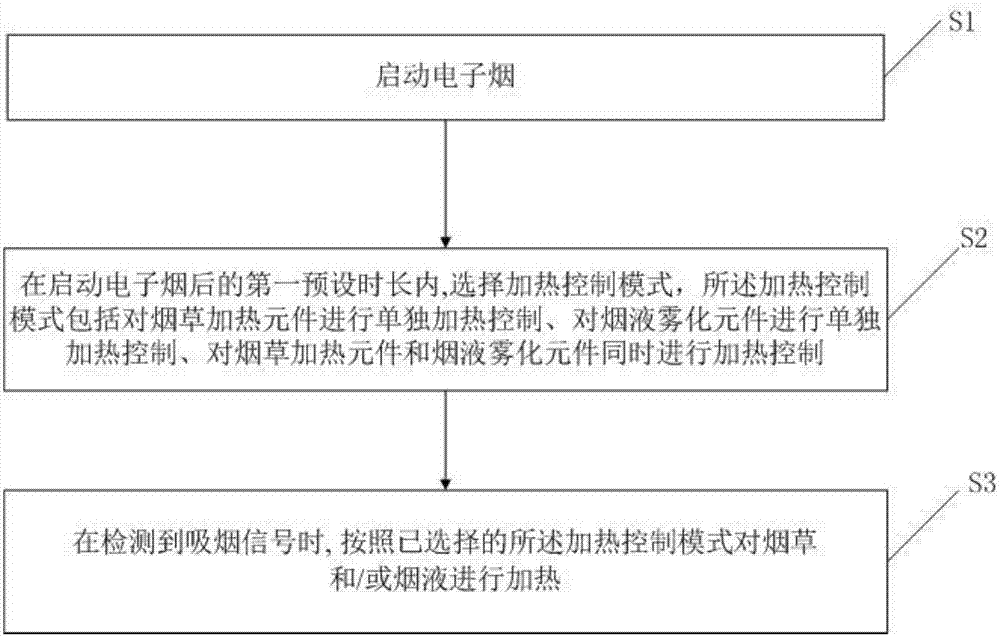

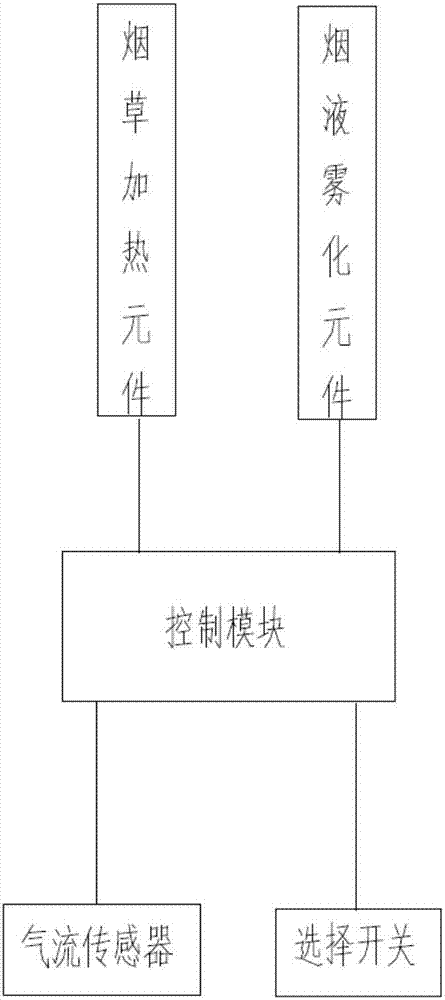

Method for controlling electronic cigarette and electronic cigarette

InactiveCN107278126AAchieve heatingMeet various smoking needsTobacco devicesHazardous substanceElectronic cigarette

The present invention discloses a method for controlling an electronic cigarette, comprising the following steps: S1, activating the electronic cigarette; S2: selecting a heating control mode for a first preset duration after starting the electronic cigarette, wherein the heating control mode includes: separately controlling heating of a heating element, and separately controlling heating of a smoke liquid atomizing element, and simultaneous control of heating of the heating element and the smoke liquid atomizing element; and S3, heating tobacco and / or tobacco oil according to the selected heating control mode when the smoking signal is detected. The method can meet diversified smoking needs of users, and can extract the aromatic smell of tobacco and can reduce the harmful substances to a large extent.

Owner:HUIZHOU KIMREE TECH

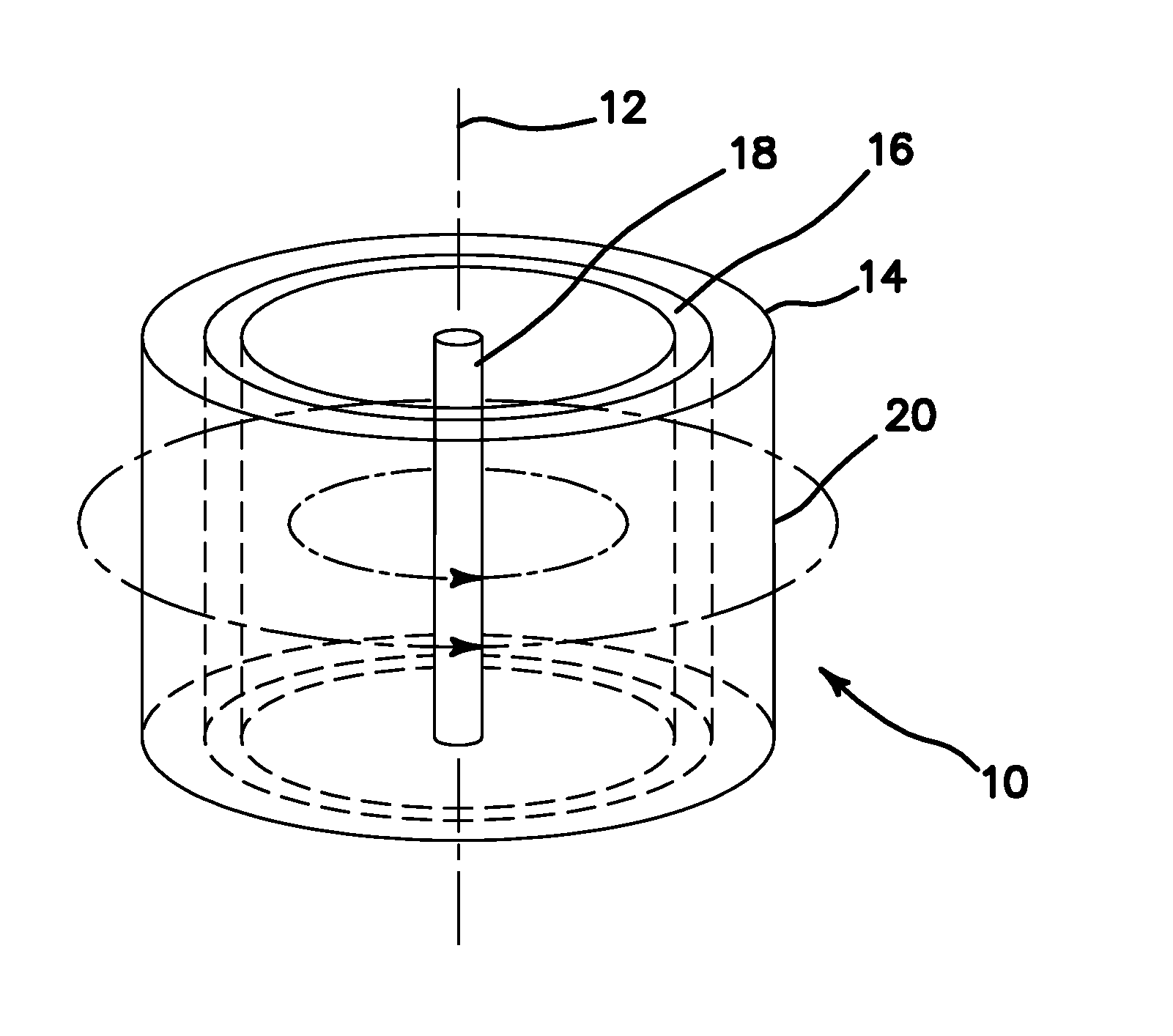

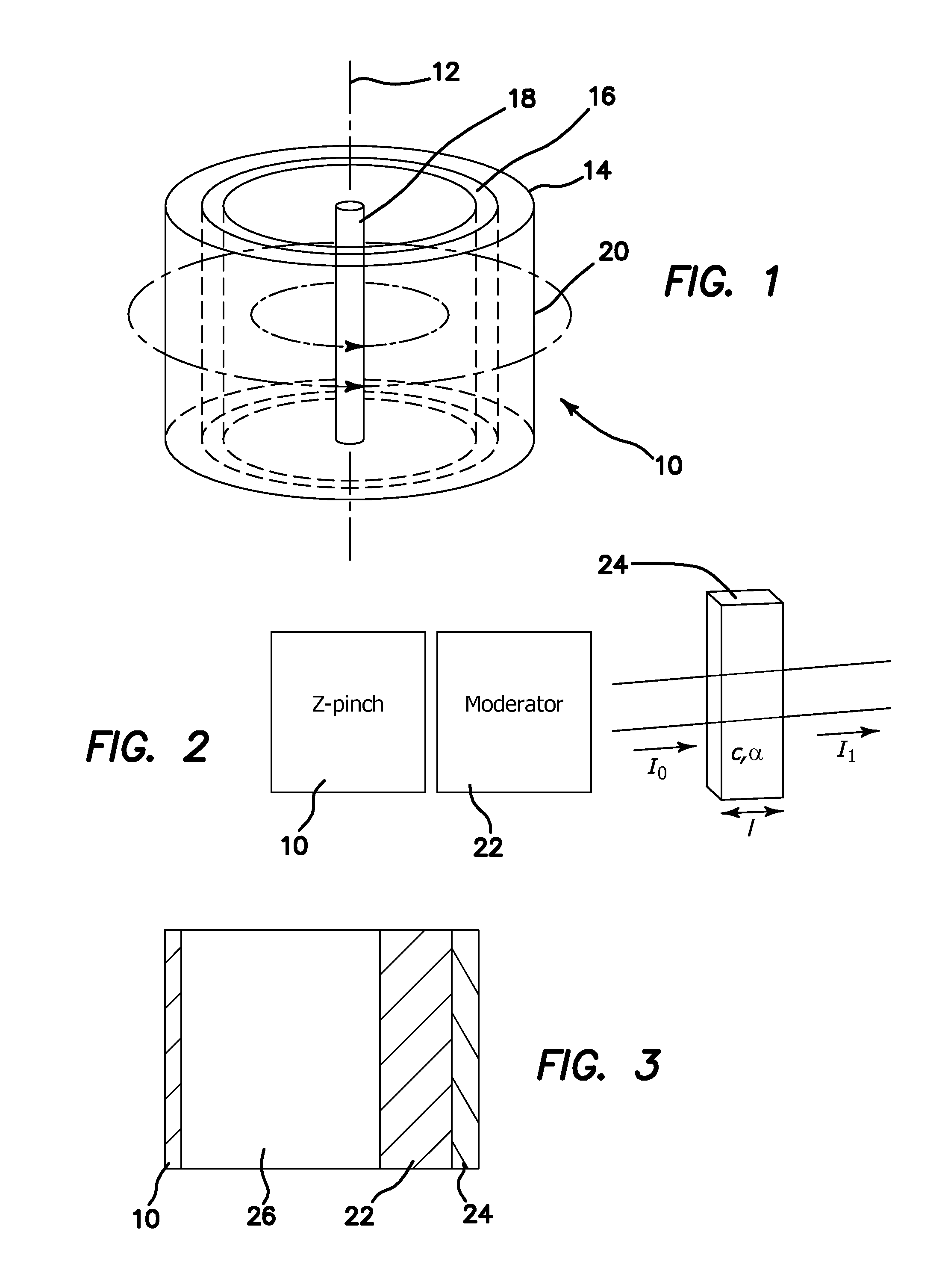

Radionuclide production using a z-pinch neutron source

ActiveUS20110019789A1Increase the number densityHigh flux of neutronsConversion outside reactor/acceleratorsNuclear energy generationShock frontBlood plasma

Radionuclides are produced with a pulsed neutron flux from a multiple repetition rate staged Z-pinch machine, the pulsed neutron flux is moderated, an activatable radionuclide precursor is exposed to the moderated pulsed neutron flux, and a corresponding radionuclide from the activatable radionuclide precursor is produced. High current pulses are passed through a target plasma of fusible material enclosed in a cylindrical liner plasma composed of a high-Z plasma to generate a magnetic field that compresses the liner plasma, and generates shock waves. The shock implodes the target plasma. The shock front propagates between an outer shock front and an axis of the target plasma so it is heated through shock dissipation and by adiabatic compression due to an imploding shock front produced in the outer liner plasma to fuse light nuclei and generate alpha particles and neutrons. Alpha particles trapped within the magnetic field further heat the target plasma.

Owner:RGT UNIV OF CALIFORNIA

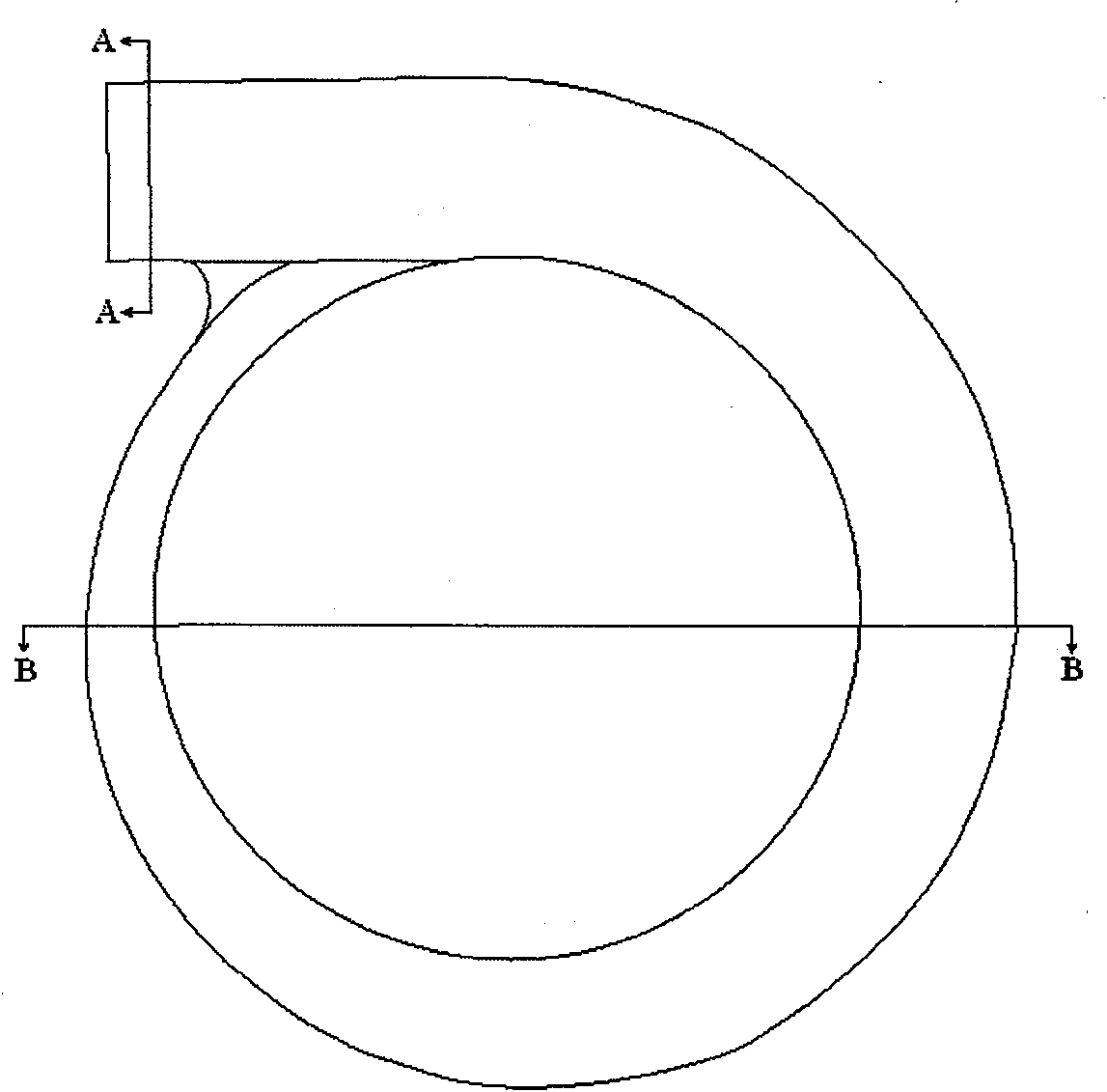

Titanium alloy volute casing piece forming method

The invention relates to a plate metal special-shaped piece processing method, in particular to a titanium alloy volute casing piece forming method, which comprises the following steps that: the size of an outer circle and an inner circle of a preform body is calculated according to a design drawing of a volute casing piece; the material is fed; the size of mould cavity is reduced by 3 to 7 percent when designing a mould, the processing method adopts a numeric-control processing center to process, and the hardness of the mould is more than or equal to HRC45; the formation is carried out in a multi-pass hot-drawing way; and finally the metal volute casing piece is obtained through the mechanical processing and the surface treatment. The titanium alloy volute casing piece is processed through the multi-pass hot-drawing formation technology; the high-temperature-resistant anti-oxidation coat is used for coating the surface of a titanium alloy sheet so as to realize that the titanium material can be heated inside an ordinary resistance furnace; the size reduction range of the mould cavity is found when designing the mould; technological seams are arranged on local part of the preform body so as to prevent local part from being cracked during the formation process; and the industrialized small mass production of the titanium alloy volute casing piece is realized, the quality of the product reaches the level of the similar product in overseas developed countries, and the urgent need of the aviation industry is solved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

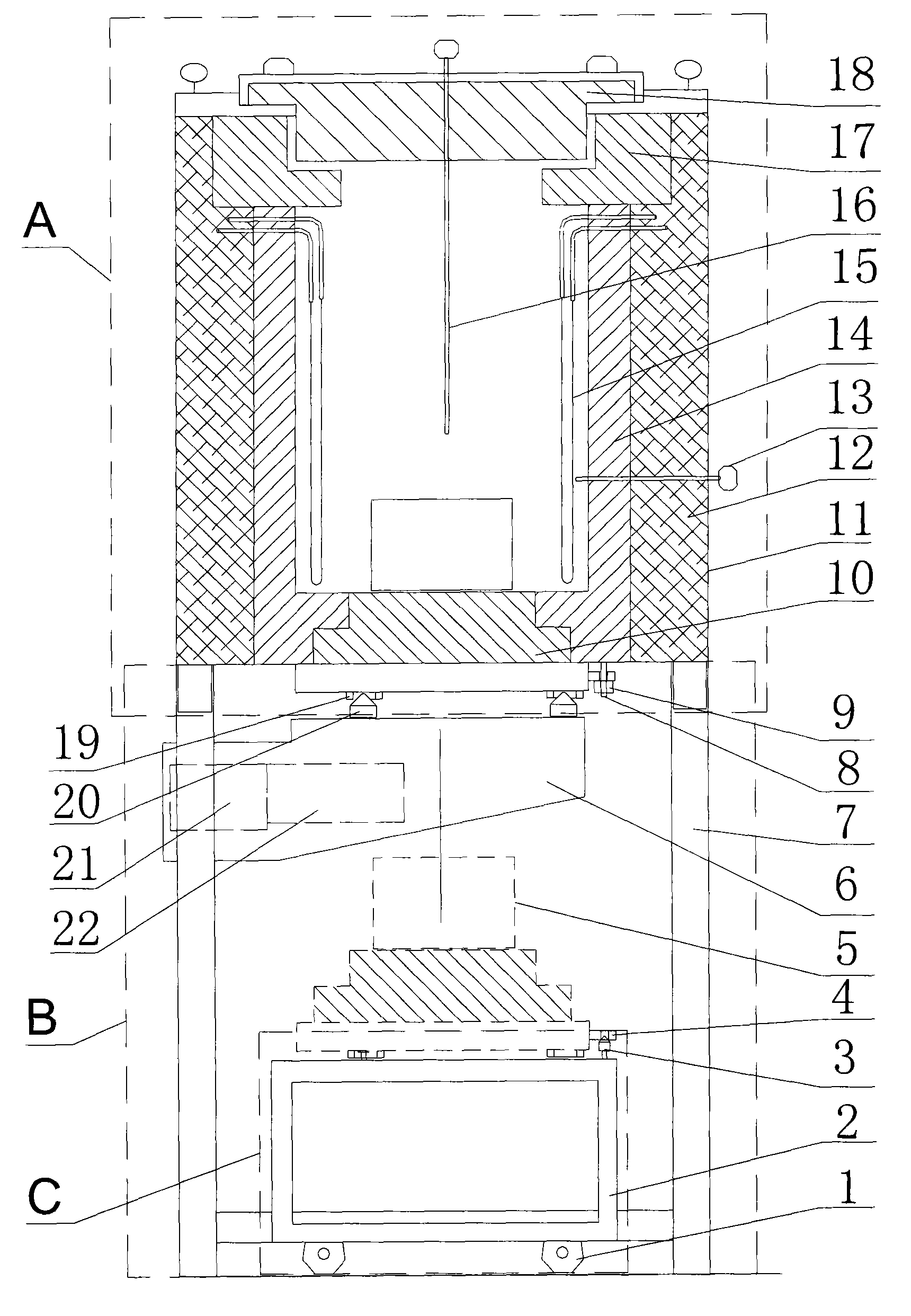

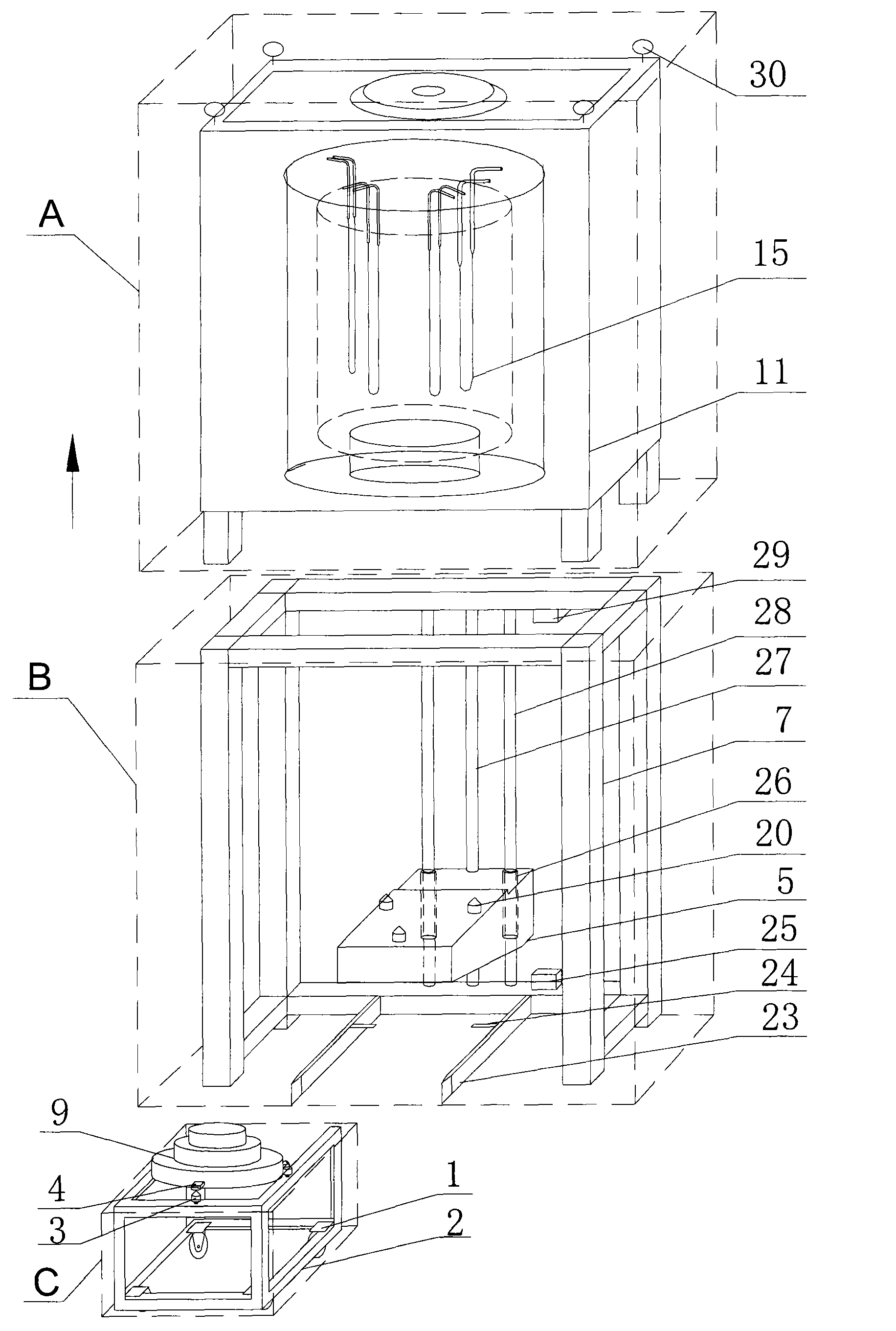

Combined multifunctional resistance furnace

The invention relates to a combined multifunctional resistance furnace comprising a furnace body A, a lifting system B and a cart C, wherein, the furnace body A is provided with an upper furnace mouthand a lower furnace mouth and is respectively provided with an upper furnace cover 18 and a lower furnace seat 10 which are matched with the upper furnace mouth and the lower furnace mouth; the lifting system B is fixedly arranged on a furnace frame 7, the dismountable furnace body A is arranged above the furnace frame 7 in a combined mode, and the cart C is arranged at the lower part in the furnace frame 7. A workpiece 5 can be stably assembled and disassembled by the lifting motion of a lifting platform 6, the plane motion of the cart C and positioning and positioning exchange to the lowerfurnace seat 10 by the above motion. The invention can disassemble the furnace body A to serve as a pit type resistance furnace according to requirements or serve as a lifting resistance furnace by closing the upper furnace cover 18, which realizes one furnace with multiple functions and simultaneously satisfies various complex operation requirements of the resistance furnace. The invention has simple structure, reliable running, safe operation and wide application range and is especially suitable for hot-working treatment and complex operation, such as sintering, smelting, solidifying and thelike of the materials.

Owner:SOUTH CHINA UNIV OF TECH

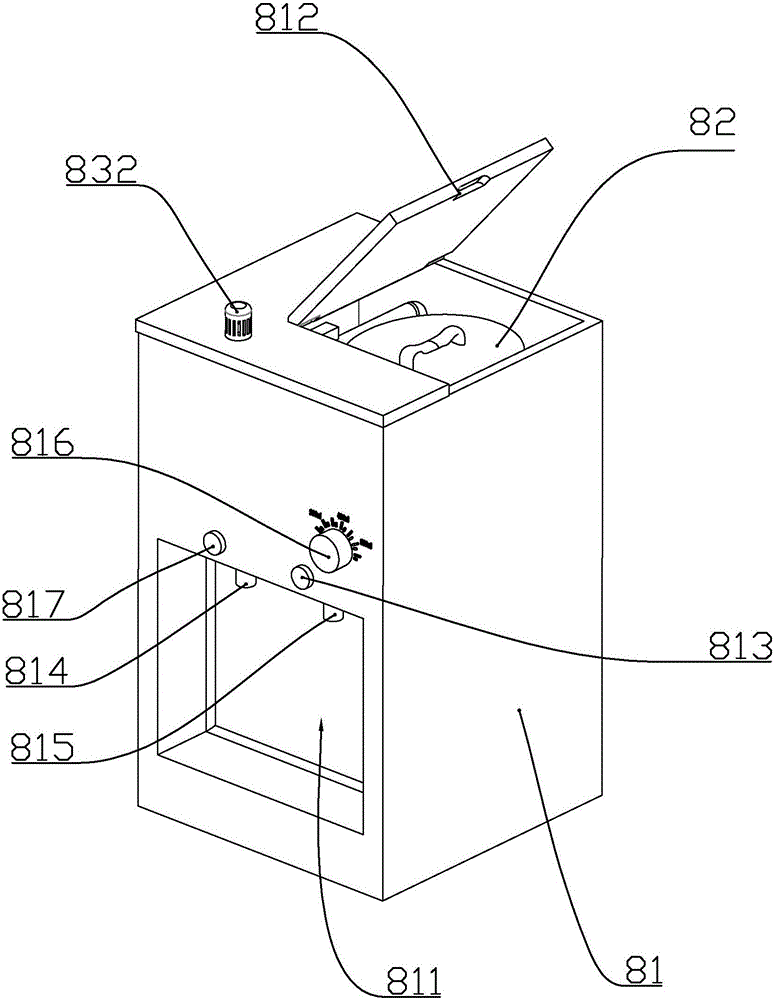

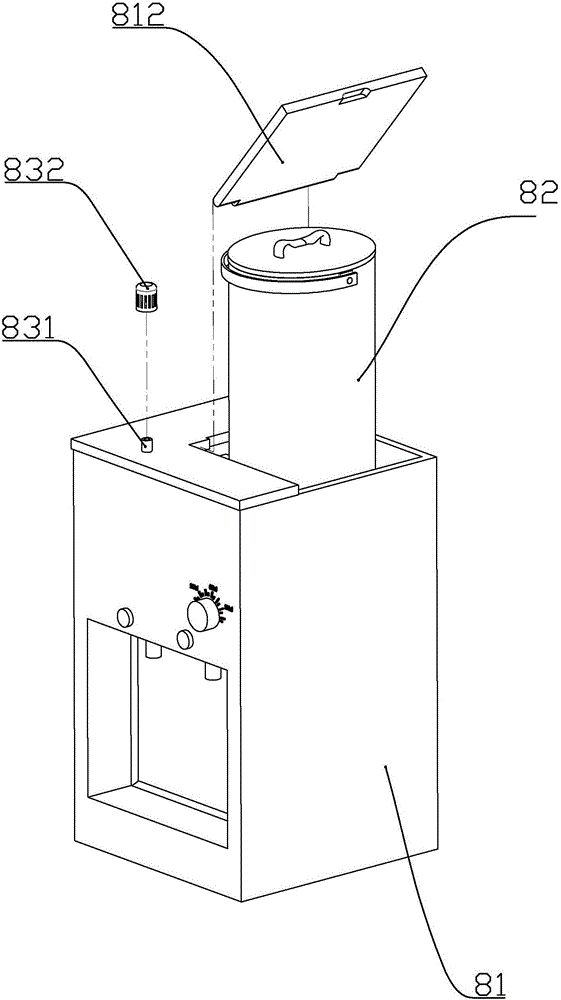

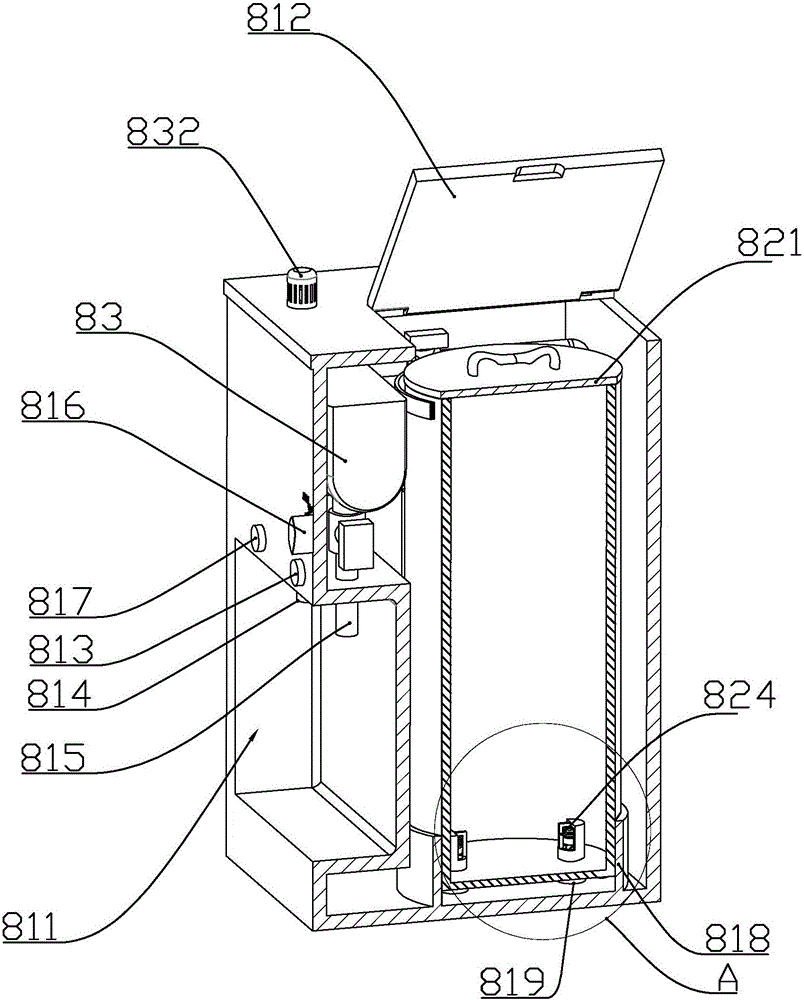

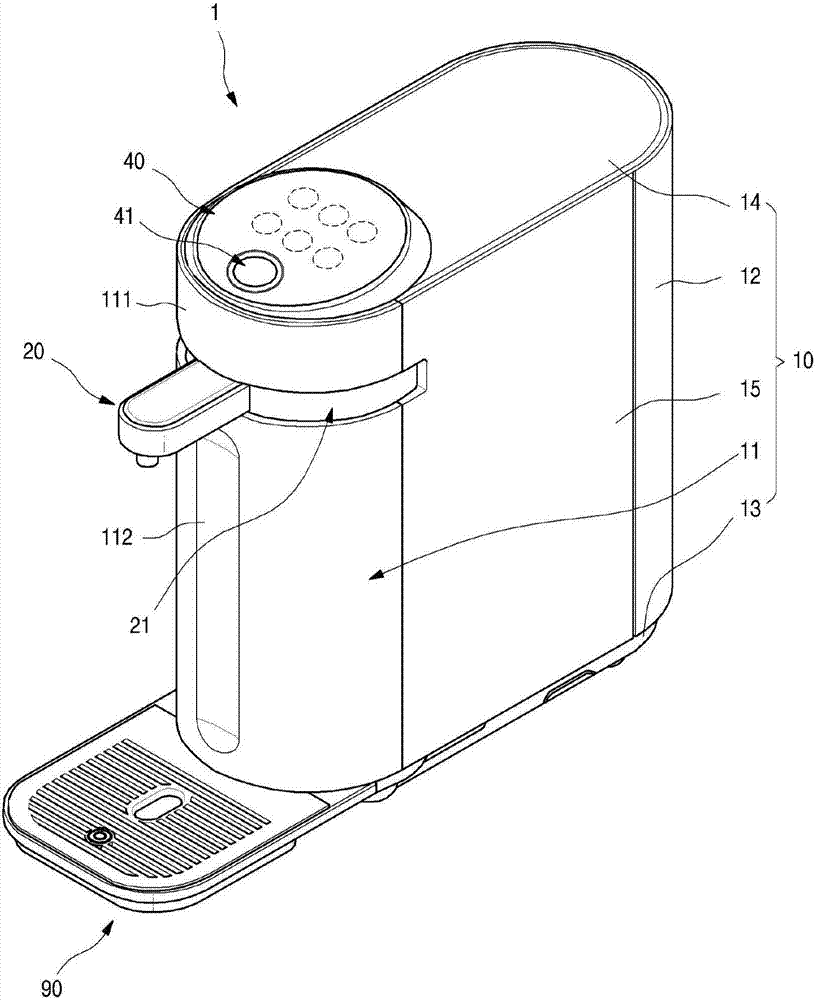

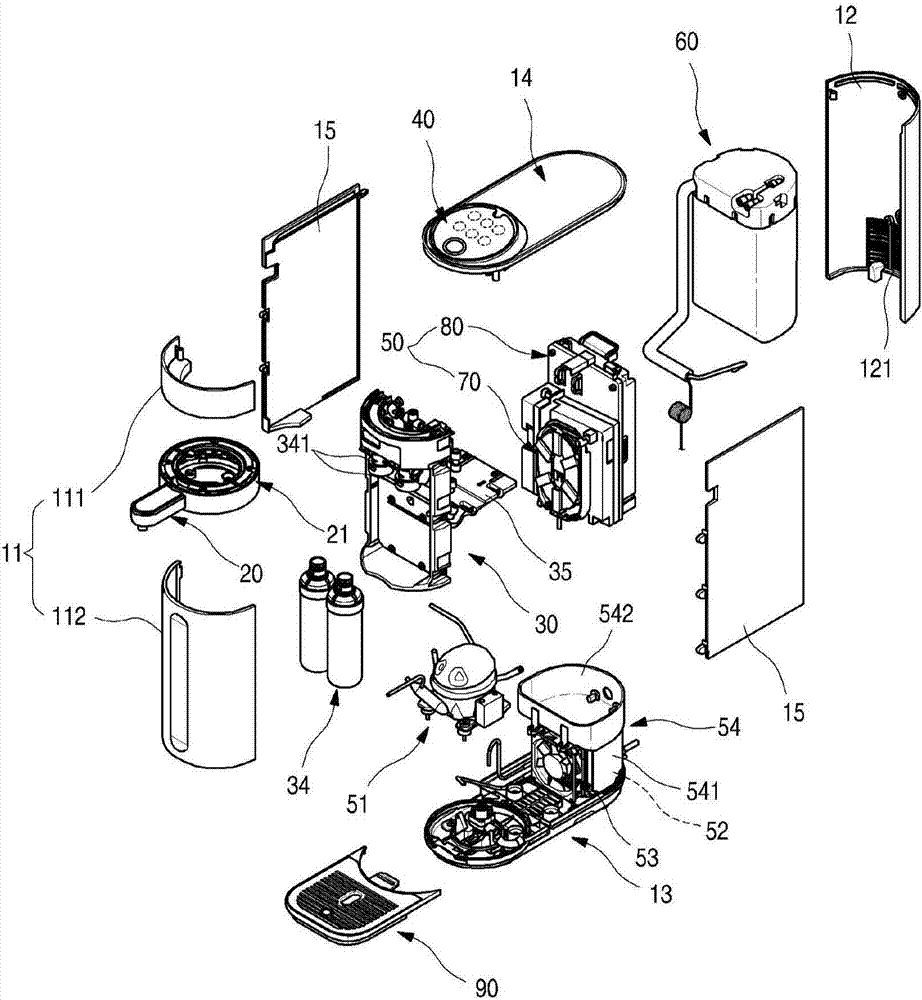

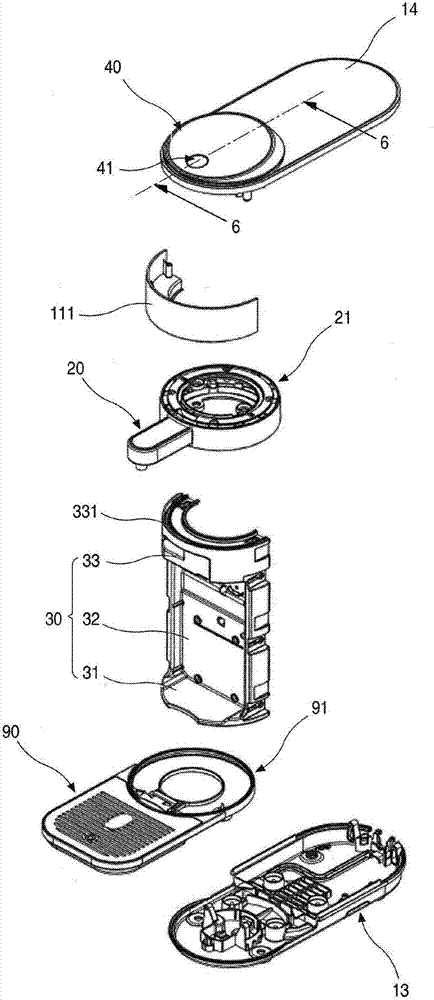

Purified water direct drinking machine

ActiveCN105662149AAchieve heatingAvoid repeated heatingBeverage vesselsPotable waterProcess engineering

The invention discloses a purified water direct drinking machine. The purified water direct drinking machine comprises a machine case as well as a water tank, a heating water tank, a filter, a water pump and a main control circuit board which are mounted in the machine case. According to the purified water direct drinking machine, the volume of water required to be heated is set through a water volume adjustment knob; the main control circuit board is used for controlling a hot water outlet electromagnetic valve, a cold water outlet electromagnetic valve, a flushing electromagnetic valve, a water addition electromagnetic valve and the like, so that drinking water required by a user can be heated and prevented from being unnecessarily and repeatedly heated, and the purpose of energy conservation is achieved; and in addition, the filter can be self-cleaned by virtue of opening and closing of the flushing electromagnetic valve.

Owner:李连洪

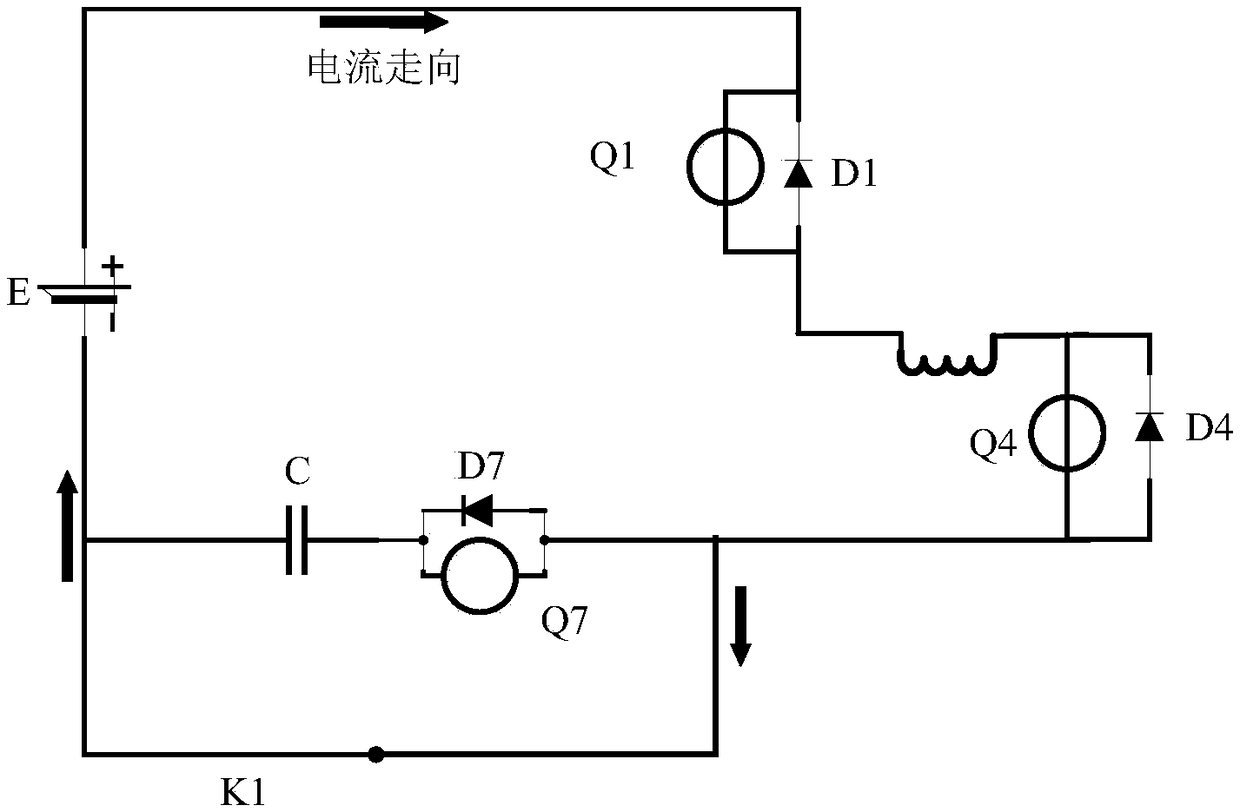

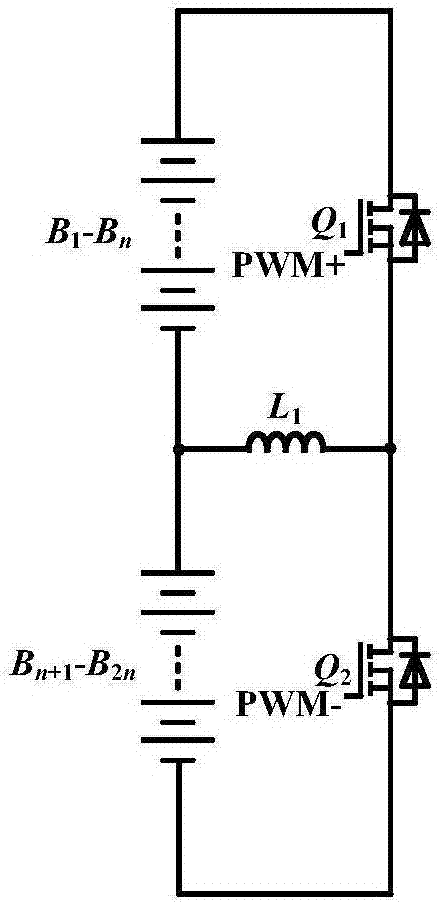

Vehicle-mounted power battery low-temperature full-time interleaving heating topology circuit and application thereof

The invention discloses a vehicle-mounted power battery low-temperature full-time interleaving heating topology circuit and application thereof. The circuit comprises a first battery pack and a secondbattery pack, wherein two Buck-Boost inverter circuits which are connected in parallel are connected in parallel with a to-be-heated battery pack; the Buck-Boost inverter circuits are respectively controlled by two pairs of PWM (Pulse-Width Modulation) signals of which phase angles are different for a set angle; when a single battery of the first battery pack is heated by a first Buck-Boost inverter circuit, a single battery of the second first battery pack is heated by the second Buck-Boost inverter circuit, and thus full-time battery heating is achieved. By adopting the interleaving heatingtopology circuit disclosed by the invention, under the condition that a battery pack is not further damaged, the heating speed can be remarkably increased, and the heating efficiency can be remarkably improved.

Owner:SHANDONG UNIV

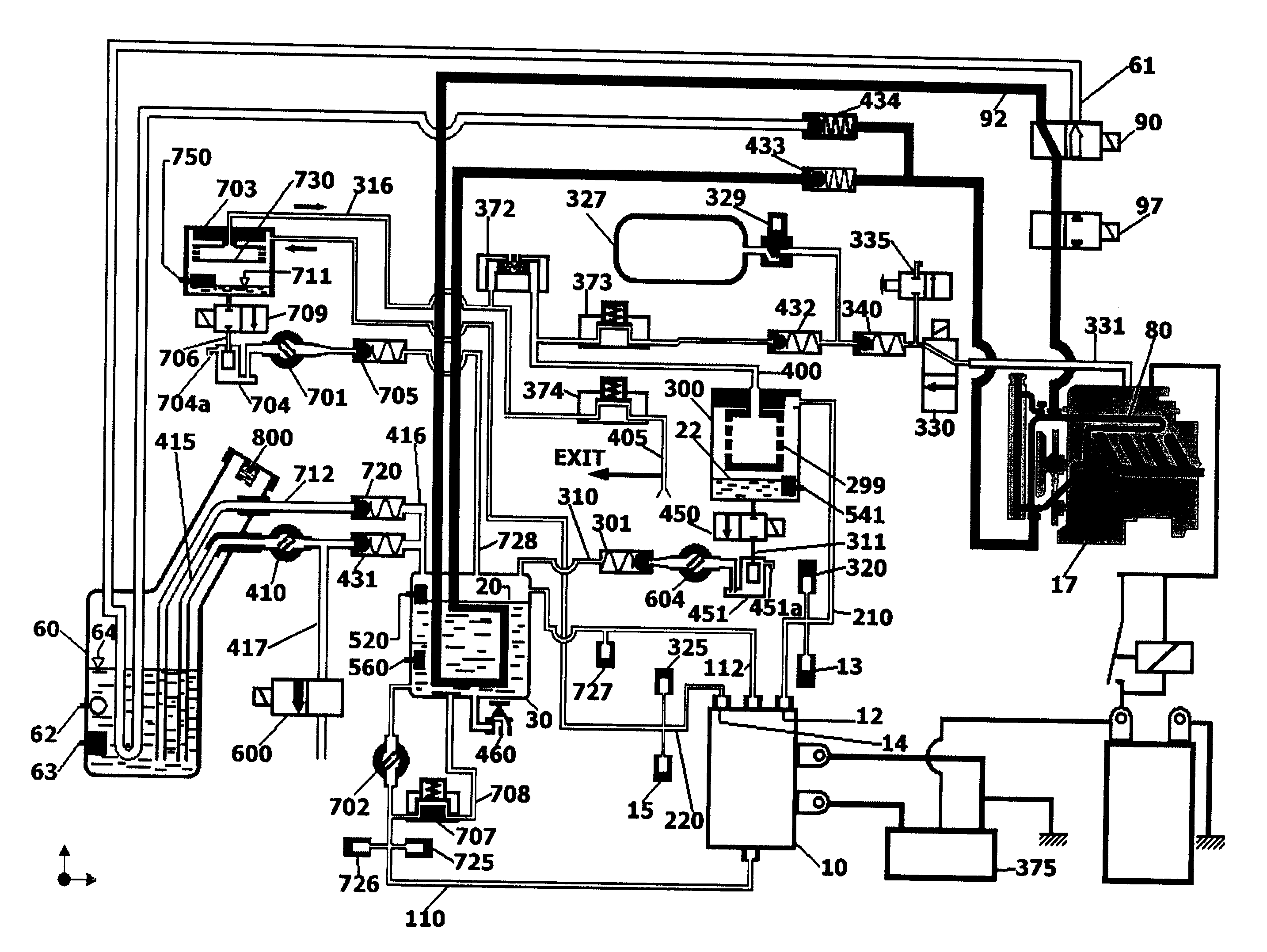

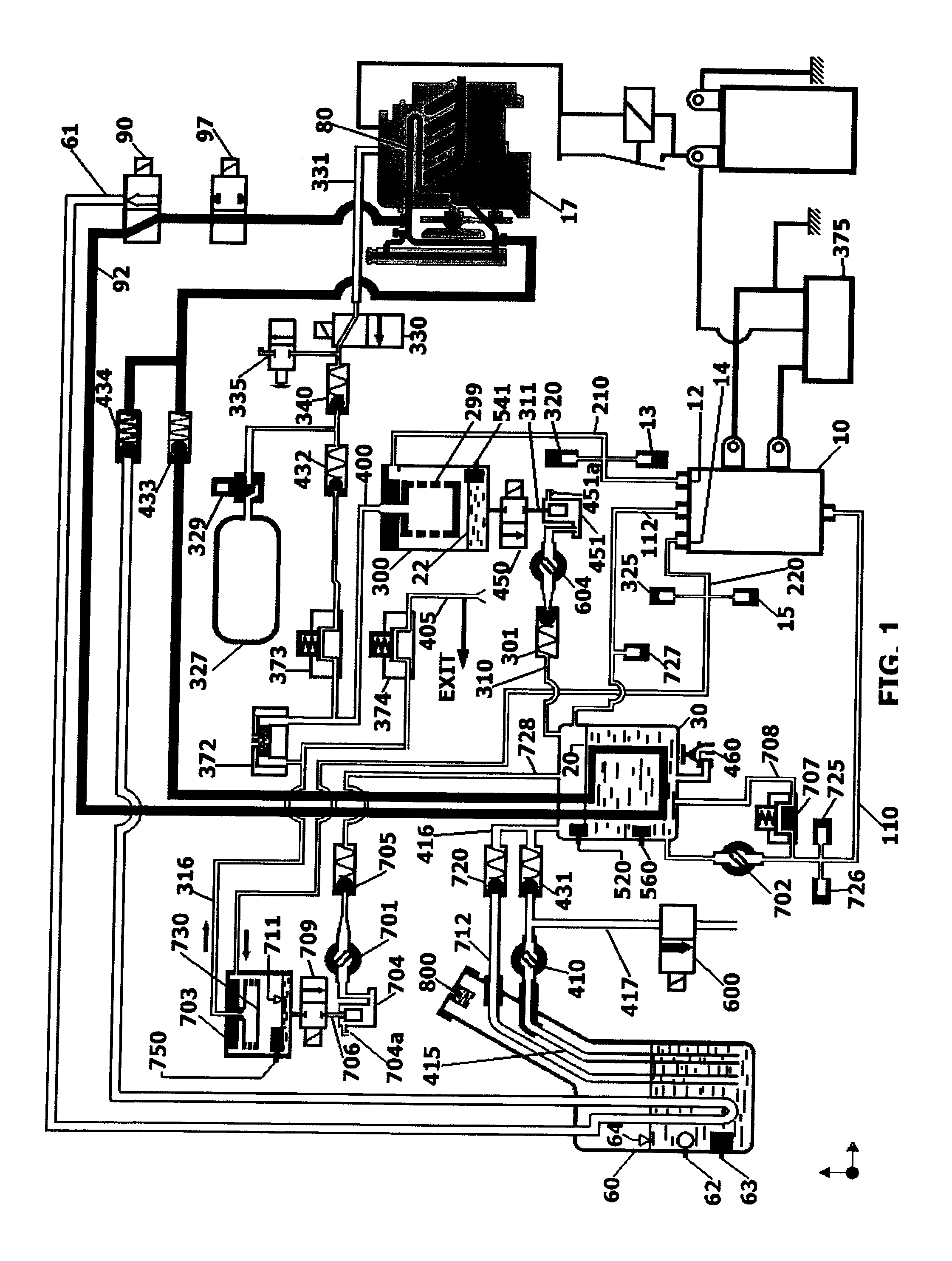

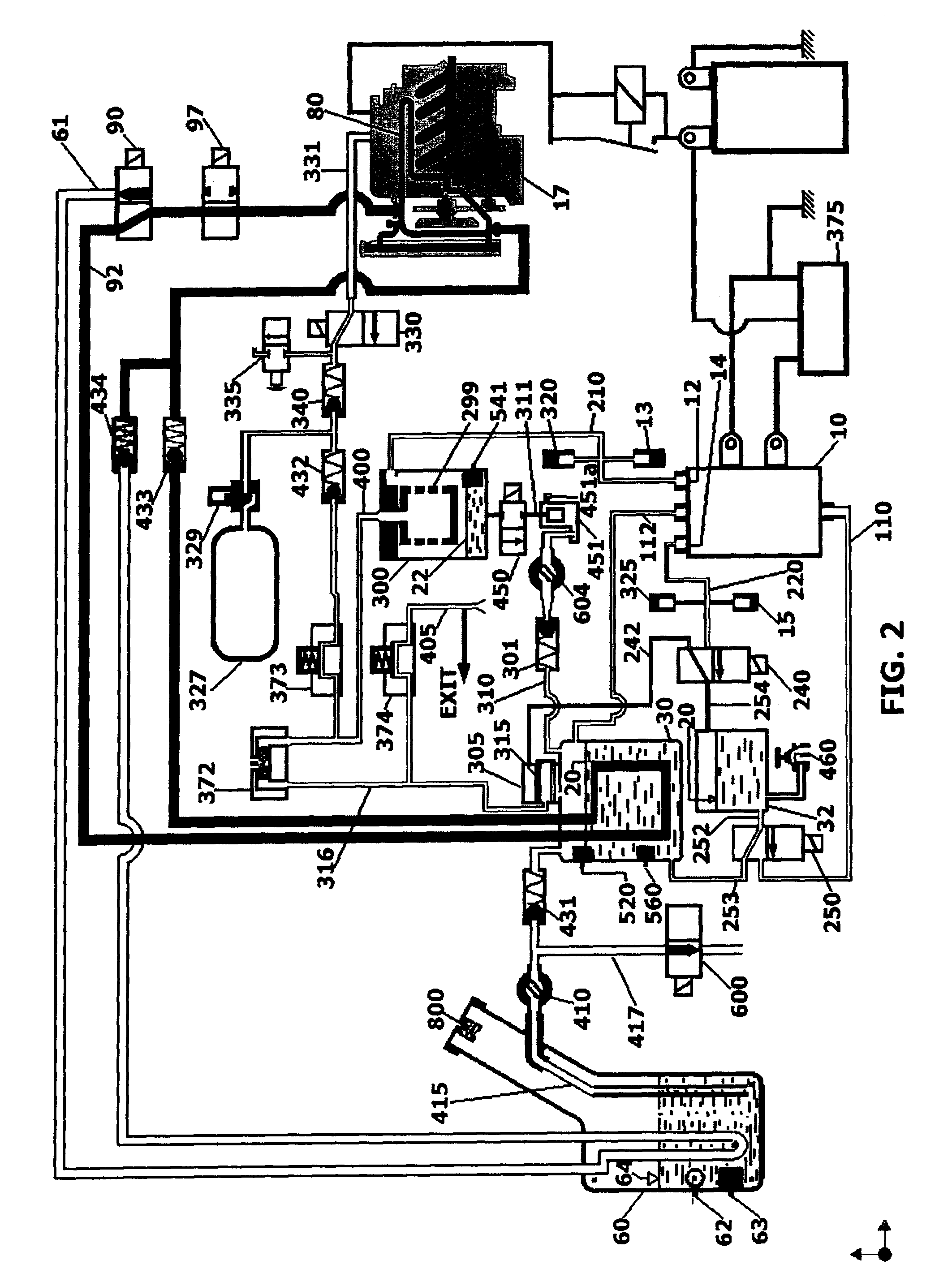

Electrolyte Delivery System

InactiveUS20090301407A1Reduce resistanceLess electric powerElectrical controlInternal combustion piston enginesWater useHydrogen

The present invention provides a system for providing electrolyte to an electrolysis cell for producing hydrogen gas to inject into the intake of an internal combustion engine. The system includes an electrolysis cell having an electrolyte input port, an electrolyte output port and at least one working gas output port. The electrolyte output port communicates with a storage reservoir. A coolant liquid conduit is in thermal communication with the electrolyte solution and in fluid communication with a portion of the engine coolant system in which the coolant liquid has been heated by the engine when the engine is running. To heat up the electrolyte solution and improve the efficiency of electrolysis, the heated liquid coolant is diverted from the engine coolant system and circulated through the heating system to transfer heat to the liquid containing the electrolyte. In freezing temperatures the heated liquid coolant may also be diverted from the engine coolant system and circulated through the distilled water store to thaw the water used to replenish the electrolyte solution.

Owner:MARTINREA INT INC

Water purifier

ActiveCN106963241AImprove efficiencyIncrease productivityWater treatment parameter controlLighting and heating apparatusWater filterFilter holder

The invention provides a water purifier. The water purifier according to the embodiment of the invention includes a shell used for forming a shape; a filter support arranged inside the shell and equipped with a filter and a valve; a condenser support arranged inside the shell and separated from the filter support, a condenser being accommodated on the condenser support; a cooling box placed at the upper end of the condenser support and used for cooling water purified by the filter; a support plate connecting the filter support and the cooling box and dividing space between the filter support and the cooling box vertically; a compressor arranged under the support plate; and a control assembly mounted on the support plate.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com