Coaxial Optical Transceiver Device Automatic Coupling, Soldering and Packaging Mechanical Device

An optical transceiver device and automatic coupling technology, applied in laser welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of large production equipment, differences in skill proficiency, unstable product quality, etc., and achieve simple control, Reduced operating time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0139] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

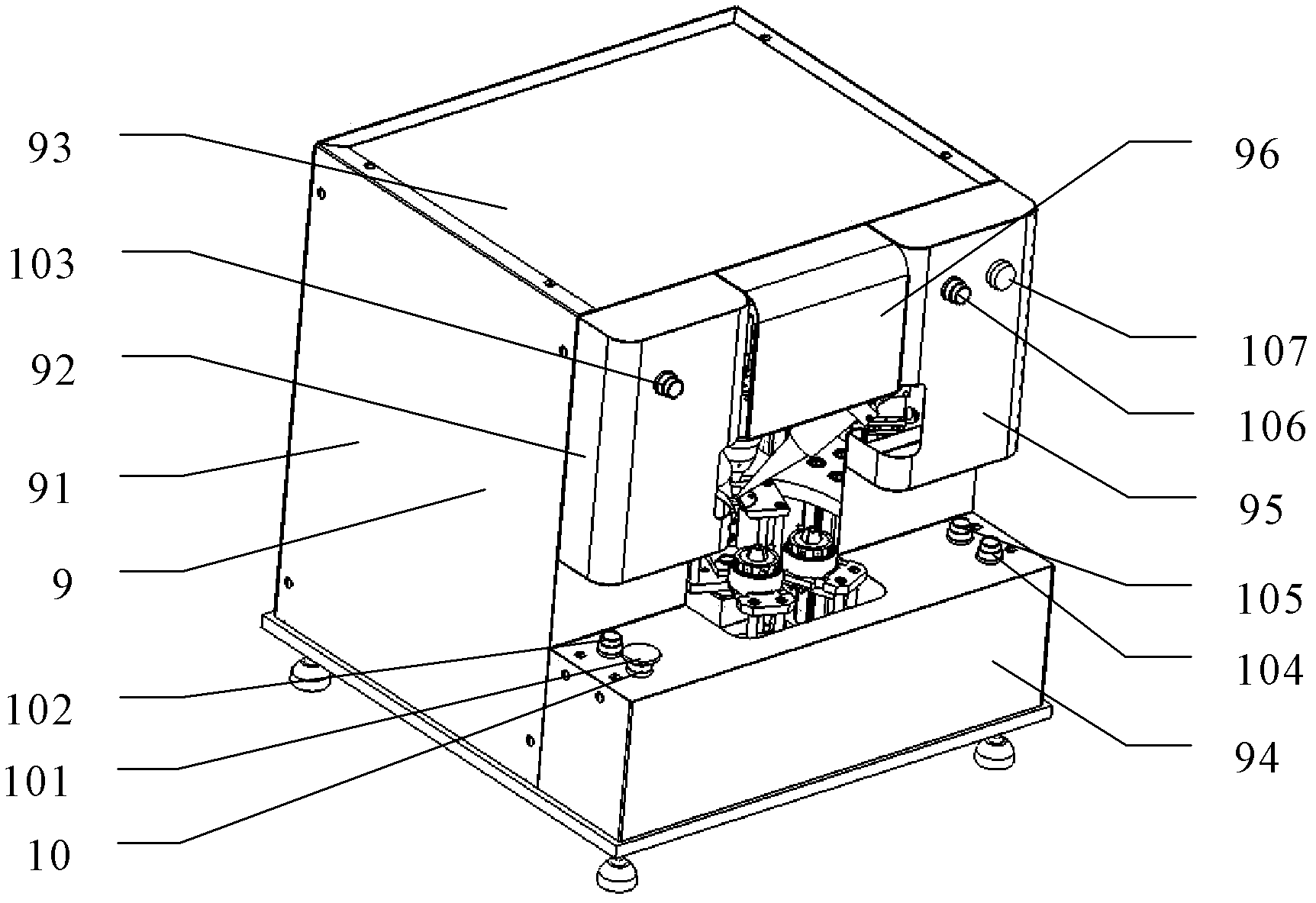

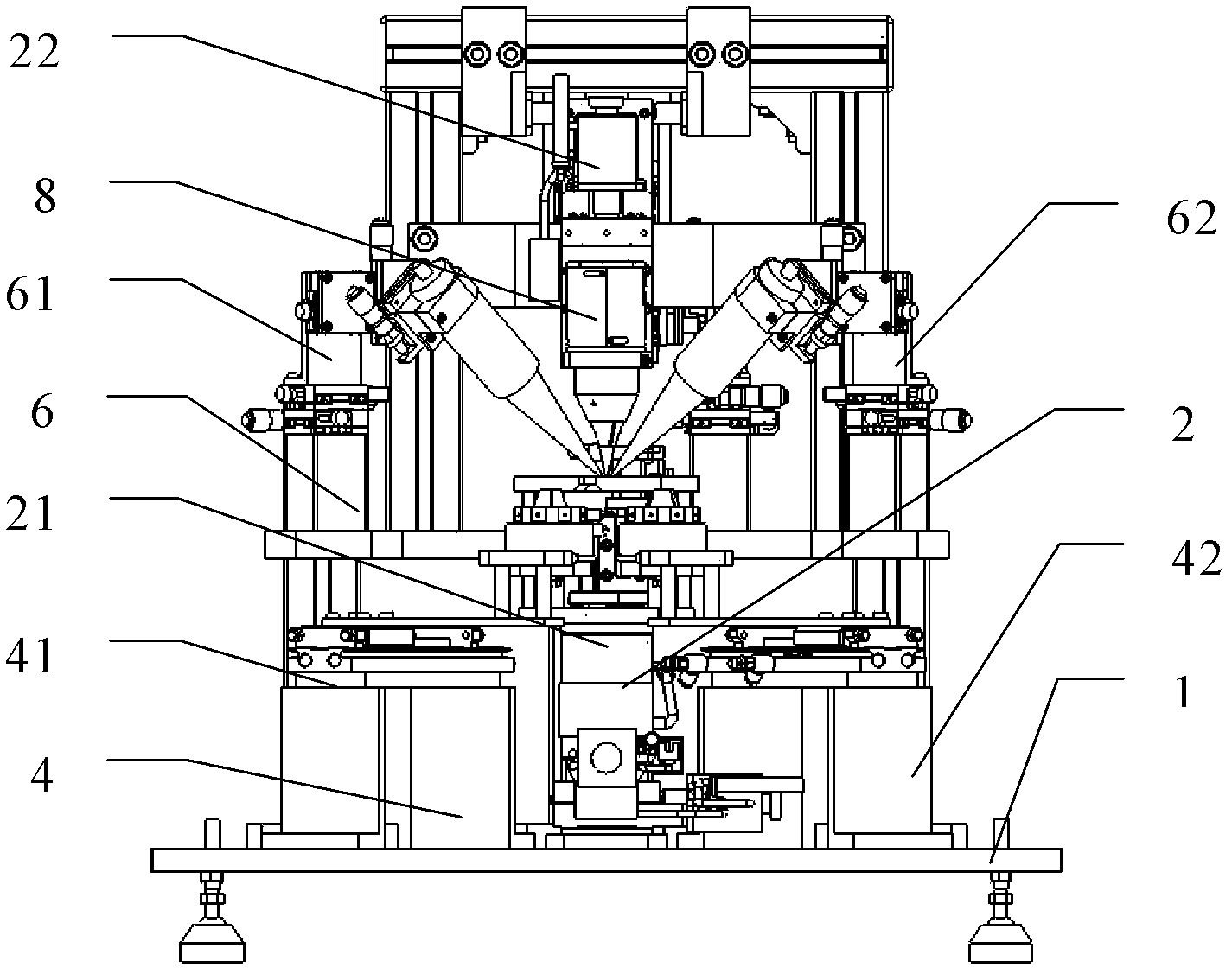

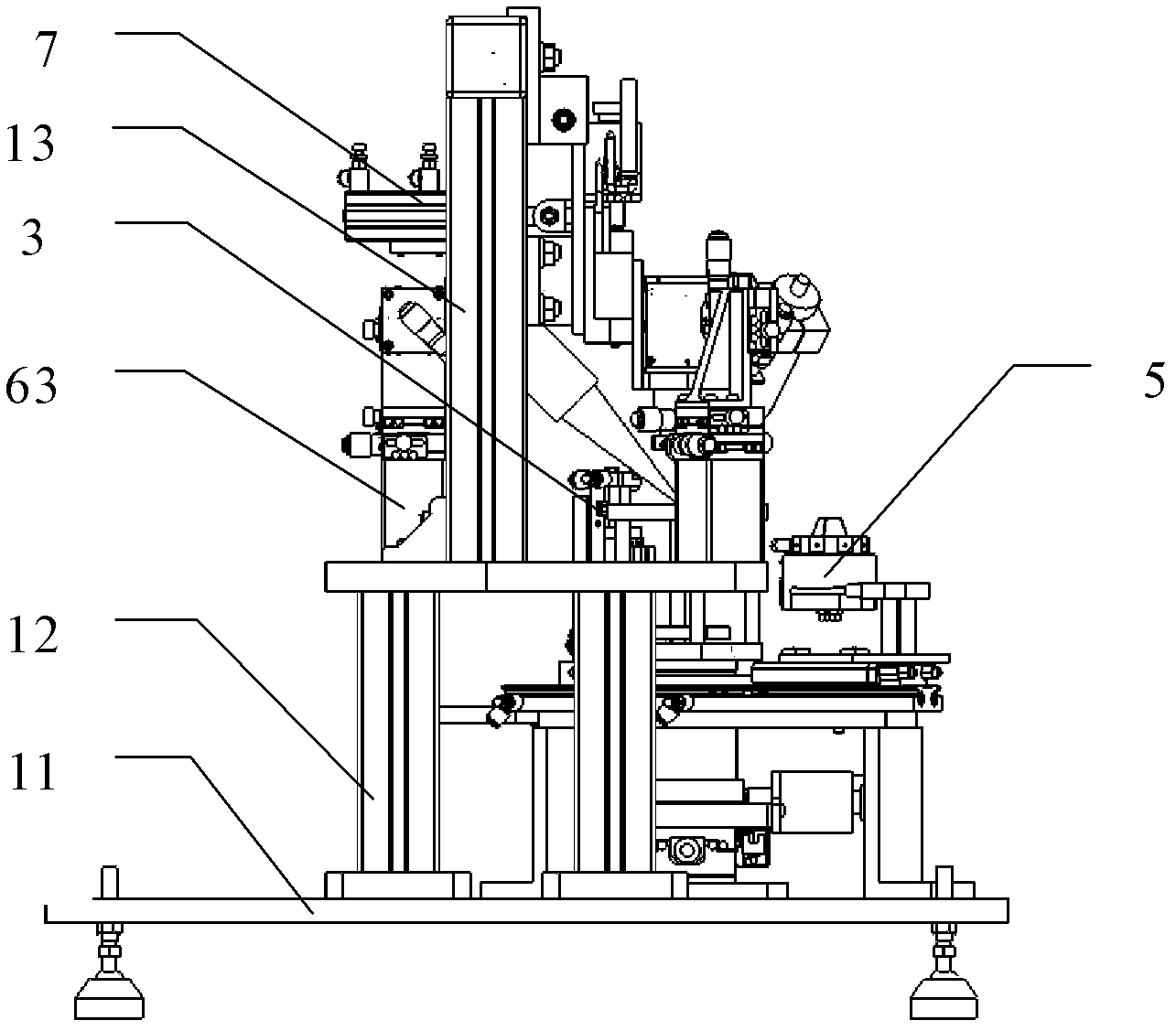

[0140] Such as figure 1 , figure 2 and image 3 As shown, the coaxial optical transceiver device automatic coupling welding packaging mechanical device of the present invention includes a workbench 1, an alignment unit 2, a lifting unit 3, a pushing unit 4, a manual lower clamp 5, a welding unit 6, a swing unit 7, an upper Clamp 8 , device housing 9 and control buttons 10 . The alignment unit 2 includes an alignment unit base platform 21 and a Z-axis automatic linear slide table 22. The alignment unit base platform 21, the propulsion unit 4 and the welding workbench 12 are all installed on the equipment workbench 11, and the propulsion unit 4 is propelled from the left Device 41 and right propulsion device 42 constitute, they revolve around θ z The rotation axis of the rotating platform 214 is distributed at 45°. The manual lower fixture 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com