Automatic circulation heat dissipation type linear motor motion control platform and control method thereof

A technology of motion control and automatic circulation, applied in motor control, automatic control device, linear motor control, etc., can solve problems such as rough algorithm, poor heat dissipation, increase of electrical time constant, etc., to solve the problem between control accuracy and dynamic response Contradictions, improve the service life, reduce the effect of temperature oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the present application.

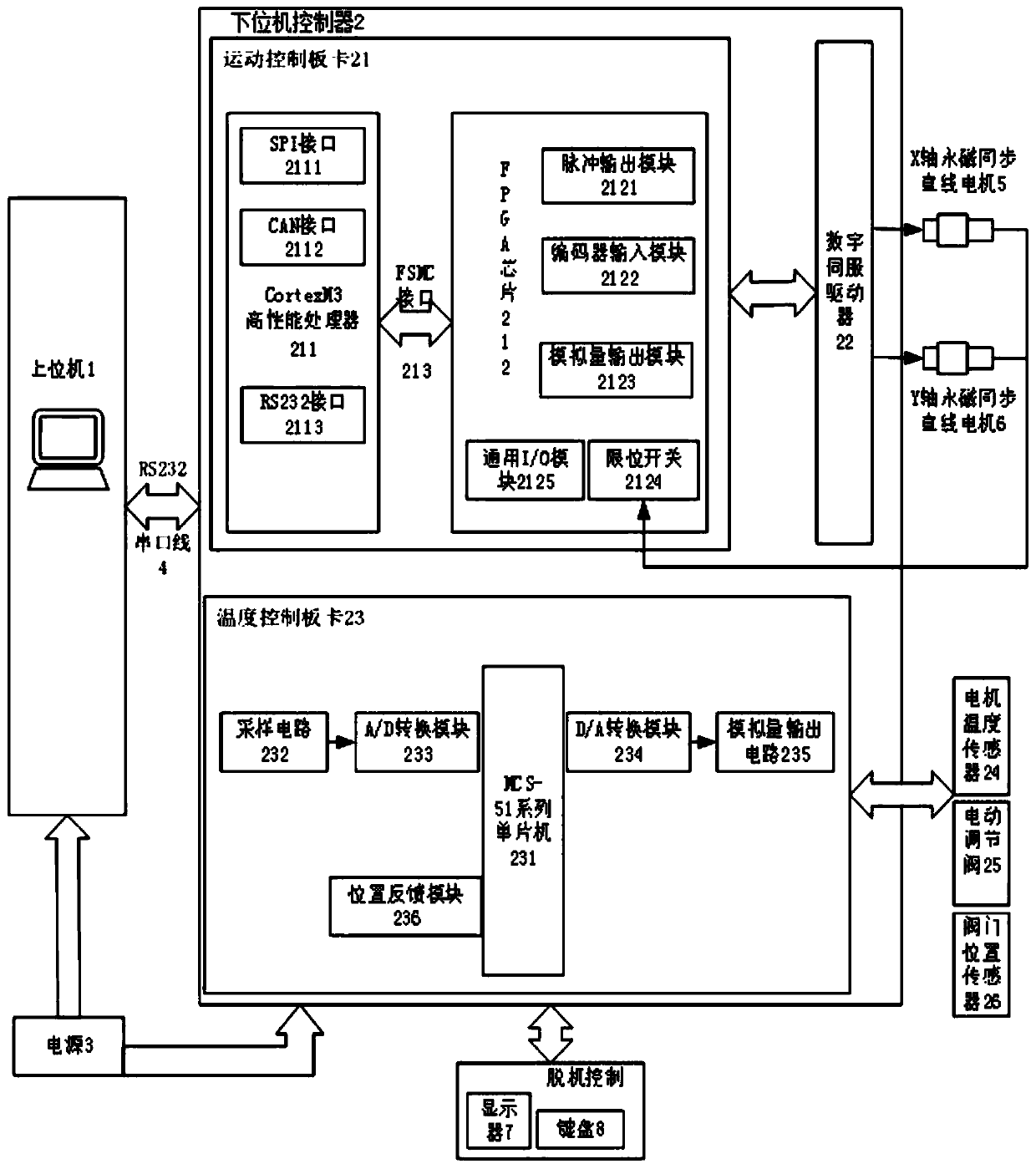

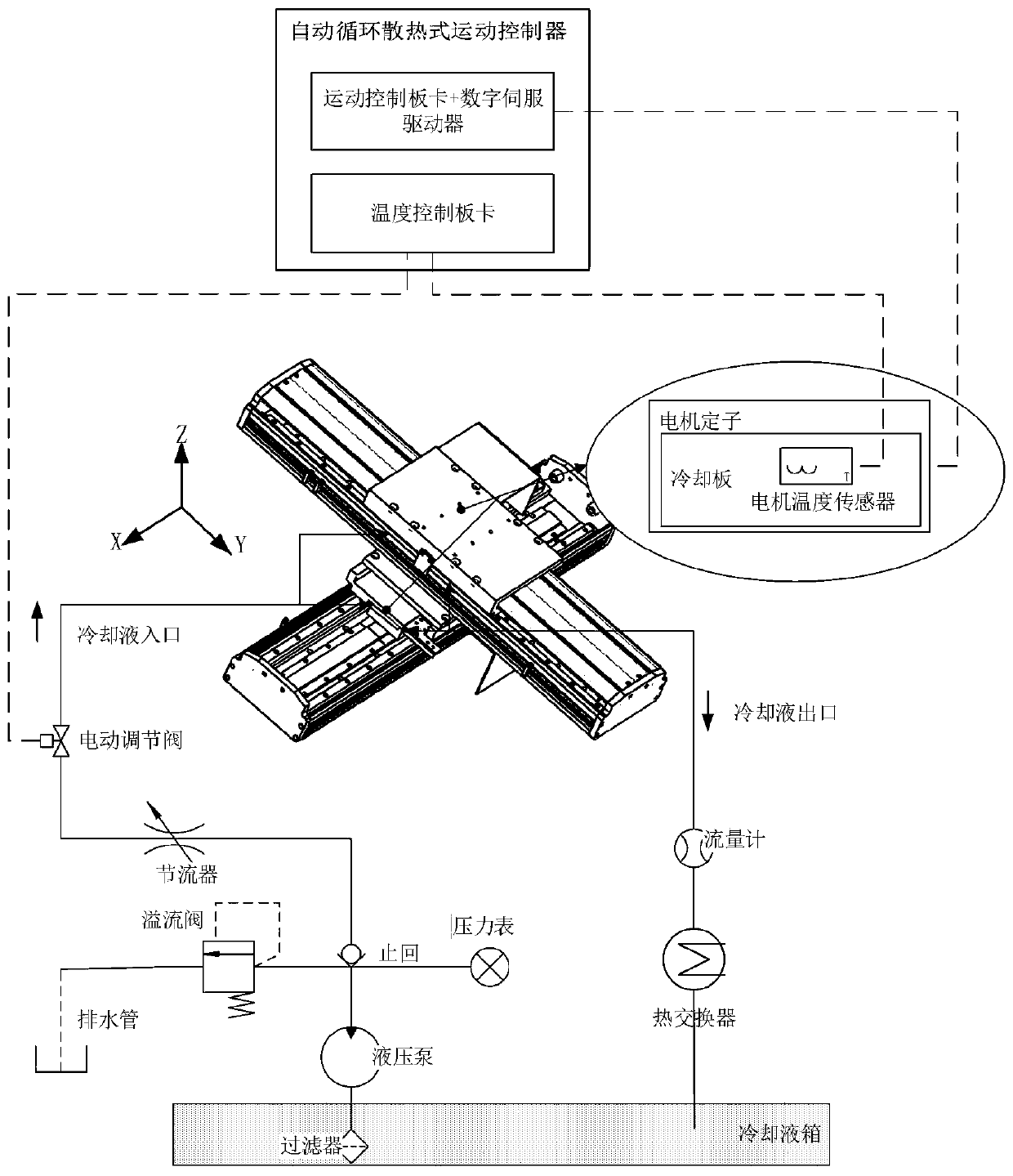

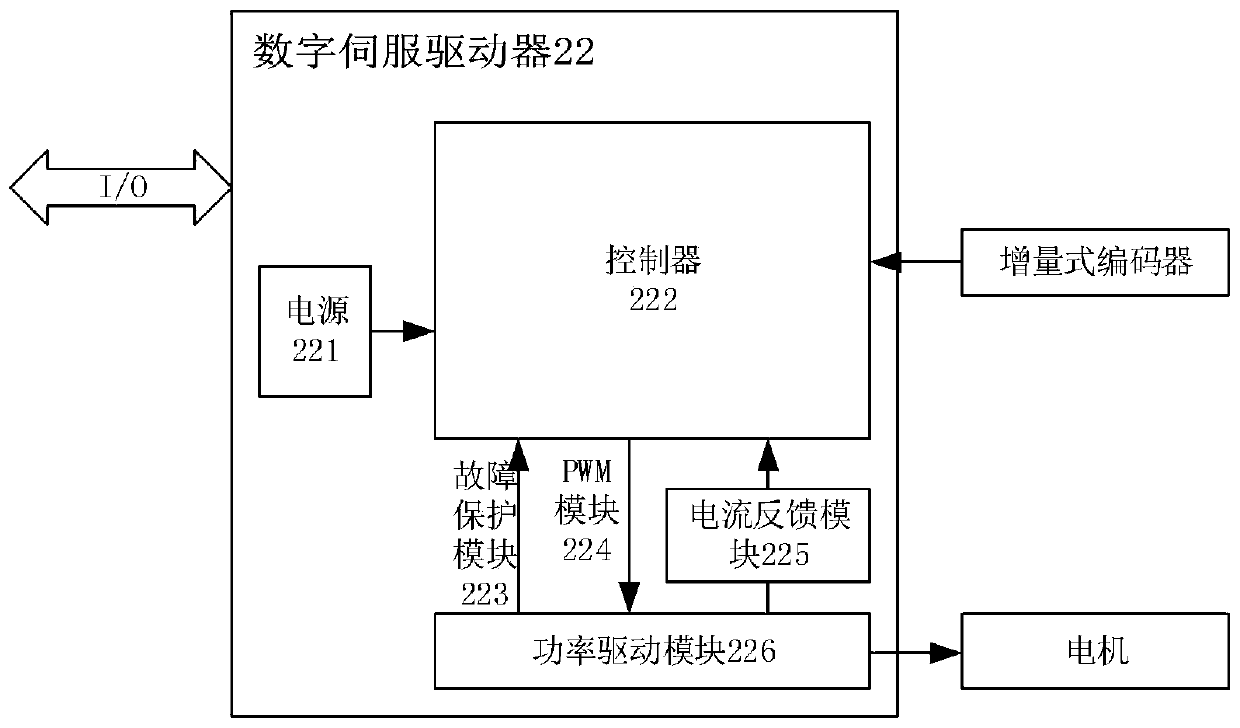

[0072] The present invention is an automatic circulation heat dissipation type linear motor motion control platform, the whole platform is composed of upper computer (PC) 1, lower computer namely automatic circulation heat dissipation motion controller 2, power supply 3, RS232 serial port line 4, X-axis permanent magnet synchronization A linear motor 5, a Y-axis permanent magnet synchronous linear motor 6, a keyboard 7, and a display 8 are composed.

[0073] The upper computer 1 is responsible for processing the input commands with strong human-computer interaction into a format conforming to the command frame of the communication protocol, and sending them to the lower computer through the serial port 4 . The upper computer software is an application s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com