Wheel for track

A wheel and rail technology, applied in the field of rail wheels, can solve the problems of only being used in two-axle bogies and not being widely used, and achieve the effects of reducing derailment coefficient, improving service life and huge economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

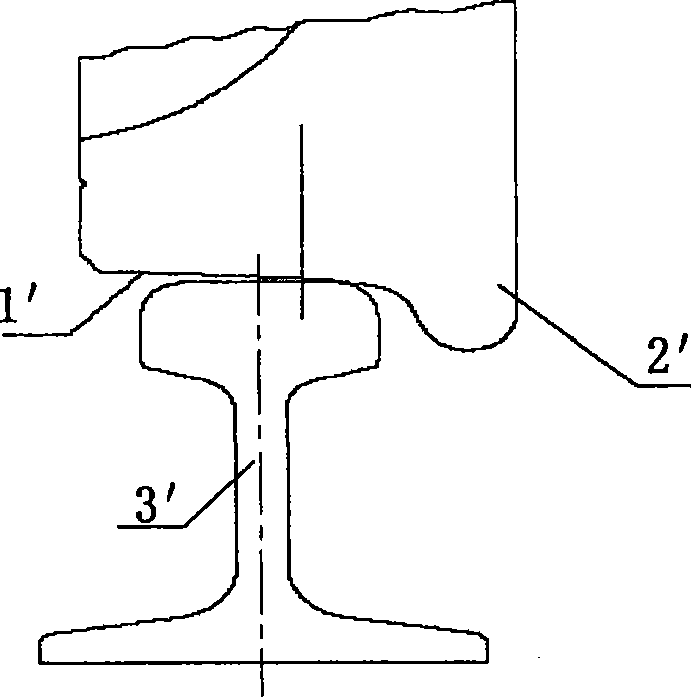

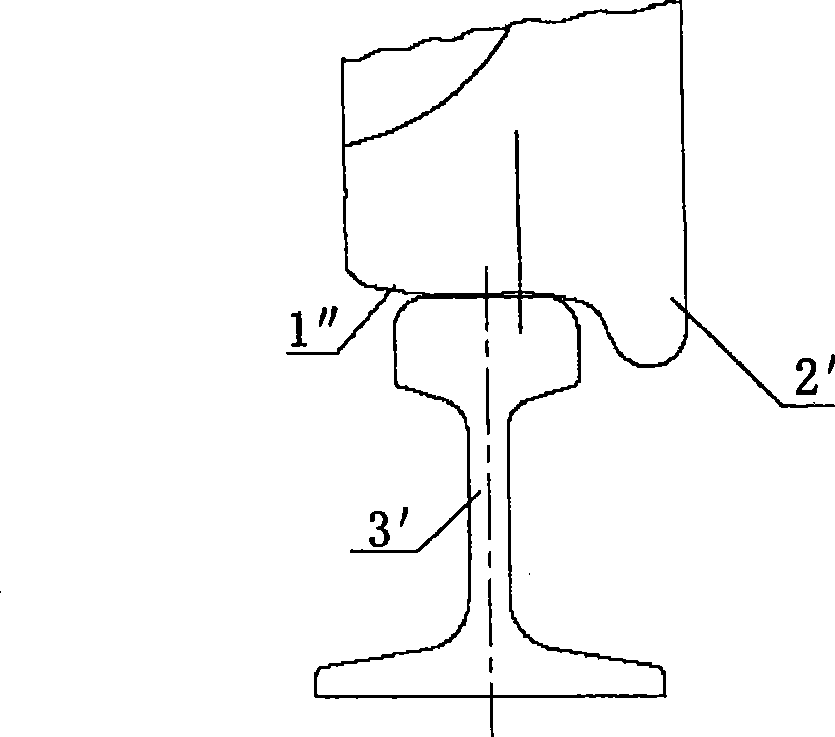

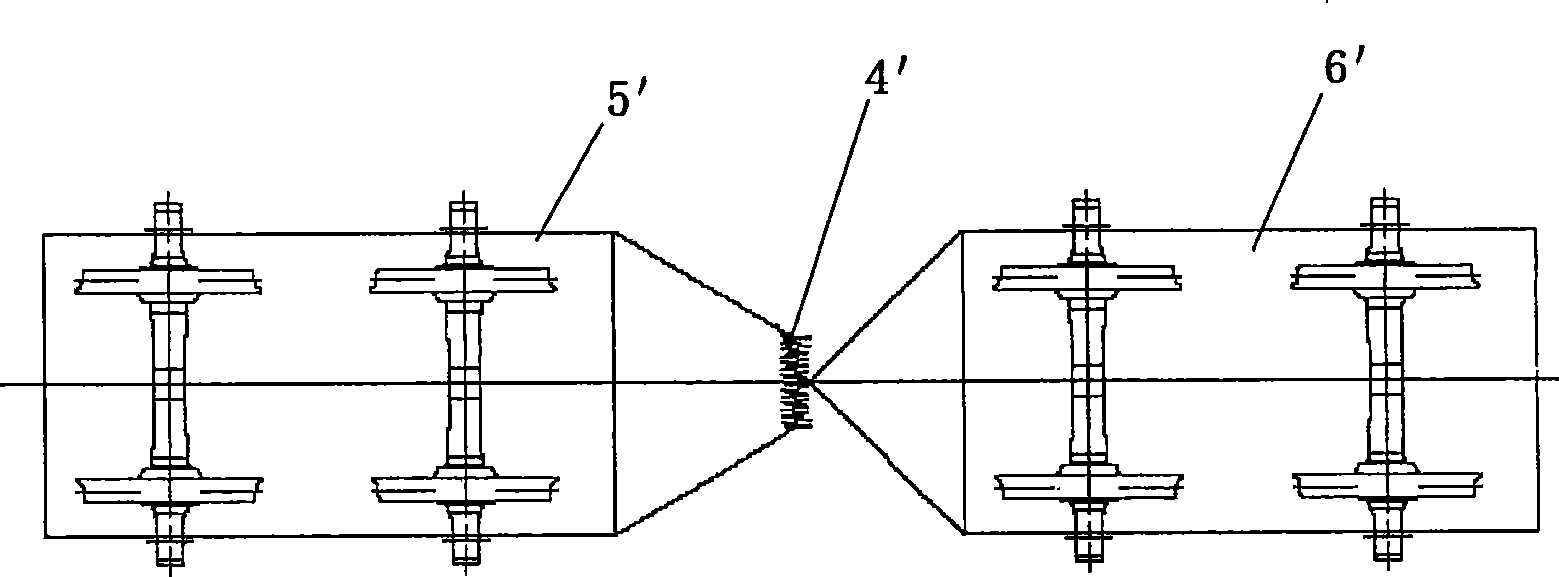

[0032] Please see first Figure 4 , which is a schematic diagram of a track wheel with a rotating rim according to the present invention. The track wheel with rotating rim of the present invention includes three parts, one part is the wheel body 1 , the other part is the rim 2 , and the third part is the rib 3 . The outer circumference of the wheel body 1 forms a tread 11 in contact with the track, and one side of the wheel body 1 is provided with a rim 2 whose outer diameter is larger than that of the tread 11. In this embodiment, the wheel The rim 2 is arranged on the inner side of the wheel body 1, wherein the rim 2 and the wheel body 1 are of a split structure, and the rim 2 is detachably and rotatably arranged on the outer circumference of the wheel body 1. In this embodiment, a reduced-diameter portion 12 with a diameter smaller than that of the tread surface 11 is provided at the inner end of the wheel body 1 , and the wheel rim 2 is rotatably sleeved on the reduced-di...

Embodiment approach 2

[0043] When the hardness of the material of the rim 2 is lower than that of the wheel body 1, in order to reduce the wear between the contact surface of the rim 2 and the wheel body 1, in addition to adopting the above-mentioned embodiment in which rolling elements 4 are arranged therebetween, as shown in Figure 10 As shown, a wear-resistant gasket 21 can also be provided at least between the wheel rim 2 and the wheel body 1 , for example, a nylon gasket can be provided to improve the wear-resistant performance of the wheel rim 2 . Nylon gaskets can also be arranged between the wheel rim 2 and the rib 3 to further improve the wear resistance between the wheel rim and the rib.

[0044] Other structures, working principles, and beneficial effects of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment approach 3

[0046] In this embodiment, a wear-resistant coating (not shown) is provided on the side of the wheel rim 2 at least facing the wheel body 1. In order to improve the overall wear resistance of the wheel rim 2, the side facing the wheel body 1 can be Both sides of the wheel body 1 and the rib 3 are provided with wear-resistant coatings. The wear-resistant coating can be, for example, a composite layer or a coating layer. For example, a tungsten carbide layer or chrome plating can be applied on the rim 2 to strengthen the surface hardness of the rim 2 and improve wear resistance. And the wear-resistant coating can also be arranged on the wheel body facing the side of the rim. Compared with the above-mentioned arrangement of wear-resistant gaskets, this embodiment reduces the number of parts and facilitates assembly.

[0047] Other structures, working principles, and beneficial effects of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com