Large-caliber thick-wall quartz glass tube and preparation method thereof

A quartz glass tube, large-diameter technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of inability to meet production needs, complex preparation process, low molding quality, etc., to prevent secondary bubbles, excellent High temperature resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

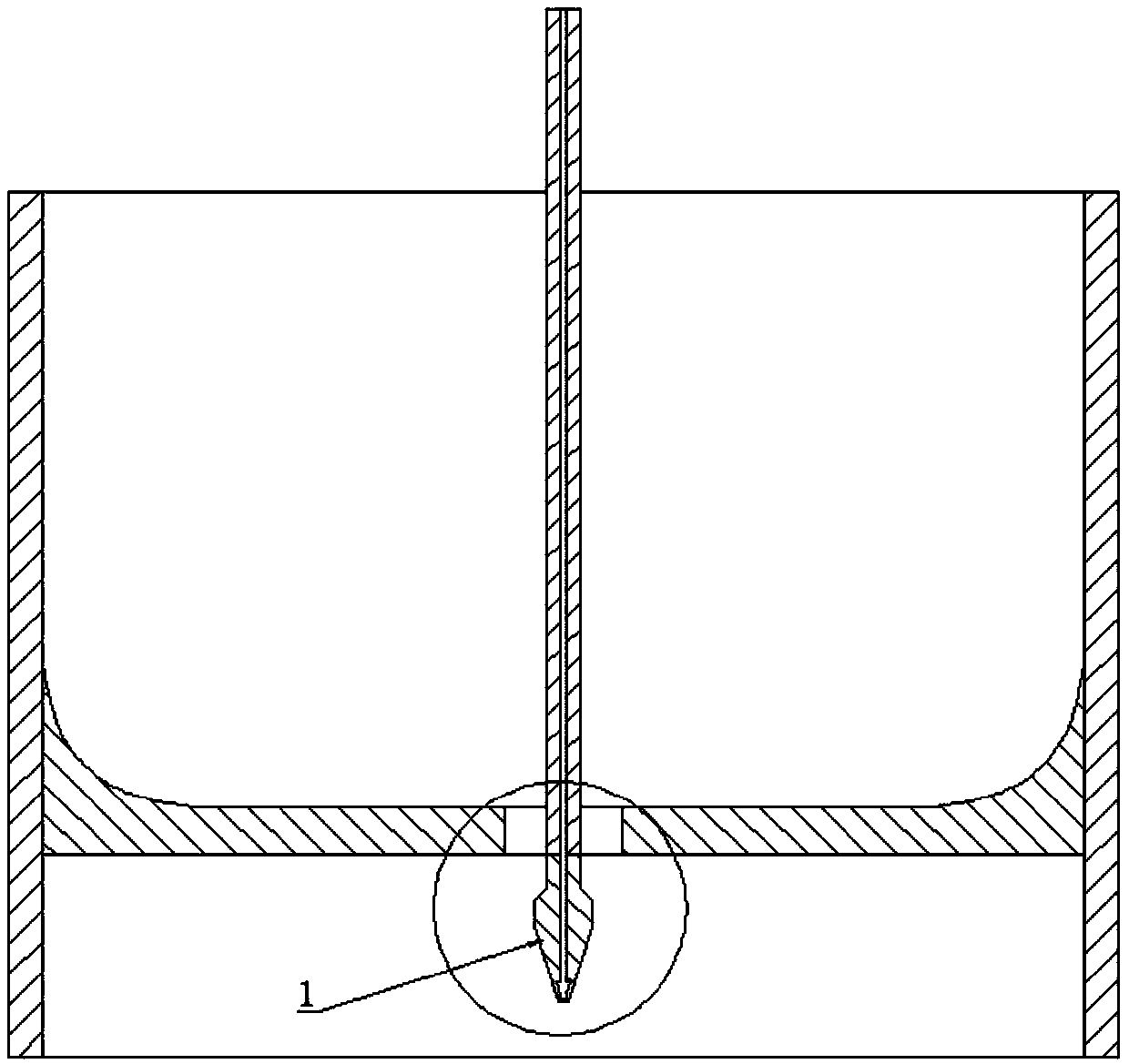

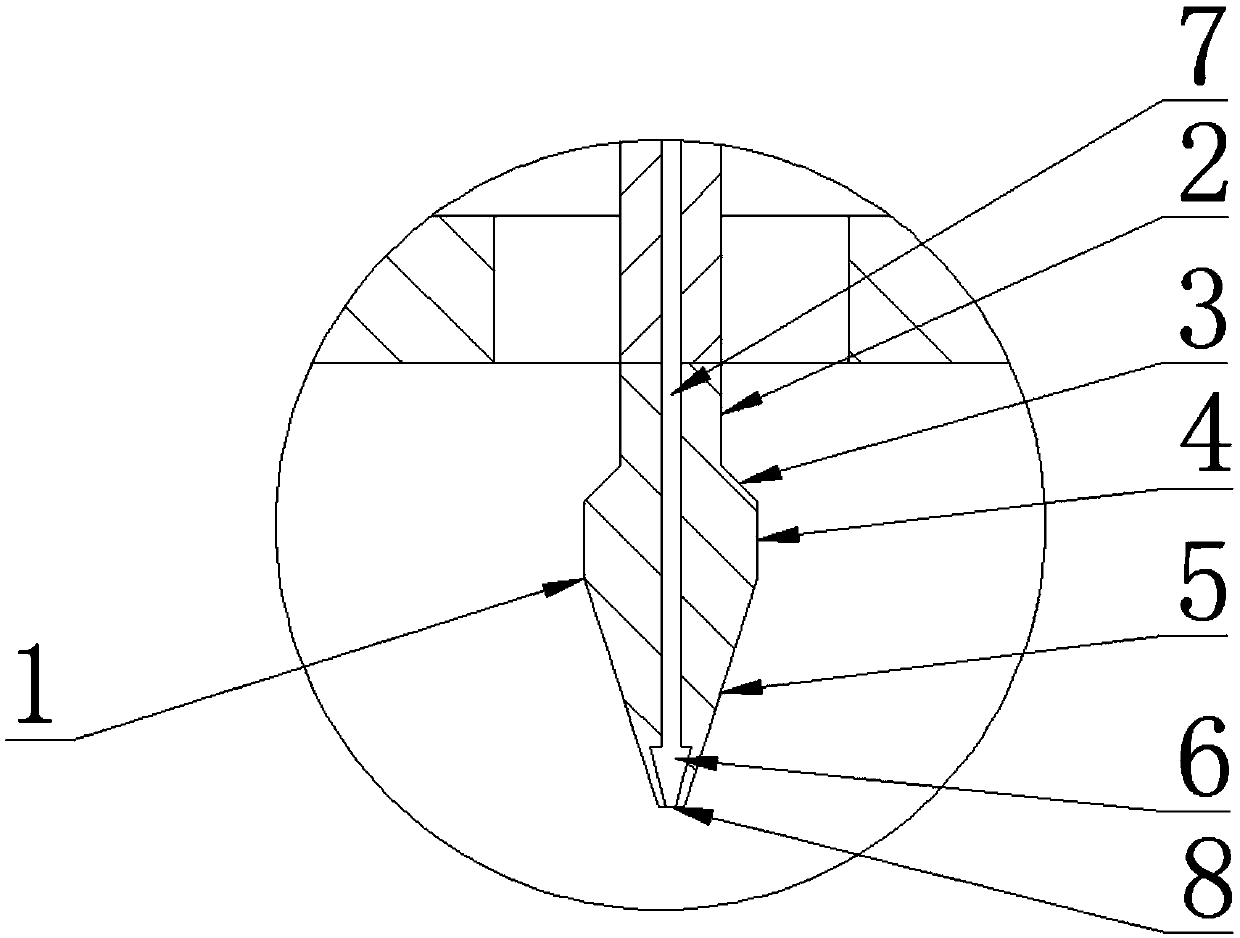

Image

Examples

Embodiment Construction

[0031] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0032] A large-diameter thick-walled quartz glass tube, which uses high-purity quartz sand as a basic material by weight, and is equipped with a trace element additive accounting for 3.1% to 4.2% by weight of the high-purity quartz sand, wherein the trace element additive is formulated by the following weight: The ratio of raw material composition:

[0033] Sodium chlorate NaClO 3 0.4~0.6,

[0034] Ammonium chloride NH 4 Cl 0.1~0.3,

[0035] Antimony trioxide Sb 2 o 3 0.2~0.4,

[0036] Cerium nitrate Ce(NO 3 ) 3 ·6H 2 O 0.3~0.5.

[0037] The weight part of the trace element additive accounts for 3.5%-4.0% of the weight part of the high-purity quartz sand.

[0038] Formula one of the trace element additive:

[0039] Sodium chlorate NaClO 3 0.4,

[0040] Amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com