Patents

Literature

1310results about "Wheel-axle combinations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

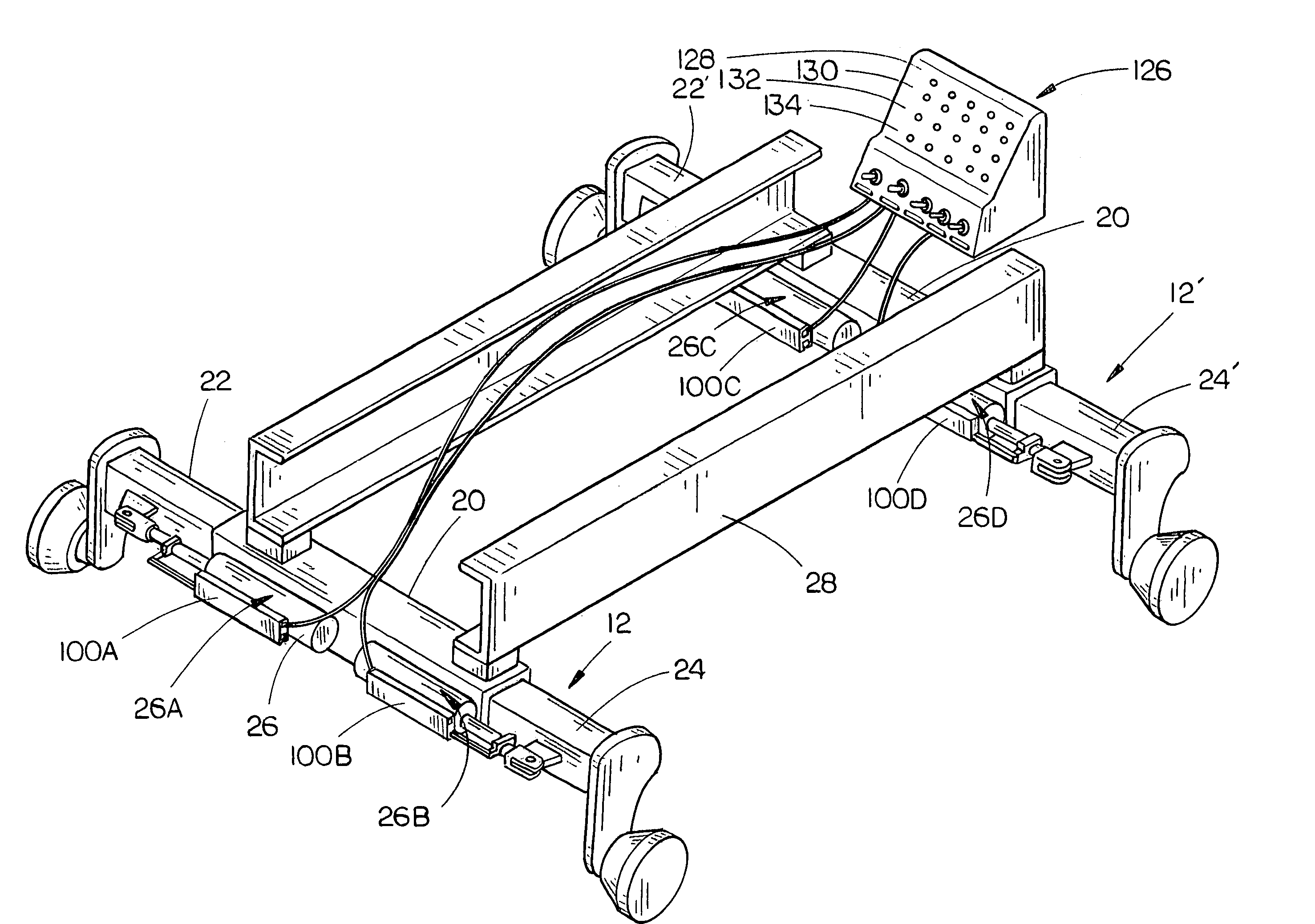

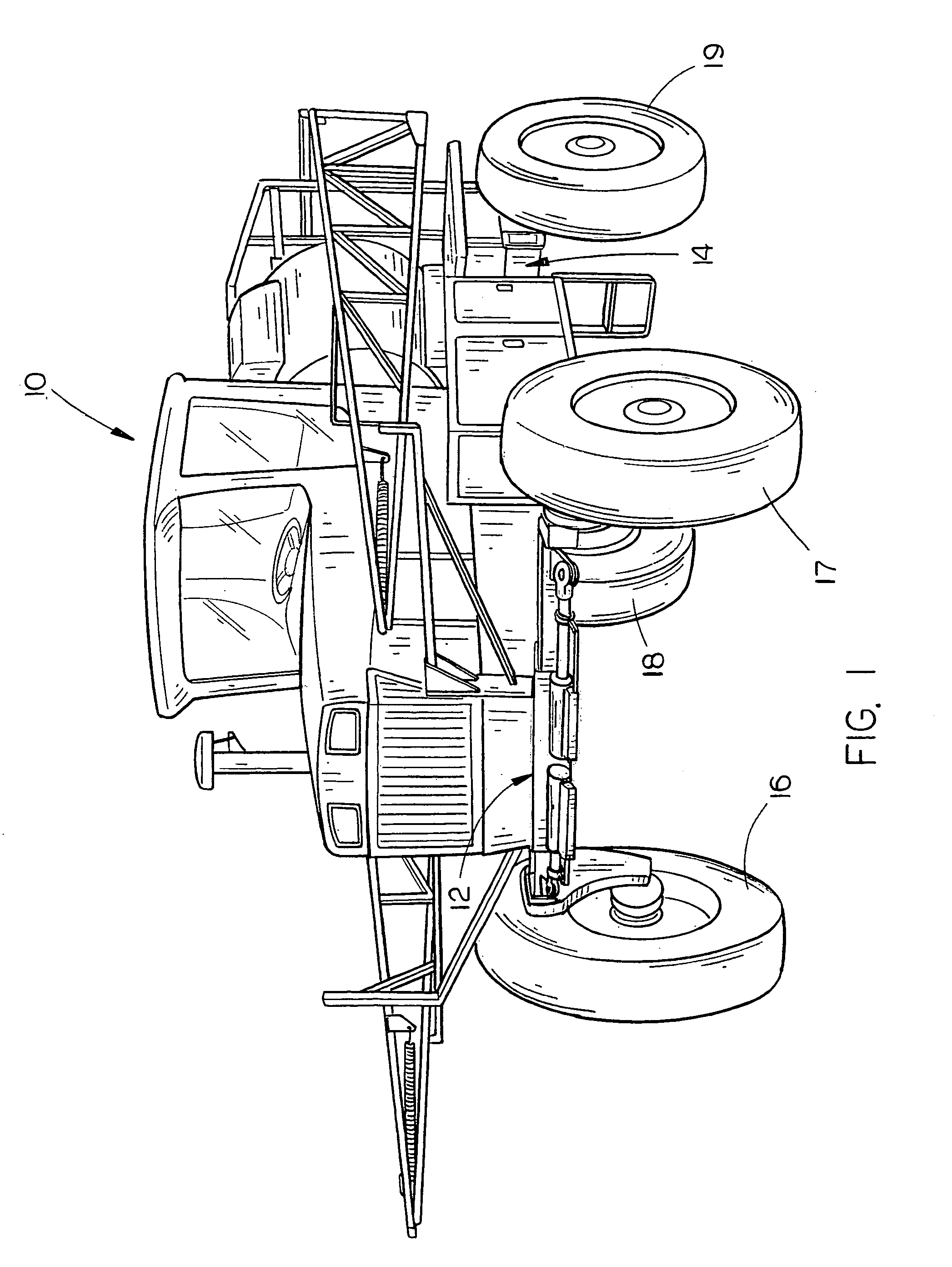

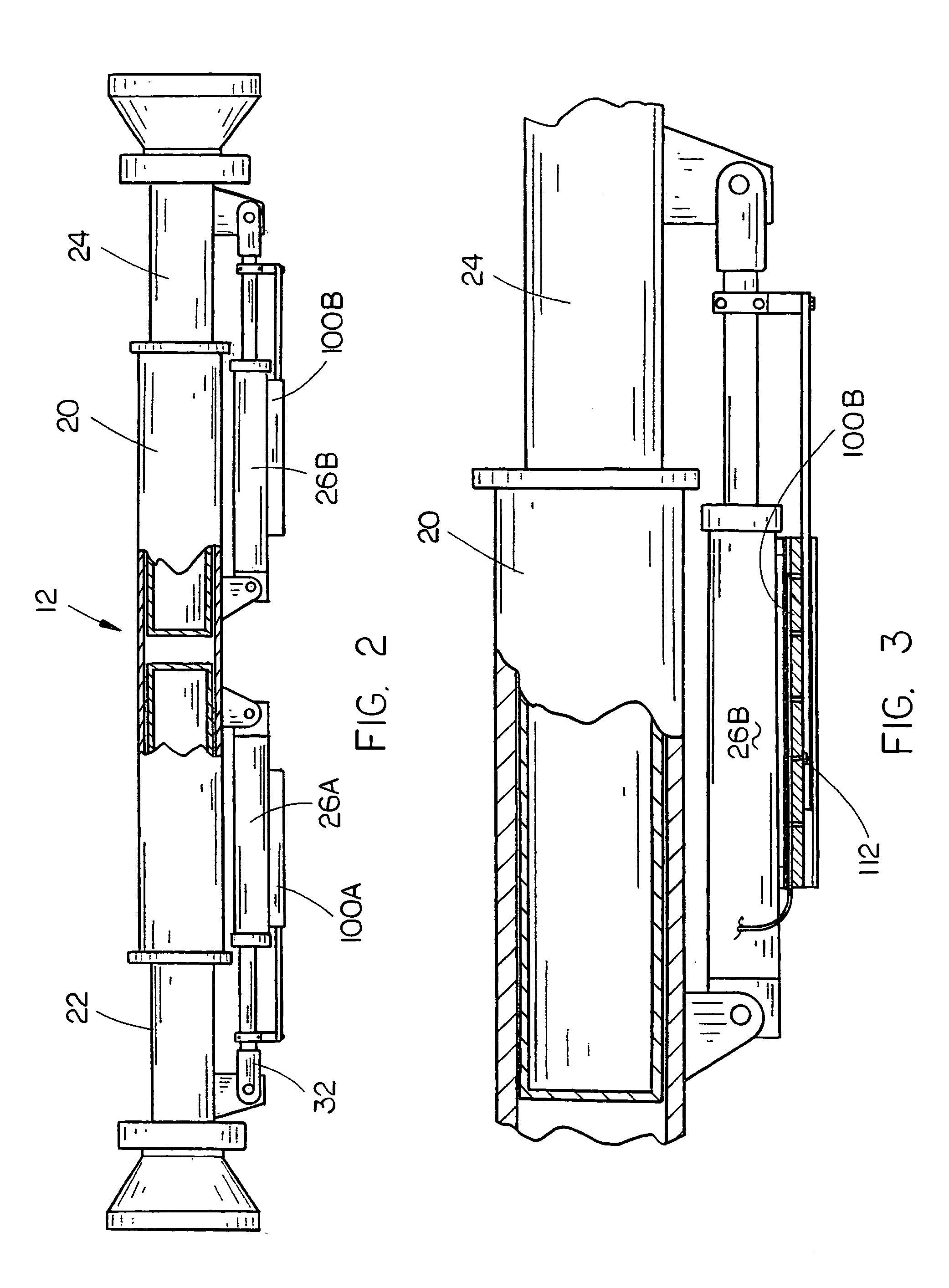

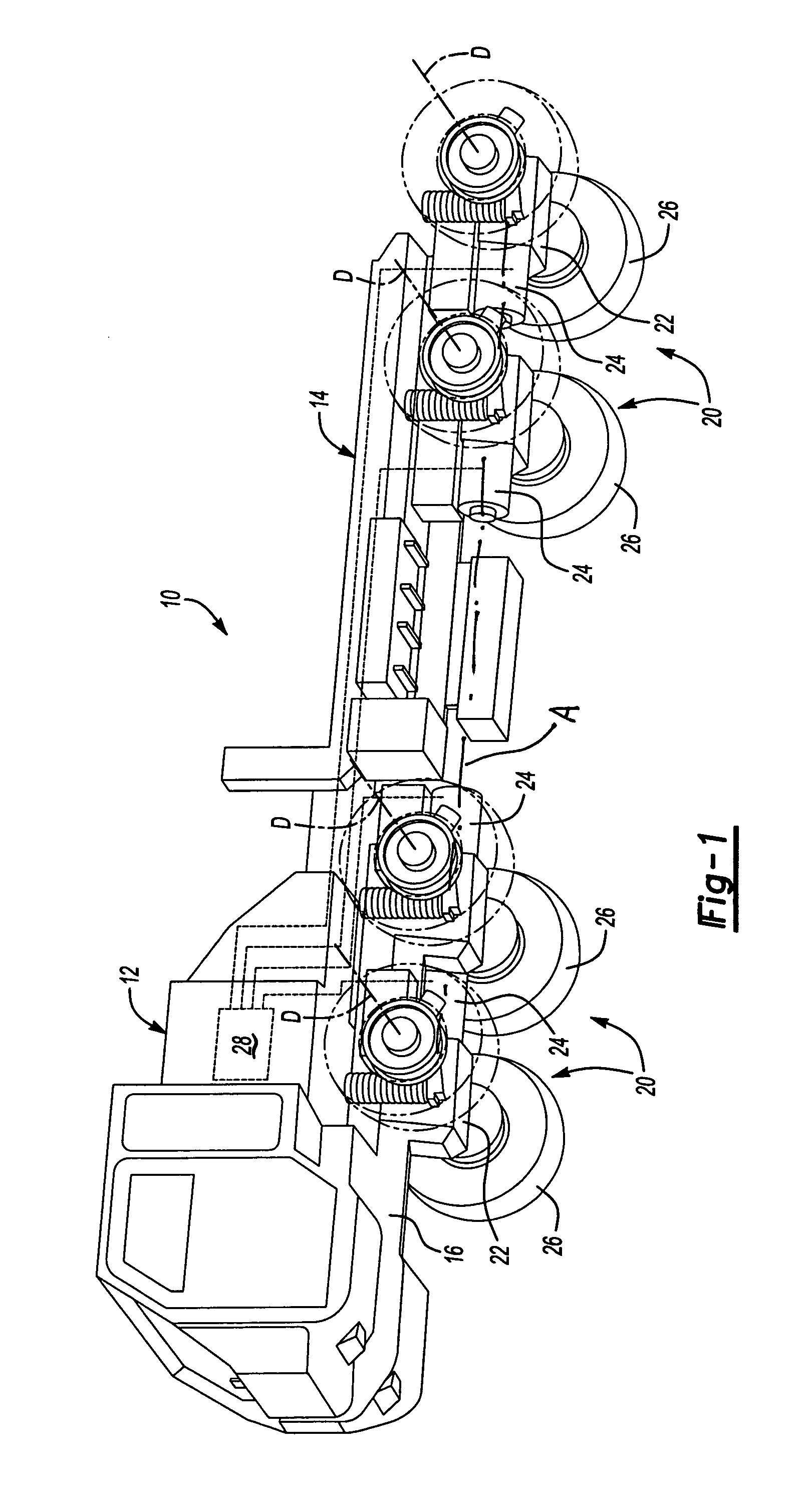

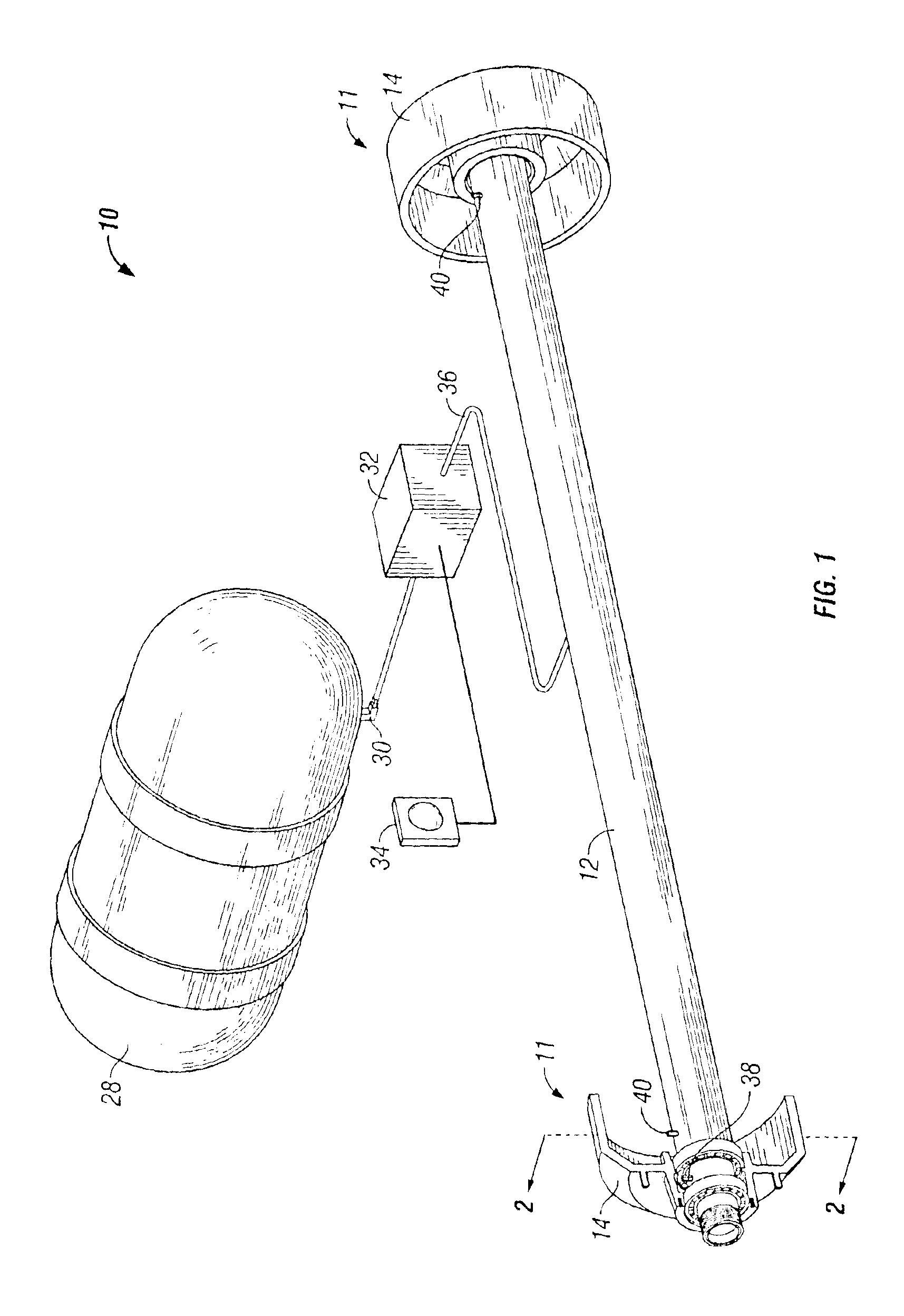

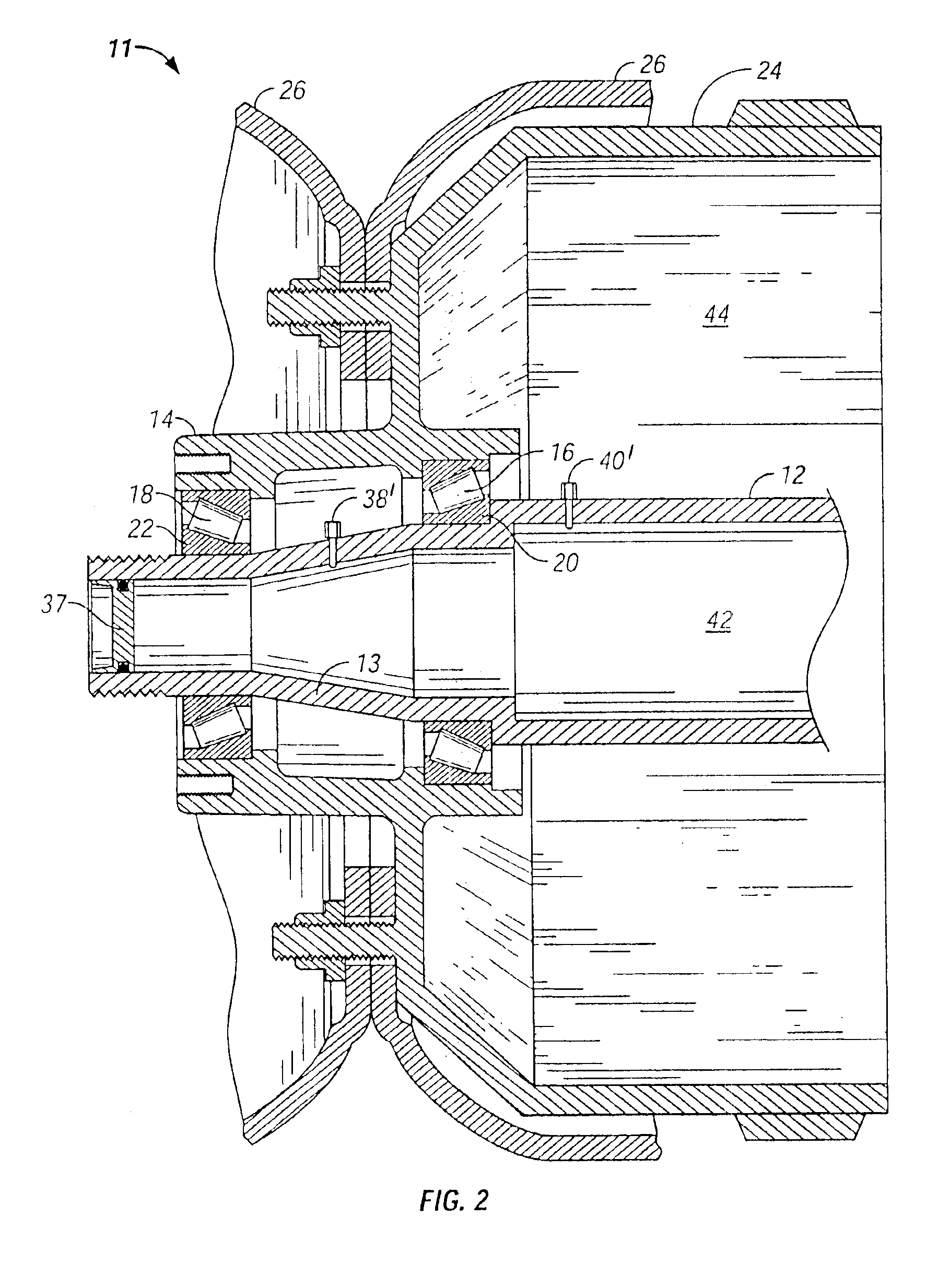

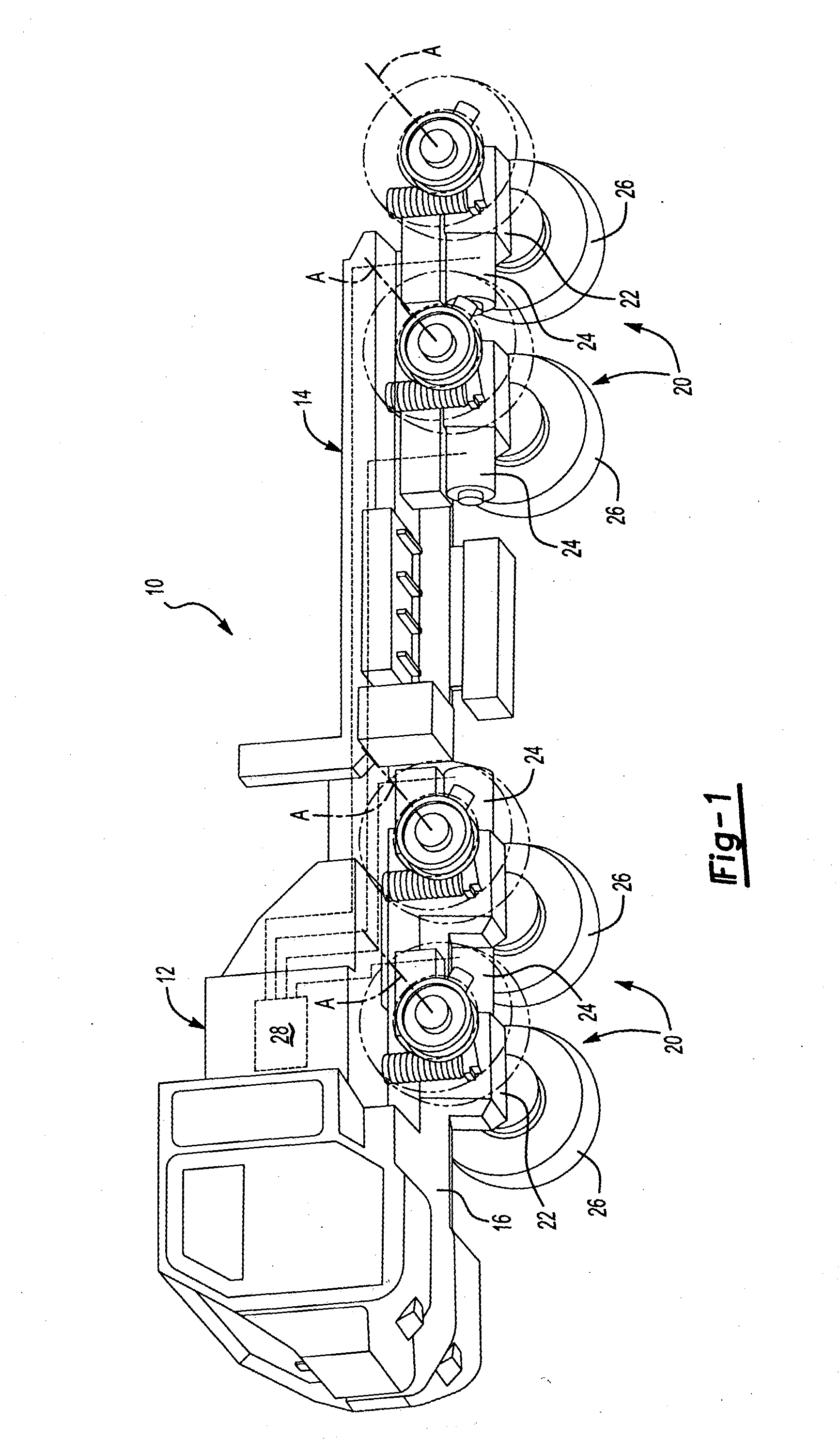

Multi-position track width sensor for self-propelled agricultural sprayers

InactiveUS7163227B1Track width can be easily and quicklyPositioning is simple and fastAgricultural vehiclesCarriage/perambulator accessoriesSprayerEngineering

A multi-position track width sensor for agricultural sprayers wherein a piston rod position sensor is connected to each of the adjustable axle members of the front and rear axle assemblies of the sprayer. A display panel is mounted in the cab of the sprayer and includes LEDs which indicate various positions of the piston rods with respect to the respective cylinder.

Owner:BURNS KERRY C

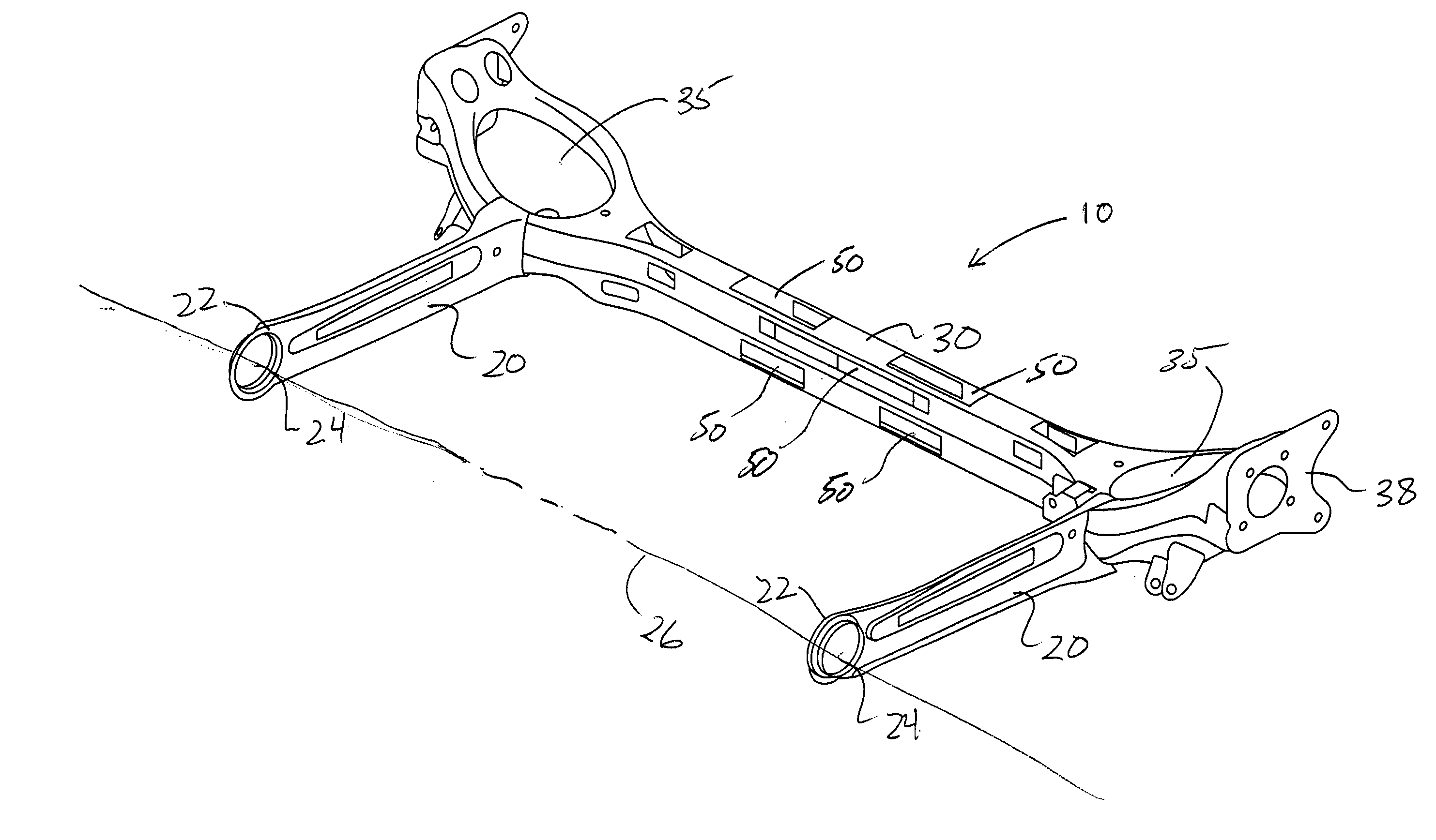

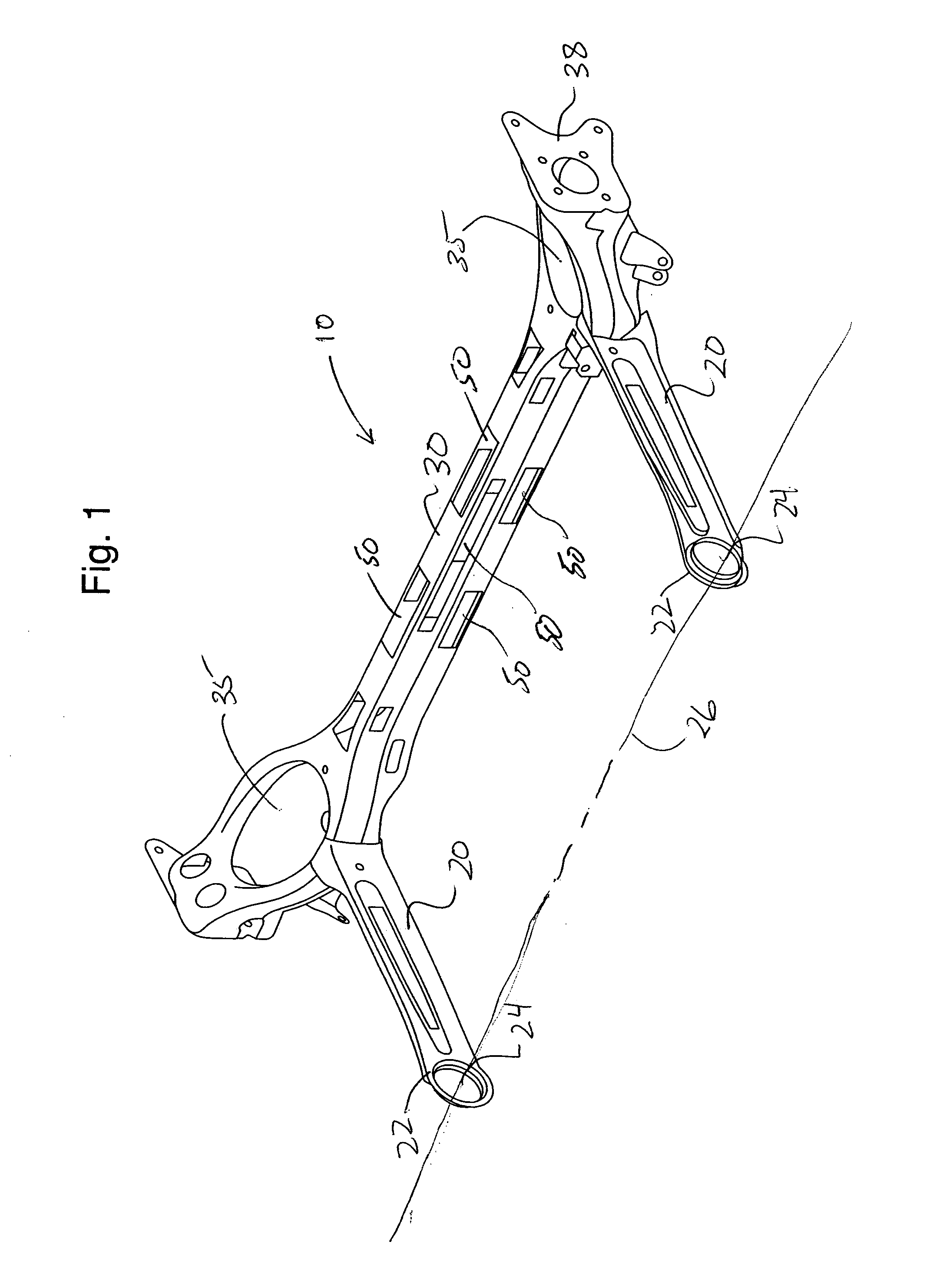

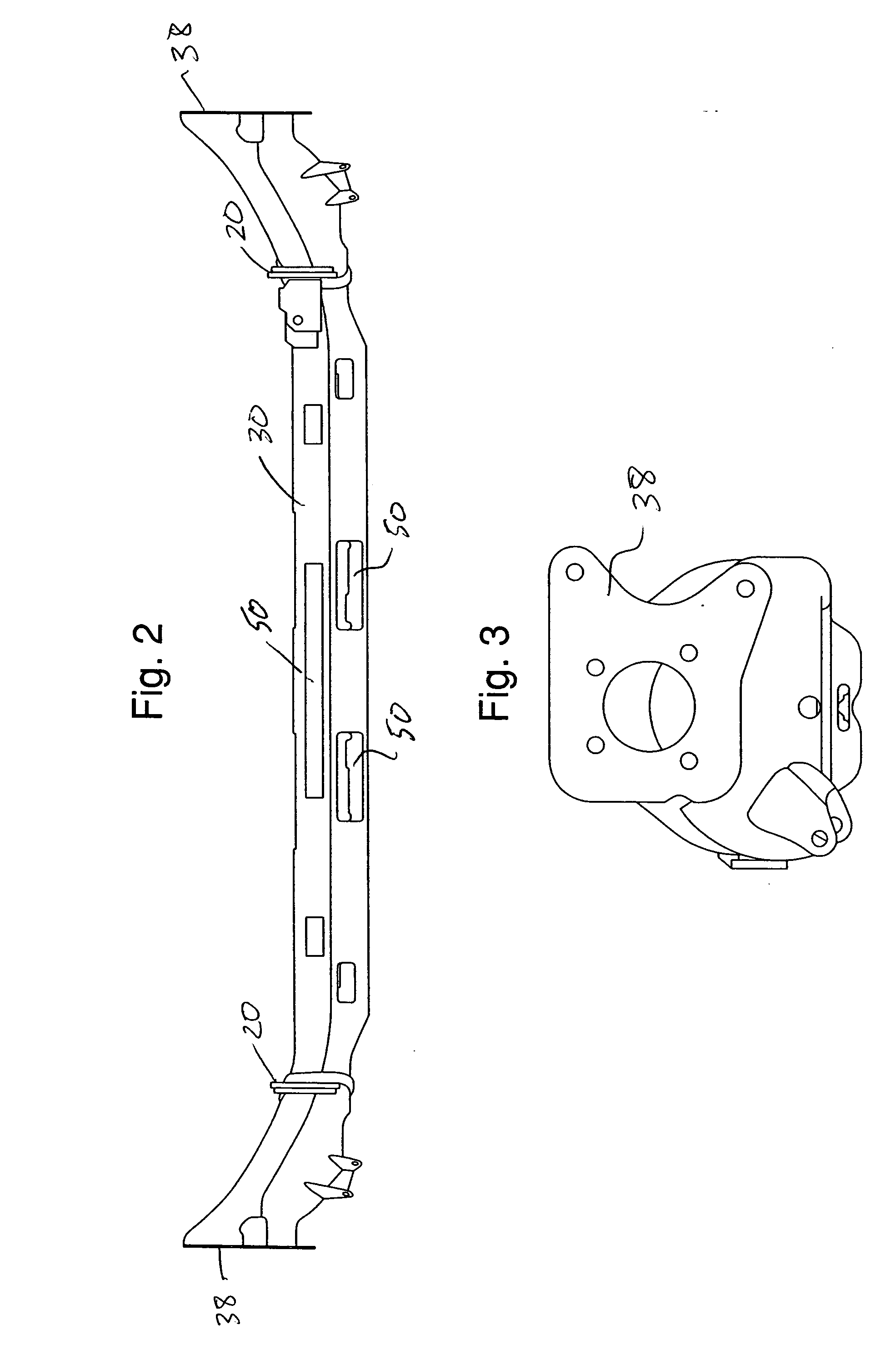

Torsion beam suspension member

A torsion beam suspension member using two u-shaped, stamped members that are superimposed and welded to form a torsion arm. No additional torsion tube or bar is needed. Tuning holes (rectangular, oblong, round or any other suitable shape) are used to change or tune the torsional resilience of the suspension. In the preferred embodiment, the tuning holes are oblong and located near the center of the cross member. The tuning holes are selected based on having target value for torsional compliance or resilience. The size, quantity and location of the tuning hole are chosen based on computer analysis. An optimization or iterative process is used to arrive at the final hole size, quantity and location.

Owner:DANA AUTOMOTIVE SYST GRP LLC

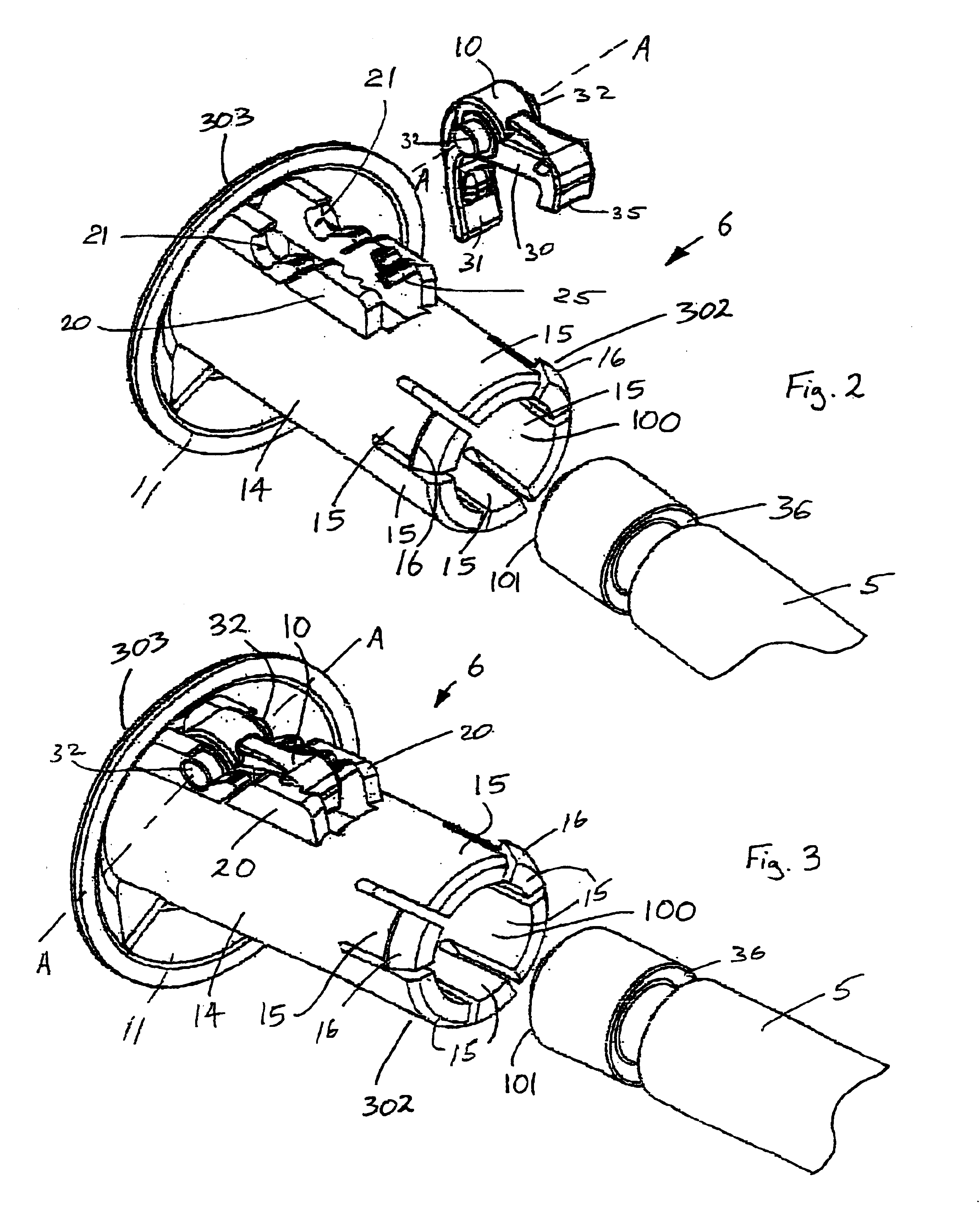

Wheel

A journal for coupling a wheel to an axle is configured to be mounted in a bore of the wheel. The journal defines a reception space for receiving an axle. A locking element is pivotally mounted on the journal from a release position in which the axle is removable from the reception space and secured position in which a tooth of the locking element is engaged with a groove in the axle. When the tooth of the locking element is engaged in the groove withdrawal of the axle is prevented.

Owner:MERGON INT

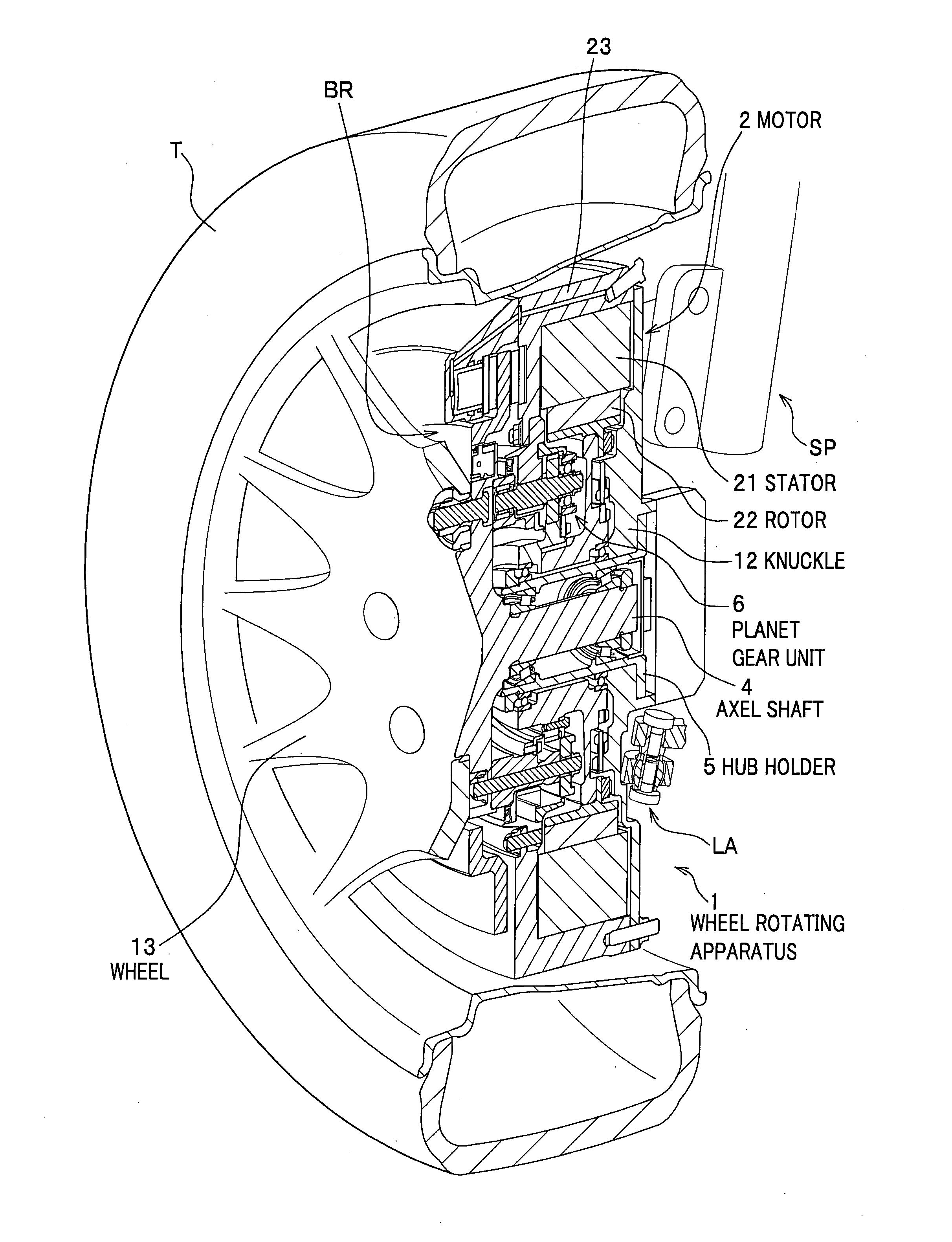

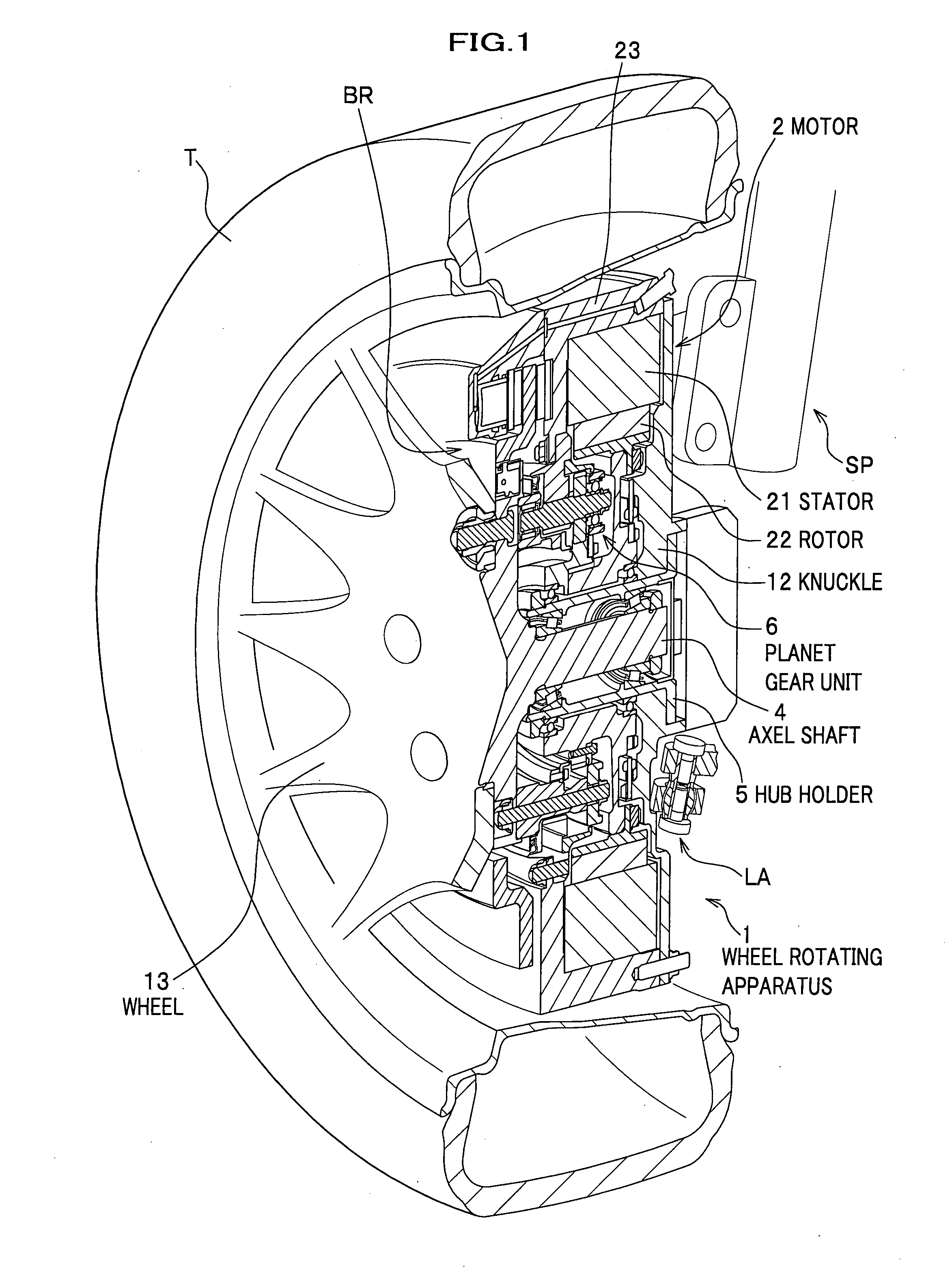

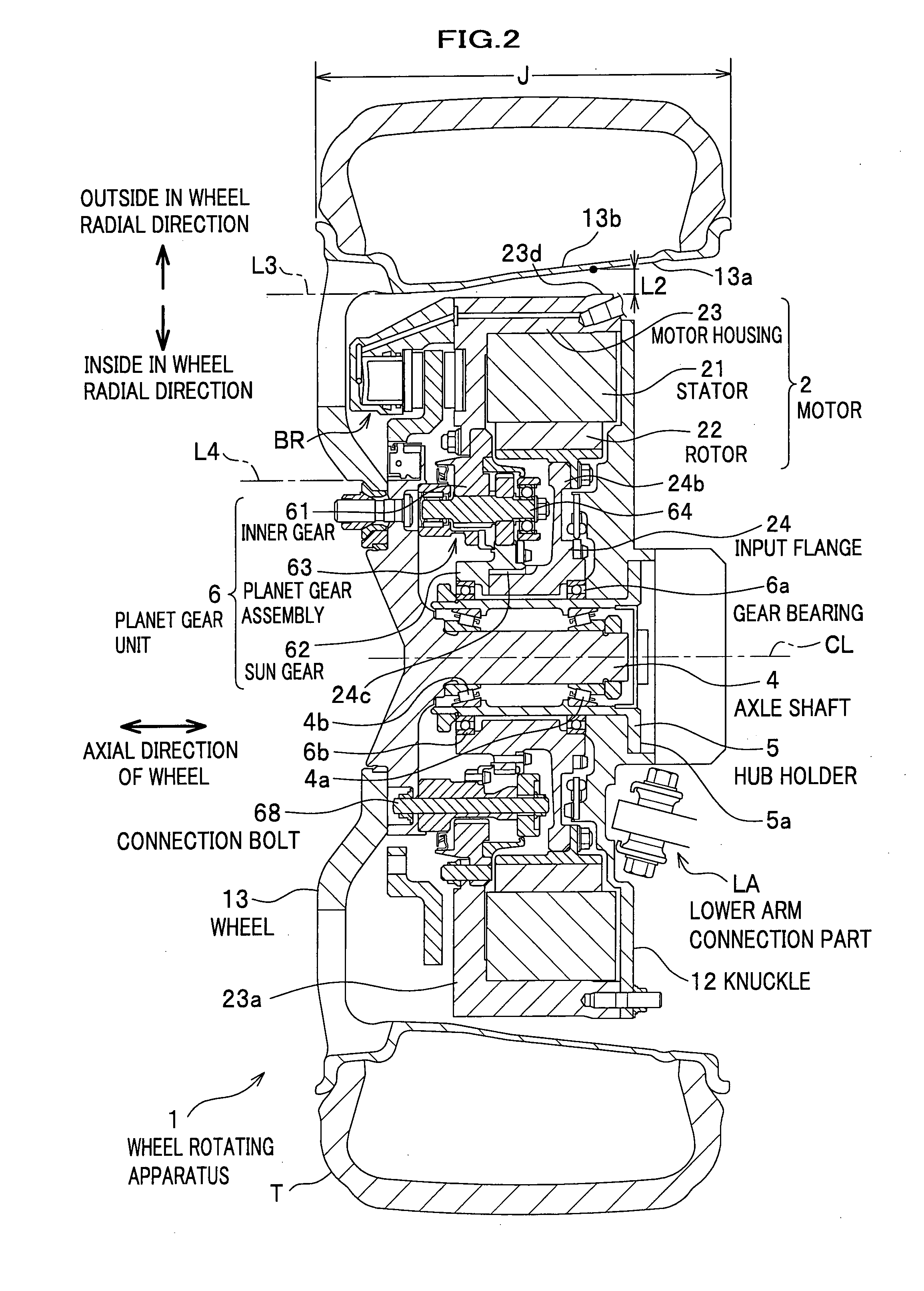

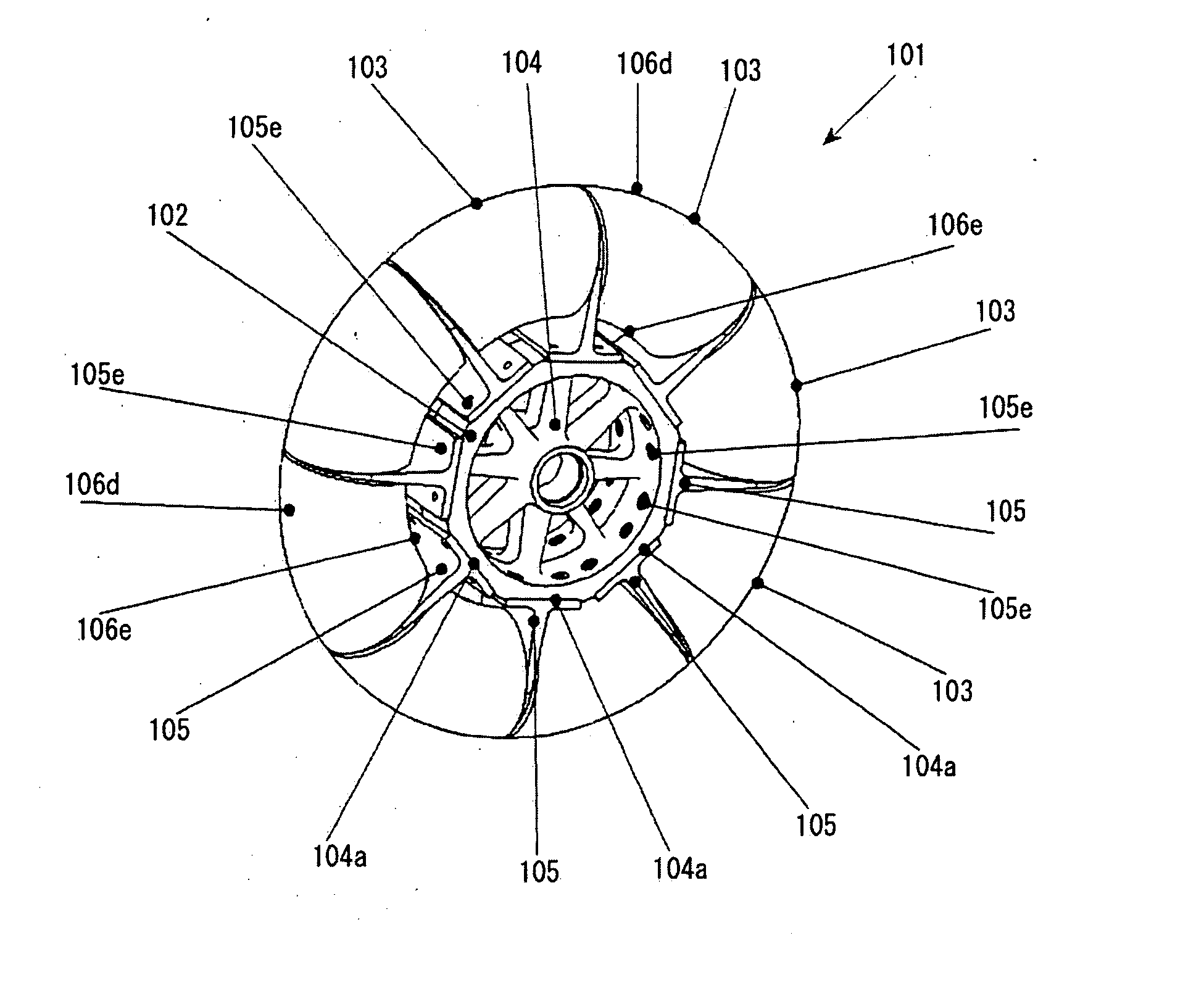

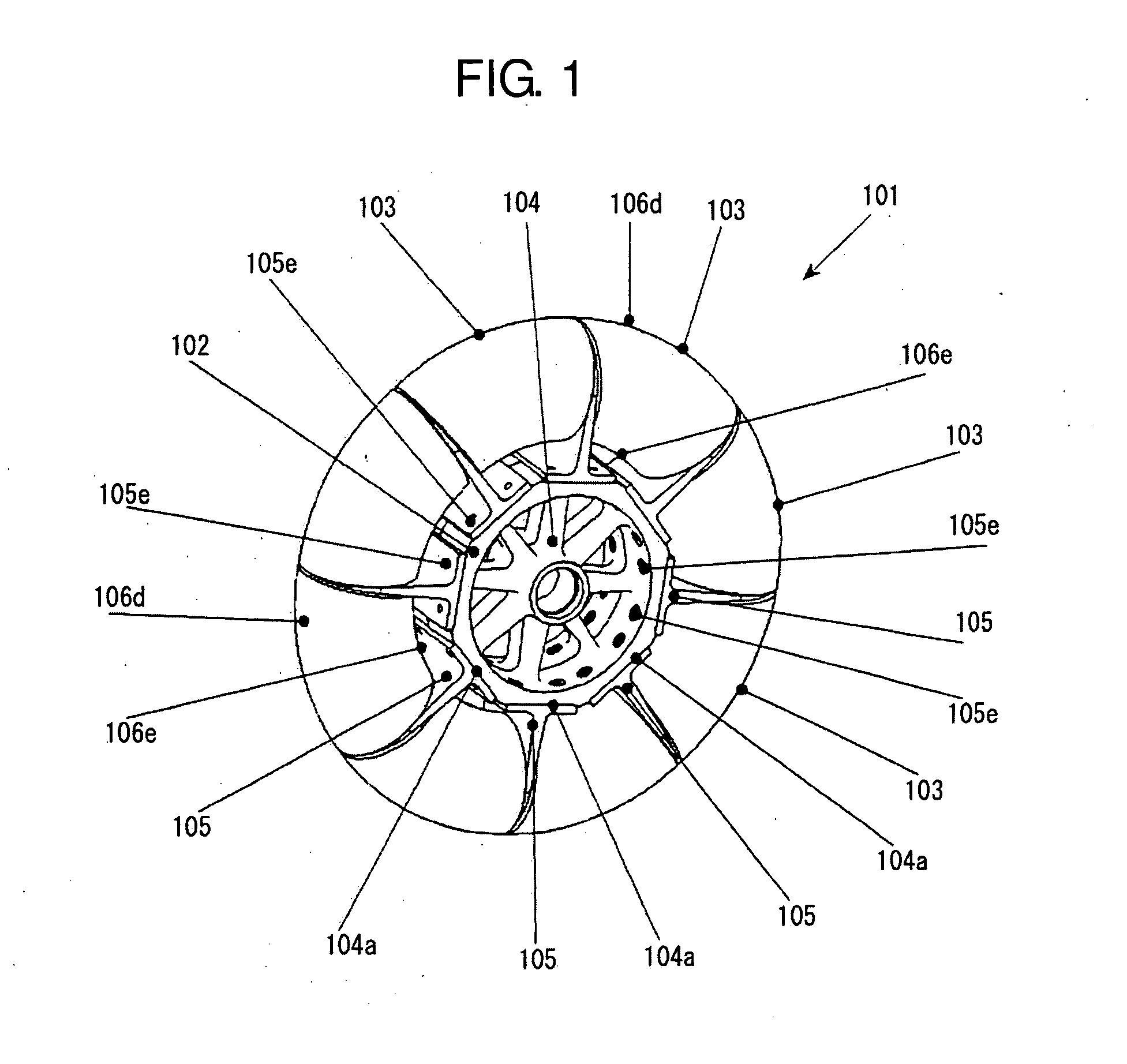

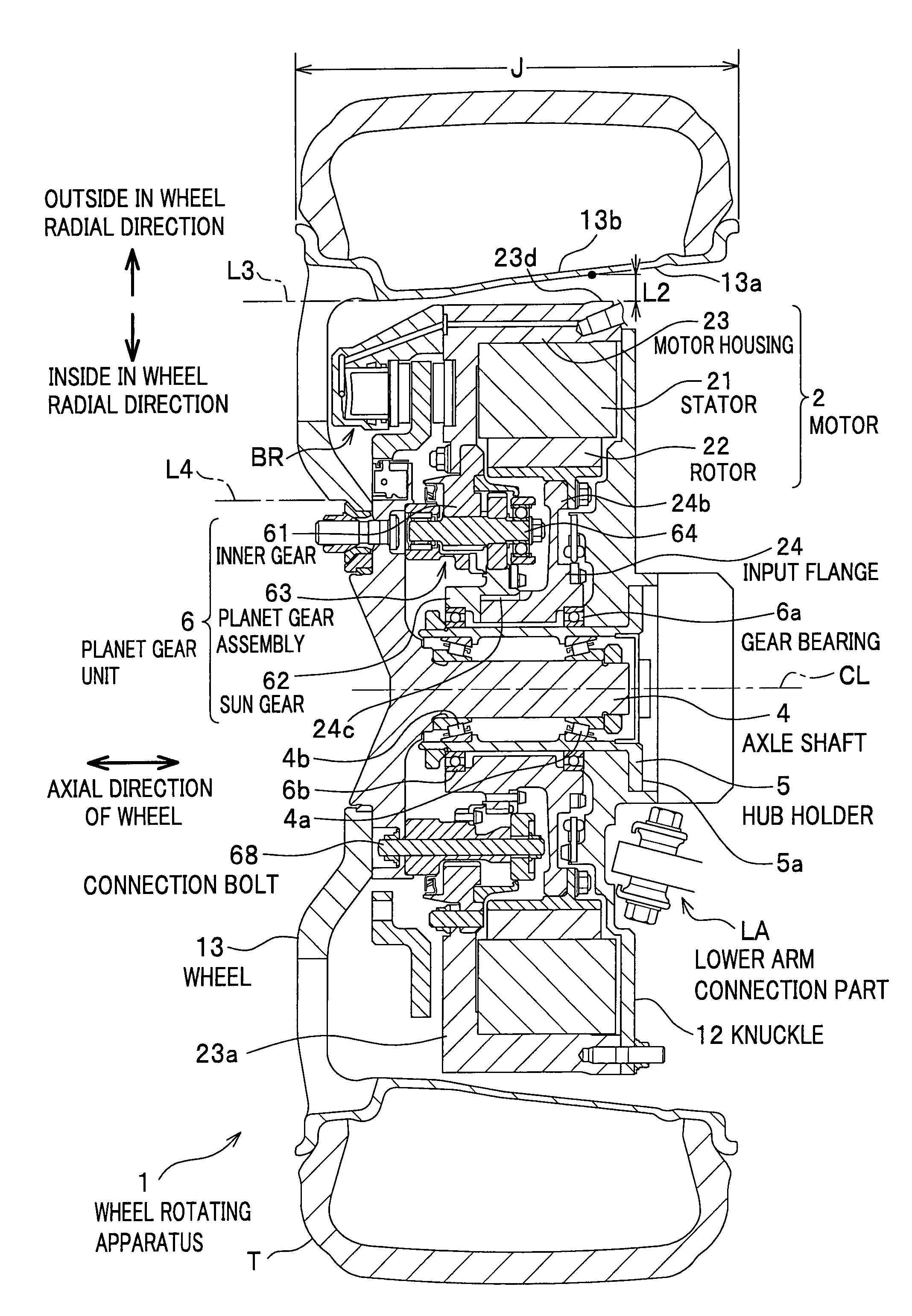

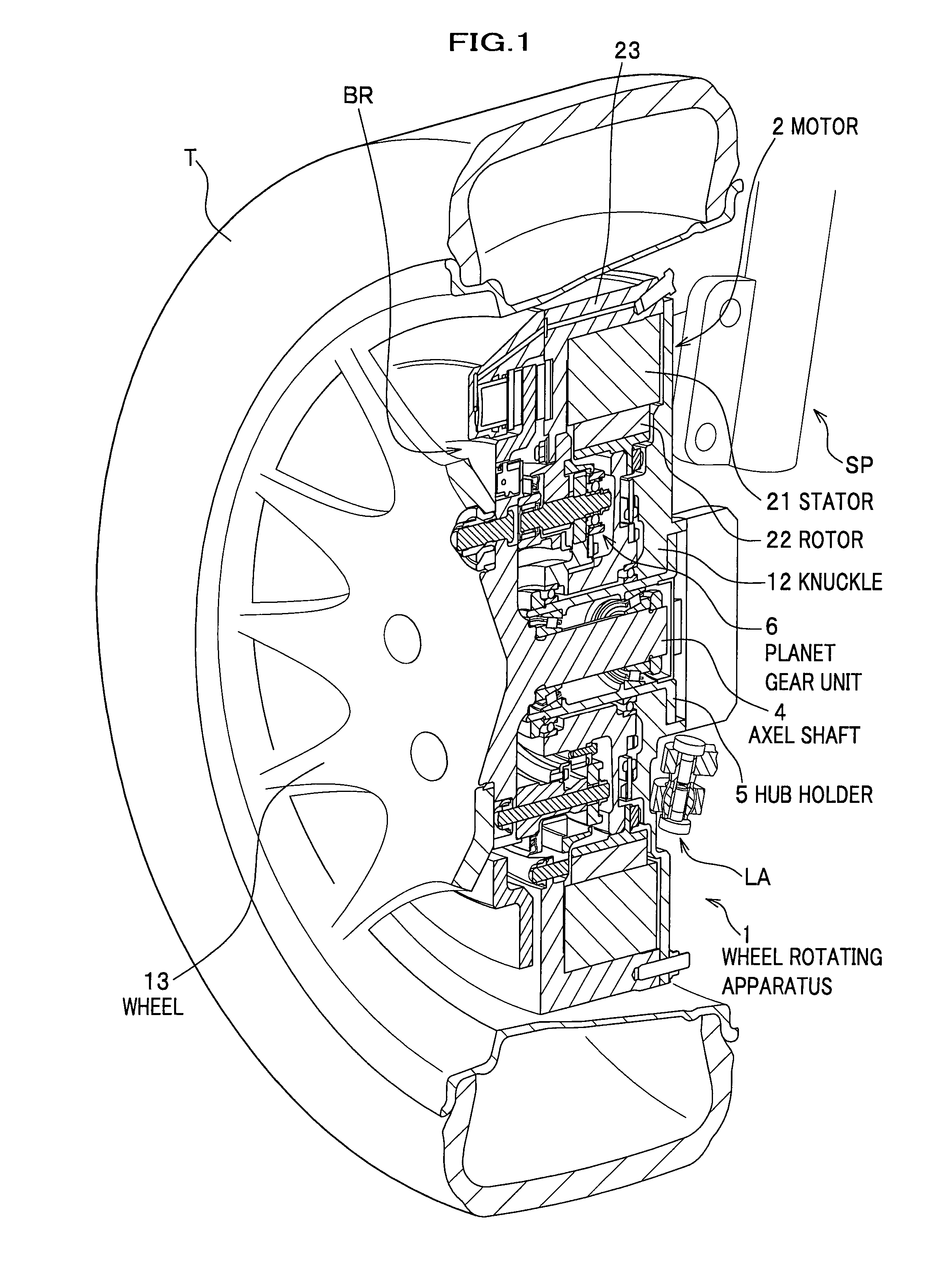

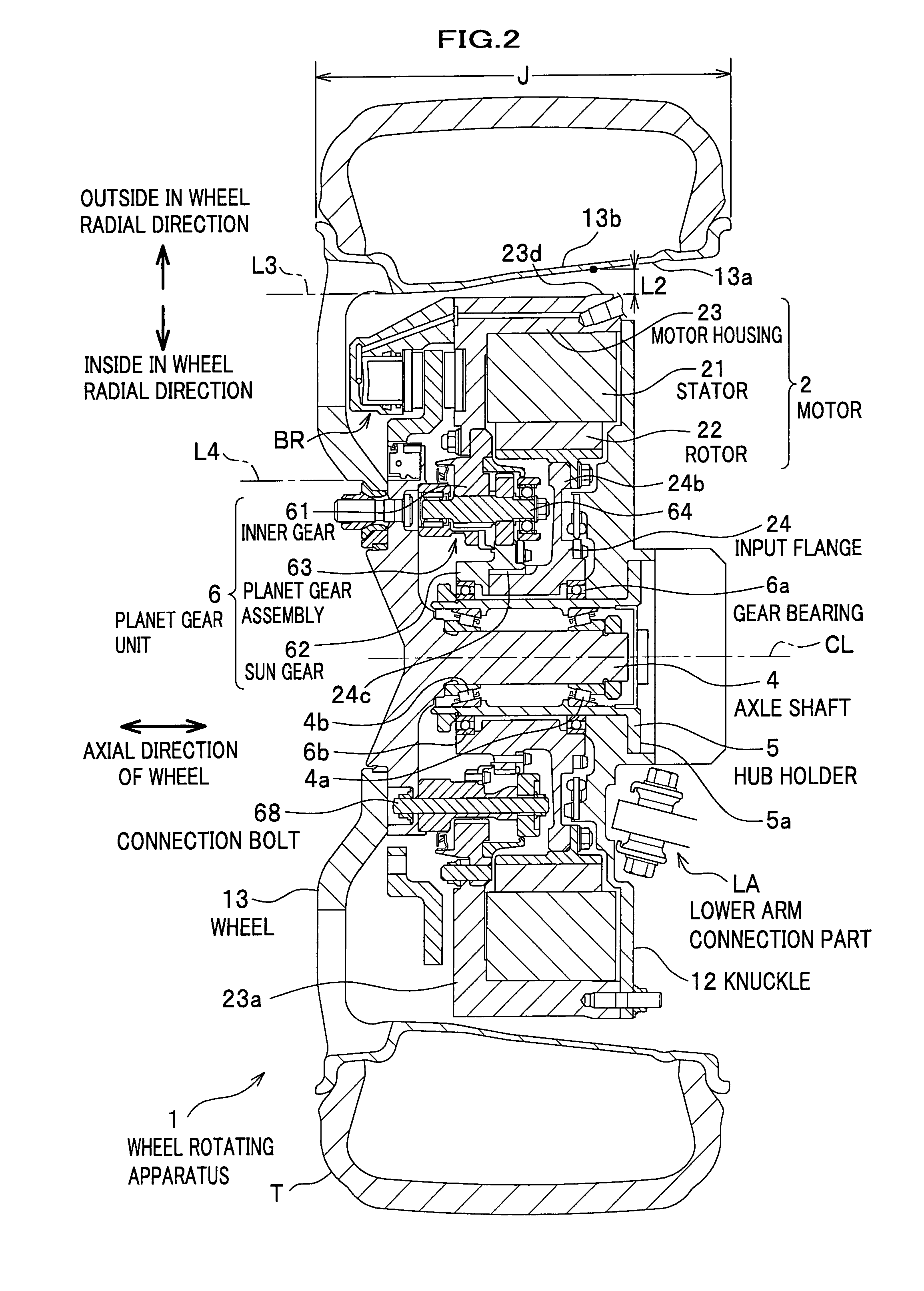

Wheel rotating apparatus and in-wheel motor vehicle

InactiveUS20080070736A1High varianceIncrease the reduction ratioHybrid vehiclesElectric propulsion mountingMechanical engineeringStator

In a wheel rotating apparatus including a motor and a planet gear mechanism to generate a drive force, the planet gear includes first and second gears having different diameters, connected to each other in an axial direction thereof with planet gear shaft. The first gear is inside the stator and the rotor in radial and axial directions of the wheel and the second gear is outside the first gear in an axial direction of the wheel. A vehicle may include a suspension connected to the base of the wheel rotating apparatus.

Owner:HONDA MOTOR CO LTD

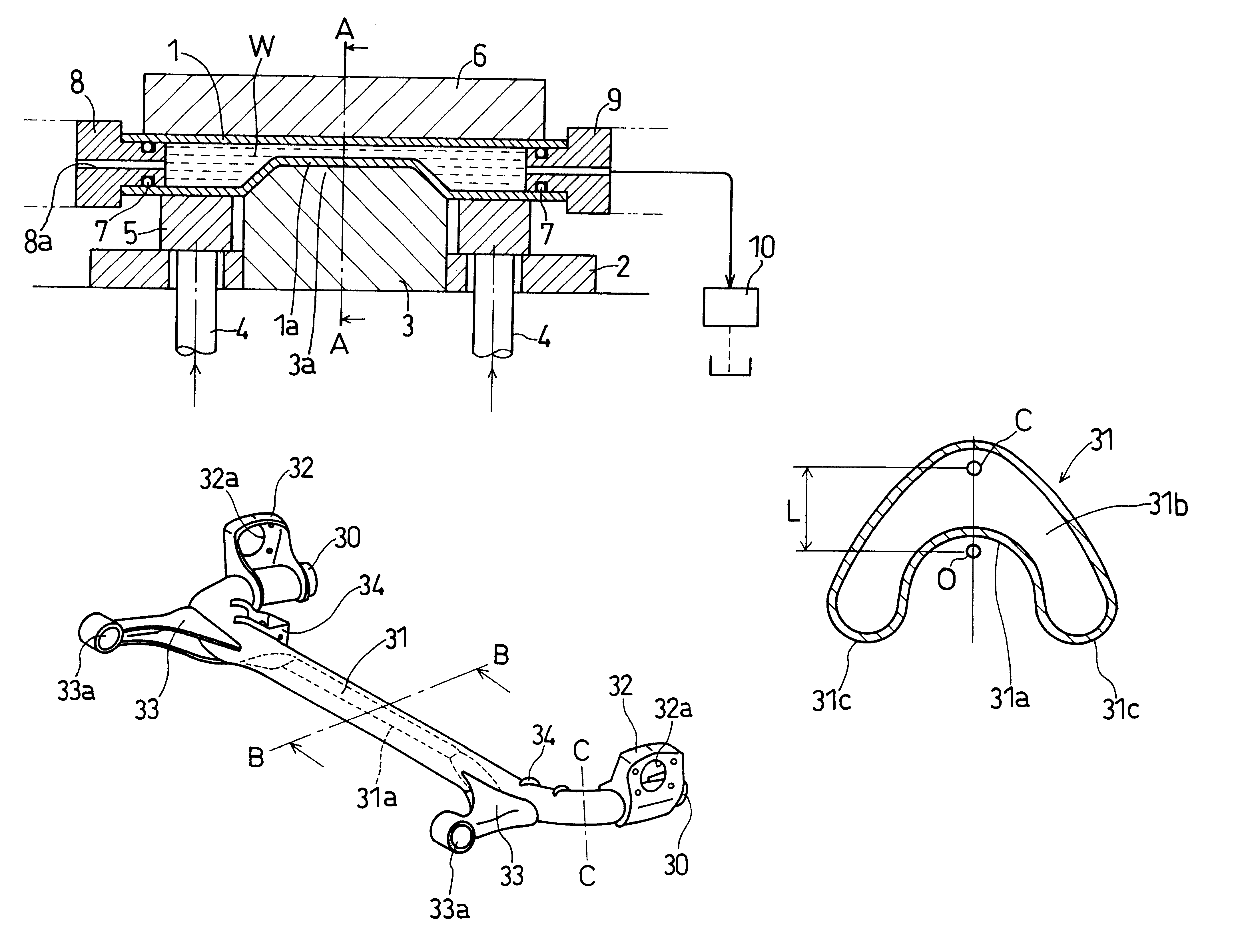

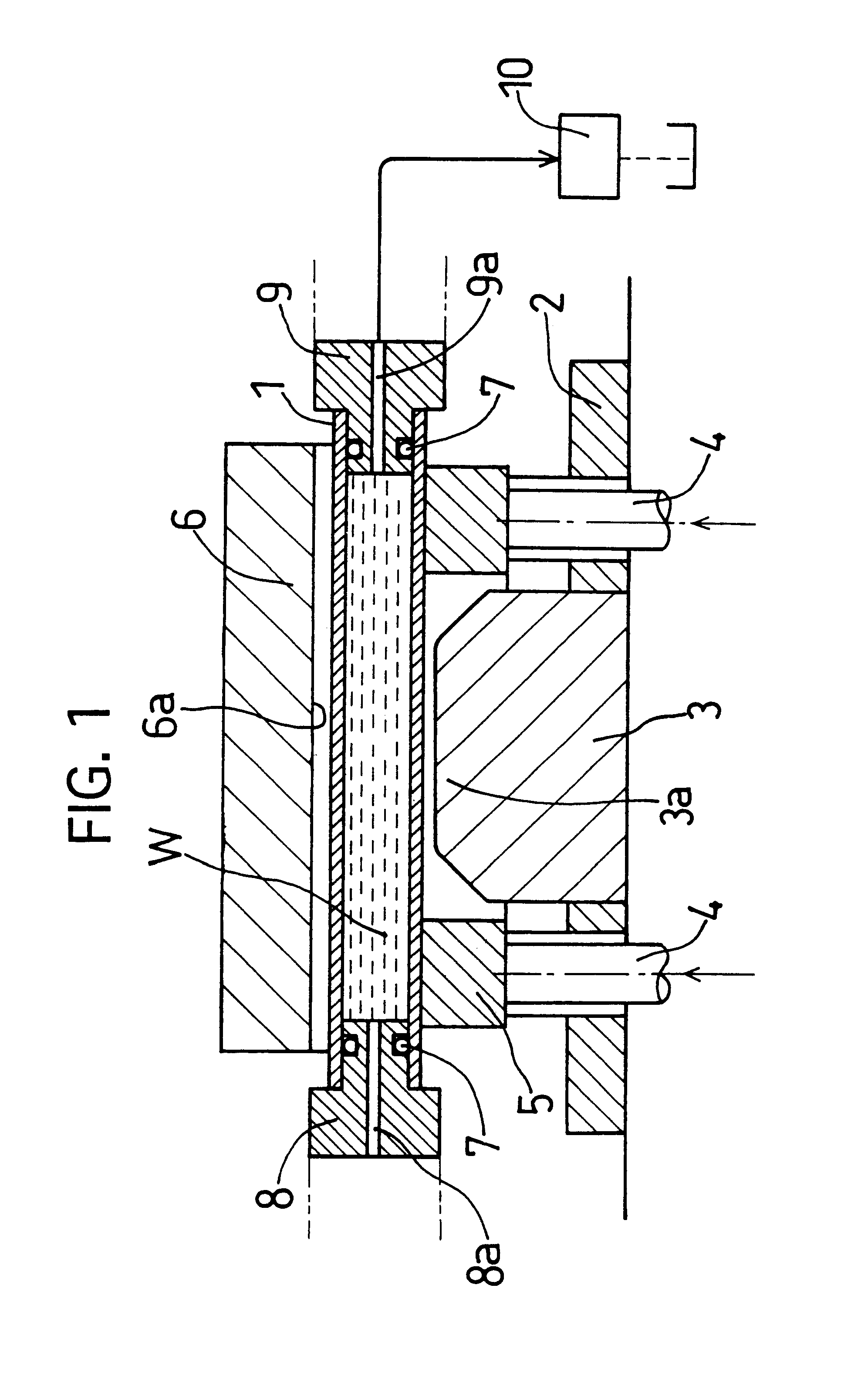

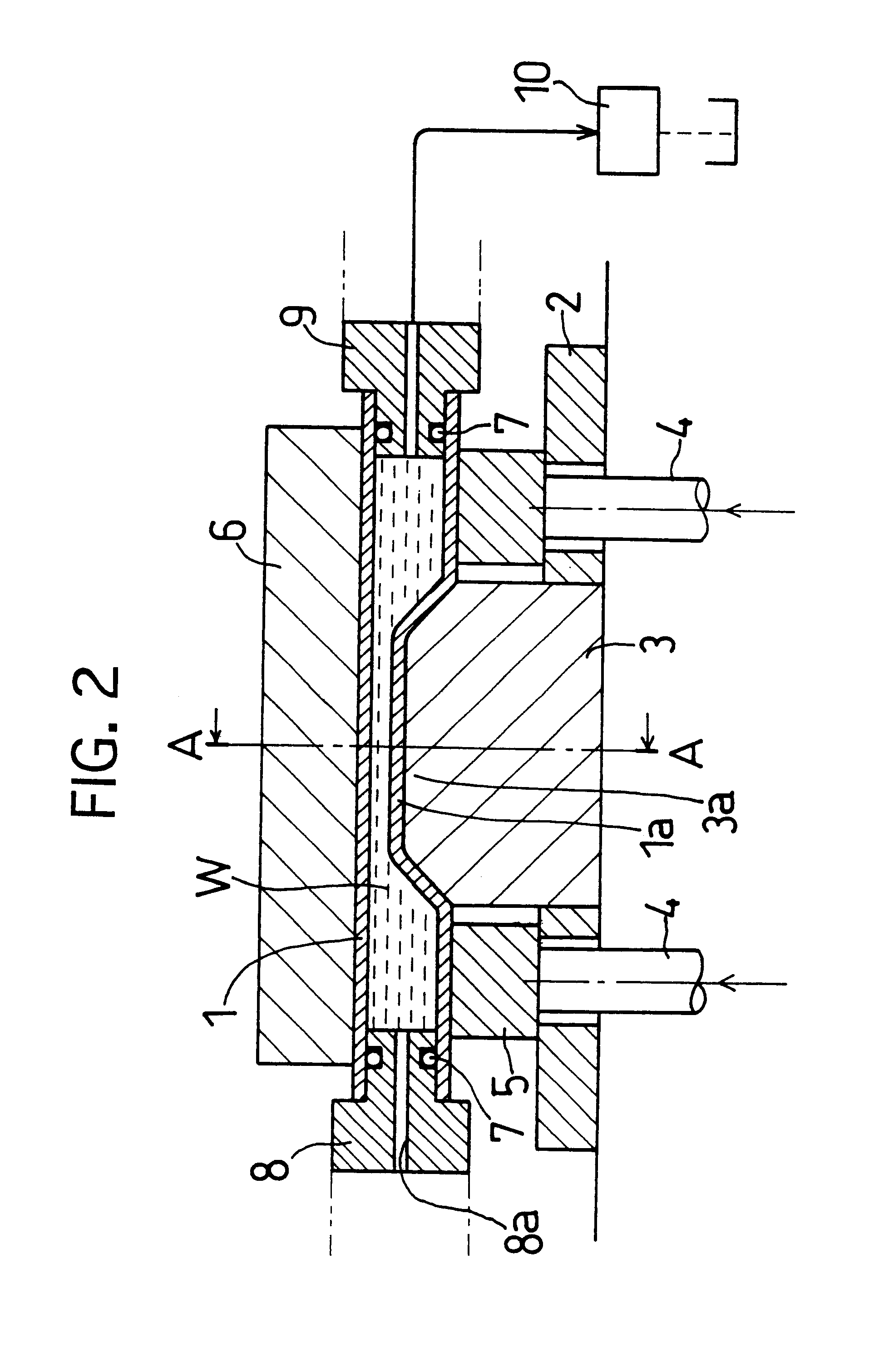

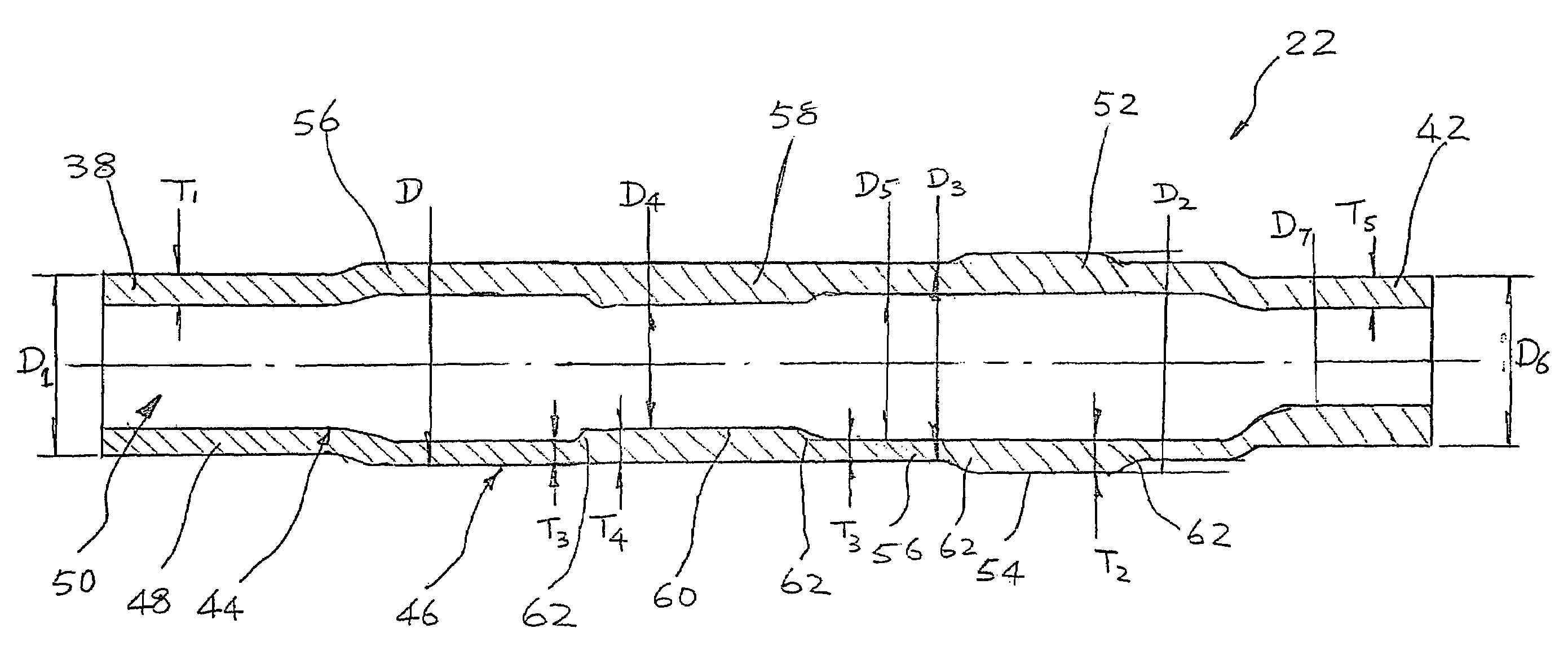

Irregular-section tubular body and axle beam for torsion beam and method of manufacturing the same

The invention provides a method of manufacturing an irregular section tubular body and axle beam. The axle beam has a tubular worked body that has sealed liquid therein and is press-formed by upper and lower press molds. One of the press molds has a convex mold portion to form a concave portion concaved in an axis perpendicular direction at an axial part of the axle beam. The press-forming of the tubular worked body is completed by a one stroke process using liquid pressure that increases as the internal volume of the worked body decreases due to formation of the concave portion. The concave portion extends substantially the length of the axle beam and has a substantially U-shaped or V-shaped cross-section forming a closed and sealed space.

Owner:TOYOTA JIDOSHA KK

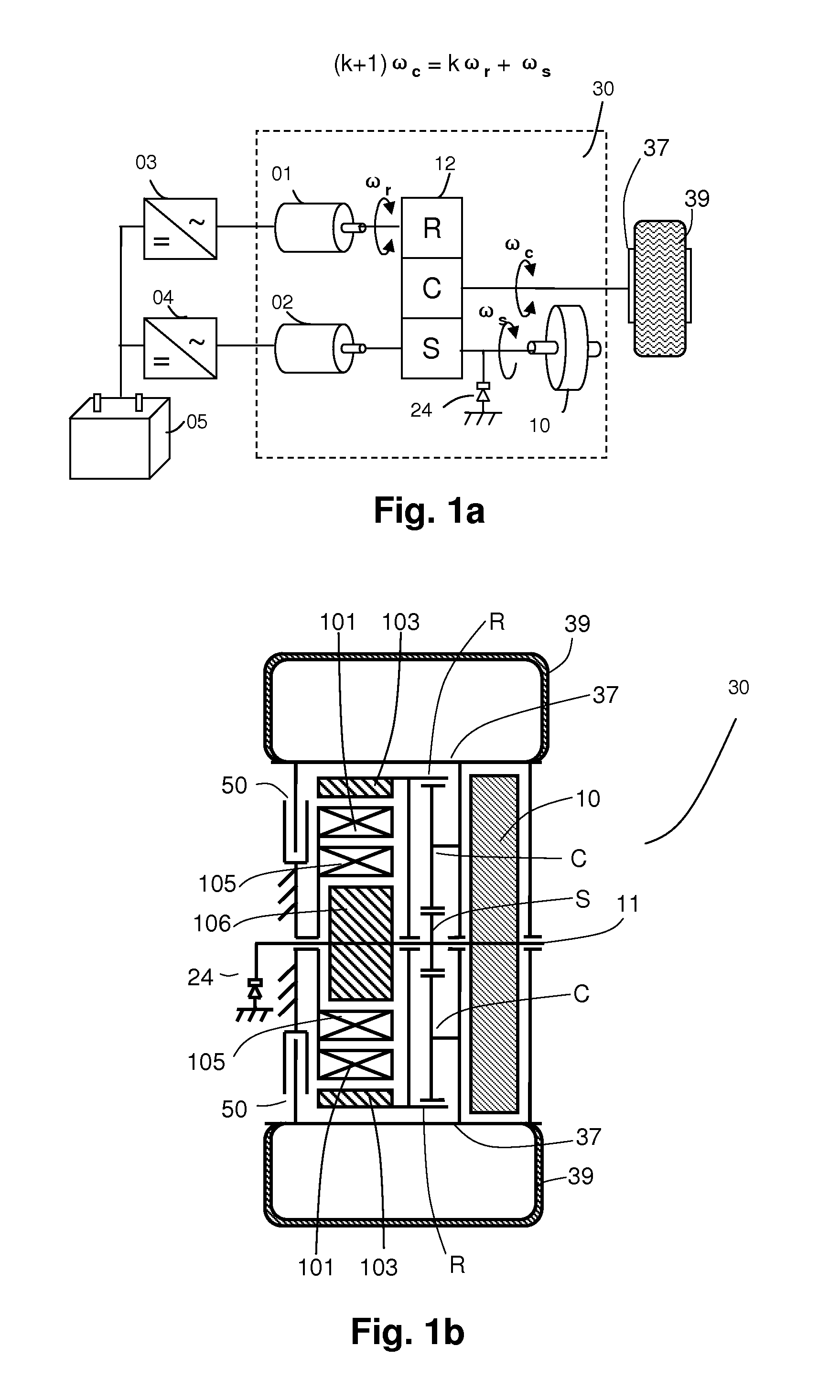

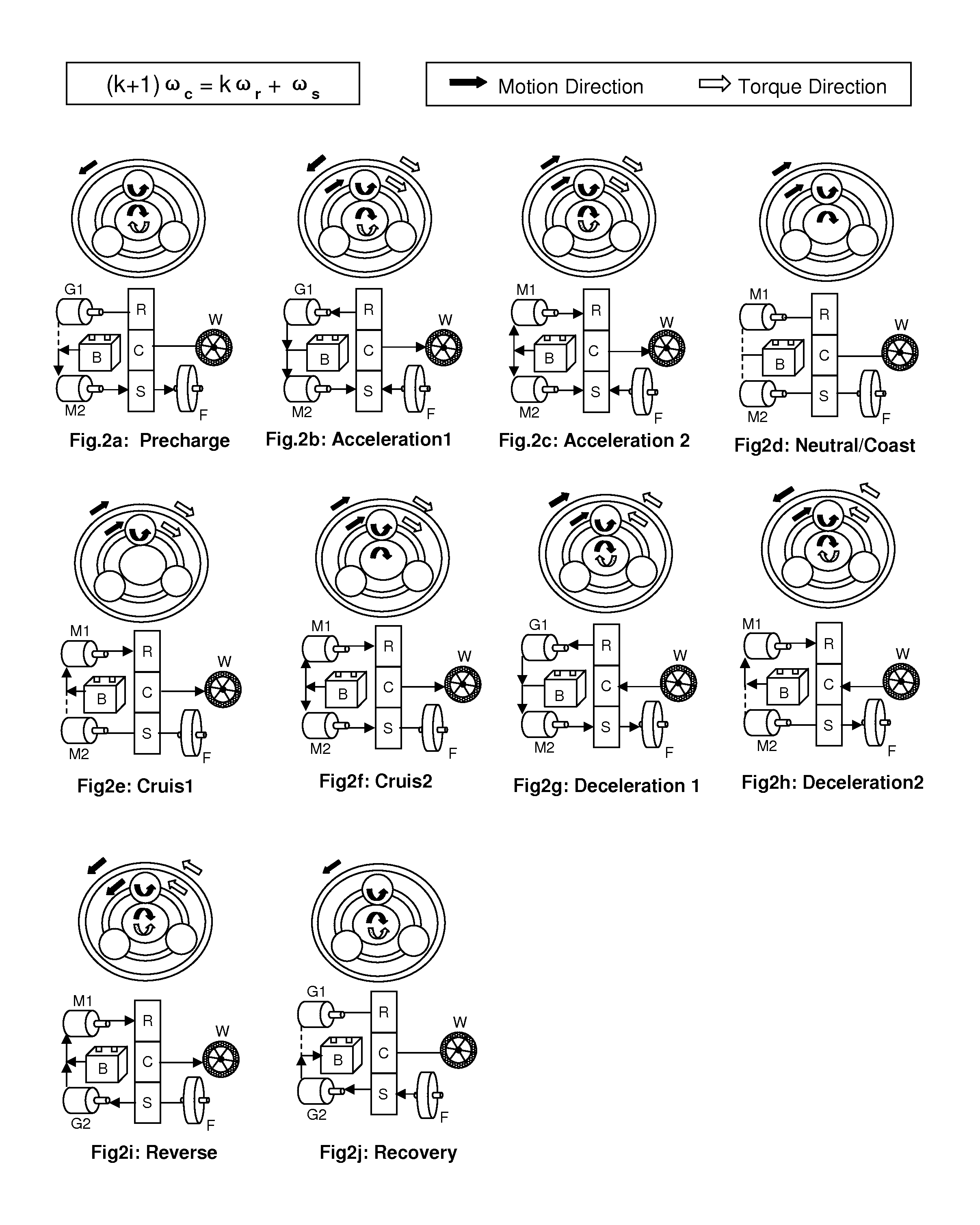

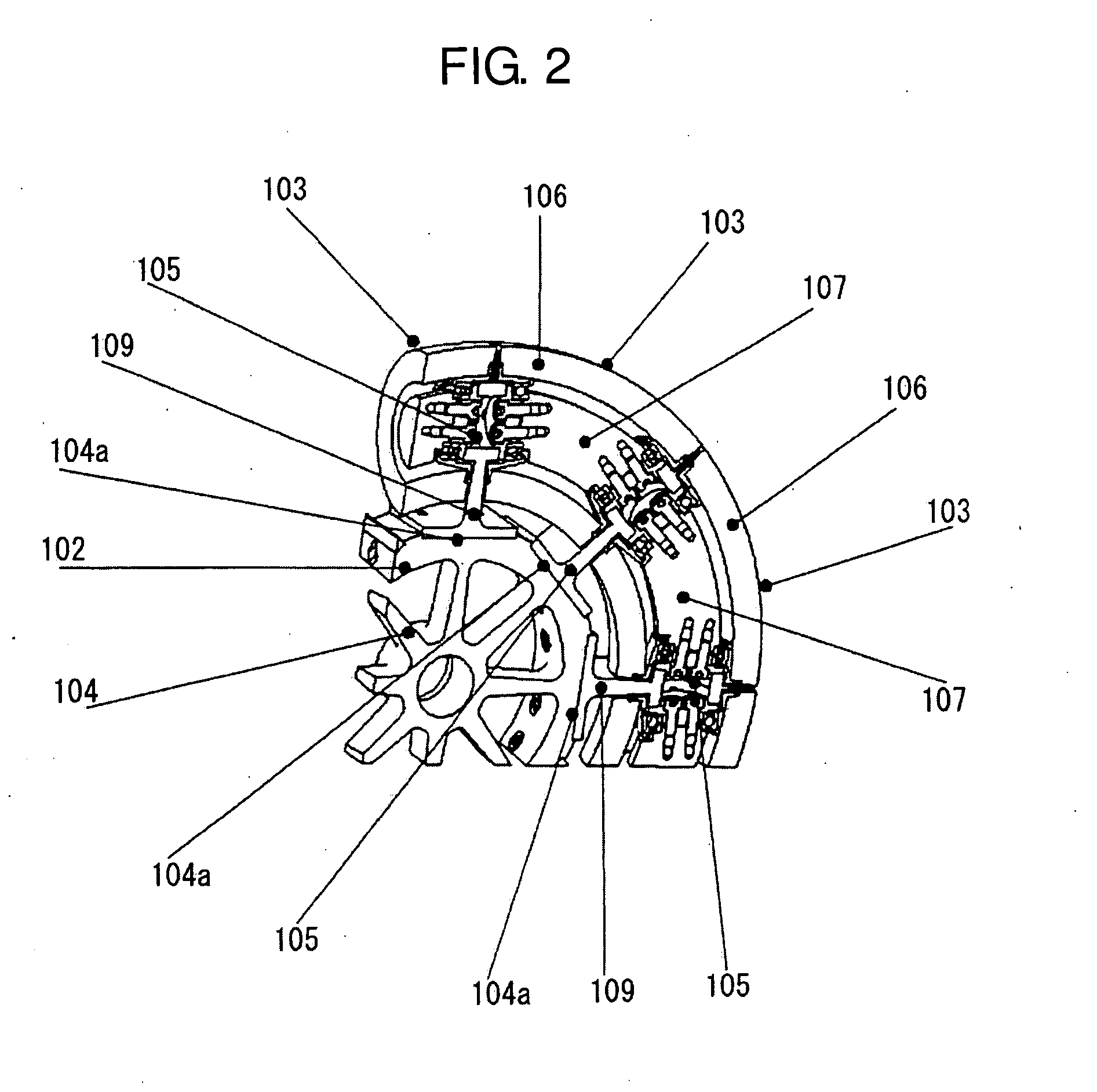

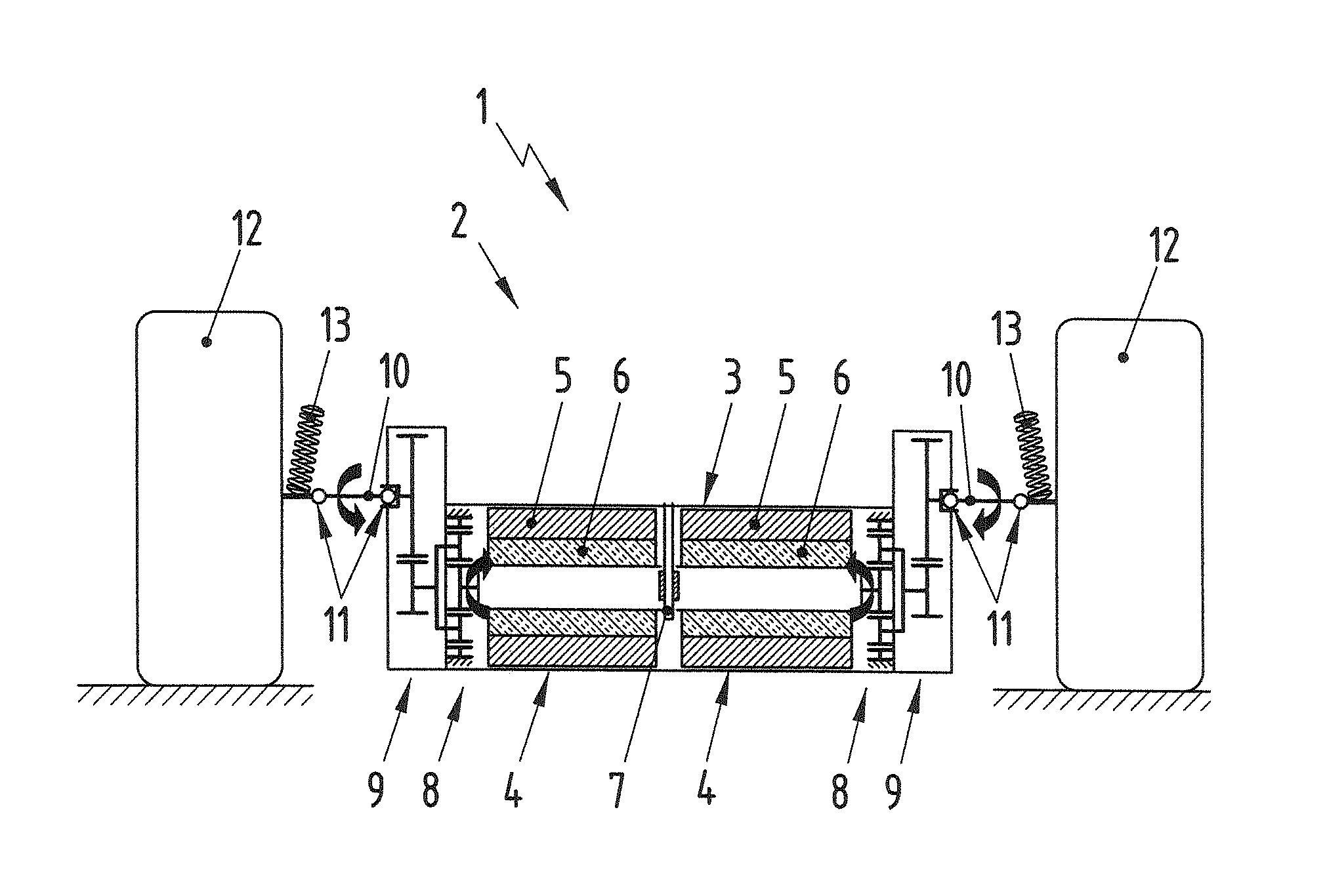

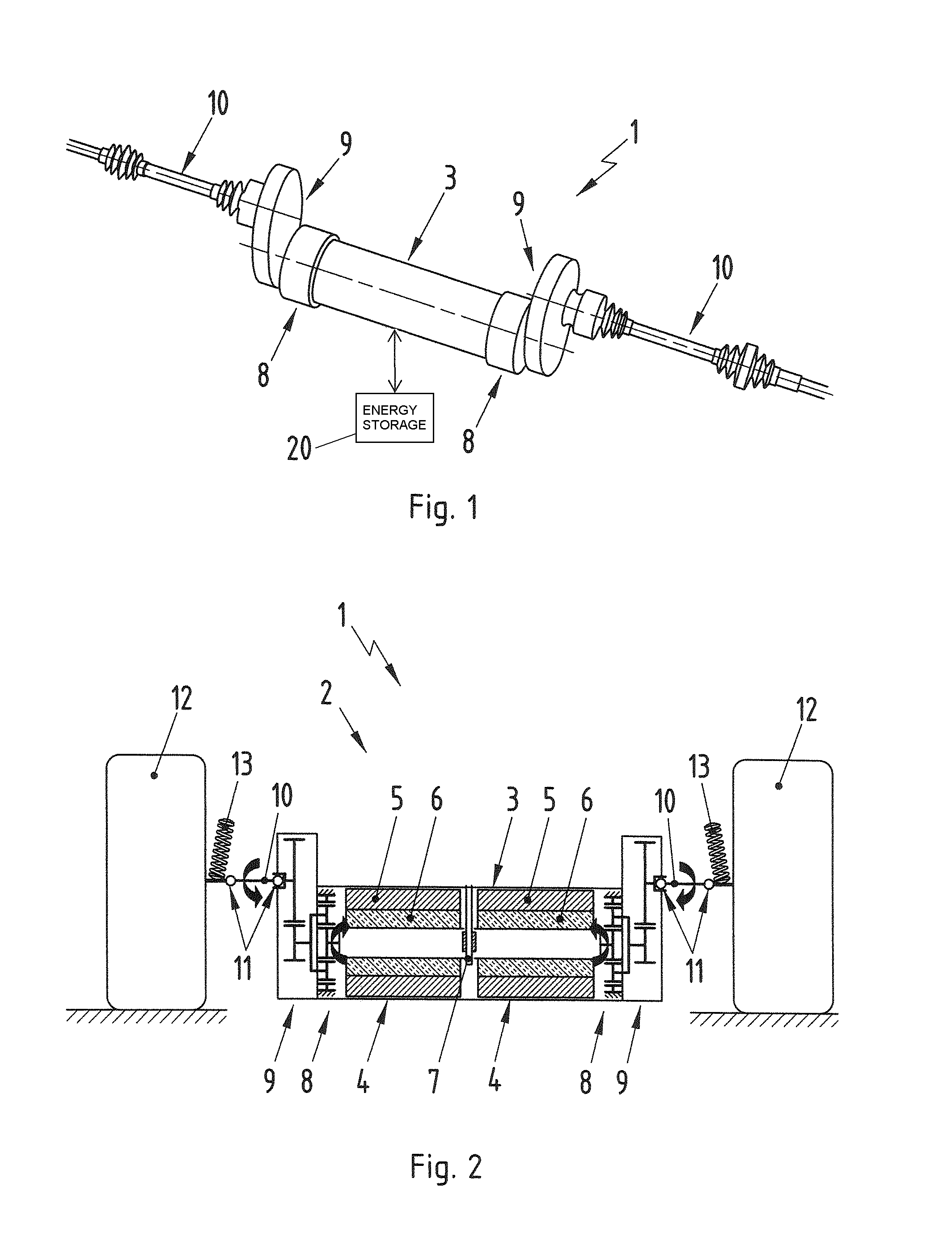

Wheel hub flywheel-motor kinetic hybrid system and method

InactiveUS20120161497A1Emission reductionReduce energy lossPlural diverse prime-mover propulsion mountingPropulsion by batteries/cellsGear wheelEngineering

System and method for the combination of a flywheel and motor / generator inside a wheel hub for hybrid vehicle propulsion. The flywheel and motor / generator are connected by a planetary gear system, in which a first port is connected to the flywheel, a second port is connected to the wheel hub, and a third port is connected to a motor / generator. An additional motor / generator may be used at one of the first port and second port. The system may be used in an electric-kinetic hybrid mode, or in a fuel-kinetic hybrid mode, when used in a vehicle having an internal combustion engine as the prime mover. Efficiency of energy storage and release is significantly improved in comparison to prior art.

Owner:HE JING +1

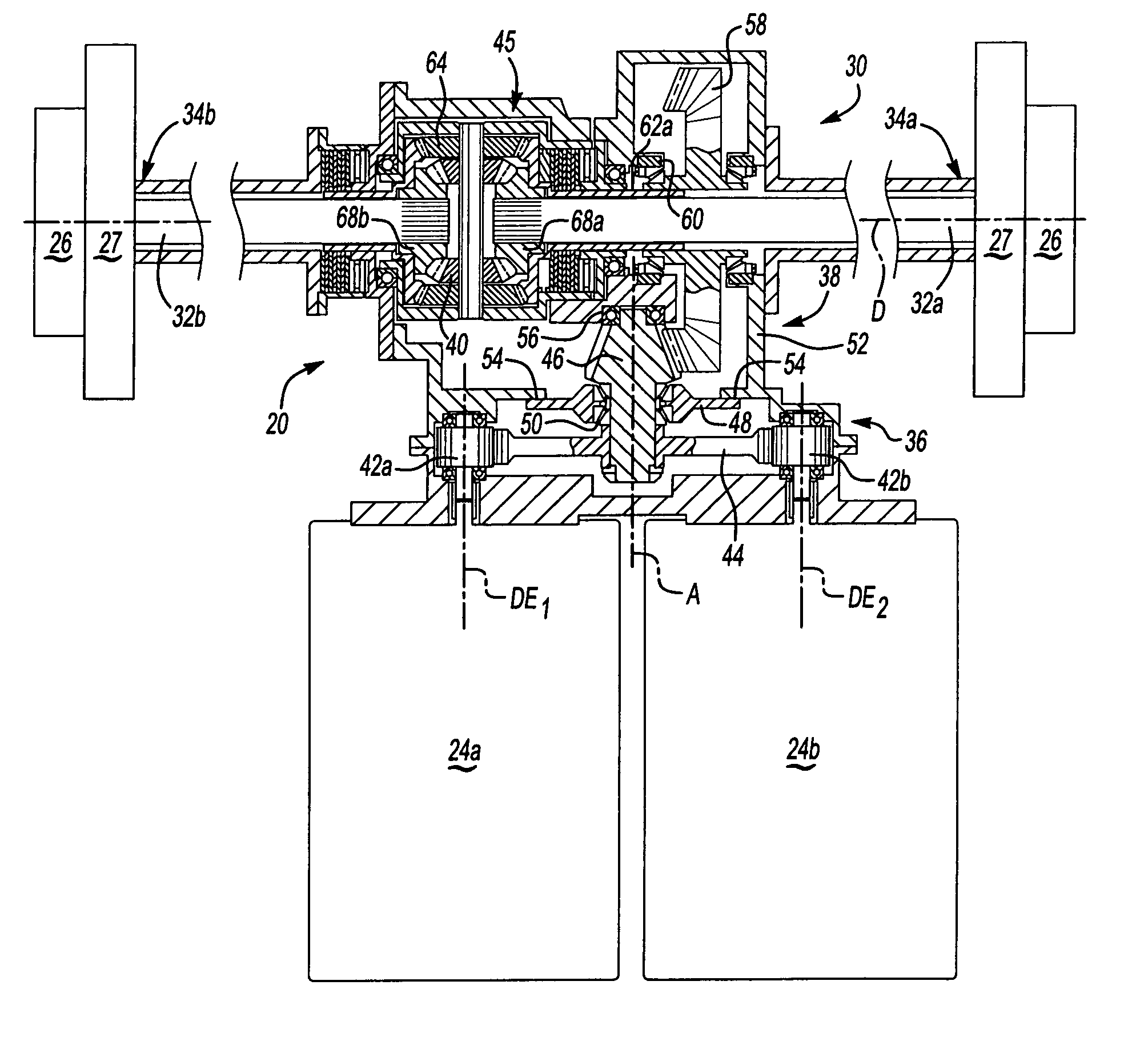

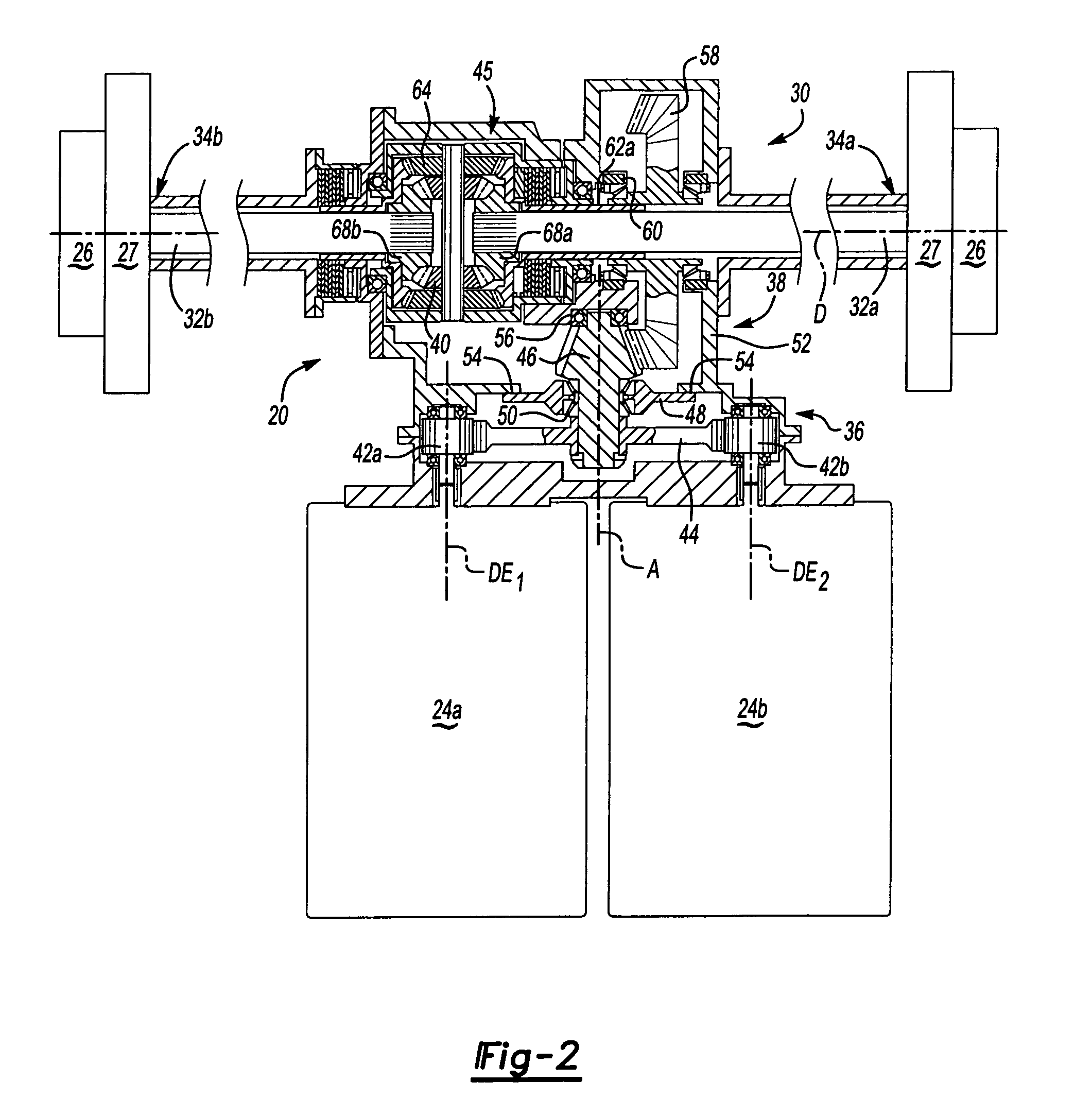

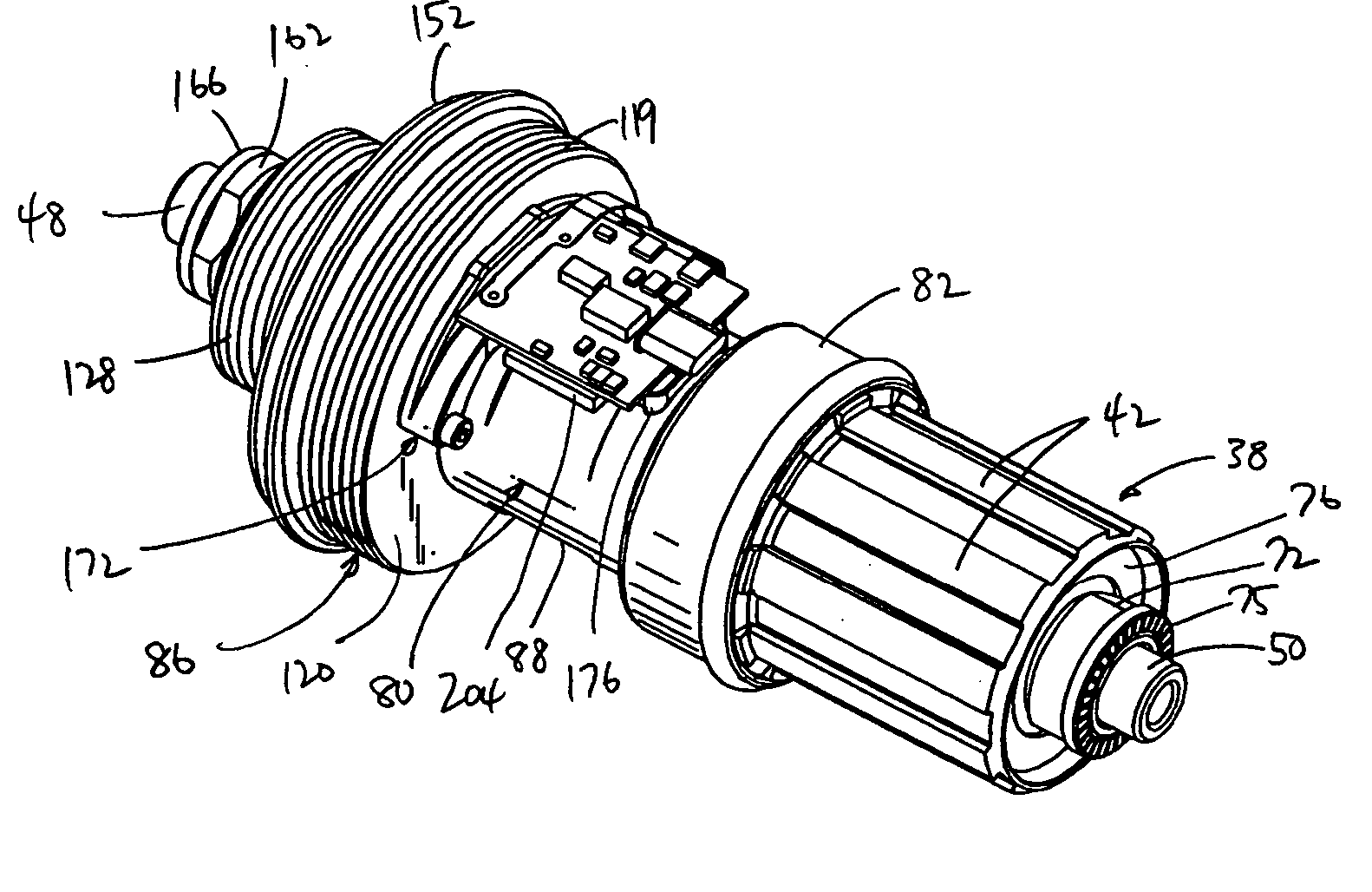

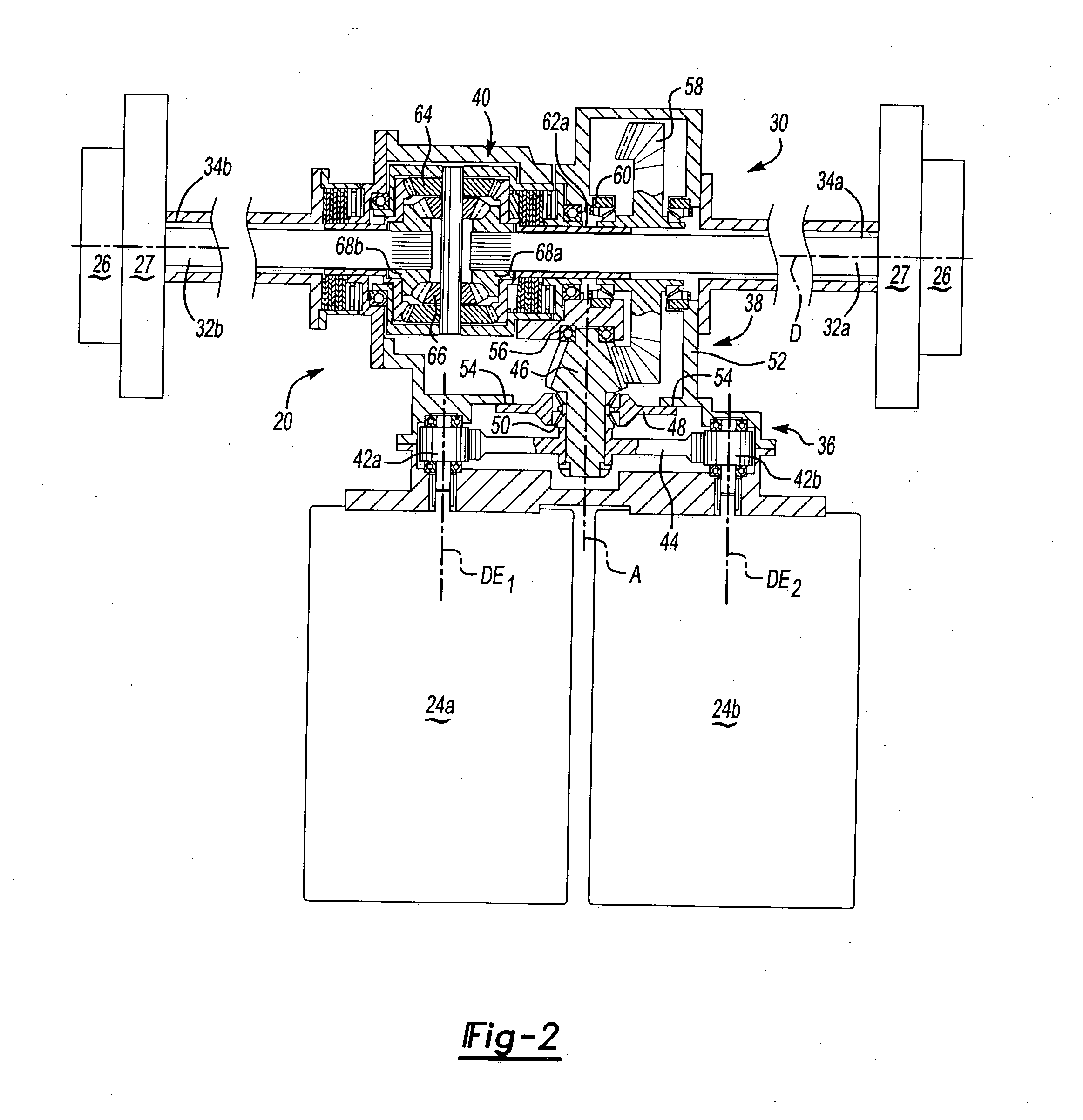

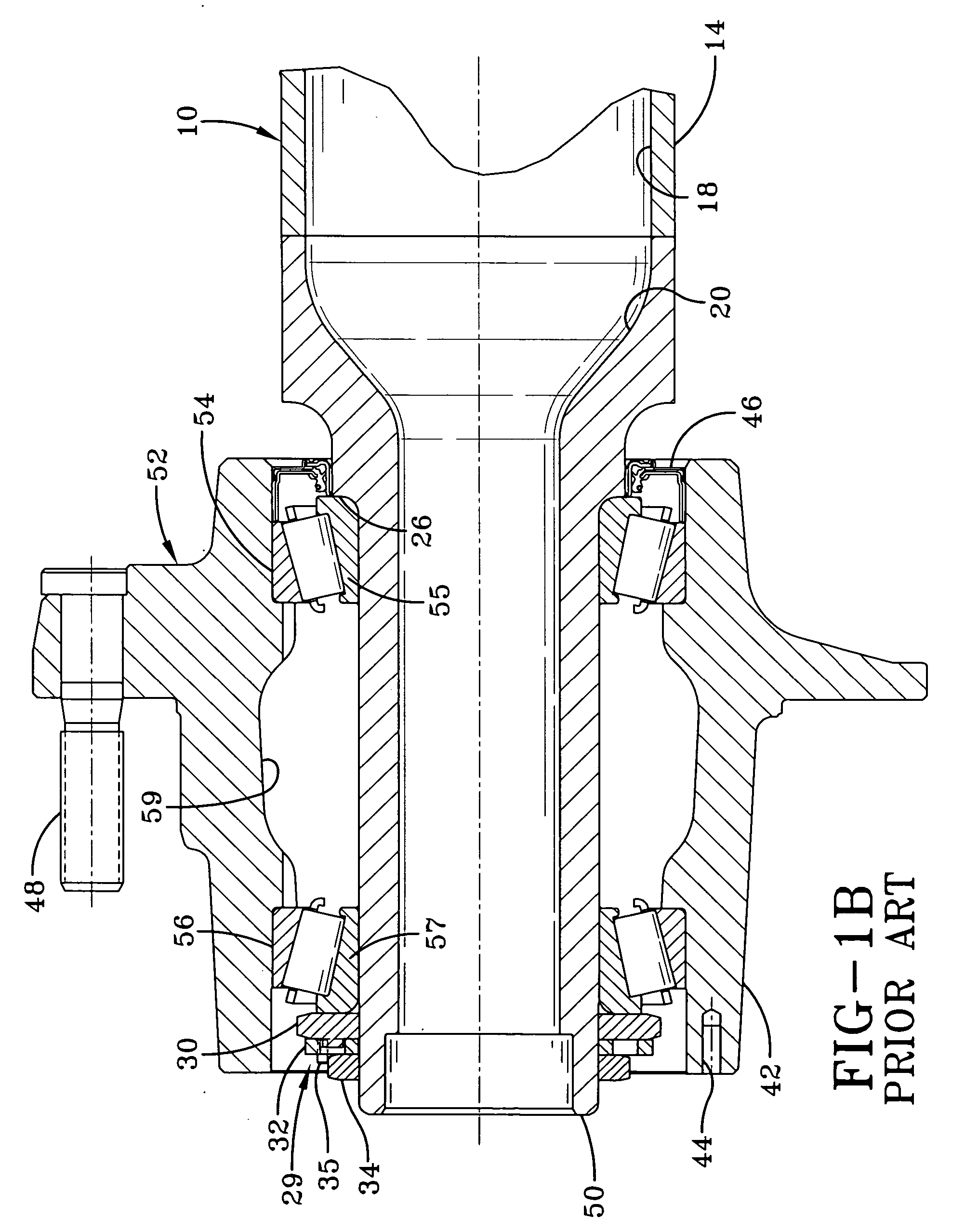

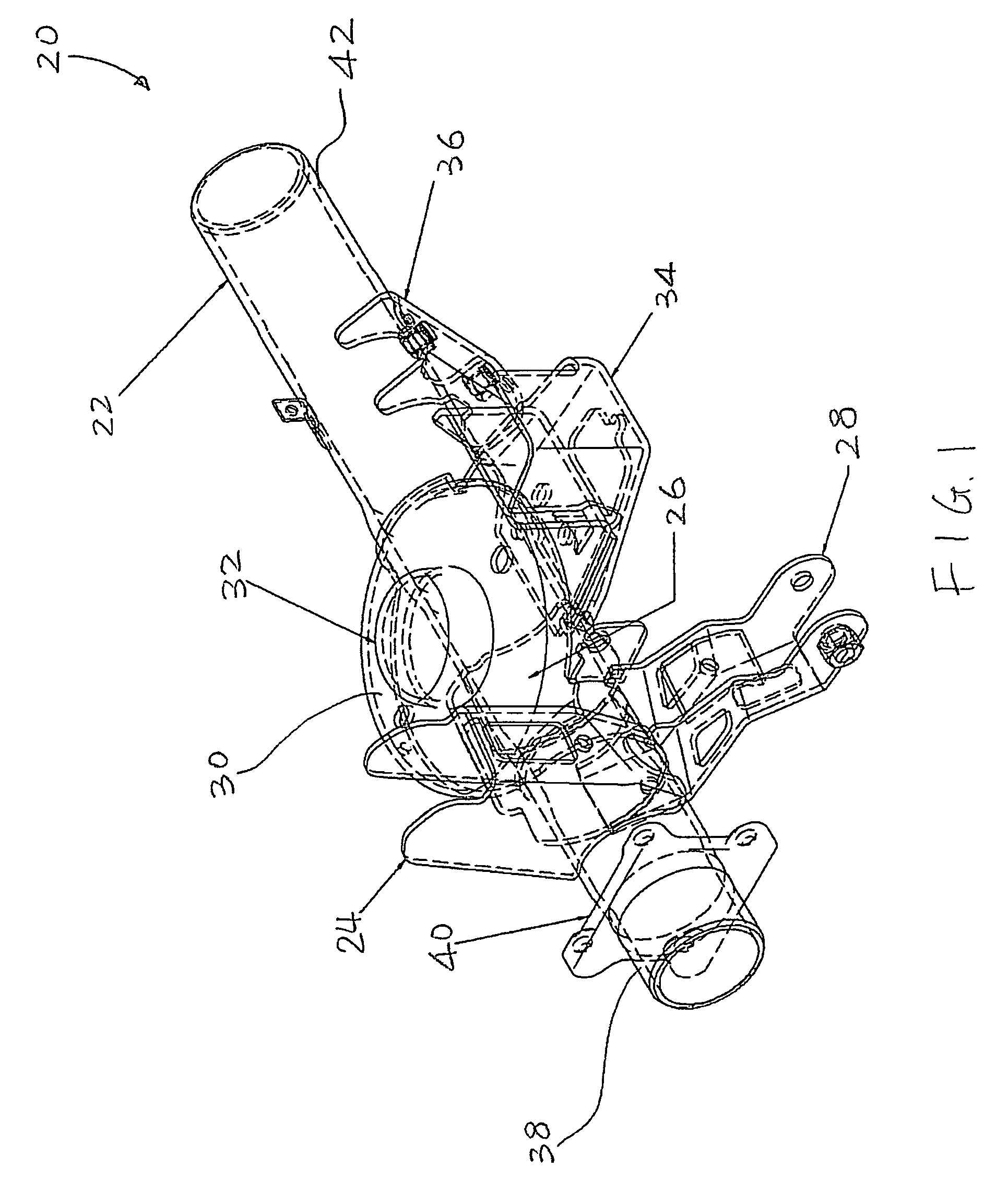

Axle assembly with transverse mounted electric motors

InactiveUS7028583B2Small sizeAllow useOff-road vehiclesTransmission elementsReduced sizeAutomotive engineering

An axle assembly includes a first and a second electric motor which drive a gearbox assembly substantially therebetween. The electric motors drive the gearbox assembly which drives the vehicle wheels through a first and second axle shaft located along a first axis. The electric motors are located along axes which are substantially transverse to the first axis. The electric motors drive the gearbox assembly which includes a first stage gear reduction, a second stage gear reduction and a third stage gear reduction. A relatively lightweight and compact axle assembly is thereby provided which will benefit from an electric motor of reduced size.

Owner:ARVINMERITOR TECH

Plastic wheel assembly and mounting sleeve with stabilizing recess

Owner:GEO PLASTICS

Omnidirectionally Moving Wheel, Moving Device, Carrying Device, and Massage Device

An omnidirectionally moving wheel includes multiple rotating bodies and a wheel, wherein each rotating body has a flexibility to be able to bend a rotational axis, is bent to encircle an outer circumference of the wheel in a ring-like shape, and is compressed in a direction of the rotational axis of each rotating body to be disposed on the wheel in a manner to allow rotation centered around each rotating body's secured rotational axis extending along a plane perpendicular to the rotational axis of the wheel.

Owner:FUJI SHINICHIRO

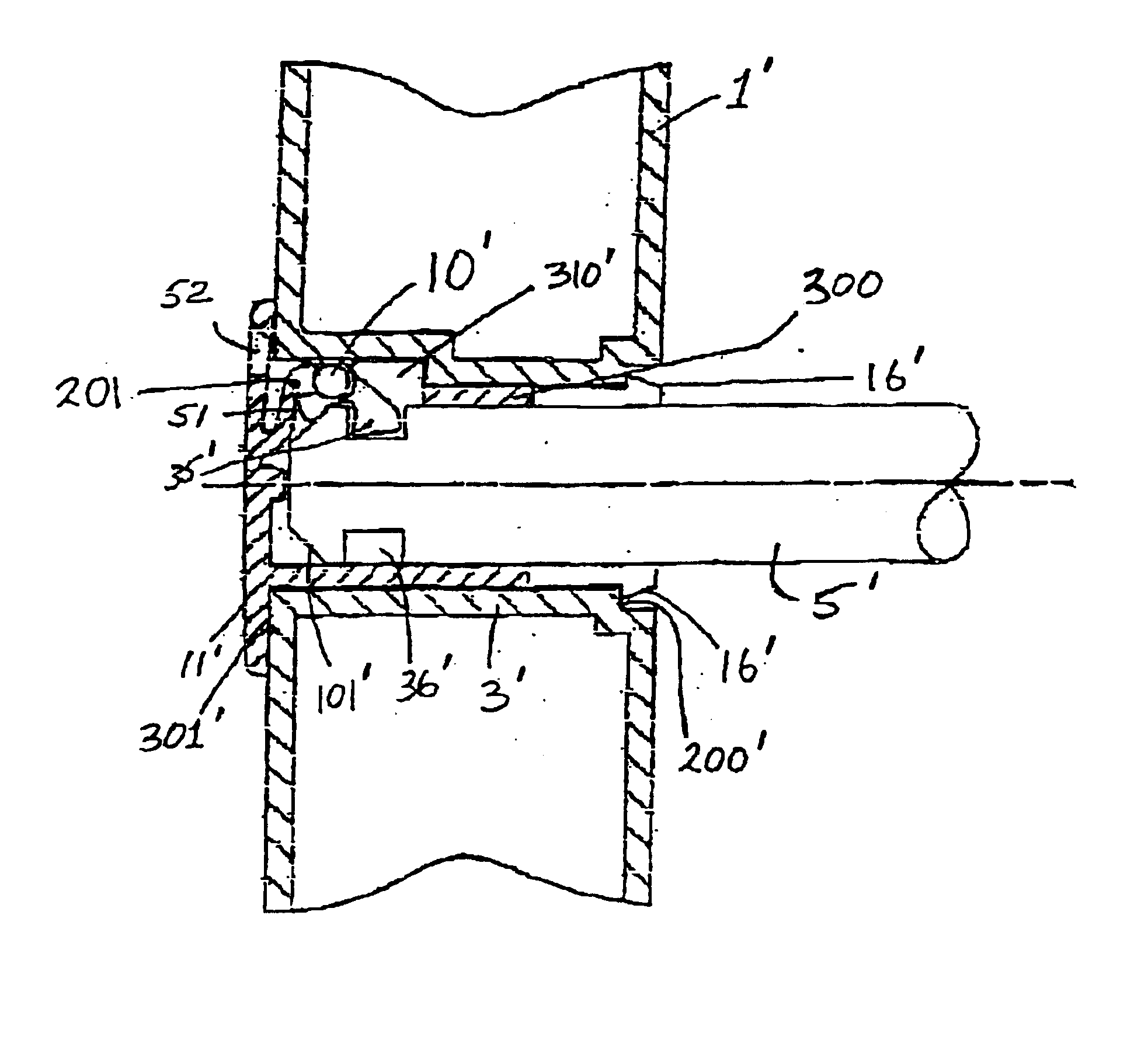

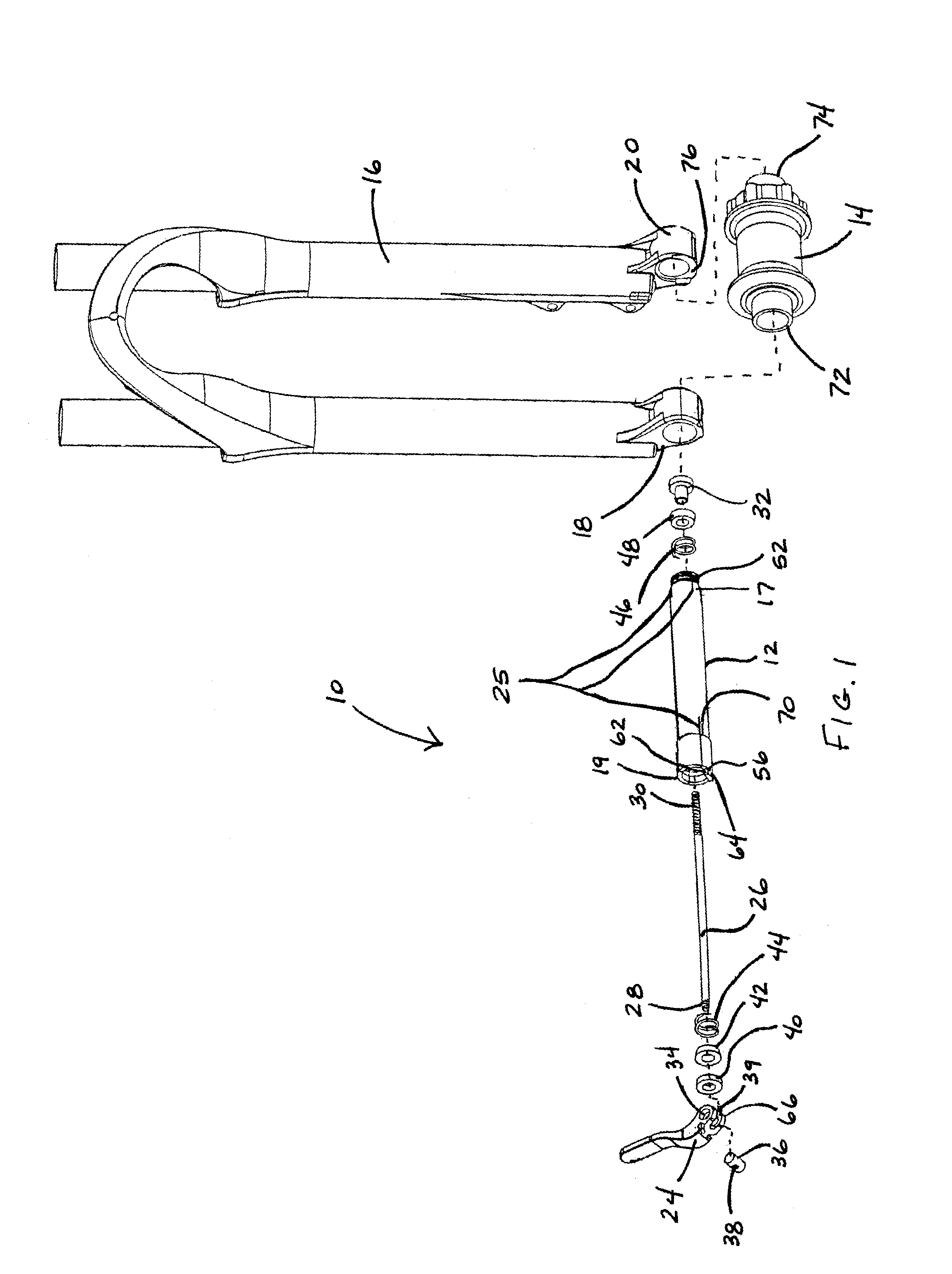

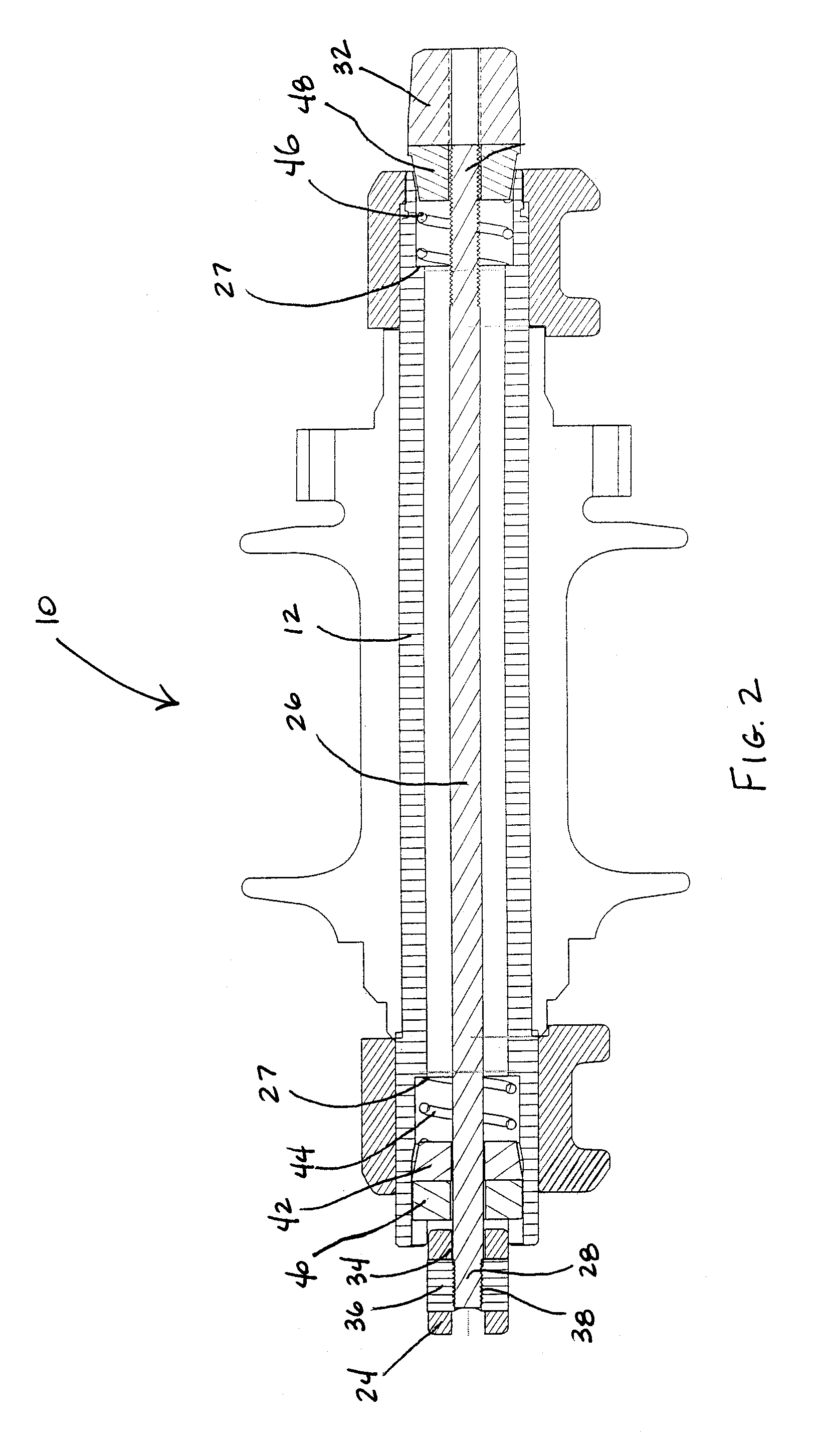

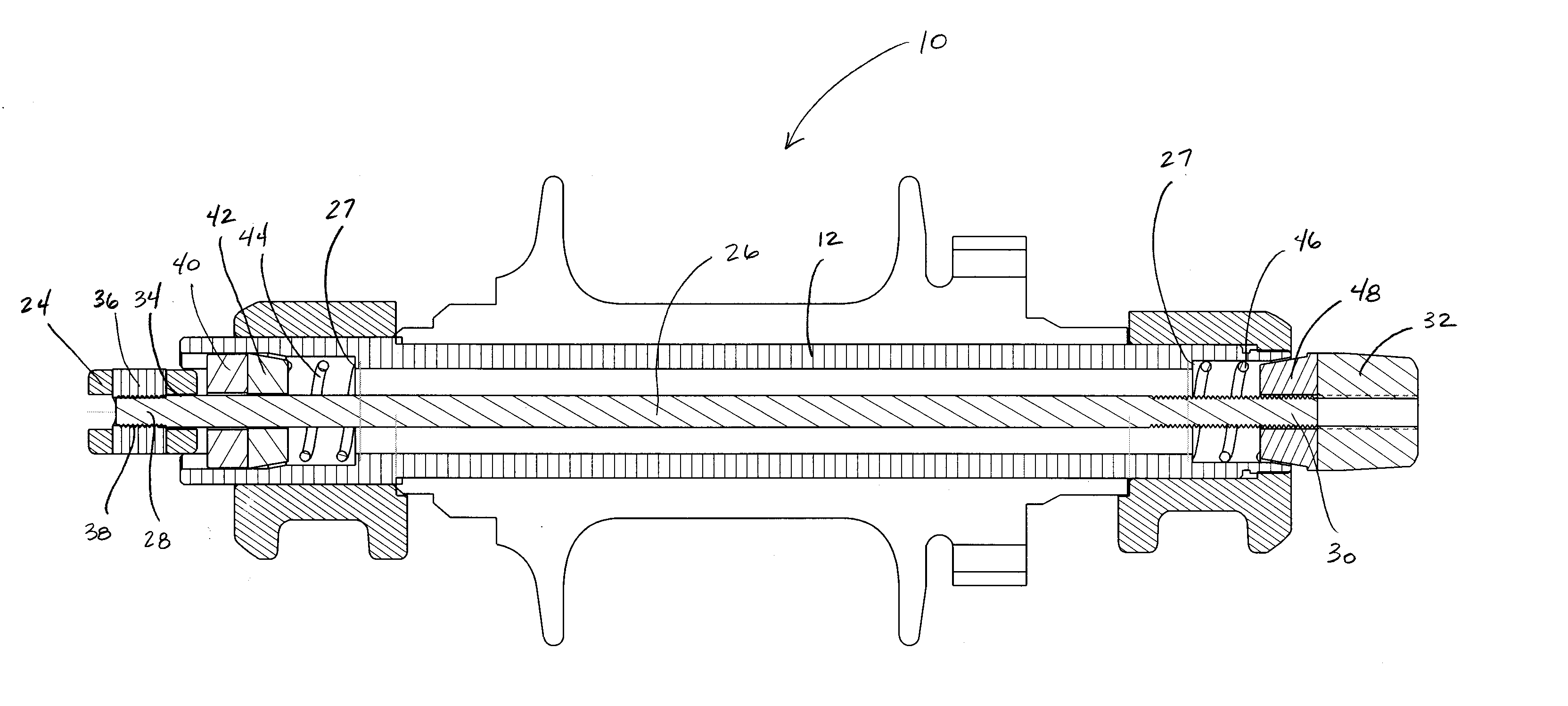

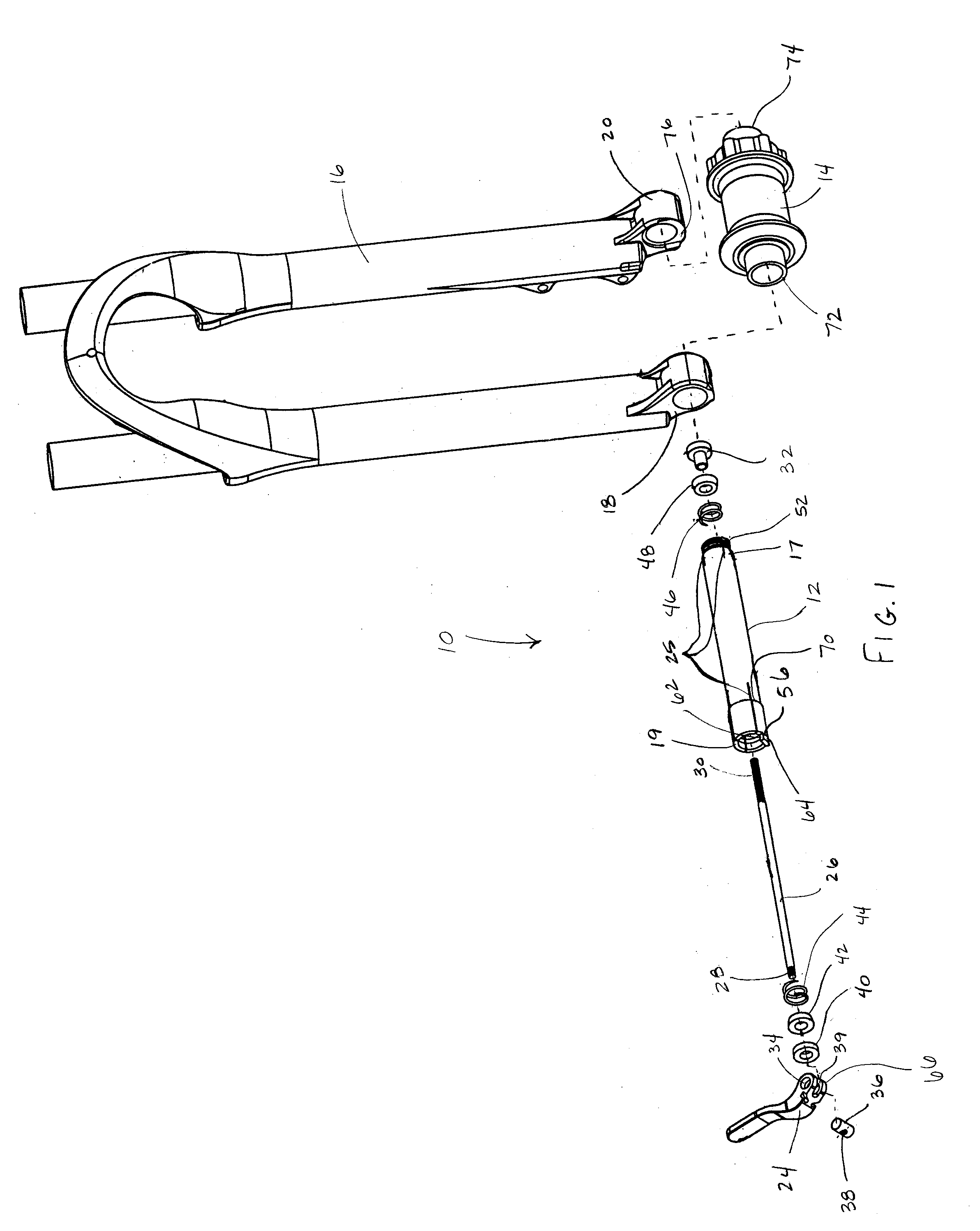

Axle assembly for mounting a wheel to a vehicle

An axle assembly connecting a wheel assembly to a vehicle frame. The axle assembly includes a tubular body having first and seconds connectable to the vehicle frame and open-ended slots disposed proximate at least one of the first and second ends of the tubular body. An expansion element is engageable with the tubular body to radially deform the tubular body at a mounting point to the vehicle frame. This configuration provides a rigid connection between the axle assembly and the vehicle frame in both the linear and radial directions.

Owner:SRAM CORPORATION

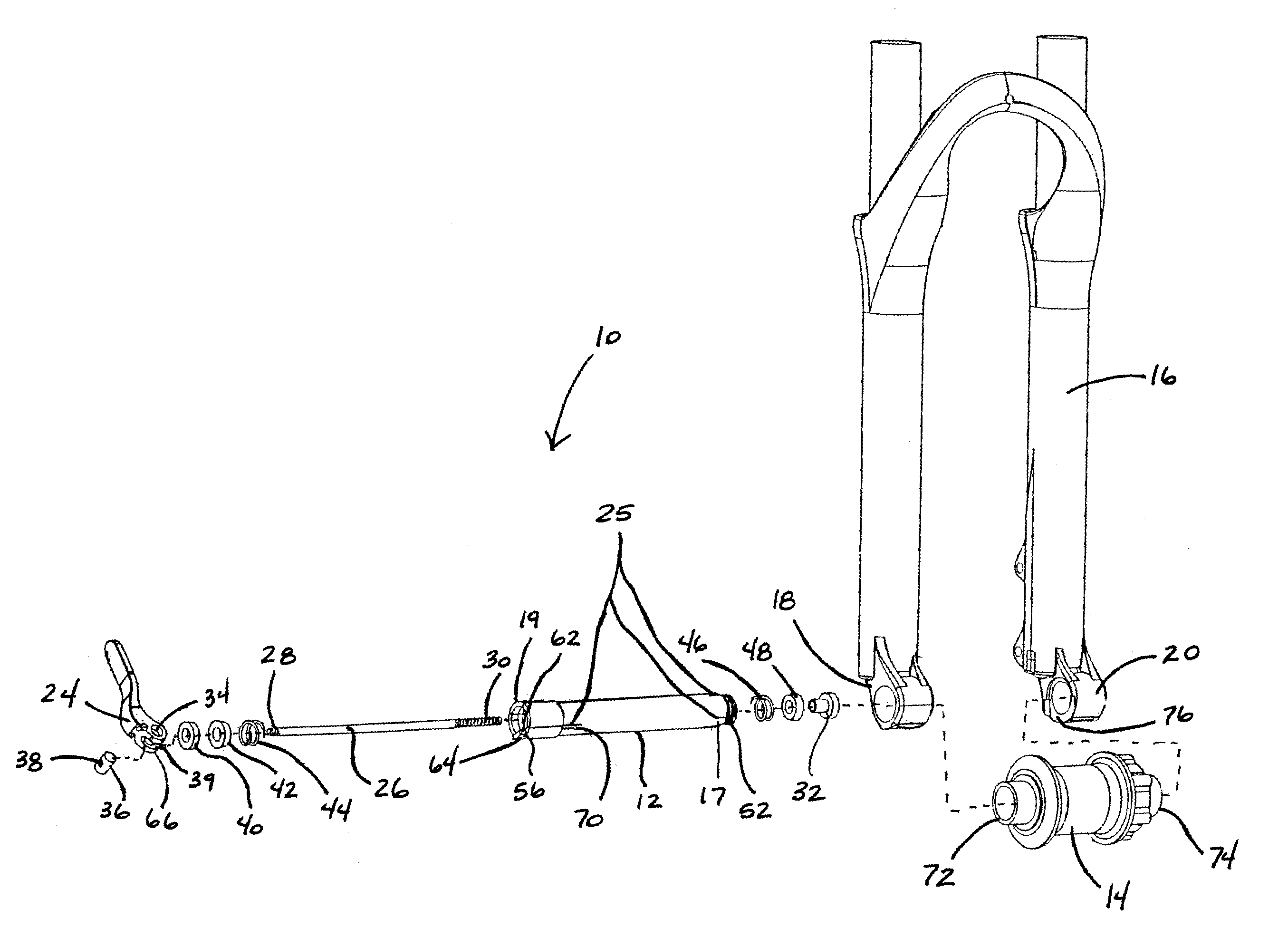

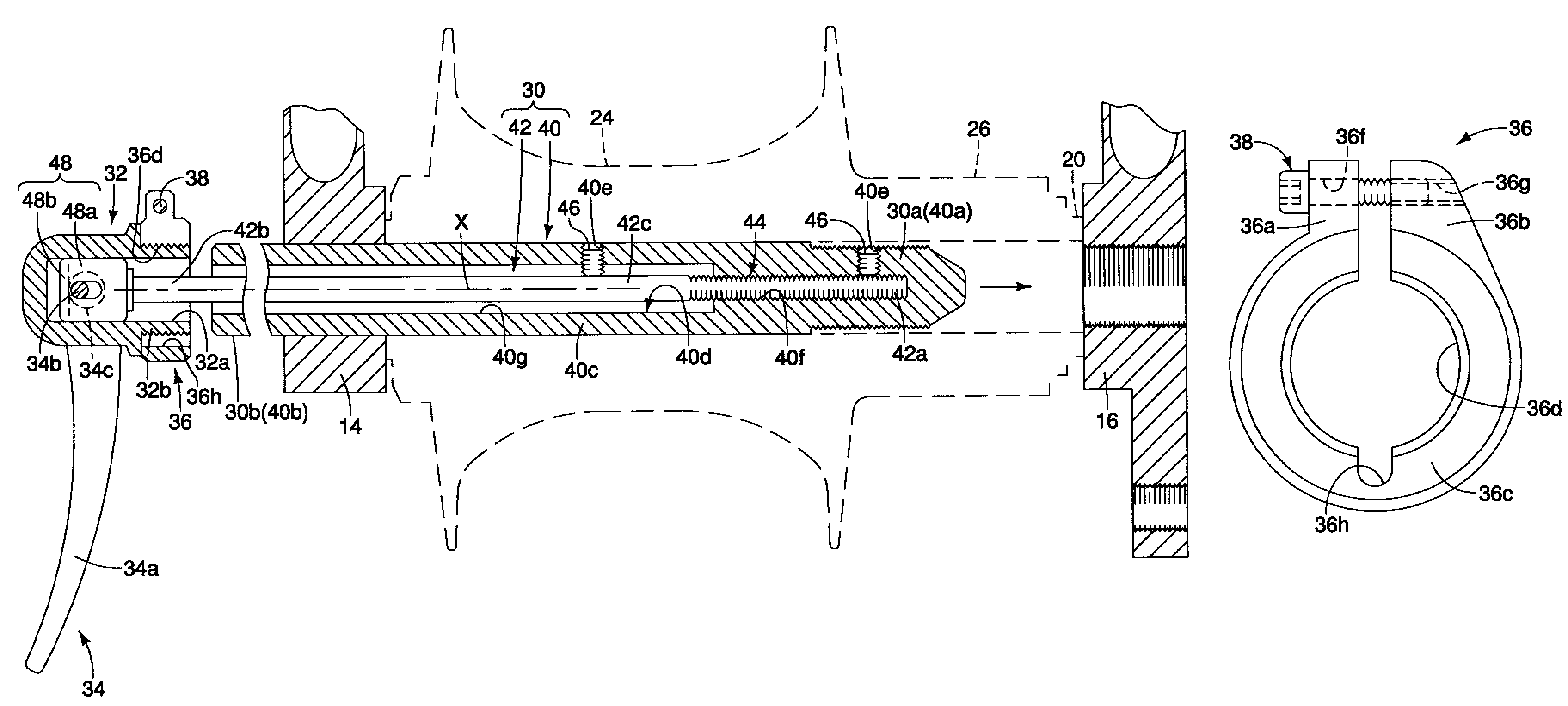

Axle assembly for mounting a wheel to a vehicle

ActiveUS20050110335A1Torsional stiffness sufficientSolve the lack of stiffnessHubsAxle suspensionsVehicle frame

An axle assembly connecting a wheel assembly to a vehicle frame. The axle assembly includes a tubular body having first and seconds connectable to the vehicle frame and open-ended slots disposed proximate at least one of the first and second ends of the tubular body. An expansion element is engageable with the tubular body to radially deform the tubular body at a mounting point to the vehicle frame. This configuration provides a rigid connection between the axle assembly and the vehicle frame in both the linear and radial directions.

Owner:SRAM CORPORATION

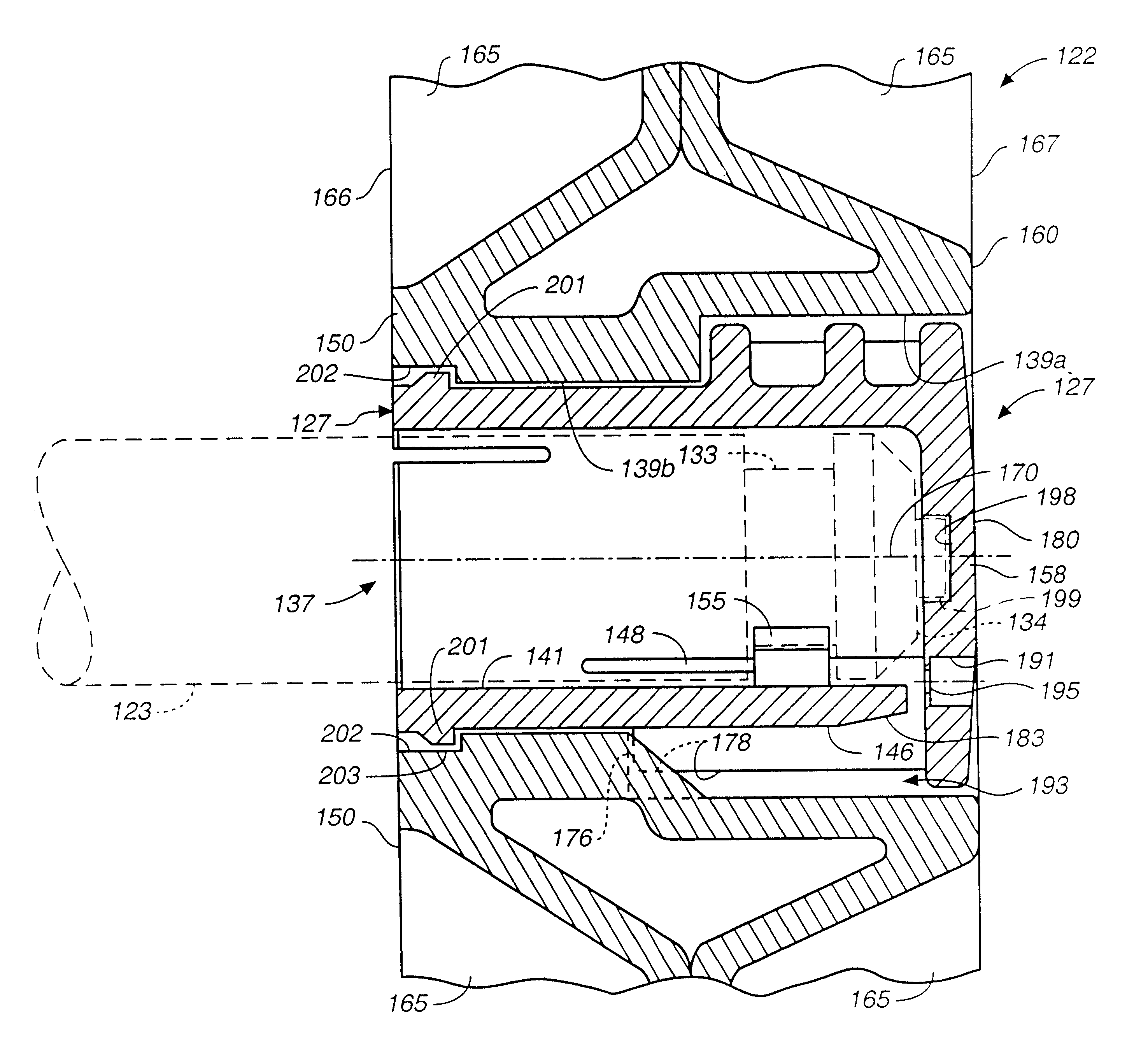

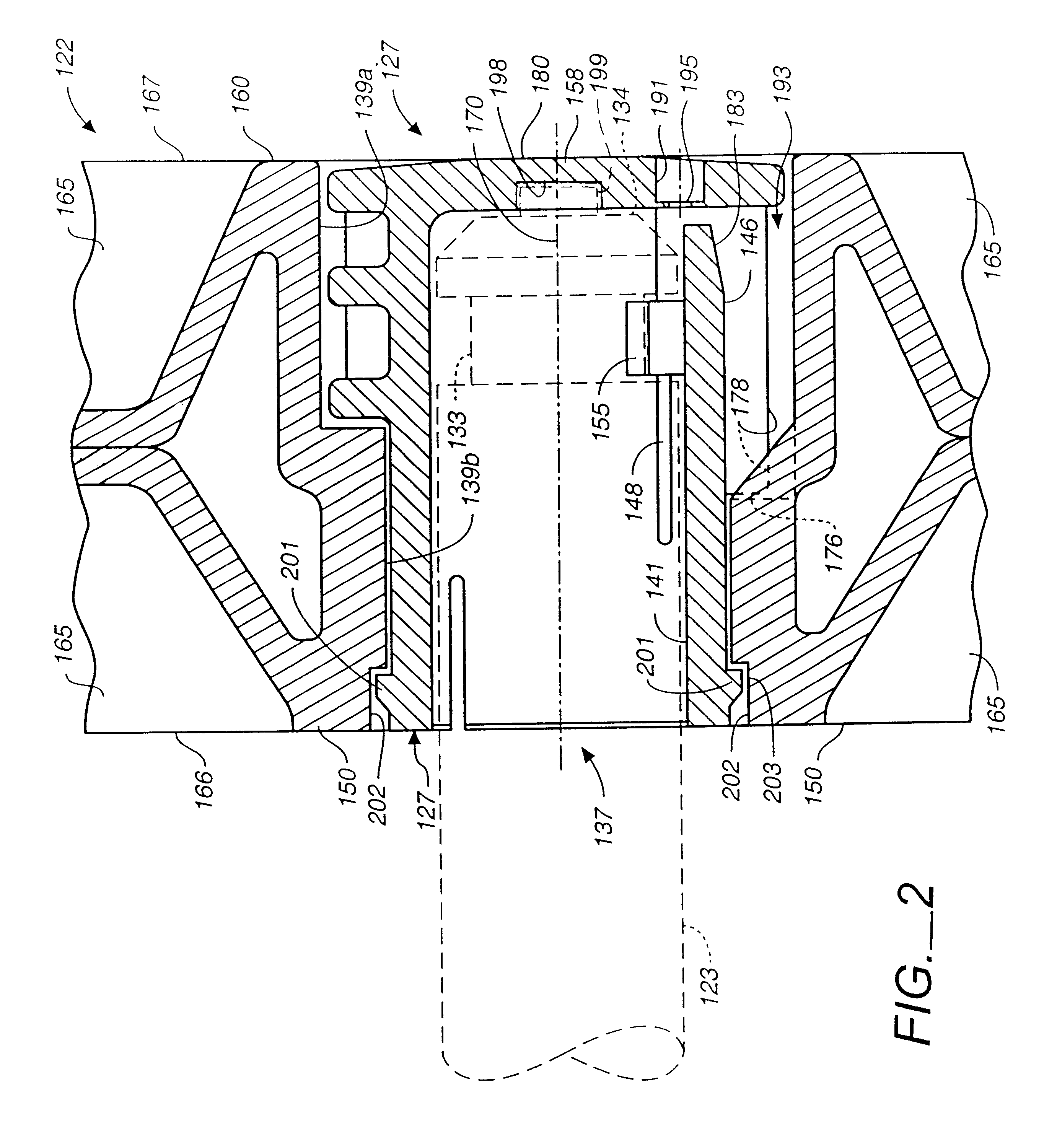

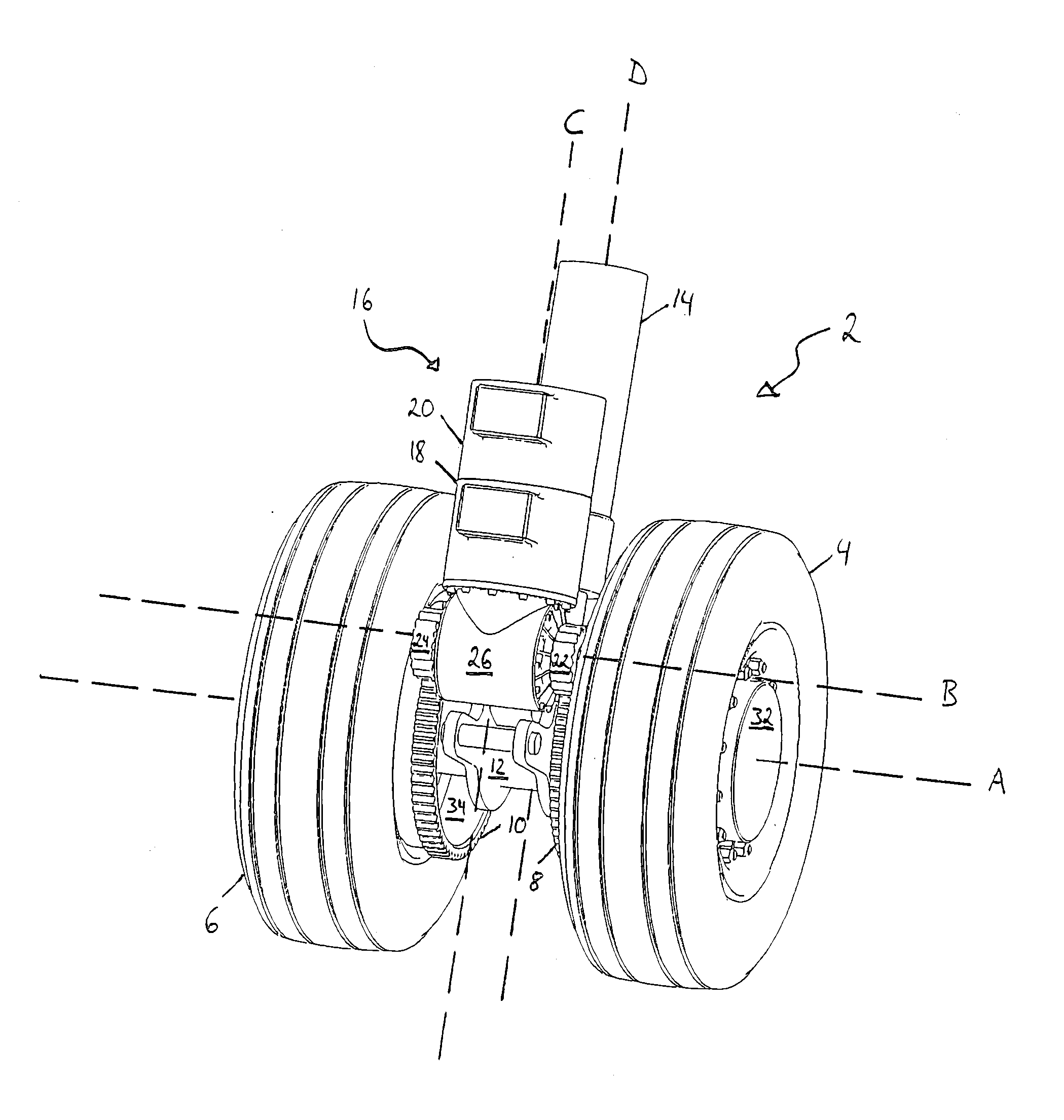

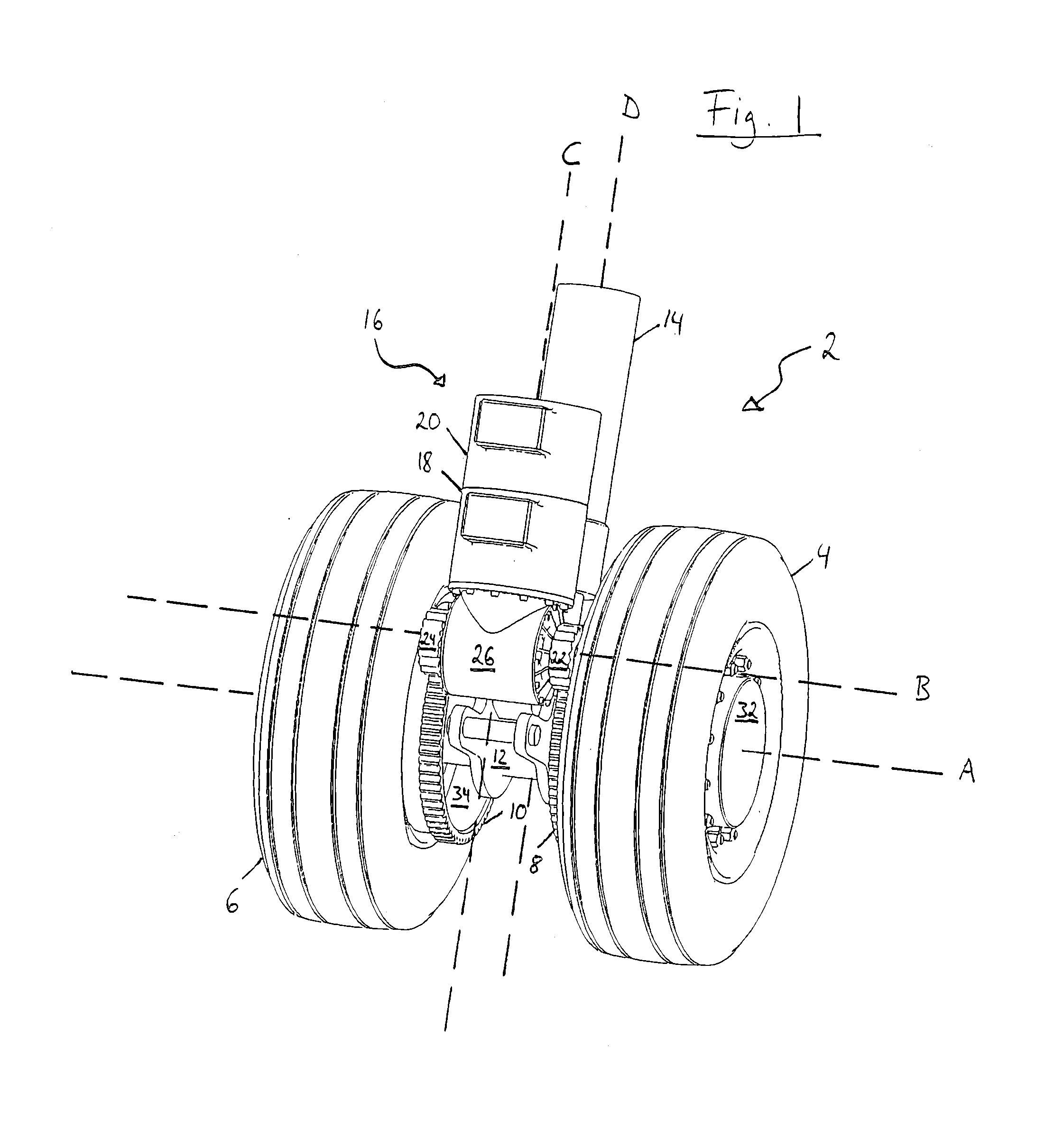

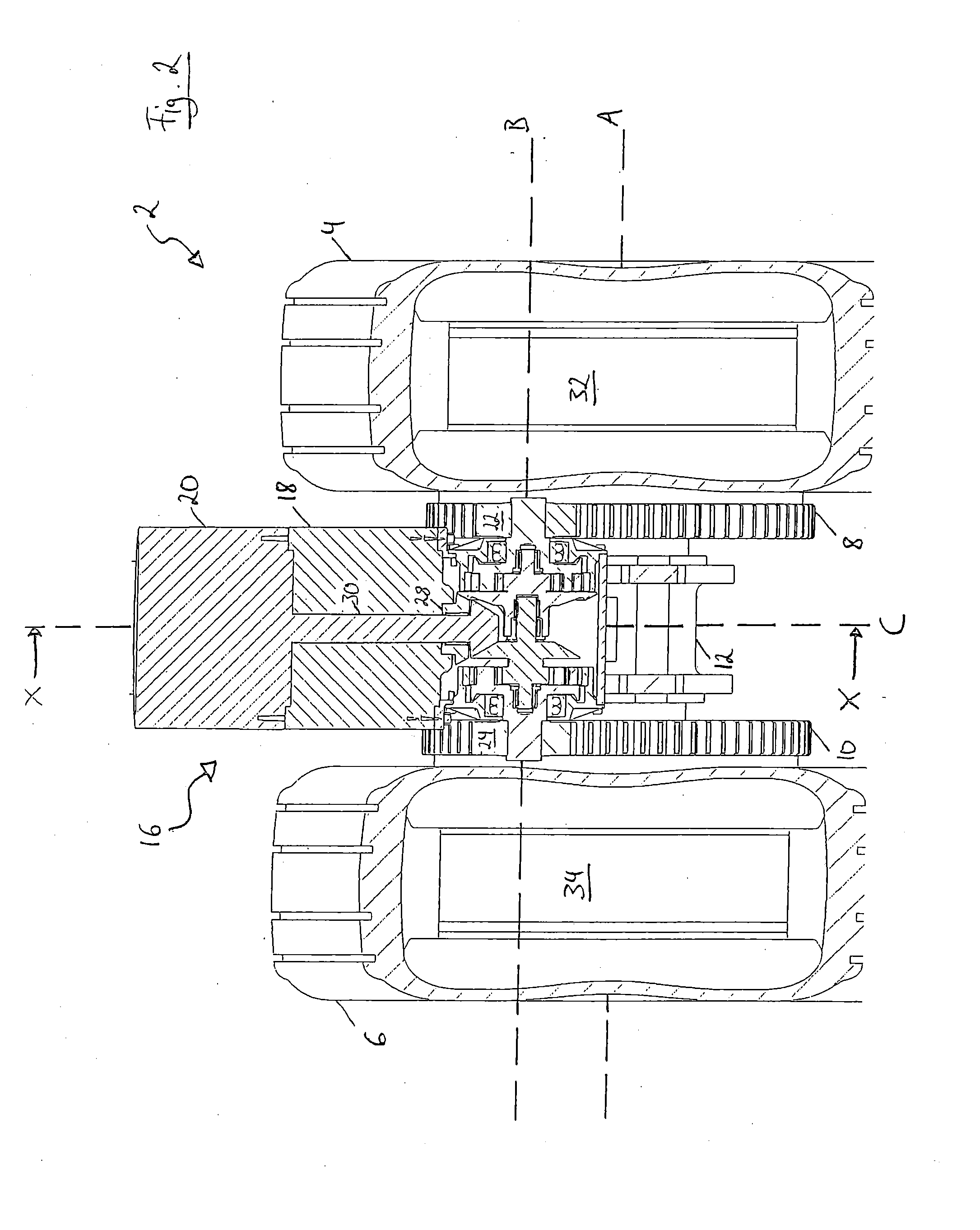

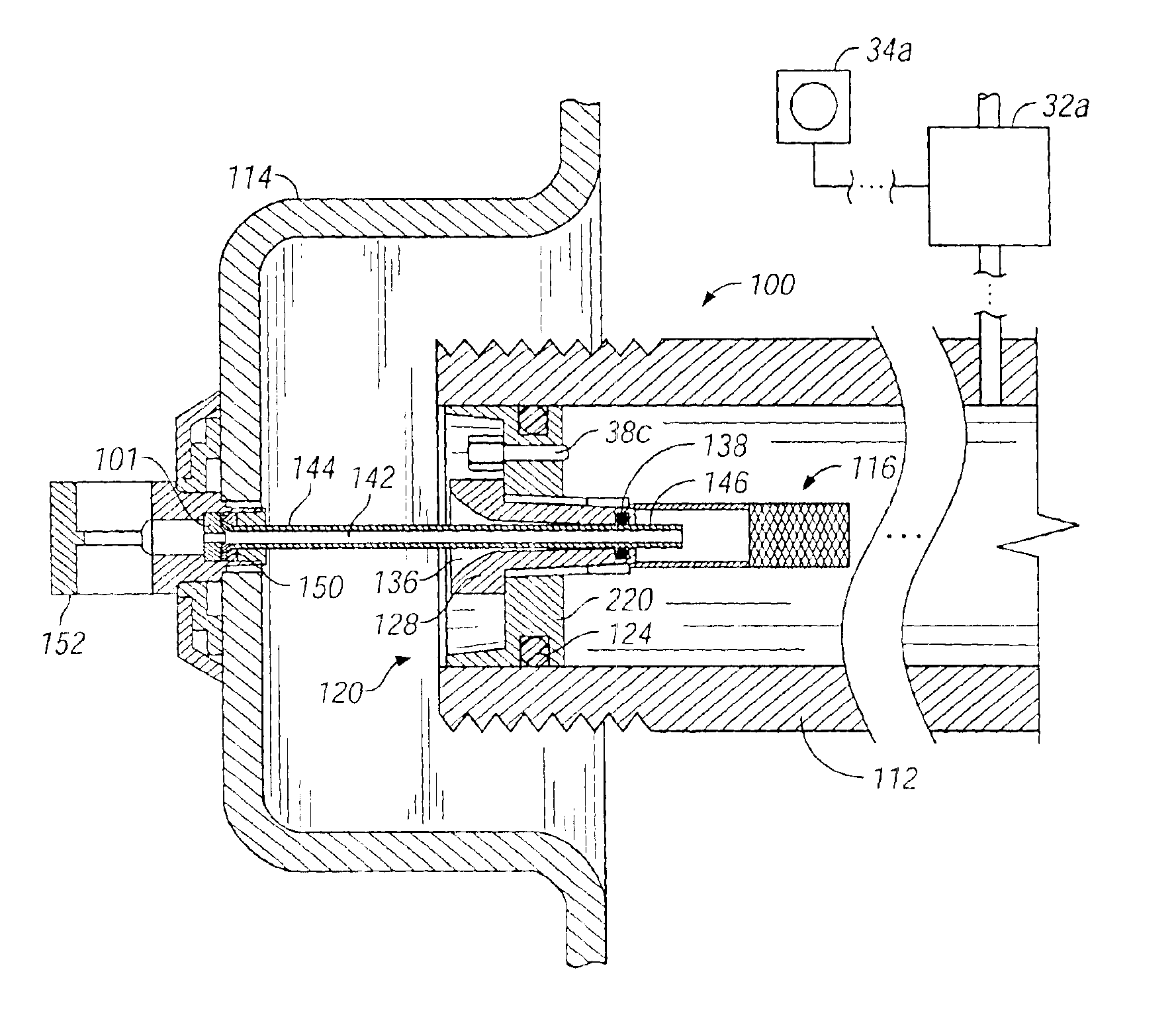

Drive unit for aircraft running gear wheels

InactiveUS20140225421A1Extended service lifeEnergy efficient operational measuresAircraft stabilisationGear wheelSprocket

A drive unit (16) for an aircraft running gear (2) having at least a first wheel (4) and a second wheel (6) on a common wheel axis (A), wherein the drive unit (16) is drivingly coupleable to at least one of the first and second wheels (4, 6), is characterized in that the drive unit (16) comprises at least one power output assembly (122, 124) for driving at least one of the first and second wheels (4, 6), with each of the at least one power output assembly (122, 124) comprising a power transmission chain (136) selectively engageable with a sprocket element (108, 110) coupled to one of the first and second wheels (4, 6).

Owner:L 3 COMM MAGNET MOTOR

Tire noise reducing system

Owner:SUMITOMO RUBBER IND LTD

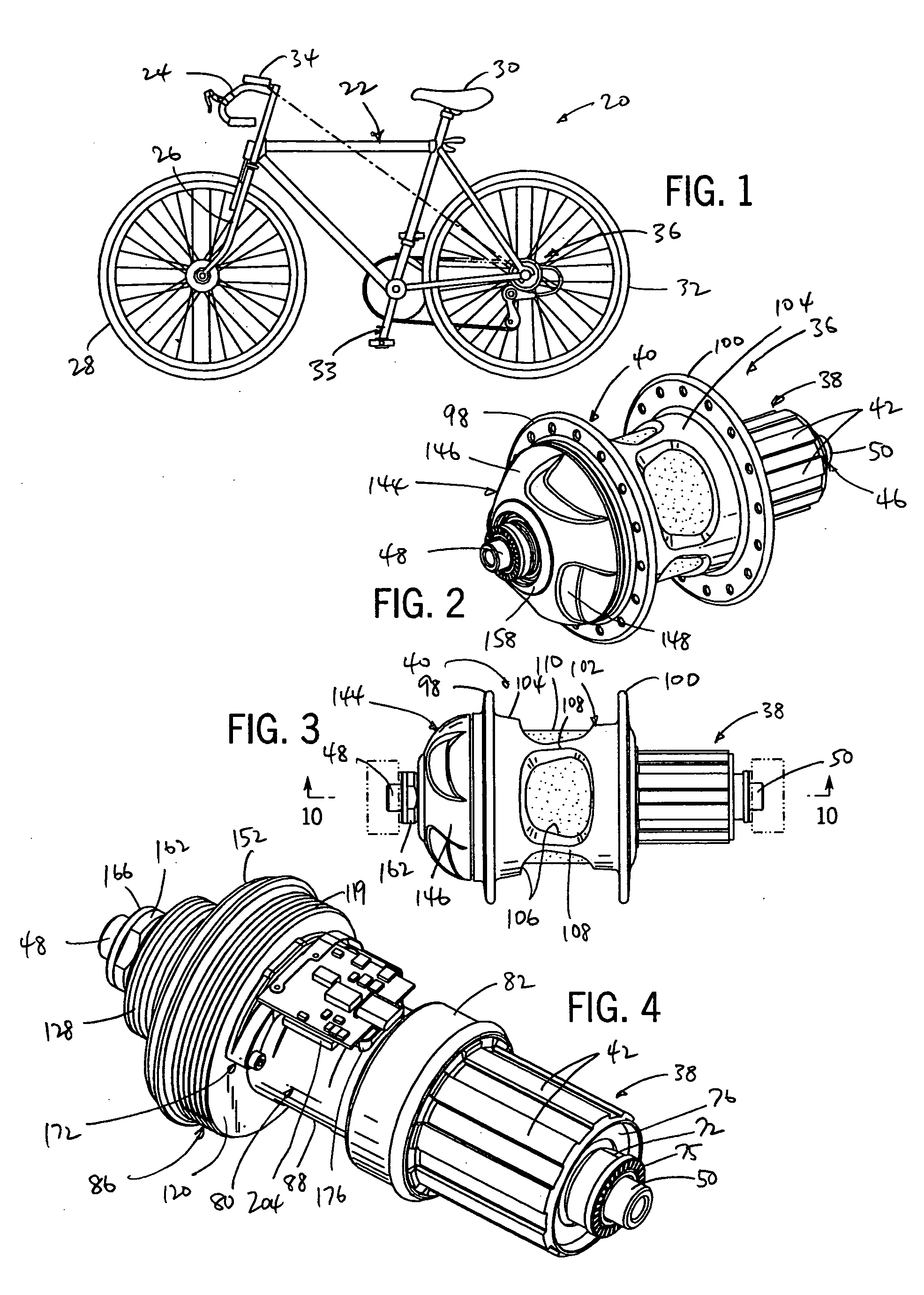

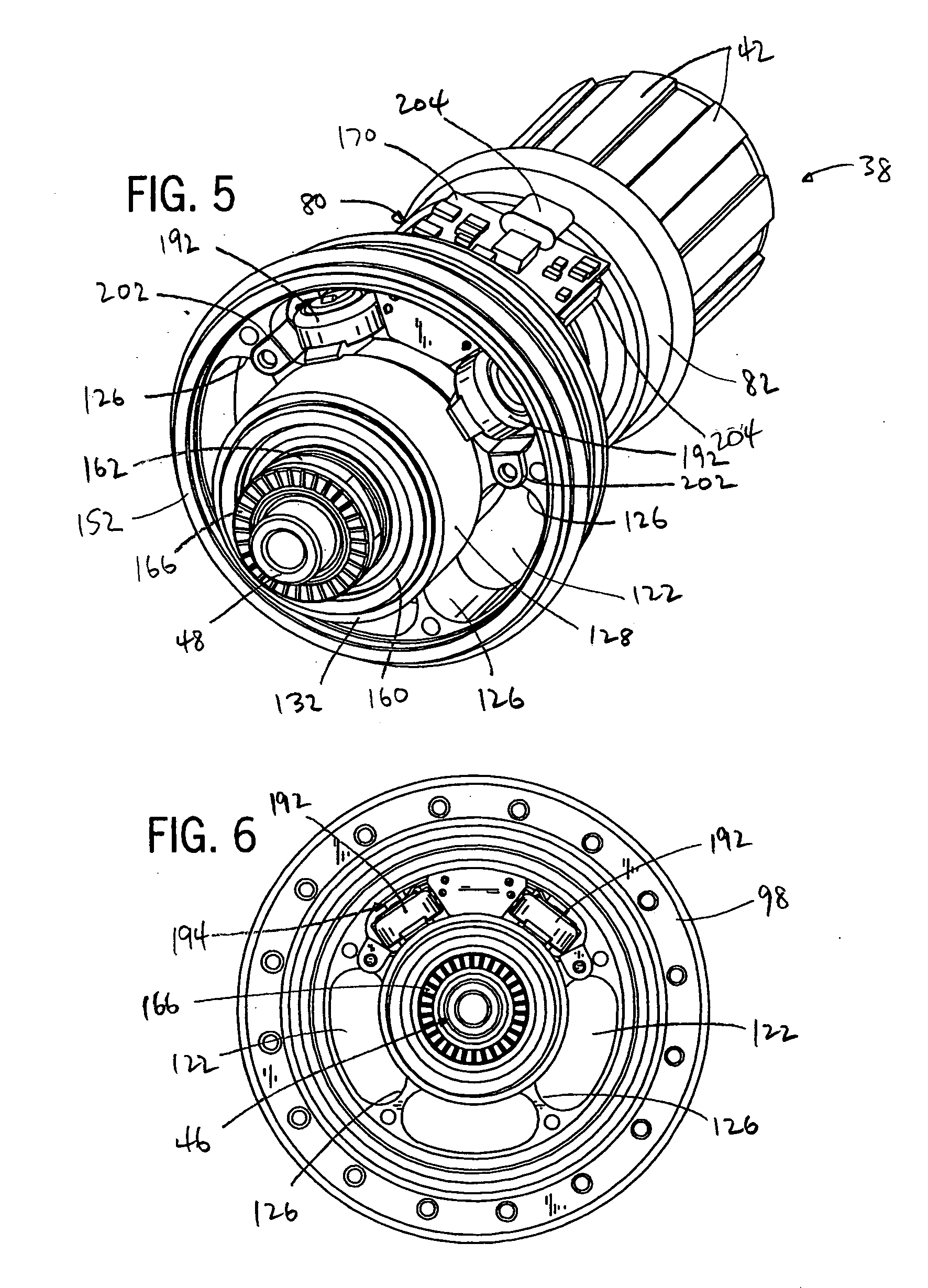

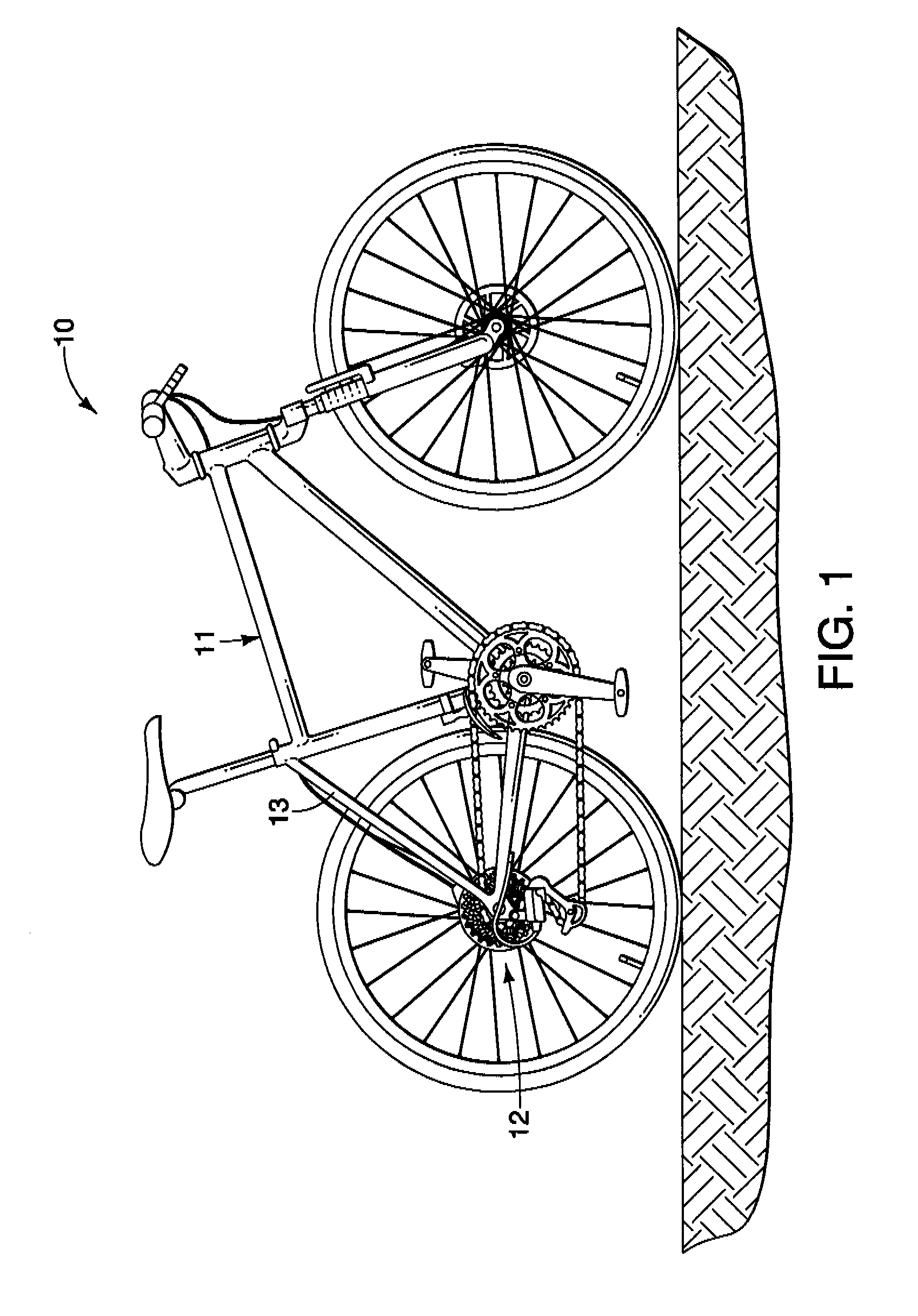

Enclosed operating characteristic sensor for a bicycle component including an emitter for emitting an operating characteristic signal

InactiveUS20050275561A1Prolong lifeAvoid contactElectric signal transmission systemsTelemetry/telecontrol selection arrangementsDrive wheelElectrical and Electronics engineering

An enclosed operating characteristic sensing system for a bicycle includes a sensing arrangement for sensing one or more operating characteristics of the bicycle, and an emitter responsive to the sensing arrangement for emitting a signal from a first location on the bicycle to a receiver located in a second location on the bicycle. The emitter is contained within an interior defined by a component of the bicycle at the first location on the bicycle, and the bicycle component is constructed so as to enable the emitted signal to pass through the component for transmission to the receiver. The sensing arrangement may be configured to sense power applied by an operator of the bicycle to impart movement to the bicycle. The bicycle component may be a hub member forming a part of a driven wheel of the bicycle, and including a non-transmissive portion defining one or more openings, and a transmissive portion that occupies the one or more openings to enable the emitted signal to pass through the hub member for transmission to the receiver. The transmissive portion may be in the form of a reinforcing member that cooperates with the non-transmissive portion to reinforce the hub member.

Owner:GRABER PRODS INC

Propulsion device for automobile with portal axle comprising an electrical machine

ActiveUS8640801B2Maximum speed reductionIncrease powerElectric devicesElectric propulsion mountingElectric machineMotorized vehicle

Owner:DR ING H C F PORSCHE AG

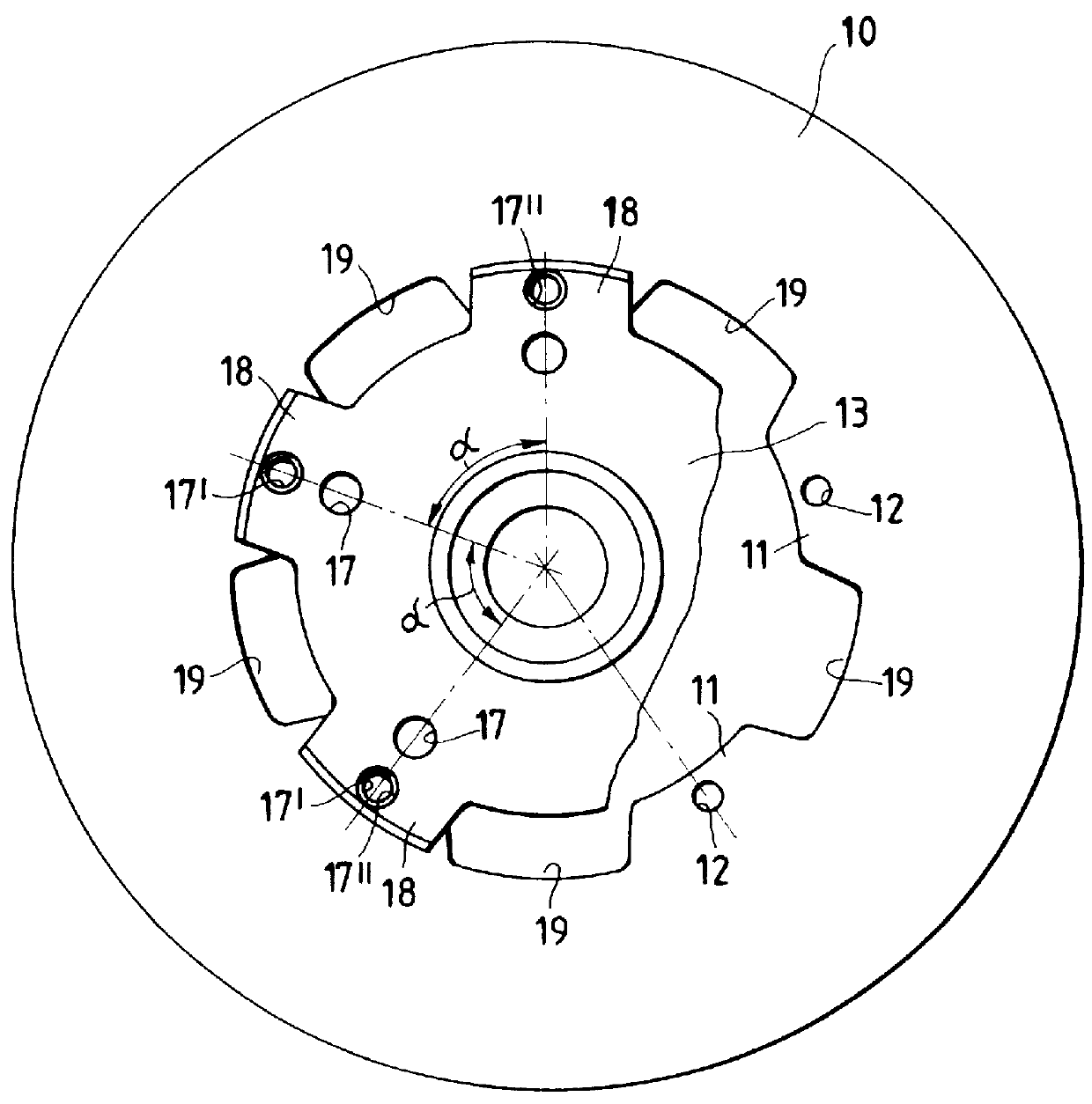

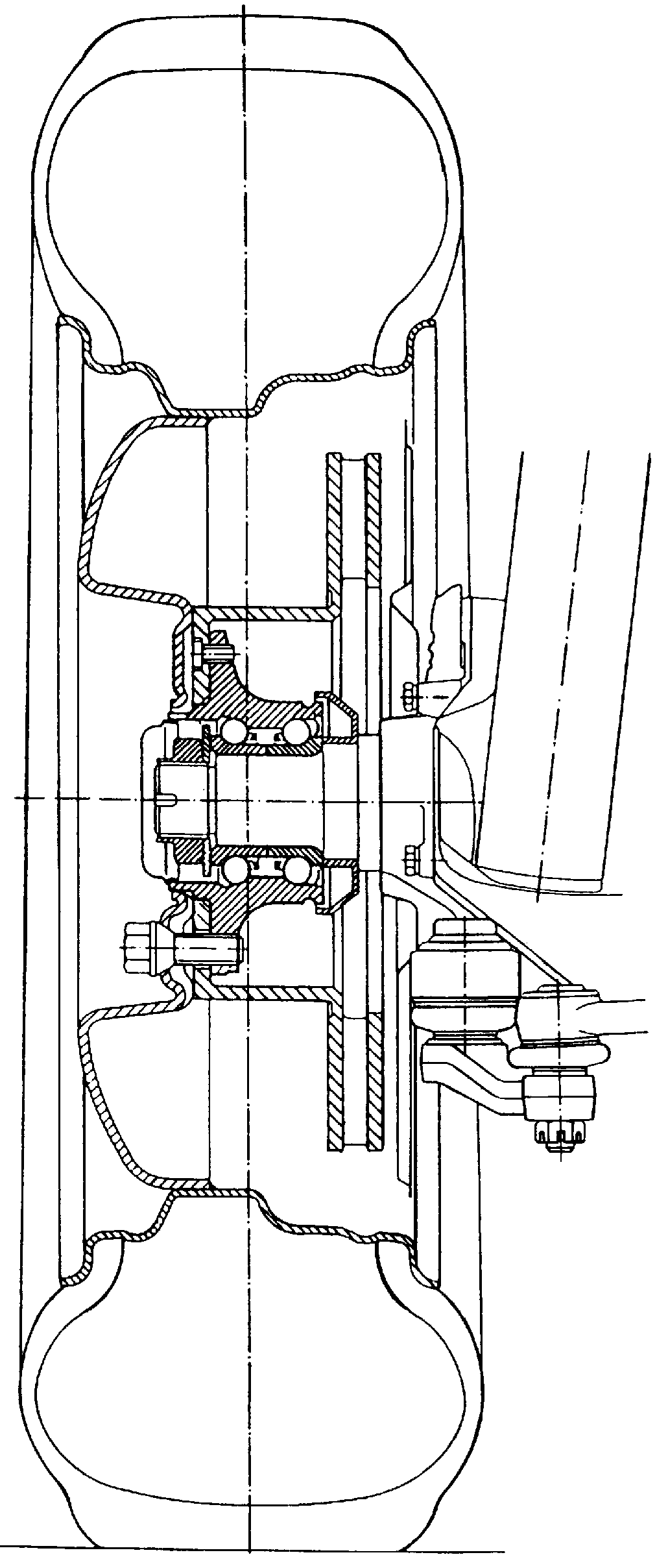

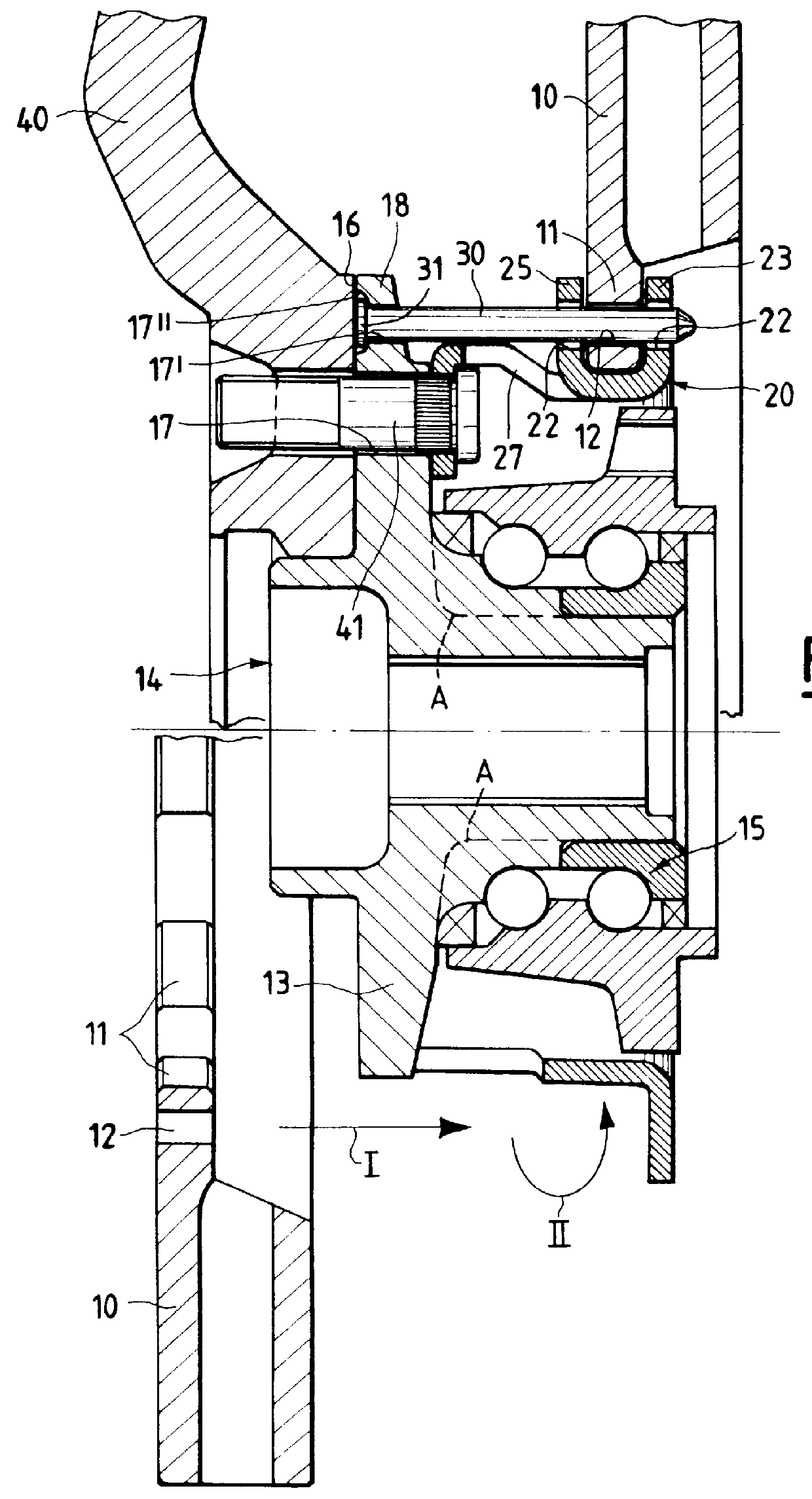

Wheel hub or hub unit allowing improved mounting and removal of a brake member

There is disclosed a wheel hub or hub unit of the type having a radial hub flange (13) providing connection to the wheel (40) and to a brake member (10) having an annular disc portion having a plurality of ears (11) radially protruding from its inner edge. The hub flange (13) defines a plurality of axial passages, in the form of peripheral radial recesses (19) or bores (17, 17') for slipping a plurality of axial pins (30) to be fitted in holes (12) obtained in the brake member ears (11) and in openings (22) obtained in at least one radial wall (23) of a brake carrier (20) rotatably fast with the hub (14) to rotationally secure the brake member (10) to the hub. When the wheel (40) is mounted on the outside of the hub flange, axial movement of the pins towards the outside is stopped by the wheel.

Owner:SKF IND SPA

Wheel end assembly high-temperature warning system

Owner:PRESSURE SYST INT LLC

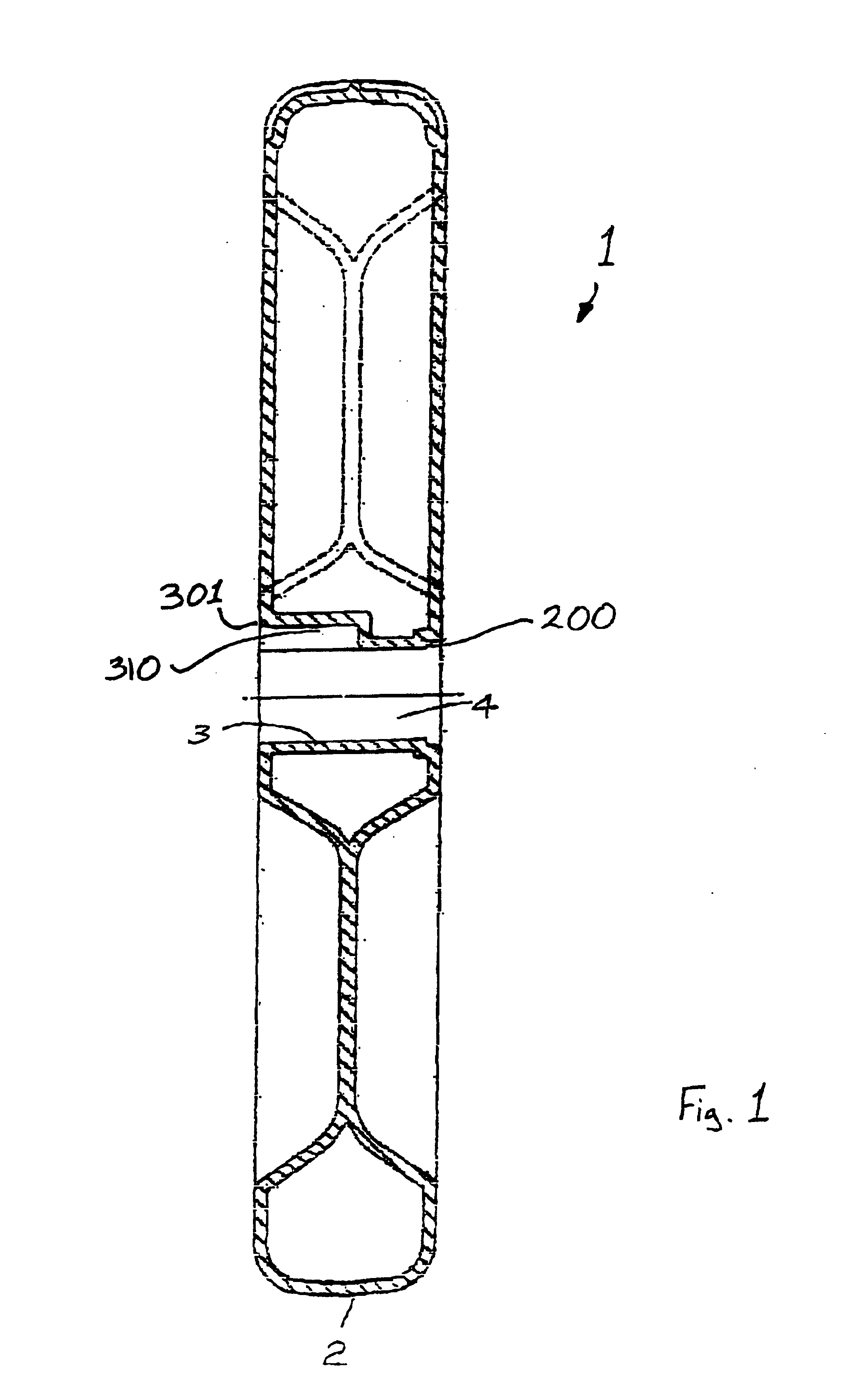

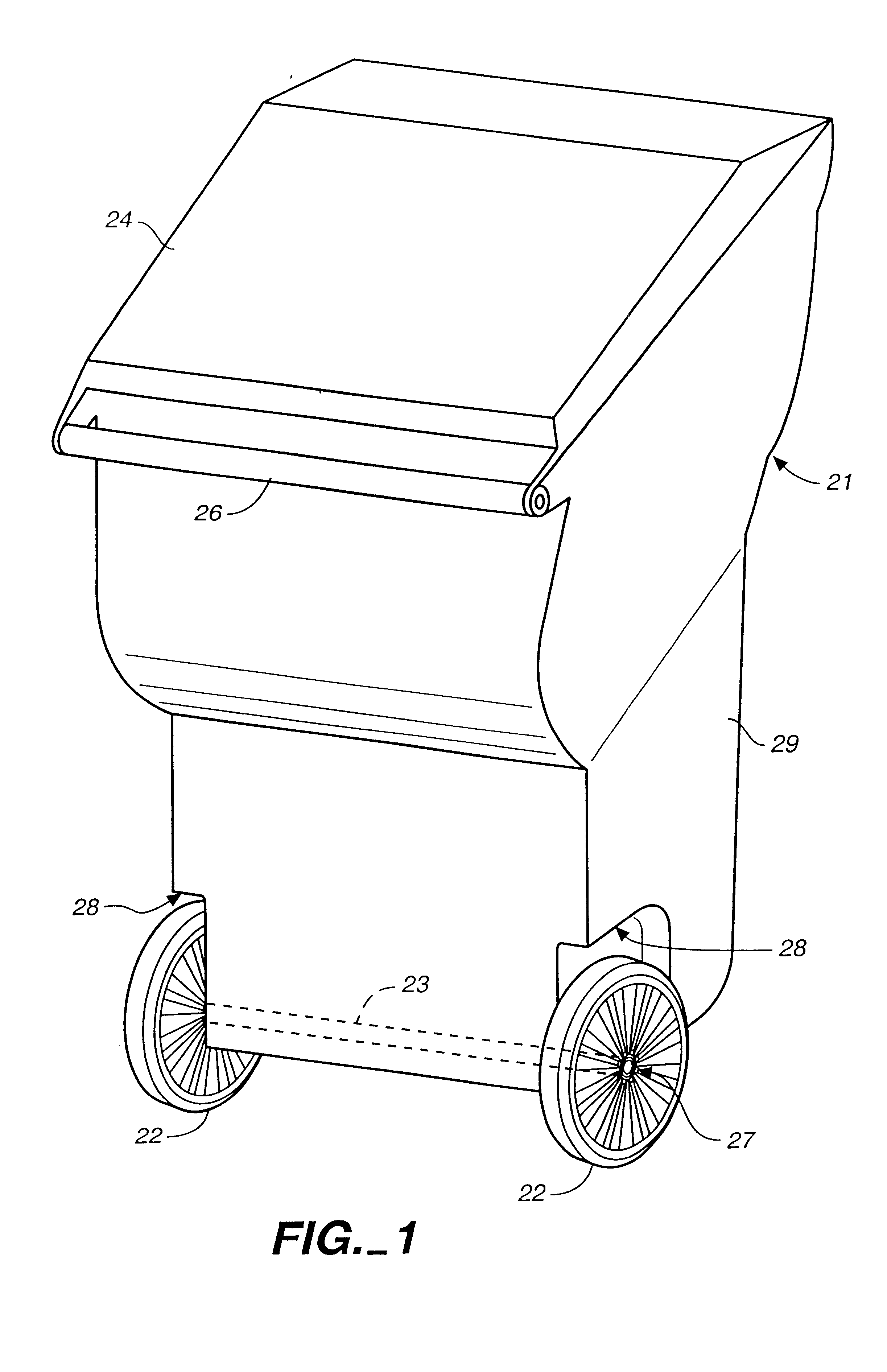

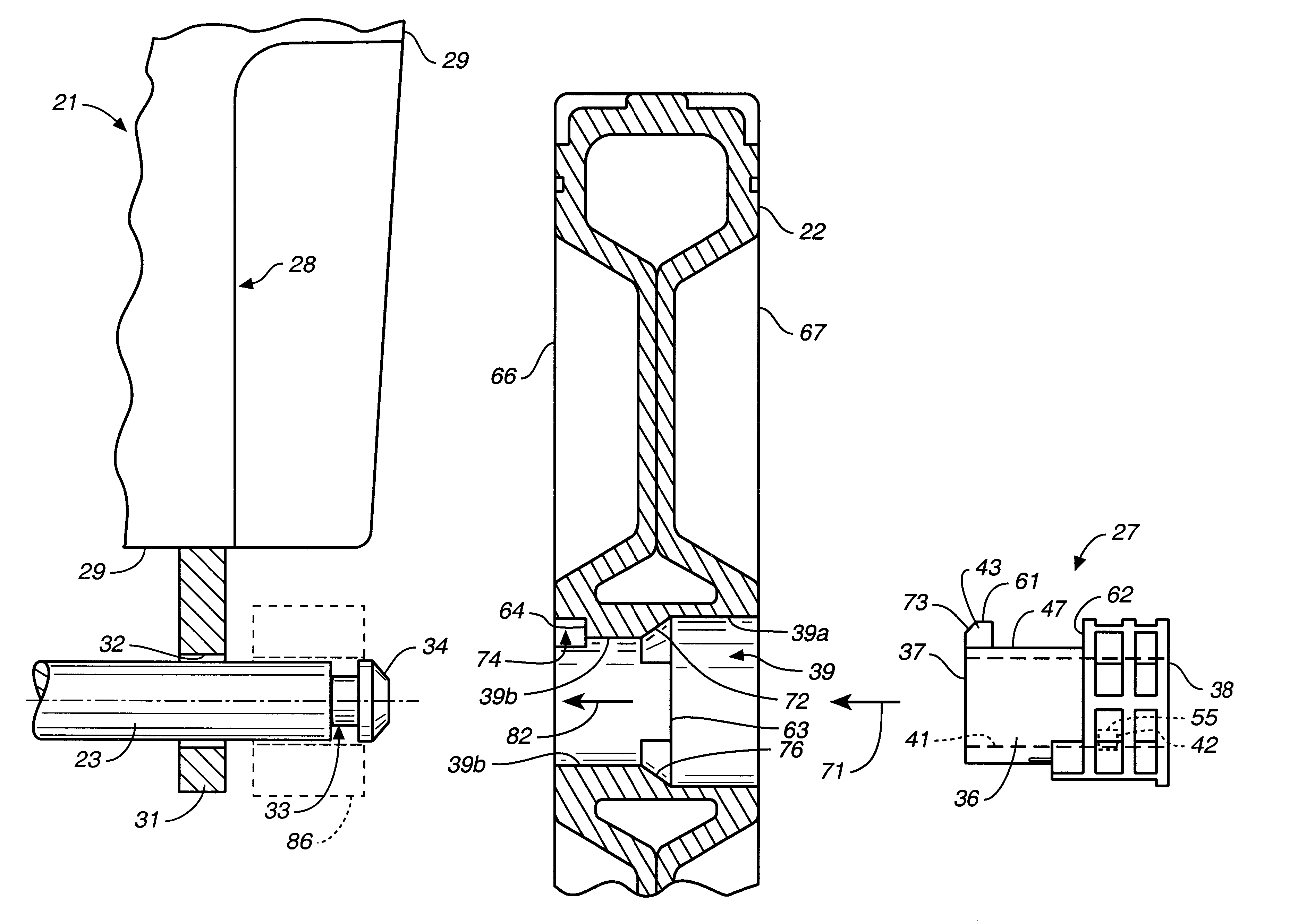

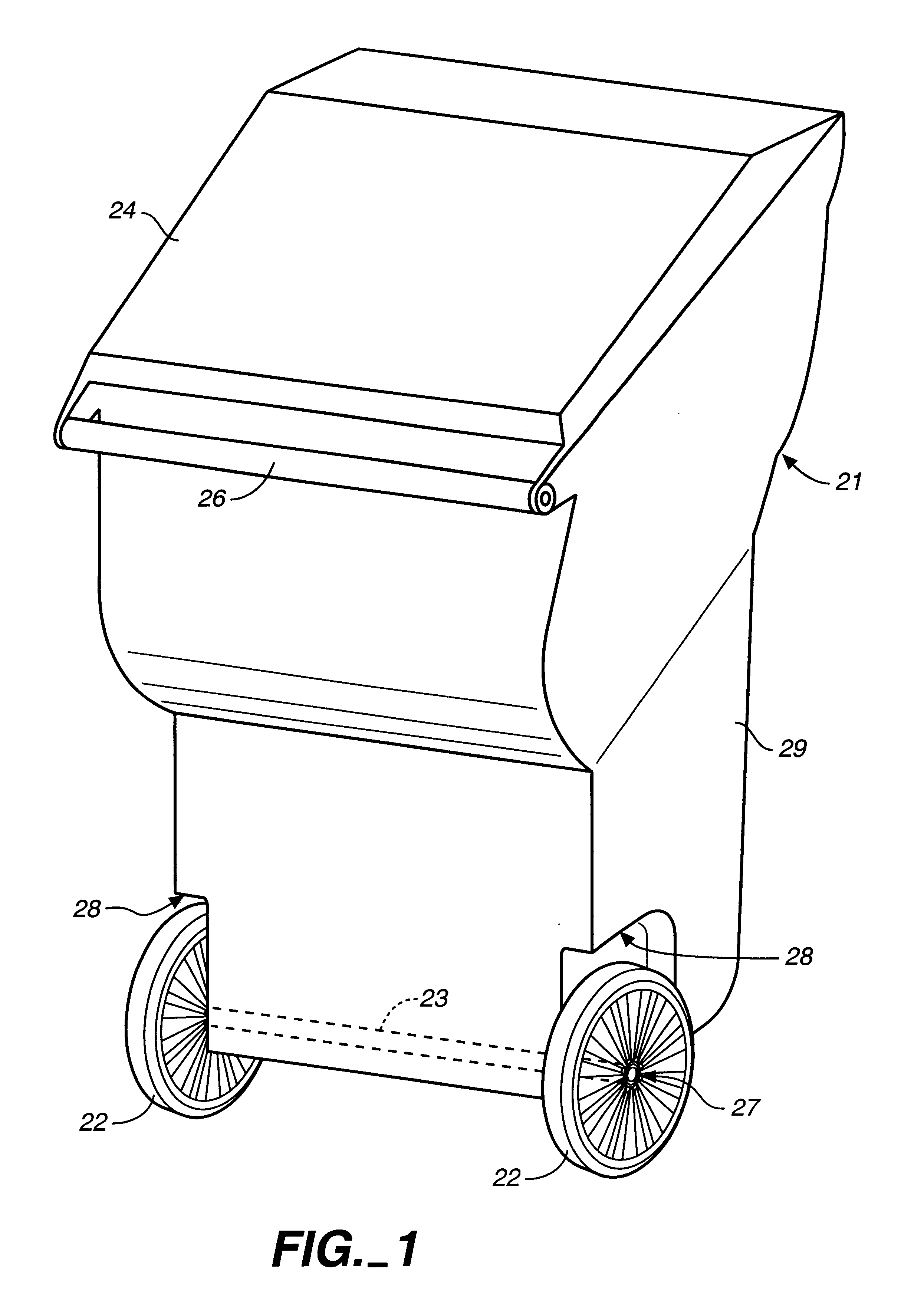

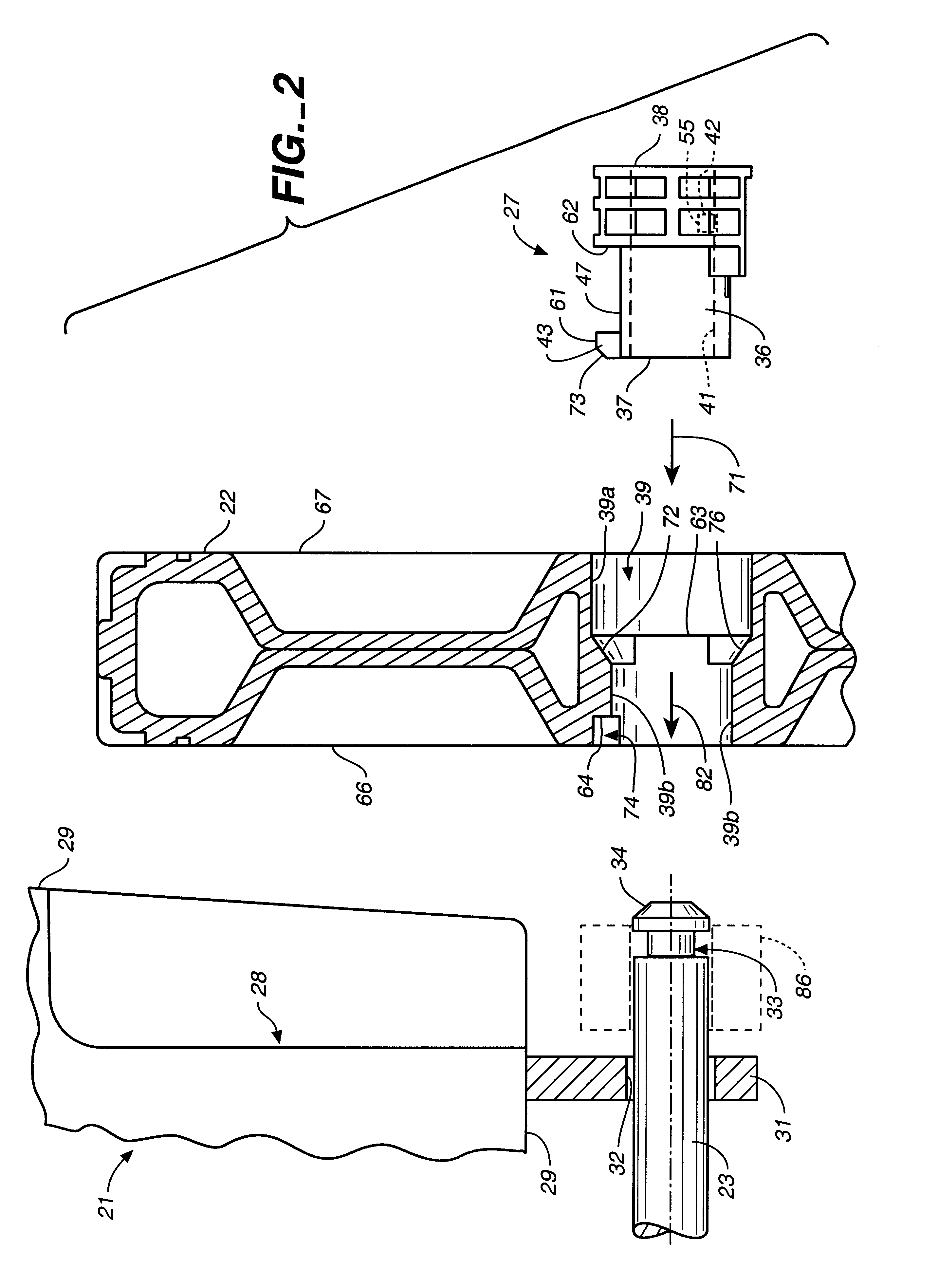

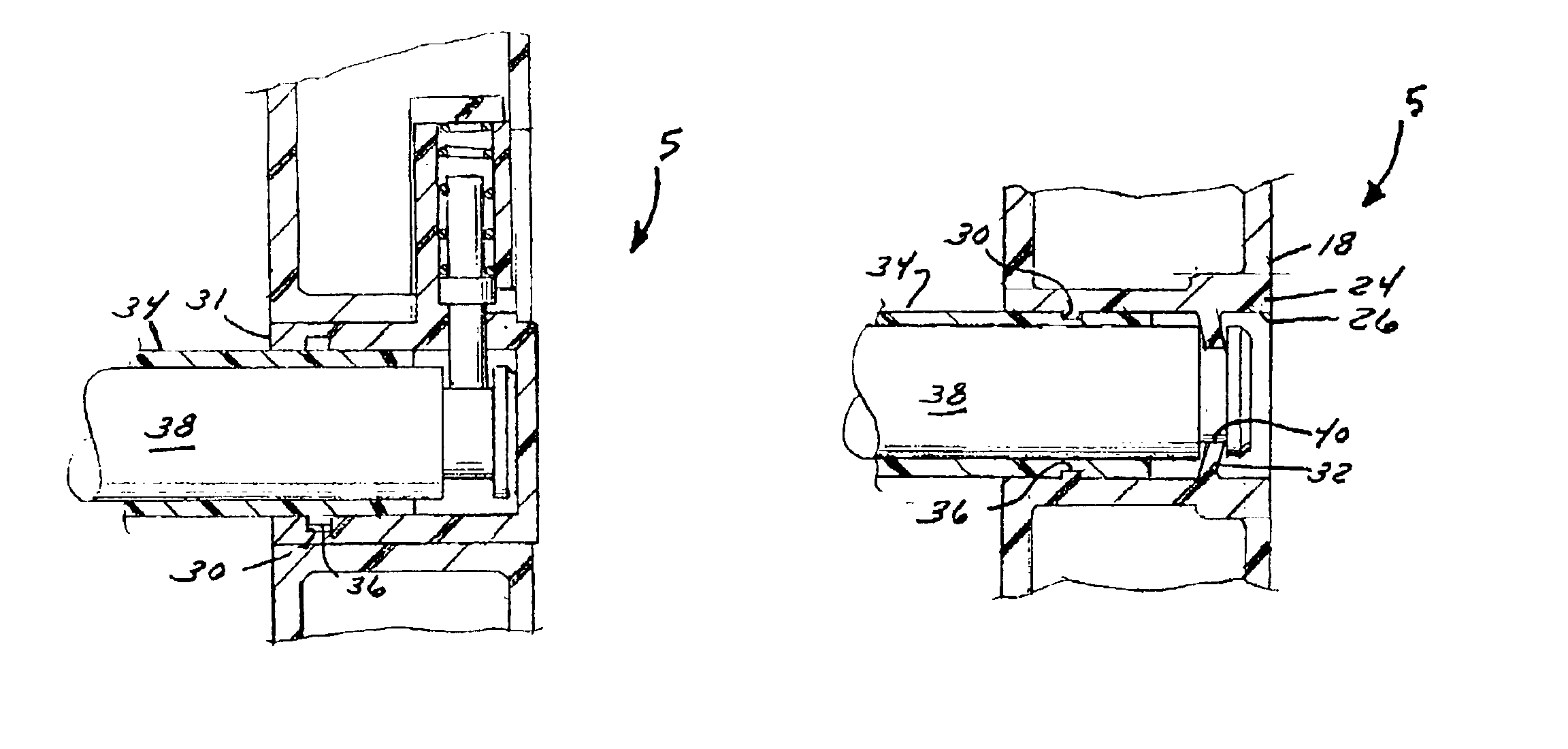

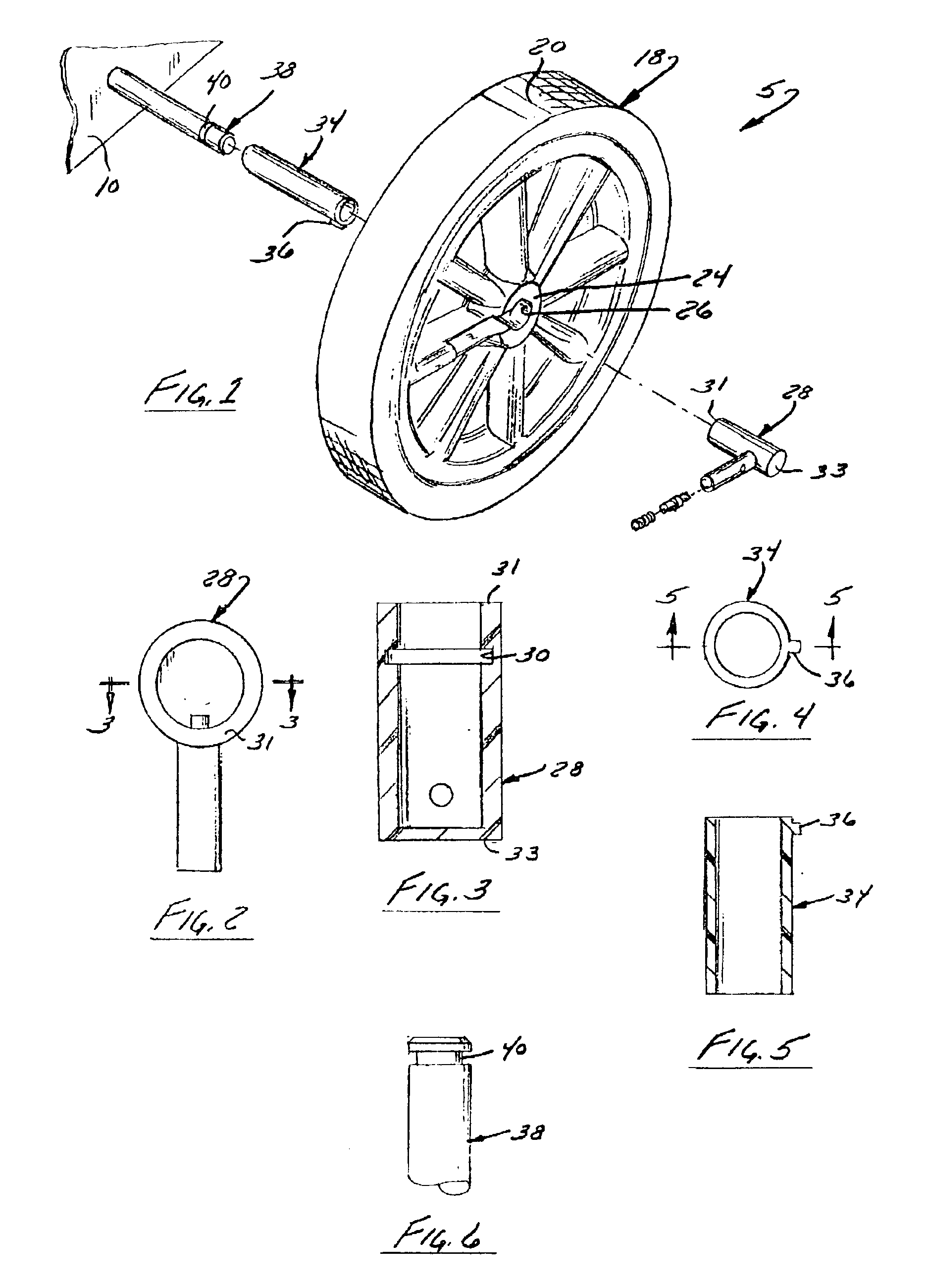

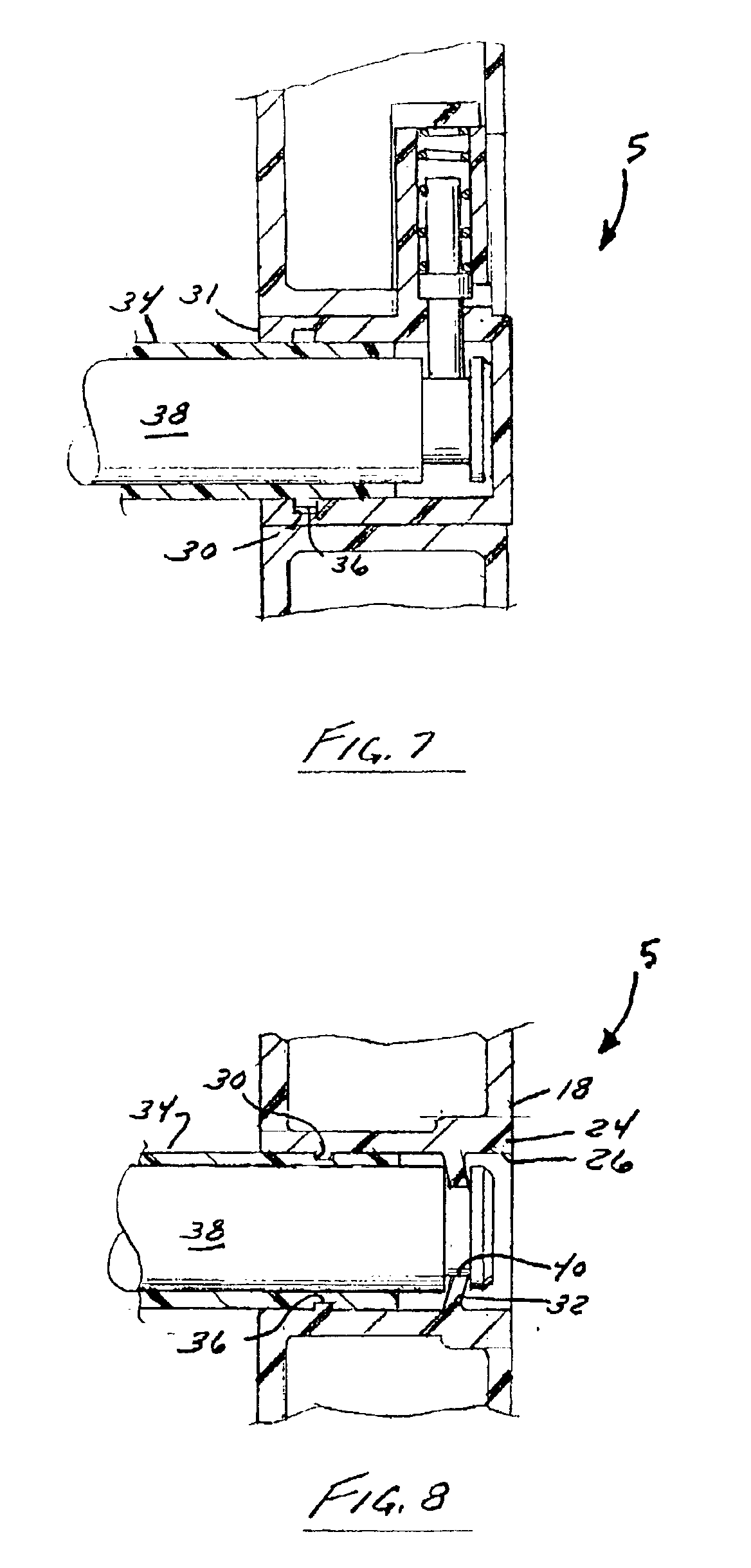

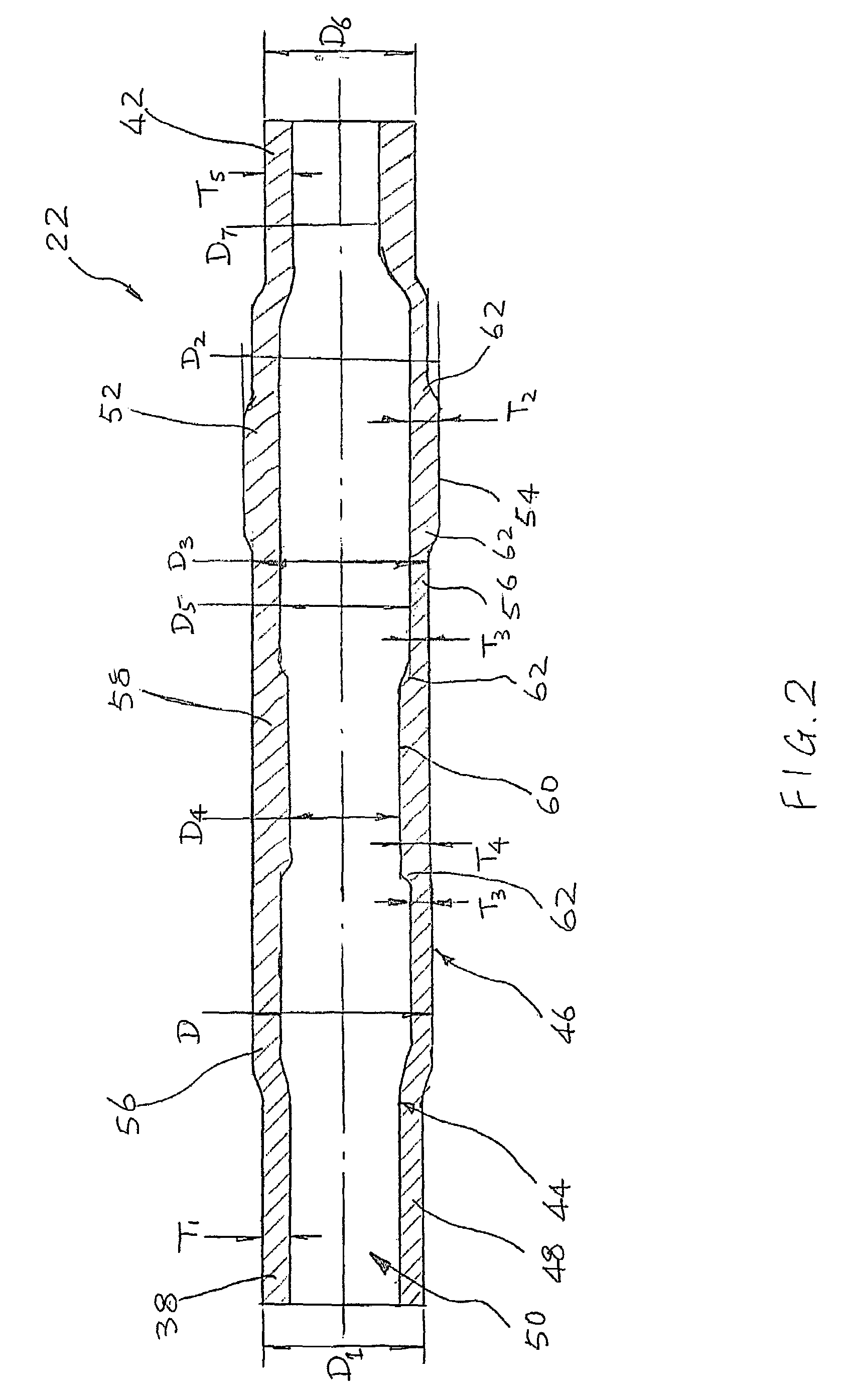

Plastic wheel assembly and mounting sleeve therefor

A plastic wheel (22) and wheel mounting sleeve (27, 27a, 27b, 27c) used to releasably secure the wheel (22) onto an axle (23). The wheel mounting sleeve (27) preferably includes two resilient, radially displaceable, axially extending, cantilevered fingers (46, 47) which are cantilevered from and extend axially in opposite directions on the sleeve (27). An axle-engaging shoulder (42) is provided on a radially inwardly extending lug (55) on one finger (46), while a wheel-engaging shoulder (43) is provided on a radially outwardly extending lug (61) on the other resilient finger (47). The respective shoulders (42, 43) cooperate with oppositely facing shoulders (58, 62) so as to releasably latch the sleeve (27) to the axle (23) and the wheel (22) to the sleeve (27). Assembly can be accomplished without any tools and a screwdriver can be used to disassemble the components. Alternative sleeves (27a, 27b, 27c) include an annular rib (101) which mates with an annular bore recess (102) to further limit relative movement between the sleeve (27a, 27b, 27c) and the wheel (22).

Owner:GEO PLASTICS

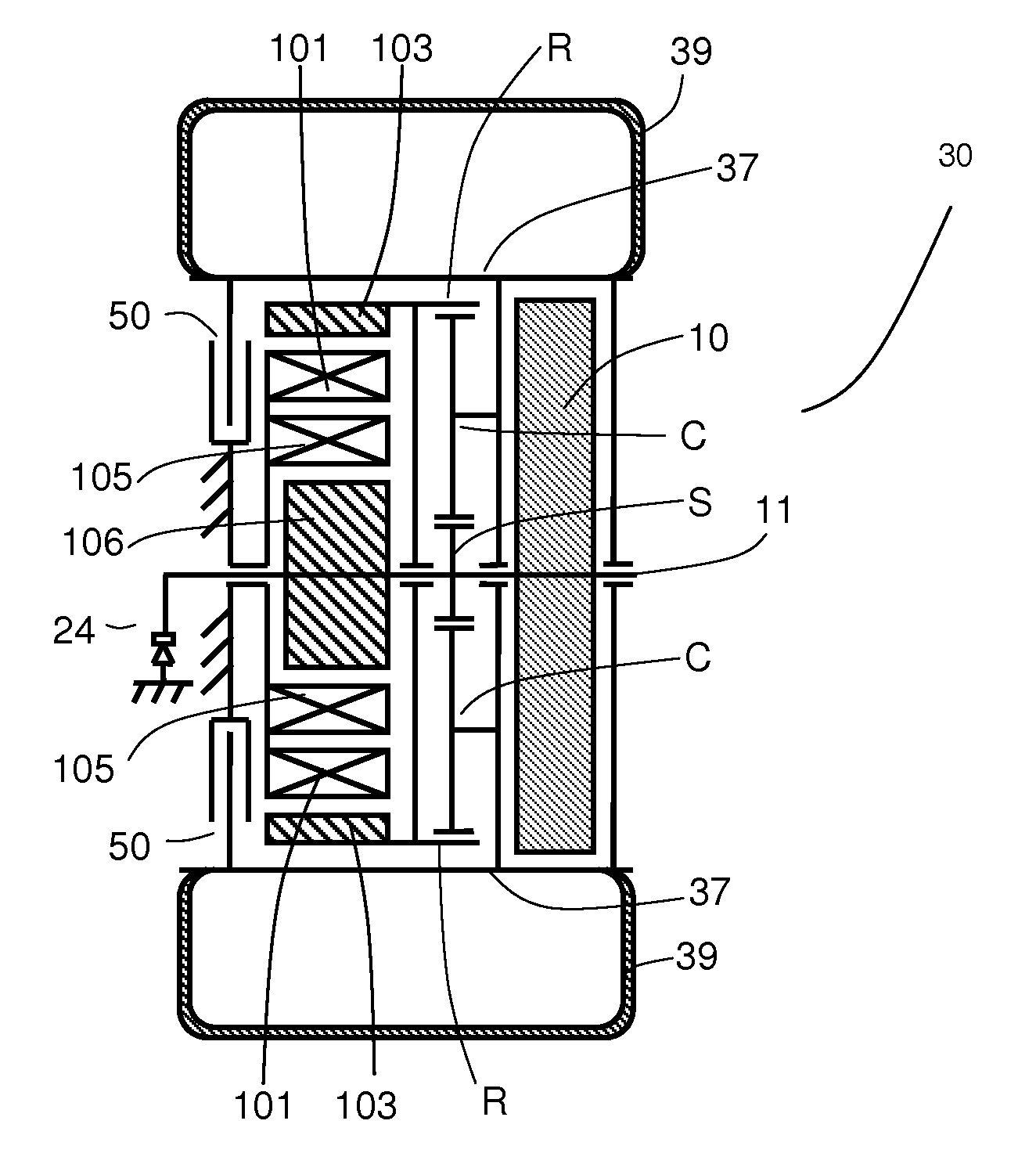

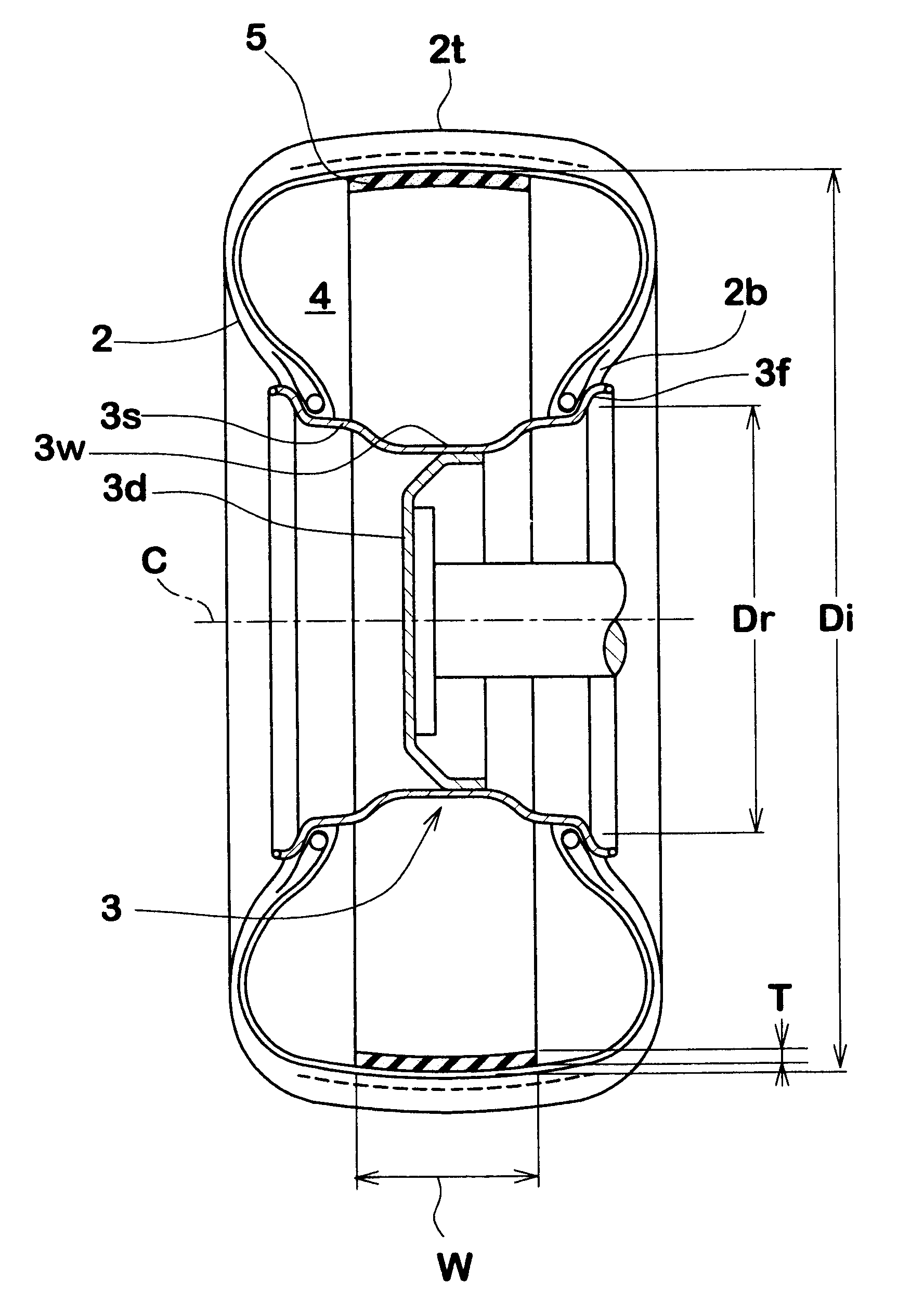

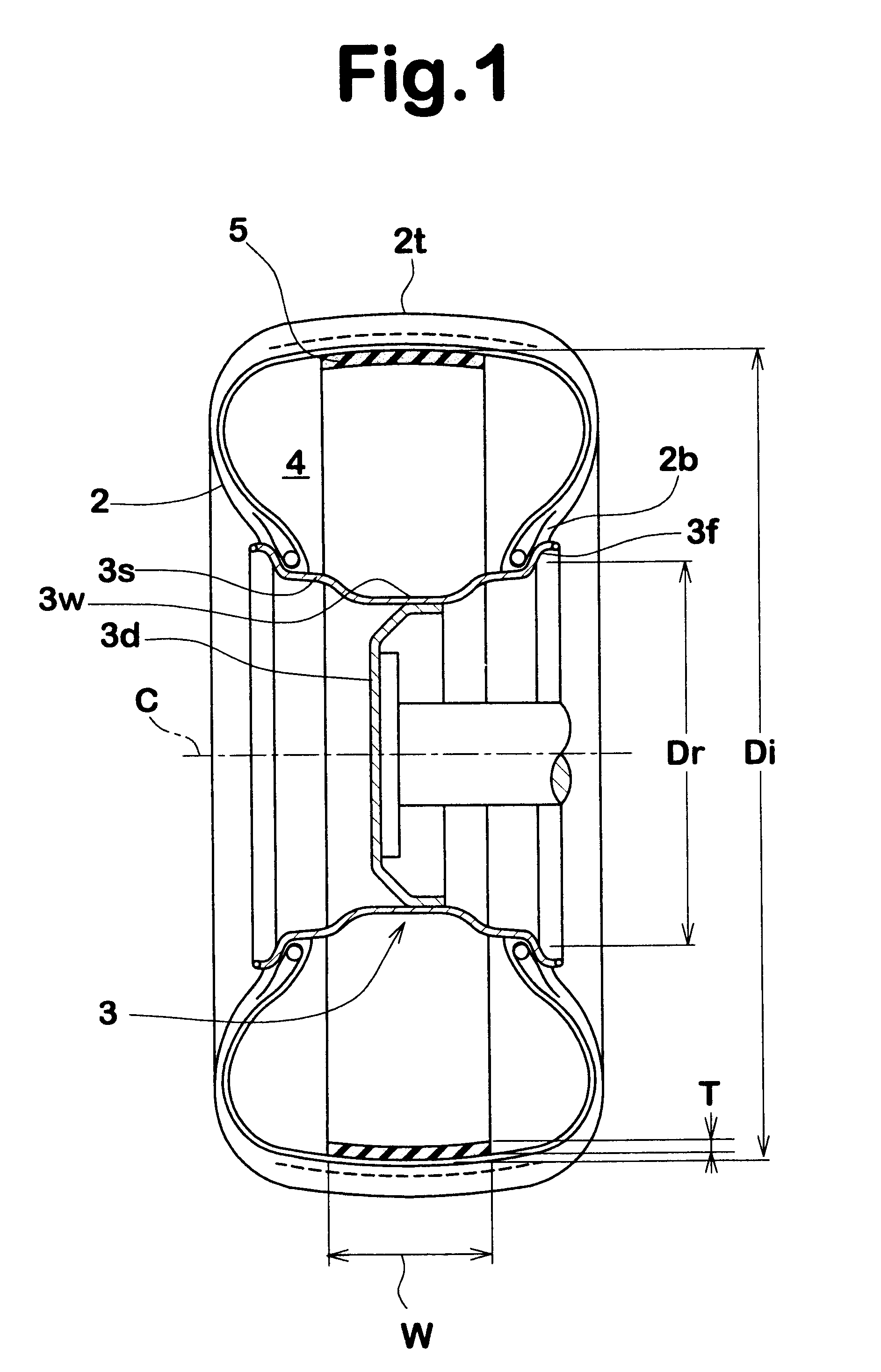

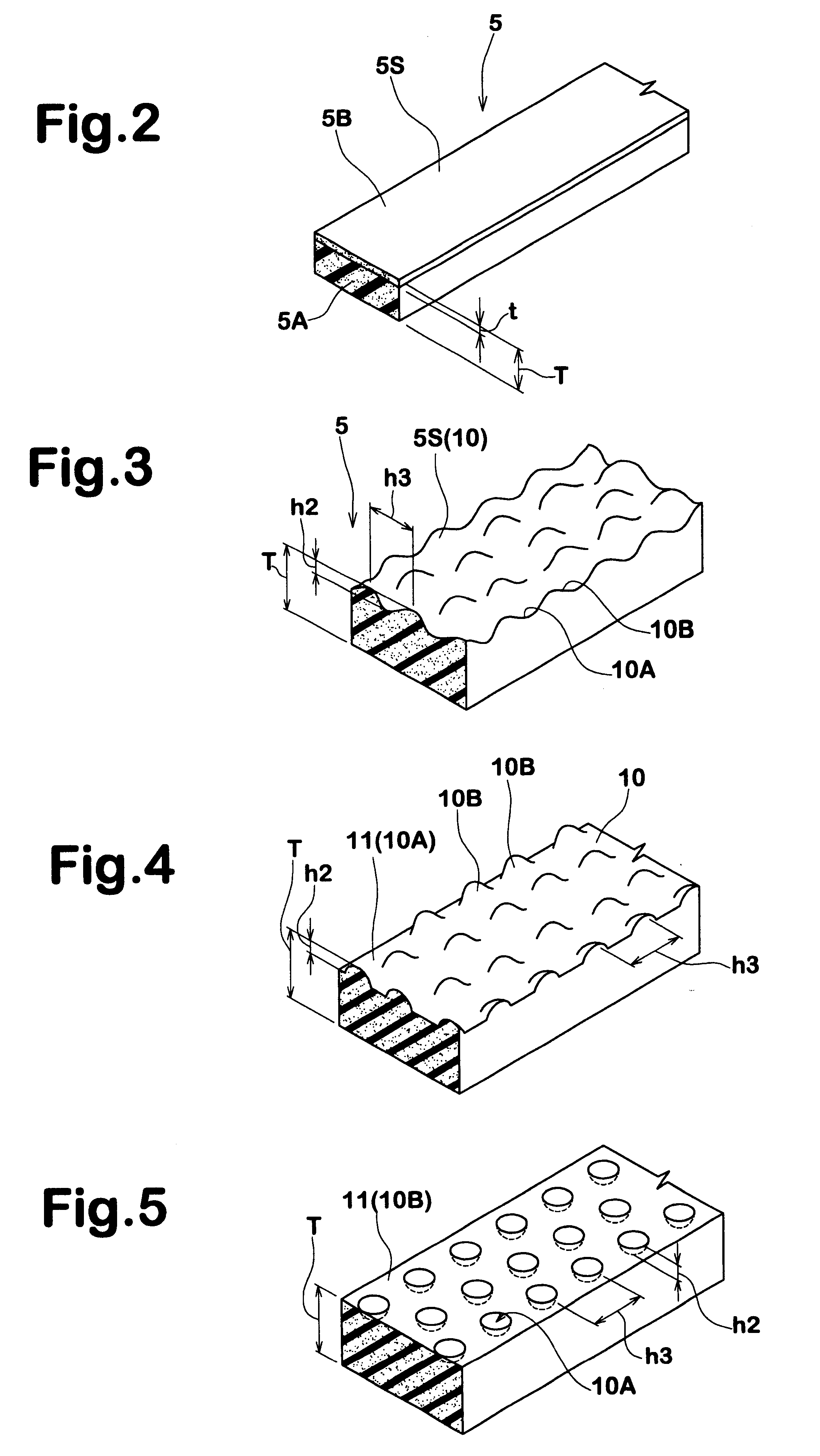

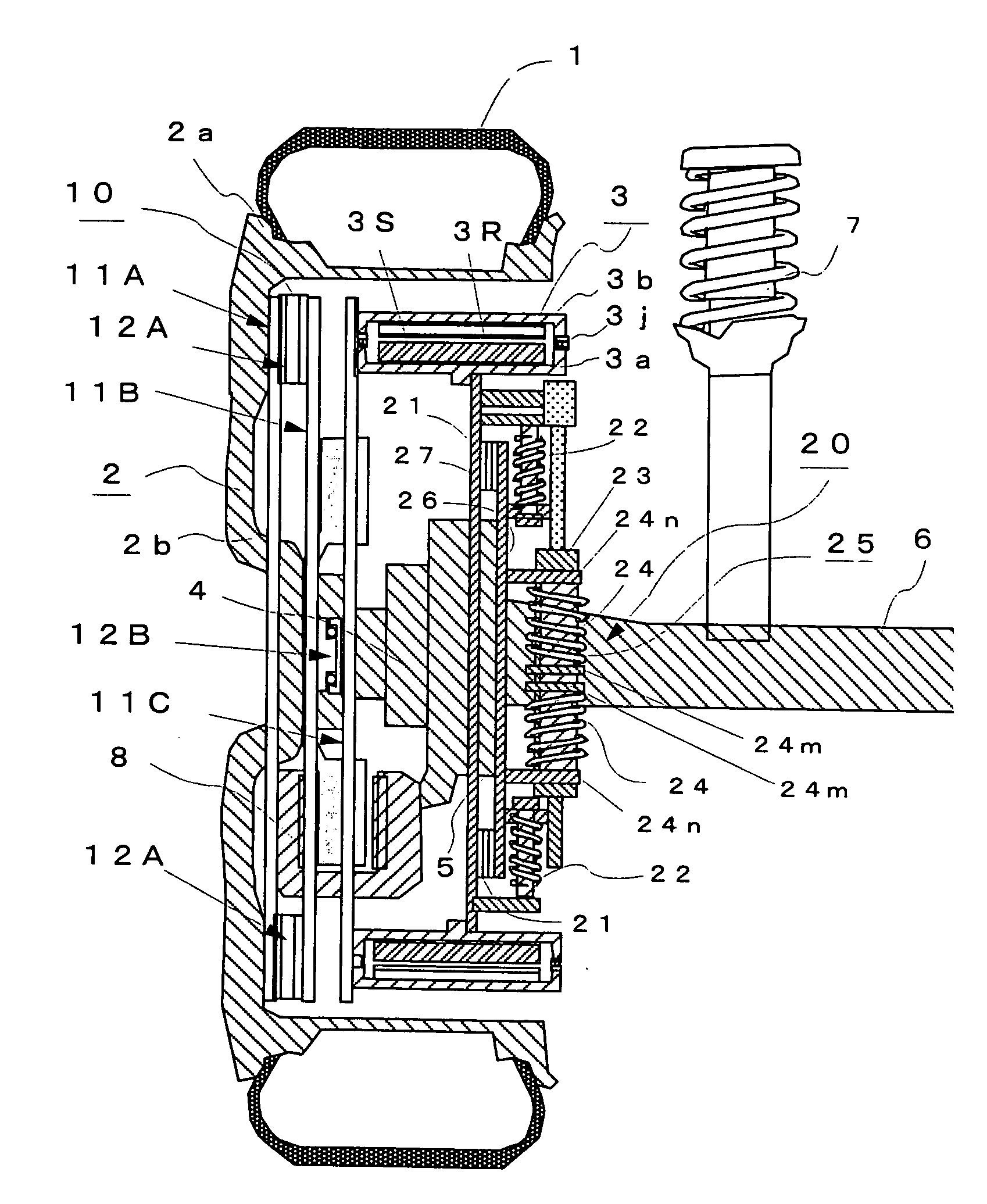

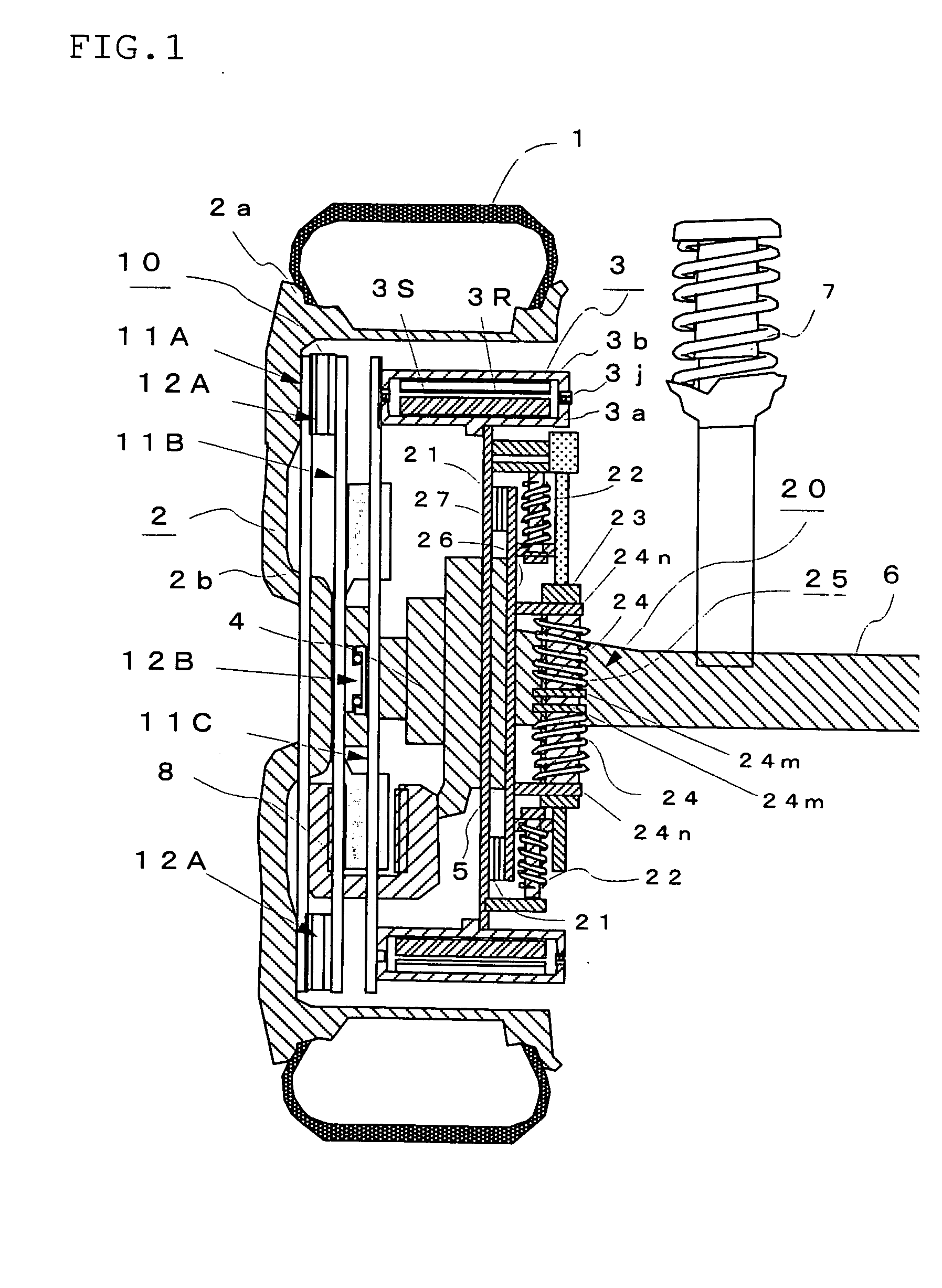

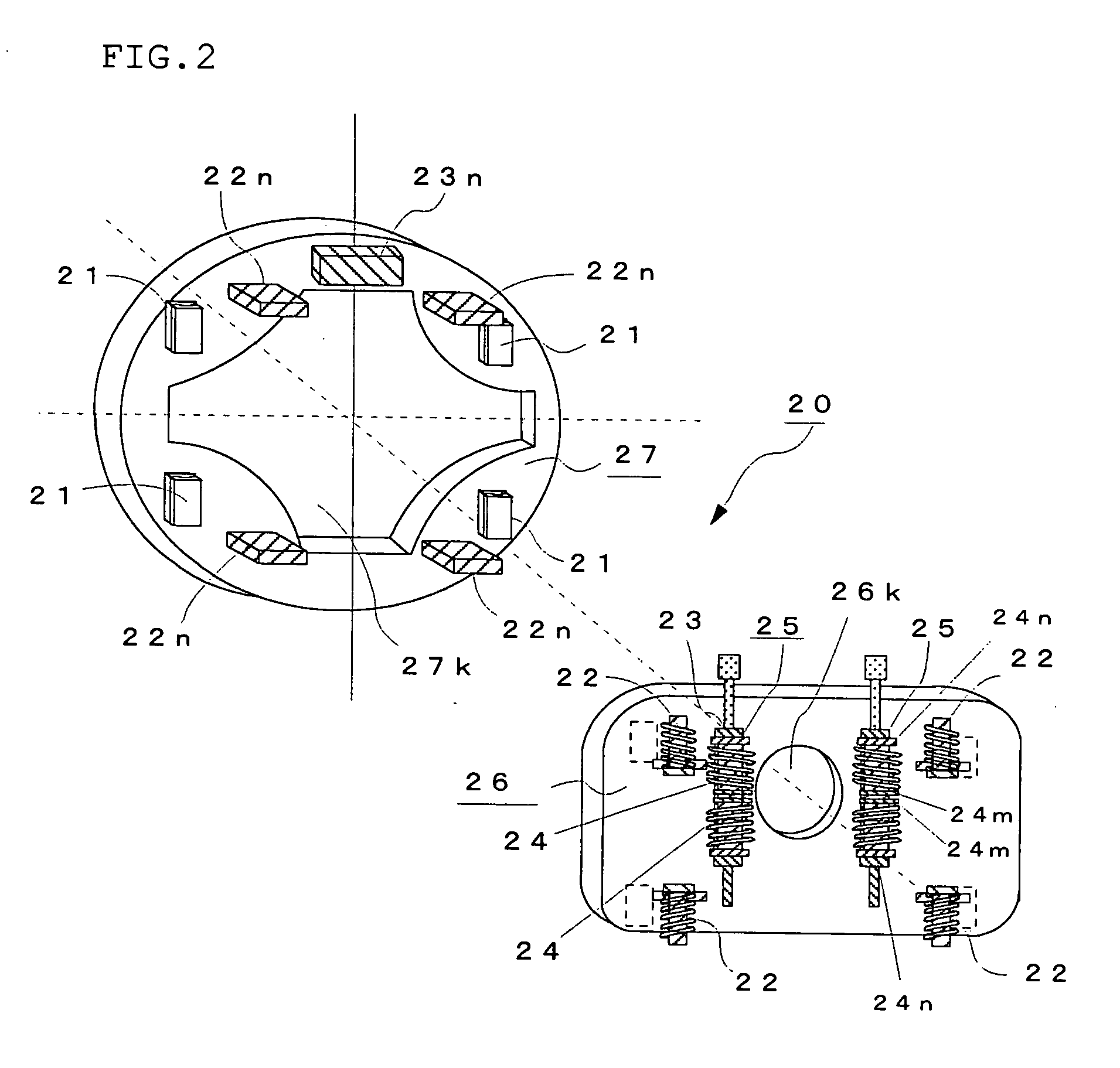

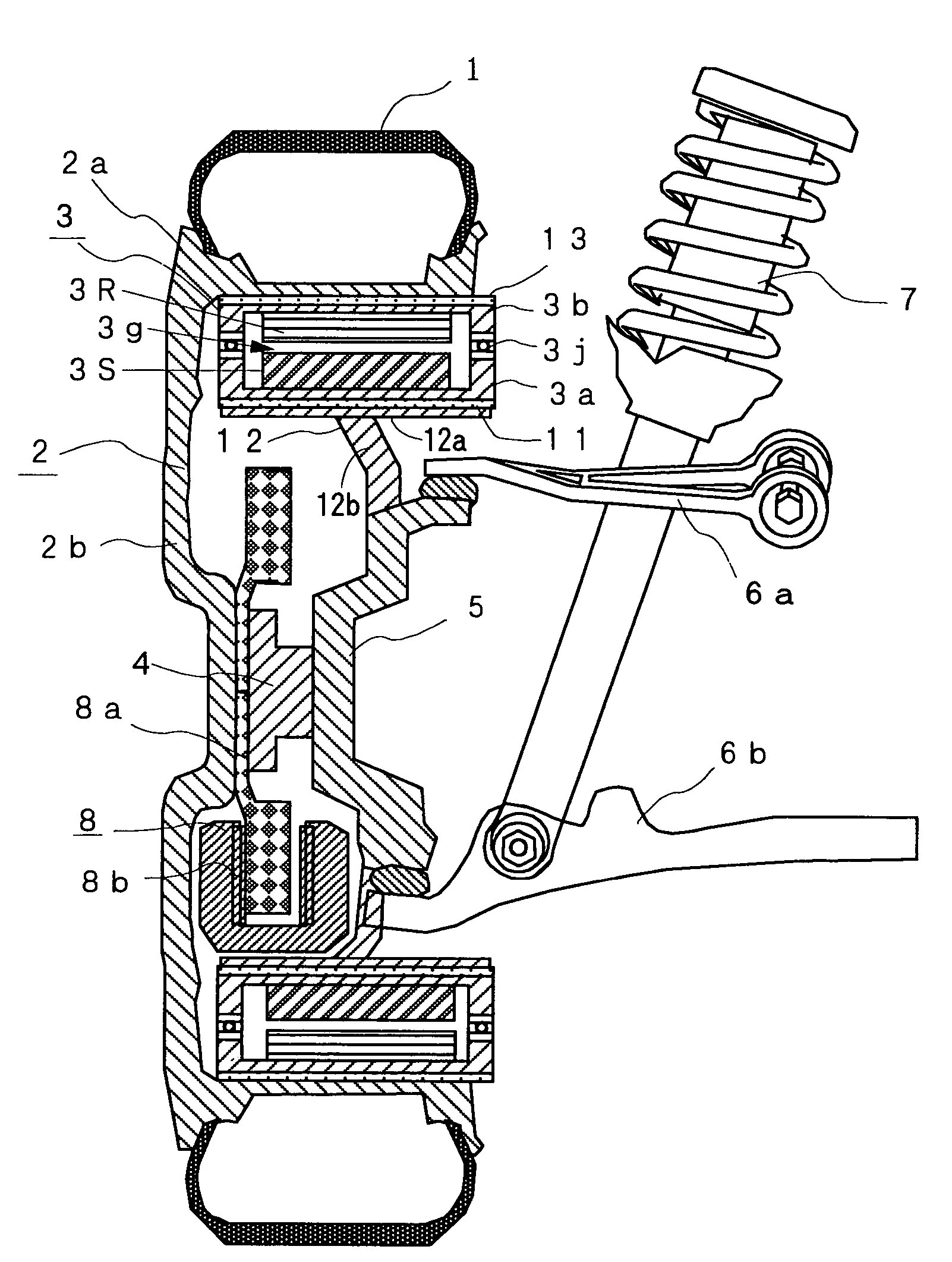

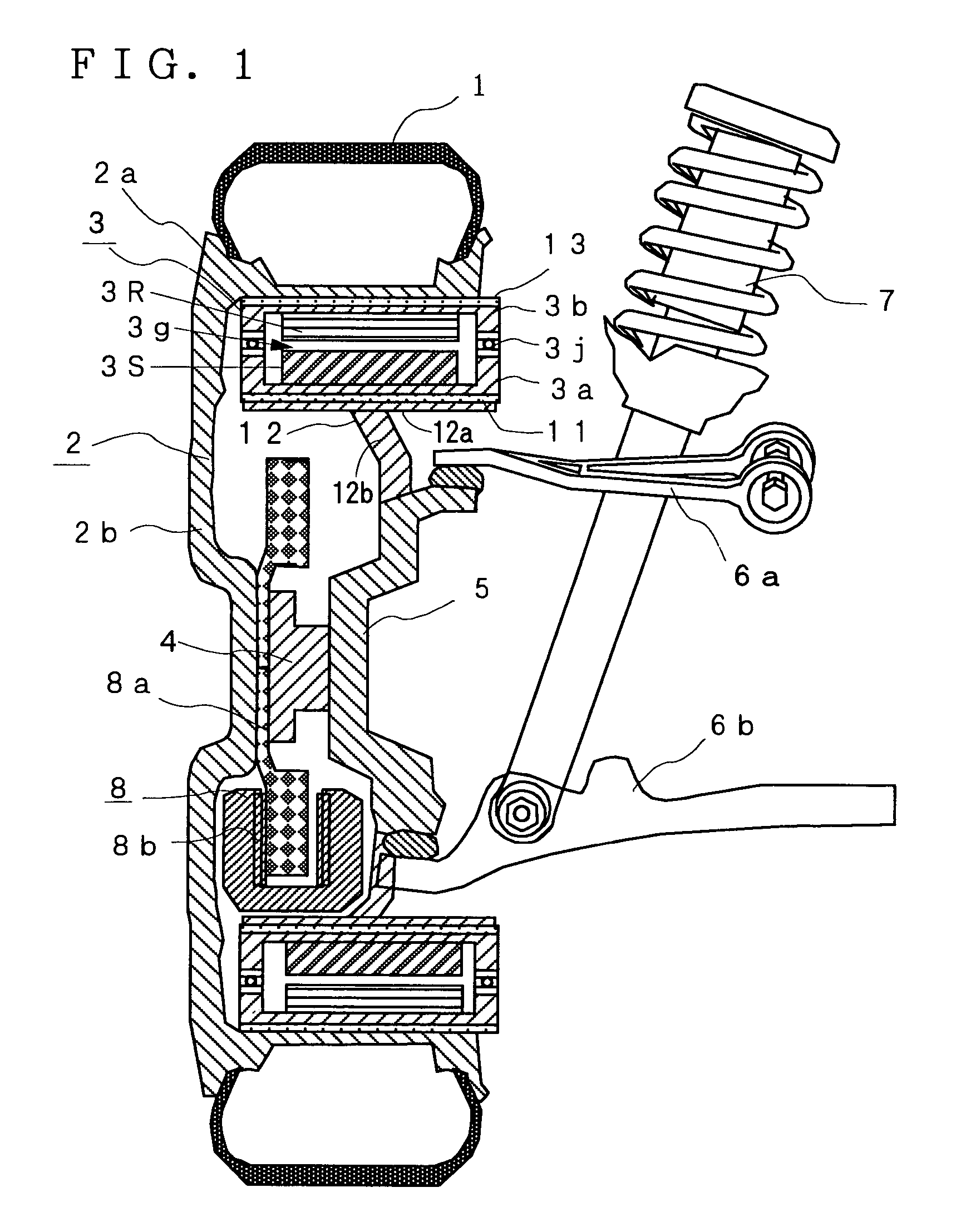

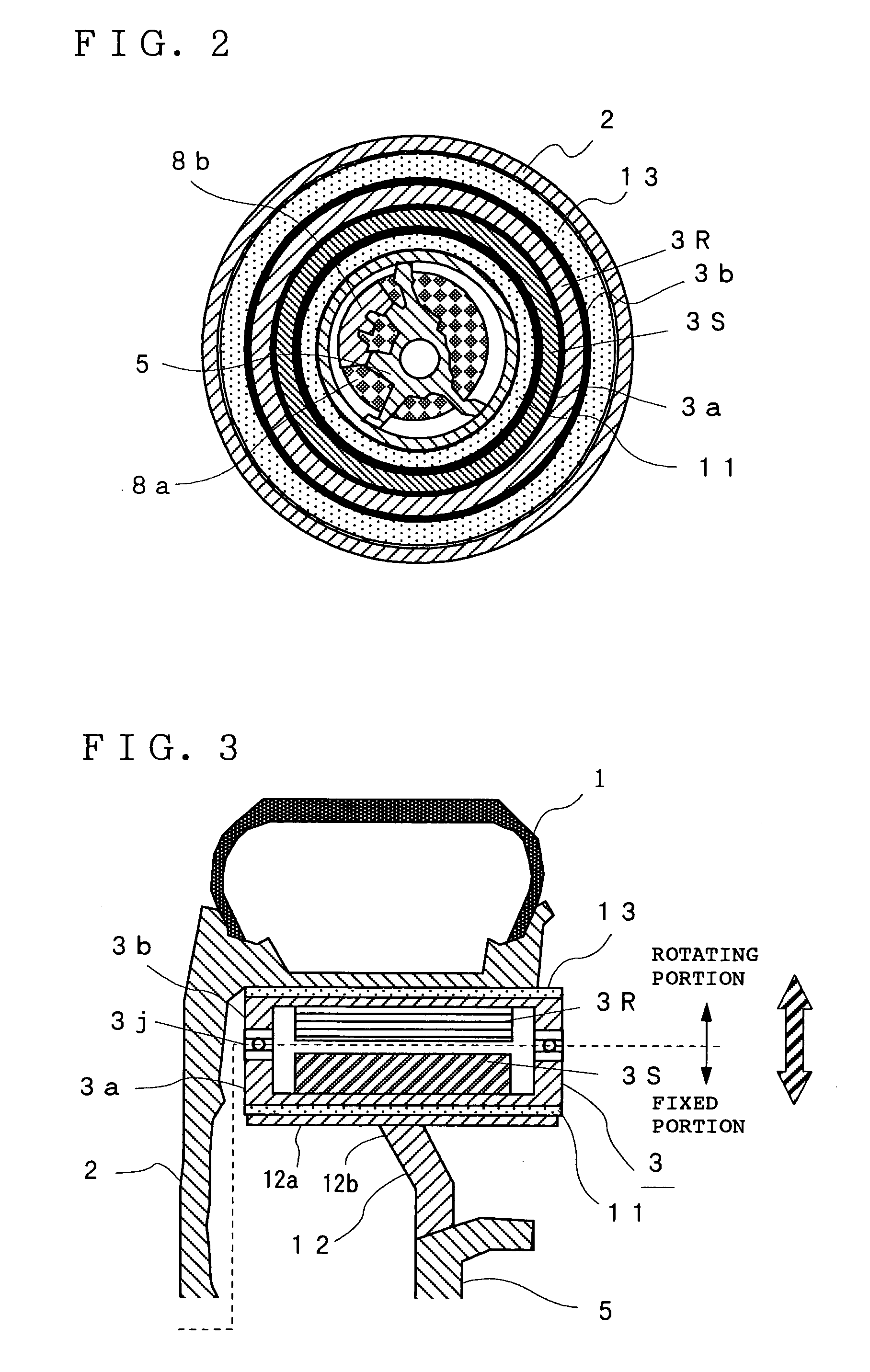

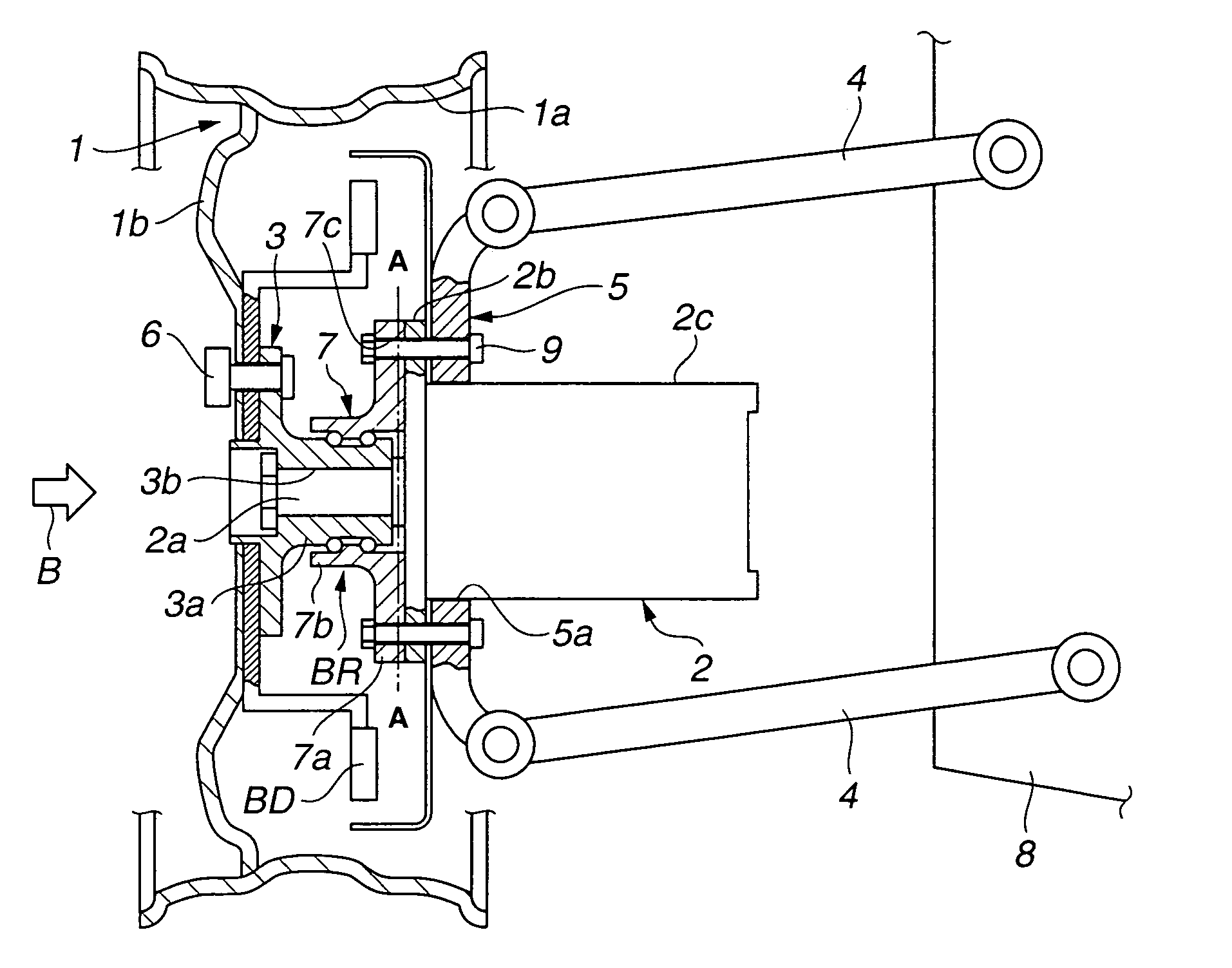

In-wheel motor system

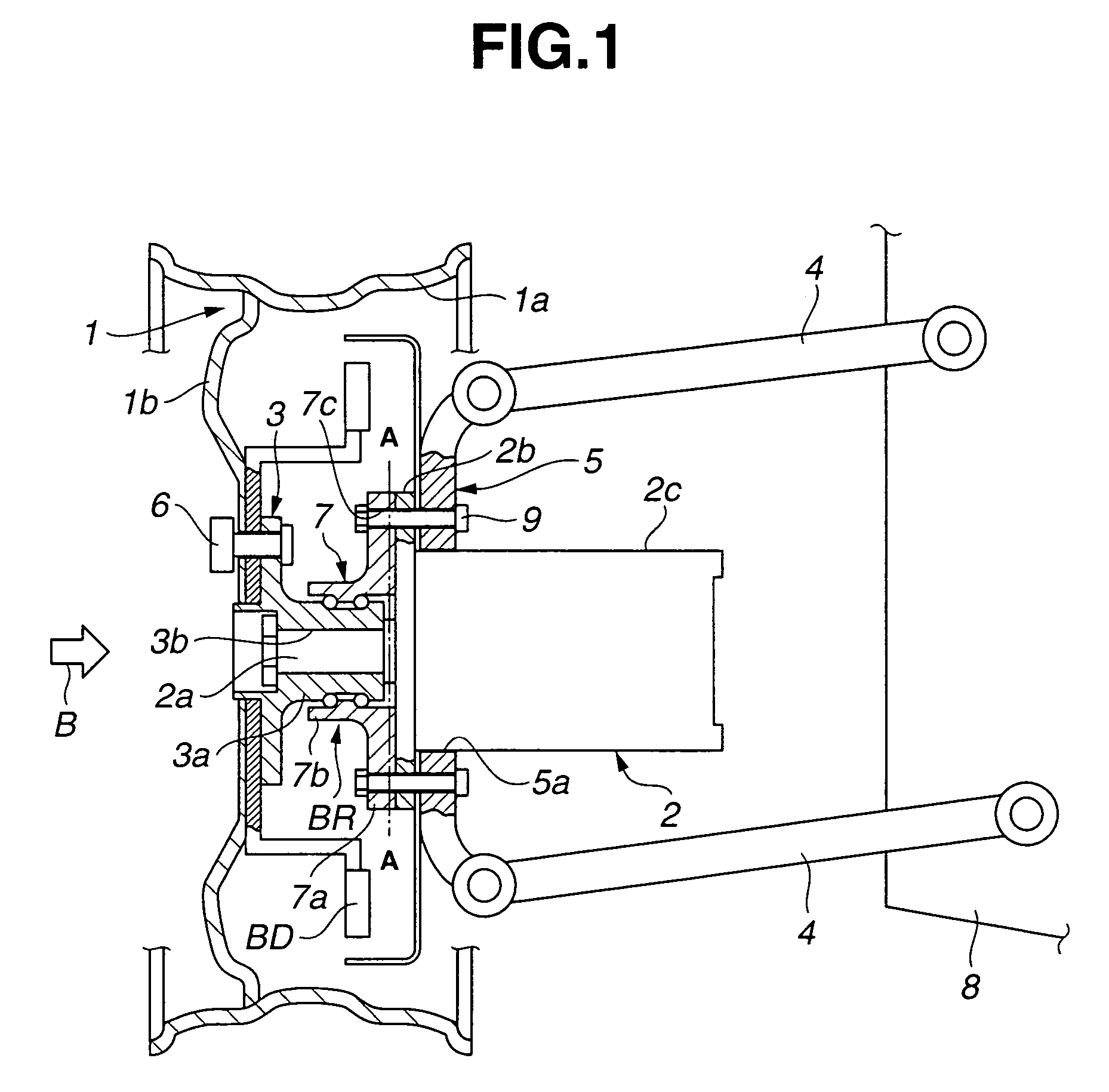

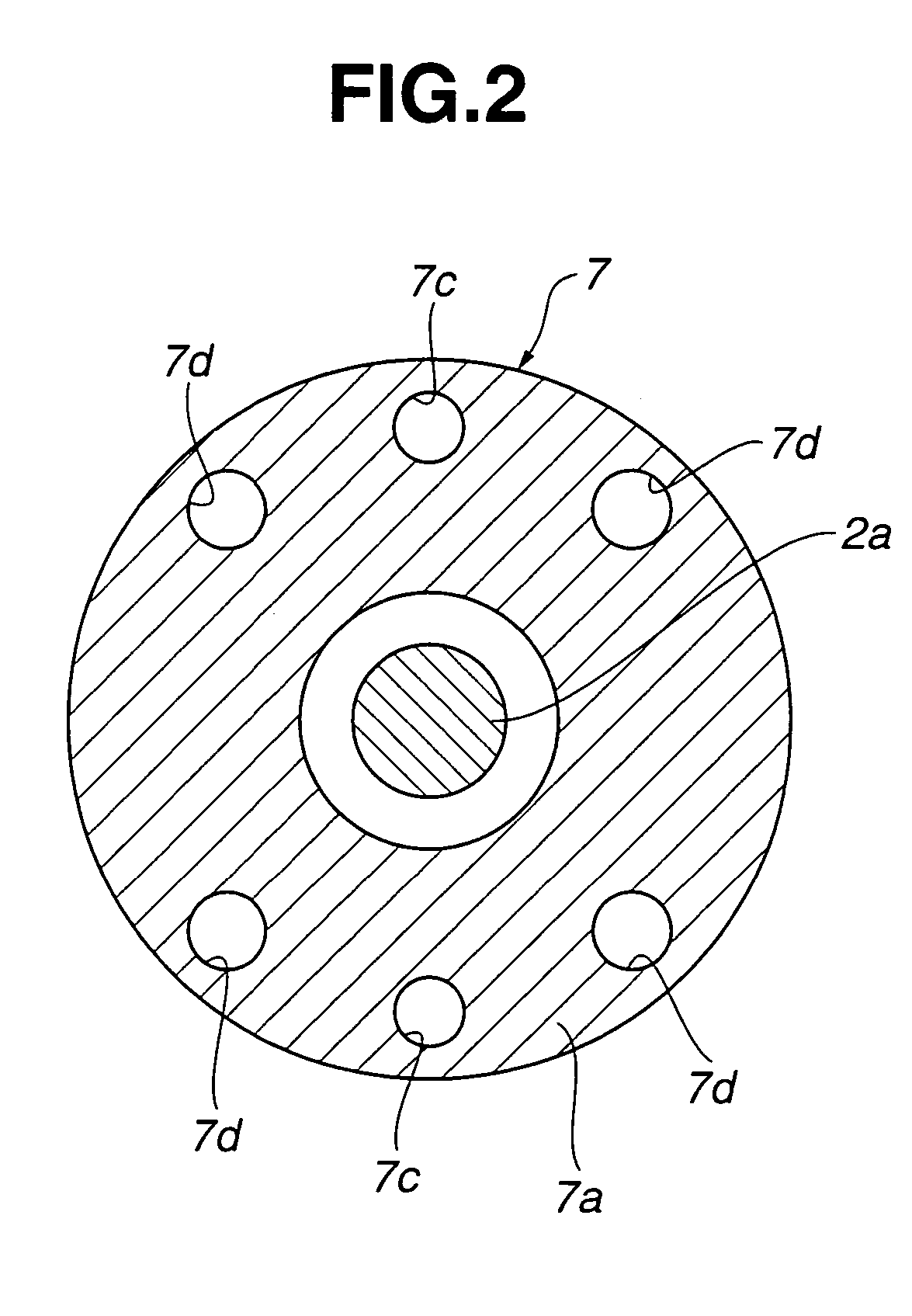

An in-wheel motor system, wherein the rotating side case 3b of an in-wheel motor 3 is connected to a wheel 2 by a flexible coupling 10 comprising a plurality of hollow disk-like plates 11A to 11C and direct-acting guides 12A and 12B, the non-rotating side case 3a of the motor 3 is connected to a knuckle 5 by a damping mechanism 20 for connecting the non-rotating side case 3a of the motor to the knuckle 5 which is a frame dress-up part of the vehicle, comprising two plates 26 and 27 whose moving directions are limited to the vertical direction of the vehicle by direct-acting guides 21 and which are interconnected by first spring elements 22 which move in the vertical direction of the vehicle and dampers 25 with a spring element, each comprising a damper 23 and a second spring element connected to the damper 23 in series and arranged parallel to the first spring elements 22, whereby the drive force of the in-wheel motor 3 can be transmitted to the wheel 2 without fail and the road holding properties of a vehicle can be further improved by greatly reducing variations in the ground-contact load of a tire.

Owner:BRIDGESTONE CORP

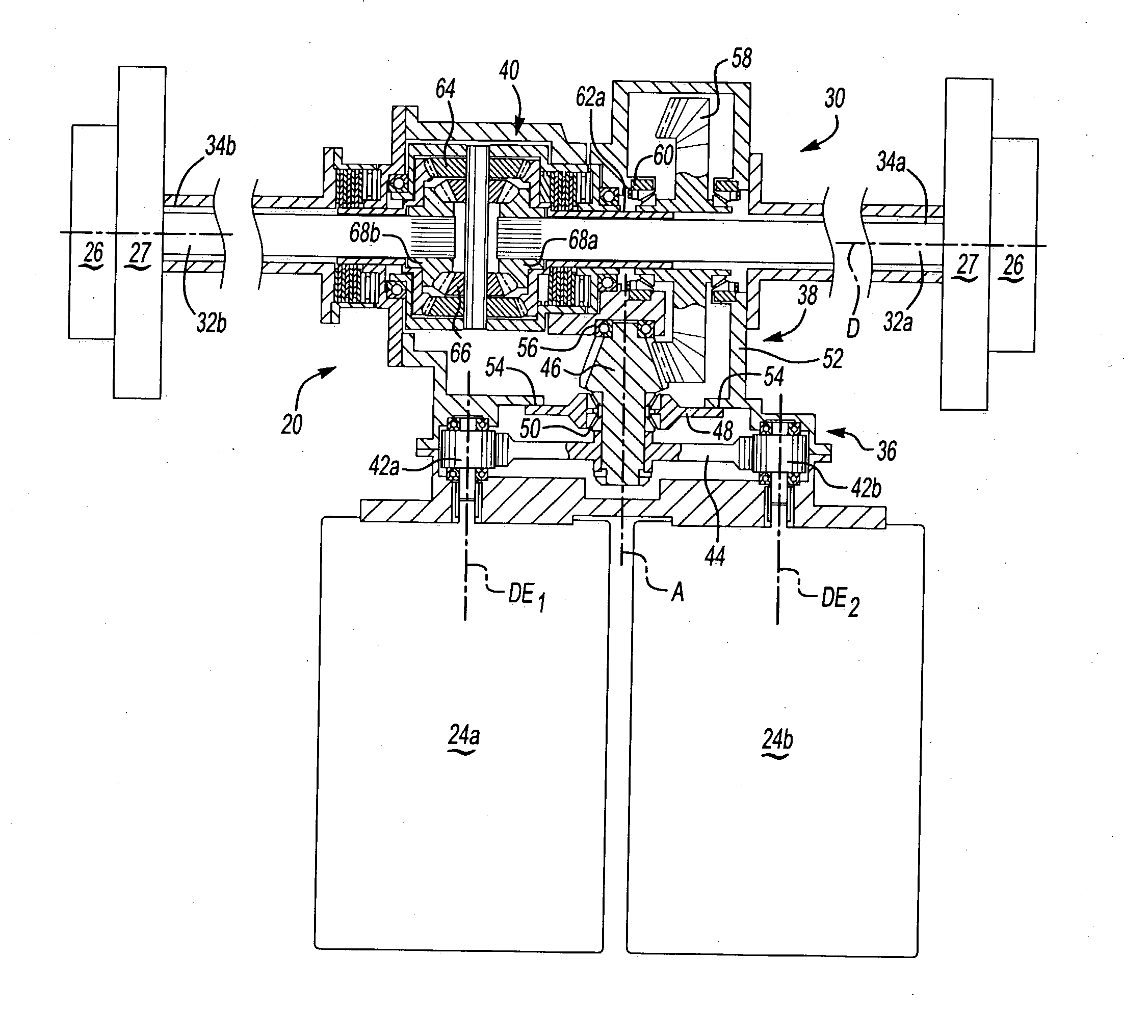

Axle assembly with transverse mounted electric motors

InactiveUS20050023885A1Small sizeAllow useOff-road vehiclesTransmission elementsReduced sizeEngineering

An axle assembly includes a first and a second electric motor which drive a gearbox assembly substantially therebetween. The electric motors drive the gearbox assembly which drives the vehicle wheels through a first and second axle shaft located along a first axis. The electric motors are located along axes which are substantially transverse to the first axis. The electric motors drive the gearbox assembly which includes a first stage gear reduction, a second stage gear reduction and a third stage gear reduction. A relatively lightweight and compact axle assembly is thereby provided which will benefit from an electric motor of reduced size.

Owner:ARVINMERITOR TECH

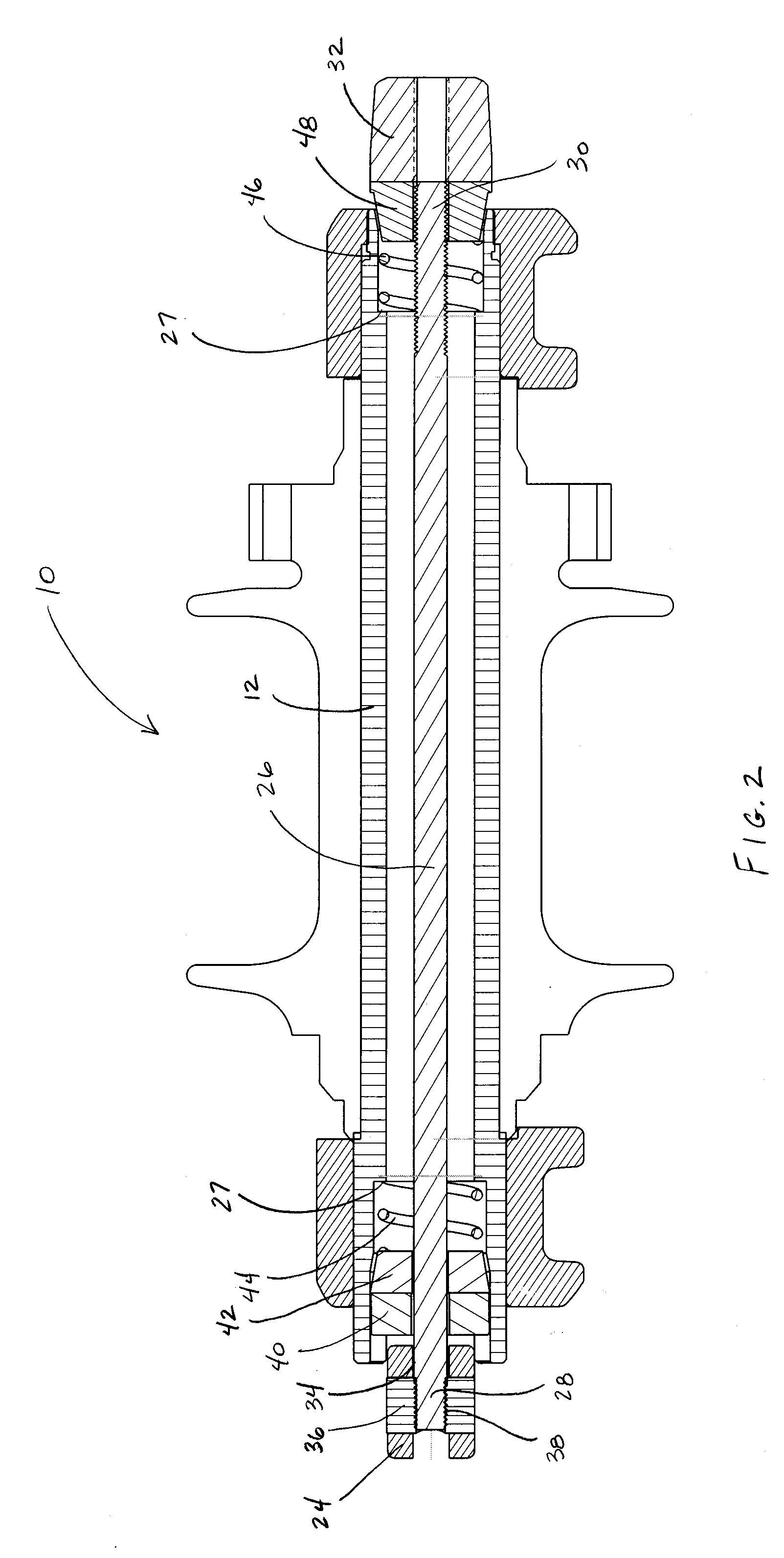

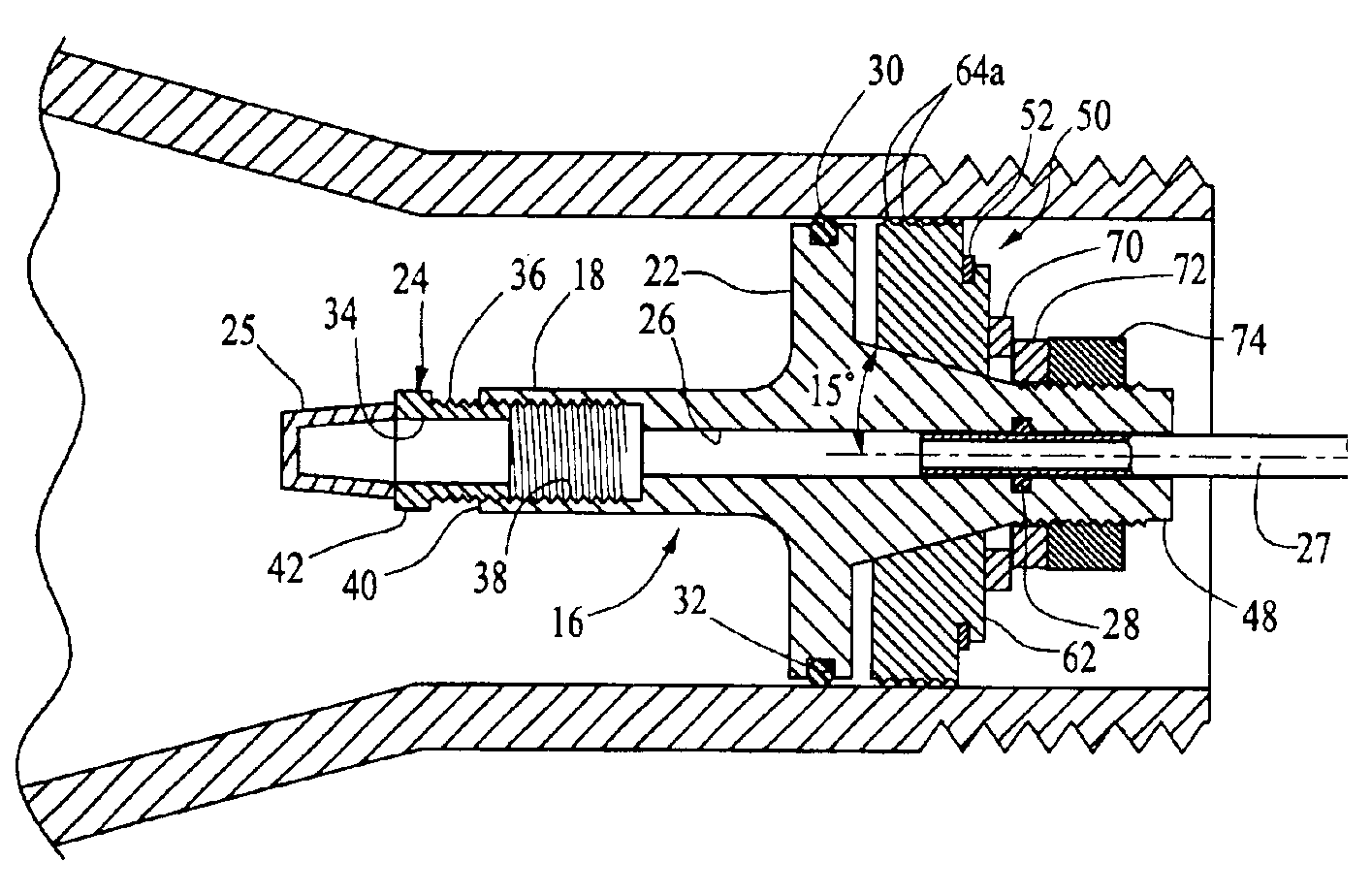

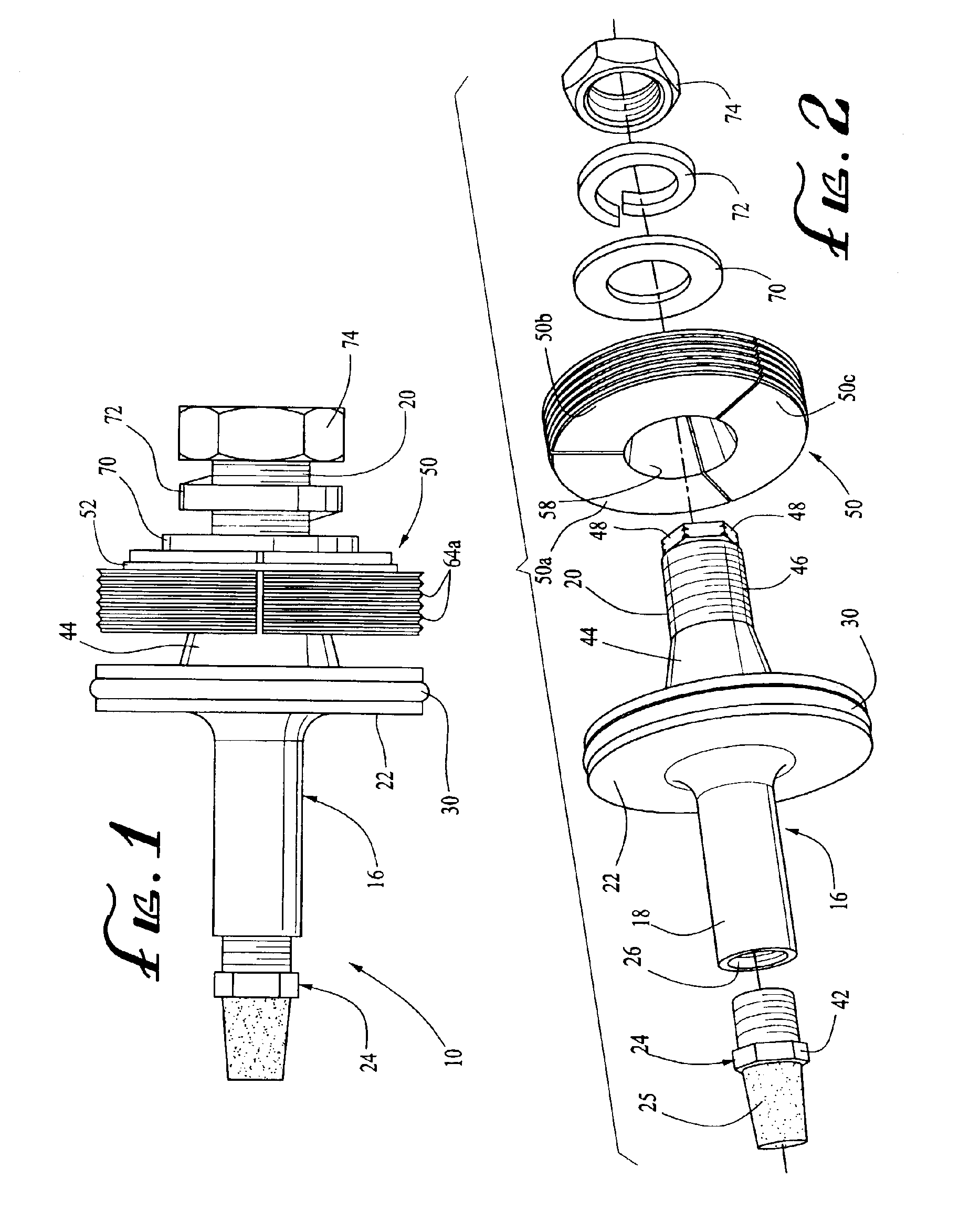

Expandable spindle plug assembly for use with automatic tire inflation systems

An assembly to be mounted in an axle spindle for communicating pressurized air from the axle to a rotary union in a tire inflation system. The assembly includes an arbor having an air flow channel extending therethrough, a flange intermediary of the arbor ends and an axially inclined portion proximate the flange. A sealing member is carried by the flange for forming an airtight seal with the axle spindle. A split ring locking assembly is disposed about the inclined portion of the arbor that is comprised of a plurality of segments held by an expansible retention spring. The segments move radially outwardly upon the locking assembly being moved along the inclined arbor portion and engage the axle spindle, securing the plug assembly within the spindle, A fastening member threadably engages the arbor for urging the locking assembly along the inclined arbor portion to effect securement of the plug assembly within the axle spindle.

Owner:AIRGO IP

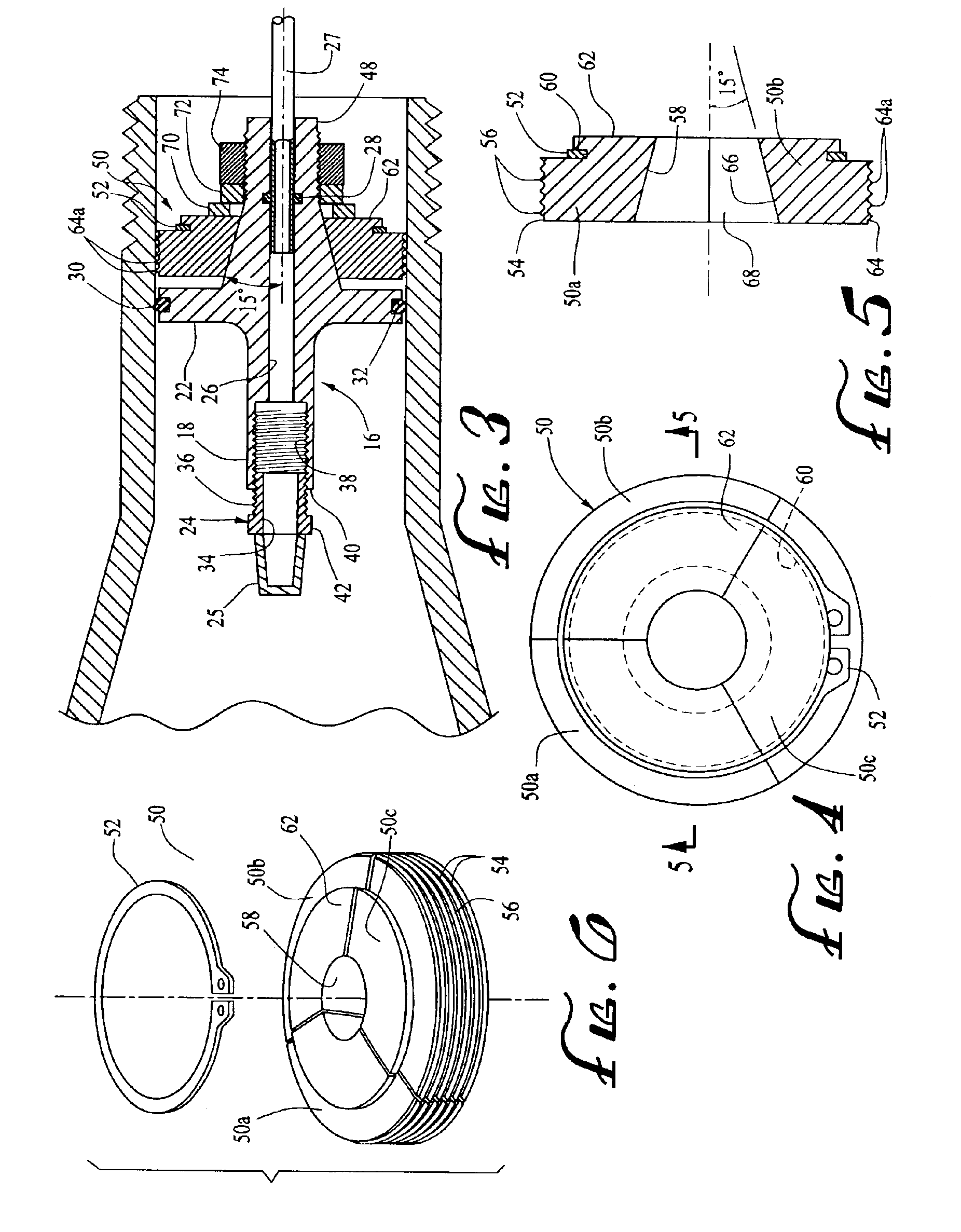

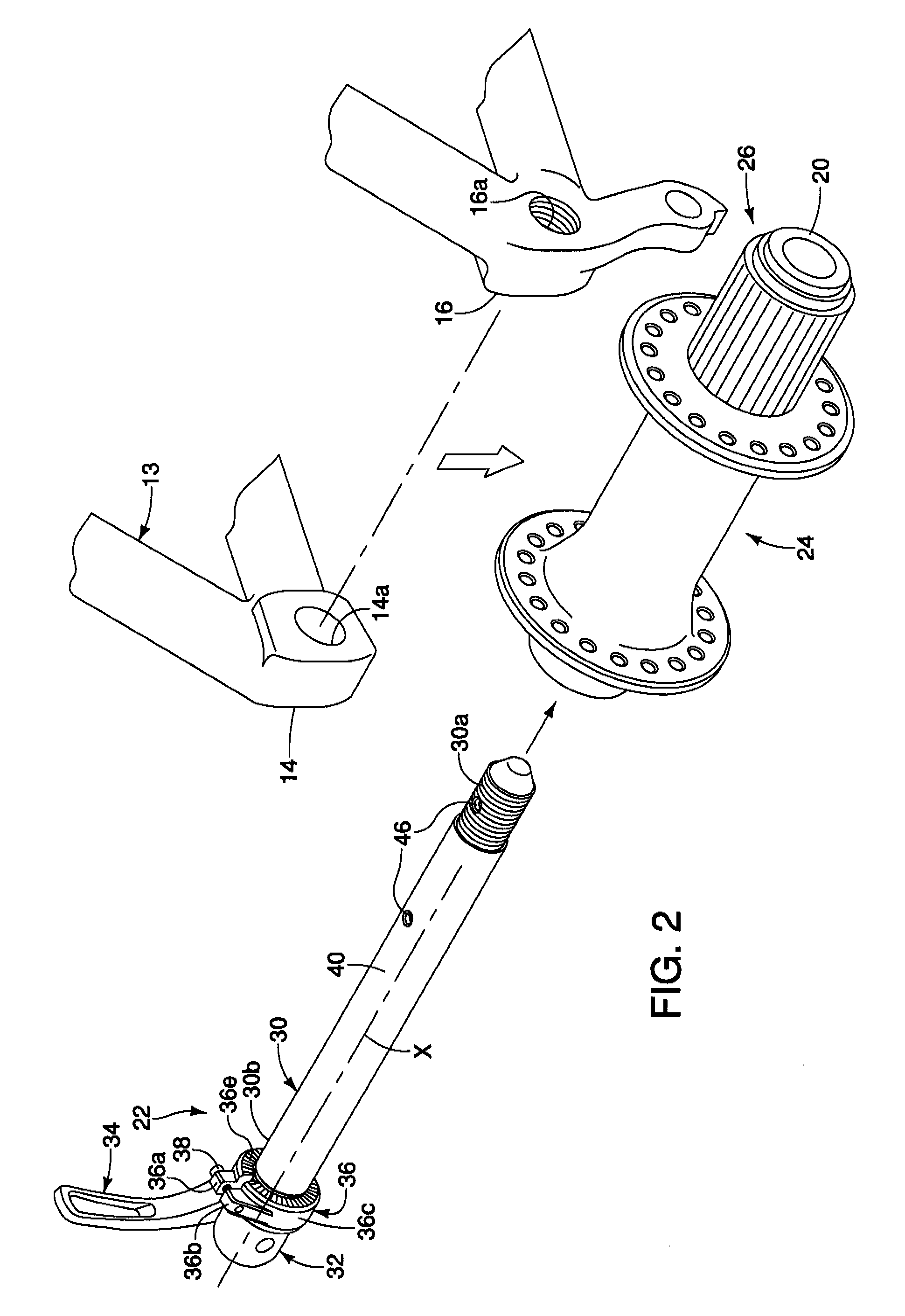

Bicycle wheel securing structure

ActiveUS7537291B2Easy to tightenClosely connectedHubsRod connectionsEngineeringMechanical engineering

A bicycle wheel securing structure includes a shaft member, a head member, a lever member and an adjustment member. The shaft member has a first threaded end and a second end with a center axis extending therebetween. The head member is disposed on the second end of the shaft member. The lever member is operatively mounted between the shaft member and the head member to move the shaft member in an axial direction relative to the head member in response to movement of the lever member. The adjustment member is axially adjustably coupled to the head member such that an axial position of an abutment surface of the adjustment member can be adjusted relative to the shaft member.

Owner:SHIMANO INC

Wheel with interlocking hub and spacer

An apparatus for allowing pre-assembly of a wheel and wheel spacer and a method of using the apparatus are disclosed. The apparatus provides a structure within the hub of a molded plastic wheel and a structure on a spacer segment for engagement of the two parts. A variety of embodiments are described in which the spacer can easily be snapped, screwed, or pressed into the wheel. This allows pre-assembly of the spacer and wheel so that when needed, a spacer need not be found or acquired, but is readily available to the user.

Owner:POLY FLEX INC

Wheel rotating apparatus and in-wheel motor vehicle

InactiveUS7717203B2Miniaturizing motorImprove output efficiencyHybrid vehiclesElectric propulsion mountingGear wheelEngineering

Owner:HONDA MOTOR CO LTD

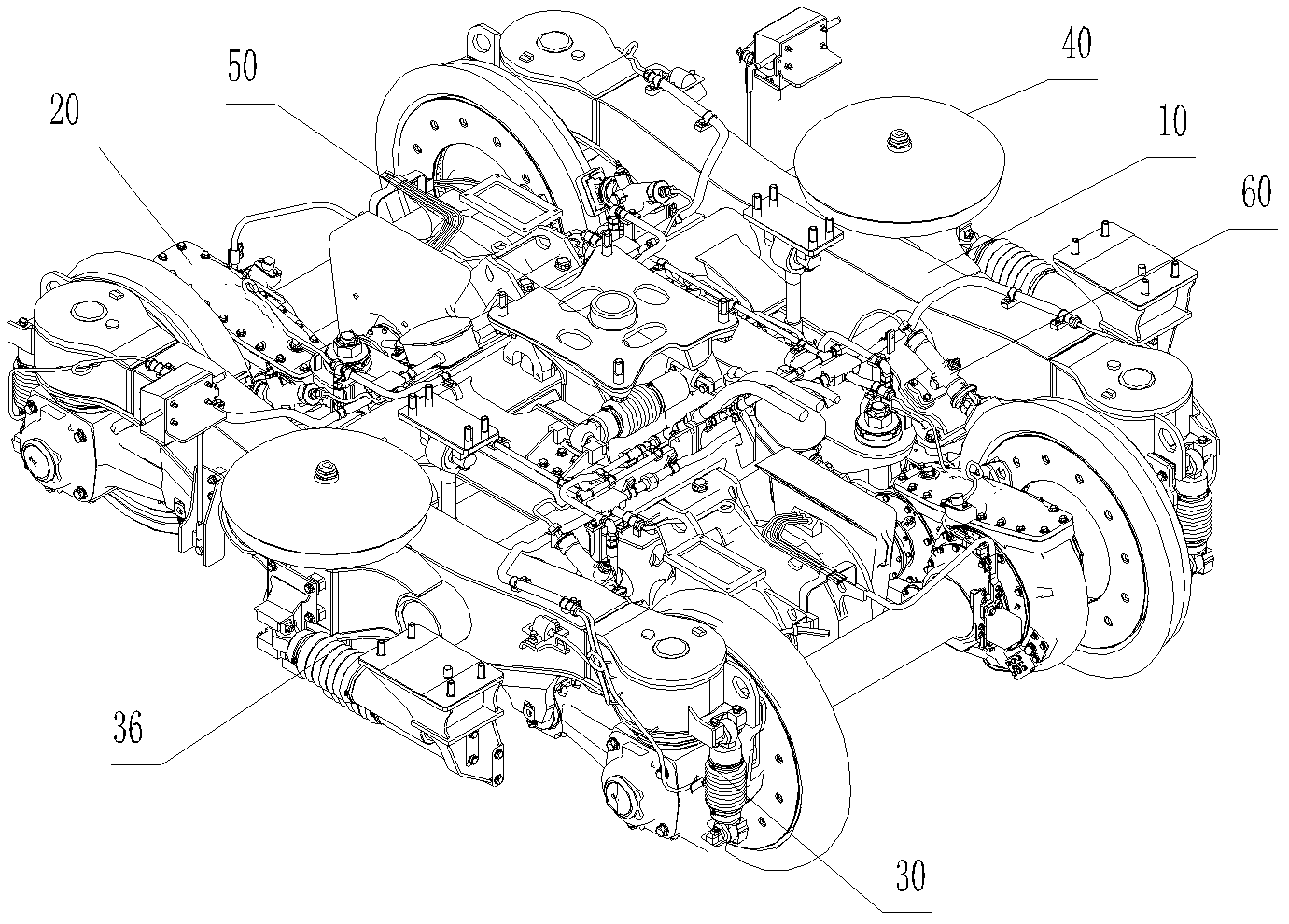

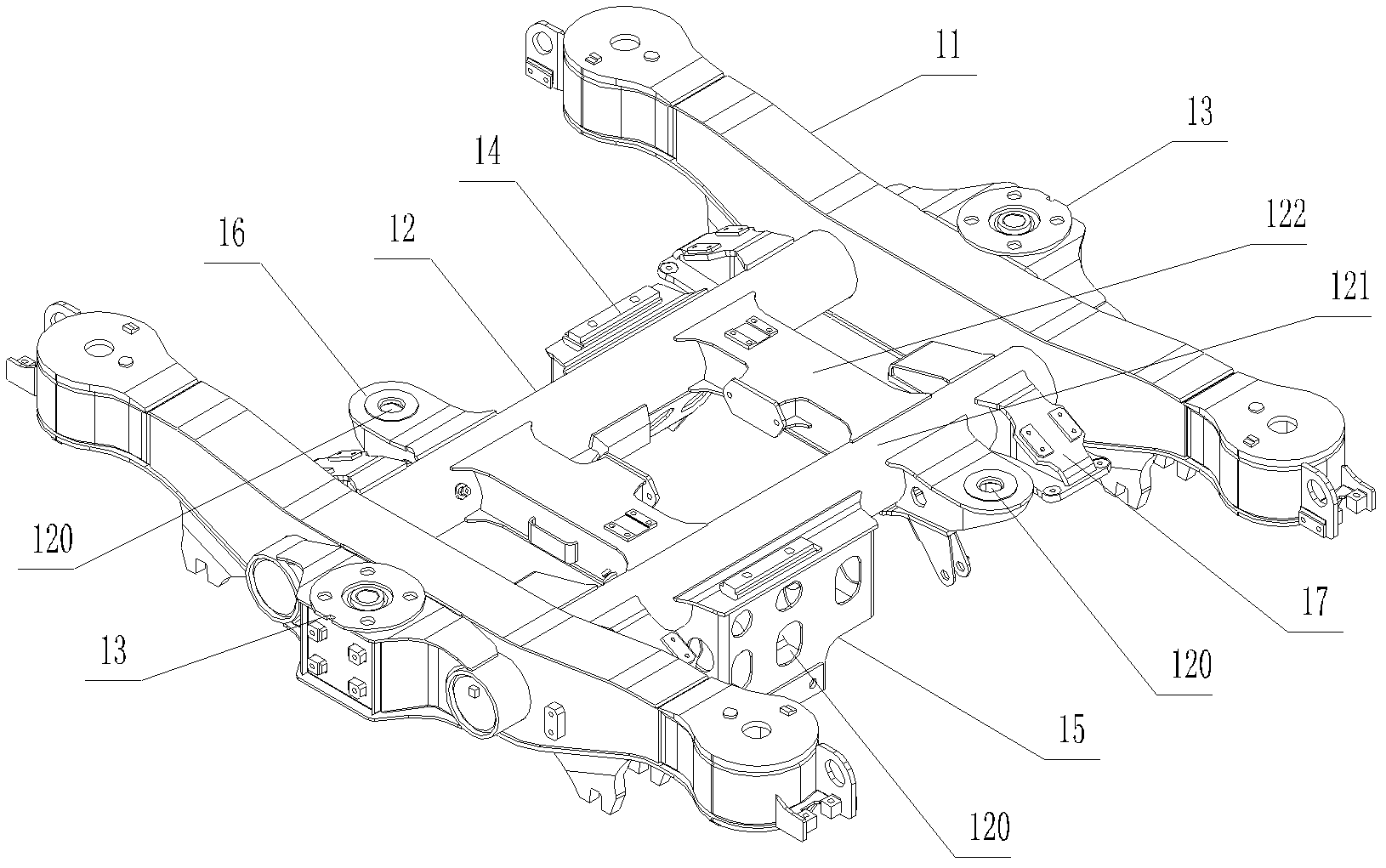

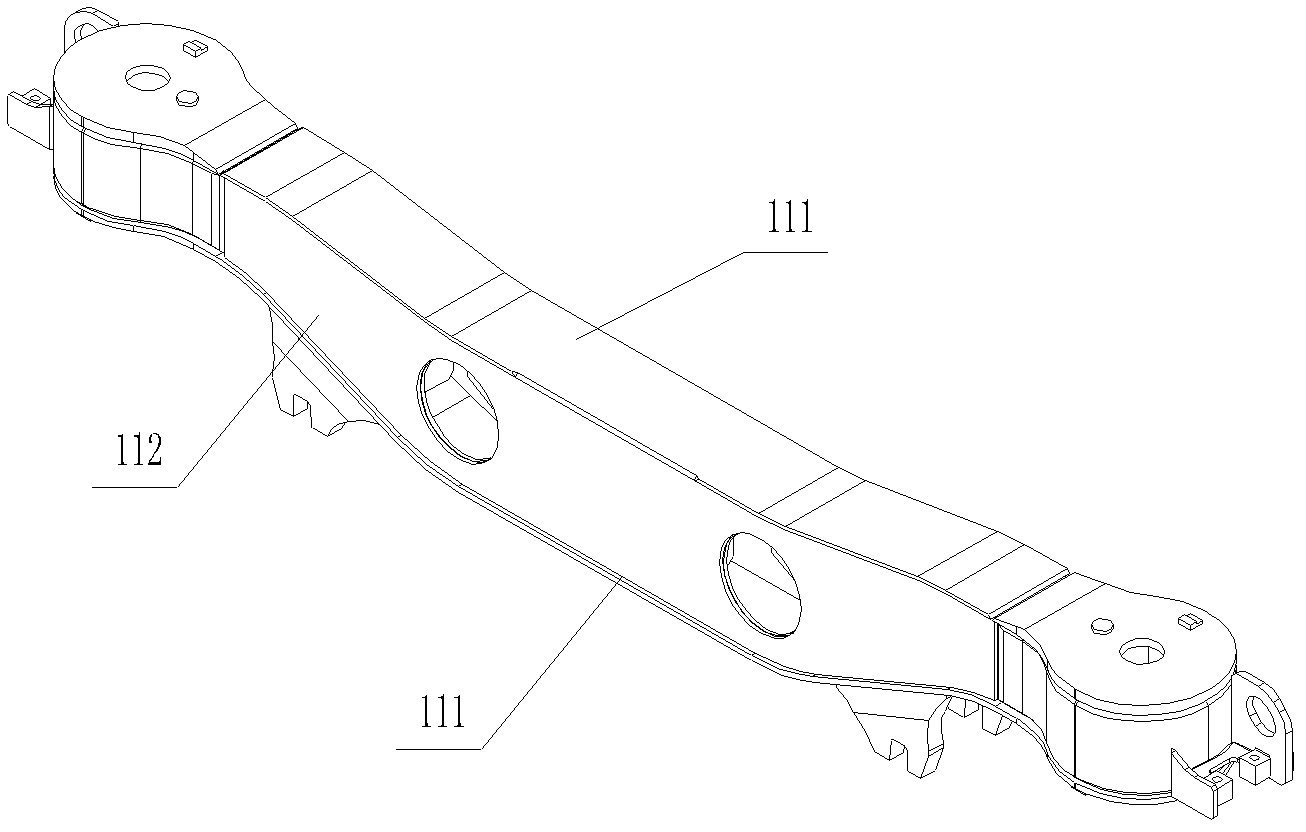

Bogie of high-speed motor train unit

InactiveCN102923153AAchieve lightweight designGuaranteed stabilityBogiesWheel-axle combinationsBogieAir spring

The invention discloses a bogie of a high-speed motor train unit. By adopting a brand-new bogie structure and a hanging connection and traction mode, overall lightweight design is realized, the unsprung weight of the bogie is reduced, and the hanging parameter between the bogie and a body is optimized. On the basis that the high-speed running speed is met, stability when the bogie passes through a big corner and good traction and braking performance are expected. The bogie comprises a framework, two groups of wheel set travelling devices, a linear motor, a first hanging device, a second hanging device, a traction device and a foundation brake device. The framework comprises a pair of side beam assemblies and a pair of cross beam assemblies which are connected with each other; each side beam assembly has a hollow box body structure, and comprises a pair of upper and lower cover plates and a pair of lateral web plates which are welded; each cross beam assembly comprises a pair of hollow steel pipes penetrating the lateral web plates and welded with the lateral web plates; and a pair of air spring supporting beams is welded at two ends of a steel pipe and outside the lateral web plates.

Owner:CRRC QINGDAO SIFANG CO LTD

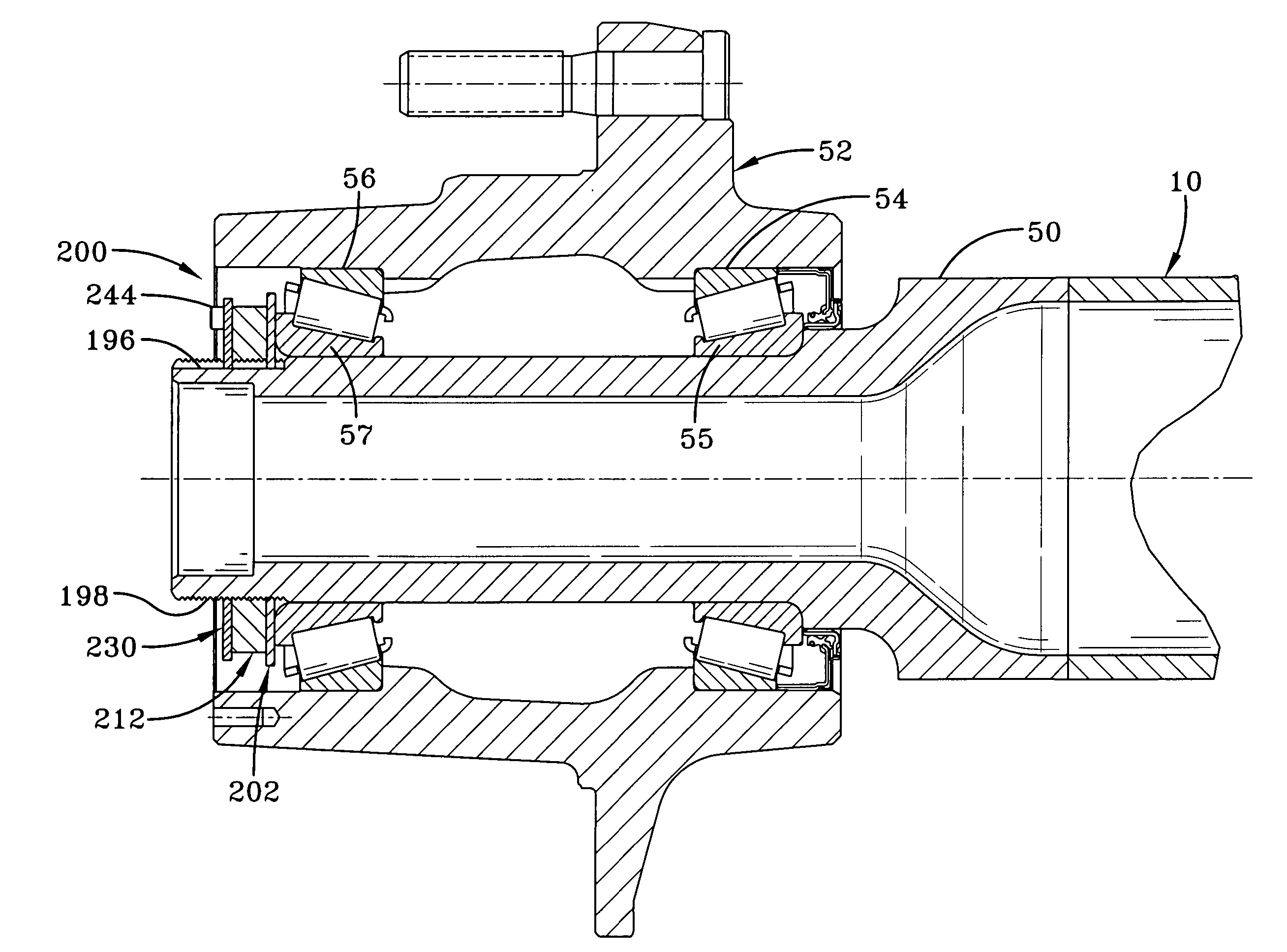

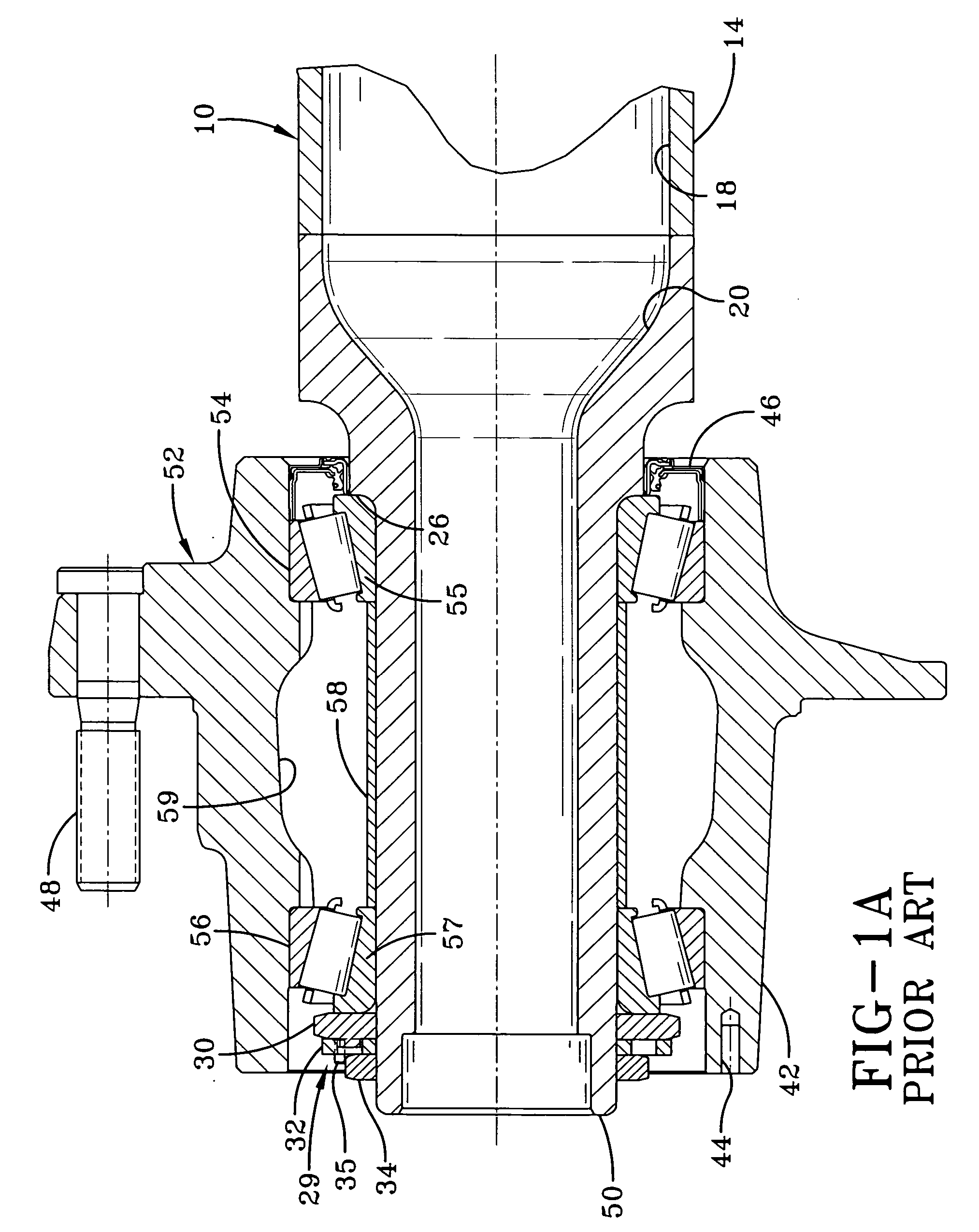

Axle spindle nut assembly for heavy-duty vehicles

InactiveUS20070052287A1Economical and durable and less to installEliminate and minimize possibilityRolling contact bearingsHubsEngineeringHeavy duty

An axle spindle nut assembly secures a wheel end assembly on an axle spindle. The wheel end assembly includes outboard and inboard outboard bearings that are immovably mounted on the axle spindle, and a wheel hub which is rotatably mounting on the bearings. The spindle nut assembly includes a nut that threads onto an outboard end of the axle spindle, and is tightened against the outboard bearing to a selected torque level. The nut includes an outboard surface that is formed with a plurality of features. A washer is formed with a tab that engages a keyway of the axle spindle outboardly of the nut, and with a plurality of mating features that mechanically engage the features formed in the outboard surface of the nut to prevent substantial rotation of the nut after the nut has been tightened to the selected torque level.

Owner:HENDRICKSON USA L L C

Fixing method of in-wheel motor and in-wheel motor system

InactiveUS7306065B2Reduce contact forceImprove road holding propertyRotating vibration suppressionNon-rotating vibration suppressionEngineeringElectric motor

Owner:BRIDGESTONE CORP

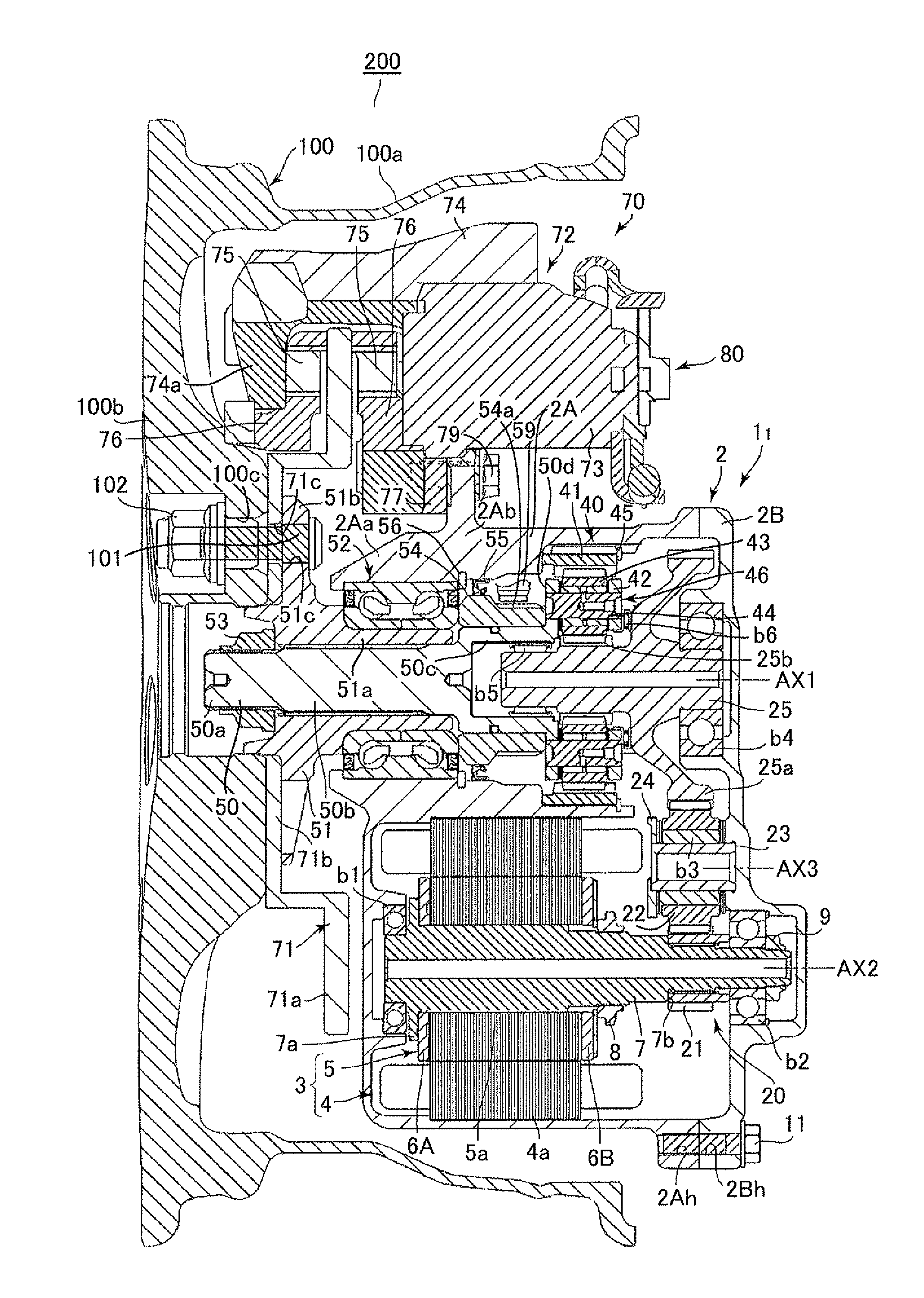

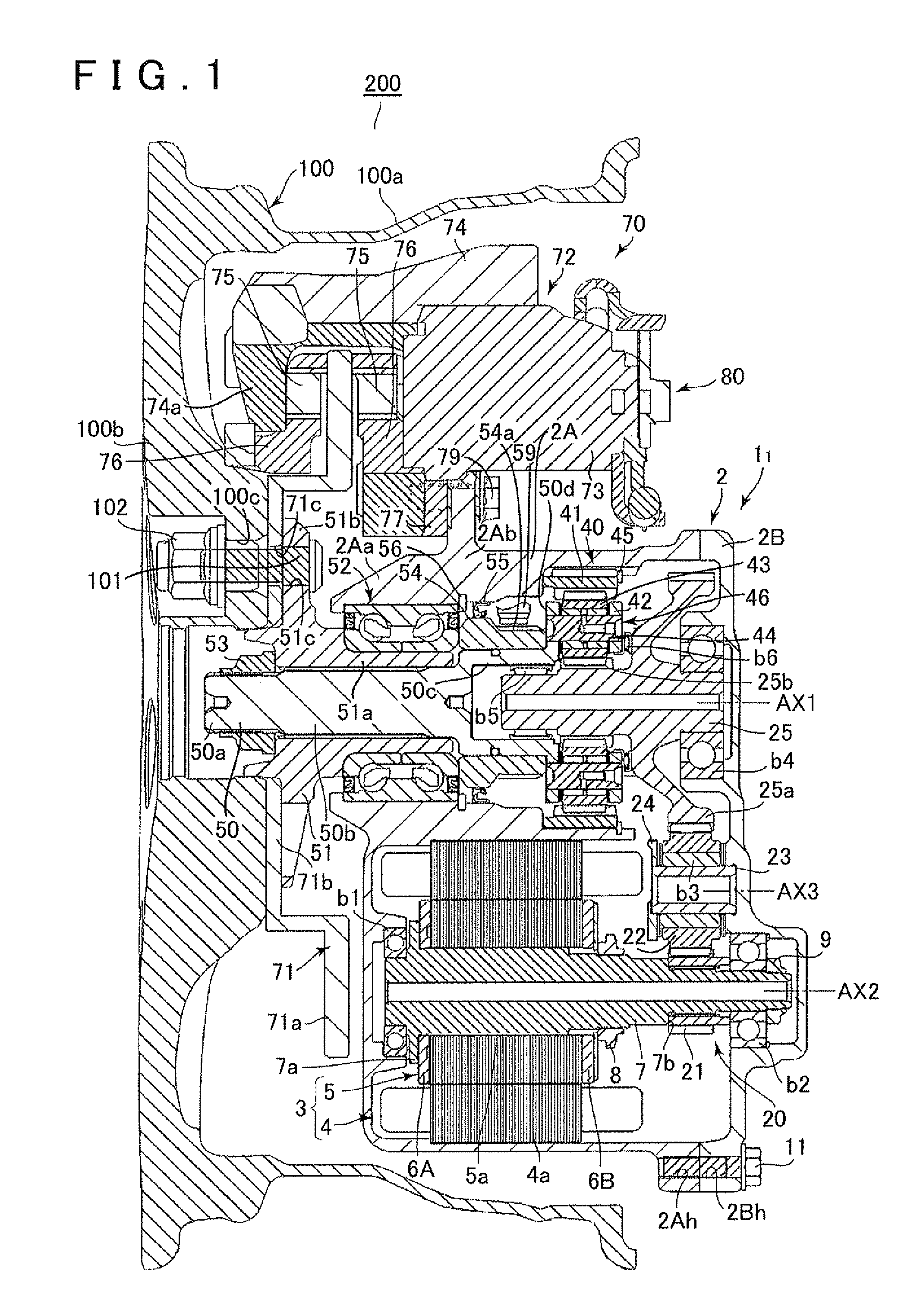

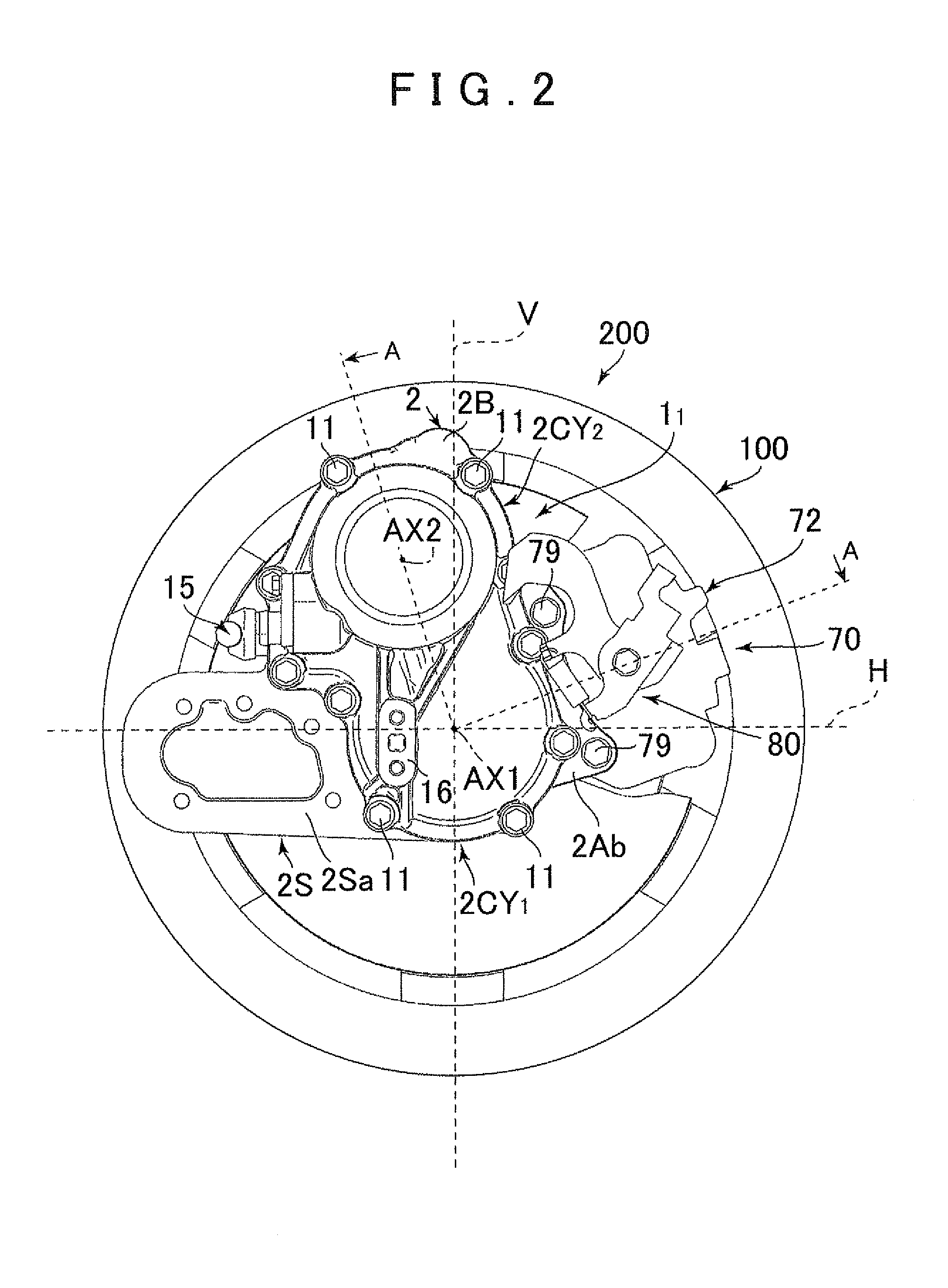

In-wheel motor drive device

ActiveUS8596395B2Increase axial lengthShorten the axial lengthSpeed controllerElectric devicesMotor driveElectric machine

An in-wheel motor drive device is attached to an inner side of a wheel of a vehicle wheel and drives the vehicle wheel. The in-wheel motor drive device includes a rotating electric machine; a transmission mechanism that transmits the rotation of the rotating electric machine; a speed reducing mechanism that reduces in speed the rotation transmitted by the transmission mechanism; and an output shaft that outputs the reduced-speed rotation of the speed reducing mechanism to the wheel. The speed reducing mechanism and the output shaft are disposed on a first axis coaxial with a center of the wheel. The rotating electric machine is disposed on a second axis parallel to the first axis, and the rotating electric machine and the speed reducing mechanism are positioned in a radial cross section perpendicular to the first axis and the second axis.

Owner:AISIN AW CO LTD

Installation structure for electric rotating machine in motor vehicle

InactiveUS7121367B2Strengthen restrictionsReduce designSuspensionsElectric propulsion mountingEngineeringFlange

An installation structure for an electric rotating machine such as an electric motor to a wheel of a motor vehicle. The installation structure comprises a wheel hub fixed to and rotatable with the wheel. A bearing through which the wheel hub is rotatably supported is provided. A suspension is installed between a vehicle body of the motor vehicle and the wheel. A bearing support member is connected to a wheel-side section of the suspension and supports the bearing. In the above installation structure, the electric rotating machine includes a power output shaft which is in fit with the wheel hub, and a flange for location of the electric rotating machine in a direction of axis of the power output shaft, the flange being brought into contact with a wheel-side section of the bearing support member.

Owner:NISSAN MOTOR CO LTD

Tubular articles with varying wall thickness and method of manufacturing same

Owner:AAM INT S A R L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com