Patents

Literature

2557results about How to "Improve cut quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

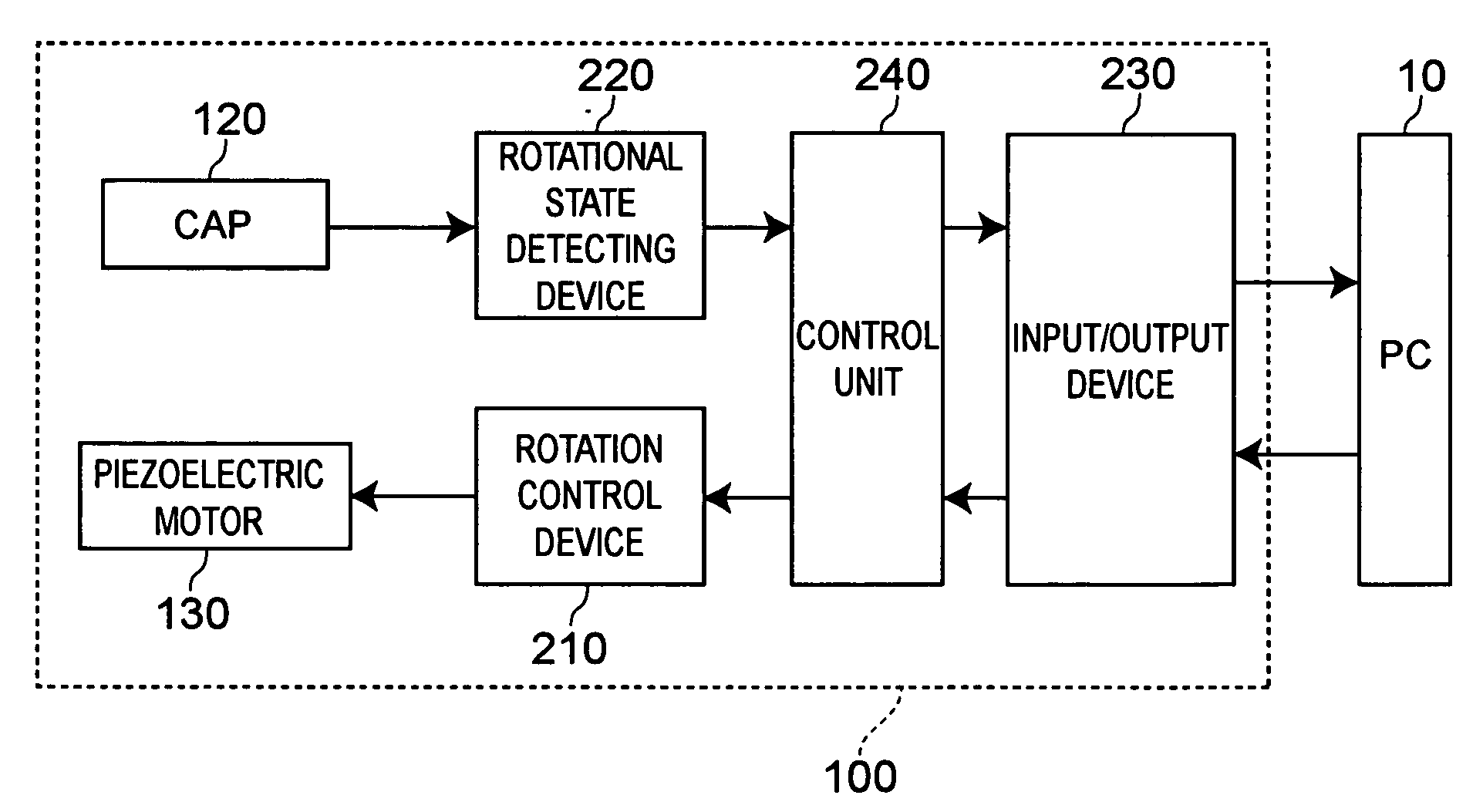

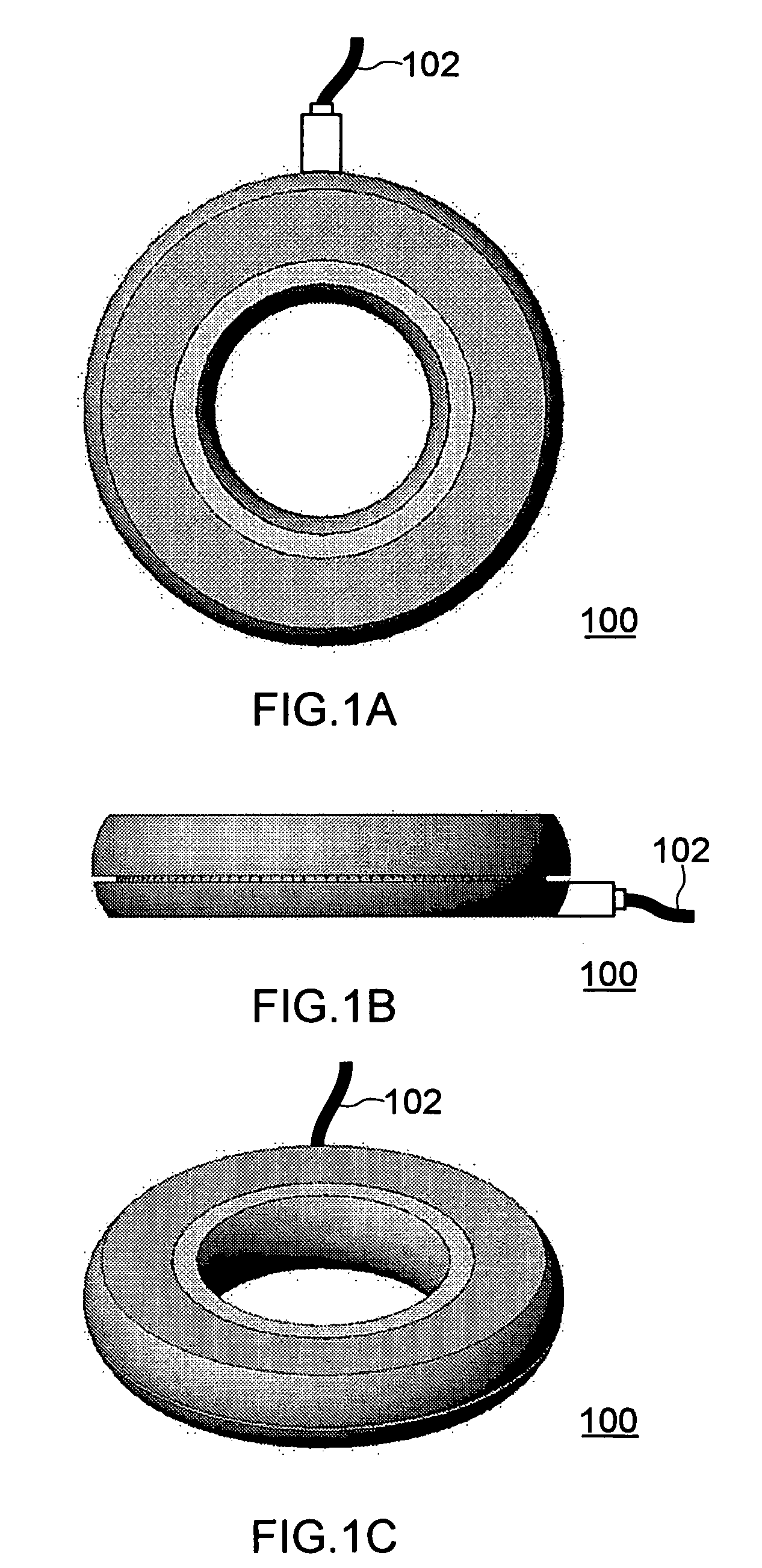

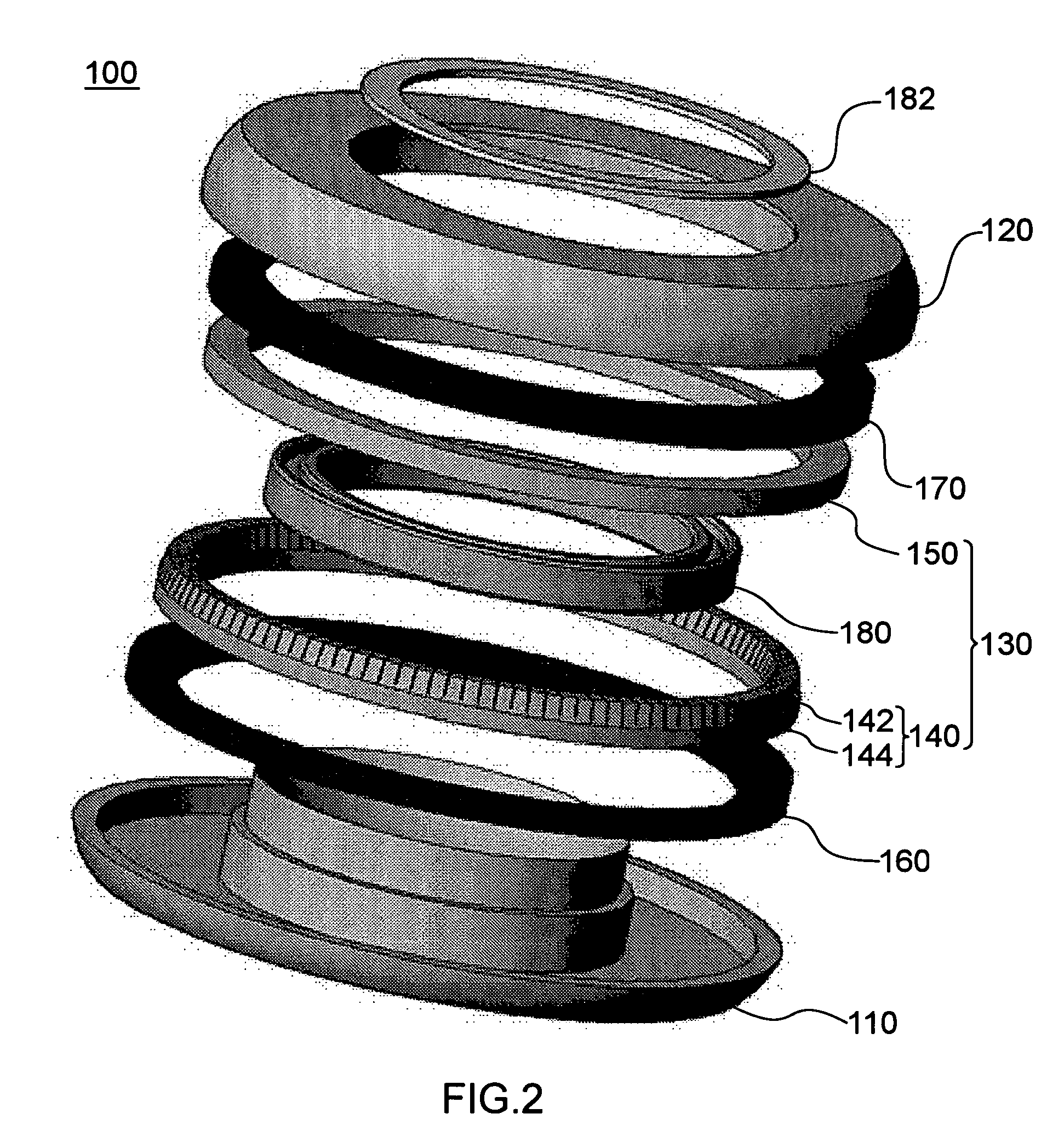

Haptic feedback controller, method of controlling the same, and method of transmitting messages that uses a haptic feedback controller

InactiveUS20060255683A1More feedbackFun to playControlling membersPiezoelectric/electrostriction/magnetostriction machinesLow speedFeedback controller

A haptic feedback controller 100 according to the present invention is a haptic feedback controller that controls a controlled appliance and includes a base 110, a cap 120, a piezoelectric motor 130, a rotation control device, and a rotational state detecting device. According to haptic feedback controller 100 of the present invention, the piezoelectric motor 130 that can produce a large torque even when rotating at low speed is used, so that even when the cap 120 is rotated at low speed, sufficiently large haptic feedback can be applied to the cap 120. Also, since the base 110 and the cap 120 are respectively fixed to the stator 140 and the rotor 150 of the piezoelectric motor 130, there is no backlash. As a result, according to the present invention it is possible to provide a haptic feedback controller for which there is no loss in the ability to express haptic feedback, so that a wide variety of haptic feedback can be expressed.

Owner:FUKOKU CO LTD

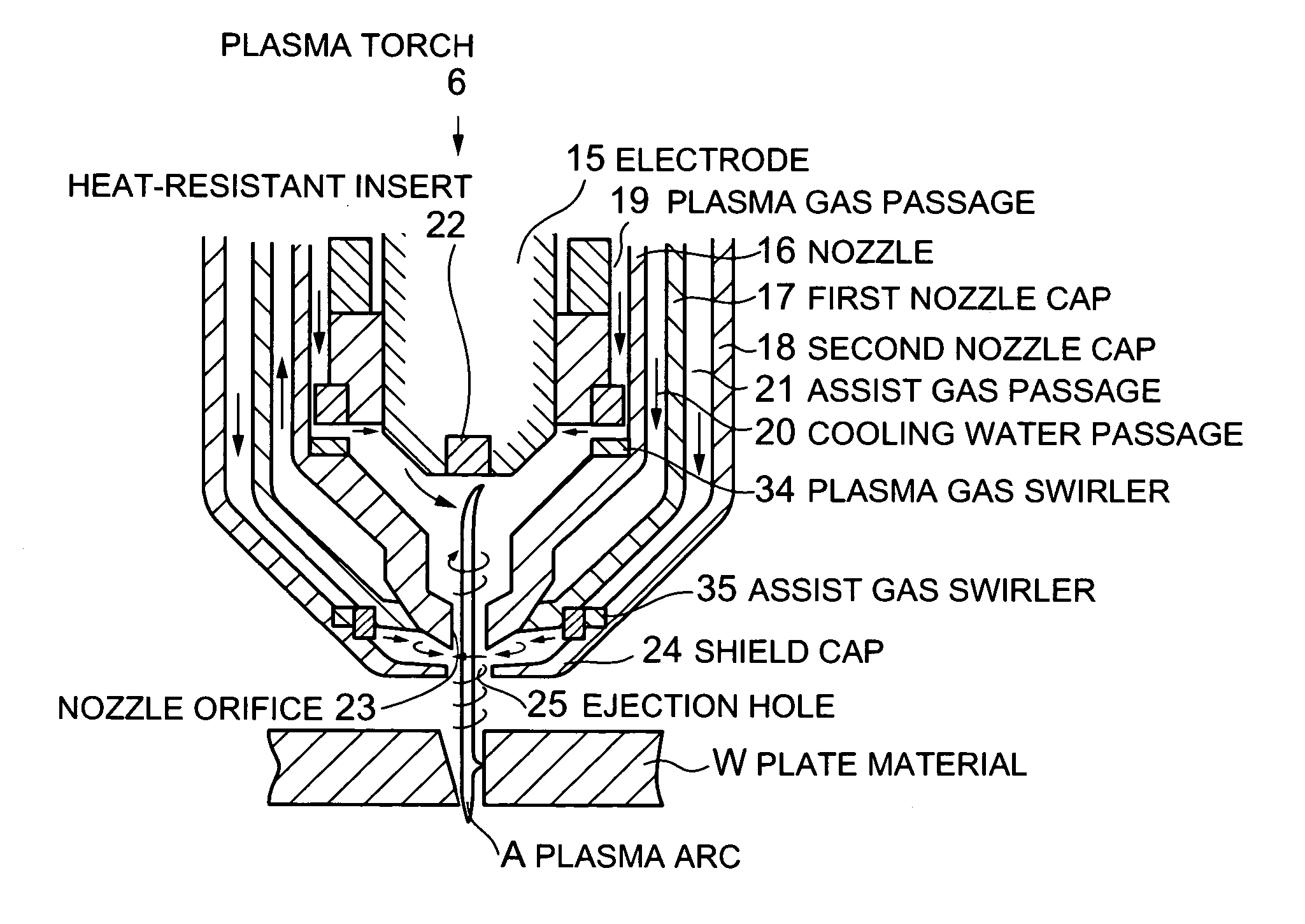

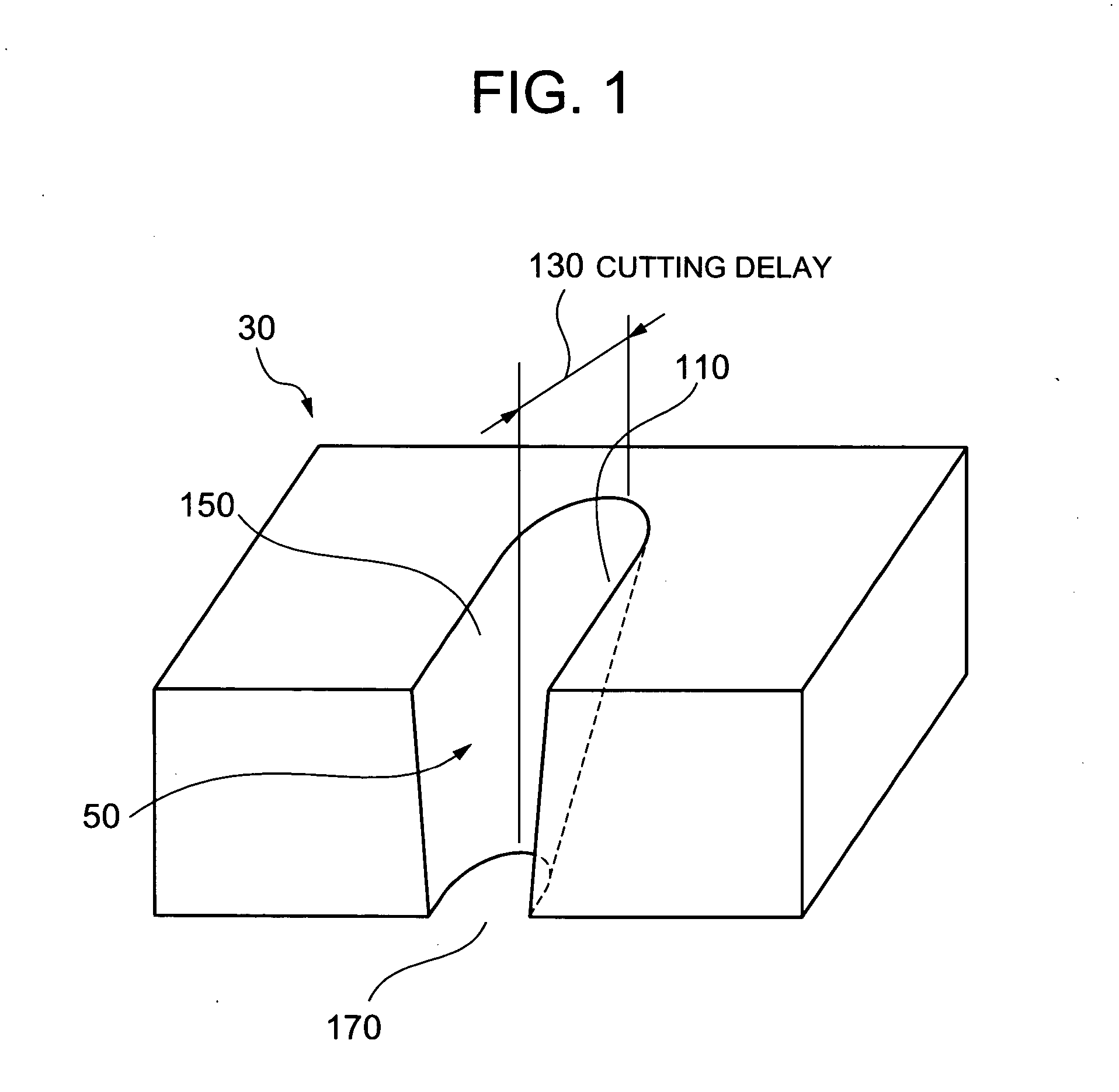

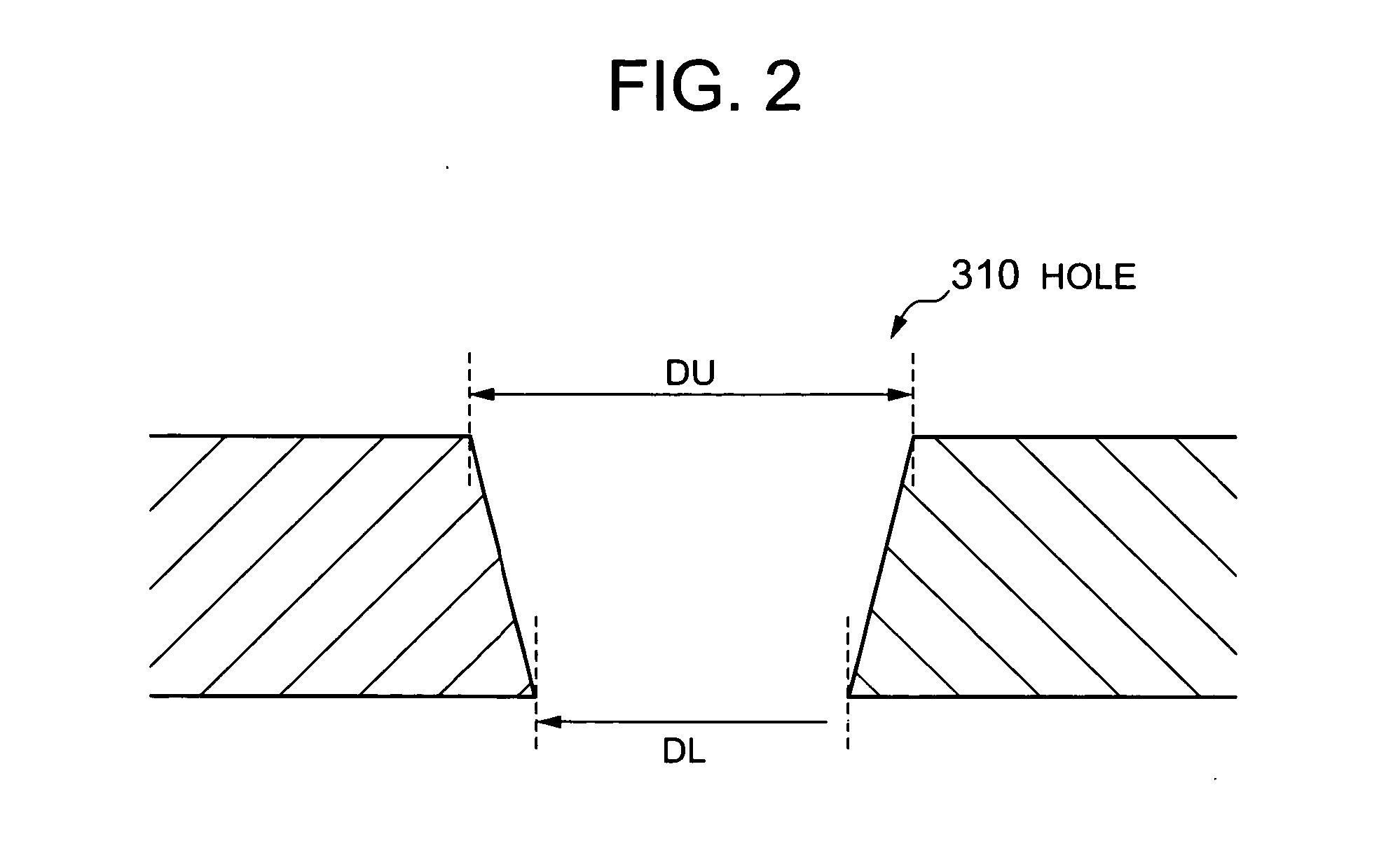

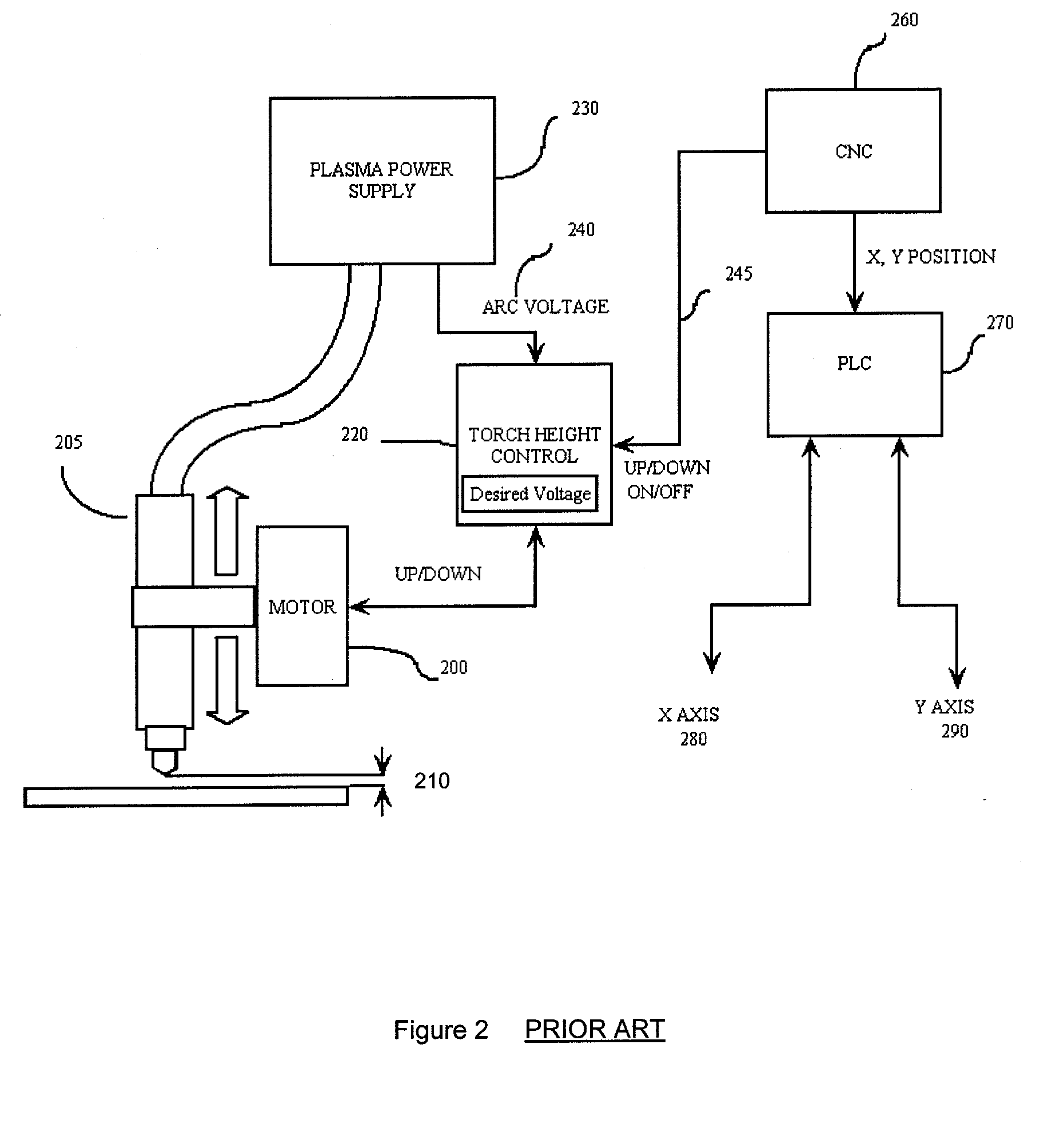

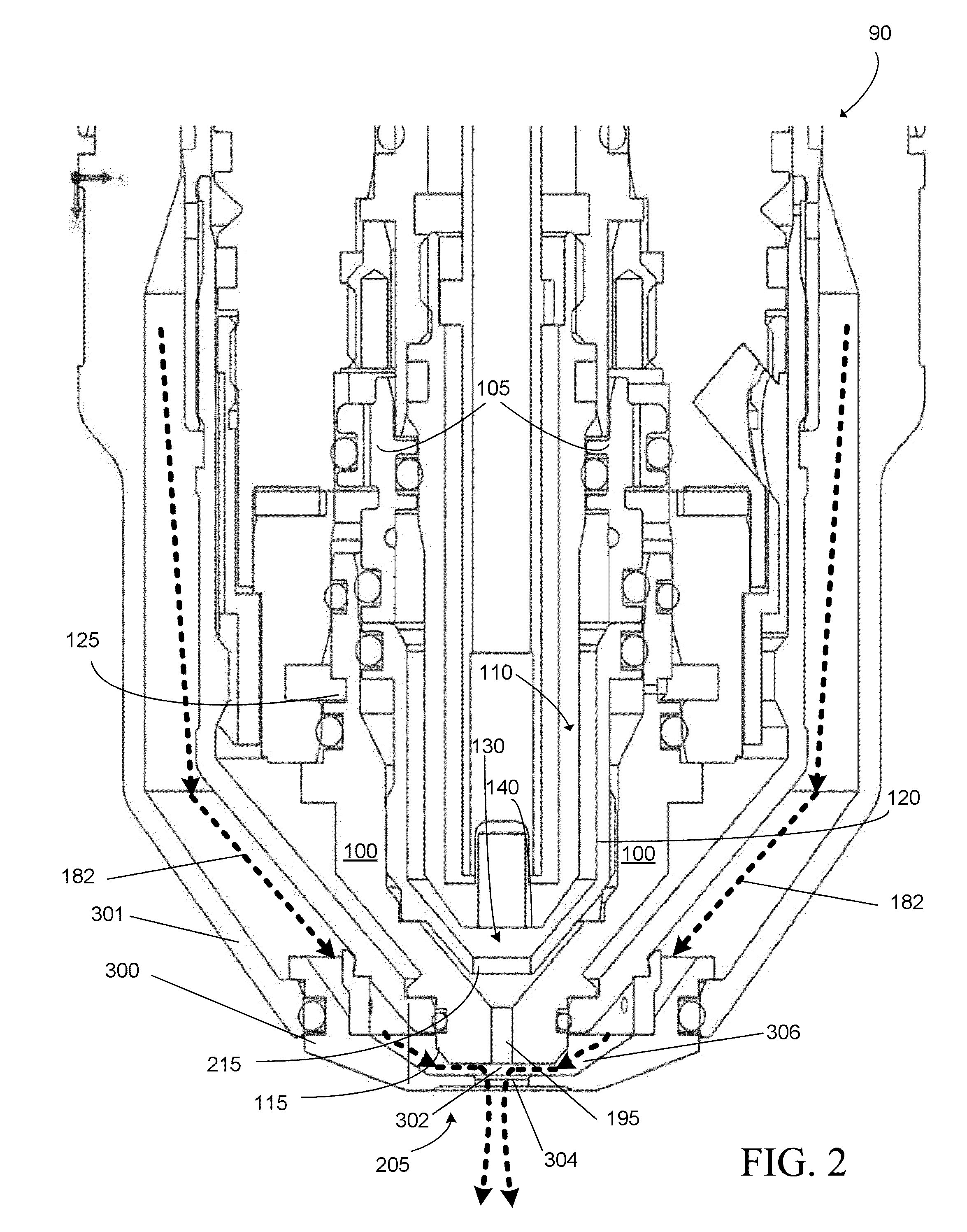

Plasma cutting apparatus and control unit thereof

ActiveUS20050035093A1Improve cut qualityWelding/cutting auxillary devicesArc welding apparatusEngineeringPlasma Gases

Cutting quality of the product, in particular, hole cutting quality, in plasma arc cutting is improved. A control unit, which controls a plasma cutting apparatus for cutting a product from a plate material by moving a plasma torch at a cutting speed along a cutting path corresponding to the product shape to cut the plate material, while supplying an arc current and a plasma gas to the plasma torch and forming a plasma arc from a nozzle of the plasma torch to the plate material, conducts control so that, when a hole is cut, a cutting speed is lower, a value of the arc current value is smaller, and a plasma gas flow rate or pressure is less than those when a contour is cut.

Owner:KOMATSU IND CORP

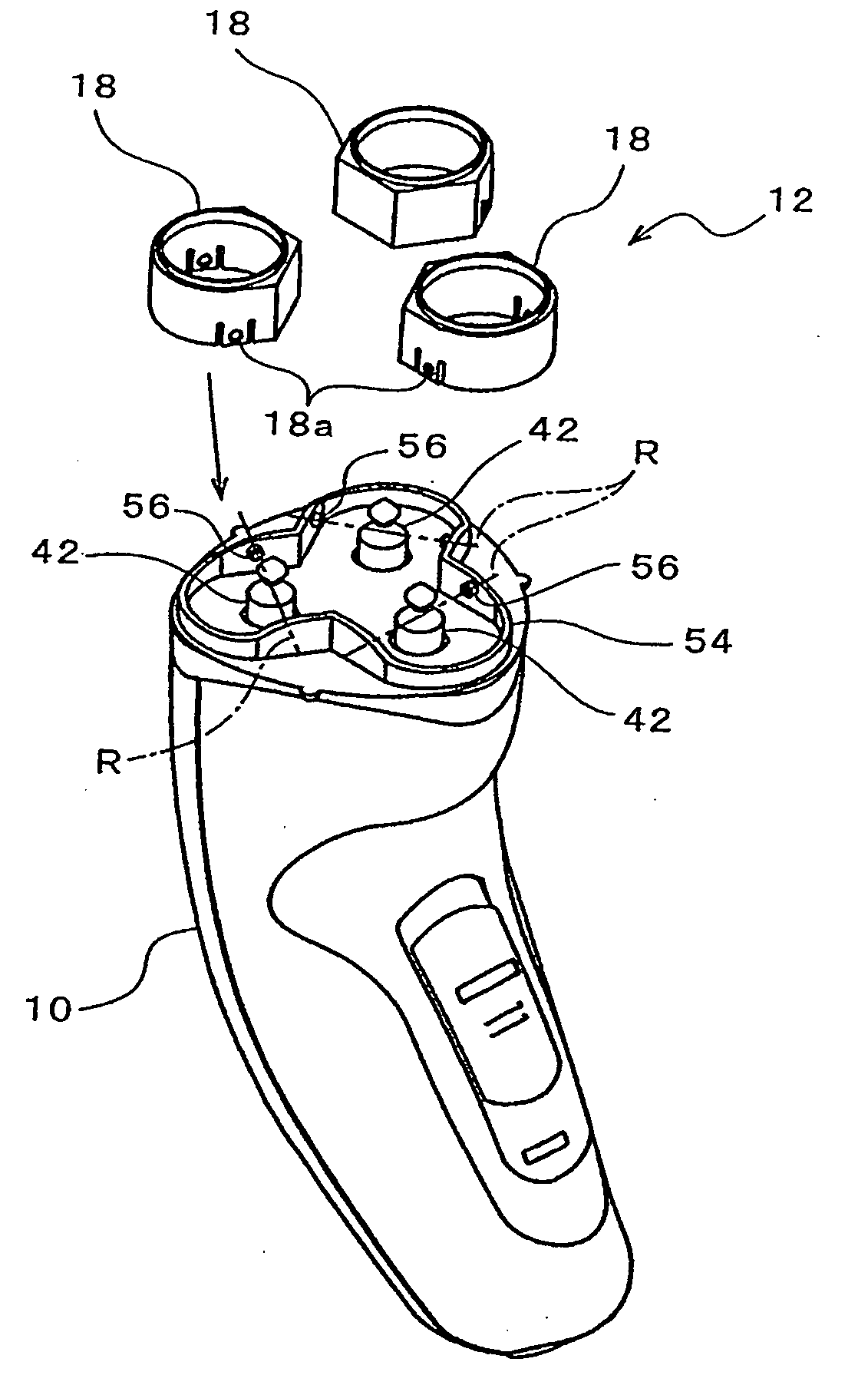

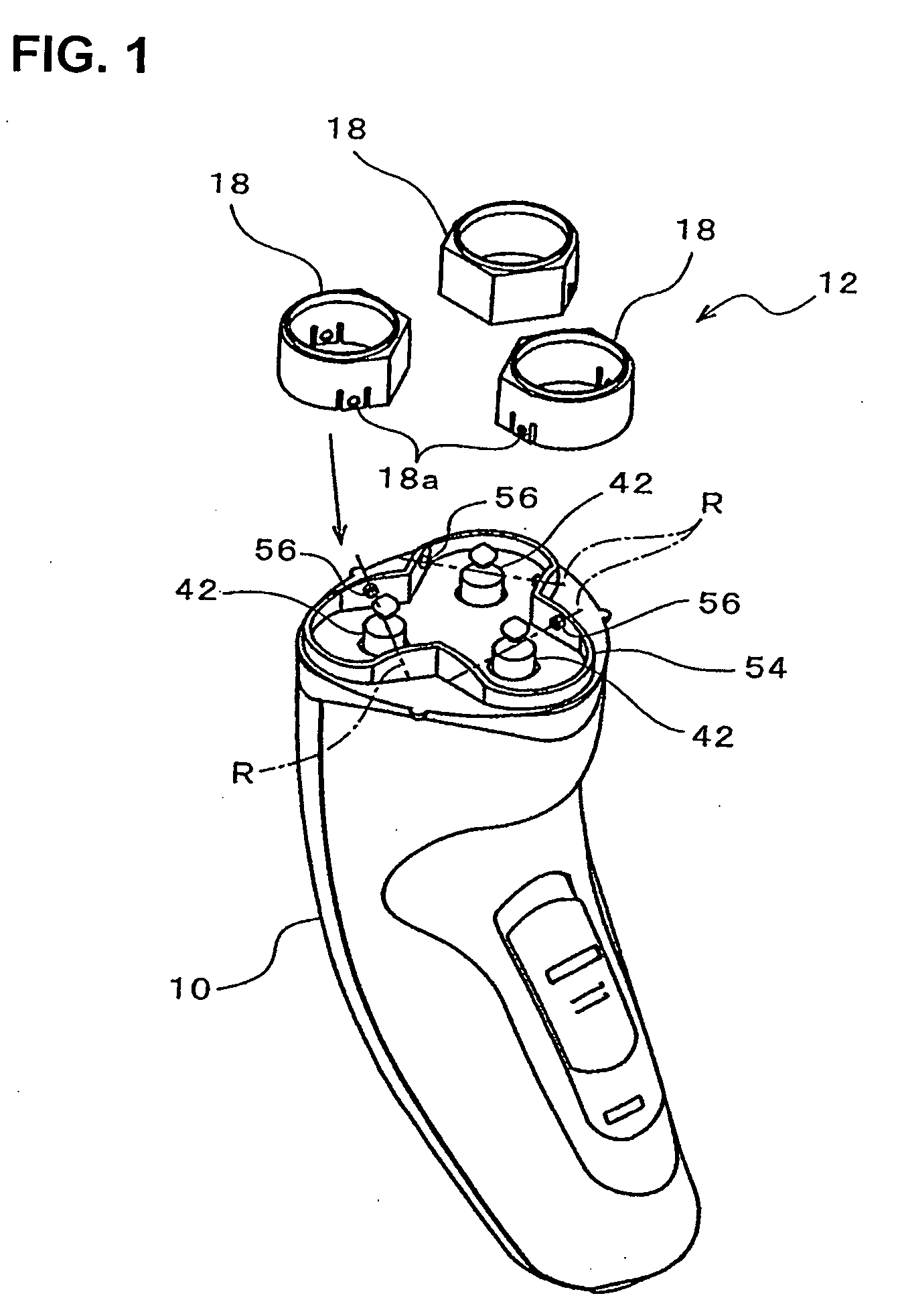

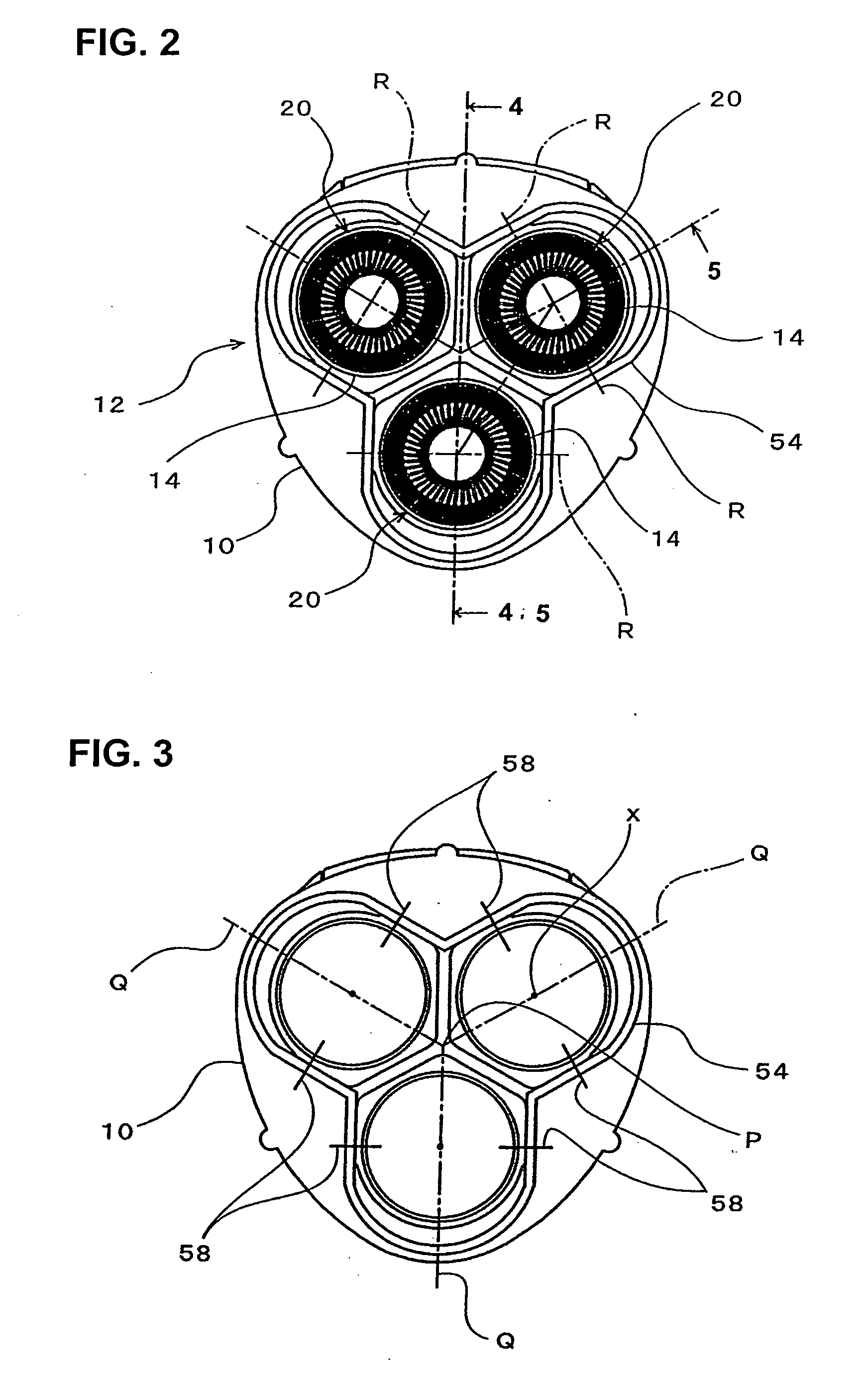

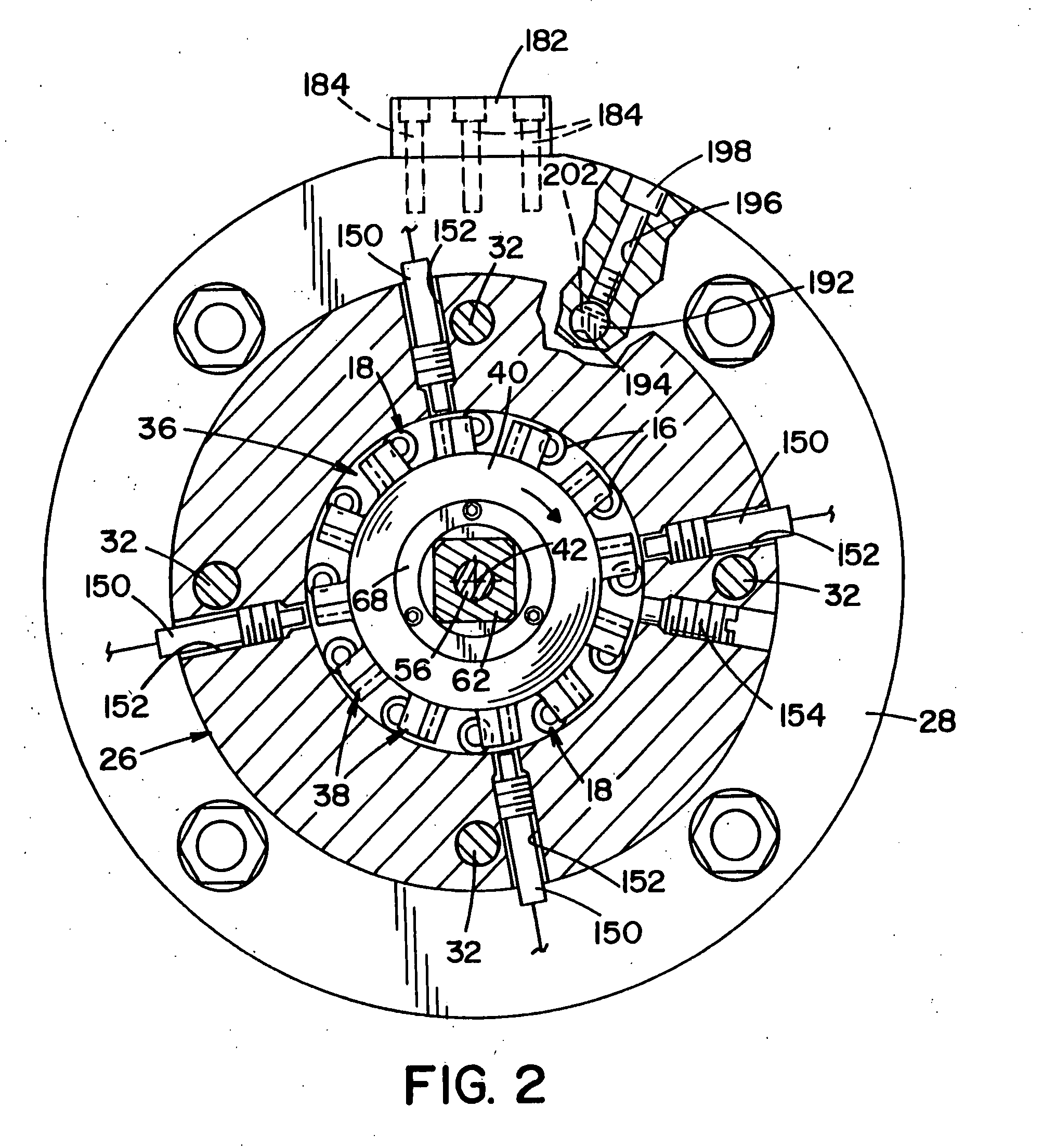

Rotary electric shaver

InactiveUS20070124936A1Extended angle rangeImprove contact tightnessMetal working apparatusElectric machineryEngineering

A rotary electric shaver including a plurality of substantially disc-shaped outer cutters, which are provided in the upper part of a shaver main body housing therein a motor, and inner cutters, which engage the outer cutters from below and are rotationally driven by the motor so as to cut hair entering into the hair introduction openings formed in the outer cutters; and in addition, substantially cylindrical cutter frames 18 for respectively holding the outer cutters in a depressible manner are provided so that cutter frames 18 can pivot in the upper surface of the shaver main body.

Owner:IZUMI PROD CO

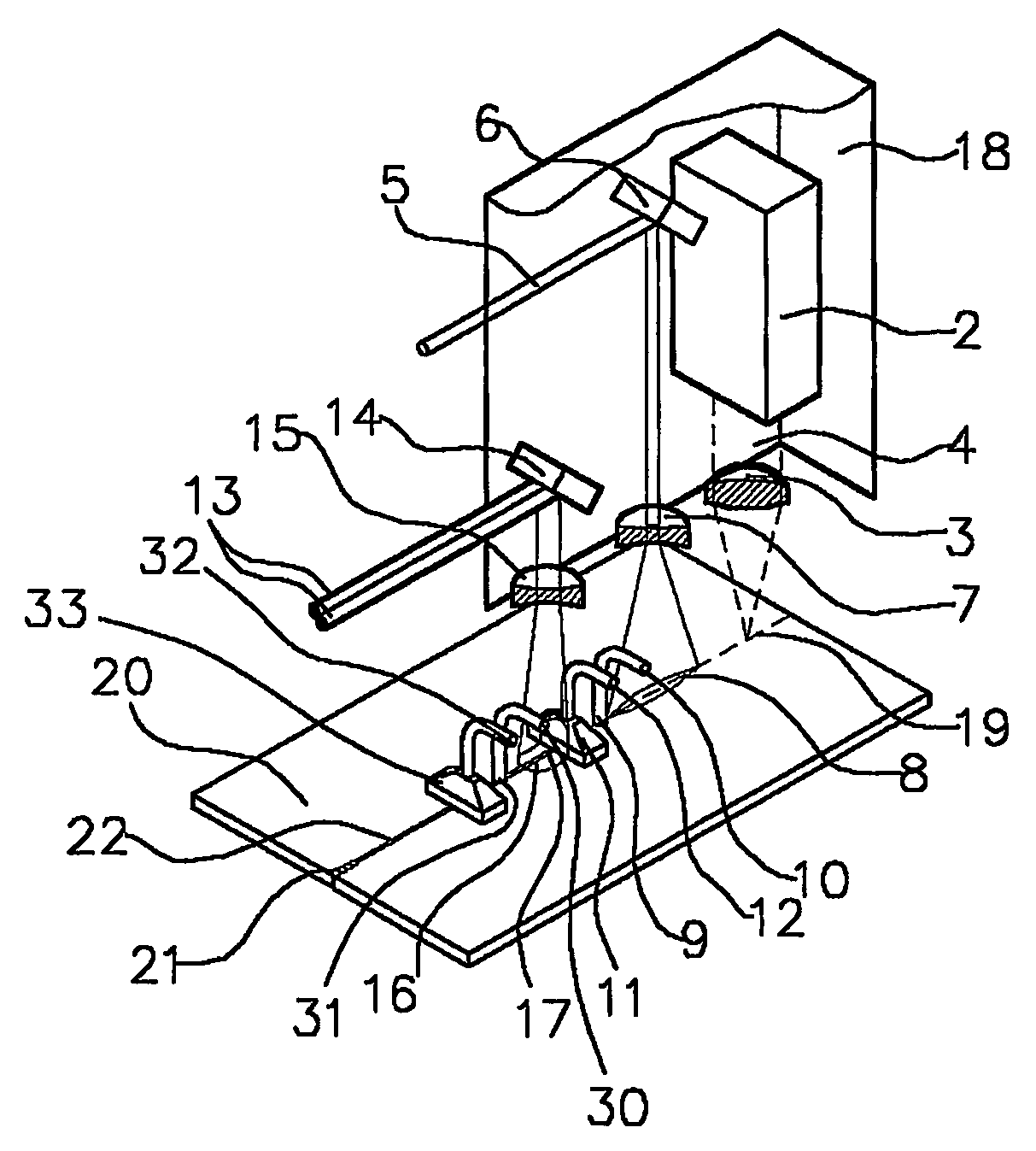

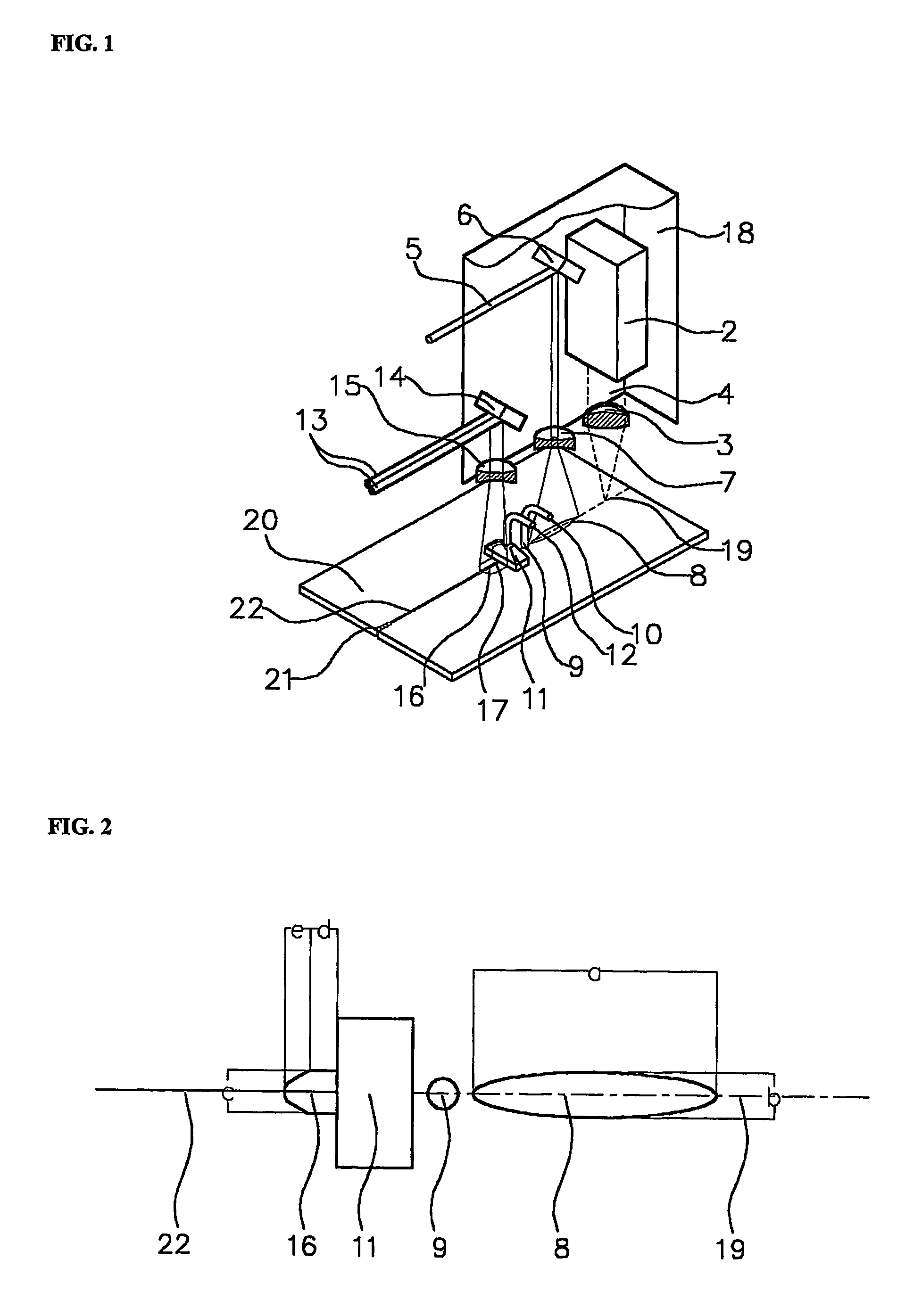

Glass-plate cutting machine

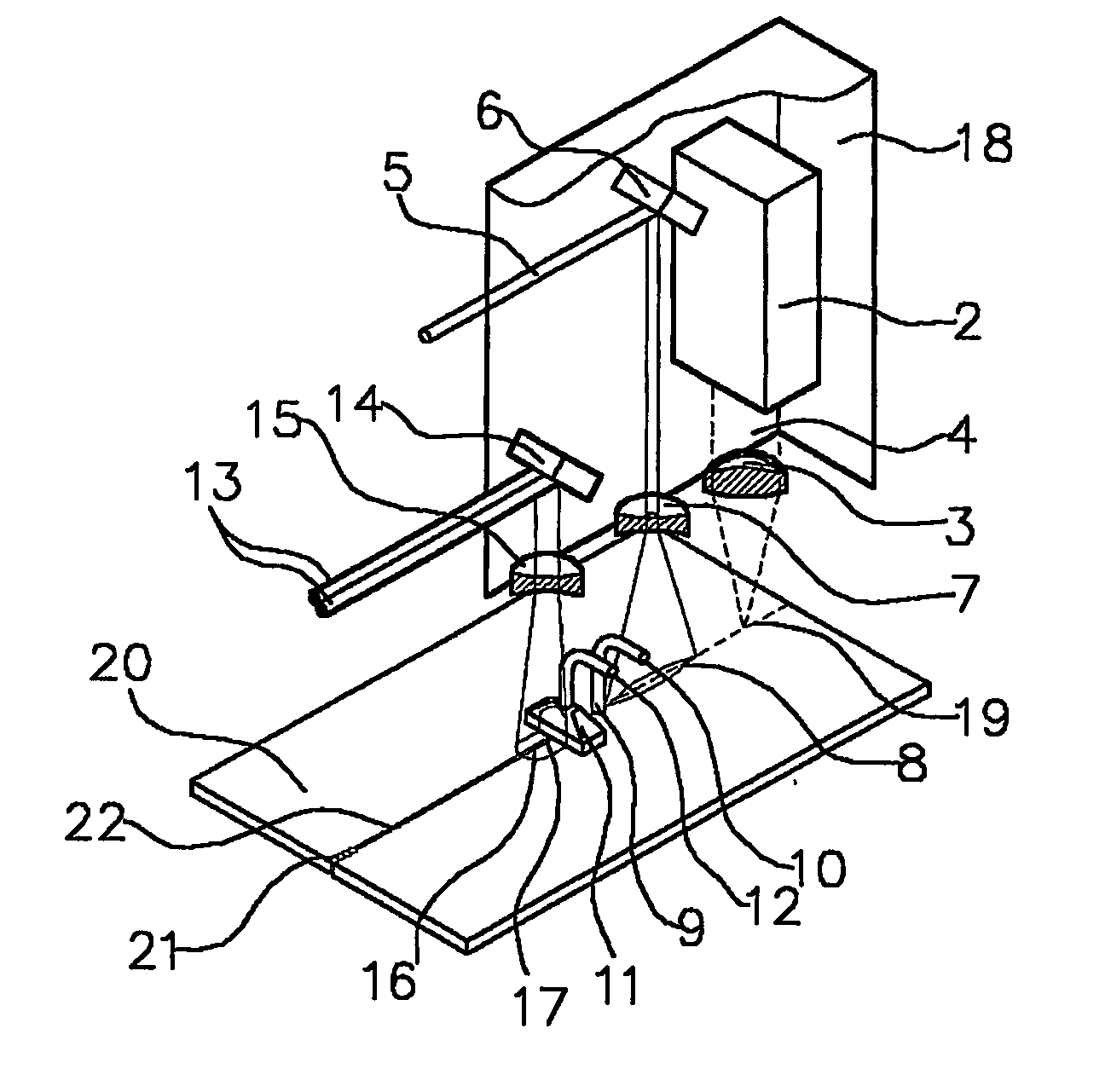

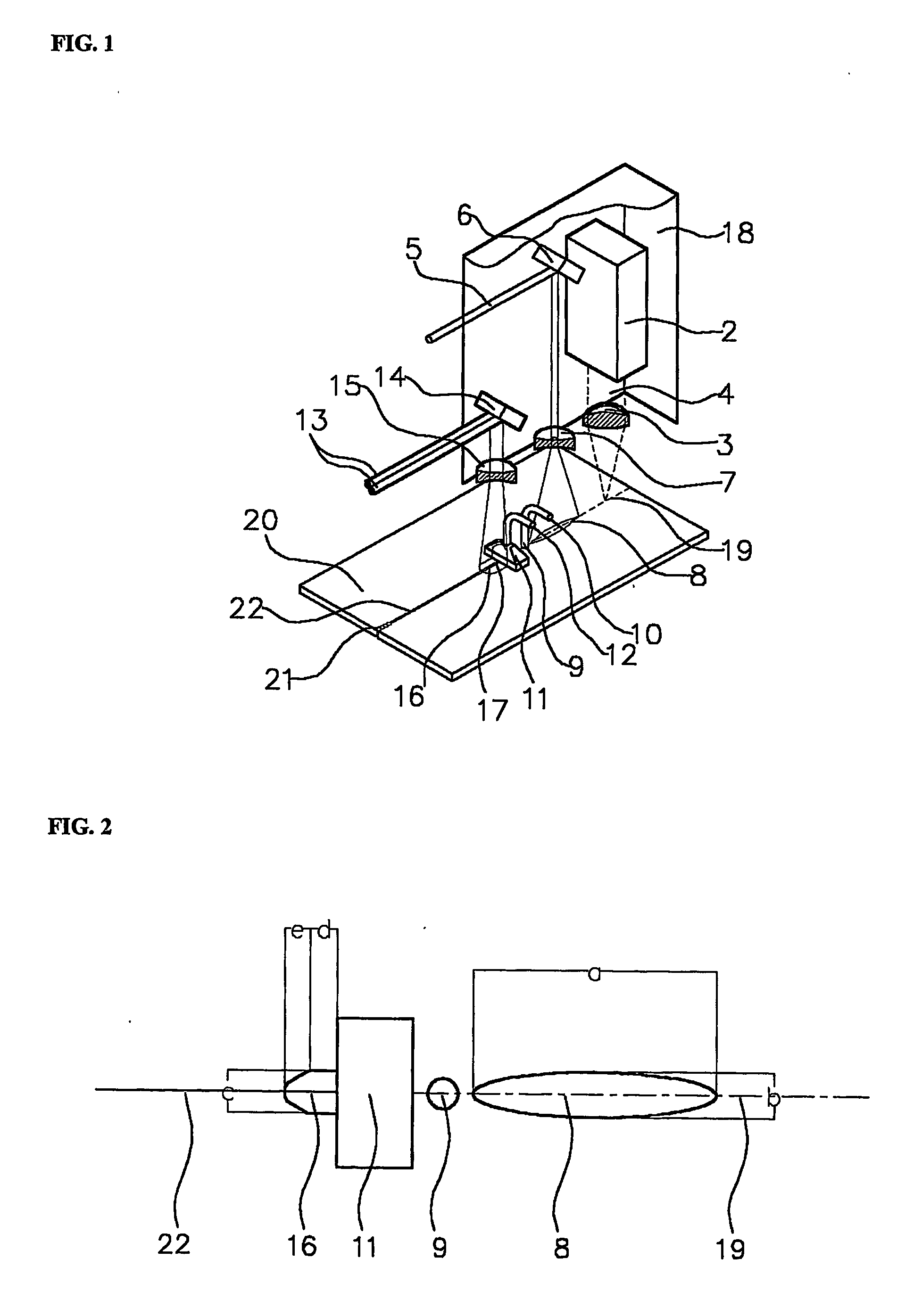

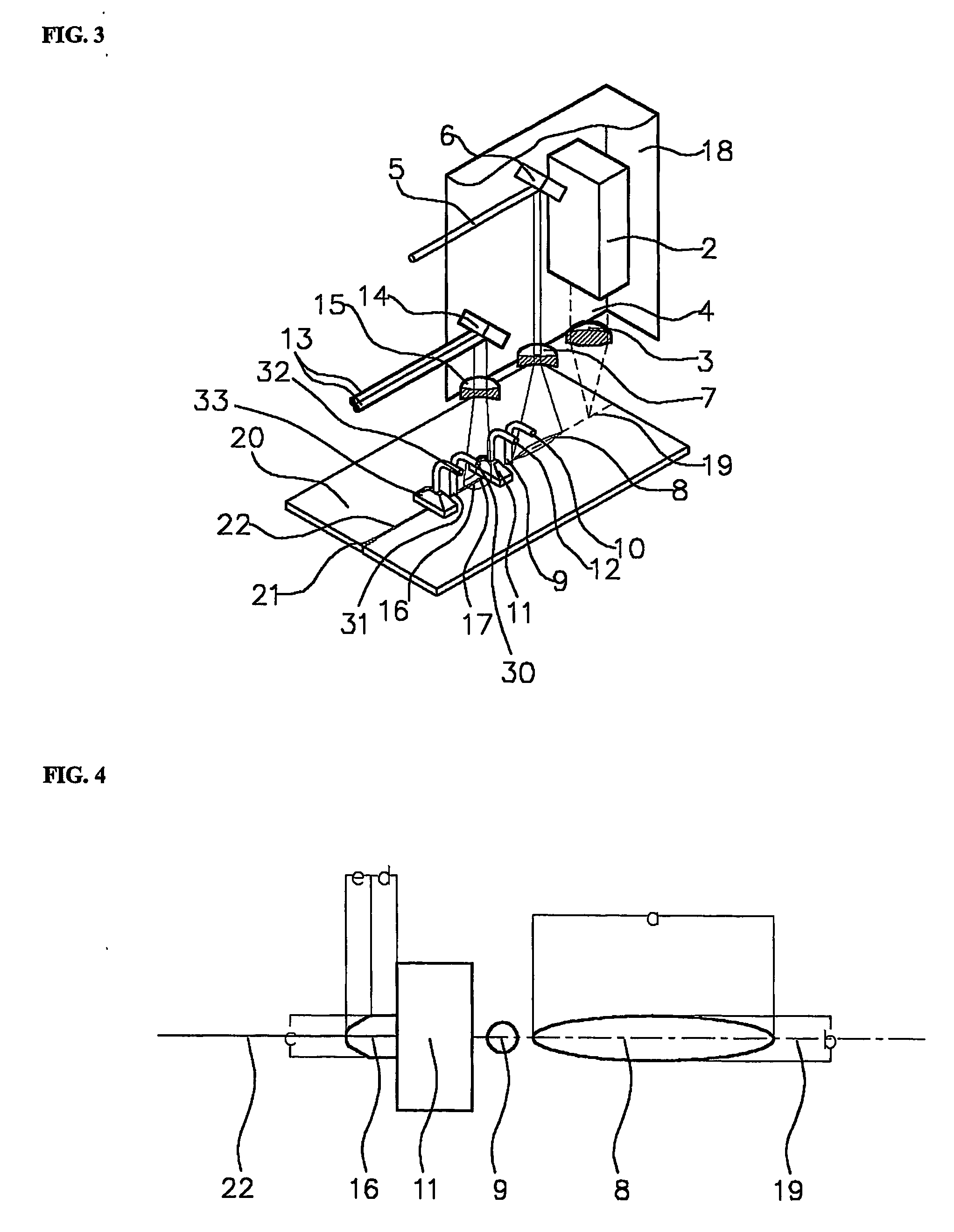

InactiveUS7642483B2Improve cut qualityQuality improvementFine working devicesGlass reforming apparatusLight beamEngineering

A glass plate cutting machine using a laser beam is provided to solve problems, such as uneven glass section and slanting cutting. By using the glass plate cutting machine of the current invention, the glass plate is irradiated with a first carbon dioxide laser beam of 0.05-2 joule / mm2 on a long oval shaped area of 20-200 mm2 according to an expected cutting line thereof, and immediately cooled with water, to generate a scribe line, which is then further irradiated with a second carbon dioxide laser beam of 0.1-0.5 joule / mm′ on the area of 20-200 mm2 thus obtaining a superior glass section.

Owner:RORZE SYST

Glass-plate cutting machine

InactiveUS20060151450A1Good cutting qualityHigh qualityFine working devicesGlass reforming apparatusCarbon dioxideCarbon dioxide laser

A glass plate cutting machine using a laser beam is provided to solve problems, such as uneven glass section and slanting cutting. By using the glass plate cutting machine of the current invention, the glass plate is irradiated with a first carbon dioxide laser beam of 0.05-2 joule / mm2 on a long oval shaped area of 20-200 mm2 according to an expected cutting line thereof, and immediately cooled with water, to generate a scribe line, which is then further irradiated with a second carbon dioxide laser beam of 0.1-0.5 joule / mm′ on the area of 20-200 mm2 thus obtaining a superior glass section.

Owner:RORZE SYST

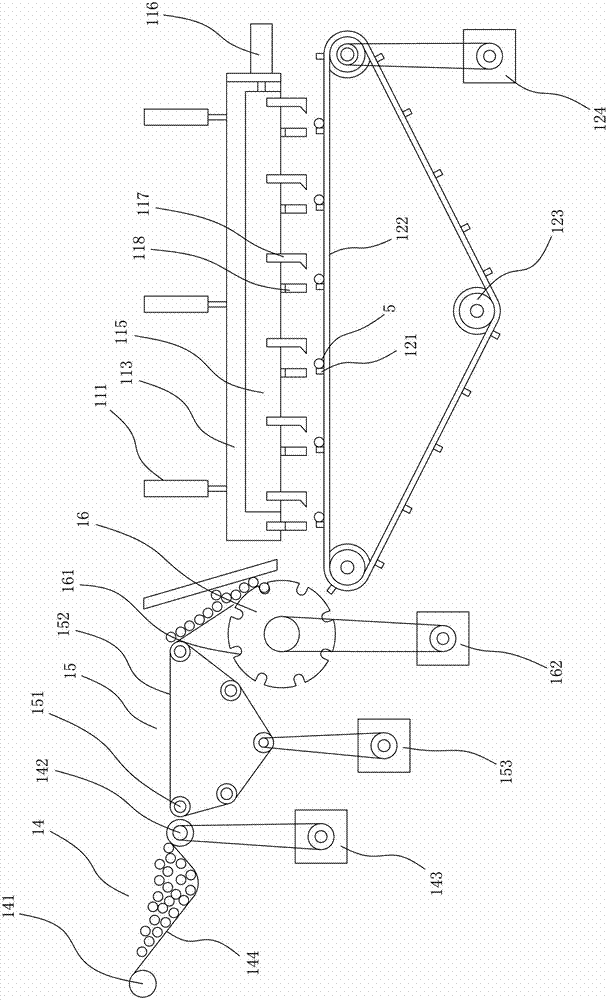

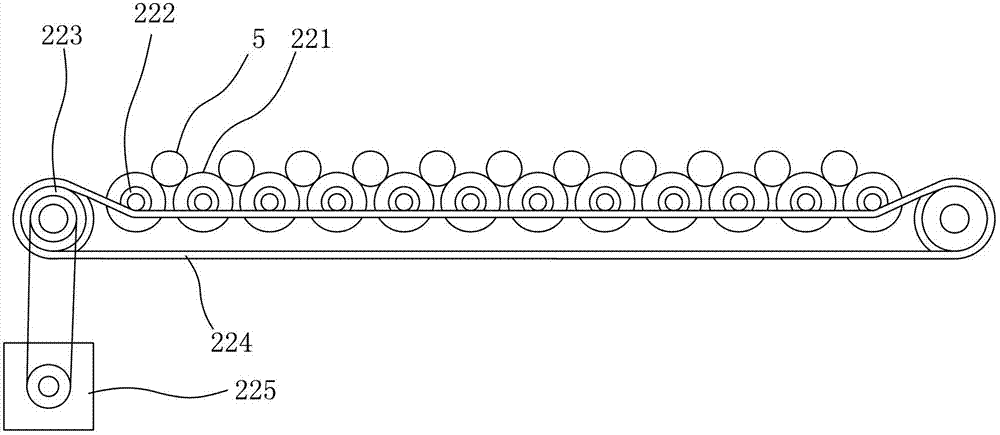

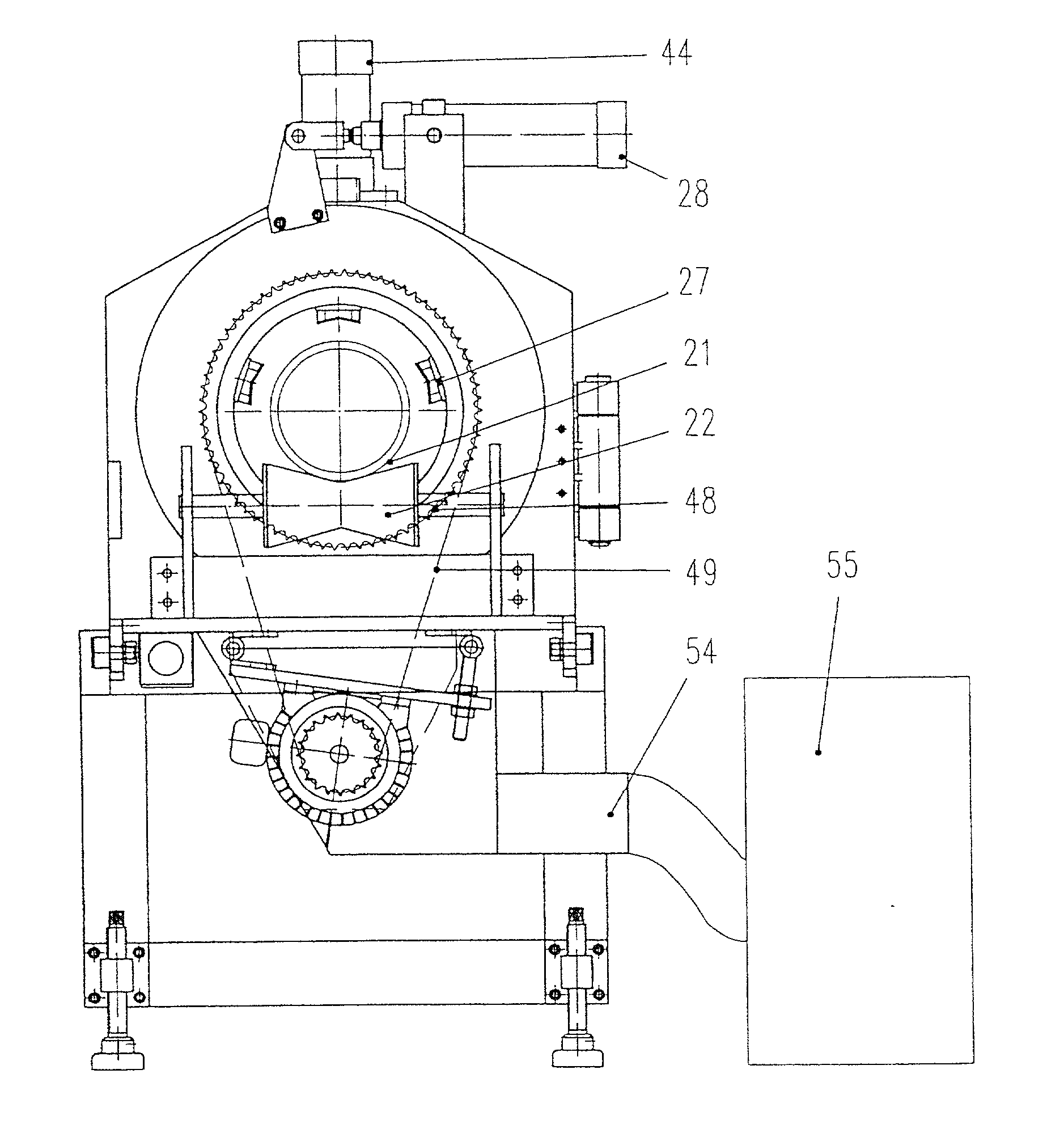

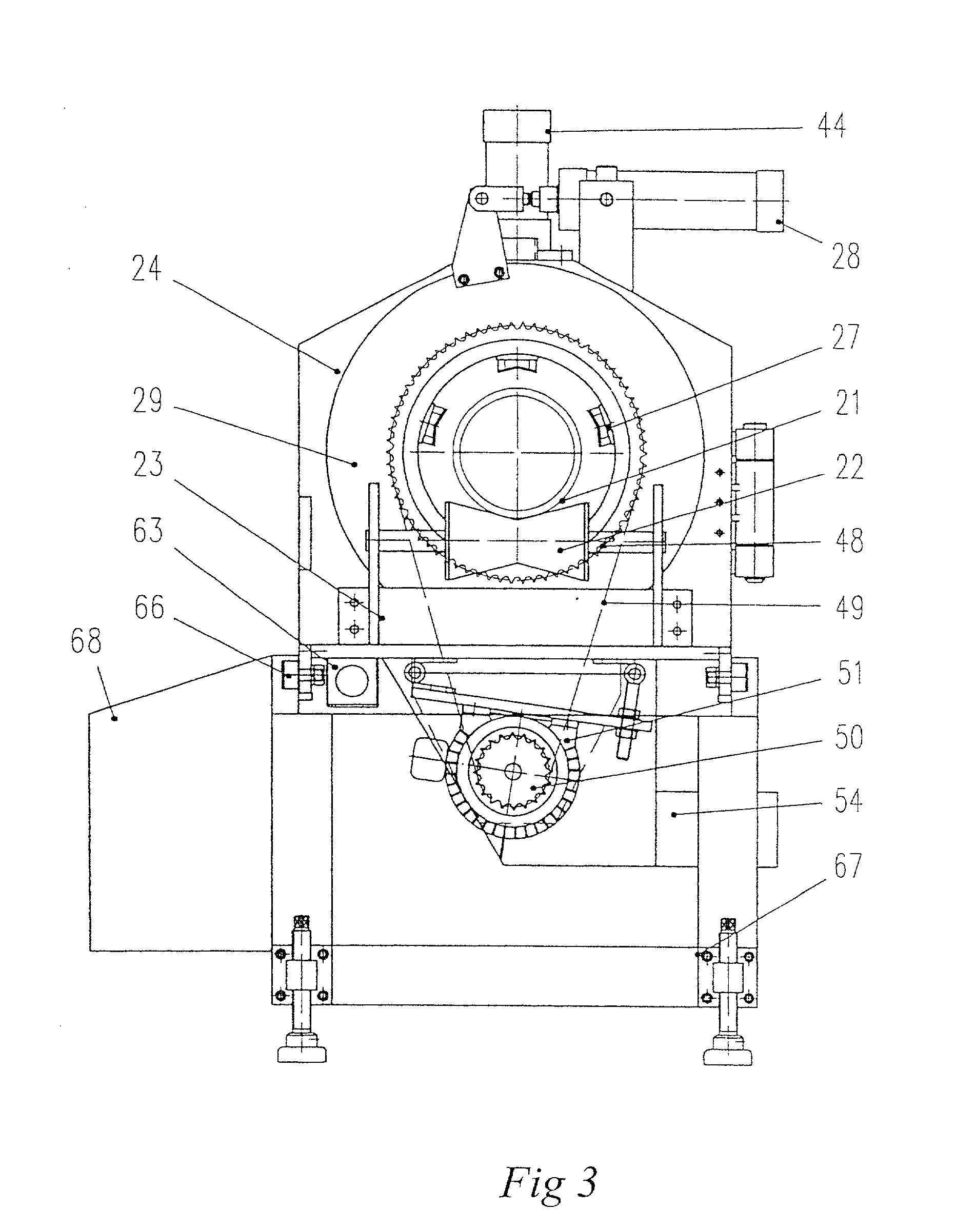

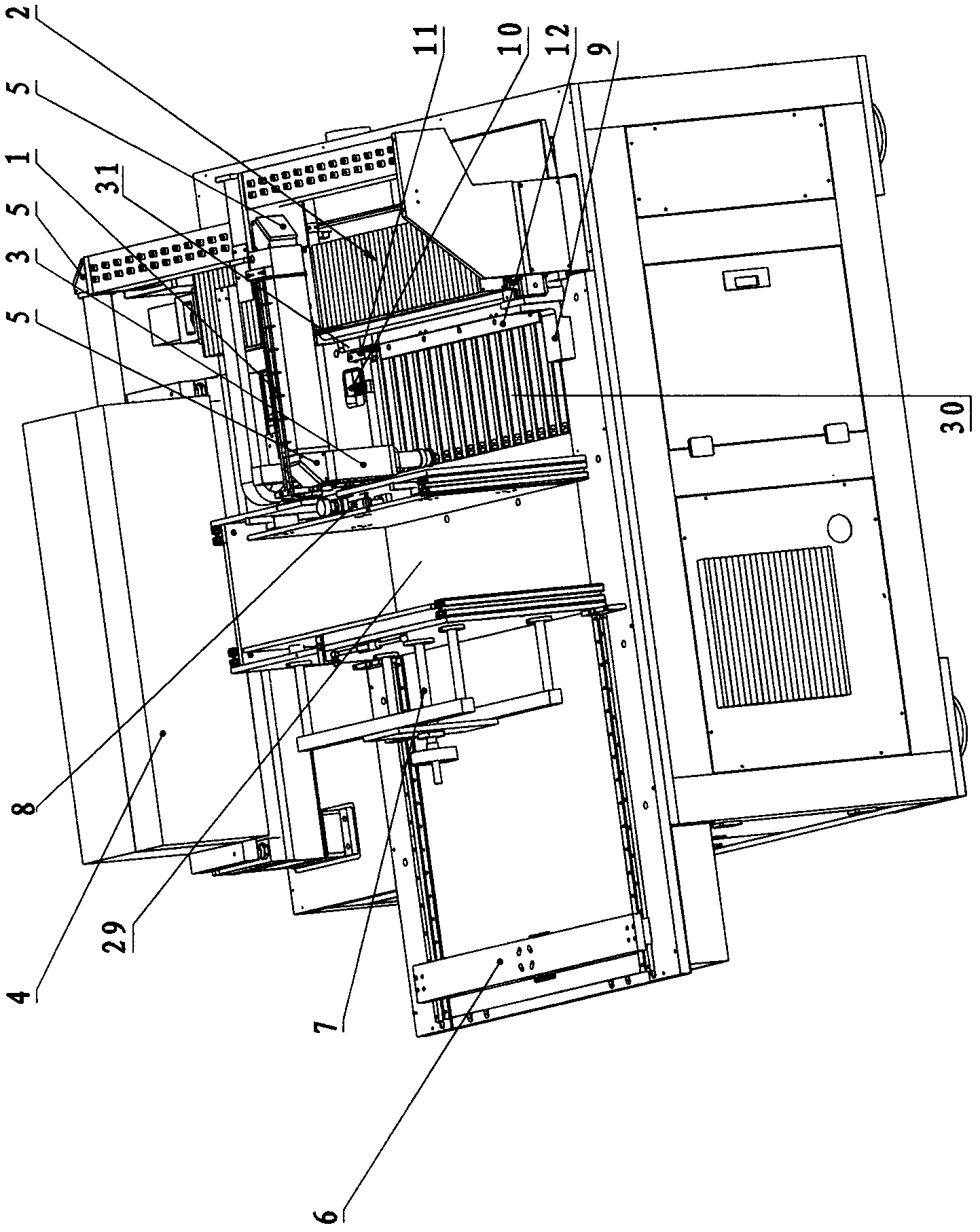

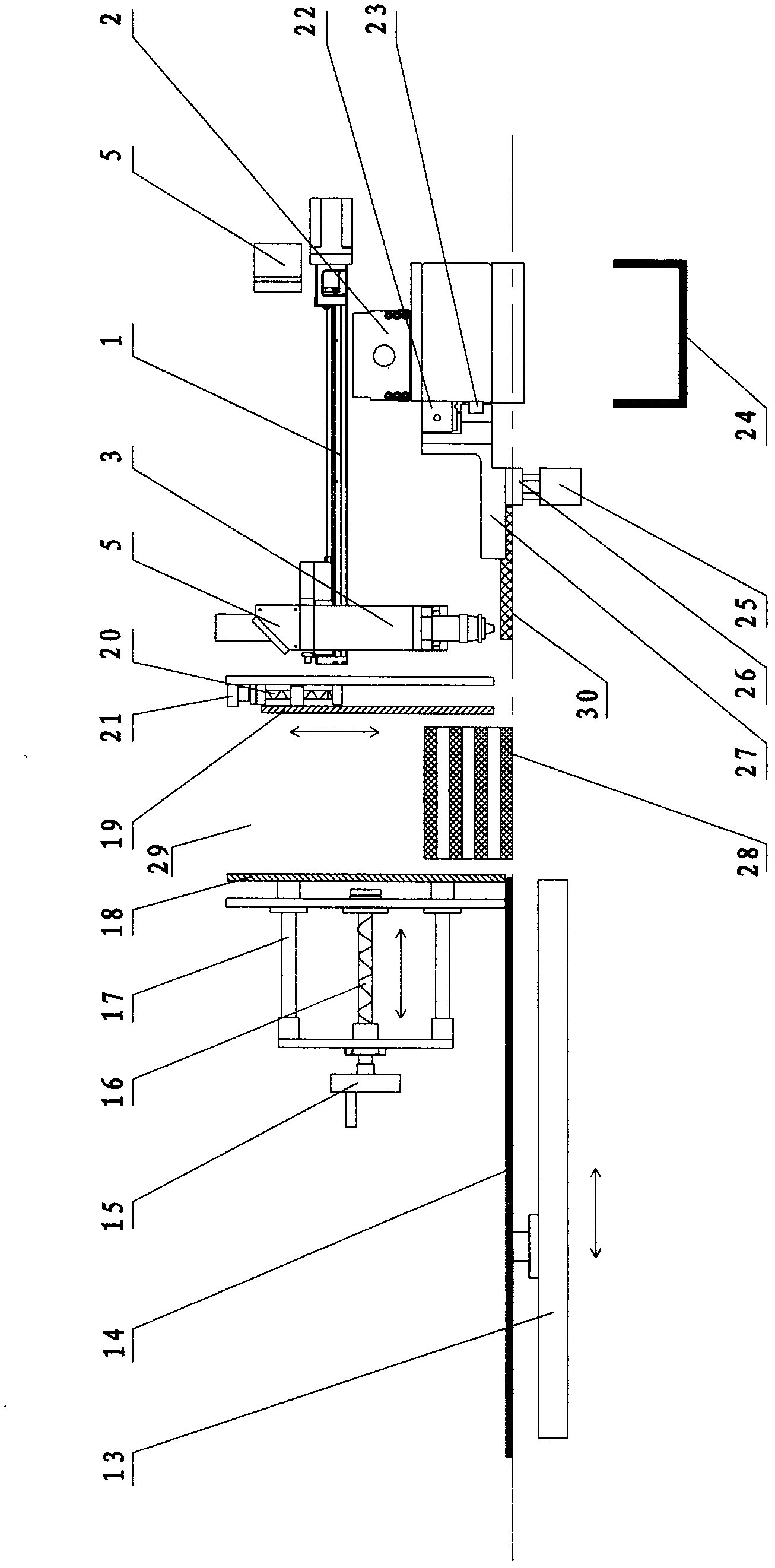

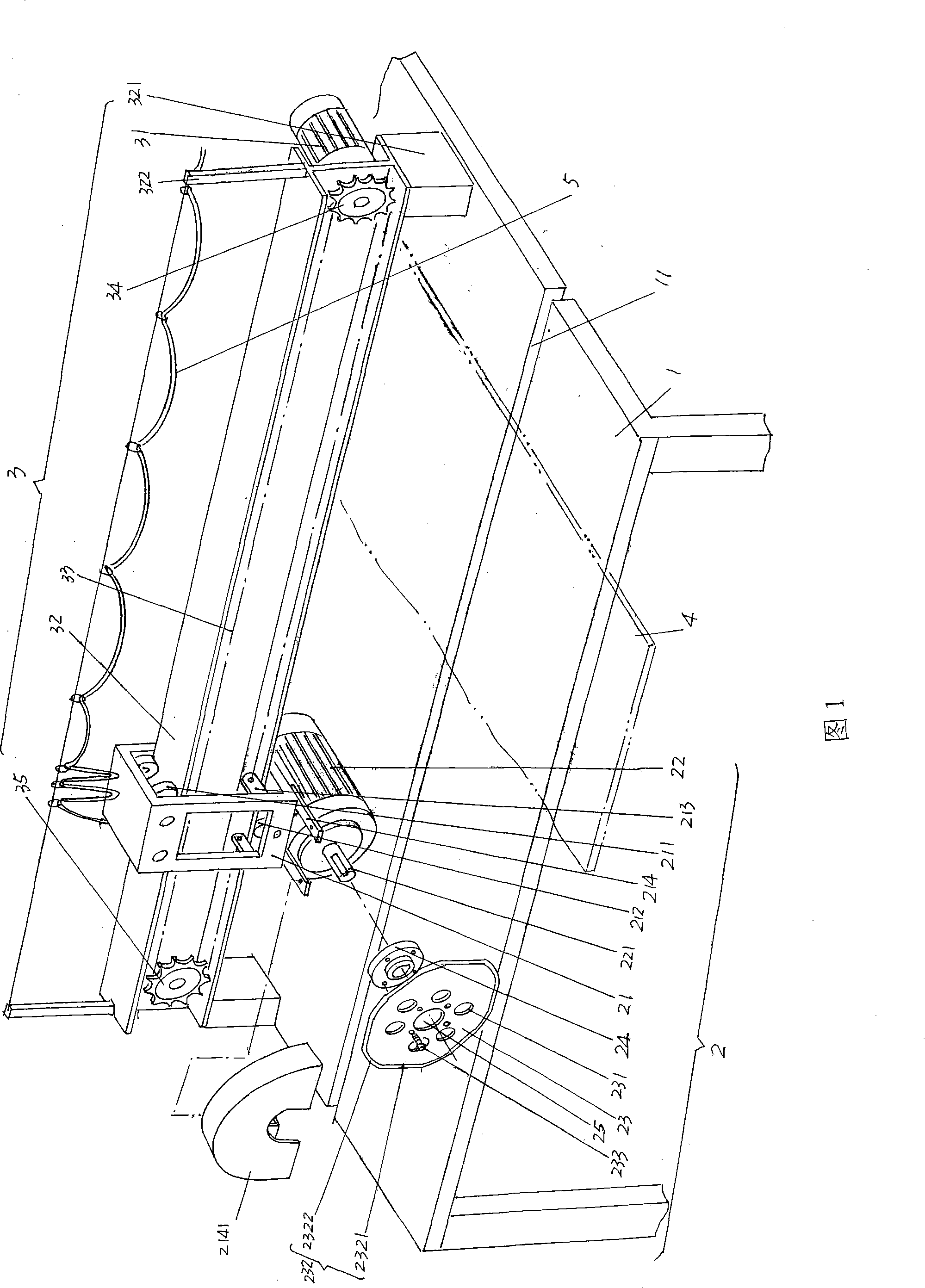

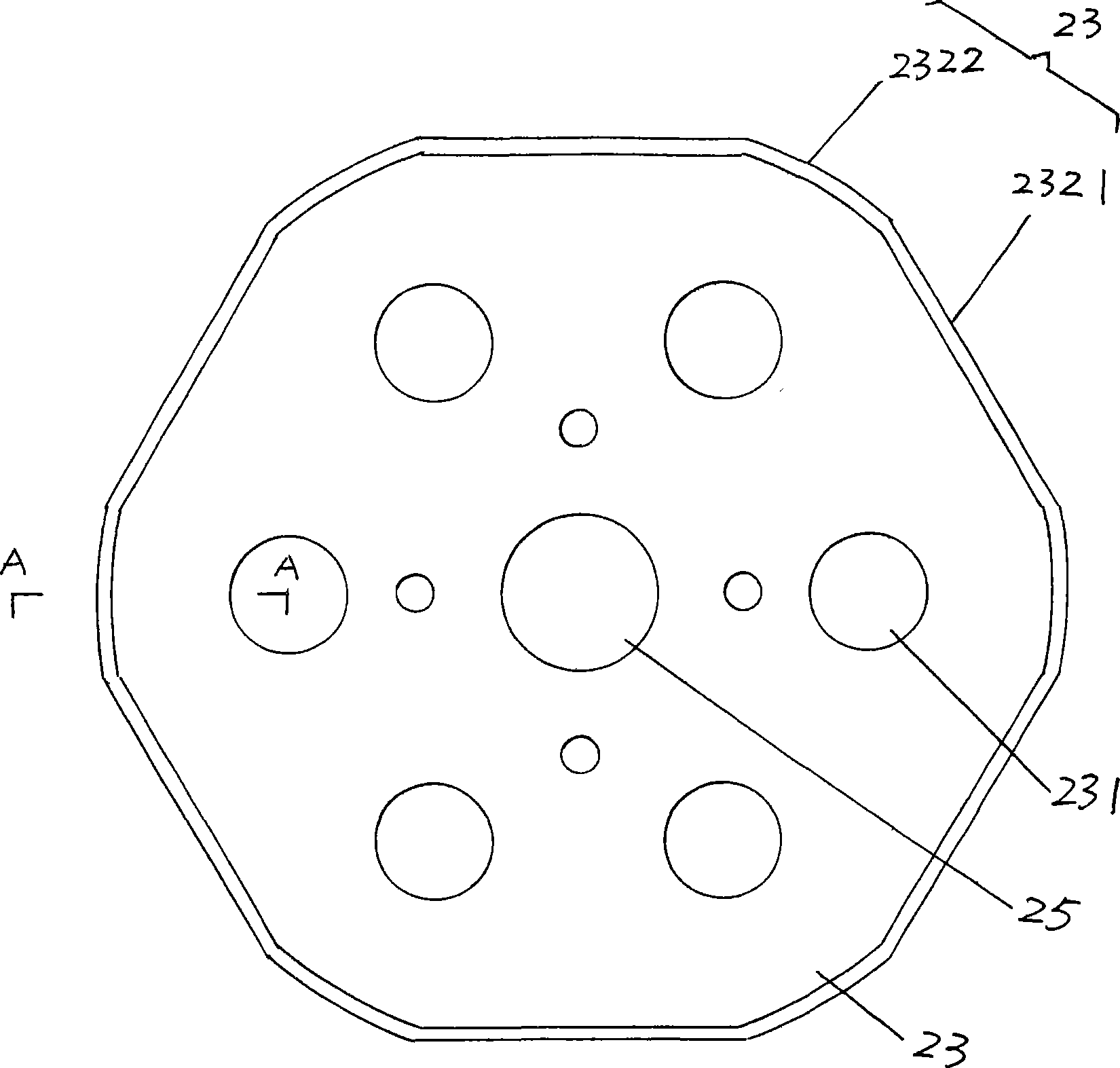

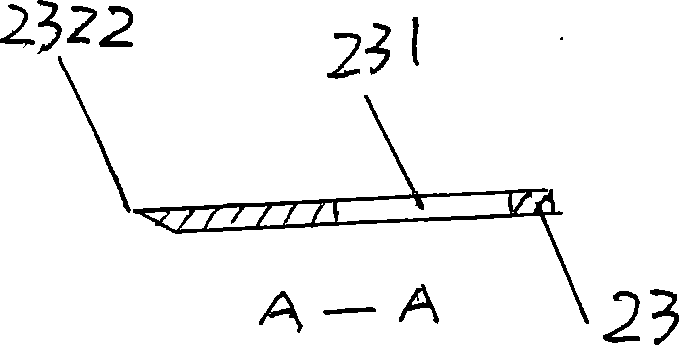

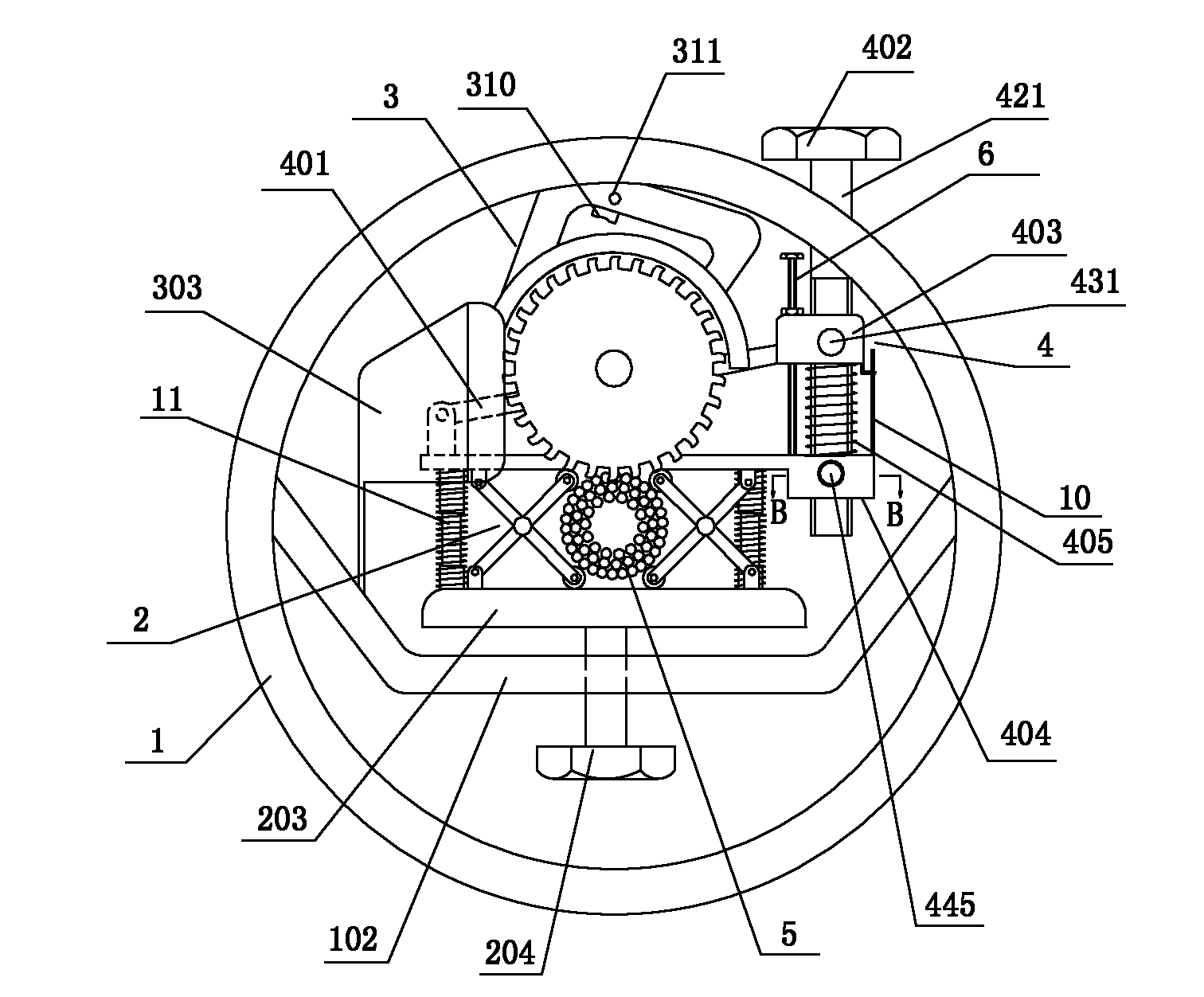

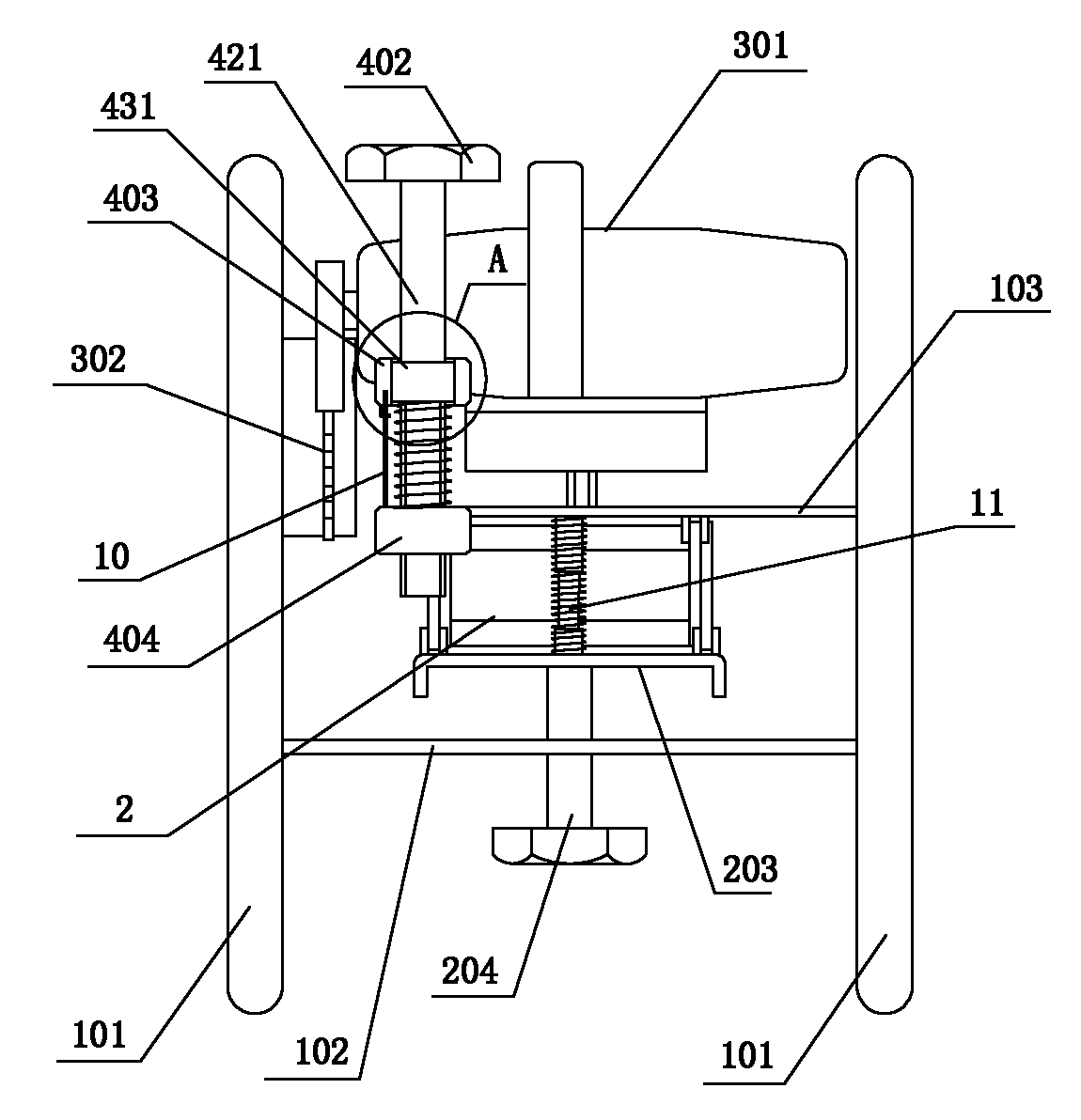

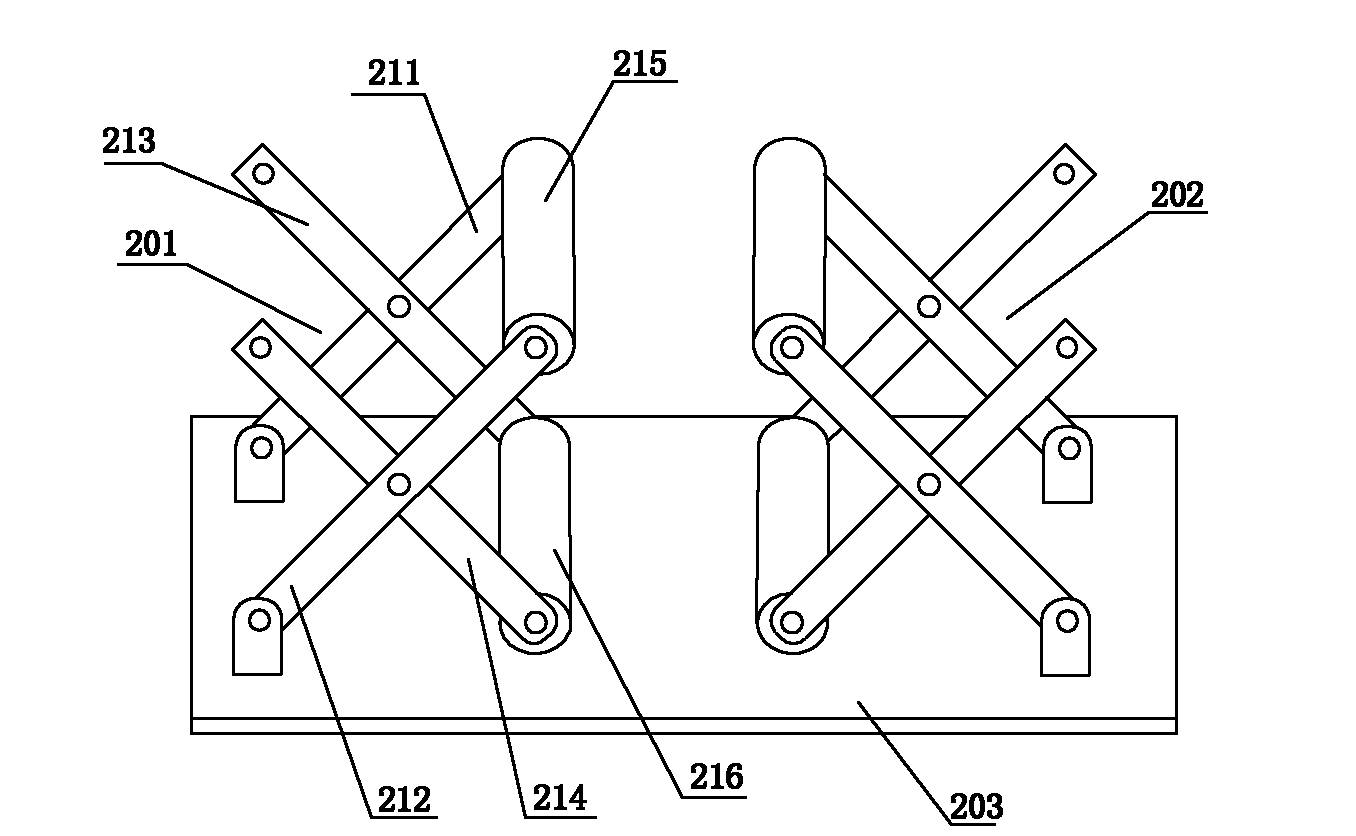

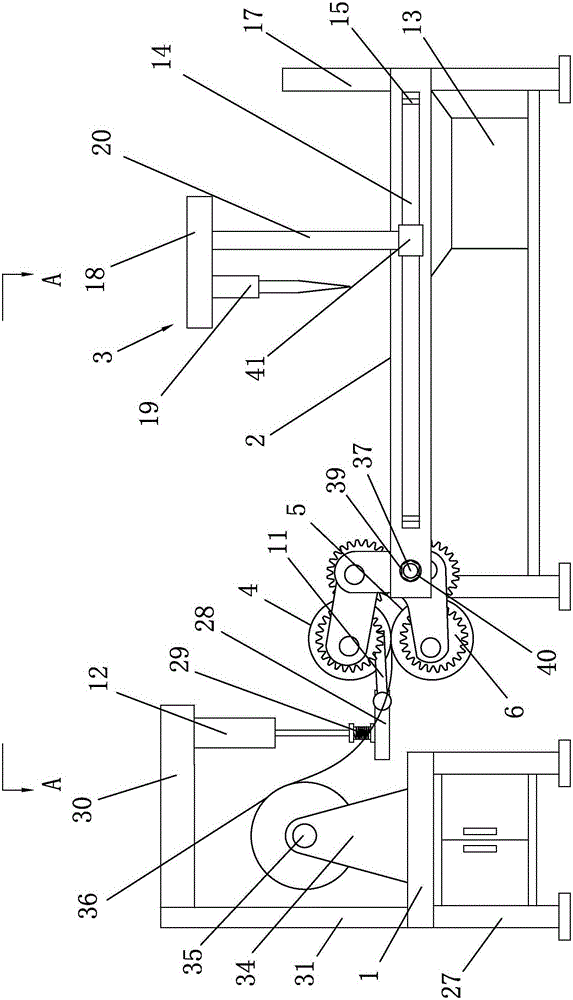

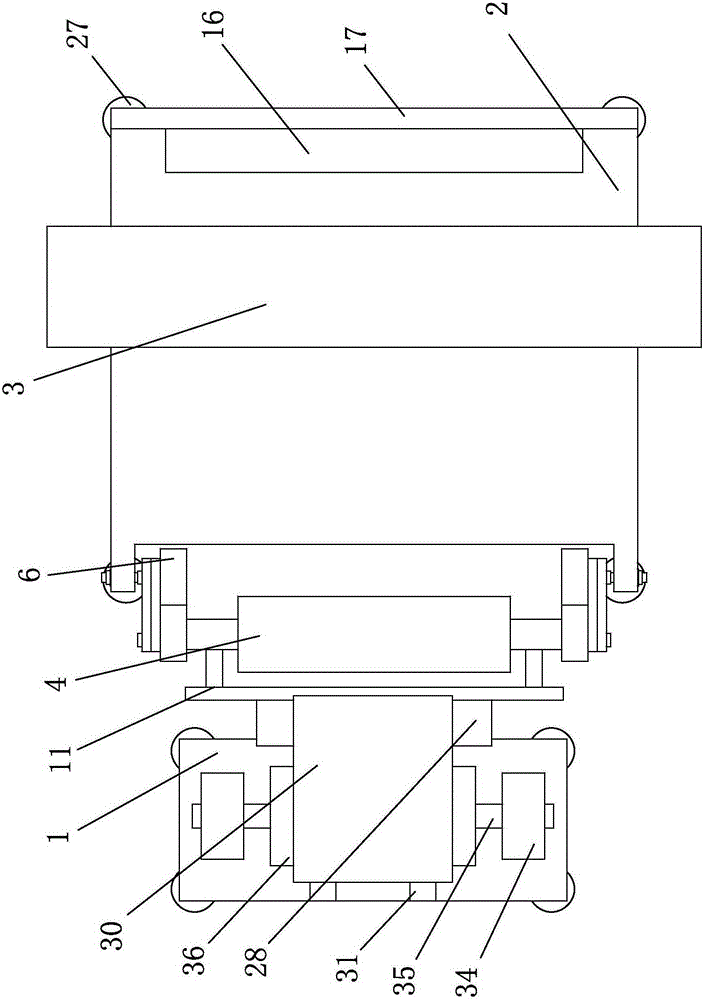

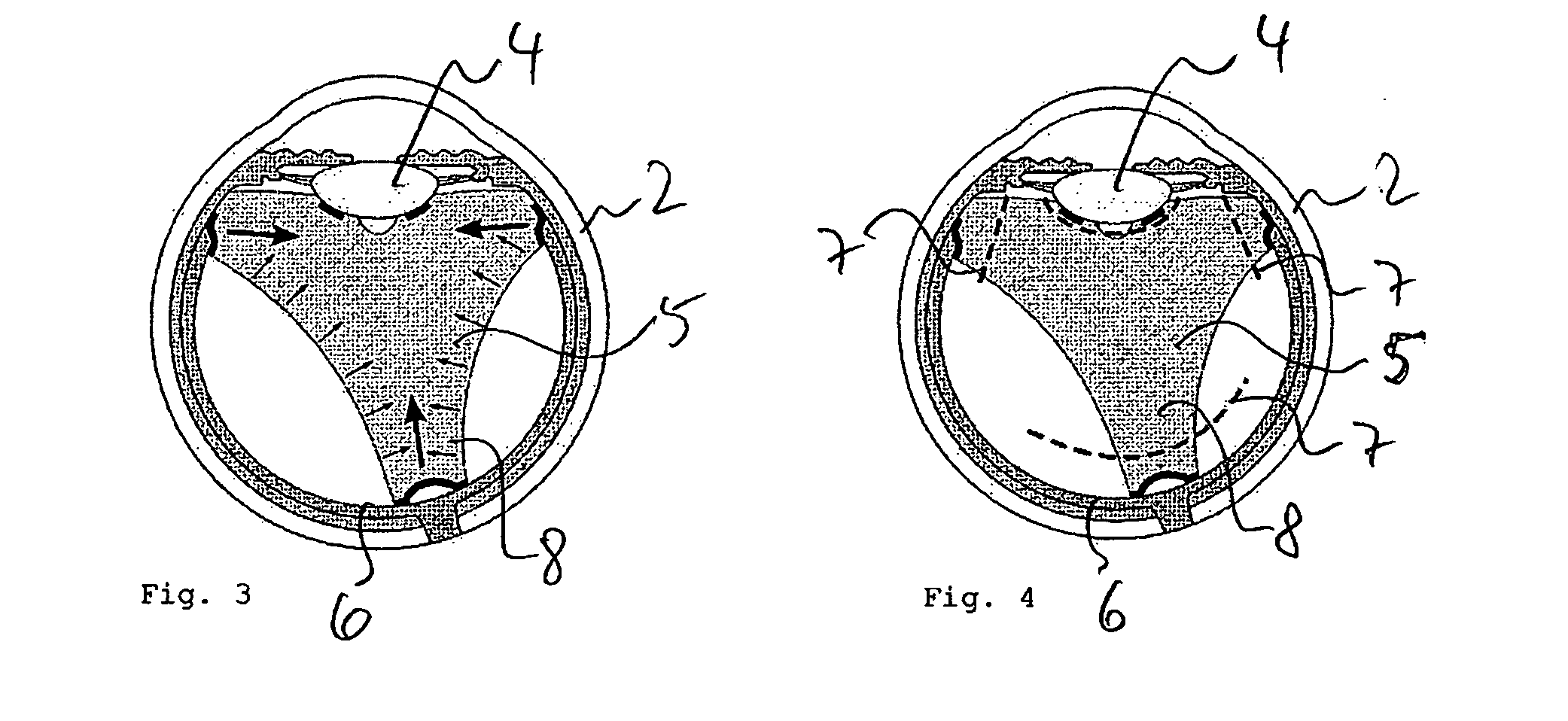

Full-automatic pipe cutting machine

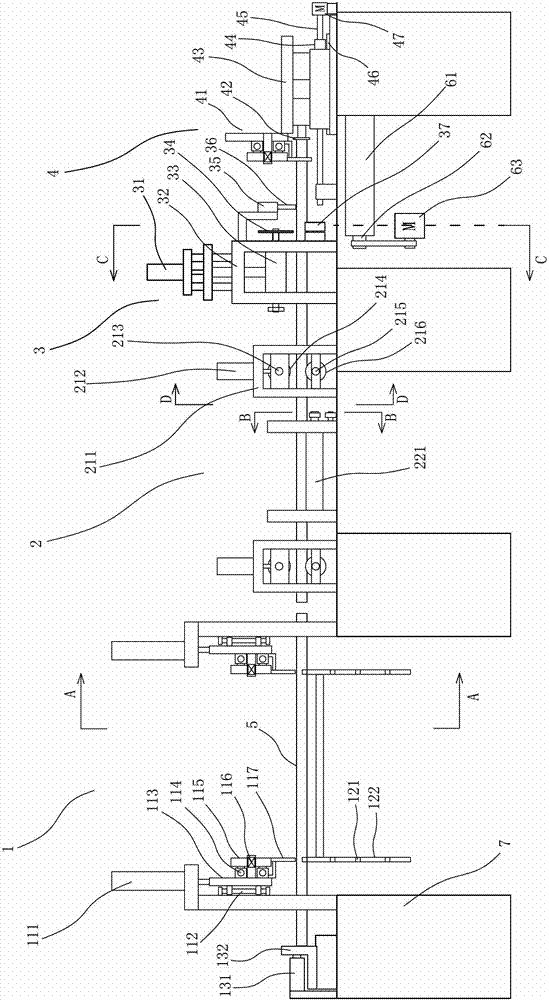

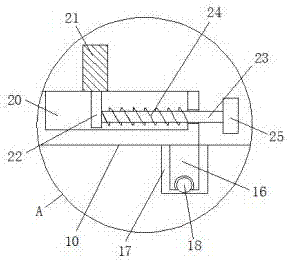

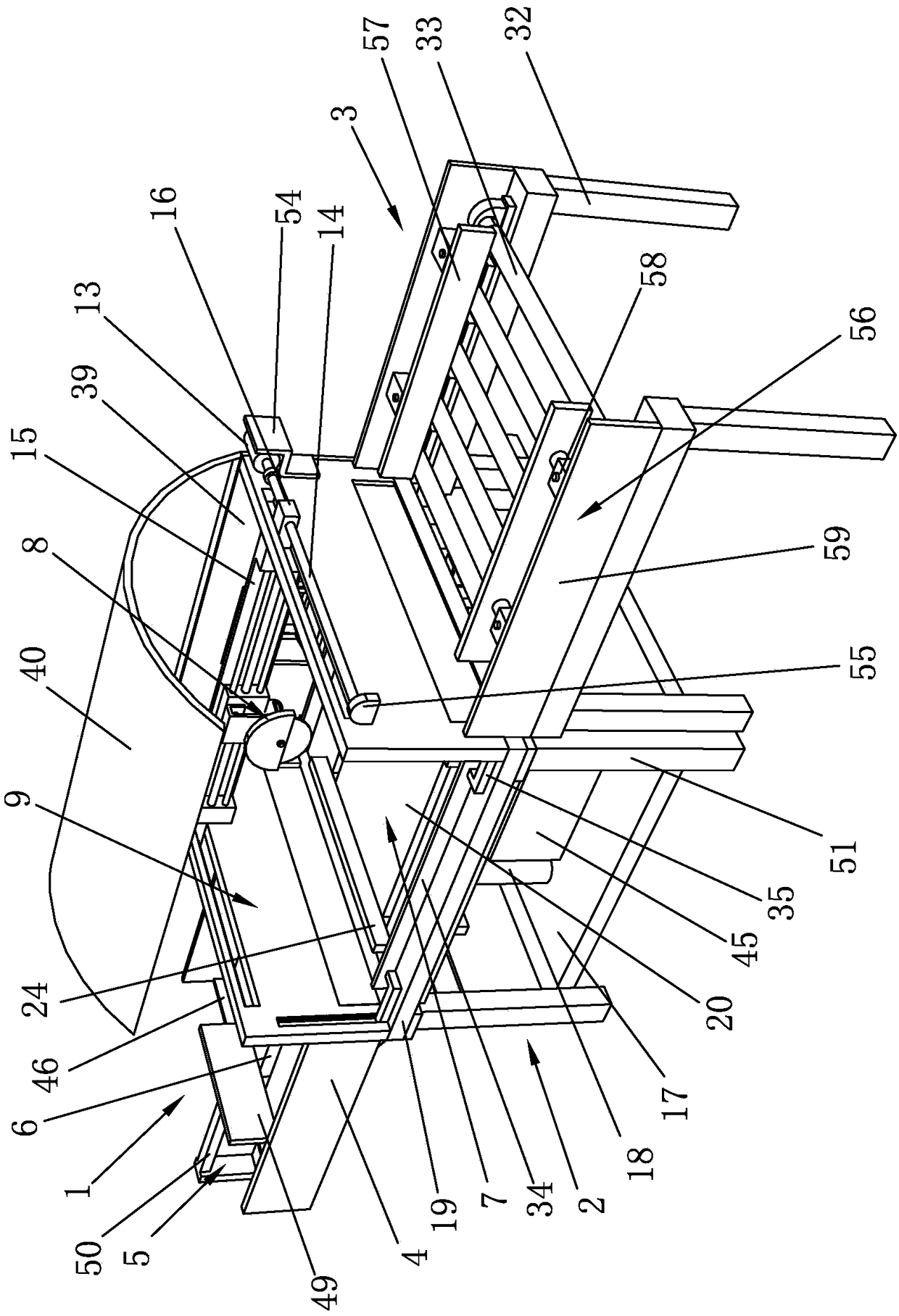

ActiveCN102814547ARealize automatic controlPrecise deliveryMetal sawing devicesCircular sawEngineering

The invention provides a full-automatic pipe cutting machine comprising a frame, and a charging device, a feeding device, a cutting device, a measuring device and a control device which are sequentially arranged on the frame horizontally; the cutting device comprises a cutter holder which is arranged on the frame, a plurality of first motors which are lined horizontally along a longitudinal direction and can be arranged on the cutter holder by moving up and down, a first cylinder which is connected with and drives each first motor to move up and down synchronously, a circular saw blade which is arranged on the output shaft of each first motor, a second motor which is in transmission connection with the input shaft of each first motor through a first transmission mechanism, and a bearing piece which is arranged on the tool rest below each circular saw blade and is used for bearing a pipe at a cut part; and the measuring device comprises a guide rail which is horizontally arranged on the frame, a slide frame which is movably arranged on the guide rail, a driving mechanism which is connected with and drives the slide frame to move along the guide rail, a pipe baffle which is arranged on the slide frame and a first pipe clamping mechanism which is horizontally arranged on the slide frame along the longitudinal direction. According to the full-automatic pipe cutting machine, more than one pipe can be cut at one time, and the machine has the advantages of high cutting efficiency, good cutting quality and the like.

Owner:冠达星股份有限公司

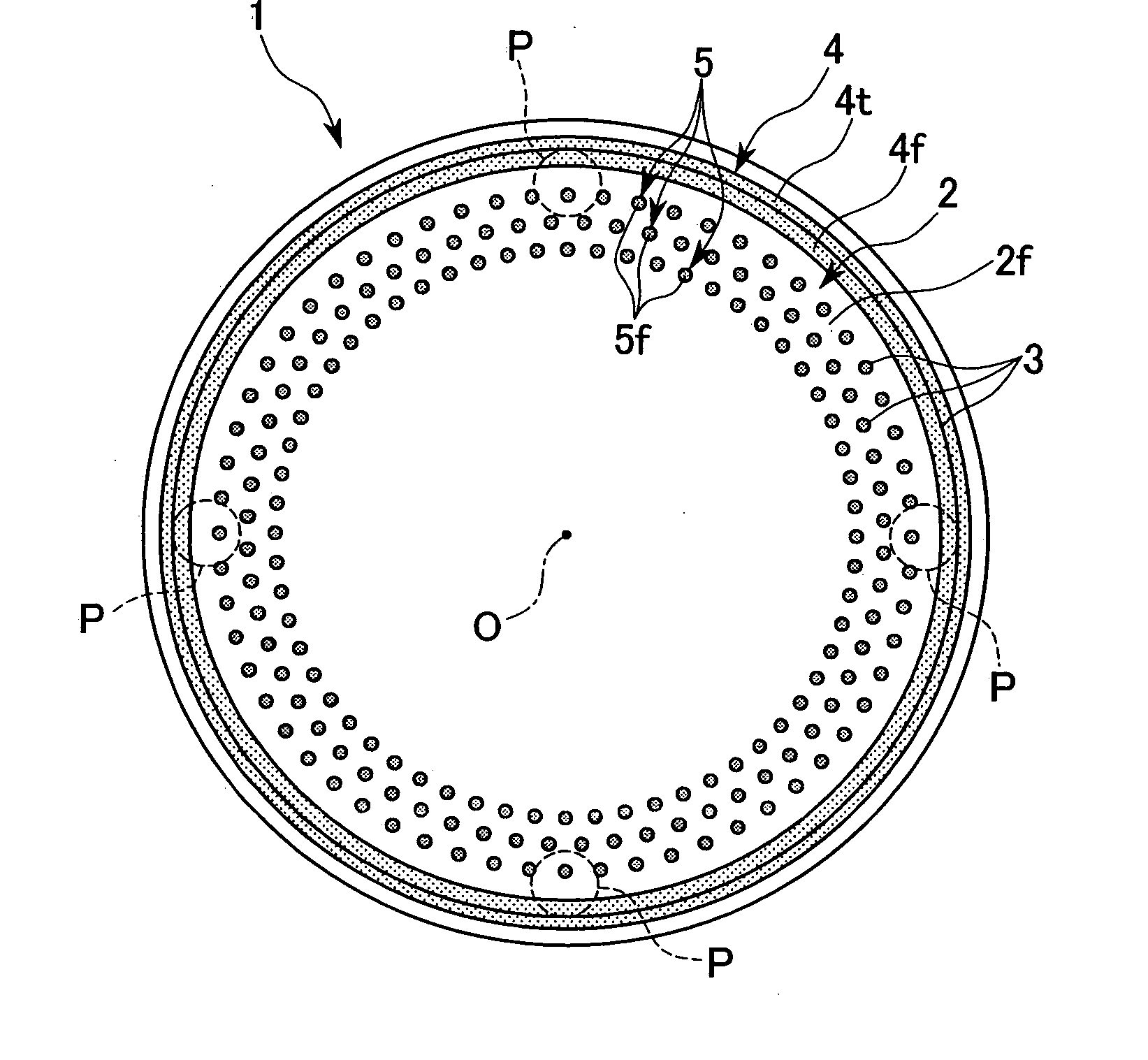

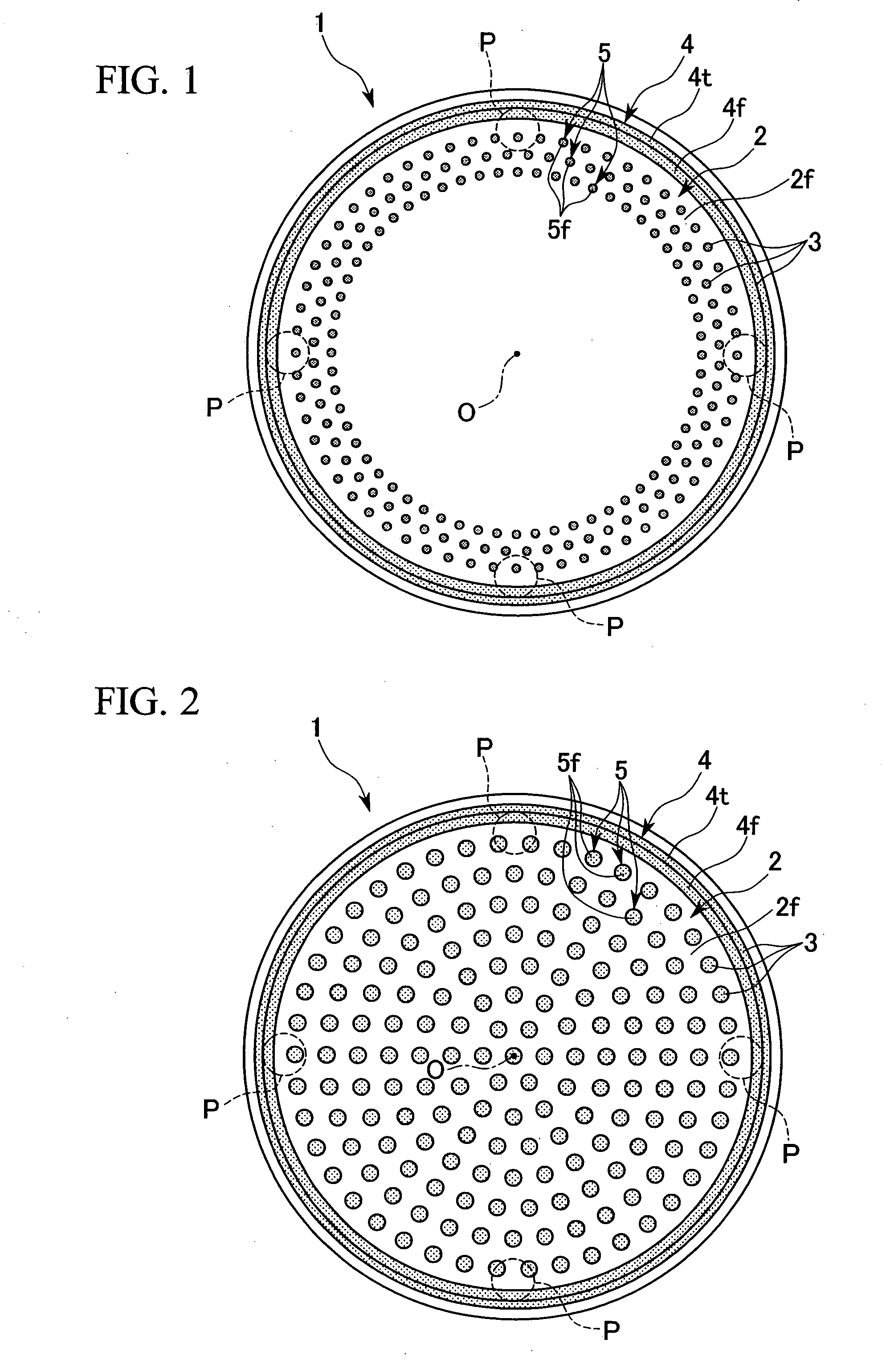

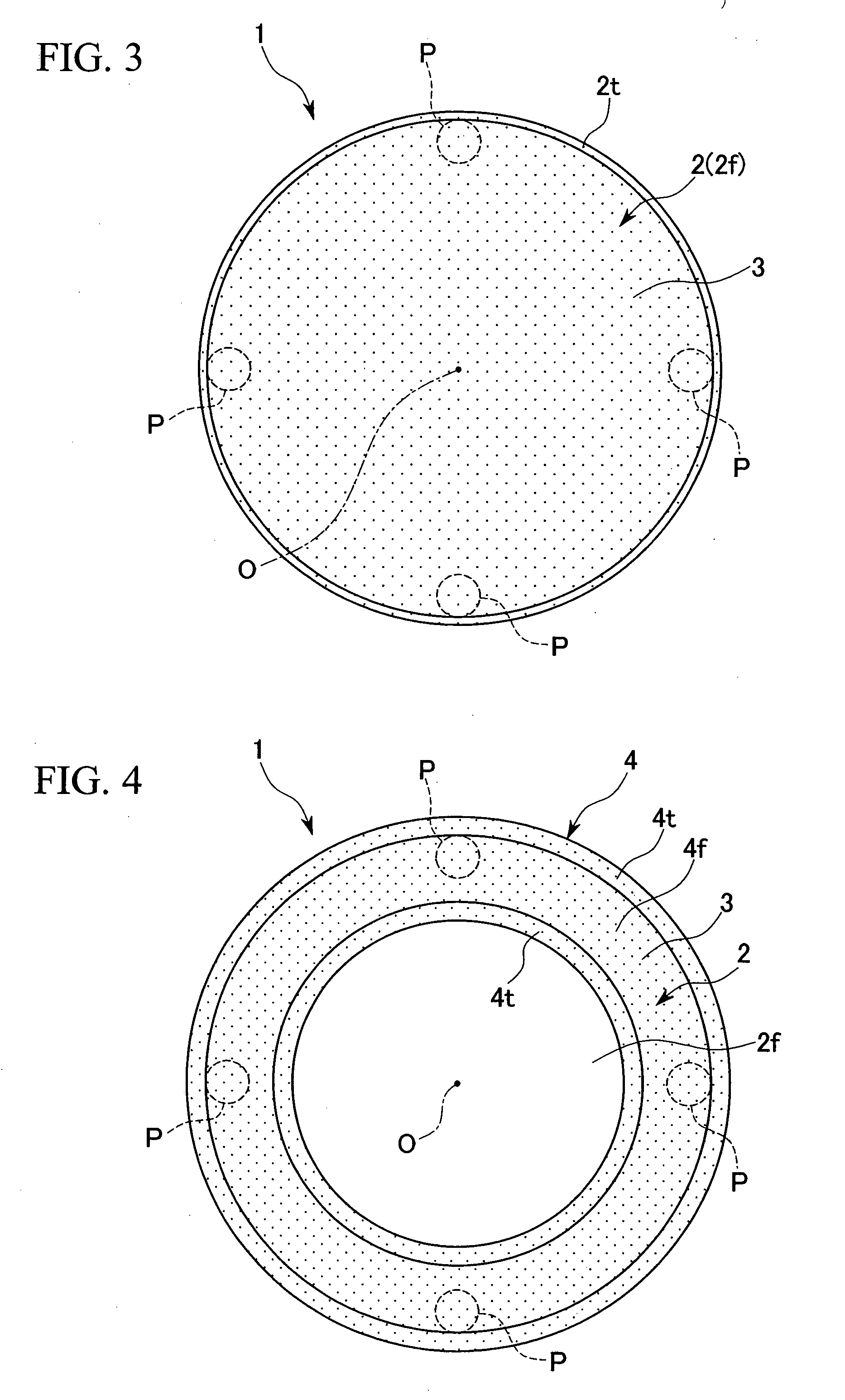

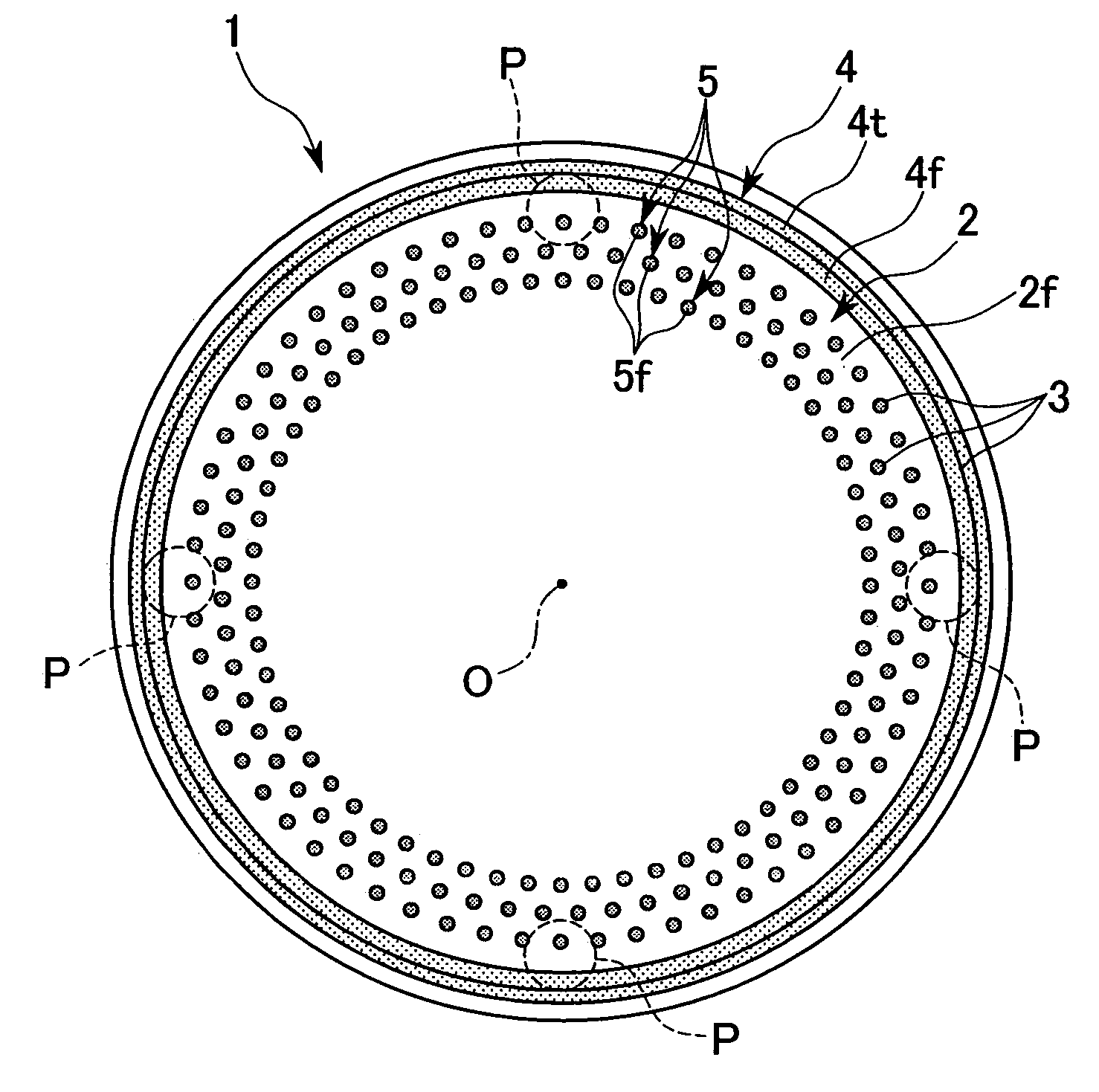

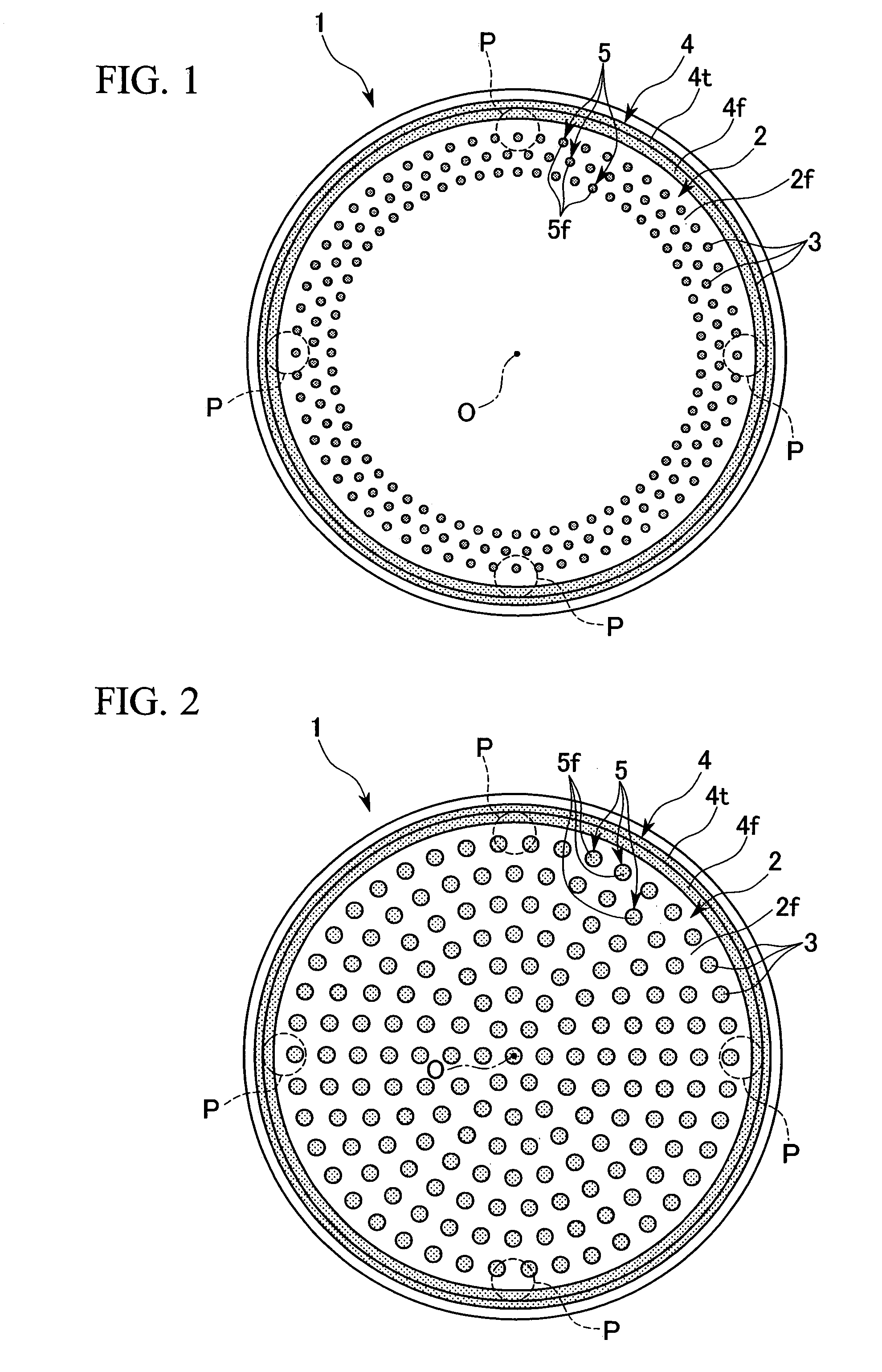

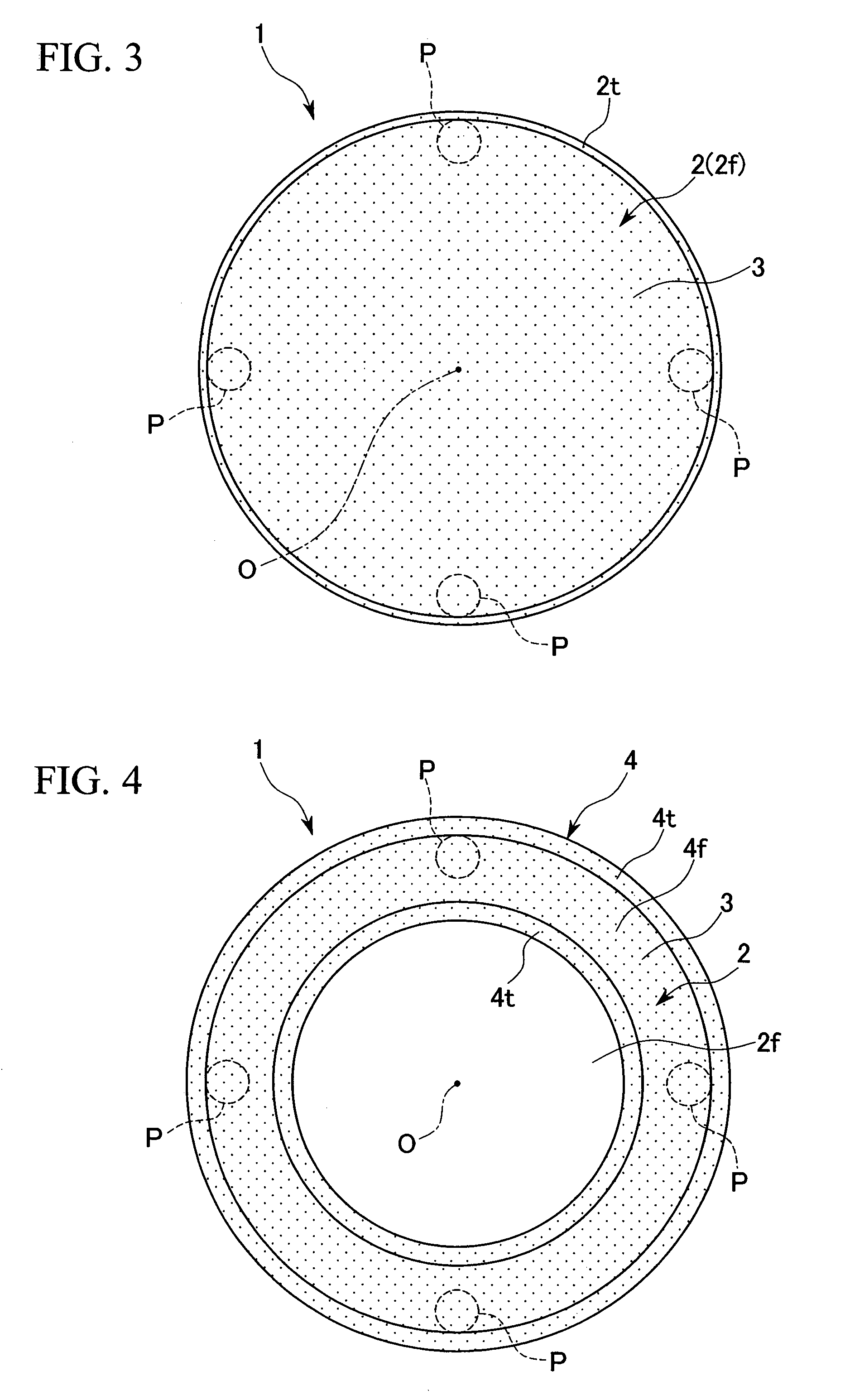

CMP conditioner

ActiveUS20060079162A1Avoid it happening againCorrosion resistanceRevolution surface grinding machinesGrinding drivesMechanical engineeringDiamond grit

A CMP conditioner is provided in which diamond grit that is adhered to a conditioning surface so as to face and be in contact with a polishing pad of a CMP apparatus is adhered such that 111 surfaces of crystal surfaces of the diamond grit are substantially parallel with the conditioning surface and face in a direction faced by the conditioning surface.

Owner:MITSUBISHI MATERIALS CORP

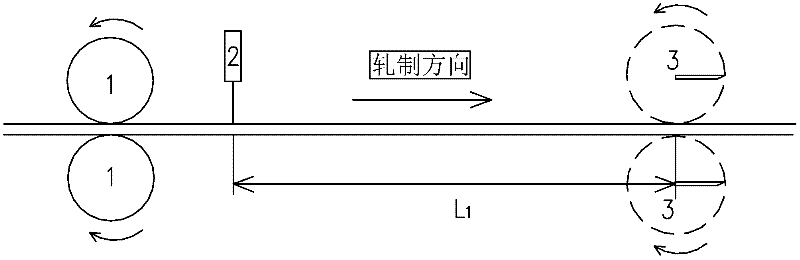

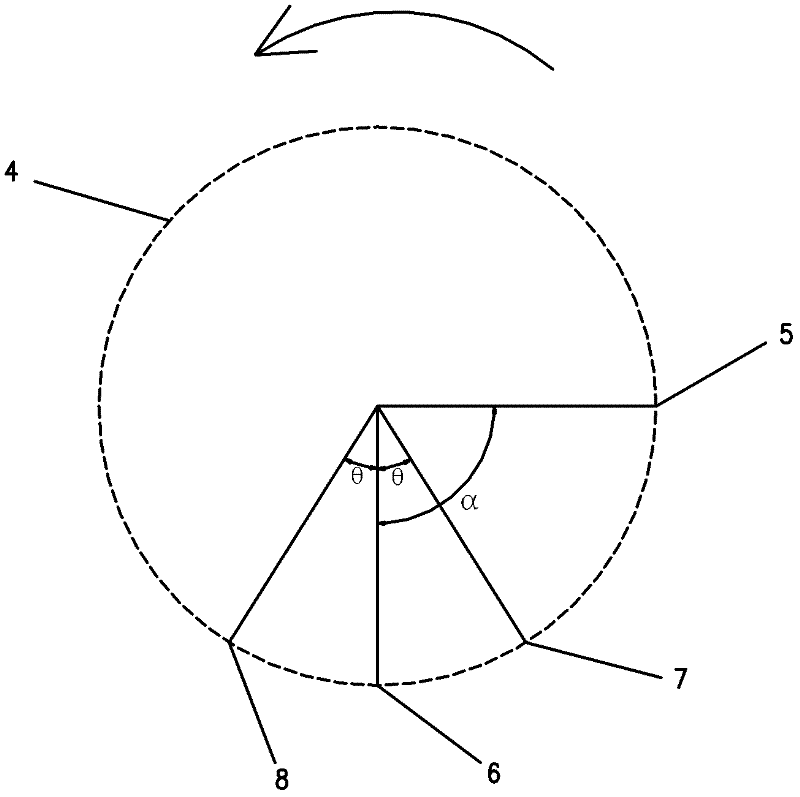

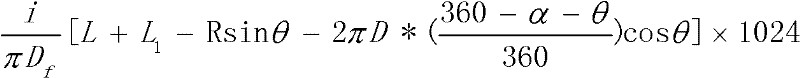

New method for controlling flying shears for bars and wires based on T400

InactiveCN102441569ASimple control structureImprove cut qualityRoll mill control devicesMetal rolling arrangementsWire rodStart stop

The invention provides a new method for controlling flying shears for bars and wires based on T400, which is an advanced electrical control method for start-stop type flying shears for bars and wires. The method comprises the steps of accurate shearing-blade position control, shearing length control and automatic shearing optimization, and the like; in the process of production, when an upstream rolling mill has an accident, or the quality of a section of a rolled piece is poor, a fragmentation function can be started on line so as to carry out partial fragmentation or complete fragmentation on the rolled piece, and the fragmentation and shearing speed is in step with the running speed of the rolled piece automatically; and when the fragmentation operation is stopped, a flying shear is automatically positioned to a start position and enters into a standby state of the normal shear mode. In the invention, the powerful computation function of the T400 is fully used, core control parts of the flying shear are completely integrated into the T400, and high-speed counters, shaft positioning modules and touch screens are not required, therefore, the cost is reduced, and high accuracy is obtained; and when the flying shear carries out double-length shearing at a speed of 21 m / s, the double-length error is basically within 75 mm, and partial double-length error can be within 30 mm.

Owner:WISDRI WUHAN AUTOMATION

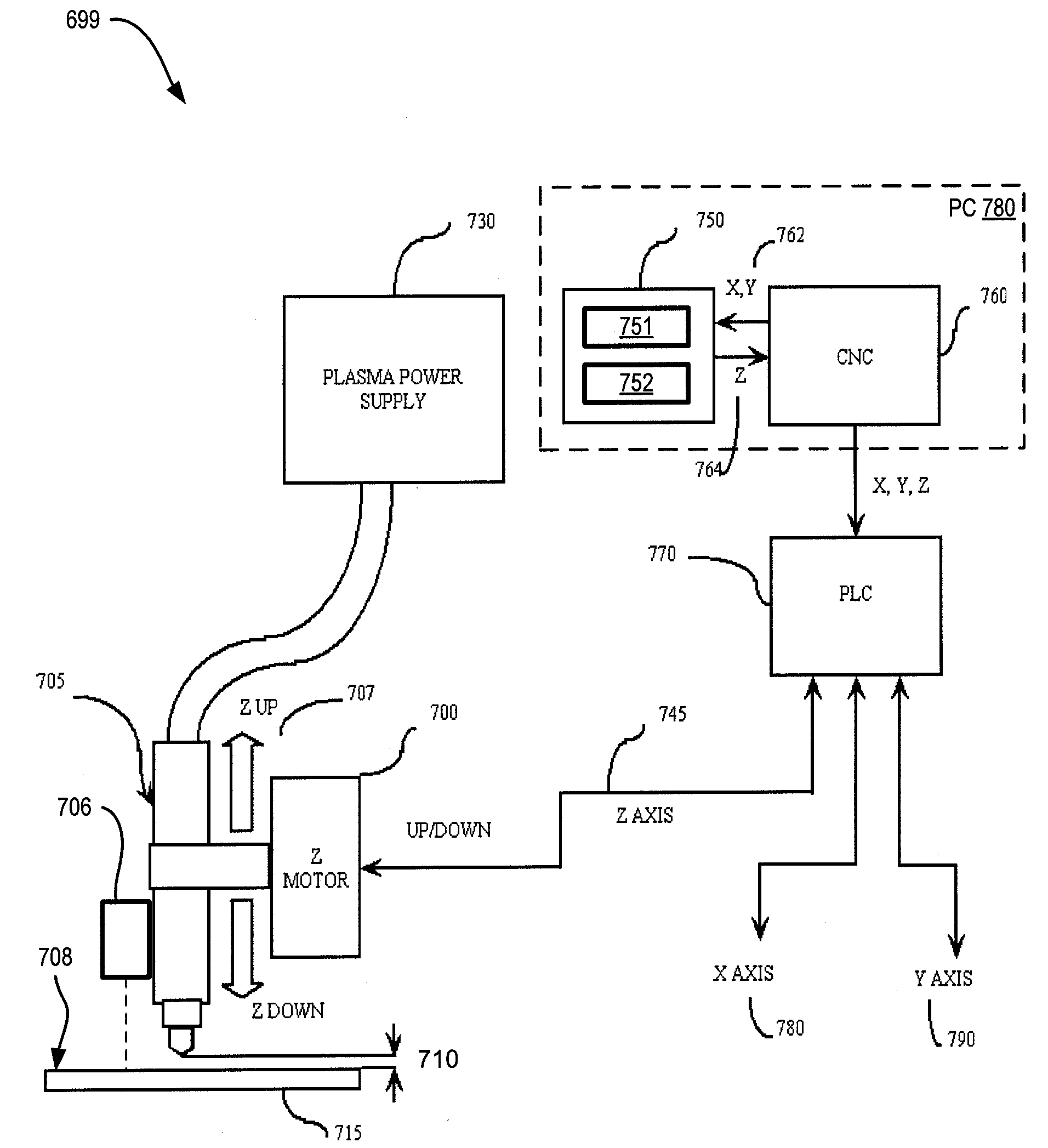

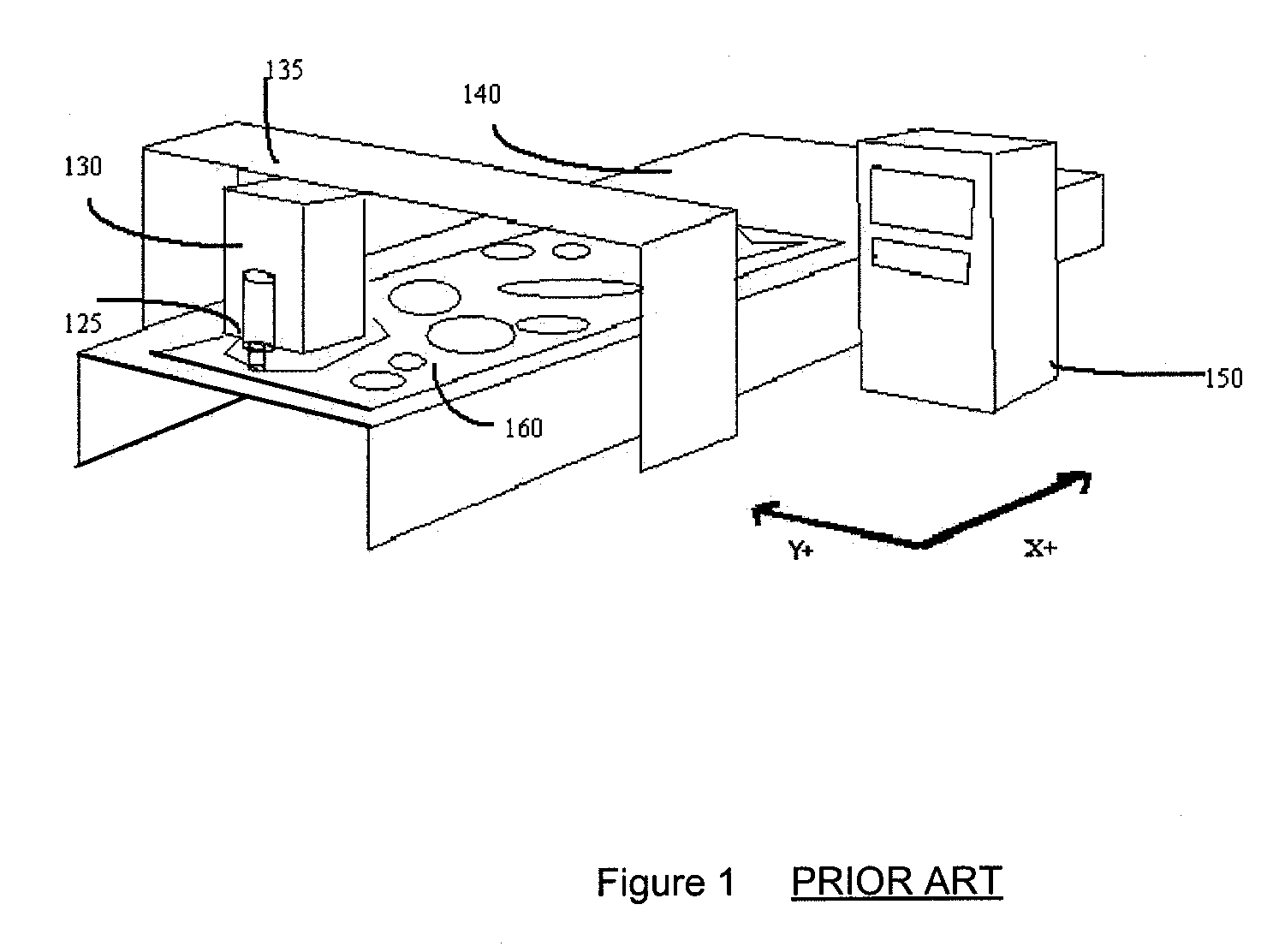

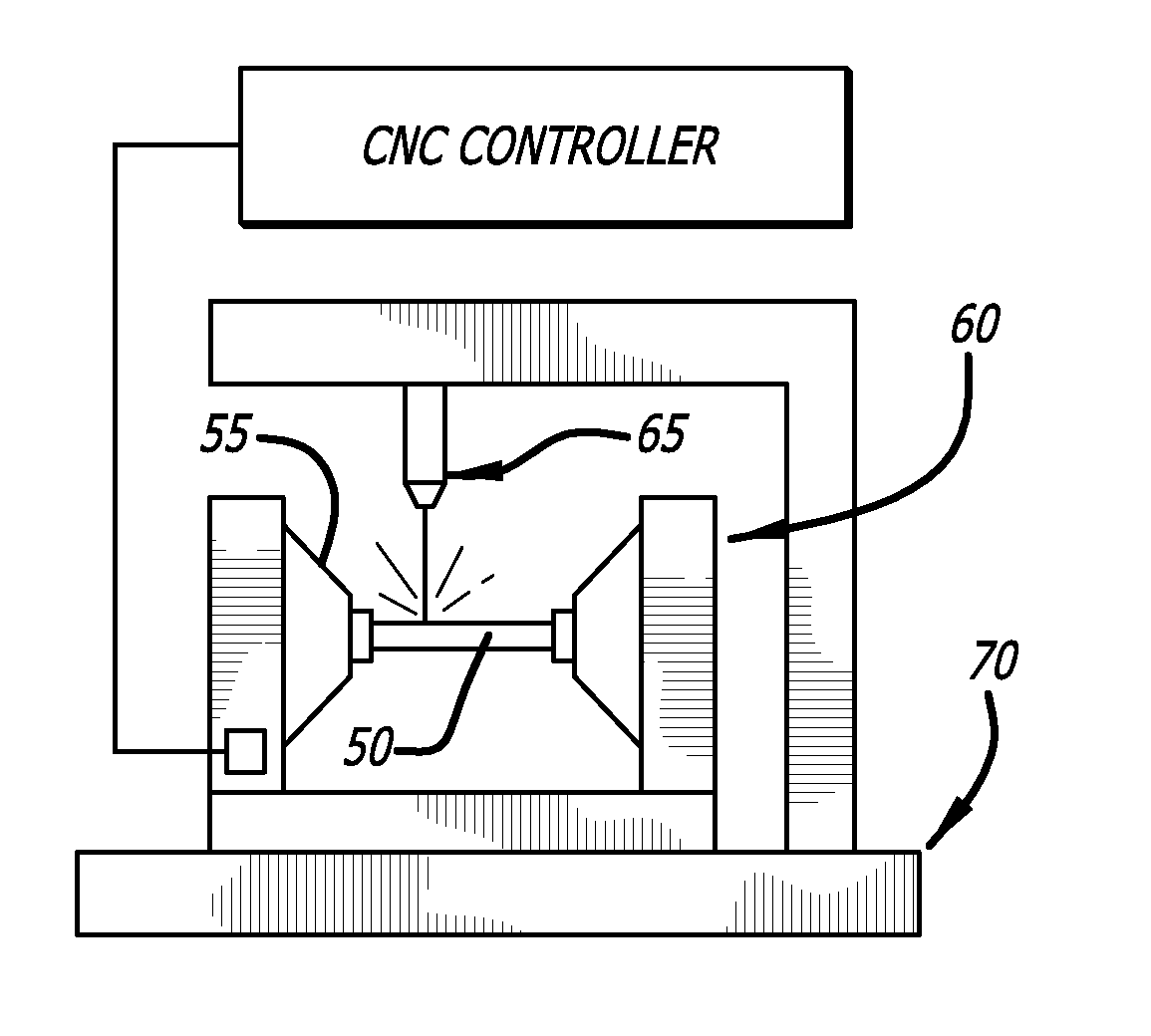

Methods And Systems For Predictive Torch Height Control

ActiveUS20090312862A1Accurate predictionEasy height controlPlasma welding apparatusSpecial data processing applicationsNumerical controlData set

A method for controlling a height of a cutting torch, includes loading a workpiece onto a numerical control machine, scanning the workpiece with a scanning device at a plurality of discrete points on an upper surface of the workpiece, measuring an X-, a Y-, and a Z-coordinate for each respective one of the scanned discrete points, where X and Y define a plane substantially parallel to the loaded workpiece and Z represents a distance between the upper surface and the scanning device at a respective discrete point, storing the measured XYZ coordinates from each of the scanned discrete points into a data set, mathematically fitting the stored data set to a smooth surface representative of the upper surface of the loaded workpiece, and cutting the workpiece along a cutting path programmed into the numerical control machine, while controlling the cutting torch height to correspond to the representative smooth surface.

Owner:FAGAN MATTHEW

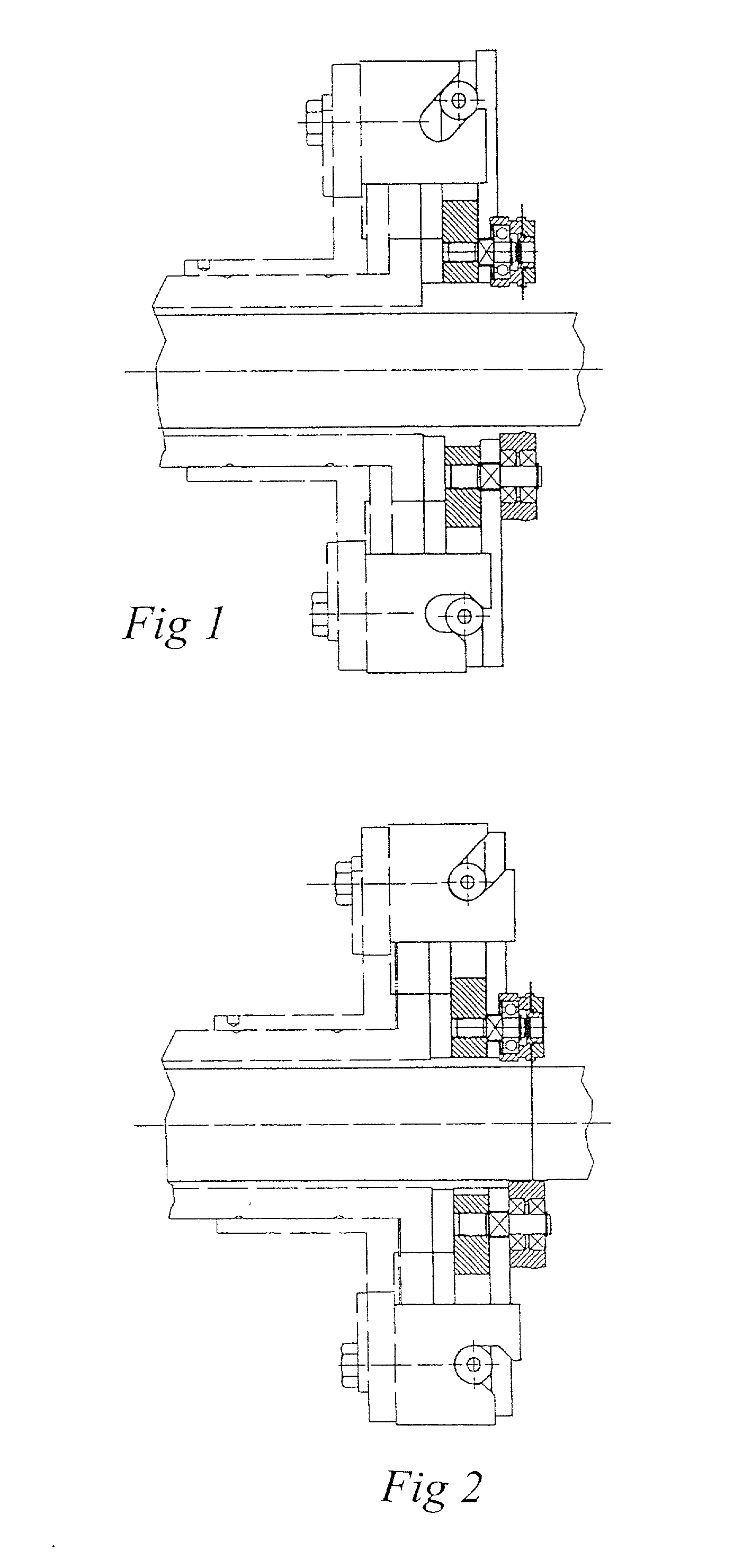

Hard pipe cutting equipment

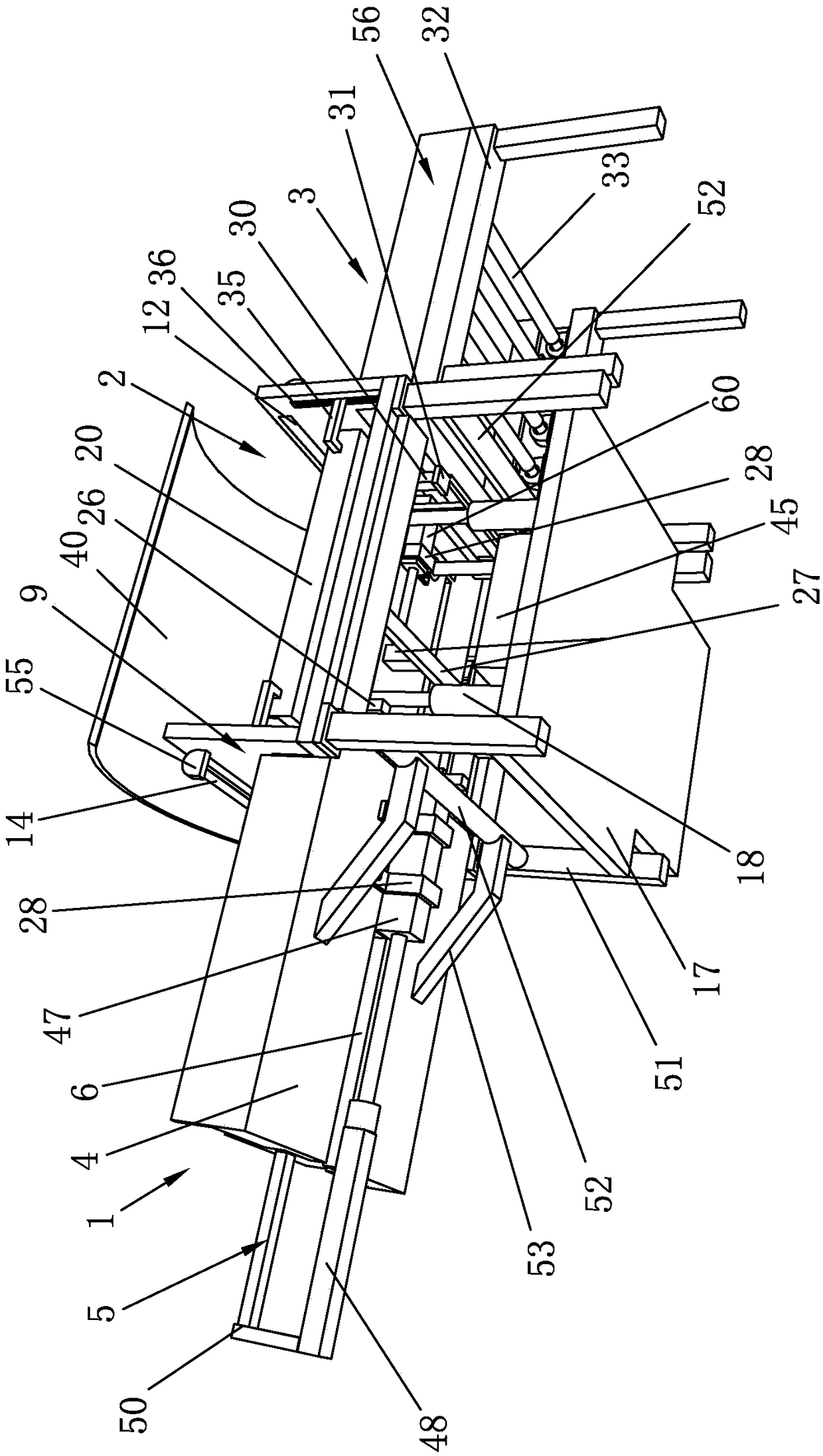

InactiveUS20030005562A1Reduce distanceImprove holding capabilityTurning machine accessoriesOther manufacturing equipments/toolsEngineeringElectric control

The present invention relates to a novel cutting equipment, which automatically cuts hard plastic pipes produced from an extruder, having a table, an input V shape leading wheel, an input fixing clamp apparatus mechanism, a cutting mechanism, a bearing transmission mechanism, an output fixing clamp apparatus mechanism, a V shape leading plate, a leading wheel, a cuttings collector, and an electric control system, which are assembled to a novel means of a hard pipe cutting machine.

Owner:NANYA PLASTICS CORP

CMP conditioner

ActiveUS7150677B2Prevents any large-scale reductionReliably prevents scratchesRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

Owner:MITSUBISHI MATERIALS CORP

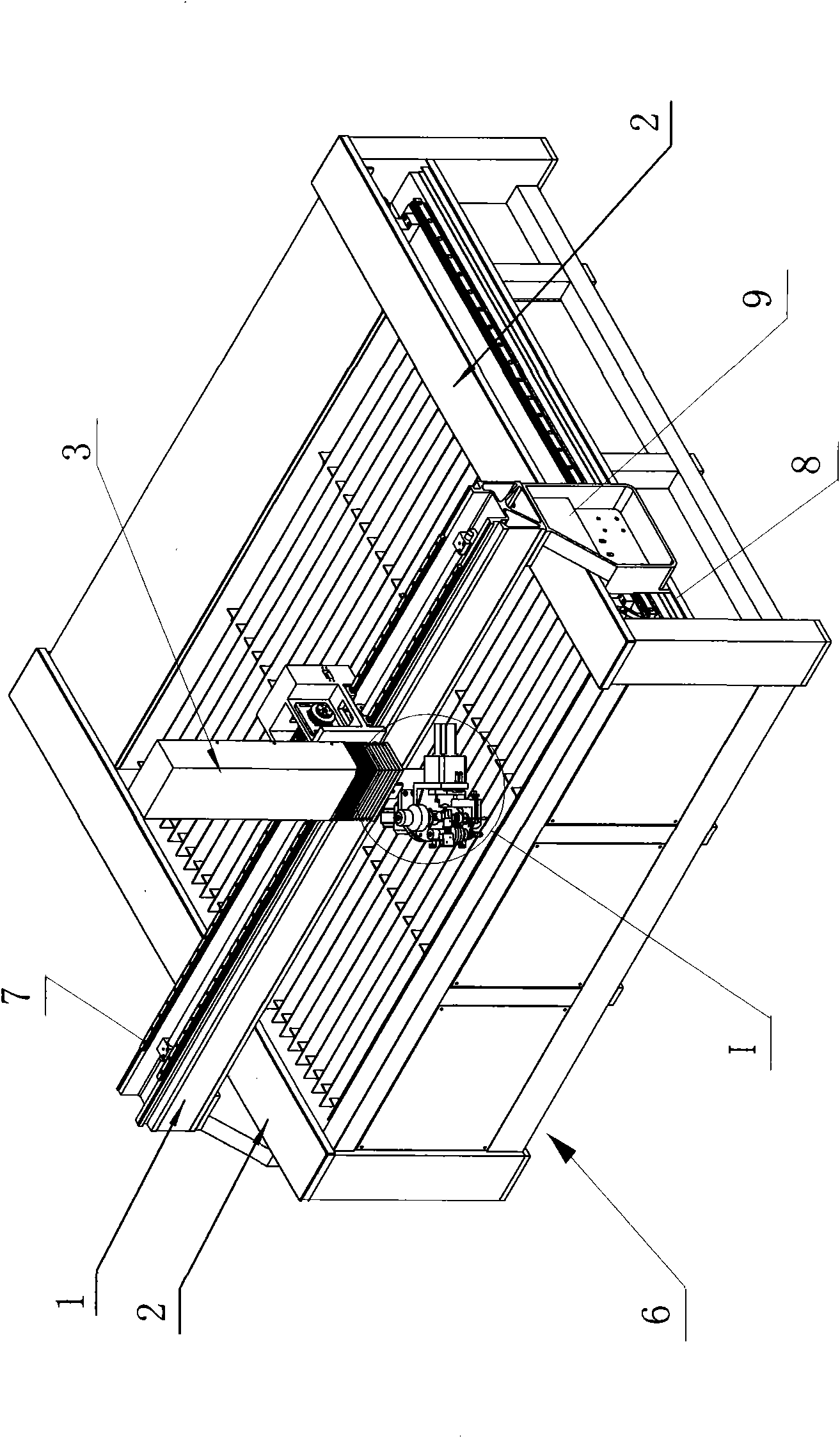

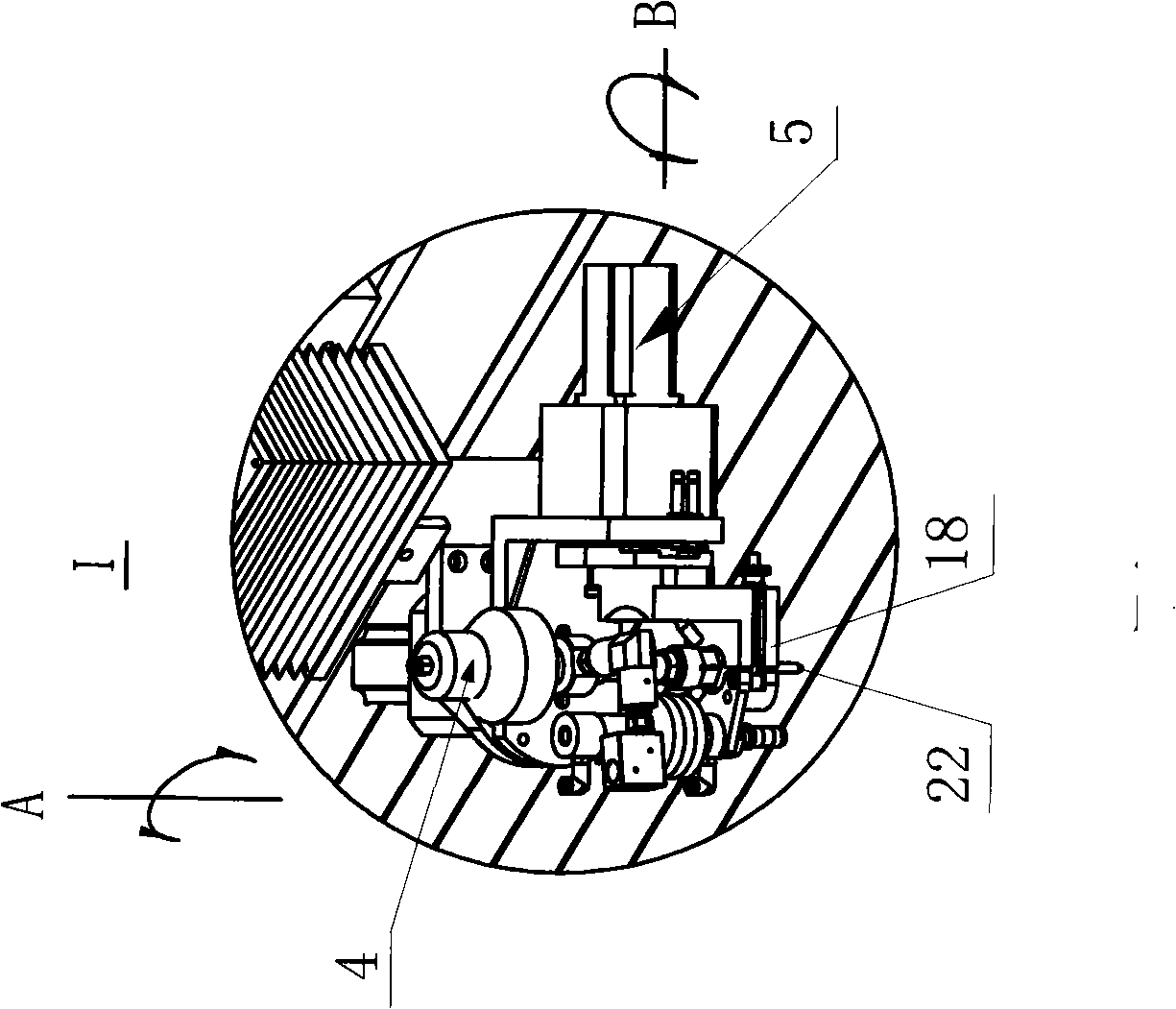

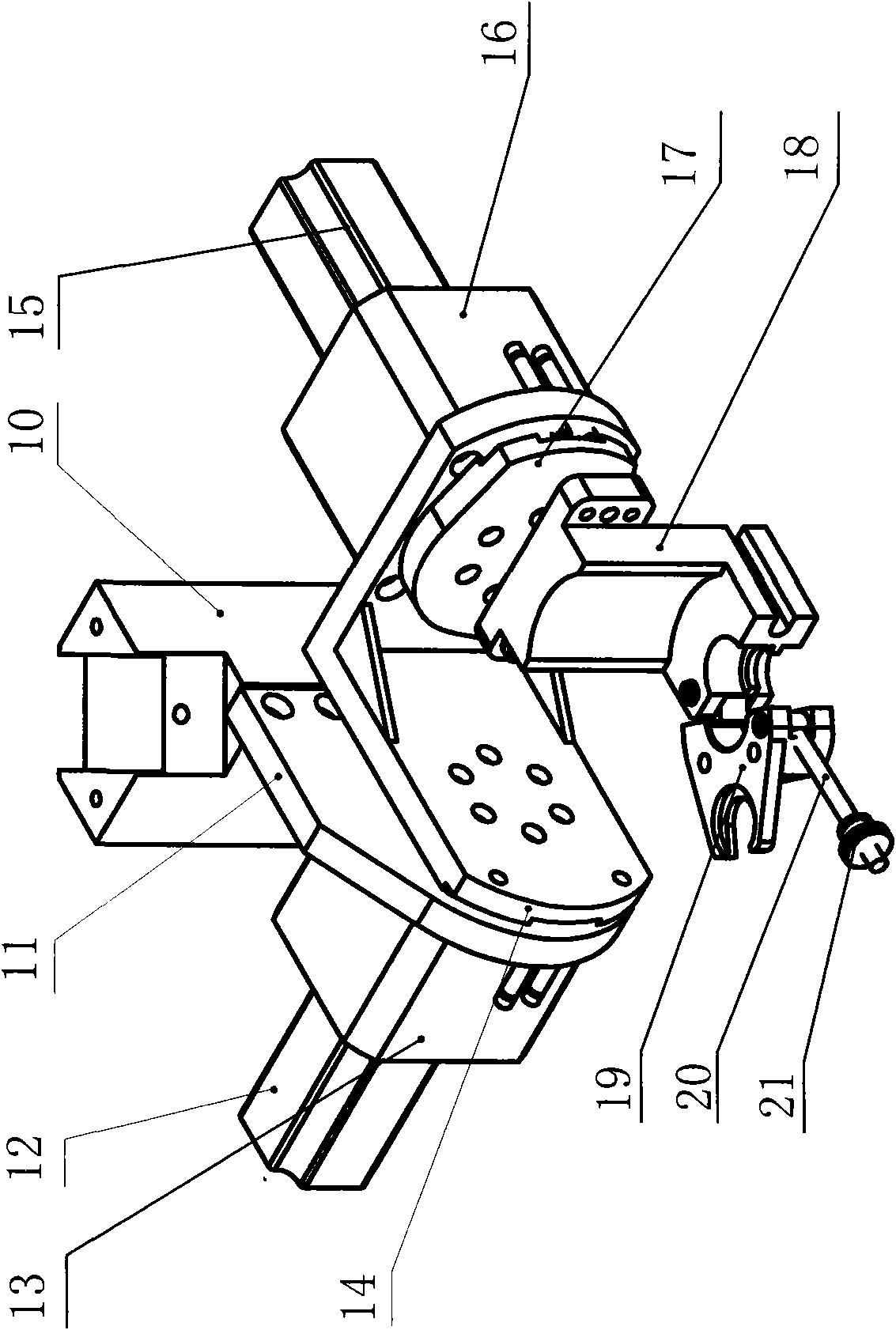

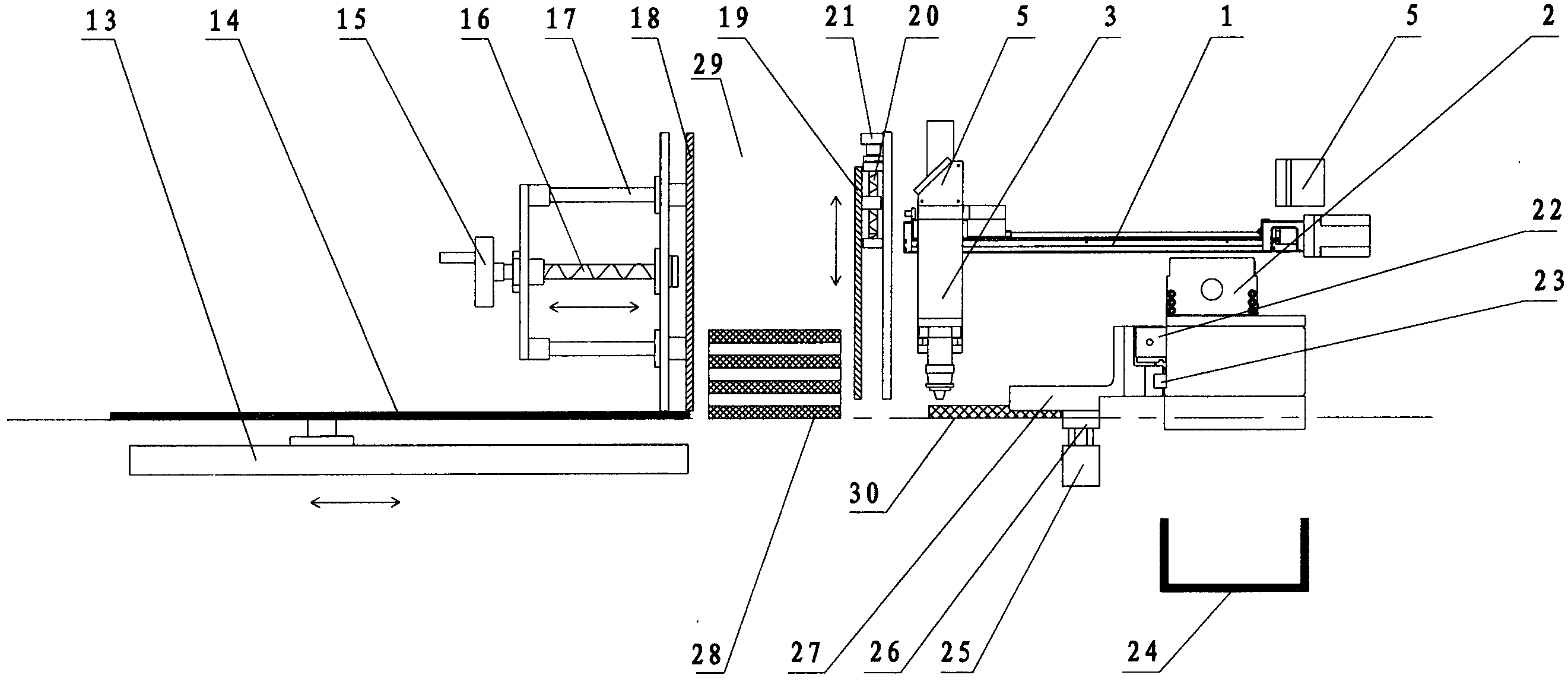

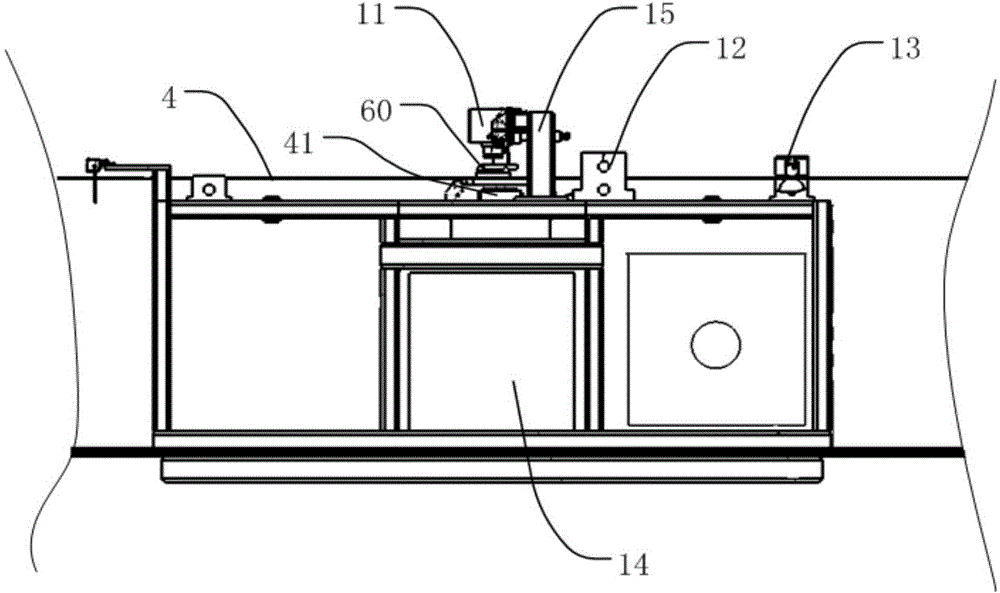

Numerical control five-axle linkage super-high pressure water jet cutting machine

ActiveCN101554738AHigh dimensional accuracyImprove cut qualityShearing machinesMetal working apparatusNumerical controlReducer

The invention relates to a numerical control five-axle linkage super-high pressure water jet cutting machine which comprises a super-high pressure water jet generator, a water jet cutting platform, an X-axle transmission mechanism, a Y-axle transmission mechanism, a Z-axle transmission mechanism and a cutting head connected with the Z-axle transmission mechanism. The numerical control five-axle linkage super-high pressure water jet cutting machine is characterized in that the cutting head has a composite rotating head of axles A and B. The composite rotating head of axles A and B comprises an A axle motor, a B axle motor, a connecting plate of axles A and B and a movable seat, wherein the A axle motor is fixedly connected to a transition plate of the Z-axle transmission mechanism through an A axle speed reducer of the A axle motor, and the output shaft of the A axle speed reducer is connected with the connecting plate of axles A and B; and the B axle motor is fixed on the connecting plate of axles A and B through a B axle speed reducer of the B axle motor, the output shaft of the B axle speed reducer is connected with the movable seat, the cutting head is clipped on the movable seat, the X-axle, the Y-axle, the Z-axle, the A axle and the B axle are interlocked under a main programmable digital controller to control the cutting head to incline in any direction, and the cut bevel edge generated after water jet cutting is filled up. The water jet cutting machine has high automation and cutting efficiency, effectively overcomes the problems of water jet lag and cut bevel edge of the traditional water jet cutting machine and has high cutting precision.

Owner:沈阳奥拓福科技股份有限公司

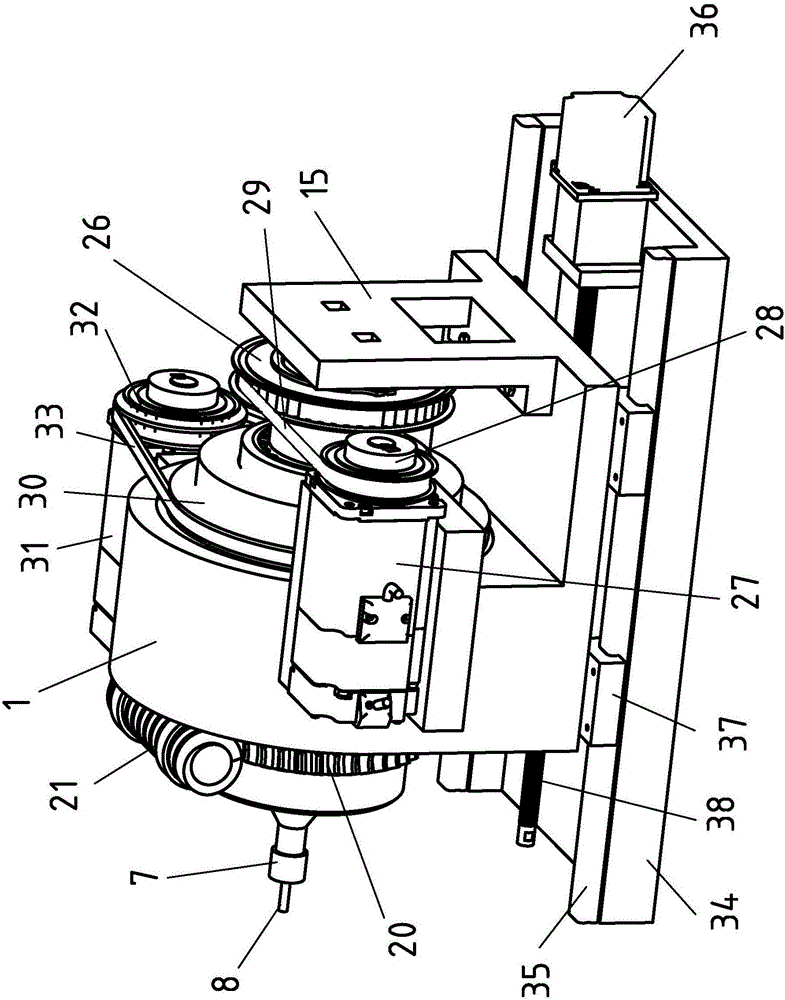

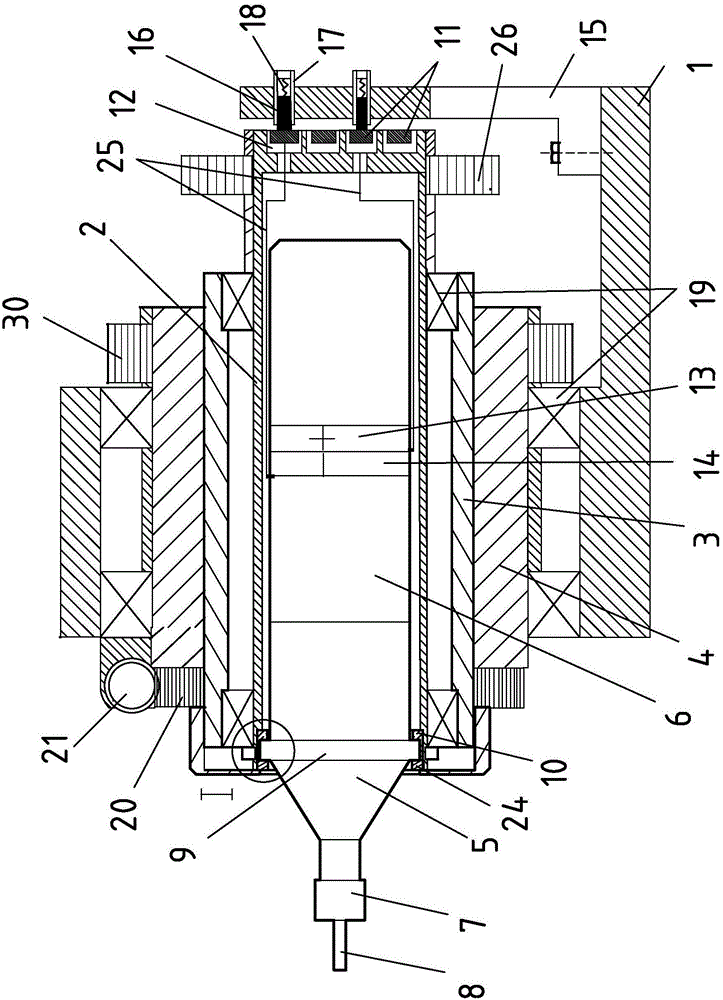

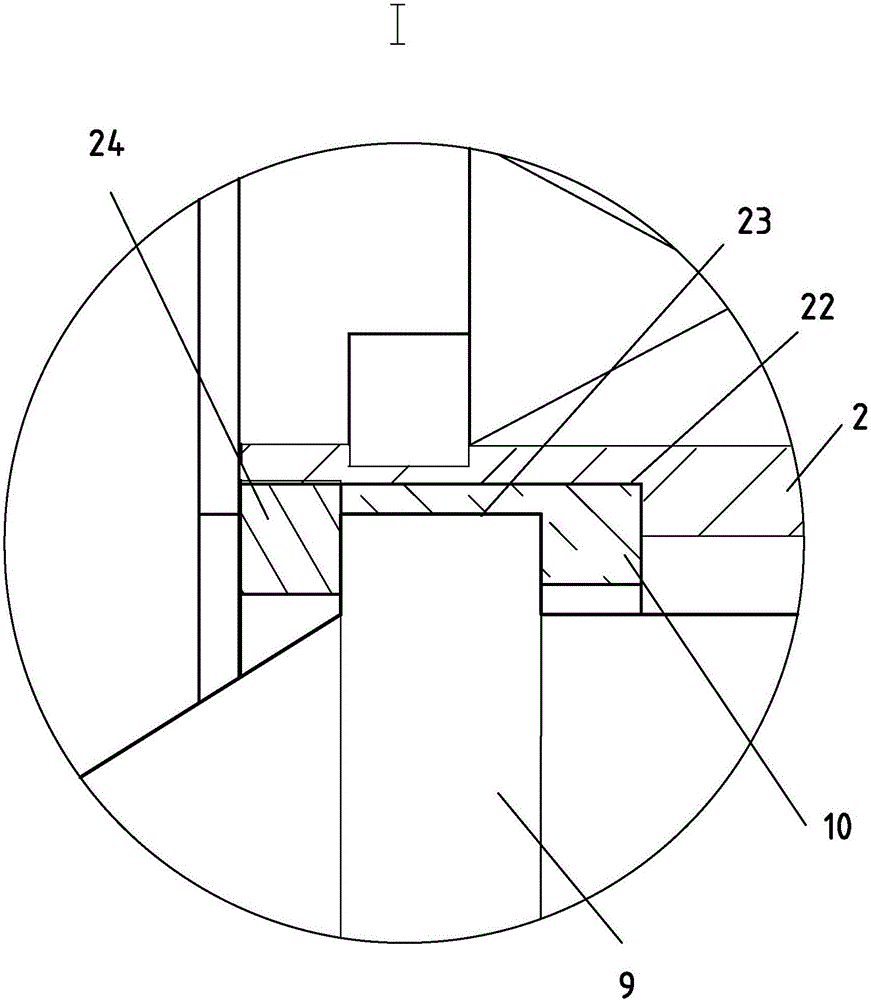

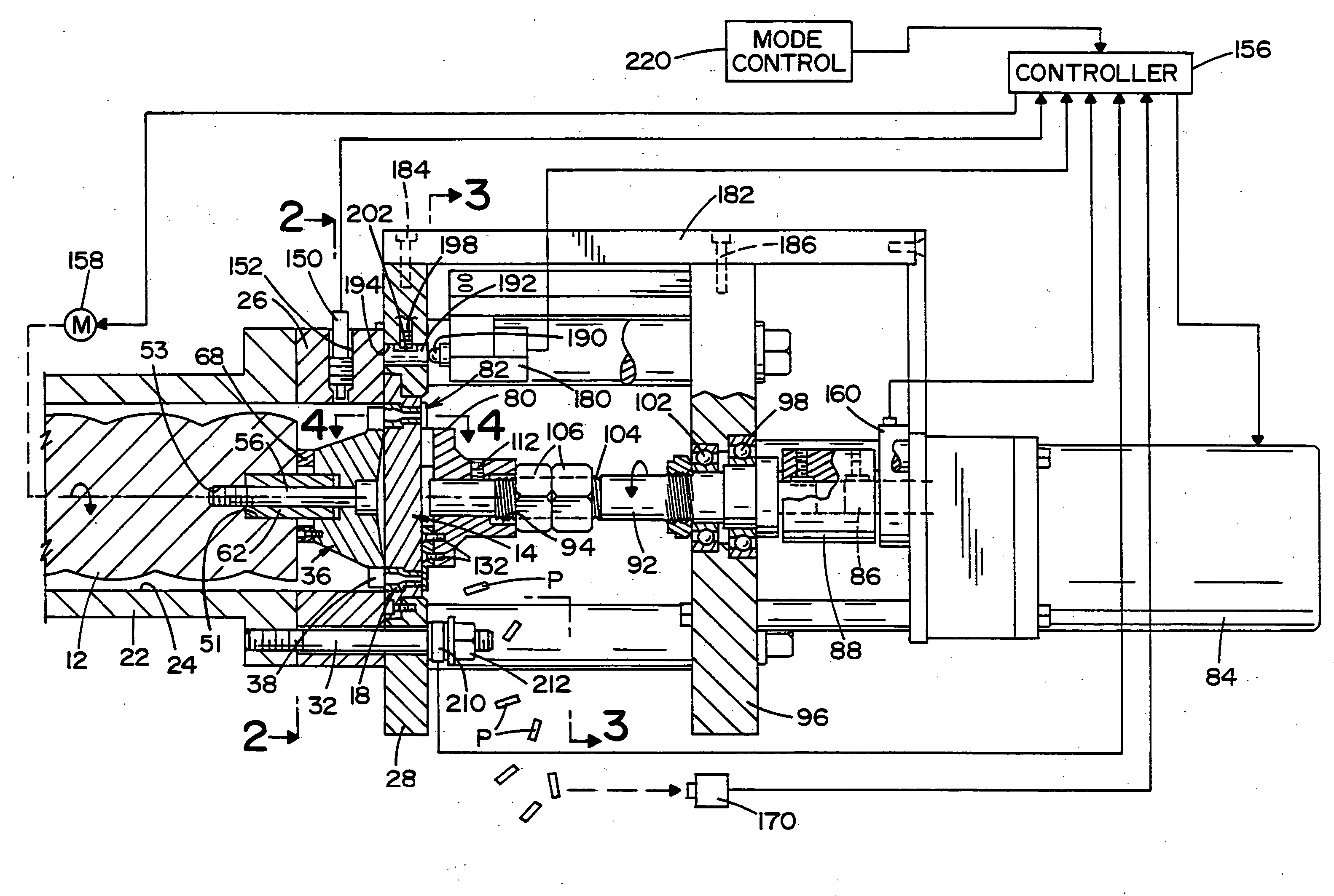

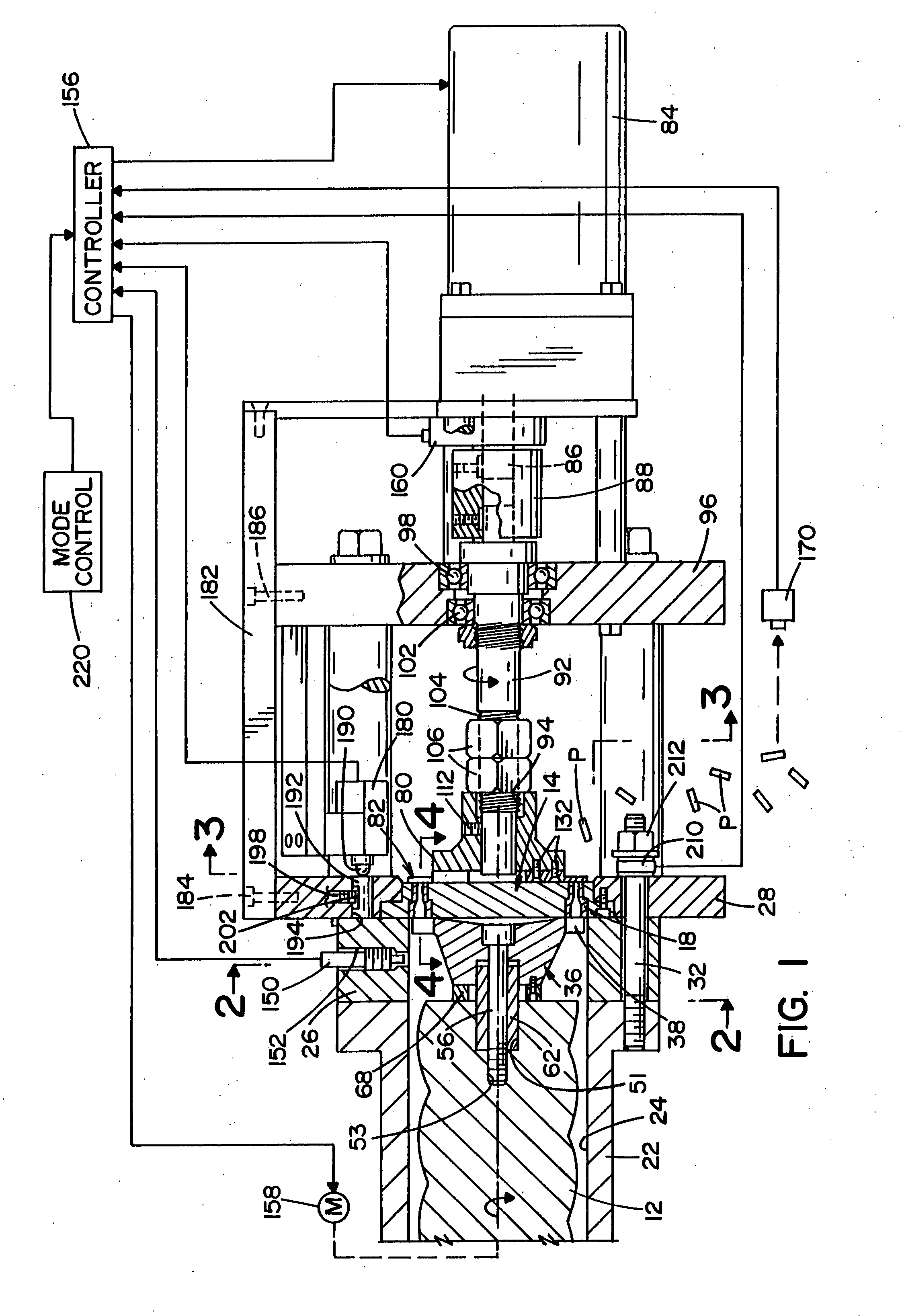

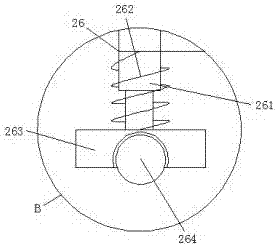

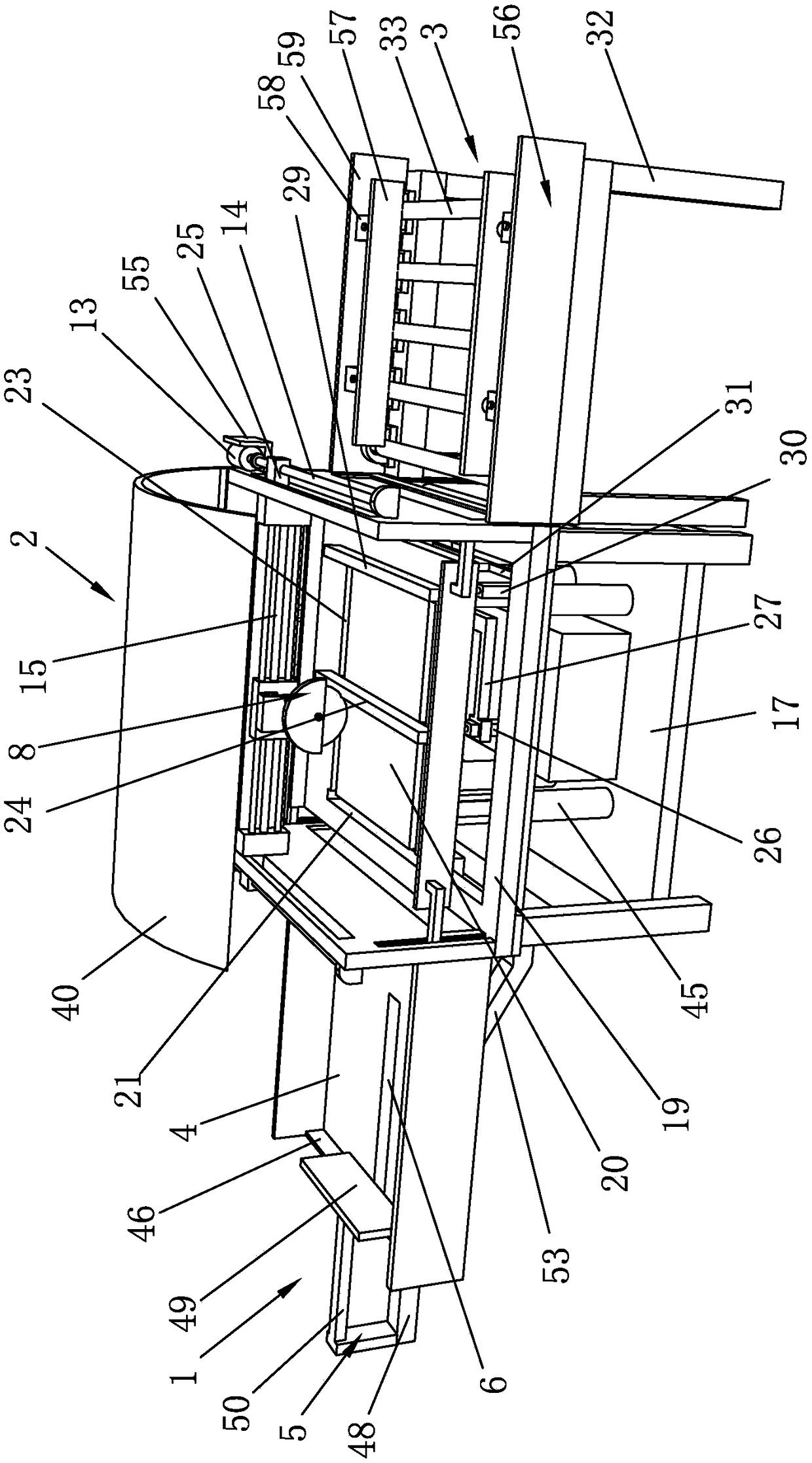

Ultrasonic helical hole milling device and machining method

ActiveCN106077774AImprove hole qualityReduce cutting forceRevolution surface grinding machinesMilling equipment detailsMilling cutterTransducer

The invention discloses an ultrasonic helical hole milling device which comprises a spindle support, an ultrasonic sleeve, an inner eccentric sleeve, an outer eccentric sleeve, an amplitude-change pole and a transducer located in the ultrasonic sleeve. The amplitude-change pole is connected with a hole forming tool through a spring chuck, and the hole forming tool is a milling cutter or a grinding wheel. The amplitude-change pole is connected with the transducer through an annular flange which is connected with the inner wall of the ultrasonic sleeve through an annular force sensor used for measuring axial and radial force borne by the annular flange. The ultrasonic helical hole milling device further comprises a helical hole-milling rotation driving device connected with the ultrasonic sleeve, a helical hole-milling revolution driving device connected with the outer eccentric sleeve and a feeding system for driving the spindle support to conduct feeding along the axis of the amplitude-change pole. The invention further discloses a machining method for conducting ultrasonic helical hole milling through the ultrasonic helical hole milling device. The ultrasonic helical hole milling device and the machining method have the advantages that the hole forming quality is high, hole forming quality consistency is good, and machining stability is good.

Owner:DALIAN UNIV OF TECH

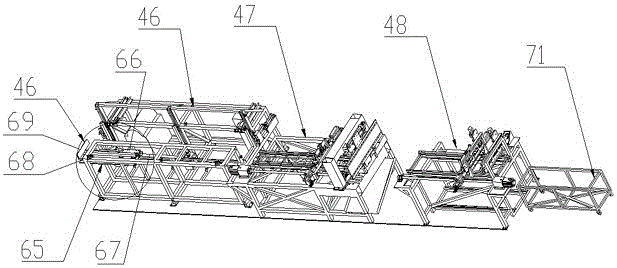

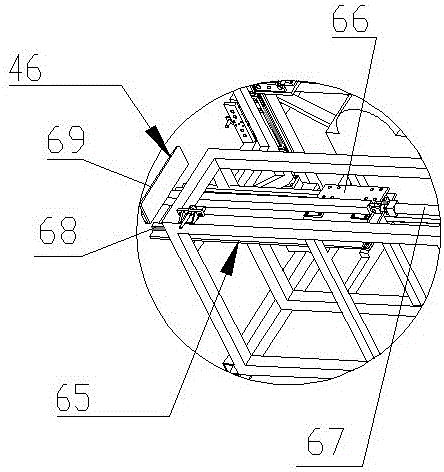

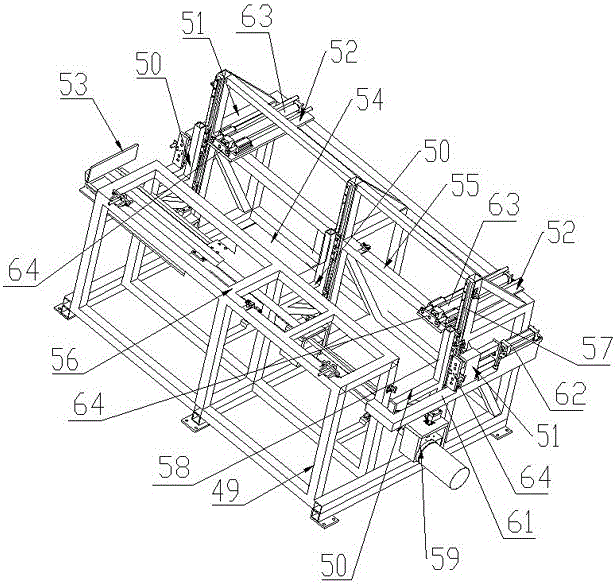

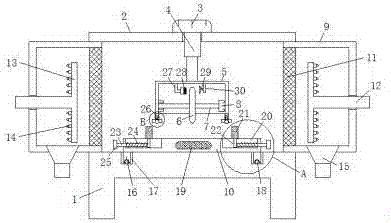

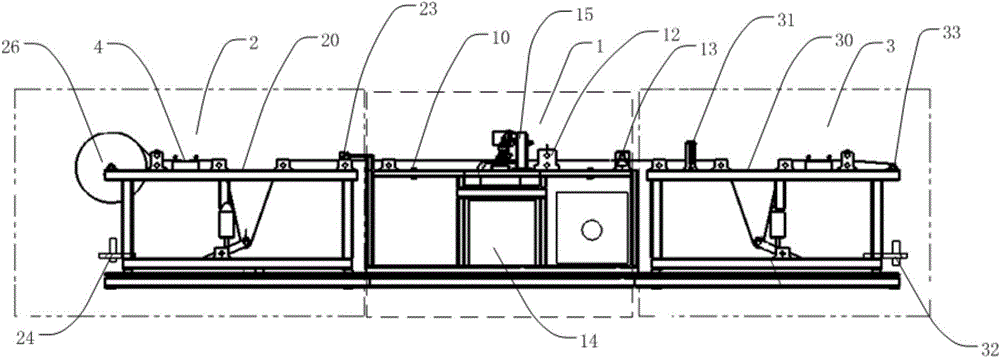

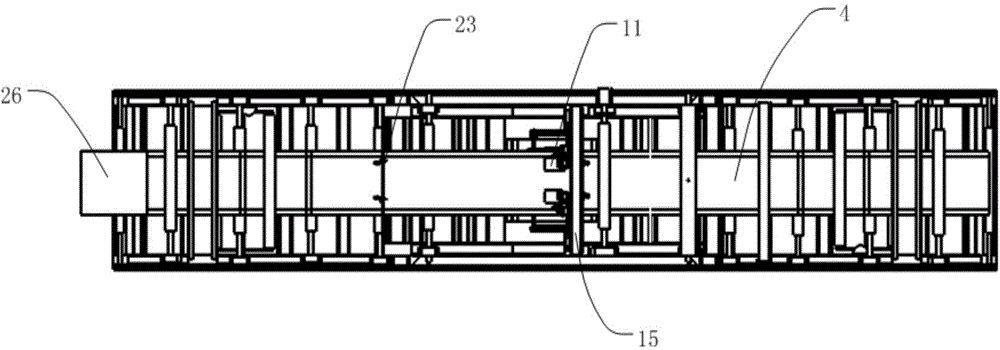

Automatic assembly line for feeding, cutting and punching pipe automatically

ActiveCN106271629AHigh degree of automationImprove cutting efficiencyMetal sawing devicesOther manufacturing equipments/toolsPunchingAssembly line

The invention discloses an automatic assembly line for feeding, cutting and punching a pipe automatically. The automatic assembly line comprises a front feeding mechanism, a middle feeding and cutting mechanism and an automatic punching and unloading mechanism which are arranged in sequence from left to right; the front feeding mechanism comprises a first supporting frame, a lifting mechanism, a pipe clamping mechanism, a transverse pushing mechanism and a longitudinal pushing mechanism; the middle feeding and cutting mechanism comprises a second supporting frame, a first clamping conveying mechanism, an automatic cutting mechanism and an automatic clamping mechanism; the automatic punching and unloading mechanism comprises a third supporting frame, a second clamping conveying mechanism, a drilling clamping mechanism and two sliding drilling mechanisms which are positioned on the right side of the second clamping conveying mechanism and are arranged at an interval. The automatic assembly line can realize automatic feeding, and is low in labour intensity and high in work efficiency; the pipe can be cut automatically; the cutting quality is good; high-efficiency cutting operation of one or more pipes can be realized synchronously; the punching operation can be performed on the two ends of the pipe simultaneously; the function of clamping a plurality of pipes at one time and punching the pipes in sequence can be realized.

Owner:JIANGSU JINPENG VEHICLE CO LTD

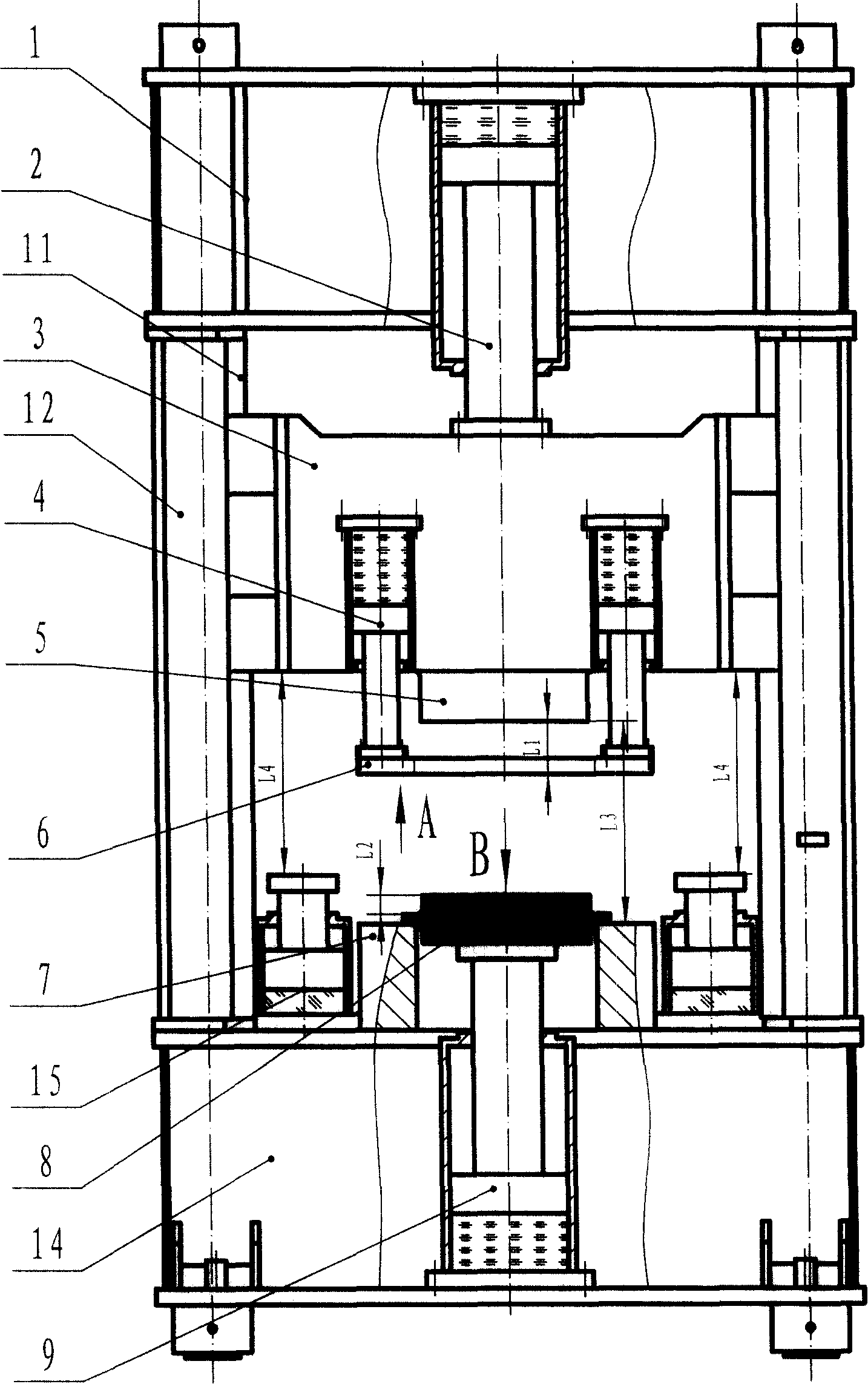

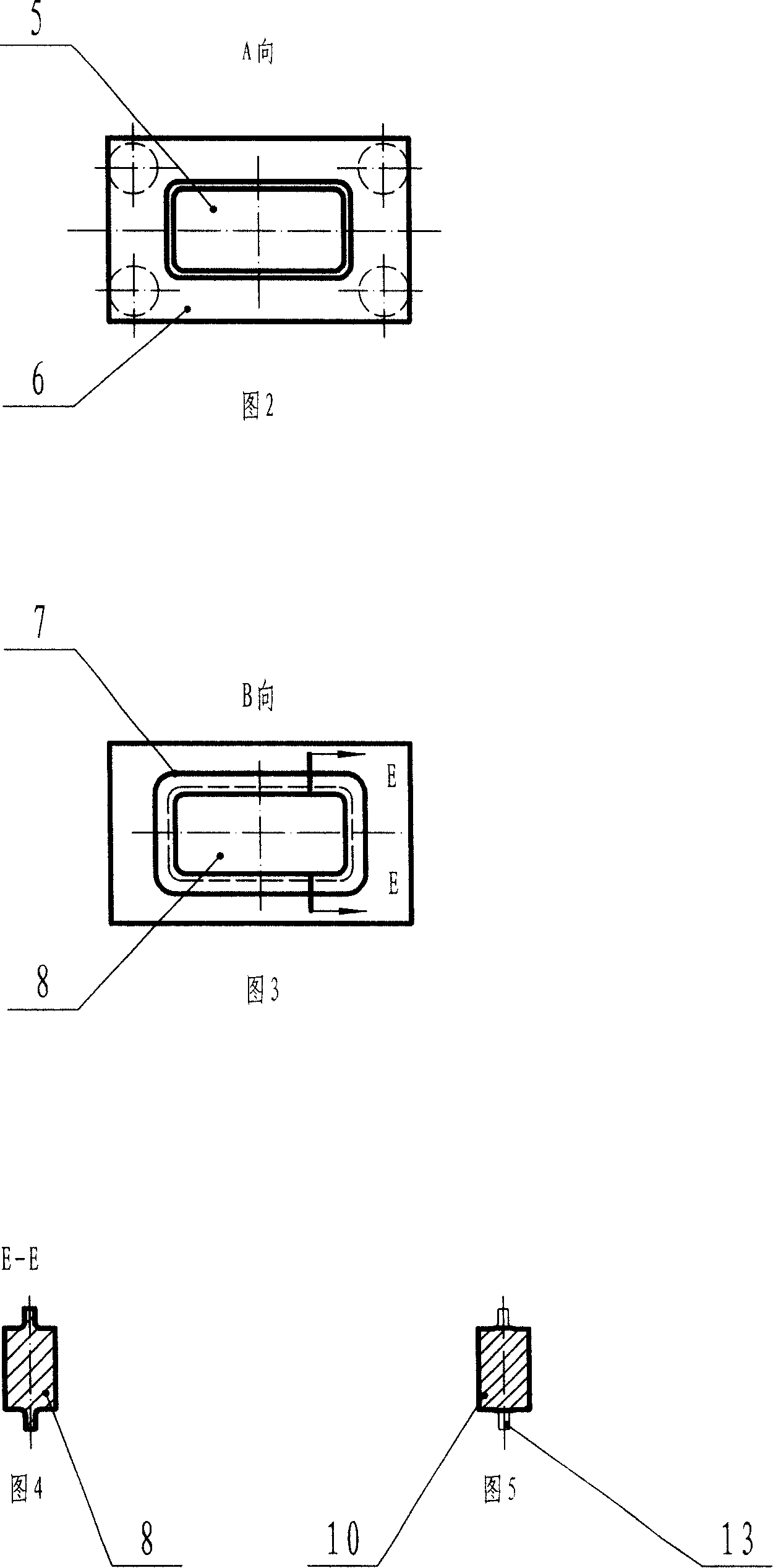

Flashing precise planning and cutting hydropress

The invention relates to a flash precise slicing hydraulic press used for the punching shear of a forging flash. The equipment combines a linear driving mechanism, a blank holding mechanism, a back pressure mechanism and a buffer device into novel special punching shear equipment. By adopting the linear unidirectional driving type of the equipment, a workpiece is only subject to a vertical unidirectional punching shear force, but not subject to a lateral force or an additional torsion in the punching-shear process; owning to the blank holding mechanism, the flash can not be warped in the punching-shear process as the flap edge is subject to a compulsive restraining force; owning to the back pressure mechanism, the forging is supported by a back pressure cylinder in the punching-shear process, and the flexible deformation of the forging is reduced; owning to the buffer device, the impact to the hydraulic system is avoided. The slicing hydraulic press which is provided by the invention can be used for the normal punching shear of the flash of the forging, and is especially suitable for the precise punching shear of the flap edge of the forging; the incision of the forging after punching shear has high precision and good quality. The invention can be suitable for all the enterprises which produce forgings.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

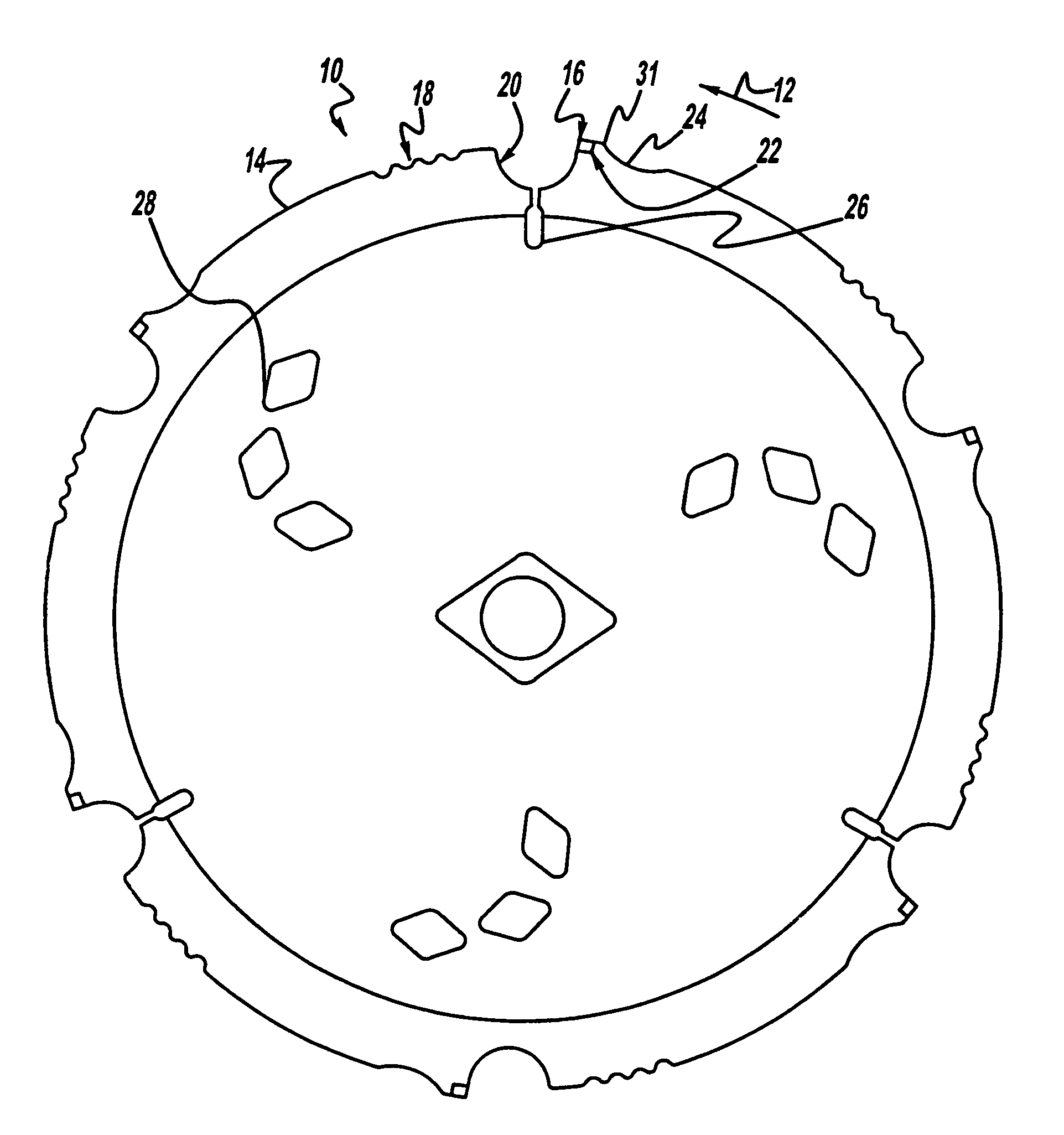

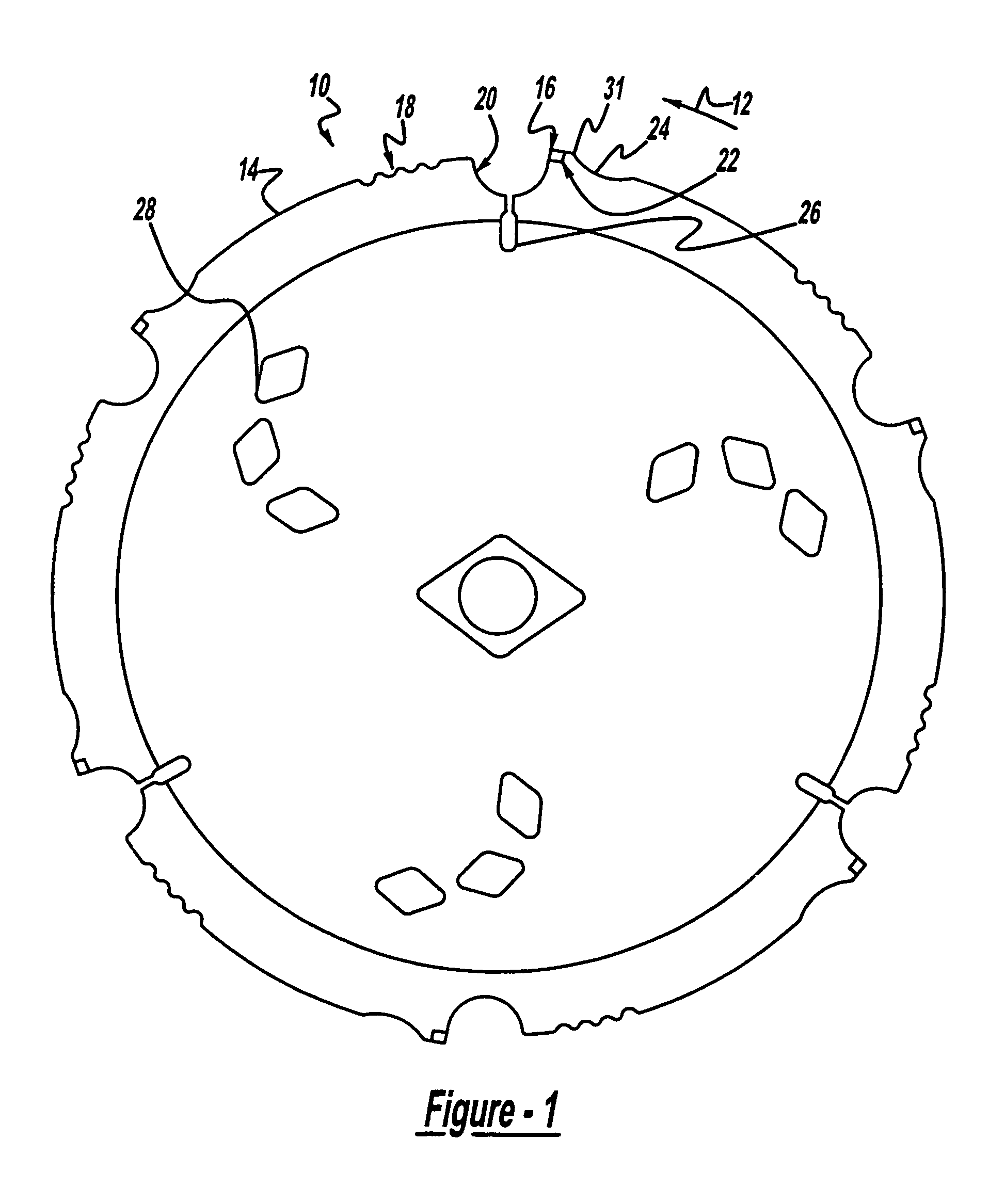

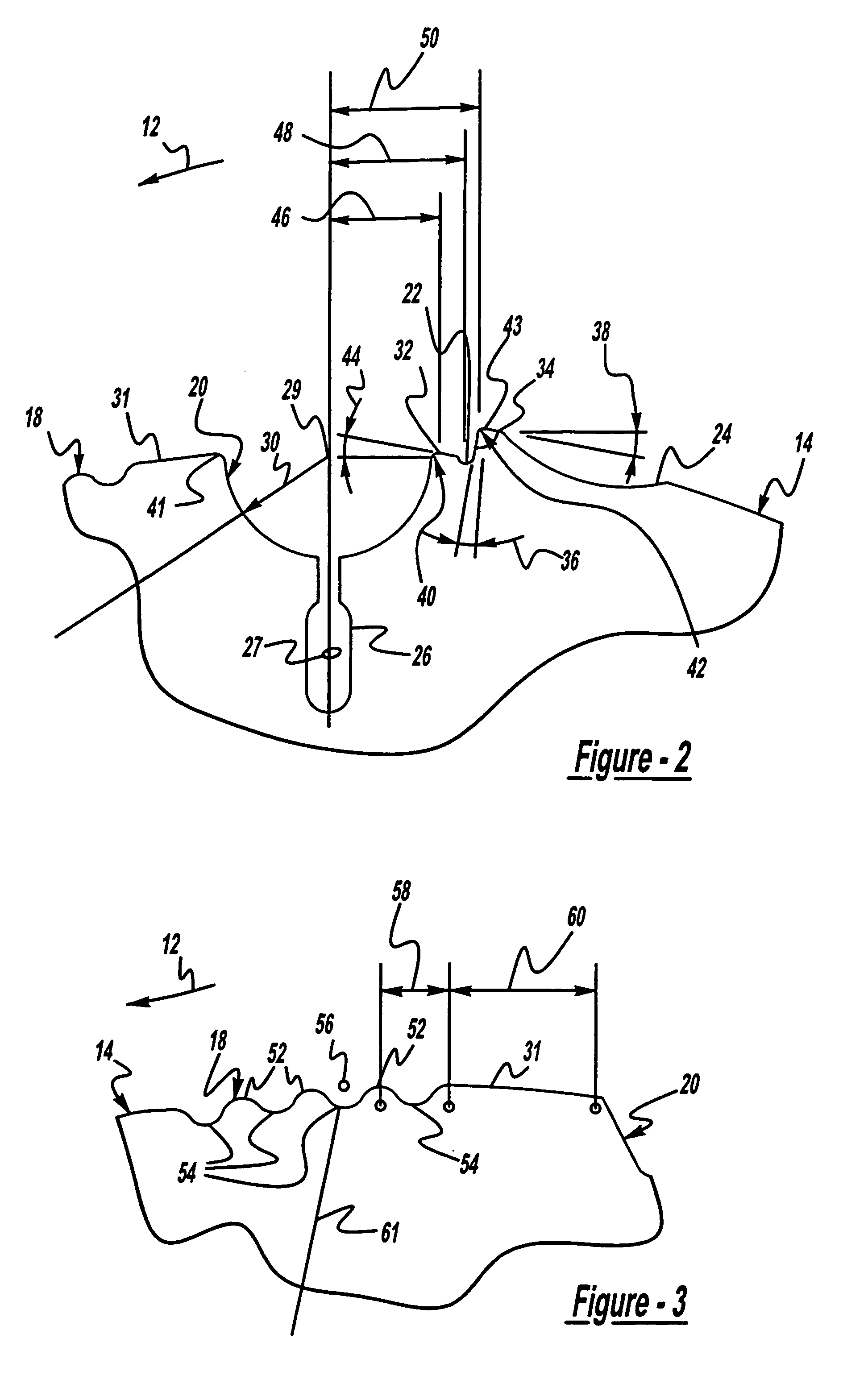

Saw blade for cutting fiber cement

InactiveUS7117863B1Reduce the amount requiredReduce the level of dustRevolution surface grinding machinesAnimal feeding devicesFiberCircular saw

An improved circular saw blade designed for cutting fiber cement workpieces, which are becoming more and more prevalent on the construction site, includes a PCD / carbide tip (16) mounted in the rim (31) of the saw blade (10) at six, rather than the usual for locations, equally spaced around the blade. The tips are mounted adjacent a relatively large-diameter, semi-circular gullet (20), which itself is preceded by a chip and dust minimizer (18). The minimizer includes several alternating hills (52) and valleys (54) formed in the rim of the saw blade, each hill and valley having the same radius, producing a sinuous array essentially centered on the rim of the blade. It has been discovered that such a dust and chip minimizer reduces the level of dust and chips produced by the blade and clears the same from the kerf generated in the blade-workpiece interface. Ideally, all of the parameters and relief angles for the surfaces on the saw blade tip can be generated by cutting an array of such tips from a large-diameter blank (110) of PCD fused to a layer of tungsten carbide (72), and by mounting the tips onto the blade in such an orientation as to present, preferably, a negative hook or rake angle (74) to the workpiece.

Owner:BLACK & DECKER INC

Automatic feeding and discharging laser cutting machine

ActiveCN102500931AShort loading and unloading timeImprove cutting efficiencyLaser beam welding apparatusEngineeringLaser cutting

The invention discloses an automatic feeding and discharging laser cutting machine, which comprises a hopper, a conveying mechanism, a stopping mechanism and a target pushing mechanism. A plurality of plates can be arranged on the hopper, a calibration mechanism is disposed on a side surface of the hopper, the plates are aligned by the calibration mechanism, a slit adjusting mechanism is arranged on another side surface of the hopper, one plate can pass through the slit adjusting mechanism, the conveying mechanism can automatically push the plate on the bottom layer in the hopper to a cutting table via the slit adjusting mechanism, the stopping mechanism is further positioned on one side of the cutting table, the plates are limited in the cutting plate by the stopping mechanism, and the stopping mechanism is connected with the target pushing mechanism capable of pushing the plates to a rib of the cutting table by a first inductive switch. The rib of the cutting table is provided with a second inductive switch connected with a laser device, after the plate contacts with the second inductive switch, laser emitted by the laser device passes through a reflector seat, reaches a cutting head arranged above the cutting table and cuts the plate after focusing and emergence, the target pushing mechanism releases the clamped plate after cutting, the plate stops being limited by the stopping mechanism, the conveying mechanism continues to push the plate into the hopper, and the plates in the hopper are cut repeatedly.

Owner:SHENZHEN GDLASER TECH CO LTD

Extruder system and cutting assembly

Owner:JMP INDS

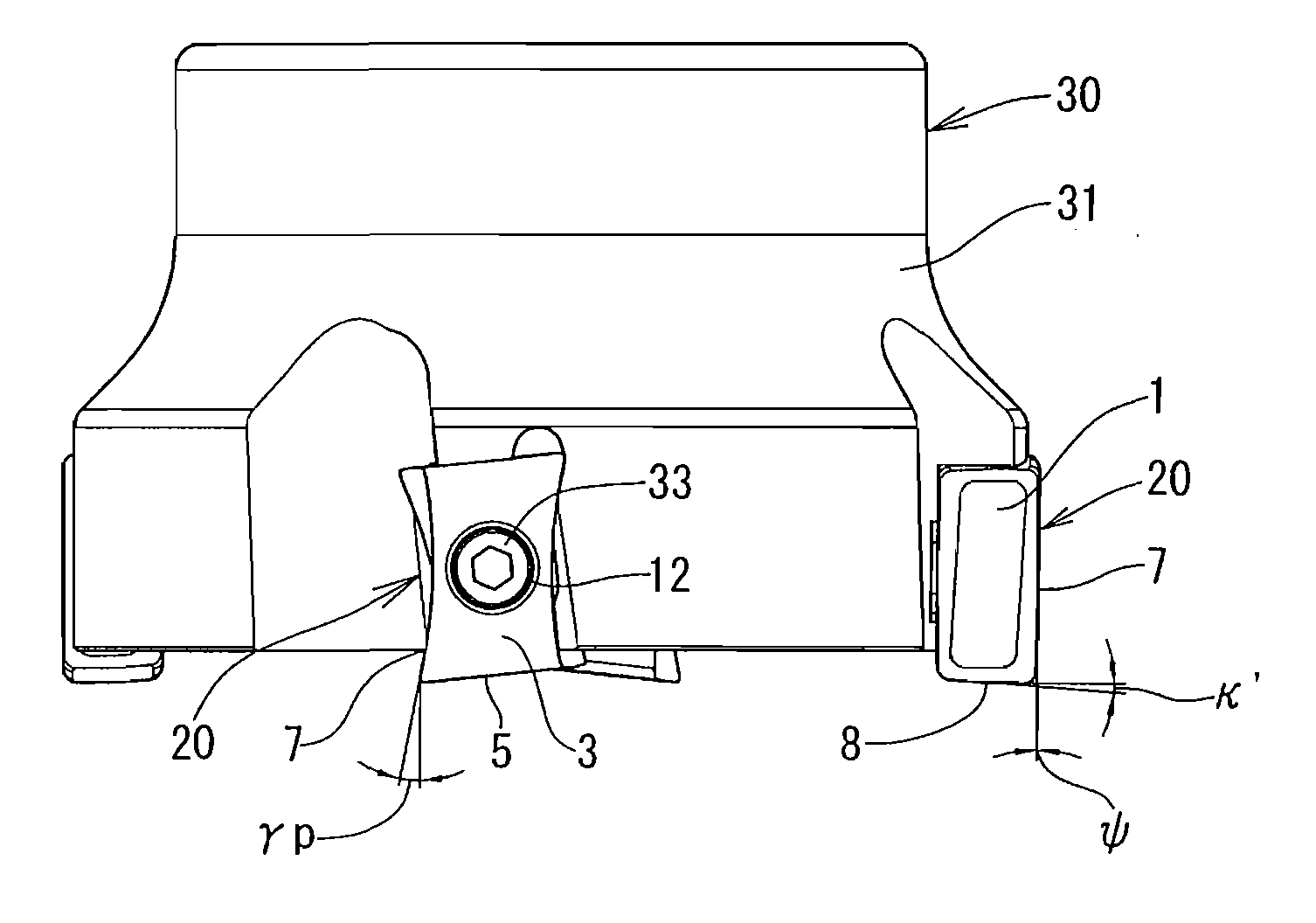

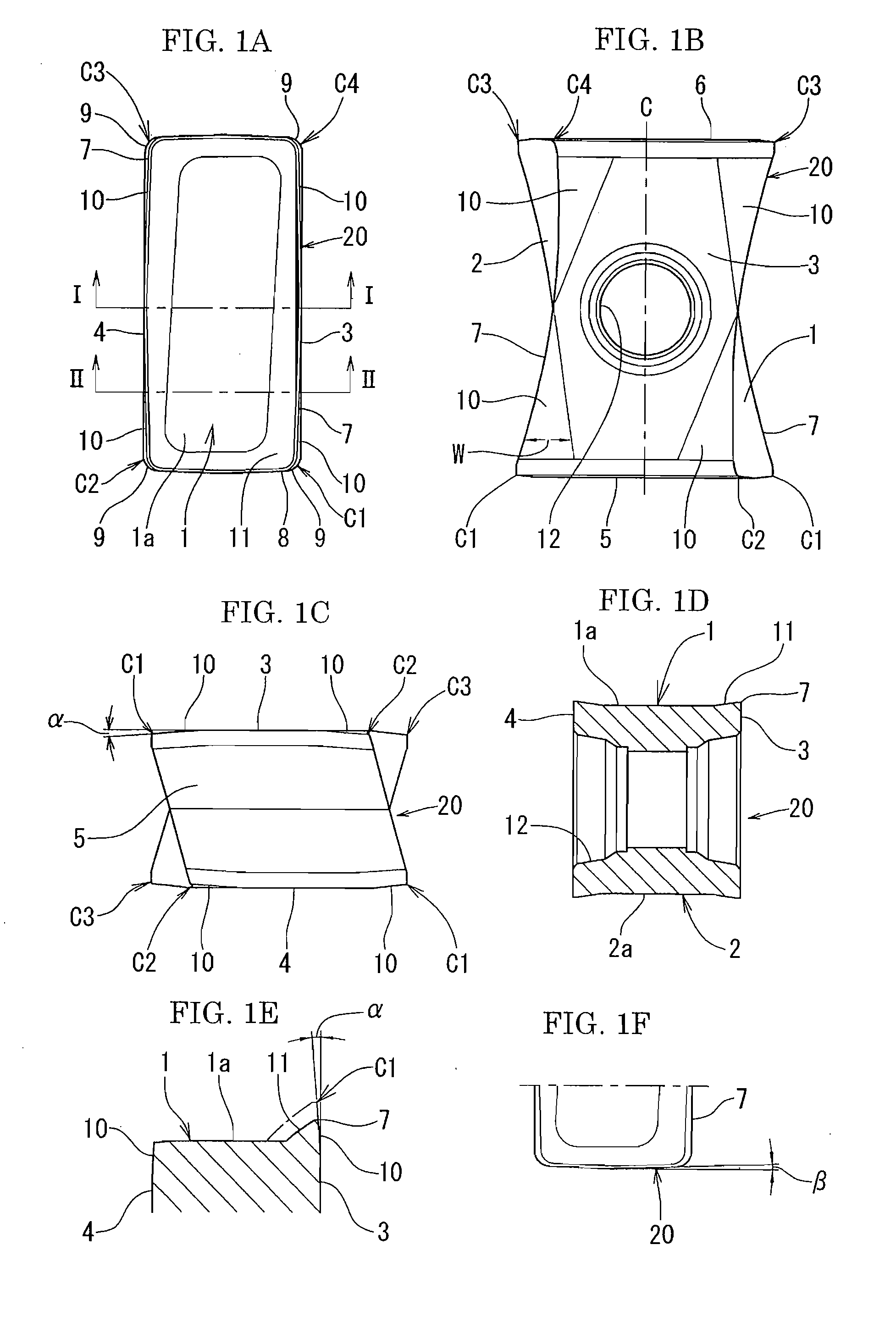

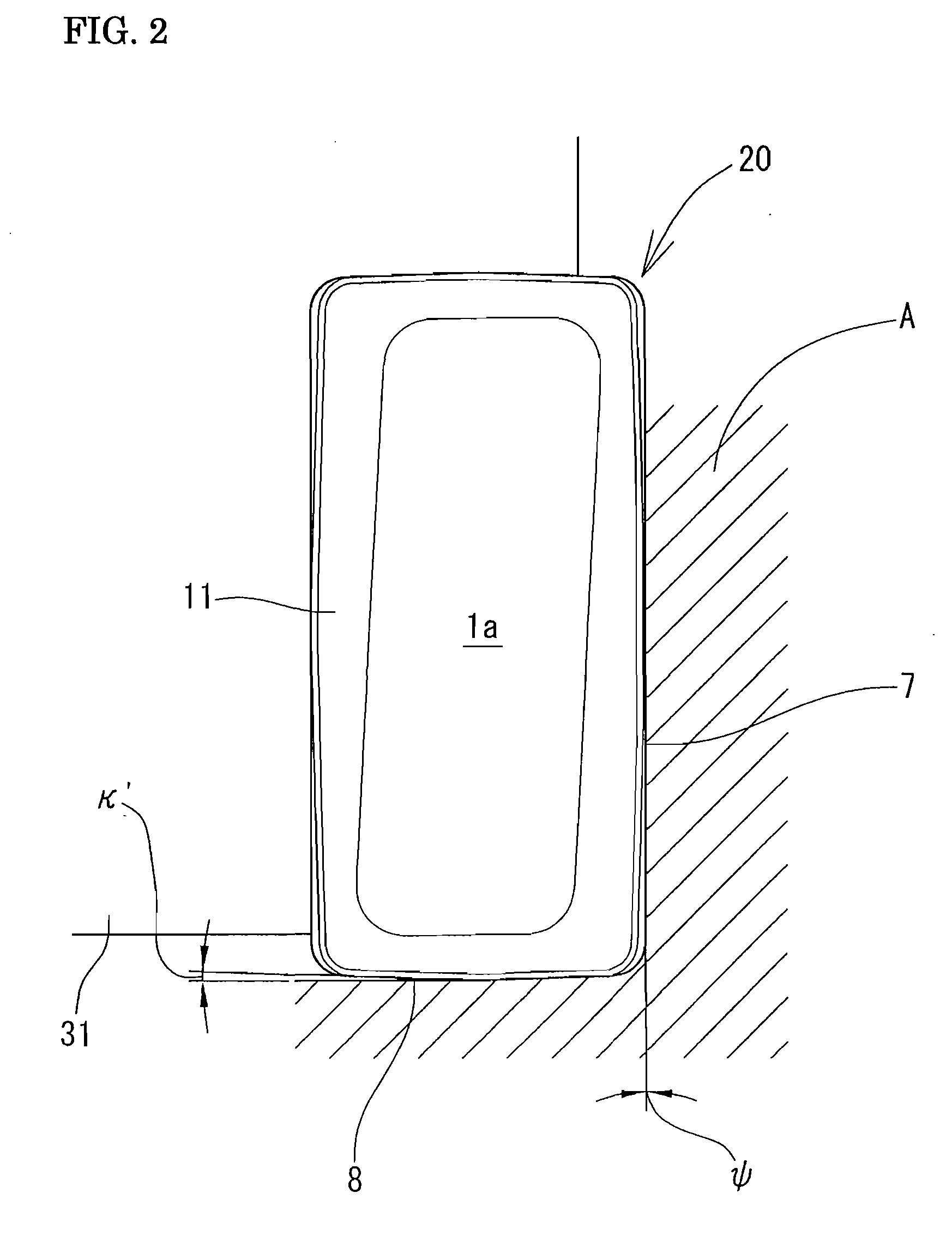

Insert with replaceable cutting edge and corner milling cutter with replaceable cutting edge

ActiveUS20070104546A1Added economic advantageEasy to shapeMilling cuttersShaping cuttersMilling cutterEngineering

A replaceable-blade cutting insert for corner milling cutters has a first and second surface; a third and fourth surface connected to a first side edge and a second side edge thereof respectively; and a fifth and sixth surface connected to a first edge and a second edge of the first surface and the second surface respectively. The first surface is used as rake face, the third surface is used as an outer perimeter flank face, and the fifth surface is used as a forward flank face. A twisted surface is disposed on a section of the third surface, forming a ridge line that acts as a main cutting edge intersecting with the first surface and interposed between the third and first surface. The first and second surface can be positioned with a height offset relative to each other so that at least one set of diagonal corners are projected.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Dart carded felt guillotine

ActiveCN101250806AExtended service lifeReduce usageSevering textilesMetal working apparatusEngineeringMechanical engineering

Disclosed is a needled felt cutting machine belonging to the technical field of non-woven machineries, which comprises a cutting table which is provided with a hob cutter groove, a cutting mechanism which comprises a hob cutter motor, a hob cutter motor seat and a hob cutter and a traction mechanism which is fixed on the cutting table, wherein the hob cutter motor is fixed on the hob cutter motor seat which is glidingly matched on the traction mechanism, the hob cutter is fixed on a power take-off shaft of the hob cutter motor and is corresponded with the hob cutter groove, and cutting edges of the hob cutter are made of a plurality of straight flange cutting edges and a plurality of circular cutting edges in alternate spreading with each other. The needled felt cutting machine has the advantages of representing intermittent suspension process when the hob cutter cuts the needled felt, thereby being unable to arose heating and insuring that a cut is not deformed and charred, not only saving numerous operations for exchanging the hob cutter every day and the numbers of usage of the hob cutters, but also guaranteeing productive efficiency, and being capable of increasing operating life of the hob cutter and improving the cut quality of the needled felt.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

Environmental-friendly multifunctional cutting device for building material

PendingCN107379287AEasy to cutAvoid pollutionWorking accessoriesStone-like material working toolsFixed frameSpray nozzle

The invention discloses an environmental-friendly multifunctional cutting device for a building material. The environmental-friendly multifunctional cutting device comprises a fixing frame. A machine body shell is fixedly connected to the upper end of the fixing frame. The lower end of a first drive motor is fixedly connected with a mounting shell through a first telescopic rod. A rotary shaft is arranged on one side of a second drive motor. A cutting blade is arranged in the center of the outer wall of the rotary shaft. Shock absorption devices are symmetrically arranged on the two sides of the lower end of the mounting shell. Suction hoods are symmetrically arranged on the two sides of the outer wall of the machine body shell. A water inlet pipe is inserted into one side of the outer wall of each suction hood. The two sides of the end, penetrating the outer wall of the corresponding suction hood and extending inwards, of each water inlet symmetrically communicate with water spray pipes. Multiple spray nozzles are uniformly arranged on one side of the outer wall of each water spray pipe. A bottom plate is arranged at the upper end of the fixing frame. Sliding blocks are symmetrically and fixedly connected to the two sides of the bottom of the bottom plate. The environmental-friendly multifunctional cutting device is simple in structure and easy to operate and has the positioning clamping and dust removal functions, meanwhile the machining quality is improved, and the pollution to the environment is avoided.

Owner:长兴县太湖编织袋有限公司

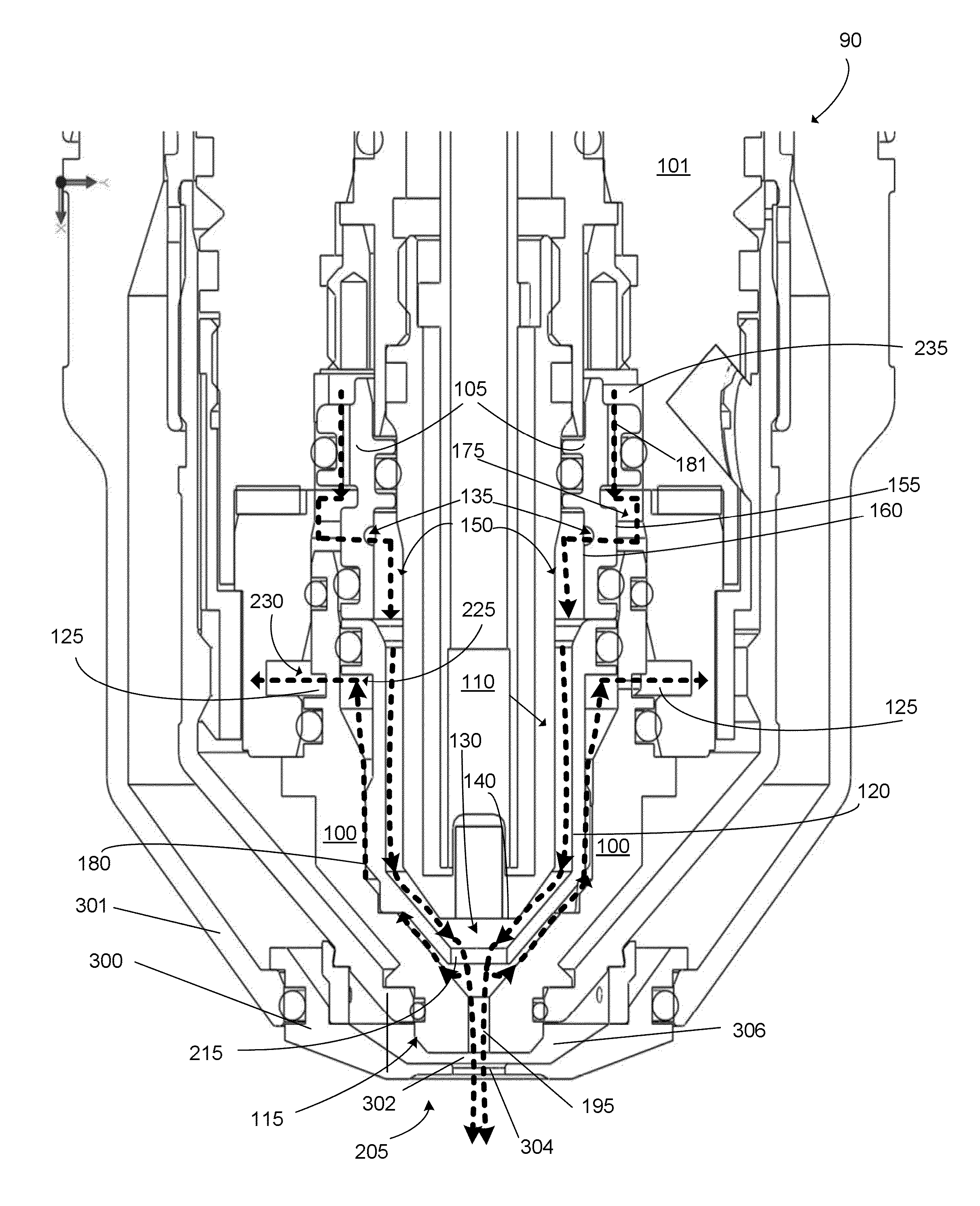

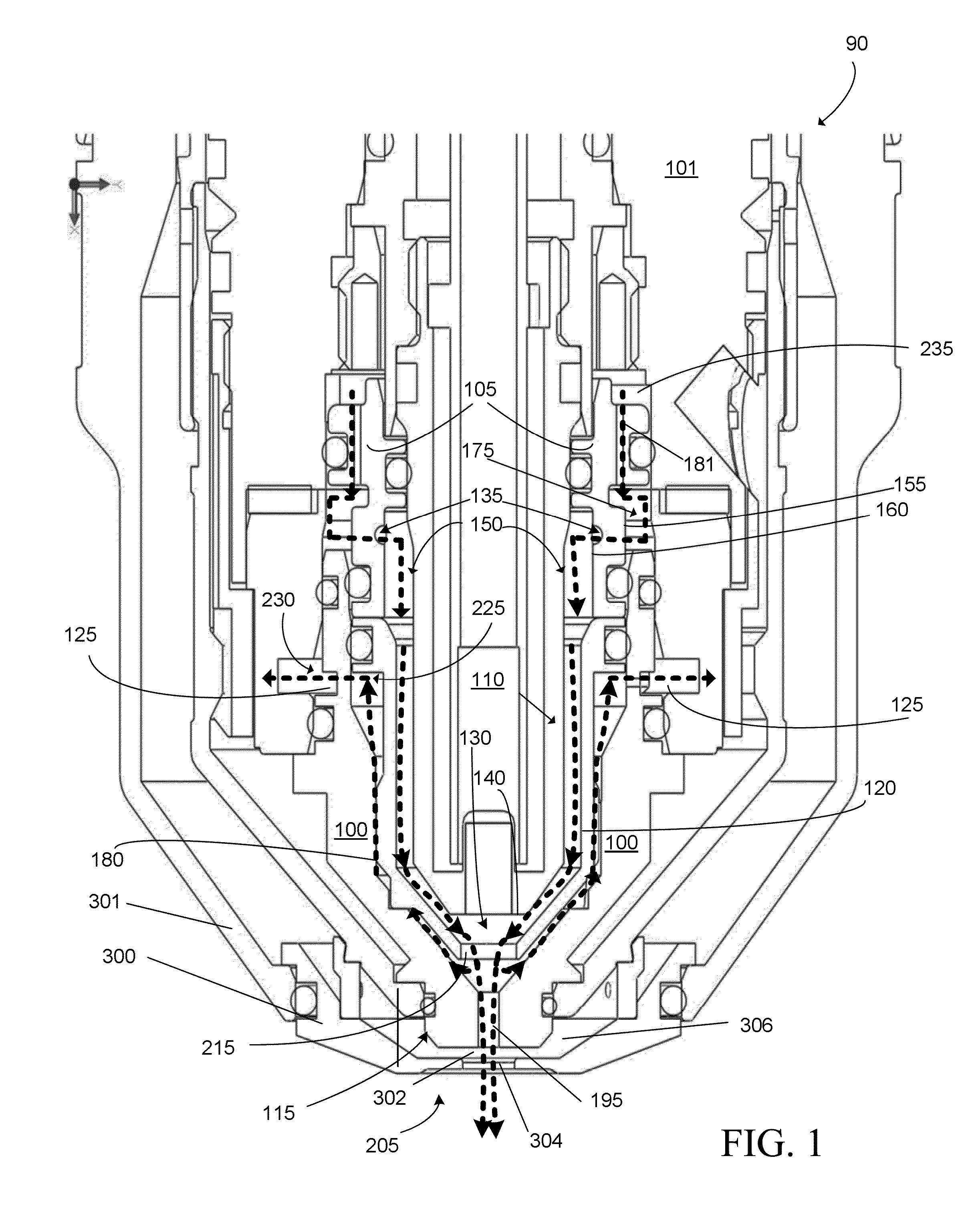

Water Injection and Venting of a Plasma Arc Torch

ActiveUS20160174353A1Cost reductionEnhance cutting qualityArc welding apparatusPlasma welding apparatusEngineeringPlasma Gases

A plasma arc torch system comprising a plasma arc torch is provided. The torch includes an electrode, a nozzle, a vent passage and a shield. The nozzle is spaced from the electrode to define a plasma chamber therebetween. The plasma chamber is configured to receive a plasma gas. The vent passage, disposed in the nozzle body, is configured to divert a portion of the plasma gas exiting the plasma chamber from a nozzle exit orifice. The shield is spaced from the nozzle to define a flow region therebetween. The flow region is configured to (i) receive a liquid and (ii) expel the liquid along with a plasma arc substantially surrounded by the liquid via a shield exit orifice.

Owner:HYPERTHERM INC

Wire stripper

ActiveCN102136703AImprove work efficiencyEasy to installLine/current collector detailsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a wire stripper comprising a frame, a wire fixed device, an electric cutting device and a cutting depth adjustment device, wherein, the wire fixed device is arranged on the frame and is used for clamping and fixing wires; the cutting depth adjustment device is arranged on the frame and is used for controlling the relative position of the electric cutting device and the wire fixed device; and the electric cutting device is arranged on the cutting depth adjustment device and is driven by the cutting depth adjustment device to move so as to adjust the cutting depth. The wire stripper provided by the invention has the characteristics of safety and high working efficiency.

Owner:STATE GRID CORP OF CHINA +2

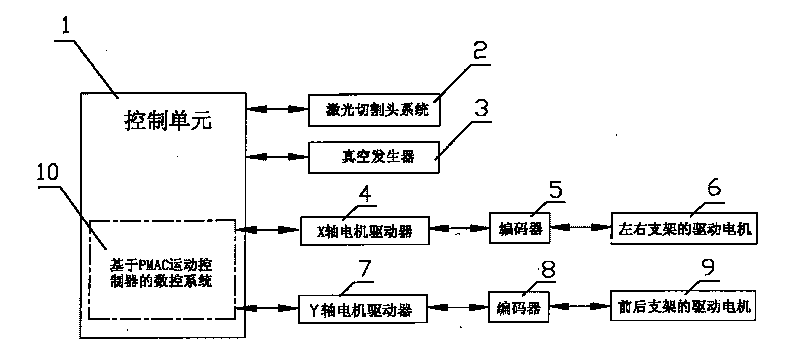

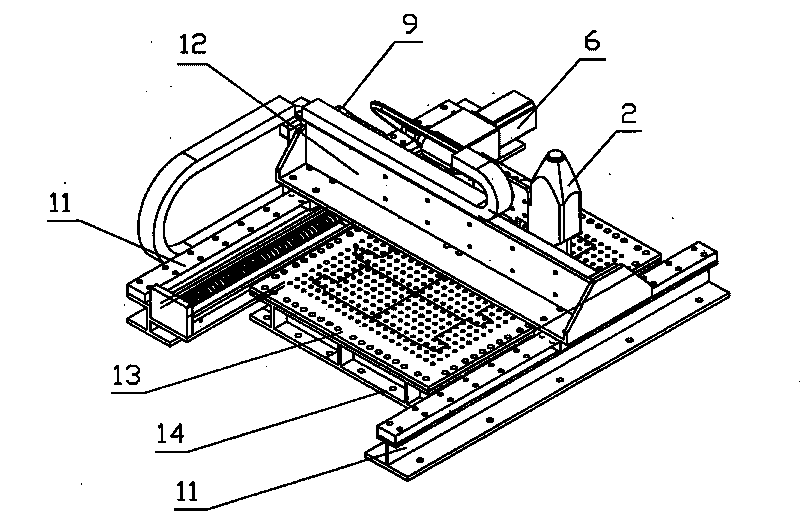

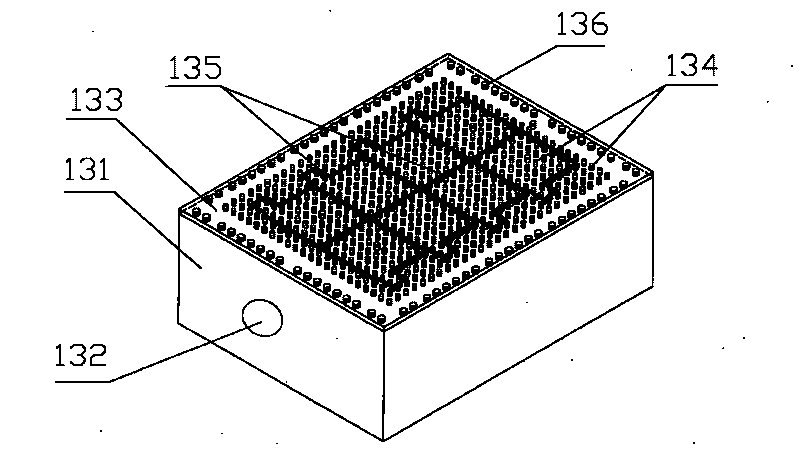

Laser cutting device for battery pole piece

InactiveCN101722370ASimple structureImprove cutting quality and efficiencyElectrode manufacturing processesSmall-sized cells cases/jacketsEngineeringLaser cutting

The invention aims to provide a laser cutting device for a battery pole piece with high cutting quality and high practicability. The laser cutting device for the battery pole piece comprises a control unit and a laser cutting head system which consists of a laser generator and a laser cutting head, and is characterized in that a vacuum adsorption device is arranged below the laser cutting head system; and a relative motion along horizontal direction can be carried out between the laser cutting head system and the vacuum adsorption device. When the battery pole piece is cut, the battery pole piece is put on the vacuum adsorption device first and is fixed by vacuum action; then the relative motion between the laser cutting head system and the vacuum adsorption device is controlled according to a set program; and meanwhile, the set program also controls the operation of the laser cutting head system, namely cutting the battery pole piece into a required shape. The laser cutting device has a simple structure, higher cutting quality and higher efficiency of the battery pole piece because a pertinent design is made according to the characteristics of the battery pole piece.

Owner:CHERY AUTOMOBILE CO LTD

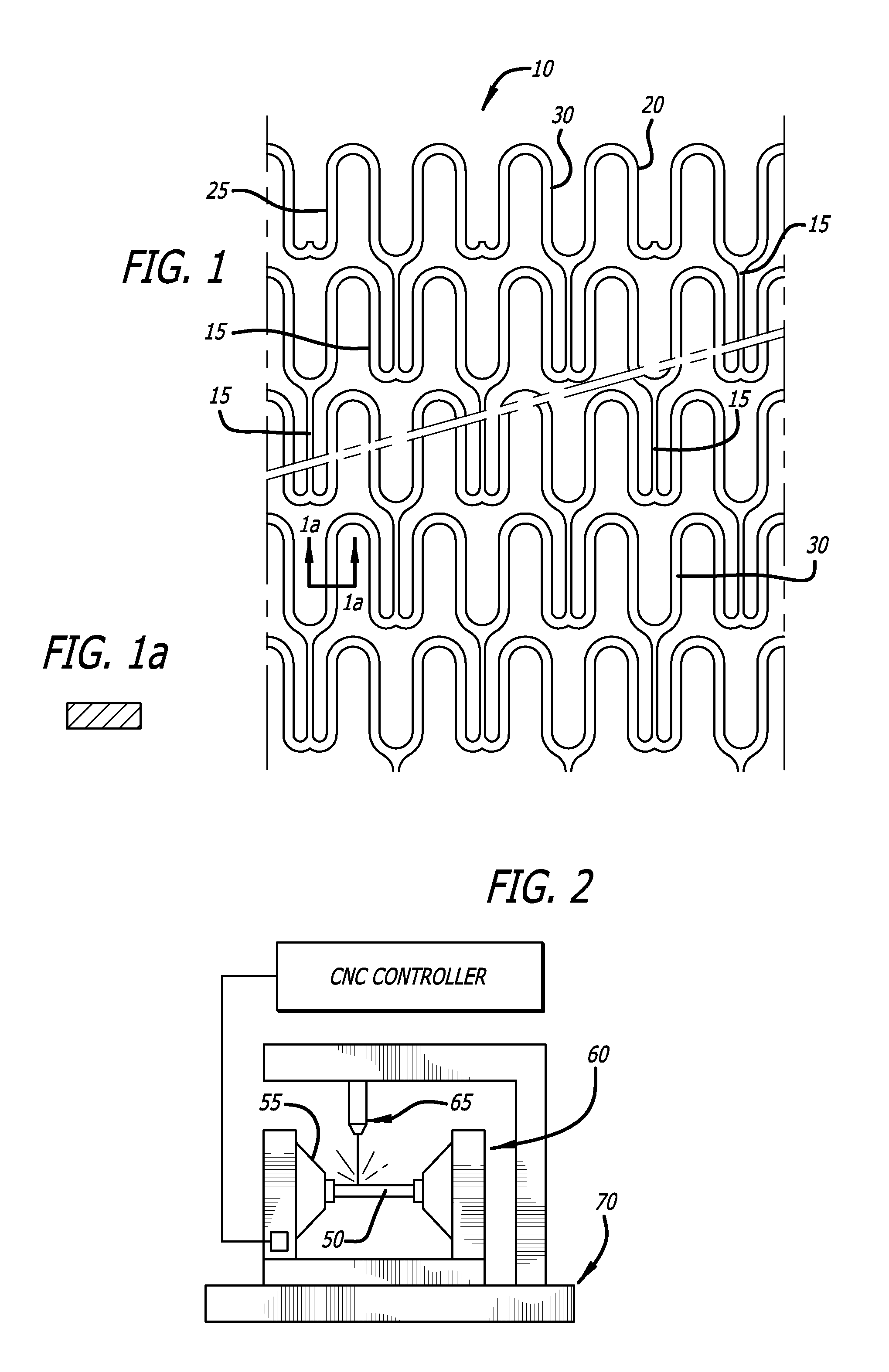

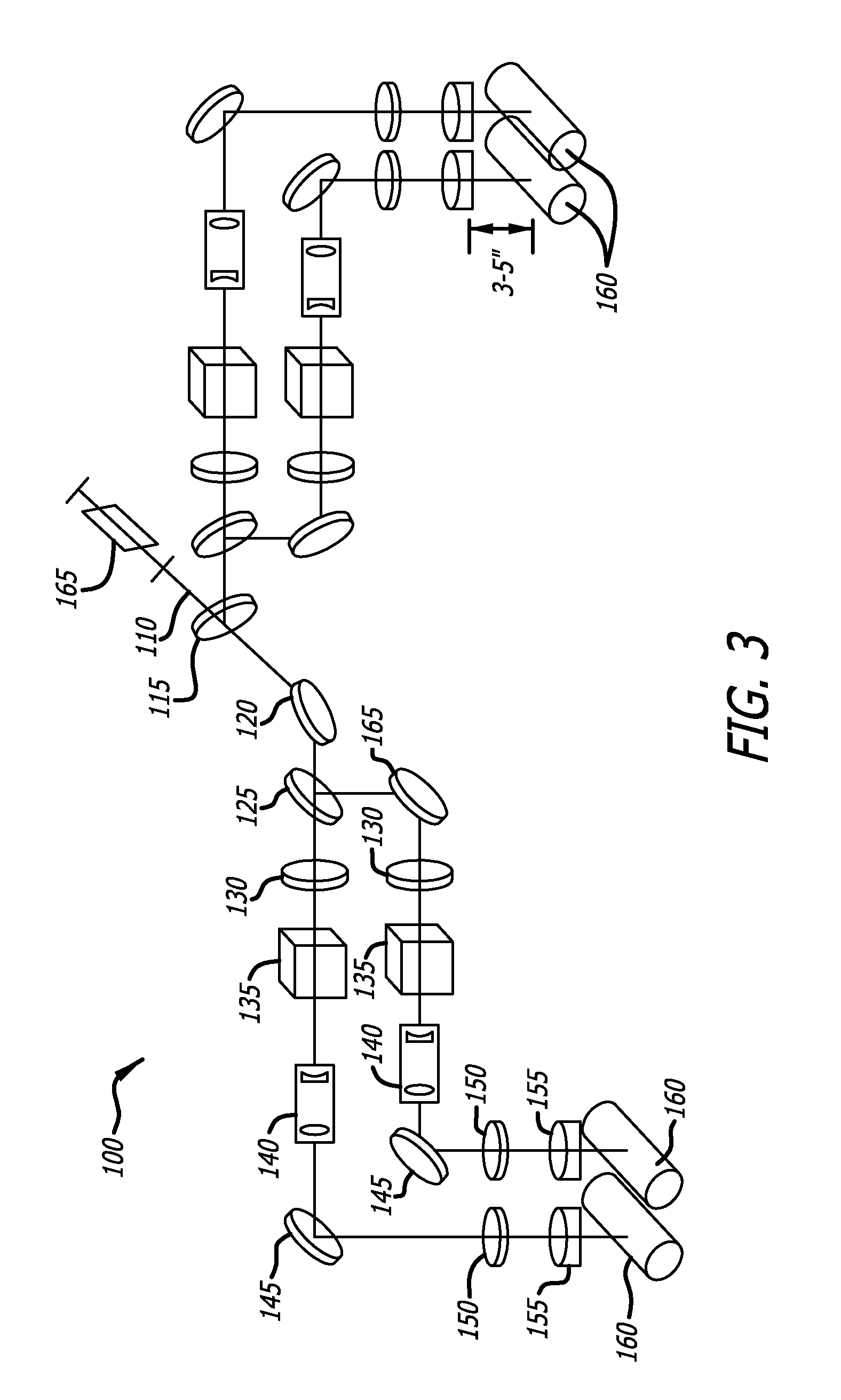

Multiple beam laser system for forming stents

A system and method for precision cutting using multiple laser beams is described, The system and method includes a combination of optical components that split the output of a single laser into multiple beams, with the power, polarization status and spot size of each split beam being individually controllable, while providing a circularly polarized beam at the surface of a work piece to be cut by the laser beam. A system and method for tracking manufacture of individual stents is also provided.

Owner:ABBOTT CARDIOVASCULAR

A cutting machine used for necktie fabric processing

InactiveCN105316928AImplement automatic transferIncrease transfer rateTextile selvedgesSevering textilesEngineeringMechanical engineering

The invention provides a cutting machine used for necktie fabric processing. The cutting machine comprises a material holding stand, a material feeding device, a cutting platform and a cutter device. The material feeding device comprises an upper clamping roller and a lower clamping roller. A driving lever device is arranged below the upper clamping roller and comprises a driving lever and a driving lever cylinder. The top surface of the cutting platform is provided with a material falling groove and a protecting plate. The cutter device comprises a horizontal guide rail and a cutting knife. A heating device is arranged in the cutter device and comprises a heater, a heat conduction plate and a heat conduction tube. The cutting machine is simple in structure and highly practical; with the material feeding device, fabric can be conveyed more conveniently; with a gear assembly, the length of fabric cutting can be controlled and the transmission is more stable; with the heating device, the temperature of the cutting knife can be made to rise and through high temperature cutting, cut fabric has the advantages of high quality, smooth cuts and zero burr and the processing of the next procedure is facilitated; energy consumption is reduced and the comprehensive utilization rate is increased.

Owner:SHAOXING HENRY TIE FASHION

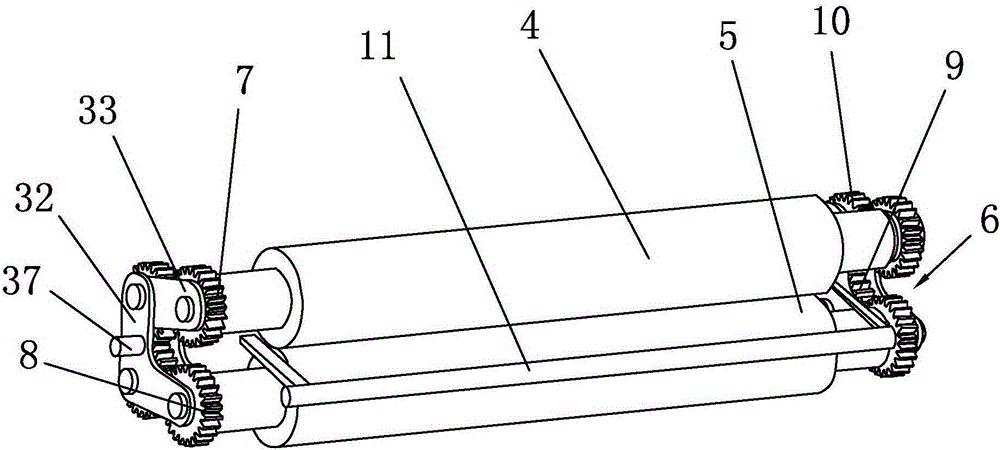

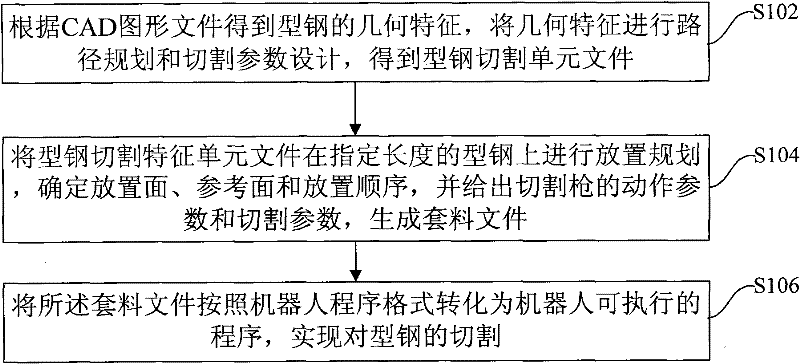

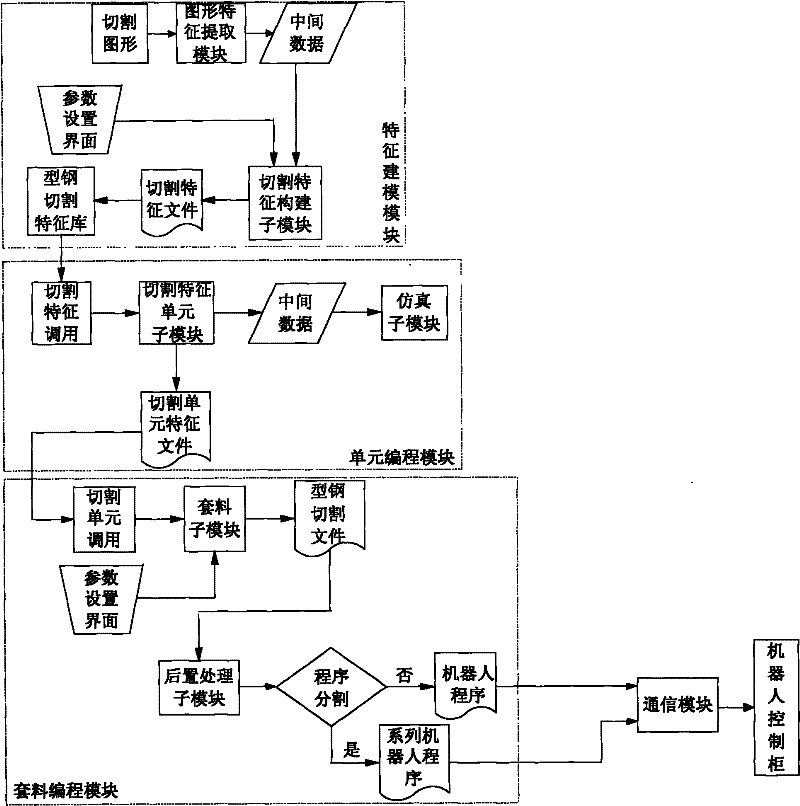

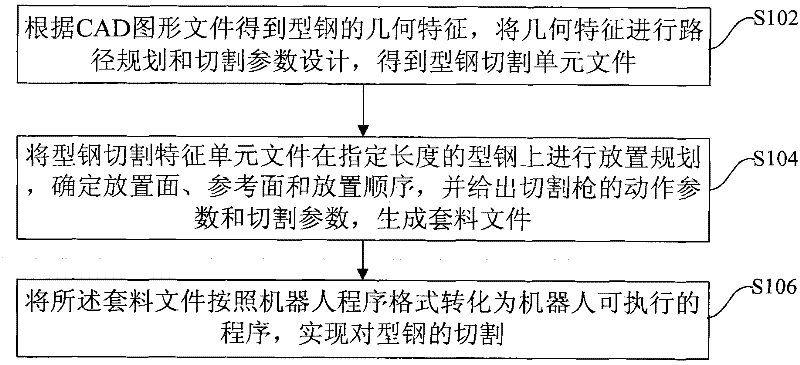

Robotic cutting method for profile steel

ActiveCN102189348AImprove cutting accuracyImprove cutting efficiencySpecial data processing applicationsWelding apparatusGraphicsDesign information

The invention discloses a robotic cutting method for profile steel, which is based on the robot offline programming. The method comprises the following steps of: reading a CAD graphics file to obtain geometrical characteristics of profile steel cutting; generating a cutting unit by a path planning and a cutting parameter design of the geometrical characteristics; determining an action parameter and a cutting parameter of a cutting gun and generating a trepanning file by a placement planning of the cutting unit on profile steel having a specific length; converting the trepanning file to be a robot executable program in accordance with the robot program format, and achieving the cutting of the profile steel. Based on the robot offline programming technology, by utilizing the designed information of CAD graphics directly, the robotic cutting precision and efficiency can be increased; the method is suitable for cutting requirements of groove-type profile steels, such as V-type, Y-type andthe like and varied-groove-type profile steel; the problem of the poor cutting quality at the edge of an angle steel or other steels is solved; the method has the characteristics of generality, flexibility, high efficiency and high precision.

Owner:HARBIN INST OF TECH

Cutting device for mechanical automatic production of spare and accessory parts

ActiveCN109227663APlay a limiting roleSwipe up and down smoothlyMetal working apparatusEngineeringOperation safety

The invention discloses a cutting device for mechanical automatic production of spare and accessory parts, which includes a feeding mechanism, a cutting mechanism and an unloading mechanism, wherein the feeding mechanism includes a feeding table and a pushing mechanism and the cutting mechanism includes a cutting table and a cutting head group. Gate components are arranged on both sides of the cutting table, a supporting plate is arranged under the cutting table, and lifter columns are evenly arranged between the supporting plate and the cutting table. The cutting table comprises a supportingbracket and a lifting table. A longitudinal chute and a transverse chute are arranged on the top face of lifting table. The longitudinal chute includes a left longitudinal chute and a right longitudinal chute, wherein a left spacing splint is arranged in the longitudinal chute and a right spacing splint is arranged in the right longitudinal chute, and the transverse chute is communicated with theleft longitudinal chute. The overall structure of the cutting device for mechanical automatic production of spare and accessory parts is ingenious and reasonable. The automatic operation is achieved by the design of the feeding mechanism and the unloading mechanism which can feed and unload workpieces automatically, thereby reducing the labor intensity and hidden safety hazard, improving the operation safety performance and the cutting speed.

Owner:柳州蒸达机械配件有限公司

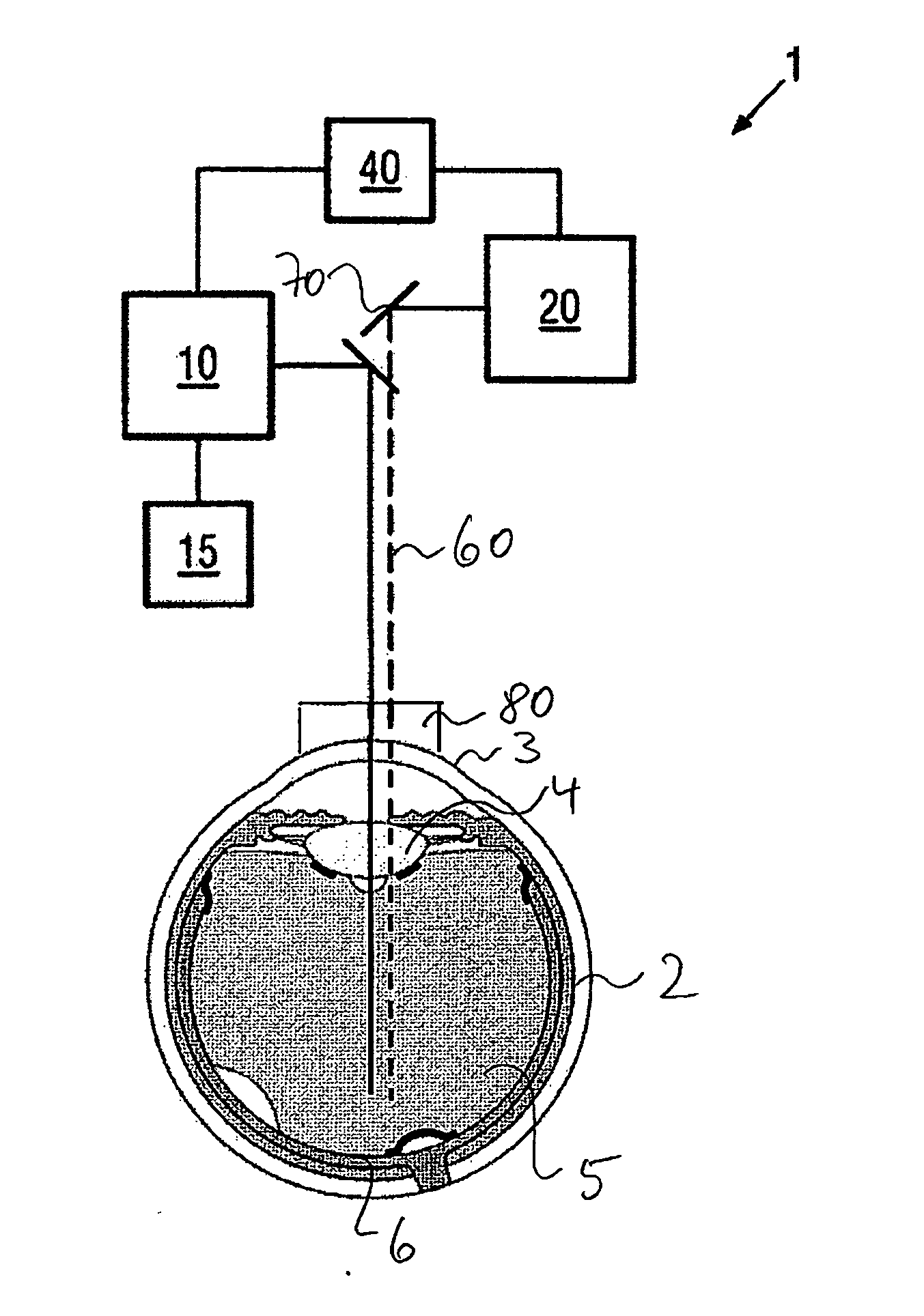

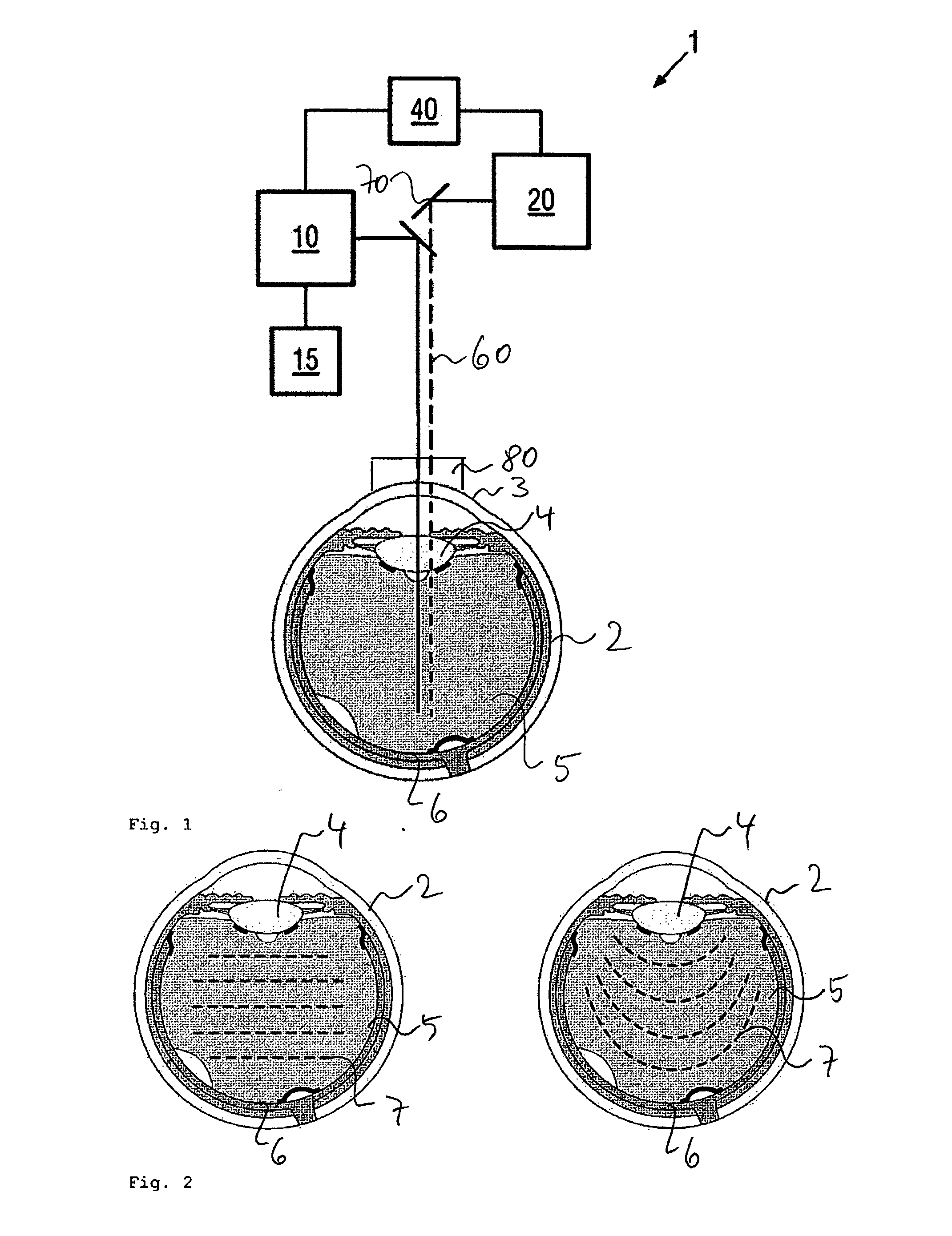

Device and method for vitreous humor surgery

ActiveUS20130131652A1Minimally invasiveReduce swellingLaser surgerySurgical instrument detailsFemto second laserLaser scanning

A device and a method for the femtosecond laser surgery of tissue, especially in the vitreous humor of the eye. The device of includes an ultrashort pulse laser with pulse widths in the range of approximately 10 fs-1 ps, especially approximately 300 fs, pulse energies in the range of approximately 5 nJ-5μJ, especially approximately 1-2 μJ and pulse repetition rates of approximately 10 kHz-10 MHz, especially 500 kHz. The laser system is coupled to a scanner system which allows the spatial variation of the focus in three dimensions (x, y and z). In addition to the therapeutic laser / scanner optical system the device includes a navigation system.

Owner:CARL ZEISS MEDITEC AG

Laser cutting equipment for cutting electrode lug and cutting method thereof

ActiveCN104384724AImprove adaptabilityImprove cutting efficiencyWelding/cutting auxillary devicesAuxillary welding devicesVacuum pumpingPulp and paper industry

The invention discloses laser cutting equipment for a cutting electrode lug. The laser cutting equipment comprises an absorptive cutting mechanism, an emptying mechanism and a collecting mechanism, wherein the absorptive cutting mechanism comprises a cutting platform; a portal frame is arranged on the cutting platform; a sliding laser cutting device is arranged on the portal frame; the laser cutting device is provided with a laser head and a laser scanner; an adsorption device corresponding to the laser cutting device is arranged at the bottom of the cutting platform; the adsorption device is provided with a vacuum cavity and a vacuum pumping device; the vacuum pumping device is connected with the vacuum cavity, and is used for generating negative pressure inside the vacuum cavity; the vacuum cavity is provided with an adsorption hole; a battery pole piece is adsorbed onto the adsorption device through the adsorption hole under the negative pressure inside the vacuum cavity. A high electrode lug cutting speed and high quality can be realized, so that the working efficiency is increased.

Owner:GUANGDONG ZHENGYE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com