Patents

Literature

170results about How to "Resolve friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

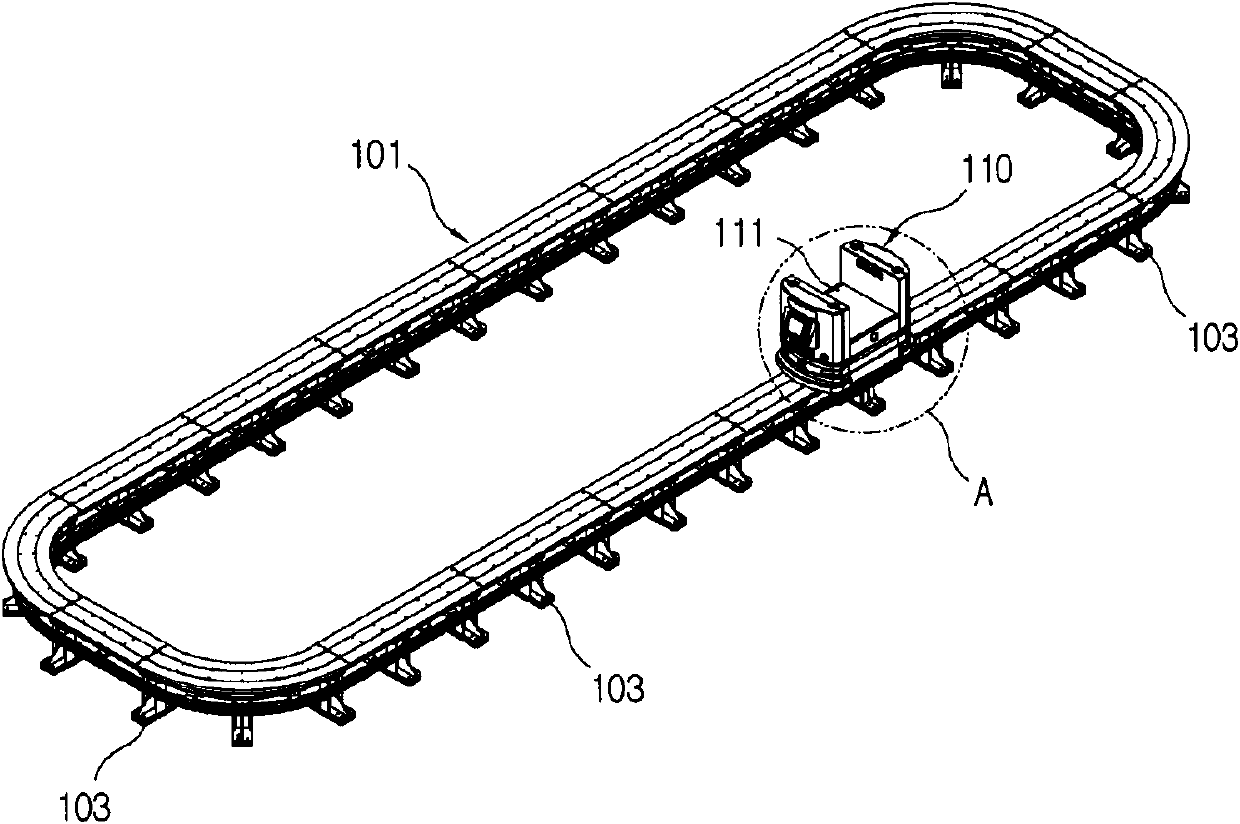

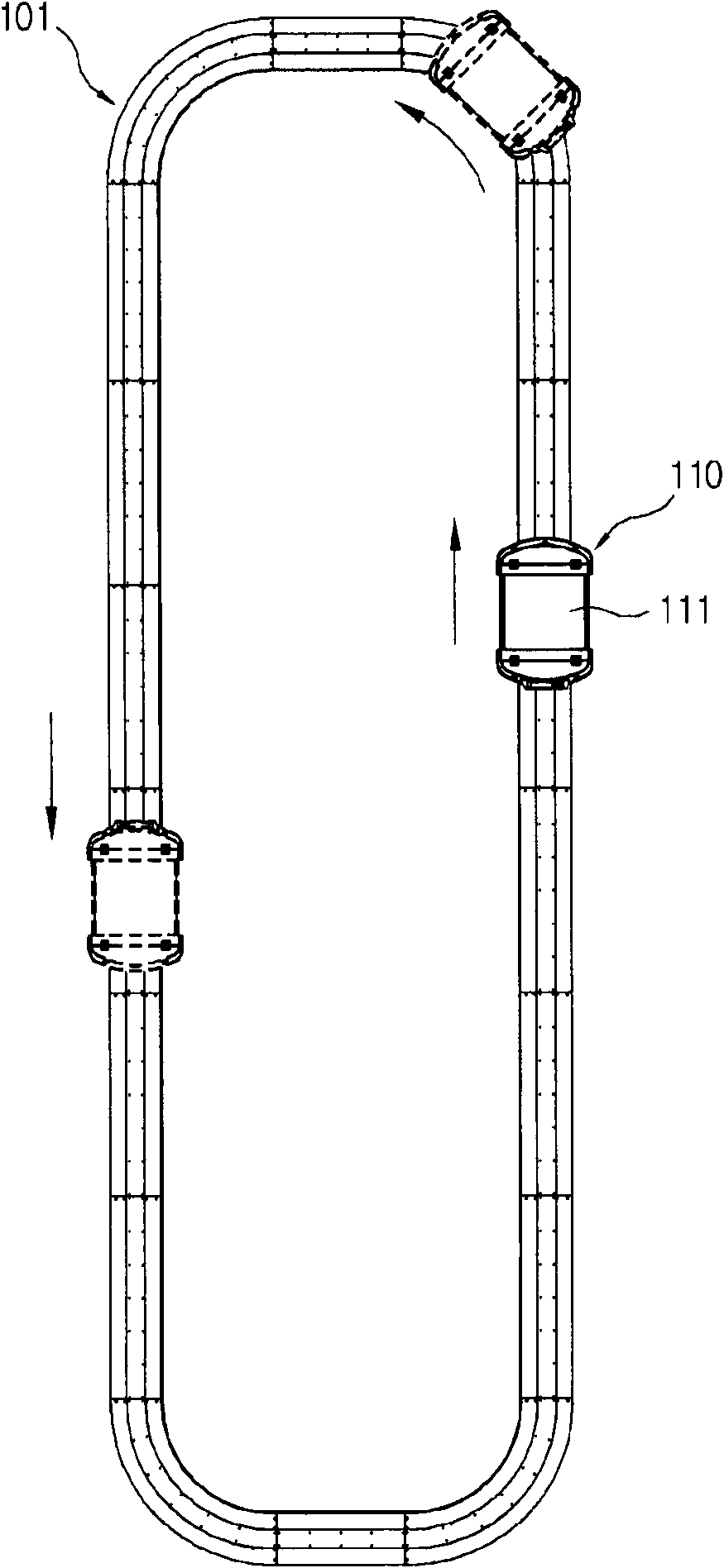

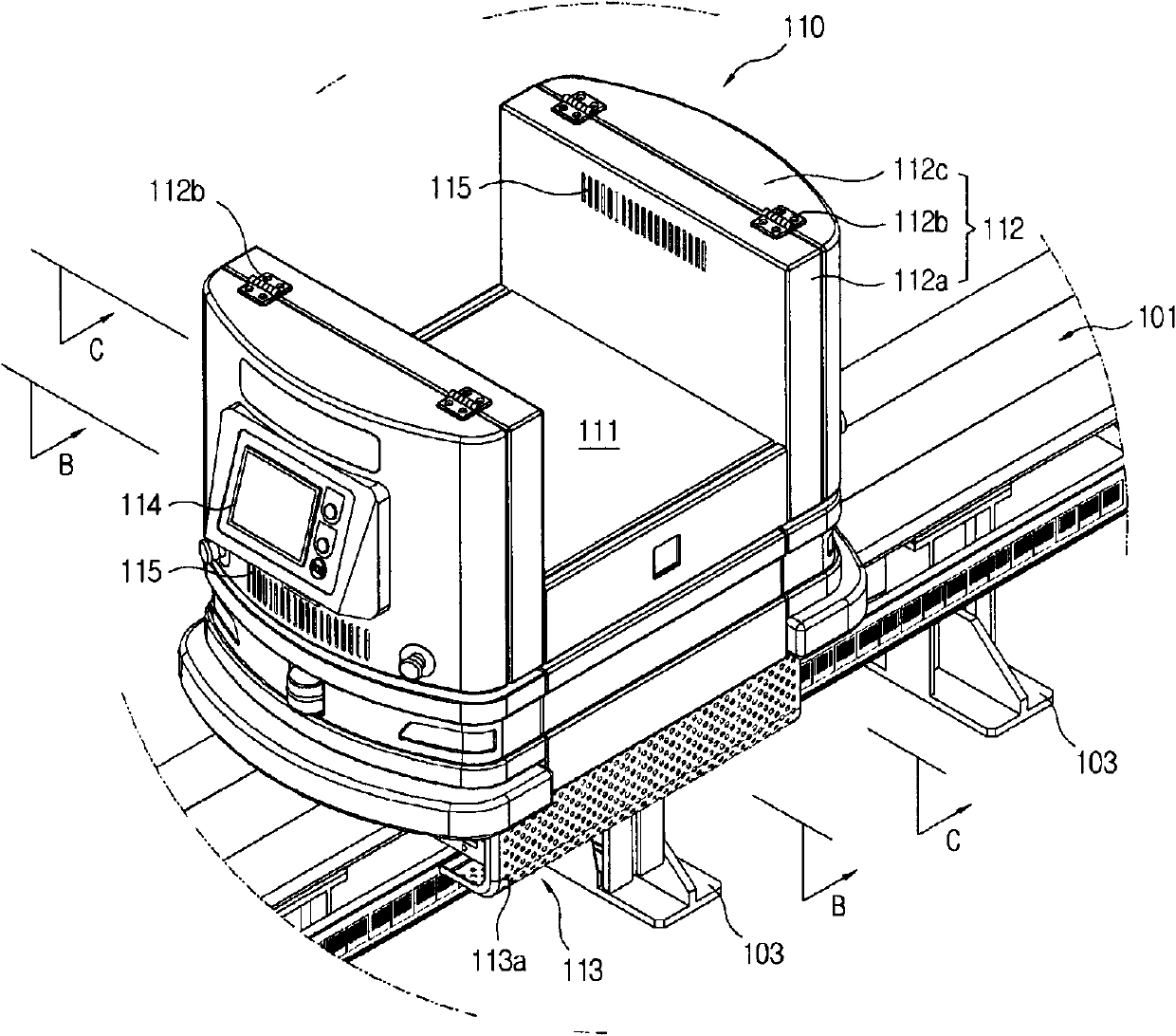

Magnetic levitation transferring system

InactiveCN102030192AStable structureAvoid vibrationNon-mechanical conveyorsNoise generationTransfer system

The present invention provides a magnetic levitation transferring system which comprises the following components: a loading unit which is loaded with object; a body transferring unit while the loading unit is coupled to the body transferring unit at one side; a rail which forms a line for transferring the body transferring unit; a levitating unit which is connected with the body transferring unit and causes the body transferring unit to levitate to a preset height relatively to the rail; a pushing unit which is connected with the body transferring unit and provides a pushing force for transferring the body transferring unit levitated by the levitating unit along the line of the rail; and a non-contact power source which receives power through a non-contact mode and supplies power for at least one in the levitating unit and the pushing unit. Through the configuration, a magnetic levitation technique is adopted in transferring object as one of the non-contact techniques thereby settling the problems of assembly damage caused by wearing and abrasion, noise generation and particle generation. Furthermore the power is supplied stably and safely while the object is transferred with a high speed.

Owner:SFA ENG CORP

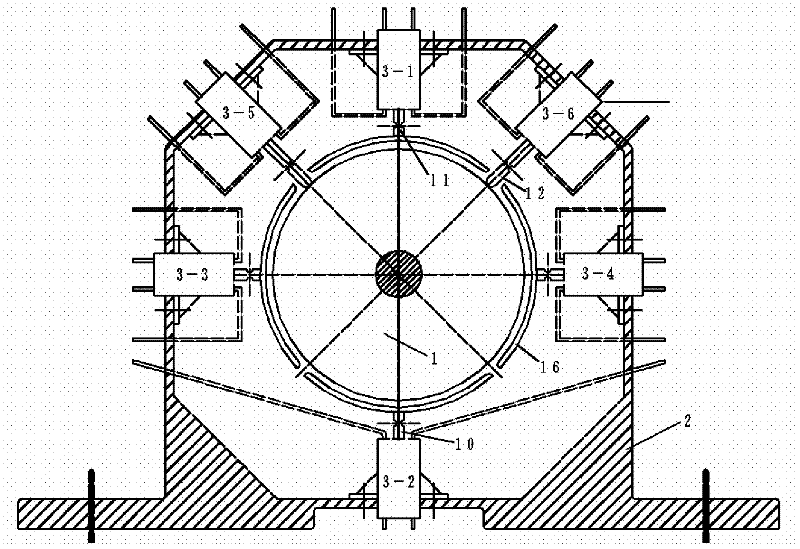

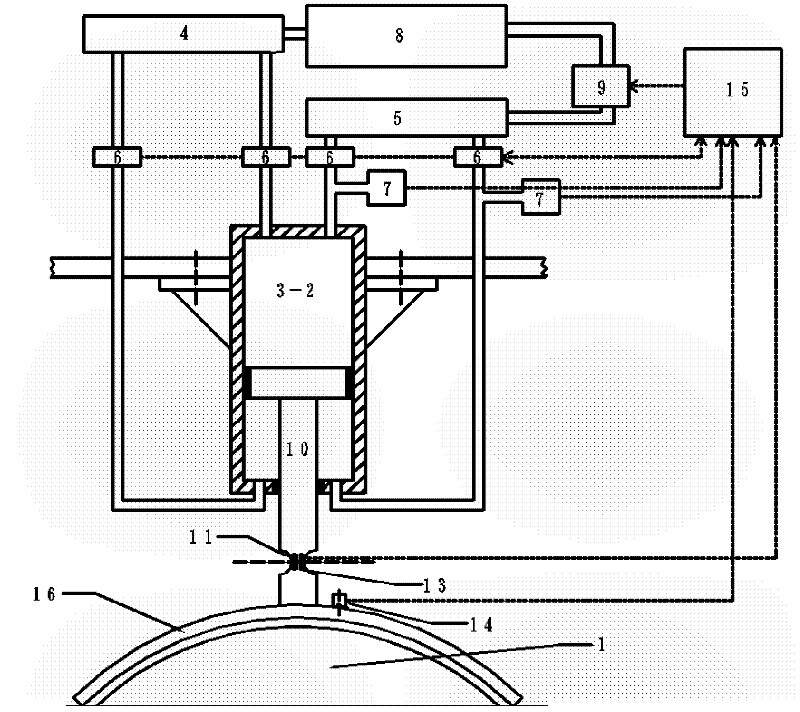

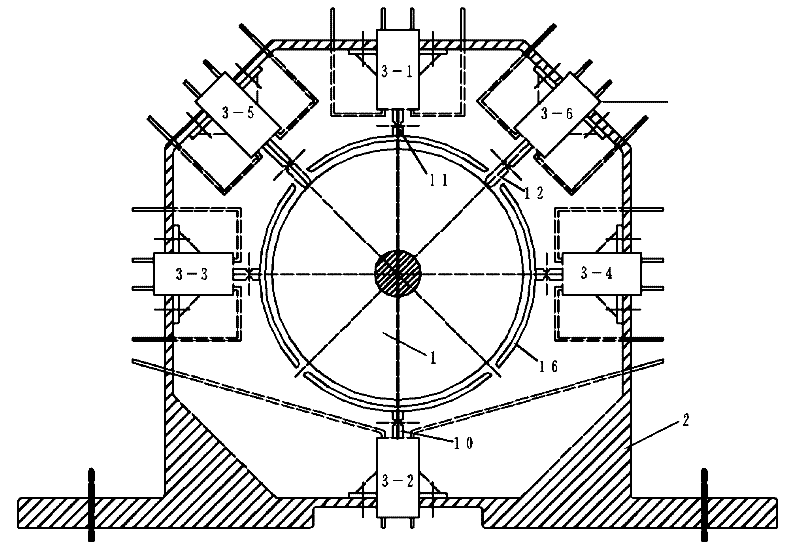

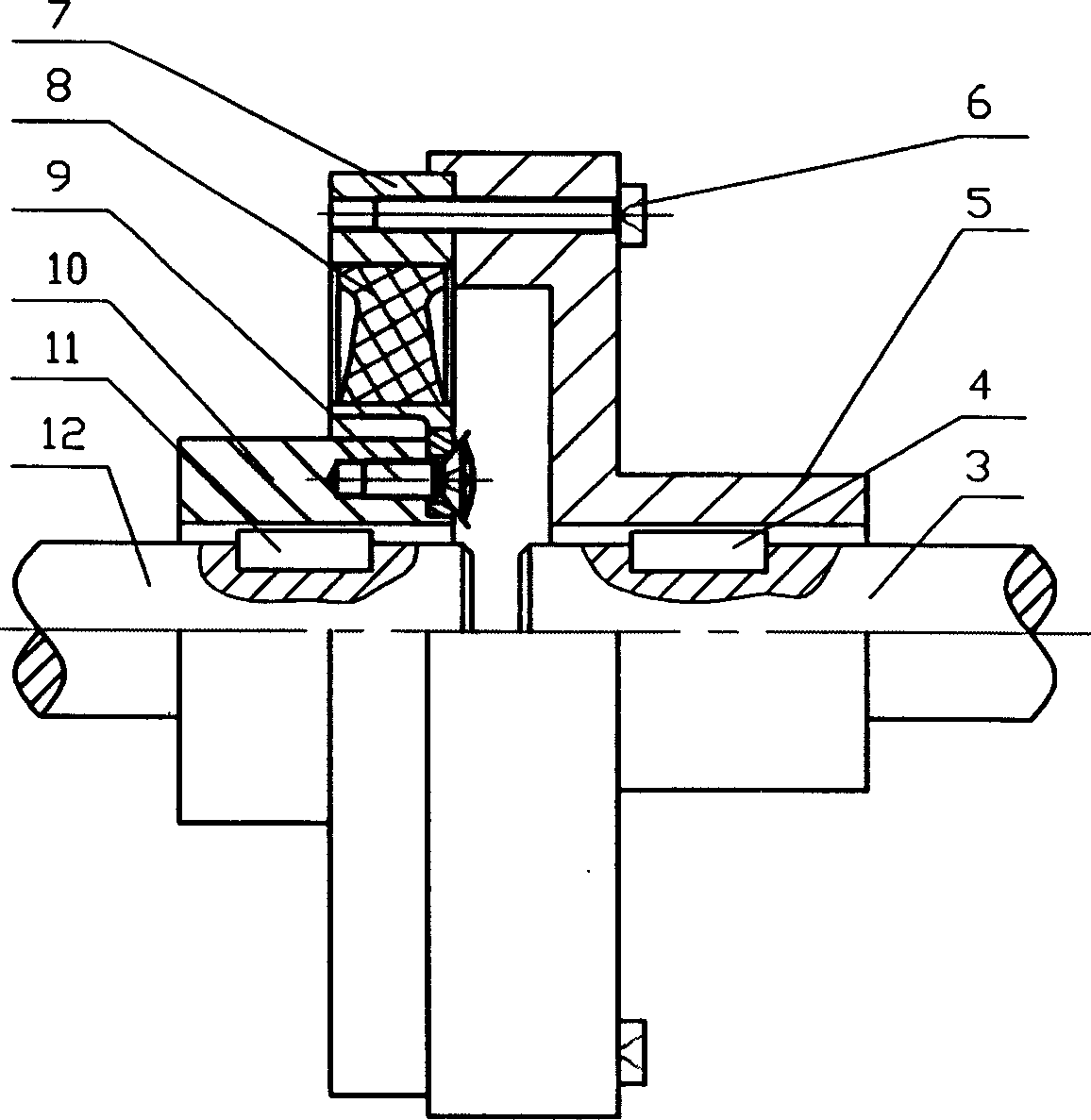

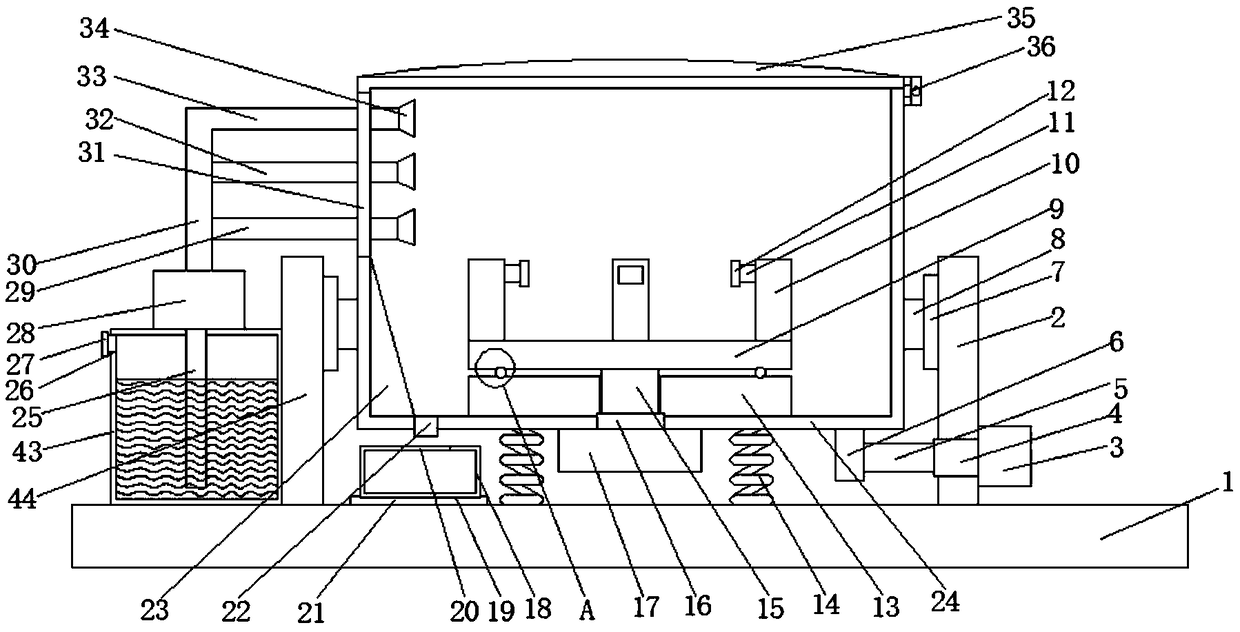

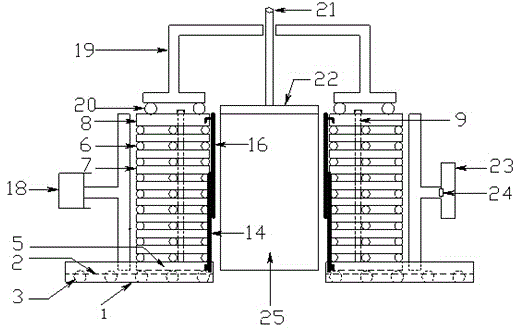

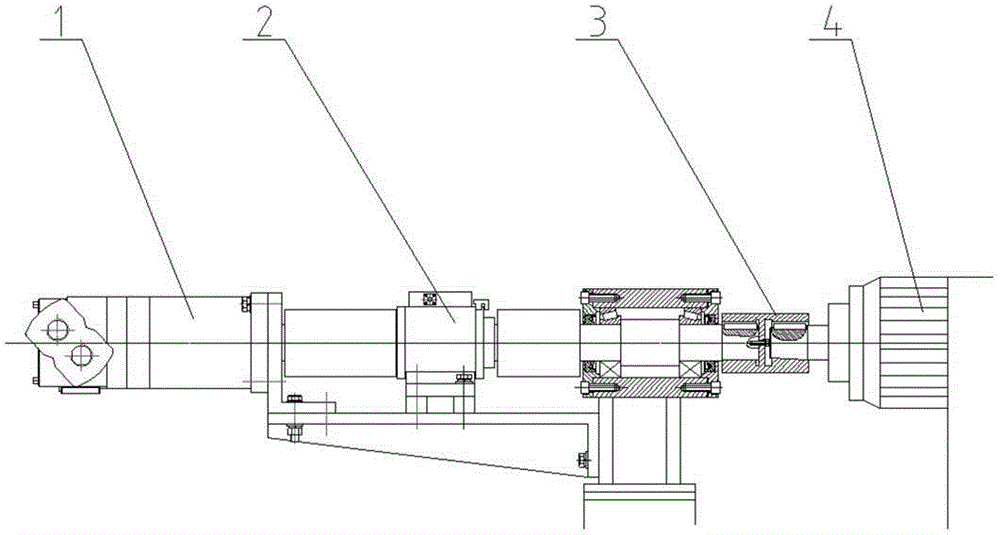

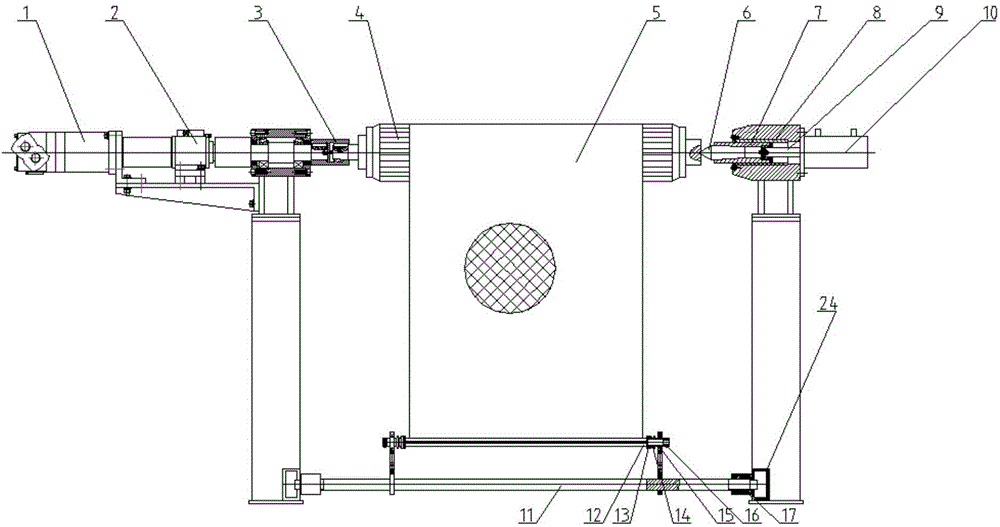

Active-control hydraulic type rub-impact fault detection test apparatus

ActiveCN102410929ASolve the problem of single rubbing failure stateIdeally control the degree of rubbing failureMachine part testingHydraulic cylinderEngineering

The invention discloses an active-control hydraulic type rub-impact fault detection test apparatus. The apparatus is characterized in that: six sets of hydraulic driving systems are arranged on a periphery of a rotor wheel disc; a first hydraulic cylinder and a second hydraulic cylinder are respectively arranged on a vertical direction of the rotor wheel disc; a third hydraulic cylinder and a fourth hydraulic cylinder are arranged on a horizontal direction; a fifth hydraulic cylinder and a sixth hydraulic cylinders are arranged at a positive / negative 45 degree direction of an upper half disc of the rotor wheel disc; the each hydraulic cylinder is provided with a hydraulic oil return tank and a constant voltage tank; inlet and outlet pipelines of the hydraulic oil return tank and the constant voltage tank are respectively provided with an electromagnetic pressure regulating valve and a pressure sensor; an oil pump, a piston connecting rod, an elastic hinge, a strain gauge and a rub-impact column, which are successively connected, are arranged between the oil tank and the constant voltage tank; in order to simulate different rub-impact states, the rub-impact column which is at the positive / negative 45 degree direction is directly contacted with the periphery of the rotor wheel disc. Rub-impact pieces at the horizontal and vertical direction contact with the periphery of the rotor wheel disc. A measurement and control computer can calculate and control a pressure applied by a rub-impact part and a stress state so as to achieve a purpose of simulating and detecting a pluralityof rub-impact fault states.

Owner:TIANJIN UNIV

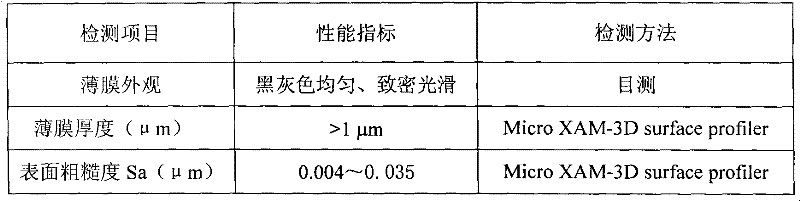

Preparation method of composite coating used for gas bearing

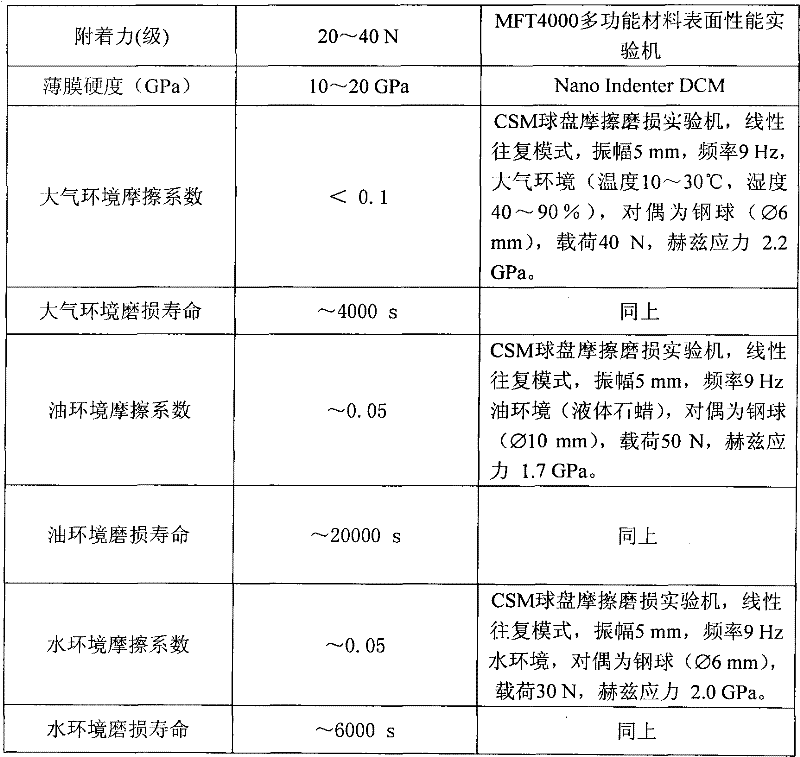

InactiveCN101798679AResolve frictionHigh hardnessVacuum evaporation coatingSputtering coatingIntermediate frequencyHardness

The invention discloses a preparation method of a composite coating used for a gas bearing, which adopts a mid-frequency reactive magnetron sputtering system to deposit a Ti / AlTiN / Ti: DLC high- hardness and high-abrasion-resistance composite membrane. The smaller the friction coefficient between a rotor and a stator of the dynamic gas bearing is, the better to the starting of a motor, and in the high-speed rotation process, the stator and the rotor can possibly collide with each other or even have instant melting lock faults. The dynamic gas bearing made of single material can not satisfy the current requirements, and the surface modification technique of the bearing material is the key technology that limits the application of the dynamic gas bearing. The coating prepared through the method reduces the friction coefficient, improves the abrasion resistance and at the same time solves the problems of corrosion resistance and abrasive resistance of the coating. The preparation method is easy to realize and all the materials are common, so the preparation method can realize industrial production.

Owner:UNIV OF SCI & TECH BEIJING

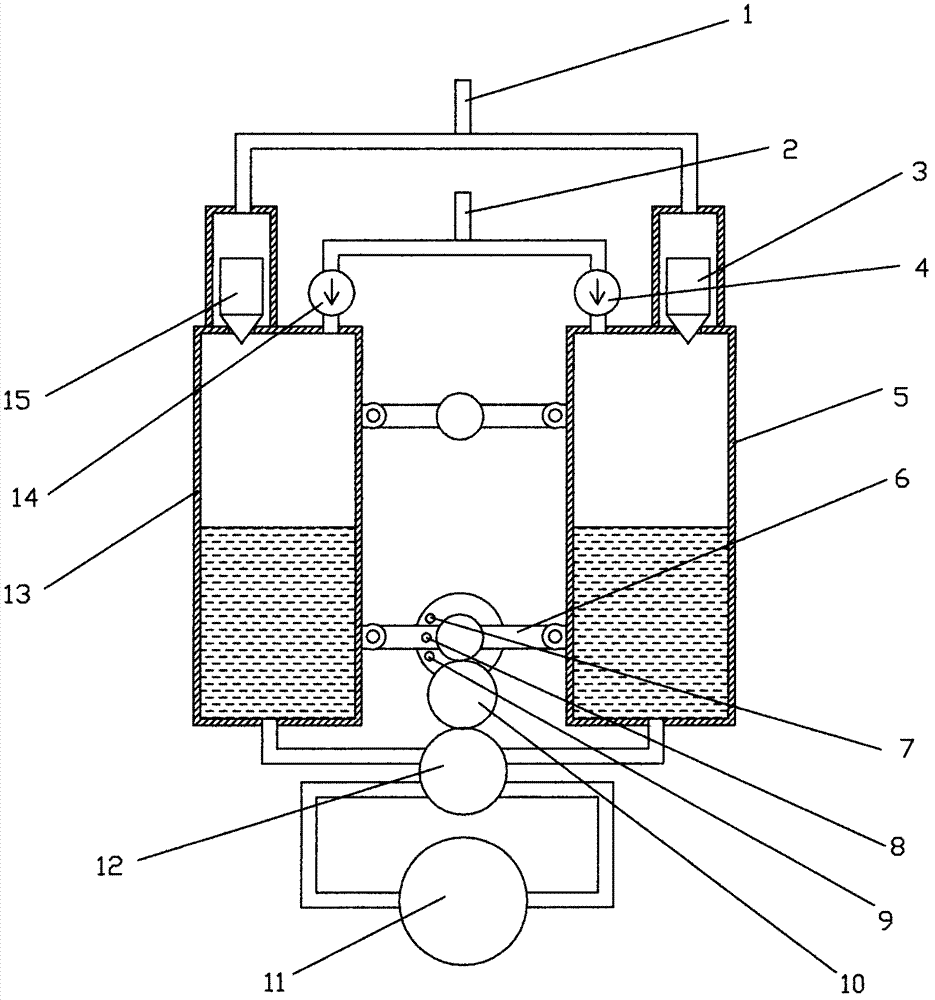

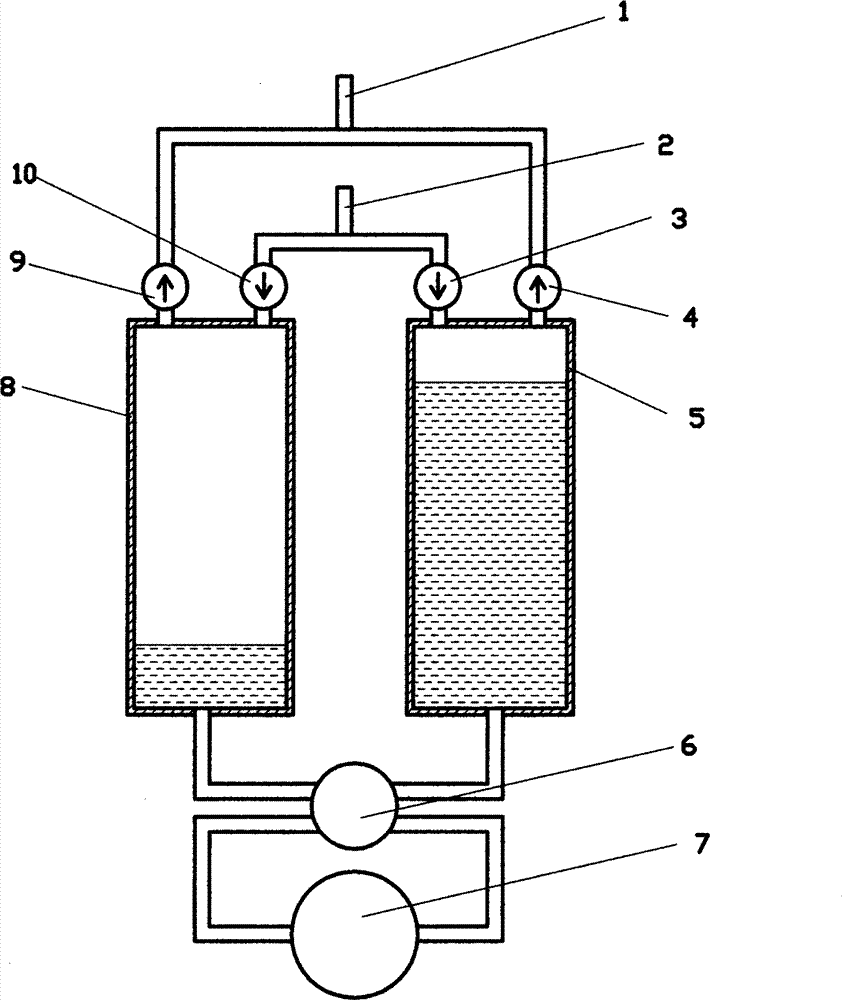

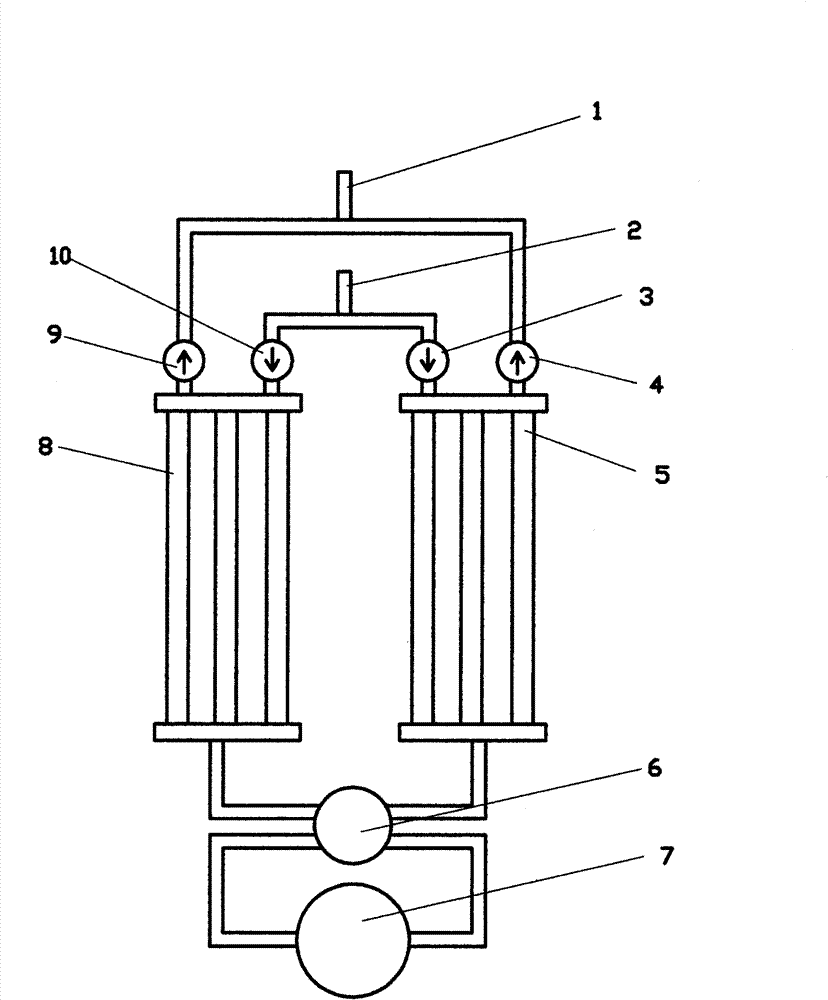

Liquid piston compressor

InactiveCN103195684AResolve frictionSolve wear and tearPositive displacement pump componentsPositive-displacement liquid enginesEngineeringCheck valve

The invention discloses a liquid piston compressor, which comprises a cylinder, pressure transmission liquid, a pump, a check valve, a buoyancy check valve, a selector valve, a lever and a transmission mechanism; the liquid piston compressor adopts the pump to drive the liquid to rise or drop in the cylinder, so that the conventional piston movement is replaced for realizing the suction and the exhaust of the cylinder; as the friction between the liquid piston and the cylinder wall is much smaller than the friction of a solid piston against the cylinder wall, the efficiency is improved and the service life is prolonged; besides, the liquid piston and the cylinder can be fabricated to be a parallel structure with a plurality of tiny pipes, so that the problem in the conventional cylinder that heat dissipation is difficult to carry out due to high cylinder diameter is solved; and the production cost is lower.

Owner:时剑

Float sealing structure for water-saving automatic washer

InactiveCN1548613AResolve frictionSolve the noiseEngine sealsOther washing machinesWater savingEngineering

The float sealing structure for water-saving automatic washer includes sealing hood, tray, draining cavity comprising outer tub, sealing hood and tray, and sealing part. It features that the sealing part is made of elastic material and has through hole in the center, outer edge and inner edge around the through hole. Of the edges, one is fixed and connected hermetically with the sealing surface, and the other is suspended with one protrudent lip for pressing the sealing surface under the action of buoyancy. The central through hole of the sealing part is jacketed onto the dewatering shaft, and the sealing part has at least one ring water pressure action surface to form end sealing under the action of the buoyancy of the water draining cavity.

Owner:叶小舟

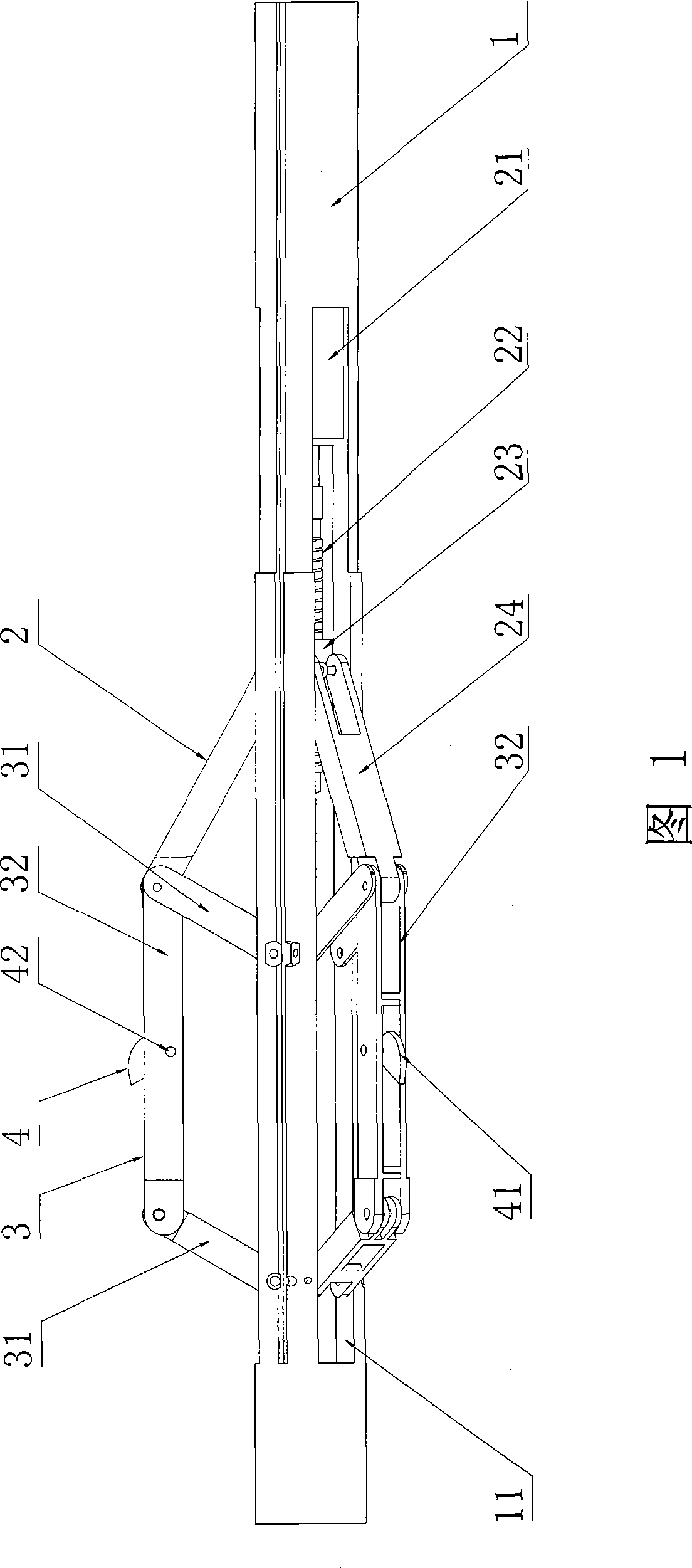

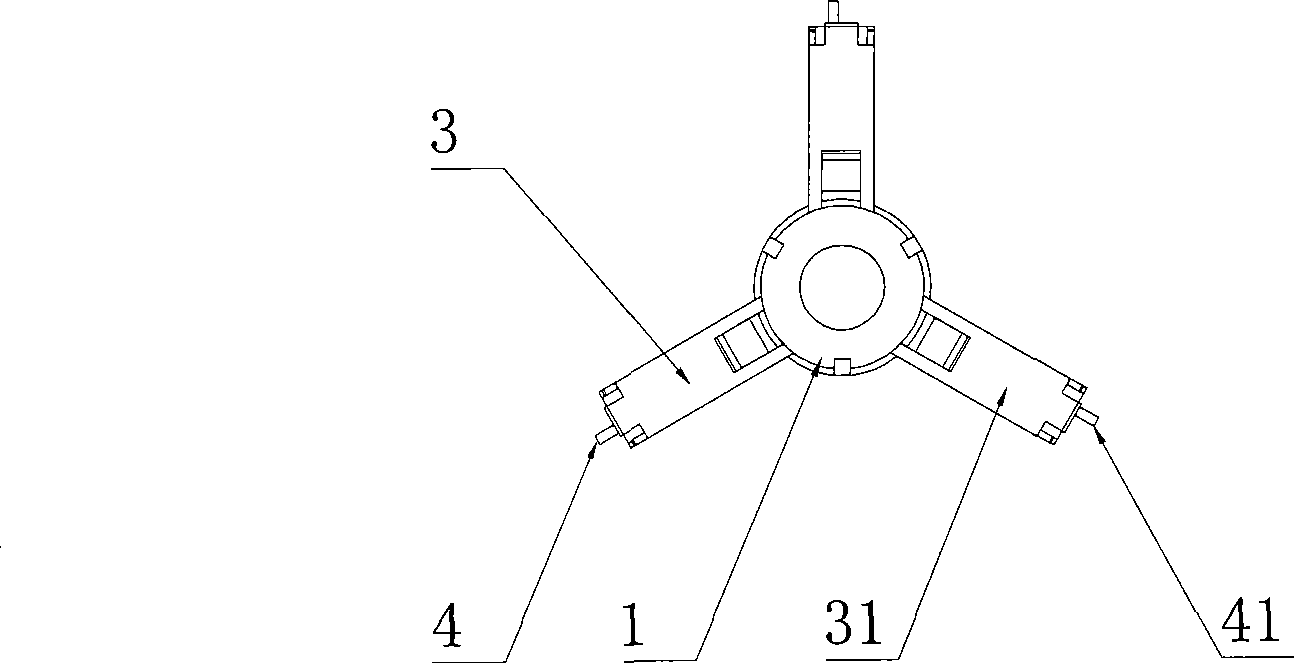

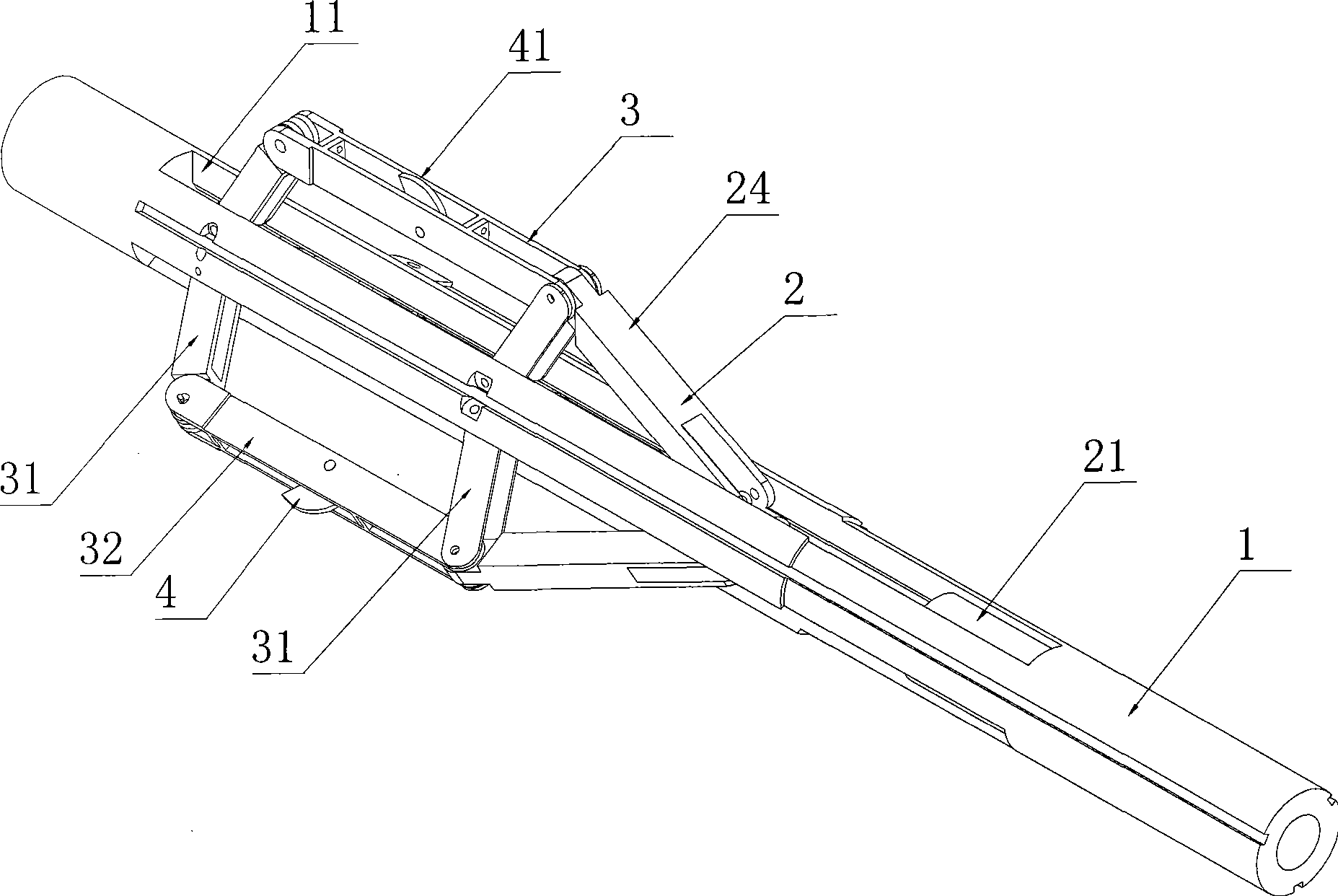

Movement mechanism of cam type pipe robot

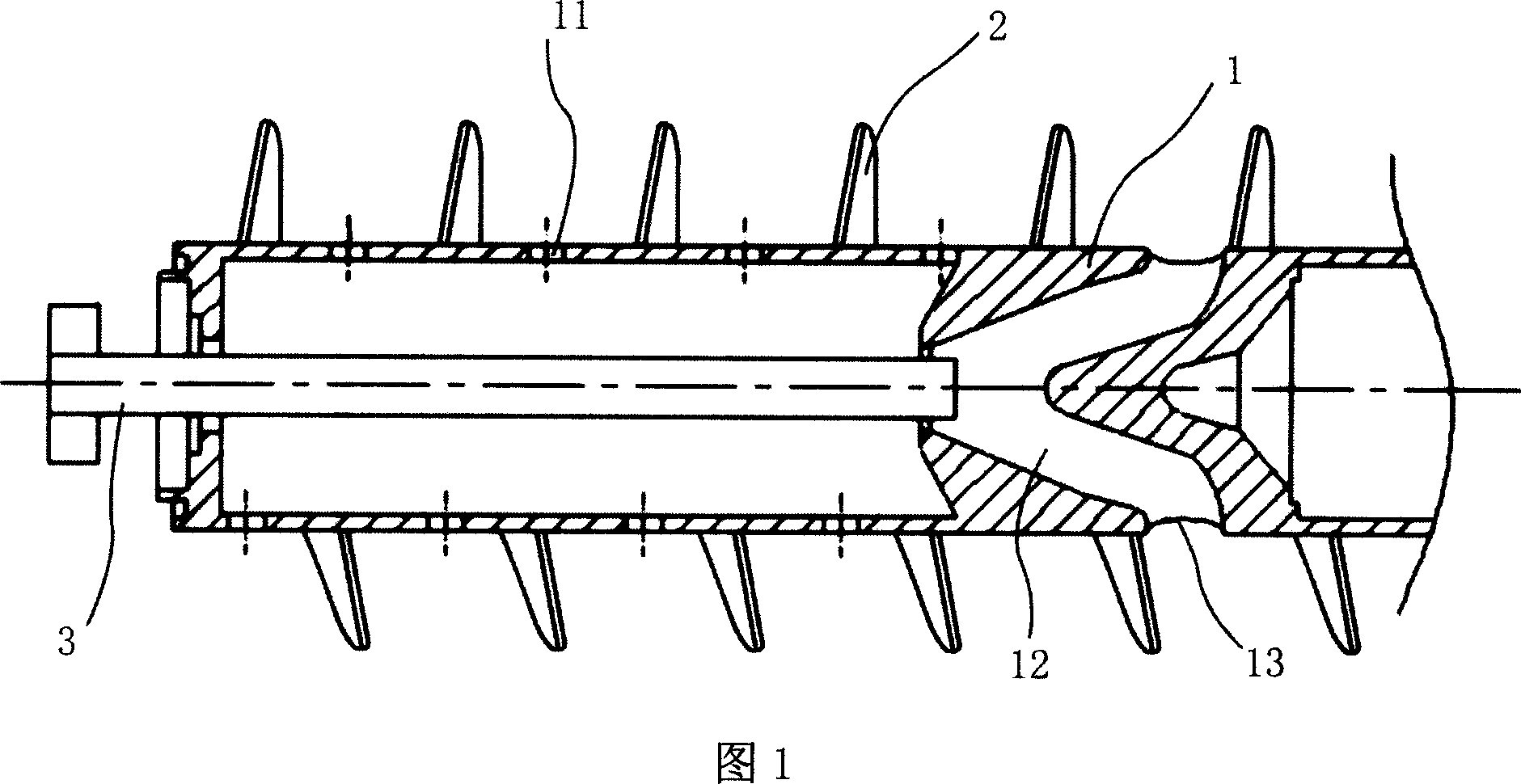

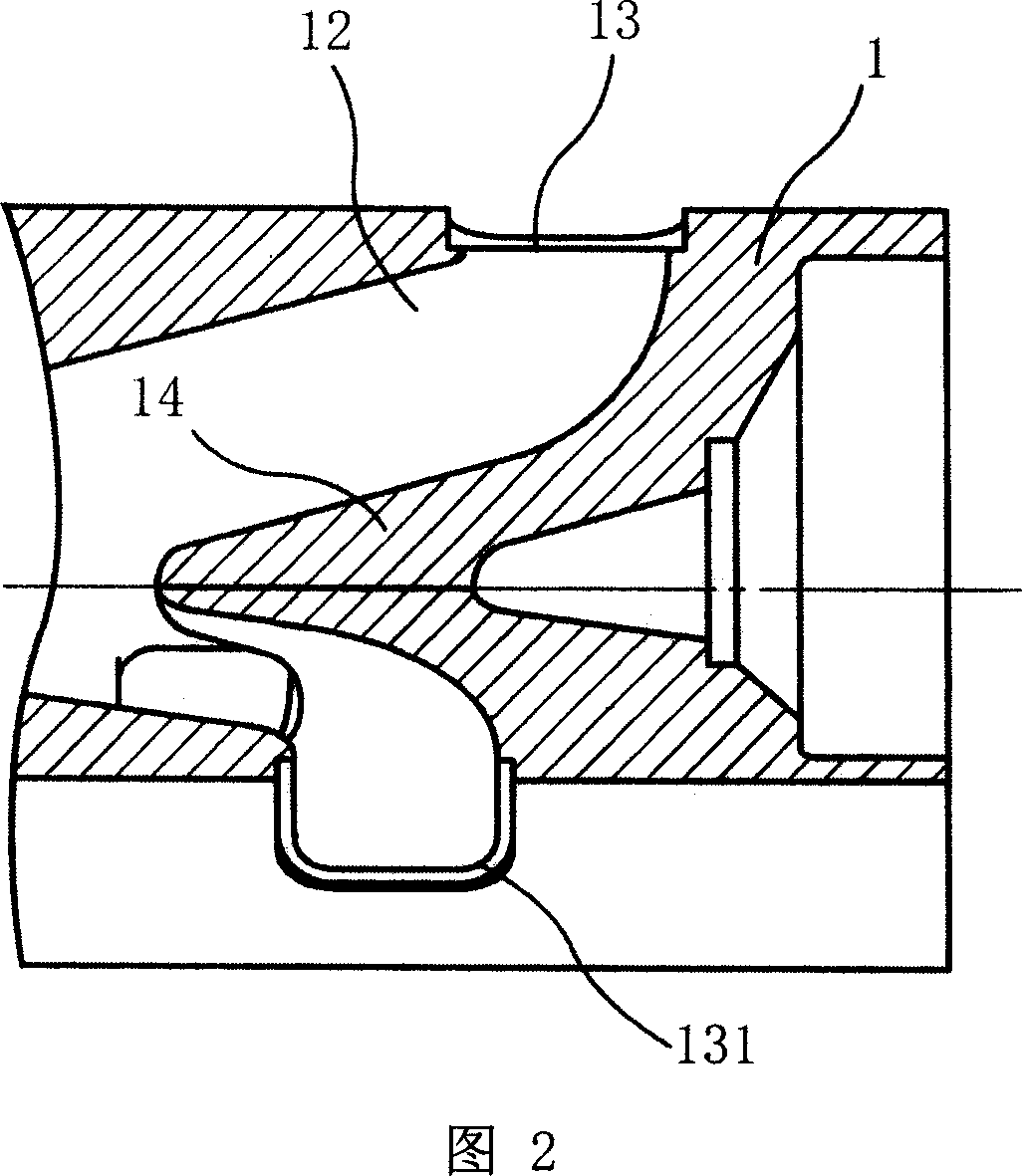

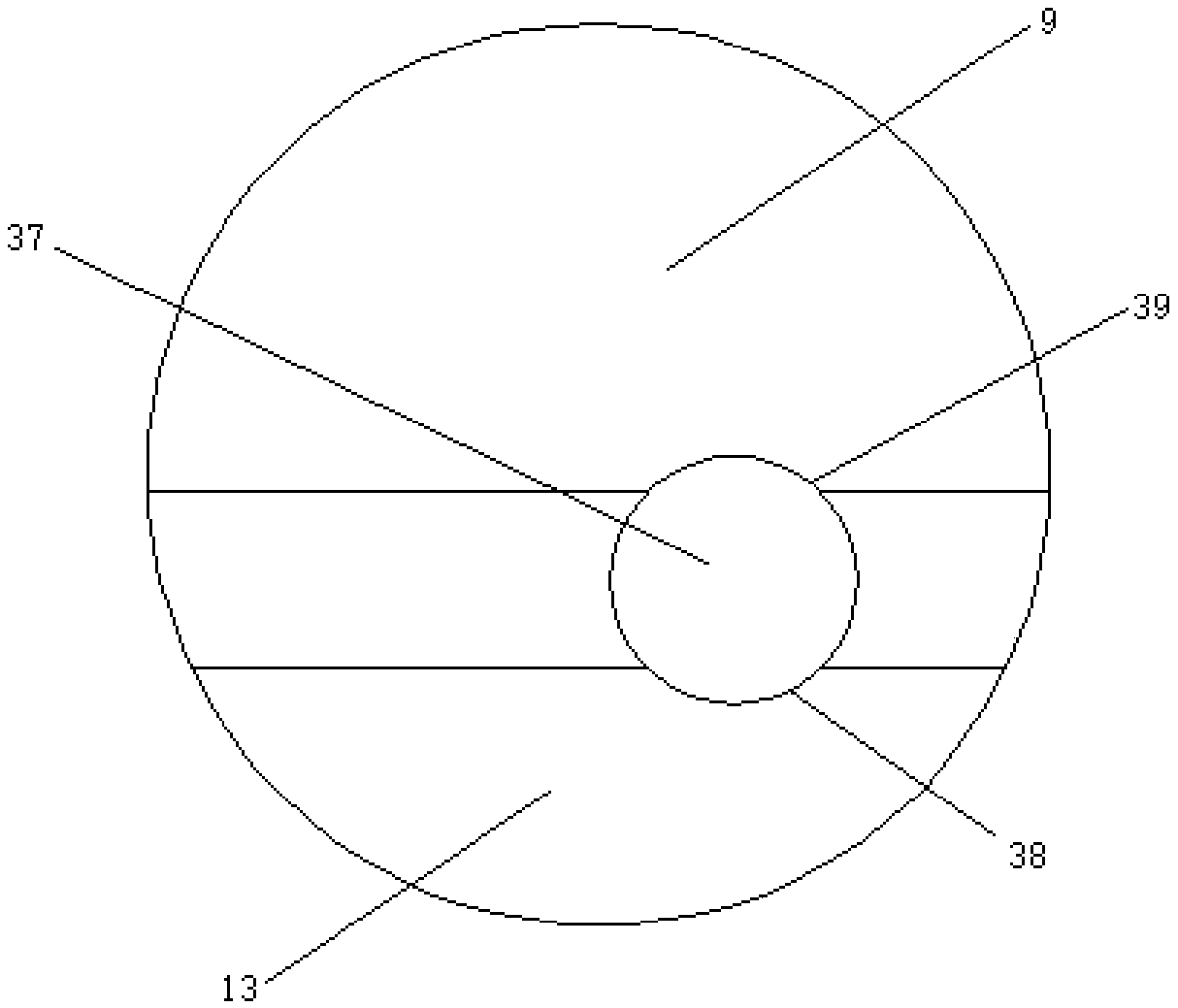

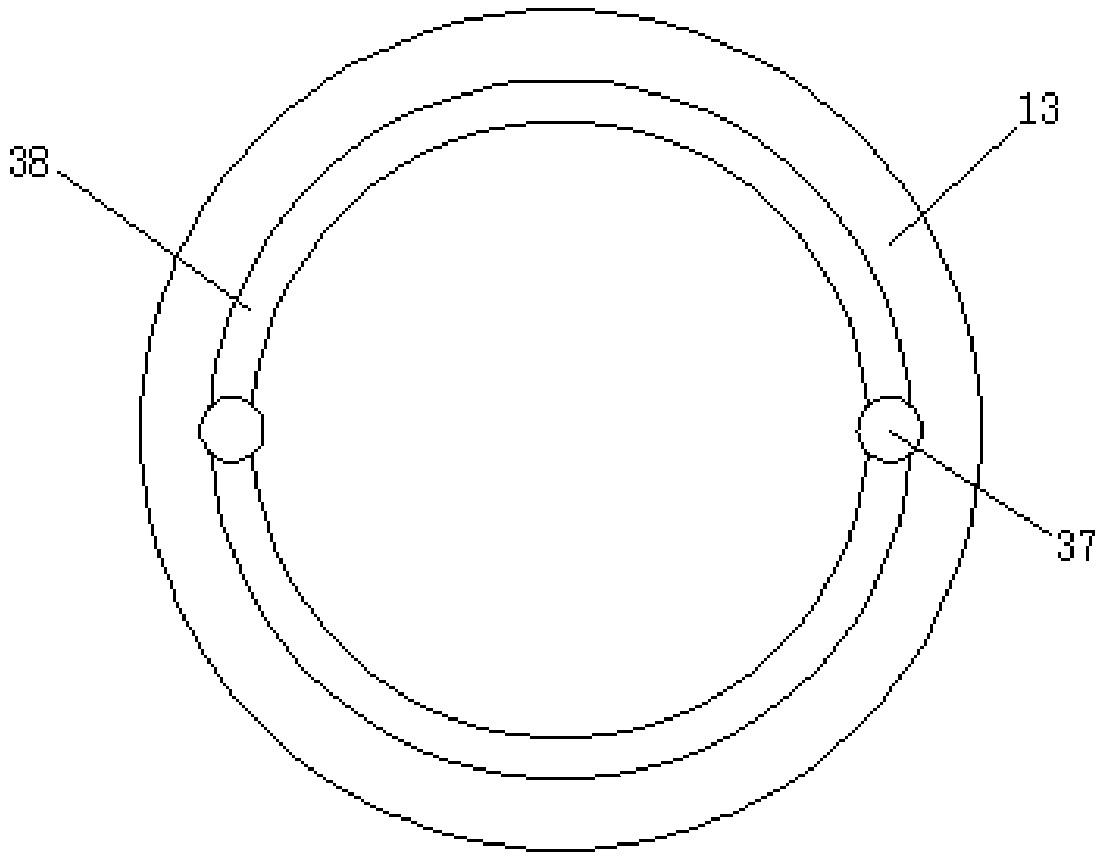

The invention discloses a cam type pipeline robot moving mechanism which includes a cylinder bracket that is provided with three groups of parallelogram four bar linkages arranged along the circumferencial direction in an equidistant way and a drive mechanism used for driving the three groups of parallelogram four bar linkages to unfold or furl, wherein, each of the parallelogram four bar linkages comprises two rockers and a connecting rod connected between the two rockers which are respectively articulated with the cylinder bracket, and one of the rockers is connected with the drive mechanism; the middle part of the connecting rod is provided with a cam mechanism that comprises a cam, a pin roll and a torsional spring arranged on the pin roll, wherein, the cam is articulated in the middle of the connecting rod by the pin roll, one end of the torsional spring is fixedly connected with the connecting rod, and the other end is fixedly connected with the cam; the cam keeps to extend out of the connecting rod under the action of pretightening force of the torsional spring. The device utilizes the self-locking of the cam to improve the pulling capacity and uses the deformation of the parallelogram four bar linkages for enhancing the adaptive capacity for pipe diameter change.

Owner:NAT UNIV OF DEFENSE TECH

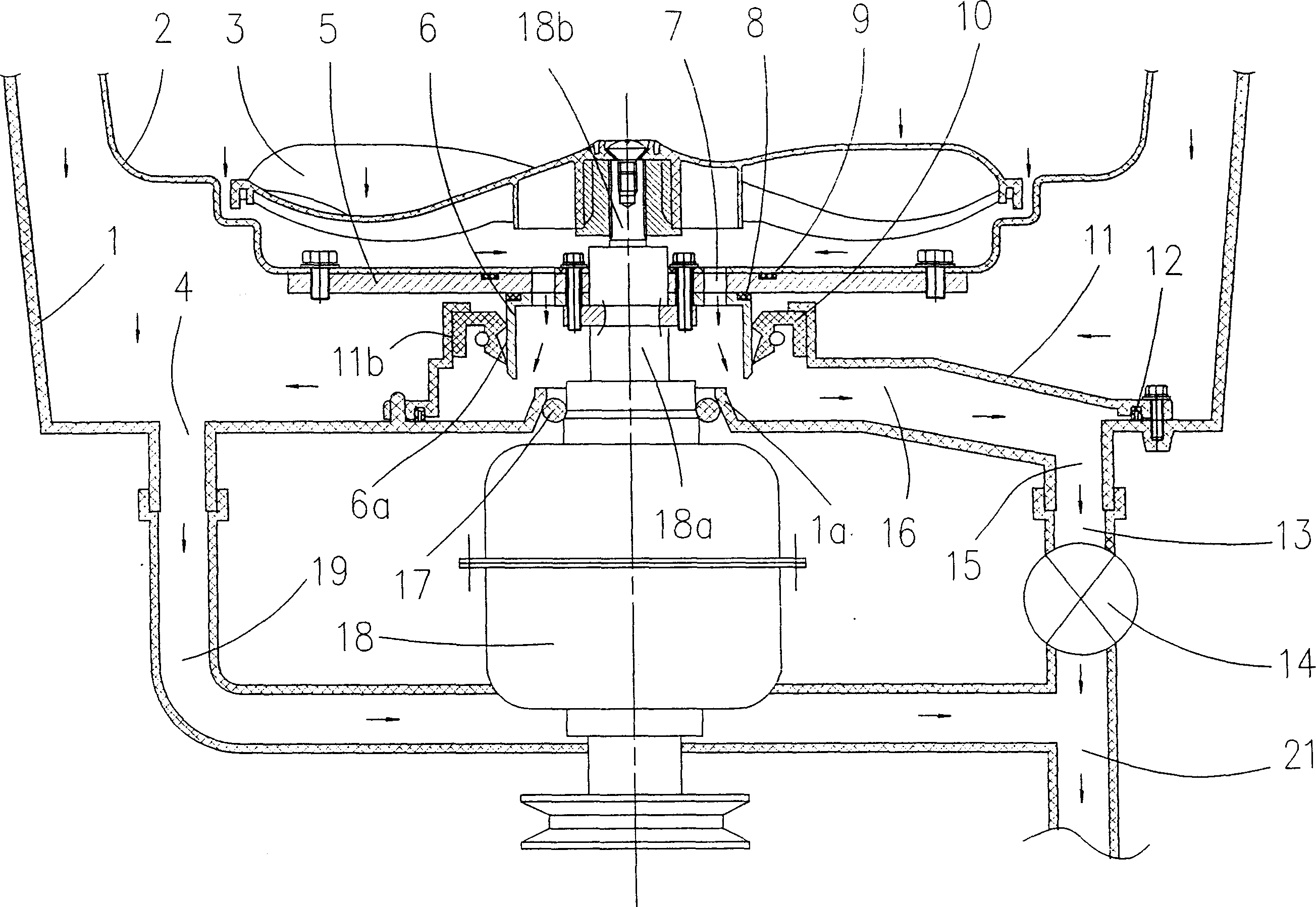

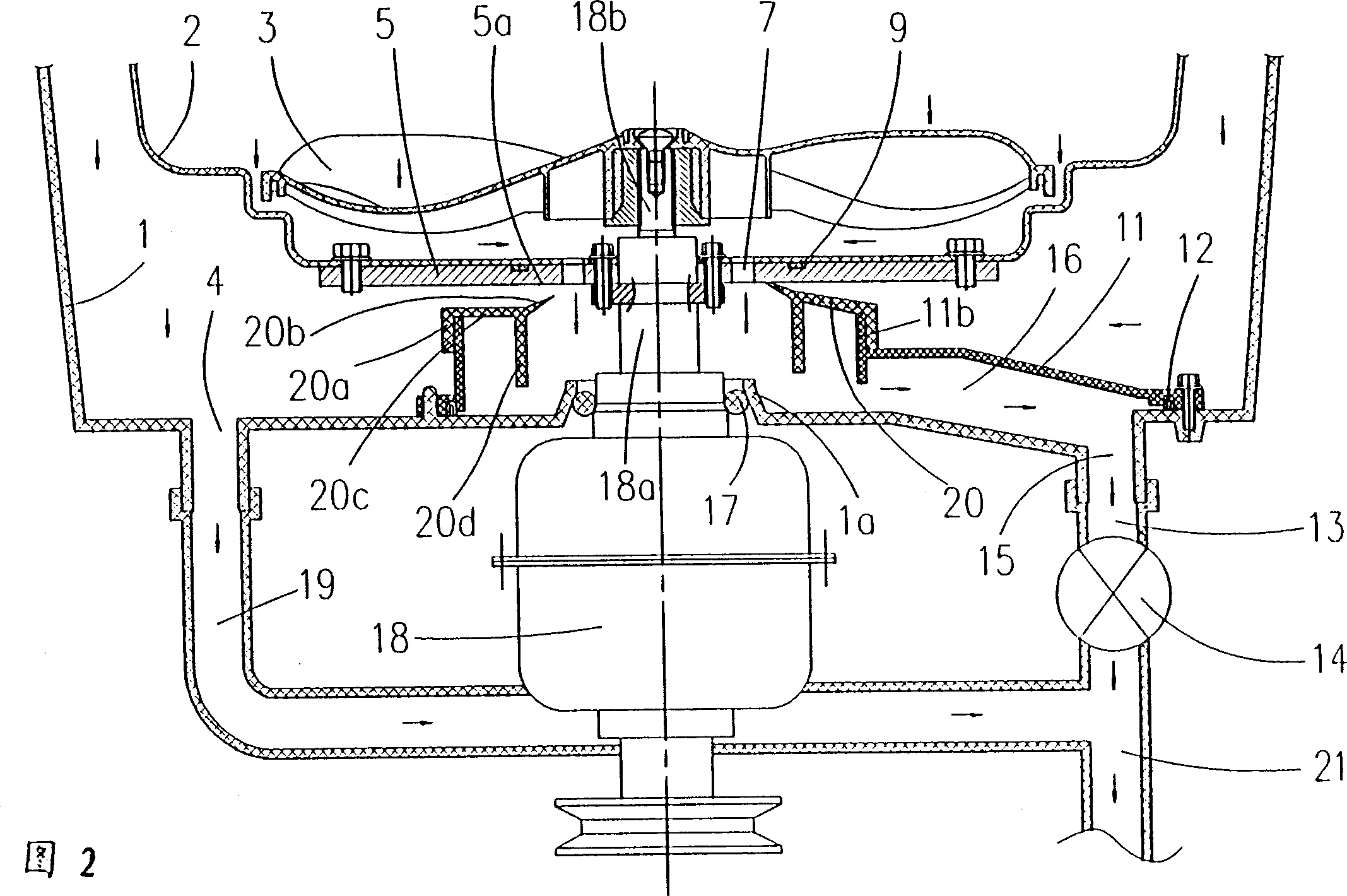

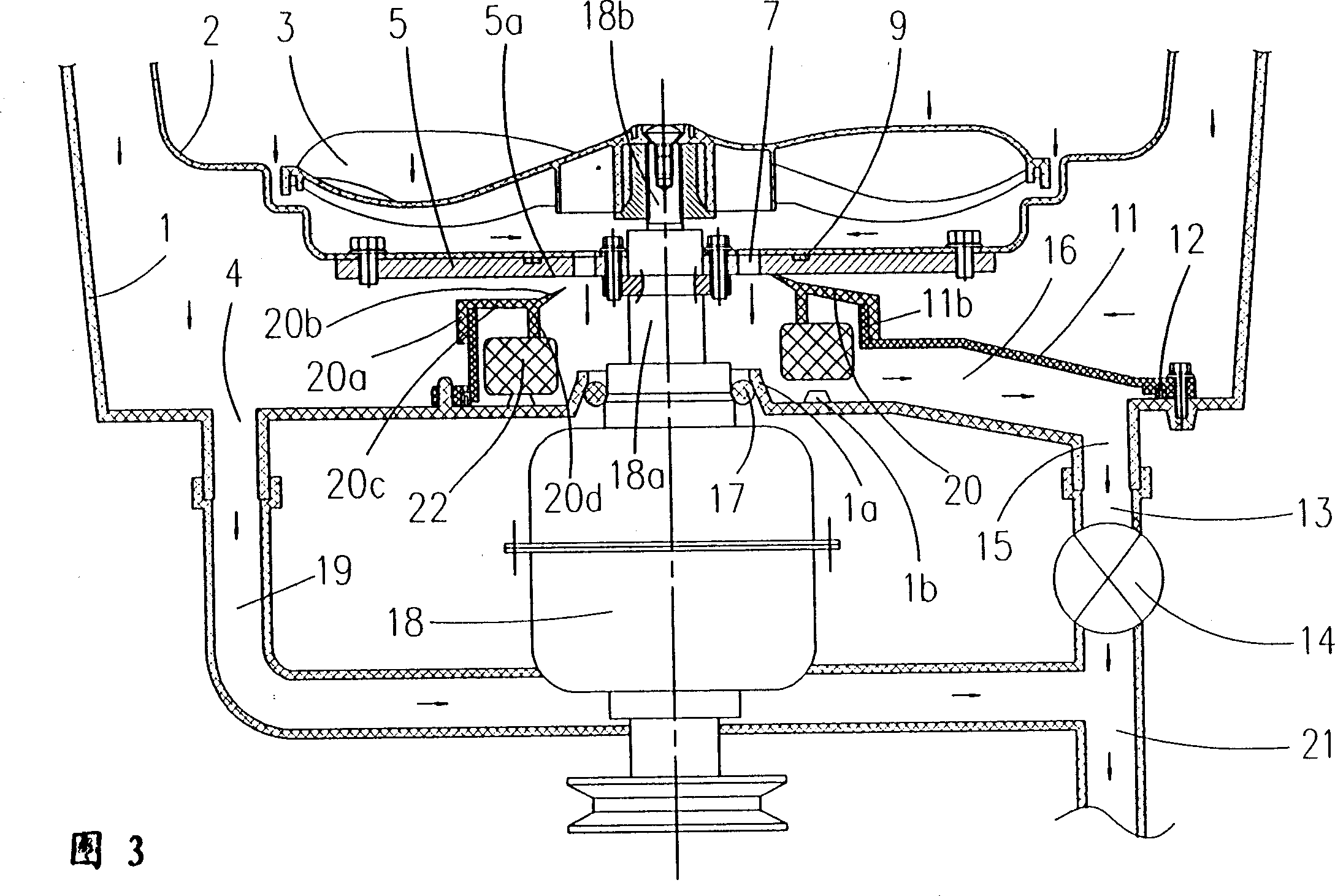

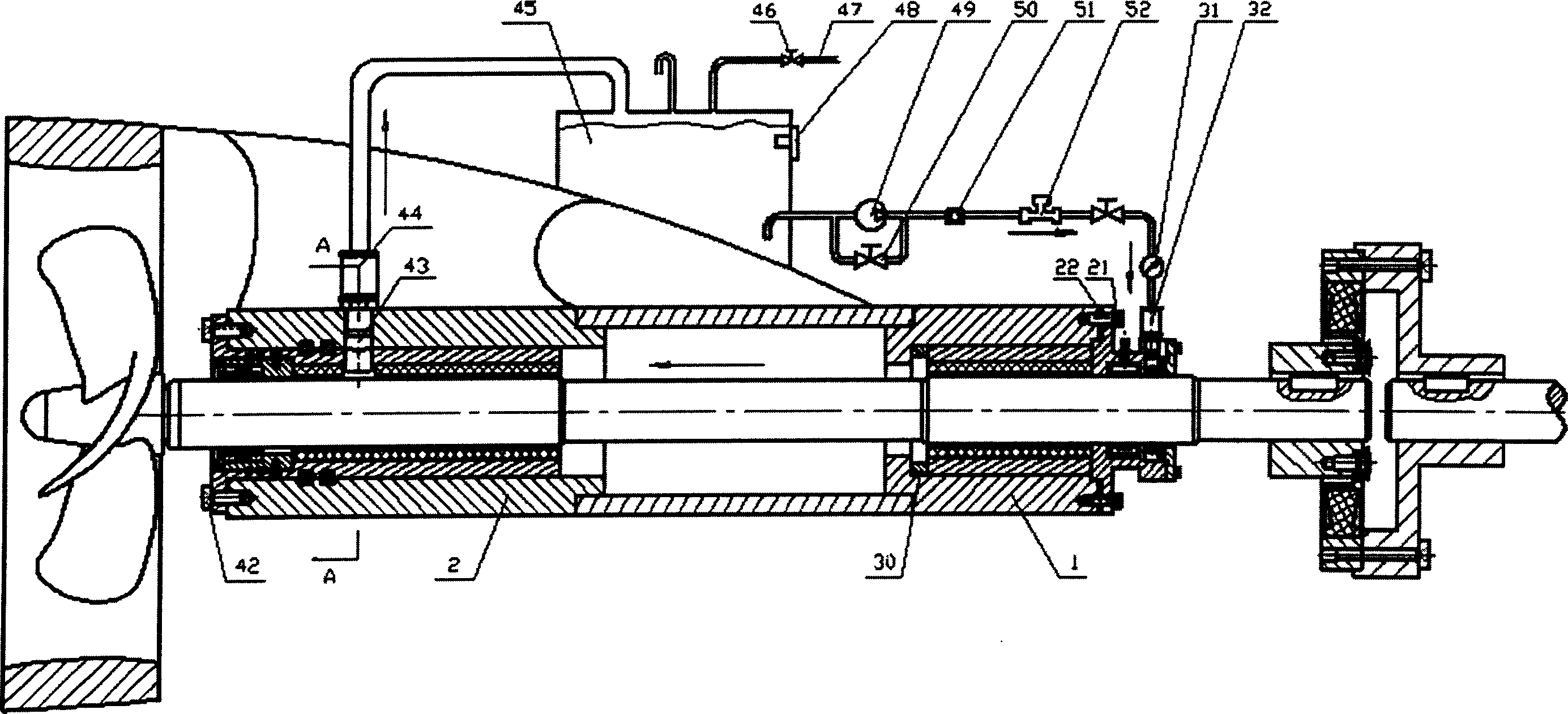

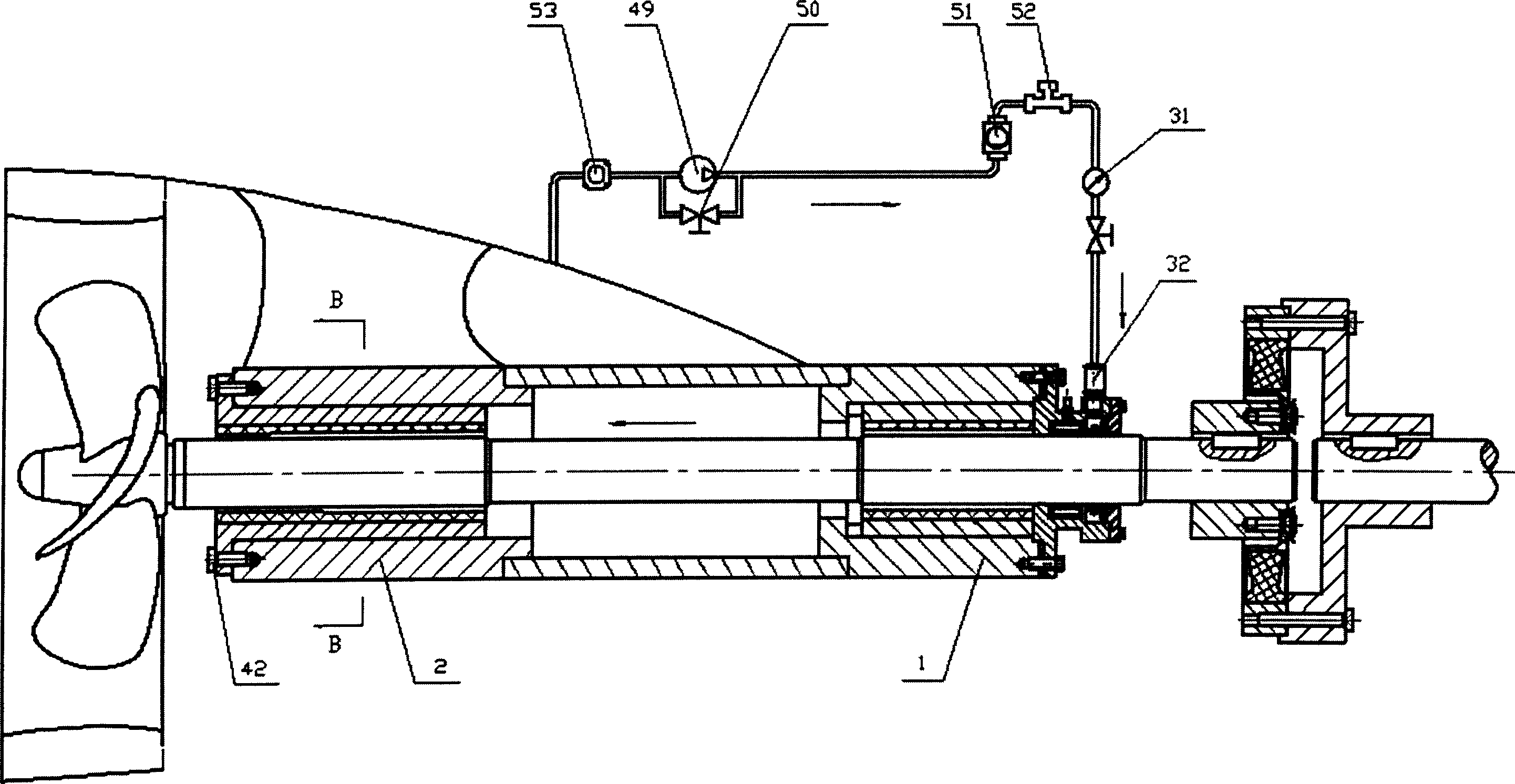

High performance water lubricating mechanical driving system

InactiveCN1821602AAchieve high efficiency and energy savingImplementation environmentYielding couplingBearing componentsOpen waterEngineering

The high performance water lubricated mechanical driving system based on new type of composite engineering material includes a high elasticity shaft coupler, a sealing device, a front water lubricated bearing, a back water lubricated bearing, and a water supplying system. It his natural water as lubricating medium and has or has not dynamic sealing device mounted through the back water lubricated bearing to constitute a closed or opened water lubricated mechanical driving system. Compared with traditional mechanical driving system, the high performance water lubricated mechanical driving system has greatly lowered friction, wear, vibration, noise and no-work loss, greatly raised reliability, saving in mineral oil and noble metal material, and environment friendship, and may be applied widely.

Owner:重庆奔腾科技发展有限公司

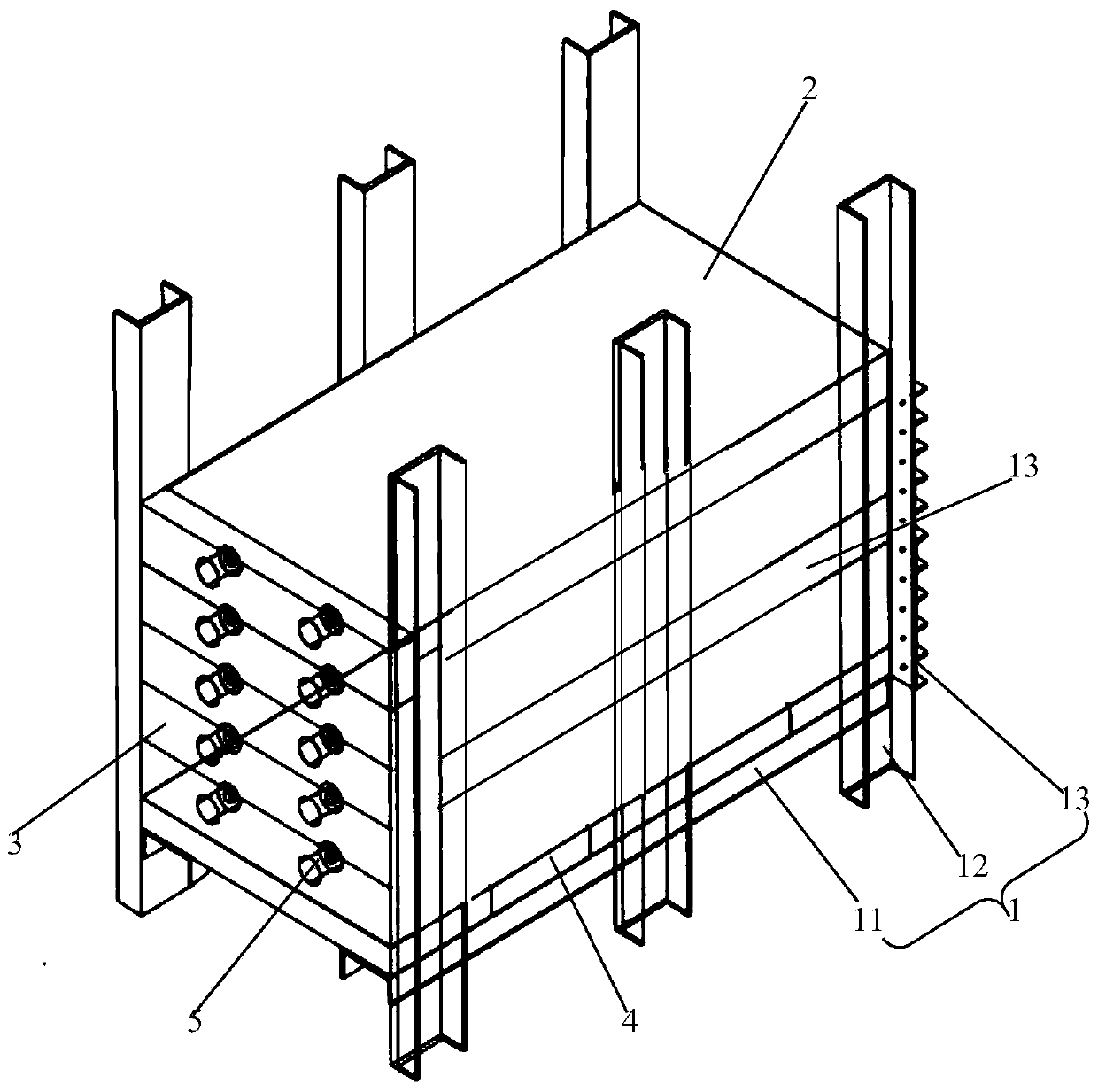

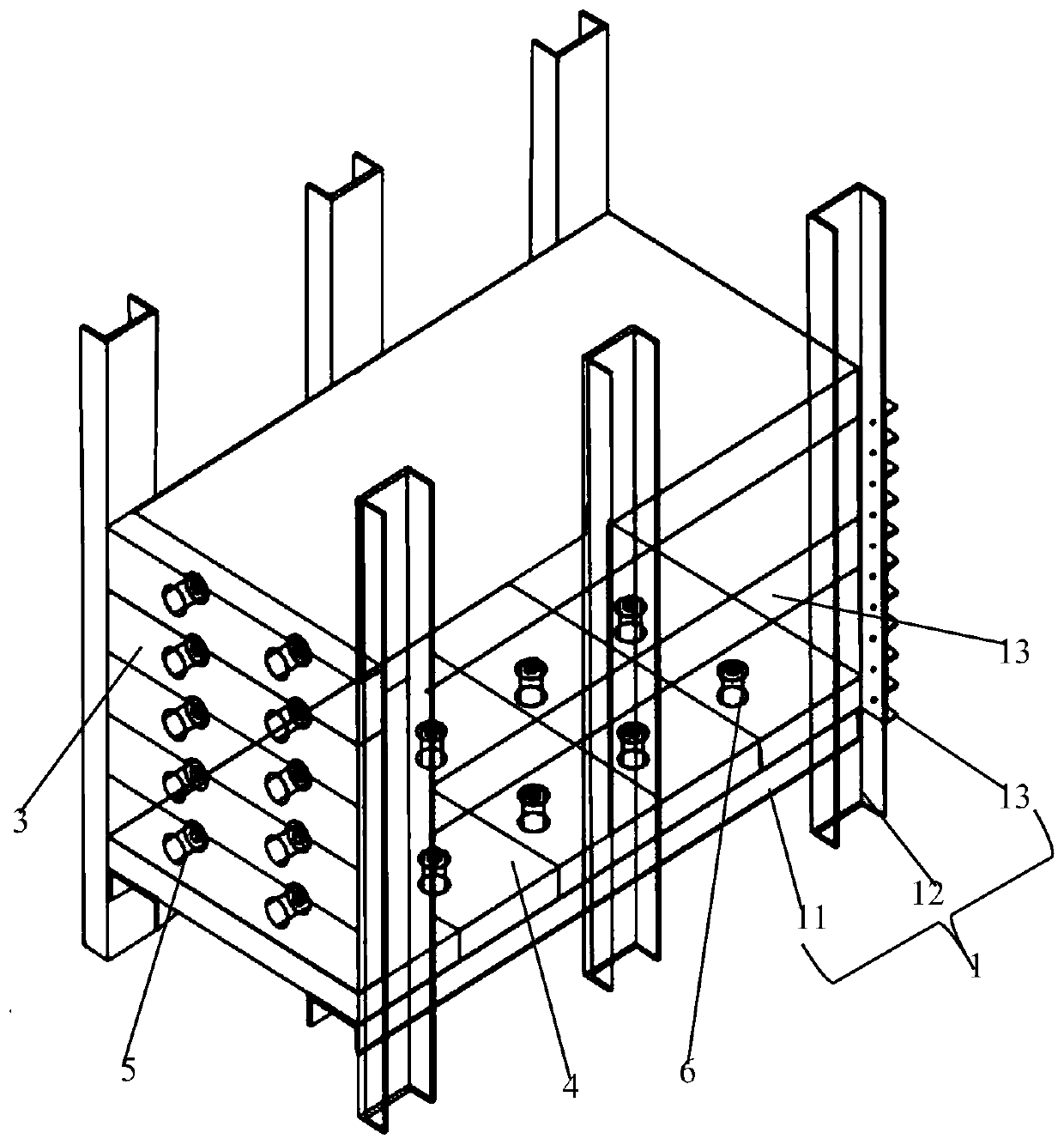

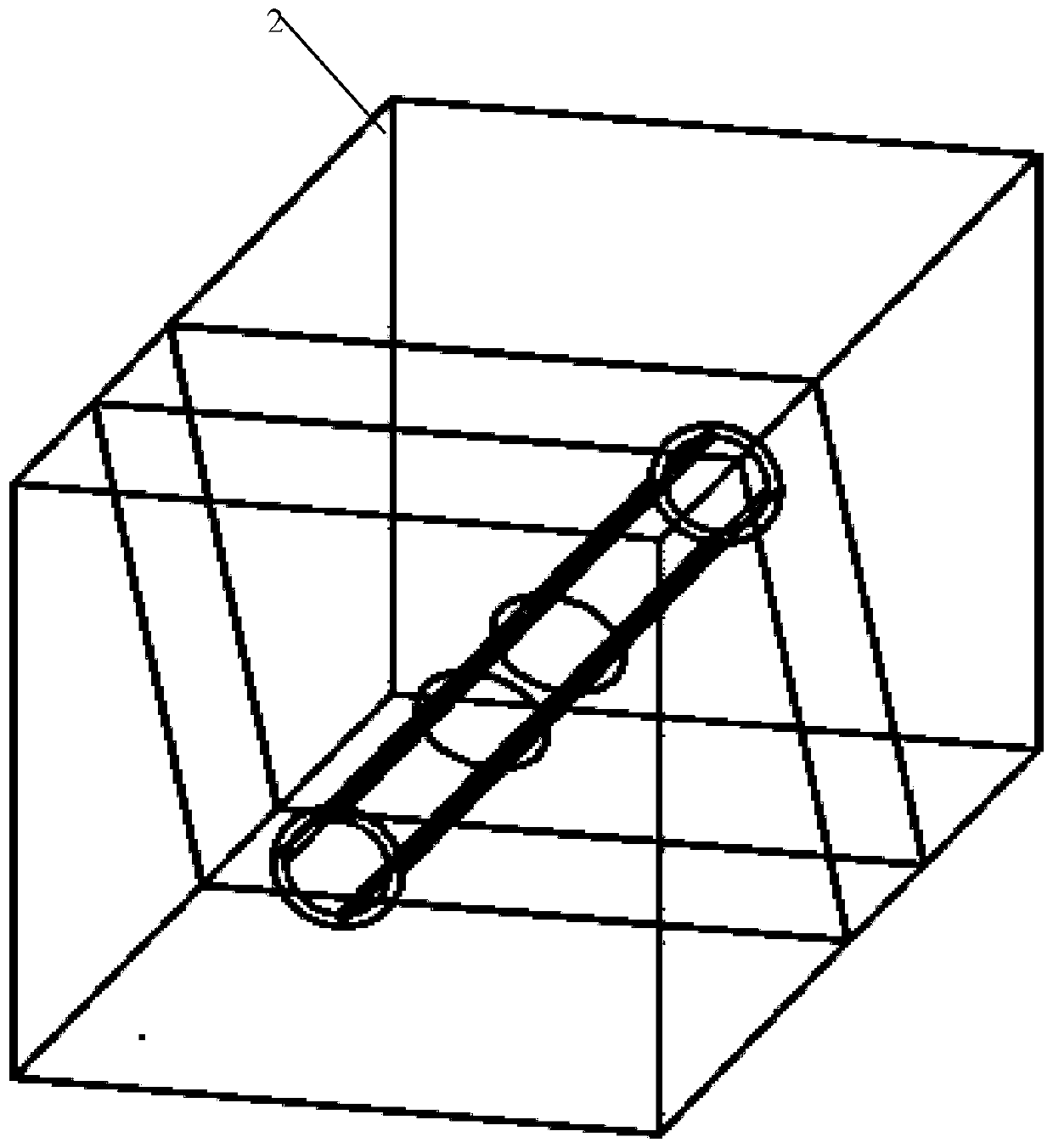

3D (Three-Dimensional) similar physical testing device for simulating fault dislocation

The invention discloses a 3D (Three-Dimensional) similar physical testing device for simulating fault dislocation. A testing stand is provided with a scale identifying structure; a testing model blockcomprises a transparent acrylic plate rectangular box body and testing soil; the transparent acrylic plate rectangular box body is filled with the testing soil; the transparent acrylic plate rectangular box body is arranged in the testing stand and is tightly fitted with the testing stand; first loading plates are horizontally arranged on the bottom end surface of the transparent acrylic plate rectangular box body; second loading plates are vertical to the first loading plates and are located on the end surface of one side of the transparent acrylic plate rectangular box body. According to the 3D (Three-Dimensional) similar physical testing device for simulating the fault dislocation, provided by the invention, the fault occurrence can be accurately simulated, meanwhile, a fault activation process can be quantitatively simulated on the premise that '3D box effect' is prevented from happening and a simulation initial stress field is ensured, observation on a lining cracking process anda failure mode can be realized, the testing accuracy and the testing reasonability are ensured, and the testing normalization and the testing operability are increased.

Owner:ANHUI UNIV OF SCI & TECH

Method for preparing carbon-based thin film material with light soft metal surface

InactiveCN102453858AEasy to makeEasy to operateVacuum evaporation coatingSputtering coatingAlloyUltimate tensile strength

The invention discloses a method for preparing a carbon-based thin film material with a light soft metal surface. Compound carbon thin film material prepared by the invention not only has excellent combination strength with a light soft metal substrate, but also expresses extremely excellent bearing ability and frictional property; the excellent performances can effectively solve the problems in function protection, friction, abrasion and corrosion of the surface of a light alloy movement member; and the method disclosed by the invention is simple in preparation progress of the thin film, and each in operation and control of operation parameters.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

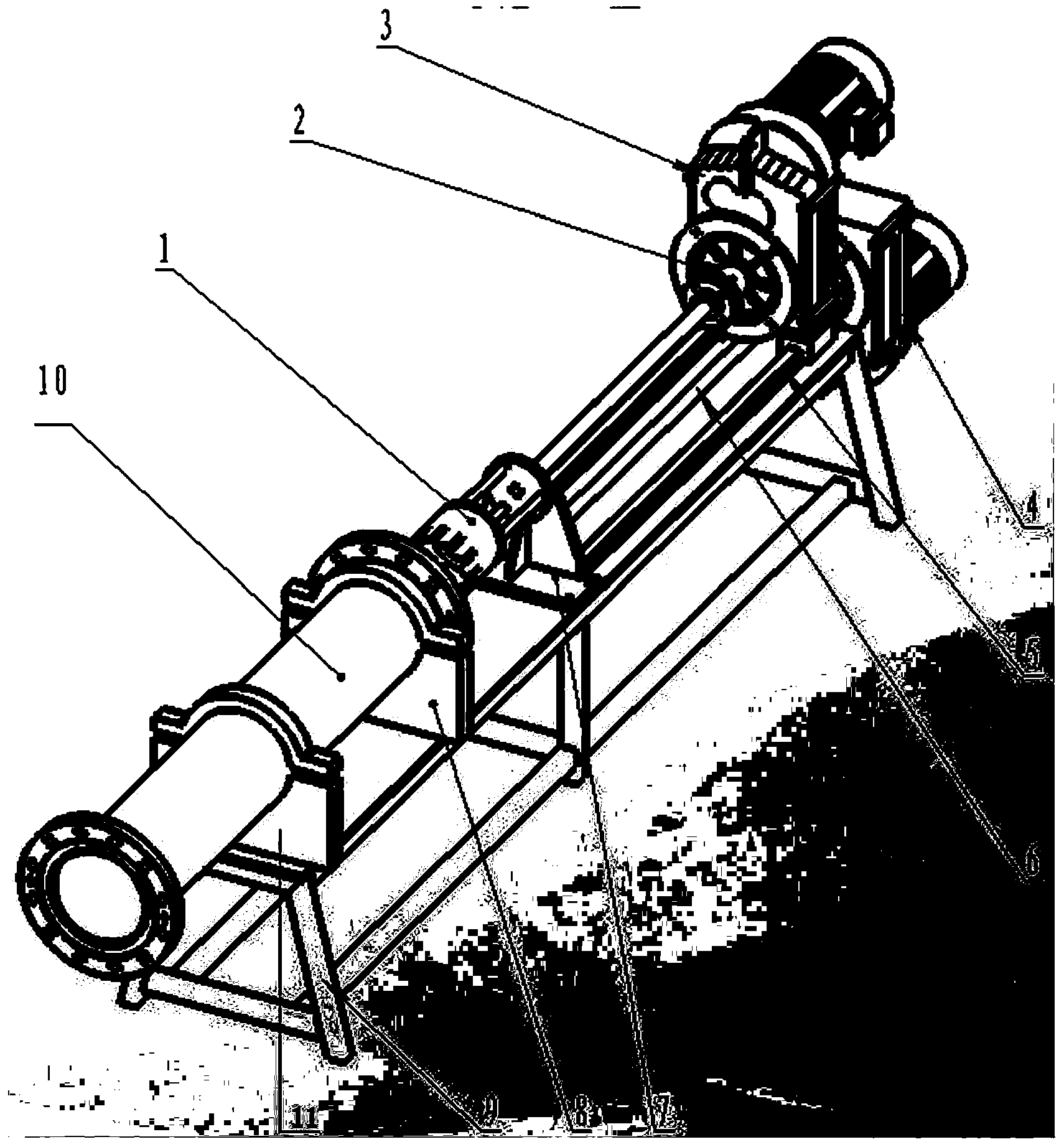

Spiral mechanism for horizontal centrifugal machine

Owner:SHANGHAI CENTRIFUGE INST

Preparation process of silicification-free rubber plug

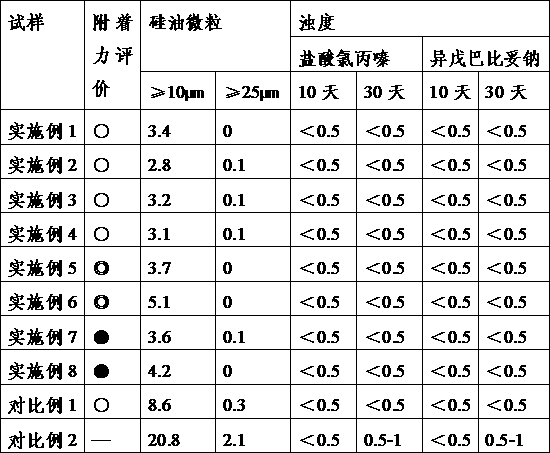

ActiveCN107629240ALower requirementReduce surface friction coefficientCoatingsPrepolymerPolyvinylidene fluoride

The invention discloses a preparation process of a silicification-free rubber plug. The preparation method comprises the steps of compounding rubber, flaking rubber, molding, volcanizing and molding,cutting, washing and drying, and packaging, and further comprises the steps of sequentially coating a dimethylsiloxane prepolymer solution and a polyvinylidene fluoride resin dispersion on the surfaceof washed and dried rubber plug, and drying and curing coating layers, wherein the dimethylsiloxane prepolymer solution is mainly prepared from the following components in parts by weight: 1-5.5 parts of dimethylsiloxane prepolymer, 0.2-0.5 part of silane crosslinking agent, 100 parts of organic solvent A, and the polyvinylidene fluoride resin dispersion is mainly prepared from polyvinylidene fluoride resin emulsion containing 5-15% of solid and silicon rubber catalyst. The cured rubber plug has a compound coating layer, low surface friction coefficient, good anti-ultraviolet performance, chemical resistance and anti-aging performance, and the silicification process in preparation of the rubber plug is prevented.

Owner:江阴市海华橡塑有限公司

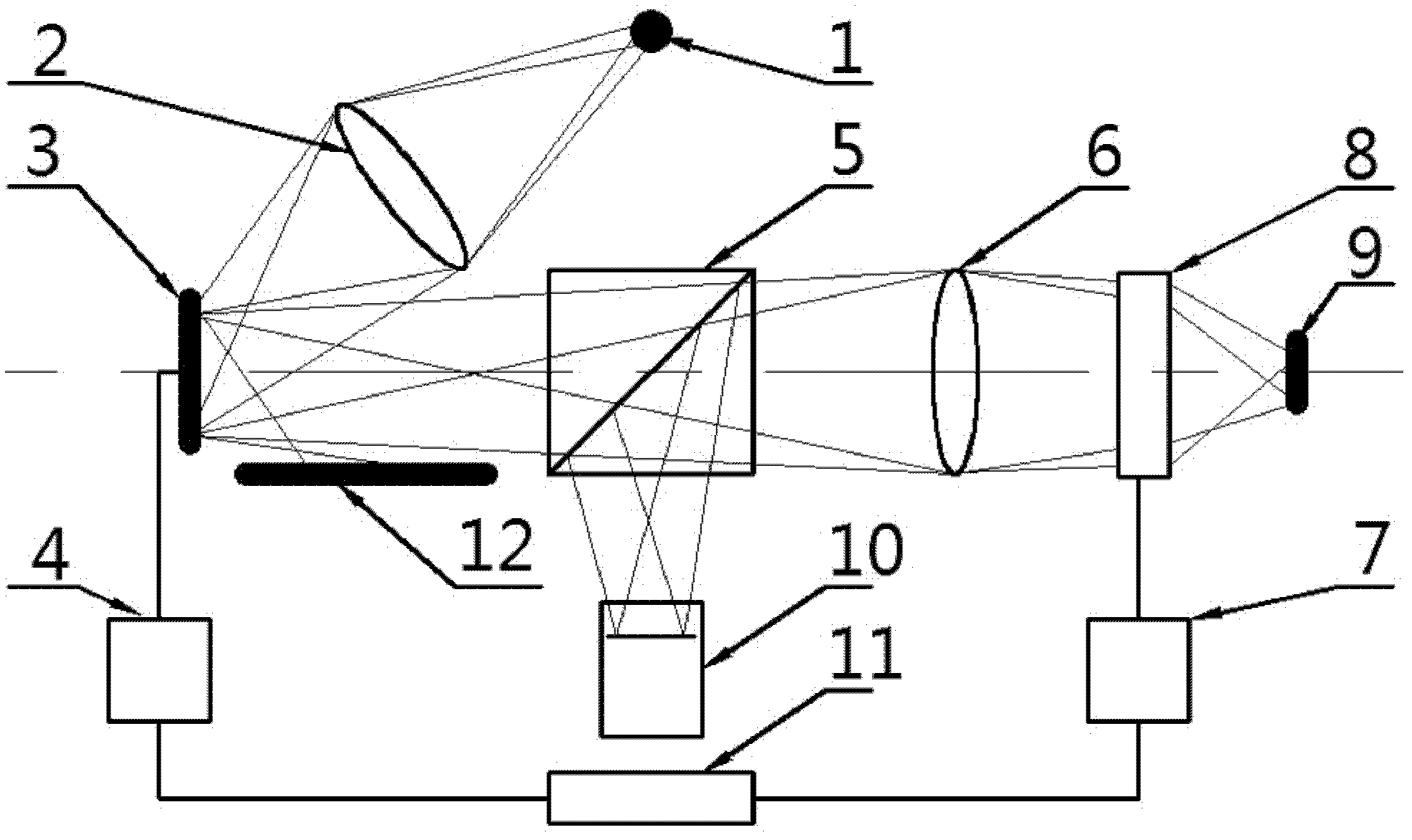

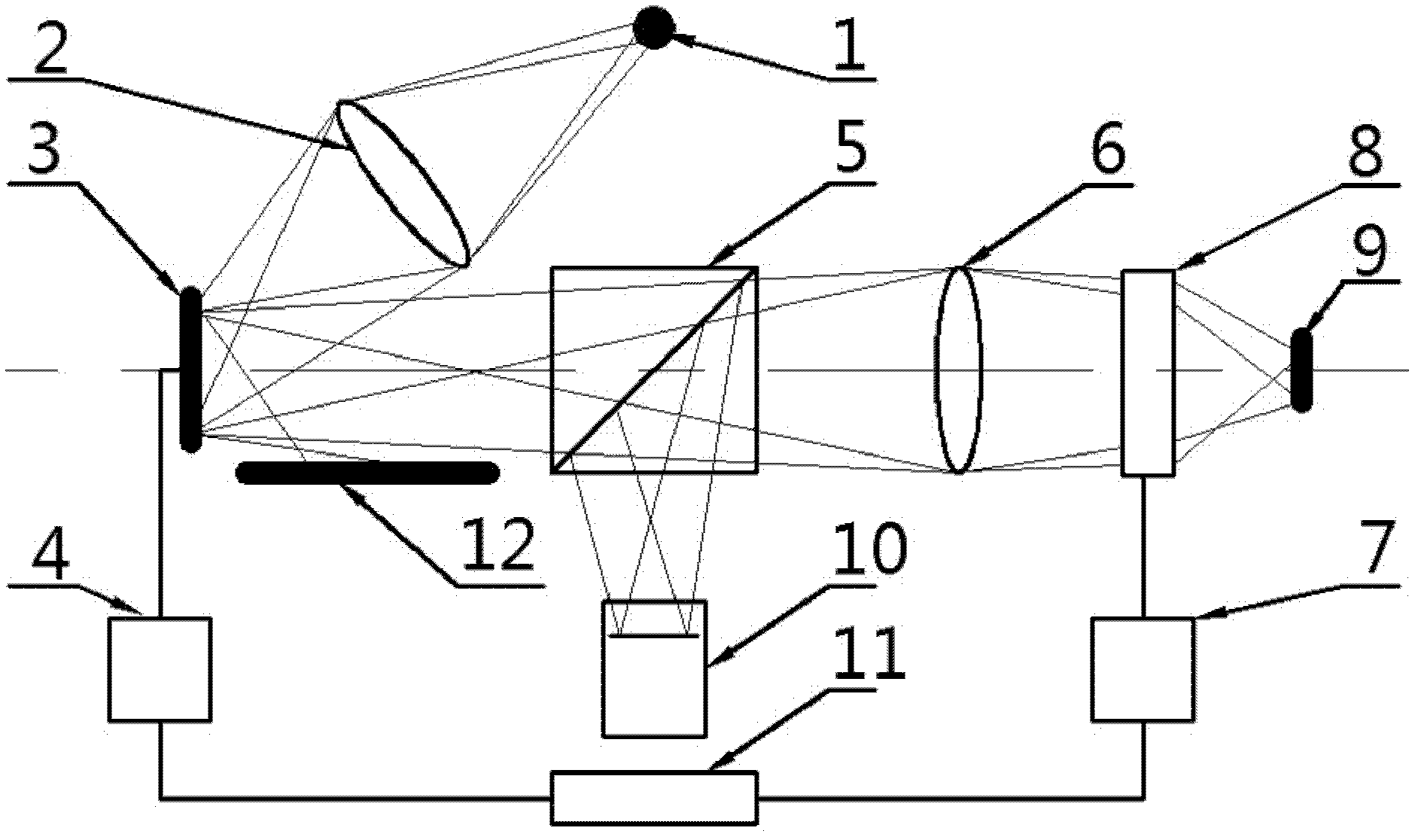

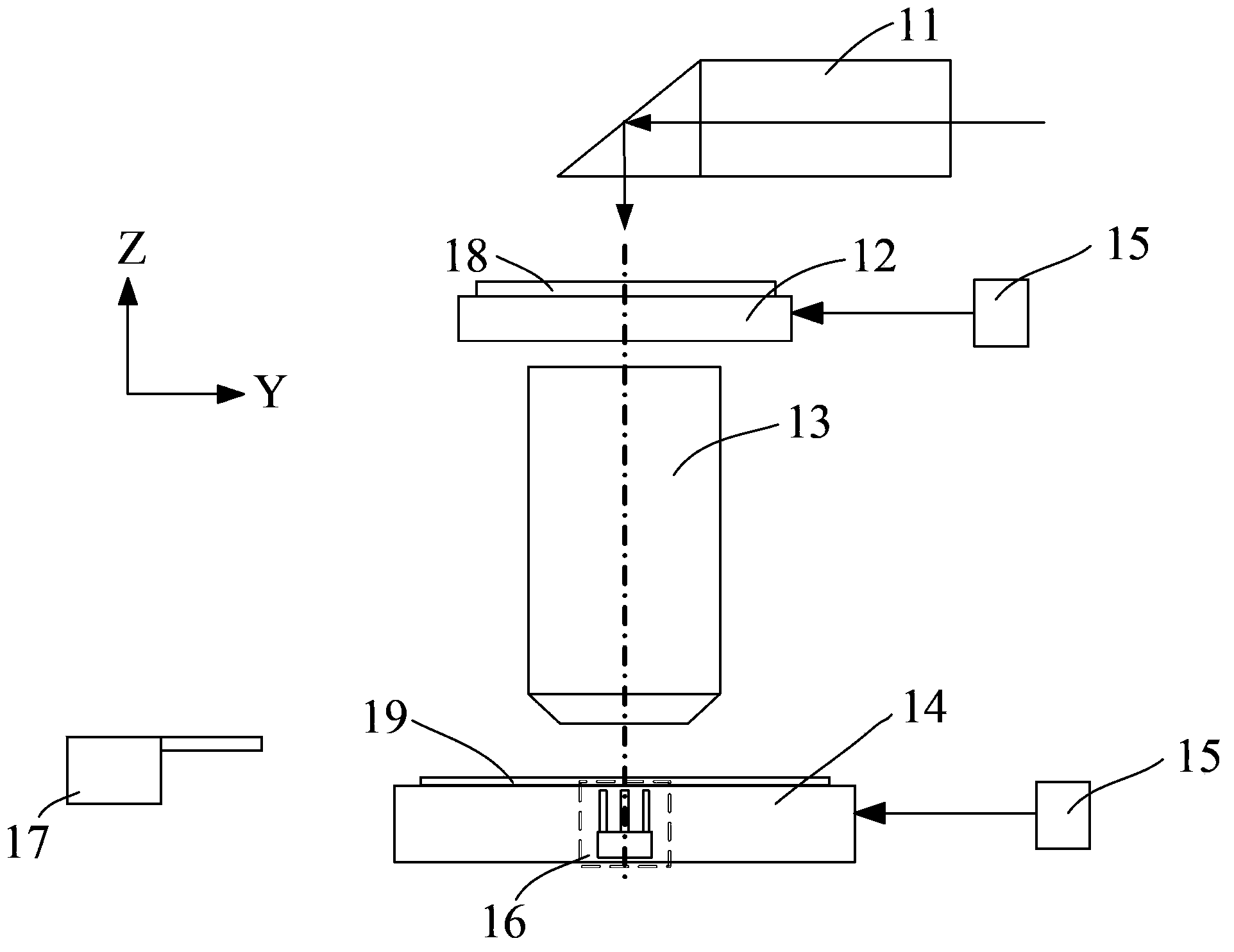

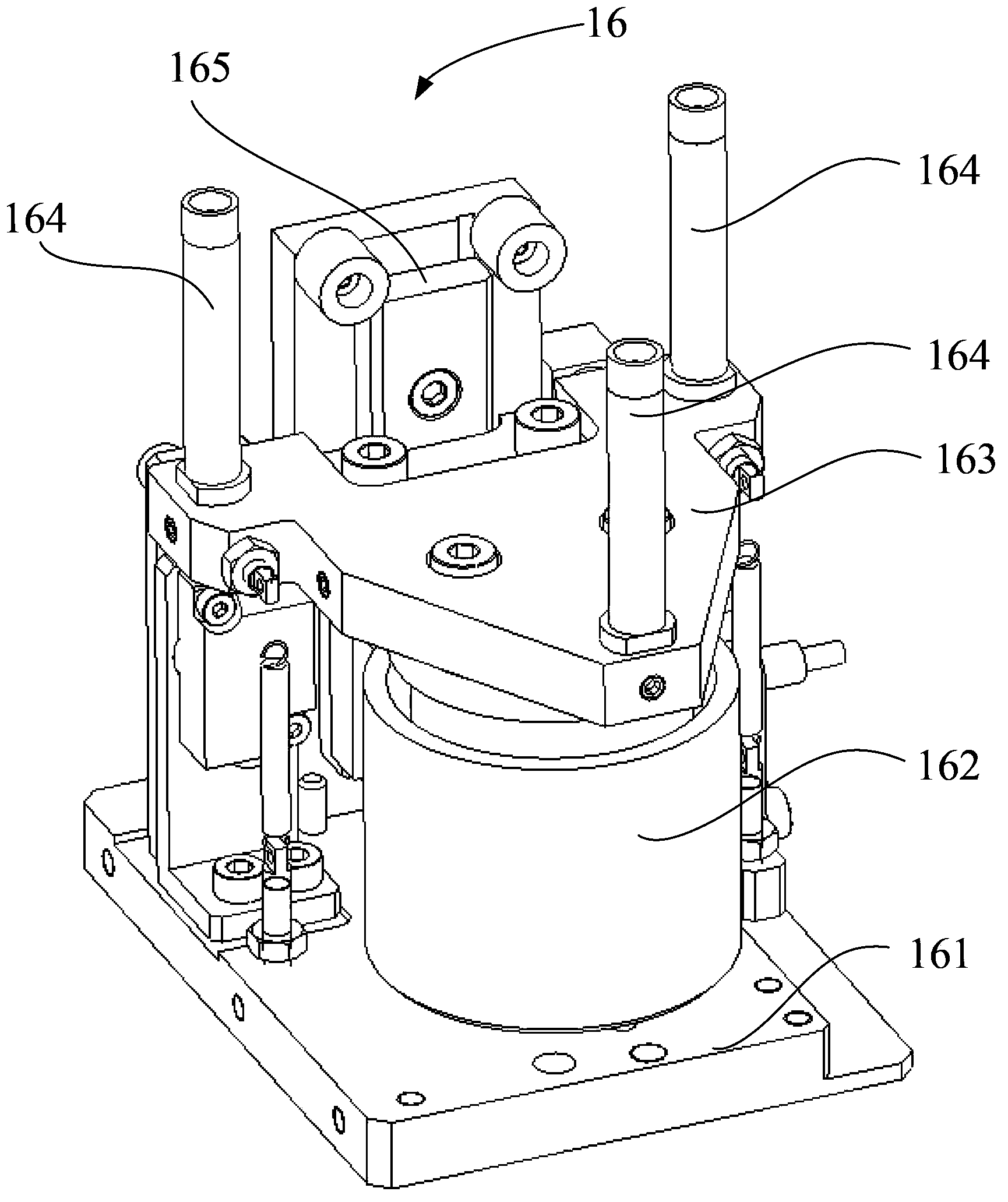

Parallel confocal detection system and method

The invention discloses a parallel confocal detection system and a parallel confocal detection method. The system comprises a mono-color LED (light-emitting diode) light source, a digital micro-lens, two lenses, a beam splitter prism, an electric-control variable focal length lens, a detection pinhole, a light strength detector, a voltage controller and a PC (personnel computer). Lights sent out by the mono-color LED light source are irradiated on the surface of the digital micro-lens through a light collection lens and a light source is modulated by the digital micro-lens to form a pinhole array; the lights are changed into a parallel light beam by the lens to be focused on the surface of an object to be detected; the lights reflected by the object to be detected are emitted into a light strength array detector; and a sample is transversely or axially scanned through a digital micro-lens device. A voltage on the electric-control variable focal length lens is controlled by the PC to change a focal length of the variable focal length lens for a tiny value delta f, and a light strength numerical value on the detector is recorded; the axial position of the corresponding point of the object to be detected is obtained according to the light strength value obtained by scanning; and the surface outline of the whole object to be detected is measured. According to the parallel confocal detection system and parallel confocal detection method, the stability and the scanning speed of the system can be improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

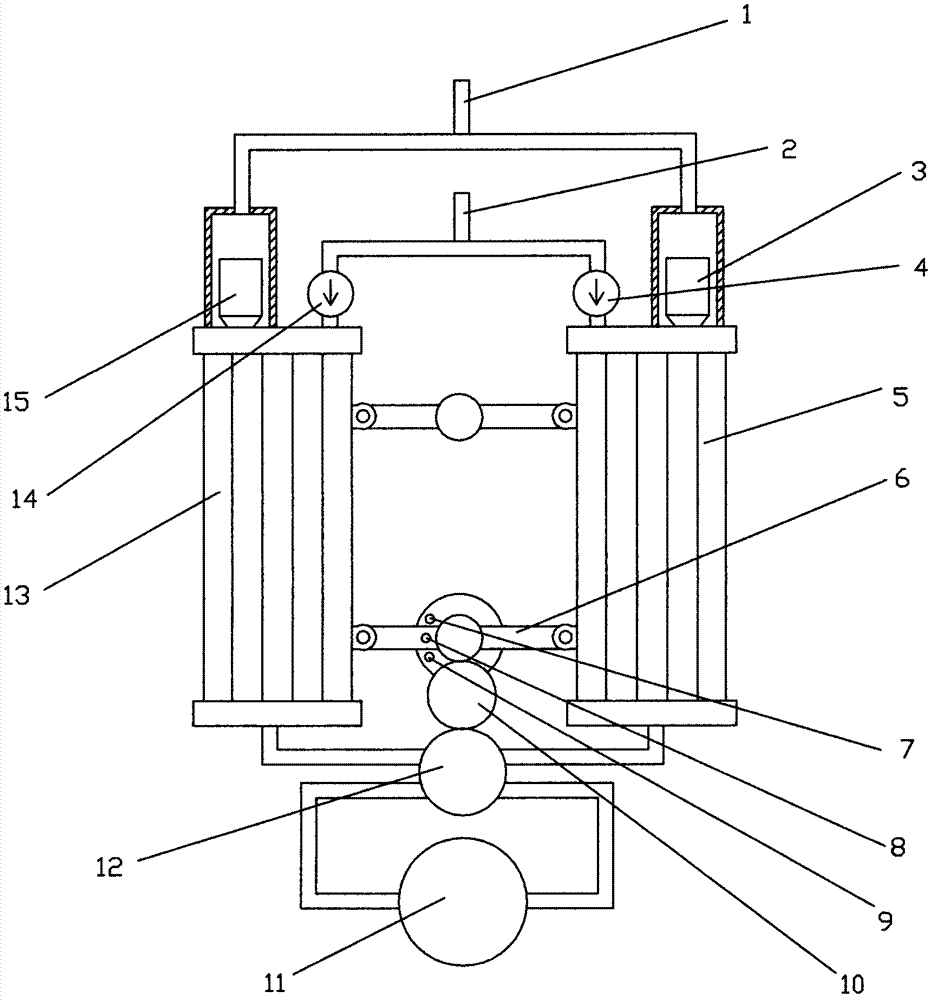

Compressor with liquid piston

InactiveCN102953955AResolve frictionSolve wear and tearPositive displacement pump componentsPiston pumpsLiquid pistonMechanical engineering

Disclosed is a compressor with a liquid piston. Suction and exhaust of a cylinder are achieved by replacing traditional piston motion with ascending and descending of liquid driven by a pump in the cylinder, friction of a liquid piston with a cylinder wall is much smaller than friction of a solid piston with the cylinder wall, and accordingly efficiency is improved and service life is prolonged. In addition, the liquid piston and the cylinder can be made into a parallel structure of a plurality of small tubes, and accordingly the defect that a traditional cylinder is hard to radiate when diameter is large is overcome and manufacture cost of the compressor with the liquid piston is low.

Owner:时剑

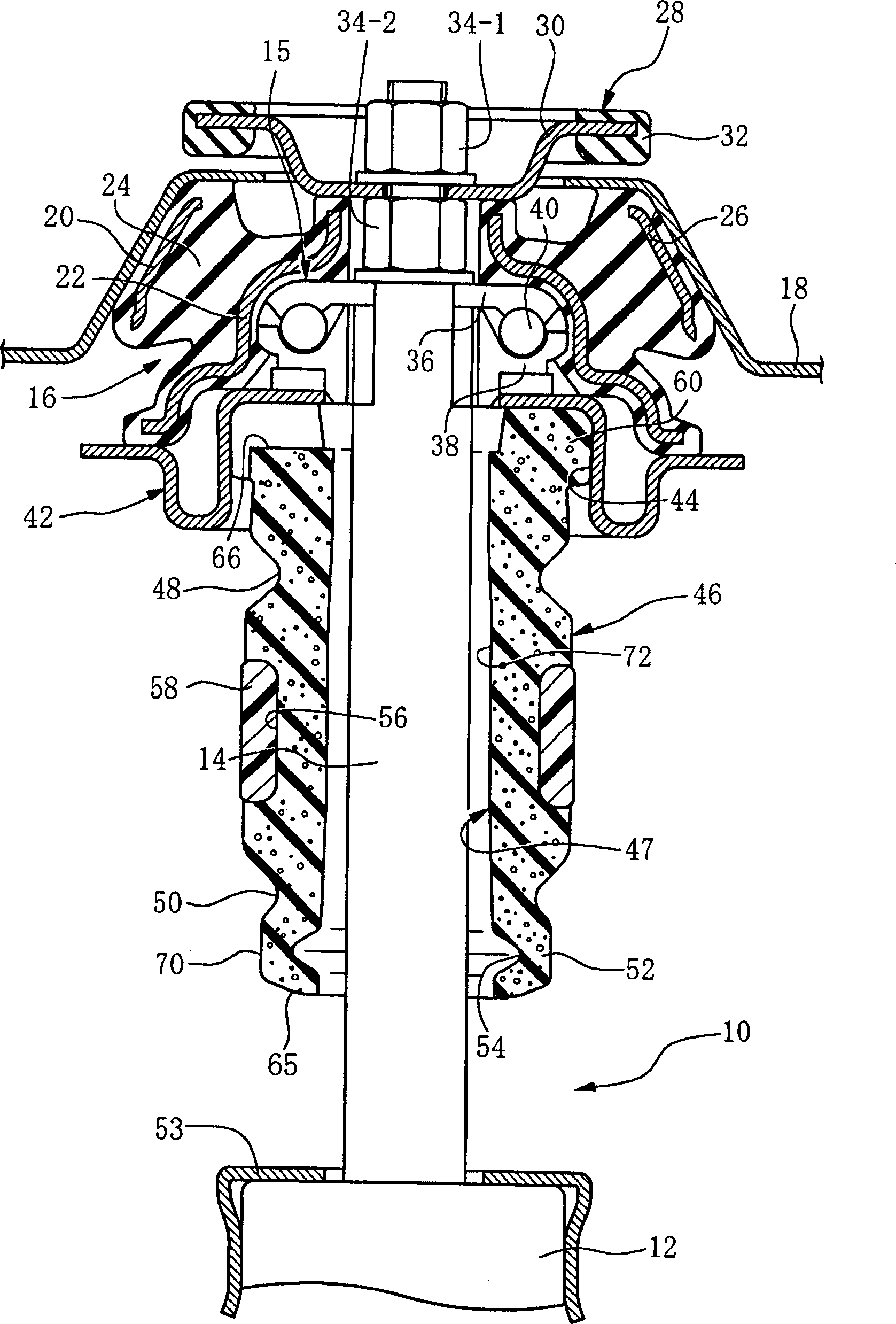

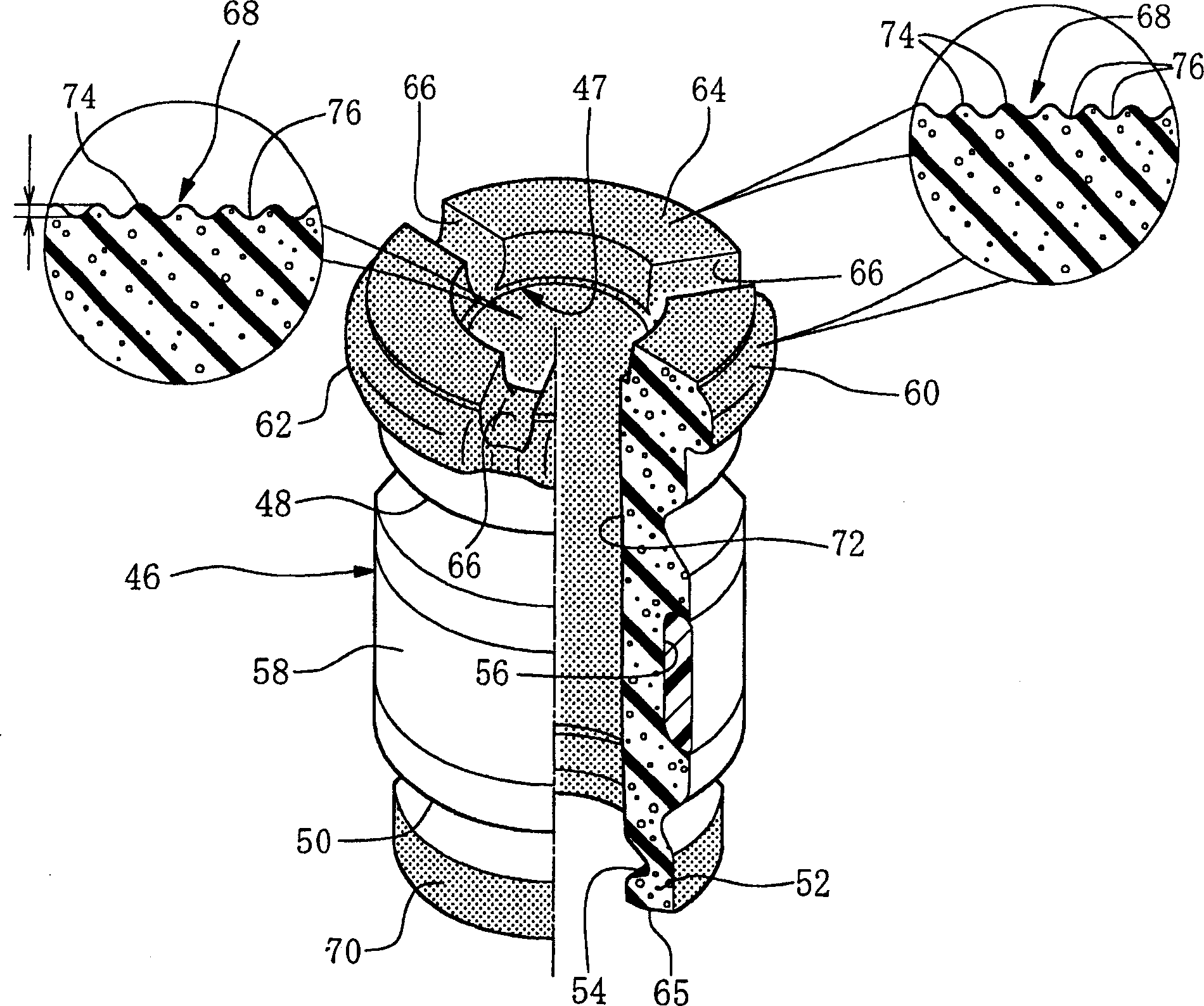

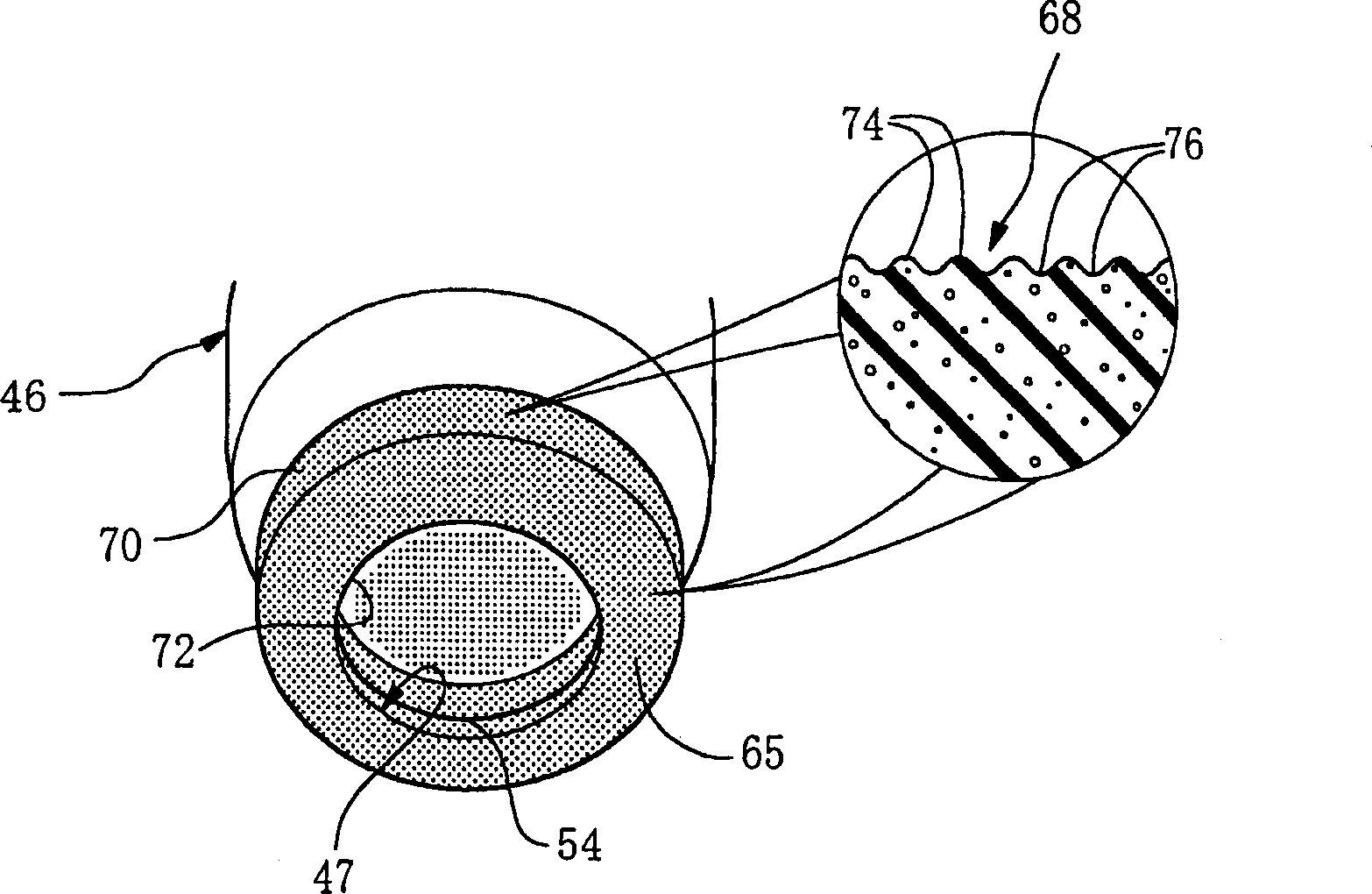

Bounce limiter for hanging apparatus

The present invention provides a bounce limiter for a suspension device, the bounce limiter is made of foamed polyurethane, does not produce unpleasant noise caused by friction, and is used for the suspension of vehicles with shock absorbers and coil springs The cylindrical elastic body on the device allows the piston rod to pass through the central hole (47), and at the same time, the upper end (60) is fitted and retained in the concave fitting part of the spring seat in an embedded state, so that when the vehicle bounces and shock absorption The outer peripheral surface (70) of the axial lower end surface (65) and the lower end portion (52) of the bounce limiter (46) made of foamed polyurethane that is elastically abutted against the cylinder of the device is made Formed into a wrinkle-forming surface (68) composed of fine concavo-convex groups.

Owner:SUMITOMO RIKO CO LTD

Centrifugal vibrating type multi-point-location daily ceramic glazing machine

The invention provides a centrifugal vibrating type multi-point-location daily ceramic glazing machine, and relates to the field of ceramic glazing. The centrifugal vibrating type multi-point-locationdaily ceramic glazing machine comprises a pedestal, wherein left and right sides of the top of the pedestal are separately connected with a second supporting plate and a first supporting plate; upperparts of opposite surfaces of the first supporting plate and the second supporting plate are connected with slide plates; and ends, away from the supporting plates, of the two slide plates are connected with slide rods. According to the centrifugal vibrating type multi-point-location daily ceramic glazing machine provided by the invention, a glaze pumping shaft is used for pumping glaze, and glaze is sprayed through a first branch tube, a second branch tube and a third branch tube; a first motor, a first rotary shaft, an eccentric wheel and a glazing box are connected, so that the glazing boxvibrates up and down; and a second motor, a second rotary shaft and a placing plate are connected, so that the placing plate rotates to generate centrifugal force, and therefore, ceramic glazing on the placing plate is more uniform and more convenient, and the inconvenient ceramic glazing problem and the uneven ceramic glazing problem are solved.

Owner:大埔县馨明园陶瓷有限公司

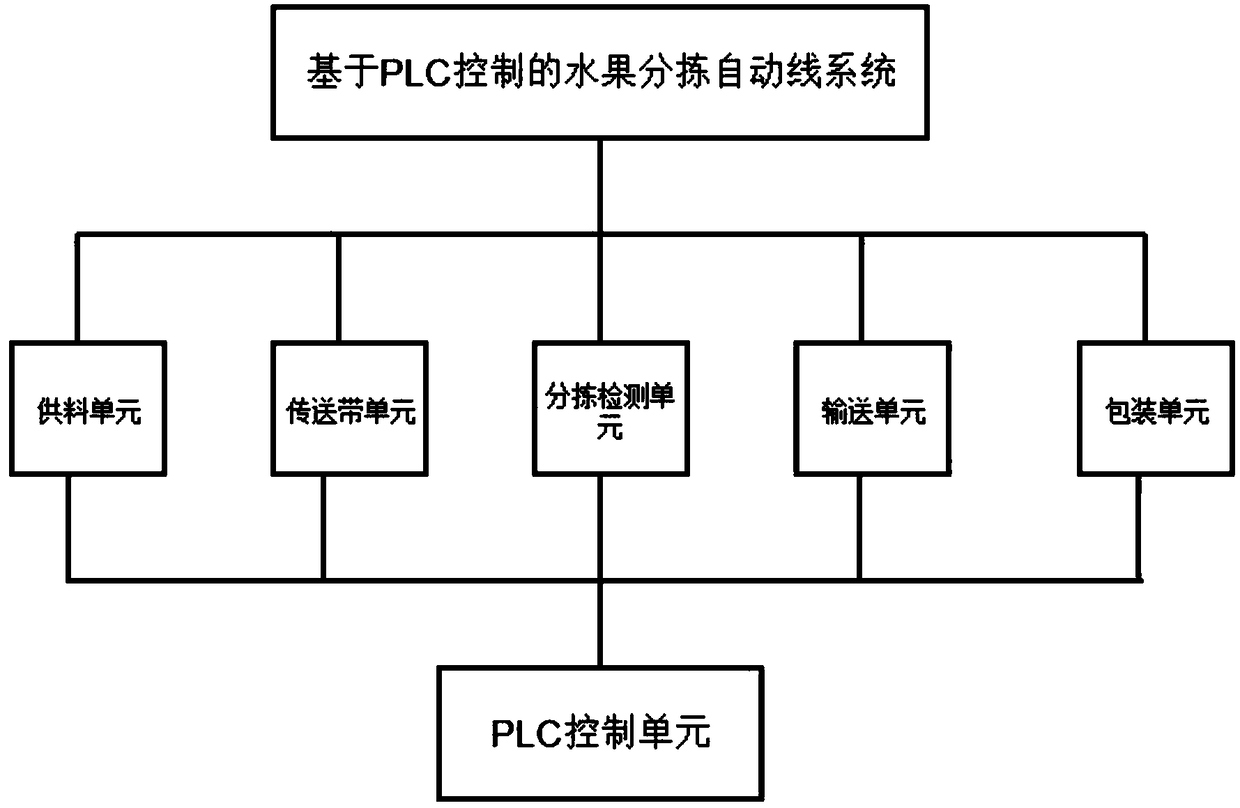

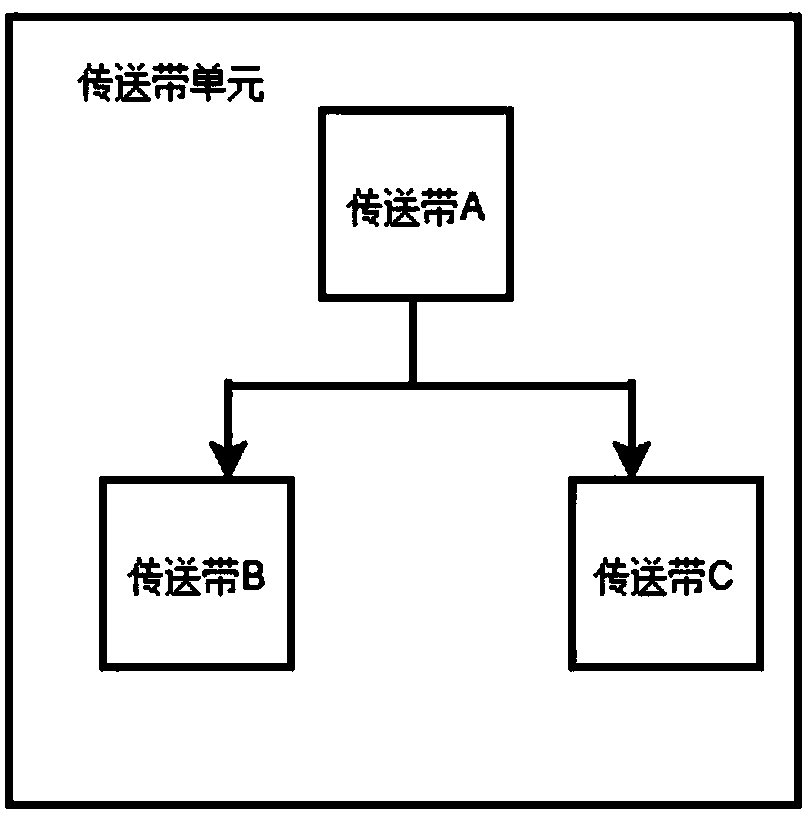

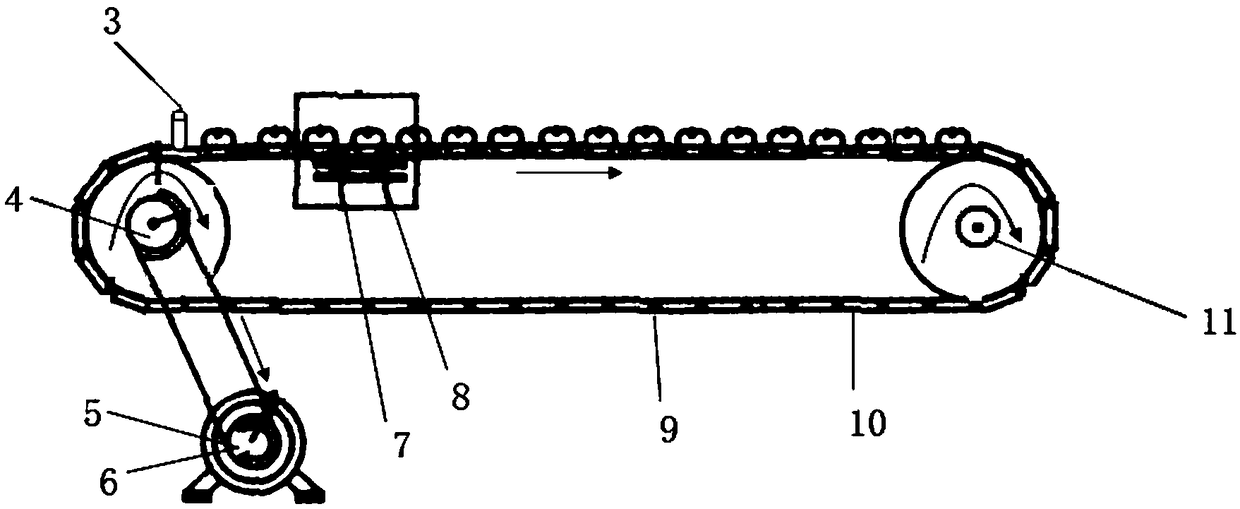

Fruit sorting automatic line system based on PLC control

PendingCN108855974AImprove fine sortingMeet different sorting requirementsSortingComputer moduleConveyor belt

The invention relates to the technical field of fruit and vegetable sorting, in particular to a fruit sorting automatic line system based on PLC control. The fruit sorting automatic line system comprises a conveyor belt unit, a sorting detection unit, a conveying unit and a PLC control unit, wherein the conveyor belt unit comprises multiple groups of conveying belts and is used for transporting fruits; the sorting detection unit comprises various types of detection modules; each group of conveyor belt is at least provided with one detection module according to the types of fruits needed to besorted; each detection module is used for detecting sorting level of the fruits on the conveyor belts; the conveying unit comprises a plurality of manipulators; each group of conveyor belt is at leastprovided with one manipulator; the conveying unit is used for grabbing and conveying the fruits on the conveyor belts under the control of the PLC control unit. According to the scheme, by automatically sorting and detecting multiple qualities and types of the fruits, fine sorting and sorting quality of the fruits are improved.

Owner:阜阳职业技术学院

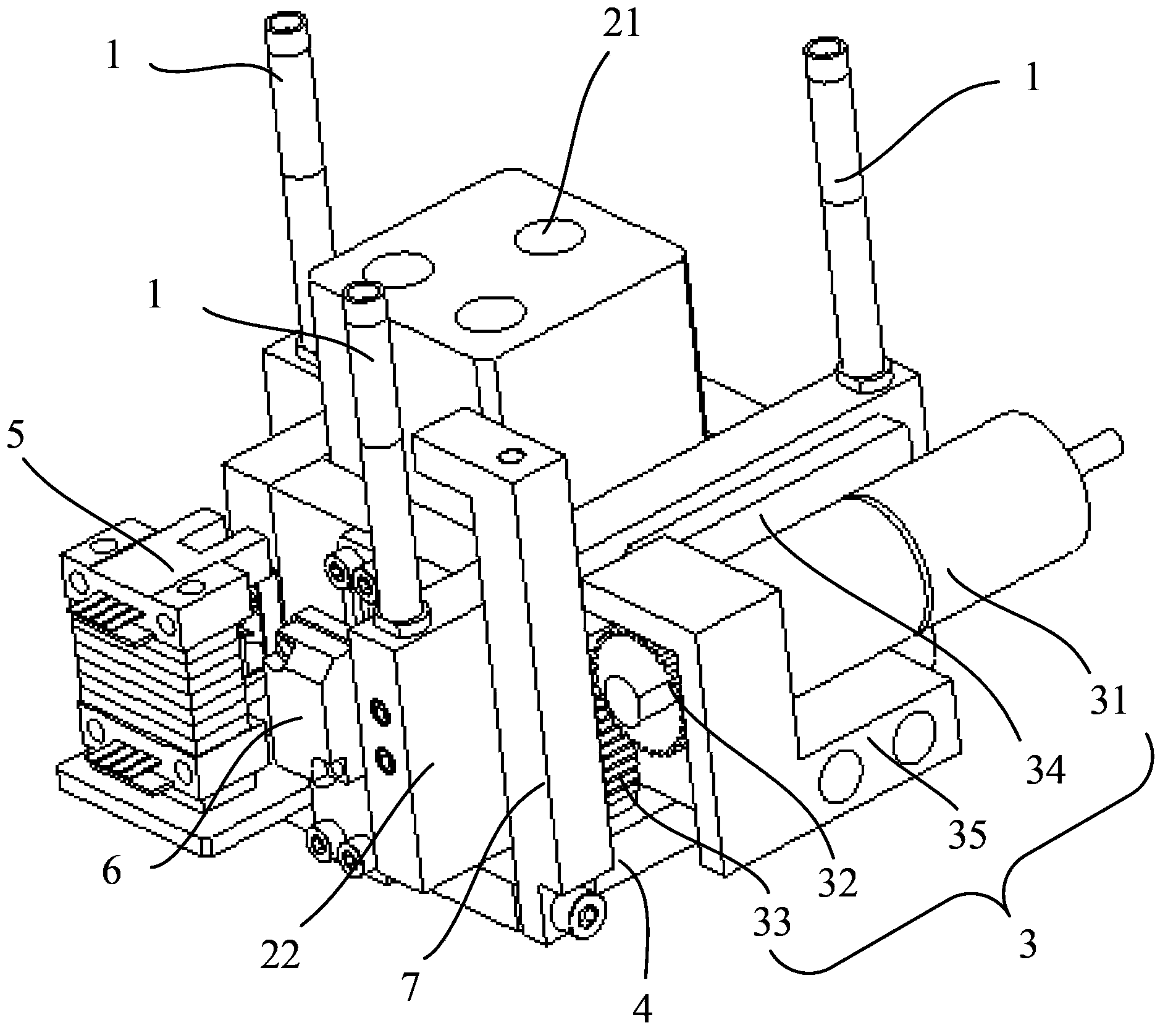

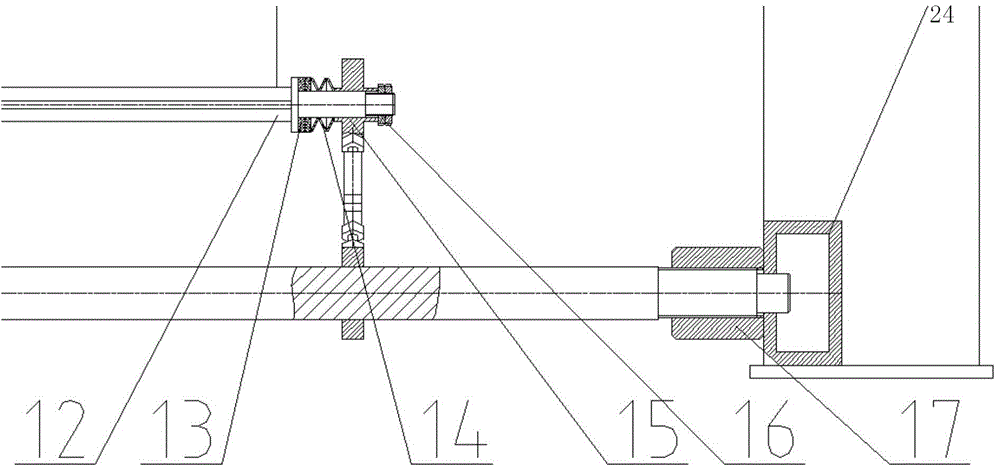

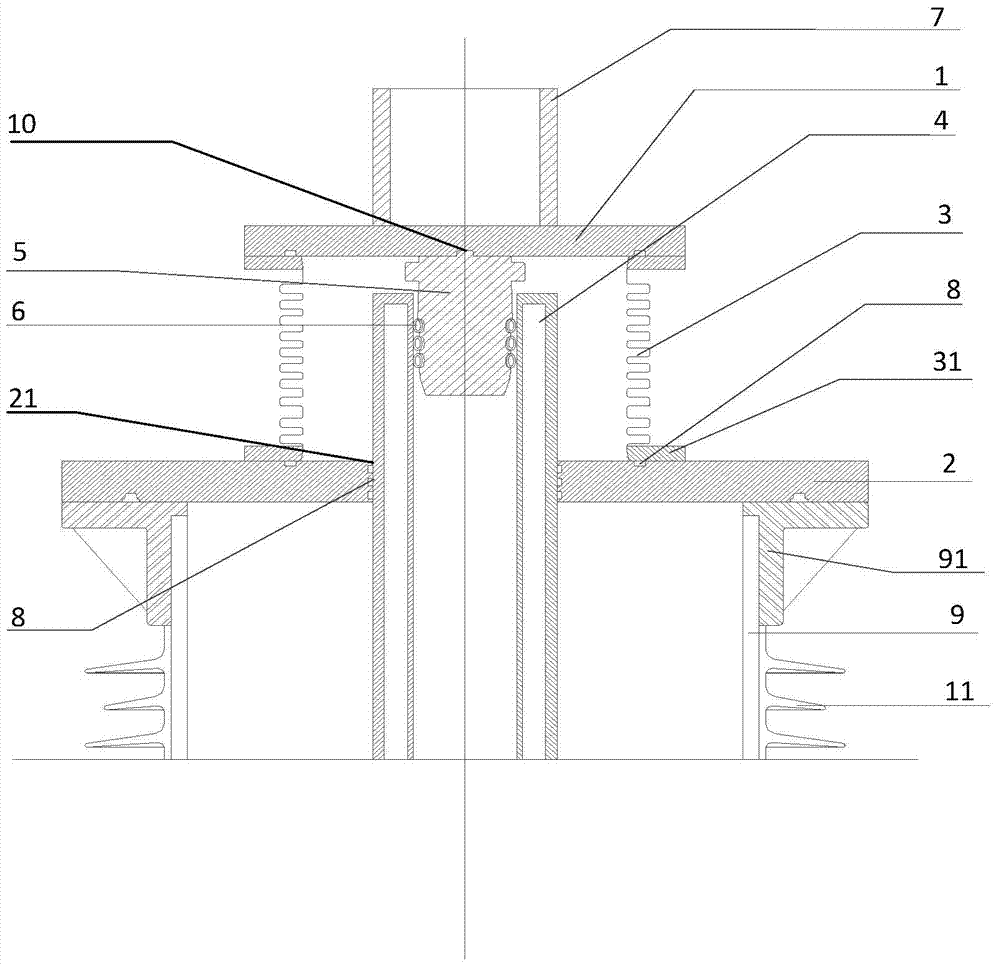

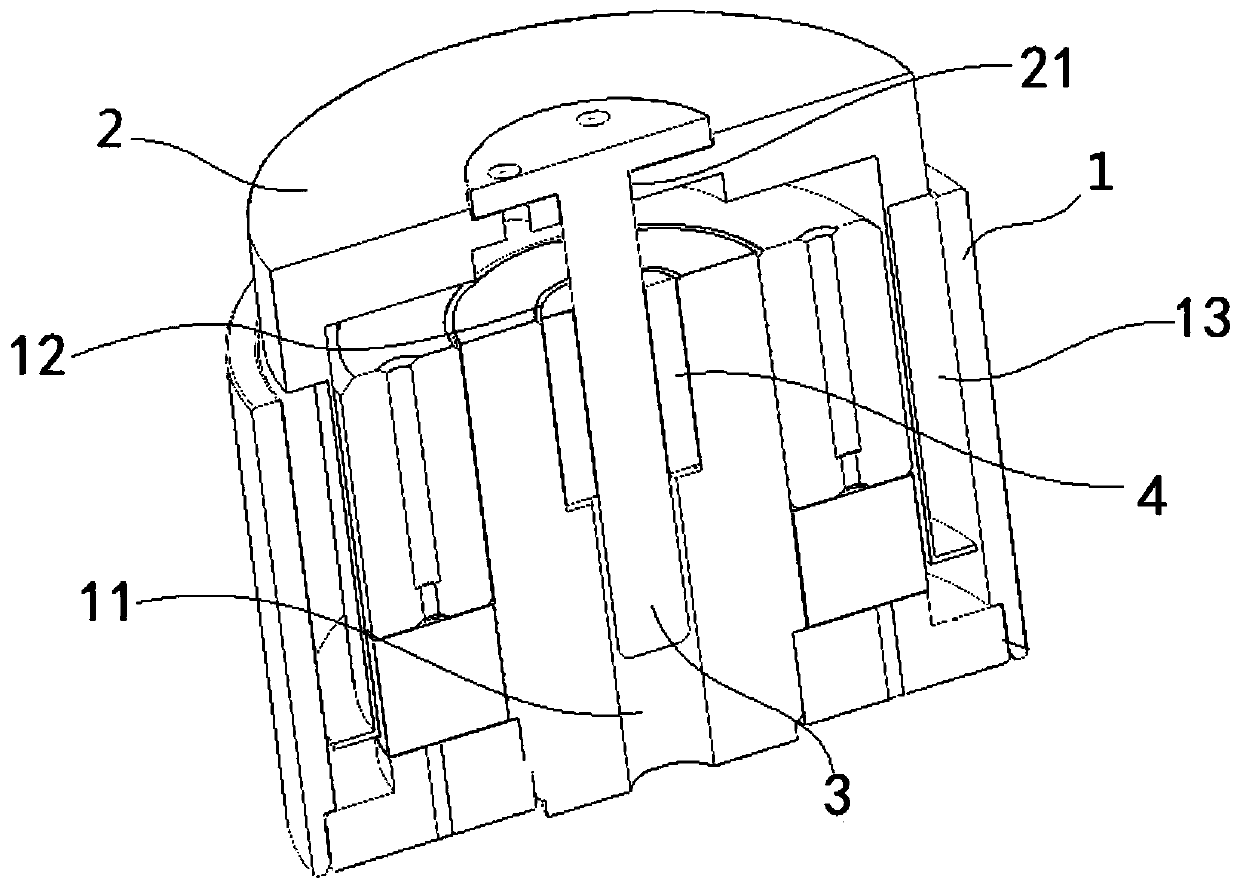

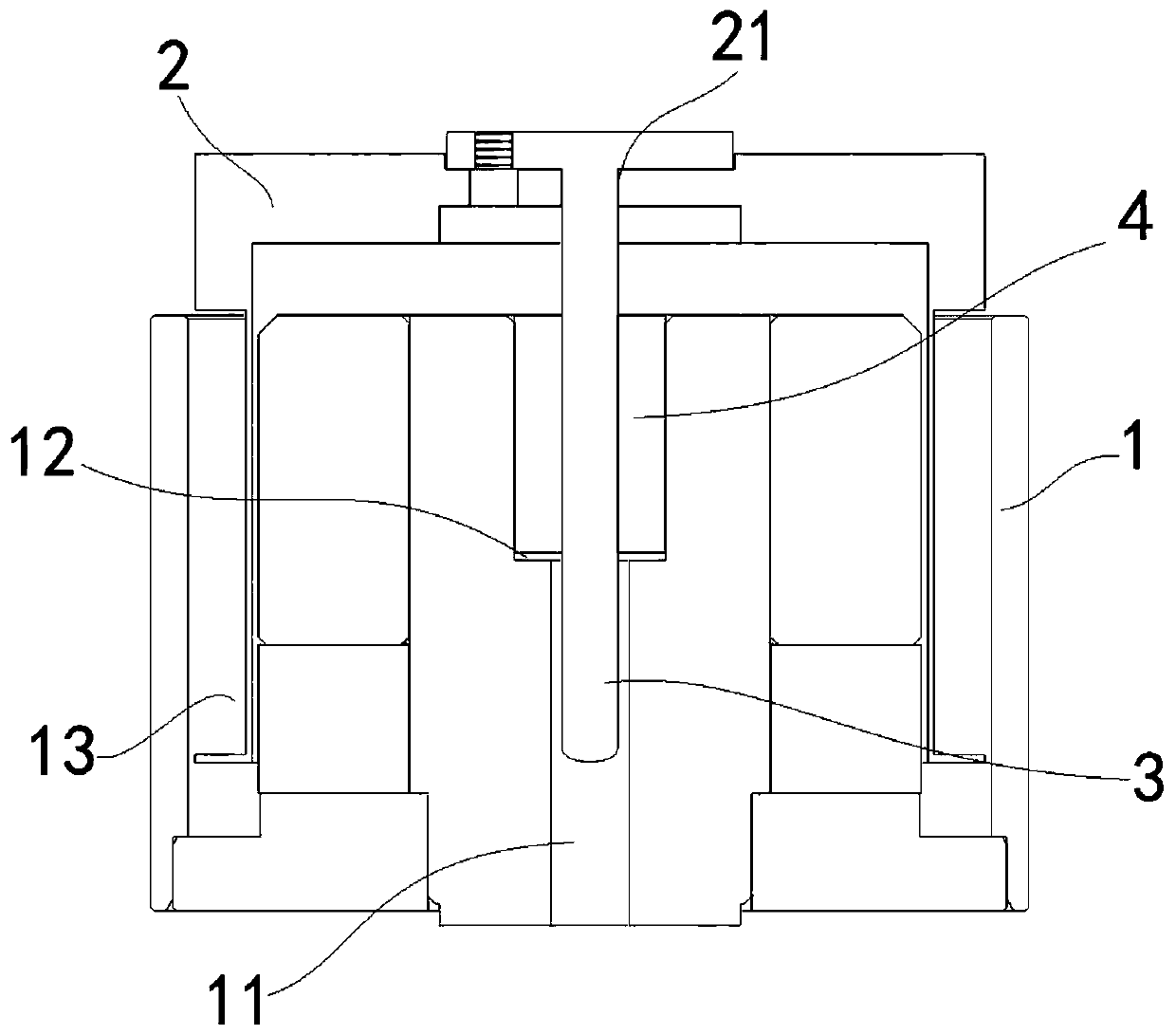

Main stress application device for true triaxial apparatus

InactiveCN104458409AAchieve independent applicationResolve frictionMaterial strength using tensile/compressive forcesTriaxial shear testTest sample

The invention discloses a main stress application device for a true triaxial apparatus. The main stress application device comprises two bases arranged on two sides of a test sample respectively, loading units are arranged on the two bases, can horizontally move on the bases and can vertically extend and retract, the outer side of the loading unit on one side of the test sample contacts with a pressurizing device, the outer side of the loading unit on the other side of the test sample contacts with a counter-force support, and a stress sensor is mounted on the counter-force support. The main stress in a true tri-axis is independently applied, the main stress application device solves the problem that an experimental error is too large as frictional force is too large and soil is squeezed into a gap when the main stress is applied in an overlapping manner by a pressurizing plate in the prior art, and experimental conditions for further analyzing soil mechanical properties in a three-dimensional stress state are created.

Owner:POWERCHINA ZHONGNAN ENG

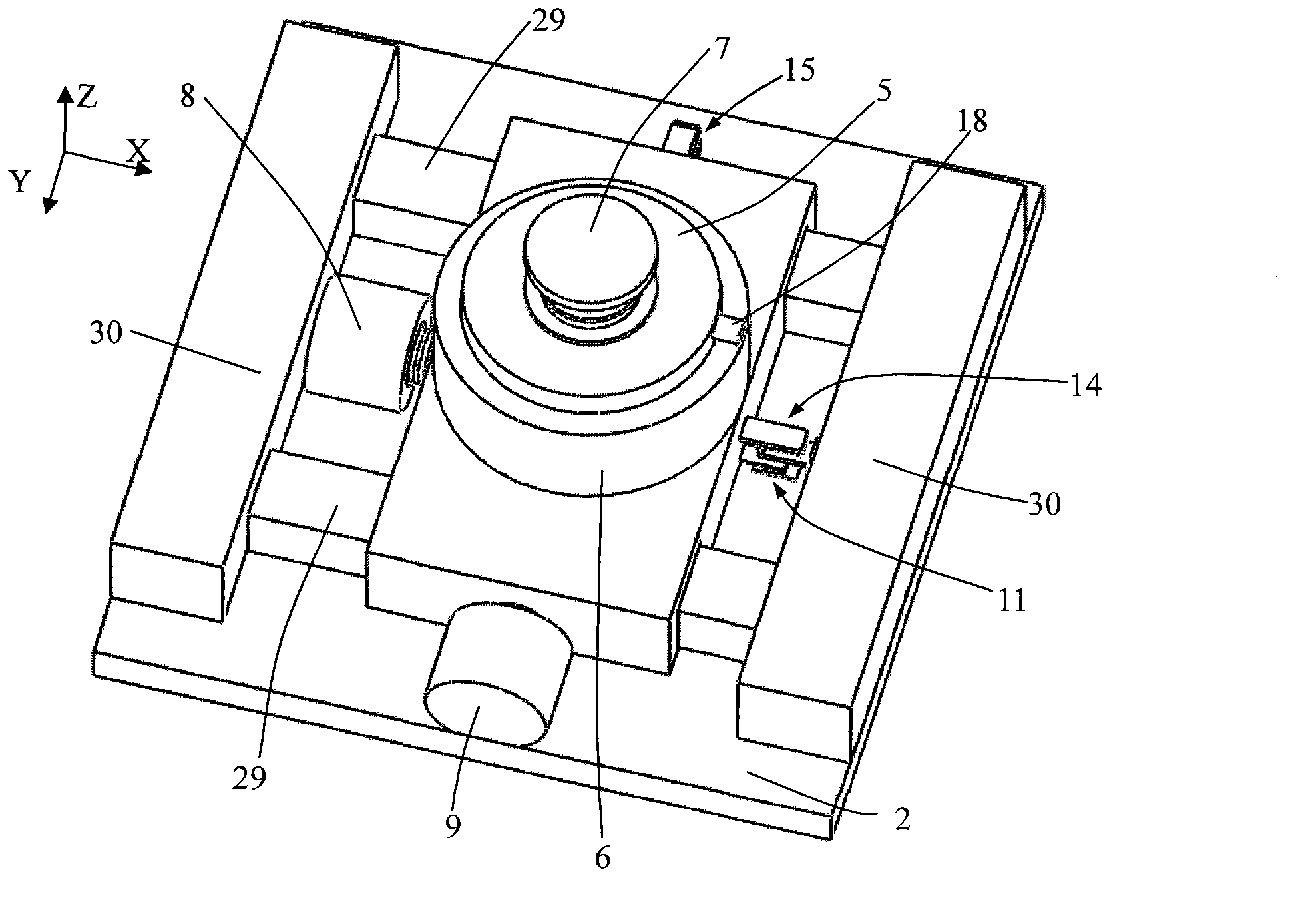

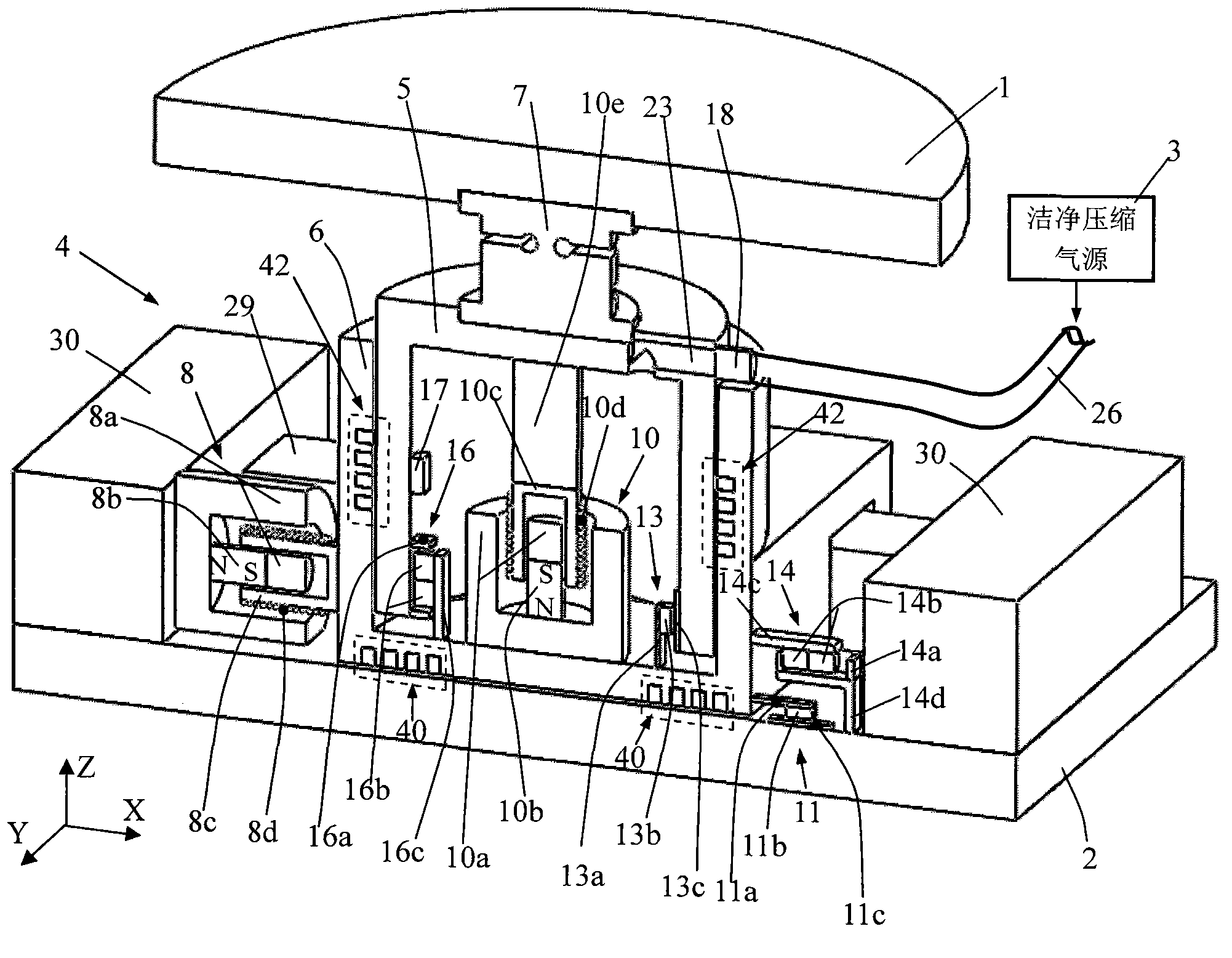

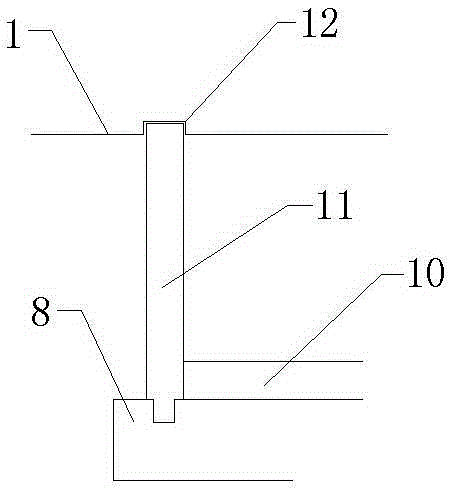

Silicon wafer transfer device

ActiveCN103901732AResolve frictionLow costPhotomechanical exposure apparatusMicrolithography exposure apparatusManipulatorSilicon

The invention discloses a silicon wafer transfer device. The silicon wafer transfer device comprises a wafer receiving manipulator, an air flotation guide rail device, a driving mechanism and a base, wherein the air flotation guide rail device comprises an air flotation guide rail stator and an air flotation guide rail rotator, the air flotation guide rail stator is fixed on the base, the air flotation guide rail rotator is arranged on the air flotation guide rail stator in a sleeving manner and is fixedly connected with the wafer receiving manipulator, and the driving mechanism drives an air flotation guide rail device to move. The silicon wafer transfer device disclosed by the invention solves the problem of friction of a guide mechanism in the prior art by adopting the air flotation guide rail device, ensures that the wafer receiving manipulator can return to the lowest position after a silicon wafer is transferred, and eliminates the potential safety hazard as the wafer receiving manipulator cannot return to the lowest position in silicon wafer transferring in the prior art, meanwhile the entire structure is simple, and the cost is low.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

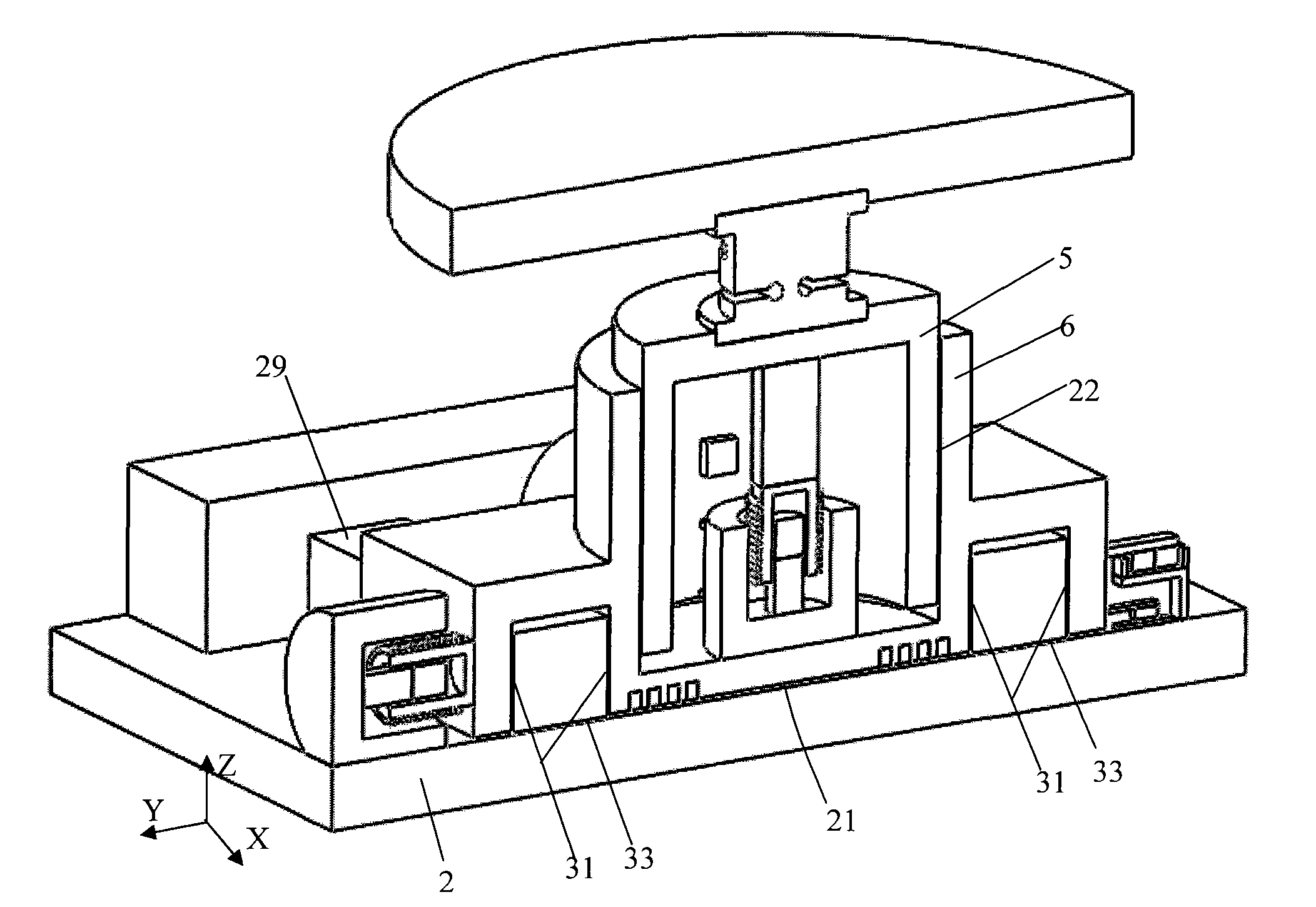

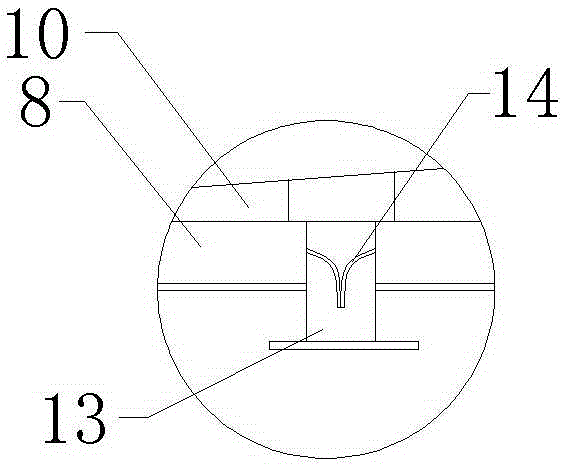

Eddy-current damping vibration isolator with coplace air flotation orthogonal decoupling and two-dimensional flexible hinge angle decoupling

ActiveCN103062307AGood effectOutstanding ultra-low frequency vibration isolation performanceNon-rotating vibration suppressionMagnetic springsLinear motionClosed loop feedback

The invention discloses an eddy-current damping vibration isolator with coplace air flotation orthogonal decoupling and two-dimensional flexible hinge angle decoupling and belongs to the technical field of precise vibration isolation. A sleeve of the main body of the vibration isolator and an air flotation plate are lubricated and supported by an air flotation surface, a piston sleeve and the sleeve are lubricated and supported by the air flotation surface, an eddy-current damper is used for attenuating vibrating energy and improving positioning stability, the freedom of the horizontal linear motion between an upper installation plate and a lower installation plate is decoupled through a coplace orthogonal air flotation guide rail, the freedom of angular motion between the upper installation plate and the lower installation plate is decoupled through a two-dimensional flexible hinge, and a voice coil motor, a displacement sensor, a limiting switch and controller and a driver form a position closed-loop feedback control system to accurately control the relative positions of the upper installation plate and the lower installation plate. The eddy-current damping vibration isolator has the advantages of being zero in three-dimensional rigidity, high in positioning accuracy, and capable of performing linear motion freedom decoupling and angular motion freedom decoupling, and can effectively meet the high-performance requirements of ultra-precise measurement instruments and processing equipment, particularly step scanning photoetching machines.

Owner:HARBIN INST OF TECH

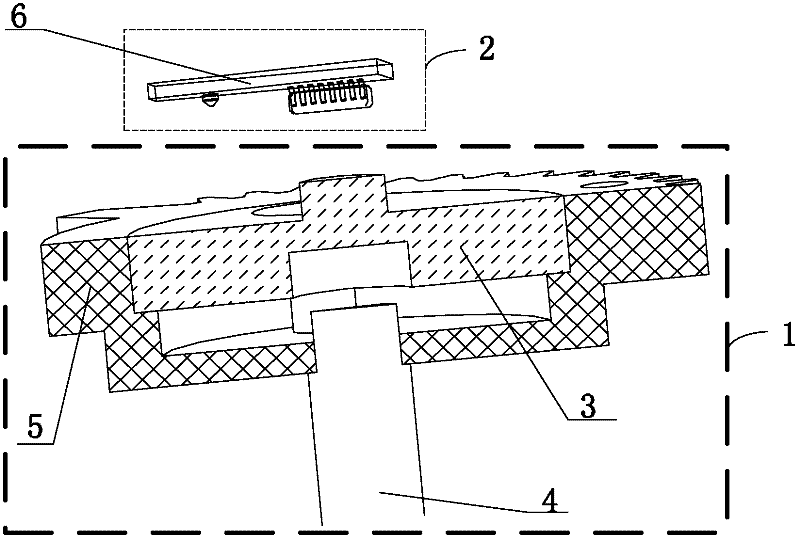

Board-side net-hauling tension testing device

InactiveCN104527936AHigh measurement accuracyConducive to optimal matchingFishing netsFishing vesselsExercise stateFriction force

The invention relates to a board-side net-hauling tension testing device which comprises a machine frame. A power device, a torque meter and a board-side roller are coaxially arranged on the machine frame, one end of the board-side roller is fixedly connected with the torque meter, and the other end of the board-side roller is axially and radially positioned by a telescopic ejection pin. A tested net piece is arranged above the board-side roller in a covering mode, the front end and the rear end of the tested net piece are respectively fixed by one net locking guide roller, band friction pressing devices are arranged on two sides of each net locking guide roller, adjusts net piece rolling friction force by adjusting clamping forces on two sides of the net piece and accordingly simulates net piece load in a static or moving state. Pull press sensors are installed at two ends of each of front and rear net locking guide rollers and used for detecting change of tightness degree of the front-rear net piece when the board-side roller rotates. The other end of each pull press sensor is fixed to a bottom sliding guide rod. A wrap angle of the net piece to the board-side roller can be changed by moving the position of the sliding guide rod on a guide rail.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Ultrahigh-voltage direct-current sleeve joint

ActiveCN104505784AIncrease contactSolve electric field distortionElectrical apparatusTime costDirect current

The invention provides an ultrahigh-voltage direct-current sleeve joint. The ultrahigh-voltage direct-current sleeve joint comprises a conducting pipe as well as an epoxy pipe and a supporting cover plate which are arranged coaxially relative to the conducting pipe, wherein the supporting cover plate is provided with a through hole which is vertical to the axial direction of the supporting cover plate and coaxial with the conducting pipe and the epoxy pipe; the conducting pipe passes through the through hole and is connected with a top cover plate; a part, surrounded between the supporting cover plate and the top cover plate, of the conducting pipe is provided with a corrugated pipe which is positioned at the upper end of the supporting cover plate and connected with the supporting cover plate and the top cover plate. Compared with the prior art, the ultrahigh-voltage direct-current sleeve joint disclosed by the invention has the advantages of solving the problem of extension and contraction of the conducting pipe by enabling the corrugated pipe to extend and contract correspondingly along with the extension and contraction of the conducting pipe, solving the problem of metal friction caused by hard connection between parts, improving the sealing reliability, guaranteeing good leakproofness of a sleeve chamber body, improving the problem of easy loosening caused by own gravity of the parts, simplifying the installation process of the conducing pipe and lowering the time cost.

Owner:STATE GRID CORP OF CHINA +1

Noncontact sensor

InactiveCN102331268AResolve frictionMeet testing needsConverting sensor output electrically/magneticallySystem integrationExhaust gas recirculation

The invention discloses a noncontact sensor which can solve the problem of friction brought by the traditional contact sensor, and can improve the detection precision and meet the detection demands of a vehicle on an electronic air throttle and an electronic exhaust gas recirculation valve. Because a programmable chip is adopted, the same type of sensors can be used in different types of electronic air throttles and electronic exhaust gas recirculation valves, the volume production is facilitated, and the product cost is lowered. Meanwhile, in research and development processes of new products, the noncontact sensor can adapt to technical requirements of different system integration factories, thus the development cost is greatly lowered, and the development period is shortened.

Owner:XIHUA UNIV

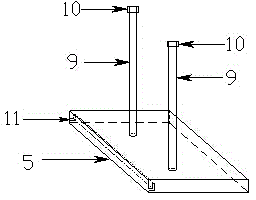

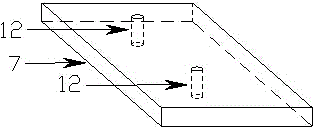

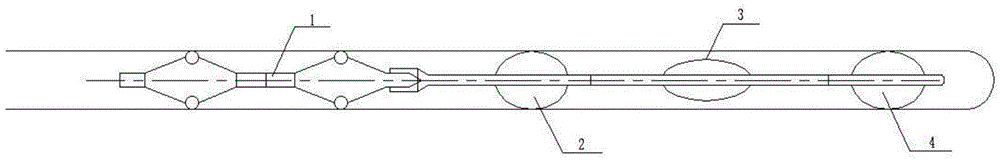

Water exploration testing device for horizontal well in offshore oilfield and dynamic dividing and positioning method of water exploration testing device

InactiveCN105484736ASolve complex structuresSolve the problem that layered testing cannot be performedSurveyStreamflowWater content

The invention discloses a water exploration testing device for a horizontal well in an offshore oilfield. The water exploration testing device comprises a downhole crawler, a lower divider, a water content tester and an upper divider which are connected in sequence. The invention further discloses a dynamic dividing and positioning method using the water exploration testing device. The method includes the steps that firstly, the water exploration testing device is lowered into the well; secondly, the downhole crawler pulls the water exploration testing device to a target interval, water exploration testing is conducted, and data is fed back to the ground; thirdly, analog computation of the flow field change of a wellhole is conducted through ground software, and a water exit interval is positioned to achieve accurate water exploration; fourthly, the downhole crawler pulls the water exploration testing device to a next target interval, water exploration testing is conducted again, and the steps are circularly conducted in sequence till water exploration testing of a whole horizontal interval is completed. The construction process is simple, the automation level is high, dynamic sectional packaging is achieved in the variable-flow wellhole, the water exit position is accurately judged, and the water exploration efficiency is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

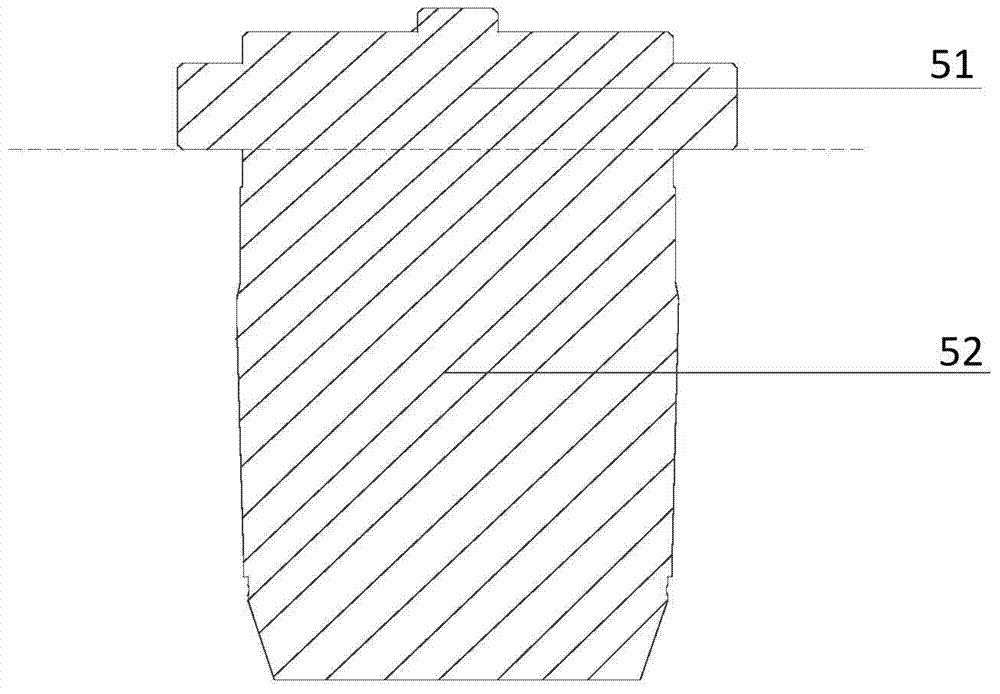

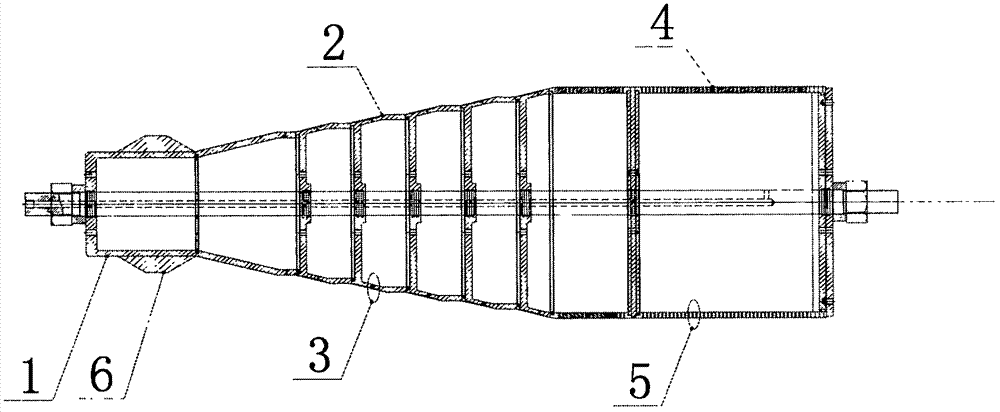

Expansion mold, production line and method for producing PVC-O, BOPVC and biaxially oriented PVC pipes

The invention discloses an expansion mold for producing PVC-O, BOPVC and biaxially oriented PVC pipes. The expansion mold comprises a guide section, pipe diameter expansion units and a fixed diameter section; the pipe diameter expansion units are of a cone structure, a small-diameter end of the pipe diameter expansion units is connected with the guide section, and first through holes are formed in the surfaces of the pipe diameter expanding units; the fixed diameter section is arranged at the rear end of the pipe diameter expanding units, and a second through hole is arranged on the fixed diameter section. According to the expansion mold, the pipe diameter expansion units can form a step-shaped pipe diameter expanding structure so that the product quality after expanding the diameter of the PVC-O pipe can be improved, and the operation difficulty of bidirectional stretching of the pipe can be greatly reduced; a plurality of the through holes are formed in the expansion units and the fixed diameter section, the pressure can be output outwards through the through holes in the expansion mold to counteract the retraction force of the tube itself so that a blank tube can pass through the mold in a small resistance state, the problem that the resistance between the blank tube and the mold is large can be greatly solved, and therefore the biaxially oriented operation difficulty of the PVC pipe is greatly reduced.

Owner:孙建凯

Automatic decoking equipment

InactiveCN103846260ATo achieve the purpose of decokingLow costHollow article cleaningAutomatic test equipmentCoupling

The invention relates to automatic decoking equipment. The automatic decoking equipment comprises a hollow bit, a coupling, a motor reduction gearbox, a stepping motor, a linear sliding rail, a ball screw, a feeding support frame, a first fixing piece, a decoking equipment support, a coke tower and a second fixing piece; the linear sliding rail is arranged above one side of the decoking equipment support, and the feeding support frame, the first fixing piece and the second fixing piece are arranged above the other side of the feeding support frame; the stepping motor is arranged at the right end part of the decoking equipment support and is connected with the motor reduction gearbox and the coupling; the hollow bit is connected in the axial direction of the coupling and is axially butted with the coke tower; the ball screw is arranged between the motor reduction gearbox and the feeding support frame; the hollow bit is fixedly arranged on the feeding support frame and a sliding block of the linear sliding rail; the coke tower is arranged on the first fixing piece and the second fixing piece. The automatic decoking equipment has the advantages that the labor intensity of operators can be greatly reduced, the working efficiency can be improved and the testing cost is reduced.

Owner:KYMSON LUOYANG PETROCHEM EQUIP

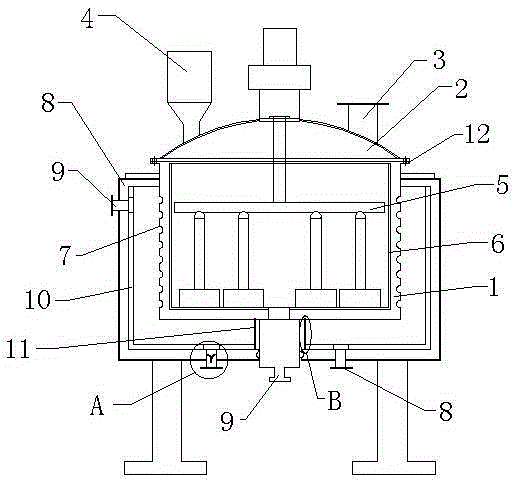

Reaction and separation integrated process and device for synthesizing poly-alpha-olefin (PAO)

InactiveCN106622039AGood dispersionAchieve reusable functionalityChemical industryChemical/physical processesLewis acid catalysisAlpha-olefin

The invention discloses a reaction and separation integrated process and device for synthesizing poly-alpha-olefin (PAO). The reaction and separation integrated process comprises the following steps: putting an alpha-olefin raw material and a magnetic lewis acid catalyst in a ratio into a reaction and separation integrated device, after the reaction is completed, powering on an electromagnetic sucker inside a reaction kettle to magnetize the magnetic lewis acid catalyst to adsorb onto the surface of the electromagnetic sucker, and feeding a discharged reaction clean liquid into a next procedure. By adopting the reaction and separation integrated device, the problem that the lewis acid catalyst in PAO synthesis is hard to separate can be solved. By adopting the process and the device, PAO process procedures can be greatly simplified, the number of production devices can be reduced, energy consumption for separating the catalyst can be reduced, the production cost of PAO can be lowered, and green, environment-friendly and efficient production of PAO can be achieved.

Owner:ZHONGBEI UNIV

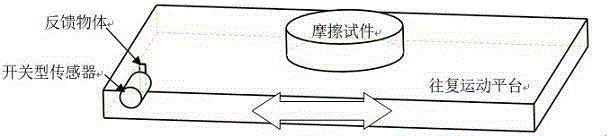

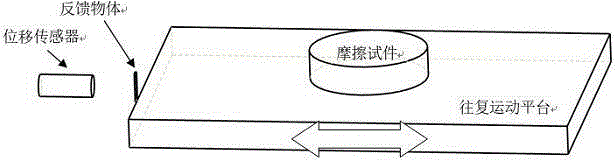

Method for recording friction force of reciprocating type friction testing machine through position information

ActiveCN105300878AHighlight substantiveResolve frictionUsing mechanical meansApparatus for force/torque/work measurementReciprocating motionData acquisition

The invention relates to a method for recording friction force of a reciprocating type friction testing machine through position information. The method includes the following specific steps that 1, a feedback object is installed at the designated position of a reciprocating motion platform fixed with a friction test piece, and then the reciprocating motion platform reciprocates; 2, a sensor is installed at the designated position, connected with an upper computer and controlled by the upper computer; when the feedback object on the reciprocating motion platform moves to the preset position corresponding to the sensor, signal information transmitted to the upper computer by the sensor is identical with preset information of the upper computer, and a control program acquires friction force data of the friction test piece to the upper computer. The problems that a fixed-period friction force data acquisition method is large in friction force data deviation, instable and large in data size can be effectively solved by judging the position information of the friction test piece and recording the friction force data of the reciprocating friction testing machine at the preset position.

Owner:SHANGHAI UNIV

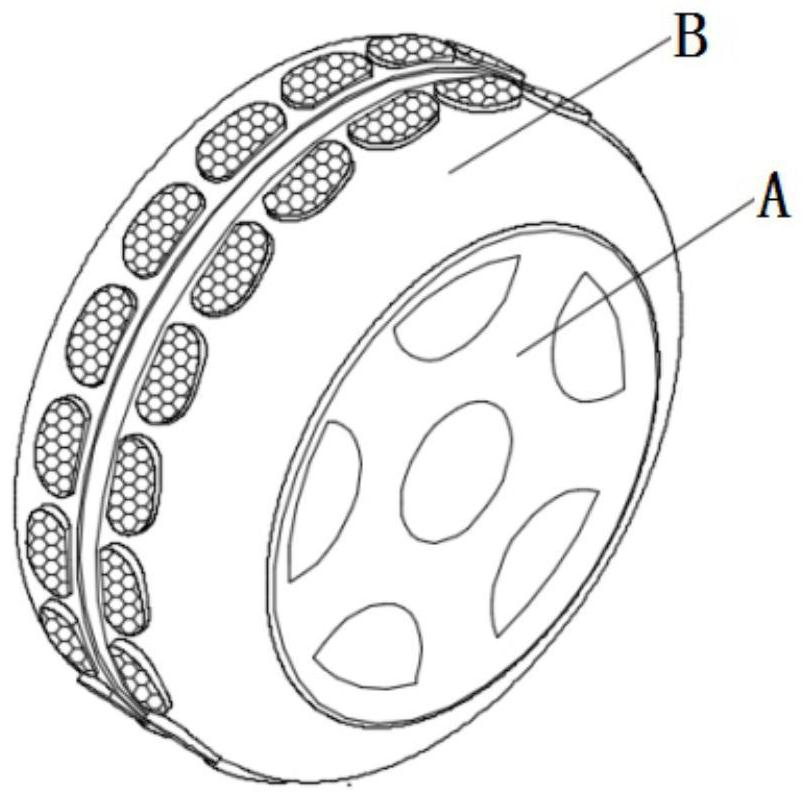

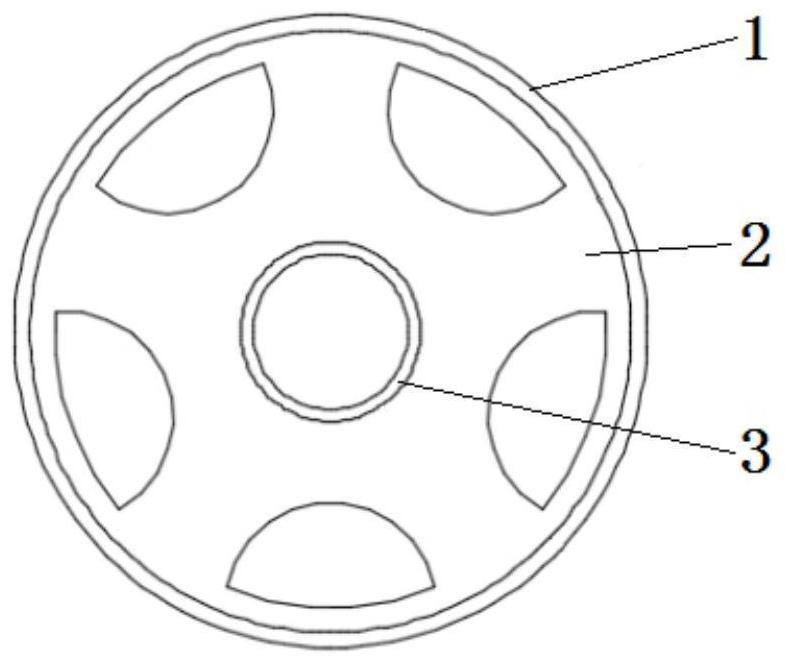

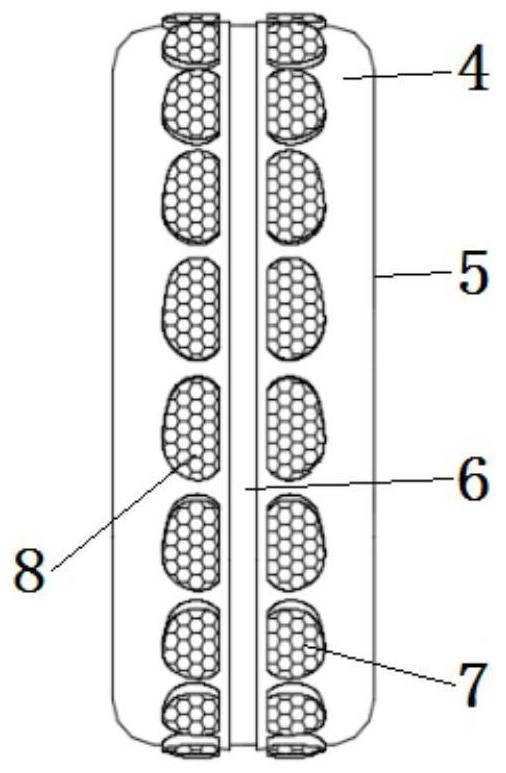

All-region bionic wheel of off-road vehicle

PendingCN113043795AGood envelopmentImprove local stiffnessTyre tread bands/patternsControl theoryTread

An all-terrain bionic wheel for off-road vehicles belongs to the technical field of tire tread pattern structure design, and is characterized in that 30-36 pattern blocks in each of two pattern block groups are uniformly distributed on the circumference of a wheel surface and are symmetrically arranged on the left and right sides of a groove; regular hexagonal column structures which are uniformly distributed are arranged in the peripheral contour line of the single pattern block, and the bottom structure L2 of the pattern block is 10-15mm; the side length L4 of the regular hexagon ranges from 15 mm to 20 mm; and the height L5 of the regular hexagonal column is 10-13 mm. And along with the change of the tire pressure, the distance between the adjacent regular hexagons is 0-5mm. According to the invention, a camel toe structure and a tree frog foot biological structure are used for reference, and a pattern structure suitable for various ground environments is formed by changing the distance between the pattern blocks, so that the adhesion capability of the tire on low-adhesion roads such as soft, muddy, frozen and slippery roads can be improved.

Owner:JILIN UNIV

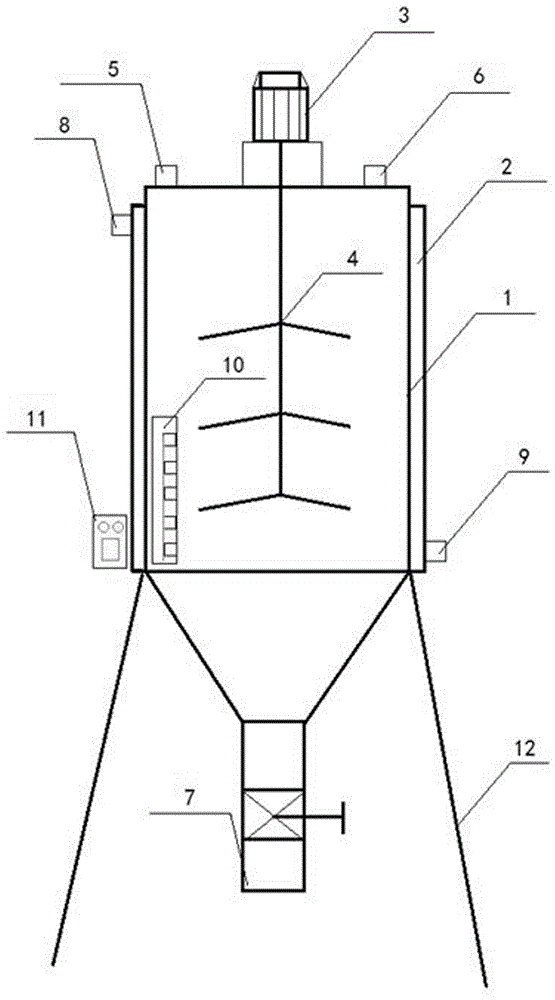

Acid- and alkali-resistant stirring drier

ActiveCN105352295AImprove heat transfer efficiencyReduce heat lossDrying solid materials without heatDrying chambers/containersMechanical engineeringInsulation layer

The invention discloses an acid- and alkali-resistant stirring drier. The acid- and alkali-resistant stirring drier comprises a barrel cover which is arranged at the upper end of a barrel cylinder, a feeding port which is formed in one upper side of the barrel cover, an air exhausting device which is arranged at the other upper side of the barrel cover, and a stirring device which is arranged in the upper middle of the barrel cover, wherein a slipping-aiding wear-resisting layer is arranged on the inner wall of the barrel cylinder; a plurality of U-shaped grooves are excavated in the outer wall of the barrel cylinder; a barrel body is arranged at the outer part of the barrel cylinder, and a discharging port is formed in the lower end of the barrel cylinder; a heat insulation layer is also arranged between the barrel body and the barrel cylinder, and a vertical slot is formed in the surface of the heat insulation layer. With the adoption of the acid- and alkali-resistant stirring drier, the problem of low efficiency of the drier in the heat exchanging process can be solved, and the damage caused by that the inside of the drier is affected with damp can be removed; meanwhile, a material for the barrel cylinder is also provided, thus various comprehensive performances of the barrel cylinder are improved, and the service life is prolonged.

Owner:四川知格科技有限公司

Voice coil motor with linear bearing guiding

InactiveCN110086319ARealize reciprocating motionResolve frictionPropulsion systemsReciprocating motionControl theory

The invention discloses a voice coil motor with linear bearing guiding. The motor comprises an external stator of the voice coil motor, a rotor coil of the voice coil motor, a guiding circular shaft and a linear bearing. A central hole of the external motor of the voice coil motor is enlarged according to the structure and shape of a voice coil motor product, the cylindrical linear bearing is pressed into the central hole, the linear bearing and guiding circular shaft are fixed to the center of the coil of the matched voice coil motor rotor to play a center fixing effect, and the guiding circular shaft cooperates with the linear bearing to realize reciprocal movement of the rotor coil, and the problem of friction between the voice coil rotor coil and stator can be overcome.

Owner:昆山同茂电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com