Volume fluid machine and piston producing method thereof

A fluid machinery, volumetric technology, applied in liquid variable volume machinery, components of pumping devices for elastic fluids, rotary piston machinery, etc., can solve the problem of balance deterioration, increased pressure loss, short shaft rotation angle, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

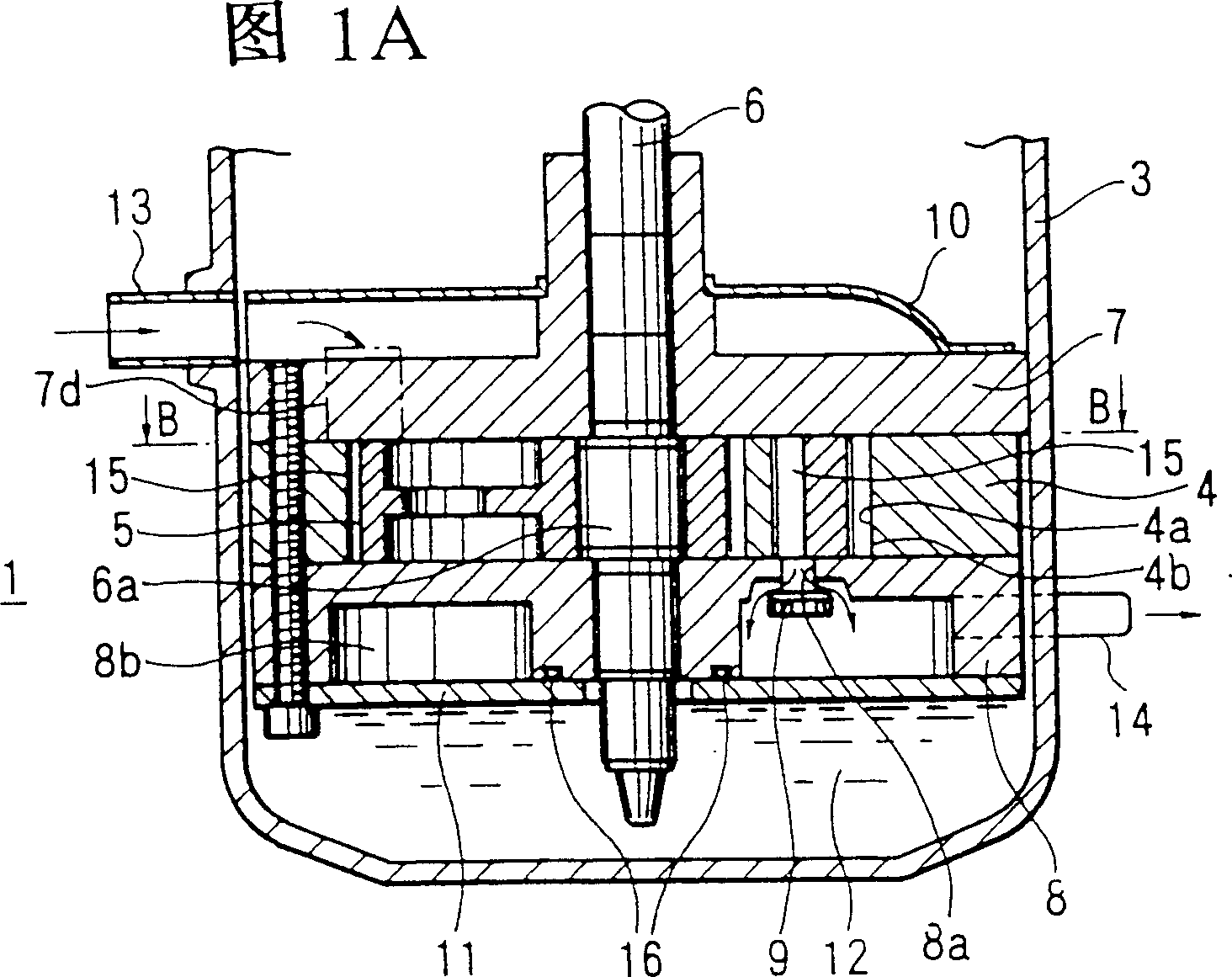

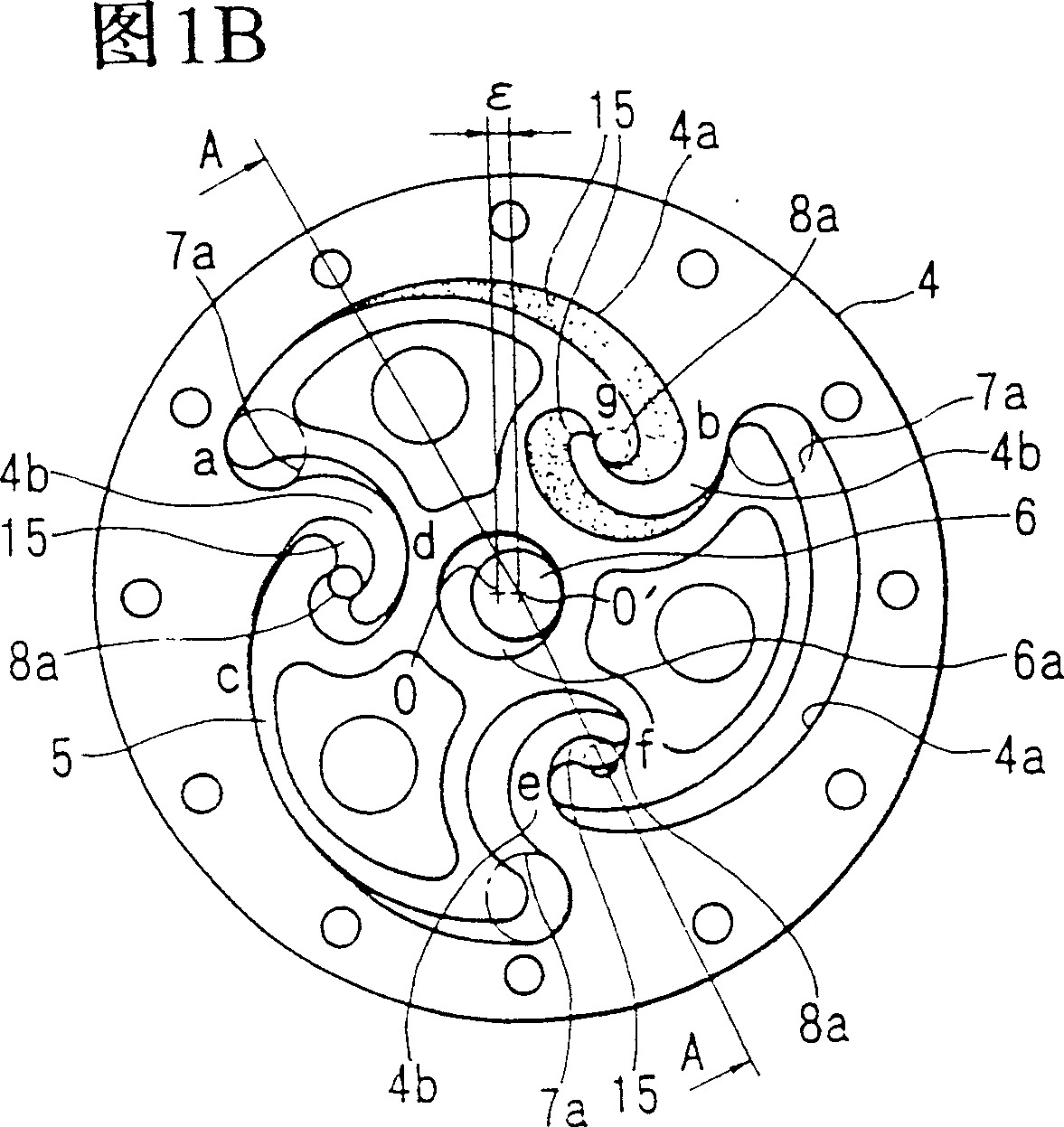

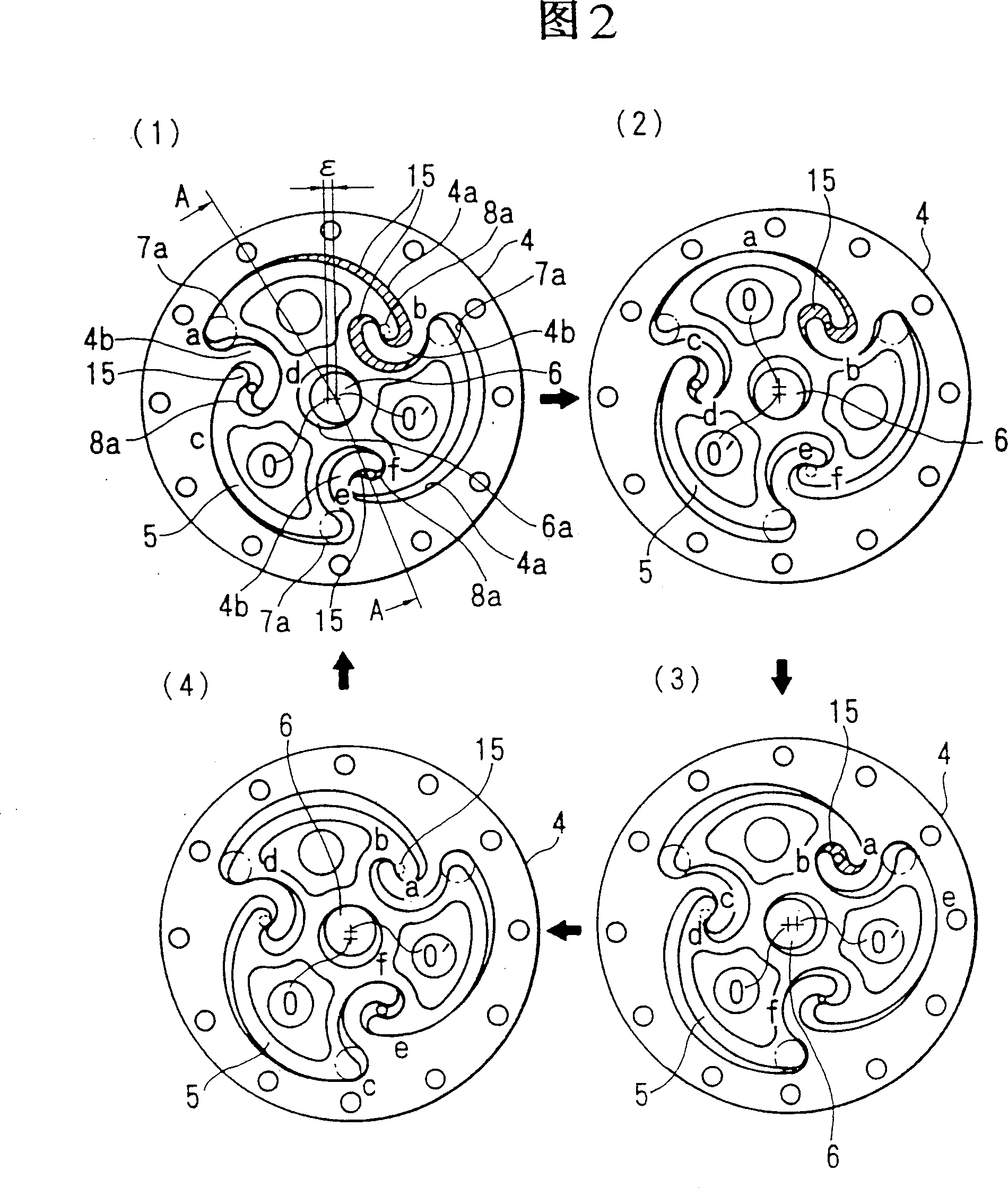

[0044] The characteristics of the present invention described above will be more clear through the following examples. An embodiment of the present invention will be described below with reference to the drawings. First, the structure of the rotary fluid machine of the present invention will be described using FIGS. 1 to 3 . Fig. 1 (A) is the longitudinal sectional view (the A-A sectional view of (B)) of the hermetic compressor when using the volumetric fluid machine of the present invention as a compressor, (B) is the B-B sectional view of (A), the figure 2 is a working principle diagram of a positive displacement compression mechanism, and FIG. 3 is a longitudinal sectional view of a hermetic compressor when the positive displacement fluid machine of the present invention is used as a compressor.

[0045] As shown in FIG. 1 , a volumetric compression mechanism 1 of the present invention and an electric mechanism 2 (not shown) for driving the compression mechanism are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com