Patents

Literature

190results about How to "Guaranteed molding accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

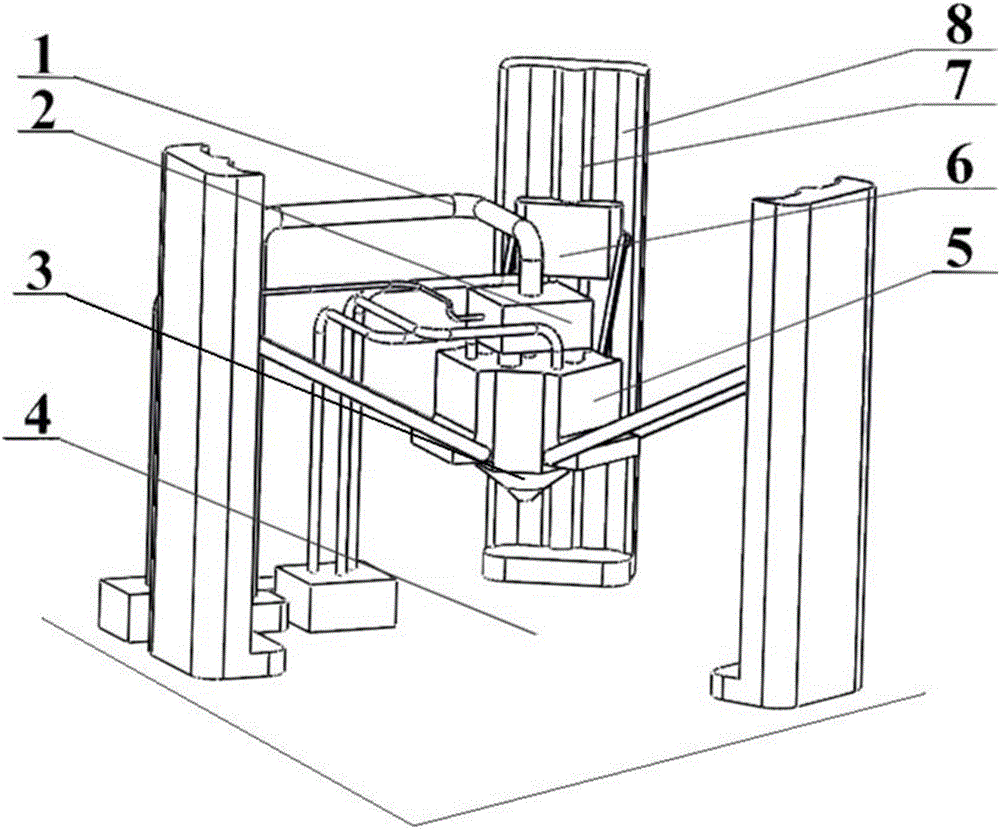

Laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method

ActiveCN104801712ASolve efficiency problemsSolve the accuracy problemAdditive manufacturing apparatusNumerical controlControl system

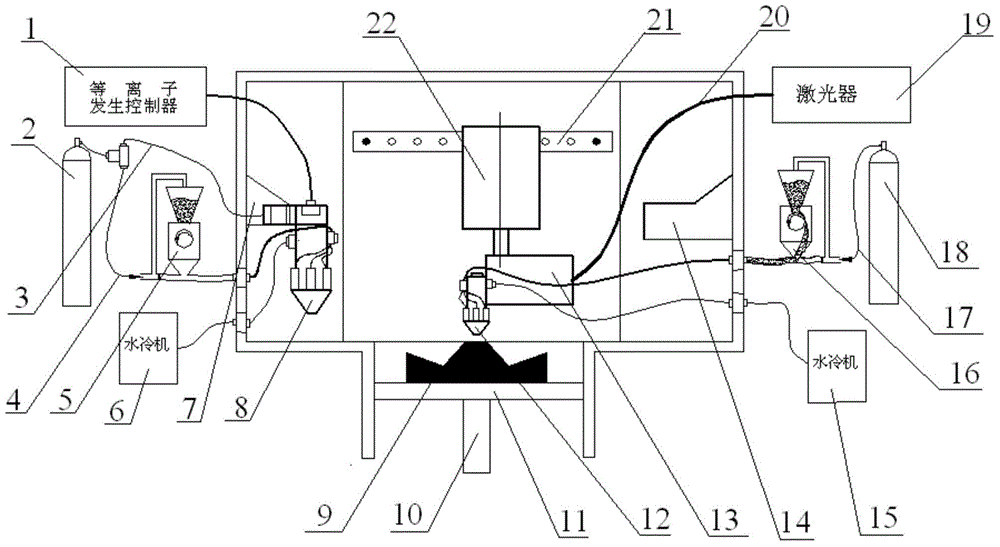

The invention discloses a laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method. The equipment comprises a central control system, a sealing forming chamber, a laser forming device and a plasma processing device, wherein a laser forming spray head and a plasma gun are correspondingly put on a support frame arranged at the left and right side inner walls of the sealing forming chamber, and the laser forming spray head or the plasma gun is clamped through a co-work numerical control main shaft, so that the laser forming spray head or the plasma gun moves in the Z, X and Y directions in the sealing forming chamber. The central control system controls the co-work numerical control main shaft for conveying back the laser forming spray head back to the support frame, then, the co-work numerical control main shaft clamps the plasma gun for filling the inside of the profile of a formed metal part, and the work is alternately carried out in such a way until the part manufacturing is completed, so that the scanning time is reduced to a great degree. The laser fast forming is combined with the plasma, the problem of conflict between the efficiency and the precision of a metal 3D printing technology is solved, and in addition, the plasma is adopted for replacing the laser to be used as a heat source, so that the high-efficiency and low-cost industrial level metal 3D printing equipment is obtained.

Owner:SOUTH CHINA UNIV OF TECH

Powder laying and recovering device for selective laser melting of heterogeneous material

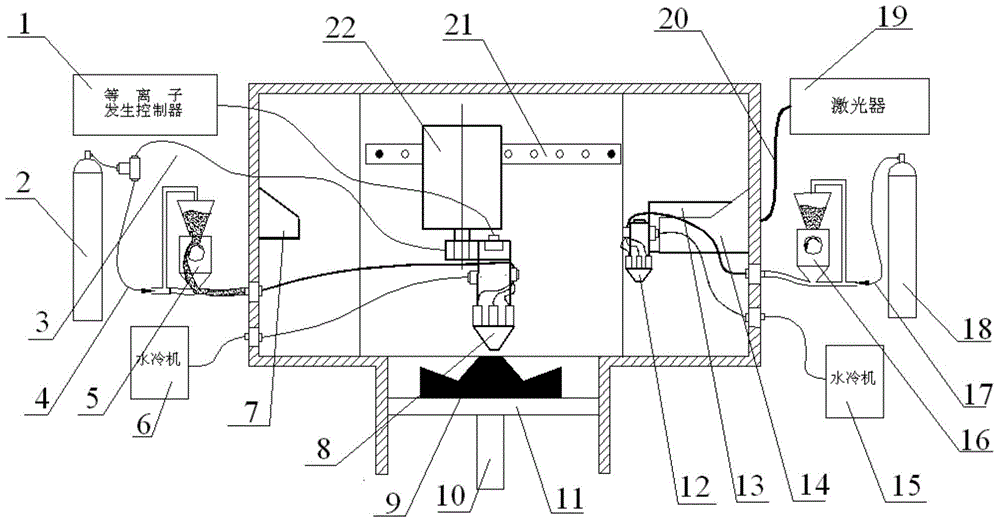

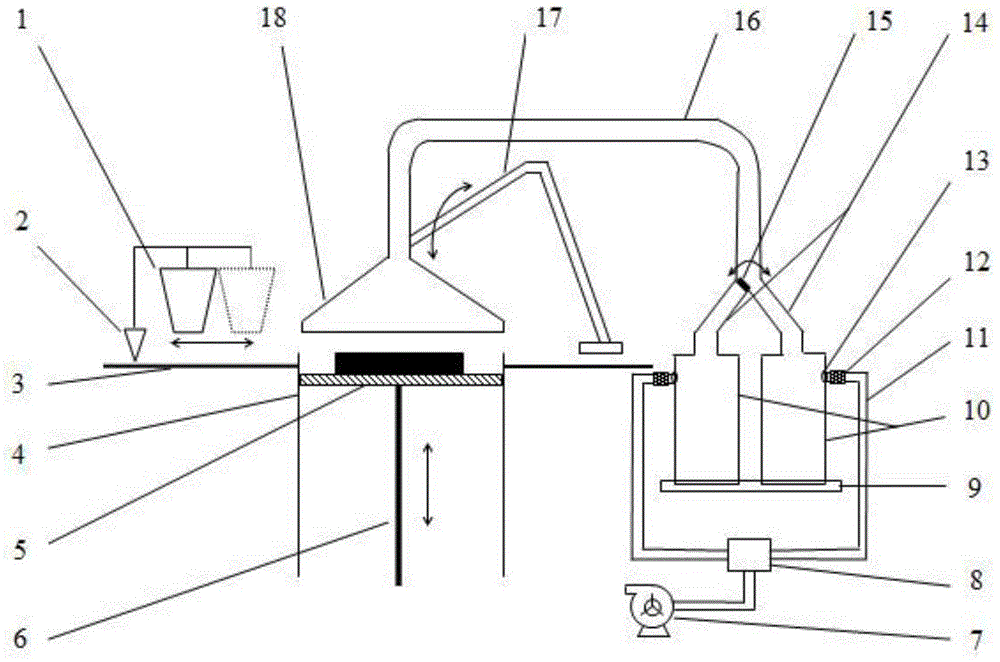

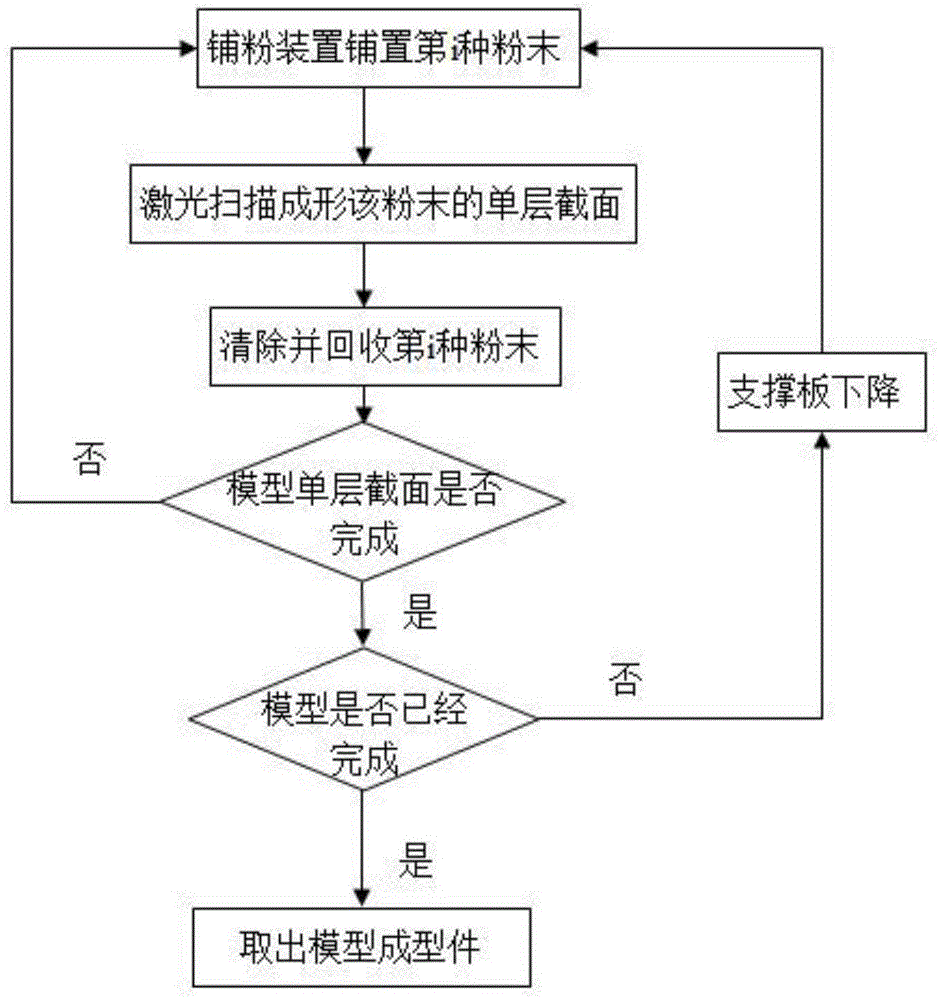

The invention relates to a powder laying and recovering device for selective laser melting of a heterogeneous material. The powder laying and recovering device comprises a powder laying device and a powder recovering device; a scrapper plate and a plurality of powder laying grooves are arranged on the powder laying device, wherein the scrapper plate can move in a reciprocating way along a horizontal fixed guide rail; the powder recovering device is provided with an absorbing cover; the absorbing cover can move above a molding cylinder to absorb and move away from an area above the molding cylinder to avoid interference on laser melting molding; a powder recovering pipeline is connected to the upper end of the absorbing cover; un-solidified powder can be absorbed and recovered into a specified recovery box through the control of an opening-closing baffle plate. According to the powder laying and recovering device for selective laser melting of the heterogeneous material, one material is solidified and un-solidified powder is completely removed, then another material is laid to be solidified and absorbed until the whole section of this layer is molded; materials are respectively solidified and absorbed by layers and continuously accumulated and overlapped to form a heterogeneous part. The powder laying and recovering device is applicable to selective laser melting molding of the heterogeneous part; the molding parts of a model can be combined at random.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

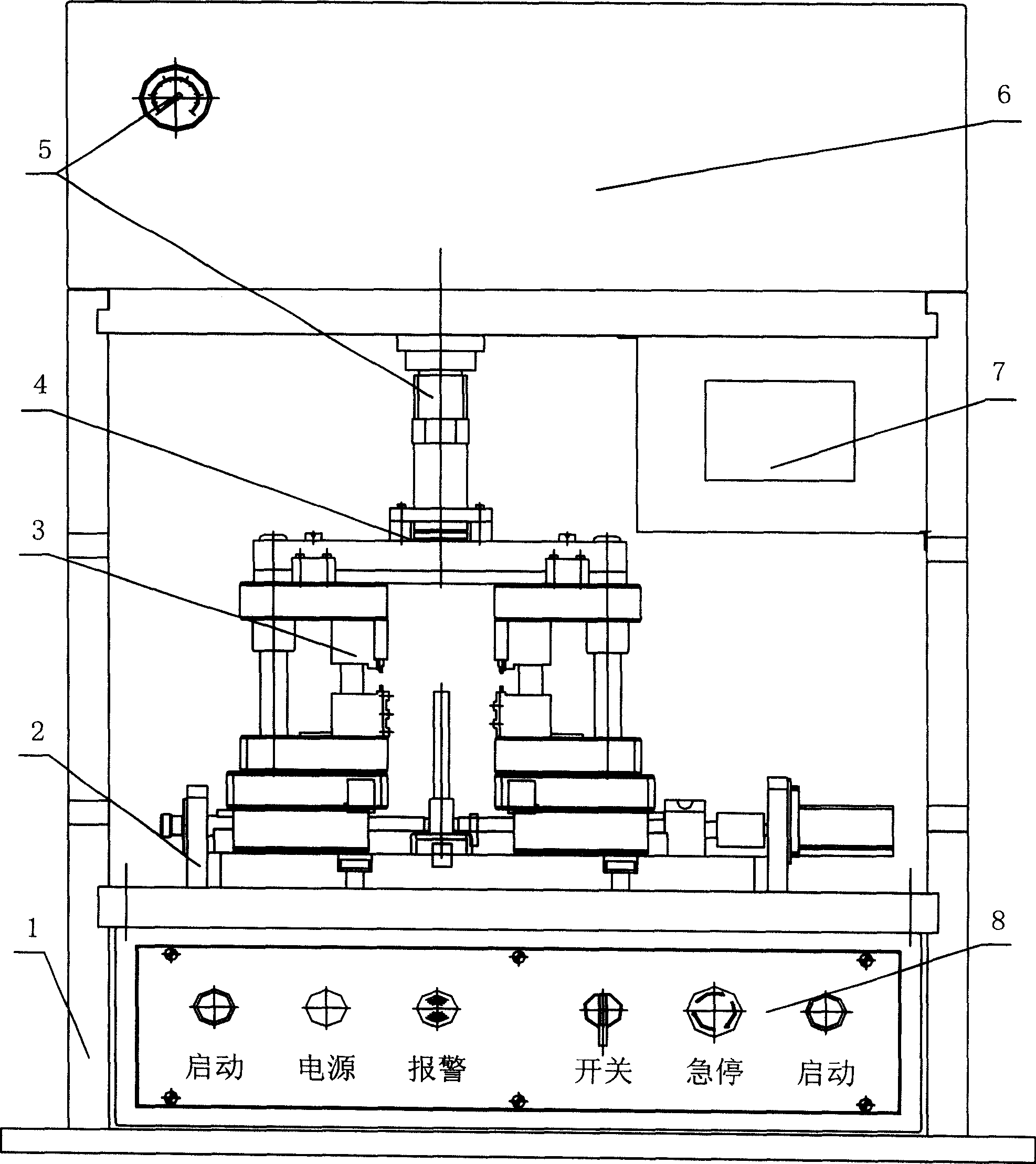

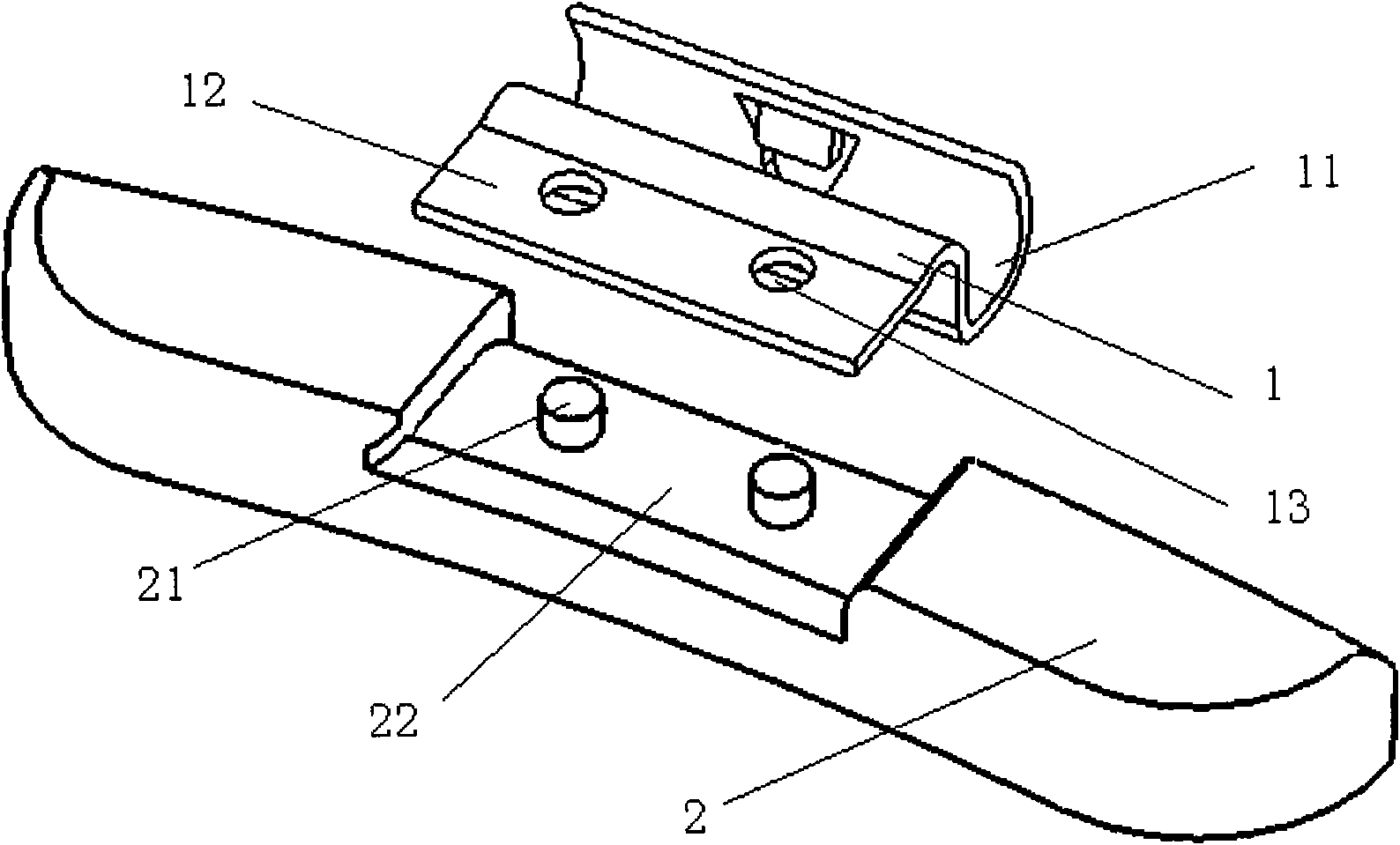

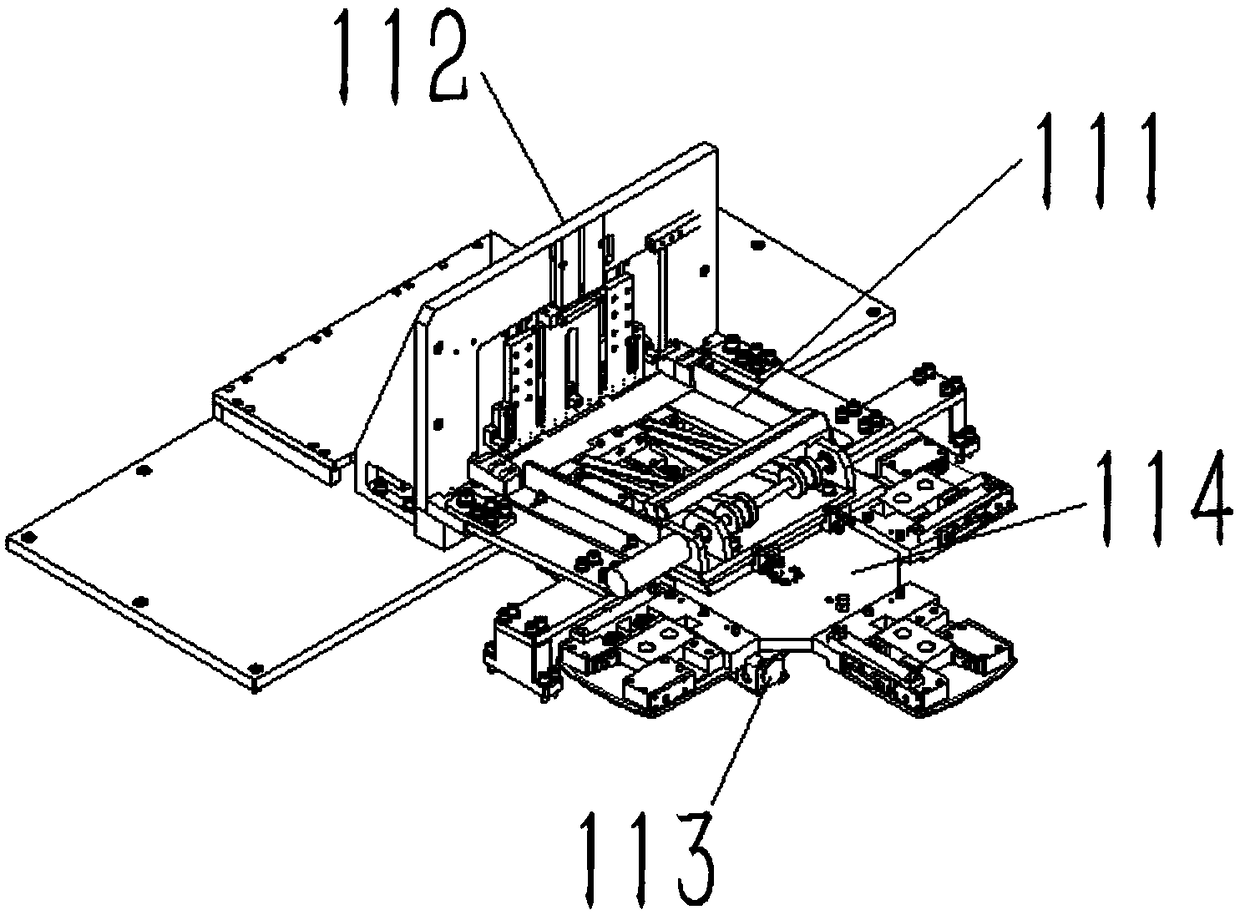

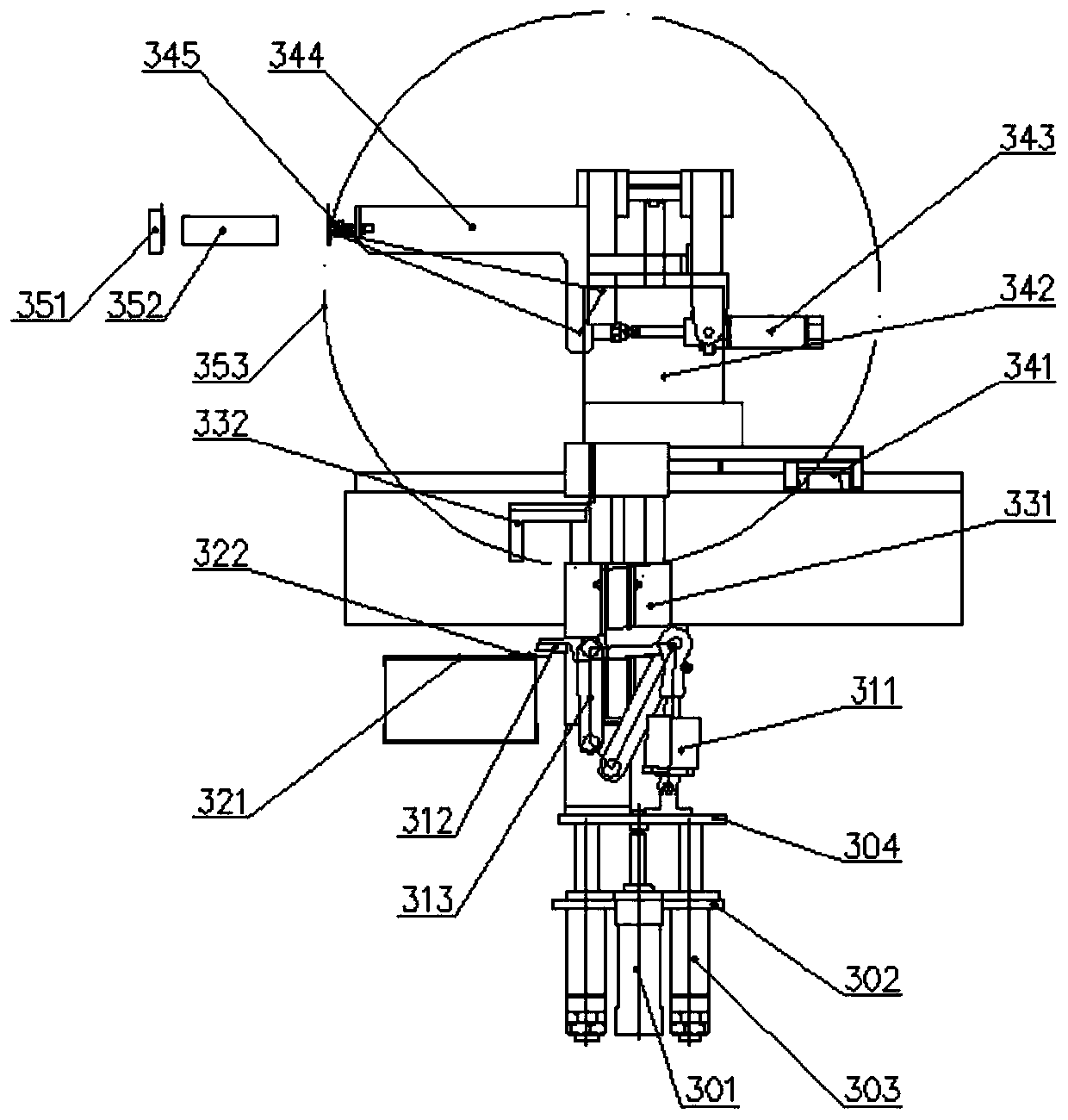

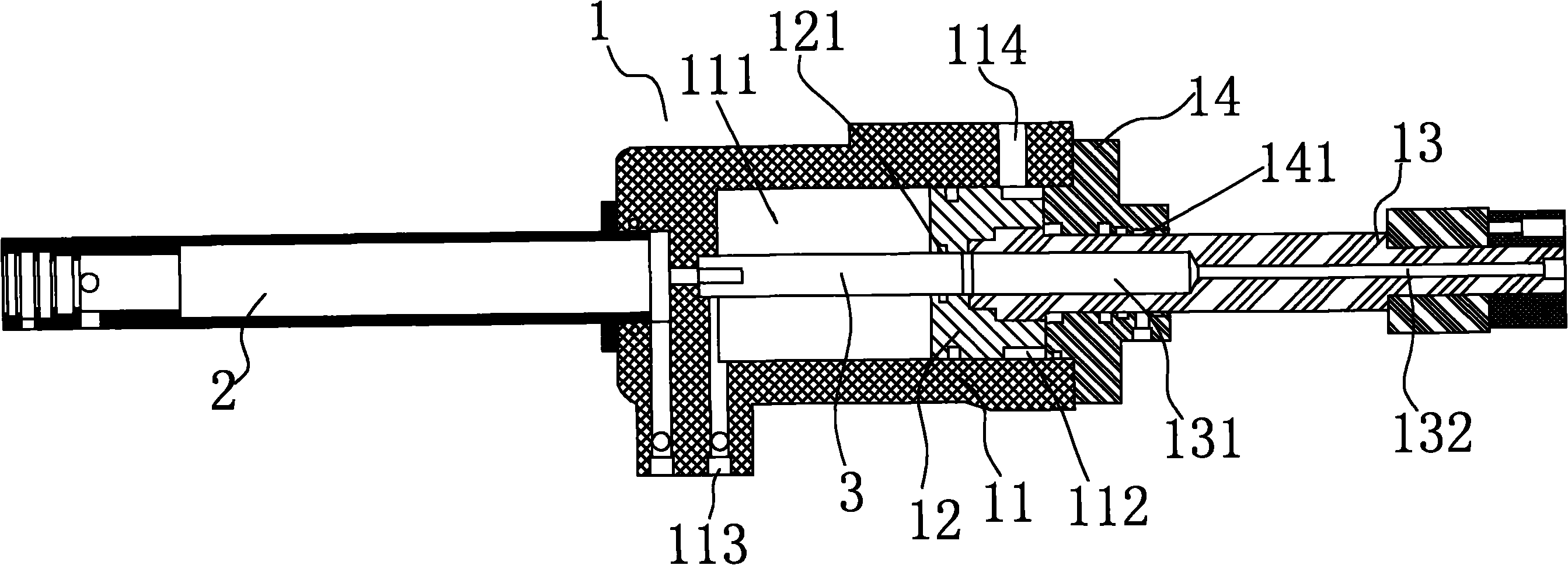

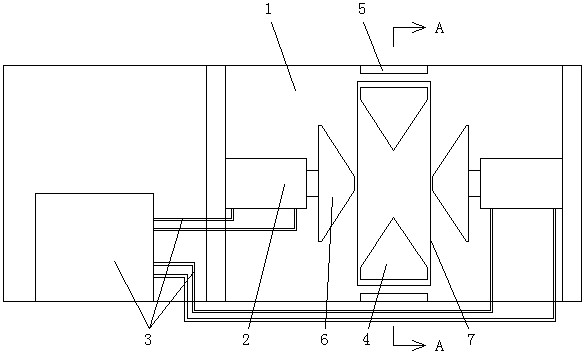

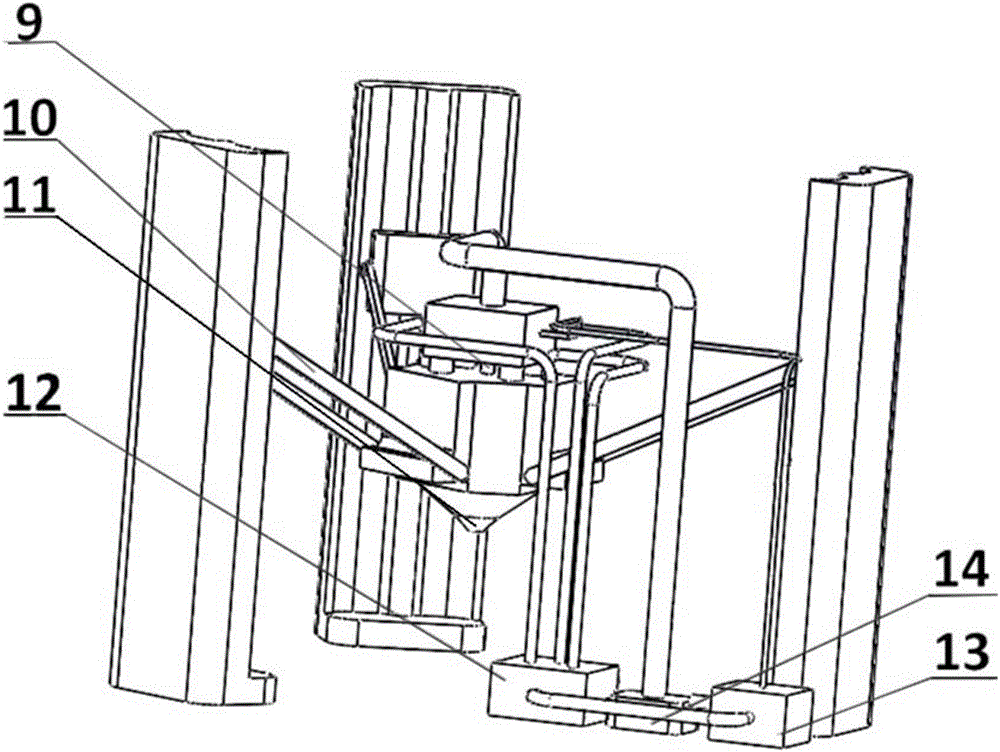

Numerical control forming machine for integrated circuit pin

InactiveCN101442898AFully automatedGuaranteed molding accuracyShaping toolsElectrical componentsNumerical controlControl system

An integrated circuit pin digital control forming machine comprises a bidirectional moving platform, a frame, a pneumatic plant, a control system and a forming mechanism; the frame is divided into three layers by three platforms; the control system is placed on the bottom layer of the frame and fixed on the bottom of the frame middle platform; the bidirectional moving platform and the forming mechanism are placed on the middle layer, the bidirectional moving platform, is fixed on the upper bottom of the frame middle platform, and the forming mechanism is fixed with the sliding block of the bidirectional moving platform; the pneumatic plant is connected with the forming mechanism through a leading mechanism. The machine in the invention can adjust the width and height in the integrated circuit pin forming, and can accomplish the bending and shearing process on one time, consequently, ensures the forming accuracy and consistency, simplifies process, improves security, and realizes the automation of integrated circuit pin forming.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

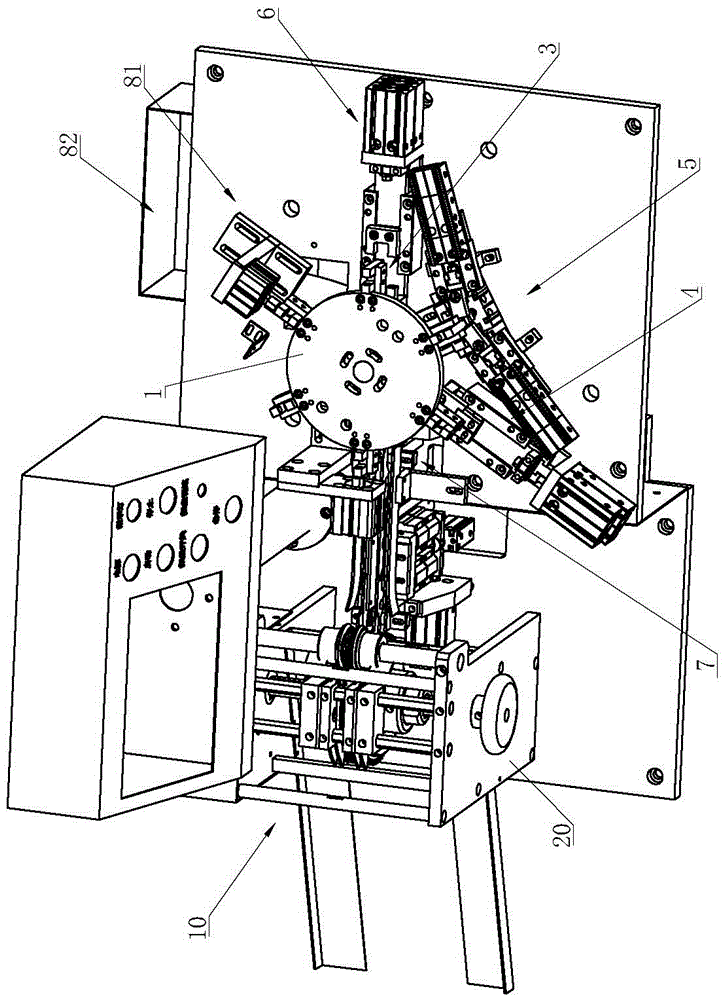

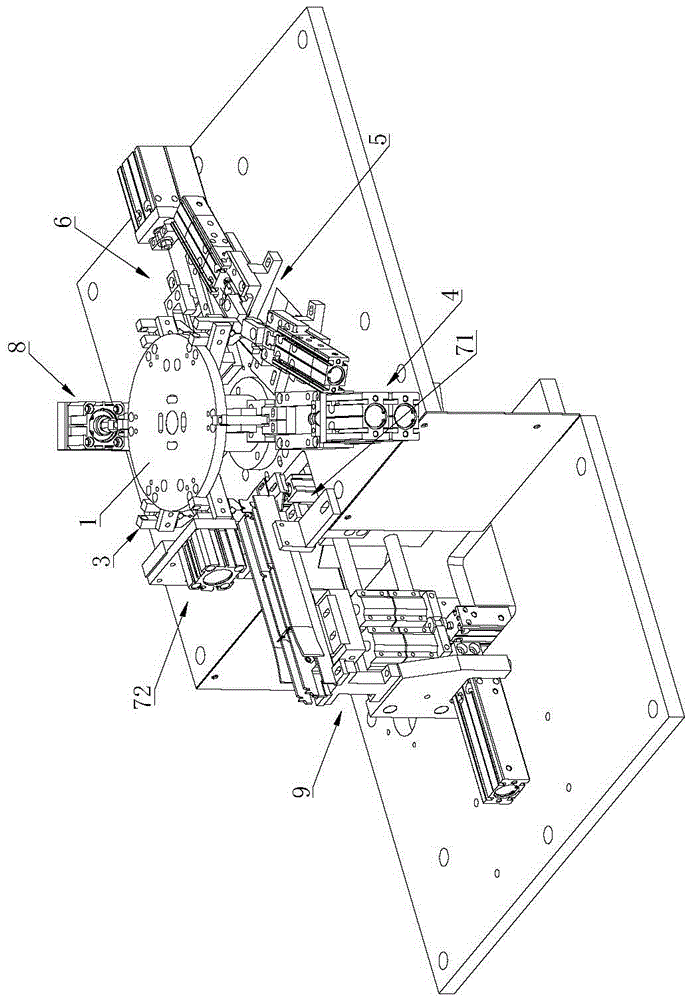

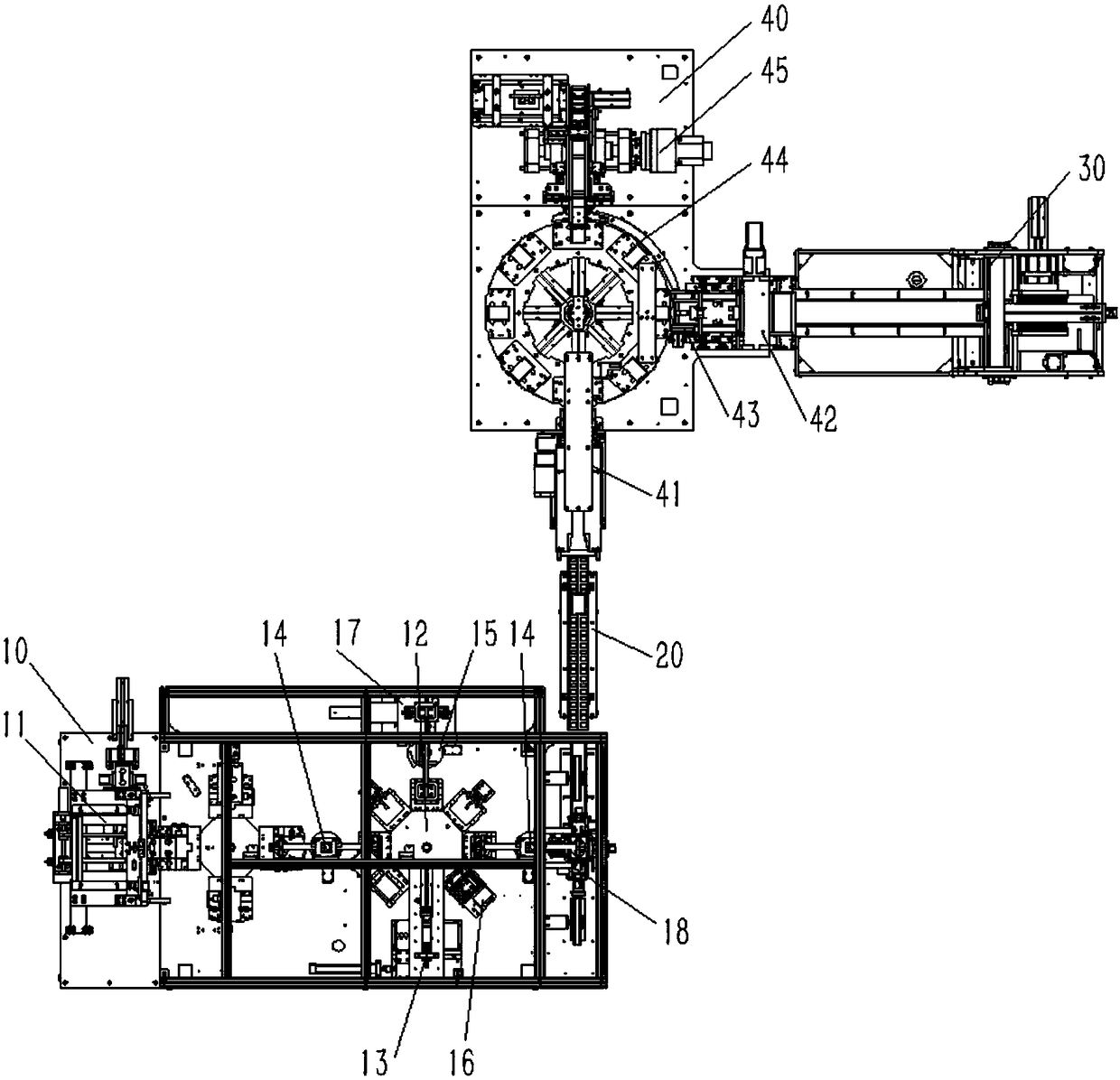

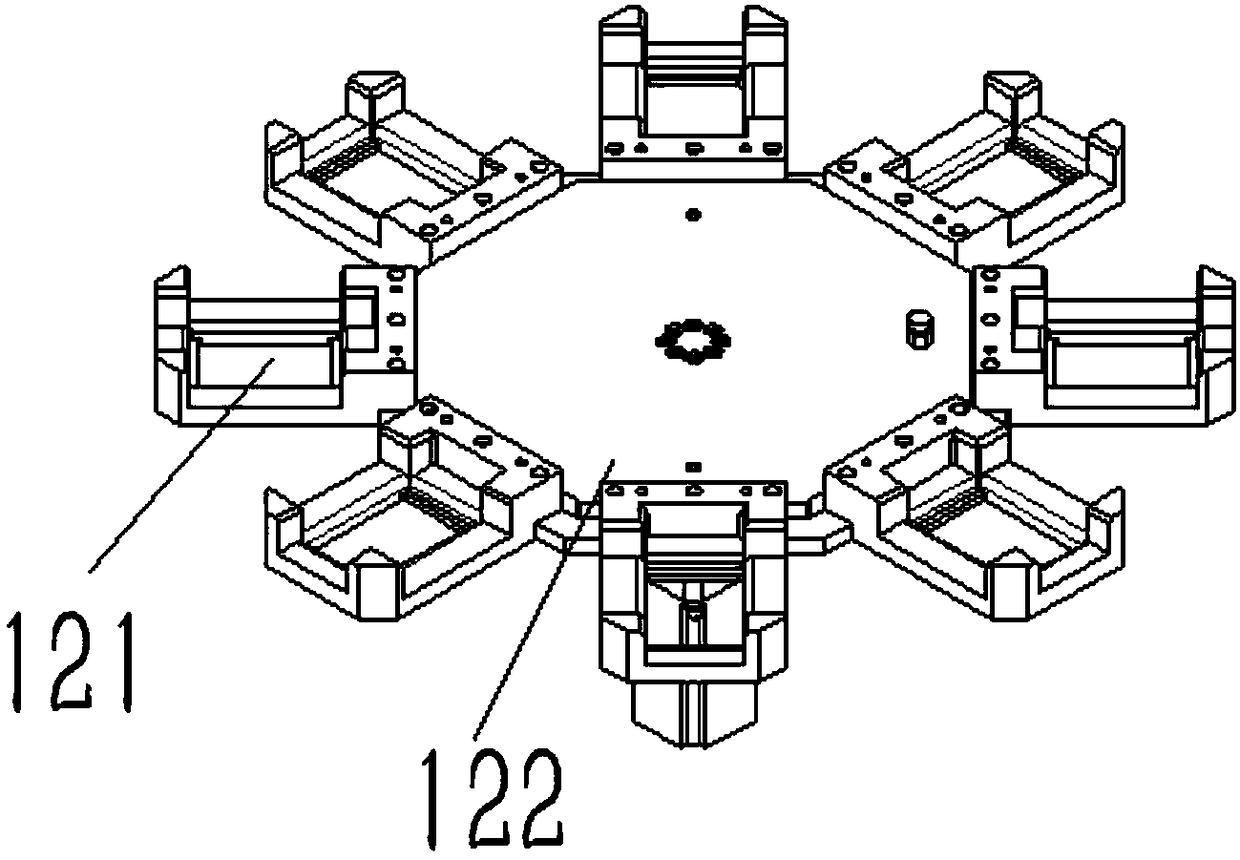

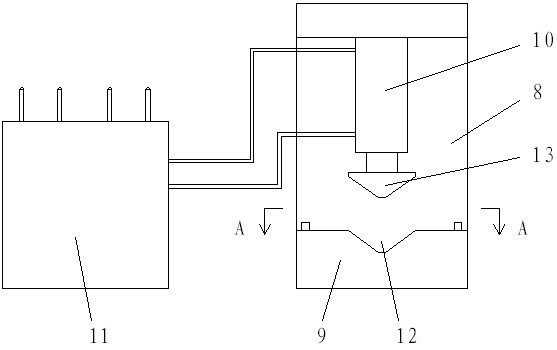

Electronic element pin forming machine

ActiveCN106391926AImprove continuityAvoid clamping errorsContact member manufacturingEngineeringElectronic component

The invention relates to the technical field of electronic element machining equipment, in particular to an electronic element pin forming machine. The electronic element pin forming machine comprises a turntable, a turntable driving mechanism, multiple clamps arranged on the turntable, a first bending device and a second bending device for bending pins of electronic elements in sequence, and a flattening device for flattening the bent pins. The electronic element pin forming machine is excellent in continuity of conveying and machining of the electronic elements, accelerates the production speed, meanwhile, prevents the clamping error generated by repeated clamping of the electronic elements, and guarantees the forming precision of the pins of the electronic elements. In addition, the electronic element pin forming machine adopts the structure of rotary feeding by the turntable, so that the equipment is compact in structure, less in occupied space and convenient for installation and transportation. After two times of bending are performed for the electronic elements, the flattening is performed, so that the forming is easier to operate, the damage and the resilience after forming of the pins caused by once forming are prevented, and the product yield is improved.

Owner:东莞市捷瑞自动化科技有限公司

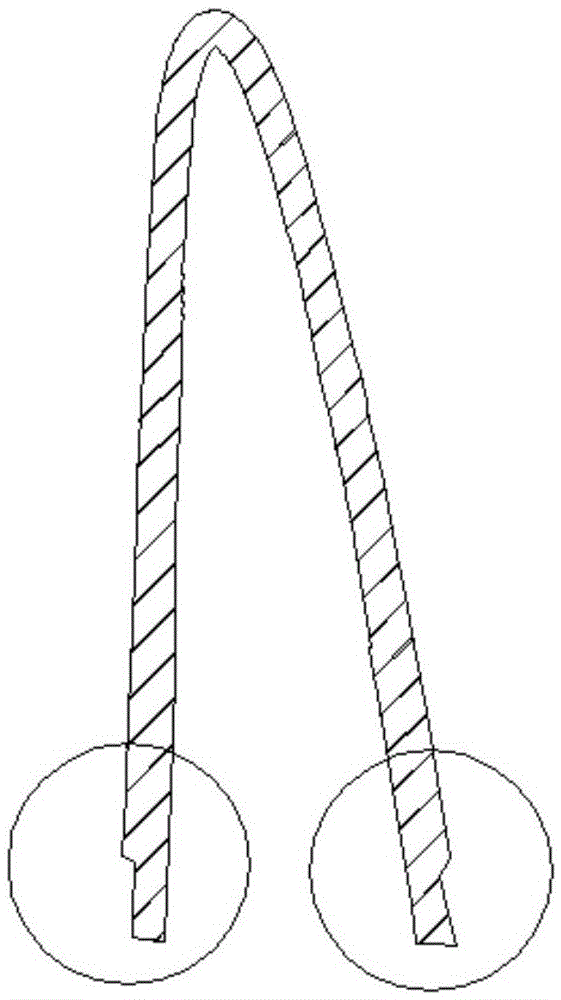

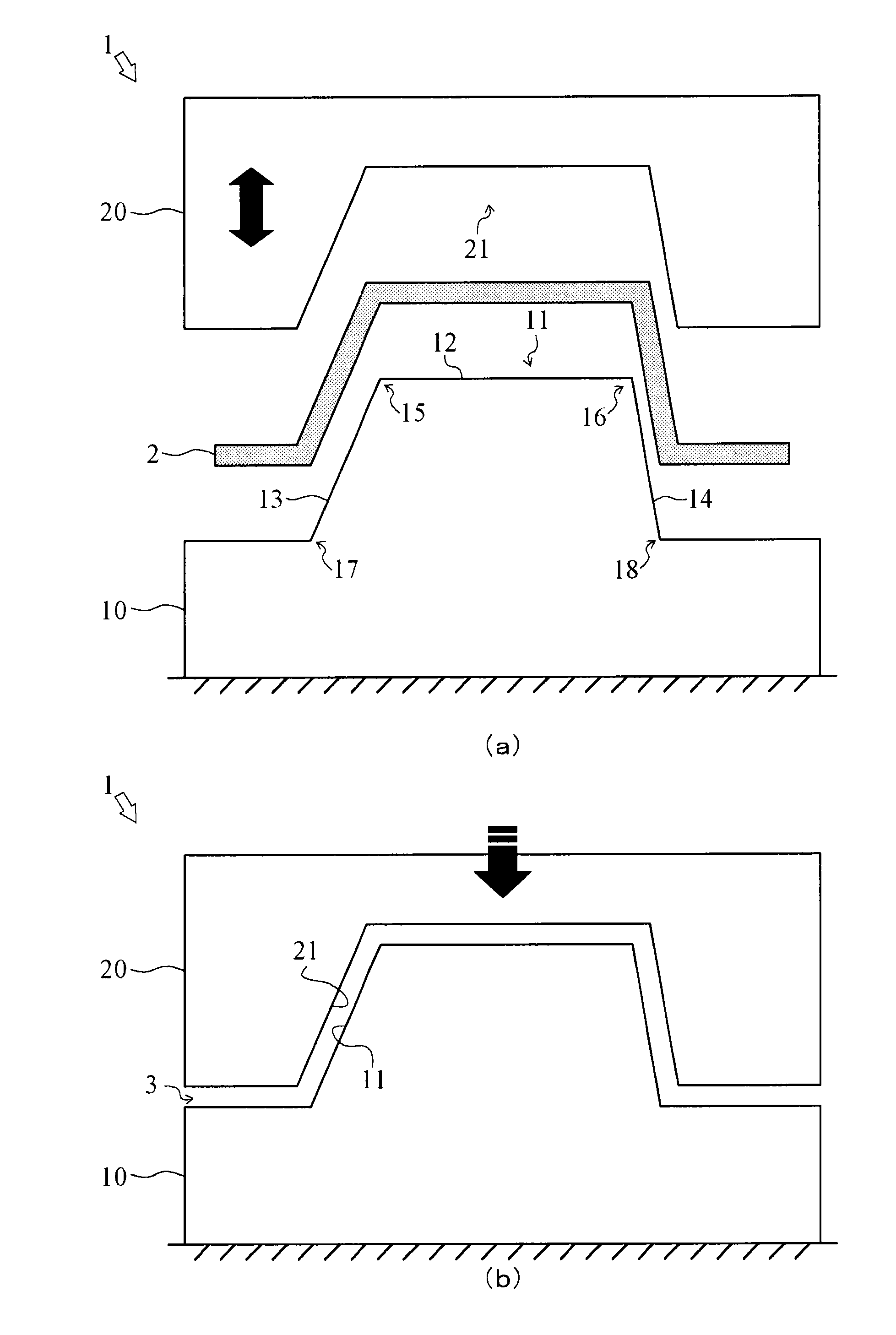

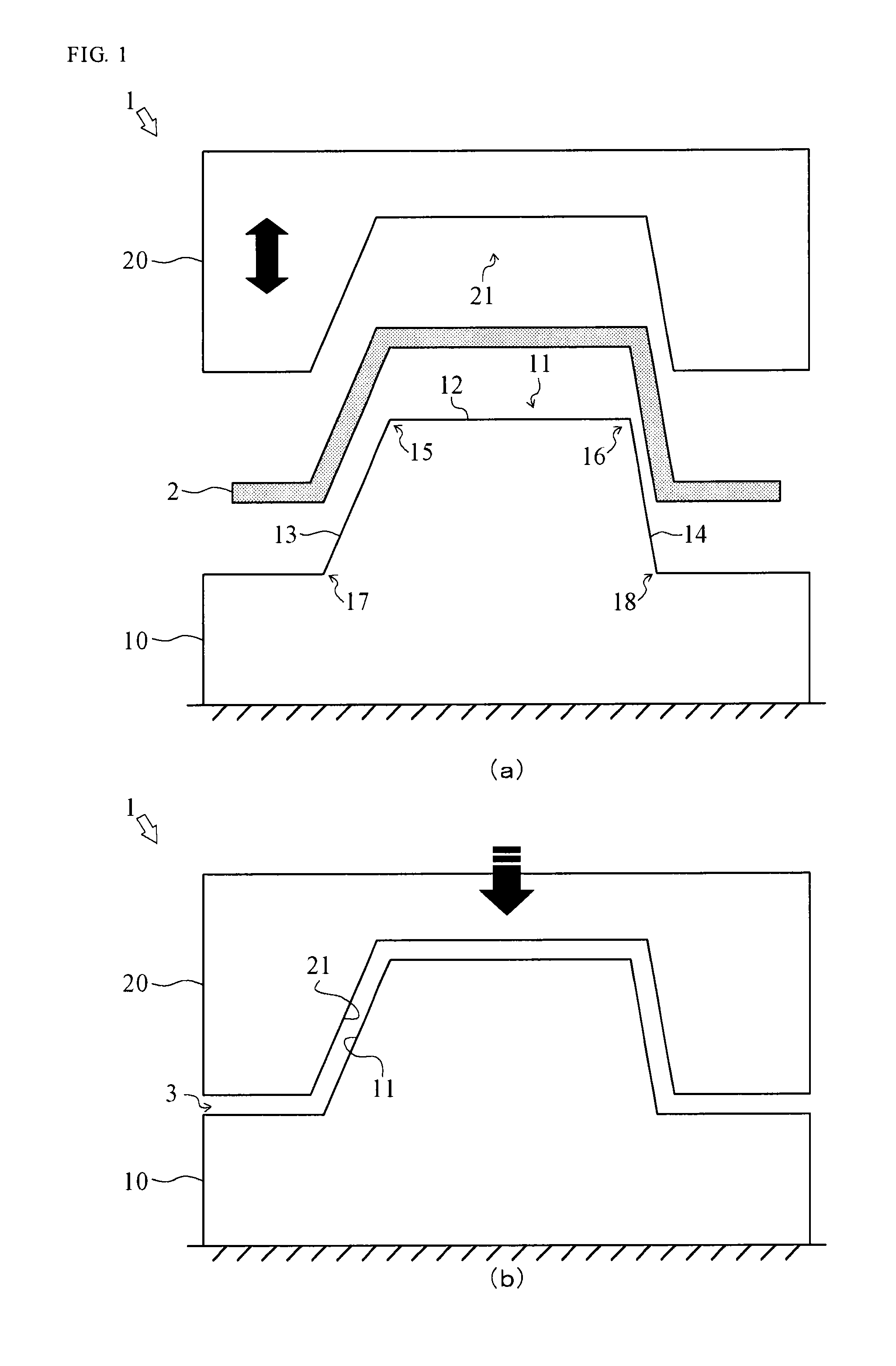

High-precision forming mold and method for thickly-laid composite material boxes

The invention relates to a composite material forming technology and specifically relates to a high-precision forming mold and method for thickly-laid composite material boxes. The high-precision forming mold for thickly-laid composite material boxes is designed in the present invention and comprises a box bottom female die (1), a box body sidewall pressure transfer block (2), a knockout plate (3), a box sidewall female die (4), a male die (5) and a bottom plate (6). On the basis of the high-precision forming mold for thickly-laid composite material boxes, box prepreg layers of a composite material are laid one by one on the male die (5); every two to three prepreg layers are vacuumized and pre-compacted, and a plurality of times of vacuumizing and pre-compacting are carried out until the prepregs are completely fitted with the die; subsequently, more than three times of pre-pressing by using a press are carried out, followed by a process of opening the mold to supplement materials and shaping, and hot press molding. The accuracy of inner and outer molded surfaces of a composite material box formed by using the mold and the method of the present invention can be above + / -mm, and therefore, the composite material box can be glued in an aerospace part as a force-bearing part and may meet later assembly requirements.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

Manufacturing method of connecting sheet circuit board

InactiveCN102223763AGuaranteed molding accuracyHigh forming precisionPrinted circuit manufactureEngineeringCopper

The invention relates to a manufacturing method of a connecting sheet circuit board, comprising the following steps: a copper cladding base plate is provided and comprises at least one processing area and a first waste area, wherein the at least one processing area comprises a plurality of product areas, a first connecting area, a second connecting area, at least one second waste area and an auxiliary locating area; a plurality of connecting locating holes are respectively arranged in the first connecting area and the second connecting area, a plurality of auxiliary locating holes are arranged in the auxiliary locating area, the copper cladding base plate is located on one worktable and is cut along the boundary of the at least one processing area, so as to remove the first waste area; and the copper cladding base plate is cut along the boundary of each second waste area sequentially from one second waste area furthest away from the auxiliary locating area, so as to remove a pluralityof the second waste areas; and the copper cladding base plate is cut along the boundaries of the auxiliary locating area and the product area connected with the auxiliary locating area, so as to remove the auxiliary locating area.

Owner:HONG HENG SHENG ELECTRICAL TECH HUAIAN +1

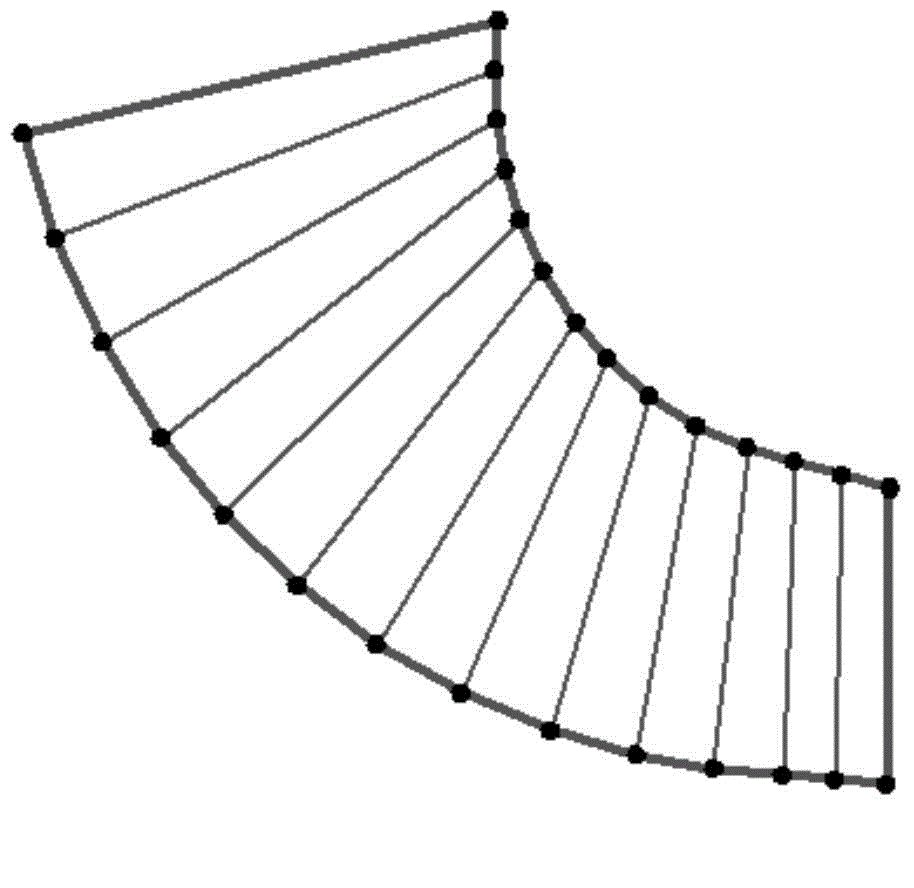

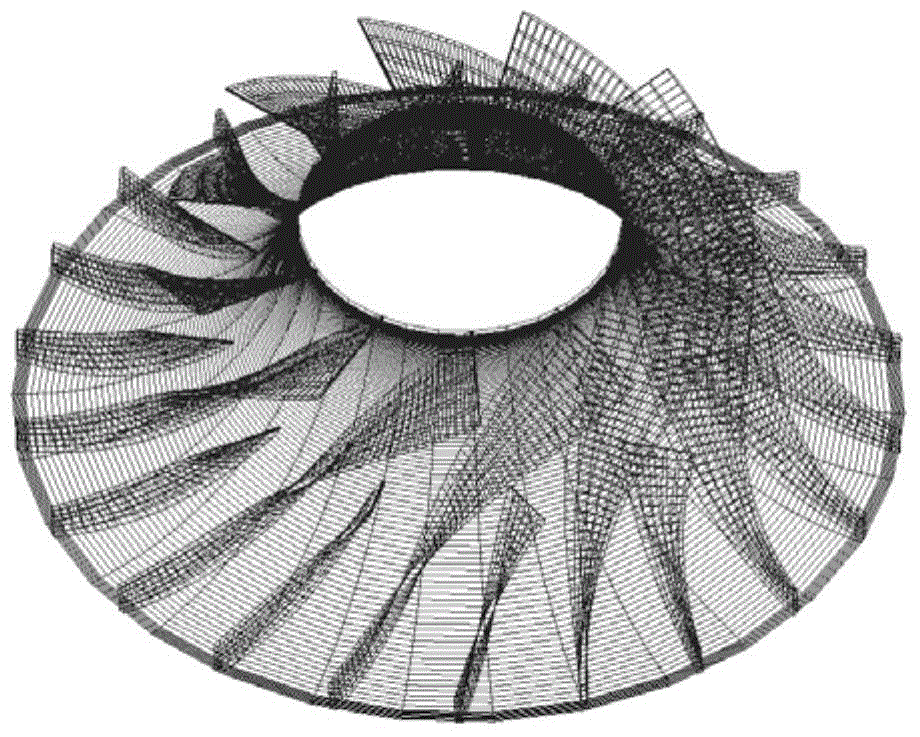

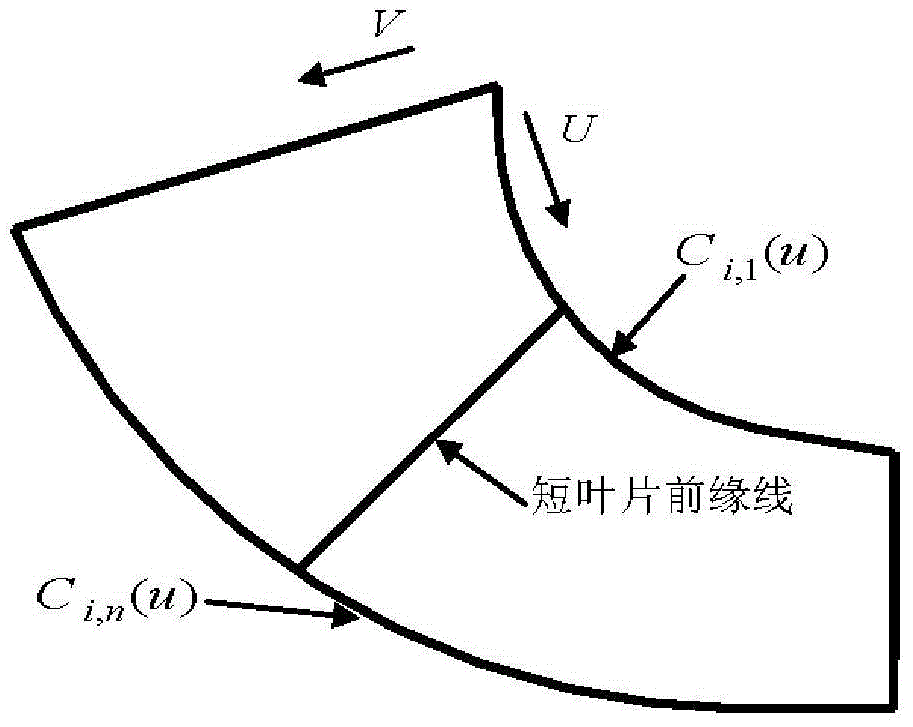

Zoning cutting-based five-axis milling method of centrifugal compressor impeller

ActiveCN104907617AGuaranteed molding accuracyLow costMilling equipment detailsNumerical controlMaximum diameter

The invention discloses a zoning cutting-based five-axis milling method of a centrifugal compressor impeller. The method comprises the following steps: inputting entity model data into a computer to complete the molding of an original centrifugal compressor impeller; defining a blade S(u, v) and a short blade Ss(u, v) in bi-cubic non uniform rational B-spline matrix form values; extracting the front edge line of the short blade and partitioning the blade S(u, v) into front and back parts Sl(u, v) and St(u, v), so as to obtain three sub machining zones; intelligently calculating the maximum diameter D1 of a cutter, selecting a cutter with circular angles and flat bottom as a milling cutter, and calculating the machining bandwidth of a rough milling stage; in the rough milling stage, planning the cutter position path with a triangle simulated method and calculating the cutter axis vector with a stationary cutter axis vector cutting algorithm; in the fine milling stage, smoothly linking the independently calculated cutter position paths of different machining zones, so as to realize fine milling of a runner; and finally, performing post-processing on the calculated cutter position paths and cutter axis vectors according to a used five-axis numerical control machine and performing practical machining on the five-axis numerical control machine.

Owner:XI AN JIAOTONG UNIV

Steel automobile wheel balancing block with large gram weight and manufacture method thereof

InactiveCN101596835AGuaranteed molding accuracyGuaranteed molding effectWheel-ballasting weightsGramEngineering

The invention discloses a steel wheel balancing block with single weight of more than 60 grams (containing 60 grams), comprising a balancing weight block and a spring hook, wherein the upper part of the spring hook is provided with a clamping part, the lower part of the spring hook is provided with a combination part which is fixed with the balancing weight block together, the upper surface of the balancing weight block is provided with a positioning groove, a protrusion is at least arranged on the bottom surface of the positioning groove, and the lower surface of the balancing weight block corresponding to the protrusion is a plane; and a rivet hole which is matched with the protrusion of the balancing weight block is arranged on the combination part of the spring hook so as to enable the spring hook to be riveted with the balancing weight block together by the protrusion. The invention also discloses a manufacture method of the balancing weight block in the balancing block, comprising the following steps: blanking and punching the positioning groove; bending blanks; cleaning the surfaces of the bent blanks; preheating; coating a lubricant; heating by induction; carrying out temperature plastic molding; deburring; carrying out surface shot blasting; pressing characters on the surface of the balancing weight block; riveting and fixing with a spring hanger; and painting on the appearance.

Owner:SHANGHAI UNIV OF ENG SCI +1

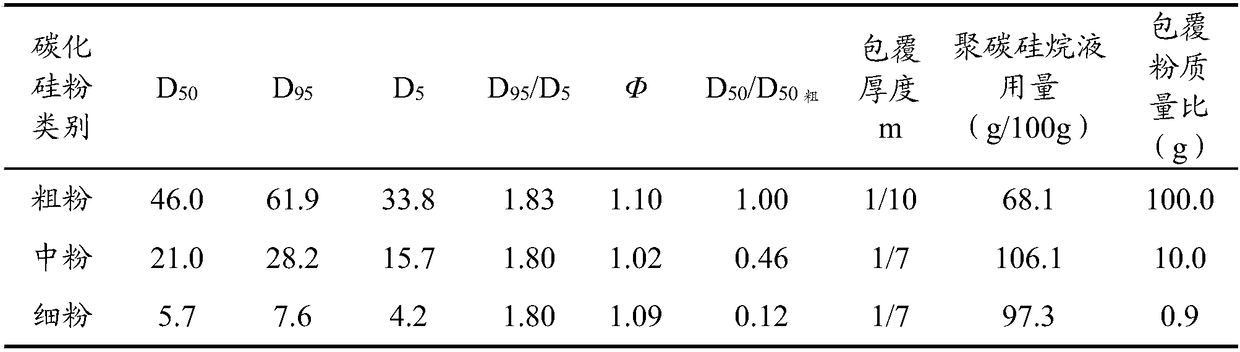

Method to prepare compact silicon carbide ceramic by 3D forming

The invention provides a method to prepare compact silicon carbide ceramic by 3D forming and belongs to the technical field of 3D printing. The method comprises the steps of coating silico carbide powders of three particle sizes evenly with polycarbosilane and silicon dioxide mixture so as to obtain coated powders in large, medium and small particle sizes; mixing the coated powders according to thick, medium and thin particle sizes according to the mass ratio of 100:(2.7-12.5):(0.2-1.6) proportionally to obtain printing powder; green ceramic is formed directly with the printing powder via a direct three-dimensional printing forming machine; ink for the three-dimensional printing former is polycarbosilane tetrahydrofuran having mass concentration of 0.5% to 1.3%; the green ceramic that is sintered at high temperature to obtain compact silicon carbide ceramic. The silicon carbide ceramic product has high compactness and high purity, as well as relative density of > / =98.0% and silicon carbide content of > / =99.0%.

Owner:MAINTOP TECH DEV CO LTD

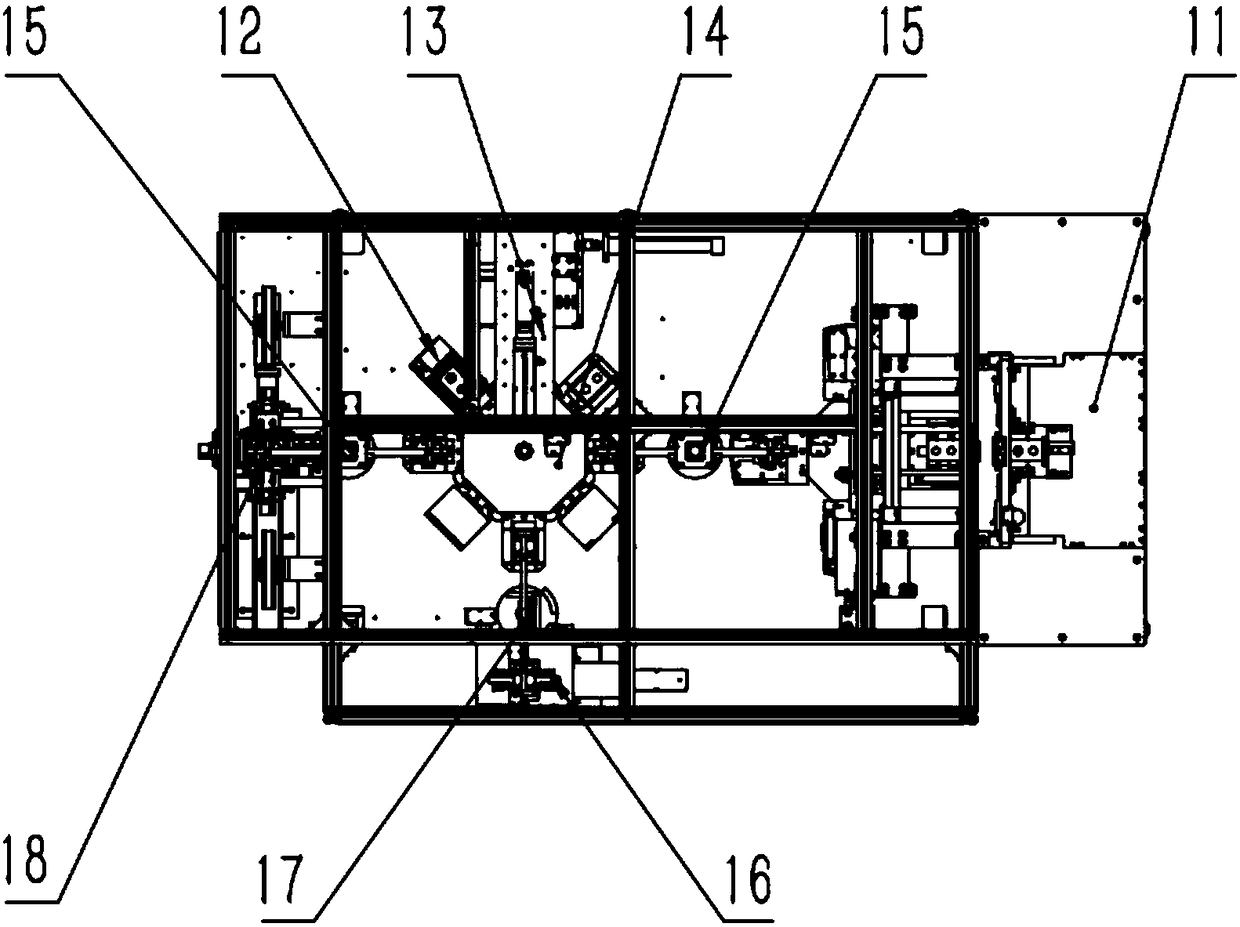

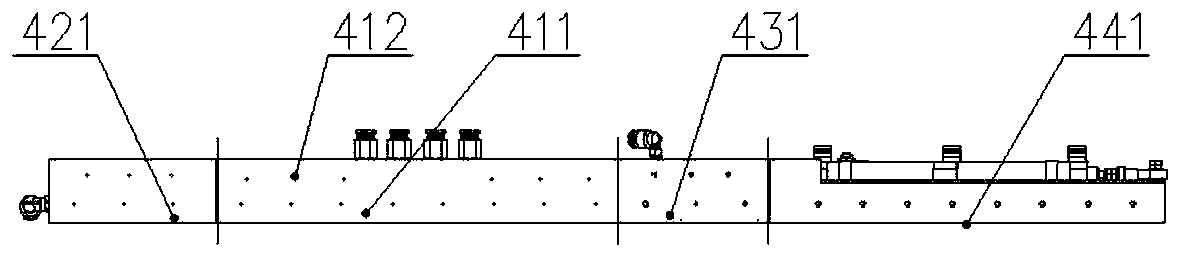

Paper box inner box forming equipment and forming method thereof

PendingCN108466449AReduce manufacturing costLow application costBox making operationsPaper-makingEngineeringMachining process

The invention discloses a paper box inner box forming equipment and a forming method thereof, and belongs to the technical field of packaging equipment. An enclosing strip mold forming mechanism, an inner box forming rotary plate mechanism, an inner box pressure maintaining rubberizing mechanism and other mechanisms are arranged for completing processing of all links in the inner box forming process correspondingly, the inner box forming process is conducted on a rotary plate, a plurality of inner box forming cavities are formed in the rotary plate and correspondingly provided with a lower cover charging mechanism, a lower cover gluing mechanism, an upper cover charging mechanism and the parts for completing charging and machining processes of all materials in the inner box forming processing, and thus inner box forming is completed. According to the paper box inner box forming equipment and the forming method thereof, through coordinate operation of the multiple mechanisms or devices,unintermittent inner box precise forming can be achieved, compared with traditional manual forming techniques, the precision in the inner box forming process is effectively ensured, the inner box forming efficiency is improved, the production cost of inner boxes even paper boxes is lowered, and the paper box inner box forming equipment and the forming method thereof have great application value.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

Paper box making equipment and box making method thereof

ActiveCN108544795AReduce manufacturing costLow application costBox making operationsPaper-makingContinuous/uninterruptedPulp and paper industry

The invention discloses paper box making equipment and a box making method thereof, and belongs to the technical field of packaging equipment. Through the arrangement of a surrounding strip die forming mechanism, a box blank forming rotation disc mechanism, a box blank pressure maintaining gluing mechanism and the like, accurate paper box blank forming is achieved. Through the arrangement of a lower cover feeding mechanism, an upper cover feeding mechanism and a face paper supply glue feeding assembly, accurate feeding of a lower cover, an upper cover and face paper is finished, and a finishedproduct box pasting assembly is arranged to achieve face paper and box blank positioning and forming. The whole box making process is continuous and is not stopped, and continuity and control precision are high. According to the paper box making equipment and the box making method thereof, through coordinated work of multiple mechanisms or devices, constant accurate paper box preparing can be achieved; compared with traditional manual box making, accuracy of various control links in the box making process is effectively guaranteed, the paper box preparing efficiency is greatly improved, the paper box production cost is reduced, and extremely high application value is achieved.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

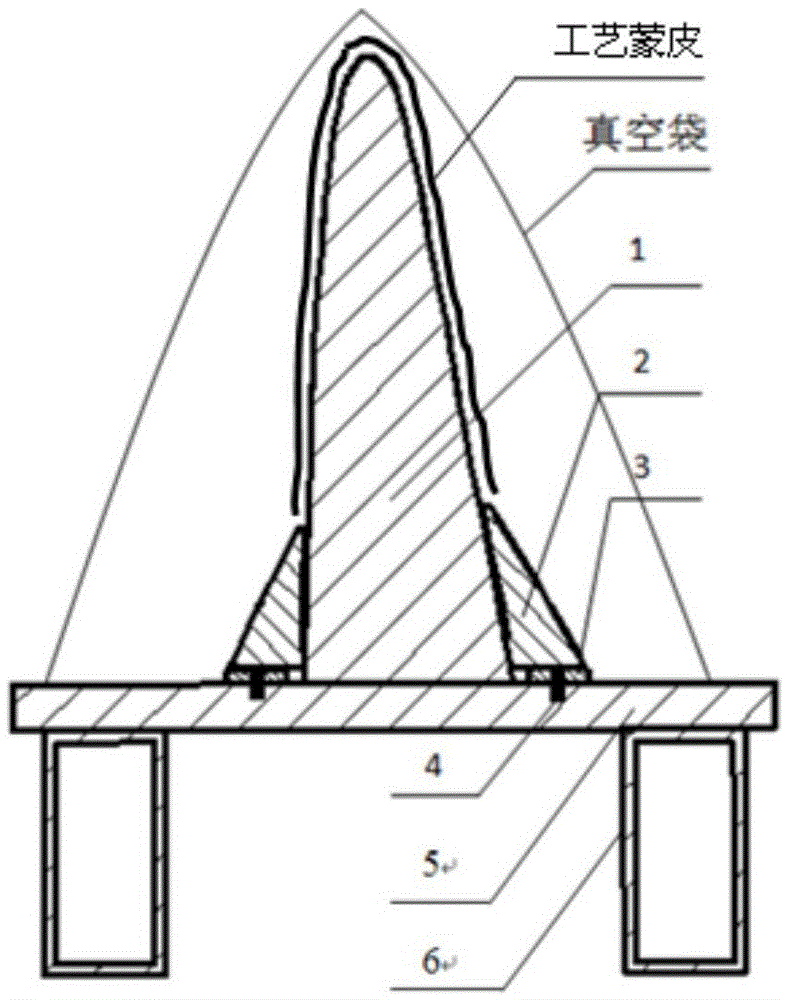

Mould and method for forming partial special-shape surface of large composite material workpiece in autoclave

ActiveCN105538746AAccurate internal and external profilesReliable internal qualityAbnormal shapedInternal bonding

The invention belongs to a composite material thermal forming technology, and particularly relates to a mould and a method for forming a partial special-shape surface of a large composite material workpiece in an autoclave. The mould is characterized in that a mould mode of a main body male die and special-shape position partial female and male die match is adopted for forming the large composite material special-shape workpiece in the autoclave. The main body male die is adopted, so that the forming precision of the inner surface of the workpiece is ensured, and the inner surface of the workpiece is applicable to internal bonding; for a partial special-shape position of the outer surface of the workpiece, the female and male die match is adopted, so that the size and the position precision of a special-shape moulding surface at an assembling part of the outer surface of the special-shape workpiece are ensured, and the internal quality of the workpiece can be ensured.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

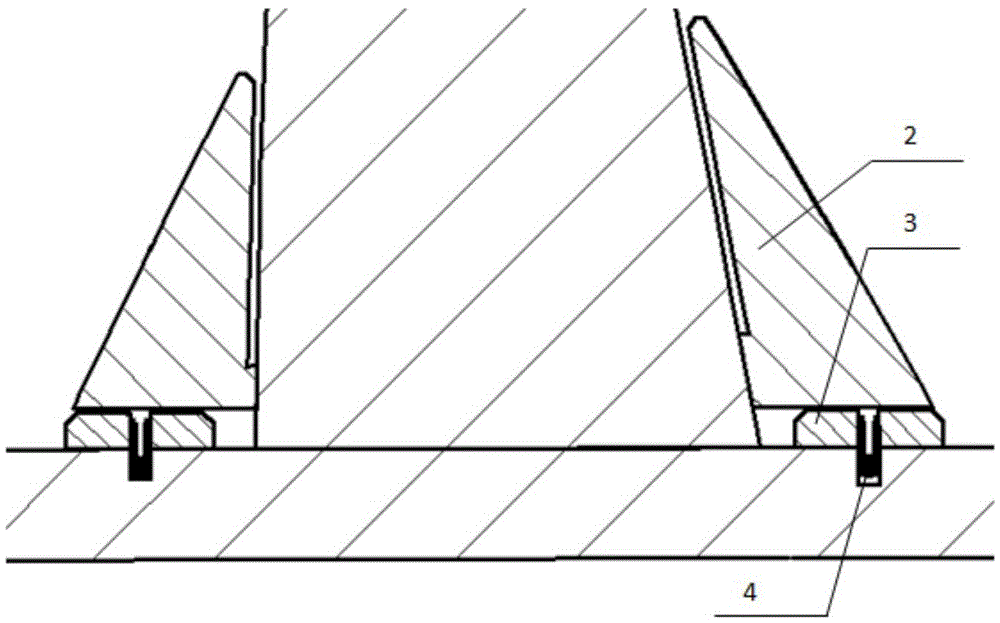

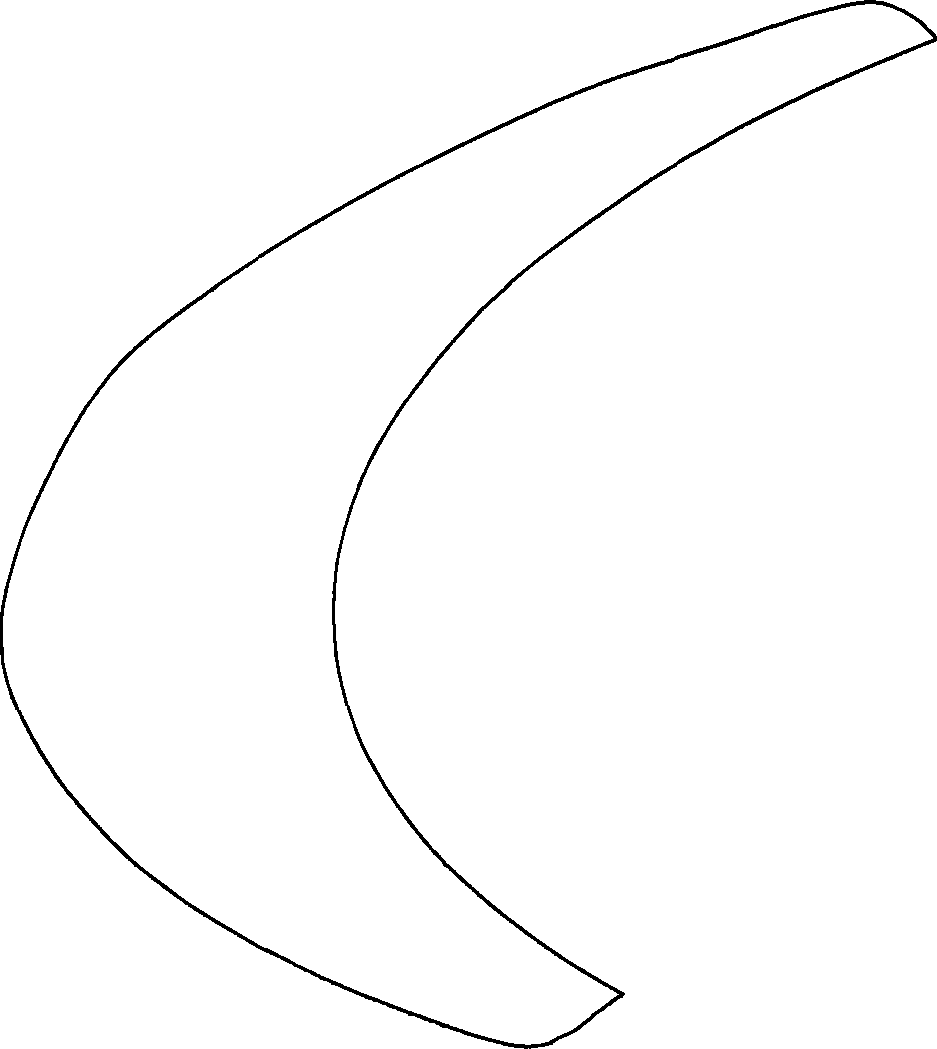

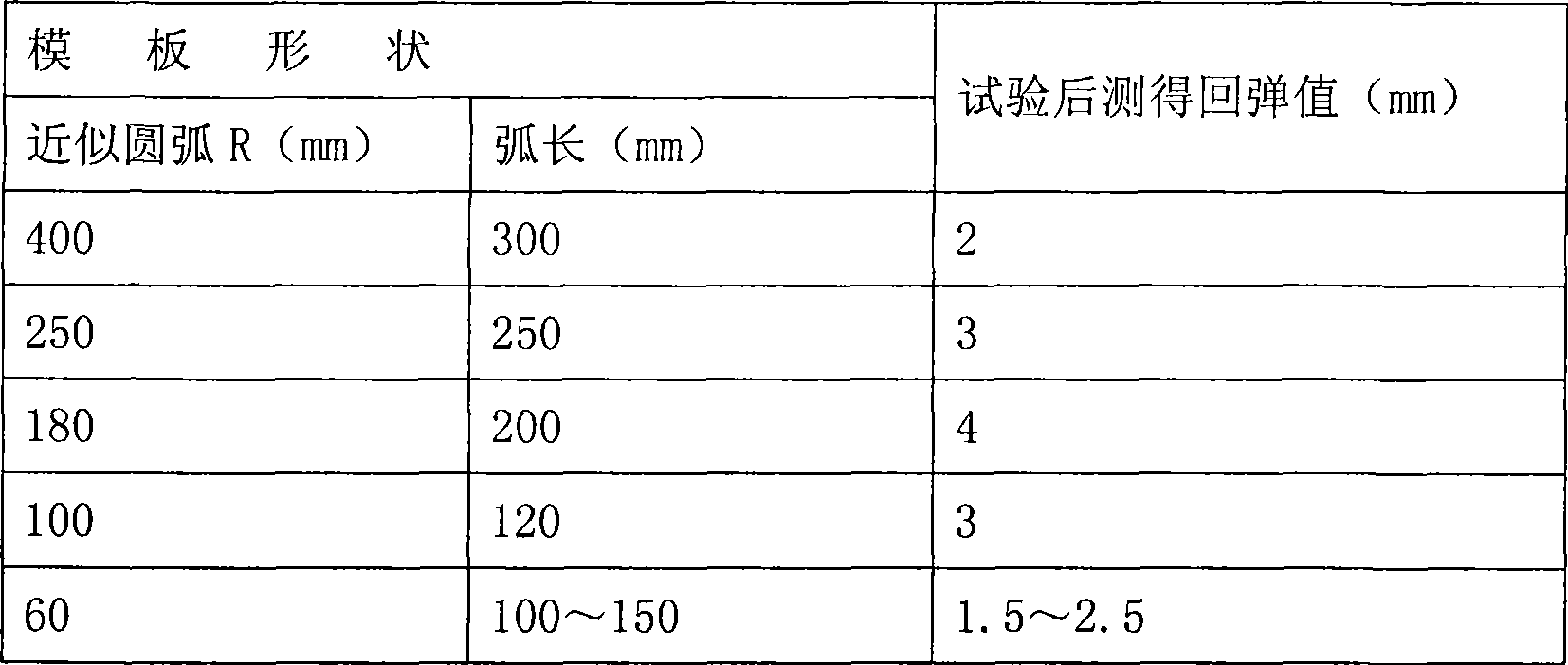

Marine water-jet propulsion passage aluminum double curved plate one-time pressure-molding technique method

ActiveCN101450365AEasy to manufactureSimple repair processForging/hammering/pressing machinesEngineeringCompression test

The invention discloses a technical method for compressing hyperbolic aluminium panels of a ship water jet flow passage to be shaped by one time. The method comprises the steps: performing linear smoothing, modeling and lay-out on the structure of a ship flow passage and manufacturing an inspection sample box and a test compression module; performing a compression test by taking an aluminium plate which is the same as a work piece plate to obtain an accurate rebound value; amending a testing compression module and manufacturing a special compression module; cutting the work piece, and drawing processing position lines on the surface of a blank; performing compression test on the special compression module to inspect the deviation values of the processing position lines of the workpiece, re-compressing to shape the workpiece after inspection and amendment and then putting the workpiece on the inspection type box to inspect the shaping accuracy; and if any error, compressing and amending again until the workpiece meets the requirements. The invention can ensure the shaping quality of workpieces, simplify the operation, improve the processing speed, and particularly can save cost, increase benefit in mass production and bring remarkable economic effect.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Method for moulding female end of heavy caliber socket reinforced concrete pipe

ActiveCN102120339AGuaranteed molding accuracyShaping reinforcementsReinforced concreteMaterials science

The invention relates to a concrete pipe joint die, in particular to a method for moulding a female end of a heavy caliber socket reinforced concrete pipe. The method comprises the following steps of: placing a bottom die on the ground and leveling, and coaxially arranging a positioning support; sleeving a steel ring of the female end in a lower die, and connecting the lower die with the steel sleeve ring; hoisting the lower die and the steel ring onto the bottom die, and cancelling the connection between the lower die and the steel sleeve ring; coaxially connecting the lower die and the bottom die, and sleeving the steel sleeve ring on the positioning support; adjusting a screw on the lower die to adjust the circular degree of the steel sleeve ring; arranging a middle die on a flange; arranging an upper die on the middle die; and arranging an inner die and pouring a concrete structure. The method has the advantages that: the shape of the bottom of the steel sleeve ring at the female end is restrained by the cylinder on the positioning support, and the shape of the end part of the steel sleeve ring at the female end is regulated by rotating the screw in a positioning hole to ensure the moulding accuracy of the steel sleeve ring.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

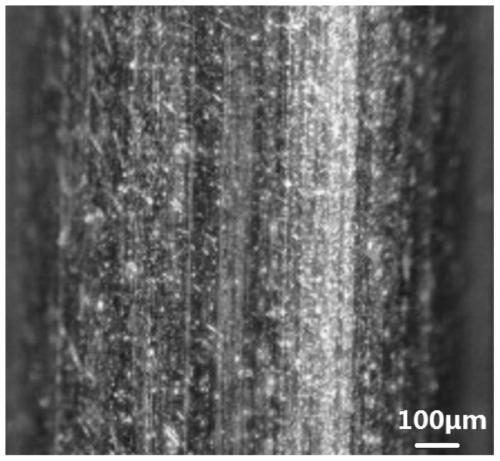

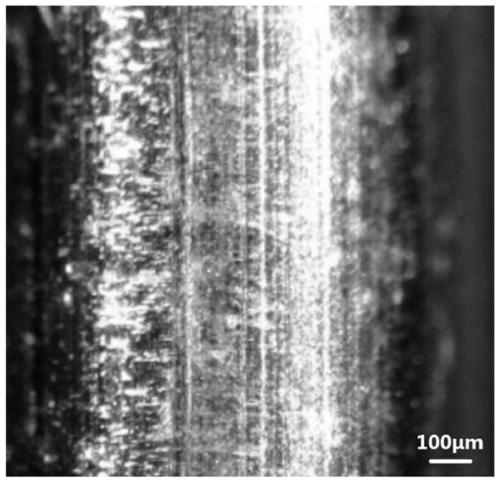

Rare earth aluminum alloy wire for 3D printing and preparation method thereof

ActiveCN110396627AImprove mechanical propertiesAvoid breakingAdditive manufacturing apparatusHigh densityRare earth

The invention relates to a rare earth aluminum alloy wire for 3D printing and a preparation method thereof. The rare earth aluminum alloy wire comprises the following materials: 3-5wt% of Mg, 0.4-1.2wt% of RE, 0.1-1.0wt% of Zr, 0.1-1.0wt% of Mn, 0.05-0.25wt% of Ti, less than or equal to 0.05wt% of O, less than or equal to 0.02wt% of N, less than or equal to 0.01wt% of H and balance of A1 and unavoidable impurities, wherein the ratio of the Mn content to the RE content is 0.5-1:1, and the ratio of the Zr content to the RE content is 0.2-1:1. The wire provided by the invention adds rare earth and zirconium element on the basis of the composition of the aluminum-magnesium alloy to refine crystal grains, and simultaneously produces Al3 (REZr) precipitation strengthening, which is used for smooth feeding on the 3D printer, is not easy to break, has high strength, and ensures the printing precision of a product; and the printed parts have high density, good mechanical properties and corrosion resistance.

Owner:HUNAN ORIENTAL SCANDIUM

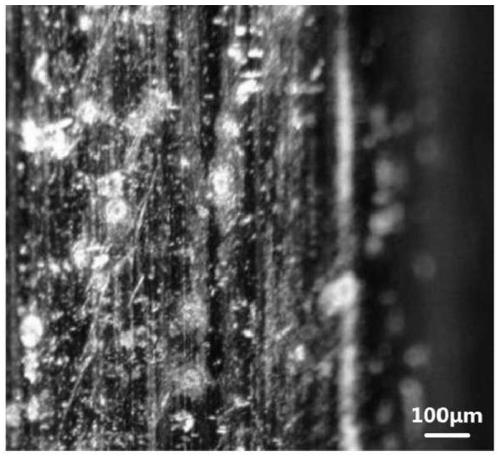

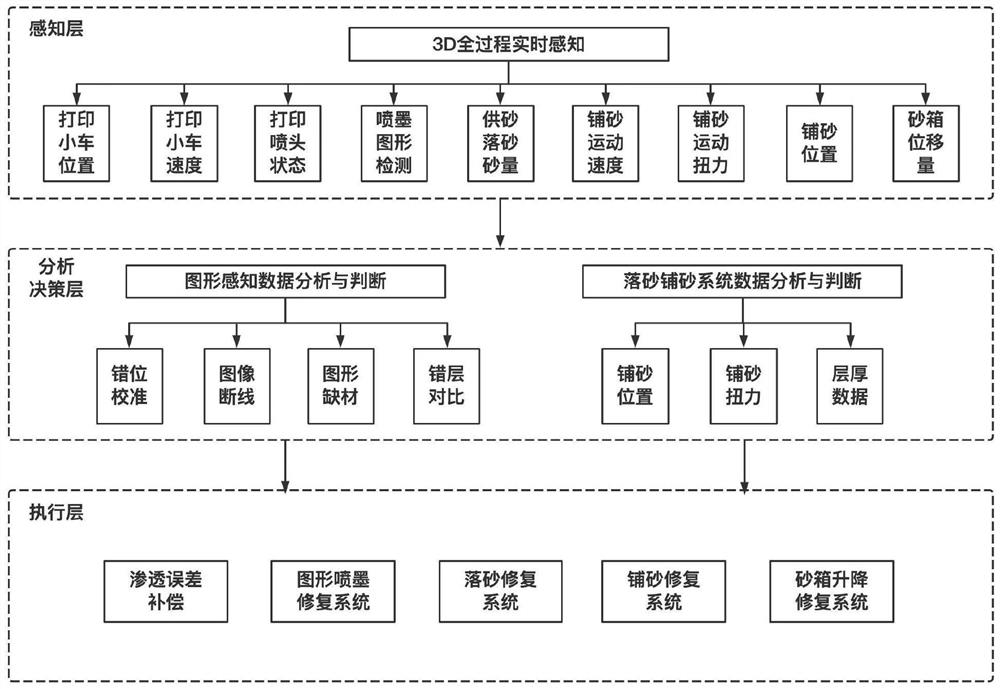

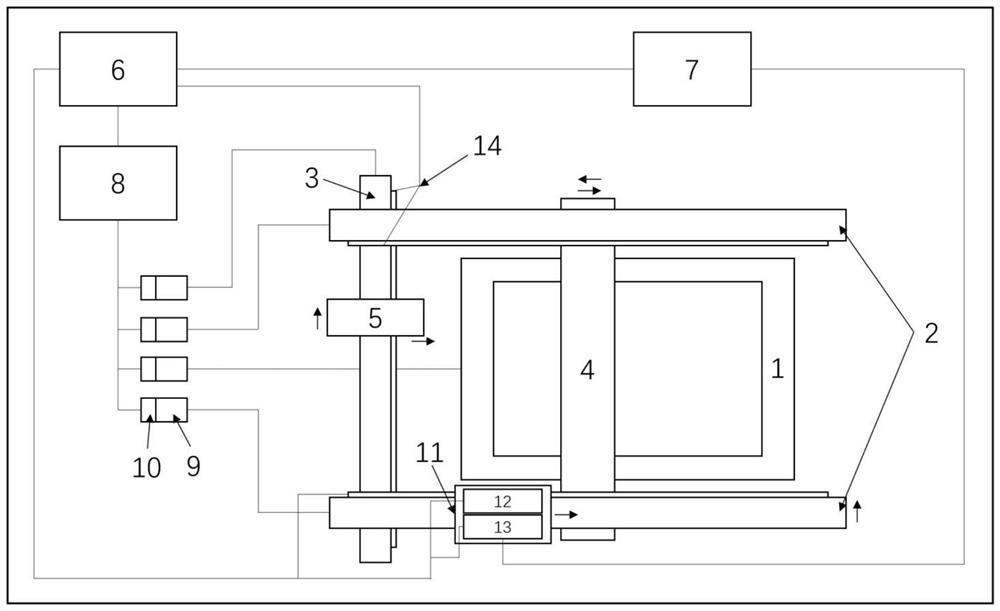

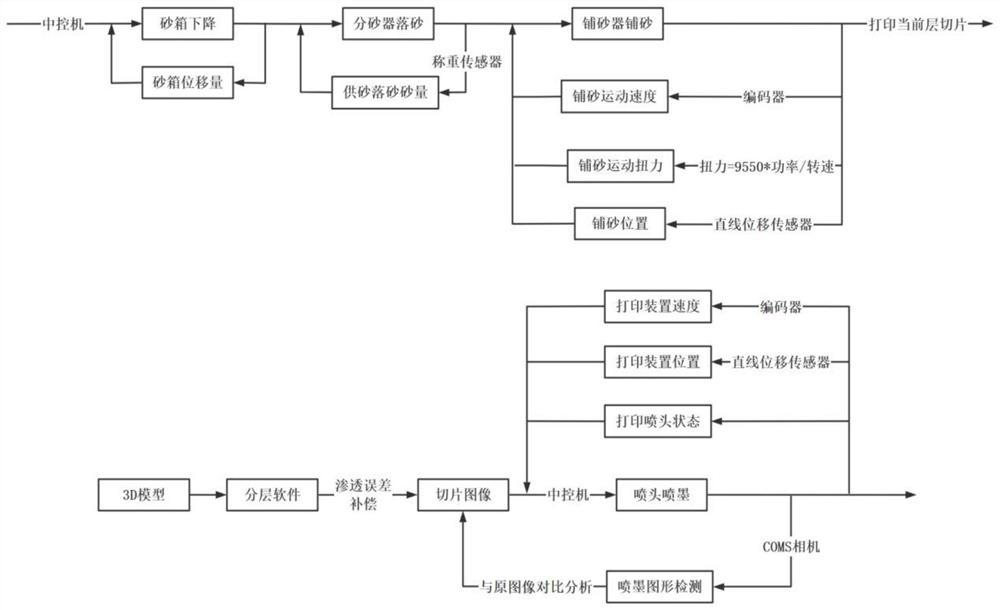

Real-time sensing and intelligent monitoring system for 3D-printed sand mold

ActiveCN113996757AReadableImprove stabilityImage enhancementAdditive manufacturing apparatus3d printGraphics

The invention relates to a real-time sensing and intelligent monitoring system for a 3D-printed sand mold. The system comprises a sensing layer, an analysis decision-making layer, and an execution layer; the sensing layer is a 3D whole-process real-time sensing module and is used for discretely collecting multi-parameter data of a 3D printed sand mold system; the analysis decision-making layer comprises a graphic perception data analysis and judgment module and a shakeout and sand laying system data analysis and judgment module, and is used for analyzing and judging discrete data; and the execution layer comprises a penetration error compensation system, a pattern ink jet repair system, a shakeout repair system, a sand laying repair system and a sand box lifting repair system, and responds to the judgment result of the analysis decision-making layer. According to the system, the whole 3D printing process of the sand mold is monitored in real time, and the molding quality and precision of the sand mold are guaranteed.

Owner:HEBEI UNIV OF TECH +1

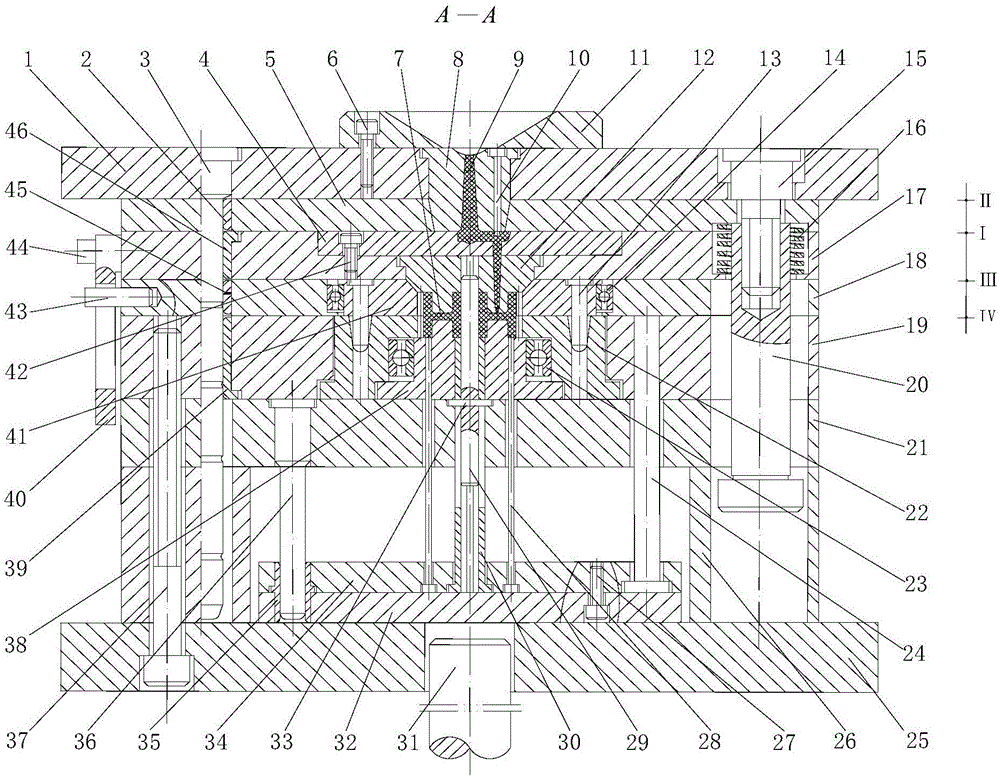

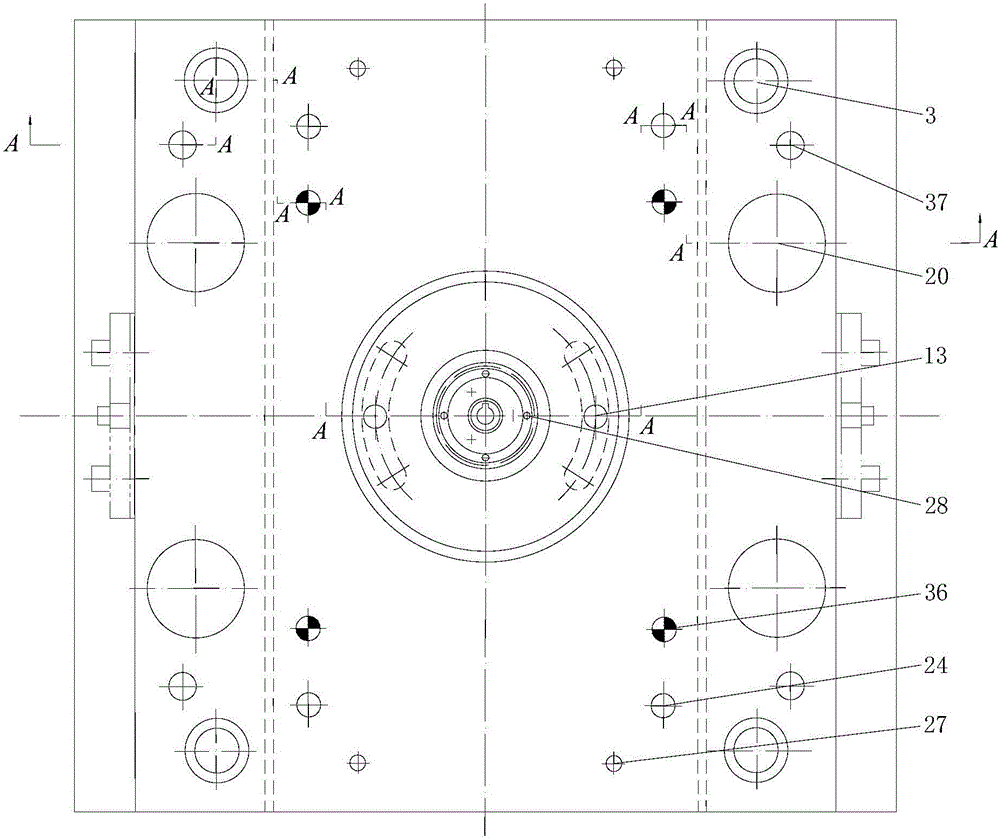

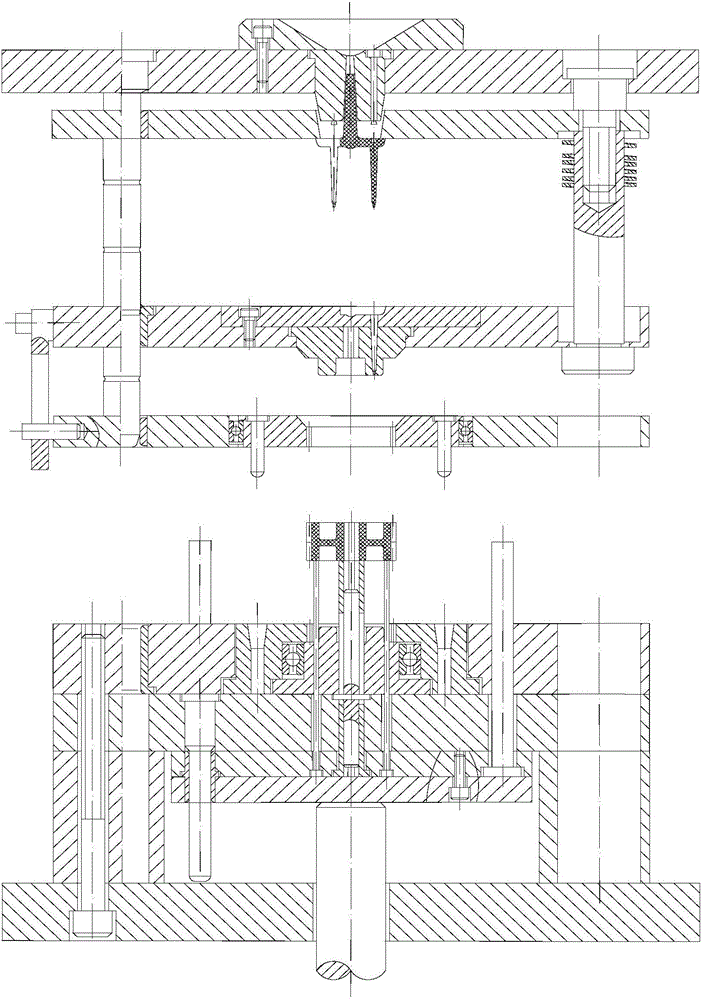

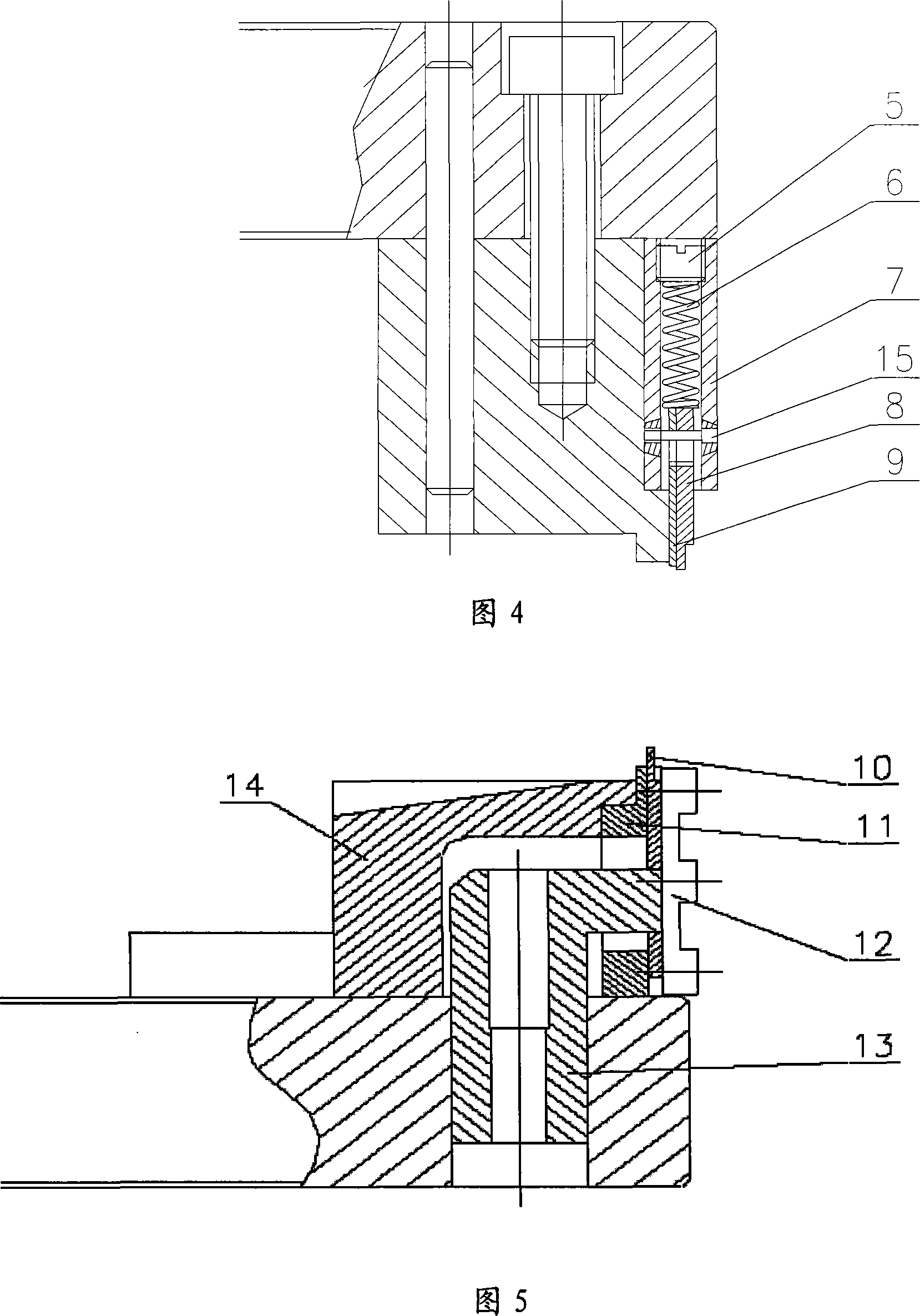

Injection molding die of equal-diameter both-way plastic helical gear

The invention discloses an injection molding die of an equal-diameter both-way plastic helical gear. The injection molding die sequentially comprises a fixed die seat plate, a pouring stopping plate, a mold core fixing plate, a cavity fixing plate, a movable die plate, a bearing plate, a mat block and a movable die base plate from top to bottom; a positioning ring is arranged above the fixed die seat plate; a first centripetal thrust bearing and a first helical gear cavity insert are arranged inside the cavity fixing plate; a second helical gear cavity insert, a second centripetal thrust bearing and a second mold core insert are arranged inside the movable die plate; and a bulb guide pin is installed inside the first helical gear cavity insert, a guide hole is formed inside the second helical gear cavity insert, and the first helical gear cavity insert and the second helical gear cavity insert are subject to helical gear groove position alignment through the bulb guide pin and the guide hole. The injection molding die is perfect in structure, efficient in motion and high in molding quality; multiple parting line sequenced parting achieves material coagulating of a gating system and automatic demolding of a helical gear plastic piece, the molding efficiency of the plastic piece is improved, and the service life of the die is prolonged.

Owner:宁波明旌电子有限公司

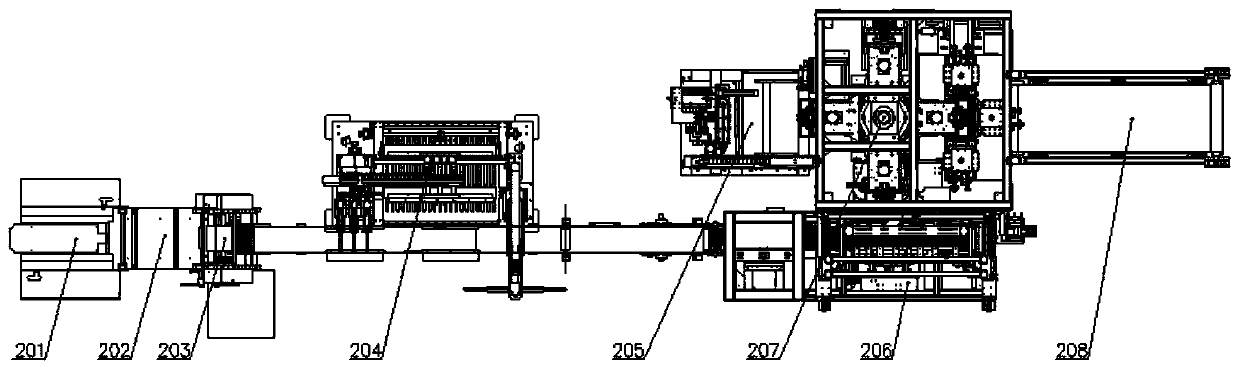

Automatic enclosure frame forming technique and equipment for packaging box

PendingCN109927347ARealize fully automatic moldingWide adaptabilityBox making operationsPaper-makingFolded formAssembly line

The invention discloses an automatic enclosure frame forming technique for a packaging box. The technique at least comprises a large-surface paper conveying guide station (2), a large-surface paper gluing station (3), a grey plate feeding positioning magnetic sheet loading station (5), a magnetic sheet conveying positioning station (7), an plasterers hawk and surface paper positioning and laminating station (8), an edge folding forming station (9), a turnover conveying station (10), a multi-turntable forming station and a box outlet conveying station (17) which are arranged in an assembly line, so that accurate feeding of the surface paper, accurate applying of the glue, accurate pasting of the grey plate, a magnetic sheet and the surface paper, and folding and overturning feeding to a multi-station rotating table for integral forming of the surface paper are realized. The invention further discloses automatic enclosure frame forming equipment for the packaging box. According to the automatic enclosure frame forming technique for the packaging box, full-automatic forming of enclosure frame forming box types is realized, the adaptability is wide, and the compatibility is high; and the technique can adapt to box making requirements of an enclosure frame packaging box with a large size range, and solves the current manual forming problem of enclosure frame forming, which is a large of box type.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

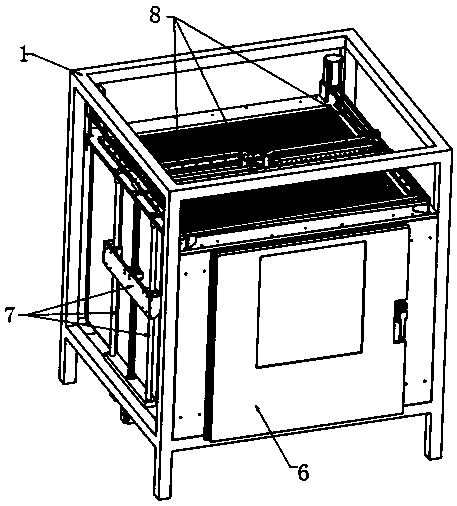

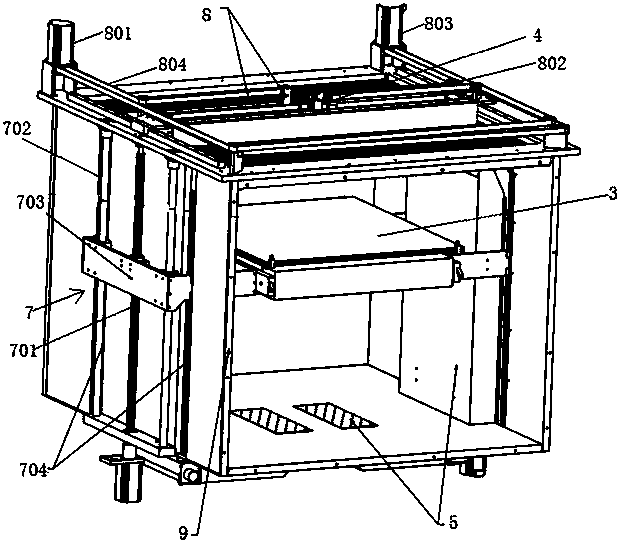

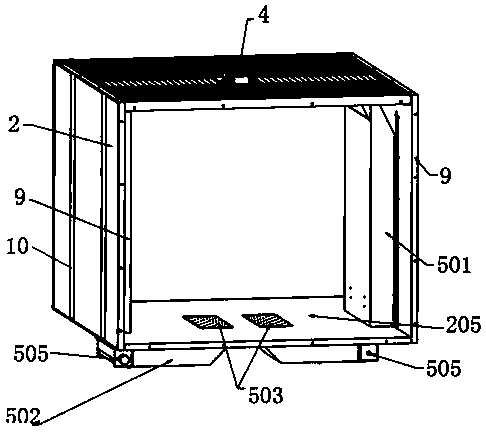

3D printer of double cycle heating constant temperature forming space

PendingCN108582782AGuaranteed accuracyReached temperatureAdditive manufacturing apparatusTemperature controlEngineering

Owner:GUANGZHOU ELECTRONICS TECH

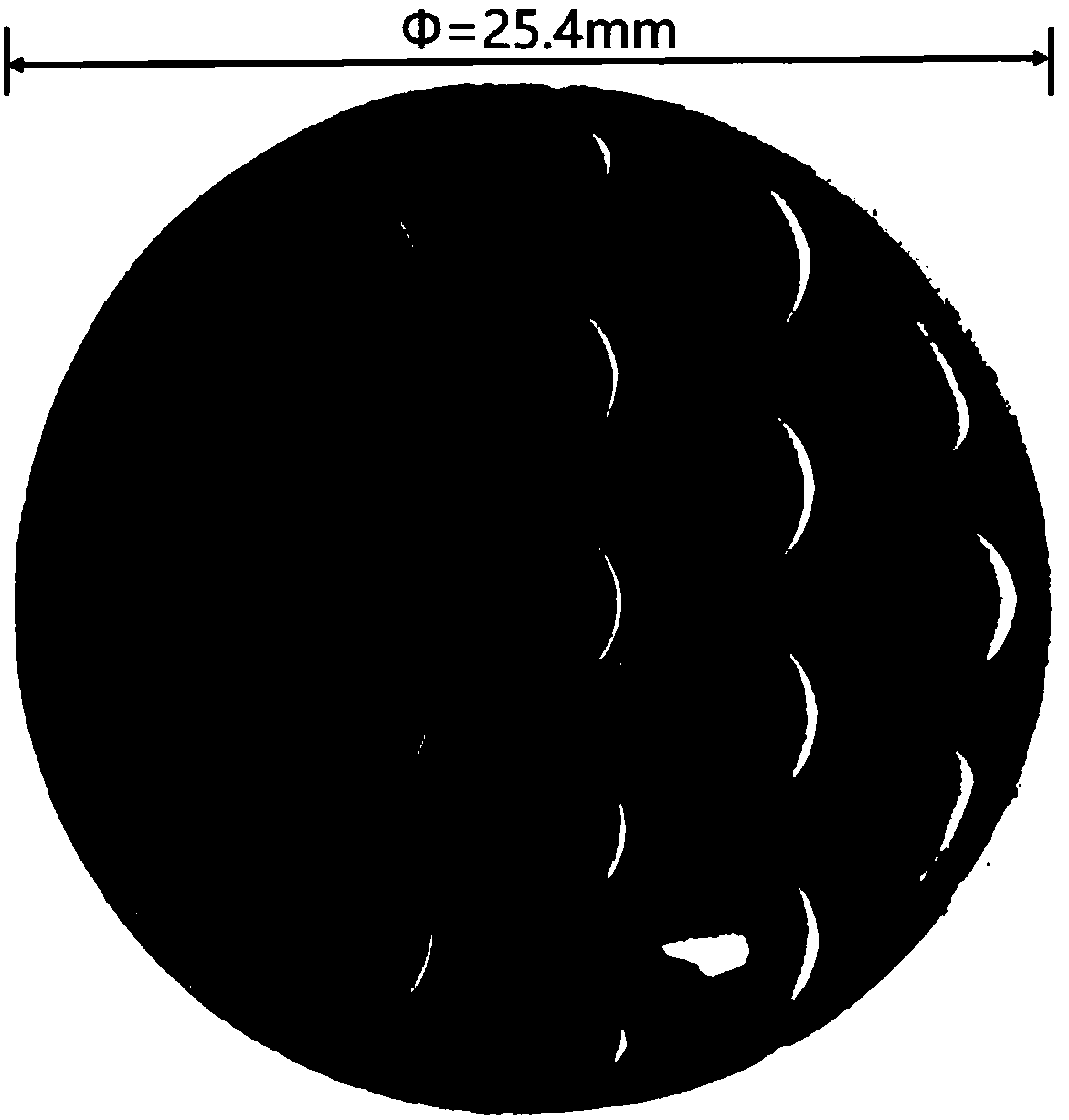

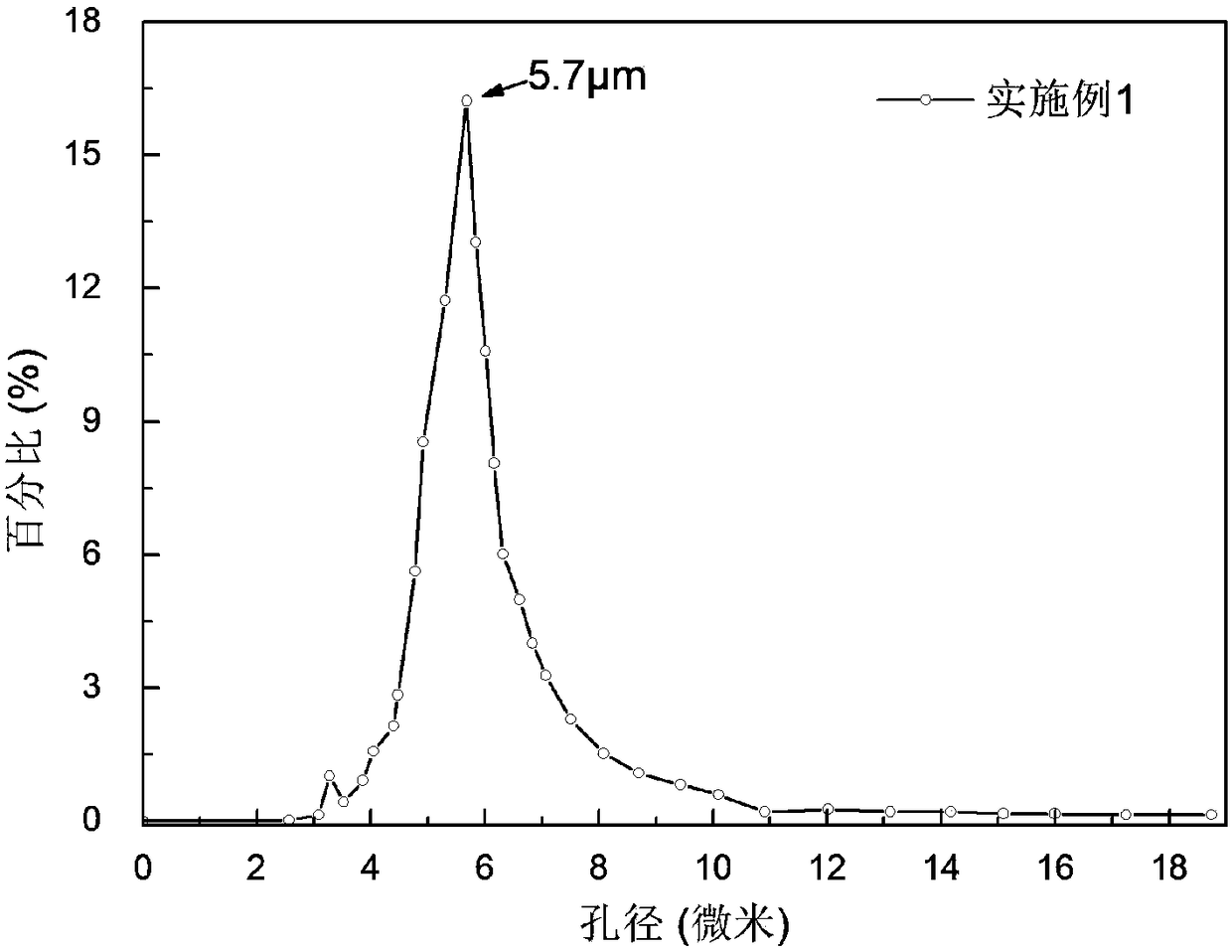

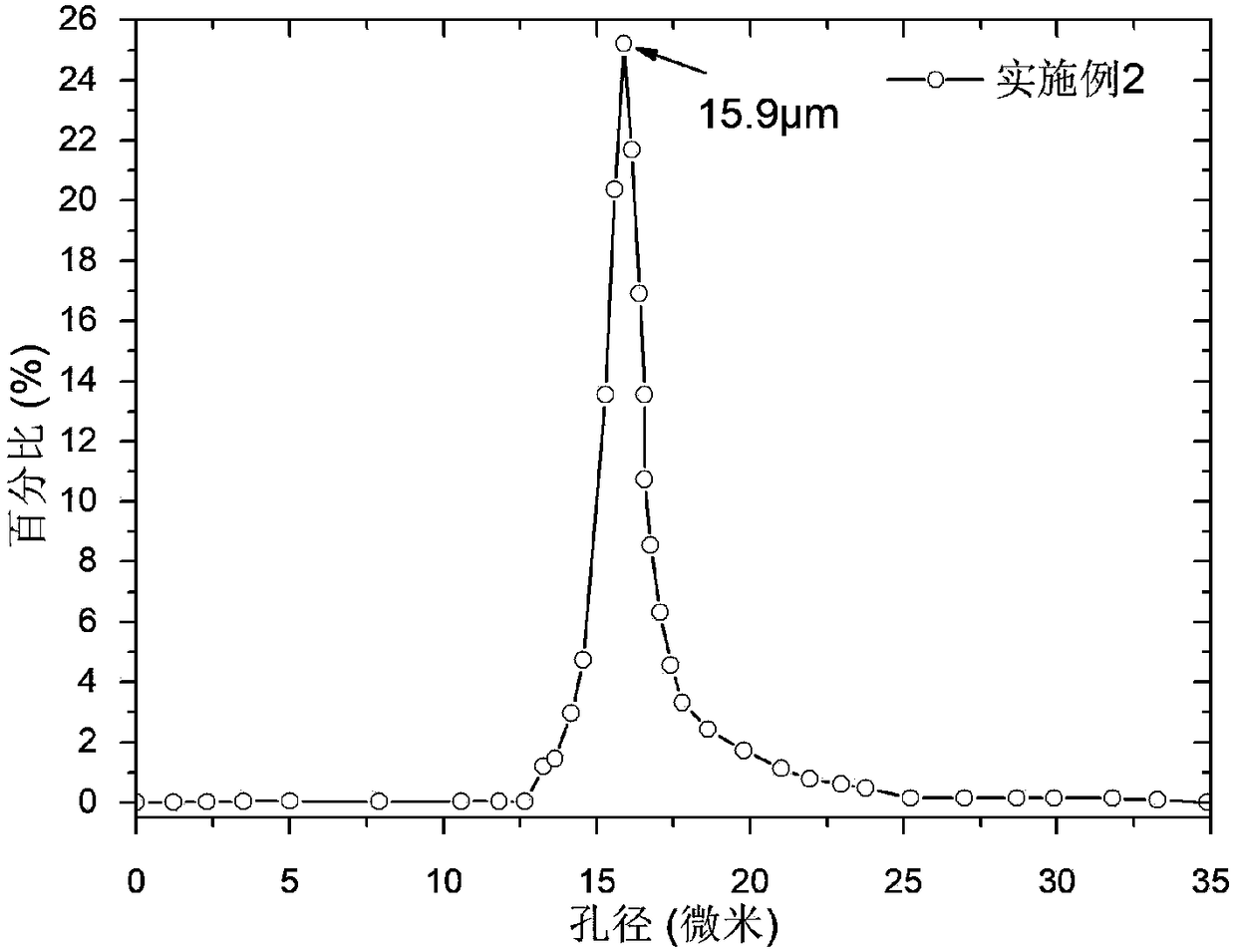

Method for preparing pore-size-controllable silicon carbide ceramic by means of three dimensional (3D) molding

ActiveCN108439987ANarrow pore size distributionAperture controlAdditive manufacturing apparatusCeramicwareSilicon dioxideTetrahydrofuran

The invention provides a method for preparing pore-size-controllable silicon carbide ceramic by means of three dimensional (3D) molding, belonging to the technical field of 3D printing. The method comprises the following steps: separately and uniformly coating two types of silicon carbide powder, having different particle sizes, with a mixture of polycarbosilane and silicon dioxide powder to obtain coarse, median and fine coated composite powder with three particle sizes, and mixing the obtained coarse, median and fine coated composite powder with three particle sizes according to a mass ratioof 100 to (0.2-1.6) to obtain printing powder; molding the printing powder by using a direct three-dimensional printing molding machine to obtain a ceramic green body, wherein ink used for the three-dimensional printing molding machine is a tetrahydrofuran solution of polycarbosilane having a mass concentration of 0.5-1.3%; sintering the ceramic green body obtained in the step (4) at a high temperature to obtain the pore-size-controllable silicon carbide ceramic. The method provided by the invention realizes the control of the pore size of the silicon carbide ceramic product by adjusting thecoarse powder median particle diameter D50.

Owner:MAINTOP TECH DEV CO LTD

Caster emitting device

The present invention relates to the technical field of a caster, in particular to a caster emitting device. An emitting oil cylinder in the caster emitting device comprises a cylinder barrel, a piston arranged in the cylinder barrel and a piston rod fixedly connected with the piston, wherein a guide rod is arranged in the cylinder barrel, and the piston matched with the guide rod can move forward and rearward along the guide rod. The guide rod can enable the whole caster emitting device to run more stably, and enables more flexible between emission and stopping; however, the guide rod is not easy to wear; the push force of pressure oil can be sufficiently used; and further, the forming precision of the caster can be ensured for a long time. The present invention has the advantages of simple structure, easy manufacture, even piston stress and large marketing competitive power.

Owner:曾明松

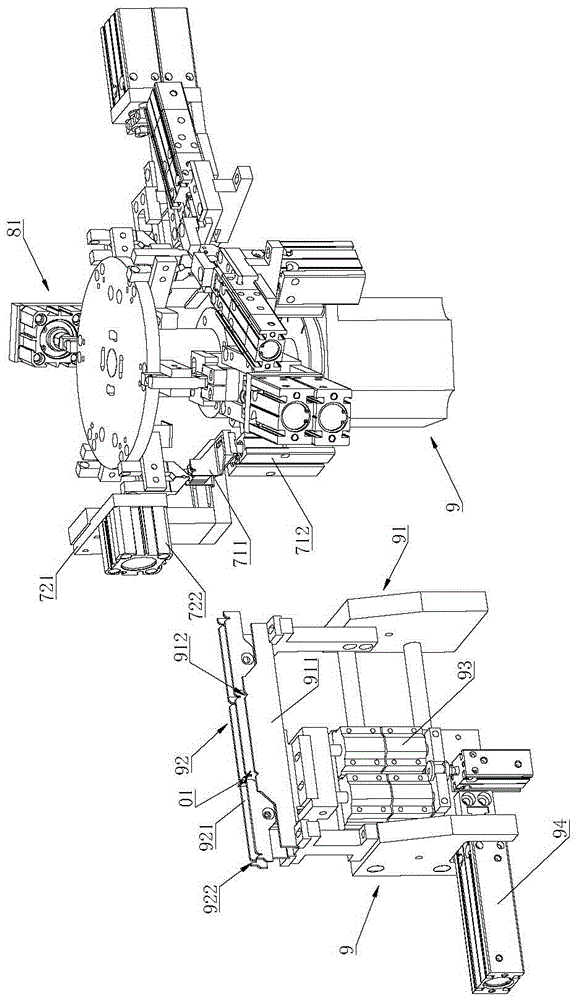

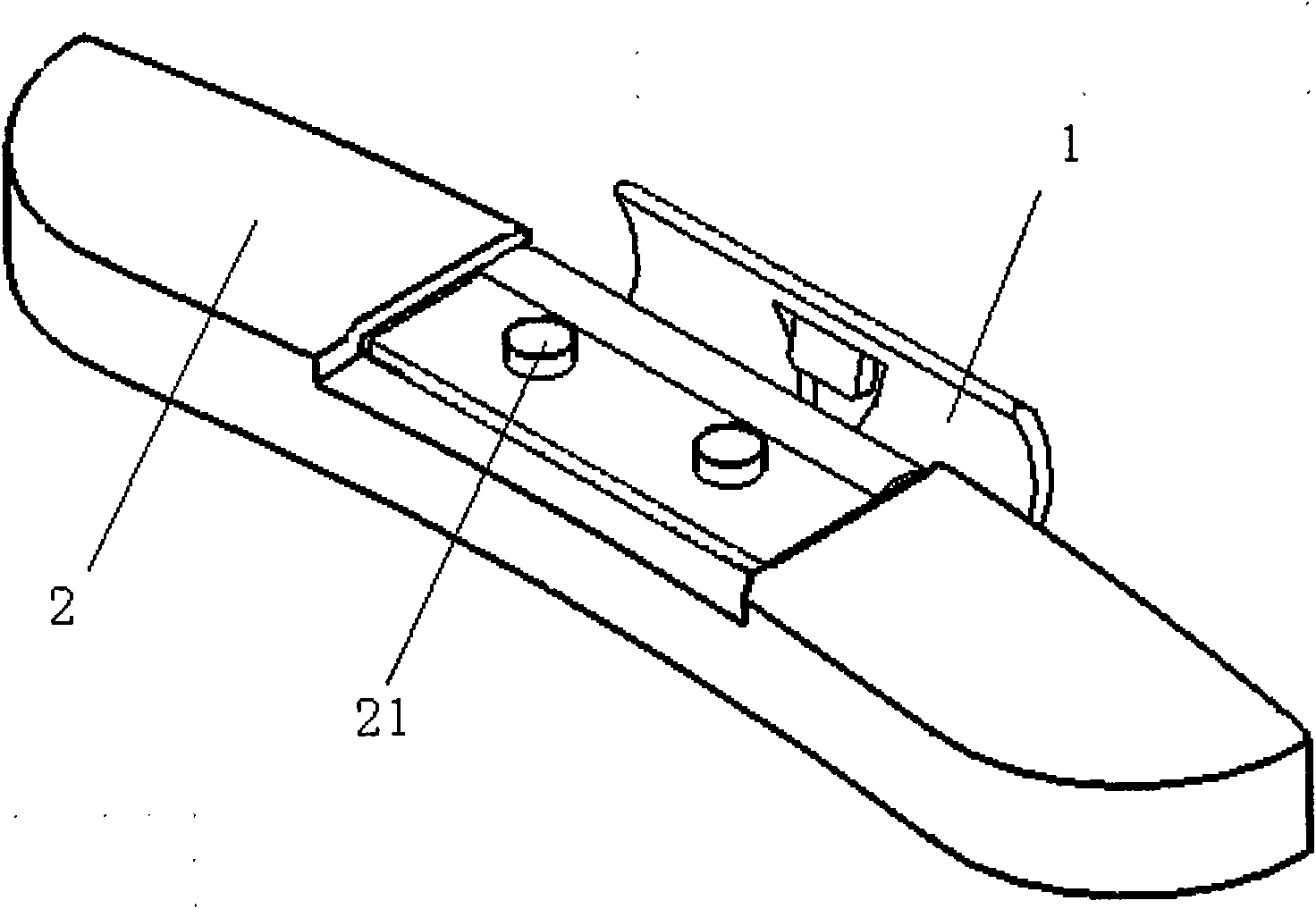

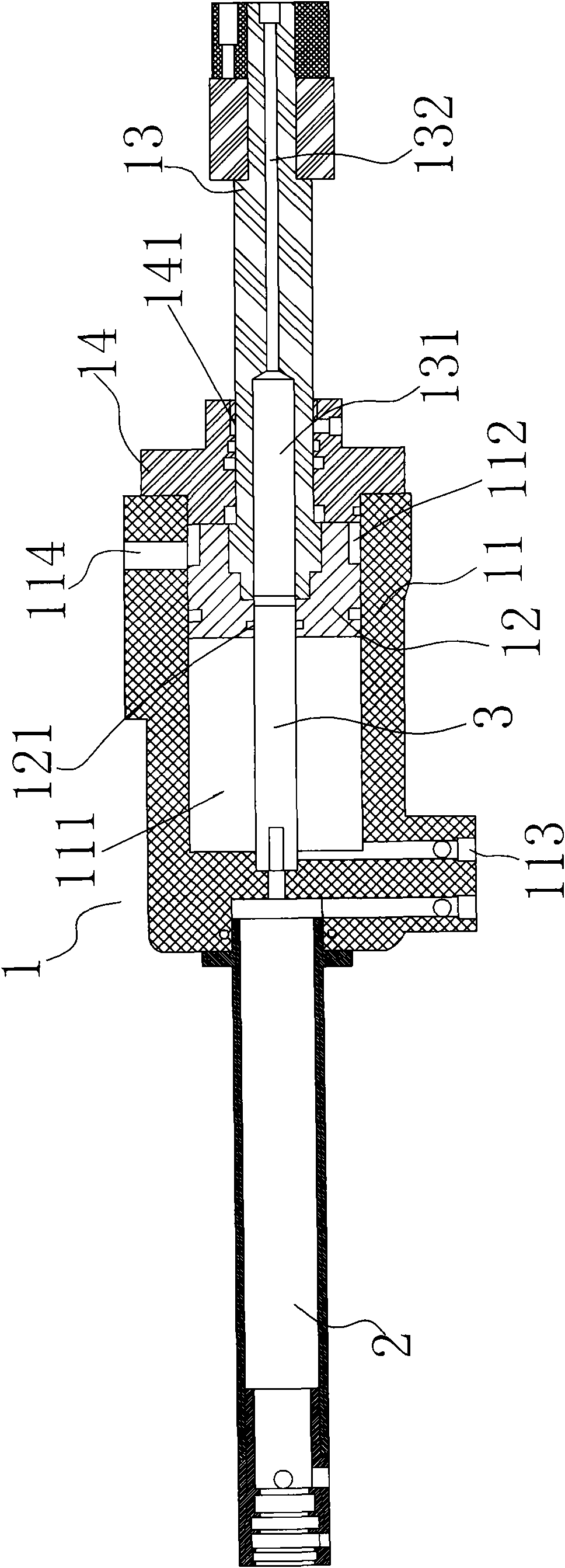

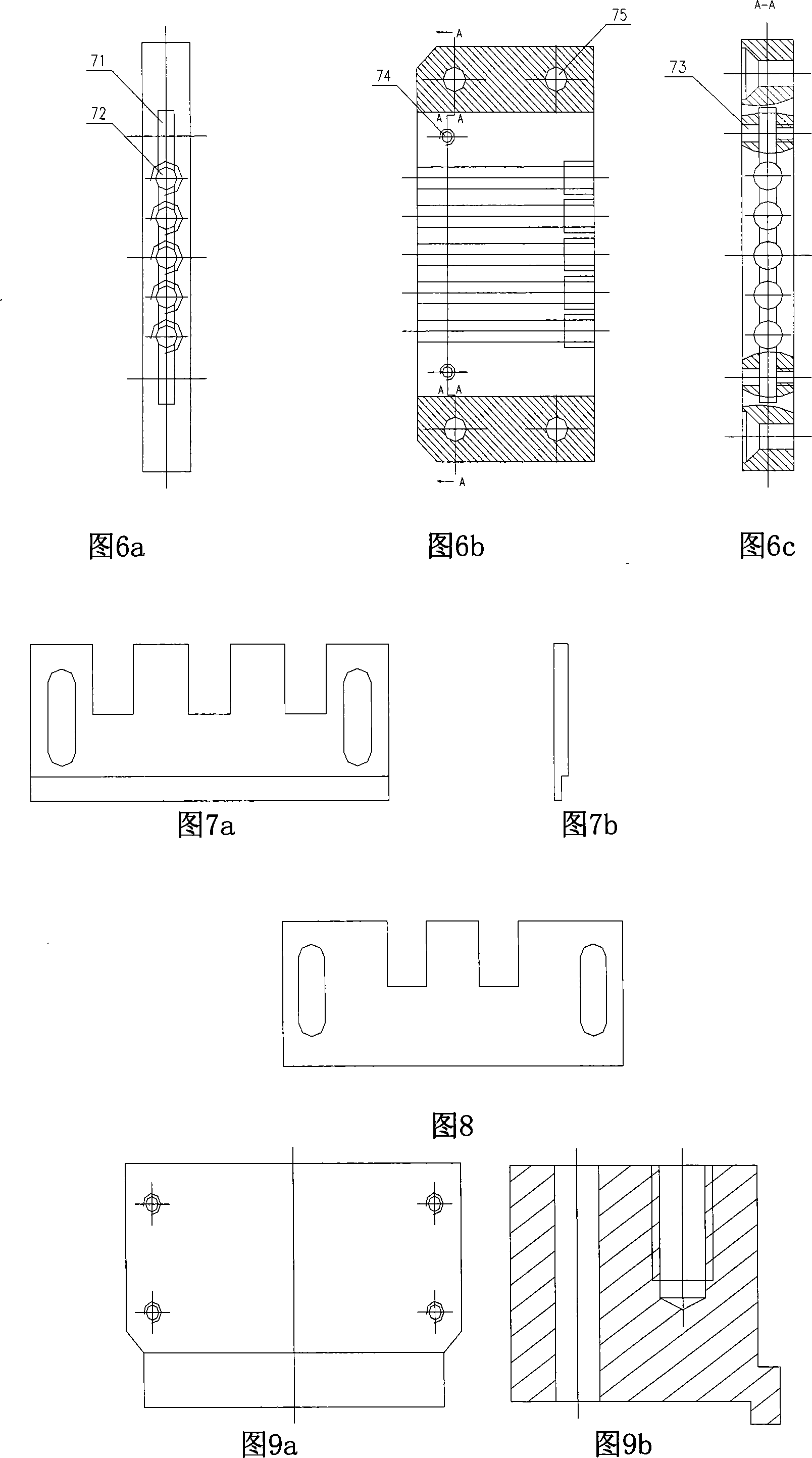

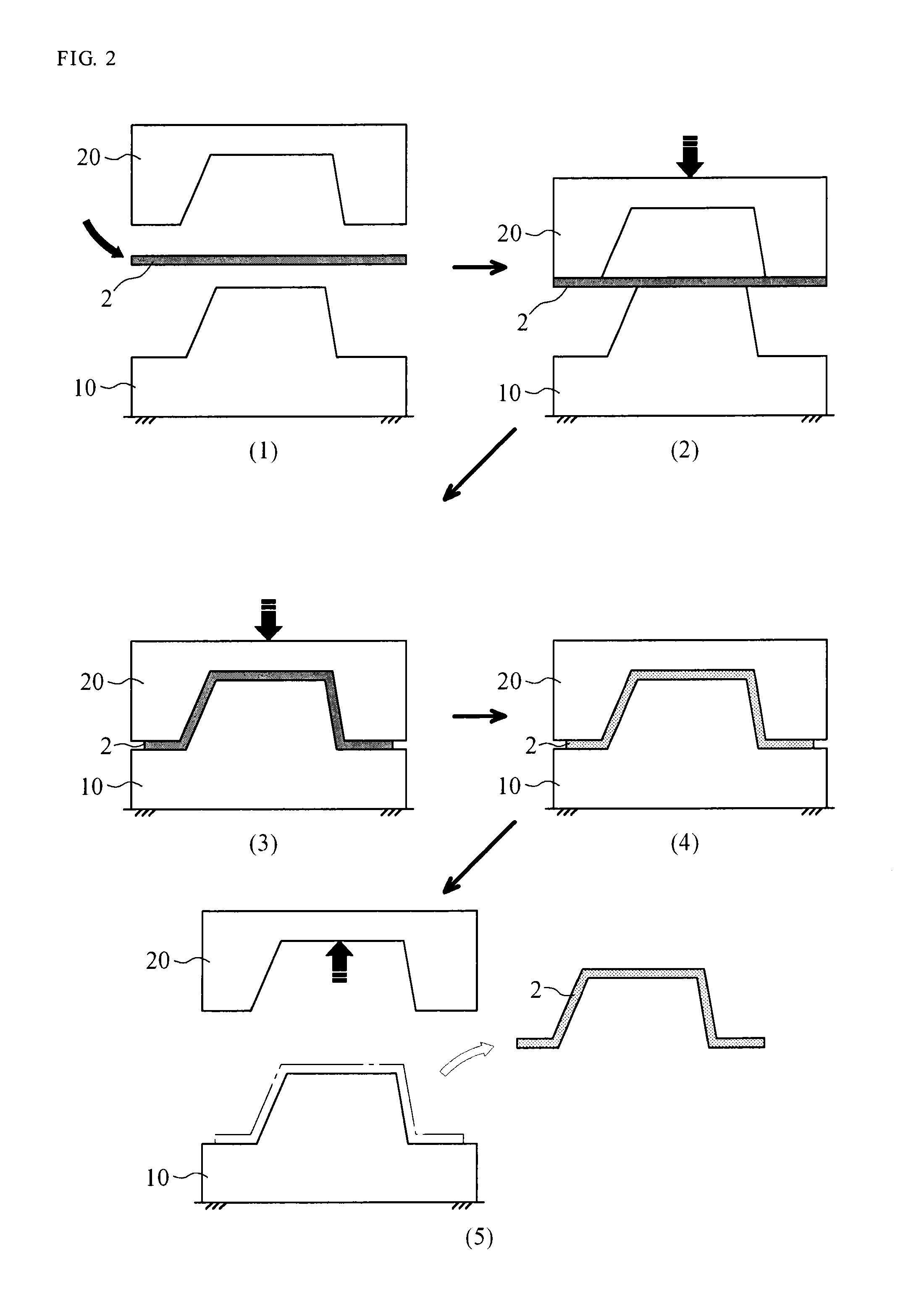

Universal bilateral composite mold integrated circuit pin forming mechanism of nesting structure

InactiveCN101179924AGuaranteed molding accuracyEnsure consistencyElectrical componentsAutomatic controlControl system

The invention provides a molding mechanism for pins on integrated circuit of general bilateral compound die with a nest structure that has a left and right symmetric structures formed by two semi-die molding mechanisms; wherein, each semi-die molding mechanism contains a compound die base, a guide pillar, an upper die and a lower die; the lower die and the guide pillar are fixed on the compound die base; the upper die is fixed on an upper support and consists essentially of a shearing die, a bolt, a spring, an upper die fixing plate, a pressing plate and an upper forming die, while the lower die essentially consists of a support plate, a lower forming die, a support plate pressing plate, a support guide block and a lower die pressing plate. The invention realizes the regulation of molding height and length of the integrated circuit pins by regulating the relative positions of molding parts and finishes pin molding and shearing work procedure in one time, which ensures the molding precision and consistency of the integrated circuit to pin and meet connection requirement of the molding mechanism and automatic control system.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

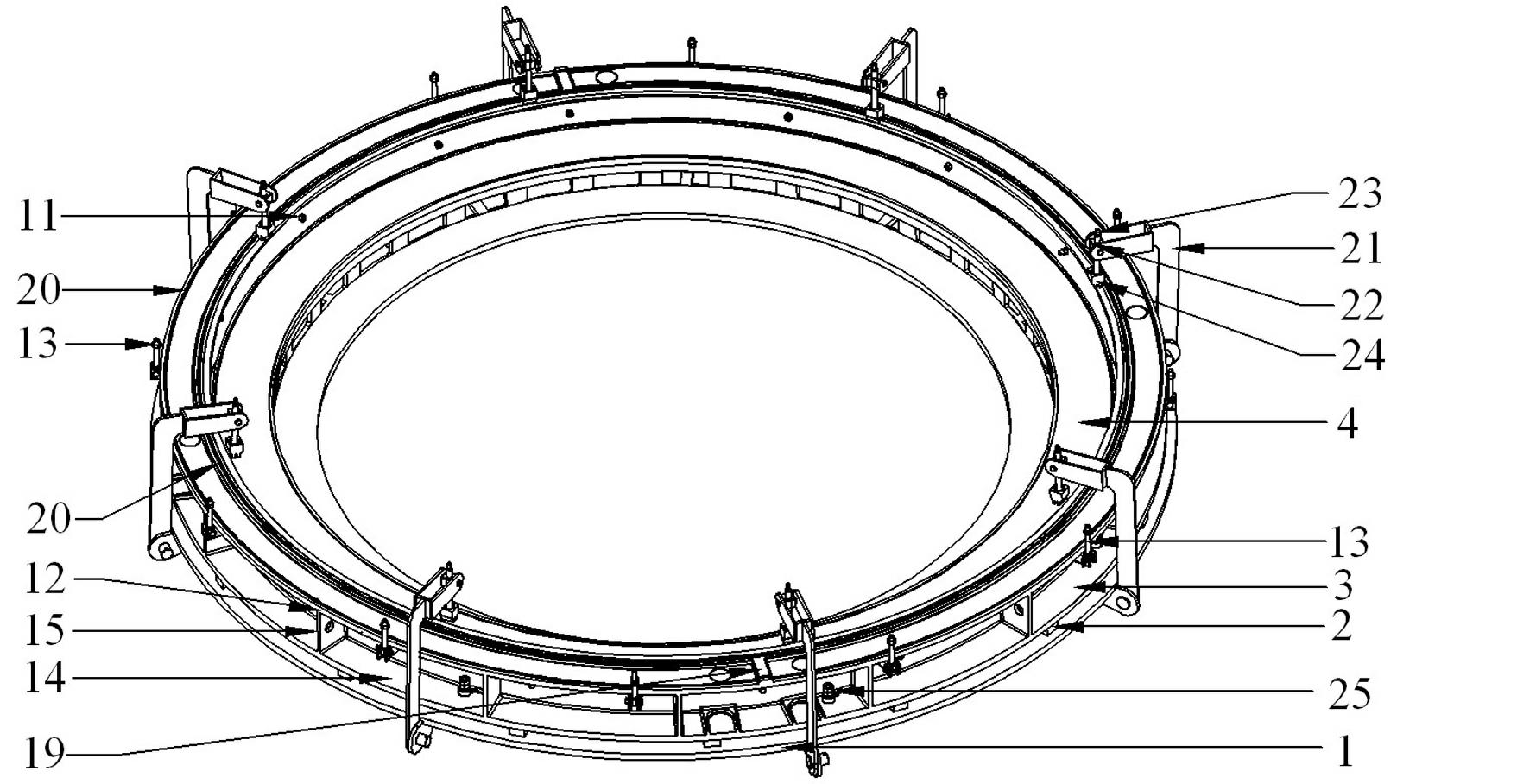

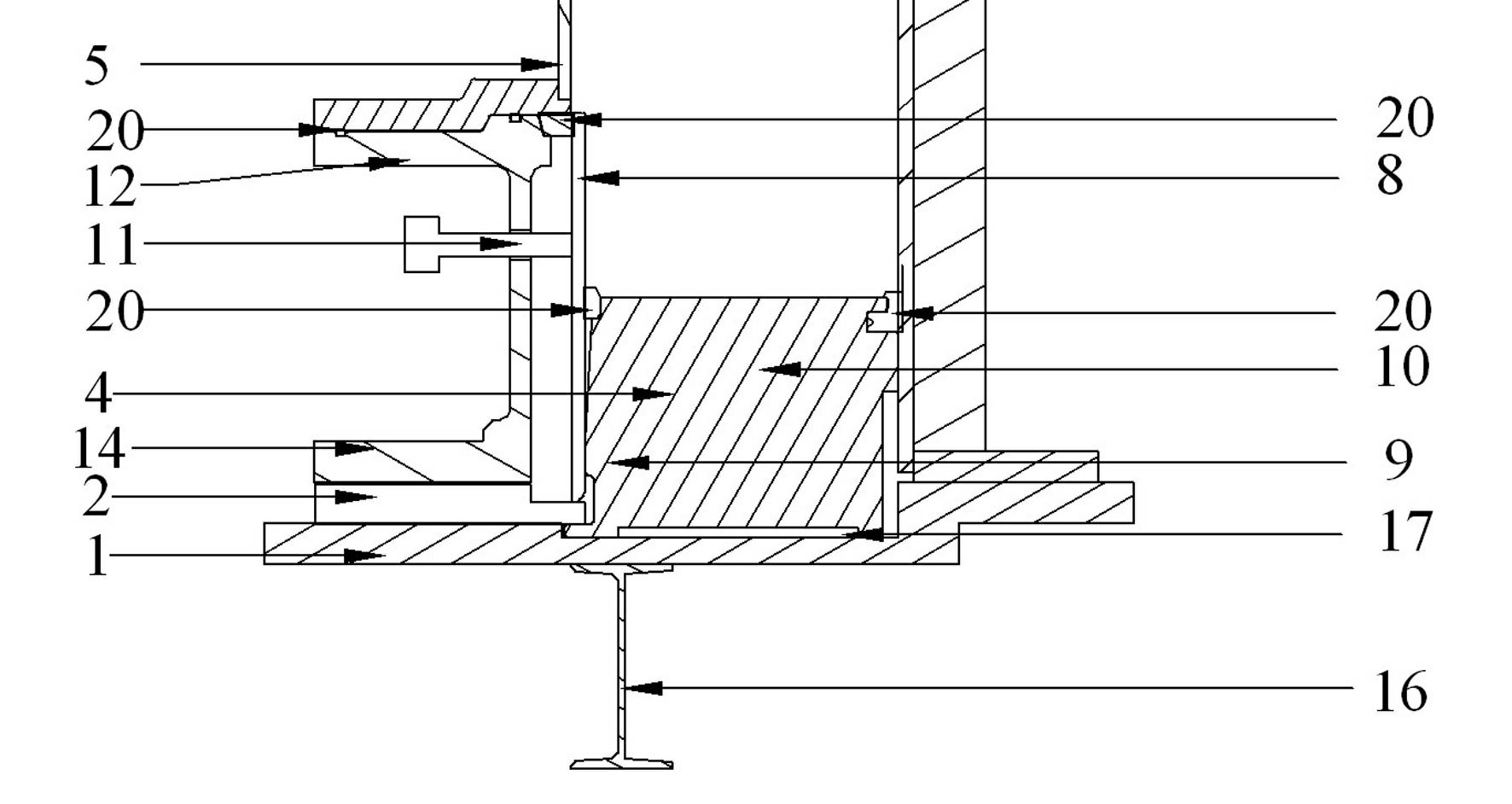

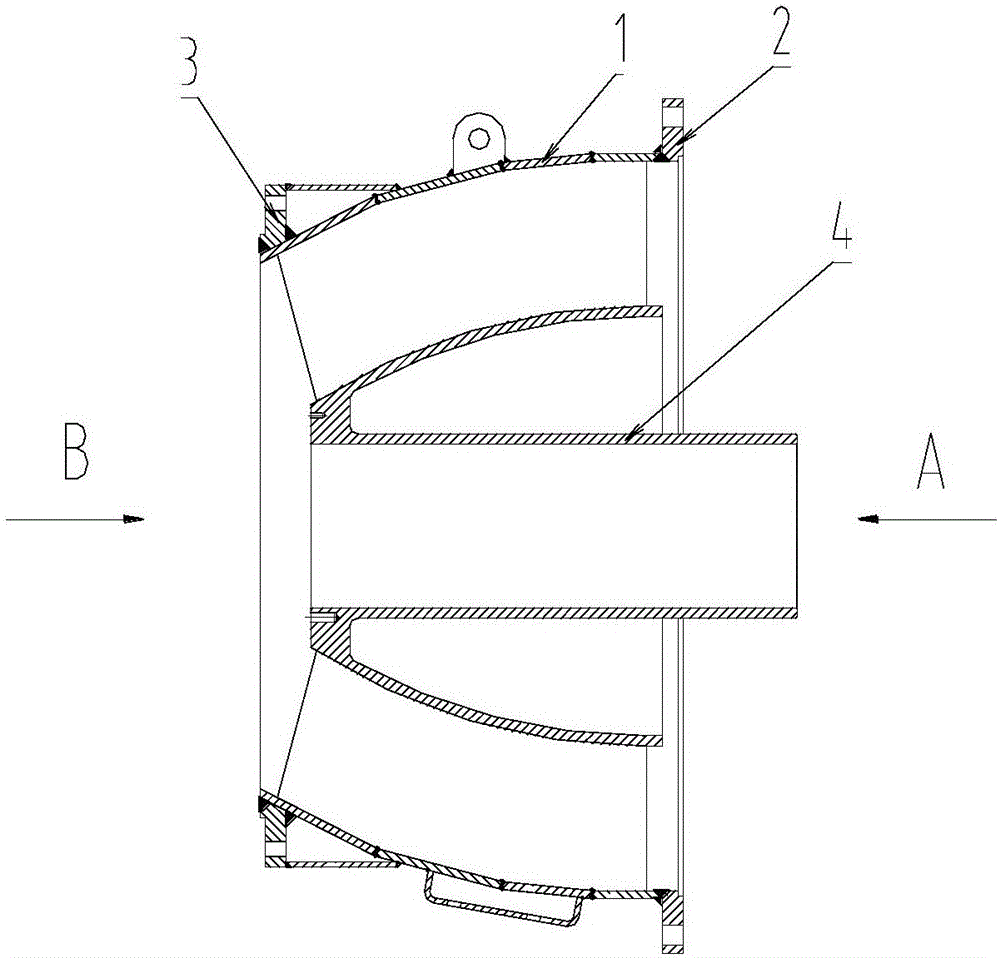

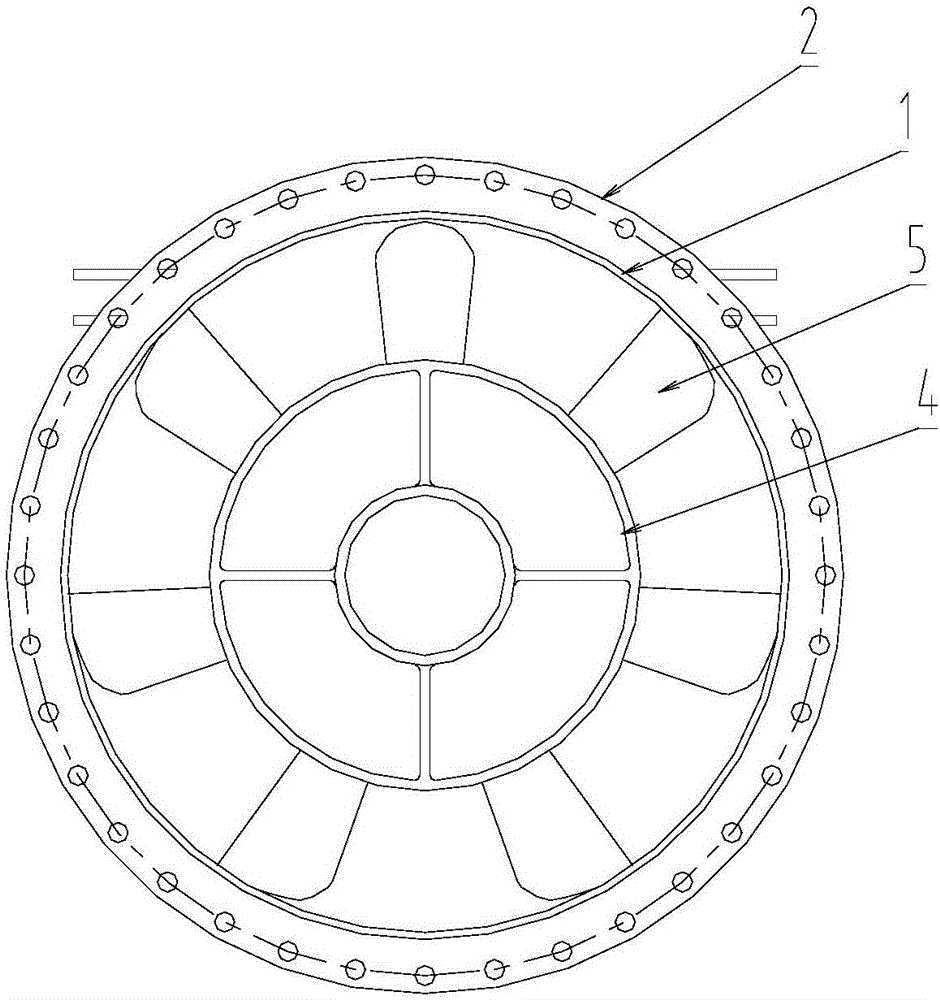

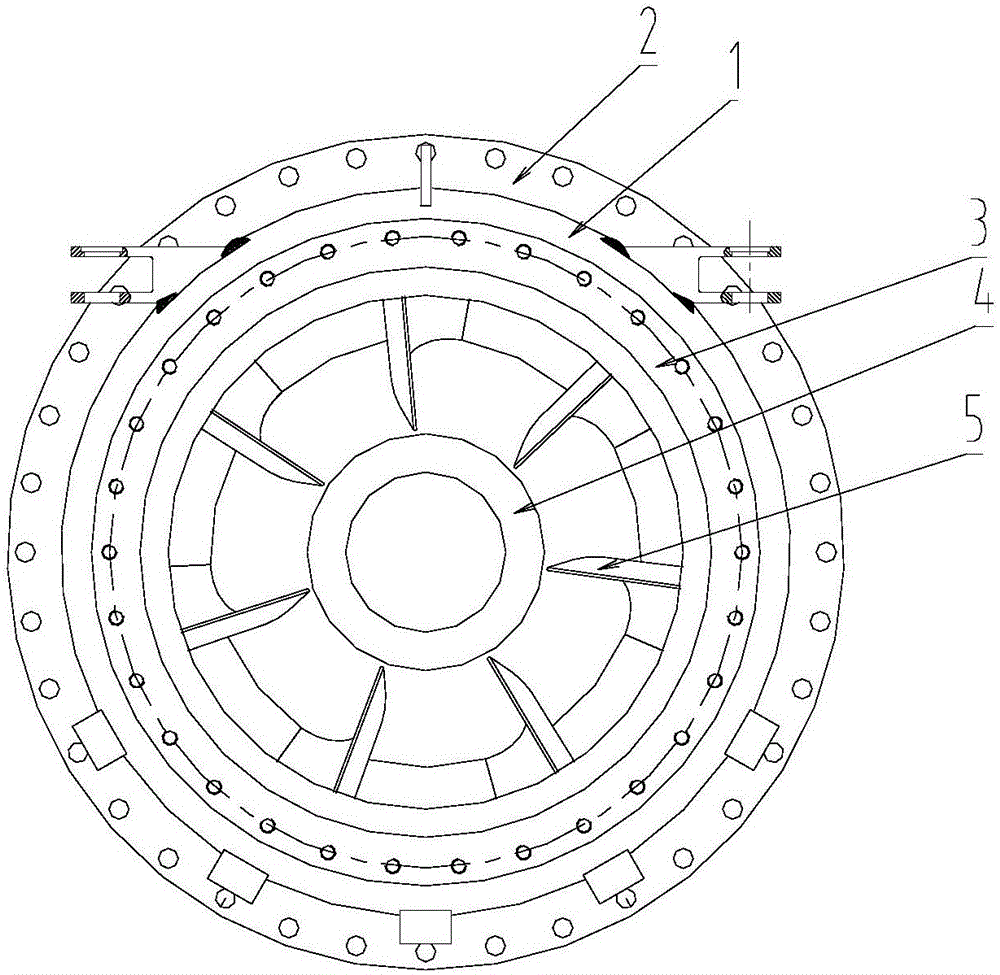

Supporting tool for guide vane nozzle in water-jet propulsion device and welding method

ActiveCN106238939AAvoid welding deformationPrevent welding deformationWelding/cutting auxillary devicesAuxillary welding devicesScrew threadWelding deformation

The invention discloses a supporting tool for a guide vane nozzle in a water-jet propulsion device and a welding method and belongs to the technical field of welding processing. According to the welding method, the supporting tool can be placed in a housing; as a plurality of connecting screw rods are arranged on the outer circumference of an inserted-connected column in the supporting tool and are correspondingly in threaded connection with one ends of supporting rods respectively, and the other ends of the supporting rods are in threaded connection with regulation bolts, by rotating the supporting rods, the supporting rods can screw in and out relative to the corresponding connecting screw rods, and the distance of each supporting rod and the inserted-connected column is changed; during using, the regulation bolts at the other ends of the supporting rods can be arranged against the inner wall of the housing, thus in the welding process of the housing, the housing can be prevented from shrinking due to welding to cause welding deformation, and the forming accuracy of the guide vane nozzle is ensured; and in addition, the universality is strong, thus the welding method can be suitable for manufacturing housings with different inside diameters, and the production efficiency of the guide vane nozzle can also be correspondingly improved.

Owner:WUHAN MARINE MACHINERY PLANT

Manufacturing process for welded honeycomb core

ActiveCN107186308AGuaranteed StrengthIncreased Speed and Accuracy of LayeringSoldering apparatusHoneycombFiller metal

The invention belongs to the manufacturing process of honeycomb cores and particularly relates to a manufacturing process for a welded honeycomb core. Metal foil materials with brazing filler metal are adopted as base materials, so that the problems of difficulties of directly placing the brazing filler metal on the metal foil materials and poor brazing filler metal positioning accuracy in the prior art are solved. Furthermore, binders are adopted to carry out preforming on the honeycomb core, the dimensional accuracy of the honeycomb core can be guaranteed, and thus the strength of the honeycomb core is guaranteed. Meanwhile, in the laminating process, changes of the shape of the binders coated on the foil materials cannot be affected, improvement of the laminating speed and laminating precision of the foil materials is facilitated, and the production speed and production quality of the honeycomb core are improved.

Owner:常州中航蜂窝技术开发有限公司

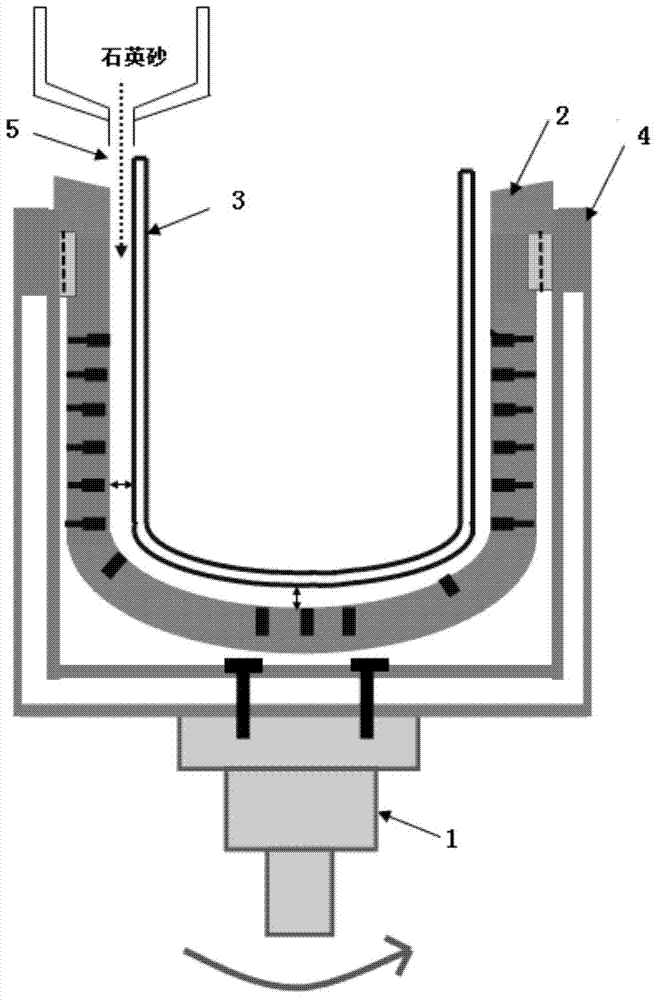

Quartz crucible forming device

InactiveCN103922571AGuaranteed molding accuracyControl thicknessGlass shaping apparatusGraphiteWater cooling

The invention discloses a quartz crucible forming device which is characterized by comprising a rotating platform, a graphite die, a forming die, a water cooling die and a feed opening, wherein the water cooling die is sleeved on the outer wall of the graphite die; the forming die is fixed inside the graphite die and is spaced from the graphite die for a certain gap with the length equal to the thickness of the quartz crucible; the forming die is made of a quartz product or stainless steel product and can rotate; the feed opening is fixed above the graphite die and aligns to the gap between the graphite die and the forming die. Compared with the prior art, the quartz crucible forming device is simple, convenient and precise; in addition, artificial feeding is replaced with automatic forming, so that the thickness and weight of the formed quartz sand raw material are controlled, artificial errors are reduced, and the forming precision of the quartz sand on the inner wall of the graphite die is ensured.

Owner:江苏华尔石英材料科技有限公司

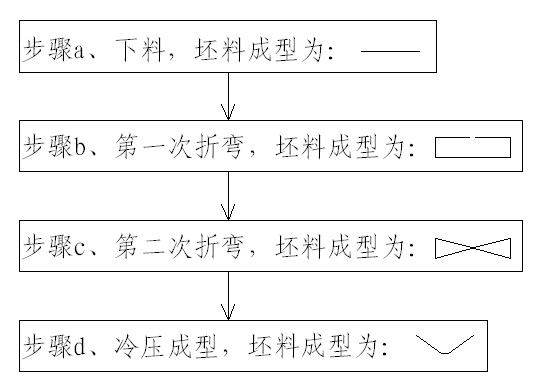

Manufacturing method of 8-byte grating steel frame

The invention discloses a manufacturing method of an 8-byte grating steel frame, comprising the following steps of: a, blanking: adopting a cutting machine to cut steel strips into the specified size; b, primary bending: bending the steel strip into a rectangular blank by a cold bending machine; c, secondary cold bending: cold-bending the rectangular blank into an 8-byte grating blank by a cold bending device; and d, cold-pressing forming: cold-pressing the 8-byte grating blank into a v shape by a cold-pressing device. According to the manufacturing method, the manufacturing steps are fewer, the process is short, and the production efficiency is high; simultaneously, the adopted cold-bending device and the cold-pressing device are respectively provided with a limiting device adaptive to the 8-byte grating steel frame, the forming accuracy of the 8-byte grating steel frame can be ensured, the cold-bending device and the cold-pressing device are respectively and automatically controlled by a hydraulic system, the labor intensity of operators can be reduced and the production efficiency can be improved.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 17TH BUREAU GRP

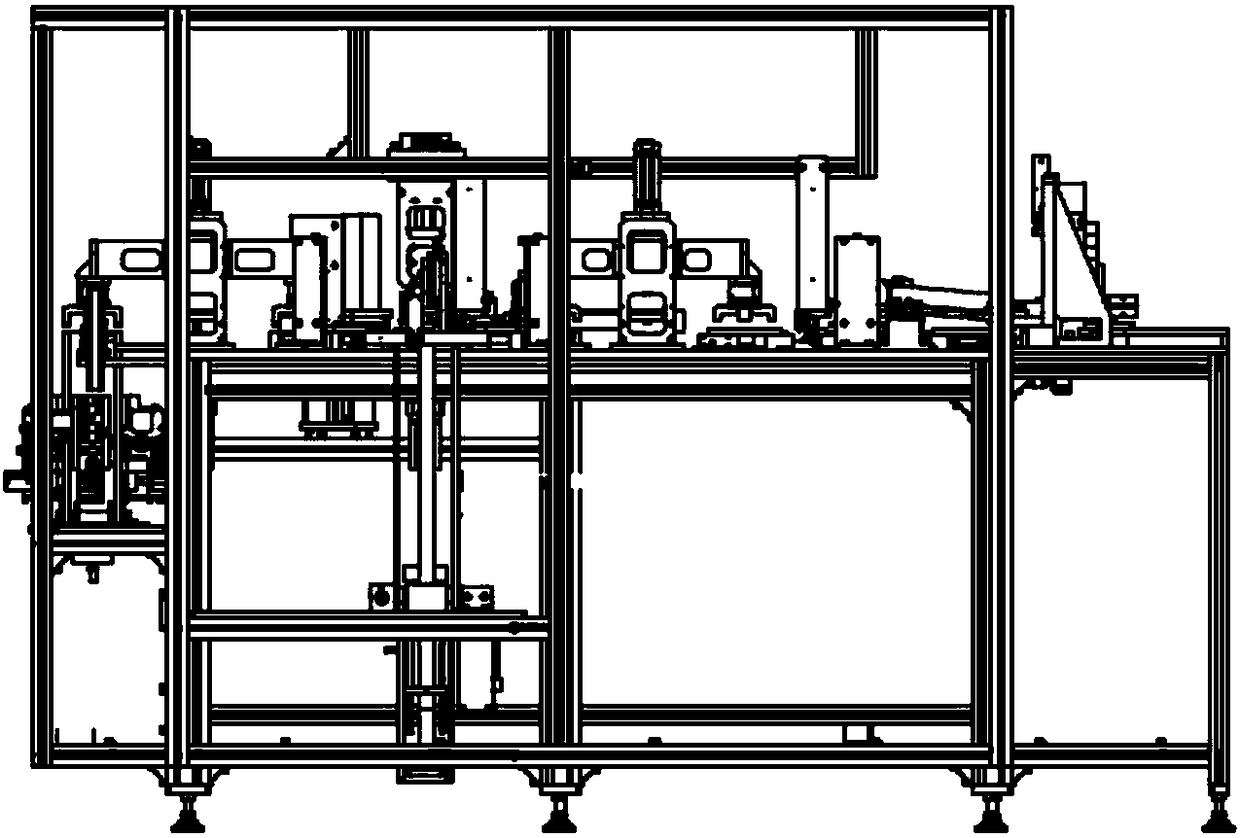

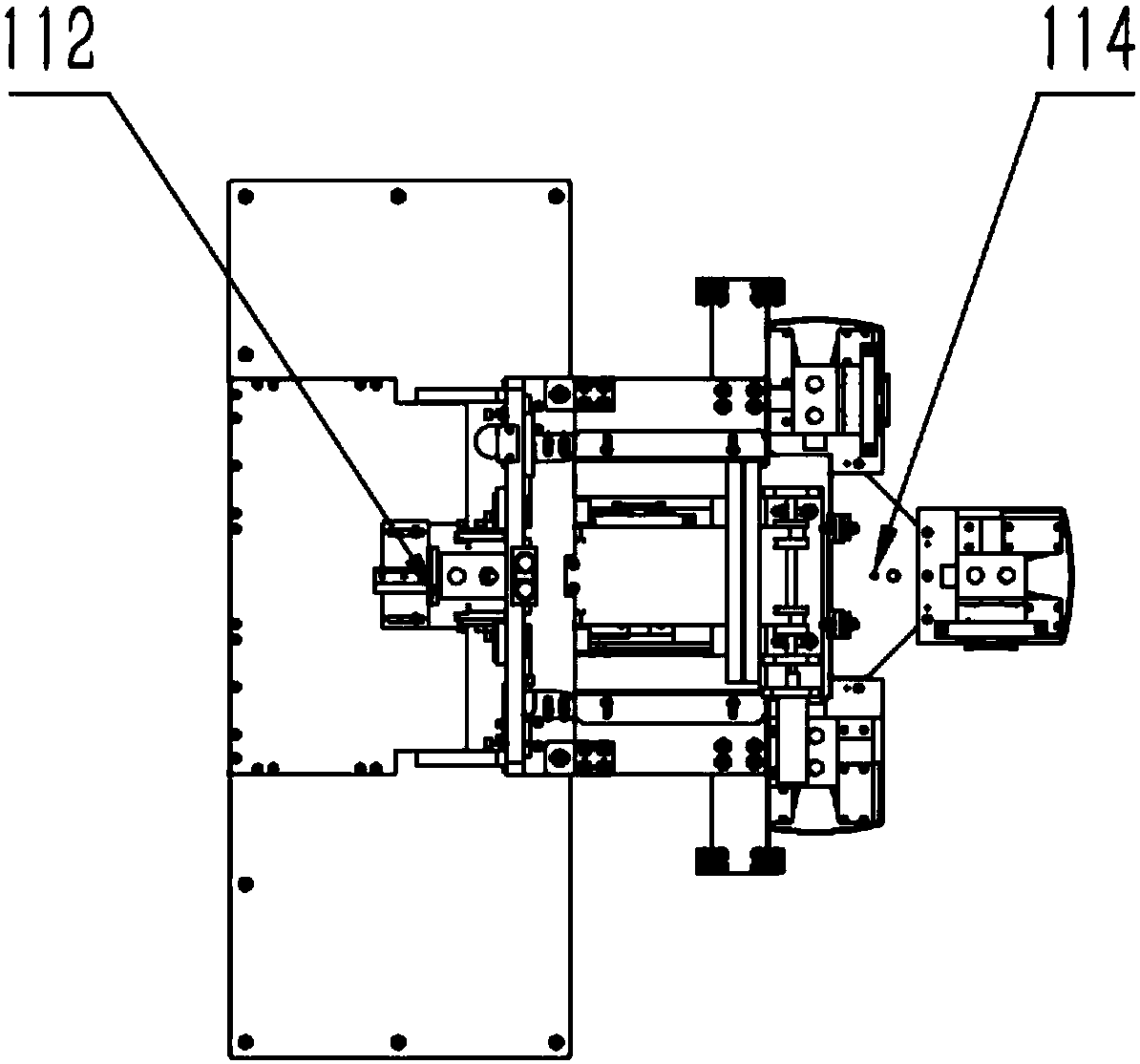

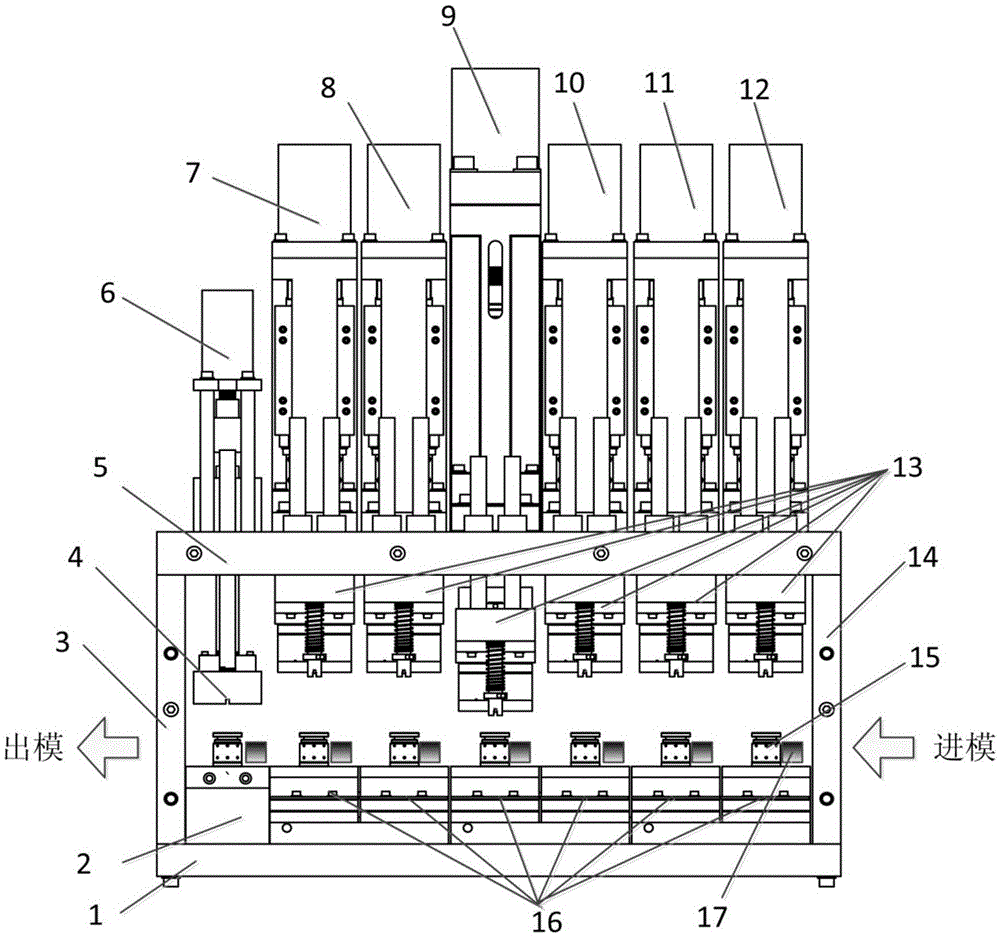

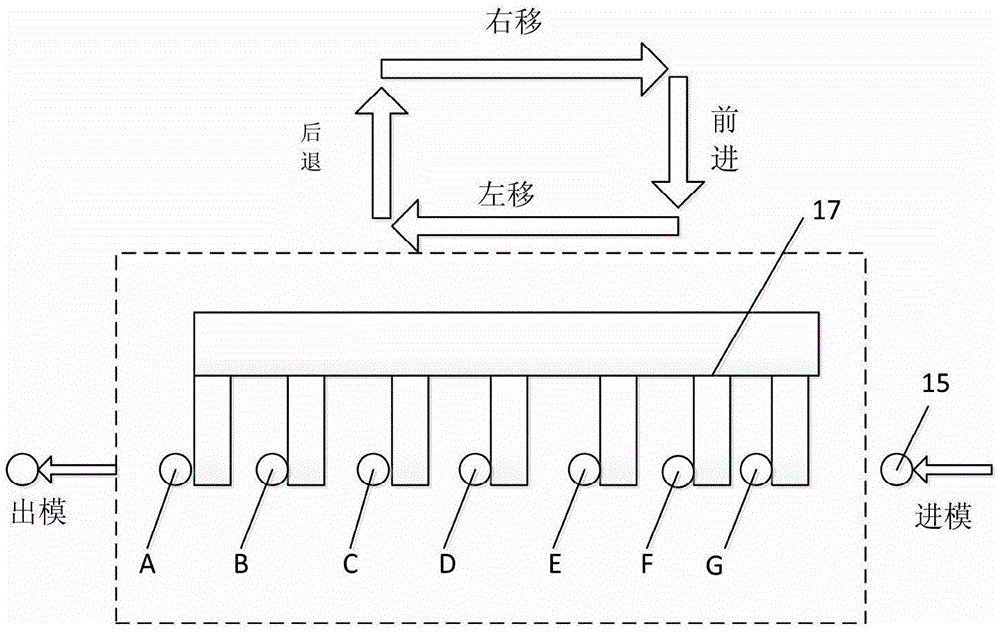

Aspherical glass lens multi-station precision molding equipment

InactiveCN105417933AIncrease productivityImprove performanceGlass pressing apparatusGlass productionTransfer mechanismOptical glass

The invention belongs to the field of thermal forming equipment and in particular relates to aspherical glass lens multi-station precision molding equipment. The equipment comprises seven precision molding stations, namely a low-temperature heating station, a high-temperature heating station, a pre-pressing station, a hot-pressing station, a pressure-maintaining station, an annealing station and a cooling station. Optical glass blank is placed into a precision mould, the module can be moved among the different stations through a mould transferring mechanism, so as to respectively realize the processes of heating, pre-pressing, hot-pressing, pressure-maintaining, annealing and cooling and realize the high-precision thermo-compression formation of an aspherical glass lens, the molding quality and production efficiency of the aspherical glass lens are improved and the industrial volume production can be realized.

Owner:HUNAN UNIV

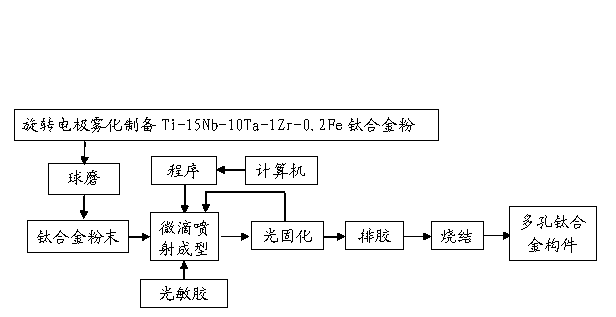

Preparation method for biomedical porous low-modulus titanium alloy

The invention discloses a preparation method for Ti-15Nb-10Ta-1Zr-0.2Fe porous titanium alloy. The preparation method comprises the following steps: step 1, preparation of Ti-15Nb-10Ta-1Zr-0.2Fe titanium alloy powder by means of a rotating electrode atomization method, step 2, preparation of photosensitive adhesives, step 3, droplet spray molding, step 4, ultraviolet light curing, step 5, removal of adhesives, and step 6, vacuum sintering. The beneficial effects of the preparation method are as follows. (1) The alloy powder prepared by means of a rotating electrode atomization method has small particle size and good allround performance, and the particles are spherical. The powder-preparing technology is one of basic technologies for preparing high-performance titanium alloy members in the prior art. (2) By utilizing a droplet spray technology, member molding is simple and rapid. The working efficiency is high, the cost is low, the raw materials can be recycled, and members with complicated shapes can be set and prepared according to computer programs. (3) Ultraviolet light irradiation curing is performed by utilizing suitable photosensitive adhesives. The equipment requirement is simple, the working efficiency is high, the molding precision of members can be ensured, and Ti-15Nb-10Ta-1Zr-0.2Fe porous titanium alloy members with different porosity sizes can be prepared through control of photosensitive adhesive types and droplet injection parameters and establishment of different sintering processes.

Owner:湖南迈迪科新材有限公司

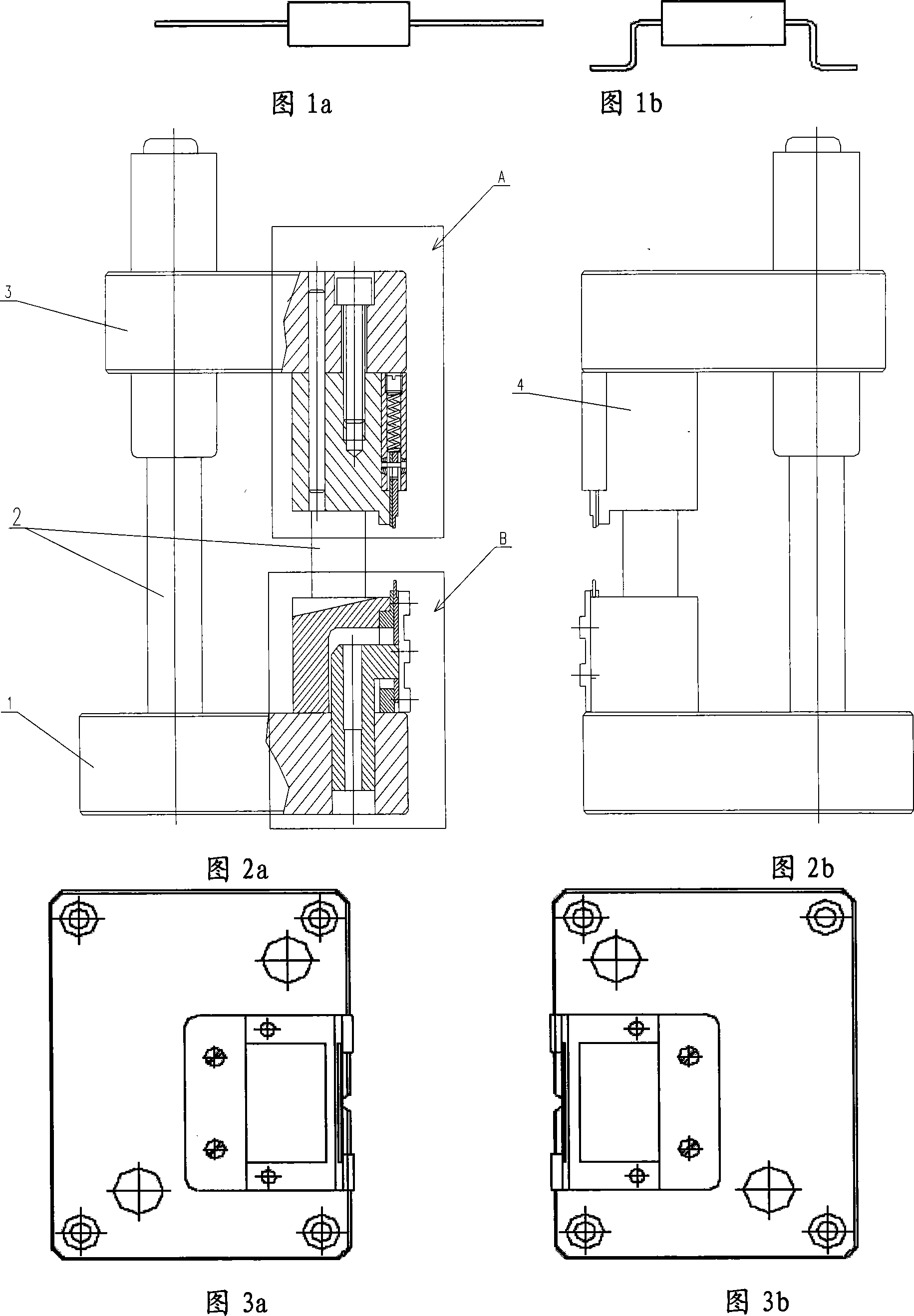

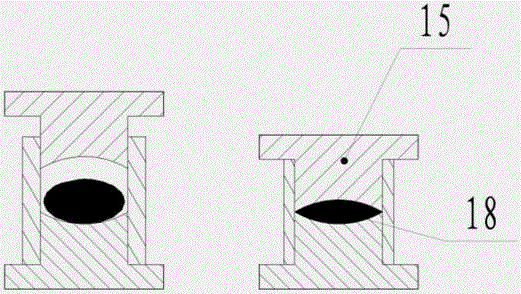

Hot press mold, temperature measuring device, and hot press molding method

ActiveUS20120234069A1Accurate measurementGuaranteed molding accuracyThermometer detailsShaping toolsStroke TypeMaterials science

Provided is a technique which can, in order to guarantee the molding accuracy of hot press molding, accurately measure the temperature of a workpiece being subjected to the hot press molding. A hot press mold is a mold used for hot press molding for hardening and molding a workpiece, which has been heated, by pressing the workpiece. The hot press mold is provided with a stroke type temperature measuring device which is extended and retracted by a pressing force applied thereto through the workpiece. The temperature measuring device is provided in such a manner that the temperature measuring device protrudes outward from the molding surface of the mold, and when subjected to the pressing force applied through the workpiece while being in contact with the workpiece, the temperature measuring device shortens in length and retracts into the mold. It is preferable that the temperature measuring device is provided with a first elastic member and a second elastic member which shorten in length when subjected to the pressing force applied through the workpiece, and that the temperature measuring device is extended and retracted in two stages by means of the first elastic member and the second elastic member.

Owner:TOYOTA JIDOSHA KK

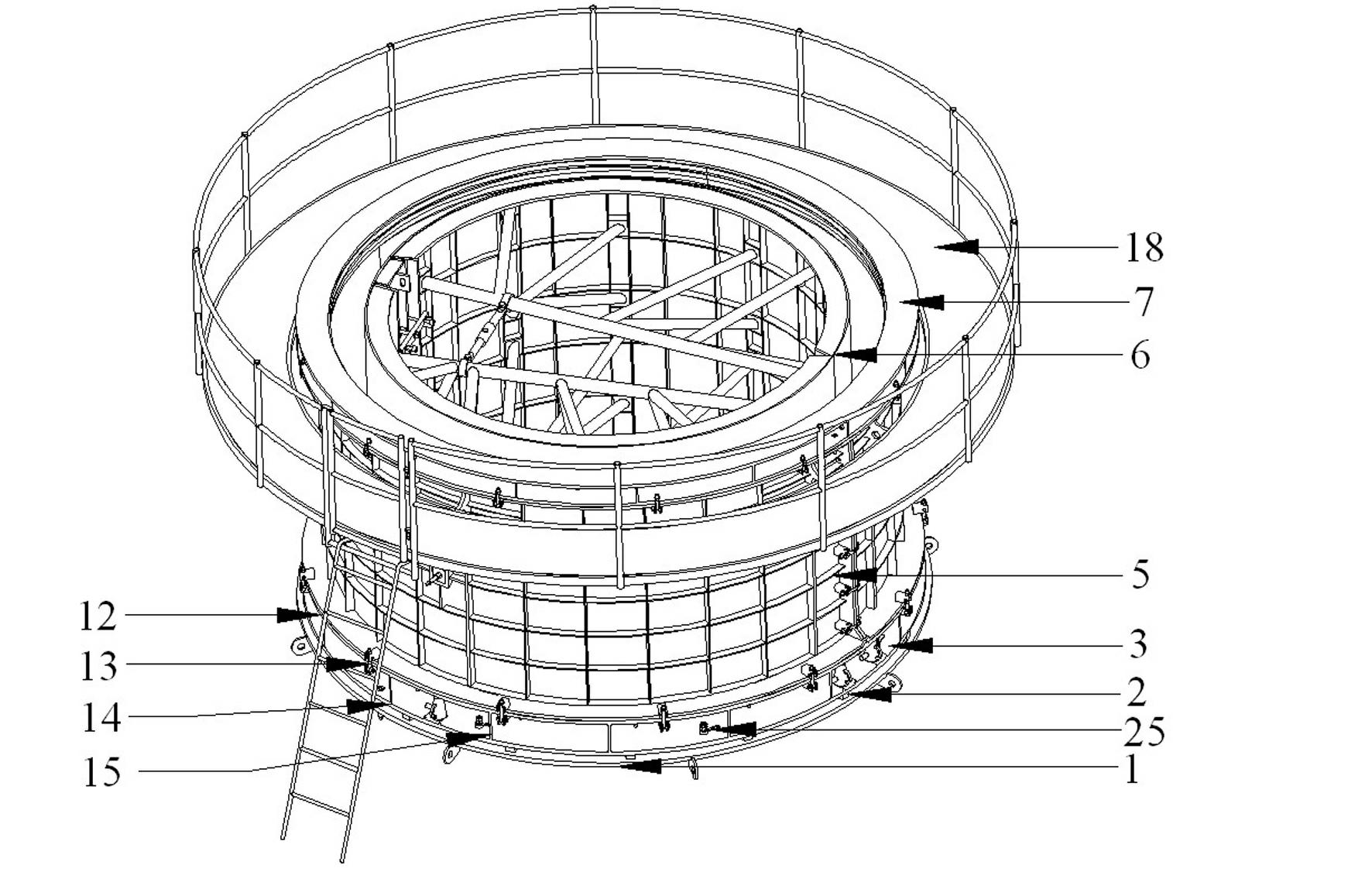

Plasma 3D printing equipment and method for directly printing building framework

InactiveCN105781110ASmall sizeBroaden the thinking spaceBuilding material handlingControl systemEngineering

The invention discloses plasma 3D printing equipment and a method for directly printing a building framework. The plasma 3D printing equipment comprises a forming table, a plurality of forming brackets which are erected around the forming table, a plasma processing device, a connector, a plurality of drive arms, a powder feeding motor and a central control system, wherein a guide rail and a slide block drive mechanism are arranged on the forming brackets; the connector is arranged on the middle part of a space defined by the forming brackets, and is movably connected with the slide block drive mechanism through the plurality of drive arms; and the plasma processing device and a plasma spray head are mounted on the connector. The central control system controls the slide block drive mechanism to move up and down in a Z direction on the guide rail according to an instruction of the central control system, so that a connected object is driven to correspondingly move in an X direction, a Y direction and the Z direction. Compared with the manufacturing of the conventional building framework, the construction cost is reduced, the engineering period is shortened, and the mechanical property and the molding precision of the building framework are improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com