Zoning cutting-based five-axis milling method of centrifugal compressor impeller

A centrifugal compressor and sub-regional technology, which is applied to milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve problems such as messy machining tracks and low cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The following is a detailed description of the five-coordinate milling method of the impeller of a centrifugal compressor based on sub-area cutting by taking the five-coordinate overall milling of a centrifugal compressor impeller as an example in conjunction with the accompanying drawings:

[0079] 1. Build the blade model

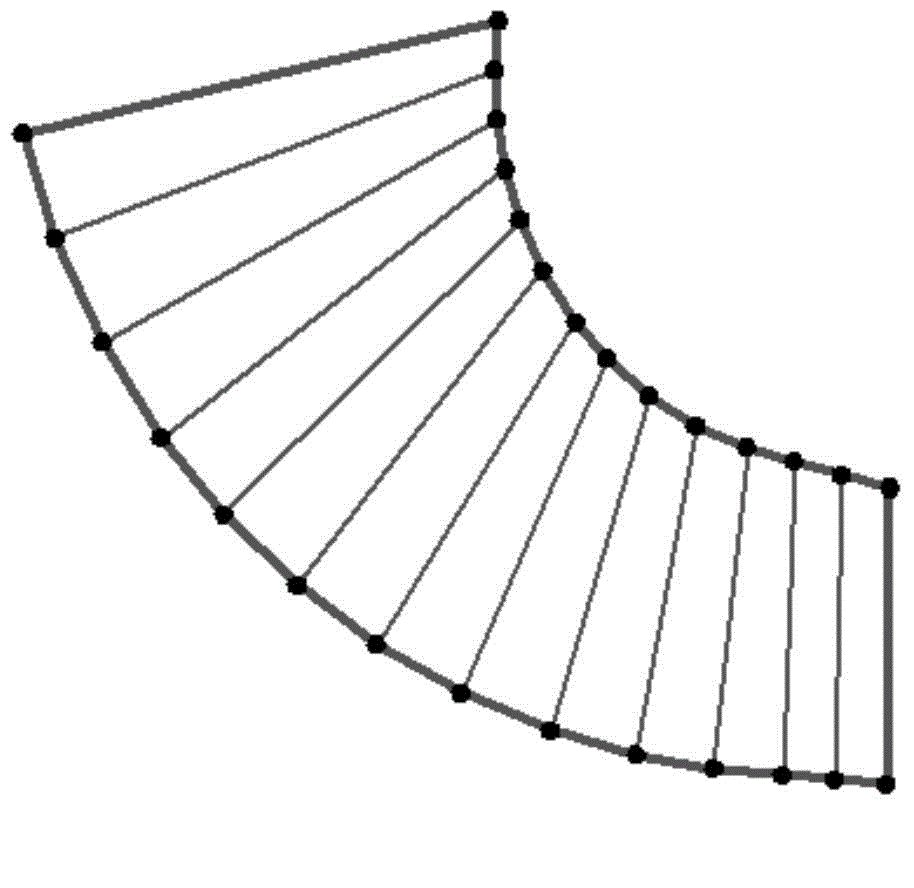

[0080] See figure 1 As shown, input the blade data into the computer to complete the modeling of the target blade.

[0081] 2. Establish impeller model

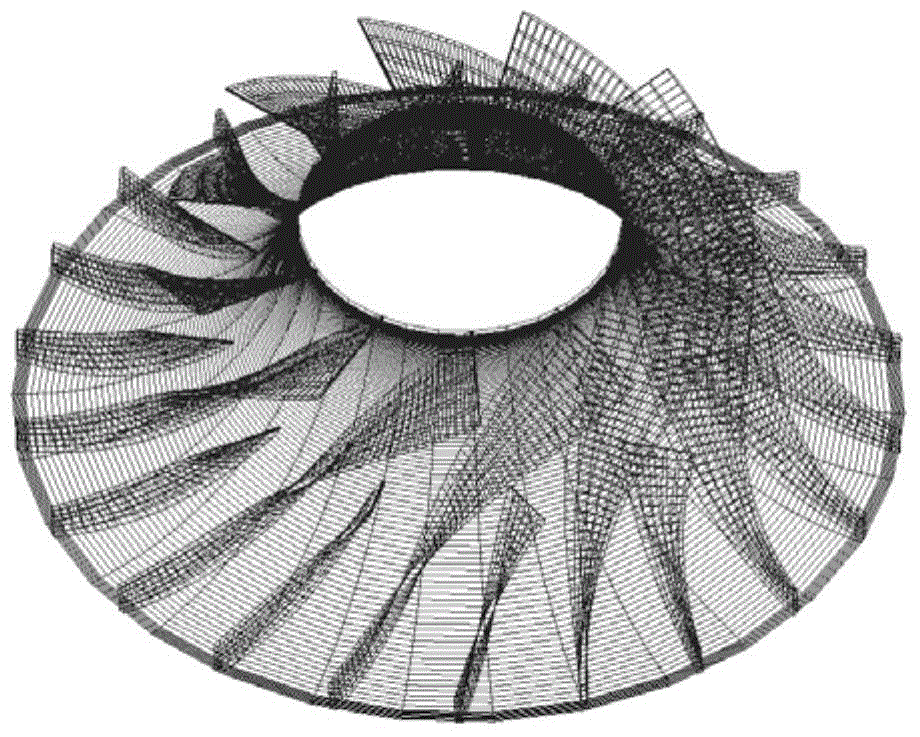

[0082] See figure 2 As shown, input the impeller solid model data into the computer to complete the modeling of the target impeller.

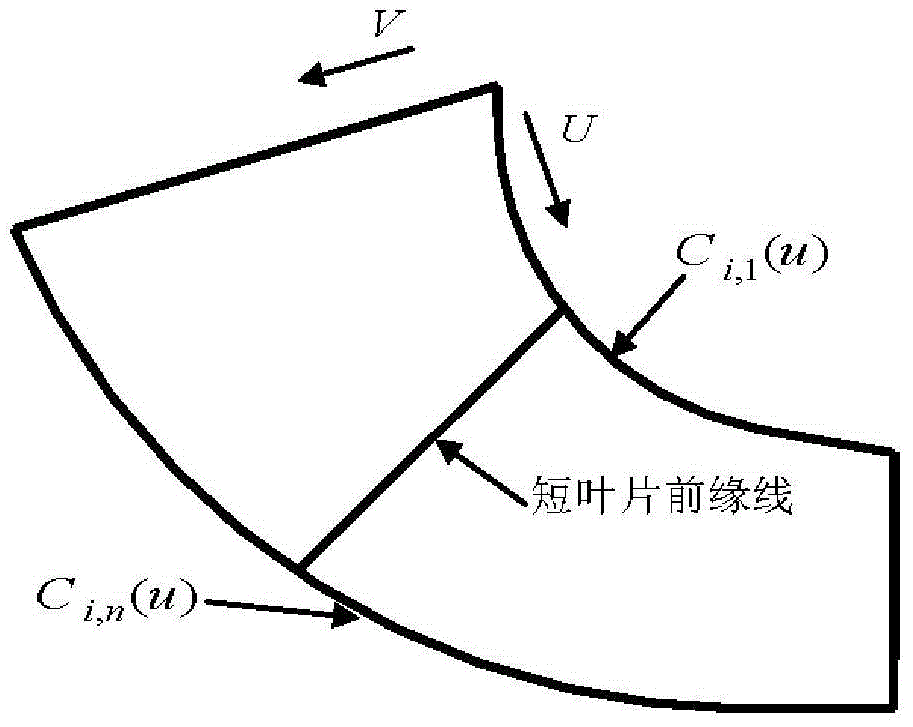

[0083] 3. Numerical representation of leaves in the form of bicubic non-uniform rational B-spline matrix

[0084] Define the blade S(u,v) from the top to the root as the v direction, and the blade inlet to the blade outlet as the u direction, then the blade S(u,v) is defined in the form of a bicubic non-uniform rational B-spline (NURBS) matrix as:

[0085] S(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com