Preparation method for biomedical porous low-modulus titanium alloy

A technology of titanium alloy and titanium alloy powder, applied in the field of porous titanium alloy, can solve the problems of low strength, low alloy powder feeding degree, long curing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

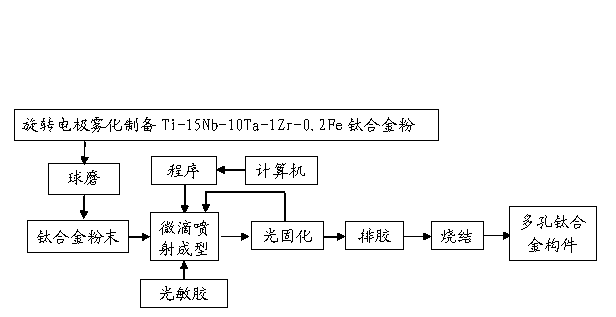

[0040] A method for preparing a porous titanium alloy, comprising the steps of:

[0041] Step 1: Preparation of Ti-15Nb-10Ta-1Zr-0.2Fe titanium alloy powder particles by rotary atomization method

[0042] Using rotating electrode atomization equipment, prepare Ti-15Nb-10Ta-1Zr-0.2Fe alloy raw powder, wherein the diameter of the electrode is φ50mm, and the rotation speed is 17500rpm;

[0043] Step 2: Prepare uniformly dispersed titanium alloy powder by ball milling

[0044] Take 100g of original Ti-15Nb-10Ta-1Zr-0.2Fe titanium alloy powder and mix it with 25g of absolute ethanol evenly, and add 1g of sodium lauryl sulfate, take 700g of stainless steel balls, ball mill for 18h in a vacuum environment, and After vacuum drying for 48 hours, titanium alloy powder with a particle size of 10-60 μm was obtained;

[0045] Step 3: Prepare Photosensitive Adhesive

[0046] Mix 15-90 parts of methacrylic epoxy resin, 20-40 parts of 1,6-hexanediol diacrylate, 1 part of benzil, 4 parts of...

Embodiment 2

[0054] A method for preparing a porous titanium alloy, comprising the steps of:

[0055] Step 1: Preparation of Ti-15Nb-10Ta-1Zr-0.2Fe titanium alloy powder particles by rotary atomization method

[0056] Prepare Ti-15Nb-10Ta-1Zr-0.2Fe alloy raw powder using rotating electrode atomization equipment, wherein the diameter of the electrode is φ50mm, and the rotation speed is 15000rpm;

[0057] Step 2: Prepare uniformly dispersed titanium alloy powder by ball milling

[0058] Take 200g of the original Ti-15Nb-10Ta-1Zr-0.2Fe titanium alloy powder and mix it with 50g of absolute ethanol evenly, and add 1g of sodium lauryl sulfate, take 1400g of stainless steel balls, ball mill for 18h in a vacuum environment, and After vacuum drying for 48 hours, titanium alloy powder with a particle size of 10-60 μm was obtained;

[0059] Step 3: Prepare Photosensitive Adhesive

[0060] 15-90 parts of glycidyl methacrylate, 20-40 parts of polyethylene glycol (200) diacrylate, 1 part of benzil, 4...

Embodiment 3

[0068] A method for preparing a porous titanium alloy, comprising the steps of:

[0069] Step 1: Preparation of Ti-15Nb-10Ta-1Zr-0.2Fe titanium alloy powder particles by rotary atomization method

[0070] Prepare Ti-15Nb-10Ta-1Zr-0.2Fe alloy raw powder by using rotating electrode atomization equipment, wherein the diameter of the electrode is φ50mm, and the rotation speed is 12000rpm;

[0071] Step 2: Prepare uniformly dispersed titanium alloy powder by ball milling

[0072] Take 300g of the original Ti-15Nb-10Ta-1Zr-0.2Fe titanium alloy powder and mix it with 75g of absolute ethanol evenly, and add 1g of sodium lauryl sulfate, take 2100g of stainless steel balls, ball mill for 18h in a vacuum environment, and After vacuum drying for 48 hours, titanium alloy powder with a particle size of 10-60 μm was obtained;

[0073] Step 3: Prepare Photosensitive Adhesive

[0074] Mix 15-90 parts of methacrylic epoxy resin, 20-40 parts of ethoxylated 1.6 hexanediol diacrylate, 1 part of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com