Air-hydraulic cylinder with dual function diaphragm

A hydraulic cylinder, double-acting technology, applied in the direction of fluid pressure actuators, reciprocating piston engines, reciprocating engines with elastic walls, etc., can solve the problems of sealing elements leakage, jamming, and inability to complete cycle work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

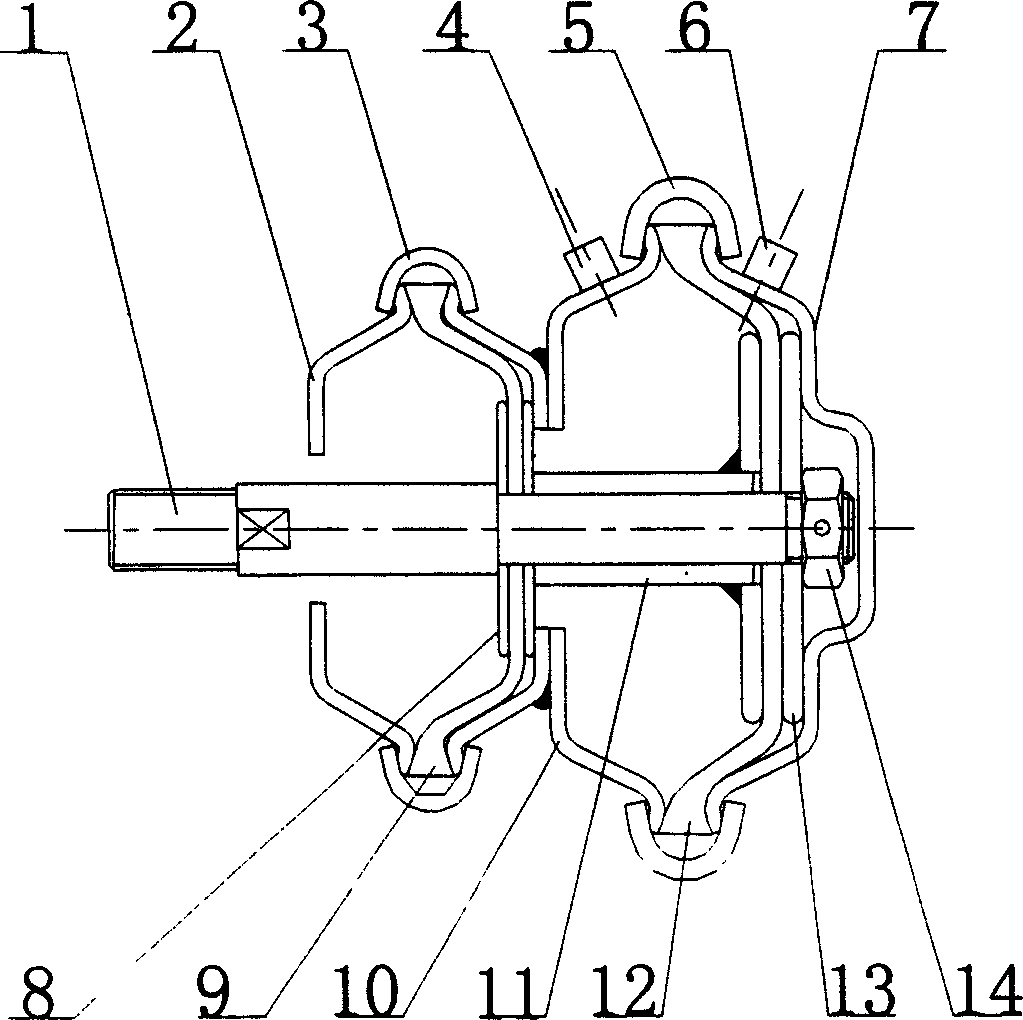

[0013] Example 1, from attached figure 1 It is shown that the present invention is a double-diaphragm, double-acting gas and hydraulic cylinder without a return spring. The overall air and hydraulic cylinder housing is composed of the front housing 2, the middle housing 10 and the rear housing 7: wherein, the front shell and the rear shell of the middle housing 10 are connected together by welding, and then the front shell 2. A small die 9 is sandwiched between the middle shell 10 and assembled together by a small clamp 3; a large die 12 is sandwiched between the middle shell 10 and the rear shell 7 and assembled together by a large clamp 5 . In order to enhance the strength of the diaphragm, when assembling the push rod, the large and small diaphragms should be assembled with two pressing plates, namely the large pressing plate 13 and the small pressing plate 8 . Push rod 1 passes large diaphragm 12, small diaphragm 9 and the pressing plate that is pressed on the front and ...

example 2

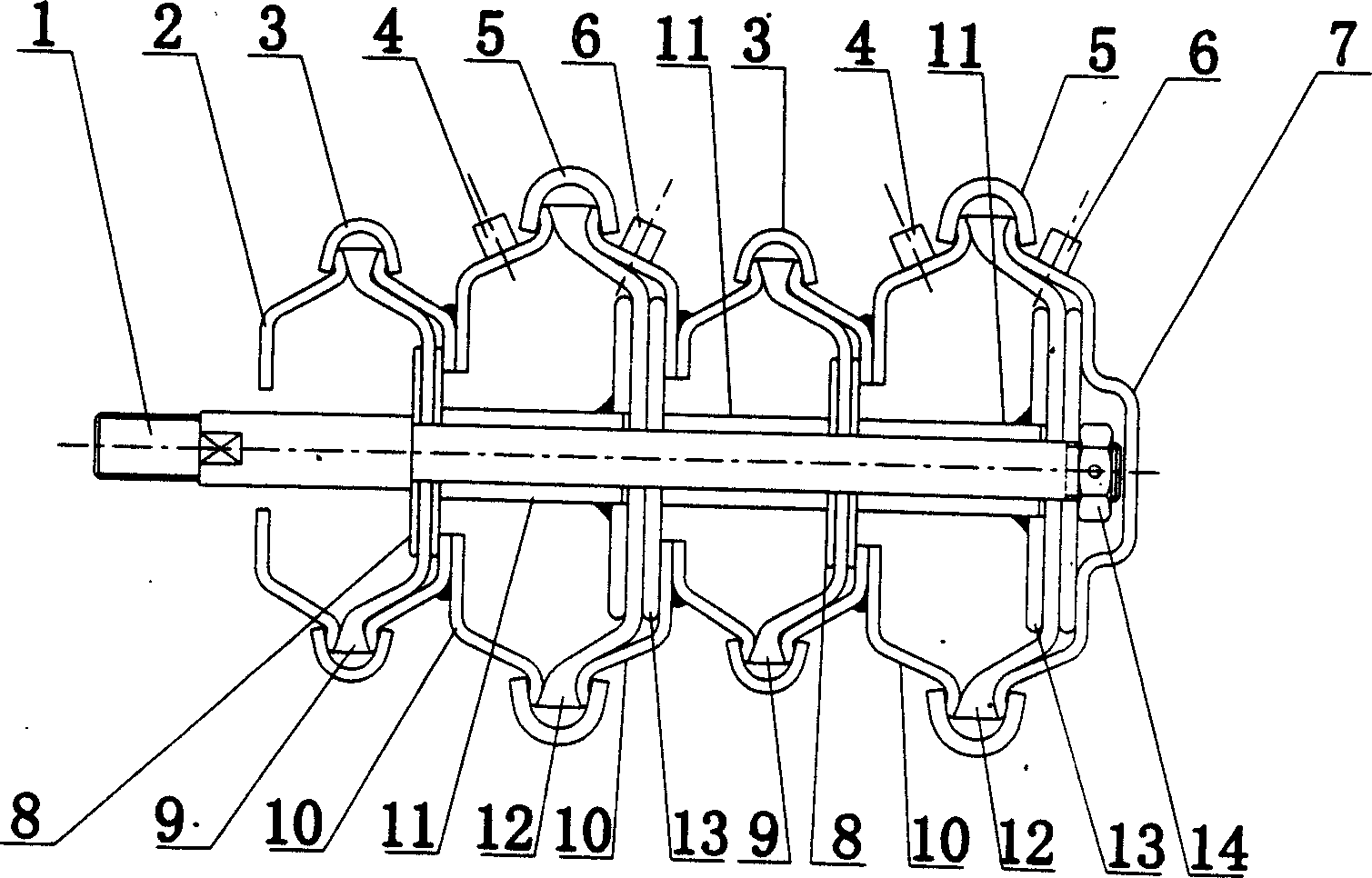

[0014] Example 2: From attached figure 2 As shown, it is composed of two sets of double-acting diaphragm air and hydraulic cylinders. The assembly of the main components is the same as in Example 1. The front casing of the cylinder is assembled together by welding, the push rod 1 passes through 4 diaphragms, its end is on the last large diaphragm, and is fixed by a nut 14, thus figure 1 The rodless cavity of the front group of air and hydraulic cylinders in the middle is changed into a rod cavity, the rear shell 7 is changed into an intermediate shell 10, the rodless gas and liquid nozzle 6 is renamed gas and liquid nozzle b, and the rod cavity gas and liquid nozzle 4 Rename the gas and liquid nozzle a.

[0015] In application, the two gas and liquid nozzles b take in air or liquid at the same time, and the two air and liquid nozzles a simultaneously exhaust or liquid. Under the same pressure, the force generated by the large diaphragm 12 of the previous group is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com