Plasma 3D printing equipment and method for directly printing building framework

A 3D printing and plasma technology, applied in the field of additive manufacturing, can solve the problems of high manufacturing cost, low precision, and difficult building frame process, so as to reduce construction costs, reduce construction risks, and reduce production costs and processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

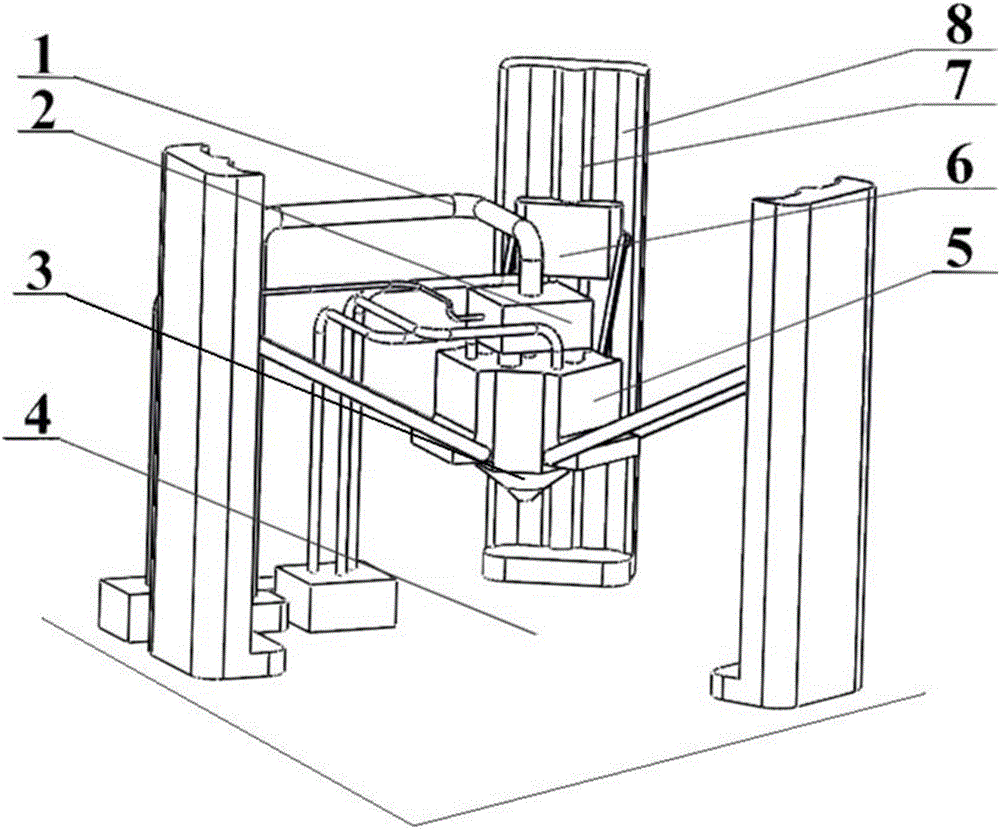

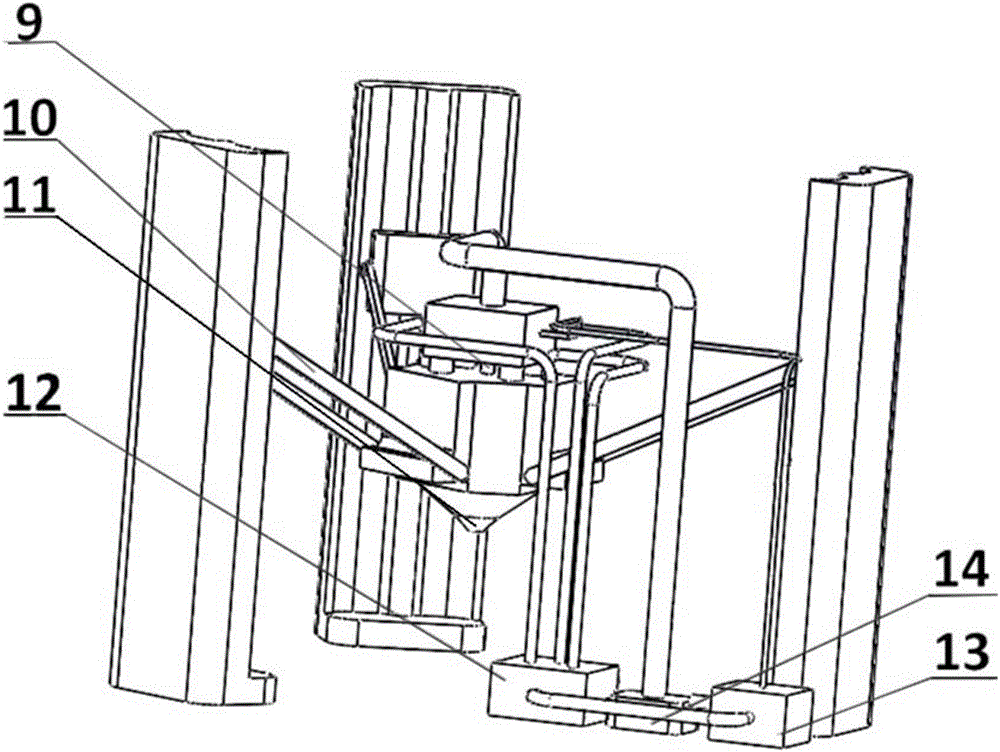

[0032] Such as figure 1 , 2 Shown. The invention discloses a plasma 3D printing equipment for directly printing a building frame, which includes a forming table 4, several forming brackets 8 erected around the forming table 4, a plasma processing device 2, a connecting piece 5, several driving arms 10, Powder motor 12 and central control system 13;

[0033] A guide rail 7 is provided on the forming bracket 8, and a slider driving mechanism 6 is provided on the guide rail 7;

[0034] The connecting member 5 is placed in the middle of the molding bracket 8, and the surrounding of the connecting member 5 is movably connected to the slider driving mechanism 6 through a plurality of driving arms 10 distributed around it;

[0035] The plasma processing device 2 is installed above the connecting piece 5, and a plasma shower head 3 connected to the plasma processing device 2 is installed below the connecting piece 5. The plasma processing device 2 is connected to the plasma shower head 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com