Measuring device for oil injection rule of each hole of oil injection nozzle of diesel engine

A technology of fuel injection law and measuring device, which is applied in the testing of measuring devices, fuel injection devices, and engines, etc., can solve the problems of difficult application and promotion of test methods, poor dynamic response characteristics of siphon devices, and substantive verification of test methods, etc. Achieve the effect of good overall air tightness, good detection and quality control, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

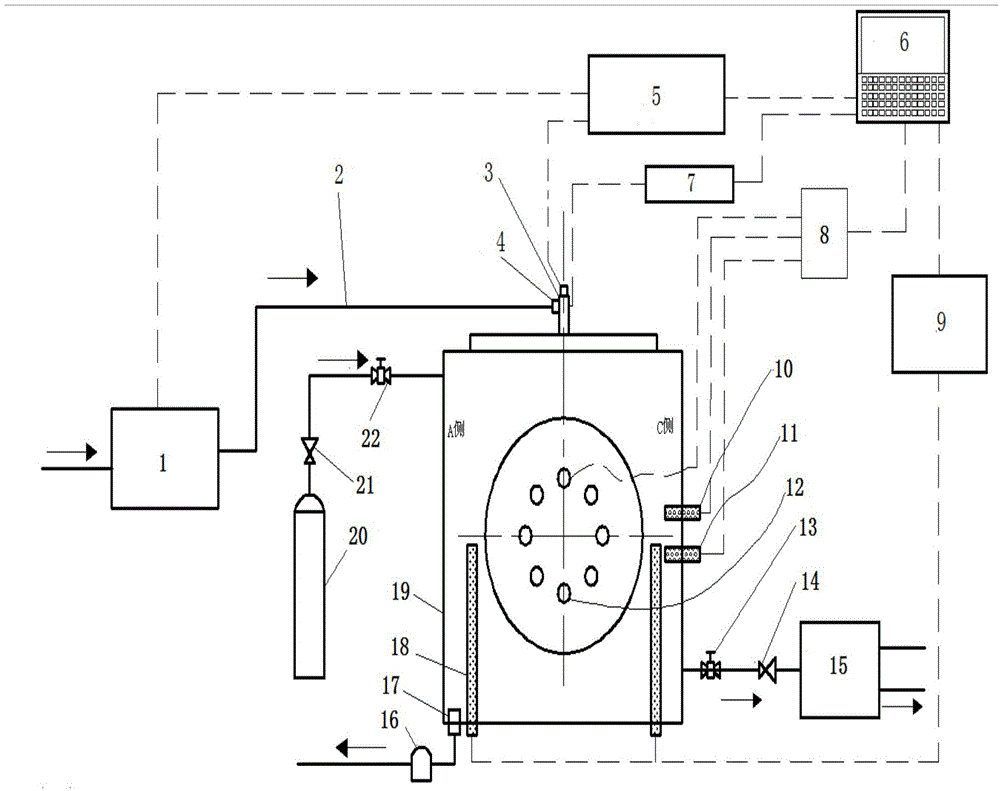

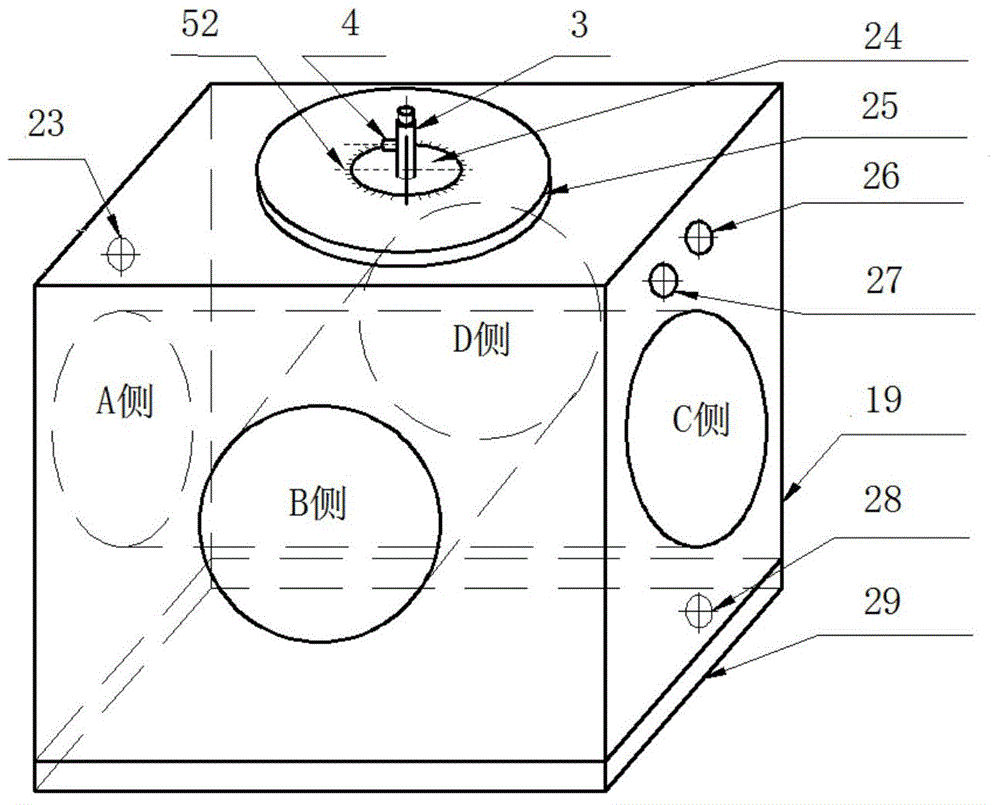

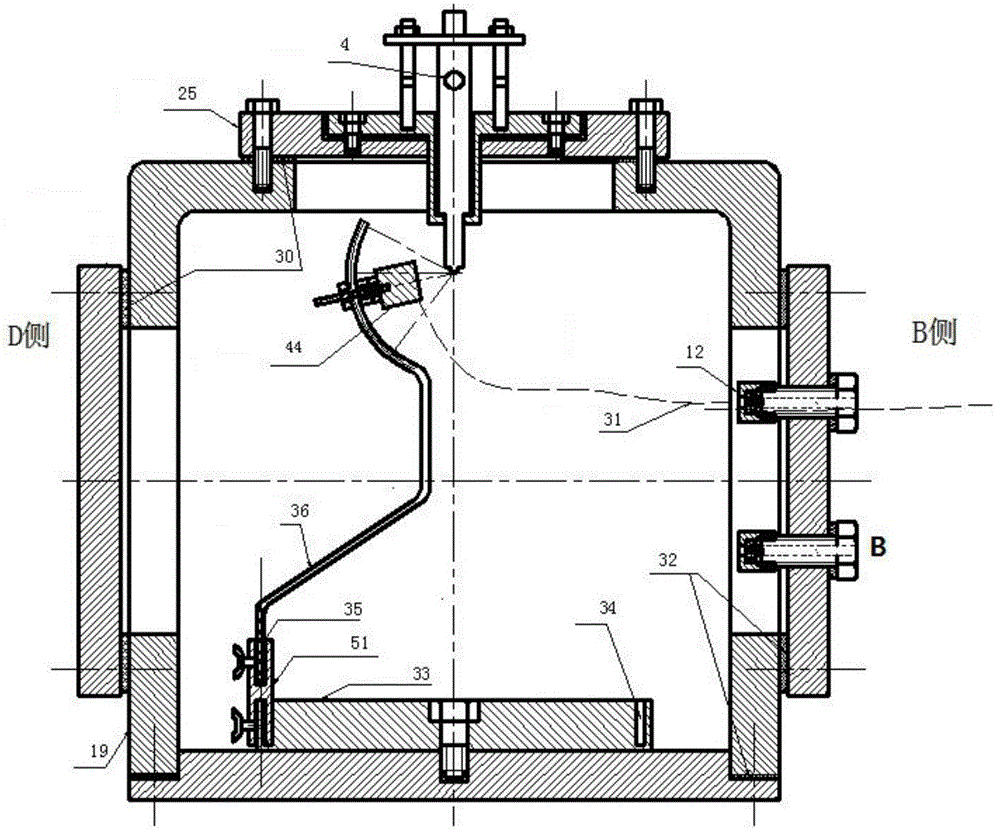

[0035] like figure 1 , figure 2 As shown, the fuel injection rule measuring device for each hole of the fuel injector of a diesel engine includes a gas distribution system, a constant-volume projectile body 19 with holes on the upper end surface, a data acquisition and analysis system 8, and a computer 6. The data acquisition and analysis system 8 and the computer 6 Connected, the gas distribution system is connected with the constant volume projectile body 19; the gas distribution system includes a high pressure nitrogen cylinder 20, a pressure reducing valve 21, an intake valve 22, an exhaust valve 13, a pressure reducing valve 14 and an oil mist filter 15; the top of the A-side end surface of the constant-volume projectile body 19 is also provided with an air intake v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com