Patents

Literature

44results about How to "Guaranteed cutting speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monocrystalline silicon high-efficient composite cutting method and cutting system thereof

InactiveCN101138869AImprove cutting effectSave the texture processFine working devicesMetalElectric spark

An efficiently composite cutting method of monocrystalline silicon is characterized in that a monocrystalline silicon rod for cutting is installed and nipped at an electric spark linear cutting machine; metallic thread which is concreted with diamond grinding material is used as cutting wire to make the electric spark linear cutting; the advantages that the processing speed of the electric spark linear cutting is high and the cutting effect of the diamond grinding material at the metallic thread of the concreted grinding material is good are completely exerted; the purpose to realize the quickly and efficiently cutting towards the monocrystalline silicon rod is achieved; at the same time the surface of the cut monocrystalline silicon naturally forms a fleece-faced texture which has the effect of anti-reflection. The present invention has a series of advantages of simple method, high efficiency of processing, good quality etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cutting method of fragile material substrate

InactiveCN101444875ALow powerGuaranteed cutting qualityFine working devicesGlass severing apparatusSurface roughnessLaser beams

The invention discloses a cutting method of a fragile material substrate. The cutting method comprises the following steps: firstly, irradiating and heating edges of the fragile material substrate along a predetermined cutting direction by a laser beam A with the power of 30-50W to manufacture an initial penetrable slit the length of which is not longer than 20mm and the width of which is shorter than 0.01mm; then irradiating to heat the substrate from the tip of the initial penetrable slit along the predetermined cutting direction by a laser beam B with the power of 5-15W, and subsequently performing forced cooling on the fragile material substrate by a coolant to cause the fragile material substrate to crack along the predetermined cutting direction. The cutting method of the fragile material substrate can help greatly reduce the power of the laser for the subsequent cutting by obtaining the initial penetrable slit, and ensure the cutting quality and the cutting speed, wherein, surface roughness of a cut side of a liquid crystal glass substrate is 50mum or less.

Owner:ZHEJIANG UNIV OF TECH

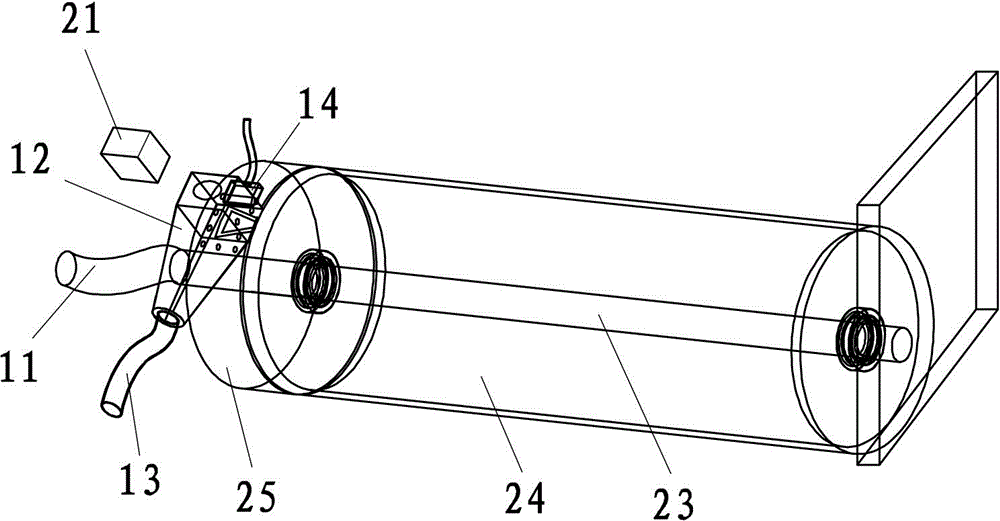

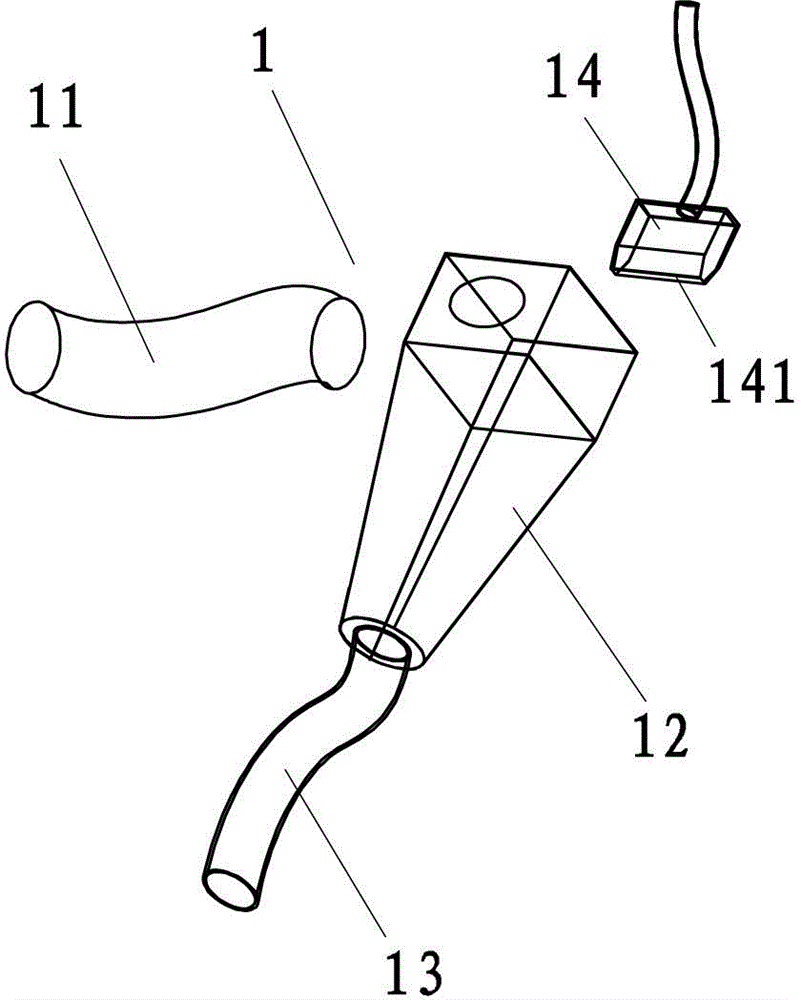

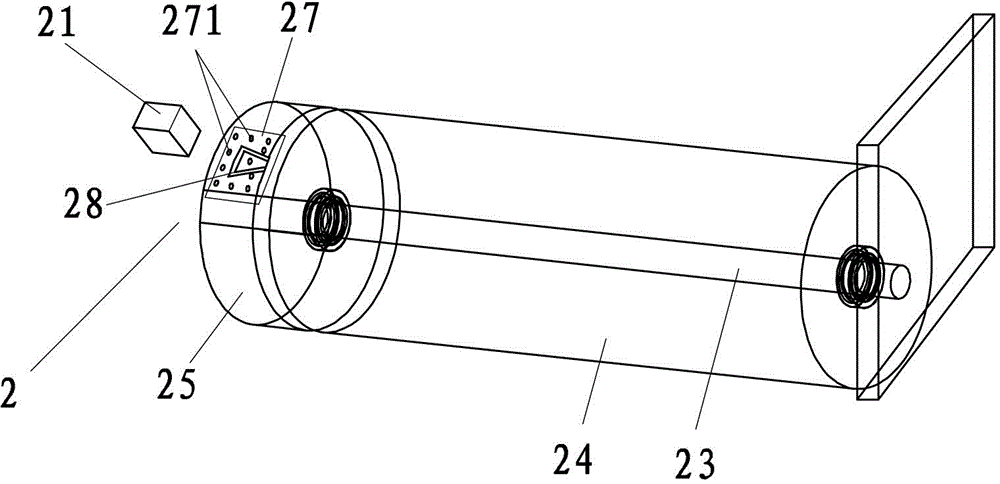

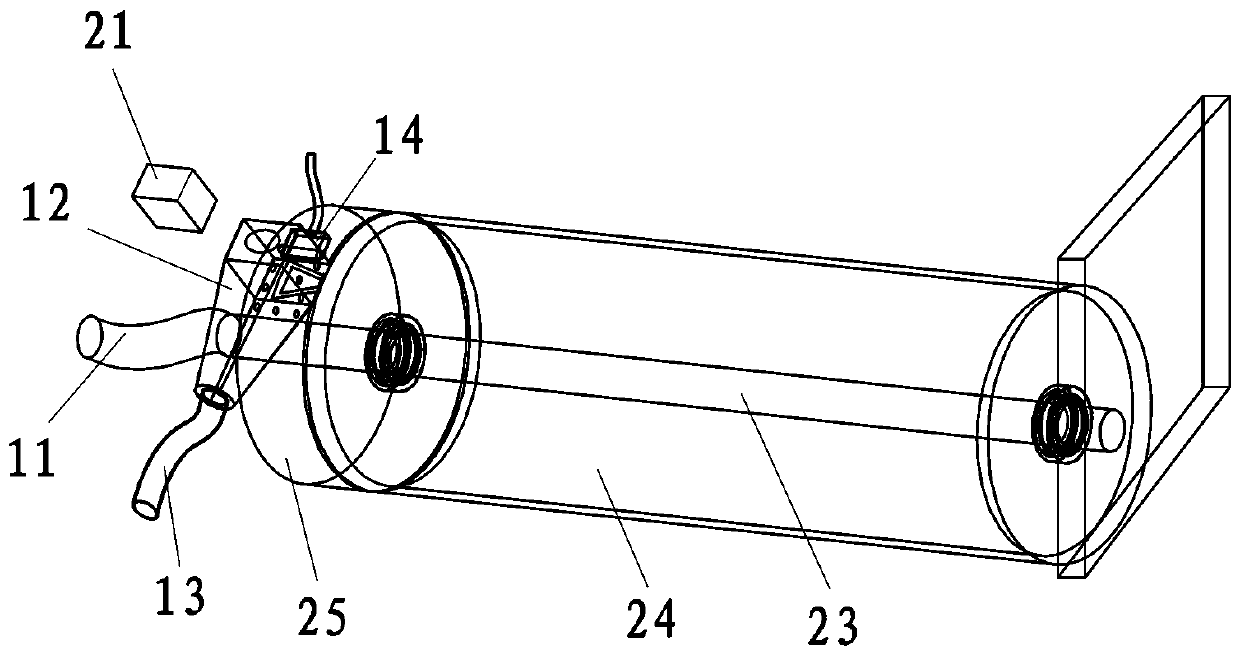

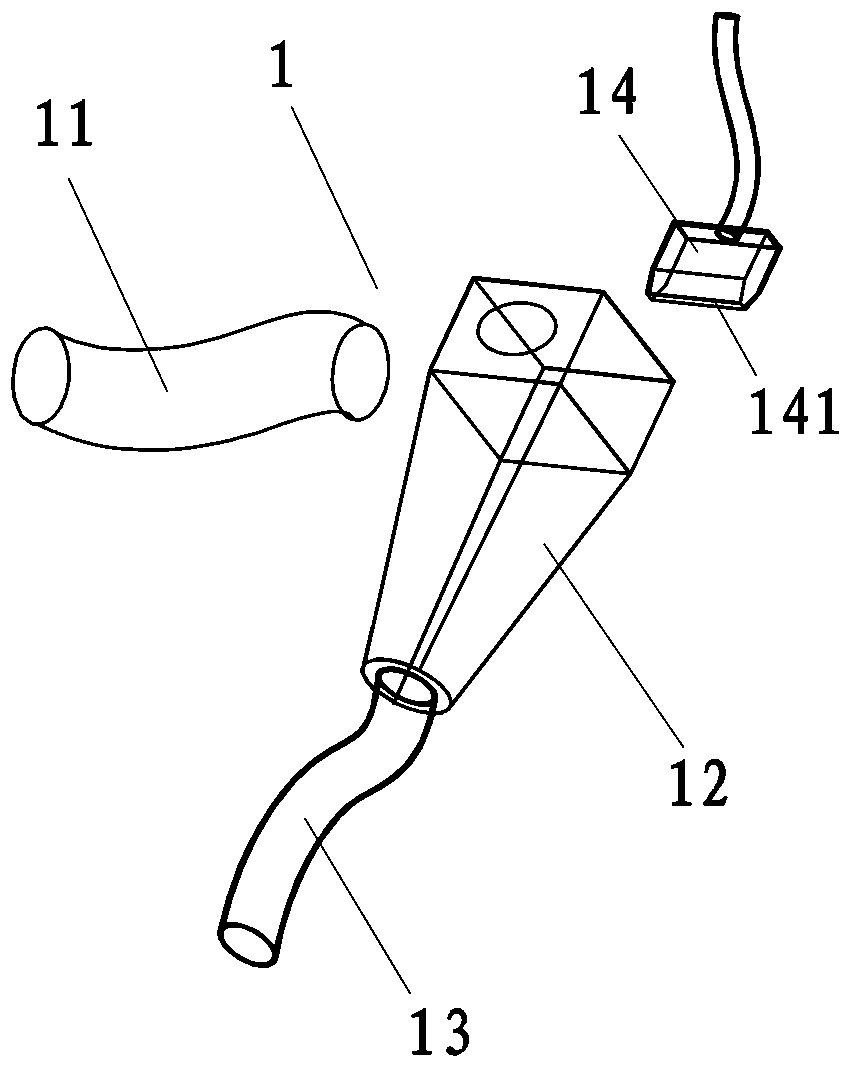

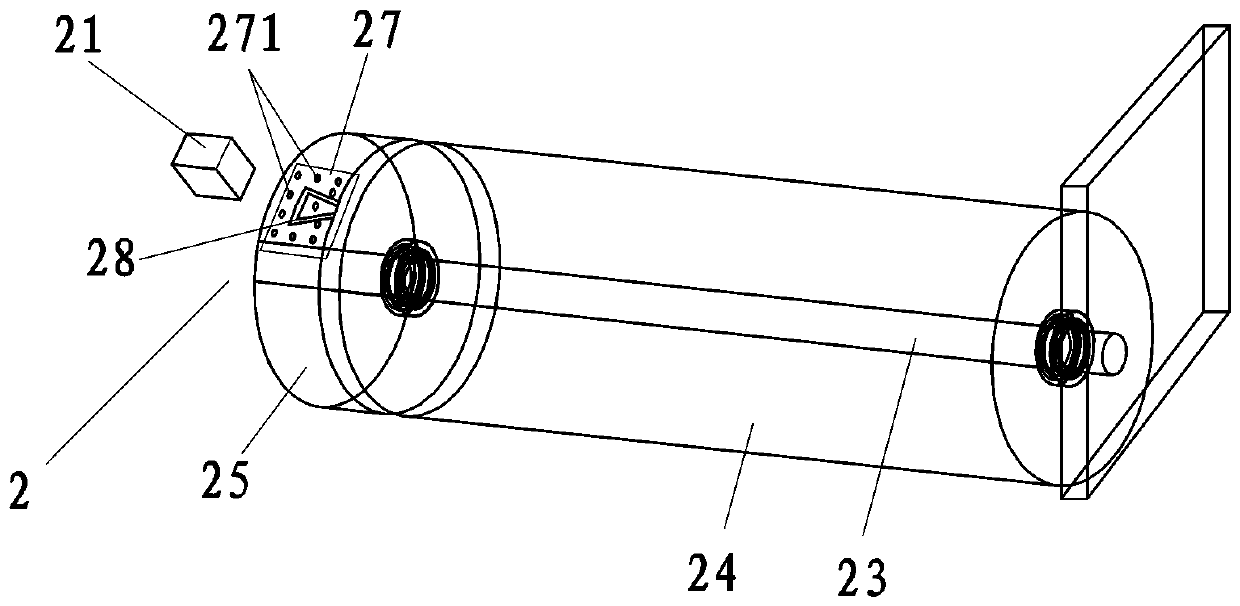

Laser continuous cutting device having dedusting function

ActiveCN104972227ANo sliding frictionAvoid damageMetal working apparatusLaser beam welding apparatusPole pieceLaser cutting

The invention belongs to the technical field of laser cutting and particularly relates to a laser continuous cutting device having a dedusting function. The laser continuous cutting device comprises a dedusting mechanism and a laser cutting mechanism. The laser cutting mechanism comprises a laser head and a cushion seat module. The cushion seat module comprises a center shaft, a rotating roller and a fixed roller. The rotating roller and the fixed roller have the same radius, the fixed roller is connected with the rotating roller through the center shaft and is fixed relative to the center shaft, and the rotating roller can rotate relative to the center shaft. When a pole piece is cut, the pole piece adheres to the rotating roller by means of tension provided by mechanical transmission during the feeding, and a to-be-cut pole lug reserved area on the pole piece adheres to the fixed roller. The linear velocity of the rotating roller and the feeding speed of the pole piece are the same, so that no sliding friction occurs between the pole piece and the rotating roller, and the damage to the pole piece caused by the sliding friction between the pole piece and the rotating roller is avoided.

Owner:CONTEMPORARY AMPEREX TECH CO

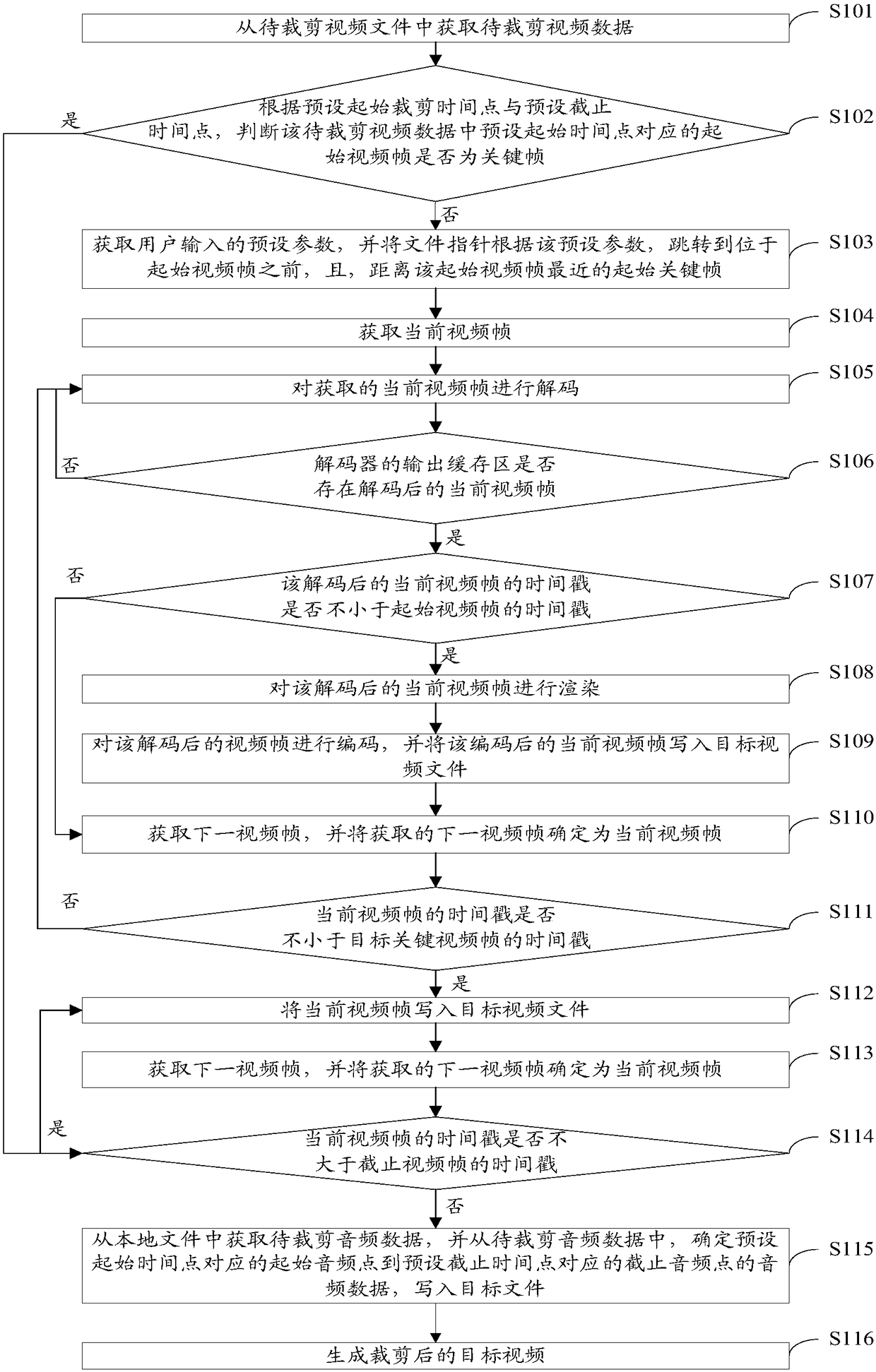

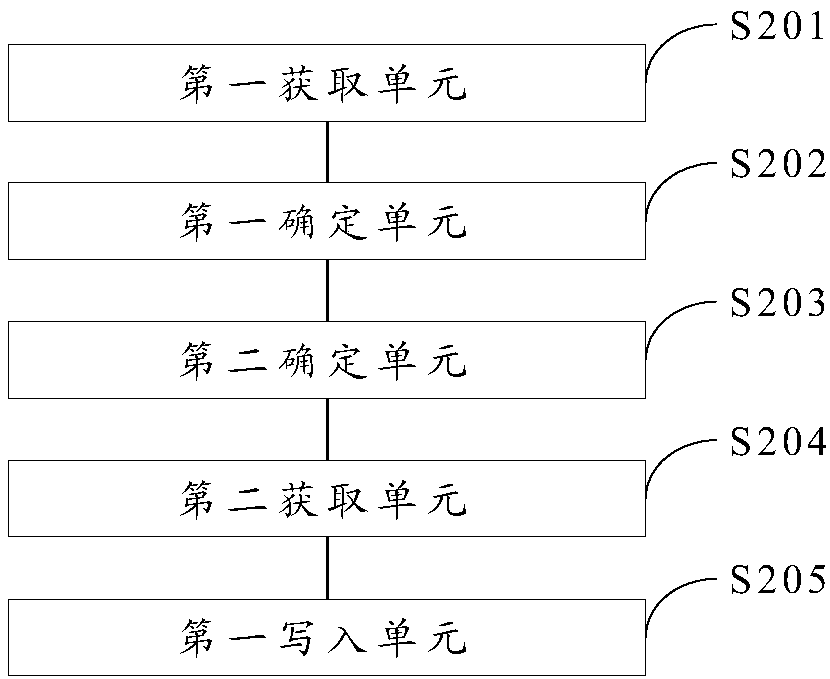

Video clipping method and device

InactiveCN108366294AGuaranteed cutting speedGuaranteed accuracySelective content distributionStop timeStart time

The invention discloses a video clipping method and device. The method comprises the following steps: acquiring a preset start time point and a preset stop time point for clipping video data to be clipped; determining a start video frame corresponding to the preset start time point in the video data to be clipped; if the start video frame is a non-key frame, respectively determining a target videoframe with a complete video picture for each video frame from the start video frame to a middle video frame, wherein the middle video frame is a video frame which is positioned behind the start videoframe and in front of a target key video frame and is adjacent to the target key video frame, and the target key video is a key video frame which is positioned behind the start video frame and is closest to the start video frame; and writing each encoded target video frame and each video frame from the target key video frame to a stop video frame into a target video file in sequence. According tothe video clipping method disclosed by the embodiment of the invention, the clipping speed of the video frame to be clipped is guaranteed, and the clipping precision is also guaranteed.

Owner:广州市千钧网络科技有限公司

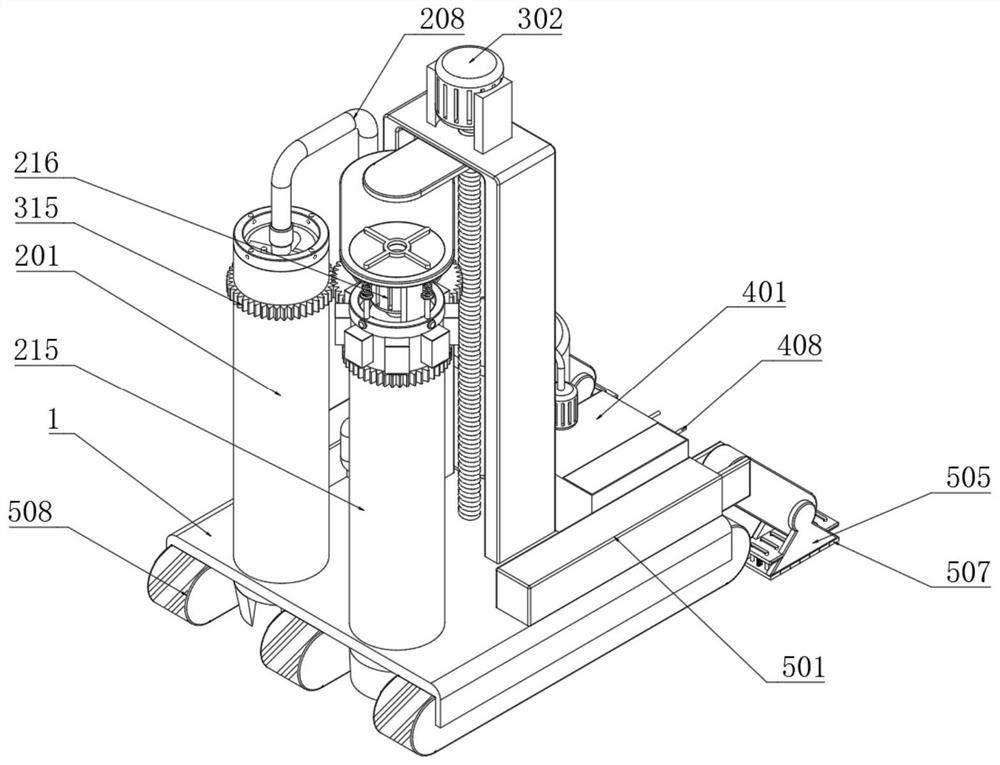

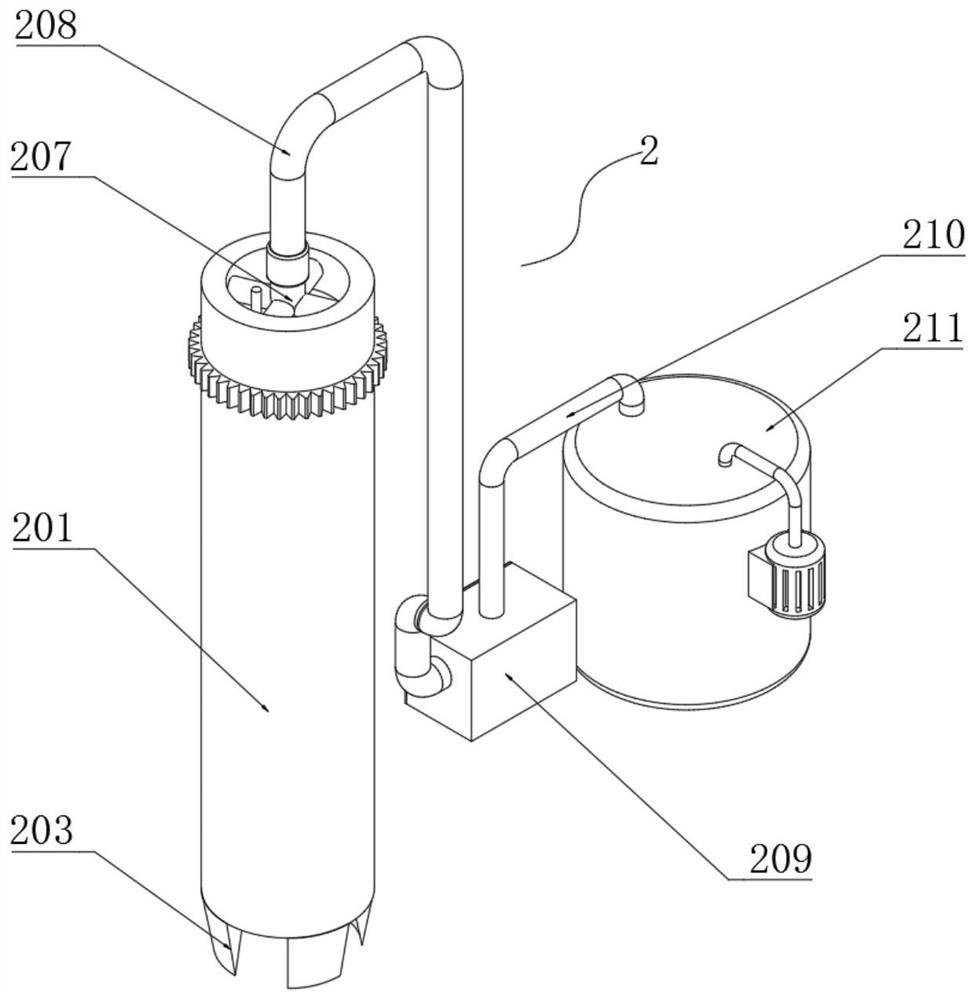

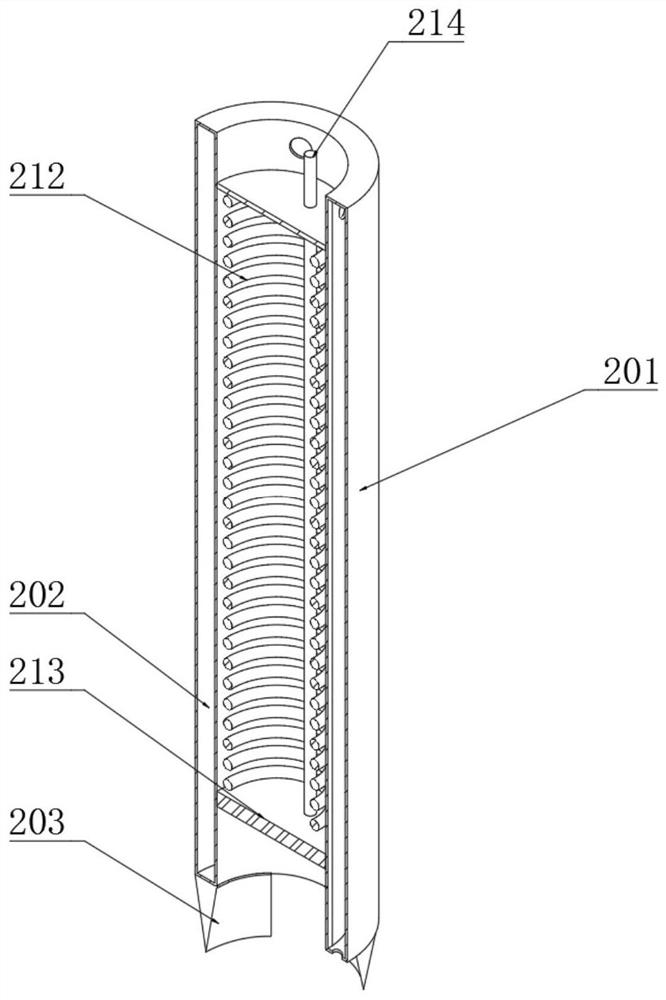

Rock-soil detection device for geological exploration

PendingCN113063623AAvoid Overturning Mixed SituationsAvoid dry conditionsWithdrawing sample devicesPreparing sample for investigationSoil scienceRock core

The invention discloses a rock-soil detection device for geological exploration. A cutting knife is hinged to the bottom end of a rock sampling barrel, a pressing spring is welded to one end of a pulling rope, a transmission motor is installed at the top end of a soil sampling barrel, a sealing limiting plate is clamped to the inner side of a discharging opening, and a soil collecting box is clamped to the side end of an installation connecting frame. Rock is sampled through the rock sampling barrel, the angle of the cutting knife is changed through the pulling rope and the pressing spring, so that the cut rock core can be conveniently and rapidly lifted, personnel can conveniently and visually observe, the soil is sampled through the soil sampling barrel and the auger, and the soil is discharged through the discharging port, the soil at different depths can be rapidly screened when needing to be collected, the situation that the soil is mixed together to influence the detection result is avoided, rock collection and soil collection are separated, mutual interference is avoided, and the situation that the detection result deviates due to mutual influence is avoided.

Owner:李晟

Diamond cutting circular saw blade

InactiveCN106272984AImprove crushing efficiencyImprove discharge efficiencyStone-like material working toolsDischarge efficiencyDiamond cutting

The invention discloses a diamond cutting circular saw blade. The diamond cutting circular saw blade comprises a base body, a diamond knife head and a central hole, wherein saw teeth which are uniformly distributed along the external circumference of the base body are fixed on the base body, the diamond knife head is welded on the saw teeth, the thickness of the diamond knife head is greater than that of the base body, a chip groove is formed in the bottom of a gap between every two saw teeth on the base body, and at least one debris baffle is fixed on each of lateral surfaces of two sides of the base body; abrasive layers are fixed on both the lateral surfaces of the two sides of the base body. The diamond cutting circular saw blade has the advantages that a cutting section is finely ground by the abrasive layers when the diamond knife head of the saw blade cuts materials to facilitate higher flatness of the cutting section while ensuring the cutting speed, thereby reducing production procedures and lowering the cost; the debris baffles crush residual materials generated while cutting again, and the crushed residual materials are discharged from the chip grooves to enhance the crushing and discharging efficiency of the residual materials to prevent the residual materials from being collided or wound on a transmission shaft of cutting equipment, so that the cutting equipment is easy to clean and is ensured to be normally operated.

Owner:江苏益林金刚石工具有限公司

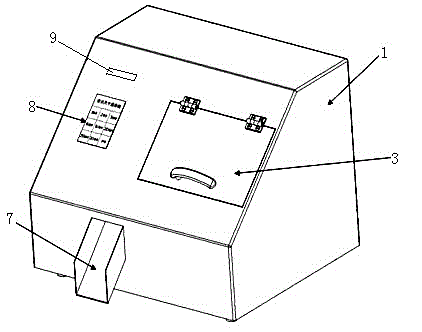

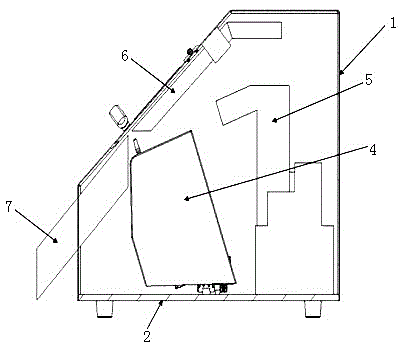

Ampoule laser automatic opening device and method thereof

ActiveCN102910568AEnsure safetyEfficient recyclingHand-operated cutting devicesMicrocomputerMicrocontroller

The invention discloses an ampoule laser automatic opening device and a method thereof. The ampoule laser automatic opening device comprises a case with a window, an ampoule installation clamping mechanism, a laser cutting device, a sliding groove and a single chip microcomputer, the ampoule installation clamping mechanism is located in the case, arranged on a bottom plate of the case in a sliding mode and used for placing an ampoule, the laser cutting device is located in the case, fixedly arranged on the bottom plate of the case and arranged opposite to the ampoule installation clamping mechanism, the sliding groove is arranged on the case in an inclined mode, the single chip microcomputer is respectively connected with the ampoule installation clamping mechanism and the laser cutting device and provided with a power drive module, the upper end of the sliding groove is located in the front of the top end of the ampoule installation clamping mechanism, and the lower end of the sliding groove extends out of the case. According to the ampoule laser automatic opening device and the method thereof, the structural design of the ampoule laser automatic opening device is reasonable, the laser is utilized for cutting, the whole cutting process is automatically operated, the operation is simple, the damage to staff is prevented, the dust is prevented from being generated during the cutting opening process, a drug liquid or a sample in the ampoule is prevented from being polluted by the dust, and the stability and cutting speed of the ampoule opening device during the laser cutting process are guaranteed.

Owner:HEFEI ZHICHANG PHOTOELECTRIC TECH

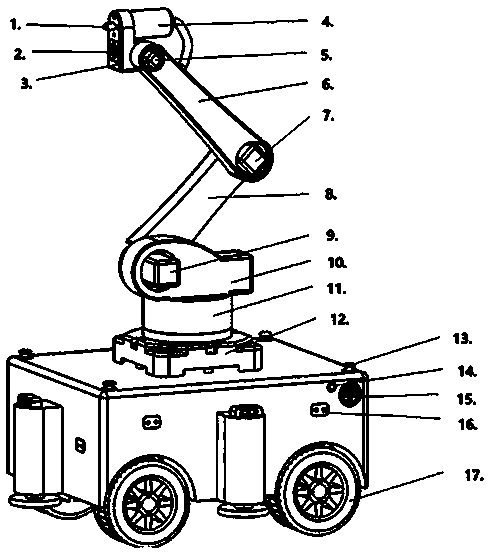

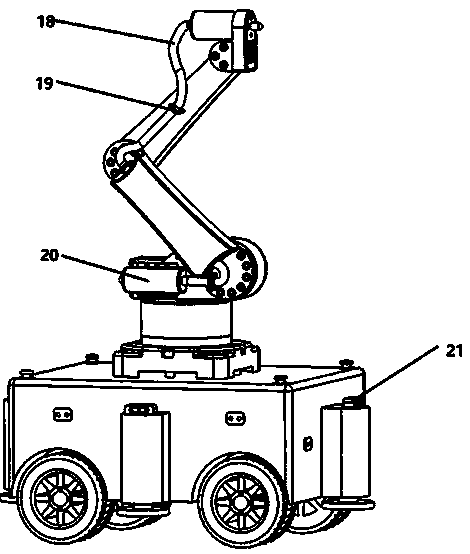

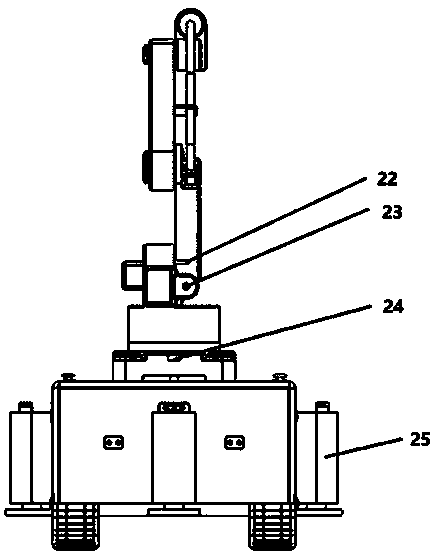

Water jet scalpel cutting robot

PendingCN110253599ASolve the drag wireSolve non-intelligent problemsManipulatorButt jointWater jet cutter

The invention provides a water jet scalpel cutting robot. The water jet scalpel cutting robot comprises a mechanical arm system, a water jet scalpel cutting system and a walking driving mechanism. The mechanical arm system is mounted on the walking driving mechanism, and the water jet scalpel cutting system is mounted on the mechanical arm system. The problem that current cutting equipment needs to drag an electric wire and is not intelligent is solved. According to the water jet scalpel cutting robot, a multi-freedom-degree mechanical and water jet scalpel cutting are combined, certain cutting speed is guaranteed, and meanwhile certain cutting precision can be guaranteed. Electric energy is provided for the whole system through a high-performance lithium battery pack, and voltage and current needed by the work of all modules of the system are guaranteed. The electric quantity of the lithium battery pack is detected through a power source detecting controller, and whether charging is carried out or completed is remaindered through the remaining electric quantity. An RFID tag in a charging reading area is recognized through an RIFD reader mounted on the robot, and interface butt joint is automatically completed for charging.

Owner:陕西中建建乐智能机器人股份有限公司

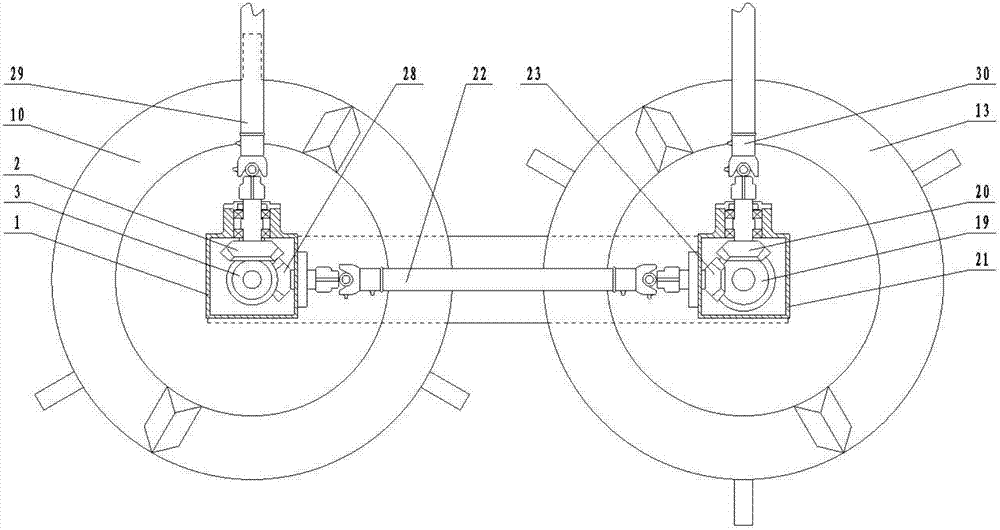

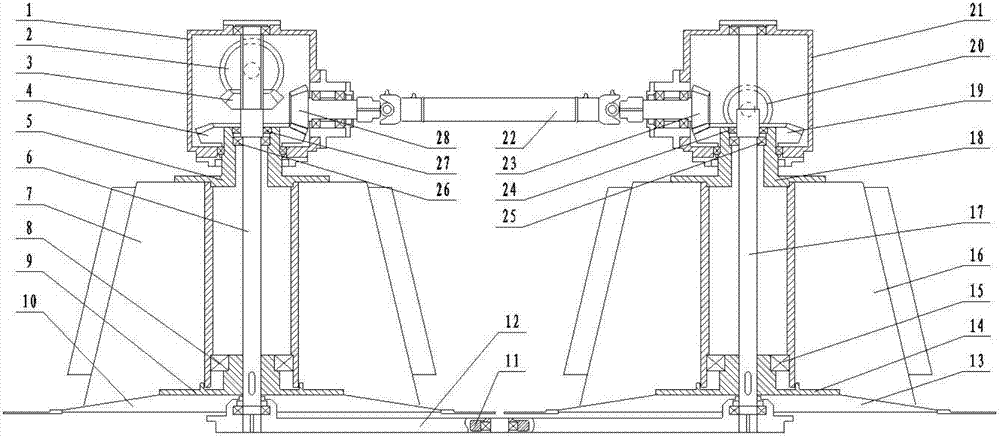

Rotatable mower header and differential feeding method

The invention relates to the technical field of agricultural machinery, in particular to a rotatable mower header and a differential feeding method. The mower header is mainly composed of a left cardan joint (29), a left gear box (1), a left material guiding cylinder (7), a left cutter disc (10), a gear box (12), a right cardan joint (30), a right gear box (21), a right material guiding cylinder (16) and a right cutter disc (13). Different revolving speeds of the cutter discs and the material guiding cylinders are achieved, and the revolving speed of the cutter discs is high so as to ensure the cutting speed, low revolving speeds of the material guiding cylinders and material drainage. With the differential feeding method, roots of mowed forage grass are arranged at the front and the following crops are conveyed backwards in order, layout of forage grass strips is in order, the following operation is convenient, and at the same time, the forge grass is prevented from tilting forwards and secondary cutting is avoided.

Owner:CHINA AGRI UNIV

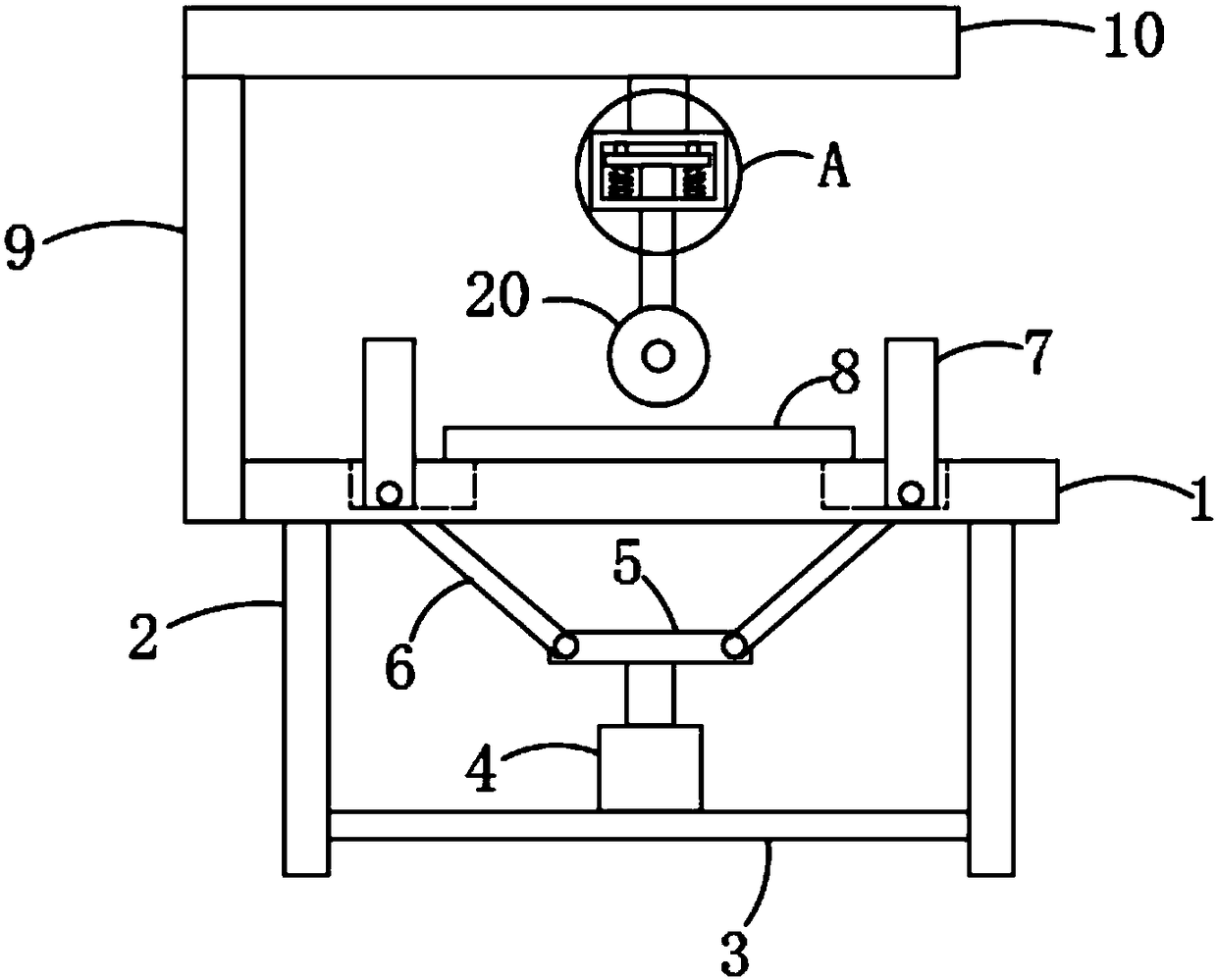

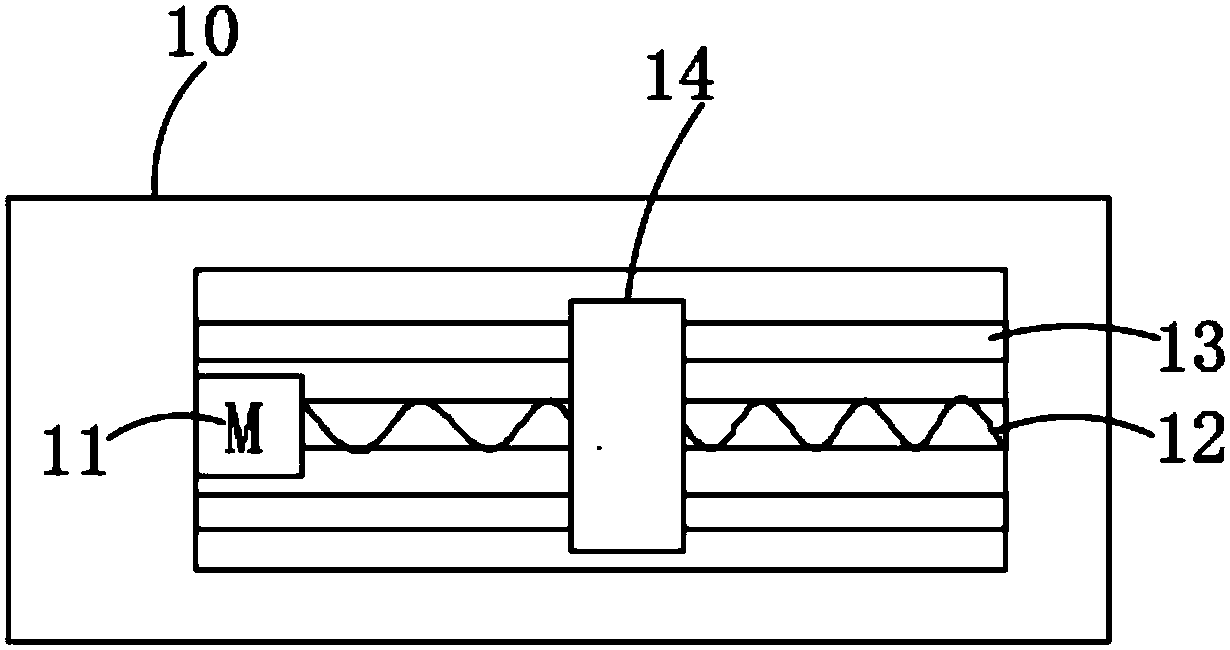

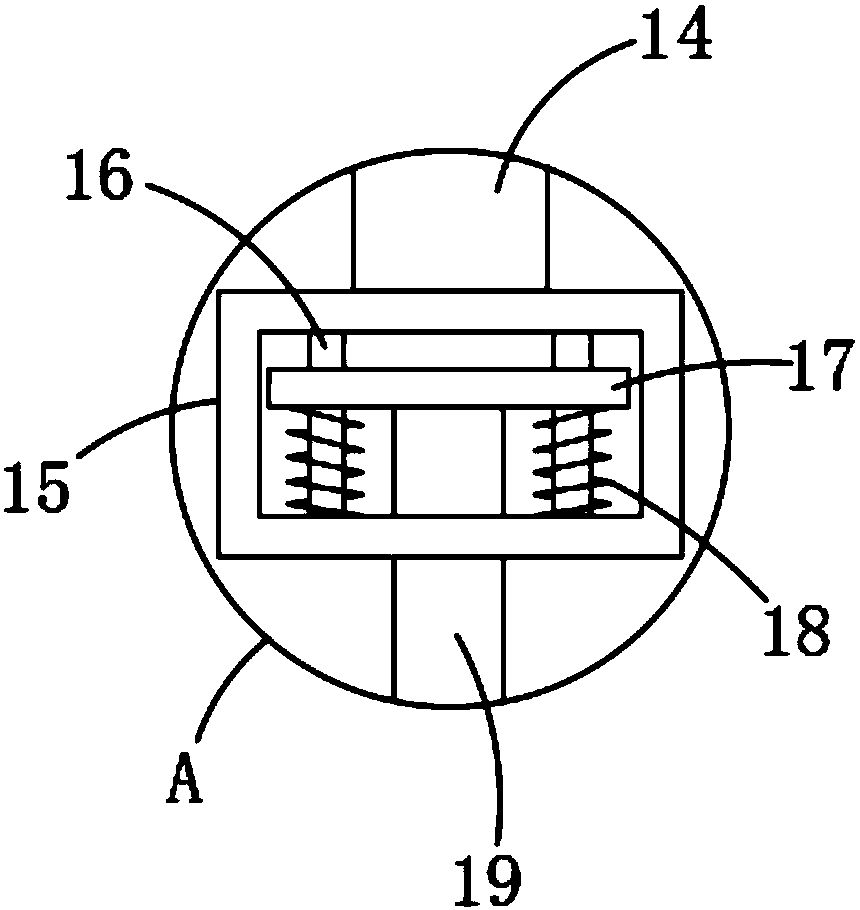

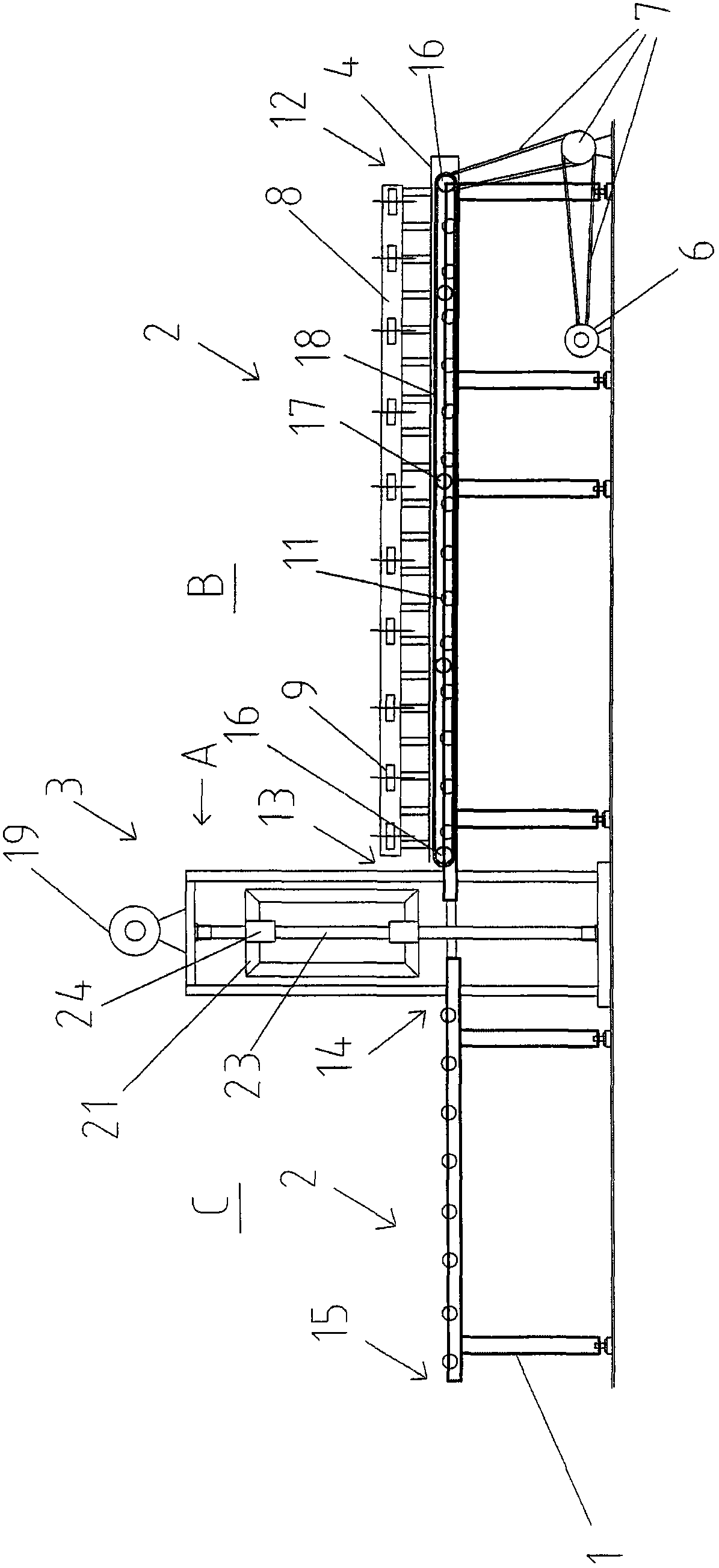

Wood plate cutting device for office chair production

PendingCN108568866ARealize the clamping effectAchieve relaxationGripping devicesClamping devicesMotor driveOffice chair

The invention discloses a wood plate cutting device for office chair production. The device comprises an operating platform, wherein four rectangularly arranged supporting legs are welded to the lowerside wall of the operating platform, a cross plate is jointly welded to the outer walls of the four supporting legs, a cutting table is welded to the upper side wall of the operating platform, a plurality of uniformly distributed cutting grooves are formed in the upper side wall of the cutting table, a connecting column is welded to the outer side wall of the operating platform, and a suspensionplate is welded to the upper end of the connecting column. By arranging a servo motor, the servo motor drives a lead screw to rotate, a ball nut moves linearly, a movable plate driven by the ball nutslides on a horizontal slide rail, and the cutting tool also moves driven by the movable plate. Staff pulls an operating rod downward through a grab handle, so that the cutting device cuts a workpiece. The semi-automatic working mode is relatively time- and labor-saving, so that the cutting quality and speed of the workpiece are guaranteed.

Owner:河南麦锐克电子商务有限公司

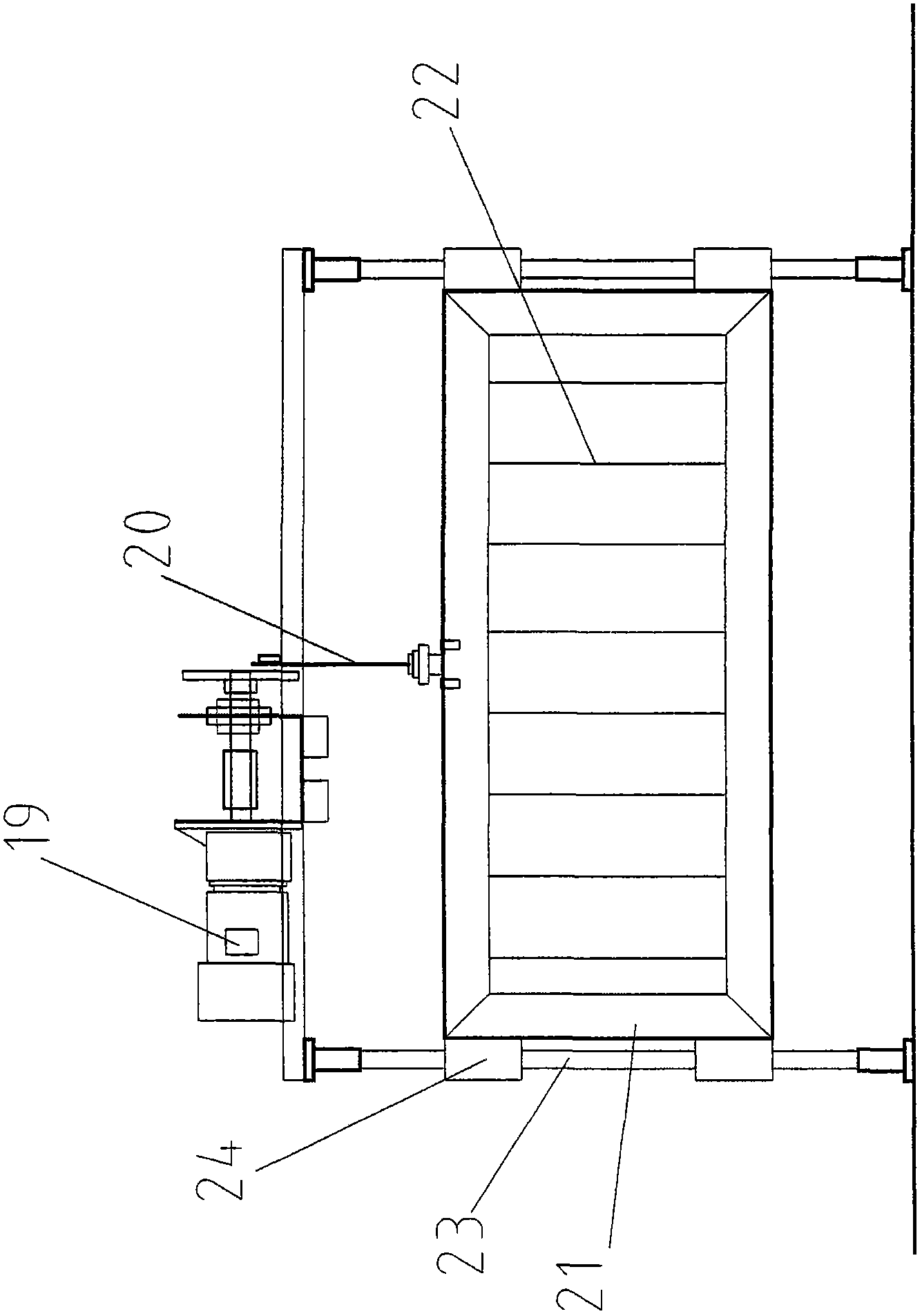

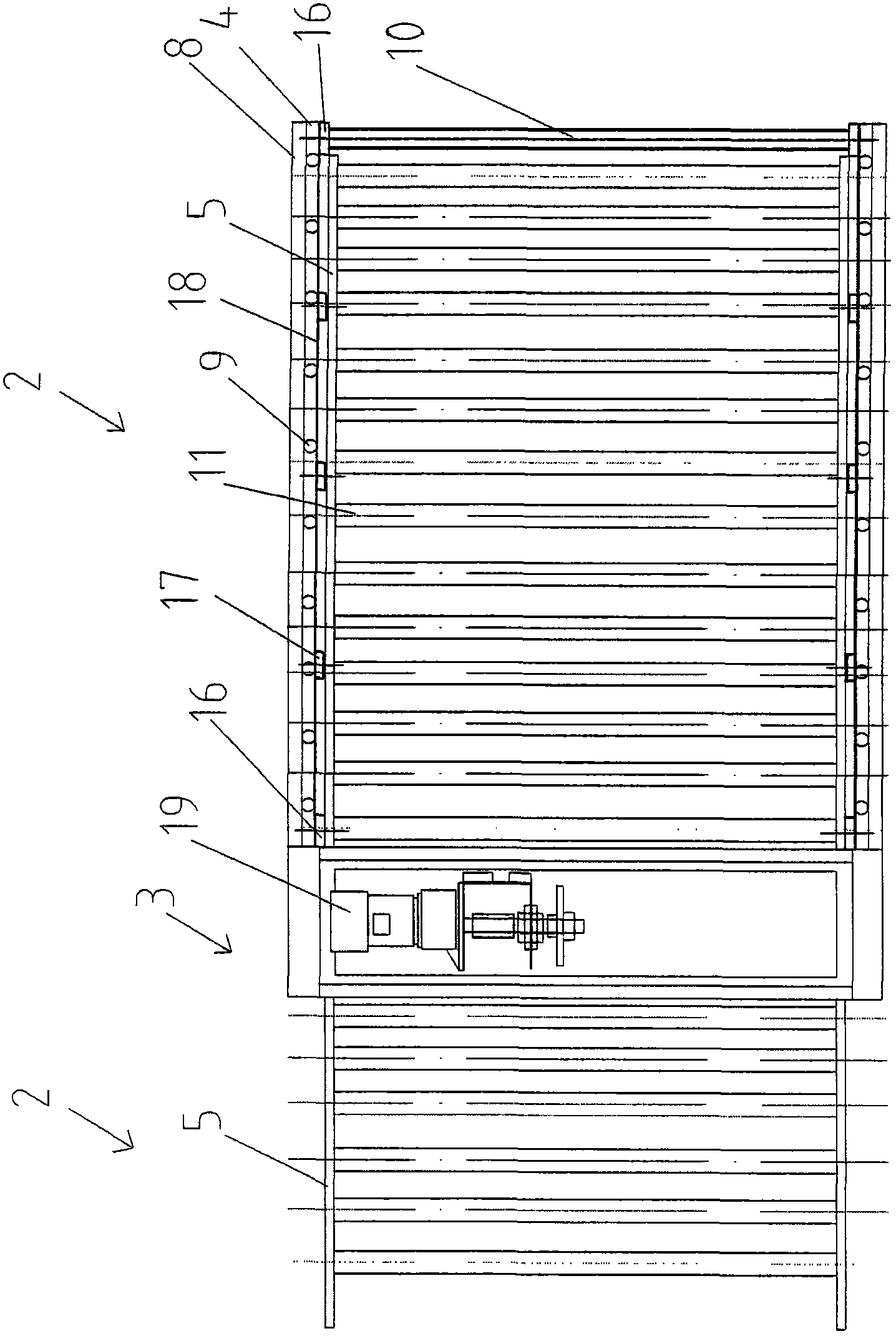

Cutting equipment for aerated block

InactiveCN102700004AIncrease productivityQuality assuranceStone-like material working toolsEngineeringOperation safety

The invention discloses cutting equipment for an aerated block and particularly relates to equipment for cutting the aerated block. The cutting equipment consists of a stand, a plane conveyor and a cutting machine. The cutting equipment has the advantages of compact structure and steps, simple and feasible process and small occupied space for saving the investment of factory buildings and capital construction; and the cutting equipment is simple in operation and can be operated by one to two person, and thus the production cost can be reduced and safety and reliability in operation are realized.

Owner:汪电和

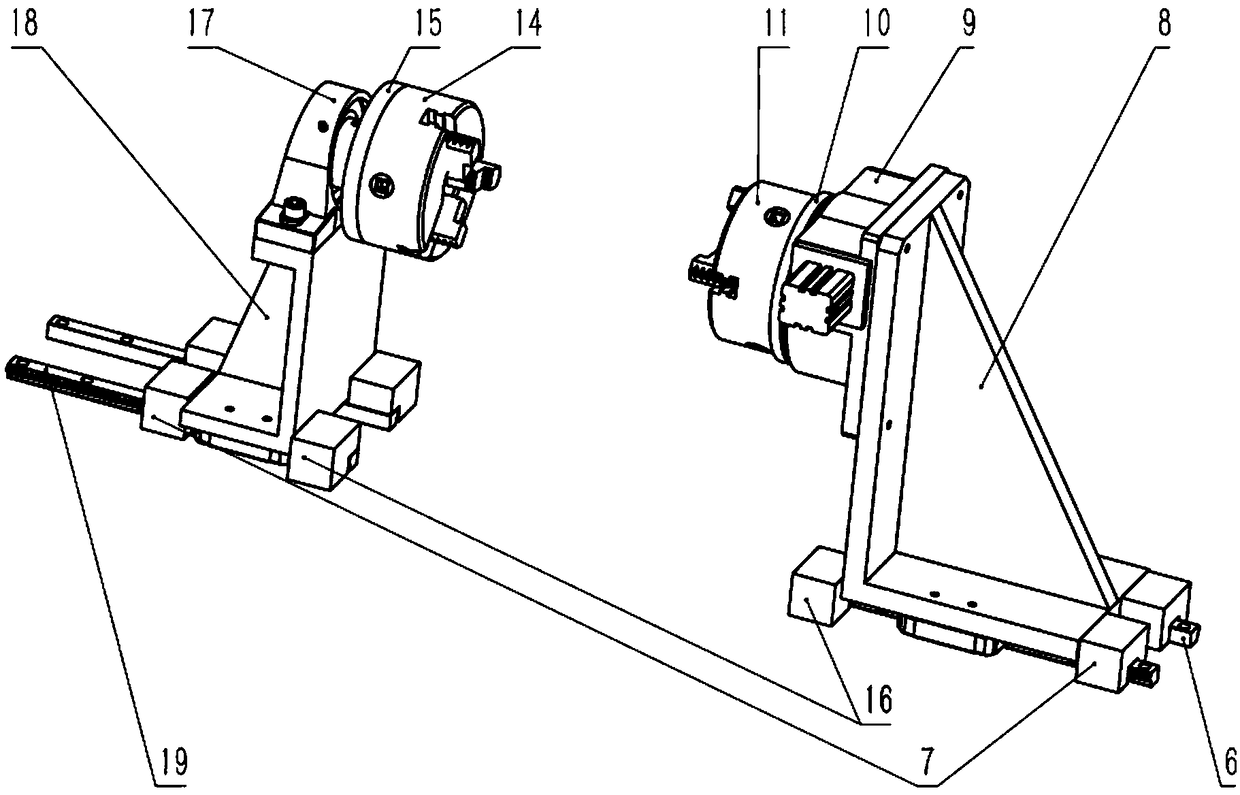

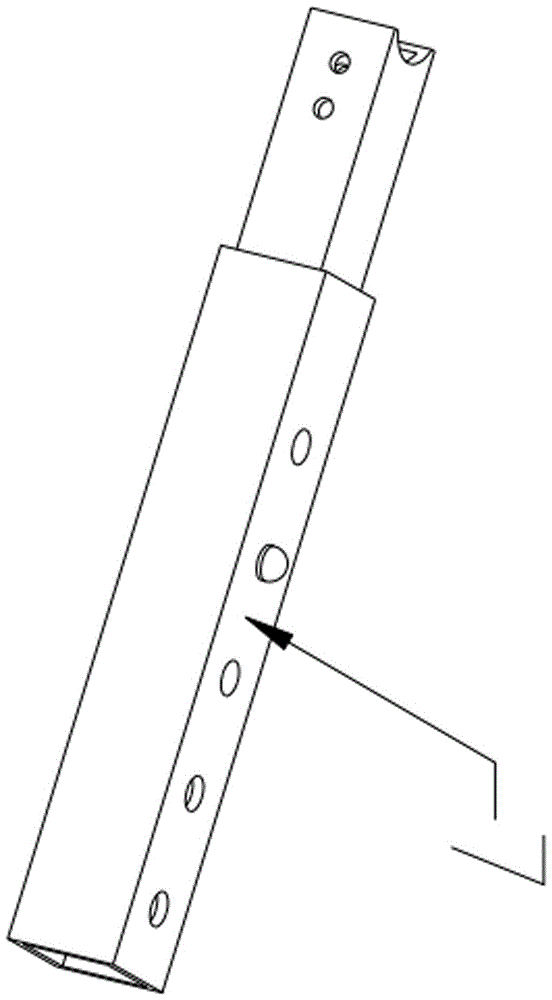

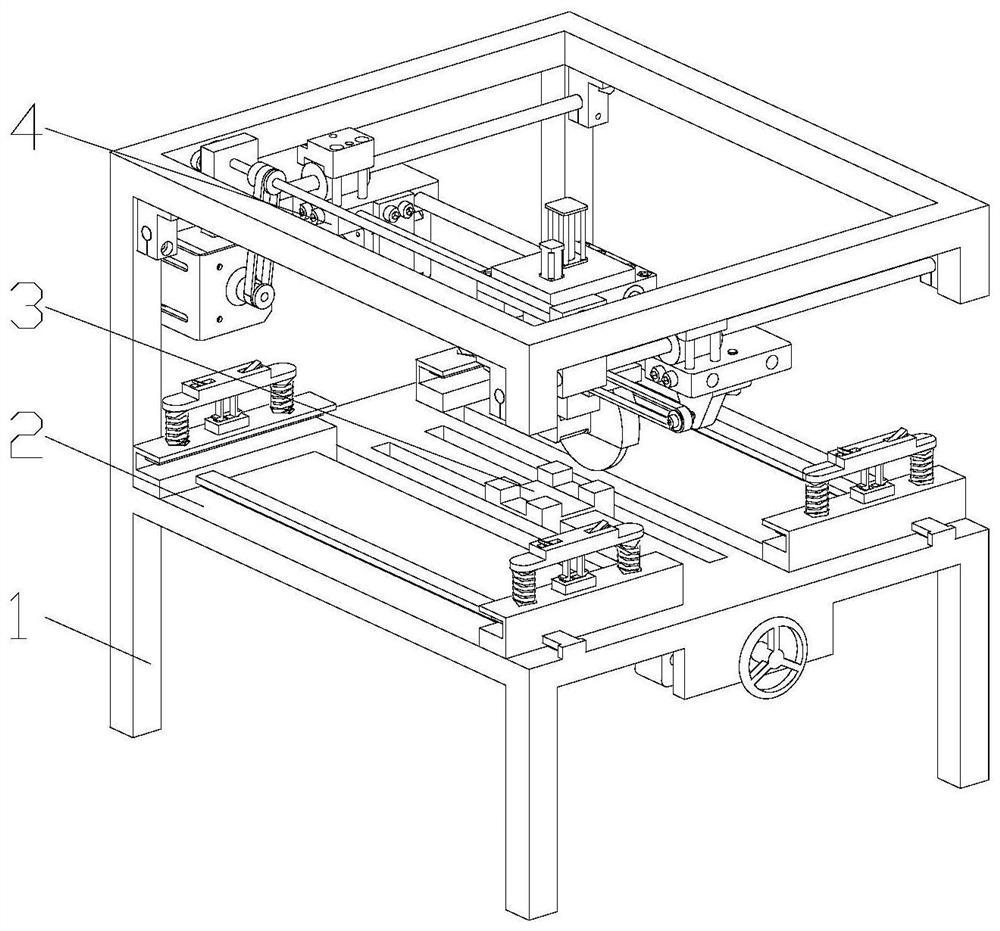

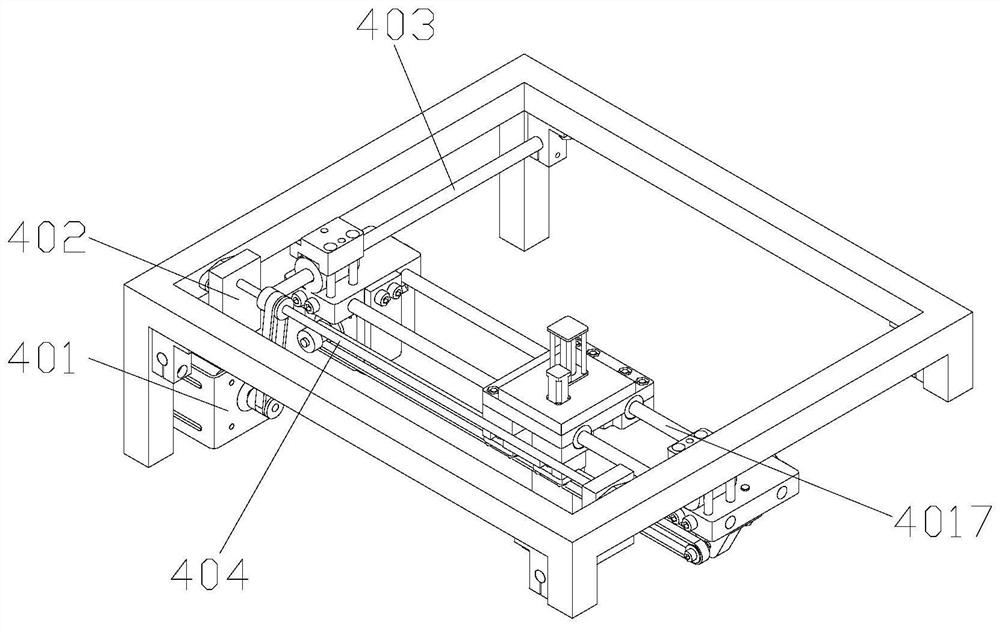

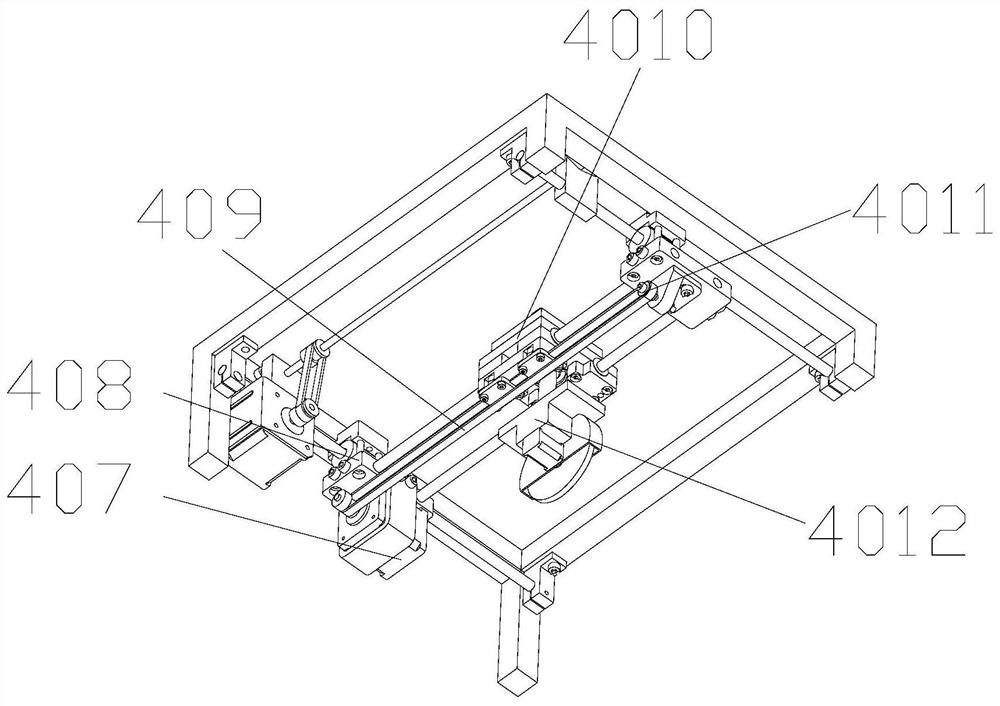

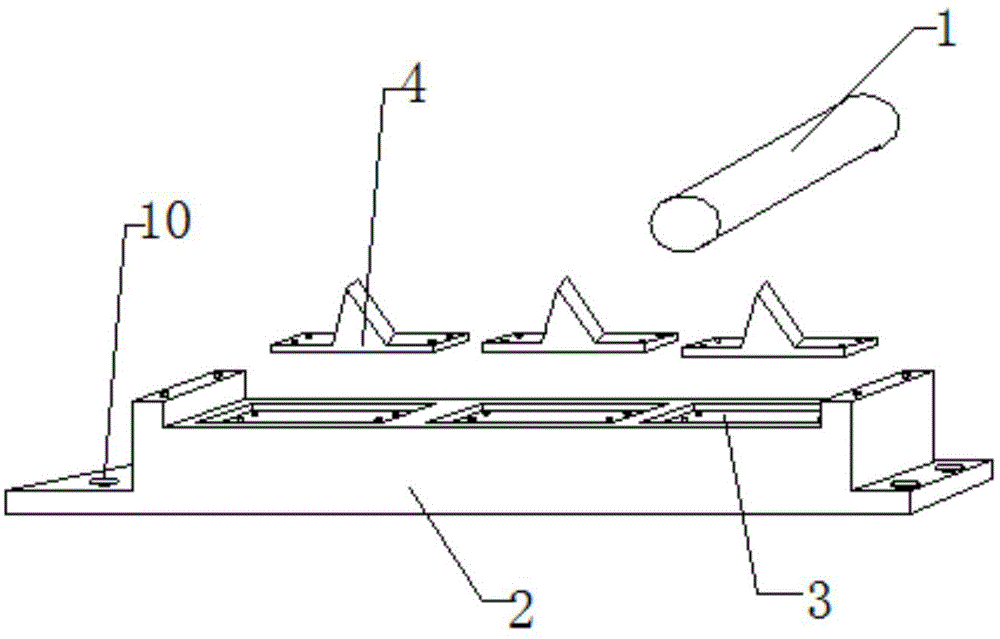

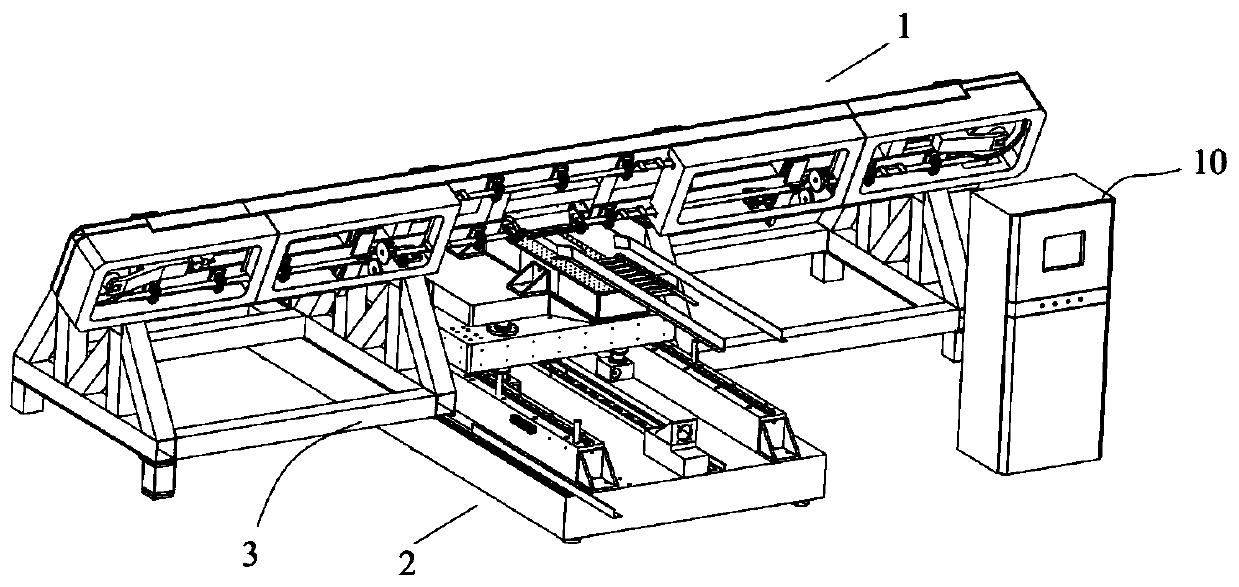

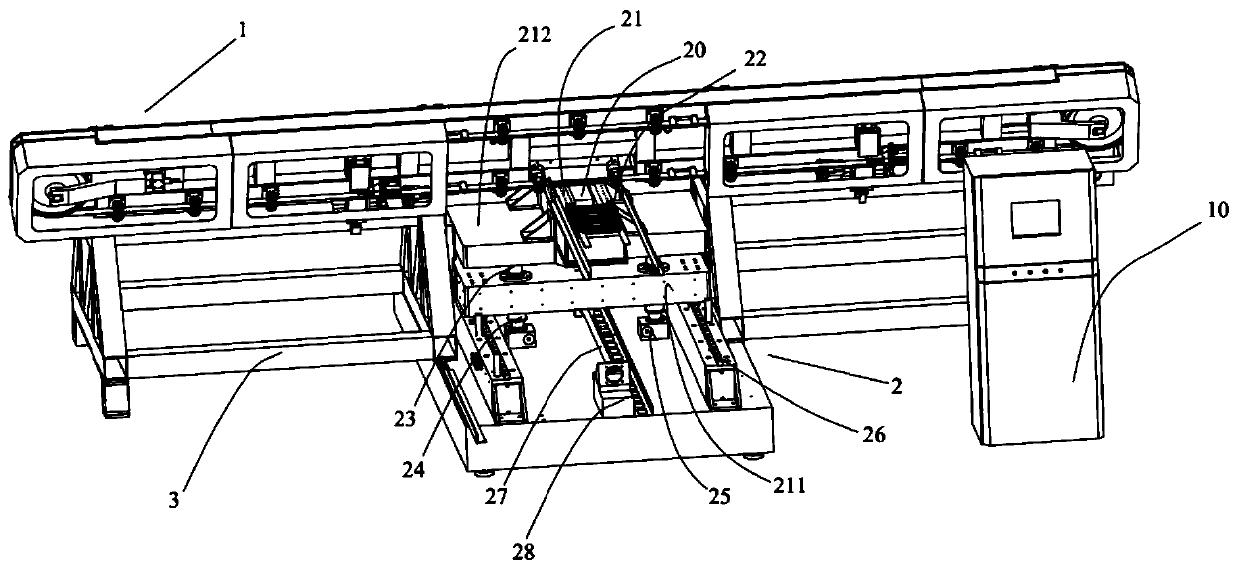

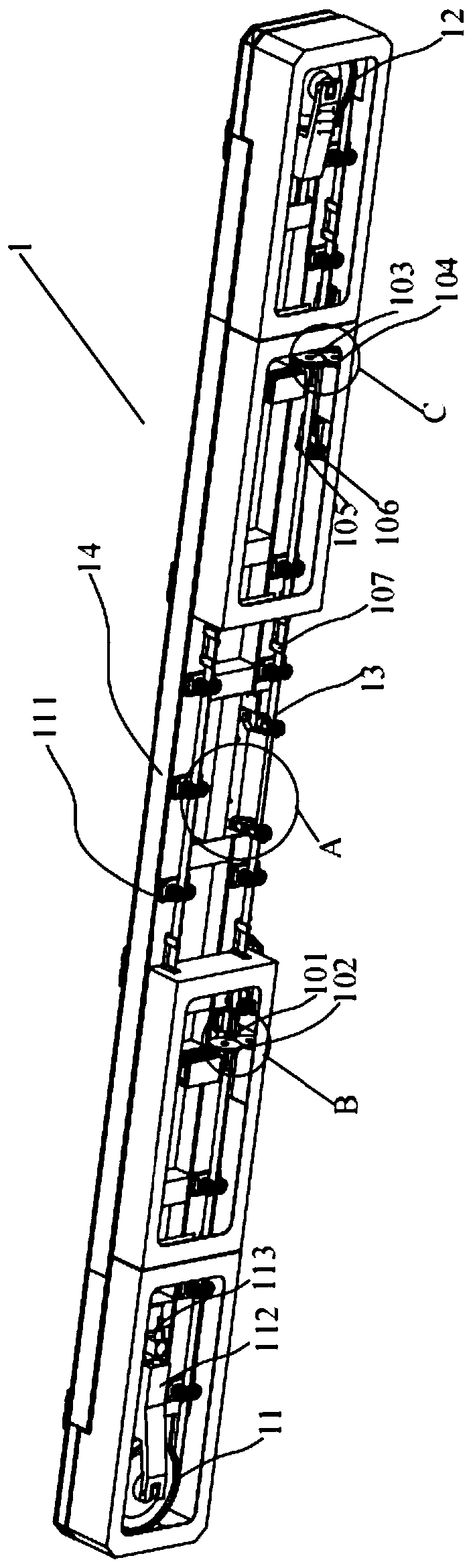

Surface polishing and grinding process and equipment used for long rod part with specially-shaped section

ActiveCN108500792AImprove polishing qualityGuaranteed cutting forceBelt grinding machinesGrinding work supportsLinear motionGrinding process

The invention discloses a surface polishing and grinding process and equipment used for a long rod part with a specially-shaped section. The equipment comprises a belt grinder, a travelling mechanismand a clamping mechanism with a turnover function, wherein the travelling mechanism comprises a slide rail and a slide base mounted on the slide rail; the slide base is driven by a linear motion drivedevice to move back and forth along the slide rail; the belt grinder is fixedly mounted on the slide base; a belt grinder contact wheel presses an abrasive belt to a to-be-polished and to-be-grindedsurface or edge of a workpiece for polishing and grinding the to-be-polished and to-be-grinded surface or edge of the workpiece; a supporting mechanism is arranged between a drive rotary mechanism anda driven rotary mechanism; the workpiece is firstly placed onto the clamping mechanism, and the travelling mechanism drives the belt grinder to move back and forth for polishing and grinding the workpiece; after one surface is polished and grinded, turnover can be performed through a turnover mechanism; and after polishing and grinding are completed, the clamping mechanism is loosened and the supporting mechanism is withdrawn, so that the workpiece can be taken out. The surface polishing and grinding equipment is consistent in polishing and grinding effect of each part of the workpiece, is good in polishing and grinding quality of the workpiece, is stable in performance, and can be suitable for various long rod parts with specially-shaped sections.

Owner:WUHAN UNIV OF TECH

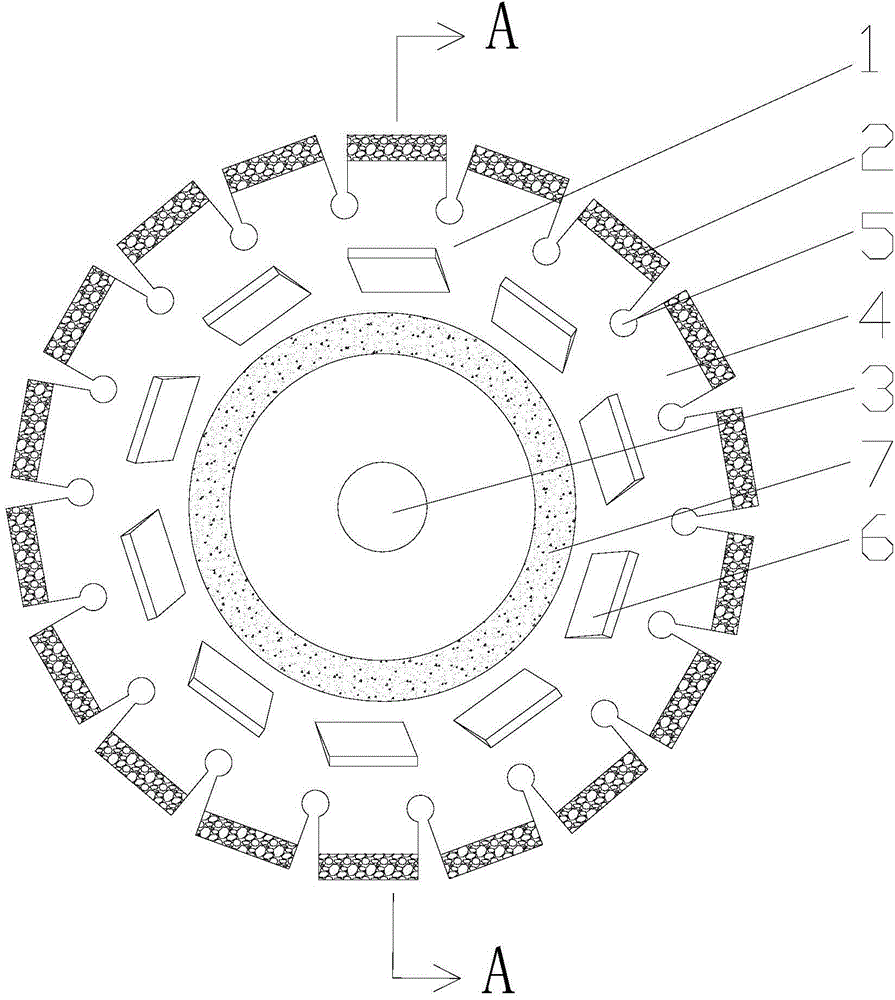

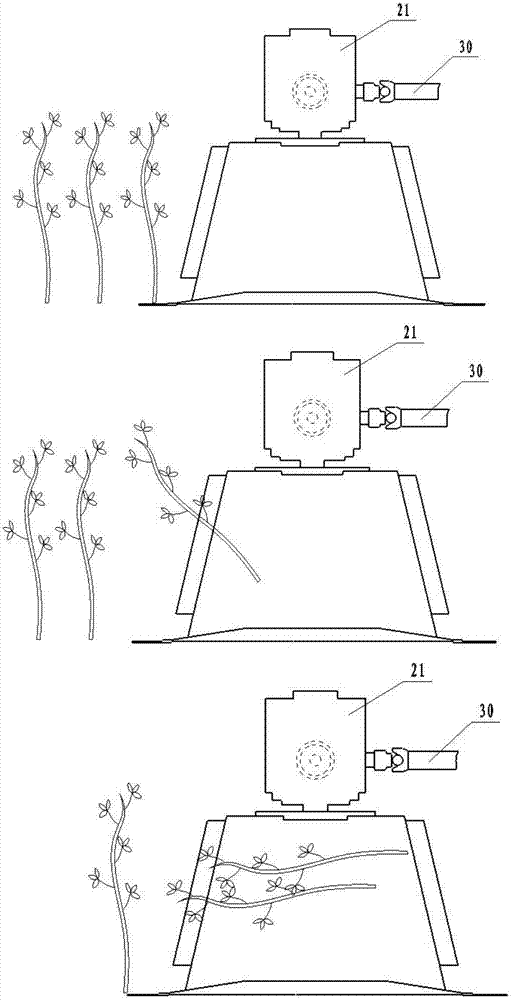

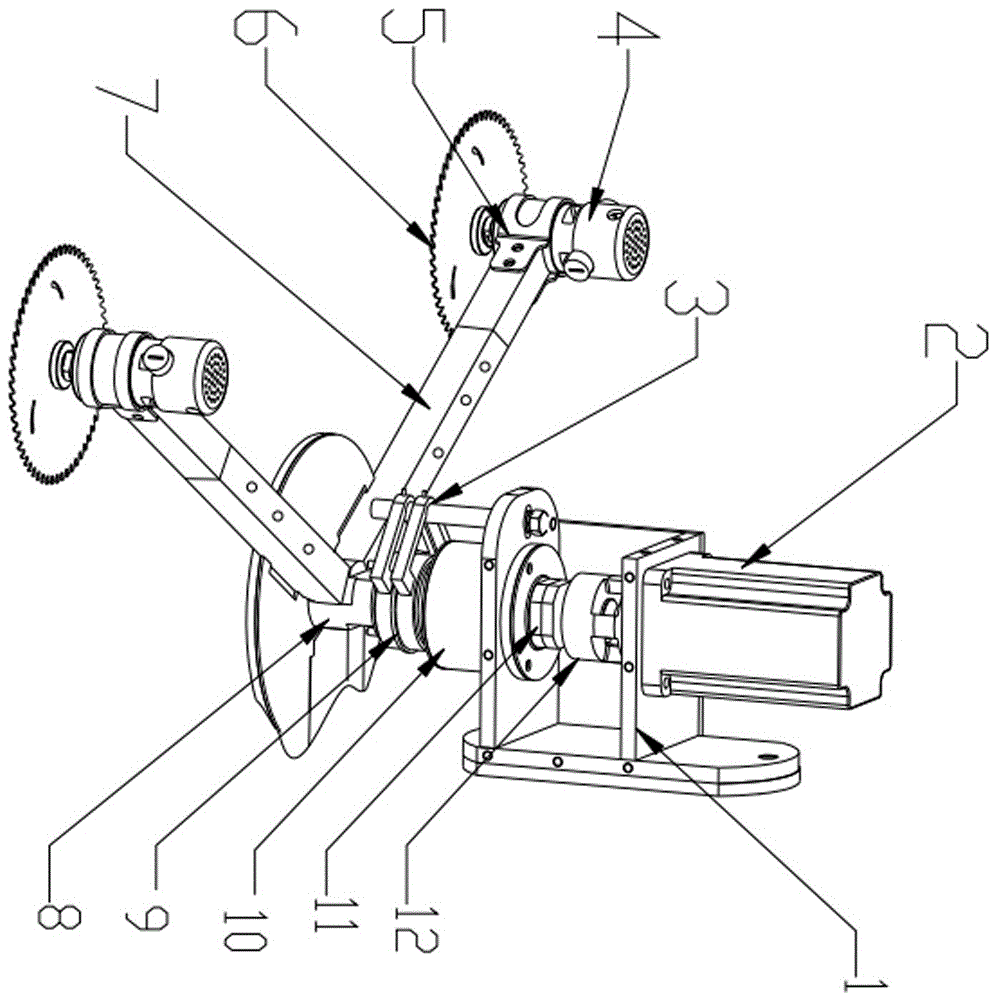

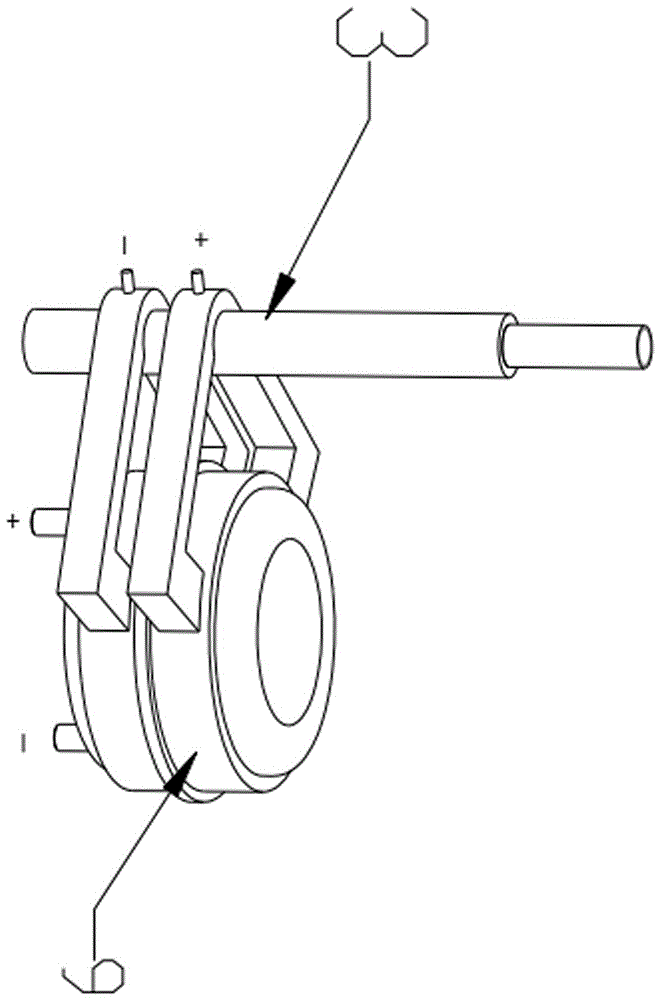

Revolution and rotation integrated nursery stock pruning device

InactiveCN106797812AGuaranteed cutting speedAvoid continuous cuttingCuttersMotor driven pruning sawsSliding contactPruning

The invention relates to a revolution and rotation integrated nursery stock pruning device. The revolution and rotation integrated nursery stock pruning device comprises a connecting piece, a motor I and a main shaft, wherein the motor I is arranged on the connecting piece; the main shaft is connected with an output shaft of the motor I; a conductive component is arranged on the main shaft; the conductive component comprises a conductive ring and an electric brush; the electric brush is in sliding contact with the conductive ring; supporting arms are arranged at the lower end of the main shaft; motors II are arranged at the tail ends of the supporting arms; saw blades are arranged on output shafts of the motors II; the motors II are connected with the conductive ring. The revolution and rotation integrated nursery stock pruning device provided by the invention has the advantages that continuous cutting of the saw blade is avoided while continuous pruning is guaranteed during pruning nursery stocks and the desired cutting speed of the saw blade during cutting is guaranteed.

Owner:ZHENGZHOU SHUNYI TECH CO LTD

Preparation method of abrasive wheel for cutting of blue glass infrared cut-off optical filter

ActiveCN106002650AEasy to controlPromote sheddingAbrasion apparatusGrinding devicesBoron carbideHardness

The invention belongs to a preparation method of an abrasive wheel for cutting of a blue glass infrared cut-off optical filter. Ultrafine-grain-size powder is adopted as raw materials of a metallic bond, better holding force on diamonds is achieved, the service life of the abrasive wheel can be prolonged, and the cutting speed of the abrasive wheel can be increased. By means of the composite mixing process adopting a three-dimensional mixer for premixing and ultrasonic wet mixing, the quality stability of the abrasive wheel and consistency of the cutting performance of the abrasive wheel are guaranteed. A certain amount of boron carbide and a certain amount of titanium diboride are added into the bond, do not participate in sintering and can fall off from the bond in time in the cutting process, and therefore keenness of the abrasive wheel is improved, the stable cutting capacity of the abrasive wheel is improved, and tool repair is avoided in the cutting process; and meanwhile due to the fact that the hardness of the two kinds of matter is high, the cutting assisting effect is achieved, and the cutting capacity of the diamond abrasive wheel is improved. The re-pressing process is adopted, an abrasive wheel blank obtained through hot-pressing sintering is strengthened, and therefore the density, rigidity and strength of the abrasive wheel are improved, and the mechanical performance of the abrasive wheel is further guaranteed.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Decorative ceramic tile cutting and positioning device

ActiveCN113547650AReduce labor intensityIncrease cutting rateWorking accessoriesVibration suppression adjustmentsCeramic tilesEngineering

Owner:阿郎装饰股份有限公司

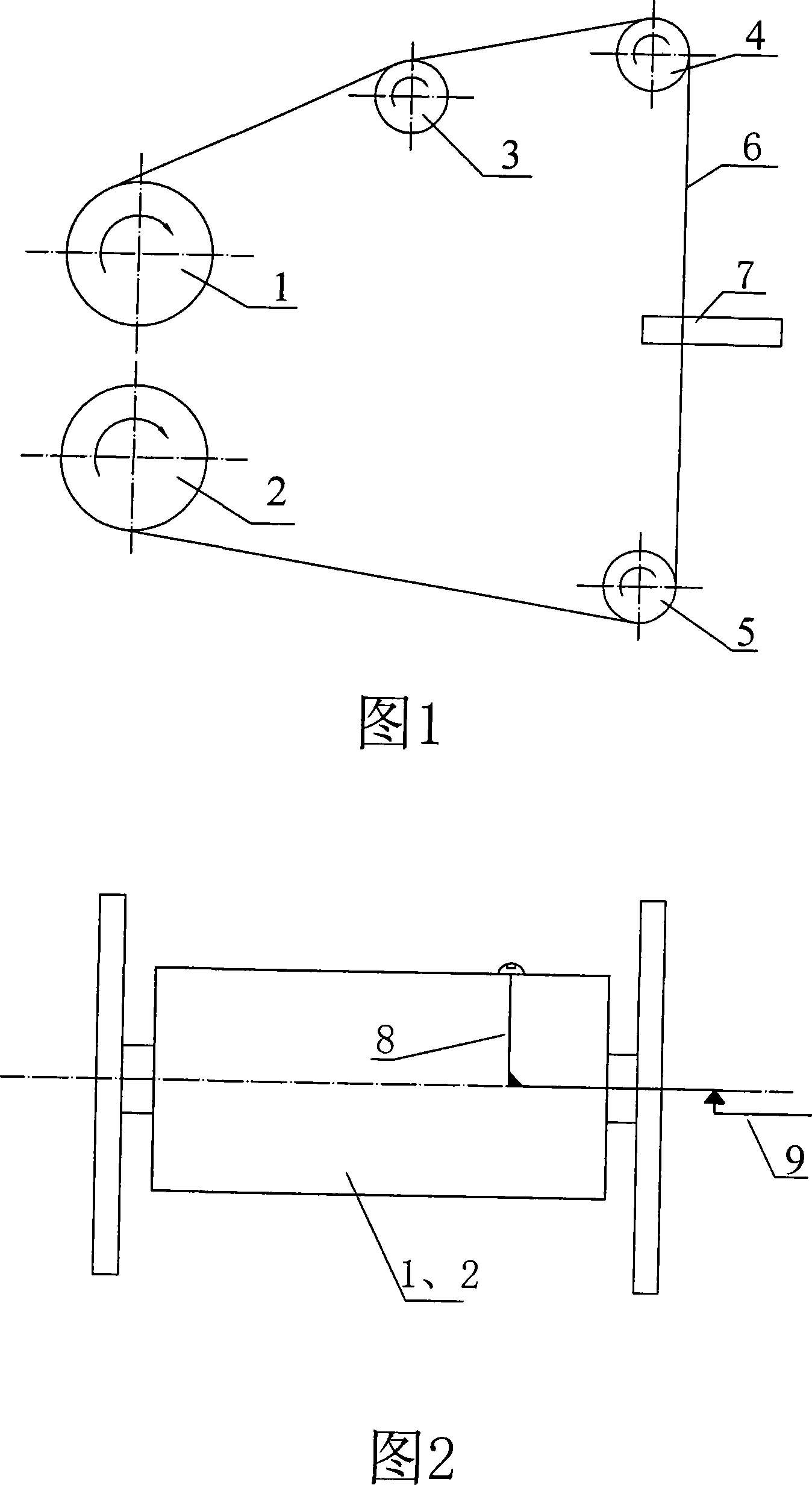

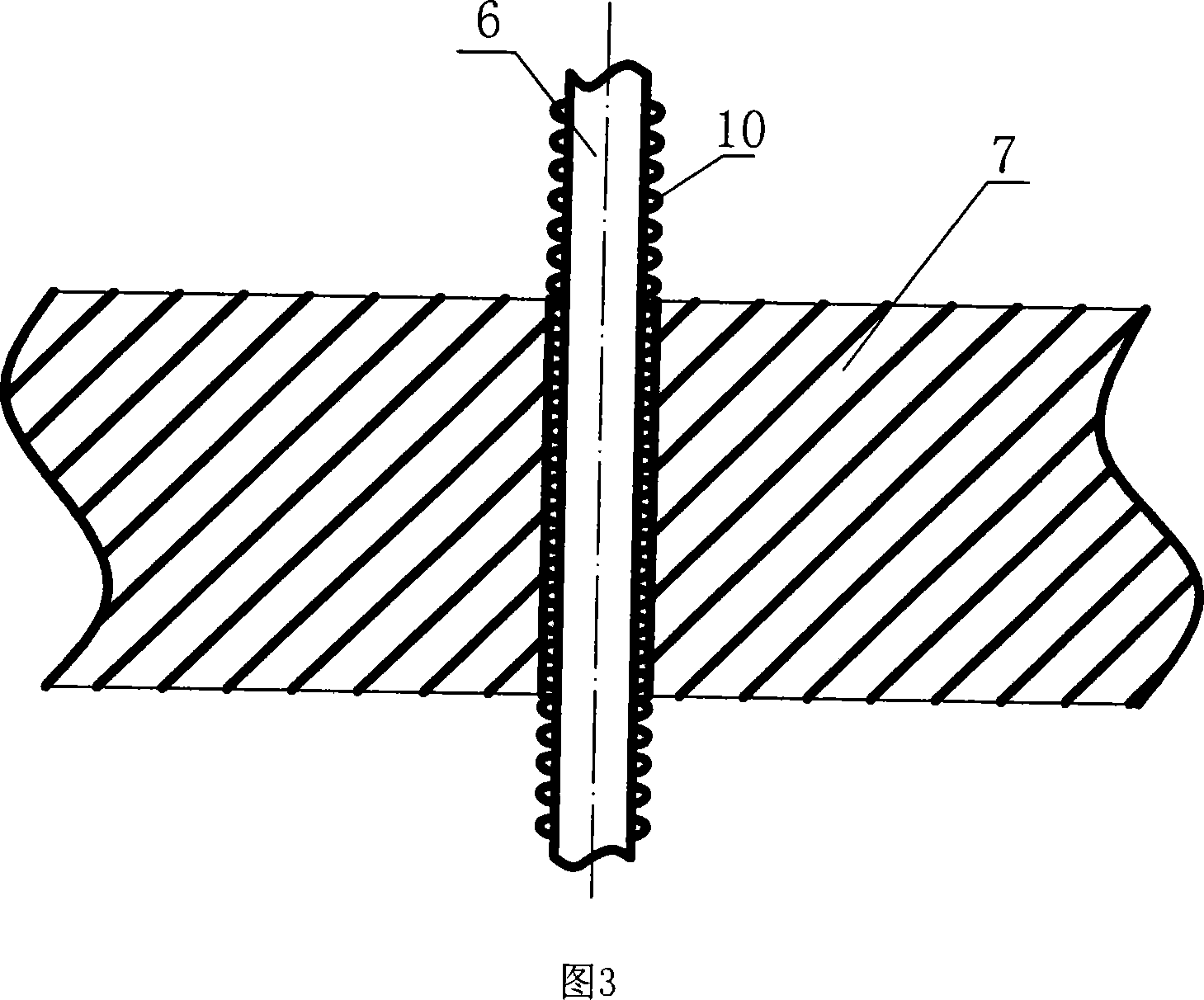

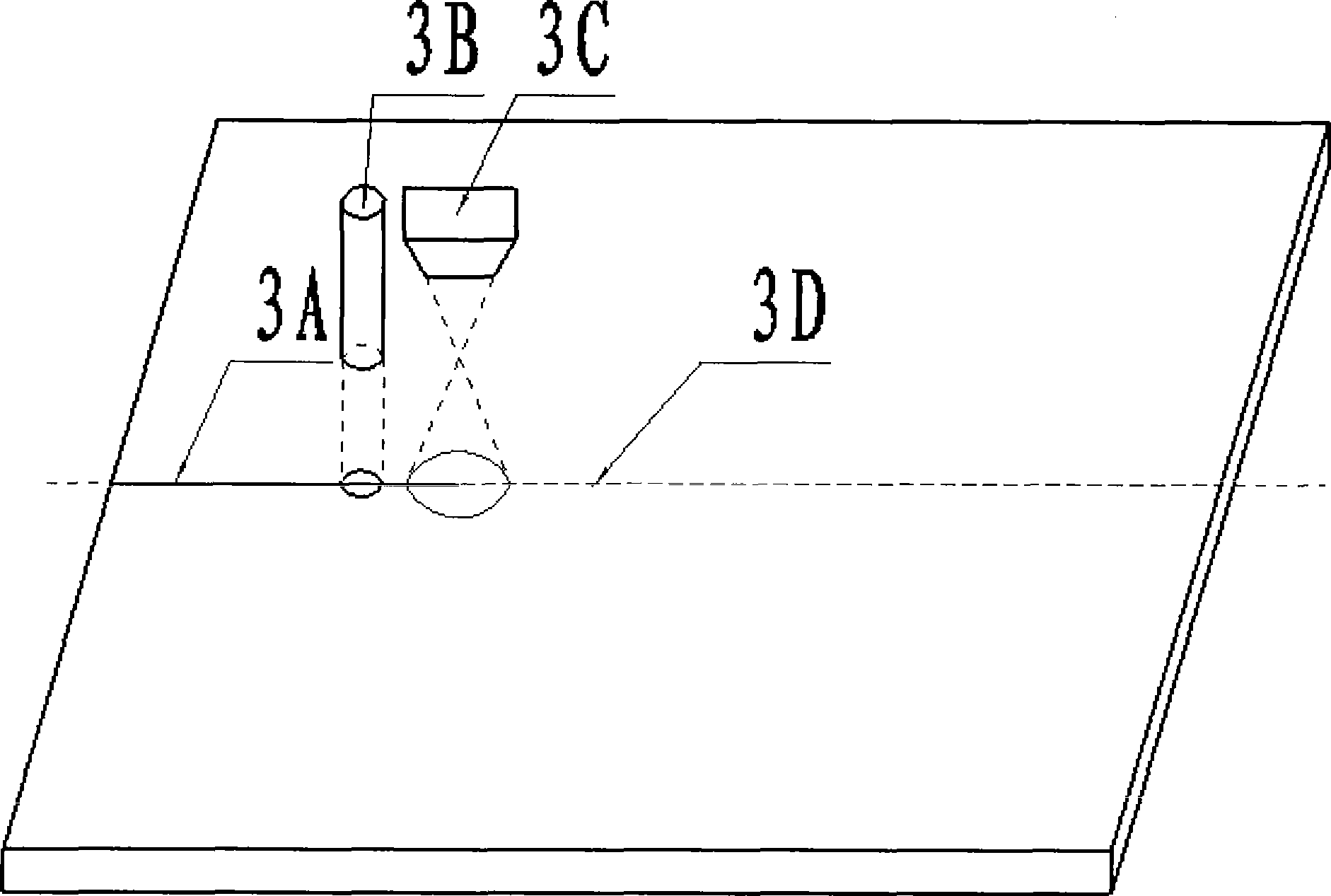

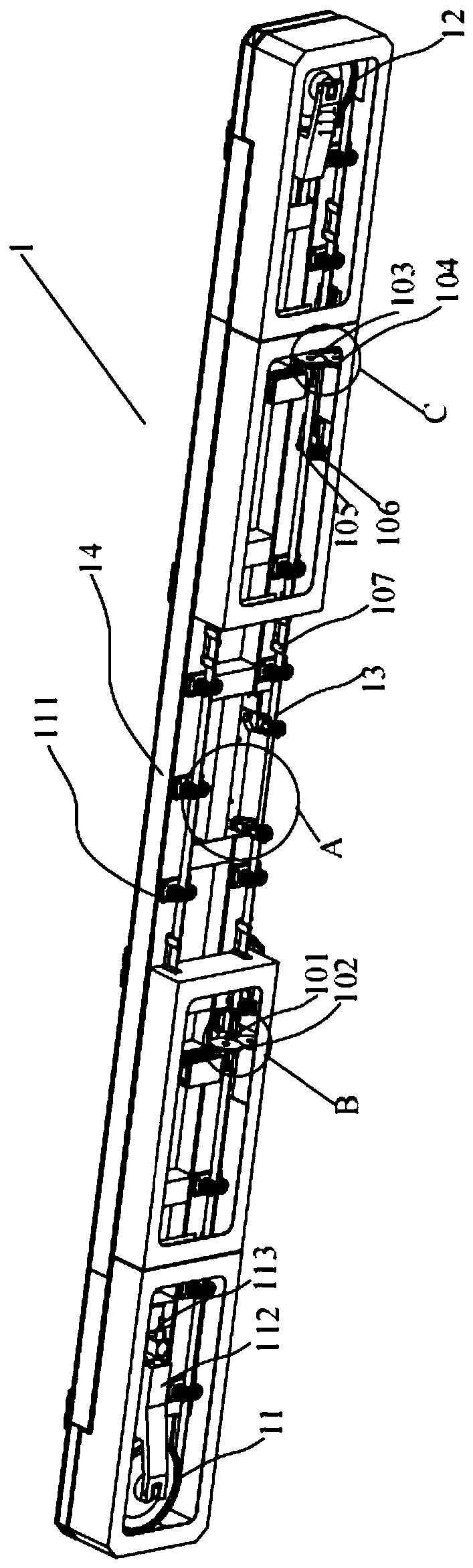

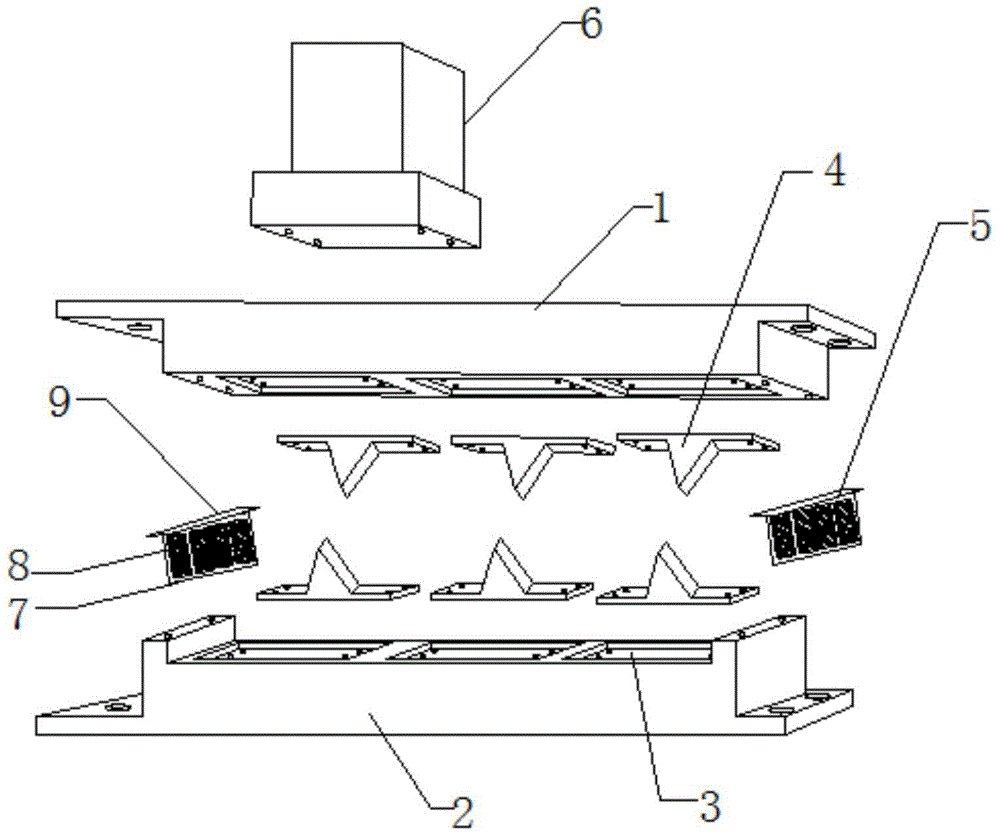

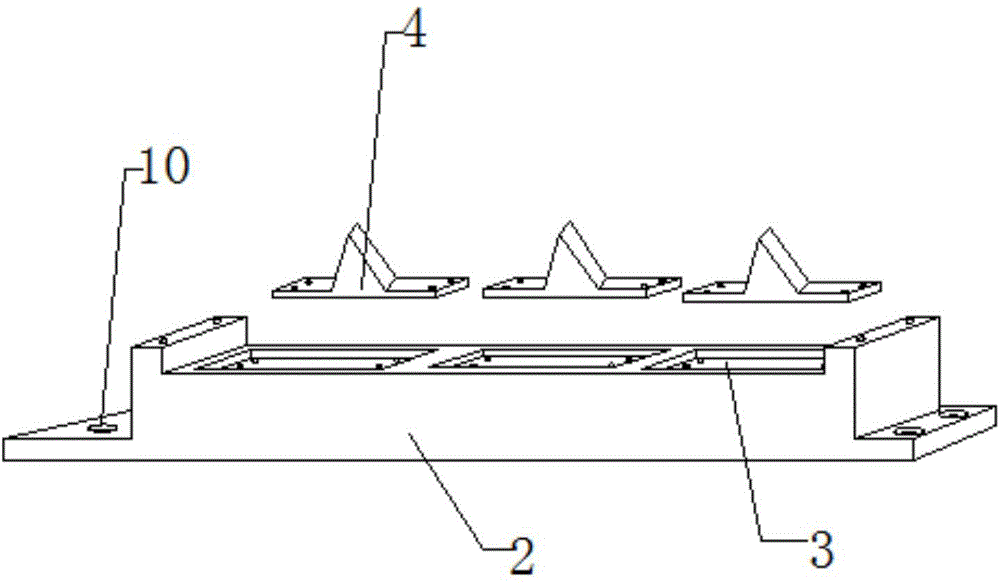

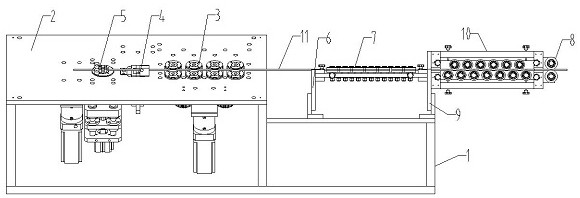

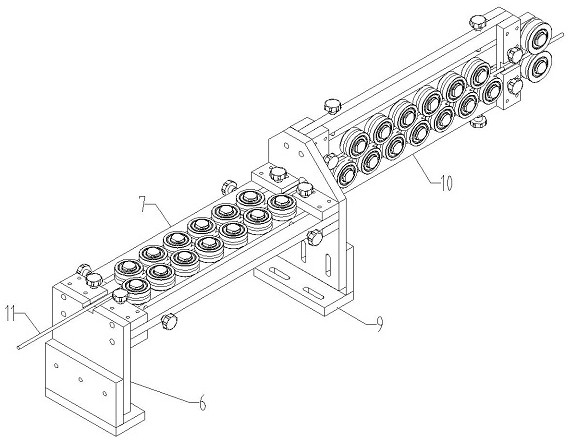

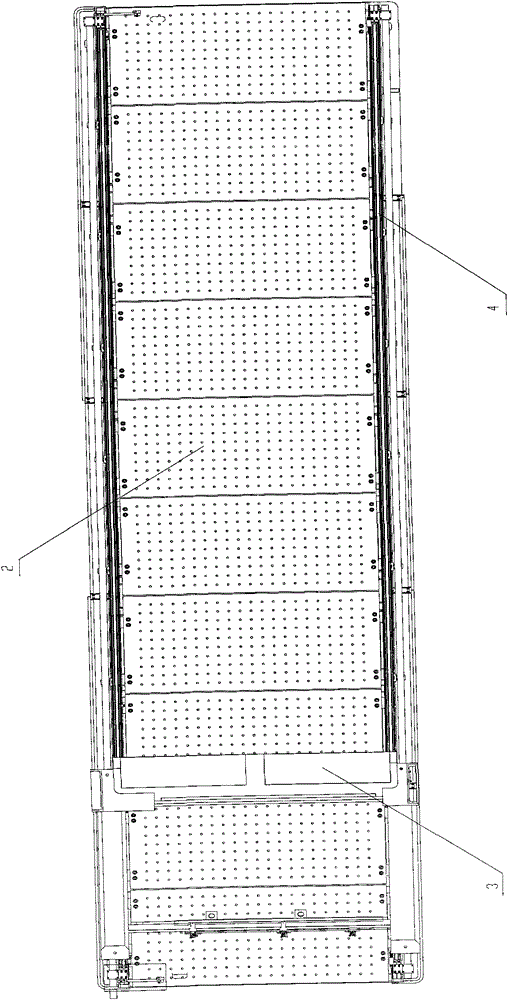

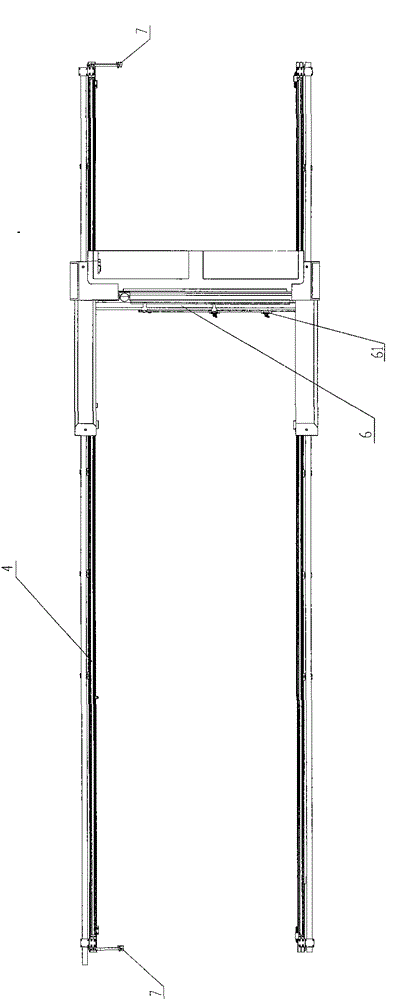

Annular cutting system and full-automatic foam slicing machine with annular cutting system

PendingCN111283789AEvenly slicedAdjustable thicknessMetal working apparatusEngineeringMechanical engineering

The invention discloses an annular cutting system and a full-automatic foam slicing machine with the annular cutting system. The annular cutting system comprises a band knife support, an annular bandknife device mounted on the band knife support, a band knife operation precision control device and an inching feeding control device. Materials are cut by the annular band knife device through a bandknife, the band knife operation precision control device is used for controlling the stability and the precision of the band knife during cutting, and the inching feeding control device is used for controlling the cutting position of a cutting edge of the band knife. According to the annular cutting system, the annular band knife device operating continuously is adopted for cutting the materials,the operation speed of the annular band knife device and the cutting angle of the cutting edge can be adjusted in the cutting process, slices are uniform, the thicknesses of the slices can be adjusted, cutting surfaces are smooth and flat, the band knife operation precision control device is used for controlling the operation stability and the precision of the band knife, precise, uniform-speed and uniform-thickness cutting is achieved, and the full-automatic foam slicing machine is especially suitable for slicing PMI foam parts.

Owner:佛山市顺德区宇顺新材料科技有限公司

Sliding knife device for automobile inner tire open mill or internal mixer

The invention discloses a sliding knife device for automobile inner tire open mill or internal mixer. The sliding knife device comprises an upper seat or a lower seat. Multiple installation seats are arranged on the upper seat and the lower seat. A sliding knife is arranged in each installation seat. The external sides of the upper seat and the lower seat are provided with a spring seat. The upper seat and lower seat are installed on the front side of the milling roll of an open mill or the front side of the feeding cavity of an internal mixer. The upper seat is also provided with a hydraulic device. The provided sliding knife device can automatically cut through a tape divider; the cutting speed can be guaranteed, at the same time, an output transmission plate is arranged on the internal side of an open mill cavity, and an individual heating mechanism is provided to ensure that discharged materials are not adhered together.

Owner:TIANJIN HUIJIA TIRE

Full-automatic foam thin cutting device

PendingCN111267164AImprove cutting efficiencySimple structureOther manufacturing equipments/toolsGrinding machinesStructural engineeringMechanical engineering

The invention discloses a full-automatic foam thin cutting device. The full-automatic foam thin cutting device comprises a rack, a foam feeding mechanism and a cutting mechanism, wherein the foam feeding mechanism and the cutting mechanism are arranged on the rack; the foam feeding mechanism comprises a feeding base and a driving device for driving the feeding base to move; the cutting mechanism comprises a band knife support, an annular band knife device installed on the band knife support, a band knife operation precision control device and an inching feeding control device; and the annularband knife device uses a band knife to cut a foam part, the band knife operation precision control device controls the stability and precision of the band knife during cutting, and the inching feedingcontrol device controls the cutting position of a band knife cutting edge. According to the full-automatic foam thin cutting device, the continuously running annular band knife is used for cutting the foam part, the running precision of the band knife is controlled, and meanwhile, the band knife and the feeding base are controlled and matched through the inching feeding control device, so that cutting marks are prevented from being left on the cutting surface by a band knife joint, uniform slicing is realized, the cutting surface is smooth and flat, few chips are generated in the cutting process, and environmental protection and health are achieved.

Owner:佛山市顺德区宇顺新材料科技有限公司

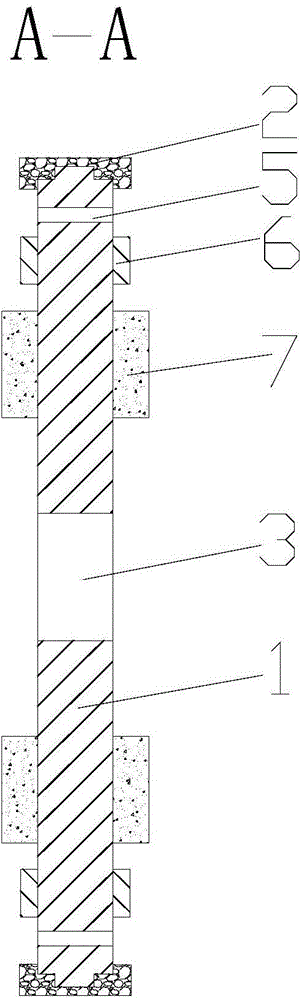

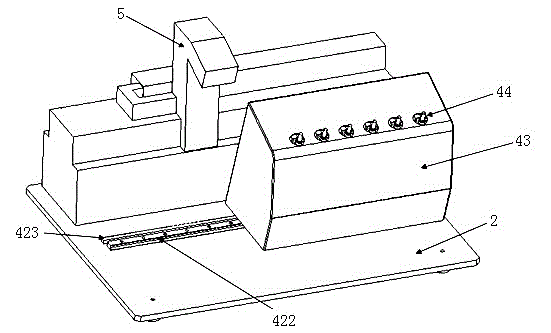

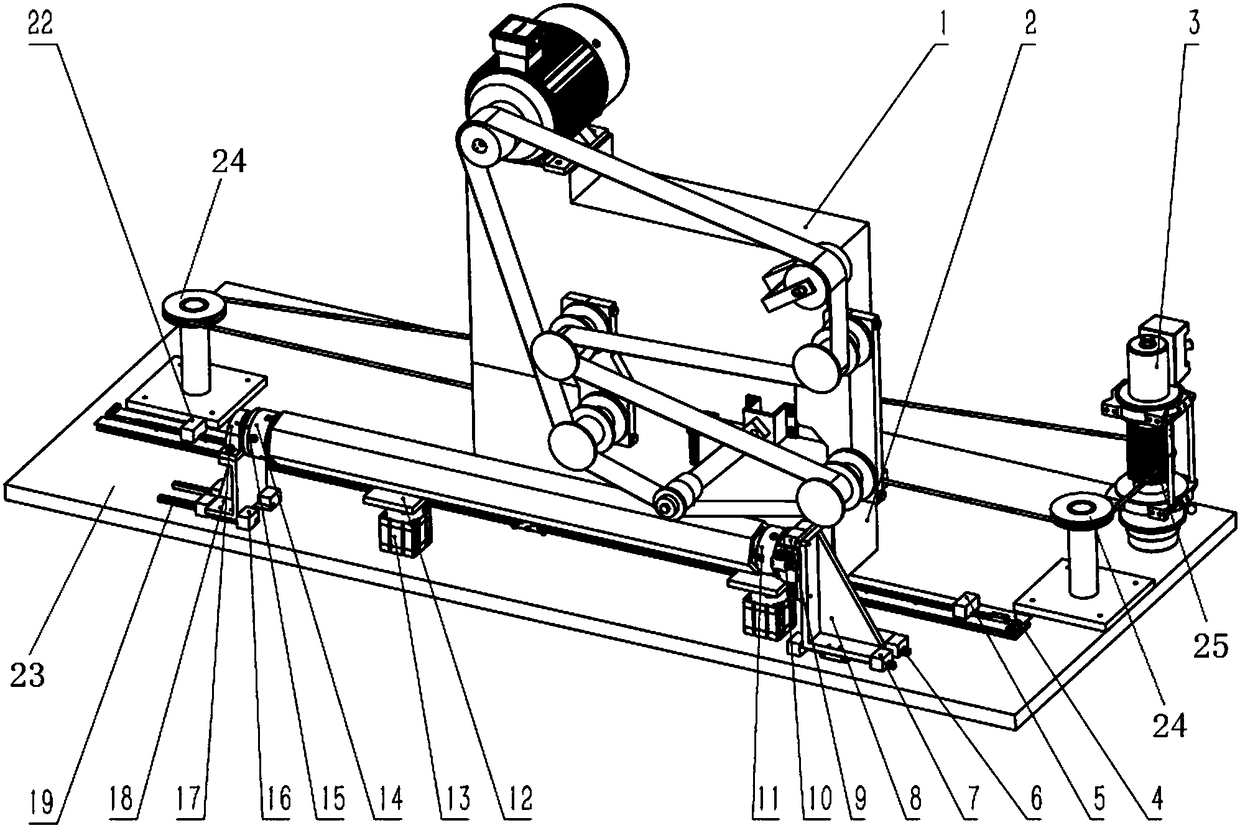

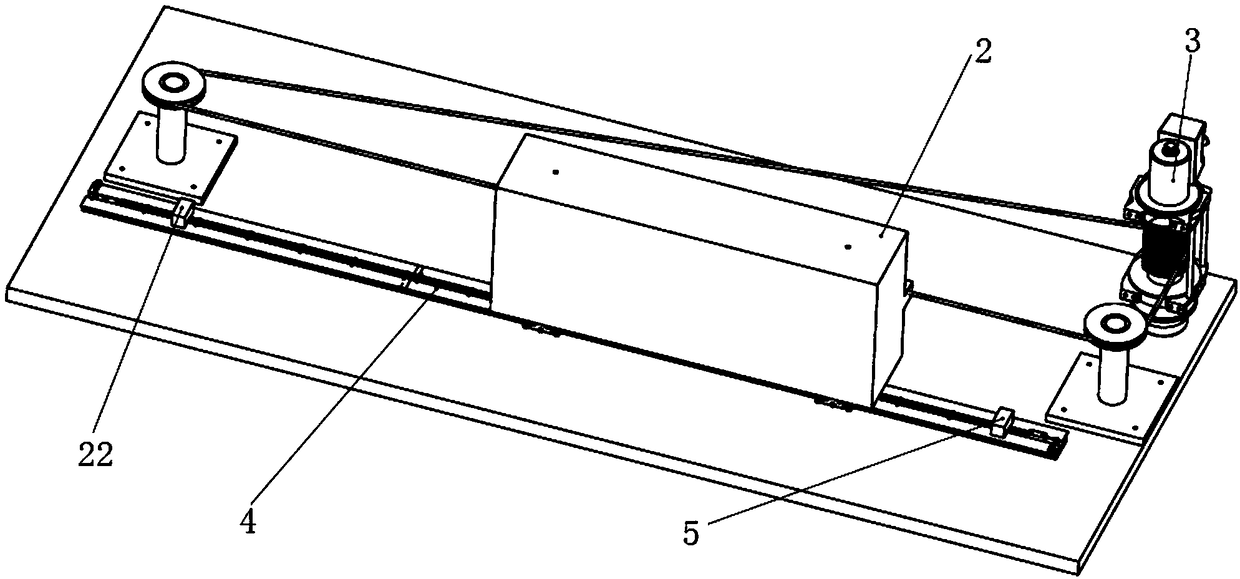

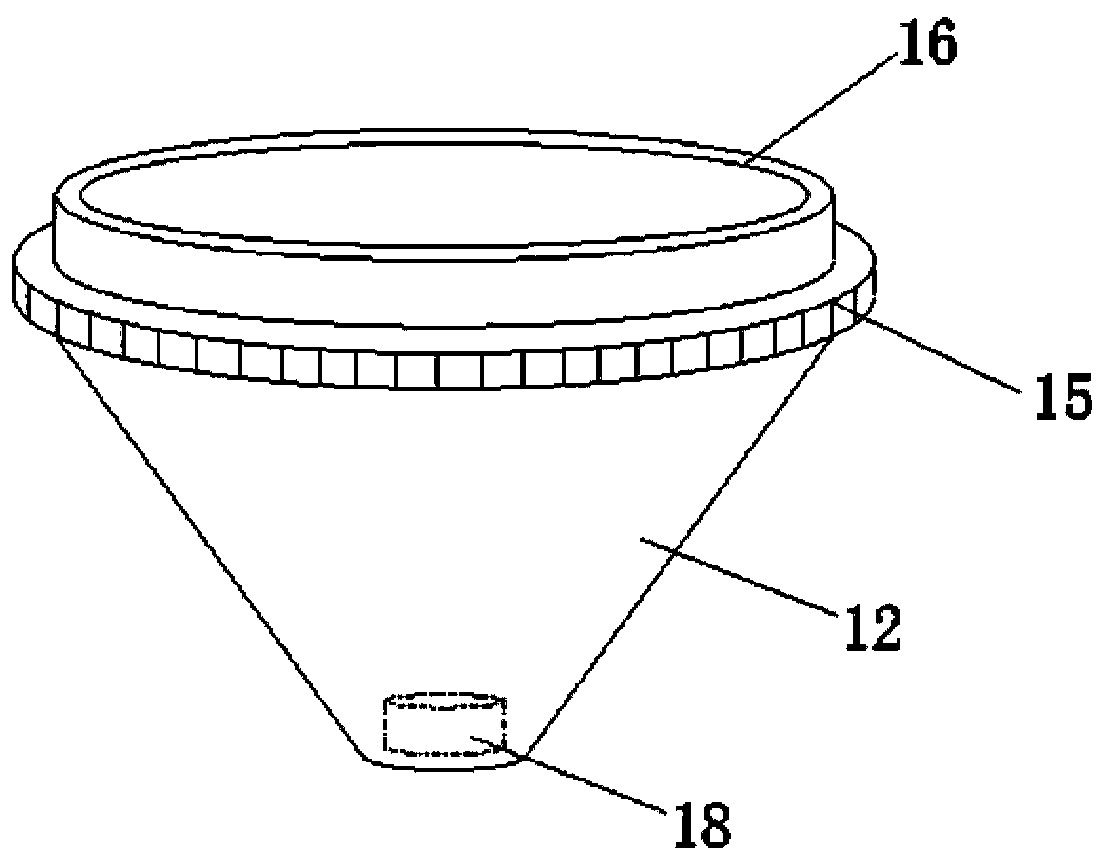

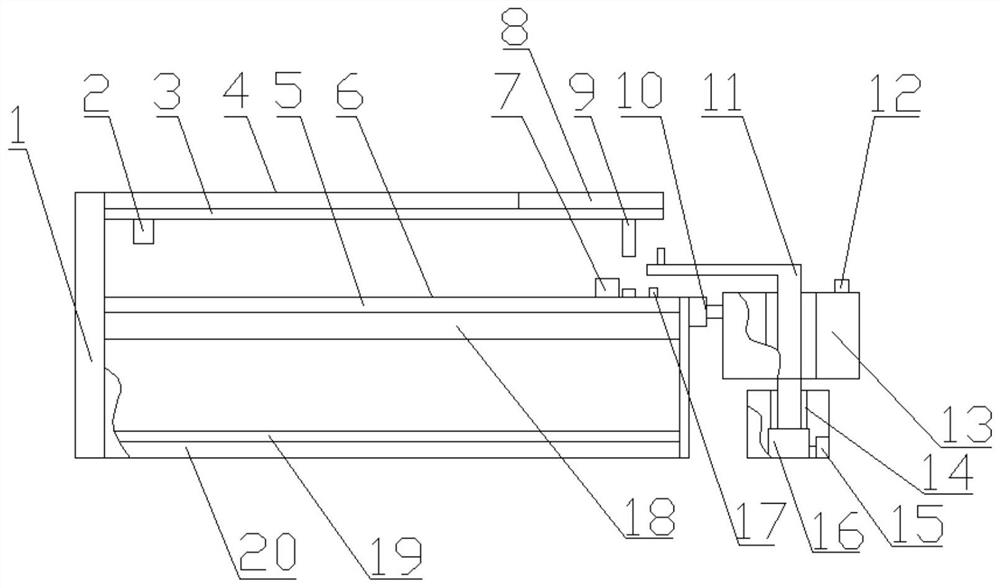

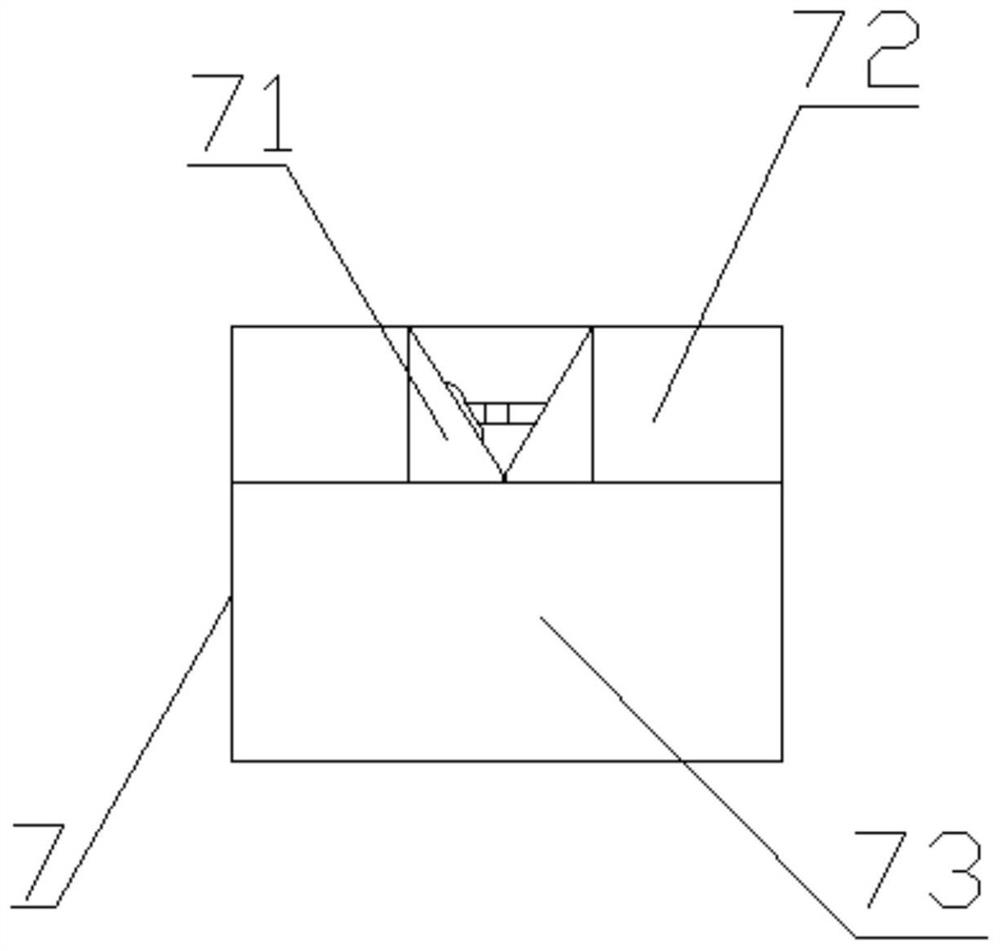

Superhard material nozzle cutting device

ActiveCN103611977BGuaranteed cutting accuracyGuaranteed cutting speedShearing machinesShearing machine accessoriesSuperhard materialEngineering

The invention discloses a superhard material nozzle cutting unit comprising a frame. The frame is provided with a feed disc, a conveyor rail, a cutting blade, a conveyor turnplate, a first drive device and a second drive device, wherein the conveyor rail is used for conveying superhard material and the second drive device is used for controlling the cutting blade to rotate. One end of the conveyor rail is abutted to a discharge hole of the feed disc. The cutting blade is disposed on the side of the other end of the conveyor rail. The conveyor turnplate is hinged to the frame in an up-down turning manner and can be driven by the first drive device to intermittently rotate, adapting to cutting progress of the cutting blade. The outer periphery of the conveyor turnplate is provided with clamp slots at equal intervals. The clamp slots can hold the superhard material on the conveyor rail to cut by the cutting blade every time the conveyor turnplate rotates. The superhard material nozzle cutting unit has the advantages that cutting precision and cutting speed are ensured, operating efficiency is improved, machining quality is good, and machining is safe.

Owner:WUZHOU UNIV

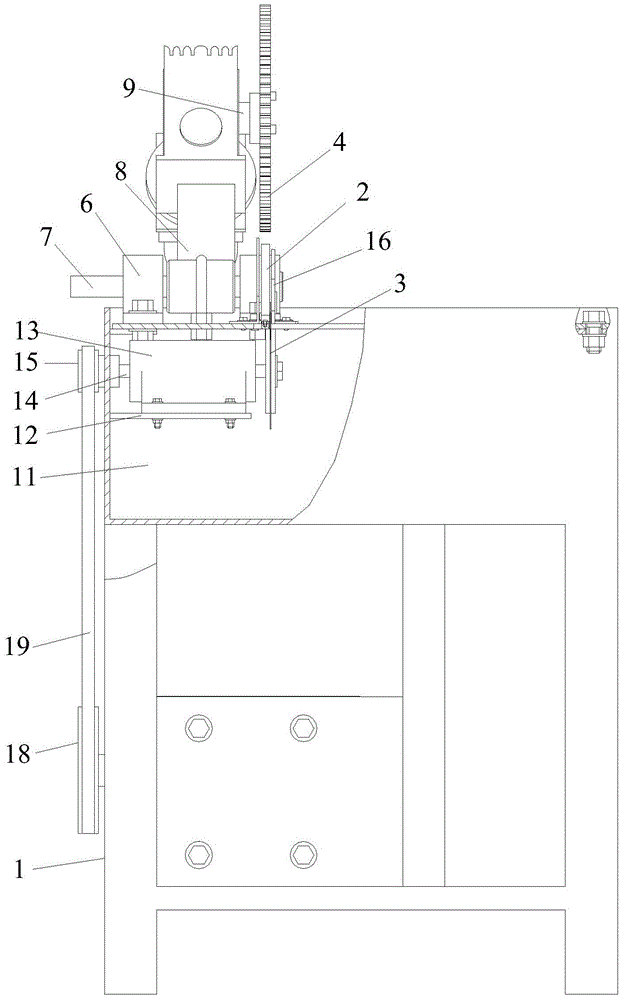

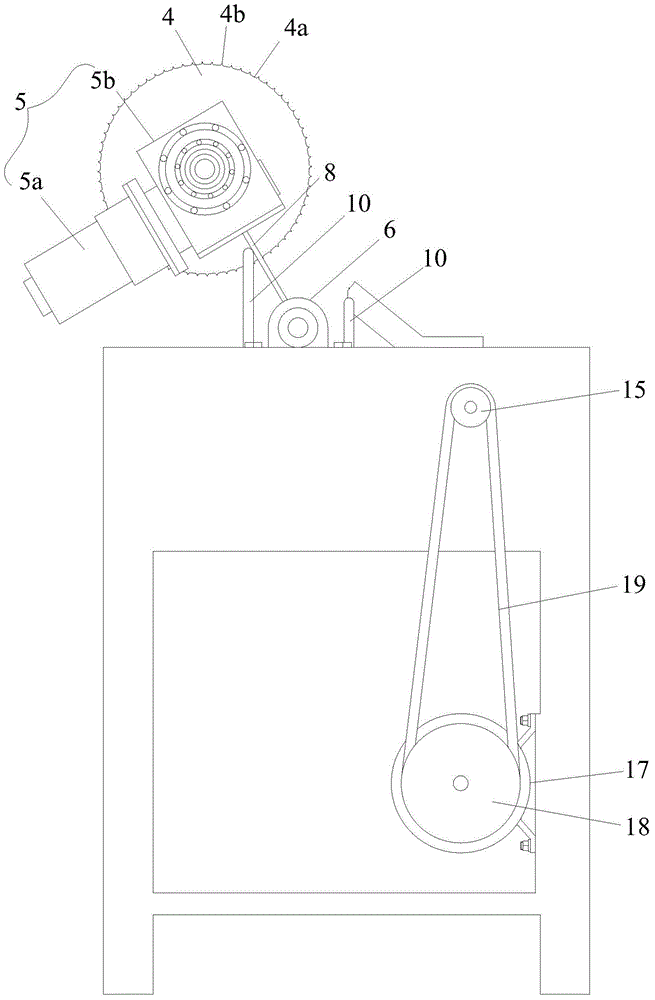

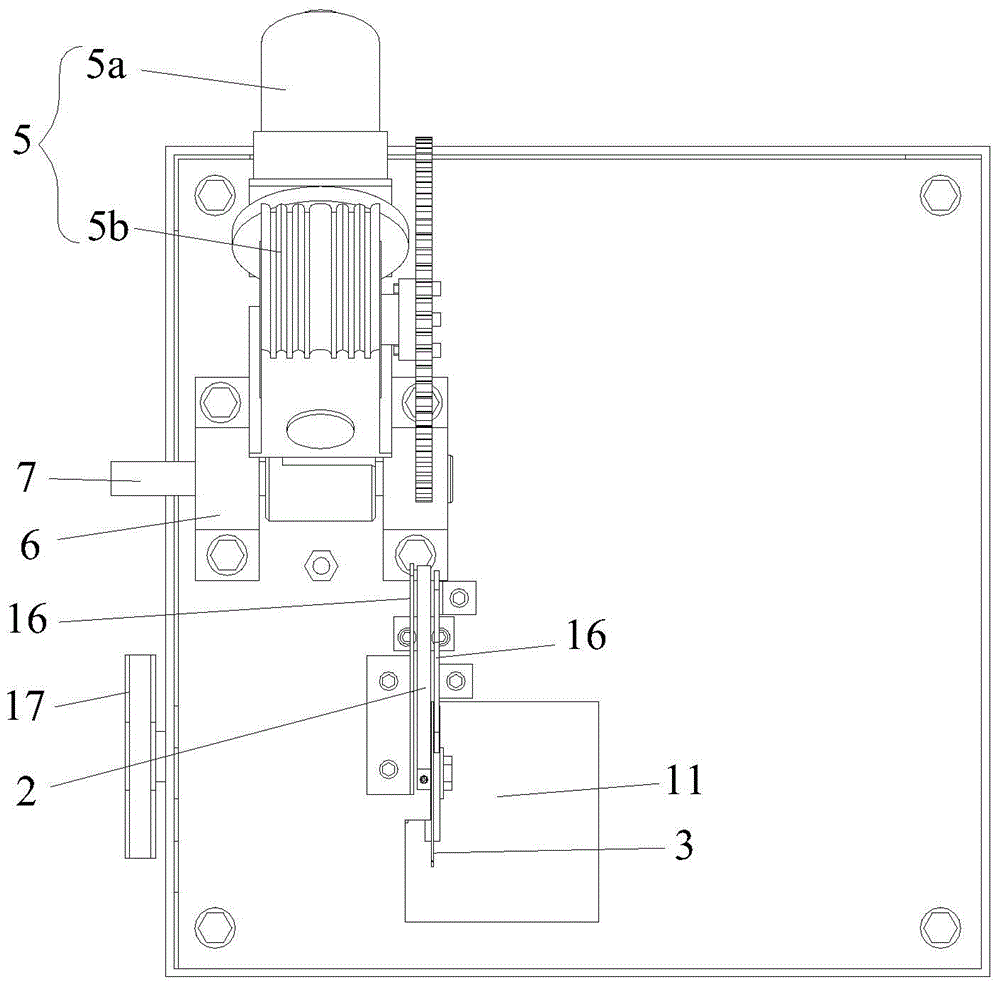

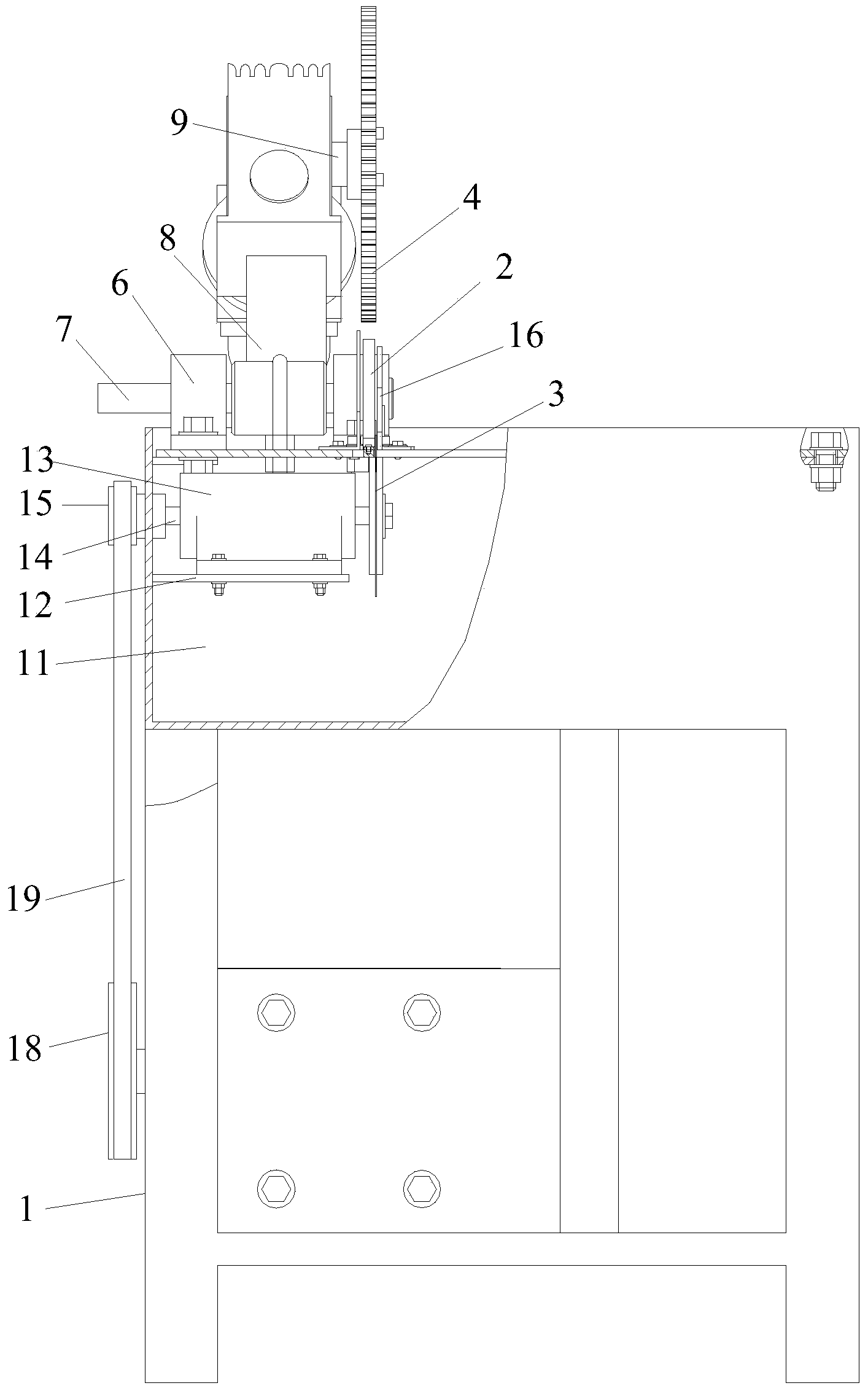

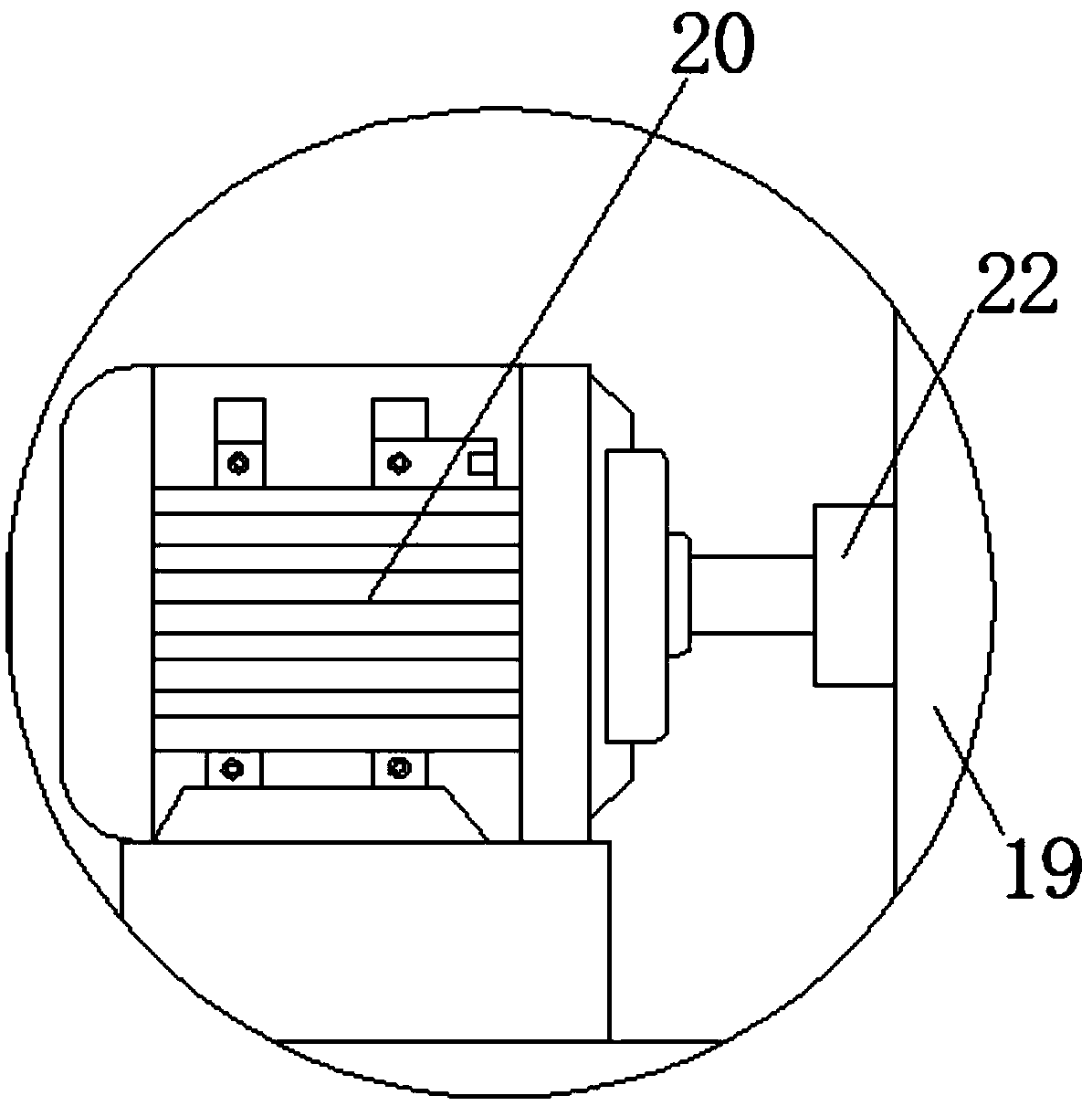

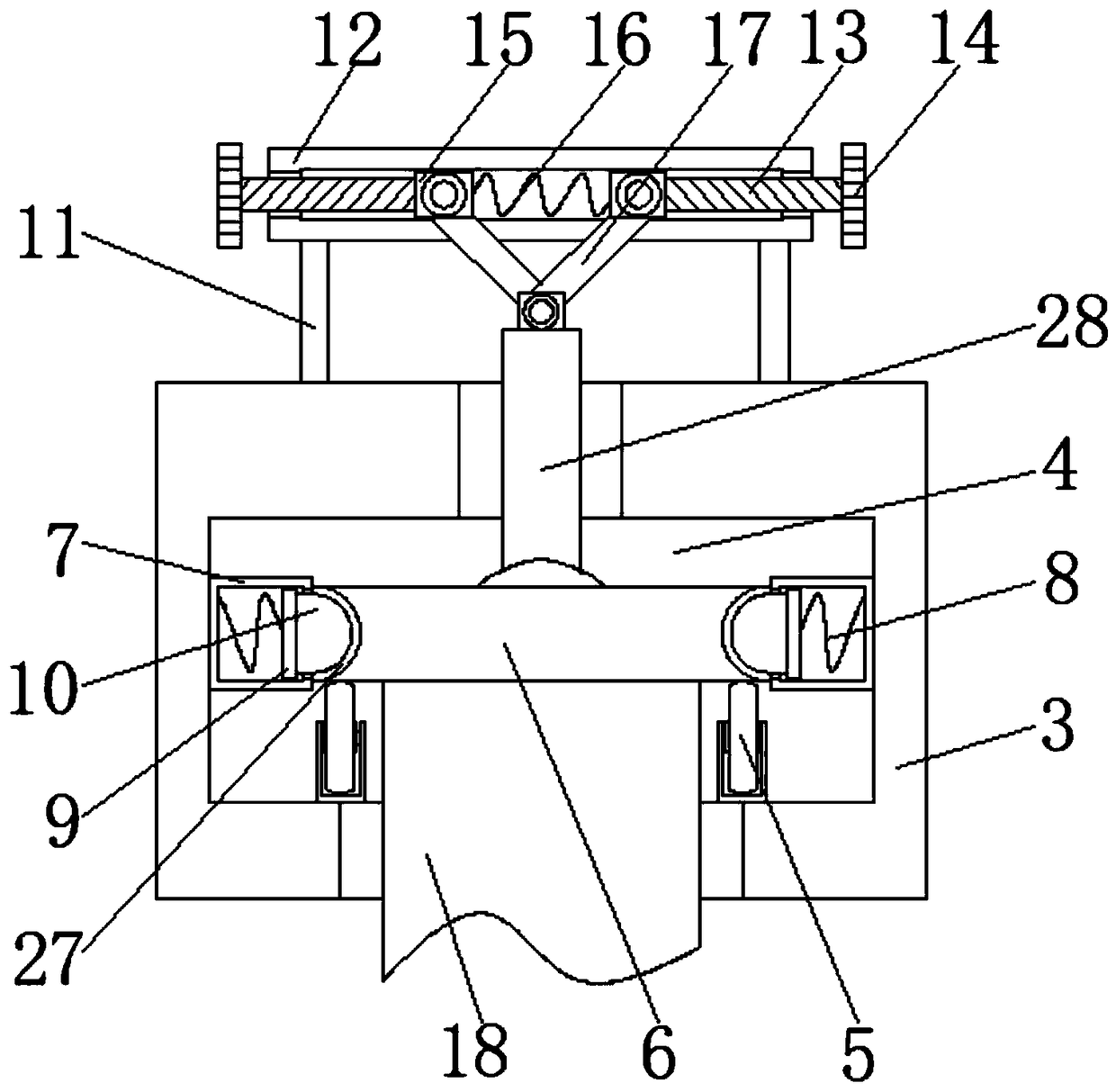

Superhard material nozzle cutting unit

ActiveCN103611977AGuaranteed cutting accuracyGuaranteed cutting speedShearing machinesShearing machine accessoriesSuperhard materialEngineering

The invention discloses a superhard material nozzle cutting unit comprising a frame. The frame is provided with a feed disc, a conveyor rail, a cutting blade, a conveyor turnplate, a first drive device and a second drive device, wherein the conveyor rail is used for conveying superhard material and the second drive device is used for controlling the cutting blade to rotate. One end of the conveyor rail is abutted to a discharge hole of the feed disc. The cutting blade is disposed on the side of the other end of the conveyor rail. The conveyor turnplate is hinged to the frame in an up-down turning manner and can be driven by the first drive device to intermittently rotate, adapting to cutting progress of the cutting blade. The outer periphery of the conveyor turnplate is provided with clamp slots at equal intervals. The clamp slots can hold the superhard material on the conveyor rail to cut by the cutting blade every time the conveyor turnplate rotates. The superhard material nozzle cutting unit has the advantages that cutting precision and cutting speed are ensured, operating efficiency is improved, machining quality is good, and machining is safe.

Owner:WUZHOU UNIV

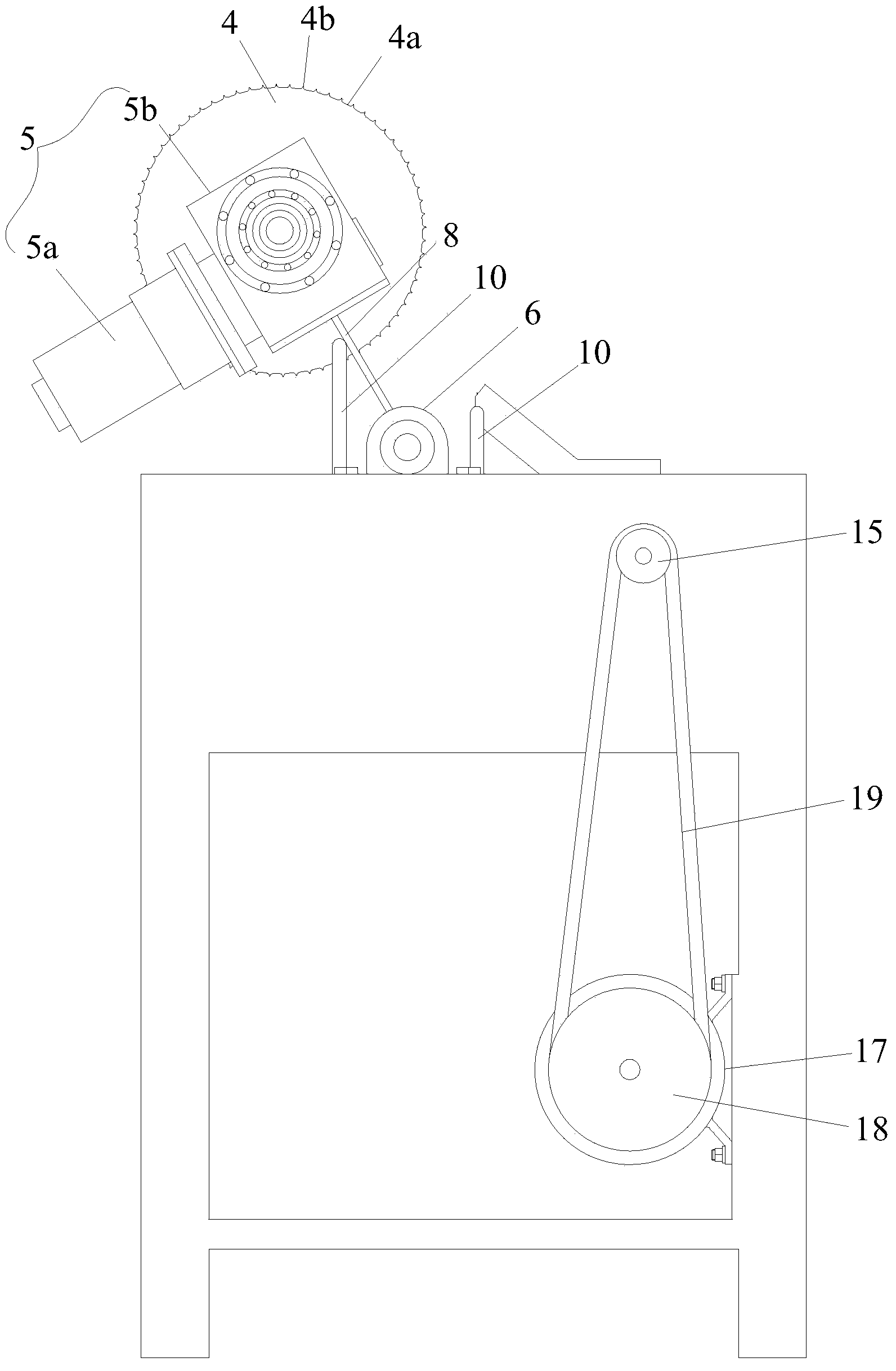

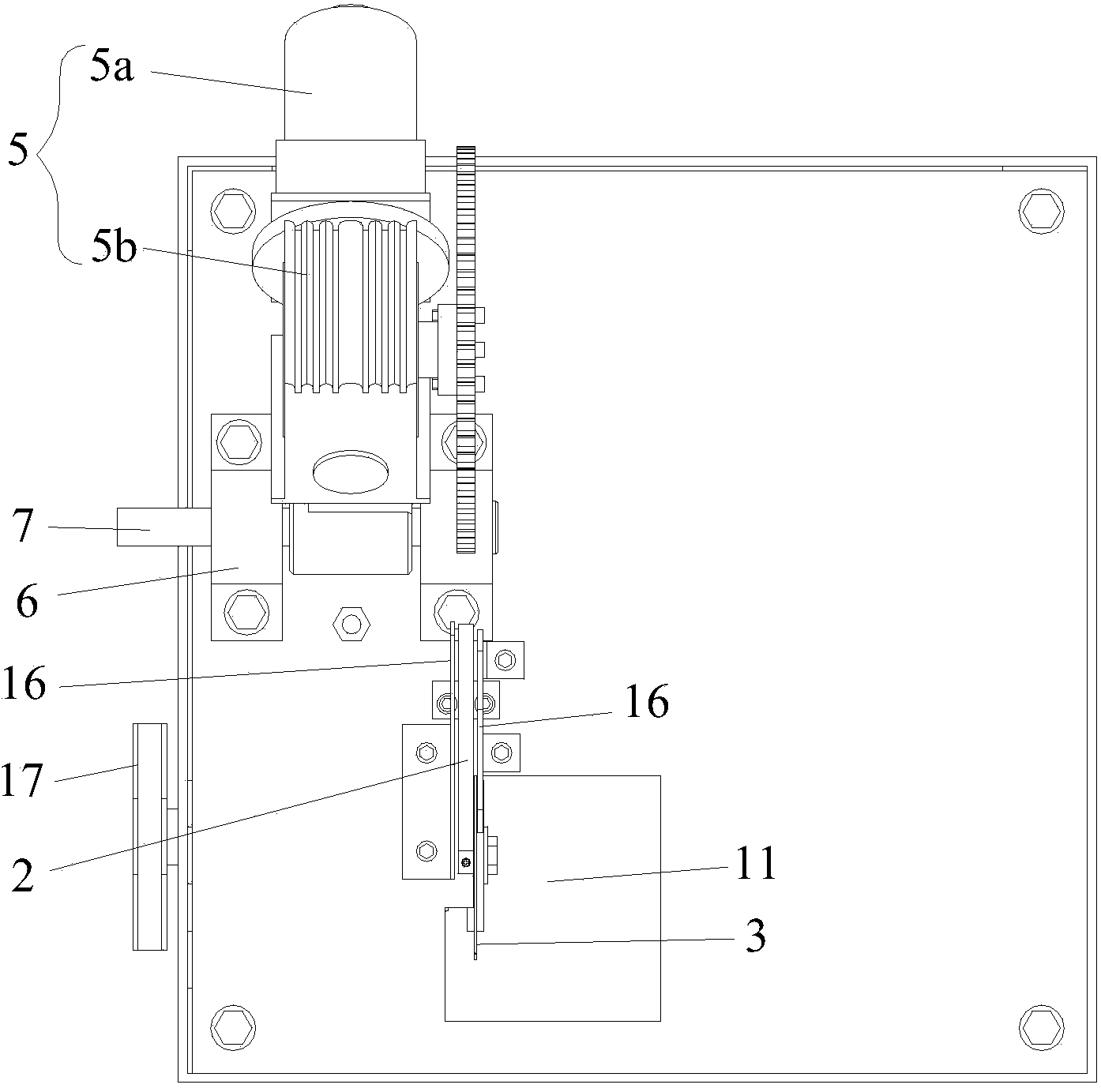

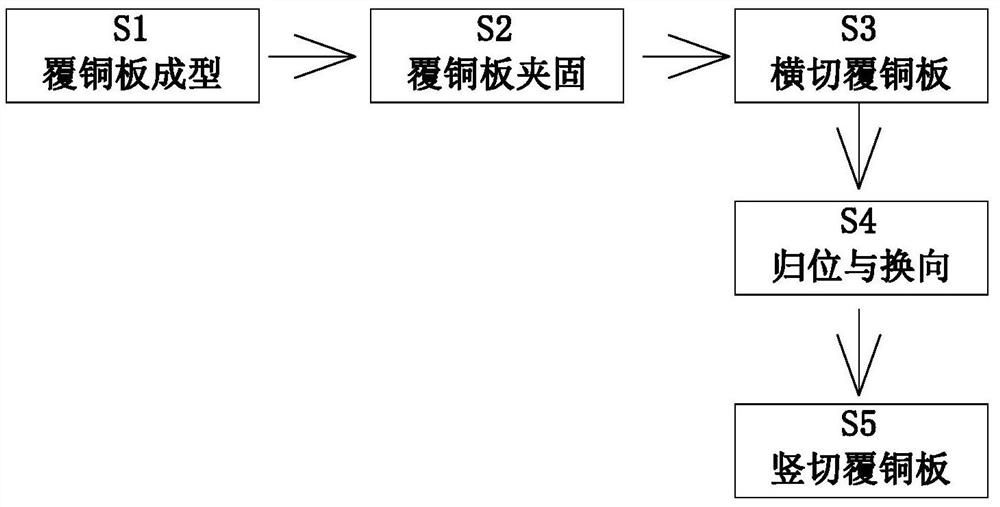

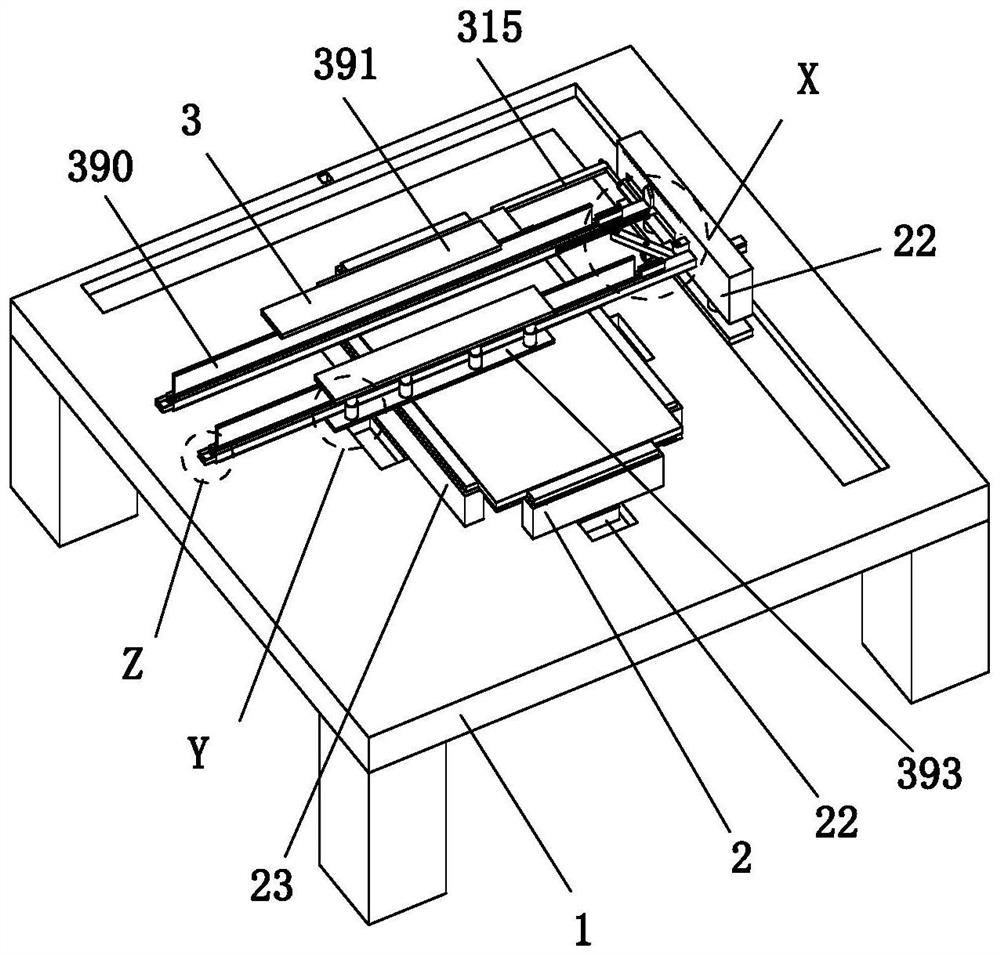

Copper-clad plate production and machining technology

InactiveCN113119176AIncrease diversityImprove cut qualityMetal working apparatusMachining processMachining

The invention relates to a copper-clad plate production and machining technology. A copper-clad plate production and machining device is used, the copper-clad plate production and machining device comprises a workbench, a clamping and fixing mechanism and a shearing mechanism, wherein the workbench is installed on the existing ground, the clamping and fixing mechanism is arranged in the middle of the upper end of the workbench, and the shearing mechanism is arranged above the clamping and fixing mechanism. According to the copper-clad plate production and machining technology, the copper-clad plate is produced and machined by adopting a design concept of combining multiple regulation and control structures, and the shearing mechanism can integrally realize rapid switching between transverse slitting and vertical slitting of the copper-clad plate, so that the diversity of the copper-clad plate machined by the device is greatly improved, meanwhile, the shearing mechanism can achieve edge pressing and slitting guiding and limiting of a slitting point of the copper-clad plate as well, then the overall slitting quality of the copper-clad plate is improved, and the distance between the clamping and fixing mechanism and the shearing mechanism can be adaptively adjusted according to the thickness size of the copper-clad plate.

Owner:王真真

Laser cutting machine cutting head

InactiveCN108817692AExtended service lifeNot easy to wearLaser beam welding apparatusSpray nozzleEngineering

The invention discloses a laser cutting machine cutting head comprising a laser cutting machine cutting head body. The laser cutting machine cutting head body is provided with a focusing lens groove,an incident light groove, a reflecting plate, a servo motor, a ball screw, an amplification controller, a control valve, a first reflecting mirror cooling water sleeve, a pressure gauge, an oxygen inlet pipe, a spraying nozzle, a regulating lens, regulating springs, clamping edges, a connecting head, a second reflecting mirror cooling water sleeve and a liner pipe; and the focusing lens groove ofthe laser cutting machine cutting head body regulates and focuses laser pulses entering the focusing lens groove through a lens in the focusing lens groove, thus energy of a laser pulse signal is enhanced, and finally the laser pulses are sprayed out through the spraying nozzle to cut a workpiece. According to the laser cutting machine cutting head, the spraying nozzle adopts the mode that the liner pipe is arranged in a hole of the spraying nozzle, thus the service life of the spraying nozzle is prolonged, the cutting speed is ensured, meanwhile, the spraying nozzle is not prone to being abraded, and the service time is greatly prolonged.

Owner:PENTA CHUTIAN LASER (WENZHOU) CO LTD

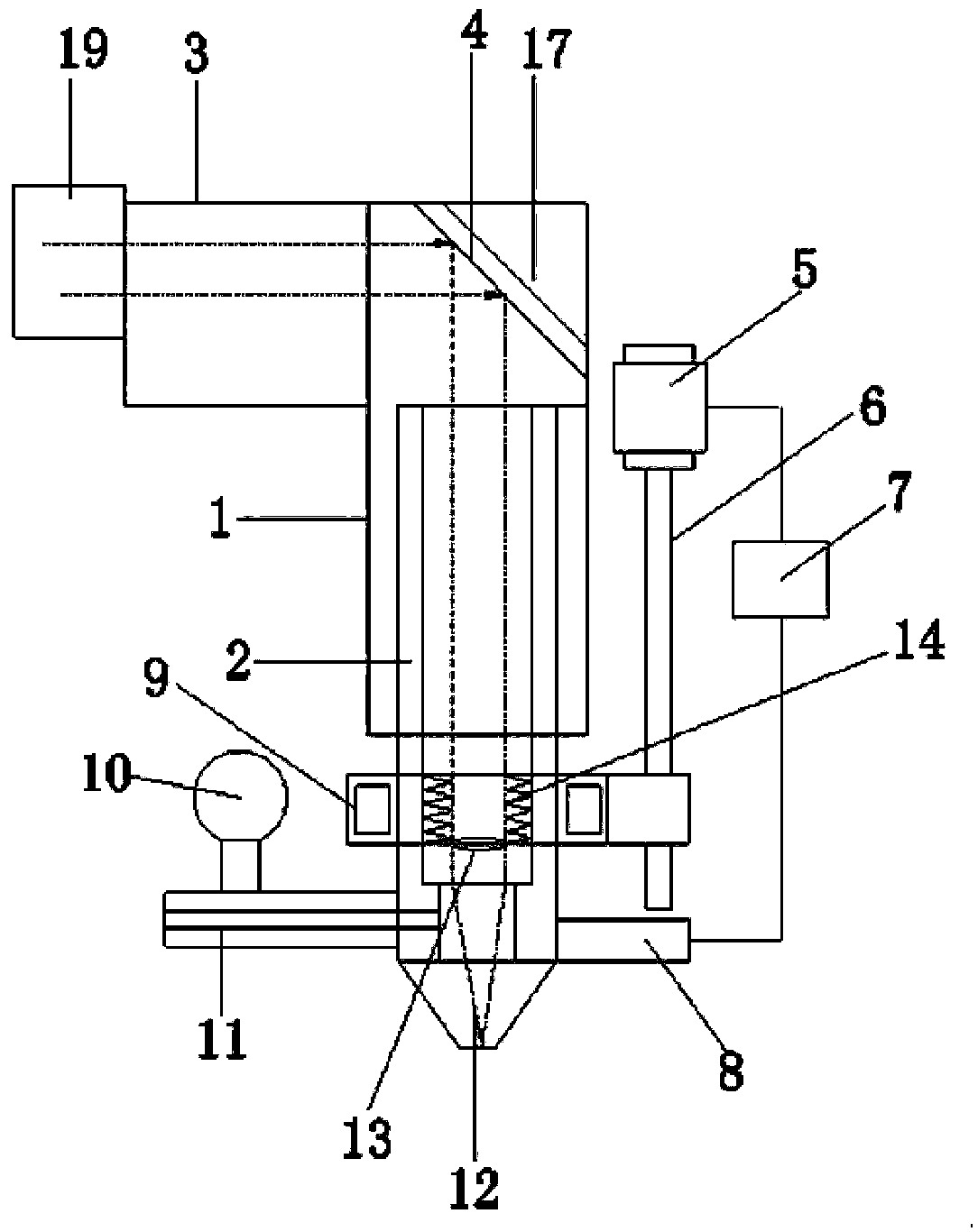

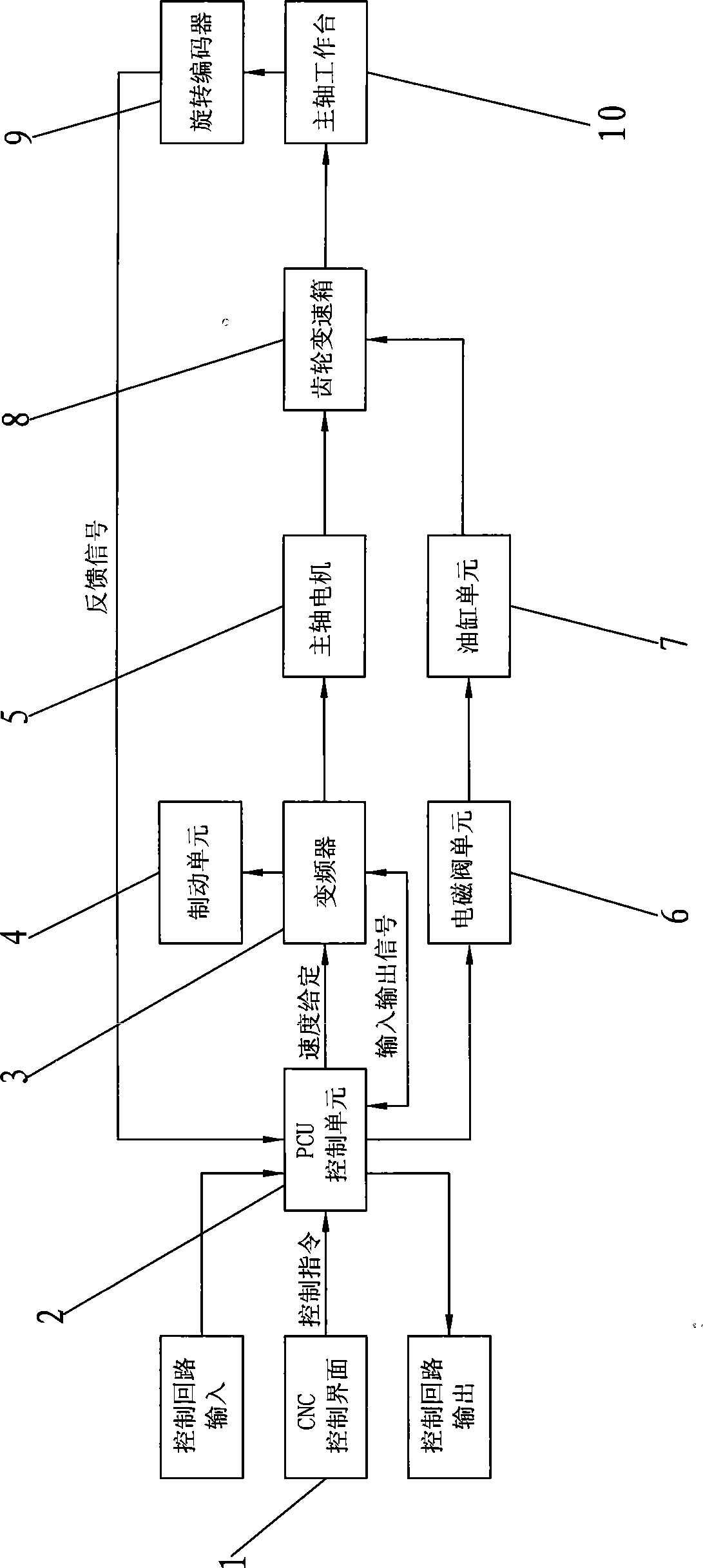

Main spindle transmission control system of economy type numerically controlled lathe

InactiveCN101486106AHigh degree of automationEasy to operateMetal-working apparatusRotary encoderFrequency changer

The invention discloses a main shaft transmission control system for an economic numerically controlled lathe, which comprises a CNC control interface, a PCU control unit, a main shaft motor, a solenoid valve unit, an oil cylinder unit, a transmission gear box and a rotary encoder, wherein the transmission gear box is a transmission gear box which adopts a shifting slide gear and is provided with a shifting fork. The main shaft transmission control system for the economic numerically controlled lathe also comprises a frequency converter and a braking unit, wherein the frequency converter is connected between the output end of the PCU control unit and the input end of the main shaft motor; and the braking unit is connected with a brake control output end of the frequency converter. Compared with the prior art, the main shaft transmission control system for the economic numerically controlled lathe adopts the frequency converter to realize speed regulation of a main shaft; the regulation range of frequency control is wide, and general frequency converters can realize stepless speed regulation within a range between 0 and 400 Hz, so that the main shaft transmission control system can meet the requirements of constant-speed cutting of a numerical control system and stepless speed changing of the rotating speed of the main shaft; and the rotating speed of the main shaft is varied along with the variation of the diameter of the current processing workpiece, so that the cutting linear speed on a cutting point of a tool can be always guaranteed to be constant, and turning technology of large-diameter workpieces can be realized.

Owner:FUJIAN CHENGGONG MACHINE TOOL CO LTD

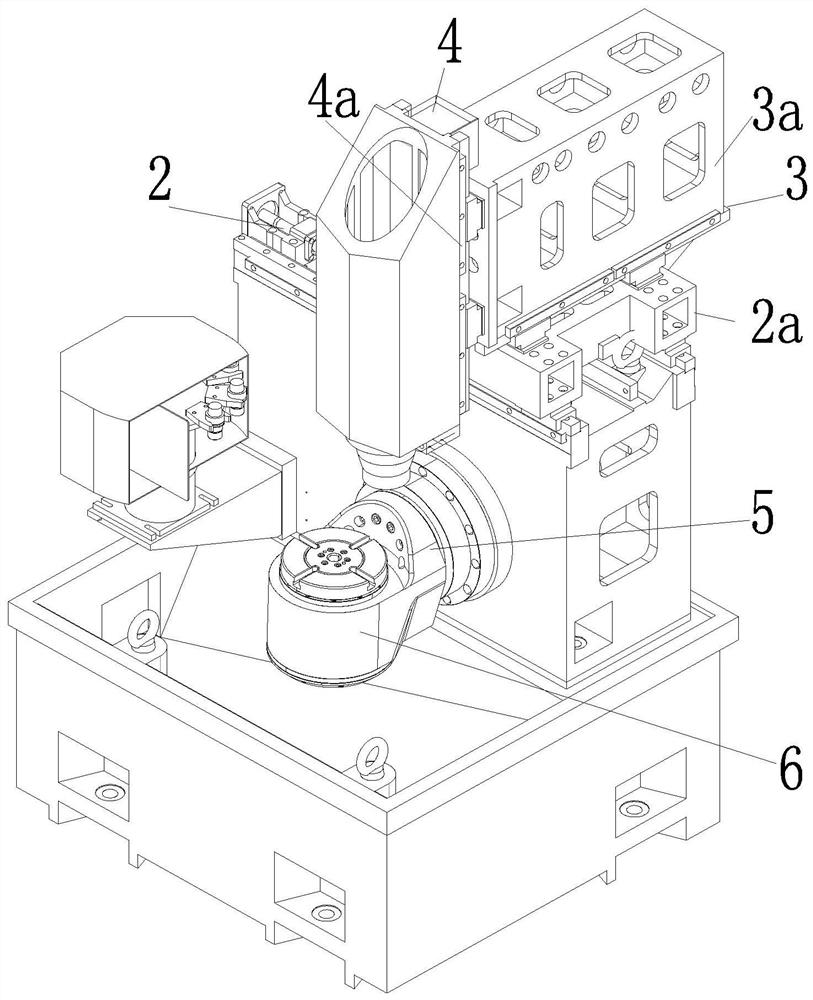

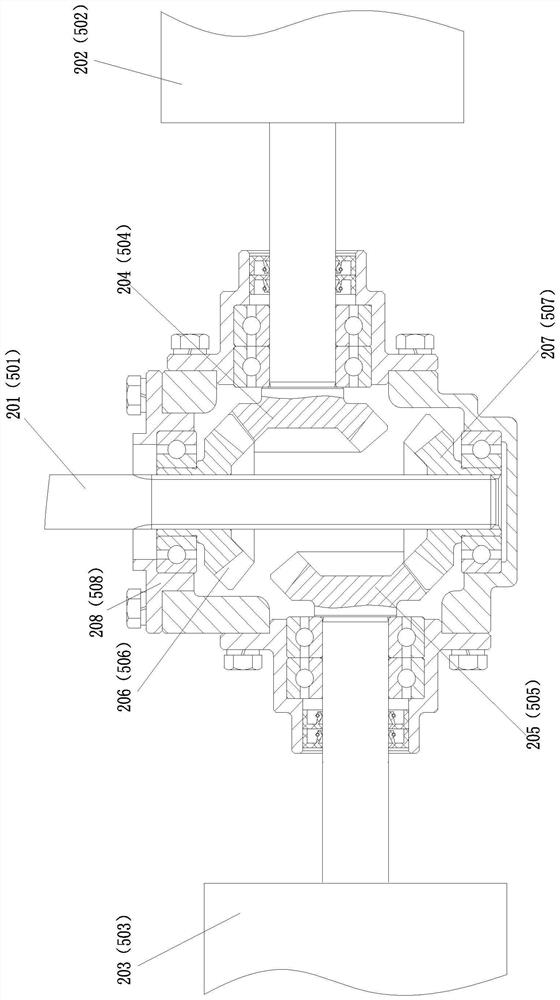

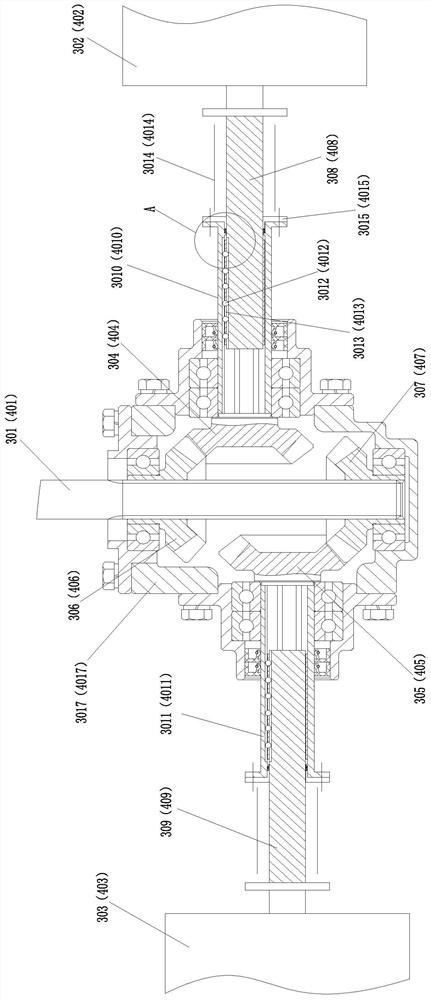

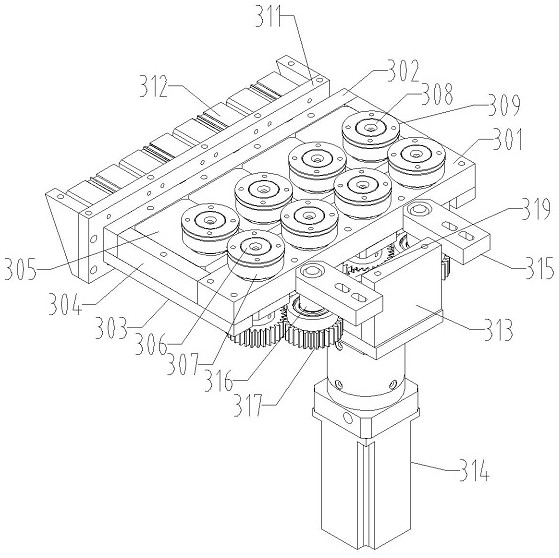

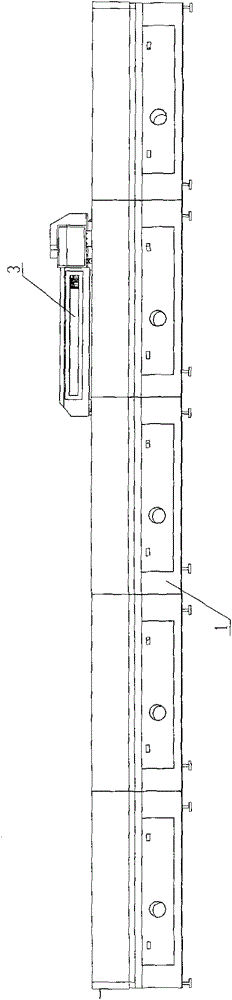

Split transmission five-shaft high-precision machining system

ActiveCN111805284AImprove dynamic characteristicsEliminate hysteresisFeeding apparatusGear wheelMachined surface

The invention discloses a split transmission five-shaft high-precision machining system. A driving motor is independent of a machine tool foundation, and thus a power source and a machine tool body are separated. In addition, single-direction driving adopts a driving mode that double motors are matched with a gear, return difference can be eliminated in the driving process, driving precision is ensured, and meanwhile, vibration generated by operation of the power source (the motors) is prevented from being transferred to a machine tool. After a long period of use, motor driving precision is lowered, precision of linear operation and rotation can be still kept, thus the advantages of the five-shaft machining system such as machining precision are ensured, higher dynamic performance, feed speed and cutting speed can be obtained, better machining surface quality can be obtained, and machining efficiency is improved. Complex curved surface machining of a plurality of planes and various procedures of parts can be completed automatically, efficiently and continuously at high speed with high precision, and the split transmission five-shaft high-precision machining system is suitable for spaceflight, the military industry, automobiles, ships, medical treatment, molds and other fields.

Owner:重庆华中数控技术有限公司 +1

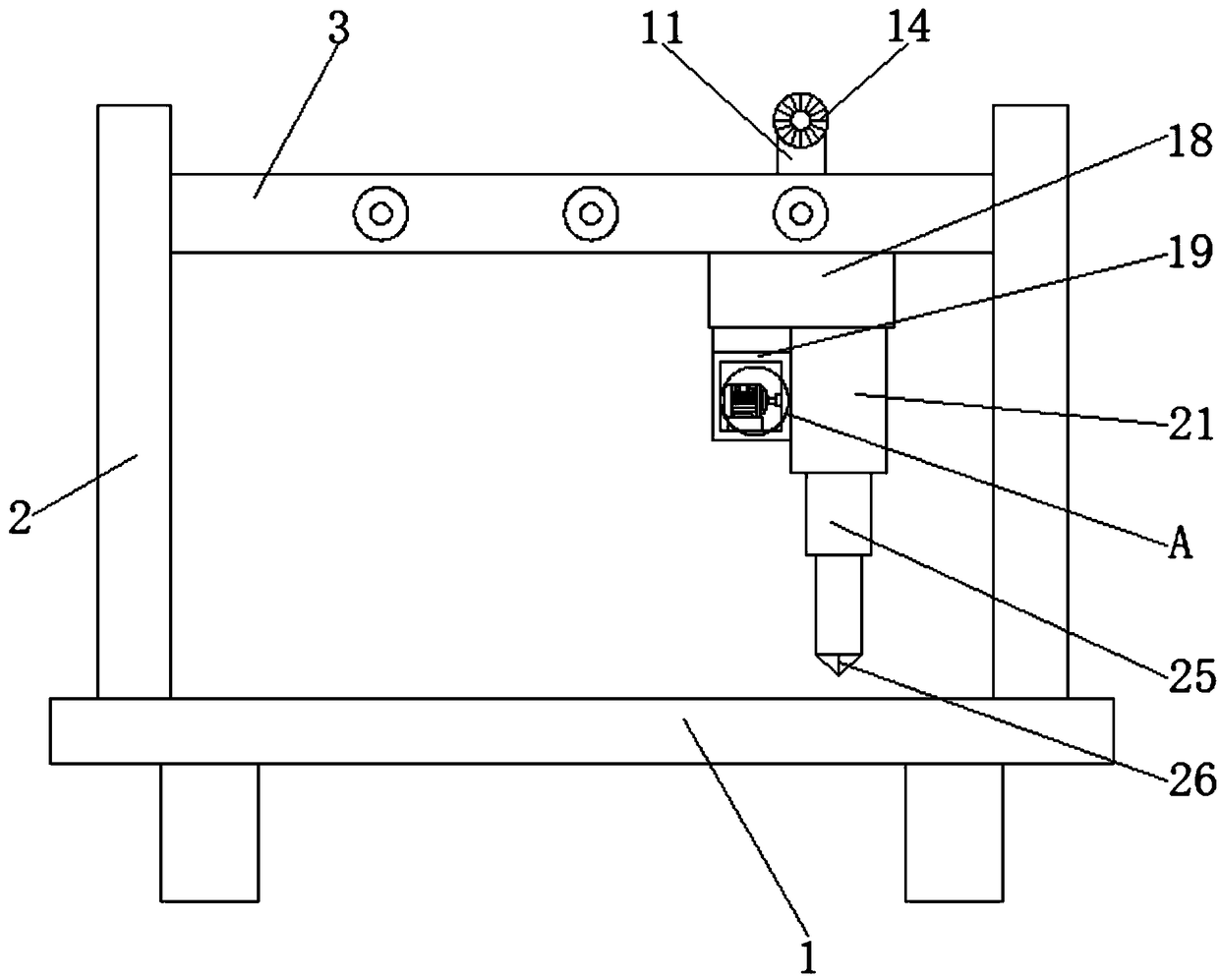

Adjustable printing cutting device

ActiveCN108943053AAvoid clipping inefficienciesGuaranteed cutting speedMetal working apparatusSlide plateComputer engineering

The invention discloses an adjustable printing cutting device. The adjustable printing cutting device comprises a horizontal bottom plate, supporting vertical plates are fixedly connected to two sidesof the top of the horizontal bottom plate, a cutting sliding plate is fixedly connected between two opposite sides of the two supporting vertical plates, a sliding groove is formed in the surface ofthe cutting sliding plate, sliding supporting wheels are fixedly connected to the two sides of the bottom of the inner surface of the sliding groove, the top of each sliding supporting wheel is connected with a supporting groove plate in a sliding mode, fixing grooves are formed in the two sides of each supporting groove plate, and the two sides of the inner surface of the sliding groove are fixedly connected with clamping boxes. The invention relates to the technical field of a printing cutting device. The adjustable printing cutting device solves the problem that in the cutting process, before paper is cut, position of the paper is manually adjusted, and avoids the problems of low cutting efficiency and low cutting qualification rate caused by manual operation of workers, cutting speed after the printing is greatly guaranteed, so the cutting speed and qualification rate are effectively improved.

Owner:吴红燕

2D wire bending machine

PendingCN114406130AHigh alignment accuracyImprove adjustment accuracy and adjustment speedWire cuttingStructural engineering

The invention belongs to the technical field of machining equipment, and particularly relates to a 2D wire bending machine which comprises a supporting seat, a workbench is fixedly connected to the supporting seat, a feeding mechanism, a cutting mechanism and a bending mechanism are sequentially arranged on the workbench, the bending mechanism comprises a bending supporting assembly, a wire limiting device and a wire bending device are installed on the bending supporting assembly, and the wire limiting device is connected with the cutting mechanism. The wire bending device comprises a bending rotating sleeve, at least one bending steel sleeve is arranged on the top face of the bending rotating sleeve, and a bending driving device used for driving the bending rotating sleeve to rotate is arranged on one side of the supporting assembly. Through reasonable design, the structure is reasonable, the wire cutting effect is good, the arc bending part is not prone to abrasion, the arc bending part is convenient to replace, and the wire feeding efficiency is high.

Owner:山东卓维智能装备有限公司

A kind of preparation method of cutting grinding wheel of blue glass infrared cut-off filter

ActiveCN106002650BEasy to controlPromote sheddingAbrasion apparatusGrinding devicesBoron carbideHardness

The invention belongs to a preparation method of an abrasive wheel for cutting of a blue glass infrared cut-off optical filter. Ultrafine-grain-size powder is adopted as raw materials of a metallic bond, better holding force on diamonds is achieved, the service life of the abrasive wheel can be prolonged, and the cutting speed of the abrasive wheel can be increased. By means of the composite mixing process adopting a three-dimensional mixer for premixing and ultrasonic wet mixing, the quality stability of the abrasive wheel and consistency of the cutting performance of the abrasive wheel are guaranteed. A certain amount of boron carbide and a certain amount of titanium diboride are added into the bond, do not participate in sintering and can fall off from the bond in time in the cutting process, and therefore keenness of the abrasive wheel is improved, the stable cutting capacity of the abrasive wheel is improved, and tool repair is avoided in the cutting process; and meanwhile due to the fact that the hardness of the two kinds of matter is high, the cutting assisting effect is achieved, and the cutting capacity of the diamond abrasive wheel is improved. The re-pressing process is adopted, an abrasive wheel blank obtained through hot-pressing sintering is strengthened, and therefore the density, rigidity and strength of the abrasive wheel are improved, and the mechanical performance of the abrasive wheel is further guaranteed.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

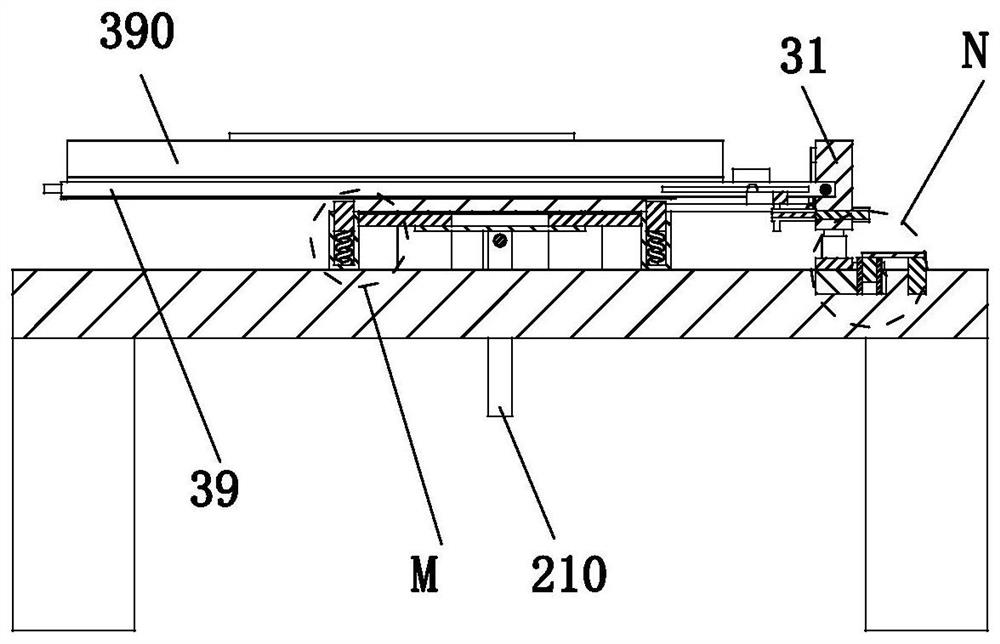

Large-breadth laser cutting machine

InactiveCN103551739AReduce loadDoes not affect the lengthLaser beam welding apparatusEngineeringLaser cutting

A large-breadth laser cutting machine comprises a supporting body, a working table fixed on the supporting body, two first guide rails located on two sides of the working table respectively, a machine frame, a first Y-direction driving device and a second Y-direction driving device, wherein the machine frame comprises two second guide rails, the two second guide rails are installed on the two first guide rails respectively, the machine frame is further provided with a fixing frame, two ends of the fixing frame are fixed on the two second guide rails respectively, a laser tube is installed on the fixing frame, the fixing frame is provided with a beam of a laser head, and two ends of the beam are slidably assembled on the two second guide rails; the first Y-direction driving device drives the machine frame to slide in the Y-direction of the machine frame; and the second Y-direction driving device drives the beam to slide in the Y-direction. An X-direction driving device drives the laser head to move in the X-direction and is light in weight, the load of the driving device is small, and accordingly the processing speed can be improved.

Owner:WUHAN GOLDEN LASER

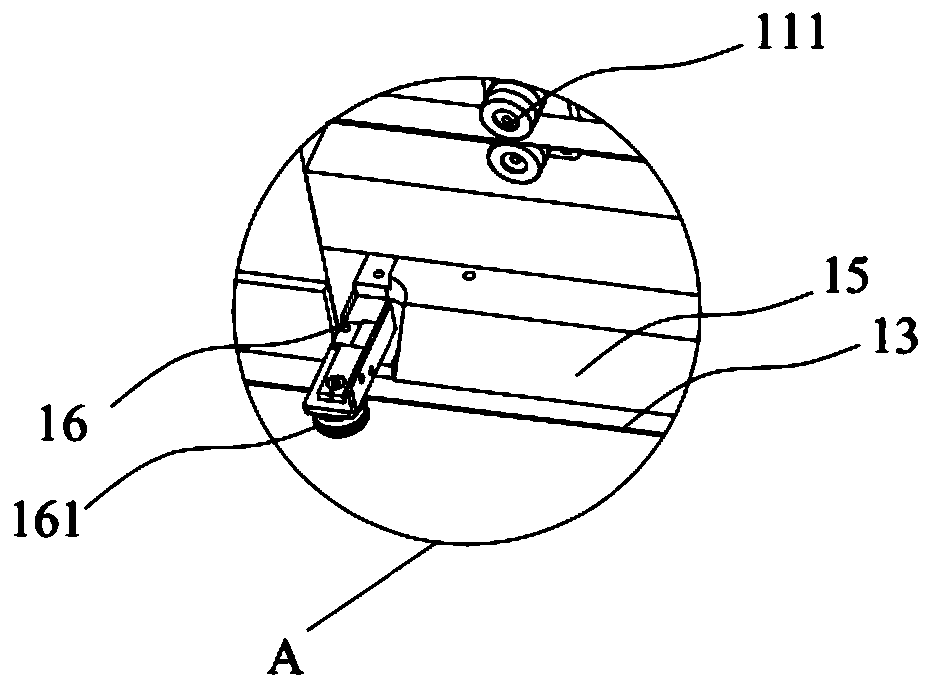

A continuous laser cutting device with dust removal function

ActiveCN104972227BNo sliding frictionAvoid damageMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention belongs to the technical field of laser cutting and particularly relates to a laser continuous cutting device having a dedusting function. The laser continuous cutting device comprises a dedusting mechanism and a laser cutting mechanism. The laser cutting mechanism comprises a laser head and a cushion seat module. The cushion seat module comprises a center shaft, a rotating roller and a fixed roller. The rotating roller and the fixed roller have the same radius, the fixed roller is connected with the rotating roller through the center shaft and is fixed relative to the center shaft, and the rotating roller can rotate relative to the center shaft. When a pole piece is cut, the pole piece adheres to the rotating roller by means of tension provided by mechanical transmission during the feeding, and a to-be-cut pole lug reserved area on the pole piece adheres to the fixed roller. The linear velocity of the rotating roller and the feeding speed of the pole piece are the same, so that no sliding friction occurs between the pole piece and the rotating roller, and the damage to the pole piece caused by the sliding friction between the pole piece and the rotating roller is avoided.

Owner:CONTEMPORARY AMPEREX TECH CO

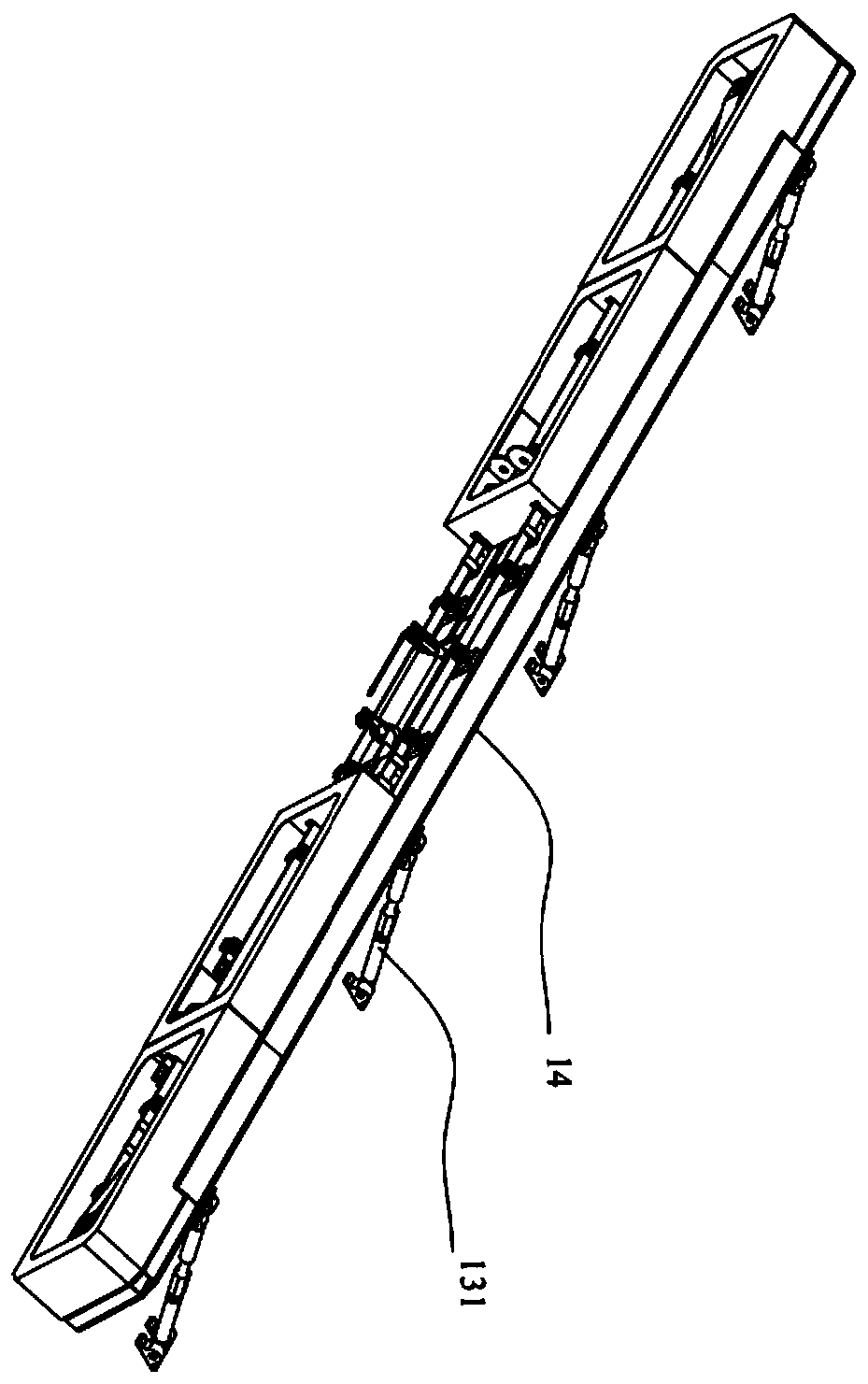

A safety rope double knife hot cutting machine

ActiveCN109465895BGuaranteed cutting speedGuaranteed high speed cuttingMetal working apparatusElectric machineryEngineering

The invention provides a double-knife hot-cutting machine for a safety rope. The double-knife hot-cutting machine comprises a side column, a sensor, a sliding chute, an upper stabilizing column, an arm sliding region, a working region, a mechanical arm, an electric heating plate, hot cutting knives, a connecting telescopic rod, a rope-provided helix, a switch, a helix base region, a rope placing region, a controller, a motor, a second sensor, a transition chamber, a falling chamber and a base; the lower side of one side of the side column is connected with the falling chamber through the base;the transition chamber is arranged above the falling chamber; the arm sliding region is arranged above the transition chamber; the working region is arranged at the surface of the arm sliding region;the mechanical arm is arranged at the rear end of the arm sliding region; and the second sensor is arranged behind the mechanical arm. The double-knife hot-cutting machine provided by the invention is beneficial for improving the work efficiency of the device by arranging the hot cutting knives, the rope-provided helix and the rope placing region, guarantees the work smoothness of the device andprovides a totally new experience of hot cutting for a user.

Owner:杭州腾力工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com