Cutting device for mechanical automatic production of spare and accessory parts

A cutting device and spare parts technology, applied in the direction of metal processing, etc., can solve the problems of reducing cutting processing speed, high manual labor intensity, increasing cost, etc., to achieve the effect of ensuring verticality, improving cutting accuracy, and ensuring levelness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

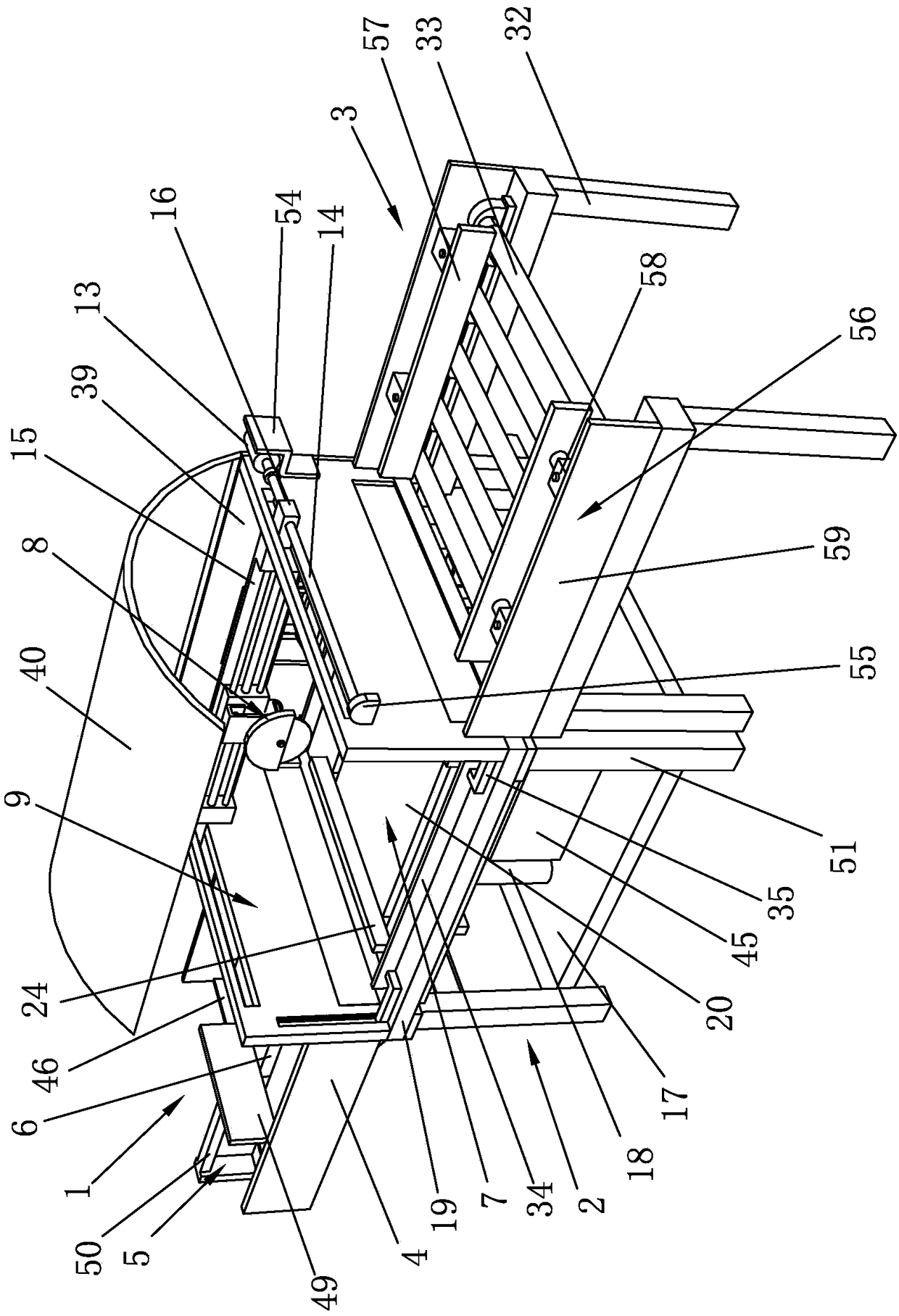

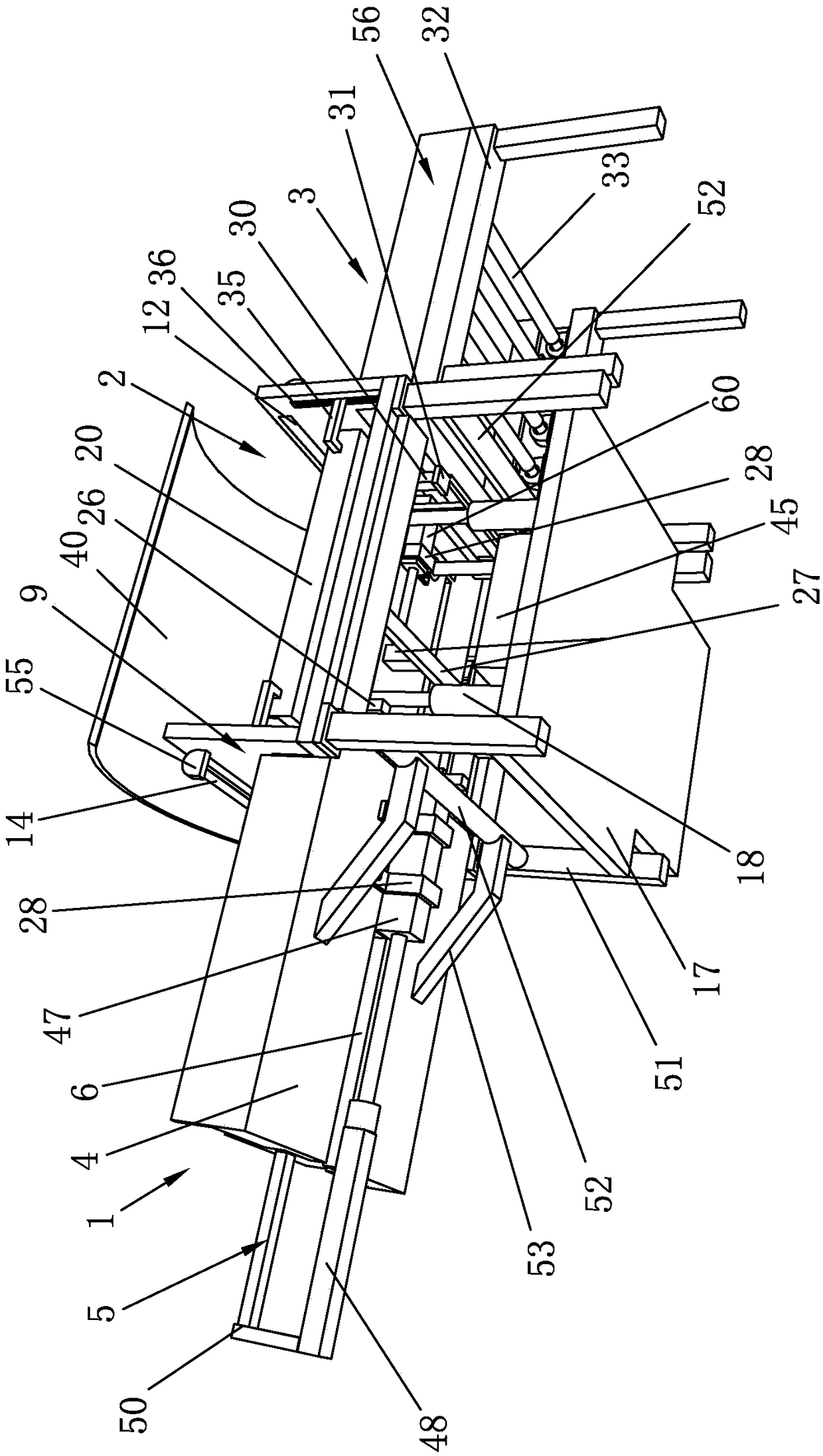

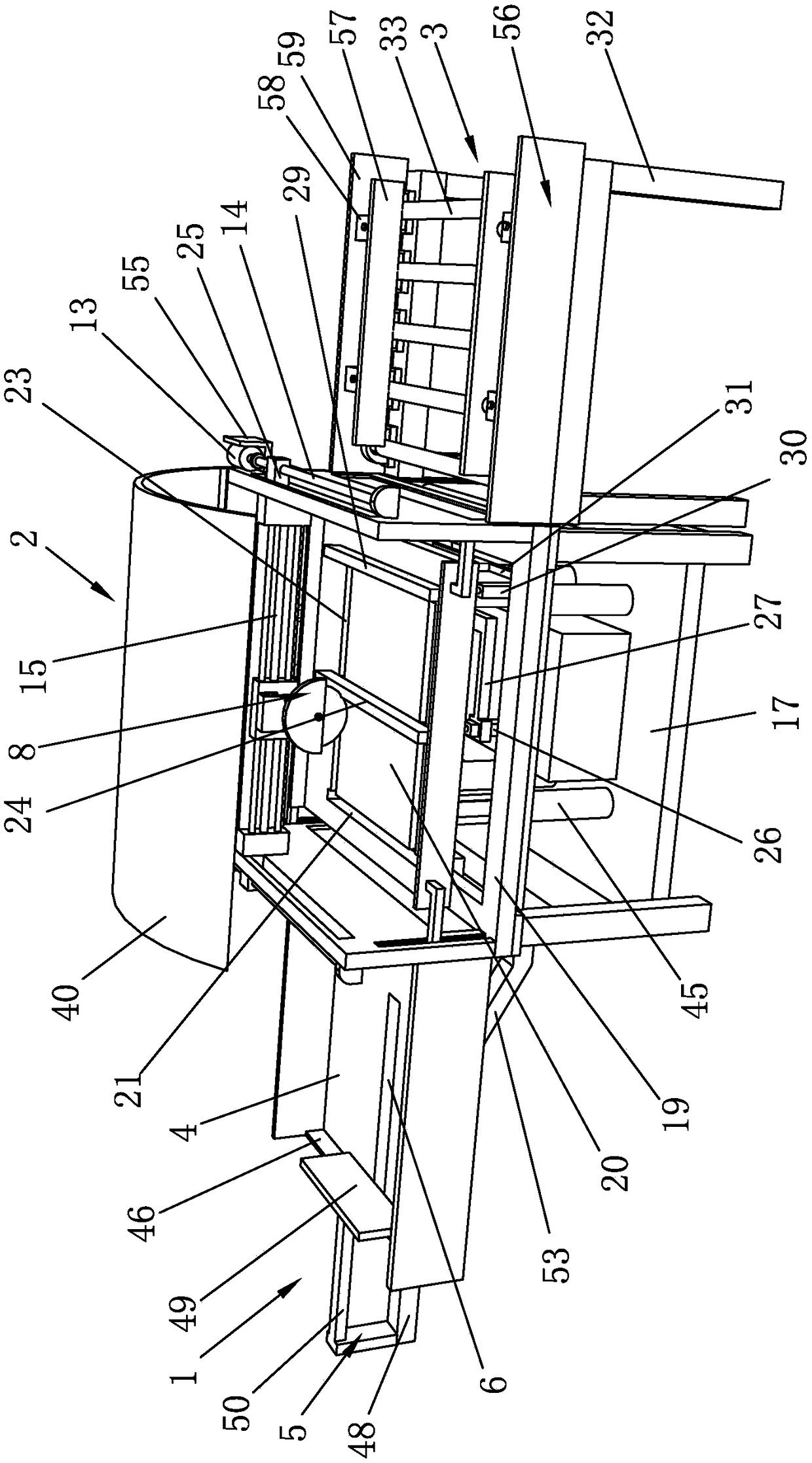

[0030] Such as Figure 1 to Figure 9 As shown, it is a cutting device for the production of mechanical automation spare parts according to the present invention, which includes a feeding mechanism 1, a cutting mechanism 2 and a blanking mechanism 3, and the feeding mechanism 1, the cutting mechanism 2 and the blanking mechanism 3 are sequentially arranged from left to right Setting, the feeding mechanism 1 includes a feeding table 4 and a pushing device 5, the feeding table 4 is provided with an embedding groove 6, and the left side of the feeding table 4 is provided with two limiting plates 46, and the two limiting plates 46 are about the embedding The groove 6 is symmetrical, and the pushing device 5 includes a pushing cylinder 47, an extension rod 48 and a pushing plate 49, and the piston rod of the pushing cylinder 47 is just below the embedding groove 6, and the pushing cylinder 47 is fixed on the On the bottom surface of the feeding table 4, the piston rod of the pusher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com