Patents

Literature

185 results about "Shaft alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shaft alignment is the process of aligning two or more shafts with each other to within a tolerated margin. It is an absolute requirement for machinery before the machinery is put in service. When a driver like an electric motor or a turbine is coupled to a pump, generator, or any other piece of equipment, it is essential that the shafts of the two pieces are aligned. Any misalignment between the two increases the stress on the shafts and will almost certainly result in excessive wear and premature breakdown of the equipment. This can be very costly. When the equipment is down, production might be down. Also bearings or mechanical seals may be damaged and need to be replaced. Flexible couplings are designed to allow a driver (electric motor, engine, turbine, hydraulic motor) to be connected to the driven equipment. Flexible couplings use an elastomeric insert to allow a slight degree of misalignment. Flexible couplings can also use shim packs. These couplings are called disc couplings. Tools used to achieve alignment may be mechanical or optical, like the Laser shaft alignment method, or they are gyroscope based. The gyroscope based systems can be operated very time efficient and can also be even used if the shafts have a large distance (e.g. on marine vessels).

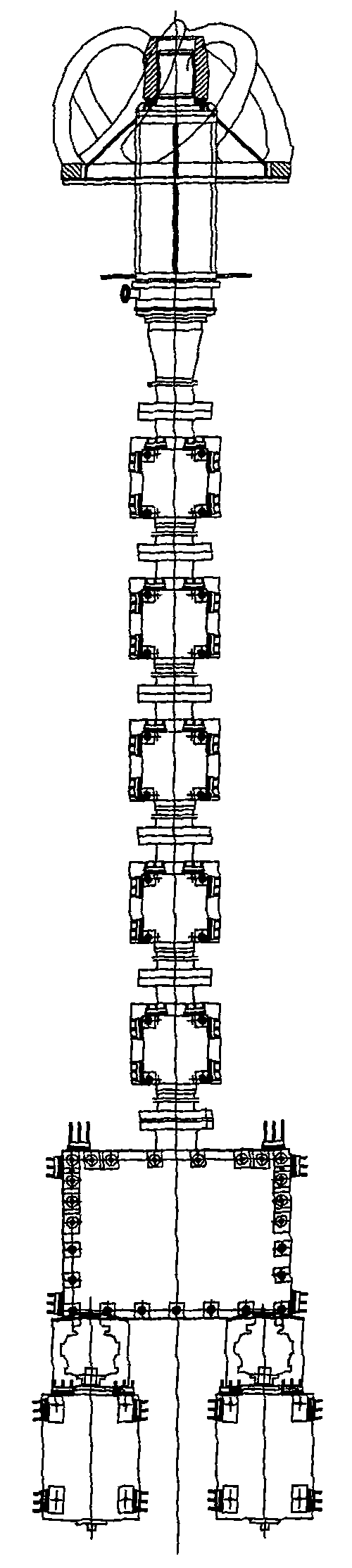

Vertical shaft alignment tool

InactiveUS20060112577A1Reduce and equalize bearing loadReduced bearing lifeAngles/taper measurementsUsing fluid meansMicrocomputerData acquisition

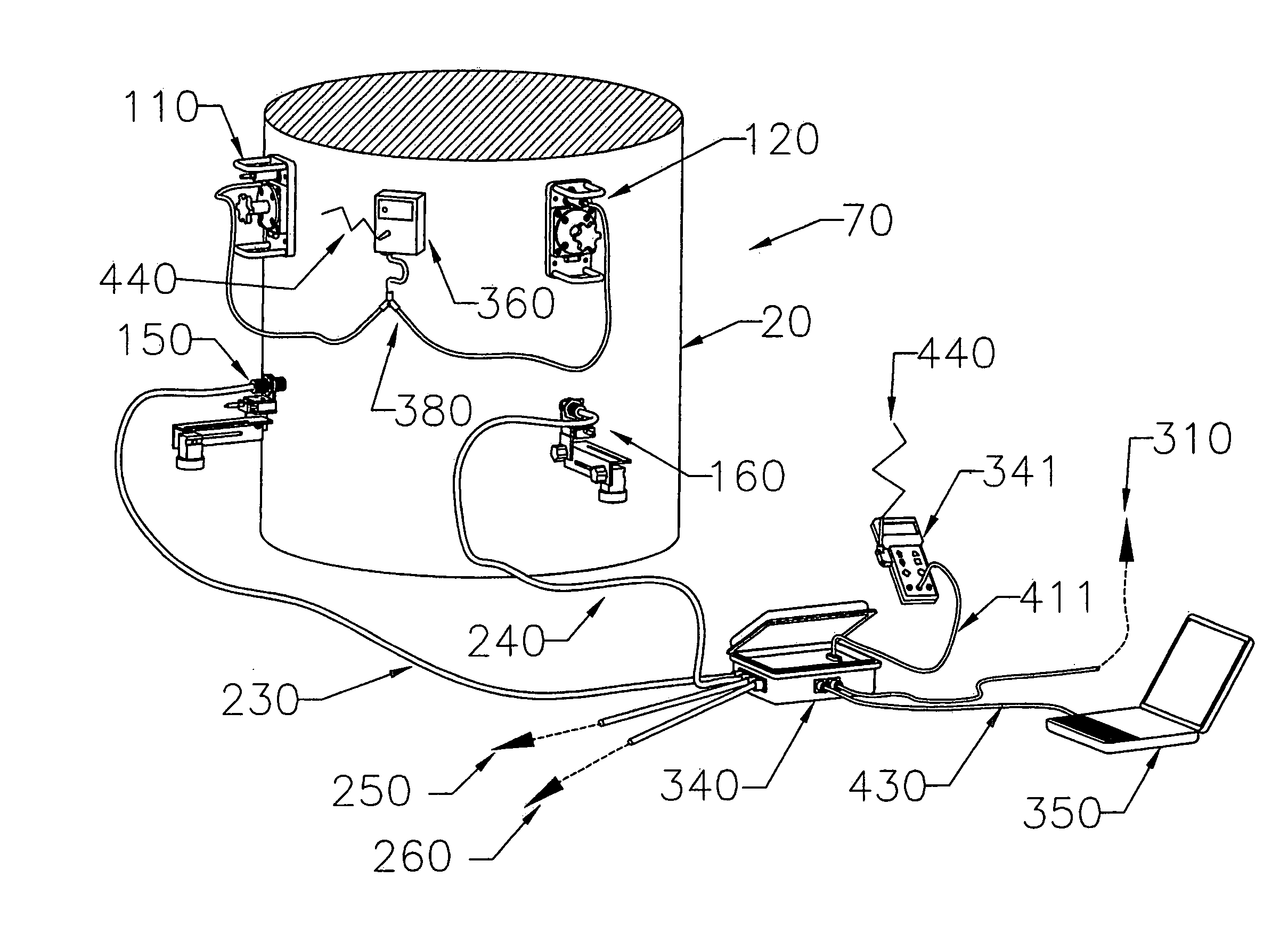

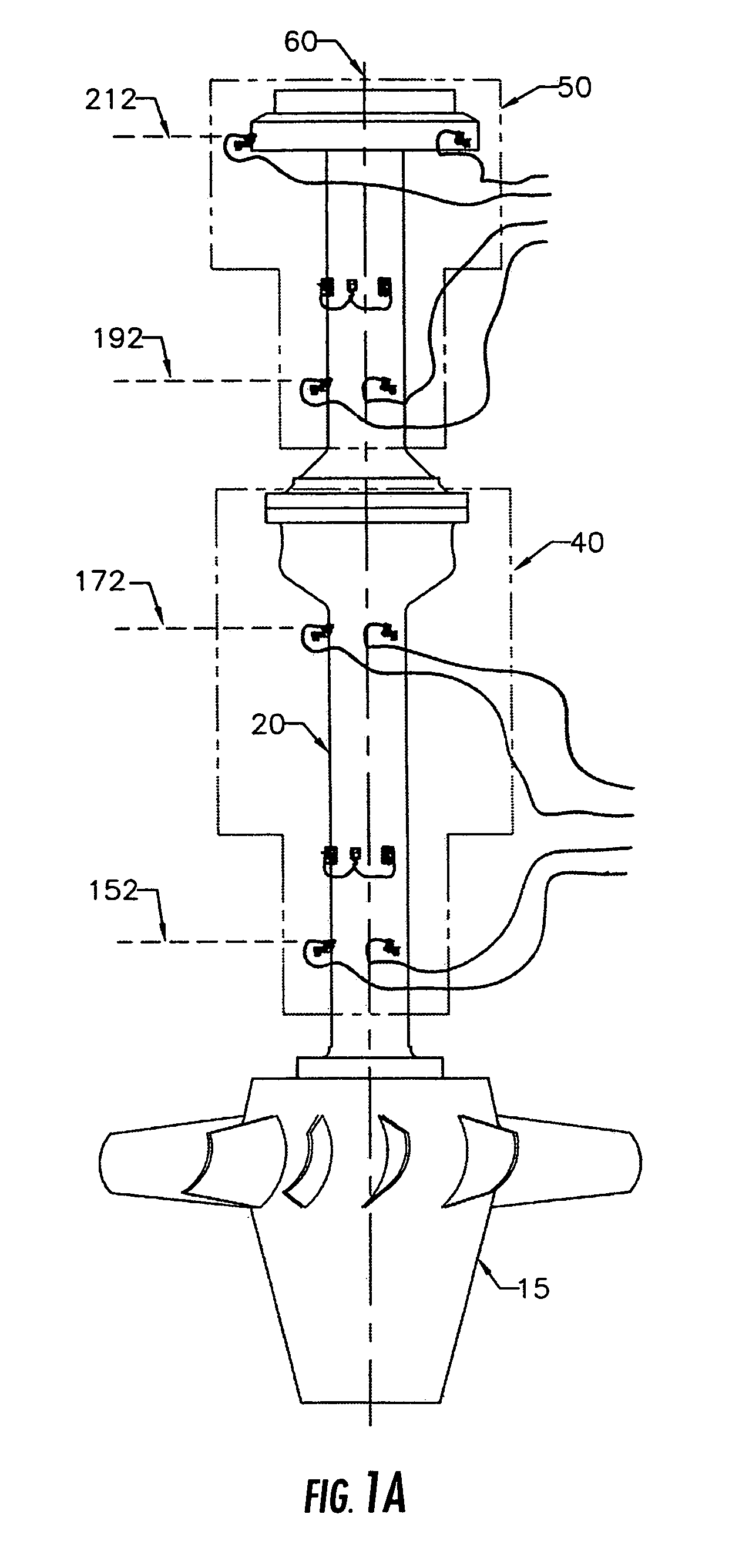

An apparatus and a method for aligning a vertical shaft or multiple axially coupled vertical shafts in a hydroelectric turbine generator or a similar vertical-shaft system, and for providing precise plumb inclination alignment of a vertical rotating shaft. Precision inclinometers attached to the vertical shaft measure plumb inclination. Proximity probe displacement devices mounted externally of the vertical shaft measure radial movement, throw, or run out at various shaft elevations as the shaft is rotated relative to a fixed point. Data acquisition devices and communication devices accumulate and transmit alignment data to a micro-computer which receives and processes such data. Methods of defining shaft plumb inclination in a static single rotational position and defining plumb inclination of the virtual centerline of a shaft's rotational throw position. A method of swinging, tilting, or adjusting a vertical shaft to a corrected or different plumb position relative to the earth's gravity.

Owner:TENNESSEE VALLEY AUTHORITY

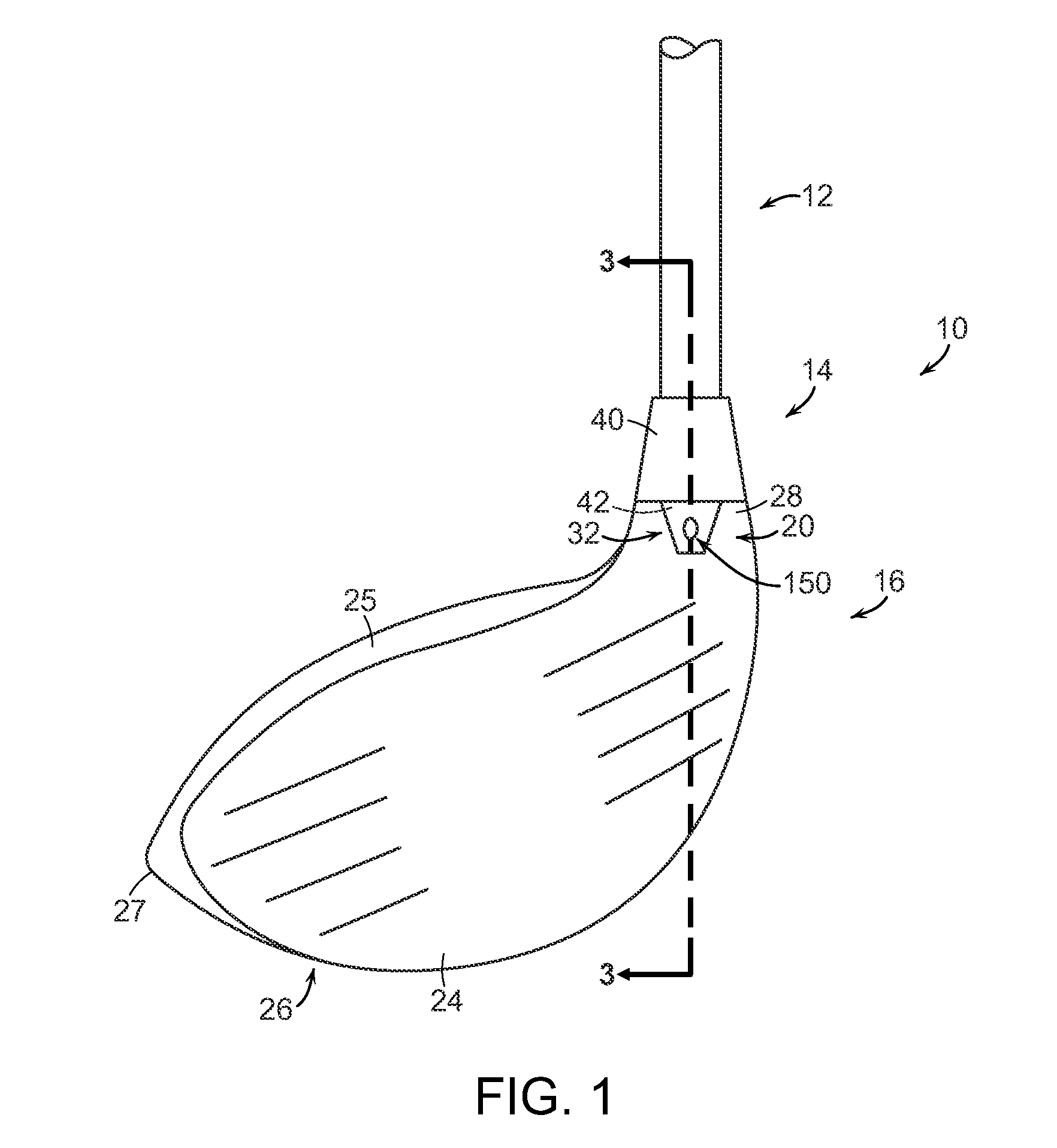

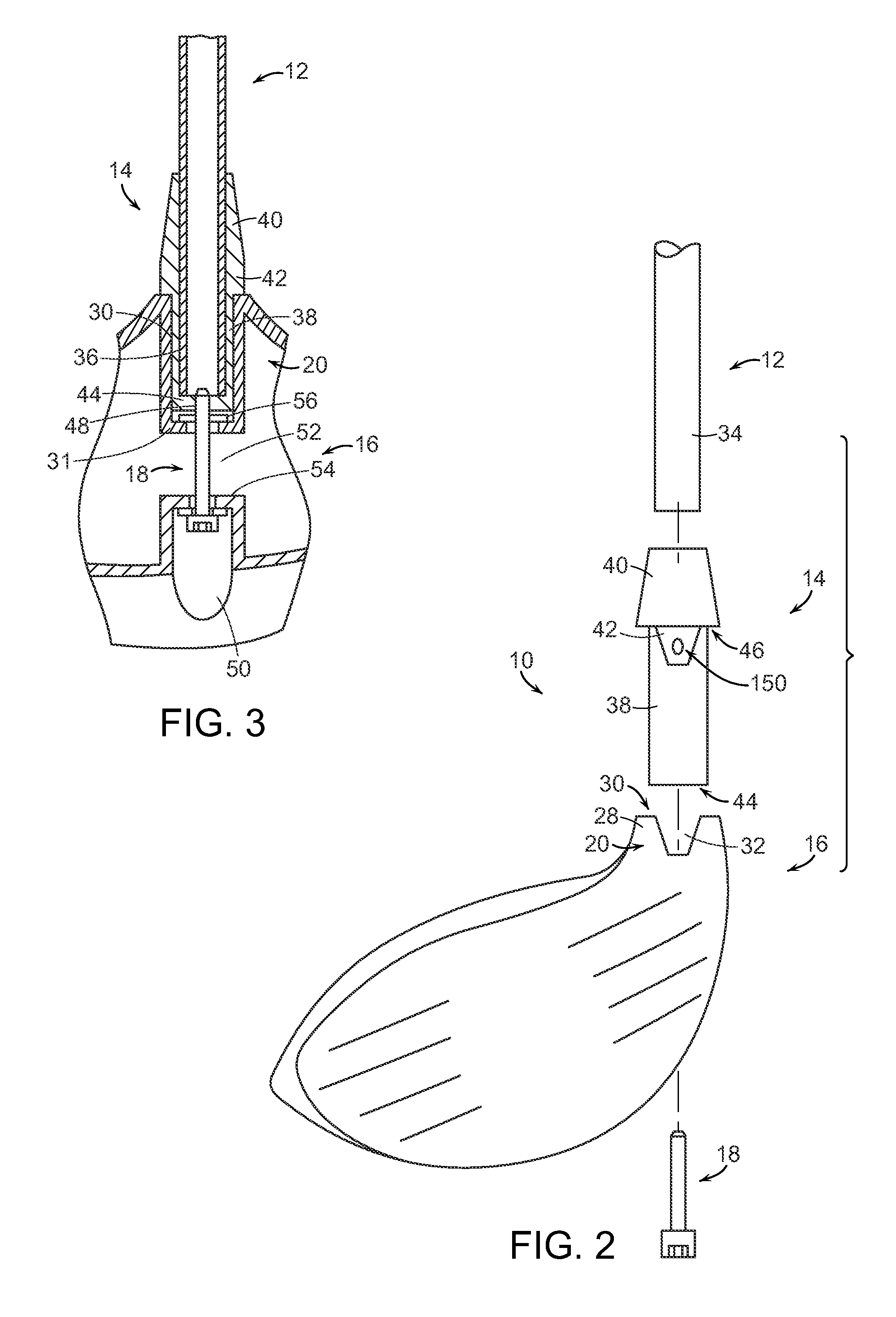

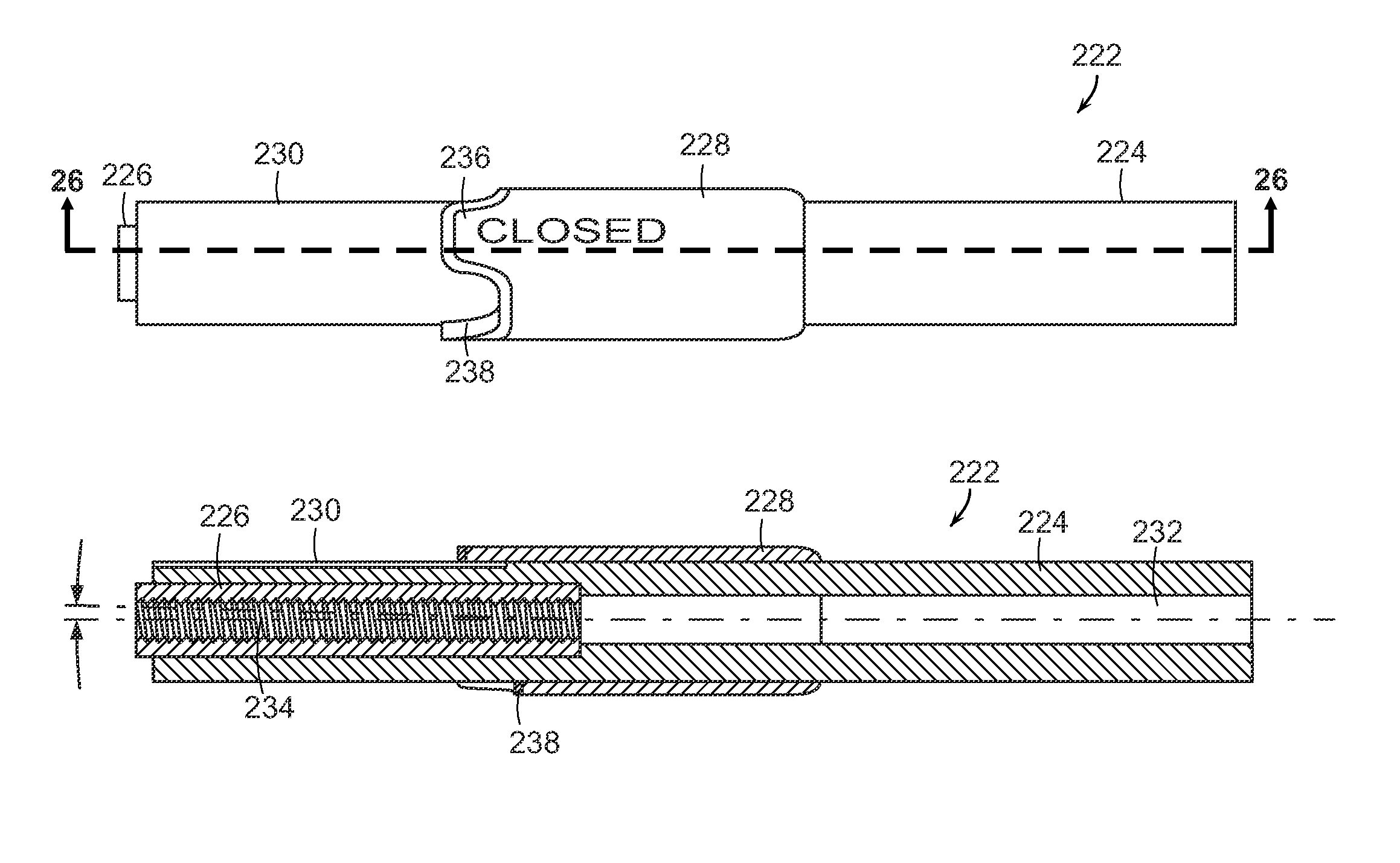

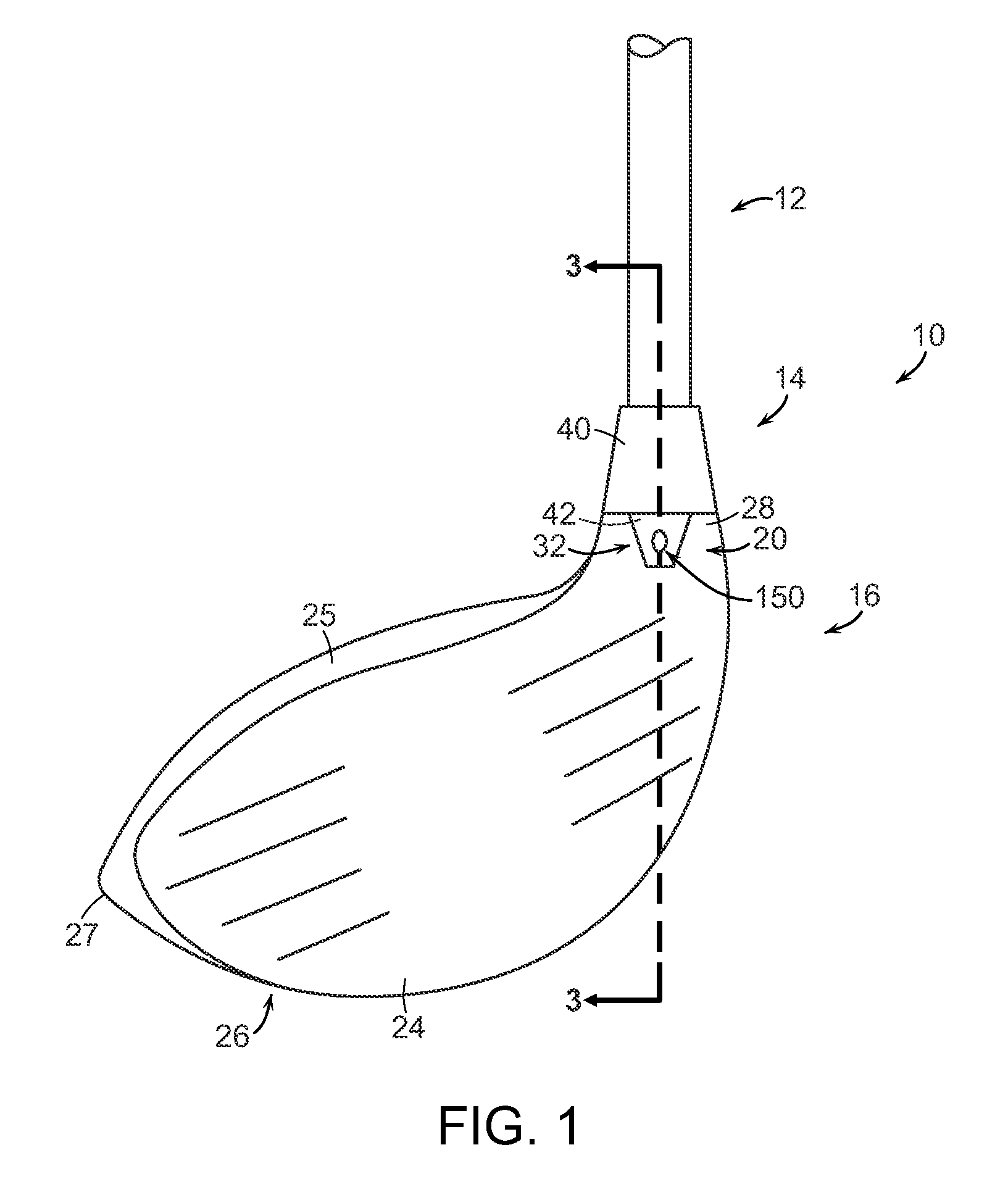

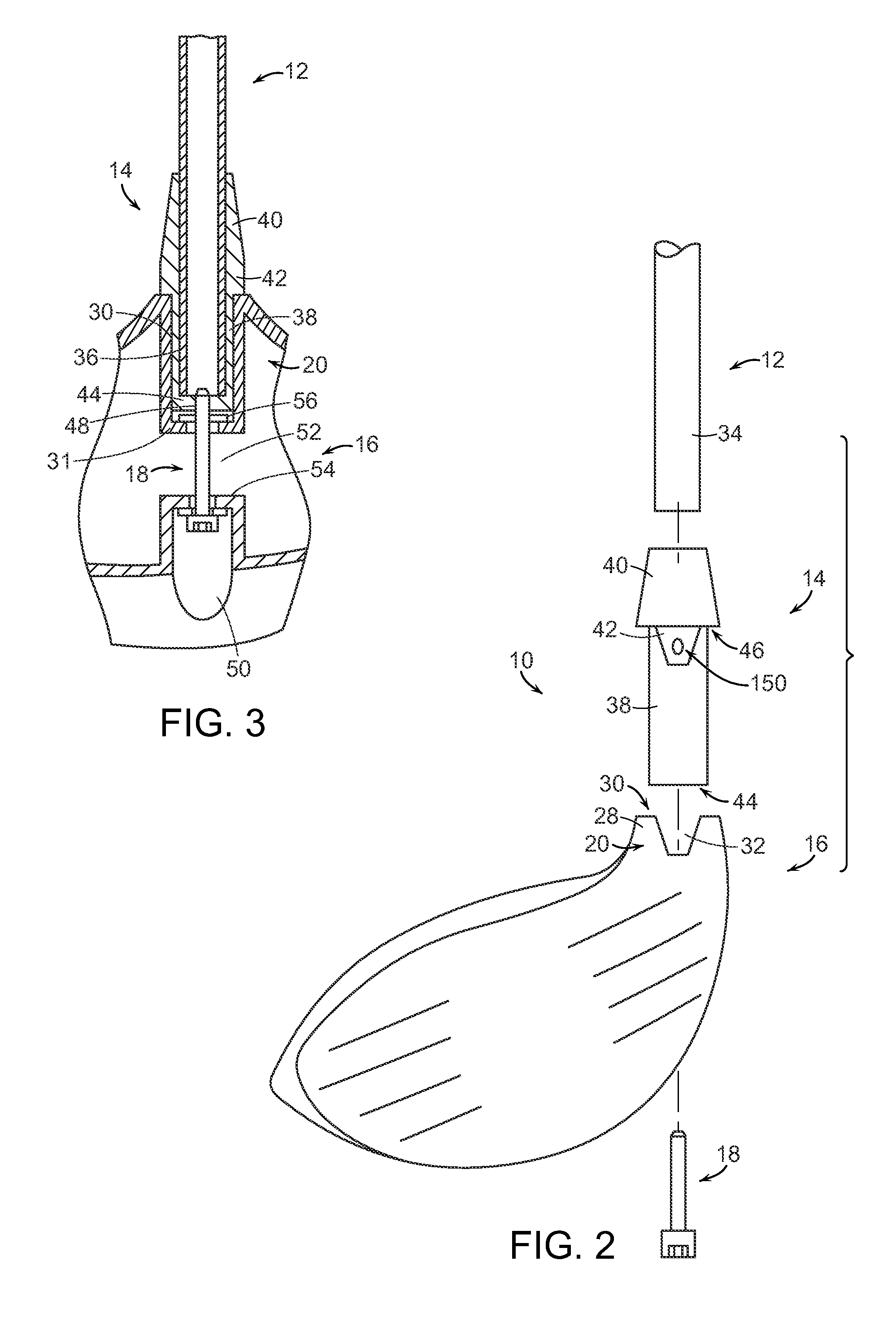

Interchangeable shaft system

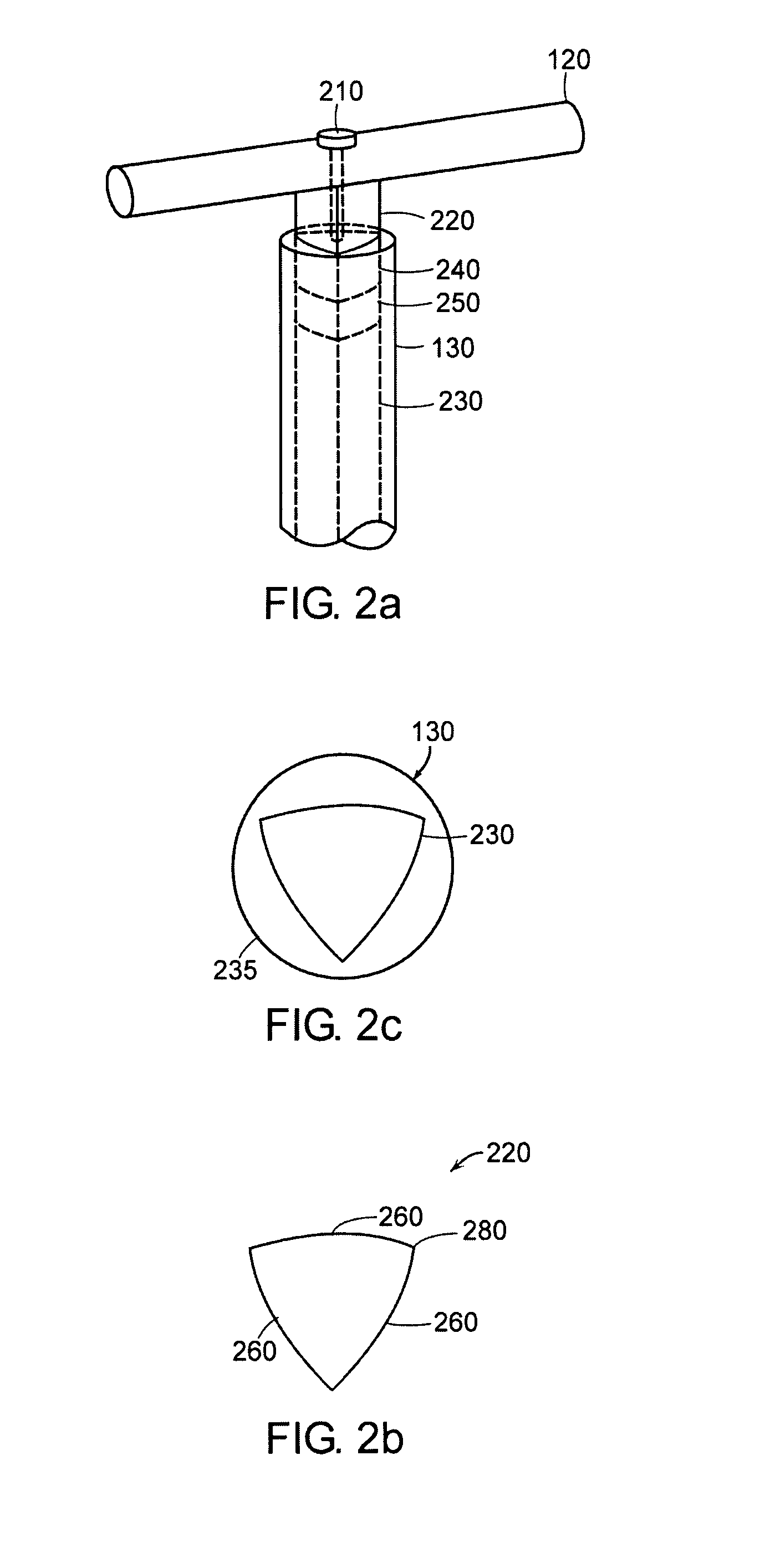

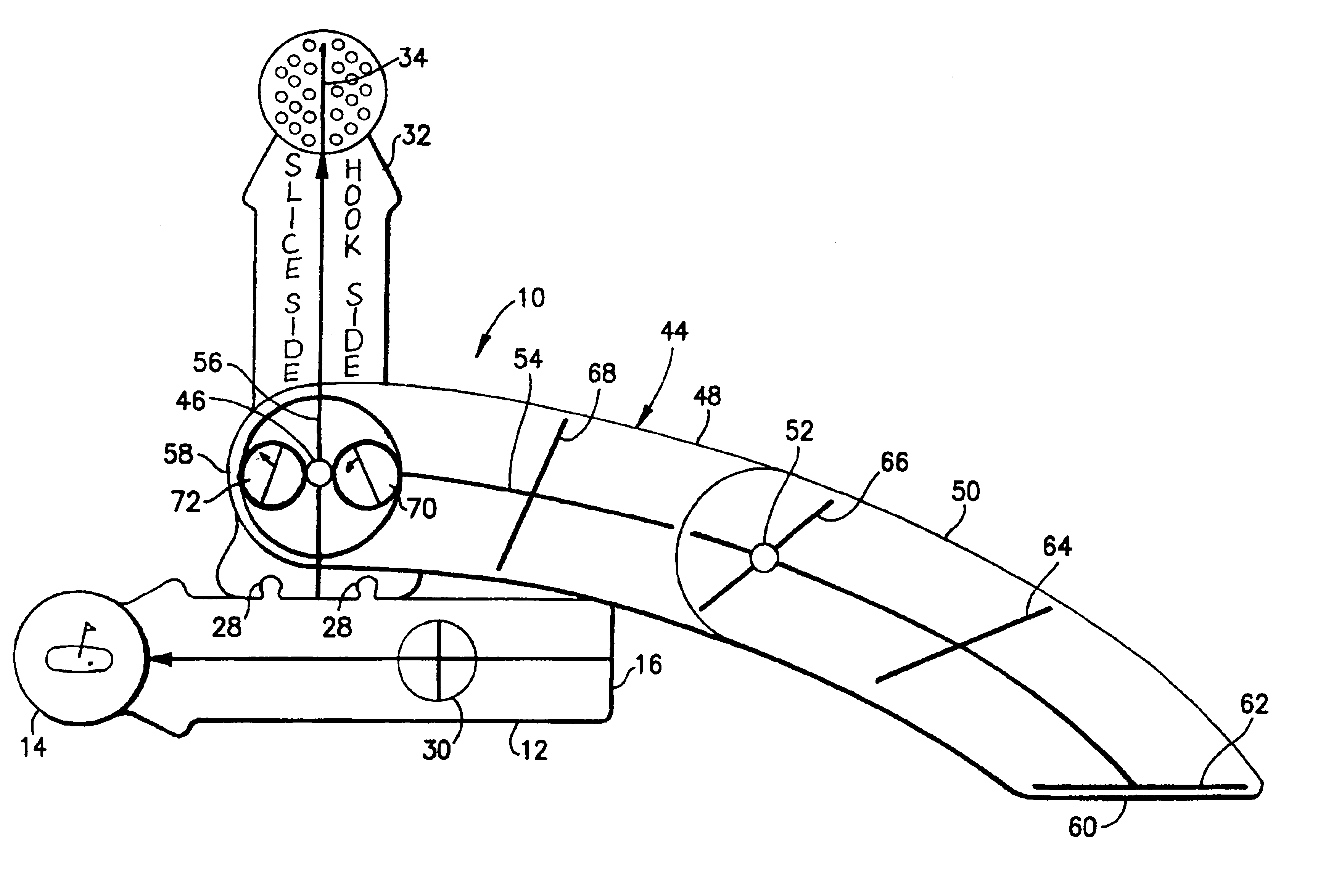

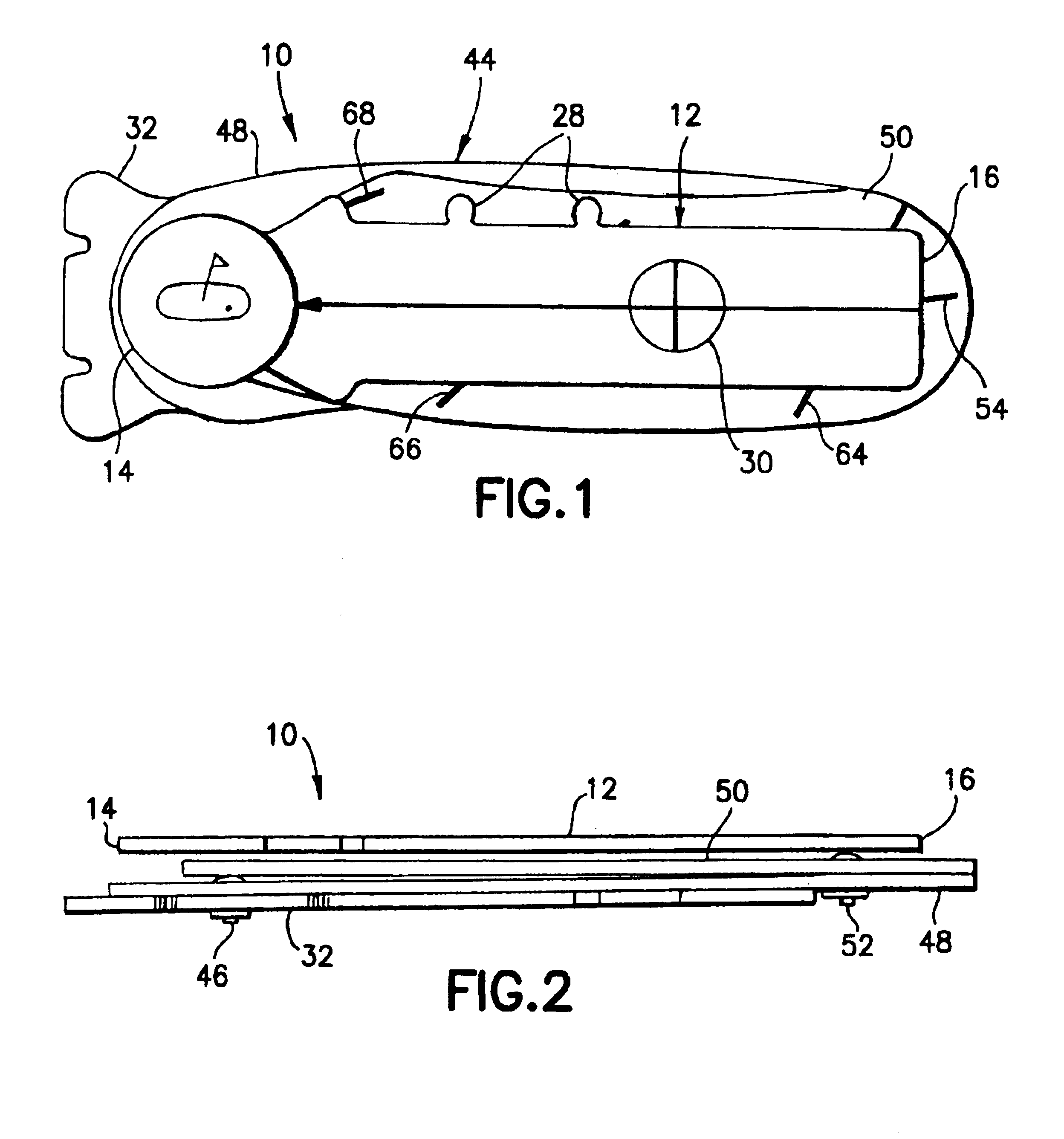

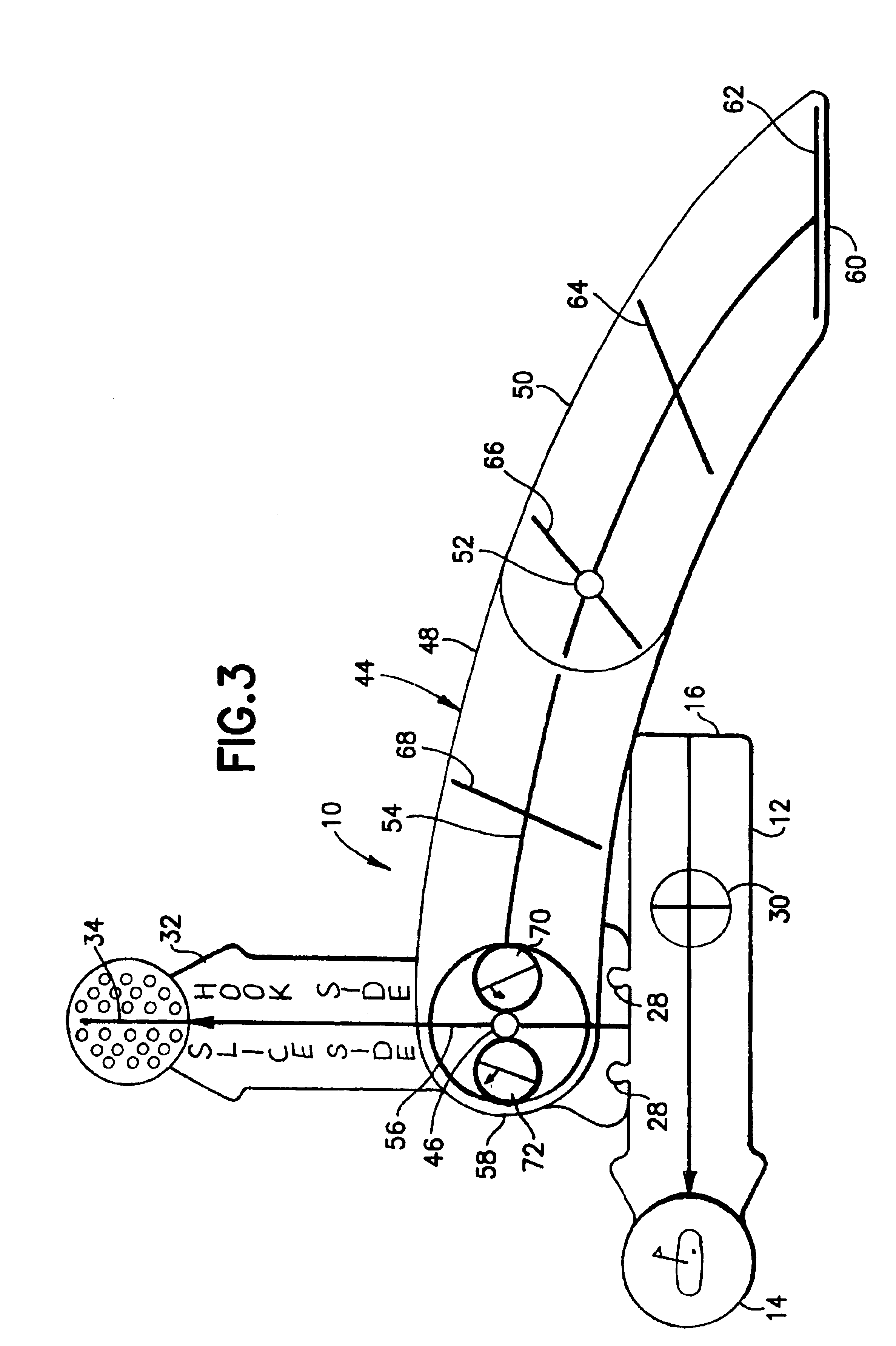

A golf club incorporating an interchangeable shaft system includes a shaft and a club head. The shaft is removably coupled to the club head. Hosel and shaft alignment features provide discreet orientations between the shaft and club head. The shaft alignment features and a fastening member are integrated into the construction of the shaft.

Owner:ACUSHNET CO

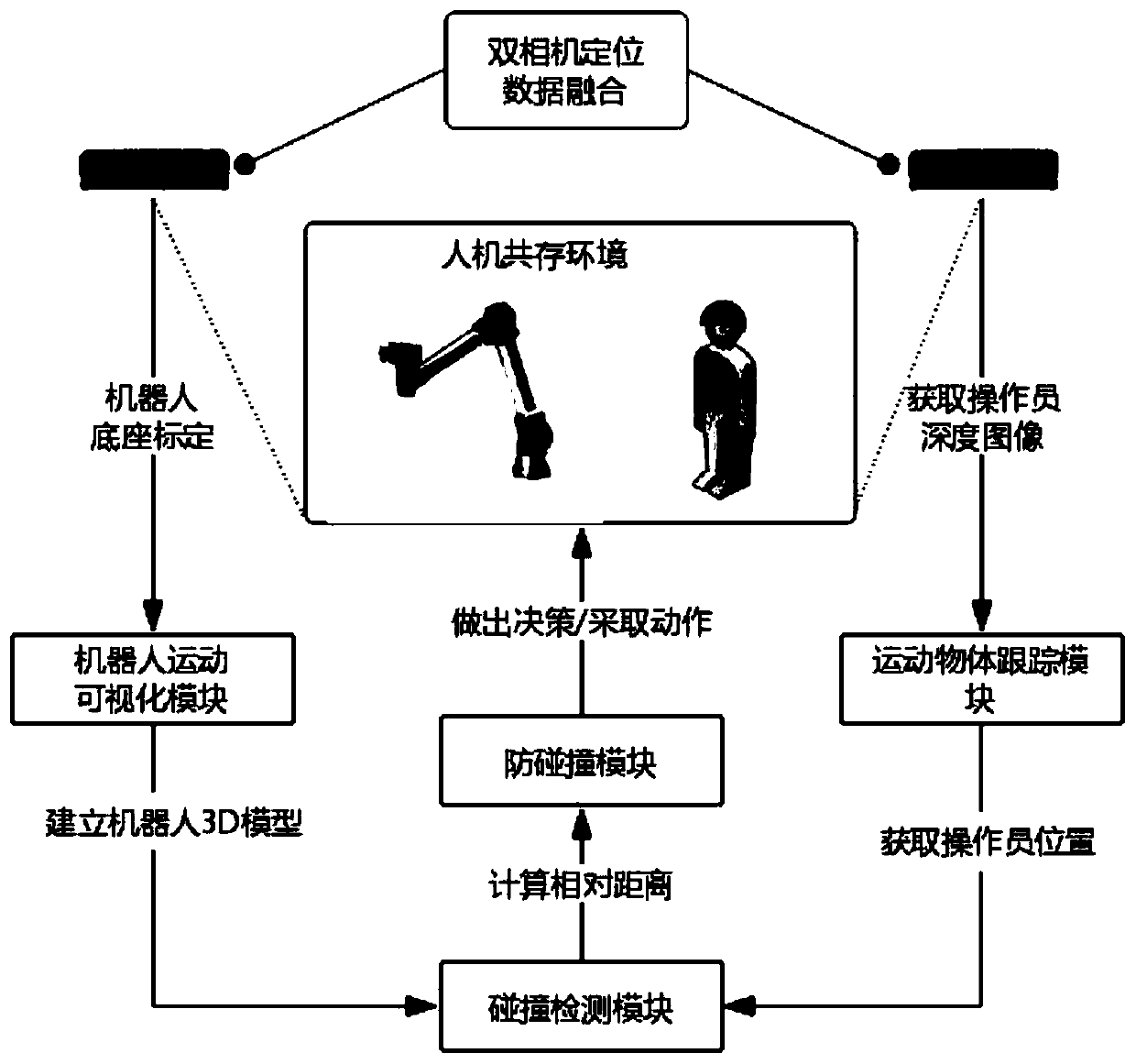

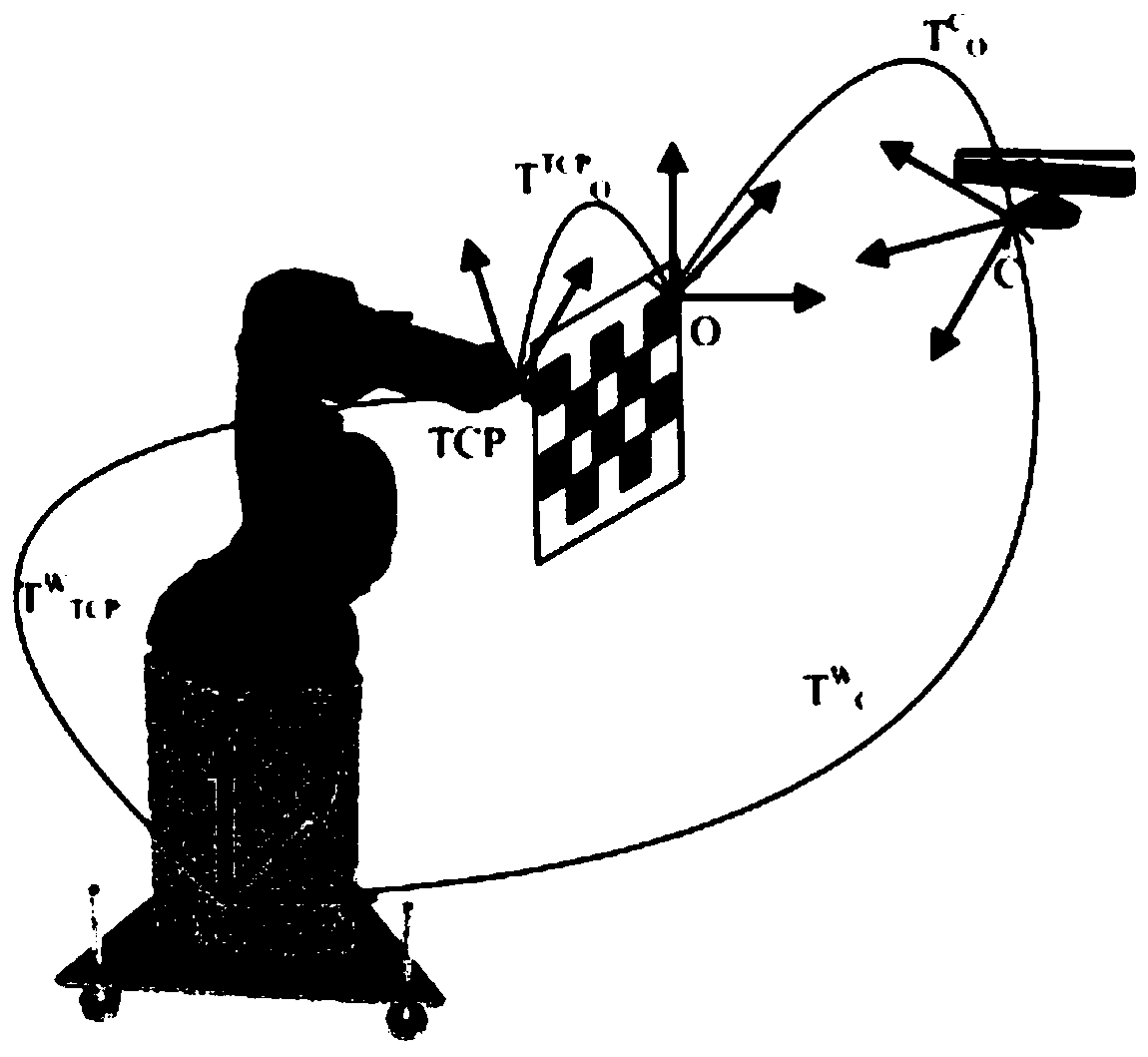

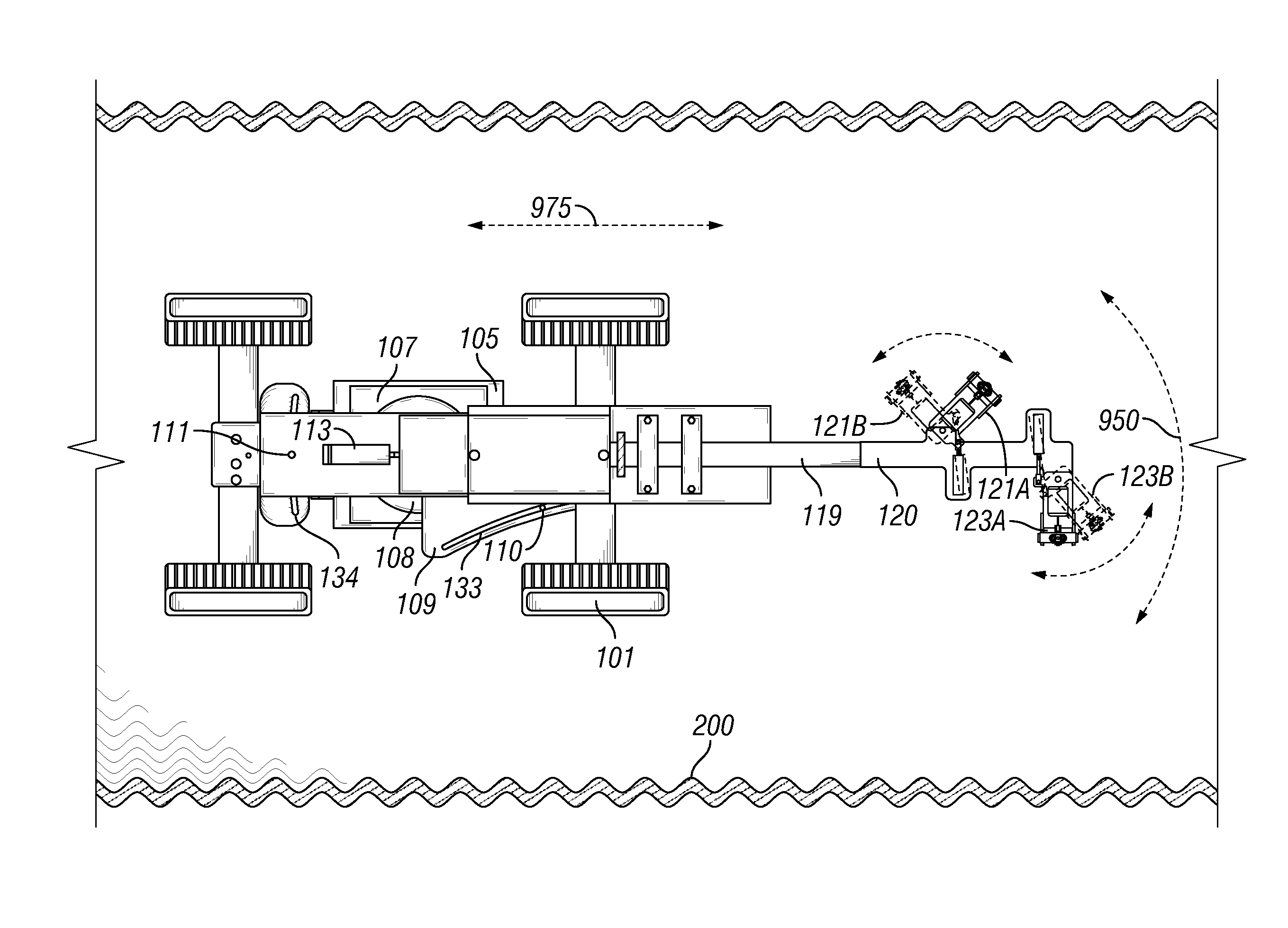

Visual-based man-machine safety system of industrial mechanical arm

ActiveCN110253570AImprove securityEnsure safetyProgramme-controlled manipulatorCollision detectionMan machine

The invention discloses a visual-based man-machine safety system of an industrial mechanical arm. The visual-based man-machine safety system of the industrial mechanical arm comprises a moving object tracking module used for capturing spatial positions of all moments of a moving object, a robot movement visualization module used for acquiring robot joint information and carrying out 3D visualization on a robot, a collision detection module used for calculating the minimum distance between a robot 3D model and an operator in the environment, and a collision avoidance module used for planning and correcting the robot motion trajectory; firstly, a system extracts image information of the operator in the environment through two kinect cameras, and data fusion is performed; then a current state of the robot is obtained, and the 3D model of the environment where the robot is located is constructed; then a shaft alignment bounding box method is used for carrying out the collision detection on the operator and the robot; and finally, according to a collision detection result, an anti-collision module can give an alarm to the operator and stop the robot or modify the trajectory of the robot, so that the robot can far away from the operator who is approaching.

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

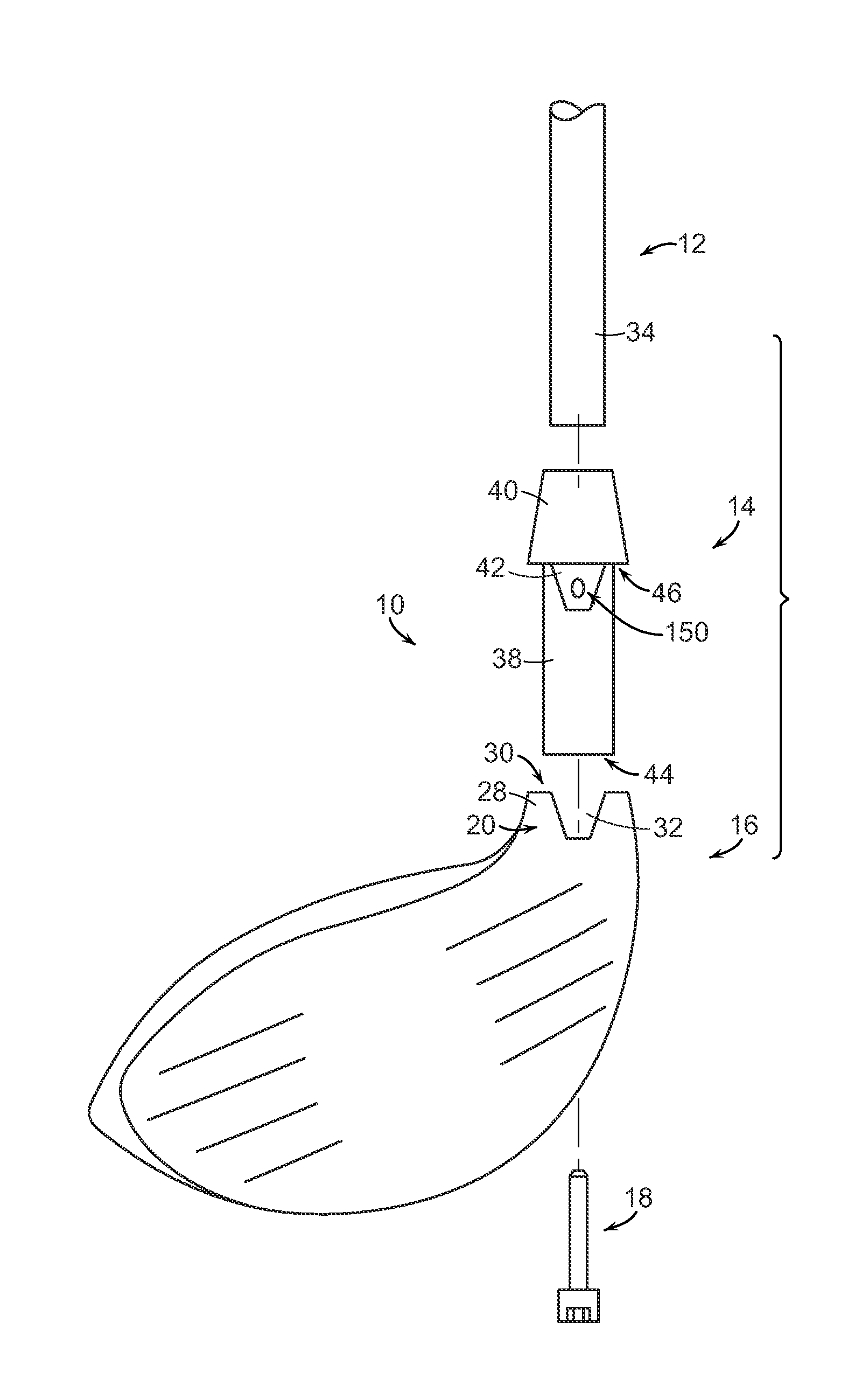

Interchangeable shaft system

A golf club incorporating an interchangeable shaft system includes a shaft and a club head. The shaft is removably coupled to the club head. Hosel and shaft alignment features provide discreet orientations between the shaft and club head. The shaft alignment features and a fastening member are integrated into the construction of the shaft.

Owner:ACUSHNET CO

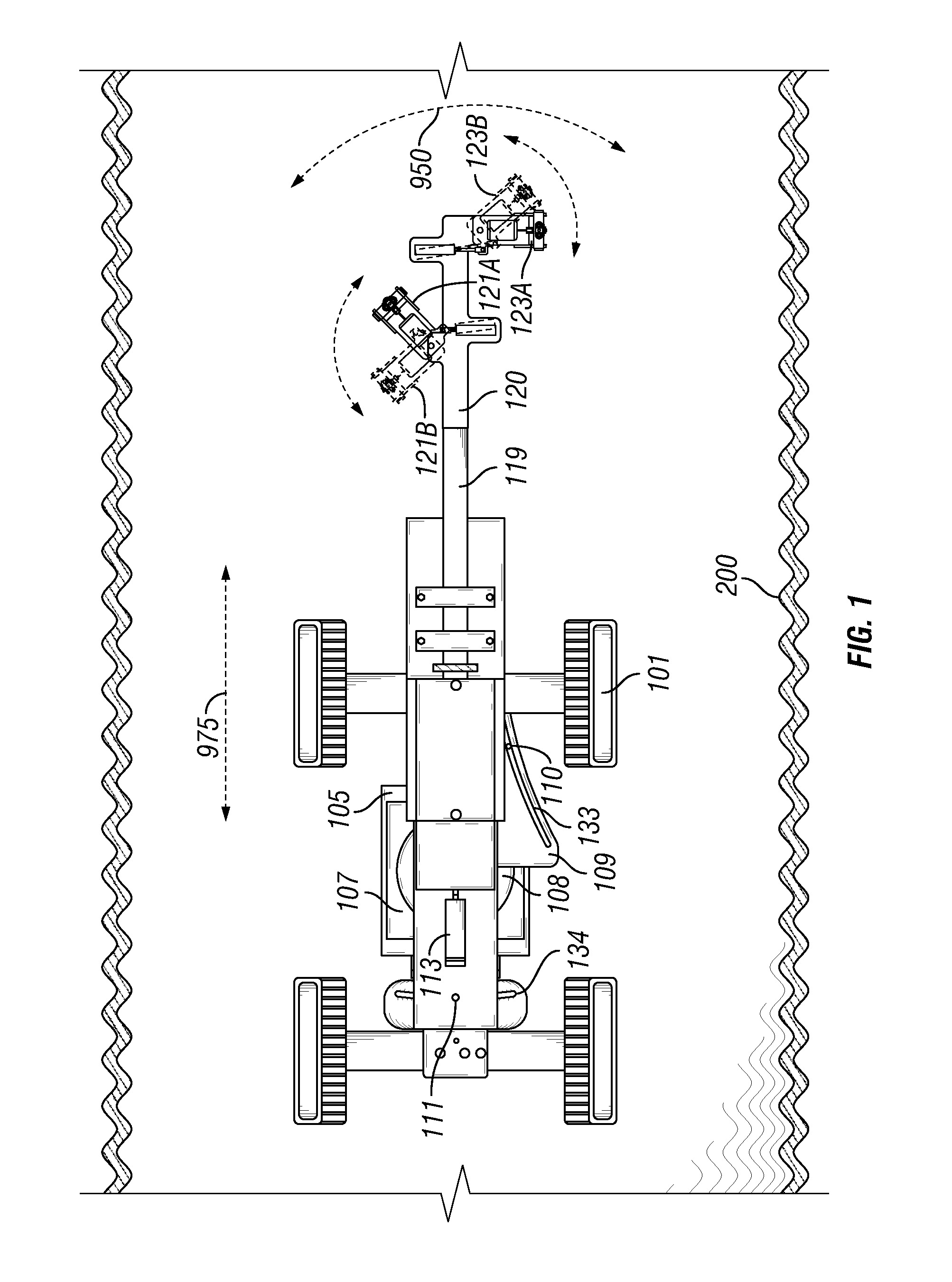

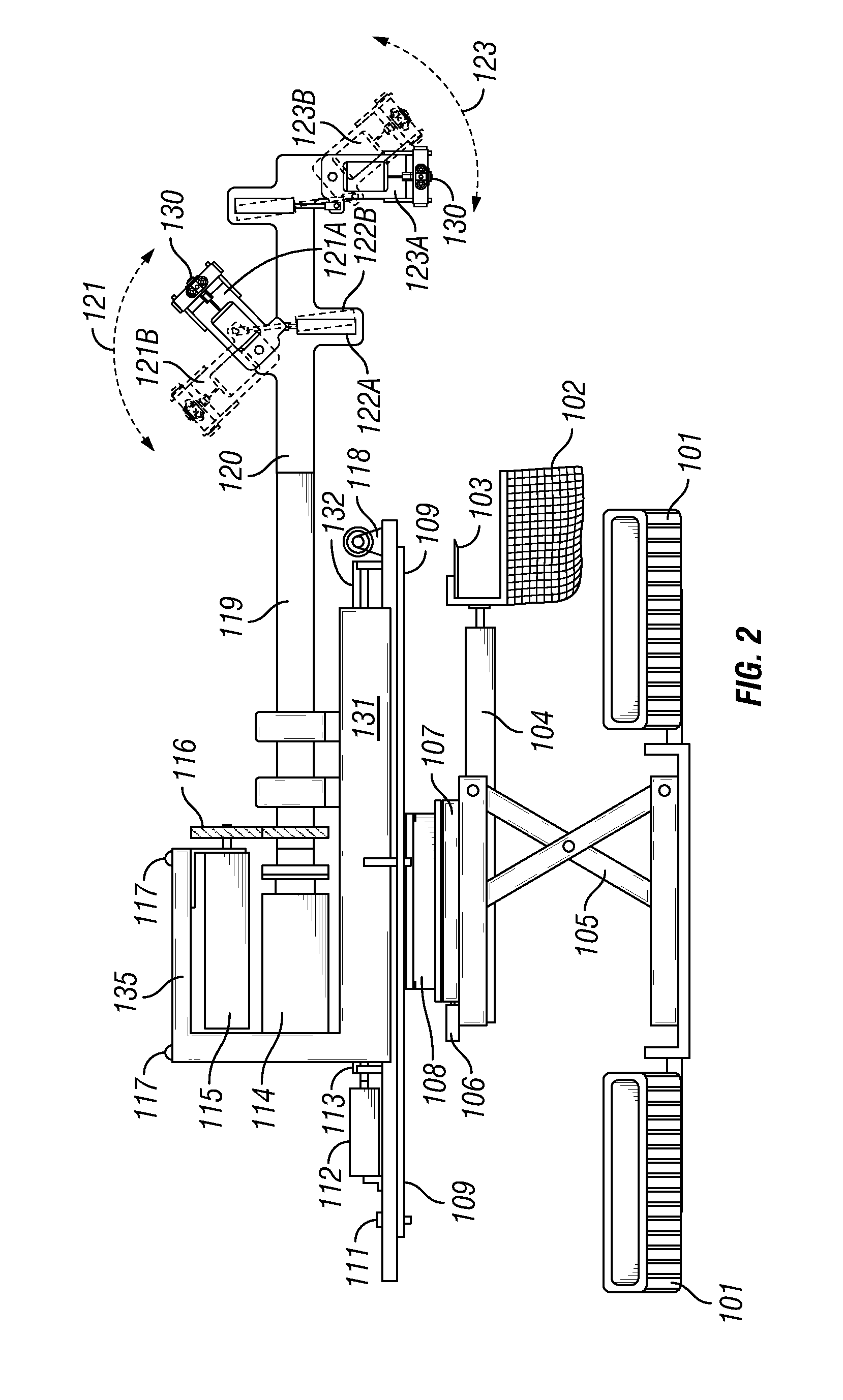

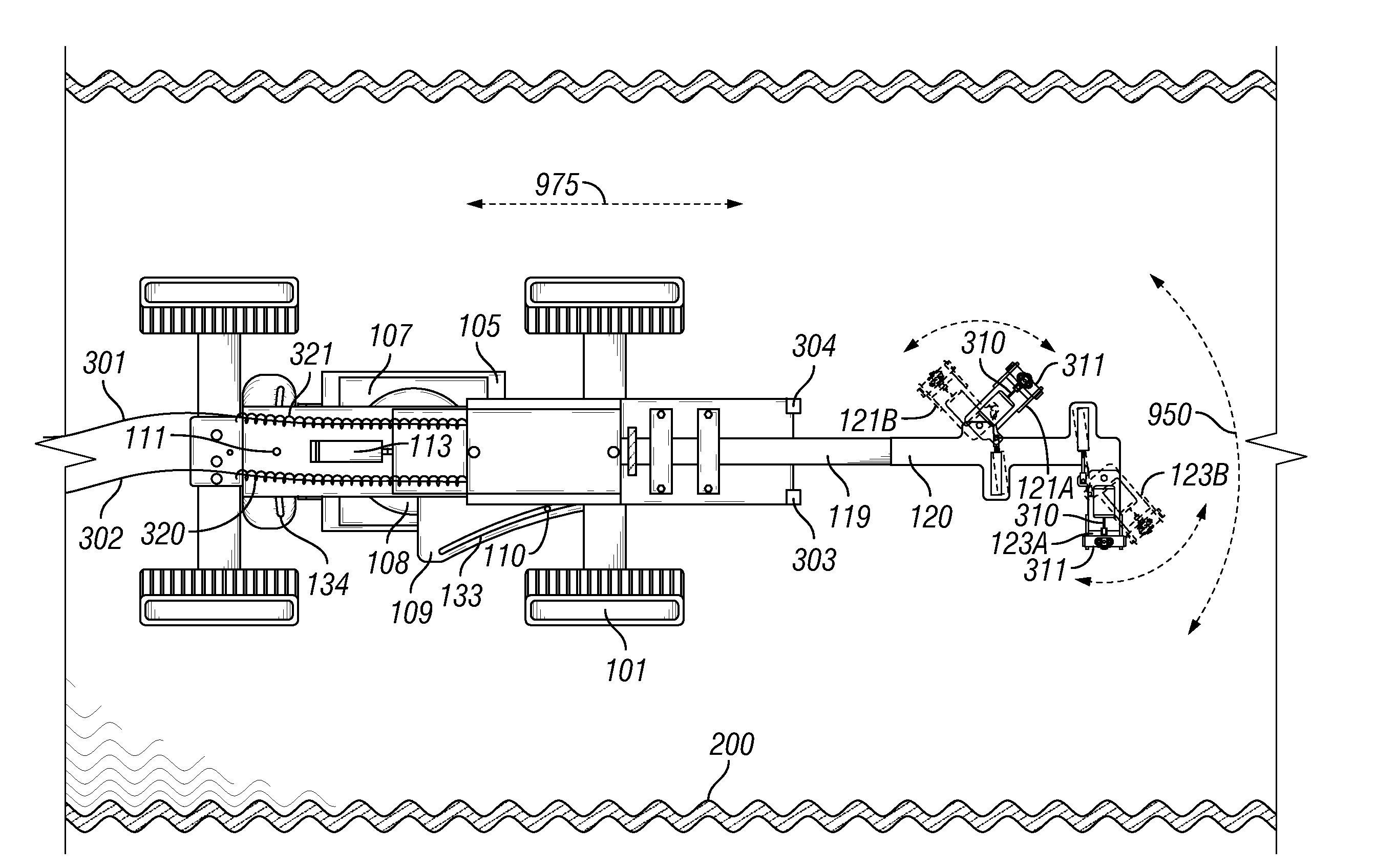

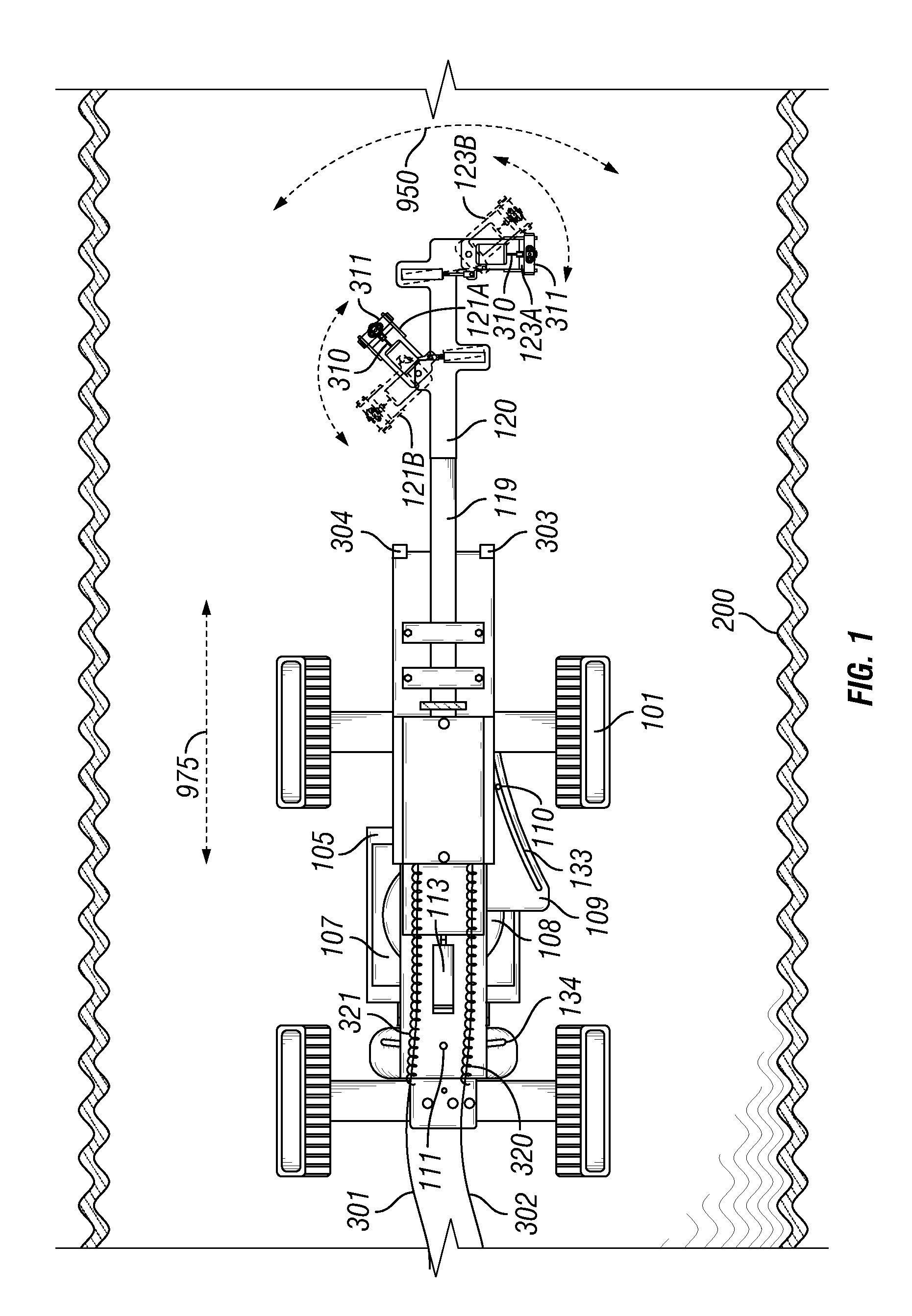

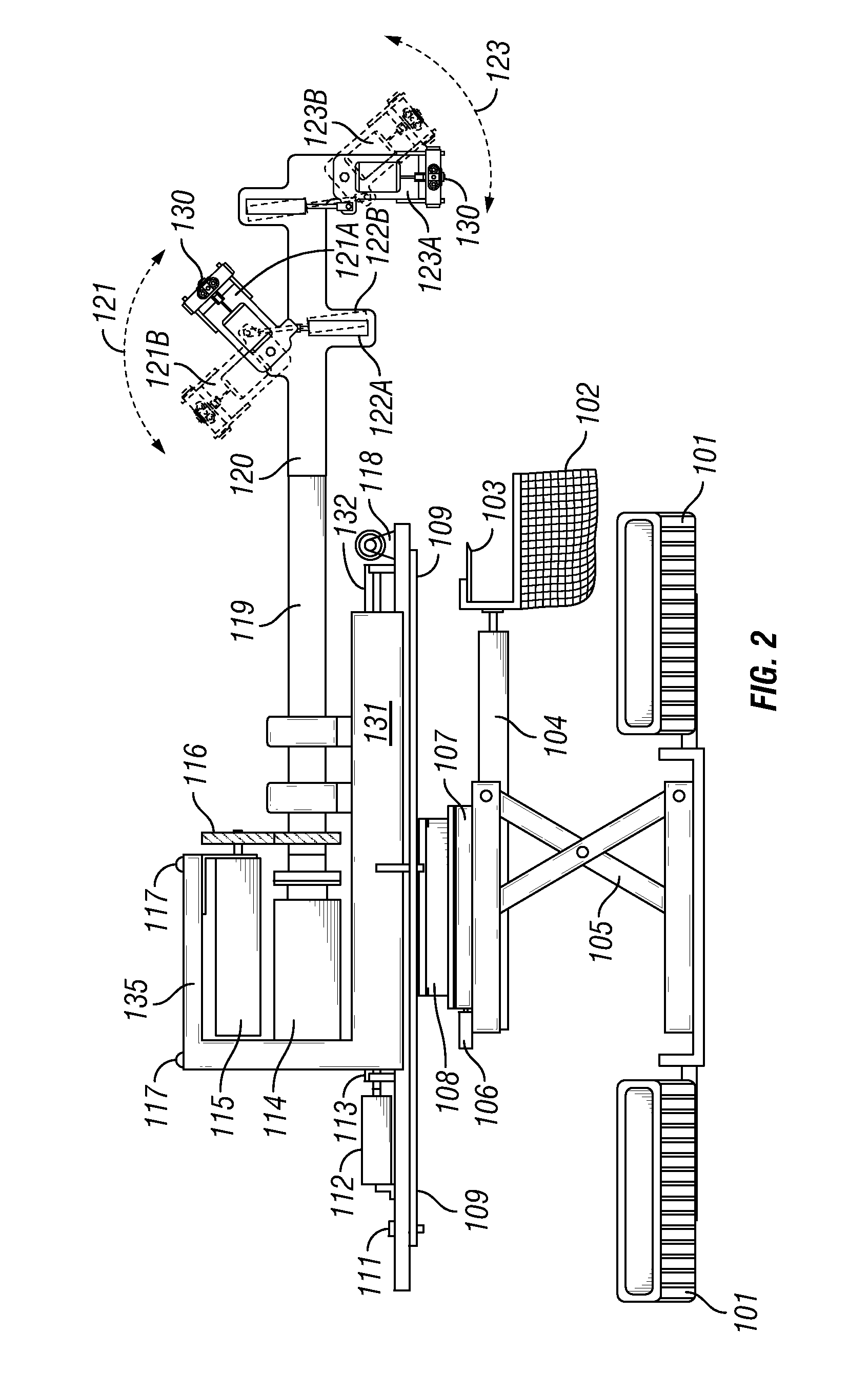

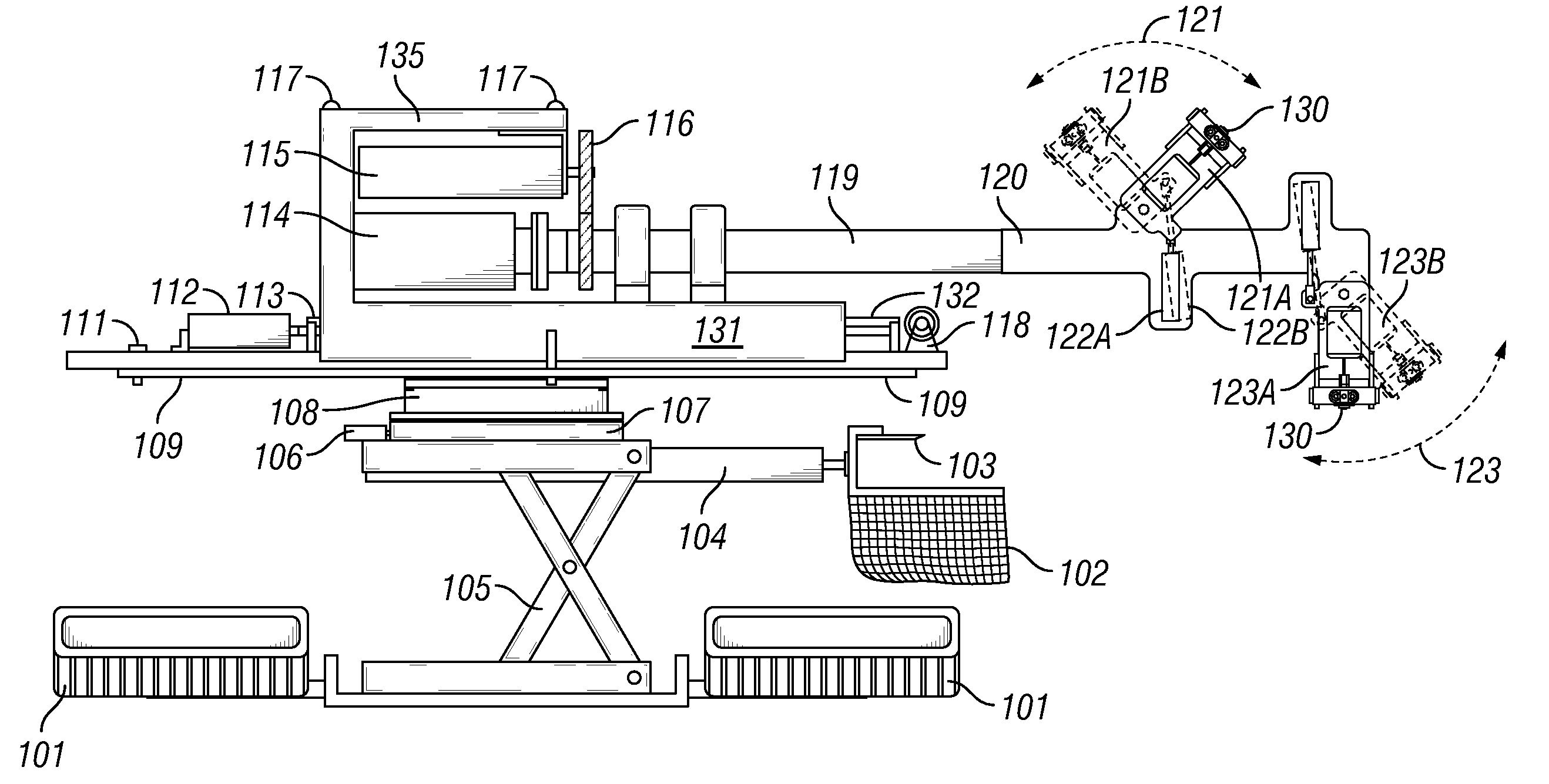

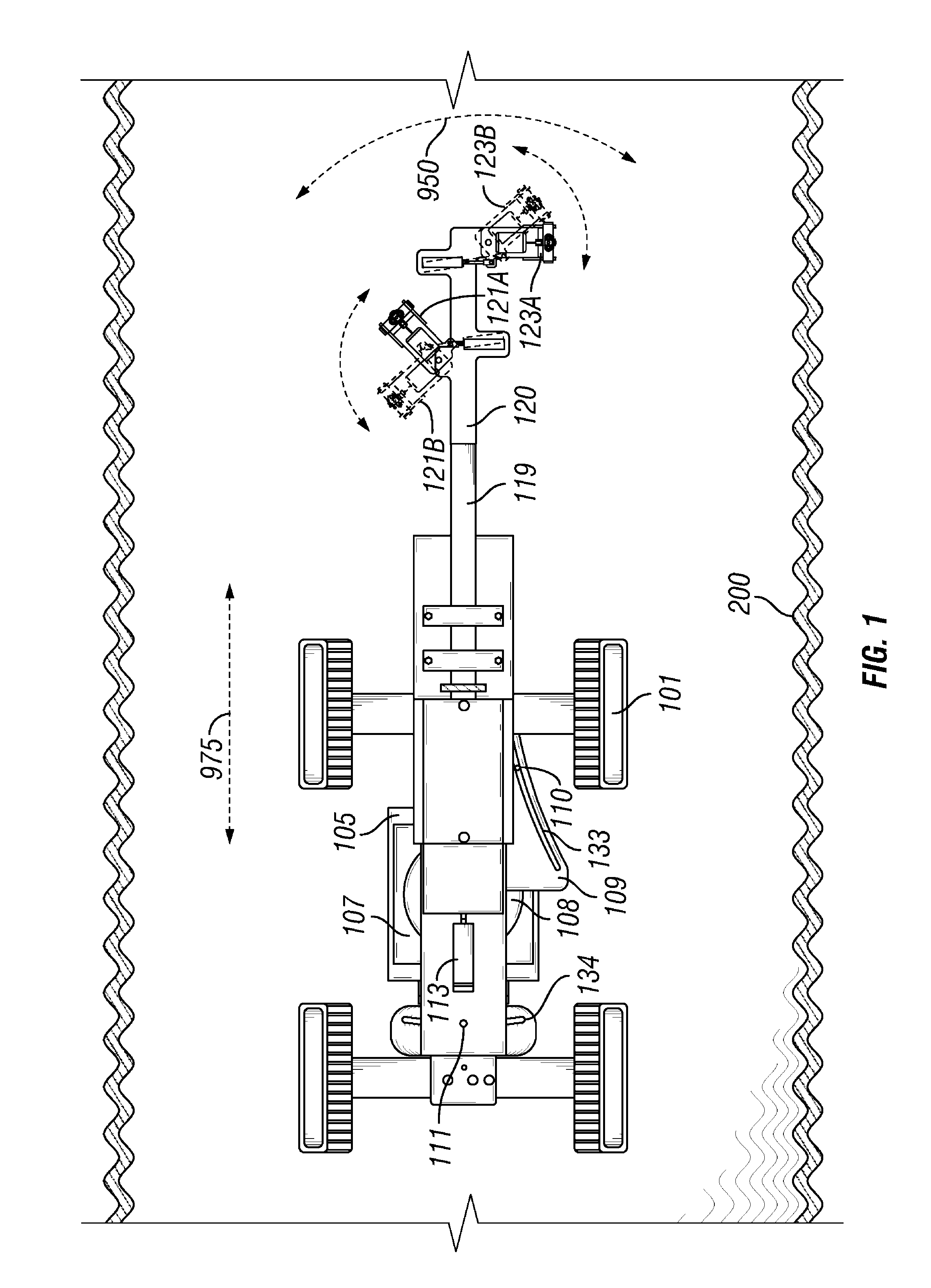

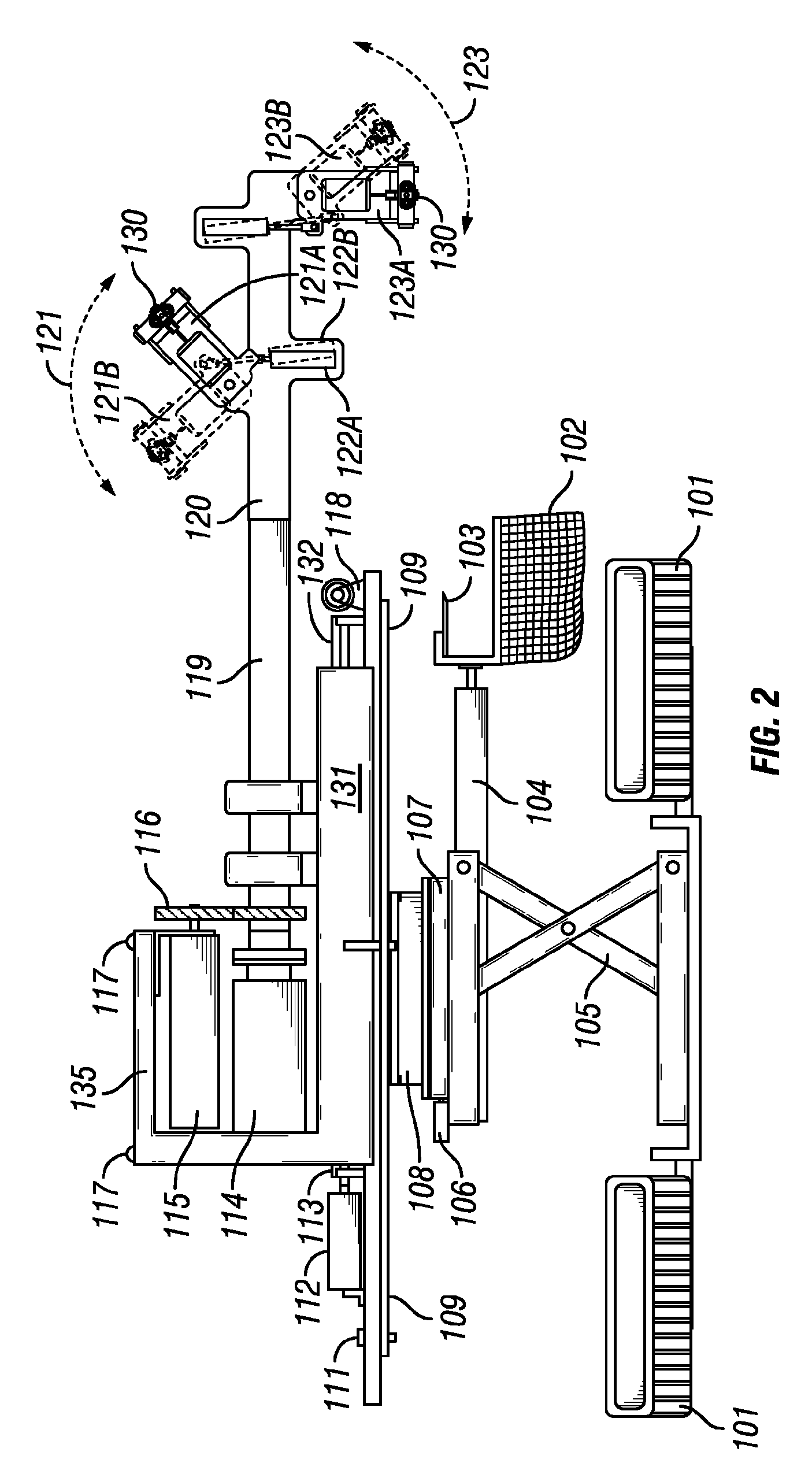

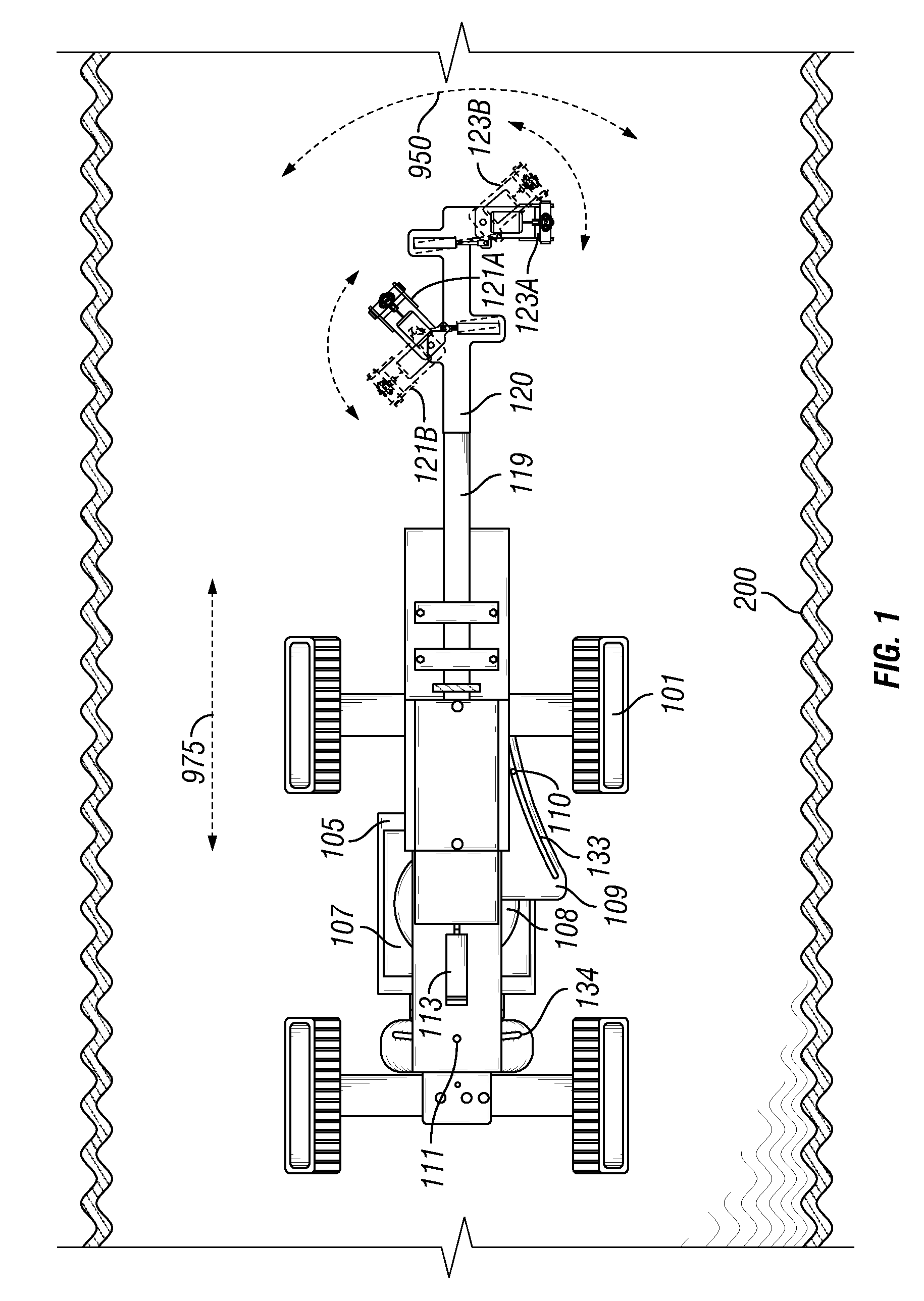

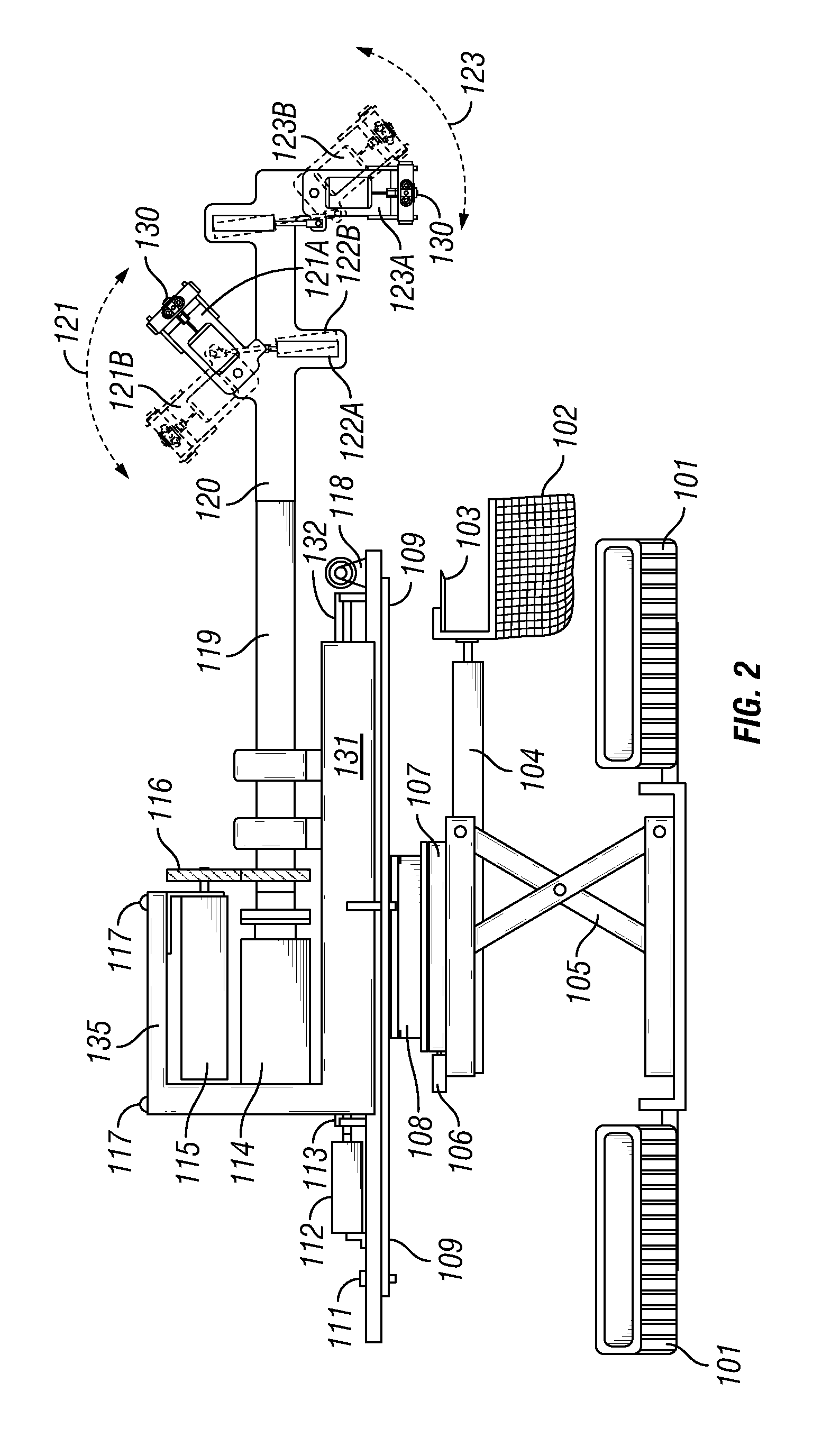

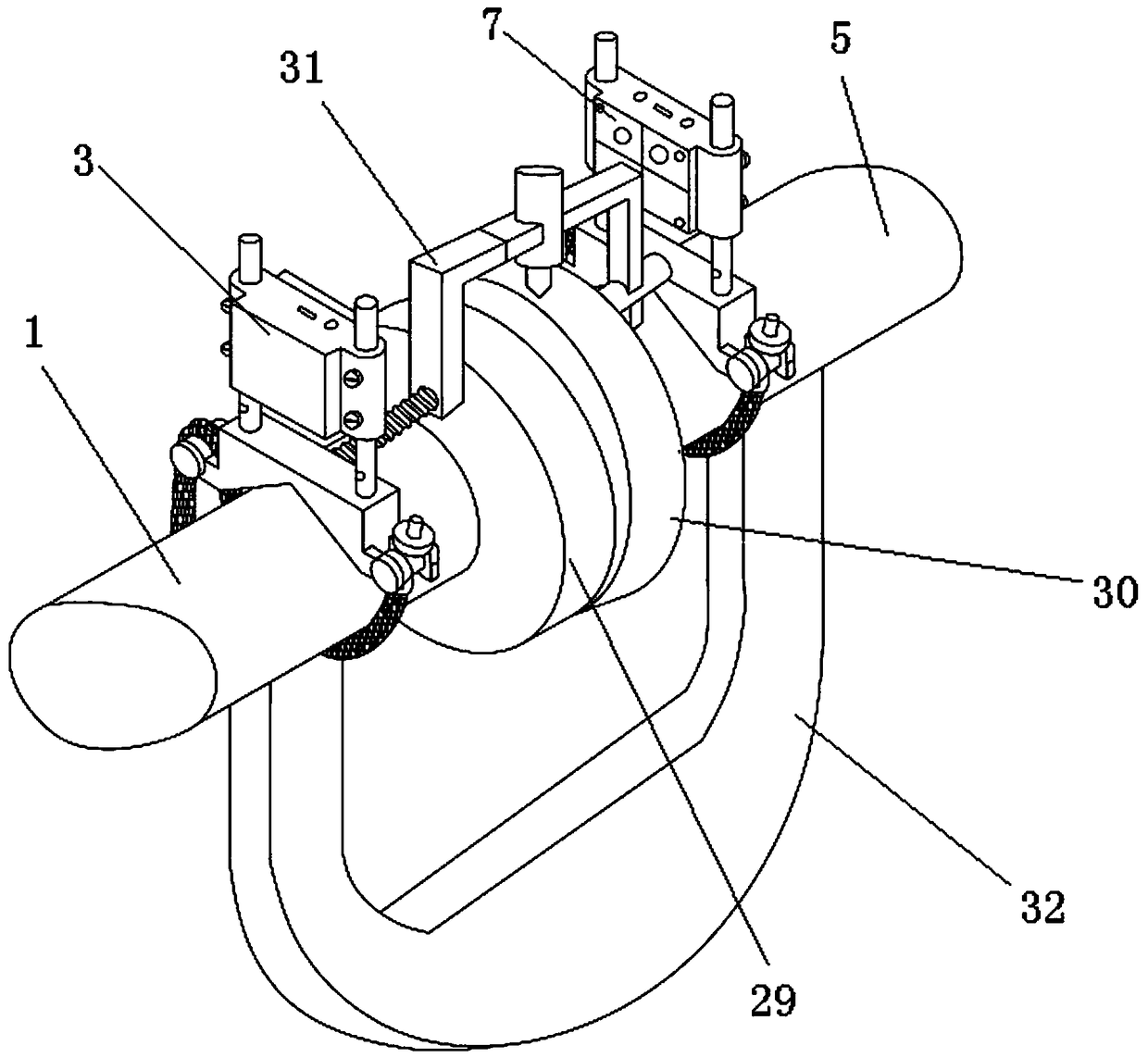

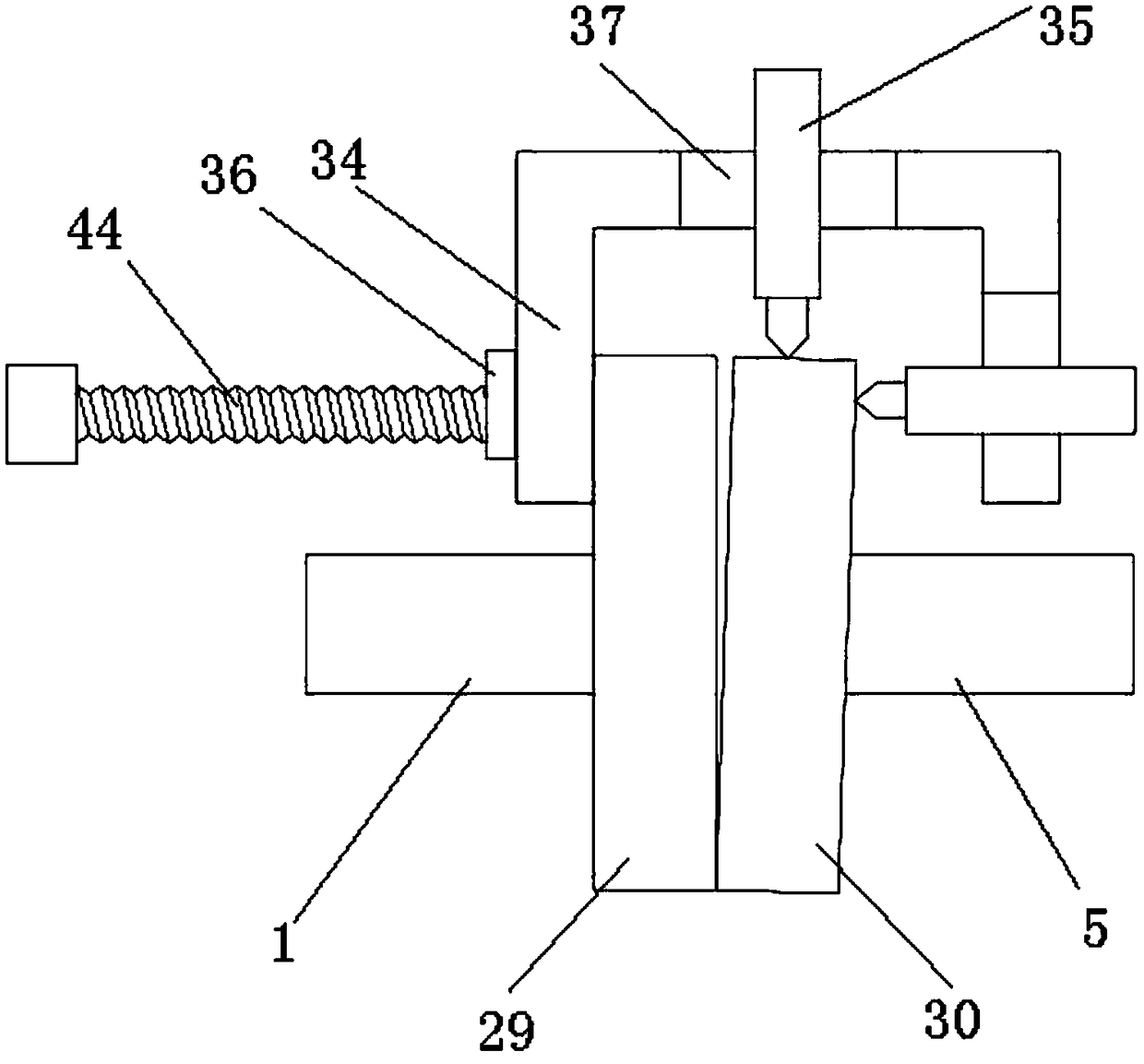

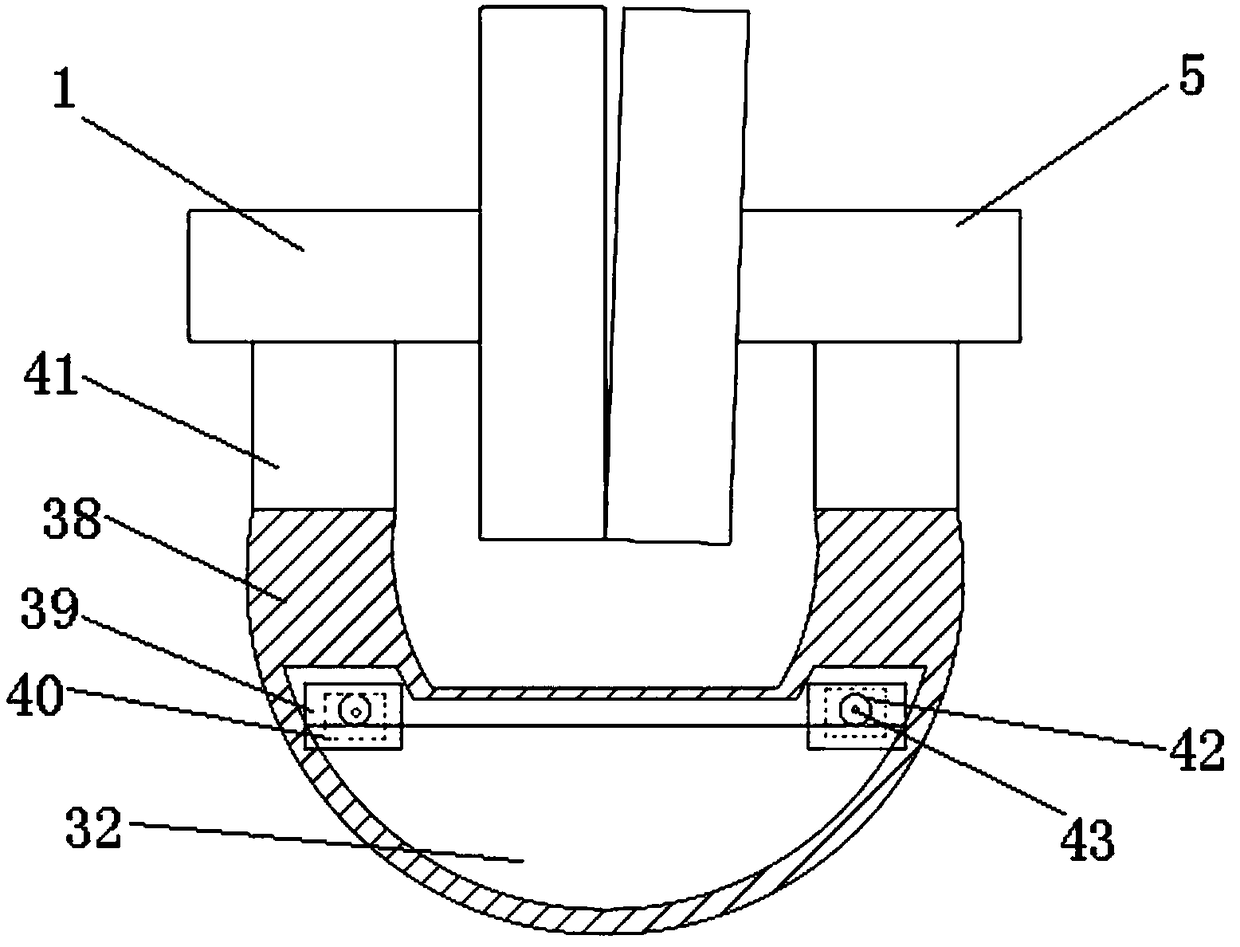

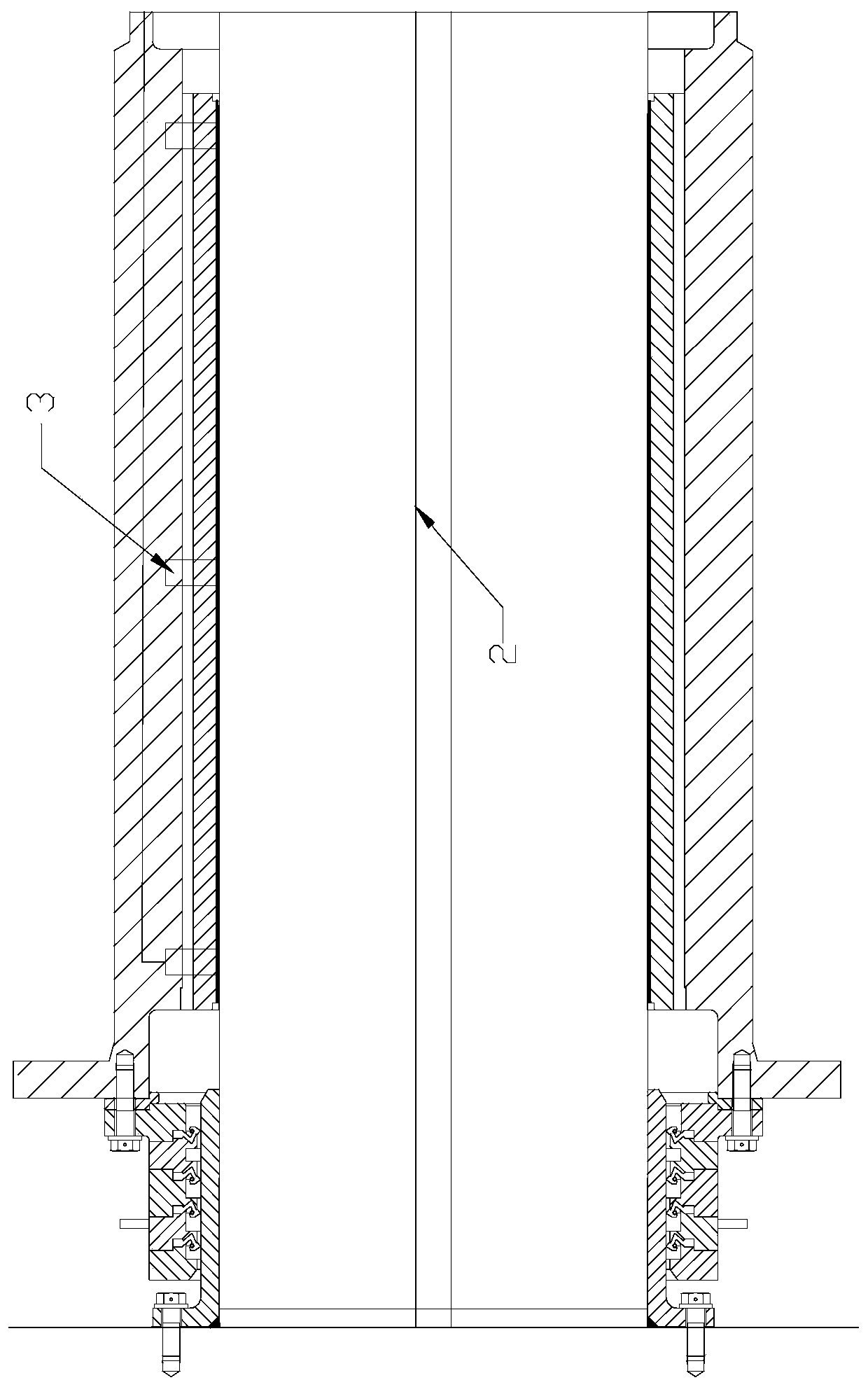

Apparatus and method for lining large diameter pipe with an environmentally compatible impervious membrane

Owner:QUEST INSPAR

Apparatus and method for lining large diameter pipe with an environmentally compatible impervious membrane

A method and apparatus is disclosed for remotely and robotically installing an organic, monolithic, structural and non structural, circumferential and partial radius membranes in conduits, pipelines or passageways. The included apparatus has the mechanical function to manually or automatically center the liner dissipation device in any geometrical shape. The included apparatus possesses the remote controlled capability to manipulate centrifugal dissipation of the liner to afford consistent thickness on any shaped profile or flat surface of the pipe wall surface. The apparatus includes a manual or automatic mechanical scissoring device for elevation changes and a manual or automatic rotational table for shaft alignment. The apparatus includes a means of automated self alignment by way of proximity sensors. The pendulum oscillation bracketing incorporates a fluid driven motor assembly communicating with a bored shaft and integrates as many as two offset dissipation devices. The included apparatus has both fluid and electrical rotary unions to transmit fluids and current from fixed ports to a rotating shaft assembly. The included apparatus has a mechanical function facilitating cutting and retrieval of cured spray build up on the spray orifice. This method and apparatus will allow for continuous lining applications of any thickness in one pass, in conduits and passageways employing multi component liquid polymers with rapid mechanical properties formation.

Owner:QUEST INSPAR +1

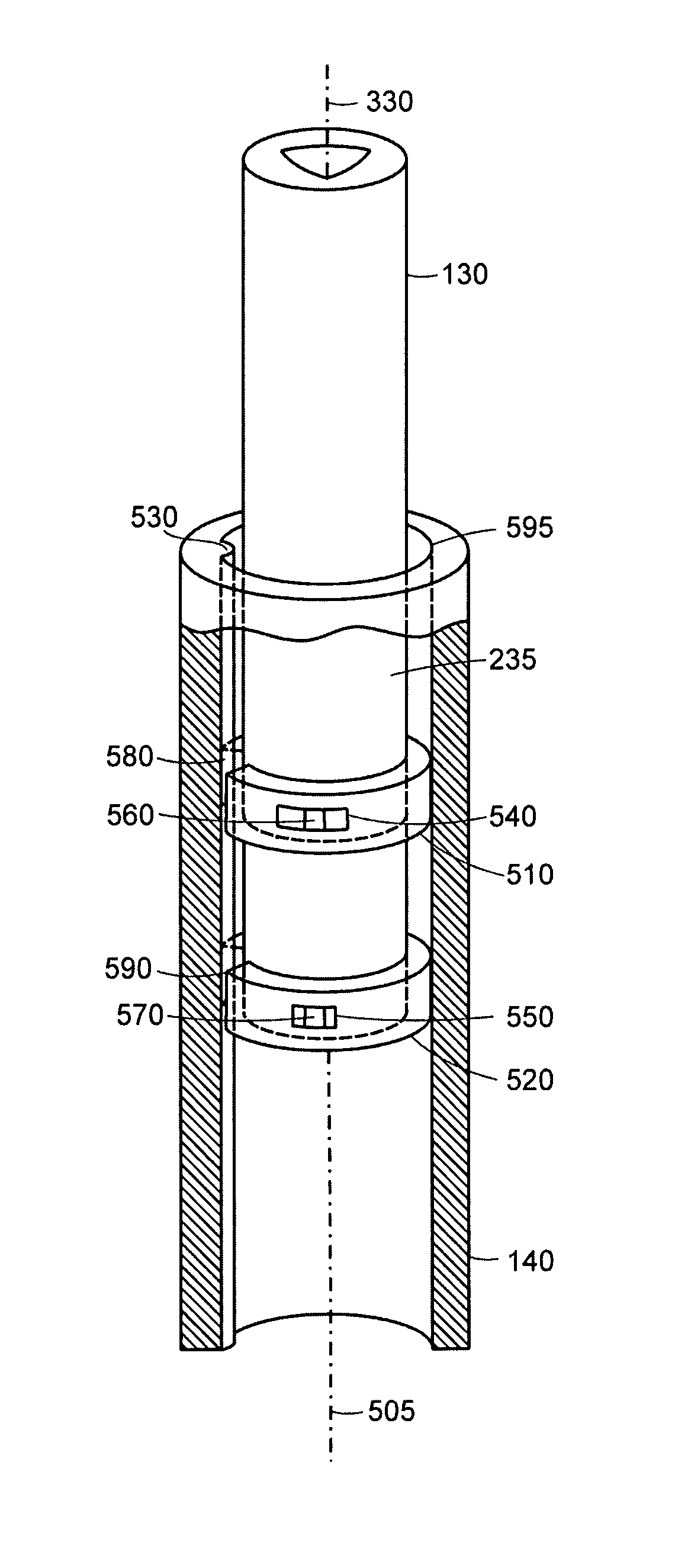

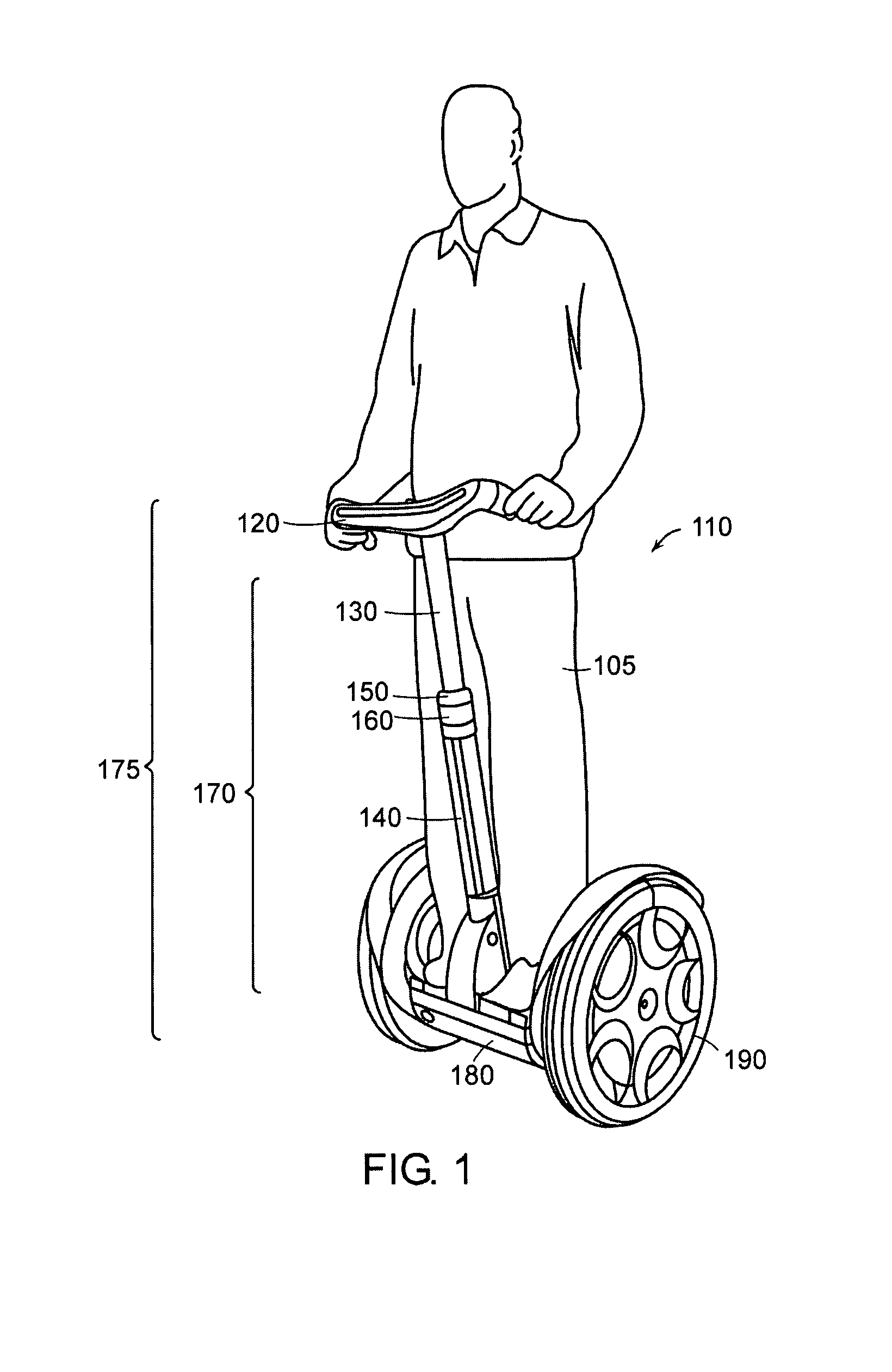

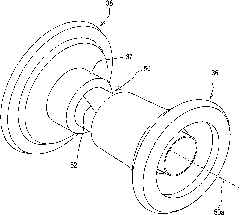

Transporter shaft coupling and uncoupling

Apparatus and methods for transporter shaft coupling and decoupling to assure alignment of a user interface with a control shaft through matching asymmetric cylindrical surfaces and alignment of an upper shaft segment and a lower shaft segment with ribs meshing with grooves on rings attached to the upper shaft. A tone confirms proper connection. Alignment apparatus is protected from damage associated with torques applied to the control shaft by tab features designed to first give way before other damage is incurred and from moisture by apparatus that seals the connection between upper and lower shaft segments. The user is protected from sudden loss of control by requiring the user interface to execute a sequence of linear and rotational manipulations during assembly of the shaft.

Owner:DEKA PROD LLP

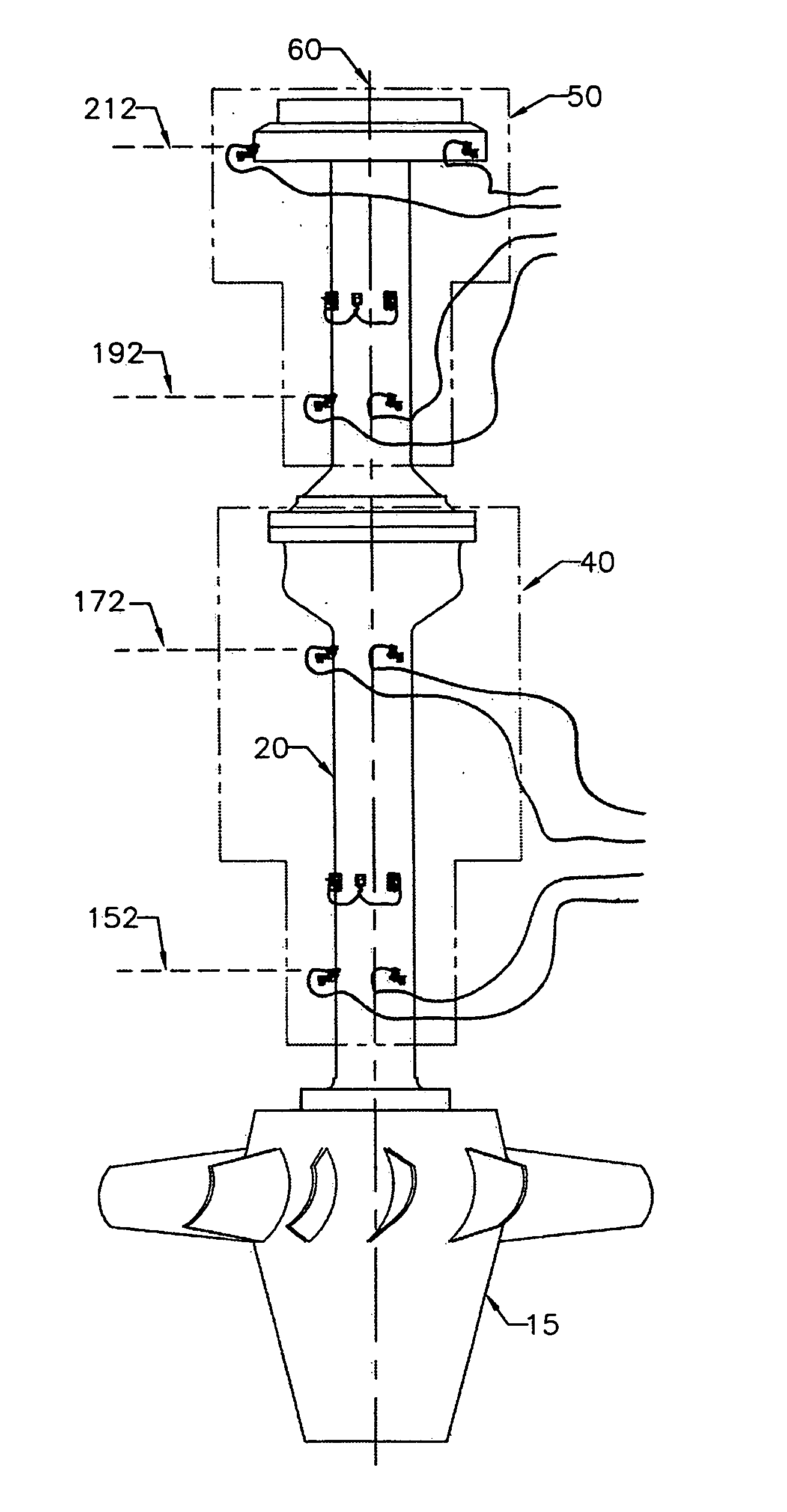

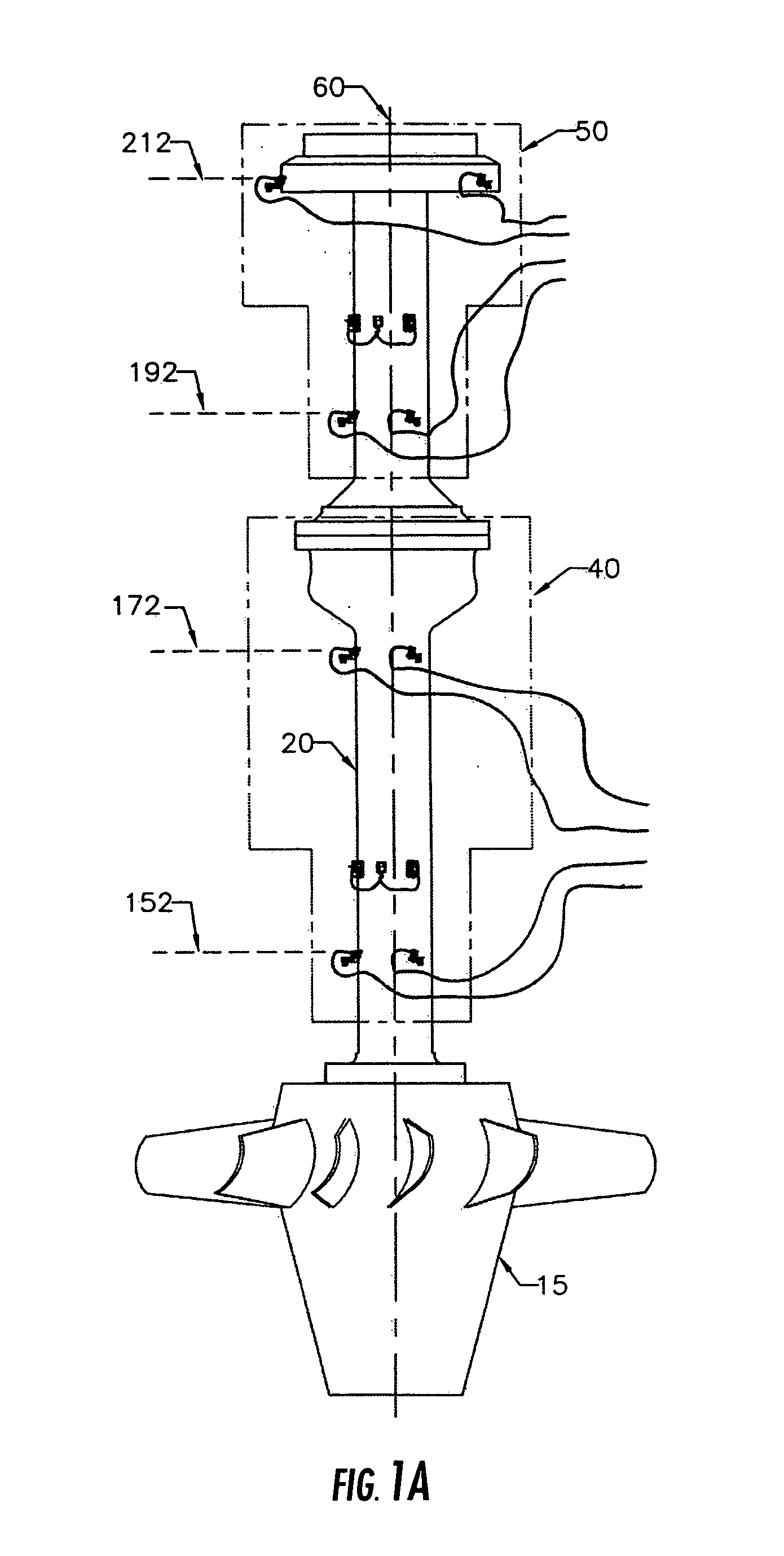

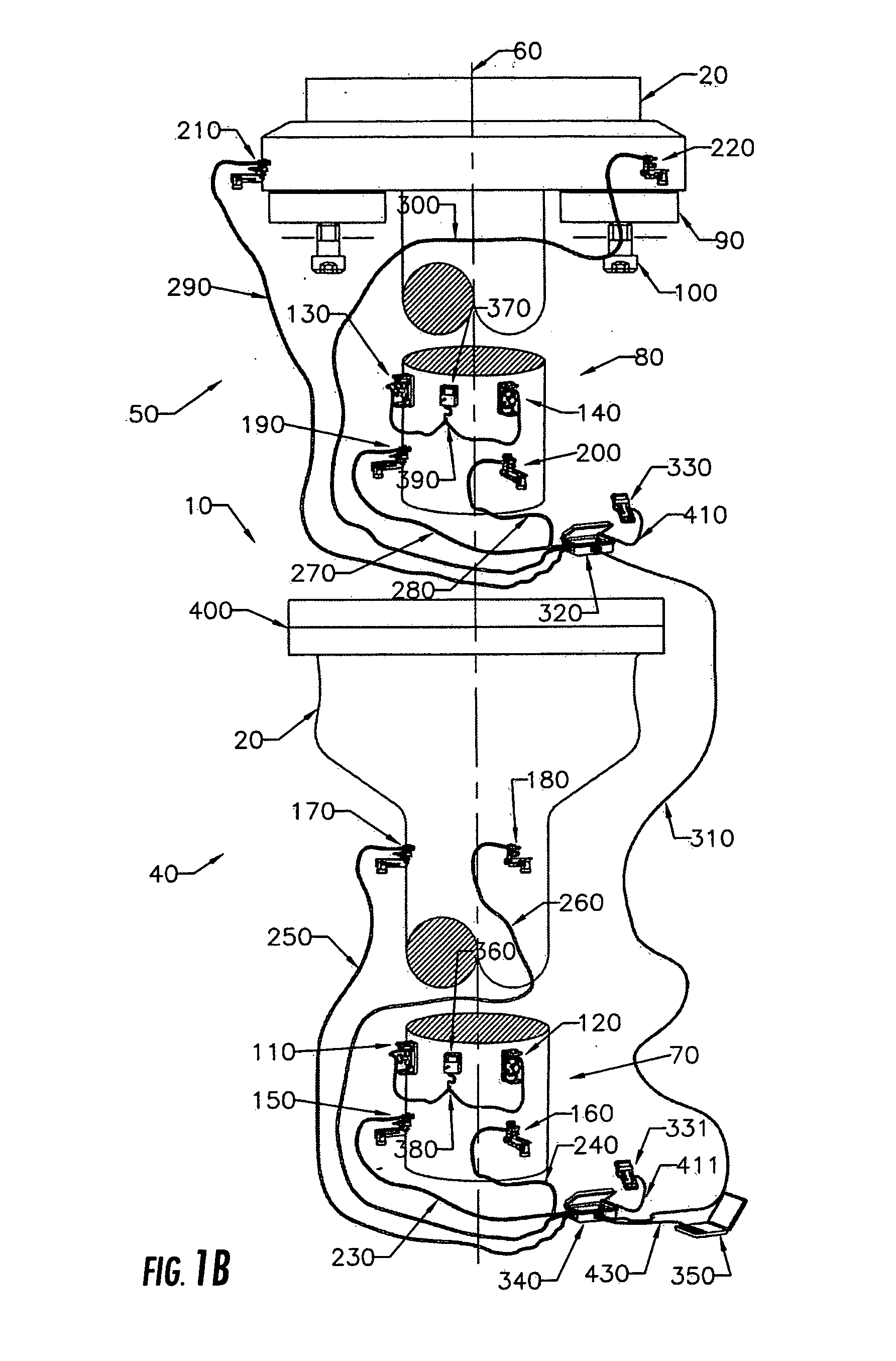

Vertical shaft alignment tool

InactiveUS7111407B2Reduce loadReduce wearAngles/taper measurementsUsing fluid meansData acquisitionEngineering

An apparatus and a method for aligning a vertical shaft or multiple axially coupled vertical shafts in a hydroelectric turbine generator or a similar vertical-shaft system, and for providing precise plumb inclination alignment of a vertical rotating shaft. Precision inclinometers attached to the vertical shaft measure plumb inclination. Proximity probe displacement devices mounted externally of the vertical shaft measure radial movement, throw, or run out at various shaft elevations as the shaft is rotated relative to a fixed point. Data acquisition devices and communication devices accumulate and transmit alignment data to a micro-computer which receives and processes such data. Methods of defining shaft plumb inclination in a static single rotational position and defining plumb inclination of the virtual centerline of a shaft's rotational throw position. A method of swinging, tilting, or adjusting a vertical shaft to a corrected or different plumb position relative to the earth's gravity.

Owner:TENNESSEE VALLEY AUTHORITY

Golf training device

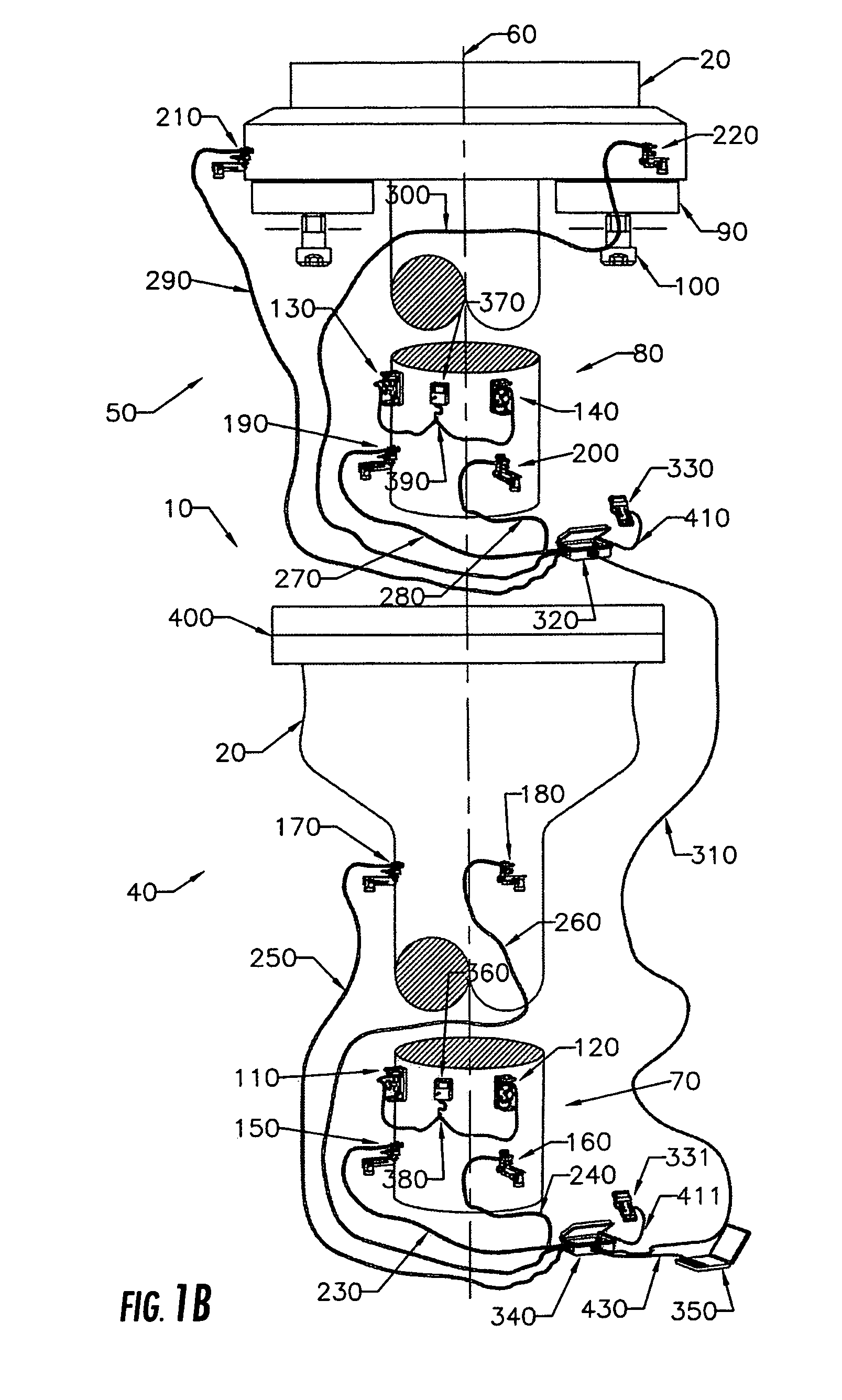

InactiveUS6945875B2Facilitates packing and shippingFacilitates storage and carryingGolfing accessoriesGolf clubsEngineeringGolf Ball

The golf training device includes a foot alignment strip generally in the form of an arrow that can be pointed towards a target. A ball alignment marker extends perpendicularly from an intermediate position along the foot alignment strip and can be pointed towards the golf ball. A hand alignment guide defines an arc that extends from the ball alignment marker to provide a visible cue that identifies a preferred path of movement of the hand through a golf swing. The shaft alignment line extend transversely across the hand alignment marker to identify preferred shaft positions at various points during a golf swing.

Owner:GAUER RICHARD

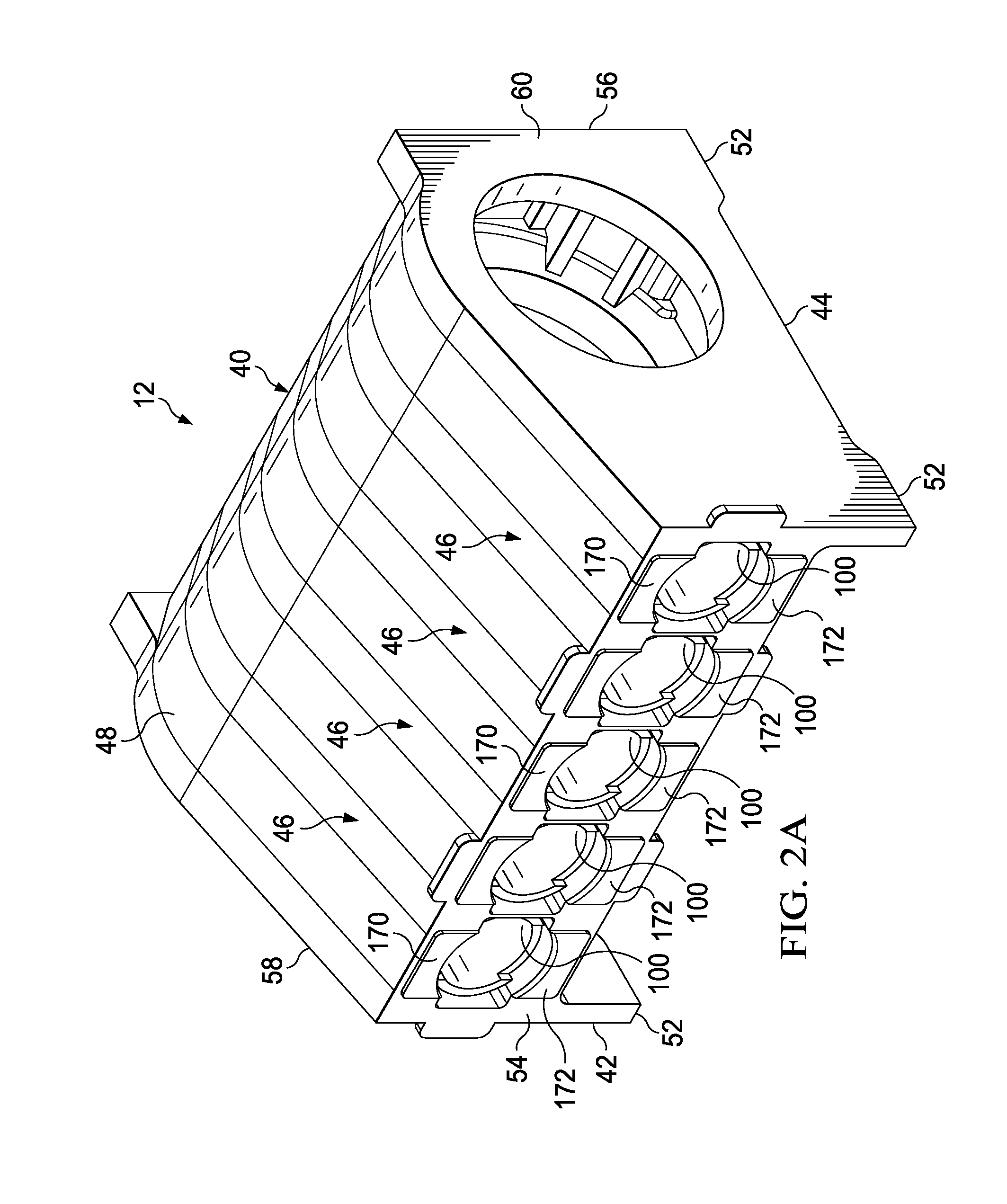

Bearing system for reciprocating pump and method of assembly

ActiveUS20160025090A1Increase temperatureInterference fit is createdPositive displacement pump componentsCrankshaft bearingsCrankshaftSupport surface

A power end frame assembly for a reciprocating pump that includes a first and second end plate segment each including annular bearing support surfaces configured to support a crankshaft bearing assembly. At least one middle plate segment is disposed between the first and second end plate segments and includes an annular bearing support surface configured to support a crankshaft bearing assembly. The annular bearing support surfaces of the first and second end plate segments and the at least one middle plate segment each have a diameter and are coaxially aligned. The diameter of at least one of the first and second end plate segments is different from the diameter of the at least one middle plate segment to facilitate insertion and removal of the crankshaft bearing assembly from the power end frame assembly.

Owner:SPM OIL & GAS INC

Ultra-elastic alloy slice mechanical arm

PendingCN106695879AReduce weightNo mechanical backlashProgramme-controlled manipulatorJointsModularityAlloy

The invention provides an ultra-elastic alloy slice mechanical arm, comprising a small joint body, a big joint body, an ultra-elastic alloy slice, a front-end camera and a driving mechanism; the joint body and the driving mechanism are connected through a wire pulling machine. The mechanical arm replaces the bearing through the ultra-elastic alloy slice and connects to every joint, thus the weight is lightened, and the mechanical arm is free from mechanical gap, high in motion precision and simple in structure; joints are in orthogonal connection, several driven joint slices are arranged between adjacent active joints, thus the bending flexibility of the mechanical arm is increased; a wire pulling hole of a joint driving pulling wire is in a cross shape, thus the coupling property between the pulling wires in movement is effectively reduced, and the control accuracy is improved; the driving mechanism is driven by a lever, and the rotating shaft of every lever is in the form of shaft alignment; the lever s are rotated in a ladder form and evenly distributed, thereby reducing the number of the driving unit and shortening the volume of the driving mechanism; for applying a tower type driver structure, every center connector adopts a modular form, and the center connector can be laminated freely so as to increase and decrease the drive unit.

Owner:北京动力京工科技有限公司 +1

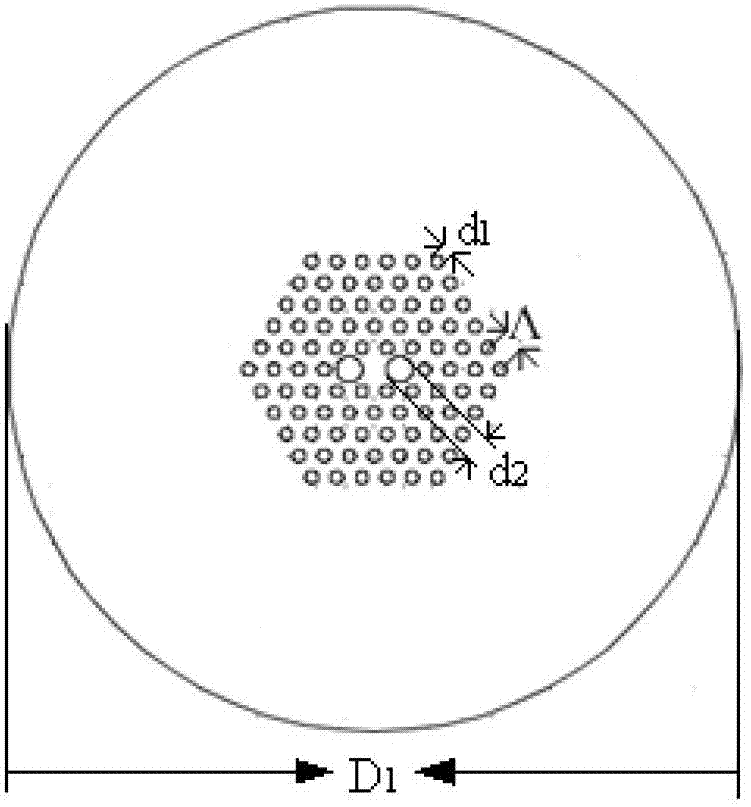

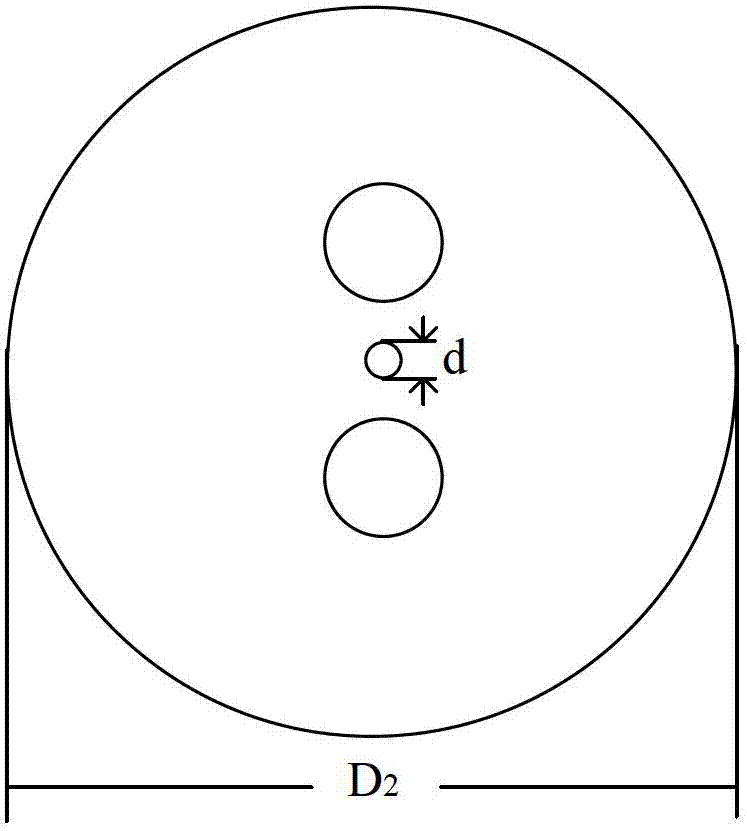

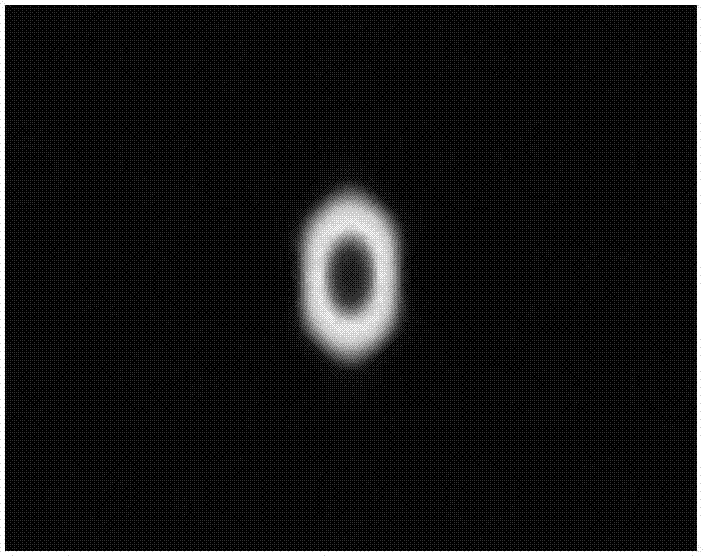

Polarization-maintaining photonic crystal fiber and panda fiber welding method

The invention discloses a polarization-maintaining photonic crystal fiber and panda fiber welding method. The polarization-maintaining photonic crystal fiber and panda fiber welding method is characterized by comprising a step 1 of selecting an initial position of a fiber, a step 2 of aligning a polarization shaft, and a step 3 of welding. The polarization-maintaining photonic crystal fiber and panda fiber welding method realizes better matching of two fiber mode fields and lowering welding consumption by controlling collapse of an air hole of a photonic crystal fiber and a diameter at the welding point of the panda fiber. The polarization-maintaining photonic crystal fiber and panda fiber welding method lowers welding consumption and improves welding intensity by adding a propelling distance in a fiber welding process appropriately. By adopting a novel welding machine and an end face imaging and shaft alignment technology, the polarization-maintaining photonic crystal fiber and panda fiber welding method can realize alignment of the polarization shafts of both the photonic crystal fiber and the panda fiber and improve shaft alignment precision. The polarization-maintaining photonic crystal fiber and panda fiber welding method, disclosed by the invention, has the advantages of being simple in technology, only needing once welding, and being easy to operate, good in repeatability and applicable for welding between photonic crystal fibers of the other types and traditional single-mode fibers.

Owner:BEIHANG UNIV

Apparatus and method for lining large diameter pipes with an environmentally compatible impervious membrane

A method and apparatus is disclosed for remotely and robotically installing an organic, monolithic, structural and non structural, circumferential and partial radius membranes in conduits, pipelines or passageways. The included apparatus has the mechanical function to manually or automatically center the liner dissipation device in any geometrical shape. The included apparatus possesses the remote controlled capability to manipulate centrifugal dissipation of the liner to afford consistent thickness on any shaped profile or flat surface of the pipe wall surface. The apparatus includes a manual or automatic mechanical scissoring device for elevation changes and a manual or automatic rotational table for shaft alignment. The apparatus includes a means of automated self alignment by way of proximity sensors. The pendulum oscillation bracketing incorporates a fluid driven motor assembly communicating with a bored shaft and integrates as many as two offset dissipation devices. The included apparatus has both fluid and electrical rotary unions to transmit fluids and current from fixed ports to a rotating shaft assembly. The included apparatus has a mechanical function facilitating cutting and retrieval of cured spray build up on the spray orifice. This method and apparatus will allow for continuous lining applications of any thickness in one pass, in conduits and passageways employing multi component liquid polymers with rapid mechanical properties formation.

Owner:QUEST INSPAR +1

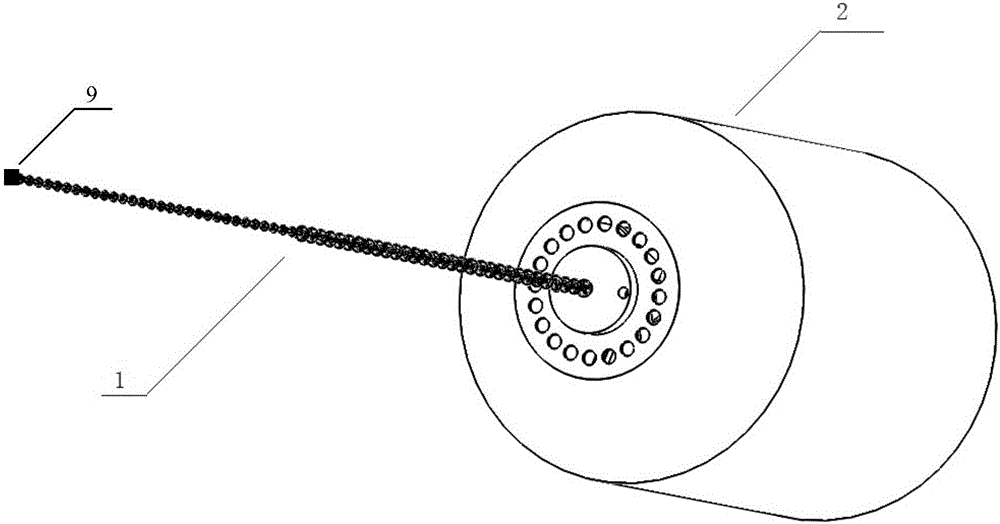

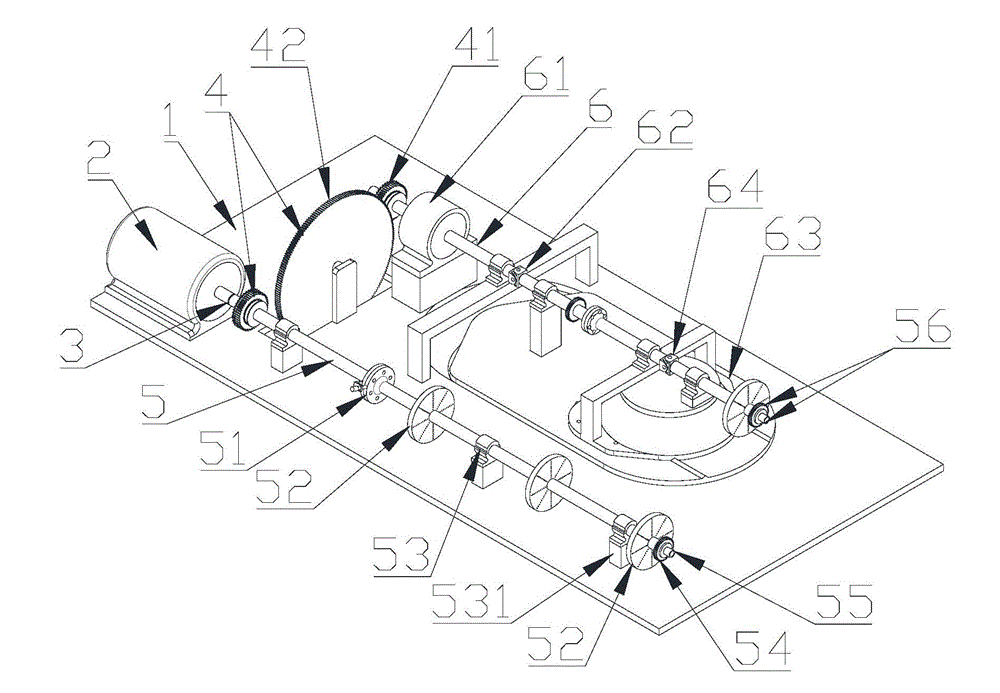

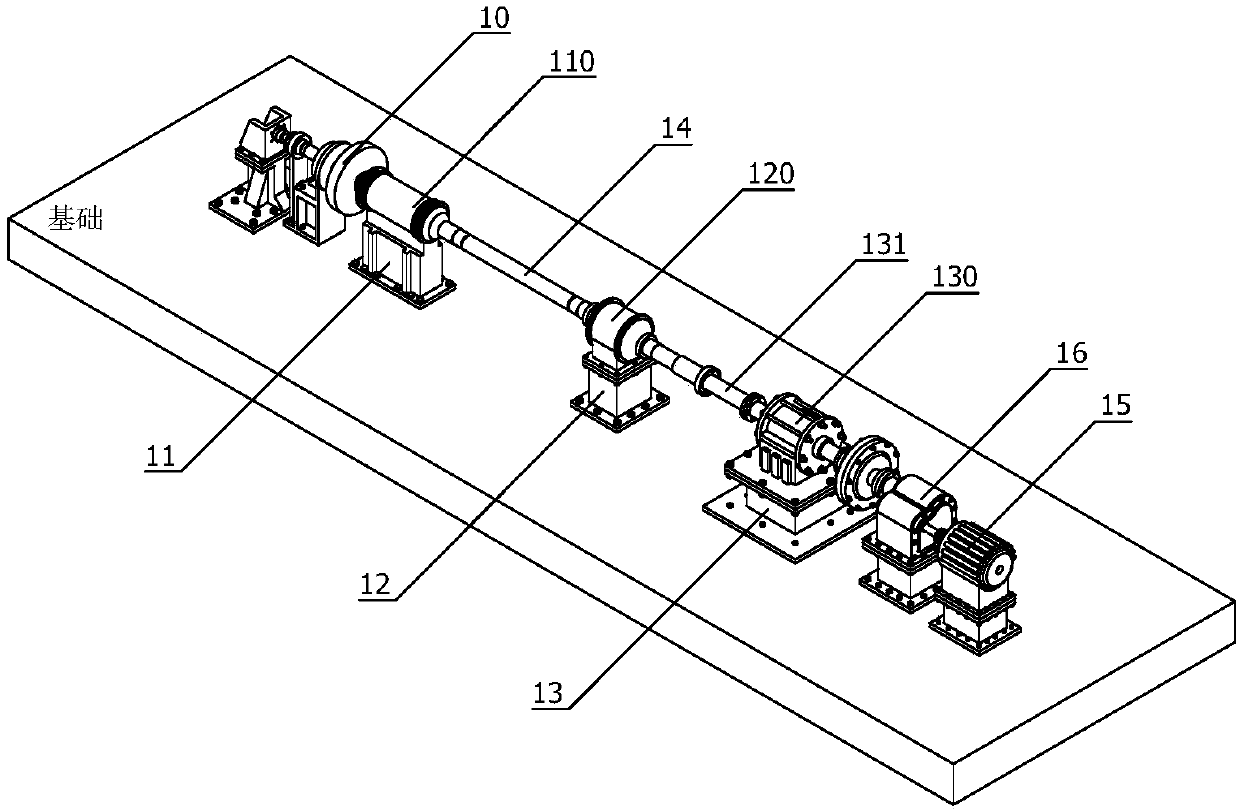

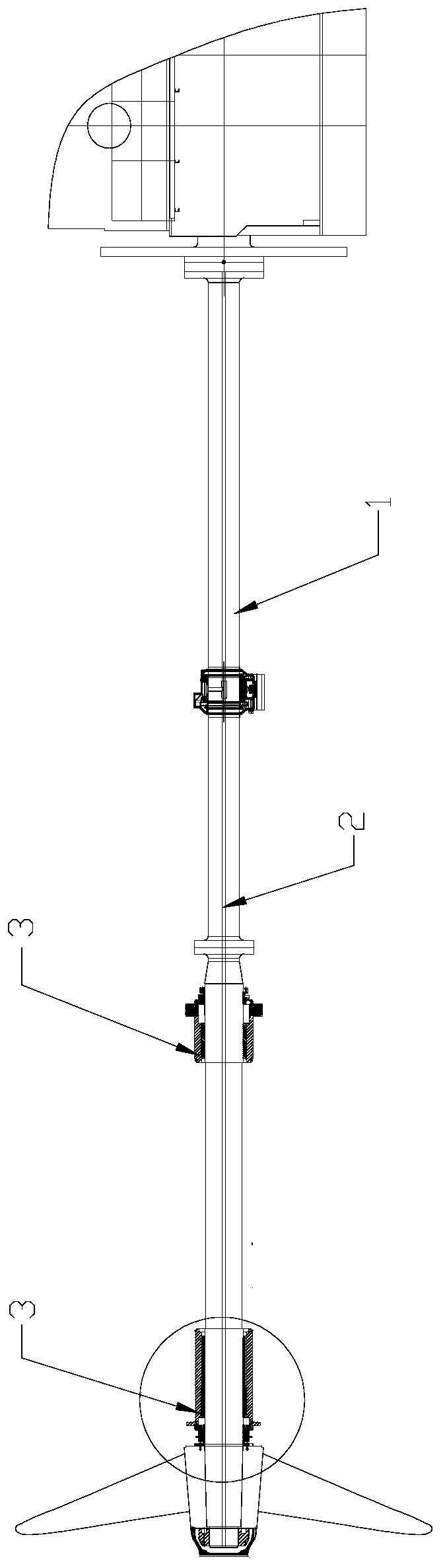

Ship propulsion shafting whirling vibration and twisting vibration simulation experiment device

The invention discloses a ship propulsion shafting whirling vibration and twisting vibration simulation experiment device. The experiment device comprises a pedestal, a motor, an inter-axial transmission mechanism, a whirling vibration shaft and a twisting vibration shaft; the motor is fixed to the pedestal, the whirling vibration shaft and the twisting vibration shaft are in parallel arranged above the pedestal; the inter-axial transmission mechanism is used for driving said two shafts, and comprises a combination wheel and inter-axial gears, and belts, gears or chains are driven as needed; the whirling vibration shaft is provided with an alignment flange, a counterweight disc, an adjustable displacement bearing and measurement interfaces; the twisting vibration shaft is provided with a shock excitation motor, universal joints, an universal joint angle control apparatus and measurement interfaces, and the rotor of the shock excitation motor is connected to the shaft and used for simulating and generating twisting vibration. The experiment device is simple in structure and strong in pertinence, and can be applied to simulation study of shafting whirling vibration and twisting vibration and impact of shafting alignment status and transmission manner to whirling vibration and twisting vibration.

Owner:WUHAN UNIV OF TECH

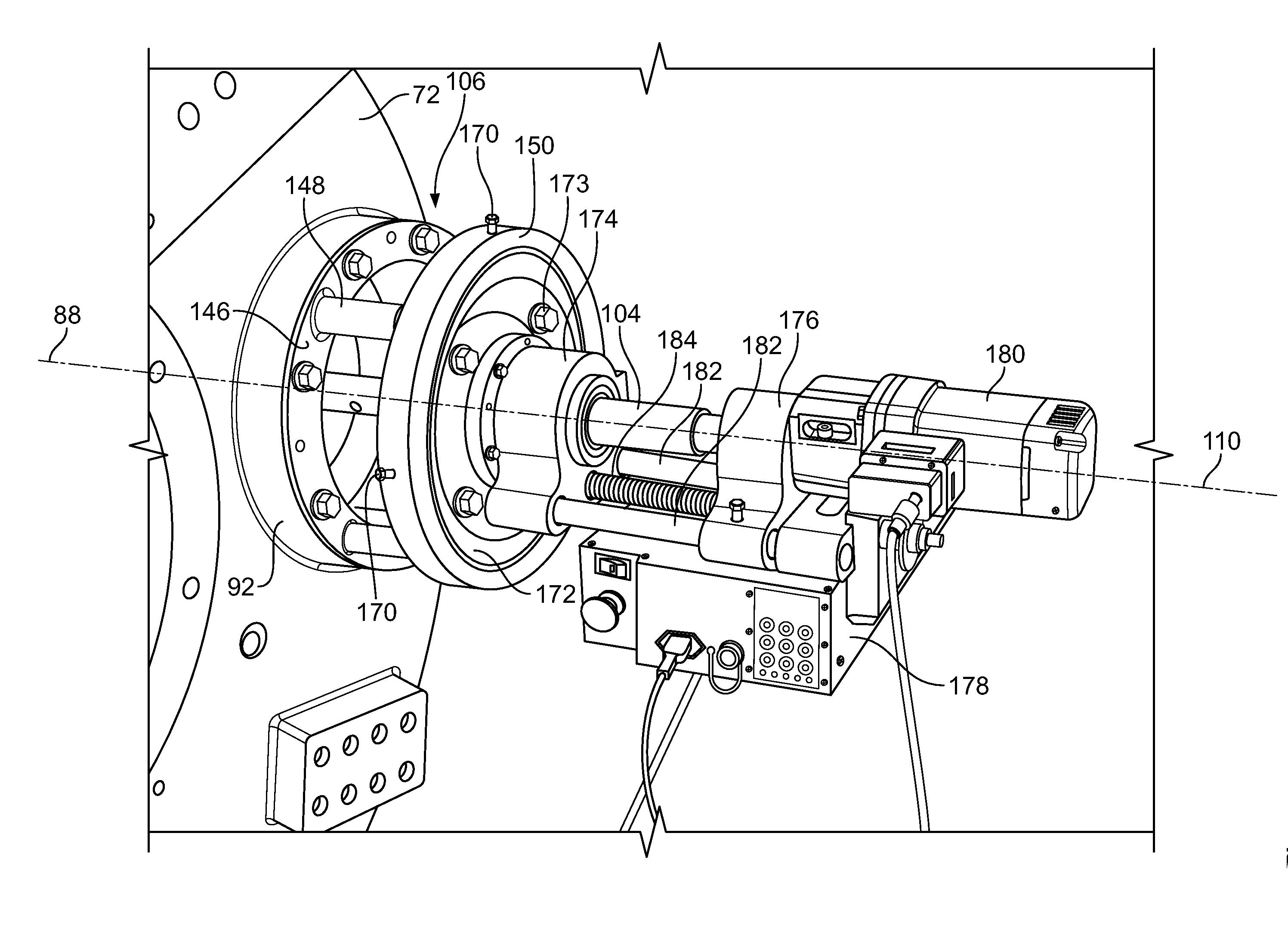

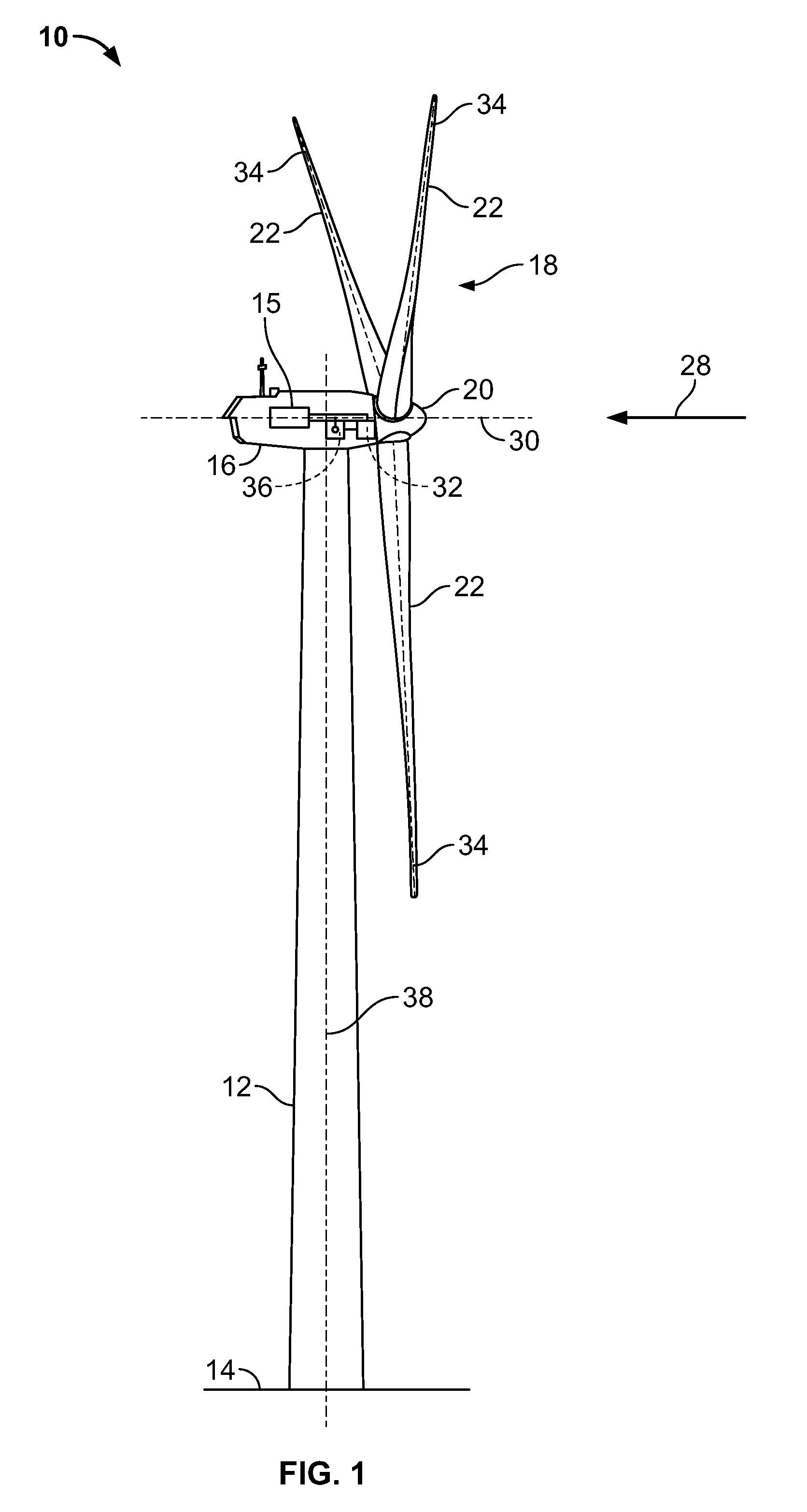

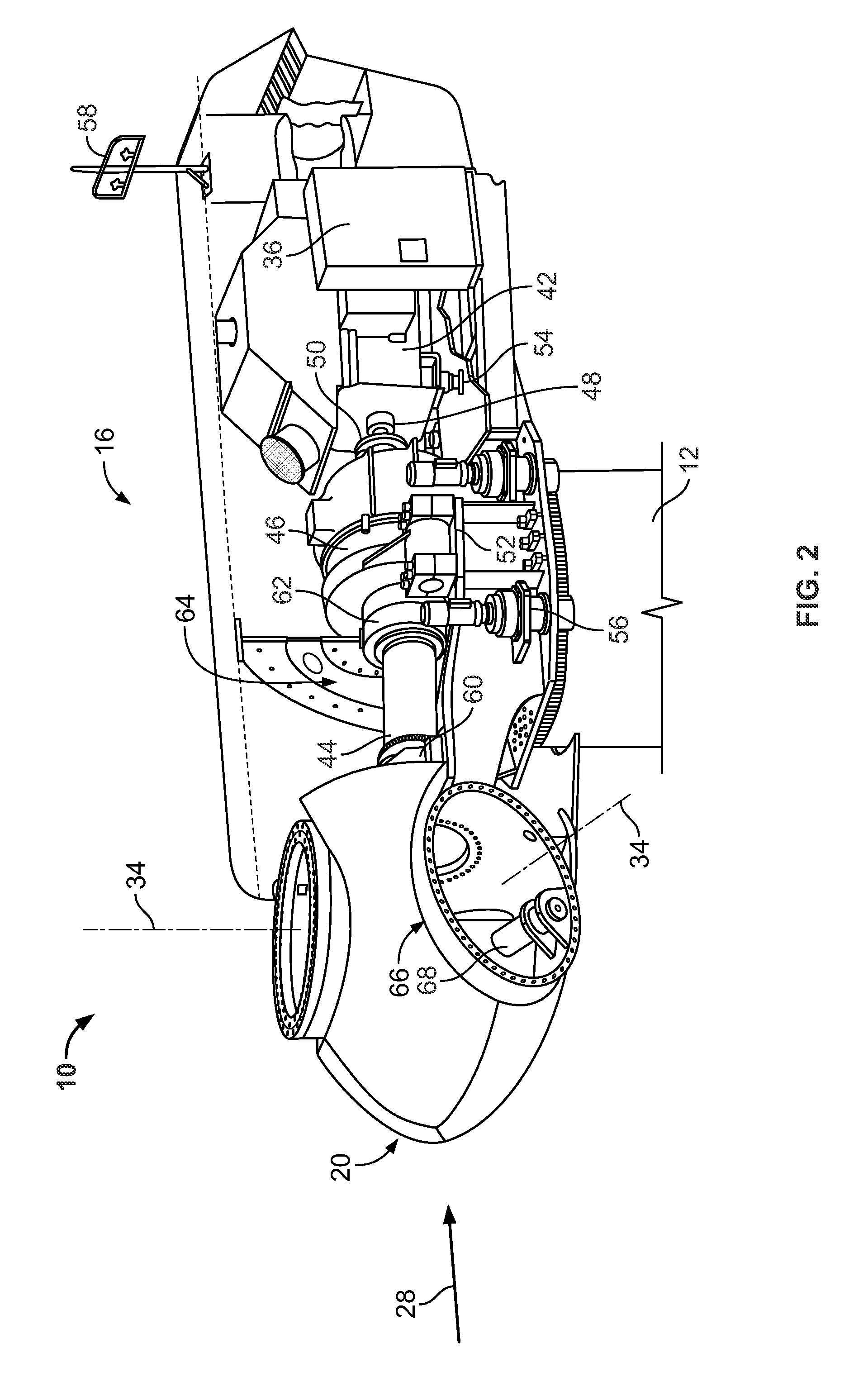

Systems and methods for assembling a bore repair assembly for use in a wind turbine

InactiveUS20110131781A1Easy to assemblePromote repairThread cutting toolsTransportation and packagingTurbineClassical mechanics

A method of assembling a bore repair assembly for use with a wind turbine. The wind turbine includes a gearbox assembly that defines a first bearing bore and a second bearing bore coaxially aligned with the first bearing bore. The method includes coupling a first support assembly with respect to the second bearing bore. A boring bar is positioned coaxially within the first bearing bore and through the second bearing bore. The boring bar is rotatably coupled to the first support assembly. A boring bar drive assembly is coupled to the boring bar for rotating the boring bar about a central bearing axis.

Owner:GENERAL ELECTRIC CO

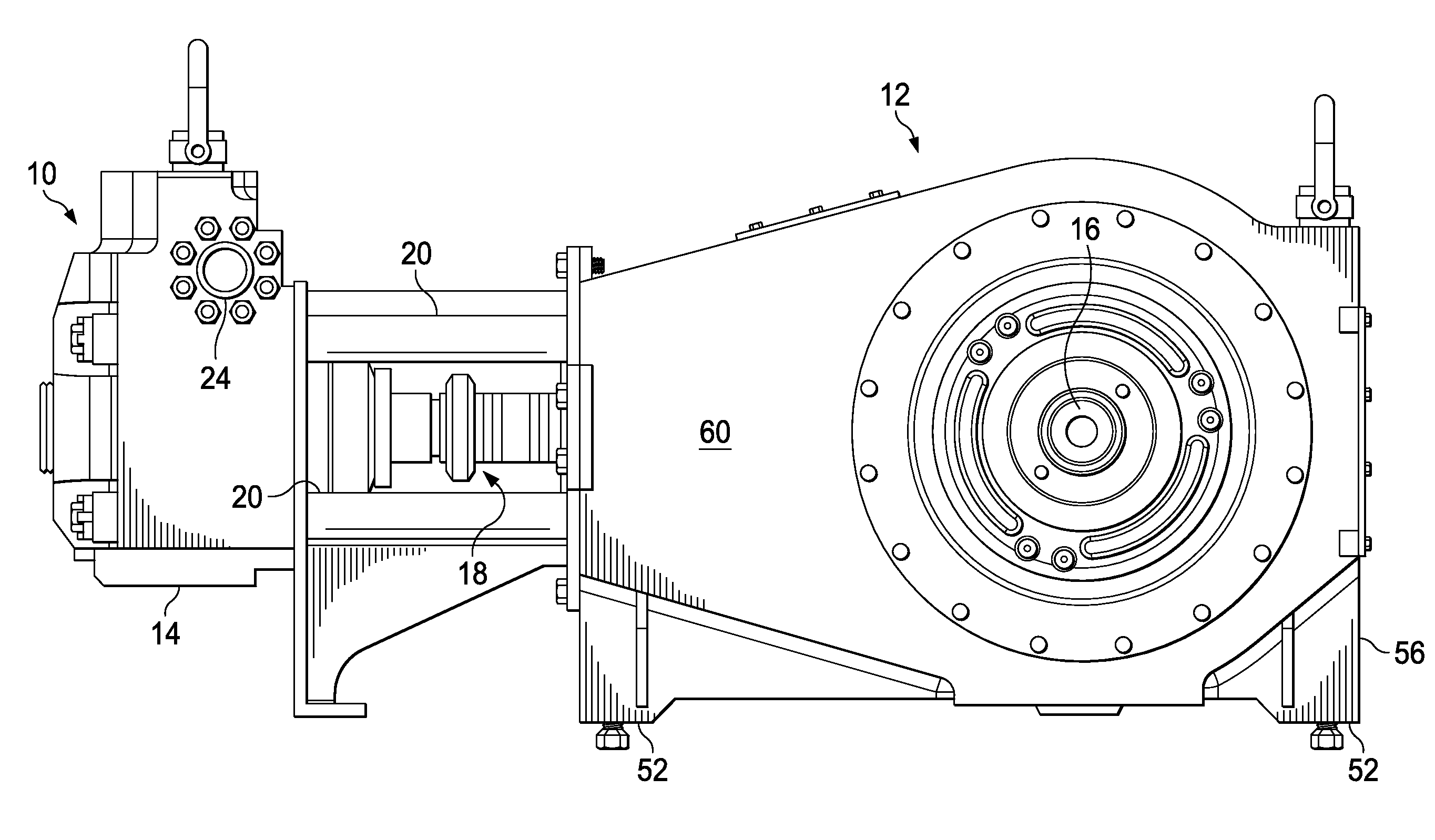

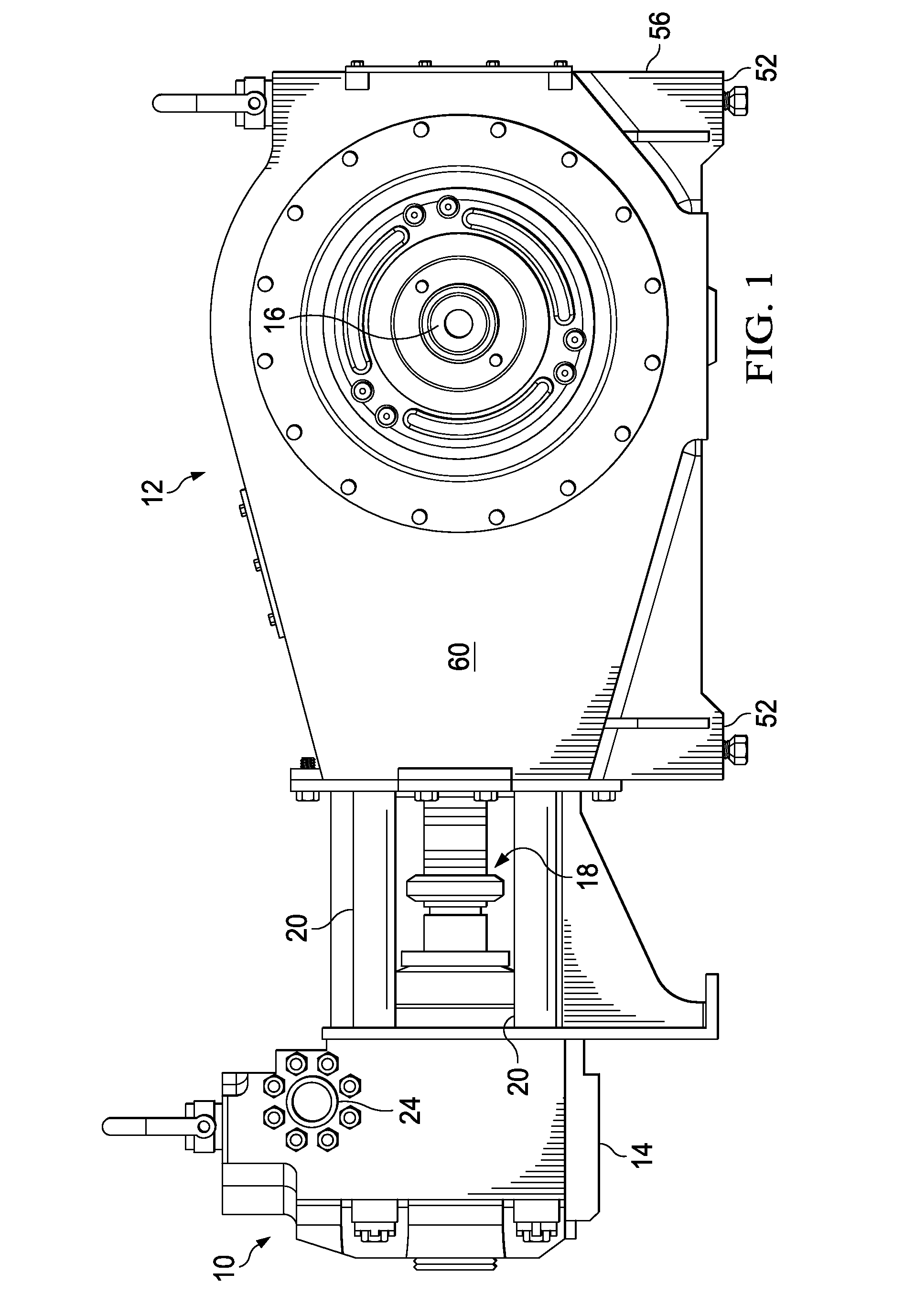

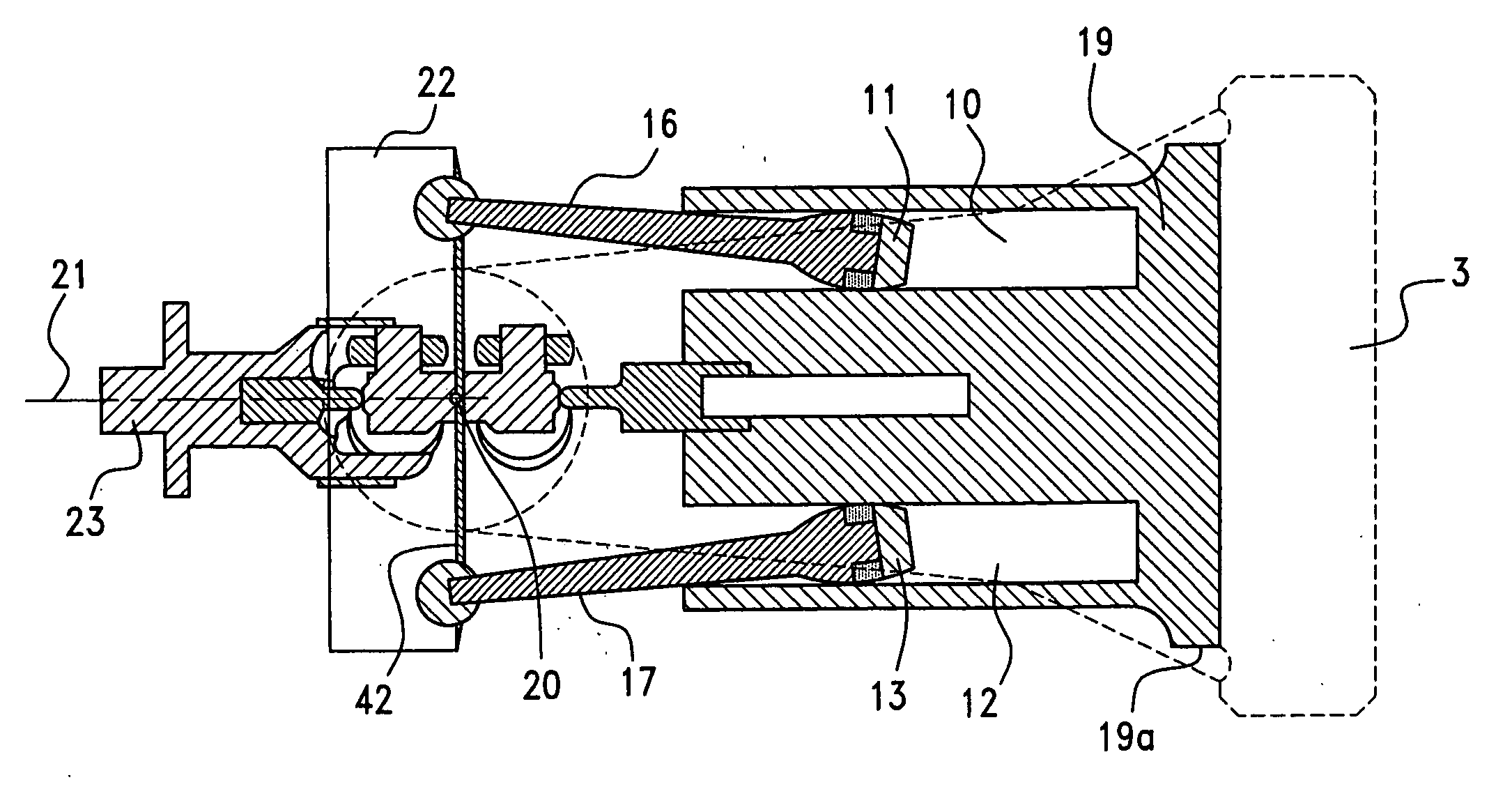

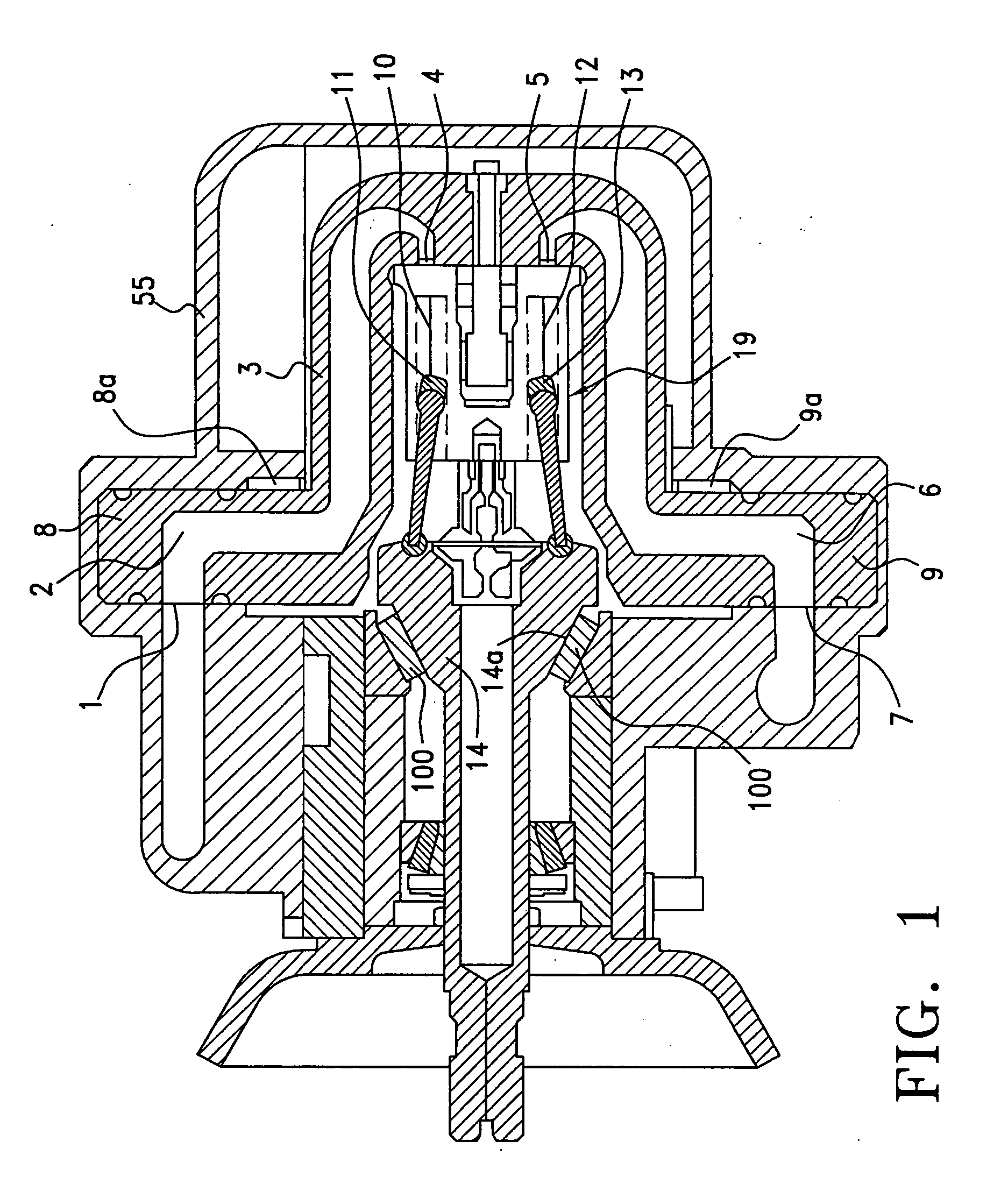

High-efficiency, large angle, variable displacement hydraulic pump/motor

InactiveUS20060051216A1Improve efficiencyHigh displacement angleYielding couplingFluid gearingsHydraulic pumpControl theory

A variable displacement hydraulic / pump motor has a yoke with a pair of shafts aligned to define a yoke pivot axis and connected to a valve plate therebetween having intake and discharge apertures. A rotatable cylinder barrel has piston cylinders open at one end to receive a piston head and opening through fluid ports at another end, flush against the valve plate surface. A drive block is mounted on an input / output shaft for rotation about a central axis of rotation inclined at an angle relative to the longitudinal axis of the cylinder barrel which may be changed by a drive engaging the yoke at a point near its pivot axis. Loads on bushings supporting the yoke shafts are reduced by providing radially extending fluid ports in the shafts and in communication with the intake and discharge apertures of the valve plate.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

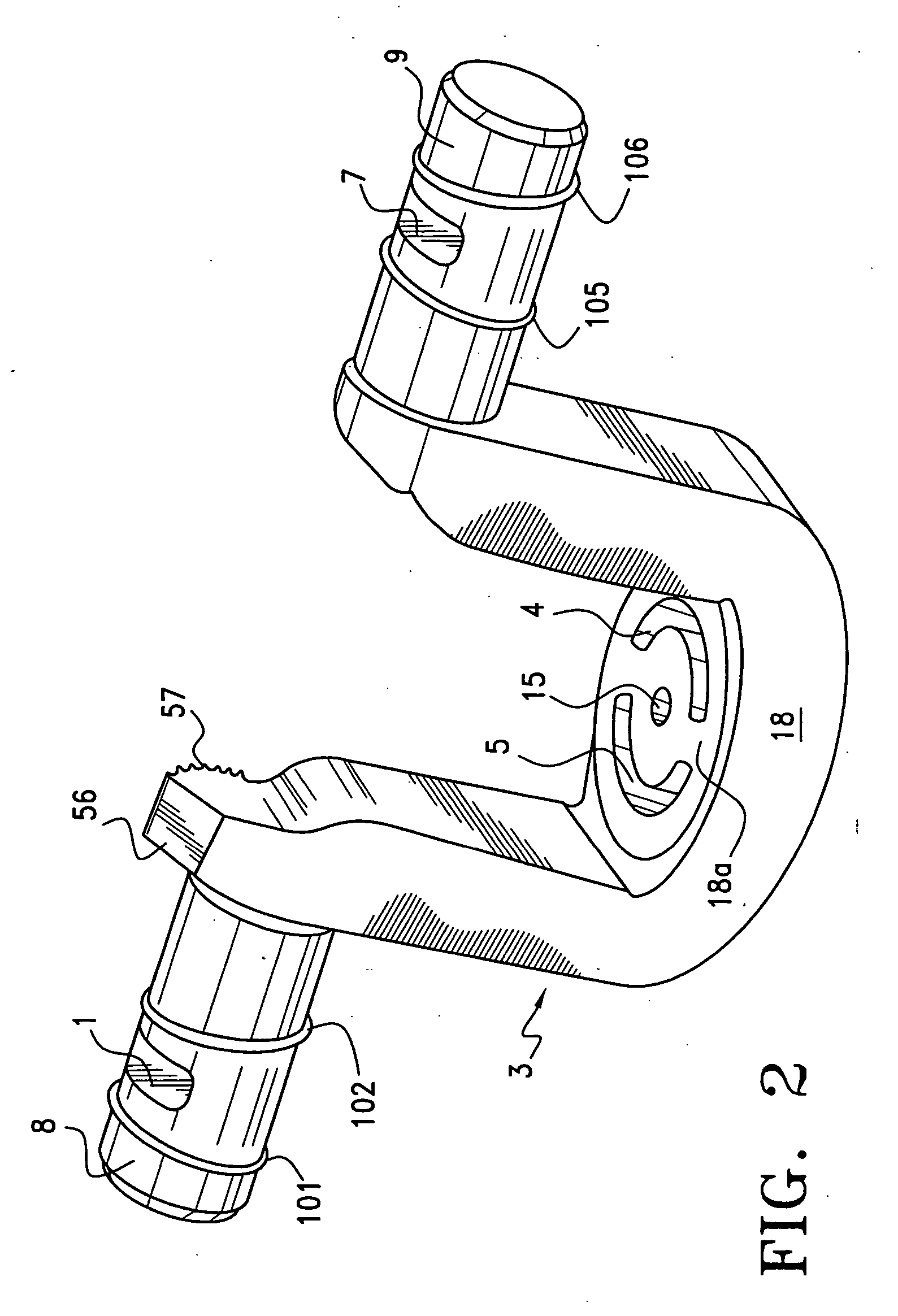

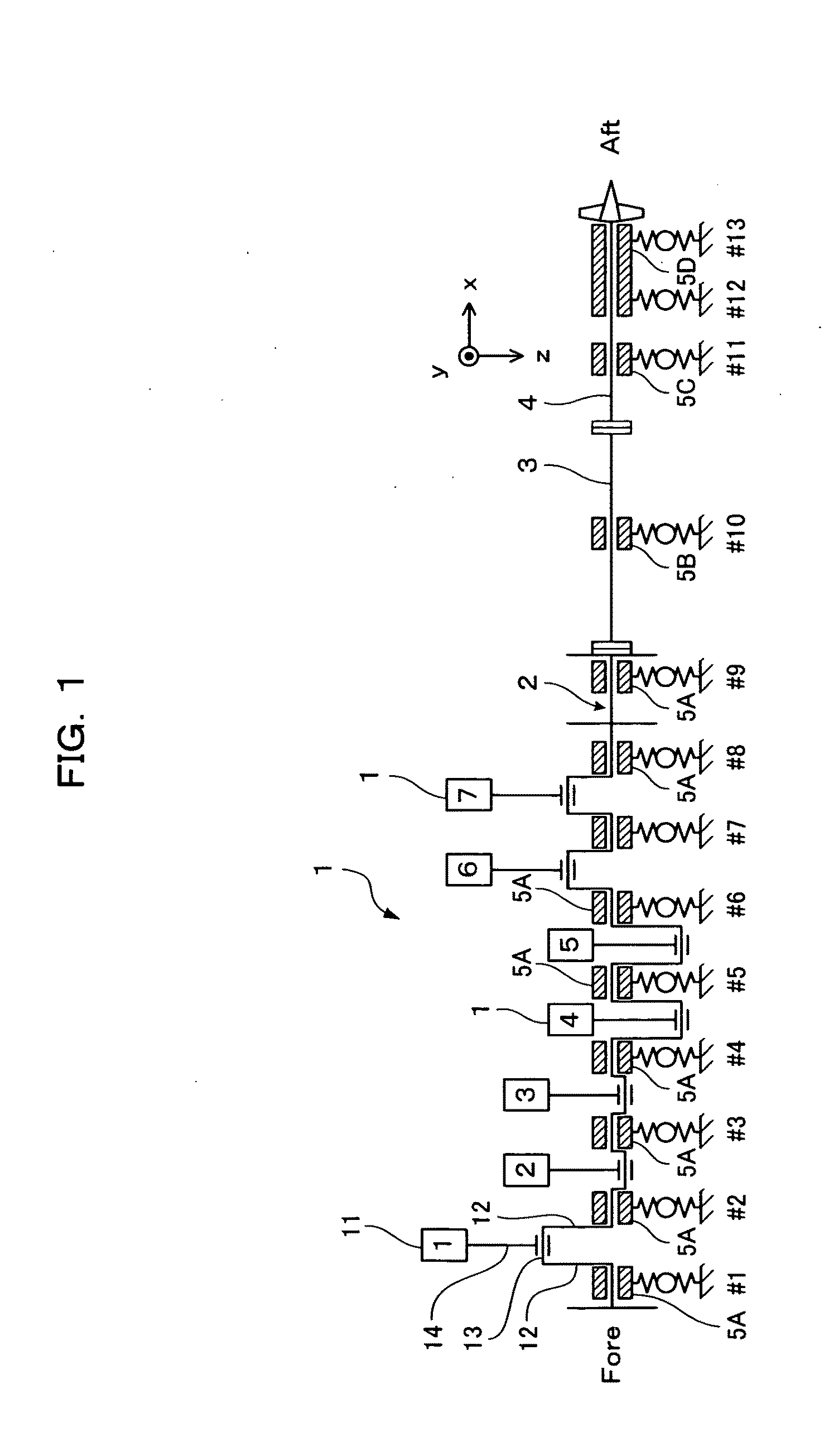

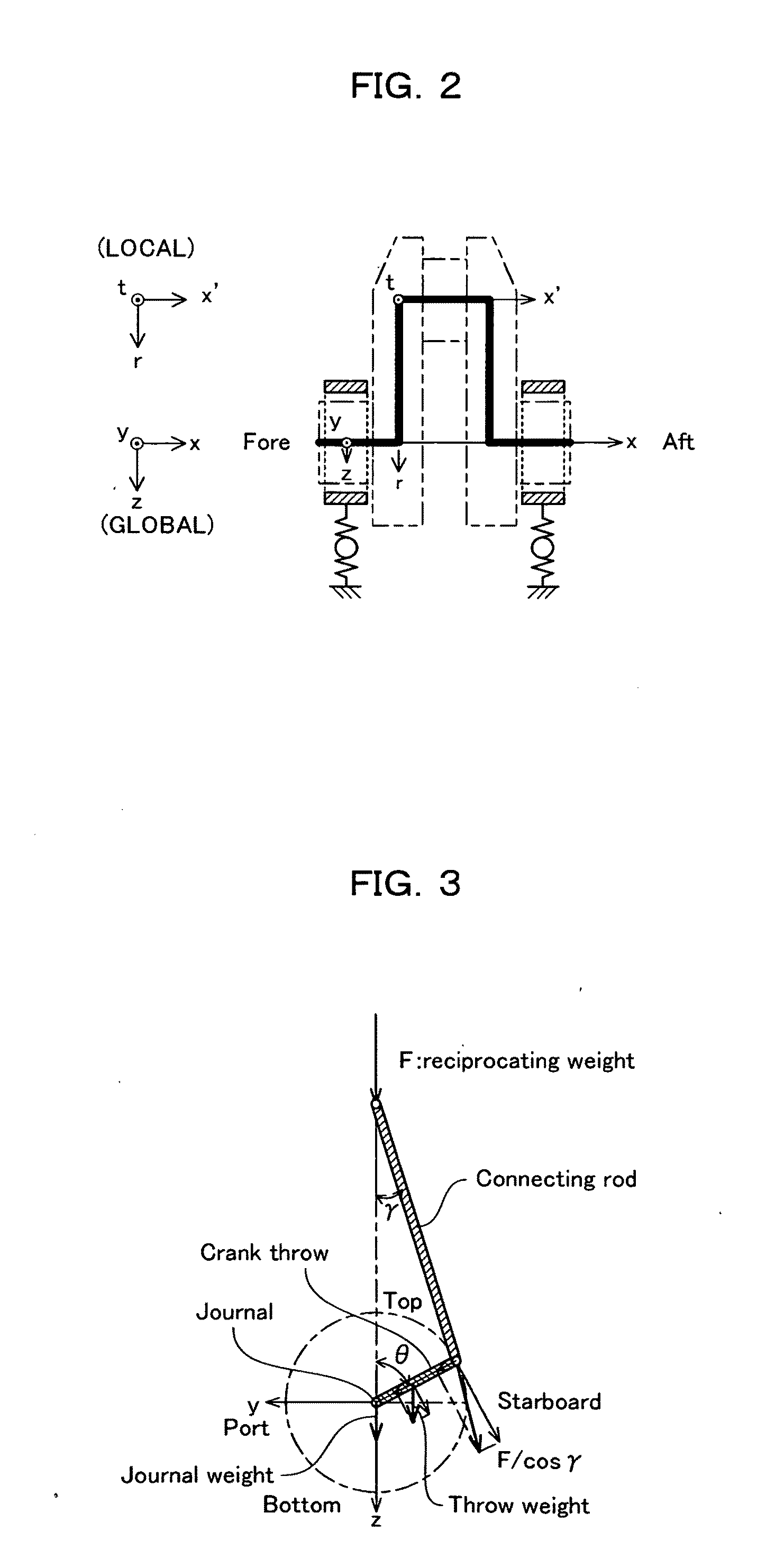

Method and device for evaluating shafting alignment of ship

InactiveUS20090271053A1Easy assessment processVehicle testingSpeed controllerMarine engineeringMedial axis

An evaluation map showing the allowable ranges (A) of the crank deflection and bearing loads determined according to the inclination of the crankshaft of an engine and the intermediate shaft is prepared beforehand. When the engine is installed in a ship, the inclination of the shafts within the allowable ranges can be easily known. While the ship is in service, the shafting alignment of the ship can be evaluated by merely measuring the inclination of the crankshaft and the intermediate shaft.

Owner:HITACHI ZOSEN CORP

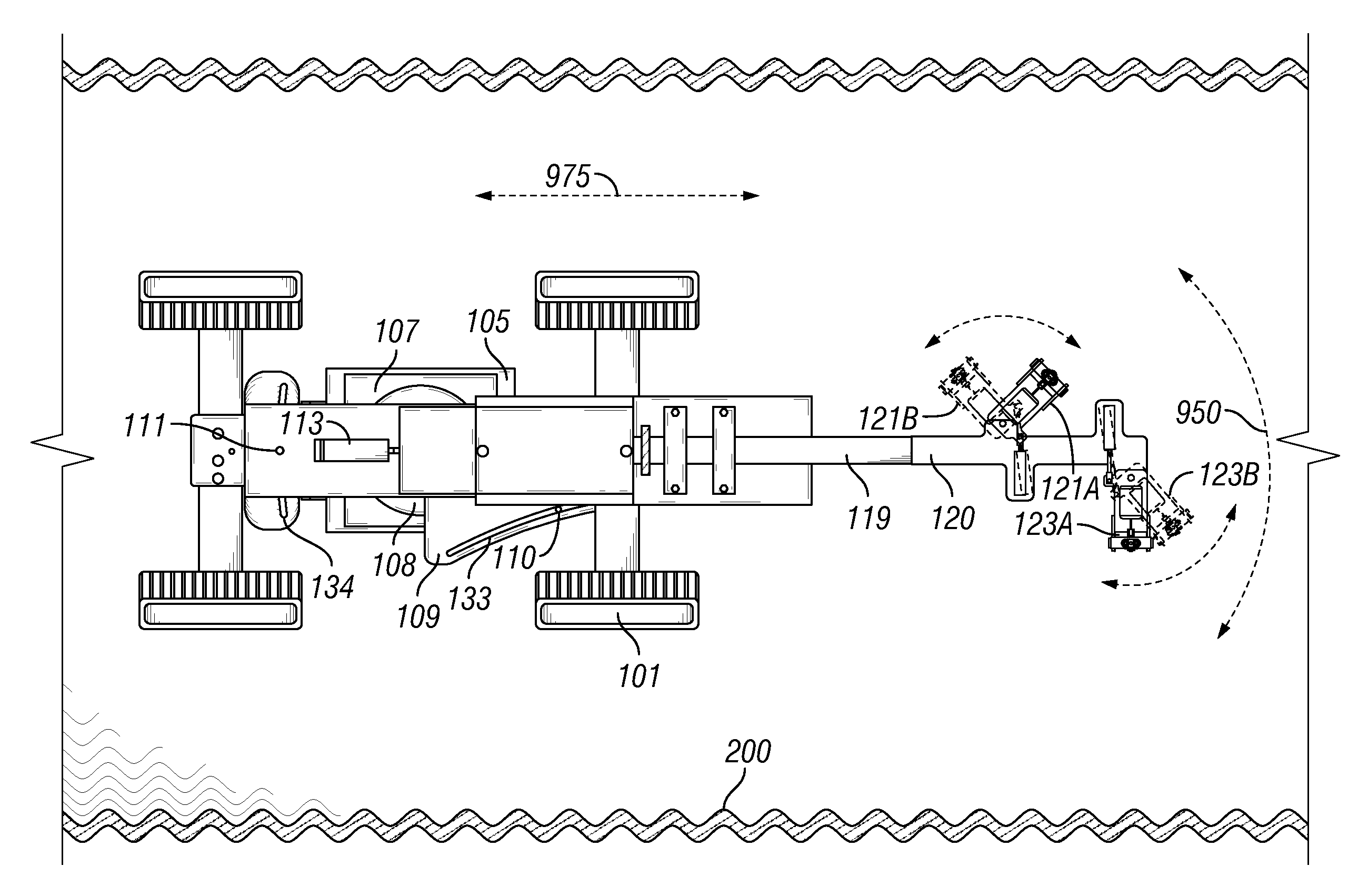

Process for installing reamer transmission shafts of cutter-suction dredge

InactiveCN101831931AEasy to installImprove work performanceMechanical machines/dredgersAgricultural engineeringReamer

Owner:南通港闸船舶制造有限公司

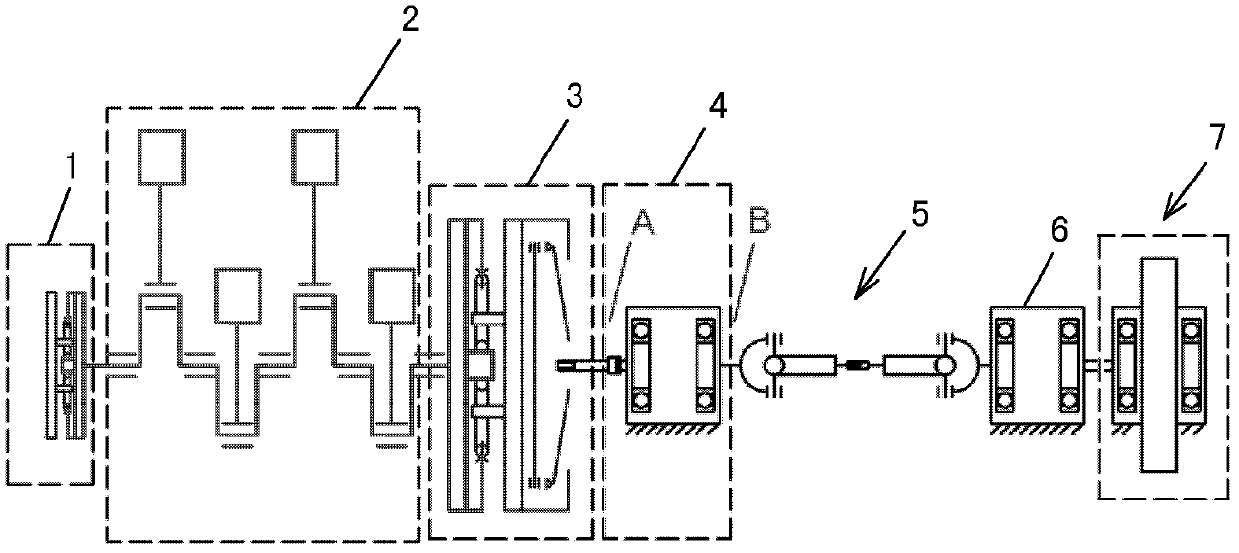

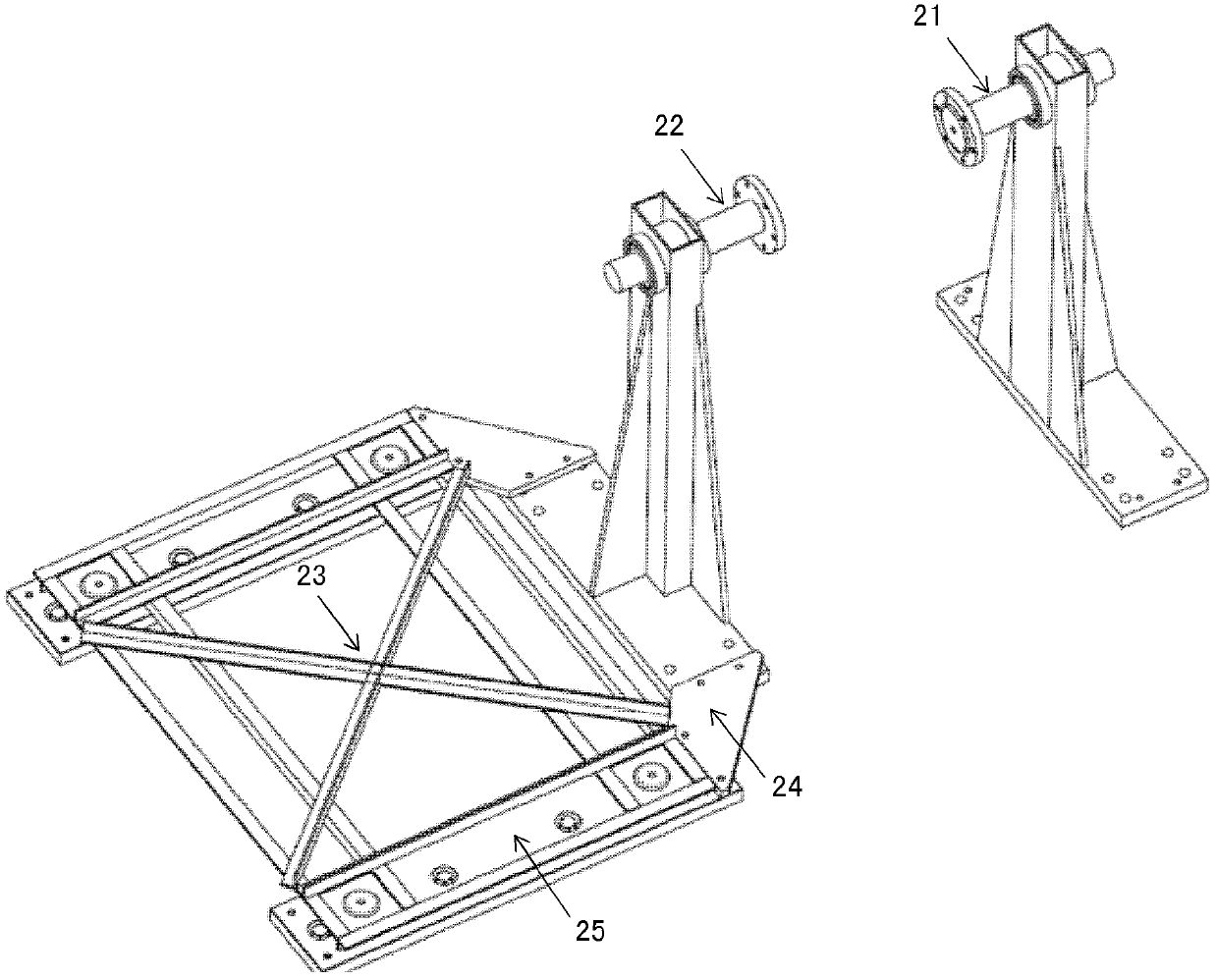

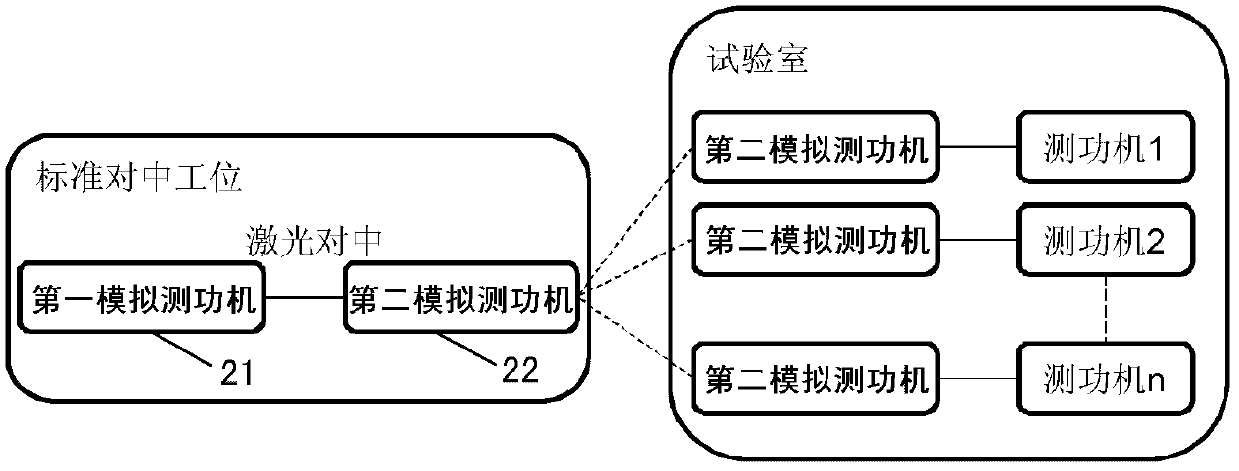

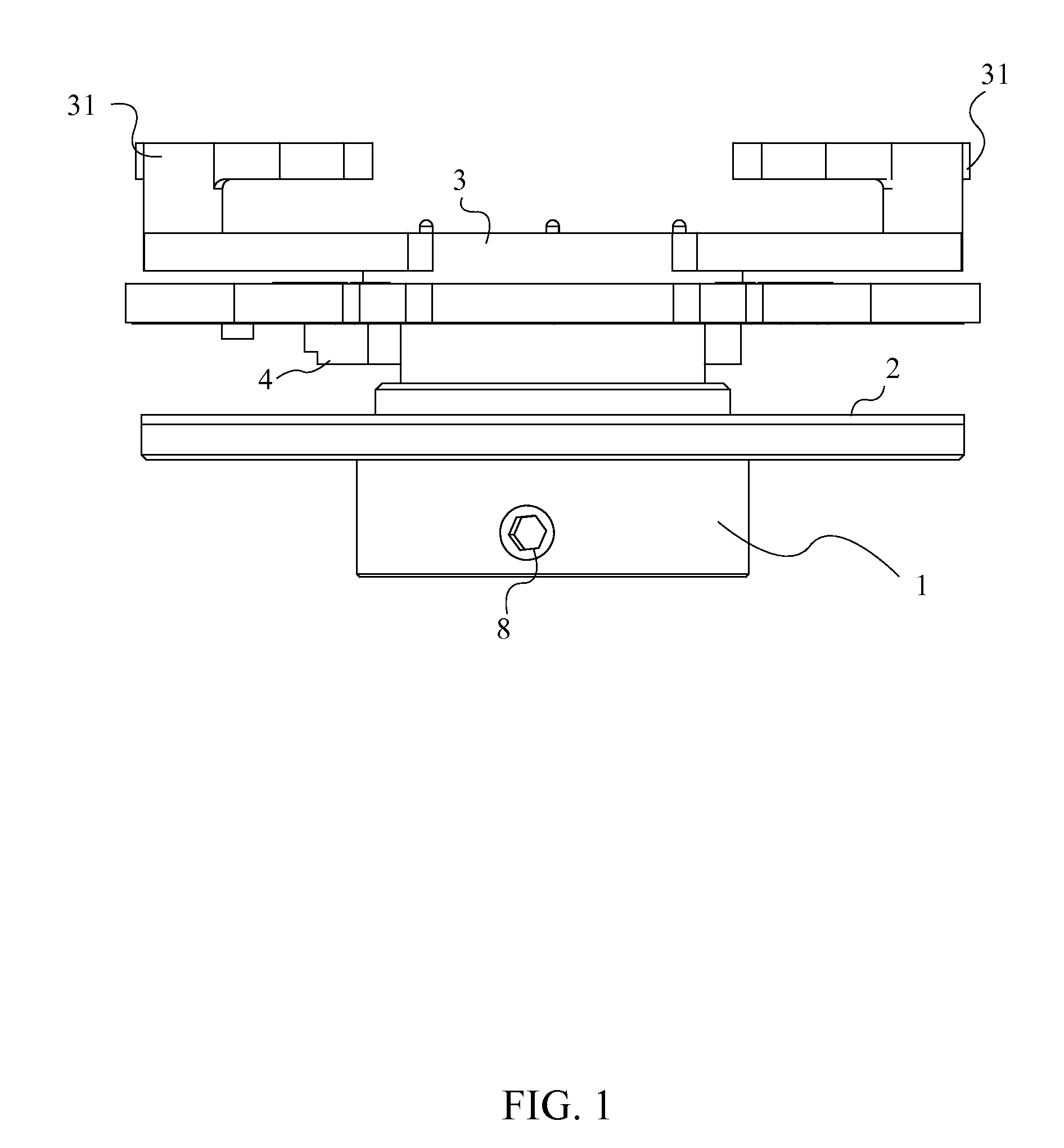

Standard centering device, engine test trolley and standard centering method

ActiveCN103308036APrecise positioningImprove installation efficiencyEngine testingSurveying instrumentsDevice formEngineering

The invention provides a standard centering device, an engine test trolley and a standard centering method. The standard centering device comprises a first simulative dynamometer, a second simulative dynamometer, a locating retaining frame, a locating connecting plate and a locating bottom plate, wherein the first simulative dynamometer is fixed on the standard centering device through locating pins and bolts and defines a reference height; the second simulative dynamometer is connected with a bottom plate locating pin of the standard centering device through the locating pins and can be dismounted from the standard centering device; a laser shaft alignment instrument is mounted between the first simulative dynamometer and the second simulative dynamometer; the locating retaining frame is used for supporting the standard centering device and locating the standard centering device so that the standard centering device forms an entirety capable of moving as a whole; and the locating connecting plate is connected with the second simulative dynamometer and the locating bottom plate.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

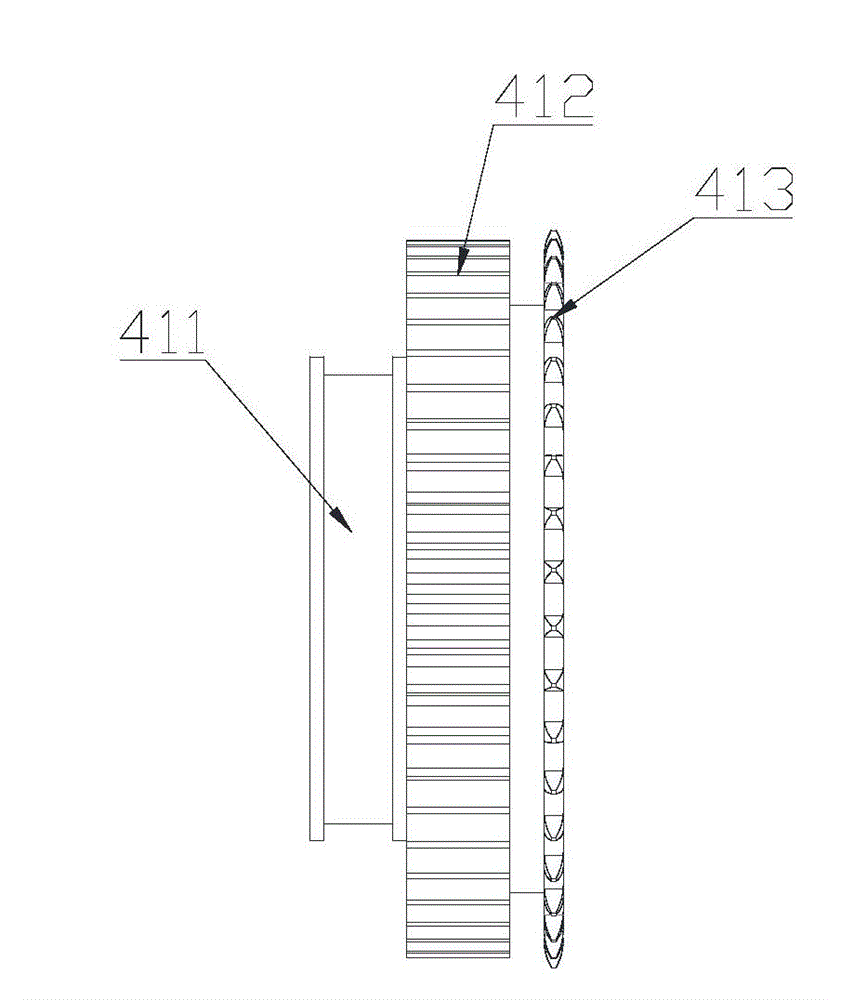

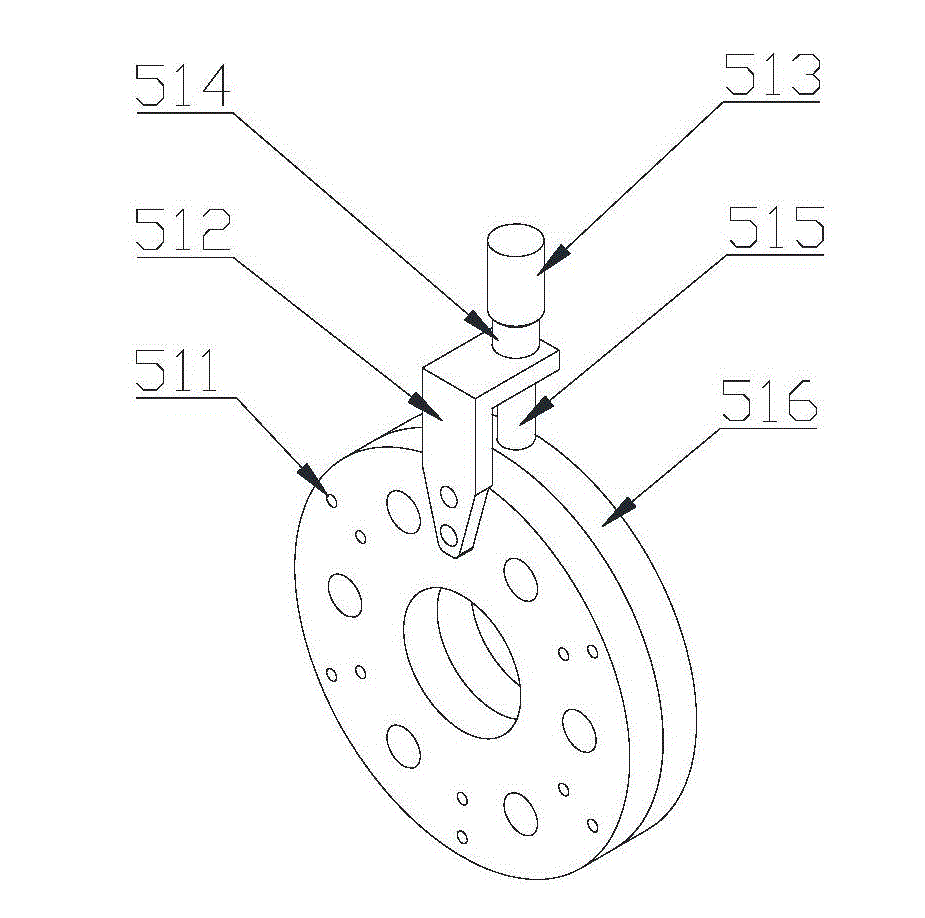

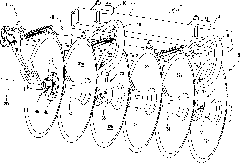

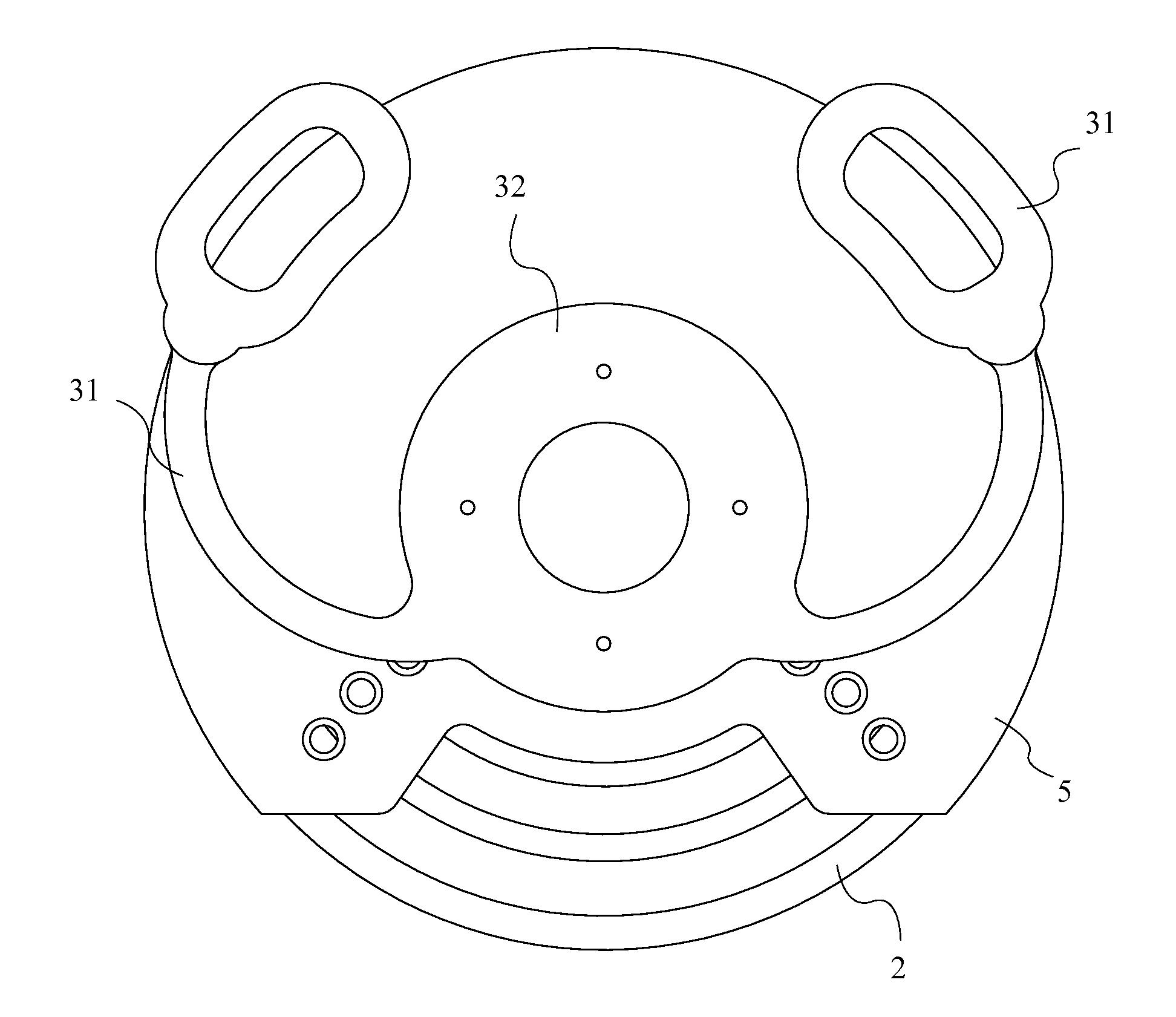

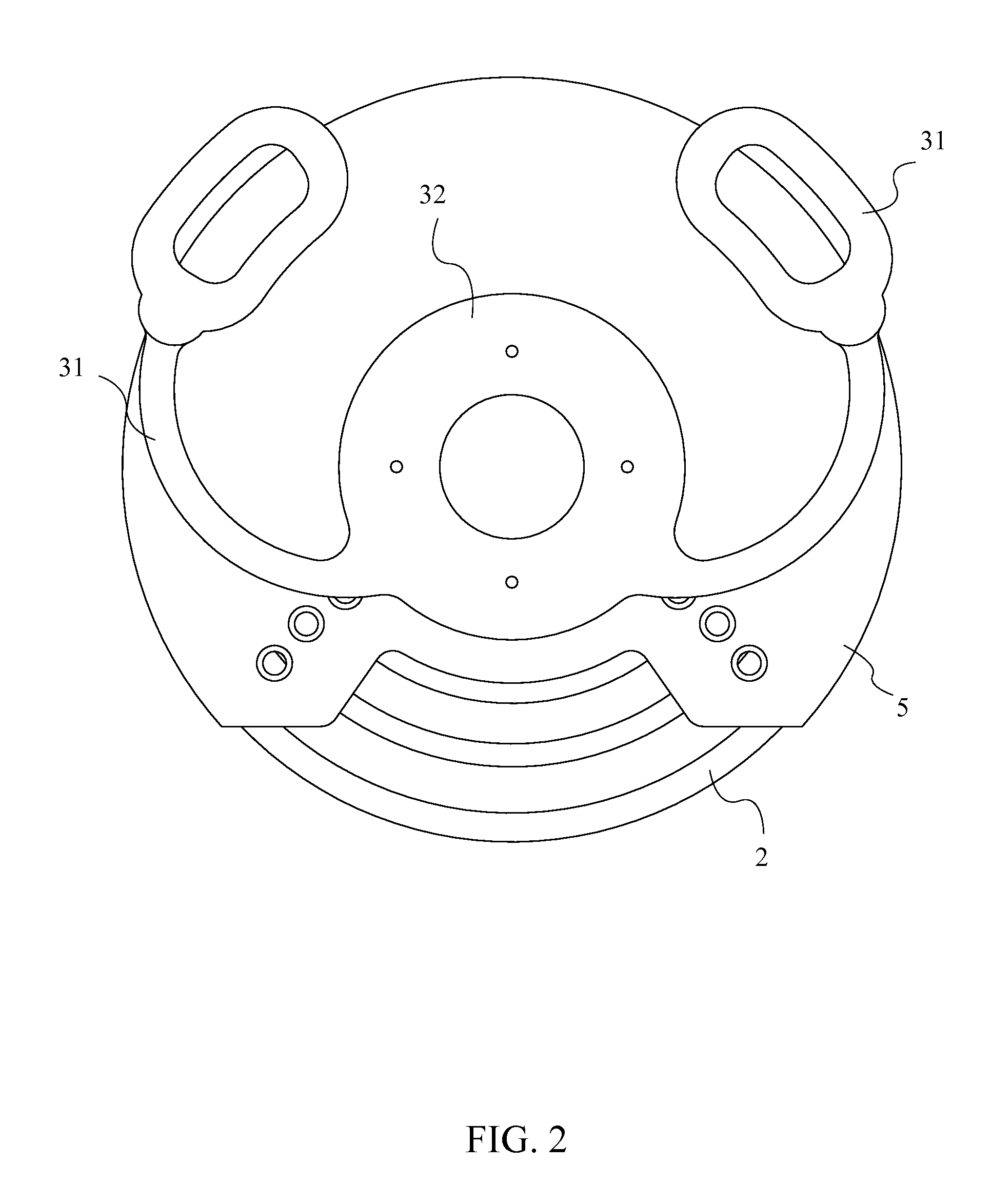

Shaft alignment and anti-corrosion liner for a disk gang

A disk gang assembly (10) includes a disk gang shaft (30) supported by a standard-mounted disk gang bearing assembly (20) having an inner race (20a) receiving a mounting portion (30m) of the disk gang shaft (30). A non-metallic anti-corrosive shaft liner (50) supported over the mounting portion (30m) between the inner race (20a) and the mounting portion (30m) protects the mounting portion from impacts and from seizure of the inner race (20a) and provides a tight fit between the shaft mounting portion (30m) and the inner race (20a) without need for close manufacturing tolerances. The shaft liner (50) aligns the bearing, spacers and washers relative to the shaft (30) and accommodates slight misalignments of the shaft (30), bearing inner race (20a) and any spacing components (34,36,37,38) between disk blades (32,32a,32b). A split (52) generally along an axis parallel to an axis of the disk gang (30a) shaft facilitates assembly of the liner (50) unto the shaft (30).

Owner:DEERE & CO

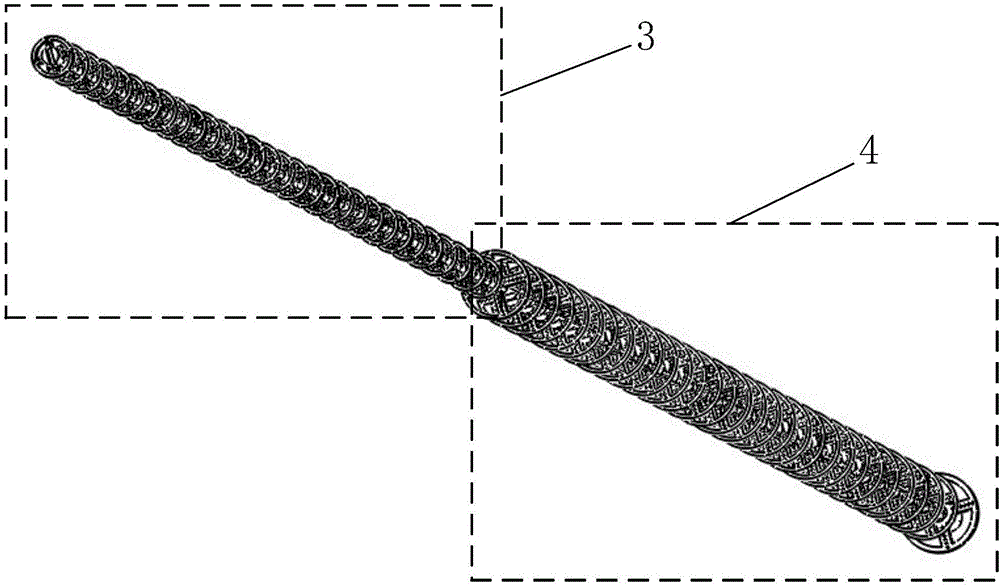

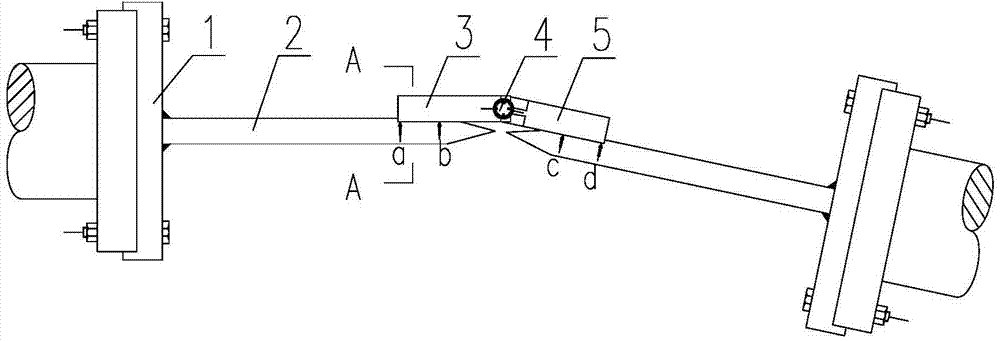

Manufacturing method for zigzag shafting alignment tool

ActiveCN103542797AIntuitive measurement resultsImprove Manufacturing AccuracyAngles/taper measurementsSteel barShaft alignment

The invention discloses a manufacturing method for a zigzag shafting alignment tool, and relates to the field of alignment of zigzag shafting. The manufacturing method includes respectively manufacturing a pair of alignment pointers between an input shaft and an output shaft, wherein the input shaft and the output shaft are adjacent and an included angle is formed between the both, and each alignment pointer is a mechanical member formed by welding of a flange and a straight steel bar with a tapered tip; manufacturing a set of alignment right-angle ruler comprising a first right-angle ruler arm, an angle indicating bolt and a second right-angle ruler arm, wherein a screw hole is formed at the ruler arm end of each of the first right-angle ruler arm and the second right-angle ruler arm, the angle indicating bolt penetrates the screw hole to fix the first right-angle ruler arm and the second right-angle ruler arm together, and the first right-angle ruler arm and the second right-angle ruler arm rotate around the angle indicating bolt which displays included angle between the first right-angle ruler arm and the second right-angle ruler arm. By the method, both angle and offset can be measured, measuring results are visual, measuring accuracy is high, construction is simple and convenient, the tool is convenient to demount, and production efficiency can be improved.

Owner:WUCHANG SHIPBUILDING IND

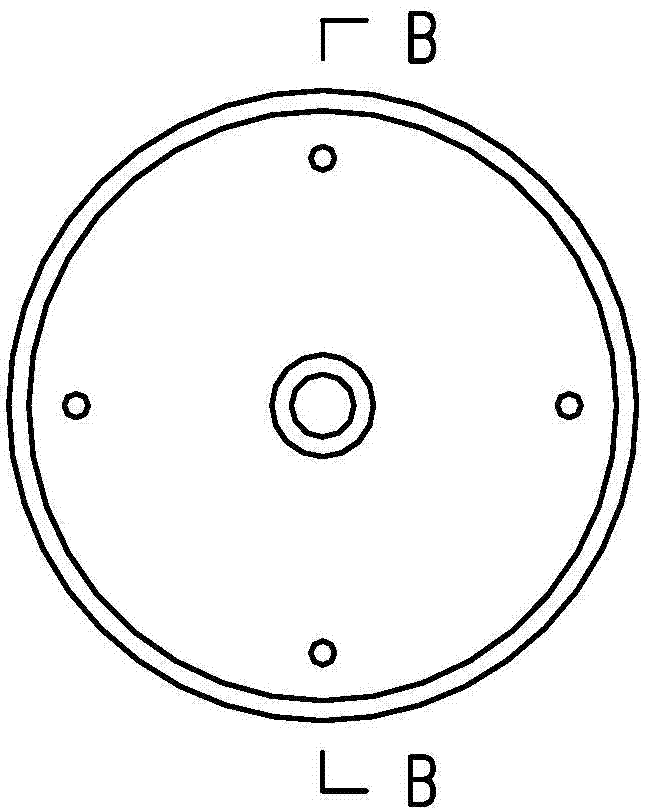

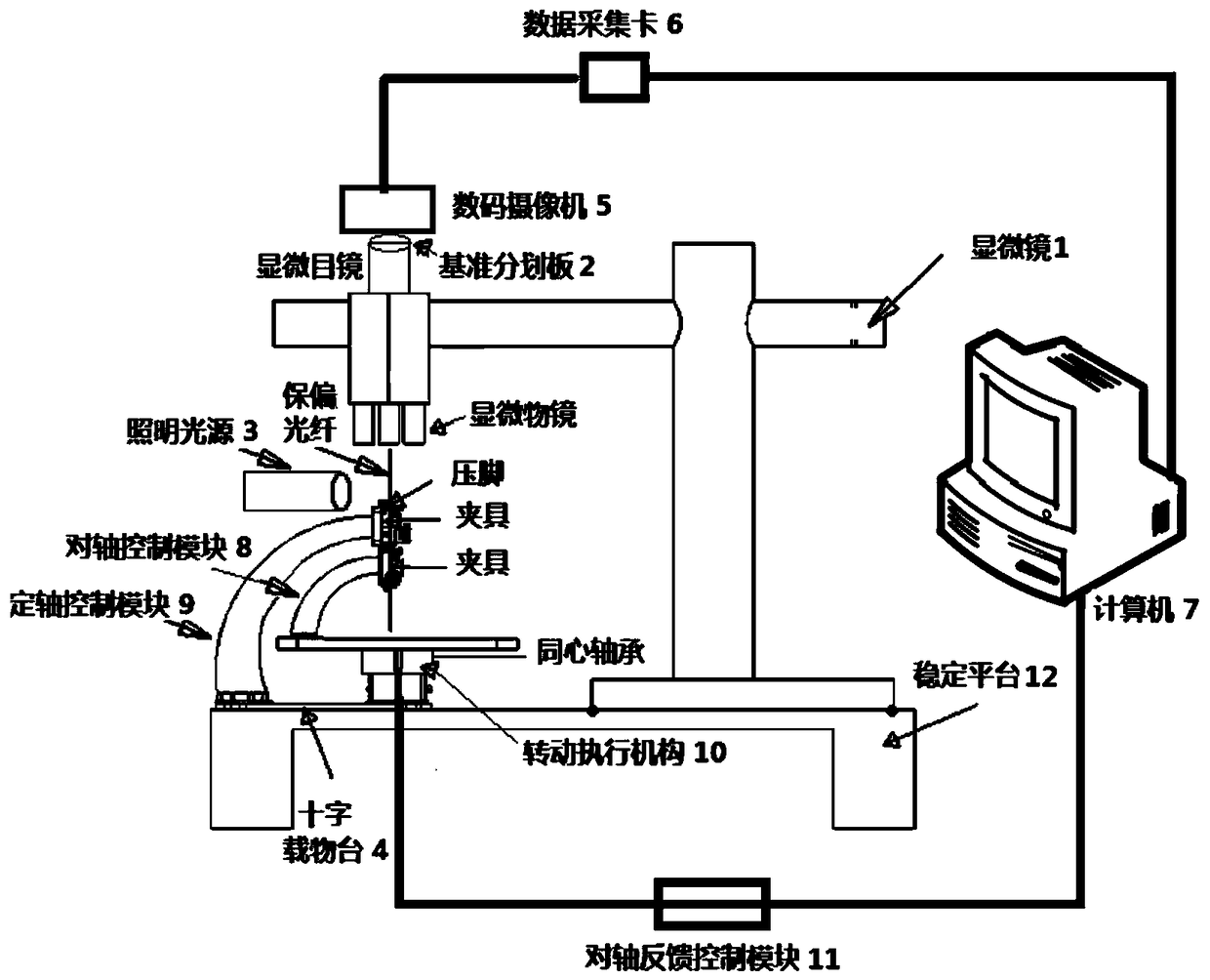

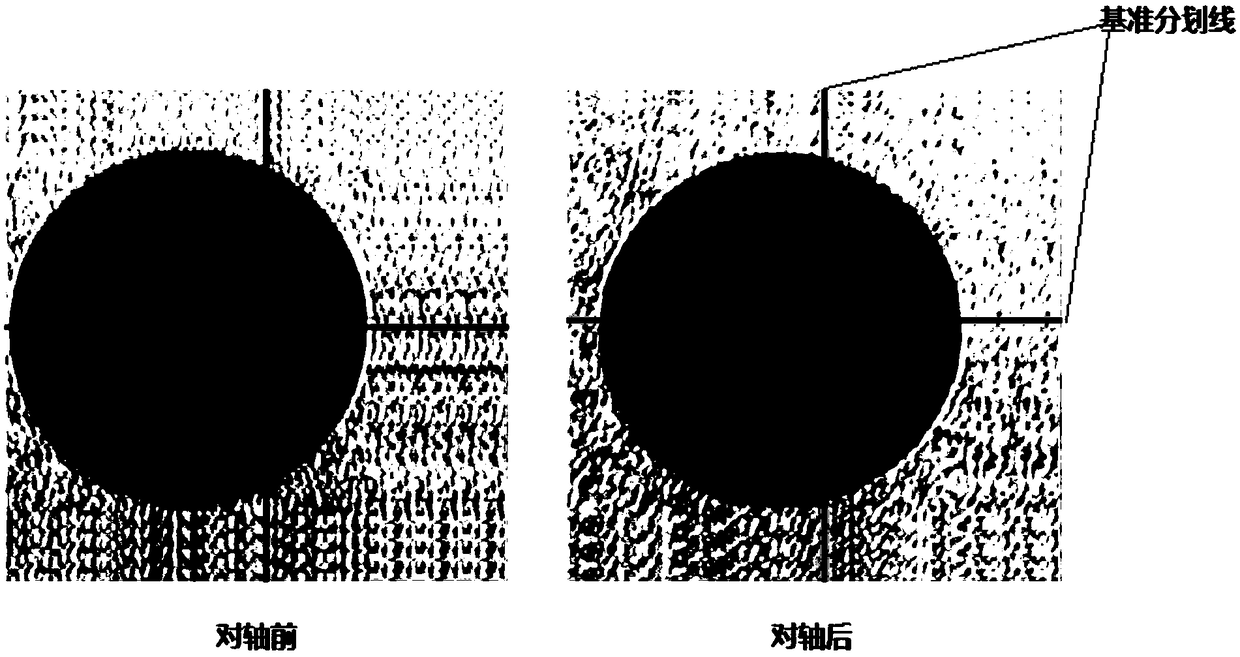

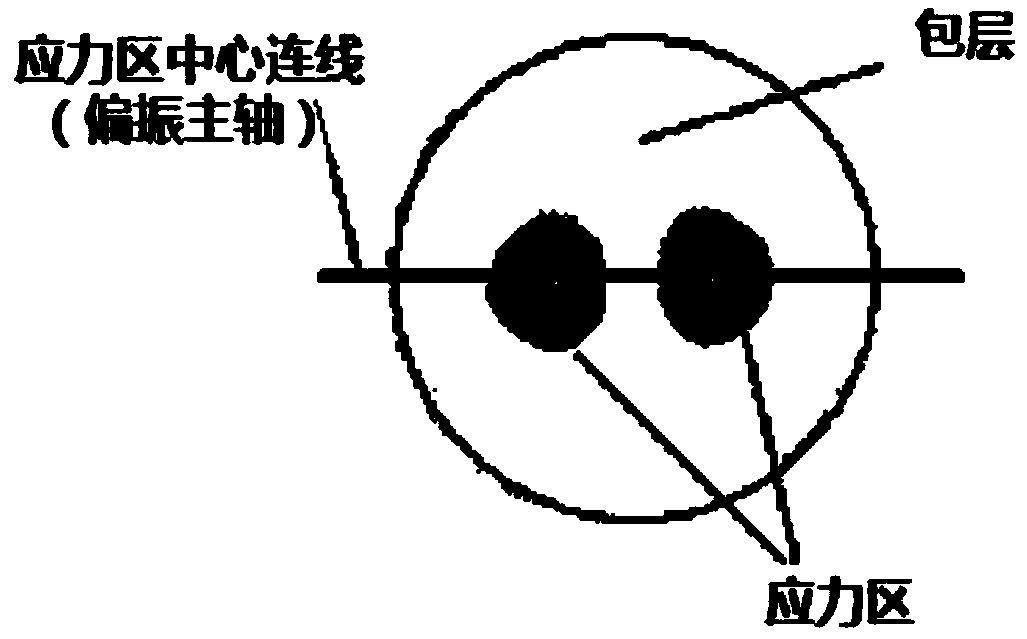

Polarization maintaining optical fiber end surface axis alignment device and method

ActiveCN109507771AShaft alignment is easy to implementLow costOptical fibre with polarisationMicroscopesPolarization-maintaining optical fiberOptoelectronics

The invention provides a polarization maintaining optical fiber end surface axis alignment device and method. The polarization maintaining optical fiber end surface axis alignment device comprises a microscope, a light source, a crossed objective table, an axis alignment control module, an axis direction control module and an executing mechanism, wherein the ocular view of the microscope is provided with a reference line; polarization-maintaining optical fiber with the end surface cut is clamped by a fixture of the axis alignment control module, and the end surface of a polarization-maintaining optical fiber to be axis-aligned is arranged under the objective of the microscope; the light source is used for lighting up the side cladding layer of the polarization-maintaining optical fiber sothat the stress area of the end surface of the polarization-maintaining optical fiber to be axis-aligned can be positioned inside the view of the objective of the microscope; the axis alignment control module and the crossed objective table are fixedly connected; the executing mechanism is used for adjusting the crossed objective table to drive the axis alignment control module to rotate so that the contour of the stress area of the end surface of the polarization-maintaining optical fiber is tangential to the reference line inside the ocular view of the microscope to achieve shaft alignment between the end surface of e polarization-maintaining optical fiber and the reference line; the axis direction control module is used for clamping the axis-aligned polarization-maintaining optical fiber through the clamping plates of the fixture to achieve axis direction between the end surface of the polarization-maintaining optical fiber and the reference line.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Apparatus and method for lining large diameter pipe with environmentally compatible impervious membrane

InactiveUS7866277B1Liquid surface applicatorsMovable spraying apparatusRotational axisProximity sensor

A method and apparatus is disclosed for remotely and robotically installing an organic, monolithic, structural and non structural, circumferential and partial radius membranes in conduits, pipelines or passageways. The included apparatus has the mechanical function to manually or automatically center the liner dissipation device in any geometrical shape. The included apparatus possesses the remote controlled capability to manipulate centrifugal dissipation of the liner to afford consistent thickness on any shaped profile or flat surface of the pipe wall surface. The apparatus includes a manual or automatic mechanical scissoring device for elevation changes and a manual or automatic rotational table for shaft alignment. The apparatus includes a means of automated self alignment by way of proximity sensors. The pendulum oscillation bracketing incorporates a fluid driven motor assembly communicating with a bored shaft and integrates as many as two offset dissipation devices. The included apparatus has both fluid and electrical rotary unions to transmit fluids and current from fixed ports to a rotating shaft assembly. The included apparatus has a mechanical function facilitating cutting and retrieval of cured spray build up on the spray orifice. This method and apparatus will allow for continuous lining applications of any thickness in one pass, in conduits and passageways employing multi component liquid polymers with rapid mechanical properties formation.

Owner:NEUBAUER KURT +1

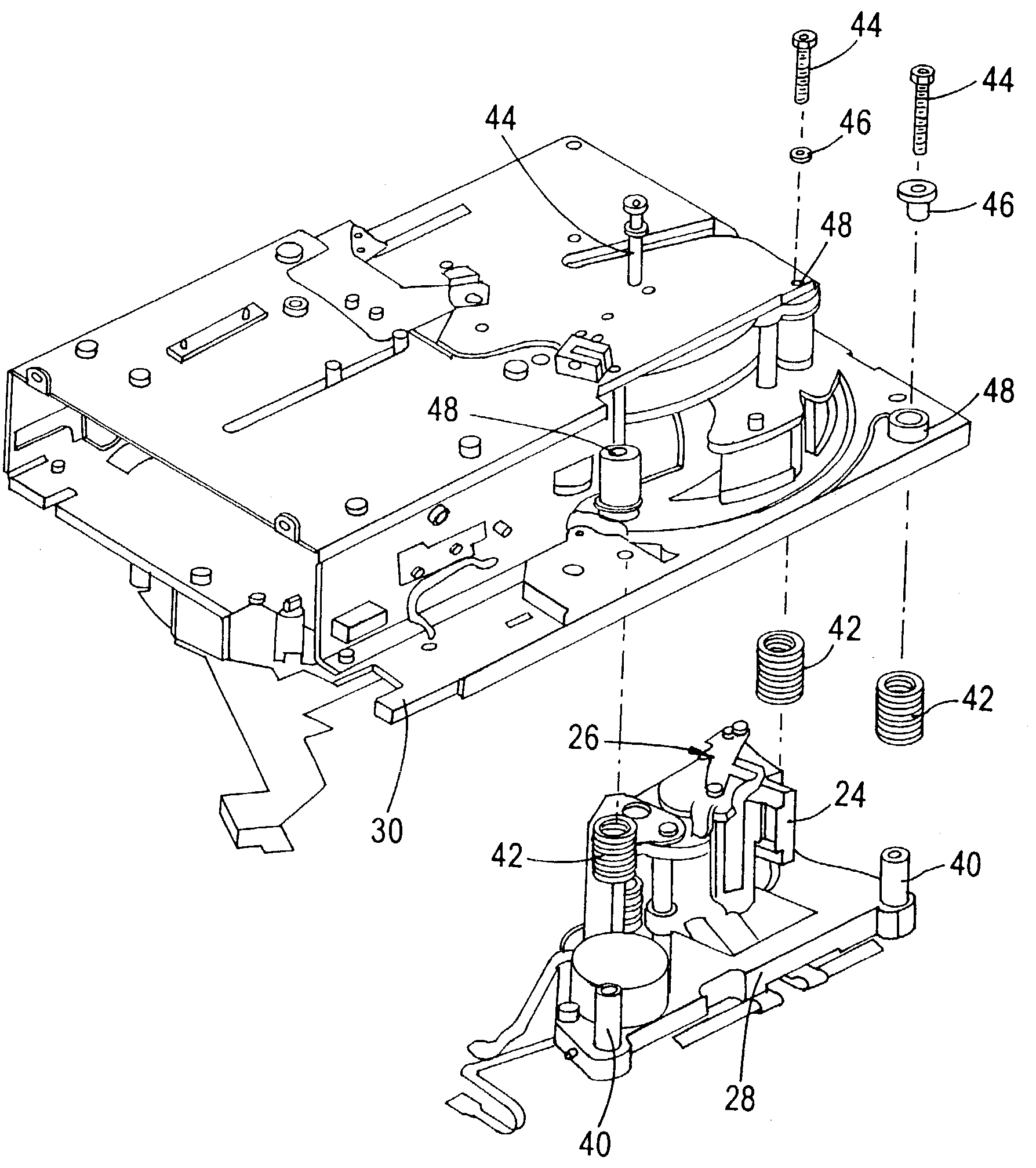

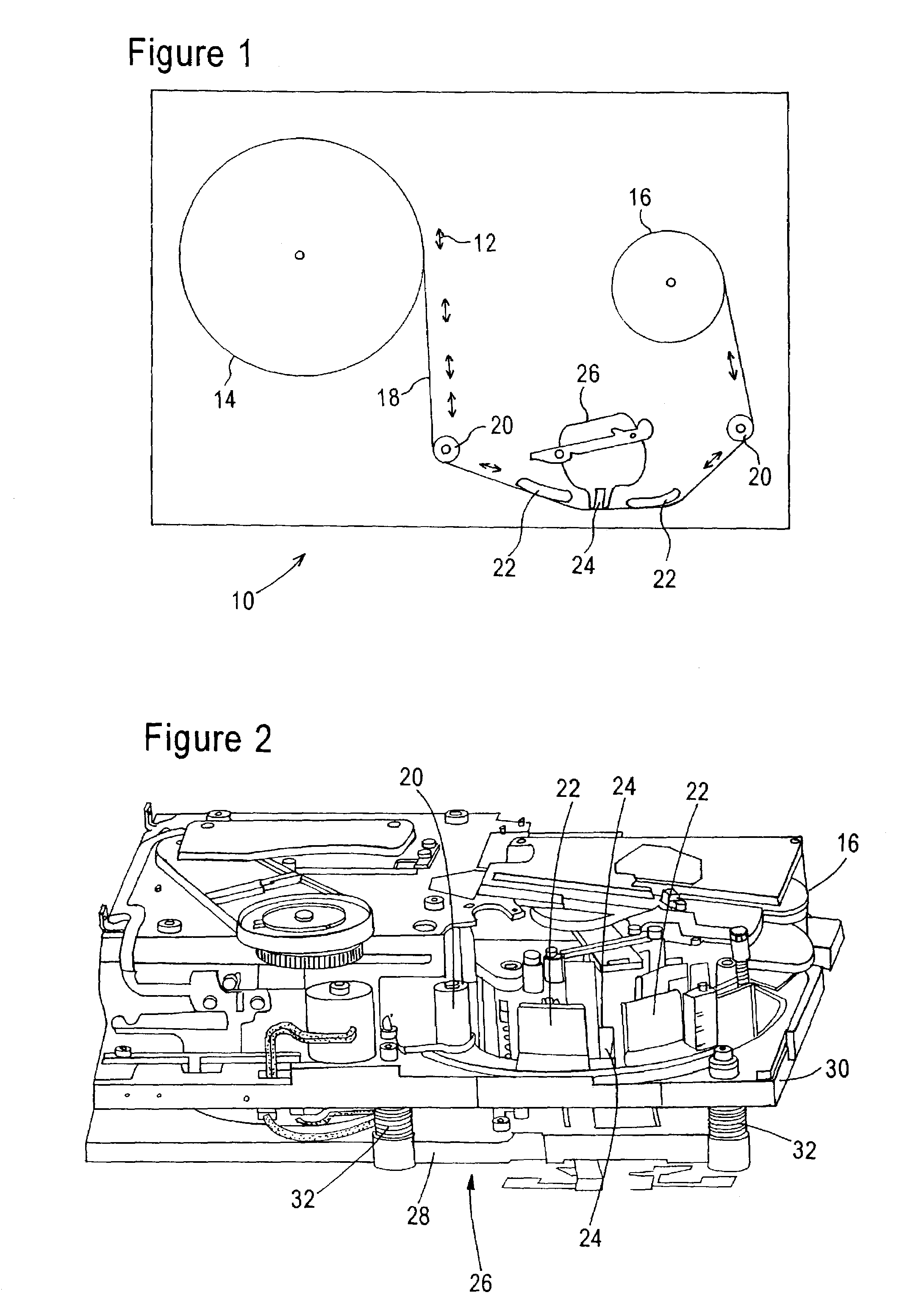

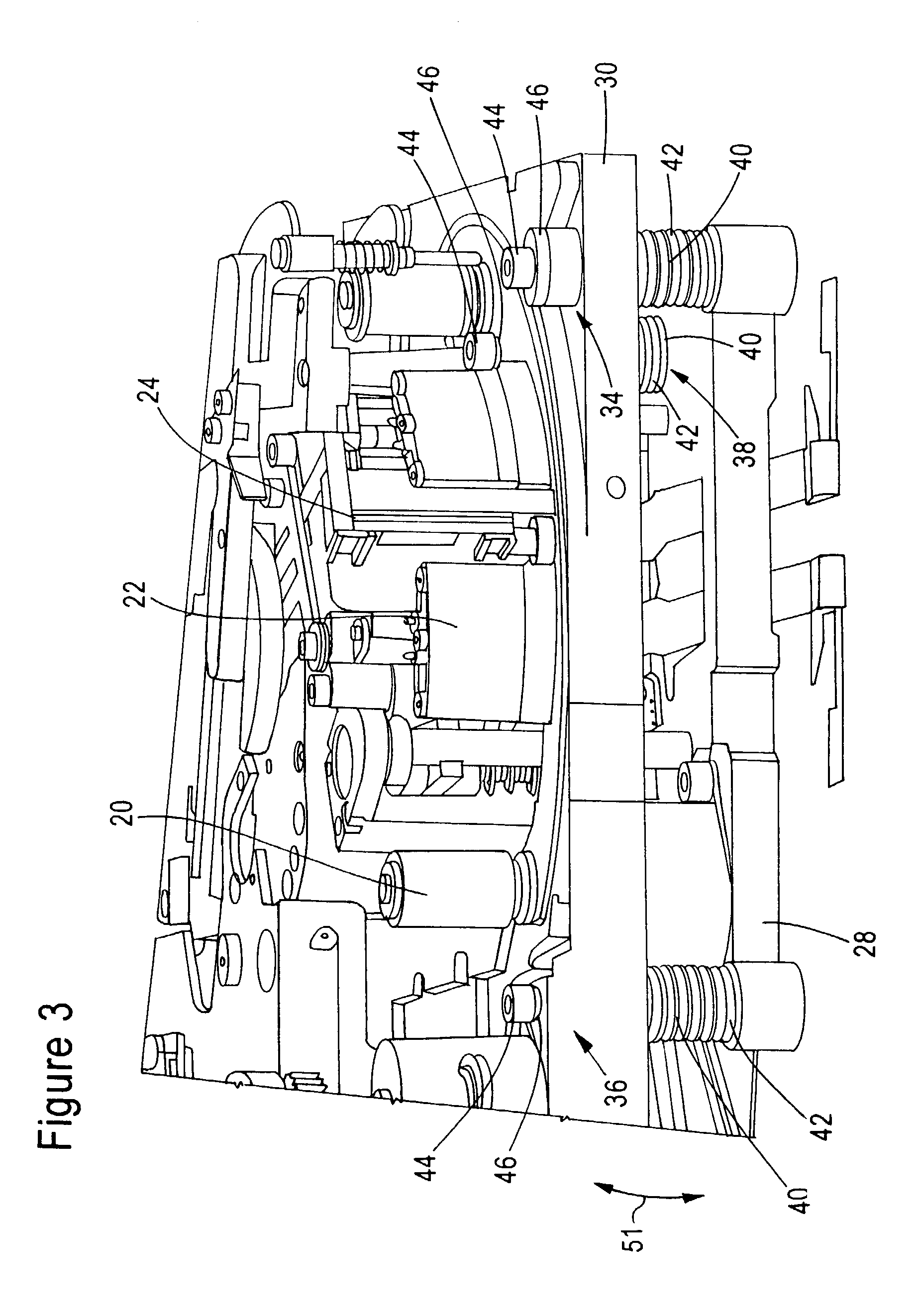

Tape drive apparatus with a head alignment system

InactiveUS7133262B1Easy accessDisposition/mounting of recording headsRecord information storageSpatial OrientationsCoupling

A tape drive apparatus is provided with a base plate and tape path components on this base plate. The apparatus includes a bracket that is adjustably coupled to the base plate, the bracket carrying a magnetic head for reading and writing to a tape transported by the tape path components. Adjustment couplings couple the bracket to the base plate and are lockably settable to adjust and lock the spatial orientation of the magnetic head with respect to a tape transported by the tape path components. Pre-loaded jackscrews of the adjustment couplings are rotated to adjust and lock the azimuth and zenith settings for the magnetic head. A separate penetration screw independently controls the penetration of the magnetic head into the path of the magnetic tape.

Owner:QUANTUM CORP

Rotary Encoder with Free Floating Flexible Sensor Carrier

ActiveUS20140263988A1Material analysis by optical meansConverting sensor output opticallyHigh accelerationEngineering

A rotary encoder with free floating flexible sensor carrier provides a sensor carrier that eliminates the traditional need for bearings and a housing in a rotary encoder, as well as allowing for significant cost savings in material and installation costs, improving acceleration and reducing startup and running torque. A bushing is rotationally fixed to a shaft the rotation of which is desired to be measured. An encoder disc is axially connected to the bushing. A sensor is held in an alignment above the encoder disc by a sensor carrier. The sensor may be connected directly to the sensor carrier or to a circuit board which is connected to the sensor carrier. A shaft alignment portion of the sensor carrier encircles the shaft and a plurality of stabilizing arms hold the sensor carrier in place, thus maintaining the sensor in proper alignment.

Owner:KIRK CHARLES R +1

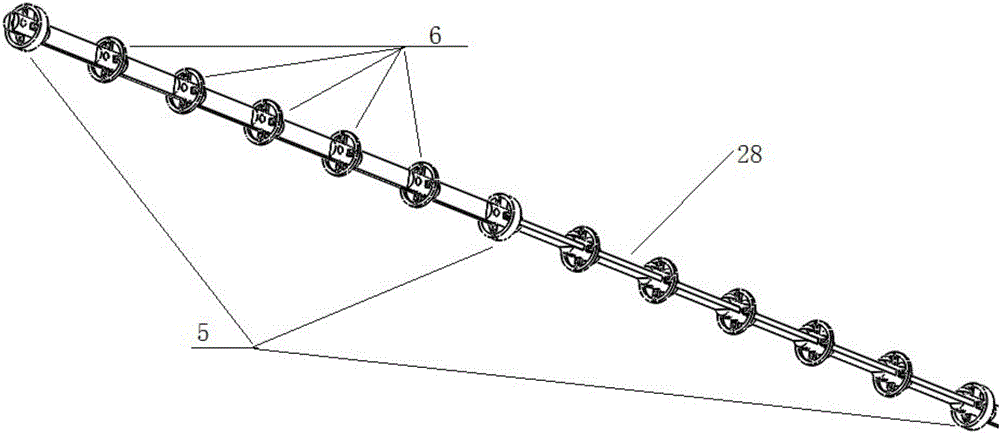

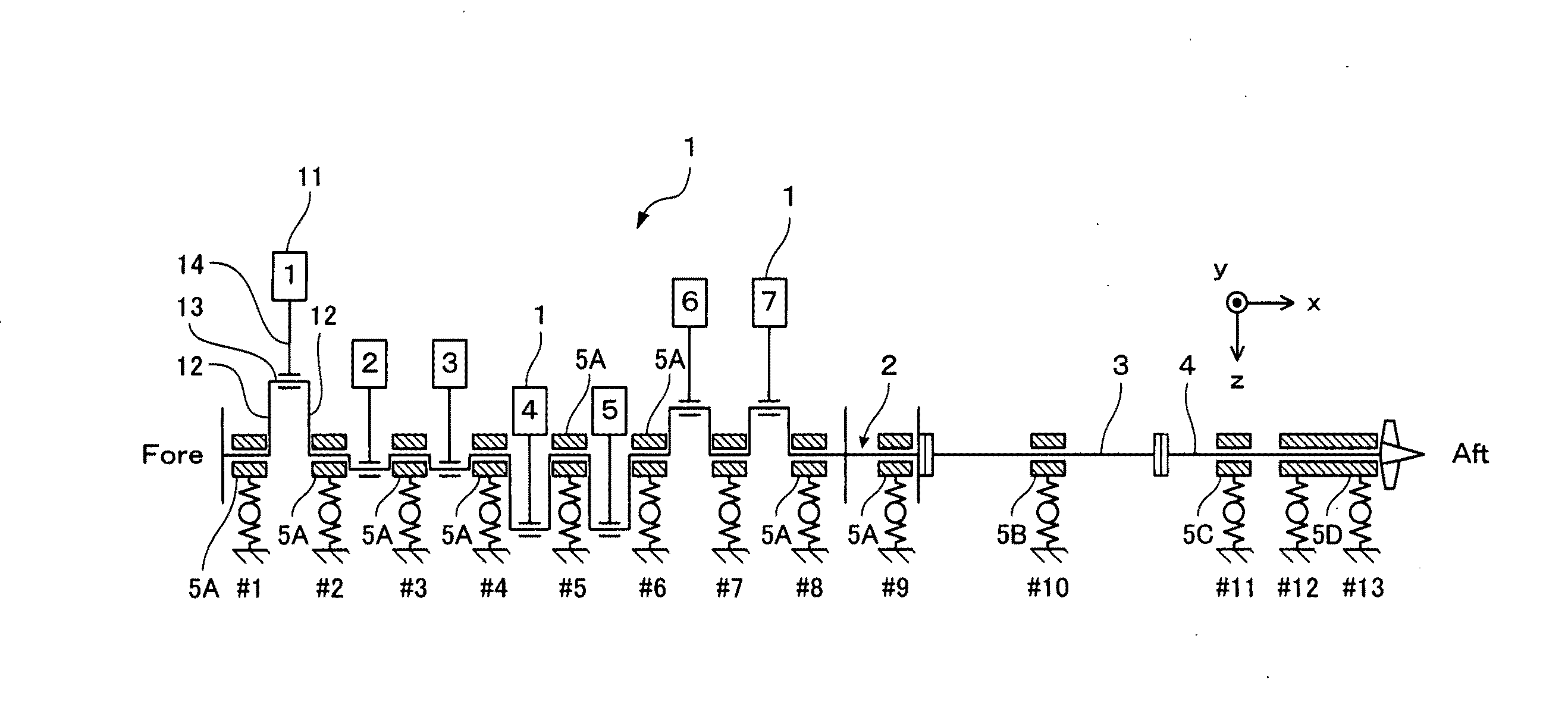

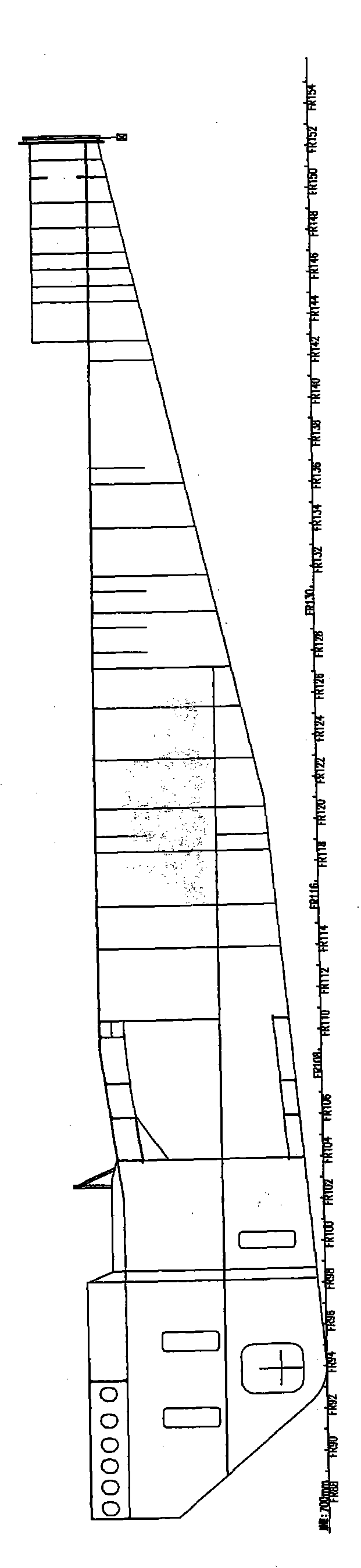

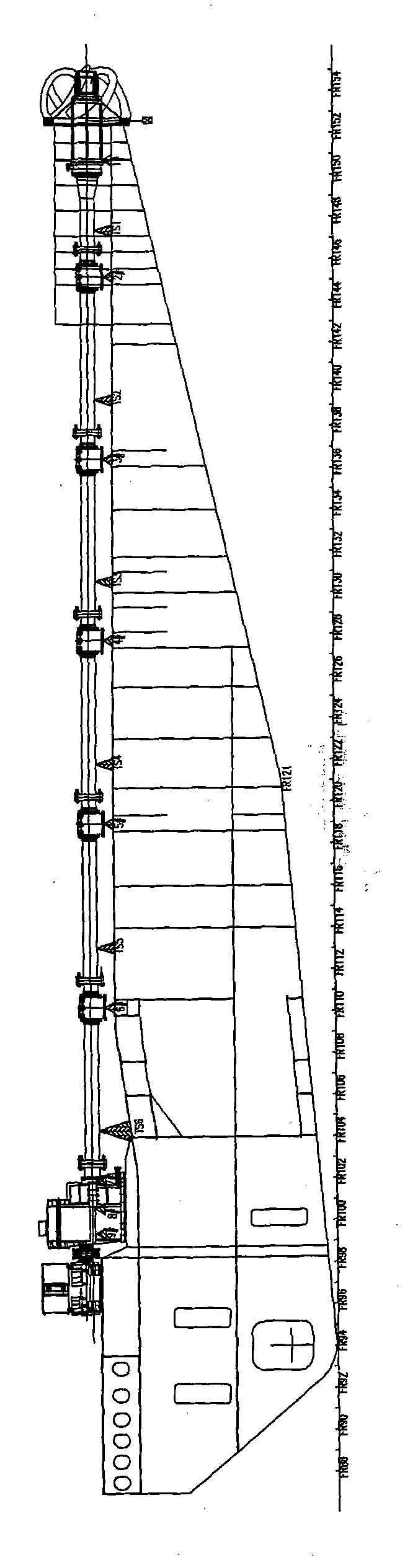

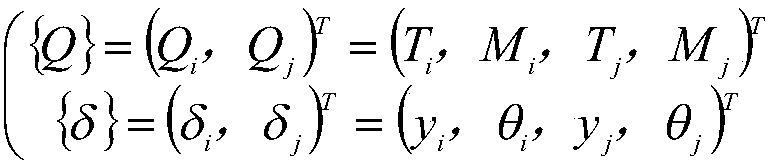

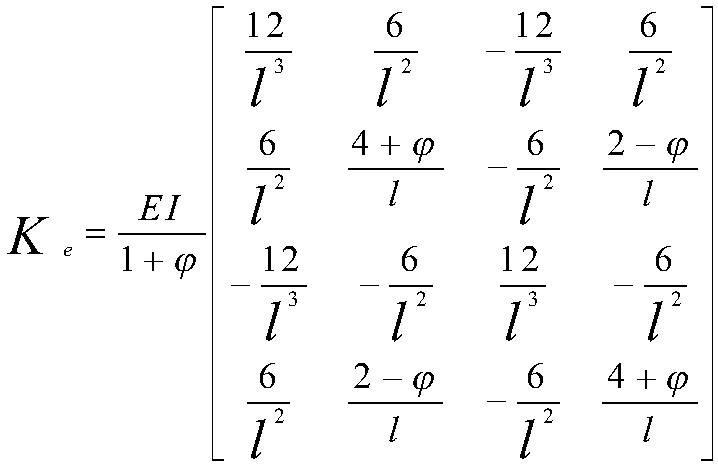

Ship shafting optimizing method and optimizing platform

ActiveCN108416159AImprove design qualityImprove the quality of schoolGeometric CADSustainable transportationQuality by DesignShip safety

The invention belongs to the field of ship design, and particularly relates to a ship shafting optimizing method and optimizing platform. By means of the method, the shafting design quality is improved, and the aims of improving the shafting alignment quality and reducing shafting vibration are achieved by optimizing the positions of shafting bearings in the primary design stage. The basis is provided for ship safety and stable operation. By means of the method, the new scheme is provided for controlling the vibration characteristics of shafting in the alignment design stage, the method has important theoretical and engineering practical value, the defects of the scheme in the prior art can be overcome, and the design quality of various types of ship shafting is improved.

Owner:NAVAL UNIV OF ENG PLA

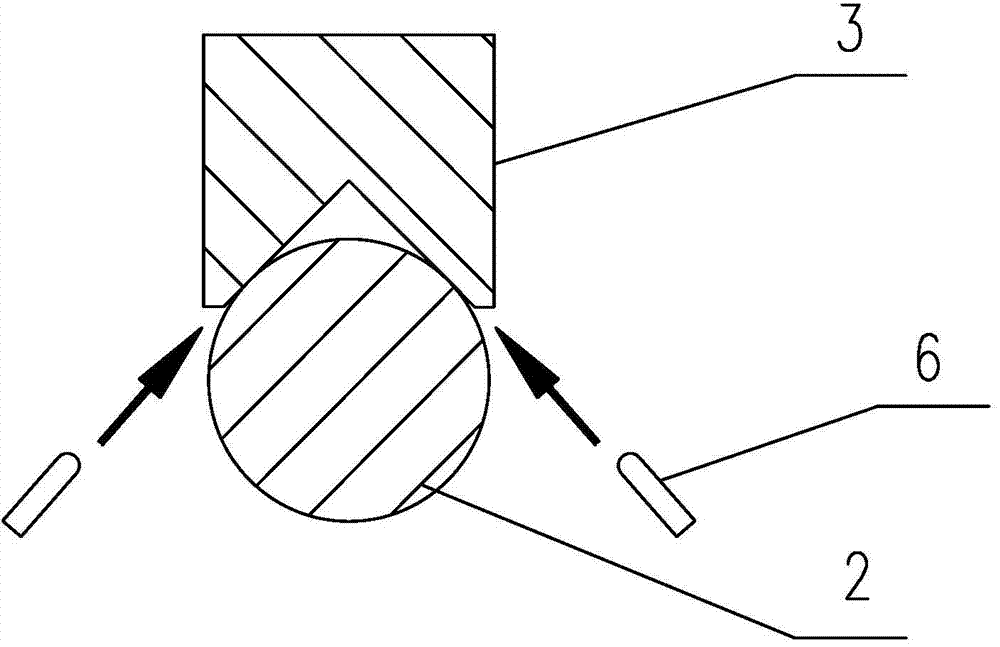

Shaft alignment regulation and measurement device

InactiveCN108458673AHigh measurement accuracyImprove measurement resolutionUsing optical meansMeasurement deviceShaft alignment

The present invention discloses a shaft alignment regulation and measurement device. The device comprises a first shaft to be measured, a laser emission device, a first connection flange, a second shaft to be measured, a laser receiving device, a second connection flange, a shaft alignment measurement support and an infrared ray measurement clamping block; the laser emission device and the laser receiving device are respectively fixed on the first shaft to be measured and the second shaft to be measured; the first connection flange and the second connection flange are respectively located at connection ends of the first shaft to be measured and the second shaft to be measured; the shaft alignment measurement support is fixedly connected with the laser emission device; and the infrared raymeasurement clamping block is absorbed at the bottom portions of the first shaft to be measured and the second shaft to be measured. The shaft alignment regulation and measurement device is taken as alaser measurement device for alignment errors based on the CCD sensing technology, is mainly applied to detection and regulation of alignment errors of two coupling drive shafts of the rotary machinery in the installation, debugging and maintenance processes and ensures that the axes of the drive shafts are located in the same line so as to meet the requirement of high-precision installation.

Owner:JILIN UNIV

Ship propulsion shaftingalignment method

InactiveCN109764832AImprove securityImprove calibration accuracyUsing optical meansMarine engineeringShaft alignment

The invention discloses a ship propulsion shafting alignment method. The ship propulsion shafting alignment method comprises the steps that an actual shafting curve is created, in the whole site construction process, the actual shafting curve can be observed, the fitting degree of the shafting curve after actual adjustment and a theoretical shafting curve is increased, alignment accuracy during shafting installation is improved, the potential safety hazard of the bearing high temperature damage risk under different operating conditions is reduced, shortcomings of the existing shafting alignment methodare made up, and ship power safety is improved. The ship propulsion shafting alignment method is used in the field of ship shafting alignment.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

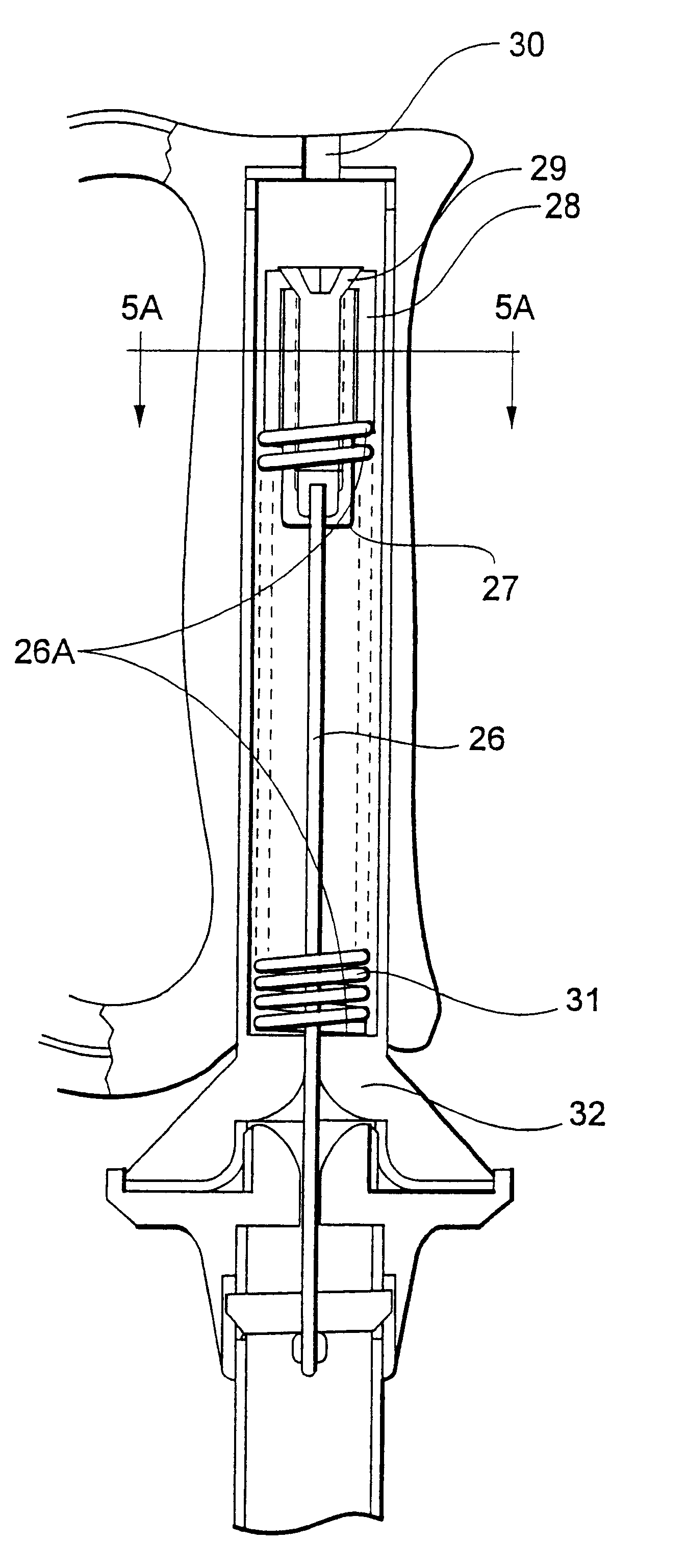

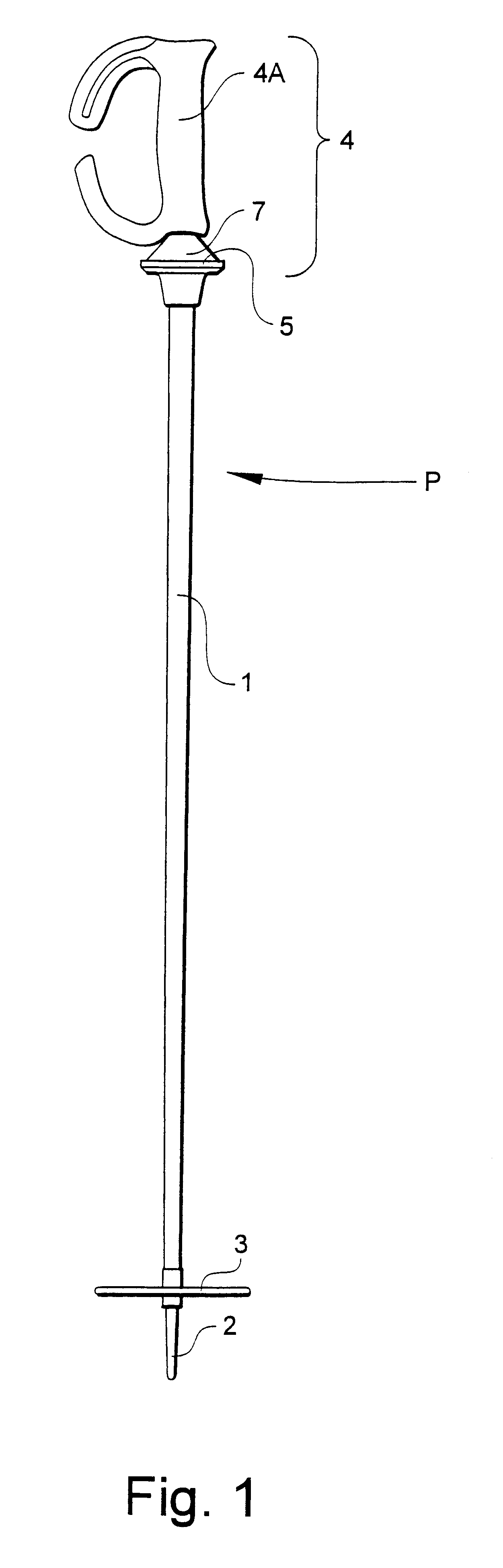

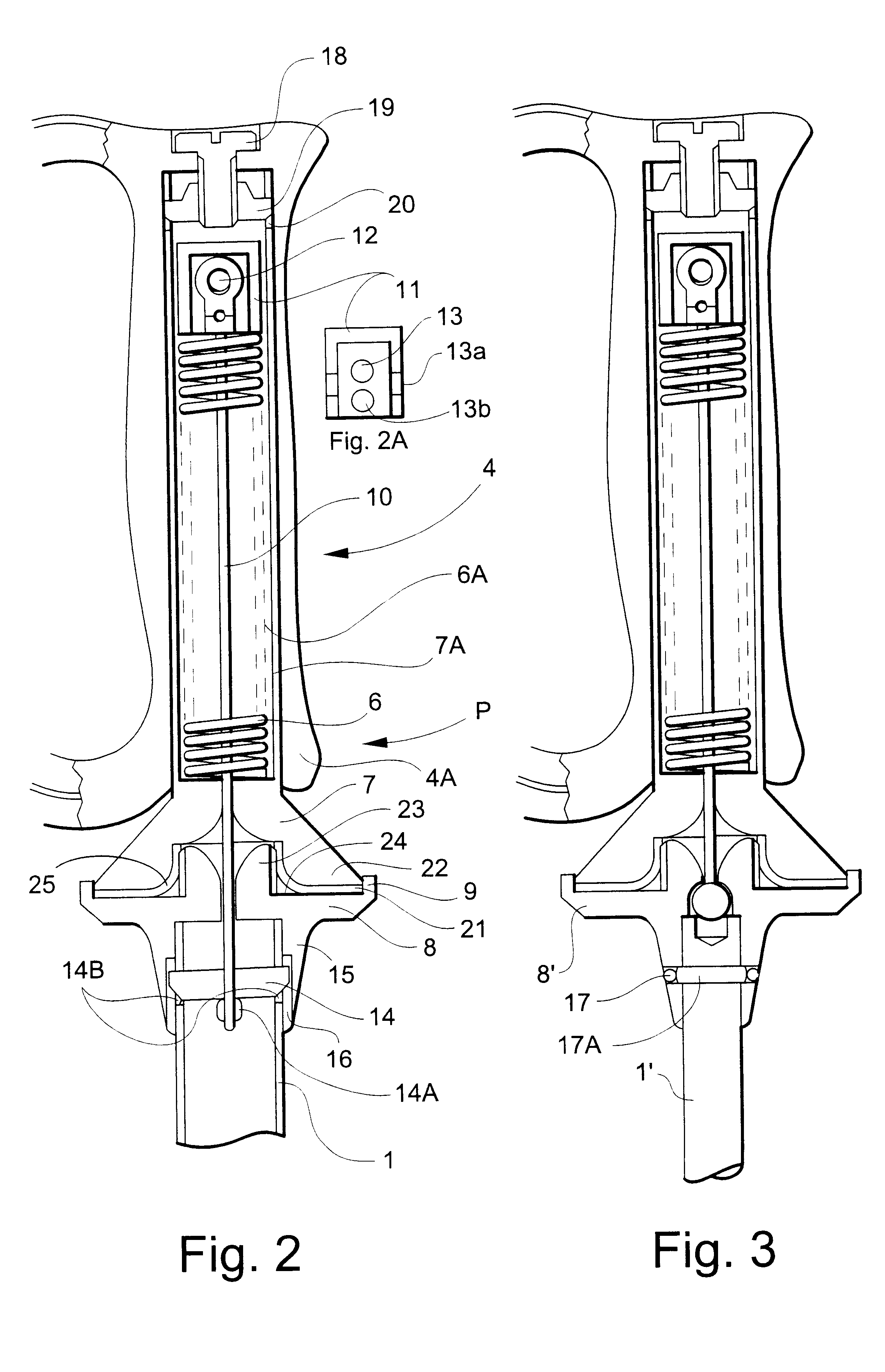

Safety athletic pole

InactiveUS6203063B1Improve user securityProlong lifeWalking sticksYielding couplingEngineeringBending force

An athletic pole including a handle, a shaft, and a handle-to-shaft transition assembly, the transition assembly adapted for allowing the handle to articulate. The transition assembly includes an enlarged shaft base on the shaft, the shaft base including a handle-base-engaging surface. The transition assembly also includes an enlarged handle base on the handle. The handle base and the shaft base are biased together by a tension force into a mating, coaxially aligned position when any bending forces applied to the pole are insufficient to overcome the tension force, the handle being pivotable to an articulated position relative to the shaft upon the application of a predetermined bending force on the pole sufficient to overcome the tension force. During handle articulation, the enlarged dimensions of the handle base and the shaft base allow the periphery of the handle base to travel across and engage the handle-base-engaging surface of the shaft base such that, after an initial range of handle articulation, the bending force necessary to continue articulation or to maintain the handle in a desired articulated position is reduced relative to the bending force that would prevail if the periphery of the handle base were not allowed to travel across the handle-base-engaging surface toward the center of the shaft base.

Owner:BUJOLD ED

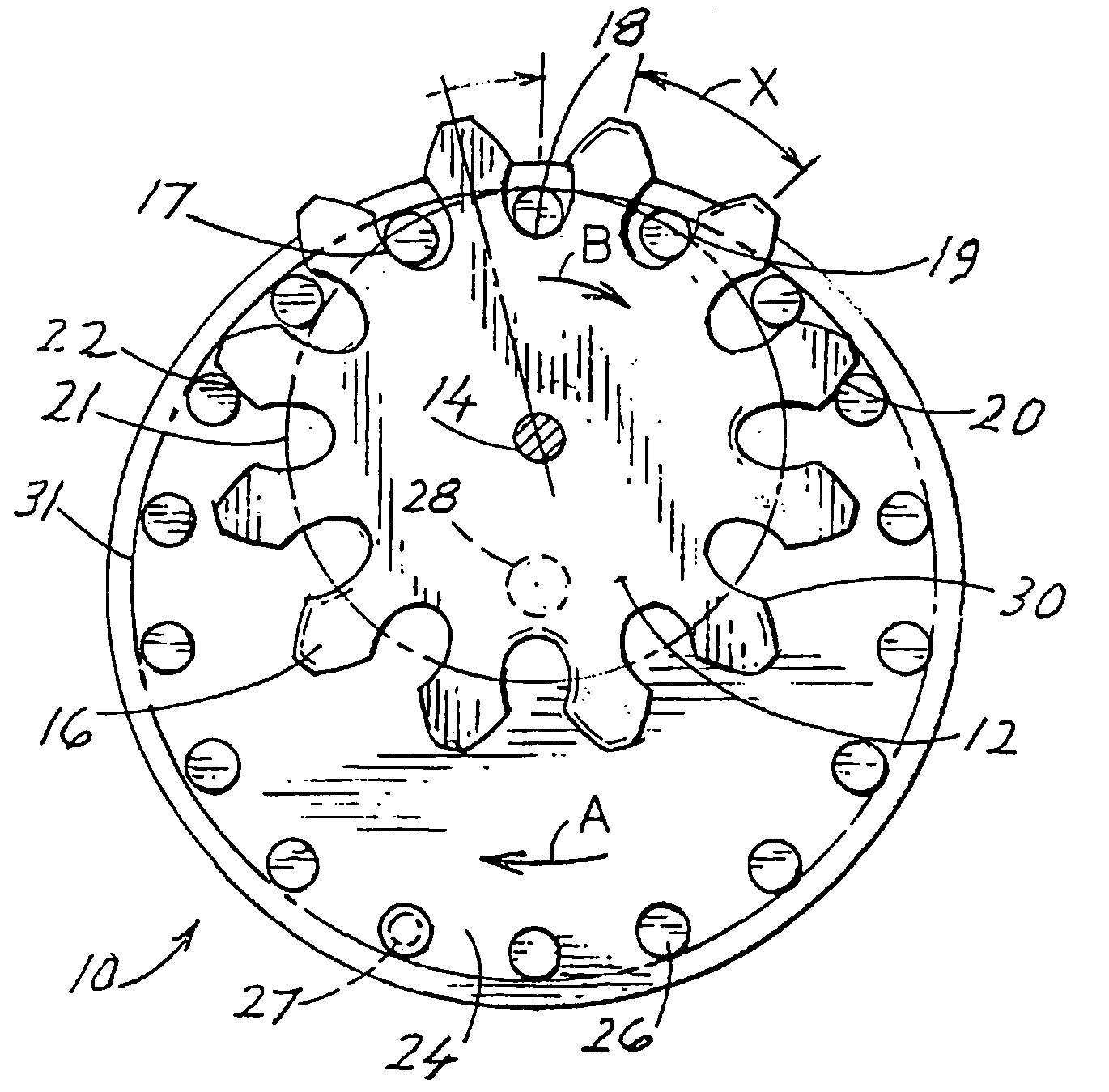

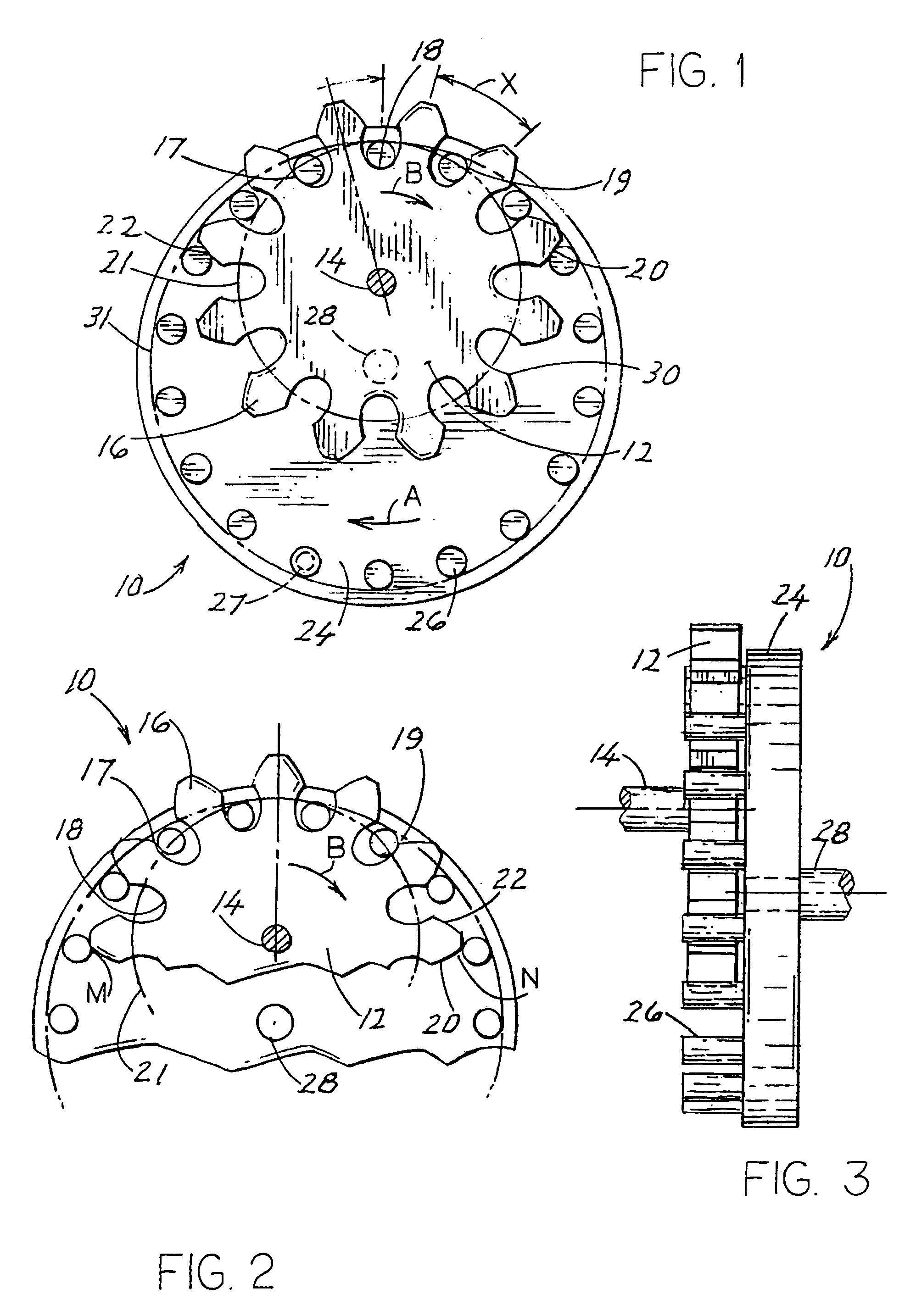

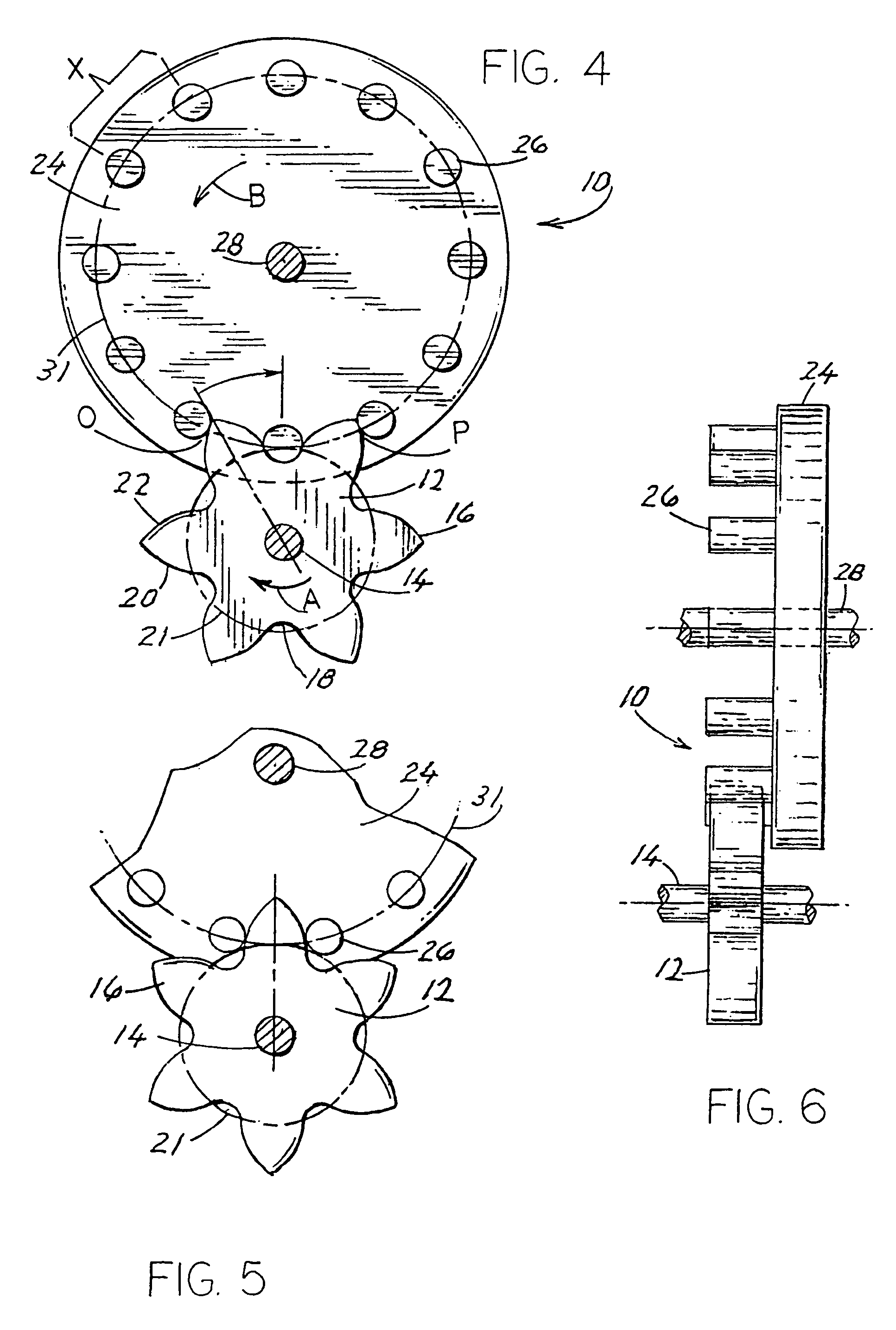

Roller cam assembly

Owner:BALLARD RICHARD N

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com