Patents

Literature

42results about How to "Eliminate air bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

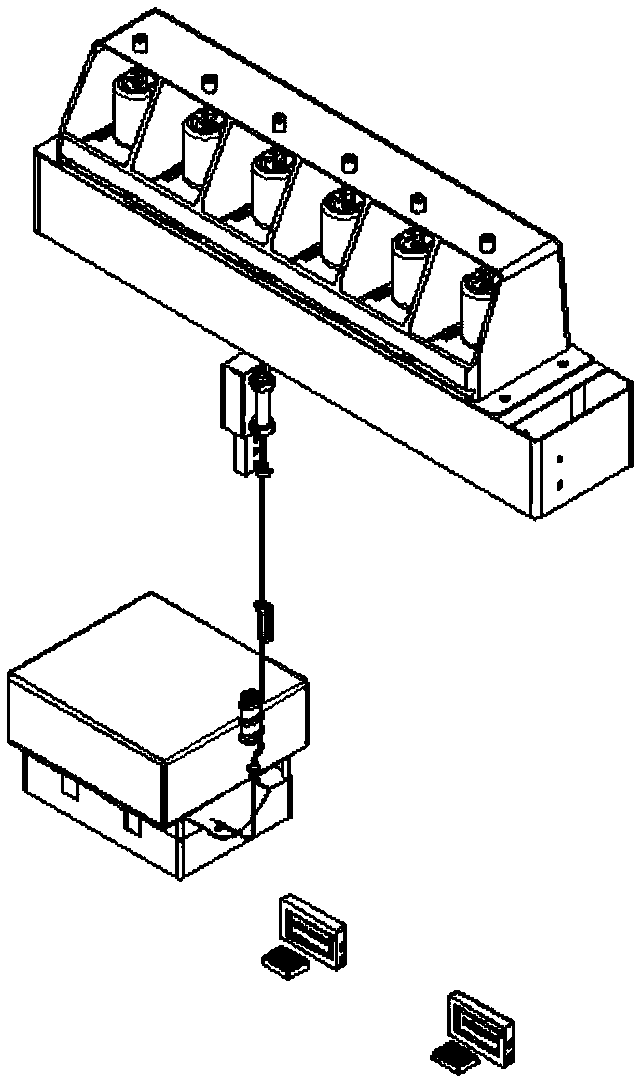

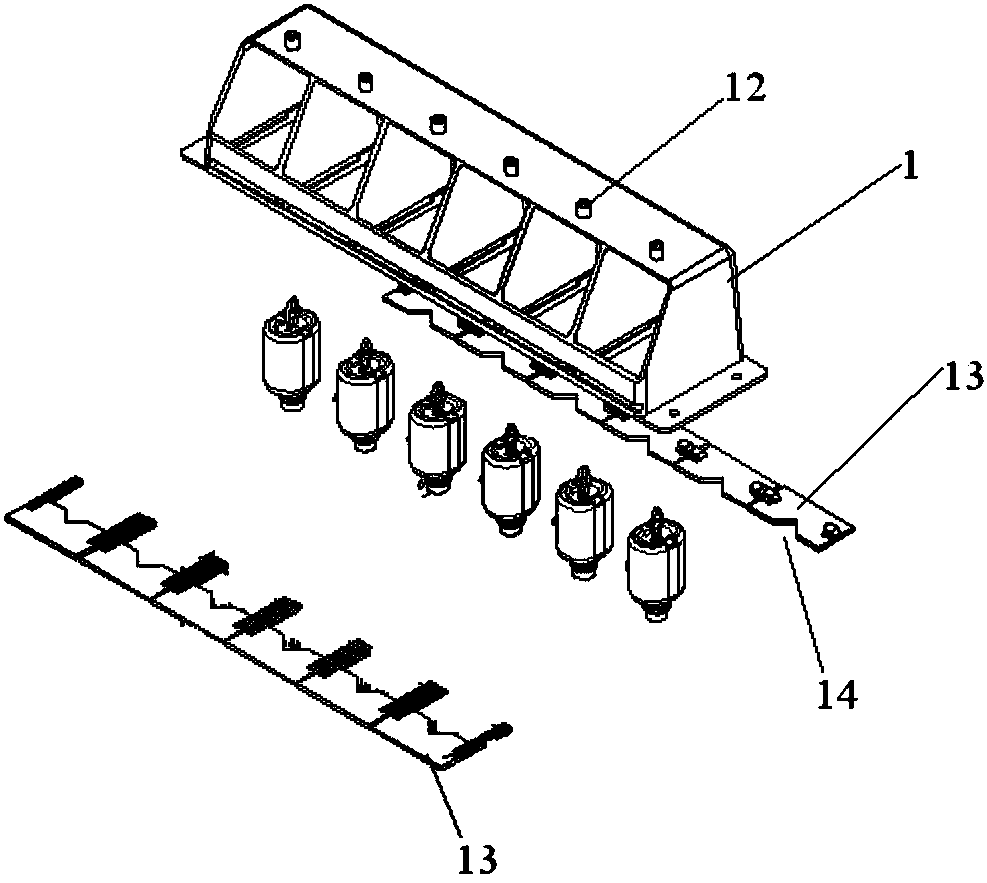

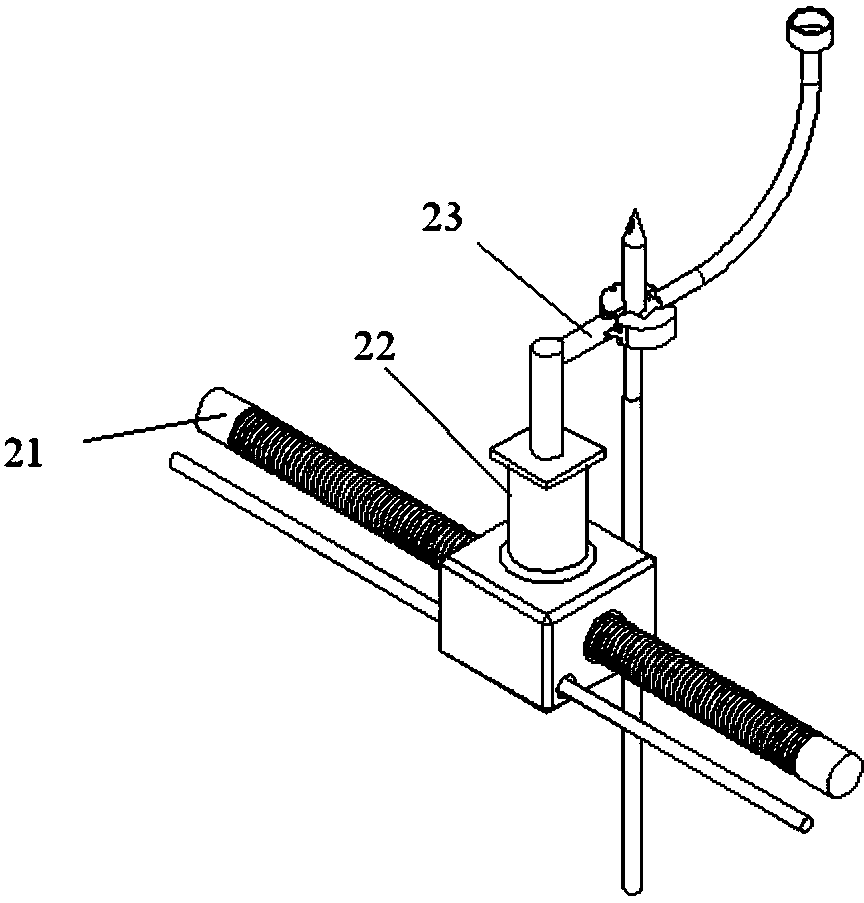

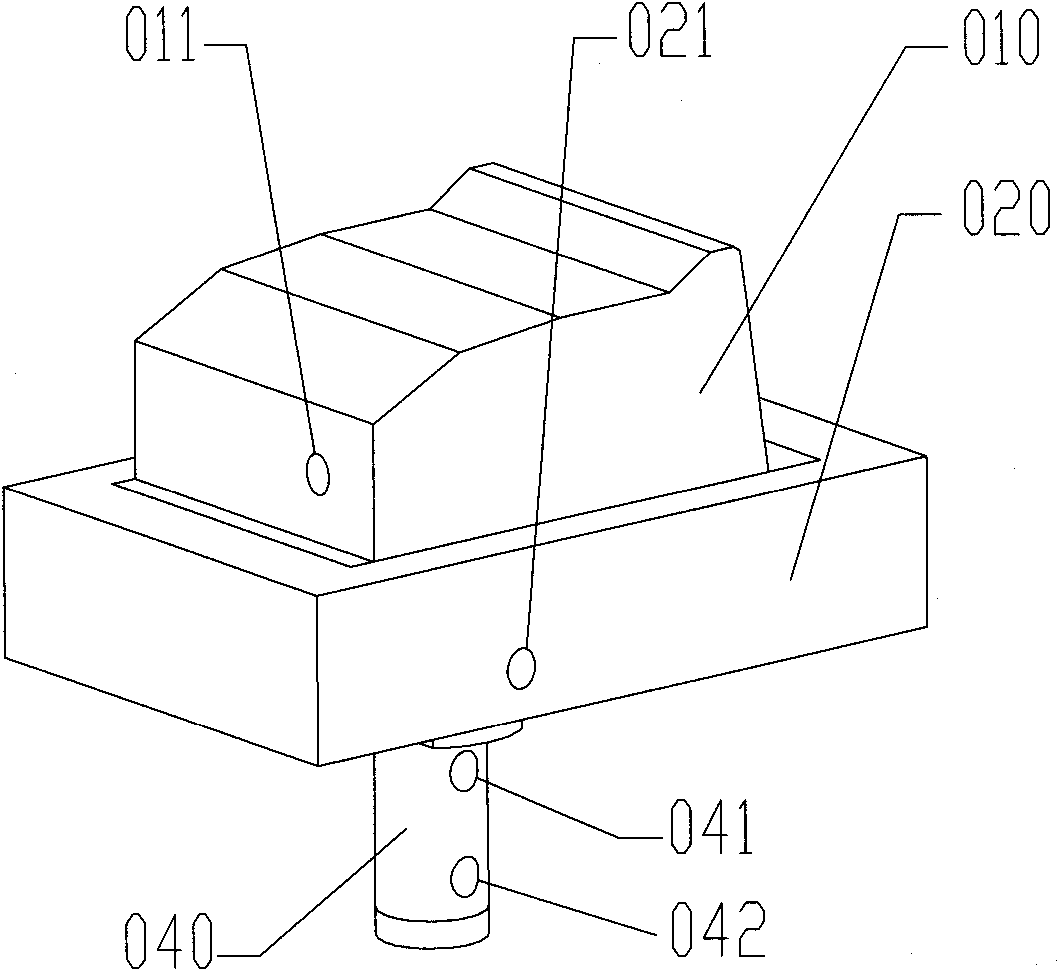

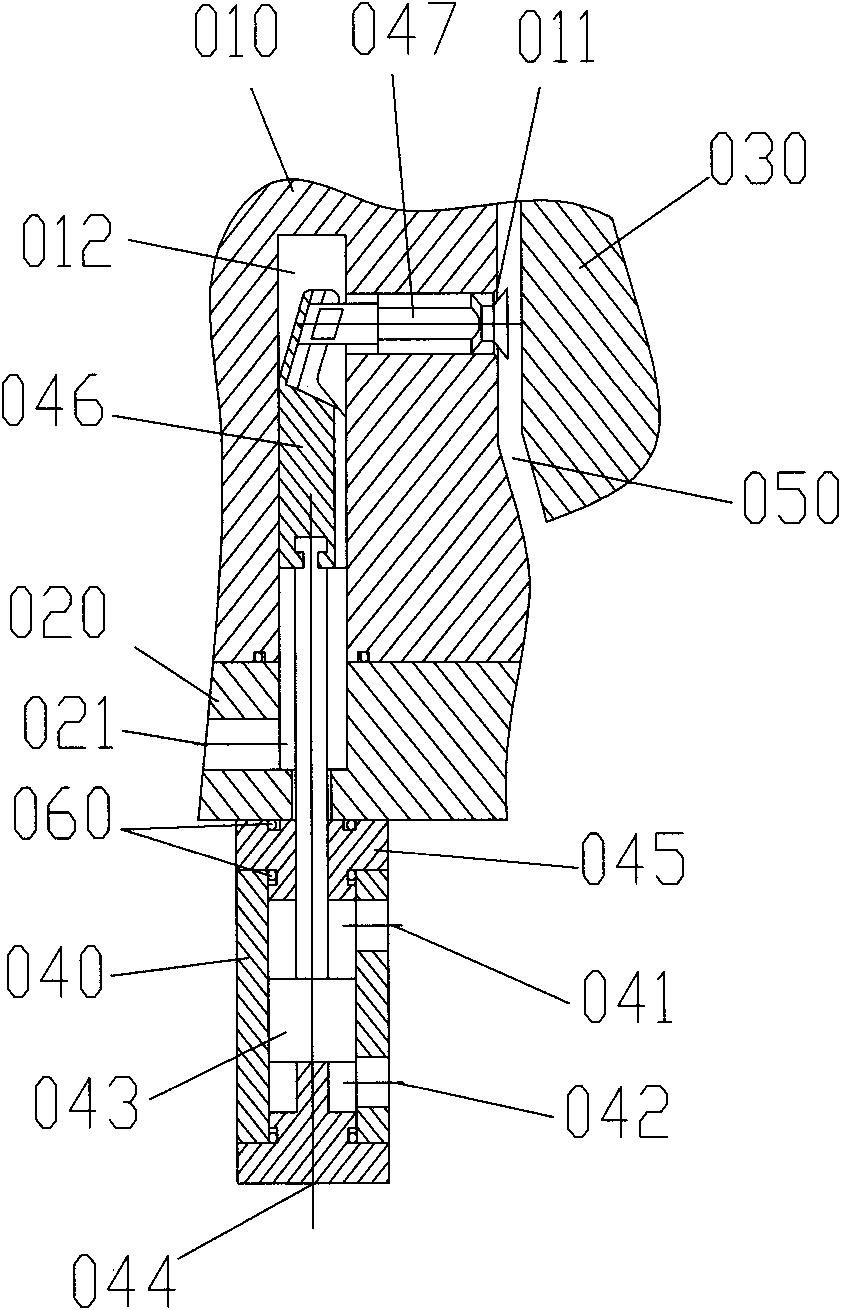

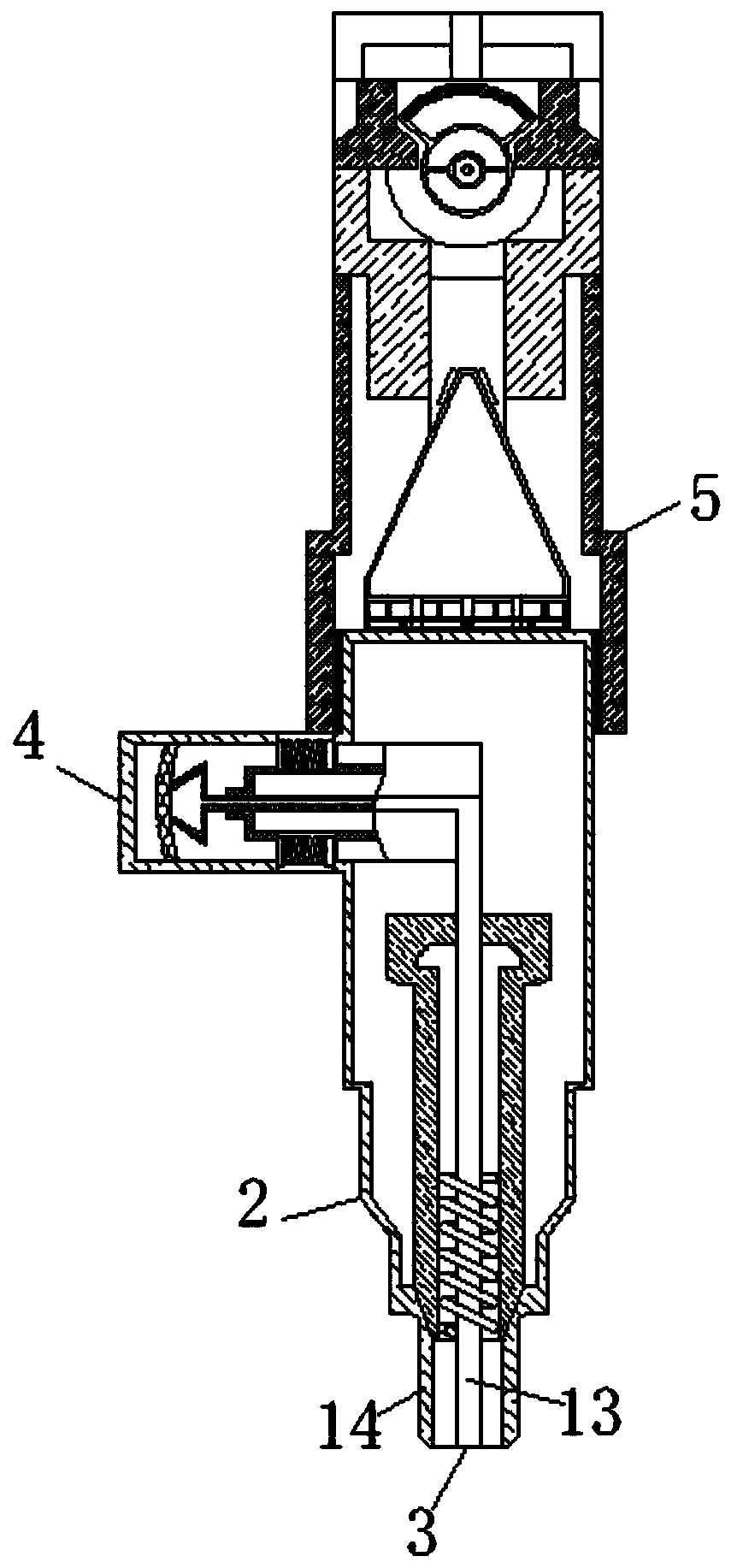

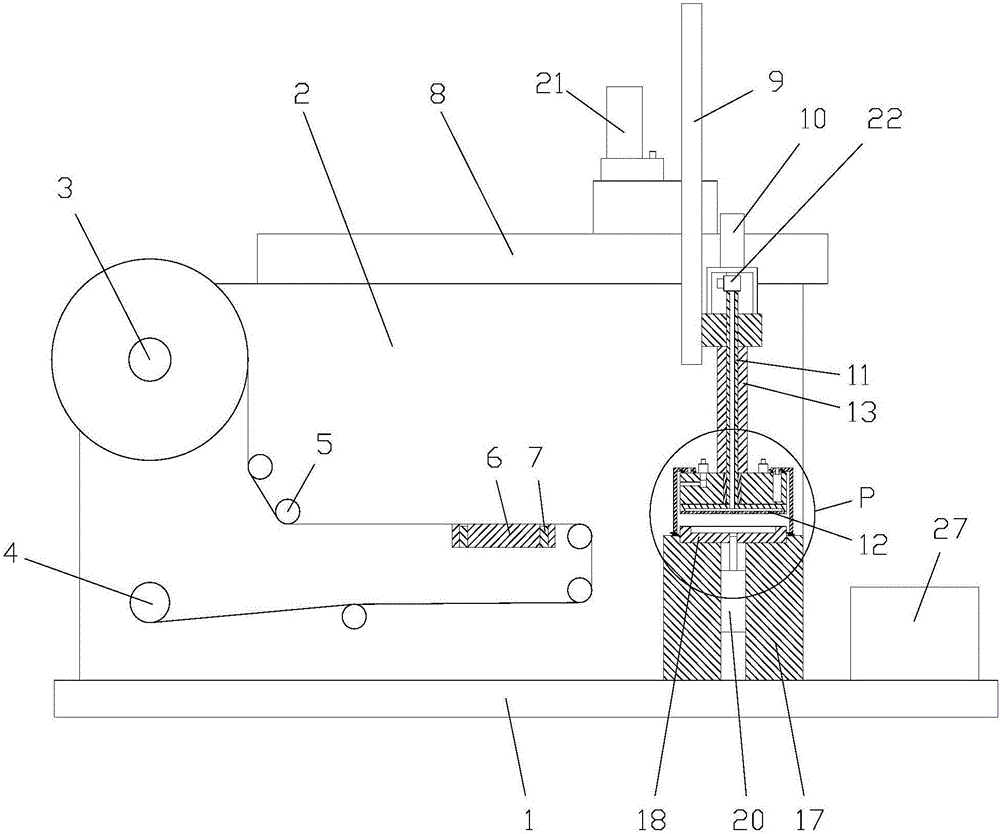

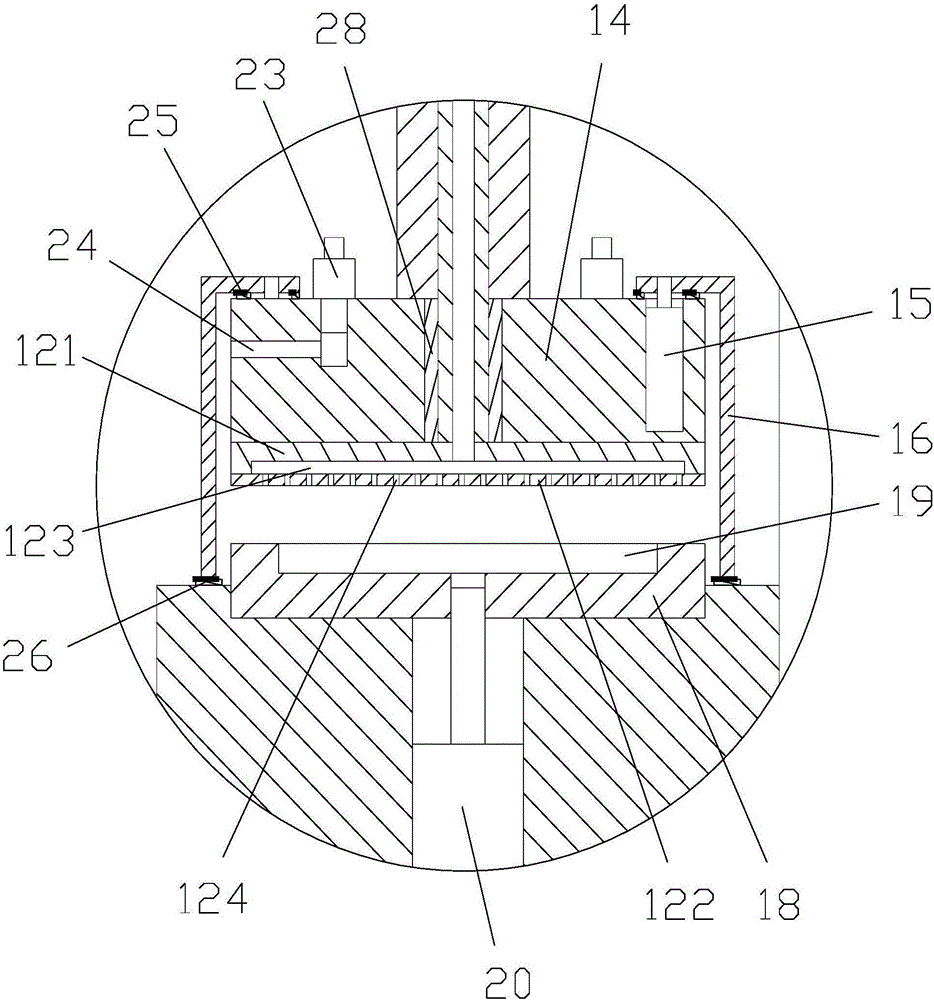

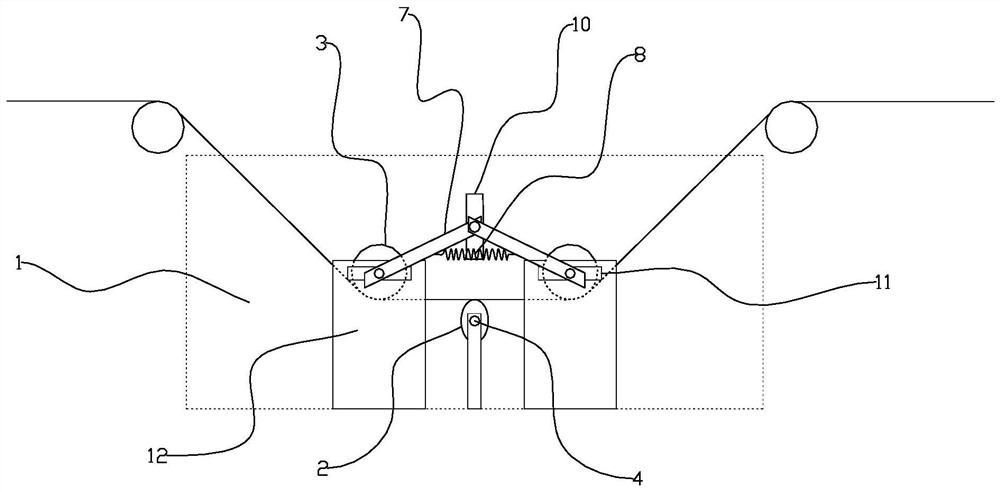

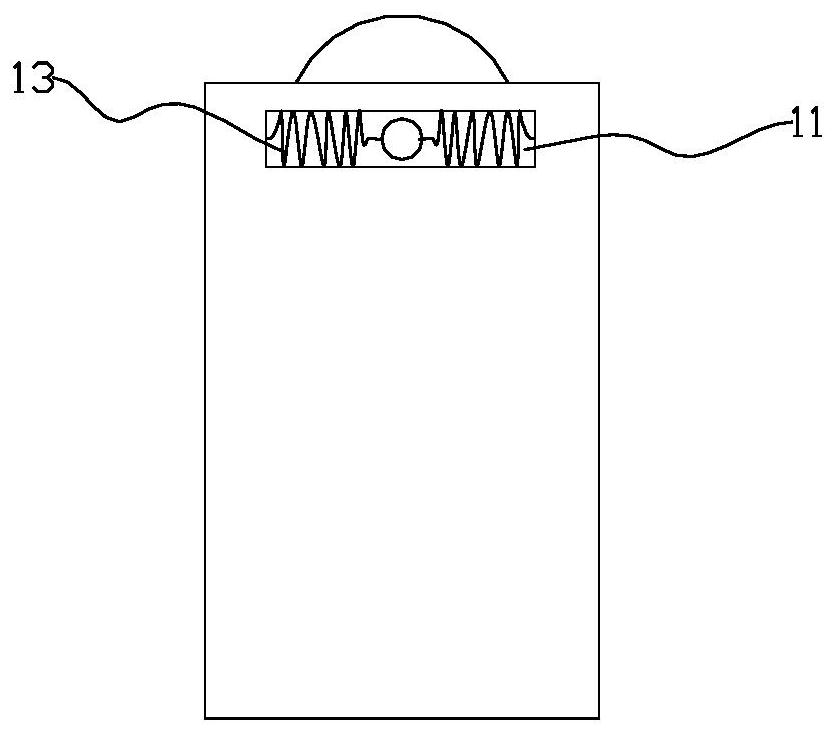

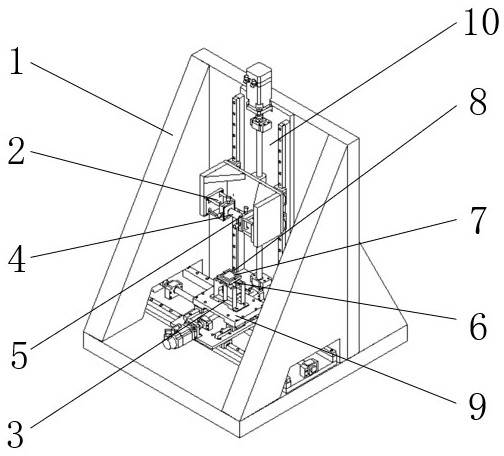

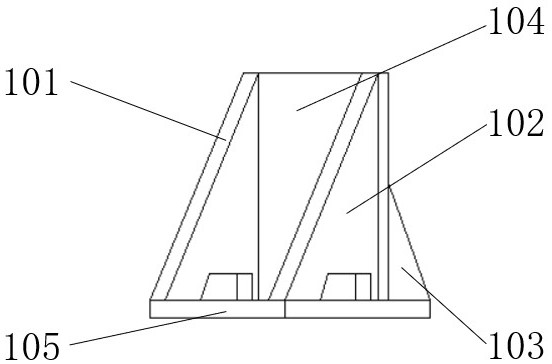

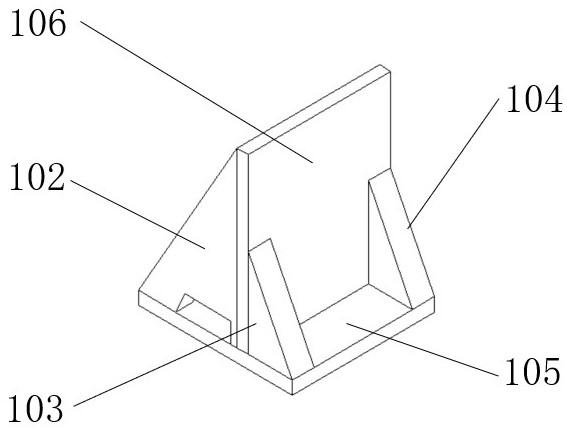

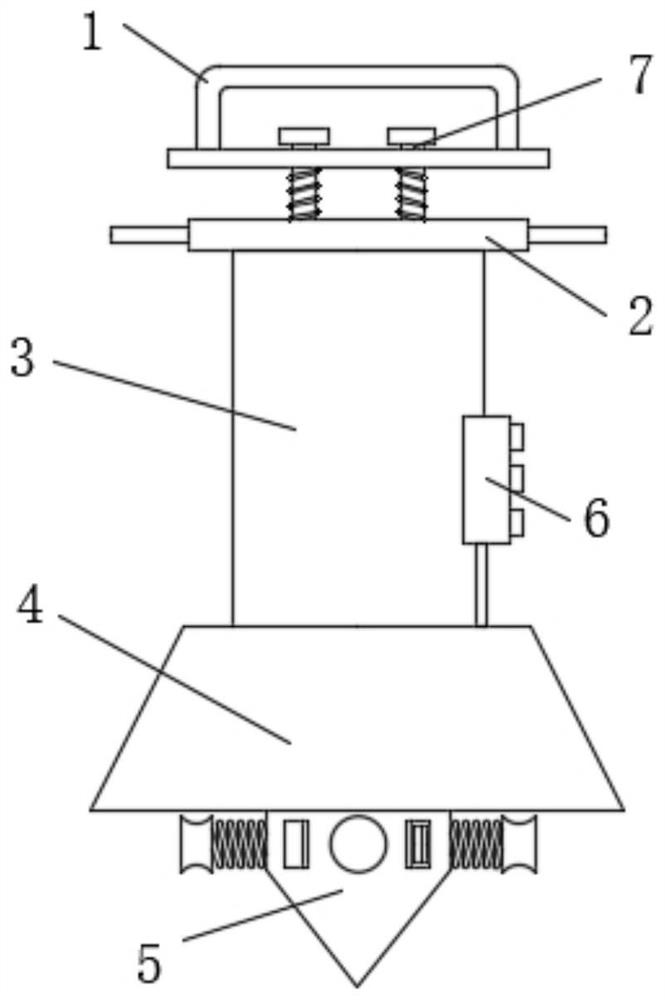

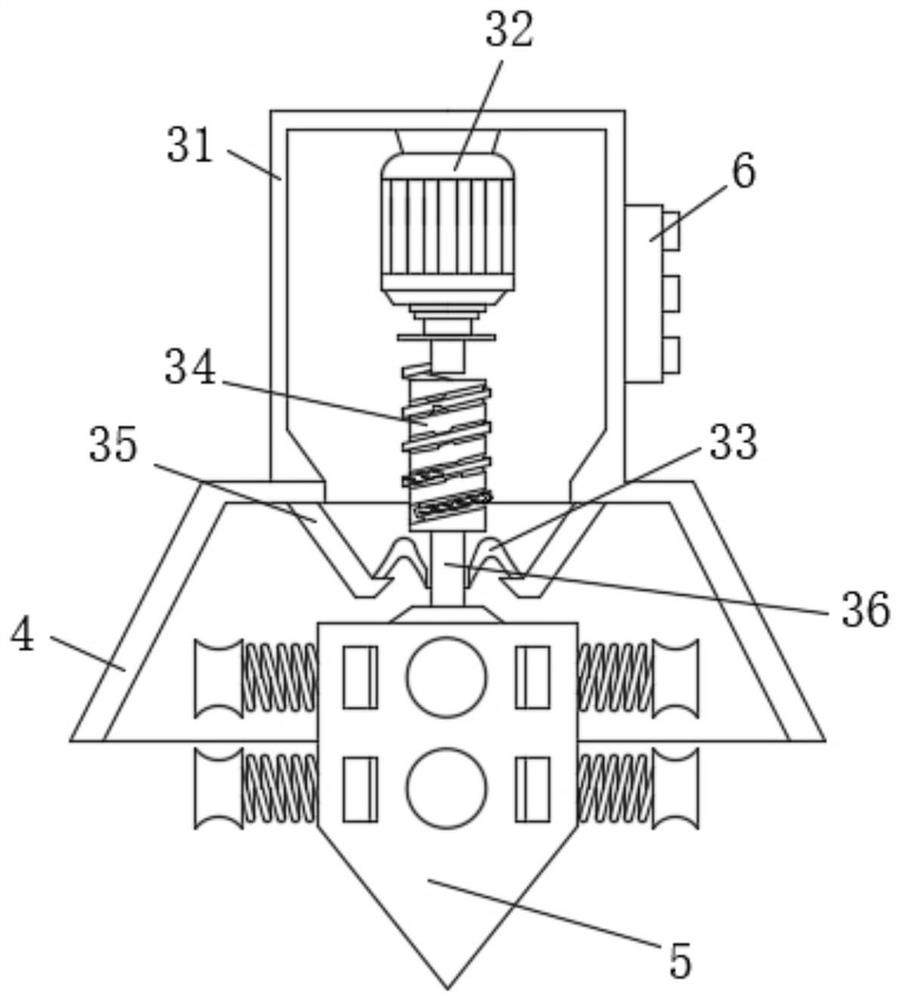

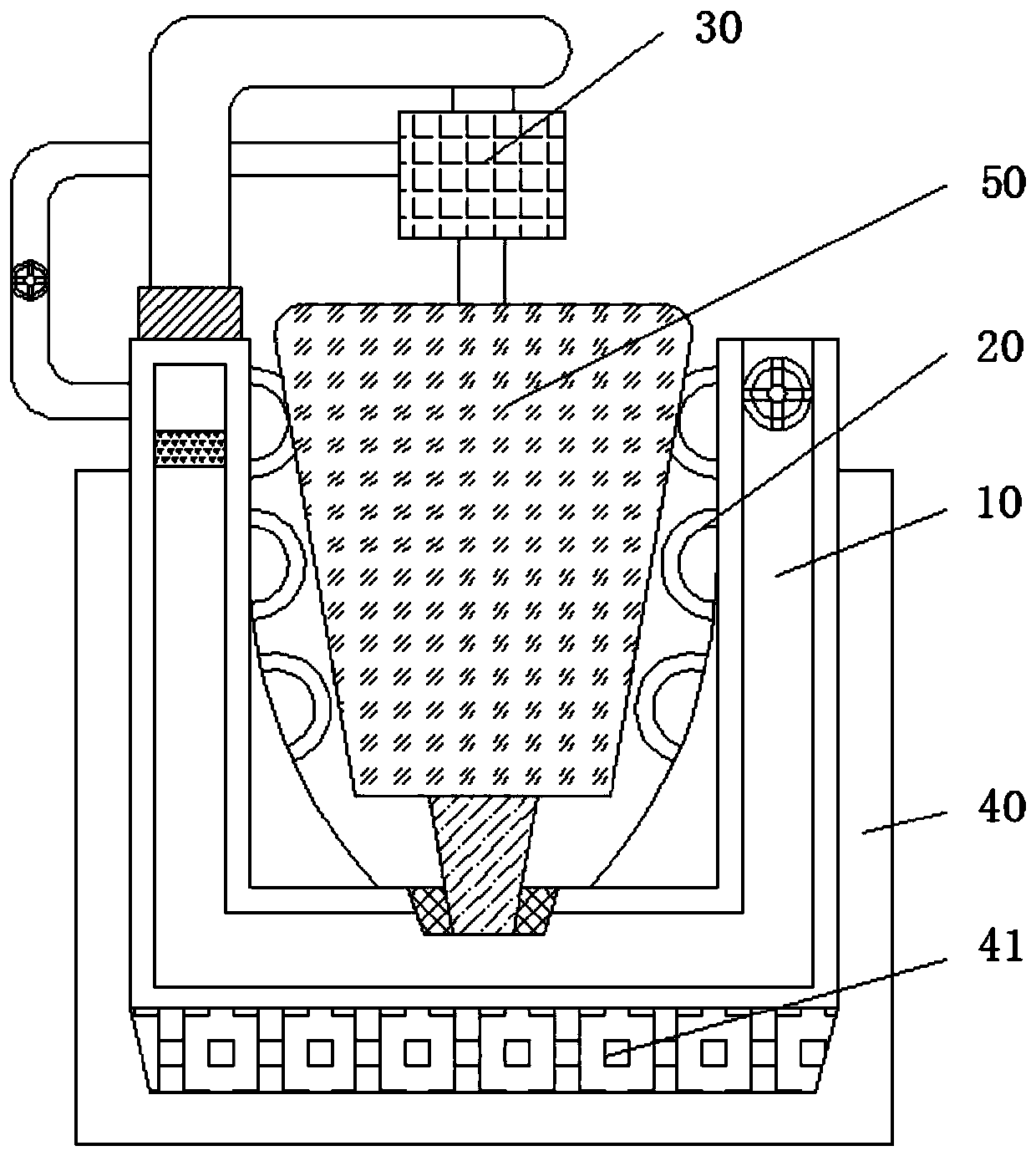

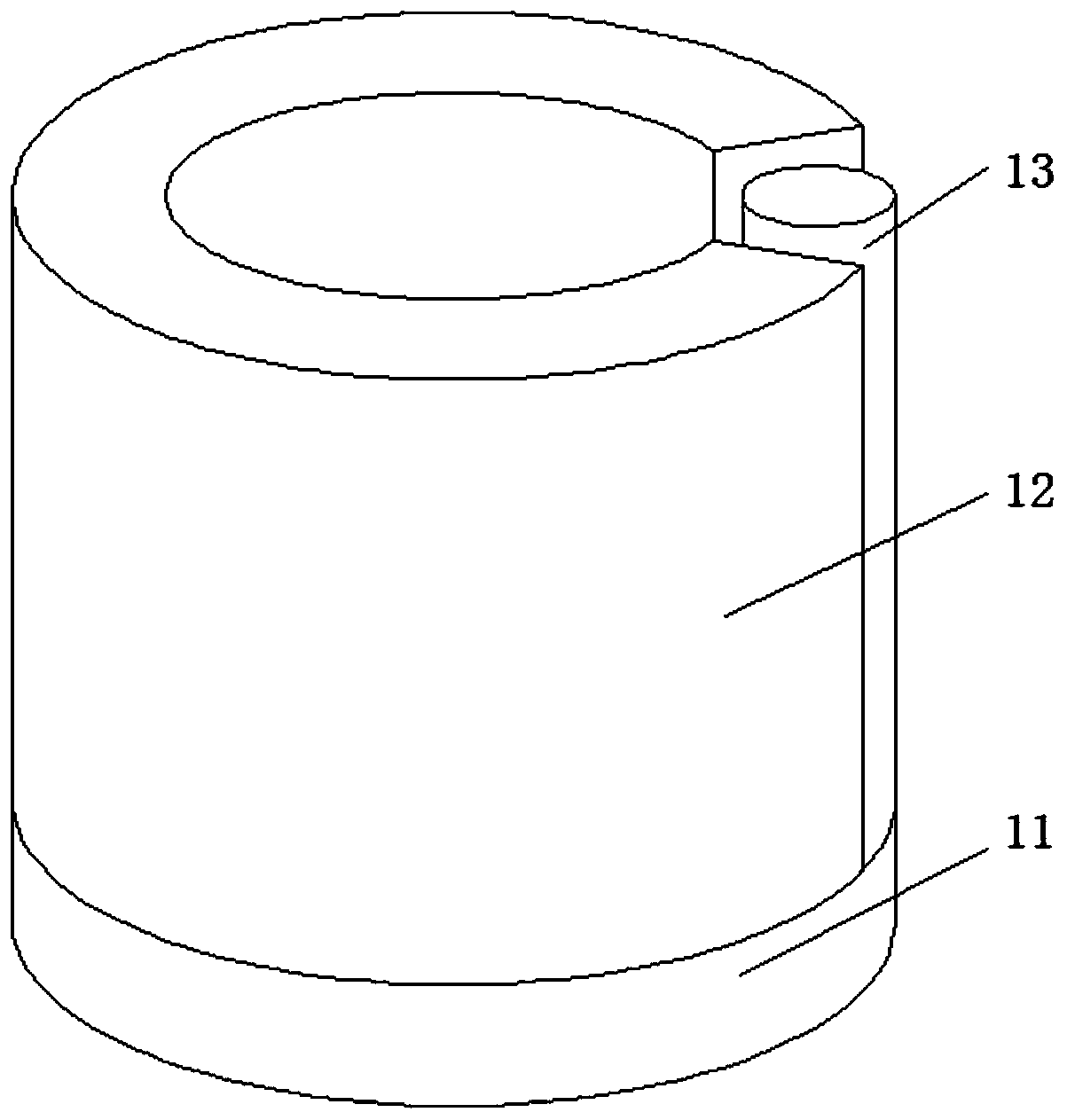

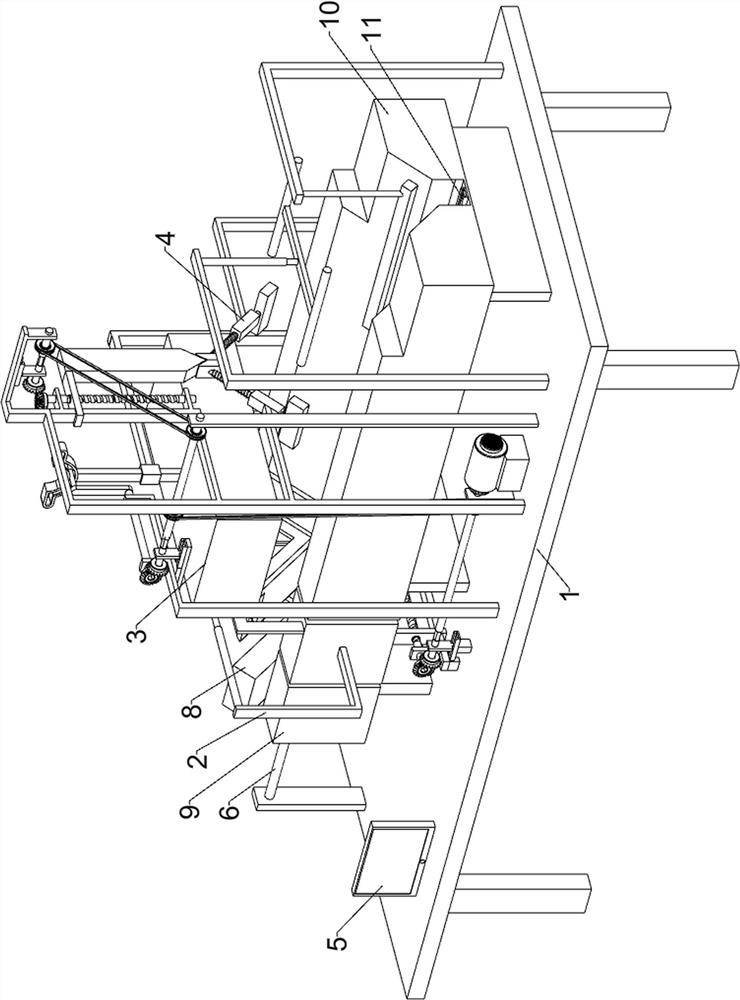

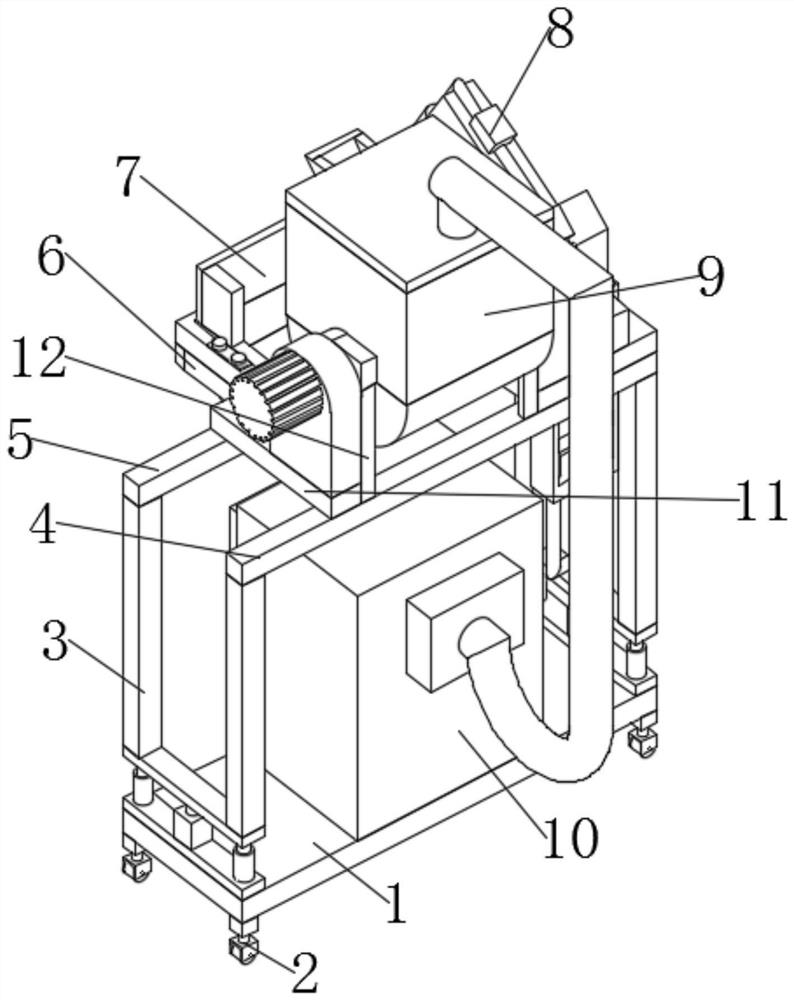

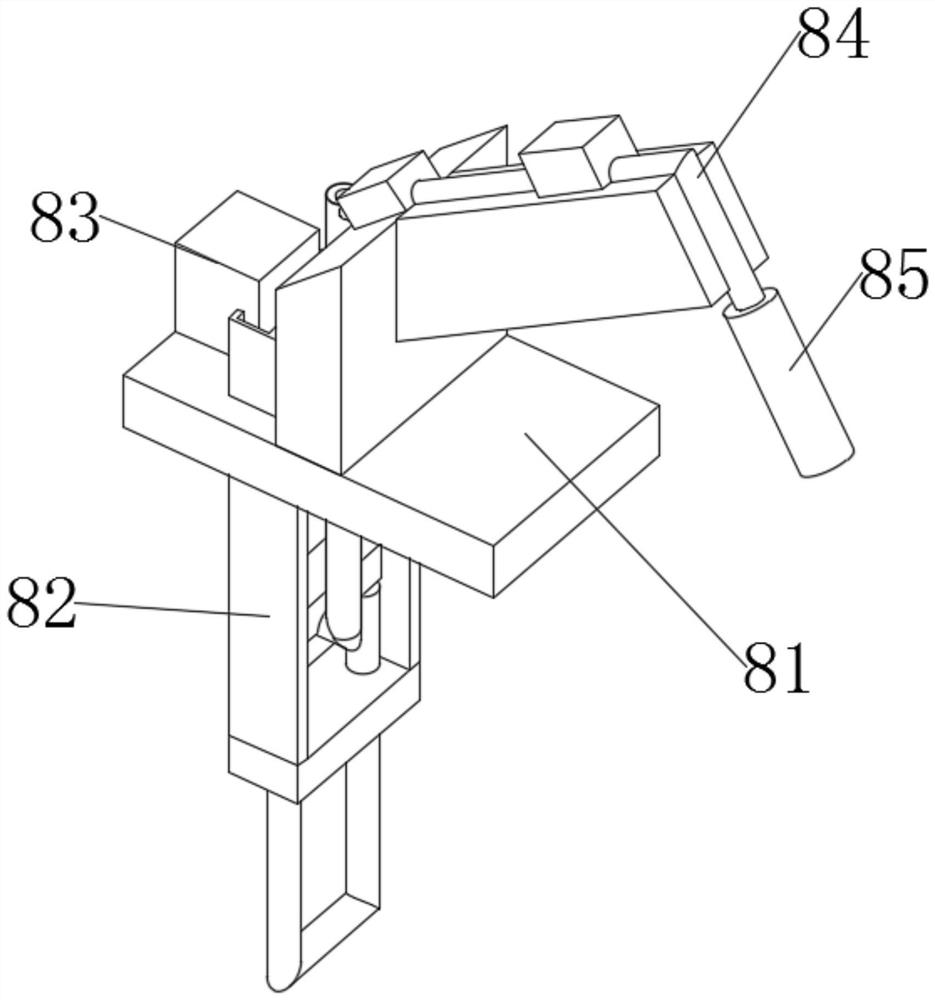

Intelligent transfusion device and operation method thereof

ActiveCN104248790AEliminate air bubblesRealize automatic integrationInfusion devicesFlow controlProcess engineeringManipulator

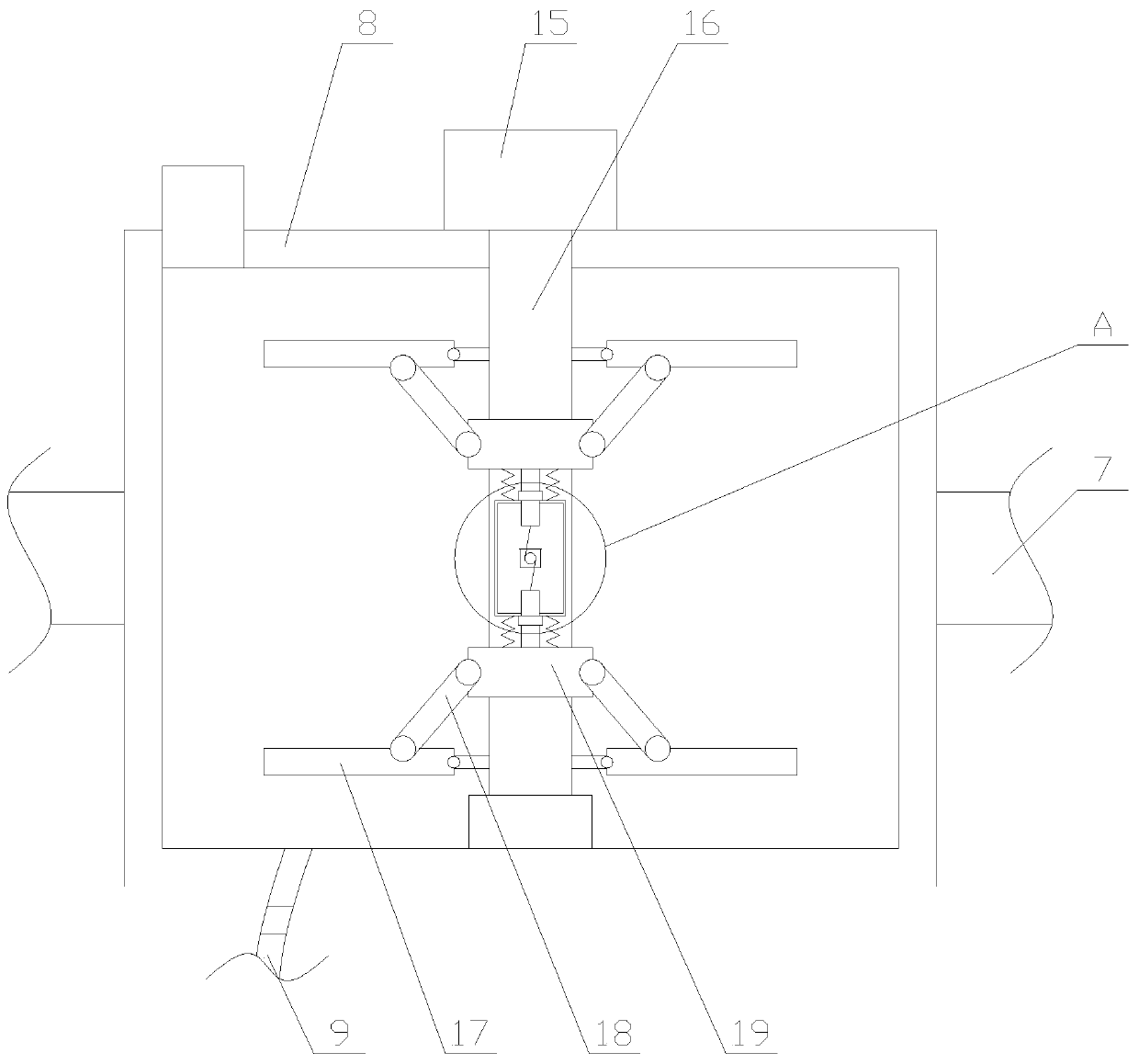

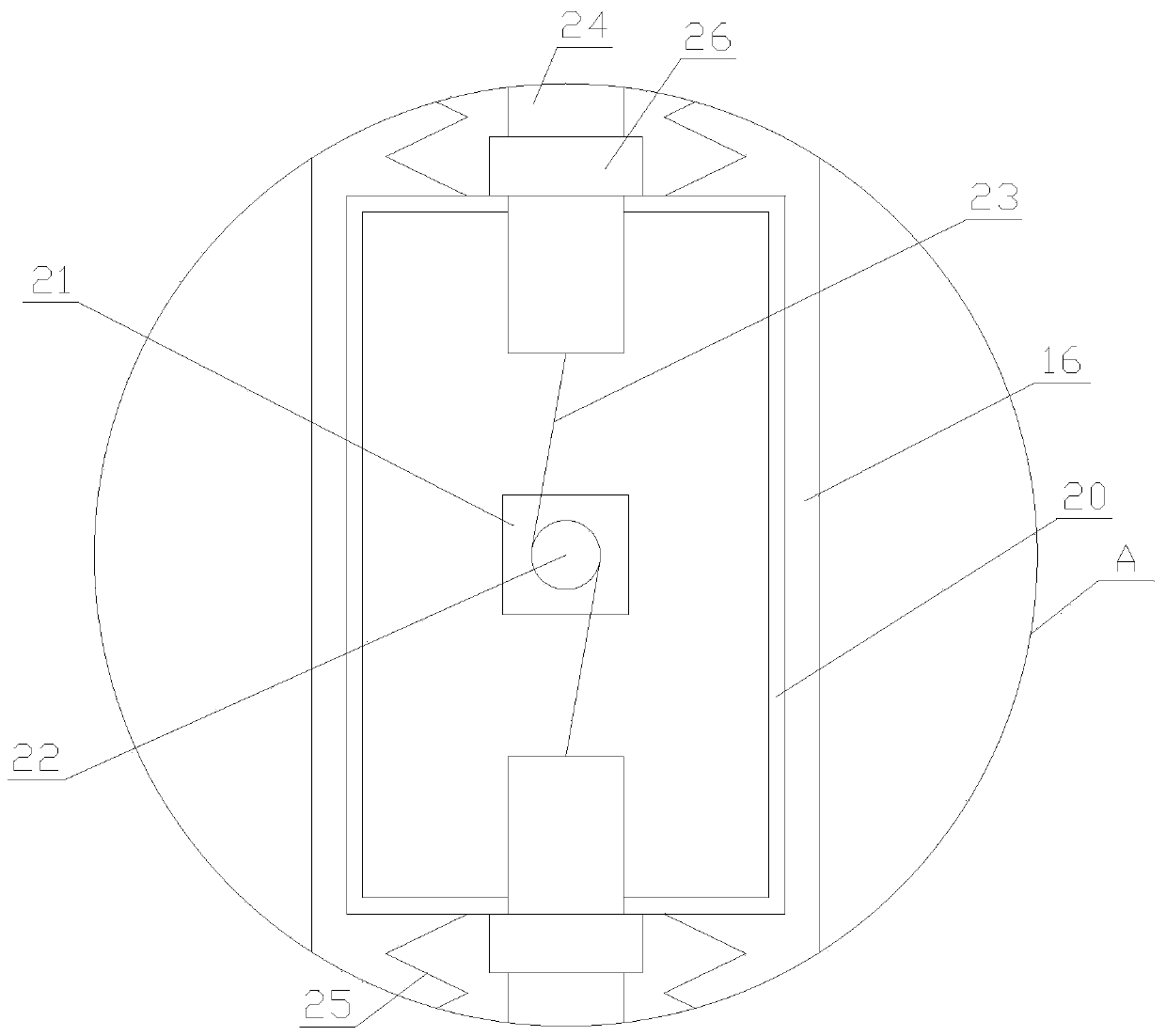

The invention discloses an intelligent transfusion device and an operation method thereof. The intelligent transfusion device comprises a transfusion bottle fixing mechanism, a bottle plug piercing mechanism, a dynamic transfusion liquid monitoring / controlling mechanism, a transfusion liquid temperature-control mechanism, an automatic needle plugging and unplugging mechanism, a central receiver and central control units corresponding to the bottle plug piercing mechanism, the liquid dynamic monitoring / controlling mechanism, the liquid temperature-control mechanism and the automatic needle plugging and unplugging mechanism. The intelligent transfusion device has the advantages that by the intelligent transfusion device, automatic integration in a transfusion process is realized; transfusion bottles can be automatically changed; the dripping speed, the flow speed and liquid bubbles can be monitored during transfusion; the dripping speed and the flow speed of transfusion liquid are controlled and the air bubbles can be timely eliminated; a transfusion tube can be heated in a transfusion process; the heating temperature is automatically controlled; a needle can be plugged or unplugged automatically under the control of a manipulator; and various stages of a transfusion process are controlled by controllers which are used for controlling the various units through the central receiver.

Owner:深圳煜睿医疗设备有限公司

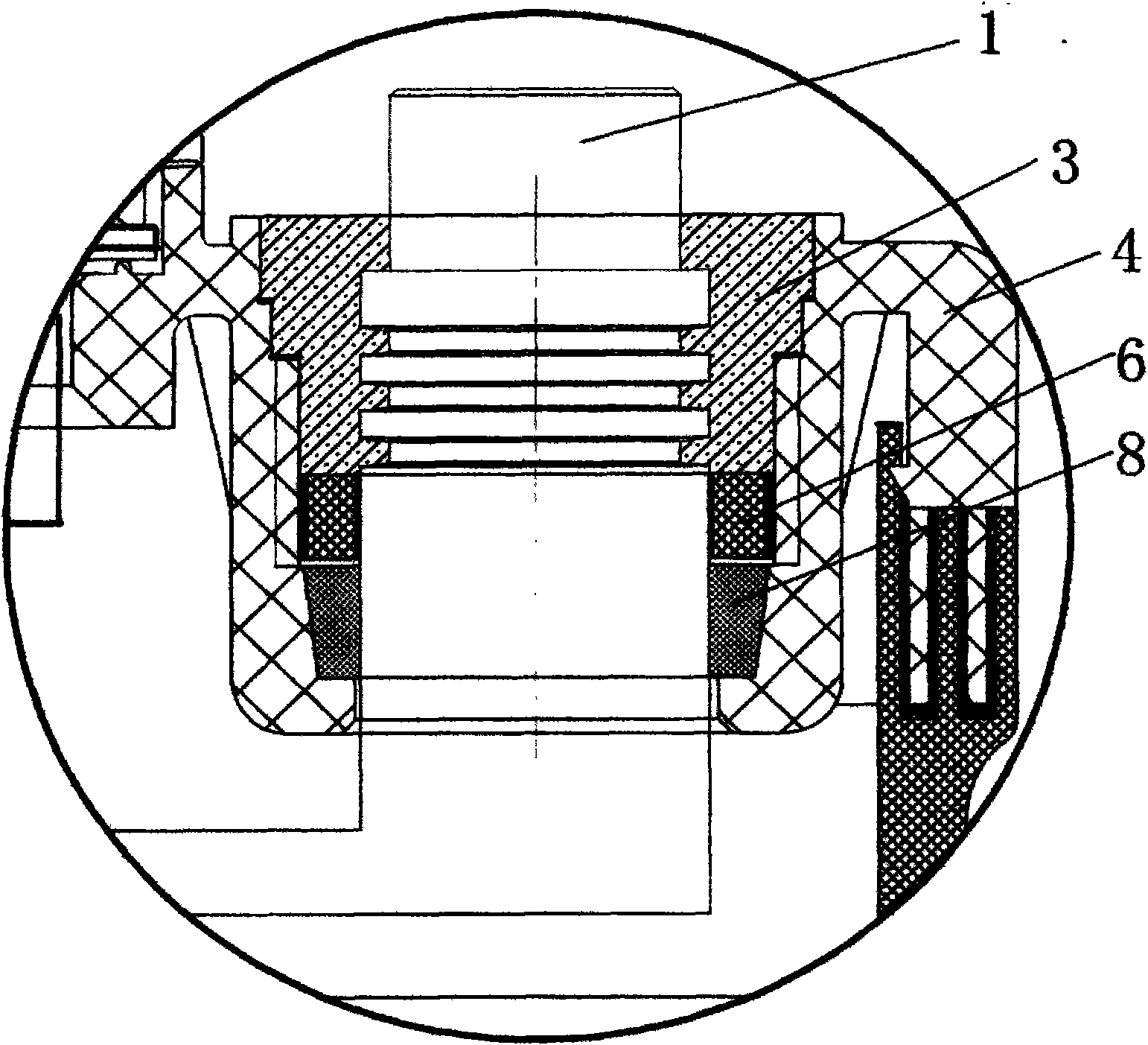

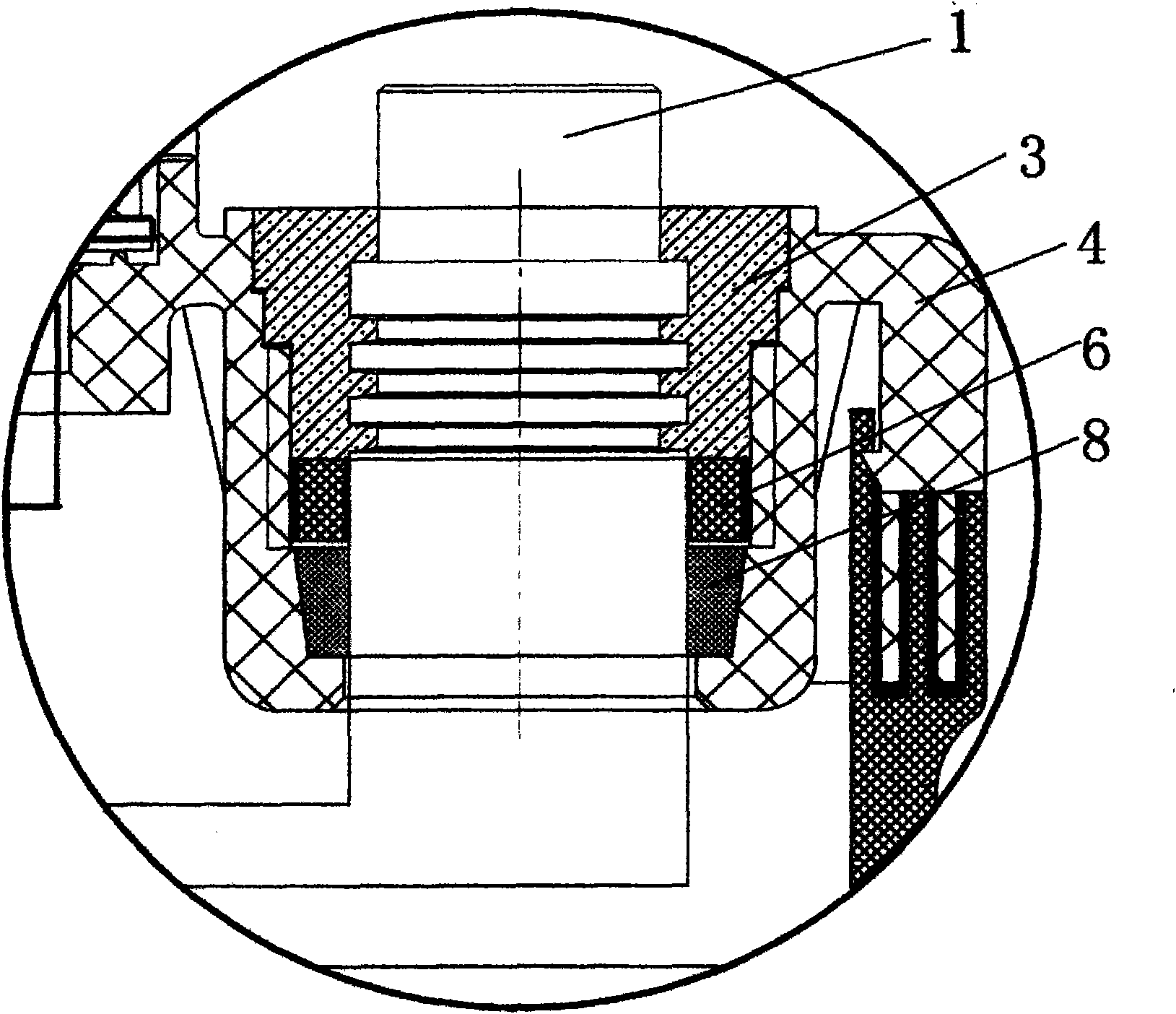

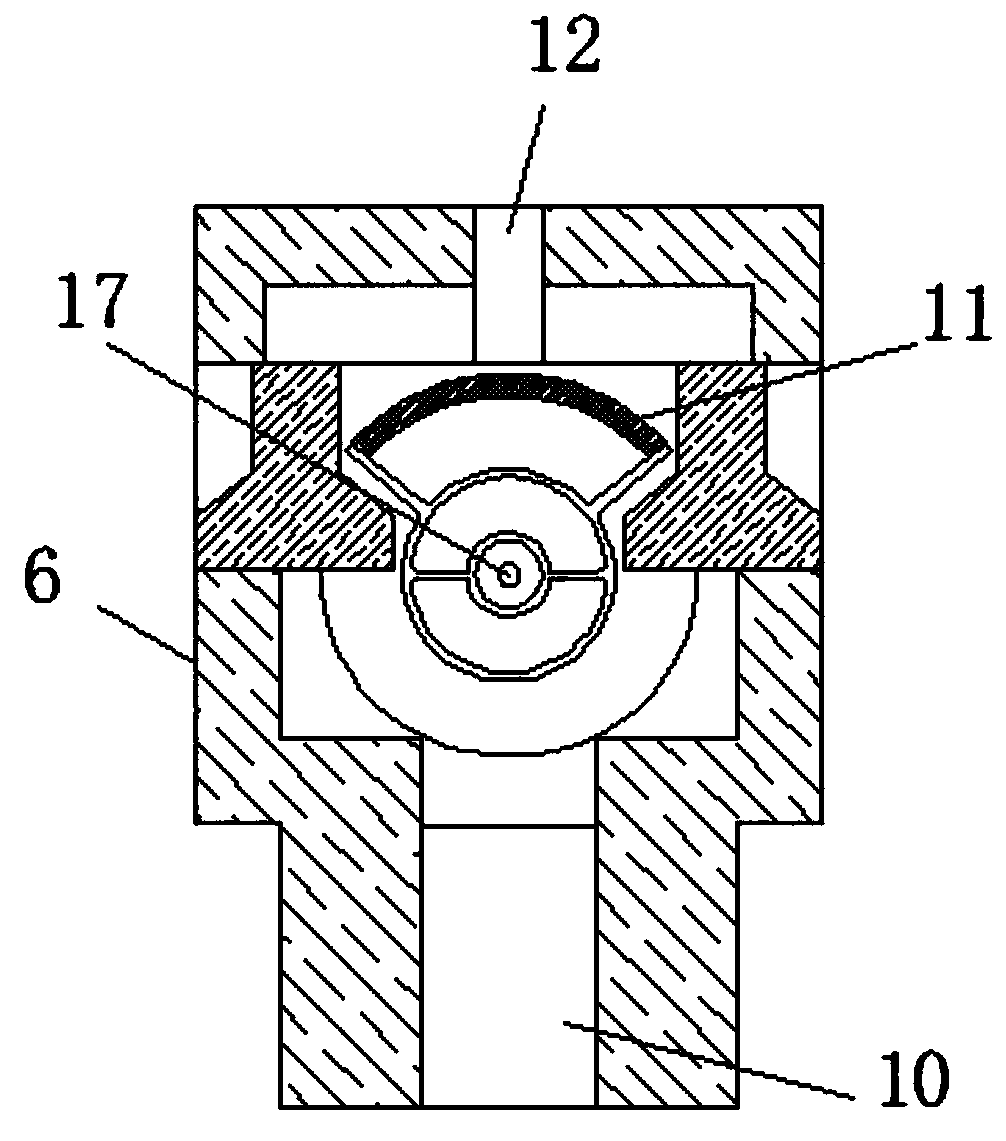

Initiative exhaust method for injection mould and vacuum valve device for injection mould

InactiveCN101780706AAvoid enteringRealize active exhaustOperating means/releasing devices for valvesMode-lockingEngineering

The invention relates to an initiative exhaust method for an injection mould and a vacuum valve device for the injection mould, relating to an injection mould. The vacuum valve device is provided with a valve core, a valve core control rod, a piston rod and a cylinder. After the mode locking of the injection mould, an external compressed air source is utilized to drive the vacuum valve device, an exhaust channel is opened, and then an external air extractor is communicated with the cavity of the injection mould through the exhaust channel. The external air extractor starts to work, the cavity of the injection mould is pumped to a negative pressure state, and then the external compressed air source is utilized to drive the vacuum valve device for the injection mould and close the exhaust channel. Fusing plastic is injected into the cavity, and after the exhaust channel of the vacuum valve is closed, air is continuously exhausted through a tiny gap between the vacuum valve device and the cavity of the injection mould. The injection mould is opened, and a moulding piece is taken out, the external compressed air source is utilized to carry out back flushing, and residues and impurities in the vacuum valve device for the injection mould and the exhaust channel are cleared. After the mould is closed, the next work circulation is performed.

Owner:XIAMEN UNIV

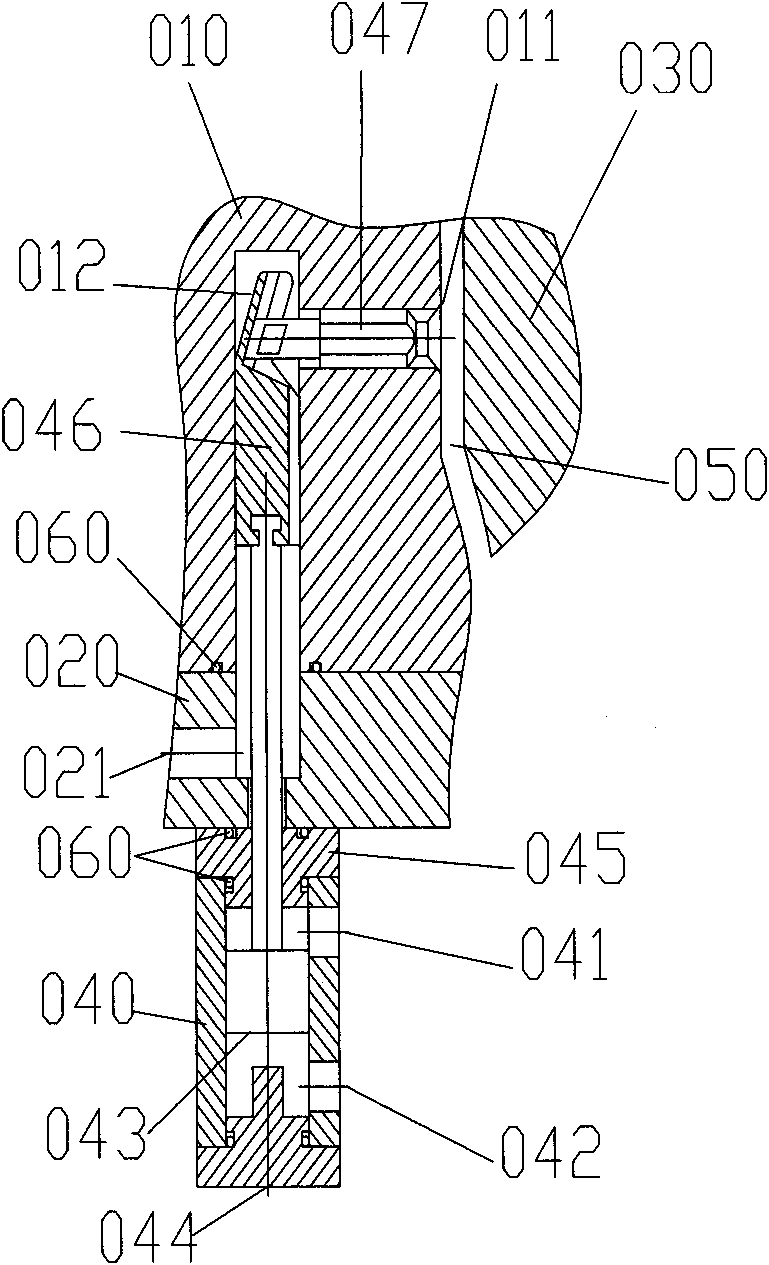

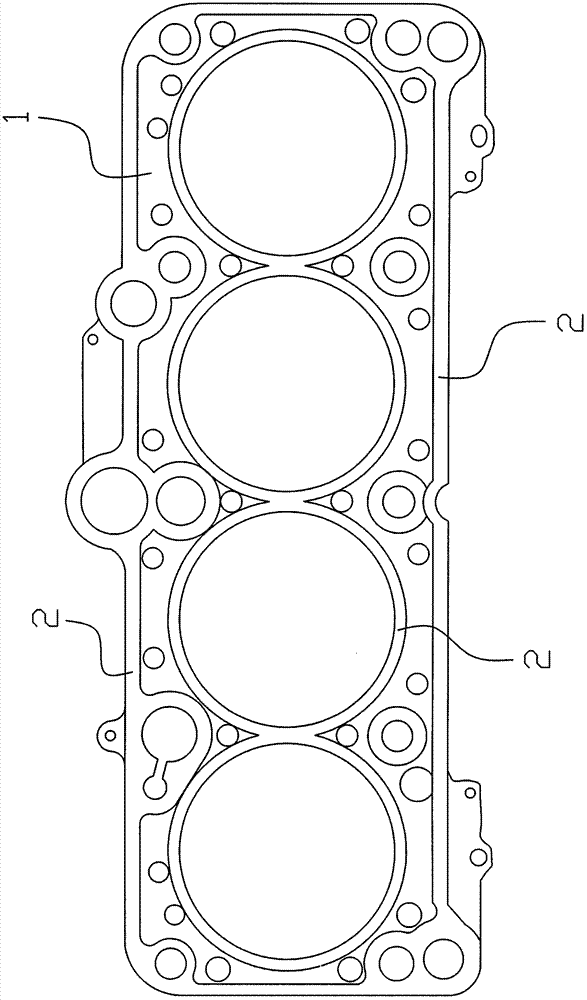

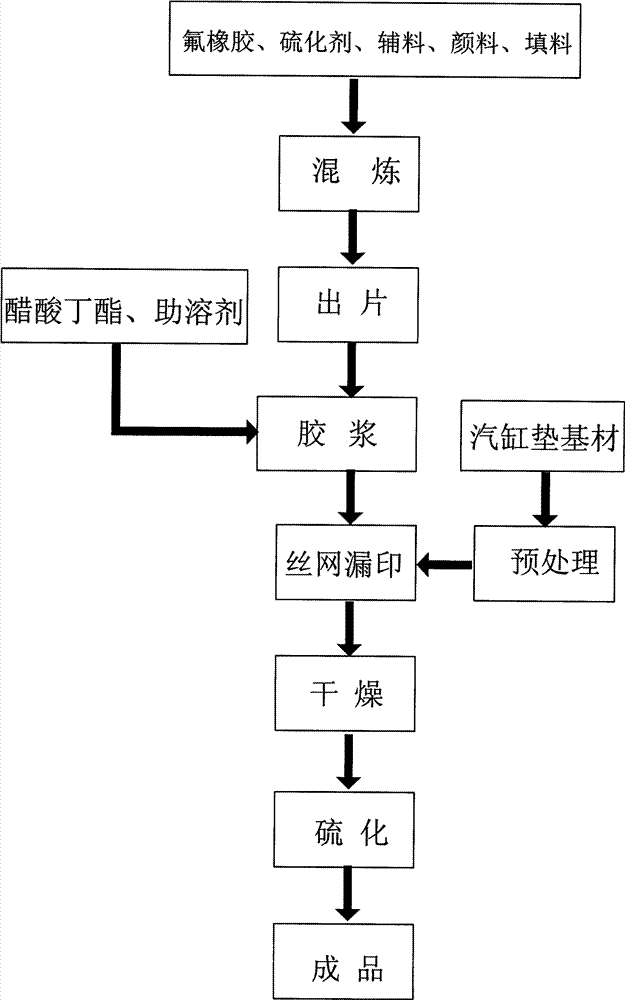

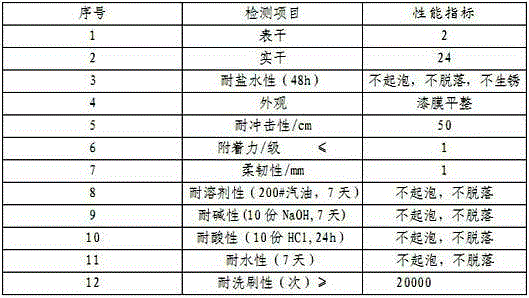

Coating on surface of cylinder ring and manufacturing method thereof

ActiveCN103694810AProcess stabilityEliminate air bubblesCoatingsOther printing apparatusAdhesive cementCalcium hydroxide

The invention discloses a coating on a surface of a cylinder ring and a manufacturing method thereof. The coating on the surface of the cylinder ring is characterized in that a formula of the coating comprises the following components: 78-85 parts of fluororubber, 15-25 parts of reinforcing agent, 8-15 parts of active magnesium oxide, 2-6 parts of vulcanizing agent, 4-8 parts of calcium hydroxide and 1-10 parts of pigment. The method for manufacturing the coating is characterized by comprising the following steps: mixing sheets, preparing adhesive cement, coating by adopting a silk-screen method, drying and vulcanizing. Compared with the prior art, the formula of the coating has high adhesive firmness, bubbles do not exist on the coating, the coating can be prepared into various different colors according to the requirements, and the waterproof and leakproof effects can be effectively achieved. Moreover, according to the method for manufacturing the coating, the process is simple and stable, the silk-screen method is adopted, and a phenomenon that the bubbles occur in the coating is eliminated, so that the adhesive firmness between the coating and the sealing gasket is high, and the technical effect of achieving better waterproof and leakproof effects is achieved.

Owner:岱山县同道密封件厂

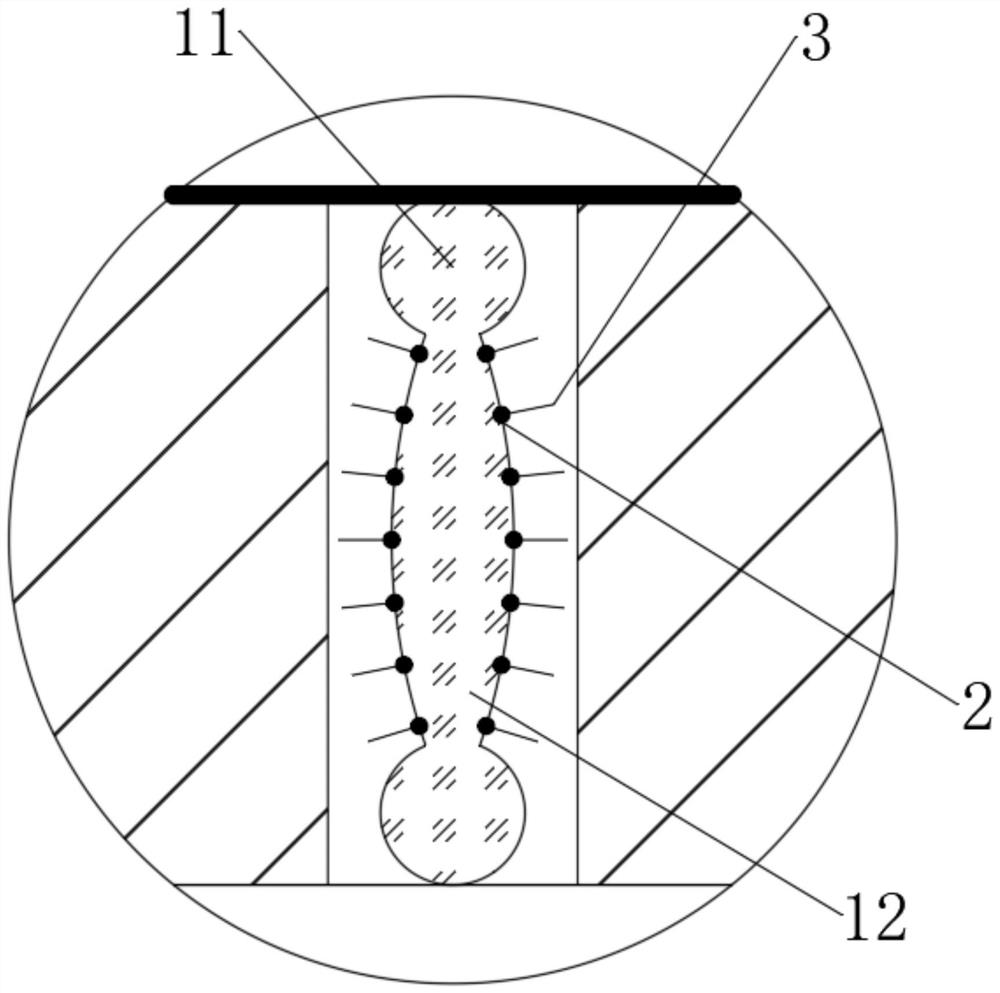

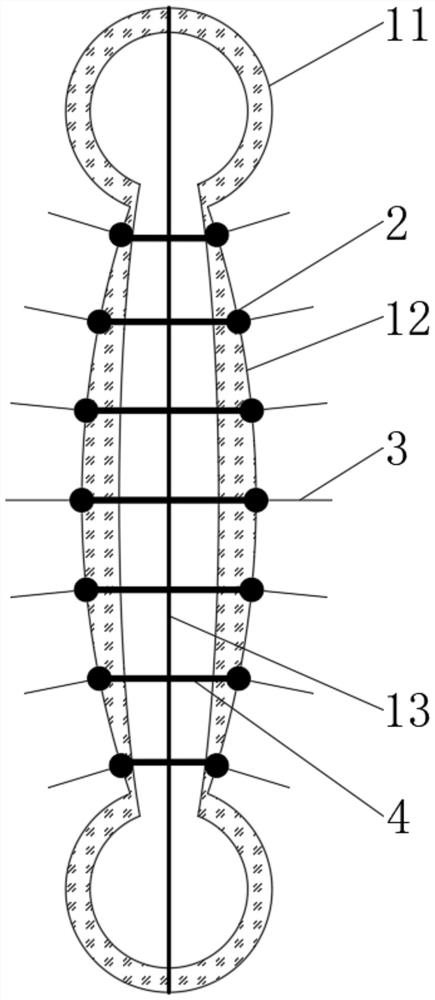

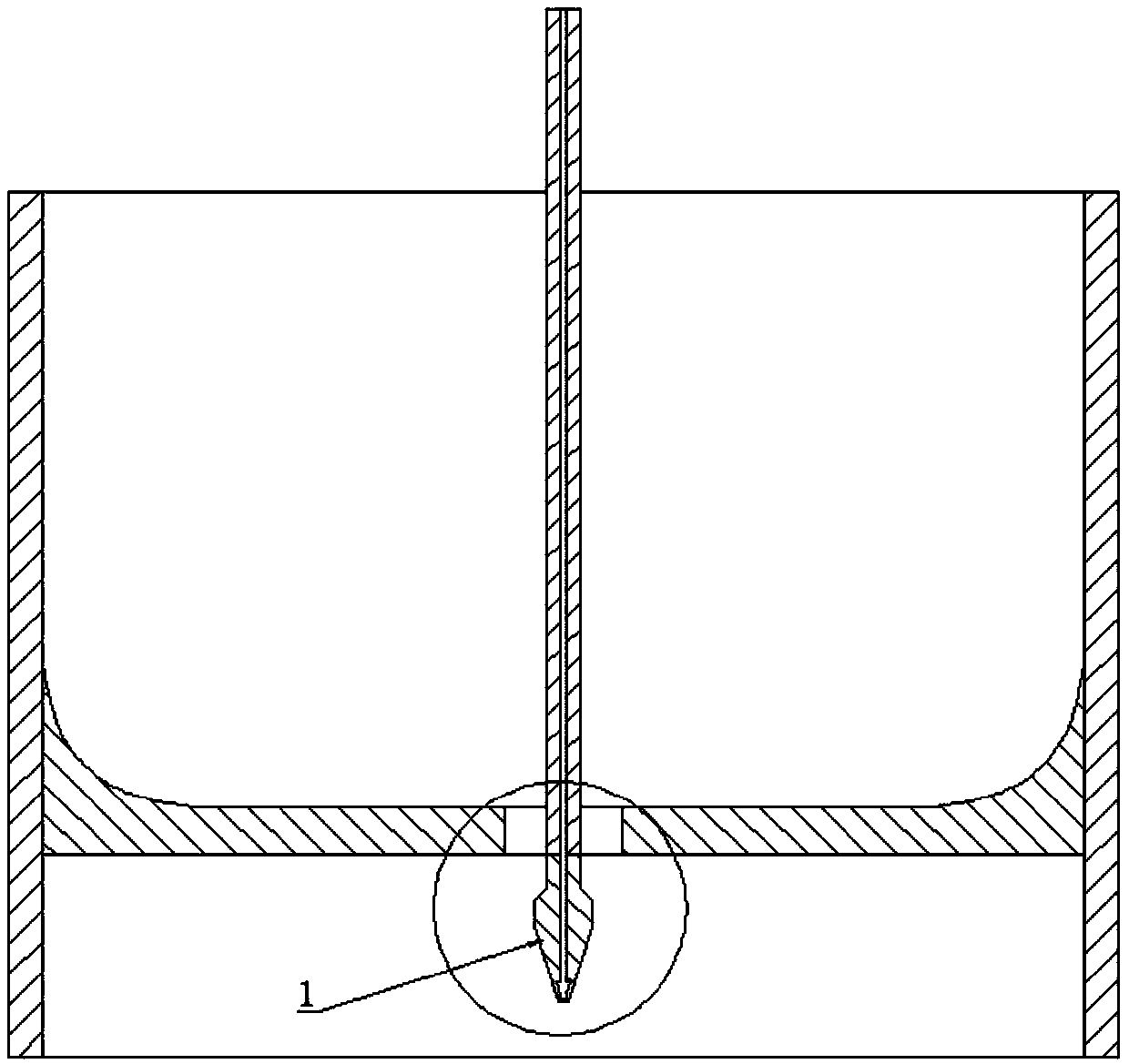

Pre-embedded full hole plugging method of printed circuit board

ActiveCN112118679AEliminate air bubblesImprove plug hole qualityPrinted circuit aspectsPrinted circuit manufactureProcess engineeringPrinted circuit board

The invention discloses a pre-embedded full hole plugging method for a printed circuit board, belongs to the technical field of circuit board manufacturing. According to the invention, a mode of pre-embedding a hole plugging rod in a through hole is innovatively adopted, then a printed hole plugging material is used for filling, and in the heating and curing process, heat is used for triggering the hole plugging action of the hole plugging rod; freedom of the defoaming ball is recovered based on the phase change characteristic of the phase change rod, high-frequency vibration is conducted under the elastic action, the defoaming wires extending into the hole plugging material are promoted to vibrate, bubbles in the hole plugging material can be effectively eliminated, escape of air in the hole plugging material to the outside is accelerated; meanwhile, during final curing, the defoaming rod body is extruded under the magnetic attraction matching effect of the defoaming wire and the phase change rod, air in the defoaming rod body is extruded into the plugging ball head to start expanding, openings in the two ends of the through hole are plugged, and tin beads are prevented from entering the through hole; compared with a conventional hole plugging method, the hole plugging quality can be remarkably improved, and the foaming problem and the tin bead problem are solved.

Owner:江西领德辉电路有限公司

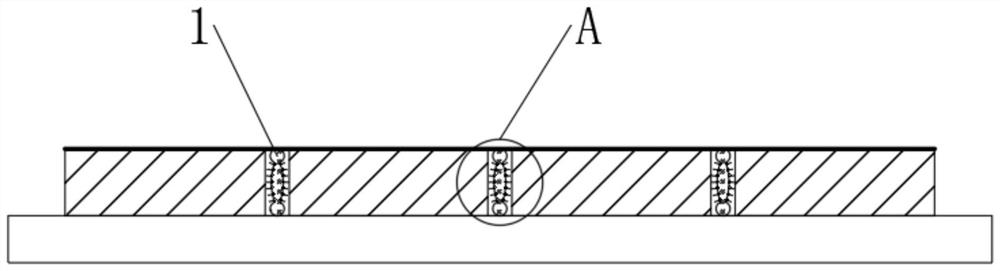

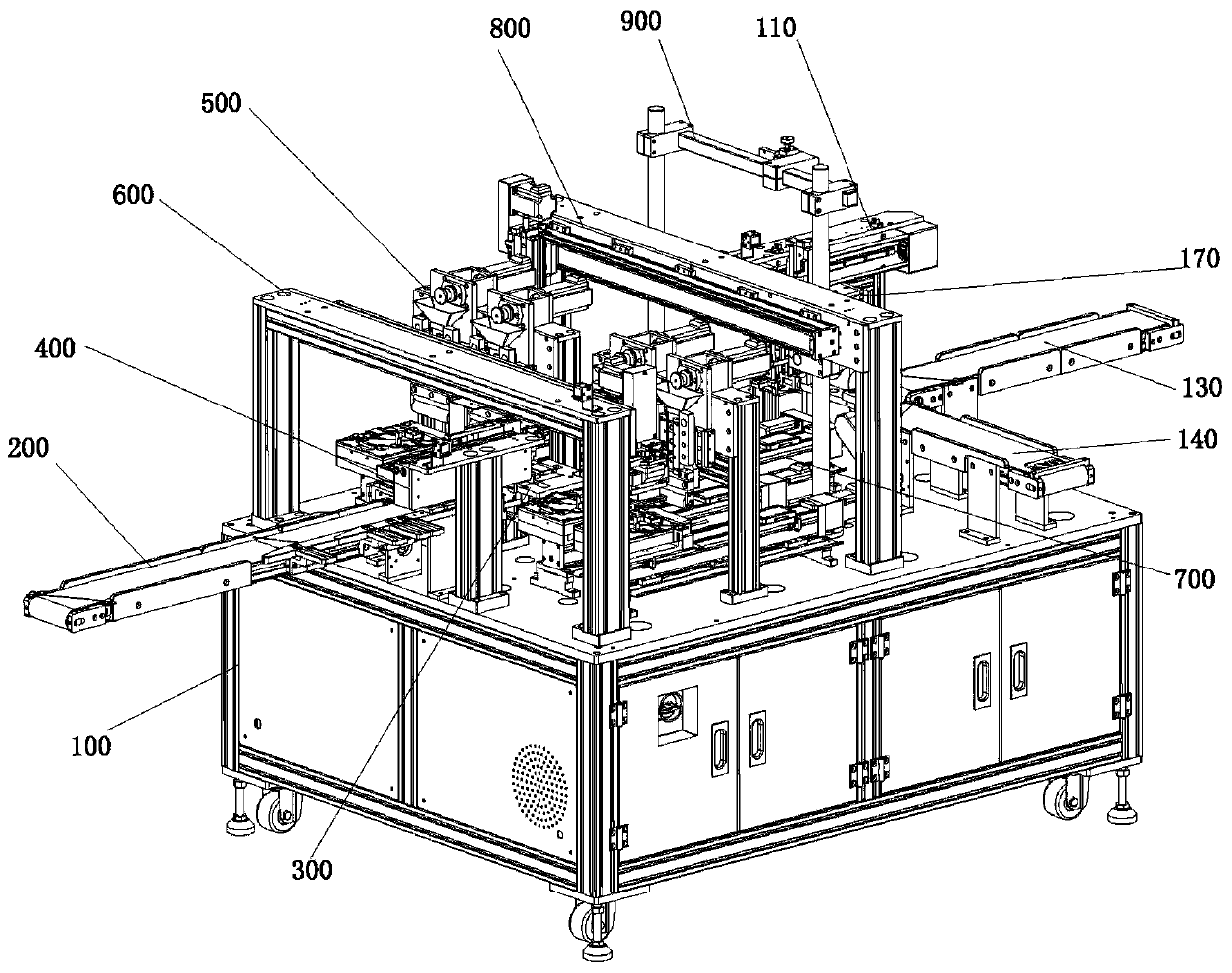

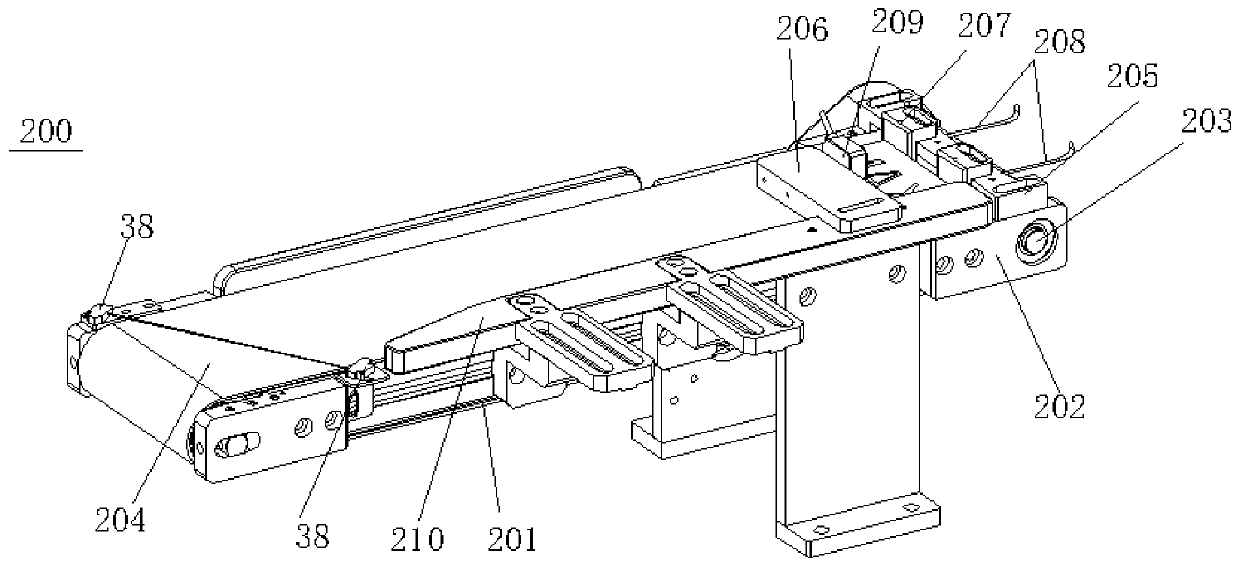

Battery membrane laminator

ActiveCN110137558AGuaranteed a tight fitEliminate air bubblesPrimary cell manufactureAssembling battery machinesManipulatorFixed time

The invention discloses a battery membrane laminator comprising a lower rack which is provided with a feeding line, a feeding manipulator for conveying a battery on the feeding line to a secondary positioning device, a membrane laminating feeding manipulator for conveying the battery on the secondary positioning device to a membrane laminating air pressure device for pressing a membrane, and a membrane laminating discharging manipulator for conveying the battery after membrane lamination of the membrane laminating air pressure device to a discharging air pressure module, wherein the secondarypositioning device is arranged between two groups of membrane laminating air pressure devices, and the discharging air pressure module conveys the membrane laminated battery to the position of a CCD detection device for quality detection. The battery with the laminated membrane can be rolled at the fixed time, and then the lamination state of the laminated membrane after rolling of the battery isdetected. The photoelectric sensor is aligned in secondary positioning to detect the height of the battery, and a rolling module is arranged to set the fixed time and the number of rolls back and forth in the rolling process of the battery so that the close contact of the membrane rolling of the battery can be ensured.

Owner:GUANGDONG DONGBO AUTOMATION EQUIP CO LTD

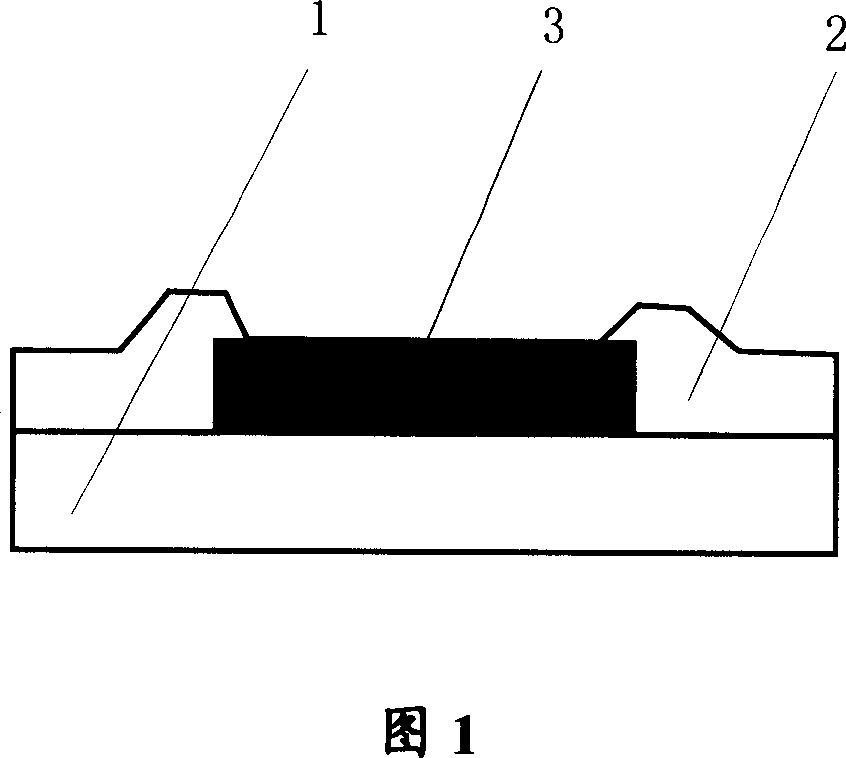

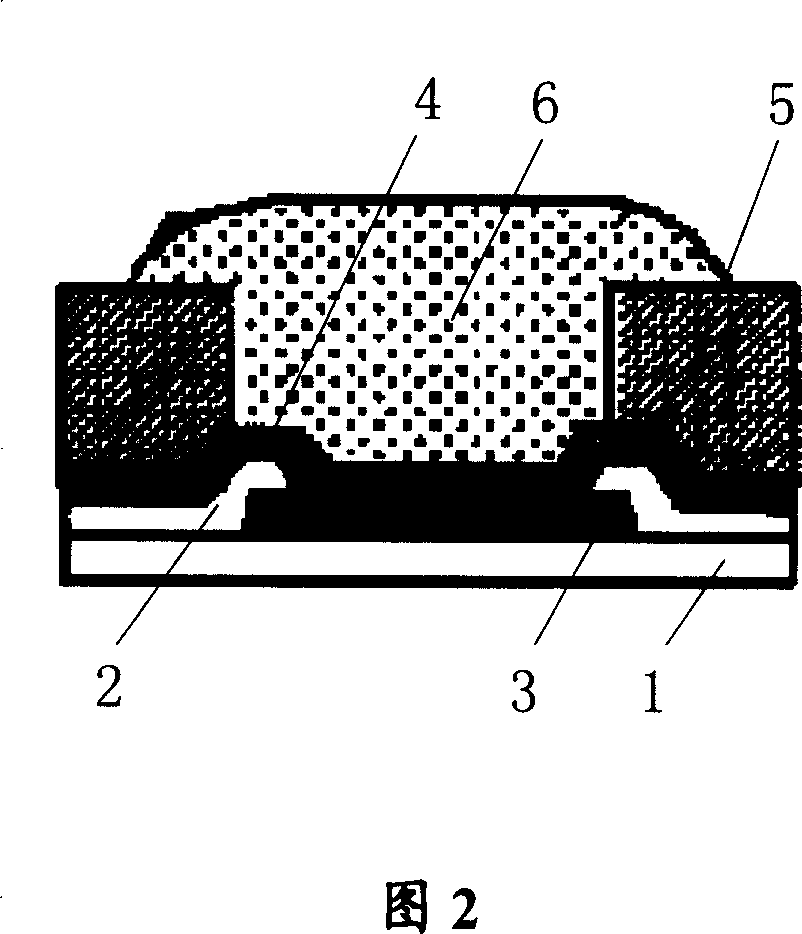

Method for eliminating air bubble from photoresist and stud bump making method

InactiveCN101078890AEliminate air bubblesEliminates the formation of air bubblesSemiconductor/solid-state device manufacturingPhotosensitive material processingResistPhotoresist

Owner:SEMICON MFG INT (SHANGHAI) CORP

Foam breaker

ActiveCN103170212AReduce white smoke from chimneysEliminate air bubblesUsing liquid separation agentEngineeringFlue gas

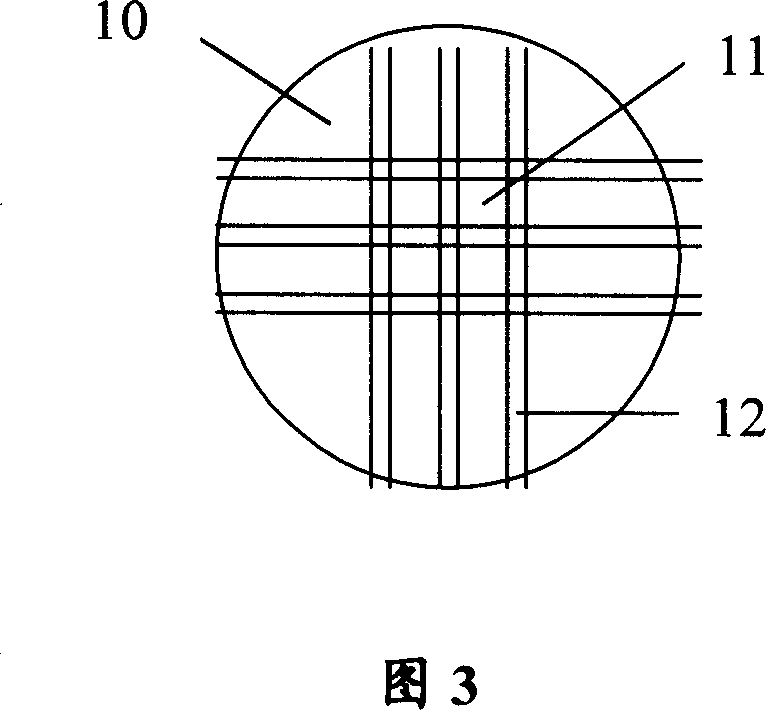

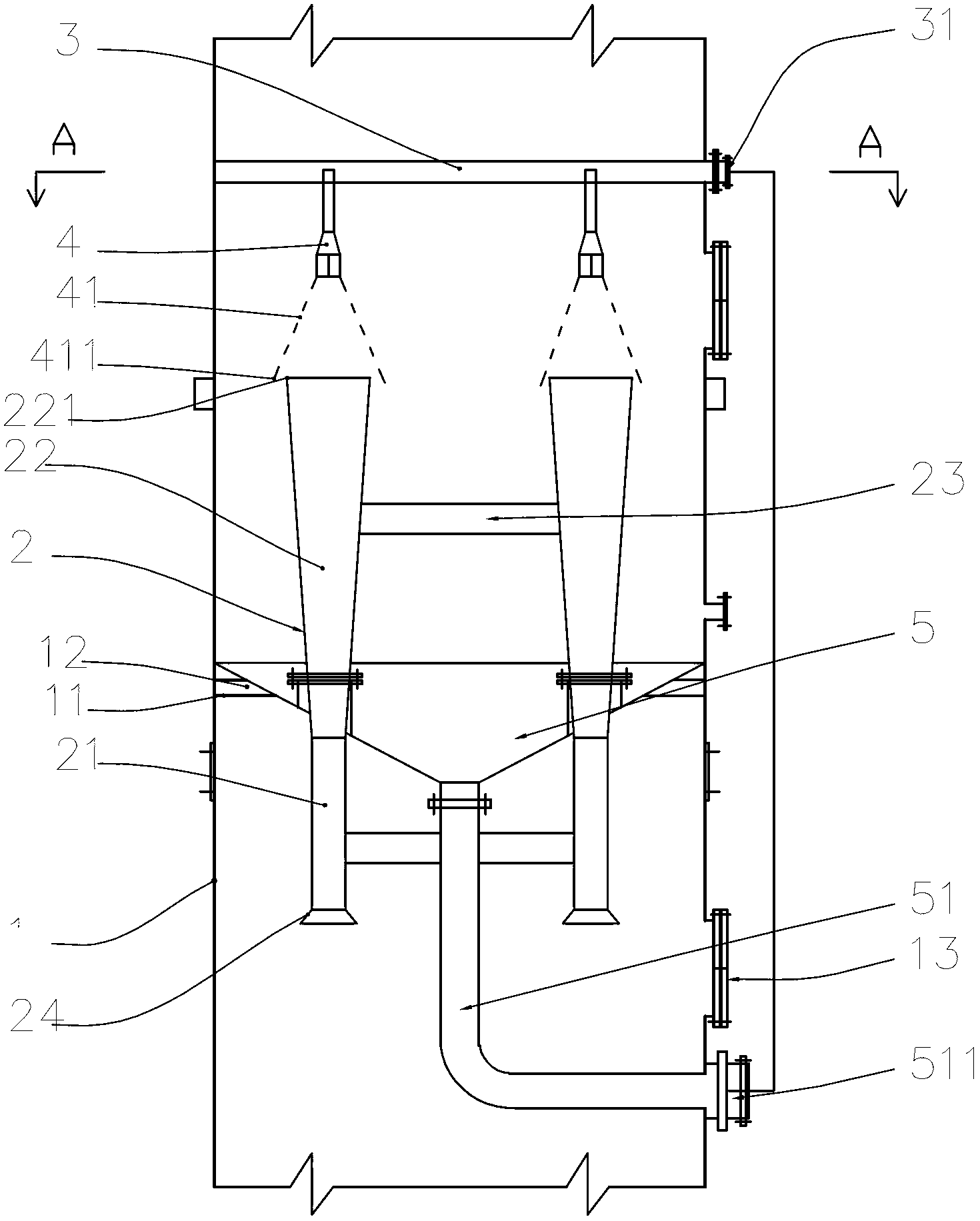

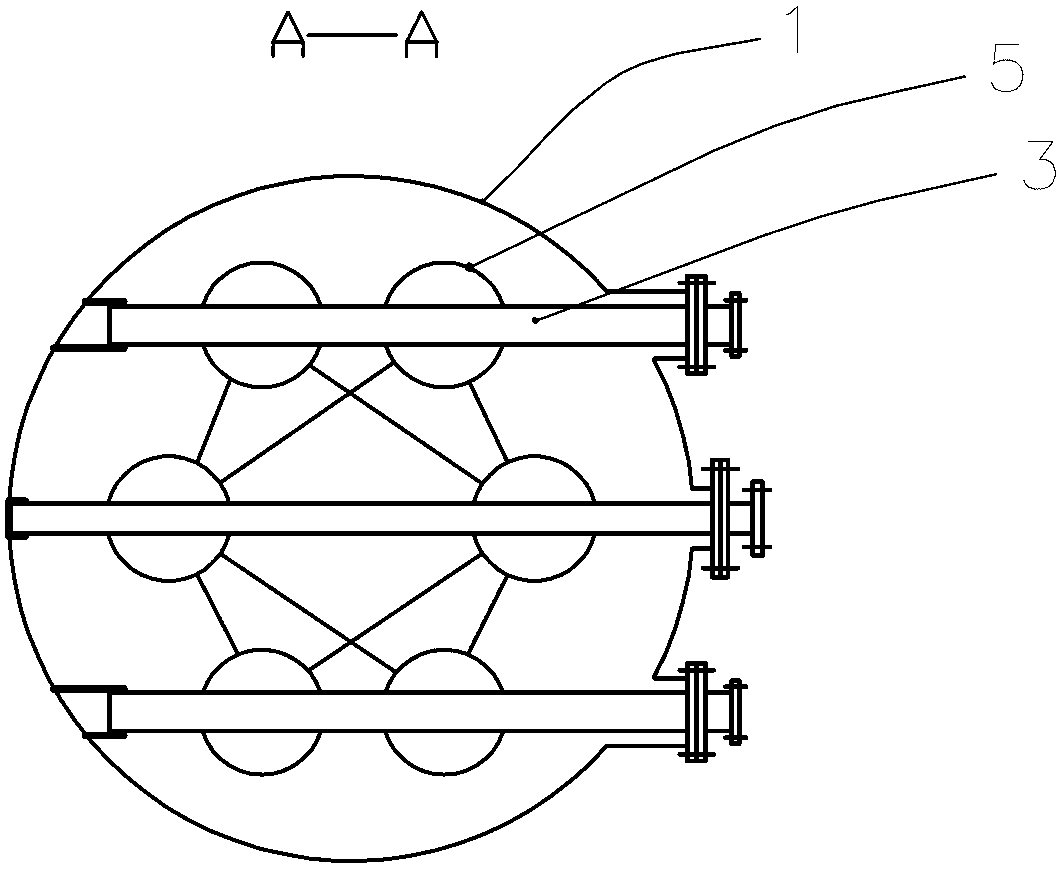

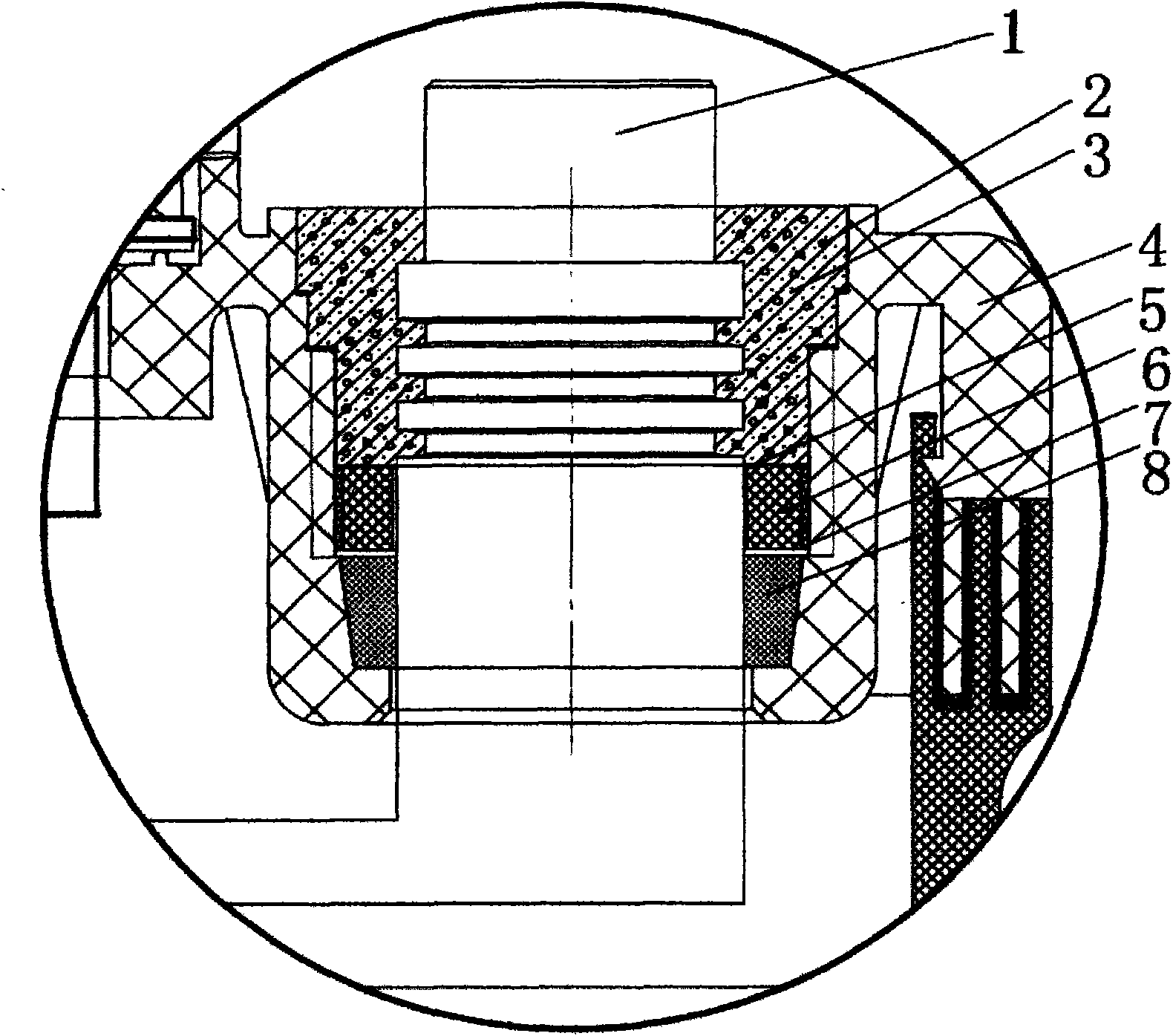

The invention discloses a foam breaker which comprises a foam breaker barrel, wherein a Venturi tube bundle consisting of multiple Venturi tubes which are arranged in parallel is fixedly arranged in the foam breaker barrel; each Venturi tube comprises a throat tube and a flaring diffusion section which is communicated with the upper end of the throat tube and of which the inner diameter is gradually enlarged in the radial direction; a spraying pipe is fixedly arranged on the inner wall of the foam breaker barrel relative to the end of the flaring diffusion section; the lower edge of an umbrella-shaped water curtain sprayed from each umbrella-shaped spraying head is positioned outside the flaring diffusion section; a liquid collecting hopper is arranged between the upper and lower ends of the Venturi tubes positioned in the foam breaker barrel; the inner cavity of the foam breaker barrel is divided into an upper cavity and a lower cavity through the liquid collecting hopper; the lower end of the liquid collecting hopper is provided with a drainage pipe; and an outlet of the drainage pipe is arranged outside the foam breaker barrel. The foam breaker has the advantages that air bubbles formed after wet-process flue gas dust removal desulfuration can be eliminated, and the entrainment generated by the broken air bubbles is eliminated, so that the phenomenon that white smoke or trailing occurs in the chimney is reduced.

Owner:SINOPEC ENG GRP CO LTD +2

Valve control type sealed cell vacuum glue filling technology

ActiveCN101989650AEliminate air bubblesSealed terminals are goodCell component detailsAdhesiveElectrolyte leakage

The invention relates to a valve control type sealed cell vacuum glue filling technology. The system adopts the following technological steps: epoxy resin terminal adhesive is filled into the gap between a cell terminal and a cell cover; a cell is placed into a vacuum tank, the vacuum tank is vacuumized in three minutes; pausing of two minutes is carried out, and vacuum of the vacuum tank is released; then the vacuum tank is vacuumized in three minutes; and pausing of two minutes is carried out, vacuum of the vacuum tank is released, and the cell is taken out. After vacuumizing, negative pressure causes bubbles in terminal glue and bubbles in plastic nut gap to be rapidly overflown, bubbles in terminal glue are eliminated, and terminal glue can be penetrated into all the gaps between the cell cover and terminal, thus achieving the aim of better sealing terminal and reducing the probability of electrolyte leakage from cell terminal, bubbles produced on glue surface can be eliminated, and product appearance quality can be improved.

Owner:HUNAN FENGRI ELECTRIC GROUP

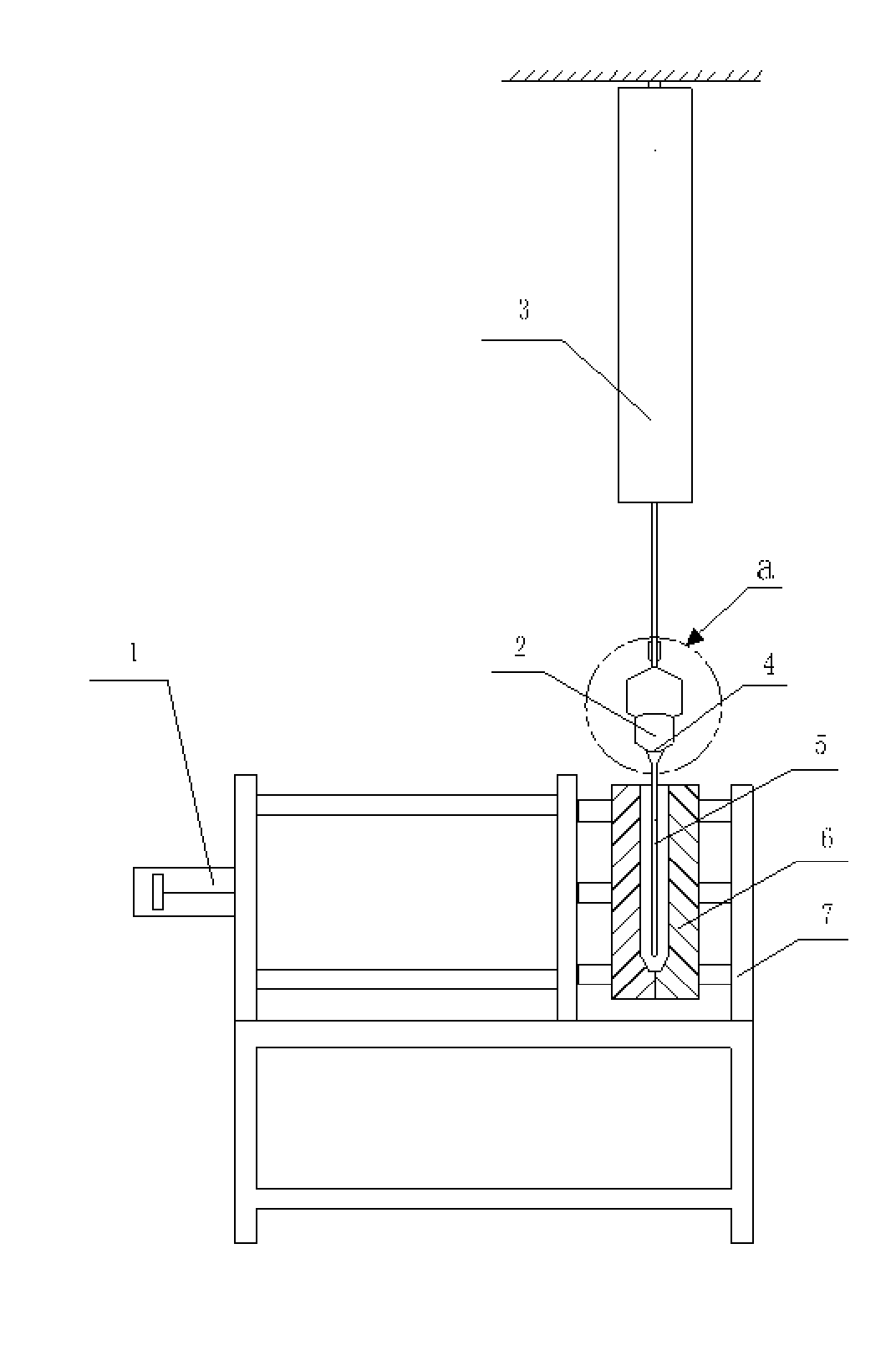

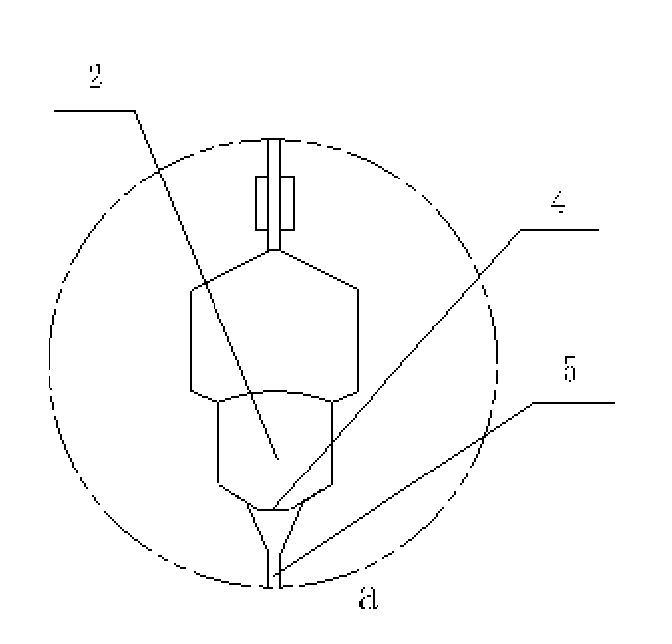

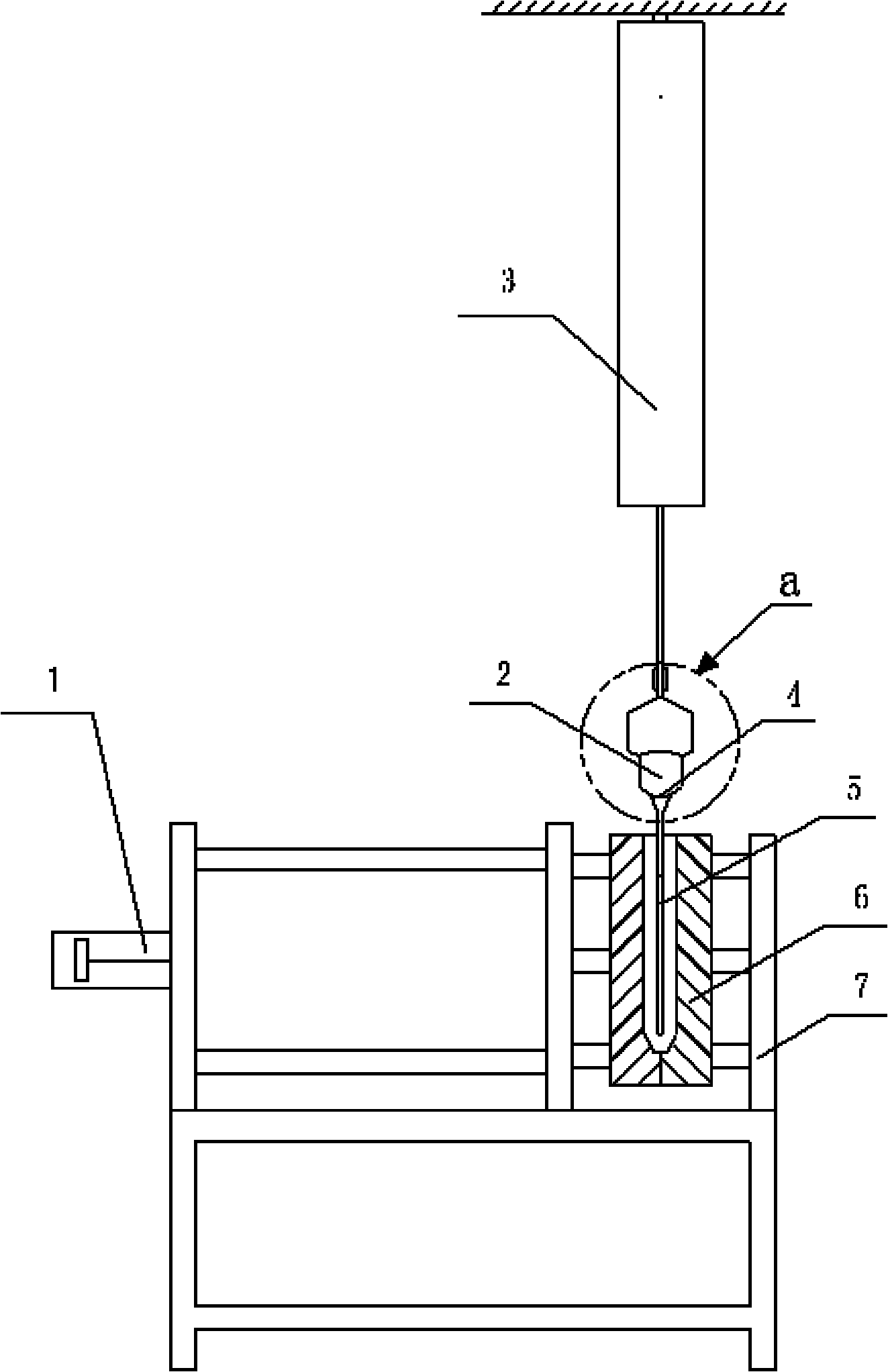

Casting method of aluminum alloy rod parts and casting equipment for realizing same

InactiveCN102133628AEliminate air bubblesEliminate air slag holesIngot casting plantsPoor qualityHigh energy

The invention relates to a casting method of aluminum alloy rod parts and casting equipment for realizing the same. The casting method is characterized in that liquid supply is carried out under the liquid level and a metal liquid is cooled and solidified from bottom to top. The casting equipment comprises a mould and a suspended funnelform ladle, wherein the mould is arranged with a mould cavity opening vertically upward; a filter screen is padded at the bottom of the inner cavity of the ladle; the inner cavity of the ladle and a funnel opening are partitioned by the filter screen; the meshes of the filter screen are fine, thereby temporarily storing molten metal foams; the funnel opening of the ladle is connected with a long and thin liquid conveying pipe for guiding and conveying molten metal; the liquid conveying pipe is inserted into the mould cavity of the mould and the bottom end of the liquid conveying pipe is close to the bottom of the mould cavity; the molten metal is injected to the mould cavity through the liquid conveying pipe; the liquid conveying pipe raises gradually relative to the bottom of the mould cavity on the premise that the bottom liquid outlet of the liquid conveying pipe is positioned below the liquid level after the molten metal overflows the bottom of the liquid conveying pipe, and the liquid level gradually raises and is sequentially cooled and solidified towards the top. By utilizing the casting method, the defects of poor quality, low molded product percent of pass and high energy consumption existing in the traditional casting method are overcome, and low energy consumption, high part percent of pass and good quality are realized.

Owner:ZHEJIANG HENGTONG MACHINERY

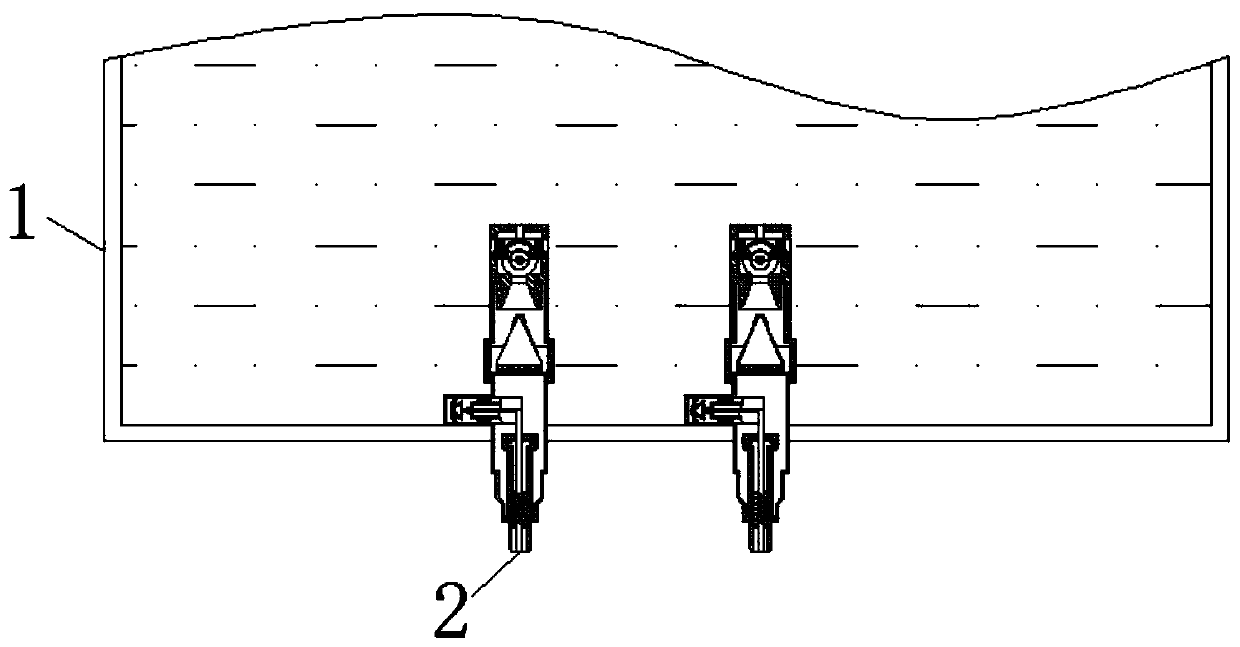

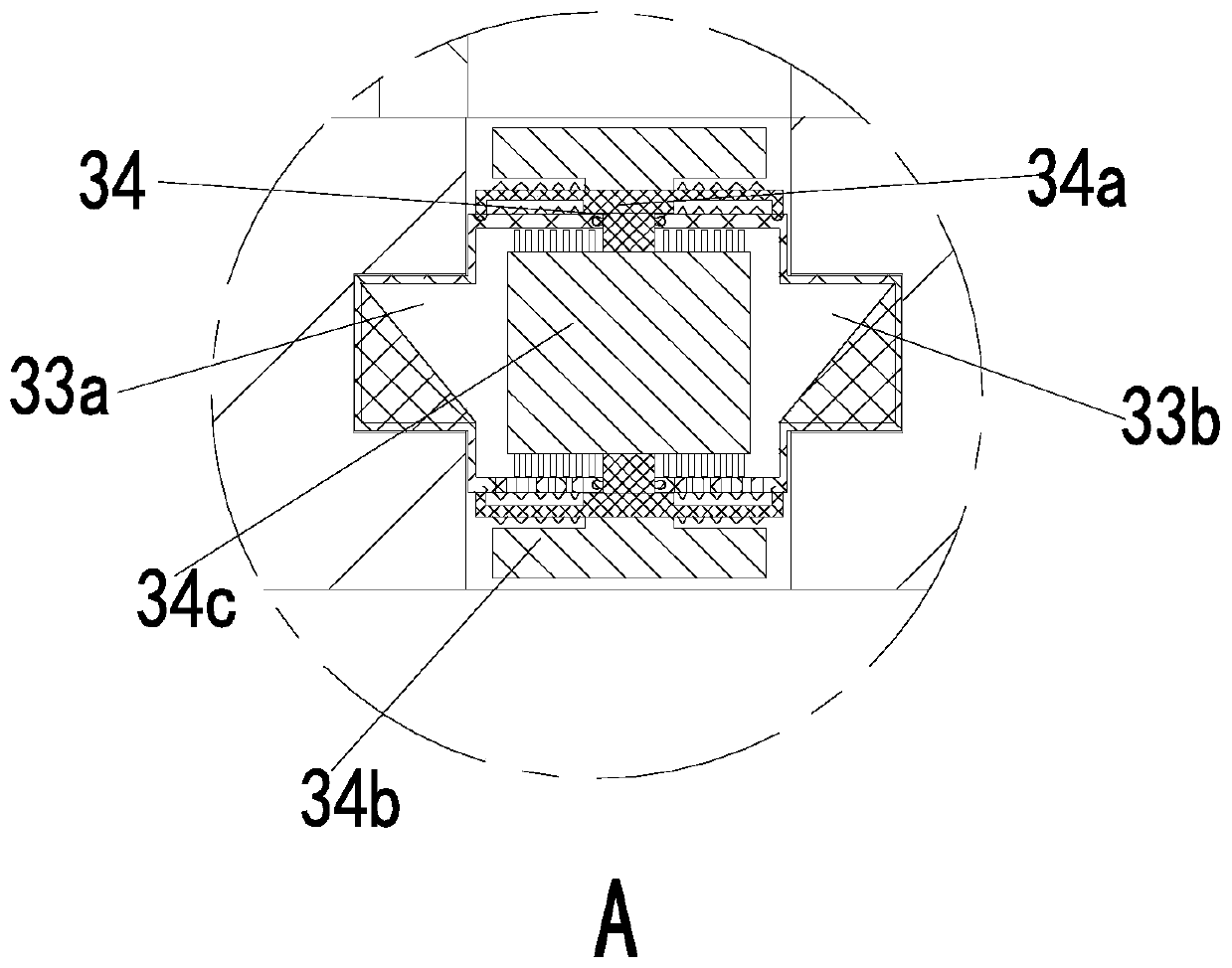

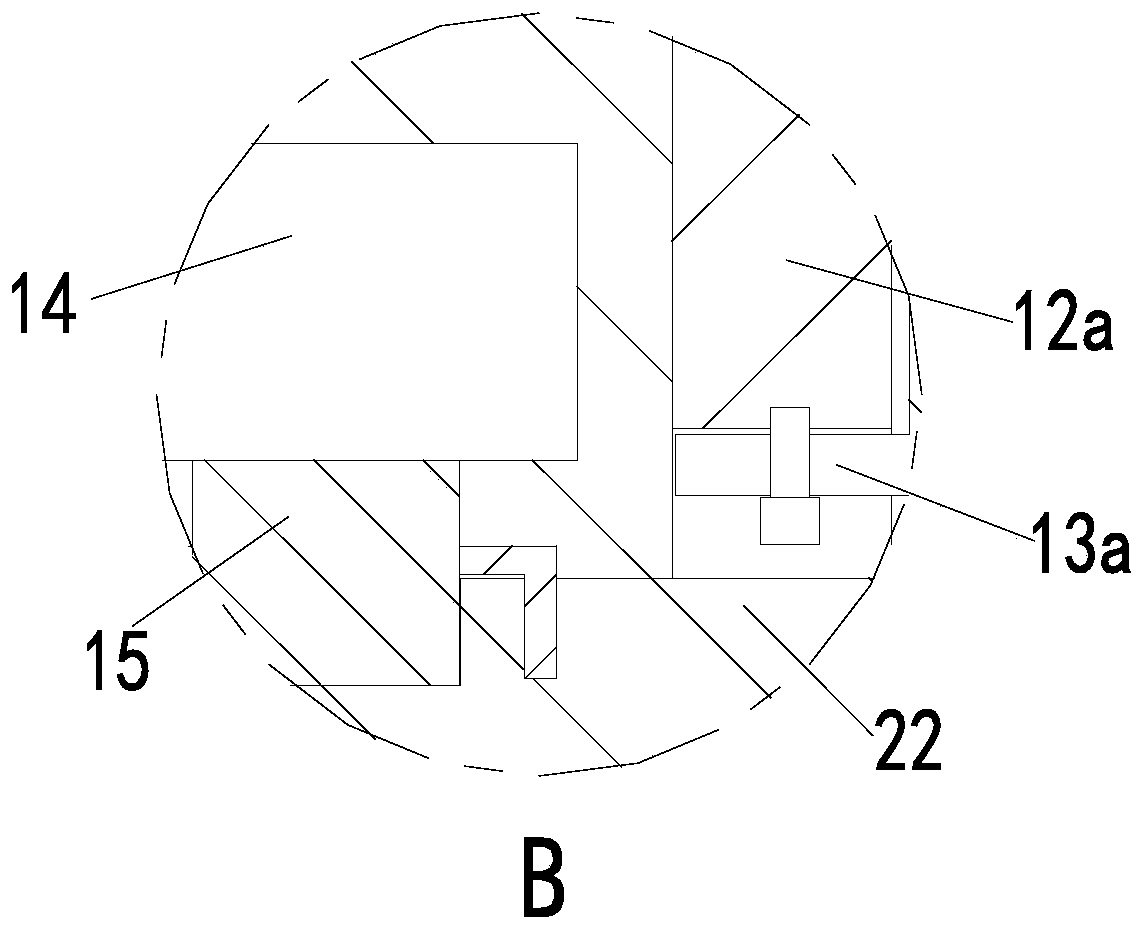

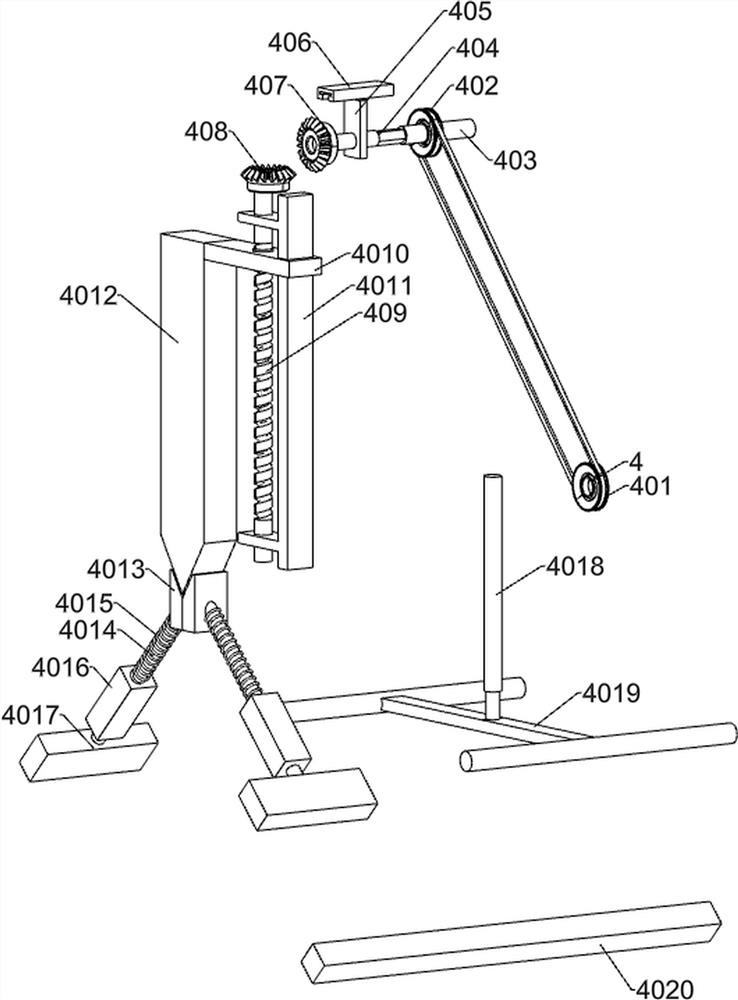

Printing ink defoaming equipment utilizing airflow positive pressure vibration

ActiveCN110201426AEliminate air bubblesTo achieve the separation effectLiquid degasification by vibrationPrinting press partsPrinting inkReturn channel

The invention relates to the technical field of printing ink, and in particular relates to printing ink defoaming equipment utilizing airflow positive pressure vibration. The equipment comprises an oil tank, and an oil outlet mechanism is fixedly connected inside the oil tank. The oil outlet mechanism comprises an oil outlet. An oil extraction port is fixedly connected at the upper part of the oiloutlet. A shell is fixedly connected at one end, remote from the oil outlet, of the oil extraction port. A defoaming mechanism is fixedly connected inside the shell. The defoaming mechanism comprisesan air outlet nozzle. And an air supply channel is fixedly connected inside the air outlet nozzle. An oil return channel is fixedly connected to the surface of the air supply channel, a hollow channel is fixedly connected to the upper part of the air outlet nozzle, and the shell is vibrated when fan blades rotate; because a vibration absorbing material is arranged between the shell and the oil outlet mechanism, the vibration does not affect the oil outlet mechanism. The vibration of the shell can cause ink in an ink tank to slightly vibrate, and at the same time, the top of the shell is accompanied by a flowing-out airflow, and the effect of separating flocculent substances can be achieved.

Owner:东莞市南粤印刷有限公司

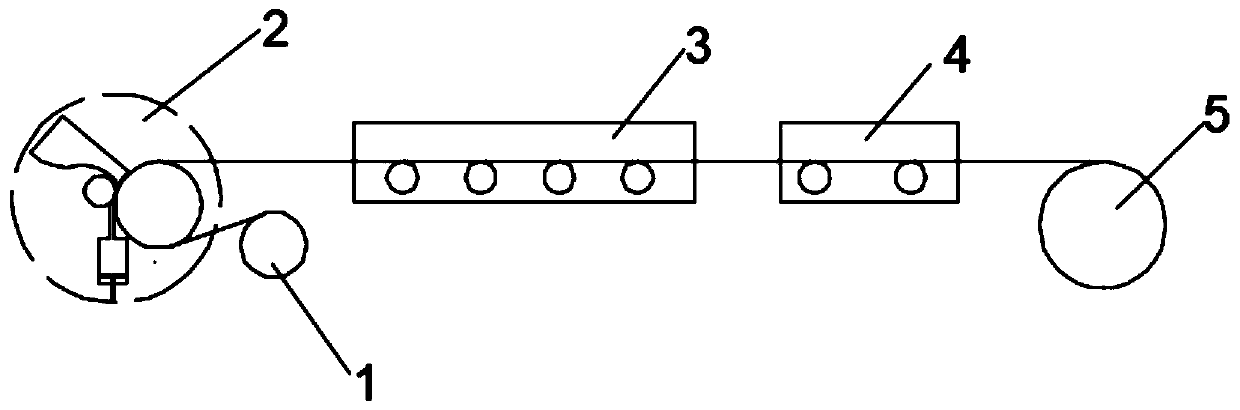

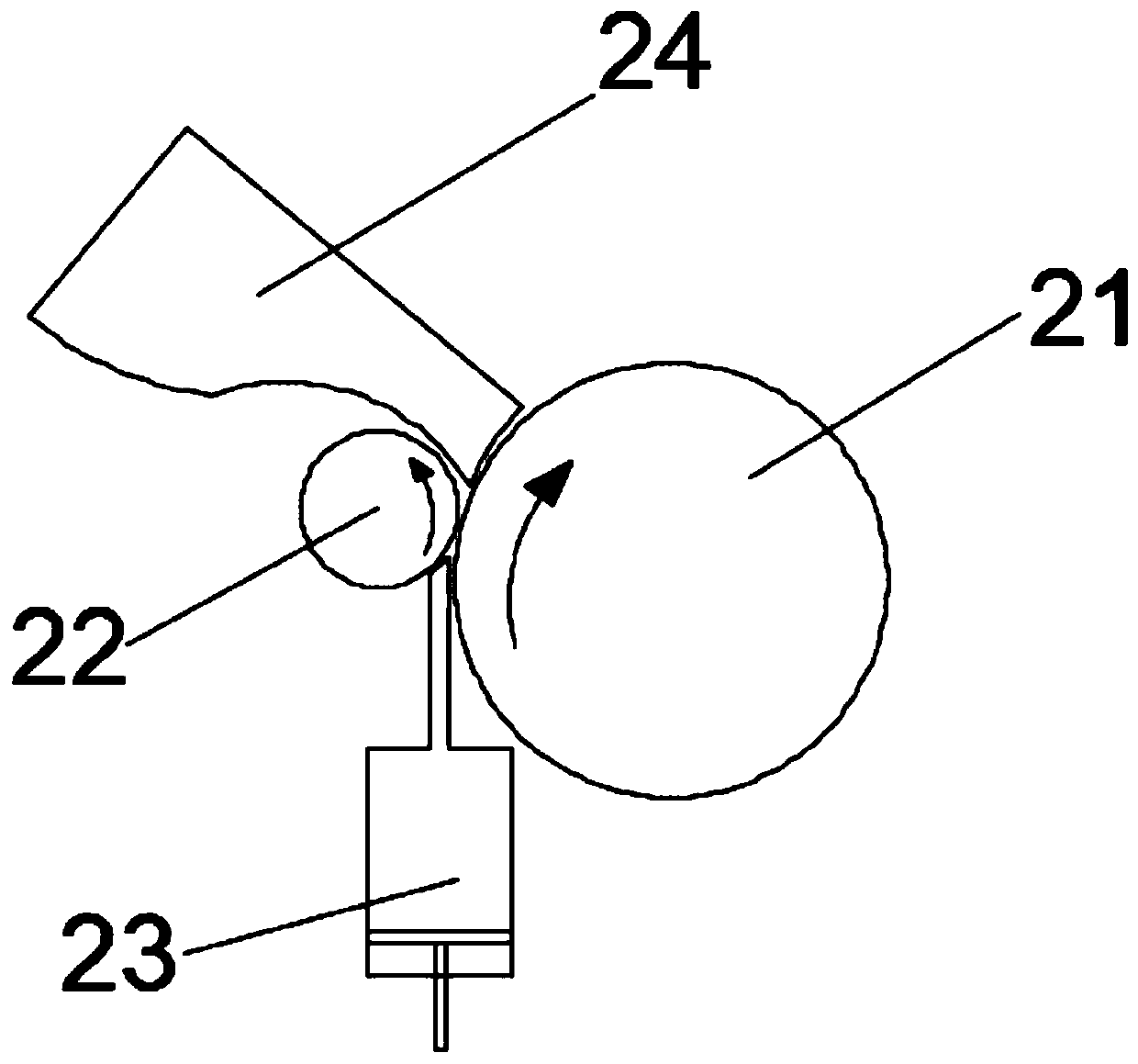

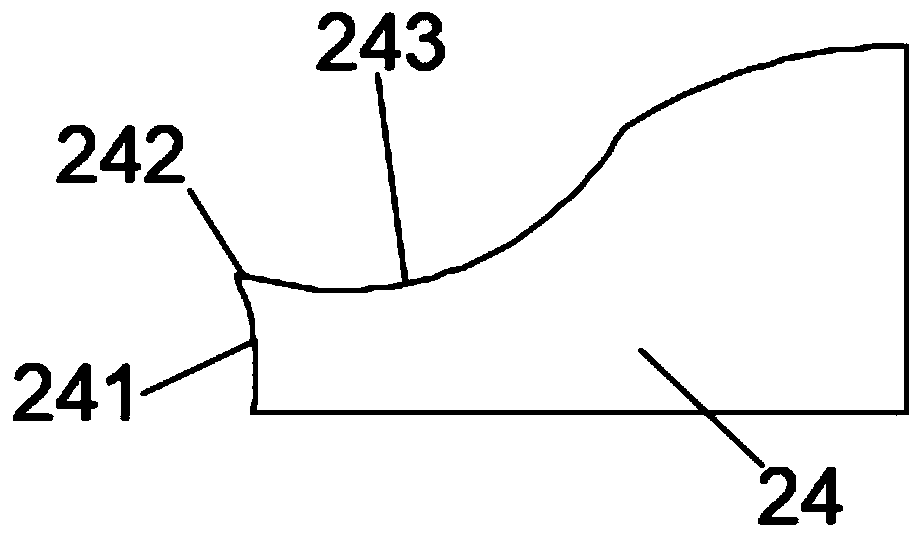

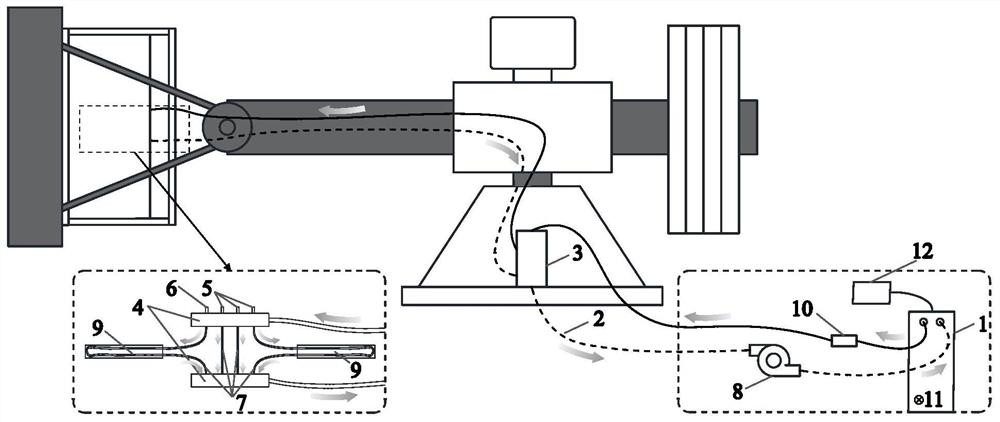

Equipment and process for coating liquid crystal film on basis of TAC base material

InactiveCN110961309AAvoid deformationExtended service lifePretreated surfacesCoatingsLiquid crystallineUV curing

The invention discloses coating equipment for coating a liquid crystal film on the basis of a TAC base material. The equipment comprises a base material roller, a coating device, a constant-temperature drying box, a UV curing lamp and a finished coiled material roller, wherein the five parts form a production line; the base material roller is used for bearing the TAC base material; the coating device comprises a feeding roller, a coating roller, a coating liquid supply device and a scraper; the constant-temperature drying box is located at the output end of the coating device; the UV curing lamp is located at the output end of the constant-temperature drying box and is used for curing liquid crystals; and the finished product coiled material roller is used for winding a coated finished product. The invention further discloses a production process for coating a liquid crystal film the basis of a TAC base material by utilizing the equipment. The coating equipment and process for coatingthe liquid crystal film on the basis of the TAC base material have the advantages of simple mechanism, high coating precision and convenience in large-scale production.

Owner:SUZHOU HAOLI CULTURE MEDIA TECH CO LTD

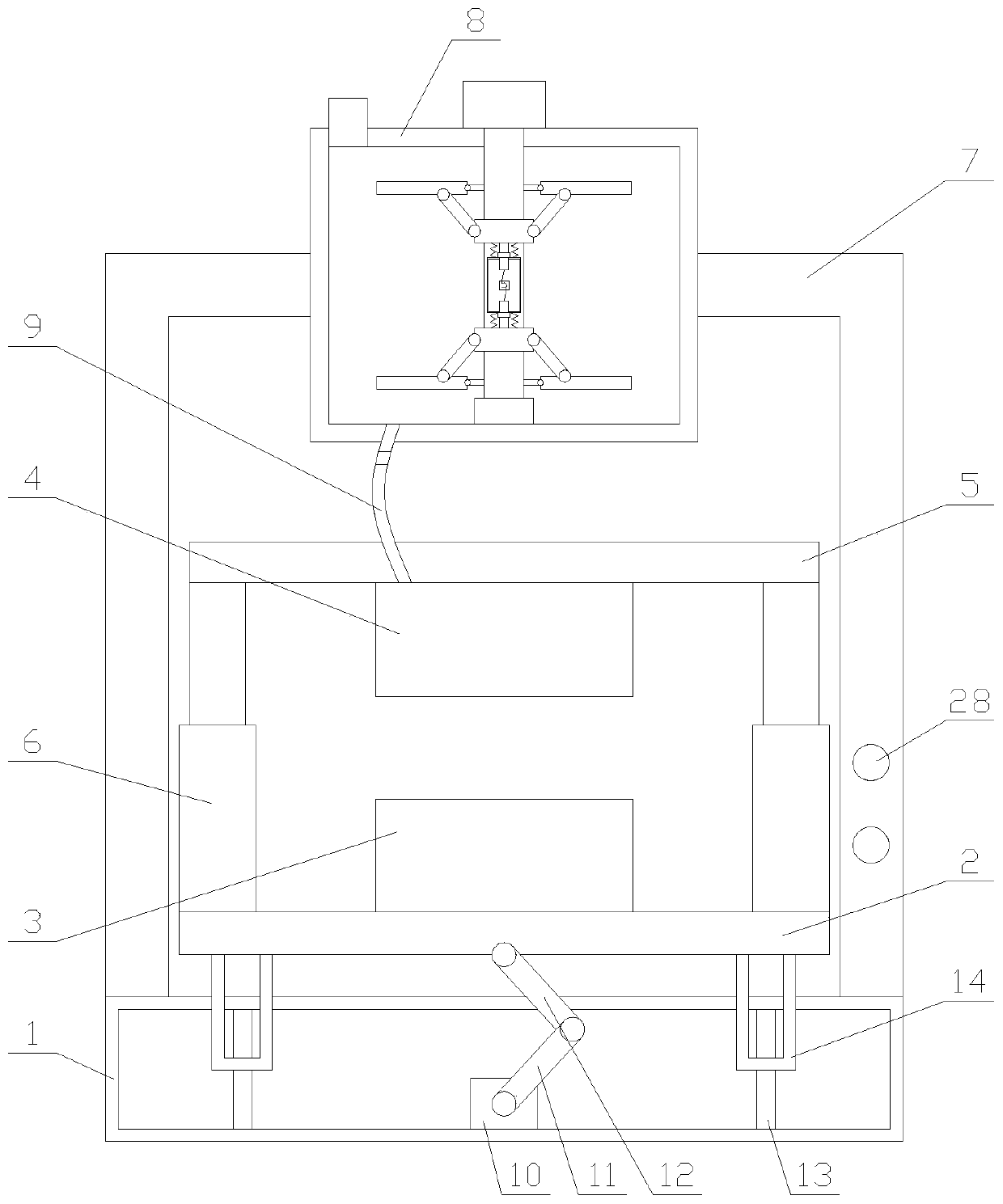

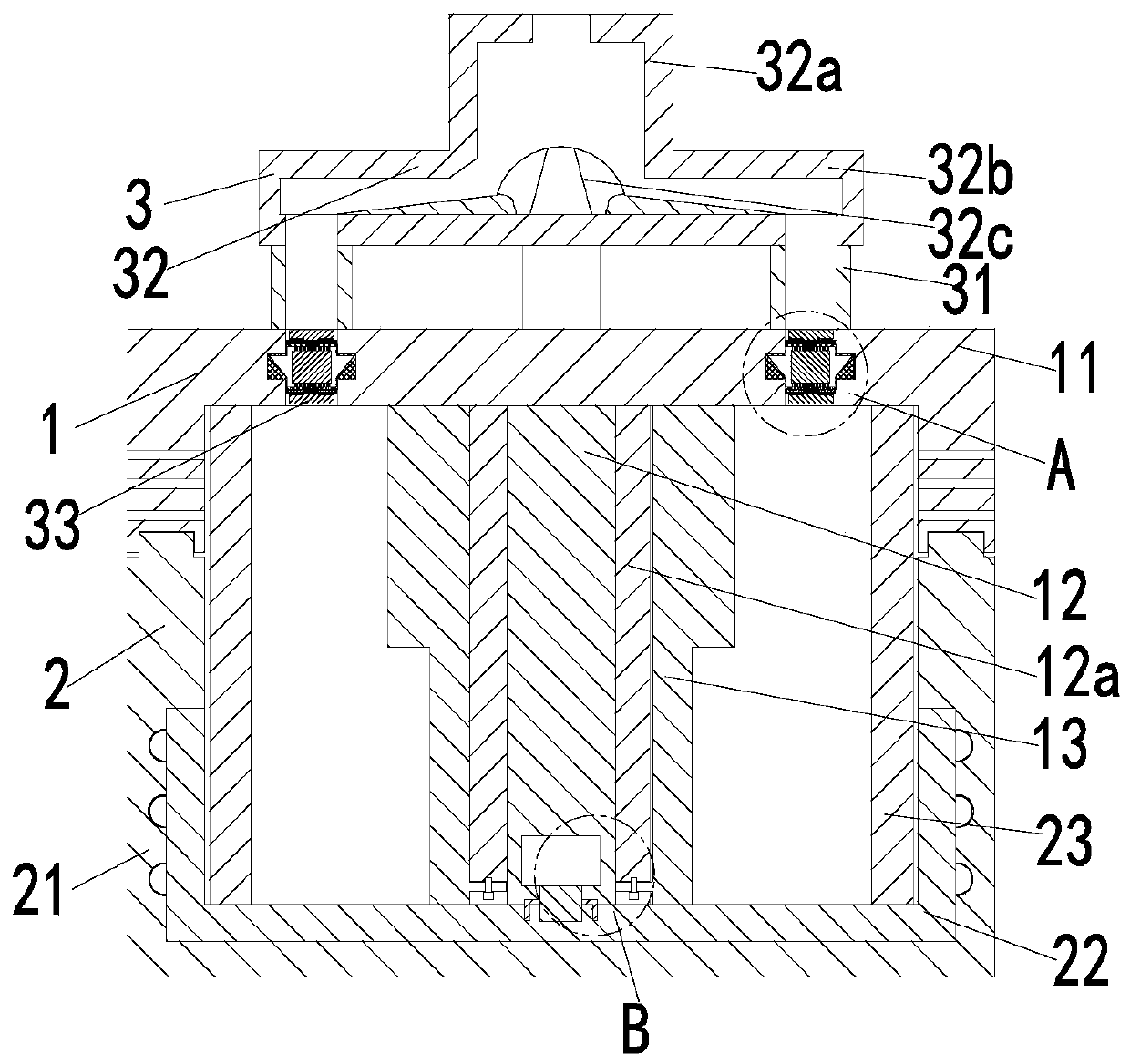

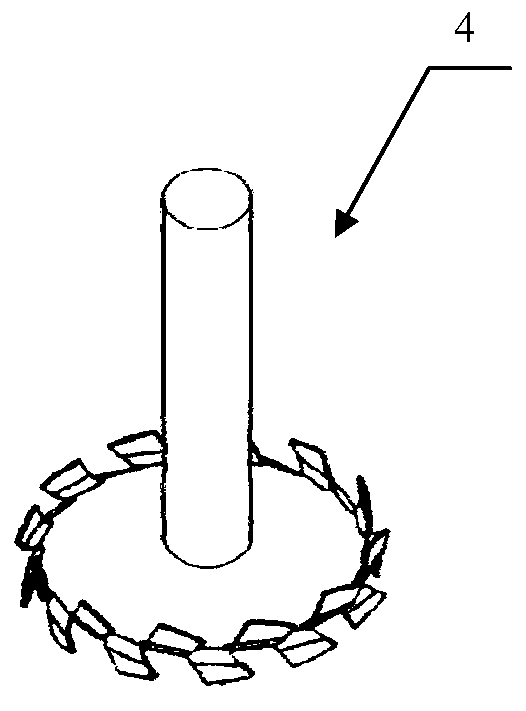

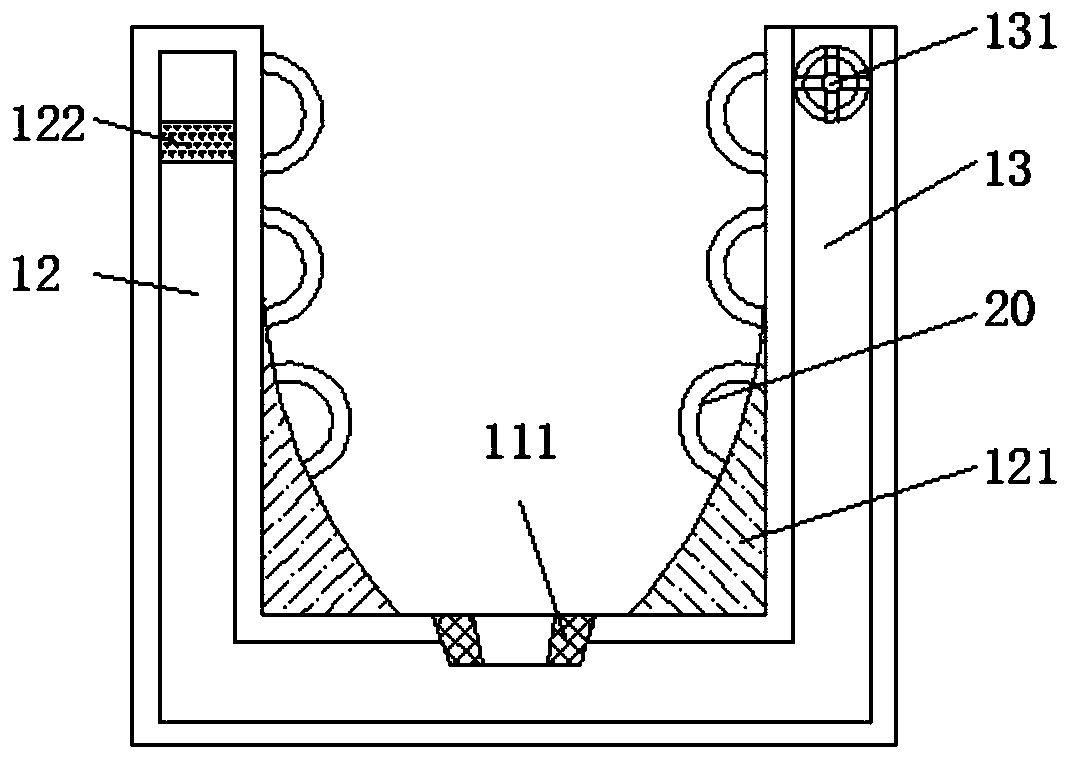

Hydraulic casting device with defoaming function

The invention relates to a hydraulic casting device with a defoaming function. The device comprises a base, a base plate, a lower mold, an upper mold, a top plate, a raw material box, a hose, two brackets and two hydraulic cylinders; a stirring mechanism comprises a first motor, a rotating shaft, a bearing, a driving assembly, and two stirring assemblies; each stirring assembly comprises a lanternring and a plurality of stirring units; and a shaking mechanism comprises a second motor, a rotating rod, a swinging rod, and a plurality of supporting assemblies. The hydraulic casting device with the defoaming function can eliminate the bubbles in casting liquid and improve the quality of casting products through the stirring mechanism. The upper mold and the lower mold can be driven to move upand down by the shaking mechanism, so that the casting liquid is evenly distributed and the unevenness of the casting products is avoided.

Owner:JIANGSU SHUNDA MACHINERY EQUIP

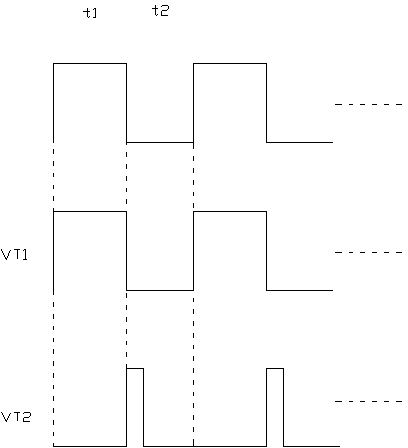

High-frequency pulse fast charging method and charging pile

ActiveCN104377796AImprove charging efficiencyEliminate air bubblesBatteries circuit arrangementsCharging stationsPhysicsPulse period

The invention discloses a high-frequency pulse fast charging method. In the multi-harmonic oscillation step, a continuous pulse signal t1 and a continuous pulse signal t2 are produced; when the pulse signal t1 is produced in the multi-harmonic oscillation step, a storage battery is charged in the forward direction within the pulse t1 period; when the pulse signal t2 is produced in the multi-harmonic oscillation step, a width-adjustable pulse control signal is produced; when a trigger pulse is produced in the mono-stability step, the storage battery is discharged within the trigger pulse period; when production of the trigger pulse is stopped in the mono-stability step, discharging of the storage battery is suspended within the stopping period; before the pulse signal t1 is reproduced in the multi-harmonic oscillation step, the charging switching step and the discharging switching step are stopped, wherein charging time is 2-3 hours, and the service life of the storage battery is prolonged by 1.5-2 times.

Owner:山东诺锐智能科技股份有限公司

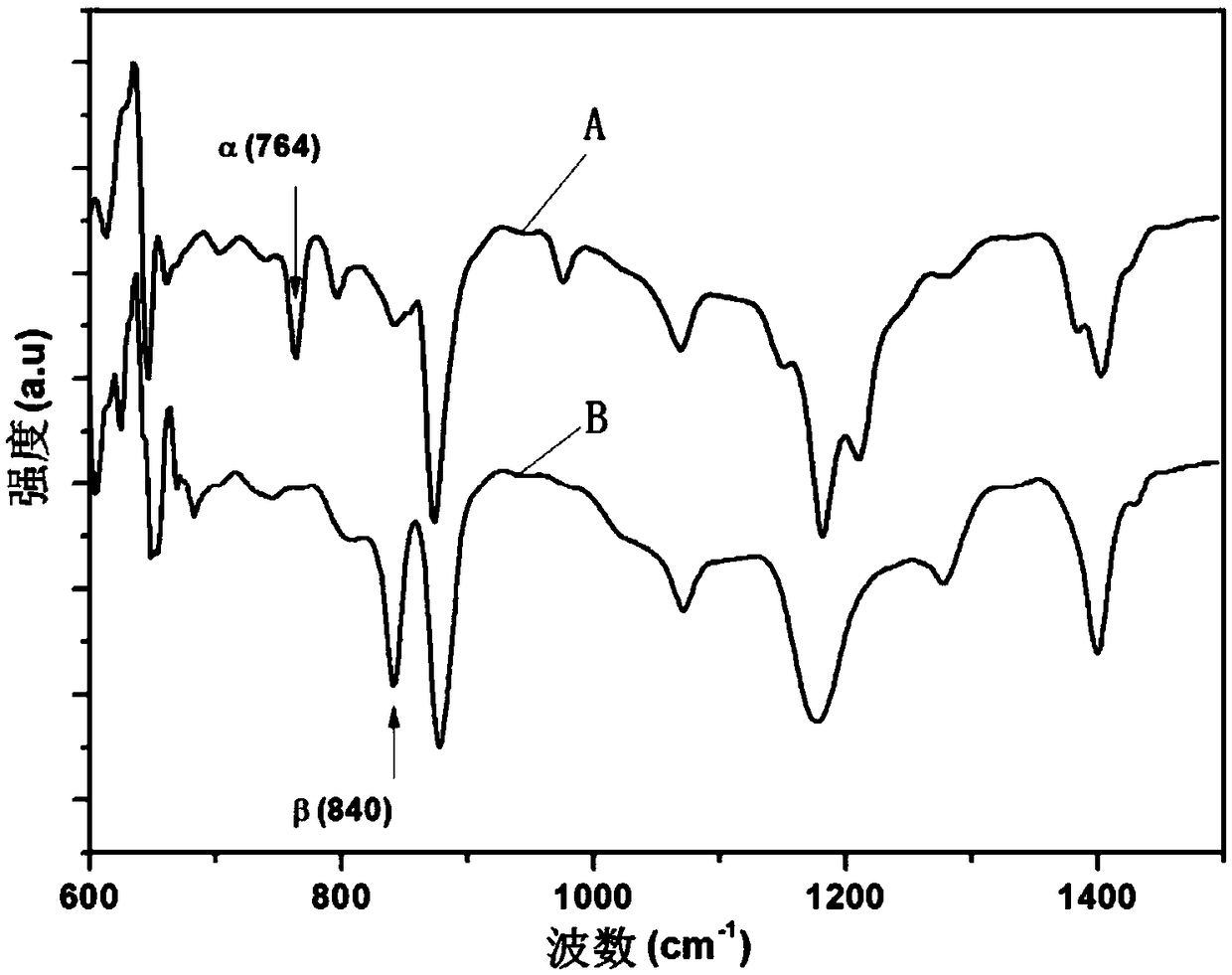

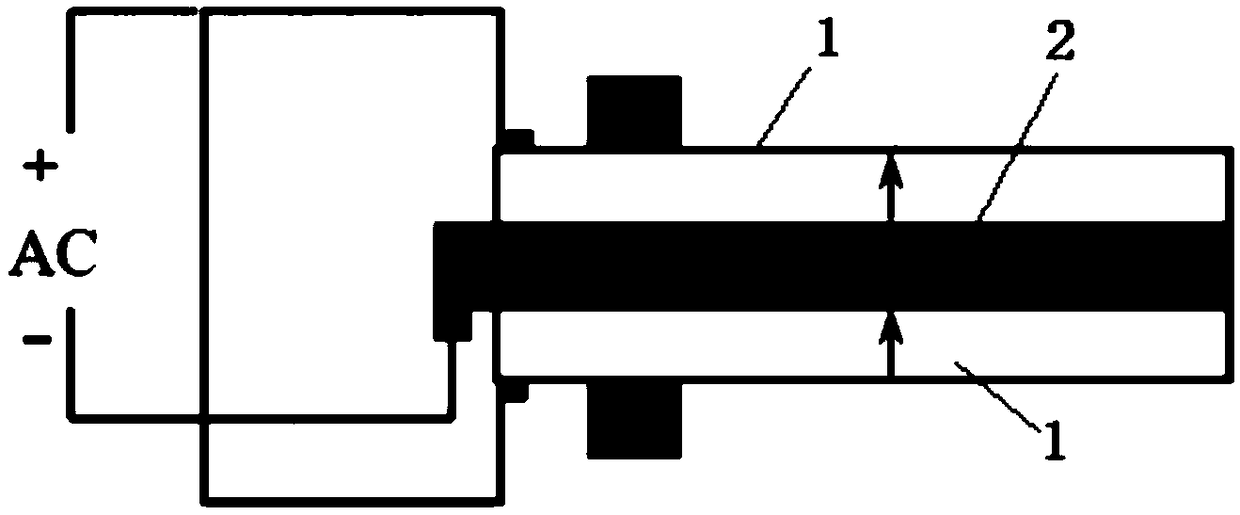

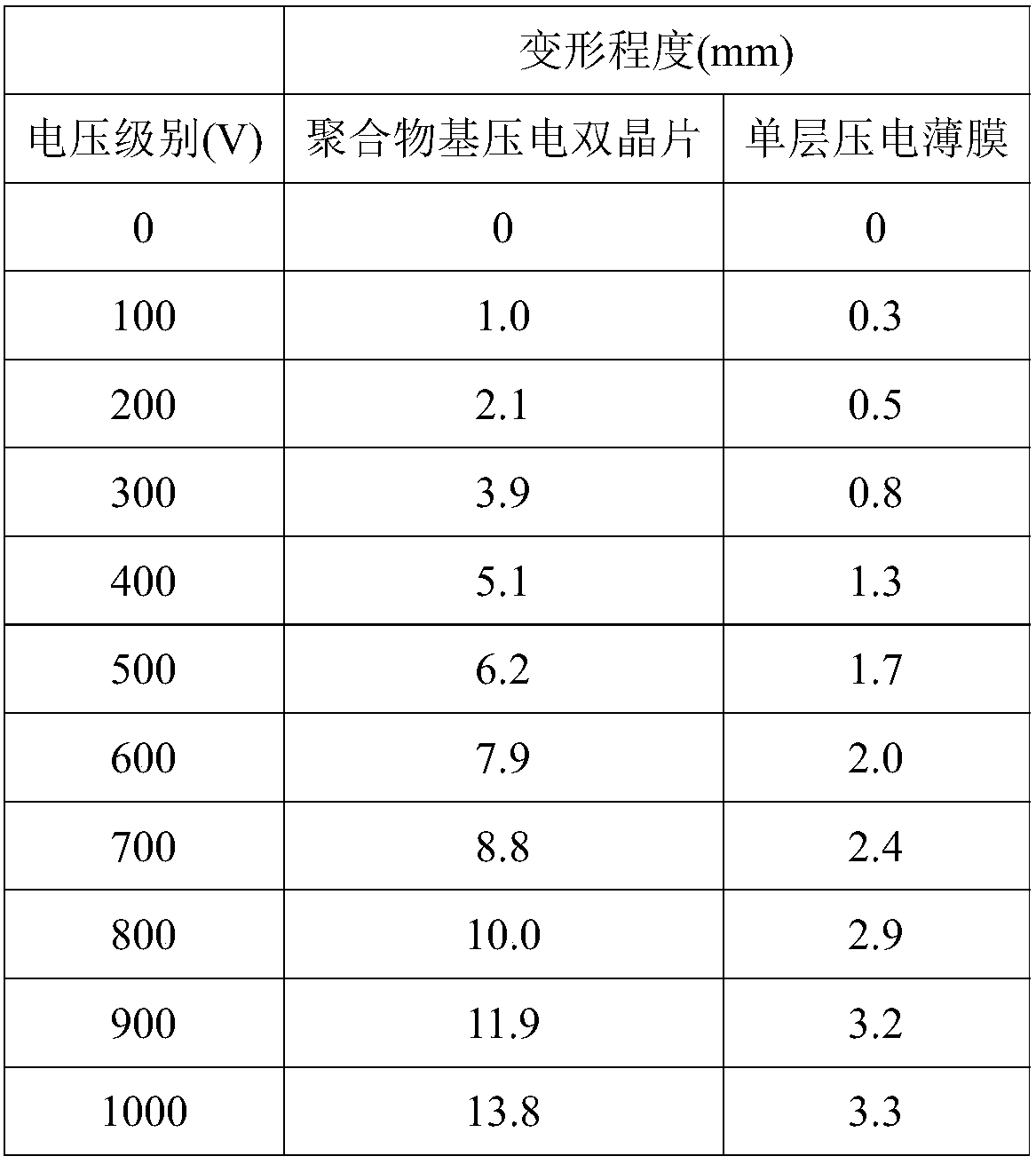

Preparation method and application for polymer-based piezoelectric bimorph

ActiveCN108666415AEliminate air bubblesImprove piezoelectric performancePiezoelectric/electrostrictive device manufacture/assemblyCoatingsEngineeringPiezoelectric polymer

Provided are a preparation method and application for polymer-based piezoelectric bimorph. The purpose of the method is to solve the problem that driving deformation of a film substrate is achieved byusing a piezoelectric polymer. The preparation method comprises the steps of first, preparing non-polarized PVDF-based film; second, preparing and coating a flexible electrode to obtain a PVDF film electrode; third, polarizing to obtain PVDF piezoelectric film; four, assembling to obtain the polymer-based piezoelectric bimorph. The polymer-based piezoelectric bimorph is used for making a drivablematerial. The method has the advantages that based on a piezoelectric polymer, a piezoelectric bimorph form is constructed, and not only the ability of the flat film to control deformation is achieved, but also the effect of the flat film on controlling deformation is increased.

Owner:HARBIN INST OF TECH

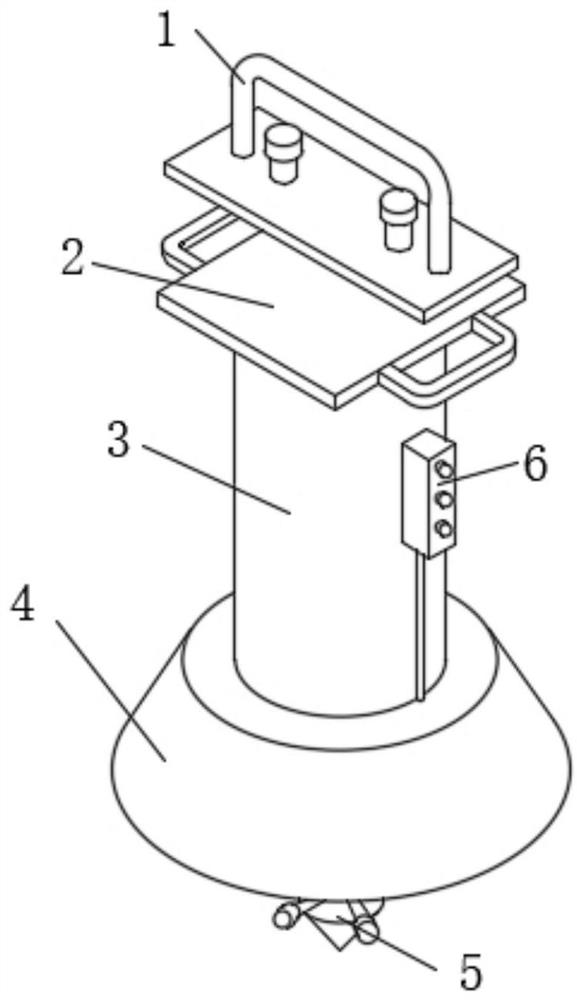

Vacuum applicator for mobile phones

The invention discloses a vacuum applicator for mobile phones. The vacuum applicator for the mobile phones comprises a bottom plate, a vertical plate, an unwinding shaft, a winding shaft, a horizontal plate, a sensor, a first linear motor, a second linear motor, a hollow rod, a film sucking plate, a sleeve, a sealing plate, a sealing cover, a mobile phone positioning mold, a vacuum pump, a controller and the like, and the sensor is electrically connected with the controller. Film pasting operation of the vacuum applicator for the mobile phones can be finished in closed vacuum space of the sealing cover, therefore, the technical problem that air bubbles exist between a mobile phone film and a mobile phone during film pasting can be solved thoroughly, and film pasting quality can be greatly improved; in addition, the closed space of the sealing cover is small, vacuum pumping time is short, and production efficiency of film pasting is high.

Owner:天津鼎拓恒远知识产权服务有限公司

Jacquard cloth printing and dyeing process

PendingCN113818169AEliminate air bubblesAvoid damageDry-cleaning apparatus for textilesTextile treatment carriersPolymer chemistryDyeing

The invention discloses a jacquard cloth printing and dyeing process which comprises the following steps of (1) singeing and desizing woven grey cloth; (2) bleaching and mercerizing the grey cloth; and (3) feeding the treated grey cloth into a dyeing tank for dyeing, wherein a bubble removing roller for pushing the cloth to shake up and down is arranged in the dyeing tank. According to the jacquard cloth printing and dyeing process provided by the invention, in the dyeing process, the bubble removing roller can drive the grey cloth to shake continuously, so that bubbles are eliminated, the grey cloth is uniformly colored, and the quality of prepared jacquard cloth is effectively improved.

Owner:浙江中才轻纺有限公司

Heating and refrigerating system applied to supergravity model test

InactiveCN112067325APrecise temperature control of the structureEliminate air bubblesStructural/machines measurementCentrifugal pumpData collector

The invention discloses a heating and refrigerating system applied to a supergravity model test. A driving acquisition system is arranged outside a supergravity centrifuge, a multistage centrifugal pump is connected with a cooling circulating water machine, the cooling circulating water machine is connected to a rotary joint through a flow meter, and the multistage centrifugal pump is connected with the rotary joint; a temperature sensor is arranged in the cooling circulating water machine and is connected with a temperature data collector; the rotary joint is arranged on a main shaft base ofthe supergravity centrifuge, the rotary joint is connected with the temperature control system, and the temperature control system is arranged on a hanging basket of the supergravity centrifuge; and two flow dividers serve as an inlet side and an outlet side respectively, flow dividing ports of the flow dividers are connected to the two ends of an energy pile silicone tube, and the energy pile silicone tube is pre-buried in the energy pile to form an underground energy structure. According to the heating and refrigerating system, the multistage centrifugal pump is adopted, the driving acquisition system is arranged outside the supergravity centrifuge, the influence of supergravity on an experimental device is reduced, and a technical problem that only the same temperature load can be applied to a single model is solved by adopting the flow divider and a temperature control valve; and the stability and the accuracy of temperature measurement can be improved.

Owner:ZHEJIANG UNIV

Waterborne epoxy wall finish paint and preparation method thereof

InactiveCN104087130AAvoid moldEliminate air bubblesEpoxy resin coatingsPolyester coatingsChemistryTitanium dioxide

The invention discloses waterborne epoxy wall finish paint and a preparation method thereof and relates to the technical field of chemical engineering. The waterborne epoxy wall finish paint comprises a component A and a component B, wherein the component A comprises 20-30 parts of waterborne epoxy acrylate resin and 5-10 parts of water; the component B comprises 10-15 parts of water-soluble saturated polyester resin, 2-5 parts of water-soluble amino resin, 0.2-0.5 part of polyether-modified silicone, 10-20 parts of titanium dioxide powder, 10-30 parts of calcium carbonate, 8-15 parts of talc powder and 7.5-11.8 parts of water. Compared with the prior art, waterborne epoxy acrylate resin, water-soluble saturated polyester resin and water-soluble amino resin as film-forming materials are added and reacted to generate amino bonds with fungicidal and antifungal effects and thus the generation of mycete is prevented.

Owner:DRAGON FISH PAINT

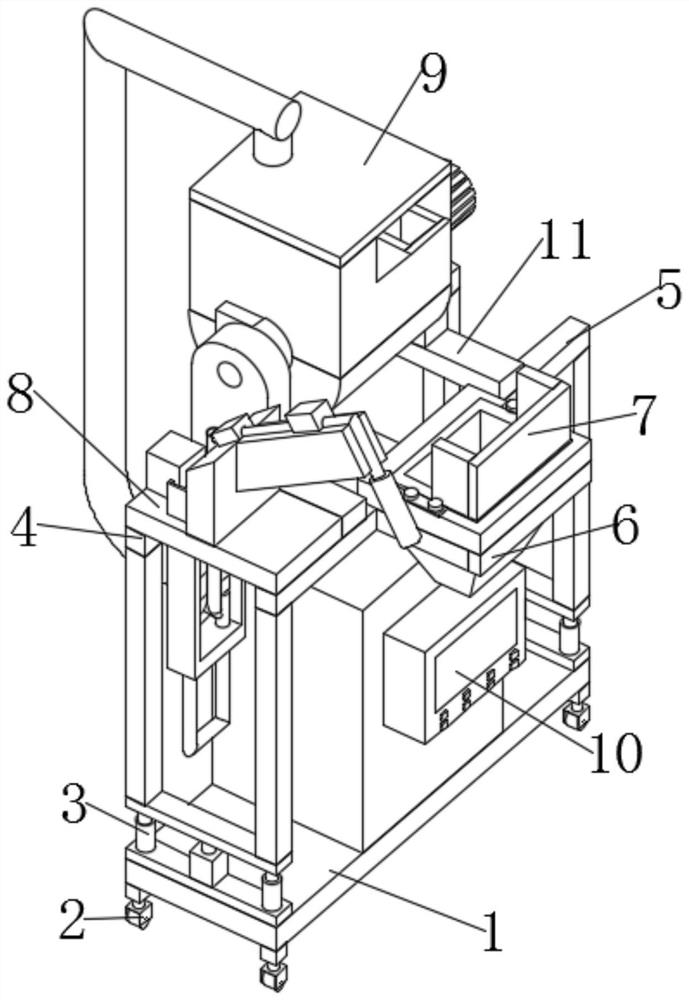

Ceramic product gelcasting mold

The invention relates to a ceramic product gelcasting mold. The mold comprises an upper mold, a lower mold and a pouring mechanism, the lower mold is arranged at the lower end of the upper mold, the pouring mechanism is arranged at the upper end of the upper mold, the upper mold comprises a cover plate, a mounting column, an upper pressing mold, a rotating motor and a connecting block, the lower mold comprises a supporting frame, a rotating frame and a lower pressing mold, the pouring mechanism comprises a pouring pipe, a main pipe body, a material placing cylinder and an uniform stirring frame, the material placing cylinder is divided into a left cylinder body and a right cylinder body, and the uniform stirring frame comprises a sleeving ring, a uniform stirring plate and a uniform stirring roller. The gelcasting work is completed in a mode that the pouring of slurry materials and putting of an initiator and a catalyst are carried out synchronously, the solidification time of the slurry materials can be effectively prolonged, the slurry materials are guaranteed to be uniformly distributed in a mold cavity, and in the pouring process, the lower mold can rotate, so that the slurry materials are driven to shake slightly, and the mold plays a role in eliminating air bubbles mixed in the slurry materials.

Owner:衡阳阳光陶瓷有限公司

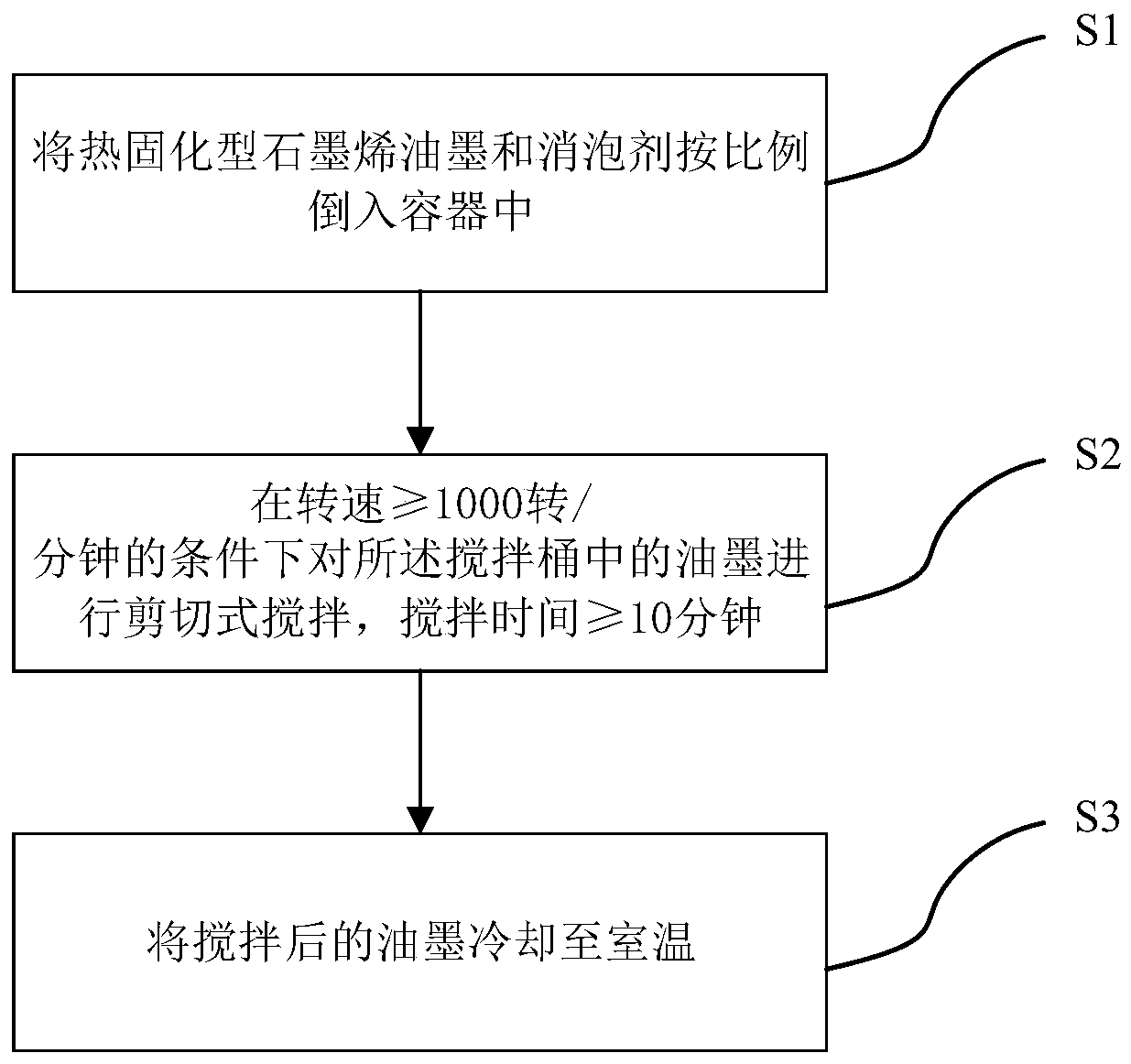

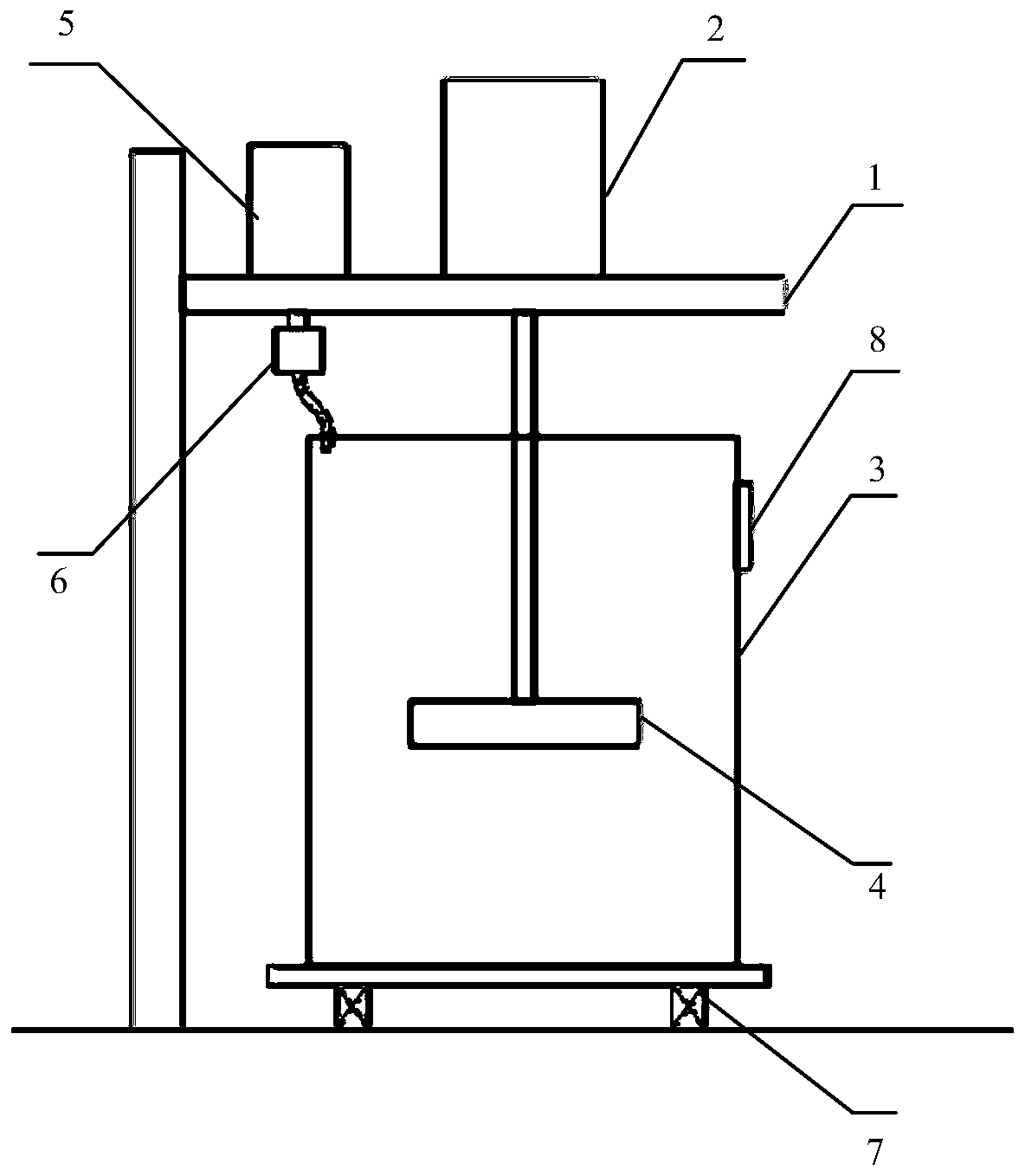

Pretreatment method and device for circuit board heat dissipation ink

PendingCN110917982AEliminate air bubblesReduce manufacturing costTransportation and packagingRotary stirring mixersChemistryDefoaming Agents

The invention discloses a pretreatment method and device for circuit board heat dissipation ink. The method comprises the steps: S1, thermosetting graphene ink and a defoaming agent are poured into astirring barrel in proportion; S2, the printing ink in the stirring barrel is subjected to shear type stirring under the condition that the rotating speed is larger than or equal to 1000 RPM, and thestirring time is larger than or equal to 10 min; and S3, the stirred ink is cooled to room temperature. The device comprises a support, a stirring motor arranged on the support, and a stirring barrelarranged below the support; the stirring motor is connected with a shearing type stirring head, and the rotating speed of the stirring motor is larger than or equal to 1000 RPM. According to the pretreatment method and device disclosed by the invention, the defoaming agent is added when the thermosetting graphene ink is stirred, elimination of bubbles in the ink can be facilitated, the thermosetting graphene ink is stirred at a high speed, graphene can be uniformly distributed in the ink, stirring can be performed in a non-vacuum environment, expensive vacuum stirring device is not needed, andreduction of the production cost can be facilitated.

Owner:珠海斗门超毅实业有限公司

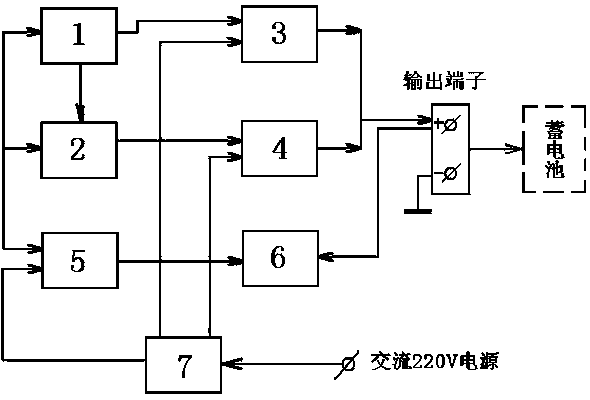

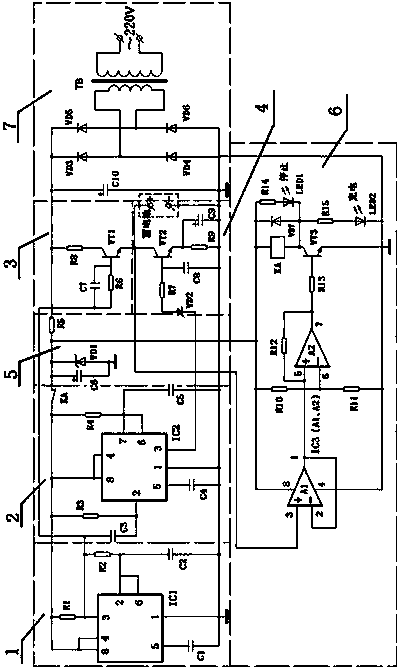

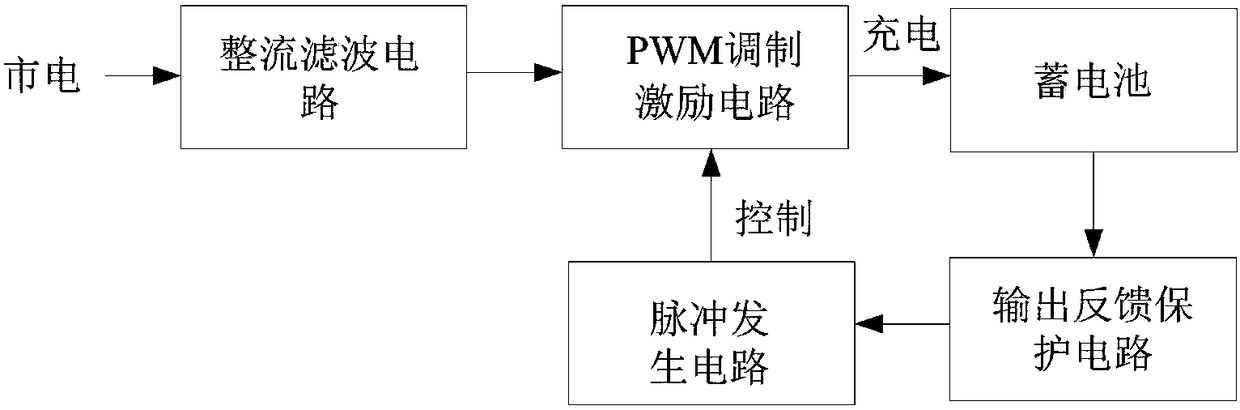

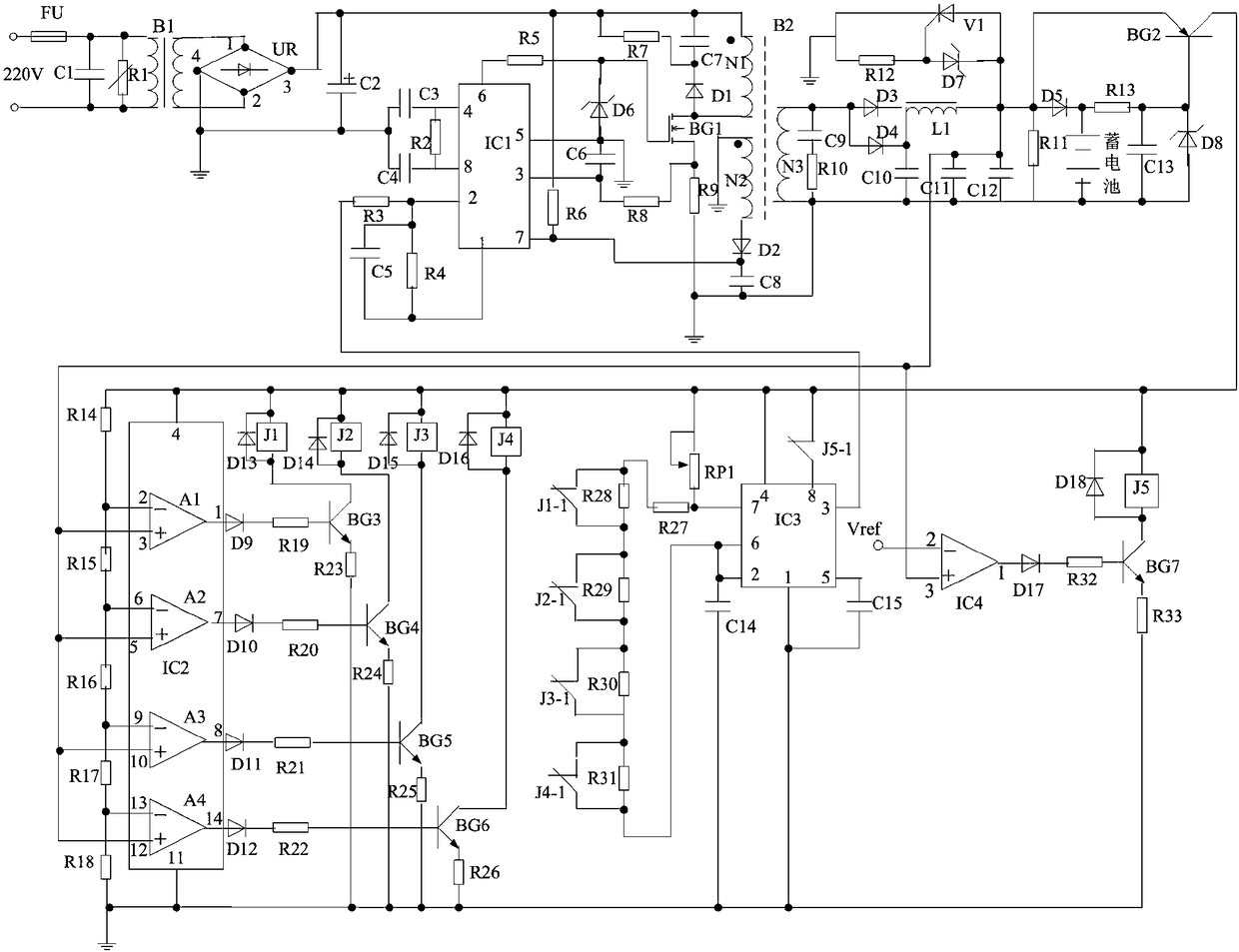

Storage battery charging circuit with capacity repair function

ActiveCN108494078AEliminate air bubblesReduce high temperatureBatteries circuit arrangementsElectrolyte/reactants regenerationFast pulseElectricity

The invention relates to a storage battery charging circuit with a capacity repairing function. The circuit comprises a rectifying and filtering circuit, a PWM excitation circuit, a storage battery, an output feedback protection circuit and a pulse generation circuit; the rectifying and filtering circuit is electrically connected with the PWM excitation circuit; the PWM excitation circuit is electrically connected with the storage battery; the storage battery is electrically connected with the output feedback protection circuit; the output feedback protection circuit is electrically connectedwith the pulse generation circuit; and the pulse generation circuit is electrically connected with the PWM excitation circuit. According to the storage battery charging circuit with the capacity repairing function of the invention, fast pulse charging is adopted, that is, short-time charging suspension during a charging process can be realized, and therefore, the quantity of air inside the storagebattery can be effectively controlled, air bubbles can be eliminated, high temperature inside the storage battery during charging can be decreased, the loss of water can be reduced, a sulfuration phenomenon can be eliminated, the capacity of the storage battery can be repaired, the number of times of the cyclic charging of the storage battery can be increased, and the service life of the storagebattery can be prolonged.

Owner:CHINA UNIV OF MINING & TECH

Gastrointestinal B-ultrasonography imaging agent

InactiveCN104667305AEliminate air bubblesPromote gastrointestinal motilityDigestive systemEchographic/ultrasound-imaging preparationsArecaCitrus medica

The invention provides a gastrointestinal B-ultrasonography imaging agent. The gastrointestinal B-ultrasonography imaging agent is prepared from the following medicinal raw materials by weight: 20g of largehead atractylodes rhizome, 20g of pinellia ternate, 20g of magnolia officinalis, 20g of white peony root, 20g of areca peel, 20g of roasted malt, 10g of endothelium corneum gigeriae galli, 10g of semen coicis, 10g of fructus aurantii, 10g of fructus evodiae, 10g of fingered citron, 10g of fructus amomi, 10g of poria cocos, 15g of scutellaria, 10g of dandelion, 6g of glycyrrhiza, 5g of liquid paraffin, 2g of fatty acid methyl polyoxyethylene ether and 2g of Tween 80. The gastrointestinal B-ultrasonography imaging agent is capable of solving the problem of inaccurate diagnosis caused by residual gas in gastric inner walls in the gastrointestinal B-ultrasonography detection process, promoting circulation of qi and relieving distension, is rapid in effect and also has the therapeutic effect to patients with gastric diseases.

Owner:郝爱华

Large-caliber thick-wall quartz glass tube and preparation method thereof

ActiveCN109516689AGuaranteed molding accuracyEliminate air bubblesGlass shaping apparatusOxideCaliber

The invention discloses a large-caliber thick-wall quartz glass tube. Quartz sand is used as a basic raw material in parts by weight, and is compounded with a microelement additive in parts by weight,accounting for 3.1% to 4.2% of the parts (by weight) of the quartz sand, wherein the microelement additive is prepared from the following raw materials in weight ratios: 0.4 to 0.6 of sodium chlorate, 0.1 to 0.3 of ammonium chloride, 0.2 to 0.4 of antimonous oxide and 0.3 to 0.5 of cerous nitrate. The sodium chlorate, the ammonium chloride and the cerous nitrate are mixed, added with water, dissolved and made into an aqueous solution; the antimonous oxide is added into hydrochloric acid and made into an acidic solution; the aqueous solution, the acidic solution and high-purity quartz sand aremixed, then are sent into a sand baking machine to carry out oven-drying swelling, next, are subjected to magnetic separation and screening, and are put into a continuous melting furnace to carry outdrawing forming; a used former is provided with an air flow convoluting chamber in an air vent hole; and the air flow convoluting chamber is used for achieving dilatation and flow stabilizing effectsand ensuring the forming precision of the tube wall of a glass tube. The large-caliber thick-wall quartz glass tube prepared by the invention has the characteristics of being excellent in high temperature resistance, high in hardness, slight in thermal expansion, free from air bubbles and free from air lines.

Owner:LIANYUNGANG HONGYANG QUARTZ PROD

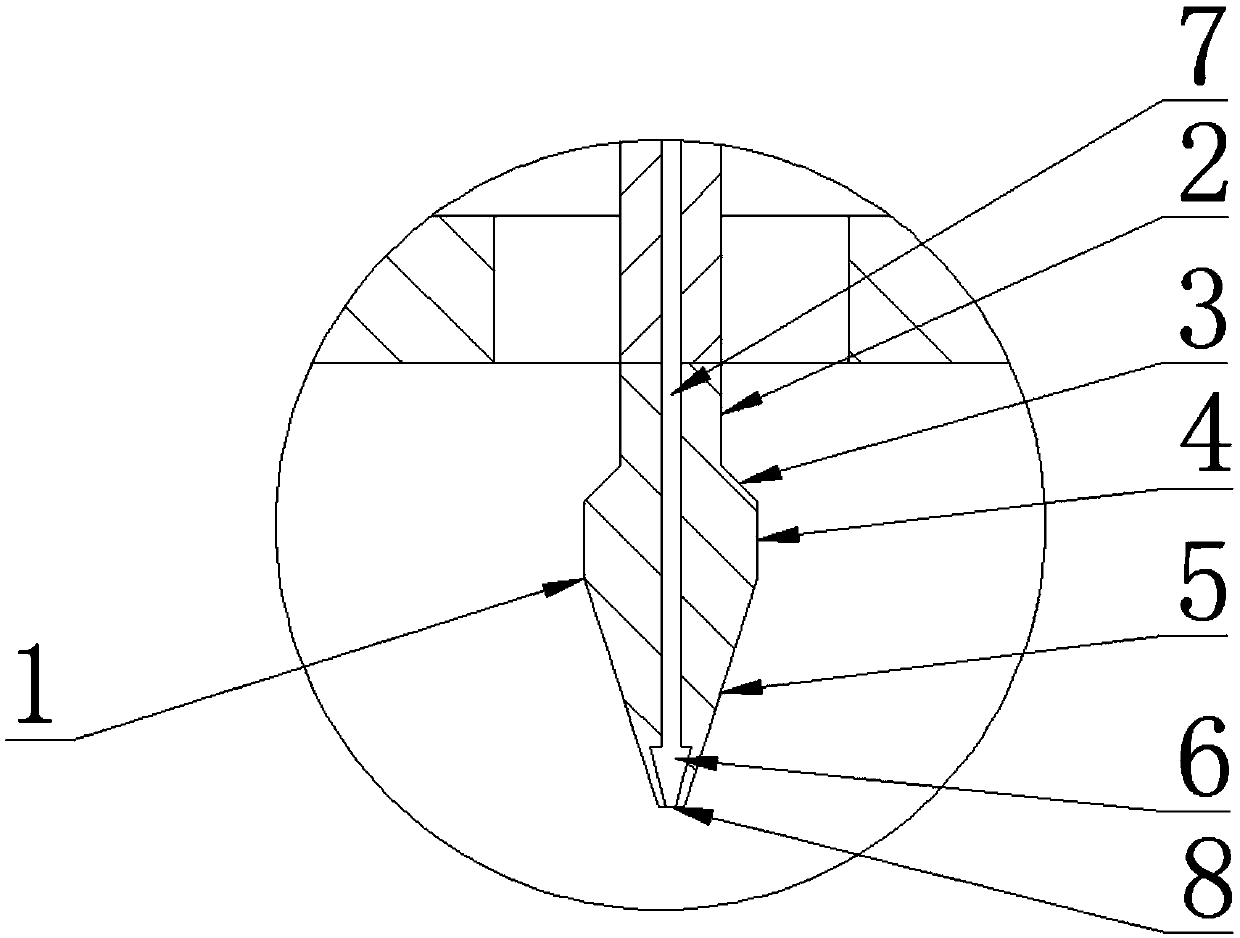

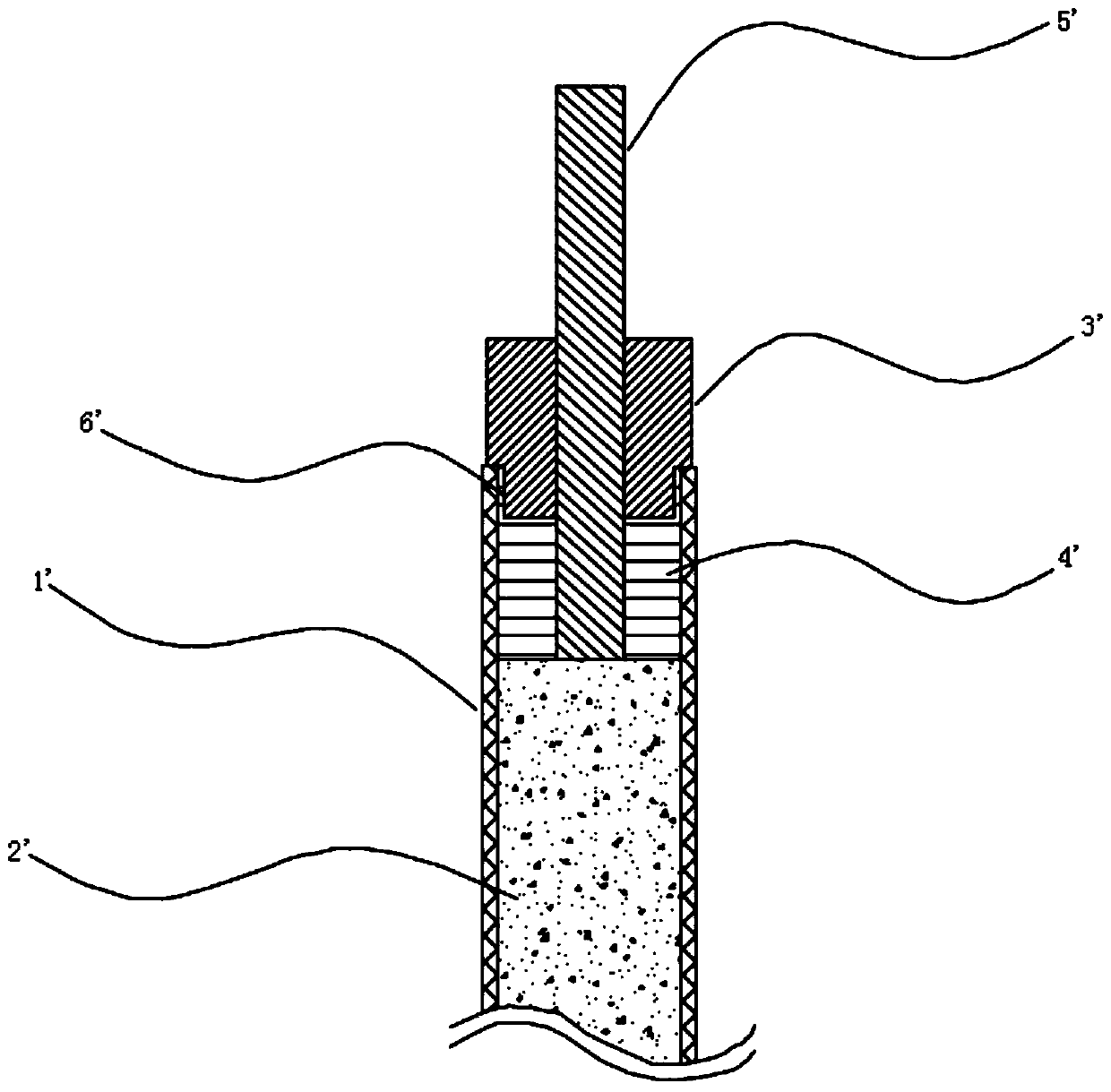

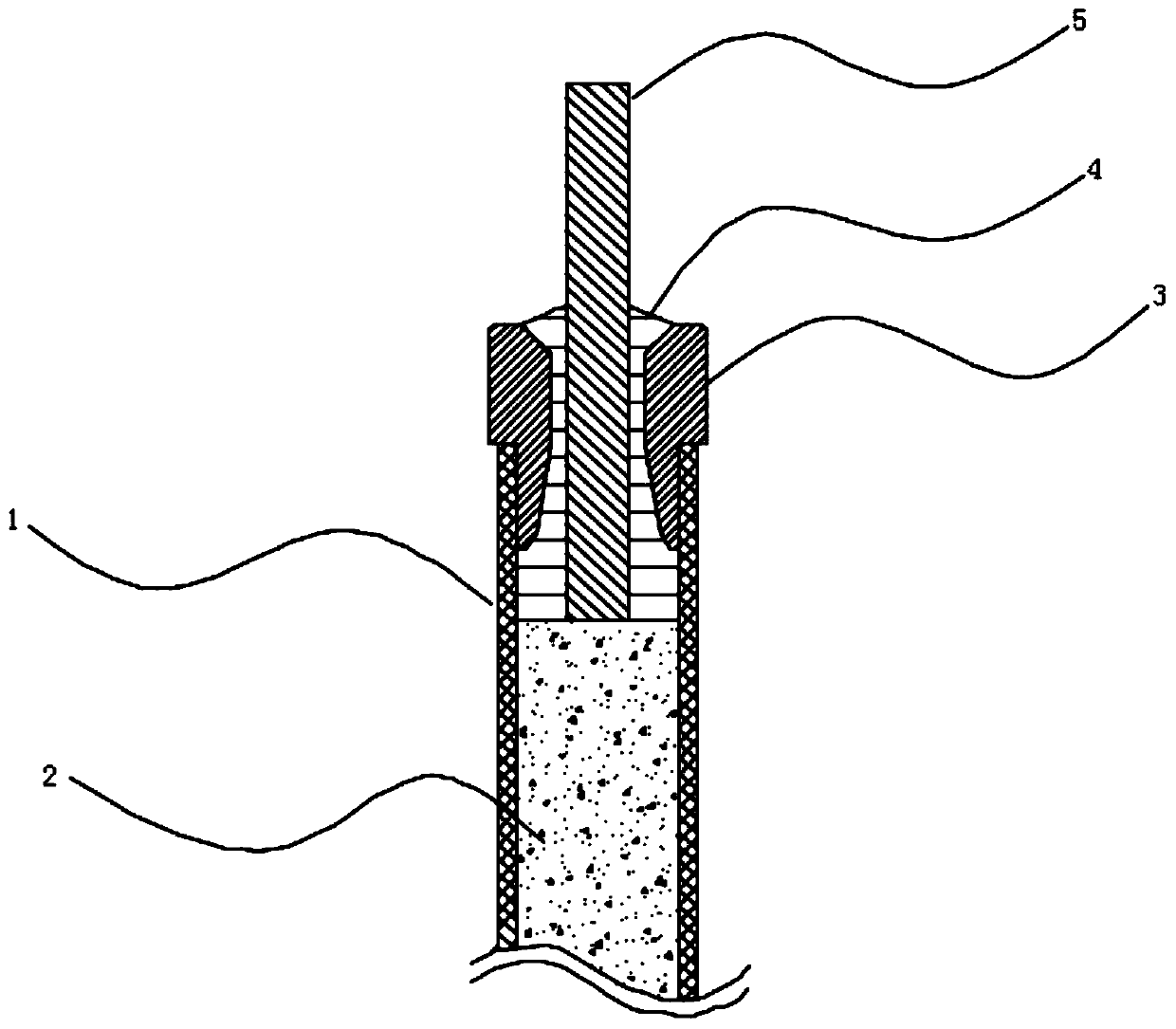

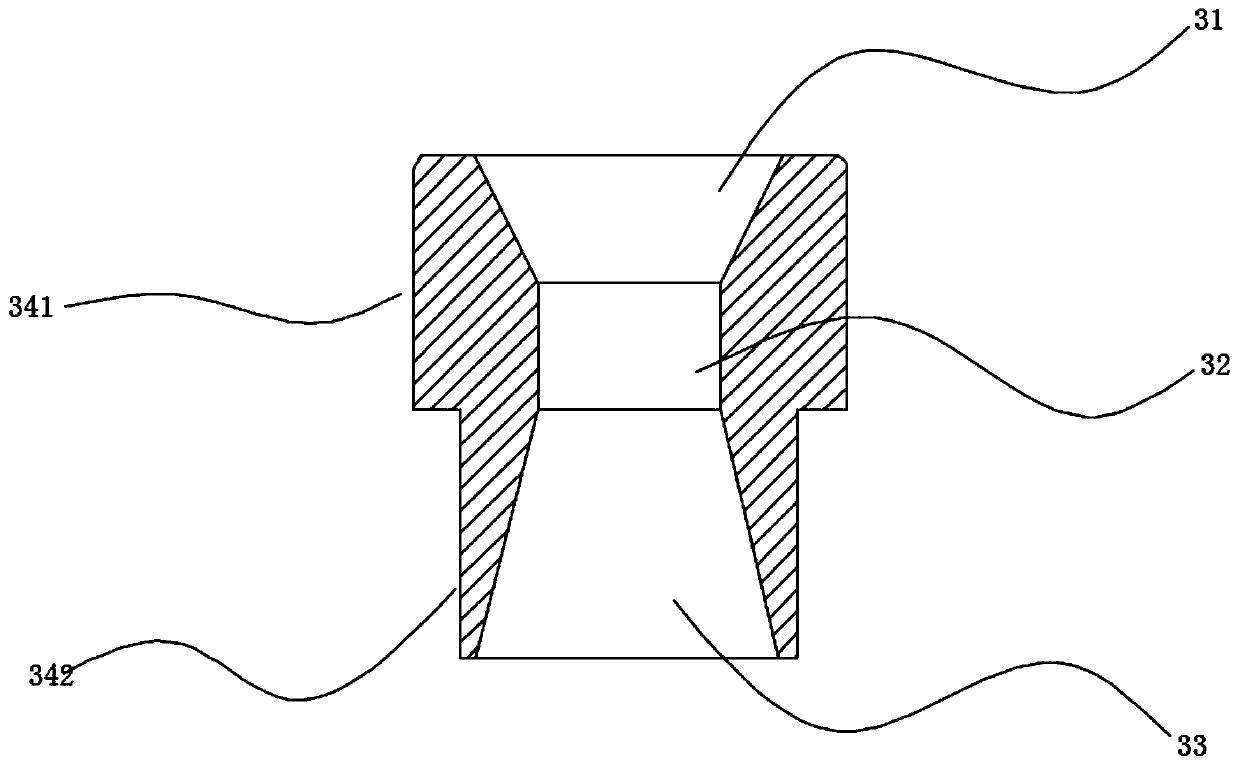

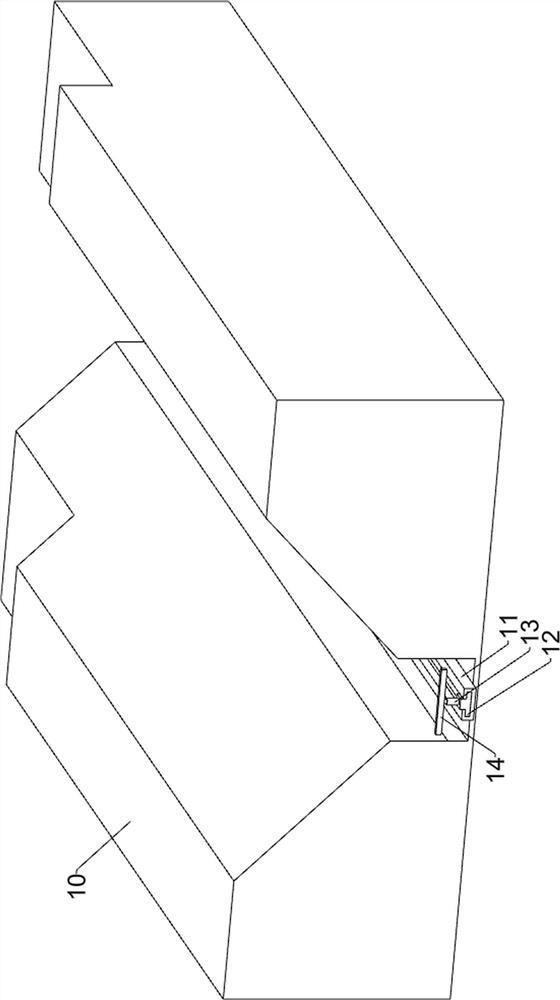

High-reliable electric heating pipe sealing structure and method

PendingCN110636649AReasonable structureGood curing adhesionOhmic-resistance waterproof/air-tight sealsHeating element shapesElectric heatingVoltage

A high-reliable electric heating pipe sealing structure and method are disclosed. A lead rod is arranged in an electric heating tube body. A space between the lead rod and the tube body is filled withmagnesium oxide powders. An insulation sealing device is disposed at the sealing port of the electric heating tube body and is composed of an upper opening, a middle channel, a lower channel, and a lower opening. The lead rod penetrates through the middle channel of a sealing port device. A sealant is arranged between the insulation sealing device and the electric heating pipe body. The outer diameter of the upper part of the insulation sealing device is larger than the diameter of the outer wall of the sealing port of the electric heating pipe body, and the outer diameter of the lower part of the insulation sealing device is smaller than the diameter of the inner wall of the electric heating pipe body. The diameter of the upper opening gradually decreases toward the middle of the sealingport device. The diameter of the lower channel gradually decreases toward the middle of the insulation sealing device. The lower opening is located below the lower channel. The diameter of the loweropening gradually decreases toward the lower channel. The smallest diameter of the lower opening is equal to the largest diameter of the lower channel. The high-reliable electric heating pipe sealingstructure has the advantages of good bonding during the curing process of the sealant and improving the insulation withstand voltage.

Owner:GUANGZHOU JIANLONG ELECTRIC APPLIANCE

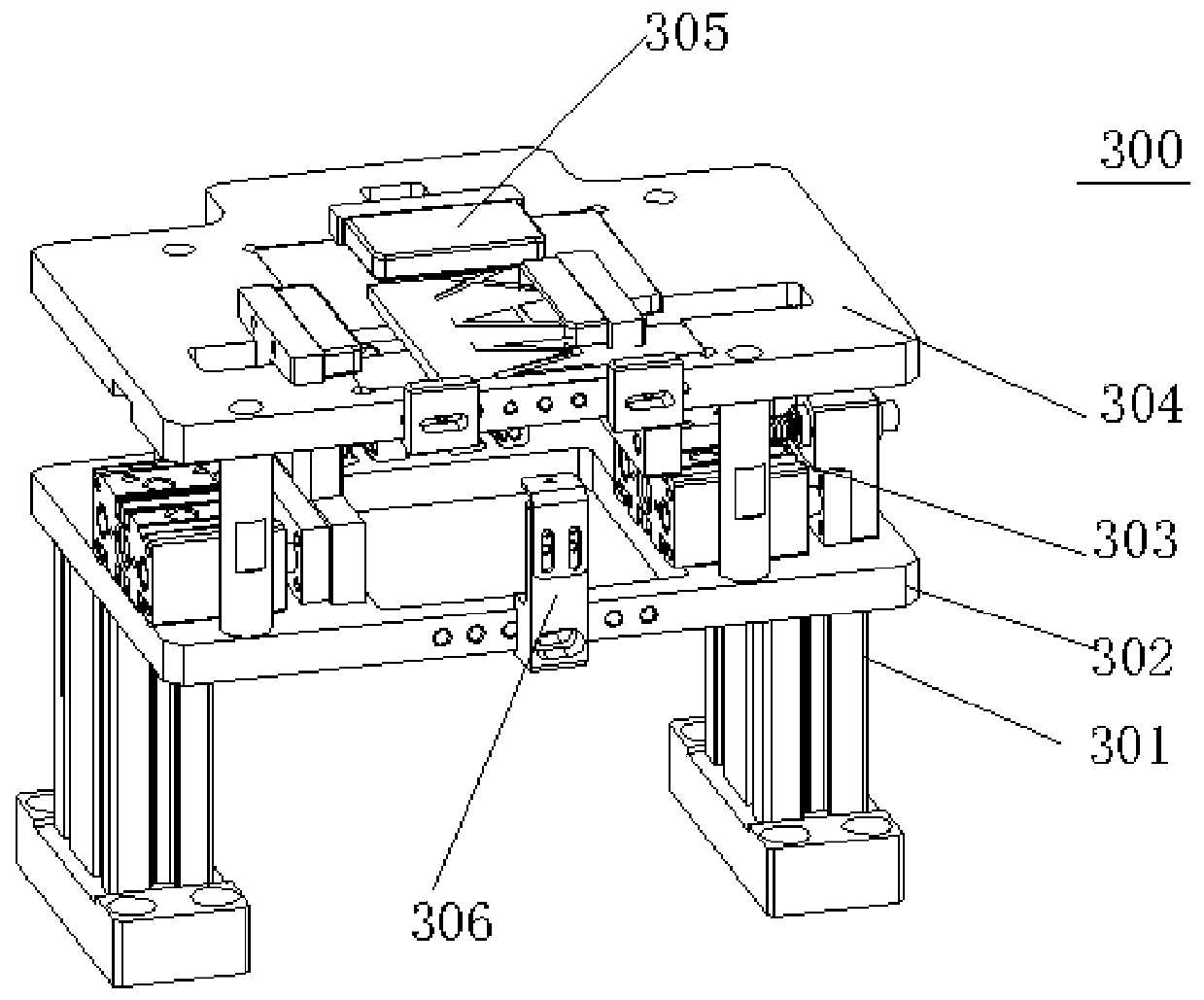

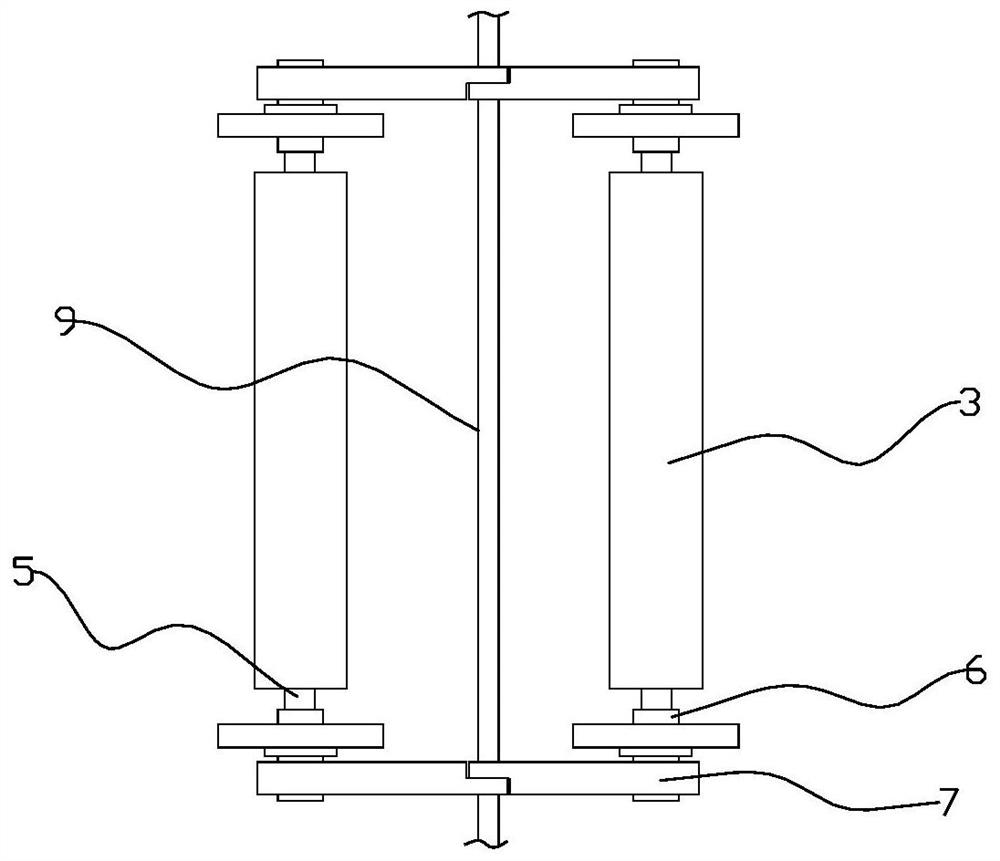

Vibration-assisted nano rolling device

The invention relates to a vibration-assisted nano rolling device, which comprises the following steps that firstly, a rack is horizontally placed on an experiment table, then an X-Y-axis displacementplatform is adjusted to enable a Z-direction vibration device to be positioned right below an imprinting roller, a glued substrate is fixed in the center of a substrate chuck, a fine adjustment device is adjusted to enable the imprinting roller to be horizontal, and then the Z-axis displacement platform is controlled to move downwards to enable the imprinting roller to be in micro contact with the imprinting glue, the heating device is started to heat the substrate, imprinting is started after heating is completed, the Z-direction vibration device starts to vibrate while imprinting is conducted, then cooling and demolding are conducted, and finally the Z-axis displacement platform is controlled to ascend, and imprinting is completed. The Z-direction vibration device is adopted, so that gap contact is generated between the template and the imprinting glue, the adhesive force between the template and the imprinting glue is reduced, friction heat production is performed through multipletimes of gap contact, the imprinting glue melts and flows, the filling degree of the imprinting glue is improved, the imprinting roller is adjusted to be horizontal through the fine adjustment device,and the cooling device is used for cooling; and the precision and fidelity of the micro-nano structure are further improved.

Owner:CHANGCHUN UNIV OF TECH

Concrete vibrating device for building

InactiveCN113719128AExtended service lifeEliminate air bubblesBuilding material handlingHandrailControl switch

The invention discloses a concrete vibrating device for a building. The concrete vibrating device comprises a handrail rod, wherein cushioning bolts are connected to two sides of the bottom of the handrail rod in a sleeving manner; a transverse plate is fixedly connected to the bottom ends of the cushioning bolts; a motor barrel is fixedly connected to the bottom of the transverse plate; a control switch is fixedly connected to the surface of the right side of the motor barrel; a protective cover is fixedly connected to the bottom of the motor barrel; a vibrating device is arranged in an inner cavity of the protective cover; the motor barrel comprises a barrel wall; a rotating motor is fixedly connected to the middle of the top of the inner cavity of the barrel wall; a rod-shaped telescopic device is fixedly connected to an output shaft at the bottom of the rotating motor; and a straight rod is fixedly connected to the bottom of the rod-shaped telescopic device. The invention relates to the technical field of buildings. According to the concrete vibrating device for the building, the rotating motor in the motor barrel is controlled by adjusting the control switch, so that the vibrating frequency of the concrete vibrating device can be adjusted, and the effect of vibrating concrete is achieved.

Owner:王胜利

Anti-swelling steel sheet casting equipment for aluminum piston

The invention provides anti-swelling steel sheet casting equipment for an aluminum piston. The equipment comprises a casting liquid storage bin, a negative pressure mechanism and a casting mold cavity; the top of the casting liquid storage cabin is provided with the negative pressure mechanism, the casting mold cavity is arranged in the casting liquid storage cabin, the negative pressure mechanismis used for absorbing air in the casting mold cavity in a negative pressure manner to enable the casting mold cavity is filled with casting liquid. The casting equipment has the advantages that air inside the casting mold cavity is absorbed through the negative pressure mechanism, so that the casting liquid enters the interior of the casting mold cavity from the bottom of the casting mold cavity,bubbles generating phenomenon in the casting liquid can be eliminated, the air discharged by the negative pressure mechanism is introduced into the casting liquid storage bin, so that a piston in thecasting liquid storage bin moves downwards, the casting liquid in the casting liquid storage bin can enter the casting mold cavity quickly, the casting efficiency can be improved while the bubbles inthe casting liquid are eliminated, and the using effect is better.

Owner:ANHUI HIGH TECH POWER TECH

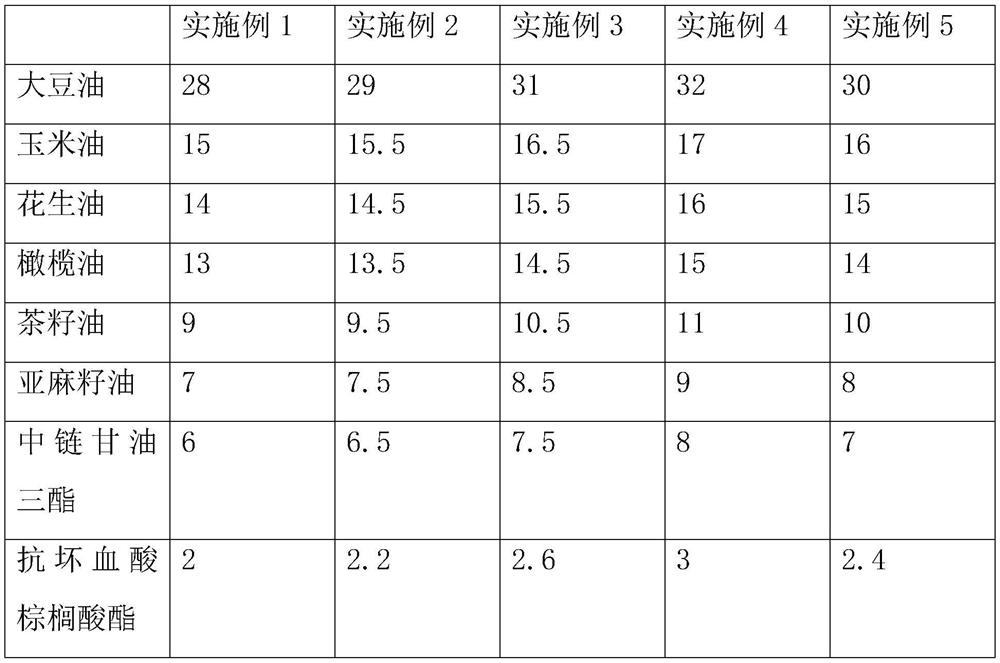

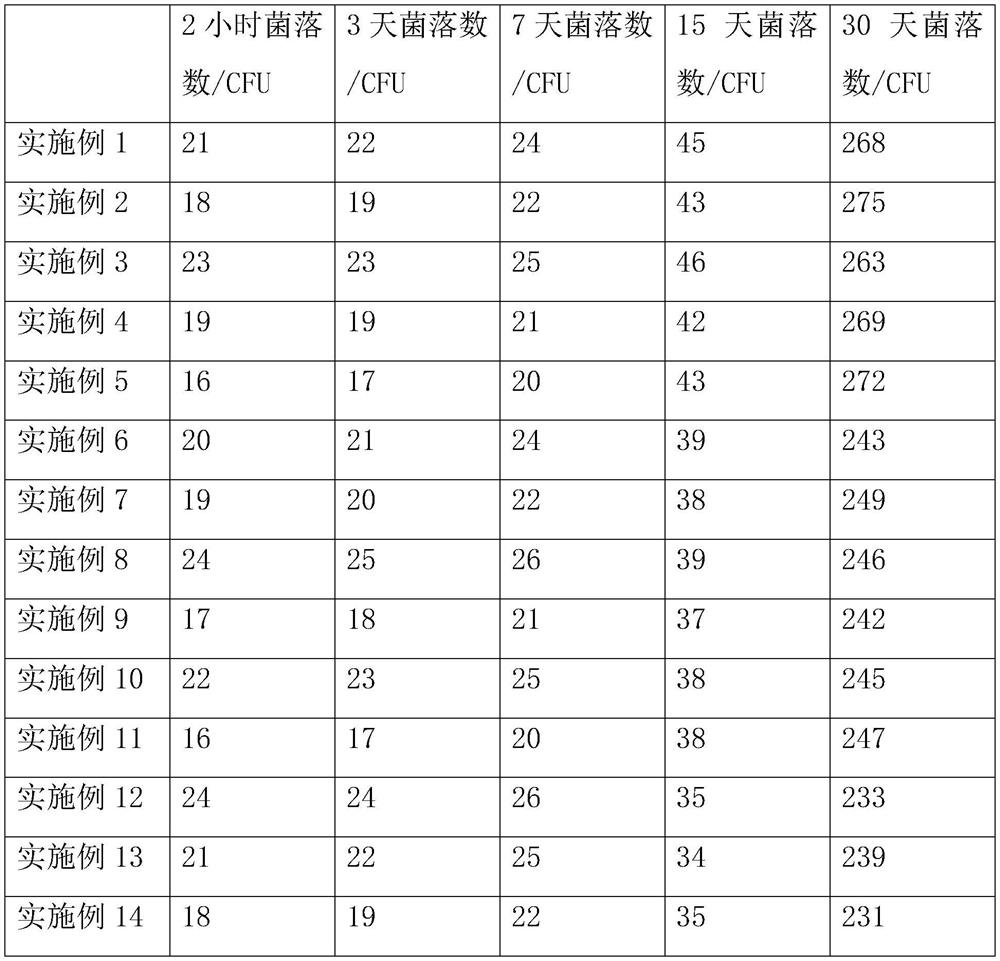

Vegetable blend oil suitable for pregnant women and lying-in women

InactiveCN112715685AEliminate air bubblesImprove finished product qualityEdible oils/fatsSOYBEAN SEED OILEdible oil

The invention relates to the field of edible oil, and particularly discloses vegetable blend oil suitable for pregnant women and lying-in women. The vegetable blend oil suitable for the pregnant women and the lying-in women comprises soybean oil, corn oil, peanut oil, olive oil, tea-seed oil, linseed oil, medium-chain triglyceride and ascorbyl palmitate. The vegetable blend oil has the advantages of being beneficial to healthy development and pregnancy of babies and health recovery of lying-in women.

Owner:广州市国味油脂食品有限公司

Imitation brick producing and processing device for constructional engineering

InactiveCN113199595AEliminate air bubblesSave materialDischarging arrangementMouldsStructural engineeringMechanical engineering

The invention relates to the field of constructional engineering, in particular to an imitation brick producing and processing device for constructional engineering. The technical problem to be solved is to provide the imitation brick producing and processing device for constructional engineering. According to the technical scheme, the device comprises a bottom frame, a filling assembly, a drying assembly, a demolding assembly and the like. The filling assembly is connected with the drying assembly. The drying assembly is connected with the demolding assembly. When the device is used, cement remaining at the included angle of a mold is automatically removed and collected, then the cement is automatically and completely attached to the interior of the mold through shaking, the bubble phenomenon is eradicated, meanwhile, the collected cement is filled into a groove in the upper portion of the mold, materials are greatly saved, the two ends of the mold are automatically separated from L-shaped imitation bricks, therefore, workers can conveniently remove the L-shaped imitation bricks, and cement sheets remaining above the mold can be automatically removed.

Owner:温海桥

Quantitative concrete wallboard pouring equipment for civil construction engineering

The concrete wallboard quantitative pouring equipment for civil construction engineering comprises a movable base, fine adjustment devices are fixedly connected to the front portion and the rear portion of the upper end of the movable base correspondingly, and a first connecting rod and a second connecting rod are jointly and fixedly connected to the upper ends of the two fine adjustment devices; a supporting frame is fixedly connected to the middle of the right end of the second connecting rod, a material guiding device is connected into the supporting frame in a penetrating mode, a vibrating device is fixedly connected to the front portions of the upper ends of the first connecting rod and the second connecting rod jointly, and two base plates are fixedly connected to the middle of the upper ends of the first connecting rod and the second connecting rod. And the upper ends of the two base plates are jointly and fixedly connected with a dumping device, the middle of the upper end of the movable base is fixedly connected with a conveying mechanism, and the middle of the upper end of the first connecting rod is fixedly connected with two positioning rods. According to the concrete wallboard quantitative pouring equipment for civil construction engineering, the flexibility and practicability of the whole device are high, the pouring stability is high, and the pouring effect is good.

Owner:JIANGSU WEIFENG BUILDING INSTALLATION GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com