Patents

Literature

835results about How to "Achieve alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

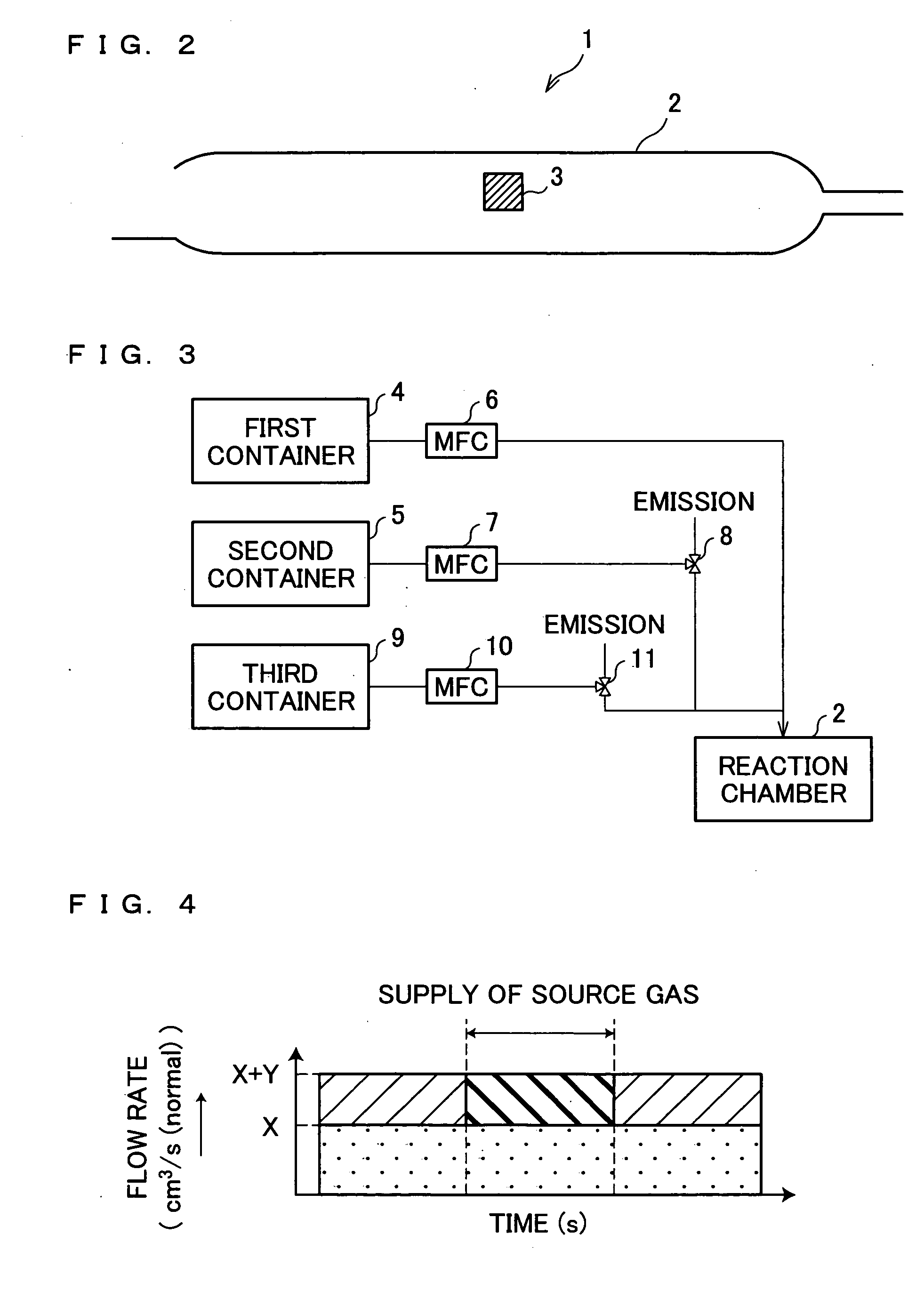

Carbon-Based Fine Structure Array, Aggregate of Carbon-Based Fine Structures, Use Thereof and Method for Preparation Thereof

ActiveUS20080095694A1Long and strong aggregateEasy alignmentMaterial nanotechnologyLayered productsFine structureStrong interaction

An aggregate of carbon-based fine structures in which a plurality of carbon-based fine structures are collected, wherein respective carbon-based fine structures are oriented in the same direction. The above aggregate of carbon-based fine structures is an aggregate of a plurality of carbon-based fine structures in a state they are pulled by one another with strong interaction, and has such a length that allows the improvement of the handleability and workability thereof.

Owner:NIPPON SANSO CORP

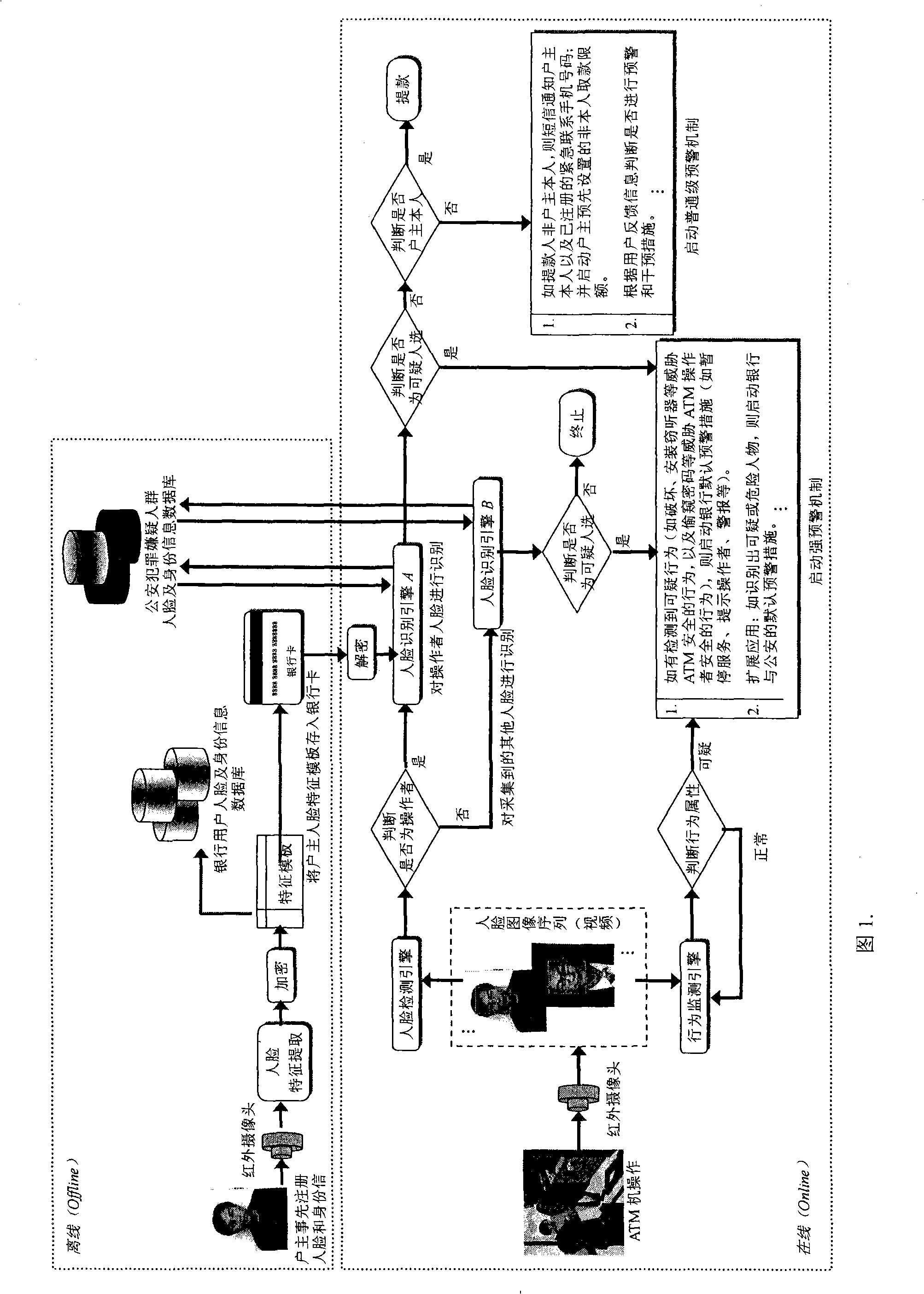

ATM secure authentication and pre-alarming method based on face recognition

ActiveCN101266704AEnsure safetyGuaranteed privacyCharacter and pattern recognitionAlarmsComputer networkAcquisition apparatus

The invention discloses an ATM security certificate and a pre-warning method based on face recognition. The invention introduces face recognition and video detection into the applications of ATM and bank card business for the first time, which can obviously improve the security of ATM financial system, effectively reduce and overawe various ATM fraud and criminal activities. The complete system operation process in the method of the invention is: firstly, registering the face information of a holder at a service window which arranges an infrared face acquisition equipment or with the registration by the users themselves on ATM in bank, and saving the encrypted face information to a bank database and a bank card. Then, determining whether the ATM operator to be recognized is the holder of the bank card or not through verifying the user's identity by a face recognition engine; determining and recognizing whether existing behaviors that threaten ATM and the users though a behavior monitoring engine; and determining whether to trigger corresponding pre-warning mechanism or not according to the recognition result. The invention can extend to the applications of bank book business, public security monitoring and pursuing escaped criminals, etc.

Owner:哈尔滨维科智能系统有限公司

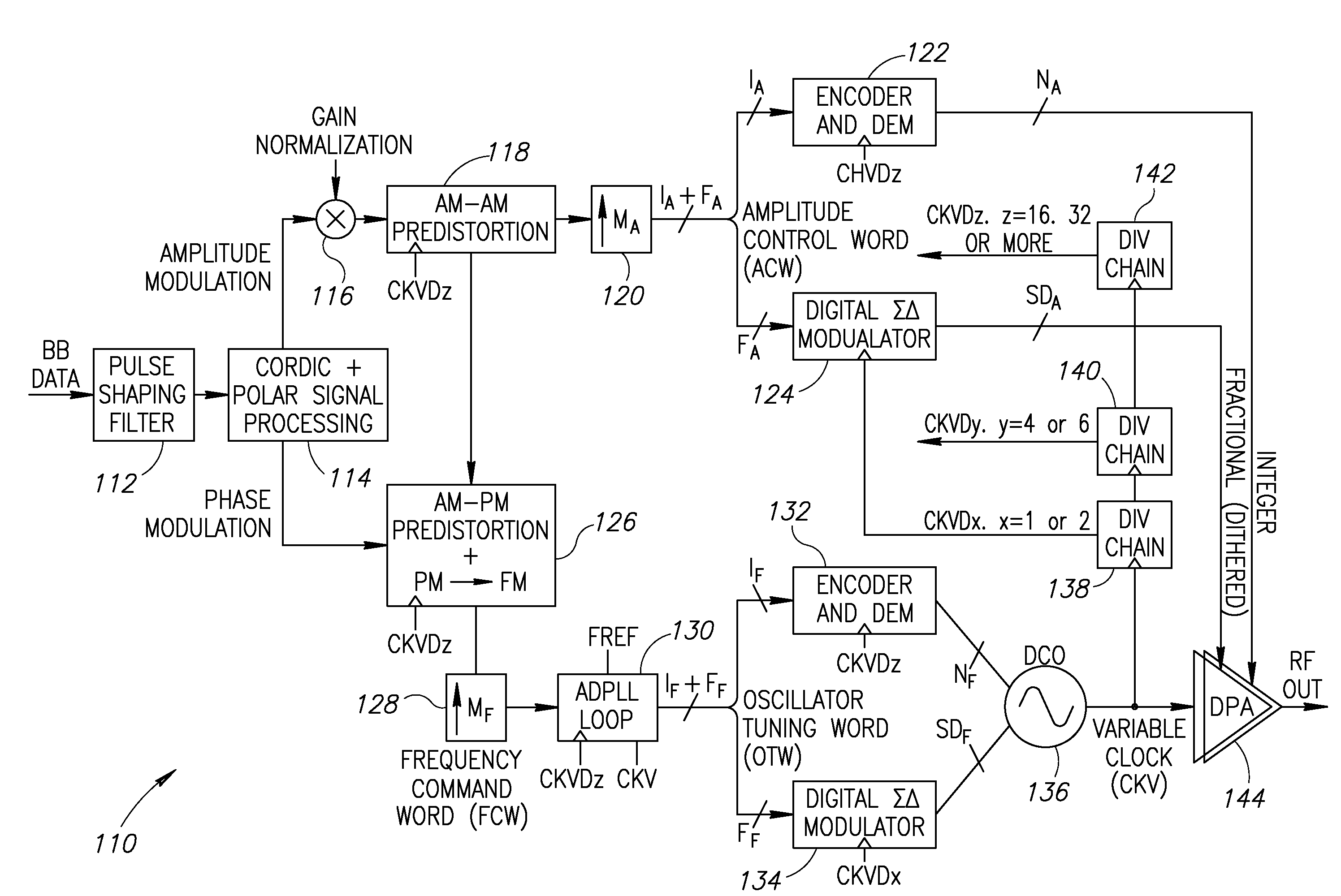

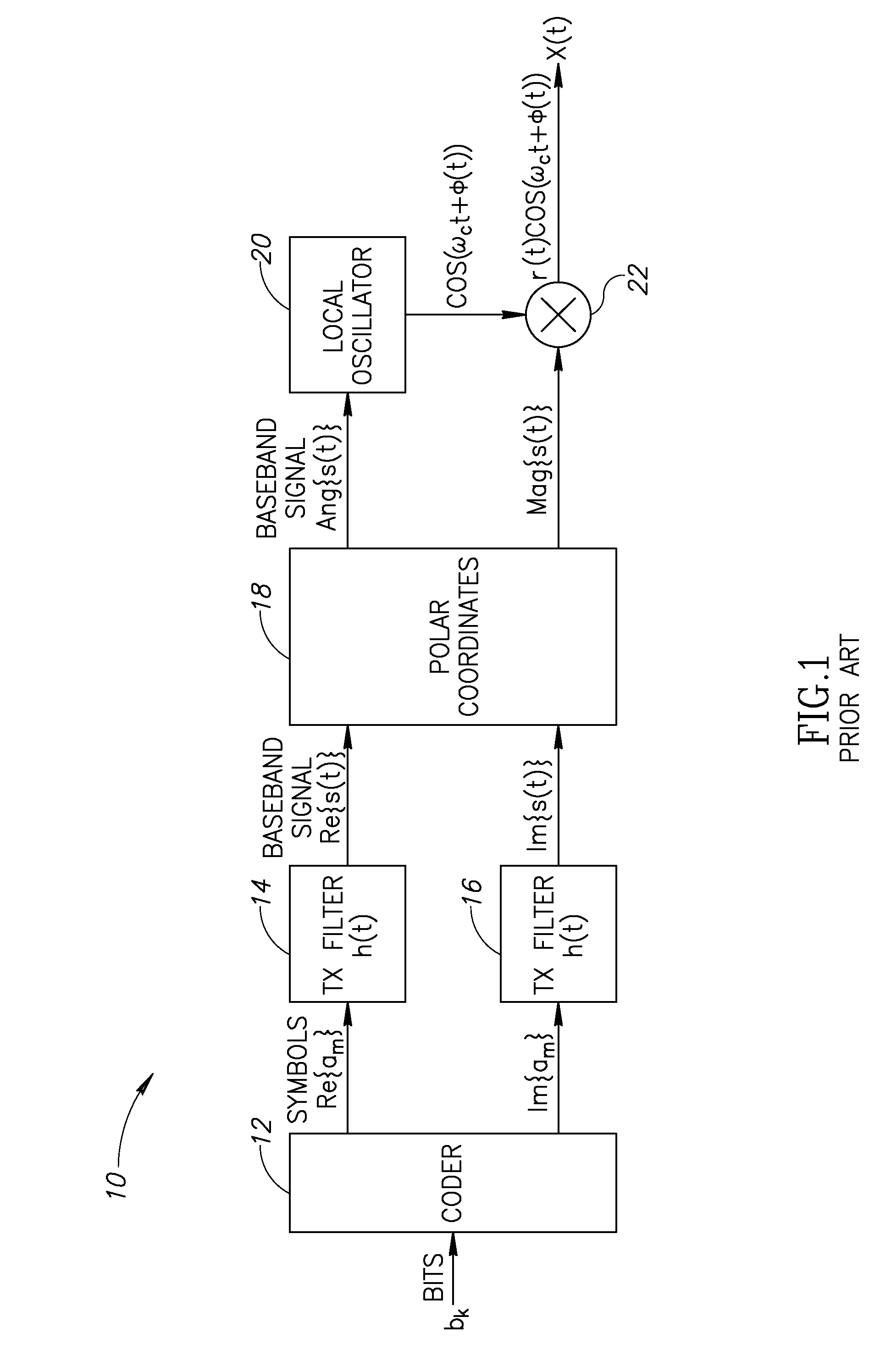

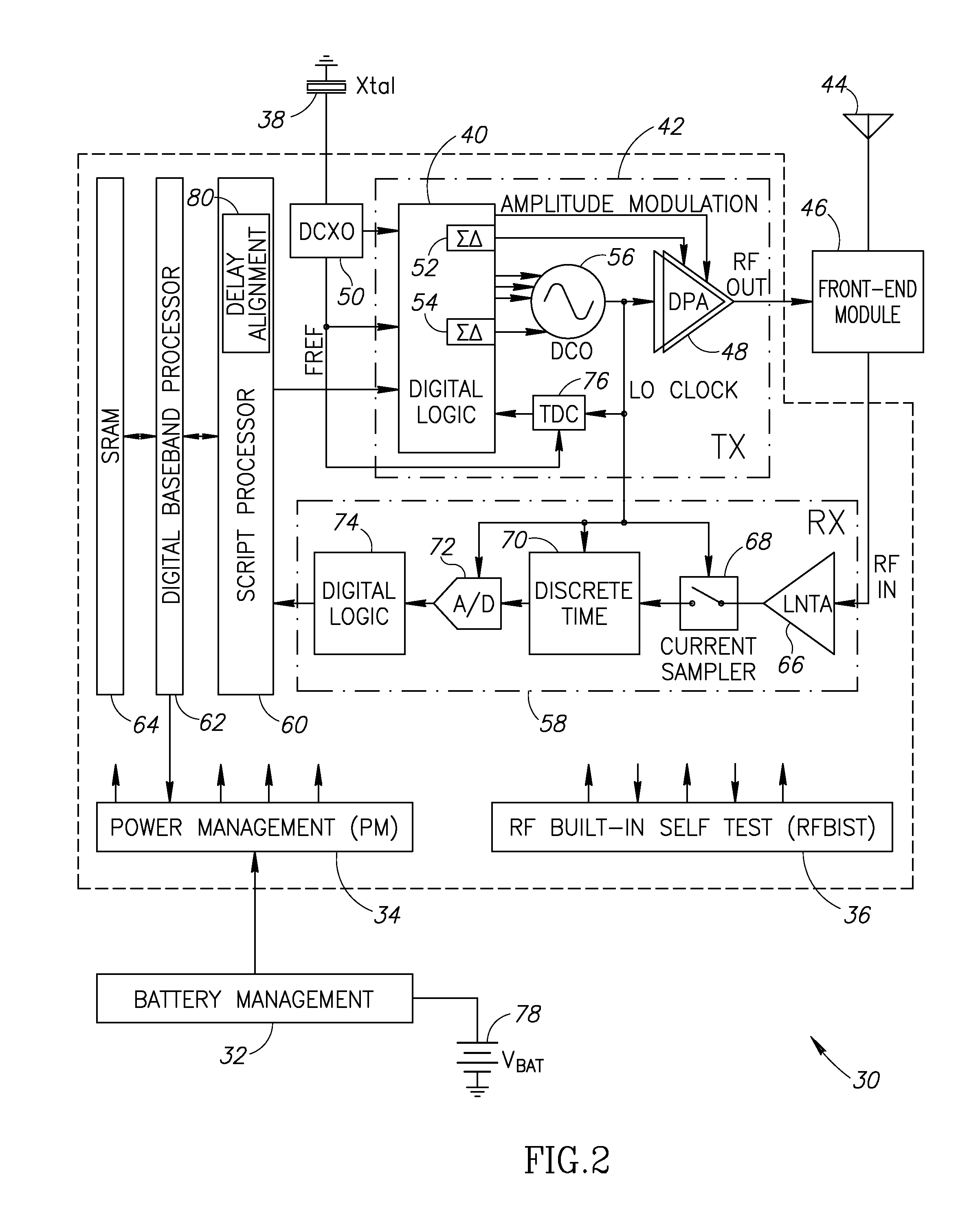

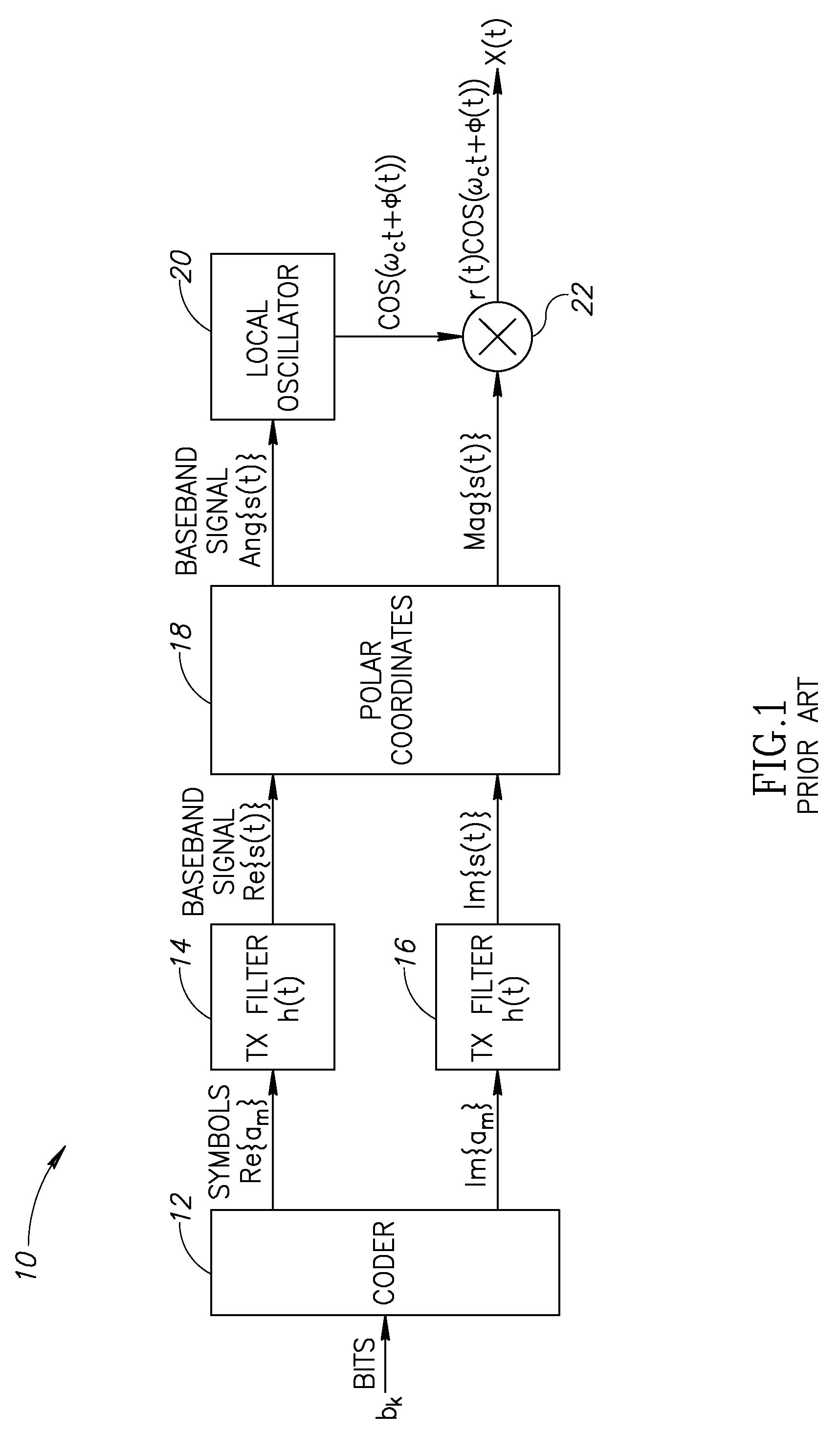

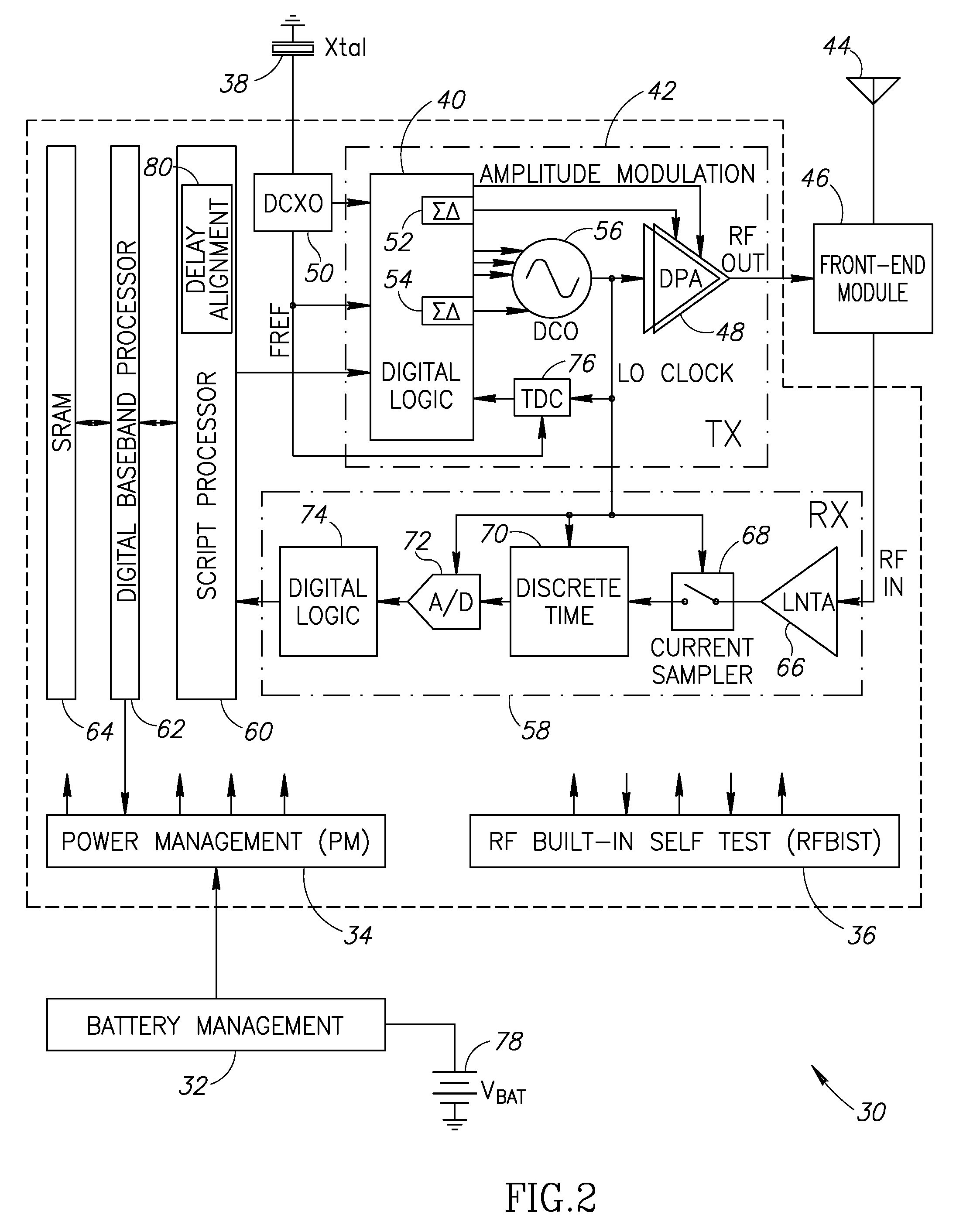

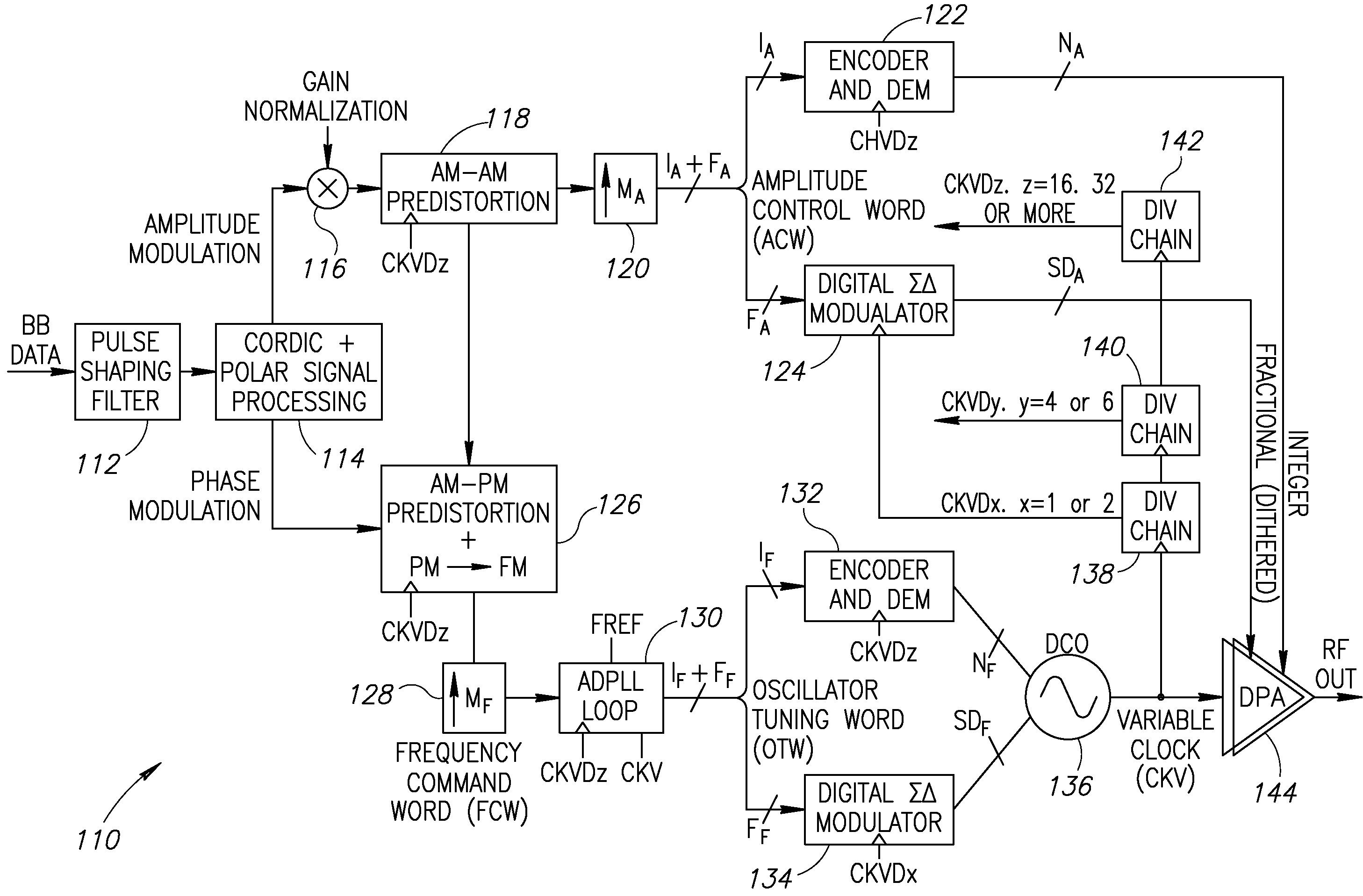

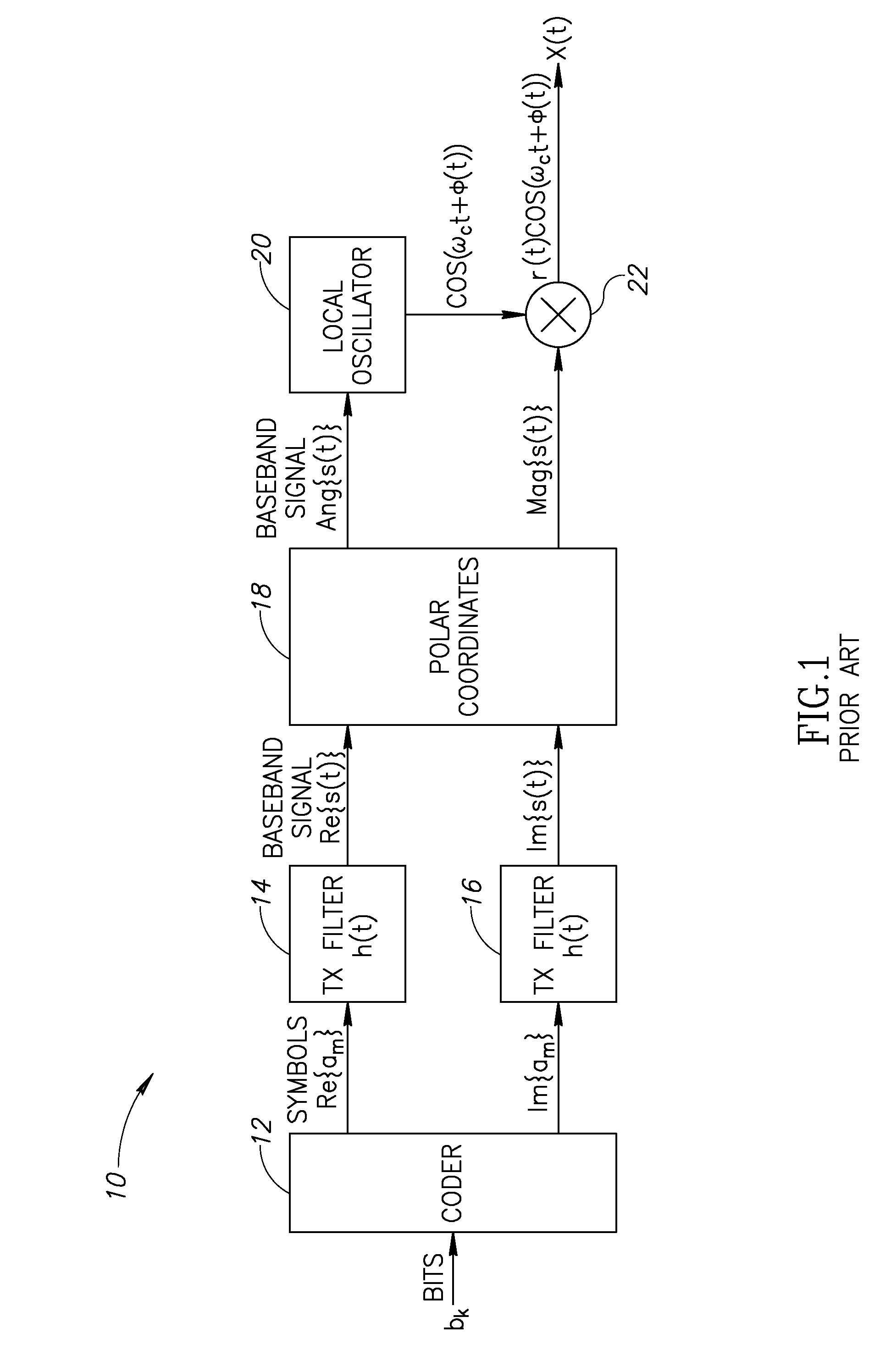

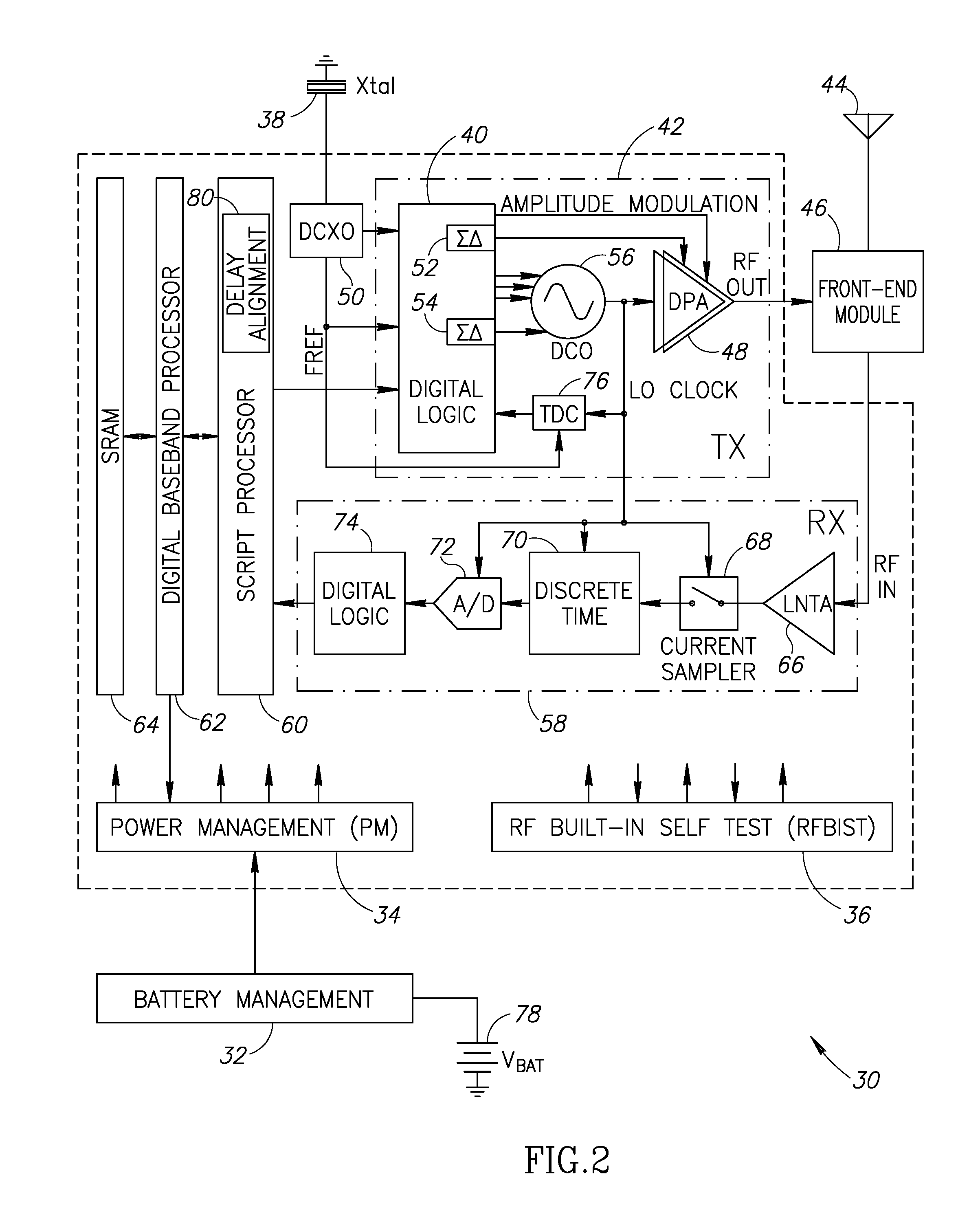

Precise delay alignment between amplitude and phase/frequency modulation paths in a digital polar transmitter

ActiveUS20070189417A1Achieve alignmentHigh phase modulation accuracy requirementSimultaneous amplitude and angle modulationModulation with suppressed carrierAudio power amplifierNanosecond

A novel apparatus for and method of delay alignment between amplitude and phase / frequency modulation paths in a digital polar transmitter. The invention provides a fully digital delay alignment mechanism where better than nanosecond alignment is achieved by accounting for processing delays in the digital circuit modules of the transmitter and by the use of programmable delay elements spread across several clock domains. Tapped delay lines compensate for propagation and settling delays in analog elements such as the DCO, dividers, quad switch, buffers, level shifters and digital pre-power amplifier (DPA). A signal correlative mechanism is provided whereby data from the amplitude and phase / frequency modulation paths to be matched is first interpolated and then cross-correlated to achieve accuracy better than the clock domain of comparison. Within the ADPLL portion of the transmitter, precise alignment of reference and direct point injection points in the ADPLL is provded using multiple clock domains, tapped delay lines and clock adjustment circuits.

Owner:TEXAS INSTR INC

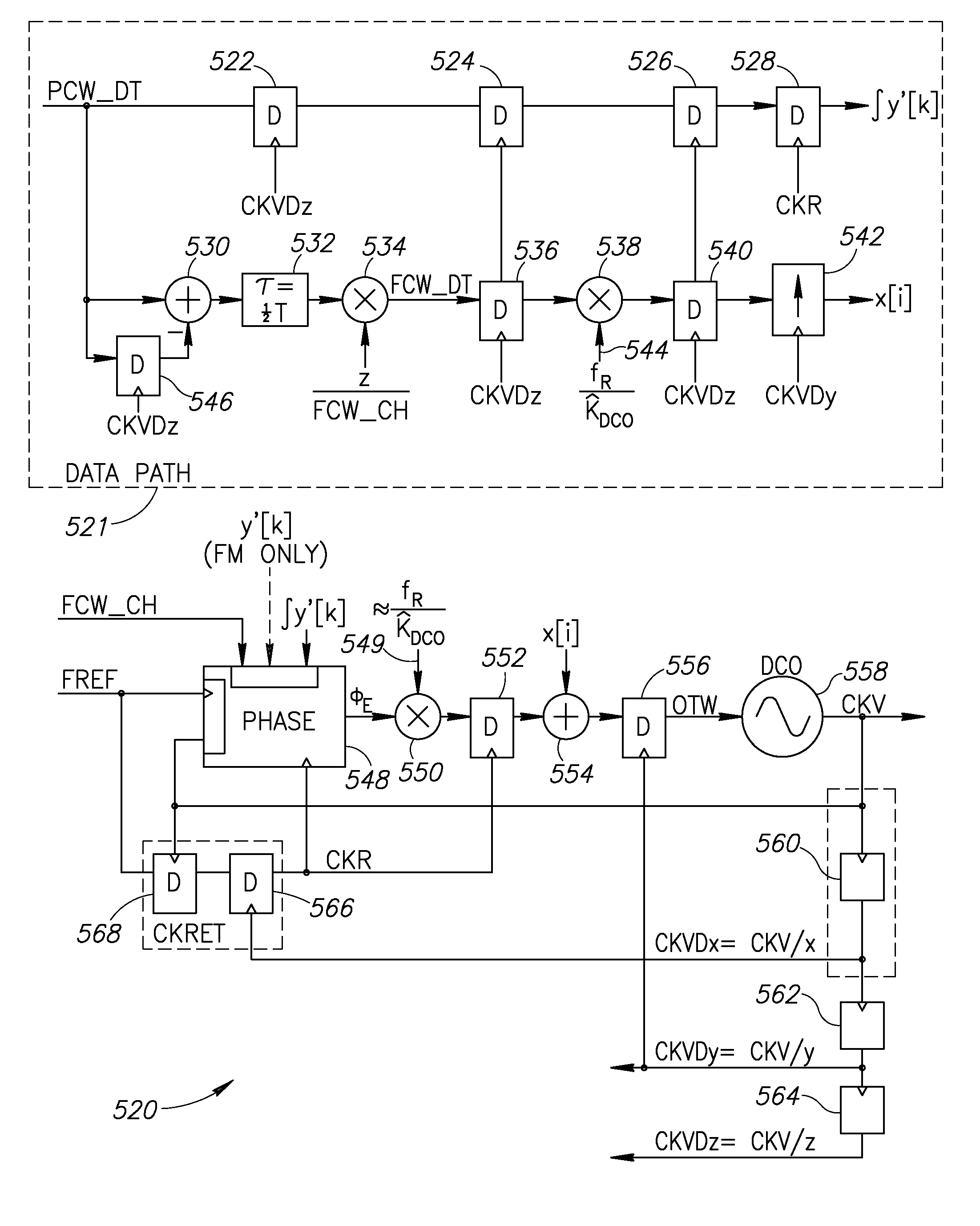

Delay alignment in a closed loop two-point modulation all digital phase locked loop

InactiveUS20070189431A1Easy to adjustAchieve alignmentSimultaneous amplitude and angle modulationPulse automatic controlNanosecondAudio power amplifier

A novel apparatus for and method of delay alignment in a closed loop two-point modulation all digital phase locked loop (ADPLL). The invention provides a fully digital delay alignment mechanism where better than nanosecond alignment is achieved by accounting for processing delays in the digital circuit modules of the transmitter and by the use of programmable delay elements spread across several clock domains. Tapped delay lines compensate for propagation and settling delays in analog elements such as the DCO, dividers, quad switch, buffers, level shifters and digital pre-power amplifier (DPA). A signal correlative mechanism is provided whereby data from the amplitude and phase / frequency modulation paths to be matched is first interpolated and then cross-correlated to achieve accuracy better than the clock domain of comparison. Within the ADPLL portion of the transmitter, precise alignment of reference and direct point injection points in the ADPLL is provided using multiple clock domains, tapped delay lines and clock adjustment circuits.

Owner:TEXAS INSTR INC

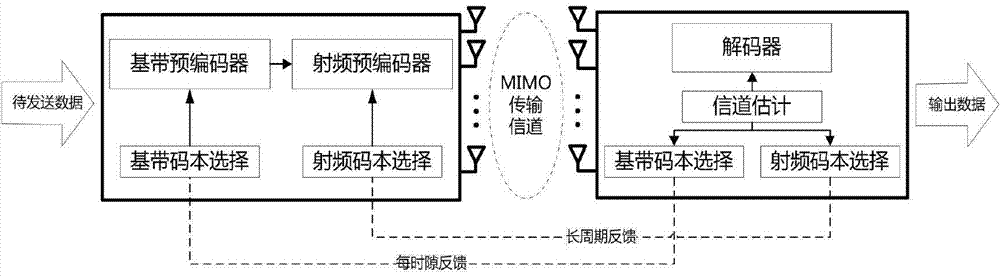

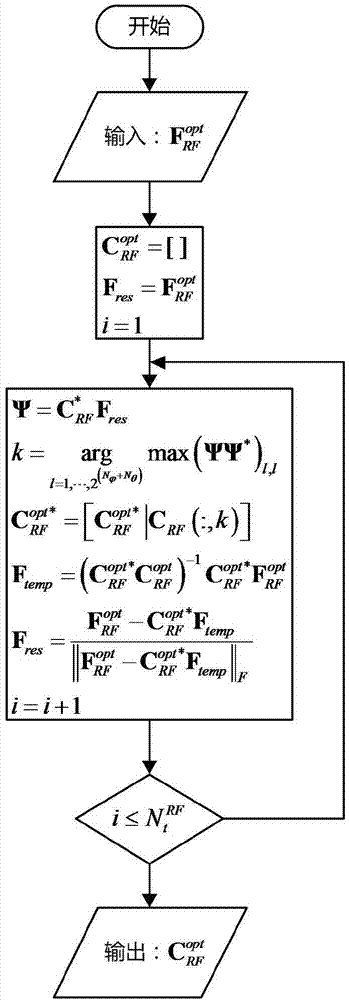

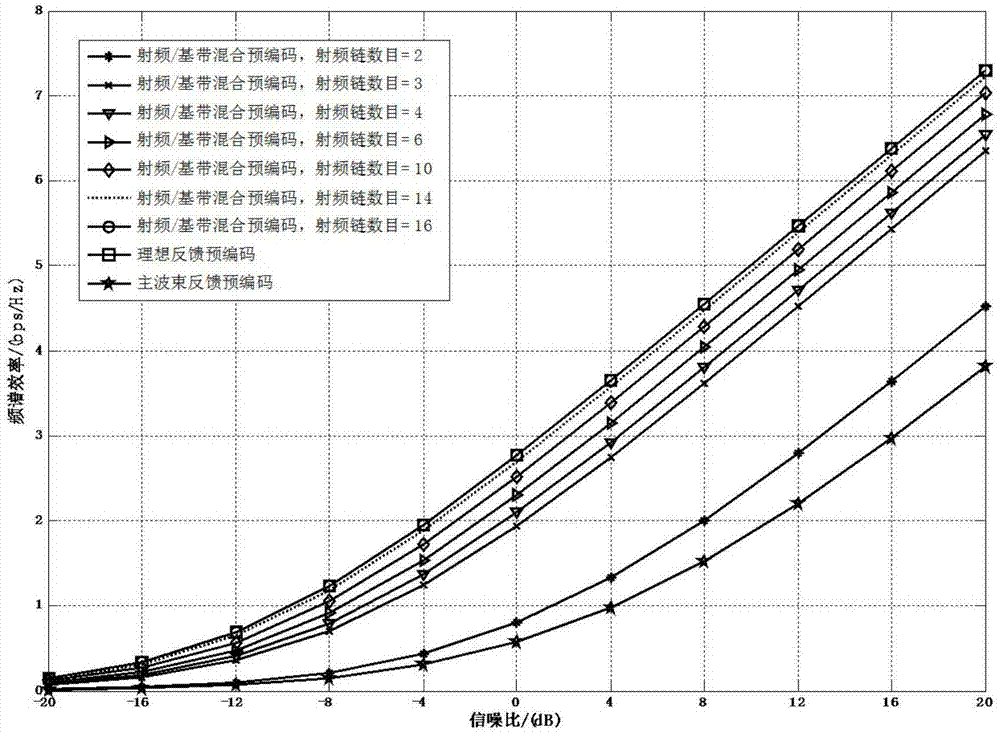

Radio frequency and base band mixing pre-coding method for 3D (three dimensional)-MIMO (Multiple Input Multiple Output) system

InactiveCN104506281AAchieve alignmentReduce dimensionalitySpatial transmit diversityLink quality based transmission modificationRadio frequencyPrecoding

The invention discloses a radio frequency and base band mixing pre-coding method for a 3D-MIMO system. The method includes the steps of 1) estimating a channel and calculating a correlation matrix; 2) constructing a radio frequency pre-coding codebook; 3) calculating and feeding back radio frequency pre-coding code words; 4) calculating and feeding back base band pre-coding code words; 5) transmitting downlink data. The radio frequency and base band mixing pre-coding method for the 3D-MIMO system is directed to channel characteristics of the3D-MIMO system to achieve user-level beam alignment, uses long-cycle and short-cycle feedback strategies to reduce the amount of real-time feedback and greatly reduce the burden on the uplink, reduces the number of radio frequency chains for reducing the cost, is easy to operate and can be applied to an actual communication system easily.

Owner:XIDIAN UNIV

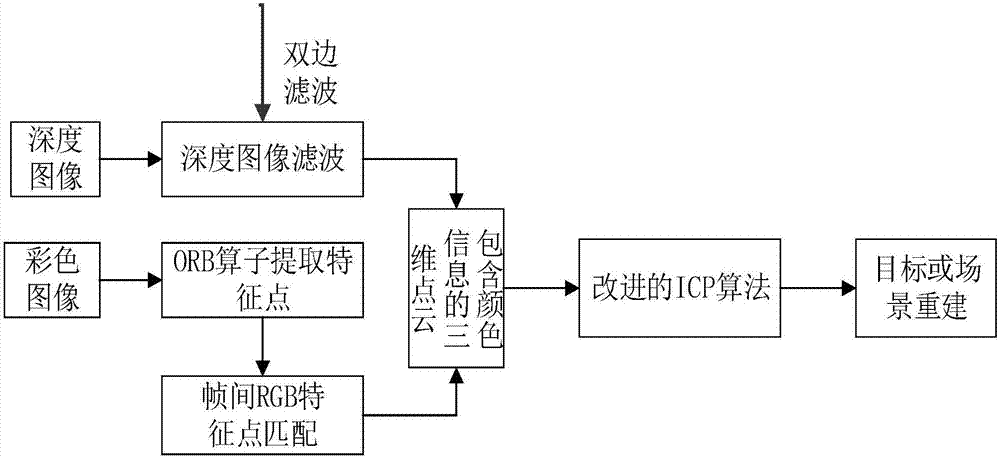

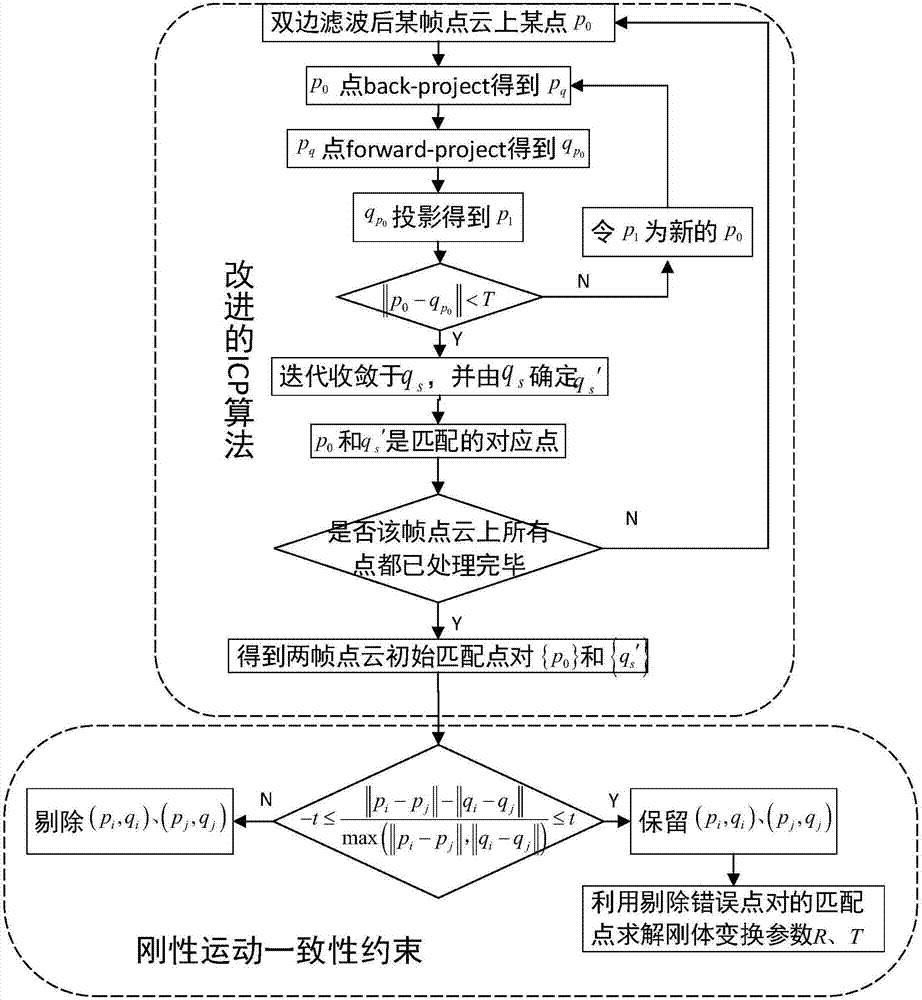

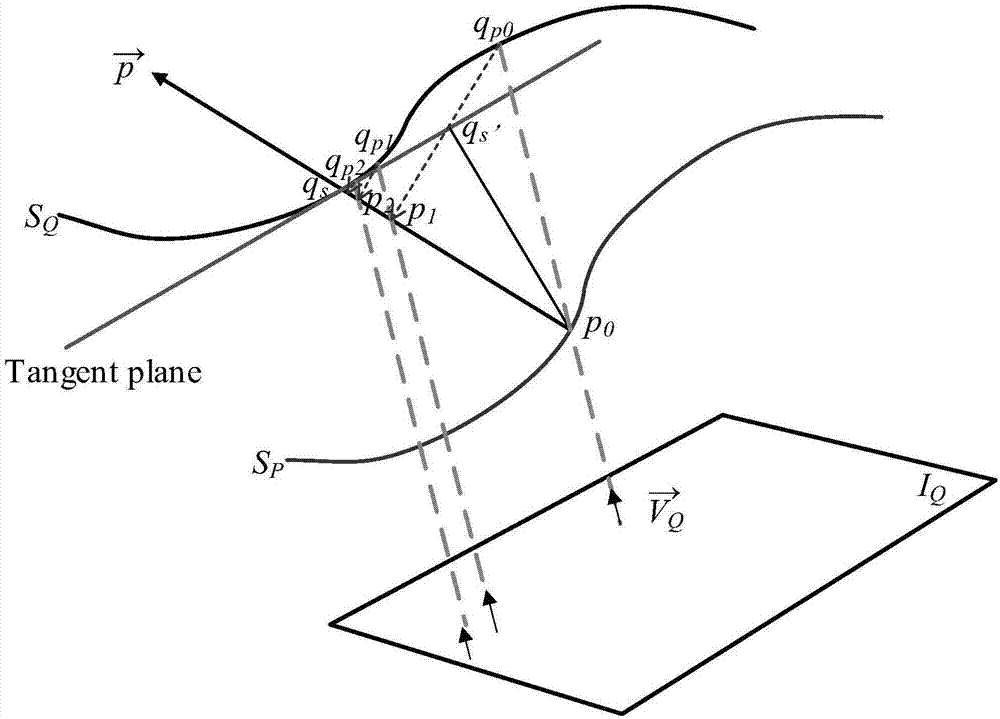

Object and indoor small scene restoring and modeling method based on RGB-D camera data

InactiveCN107240129AImprove accuracyShort runtimeImage enhancementImage analysisPoint cloudProjection algorithms

The purpose of the invention aims to provide an object and indoor small scene restoring and modeling method based on RGB-D camera data. In summary, the method comprises: in the RGB-D depth data (point cloud) registering and modeling, integrating the restraining conditions for point-to-face and point-to-projection together so that they are applied to the accurate registering of the sequence depth data (point cloud) obtained by the RGB-D camera; and finally obtaining a point cloud model (.ply format) for an object or a small scene wherein the model is able to be used for object measurement and further CAD modeling. The registering method of the invention considers the speed advantage of the point-to-projection algorithm and integrates the precise advantage of the point-to-tangent plane algorithm. This overcomes the problems with the slow speed and low scene precision in a traditional point cloud registering method, and is capable of finding out the corresponding point of a point on the source point cloud to a target point cloud quickly and accurately so as to realize the cloud splicing of multiple view points.

Owner:TONGJI UNIV

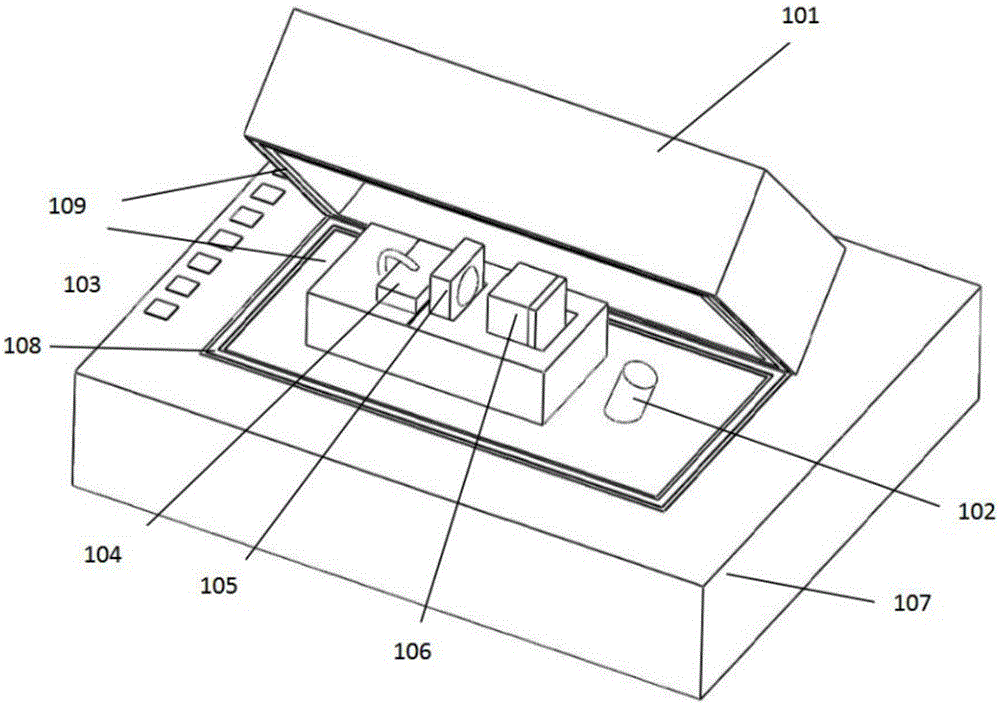

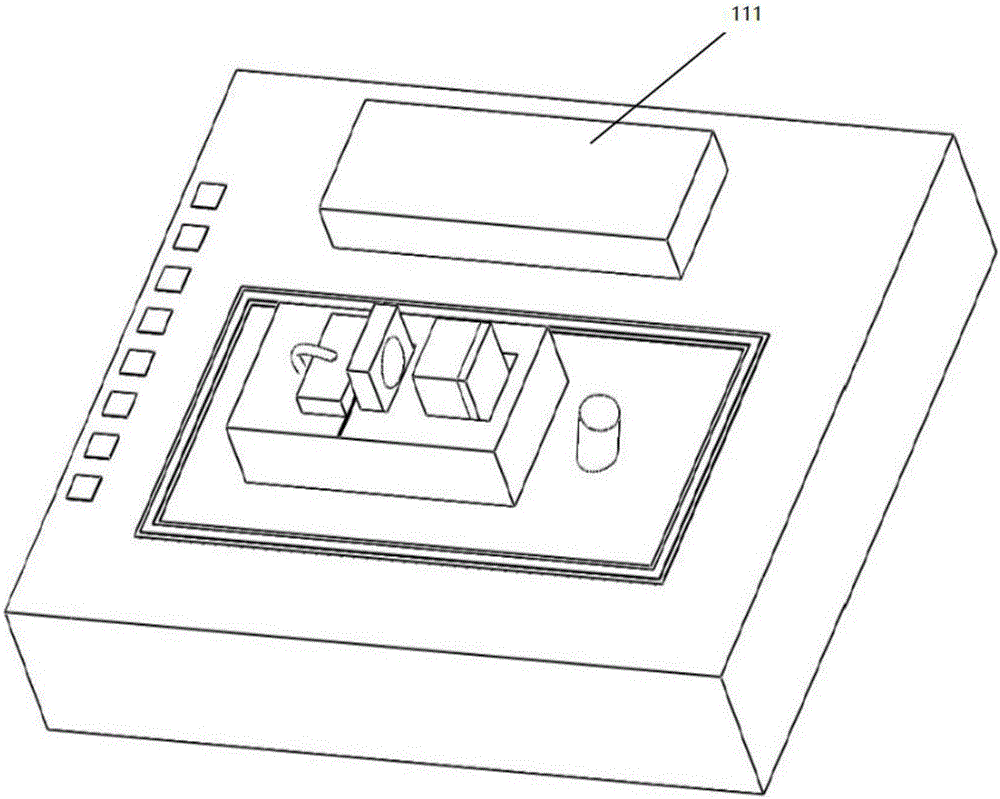

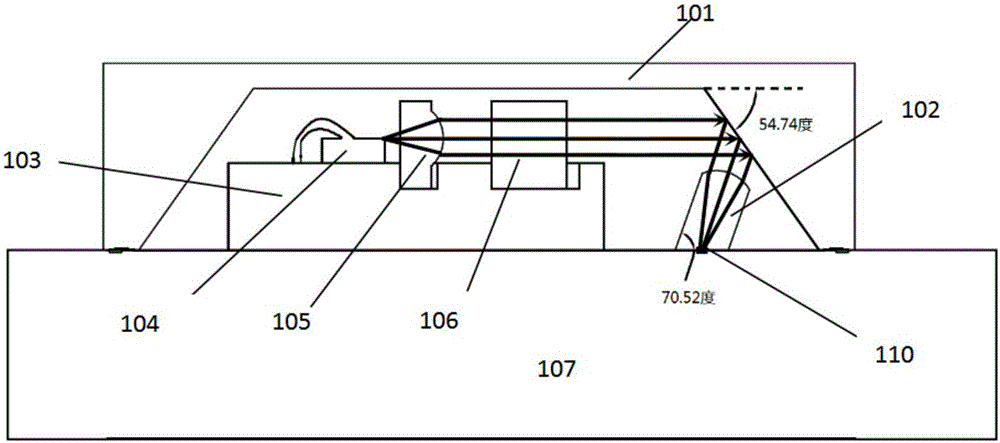

Light source packaging structure, and positioning and coupling method thereof

ActiveCN106019496AExtended service lifeInsulate from moistureCoupling light guidesPosition toleranceGrating

The invention provides a light source packaging structure, and a positioning and coupling method thereof. The light source packaging structure comprises a sealing box cover (101), a C lens (102), a silicon based heat sink (103), a laser chip (104), an isolator assembly (106), and a silicon light chip (107). The laser chip (104), a collimating lens (105), and the isolator assembly (106) are sequentially disposed on the silicon based heat sink (103). The C lens (102) is aligned with the grating coupler (110) of the silicon light chip (107) in a fixed and coupled manner. The sealed box cover (101) is provided with an inclined inner wall used to reflect light emitted by the laser chip (104) to the C lens, and the lower surface of the C lens (102) is provided with a polishing surface matched with the incident angle of the reflected light. The side of the C lens (102) inclined toward the direction away from the silicon based heat sink (103), and the optical axis of the C lens (102) is consistent with the transmission direction of the light, and the main light is superposed with the optical axis. A coupling structure is compact, and position tolerance is large.

Owner:GUANGXUN SCI & TECH WUHAN

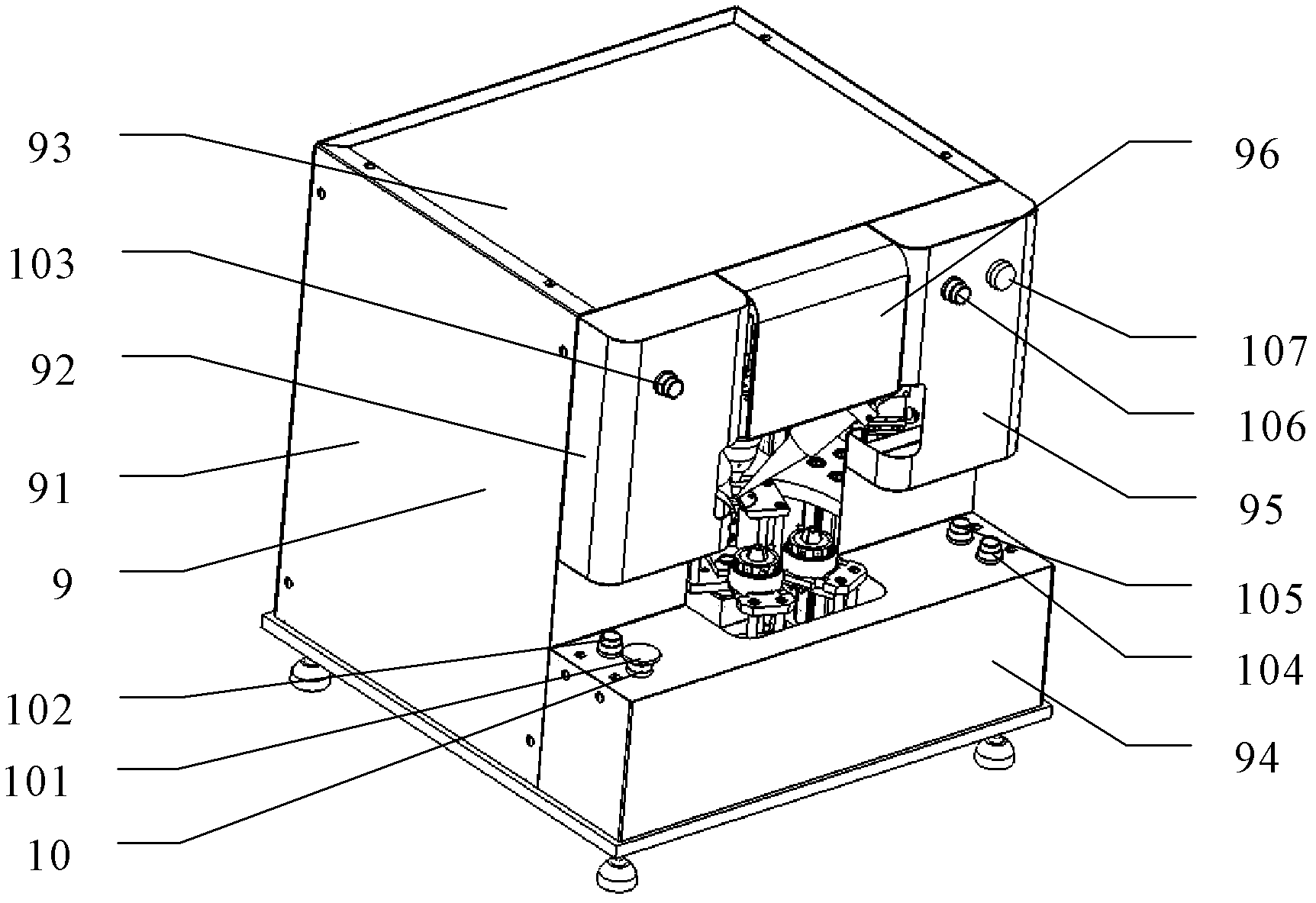

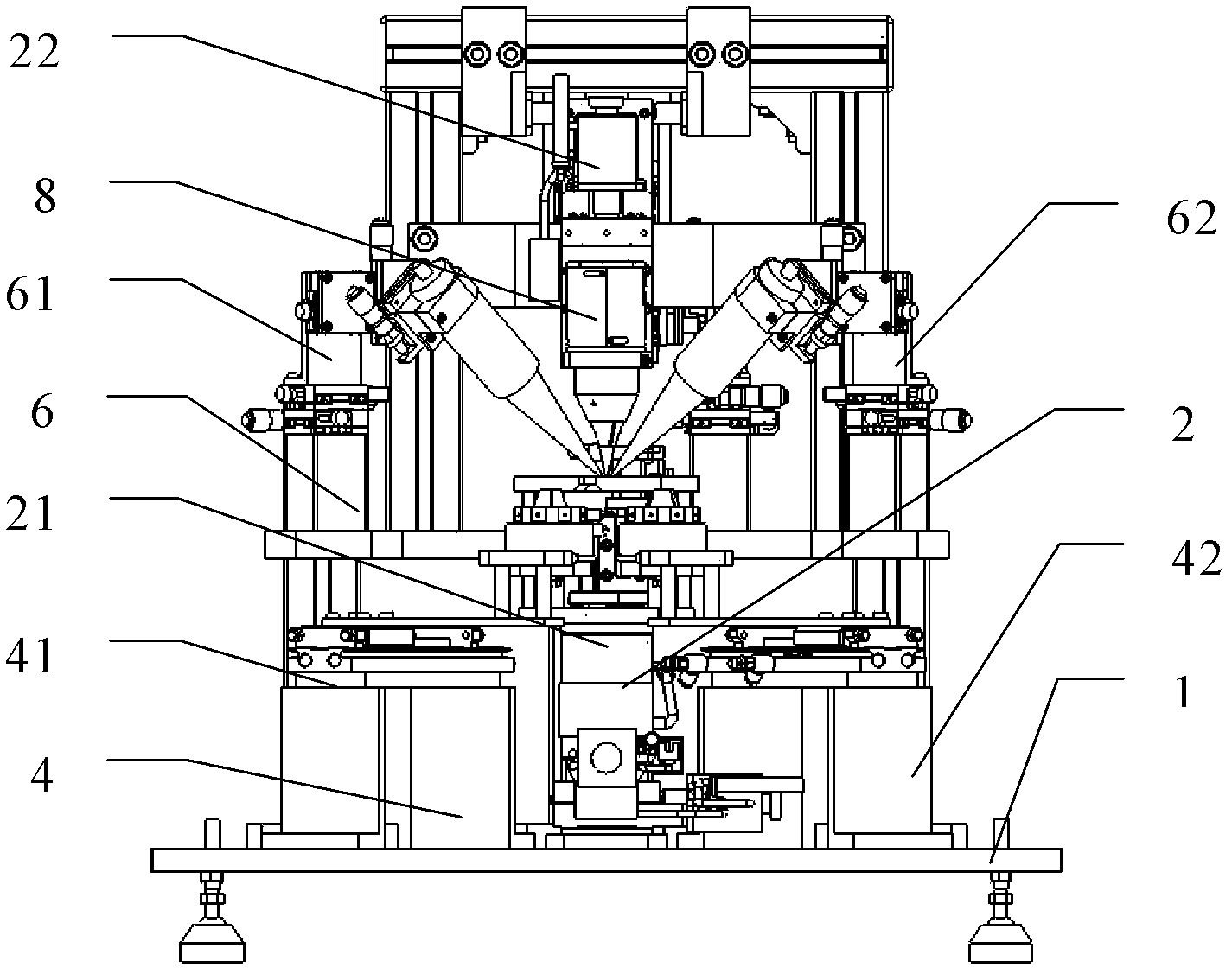

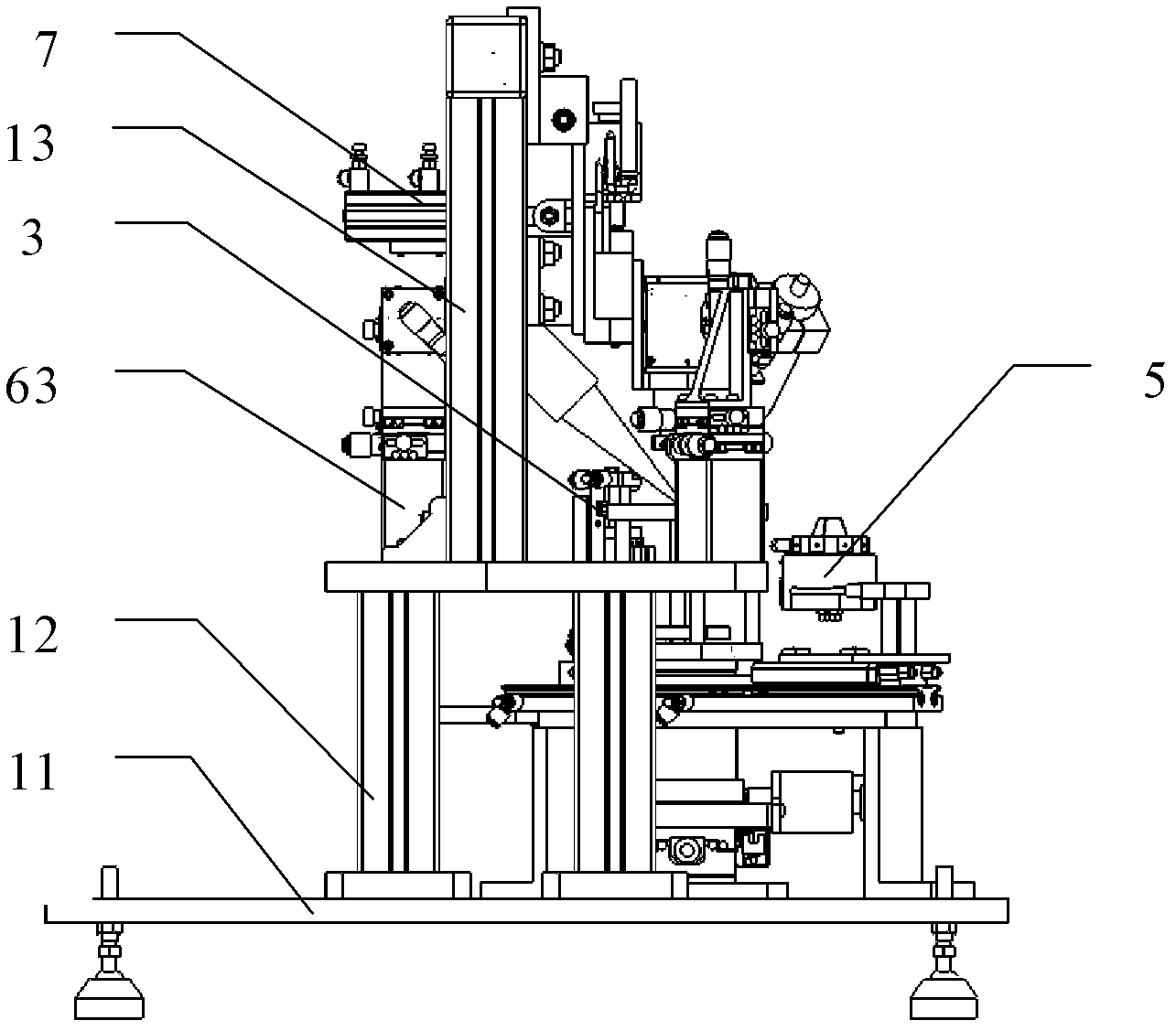

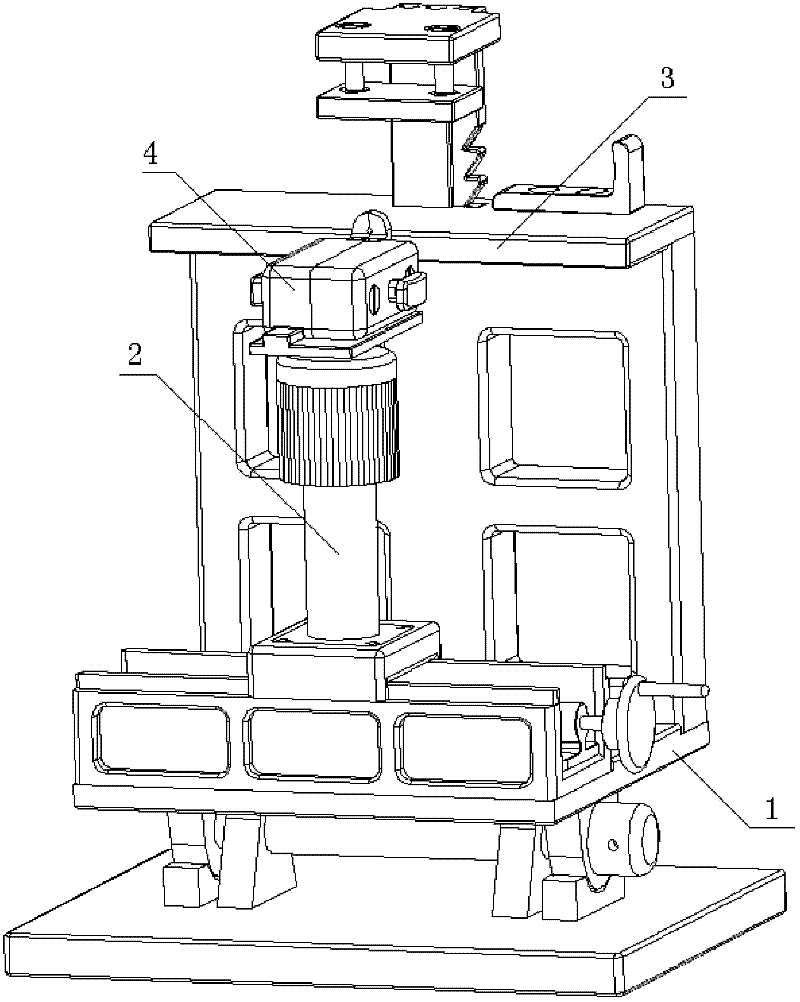

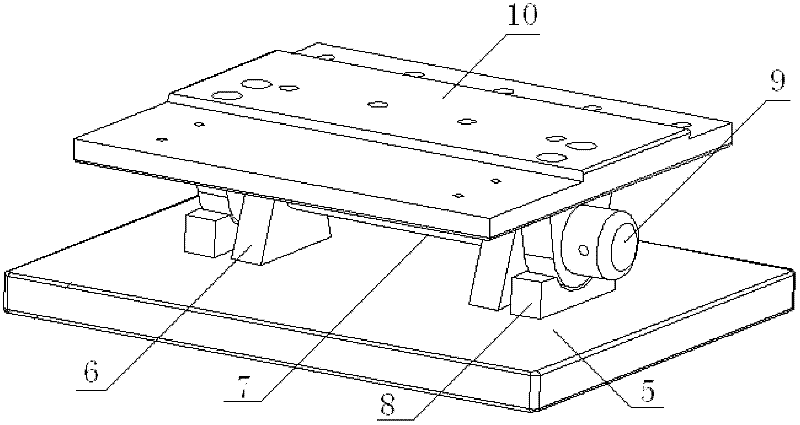

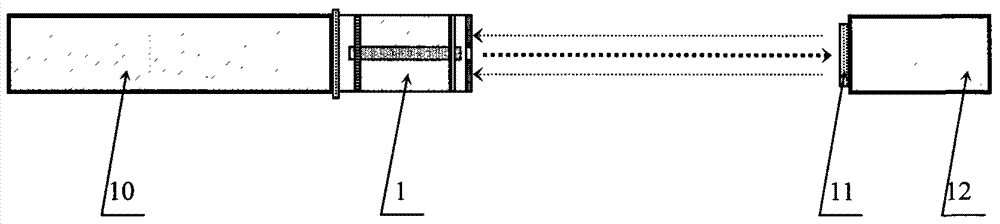

Coaxial Optical Transceiver Device Automatic Coupling, Soldering and Packaging Mechanical Device

ActiveCN102275040AStrong applicabilityIncrease flexibilityWelding/cutting auxillary devicesAuxillary welding devicesTransceiverEngineering

The invention discloses an auto-coupling welding and packaging mechanical device of a coaxial-type optical transceiving device, which comprises a workbench, an aligning unit, a lifting unit, a propelling unit, a manual lower fixture, a welding unit, a swinging unit, an upper fixture, an equipment housing and a control button, wherein an aligning unit base platform, the propelling unit and a welding workbench are installed on an equipment workbench; the propelling unit comprises a left propelling device and a right propelling device which are distributed in an angle of 45 DEG around a rotating shaft of a Theta z r autorotation platform; the manual lower fixture is placed on the left propelling device; the lifting unit is installed on the Theta z rotating platform; the welding unit and a portal-type frame are installed on the welding workbench, and the welding unit comprises three welding devices which are uniformly disturbed in an angle of 120 DEG around the rotating shaft of the Theta z autorotation platform; the swinging unit is installed on the portal-type frame; a Z-axis automatic linear slipway is installed on a swinging plate of the swinging unit; the upper fixture is installed on the Z-axis automatic linear slipway, and can realize pitching actions by depending on the action of the swinging unit; the equipment housing is installed on the equipment workbench; and the control button is installed on the equipment housing. The auto-coupling welding and packaging mechanical device has the advantages of reasonable and ingenious structural design, strong extendibility, space economization, high degree of automation, convenience for control, simpleness in operation and short operation time, therefore the cost of products is low and the quality is stable; and the problems of coupling, aligning and welding of the coaxial-type optical transceiving device are effectively solved, and the requirements of an industrialized production line are satisfied.

Owner:CENT SOUTH UNIV

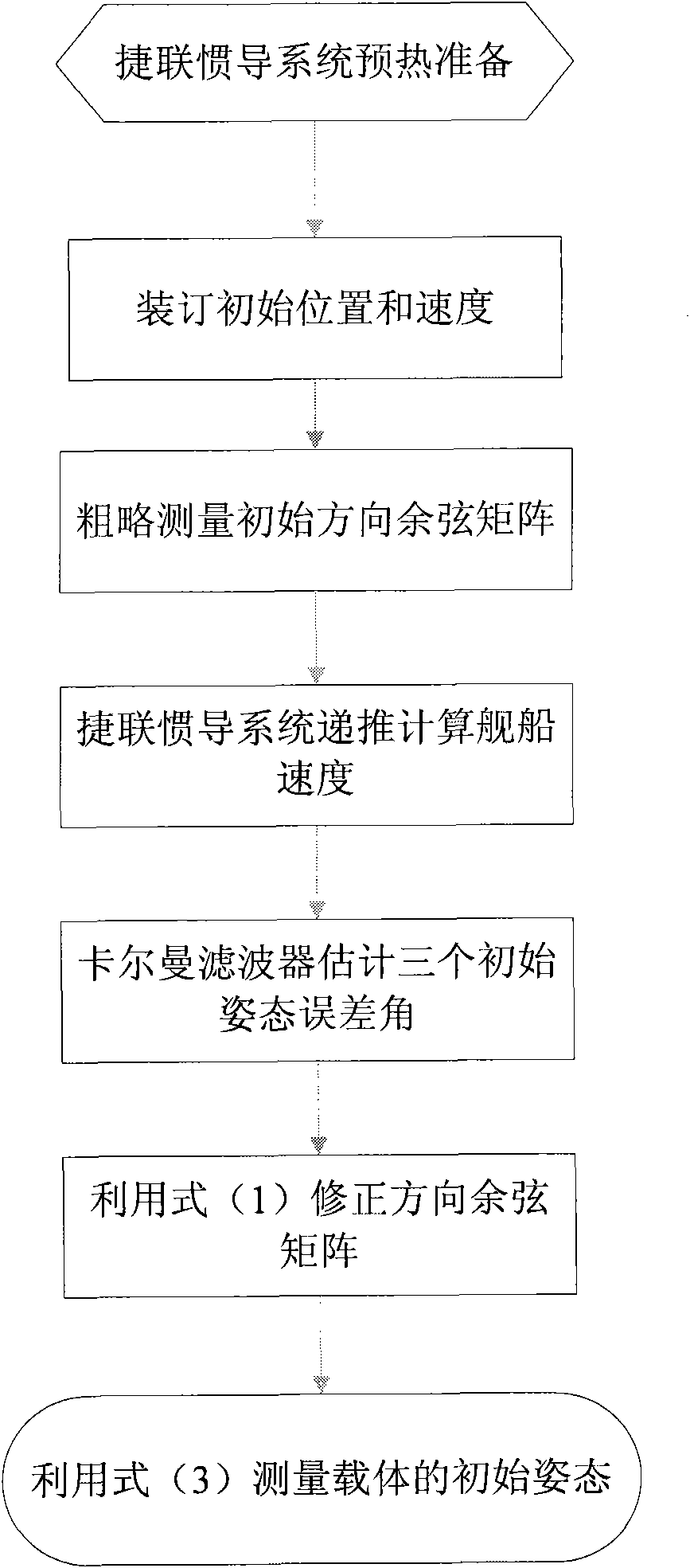

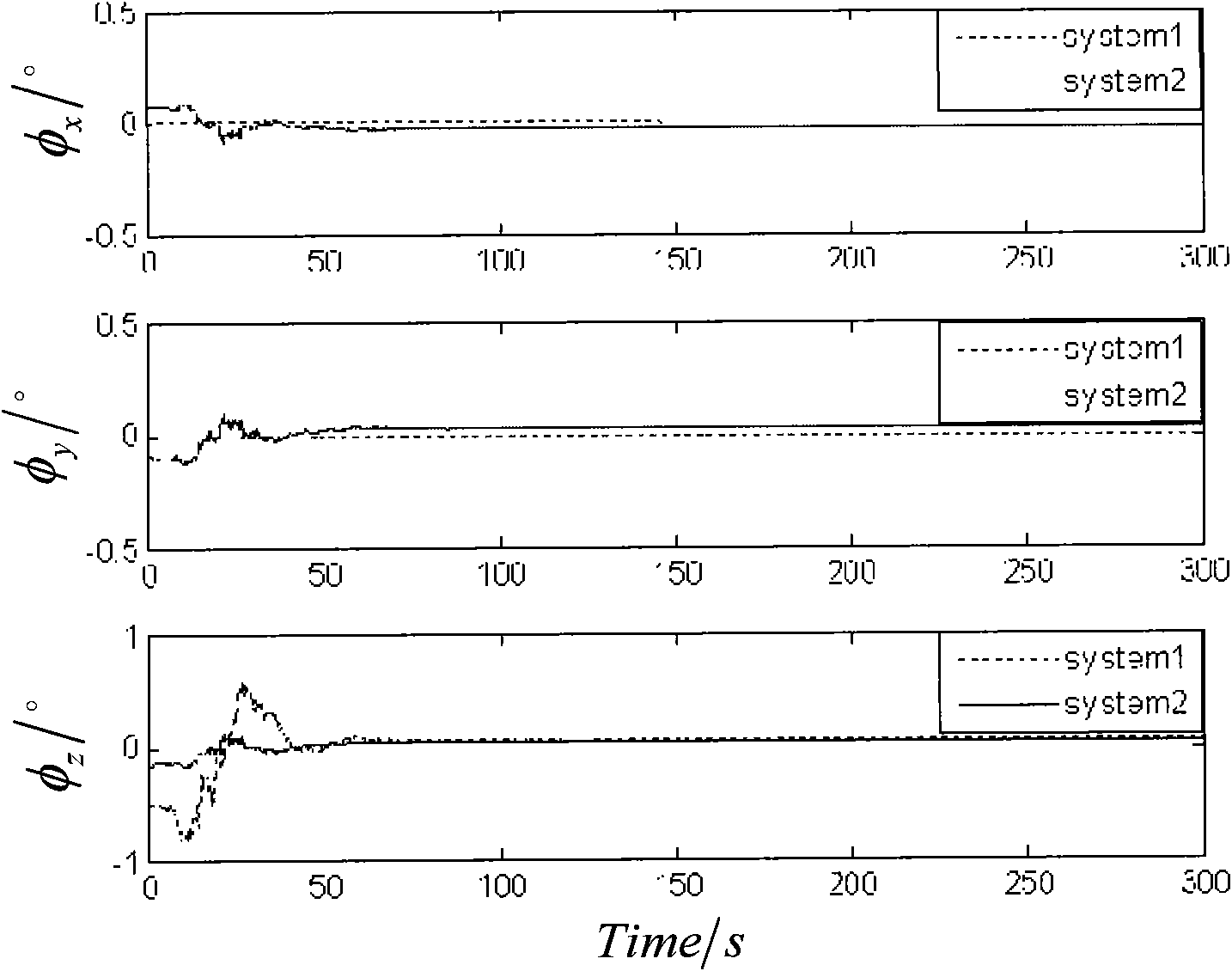

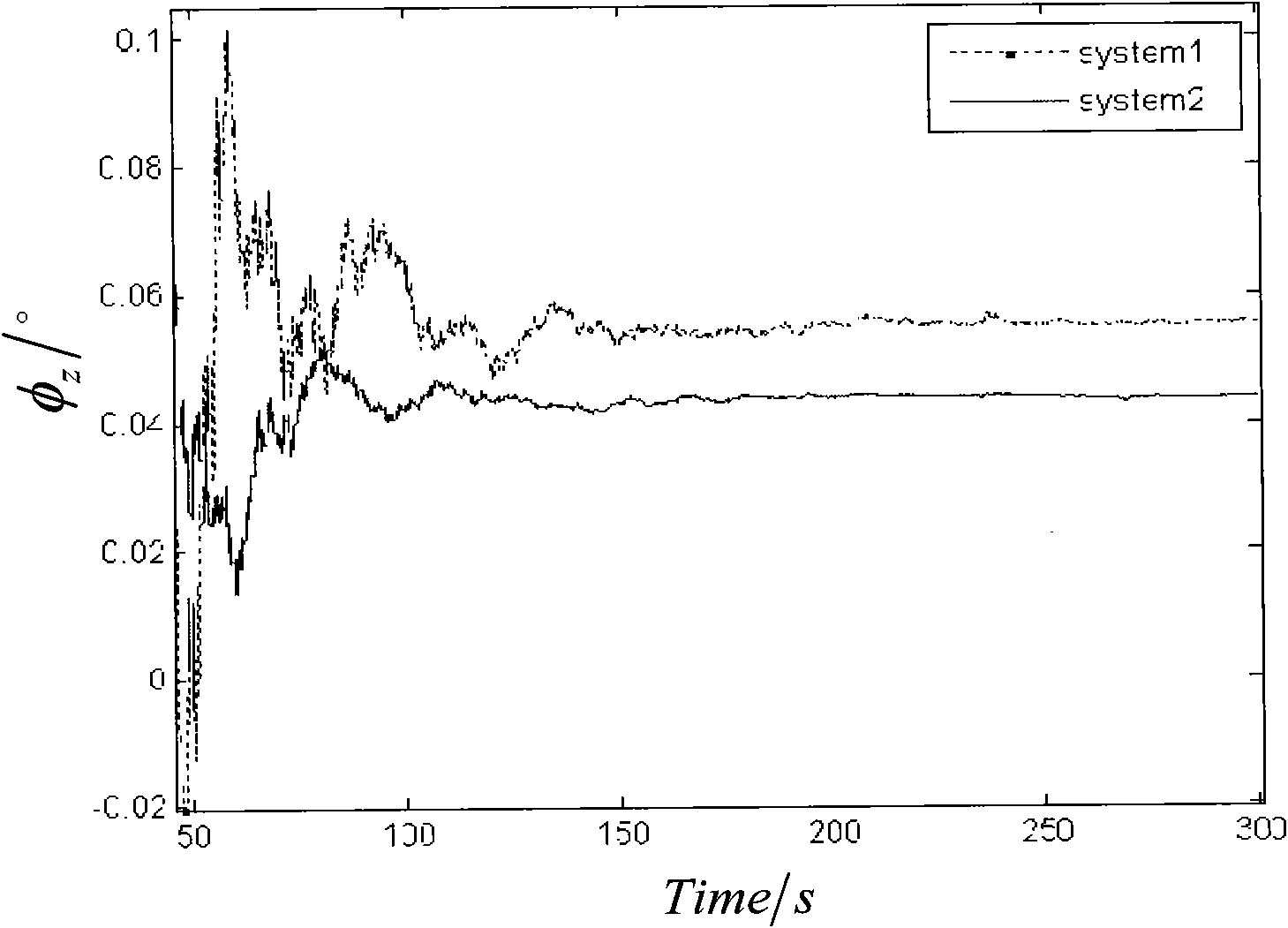

Method for acquiring initial course attitude of fiber optic gyro strapdown inertial navigation system

InactiveCN102486377AAccurate estimateImprove alignment accuracyNavigational calculation instrumentsNavigation by speed/acceleration measurementsEarth's rotationAngular velocity

The invention relates to a method for acquiring an initial course attitude of a fiber optic gyro strapdown inertial navigation system. The method is characterized by: extracting gravitational acceleration information from an acceleration meter through filtering processing and compensation, projecting an earth gravitational vector to an inertial coordinate system, with rotational-angular velocity information of the earth included in a projecting component, taking the earth gravitational vector in the inertial coordinate system as reference information, and making use of the output of a gyro and the acceleration meter to estimate an initial attitude angle. On the basis of ensuring that an initial horizontal angle satisfies a precision requirement, the method of the invention substantially improves the precision of an initial course angle of the fiber optic gyro strapdown inertial navigation system.

Owner:HARBIN ENG UNIV

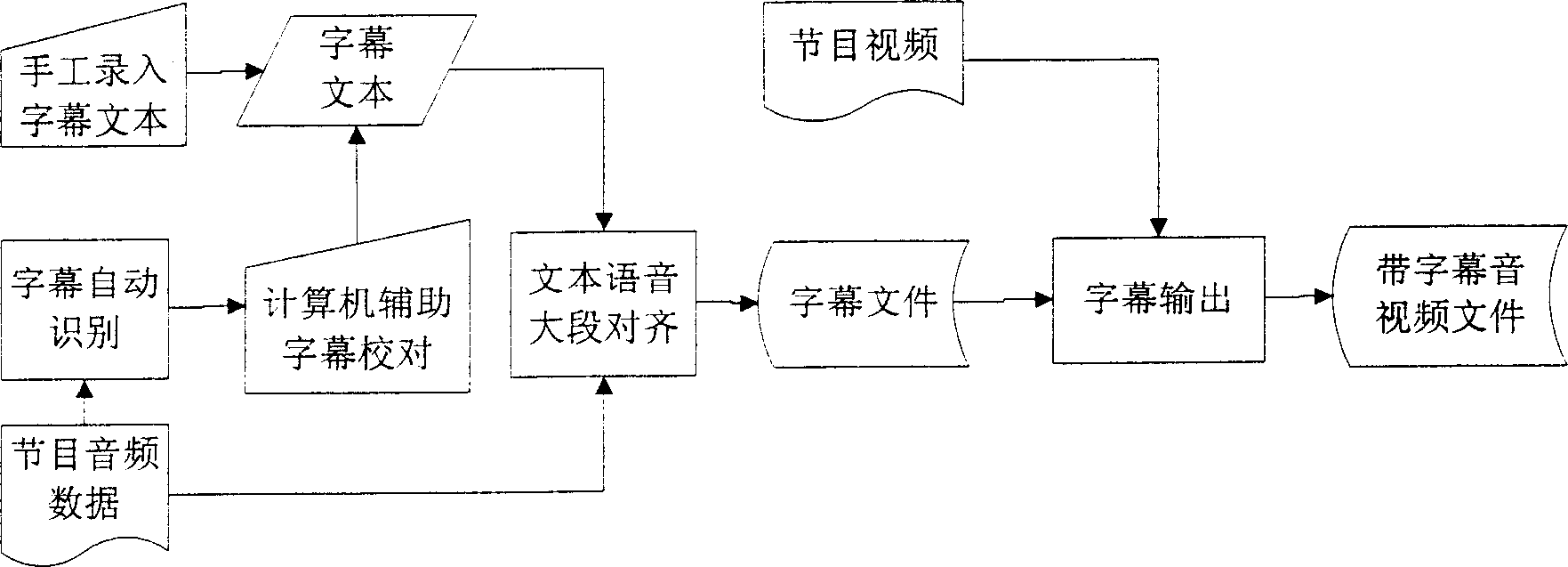

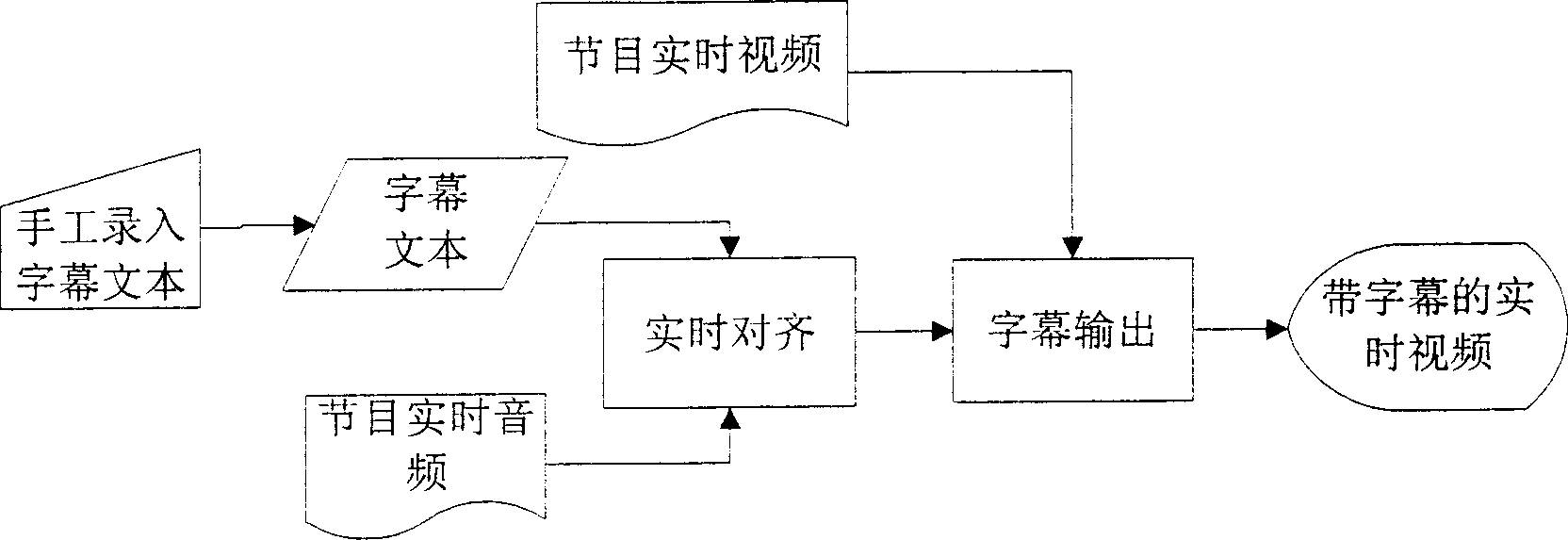

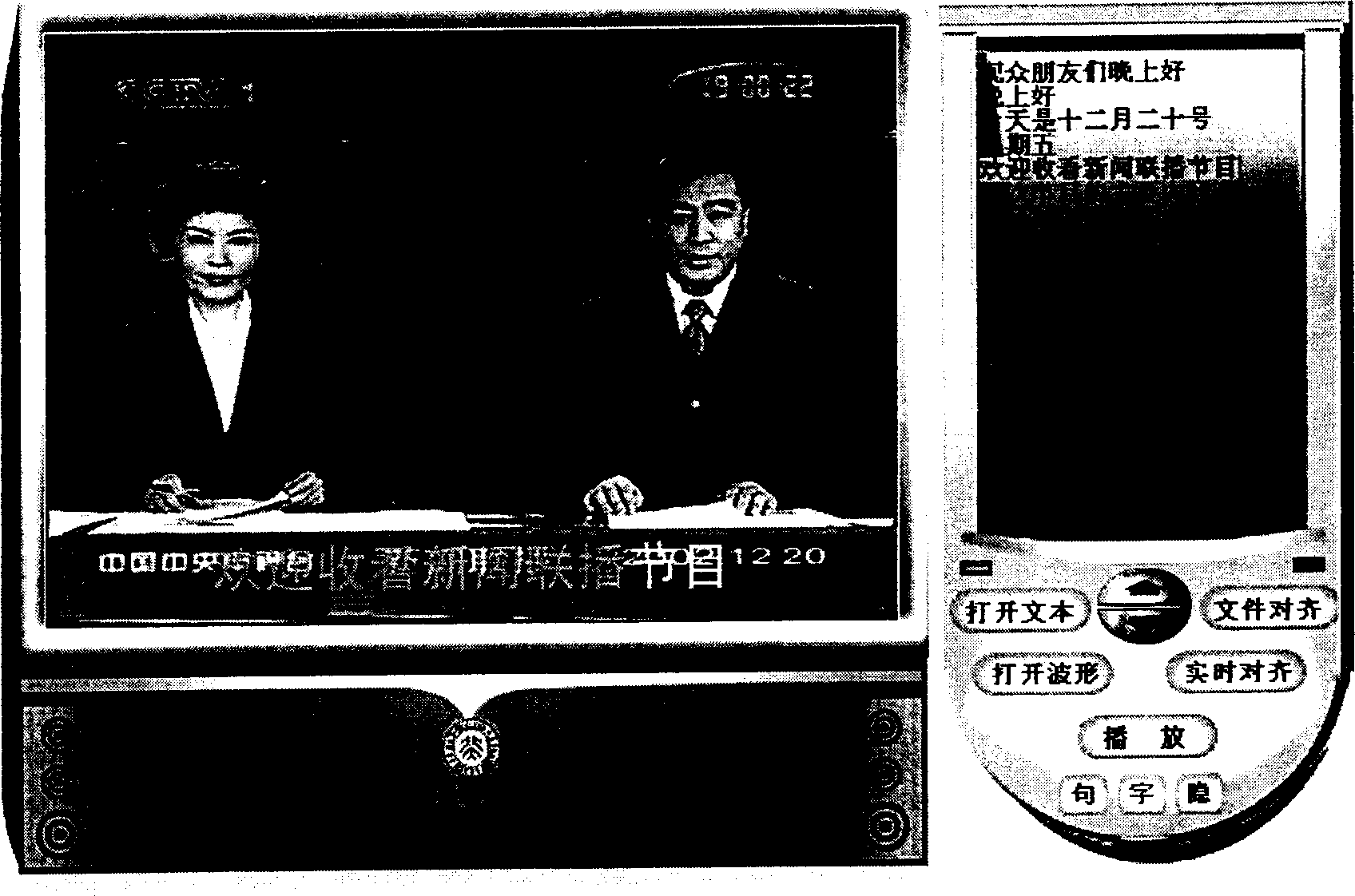

Method and system for automatic subtilting

InactiveCN1870728AAchieve alignmentGuaranteed accuracyTelevision system detailsColor television detailsAudio frequencyAutomatic testing

This invention designs and realizes an automatic matching sytem and a solving plan for captions of VCD programs and TV programs of living broadcast and non-living broadcast, in which, the plan includes: the caption automatic matching system against the non-living kind includes three modules: a caption automatic identifying module used in identifying automatically the caption scripts related to video flows in a VCD works, a caption assistant correction module for correcting captions and a large segment aligning module used in aligning the obtained audio frequency and caption scripts automatically in terms of a certain language unit to display related captions synchronously when playing VCD programs and the caption automatic matching system-the real time aligning module used in aligning a program manuscript prepared in advance and audio flows input timely on a time shaft and displaying the captions timely against the living TV programs.

Owner:PEKING UNIV

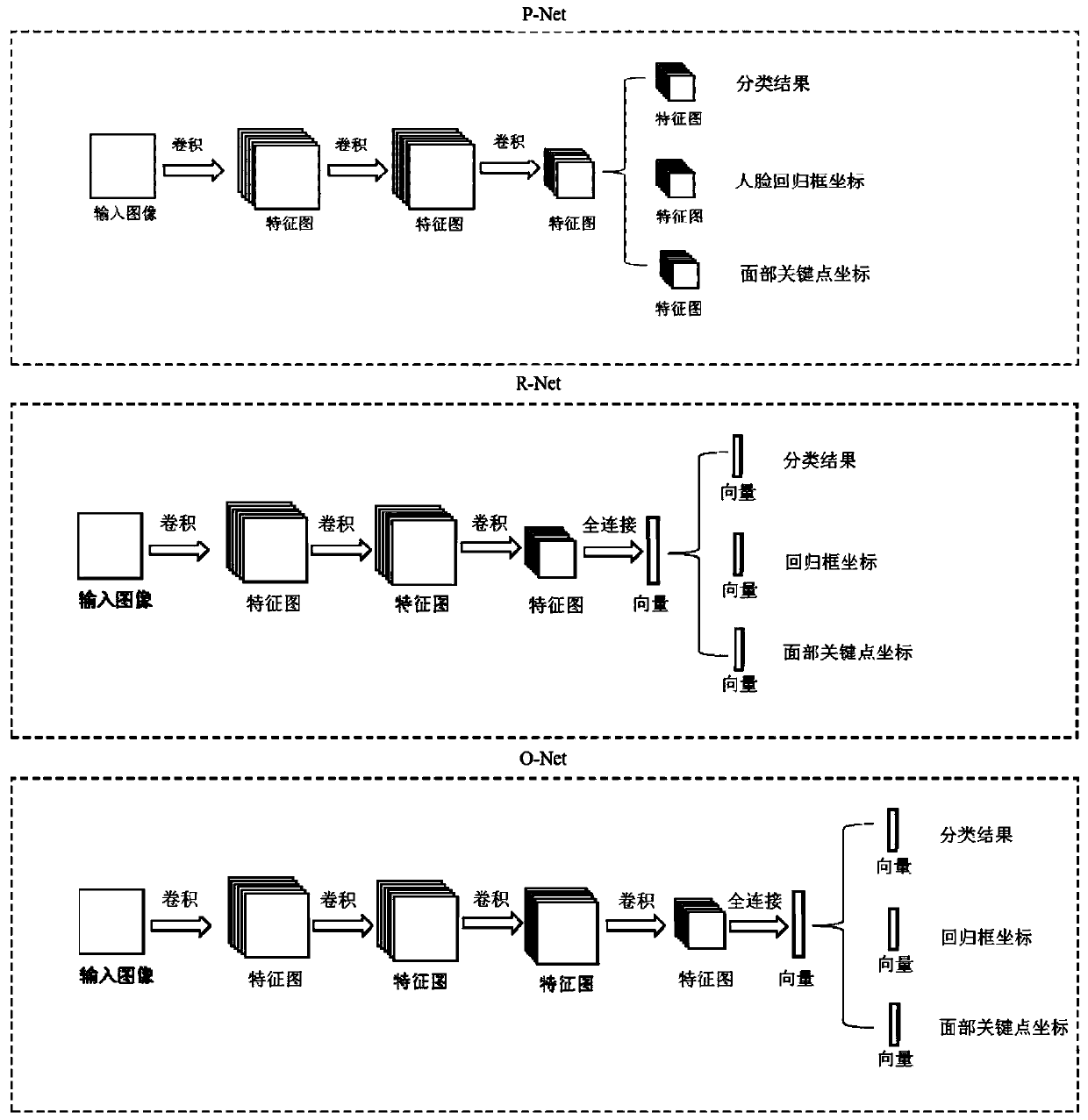

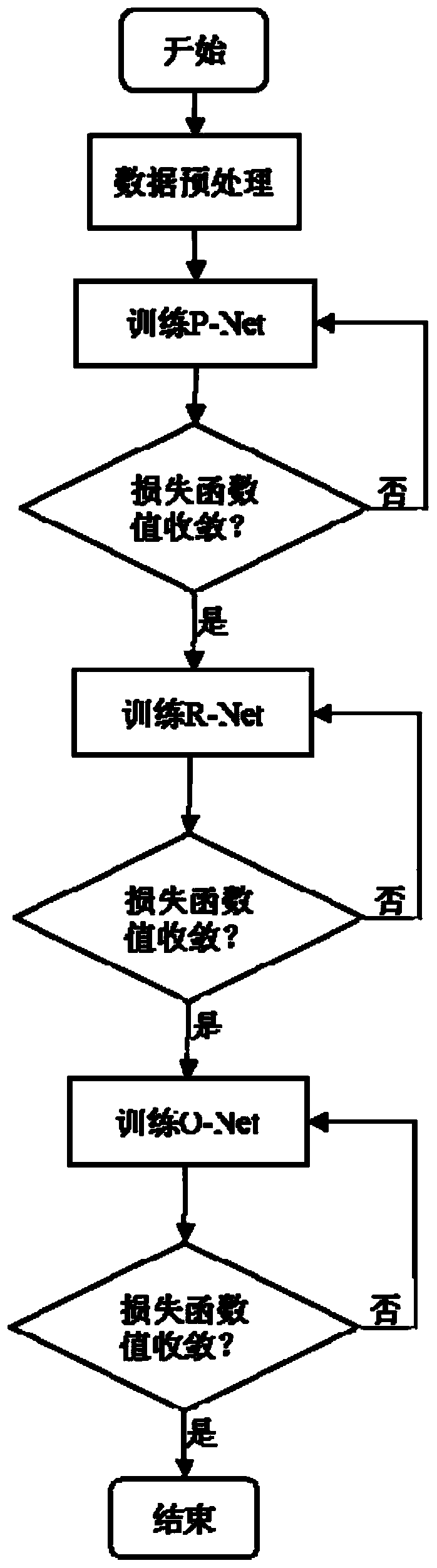

Low-pixel multi-target face detection and key point positioning method and alignment method

InactiveCN109961006ASolve the problem of difficult detection and key point positioningAchieve alignmentCharacter and pattern recognitionNeural architecturesFace detectionPattern recognition

The invention relates to a low-pixel multi-target face detection and key point positioning method and an alignment method. The positioning method comprises the steps that a low-pixel multi-target faceimage is preprocessed and then input into a trained deep neural network based on a deep learning model and a trained integrated regression tree based on a cascade shape regression framework, and output results of the low-pixel multi-target face image and the trained integrated regression tree are combined to obtain coordinates of a face regression frame and face key points; the alignment method comprises the following steps: carrying out similarity transformation on a human face by utilizing a human face regression frame determined by the low-pixel multi-target human face detection and key point positioning method and coordinates of human face key points, and aligning a standard human face to a reference human face. According to the low-pixel multi-target face detection and key point positioning method, the problem that a low-pixel multi-target face image is difficult to detect and carry out key point positioning is successfully solved; the low-pixel multi-target face alignment methodlays a foundation for face recognition of a low-pixel multi-target face image.

Owner:DONGHUA UNIV

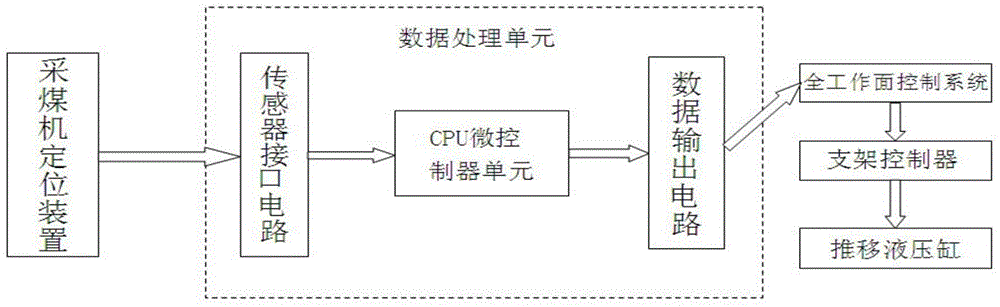

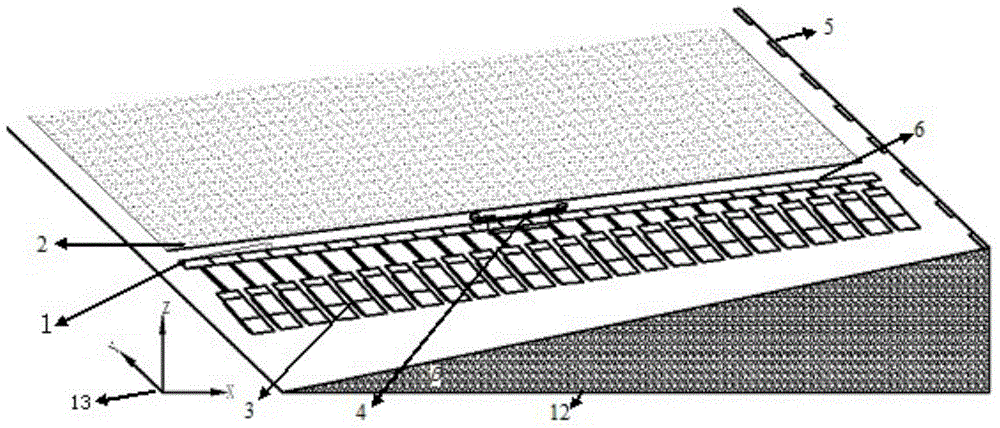

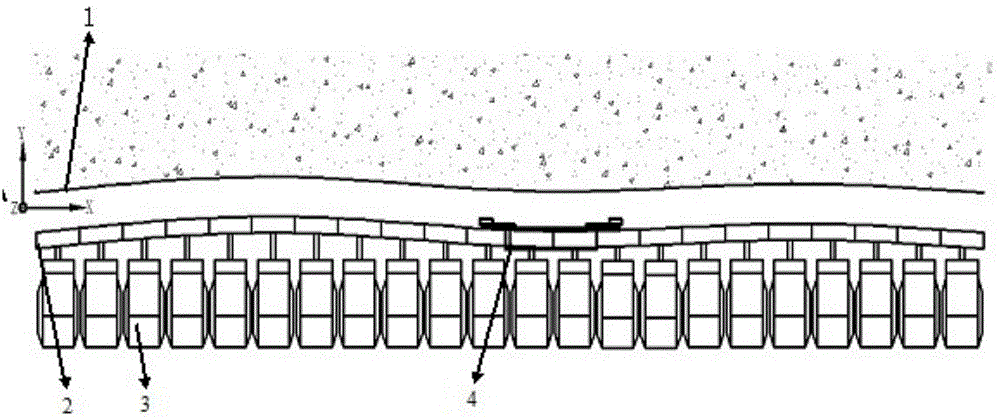

Scrapping plate conveyor dynamic straightening method based on absolute motion trajectory of coal cutter

ActiveCN104058215ARealize false tiltAchieve alignmentConveyorsMine roof supportsTerrainSignal processing circuits

The invention provides a scrapping plate conveyor dynamic straightening method based on the absolute motion trajectory of a coal cutter and belongs to a scrapping plate conveyor dynamic straightening method for a full-mechanized mining face. In the dynamic straightening method, a positioning device mounted on the coal cutter is utilized, so as to conduct real-time monitoring to the moving trajectory of the coal cutter along the scrapping plate conveyor; a signal processing circuit analyzes the dynamic position data of the coal cutter moving along the scrapping plate conveyor under the set spatial coordinate system; the absolute motion trajectory curve of the coal cutter and target reference motion trajectory of the quire under the geographical spatial coordinate system are concluded; a micro controller draws a target reference motion trajectory of a next quire according to the target reference trajectory and the working face coal bed terrain; the displacement distance of each hydraulic support is calculated; the micro controller controls an electro hydraulic control system via an output circuit; the electro hydraulic control system controls each bracket controller, so as to push a jack forward and enables the scrapping plate conveyor to meet the linear requirement. The positioning device on the coal cutter detects the orientation of the full-mechanized mining face in the geographical spatial coordinate system, so that adjusting false inclination of the full-mechanized mining face can be achieved.

Owner:CHINA UNIV OF MINING & TECH

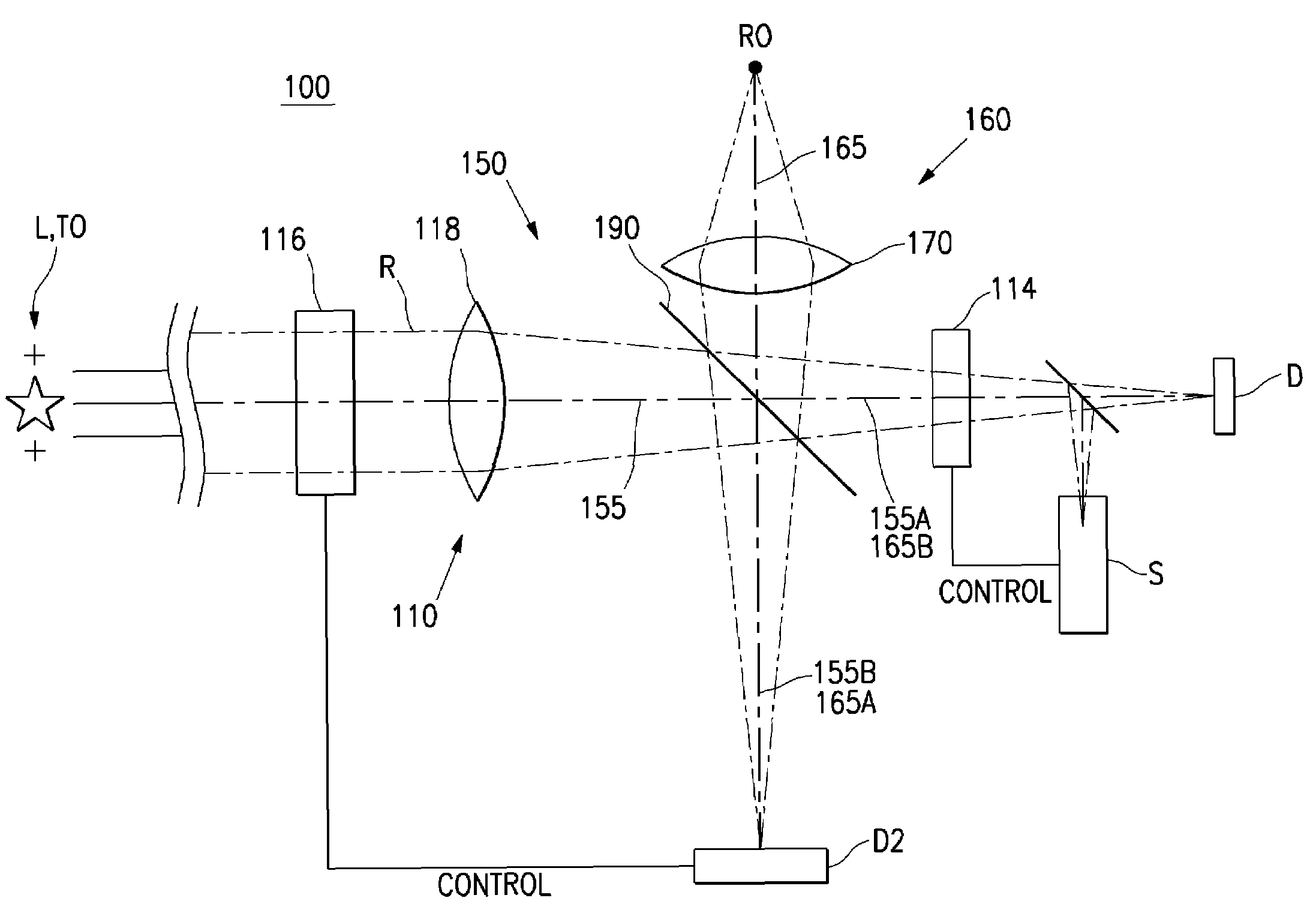

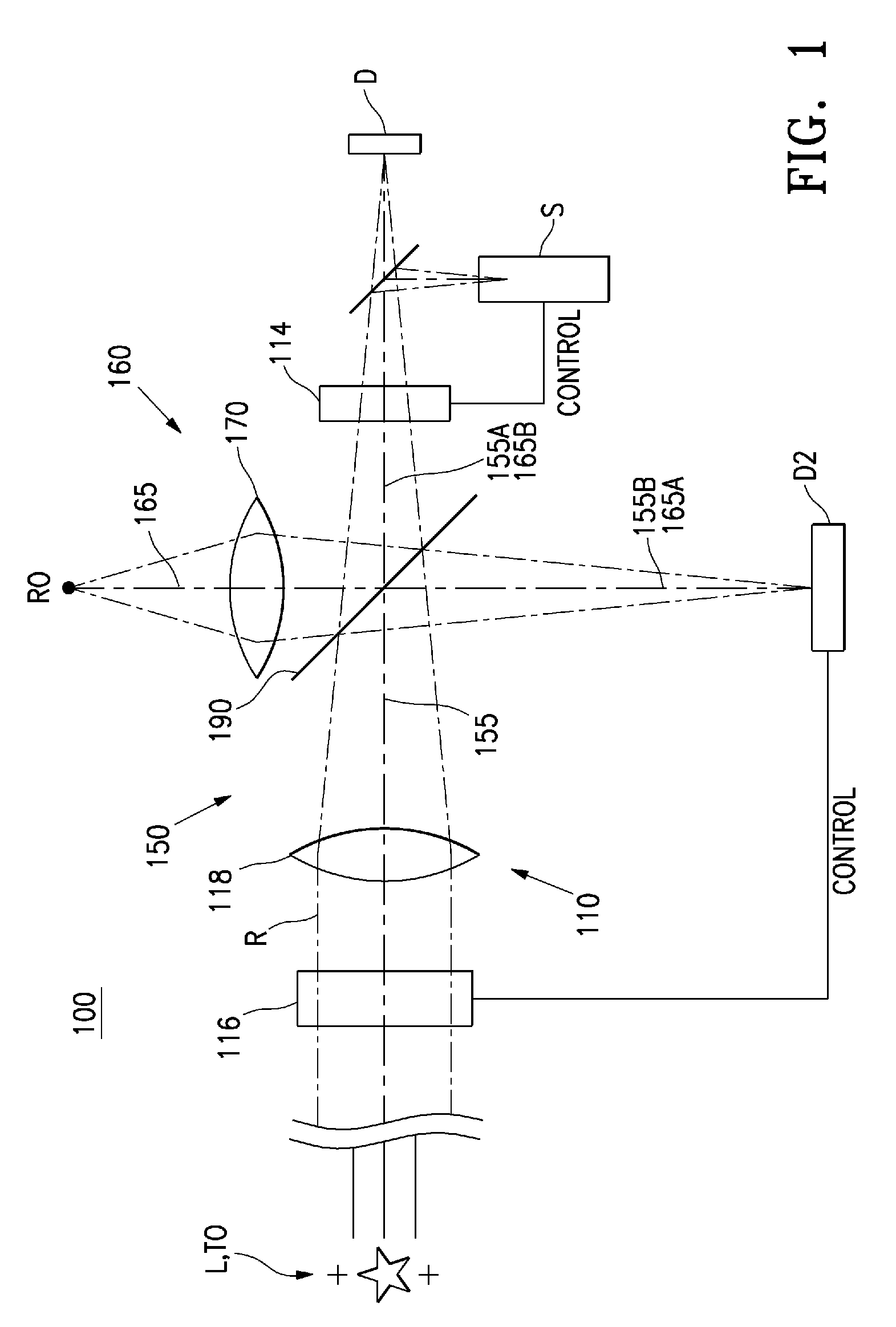

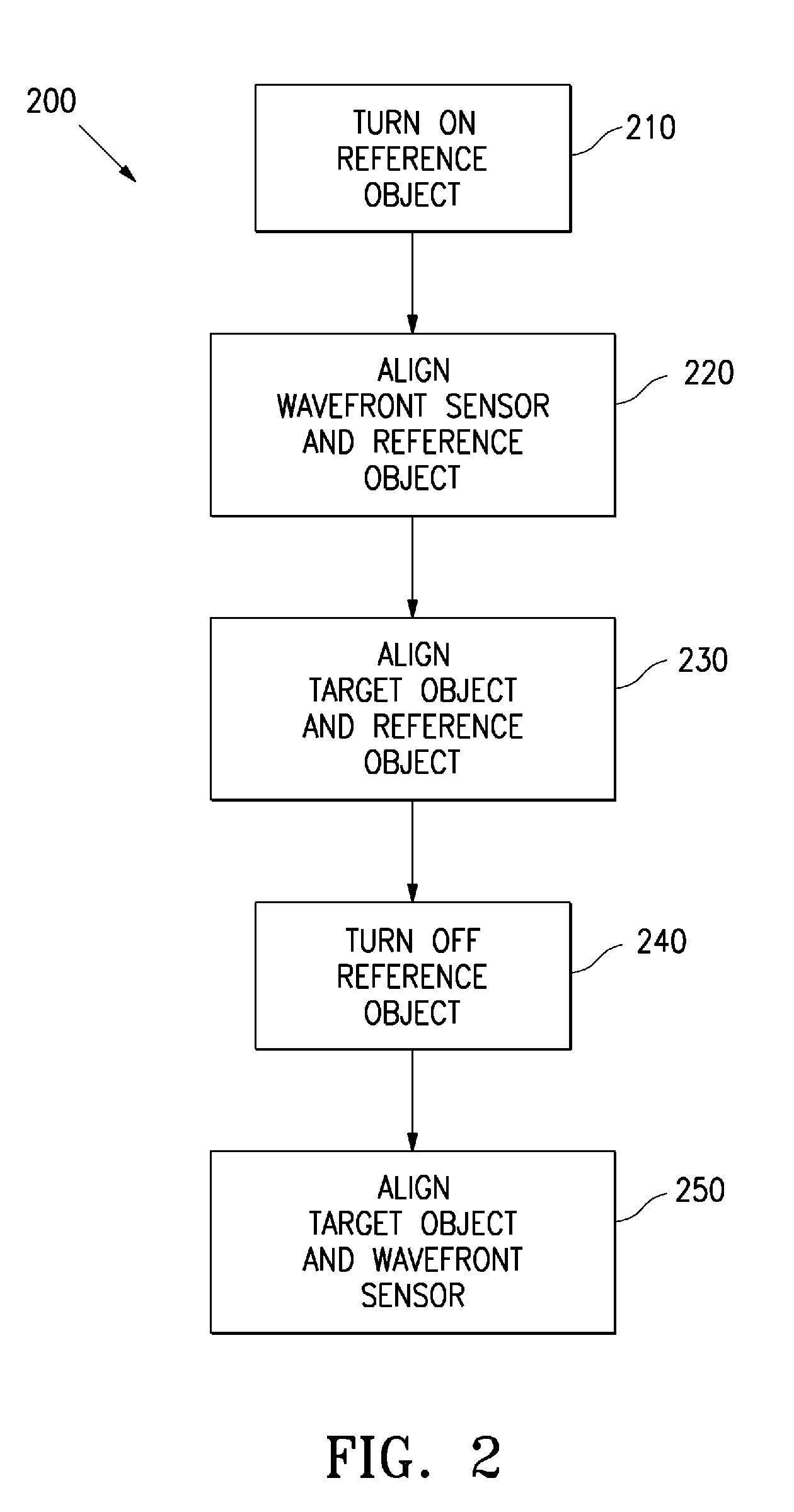

Adaptive optics imaging system with object acquisition capability

ActiveUS7289736B1Overcome limitationsAchieve alignmentLine-of-sight transmissionOptical elementsWavefront sensorSelf adaptive

An adaptive optics imaging system has an acquisition imaging subsystem to assist in initial acquisition and alignment of the system to a target object. A wavefront sensor in the adaptive optics imaging system is aligned to a reference object in the acquisition imaging subsystem. The target object is also aligned to the reference object. In this way, alignment of the target object with the wavefront sensor is achieved.

Owner:EOS DEFENSE SYST USA INC

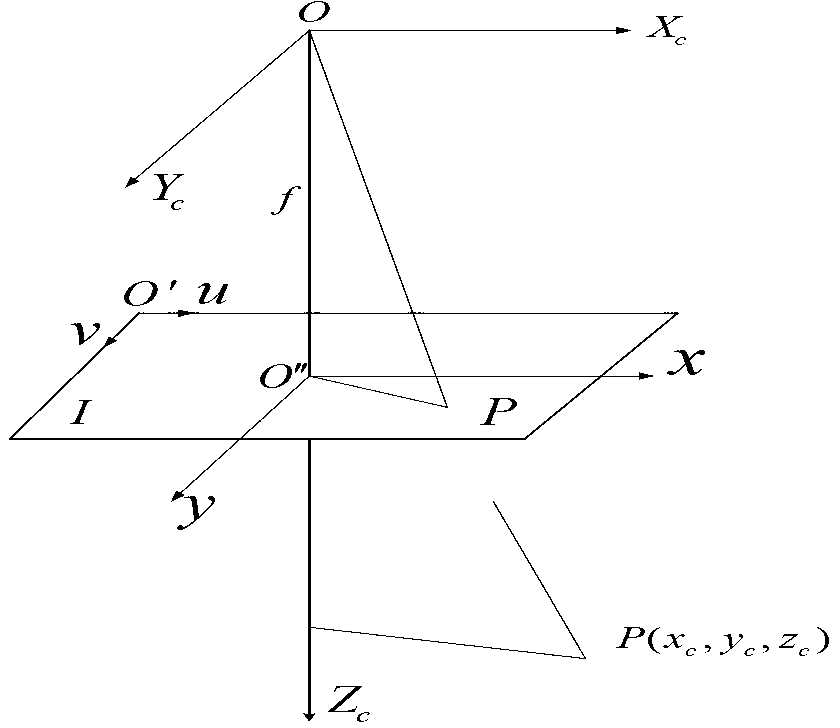

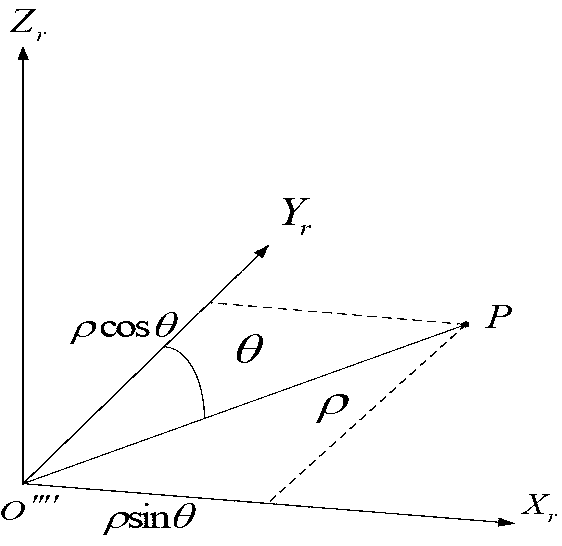

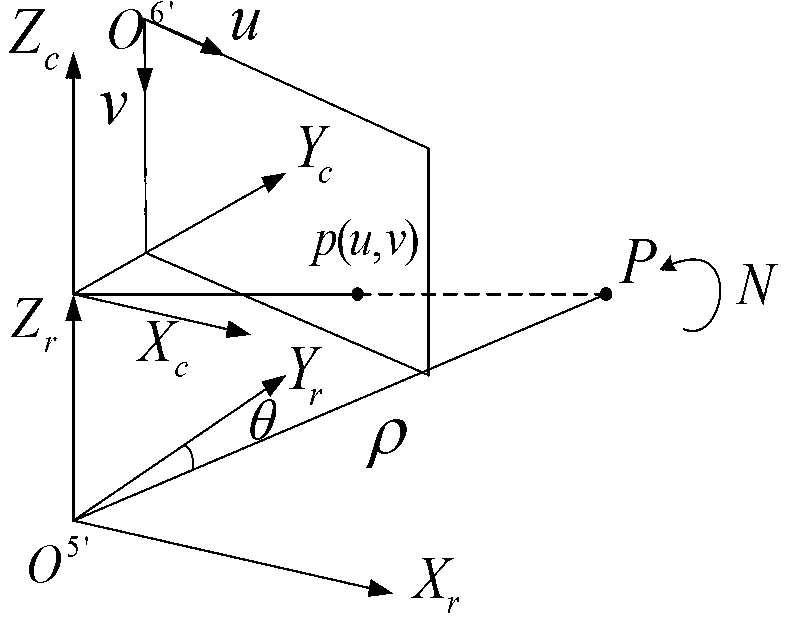

Subsection space aligning method based on homography transformational matrix

The invention discloses a subsection space aligning method based on a homography transformational matrix. According to the subsection space aligning method based on the homography transformational matrix, large marked distance is sectioned, the homography transformational matrix between a camera coordinate system and a millimeter-wave radar coordinate system of each subsection is acquired, errors caused by using a same homography transformational matrix to represent coordinate relations of two sensors in the prior art are avoided, and space aligning of target detection of the large marked distance can be achieved. Relations of different coordinate systems between the camera and the millimeter-wave radar are deduced and represented, and finally the relations of the coordinate systems between the camera and the millimeter-wave radar are represented by the homography transformational matrix N. The two sensors are used for obtaining target data and solving the homography transformational matrix N, and a camera internal parameter matrix and a rotation matrix which are composed of solving scaling factors, focal distance and the like are avoided and a camera external parameter matrix composed of translation vectors is avoided. Therefore, operation process is greatly simplified and operation time is saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

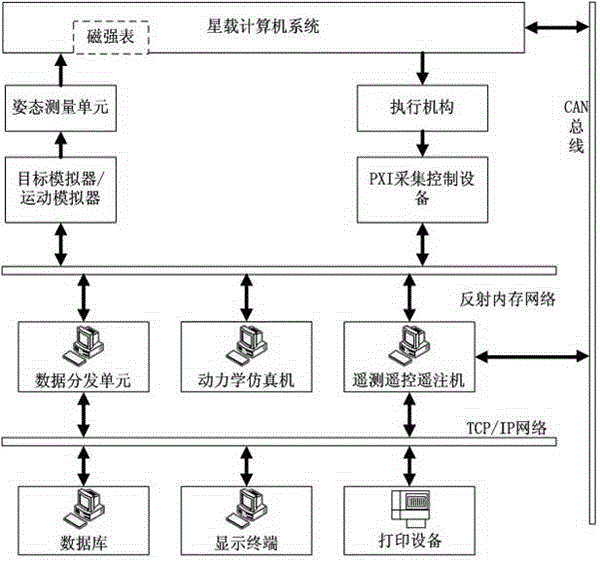

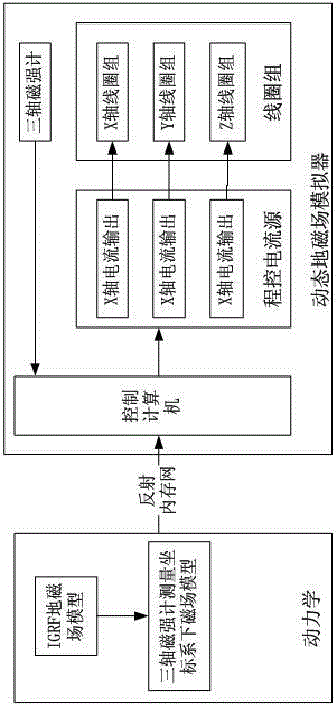

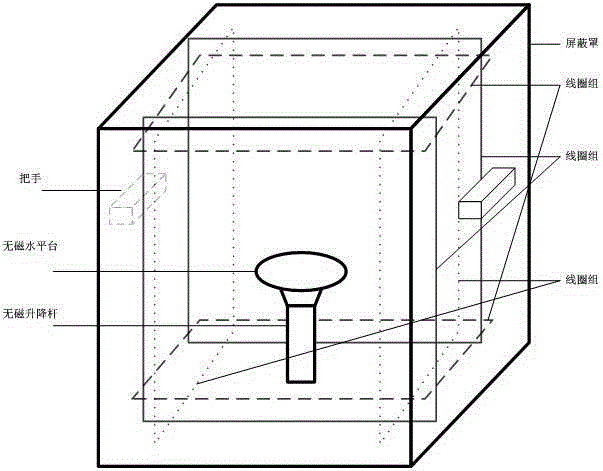

Three-axis magnetometer closed loop test system and method based on dynamic earth magnetic field simulation

ActiveCN105425764ARealize dynamic simulationEasy CalibrationElectric testing/monitoringDriving currentClosed loop simulation

The invention relates to a three-axis magnetometer closed loop test method and system based on dynamic earth magnetic field simulation. A three-axis magnetometer is placed inside an enclosed earth magnetic field simulator to shield interference of an external environment electromagnetic field and a local earth magnetic field; a high-precision IGFR earth magnetic field model is adopted, the earth magnetic field intensity of an aircraft on a track is calculated according to the track information of the aircraft, and the intensity is converted into current outputs to drive the earth magnetic field simulator to generate a corresponding magnetic field; the three-axis magnetometer measures the intensity of the magnetic field generated by the earth magnetic field simulator in real time and outputs the intensity to a spaceborne computer to assist other attitude sensors in conducting attitude and navigation solution; and magnetron currents and control instructions needed for attitudes are also calculated. In this way, closed loop control is formed. A corresponding relation between simulator drive currents and the magnetic field intensity of the simulator is calibrated through the high-precision three-axis magnetometer, and external interference is compensated by means of correction. During a closed loop simulation test process, the precision of the magnetic field generated by the simulator is increased by means of real-time monitoring and dynamic closed loop correction.

Owner:SHANGHAI XINYUE METER FACTORY

Precise delay alignment between amplitude and phase/frequency modulation paths in a digital polar transmitter

ActiveUS7817747B2Achieve alignmentHigh phase modulation accuracy requirementSimultaneous amplitude and angle modulationSynchronisation receiversNanosecondAudio power amplifier

A novel apparatus for and method of delay alignment between amplitude and phase / frequency modulation paths in a digital polar transmitter. The invention provides a fully digital delay alignment mechanism where better than nanosecond alignment is achieved by accounting for processing delays in the digital circuit modules of the transmitter and by the use of programmable delay elements spread across several clock domains. Tapped delay lines compensate for propagation and settling delays in analog elements such as the DCO, dividers, quad switch, buffers, level shifters and digital pre-power amplifier (DPA). A signal correlative mechanism is provided whereby data from the amplitude and phase / frequency modulation paths to be matched is first interpolated and then cross-correlated to achieve accuracy better than the clock domain of comparison. Within the ADPLL portion of the transmitter, precise alignment of reference and direct point injection points in the ADPLL is provded using multiple clock domains, tapped delay lines and clock adjustment circuits.

Owner:TEXAS INSTR INC

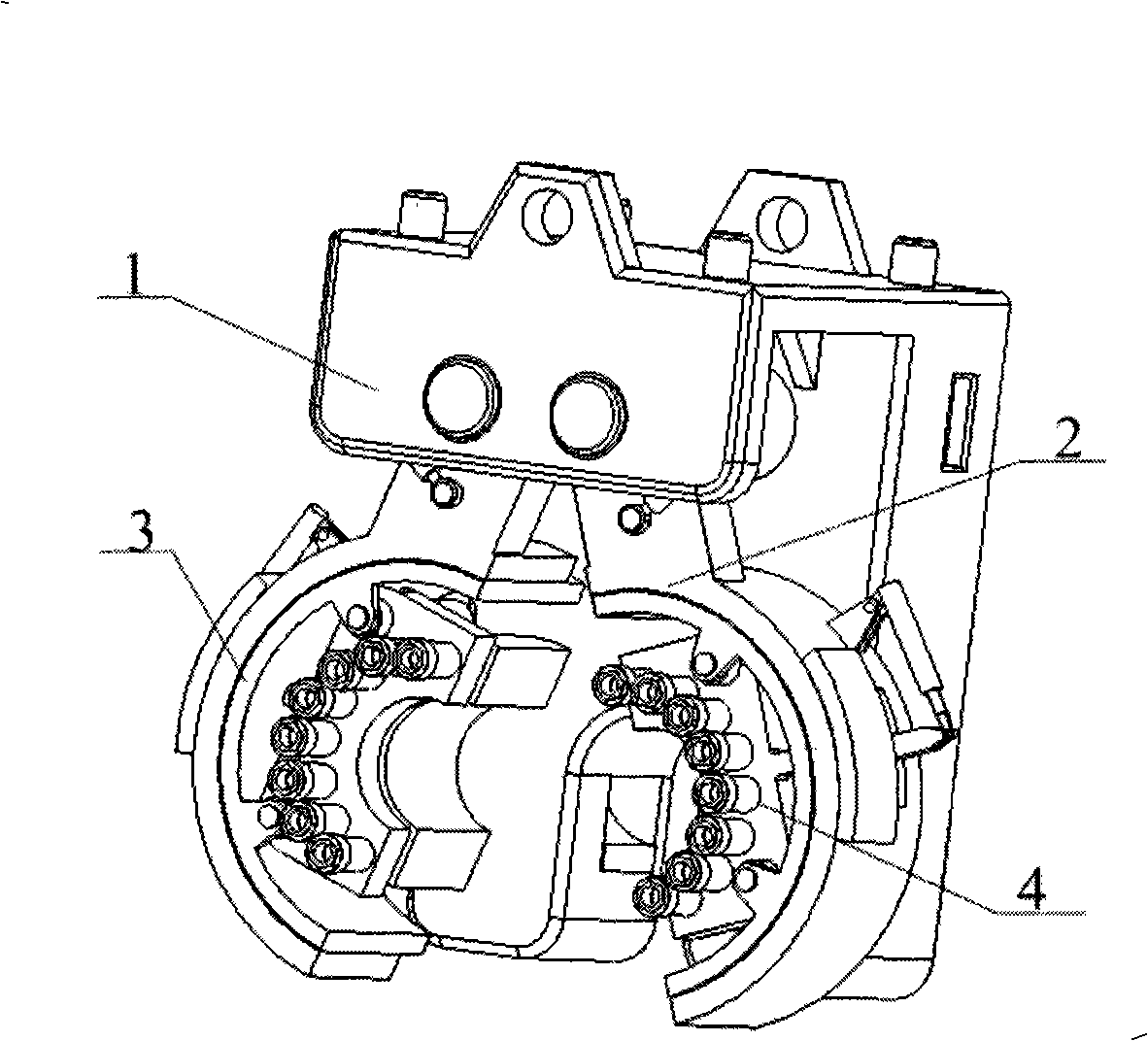

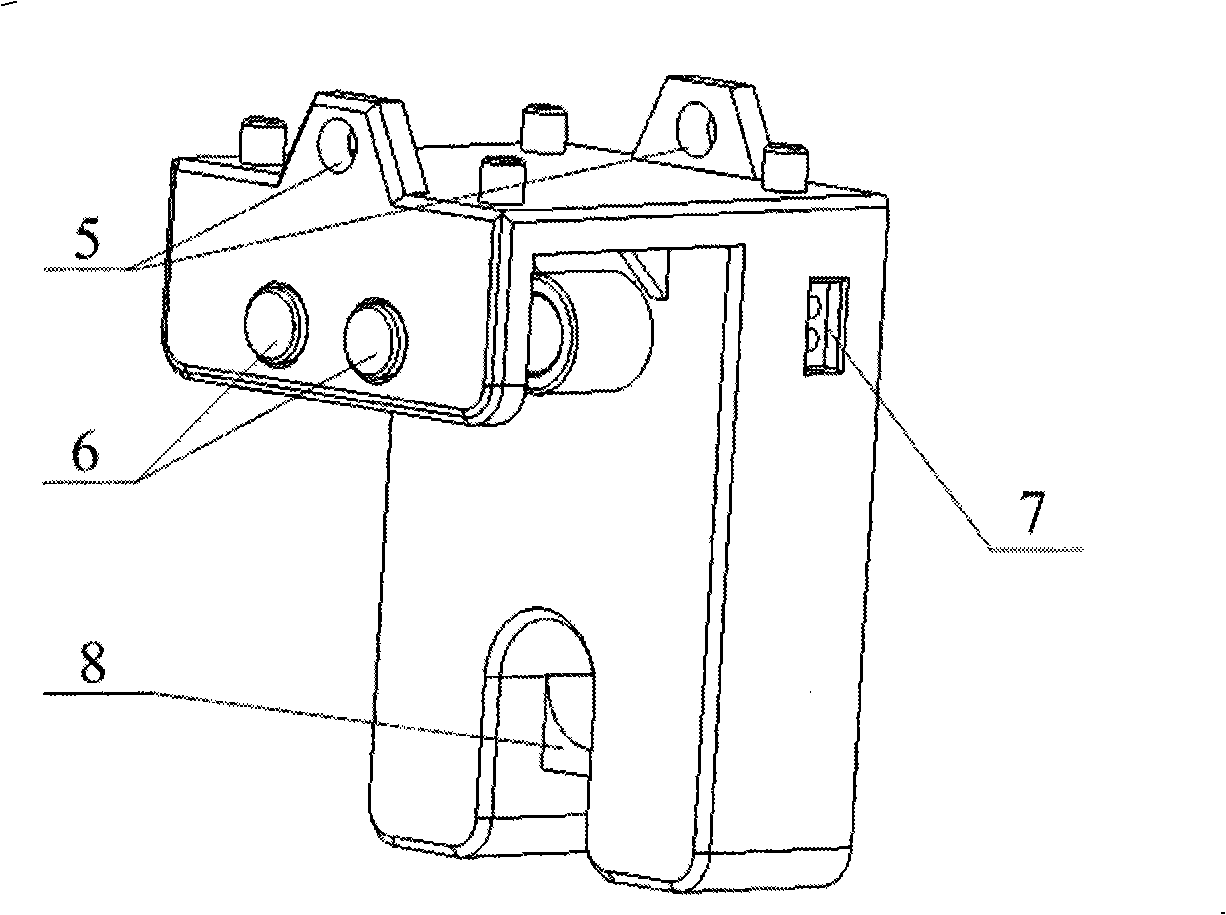

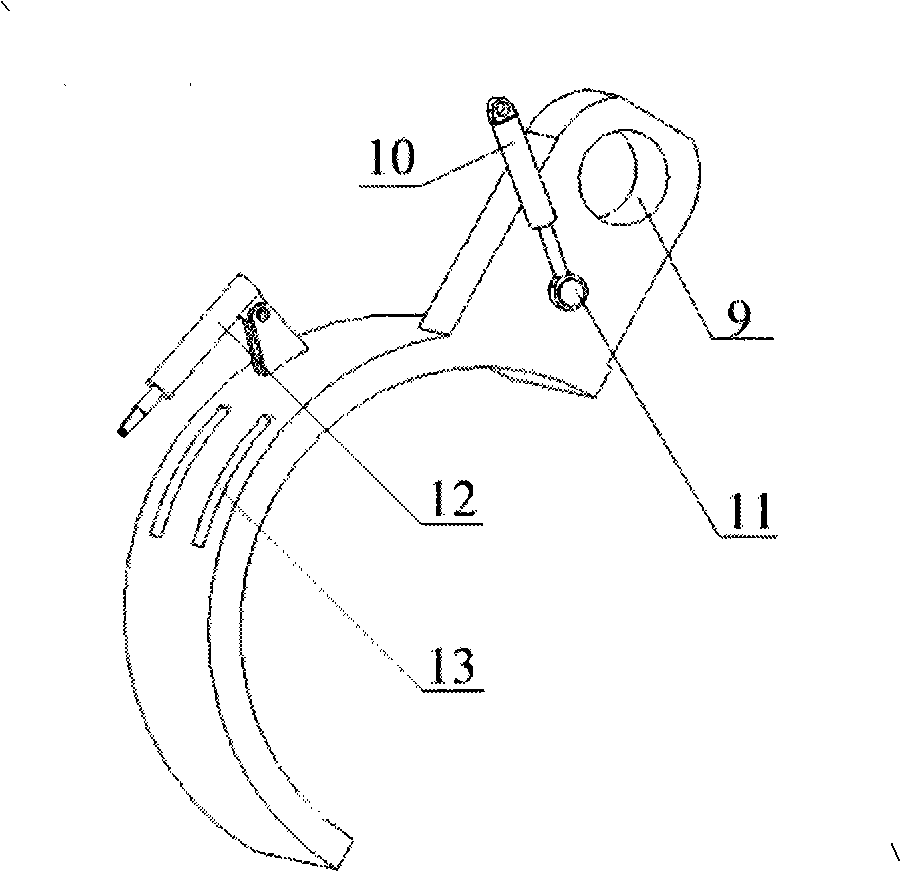

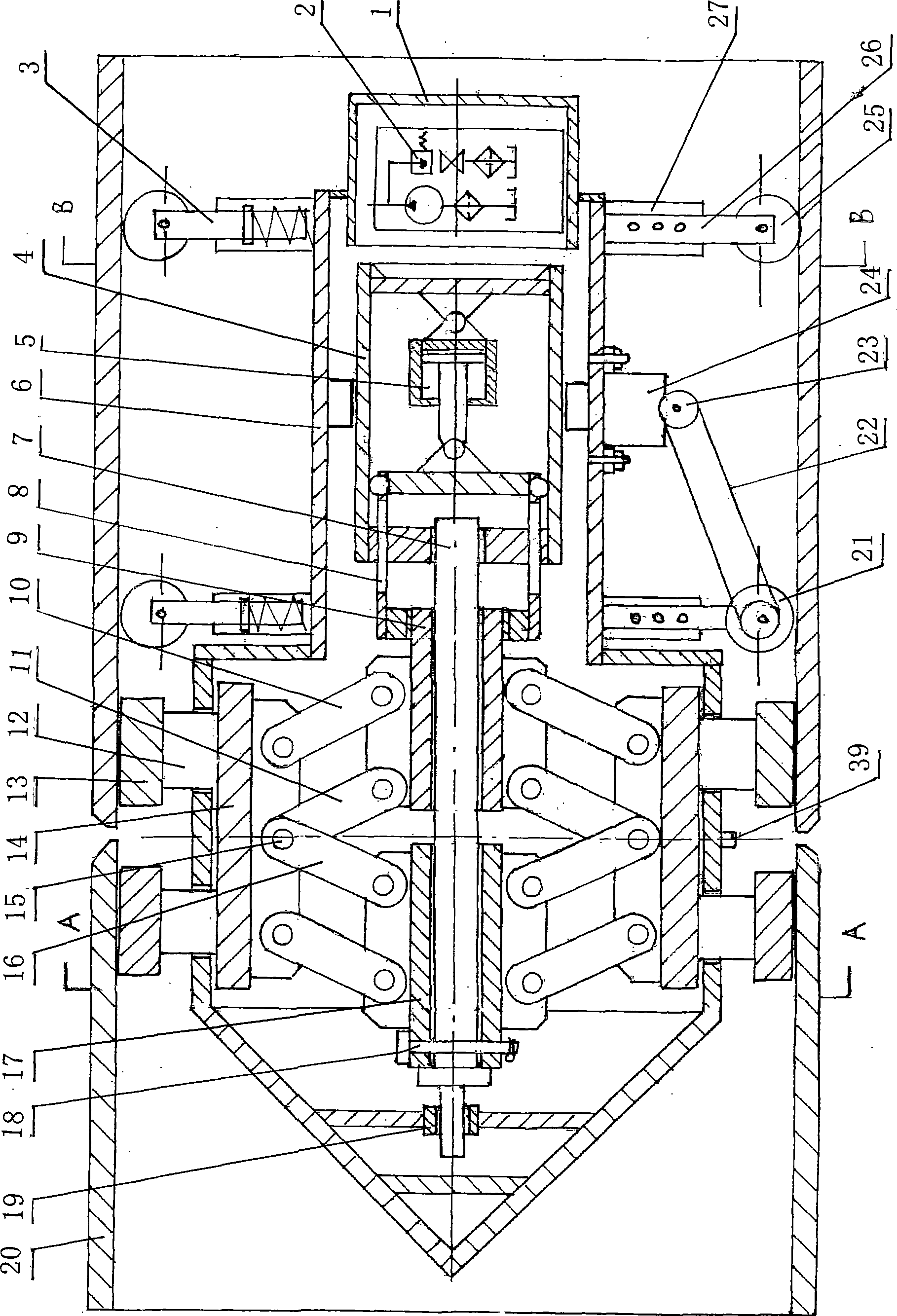

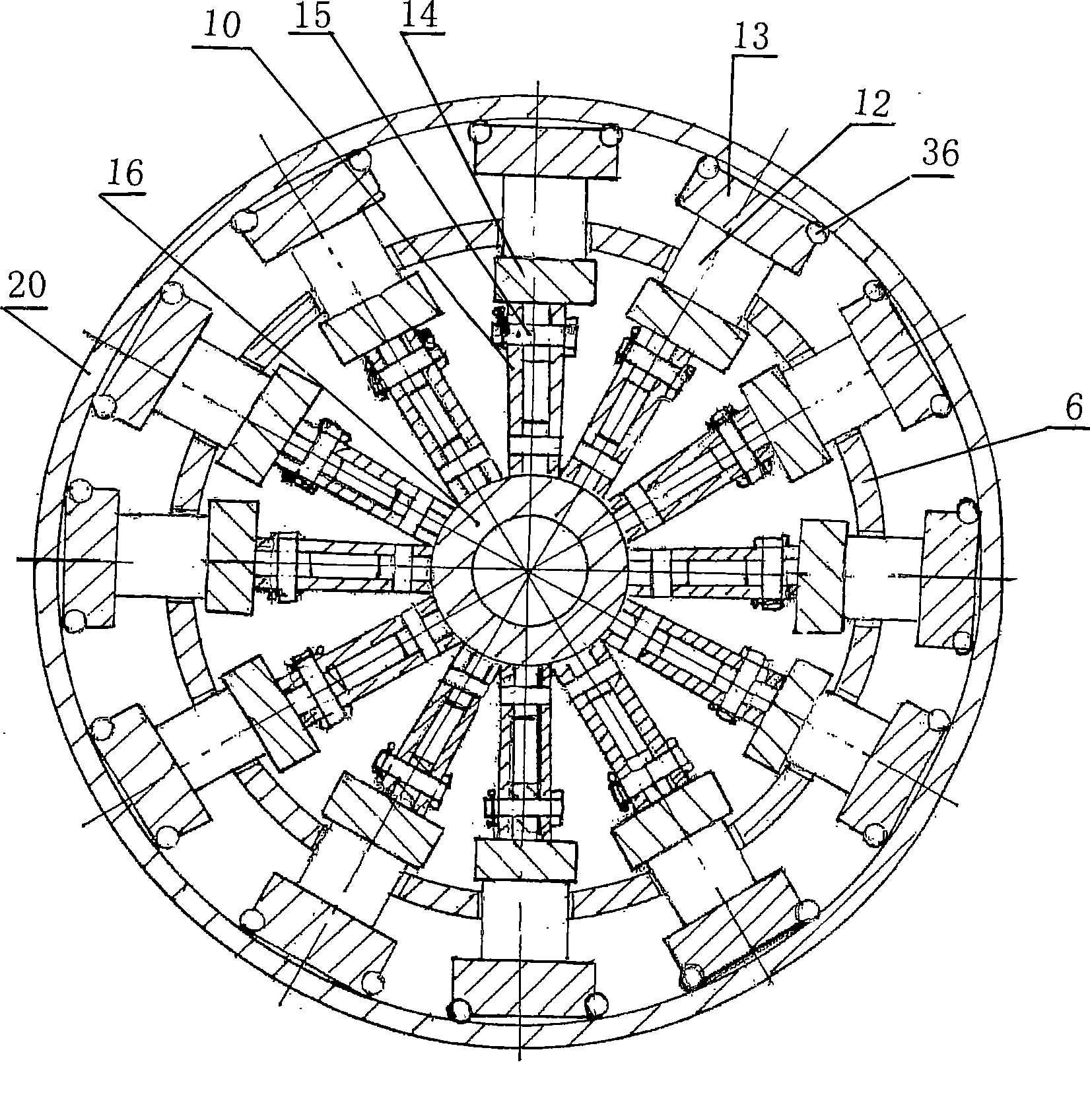

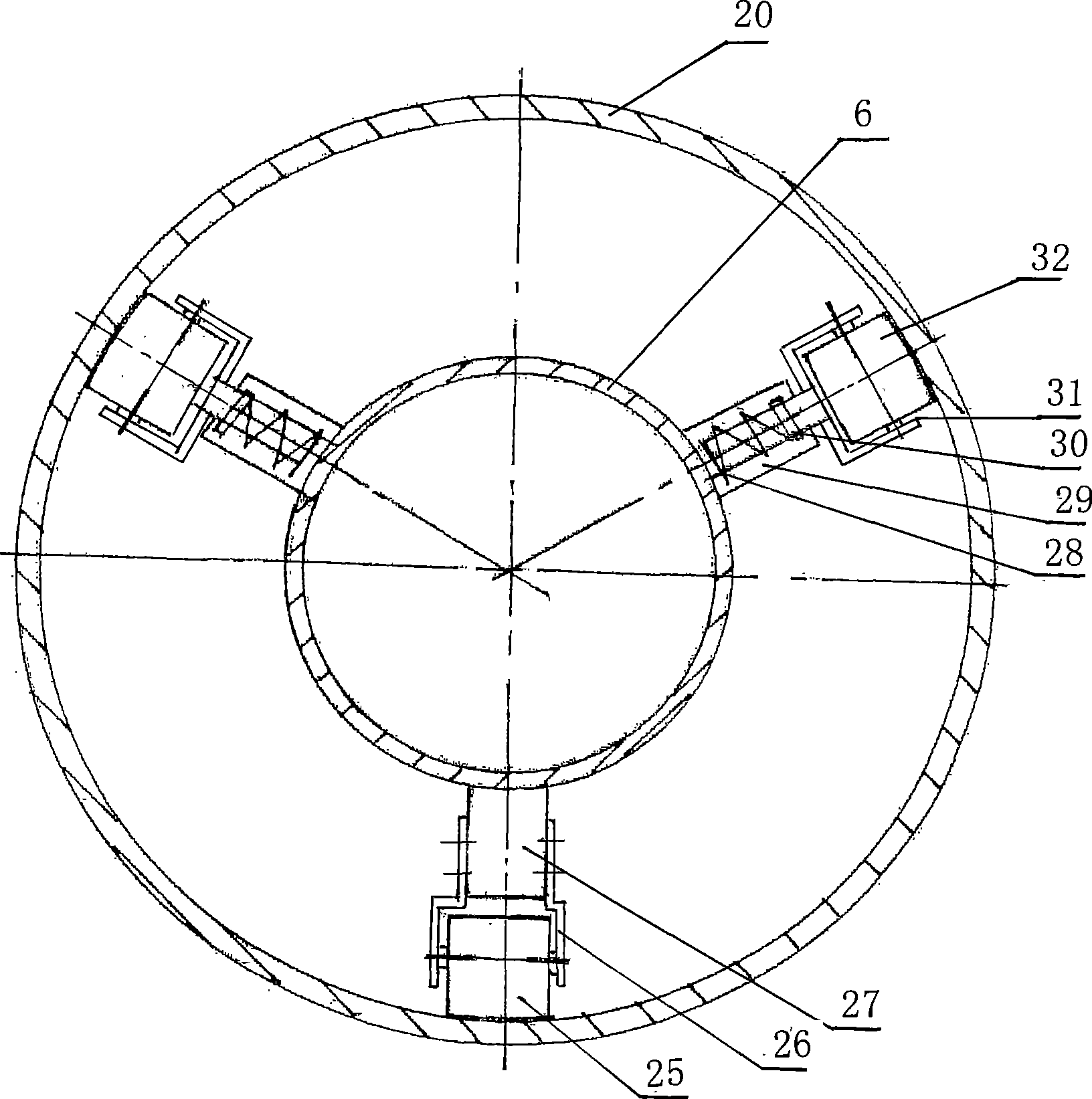

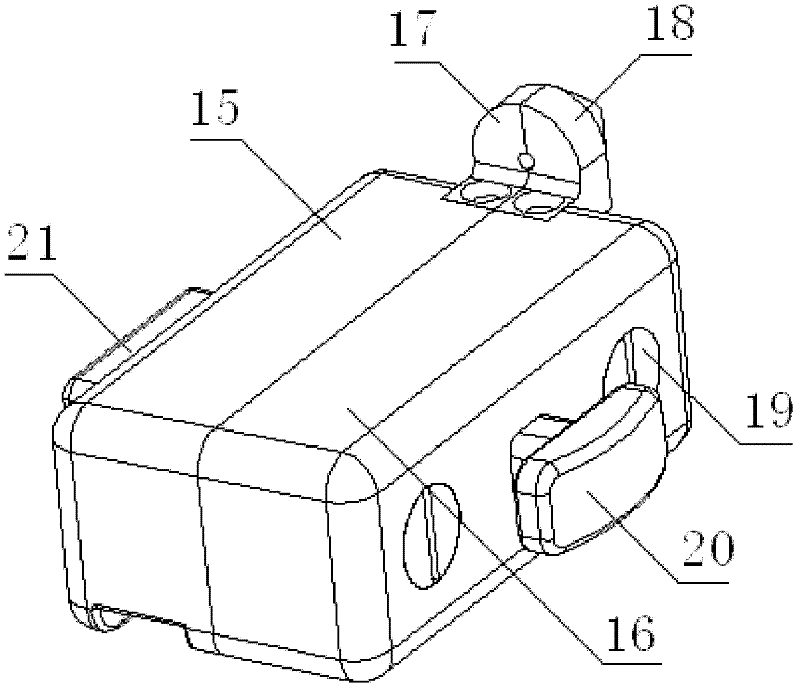

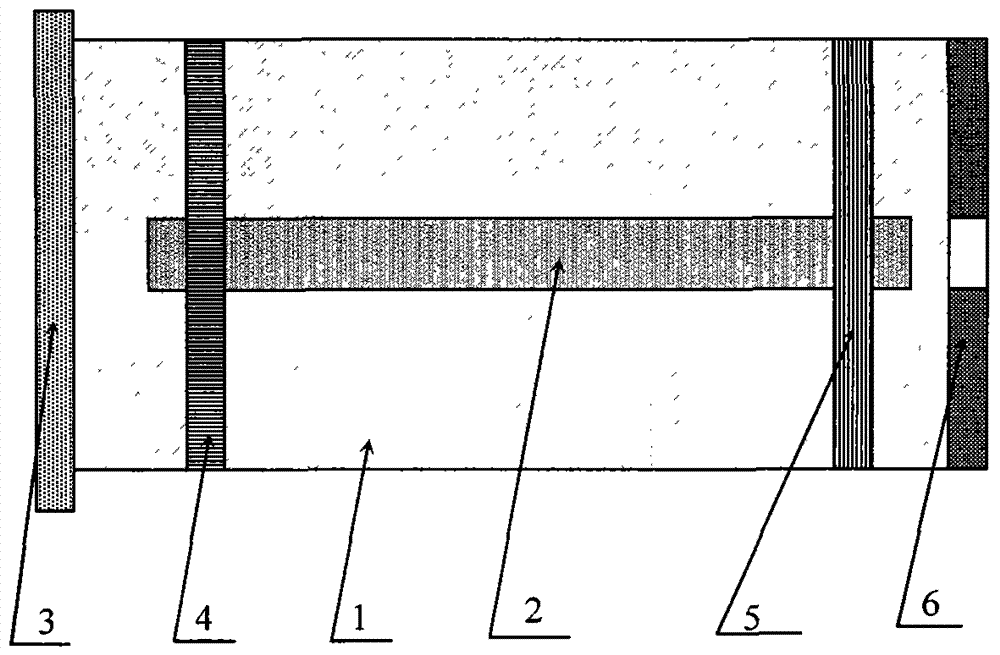

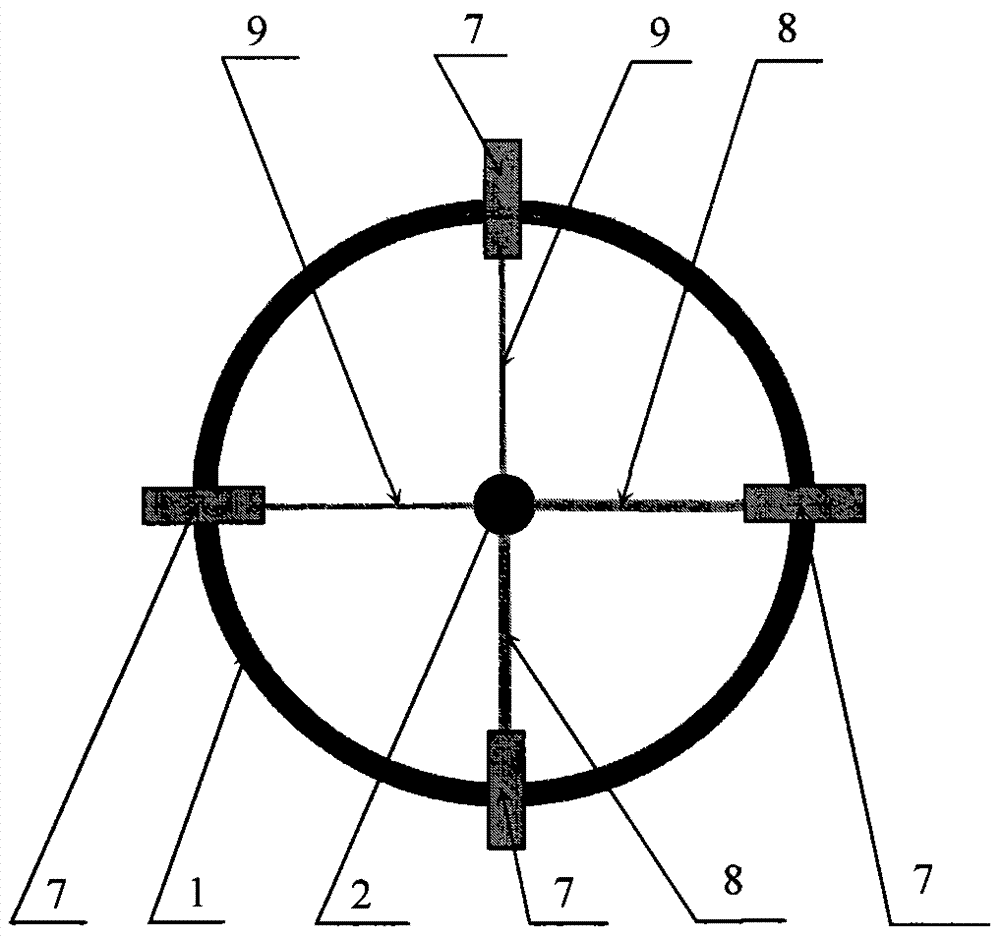

Deep water flange automatic connection nut aligning and screwing device

ActiveCN101260951ASimple structureImprove reliabilityPipe laying and repairFlanged jointsHydraulic cylinderEngineering

The invention provides a device for aligning and screwing nuts used for automatic connection of deepwater flanges. The device consists of a support (1), an opener (2), an orifice regulator (3) and a spanner seat (4), the opener (2) is arranged on the support (1) through an opening positioning shaft (6), the inside of a baffle of the front of the support is provided with two hydraulic cylinders which are used for driving the opener (2), the orifice regulator (3) is arranged on the inside of the opener (2), the orifice regulator is provided with a deflector rod (15), the opener (2) is provided with an orifice regulating hydraulic cylinder (12) matched with the deflection rod (15), the spanner seat (4) is arranged on the orifice regulator (3) through a shaft serving as a lead rail, the orifice regulator (3) is provided with a feeding hydraulic cylinder (17). The device has the advantages of simple structure and high reliability; moreover, the device is suitable for automatic connection of pipe flanges at a depth 3000 meters under water.

Owner:CHINA NAT OFFSHORE OIL CORP +2

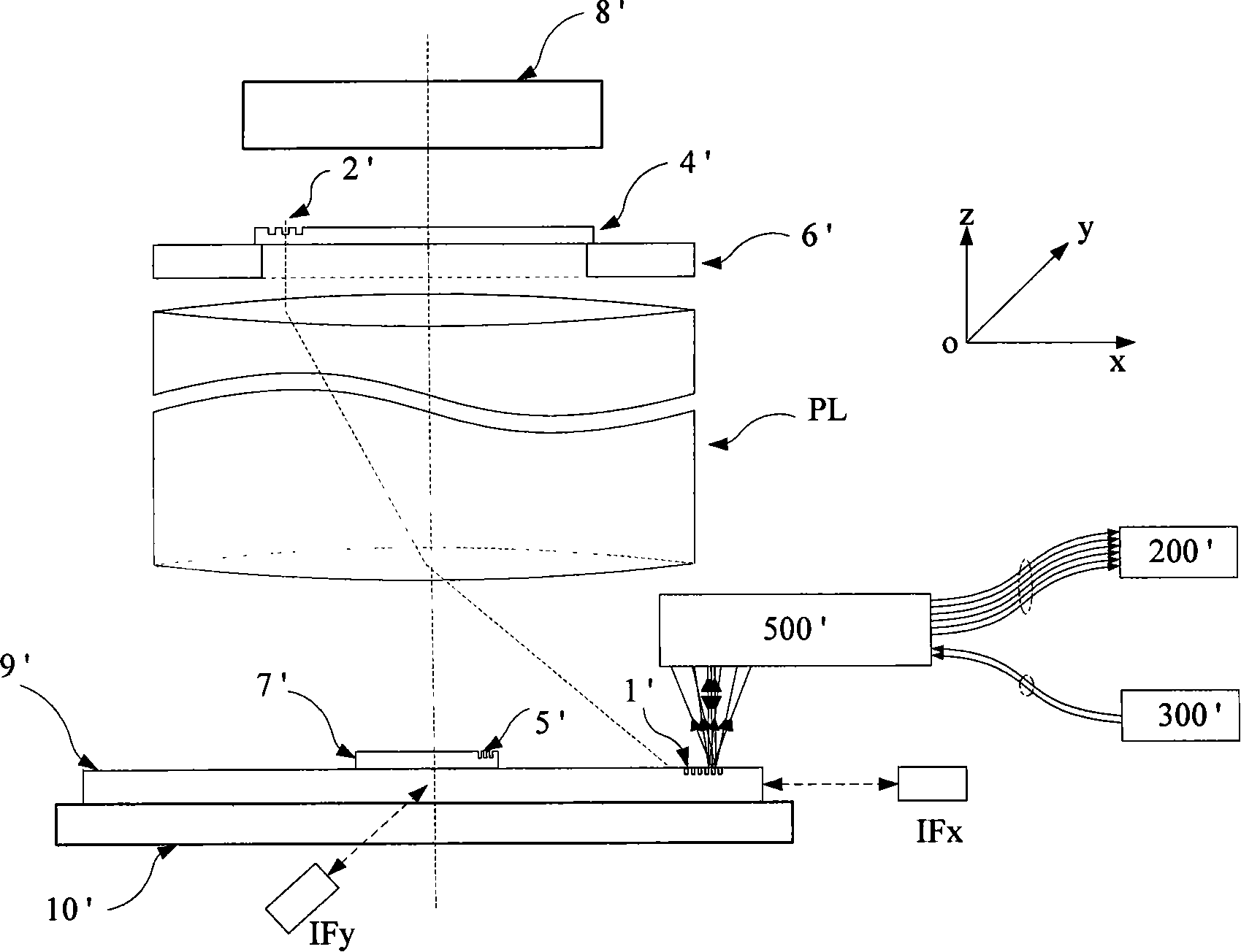

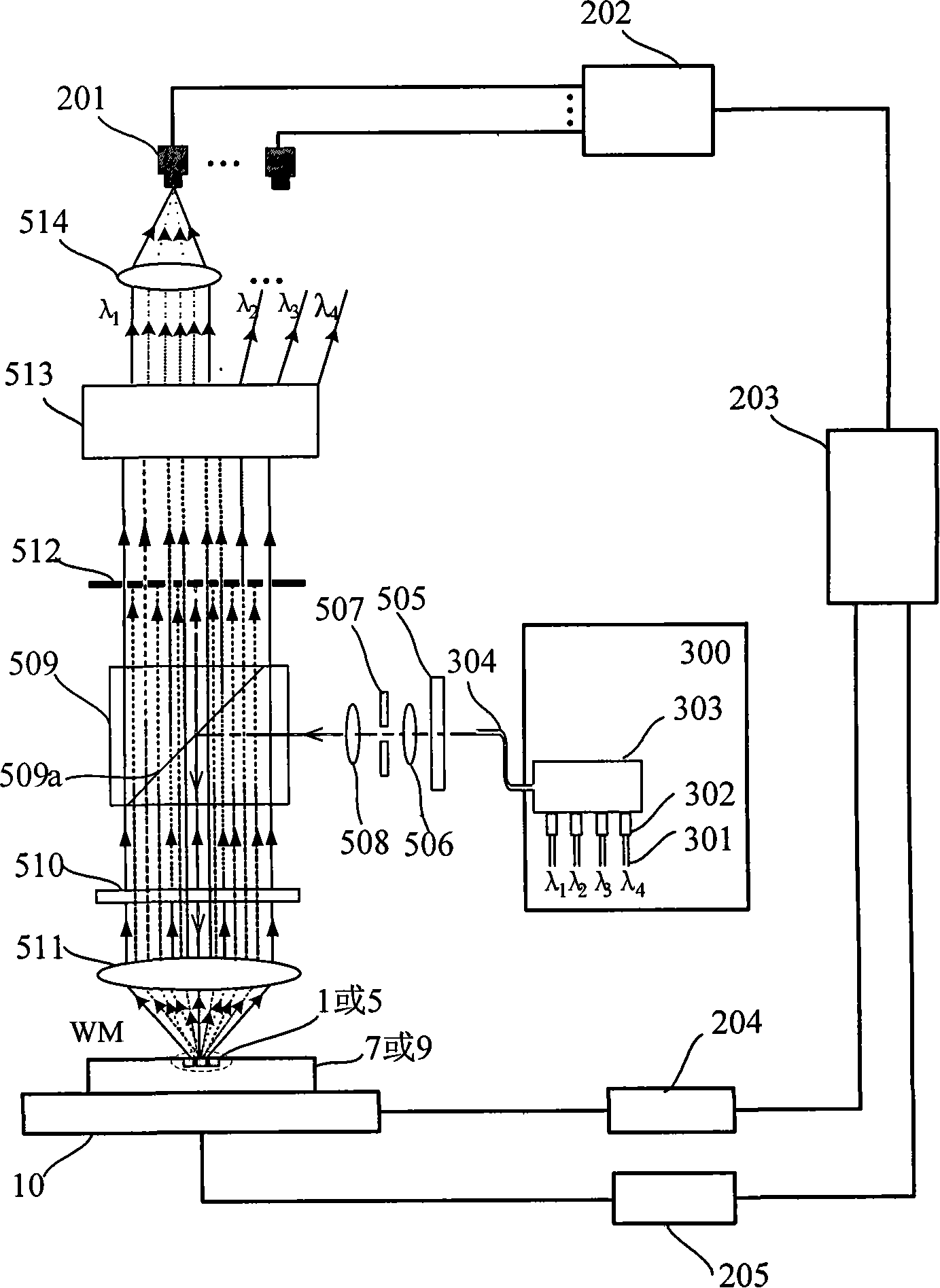

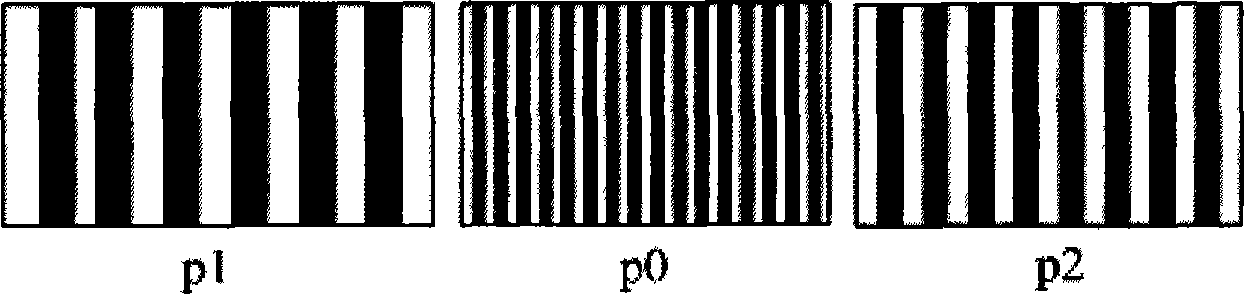

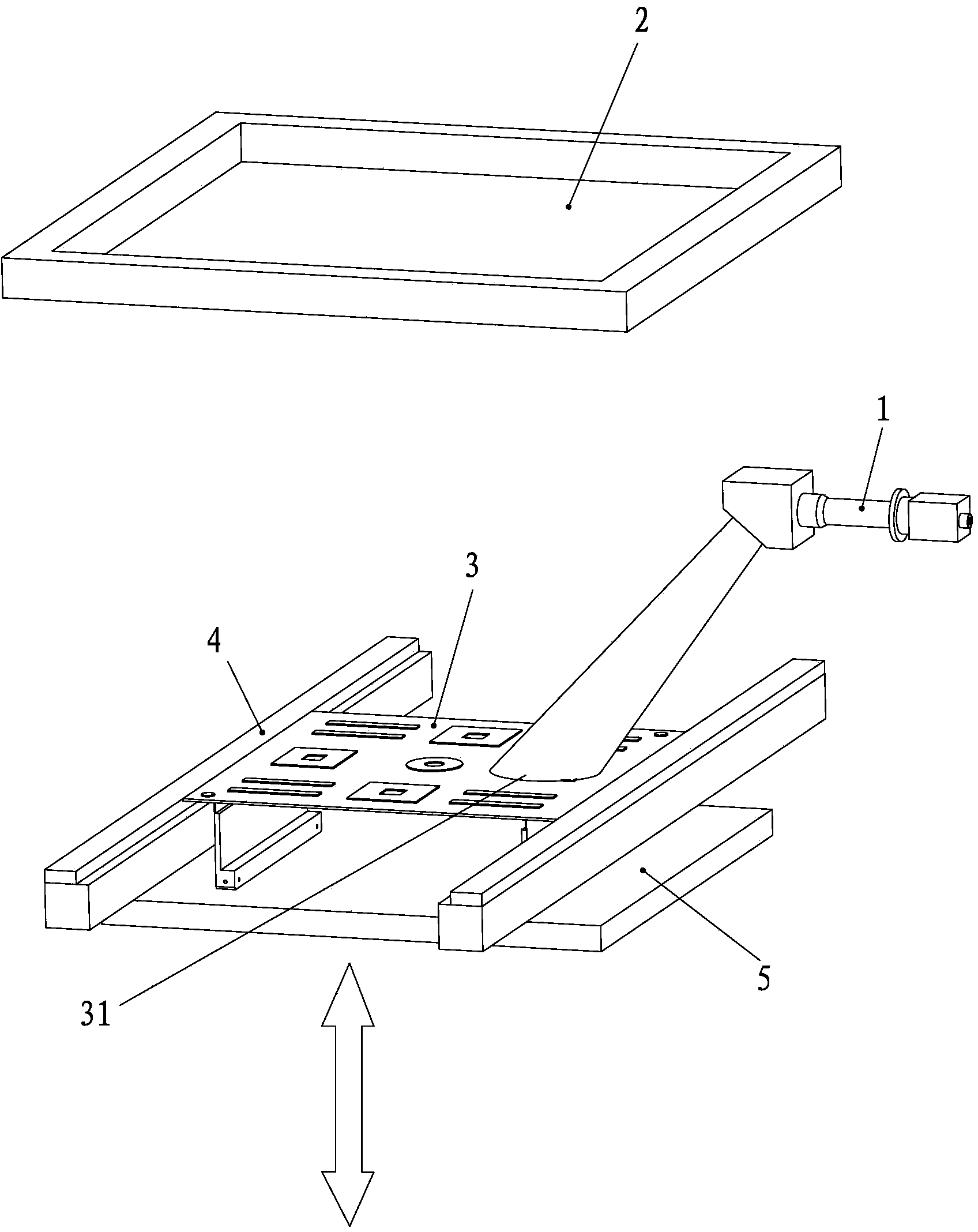

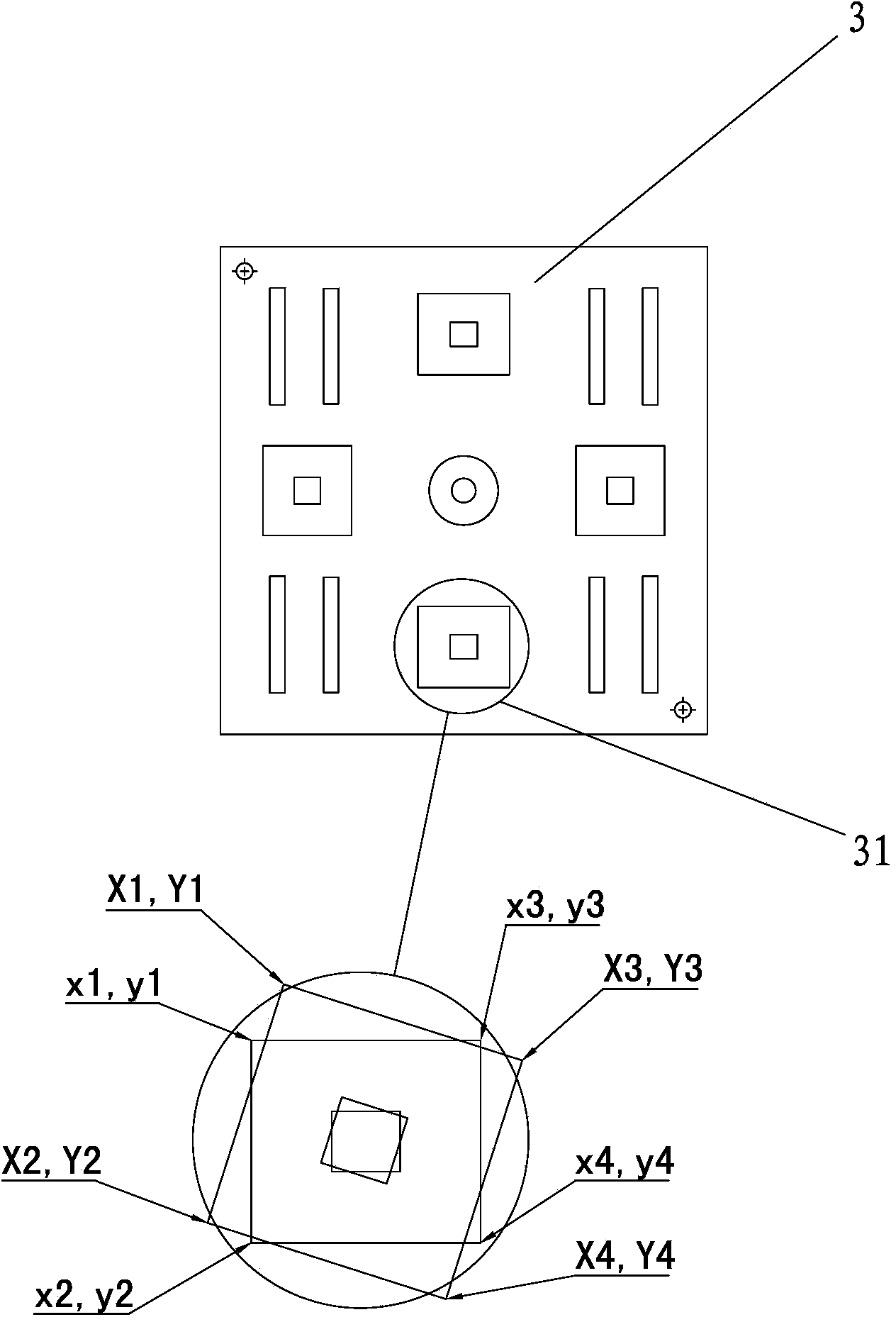

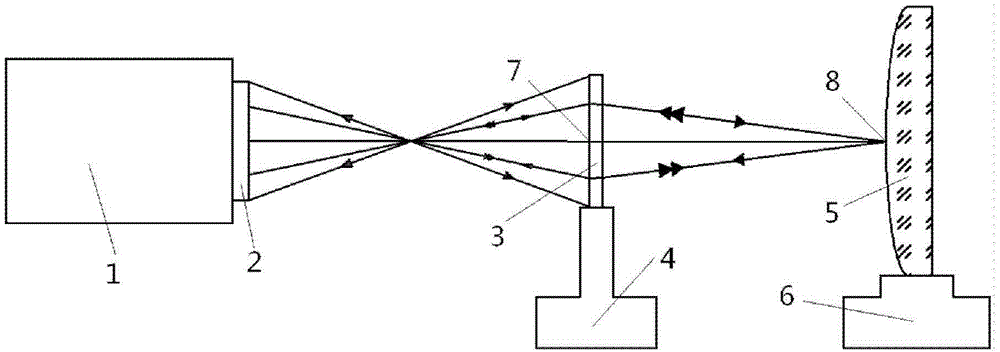

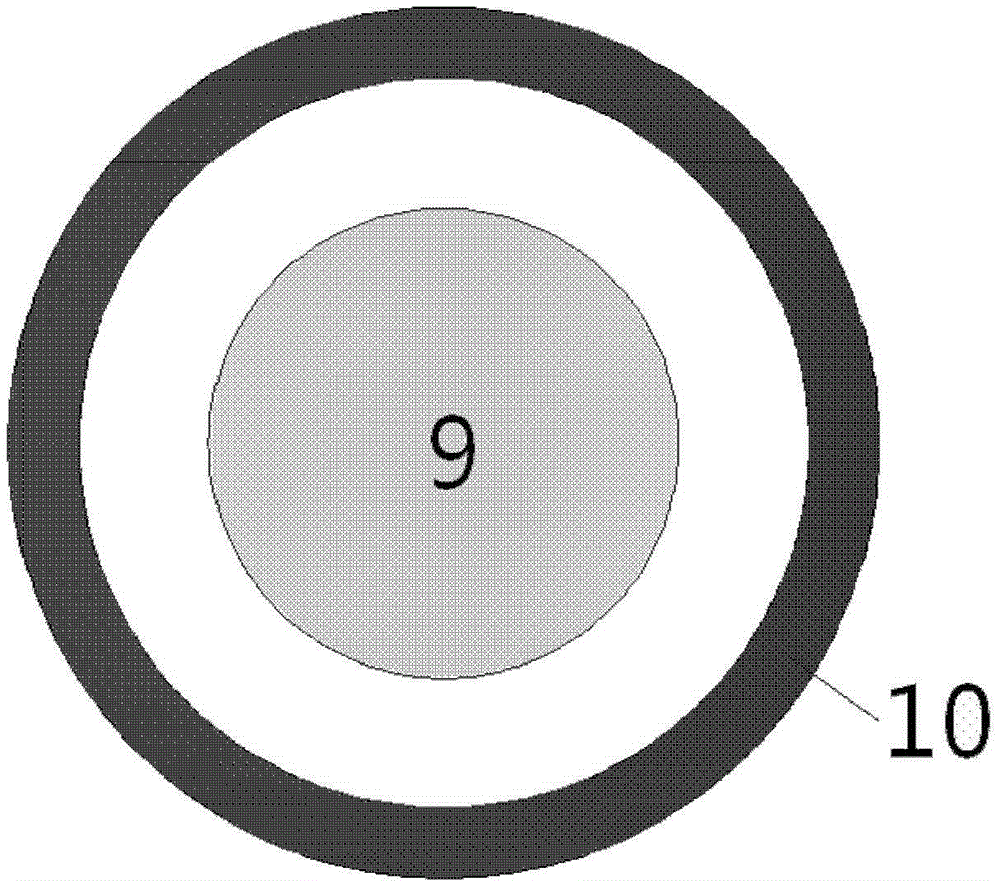

Lithographic equipment aligning system based on machine vision and alignment method

ActiveCN101241313AAchieve alignmentImprove alignment accuracyTelevision system detailsCladded optical fibreImaging processingMachine vision

The invention provides a photoeching device alignment system and a method thereof based on machine vision by using grids with different periods as alignment marks. +-1 level diffracted light dark field images are obtained by an optical lighting system and an imaging system. The images are gathered by a CCD camera and an image gathering card, and image signal processing and alignment operation are performed by an image processing module to obtain an accurate alignment position finally and alignment between the wafer and the base stage is implemented. The whole system is simpler by combining Image processing with alignment marked grid phase information in a precondition of obtaining a rather high alignment precision.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Hydraulic pipeline inner butt-jointing device

InactiveCN101480770ABig top thrustSimple structureWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderPower station

The invention relates to a hydraulic type aligning device inside a pipeline, which is used for the welding construction of a long-distance oil and gas transporting pipeline and mainly comprises a shell, a hydraulic power station, a sliding mechanism, an expanding mechanism, a running mechanism and a straightening mechanism. Furthermore, the hydraulic type aligning device inside a pipeline is characterized in that a jacket of a hydraulic station is internally fixed with the hydraulic power station, a jacket of a liquid tank is internally provided with a hydraulic cylinder, a main shaft is sleeved with a rear sliding sleeve and a front sliding sleeve, and the other end of a traction frame is fixed to the end part of the rear sliding sleeve. Furthermore, the rear sliding sleeve is driven by the hydraulic cylinder to reciprocate on the main shaft, each sliding sleeve adopts an articulated axle fixed with two main top plates and a parallel top plate, an isoceles triangle is formed by the two main top plates, and the parallel top plate is fixed with two support pillars and a jacking. The invention can realize pipe opening alignment, stable and reliable positioning, large pushing force and pipe opening shaping, and can slightly adjust the lifting height and enhance the centric precision of fitted up pipe openings. In addition, the invention has light weight, low price and simple structure.

Owner:冯岩

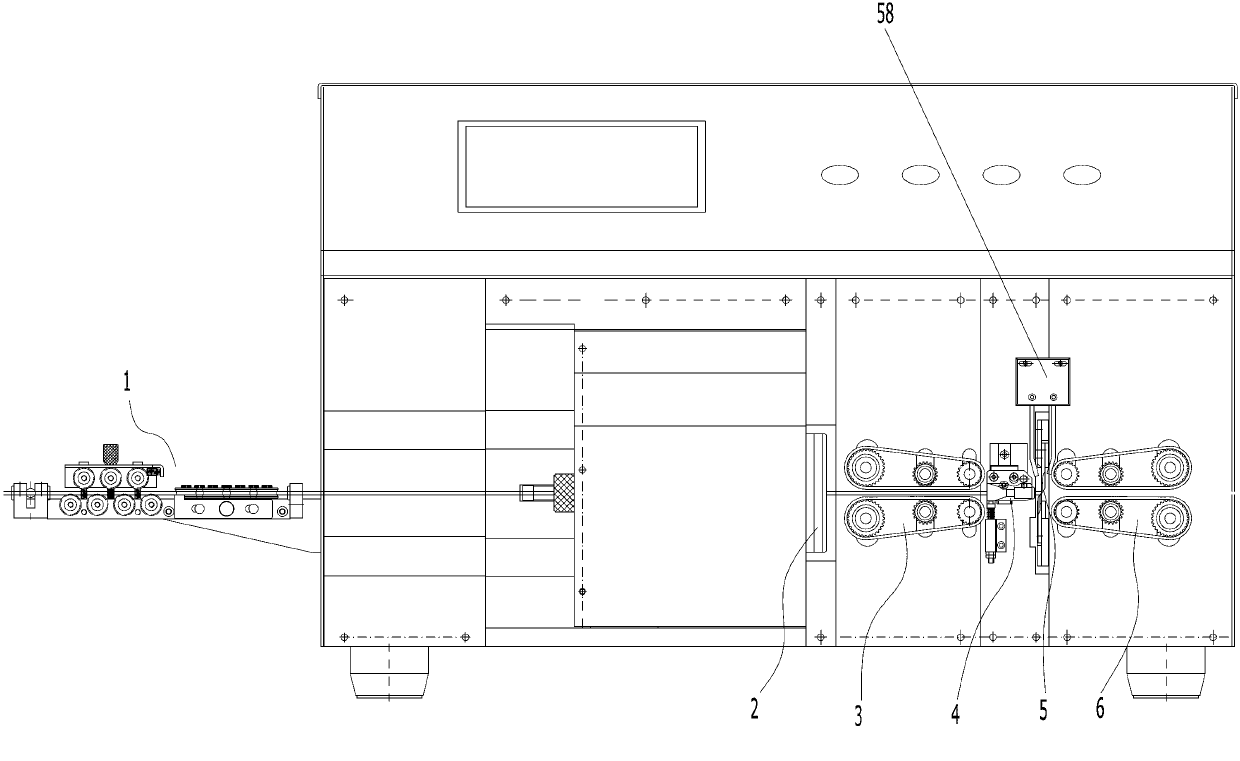

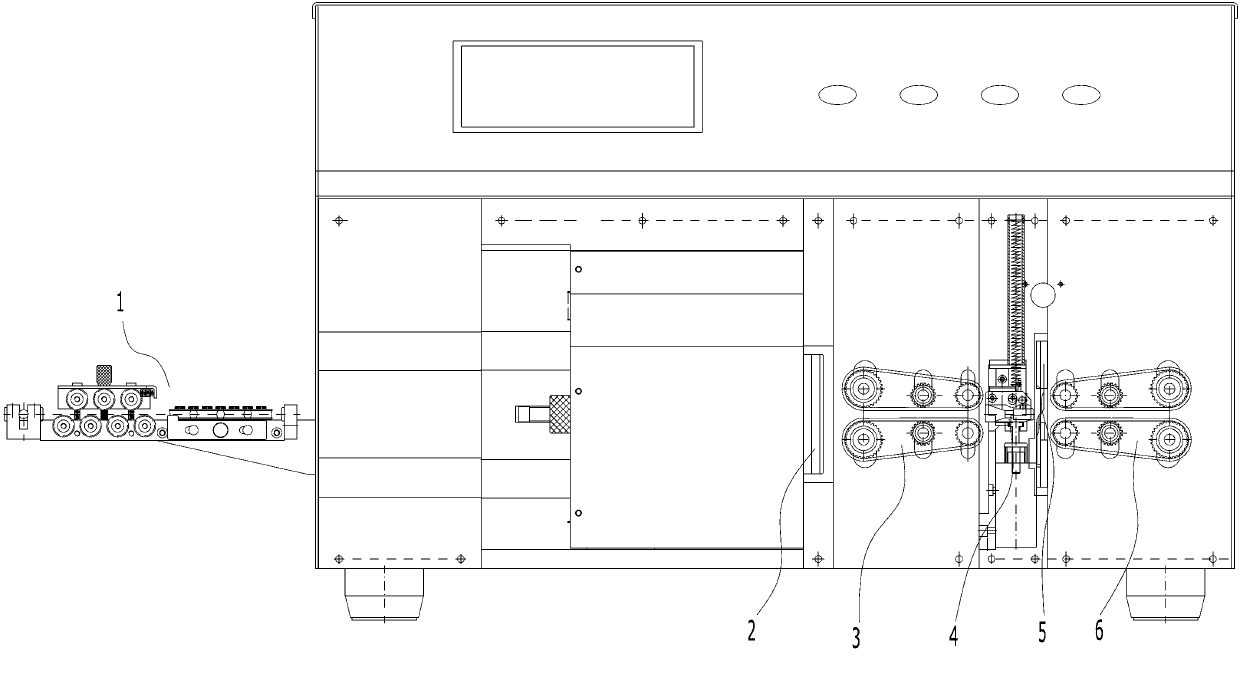

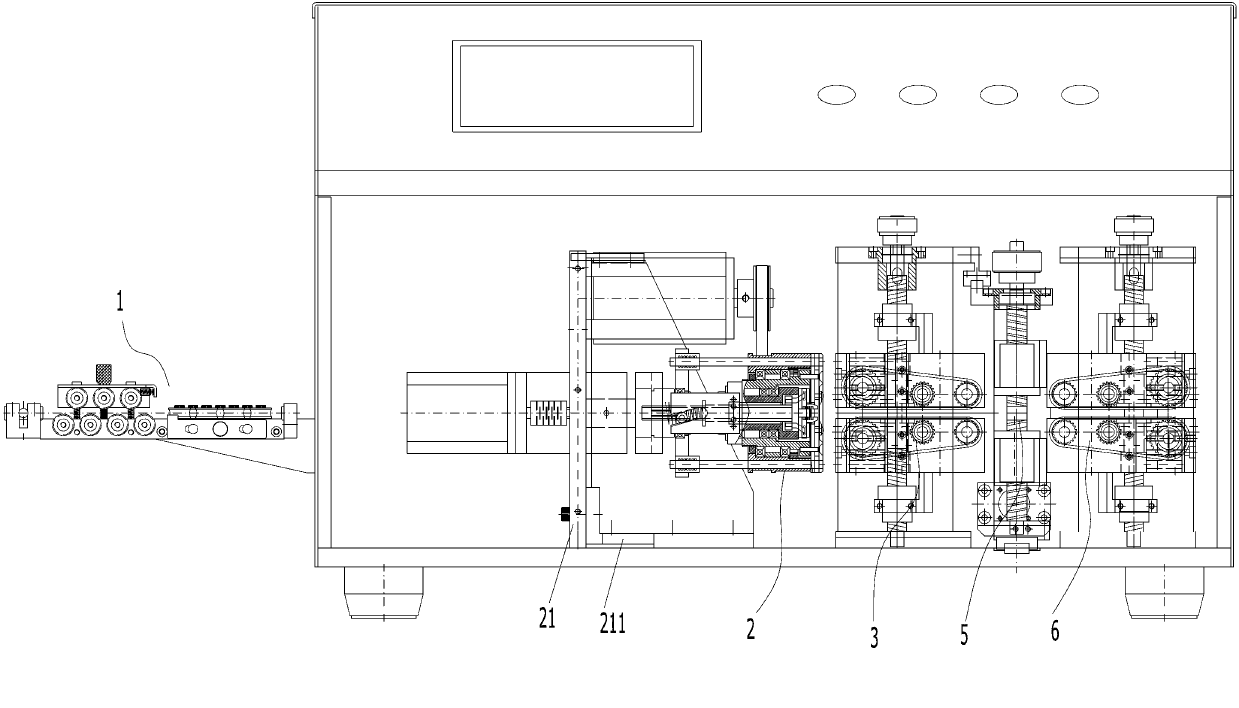

Full-automatic coaxial wire stripping machine

ActiveCN103280743ARealize wire feedingAchieve alignmentApparatus for removing/armouring cablesElectric machineryCoaxial line

The invention relates to the technical field of a wire stripping machine, in particular to a full-automatic coaxial wire stripping machine. The full-automatic coaxial wire stripping machine comprises a case body, wherein a control unit is arranged in the case body; and a feeding alignment unit, a rotary-cut unit, a first wire feeding stripping unit, an automatic demising mechanism, a cutting and stripping unit and a second wire feeding stripping unit are sequentially arranged on the case body in a coaxial wire moving direction. The full-automatic coaxial wire stripping machine has functions of alignment, cutting off wires and both-end peeling. According to parameters including diameters of coaxial wires, thickness of each layer, set lengths of wire sections, stripping length of each layer and the like, the work of wire feeding, alignment, rotary cut, cutting off and both-end peeling can be automatically and quickly realized, and the wire stripping speed can be controlled according to the operation speed of each drive motor, so that the degree of automation of the full-automatic coaxial wire stripping machine can be greatly improved, and production efficiency can be greatly improved.

Owner:DONGGUAN WINGUD MECHANICAL EQUIP CO LTD

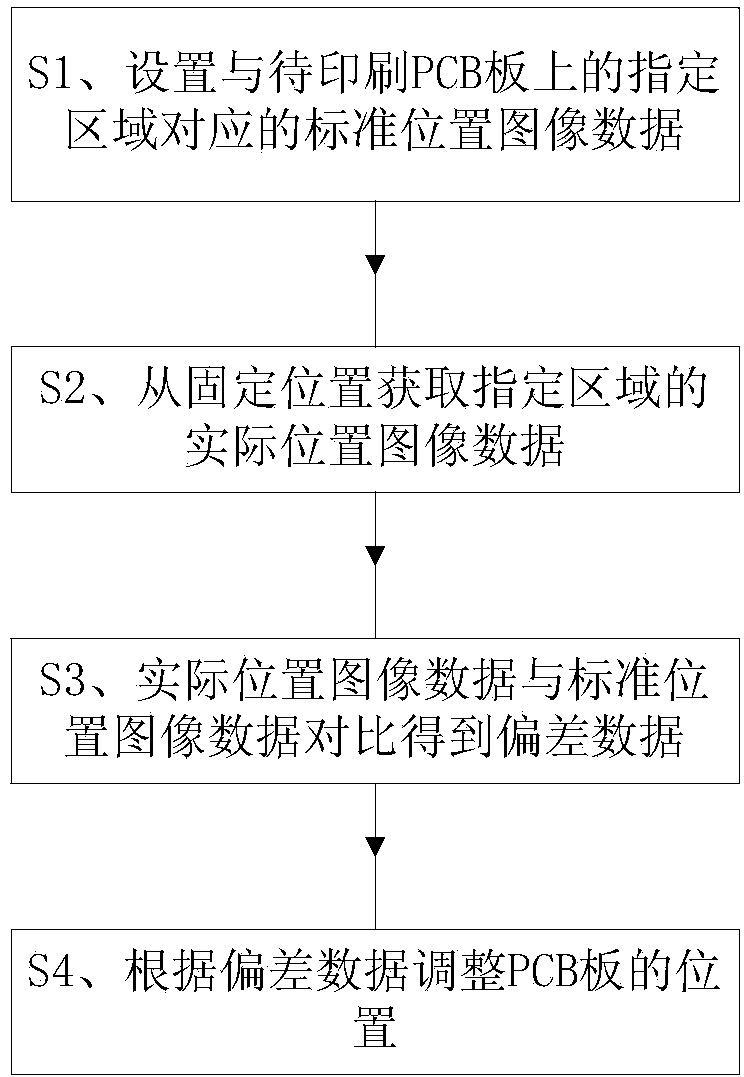

Solder paste printing press and vision aligning method thereof

InactiveCN103407283AAlignment time is longReduce printing efficiencyScreen printersPrinting press partsImage sensorSolder paste

The invention discloses a vision aligning method of a solder paste printing press. The method comprises the following steps: S1, setting standard position image data corresponding to an appointed area on a PCB (Printed Circuit Board) to be printed; S2, acquiring practical position image data of the appointed area on the PCB to be printed from a fixed position; S3, comparing the acquired practical position image data with the standard position image data so as to acquire deviation data of the practical position and the standard position; and S4, adjusting the position of the PCB according to the deviation data so as to position the appointed area on the PCB in the standard position. The invention further discloses the solder paste printing press which comprises an image sensor which is fixedly arranged on a circumferential side between the PCB and a mold plate. According to the solder paste printing press and the vision aligning method, the image data of the appointed area can be acquired from the fixed position, the speed for acquiring the image data is improved, mechanical structures for supporting acquisition equipment such as a CCD (Charge Coupled Device) image sensor to move along an X-axis and a Y-axis are reduced, the structure is simple, and the cost is lowered.

Owner:SUNEAST ELECTRONICS TECH SHENZHEN

Device and method for aligning position of optical element in direction of optical axis

The invention discloses a device and a method for aligning a position of an optical element in a direction of an optical axis. The device comprises a normal lens, a computed hologram and the to-be-measured optical element which are sequentially placed in an optical axis of an output beam of an interferometer, wherein the computed hologram is fixed on a small five-dimensional adjustment rack; the to-be-measured optical element is fixed on a large five-dimensional adjustment rack; the computed hologram is placed in a design position behind a focus of the normal lens; a beam from the interior of the interferometer passes through the normal lens and emits to the computed hologram to allow a divergent spherical wave front to become a convergent spherical wave front; and a convergent focus is formed in the position in the direction of the optical axis of the to-be-measured optical element. The convergent spherical wave front returns along a symmetrical light path position when being irradiated onto the to-be-measured optical element, so that the convergent spherical wave front and a reference wave front in the interferometer form an interference fringe, and by monitoring the interference fringe, and adjusting the large five-dimensional adjustment rack, the position of the to-be-measured optical element in the direction of the optical axis is controlled at a wavelength order.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

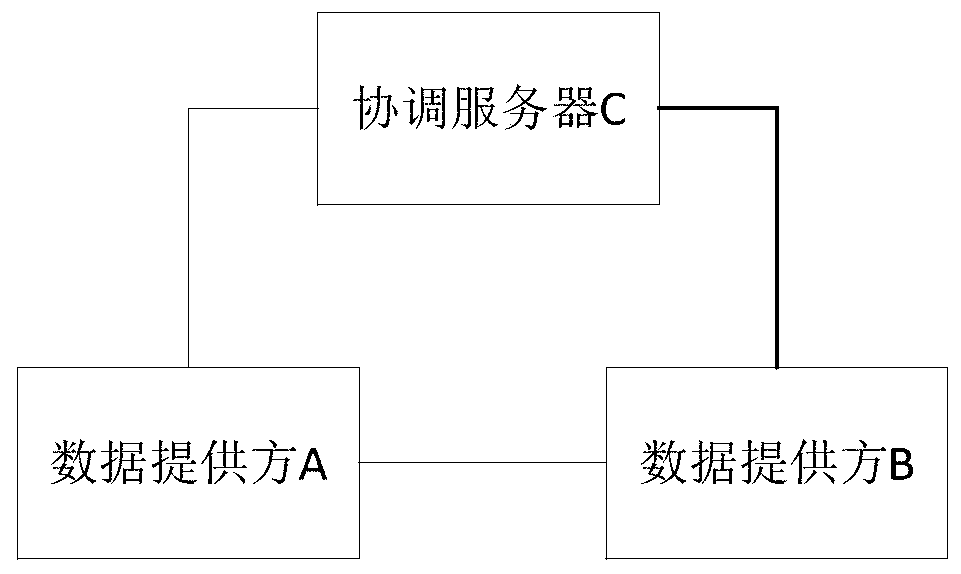

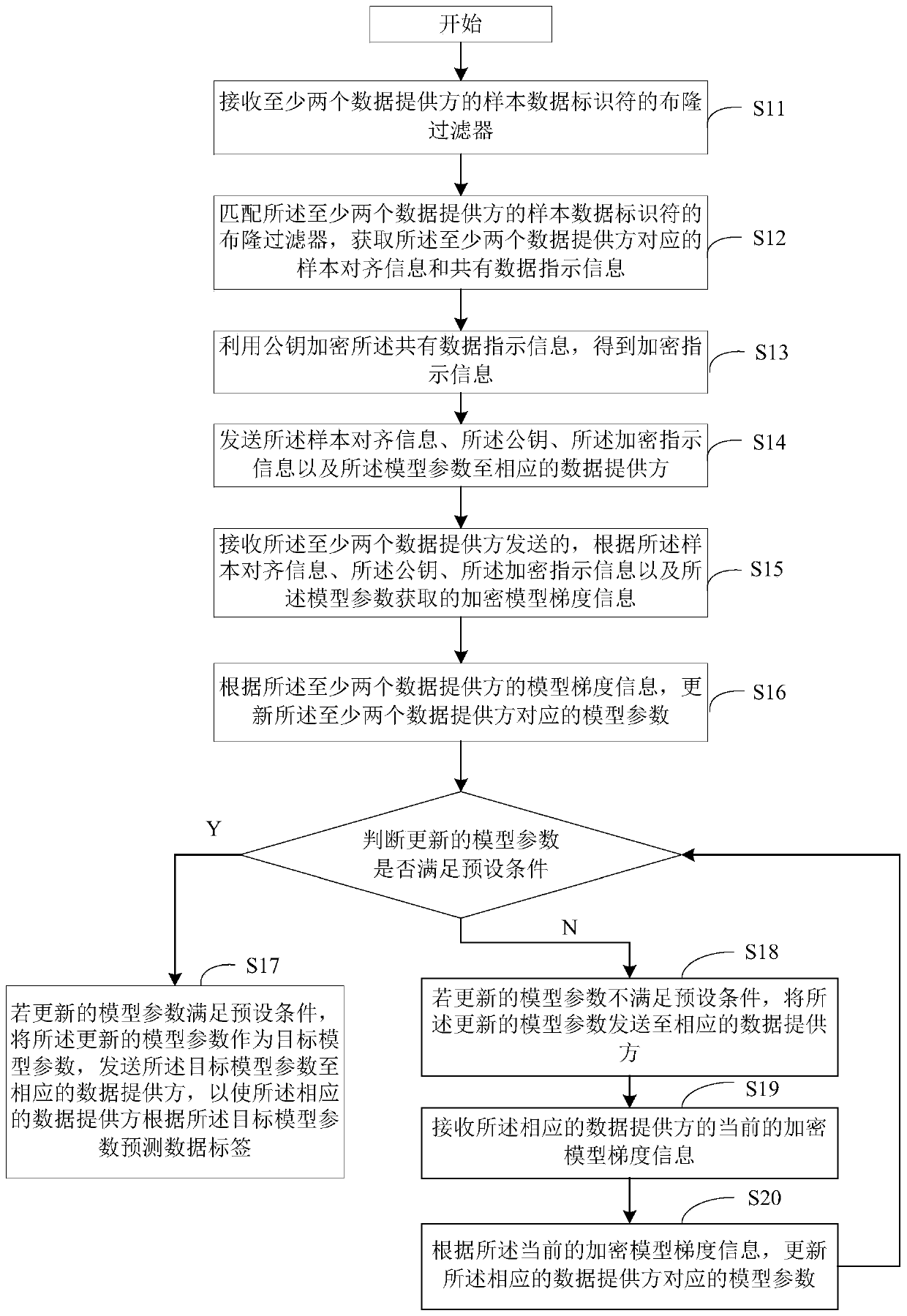

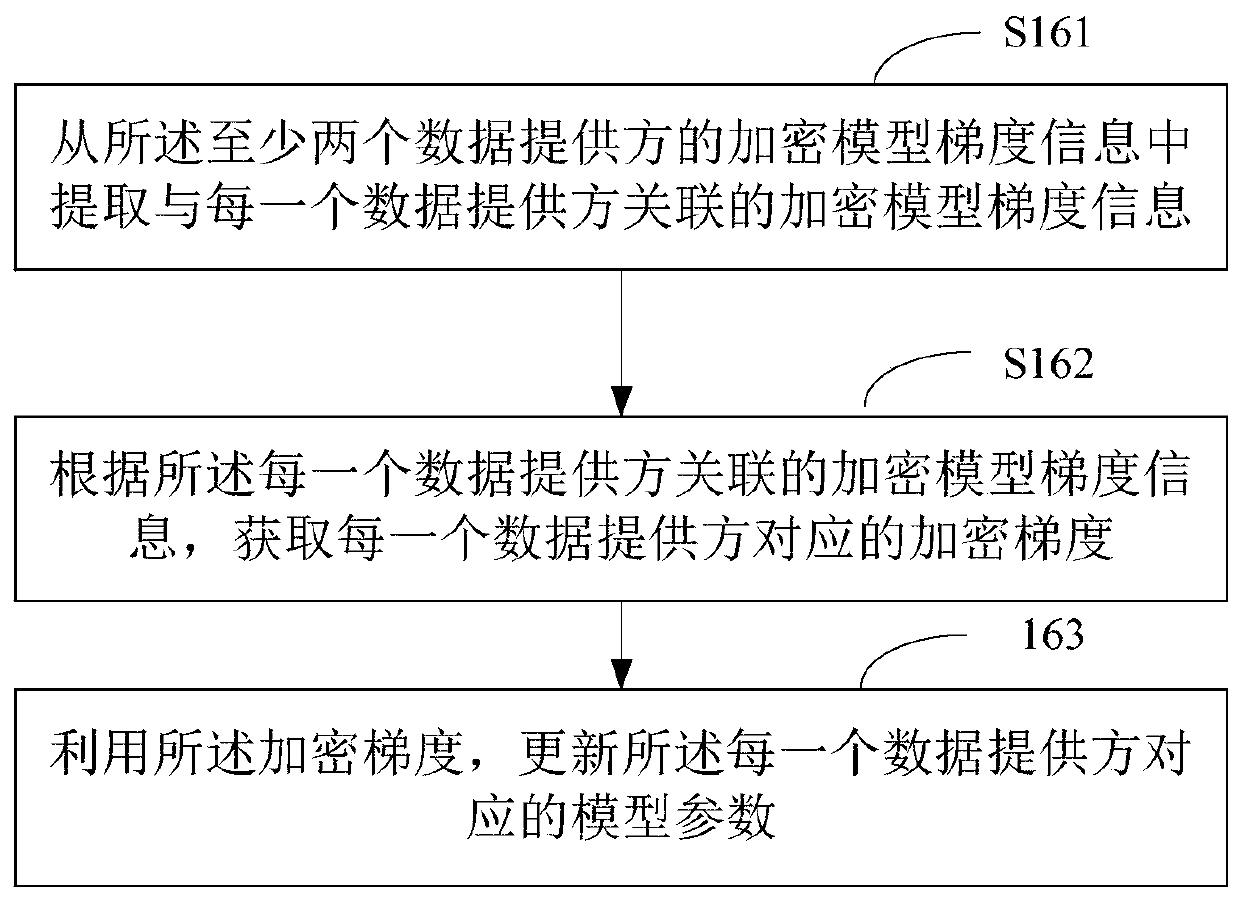

Federated learning method and device for vertical data

PendingCN111178538AImprove Common Model BenefitsImprove applicabilityDigital data protectionMachine learningData providerFederated learning

The invention relates to a federated learning method and device for vertical data. The method is applied to a coordination server, and comprises the following steps: receiving Bloom filters of sampledata identifiers of at least two data providers; matching the Bloom filters of the sample data identifiers of the at least two data providers, and obtaining sample alignment information and common data indication information corresponding to the at least two data providers; encrypting the common data indication information by using a public key to obtain encrypted indication information; sending the sample alignment information, the public key, the encryption indication information and the model parameters to a corresponding data provider; receiving encryption model gradient information of atleast two data providers; and updating model parameters corresponding to the at least two data providers according to the encryption model gradient information of the at least two data providers. According to the method, fuzzy matching of a plurality of identifiers can be realized, the applicability of an application scene is improved, and model parameters can be updated under the condition of ensuring data privacy.

Owner:杭州睿信数据科技有限公司

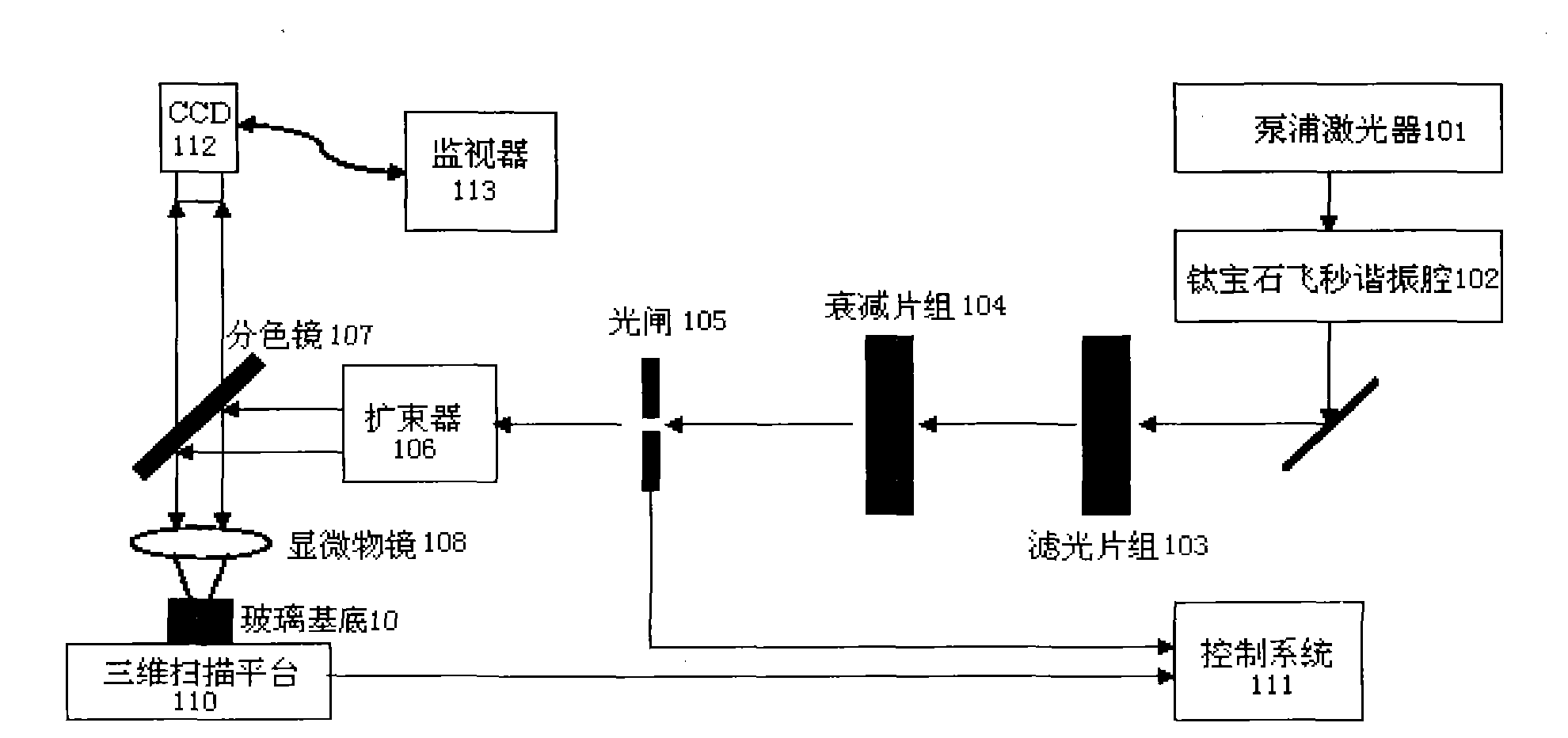

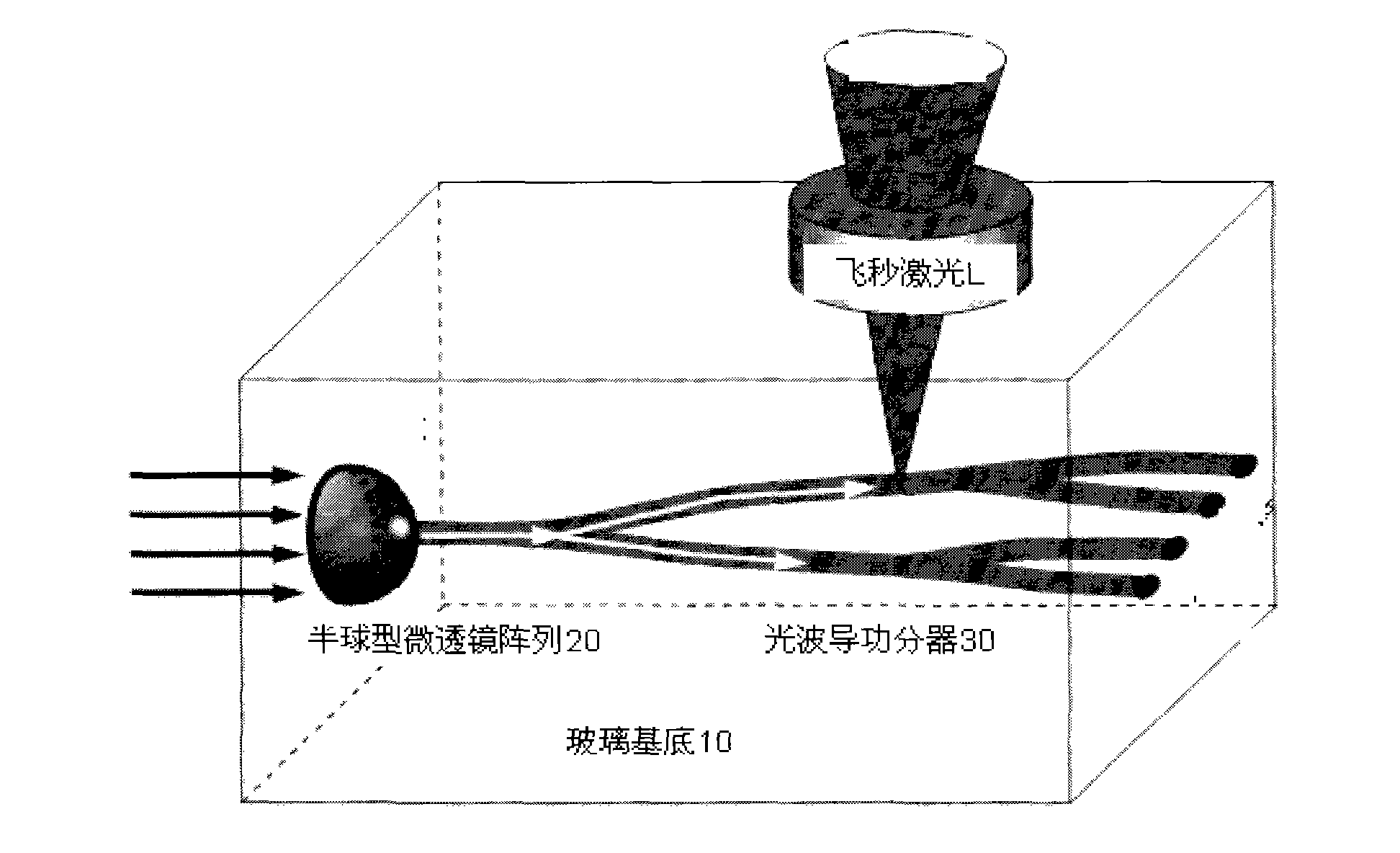

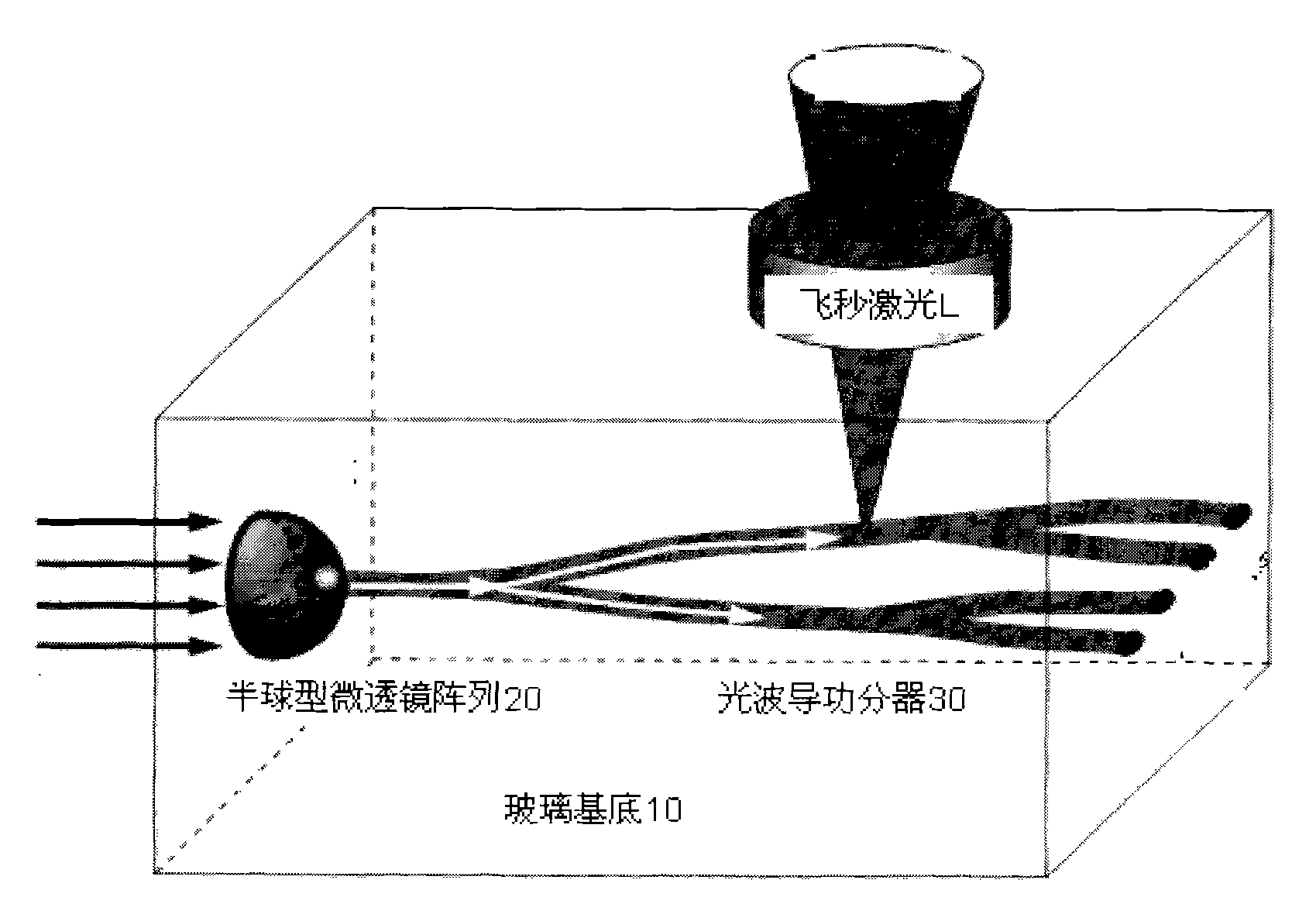

Micro lens and optical waveguide power divider integrated component and manufacturing method thereof

InactiveCN102116898AAchieve alignmentAchieve couplingOptical waveguide light guideMicrometerCoupling

The invention provides a micro lens and optical waveguide power divider integrated component and a manufacturing method thereof. In the invention, a hemispherical focusing micro lens array is formed on a glass substrate by the application of an ion exchange technology and further femtosecond laser is utilized to induce to change the refractive index inside the glass substrate to form the optical waveguide power divider with the micrometer width so as to realize integration of two basic micro optical components, namely a micro lens and the optical waveguide power divider, onto one glass substrate, realize alignment and coupling of the micro lens and the optical waveguide, generate a micro optical integrated device with the optical performance and fill a technical gap of the field.

Owner:SOUTHWEAT UNIV OF SCI & TECH

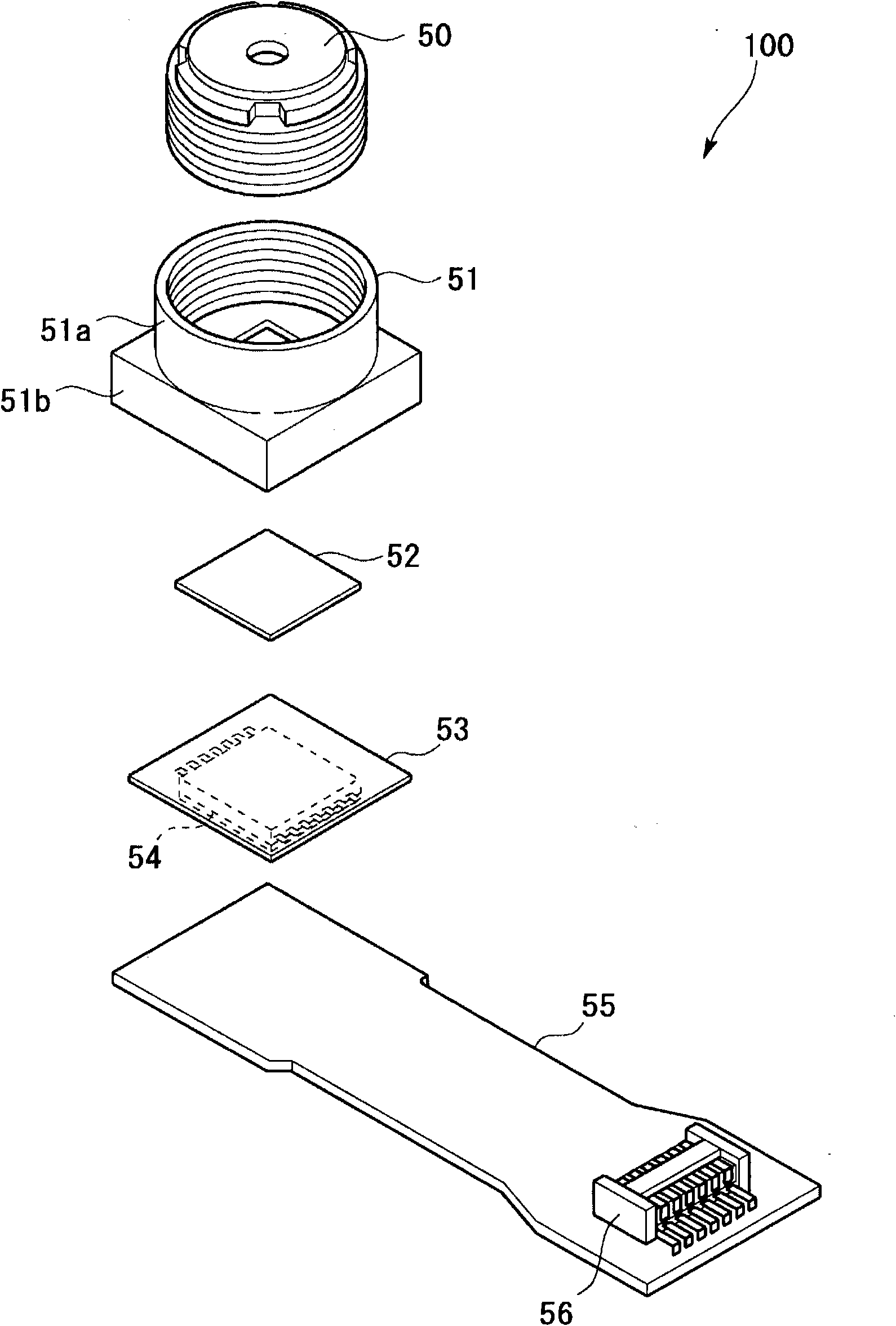

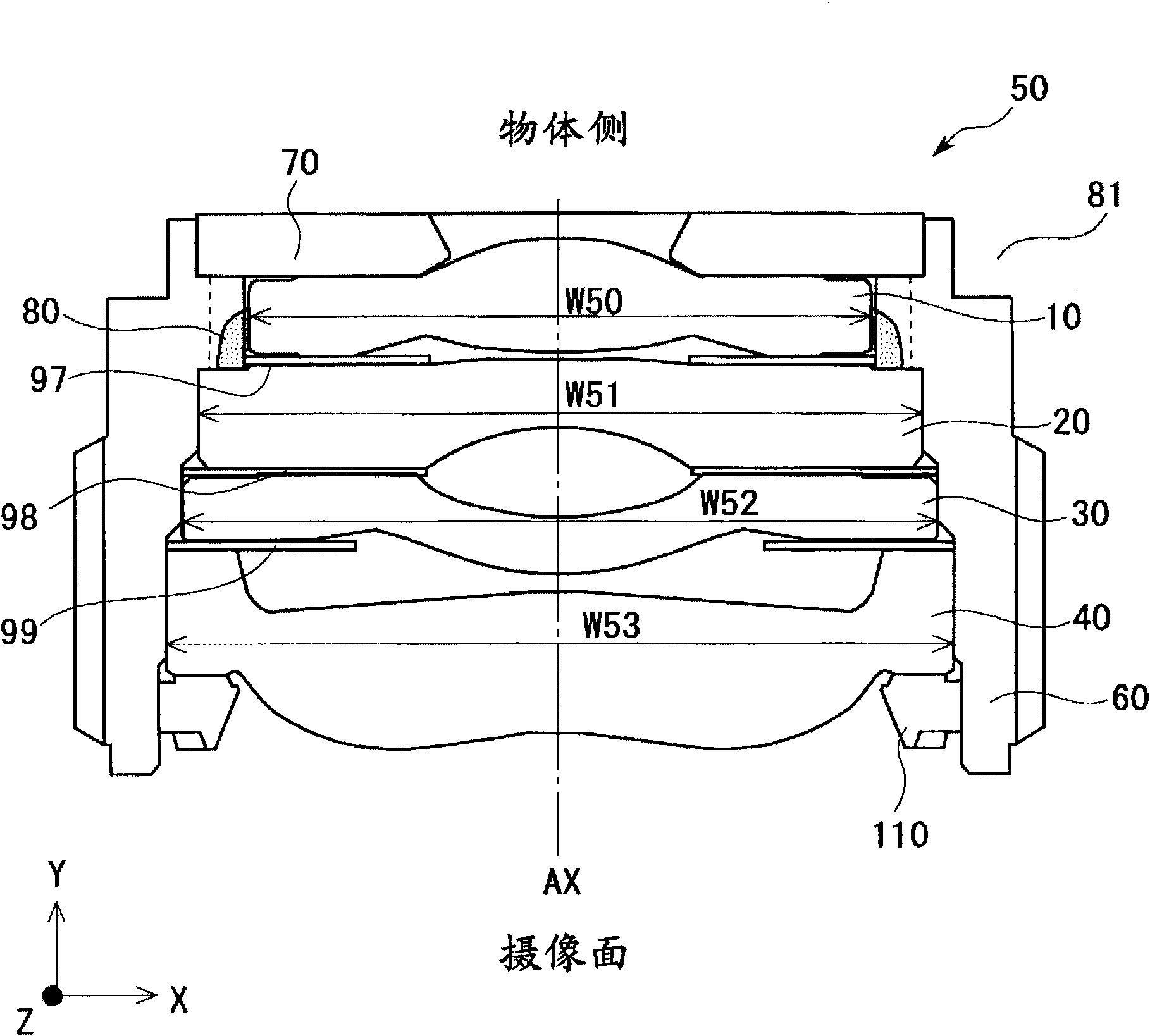

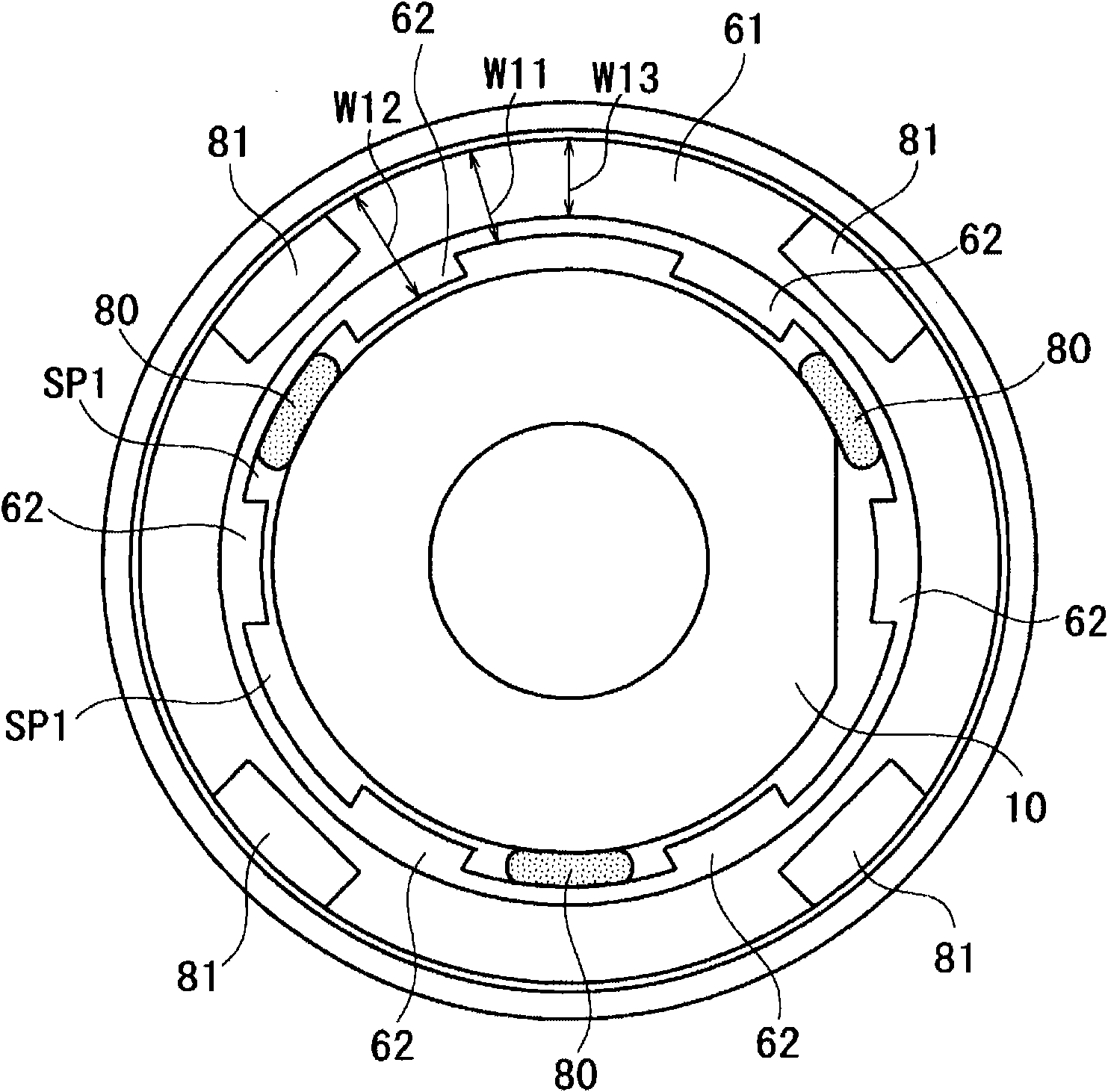

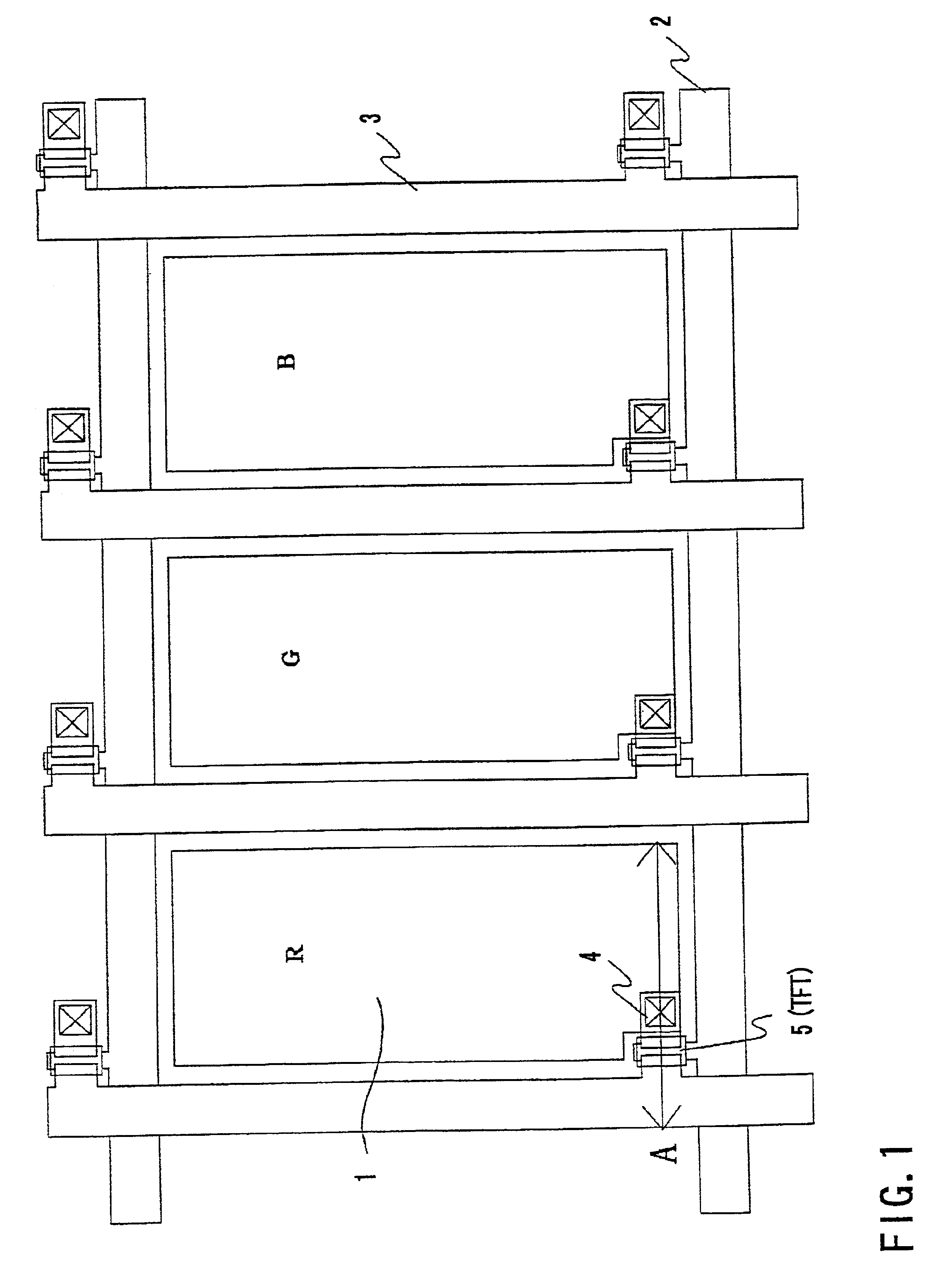

Lens unit, camera module and lens unit manufacturing method

Lens alignment is performed by a simple constitution or an easy method. A lens unit (50) is provided with a plurality of lenses (10-40) each of which has a lens section and a flange section surrounding the lens section; and a holding body (60) which holds the lenses (10-40) sequentially arranged along an optical axis. The holding body (60) has first and second receiving sections sequentially formed along the optical axis. The first receiving section presses a flange section side surface along the optical axis and holds the lenses (20-40), and the second receiving section receives the lens (10) in a state where the second receiving section can be moved in a direction intersecting with the optical axis.

Owner:MAXELL HLDG LTD

Tool clamping apparatus for operations of tin-plating and welding leads of wire-welded type components and parts

ActiveCN102357699AAchieve fixationAchieve deflectionMetal working apparatusSoldering auxillary devicesTin platingEngineering

The invention relates to a tool clamping apparatus for the operations of tin-plating and welding the leads of wire-welded type components and parts, belonging to the technical field of welding. The clamping apparatus comprises a turntable, a transverse / longitudinal adjustment mechanism, a component fixing mechanism and a tin-leakage preventing clamp; the bottom face of the tin-leakage preventing clamp is matched with a slide rail of a transverse / longitudinal adjustment mechanism supporting plate; the transverse / longitudinal adjustment mechanism is fixedly mounted on a seat board of the turntable as a whole through a slide rail bottom plate; and the component fixing mechanism is fixedly mounted on the seat board of the turntable through a fixing mechanism body and is opposite to the transverse / longitudinal adjustment mechanism. According to the invention, core wires of the leads are clamped through the tin-leakage preventing clamp so as to exert effects of clamping and tin-leakage preventing, a fixing surface can deflect within 30 DEG towards two sides from the vertical direction through the adjustment of the turntable, and the alignment between the leads and a welding pin (groove)can be realized through adjusting the transverse / longitudinal adjustment mechanism and adjusting the sliding of the tin-leakage preventing clamp on the transverse / longitudinal adjustment mechanism. The tool clamping apparatus can effectively standardize various operations in processes of assembling and connecting and reduces the influence on welding quality caused by human factors.

Owner:NO 513 INST THE FIFTH INST OF CHINA AEROSPACE SCI & TECH

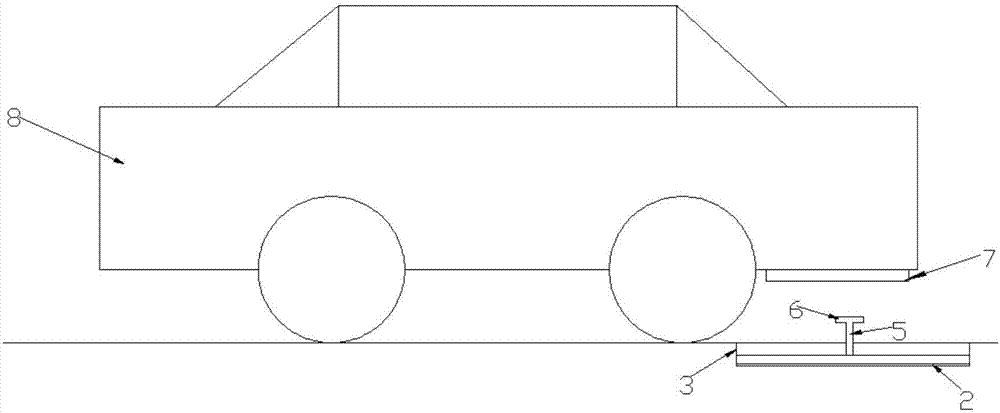

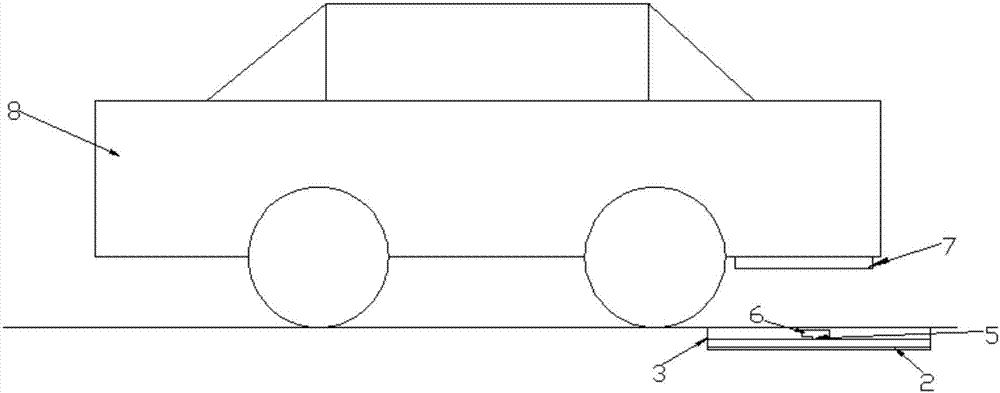

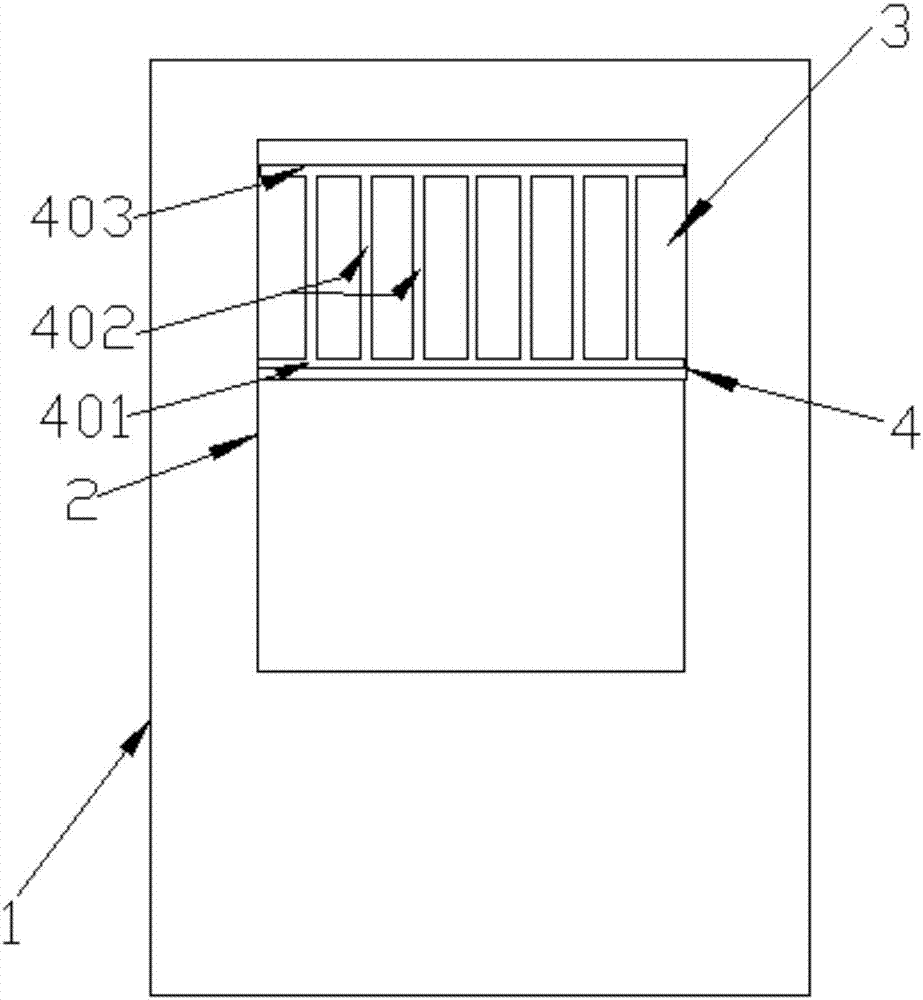

System and method for electric vehicle wireless charging

ActiveCN107199897AImprove securityRealize the operationBatteries circuit arrangementsCharging stationsAutomatic controlElectric vehicle

The invention discloses a system and method for electric vehicle wireless charging. A lifting device and a charging coil sliding rail are arranged on a wireless charging emission device, a controller on the wireless charging emission device controls the lifting device to move and position on the charging coil sliding rail, and the position of the lifting device is determined according to the curve chart of the conversion rate of received power and transmitted power, so that alignment of a transmitting coil and a receiving coil is achieved. According to the system and method, by means of the technical means of wireless charging, transmission of energy between a transmitting device and a receiving device is achieved, contact and exposure of parts are avoided so that the durability and service life of charging parts can be improved, and the safety of charging is improved; according to the curve chart of the conversion rate of the received power of the receiving coil and the output power of the charging coil, the controller determines the final position of the lifting device, then alignment of the charging coil and the receiving coil is achieved through rotation of the chainwheel of the charging coil, and automatic control is achieved through minimum operation.

Owner:NINGBO SANXING INTELLIGENT ELECTRIC

Auxiliary collimation device of autocollimator

InactiveCN103925891AAchieve alignmentImprove test efficiencyUsing optical meansOptical axisLight beam

The invention discloses an auxiliary collimation device of an autocollimator, and belongs to the technical field of optical detection. When auto-collimation testing is carried out, the optical axis of the autocollimator needs to be collimated with a light reflector, and meanwhile the normal of a light reflector face is parallel to the optical axis of an objective lens of the autocollimator. If the distance between the autocollimator and the light reflector is large, time and labor are wasted when the light path is adjusted, and therefore the measuring efficiency and the measuring accuracy are reduced. According to the auxiliary collimation device of the autocollimator, the relative positions and the relative directions of the autocollimator and the light reflector can be coarsely adjusted, the position of a center light beam of the autocollimator is indicated through a visible laser beam, and the position and direction relation between the autocollimator and the light reflector is judged by observing the position of a laser spot on the light reflector and the position of the reflected laser spot. On the premise that the autocollimator and the light reflector are already accurately collimated, matched calibration of the auxiliary collimation device of the autocollimator and the end face of a lens cone of the autocollimator can be further achieved.

Owner:中国人民解放军63863部队

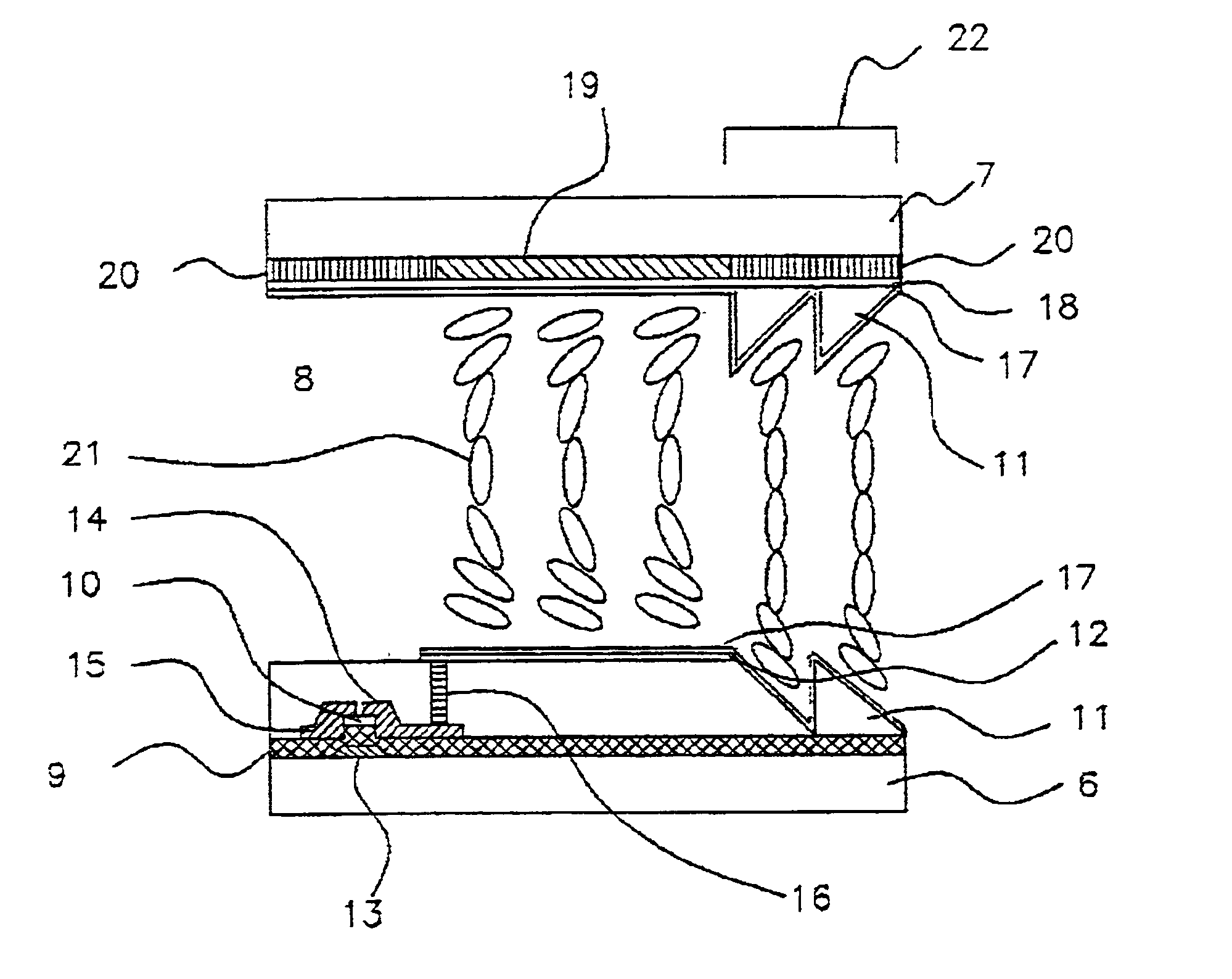

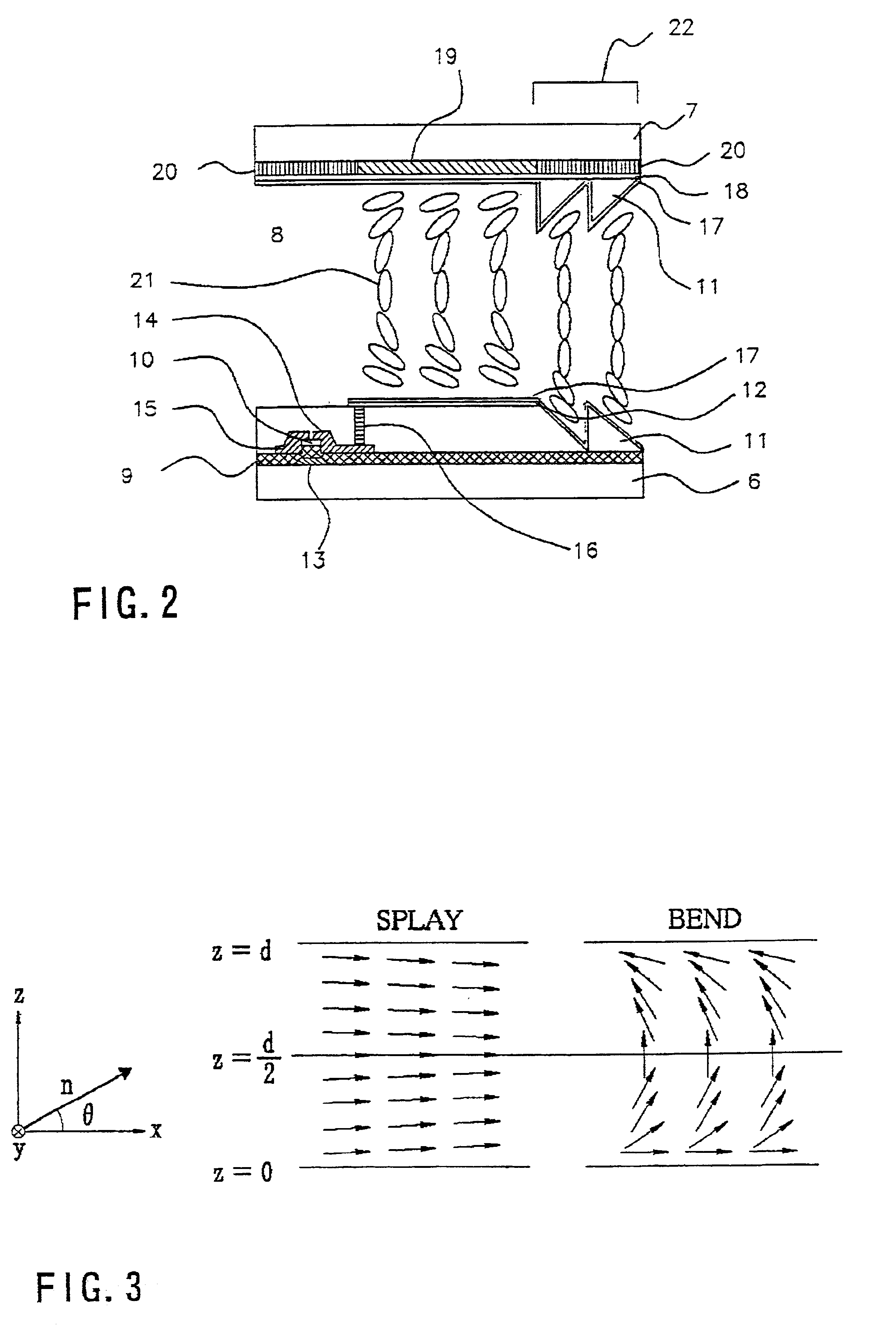

OCB type liquid crystal display having transition nucleus area from splay alignment to bend alignment

InactiveUS6859246B2Easy to produceEasily stably maintain bend alignment conditionLiquid crystal compositionsStatic indicating devicesLiquid-crystal displayVoltage reference

An OCB type liquid crystal display having first and second substrates opposed to each other via a liquid crystal layer such that rubbing directions of the first and second substrates become parallel to each other, a plurality of pixel electrodes which correspond to respective pixels, and a common electrode formed on the second substrate which receives a reference voltage commonly to a plurality of the pixels. A first transition nucleus area is formed in the first substrate layer and has a plurality of continuous slant surfaces having a saw-tooth cross sectional profile, and a second transition nucleus area is formed in the second substrate and has a plurality of continuous slant surfaces having a saw-tooth cross sectional profile. The slant surfaces in the first and second transition nucleus areas oppose to each other and slope toward mutually opposite angular directions.

Owner:VISTA PEAK VENTURES LLC

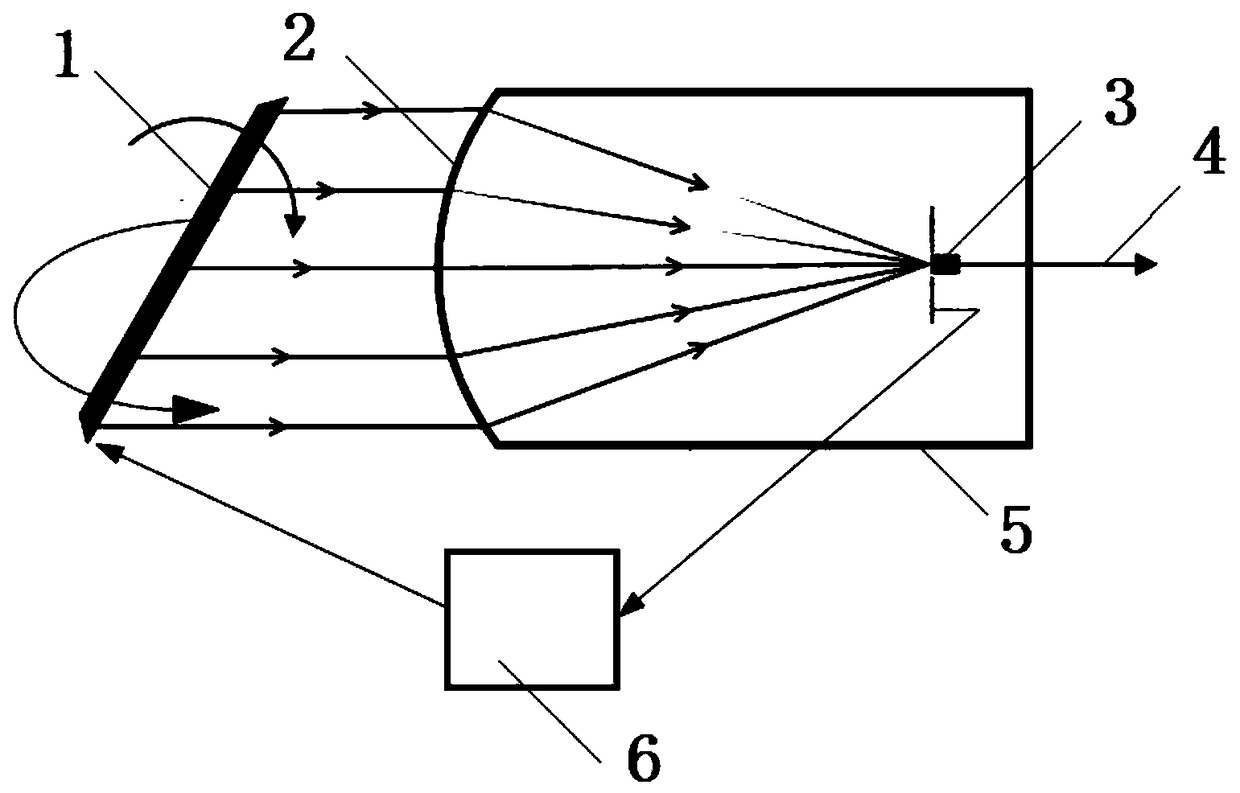

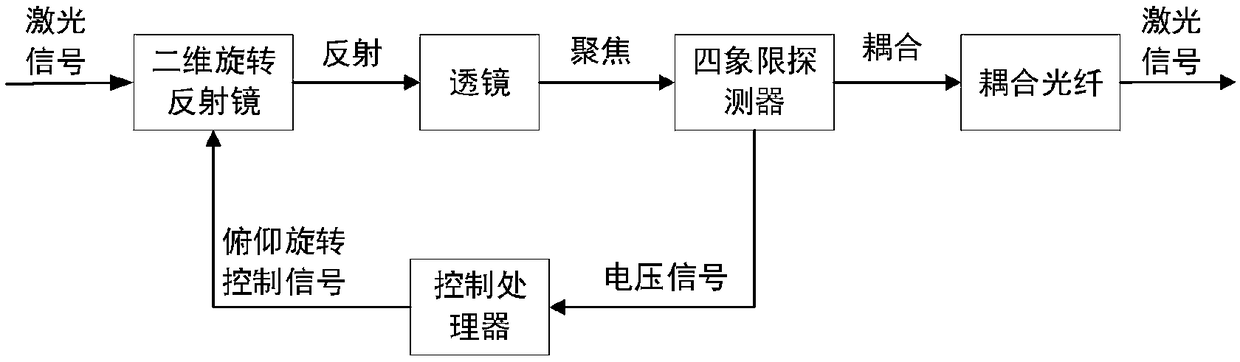

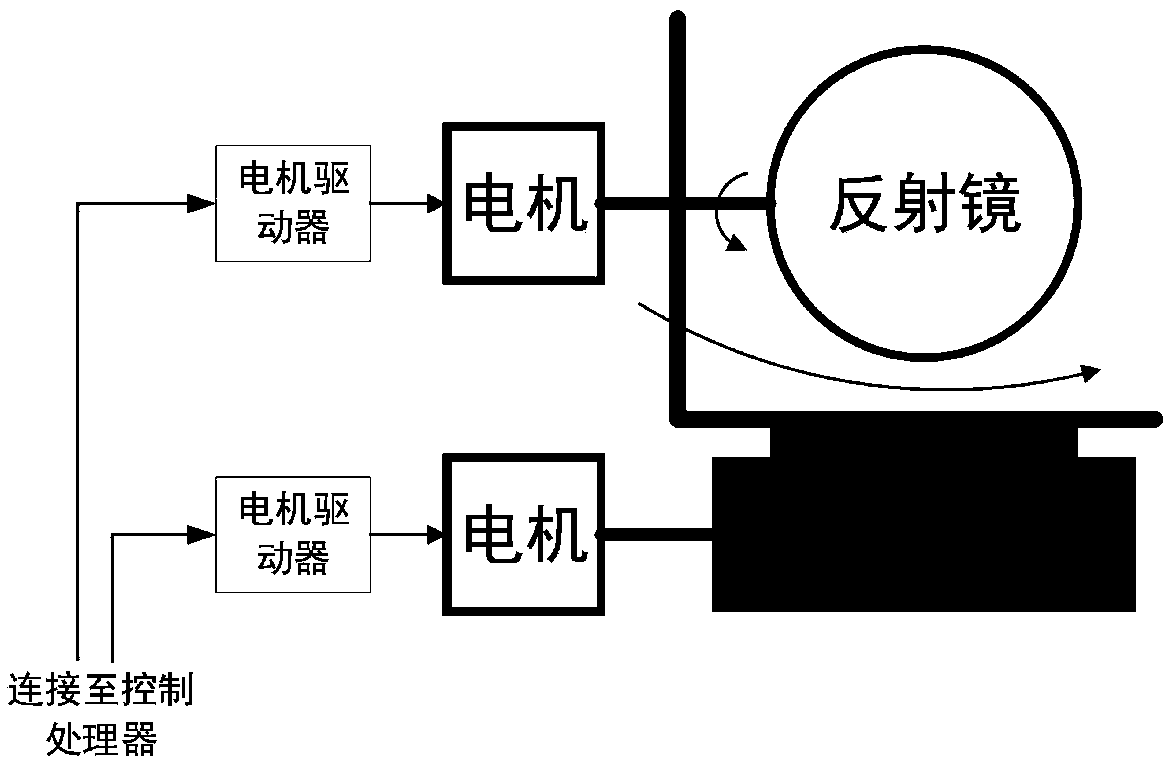

Wireless laser communication reflection type aiming tracking system and laser aiming tracking method

ActiveCN109061831AAchieve alignmentImplement trackingClose-range type systemsCoupling light guidesFiberFour quadrants

The invention discloses a wireless laser communication reflection type aiming tracking system and a laser aiming tracking method. A controller is controlled to control pitch and horizontal motion of atwo-dimensional rotating reflection mirror; a laser transmitted by the wireless laser communication transmitting end is reflected into an optical receiving antenna; the optical receiving antenna focus the later into a small facula, and the small facula hits a four-quadrant detectorin the optical receiving antenna; the four-quadrant detector output corresponding voltage to a control processor, andthe control processor controls pitch and horizontal motion of the reflection mirror based on the received voltage until the facula hits in a small hole at the center of the four-quadrant detector; acoupling fiber is fixed to the center through hole of the four-quadrant detector, and when the facula enters the center through hole, a laser signal transmitted by the transmitting end can be coupledinto the fiber; and the fiber is used for transmitting the laser signal to sequential signal processing portion, and establishment of wireless laser communication link is achieved. The aim of the APTsystem establishes the wireless laser communication link in a short time is achieved.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com