Laser continuous cutting device having dedusting function

A cutting device and laser technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of backing plate pollution, scratches, pole piece damage, etc., to improve production efficiency, reduce friction, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention and its beneficial effects will be further described in detail below with reference to the specific embodiments and the drawings of the specification, but the specific embodiments of the present invention are not limited thereto.

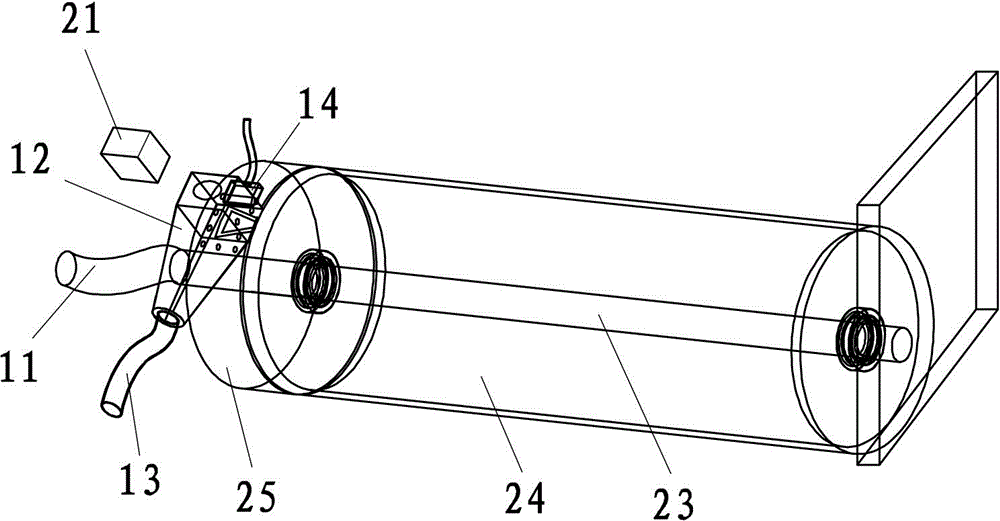

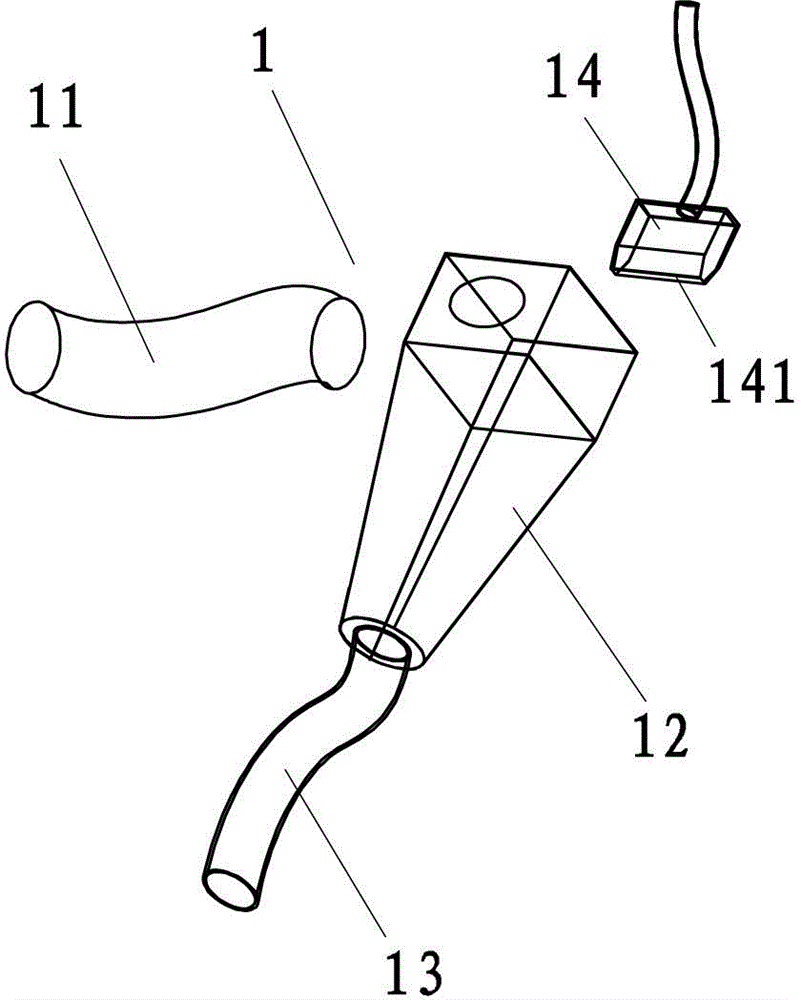

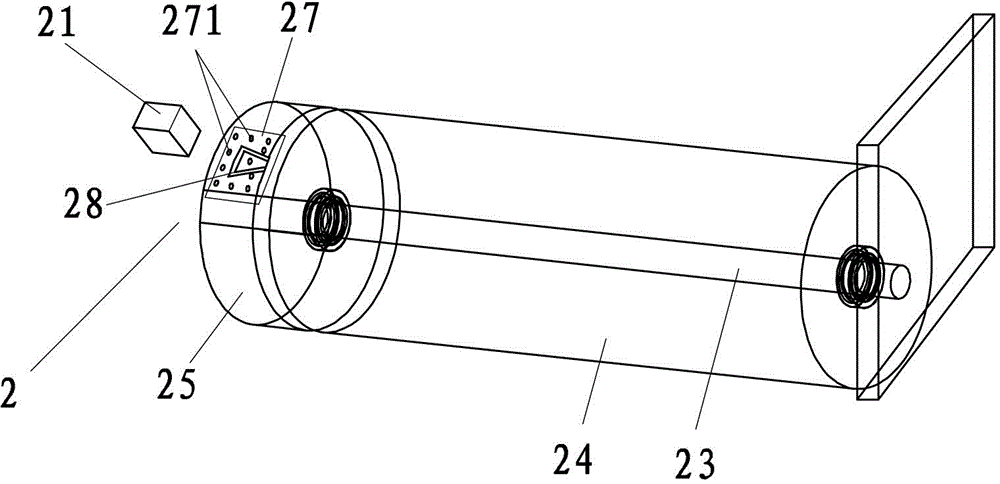

[0030] Such as Figure 1 to 4 As shown, a laser continuous cutting device with dust removal function includes a dust removal mechanism 1 and a laser cutting mechanism 2. The laser cutting mechanism 2 includes a laser head 21 and a pedestal assembly 22. The pedestal assembly 22 includes a central shaft 23 and a rotating roller 24 And the fixed roller 25. The rotating roller 24 and the fixed roller 25 have the same radius. The fixed roller 25 is connected with the rotating roller 24 through the central shaft 23. There is a distance 26 between the fixed roller 25 and the rotating roller 24 corresponding to the cutting path of the laser head 21. The size of the gap 26 is adjustable from 1mm to 5mm. The fixed roller 25 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com