Deep hole blasting explosive feeding equipment and method

A technology of deep hole blasting and drug delivery, which is applied in the direction of drilling equipment and methods, blasting, drilling equipment, etc., and can solve problems such as poor spring clamping effect, safety accidents, and impact on pre-splitting blasting, so as to ensure pre-splitting The effect of the explosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

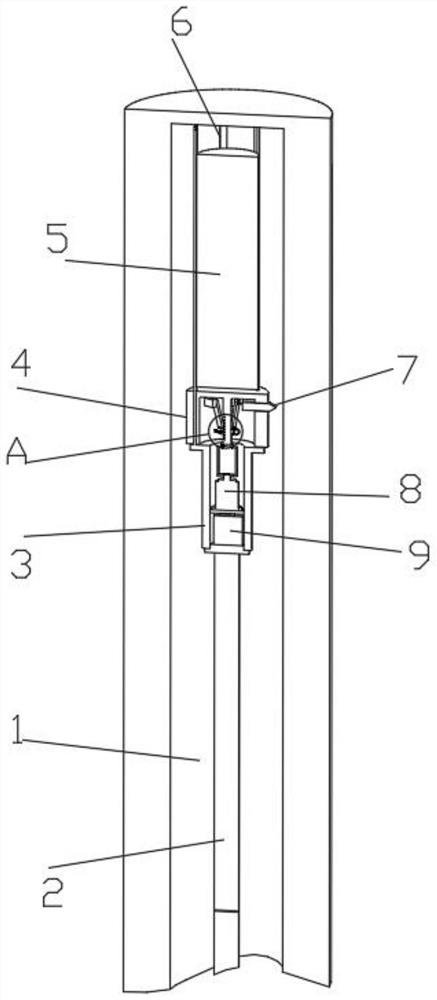

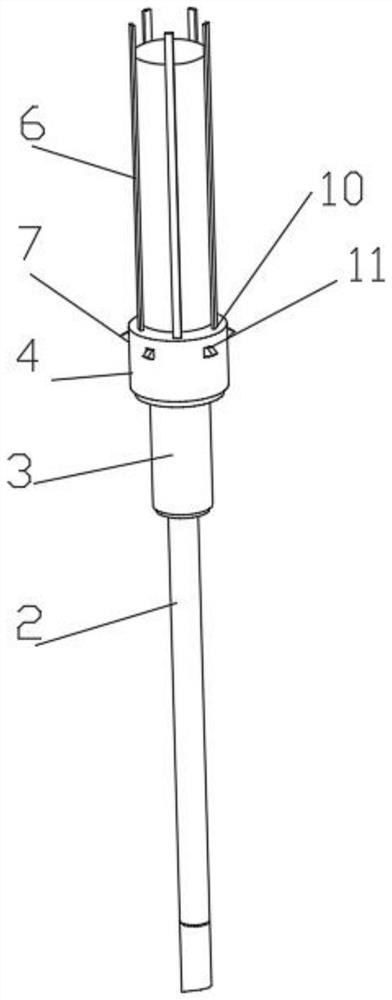

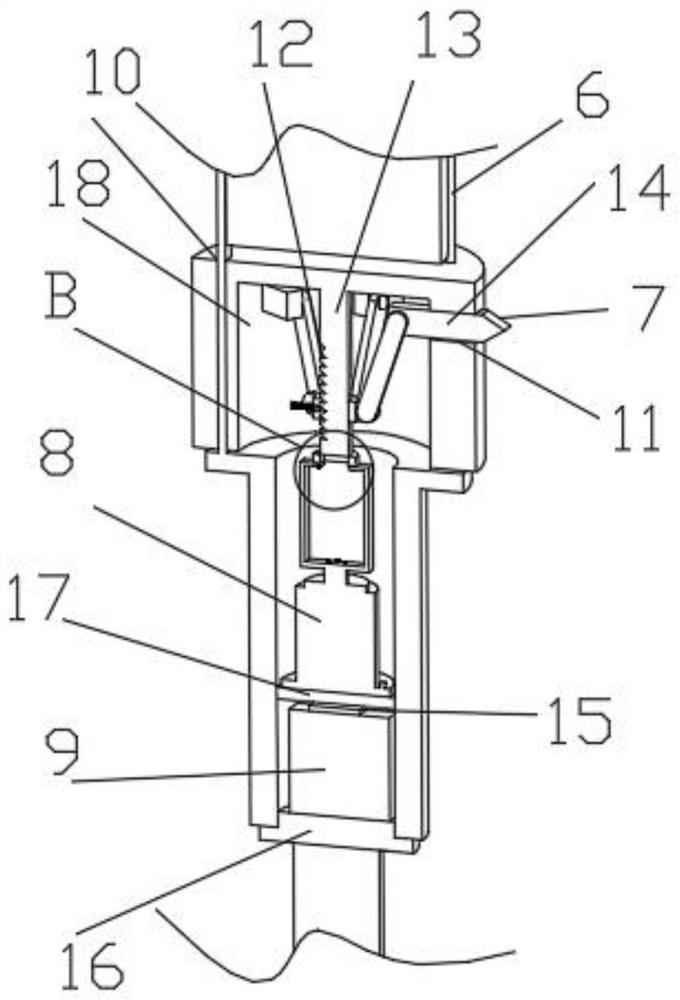

[0035] Such as Figure 1-3 , 5 and 8, a kind of deep-hole blasting charge delivery equipment includes a drill hole 1, a drill pipe 2 and a charge column 5, the top of the drill pipe 2 is connected with a limit structure, and the limit structure includes a clamping tube 4, an arc limit The position plate 6, the base 16 and the top ring 27, the top of the base 16 is threadedly connected with the straight cylinder 3, the top of the straight cylinder 3 is connected with the top ring 27, and the top of the top ring 27 is evenly fixed and connected with the arc-shaped limiting plate 6 along the circumferential direction, and the drug column 5. The outer wall is in contact with the inner wall of the arc-shaped limiting plate 6;

[0036] The grain 5 is placed in the limit structure, and the arc-shaped limit plate 6 of the limit structure limits the position of the grain 5. When the grain 5 moves, it will not contact the inner wall of the borehole 1, and there will be no sliding fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com