Sealing structure and device with the sealing structure

A sealing structure and valve device technology, which is applied to the surface coating liquid device, shaft seal, valve device, etc., can solve problems such as poor movement and inability to move, and achieve the effect of solving heat or wear and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

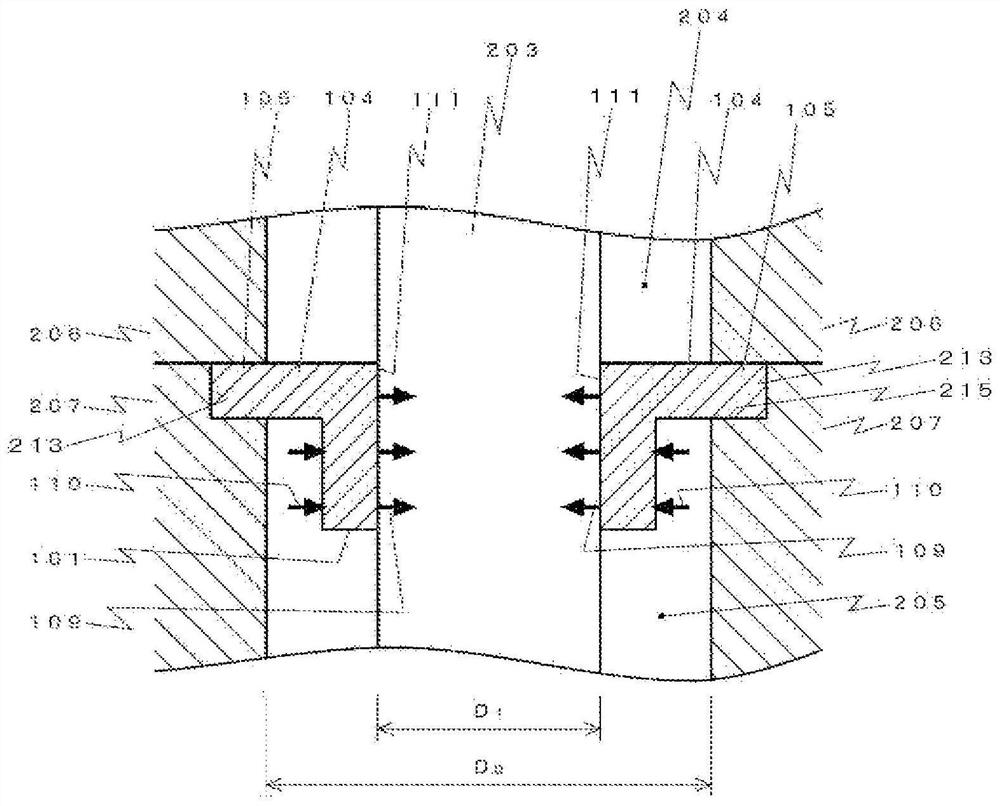

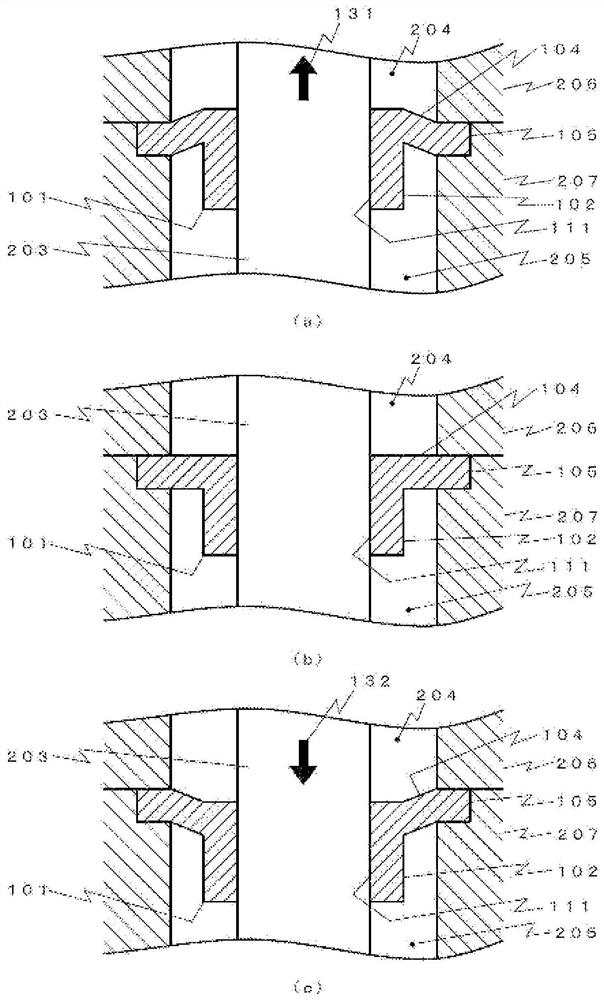

[0043] The seal structure according to the first embodiment is configured to include a seal 101 , upper and lower case members ( 206 , 207 ) in which a fluid chamber 205 is formed, and a needle 203 .

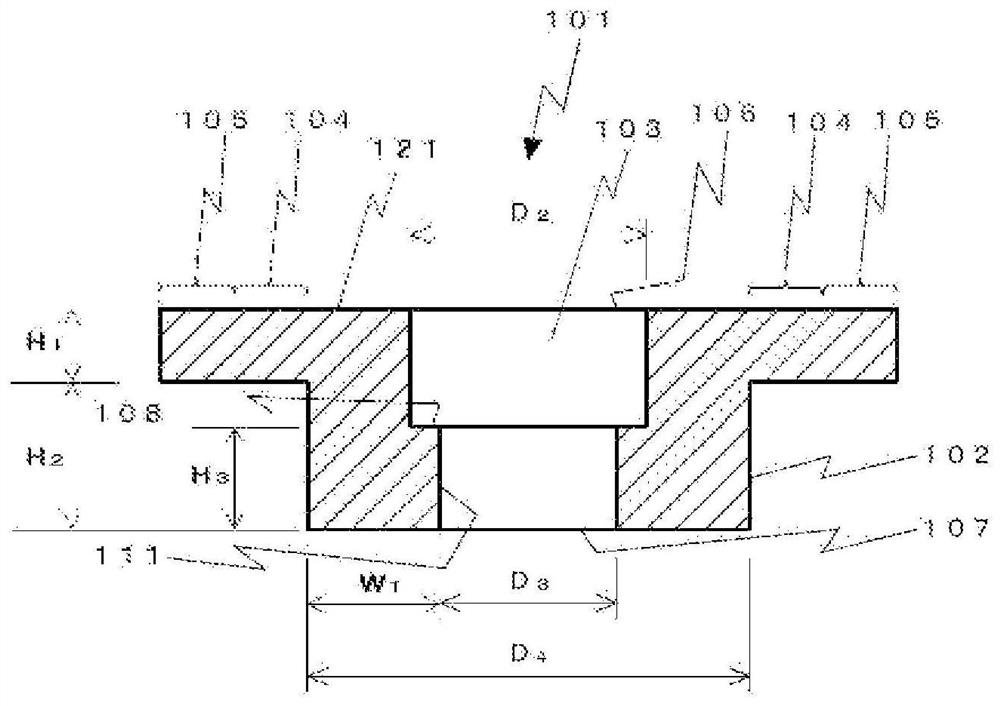

[0044] Such as figure 1 As shown, the sealing member 101 is composed of a cylindrical main body 102, a through-hole 103 formed to pass through the main body 102 and having a different inner diameter on the upper side and the lower side, and a convex hole formed on the outer periphery of the main body 102. The flange part (104, 105) constitutes.

[0045] The main body 102 is a cylindrical member, and extends in a direction parallel to the needle 203 (ie, in an up-down direction). The length of the main body 102 (H 1 +H 2 ) is, for example, 2 to 4 mm, and from another point of view, it is the thickness H of the flange portion (104, 105) 1 (or the thickness W of the through-hole sidewall 111 1 ) of, for example, 2 to 5 times. By setting the length of the main body 102 (H 1 +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com