Polarization-maintaining photonic crystal fiber and panda fiber welding method

A photonic crystal fiber, panda fiber technology, applied in the direction of coupling of optical waveguides, can solve the problems of unsuitable application of ordinary photonic crystal fibers, high hardware and operation requirements, difficult polarization axis alignment, etc. Shaft accuracy and the effect of improving weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

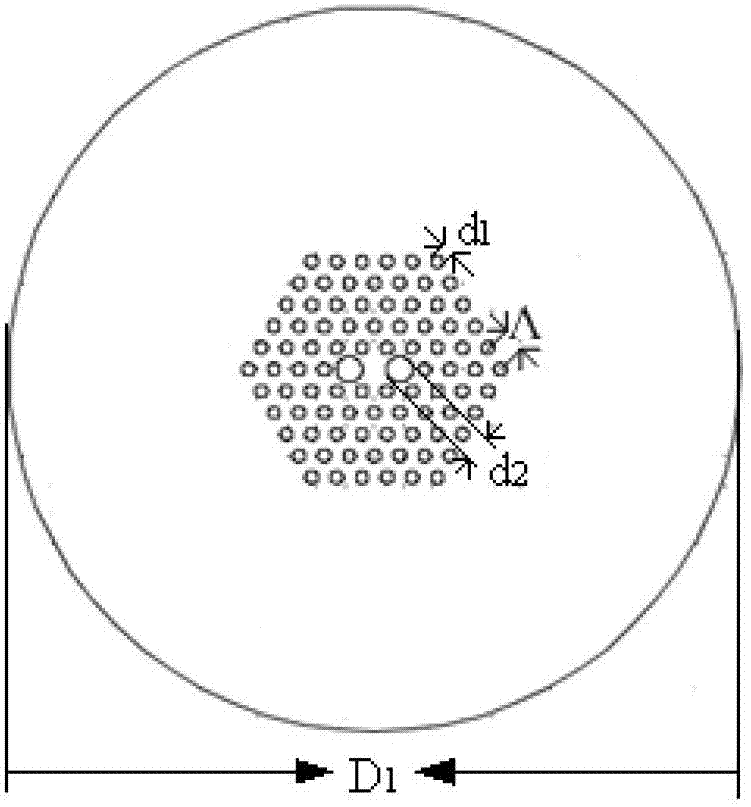

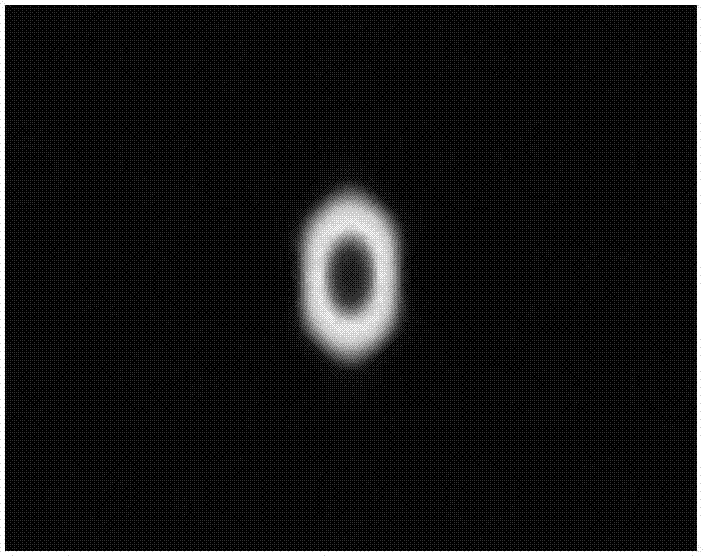

[0043] Polarization-maintaining photonic crystal fiber (YOFC) such as Figure 1a As shown, its microstructure consists of air holes arranged in a hexagon on the outside and two large holes symmetrically distributed close to the core. D 1 is the outer diameter of the fiber (D in this example 1 = 125 μm), d 1 is the hole diameter (d in this example 1 = 2.2 μm), d 2 is the diameter of the large hole (d in this example 2 =4.5μm), Λ is the hole spacing (Λ=4.4μm in this example). By simulating and measuring the mode field of polarization-maintaining photonic crystal fibers, such as Figure 2a and Figure 2b As shown, the mode field of the polarization-maintaining photonic crystal fiber is 2.8 μm / 4.6 μm and the principal axes of polarization (fast axis and slow axis) are obtained.

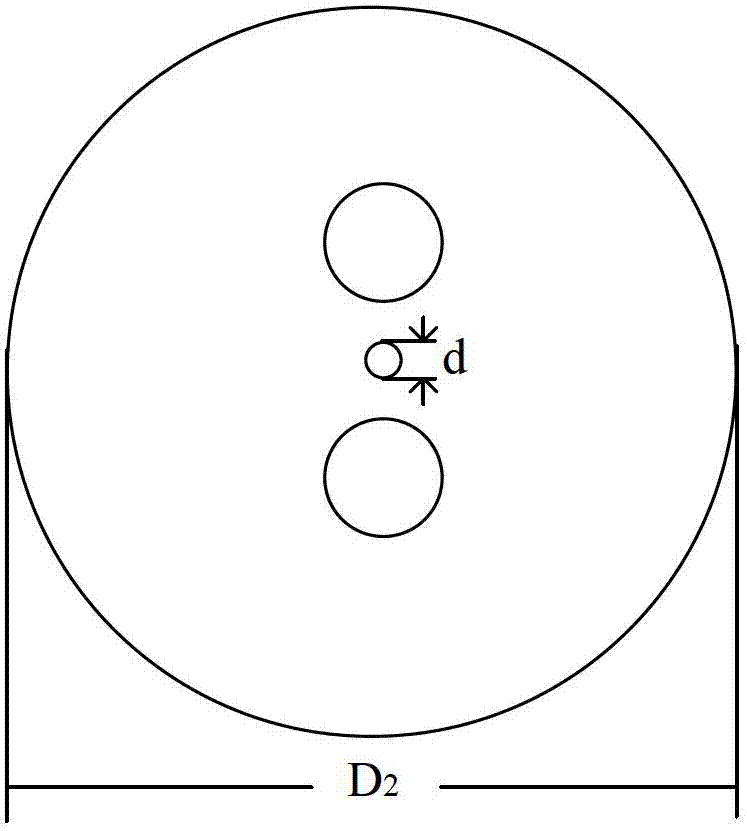

[0044] Panda Fiber (YOFC) such as Figure 1b As shown, from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com