Acid- and alkali-resistant stirring drier

A stirring dryer, acid and alkali resistant technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problem of low efficiency of dryers, improve heat exchange efficiency, reduce impact, and reduce heat the effect of the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

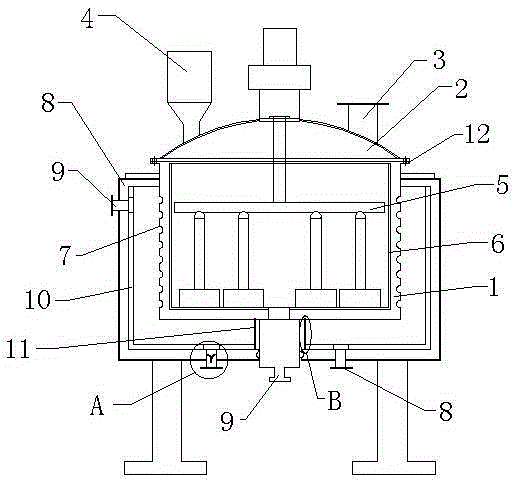

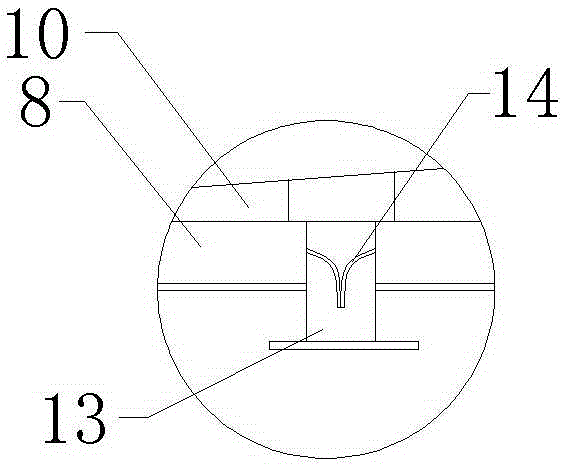

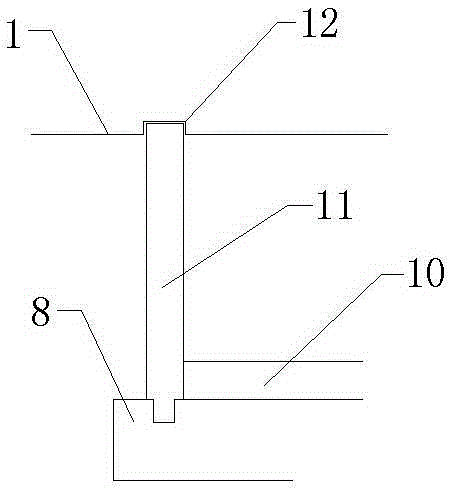

Embodiment 1

[0031] like figure 1 It shows, a acid -alkaline -resistant mixing dryer, including a tube cover 2 on the upper end of the cylinder cylinder, the inlet of the feed inlet on one side of the tube cover 2, and the pump on the other side above the tube cover 2Qi Device 4, a stirring device 5 in the middle of the tube cover 2, the inner wall of the cylinder 1 is provided with a layer of sliding wear -resistant layer 6, and several U -shaped grooves 7 in the outer wall of the tube cylinder 1.There is a cylindrical body 8 on the outside of the cylinder, and a purse port 9 is provided with the lower end of the cylinder 1. There is also a thermal insulation layer 10 between the cylinder 8 and the cylinder 1.Groove; the thickness of the cylinder 1 is 1-5mm (the best thickness is 3mm, of course, you can also choose 1mm or 5mm), the depth of the U-shaped groove 7 of the outer wall of the cylindrical cylinder 10.8mm, according to the thickness of the cylinder 1, you can also choose 0.5mm or 1mm)....

Embodiment 2

[0041] The embodiment is the same as the embodiment. The difference is that the components of the acid -alkali -resistant stainless steel are calculated based on the weight percentage (the following%indicate the weight percentage): 0.17%, nickel is 7%, chromium is 9 to 9%, Manganese is 11%, 0 is 0.58 %%, 钒 0.32%, molybdenum is 1.8%, titanium is 4%, rare earth is 0.53%, the total amount of phosphorus and sulfur does not exceed 0.035%.Unavoidable impurities, the preparation process of acid -alkali -resistant stainless steel includes the following steps:

[0042] Step 1. Use the medium -frequency induction electric furnace to melt. The sequence of metal furnaces is the order of raw iron, scrap steel, molybdenum, nickel iron, manganese iron, chromium iron, and the felting temperature is 1610 ° C.After that, the molybdenum, iron, titanium iron, and iron iron are added. At the end of the melting, the rare earth is added to make the alloy composition in the steel reaches the predetermine...

Embodiment 3

[0047] The embodiment is the same as the embodiment 1 and the embodiment two. The difference is that the components of the acid -alkali stainless steel are calculated at the weight percentage (the following%indicate the weight percentage), Chromium is 10%, manganese is 9.5%, 铌 is 0.65%, 钒 0.27%, molybdenum is 1.5%, titanium is 3.7%, rare earth is 0.46%, the total amount of phosphorus and sulfur does not exceed 0.035%, and the remaining amount is to be the amount.The unavoidable impurities of iron, the preparation process of acid -alkali -resistant stainless steel includes the following steps:

[0048] Step 1. Use the medium -frequency induction electric furnace to melt. The sequence of metal furnaces is the order of raw iron, scrap steel, molybdenum, nickel iron, manganese iron, chromium iron, and the felting temperature is 1610 ° C.After that, the molybdenum, iron, titanium iron, and iron iron are added. At the end of the melting, the rare earth is added to make the alloy composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com