High performance water lubricating mechanical driving system

A mechanical transmission system, water lubrication technology, applied in mechanical equipment, elastic couplings, shafts and bearings, etc., can solve problems such as difficult debugging, complex shaft structure, shaft alignment, seal leakage, etc., to achieve high efficiency, energy saving and environmental friendliness , The effect of solving lubricating oil pollution and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

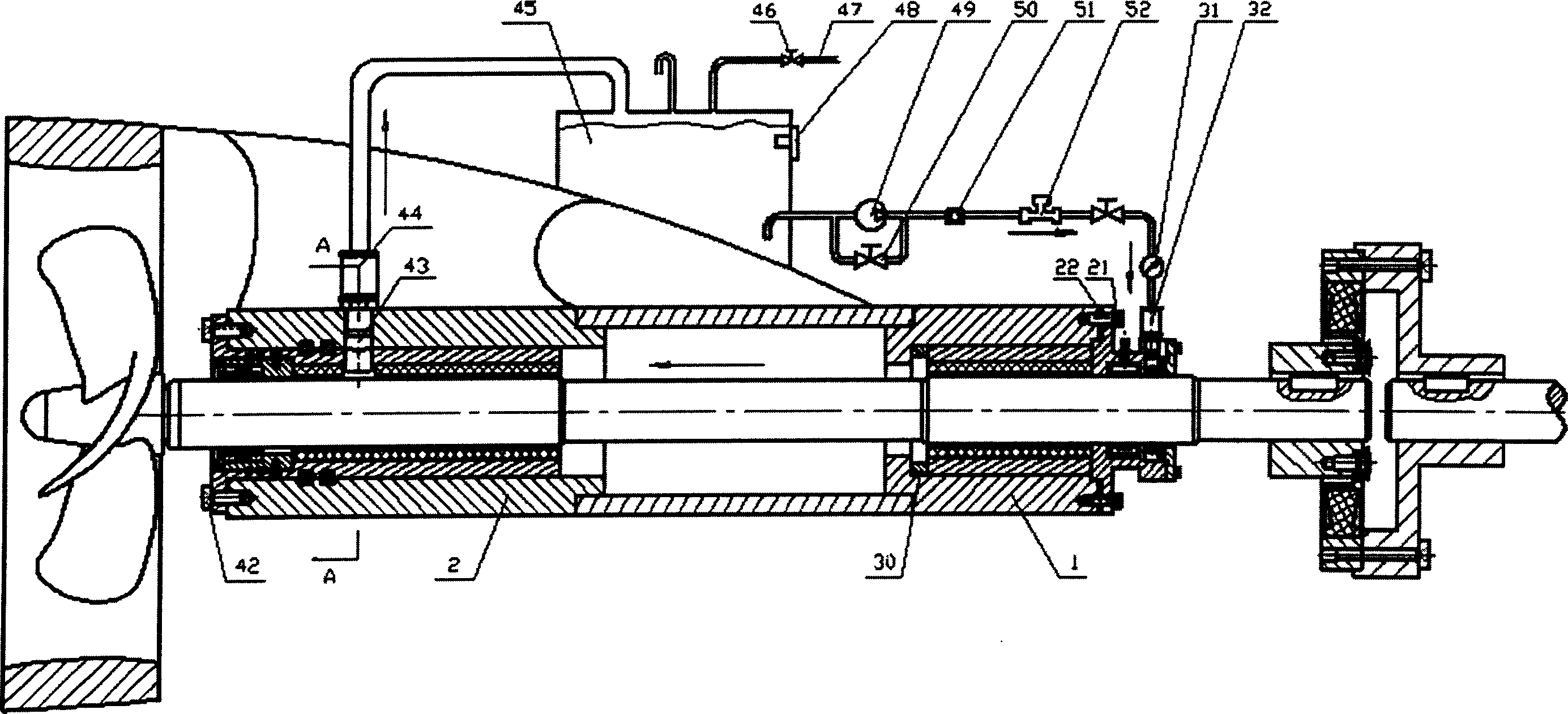

[0029] The high-performance water-lubricated mechanical transmission system uses a closed-type water-lubricated transmission device to apply to the working process of the ship's stern shaft propulsion system:

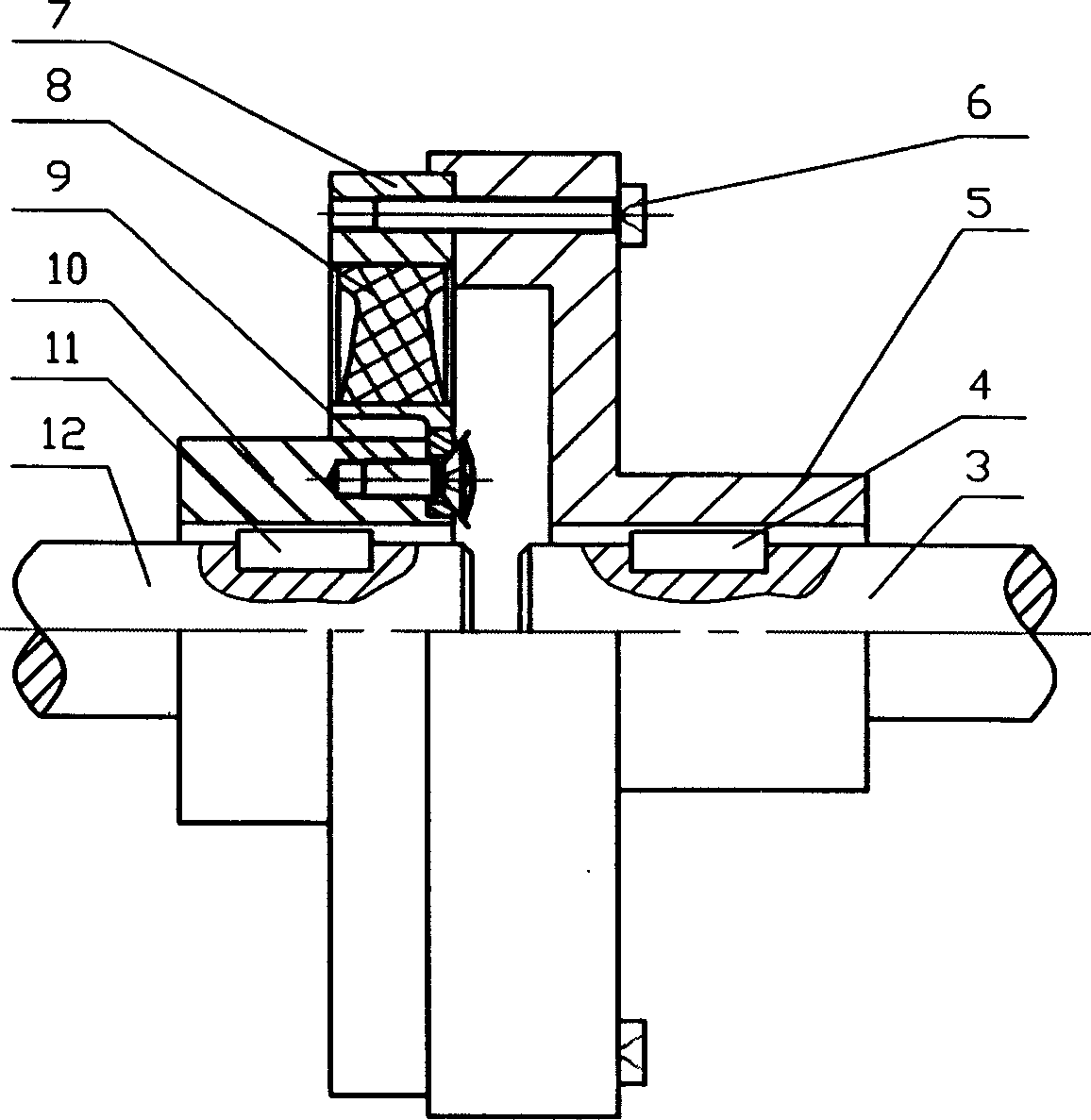

[0030] Such as figure 1 As shown, the high elastic coupling connects the driving shaft 3 and the driven shaft 12 respectively, and the sealing device, the front water-lubricated bearing and the front bearing seat 1, the water-lubricated dynamic sealed bearing and the rear Set the bearing seat 2. Water is first injected into the water tank 45 through the water supply channel, and the low water level switch 48 can control the height of the water level in the water tank. Turn on the water flow switch 52, the pump 49 enters the water in the water tank into the sealing device through the water inlet screw head 32, the airbag seal 20 is not inflated, and the water can enter the front water lubricated bearing and the water lubricated dynamic sealed bearing for lubrication , ...

Embodiment 2

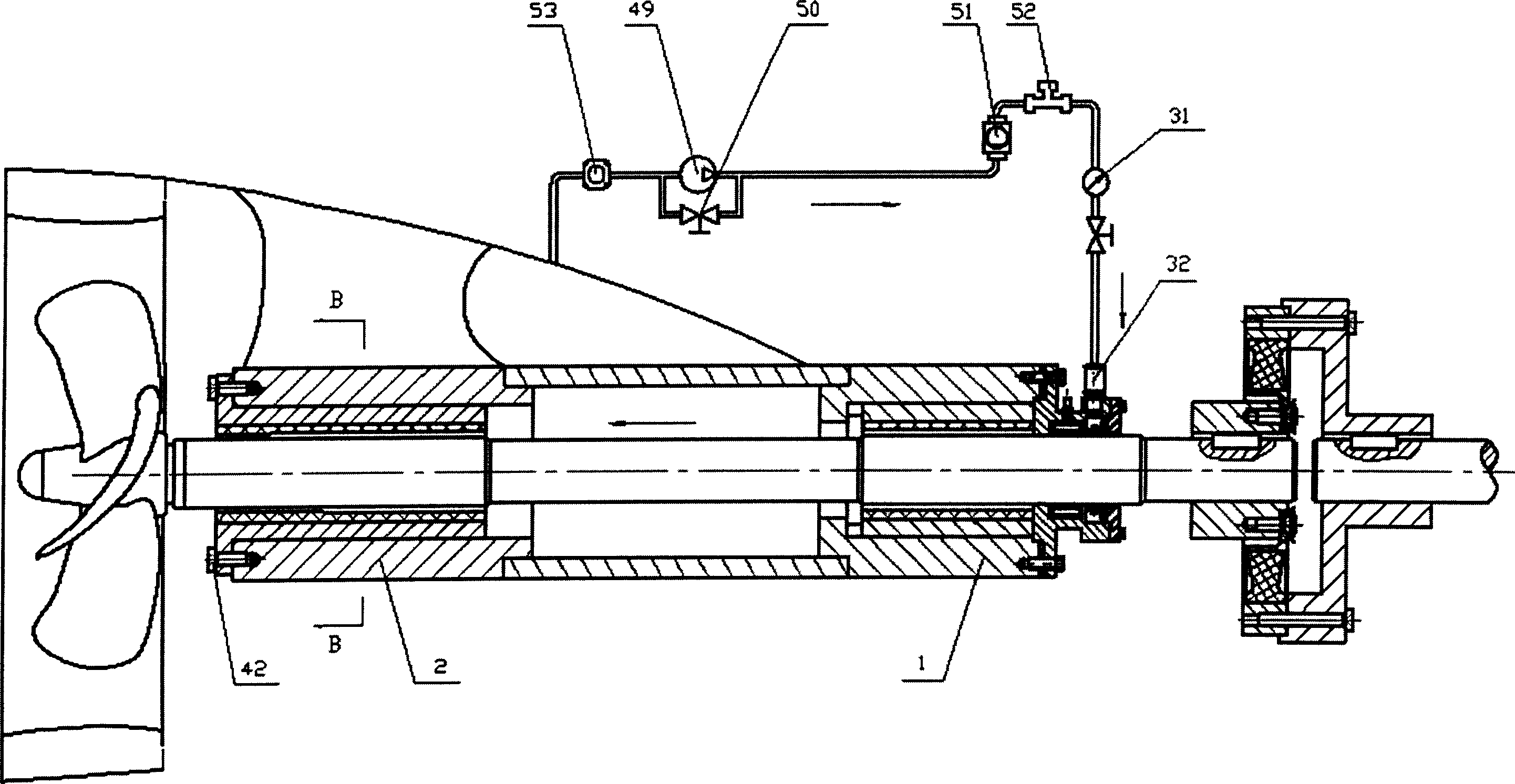

[0036] The high-performance water-lubricated mechanical transmission system adopts the open water-lubricated transmission device and is applied to the working process of the ship stern shaft propulsion system:

[0037] Such as figure 2 As shown, the high elastic coupling connects the driving shaft 3 and the driven shaft 12 respectively, and the sealing device, the front water lubricated bearing and the front bearing seat 1, the flanged water lubricated bearing and the Rear bearing seat 2. Turn on the water flow switch, the pump 49 will directly enter the seawater outside the hull into the sealing device through the filter device 53, the flow meter 51 and the water inlet coil head 32, the airbag seal 20 is not inflated, and the water can enter the front water lubricating bearing and the method. Lubricated in blue-type water-lubricated bearings.

[0038] When the propulsion shaft rotates in the front water-lubricated bearing and the flange-type water-lubricated bearing, on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com