Patents

Literature

91results about How to "No sliding friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

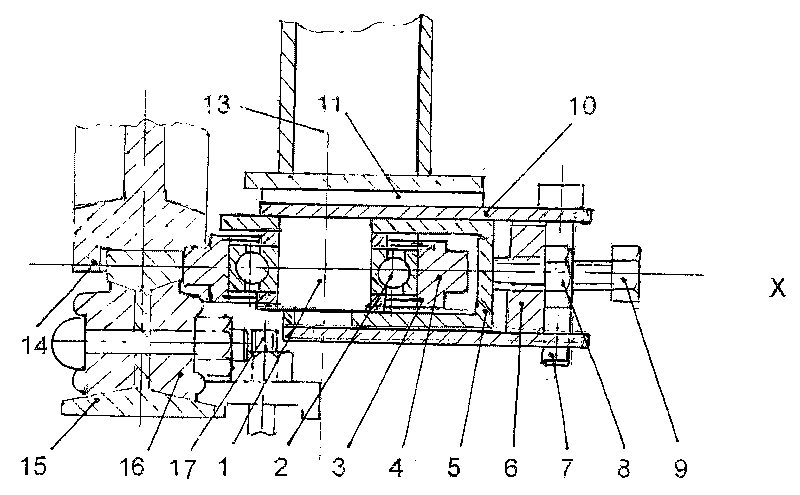

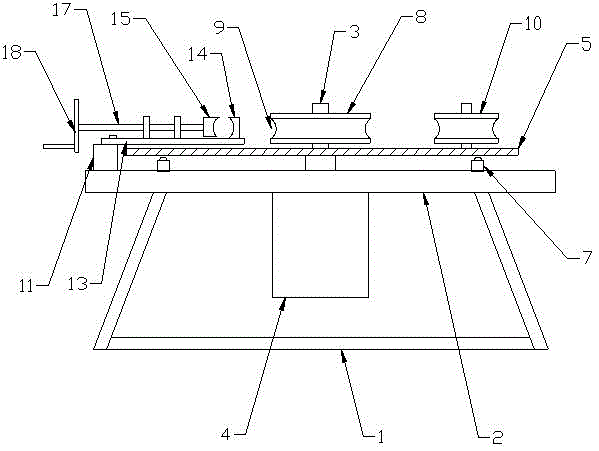

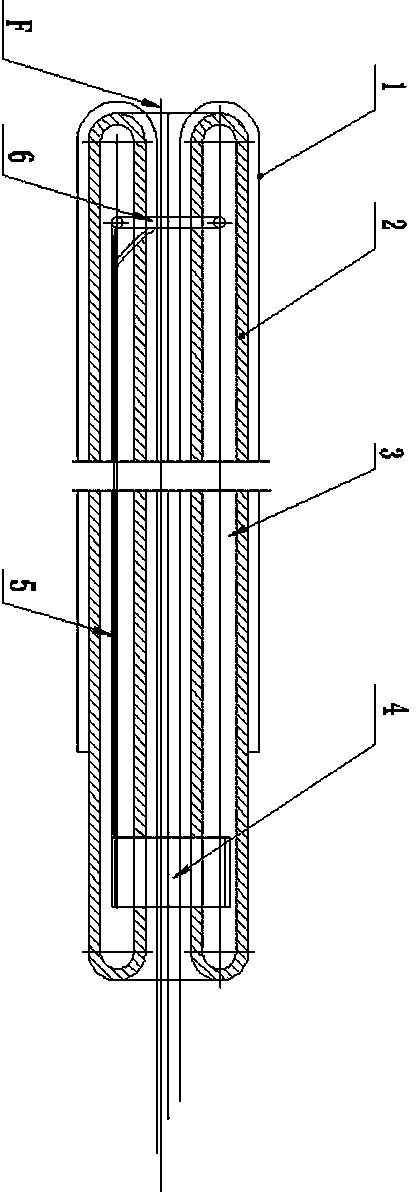

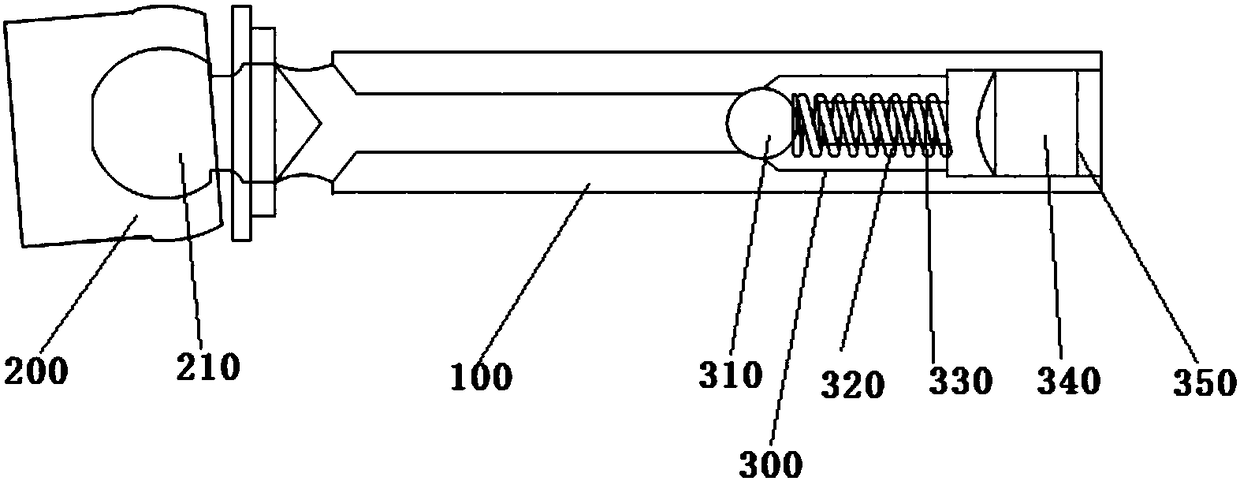

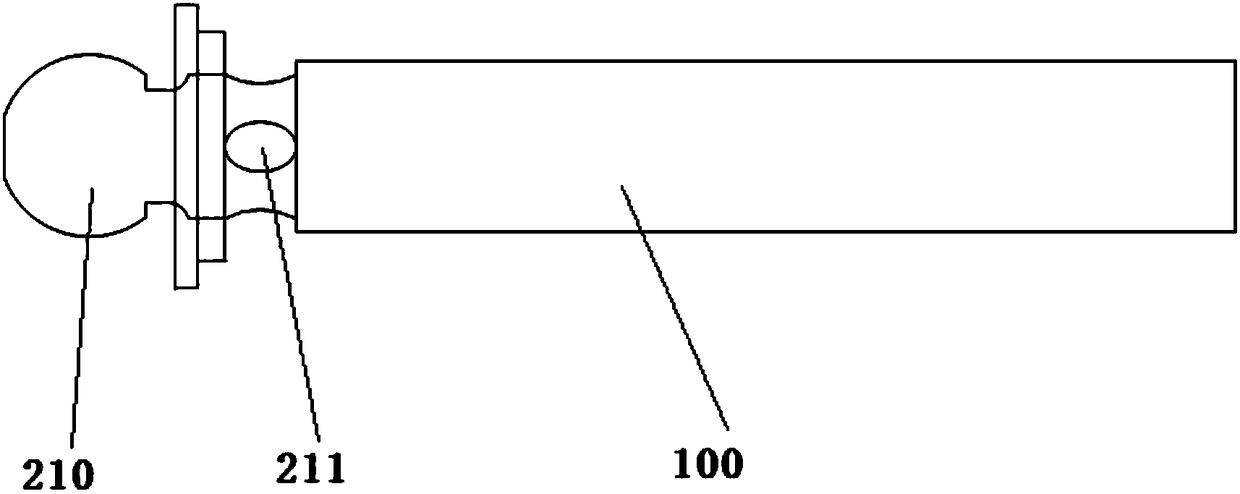

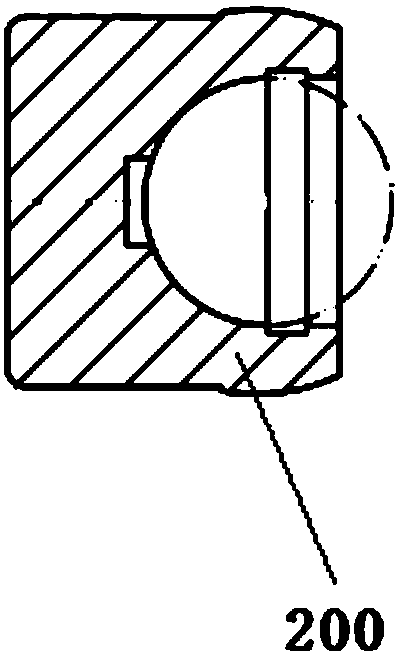

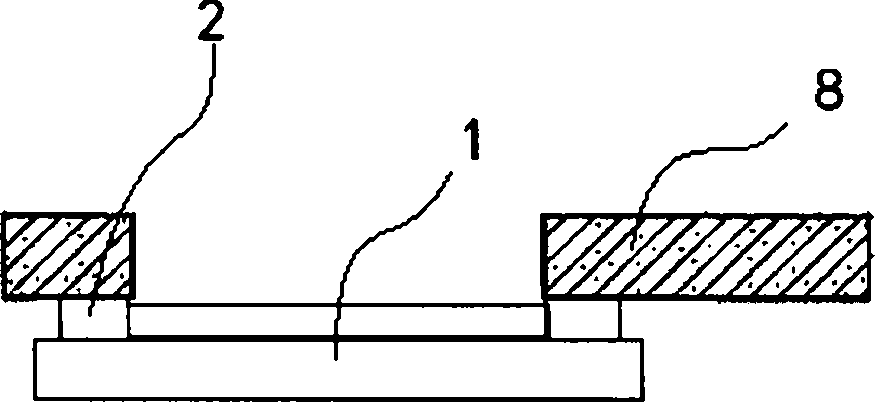

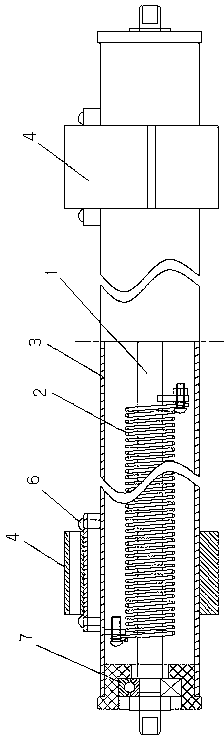

Device capable of elastically clamping two ends of long hole

InactiveCN102069207AEasy to removeRemove effectiveExpansion mandrelsProcess qualityMechanical engineering

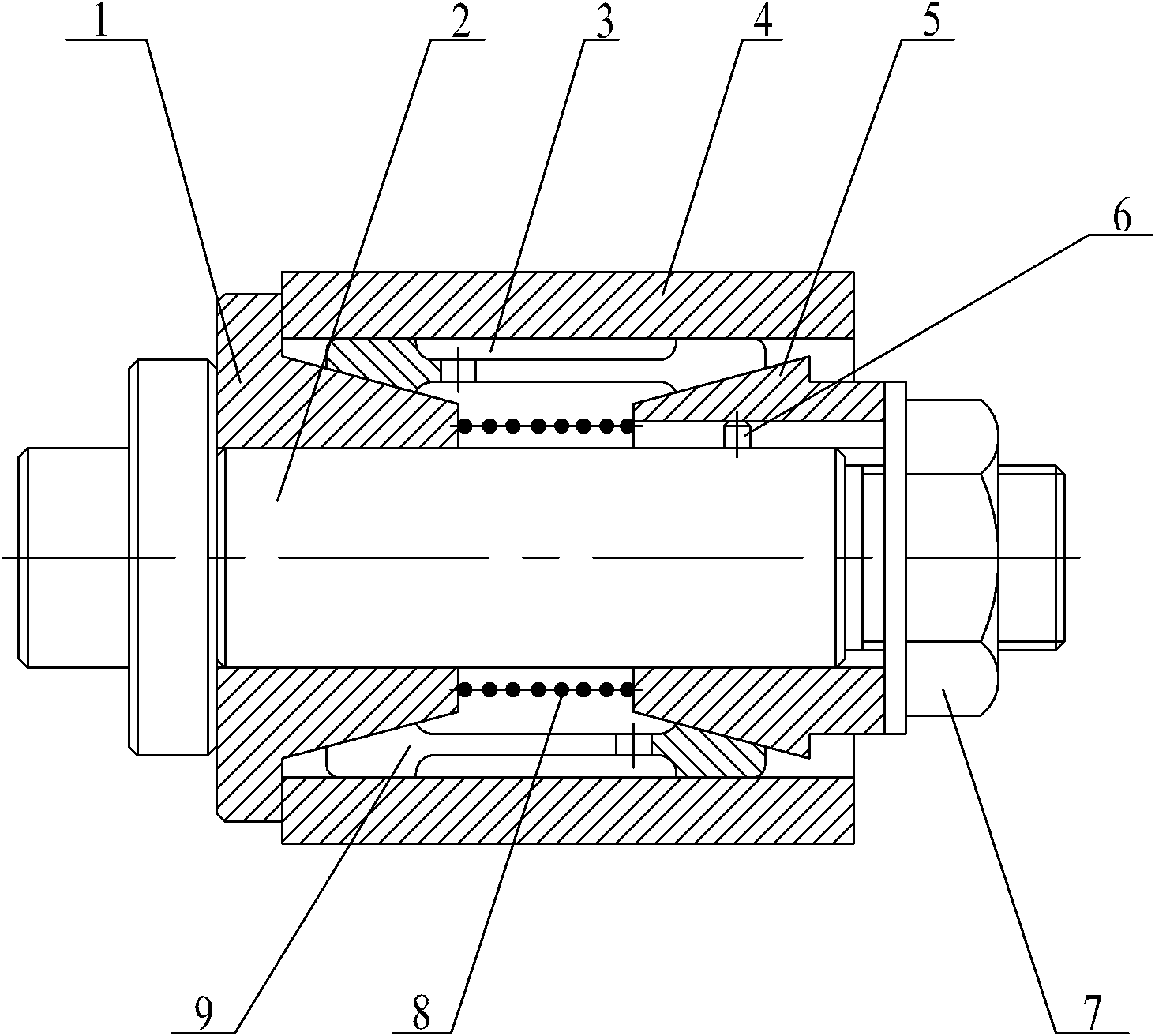

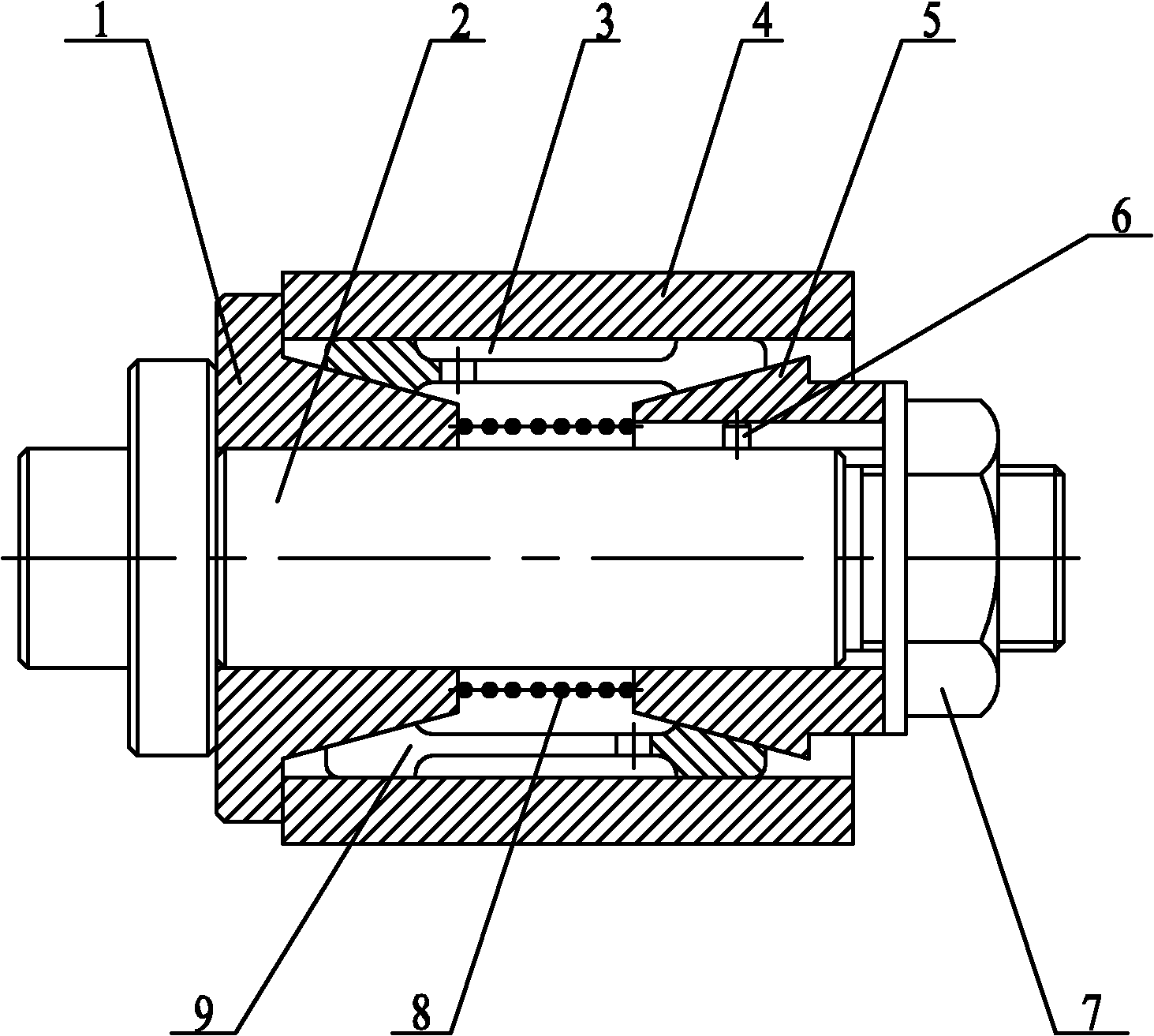

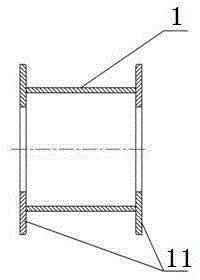

The invention relates to a device capable of elastically clamping two ends of a long hole. The device comprises a central spindle, wherein a left taper sleeve is arranged at one end of the central spindle, and a right taper sleeve is arranged at the other end; elastic clamping heads are arranged at correspondingly connected ends of the left taper sleeve and the right taper sleeve; a plurality of flexible open slots are evenly distributed on peripheral surfaces of the elastic clamping heads; and the ends of the left and right taper sleeves connected with the elastic clamping heads are both extended into the elastic clamping heads. The elastic clamping device provided by the invention is simple in structure and low in manufacturing cost and has the following advantages: when a locknut is screwed, the right taper sleeve can be pushed to move to cause the elastic clamping heads to extend outwardly, thus achieving the purpose of fastening and installing a workpiece; in addition, when the locknut is loosened, the elastic clamping heads shrink and the processed workpiece is convenient to remove; the workpiece is fixed effectively and reliably, and the stability of process quality is improved greatly; since the elastic clamping heads have low requirements on hole tolerance of a blank to be processed, the manufacturing cost is reduced; since the elastic clamping device provided by the invention is convenient to clamp, the work efficiency is improved greatly; and the elastic clamping device provided by the invention has a wide application scope and longer service life because of no sliding friction.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

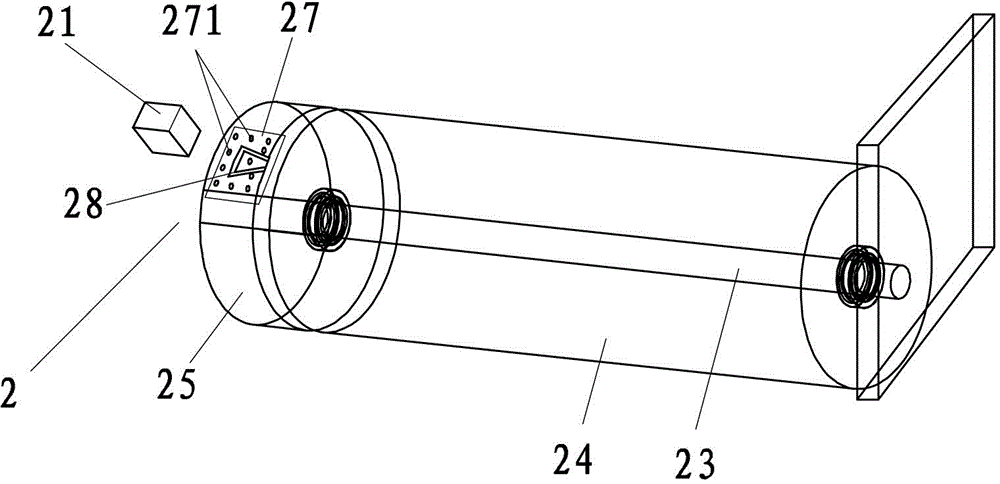

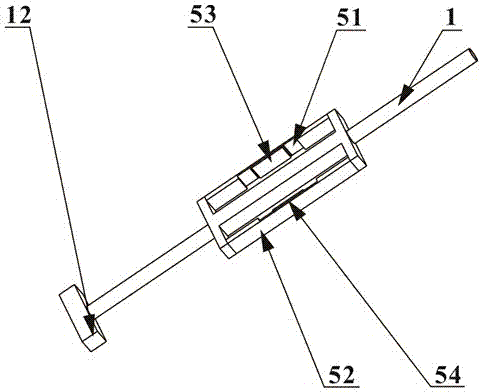

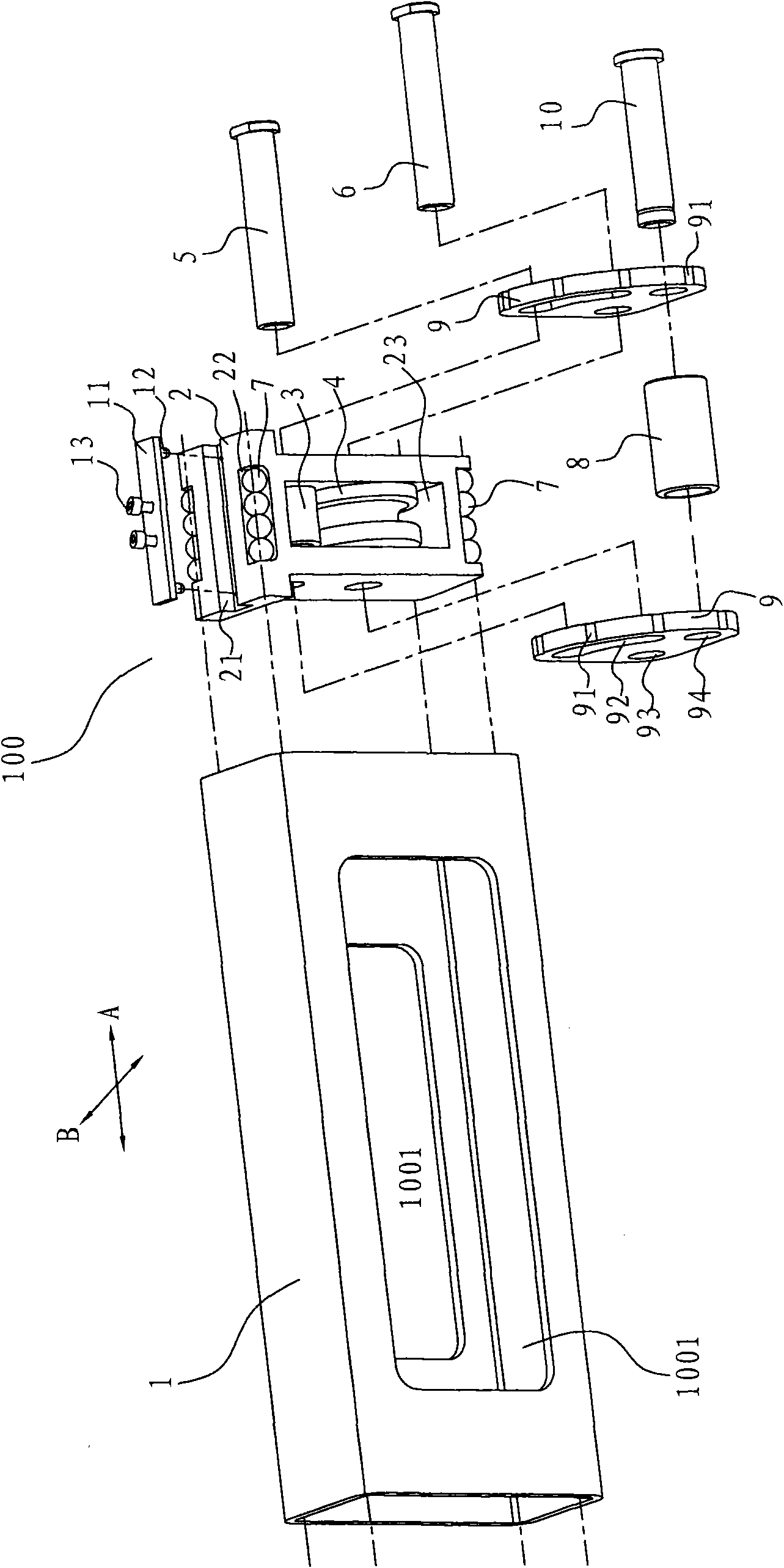

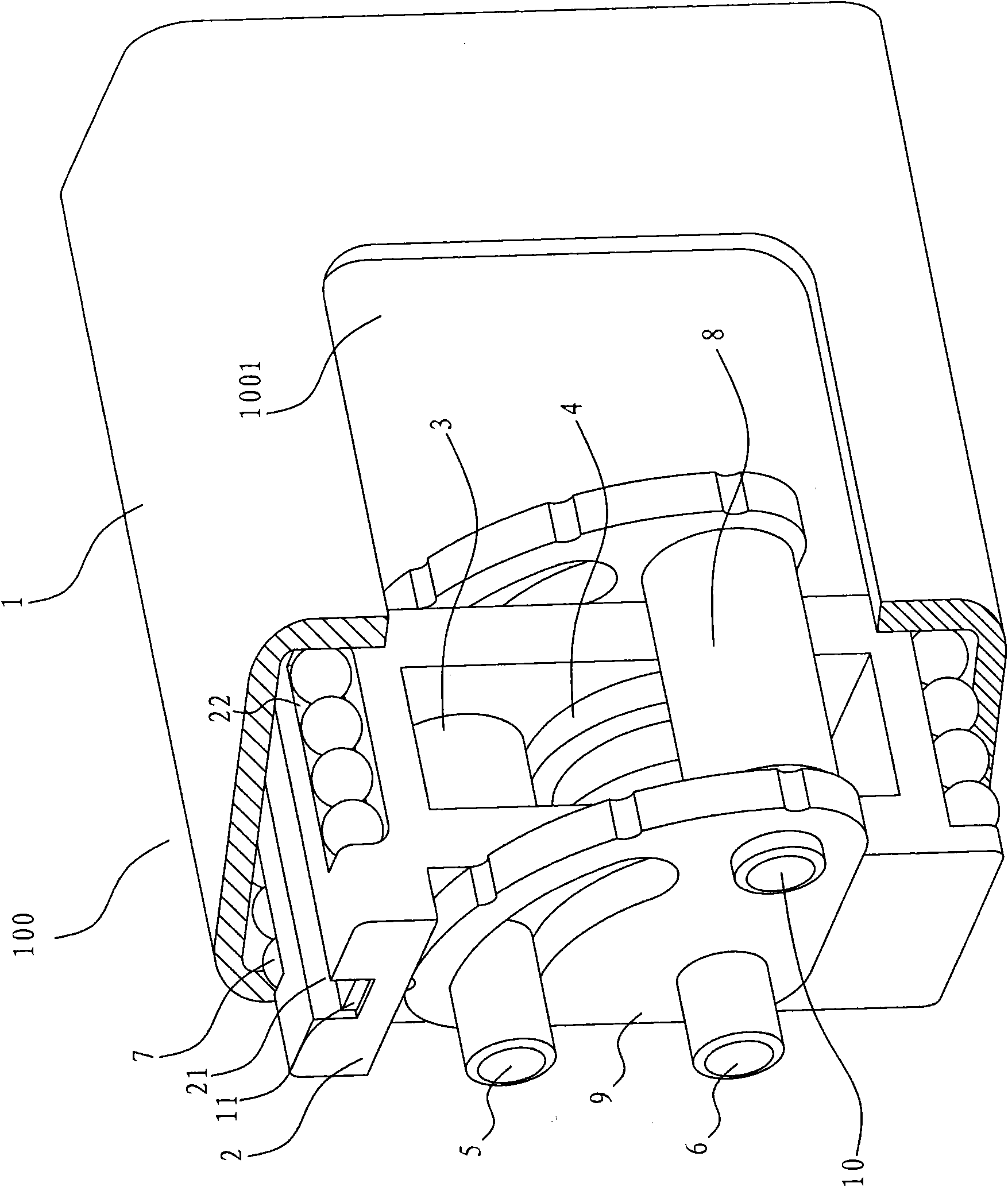

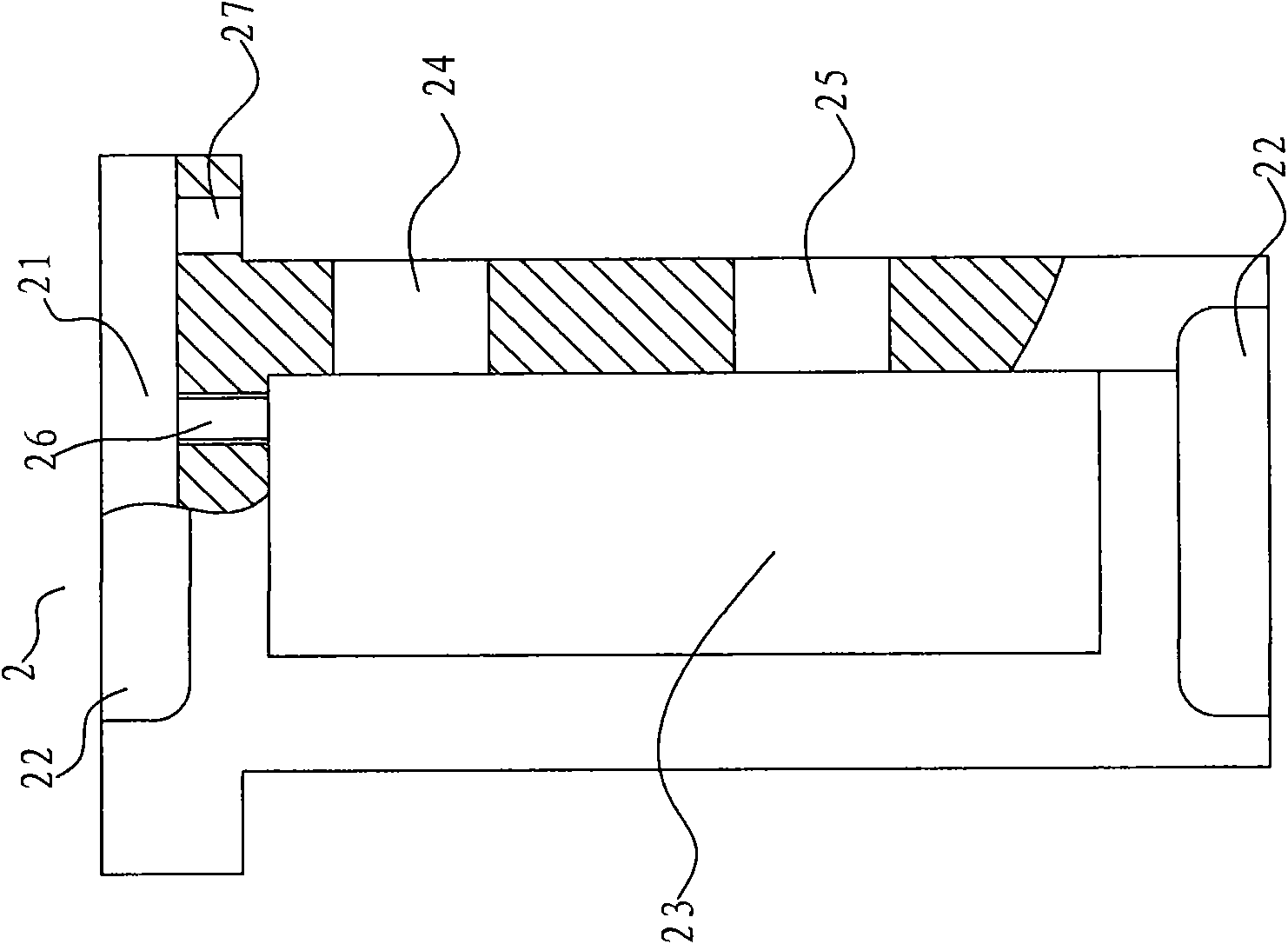

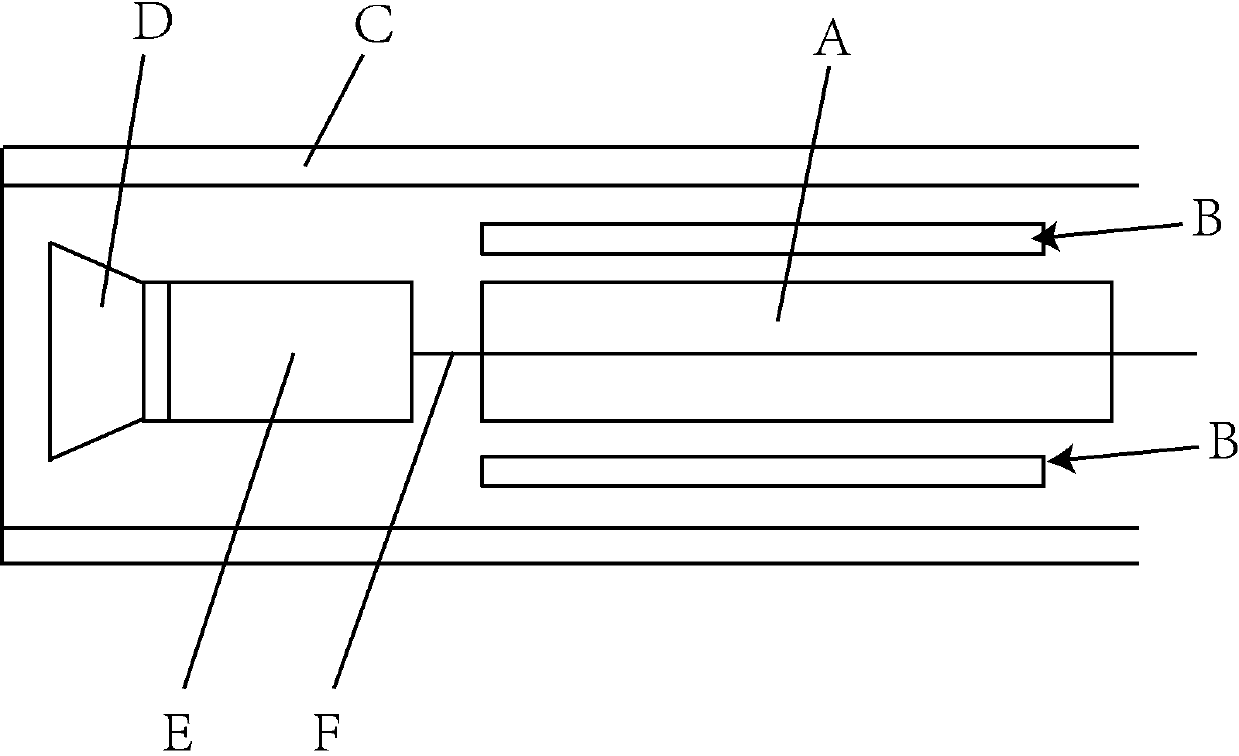

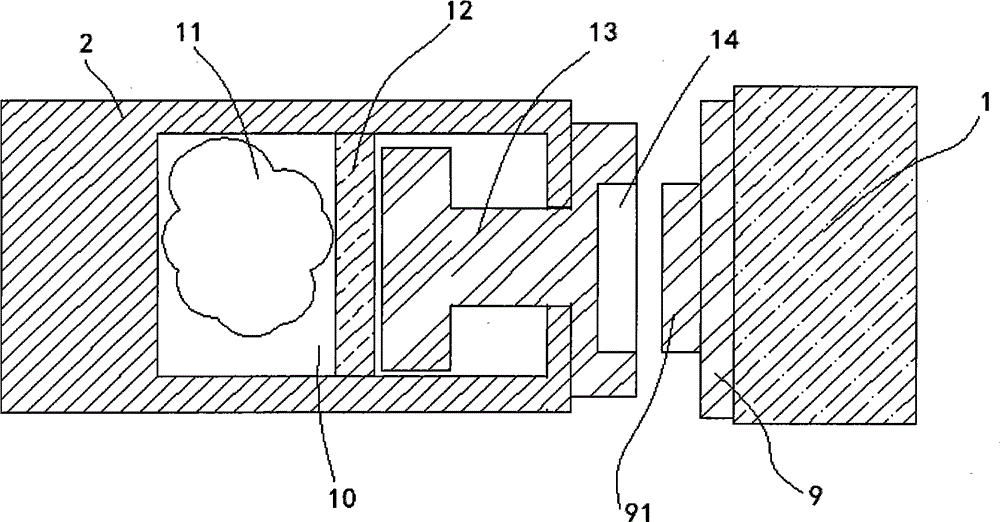

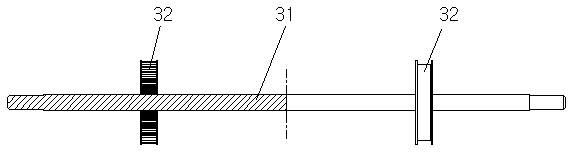

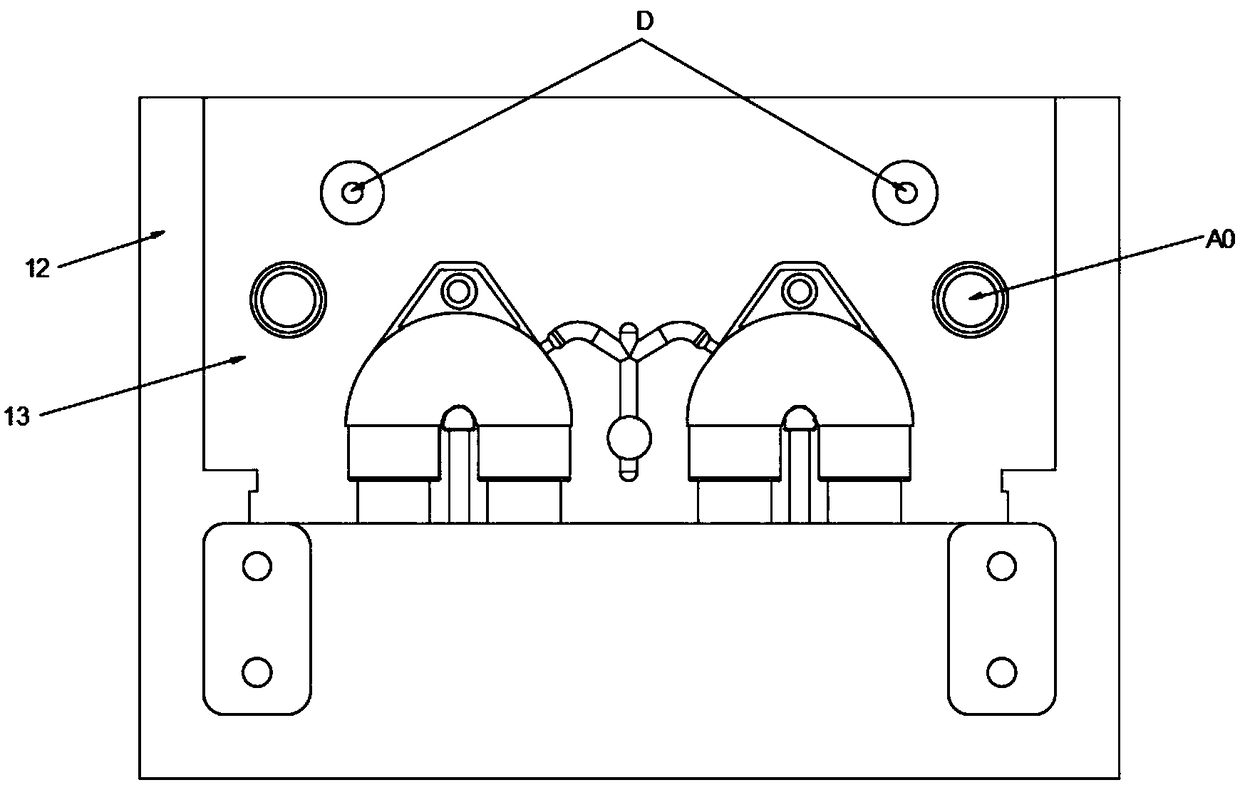

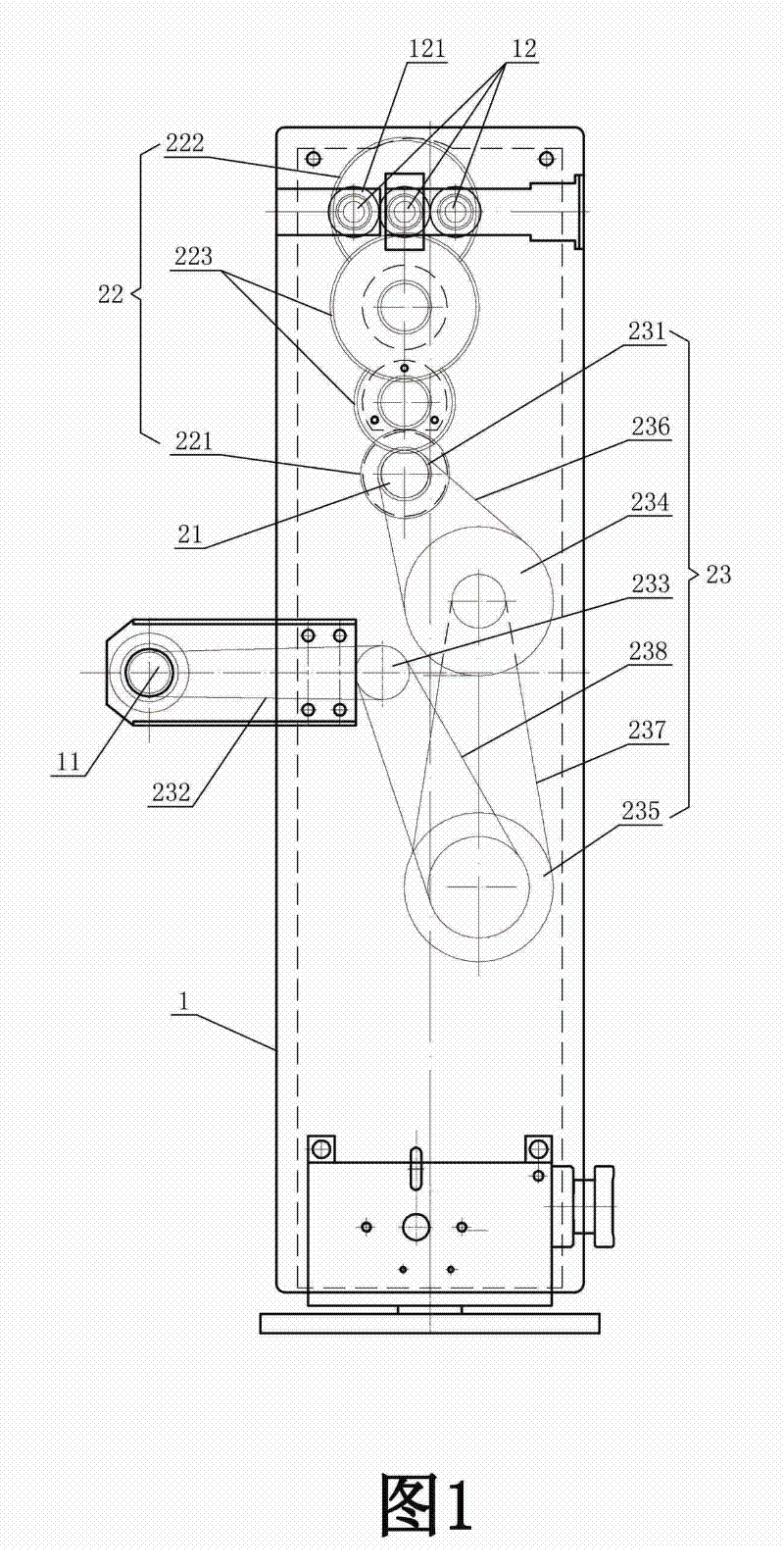

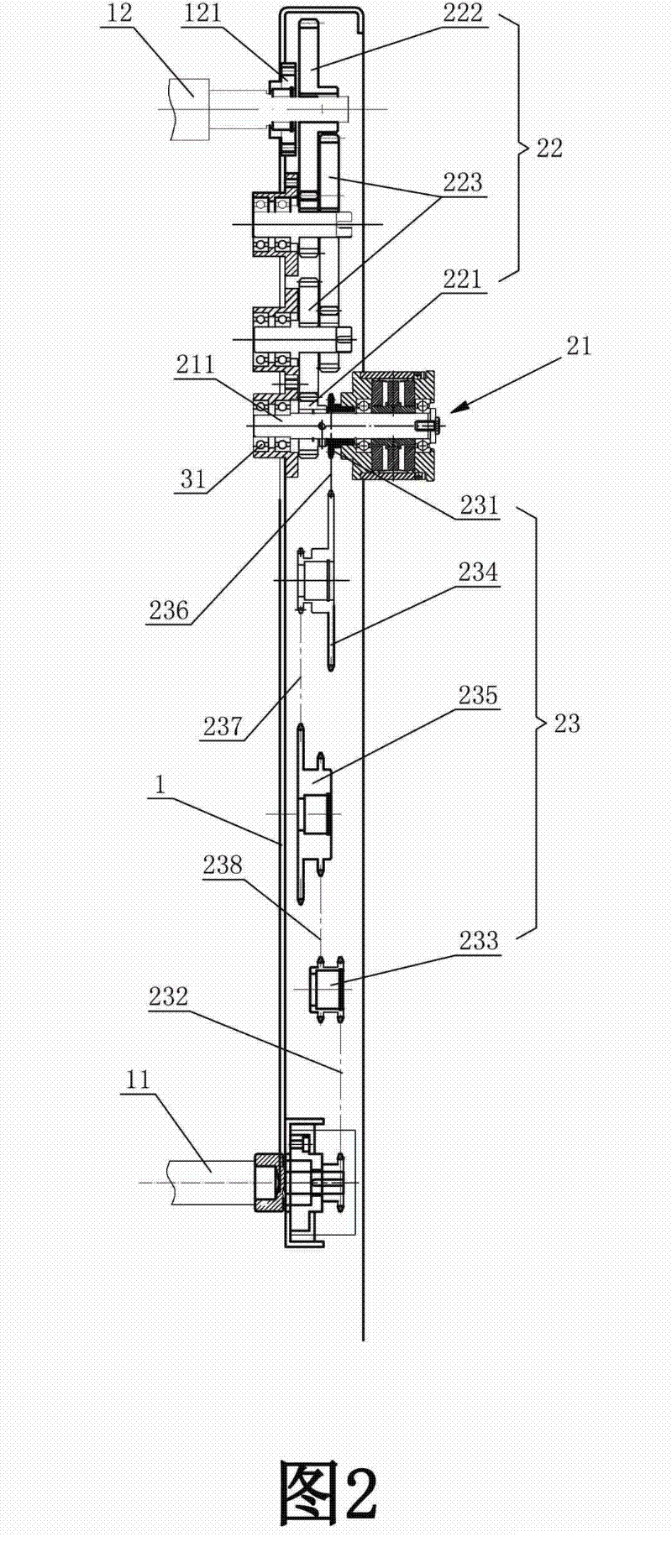

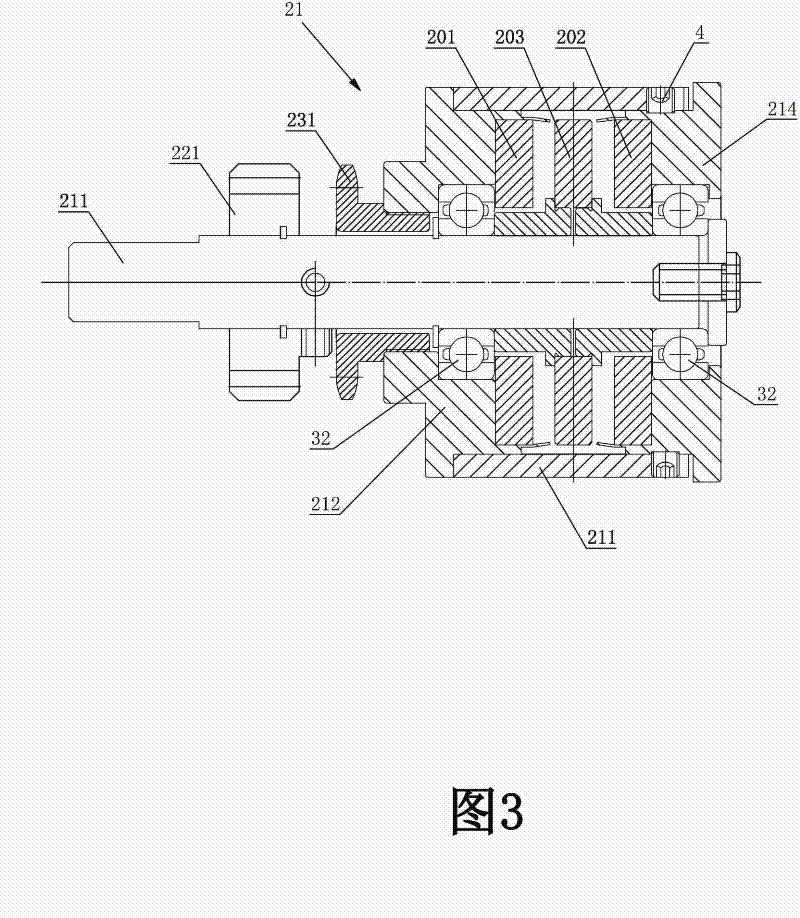

Laser continuous cutting device having dedusting function

ActiveCN104972227ANo sliding frictionAvoid damageMetal working apparatusLaser beam welding apparatusPole pieceLaser cutting

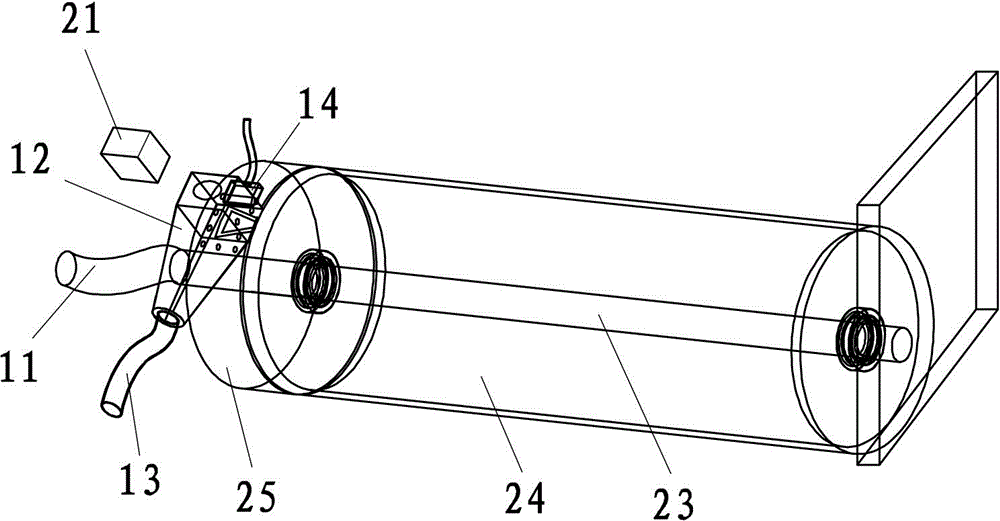

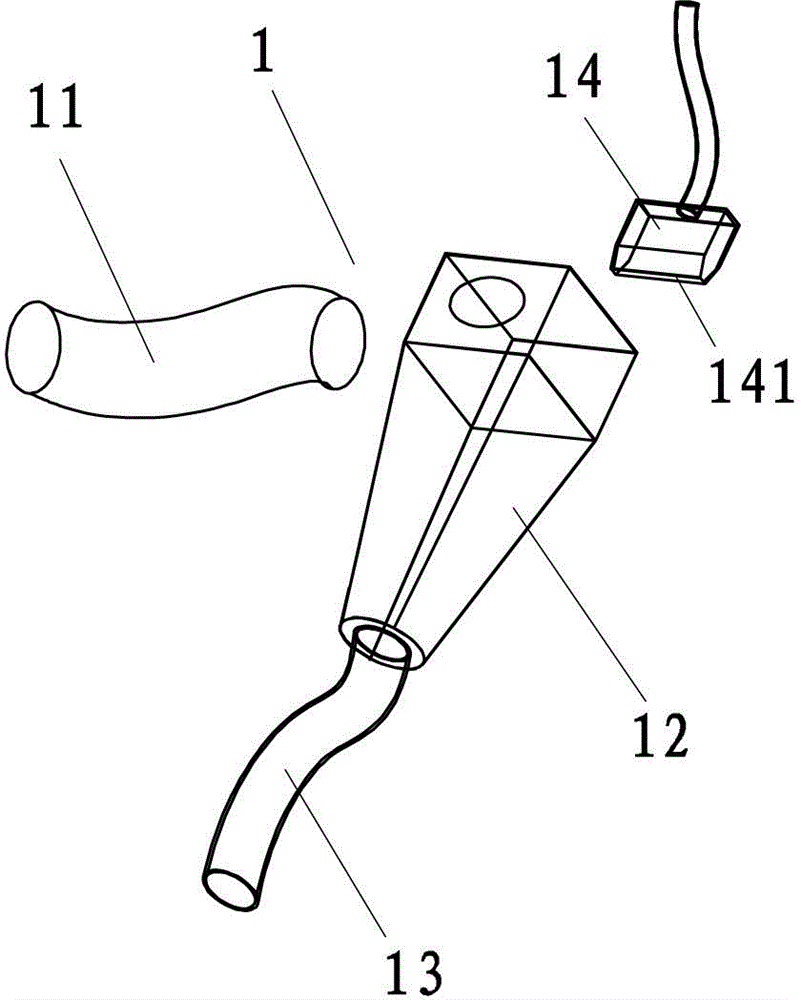

The invention belongs to the technical field of laser cutting and particularly relates to a laser continuous cutting device having a dedusting function. The laser continuous cutting device comprises a dedusting mechanism and a laser cutting mechanism. The laser cutting mechanism comprises a laser head and a cushion seat module. The cushion seat module comprises a center shaft, a rotating roller and a fixed roller. The rotating roller and the fixed roller have the same radius, the fixed roller is connected with the rotating roller through the center shaft and is fixed relative to the center shaft, and the rotating roller can rotate relative to the center shaft. When a pole piece is cut, the pole piece adheres to the rotating roller by means of tension provided by mechanical transmission during the feeding, and a to-be-cut pole lug reserved area on the pole piece adheres to the fixed roller. The linear velocity of the rotating roller and the feeding speed of the pole piece are the same, so that no sliding friction occurs between the pole piece and the rotating roller, and the damage to the pole piece caused by the sliding friction between the pole piece and the rotating roller is avoided.

Owner:CONTEMPORARY AMPEREX TECH CO

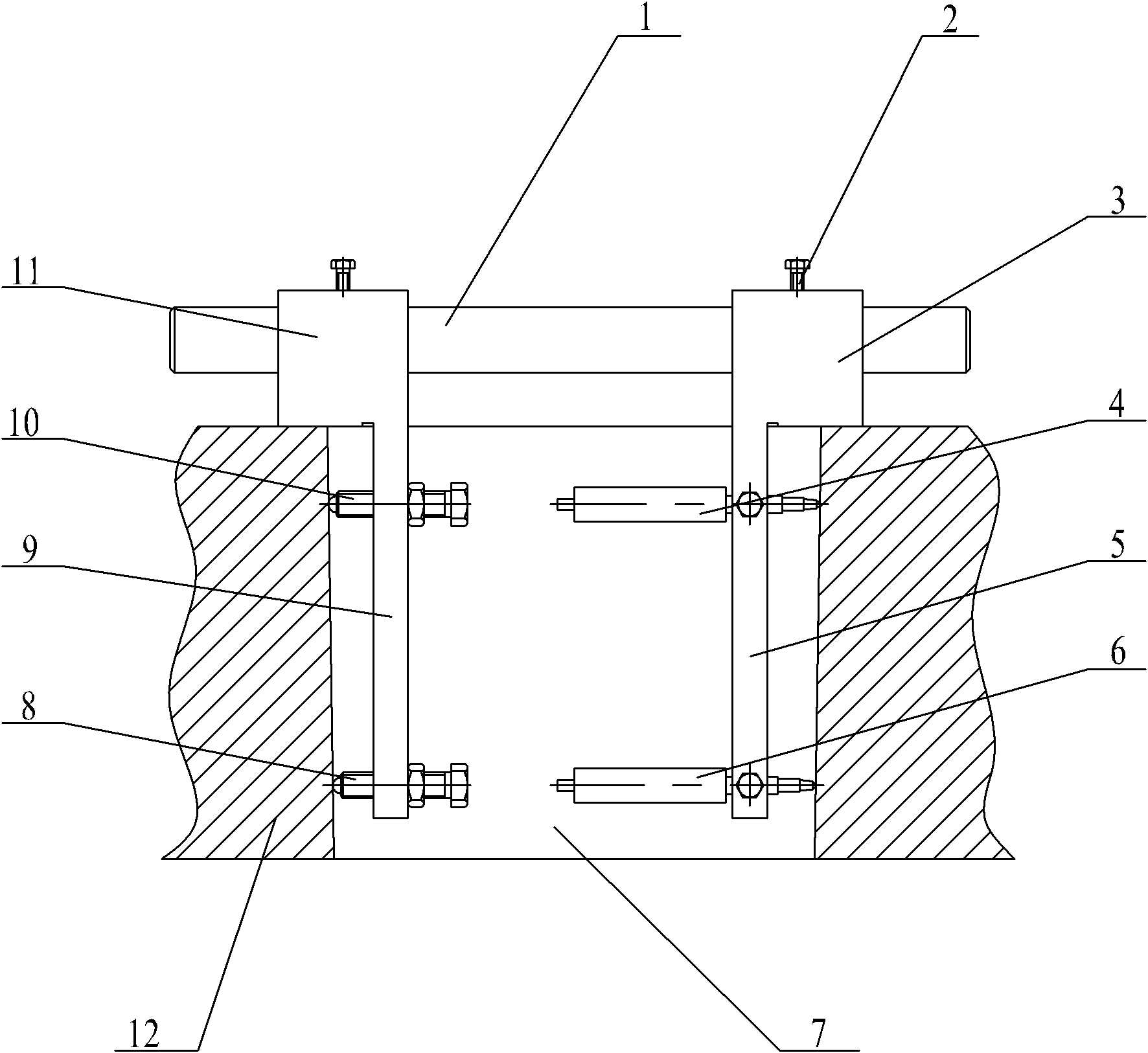

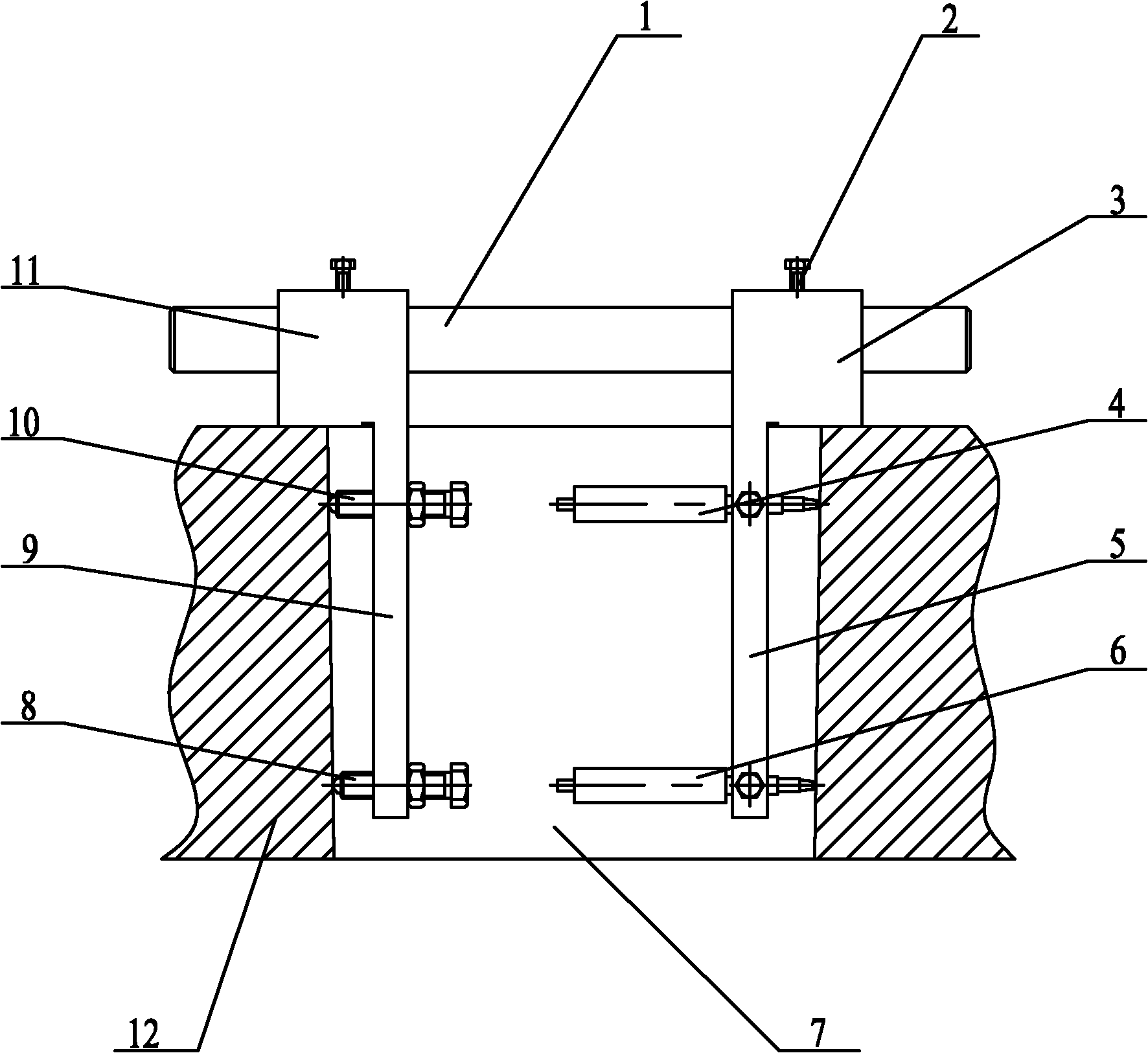

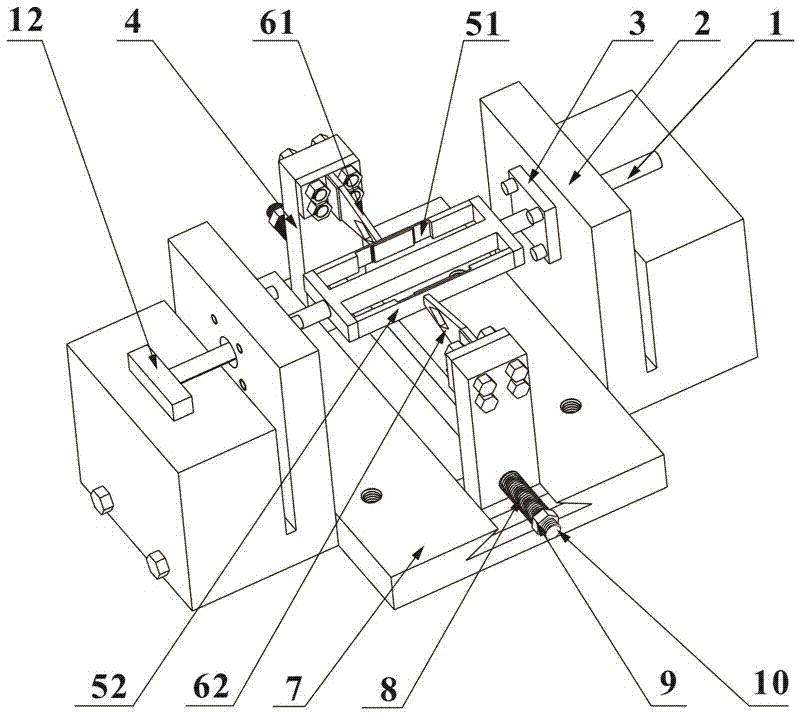

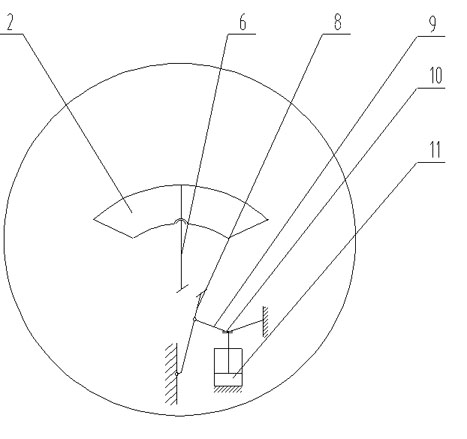

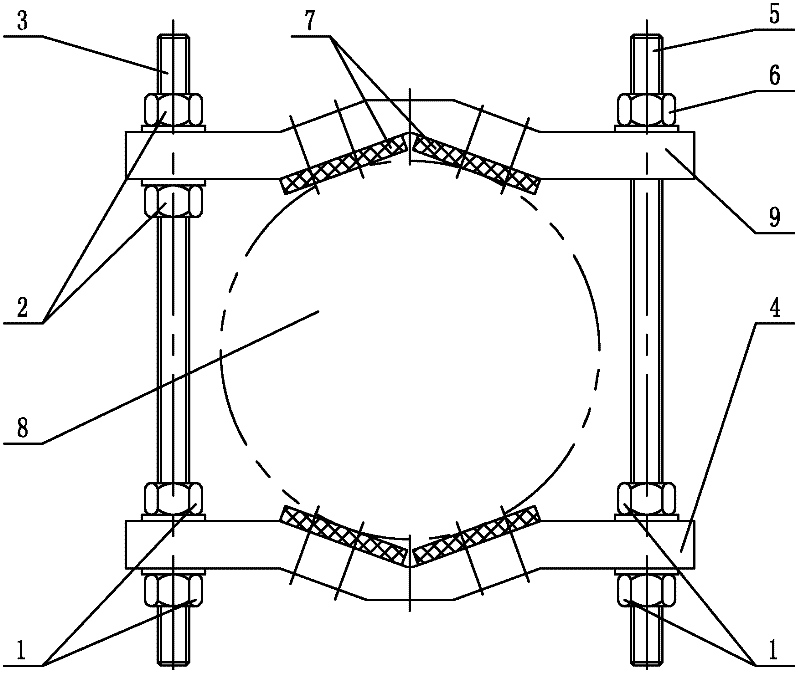

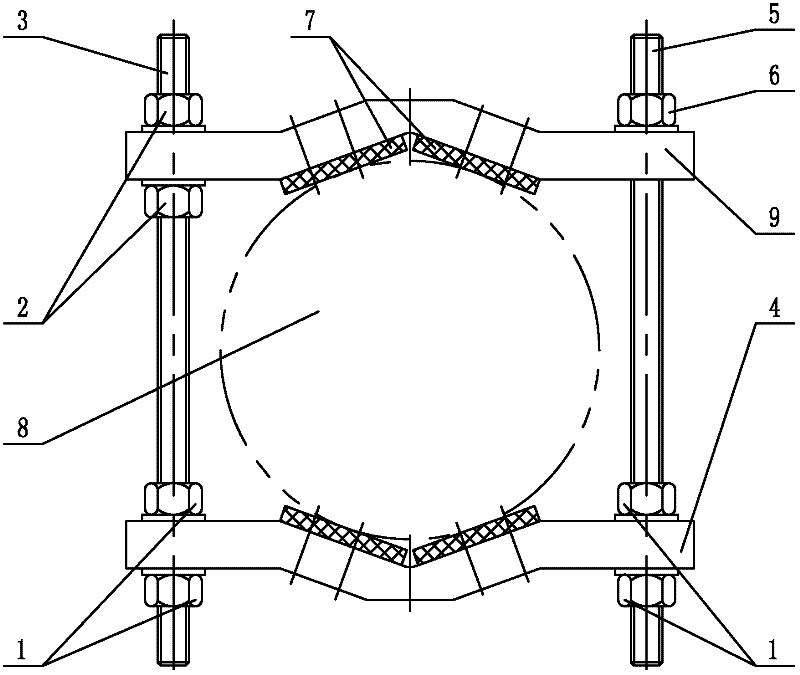

Rapid detection tool for large taper hole

InactiveCN102109315ANo sliding frictionSolution to short lifeAngles/taper measurementsMechanical diameter measurementsEngineeringAngular error

The invention relates to a rapid detection tool for a large taper hole. The detection tool comprises a detection tool pedestal, wherein the detection tool pedestal is provided with an adjusting arm and a measuring arm which are vertically distributed; the measuring arm is provided with dial indicators for measuring angular error of the taper hole; and the adjusting arm is provided with adjusting screws for demodulating the dial indicators. In the detection tool, an instrument support is provided with the measuring arm; an adjusting support is provided with the adjusting arm; the adjusting arm is provided with a first adjusting screw and a second adjusting screw; the measuring arm is provided with a first detection dial indicator and a second detection dial indicator; the first detection dial indicator and the second detection dial indicator perform zero reset through the first adjusting screw and the second adjusting screw; the aperture and the taper of the large taper hole can be rapidly measured according to tape error values of the first detection dial indicator and the second detection dial indicator in comparison with the standard taper of a standard taper ring gauge; the detection is convenient and fast, and the working efficiency is greatly improved; and the detection tool has a wide application range, no sliding friction, long life and a simple structure and is lower in manufacturing cost.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

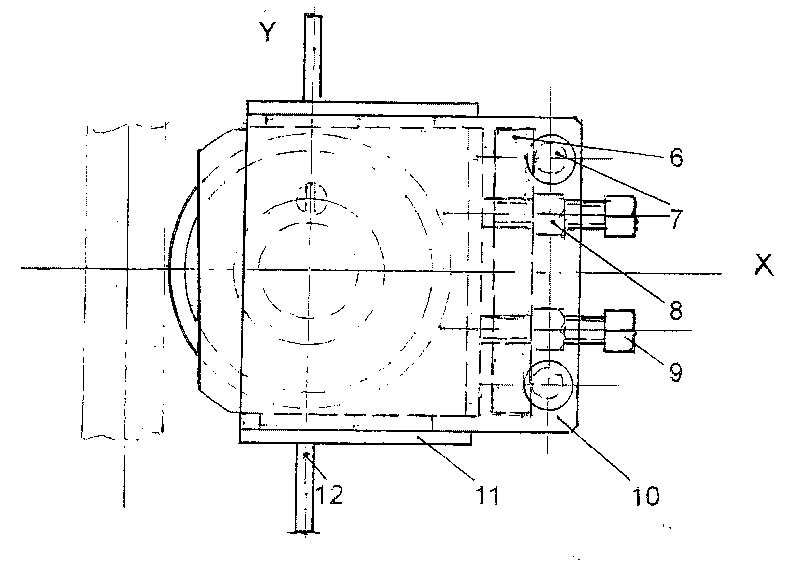

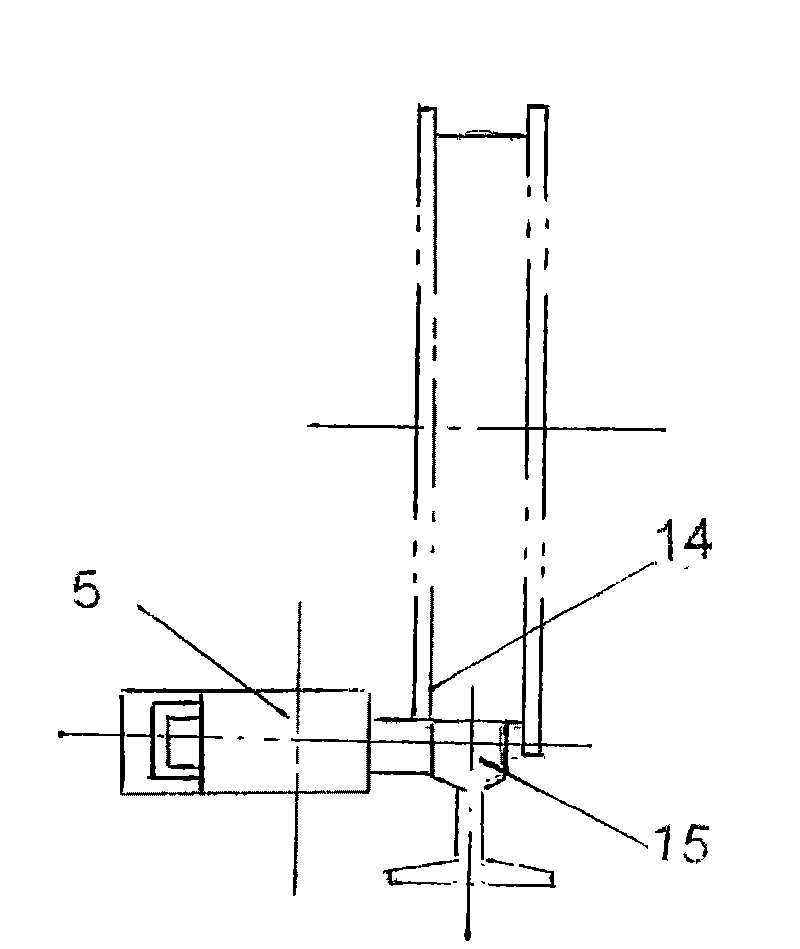

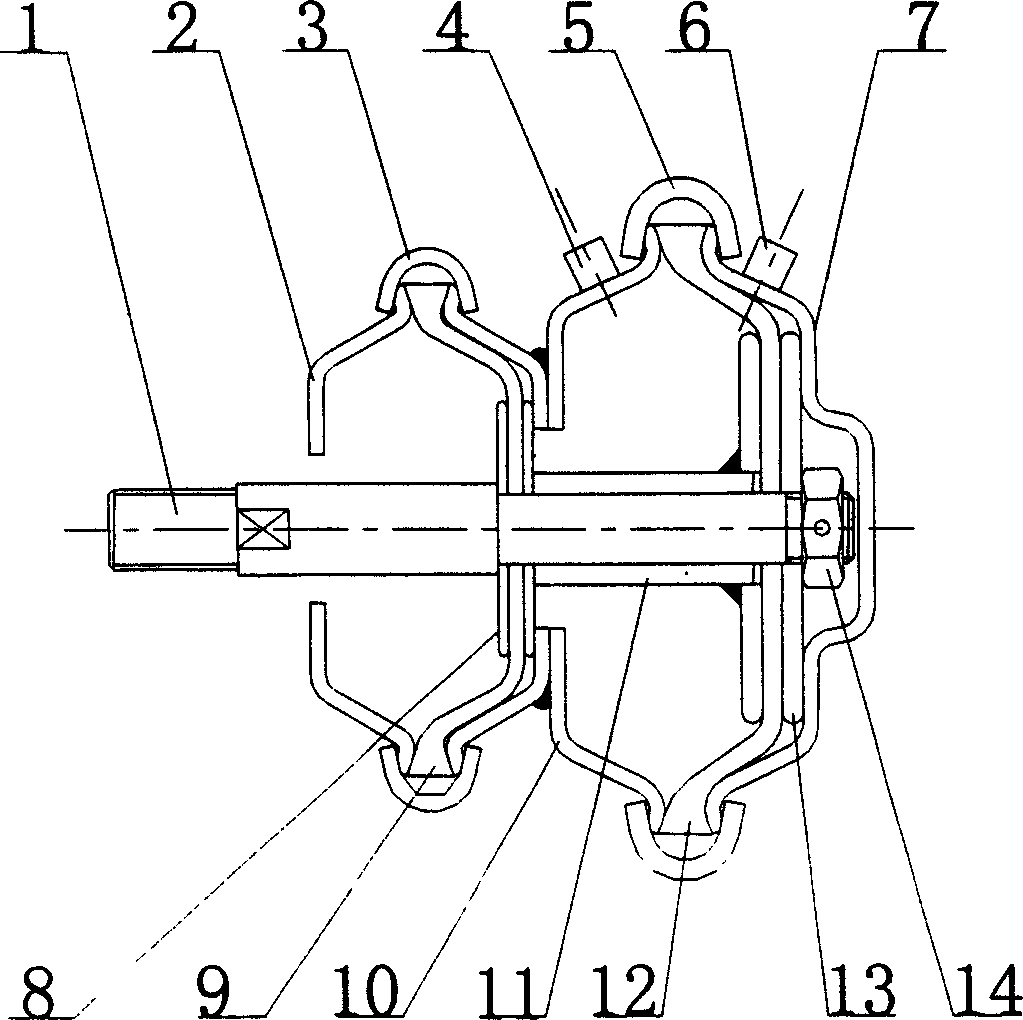

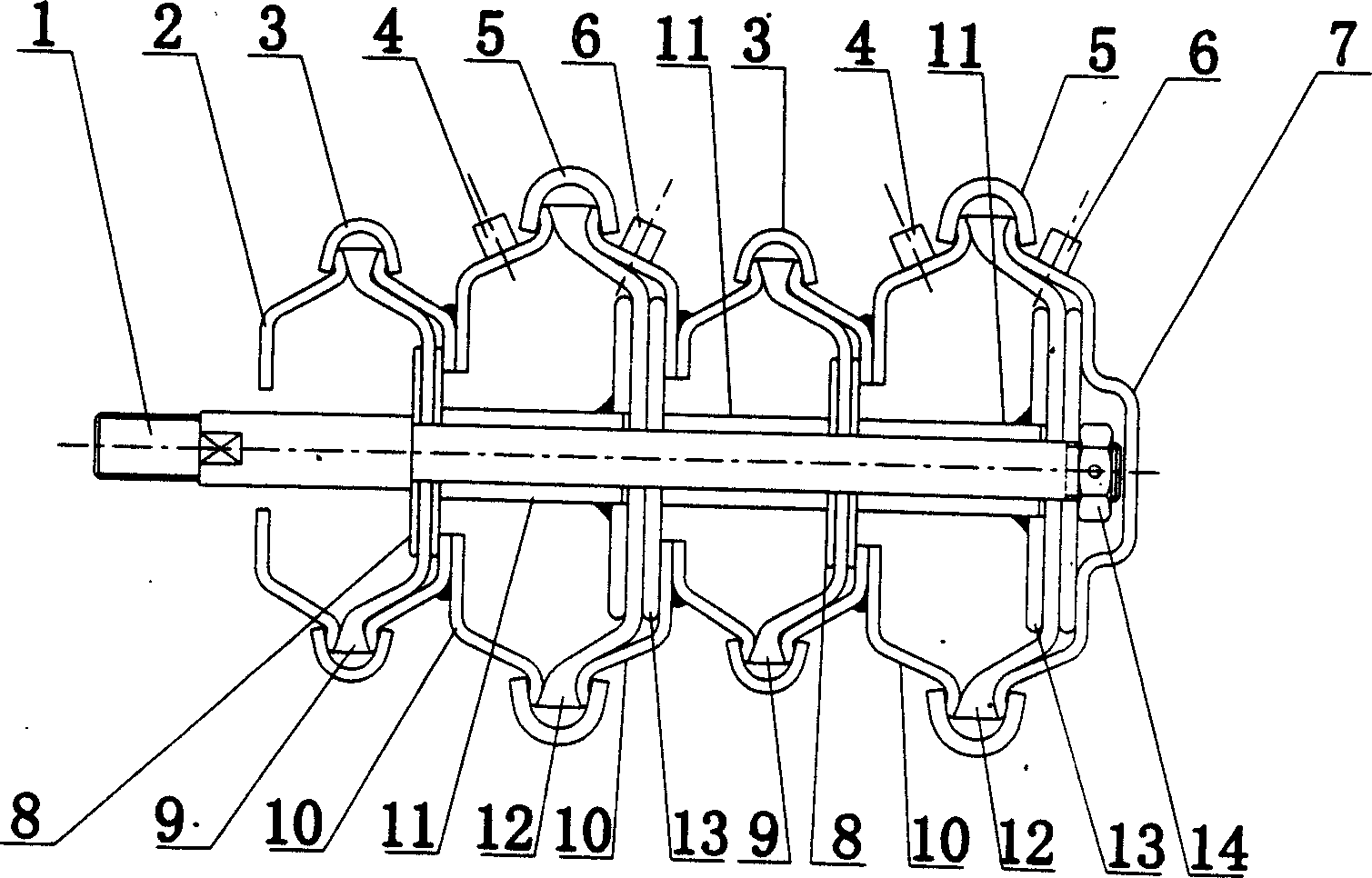

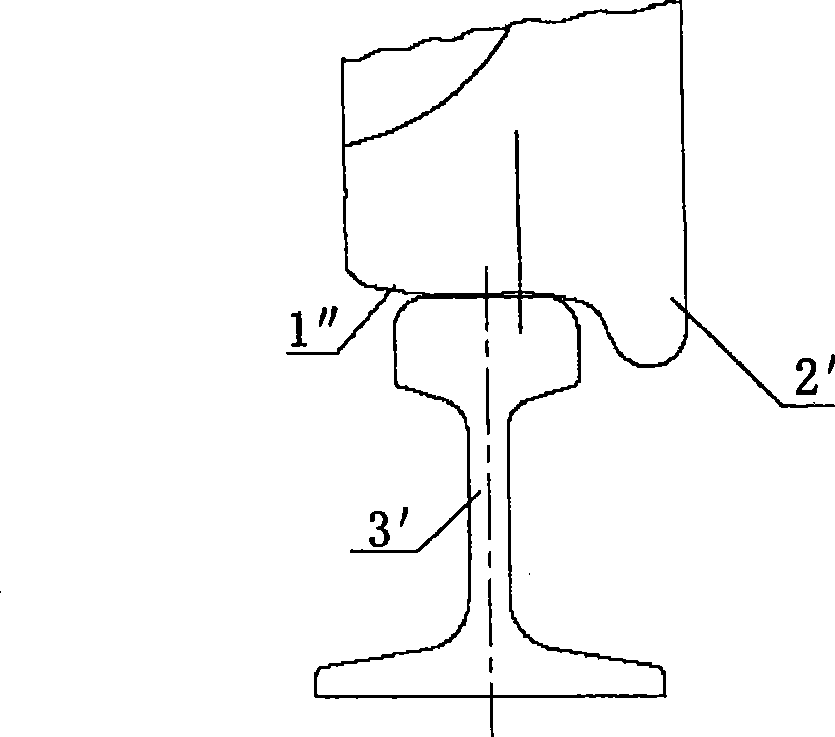

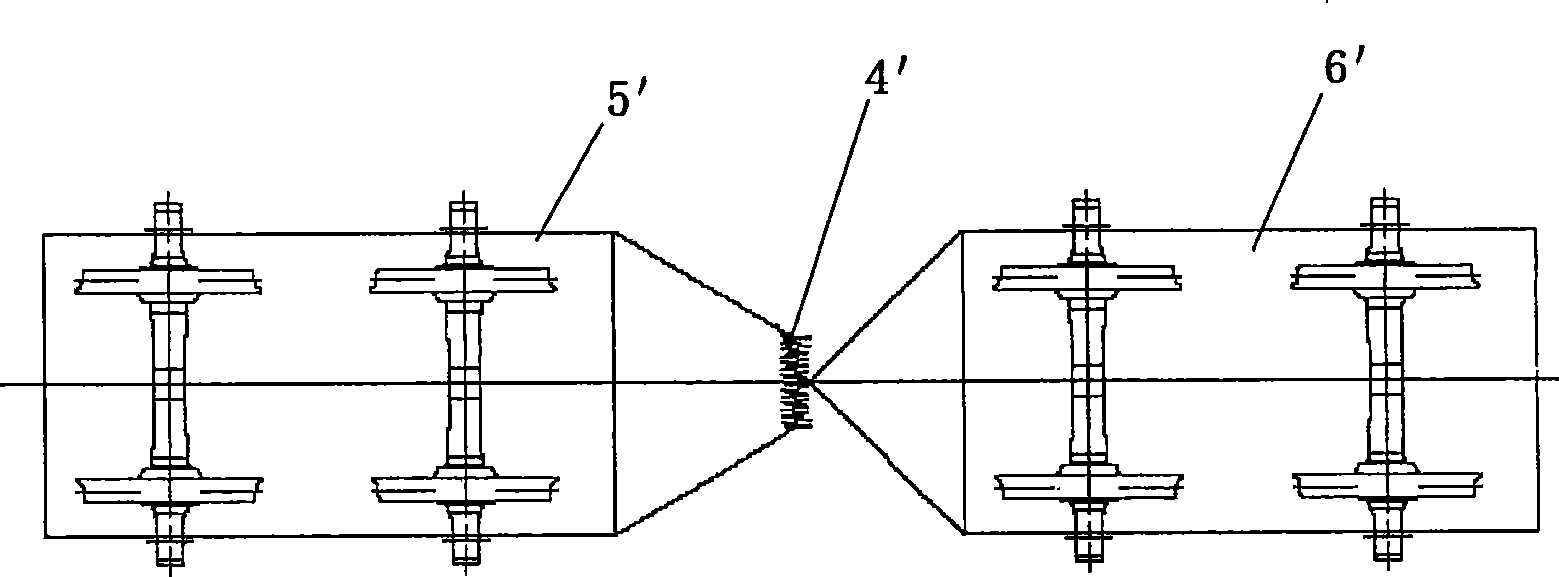

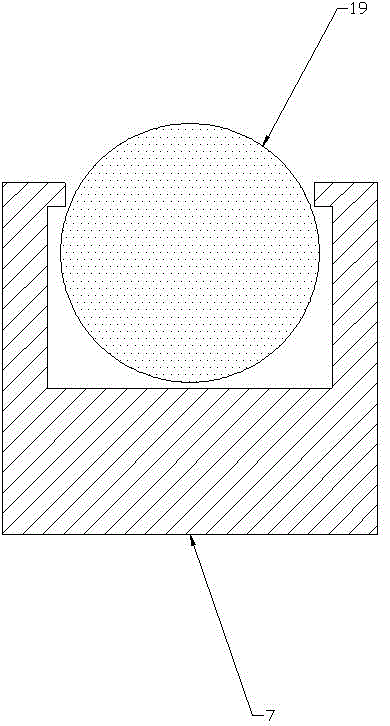

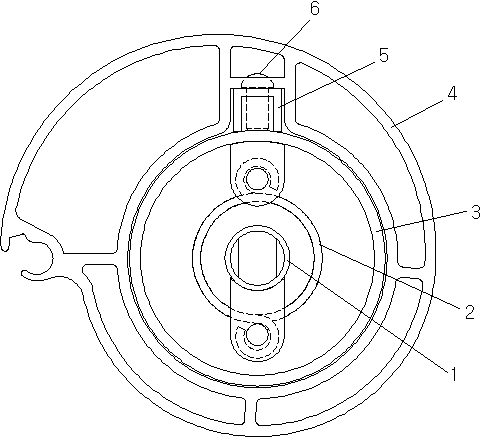

Side guide wheel of crane for preventing track biting of rim

The invention relates to a side guide wheel assembly of bridge type and gantry type cranes for preventing the track biting of a rim. The side guide wheel assembly comprises a side guide wheel (4), a bearing (2), a guide wheel shaft (1) and a guide wheel frame (5). In box-shaped slide slots (10) (11), the acting position of the side guide wheel of the assembly is regulated by a screw rod (9) so as to ensure that a minute gap is reserved between a crane rim (14) and the side face of a steel wheel to prevent that the rim has contacts and frictions with the side face of a steel track and thoroughly avoid a phenomenon that the rim bites the side face of the steel track.

Owner:沈炎源

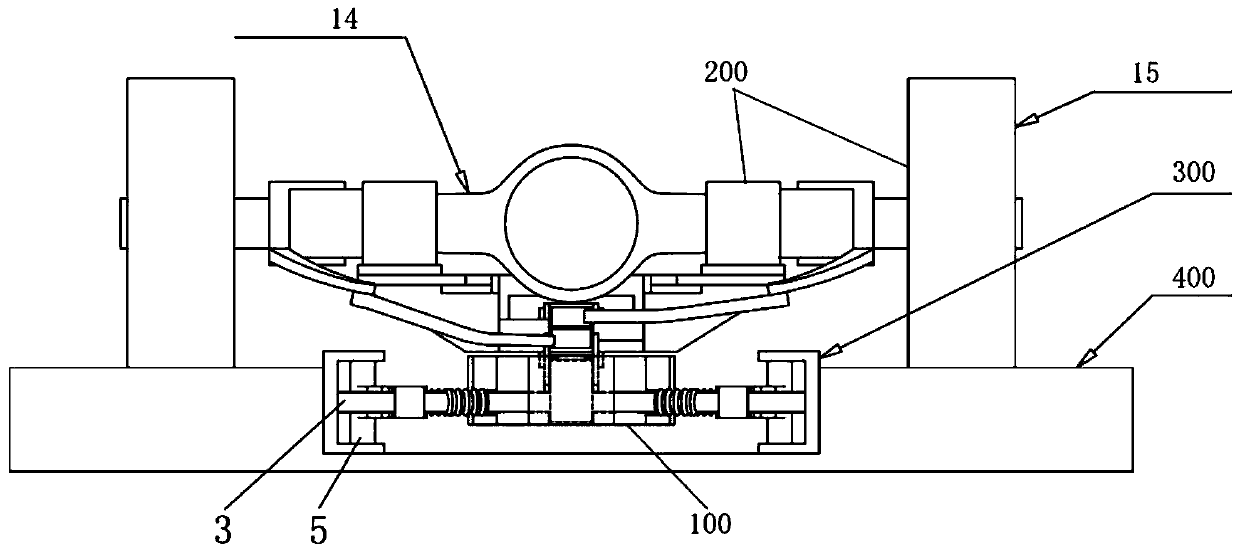

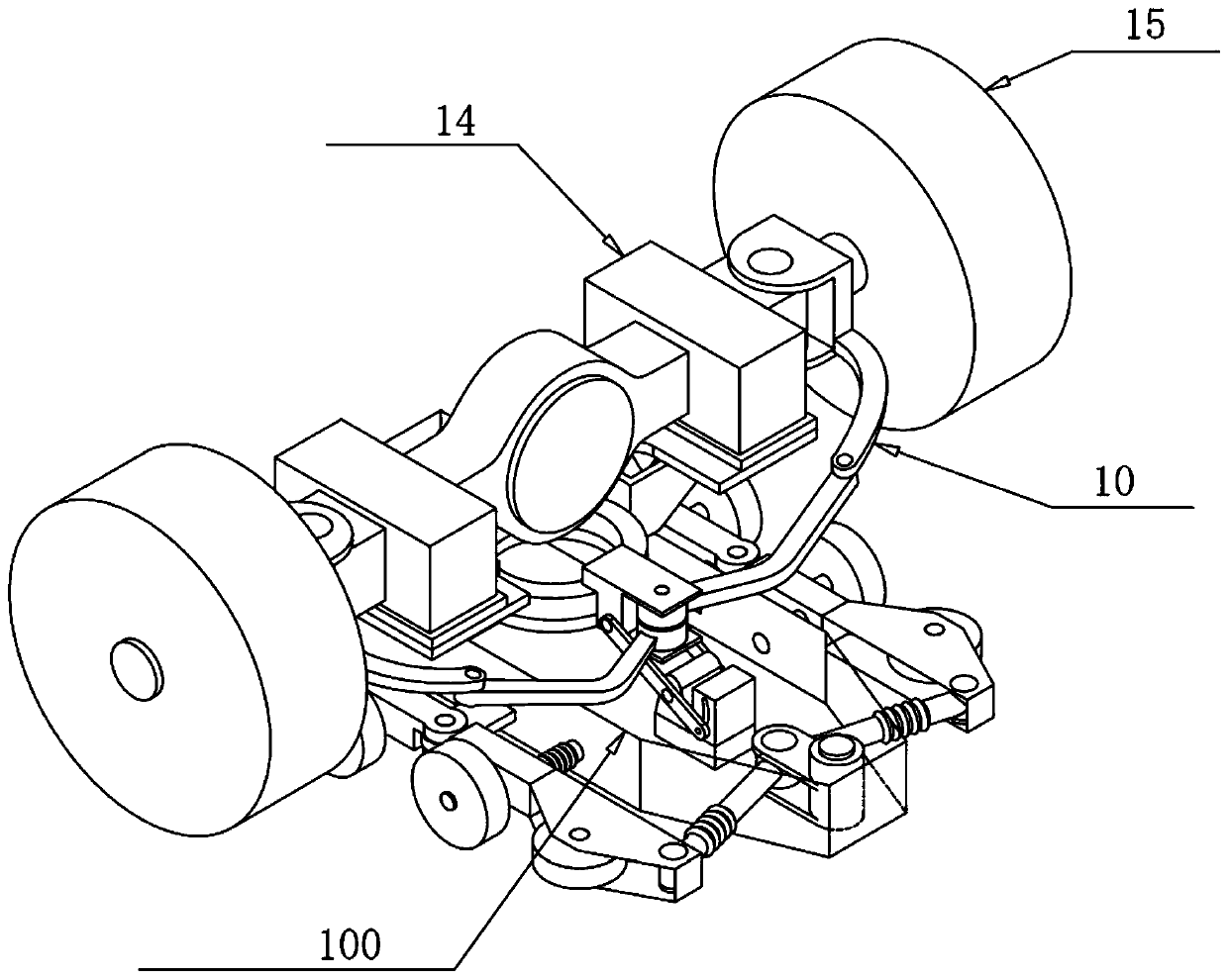

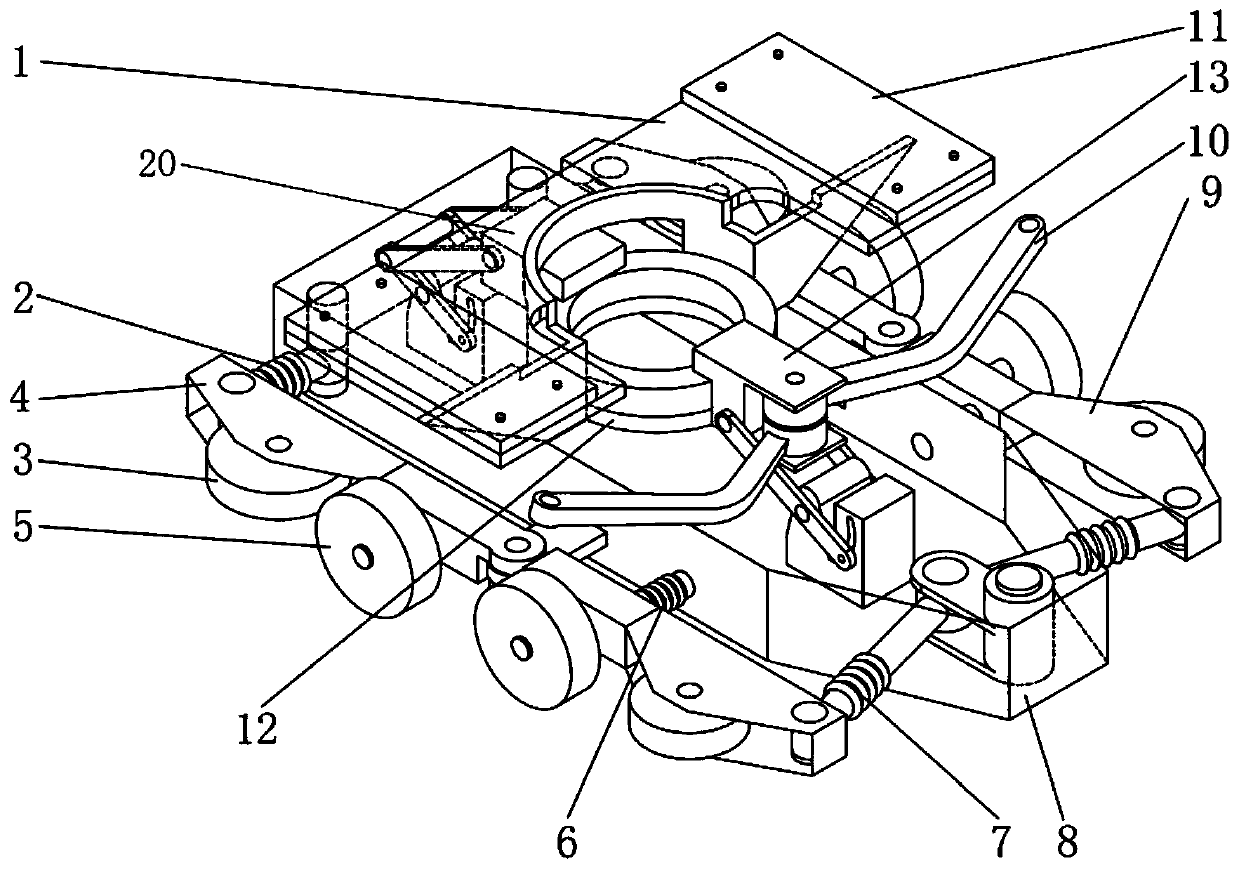

Rail adaptive guiding trolley

ActiveCN110496397ARealize follow-up steeringNo sliding frictionHelter-skeltersSelf-driversRolling chassisActive steering

The invention discloses a rail adaptive guiding trolley; the rail adaptive guiding trolley comprises a frame body, a steering driving mechanism and an adaptive guiding chassis, wherein the frame bodyis fixedly arranged on the steering driving mechanism; the steering driving mechanism is arranged on the adaptive guiding chassis and is connected with the adaptive guiding chassis through a rotatingsupport of the adaptive guiding chassis; and buffering type supporting guiding wheel assemblies are arranged on the two sides of the adaptive guiding chassis respectively. According to the rail adaptive guiding trolley, due to the fact that the steering driving mechanism is connected with the adaptive guiding chassis through the rotating support, the wheel follow-up guide steering of the steeringdriving mechanism can be realized; due to the fact that the buffering type supporting guide wheel assemblies are arranged on the two sides of the adaptive guiding chassis respectively and can run in the rails, guiding and supporting in the rails are achieved; and due to the fact that the driving steering wheels are driven to actively steer, passive sliding friction and non-pure rolling conditionsare avoided, the steering resistance is small, and abnormal abrasion of tires is avoided.

Owner:华强方特(深圳)科技有限公司

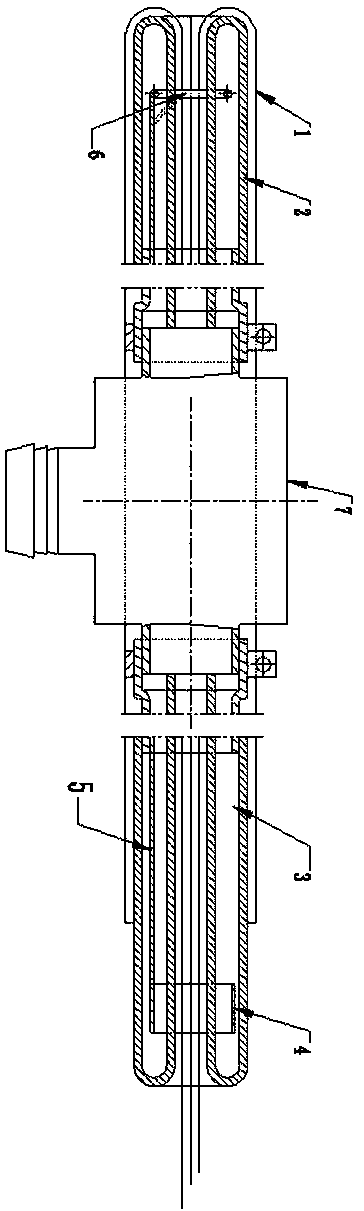

Linear piezoelectric motor

ActiveCN107171590AReduce lossRealize linear motionPiezoelectric/electrostriction/magnetostriction machinesLinear motionLow speed

The invention relates to a linear piezoelectric motor. The linear piezoelectric motor includes a drive pre-tensioning mechanism, an output mechanism and a bearing pedestal, wherein the drive pre-tensioning mechanism includes a pair of driving vibrators on the pedestal; the pair of driving vibrators are each provided with a vibrator piezoelectric patch; the output mechanism includes an output rod; the middle part of the output rod is provided with a +-shaped framework in the axial direction; two side bars of the +- shaped framework are vibration plates; and the vibration piezoelectric patches are arranged on the vibration plates. The linear piezoelectric motor controls the bending vibration modal of the vibration plates and the driving vibrators by means of the waveform synthesis principle so as to form coordinate action between the vibration plates and the driving vibrators to realize linear motion, and does not generate sliding friction in theory, thus being less in energy loss and being high in efficiency. The operating frequency of the linear piezoelectric motor is greater than 2000Hz; the linear piezoelectric motor has high output speed and has two operating states; and the linear piezoelectric motor can realize low speed high torque output and high speed low torque output through high and low level coordination of the first and second driving vibrators.

Owner:HEFEI UNIV OF TECH

Rope guider

ActiveCN101549839AShorten the lengthReduce wearWinding mechanismsPerpendicular directionMechanical engineering

The invention discloses a rope guider, which includes basic frame, sledge, upper guide roller and lower guide roller. The aforementioned sledge is movably setup at the basic frame along the wire direction of basic frame, the upper guide roller and the lower guide roller are rotatablely installed at the sledge, wherein the lower guide roller is under the upper guide roller and in the perpendicular direction there is a preconcerted distance between the upper guide roller and lower guide roller. The invention can reduce the abrasion of the upper and lower guide rollers to anchor line and prolong the service life of anchor line as the sledge can move along the basic frame.

Owner:HANGZHOU TIANMING TECH CO LTD

Air-hydraulic cylinder with dual function diaphragm

InactiveCN1598247ANo lubricationNo sliding frictionFlexible wall reciprocating enginesFluid-pressure actuatorsHydraulic cylinderProduct gas

The invention relates to a double-effect film air pressure or hydraulic cylinder using pressure air or liquid as power, which includes the shell and film of the cylinder. The double-effect film plate air pressure or hydraulic cylinder is made up of at least one group, each shell is assembled with two film plates including a big one and small one, and forms tow sealed cavities, which is divided into cavity with pole and cavity without pole; the pushing pole penetrates the two film plate, and they are connected to the film plate and sealed. There has a cavity air and liquid nozzle in the cavity with a pole on top of the middle shell and the post shell, and the inlet and outlet of the air pressure and hydraulic in the cavity without pole; according to the demands, it can form several groups of double-effect film plate air pressure and hydraulic cylinder, thus the air pressure and hydraulic pushing poles can generate multiplied forces.

Owner:马成贵

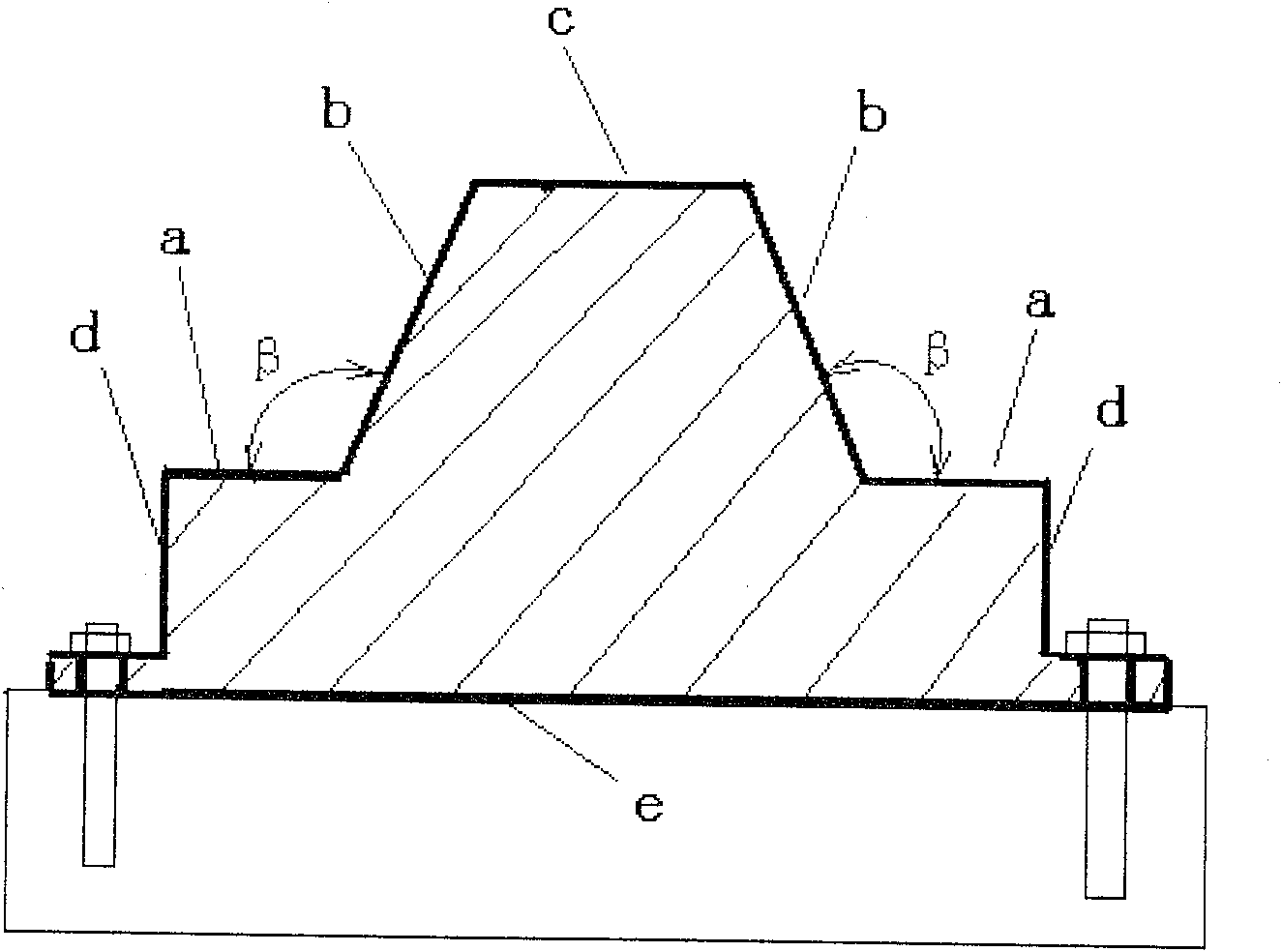

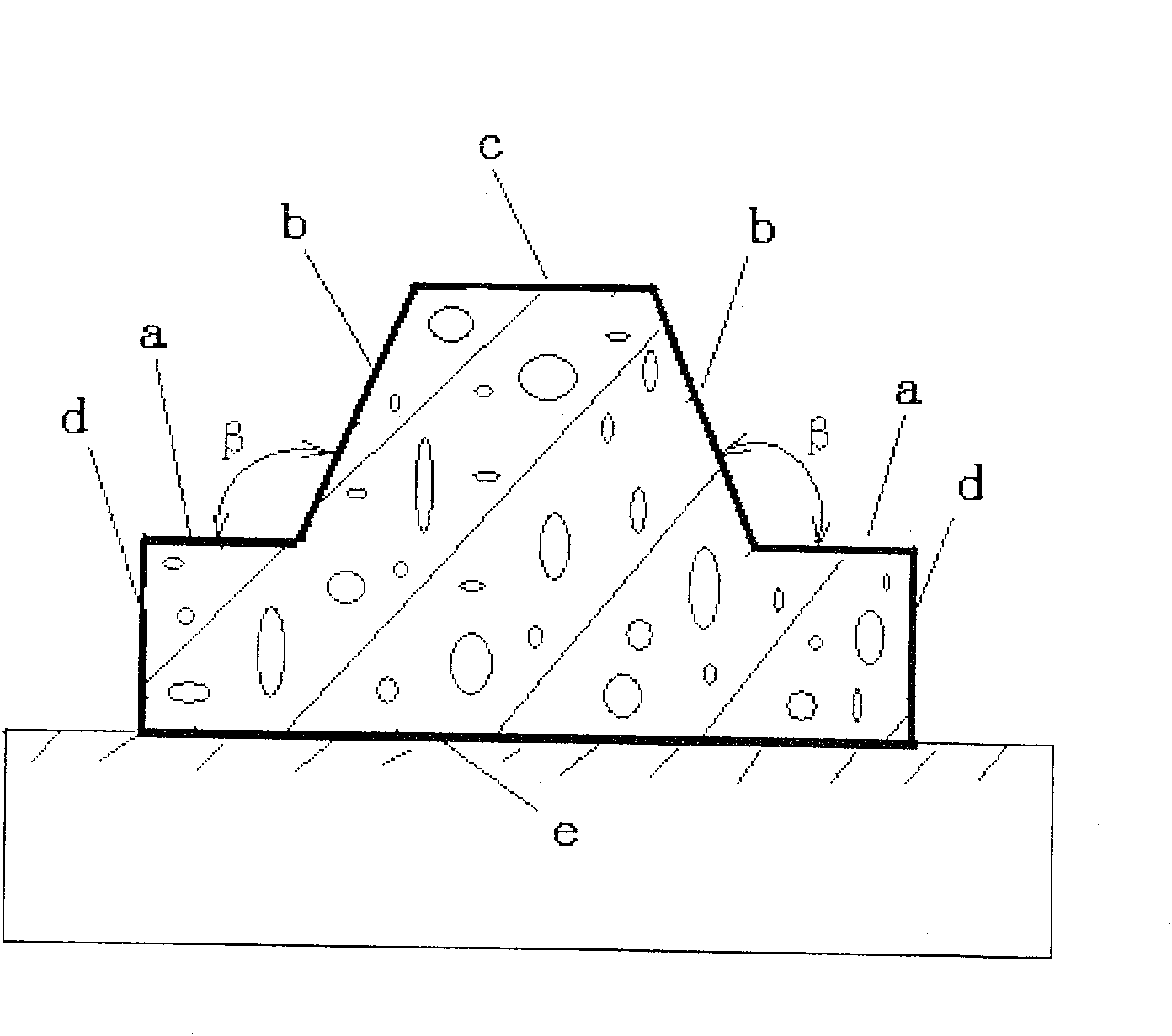

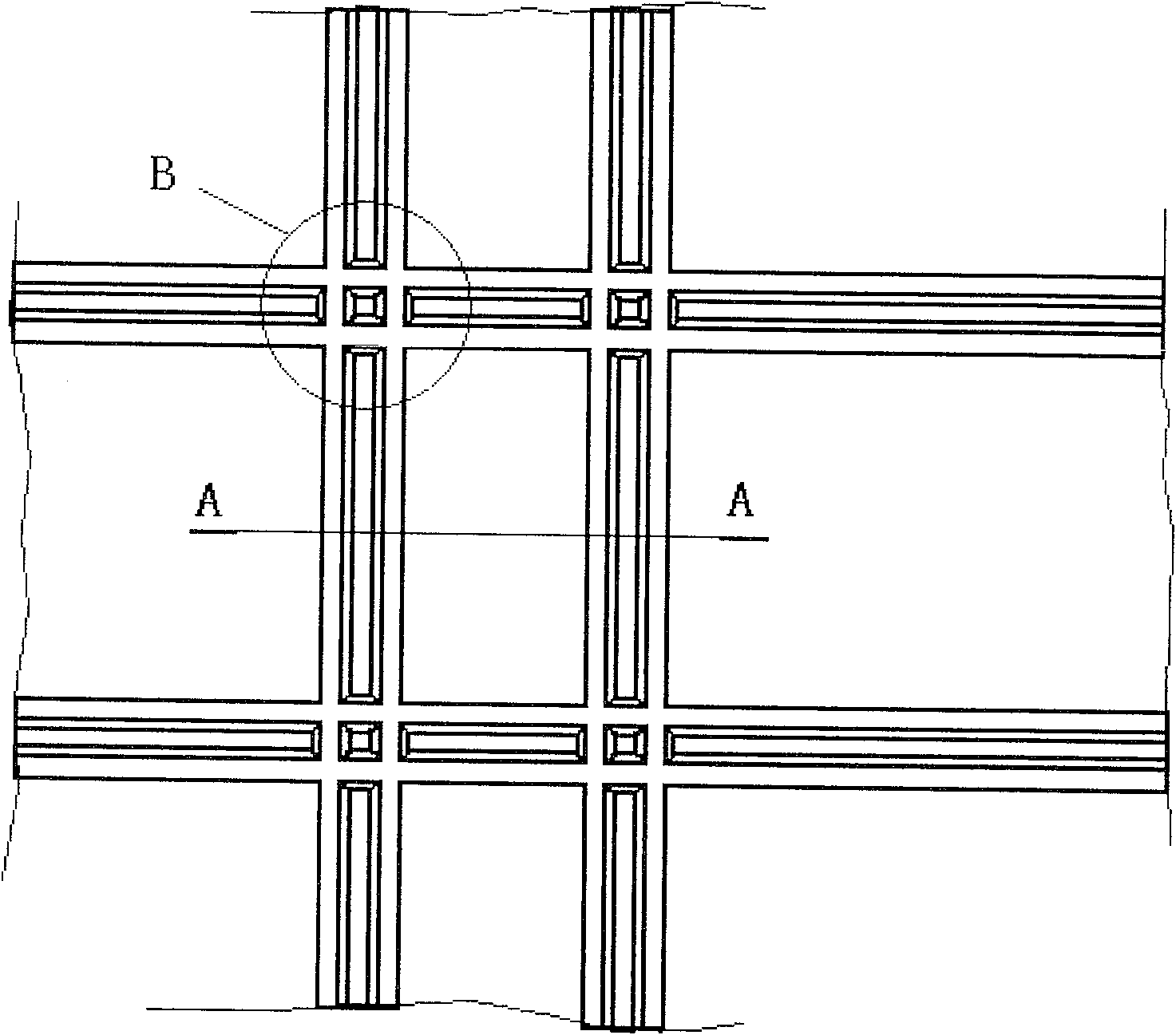

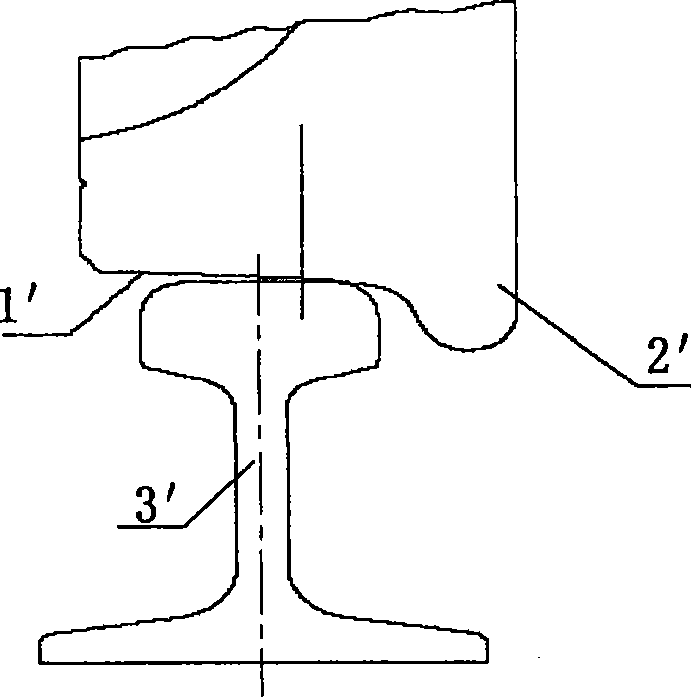

Double crossed vehicle running track

InactiveCN100554582CNo sliding frictionReduce frictional resistanceRailsRail switchesAxial displacementEngineering

The invention discloses a "well" shaped intersecting vehicle running track, which comprises a bearing surface for carrying the weight of the vehicle and a limiting surface for limiting the axial displacement of wheels. The bearing surface and the limiting surface are bilaterally symmetrical, and the section is in the shape of "convex". The invention solves the defects of the existing "I"-shaped track that the bearing surface cannot be continuous at the vertical and horizontal intersections, the vehicle is not running smoothly, and the limit surface and the wheel edge have high friction. The vehicle running track of the invention runs smoothly at the intersection, has small friction, and the force on the bearing surface is symmetrical and even.

Owner:NORTHWEST A & F UNIV

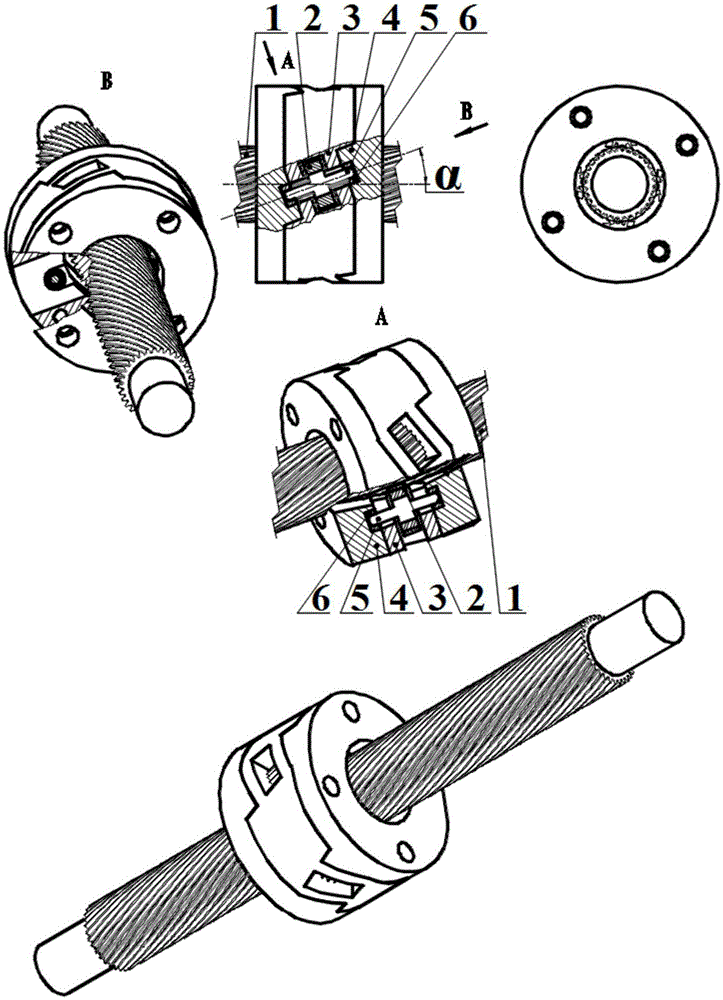

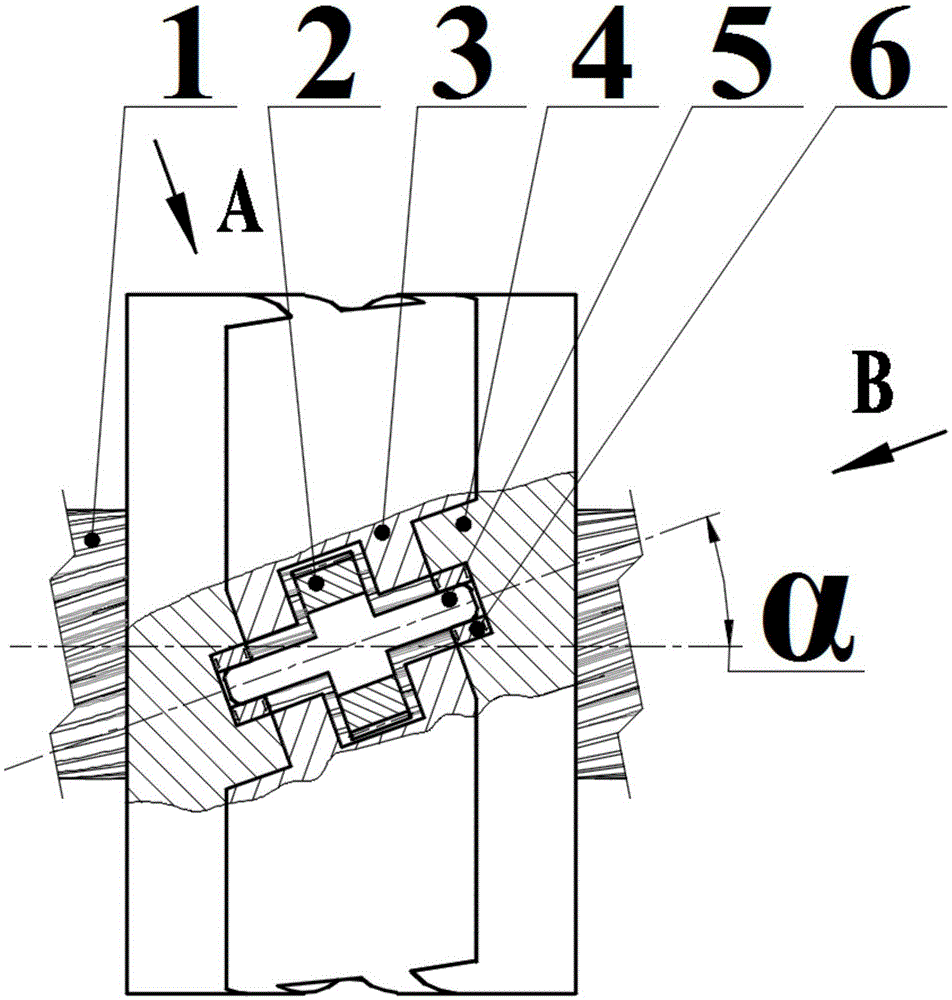

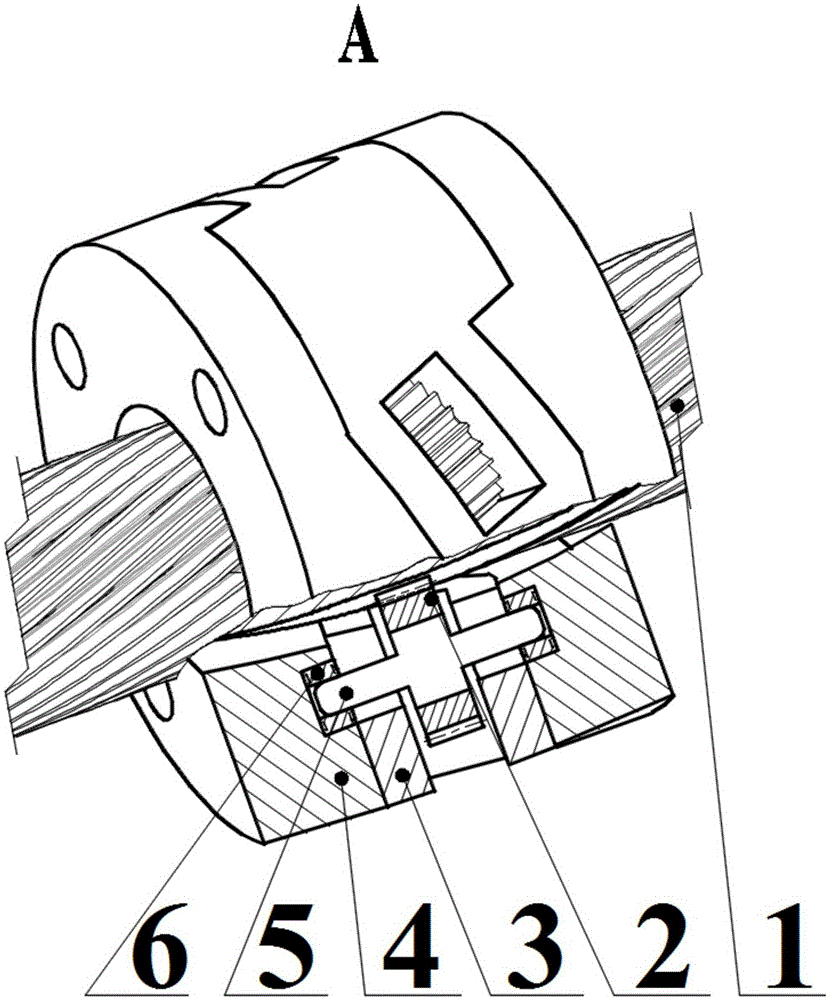

Gear lead screw

ActiveCN105422740AReliable transmissionNo sliding frictionToothed gearingsPortable liftingHelical lineEngineering

The invention discloses a gear lead screw which comprises a helical tooth shaft, a straight tooth gear, a sleeve, end covers, a straight tooth gear shaft, a rolling bearing and the like. A long shaft of which the surface is provided with helical teeth with a certain helical angle alpha is adopted as the helical tooth shaft; the straight tooth gear shaft penetrates through a U-shaped groove which is formed in a square groove, wherein the square groove is formed in the sleeve and inclined to the sleeve axis in an angle which is equal to and has the same direction with the helical angle alpha of the helical tooth shaft; by installing the rolling bearings in blind holes which are formed in the end covers arranged at the two ends of the sleeve and are coaxial with the U-shaped groove, the straight tooth gear installed on the straight tooth gear shaft is driven by a motor to roll along the helical line on the helical tooth shaft; helical transmission is achieved through the mechanical bite force of the straight tooth gear and the helical tooth shaft, and the helical line of a helical motion trail is orthogonal to the helical line of a helical structure of the helical teeth. Compared with a traditional lead screw, the gear lead screw has the advantages that not only is the sliding friction not generated, but also the motion lead angle can be significantly increased, the transmission efficiency is higher, and transmission is more reliable.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Wheel for track

The invention relates to a track-used wheel. The track-used wheel has a wheel body, and the periphery of the wheel body forms a tread in contact with the track. One side of the wheel body is provided with a flange with the outer diameter larger than that of the tread, wherein, the flange and the wheel body are split structures, and the flange can be detachably and rotatably arranged on the periphery of the wheel body; a blocking edge is positioned outside the wheel body and the flange, and fixed on the wheel body by a fixture. The track-used wheel is provided with a rotary flange, and the flange and the wheel body are the split structures, thus overcoming the disadvantages of the known technology, greatly improving the service life of the whole wheel, lowering the use and maintenance cost, and having huge economic benefit. The track-used wheel has simple structure and wide application range, and can be applied to motor cars, trail cars and the like which run on tracks.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

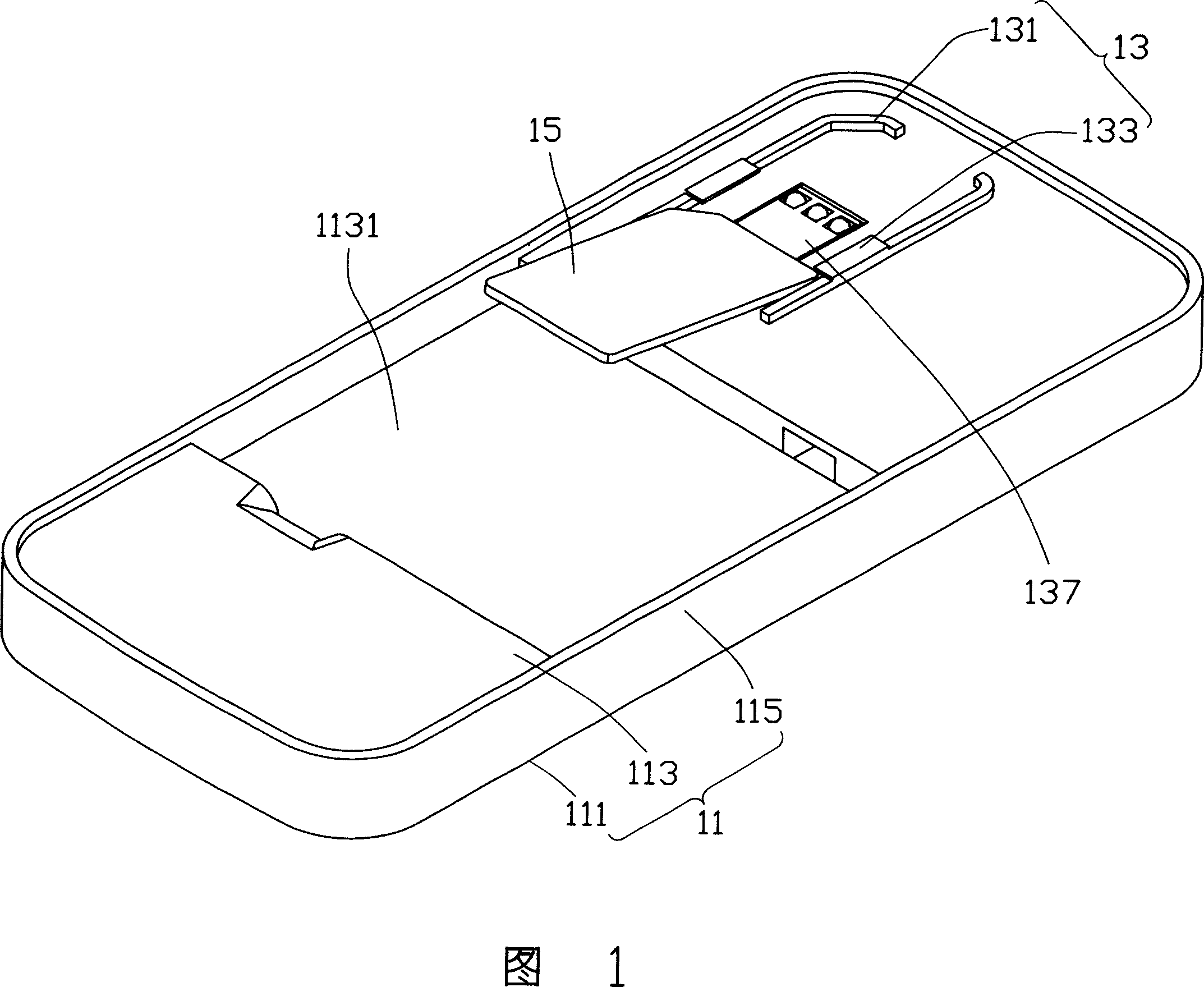

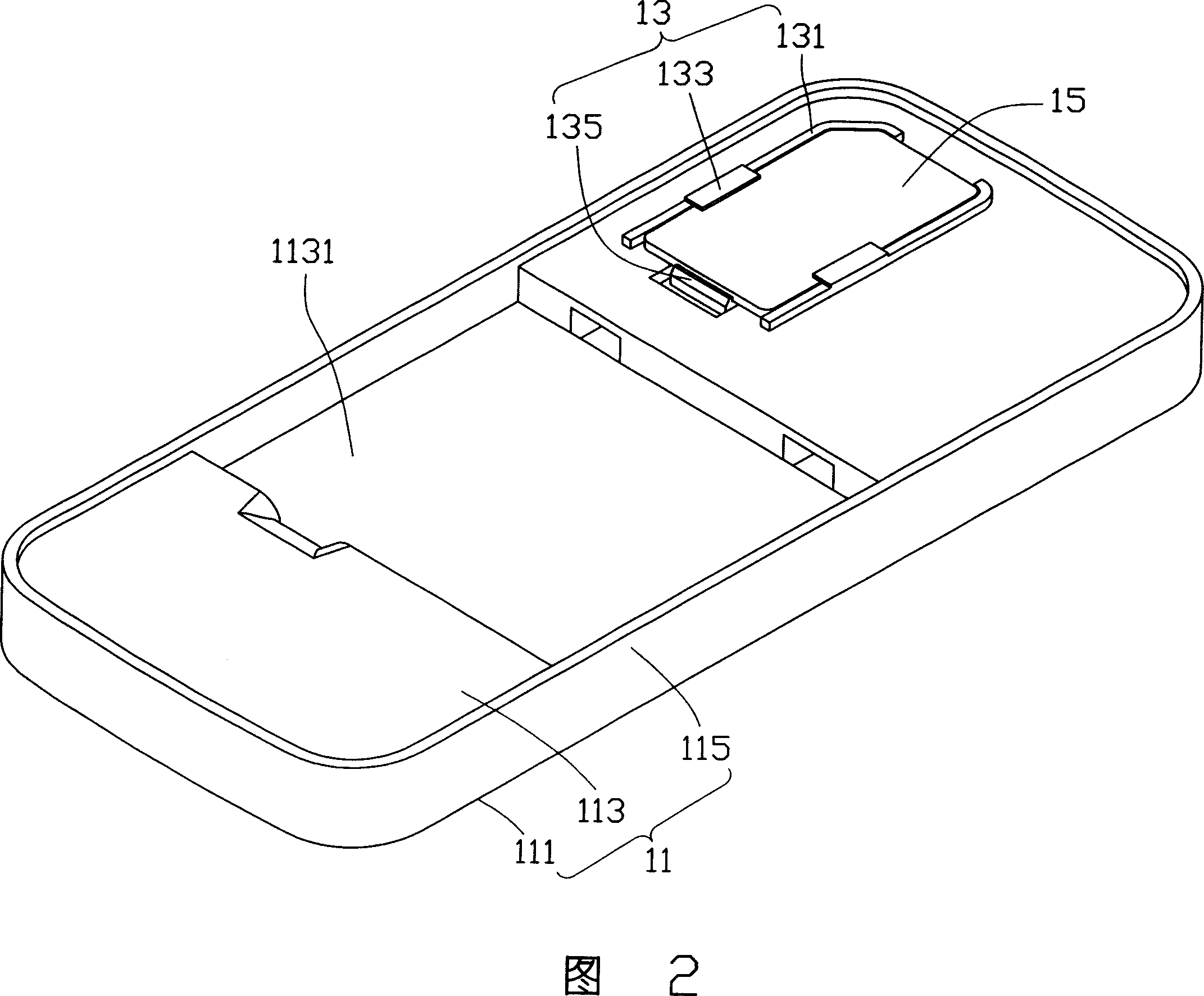

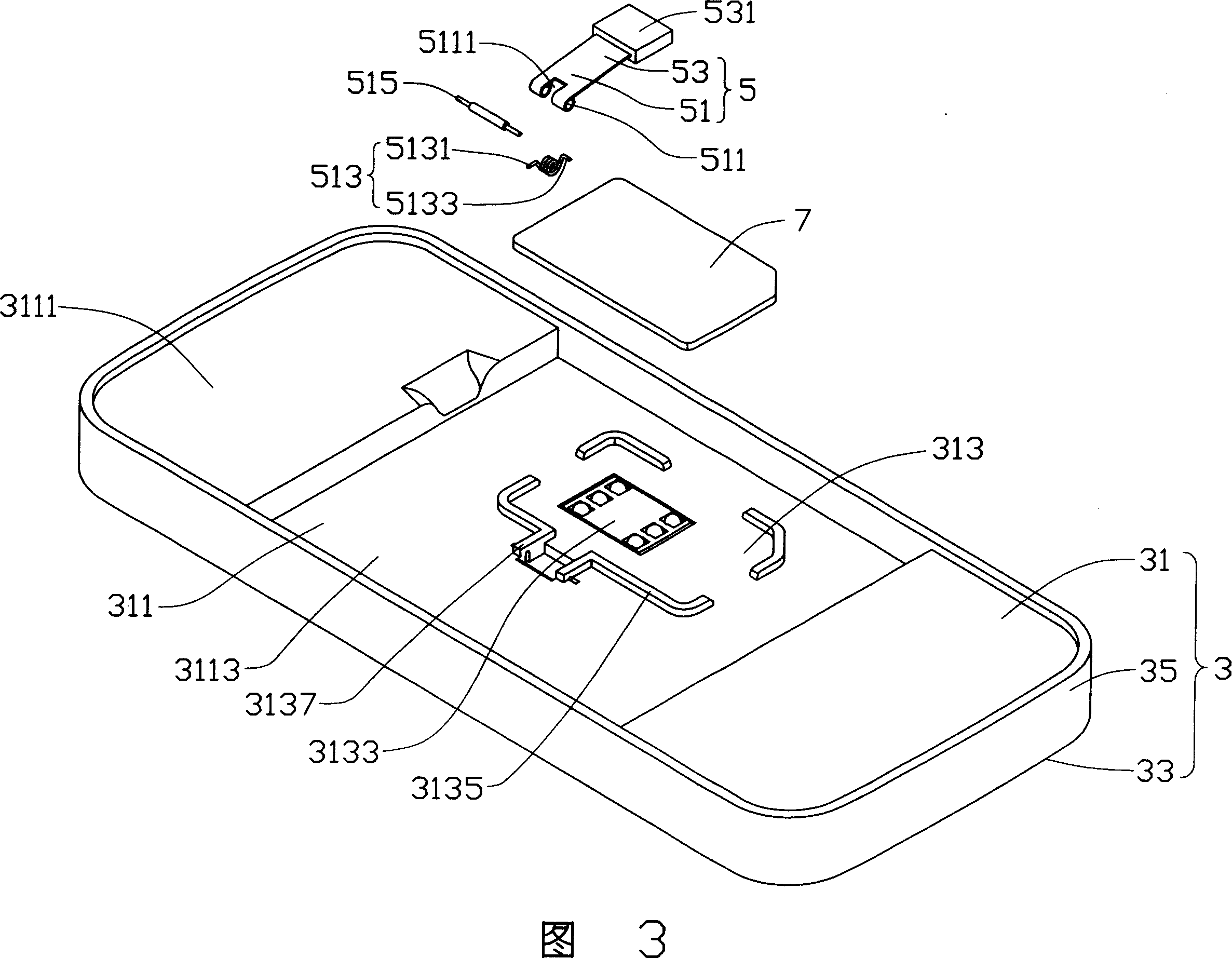

Portable electronic production chip card fixing device

InactiveCN101022707AAffects the stability of the conductive connectionNo sliding frictionResilient/clamping meansCircuit arrangements on insulating boardsEngineering

A fixing device of chip card on portable electronic product is prepared as arranging a containing cavity for holding said chip card on shell, fixing elastic arm relatively on shell in rotary mode and enabling elastic unit to exert force on said elastic arm for making said elastic arm be supported against on said containing cavity for holding said chip card.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

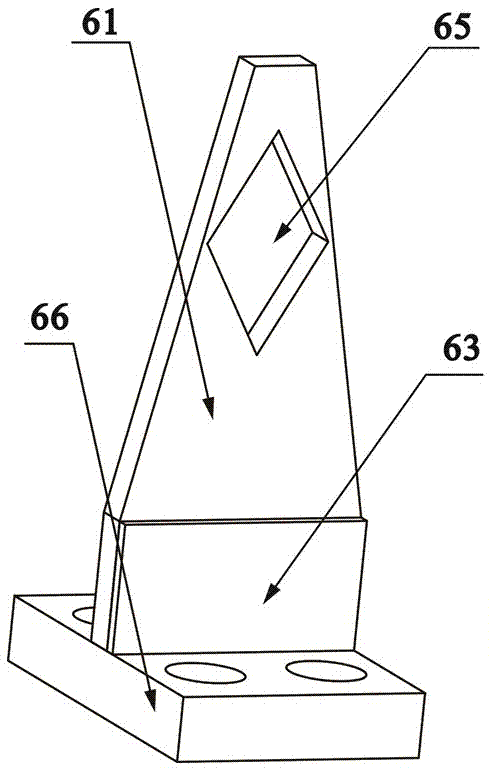

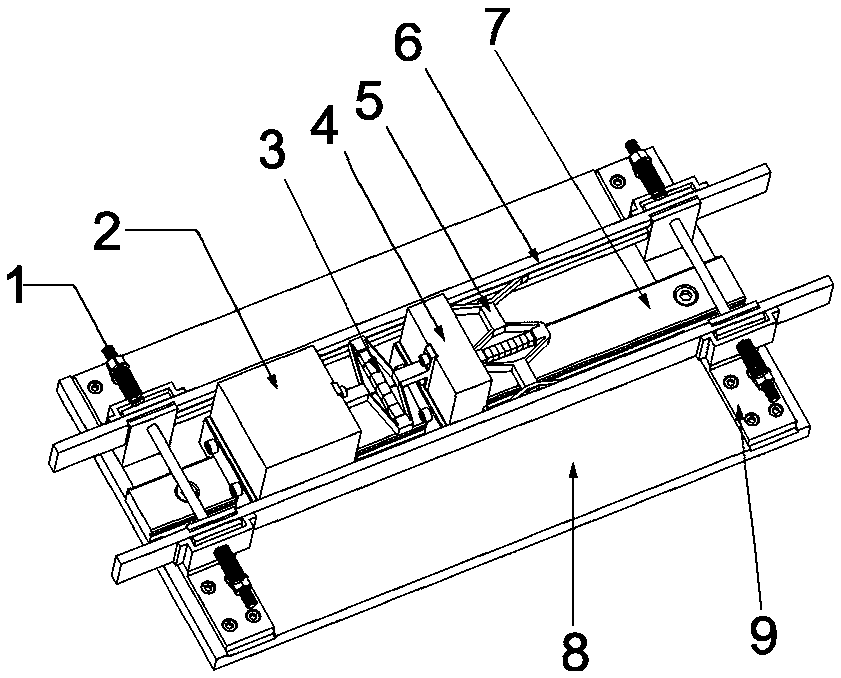

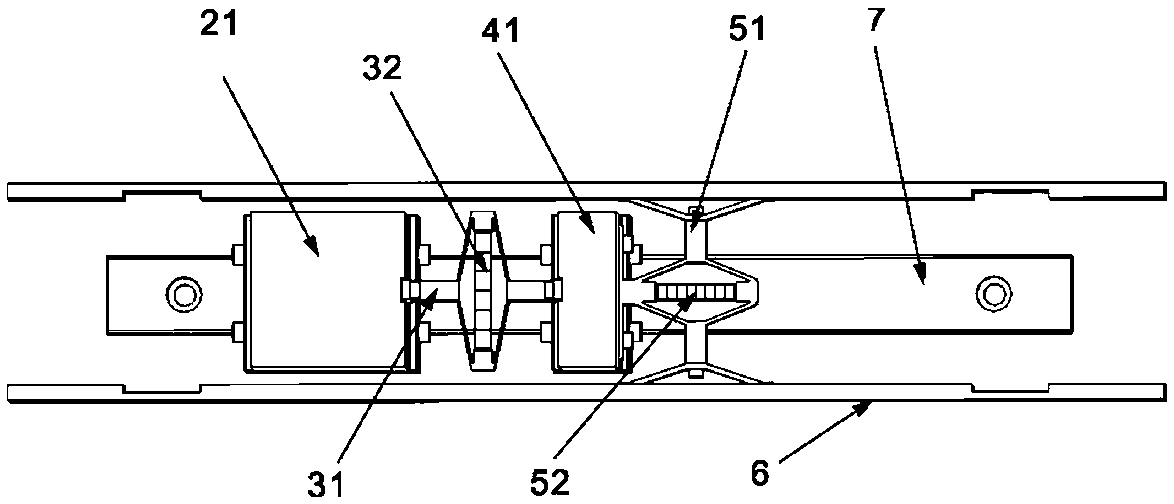

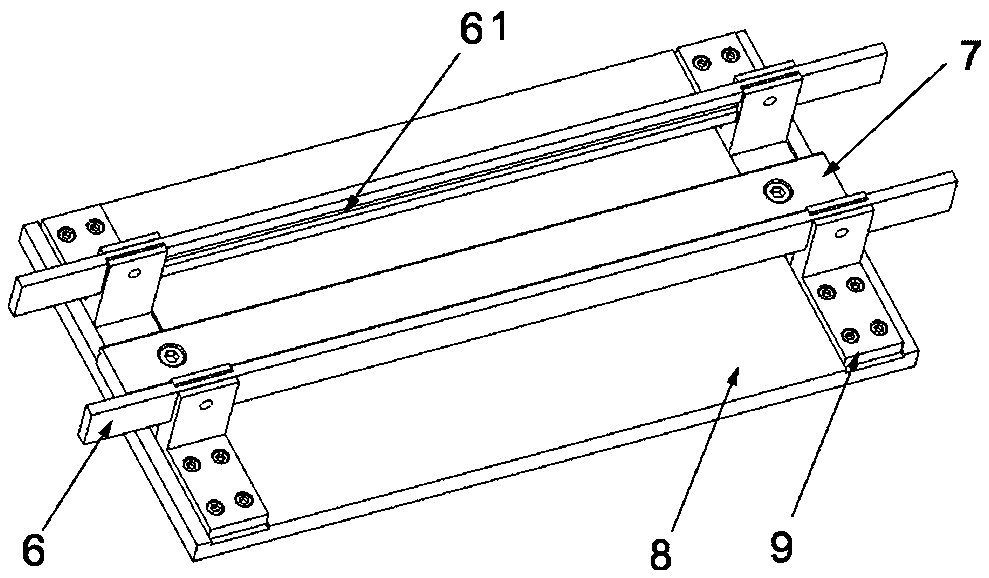

Clamping control inertial impact motor

ActiveCN111049422AStrong ability to withstand pressureSimple structurePiezoelectric/electrostriction/magnetostriction machinesLinear motionRhombic drive

The invention relates to a clamping control inertia impact motor, and belongs to the technical field of precision driving and positioning. The motor comprises a base, a pair of clamping guide rails, alinear slide rail, a weight balancing mechanism, a mass mechanism, a driving mechanism and a clamping mechanism; the two clamping guide rails are arranged on the base in parallel; the linear slide rail is arranged on the base and is located between the two clamp guide rails; the weight balancing block of the weight balancing mechanism and the mass block of the mass mechanism are arranged on the linear sliding rail in a sliding mode through sliding blocks respectively; the driving mechanism comprises a hollow rhombic driving piece and a driving piezoelectric stack; the clamping mechanism comprises a hollow rhombic clamping piece and a clamping piezoelectric stack; the driving mechanism controls the extension and contraction of a pair of driving feet by utilizing the inverse piezoelectric effect of the driving piezoelectric stack; the clamp mechanism controls the extension and contraction of the pair of clamping feet by utilizing the inverse piezoelectric effect of the clamping piezoelectric stack; the bidirectional linear motion of the piezoelectric motor is realized through the cooperative work of the driving mechanism and the clamping mechanism. Theoretically, the clamping mechanism does not generate sliding friction force, and therefore, energy loss is small.

Owner:HEFEI UNIV OF TECH

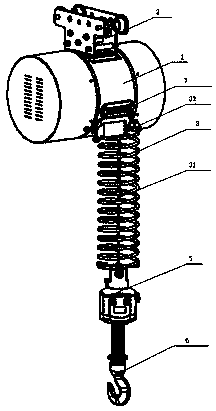

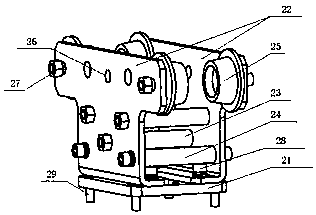

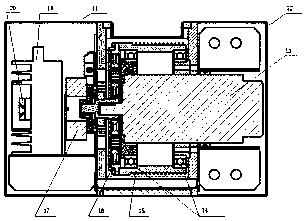

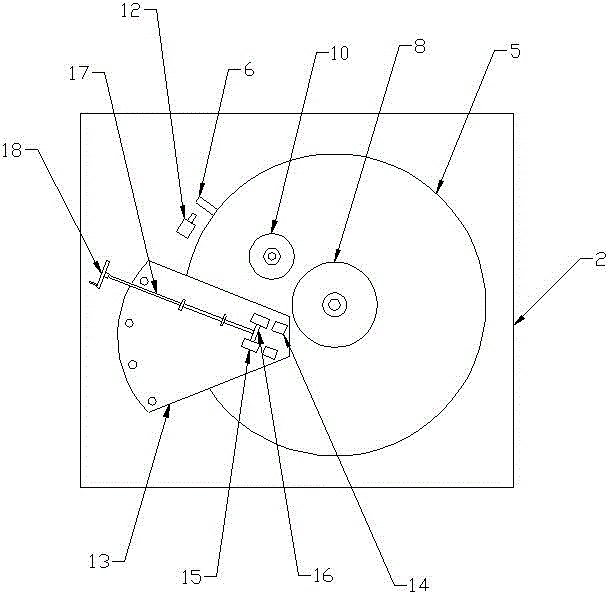

Steel wire rope intelligent hoisting and lifting device

InactiveCN109911788AExtend your lifeNo sliding frictionDynamo-electric machinesWinding mechanismsProximity sensorEngineering

The invention discloses a steel wire rope intelligent hoisting and lifting device comprising a main machine, an I-shaped trolley mounted on the top surface of the main machine, a spring mounted on thelower bottom surface of the main machine, a handle mounted at the lower end of the spring through a spring clip, a rotating hook assembly installed at the lower end of the handle and a proximity sensor mounted on the lower side face of the main machine; a steel wire rope in the main machine extends out from an opening below the main machine to penetrate the spring to be fixedly connected with theupper end of the handle; the main machine includes a front cover and a rear cover, the rear cover is internally provided with a first stepping motor and a steel wire rope winding disc, the steel wirerope winding disc is connected to the outside of the first stepping motor in a sleeving manner through a rolling bearing, the driving end of the first stepping motor is connected to the steel wire rope winding disc through a planetary reducer so as to be used for driving the steel wire rope winding disc to rotate, and the front cover is internally provided with a 103v electromagnetic brake pad matched with the driving end of the first stepping motor. The equipment and accessories of the steel wire rope intelligent hoisting and lifting device are all made in China, the cost is reduced, the body shape becomes small, the center of gravity is in the middle portion and is not inclined, and the steel wire rope is not prone to being abraded.

Owner:袁匡柳

Bending device capable of adjusting pipe angle

The invention relates to a bending device capable of adjusting the pipe angle. The bending device comprises a supporting frame. A fixing plate is arranged at the upper portion of the supporting frame. A rotary shaft is arranged at the lower portion of the center of the fixing plate, the lower end of the rotary shaft is connected with a rotating motor, and the rotating motor is connected with an angle sensor. A rotary disc is fixedly connected with the upper portion of the rotary shaft. A limiting blocking piece is arranged at the outer edge of the rotary disc, and a supporting base is arranged at the lower portion of the rotary disc. A main bending wheel is connected with the upper end of the rotary shaft, and an arc groove is formed in the outer edge of the main bending wheel. An auxiliary bending wheel is arranged on one side of the upper surface of the rotary disc. A fixing base and a reset switch are arranged on the upper surface of the fixing plate. A supporting plate is arranged on the upper surface of the fixing base. Pipe fixing bases A and pipe fixing bases B are arranged at the end of the upper surface of the supporting plate. A connecting rod is arranged between the pipe fixing bases B and connected with a threaded rod, and a hand wheel is arranged at one end of the threaded rod. The bending device capable of adjusting the pipe angle has the beneficial effects of being simple in structure, reasonable in design and high in production efficiency, reducing the labor intensity of workers and facilitating adjustment of the bending angle.

Owner:HENAN SINOKO CRANES

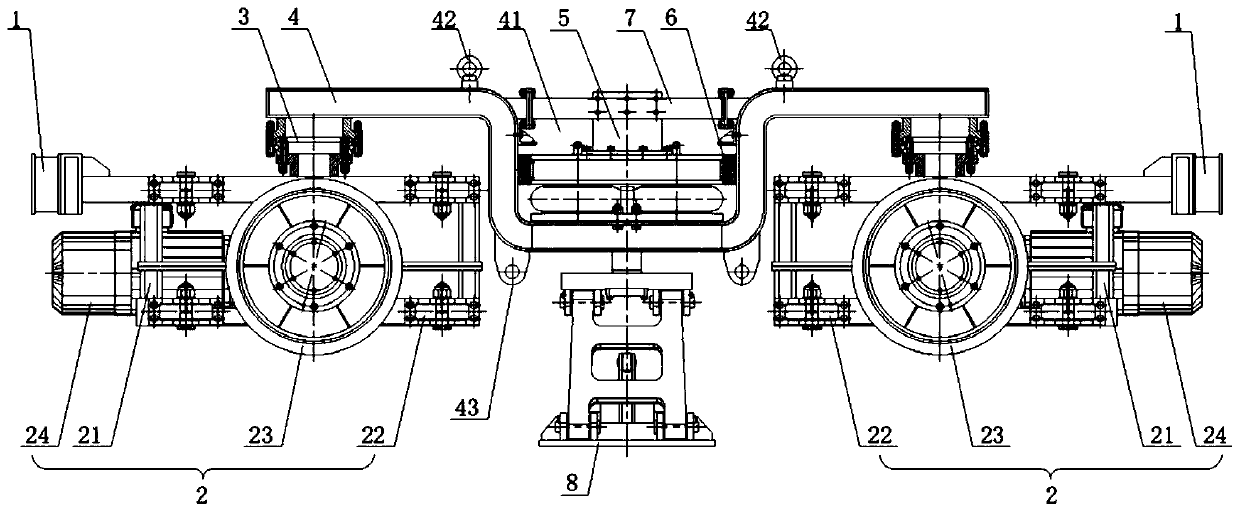

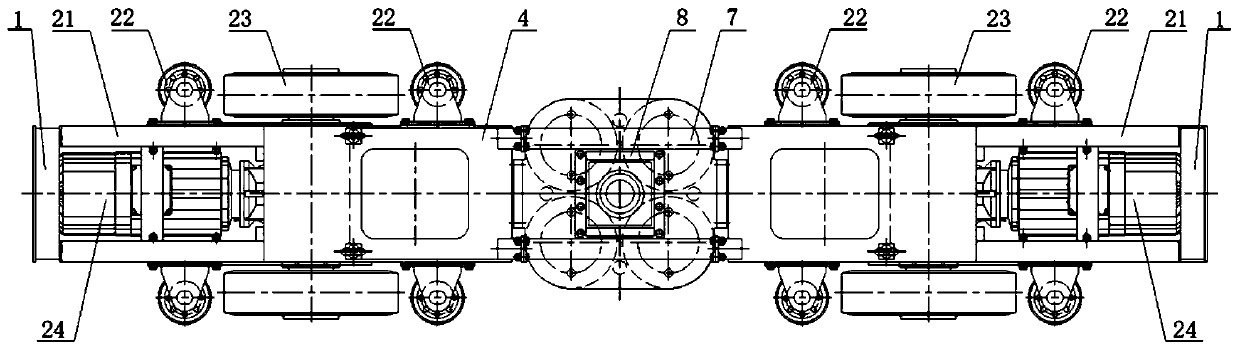

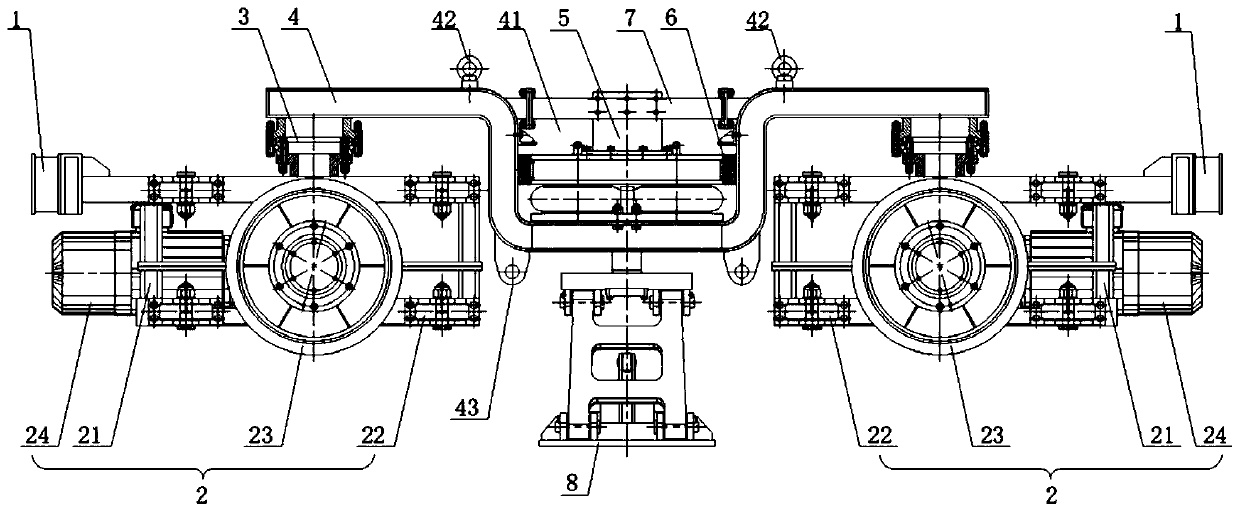

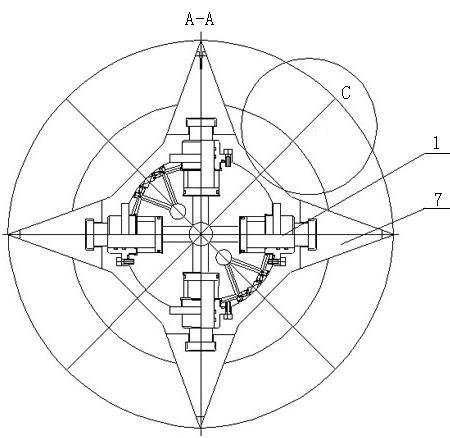

Sky train bogie

ActiveCN111152798AExtended service lifeNo sliding frictionElevated railway with suspended vehicleBogiesSlewing bearingBogie

The invention discloses a sky train bogie which comprises a bearing frame, wherein a center shaft device is arranged in the middle of the bearing frame; and the two swing mechanisms which are arrangedat the two end parts of the bearing frame respectively and are connected with the bearing frame through slewing bearings, so that the swing mechanisms and the bearing frame can rotate around the axial directions of the slewing bearings. Each swing mechanism comprises a frame body, guide wheels, walking wheels and a driving device for driving the walking wheels to rotate, and the guide wheels areconnected to the positions, on the front sides and the rear sides of the walking wheels, of the frame body. The sky train bogie can adapt to a track with a small turning radius, meanwhile, sliding friction between the walking wheels and the track is avoided, and the service lives of the walking wheels and the track is prolonged.

Owner:北京中冶设备研究设计总院有限公司

Free noninvasive endoscope pushing device

The invention discloses a free noninvasive endoscope pushing device which comprises an inner film tube assembly and an outer film tube assembly. The inner film tube assembly is used for pushing a lens, and the outer film tube assembly sleeves the outside of the inner film tube assembly; the inner film tube assembly and the outer film tube assembly respectively comprise liquid-filled film tubes, and the outer wall of the film tube of the inner film tube assembly is in contact with the inner wall of the film tube of the outer film tube assembly under the effects of liquid pressures; the inner wall of the outer film tube assembly is driven to be extended when the inner film tube assembly moves. The free noninvasive endoscope pushing device has the advantages that the pushing speeds can be controlled, the pushing device can be taken out instantly, and accordingly the examination operation time can be greatly shortened; sliding friction between the pushing device and the inner walls of the small intestines of patients can be prevented, and accordingly noninvasive examination can be carried out on the small intestines of the patients.

Owner:YANTAI QIUYIN SIGHT GLASS

Plunger part of high pressure plunger type hydraulic pump

PendingCN108105083AExtended service lifeSmall pull-out forcePositive displacement pump componentsPositive-displacement liquid enginesReciprocating motionHydraulic pump

The invention discloses a plunger part of a high pressure plunger type hydraulic pump. The plunger part of the high pressure plunger type hydraulic pump comprises a plunger body and a sliding shoe connected with the front end of the plunger body; the front end of the plunger body is provided with a ball head used for being wrapped by the sliding shoe; a hole cavity for hydraulic oil flowing is formed in the plunger body; a through hole communicated with the hole cavity is formed in the portion, behind the ball head, of the plunger body; a check valve used for guaranteeing one-way flowing of hydraulic oil is arranged in the hole cavity; and when the hydraulic pump works, the plunger part is pushed to reciprocate, and the hydraulic oil is pushed by the plunger part to achieve one-way flowingthrough the hole cavity in the plunger body. The structural change is large, the plunger part is matched with the existing high pressure plunger type hydraulic pump, the pulling and disengaging forceof the plunger body and the sliding shoe is very small, the acting force of a reset spring is located on the plunger body, and therefore the closing requirement of the plunger part is greatly lowered; and meanwhile, the sliding shoe in the scheme is free of sliding friction, a plunger pair is free of complicated stress, the work stability is improved, and the service life of the plunger part is greatly prolonged.

Owner:QINGDAO LIKECHUAN HYDRAULIC MASCH CO LTD

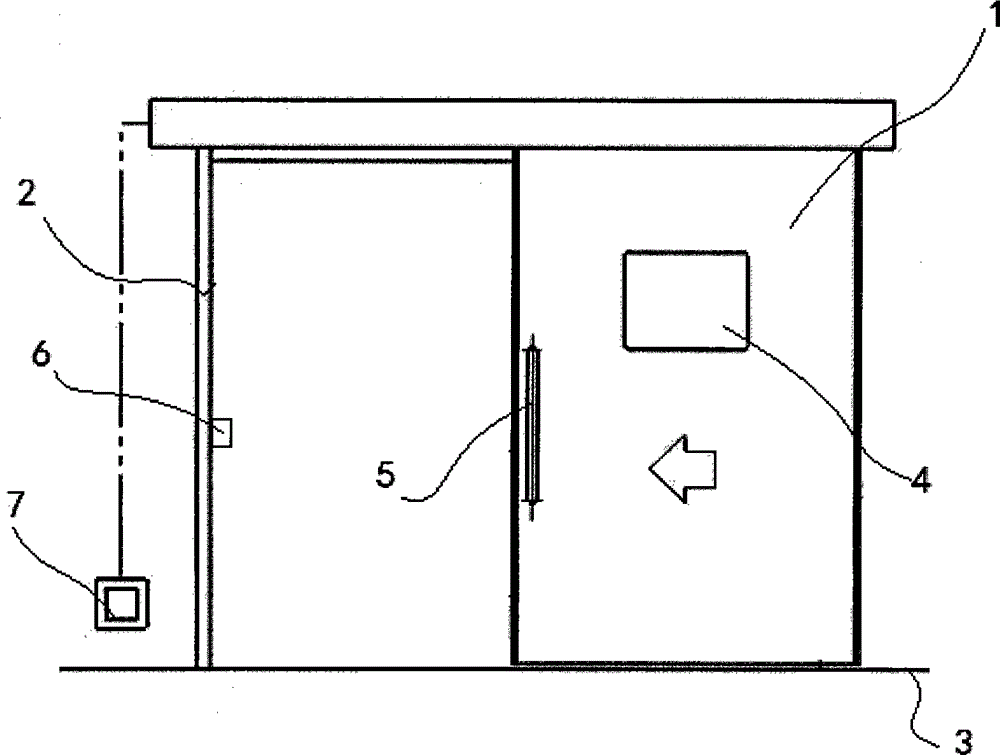

Workshop sealing door

InactiveCN105888457ANo sliding frictionExtended service lifeSealing arrangementsWing arrangementsEngineeringElectrical and Electronics engineering

The invention relates to a workshop sealing door which comprises a door body. The door body is arranged outside a door frame arranged on an entrance of a workshop. Guide wheel devices used for the door body to linearly move are arranged on the upper portion and the lower portion of the door frame. Door frame sealing rubber strips are arranged on the periphery of the outer side of the door frame, door body sealing rubber strips corresponding to the door frame sealing rubber strips are arranged on the periphery of the inner side of the door body, the door frame sealing rubber strips are installed in grooves in the door frame, an air bag is arranged in the groove and located behind the door frame sealing rubber strips, and the air bag is fixed to the door frame sealing rubber strips by means of a rigid connection flat plate. One side of the door frame is provided with a photoelectric detection switch used for detecting whether the door body is in a preset closing position, the photoelectric detection switch is connected with a controller, and the controller is connected with and controls an inflation valve used for inflating the air bag. According to the door, the door body sealing rubber strips and the door frame sealing rubber strips cannot rub one another in a sliding mode, the service life of the rubber strips is prolonged, and the peripheral sealing effect is good.

Owner:TIANJIN HAITAO DOOR & WINDOW CO LTD

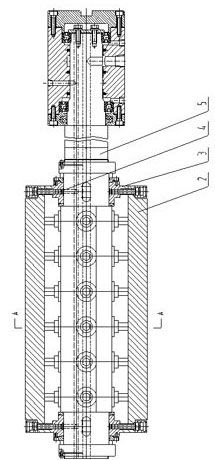

Expansion and shrinkage seamless recoiling machine of radial oil cylinders of twenty-high roll steel plate cold rolling mill

The invention belongs to the field metallurgical equipment, in particular to an expansion and shrinkage seamless recoiling machine of radial oil cylinders of a twenty-high roll steel plate cold rolling mill. The recoiling machine is characterized in that four radial oil cylinders are radially distributed by a revolution main shaft in a four-leaved block in a way that the four radial oil cylinders are vertical with each other; the four-leaved boosting pistons of the four radial oil cylinders are radially connected with telescopic oblique blocks; the triangular oblique planes of the telescopic oblique blocks form interval connection with the four-leaved block; the four-leaved boosting pistons make telescopic movement after pressure oil respectively enters the four radial oil cylinders, the four-leaved boosting pistons drive the connected oblique blocks to also make the telescopic movement, and then the four telescopic oblique blocks push the four-leaved block to be expanded and shrunk, and meanwhile, under the action of the four-leaved boosting pistons, the four-leaved block is smoothly retracted and forms gaps with coiled stocks, which is beneficial to debatching. The invention provides the expansion and shrinkage seamless recoiling machine of the radial oil cylinders of the twenty-high roll steel plate cold rolling mill, with good processing manufacturability, high precision, flexible movement, convenient use and long service life.

Owner:王胜翔 +1

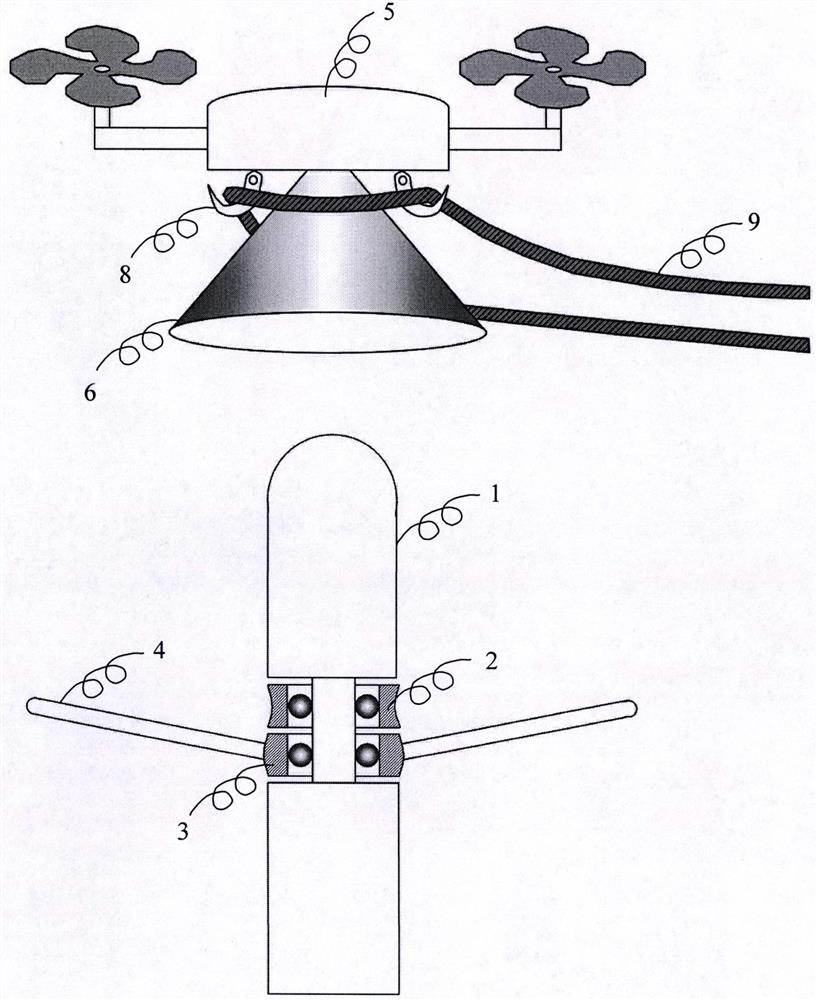

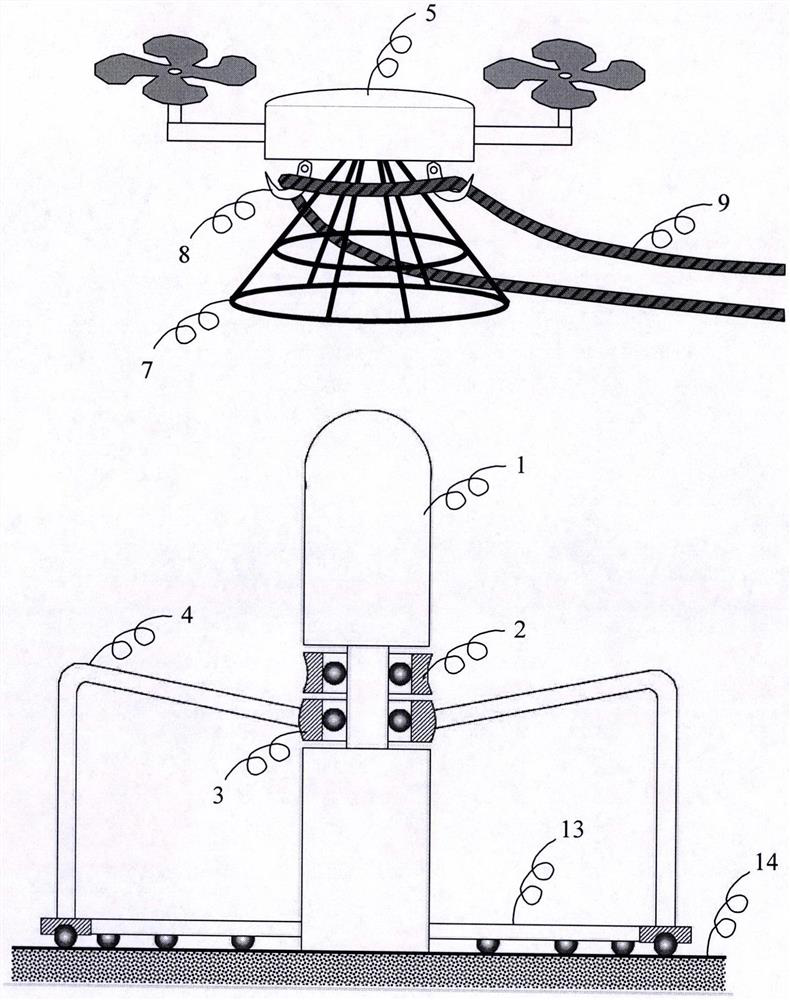

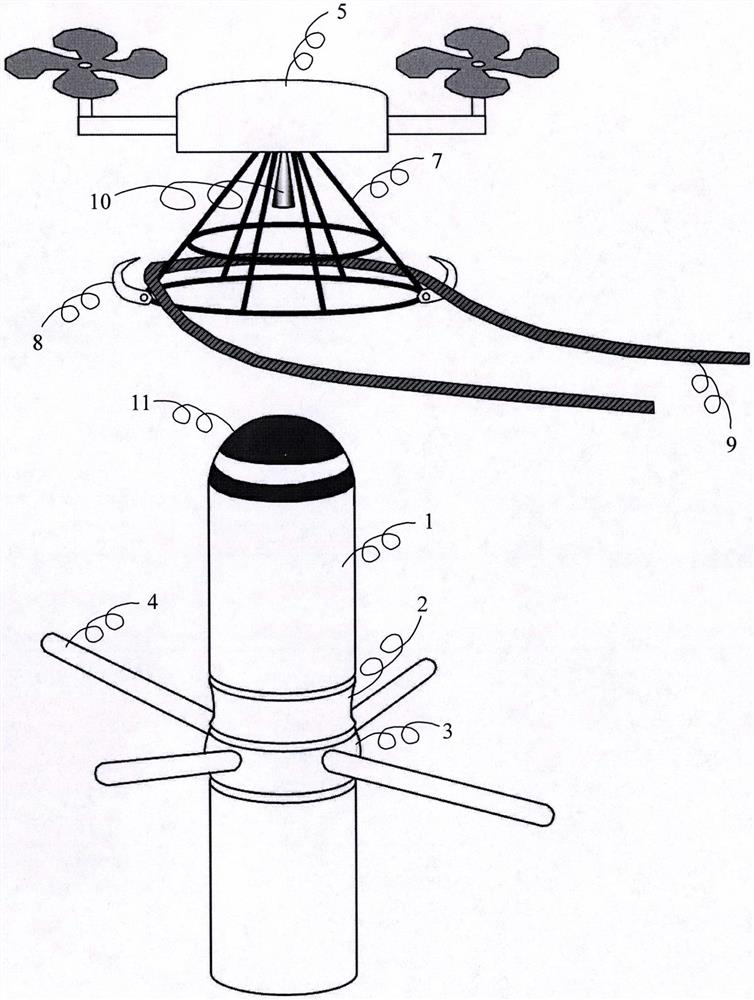

An automatic rope erection system between tall buildings

ActiveCN110354408BReciprocating motion is efficient and safeNo sliding frictionBuilding rescueMarine engineeringReciprocating motion

The invention discloses an automatic rope erecting system between tall buildings. The system aims at achieving automatic erecting of a rope capable of doing reciprocated motion between roofs of two tall buildings. The system comprises stand columns on the roofs and an unmanned aerial vehicle for conveying the rope, the tops of the stand columns are in smooth blunt tip shapes, the middle of each stand column is sleeved with a pulley, the outer ring of the pulleys is slightly smaller than the diameter of the stand columns, a trumpet-shaped guide rail is arranged on the lower face of an unmannedaerial vehicle body, and is used for guiding the unmanned aerial vehicle to hover above the stand columns, a ring of hooks are arranged on the lower face of the unmanned aerial vehicle body in a manner of surrounding the trumpet-shaped guide rail, the rope required to be erected is hung on the hooks around the trumpet-shaped guide rail, after the rope is hung, the hooks are put away to ensure thatthe rope cannot fall off from the unmanned aerial vehicle in the conveying process, after the unmanned aerial vehicle hovers above the stand columns, the hooks are opened to enable a rope sleeve to fall to sleeve the stand columns, and the rope sleeve further slides to sleeve the pulleys of the lower ends of the stand columns. The erected rope can do reciprocation motion around the pulleys, and the rope can conveniently convey the persons and goods and materials in a reciprocated manner between the roofs of the tall buildings.

Owner:CIVIL AVIATION UNIV OF CHINA

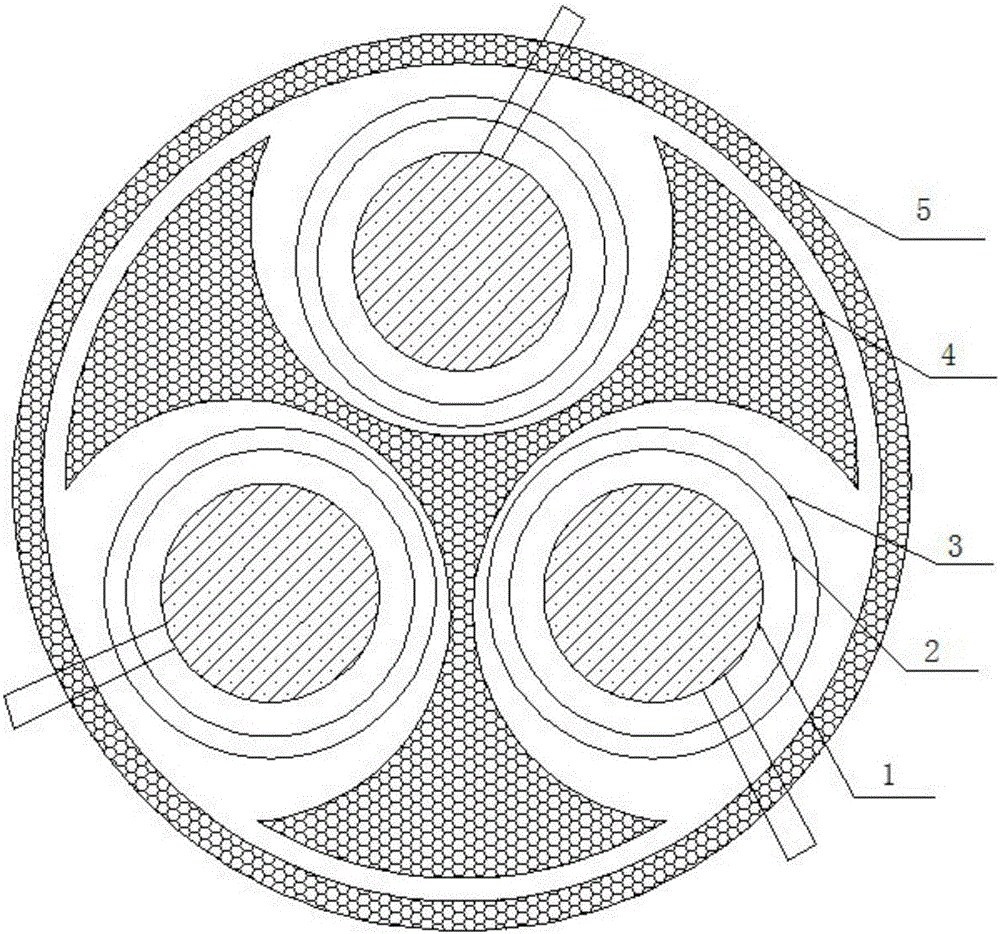

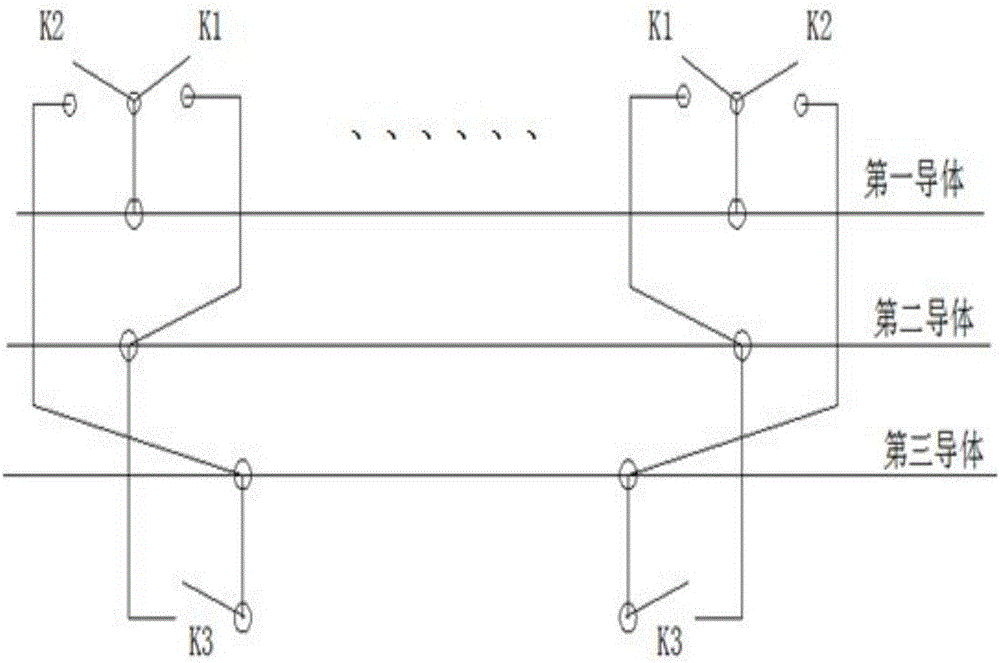

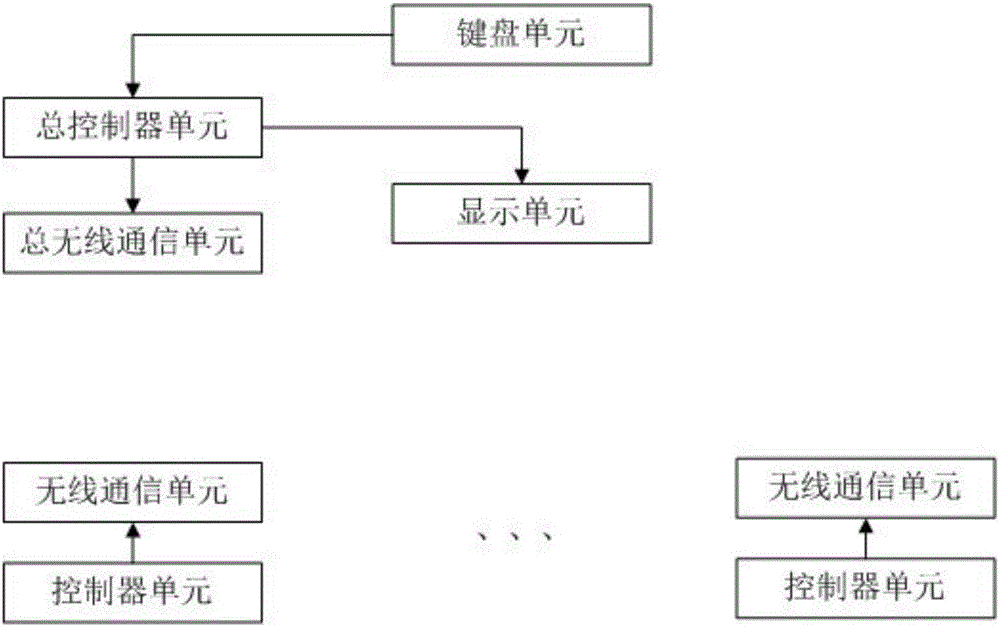

High-strength low-resistivity high-voltage transmission power cable

InactiveCN105761818ASolve the problem of long-term large-scale power outagesNo sliding frictionConductive materialPower cables with screens/conductive layersElectrical conductorPower cable

The invention discloses a high-strength low-resistivity high-voltage transmission power cable, which comprises three conductors, conductor shielding layers, an insulated layer, a protection layer, a cylindrical fixing device, a remote breakpoint detection unit and N terminal breakpoint detection units, wherein the conductor shielding layers are arranged outside the conductors; the insulated layers are arranged outside the conductor shielding layers; the three conductors are arranged in the protection layer; the cylindrical fixing device is located in the protection layer; the side surface of the cylindrical fixing device is provided with three arc-shaped grooves at equal intervals; the three conductors are respectively located in the arc-shaped grooves; the cavity formed between the conductors, the cylindrical fixing device and the protection layer is filled with an insulated filler; and the N terminal breakpoint detection units are arranged on the high-strength low-resistivity high-voltage transmission power cable line at equal intervals. The problem of short circuit caused by friction does not happen, the breakpoint can be quickly judged once the broken circuit problem happens to the power cable, and the wire core has high strength and low resistivity.

Owner:谢春梅

Winding device of roller shutters

InactiveCN102704825ASmall footprintReduce use noiseDoor/window protective devicesTorsion springPulp and paper industry

The invention discloses a winding device of roller shutters, relates to the technical field of the roller shutters, and aims to reduce the space usage, improve the rotation flexibility and reduce the noise in use. The device comprises a main supporting shaft, wherein the main supporting shaft is a straight shaft; and a spring is sleeved on the left end and the right end of the main supporting shaft respectively. The device is characterized in that: a movable revolving drum is coaxially sleeved on the periphery of the main supporting shaft; the revolving drum is a straight drum of which the two ends are connected with the main supporting shaft through bearings respectively and the outer walls at the two ends are fixed with a roller shutter seat for fixing the roller shutters respectively; the springs are torsion springs; and one end of each torsion spring is fixedly connected with the main supporting shaft, and the other end of each torsion spring is fixedly connected with the revolving drum. The device provided by the invention is suitable for the roller shutter type doors and windows.

Owner:SHANGHAI POWERWAY LOGISTICS EQUIP

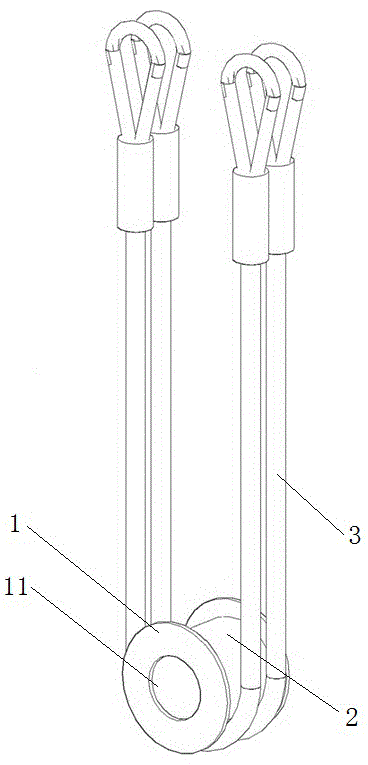

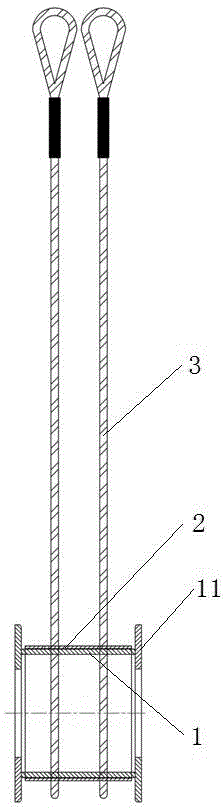

Shaft type lifting system for protecting steel wire rope

InactiveCN104860187APrevent slippingAvoid damageLoad-engaging elementsEngine lubricationControl theoryRubbing

The invention discloses a shaft type lifting system for protecting a steel wire rope, and belongs to the technical field of lifting equipment. The shaft type lifting system for protecting the steel wire rope comprises a shaft type lifting point and the steel wire rope, wherein an external contour type protective cover in sliding fit with the shaft type lifting point is arranged outside the shaft type lifting point, and covers the external of the shaft type lifting point; the steel wire rope is lifted outside the external contour type protective cover; and baffle plates respectively in stop fit with the external contour type protective cover are fixed at the two ends of the shaft type lifting point. The shaft type lifting point generates no direct contact with the lifting steel wire rope; in the lifting and overturning process, the lifting steel wire rope is only contacted with the external contour type protective cover; and the lifting steel wire rope and the external contour type protective cover are kept relatively stationary without sliding and rubbing, so that the damage caused by the sliding and the rubbing of the steel wire rope is reduced, and the service life of the steel wire rope is prolonged. Therefore, the shaft type lifting system can guarantee difficult damage of the steel wire rope in the lifting process.

Owner:SINOPEC NANJING ENG & CONSTR +1

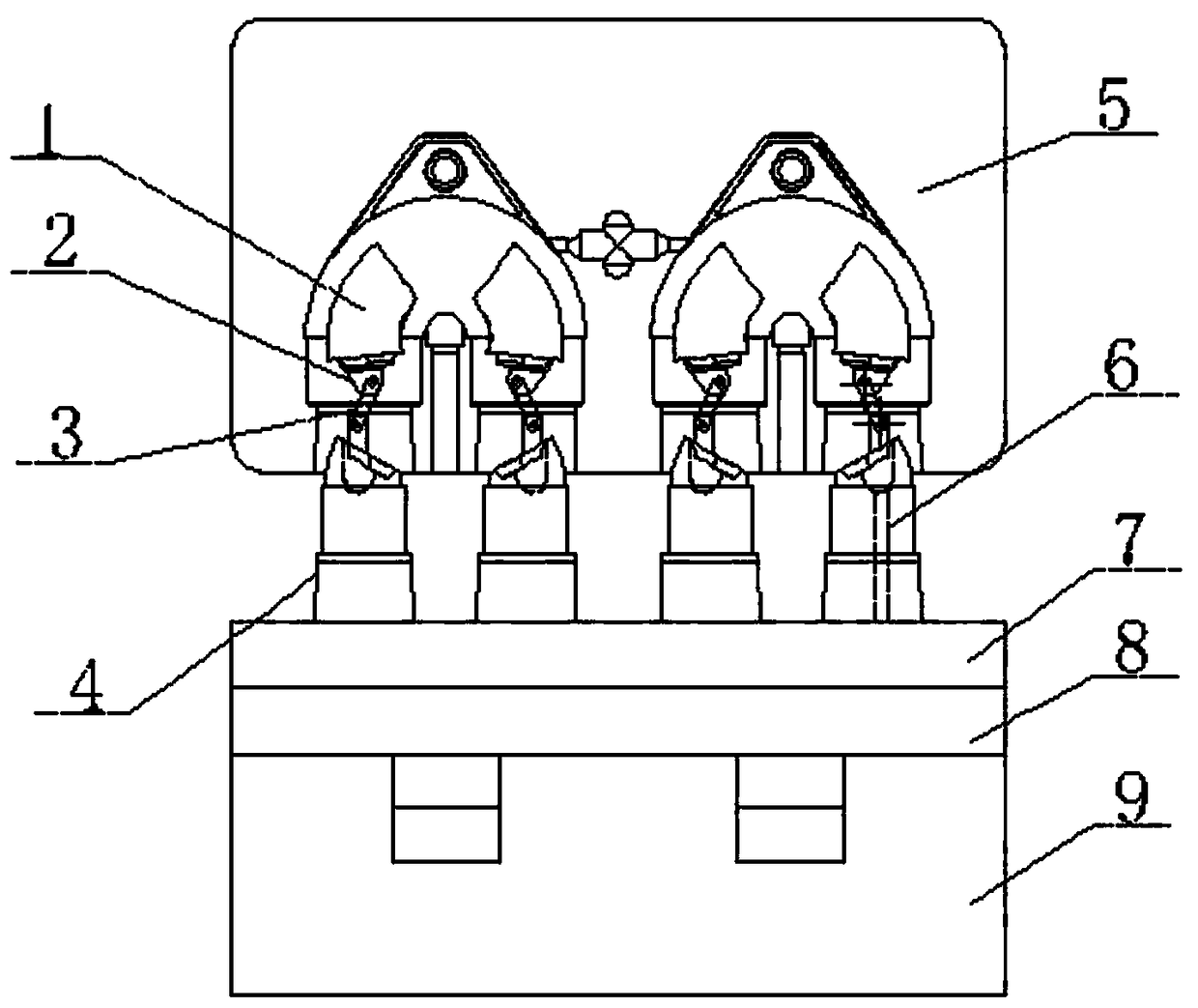

Universal chuck device for cylindrical grinding machine

InactiveCN102229070AEffectively fixedEasy to fixRevolution surface grinding machinesStructural engineeringMachine

The invention relates to a universal chuck device for a cylindrical grinding machine. The device is characterized by comprising a first clamping block and a second clamping block which are symmetrically arranged, wherein an adjusting bolt and a fastening bolt are arranged at the left ends and the right ends of the first clamping block and the second clamping block respectively; the first clamping block is connected with the second clamping block through the adjusting bolt and the fastening bolt; one end of the fastening bolt is fixedly connected with the first clamping block through a fixing nut, and the other end of the fastening bolt is provided with a fastening nut for fixing the fastening bolt and the second clamping block; one end of the adjusting bolt is fixedly connected with the first clamping block through the fixing nut, and the other end of the adjusting bolt is provided with an adjusting nut; and inwards recessed clamping surfaces are formed on the middle parts of the sides on which the first clamping block and the second clamping block are arranged oppositely. By the device, a workpiece can be effectively and reliably fixed, and the stability of machining quality is greatly improved; and the device makes clamping convenient and greatly improves working efficiency.

Owner:WUXI XINYINYE MACHINERY

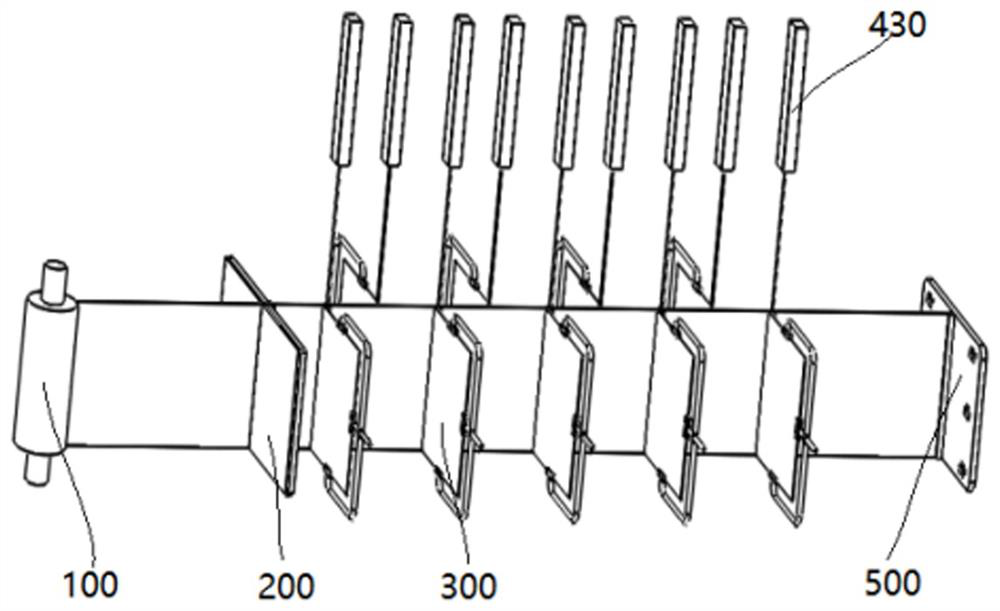

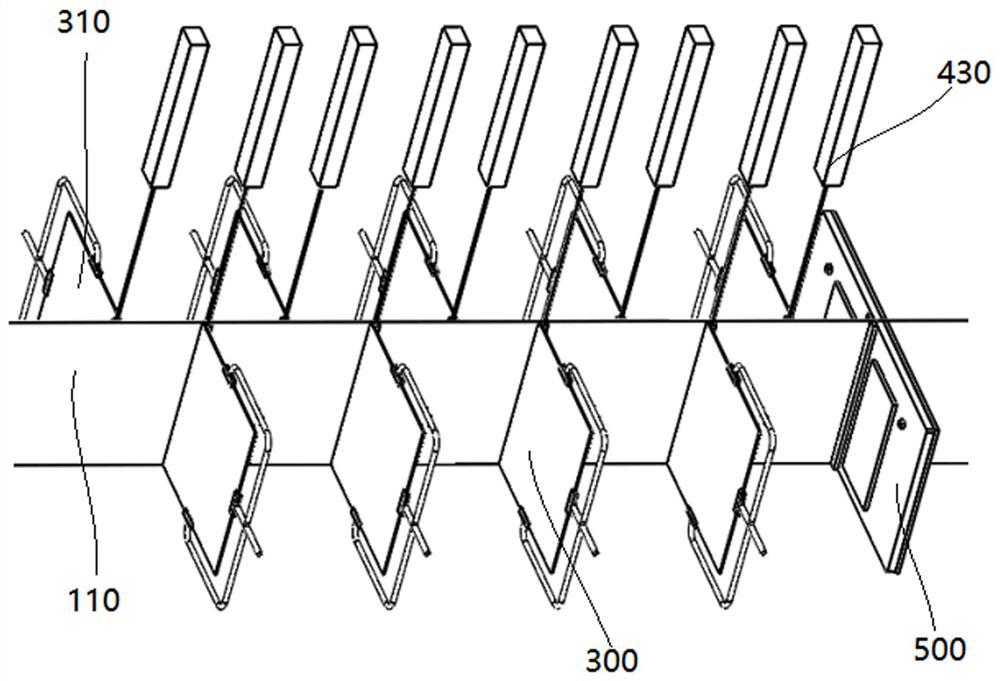

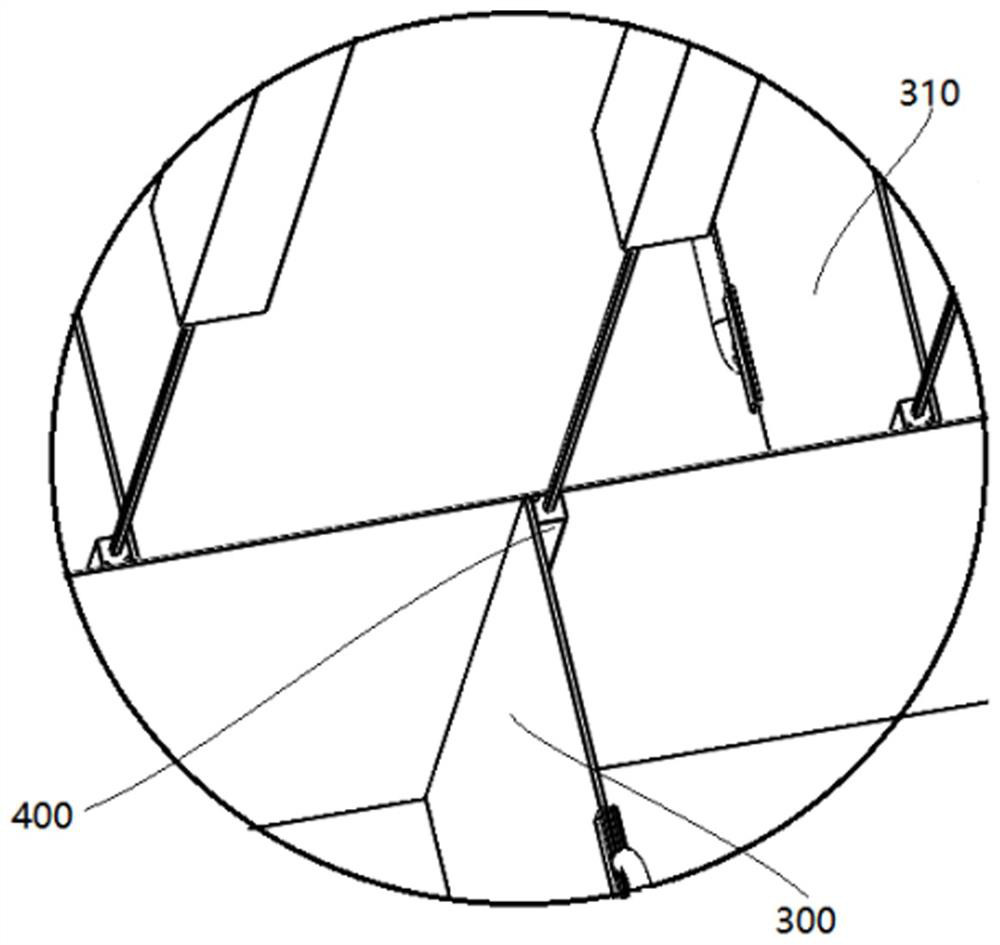

Lithium battery core lamination device and use method thereof

ActiveCN112151880AImprove production efficiencyImprove product qualityAssembling battery machinesFinal product manufactureStructural engineeringLithium battery

The invention discloses a lithium battery core laminating device, which comprises a diaphragm wound on an unwinding device, a tension mechanism connected with a winding device through the diaphragm, and a plurality of positive electrode sheets and a plurality of negative electrode sheets which are regularly arranged on the two sides of the diaphragm, wherein each positive electrode sheet and eachnegative electrode sheet are connected with a clamping device, each positive electrode sheet and each negative electrode sheet are correspondingly provided with a sheet laminating drill rod, each sheet laminating drill rod is a square cylinder, each positive electrode sheet and each negative electrode sheet are attached to the side surface of the corresponding sheet laminating drill rod, separating type laminating devices are further arranged on the two sides, close to the unwinding device, of the diaphragm, a plurality of telescopic protruding plates are further arranged on the separating type laminating devices, a telescopic clamp arranged in the tension mechanism is connected with the diaphragm, a plurality of tension sensors are regularly distributed on the telescopic clamp, and the separating type laminating devices move in the direction of the tension mechanism. According to the equipment, rapid lamination action of the multi-electrode sheet and the diaphragm can be completed simultaneously in one process, so that the lamination accuracy is improved, and the preparation efficiency of the lithium battery is greatly improved.

Owner:山东德晋新能源科技有限公司

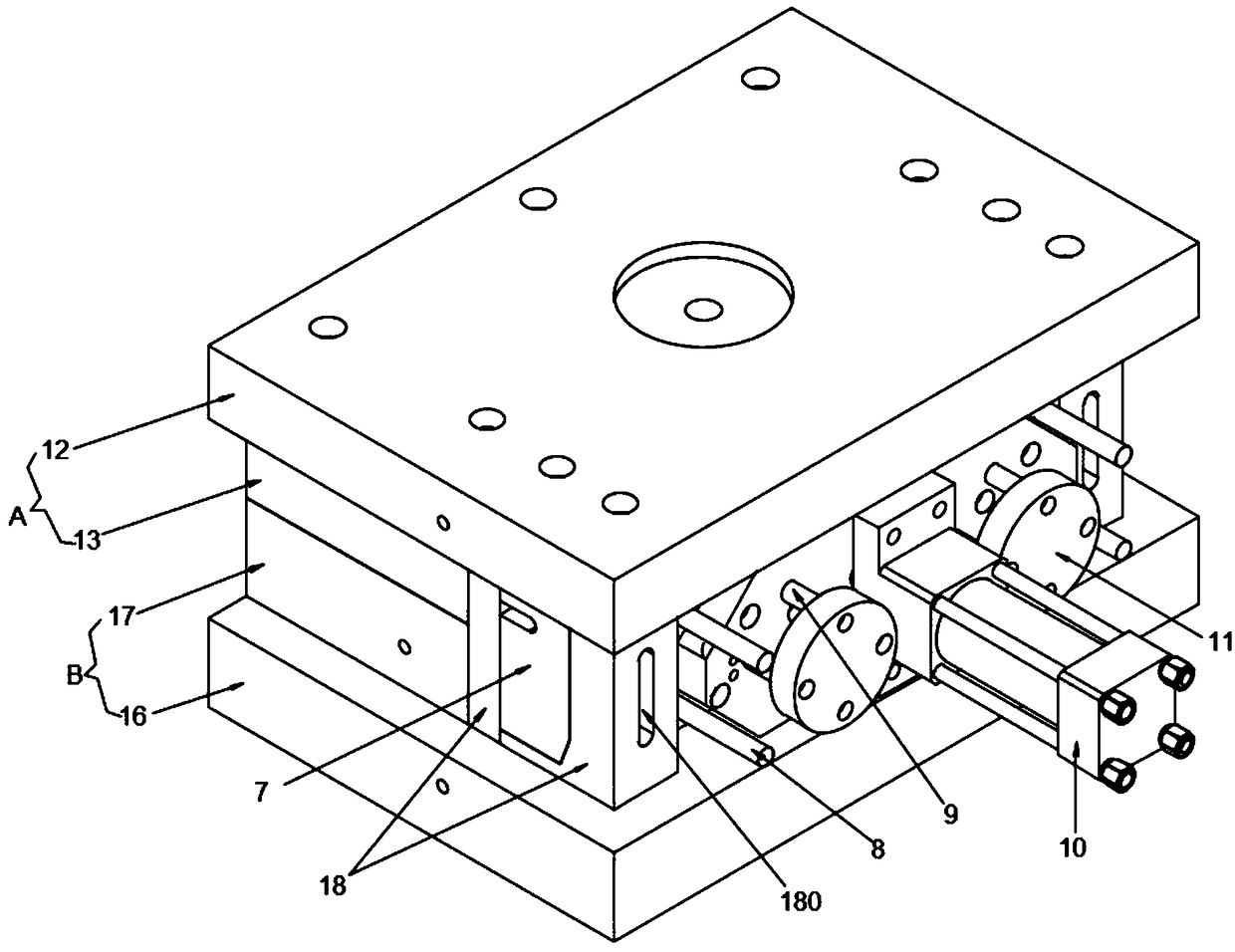

Mold for injection molding of U-shaped bent pipe fitting

The invention relates to the technical field of pipe fitting forming molds, in particular to a mold for injection molding of a U-shaped bent pipe fitting. The mold for injection molding of the U-shaped bent pipe fitting comprises a sliding seat capable of moving along the mold closing direction of a movable mold, a demolding plate capable of moving towards movable cores between a mold locking position and a demolding position, and a telescopic device used for driving the demolding plate; a core mold comprises a pair of movable cores and a pair of fixed cores, when the demolding plate moves towards the demolding position from the mold locking position, the demolding plate extrudes the end surface of the formed U-shaped bent pipe fitting, so that the U-shaped bent pipe fitting is separated from the movable cores and the fixed cores. In the mold for injection molding of the U-shaped bent pipe fitting, the U-shaped bent pipe fitting is pushed to be separated from the core mold by the aid of the demolding plate, automatic demolding can be completed without arranging an ejector pin, so that the surface of the U-shaped bent pipe fitting has no ejection marks and is more attractive.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Cloth roller transmission device of friction-free cloth rolling machine

InactiveCN102328857AReliable internal and external tensionSame tension inside and outsideEngineeringTransfer constant

The invention relates to a cloth roller transmission device of a friction-free cloth rolling machine, which comprises a base, a transmission case and a reversing frame with two sides being correspondingly and respectively provided with a side case. A cloth pulling shaft set is arranged at the top of the two side cases, and a cloth roller is arranged at the front of the two side cases. The cloth roller is connected with the cloth pulling shaft set in a driving way through a transmission mechanism which is installed in one side case. The transmission mechanism comprises a permanent magnet tension controller which is provided with a power input shaft and a power output shaft, a first transmission assembly which is arranged between the power input shaft of the permanent magnet tension controller and the cloth pulling shaft set, and a second transmission assembly which is arranged between the power output shaft of the permanent magnet tension controller and the cloth roller. By using the permanent magnet tension controller which transfers constant torque force by using a magnetic field as a medium, the cloth roller transmission device of the friction-free cloth rolling machine has the advantages that the friction-free transmission is realized, the output torque force is convenient to adjust, the service life of the transmission mechanism is greatly prolonged, the magnitudes of internal tension and external tension of rolled cloth are consistent, and the quality of the cloth is improved.

Owner:QUANZHOU LUOJIANG YONGTAI MACHINERY

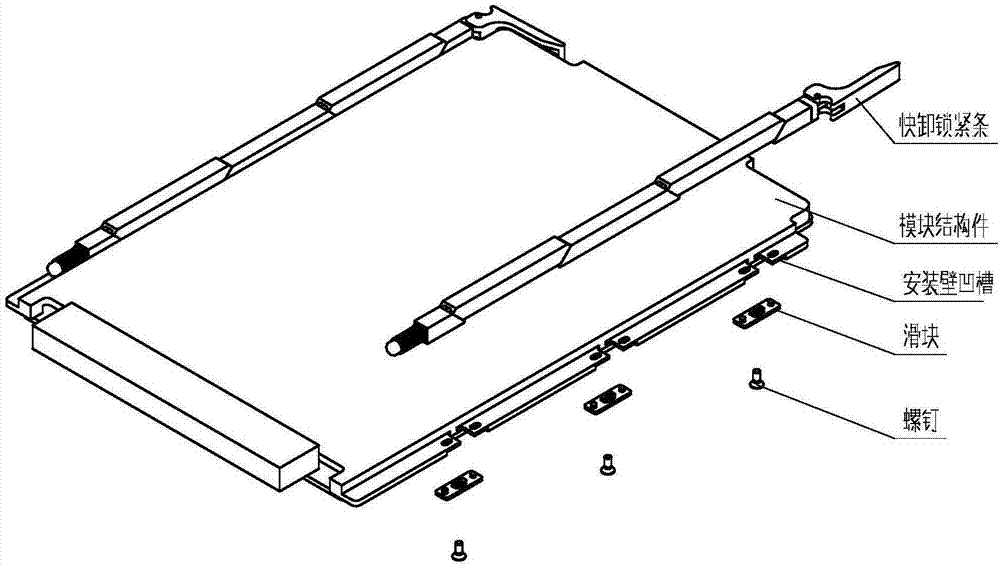

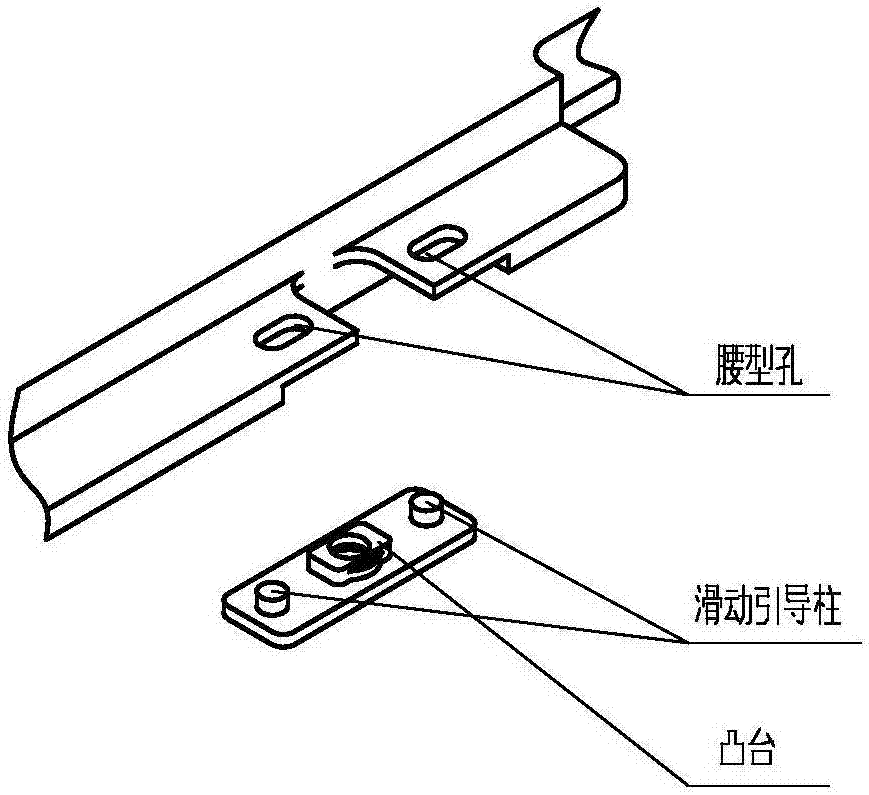

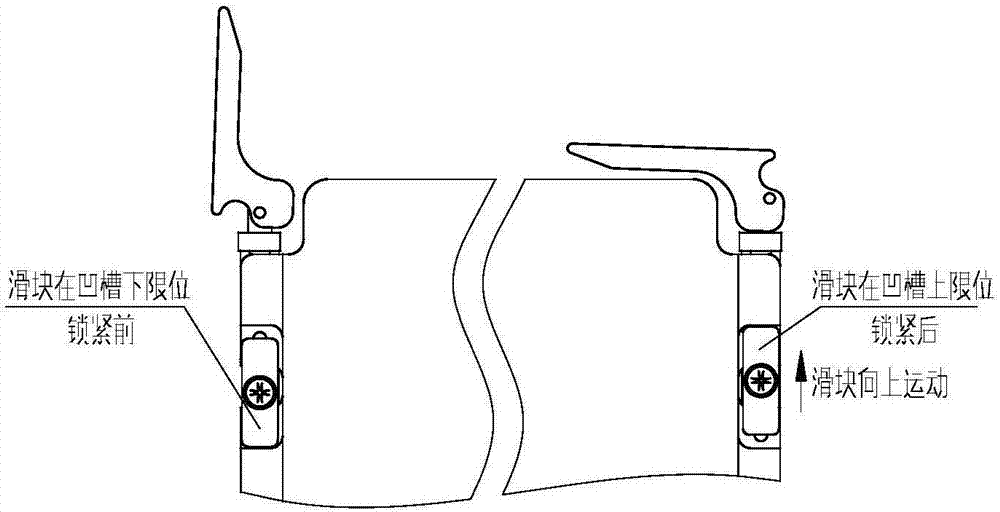

Locking strip float mounting mechanism and mounting method thereof

ActiveCN107979940APrevent lockOnly positive extrusionClamping/extracting meansComputer moduleMechanical engineering

The invention belongs to the technical field of electronic equipment mechanical structures, and relates to a locking strip float mounting mechanism and a mounting method thereof. A float mounting mechanism is employed, grooves and slide blocks are arranged in mounting walls of a module structure, locking strips can be mounted on the module structure in a float manner, only a positive extrusion force is generated between each locking strip and a corresponding guide-track groove, the locking strip and the corresponding guide-track groove do not generate sliding friction, and locking of the locking strips is avoided. The locking strip float mounting mechanism is simple in structure and convenient to use, and can effectively overcome the locking problem of locking strip wedge blocks.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

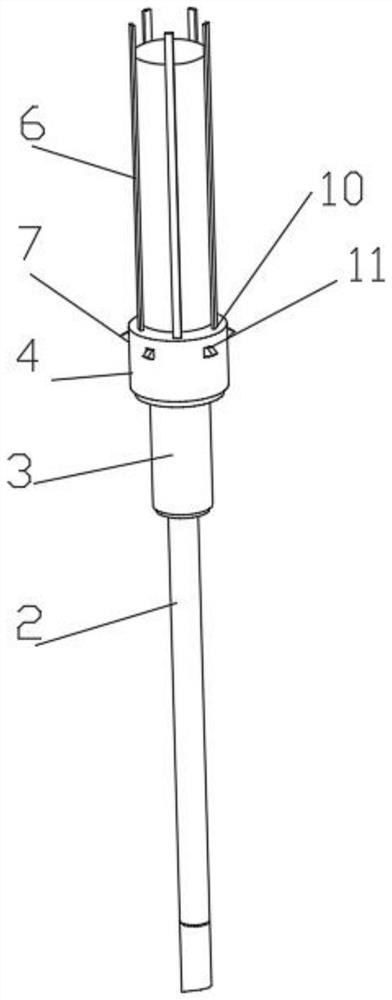

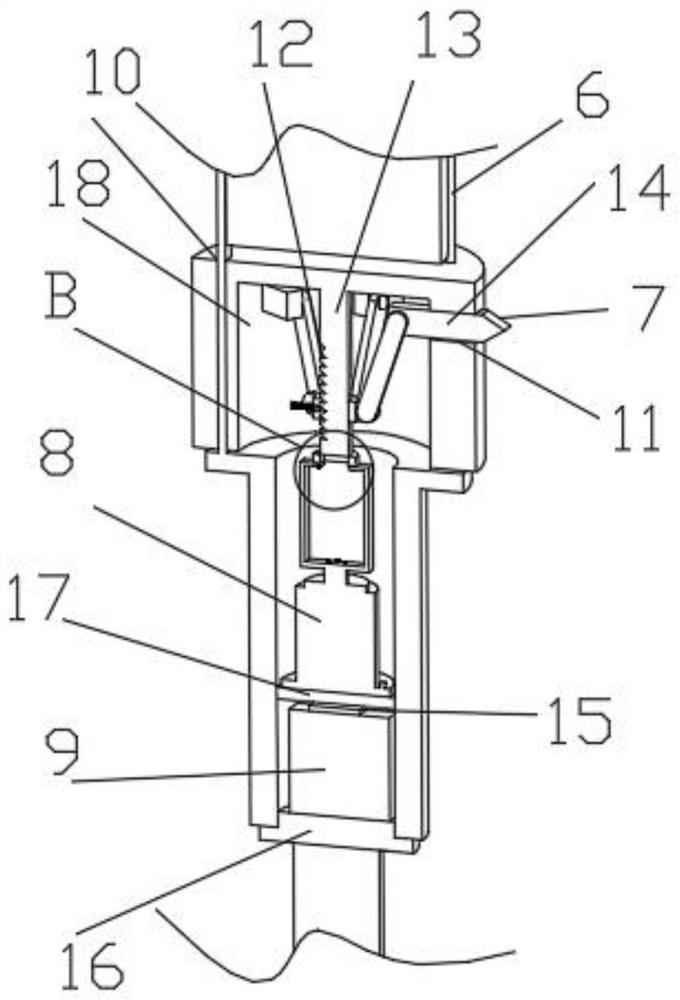

Deep hole blasting explosive feeding equipment and method

ActiveCN114046701AGuaranteed pre-splitting blasting effectNo sliding frictionDrilling using explosivesBlastingDrill holeEnvironmental geology

The invention discloses deep hole blasting explosive feeding equipment and method, and relates to the technical field of deep hole blasting. The deep hole blasting explosive feeding equipment comprises a drill hole, a drill rod and an explosive column, wherein the top of the drill rod is connected with a limiting structure, a pushing structure is connected in the limiting structure, the top of the limiting structure is connected with a clamping structure, the top of the clamping structure is connected with an explosive column in an attached mode, and the outer wall of the explosive column is connected with the limiting structure; when the explosive column moves to the blasting position, the pushing structure pushes the clamping structure to be unfolded, the clamping structure is unfolded and fixed to the inner wall of the drill hole in an inserted mode, and the explosive column is accurately and stably clamped to the blasting position. By means of the mode, the explosive column is placed in the limiting structure, the arc-shaped limiting plate of the limiting structure limits and protects the explosive column, the explosive column does not make contact with the inner wall of a drill hole when moving, the sliding friction phenomenon does not occur, and explosive feeding is safer.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com